Patents

Literature

162results about How to "Good mouth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for edible fungus flavor food

The invention discloses a preparation method for an edible fungus flavor food. The edible fungus can be any one from edible agaricus bisporus, straw mushrooms, oyster mushrooms, shii-take, needle mushrooms, pleurotus nebrodensis, pleurotus eryngii, agrocybe aegerita, hypsizigus marmoreus, agaricus pratensis schaeff, spring mushrooms, stropharia rugoso-annulata, sparassis crispa, macrolepiota procera, tremellodon gelatinosum, black trumpet mushrooms, hericium erinaceus, pholiota nameko, lepista personata, mitake mushrooms, lactarius hatsudake, golden oyster mushrooms, pholiota adiposa, cantharellus cibarius, termitomyces albuminosus, tricholoma giganteum, pleurotus citrinopileatus, calocybe gambosa, truffle, amillariella mellea, fungus suillus, beef-steak fungus, lactarius deliciosus, tricholoma matsutake, agaricus bitorquis, pleurotus pulmonarius, toadstool and russula vinosa, and after treatment, the edible fungus is steeped into a steeping liquor prepared from red wine vinasse, high quality dry red wine and a flavouring agent in a vacuum and normal temperature and normal pressure combined condition, so as to obtain the flavor food; the edible fungus flavor food for leisure is prepared through oil-bath dewatering; a flavor food flavor puffed food is obtained through a swelling process, so as to meet consumers' hobbies and requirements.

Owner:徐州绿之野生物食品有限公司

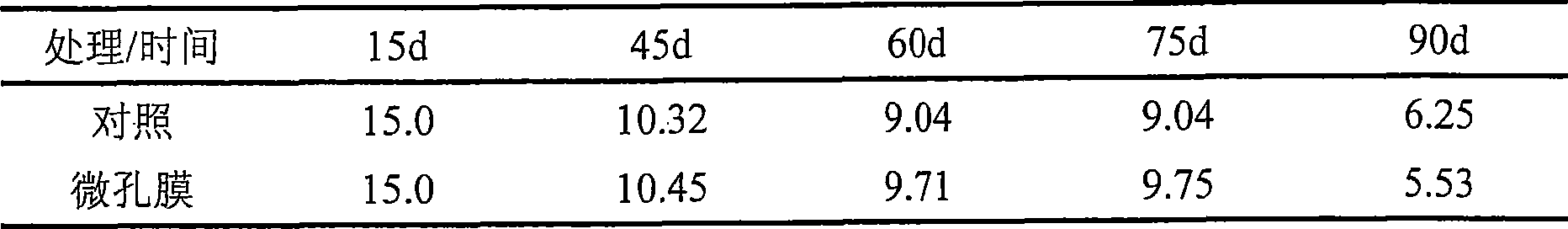

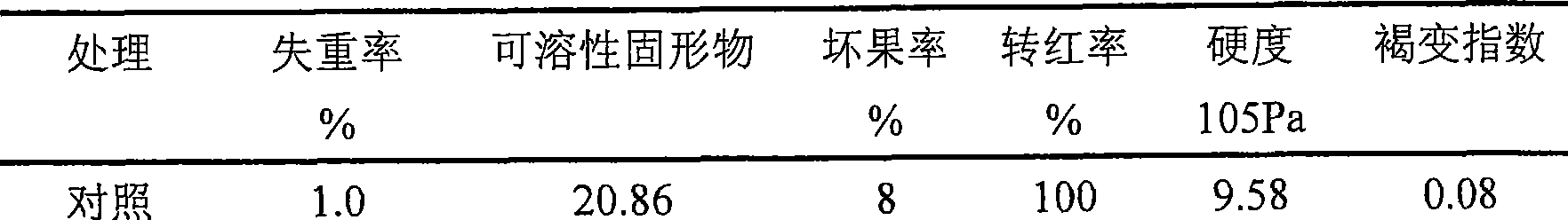

Micropore preservative film for garden stuff

InactiveCN101497712AEffective regulationStable stateFlat articlesFruits/vegetable preservation by coatingLow-density polyethylenePorosity

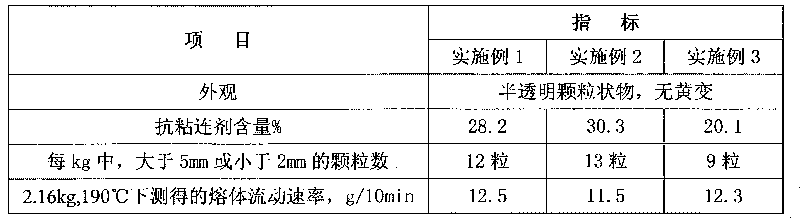

A fruit and vegetable millipore preservative film comprises the following components of 100 portions of low-density polyethylene resin, 20 portions of ethene-vinyl acetate resin, 10 portions of linear polyethylene resin, 13 portions of superfine calcium carbonate, 8 portions of superfine medical stone, one portion of Tween 80, 0.5-1.5 portions of antifogging agent, 1.5 portions of SWJU-1 anlistatig, 0.5 portions of antioxidizer1076 and 0.6 portions of polyethylene wax. After organized processing by acetic acid, inorganic functional materials are used to prepare master batch together with polyethylene base material and other functional components by coextrusion; the materials are mixed through diatexis according to the proportion; blow molding is carried out on a single screw extruder; a film is formed through bidirectional biaxial tension in a longitudinal and transverse way; and the rotate speed of the screw and the traction speed are adjusted to ensure that the aperture of the millipore of the formed film is 0.1-3 microns, and the poriness is 40-55 percent. The manufactured film has bidirectional adjusting ability of O2 and CO2, and therefore, when used for small-package storage, the film can spontaneously adjust air and has good moisture permeability without condensation of moisture in the bag.

Owner:天津市食品加工工程中心 +1

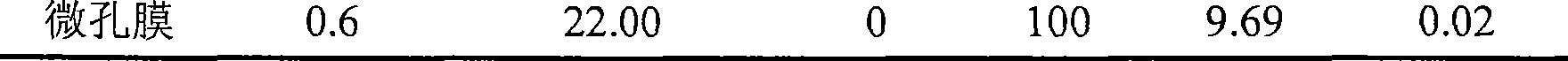

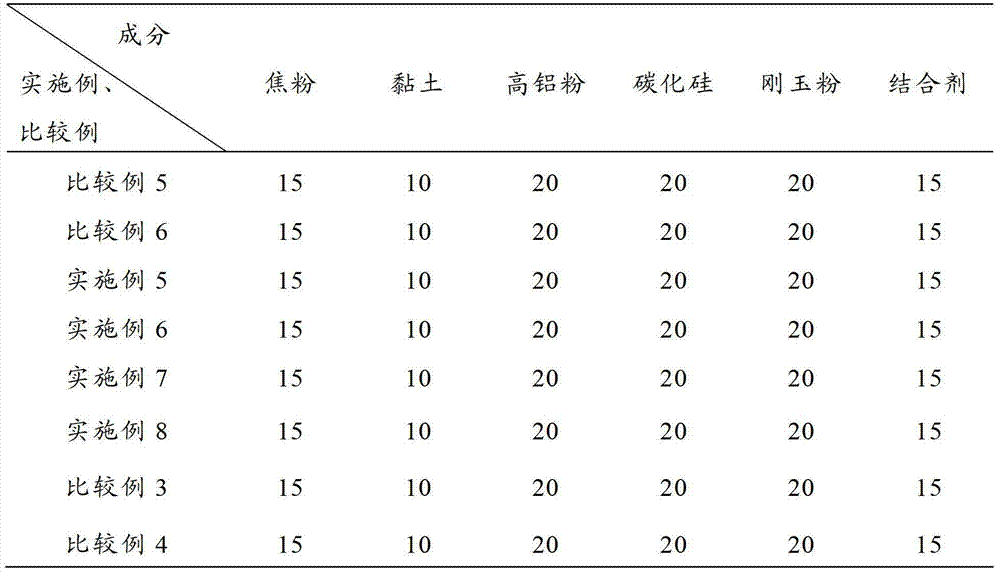

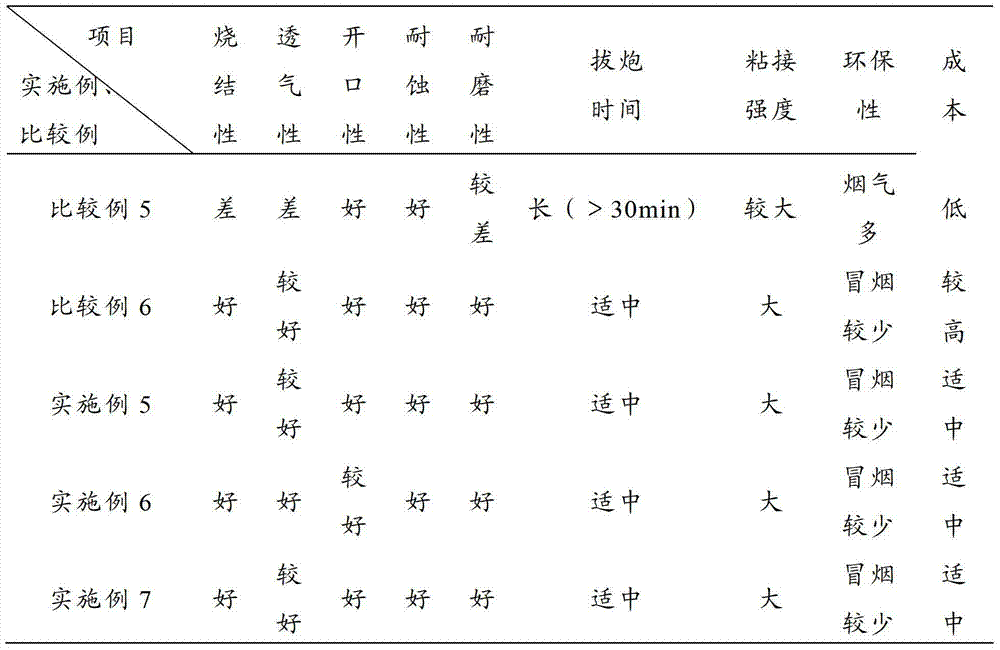

Anhydrous stemming for blast furnace tapping hole

The invention discloses anhydrous stemming for a blast furnace tapping hole, belonging to the technical field of refractory material for blast furnaces. The anhydrous stemming for a blast furnace tapping hole disclosed by the invention is composed of refractory aggregate and bonding agent, wherein the refractory aggregate comprises the following components in parts by mass: 12-14 parts of titanium dioxide, 3-5 parts of titanium carbide, 20-25 parts of corundum, 15-18 parts of silicon carbide, 30-38 parts of mullite, 5-7 parts of calcium-free chromium slag, 6-8 parts of blast furnace gas ash, and 9-11 parts of coke; and the bonding agent comprises the following components in parts by mass: 40-50 parts of asphalt, 4-6 parts of hydrogenated terphenyl, 10-12 parts of organic silicon resin, 8-11 parts of furan resin, and 11-15 parts of melamine-formaldehyde resin, wherein the mass ratio of the refractory aggregate to the bonding agent is 100:13-15. The anhydrous stemming disclosed by the invention has good opening performance, moderate plasticity, can resist scouring and erosion of high-temperature iron slag, does not pollute the environment, and is low in production cost.

Owner:ANHUI SAFE ELECTRONICS

Novel stemming at tap hole

The invention discloses novel stemming at a tap hole. The stemming comprises the components in parts by weight as follows: 5-25 parts of corundum, 5-25 parts of high aluminum aggregate, 10-30 parts of silicon nitride combined with silicon carbide, 2-3 parts of silicon nitride iron, 5-15 parts of coke powder, 8-20 parts of clay, 1-5 parts of crystalline flake graphite, 5-10 parts of pyrophyllite, 4-7 parts of sericite, 5-10 parts of magnesium-aluminum spinelle, 2-4 parts of active alumina micro powder, 1-3 parts of metal powder and 15-20 parts of external composite binding agent. The composite binding agent comprises tar, modified phenolic resin and an organic solvent. The volume ratio of tar, modified phenolic resin to the organic solvent in the composite binding agent is 1:3:1. According to the invention, with the adoption of the composite binding agent formed by mixing tar and modified phenolic resin, smoke generated is less, the same plasticity to be combined with tar is met, the opening performance is good, the pressure resisting thermal shock resistance is good, and the adhesion strength is high. The depth of the tap hole can be prolonged and the furnace cylinder can be protected, the tapping time is prolonged, and the number of casts every day is reduced.

