Patents

Literature

59results about How to "Improve heat transfer conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

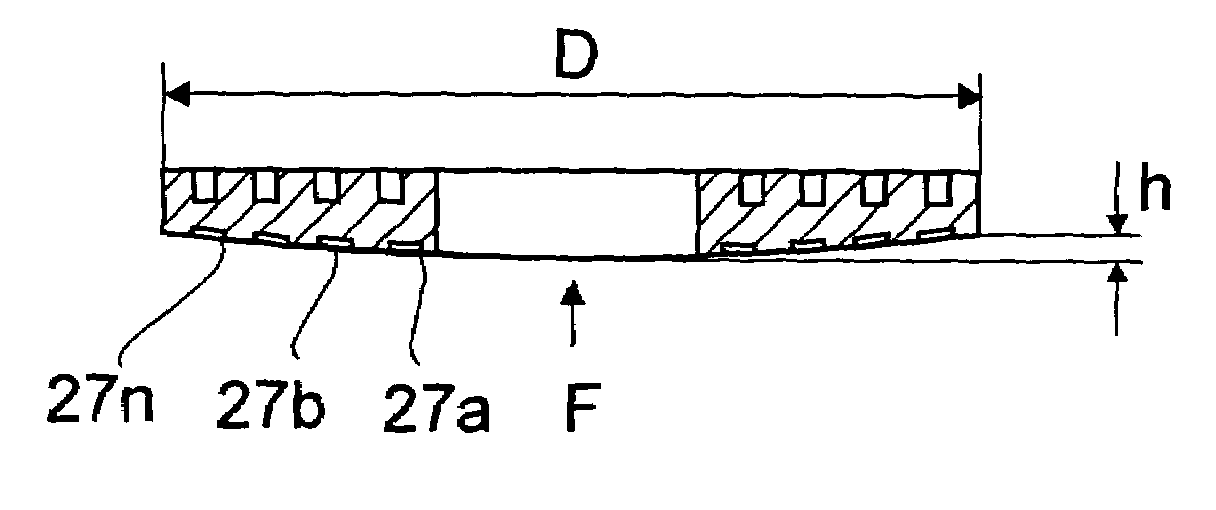

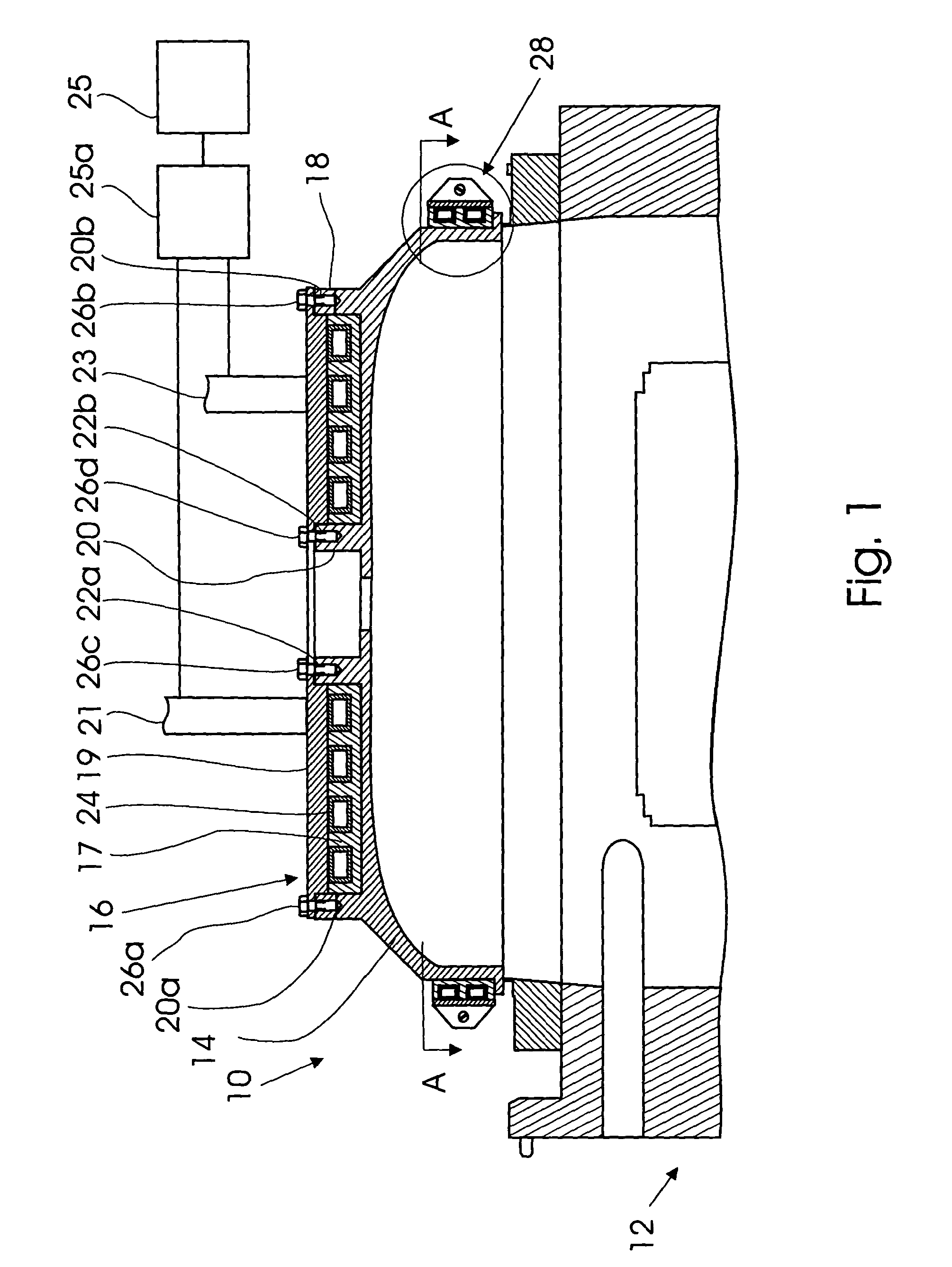

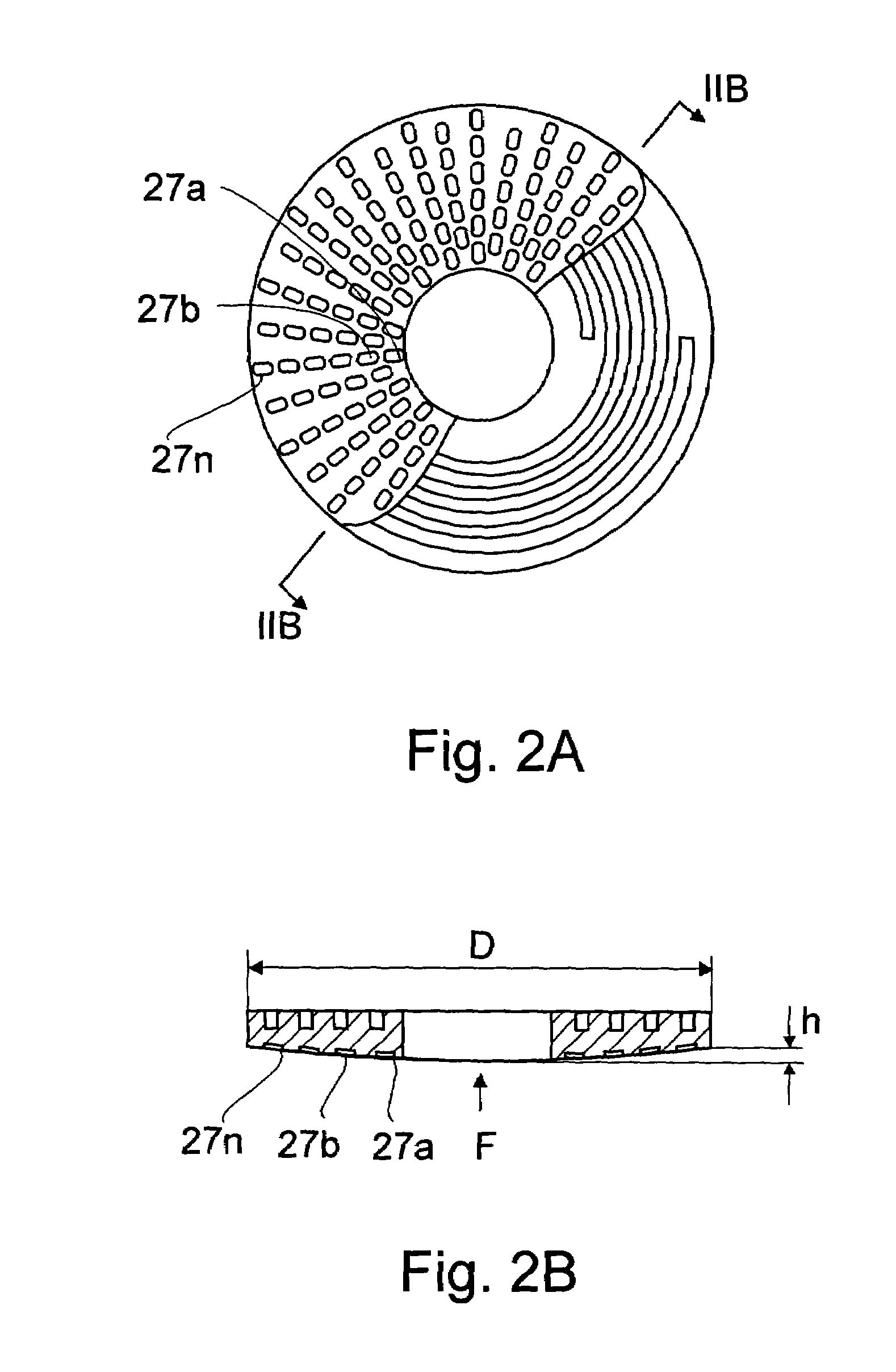

Heat-transfer interface device between a source of heat and a heat-receiving object

InactiveUS7137444B2Reliable and stable thermally-conductiveImproving and stabilizing a heat-transfer interfaceElectric discharge tubesSynthetic resin layered productsElastomerWorking temperature

Owner:PACIFIC RUBBER & PACKING

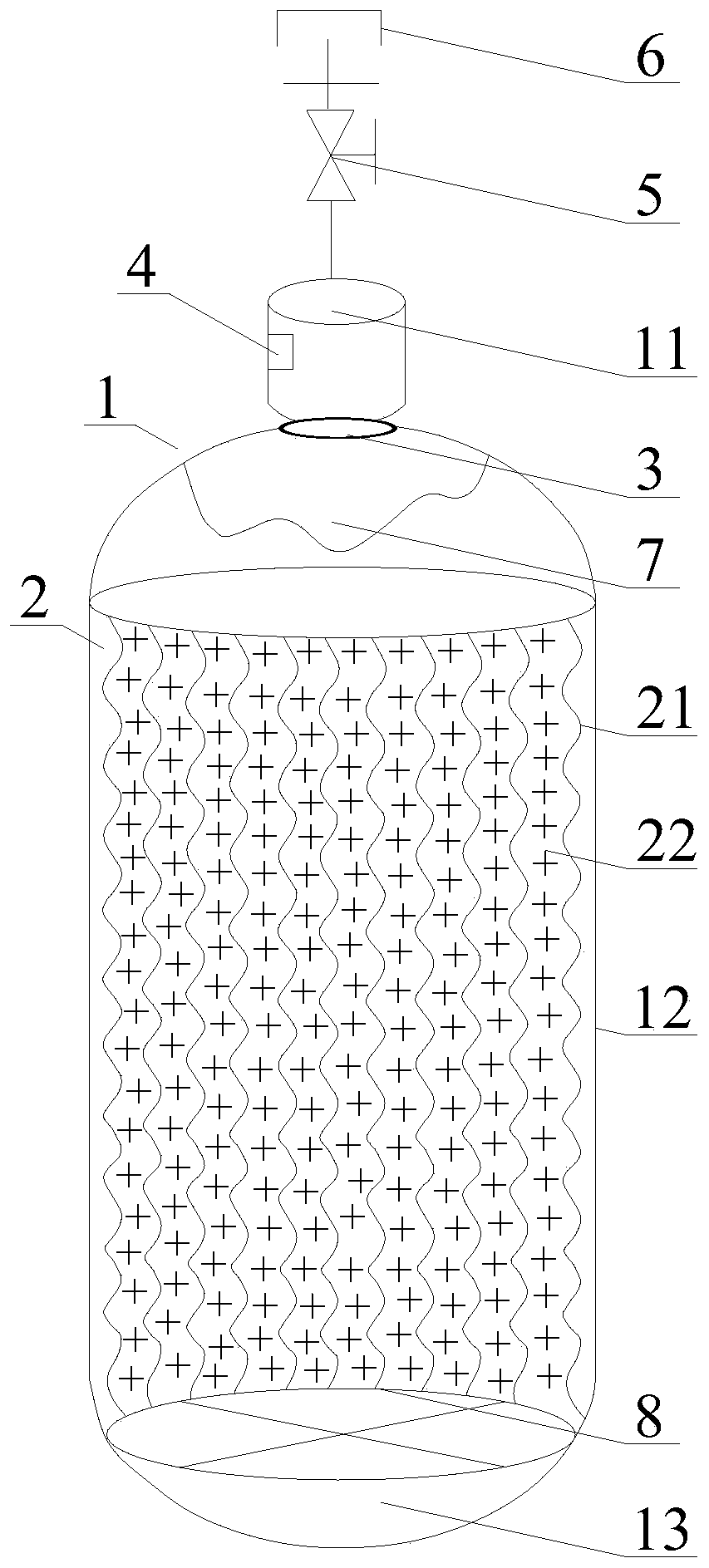

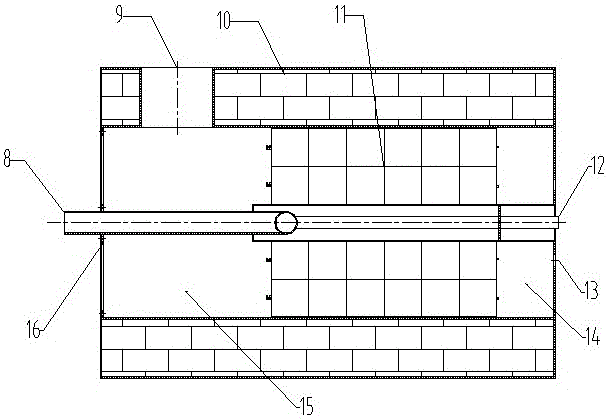

Evaporator for separated heat tube

InactiveCN1535748AIncrease the evaporative heat transfer areaSave the amount of working fluidEvaporationEvaporationEngineering

The present invention discloses an evaporator for separated heat pipe. It includes parallel-connected channels and metal plate. Said parallel-connected channels are integrally formed in the interiour of metal plate along the vertical direction. The top portion of the metal plate is equipped with a steam header formed into a hollow cavity communicated with upper end hole of the described channel, on the top cover of the steam header a steam outlet is set. The metal plate also includes a reflux system including recycle tube and liquid header formed into hollow cavity, the liquid header is communicated with exteriour of metal plate by means of recycle tube, and said liquid header is communicated with the described channel. Said invention also provides a reflux system correspondent to falling-film evaporation, the liquid header is positioned in the lower portion of upper end hole of the channel and close to upper end hole of the channel, and the upper end hole of liquid header is communiated with upper end hole of channel by means of steam header.

