Patents

Literature

52 results about "Antistatic bag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antistatic bag is a bag used for storing electronic components, which are prone to damage caused by electrostatic discharge (ESD). These bags are usually plastic polyethylene terephthalate (PET) and have a distinctive color (silvery for metallised film, pink or black for polyethylene). The polyethylene variant may also take the form of foam or bubble wrap, either as sheets or bags. Multiple layers of protection are often used to protect from both mechanical damage and electrostatic damage. A protected device can be packaged inside a metalized PET film bag, inside a pink polyethylene bubble-wrap bag, which is finally packed inside a rigid black polyethylene box lined with pink poly foam. It is important that the bags only be opened at static-free workstations.

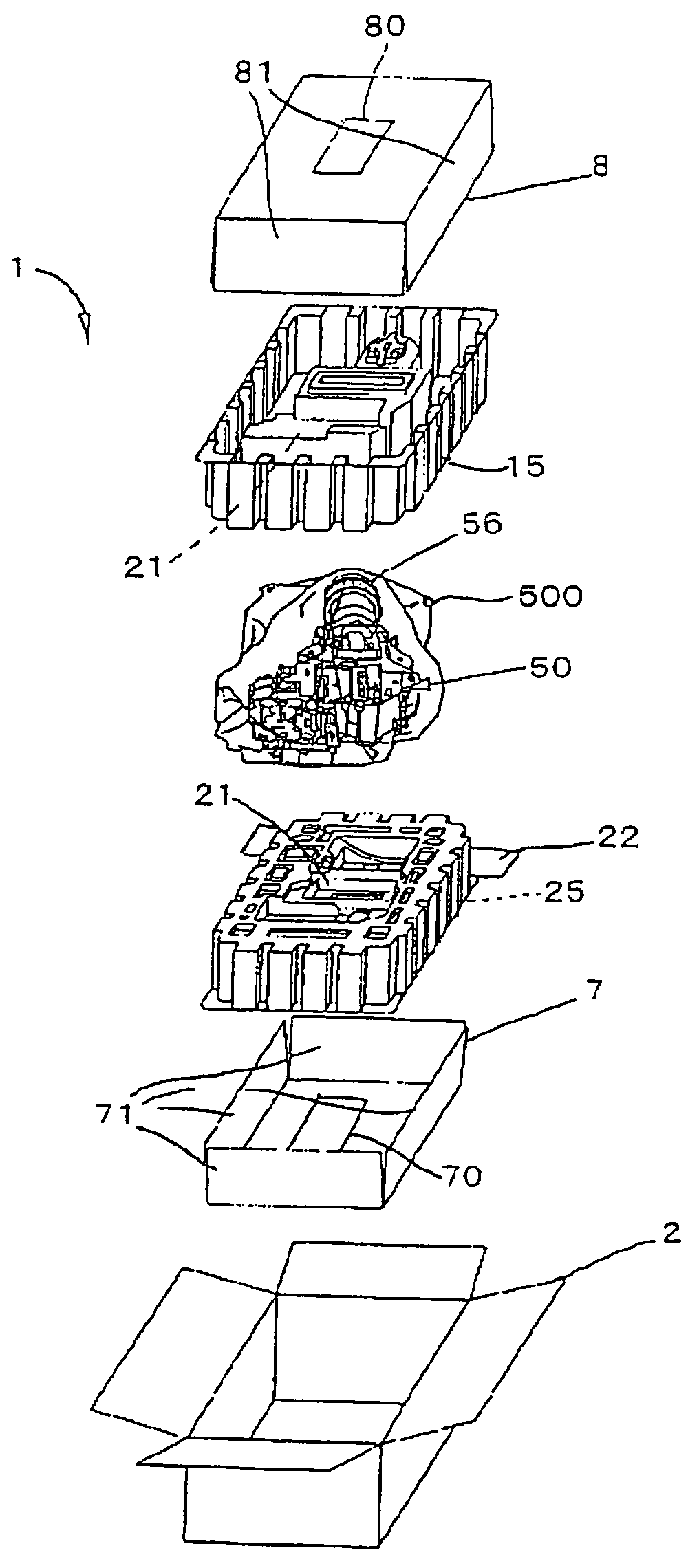

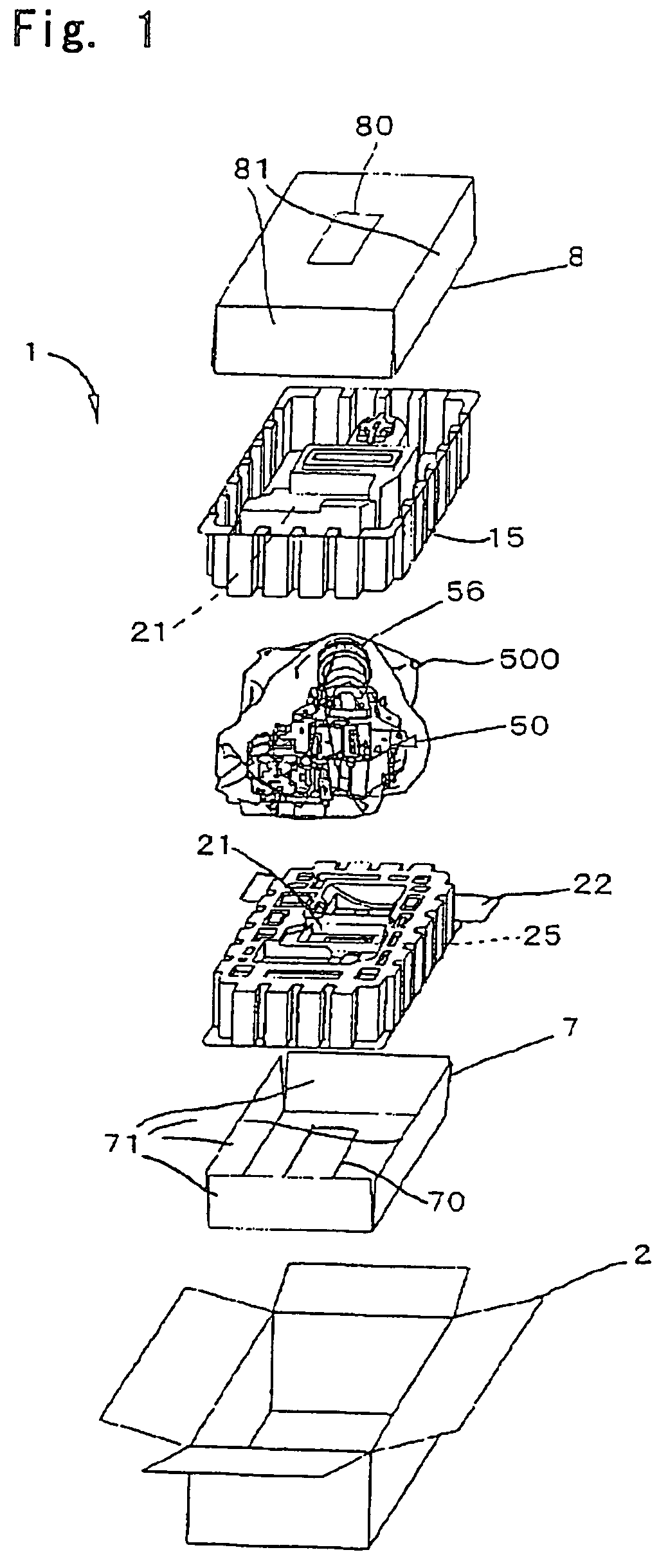

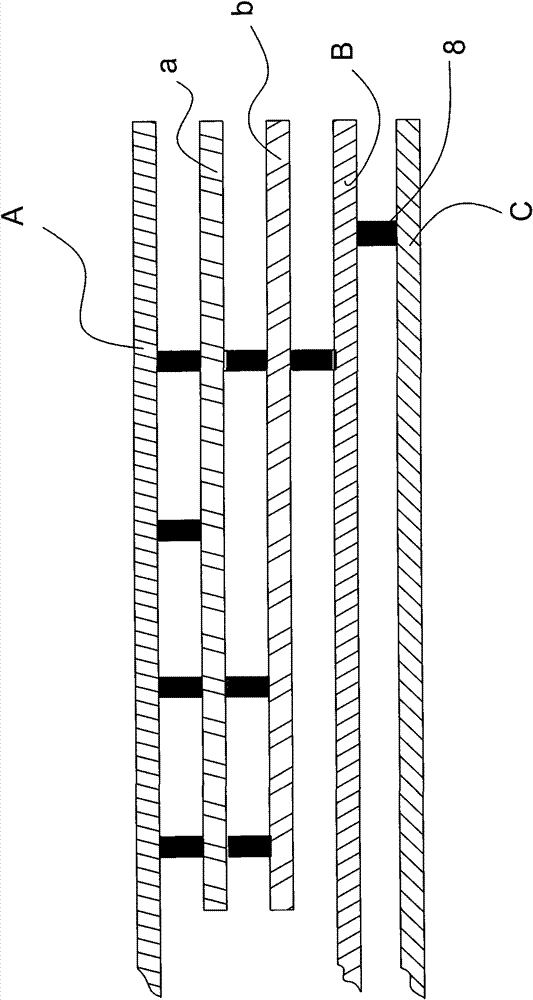

Cushioning material for packaging and packaging matter

InactiveUS7328800B2Improve protectionEasy to replaceContainers to prevent mechanical damageRigid containersCushioningAntistatic bag

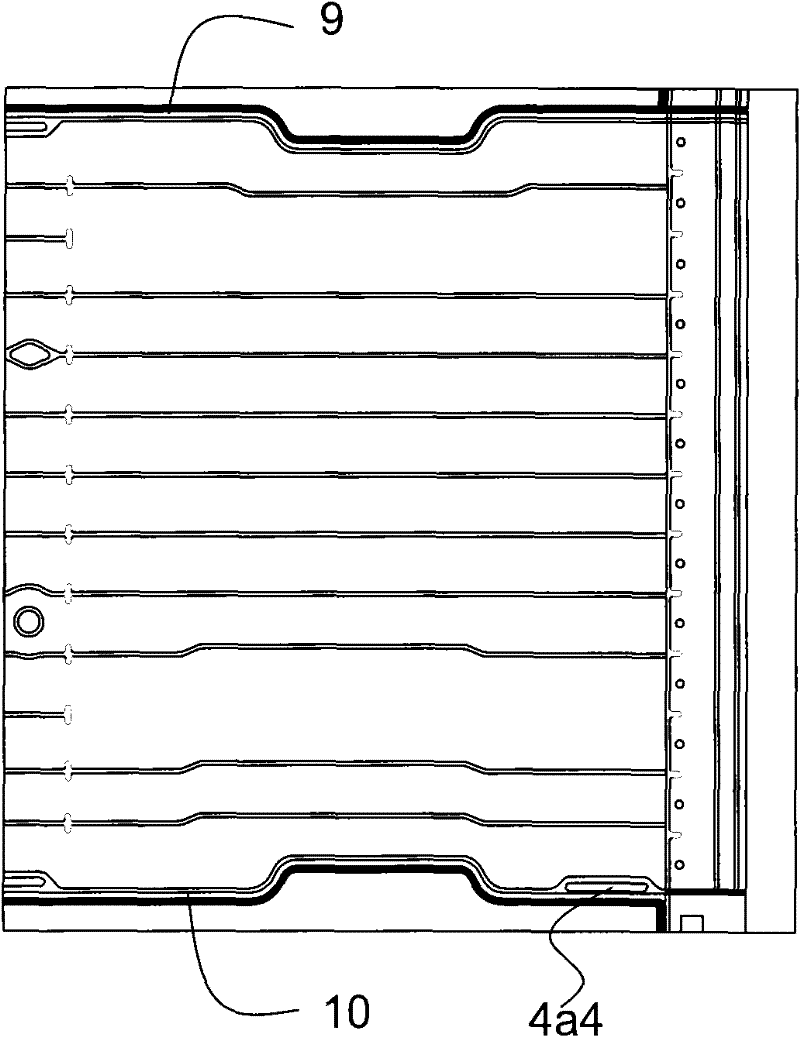

The invention provides a cushioning material for packaging that is suitable for packaging an electronic apparatus, an optical apparatus or an electronic apparatus having an optical system mounted therein, and a package that uses the cushioning material for packaging. In the invention, a lower spacer formed of corrugated cardboard, a lower pad, a projector as an article to be packaged that is wrapped in an anti-static bag having electrical conductivity, an upper pad and an upper spacer formed of a corrugated cardboard can be stacked inside a corrugated cardboard box. The upper and lower pads are, respectively, provided with a plurality of upper pad side hollow convex portions and a plurality of lower pad side hollow convex portions protruding in such a fashion as to encompass an accommodation space for the projector. Upper and lower side reinforcing plate portions of the upper and lower spacers, respectively, enter deep into these convex portions.

Owner:SEIKO EPSON CORP

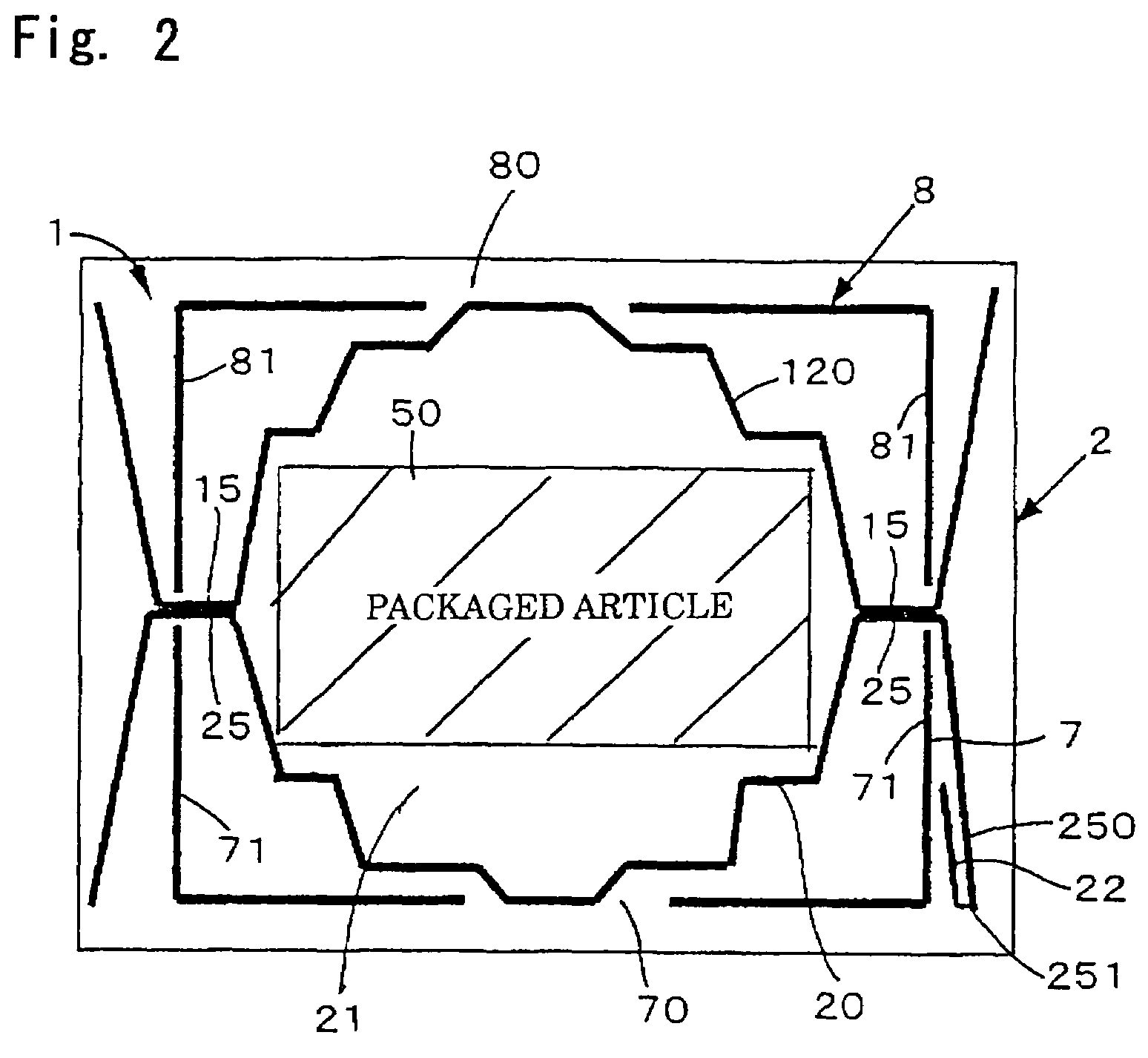

Method and apparatus for drying copolymer of methyl methacrylate-styrene-butadiene

InactiveCN1731057APrevent leakageReduce pollutionDrying solid materials with heatHearth type furnacesEngineeringMethacrylate methyl

The combined continuous airflow-cyclone MBS drying process includes drying wet MBS with hot air in a pulse drier to reduce water content to 10-15 %, making MBS enter to the cyclonic drier tangently in eddy flow mode to delay dry with hot water as heat source to water content of 0.5 %, and further processing in cyclonic separator and bag type dust collector. The operation conditions include air temperature of 125-130 deg.c, water temperature of 70-80 deg.c, average material residence time of 15-25 min, negative pressure operation and temperature in the cyclonic drier of 55-60 deg.c. The apparatus includes mainly screw conveyer, steam heat radiator to heat air, pulse drier, cyclonic drier, cyclonic separator, antistatic bag type dust collector, hot water tank, induced draft fan, etc. The present invention has high drying efficiency, low power consumption, and other advantages.