Owner:长兴云峰炉料有限公司

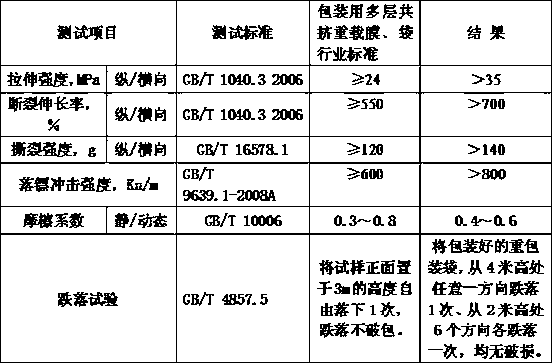

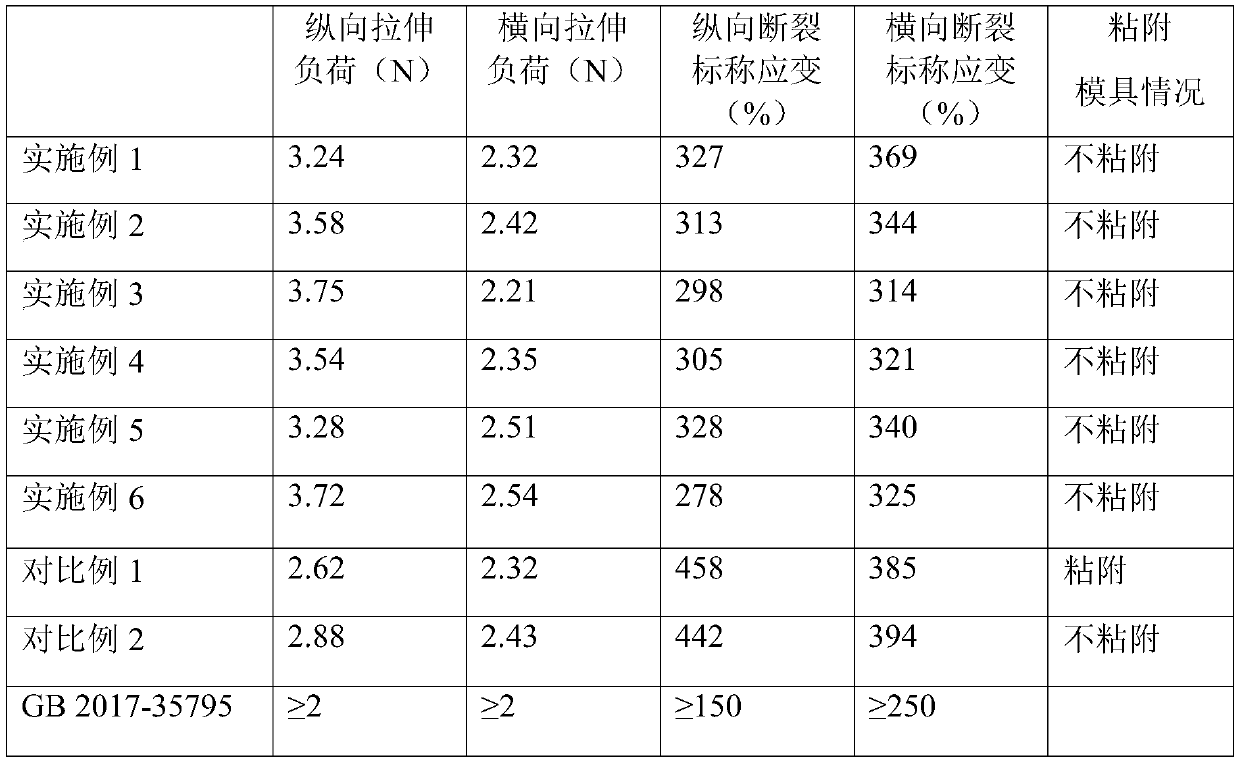

A form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof

ActiveCN103059402AHigh tensile strengthHigh impact strengthLinear low-density polyethyleneLow-density polyethylene

The present invention relates to the technical field of packaging film, and concretely relates to a form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof. The single layer heavy-duty film is composed of 30-50% of metallocene linear low density polyethylene, 5-20% of an ethylene-vinyl acetate copolymer, 5-20% of ultra low density polyethylene, 20-50% of linear low density polyethylene, and 3-5% of masterbatch, and is obtained via blending in a single screw extruder, and processes of extrusion molding via a machine head, traction, cooling, winding, and printing. Compared with the prior art, the single layer heavy-duty film of the present invention optimizes product formulation, has good tensile strength, impact strength and tear strength; in the preparation process, a gradual cooling mode is adopted, so the resulting product is more stable in performance; and aids are not added in the raw materials, so the product is low in cost and has a good market prospect.

Owner:GUANGDONG SUNION CHEM & PLASTIC

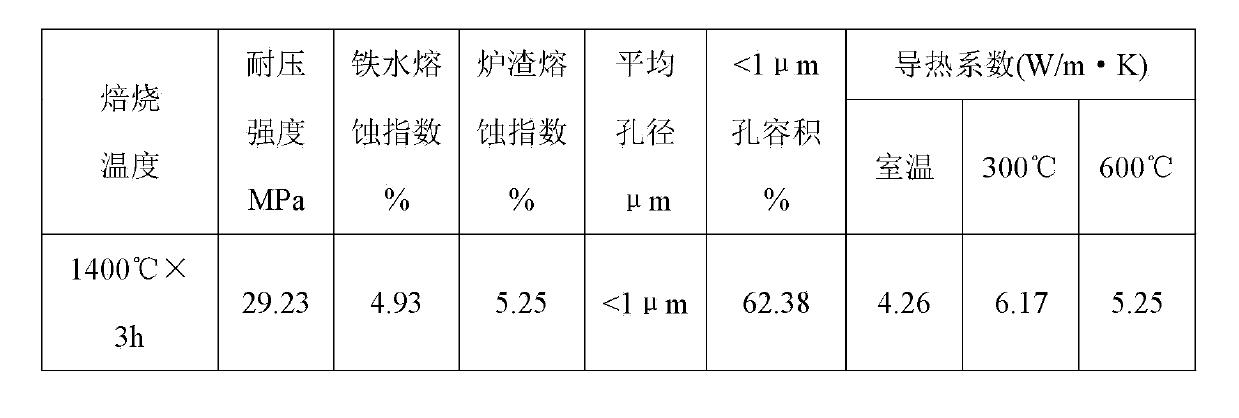

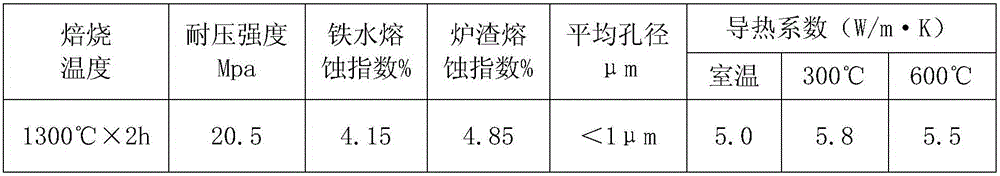

Tap hole stemming for large-scale blast furnace and preparation method

The invention discloses a tap hole stemming for a large-scale blast furnace and a preparation method. The stemming is composed of a binder and the following ingredients: by weight, 40-50 parts of brown aluminum oxide, 8-15 parts of silicon carbide, 6-12 parts of ferro-silicon nitride, 10-15 parts of clay, 6-9 parts of silicon powder, 2-5 parts of alpha-Al2O3, 6-10 parts of coke powder, 1-3 parts of graphite, and 4-6 parts of high-temperature pitch. The binder is tar. The preparation method comprises steps: according to the above ingredients and weight parts, raw materials are prepared, and mixed uniformly, then tar is added into the raw materials, the mixture is subjected to roller compaction and mixing to form a stemming material. The addition amount of the tar is controlled to make the Marshall value of the stemming material be 1100-1400 KPa, the stemming material is then subjected to pressing and molding to obtain final products. The prepared stemming is advantaged by good integrated performances, high intensity, small average hole size, good heat conductivity coefficient and good performances of resistance to slag and iron, corrosion and washing.

Owner:武钢集团有限公司

Film and Bag specially for keeping fresh of Jinling jujube

InactiveCN101040631AEffective regulationStable best conditionFruits/vegetable preservation by coatingHigh pressureZiziphus jujuba

Disclosed are special-purpose films and bags for the fresh-keeping of jujubes, wherein the constituents of the raw materials include (by weight portions) linear polyvinyl resin (LLDPE) 100, high-tension polyvinyl resin (LDPE) 50-100, ethylene-vinyl acetate resin (EVA) 15-25, 10% antifog pellets (MD / PE) 5-10, 20% silver-containing antibiotic pellets (Ag / PE) 5-10, 20% calcium carbonate pellets (CaCO3 / PE) 5-15 and 2-ethylhexyl oleate 0.2-1.

Owner:SHENYANG AGRI UNIV

Water-free stemming for medium and large blast furnace

The invention discloses water-free stemming for a medium and large blast furnace. The water-free stemming is prepared from the following raw materials in percentage by weight: 3-7% of special-grade homogenized bauxite particles, 18-25% of brown fused alumina particles, 2-7% of white fused alumina particles, 3-7% of tabular corundum powder, 3-6% of chromite sand powder, 11-21% of carbon resistance material, 3-6% of asphalt powder, 2-5% of carbon composite micropowder, 5-11% of silicon carbide powder, 3-6% of silicon carbide particles, 1-3% of ferro silicon nitride particles, 3-7% of silicon powder, 7-10% of guangxi soil, 2-5% of sericite and 10-13% of compound oil. The water-free stemming has the advantages that the slag erosion resistance of the traditional water-free stemming is improved; the high-temperature molten iron scouring resistance and wear resistance of the water-free stemming are enhanced; the anti-blocking property and iron cinder scouring resistance of the traditional water-free stemming are improved; the quality stability of the water-free stemming is improved; meanwhile, a resistance material of a byproduct generated by melting carbon electrodes is also utilized, so that the resource and the environment are more favorably protected.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Multilayer coextruded polyethylene film processed in down-blowing water-cooling ring film method

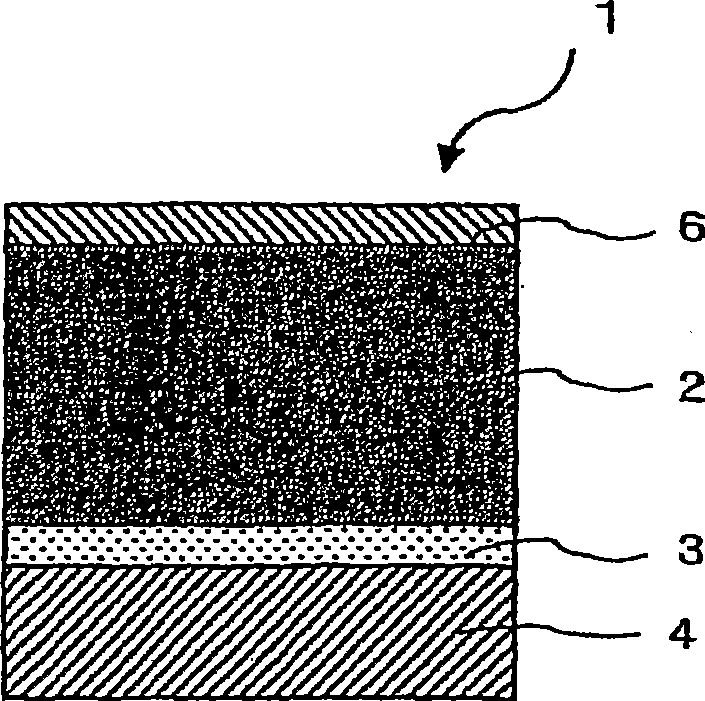

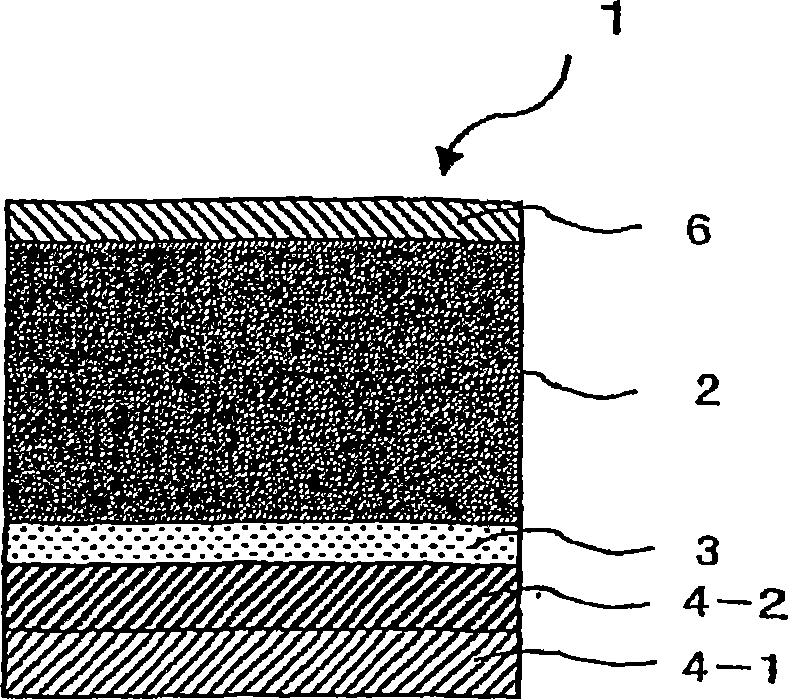

InactiveCN101927590AHigh composite strengthGood mouthSynthetic resin layered productsPolymer scienceCrystallinity