Owner:中科热科技江苏有限公司

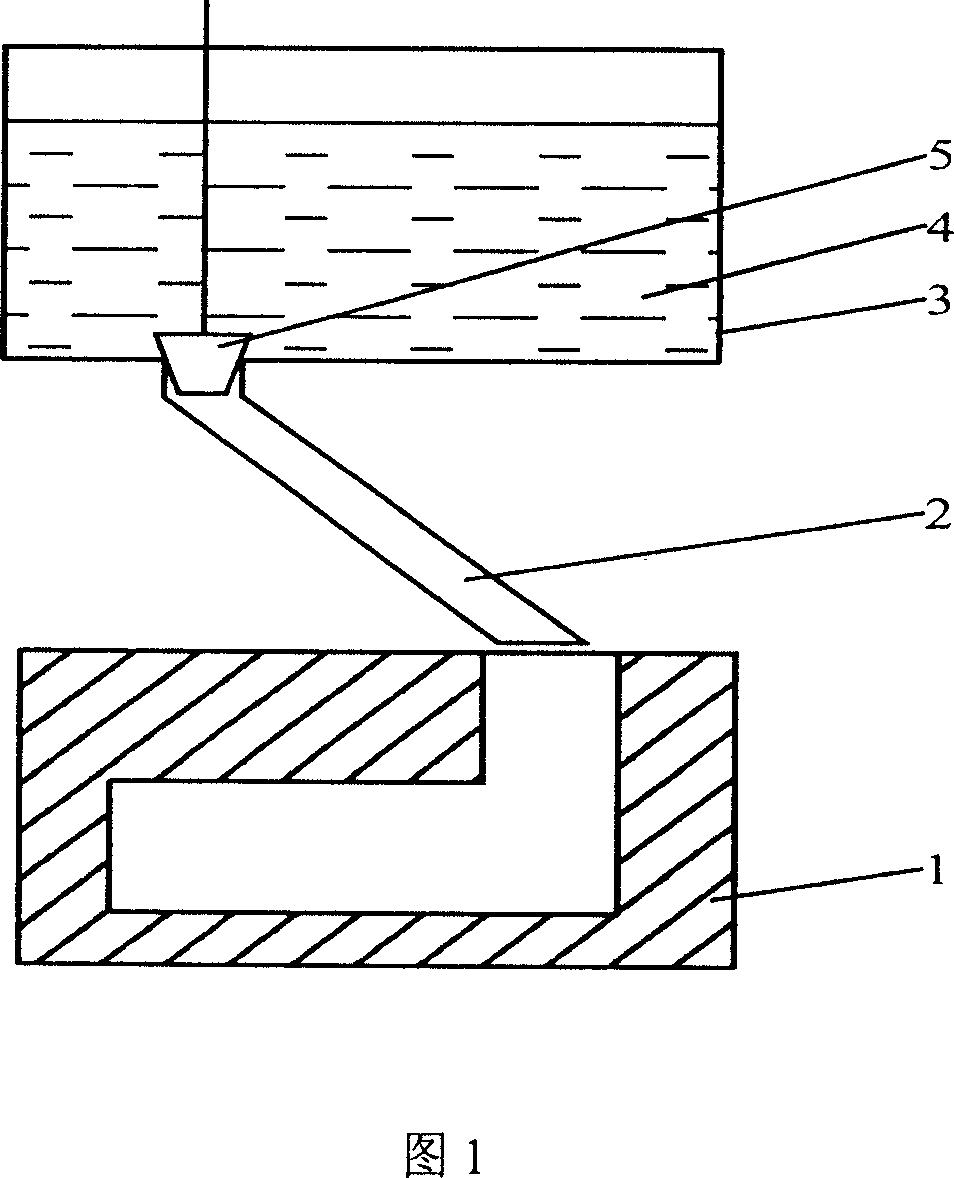

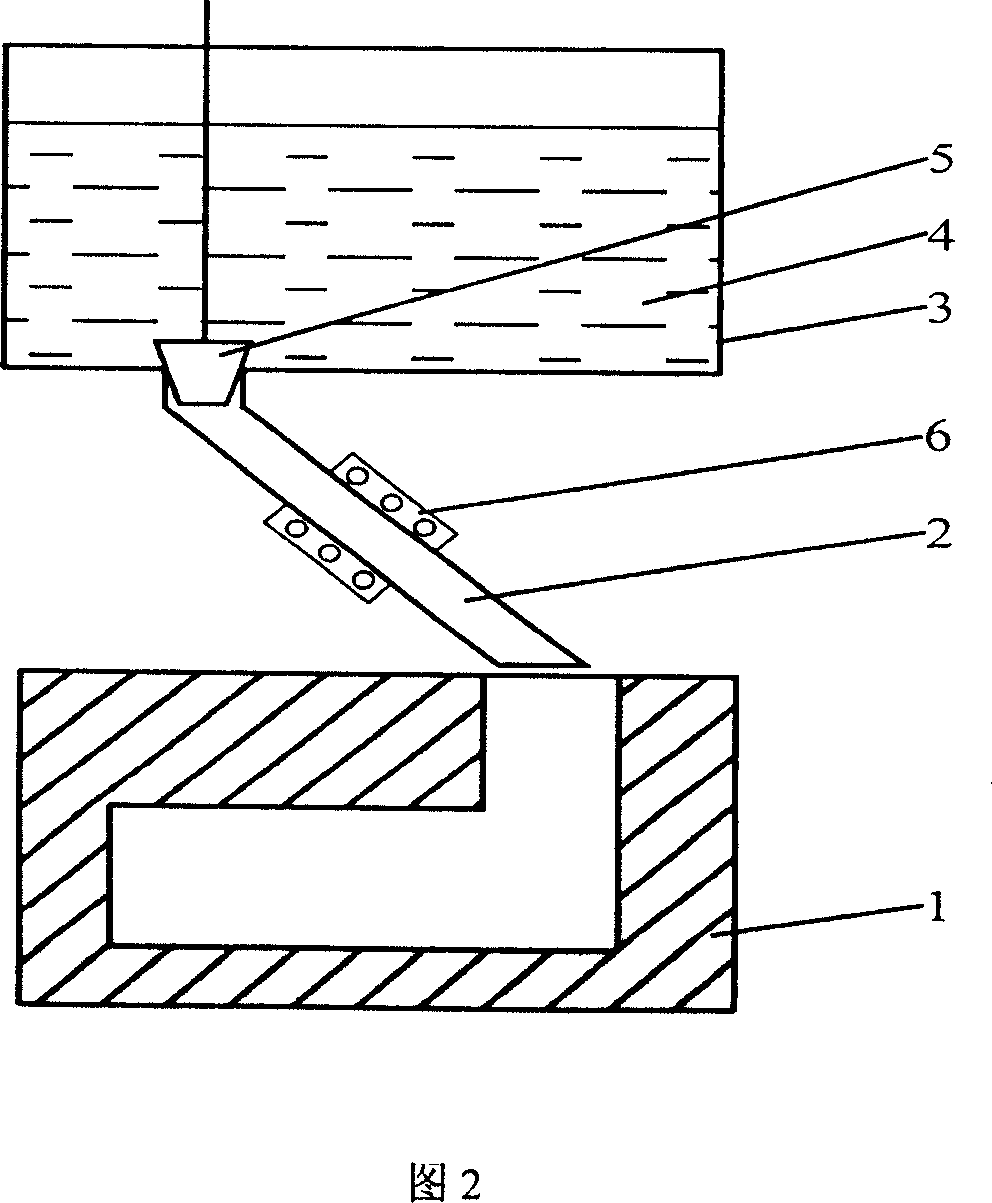

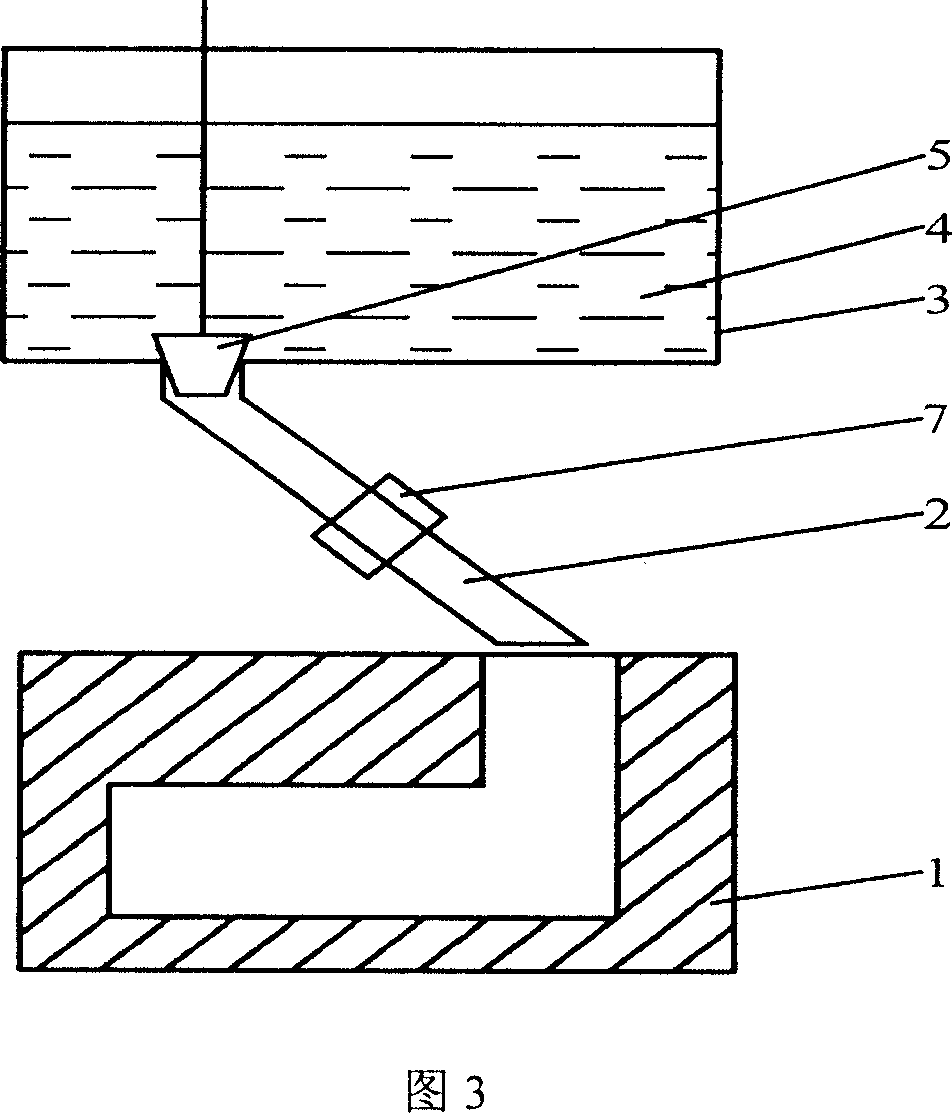

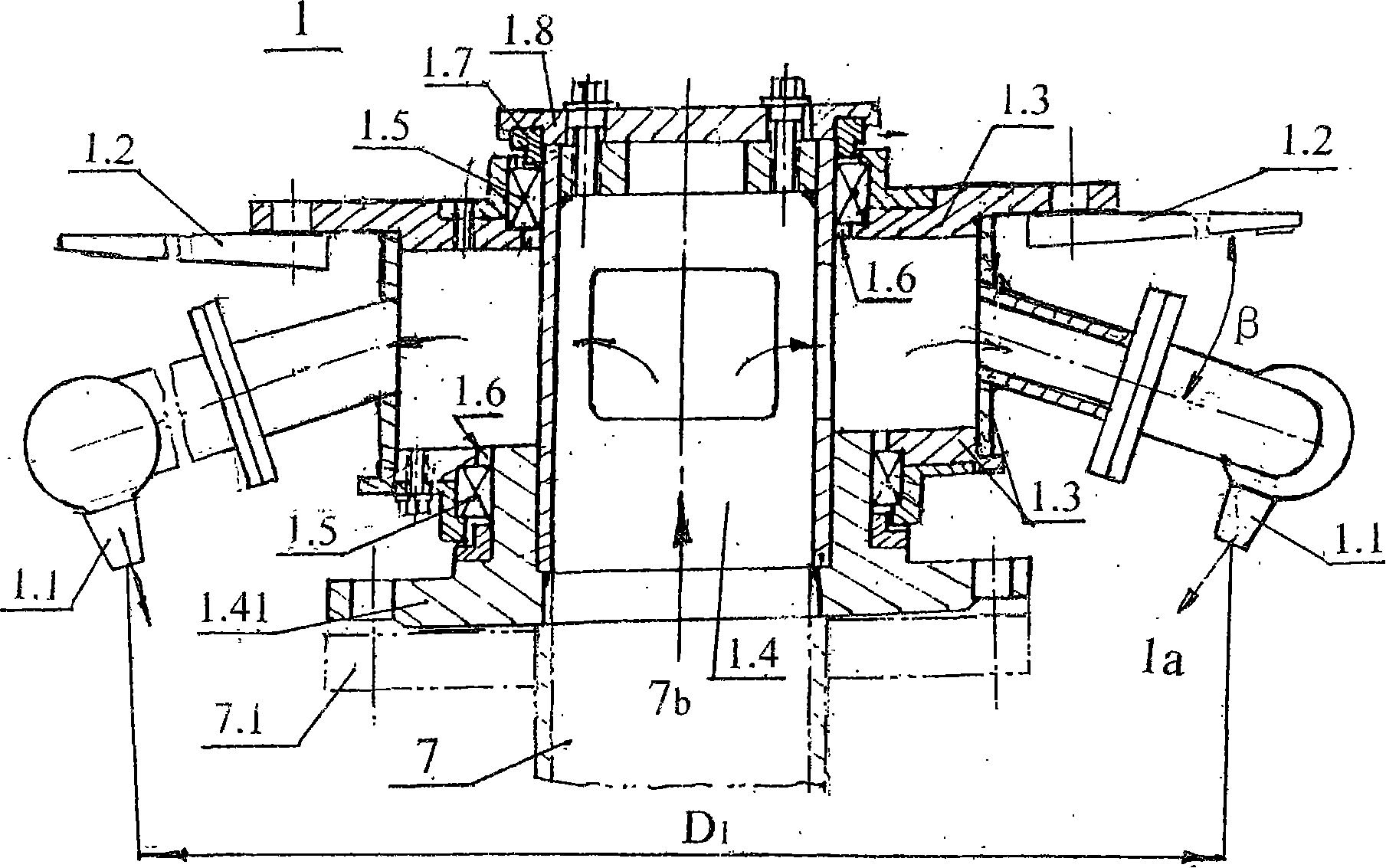

Method for producing semi-solid state sizing agent for founding and the producing device

The present invention relates to process and apparatus for preparing semi-solid slurry for casting, and aims at raising quality of semi-solid slurry. The process of preparing semi-solid slurry with chilling and / or mechanical vibrating includes making molten metal liquid flow to the casting mold in a flow guide device with cooling effect, controlling the temperature of the flow guide device below liquid temperature of the metal for the metal liquid to grow crystal via chilling, flushing the fine crystal with the flowing metal liquid to make it produce necking, crack and breaking and fuse into the liquid flow so as to form semi-solid slurry, and injecting the slurry into casting mold to complete semi-solid casting. The present invention has the features of low cost, simple technological process, and capacity of obtain semi-solid slurry with rich well dispersed and well nodularized solid particles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

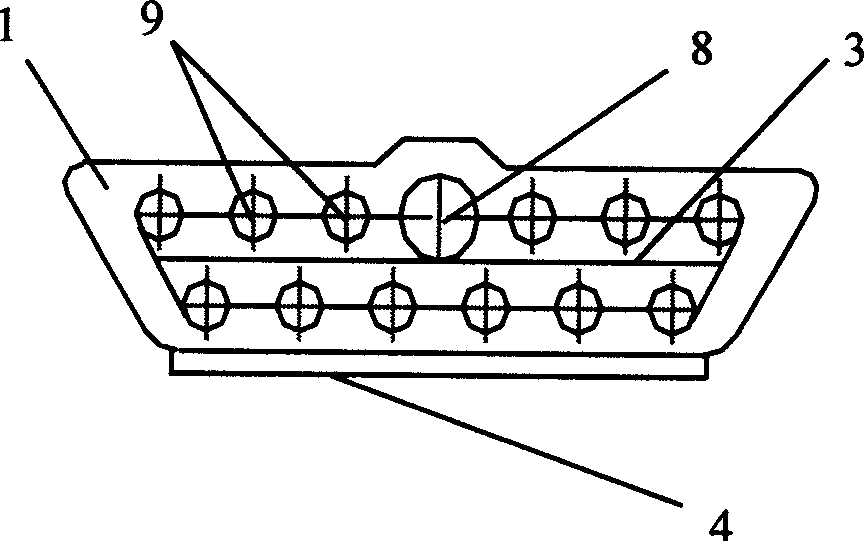

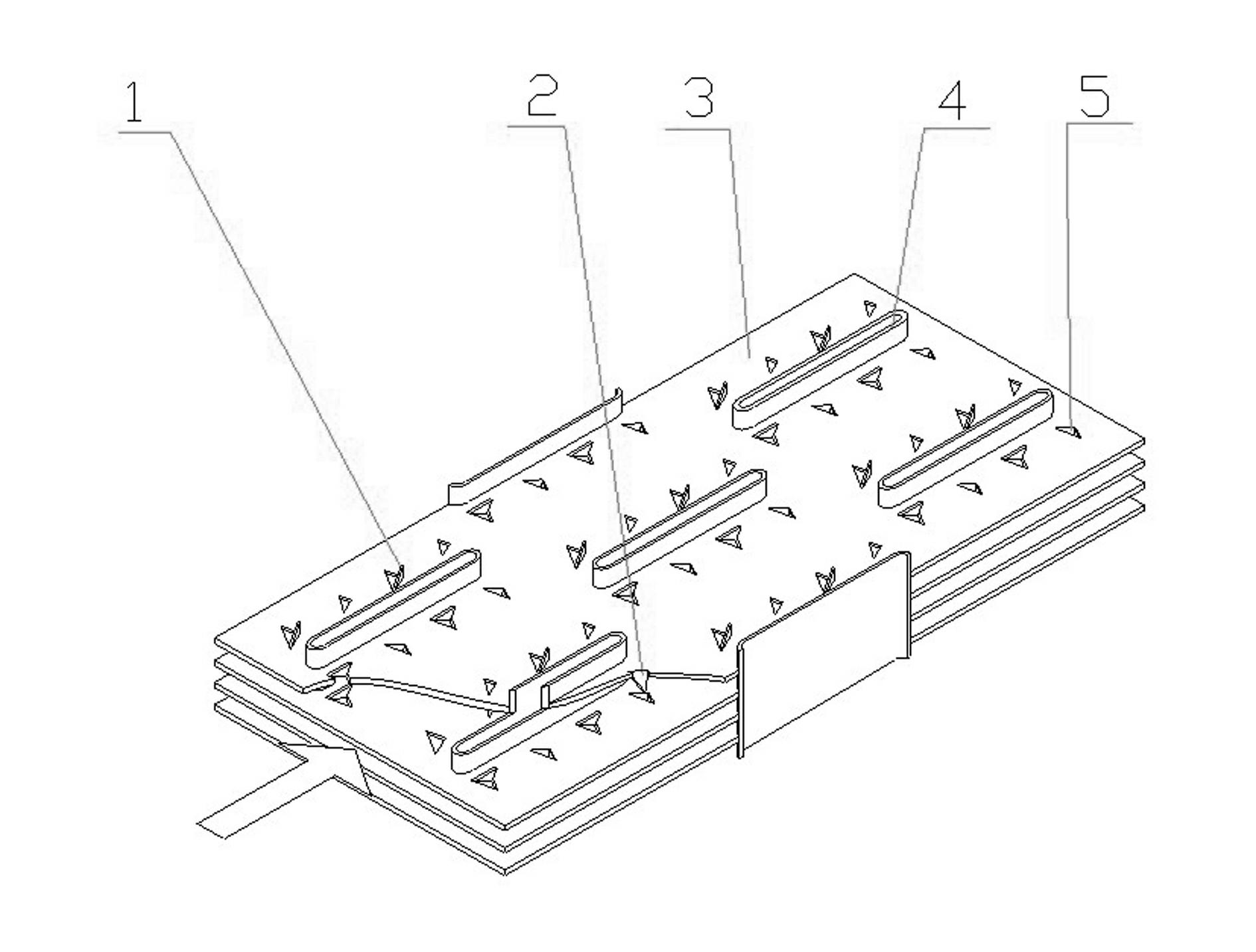

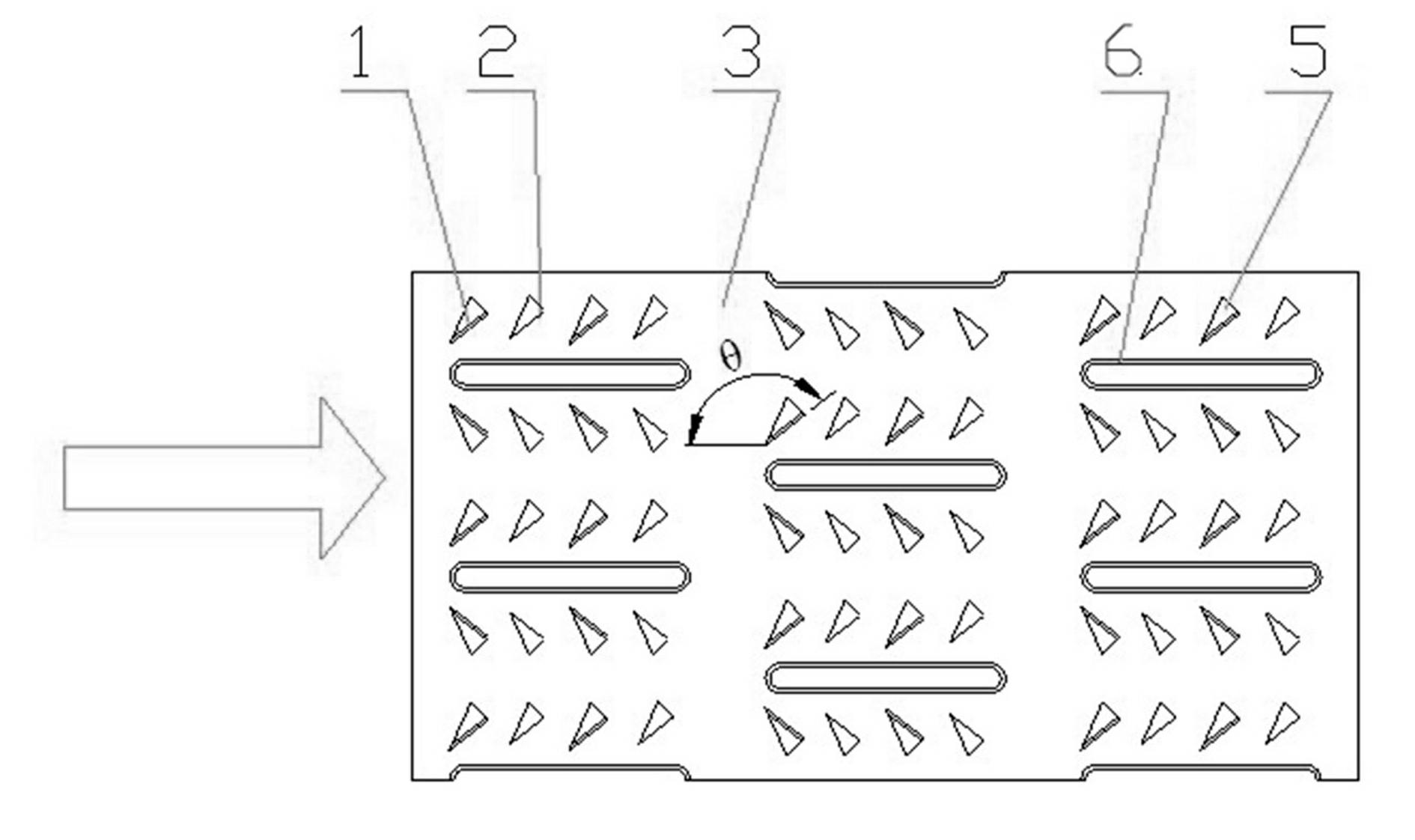

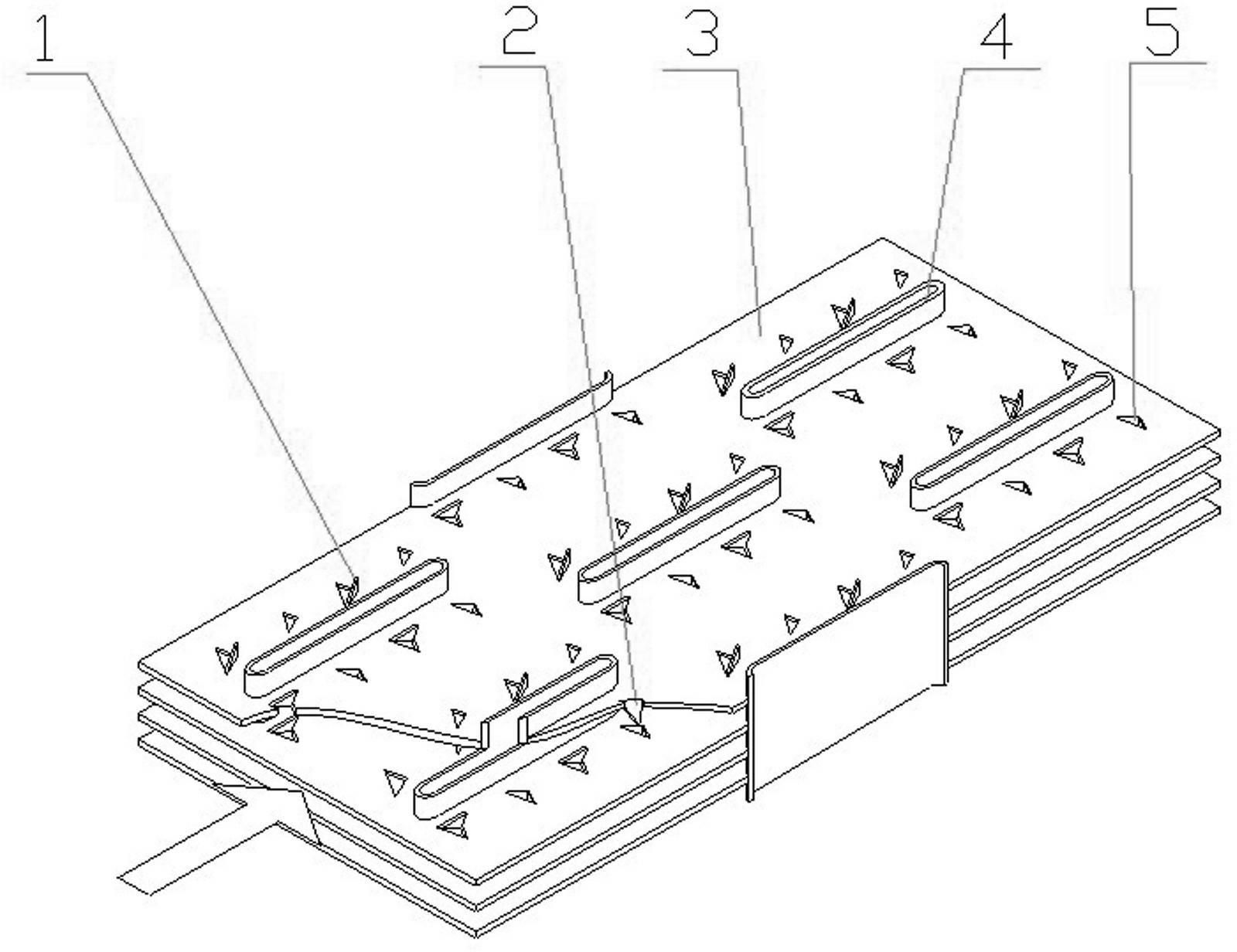

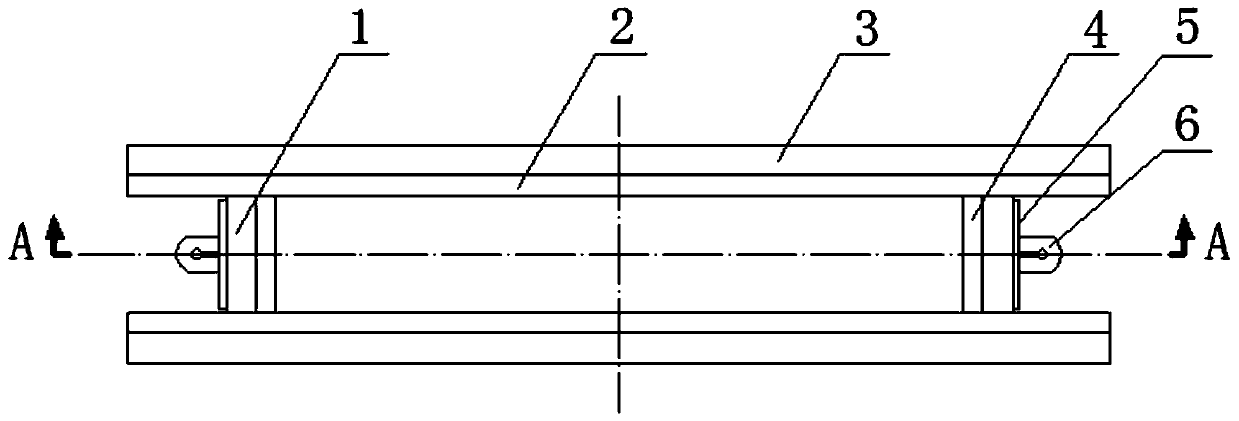

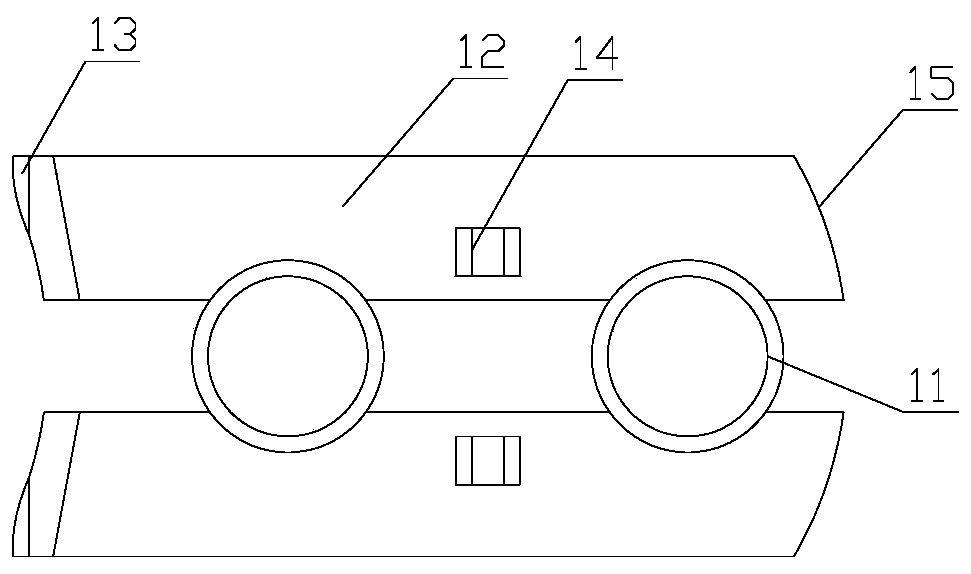

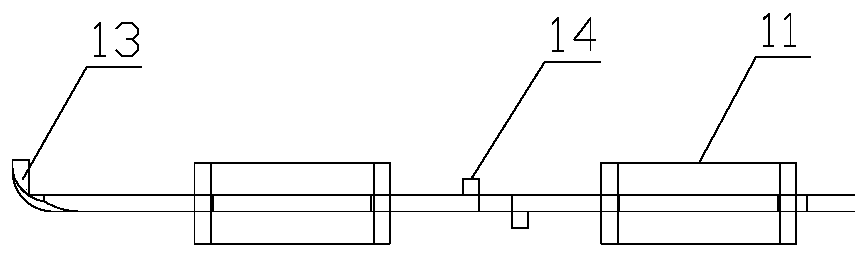

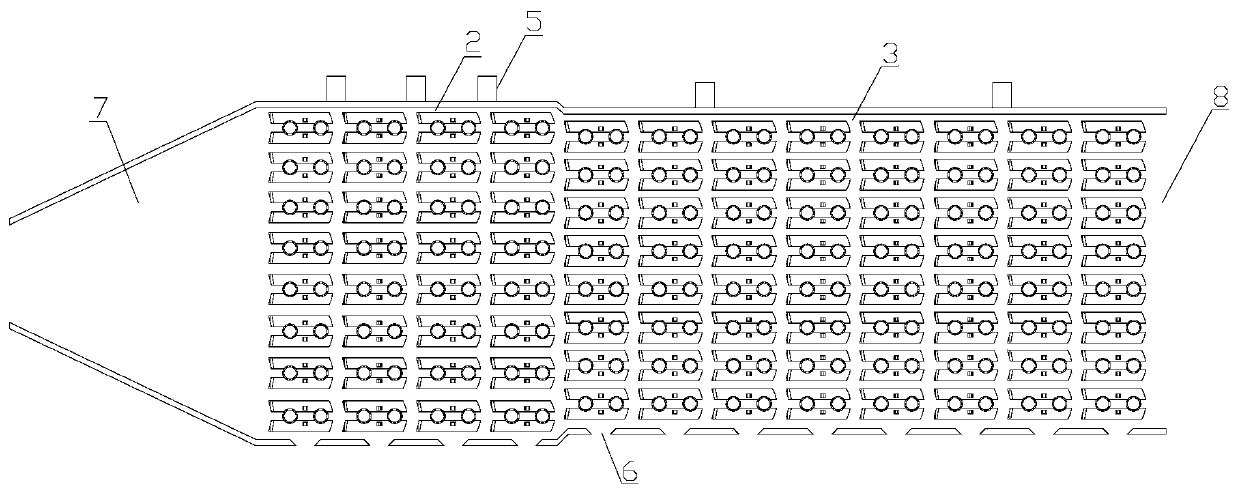

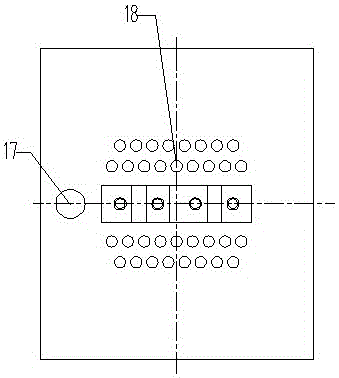

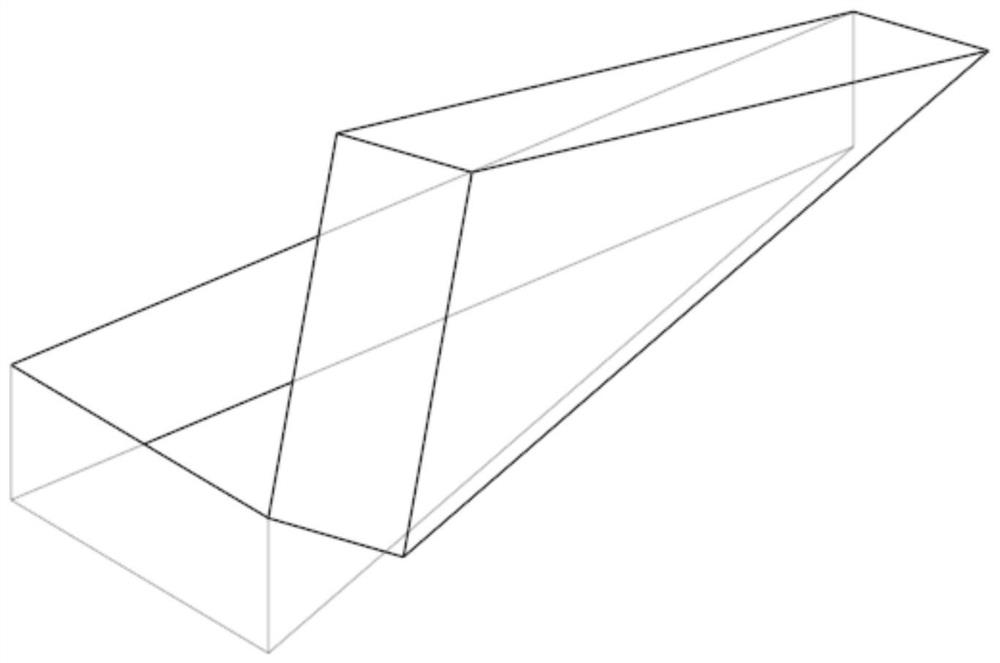

Flat tube-fin heat exchanger with double-side vortex generator

InactiveCN102121798AImprove heat transfer conditionsImprove heat transfer performanceStationary conduit assembliesHeat transfer modificationPhysicsEngineering

The invention discloses a flat tube-fin heat exchanger with a double-side vortex generator, which belongs to the technical field of flat tube-fin heat exchangers and comprises flat tubes arranged along the direction of air flow and fins sleeved on the flat tubes. The fins are provided with holes used for sleeving the flat tubes, two pairs of vortex generators facing upwards and two pairs of vortex generators facing downwards are stamped respectively by the upper side and the lower side of each hole, and corresponding small holes are left on the fins; and the front edge points of the first pair of the vortex generators facing upwards are located at front-end tangent lines of the holes used for sleeving the flat tubes, and the front edge points of the second pair of the vortex generators facing upwards are located at middle perpendicular lines of the holes used for sleeving the flat tubes. Compared with a traditional single-side fin for stamping the vortex generators, two sides of the fins disclosed by the invention are simultaneously turned over to stamp out the vortex generators, thereby the heat exchange capability of the fins can be improved, and the flow resistance of an air side can be simultaneously reduced. Moreover, the compactedness of a heat exchange device is increased, the power of a pump is reduced, and the energy sources are saved under an identical heat load.

