Patents

Literature

188results about How to "Avoid effusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

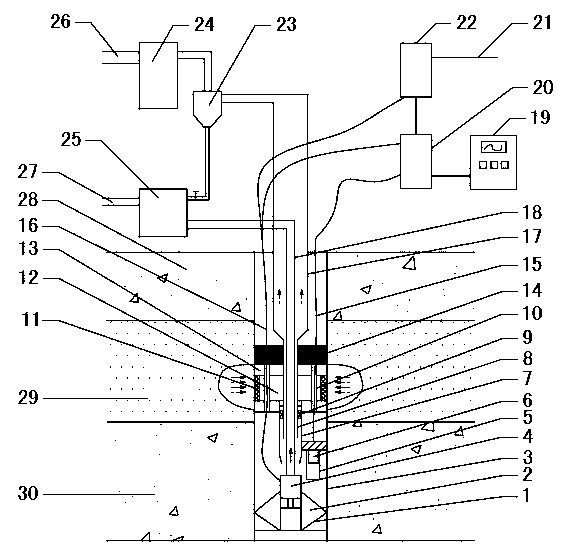

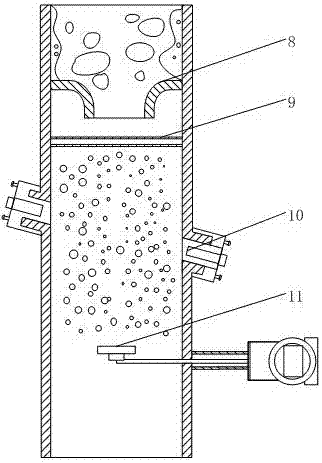

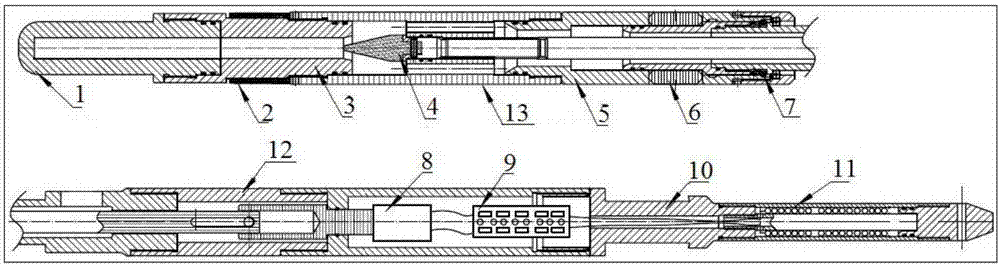

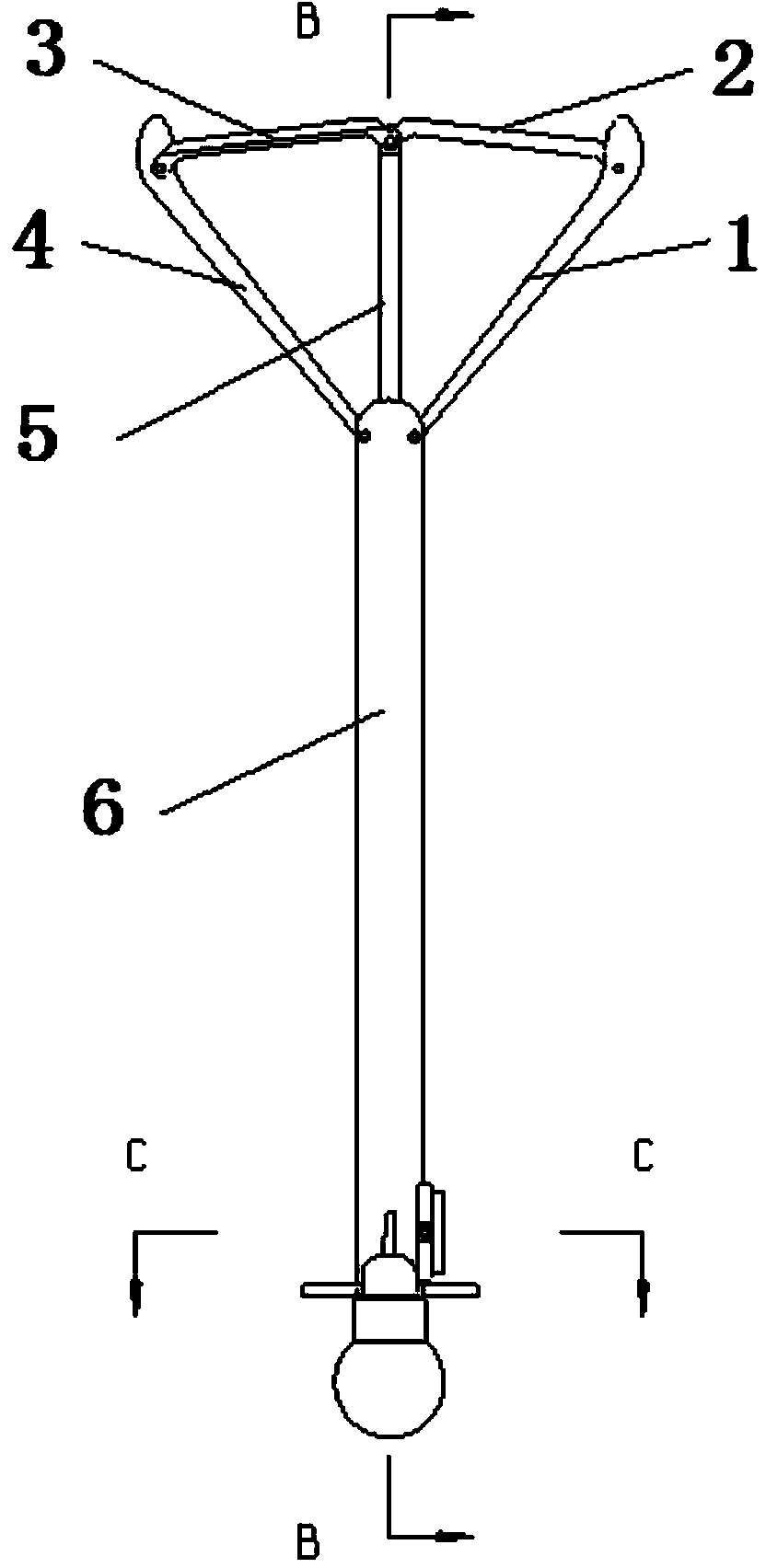

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

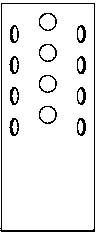

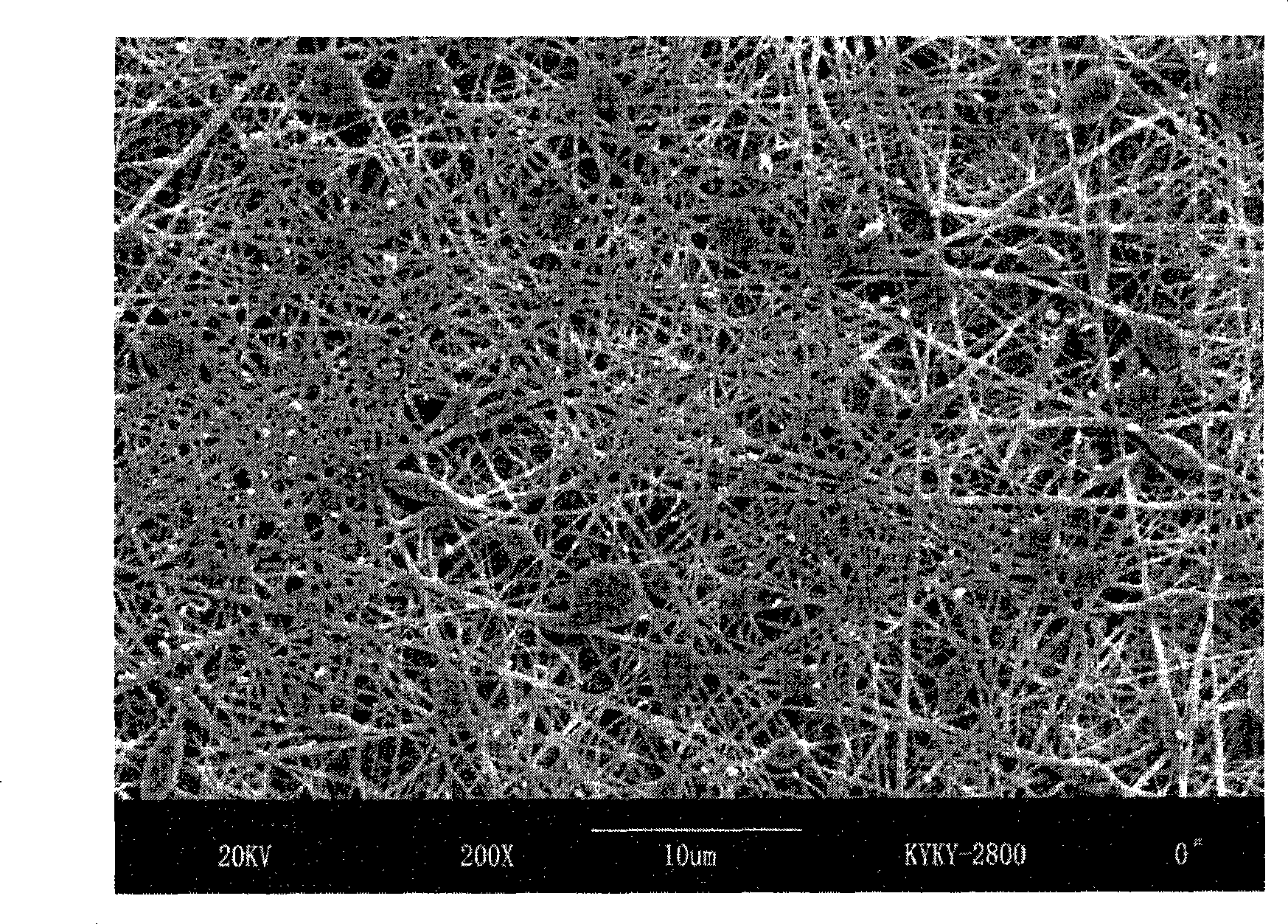

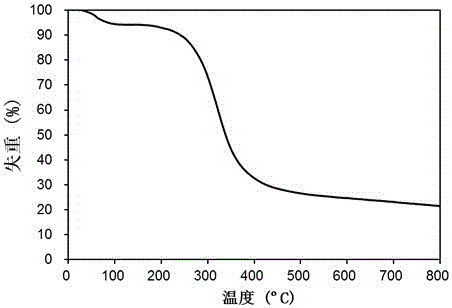

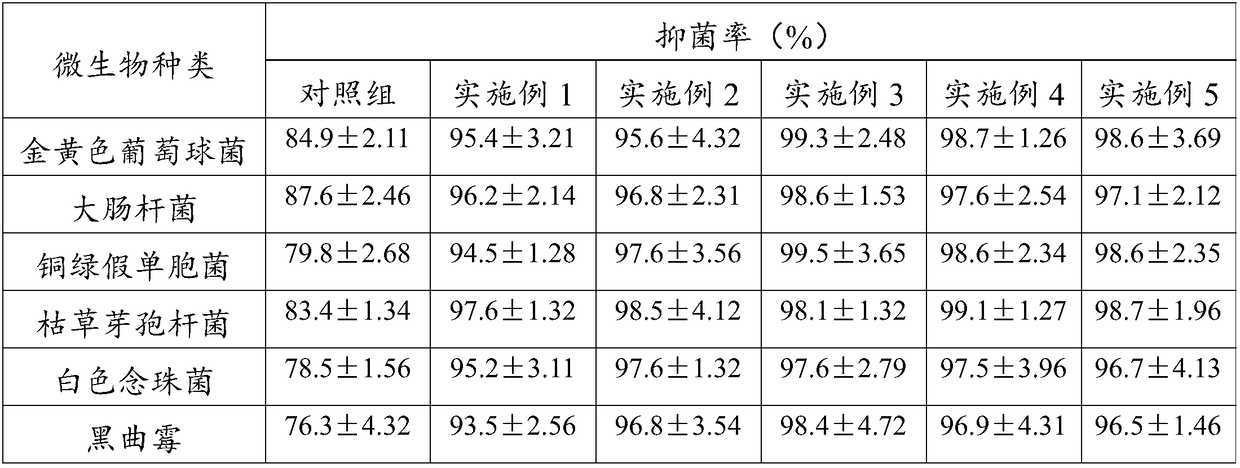

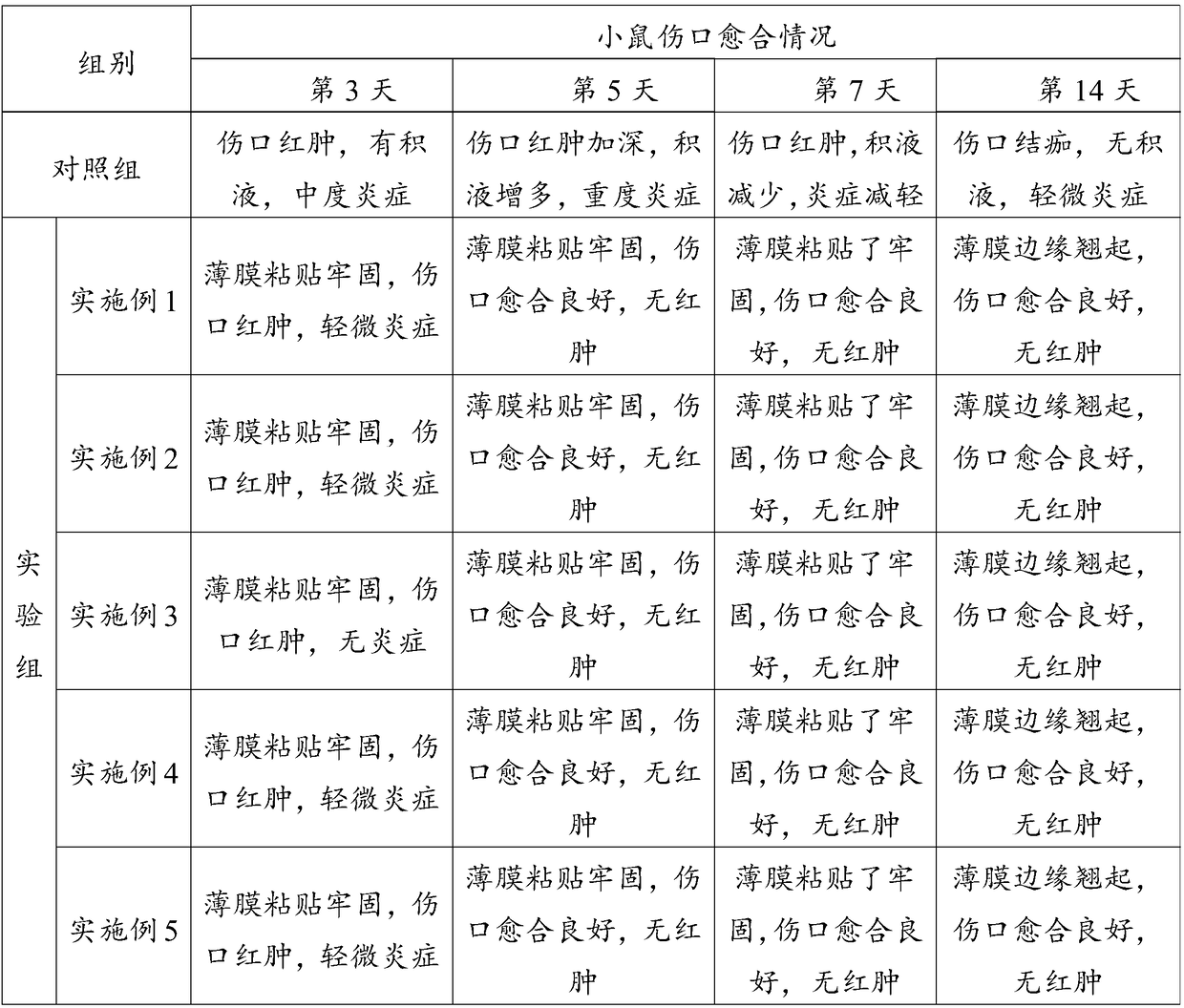

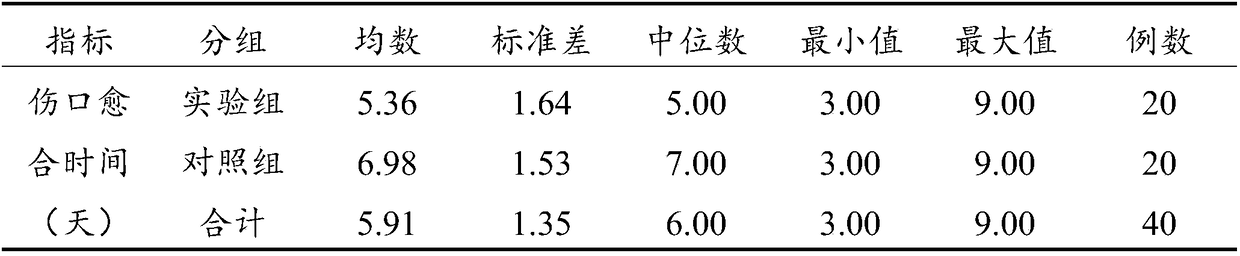

Degradable compound biomaterial membrane for medical purpose

InactiveCN1994476AHigh porosityLarge specific surface areaAbsorbent padsBandagesFiberElectrospinning

The invention relates to a method for preparing composite biological medical material used to avoid adhering organisms, wherein said film is formed by two layers; the layer used as base material is formed by degradable composite macromolecule polylactic acid, glycolic acid, or their copolymer, treated by static spin technique, to make film fiber into nanometer level; then coats one layer of degradable natural macromolecule chitose or relative derivant on the base film, to be treated to obtain the degradable composite biological medical film; and the invention can add different amounts of medical elasticizer between two layers to adjust the degrade speed. The invention can improve immunity with haemostasis function, etc.

Owner:BEIJING HUASHI BENQUAN TECH

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Anti-adhesion hernia repair patch

The invention relates to an anti-adhesion hernia repair patch which comprises a mesh fabric substrate and an electrostatic spinning anti-adhesion layer connected with the mesh fabric substrate. The pore diameter of the electrostatic spinning anti-adhesion layer is 10nm to 2,000nm, while the preferred pore diameter is 50nm to 1,500nm and the more preferred is 100nm to 800nm. After being transplanted into human body, the anti-adhesion hernia repair patch can not only repair hernia, but also prevent post-operation adhesion and can reduce effusion, thus reducing infection.