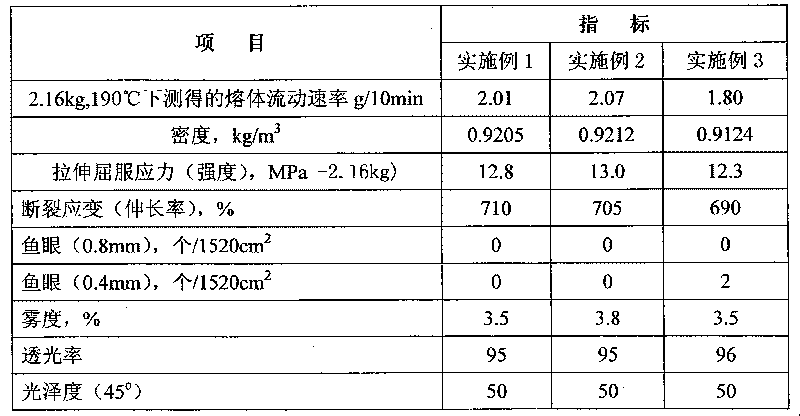

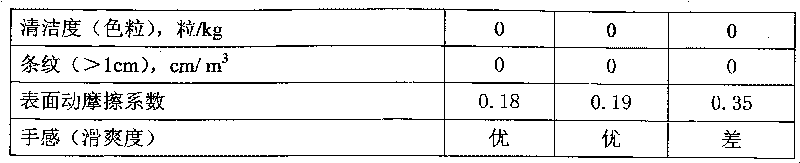

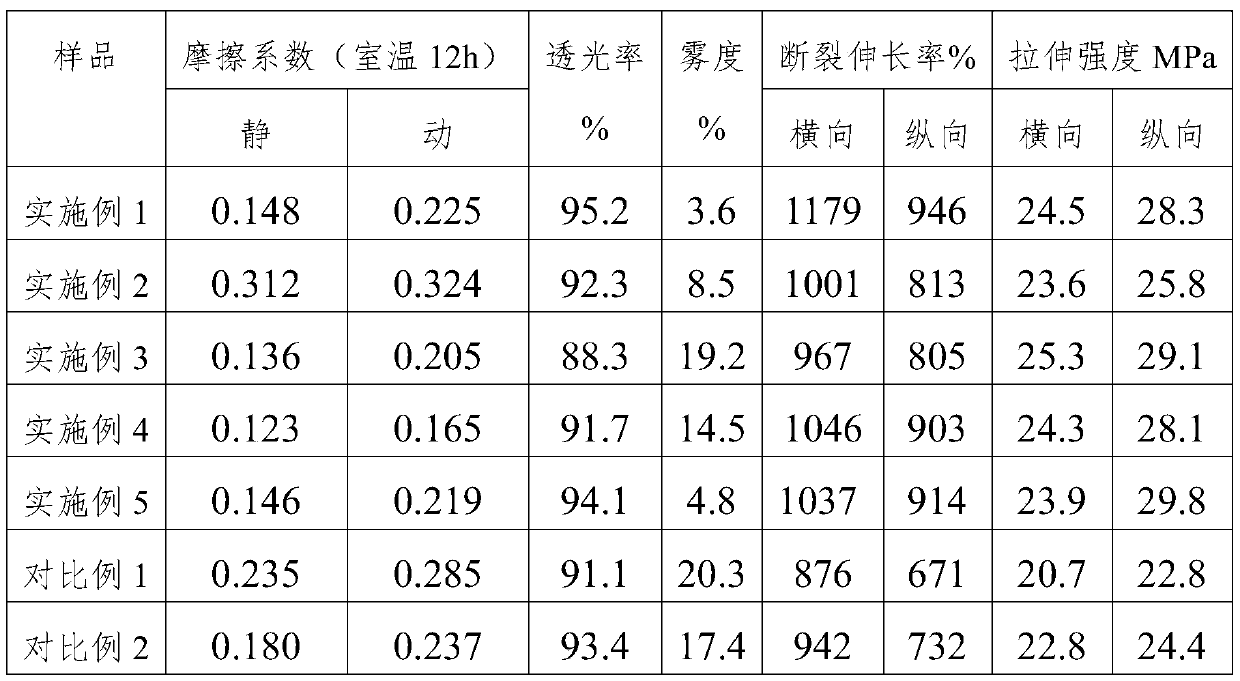

The invention discloses a multilayer coextruded polyethylene film processed in a down-blowing water-cooling ring film method. The multilayer coextruded polyethylene film comprises a corona disposal layer and a heat seal layer, and can also consist of a core layer, wherein the formula for each layer comprises: 60-95 parts of polyethylene, 5-40 parts of butylene polymer or propylene polymer, 0.005-1 part of anti-blocking agent, 0.005-1 part of slipping agent, 0.005-0.5 part of nucleating agent, and 0-0.5 part of fluorocarbon resin. By introducing sphaerocrystal through adding the butylene polymer or the propylene polymer in the formula, improving the crystallinity under the effect of the nucleating agent, and regulating the microcosmic planeness of the film surface in the present of fluorocarbon resin, the film has both the high composite strength and good anti-blocking property of a composite film and high transparency, can withstand water boiling sterilization at a temperature over 100 DEG C and stewing sterilization at a temperature below 121 DEG C, has low friction coefficient and attractive appearance. The product prepared in the formula reaches the ideal mutual balance among processability, optical property, mechanical property and temperature tolerance, and can be used for mass production with low industrial production cost.

Owner:成都思雅科高分子材料有限公司

Special compound additive for polyethylene film with high tranparency and low density

ActiveCN101717538ATransparent highHigh transparency, good physiological safetyLow-density polyethyleneLinear low-density polyethylene

The invention relates to a special compound additive for a polyethylene film with high tranparency and low density, which is a particle prepared by the following steps of: stirring and mixing 25-30 percent of silicon dioxide anti-block agent, 5-15 percent of organic silicon glidant, 2-8 percent of organic silicon active crosslinking agent, 1-10 percent of organic silicon antioxidant and the balance of high pressure polyethylene resin by taking high-pressure polyethylene as a carrier; carrying out treatments including preheating, ball milling and dispersing at the temperature of 75-85 DEG C; and finally, extruding pelletization through a twin-screw granulator at the temperature of 140-170 DEG C. The low density polyethylene film prepared by adding the compound additive is tasteless, has high transparency, favorable physiological safety, high anti-blocking property, favorable smoothness and favorable transference resistance and can be particularly used for fields including food covering films, drug covering films, business card covering films, identification card covering films, advertisement packaging and the like which have the requirements of high transparency, high safety and high anti-blocking property.

Owner:南京淳达科技发展有限公司

Preparation method of EVA foamed thin film

The invention discloses a preparation method of an EVA foamed thin film. The method includes the steps of preparing a foaming master material, preparing a foaming promoting master material and conducting extruding, blow molding and foaming of the thin film. When the master material is prepared, the foaming master material is prepared through a low-temperature extrusion method so that foaming in the extrusion granulating process can be avoided; by means of the foaming promoting master material, foaming agents can be promoted to decompose as completely as possible in the film blowing process; the two types of master materials and EVA resin are evenly mixed according to the ratio of 1 to 1 to 10 and then added into an extruder to be plasticized and blown to form the film. The master materials are foamed during plasticizing and extruding, and the structure and shape of foams can be adjusted by adjusting the main machine speed and the traction speed. According to the method, the film foaming product can be easily obtained. The film foaming product is suitable for producing rubber feeding bags, low in melting point, easy to tear off, small in density, capable of lowering material consumption, and capable of reducing production cost. Due to the fact that the product is good in mechanical property and tear-off performance, the application range of the product can be further enlarged; when the film is applied to rubber small component packaging bags and the like, resource waste can be greatly reduced, and recycling can be improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

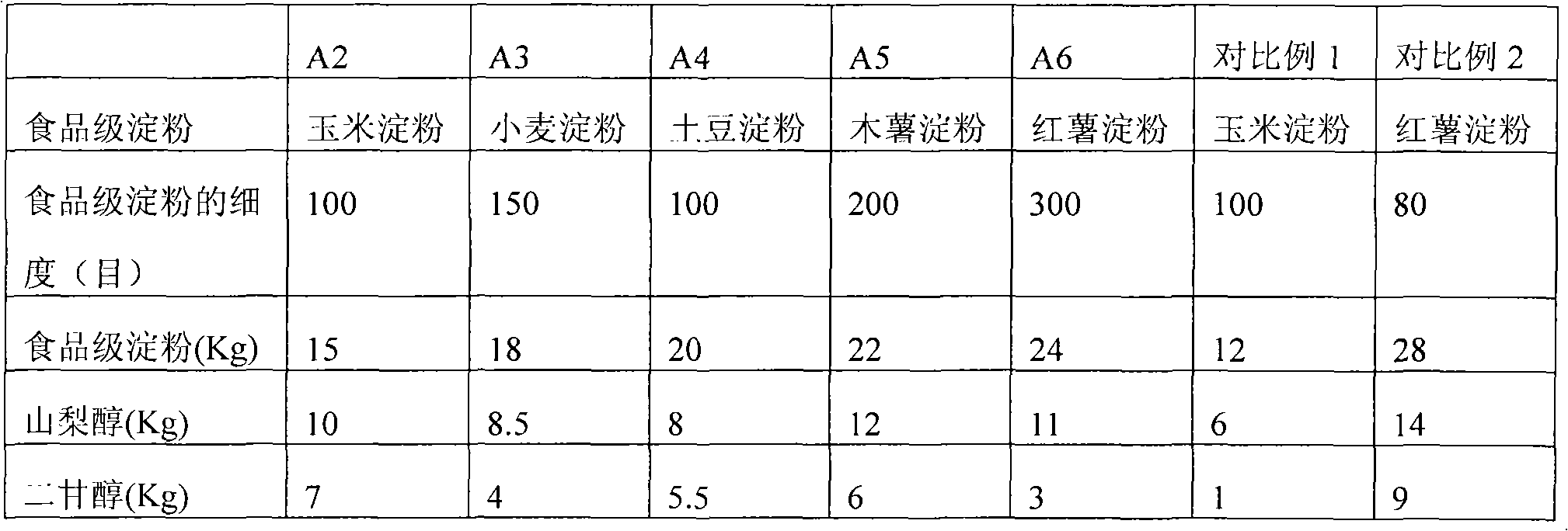

High-strength biodegradable thermoplastic starch resin, and preparation method and use thereof

ActiveCN102134333AHigh strengthGood compatibilityLow-density polyethyleneLinear low-density polyethylene