Owner:CNPC JILIN CHEM GROUP CORP

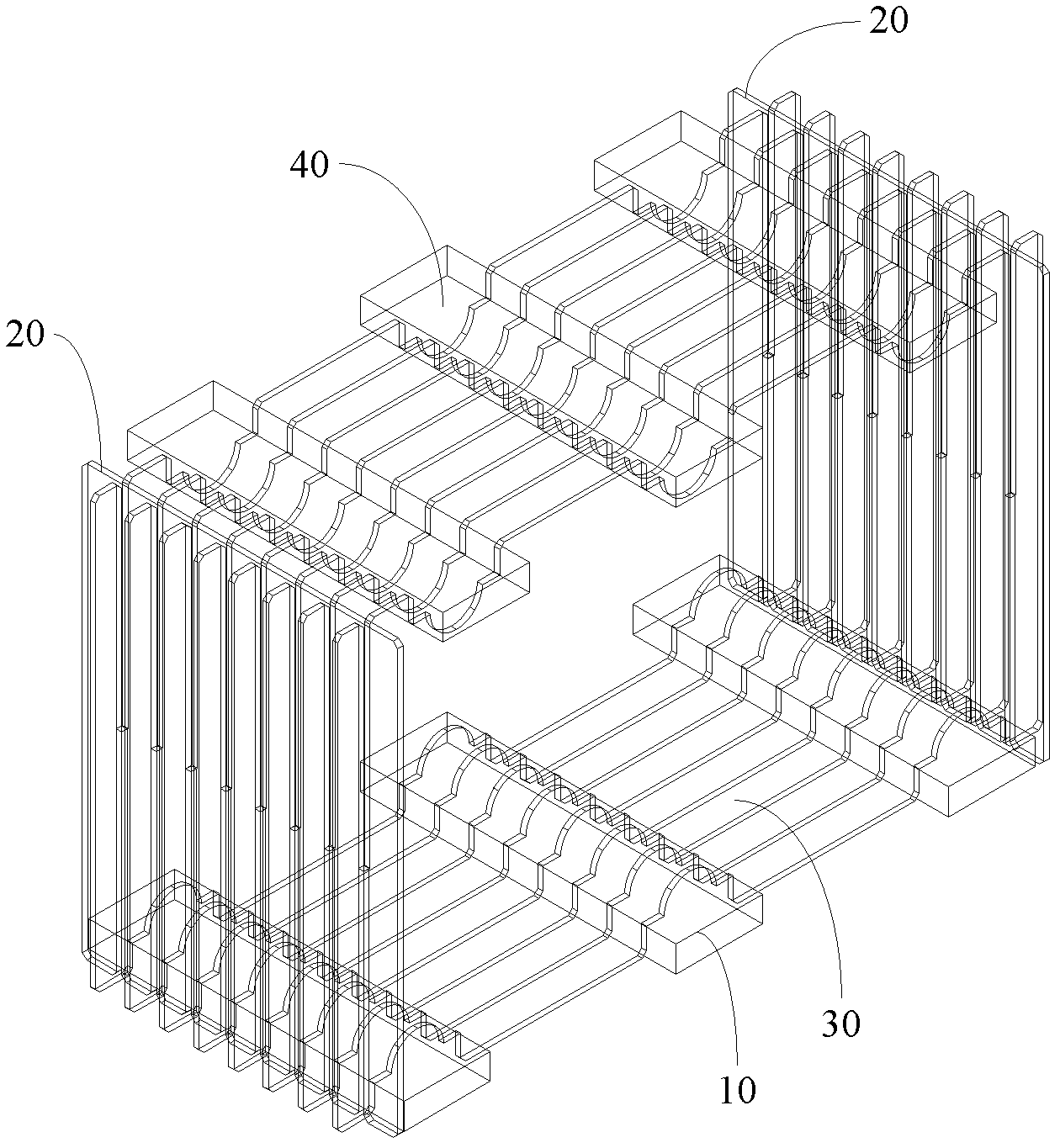

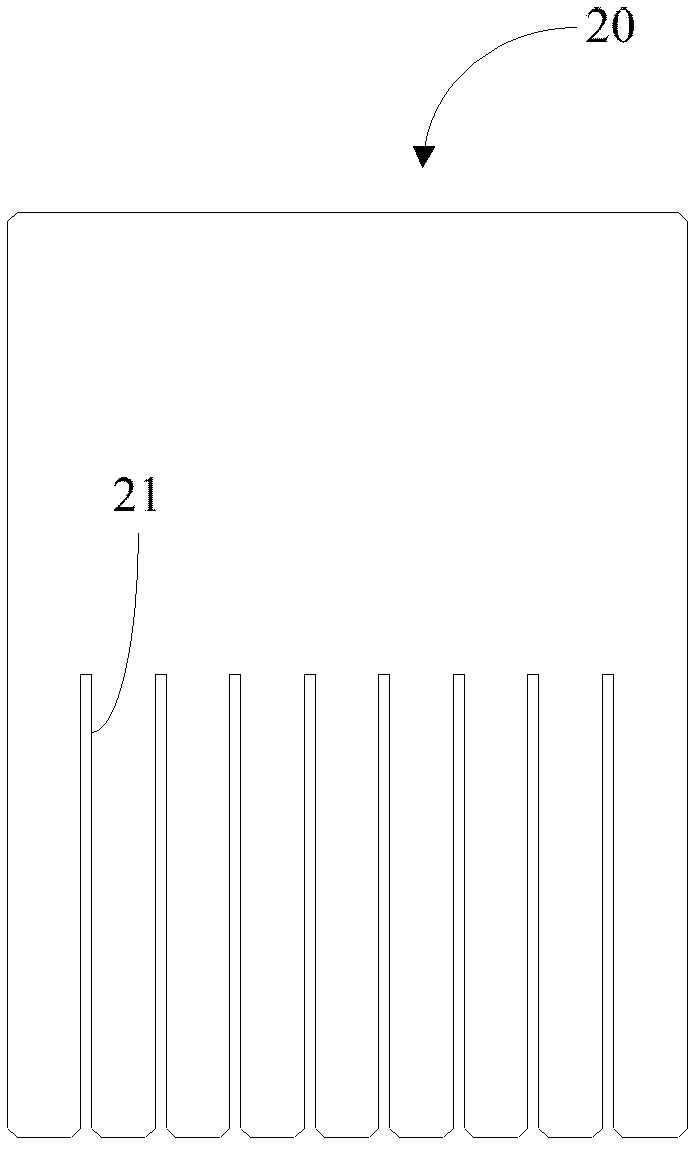

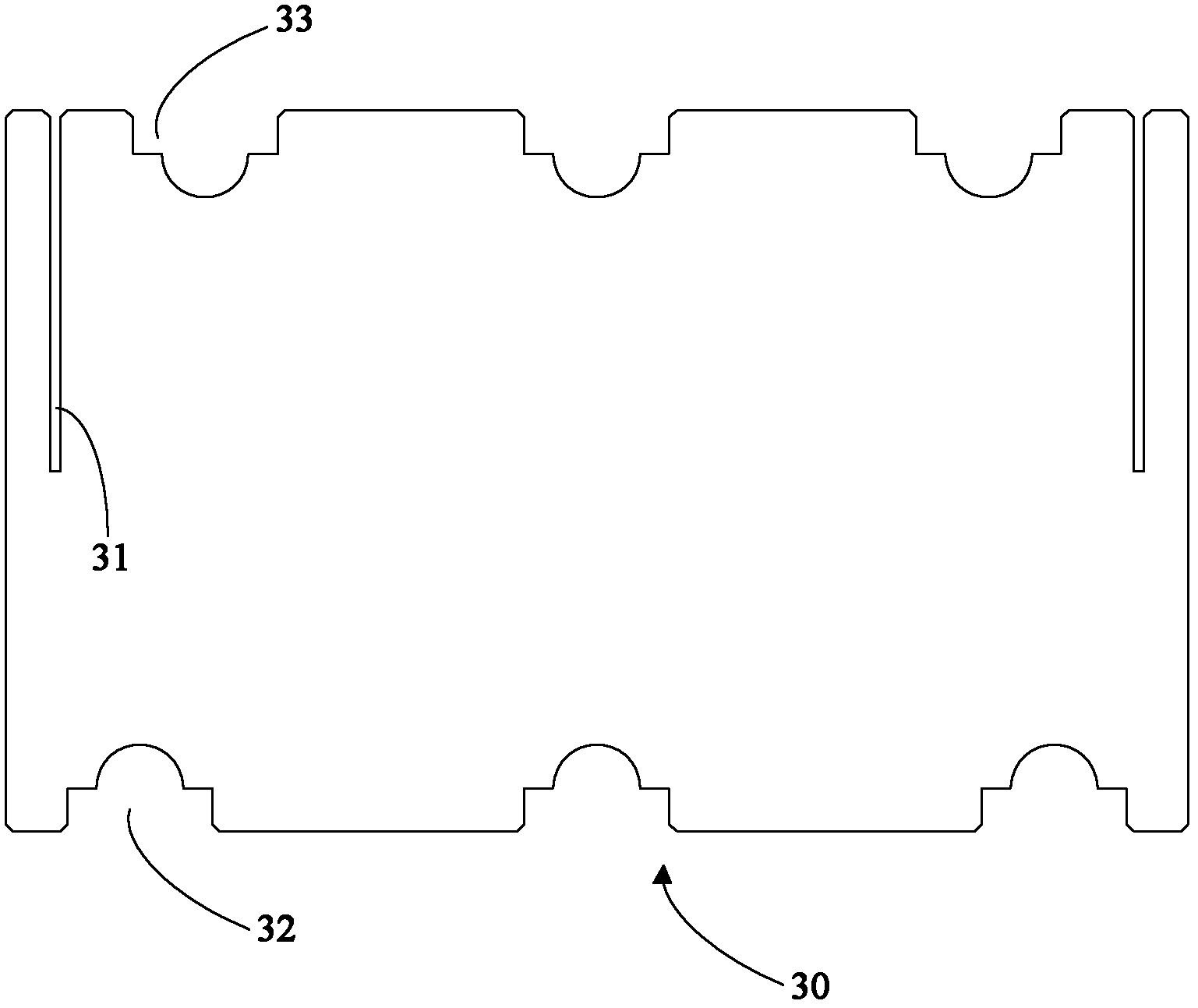

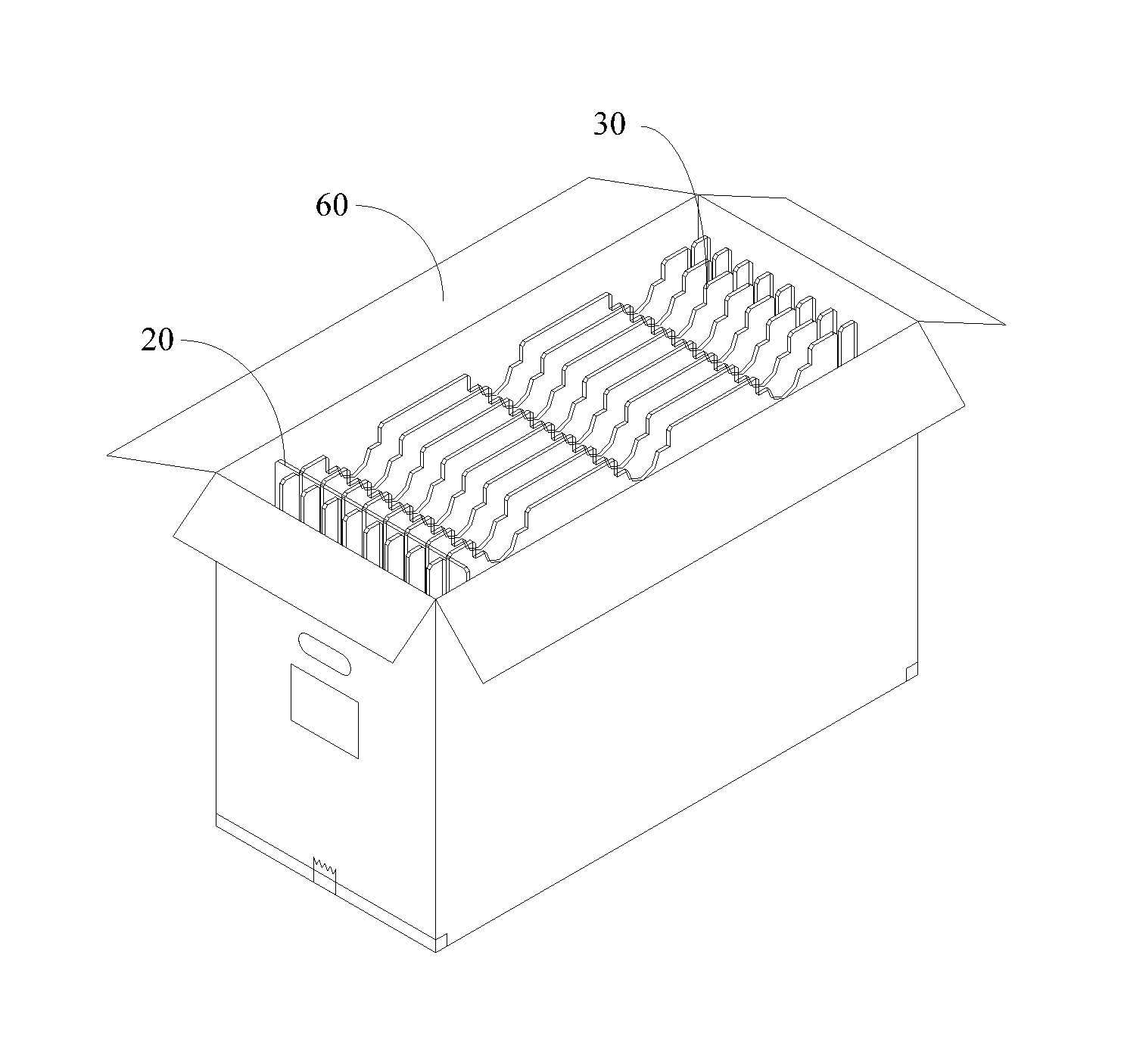

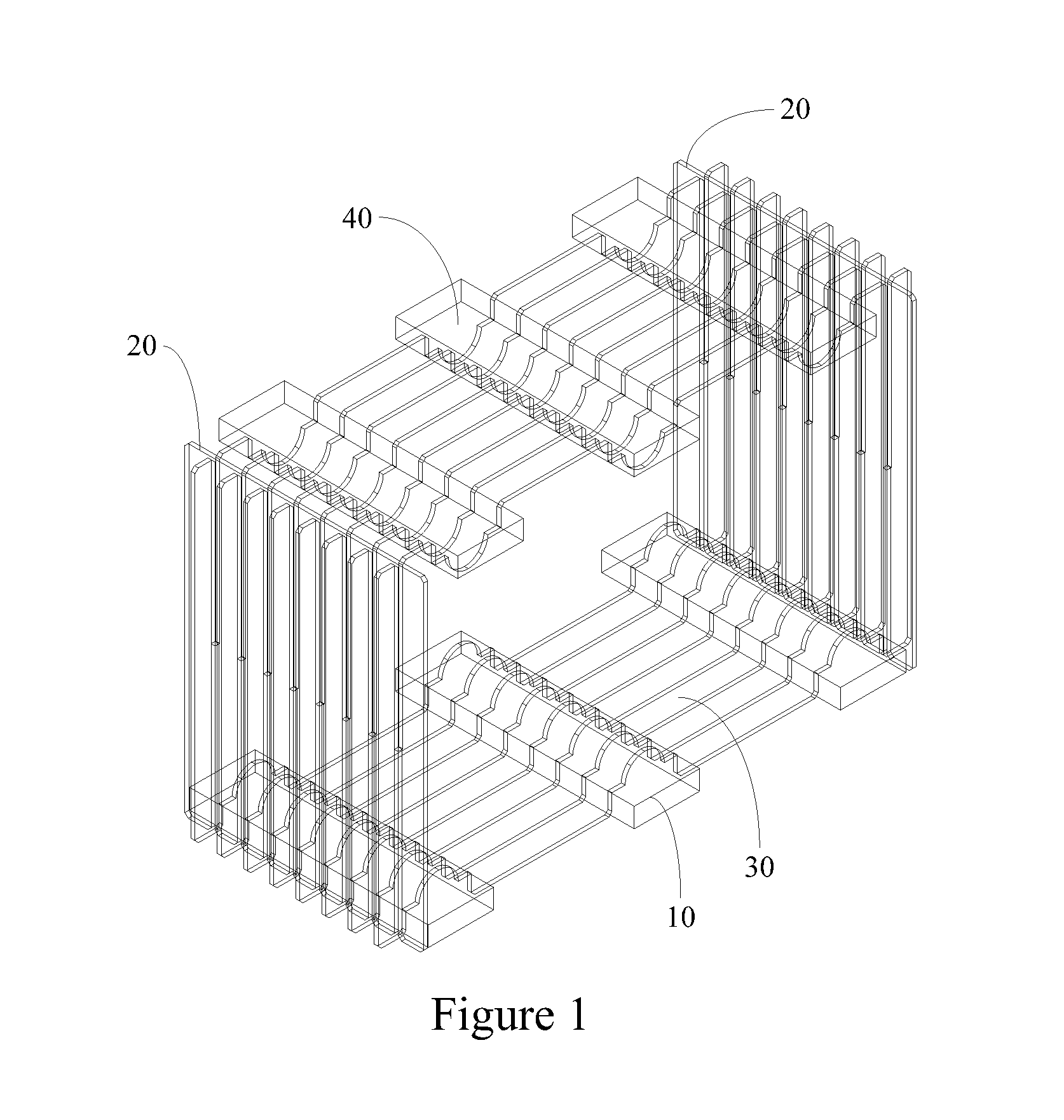

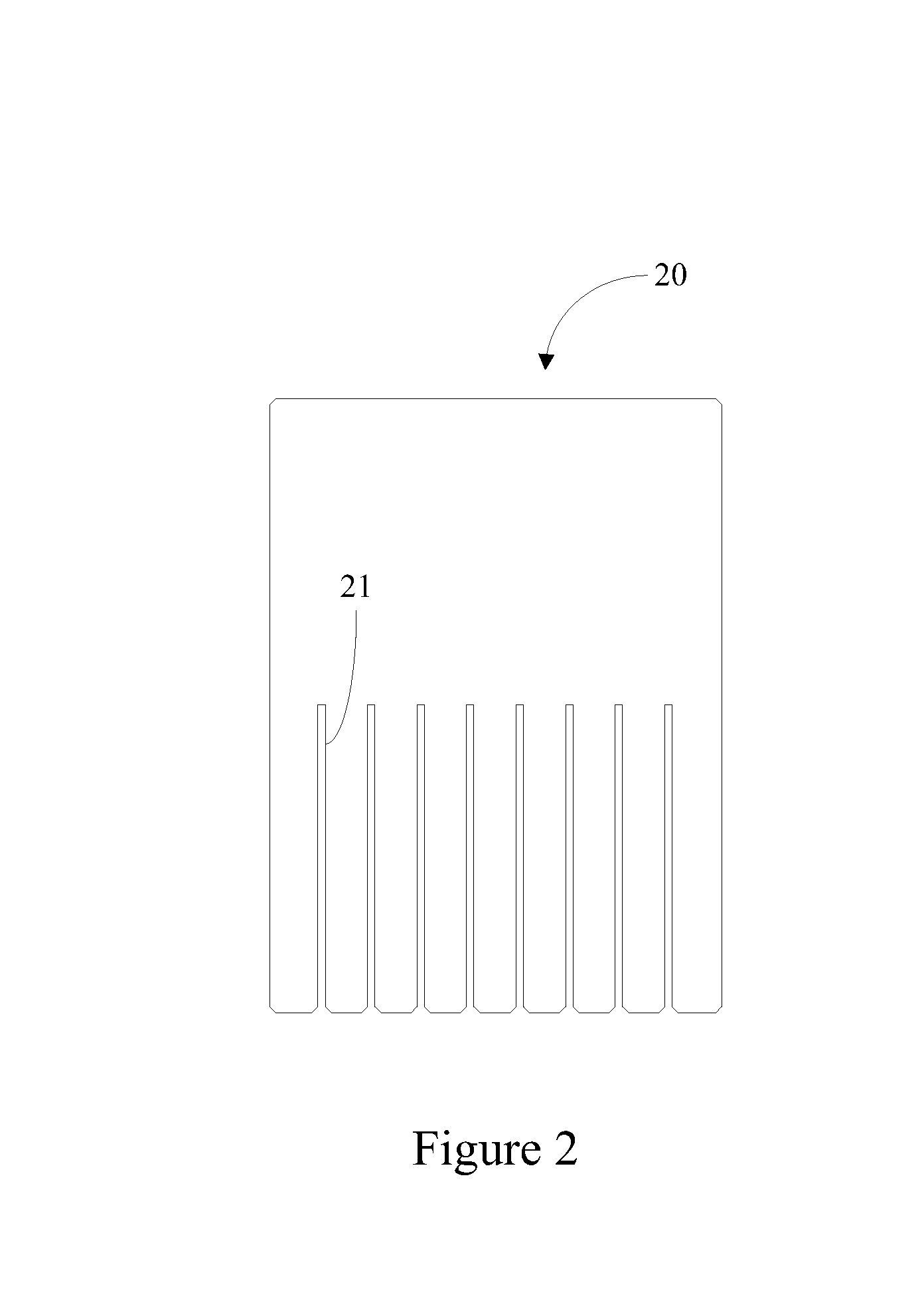

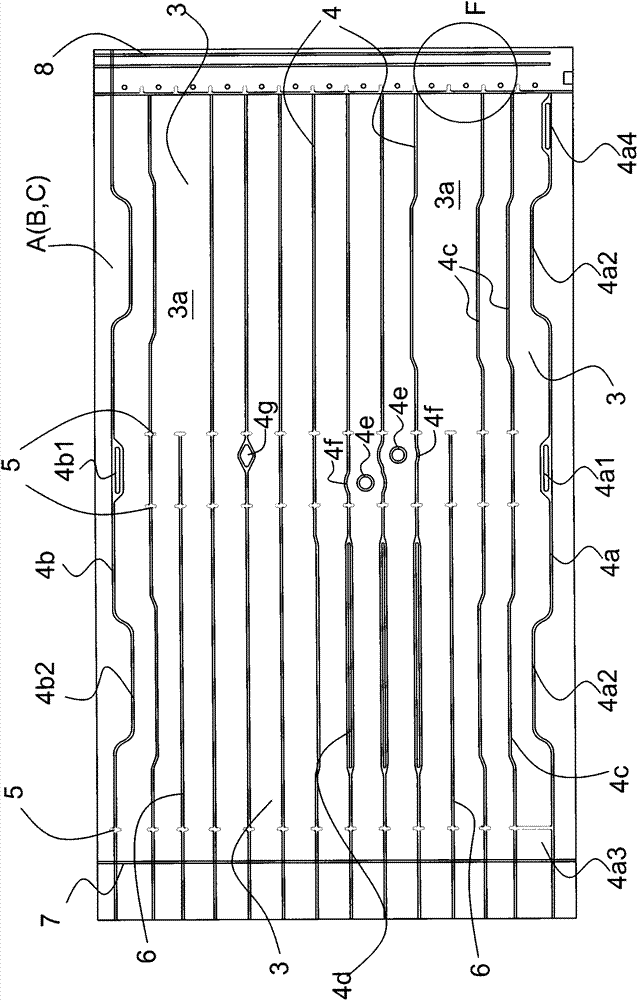

Package and packaging method of display module

InactiveCN102616463AOmit the anti-static bagLow costConnecting packagesContainers to prevent mechanical damageAntistatic bagEngineering

The invention discloses a package and a packaging method of a display module. The package comprises a pair of side baffles and a plurality of antistatic separating plates. Each side baffle is provided with a plurality of inserting grooves distributed at equal intervals. Both sides of each separating plate are respectively provided with an open groove. The open grooves and the inserting grooves adopt a cutter card mutual fastening mode to enable the plurality of separating plates to be arranged at intervals. The display module is placed in a gap formed by adjacent separating plates. By means of the mode, the package and the packaging method of the display module omit an antistatic bag. In addition, the package can be recycled time and time again, thereby being capable of saving cost and improving environmental protection performance.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Packaging device of display module and method for packaging

InactiveUS20130255189A1Reduce manufacturing costConnecting packagesOther accessoriesCardboardAntistatic bag

The present invention provides a packaging device and a method of packing the display module with the packaging device. The packaging comprises a pair of cardboards each defines a plurality of slots equidistantly arranged over each of the cardboard and extends upward from a lower