Owner:TRANSEASY MEDICAL TECH

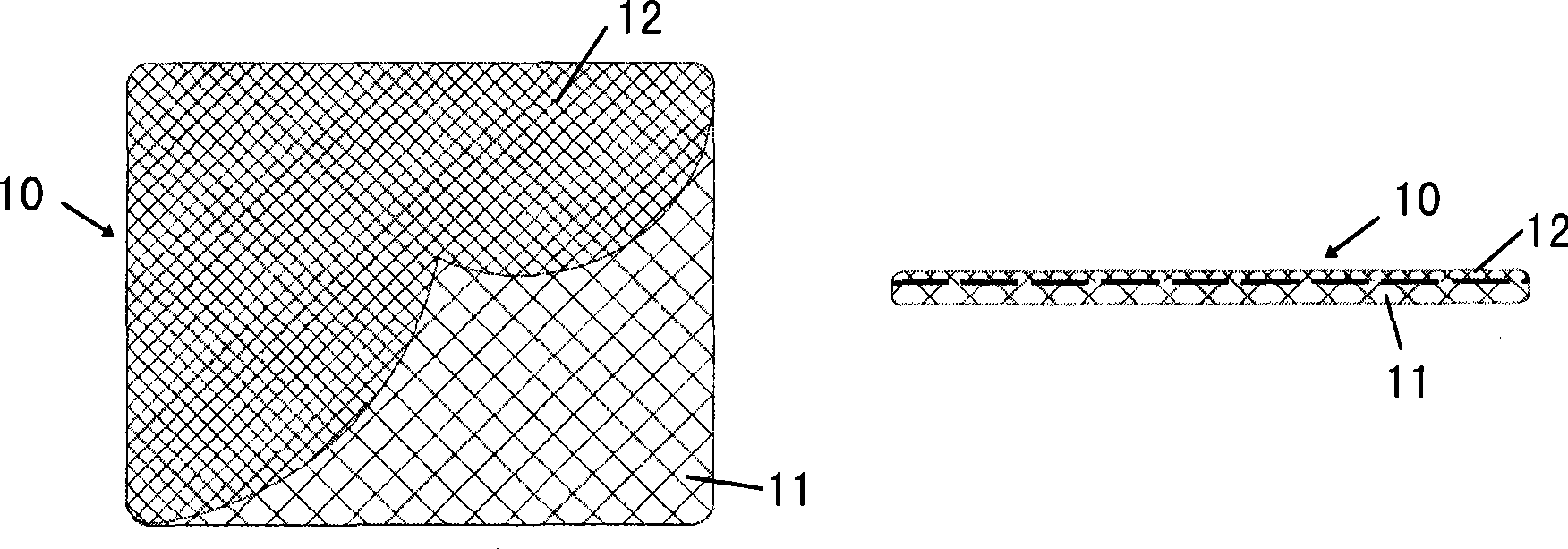

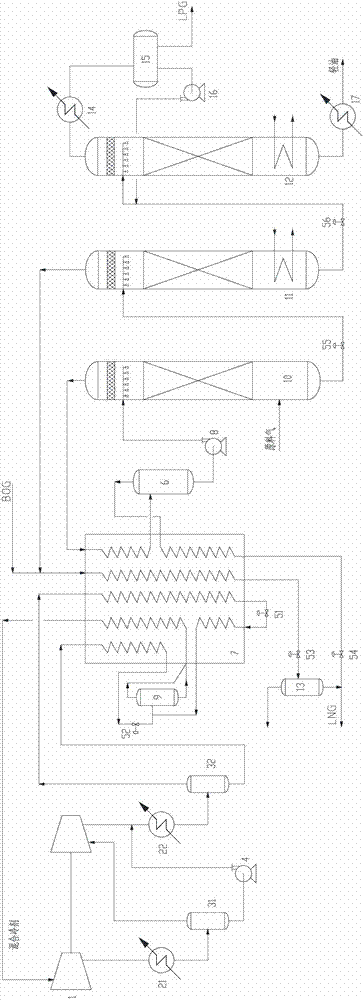

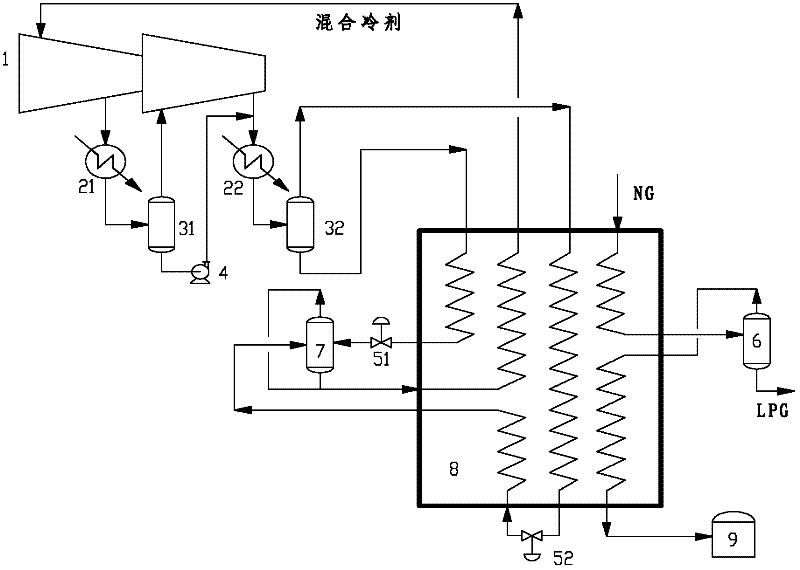

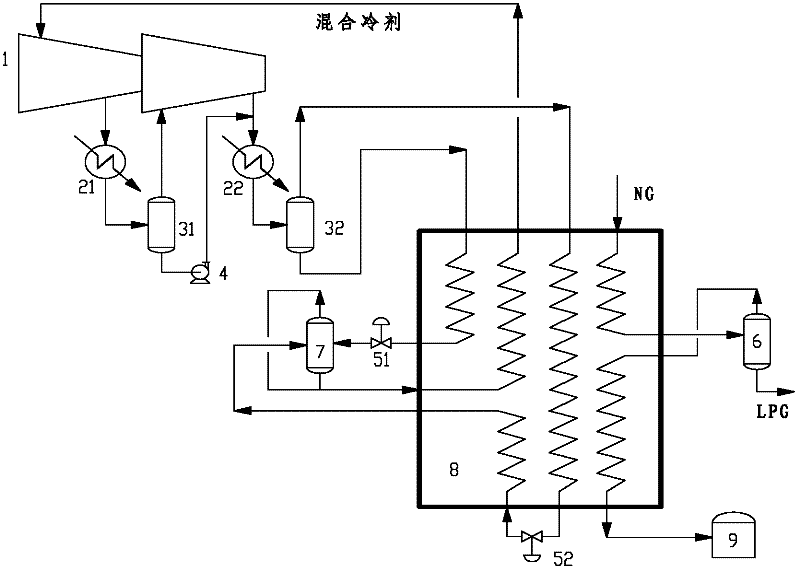

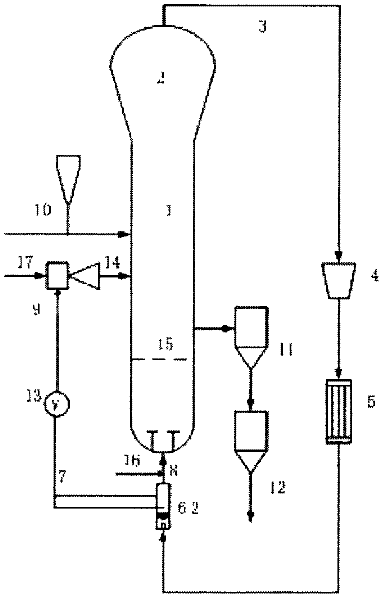

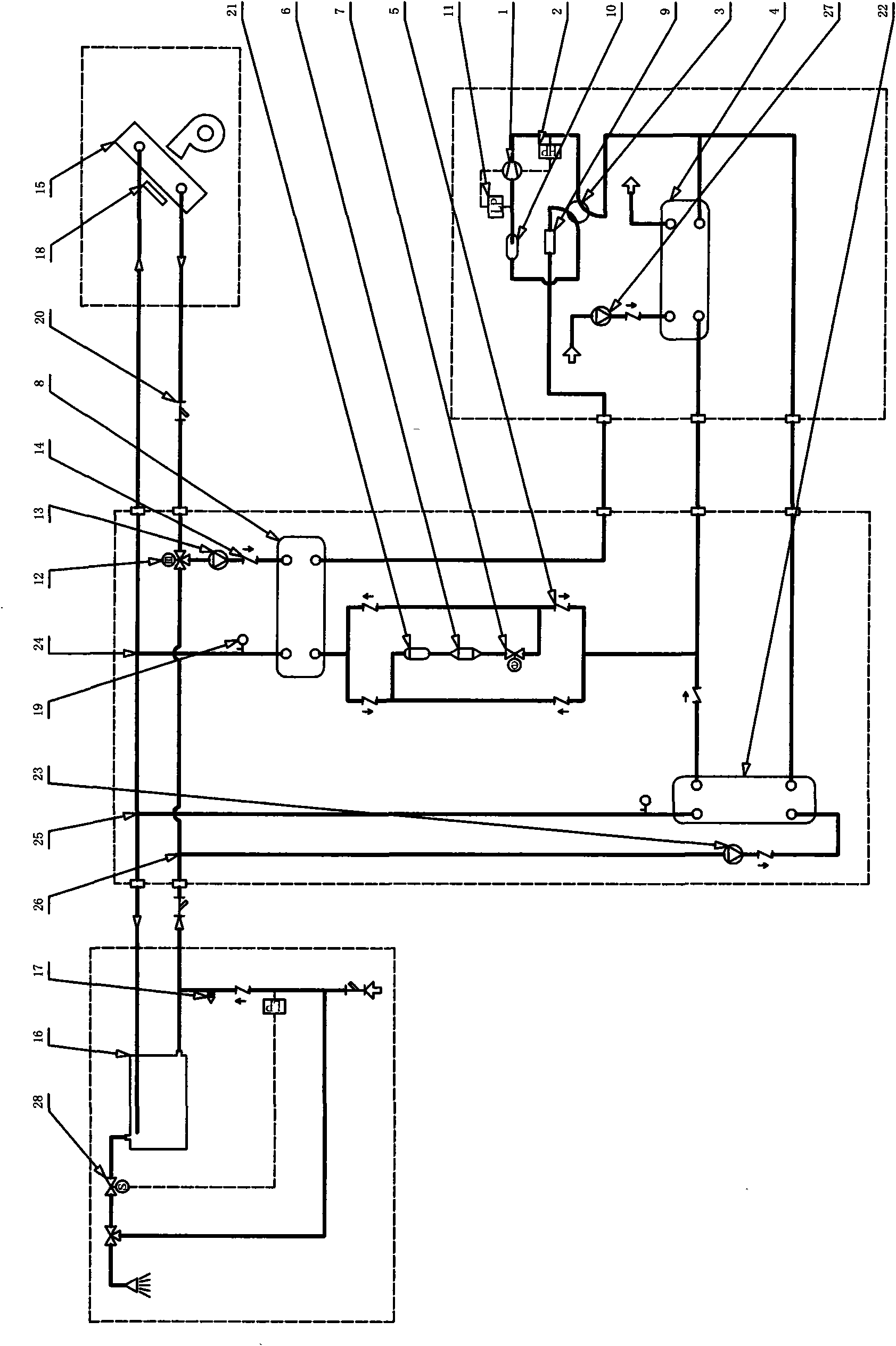

Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

ActiveCN103031169AEconomical and reliableReasonable designSolidificationLiquefactionGas phaseLarge range

The invention relates to a process for carrying out liquefaction and heavy hydrocarbon treatment on natural gas, which comprises a low temperature liquefaction process and a heavy hydrocarbon treatment process. The low temperature liquefaction process comprises the following step that mixed refrigerant provides refrigerating capacity for the natural gas which is subjected to partial heavy hydrocarbon removal in the heavy hydrocarbon treatment process so as to implement cooling, complete heavy hydrocarbon removal and liquefaction on the natural gas in a cold box to obtain LNG (Liquefied Natural Gas); the heavy hydrocarbon treatment process comprises the following steps that the natural gas rich in heavy hydrocarbon is subjected to partial heavy hydrocarbon in a heavy hydrocarbon washing tower and the removed heavy hydrocarbon sequentially enters a deethanizing column and a rectifying column to be subjected to removal of light components and be separated into LPG (Liquefied Petroleum Gas) and light oil. According to the process disclosed by the invention, by-products, i.e. the LPG and the light oil, are also produced when the LNG is produced, the process route is advanced and the process is economical and reliable; the process can be suitable for the condition that raw material gas comprises aromatic hydrocarbon such as benzene and the like, the aromatic hydrocarbon such as the benzene and the like are removed along with the heavy hydrocarbon component and the cold box is prevented from being frozen and blocked; the process has large operation elasticity and can be suitable for natural gas heavy hydrocarbon content in a large range; the mixed refrigerant is adopted to circulate the flow and provide refrigerating capacity and gas-phase and liquid-phase refrigerants respectively enter the cold box to carry out heat exchange, so that heat exchange curves of cold and hot fluids are further matched; and the adopted refrigerating flow can effectively avoid liquid accumulation at the bottom of the cold box.