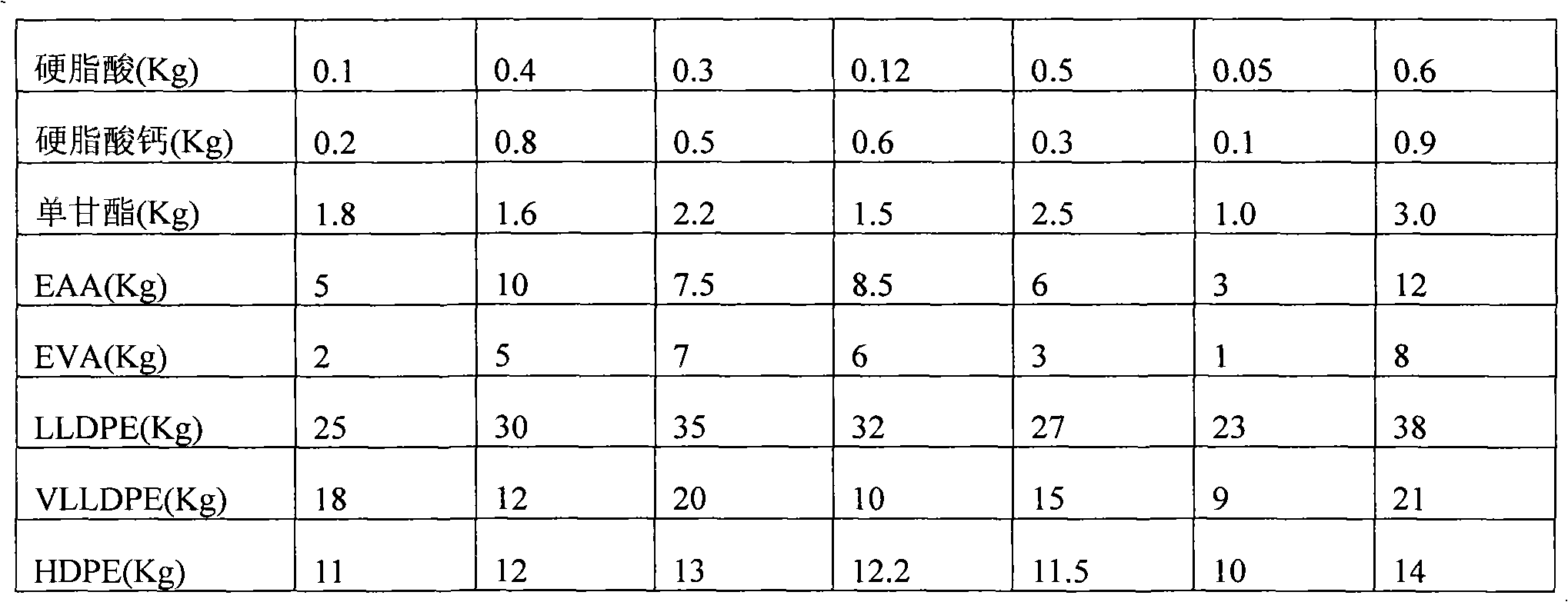

The invention discloses a high-strength biodegradable thermoplastic starch resin, which comprises the following components in part by weight: 15 to 24 parts of food-grade starch, 8 to 12 parts of sorbitol, 3 to 7 parts of diglycol, 0.1 to 0.5 part of stearic acid, 0.2 to 0.8 part of calcium stearate, 1.5 to 2.5 part of monoglyceride, 5 to 10 parts of ethylene acrylate copolymer, 2 to 7 parts of ethylene vinyl acetate copolymer, 25 to 35 parts of linear low density polyethylene, 10 to 20 parts of ultra low density polyethylene and 11 to 13 parts of high density polyethylene. The high-strength biodegradable thermoplastic starch resin disclosed by the invention has high tensile strength, high elongation at break, high tearing strength, high thermal sealing strength and a biodegrading rate ofover 40 percent. The resin is mainly used for producing various high-strength films and is particularly suitable for producing industrial packaging films, bags, commercial gift bags and trash bags. The resin has good handfeel, desirable thermal sealing effect, high colorizing rate and bright and natural printing color, and is antistatic and particularly suitable for electronic package.

Owner:南京艾道博环保科技有限公司

Easy-to-open lid with excellent suitability for high-temperature opening

InactiveCN101394999AGood mouthEasy open operationSynthetic resin layered productsThin material handlingEpoxyPolyester resin

An easy-to-open lid which comprises a resin-coated metallic sheet obtained by coating a metallic base with a polyester film through a primer, wherein the primer comprises an epoxy resin or polyester resin and a resol resin, the resol resin having 0.2-2.0 methylol groups per benzene ring. When an end of the opening tab is plunged to break the score for opening, no opening failure occurs and the opening operation can be conducted lightly. In particular, even when the lid is in the state of being heated at a high temperature, it has excellent suitability for high-temperature opening and does not pose that problem. It is excellent also in corrosion resistance, resistance to the contents, and retortion resistance.

Owner:TOYO SEIKAN KAISHA LTD

Polyethylene film for automatic packaging and preparation method thereof

ActiveCN108773137AAnti-pollutionComposite strongSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

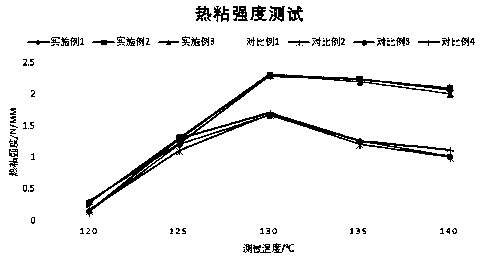

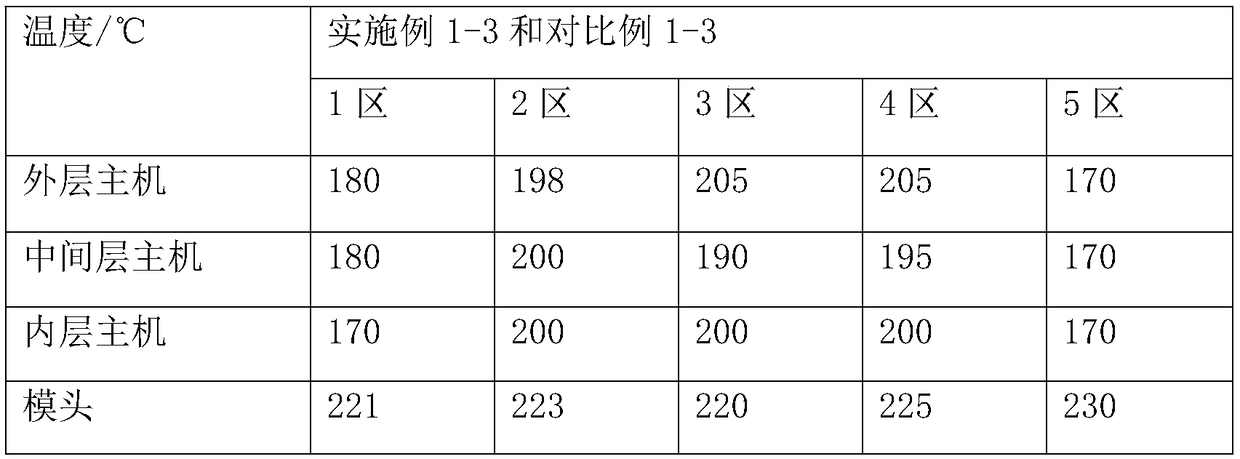

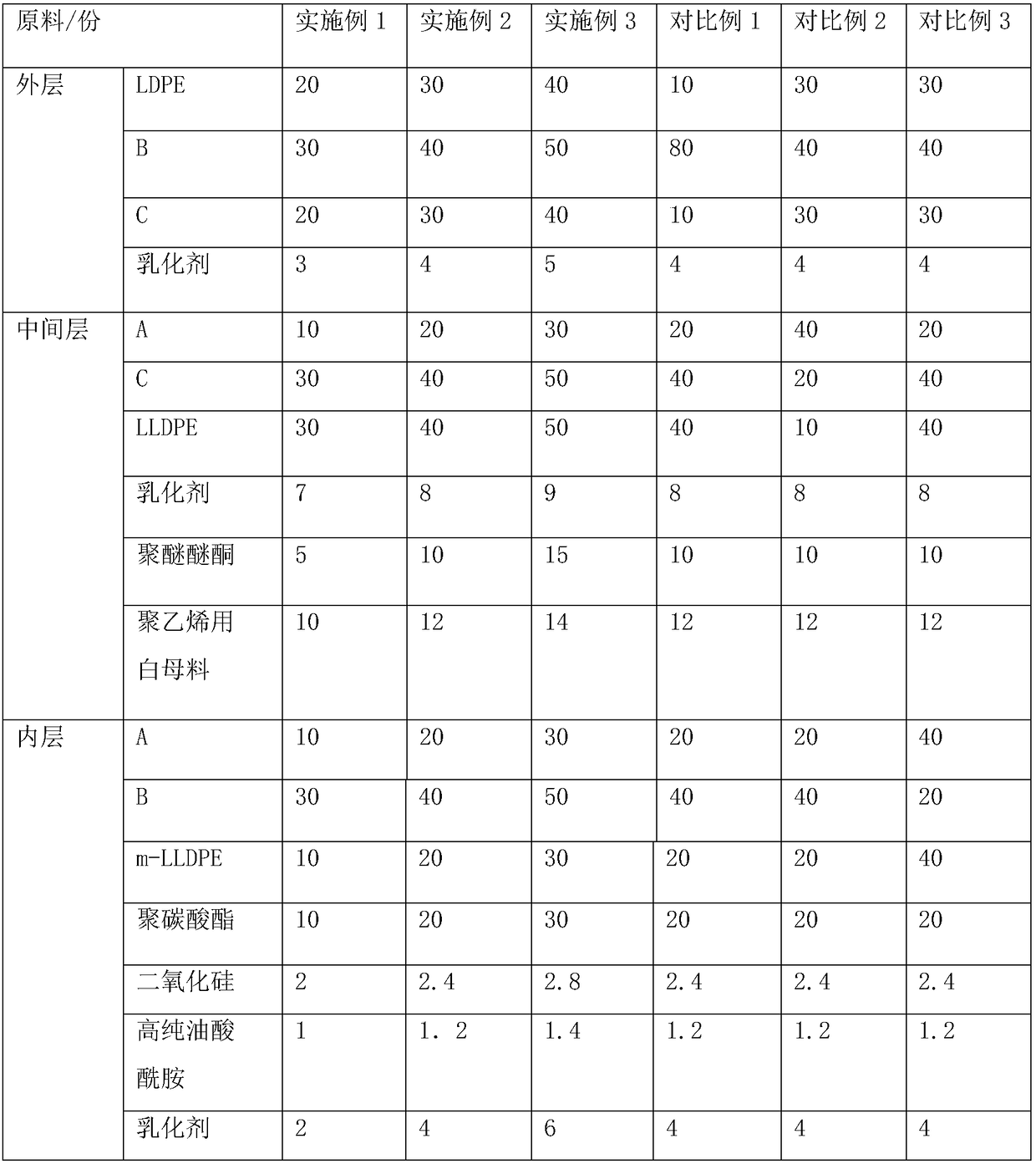

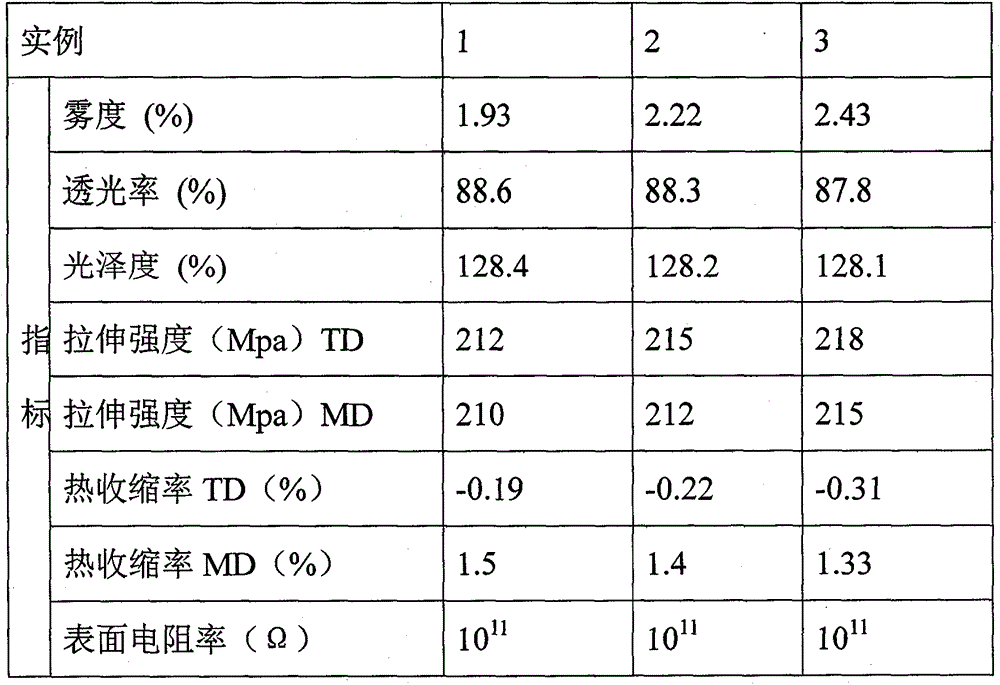

The invention discloses a polyethylene film for automatic packaging. The polyethylene film comprises an outer layer, an intermediate layer and an inner layer which are sequentially laminated. The outer layer is prepared from the following substances in parts by weight: 20-40 parts of low density polyethylene (LDPE), 30-50 parts of linear low density polyethylene (LLDPE), and 20-40 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>. The intermediate layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>, and 30-50 parts of LLDPE with melt index of 2.4 g / 10 min and density of 0.921 g / cm<3>. The inner layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE, and 10-30 parts of LLDPE. The invention solves the problem that the polyethylene film has lower thermal viscosity and higher bag breaking rate.