edge thereof. A plurality of static-proof partitions are provided and each defines with a pair of grooves arranged adjacent to transversal ends thereof, and extends downward from a top edge thereof to interferentially interengaging with those equidistantly arranged slots of the cardboard to define a plurality of receiving compartments in which a display module can be disposed therein. By the provision of the packaging device of the present invention, the static-proof bag can be replaced by the cardboards and partitions. Specially, the cardboards and the partitions can be repeatedly used so as to reduce the manufacturing cost. Additionally, both the cardboards and partitions, the upper and bottom buffer stands are all made from environmental-friendly material.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

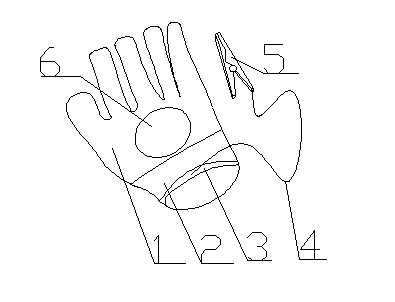

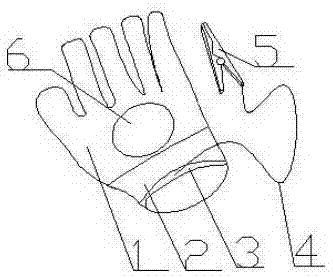

Antistatic gloves

InactiveCN103734946AAvoid it happening againAvoid accumulationProtective garmentAntistatic bagEngineering

The invention discloses a pair of antistatic gloves. The pair of antistatic gloves comprises glove main bodies, closing holes, adapter rings, discharging belts and clips, wherein openings are formed in the finger parts at the front ends of the glove main bodies; closing holes are formed in the rear sides of the glove main bodies; the adapter rings are arranged on the outer sides of the closing holes; the adapter rings are connected with the discharging belts; the clips are arranged at the ends of the discharging belts. By virtue of the manner, the pair of antistatic gloves is high in reliability, comfortable to wear, free from influence to fingers, excellent in the discharging performance, capable of keeping touch with a human body, and low in price, and has a wide market prospect in the antistatic product market.