Owner:XINDI ENERGY ENG TECH

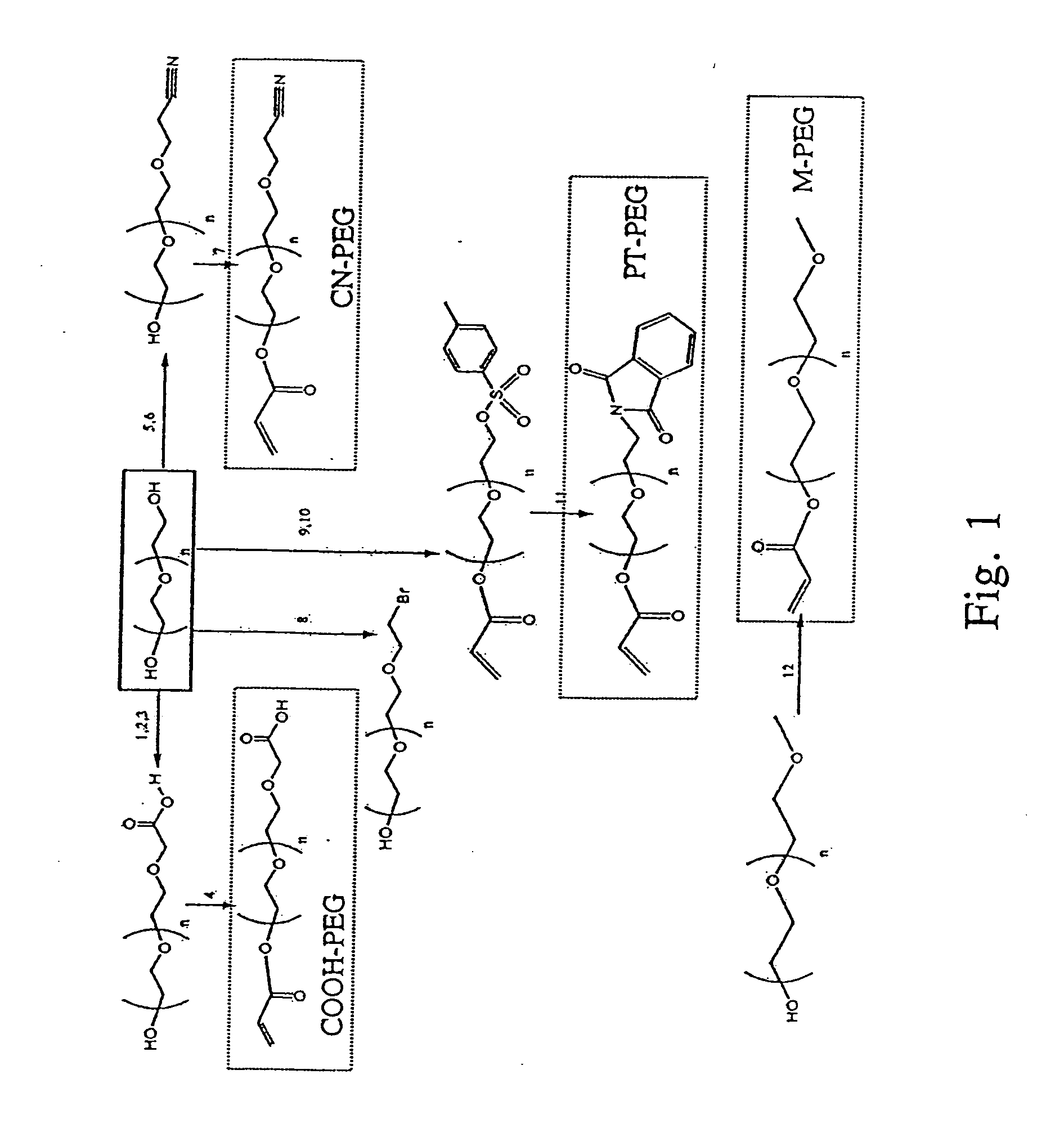

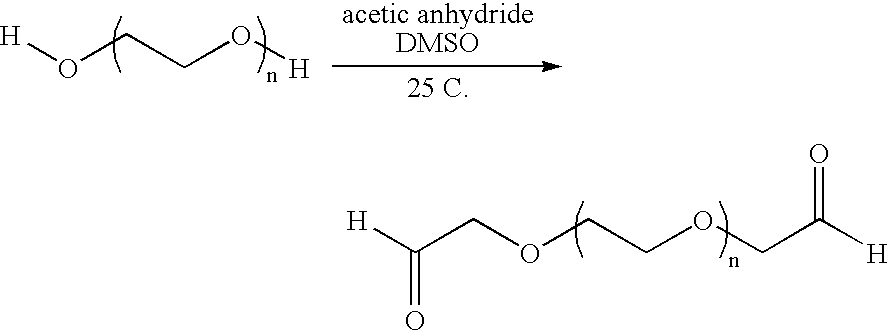

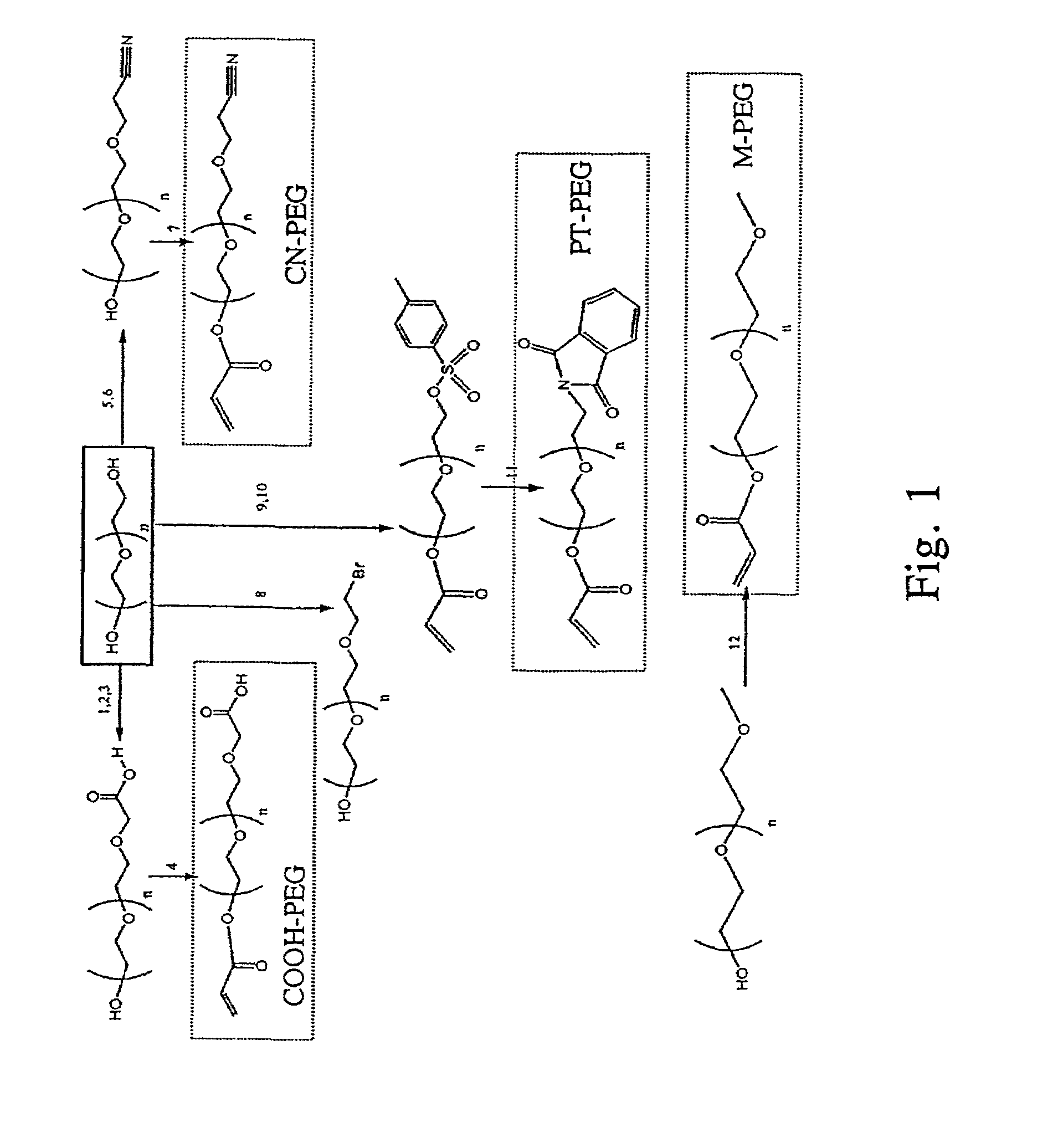

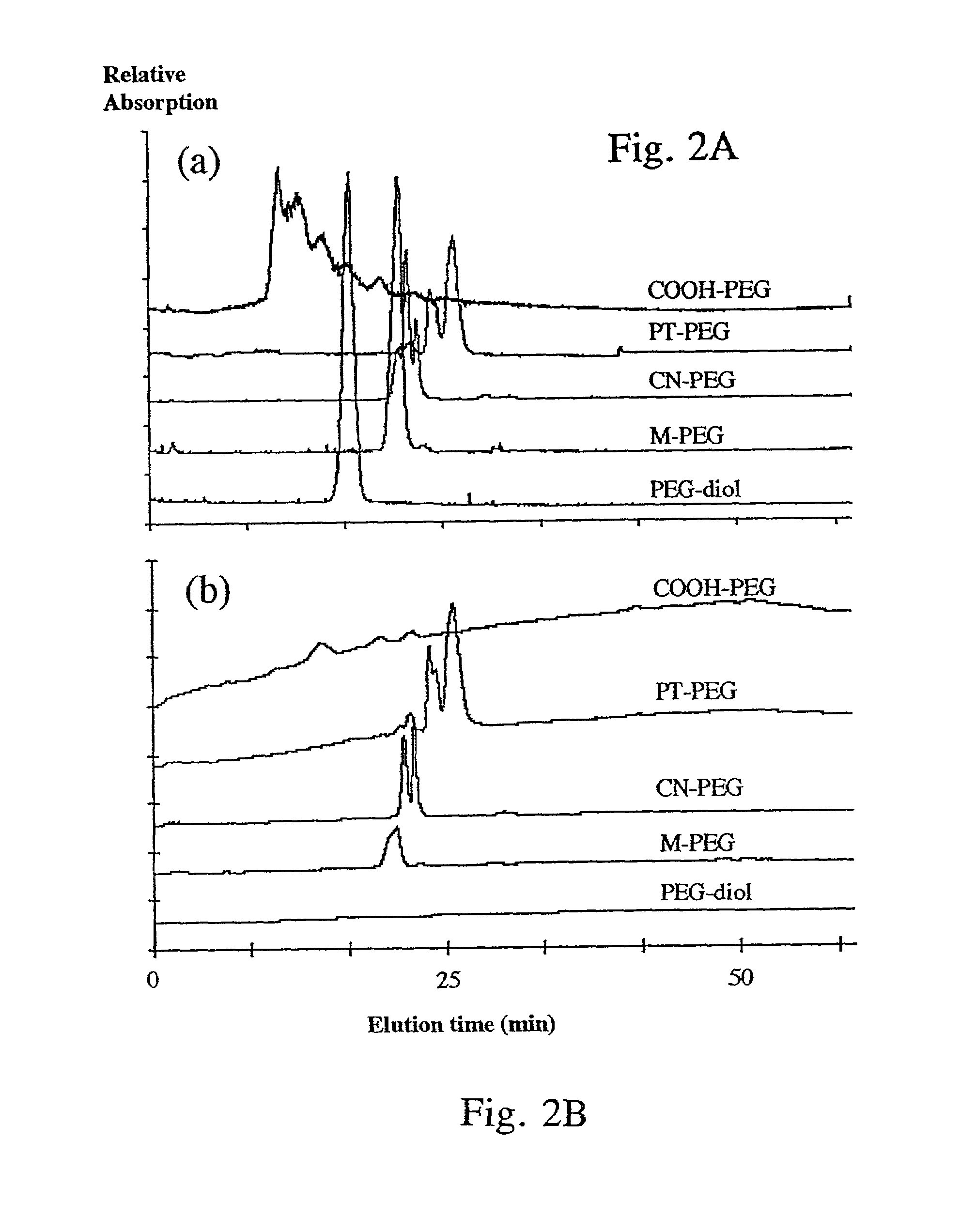

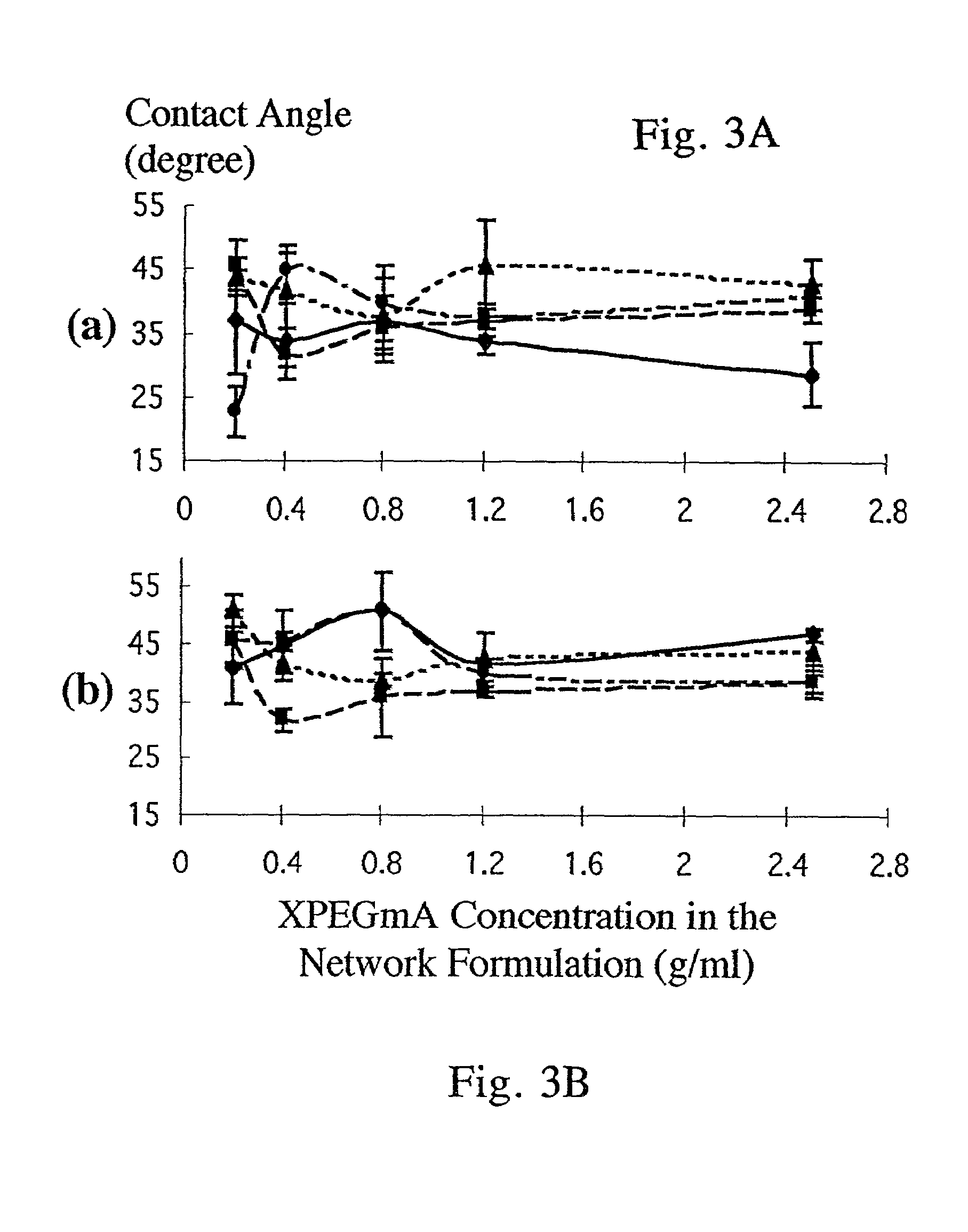

Bifunctional-modified hydrogels

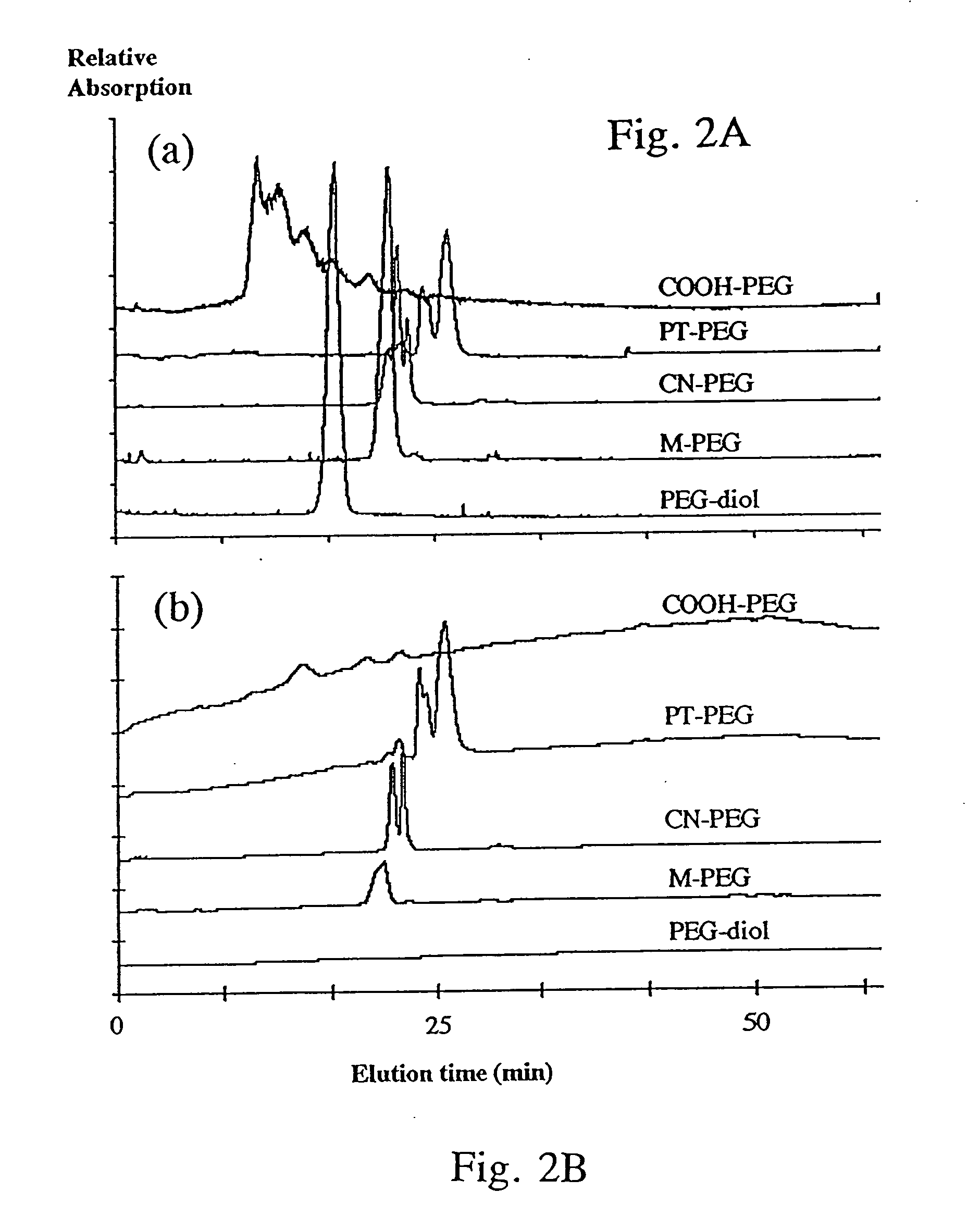

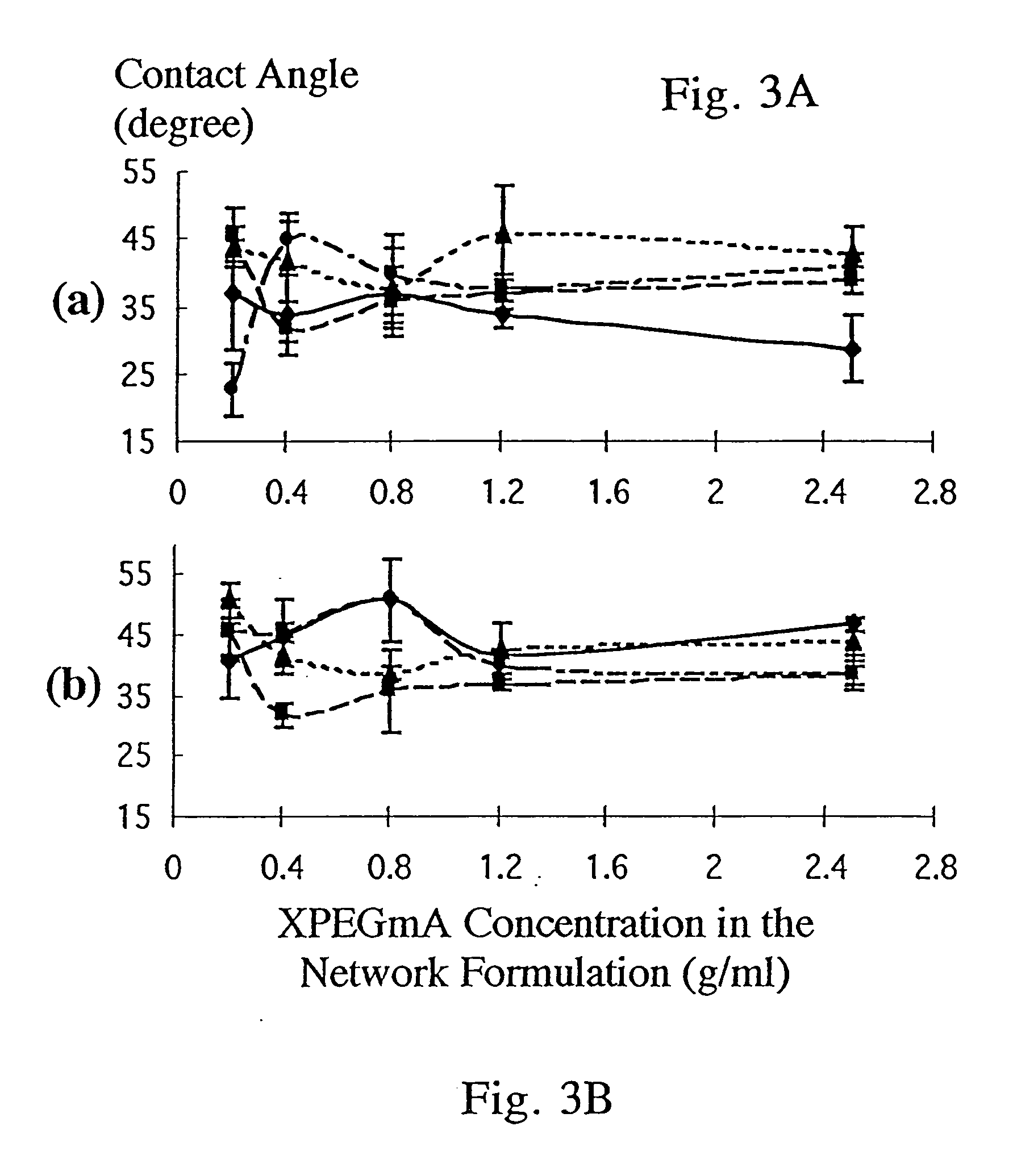

InactiveUS20050276858A1Promote exchangeAssist in removingPowder deliveryPharmaceutical non-active ingredientsActive agentAcrylate

Disclosed are hydrogels wherein a polymer matrix is modified to contain a bifunctional poly(alkylene glycol) molecule covalently bonded to the polymer matrix. The hydrogels can be cross-linked using, for example, glutaraldehyde. The hydrogels may also be crosslinked via an interpenetrating network of a photopolymerizable acrylates. The hydrogels may also be modified to have pharmacologically-active agents covalently bonded to the poly(alkylene glycol) molecules or entrained within the hydrogel. Living cells may also be entrained within the hydrogels.

Owner:WISCONSIN ALUMNI RES FOUND

Bifunctional-modified hydrogels

InactiveUS20060100369A1Facilitate communicationAssist in removingAerosol deliveryOintment deliveryActive agentLiving cell

Disclosed are hydrogels wherein a polymer matrix is modified to contain a bifunctional poly(alkylene glycol) molecule covalently bonded to the polymer matrix. The hydrogels can be cross-linked using, for example, glutaraldehyde. The hydrogels may also be crosslinked via an interpenetrating network of a photopolymerizable acrylates. The hydrogels may also be modified to have pharmacologically-active agents covalently bonded to the poly(alkylene glycol) molecules or entrained within the hydrogel. Living cells may also be entrained within the hydrogels.

