Aluminum-alloy reflection film for optical information-recording, optical information-recording medium, and aluminum-alloy sputtering target for formation of the aluminum-alloy reflection film for optical information-recording

a technology of optical information recording and aluminum alloy, which is applied in the field of aluminum alloy sputtering target for formation of aluminum alloy reflection film for optical information recording, can solve the problems of low corrosion resistance, high thermal conductivity, and difficulty in coping with laser marking application in respect, and achieve low thermal conductivity, high corrosion resistance, and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

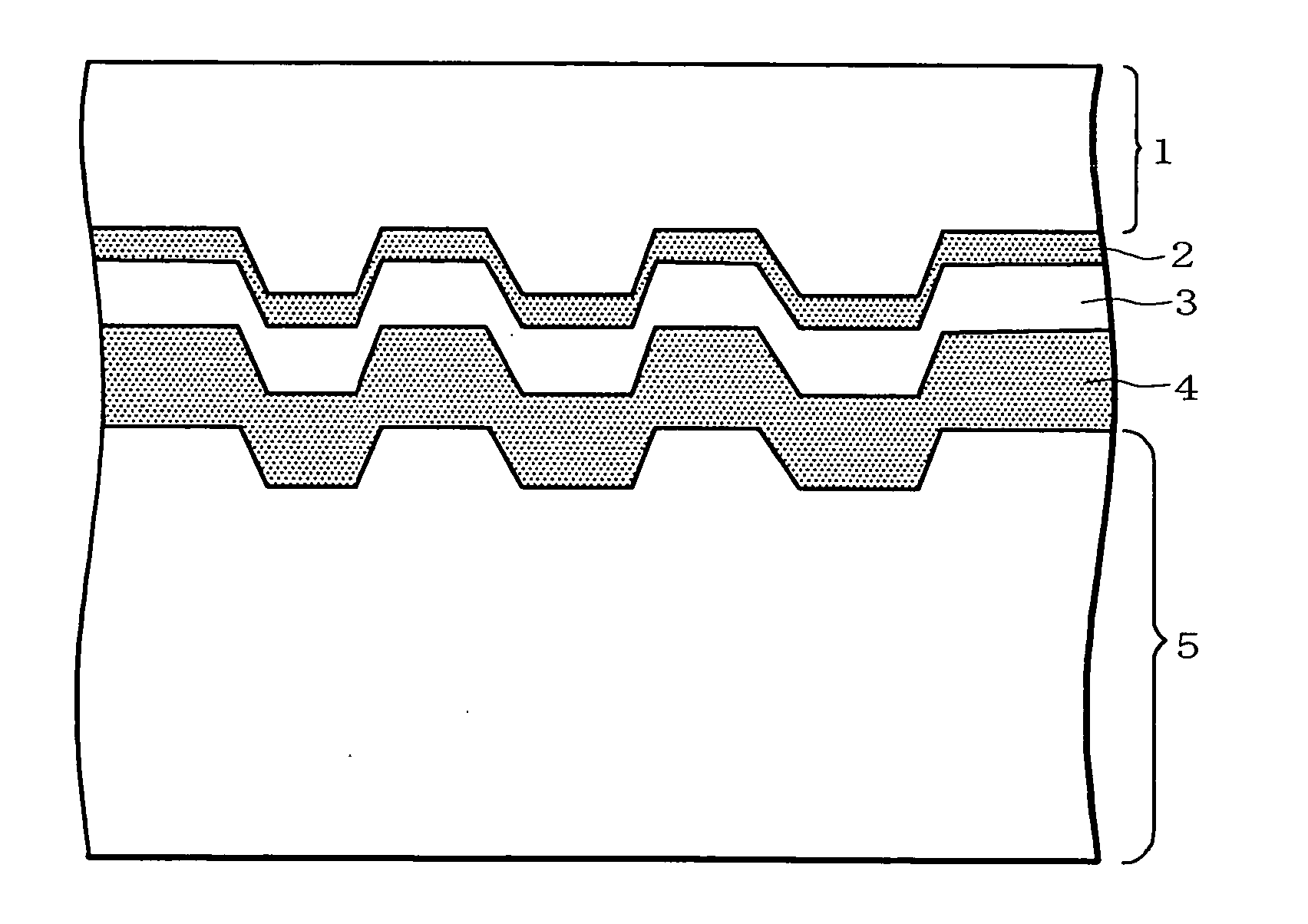

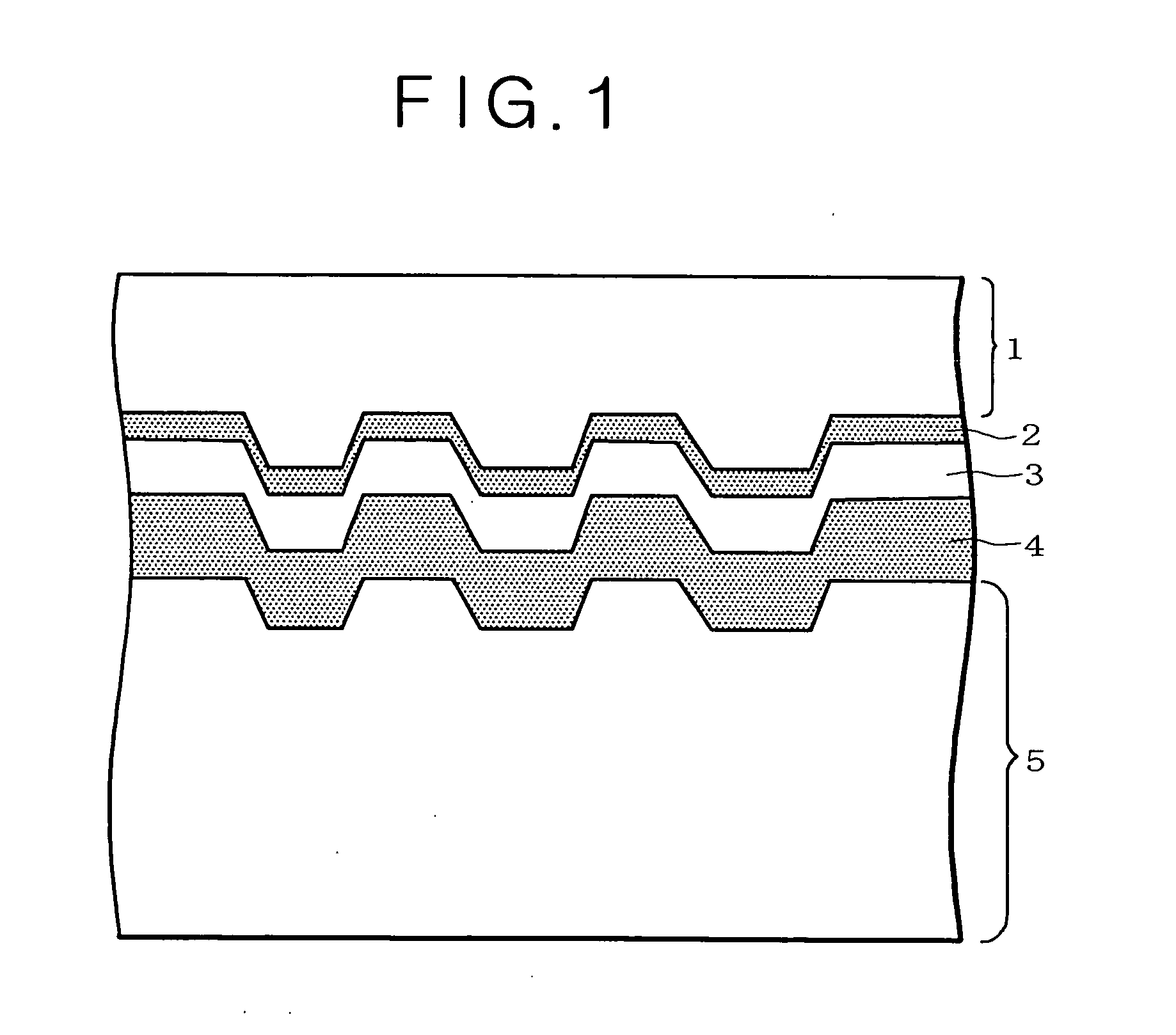

Image

Examples

working examples

[0061] Working examples, and comparative examples of the present invention will be described hereinafter. Although the invention has been described in terms of preferred embodiments, it will be understood that the invention is not limited thereto, and that various changes and modifications may be made in the invention without departing from the spirit and scope thereof. It is therefore intended to cover in the appended claims all such changes and modifications as fall within the spirit and scope of invention.

working example 1

[0062] An Al—Nd (an Al alloy containing Nd) thin film, and an Al—Y (an Al alloy containing Y) thin film were fabricated, having examined relationships of respective addition amounts (respective contents) of Nd, Y, with the melting temperature, thermal conductivity, reflectance of the respective thin films, and BCA (Burst Cutting Area) marking property, respectively.

