Tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and preparation method of tap hole medium-temperature-sintering environment-friendly stemming

A tap hole, large and medium-sized technology, which is applied to the medium-temperature sintering environment-friendly taphole clay for large and medium-sized blast furnaces and its preparation field, can solve the problem of poor rapid sintering performance, low strength and thermal conductivity, and resistance to slag iron erosion and scouring. Poor performance and other problems, to achieve the effect of improving microporation index, improving medium and high temperature sintering performance, resistance to slag iron erosion and scouring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

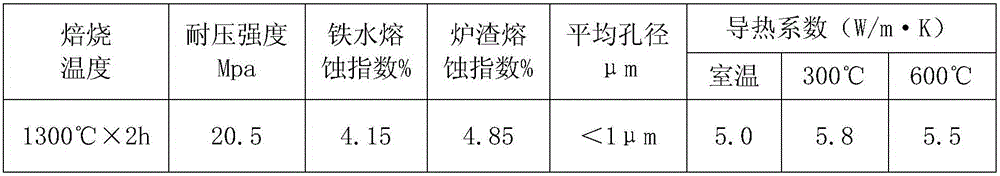

Examples

Embodiment 1

[0031] A medium-temperature sintering environment-friendly taphole clay for large and medium-sized blast furnaces, comprising, in parts by weight: binder, anti-explosion fibers and the following dry material components in parts by weight:

[0032] Sprinkle dry material to carry out batching according to following requirements, and its component is counted as by weight:

[0033] 12 parts of brown corundum: of which 0.051mm < particle size ≤ 1mm accounted for 75%, particle size ≤ 0.051mm accounted for 25%;

[0034] 45 parts of high-alumina clinker, of which the weight percentage of high-alumina clinker with 1mm<particle size≤3mm in the whole high-alumina clinker is 60%; the high-alumina clinker with particle size≤0.074mm in the whole The weight percentage is 40%;

[0035] Silicon carbide: 12 parts, silicon carbide particle size ≤ 0.08mm;

[0036] 1.5 parts of ferrosilicon nitride, in the ferrosilicon carbide, Si 3 N 4 Accounted for 75%, Fe accounted for 16%, and the balance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com