Patents

Literature

77results about How to "Improve sintering strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Casting coated sand suitable for selective laser sintering forming and manufacturing method thereof

ActiveCN102343415AReduce dosageGood sintering strengthFoundry mouldsFoundry coresSelective laser sinteringLight absorber

The invention discloses casting coated sand suitable for selective laser sintering forming and a manufacturing method thereof. The coated sand is made from roughing sands, an organic binder, an inorganic binder, a coupling agent and a curing agent, further, additives, such as a lubricant, a light absorber and the like are not required; and the roughing sand is spherical pearl sand with the angular coefficient less than or equal to 1.1, wherein the sand grains consist of adjacent four-sieve sands or five-sieve sands. The manufacturing method of the casting coated sand comprises the following steps of: sieving the roughing sands to obtained the required four-sieve sands or five-sieve sands; carrying out thermal coating on the roughing sands by using phenolic resin powder, the coupling agentand the curing agent according to a certain proportion so as to obtain phenolic resin coated sand; and evenly mixing monoammonium phosphate fine powder and the phenolic resin coated sand which are ina certain proportion to obtain the casting coated sand suitable for the selective laser sintering forming. The coated sand laser sintering forming part has high preform strength, good forming accuracy and little gas forming amount and can be applied to a casting sand mold (core) with an intricate structure in laser fast forming, therefore, the fast trial-production and the manufacturing capacity of intricate castings are enhanced.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

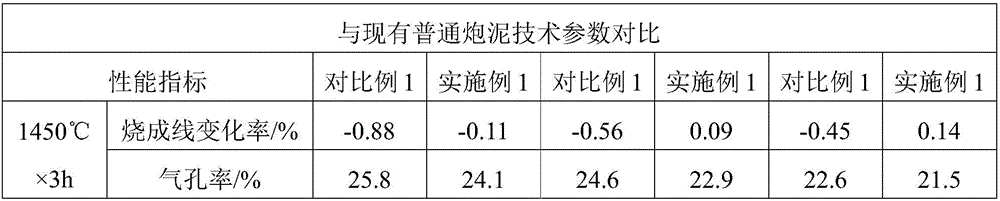

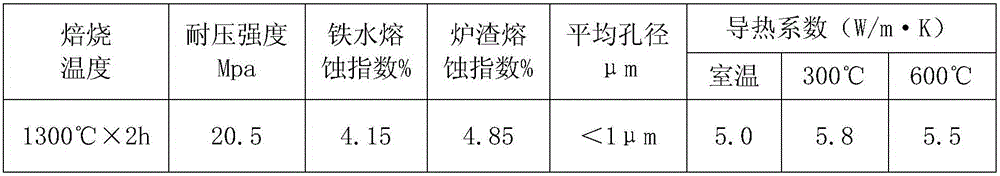

Heating furnace mending material and preparation method thereof

Owner:北京利尔高温材料股份有限公司 +2

Anhydrous stemming for large and medium sized blast furnace and preparation method of anhydrous stemming

The invention relates to an anhydrous stemming for a large and medium sized blast furnace and a preparation method of the anhydrous stemming. The stemming comprises the raw materials of bauxites aggregate and fine powder, silicon carbide aggregate and fine powder, coke, plastic clay powder, asphalt powder and a micro powder additive, the micro powder additive comprises metallic silicon powder, metallic aluminum powder, high-carbon resin powder, alumina micro powder, silica fume, sodium carboxymethyl cellulose and sodium hexametaphosphate in parts by weight, and tar is taken as a binding agent in the producing and stirring processes. The anhydrous stemming realizes high-temperature rapid sintering of the stemming, the binding degree of new and old stemming is strengthened, the capability of resisting scouring of an iron slag of a mud drum of an iron notch is improved, the porosity of the stemming material is low, the compactness of the stemming material is good, the property of resisting corrosion and permeation of an iron slag liquid of the stemming is strengthened, the stemming is favorable for keeping the depth of the iron notch and the stability of the pore size of the iron notch, and can well adapt to the performance requirement of enlargement of the blast furnace on the stemming of the iron notch.

Owner:CHINA JINGYE ENG +1

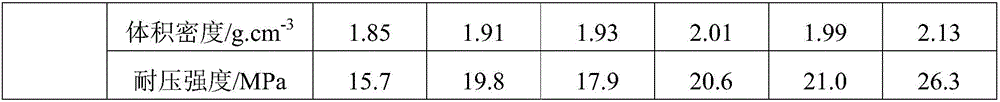

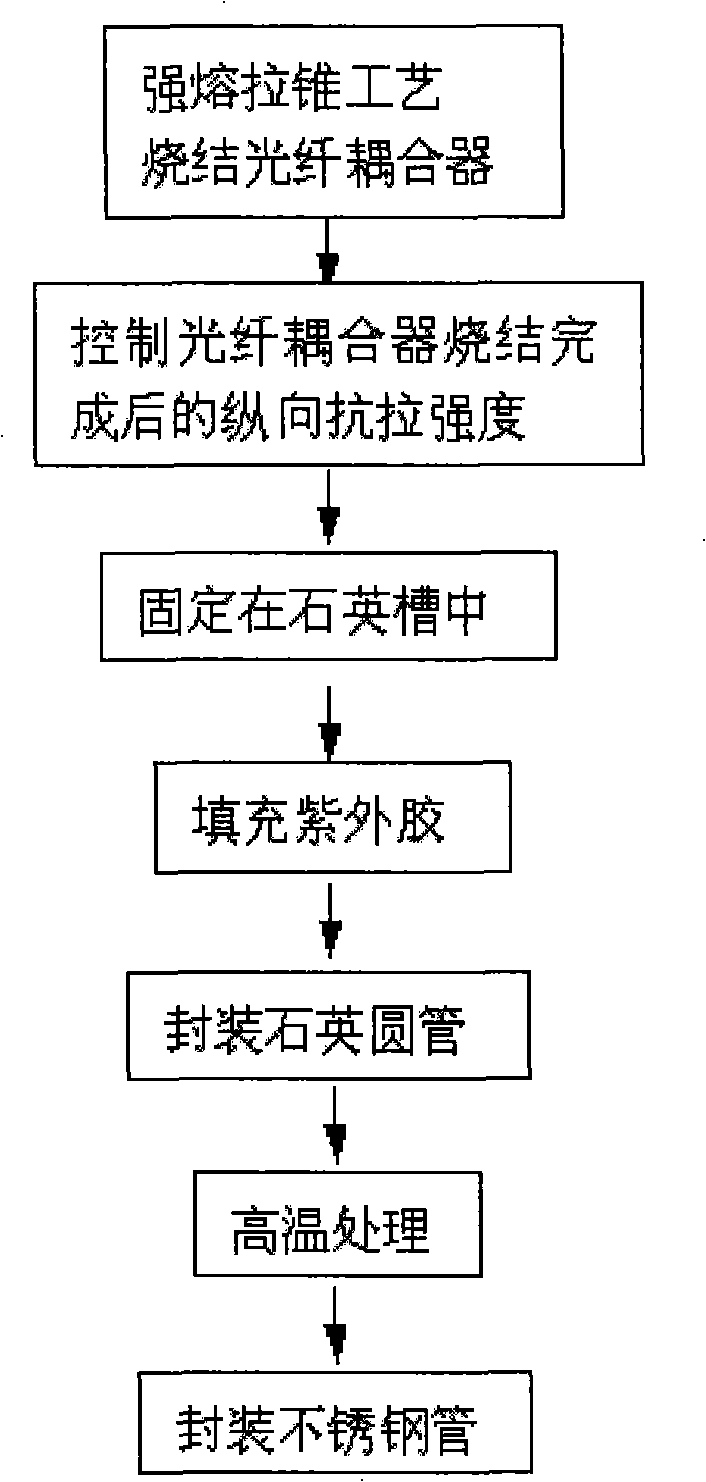

Method for preparing high-reliability optical fiber coupler

ActiveCN101408644AAvoid large internal stress defectsImprove sintering strengthCoupling light guidesSilicon rubberOptical fiber coupler

The invention discloses a preparation method of a high-reliability optical fiber coupler. The method comprises the following steps: (1) the optical fiber coupler is prepared by a parallel sintering dense melting tapering process, after the optical fiber coupler is sintered, the longitudinal tensile strength is detected by tensile force, and the longitudinal tensile strength is required to be more than 1N; (2) the two ends of the sintered optical fiber coupler are fixed in a U-shape quartz groove by thermo-curing glue, the inside at the two ends of the quartz groove is filled with UV glue, and the span length of the intermediate optical fiber is shortened; (3) the optical fiber coupler is sheathed in a quartz circular tube, and the two ends of the quartz circular tube are fixed by the thermo-curing glue; (4) high-temperature treatment is carried out on the optical fiber coupler, firstly the high-temperature treatment is carried out at the temperatures of 83-87 DEG C for 2-3 hour storage; and then carried out at the temperatures of 108-112 DEG C for 1-2 hour storage; and (5) the optical fiber coupler is sheathed on a stainless steel tube after the quartz circular tube is coated with silicon rubber, and the two ends of the stainless steel tube are sealed.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Corrosion-resistant silicon carbide wear-resistant plastic material

InactiveCN103319188AImprove wear resistanceImprove thermal shock resistancePlastic materialsWear resistant

The invention relates to an amorphous refractory material, and particularly relates to a corrosion-resistant silicon carbide wear-resistant plastic material applicable to the poor operating environment parts of garbage incinerators and circulating fluidized beds and the like. The plastic material is prepared from the following raw materials in percentage by mass: 70-78% of high-alumina aggregates, 10-15% of 98% silicon carbide, 4-6% of alumina micro-powder with the particle size of less than or equal to 2 mu m, 2-3% of chrome oxide, 4-5% of 94% micro silicon powder, and 2-3% of silicon metal powder. The corrosion-resistant silicon carbide wear-resistant plastic material provided by the invention is high in compression strength and rupture strength, small in line change rate and strong in wear resistance, and can satisfy the application requirements of circulating fluidized bed boilers under harsh working conditions for a long time.

Owner:YIXING XINGBEI REFRACTORIES PROD

Sintered metallic bearing and fluid dynamic bearing device equipped with the bearing

ActiveCN102356249AImprove wear resistanceImprove sintering strengthTransportation and packagingShaftsMetalRaw material

A sintered metallic bearing obtained by compacting raw-material powders comprising Cu powders, SUS powders, and pure-Fe powders and thereafter sintering the compact at a given temperature.

