Heat pipe device

A heat pipe device and pipe body technology, applied in the field of thermal control equipment, can solve the problems of high flexibility of heat pipe device heat transfer, large heat transfer area can not be taken into account, to achieve compact structure, long-distance heat transfer, and extended evaporation heat transfer area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

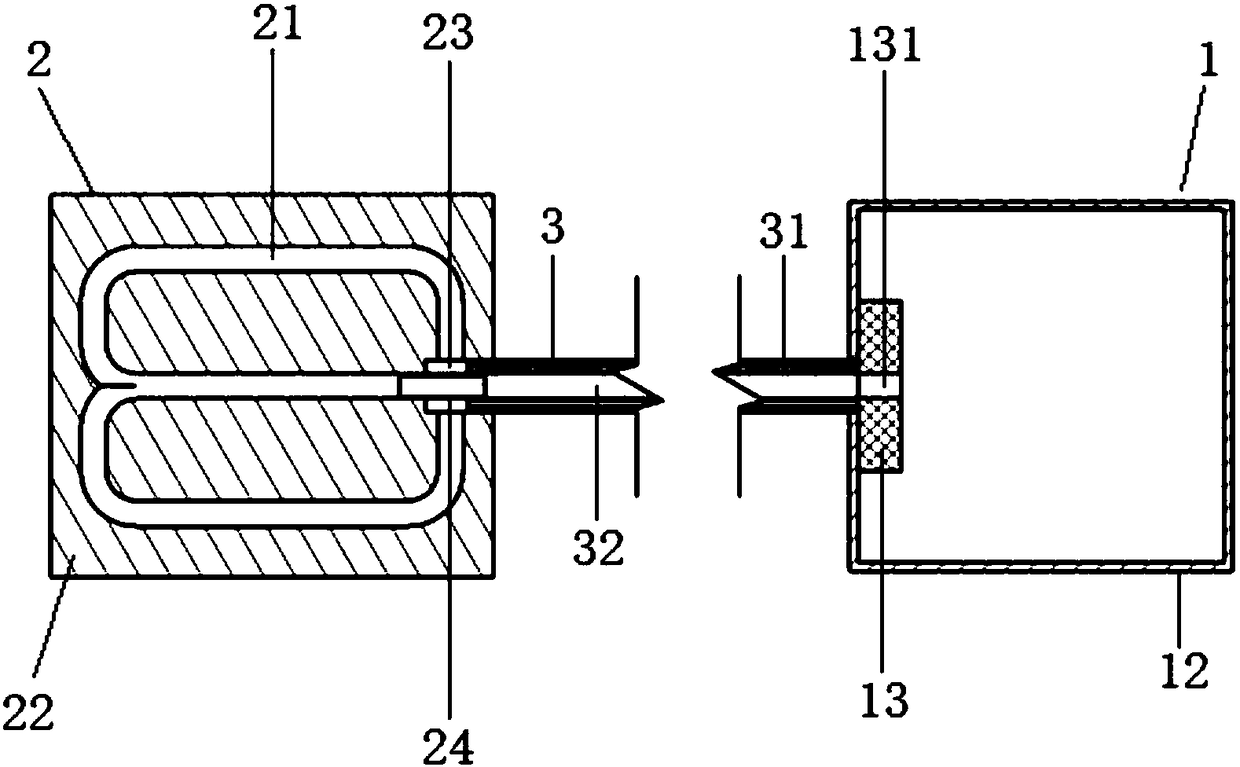

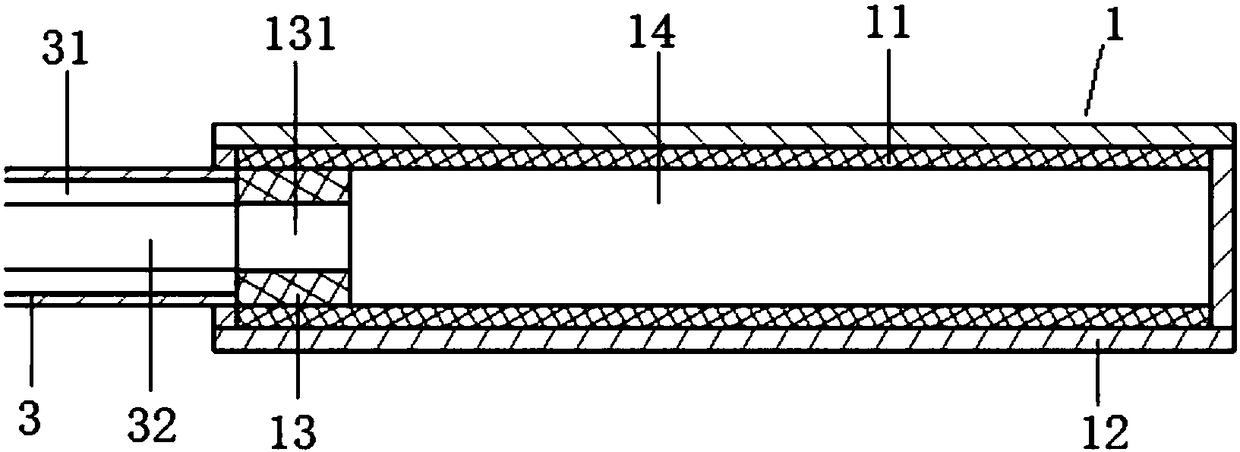

[0037] Such as Figure 1 ~ Figure 3 As shown, this embodiment provides a heat pipe device, including a condenser 2 , a transfer pipe and an evaporator 1 . The condenser 2, the transfer pipe and the evaporator 1 jointly form a closed chamber, which is filled with a working medium (ie, working fluid), and the condenser 2, the transfer pipe and the evaporator 1 are connected in sequence to form a working medium circuit. In the direction perpendicular to the length of the heat pipe device, the evaporator 1 has at least one cross-sectional dimension larger than the cross-sectional dimension of the transfer pipe. Compared with the internal section of the transfer tube, the interior has a larger evaporation heat exchange area.

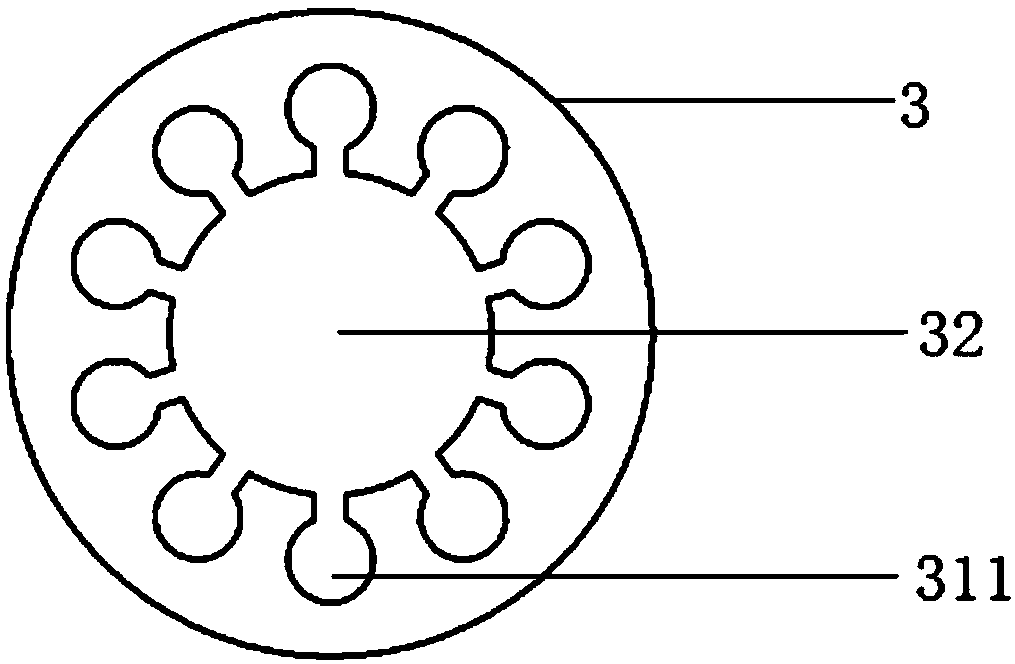

[0038] The transfer tube specifically includes a tube body 3 , a cavity 32 inside the tube body 3 , and a first capillary structure 31 on the inner wall of the tube body 3 . A first end of the cavity 32 communicates with the air inlet of the condenser 2 , a...

Embodiment 2