Owner:KAO WEIYUAN +3

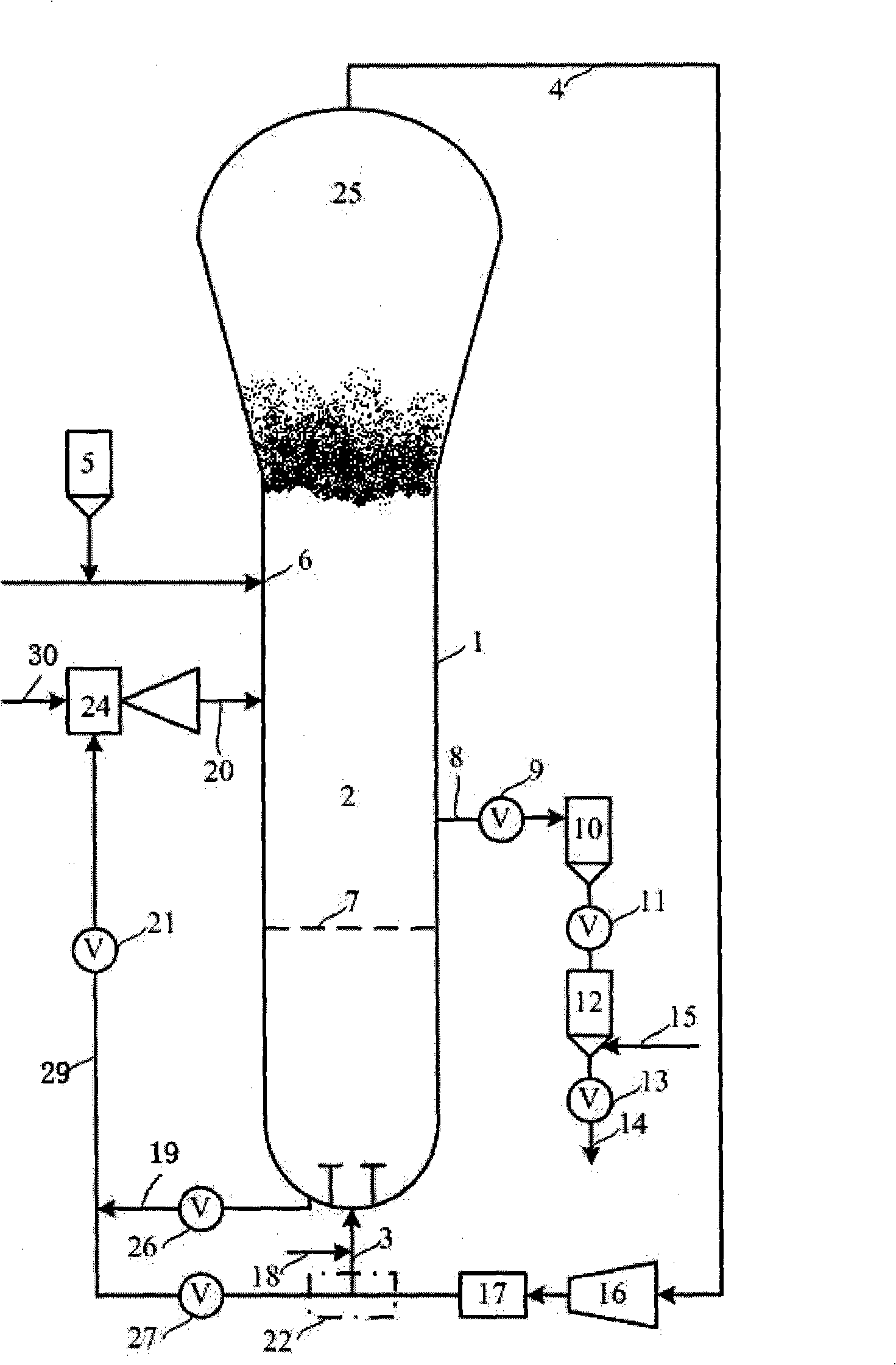

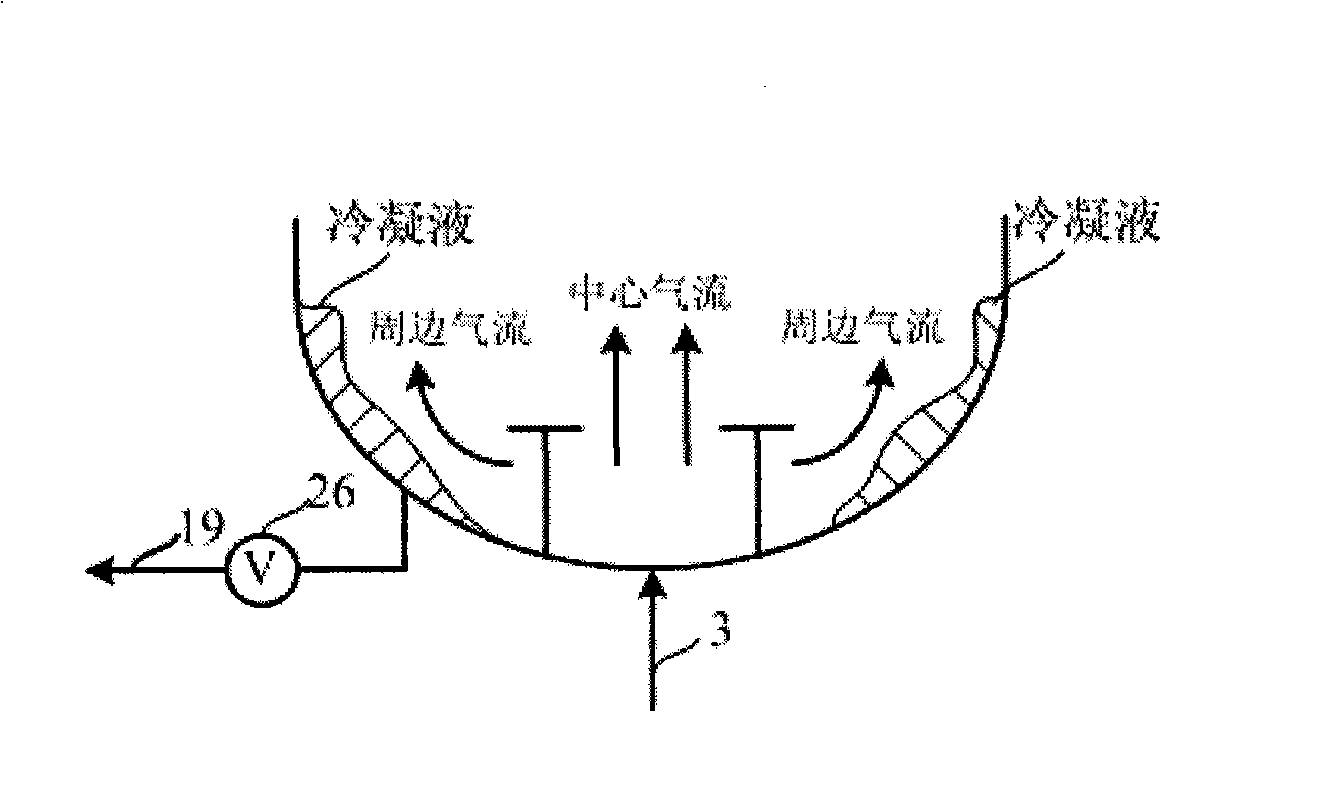

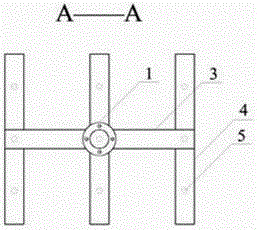

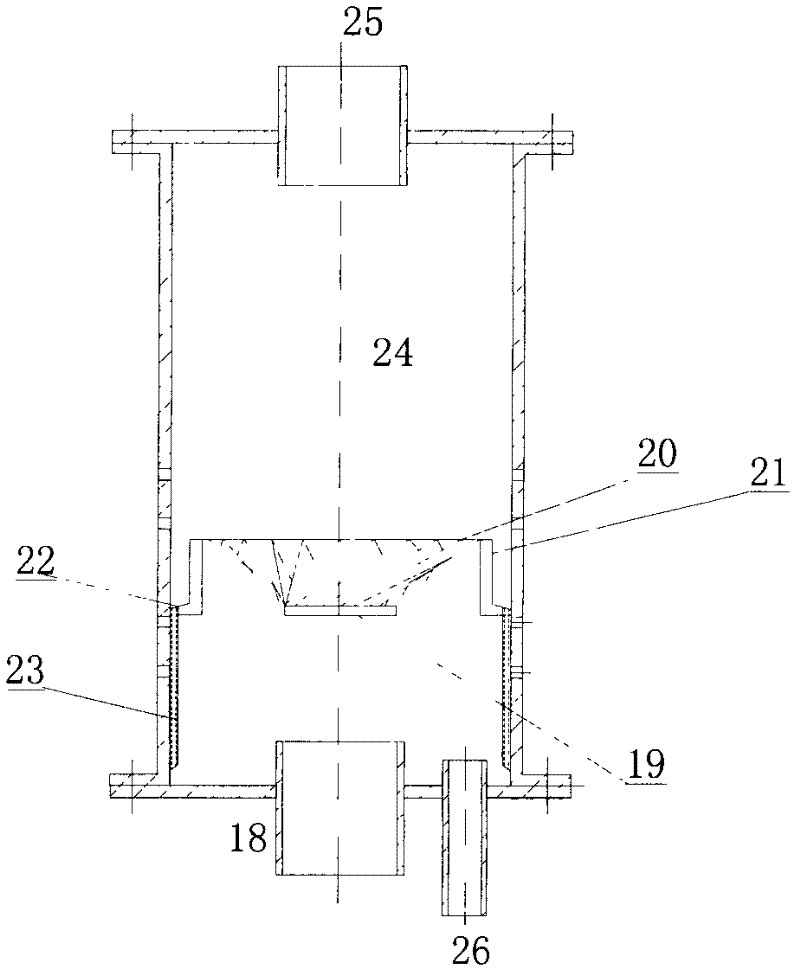

Improvement of manner for introducing condensation agent into fluidised bed polymerisation reactor and device

InactiveCN101284889AAvoid head effusion phenomenonReduce the amount of solutionChemical/physical processesFluidized bedEffusion

The invention discloses an improvement of introducing the way of a condensing agent into a fluidized bed polymerization reactor and a device thereof. The improvement comprises the following steps that: a circulating airstream is exported from the top of the fluidized bed and is compressed as well as condensed and separated to form a main portion and a small portion rich in condensed fluid, the main portion flows back to the bottom of the fluidized bed, a jet pump is adopted, a reaction feed gas is taken as a power airstream, the condensed fluid with a content occupying 30 to 100 weight percent of the total content of the condensed fluid in the circulating airstream and the reaction feed gas are jetted to the upper part of a gas distributing plate inside the fluidized bed, the power of the jet pump is adopted to draw off the condensed fluid effusion at the bottom of the fluidized bed back to the upper part of the gas distributing plate. The improvement can greatly increase the quantity of the condensed fluid which returns to the fluidized bed reactor from the upper part of the distributing plate and avoids the phenomenon of the effusion at the bottom of the fluidized bed; meanwhile, the reaction feed gas is taken as the power fluid body of the jet pump, the energy inside the system is used comprehensively, the production ability is greatly increased, therefore, the improvement has great operation significance and the application value.

Owner:ZHEJIANG UNIV +1

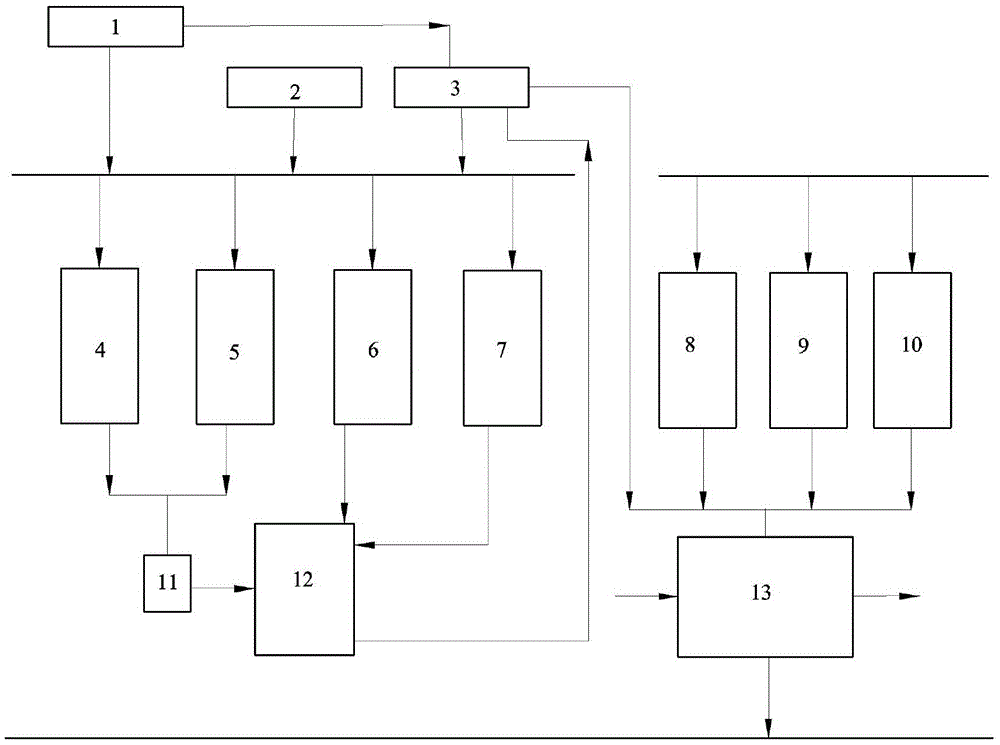

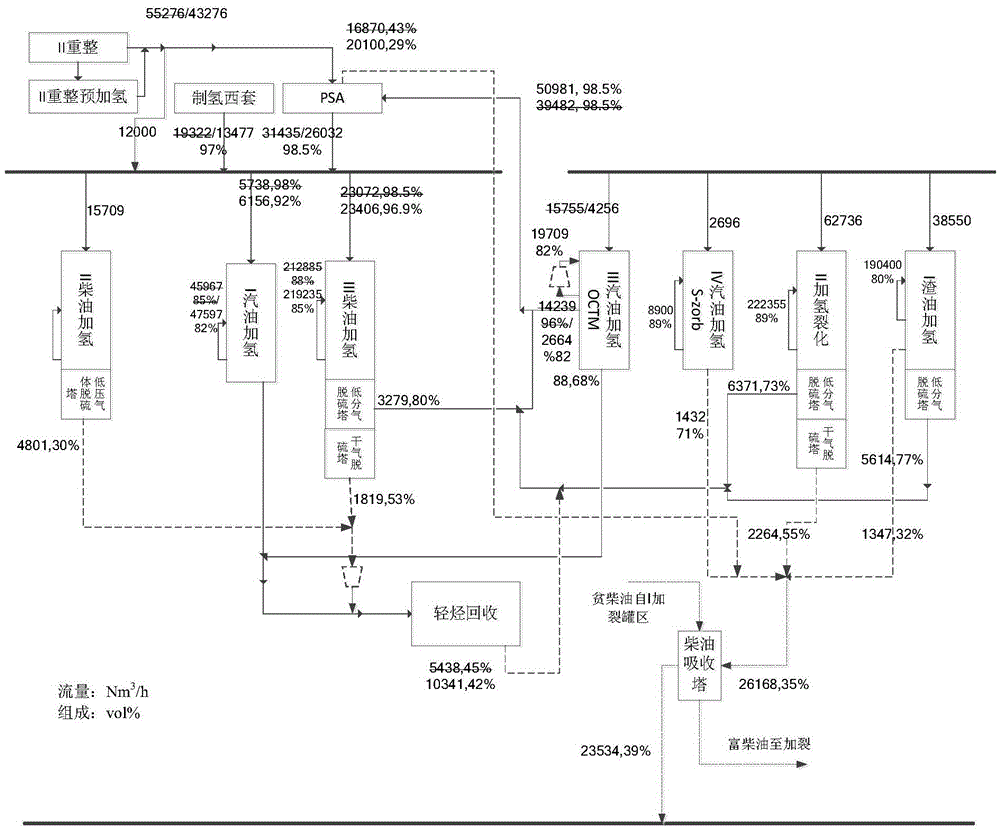

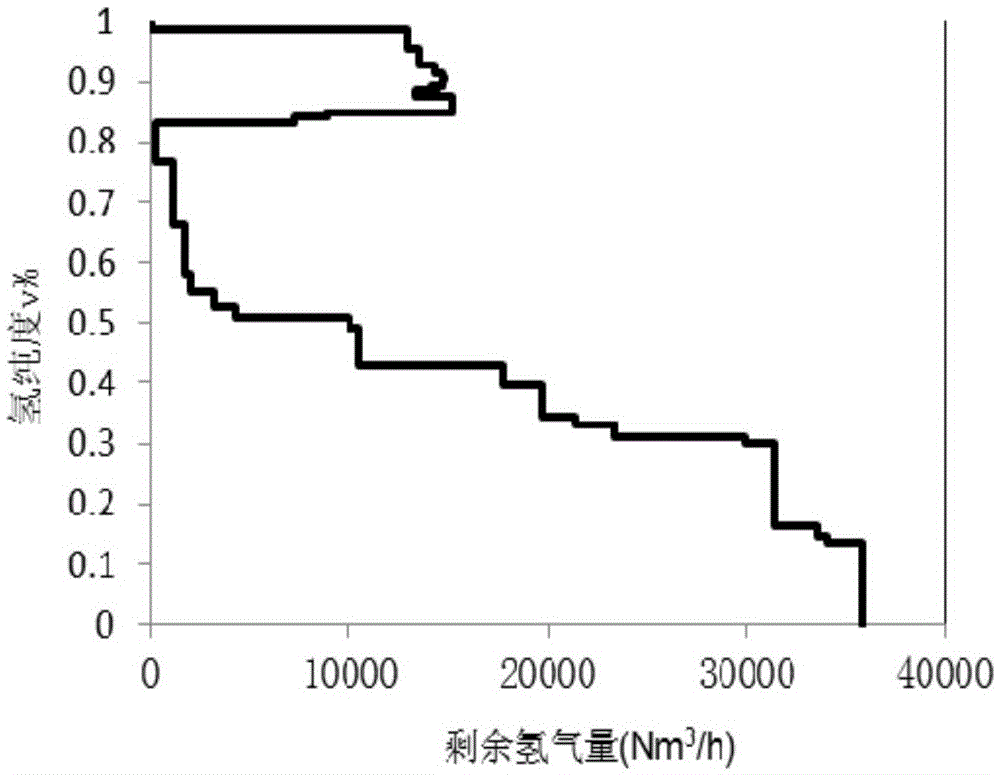

Optimization method of oil refinery hydrogen system and application thereof

ActiveCN106485341ASimple processProtect the optimization processForecastingProcess engineeringHydrogen system

The invention relates to an optimization method of an oil refinery hydrogen system. According to the system provided by the invention, the maximum benefit of the oil refinery hydrogen system is targeted, constraint conditions are optimized, and a new mathematical programming algorithm including light dydrocarbon resource optimization is formed; and compared with the mathematical programming algorithm of an existing hydrogen system, the optimization method is more suitable to actual circumstances, and more benefits can be obtained to meet the requirements of hydrogen conservation and synergy for oil refinery. The invention further provides application of the method in the optimization of the oil refinery hydrogen system, and after the method is optimized, efficient utilization of hydrogen and light dydrocarbon can be realized, so that considerable comprehensive benefit is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

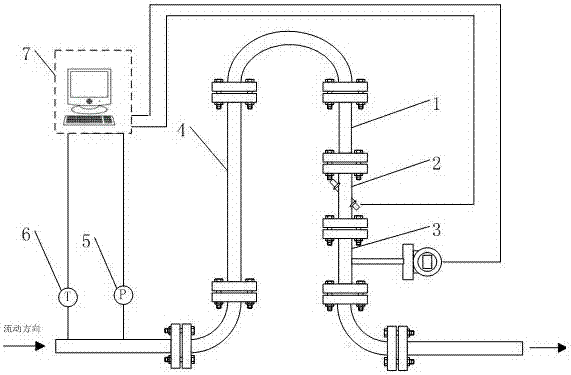

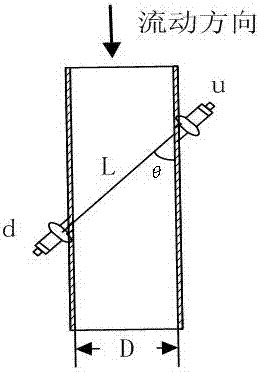

Method for measuring wet natural gas flow rate by combining ultrasound with target flowmeter

ActiveCN106979808ARealize online non-separation measurementSimple structureVolume flow measuring devicesSonificationGas phase

The invention discloses a rectification-technology-based method for measuring a wet natural gas flow rate by combining ultrasound with a target flowmeter. A measuring system includes an inverted U-shaped measuring pipeline, a nozzle rectification machine, an ultrasound flowmeter, the target flowmeter, a pressure sensor, a temperature sensor and the like. The nozzle rectification machine, the ultrasound flowmeter and the target flowmeter are mounted at the descending side of a U-shaped measuring pipe. Wet gas flows through the nozzle rectification machine and is adjusted into approximate homogeneous phase flow; when ultrasonic is propagated, the ultrasonic flowmeter which works in a transit time mode measures the apparent volume flow rate of the wet gas; in combination with the apparent volume flow rate measured by the ultrasonic flowmeter, the target flowmeter measures the apparent density of the wet gas; under the conditions that gas-phase components of the wet gas are known, the liquid phase is incompressible and the liquid-phase density is known, according to pressure and temperature parameters, the gas-phase density can be calculated; finally, according to the apparent volume flow rate and apparent density of the wet gas, the liquid-phase density and the gas-phase density, a liquid-phase volume fraction, a liquid-phase volume fraction, a liquid-phase volume flow rate, a liquid-phase mass flow rate, a gas-phase volume flow rate and a gas-phase mass flow rate are calculated, and therefore the online non-separation measurement of the wet natural gas flow rate is achieved.

Owner:大庆嘉鸿达石油钻采设备有限公司

Bifunctional-modified hydrogels

InactiveUS7615593B2Facilitate communicationAssist in removingPowder deliveryBiocideActive agentLiving cell

Disclosed are hydrogels wherein a polymer matrix is modified to contain a bifunctional poly(alkylene glycol) molecule covalently bonded to the polymer matrix. The hydrogels can be cross-linked using, for example, glutaraldehyde. The hydrogels may also be crosslinked via an interpenetrating network of a photopolymerizable acrylates. The hydrogels may also be modified to have pharmacologically-active agents covalently bonded to the poly(alkylene glycol) molecules or entrained within the hydrogel. Living cells may also be entrained within the hydrogels.