Owner:LANZHOU JIAOTONG UNIV

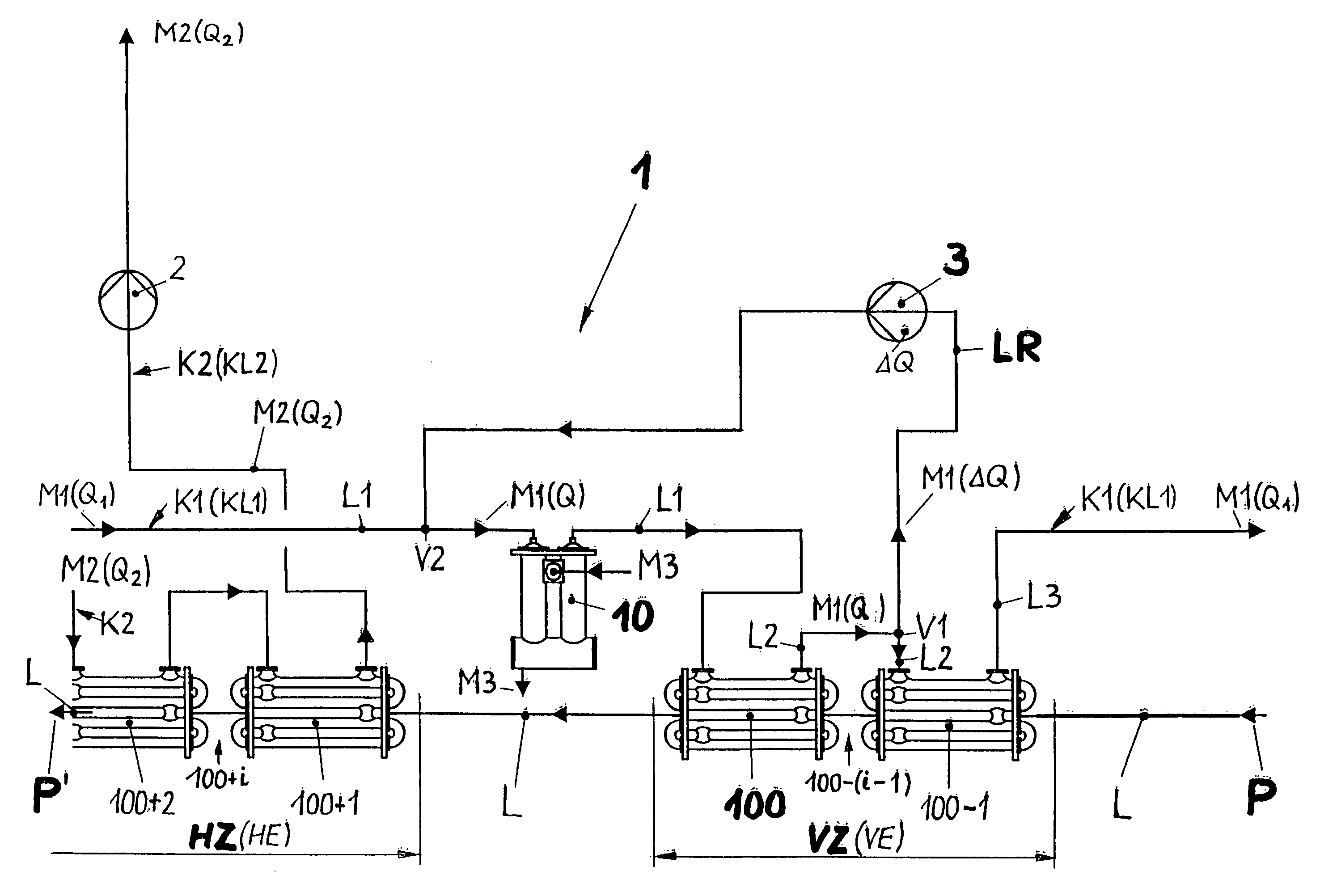

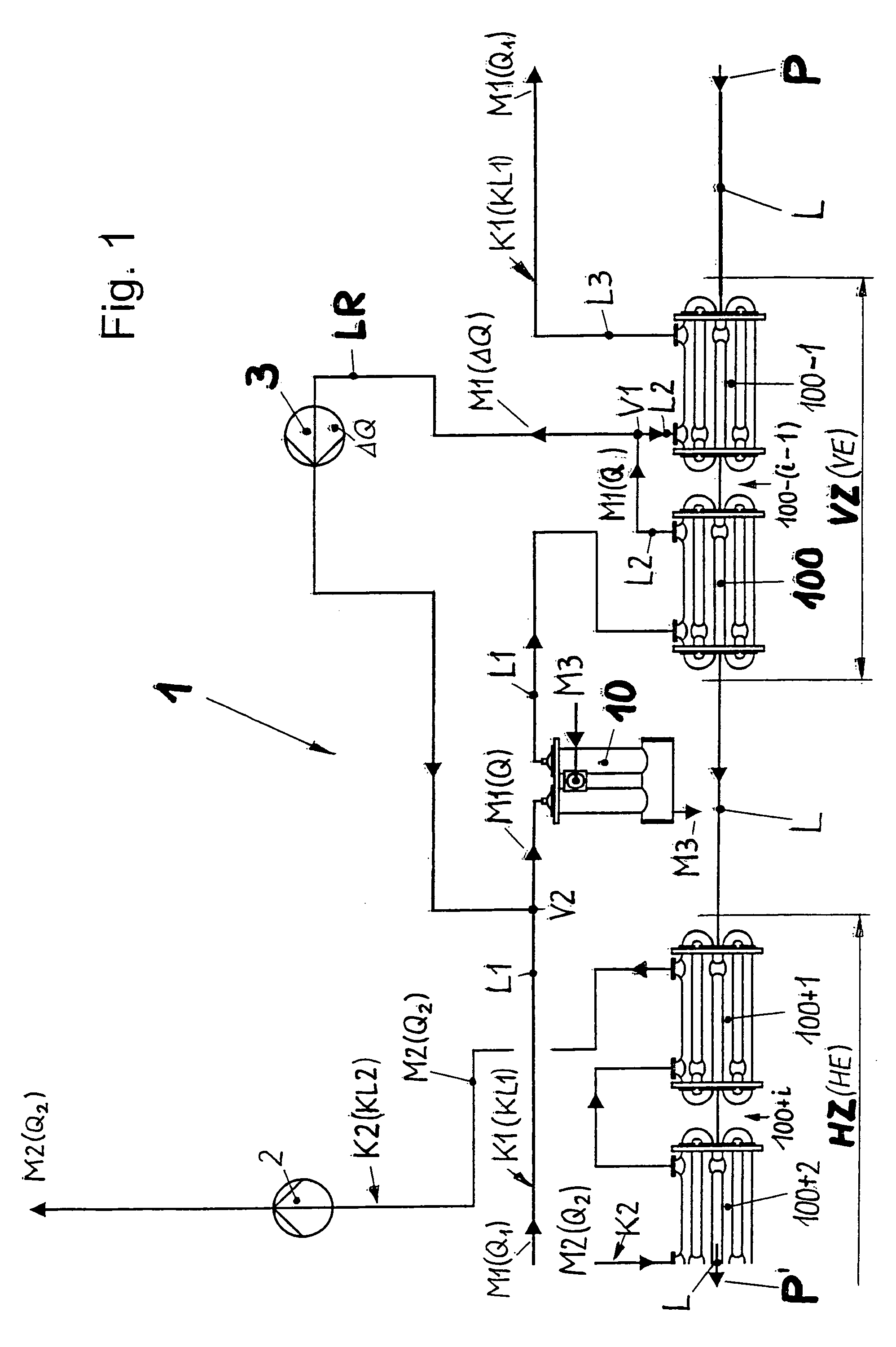

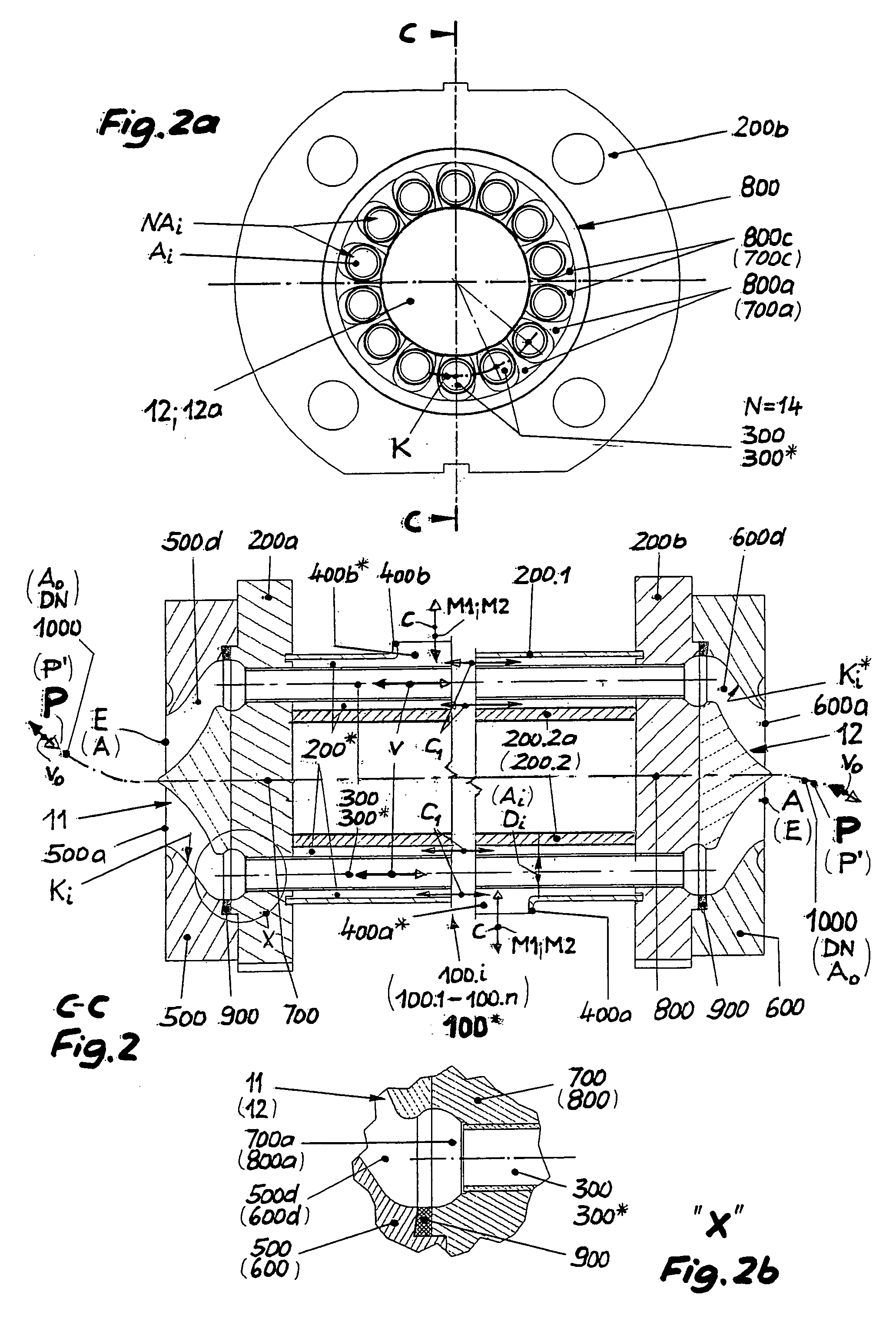

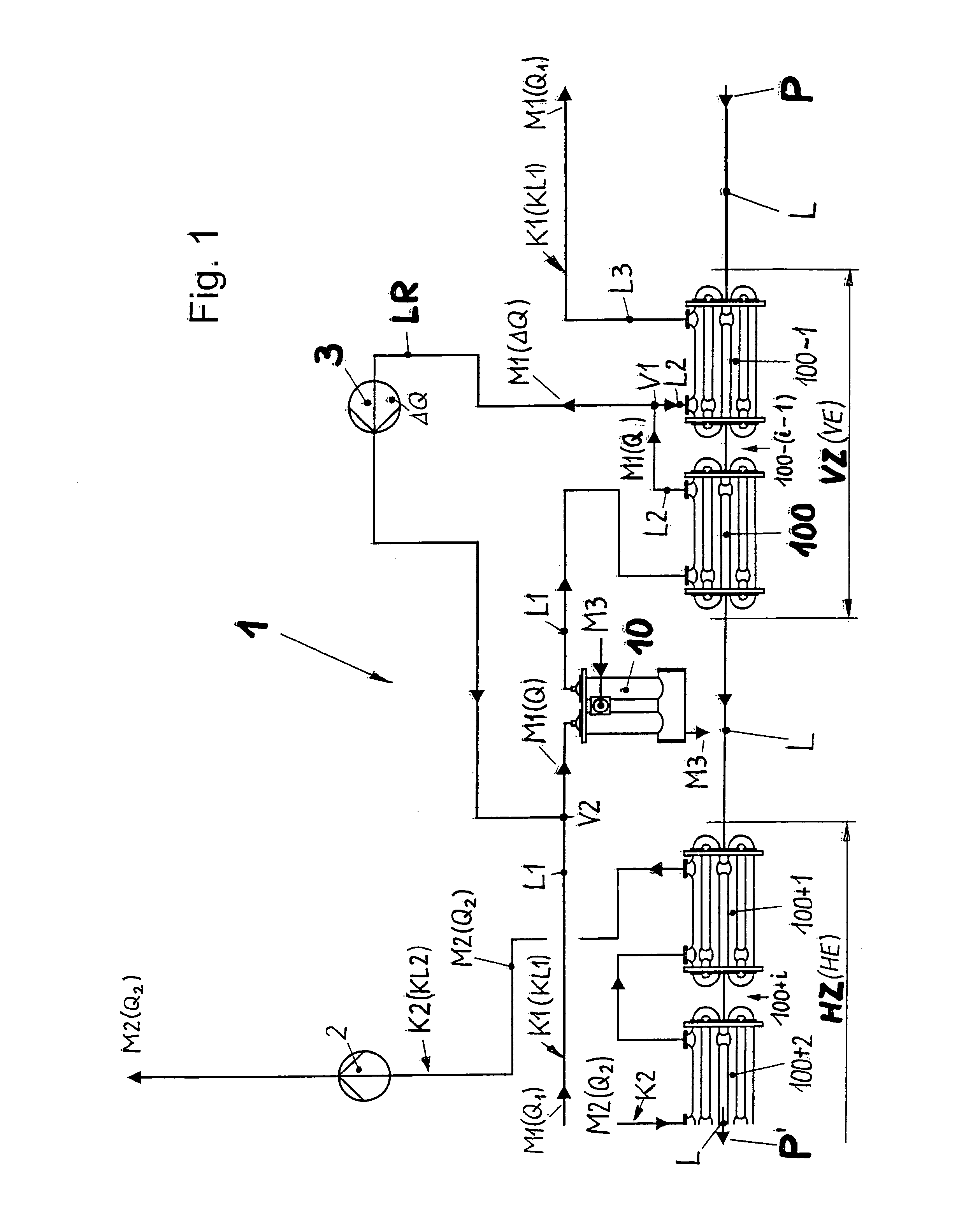

UHT System and Method for Heat Treating Temperature-Sensitive Food Products

ActiveUS20120276266A1Velocity increasesPerform this temperature adjustment promptly and efficientlyFood preservationHeat exchanger casingsEngineeringTemperature sensitive

The invention relates to a UHT system for heat treating temperature-sensitive food products, in particular desserts or dessert-like products, comprising a pre-heating zone and a subsequent high-heating zone. The aim of the invention is to achieve accurate and fast temperature adjustment of the food product leaving the pre-heating zone to the temperature conditions at the inlet of the high-heating zone in a UHT system of the generic type, and at the same time, with an equal dwell time for all partial amounts of the food product, to ensure that the food product is treated in a particularly thermally gentle manner and to keep the mechanical loading of the food product as low as possible.