Owner:TAICANG MINGJING TEXTILE

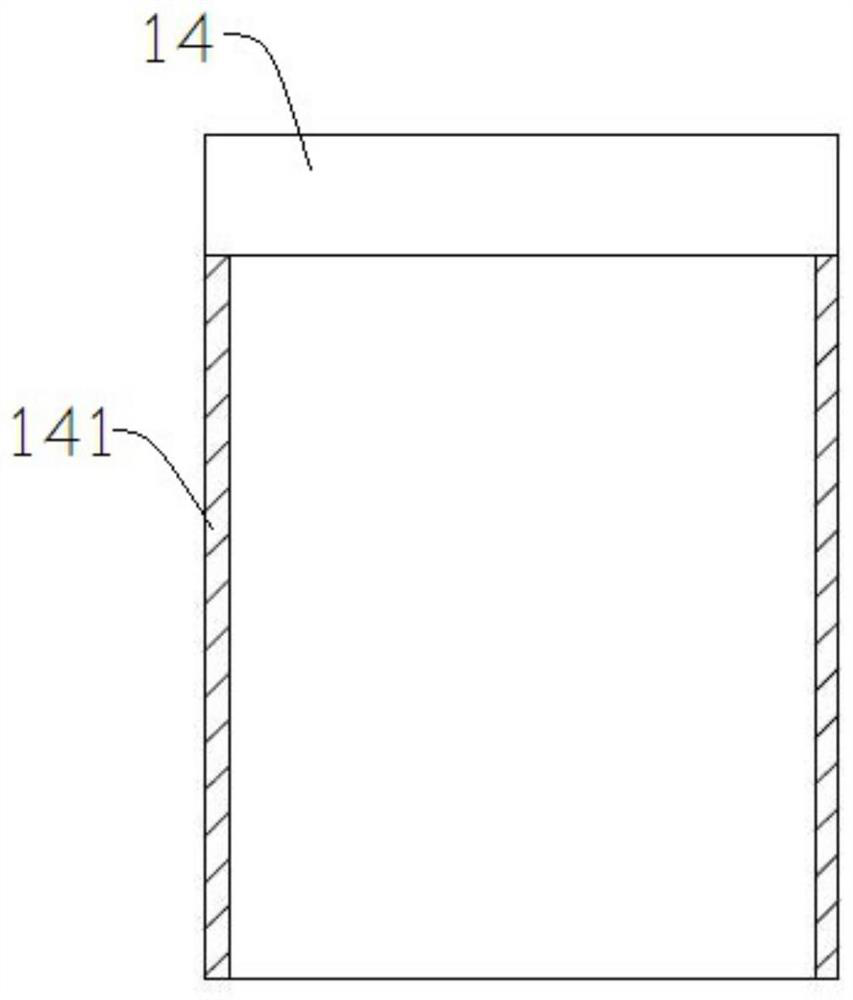

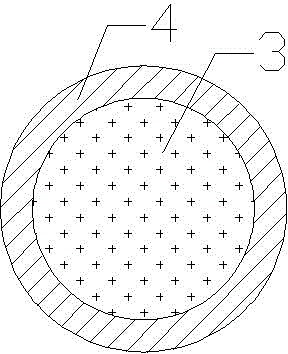

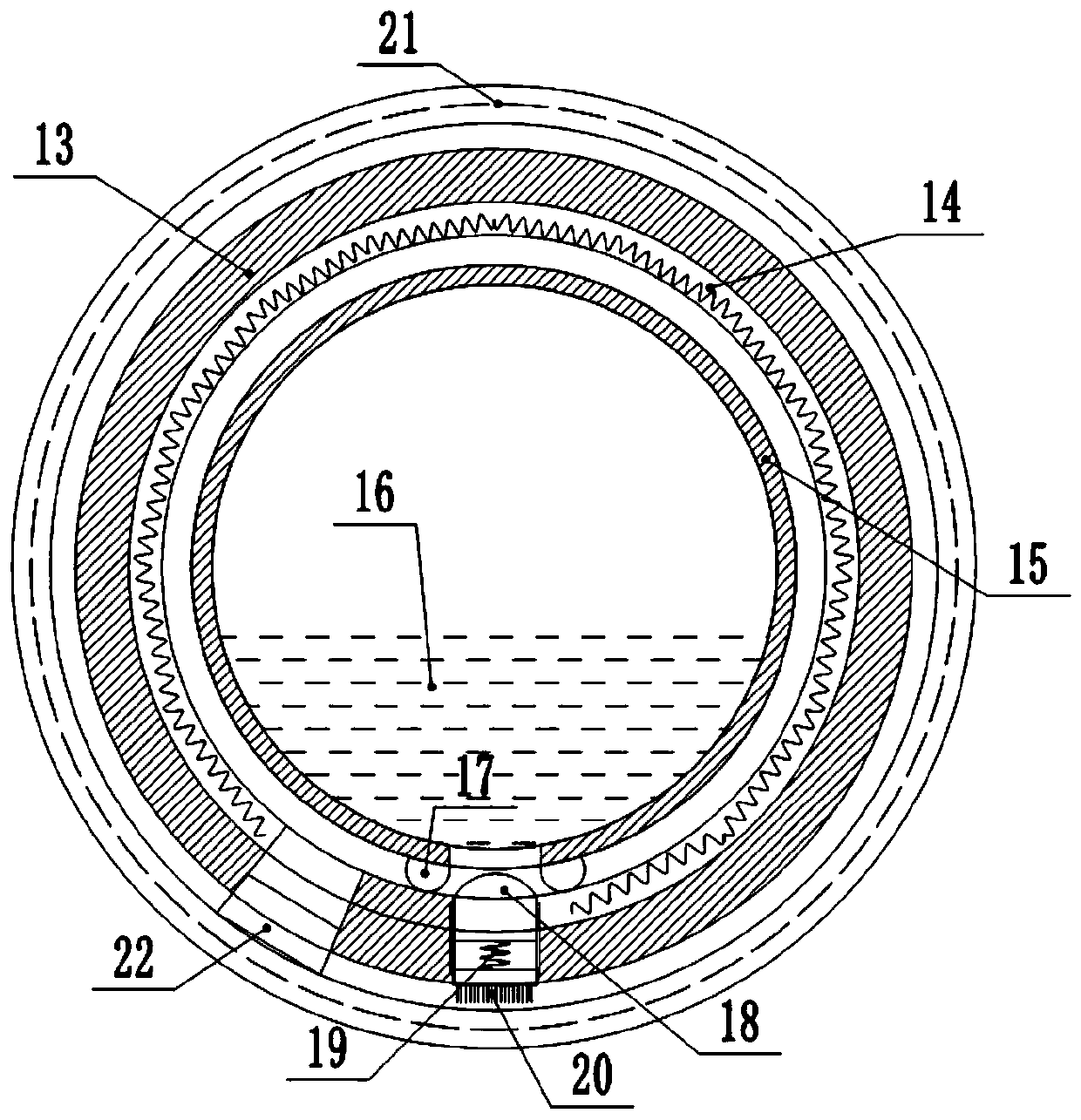

Cloth bag for anti-static bag type dust collector

The invention provides a cloth bag for an anti-static bag type dust collector. The cloth bag comprises an internal skeleton, a filter material layer wrapping the skeleton and a covering film covering the outer surface of the filter material layer, wherein the filter material layer is a combination fabric of polyamide fabrics, aramid fibers and anti-static carbon fibers; the covering film is a polytetrafluoroethylene microporous film. The cloth bag for anti-static bag type dust collector provided by the invention can be used for collecting dust in a static environment and preventing explosion.

Owner:HAIAN TIANPENG MACHINERY MFG

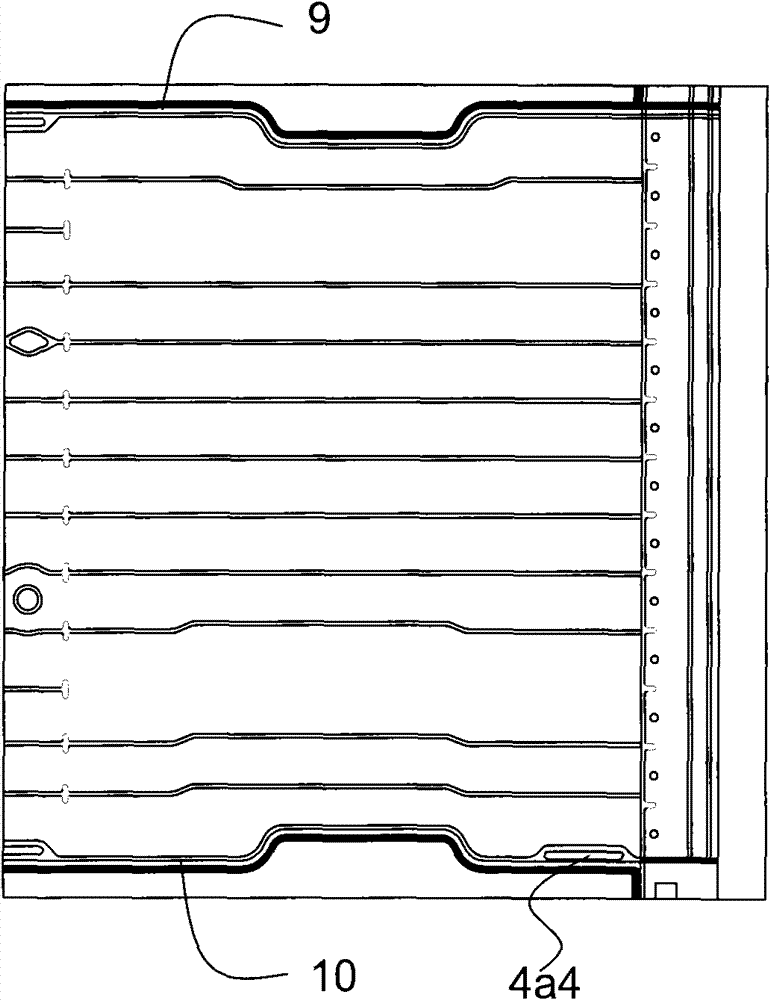

Three-layer air packing device and production method thereof

ActiveCN102233981AImprove reliabilitySave packing timePaper-makingBox making operationsAntistatic bagMain channel

The invention discloses a three-layer air packing device. Two rectangular thermoplastic films are subjected to secondary hot laminating to form a three-dimensional packaging body which is provided with an opening and can seal air; the three-dimensional packaging body comprises a plurality of independent sealed air chambers and a main channel; the main channel is provided with an air inlet; each sealed air chamber is communicated with the main channel through a one-way valve consisting of a one-way valve film; the inner side of the three-dimensional packaging body is provided with an inner bag; and the inner bag is formed by fixing four sides of a rectangular lightproof and / or antistatic thermoplastic film on the four sides of the rectangular thermoplastic film on the inner side of the outside three-dimensional packaging body. By the packing device, the consumption of lightproof or antistatic bags for packaging objects to be packaged is reduced, a procedure of sleeving the lightproof or antistatic bag is eliminated, the packaging time is greatly shortened, and possible accidents in the packaging process are further reduced, so that the cost is saved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Antistatic weaving bag

InactiveCN104590670AImprove flame retardant performanceReduced tensile strengthBagsSacksAntistatic bagEngineering

The invention relates to the field of packaging, in particular to an antistatic weaving bag. The antistatic weaving bag is made of a PVC material, and the upper surface and the lower surface of the weaving bag are each provided with an antistatic layer; and a light-emitting layer is arranged on the antistatic layers and is a fluorescent powder layer. The antistatic weaving bag has the beneficial effects that the antistatic layers are arranged on the surfaces of the weaving bag made of the PVC material, so that the requirement of the bag for the antistatic performance is met; the manufacturing process is simple, the manufacturing cost is low, the antistatic performance of the surfaces is stable, and the excellent fire resistance of the PVC material is not affected; and the tensile strength and the piercing-prevention capability of the weaving bag are not reduced. The fluorescent powder layer is arranged on the antistatic layers, and can emit light in the dark environment, and great convenience is brought to seeking.

Owner:CHANGZHOU DONGHUA PACKAGING MATERIAL

Antistatic breathable fabric

InactiveCN107512048ASimple structureReasonable structureSynthetic resin layered productsClothingsAntistatic bagNitrate

The invention discloses an antistatic breathable fabric. The antistatic breathable fabric comprises a base layer, an antistatic layer and a breathable layer, wherein the antistatic layer is arranged on the base layer; the breathable layer is arranged under the base layer; and the base layer comprises the following components in parts by weight: 20-50 parts of rabbit hair, 10-30 parts of rabbit wool, 3-12 parts of polyacrylonitrile fiber, 1-5 parts of iron nitrate, 2-12 parts of polyester resin, 3-5 parts of ammonium persulfate and 2-10 parts of polyurethane. The antistatic breathable fabric disclosed by the invention is simple and reasonable in structure, easy to implement, favorable in softness, fine in comfort and excellent in fluffiness and flexibility; and the fabric has the advantages of favorable wrinkle resistance, low water shrinkage, favorable wearability and the like.