Owner:NTN CORP

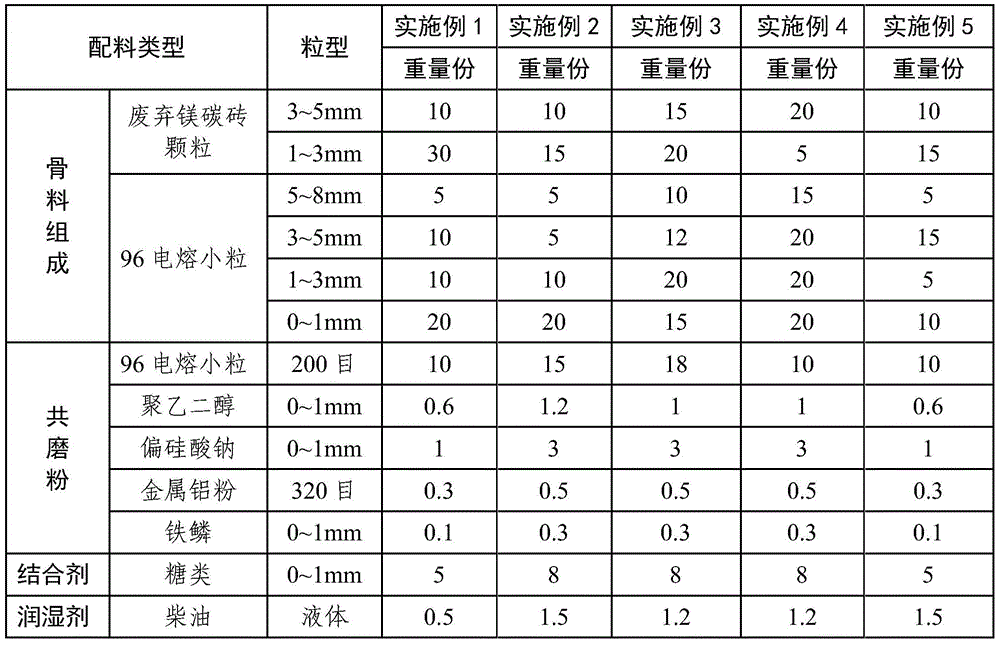

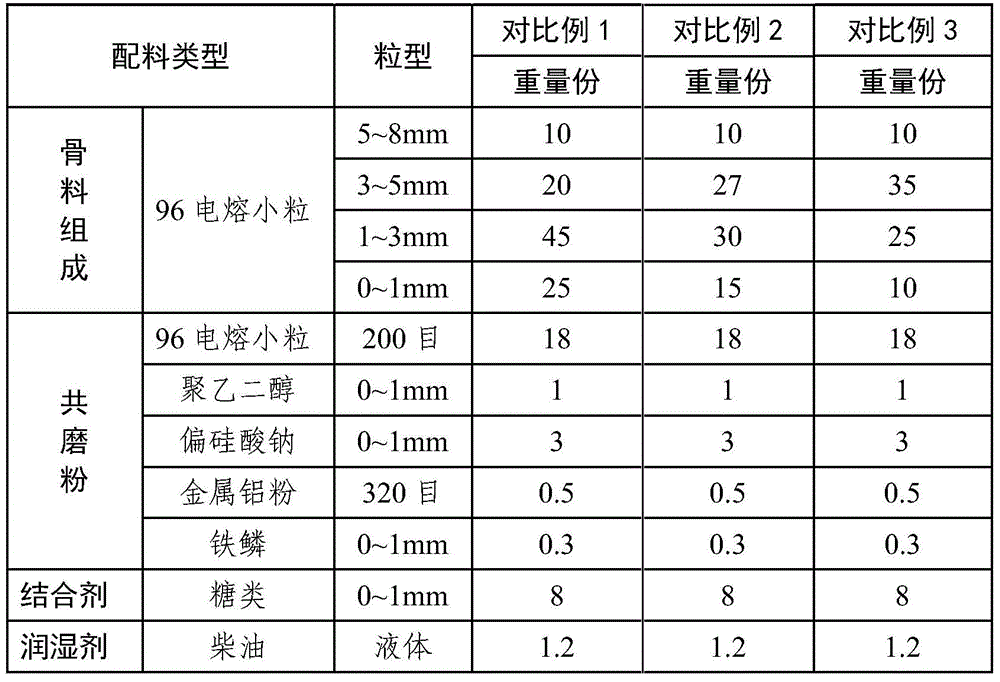

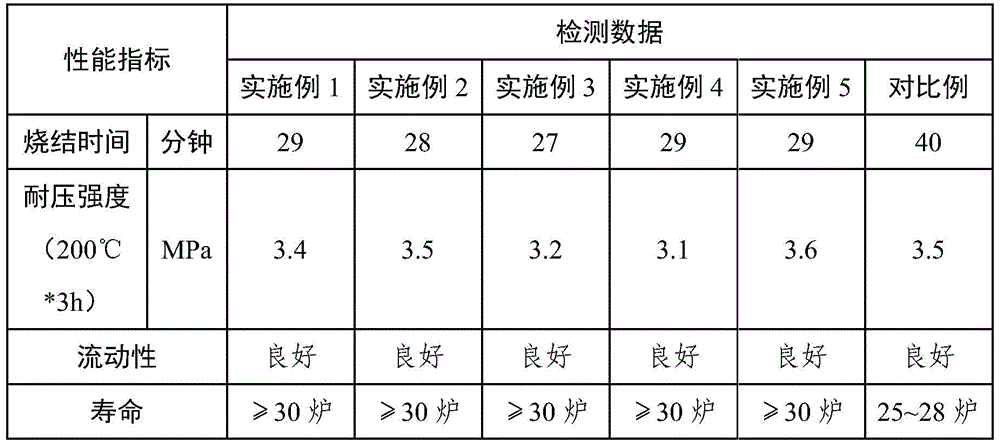

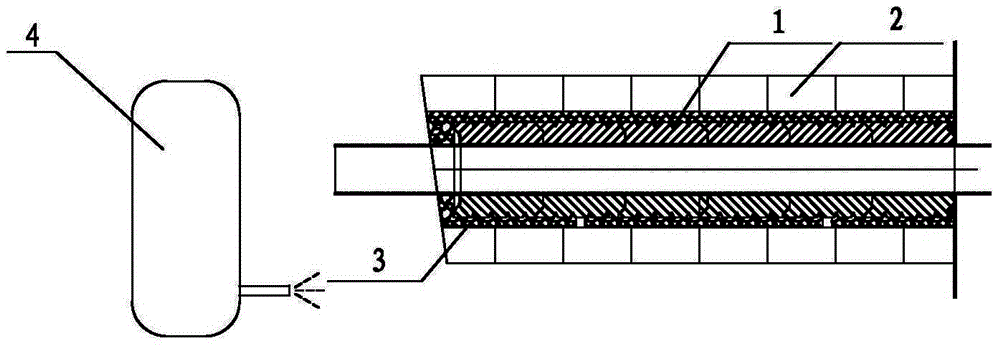

Converter repairing mass and preparation method thereof

The invention relates to the technical field of unshaped refractory materials in converter steelmaking and particularly relates to a converter repairing mass and a preparation method thereof. The converter repairing mass is prepared from the following raw materials in parts by weight: 70-110 parts of mixture of fused magnesite and waste magnesia carbon brick particles, 10-30 parts of fused magnesite fine powder, 5-8 parts of bonding agent and 2-5 parts of filler, wherein the mixture of fused magnesite and waste magnesia carbon brick particles at least comprises 10-30 parts of fused magnesite fine powder. The preparation method of the converter repairing mass comprises the following steps of: adding 0.5-1.5 weight parts of wetting agent into the raw materials of the converter repairing mass, and mixing and stirring to obtain loose, dry and uniform aggregate. According to the converter repairing mass and preparation method thereof, the waste magnesia carbon brick serves as a raw material, and the converter lining built by the magnesia carbon bricks realizes a better protection effect; the converter repairing mass has the advantages of good high-temperature fluidity, short sintering time, high sintering strength, long service life, environmental protection and the like.

Owner:北京利尔高温材料股份有限公司

Replacing method of converter tap hole

The invention relates to a replacing method of a converter tap hole and belongs to the technical field of steel smelting. The replacing method of the converter tap hole provided by the invention comprises the following steps: 1, placing a whole set of brick in a brick cup channel and adjusting the angle and position; and 2, fixing the whole set of brick on the converter body, filling the gap between the brick cup and whole set of brick with a tapping hole grouting material and sintering the tapping hole grouting material by the waste heat in the converter. The invention has the following beneficial effects of the replace time shortened by about 10 minutes compared with an existing method, the service life of the tapping hole prolonged by about 250 furnace compared with the existing method, the success rate for pushing off the slag improved by 10% compared with the existing method and the cost on per ton of steel reduced by about 0.15 yuan, so as to achieve the purposes of shortening replace time for converter tapping hole, prolonging the service life of tapping hole, improving slag pushing-off rate, reducing production mistake, improving product quality and reducing production cost.

Owner:张家港联峰钢铁研究所有限公司

Silicon carbide ceramic and preparation method thereof

ActiveCN106588021AImprove sintered densityImprove bending strengthDensity distributionFlexural strength

The invention provides silicon carbide ceramic and a preparation method thereof. The preparation method includes: subjecting a ceramic main raw material, a binder accounting for 2.5-3% of weight of the ceramic main raw material and a dispersant accounting for 1.5-2.5% of the weight of the ceramic main raw material to cold isostatic pressing and liquid phase sintering. Generally, dry pressing is adopted for forming a ceramic material; during dry pressing, various performances of a material are influenced by nonuniform density distribution inside a blank caused by nonuniform pressure distribution; compared with dry pressing, cold isostatic pressing is uniform in pressurizing, pressures received by the material in all directions are identical, and sintering density, bending strength and rupture strength of the material are improved.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV +1

Electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352AHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

Sintering additive and preparation method and application method thereof

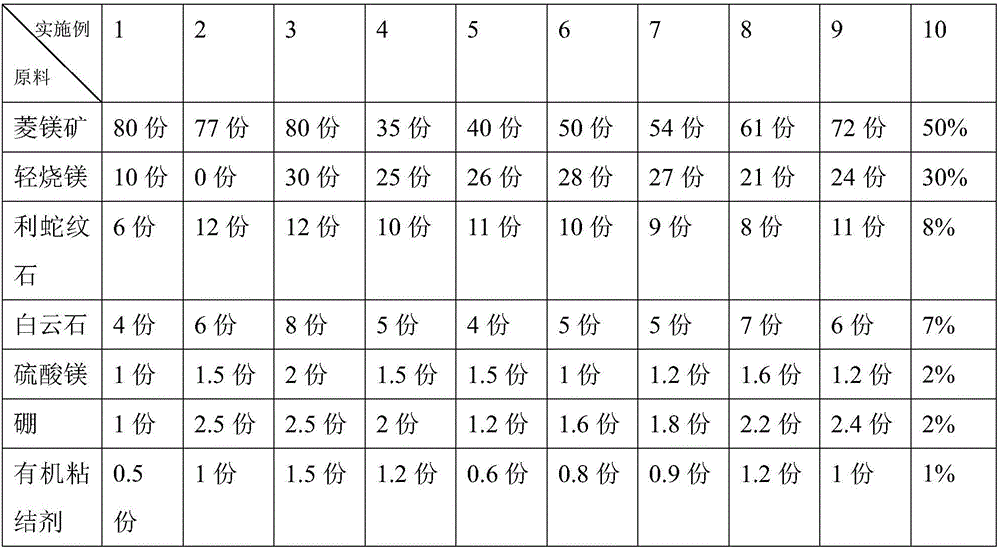

ActiveCN105907951ALower melting temperatureImprove ignition conditionsDolomiteMagnesium sulphate heptahydrate

The invention relates to a sintering additive and a preparation method and application method thereof. The sintering additive comprises, by weight, 30-80 parts of magnesite, 0-30 parts of light-burned magnesia, 6-12 parts of lizardite, 4-8 parts of dolomite, 1-2 parts of magnesium sulfate, 1-2.5 parts of boron and 0.5-1.5 parts of organic binding agents. The magnesite, the light-burned magnesia, the lizardite, the dolomite, the magnesium sulfate, the boron and the organic binding agents are put into a mixer to be mixed and crushed and ground in a crushing machine until the granularity is below 200 meshes. The mixture is dried and bagged. The sintering additive has the advantages that the melting temperature of the mixture is reduced, the ignition conditions are improved, the return mine quantity is reduced, and the rate of finished products is increased; the heat transfer conditions of gas-solid-liquid phases in the sintering process are improved, so that the sintering speed is increased, the sintering time is shortened, and the production efficiency is improved; the sintering additive can have a catalytic effect on gasification combustion of solid fuel, enhance the reactivity of the fuel, enable the temperature of a combustion zone in the sintering process to be increased, facilitate mineralization reactions and generate more liquid phases.

