Flexible preprinting cardboard box, production method and production equipment thereof

A manufacturing method and carton technology, applied in box making operations, carton/carton manufacturing machinery, chemical instruments and methods, etc., can solve problems such as low screen printing accuracy, reduced cardboard strength, and long production cycle, and achieve improved slitting The effect of improving the yield, improving the grade of the carton, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

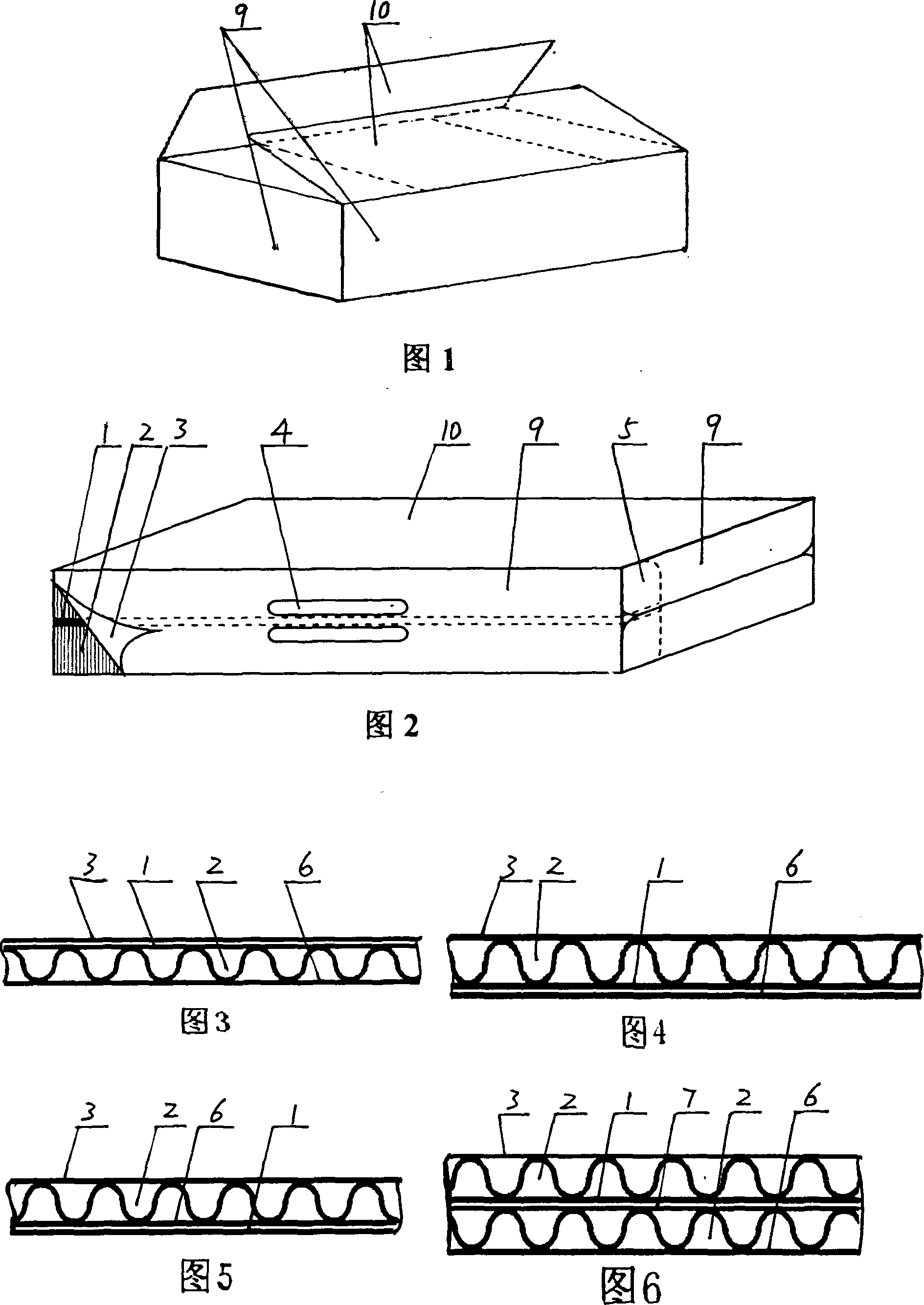

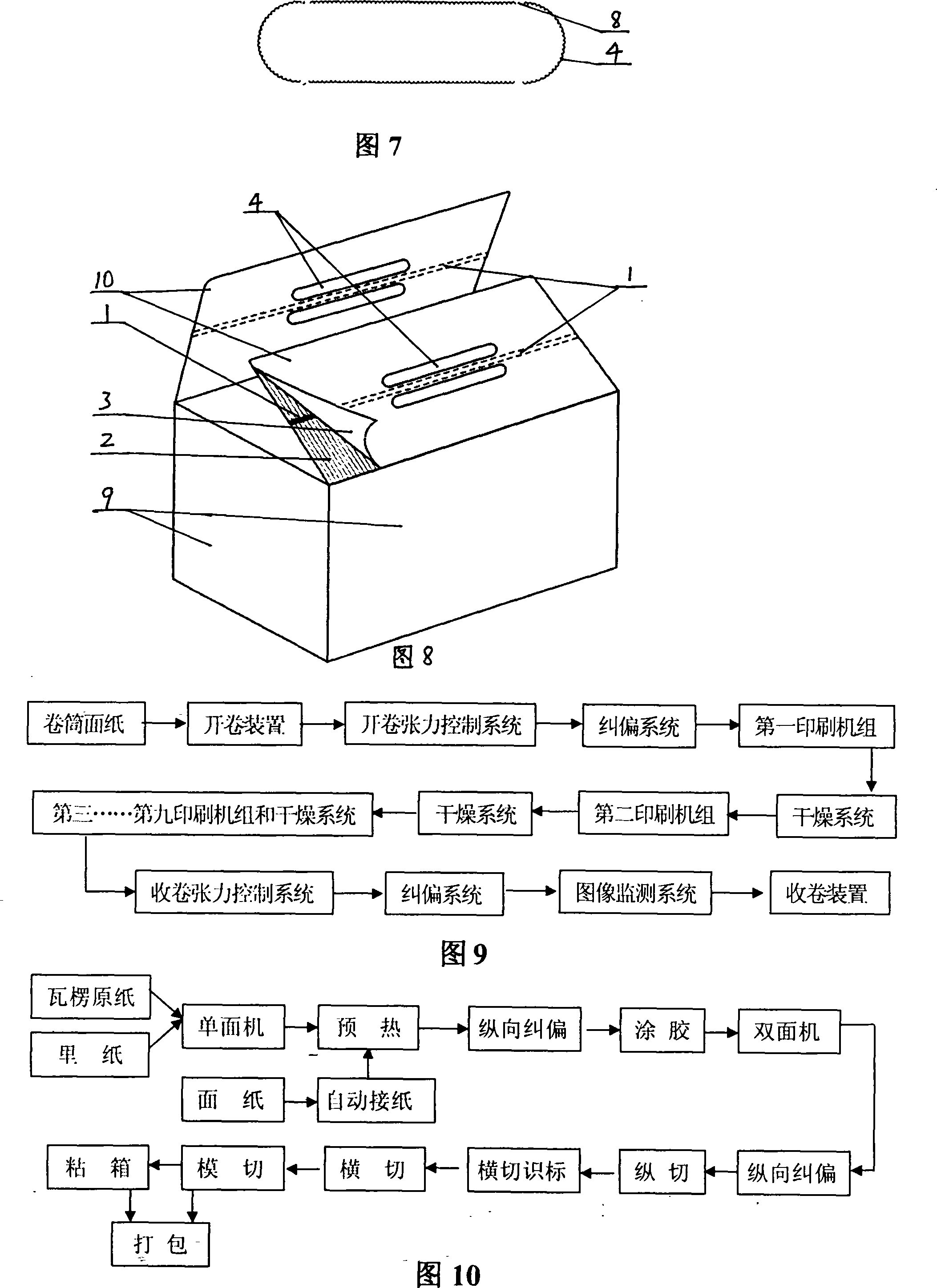

[0040] Embodiment 1 shown in Fig. 1, Fig. 9, Fig. 10, Fig. 11, Fig. 12, Fig. 13, and Fig. 14: the flexo pre-printed carton of this embodiment is made of face paper, corrugated paper and inner paper, or is made of face paper The rectangular six-panel box of the hollow box made of paper, corrugated paper, core paper and inner paper, the rectangular six-panel is made up of top wall panel 10, four side panels 9 and the bottom panel. The color patterns on the face paper are flexo printed color patterns on the face paper and coated with water-based varnish before making the carton.