Owner:青岛东海包装产业有限公司

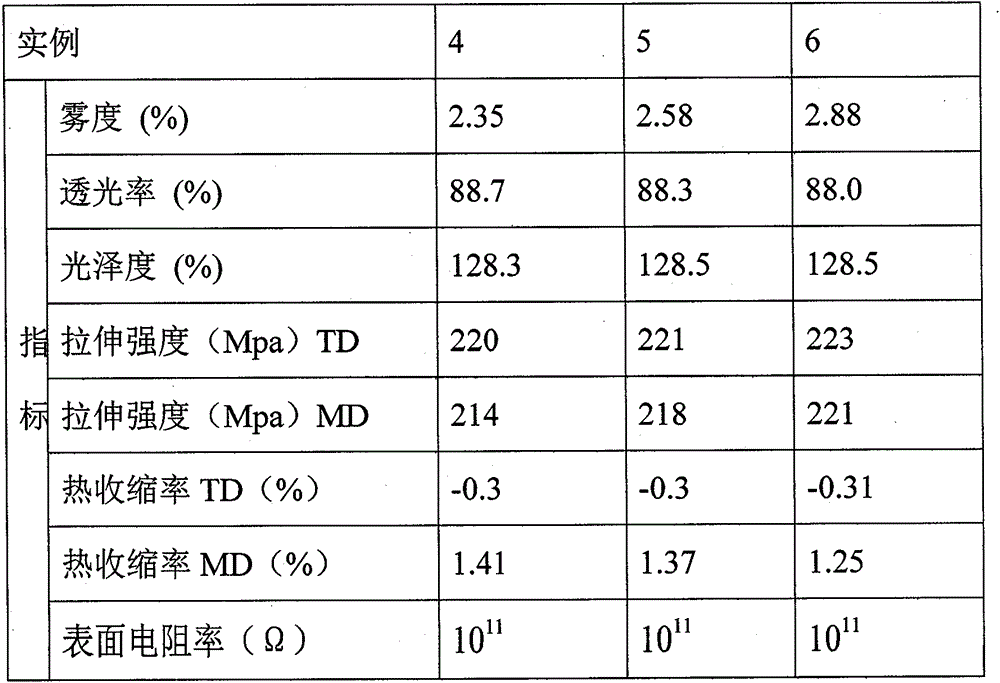

Anti-static polyester film and preparing method thereof

The invention relates to an anti-static polyester film and a preparing method thereof. The anti-static polyester film comprises a structure layer A, a structure layer B and a structure layer C. The layer B is a middle core layer and is made of a super bright polyester chip. The layer A is an upper surface layer anti-static layer and is made of an anti-static anti-blocking polyester chip and a super bright polyester chip. The layer C is a lower surface layer anti-static layer and is made of an anti-static anti-blocking polyester chip and a super bright polyester chip. Modified synthetic PET materials containing organic metal positive ions and silicon dioxide are selected as anti-static anti-blocking additives, a special production technology is used for changing the structure of a BOPET polyester film and the overall crystallization rate of a production process and the crystallinity of final products, accordingly, polyester molecular structures are changed, the effects of good glossiness, normal haze and static resistance are achieved, and meanwhile good opening performance is achieved.

Owner:福建百宏高新材料实业有限公司

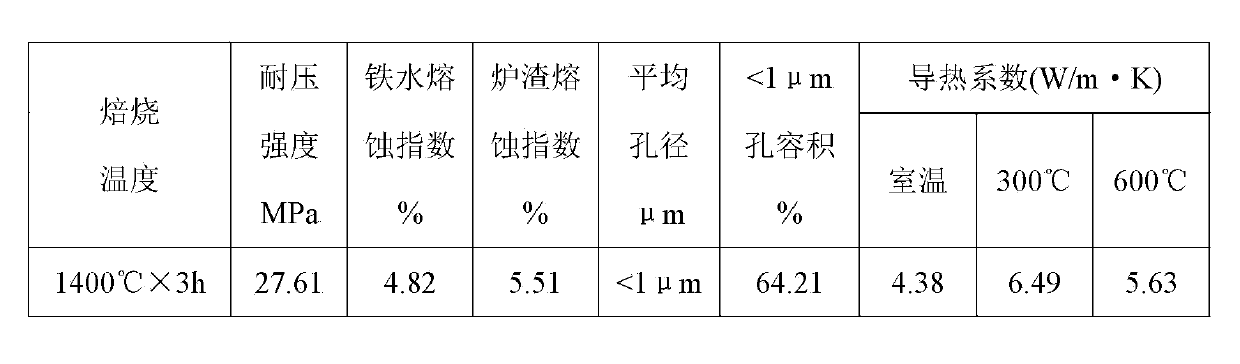

Tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and preparation method of tap hole medium-temperature-sintering environment-friendly stemming

The invention relates to tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and a preparation method of the tap hole medium-temperature-sintering environment-friendly stemming.The spreading drying material of the stemming is reasonable in composition and combination and is characterized in that the spreading drying material uses high-aluminum clinker and coke powder as aggregate and brown aluminum oxide, clay and silicon carbide as powder, ferro-silicon nitride content is adjusted, micro-powder such as silicon powder and alpha-aluminum oxide and anti-burst fibers are added, and the binder is the mixture of 9-11 parts of tar, 2-5 parts of resin and 1-3 parts of anthracene oil.The tap hole medium-temperature-sintering environment-friendly stemming has the advantages that the anti-burst fibers are added, so that the heat conduction ability of the stemming is increased, combustion carbonization of the tap hole stemming can be achieved during high-temperature exhausting, and the opening performance of the stemming is improved; the small amount of fire-resistant materials such as the brown aluminum oxide, the silicon carbide and the ferro-silicon nitride with excellent slag iron corrosion resistance are combined with the anti-burst fibers which can exhaust and combust fast and the high-aluminum clinker which is low in cost, the molten iron and slag corrosion resistance of the stemming is increased greatly, and the tapping time of the stemming is guaranteed, and environment pollution is reduced.

Owner:HEBI RONGMING TECH CO LTD

High-transparency multilayer polyester film

InactiveCN104260526AHigh light transmittanceGood mouthSynthetic resin layered productsPolyesterOptical transmittance

The invention discloses a high-transparency multilayer polyester film which has at least three layers and takes high-refractive-index polyester as a core layer, wherein a layer of low-refractive-index polyester or multiple layers of polyesters with sequentially reduced refractive indexes are compounded on one or two surfaces of the core layer. Compared with the prior art, the high-transparency multilayer polyester film has the superiorities that the film does not need to be coated and is high in transparency and good in opening performance, the transparency of a later optical functional film is improved, and the finally used transparency effect or brightness is enhanced; in addition, the film can be coated with one or more layers of coatings with the refractive indexes smaller than those of polyesters, and the effect after the coating process is better.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

Modified multifunctional polyester film and preparation method thereof

The invention relates to a modified multifunctional polyester film and a preparation method thereof. The surface layer of the modified multifunctional polyester film is made from modified PEN (polyethylene naphthalate) polyester; the middle layer is made from modified polyester; the bottom layer is made from modified PEN polyester; the thickness of the middle layer accounts for 60-80%; the thickness of the surface layer accounts for 10-20%; the thickness of the bottom layer accounts for 10-20%. By using a modified nano-particle-containing material to prepare a functional auxiliary and using a production process, the structure of BOPET (Biaxially Oriented Polyester Film) polyester, the total crystallization rate of the production process and the crystallinity of the final product are changed, so that the molecular structure of the polyester is changed, the effects of good glossiness, normal haze and antistatic property are achieved and relatively good opening property is also provided.

Owner:福建百宏高新材料实业有限公司

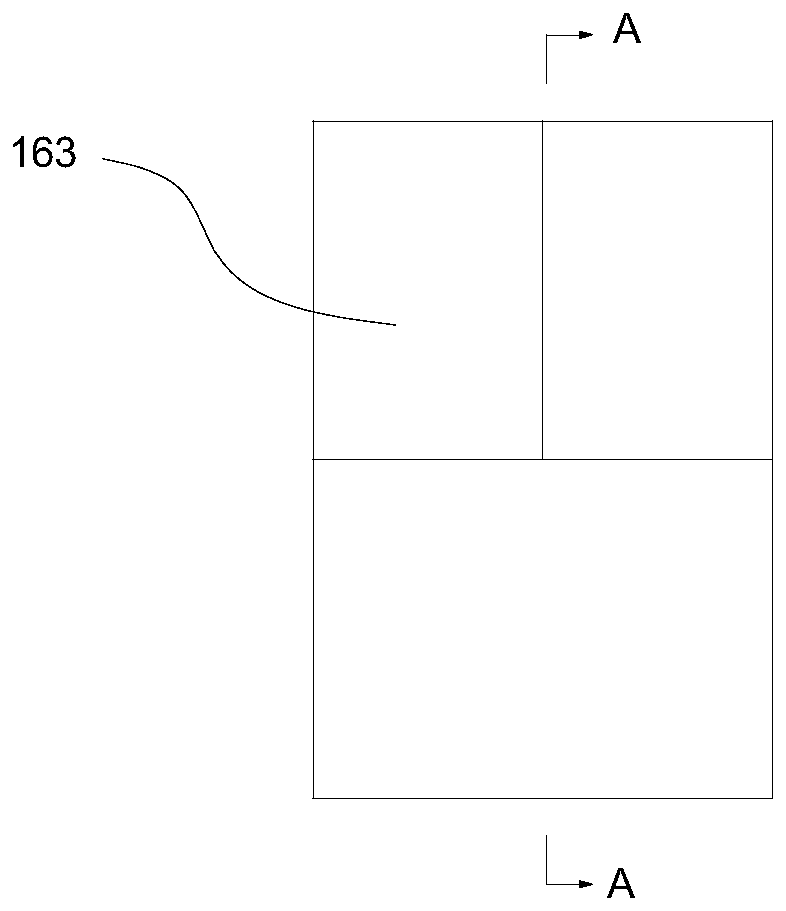

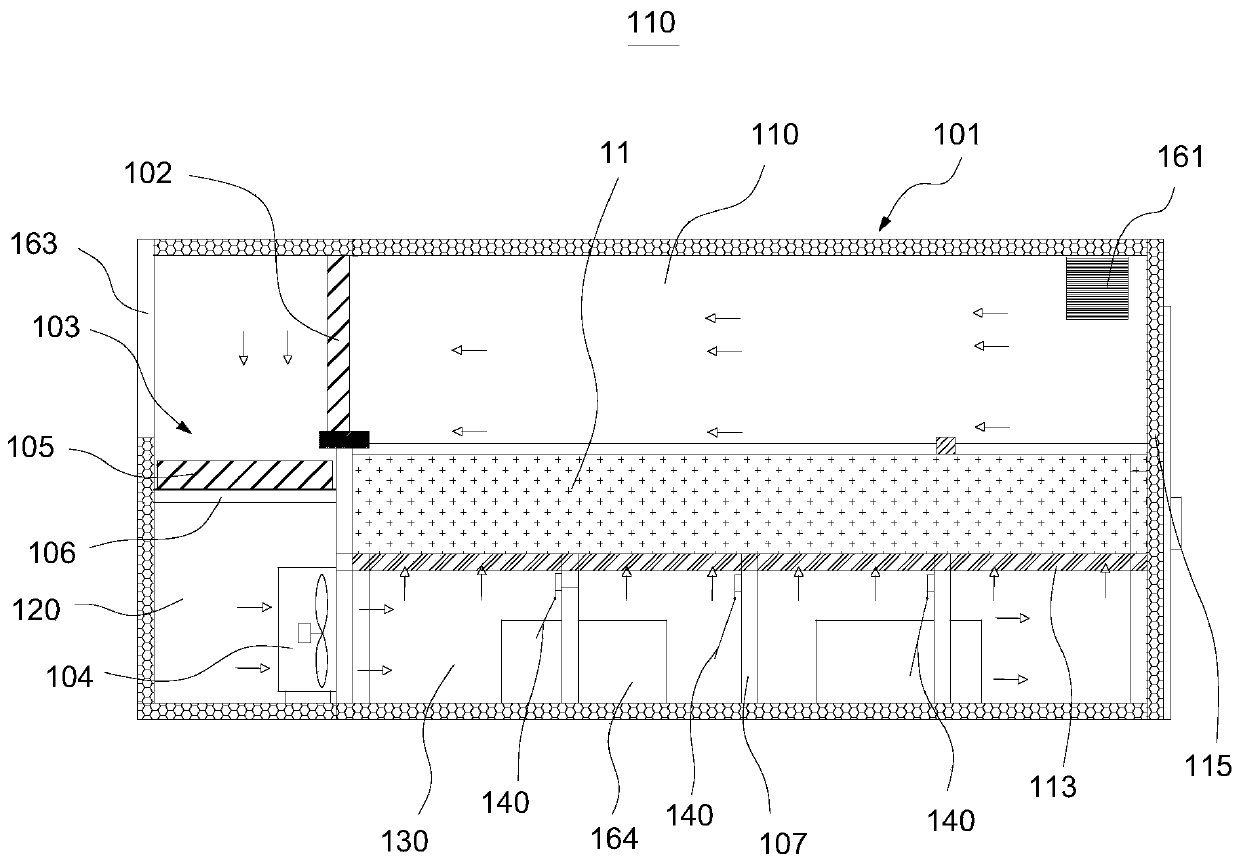

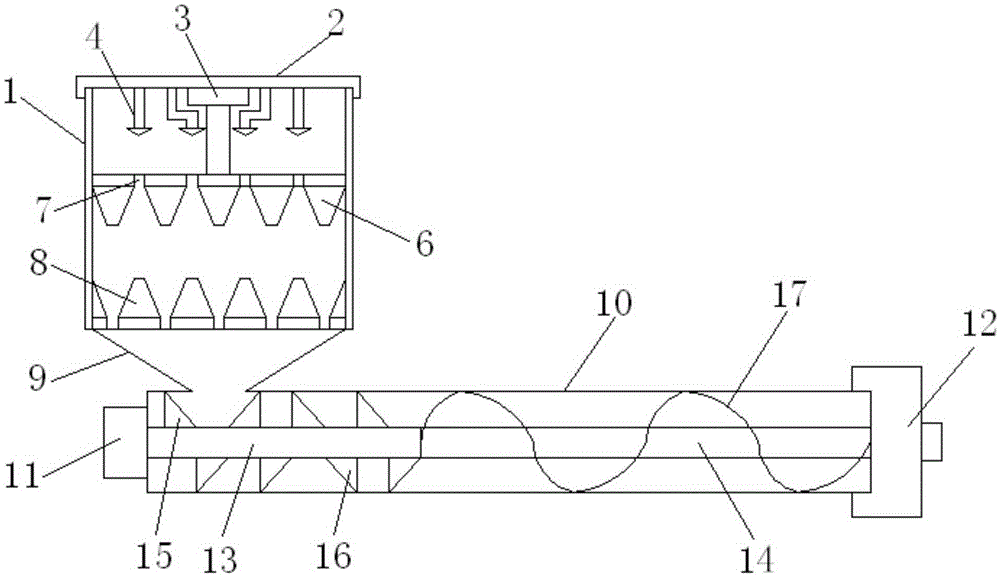

Pepper dew extracting and drying method and device

ActiveCN109959218AEven drying and heatingImprove use valueDrying solid materials with heatGranular material dryingEconomic benefitsDew