Owner:UNIV OF SCI & TECH LIAONING

Tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and preparation method of tap hole medium-temperature-sintering environment-friendly stemming

The invention relates to tap hole medium-temperature-sintering environment-friendly stemming for large- and medium-sized blast furnaces and a preparation method of the tap hole medium-temperature-sintering environment-friendly stemming.The spreading drying material of the stemming is reasonable in composition and combination and is characterized in that the spreading drying material uses high-aluminum clinker and coke powder as aggregate and brown aluminum oxide, clay and silicon carbide as powder, ferro-silicon nitride content is adjusted, micro-powder such as silicon powder and alpha-aluminum oxide and anti-burst fibers are added, and the binder is the mixture of 9-11 parts of tar, 2-5 parts of resin and 1-3 parts of anthracene oil.The tap hole medium-temperature-sintering environment-friendly stemming has the advantages that the anti-burst fibers are added, so that the heat conduction ability of the stemming is increased, combustion carbonization of the tap hole stemming can be achieved during high-temperature exhausting, and the opening performance of the stemming is improved; the small amount of fire-resistant materials such as the brown aluminum oxide, the silicon carbide and the ferro-silicon nitride with excellent slag iron corrosion resistance are combined with the anti-burst fibers which can exhaust and combust fast and the high-aluminum clinker which is low in cost, the molten iron and slag corrosion resistance of the stemming is increased greatly, and the tapping time of the stemming is guaranteed, and environment pollution is reduced.

Owner:HEBI RONGMING TECH CO LTD

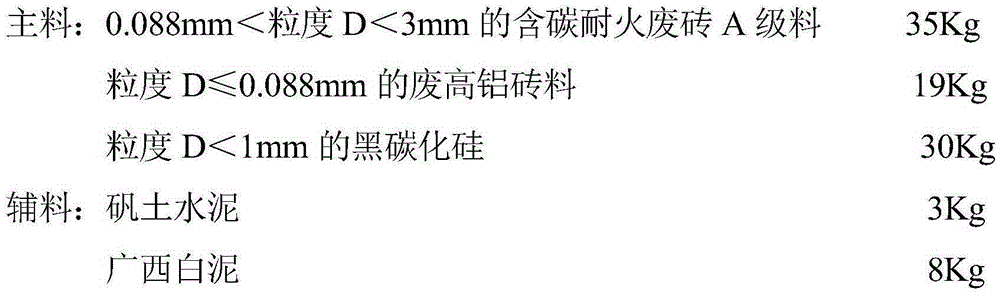

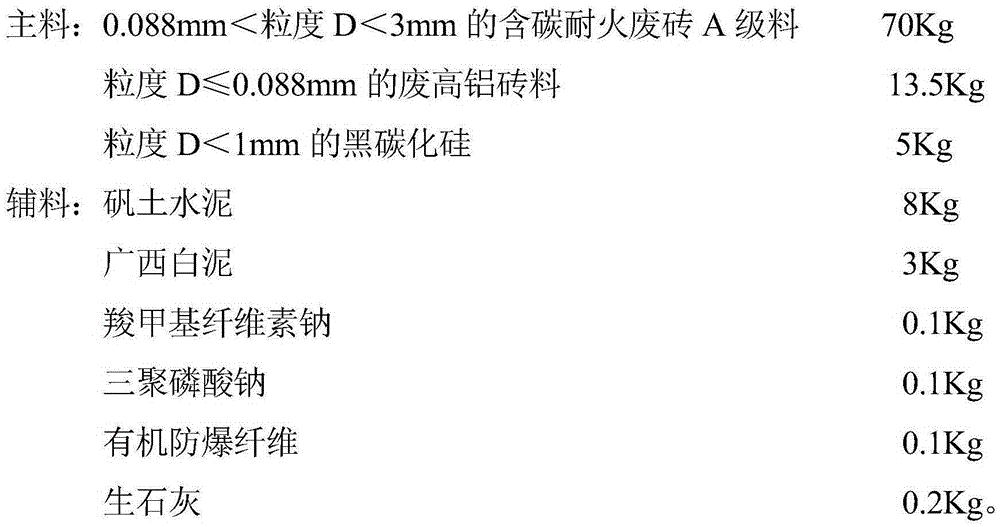

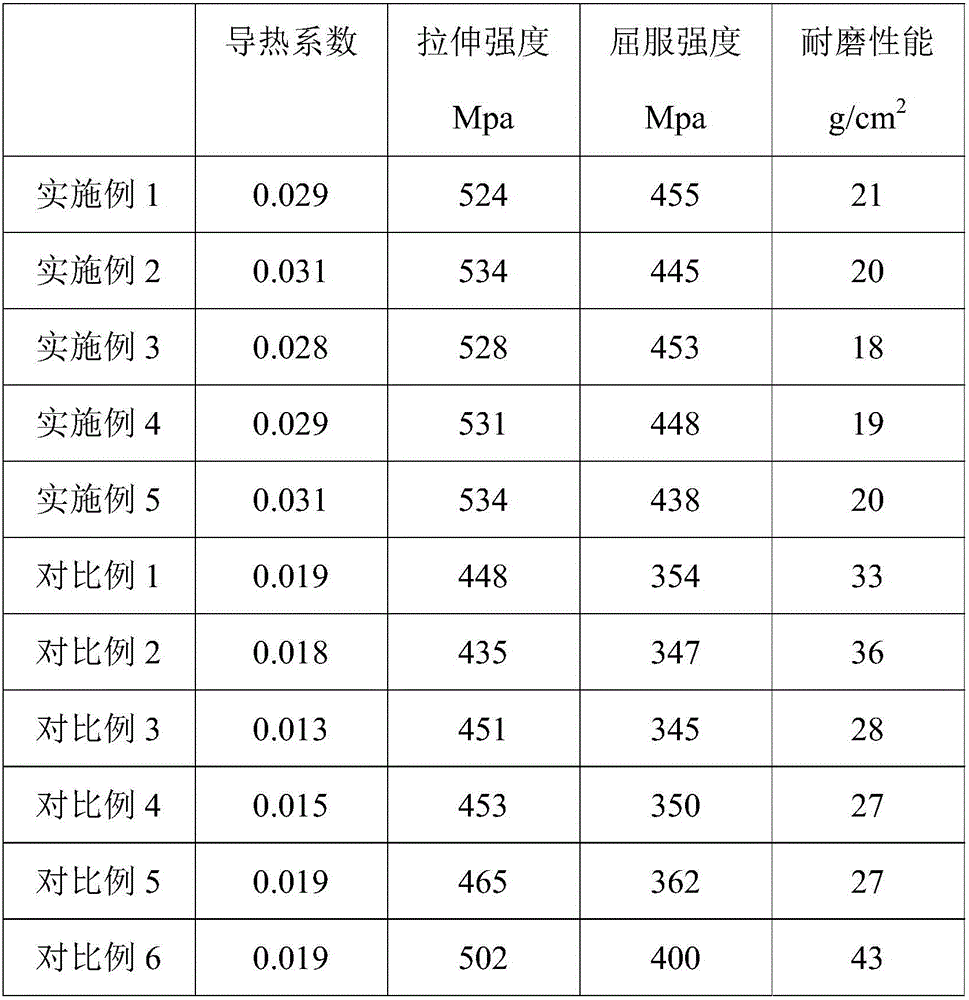

Slag anti-adhesion coating for hot metal ladle

The invention discloses a slag anti-adhesion coating for a hot metal ladle. The slag anti-adhesion coating consists of the following components in percentages by weight: 35-70wt% of carbonaceous fireproof waste brick A-level materials, 10-35wt% of waste high-aluminum brick materials, 5-30wt% of black silicon carbide, 3-8wt% of aluminous cement, 3-8wt% of Guangxi white clay, 0.1-2wt% of carboxymethyl cellulose sodium, 0.1-1wt% of sodium tripolyphosphate, 0.1-1wt% of organic explosion-proof fibers, and 0.01-1wt% of quick lime. According to the slag anti-adhesion coating for the hot metal ladle disclosed by the invention, the preparation process is simple; besides, in the construction project of slag anti-adhesion treatment for the hot metal ladle, the slag anti-adhesion coating has the characteristics of being simple in construction, excellent in slag anti-adhesion property, high in sintering intensity, low in cost and the like, and is obvious in economic benefit and social benefit.

Owner:WUGANG REFRACTORY CO LTD

Brushless DC motor and preparation technology thereof

ActiveCN106191501AImprove mechanical propertiesGood thermal conductivityElectrolytic coatingsSupports/enclosures/casingsMetallurgyEngineering

The invention provides a brushless DC motor and belongs to the electromechanical field. The brushless DC motor is made of aluminium alloy and comprises a shell, wherein the shell is composed of a first end cover and a second end cover; a stator assembly and a rotor connected with the stator assembly are arranged in the shell; the stator assembly is fixedly arranged on a first bearing and a second bearing; the aluminium alloy comprises the following components in mass percent: 0.45-0.9% of Mg, 0.2-0.6% of Si, 0.1-0.2% of Mn, 0.1-0.2% of Cr, 0.1-0.2% of Fe, 0.1-0.2% of Ti, 0.18-0.2% of Zr, 0.5-0.6% of Sc and the balance of Al. The brushless DC motor obtained through reasonable element matching and the smelting, sintering and electroplating technologies has high strength, abrasion resistance and corrosion resistance.

Owner:卓尔博(宁波)精密机电股份有限公司

Method for producing premixed copper-tin 10 bronze

ActiveCN105382253AAvoid compositional segregationImprove toughnessTransportation and packagingMetal-working apparatusPrillMaterials science

The invention discloses a method for producing premixed copper-tin 10 bronze. The method comprises the steps that copper powder is subjected to water atomization by a conical spray tray and then is subjected to thermal treatment, the copper powder subjected to thermal treatment is crushed and subjected to oxidation resistance, and raw material copper powder is obtained through screening; the prepared copper powder and tin powder are evenly mixed according to the mass fraction; the powder is subjected to thermal treatment in a reducing atmosphere, and copper powder particles and tin powder particles are bonded with each other in a diffusion mode in the thermal treatment process; the thermal treatment powder is crushed, and powder is obtained through screening; a lubricating agent is added into the powder to be mixed evenly. According to mixed bronze powder produced by the method, the water atomization copper powder in irregular shapes is used and then is subjected to thermal treatment, so that the raw material copper powder has good toughness, and composition segregation of the bronze powder is avoided; in addition, the water atomization copper powder is likely to form communicated pores after being sintered, and the environment can not be polluted by the water atomization method for producing the bronze powder. The premixed bronze prepared by the method is free of composition segregation, stable in apparent density, good in forming property and high in sintered strength; well distributed pores are formed in a sintered mode.

Owner:湖南省天心博力科技有限公司

Environment-friendly acid furnace lining dry vibration material

The invention relates to the technical field of acid furnace lining refractory materials and in particular relates to an environment-friendly acid furnace lining dry vibration material which comprisesthe following raw materials in parts by mass: 15-20% of waste silica brick particles with a particle size of 5-8mm, 8-15% of waste silica brick particles with a particle size of 3-5mm, 18-25% of waste silica brick particles with a particle size of 1-3mm, 25-33% of waste silica brick particles with a particle size of 0-1mm, 25-30% of natural quartz sand powder of 325 meshes, 1-2% of B2O3 and 0.1-0.3% of a special sintering agent, wherein the mass percentages of main chemical components of the raw materials are as follows: greater than or equal to 97.5% of SiO2, less than or equal to 0.5% of Al2O3, less than or equal to 0.6% of Fe2O3, less than or equal to 0.8% of CaO, less than or equal to 0.16% of MgO, less than or equal to 0.09% of TiO2, less than or equal to 0.1% of an alkali metal oxide and less than or equal to 0.5% of H2O. Regenerated waste silica brick particles are adopted as a raw material, and meanwhile, the natural quartz powder and the sintering agent are added, so that thesintering strength can be improved, the thermal expansion coefficient is small, the service life of a furnace lining is greatly prolonged, meanwhile, waste silica brick resources of a large scale inChina are reasonably utilized, the raw material cost can be reduced, and recycling and utilization of resources can be achieved.