[0063] The thin films were fabricated as follows. More specifically, the Al—Nd thin film, or the Al—Y thin film was fabricated (formed) on a glass substrate (Corning #1737, substrate size; 50 mm in diameter, 1 mm in thickness) by DC magnetron sputtering. At this point in time, there were adopted film forming conditions of substrate temperature: 22° C., Ar gas pressure: 2 mTorr, film forming rate: 2 mm / sec, and back pressure: −6 Torr. For a sputtering target, use was made of an aluminum-alloy sputtering target of the same composition as that for the Al alloy thin film that is to be obtained.

[0064] The respective melting ...

working example 2

[0071] An Al-4.0Nd—(Ta, Cr, Ti) thin film (a thin film made of an Al alloy containing 4.0 at. % of Nd, together with at least one element selected from the group consisting of elements Ta, Cr, and Ti) was fabricated, having examined relationships of respective addition amounts of Ta, Cr, and Ti, with the melting temperature, thermal conductivity, reflectance, corrosion resistance of the thin film, and BCA marking property, respectively.

[0072] The thin film was fabricated as follows. More specifically, the Al-4.0Nd—(Ta, Cr, Ti) alloy thin film was fabricated (formed) on a glass substrate (Corning #1737, substrate size; 50 mm in diameter, 1 mm in thickness) by DC magnetron sputtering. At this point in time, there were adopted film forming conditions of substrate temperature: 22° C., Ar gas pressure: 2 mTorr, film forming rate: 2 mm / sec, and back pressure: −6 Torr. For a sputtering target, use was made of an aluminum-alloy sputtering target of the same composition as that for the Al a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com