The invention relates to the technical field of pepper processing technologies, and provides a pepper dew extracting and drying method. The drying method includes the steps that pepper are placed in flowing hot wind; a condensation collector is used for collecting steams sent by the peppers; and drying is controlled by detecting the humidity. According to the pepper dew extracting and drying method, the dried peppers is good in quality, and pepper dew extracting also can be collected. The invention further provides a pepper dew extracting and drying device, the pepper dew extracting and dryingdevice includes a work box body, an evaporator, the condensation collector, and an air blower, an evaporating chamber, an air inducing chamber, and an air blowing chamber communicating in sequence are arranged in the work box body, a feeding inlet is formed in the top of the evaporator, a discharging door is arranged on the side wall of the work box body, the evaporator is arranged in the evaporating chamber, the air inducing chamber is provided with the condensation collector, and the air blowing chamber is provided with a baffle plate. During pepper drying, the pepper steams evaporated by the peppers can be collected by the drying device, the using valve of the peppers is improved greatly, the economic benefits are increased, and the quality of the peppers dried by the drying device isgood.

Owner:四川丁点儿食品开发股份有限公司

Anhydrous stemming for tapping hole of blast furnace and preparation method thereof

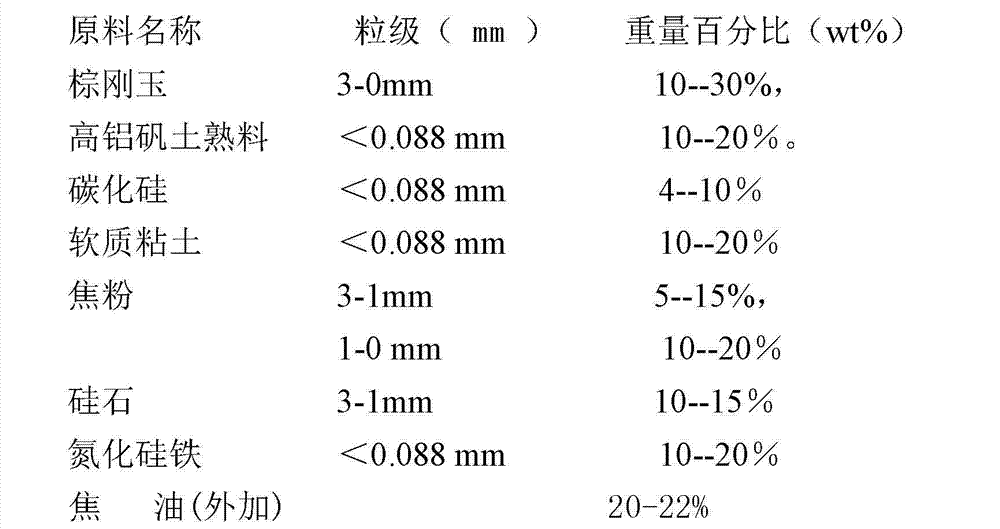

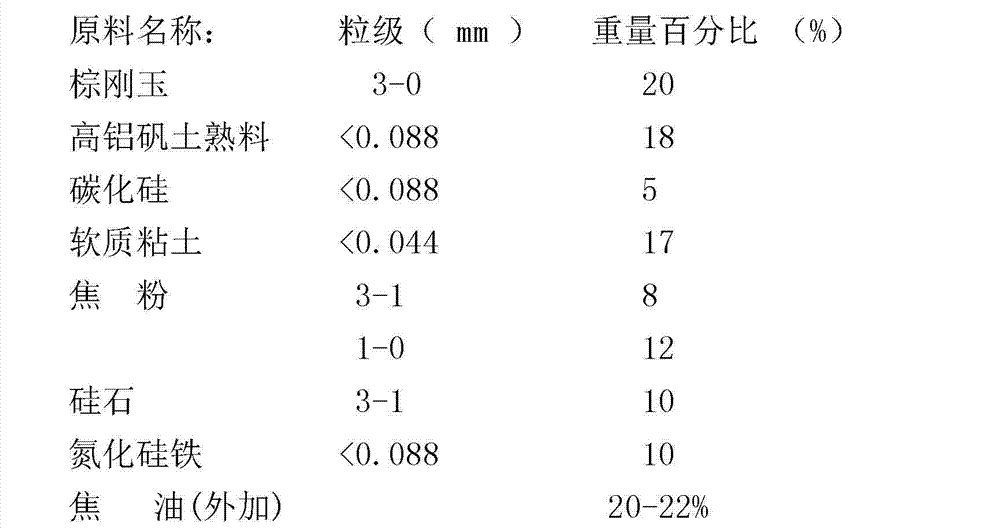

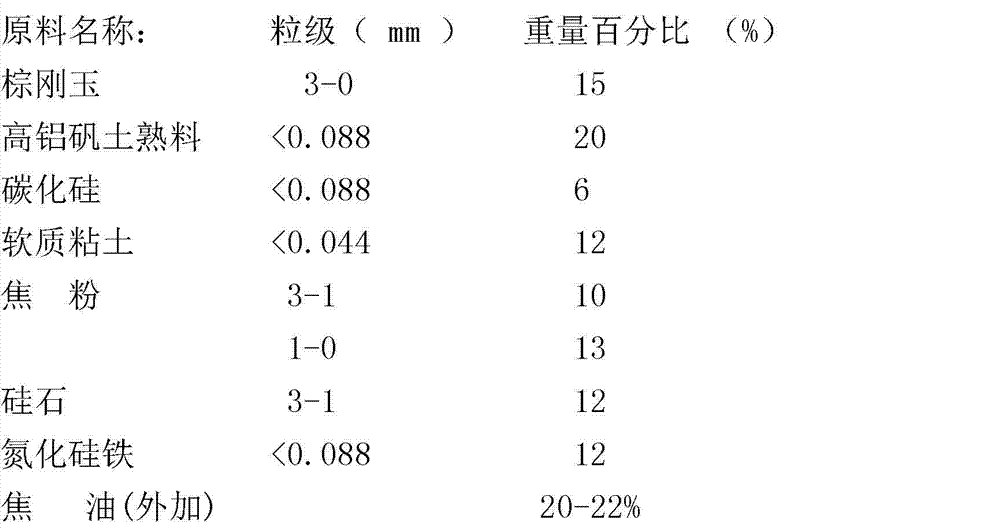

ActiveCN103044040AMeet the requirements of intensified smeltingImprove corrosion resistanceSoft claySlag

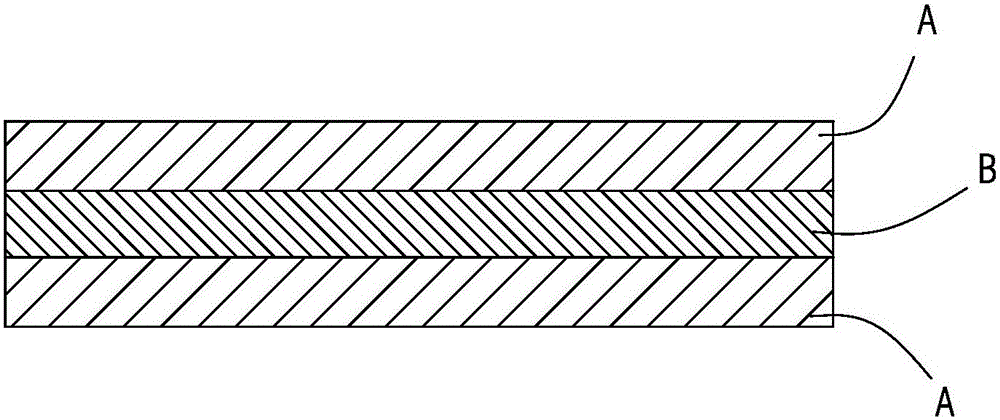

The invention relates to anhydrous stemming for a tapping hole of a blast furnace. The anhydrous stemming comprises the following raw materials in percentage by weight: 10 to 30 percent of brown fused alumina of 3 to 0 mm, 10 to 20 percent of bauxite clinker smaller than 0.088 mm, 4 to 10 percent of silicon carbide smaller than 0.088 mm, 10 to 20 percent of soft clay smaller than 0.088 mm, 5 to 15 percent of coke powder of 3 to 1 mm, 10 to 20 percent of coke powder of 1 to 0 mm, 10 to 15 percent of silica of 3 to 1 mm and 10 to 20 percent of ferro-silicon nitride smaller than 0.088 mm. A preparation method for the anhydrous stemming comprises the following steps: (a) weighing the raw materials according to the proportion, pouring the raw materials into a heating type edge runner mill, performing dry-blending for 20 to 30 minutes, adding hot tar with the oil temperature of 80 DEG C, controlling the temperature of the mill to be 70 to 80 DEG C, performing wet mixing for 35 to 45 minutes, and measuring the Marshall value of pug at the temperature of 50 DEG C to be 650 to 680 KPa; and (b) entering a mud extruding machine through a disc feeding machine, extruding mud and wrapping by using a plastic film to obtain the finished product, placing the finished product mud into a hopper and ageing for 48 hours to use. According to the invention, the iron slag scouring resistance is high, the iron notch hole is smooth, the aperture change is little, the corrosion resistance is excellent, spattering during tapping is avoided, the tapping time is long, the mud beating pressure is proper, and the opening performance is excellent.

Owner:内蒙古包钢利尔高温材料有限公司

Solar battery backplane, and preparation method of film polyester used for backplane

ActiveCN106008940AImprove flame retardant performanceGood mouthPhotovoltaic energy generationSemiconductor devicesPolyesterMoisture resistance

A preparation method of film polyester used for a backplane comprises the following steps: uniformly dispersing a flame retardant agent and a dispersant in glycol to prepare a flame retardant suspension, mixing fluorine-containing diacid, diol, a catalyst and the flame retardant suspension, carrying out an esterification reaction, adding a stabilizer after the esterification reaction ends, and carrying out a polycondensation reaction. The invention also discloses a method for producing the solar battery backplane by using the film polyester, and the solar battery backplane formed through coextruding slices produced from the film polyester. The film polyester has the advantages of excellent mechanical performances, excellent electrical insulation performance, excellent dimension stability, and excellent flame, weather and moisture resistance, can be widely applied to the fields of building, electronic appliances and solar photovoltaics, and is especially suitable for high-grade solar battery back materials.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