Owner:湖北安耐捷炉衬材料有限公司

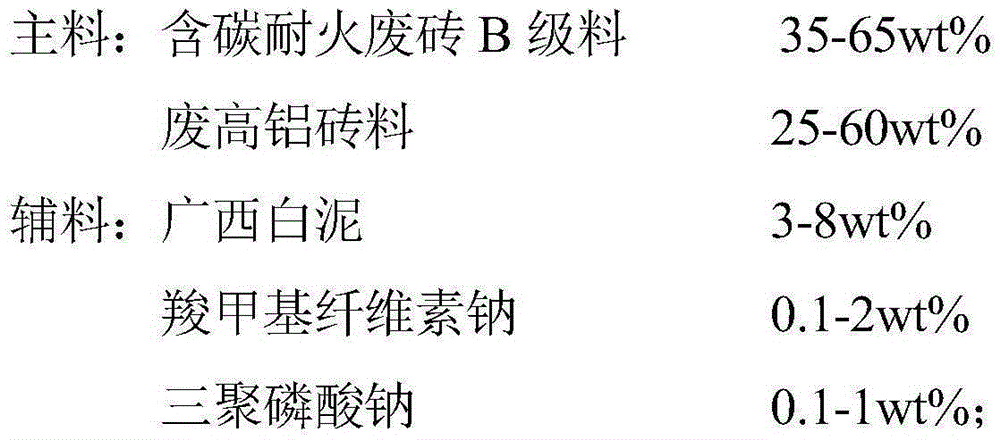

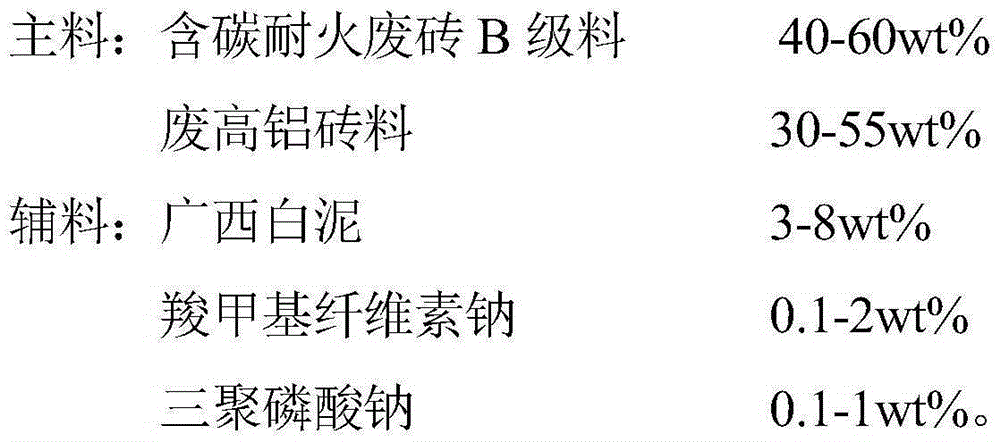

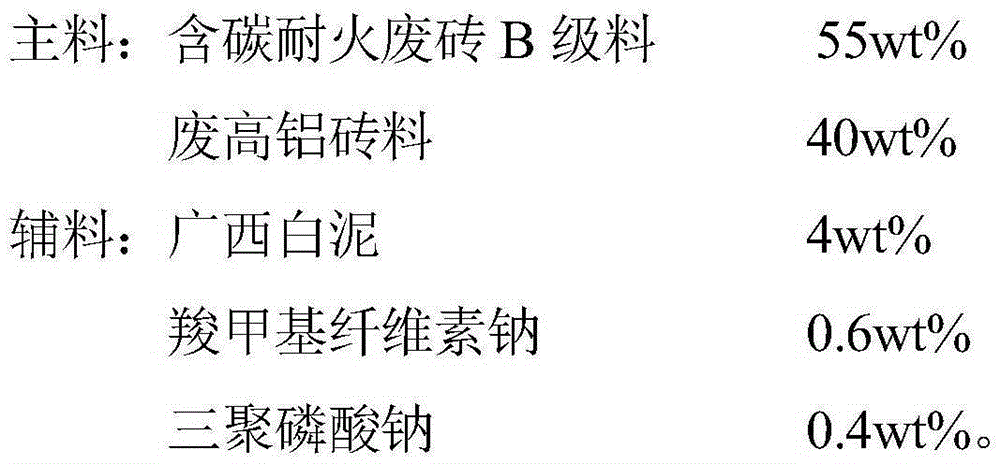

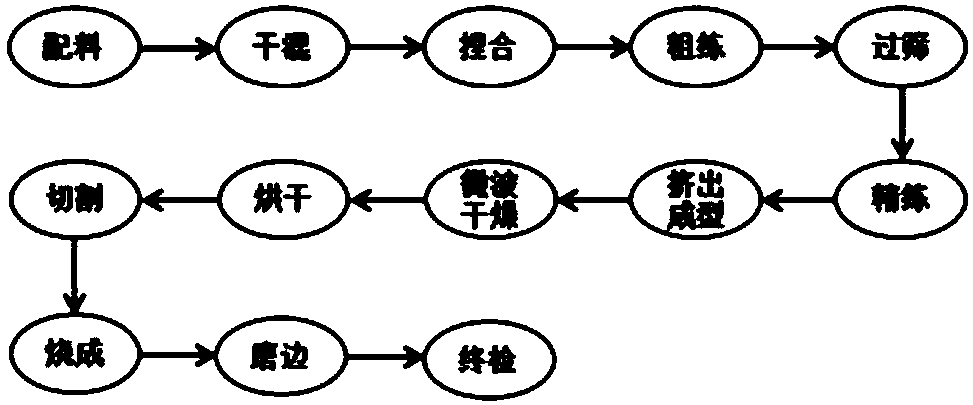

Anti-sticking slag gunning material for hot-metal bottle

The invention discloses an anti-sticking slag gunning material for a hot-metal bottle. The anti-sticking slag gunning material comprises the following components in percentages by weight: 35wt% to 65wt% of carbonic fire-retardant waste brick B-level material, 25wt% to 60wt% of waste high-alumina brick material, 3wt% to 8wt% of Guangxi white mud, 0.1wt% to 2wt% of sodium carboxymethylcellulose and 0.1wt% to 2wt% of sodium tripolyphosphate. The preparation process of the anti-sticking slag gunning material for the hot-metal bottle disclosed by the invention is simple, anti-sticking slag treatment construction can be carried out under cold and hot conditions of equipment, and the material can be used immediately after the construction is finished. The anti-sticking slag gunning material has the characteristics of simple construction, excellent anti-sticking slag performance, high sintering strength, low cost and the like, and is significant in economic benefit and social benefit.

Owner:WUGANG REFRACTORY CO LTD

Concentrated rotating wheel adsorbing material and preparation method thereof

ActiveCN109589912ASmall particle sizeLarge specific surface areaGas treatmentOther chemical processesAlcoholDesorption

The invention belongs to the technical field of adsorbing materials, and particularly relates to a concentrated rotating wheel adsorbing material and a preparation method of the adsorbing material. The adsorbing material comprises a base material, a high-silicon type zeolite molecular sieve ZSM-5, an inorganic binding agent, fumed silica, an activated aluminum oxide precursor, a dispersing agent,alcohol ether, a lubricating agent, oil, an organic binding agent, alcohol and / or cellulose and pure water. The concentrated rotating wheel adsorbing material has the beneficial effects that the adsorbing material prepared from the raw materials by adopting the technology has the advantages of high molecular sieve content, high strength, high specific surface area, high adsorption and desorption ratio, low specific heat capacity, low wind resistance and the like, and solves the problems that a traditional molecular sieve adsorbing material is low in adsorption efficiency, low in strength, poorin thermal stability, short in usage period and the like.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Iron nickel aluminum base bonding agent diamond tool and preparation method thereof

ActiveCN107914019AChanging the Low Creep Strength FeatureImprove bindingTurbinesOther manufacturing equipments/toolsDry machiningUltimate tensile strength

The invention discloses an iron nickel aluminum base bonding agent diamond tool and a preparation method thereof. The diamond tool comprises a metal bonding agent, a sintering aid and an abrasive; themetal bonding agent consists of 35-45 mass parts of Fe3Al powder and 35-45 mass parts of Ni3Al; the sintering aid consists of 5-20 mass parts of Cu-Sn prealloy powder, 0.5-2 mass parts of Si powder,0.5-2 mass parts of B powder and 0.5-2 mass parts of TiH2 powder; the abrasive is diamond; and the diamond abrasive is 5-25 volume% of a grinding layer. Meanwhile, the invention discloses the preparation method of the iron nickel aluminum base bonding agent diamond tool. Fe3Al and Ni3Al are fully mixed as a bonding agent of a dry machining diamond tool; the high-temperature creep strength and themedium-temperature strength can be fully used to obtain the performance of resisting microscale high-temperature creep in grinding; and Fe3Al and Ni3Al can be preferably bonded with a basal body to change the low-creep strength characteristic of a traditional metal bonding agent.

Owner:GUANGDONG UNIV OF TECH

Strong alkali-resistant aluminum oxide bubble bricks and preparation method thereof

InactiveCN108455975APromotes hard-to-sinter problemsImprove sintering strengthCeramicwareMicro nanoBrick

The invention discloses strong alkali-resistant aluminum oxide bubble bricks. The strong alkali-resistant aluminum oxide bubble bricks are prepared from aluminum oxide hollow balls used as aggregates,aluminum oxide micro powder and aluminum titanate which are used as matrixes and a methylcellulose solution used as a binding agent. In addition, the invention further discloses a preparation methodof the strong alkali-resistant aluminum oxide bubble bricks. The problem that a product is difficult to sinter is solved by the micro-nano-level aluminum oxide micro powder, so that the sintering intensity is enhanced; chemical components of the raw materials are high in purity, so that the product contains a small number of harmful chemical components and is high in corrosion resistance; by introduction of the aluminum titanate with a low thermal expansion coefficient and a high melting point, the alkaline corrosion resistance and the high-temperature thermal shock property of the product areimproved.