Owner:GEA TDS

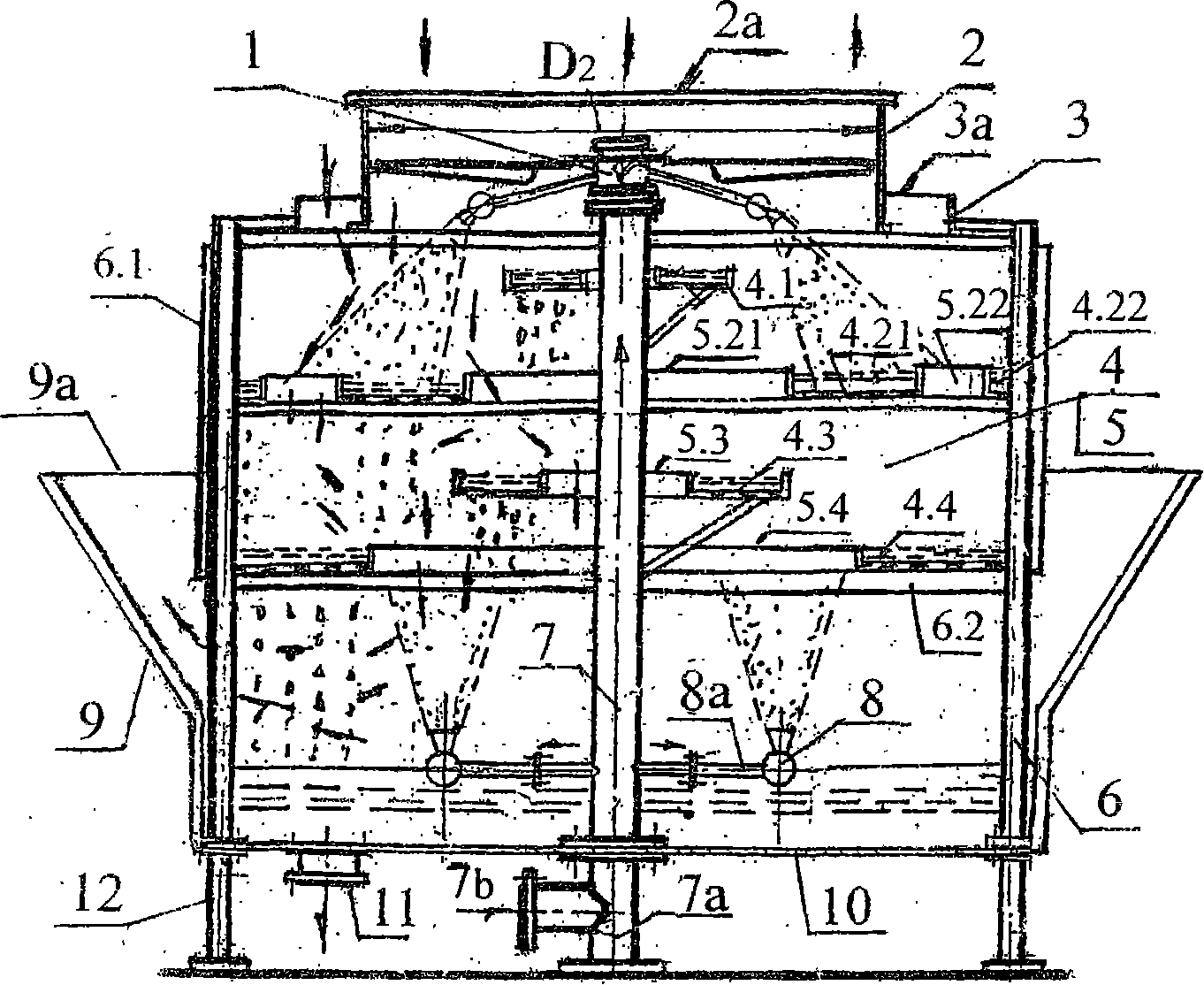

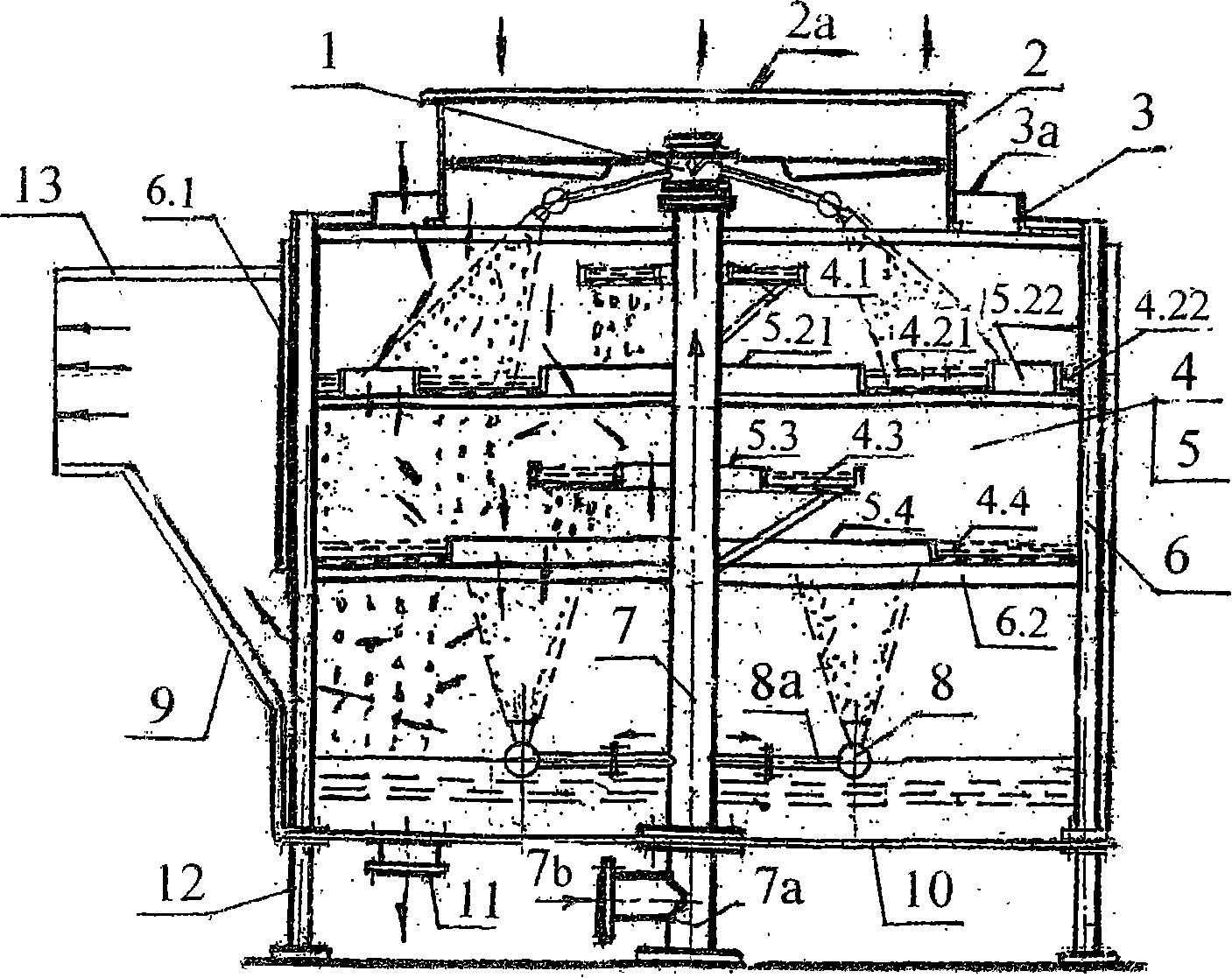

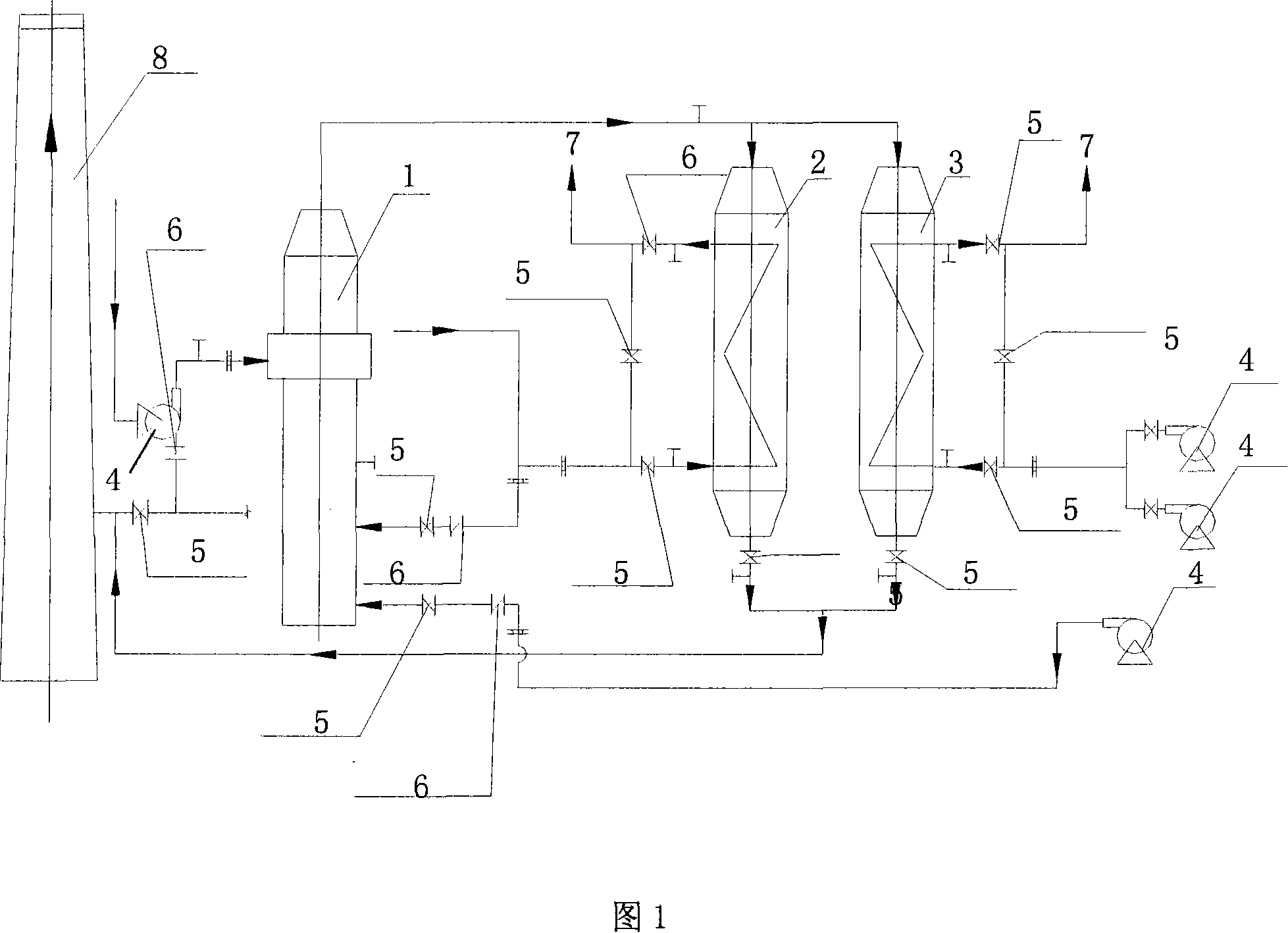

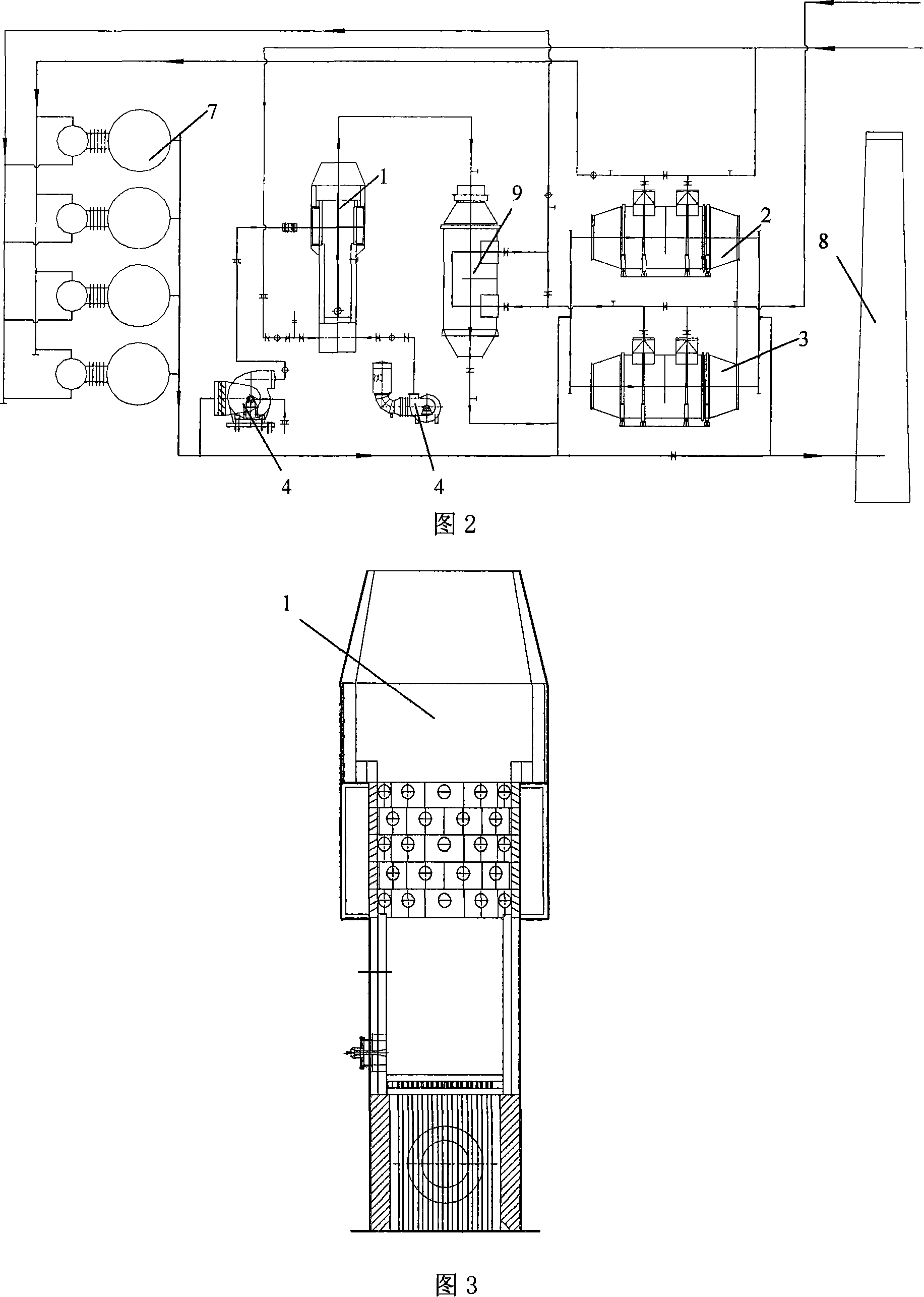

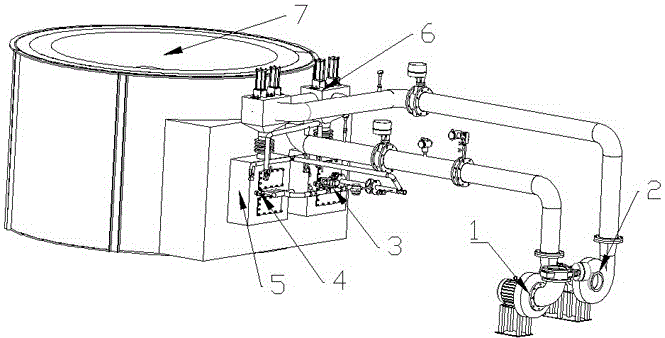

Lower jet type spraying thrust aerating and cooling tower, and jet flow cool wind machine

InactiveCN101169312AIncrease temperature dropEasy windingTrickle coolersAir conditioning systemsCooling towerEngineering

The invention relates to a downward spraying type spray boosting aeration cooling tower and shooting flow air-cooler. A tower body is provided with an out revolving type spray boosting wind pumping device inside which sprays frog flow by being connected pressure hot water, a nozzle downward sprays and laminas downward pump wind; cooling medium wind enters a wind channel for one time and two times from the tower top and a wind outlet is arranged on the middle lower part of the tower wall and is provided with a wind bucket. The lower part of the spraying device is provided with layers of drenching screen stencils, the water distribution and wind leading enable the drenching even and the cold winter passes amongst the water frog flow for a plurality of times, thereby greatly elevating the heat passing efficiency. Because the wind has the same direction with the water, the disturbance of the water frog to the laminas is reduced and the wind force of the ejection flow is increased, and the praying flow injection wind is downward and also be utilized, namely the generated three air flows of lamina mechanical wind, spray injection wind and the lamina injection wind proceed the heat exchanging with the spray flow, the wind rate is increased, the gas and water rate reaches above 1.0 which is 29 to 90 percent higher than the prior upward spraying cooling towers, and the reducing temperature can be greatly elevated. The noise of the tower water flow is reduced; the tower top has no drift ice, and the working hydraulic pressure is 0.08 to 0.12MPa. Because the wind temperature is near to the water temperature, the invention can be simultaneously used as the injection flow air-cooler, and the refrigerating air-condition in winter, summer and autumn.

Owner:魏仕英

Cooler descaling device

InactiveCN103438756AImprove heat transfer conditionsExtend your lifeNon-rotary device cleaningParticulatesHigh energy

The invention relates to a cooler descaling device, which comprises a high pressure air pump and a high pressure air inlet pipe, wherein the high pressure air inlet pipe is connected with the high pressure air pump, an outlet of the high pressure air pipe is arranged in a high pressure cavity, the upper part of the high pressure cavity is provided with a particle material bin, the particle material bin is communicated with the high pressure cavity through a vertical material falling pipe, a high pressure branch pipe is further arranged between the high pressure air inlet pipe and the material falling pipe, the high pressure branch pipe and the material falling pipe are connected in a downward inclining way, and the front end port of the high pressure cavity is connected with a water inlet of a cooler. The cooler descaling device has the advantages that particle materials are converted into high-energy physical kinetic energy by a high pressure spray nozzle of compressed air, and then a metal surface is treated; a cooling wall and a water pipe are cleaned by the technique, water scale can be removed, and the toughness of the cooling wall and that of a pipeline are reduced, so the heat transfer condition of the cooling wall is improved, the drag loss is reduced, and the service life of the cooling wall is prolonged; the method can replace a traditional acid cleaning method, the equipment structure is simple, the efficiency is high, the cost is low, and the pollution is avoided.

Owner:山西新泰钢铁有限公司

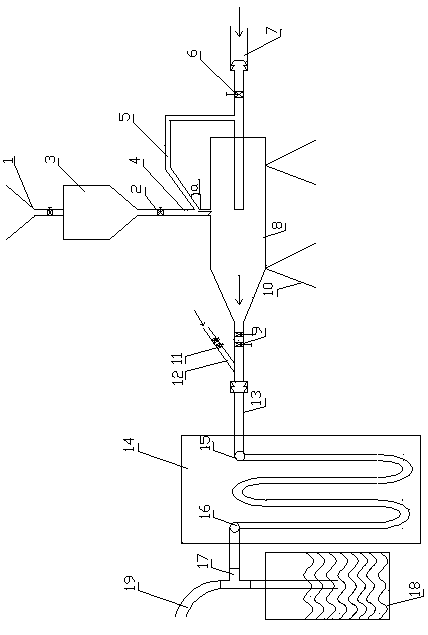

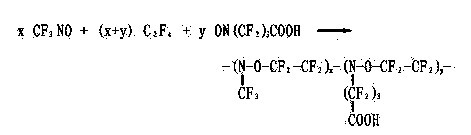

Carboxyl nitroso-fluoro rubber (CNR) solution polymerization process

The invention relates to a process for synthesizing a crude carboxyl nitroso-fluoro rubber (CNR) by copolymerizing trifluoronitrosomethane, tetrafluoroethylene and perfluoro(nitrosobutanoic acid) in a dichloromethane solvent under low temperature, belonging to the technical field of organofluorine chemistry. The method is characterized by displacing gas in a polymerizer with nitrogen, and then vacuumizing the polymerizer; pumping a circulating low-temperature cold medium into a jacket; adding perfluoro(nitrosobutanoic acid), dichloromethane, trifluoronitrosomethane and tetrafluoroethylene in sequence; displacing the residual gas in the polymerizer with nitrogen after the reaction is completed; opening a bottom valve of the polymerizer to discharge dichloromethane; taking the CNR from the upper part of the polymerizer; and obtaining the crude CNR through aftertreatment procedures such as washing, dehydration and low molecule removal and the like. The CNR solution polymerization process has the following technical effects: mass and heat transfer conditions of polymerization reaction are greatly improved, so that the reaction is carried out stably in the easily controlled state, and the explosion danger is avoided; and the polymer and the solvent are simple and convenient to separate, and the yield is high.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

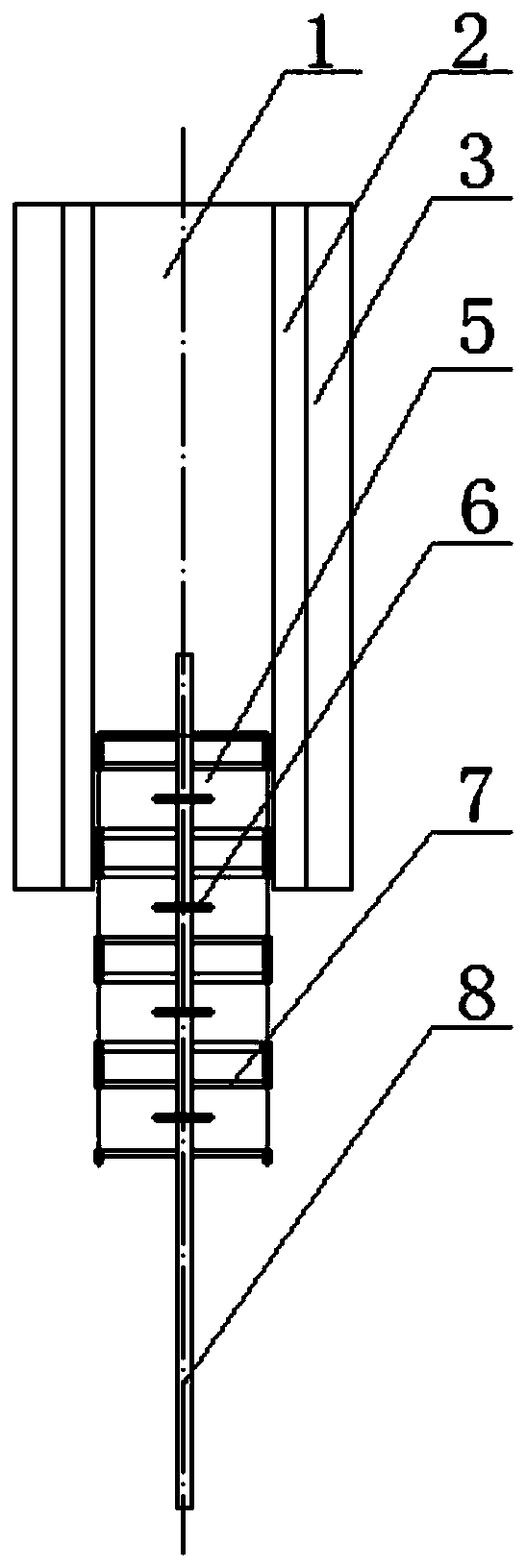

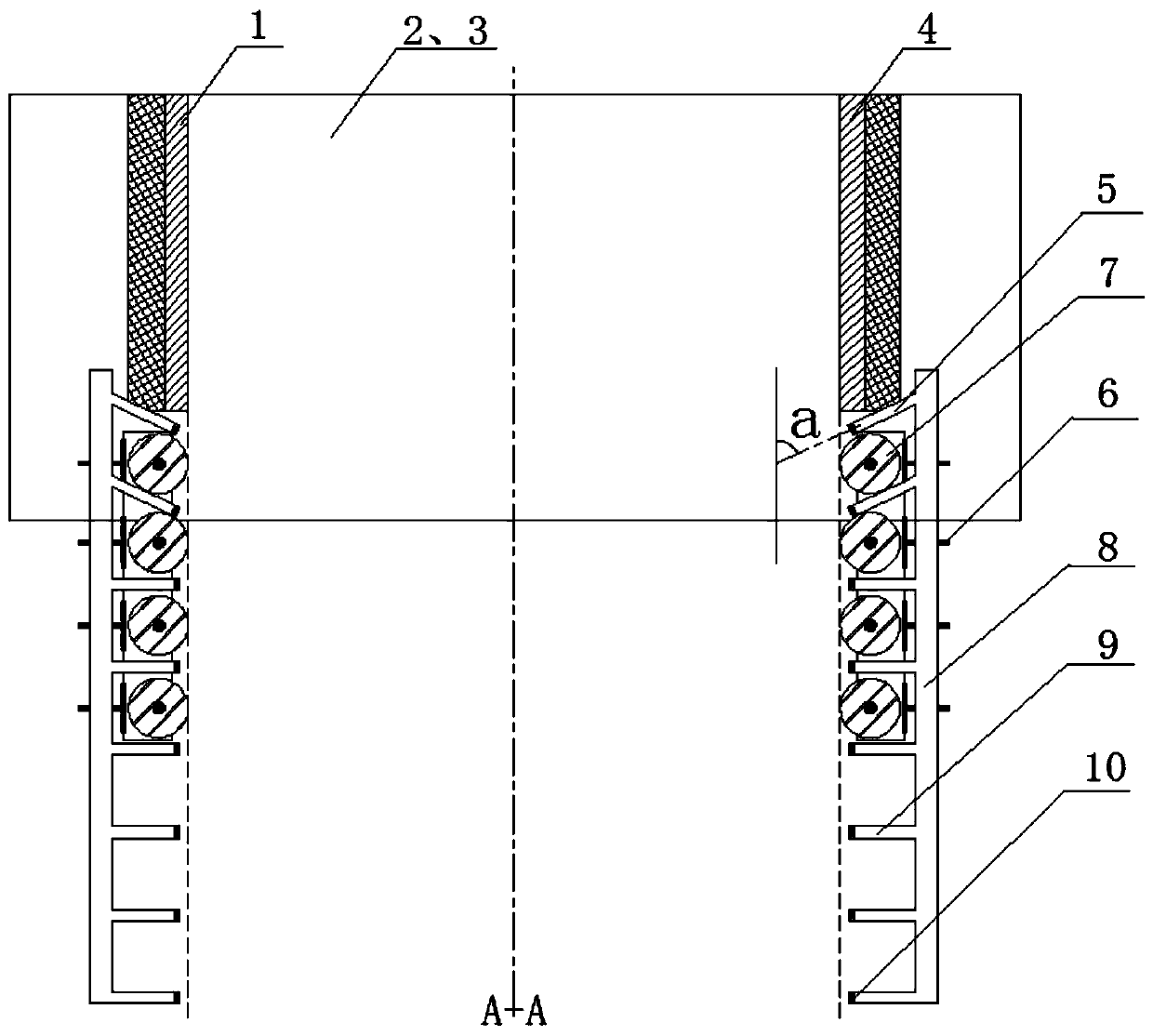

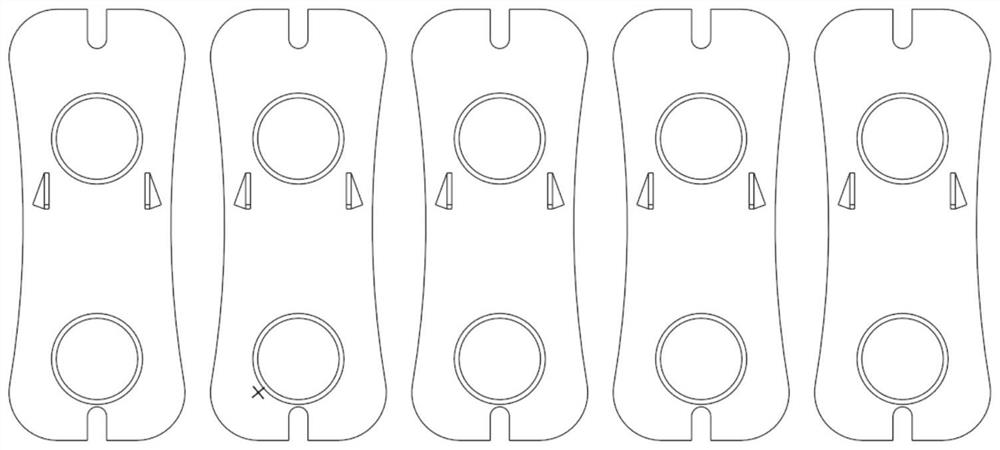

Method and device for inhibiting size of austenite grains at corners of continuous casting slab

InactiveCN110860662AImprove Narrow Face QualityPromoting disperse distribution precipitationAustenite grainNarrow face

The invention discloses a method and device for inhibiting size of austenite grains at corners of a continuous casting slab, and belongs to the technical field of metallurgical continuous casting. Thedevice comprises a wide-face copper plate fixed to a wide-face supporting plate and a narrow-face copper plate fixed to a narrow-face supporting plate, wherein the upper end face of the narrow-face copper plate is flush with the upper end face of the wide-face copper plate; the lower end face of the narrow-face copper plate is 100-300mm shorter than the lower end face of the wide-face copper plate; foot roller supports are symmetrically fixed to the lower end face of the narrow-face supporting plate; foot rollers are symmetrically arranged on the foot roller supports; the inner roller face formed by the foot rollers positioned on one side and the inner wall of the narrow-face copper plate are positioned on the same plane; a spraying rod is fixed to the foot roller supports through spraying rod supports; and one end of a spraying branch pipe is fixed to the spraying rod and communicates with an inner cavity of the spraying rod, and a nozzle is mounted at the other end of the spraying branch pipe. The heat transfer condition is improved, the cooling rate is increased, surface grain refinement and dispersion distribution and precipitation of precipitates in crystals are effectively promoted, and the quality of the narrow face of the casting slab is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Diffusion tower for mine air return and heat exchange

InactiveCN105003289AReduce return air speedImprove uniformityTunnel/mines ventillationEngineeringTower

The invention relates to a diffusion tower for mine air return and heat exchange. The diffusion tower is characterized by comprising a circular pipe section, a connecting section, a bent pipe section and a plurality of guide plates which are sequentially connected, wherein the circular pipe section can be liner type or divergent type; the bent pipe section is a perpendicular type bent pipe which adopts a straight line inside and an arc line outside; the top air outlet part of the bent pipe section can be externally connected with a mine air return and heat exchange device; a plurality of the guide plates are uniformly arranged inside the bent pipe section; the guide plates are connected with the two side walls inside the bent pipe section; the guide plates comprise horizontal guide sections and arc-shaped guide sections; the horizontal guide sections with equal intervals and sequentially enlarged length are arranged from the vertical position of the air inlet part of the bent pipe section; the arc-shaped guide sections correspondingly connected with the horizontal guide sections are arranged in the arc-shaped section range between the inner arc line of the connecting section and the outer arc line of the bent pipe section. According to the diffusion tower, the outlet part airflow is good in uniformity and stable in flow velocity, and a full and good heat exchange condition is provided for mine air return and heat exchange.