Owner:WISCONSIN ALUMNI RES FOUND

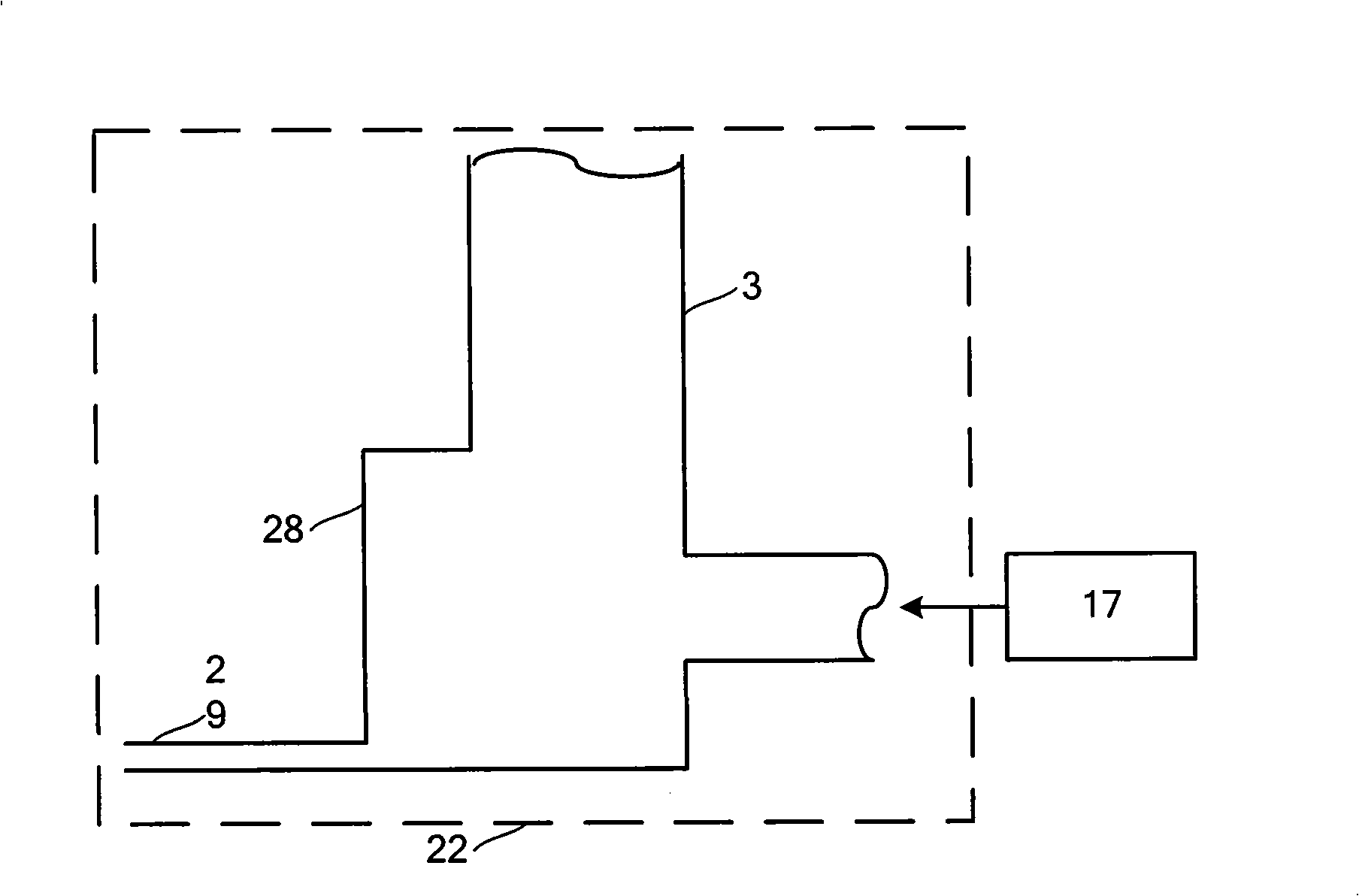

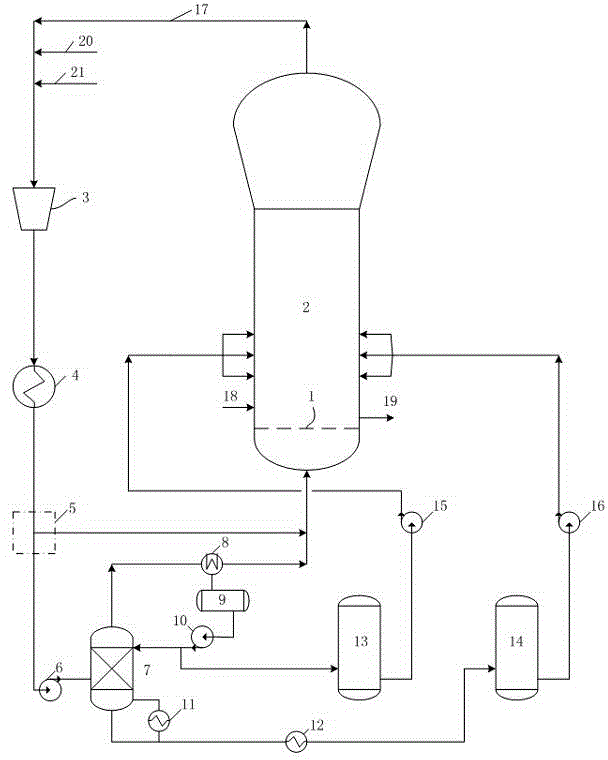

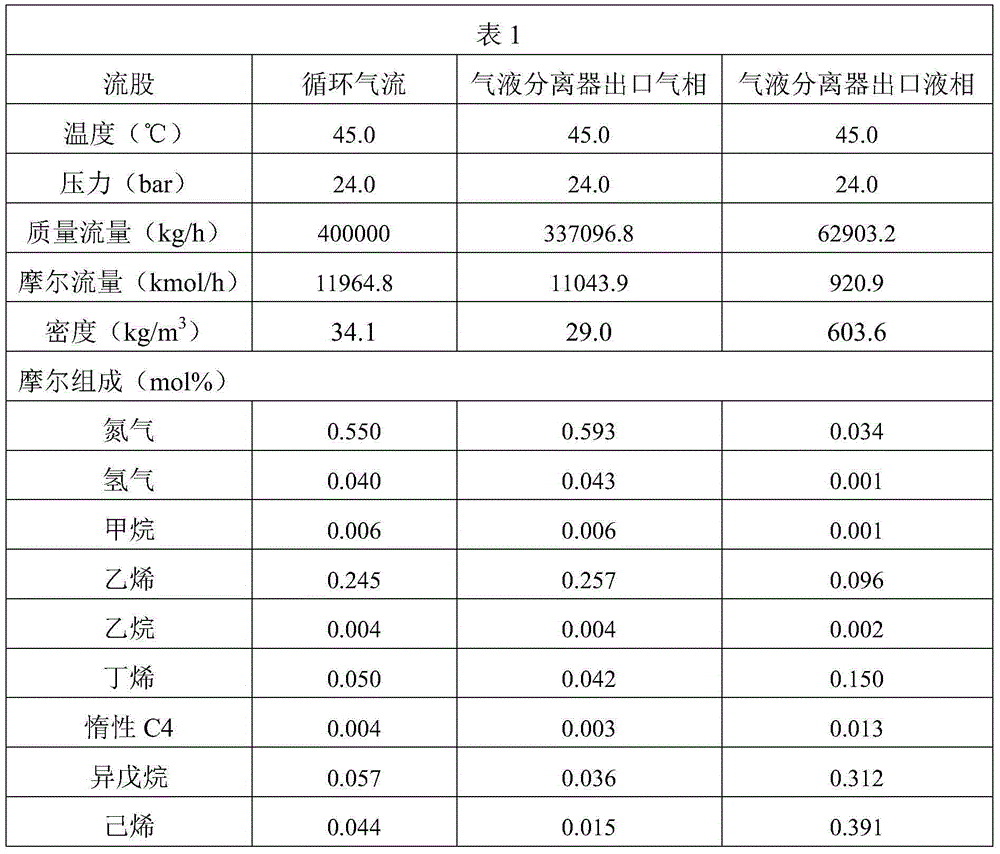

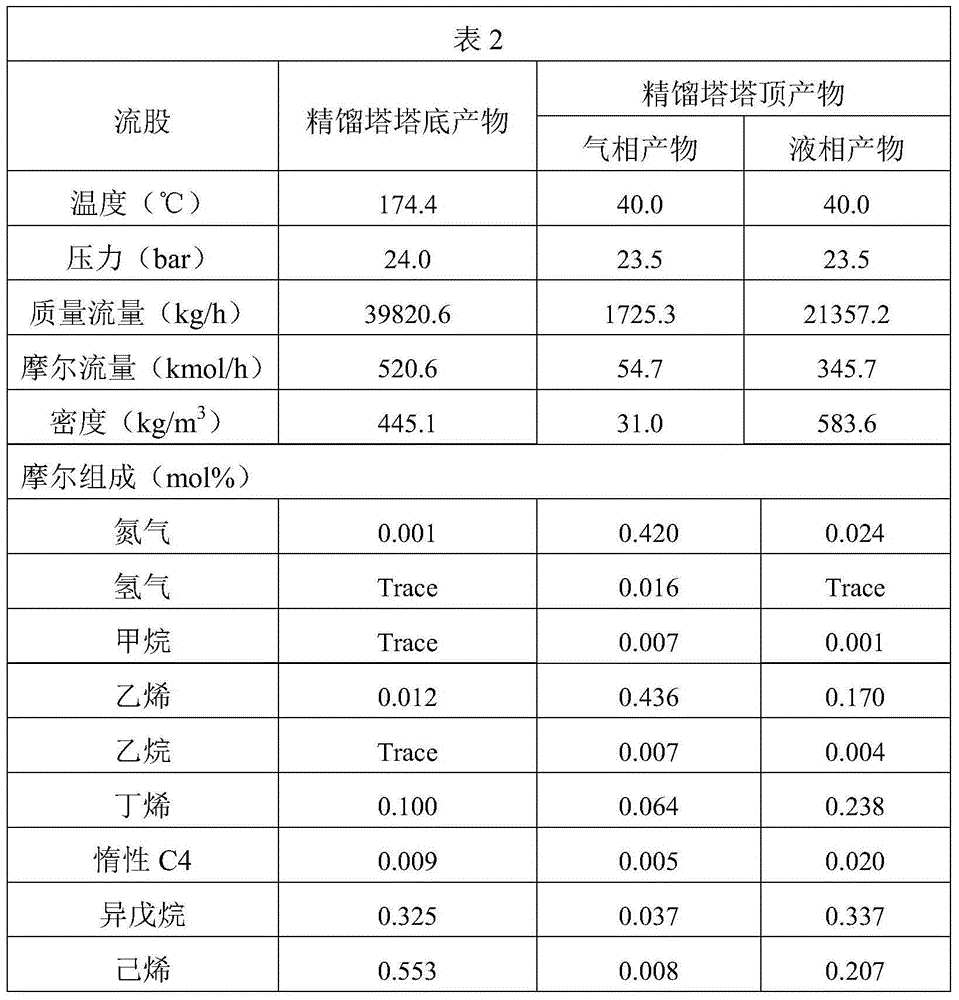

Method and device for polymerization of olefins

The invention discloses a method and a device for the polymerization of olefins. The method comprises the following steps: introducing an unreacted gas material out from the outlet of a fluidized bed reactor, compressing, condensing and carrying out gas-liquid separation in a circulation pipeline, feeding partial and all liquid material into a rectifying tower, cooling top products and bottom products and introducing into a reactor from different positions above a reactor distribution plate; introducing a residual liquid material and a gas material below a polymerization reactor distribution plate; contacting the gas material and the liquid material in the fluidized bed and the added catalyst to form solid phase polyolefin and continuously or intermittently introducing the solid phase polyolefin from the reactor out. According to the method, co-monomer is further separated by virtue of the rectifying tower and the separated co-monomer is introduced into the different positions of the reactor, so that different reaction environments are caused in the same reactor and the products with excellent properties are obtained.

Owner:ZHEJIANG UNIV

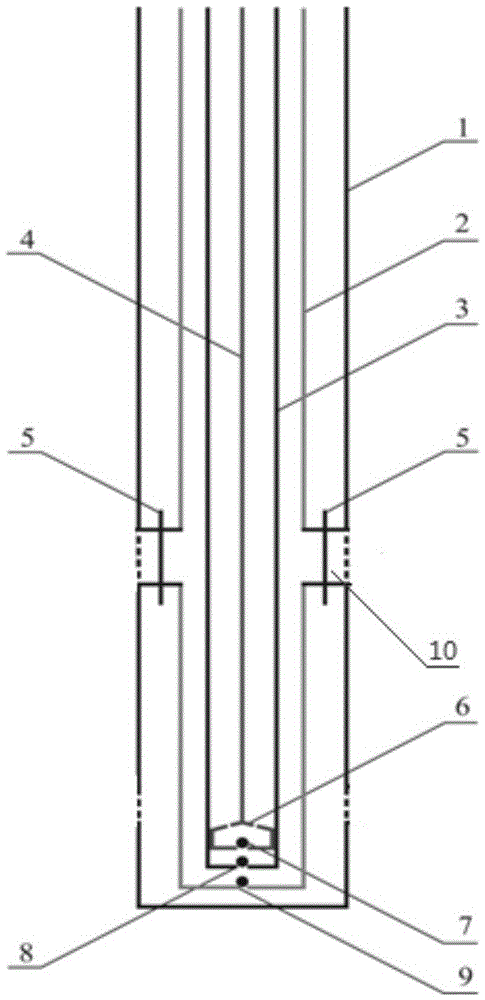

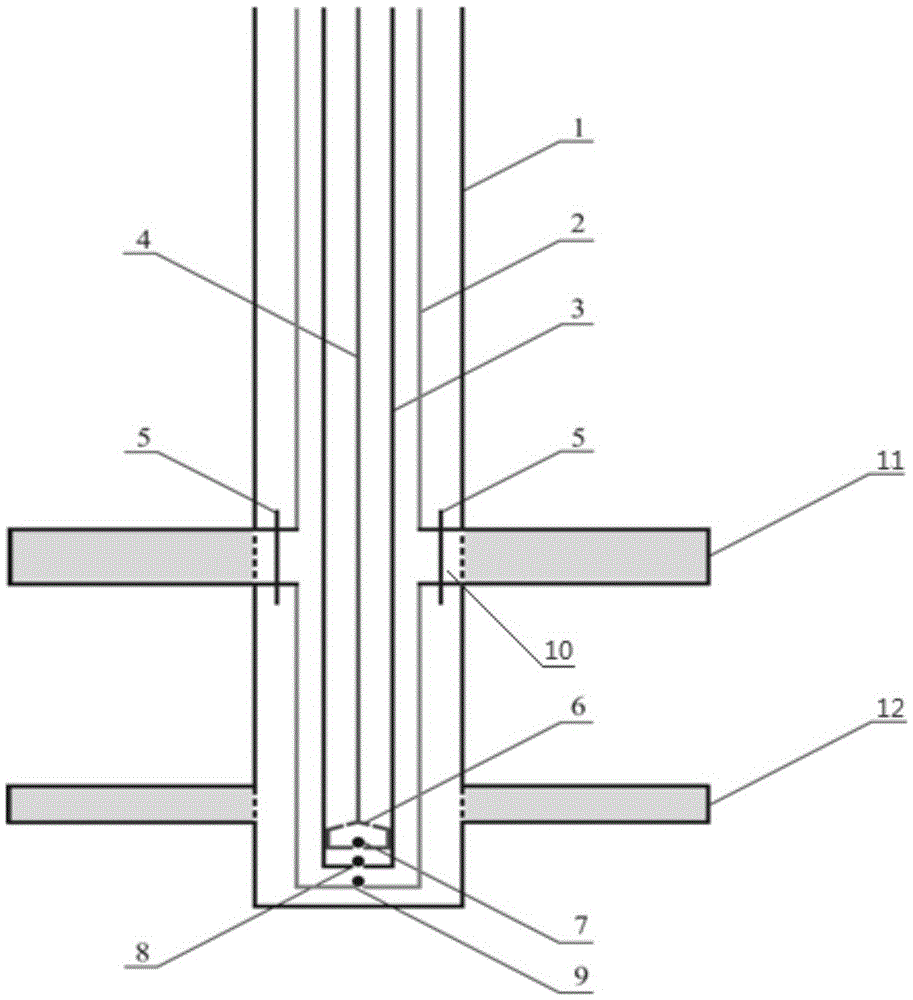

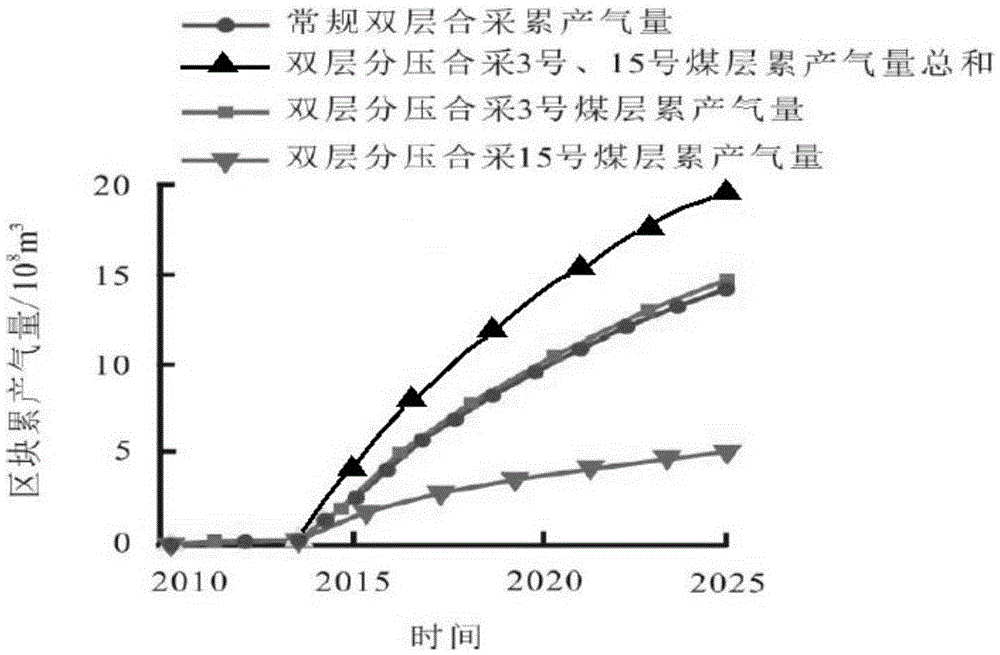

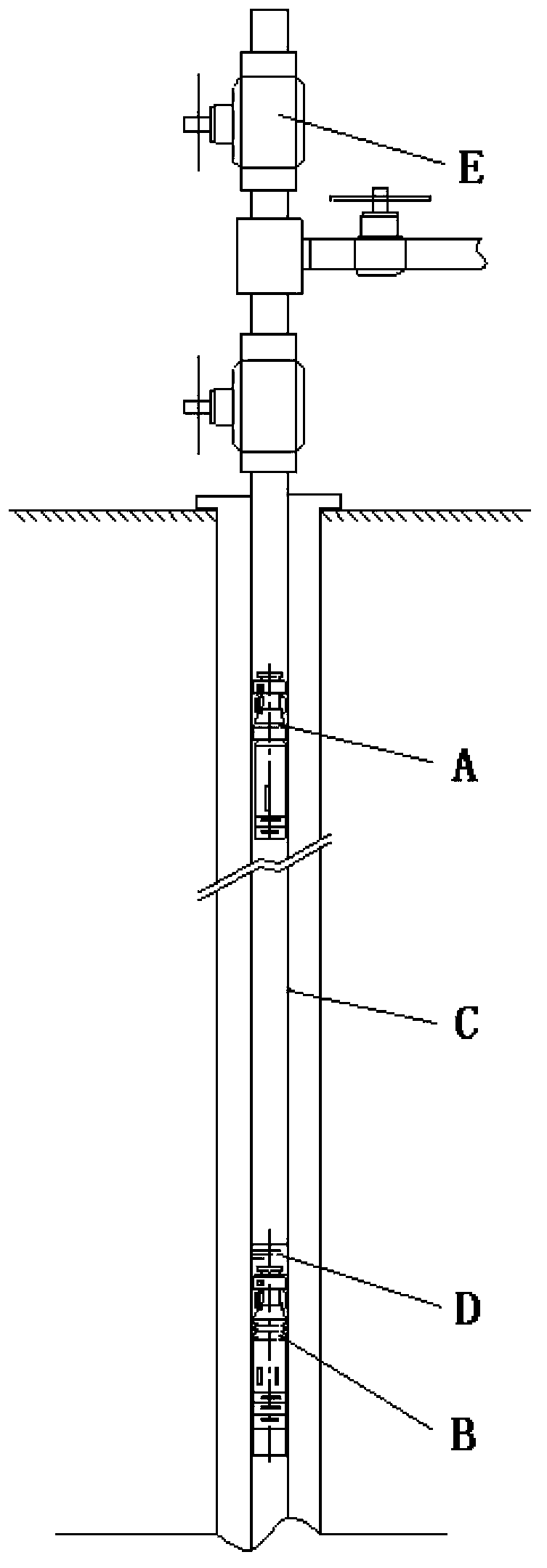

Vertical-well double-layer partial-pressure commingling method and device for coalbed methane