Owner:江苏三恒高技术窑具有限公司

Environment-friendly high-iron-flux baking-free tapping channel ramming material and preparation method thereof

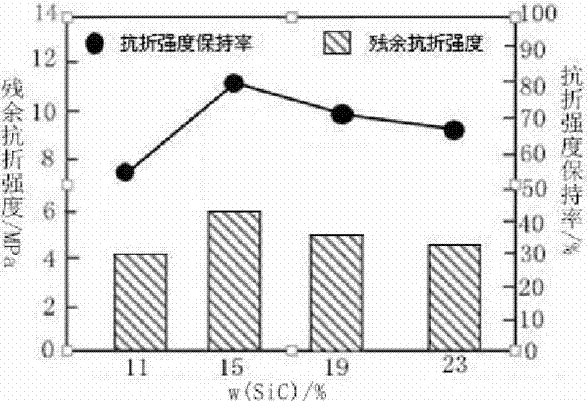

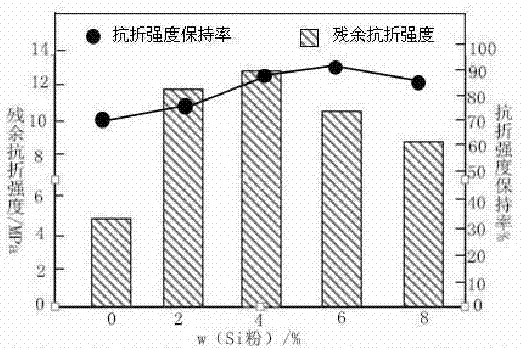

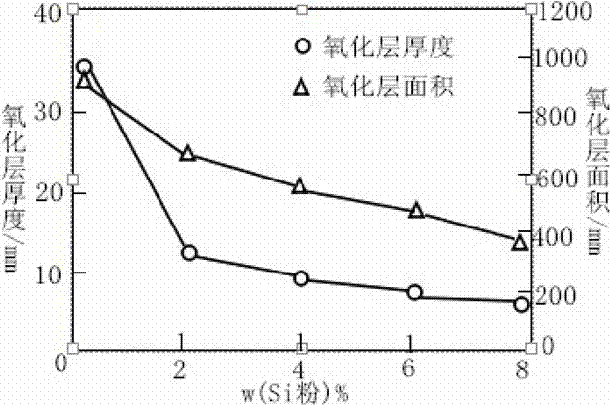

The invention relates to an environment-friendly high-iron-flux baking-free tapping channel ramming material and a preparation method thereof, belonging to the field of refractory materials. The environment-friendly high-iron-flux baking-free tapping channel ramming material is prepared from the following raw materials in parts by weight: 45-55 parts of brown corundum, 19-27 parts of dense corundum, 11-23 parts of SiC, 0-8 parts of Si powder, 0-12 parts of Si3N4, 3-6 parts of active alpha-Al2O3 powder, 1-5 parts of flake graphite and 3-8 parts of a bonding agent, wherein the total parts of all the other raw materials except the bonding agent is 100 parts; the bonding agent comprises the following components in parts by weight: 40-80 parts of carbon-containing resin, 10-40 parts of vegetable oil and fat, 5-15 parts of melamine urea-formaldehyde resin and 2-8 parts of carbon powder. An environment-friendly anhydrous tamping plug disclosed by the invention has the advantages that (1) the anhydrous tamping plug has small content of harmful substances, so that harms to the human body can not be caused; and (2) the anhydrous tamping plug does not have smoke and dust, so that the influence to the environment is small; (3) the anhydrous tamping plug has high iron flux and long service cycle, and can be used for reducing the labor intensity of workers.

Owner:渑池金华新材料有限公司

Submerged arc furnace drying method

The invention discloses a submerged arc furnace drying method. The submerged arc furnace drying method includes the following steps that firstly, a layer of fire-resisting material is flatly laid at the bottom of a submerged arc furnace lining bottom, and a fire-resisting material layer is formed; secondly, three iron roasting cylinders are placed on the fire-resisting material layer, and the three iron roasting cylinders are distributed in a regular triangular shape; thirdly, coke is contained in the roasting cylinders, and the coke particle size ranges from 10 mm to 40 mm; fourthly, a layerof coke is laid in the space between each roasting cylinder and the inner wall of a submerged arc furnace lining, the coke particle size ranges from 10 mm to 40 mm, coke layers are formed, the thickness of the coke layers is smaller than the height of the roasting cylinders, and a layer of slag making material is laid on each coke layer to form a slag making material layer; and fifthly, three electrodes matched with a submerged arc furnace are inserted into the coke in the corresponding three iron roasting cylinders and electrified to form electric loops, and furnace drying is completed afterthe slag making material layers are completely melted.

Owner:重庆大朗冶金新材料有限公司

Magnesium-iron-zinc-aluminum composite spinel refractory brick for cement kiln firing zone and preparation method of magnesium-iron-zinc-aluminum composite spinel refractory brick

The invention belongs to the technical field of refractory products for high-temperature industrial kilns, relates to a refractory brick, and in particular, relates to a magnesium-iron-zinc-aluminum composite spinel refractory brick for a cement kiln firing zone and a preparation method of the magnesium-iron-zinc-aluminum composite spinel refractory brick. The magnesium-iron-zinc-aluminum composite spinel refractory brick for the cement kiln firing zone is composed of the following components in parts by weight: 15 to 25 parts of 5-3 mm high-purity magnesite clinker, 15 to 20 parts of 3-1 mm high-purity magnesite clinker, 5 to 10 parts of 1-0.1 mm high-purity magnesite clinker, 5 to 10 parts of 1-0.1 mm high-iron high-purity magnesite clinker, 5 to 10 parts of 1-0.5 mm fused magnesia-alumina spinel, 20 to 35 parts of high-purity fused magnesia, 5 to 12 parts of magnesia-alumina spinel micro powder, 3-10 parts of nano zinc oxide micro powder and 3-5 parts of a composite binding agent. The product prepared by the method has excellent kiln coating hanging performance, alkali corrosion resistance and thermal shock resistance stability, the using effect and the service life of the product are superior to those of traditional magnesia-chrome bricks and magnesia (ferrum) aluminate spinel bricks, and the product has important significance for prolonging the service life of a cement kiln and reducing unit consumption of refractory materials.

Owner:营口丰华耐火材料有限公司

Preparation method of modified coal cinder and application thereof

ActiveCN111792918AImprove sintering performanceImprove sintering strengthCeramic materials productionCeramicwareFiberBrick

The invention belongs to the technical field of buildings, and particularly relates to a preparation method of modified coal cinder and an application thereof. The composite acid solution is adopted to treat coal cinder, part of aluminum oxide, magnesium oxide and the like in the coal cinder can be dissolved in the composite acid solution, the aluminum oxide and the magnesium oxide in the composite acid solution react with zircon powder and boron powder and then are solidified and adsorbed in a pore structure of the coal cinder, the sintering performance of the coal cinder is improved, and thesintering strength of the coal cinder is improved; then surface modification liquid is adopted for modification, so that the dispersing performance of coal cinder can be improved; then the reinforcing fibers and a coupling agent are blended for modification, the reinforcing fibers are grafted into the coal slag under the action of the coupling agent, and the frost resistance and corrosion resistance of the coal slag are improved. The strength, frost resistance, dispersity, sinterability and other properties of the coal cinder subjected to acid modification, surface modification and blending modification are obviously improved, and the coal cinder can be used for preparing water-permeable shale bricks. The prepared water-permeable shale brick has good water permeability, frost resistance and corrosion resistance, and is high in strength.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