Owner:TECH DEV OF SHANXI COAL IMPORT & EXPORT GROUP +2

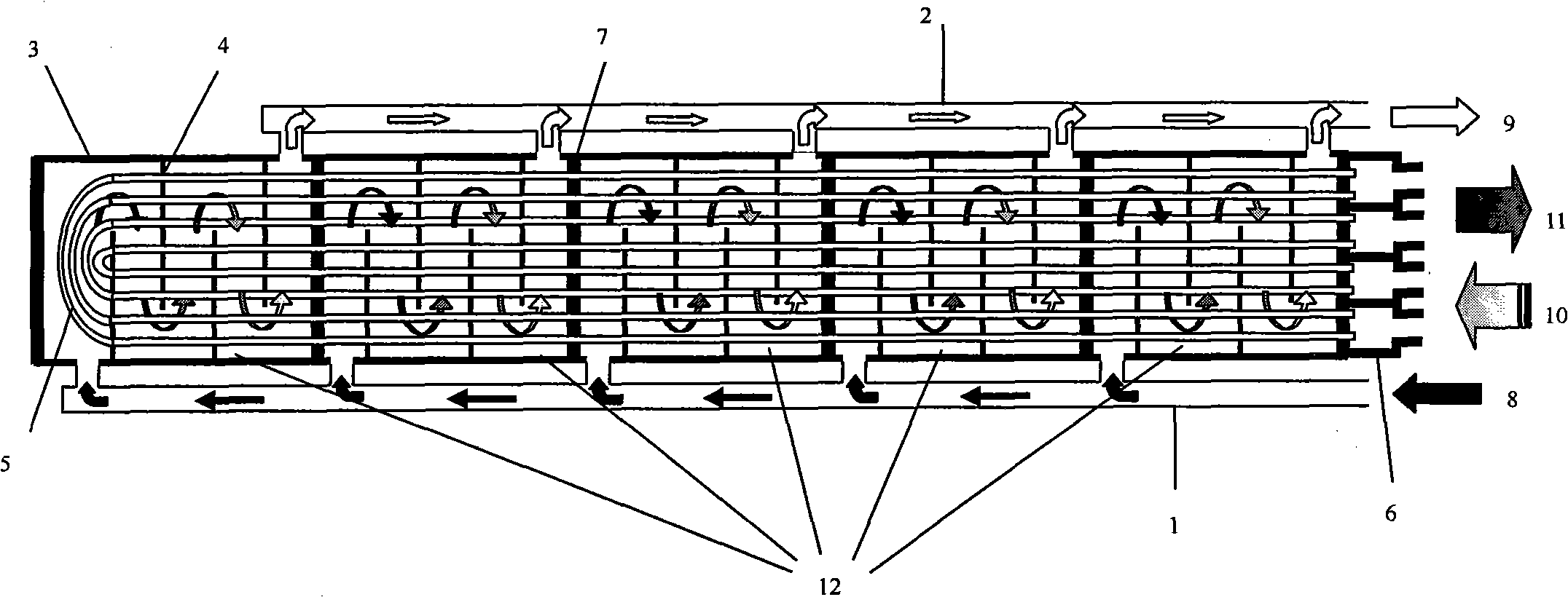

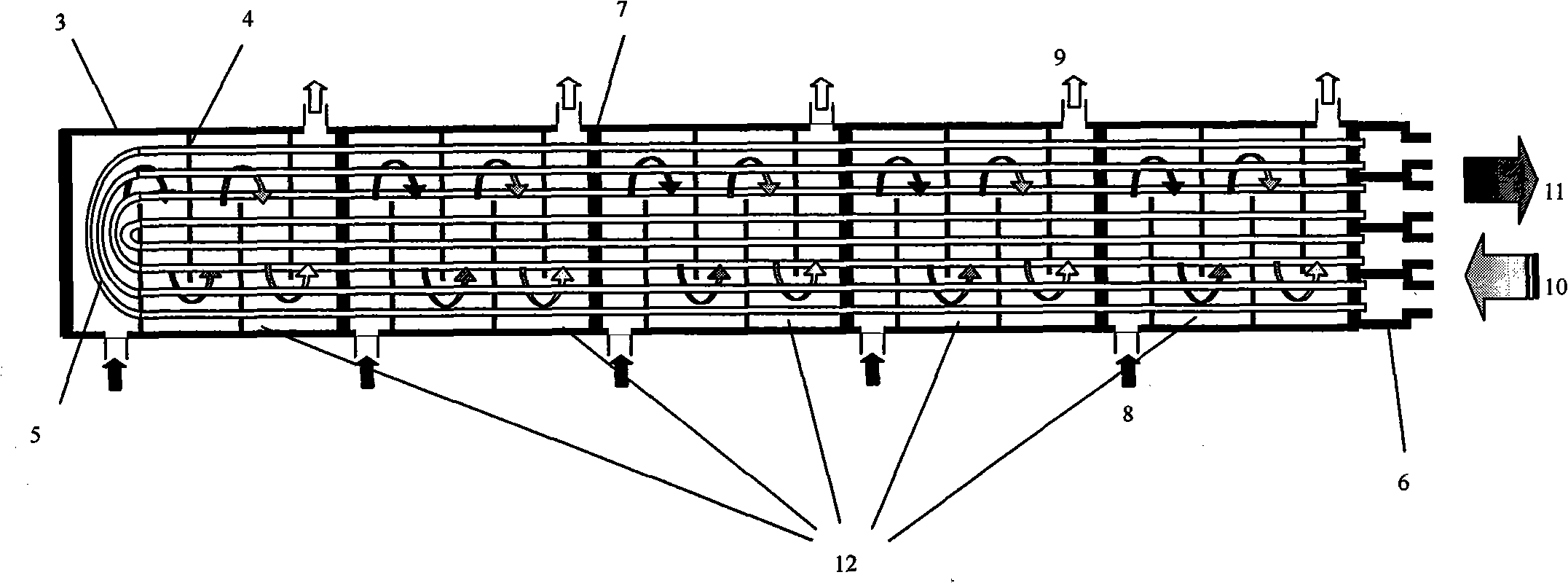

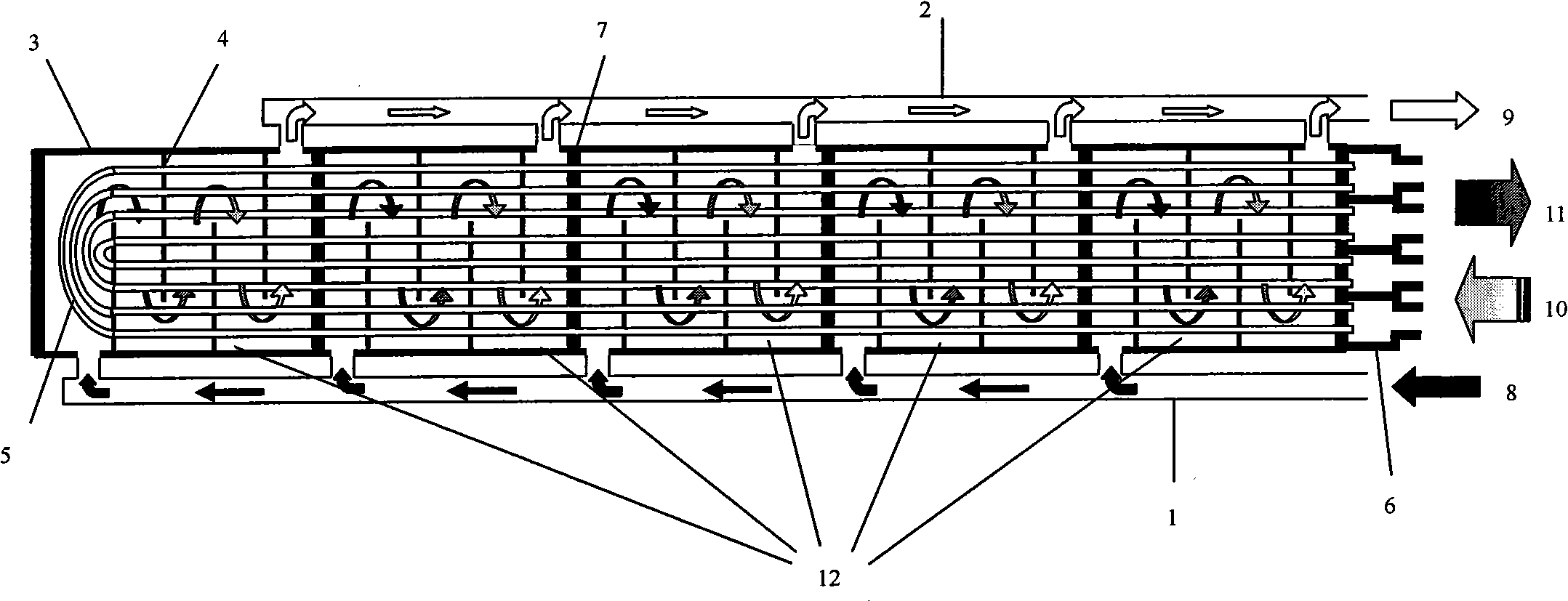

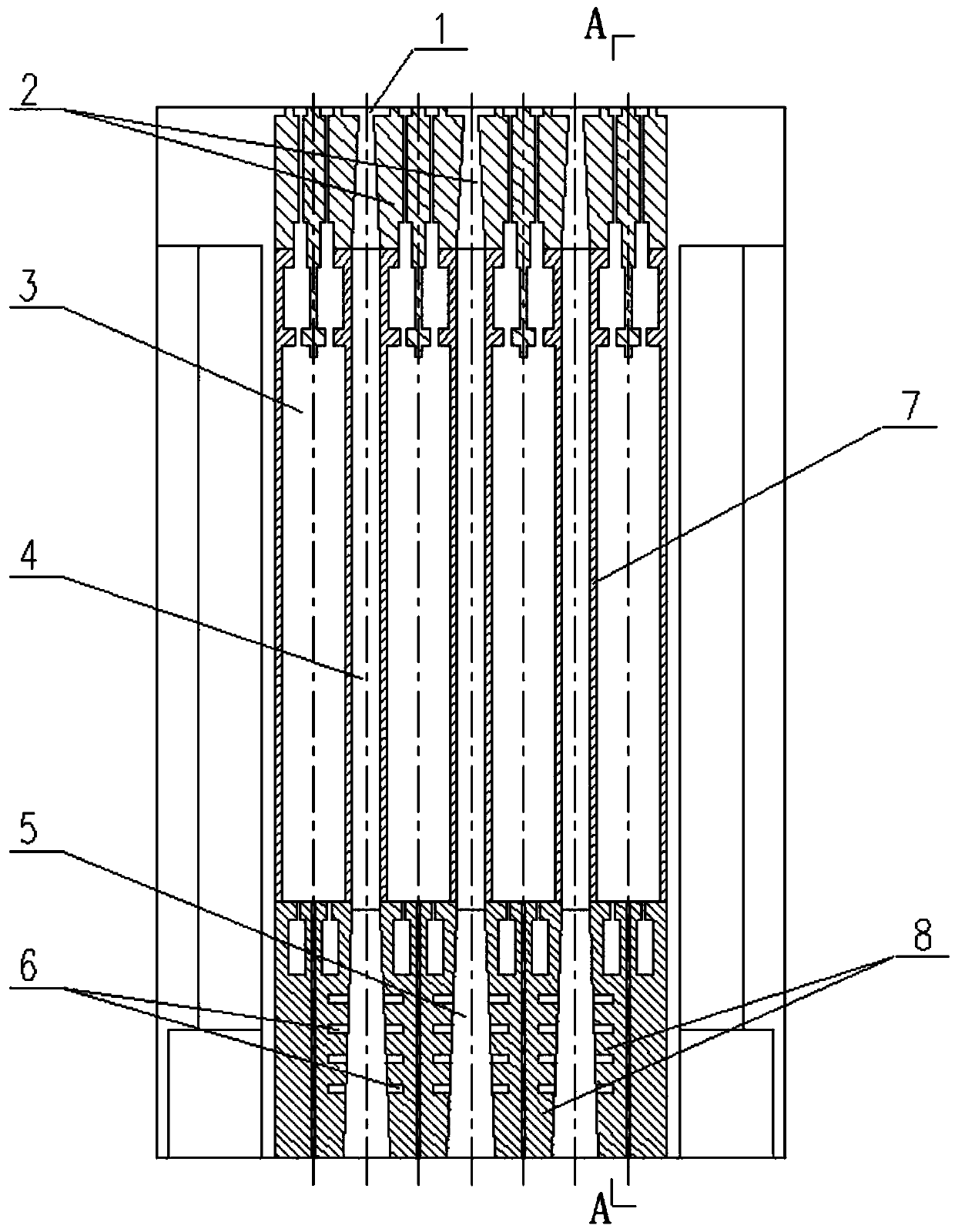

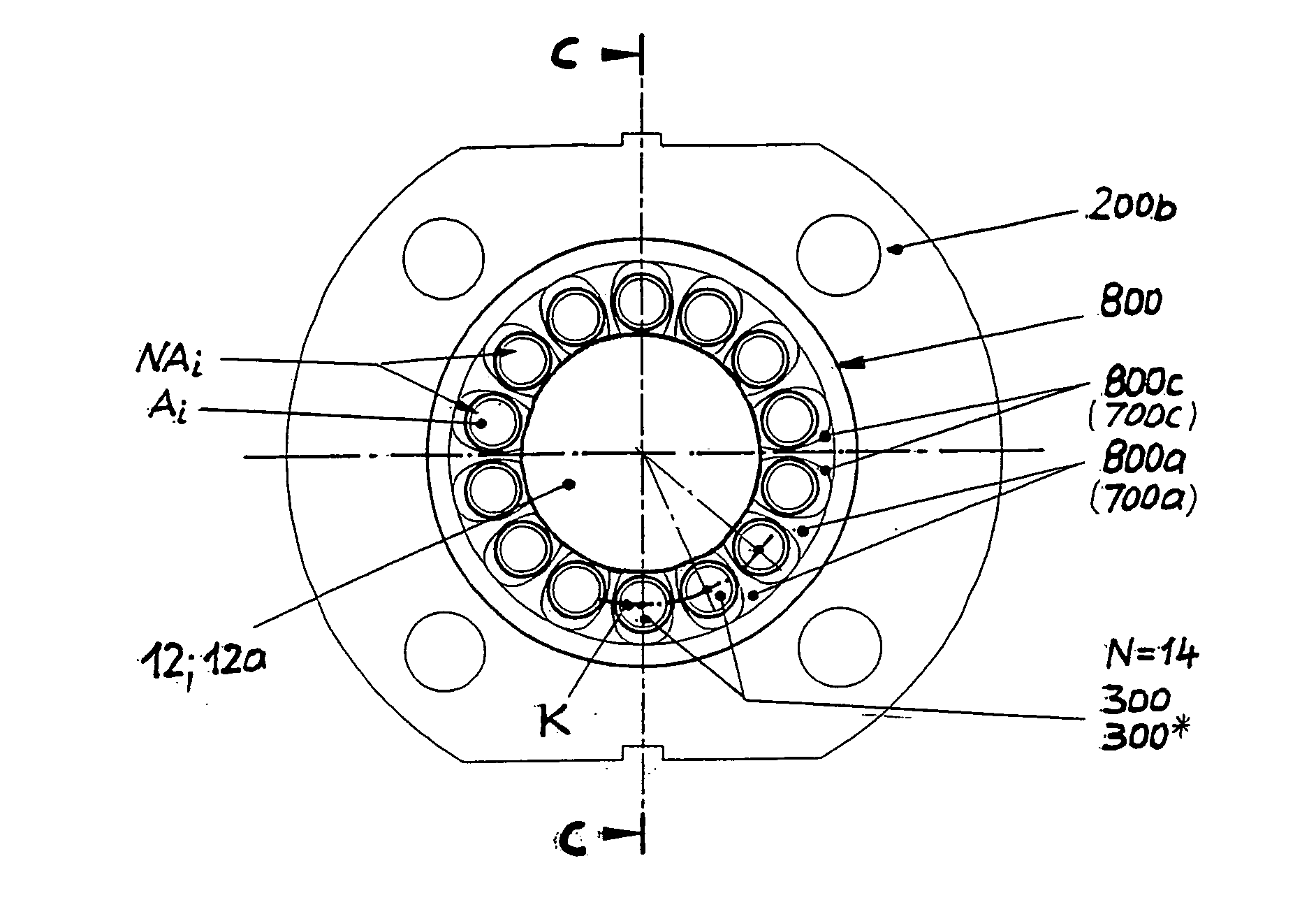

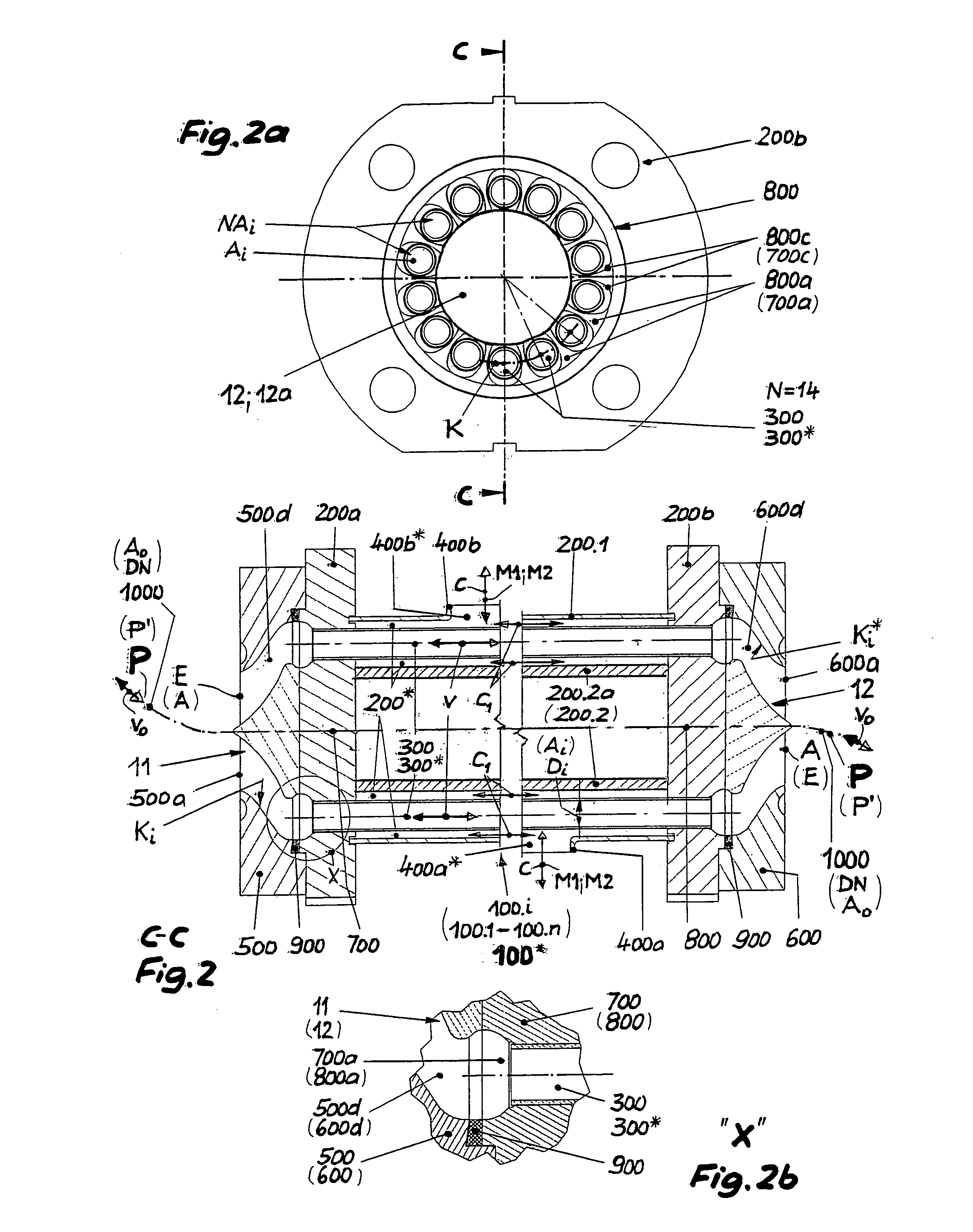

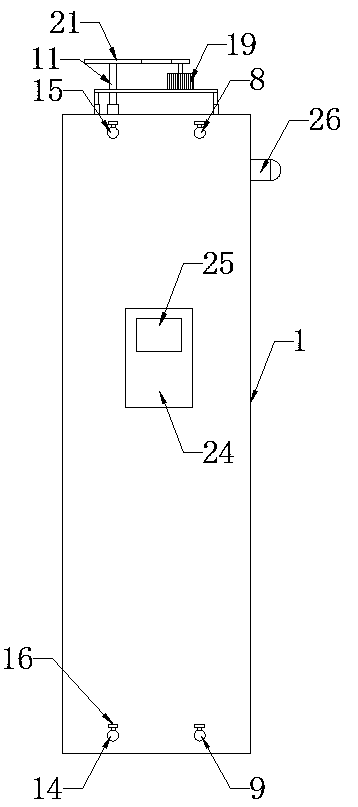

Multi-stage heat exchanger

InactiveCN101893351AImprove heat transfer efficiencyImprove heat transfer conditionsEvaporators/condensersPlate heat exchangerEngineering

The invention relates to a multi-stage heat exchanger. A liquid-collecting inlet tube and a liquid-collecting outlet tube are arranged on two sides of a cylinder, the beginning end of the liquid-collecting inlet tube is a liquid inlet while the tail end of the liquid-collecting outlet tube is a liquid outlet, and a baffle plate is connected in the middle of the liquid-collecting inlet tube and the liquid-collecting outlet tube. The multi-stage heat exchanger is mainly technically characterized in that a separator plate divides the cylinder into a plurality of cavities, and the opening end of a tube bundle is divided into a plurality of pairs of refrigerant inlets and refrigerant outlets by a seal head to form a separate refrigerant in-out system. The invention solves the defects of continuous improvement of single circuit cooling water along with the traveling of the course, gradual reduction of heat exchange efficiency, high manufacture cost, low heat exchange efficiency of a dry-steaming type heat exchanger, high power consumption, large input of materials and the like. The invention has the advantages of high heat exchange efficiency, energy-saving, reduction of product cost and operation cost as well as larger temperature difference of refrigerant temperature, thereby a favorable heat exchange condition is formed.