[0050] In order to make the heat pipe device have a more excellent flexible heat transfer effect, all or part of the pipe body 3 can also be designed as a flexible pipeline, which can be a non-metallic pipe or a metal pipe, such as a plastic pipe, rubber pipe, stainless steel pipe, etc. Thin-walled tubes, copper tubes, etc., or corrugated tubes, metal hoses, etc., or a combination of at least two of the above structures. By arranging flexible pipelines, the heat pipe device can be made more flexible, not only capable of bending, torsion, and even reciprocating swing, to meet the heat dissipation requirements of relative motion between the cold source and the heat source.

[0051] Such as Figure 5 ~ Figure 7 As shown, this embodiment also provides a heat pipe device, which is basically the same as the heat pipe device in Embodiment 1, and the similarities will not be repeated. The difference is that the first capillary structure 31 of this embodiment is the same as that of Emb...

Embodiment 3

[0056] This embodiment provides another heat pipe device, the structure of which is basically the same as that of Embodiment 1 or Embodiment 2, and the similarities will not be repeated. The difference lies in: Figure 4 As shown, the heat pipe device of this embodiment defaults to the condensation pipeline 21, but a section of the left end of the pipe body 3 is coupled with the plate body 22, that is, the pipe body 3 of the transfer pipe directly extends into the condenser 2, and the pipe body 3 The part extending into the condenser 2 replaces the condensing pipeline 21, so that the gaseous working medium is condensed into a liquid at a certain length of the condensation section at the end of the tube body 3, and gathers in the condensation section, and then passes through the first capillary structure in the tube body 3 31 flows into evaporator 1. In this embodiment, the length of the condensation section of the tube body 3 can be designed according to the size of the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com