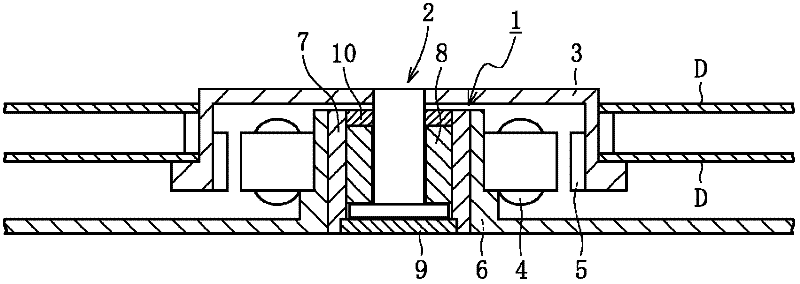

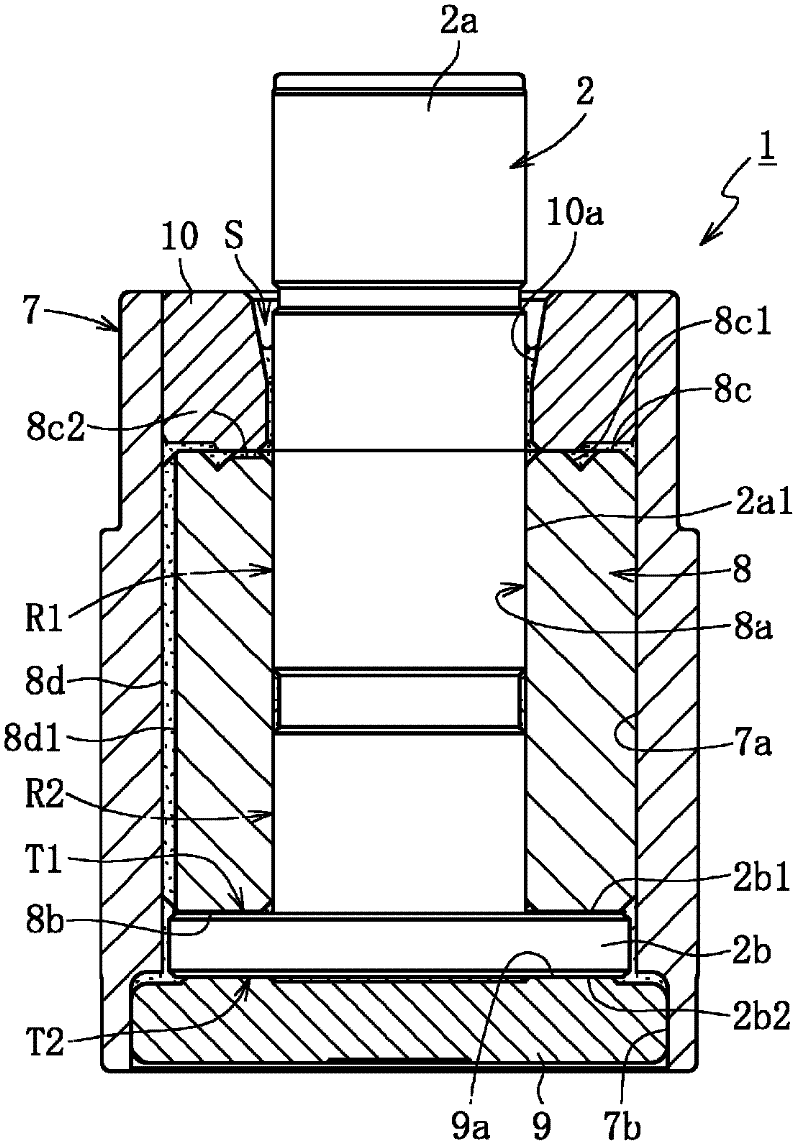

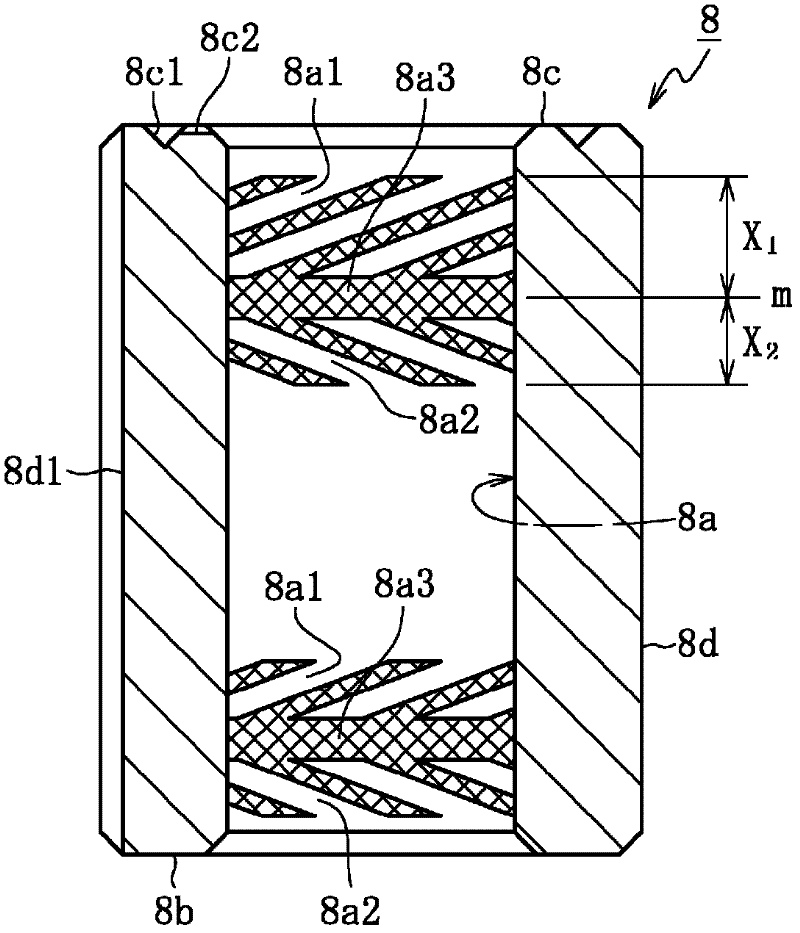

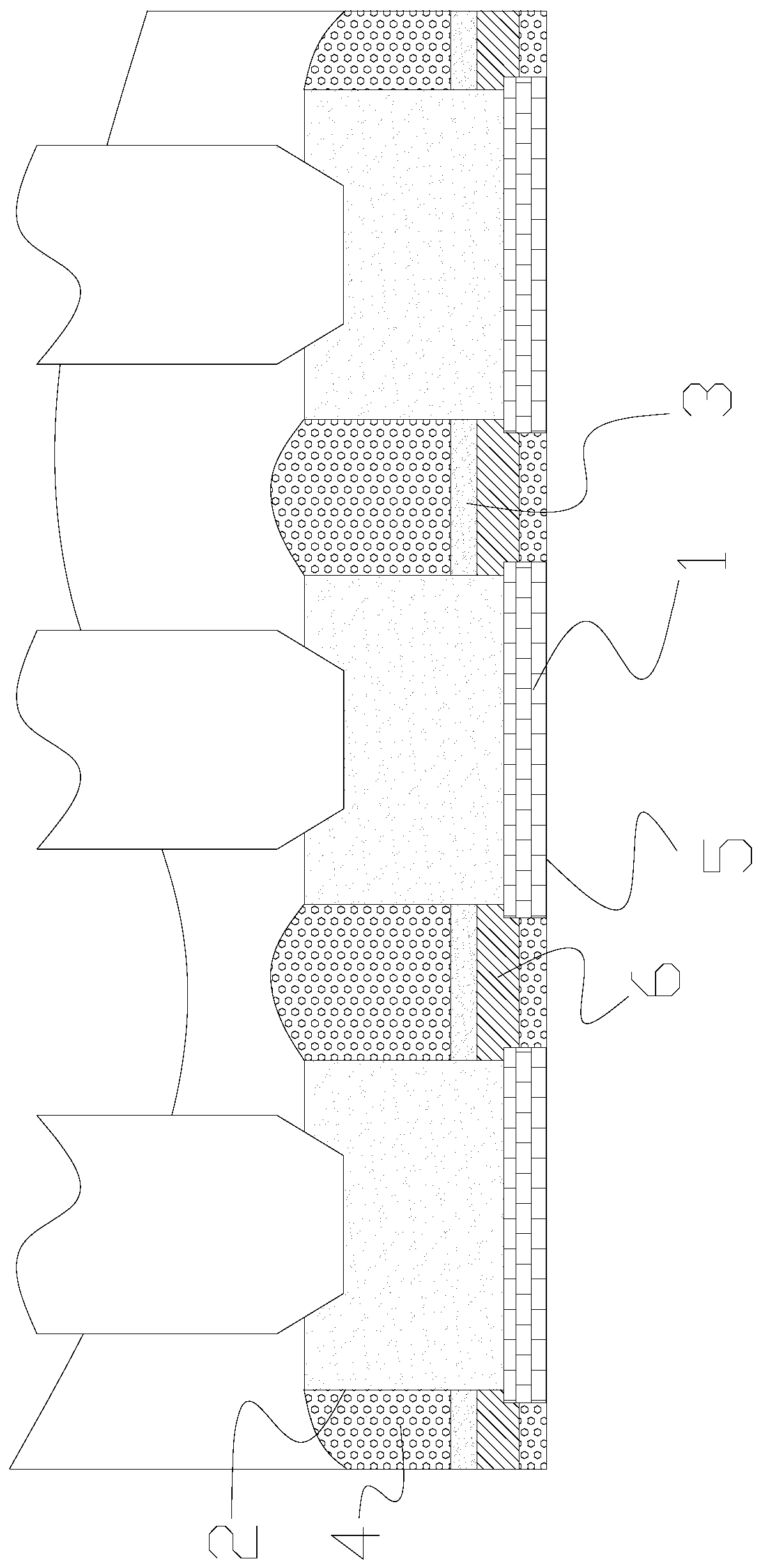

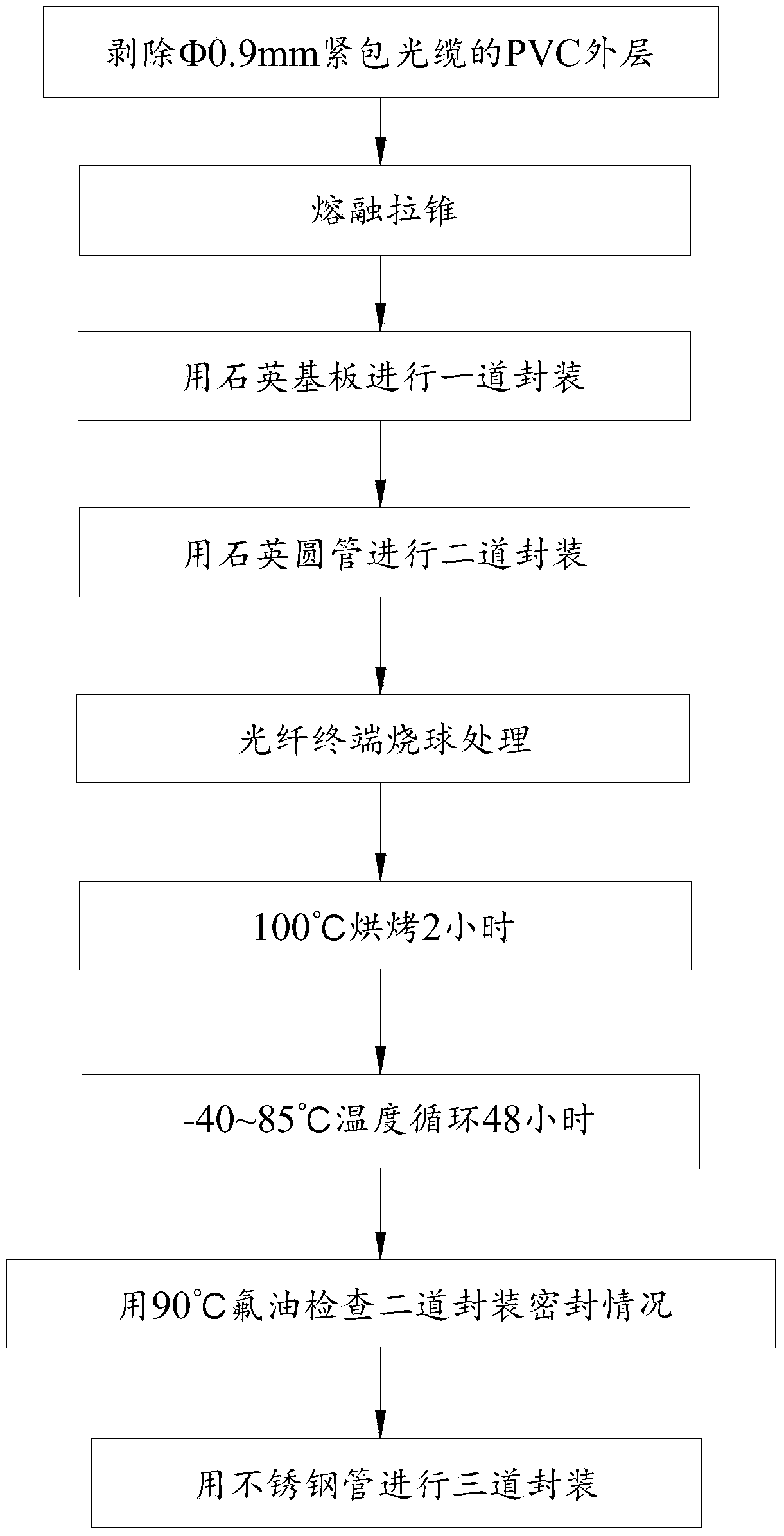

Optical fiber coupler, manufacturing method of optical fiber couplers and detection method for packaging efficacy losing of optical fiber couplers

InactiveCN104238016AImprove sintering strengthHigh strengthCoupling light guidesFluid-tightness measurement using fluid/vacuumWork in processPull force

The invention relates to the technical field of optical fiber couplers, and discloses an optical fiber coupler, a manufacturing method of optical fiber couplers and a detection method for packaging efficacy losing of the optical fiber couplers. The manufacturing method includes the steps of stripping an optical cable PVC outer layer; manufacturing the optical fiber couplers with the parallel clamping fused biconical taper process, and detecting the longitudinal tensile strength of the optical fiber couplers through pulling force after completion of sintering; conducting primary packaging on the sintered semi-finished products; then conducting secondary packaging on the sintered semi-finished products; conducting hot bulb processing on terminals of optical fibers; placing the semi-finished products in the environment with the temperature ranging from 95 DEG C to 105 DEG C for baking for 1.5 hours to 2.5 hours, cooling the semi-finished products to the normal temperature, placing the semi-finished products in the environment with the temperature ranging from -40 DEG C to 85 DEG C for circulating for 45 hours to 51 hours, checking the sealing condition of secondary packaging through fluorine-contained oil with the temperature ranging from 85 DEG C to 95 DEG C, and screening defective products; conducting tertiary packaging on the qualified semi-finished products. By means of the manufacturing method of the optical fiber couplers, the problem that insertion losses of traditional optical fiber couplers in the low-temperature state are increased is solved, and the stability of the optical fiber couplers is improved.