Owner:南京平欧空调设备有限公司

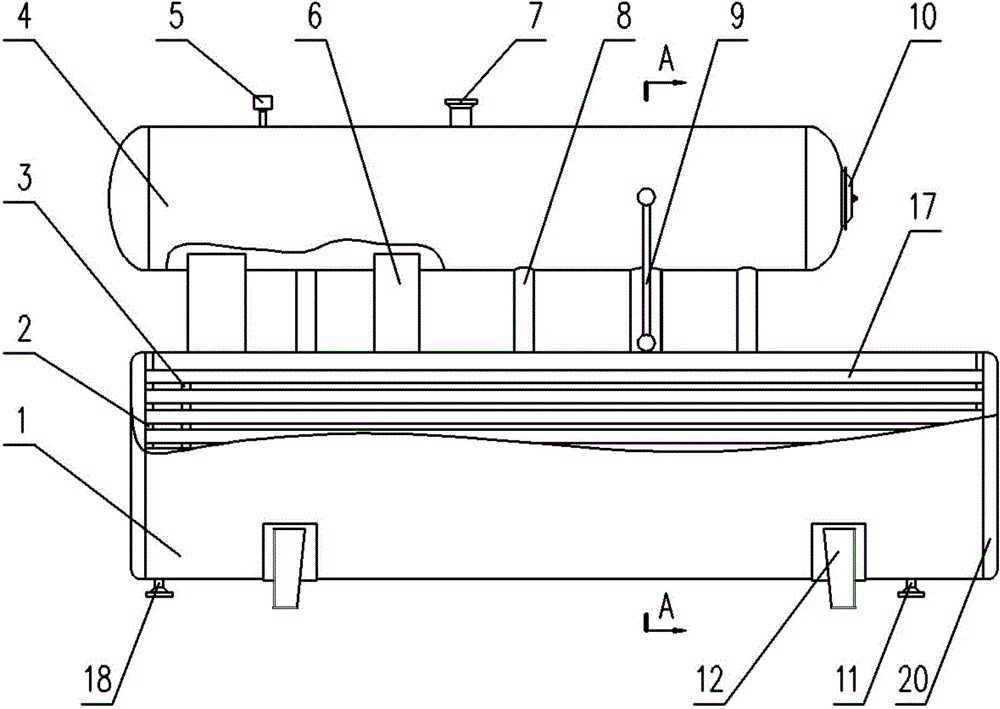

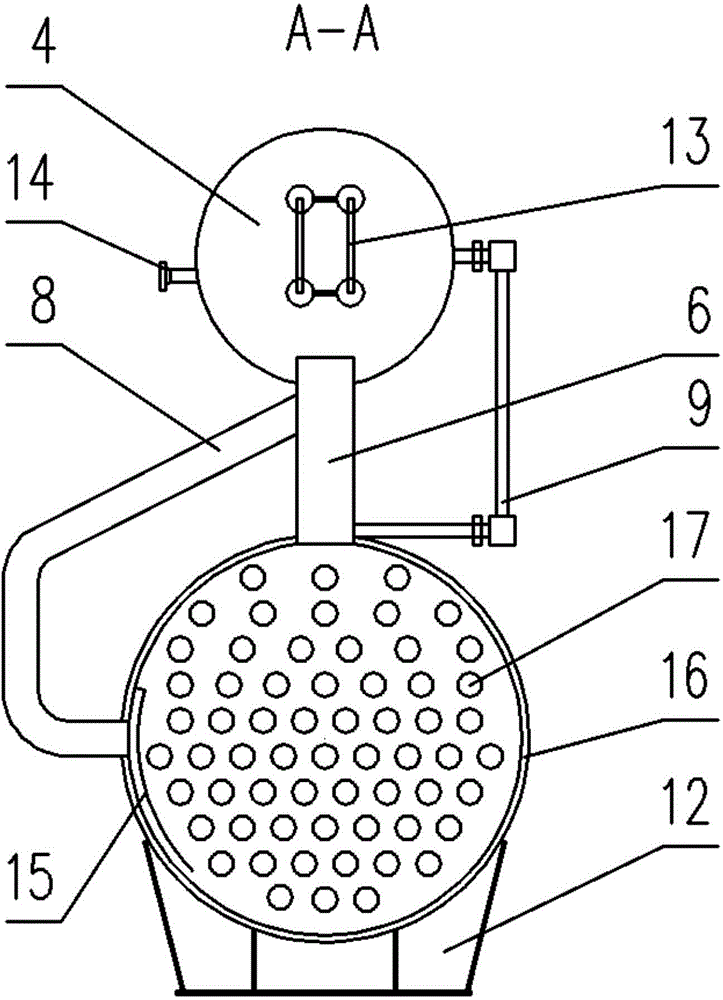

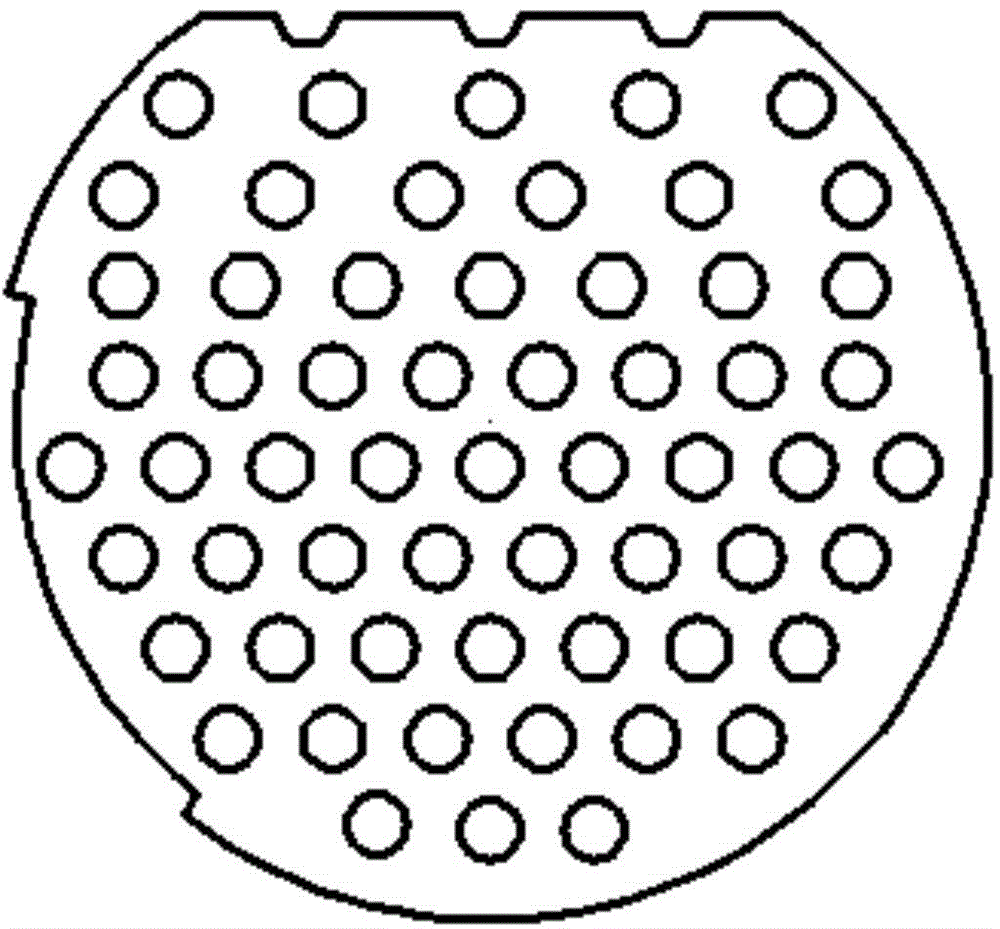

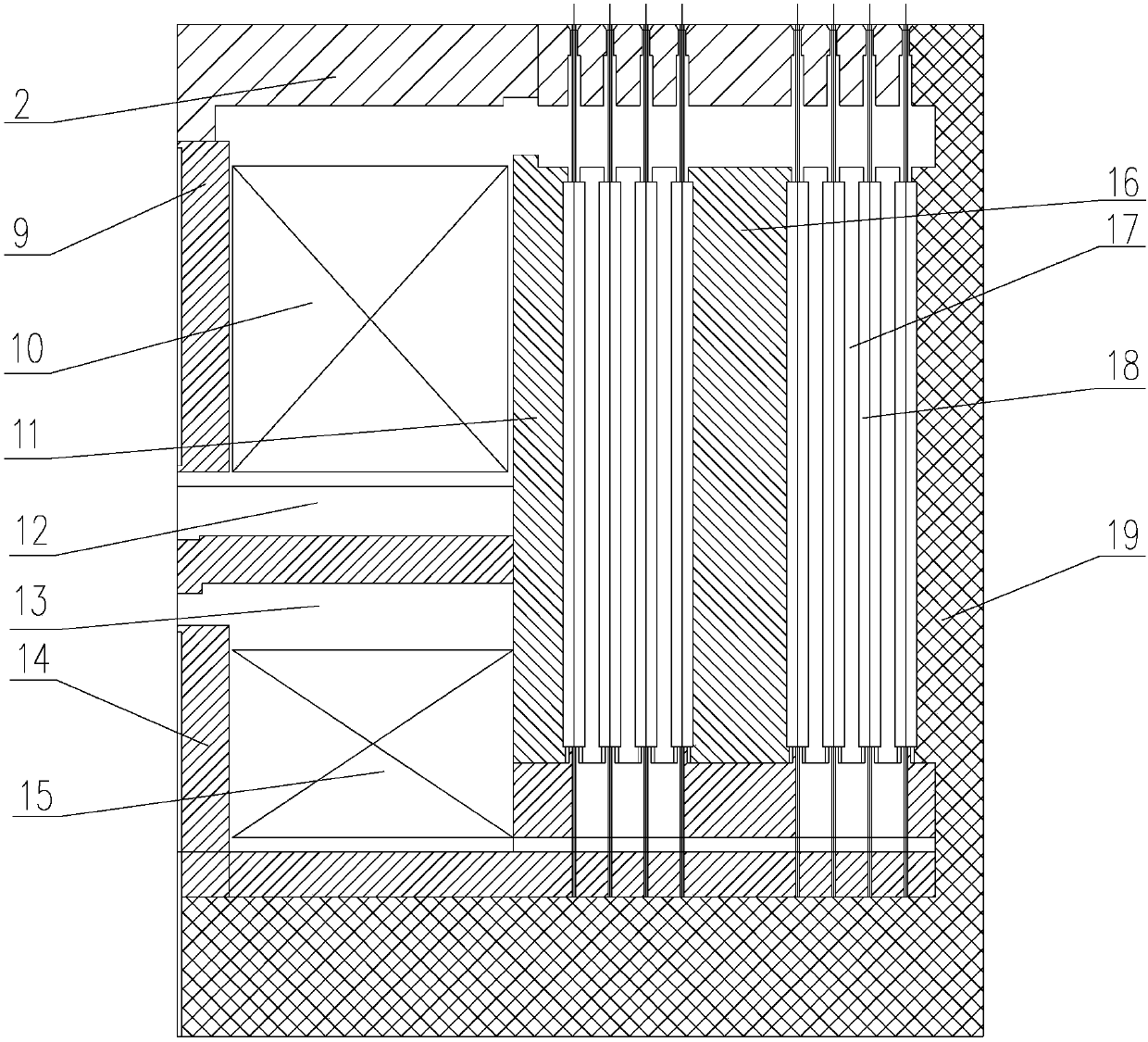

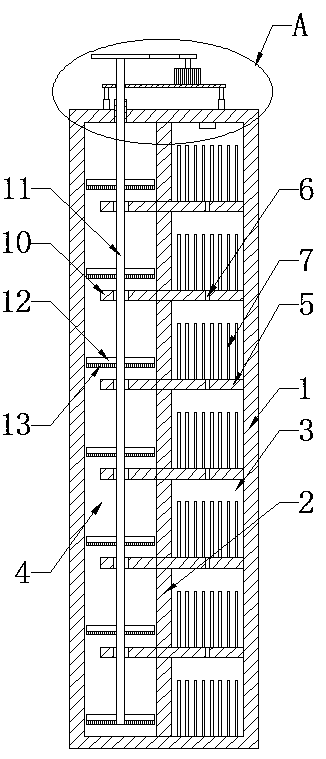

Partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler

ActiveCN103982886AImprove uniformityLow flow resistanceChemical industryStationary tubular conduit assembliesFlue gasEvaporation

The invention discloses a partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler comprises a boiler cylinder and a pipe casing type evaporation heat exchanger which are vertically arranged; the boiler cylinder and the pipe casing type evaporation heat exchanger are arranged in a horizontal type; the boiler cylinder and the pipe casing type evaporation heat exchanger are connected through an ascending pipe assembly and a declining pipe assembly; the boiler cylinder is connected with a water inlet connecting opening formed in the pipe casing type evaporation heat exchanger through a high temperature high pressure water pipe; a high temperature high pressure water pump is arranged on the high temperature water pipe. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler has the advantages of being small in circulating ratio, efficient and energy saving, long in service life, small in occupied space, benefited to site installation and original facility reconstruction and reasonably utilizing high temperature flue gas waste heat in the chemical engineering field.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

Air gas primary heater unit of hot-air stove

InactiveCN101182957AExtended service lifeAvoid breakingLiquid fuel feeder/distributionAir heatersCombustionFlue gas

The invention provides an air and coal gas preheating device of an air heating furnace and comprises a combustion mixing furnace, an air heat interchanger, a coal gas heat interchanger and an assorted blower as well as a valve. A draft fan is adopted to lead waste gas in a flue of the air heating furnace into a mixing chamber of the combustion furnace and then waste gas is mixed with high temperature flue gas generated by the combustion furnace so that air and coal gas can be heated while mixed flue gas conducts heat exchanging. A high temperature air heat interchanger is added on the basis of the preheating device so that the preheating device can become a second preheating device; the second preheating device preheats air and coal gas with flue in the air heating furnace and then leads waste gas in the flue of the air heating furnace into the mixing chamber of the combustion furnace with the high temperature draft fan, moreover, waste gas is mixed with high temperature flue gas and combustion-supporting air is preheated secondly. The invention not only takes use of afterheat of large amount of low temperature waste gas, but also transforms coal gas with low thermal valve into wind temperature with high value, meanwhile, the invention preheats combustion-supporting air and has the advantages of compact structure, reasonable arrangement, low investment, low operation cost, etc.

Owner:袁长胜

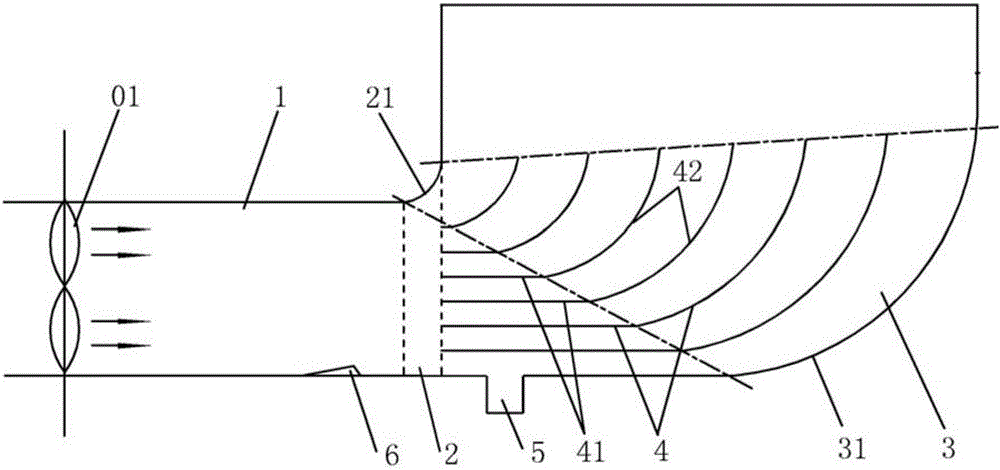

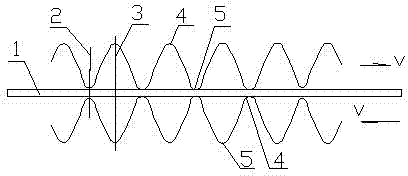

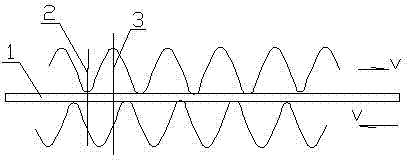

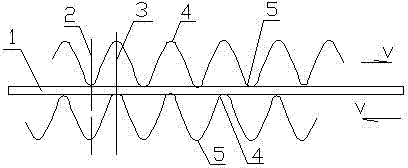

Method for improving heat transfer coefficient of heat exchanger by utilizing medium shear force

InactiveCN102445104AReduce thermal resistanceImprove heat transfer conditionsHeat transfer modificationHeat resistanceEngineering

The invention discloses a method for improving the heat transfer coefficient of a heat exchanger by utilizing medium shear force, which is characterized in that: a pulsating generator capable of allowing fluids in the whole runner of the heat exchanger to generate pulsating flow is arranged in front of an inlet of the heat exchanger; by adjusting the pulse generator, the pulsating frequencies of two fluids change, and pulsating waveforms of the fluids at the two sides of a heat exchange surface (1) are mutually staggered until peaks (4) and peaks, and troughs (5) and troughs respectively and homogeneously correspond to each other at one point on the heat exchange surface, so that the fluids pulsate to generate shear force; and the heat exchange surface vibrates under the action of the shear force, the vibration of the heat exchange surface damages a fluid stagnant layer and strips a dirt layer, and the heat resistance value of the fluids is reduced, thereby the heat transfer coefficient of a dividing wall type heat exchanger is improved. According to the method for improving the heat transfer coefficient of the heat exchanger, the heat exchange surface can vibrate under the action of the shear force without changing the structure of the heat exchanger by only needing to adjust the pulsating generator appropriately, therefore, the heat transfer coefficient of the heat exchanger is improved, the structure is simple, the applicability is strong, and the operation and maintenance are convenient.

Owner:姚光纯

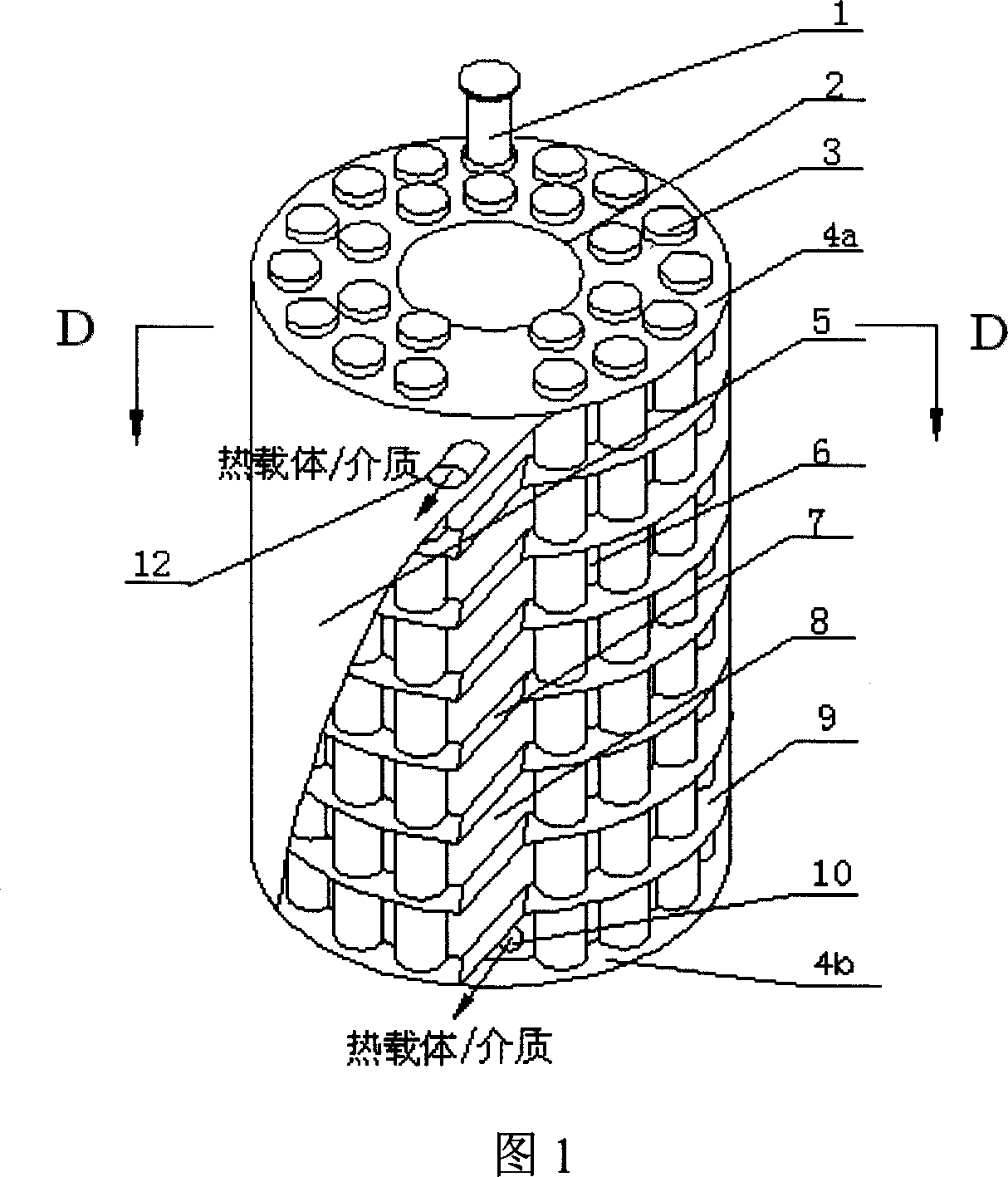

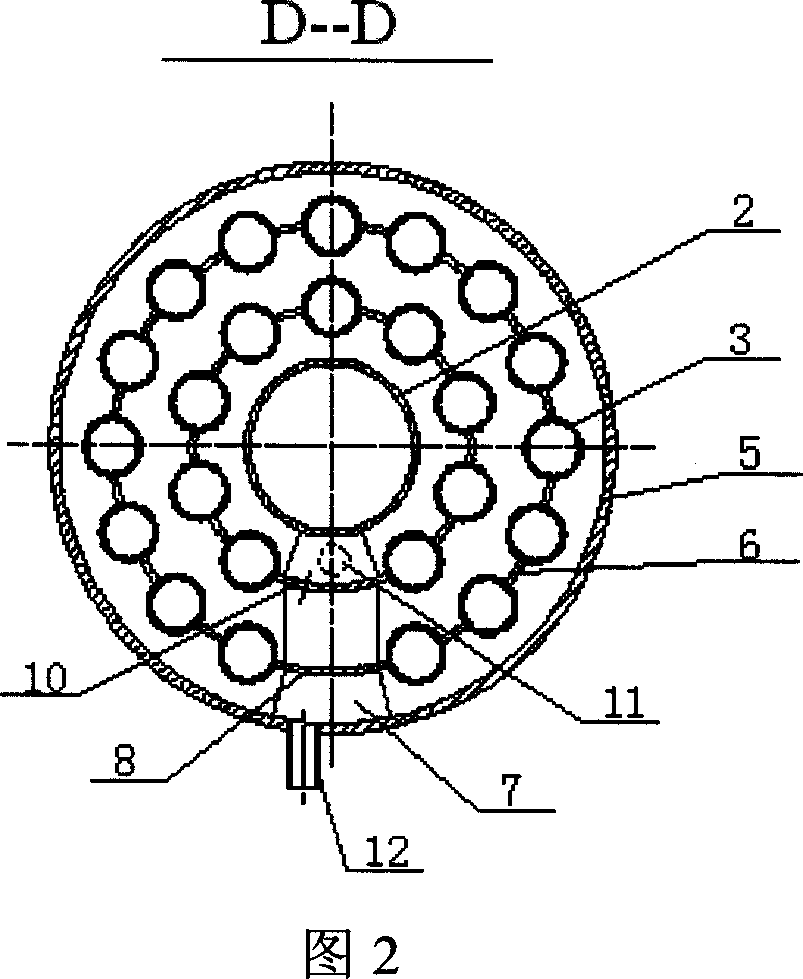

Multipurpose direct flow pipe shielded heat carrier boiler

The multipurpose direct flow pipe plate type heat carrier boiler can realize the turbulent flow, circulation and flow speed control of heat carrier, the lateral flushing to heat releasing pipes and other uses, and has obviously increased heat transfer coefficient and heat transfer area, greatly improved heat transfer condition, effective prevention of overheat and cracking of heat carrier, carbon deposit, coking and electric heating element damage, and convenient boiler cleaning and maintenance. The heat carrier boiler has cylindrical kettle, and spiral flow channels comprising pipe plate barrel, partition boards, pipe plate and cylinder, with the flow channels being connected serially or in parallel. The heat carrier is forced to flow inside the flow channels for heat exchange. The heat carrier boiler can bear pressure and may be vertical or horizontal, and the technology of the present invention is especially suitable for indirect resistive boiler with organic heat carrier, direct flow hot water boiler, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

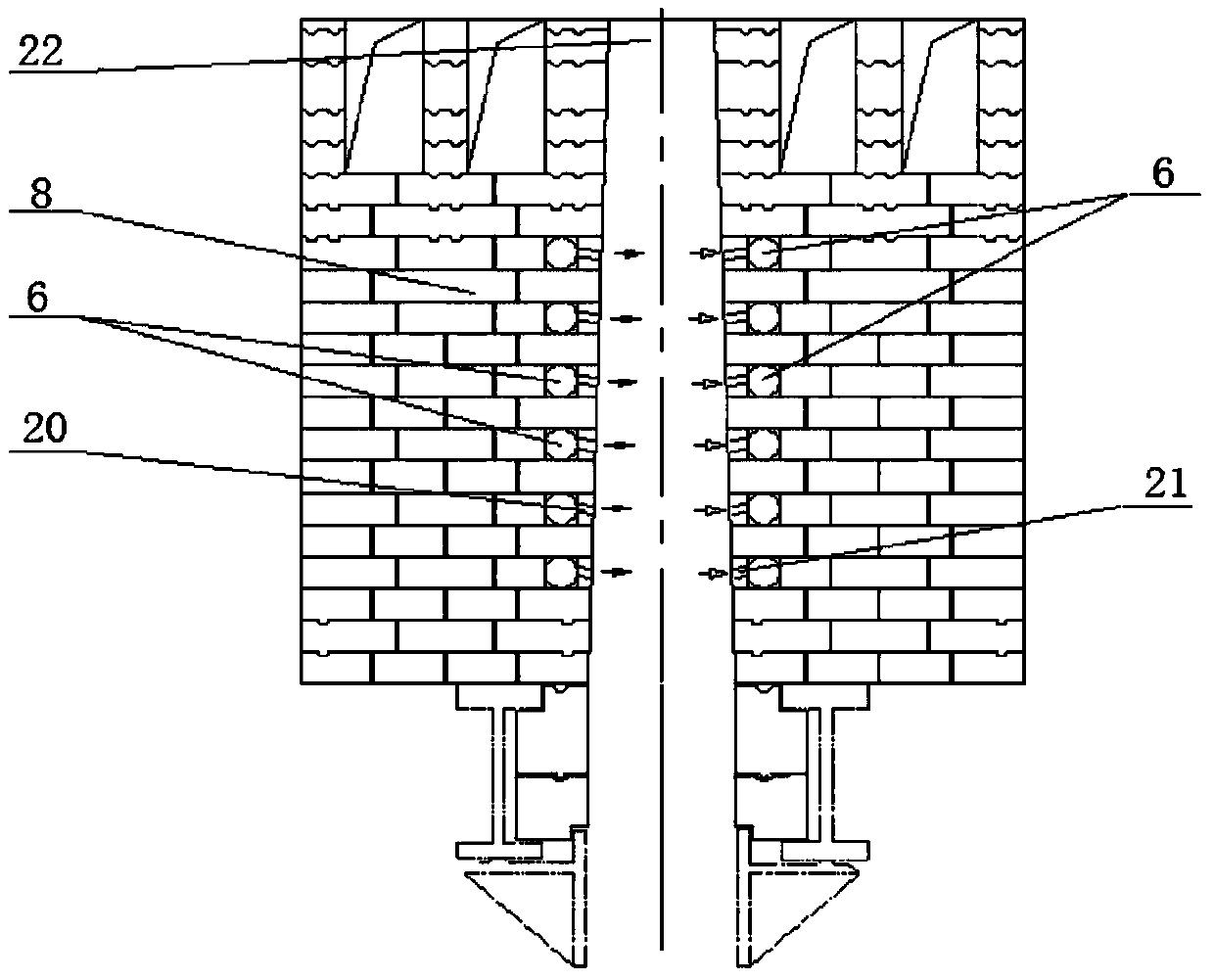

External thermal coal base vertical furnace for producing direct reduction iron

ActiveCN107815516AReasonable structureImprove heat transfer conditionsShaft furnaceGas emission reductionCombustion chamberFlue gas

The invention relates to an external thermal coal base vertical furnace for producing direct reduction iron. Cooling chamber walls on the both sides of a cooling chamber are provided with cooling gaschannels in the height direction inward separately, and each cooling gas channel is provided with a plurality of cooling gas outlets or cooling gas inlets; the cooling gas outlets and the cooling gasinlets communicate with the inner space of the cooling chamber; the top of an upper regenerative chamber is provided with a top convergence airway communicating with the top of a combustion chamber, and the bottom of the upper regenerative chamber is provided with an upper regenerative chamber bottom flue; and the top of a lower regenerative chamber is provided with a lower regenerative chamber bottom flue, and the bottom of the lower regenerative chamber is provided with a bottom convergence airway communicating with the bottom of the combustion chamber. According to the vertical furnace provided by the invention, the oxidation reaction of fuel combustion, gasification reaction and reduction reaction of raw materials, cooling process of generated sponge iron, and waste heat recycling process of high temperature flue gas in the direct reduction iron-making process are implemented in the vertical furnace in a centralized way, and the vertical furnace has the characteristics of rationalfurnace structure, long service life, high thermal efficiency, low investment in accessory equipment, easy implementation of engineering, etc.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