The invention relates to a vertical-well double-layer partial-pressure commingling method and device for coalbed methane. The method includes the steps that a pipe is arranged in the well, and three isolated channels including the first channel, the second channel and the third channel are arranged in the pipe; the side wall of the first channel and the side wall of the second channel are communicated with two coal beds respectively, gas of the two coal beds is discharged to a well opening through the first channel and the second channel respectively, liquid of the two coal beds flows to the bottom of the first channel and the bottom of the second channel respectively, and gas-liquid separation is achieved in the well; one-way valves are arranged between the first channel and the second channel and between the second channel and the third channel, and the liquid of the two coal beds is jointly drawn out of the well while accumulated liquid in the well bottom is avoided. According to the method and device, the gas and the water generated by the upper coal bed and the lower coal bed are jointly mined and jointly drawn through the single well, gas-liquid separation is carried out at the well bottom, the gas is drawn through a gas path, the liquid is drawn through a liquid path, pressure systems of the two coal beds are separated, interlayer interference generated during exploitation is reduced, and the gas yield is effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV +1

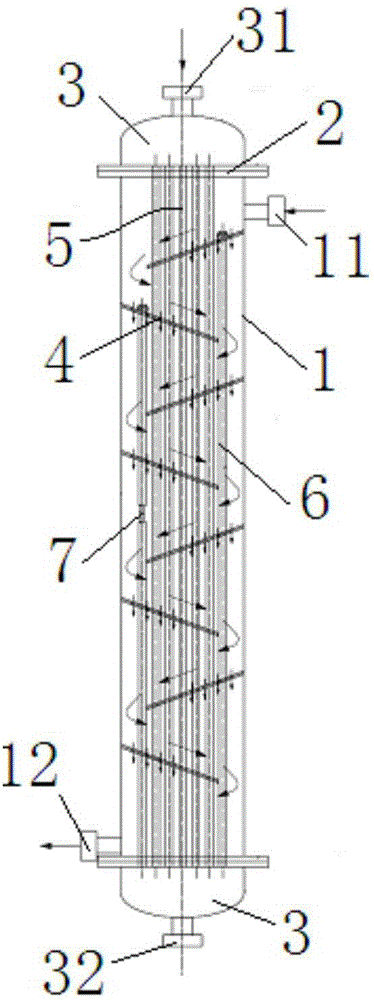

Vertical type shell-and-tube heat exchanger

ActiveCN106017136AEasy dischargeRealize a tight connectionHeat exhanger conduitsStationary conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention relates to a vertical type shell-and-tube heat exchanger. The vertical type shell-and-tube heat exchanger is characterized by comprising a vertically arranged shell; the upper end and the lower end of the shell are each connected with a channel through a tube plate; a shell side inlet tube is arranged on one side of the upper end of the shell; a shell side outlet tube is arranged on one side of the lower end of the shell; a tube side inlet tube is arranged at the top of the channel arranged at the upper end of the shell, and a tube side outlet tube is arranged at the bottom of the channel arranged at the lower end of the shell; a plurality of baffle plates provided with notches are arranged inside the shell at intervals in a staggered mode; every two adjacent baffle plates are fastened to the side walls on different sides of the shell correspondingly; passages allowing fluid to flow are formed between the baffle plates; the free end of each baffle plate is lower than the connecting end of each baffle plate; a heat exchange tube bundle penetrates through the baffle plates; and the two ends of the heat exchange tube bundle are fastened to the two tube plates. The baffle plates located on the same side of the shell are mutually parallel. An included angle between each baffle plate and the horizontal plane is 15-25 degrees. The vertical type shell-and-tube heat exchanger can prevent accumulated liquid from forming on the baffle plates, the heat exchange effect is improved, and the service life of the vertical type shell-and-tube heat exchanger is prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

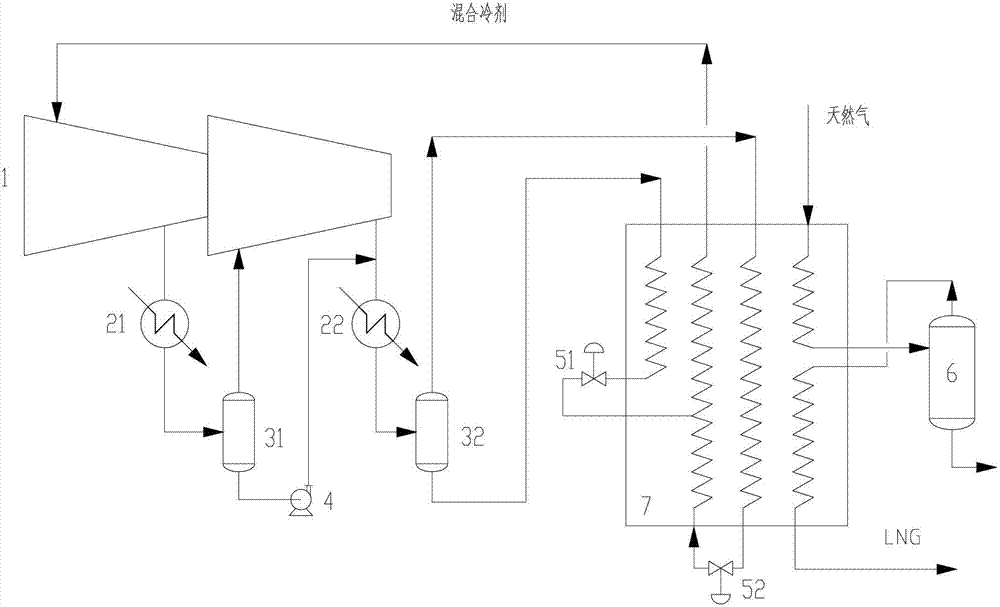

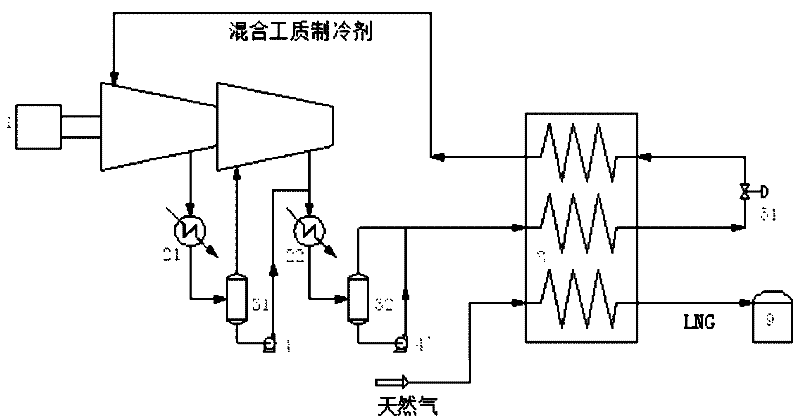

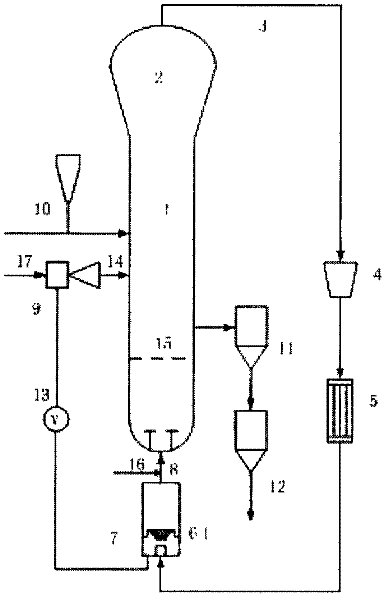

Method for refrigerating liquefied natural gas by aid of single mixed working medium and device

ActiveCN102636000AAvoid effusionImprove adaptabilitySolidificationLiquefactionVapor–liquid separatorProcess engineering

The invention relates to a method for refrigerating liquefied natural gas by the aid of a single mixed working medium and a device. The device comprises a mixed working medium compressor, a cooler, a gas and liquid separator, a throttling device, a plate-fin heat exchanger group and an LNG (liquefied natural gas) storage tank. In the technological process, mixed refrigerant is compressed and separated step by step, and gas compression power consumption is reduced. Heat exchange curves of cold fluid and hot fluid in a total heat exchange process match with each other better by the aid of multi-stage heat exchange, and flow of the mixed refrigerant is reduced effectively. In addition, the technological process is excellently adaptable to variable-load operation of the device, and liquid accumulation at the bottom of a refrigerating box can be avoided effectively.

Owner:XINDI ENERGY ENG TECH +1

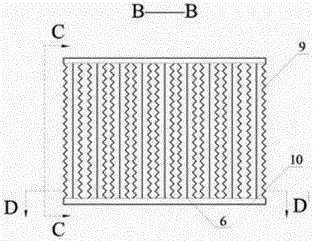

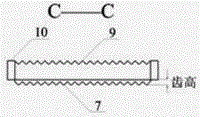

Uniform overflow type liquid distributor

InactiveCN104307192AAvoid effusionEasy to overflowEvaporator accessoriesEvaporators with horizontal tubesButt jointEngineering

The invention relates to a liquid distribution device, and particularly relates to a uniform overflow type liquid distributor used for uniformly distributing liquid on a horizontal heat exchange pipe. The liquid distributor comprises a flange, a feeding pipe, a horizontal branch pipe, a spray pipe, a folded-plate type overflow groove, a connecting channel and liquid distributing teeth, wherein the flange is arranged at a feeding opening; one end of the feeding pipe is connected with the flange, and the other end of the feeding pipe is connected with horizontal branch pipe; the spray pipe and the horizontal branch pipe are not in central butt joint, and occurrence of liquid accumulation in the spray pipe can be avoided; liquid in the overflow groove slowly increases by using the spray pipe, so that liquid overflows stably and has small fluctuation.

Owner:SHENYANG AEROSPACE UNIVERSITY

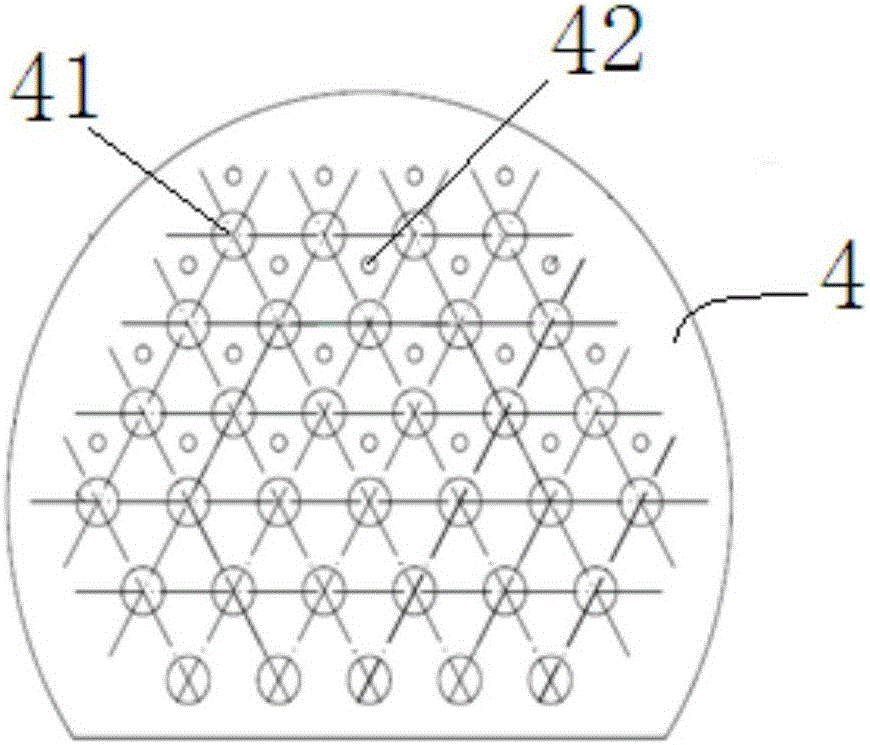

Method for using rotating-stream tray in phase-phase polyethylene process and rotating-stream tray device

ActiveCN102532359AHigh precisionIncrease flexibilityDispersed particle separationFluid phaseFluidized bed

The invention discloses a method for using a rotating-stream tray in a phase-phase polyethylene process and a rotating-stream tray device. The method comprises the following steps of: arranging a rotating-stream tray separator on a circulating pipeline, leading circulating air current out of the top of a fluidized bed, compressing, condensing, and performing gas-liquid separation in the rotating-stream tray separator to form stream which is rich in liquid phases and stream which is rich in gas phases; and spraying the stream which is rich in liquid phases into the fluidized bed from the upper part of a distributing plate, and introducing the stream which is rich in gas phases into a reactor from the lower part of the distributing plate for fluidizing a material and participating in polymerization, wherein the content of a condensate in the stream which is rich in liquid phases is 60-100 percent by weight of the total content of a condensate in a circulating air current; and the pressure drop through the rotating-stream tray separator is 1,500-6,500 Pa. According to the method and the device, the quantity of the condensate entering a fluidized bed reactor from the upper part of the distributing plate can be increased greatly, the phenomenon of liquid accumulation is avoided, the pressure drop of a gas-liquid separating device is reduced, the adjusting and controlling accuracy and ranges of the condensate quantity are increased, and the energy consumption of a system is lowered; and moreover, the form of the rotating-stream tray separator is optional, and operation is flexible.

Owner:CHINA PETROCHEMICAL CORP +2

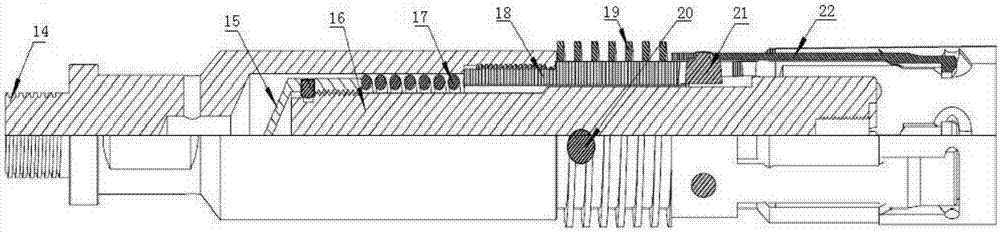

Down-hole real-time adjustable throttling technology

ActiveCN106988709AImprove efficiencyImprove effectivenessFluid removalRegular ProductionUltimate tensile strength

The invention relates to a down-hole real-time adjustable throttling technology. The technology comprises the four steps of mounting a preset working barrel; placing a preset type down-hole adjustable throttle; adjusting the preset type down-hole adjustable throttle; and refloating the preset type down-hole adjustable throttle. Wireless signal transmission and a wireless charging method are adopted by the technology, it can be ensured that the down-hole throttling technology achieving automatic real-time regulating of a throttling air tap and in-time adjusting and control of the pressure and the output, so that a gas well production is greater than a wellbore critical liquid carrying flow rate all the time, liquid loading in well bore is avoided, meanwhile the wellhead pressure of a gas well is kept in a reasonable requirement range all the time, regular production of the gas well is ensured, replacing and dismounting are not needed, and refloating is not needed; and aperture adjusting of the throttling air tap is accurate and sensitive, the technology is reliable and steady, the entire production period of a traditional gas well down-hole throttling technology is prolonged greatly, efficiency and effectiveness of down-hole throttling are improved, practicability is high, an application effect is outstanding, the entire life period of the gas well is prolonged remarkably, and strength and cost of a gas well down-hole remedial work are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

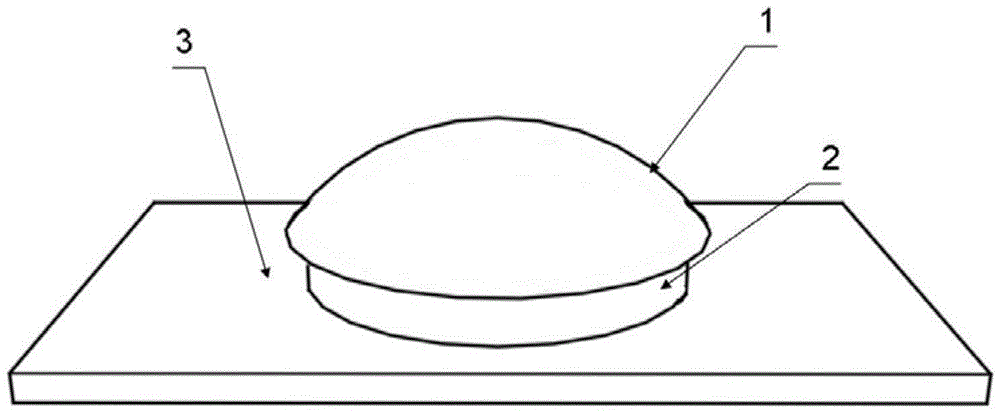

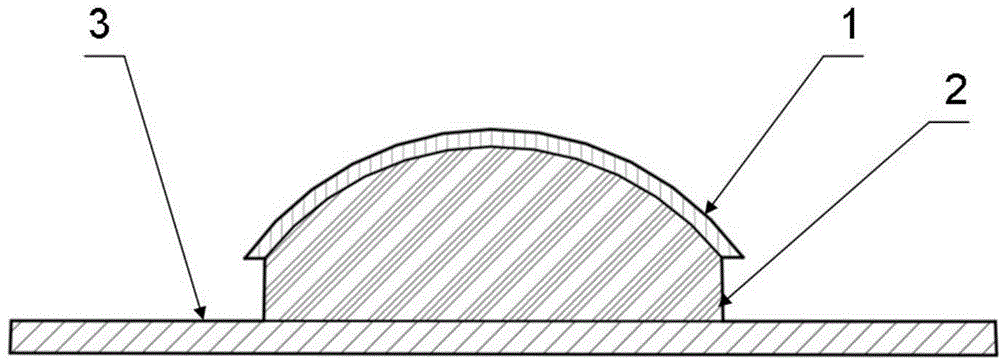

Three-dimensional nanocomposite adhesive bandage as well as preparation method and use method thereof

ActiveCN104383585ADefend against invasionNot easy to hurtAbsorbent padsNon-woven fabricsCelluloseWound dressing

The invention discloses a three-dimensional nanocomposite adhesive bandage as well as a preparation method and a use method thereof. The three-dimensional wound-protection layer of the adhesive bandage has a curved surface, and the curved surface is complementary to the uneven wound surface and comprises a nanobacterial cellulose frozen-dried membrane and an eletrospun chitosan-containing nanofiber film. The three-dimensional wound-protection layer can carry a part of liquid medicine. When in use, the adhesive bandage fully fits the wound surface, has air permeability, can keep the wound surface wet, has the functions of stop bleeding, inhibiting bacteria, promoting the healing of a wound and preventing the adhesion of the wound surface to the wound dressing and can be used widely. The adhesive bandage can well fit the concave wound surface and the convex wound surface, is applicable to the wet wound surface with many exudates, the dry wound surface which needs to be wetted by the wound dressing and the potential wound surface which needs protection, thereby being an ideal wound dressing.