Owner:深圳朗光科技有限公司

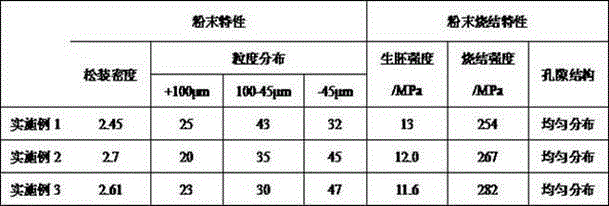

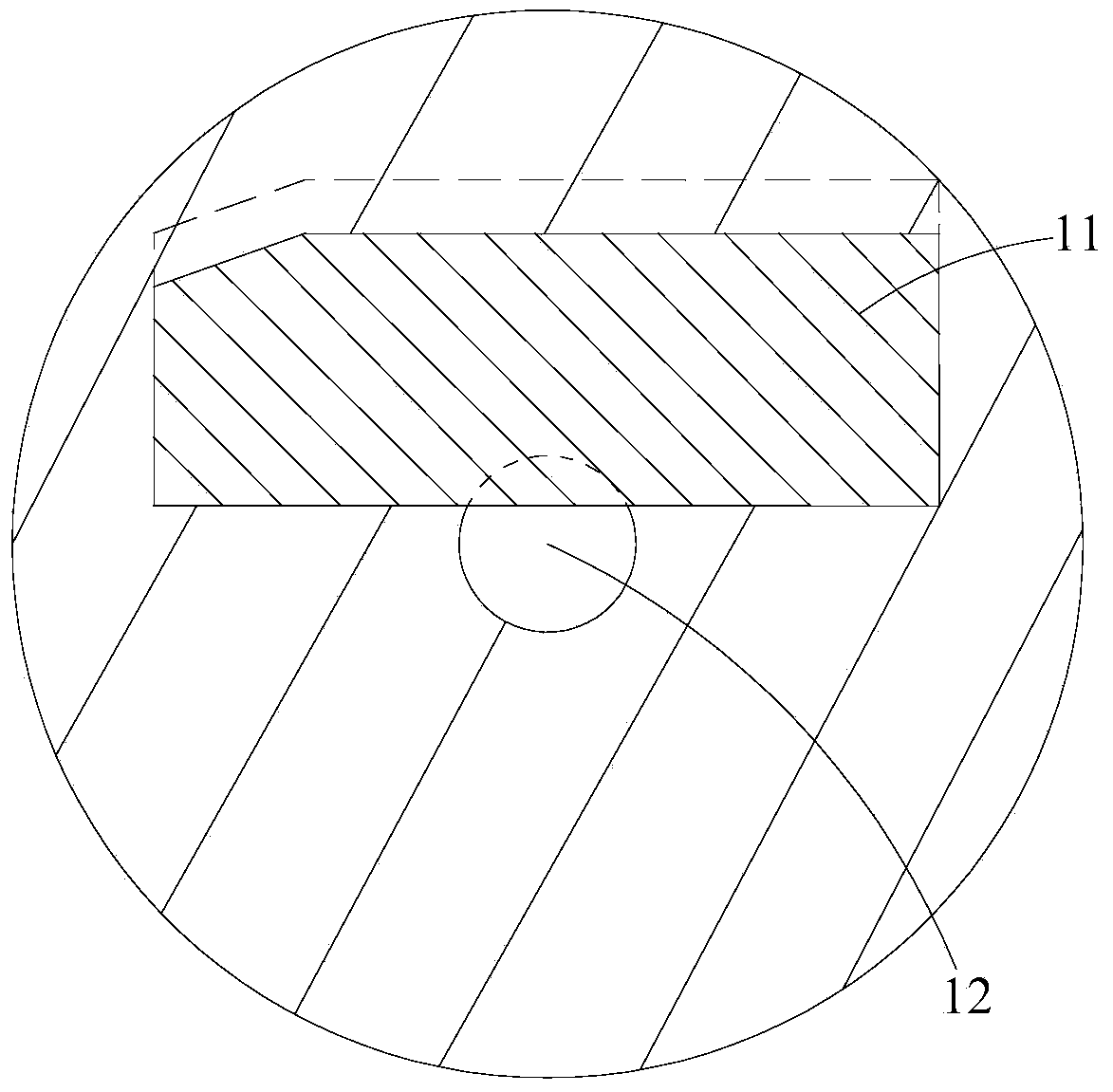

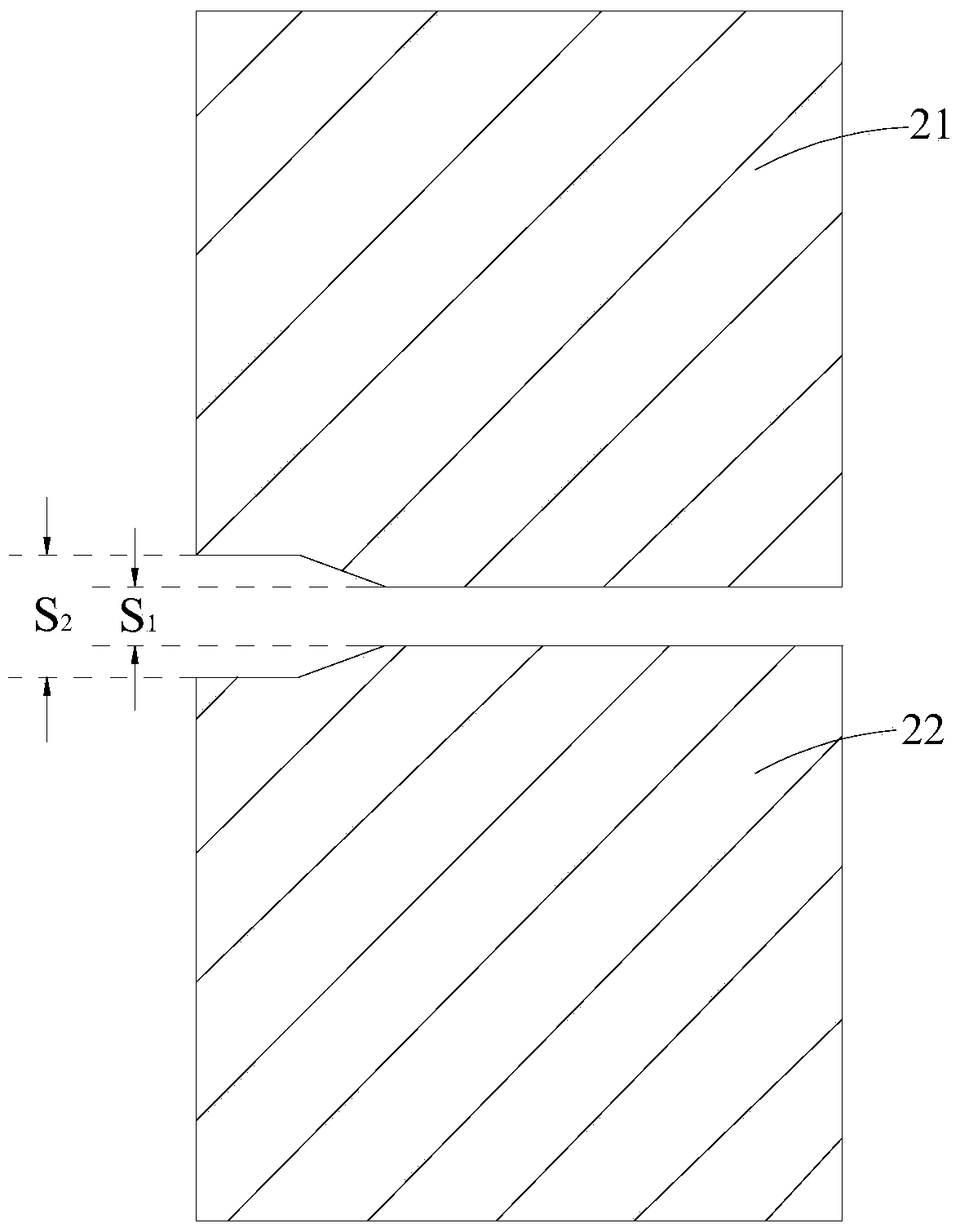

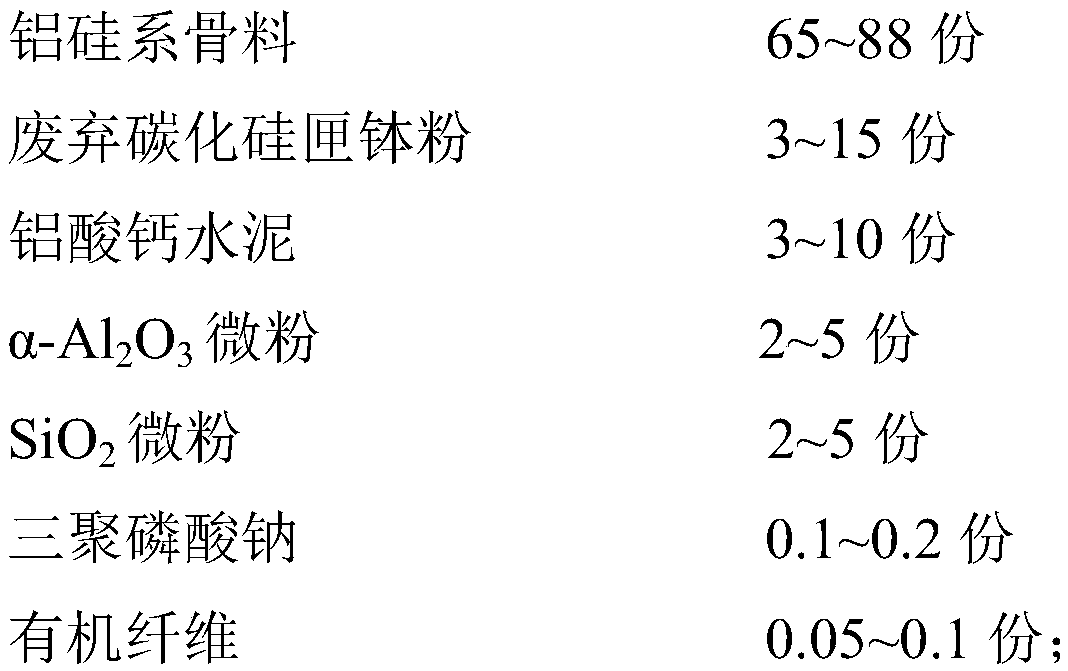

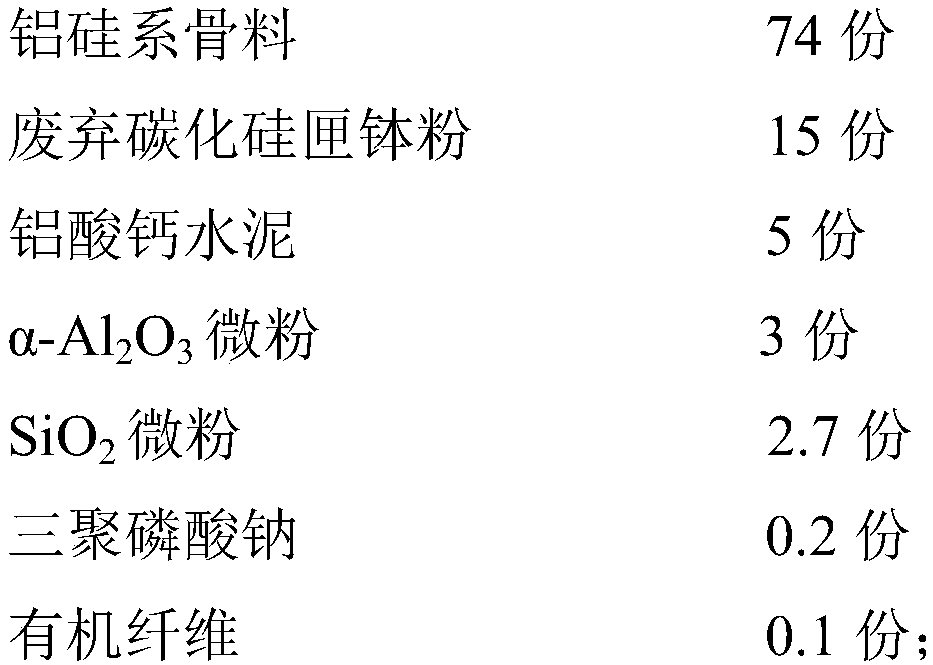

Aluminum silicon carbide castable for hot metal bottles and preparation method thereof

The invention discloses an aluminum silicon carbide castable for hot metal bottles and a preparation method thereof. The aluminum silicon carbide castable for hot metal bottles is prepared from the following raw materials by weight: 65-88 parts of aluminum-silicon aggregate, 3-15 parts of waste silicon carbide sagger powder, 3-10 parts of calcium aluminate cement, 2-5 parts of alpha-Al2O3 micropowder, 2-5 parts of SiO2 micropowder, 0.1-0.2 part of sodium tripolyphosphate, and 0.05-0.1 part of organic fiber. The aluminum-silicon aggregate is selected from one or more of clay clinker, mullite and bauxite clinker. The waste silicon carbide sagger powder is prepared by crushing waste silicon carbide sagger and performing fine grinding treatment. The aluminum silicon carbide castable for hot metal bottles provided by the invention contains waste silicon carbide sagger powder, thus not only reducing the manufacturing cost, but also improving the compactness, sinterability and iron slag resistance of the castable.

Owner:WUGANG REFRACTORY CO LTD

Baking-free ramming mass for blast furnace iron runners

ActiveCN105732056AImprove antioxidant capacityImprove thermal shock resistanceCarbide siliconHexamethylenetetramine

The invention discloses a baking-free ramming mass for blast furnace iron runners. The baking-free ramming mass for blast furnace iron runners is mainly prepared from the following raw materials in percentage by weight: 10-15% of 0-1mm bauxite, 12-18% of 1-3mm bauxite, 15-20% of 3-5mm bauxite, 18-23% of brown fused alumina, 10-15% of silicon carbide, 8-10% of modified asphalt, 7-10% of phenolic resin, 2-3% of urotropine and 1-2% of spodumene powder. The baking-free ramming mass product has the advantages of favorable oxidation resistance, higher thermal shock resistance, higher erosion resistance and compact structure. When in use, the product has favorable combination effect and higher sintering strength. The baking-free ramming mass is easy for construction, has high repair efficiency, and saves the time.