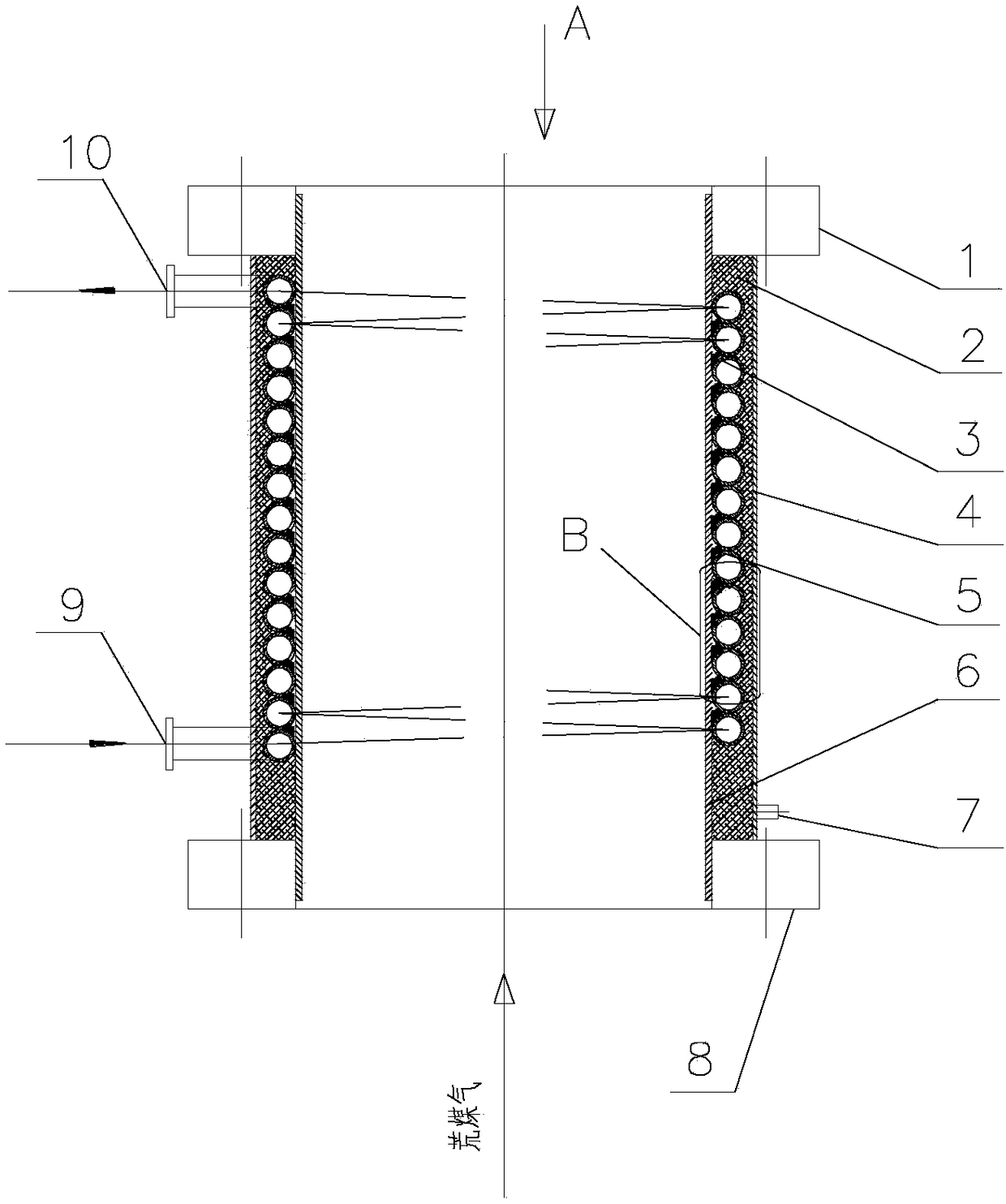

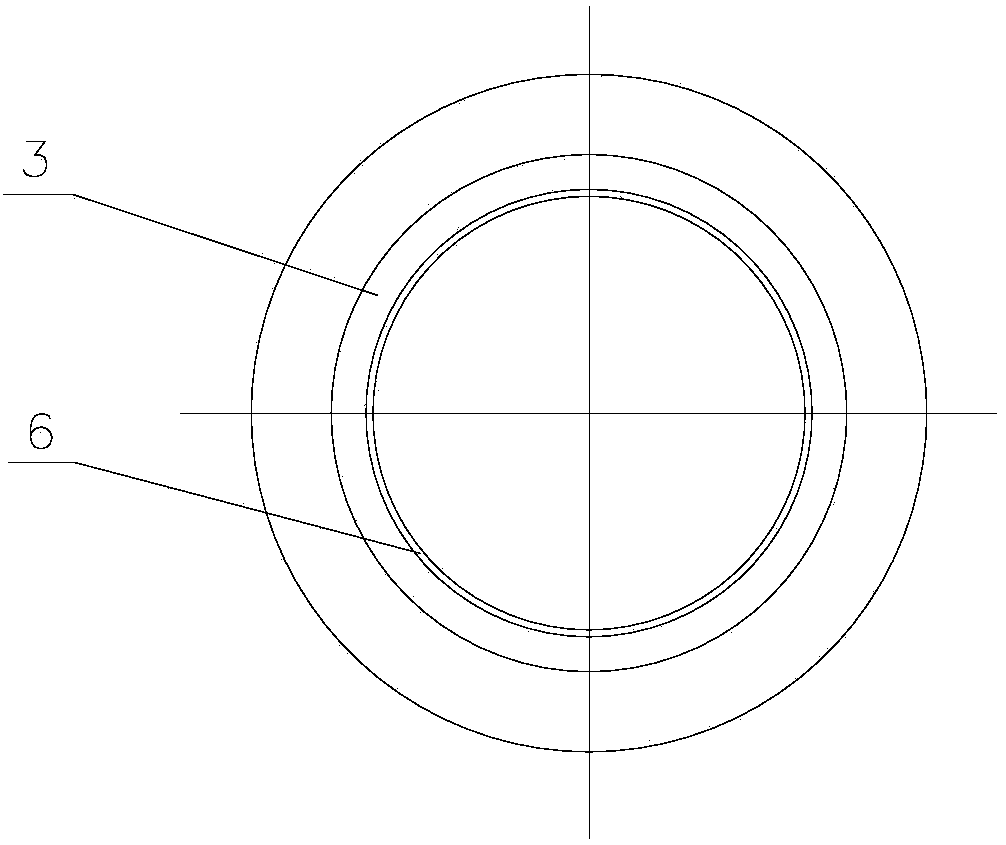

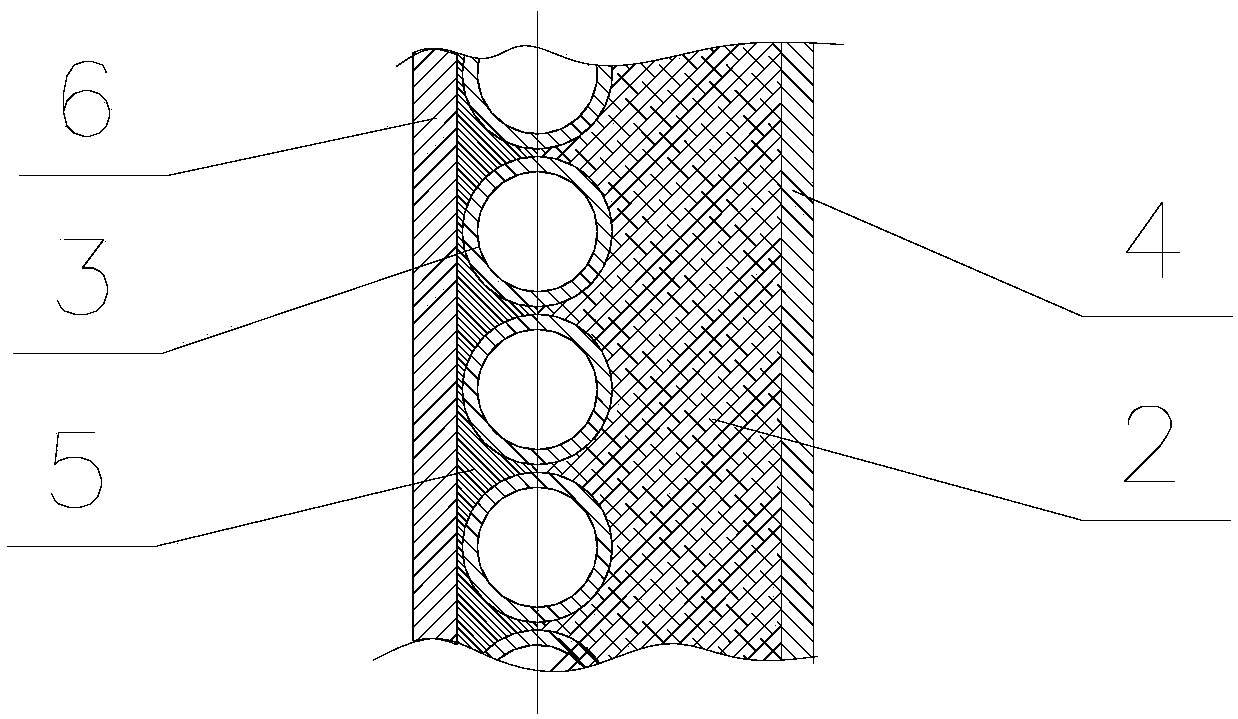

Spiral coil conduction type raw coke oven gas waste heat recovery equipment

PendingCN108467737AImprove securityFacilitate production operation managementEnergy inputIndirect heat exchangersWaste heat recovery unitTar

The invention discloses spiral coil conduction type raw coke oven gas waste heat recovery equipment. The spiral pipe conduction type raw coke oven gas waste heat recovery equipment comprises an ascending pipe inner barrel, an ascending pipe outer barrel and a heat transfer coil, wherein connecting flanges are arranged at the upper end and the lower end of the ascending pipe inner barrel and the ascending pipe outer barrel, the heat transfer coil is spirally wound on the outer side of the ascending pipe inner barrel, a heat transfer base plate is arranged between the heat transfer coil and theascending pipe inner barrel, the inner wall of the heat transfer base plate is tightly fitted with the outer wall of the ascending pipe inner barrel, the shape of the outer wall of the heat transfer base plate is matched with that of the heat transfer coil spirally wound on the heat transfer base plate, an insulating layer fills between the heat transfer coil and the ascending pipe outer barrel, and a vent nozzle is arranged at the bottom of the ascending pipe outer barrel. Compared with the prior art, the spiral coil conduction type raw coke oven gas waste heat recovery equipment has the beneficial effects that the heat transfer condition between the heat transfer coil and the ascending pipe inner barrel is improved, and the recovery rate of the heat of the raw coke oven gas is increased;the phenomenon that the tar in the raw coke oven gas is condensed on the cold wall is avoided; and the manufacturing cost of the waste heat recovery equipment is reduced.

Owner:樊晓光

Finned tube and heat exchanger

PendingCN111442681AImprove heat transfer conditionsImprove heat transfer effectCombustion technology mitigationStationary tubular conduit assembliesEngineeringMirror image

The present invention provides a finned tube and a heat exchanger. The finned tube comprises a base tube and a plurality of fin groups arranged in the axial direction of the base tube and connected with the outer wall of the base tube, and the fin groups are arranged in parallel; each fin group comprises two fins arranged in a mirror image, each fin is divided into three parts in the length direction of the corresponding fin, the first part is the windward area, the second part is the reflux area, and the third part is the leeward area; and a vortex generator is arranged on each windward area,a reflux blocking device is arranged on each reflux area, and the end of each leeward area is of a fillet structure. According to the finned tube, each windward area has better heat transfer condition and has better heat transfer capacity by additionally arranging the corresponding vortex generator; each reflux area is provided with the corresponding reflux blocking device, the reflux can be reduced or even eliminated, and the ash deposition is reduced; and the heat transfer effect of each leeward area is poor, the ash deposition is more, and the fillet structure is adopted on the reflux so as to reduce the flow resistance effectively.

Owner:DATANG ENVIRONMENT IND GRP +1

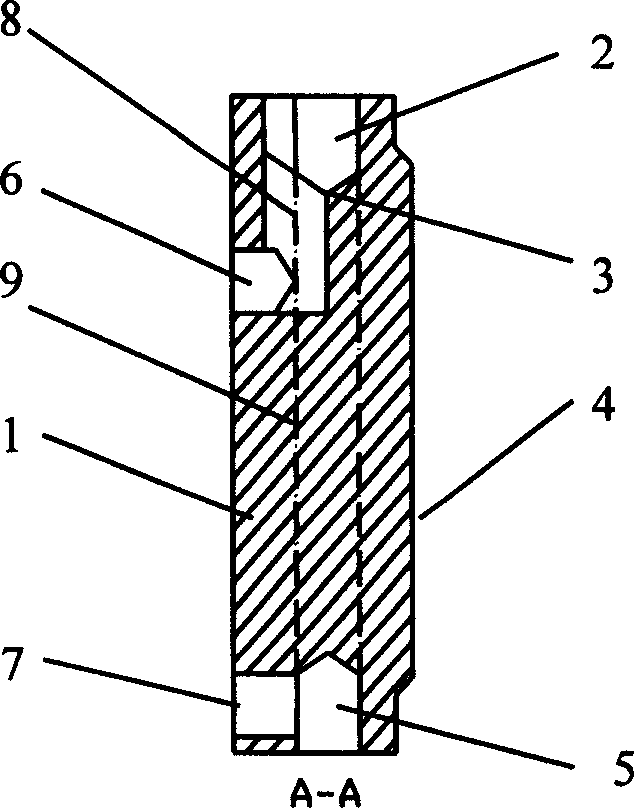

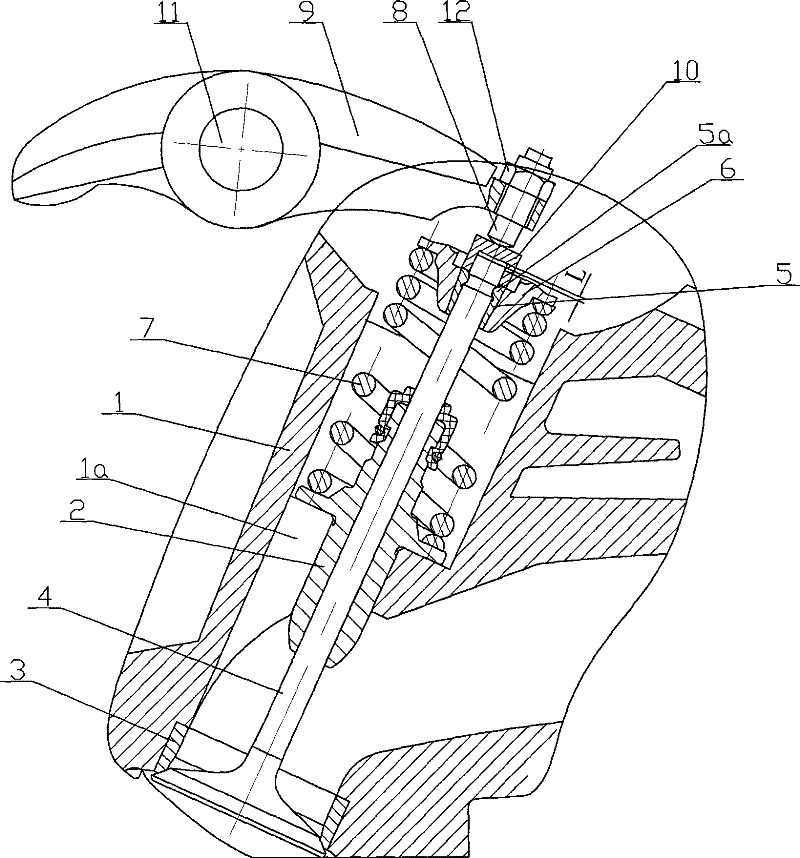

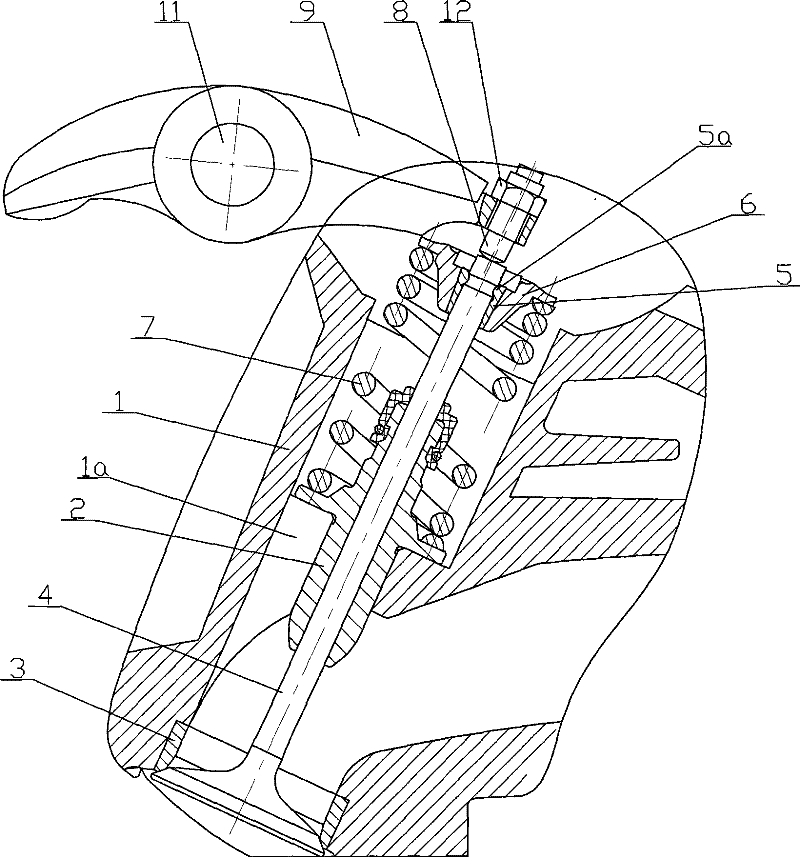

Engine exhaust valve structure

InactiveCN101100952BSmooth rotationAvoid overall overheatingValve arrangementsMachines/enginesExhaust valveEngineering

This invention is engine exhausting valve structure. The exhausting valve stem passes through exhausting valve base and valve guide pipe. The top of the exhausting valve stem is assembled with valve lock clamp. Outside of the valve lock clamp is spring base. The valve spring is arranged on the exhausting valve stem. There is valve gap setting screw above the top of the exhausting valve stem. The axes of the said screw and exhausting valve stem are at the same line. There is end cap between valve gap setting screw and exhausting valve stem. The said end cap covers on the exhausting valve stem through its dead hole which is at the bottom. There is certain space between the end face of the said dead hole and the top face of exhausting valve stem. This invention can prevent the local overheatof exhausting valve stem and prevent rupture of exhausting valve stem.

Owner:力帆科技(集团)股份有限公司

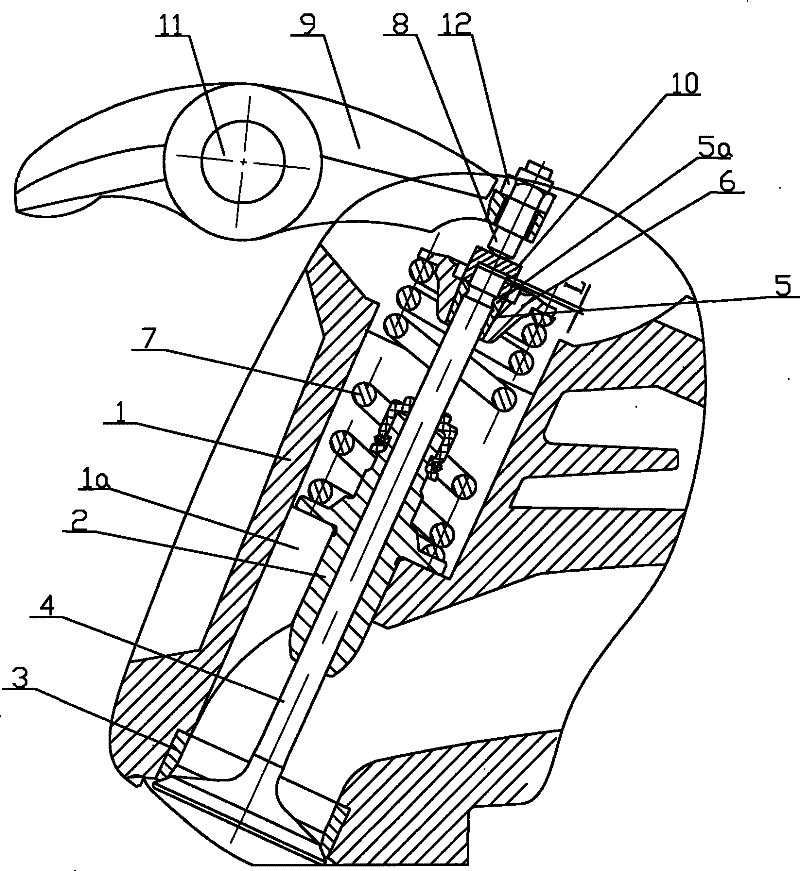

Efficient and convenient low-pressure metal hydride hydrogen storing device

ActiveCN109869625AImprove thermal efficiencyImprove heat transfer efficiencyContainer filling methodsPressure vesselsEngineeringHydride

The invention belongs to the technical field of hydrogen storing, and particularly relates to an efficient and convenient low-pressure metal hydride hydrogen storing device. The efficient and convenient low-pressure metal hydride hydrogen storing device comprises a hydrogen storing tank and a hydrogen storing material bed body; the hydrogen storing tank is used for providing installing space for the hydrogen storing material bed body; the hydrogen storing material bed body is installed in the hydrogen storing tank, the hydrogen materials and aluminum tiles of the hydrogen storing material bedbody are successively arranged in a laminating mode, and the hydrogen storing material bed body is arranged parallel to the axis of the hydrogen storing tank. According to the efficient and convenientlow-pressure metal hydride hydrogen storing device, the aluminum tiles are adopted as partition materials and supporting bodies of the hydrogen storing materials, heat guiding and exchanging efficiency are improved, the manual cost is low, and the efficient and convenient low-pressure metal hydride hydrogen storing device has the characteristics that the heat exchanging effect is great, and the manual cost is low.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Uht system and method for heat treating temperature-sensitive food products

ActiveUS20160106139A1Velocity increasesPerform this temperature adjustment promptly and efficientlyFood preservationHeat exchanger casingsTemperature conditioningEngineering

The invention relates to a UHT system for heat treating temperature-sensitive food products, in particular desserts or dessert-like products, comprising a pre-heating zone and a subsequent high-heating zone. The aim of the invention is to achieve accurate and fast temperature adjustment of the food product leaving the pre-heating zone to the temperature conditions at the inlet of the high-heating zone in a UHT system of the generic type, and at the same time, with an equal dwell time for all partial amounts of the food product, to ensure that the food product is treated in a particularly thermally gentle manner and to keep the mechanical loading of the food product as low as possible.

Owner:GEA TDS

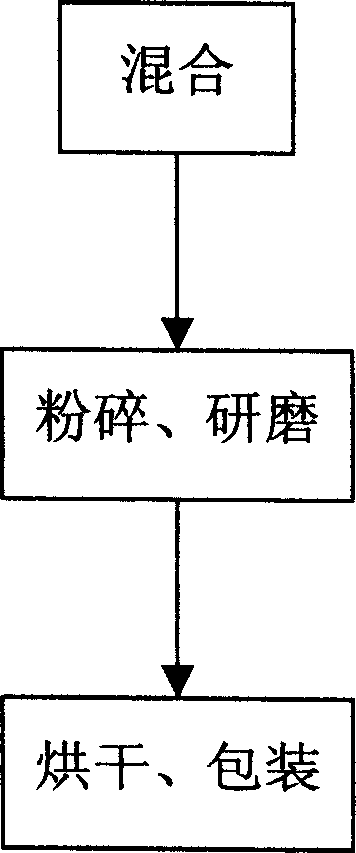

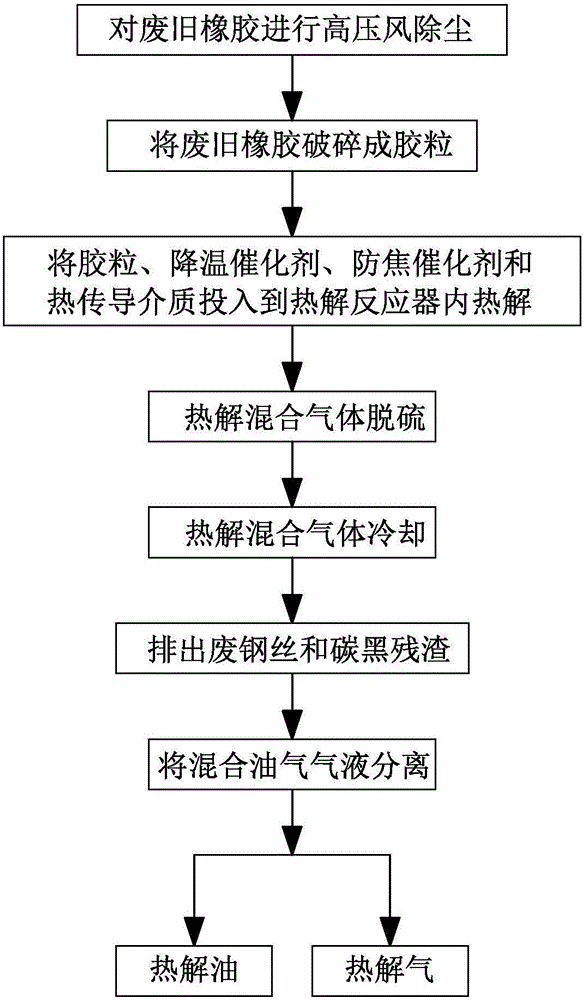

Waste rubber pyrolysis treatment method

ActiveCN106701141AIncrease the heating areaLow pyrolysis temperatureLiquid hydrocarbon mixture productionCooling towerWaste rubber

The invention discloses a waste rubber pyrolysis treatment method which comprises the following steps: crushing waste rubber into rubber particles; adding the rubber particles, a cooling catalyst, an anti-coking catalystand a heat transfer medium into a pyrolysis reactor, enabling the heated materials to produce pyrolysis mixed gases on the upper part of the reactor, and remaining waste steel wires and carbon black at the bottom of the reactor; delivering the pyrolysis mixed gases to a cooling tower so as to obtain mixed oil gas; and filling the mixed oil gas into a gas-liquid separation tank, outputting pyrolysis oil into a liquid storage tank from the tank bottom of the gas-liquid separation tank, and outputting the pyrolysis gas into a gas storage tank from the top of the gas-liquid separation tank. According to the method disclosed by the invention, continuous waste rubber pyrolysis can be well realized, the rubber is prevented from coking in the pyrolysis process, the environmental pollution caused by the waste rubber is avoided, and the resources are effectively recycled.