Owner:SUZHOU JINGCUN GARMENT CO LTD

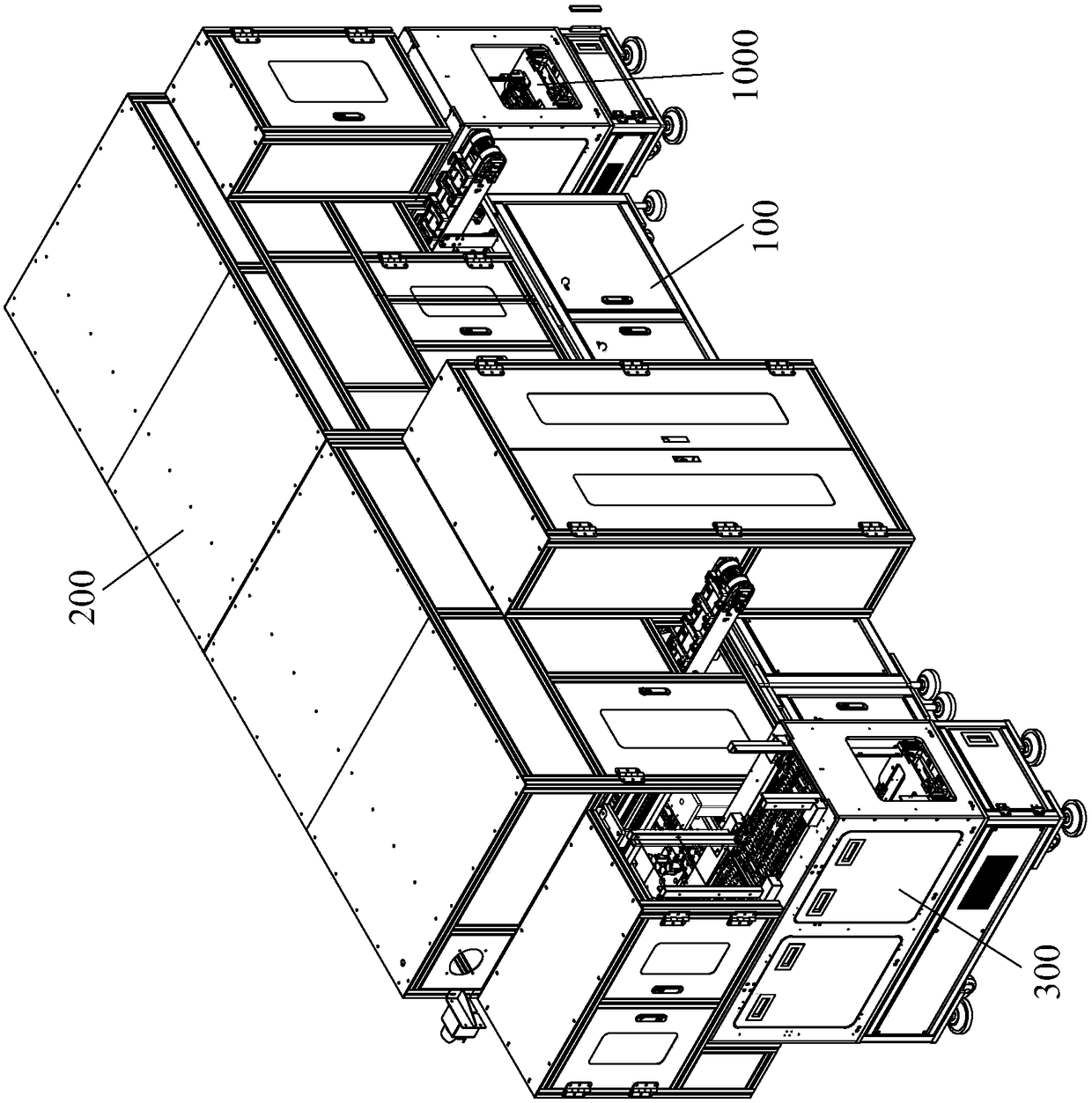

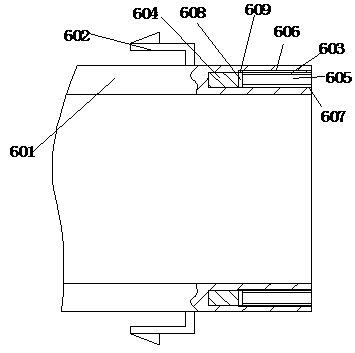

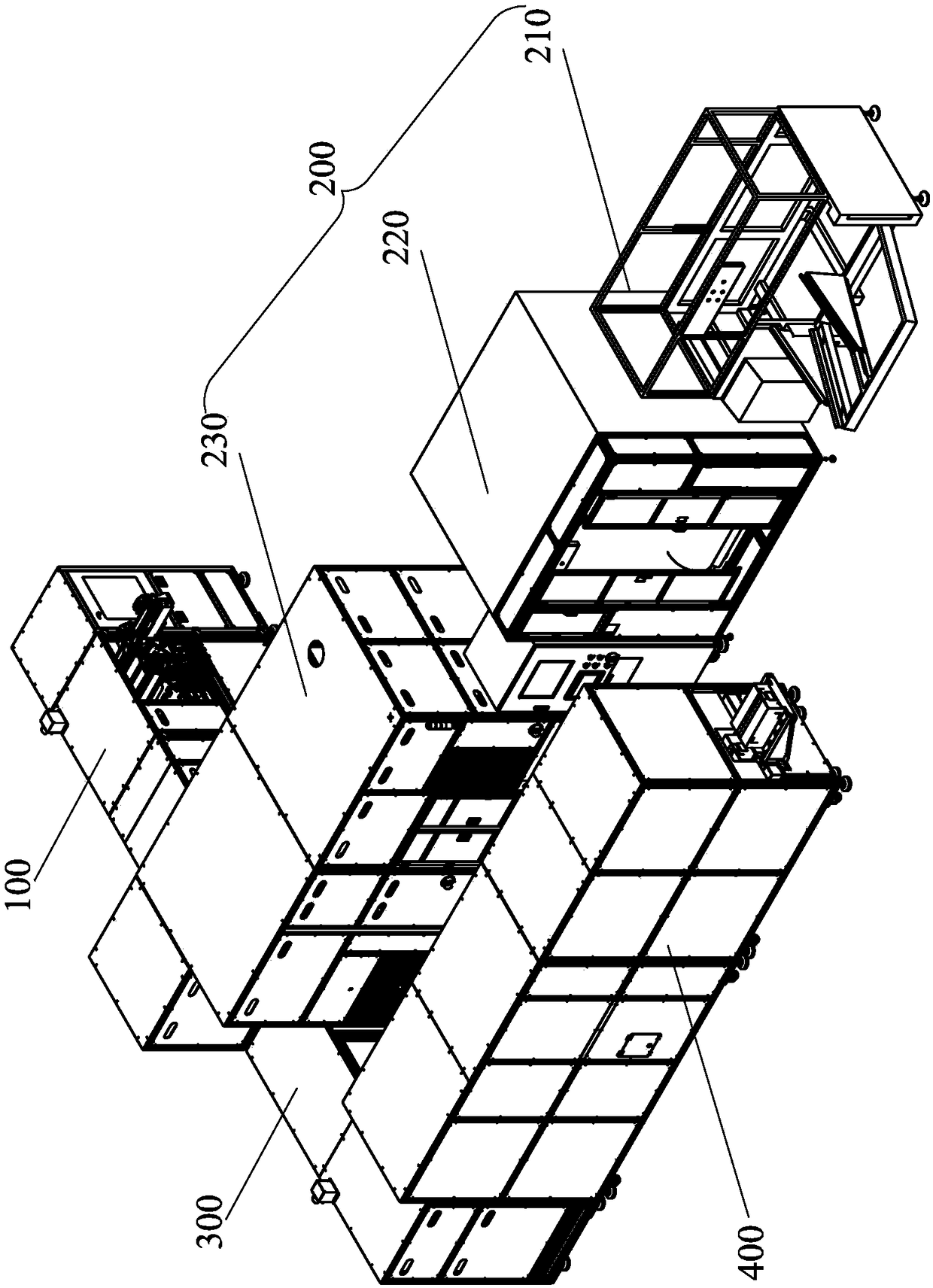

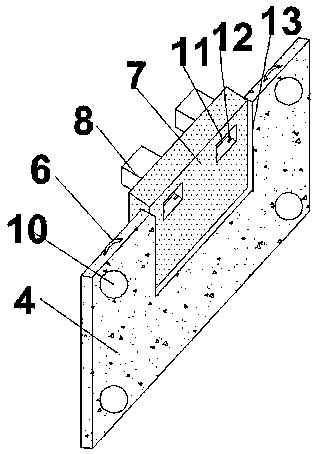

Antistatic bag encapsulating device

PendingCN108423249AAvoid bumpingReplace operationWrapper twisting/gatheringSolid-stateAntistatic bag

The invention discloses an antistatic bag encapsulating device for assembling an antistatic bag to a solid-state hard disk. The antistatic bag encapsulating device comprises an antistatic bag baggingmechanism, wherein the antistatic bag bagging mechanism comprises an antistatic bag positioning unit for positioning an antistatic bag mouth, a bag inlet unit for pushing the solid-state hard disk directly facing the antistatic bag mouth into the antistatic bag, and a cutting unit for cutting the antistatic bag after the solid-state hard disk enters the antistatic bag. According to the antistaticbag encapsulating device provided by the invention, the manual operation of assembling the solid-state hard disk with the antistatic bag can be effectively replaced, thereby effectively avoiding the collision and damage of the solid-state hard disk caused by the manual operation and improving the production efficiency at the same time.

Owner:DONGGUAN WORLD PRECISION MACHINERY

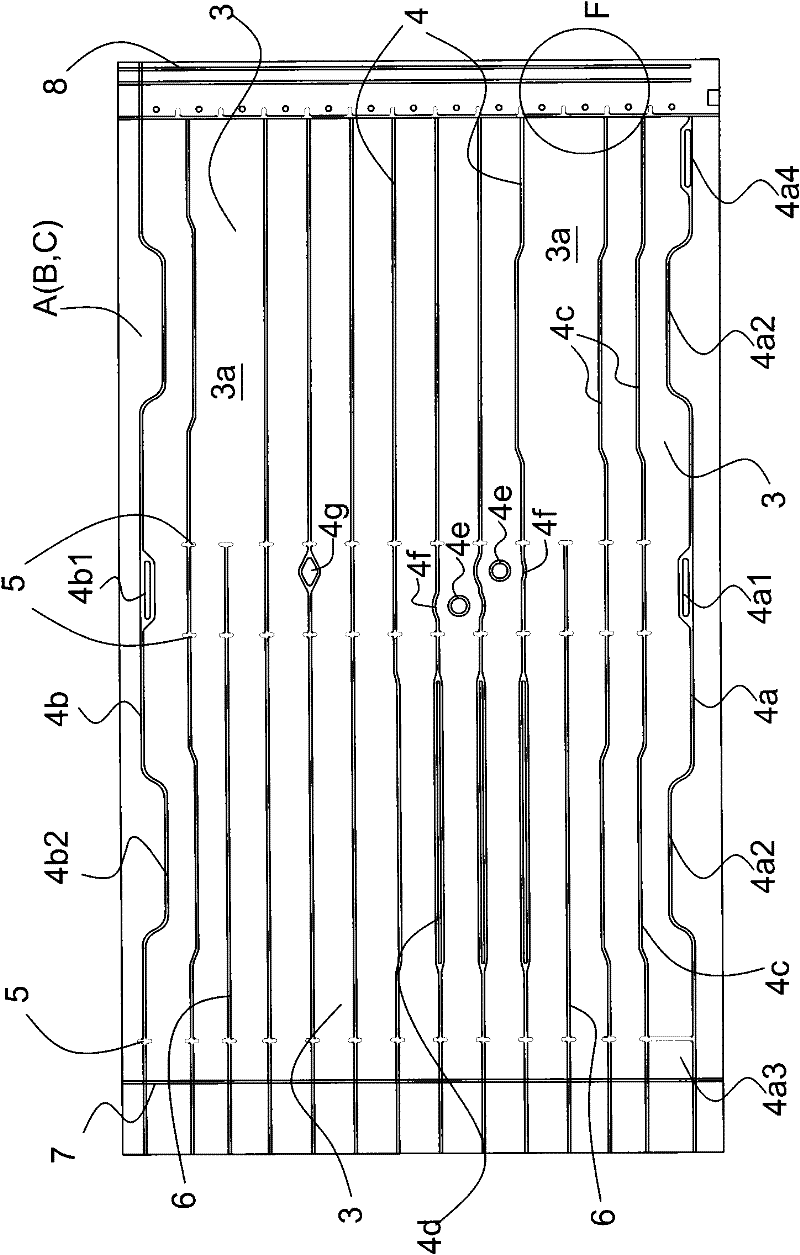

Antistatic, heat-insulated, deodorant and breathable fabric

InactiveCN104249526AImprove securityImprove performanceSynthetic resin layered productsAntistatic bagDeodorant

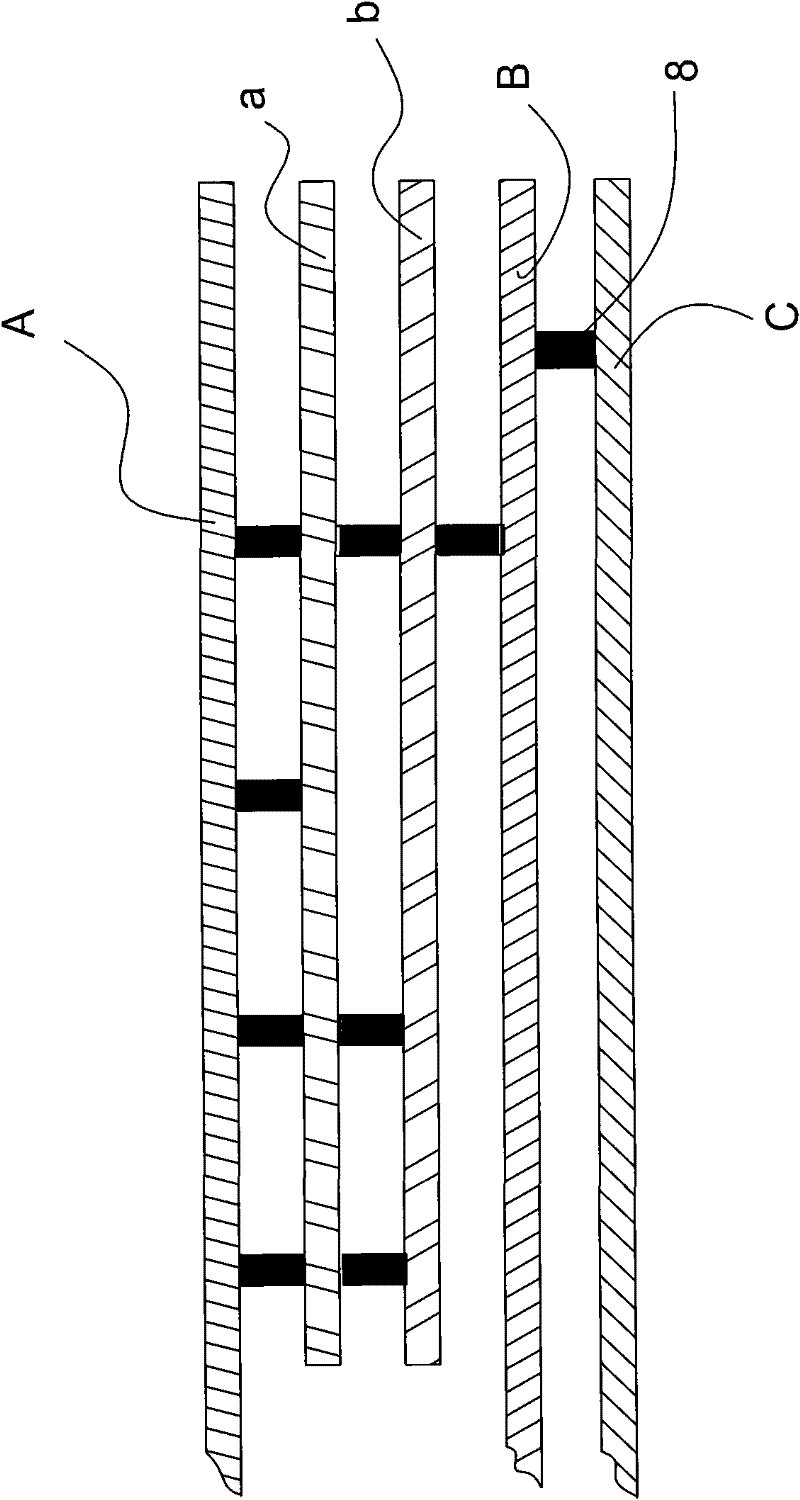

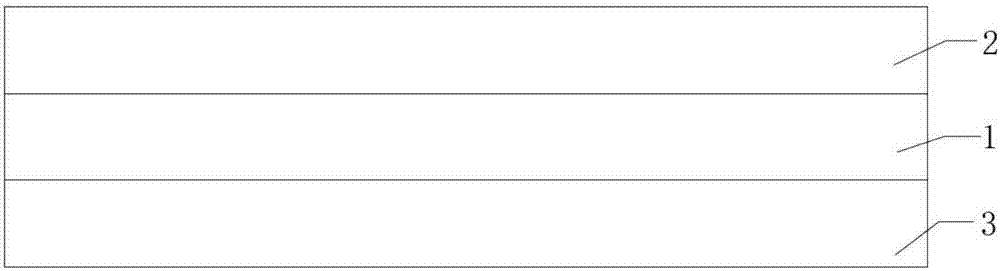

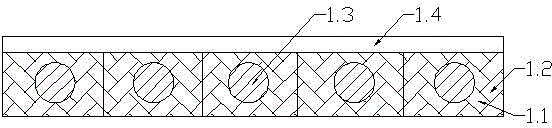

The invention relates to antistatic, heat-insulated, deodorant and breathable fabric. The antistatic, heat-insulated, deodorant and breathable fabric comprises a basal layer (1), wherein an antistatic layer (2) is arranged on the surface of the basal layer (1); the antistatic layer (2) is formed by mutually weaving warp yarns and weft yarns; the warp yarns are cotton yarns; the weft yarns are formed by conductive fibers; the conductive fibers are striped, with intervals of 5-10 mm; the basal layer is made of fabric; the fabric is formed by compound base cloth, a polytetrafluoroethylene film and a bamboo charcoal anionic PU (polyurethane) film; the polytetrafluoroethylene film and the bamboo charcoal anionic PU film are sequentially adhered to one side surface of the base cloth. The antistatic, heat-insulated, deodorant and breathable fabric has very good antistatic property, so that the safety of the antistatic, heat-insulated, deodorant and breathable fabric is improved; the antistatic, heat-insulated, deodorant and breathable fabric has multiple functions of water resistance, moisture permeability, heat insulation, deodorization, bacterial resistance and the like.