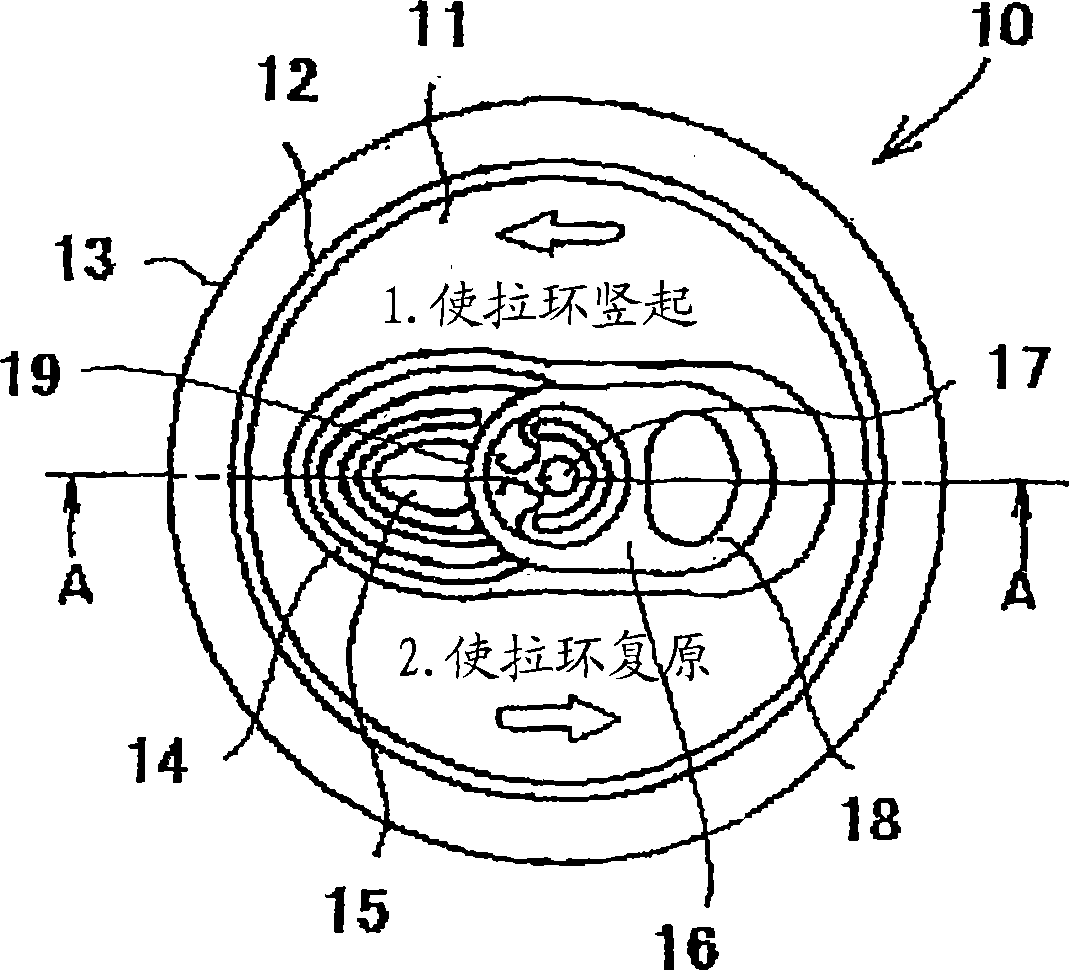

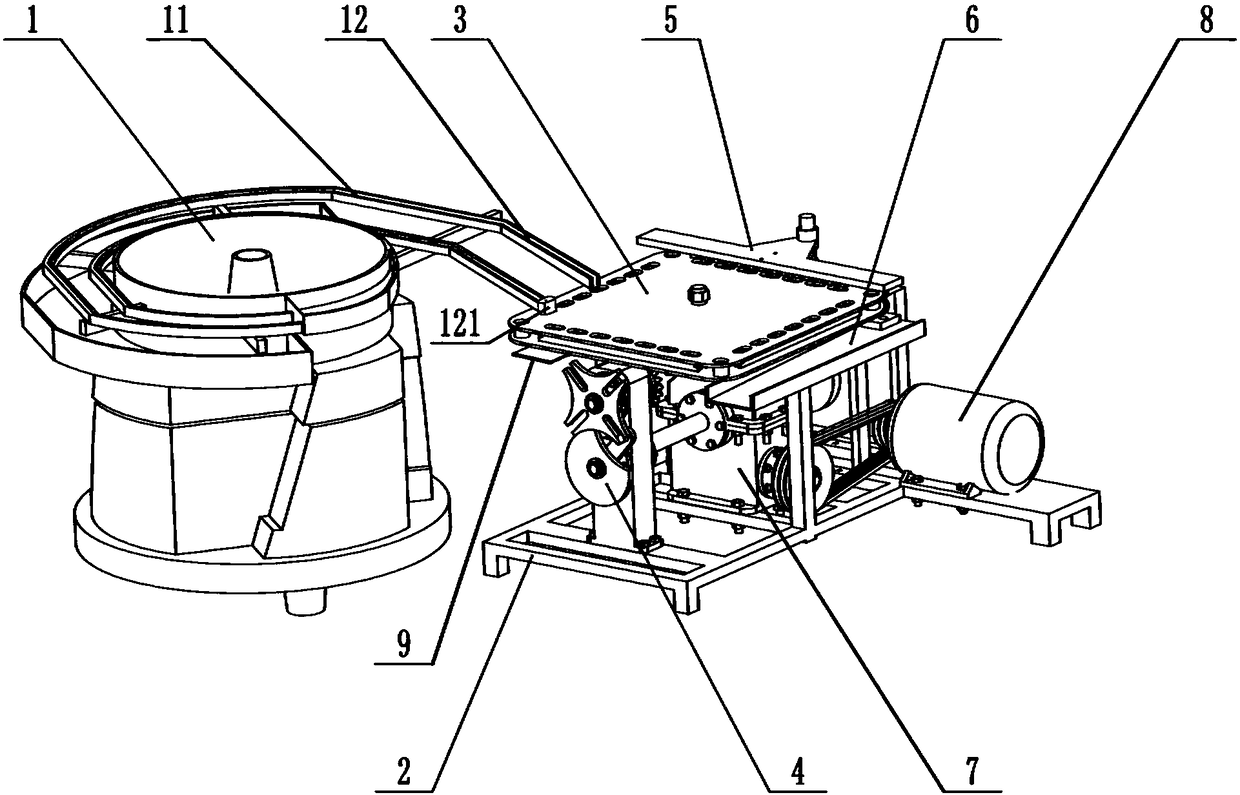

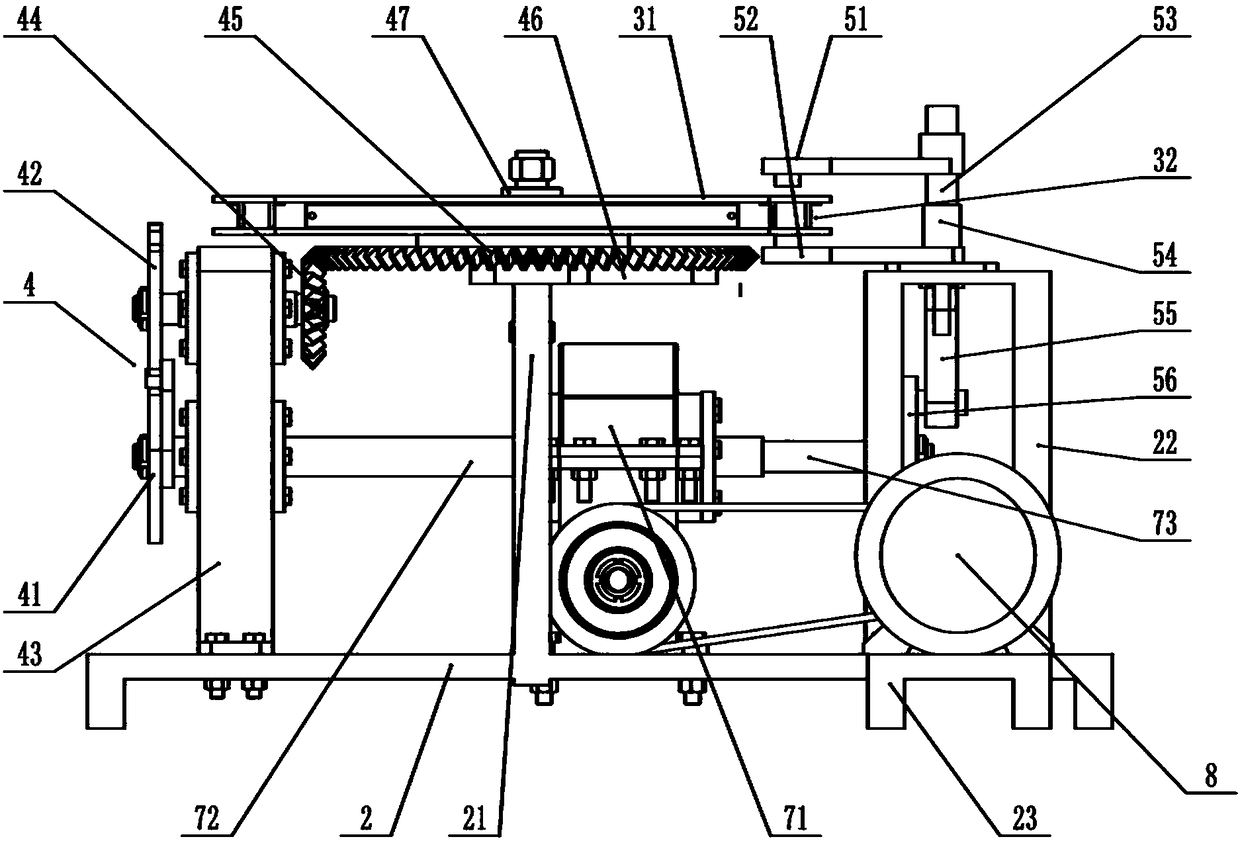

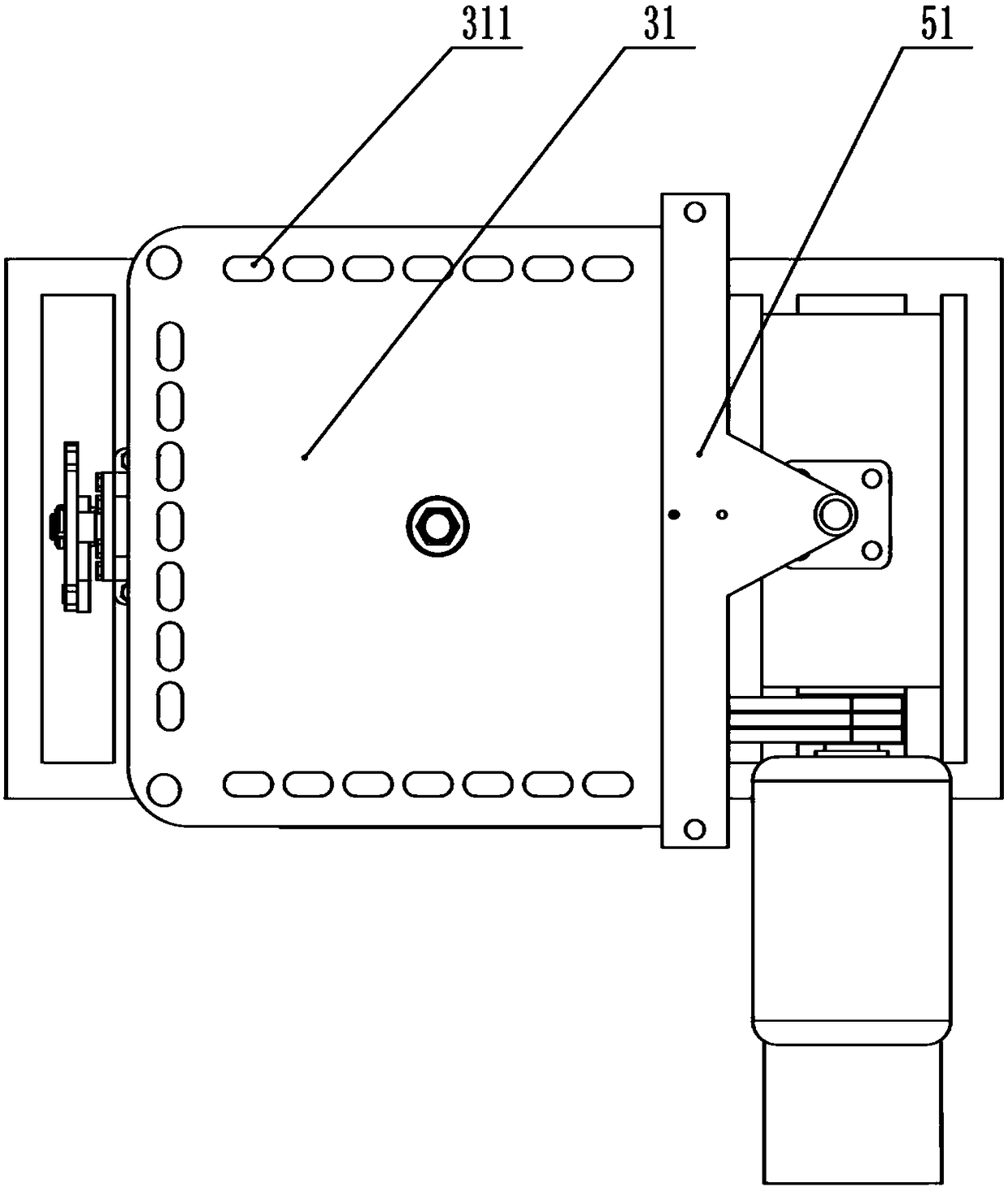

Device for forming opening in pistachio and capable of performing feeding based on vibrating disk

InactiveCN108497509ASolve problems that require manual processingSolve the problem of manual processingHuskingHullingEngineeringMechanical engineering

The invention discloses a device for forming an opening in a pistachio and capable of performing feeding based on a vibrating disk. The device comprises a feeding mechanism, a machine frame, a material bearing mechanism, a charging mechanism, an opening forming mechanism and a discharging mechanism, wherein the material bearing mechanism, the charging mechanism and the opening forming mechanism are arranged on the machine frame; the material bearing mechanism is connected with the charging mechanism; the charging mechanism and the opening forming mechanism are connected with a transmission mechanism; the discharging mechanism is arranged under the material bearing mechanism; the transmission mechanism is connected with a power mechanism; the feeding mechanism is the vibrating disk; a plurality of discharging channels are formed in the vibrating disk; each discharging channel is connected with a corresponding sliding rail; a clamping mechanism is arranged in the material bearing mechanism; the power mechanism is used for driving the opening forming mechanism and the feeding mechanism to move through the transmission mechanism; and an auxiliary material bearing plate is also arrangedunder the material bearing mechanism. Through the adoption of the device disclosed by the invention, the problems that in the prior art, the pistachio is vertically arranged, so that the direction isnot liable to control, an opening formed through extrusion does not confirm to specification, and the effect of manual opening forming is not achieved are solved.