Owner:山东宜群木塑科技有限公司

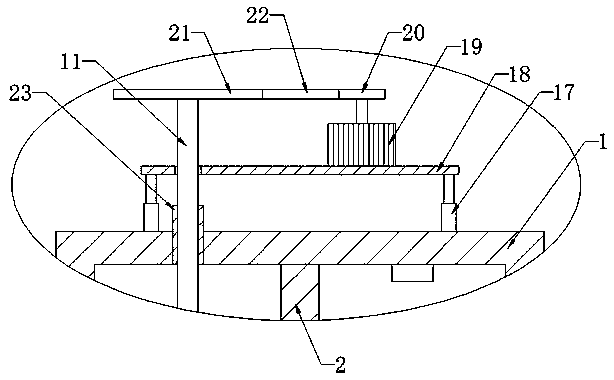

A regenerative combustion system

ActiveCN103759254BImprove combustion efficiencyImprove heat transfer conditionsFuel supply regulationCombustion apparatusCombustion systemHearth

The invention discloses a regenerative combusting system which comprises at least two regenerative combustors arranged on a kiln, an air supply system, a fuel supply system, a smoke exhausting system, a continuous flame system and a reversing system, wherein each regenerative combustor comprises a regenerative chamber which comprises an upper regenerative chamber and a lower regenerative chamber, a front buffer chamber and a rear buffer chamber are arranged at the front part and the rear part of the regenerative chamber; the front buffer chamber and the rear buffer chamber are separated by the upper regenerative chamber and the lower regenerative chamber; the rear buffer chamber is connected with the air supply system and the smoke exhausting system respectively; a fuel cavity is formed between the upper regenerative chamber and the lower regenerative chamber and connected with the fuel supply system; the fuel cavity is communicated with the hearth of the kiln; an air distributing plate is arranged between the front buffer chamber and the hearth of the kiln; a continuous flame burner hole, a fuel spray nozzle hole and an air distributing hole are formed in the air distributing plate. The regenerative combusting system is long in service life, stable in work, high in heating efficiency and obvious in energy saving and emission reduction effect.

Owner:长沙恒威热能科技有限公司

Carboxyl nitroso-fluoro rubber (CNR) solution polymerization process

Owner:CHINA BLUESTAR CHENGRAND CO LTD

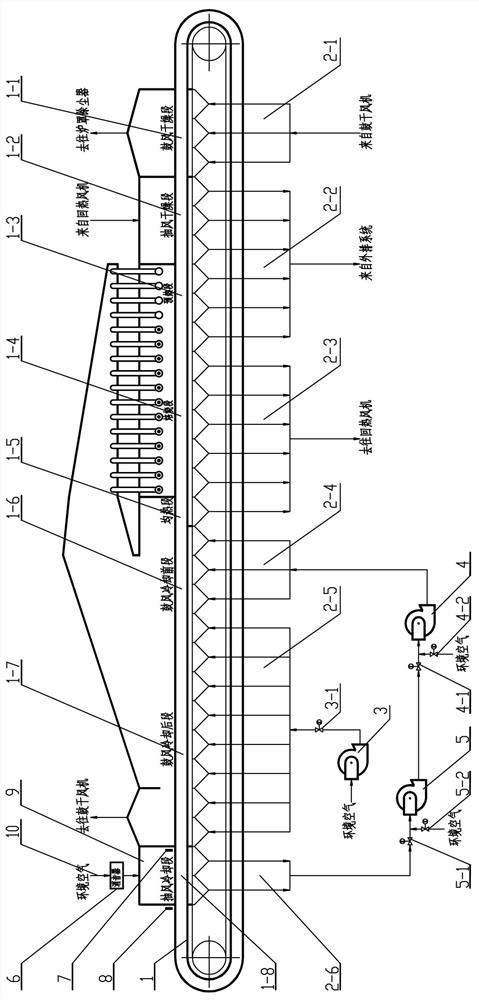

Segmented cooling system of belt type roasting machine

InactiveCN112066721AImprove heat transfer efficiencyImprove utilization factorFurnace typesCooling effectProcess engineering

The invention relates to a sectional cooling system of a belt type roasting machine. The sectional cooling system of the belt type roasting machine comprises a belt type roasting machine body, the belt type roasting machine body is divided into an forced air drying section, a down-draft drying section, a preheating section, a roasting section, a soaking section and an blast cooling section along the material flow direction, an air bellow is divided into four, the sectional cooling system of the belt type roasting machine further comprises a first air blower, a second air blower, a cooling exhaust fan, a silencer, a temperature measuring device I and a temperature measuring device II, wherein the blast cooling section is divided into a blast cooling front section, a blast cooling rear section and a down-draft cooling section, and the fourth air bellow is divided into a blast cooling front section air bellow, a blast cooling rear section air bellow and a down-draft cooling air bellow. The sectional cooling system of the belt type roasting machine has the advantages that airflow direction of the blast cooling rear section penetrates through a material layer from top to bottom, the cooling effect is improved, the cooling speed is increased, the belt type roasting machine utilization rate is increased, the service life of a finished belt type roasting machine is prolonged, power consumption of a cooling fan is reduced, and heat exchange conditions of the forced air drying section are improved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

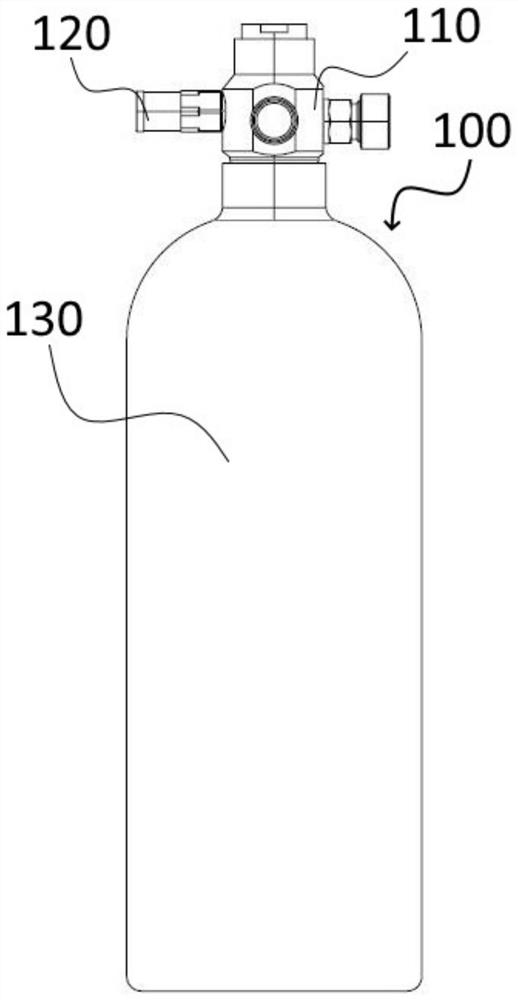

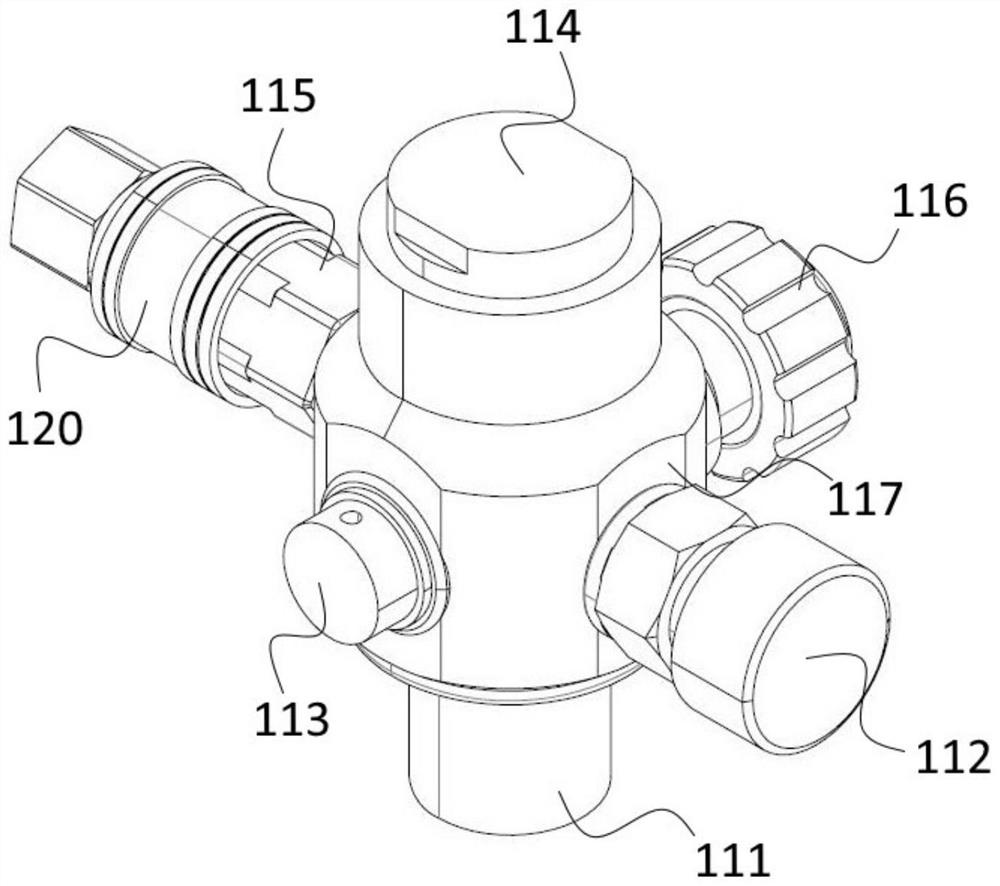

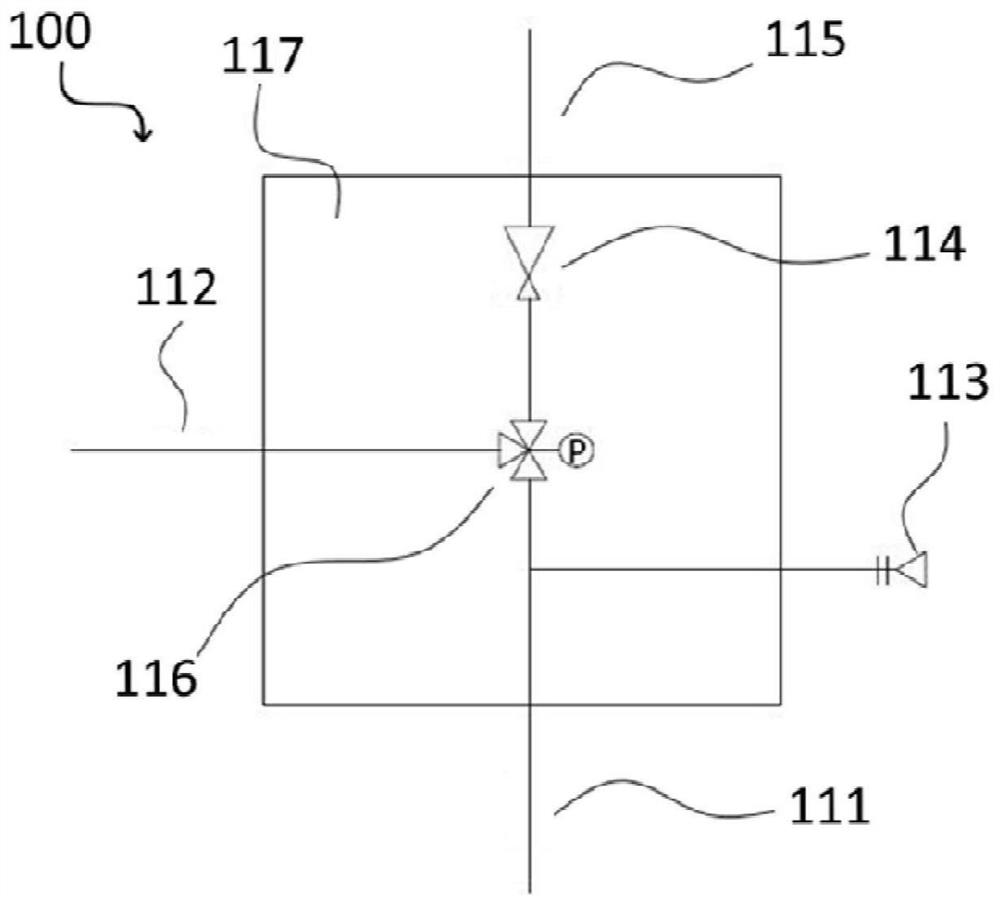

A hydrogen storage device and its hydrogen fuel electric bicycle

ActiveCN113063090BAvoid accumulationGive full play to hydrogen storage performanceVessel mounting detailsReactant parameters controlEngineeringHydrogen fuel

The invention discloses a hydrogen storage device and a hydrogen fuel electric bicycle thereof, belonging to the field of energy equipment. Including a bottle body, the inside of the bottle body is provided with a guide tube, the guide tube is installed on the central axis of the bottle body, and is fixedly installed along the guide tube according to a predetermined distance and a predetermined angle. A screen mesh divides the bottle body into a first cavity and a second cavity; the first cavity and the second cavity are arranged at intervals in sequence, and a solid hydrogen storage material is stored in the first cavity. In the present invention, by laying the solid hydrogen storage material on the first cavity, the accumulation of the solid hydrogen storage material is avoided, and the contact area between the hydrogen and the solid hydrogen storage material is increased, no matter in the hydrogen charging process or the hydrogen releasing process. It can achieve faster and more hydrogen charging and desorption, and give full play to the hydrogen storage performance of solid-state hydrogen storage materials.

Owner:YOUON TECH CO LTD

Cooling equipment for solar hydrogen production

PendingCN111334813AInaccessibleImprove heat transfer conditionsElectrolysis componentsThermodynamicsSolar hydrogen

The invention discloses cooling equipment for solar hydrogen production. The equipment includes a box body, the interior of the box body is divided into a heating medium cavity and a cold water cavitythrough a partition plate, a plurality of first heat conduction plates are fixedly arranged in the heating medium cavity at equal intervals, an opening is formed in the middle of each first heat conduction plate, a plurality of heat conduction rods are fixedly arranged at the top end of each first heat conduction plate at equal intervals, a heating medium inlet pipe and a heating medium outlet pipe are fixedly connected to the top end and the bottom end of one side of the heating medium cavity in a penetrating mode, and one side of each first heat conduction plate is fixedly connected to a second heat conduction plate. The invention has the beneficial effects that: stirring and heat exchange can be carried out on cold water through stirring blades on rotating shafts, the situation that the cold water located inside cannot make contact with the second heat conduction plates and the partition plate is avoided, the heat exchange condition is improved, meanwhile, heat of a heating mediumlocated inside can be better transmitted to the second heat conduction plates through the heat conduction rods for heat exchange, and then the cooling effect and efficiency can be improved.

Owner:柳州紫荆八度阳光新能源有限责任公司

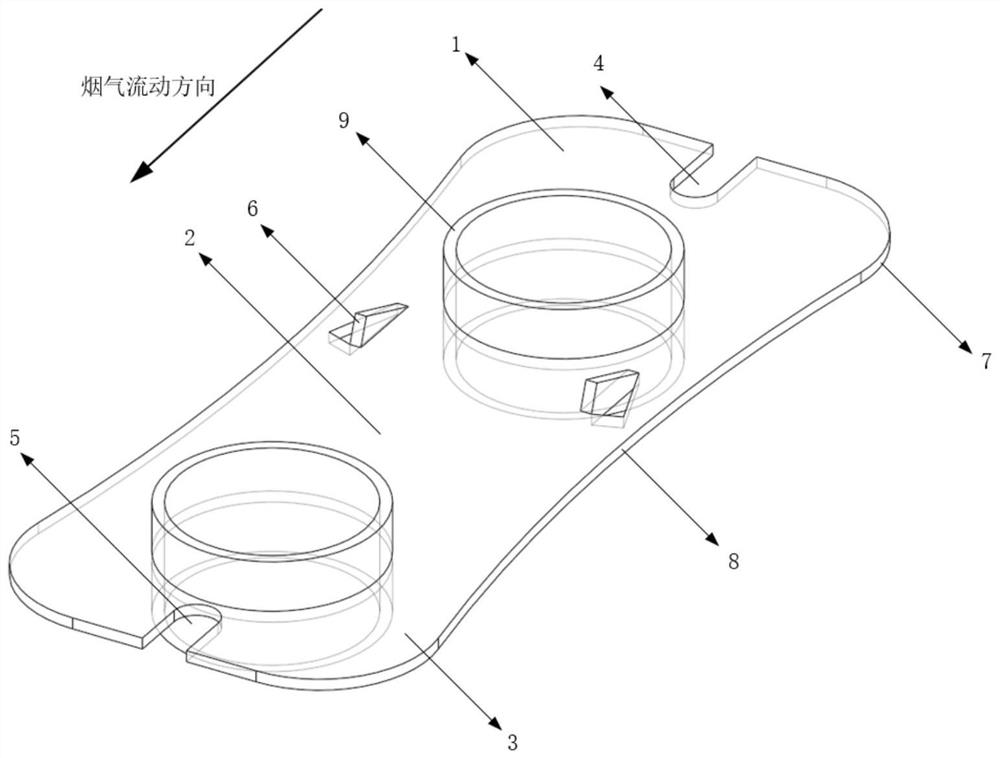

Integrated fin with triangular winglet

PendingCN113108638ASmall thermal deformationImprove assembly accuracyHeat exhanger finsTubular elementsSurface heatFlue gas

The invention discloses an integrated fin with a triangular winglet. Four corners of the fin are filleted corners, the edges of the fin are inward concave arcs, and the front and the back of the fin are both provided with U-shaped grooves; a fin surface heat exchange strengthening area is provided with one or more pairs of triangular winglets, and the fin surface heat exchange strengthening area is divided into a windward area, a heat exchange strengthening area and a leeward area in the smoke flowing direction. Eccentric treatment is adopted between the fins and the base tube, so that the windward area is larger than that of the leeward area. The structure is good in heat exchange performance, small in flowing resistance and good in flue gas waste heat recovery effect, the airflow separation and vortex phenomena occurring in a windward area and a leeward area can be effectively improved, the fin temperature field and flue gas speed collaboration is enhanced, the heat exchange efficiency is improved, meanwhile, abrasion is effectively reduced, and the service life of the finned tube is prolonged.

Owner:XI AN JIAOTONG UNIV

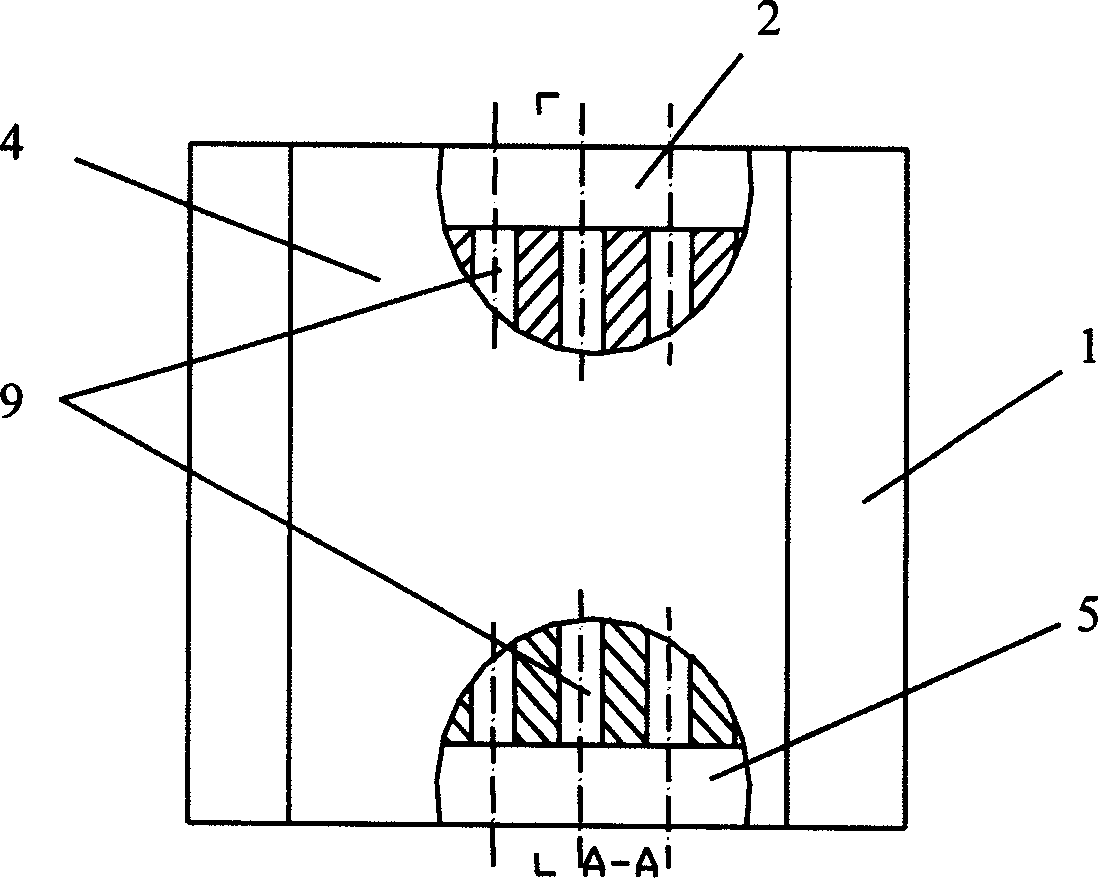

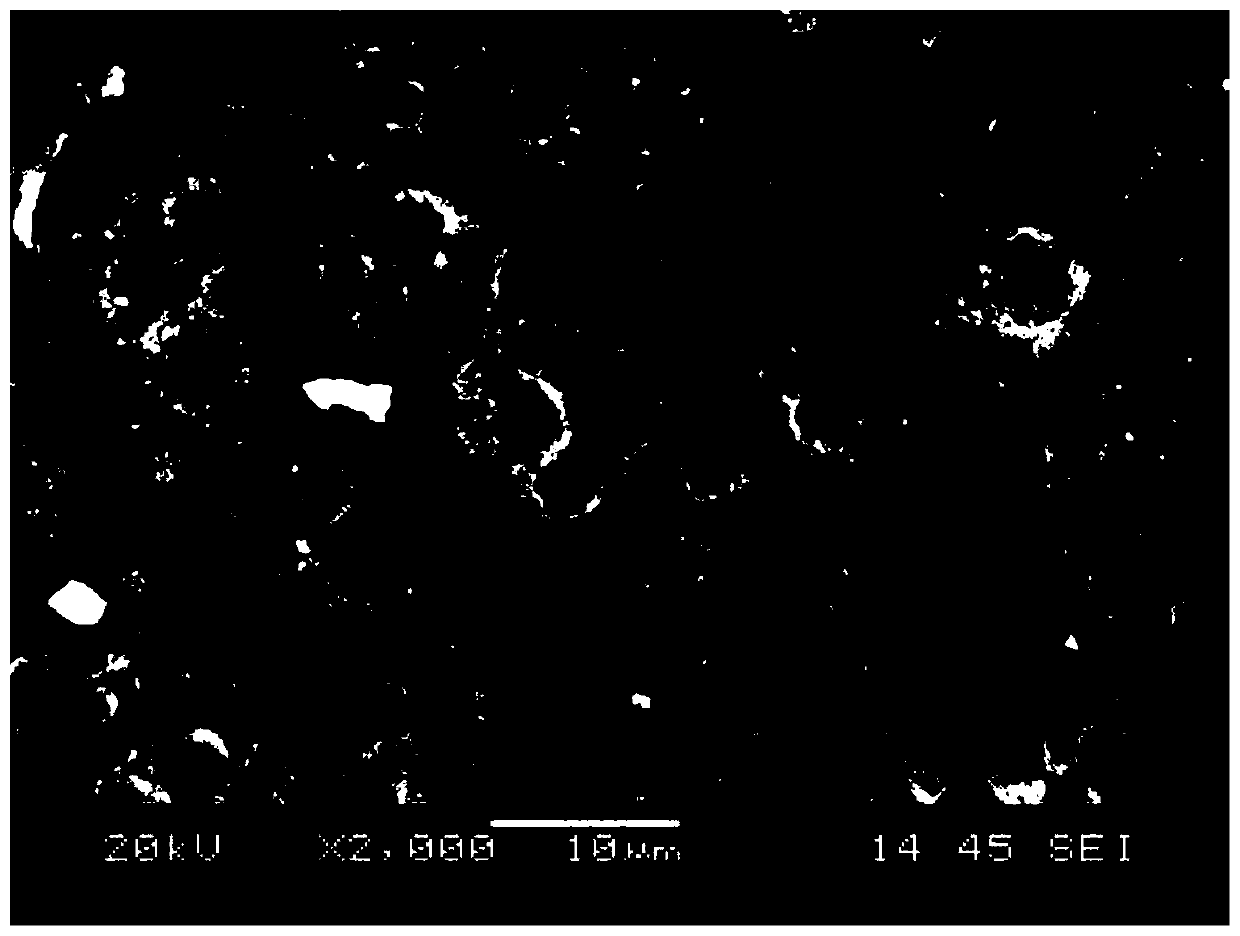

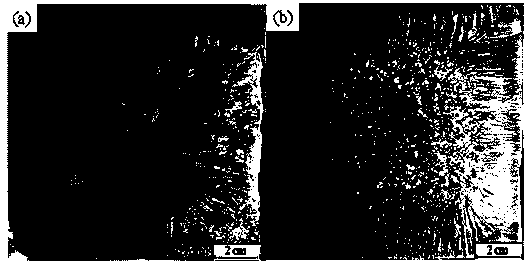

Method of continuously casting nickel base corrosion-resistant alloy in composite alternating electromagnetic field

The invention discloses a method of continuously casting a nickel base corrosion-resistant alloy in a composite alternating electromagnetic field. The method comprises the processing steps that (1) a high-frequency alternating electromagnetic field device is arranged near a crystallizer of a vertical continuous casting machine, a low-frequency electromagnetic stirrer is arranged below a vibrating system and is close to a second cold area spraying system, a dummy bar rises to the lower end part of the crystallizer, and condensation water of the crystallizer and the high-frequency alternating electromagnetic field device are started; (2) refined nickel base corrosion-resistant alloy liquid is poured into the crystallizer, the liquid level of molten metal is kept to be flush with the upper edge of a high-frequency alternating electromagnetic coil, the vibrating system is started, and the second cold area spraying system and the low-frequency electromagnetic stirrer are started simultaneously; (3) the vertical continuous casting machine is started, the dummy bar moves downwards, and a casting speed is kept at 0.4-1.5m / min; and (4) after a casting blank reaches the required size, the nickel base corrosion-resistant alloy casting blank is captured, and the casting of casting blanks of next batch begins. The surface quality and internal quality of the nickel base corrosion-resistant alloy continuous casting blank prepared by the method are improved greatly.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com