Owner:JIANGYIN TIANCHENG TEXTILE

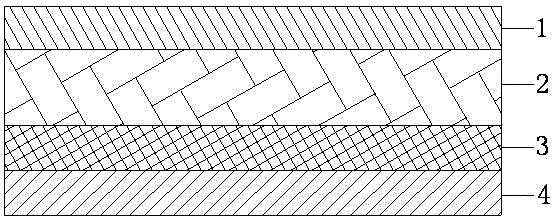

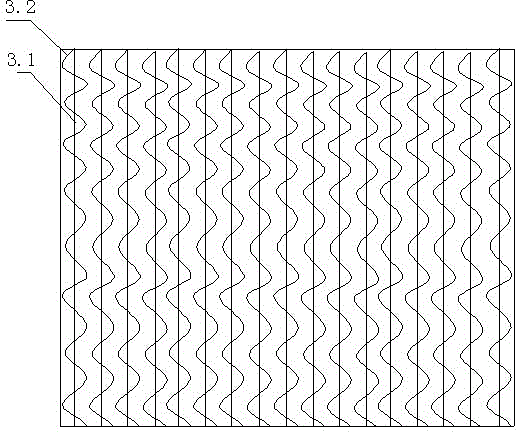

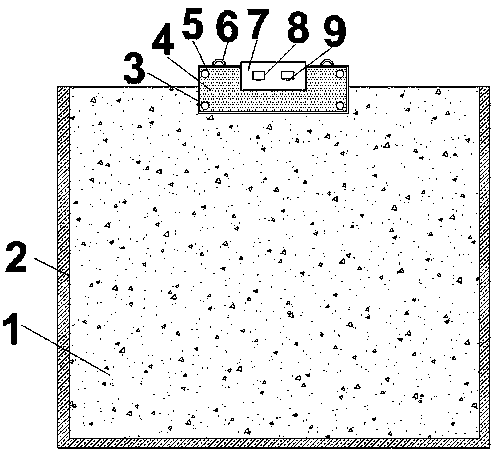

Antifouling breathable velvet fabric

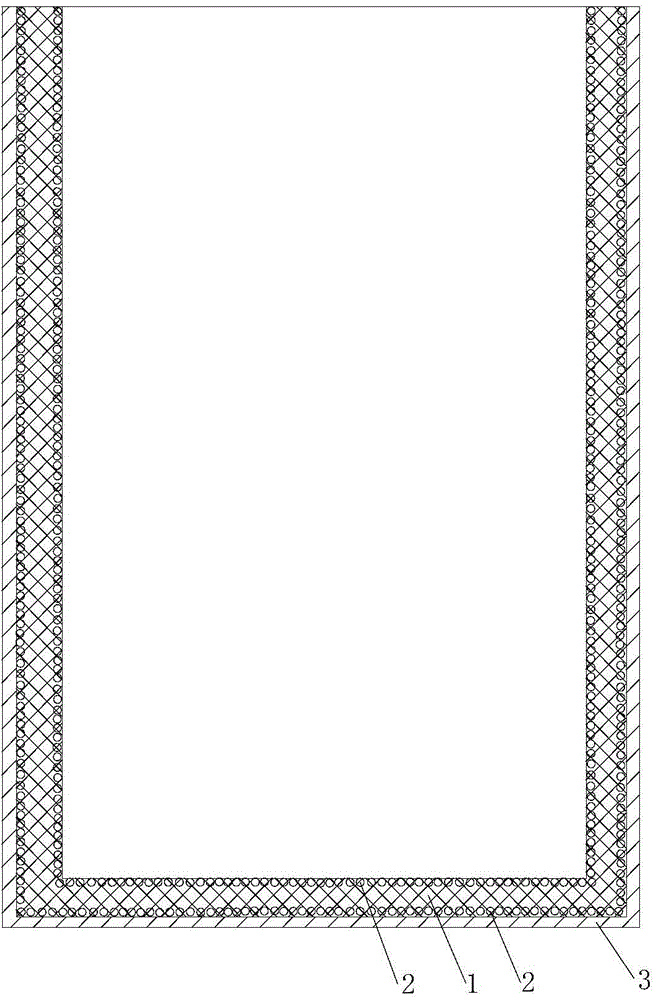

The invention relates to an antifouling breathable velvet fabric. The fabric comprises velvet cloth (1). A sponge layer (2) is arranged below the velvet cloth (1). An antistatic layer (3) is arranged below the sponge layer (2). The antistatic layer (3) is prepared with core-spun fiber. The fiber comprises yarn (3.1) and metal filament (3.2). The metal filament (3.2) is wound on the yarn (3.1). A base layer (4) is arranged below the antistatic layer (3). The base layer is prepared with textile. A fluorine monomer aqueous polyurethane coating layer is coated on the surface of the textile. The fabric provided by the invention has an elegant shade, and is luxuriant, firm, and wear-resistant. The fabric is not prone to deformation. The fabric is rich in elasticity. The fabric can absorb moisture, and is breathable. The fabric is antifouling and breathable.

Owner:李士清

Antistatic bag shining under illumination and having high bag belt strength

The invention relates to an antistatic bag that shines when exposed to light and has high tape strength. It includes a bag body. The belt is composed of the first wrapping tape, the second wrapping tape and the third wrapping tape which are wound alternately. The invention is an antistatic bag that shines when exposed to light and has high tape strength. The surface of the bag body is closely arranged with a plurality of beads, so the surface of the bag body will shine when it is illuminated, which satisfies some pursuits of being different, The needs of unconventional young people, and the strap is composed of the first strap, the second strap and the third strap interlaced, so the strap has high strength and is convenient for people to use.

Owner:翟文卓

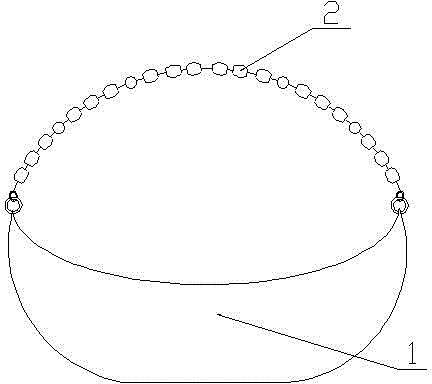

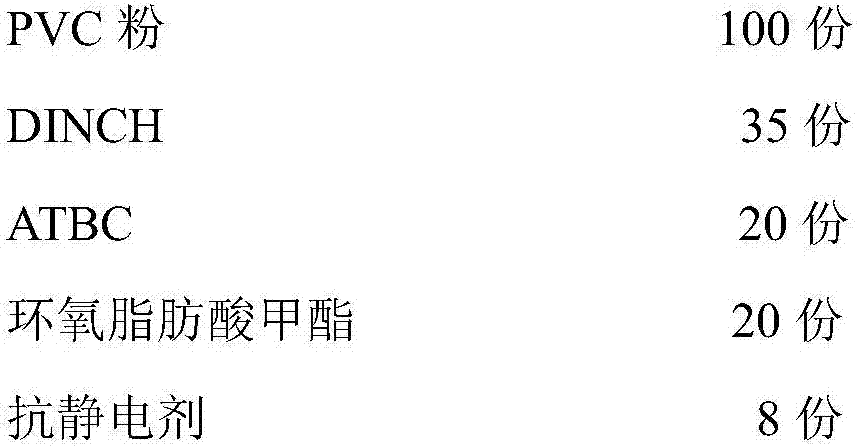

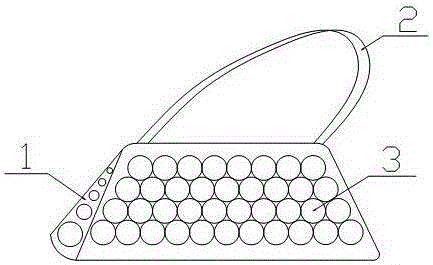

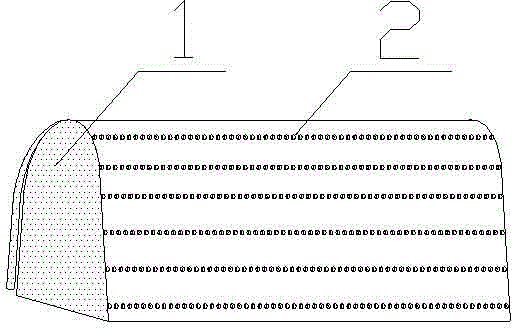

Antistatic bag with good hand feeling

The invention relates to a bag, in particular to an antistatic bag with good hand feeling. The bag comprises a bag body (1), wherein the bag body (1) is crescent-shaped, and a bag belt (2) is a bead chain consisting of spherical beads and elliptical beads. According to the antistatic bag with good hand feeling disclosed by the invention, due to the fact that the bag belt is the bead chain consisting of the spherical beads and the elliptical beads, people have relatively good hand feeling during handling, and the requirement of people is met.

Owner:刘正华

Slip-proof antistatic bag in which articles are easy to take out

InactiveCN107198310AEasy accessIncrease coefficient of frictionHandbagsLuggageAntistatic bagEngineering

The invention relates to an antistatic bag that is not easy to slip off and is easy to take items, comprising a bag body, the bag body is a rectangular bag body, and is characterized in that: the outer surface of the bag body is horizontally arranged with a plurality of bead strings in parallel and a bag buckle is arranged on the side edge of the opening of the bag body. The invention is an anti-static bag that is not easy to slip off and is easy to take items. The outer surface of the bag body is provided with a plurality of bead strings in parallel horizontally, so the friction coefficient of the outer surface of the bag is increased, and it is not easy for people to slip off when taking the bag. , the side of the opening of the bag body is provided with a bag buckle, so it is convenient for people to take items and meets people's needs.

Owner:翟文卓

Antistatic gloves

InactiveCN106858841AAvoid it happening againAvoid accumulationProtective garmentAntistatic bagElectrical and Electronics engineering

The invention discloses an anti-static glove, comprising: a glove body, a closure, a connecting ring, a discharge belt and a clip, an opening is arranged at the front finger of the glove body, a closure is arranged at the back of the glove body, and a connection ring is arranged outside the closure , the connecting ring is connected with the discharge belt, and the end of the discharge belt is provided with a clip. Through the above method, the antistatic gloves of the present invention have the advantages of high reliability, comfortable wearing, no influence on finger movements, excellent discharge capacity, reliable contact with the human body, low price, etc., and have broad market prospects in the antistatic product market.

Owner:李晓娜

Three-layer air packing device and production method thereof

ActiveCN102233981BImprove reliabilitySave packing timePaper-makingBox making operationsAntistatic bagMain channel

The invention discloses a three-layer air packing device. Two rectangular thermoplastic films are subjected to secondary hot laminating to form a three-dimensional packaging body which is provided with an opening and can seal air; the three-dimensional packaging body comprises a plurality of independent sealed air chambers and a main channel; the main channel is provided with an air inlet; each sealed air chamber is communicated with the main channel through a one-way valve consisting of a one-way valve film; the inner side of the three-dimensional packaging body is provided with an inner bag; and the inner bag is formed by fixing four sides of a rectangular lightproof and / or antistatic thermoplastic film on the four sides of the rectangular thermoplastic film on the inner side of the outside three-dimensional packaging body. By the packing device, the consumption of lightproof or antistatic bags for packaging objects to be packaged is reduced, a procedure of sleeving the lightproof or antistatic bag is eliminated, the packaging time is greatly shortened, and possible accidents in the packaging process are further reduced, so that the cost is saved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

Antistatic bag good in hand feeling and less prone to slipping off

The invention relates to an antistatic bag good in hand feeling and less prone to slipping off. The antistatic bag good in hand feeling and less prone to slipping off comprises a bag body which is a transverse hollow cylinder, a bag strap is arranged on one end face of the bag body and is a bead chain formed by spherical beads, and a plurality of bead strings parallel to an axis are arranged on the circumferential surface of the bag body. The antistatic bag good in hand feeling and less prone to slipping off has the advantages that the bag strap is the bead chain formed by the spherical beads, the bead strings parallel to the axis are arranged on the circumferential surface of the bag body, and accordingly the antistatic bag is good in hand feeling when being carried by a user; the antistatic bag is less prone to slipping off, so that people's needs are met.

Owner:JIANGYIN JIAYI GIFT

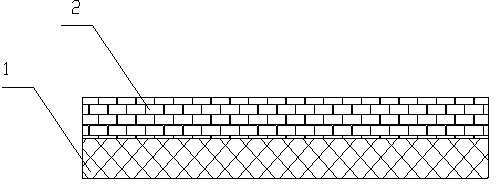

An antistatic floor mat

ActiveCN105729946BImprove anti-static effectNot easy to warpSynthetic resin layered productsLaminationAntistatic bagEngineering

The invention provides an antistatic floor mat comprising a bottom layer and a surface layer.The antistatic floor mat is characterized in that an electroconductive rubber layer serves as the bottom layer, an antistatic resin layer serves as the surface layer, the bottom layer and the surface layer are adhered to form the antistatic floor mat through adhesion, and surface resistance of the surface layer is smaller than that of the bottom layer.The antistatic floor mat attains excellent antistatic performance by combining the surface layer and the bottom layer, and is not less prone to warping and convenient to mount by the aid of the bottom rubber layer.

Owner:南京固瑞橡胶有限公司

Anti-static polyethylene film material and preparation method thereof, as well as anti-static bag

InactiveCN109776932AImprove anti-static effectGood mouthLinear low-density polyethyleneAntistatic bag

The invention discloses an anti-static polyethylene film material and a preparation method thereof, as well as an anti-static bag. The anti-static polyethylene film material is prepared from the following raw materials in percentage by weight: 60-70 percent of linear low-density polyethylene, 20-30 percent of high-pressure polyethylene, 2-5 percent of low-pressure polyethylene and 3-5 percent of anti-static masterbatches. The preparation method of the anti-static polyethylene film material comprises the following steps: respectively weighing all the components in part by weight; putting all the components in an extruder for extrusion, wherein the temperature of a first zone of the extruder is 145-155 DEG C, the temperature of a second zone is 150-160 DEG C, the temperature of a third zoneis 150-160 DEG C, the temperature of a die head of the extruder is 150-170 DEG C, the rotating speed of a lead screw is 100-120 r / min, and the host frequency is 12-14 HZ; after extrusion, cooling, forming and winding to obtain the anti-static polyethylene film material. As the anti-static masterbatches and the low-pressure polyethylene are added, the anti-static polyethylene film material disclosed by the invention not only has a very good anti-static effect, but also is good in opening performance.

