Evaporator for separated heat tube

A separate heat pipe and evaporator technology, applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of heat source and evaporator thermal resistance increase, evaporator heat transfer capacity limitation, heat transfer deterioration, etc., to achieve Reduce the superheat of the wall surface, improve the characteristics of variable working conditions, and save the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

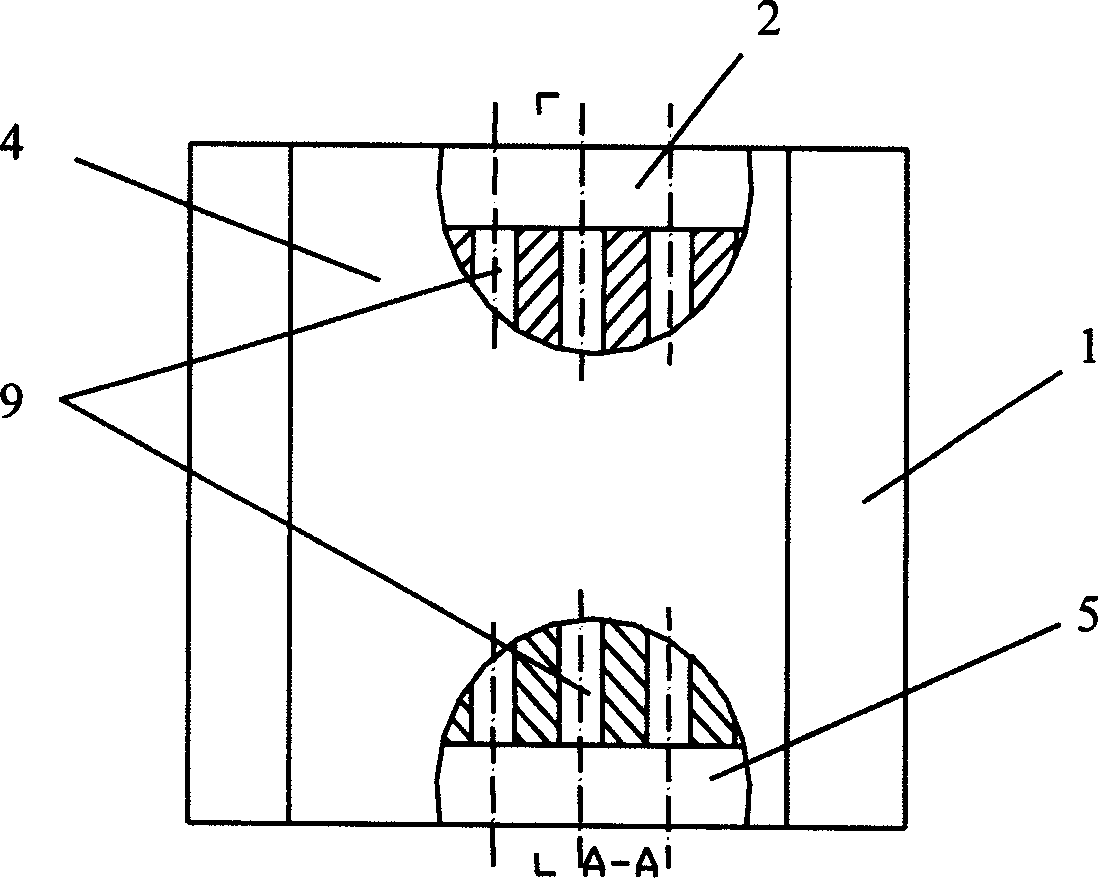

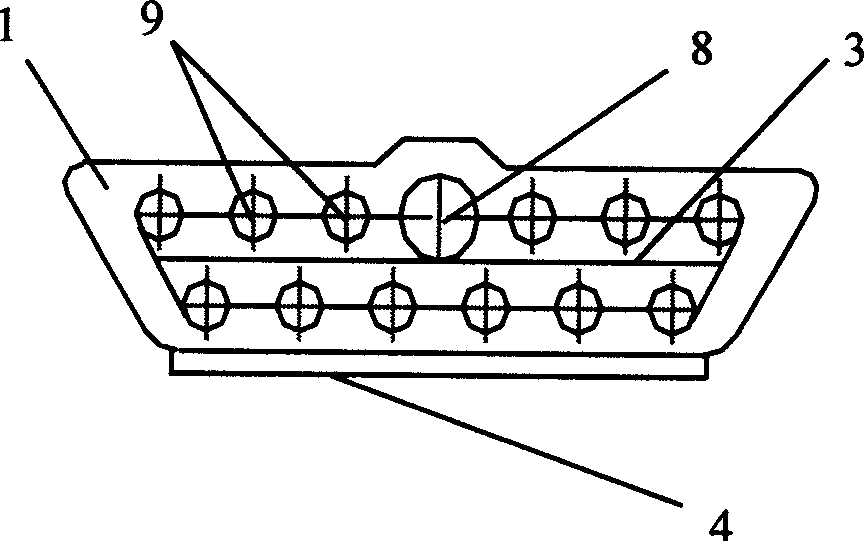

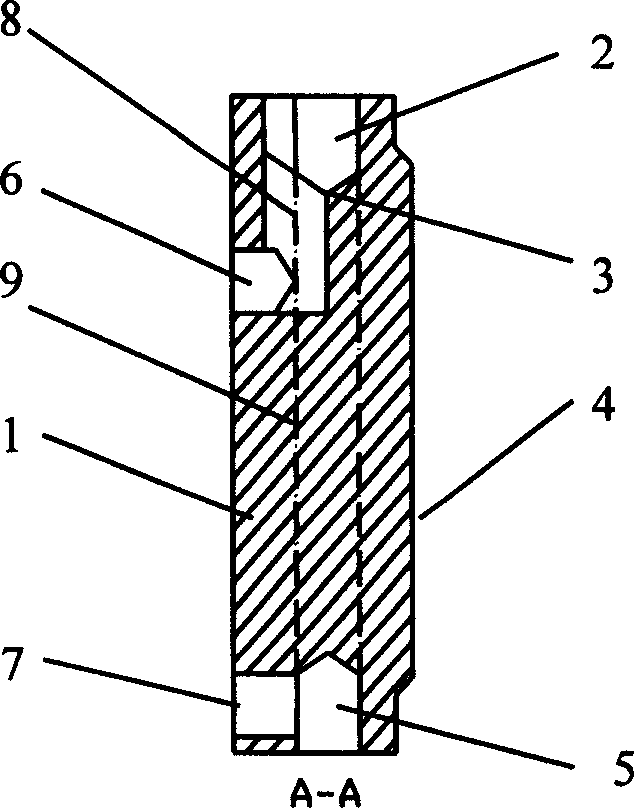

[0026] like figure 1 The shown evaporator is a metal plate 1 as a whole, and its front surface is a heating surface 4, which is in use against the solid wall of the heat source to absorb heat by conduction. A plurality of vertical parallel straight channels 9 are opened in the metal plate 1, and a liquid working medium is contained therein. In this way, when the heating surface 4 absorbs heat, the heat is rapidly conducted to various positions of the metal plate 1, so that the liquid working medium in the straight channel 9 absorbs heat and evaporates. Therefore, the evaporative heat exchange area of the evaporator can be expanded by the evaporating surface of one coupling heating surface 4 of the metal plate to the sum of the column areas of all channels 9 . Generally speaking, the evaporation heat exchange area of the evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com