Owner:GONGYI CITY HONGYU REFRACTORIES CO LTD

Low density fire resistant pouring material for KR stirring paddle

The invention provides a KR stirring paddle desulfuration used low density fireproof casting material, which belongs to the field of a fireproof material used for pretreatment of ladle desulfuration and desilication before pneumatic steelmaking. The volume density of the fireproof casting material is 2.3 to 2.7g / cm<3>; the granule is primarily prepared with superfine flint clay, silica and carborundum. The casting material further comprises alumina powder, carborundum, silica micropowder and alundum cement of less than 0.074mm. The components and the mass percentages of the KR stirring paddledesulfuration used low density fireproof casting material are as follows: 60 to 80 percent of aggregate; 20 to 40 percent of fine powder; an additive of 0.03 to 0.35 percent of the total weight of the aggregate and the fine powder; a detonation inhibitor of 0.02 to 0.5 percent of the total weight of the aggregate and the fine powder; and stainless steel fiber of 0 to 7 percent of the total weightof the aggregate and the fine powder. After the raw materials are mixed, water is added, the mixture is beaten, cast and moulded. After the moulded mixture is cured, and molded mixture is baked at moderate temperature, thus getting the KR stirring paddle desulfuration used low-density fireproof casting material. The KR stirring paddle desulfuration used low density fireproof casting material has the advantages of low cost, high wear resistance at high temperature, high service life and so on.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

Diamond dry-cutting saw web and manufacturing method thereof

InactiveCN104759696AHigh bonding strengthLong dry cutting timeMetal sawing tool makingStone-like material working toolsFiberCarbon fibers

The invention relates to a diamond dry-cutting saw web and specifically relates to a diamond dry-cutting saw web and a manufacturing method thereof. The diamond dry-cutting saw web comprises a substrate and a tool bit; the substrate is combined with the tool bit by use of a hot-pressing process; a plurality of metal powders used for the tool bit contain a carbon fiber powder; the weight of the carbon fiber powder accounts for 0.5%-1.5% of the weight of the plurality of metal powders; the granularity of the carbon fiber powder ranges from 200 to 500 meshes; the manufacturing method comprises the following steps: the substrate is combined with the tool bit by use of the hot-pressing process; the carbon fiber powder is added to the plurality of metal powders used for the tool bit and mixed evenly; the weight of the added carbon fiber powder accounts for 0.5%-1.5% of the weight of the plurality of metal powders; the granularity of the carbon fiber powder ranges from 200 to 500 meshes; the carbon fiber diamond dry-cutting saw web manufactured has the advantages of no tooth burning, high combination strength of the substrate and the tool bit, long dry cutting time, and safety and reliability, and also the advantage of high sintering strength.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

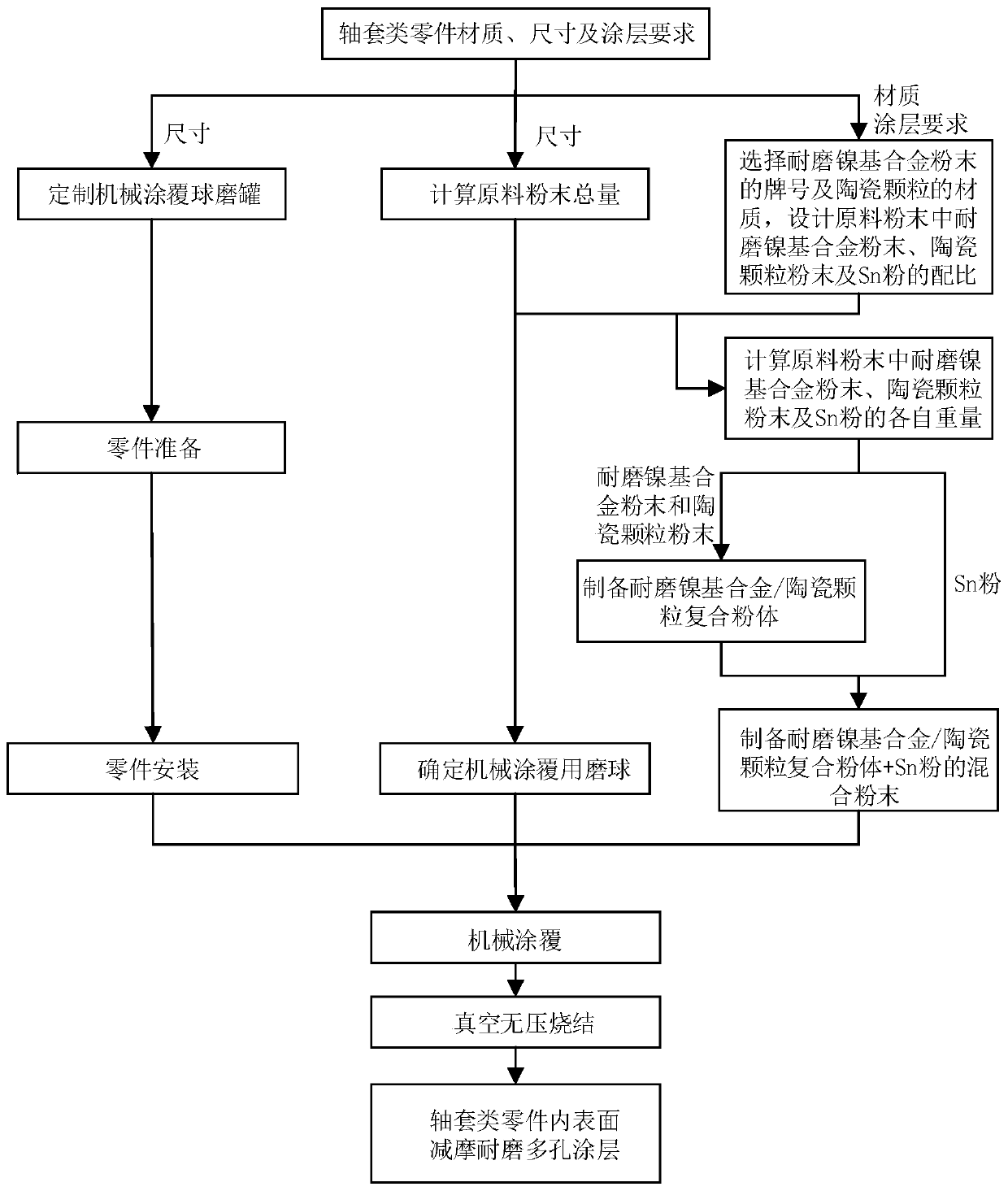

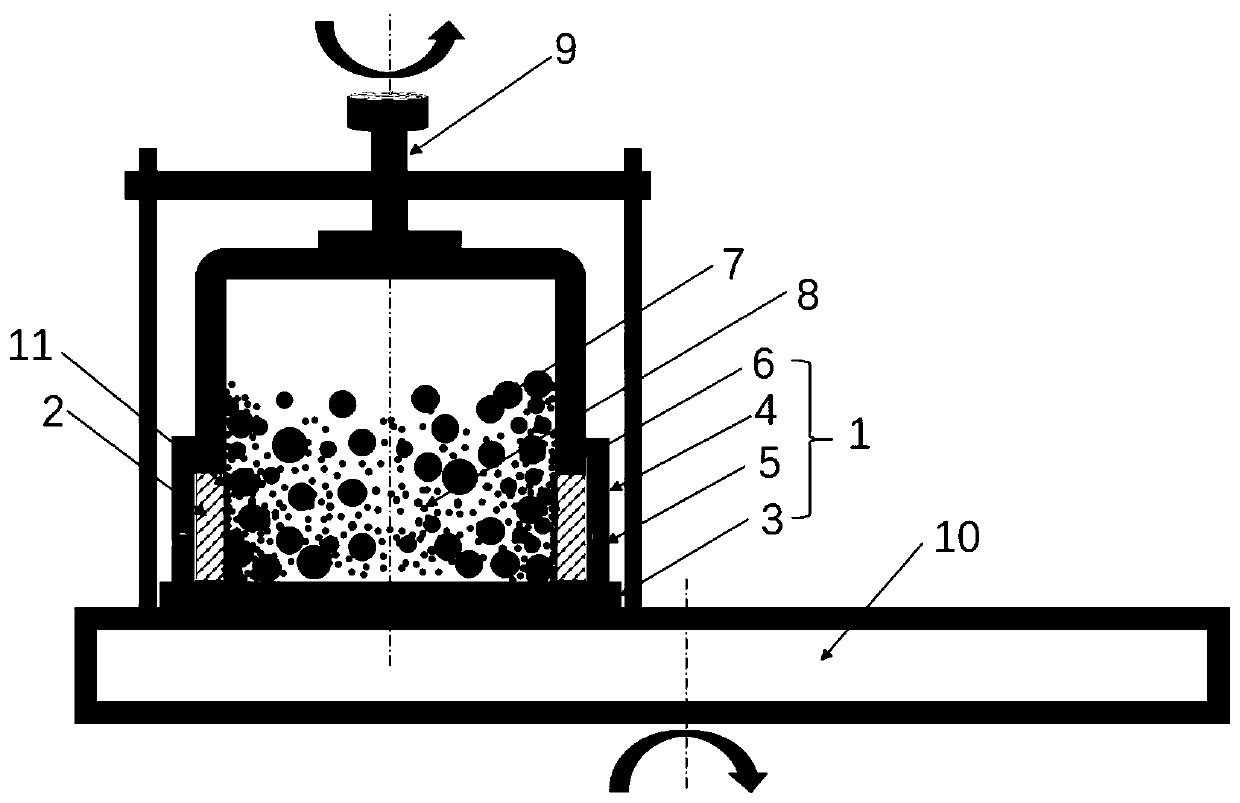

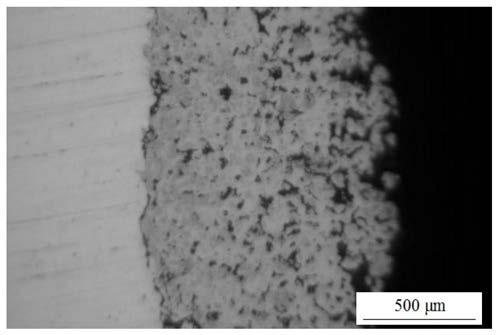

Method for preparing friction-reducing and wear-resistant porous coating on inner surface of shaft sleeve type part

ActiveCN110484915AIncrease profitLess investmentMetallic material coating processesWear resistantAlloy

The invention discloses a method for preparing a friction-reducing and wear-resistant porous coating on the inner surface of a shaft sleeve type part. The method comprises the following steps of: polishing the inner surface of the part, washing and drying the part; installing the part in a mechanically coating ball-milling tank; putting a certain amount of mixed powder and several hard alloy grinding balls in a ball grinding tank, wherein the mixed powder comprises nickel-based alloy powder, ceramic particle powder and Sn powder; closing the ball-milling tank, and carrying out ball milling under the protection of an inert gas to achieve mechanical coating of the inner surface of the part; and putting the coated part in a vacuum furnace, and carrying out vacuum pressureless sintering to form the friction-reducing and wear-resistant porous coating with the thickness of 1.2mm and the porosity of 5 to 25%. The prepared coating is tightly bonded to the inner surface of the part, and has small residual stress, connected and uniformly distributed pores, and excellent mechanical properties and tribological properties under oil lubrication. The method is suitable for shaft sleeve type partsmade from various materials including non-ferrous metals, is simple in process and low in cost and has no environmental pollution.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com