Owner:苏州汤志塑料制品有限公司

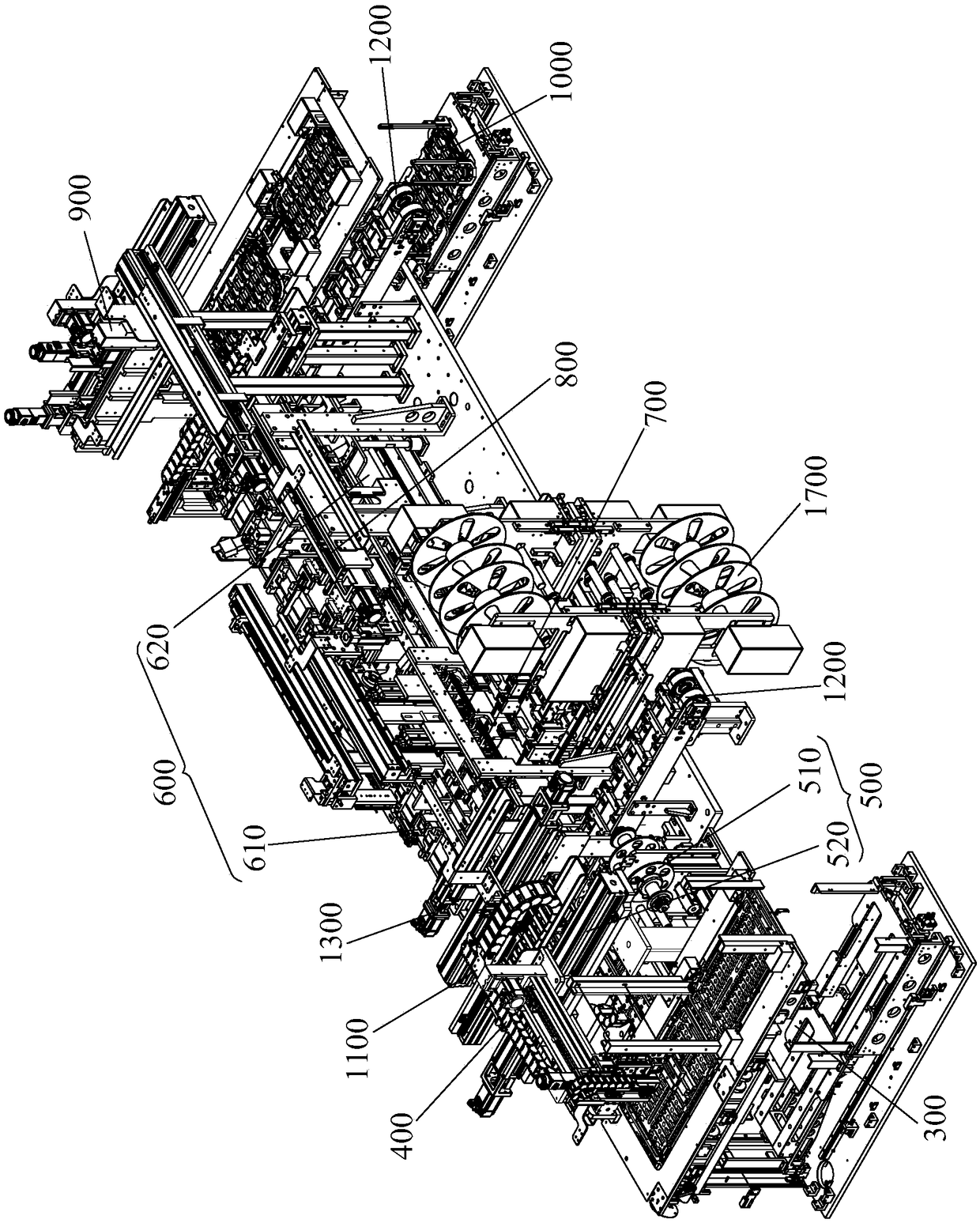

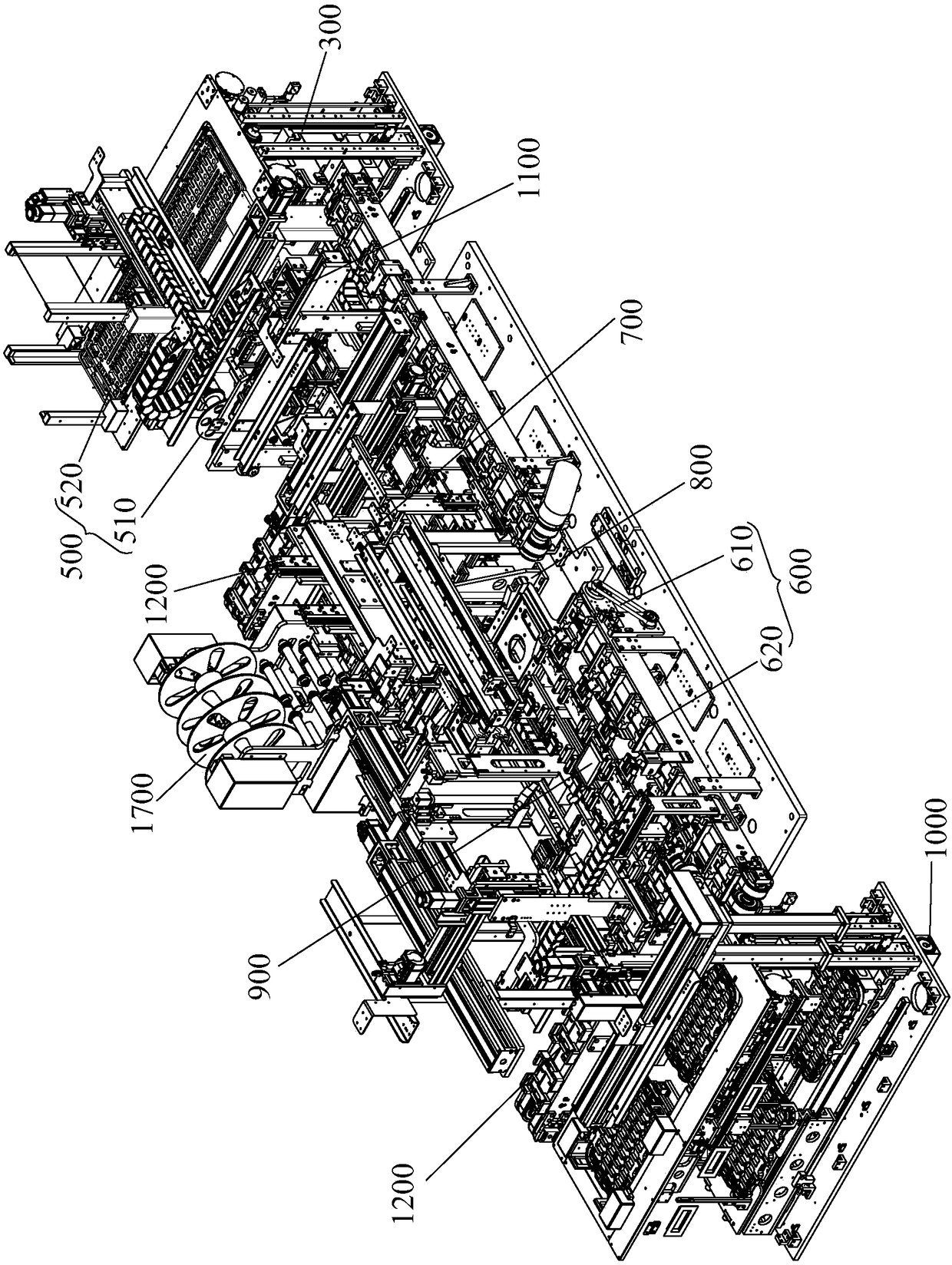

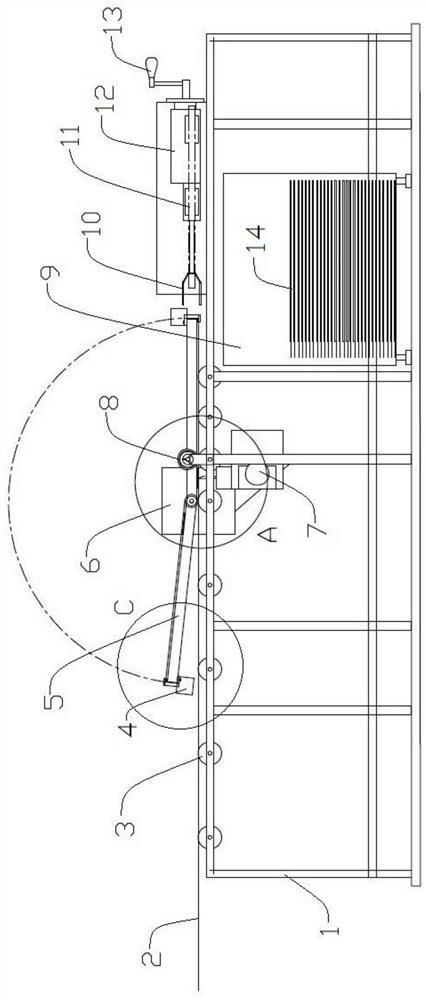

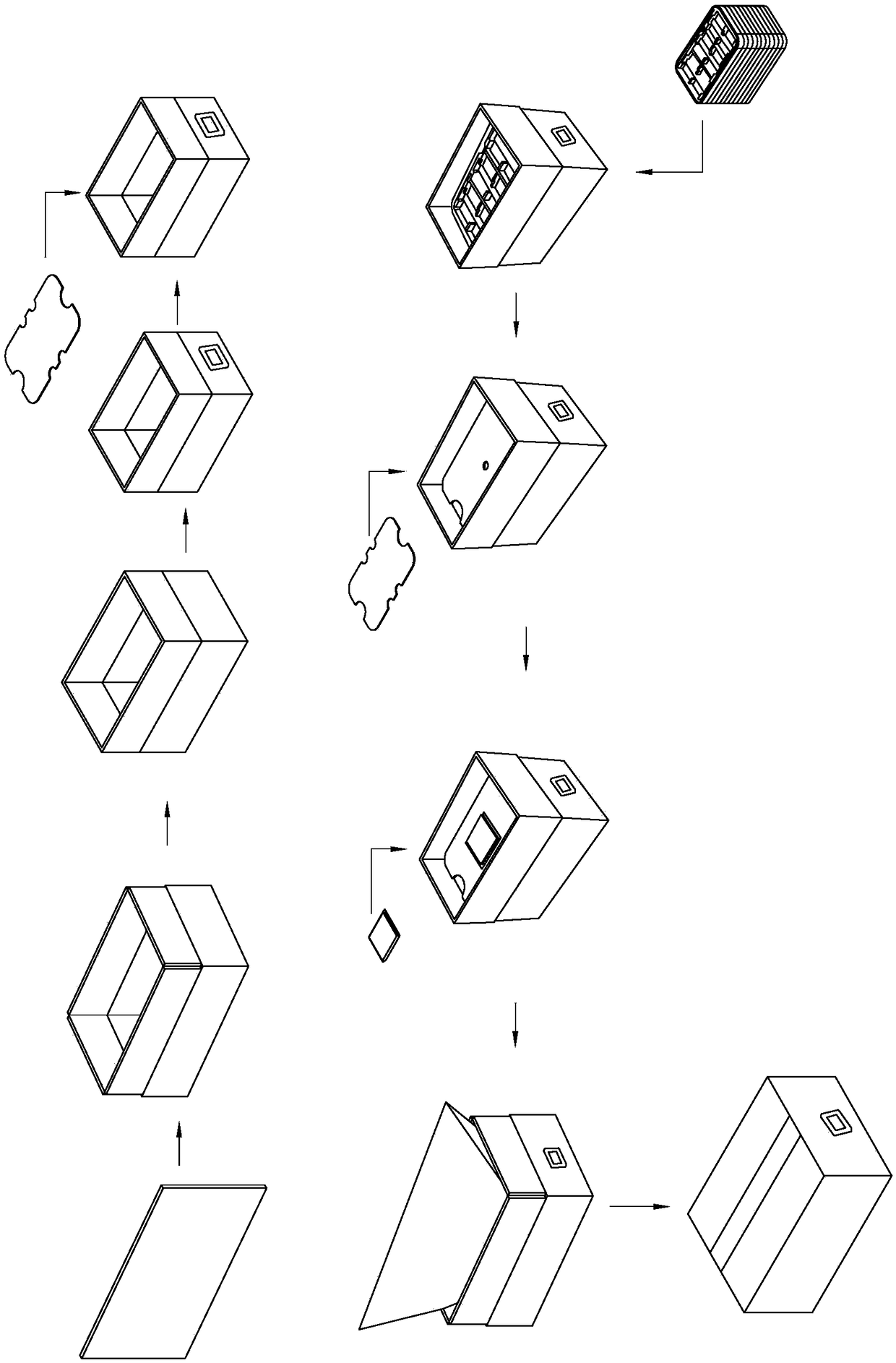

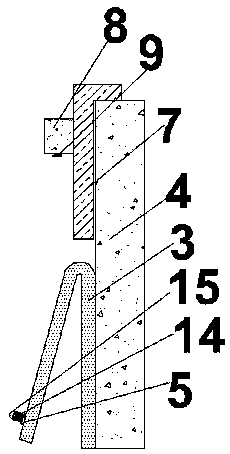

An anti-static film double-sided hot-melt welding edge sealing bag forming machine

ActiveCN111267364BImprove the efficiency of automatic edge bandingDomestic articlesAntistatic bagHot melt

The invention discloses an antistatic film double-sided hot-melt welding edge-sealing bag forming machine, which includes a frame with a conveying roller, an automatic clamping and folding component, a distance-adjustable pulling component, a hot-melt welding component, and an automatic cutting Assemblies and output boxes, the automatic clamping and turning components include a transmission box on one side, two turning rollers, a turning lever and an automatic clamping component fixed at the front end of the turning lever. The bracket and the outer ring of the heat-welding roller are equipped with a heat-welding roller, which is connected to an electric heating device. It adopts the method of symmetrical folding and synchronous pulling and heat-bonding to realize automatic edge sealing into bags, and the single-layer anti-static material fed flat After the film is clamped and reversely folded 180 degrees, the upper and lower layers of the anti-static film are hot-melt bonded to the edges to be sealed on both sides of the anti-static film through the hot-melt welding component, and at the same time, the gradually formed part The anti-static bag is pulled forward to the forming position, and then the anti-static film is cut horizontally by the cutting knife, and then the material is unloaded, which can realize continuous heat bonding and edge sealing to form a bag.

Owner:苏州光大塑料包装有限公司

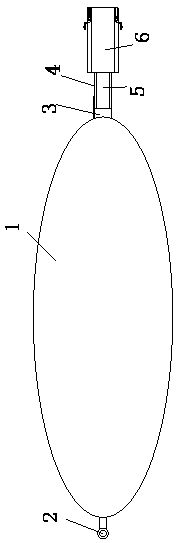

Antistatic anesthesia air storage bag

The invention discloses an antistatic anesthesia air storage bag which comprises an antistatic bag body. A tail ring is arranged at the bottom end of the antistatic bag body; an air inlet and outlet is formed in the upper end of the bag body; and a connector is arranged on the air inlet and outlet. The connector comprises a fixed head connected with the air inlet and outlet; and a multifunctionaladapter is arranged at the end part of the fixed head and includes an adapter body; a group of annularly distributed buckles are arranged on the adapter body; an annular groove is formed in the end part of the adapter body; a plurality of uniformly distributed magnetic touch switches are arranged in the annular groove; and a threaded connector is arranged above the magnetic touch switches. The antistatic anesthesia air storage bag has the characteristic that the application range can be effectively expanded.

Owner:姚俊

pvc antistatic gloves

Owner:山东蓝帆新材料有限公司

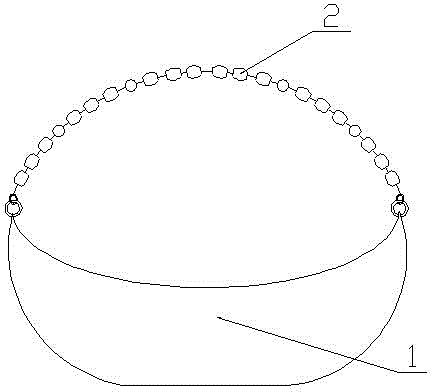

Self-luminous and antistatic bag

InactiveCN105433546AHighlight the decorative effectReduce coefficient of frictionSynthetic resin layered productsHandbagsFiberCarbon fibers

The invention relates to a bag. The bag comprises a bag body (1), the bag belt (2) of the bag is a bead chain composed of spherical beads and elliptical beads, each of the spherical beads and elliptical beads comprises a pearl body (3), the surface of the pearl body (3) is wrapped with a transparent luminous layer (4), the bag body (1) comprises a fabric matrix, the fabric matrix is a twill fabric matrix formed by interlacing warp yarns (1.1) and weft yarns (1.2), carbon fibers (1.2) are woven in the fabric matrix, and one side of the fabric matrix is coated with a polyurethane film (1.4). Pearl bodies of the self-luminous and antistatic bag can shine in a dark place, and show the self color under the refraction of lights, so a wearer has an obvious pearl decoration effect in the dark place; and the friction coefficient of the surface of the bag body is effectively reduced, and the generation amount of static charges in the friction process is reduced, so the bag has a high antistatic performance.