Owner:于洋

Blast-furnace anhydrous stemming and production device thereof

The invention discloses a blast-furnace anhydrous stemming and a production device thereof. The blast-furnace anhydrous stemming is prepared from the following raw materials by weight: 4 to 8% of superfine homogenized bauxite particles, 17 to 20% of brown fused alumina particles, 3 to 7% of white fused alumina powder, 4 to 8% of tabular corundum powder, 2 to 6% of chromite sand powder, 9 to 18% of a carbon material, 4 to 10% of high-purity silicon carbide, 5 to 7% of silicon carbide particles, 10 to 13% of submicron powder, 8 to 12% of soft clay, 2 to 5% of sericite, 2 to 4% of metal silicon powder and 10 to 12% of composite oil. The invention has the following advantages: slag erosion resistance of the anhydrous stemming is increased; resistance of the anhydrous stemming to high-temperature molten iron erosion and wear is strengthened; opening performance and iron slag erosion resistance of the traditionally-used anhydrous stemming are improved; the quality stability of the anhydrous stemming is enhanced; meanwhile, a by-product electrical resistance material of carbon electrode smelting is utilized, so the anhydrous stemming is more beneficial for protection of resources and the environment.

Owner:广东悦江节能技术有限公司

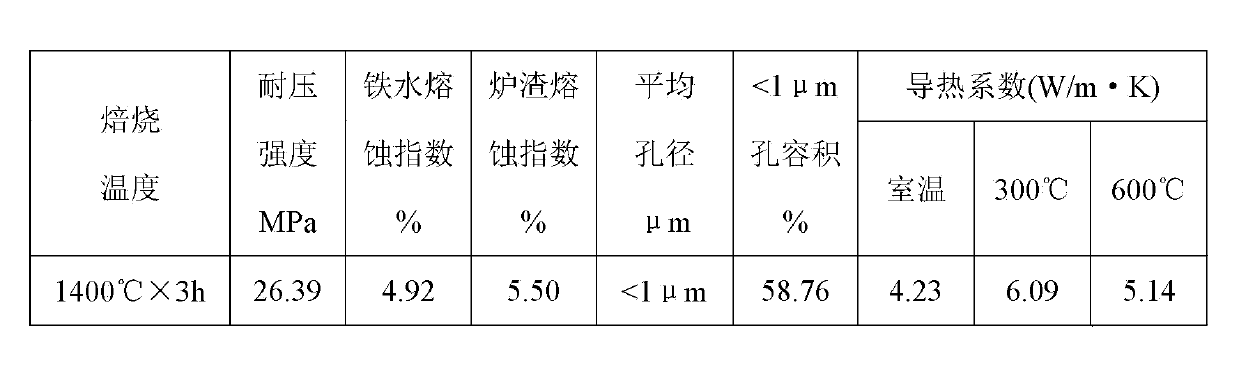

Phenolic resin composition for stemming, preparation method of composition and stemming

The invention provides a phenolic resin composition for a stemming and a preparation method of the composition. According to the method, 30-50wt% of thermosetting phenolic resin, 5-20wt% of organic solvent and the balance of a carbon-containing organic binder are mixed to obtain the phenolic resin composition for stemming. The invention further provides a stemming. The stemming comprises a refractory aggregate and a binding agent, wherein the binding agent is the phenolic resin composition provided by the invention. According to the phenolic resin composition for the stemming, the thermosetting phenolic resin and the carbon-containing organic binder are mixed and used together, and the proportions of the thermosetting phenolic resin and the carbon-containing organic binder are controlled in the specified ranges, and then an appropriate amount of the organic solvent is added, so that the stemming has a moderate curing speed. Moreover, the stemming comprising the phenolic resin composition provided by the invention has the advantages of good plasticity and cohesive property, proper porosity, small high-temperature volume shrinkage, good sintering performance, high strength, scouring resistance, erosion resistance, good opening performance and the like and hardly causes environmental pollution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

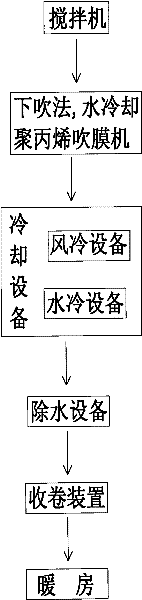

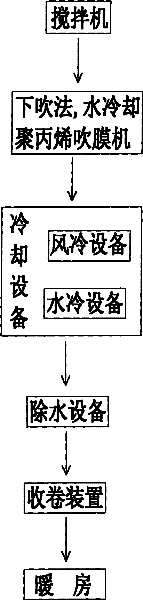

Plastic packaging film processing method and system

The invention relates to a plastic packaging film processing method and system. The method is to add an anti-blocking agent to the raw material of the plastic film and stir it evenly, and then make the primary product of the plastic packaging film, and then place the primary product of the plastic packaging film in an environment with a temperature of 15°C to 80°C for more than 10 hours to form a plastic package. Finished film. The system includes: mixing equipment, film blowing machine, cooling equipment, water removal device, winding device and temperature control equipment. The beneficial effect of the present invention is that: the polypropylene film and other plastic packaging films have good smoothness and openness, thereby reducing waste and cost in the process of printing, bag making and packaging, reducing labor intensity of workers and improving production efficiency.

Owner:WUJIANG ZHONGYA PLASTIC PACKAGING

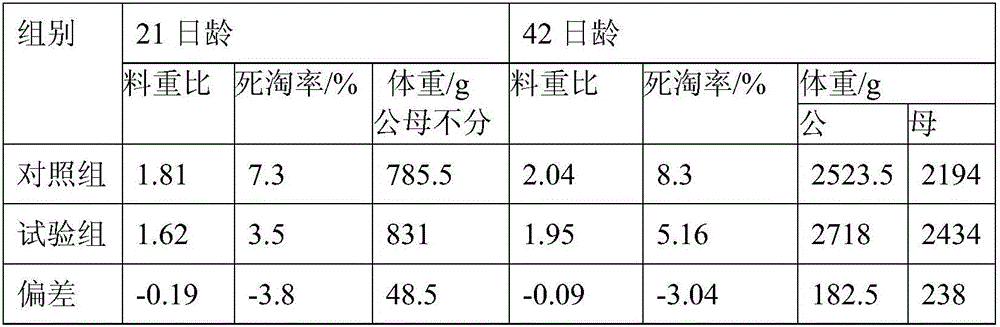

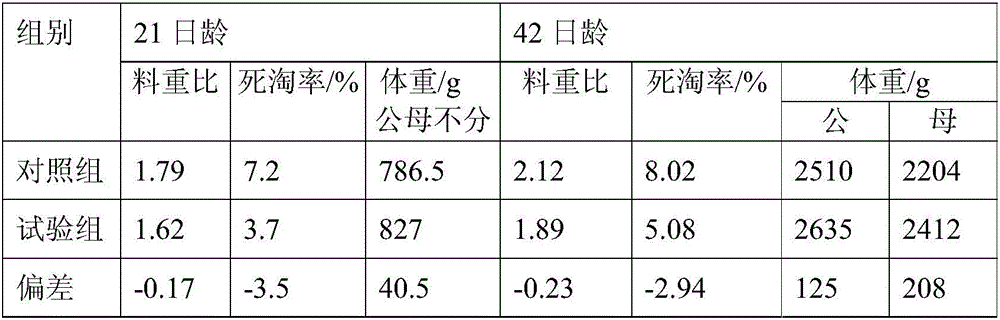

Small meat chicken feed containing 4% of premix

InactiveCN106107185AGood mouthNutritional diversityFood processingAnimal feeding stuffAnimal scienceRapeseed

The invention discloses small meat chicken feed containing 4% of premix. The small meat chicken feed is composed of the following components in parts by weight: 50-60 parts of corn, 3-7 parts of wheat bran, 0.2-0.5 part of rapeseed oil, 22-30 parts of bean pulp, 2-4 parts of rapeseed meal, 1-3 parts of cottonseed meal, 2-5 parts of fish meal, 5-8 parts of buckwheat flour, 2-5 parts of premix, 0.05-0.2 part of methionine, and 0.1-0.3 part of choline chloride. Small meat chickens fed with the small meat chicken feed containing 4% of premix provided by the invention are low in the feed to gain ratio, and the death rate is reduced, so that the breeding cost is reduced, and the breeding benefit is improved.

Owner:安徽麒麟正大饲料有限公司

Full biodegradable mulch material for crops in irrigated area and preparation method and application of full biodegradable mulch material

InactiveCN110105727AGood mouthSimple process conditionsClimate change adaptationPlant protective coveringsPolymer scienceZinc compounds

The invention relates to a full biodegradable mulch material for crops in an irrigated area and a preparation method and application of the full biodegradable mulch material. The material is preparedfrom poly terephthalic acid-adipic acid-butyl glycol ester, polyethylene furandicarboxylate ester, an aliphatic carboxylic acid zinc compound, a compatibilizer, a filler, an antioxidant and an ultraviolet absorber. The full biodegradable mulch film material has the advantages that PEF with stronger rigidity is used for performing rigidity enhancement and modification on PBAT under the action of the compatibilizer, thereby improving the rigidity of the PBAT and improving the rigidity and toughness balance of the PBAT. In addition, after the aliphatic carboxylic acid zinc compound is added, thephenomenon disappears that modified materials of PBAT and PEF adhere to equipment during membrane blowing processing, the blow-molded mulch has good opening performance, the mechanical properties of the modified material are not affected, and the cost can be greatly reduced through the cooperative use of the inorganic filler; the full biodegradable mulch material has simple processing conditions,excellent mechanical properties, low cost and a good development prospect.

Owner:LANZHOU XINYINHUAN RUBBER & PLASTIC PROD CO LTD

Smooth opening master batch and preparation method thereof

InactiveCN108299719AGood mouthImprove the lubrication effectOrganic compound preparationAmino-hyroxy compound preparationMaleic anhydrideEngineering

The invention relates to the technical field of a high polymer material, and concretely discloses a smooth opening master batch and a preparation method thereof. The smooth opening master batch is prepared from the following raw material ingredients in parts by weight: 80 to 100 parts of PE resin, 30 to 50 parts of slipping agents,30 to 50 parts of opening agents, 20 to 30 parts of maleic anhydride grafting compatibilizer and 1 to 3 parts of antioxidants. The master batch is the smooth opening master batch with the fire-new composition; the organic opening agents obtained through fire-new preparation are added into the smooth opening master batch; the opening performance and the lubricating performance are good.

Owner:广州禾工材料科技有限公司

Production technology of polyethylene anti-blocking agent master batch composition

The embodiment of the invention discloses a production technology of a polyethylene anti-blocking agent master batch composition and relates to the technical field of polyethylene production. The technology comprises the following steps: low-temperature crushing treatment of polyethylene; screen mesh; high-speed dispersion of a part on the screen mesh and an anti-blocking agent; melt blending by atwin-screw extruder, extrusion, cooling, blow-drying and grain-sized dicing to obtain the polyethylene anti-blocking agent master batch composition. Raw materials except the anti-blocking agent successively undergo low-temperature crushing, sieving and high-speed mixing to obtain fully-dispersed anti-blocking agent inorganic primary particles. Through the method, inorganic primary particles are effectively prevented from being agglomerated into large granular inorganic particles. In comparison with an anti-blocking agent master batch composition prepared by a traditional process, the invention has the following beneficial effect: under the condition of equal addition amount, the prepared film product has better opening performance and lower friction coefficient, and mechanical propertiesof the film product are improved and its haze is reduced.

Owner:锦州英诺威科技服务有限公司

Compound additives for polyethylene packign film

The invention relates to a polyethylene packaging compounding additive that could improve the physical capability of polyethylene. The constituents are 10-30% silicide, 20-40%stearamide, 5-25% antioxidant, 10-22% antistatic agent, and 10-22% zinc stearate. The invention could keep the diaphaneity of polyethylene and could make the film has the function of sliding and high efficiency anti oxygen and antistatic.

Owner:广州赫尔普化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com