Brushless DC motor and preparation technology thereof

A technology of brush DC motor and DC motor, which is applied in the field of brushless DC generator and its preparation technology, can solve the problems of poor heat conduction, high motor performance of the motor, and low mechanical performance, so as to suppress the nucleation of bubbles and improve the durability Good thermal performance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

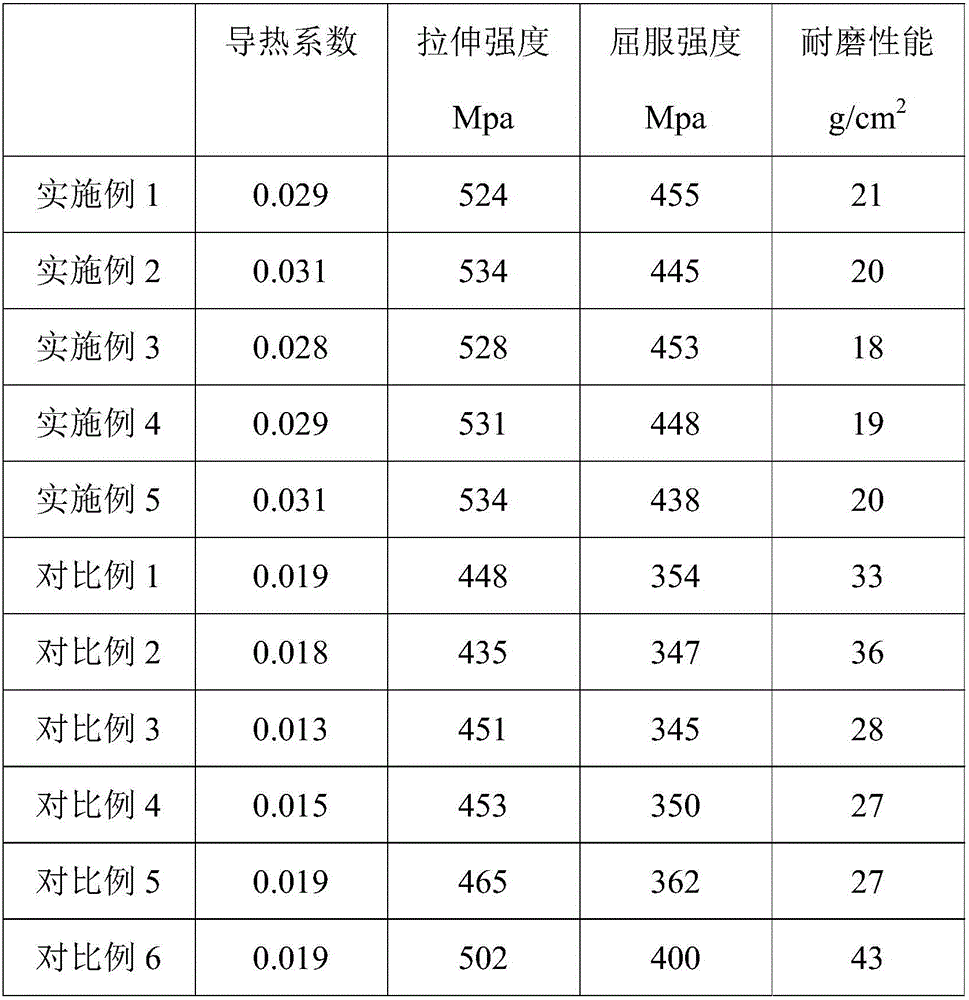

Examples

Embodiment 1

[0028] Raw materials for configuring required components: Mg0.6%, Si0.4%, Mn0.1%, Cr0.1%, Fe0.1%, Ti0.1%, Zr0.18%, Sc0.5%, balance For Al, the raw materials are mixed and melted into molten aluminum, and then refined, the refining temperature is 690°C, the refining agent is hexachloroethane and titanium dioxide with a mass ratio of 2.3:1, and the refining time is 20 minutes;

[0029] The refined aluminum liquid is dripped out through the nozzle, and the dropped aluminum liquid is blown down to a powder form with a gas with a pressure of 3Mpa. The direction of the gas blowing out is at an angle of 45° to the direction of the solution dripping;

[0030] Screen the powder to obtain a powder with a particle size distribution of 9%% below 2μm, 39%% between 2-4μm, 39%% between 4-6μm and 9% above 6μm, and then press the powder with a density of 2.4 g / cm 3 , in the atmosphere of protective gas, the temperature was raised to 595°C at a rate of 10°C / min, and then kept at a temperature ...

Embodiment 2

[0033] Raw materials for configuring required components: Mg0.9%, Si0.6%, Mn0.2%, Cr0.2%, Fe0.2%, Ti0.2%, Zr0.2%, Sc0.6%, the balance is Al, the ratio of Mg to Si in the aluminum alloy is 1.7:1, the raw materials are mixed, melted into aluminum liquid, and then refined, the refining temperature is 710°C, and the refining agent is hexachloroethane with a mass ratio of 2.5:1 and titanium dioxide, the refining time is 25 minutes;

[0034] The refined aluminum liquid is dripped out through the nozzle, and the dropped aluminum liquid is blown down to a powder form with a gas with a pressure of 4Mpa, and the gas blowing direction is at an angle of 60° to the solution dripping direction;

[0035] Screen the powder to obtain a powder with a particle size distribution of 9% below 2 μm, 39% at 2-4 μm, 39% at 4-6 μm, and 9% above 6 μm, and then press the powder with a density of 2.5 g / cm 3 , in the atmosphere of protective gas, the temperature was raised to 597°C at a rate of 13°C / min, ...

Embodiment 3

[0038] Raw materials for configuring required components: Mg0.8%, Si0.5%, Mn0.1%, Cr0.1%, Fe0.1%, Ti0.1%, Zr0.18%, Sc0.5%, balance For Al, the raw materials are mixed and melted into molten aluminum, and then refined, the refining temperature is 700°C, the refining agent is hexachloroethane and titanium dioxide with a mass ratio of 2.4:1, and the refining time is 22 minutes;

[0039] The refined aluminum liquid is dripped out through the nozzle, and the dropped aluminum liquid is blown down to a powder form with a gas with a pressure of 3Mpa. The gas blowing direction and the solution dripping direction form an angle of 50°;

[0040] Screen the powder to obtain a powder with a particle size distribution of 9% below 2 μm, 40% at 2-4 μm, 40% at 4-6 μm, and 11% above 6 μm, and then press the powder with a density of 2.45g / cm 3 , in the atmosphere of protective gas, the temperature was raised to 596°C at a rate of 12°C / min, then kept at a temperature of 30min, extruded into an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com