Owner:朱留平

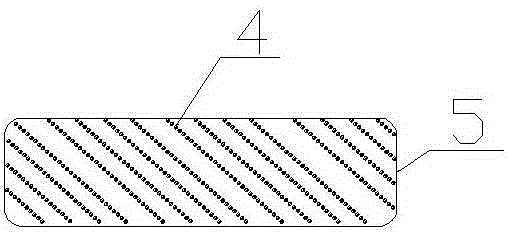

Antistatic bag less prone to slipping and shiny under illumination

The invention relates to a bag, in particular to an antistatic bag less prone to slipping and shiny under illumination. The antistatic bag comprises a bag body (1), a strap (2) is arranged on the upper portion of the bag body (1), a plane of the bottom of the bag body (1) serves as a bag body bottom plane (5) which is a rectangular plane, a plurality of sequins (3) are closely arrayed on the surface of the bag body (1), and a plurality of parallel bead strings (4) forming inclination angles with the rectangular plane are arranged on the bag body bottom plane (5). Owing to the plurality of sequins closely arrayed on the surface of the bag body, the bag body is shiny under illumination, so that requirements of young mavericks pursuing distinctiveness can be met. Due to the fact that the plurality of parallel bead strings forming the inclination angles with the rectangular plane are arranged on the bag body bottom plane, the bag placed on a smooth tabletop is less prone to slipping, so that requirements of people can be met.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

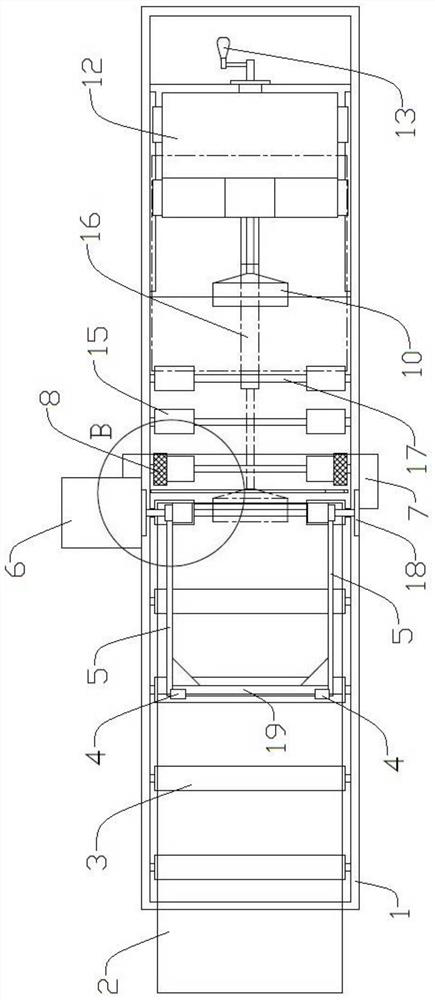

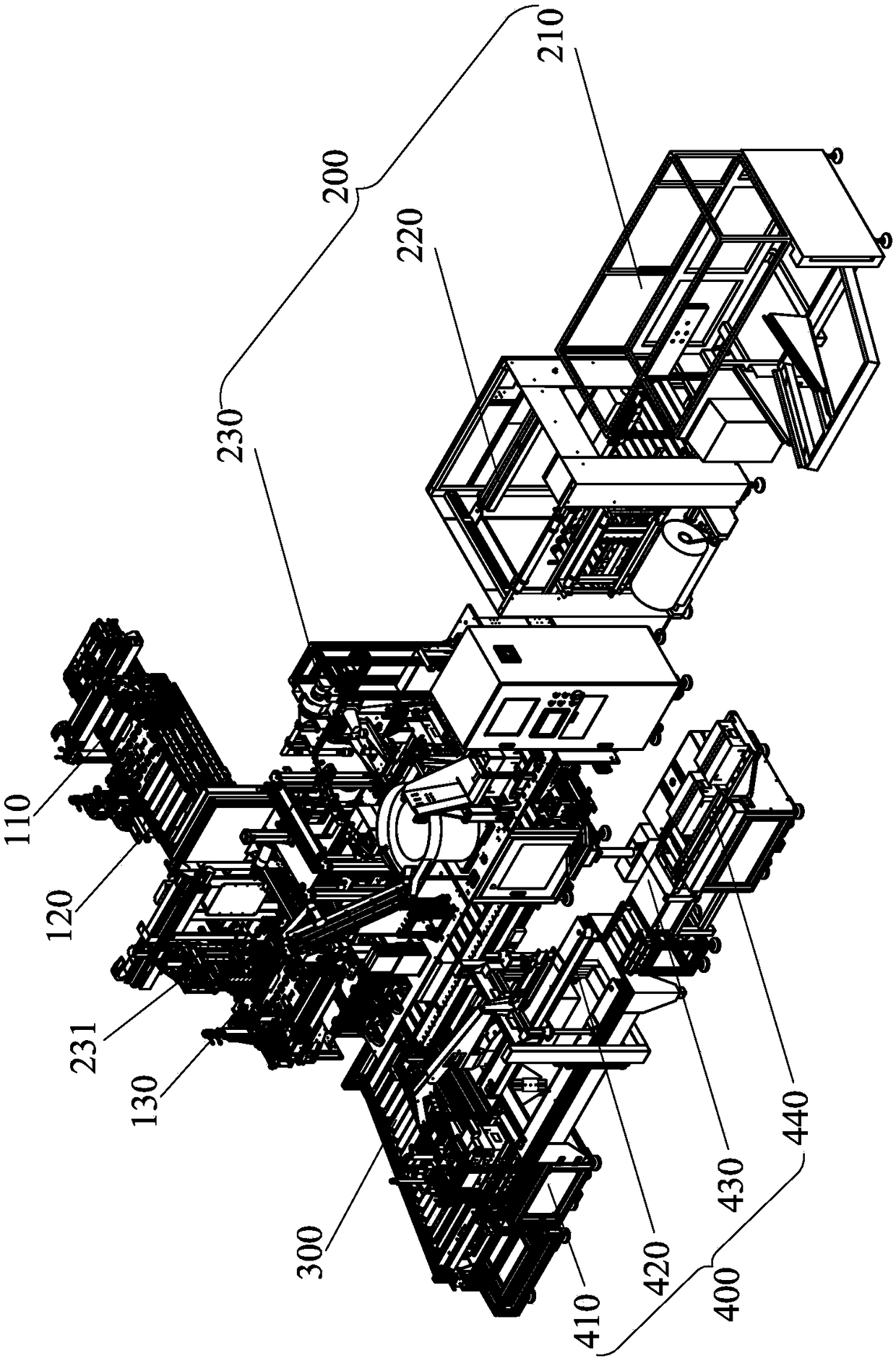

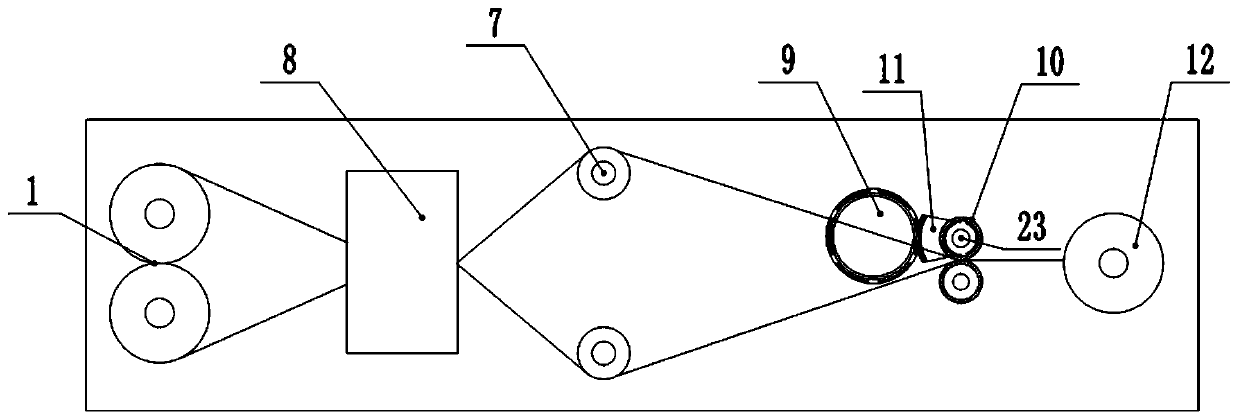

Vacuum heat sealing device for antistatic bag

PendingCN108454975AAutomate the packaging processConvenient vacuum heat sealingPackaging by pressurising/gasifyingWrapper twisting/gatheringAntistatic bagEngineering

The invention discloses a vacuum heat sealing device for an antistatic bag. The vacuum heat sealing device comprises a driving part capable of vertically moving relative to the antistatic bag, a heatsealing mechanism, a vacuumizing mechanism and a stretching and positioning mechanism arranged at the driving end of the driving part; the stretching and positioning mechanism comprises two positioning plates capable of stretching into an opening of the antistatic bag, and the two positioning plates can oppositely move to stretch the opening of the antistatic bag; the vacuumizing mechanism can stretch into the antistatic bag to vacuumize the antistatic bag; and the heat sealing mechanism is provided with two heat sealing strips moving in the stretching direction of the antistatic bag. The vacuum heat sealing device for the antistatic bag can effectively replace manpower to efficiently and reliably conduct vacuum heat sealing on the antistatic bag with a solid hard disk, and then automatedpackaging of the solid hard disk is achieved.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Multilayered and multi-bag antistatic bag uneasy to slide off

InactiveCN105661801ANot easy to slipSuit one's needsLayered productsBagsAntistatic bagMechanical engineering

The invention relates to a multi-layer multi-pocket anti-static bag which is not easy to slip. A pocket is provided, namely the first pocket, the second pocket and the third pocket, and a plurality of bead strings are arranged on the outer surface of the bag parallel to the axial direction. The present invention is a multi-layer multi-pocket antistatic bag that is not easy to slip. There are three layers of bags in the bag, each layer of bags is provided with a pocket, and the outer surface of the bag is parallel to the axial direction. There are many beads strings, so it can be placed more The items are easy to classify, and people are not easy to slip when they take the bag, which meets people's needs.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

Antistatic bag not easy to slide off

InactiveCN104872960AIncrease coefficient of frictionNot easy to slipHandbagsLuggageAntistatic bagEngineering

The invention relates to a bag, and particularly relates to an antistatic bag not easy to slide off. The bag comprises a bag body (1), and multiple bead strings (2) are transversely arranged in parallel on the back face of the bag body (1). According to the antistatic bag not easy to slide off disclosed by the invention, the multiple bead strings are transversely arranged in parallel on the back face of the bag body, so that the friction coefficient of the back face of the bag is increased; and the bag is not easy to slide off when taken by people, thereby meeting the needs of people.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

Dust-free PE antistatic bag

InactiveCN109160070ANot easy to damageEasy to carryBagsSacksAntistatic bagElectrical and Electronics engineering

The invention discloses a dust-free PE antistatic bag which comprises a bag body, a clamping block and a clamping groove. When a connecting module is installed, four insertion rods and tip ends on a first connecting block on the bag body penetrate openings in a second connecting block for tight cooperation so that the first connecting block and the second connecting block can be connected together, the connecting module is then successfully installed on the bag body, and the bag body is better not likely to be damaged; and two connecting protruding blocks which are arranged in parallel are arranged on the clamping block, fixing inclined blocks are arranged on the lower sides of the connecting protruding blocks; connecting grooves which are formed in parallel are formed in the back face ofthe clamping block, fixing grooves are formed in the bottom sides of the interiors of the connecting grooves, due to cooperation of the connecting protruding blocks and the connecting grooves and cooperation of the fixing inclined blocks and the fixing grooves, two connecting modules can be connected, and connection between multiple bag bodies can be successfully achieved. When too many bag bodiesexist and one hand cannot pinch all the bag bodies, a connecting line can be used for penetrating connecting rings, then the multiple connecting modules are connected, carrying is more convenient, and operation is convenient and fast during use.

Owner:孙立强

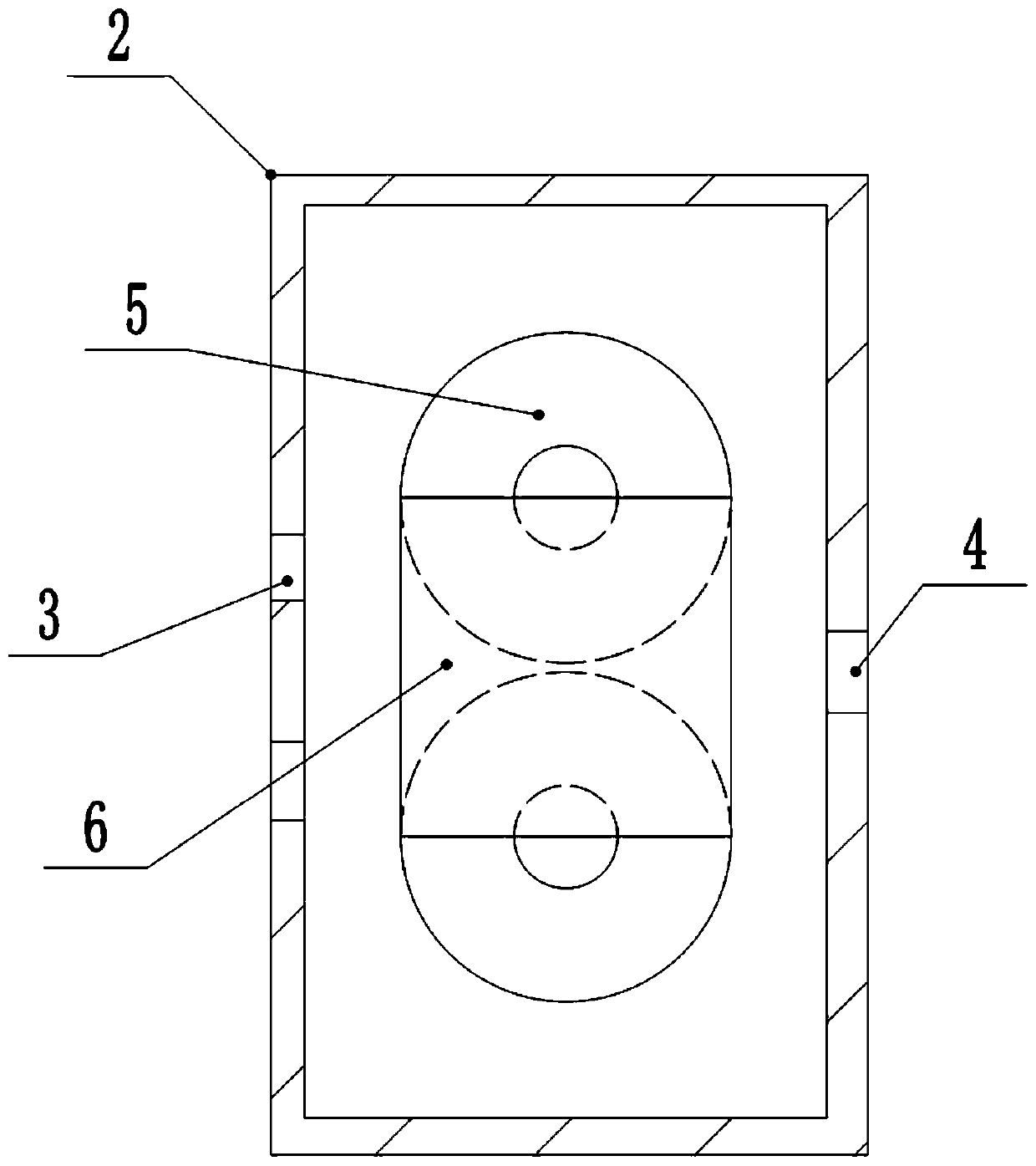

Anti-static PE bag processing compound machine

ActiveCN109605829BSolve the problem that the amount of glue is not easy to controlBag making operationsPaper-makingAntistatic bagProcess engineering

Owner:DINGSHENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com