Owner:SHANDONG PROVINCIAL HOSPITAL

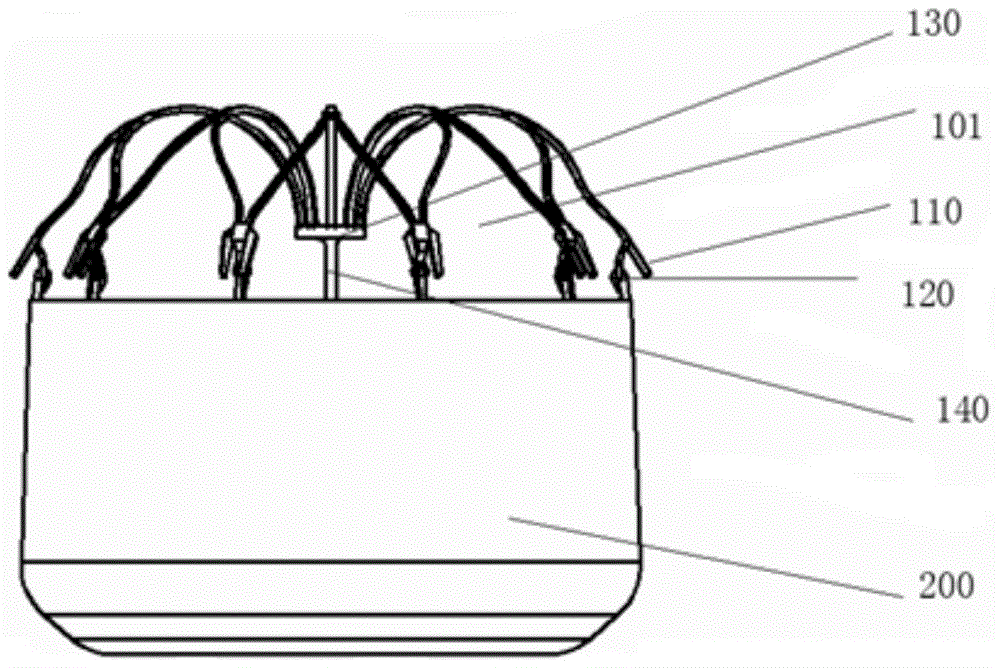

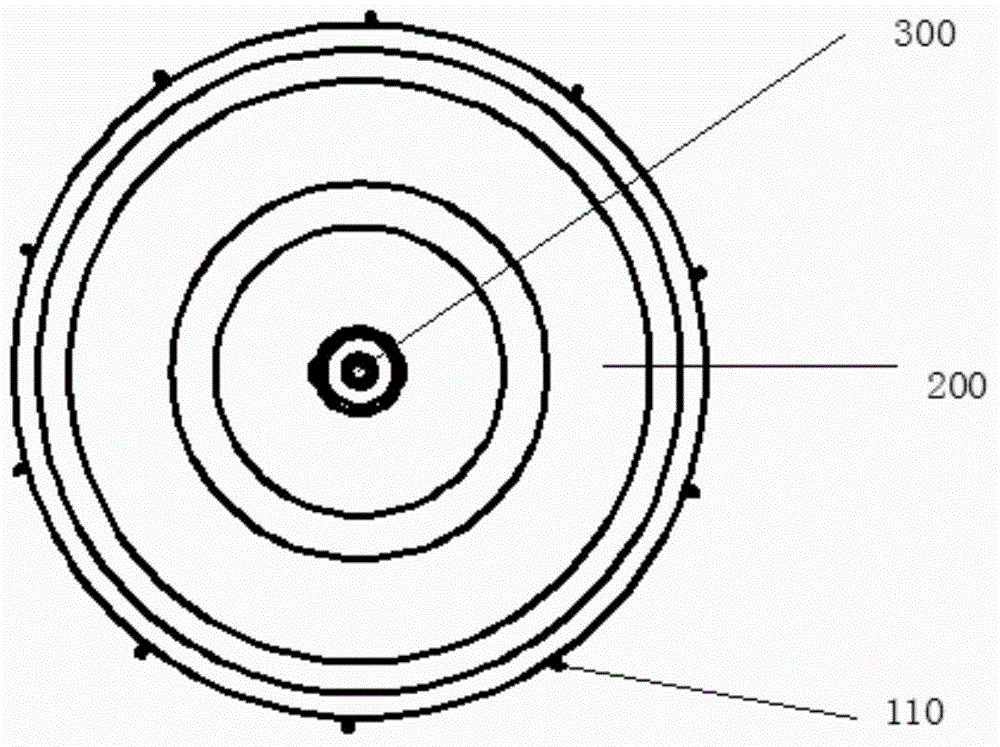

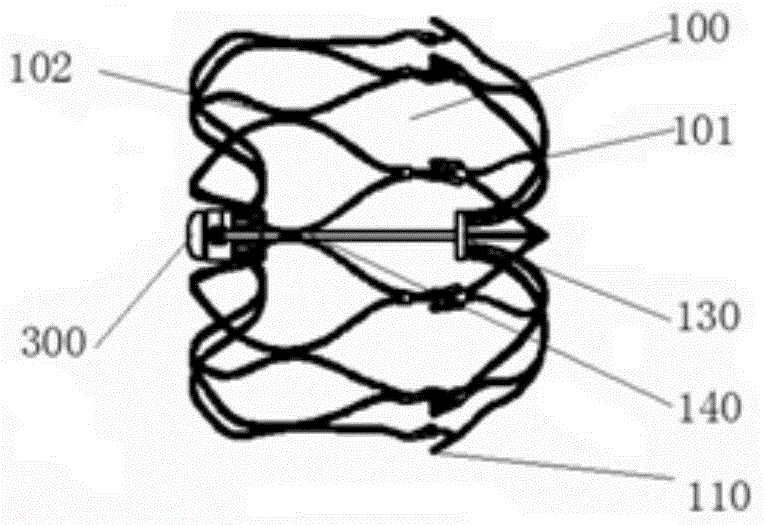

Left atrial appendage plugging device and plugging system

The invention relates to the field of medical instruments, and discloses a left atrial appendage plugging device which comprises a support skeleton e and a choke membrane; the support skeleton is a hollow near-spherical body having elasticity; the choke membrane is cap-shaped and is arranged on the proximal periphery of the support skeleton; an anchor thorn is arranged on the distal circumference of the support thorn, and is used for grasping on the inner wall of a left atrial appendage. The invention further discloses a left atrial appendage plugging system which comprises a conveying device and the left atrial appendage plugging device mentioned in the technical scheme above; the conveying device comprises a conveying sheath and a push rod; the left atrial appendage plugging device is arranged in the conveying sheath; one end of the push rod is arranged in the conveying sheath, and is detachably connected with the fixed end of the left atrial appendage plugging device. According to the left atrial appendage plugging device and system, the damage to vascular access can be reduced so as to reduce the operation risk.

Owner:SHANGHAI SHAPE MEMORY ALLOY

Water source heating-air conditioning-hot water three-way set

InactiveCN101592418AAvoid effusionRealize the heating functionEnergy recovery in ventilation and heatingFluid heatersEngineeringCheck valve

The invention relates to a water source heating-air conditioning-hot water three-way set. The asymmetric phase change rate with magnitude difference among parallel heat exchangers is formed by switching on and switching off the driving force of a refrigerating medium side and matching the guiding of a check valve of a refrigerant side to radically replace an electromagnetic valve switch refrigerant loop; and five functions of heating, air conditioning, hot water, air conditioning and hot water (an ordinary type / an energy saving type), and the like are realized in a mode of simpler structure, lower cost, more reliable operation and higher efficiency. The water source heating-air conditioning-hot water three-way set accords with a natural law of 'Dujiang Dam' action through inaction, radically eliminates hidden trouble of lack of fluorine of heat exchanger operation caused by stopping using refrigerant fluid stored in the heat exchanges in the prior three-way set, and is favorable for home application of products.

Owner:合肥天鹅制冷科技有限公司

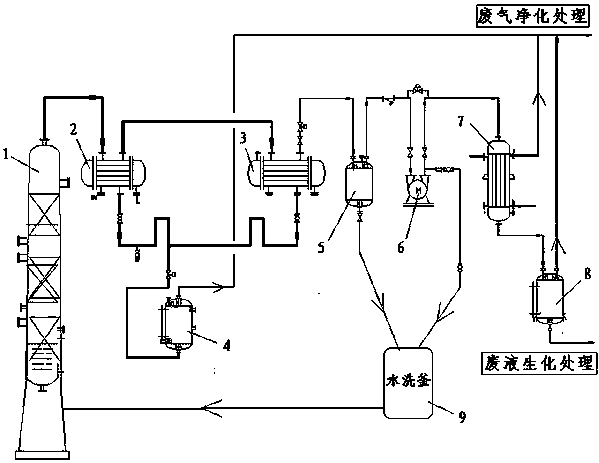

Trimethyl phosphite continuous reduced-pressure rectifying technology

InactiveCN107840858AReduce wearHigh tail gas recovery rateGroup 5/15 element organic compoundsExhaust gasSalt water

The invention discloses a trimethyl phosphite continuous reduced-pressure rectifying technology. A first-level water cooling condenser and a second-level salt water condenser are arranged at the top of a rectifying tower; a gas phase temperature at the top of a control tower is lower than 0 DEG C; after two levels of condensation, the gas phase is demisted by a demister and finally enters a vacuumpump; pressures in the control tower and the rectifying tower are negative pressures. After being condensed by the first-level condenser and the second-level condenser, liquid enters a rectifying reflux tank; the liquid after third-level condensation enters a receiving tank. The technology disclosed by the invention remarkably reduces loss of trimethyl phosphite, has high yield, lowers abrasion of the vacuum pump and realizes high recovery rate of tail gas.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

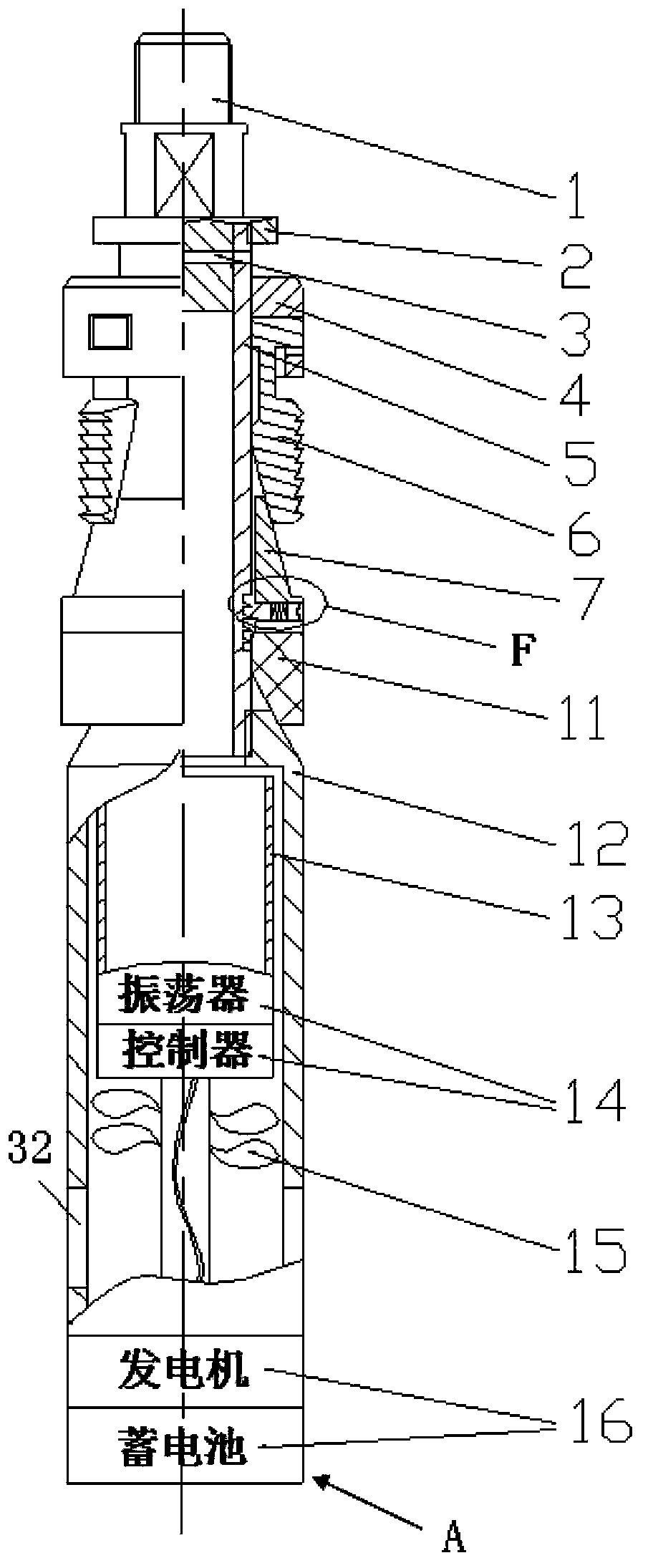

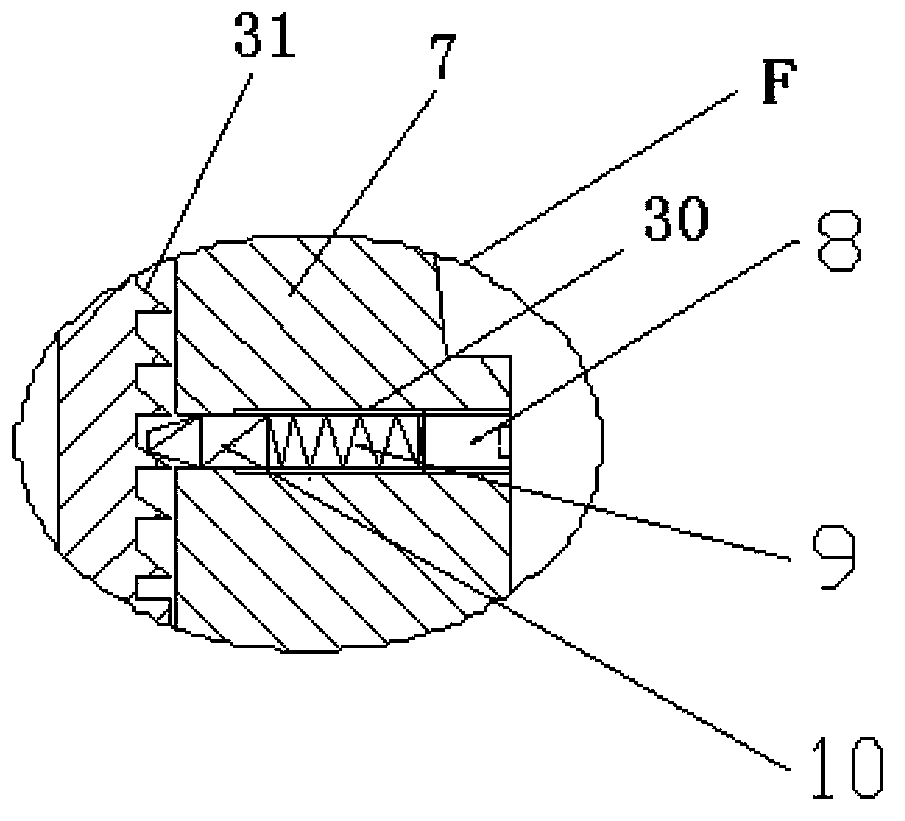

Gas well downhole multistage ultrasonic atomization water drainage and gas production device

ActiveCN103628841ATimely collectionAvoid effusionFluid removalLiquid spraying apparatusUltrasonic atomizationWellbore

The invention discloses a gas well downhole multistage ultrasonic atomization water drainage and gas production device, and belongs to the field of oilfields. The device is arranged in a shaft and comprises a downhole self-power-generation ultrasonic atomization device and a floating type self-power-generation ultrasonic atomization device; the downhole self-power-generation ultrasonic atomization device is arranged in the position where condensed liquid starts to appear in the shaft, and the downhole self-power-generation ultrasonic atomization device is used for timely collecting the condensed liquid starting to drop and atomizing the condensed liquid in liquid phase into small liquid drops; the floating type self-power-generation ultrasonic atomization device is arranged below the liquid level at the bottom of the shaft and used for atomizing the condensed liquid dropped in the shaft in the liquid phase. According to the device, the downhole self-power-generation ultrasonic atomization device and the floating type self-power-generation ultrasonic atomization device can generate power by themselves under the effect of airflow in the shaft, external power sources are not needed, the condensed liquid in the liquid phase can be dispersed into droplets and drained out of the shaft, wherein the droplets can be carried by the airflow at a certain flow rate and are small in diameter, and therefore energy can be greatly saved.

Owner:PETROCHINA CO LTD

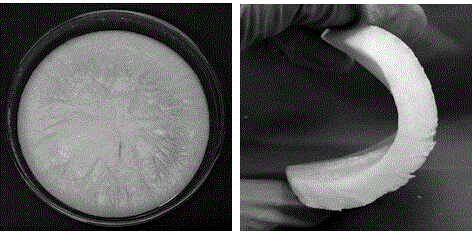

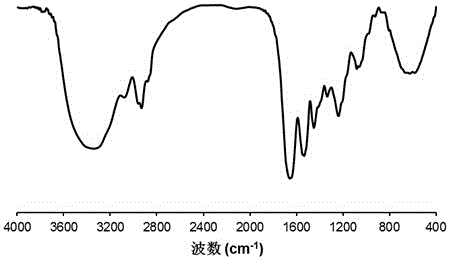

Feather keratin-based biopolymer external application material and preparation method thereof

ActiveCN105879101AGood flexibilityEliminate wound odorPharmaceutical delivery mechanismAbsorbent padsPlasticizerKeratin protein

The invention provides preparation of a feather keratin-based biopolymer external application material. The preparation method comprises the steps that feather keratin is dissolved into dispersion liquid to prepare a feather keratin solution; gelatin is dissolved into distilled water and then added into the feather keratin solution, and the solutions are mixed to be uniform under stirring at room temperature; a condensing agent is added, stirring is conducted, then a condensing auxiliary is added, the pH value of the system is regulated to be 5-7, and stirring is continuously conducted; a plasticizer is added, and reacting under stirring is conducted for a certain time; after reacting is finished, dialyzing is conducted with distilled water for 18-36 h under the dark condition, freeze drying is conducted, and then the biopolymer external application material is obtained. The biopolymer external application material is a spongy solid material, and a microporous sheet structure is arranged in the material; the good flexibility, adsorptivity, water-retaining property and vapor permeability are achieved. Antibacterial property and external releasing research shows that the material has the good bacteriostatic property and the quick releasing effect on micromolecular model drugs and is expected to be applied to the biomedicine field by serving as a quick sterilizing and inflammation diminishing external application material for acute wounds.

Owner:大有药业扬州有限公司

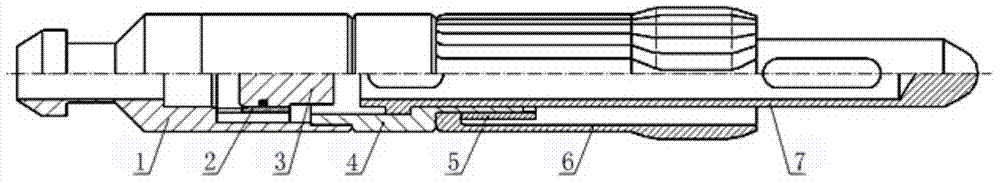

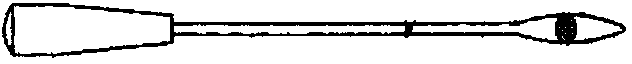

Moving plunger for gas well production with water withdrawal

InactiveCN104500020AAvoid effusionImprove production conditionsPositive displacement pump componentsFlexible member pumpsProduction rateWater withdrawal

The present invention provides a moving plunger for gas well production with water withdrawal which is simple in structure and good in accumulated fluid withdrawal effect. The moving plunger comprises a fish head, a sealing rod in the fish head, a retaining sleeve which is arranged between the fish head and the sealing rod and used for limiting the movement range of the sealing rod, wherein the lower part of the fish head is screwedly connected with an outer sleeve, a drop bar is movably arranged in the outer sleeve; and the outer part of the outer sleeve is sleeved with an elastic sealing claw. The tool vertically floats due to the pressure in well, so that the shaft accumulated fluid is lifted and discharged through a well opening, and finally natural gas is developed or water flooding of other gas wells in the same air reservoir is delayed and avoided, so as to improve the production state of the whole air reservoir and increase the final production rate of the air reservoir. The moving plunger has features of simple structure, good accumulated fluid withdrawal effect, long service life, and achieves the purpose of gas production and yield increase.