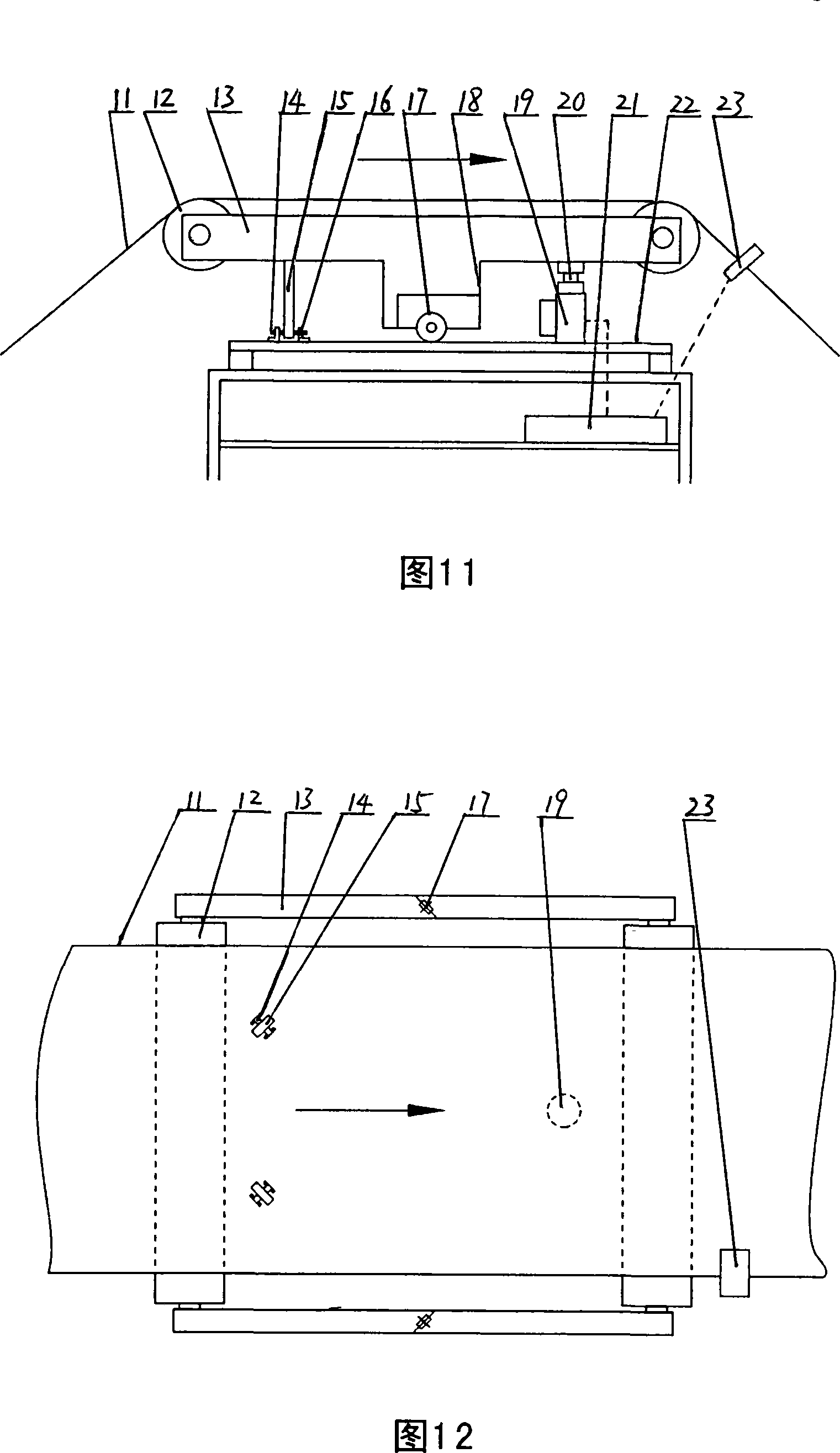

[0041] The manufacturing equipment of flexo pre-printed carton of the present embodiment 1, it comprises flexo printing machine, corrugated cardboard manufacturing equipment and die-cutting machine. The flexo printing machine is composed of an unwinding device including a paper release shaft, an unwinding tension control system, and a deviation correction system. It is composed of the first printing uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com