Cardboard box

a cardboard box and side wall technology, applied in the field of cardboard boxes, can solve the problems of poor operating efficiency, poor working efficiency of large-sized cardboard boxes as above-mentioned, and the operation of cutting the side wall with a cutter to form the opening requires considerable time and effort, and achieves enhanced working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

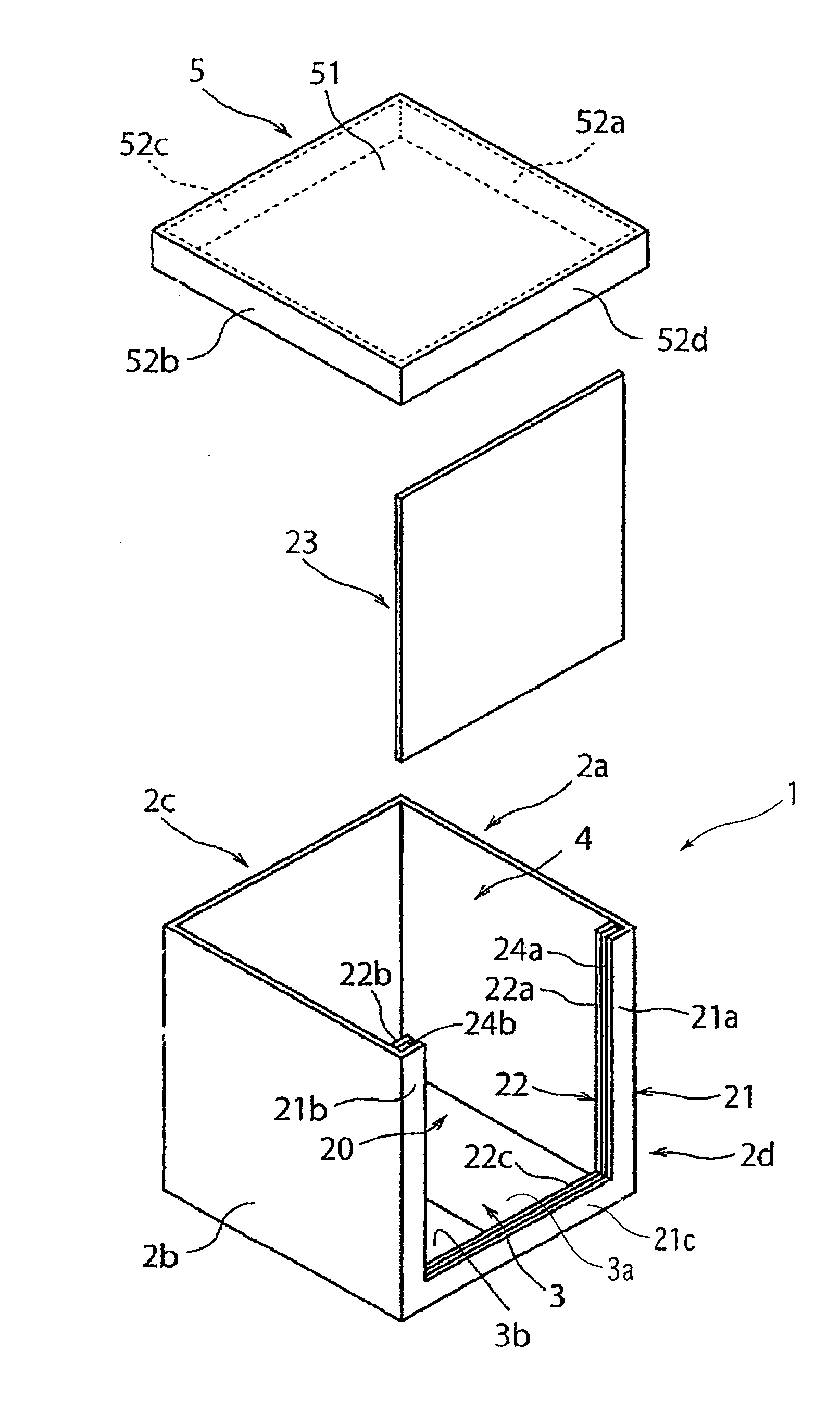

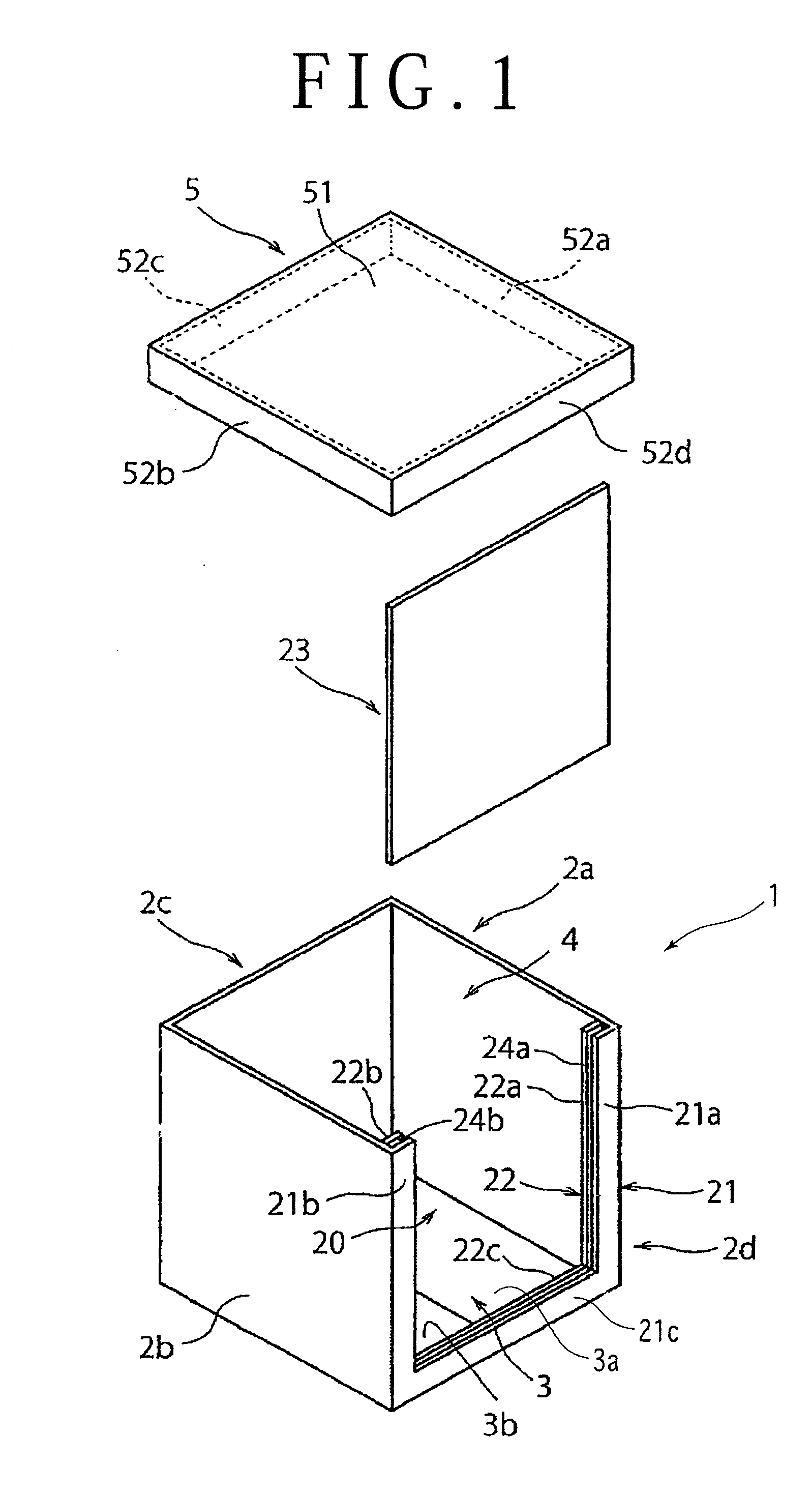

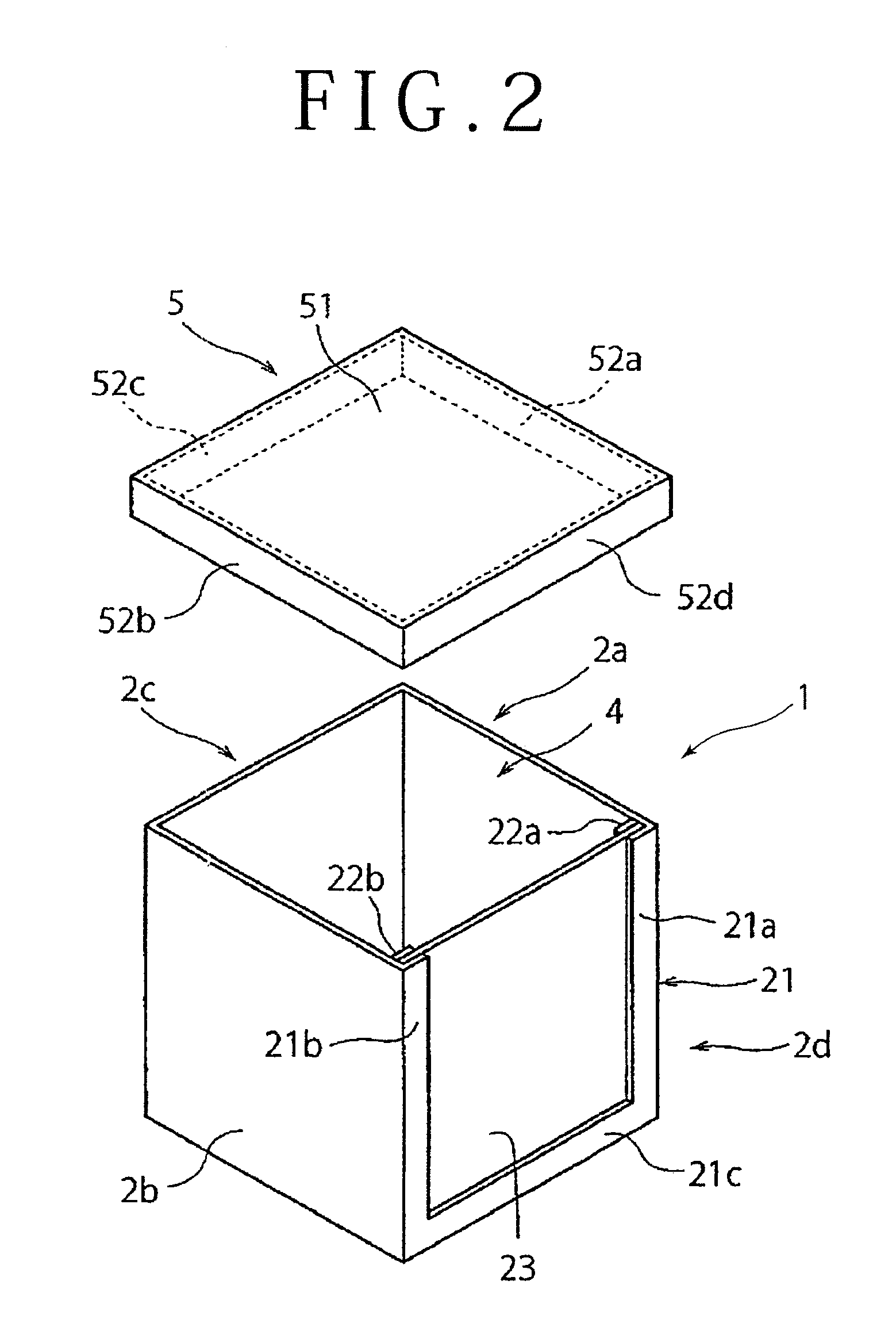

[0015]Now, a preferred embodiment of a cardboard box 1 configured according to the present invention will be described in detail below, referring to the attached drawings. FIG. 1 shows a perspective view of component members of the cardboard box 1 configured according to the present invention, in a disassembled state; FIG. 2 shows a perspective view of the cardboard box 1 configured according to the present invention, in a partly assembled state; and FIG. 3 shows a perspective view of the cardboard box 1 configured according to the present invention.

[0016]The cardboard box 1 in the embodiment shown in the drawings includes: two pairs of opposed side walls 2a and 2b, 2c and 2d; a bottom wall 3 closing a region defined by the lower ends of the two pairs of side walls 2a and 2b, 2c and 2d; and a lid 5 covering an upper opening 4 defined by the upper ends of the two pairs of side walls 2a and 2b, 2c and 2d. These component members are formed of a corrugated fiberboard having a thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com