Sintering additive and preparation method and application method thereof

A technology of sintering additives and additives, which is applied in the field of sintering additives, can solve problems such as uneven use effects, and achieve the effects of improving production efficiency, benefiting sintering strength, and improving utilization coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below, but it should be noted that the implementation of the present invention is not limited to the following embodiments.

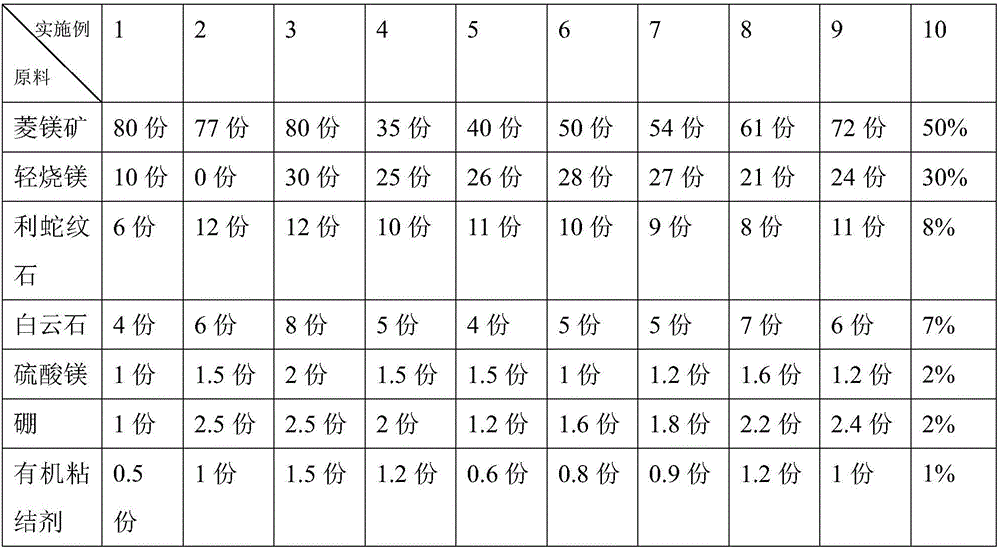

[0020] Sintering additives, the ratio of each component by weight is: 30-80 parts of magnesite, 0-30 parts of light burnt magnesium, 6-12 parts of lizardite, 4-8 parts of dolomite, 1-2 parts of magnesium sulfate parts, boron 1-2.5 parts, organic binder 0.5-1.5 parts. The organic binder adopts pulp waste liquid, which is the waste discharged from various paper mills. Its components include various sugars, organic acids, free sulfite, sodium sulfide, lignin derivatives, organic acid salts, free sodium hydroxide and sodium sulfide. Or purchased, such as: Baoding Shenghui Polymer Technology Co., Ltd. production of mineral powder pellet binder.

[0021] The preparation method of sintering additives is to put magnesite, light burned magnesia, lizardite, dolomite, magnesium sulfate, boron and organic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com