Owner:BEIJING JINKELONG PETROLEUM TECH DEV

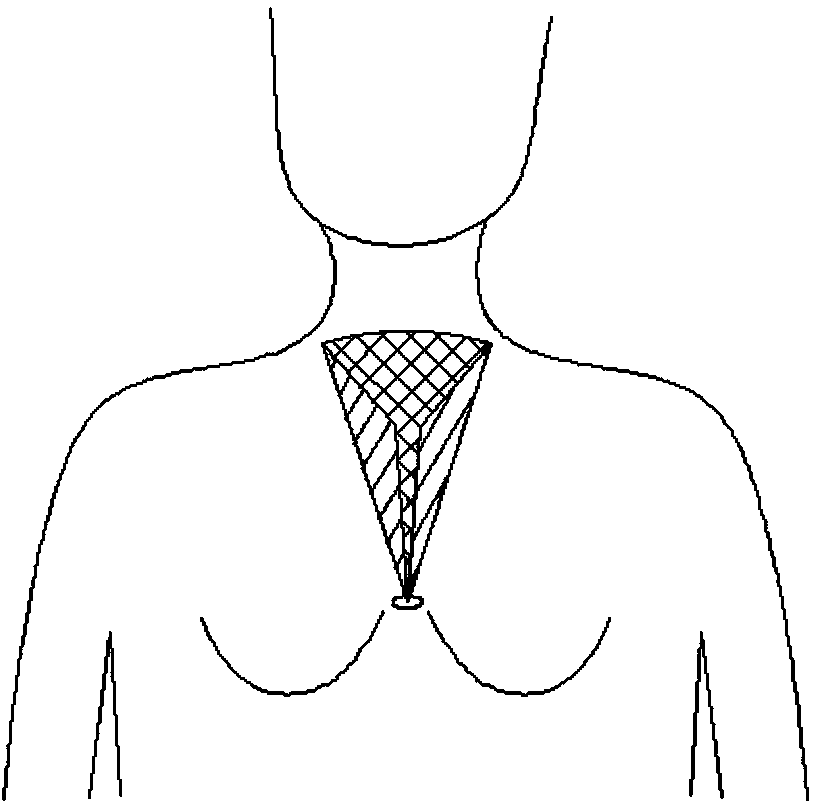

Spatial dilator for endoscopic thyroidectomy

The invention discloses a spatial dilator for endoscopic thyroidectomy. The spatial dilator comprises a sleeve, a push rod capable of telescoping along the axial direction is arranged in the sleeve, a button matched with the push rod and capable of pushing the push rod to telescope is arranged outside the sleeve, the left side of an extending end of the push rod is movably connected with one end of a left connecting rod blade, and the right side of the same is movably connected with a right connecting rod blade. The other ends of the left connecting rod blade and the right connecting rod blade are respectively connected with a left cutter and a right cutter which are movably connected with ends of the sleeve. The other end of the push rod is connected with a handle. By the spatial dilator for endoscopic thyroidectomy, hurt to breast skin of patients is reduced, operation is simplified, and operation time can be effectively shortened.

Owner:SHANDONG UNIV QILU HOSPITAL

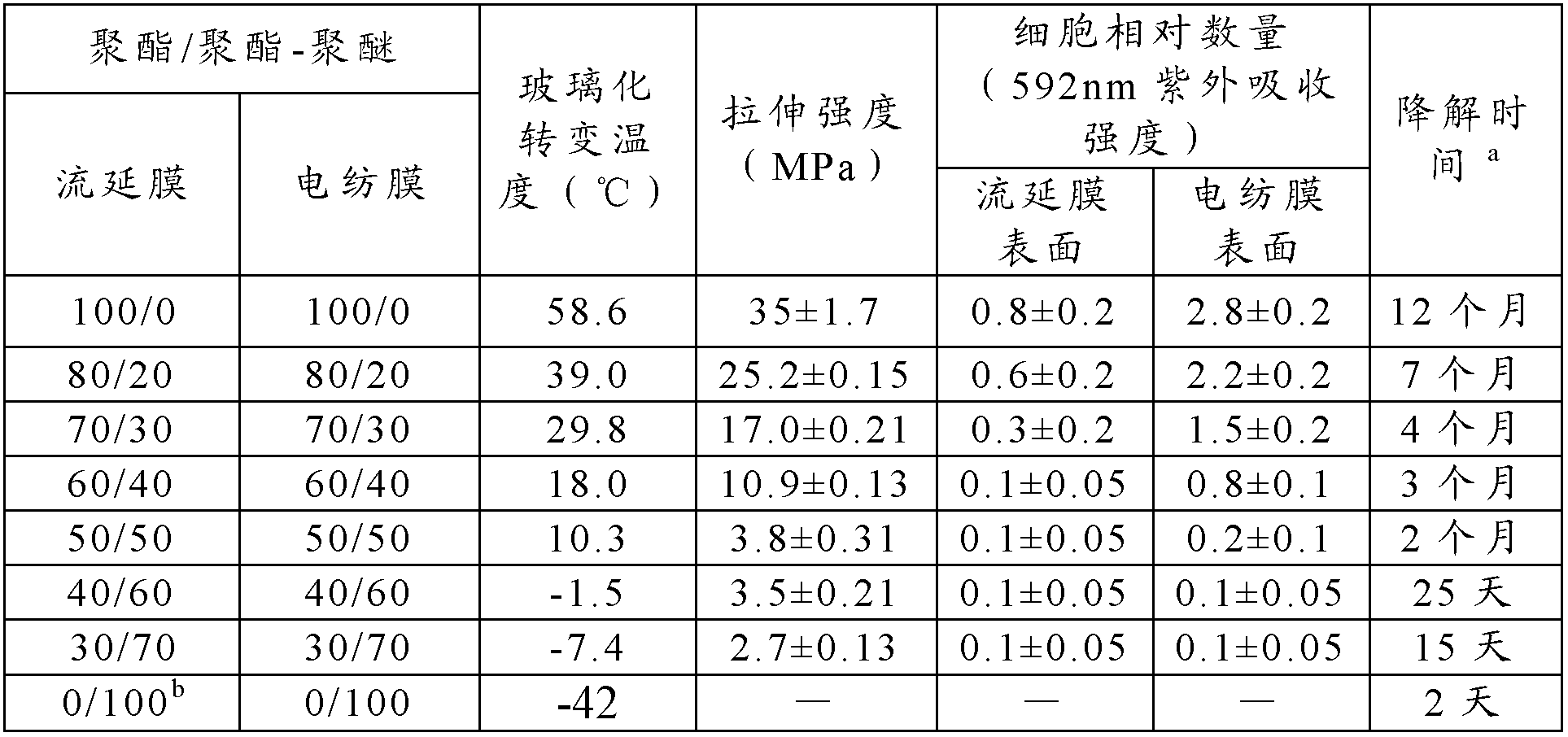

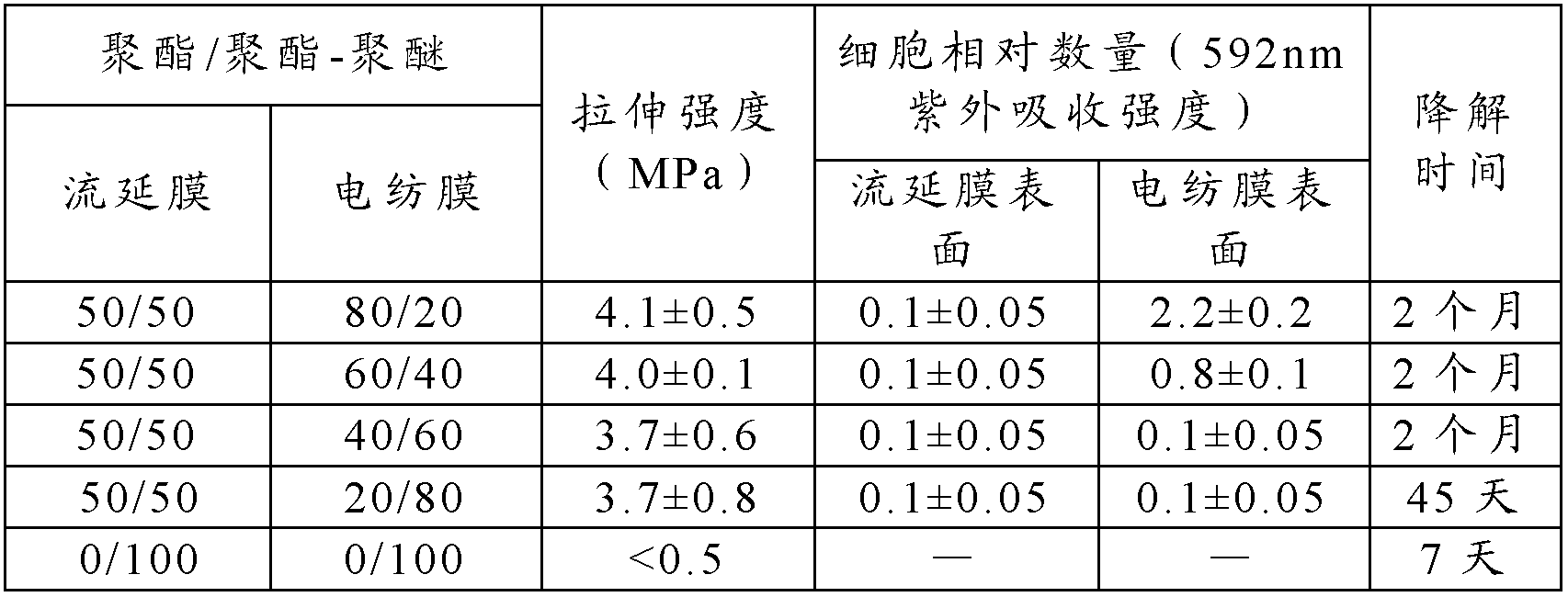

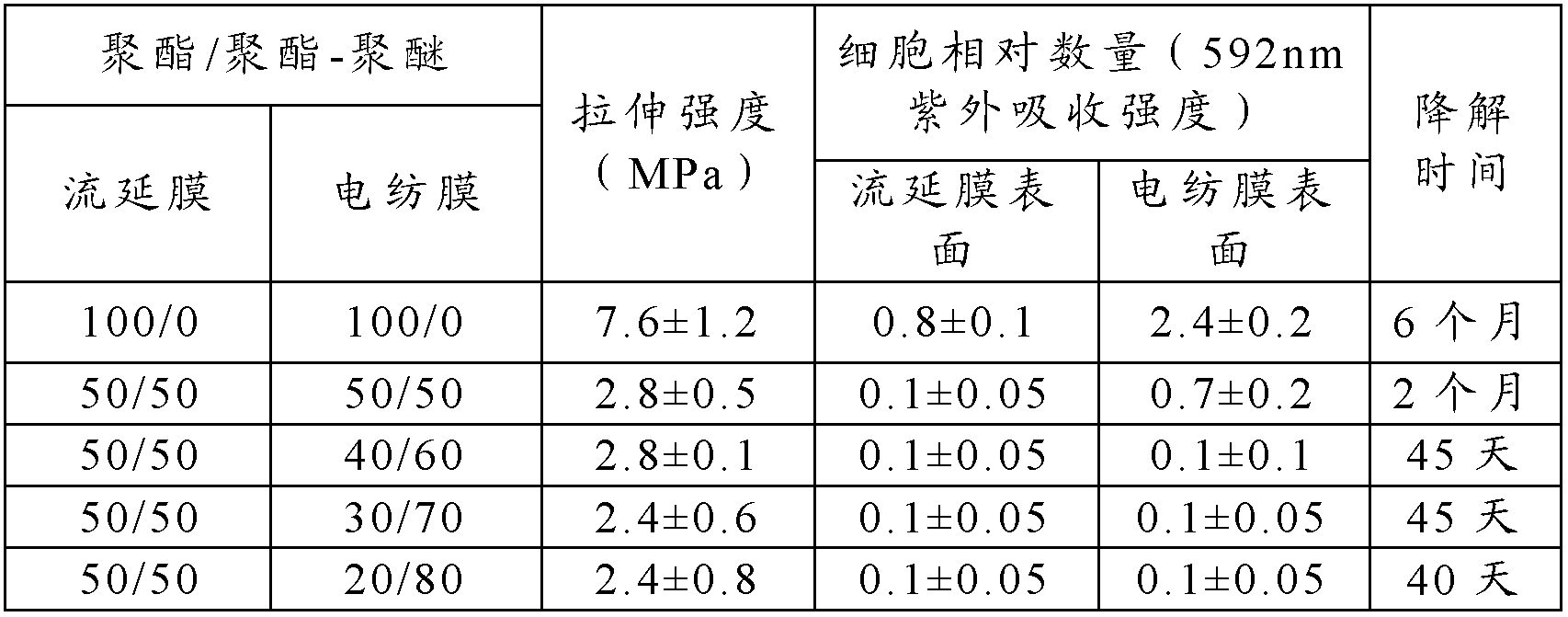

Degradable anti-adhesion compound membrane and preparation method thereof

The invention discloses a degradable anti-adhesion compound membrane which has two layers, wherein one layer of the anti-adhesion compound membrane is a base membrane, and the other layer of the anti-adhesion compound membrane is an electrospinning film; a material of the base membrane and the electrospinning film is a blending material of polyester-polyether copolymer and polymer; and the blending material comprises the following components in percentage by weight, 10%-90% of polyester and 10%-90% of polyester-polyether copolymer. The anti-adhesion compound membrane can be excellently attached to tissues and has a good inhibition effect on fibroblasts, so that the tissues can be effectively isolated and the anti-adhesion effect is achieved. The invention further discloses a preparation method for the anti-adhesion compound film, and the electrospinning membrane of the prepared compound membrane has micro-grade holes and can be effectively attached to the tissues.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

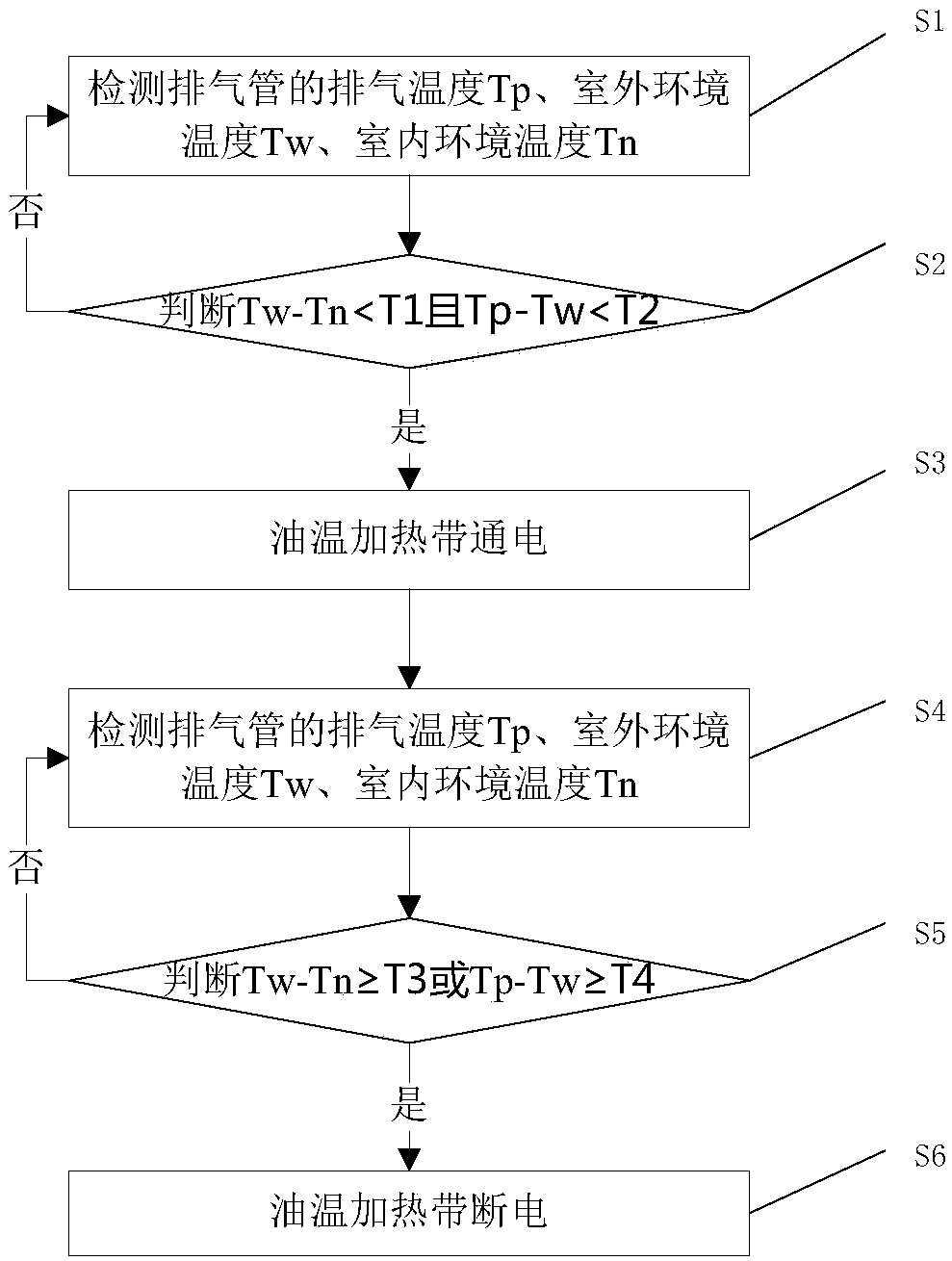

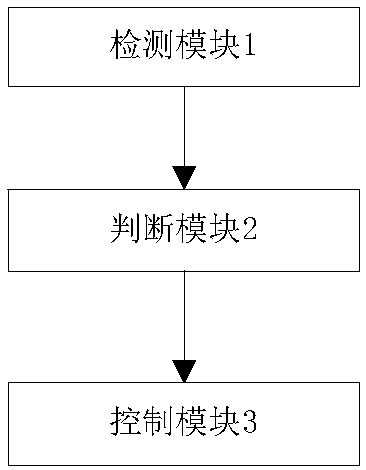

Oil temperature heating belt control method and air conditioner

ActiveCN109424547AExtended service lifeSatisfy the requirement of no effusionRotary/oscillating piston pump componentsLiquid fuel engine componentsElectricityStandby power

The invention discloses an oil temperature heating belt control method and device. The control method comprises the following steps that the exhaust temperature Tp, outdoor ambient temperature Tw andindoor ambient temperature Tn of an exhaust pipe are detected; whether the difference between Tw and Tn is less than the preset temperature T1 or not is judged, and whether the difference between Tp and Tw is less than the preset temperature T2 or not is judged; when Tw-Tn is smaller than Ti and Tp-Tw is smaller than T2, an oil temperature heating belt is controlled to be energized; when the oil temperature heating belt is energized, Tp, Tw and Tn are detected continuously; whether Tw-Tn is larger than or equal to T3 or not or Tp-Tw is larger than or equal to T4 or not is judged; and when Tw-Tn is larger than or equal to T3 or Tp-Tw is larger than or equal to T4, the oil temperature control heating belt is controlled to be powered off, and a regulation process is completed. By means of thecontrol method, on-demand starting is realized, unnecessary power consumption of the air conditioner is reduced, standby power of the air conditioner is reduced, energy conservation is improved, andthe service life of the oil temperature heating belt is prolonged.

Owner:NINGBO AUX ELECTRIC

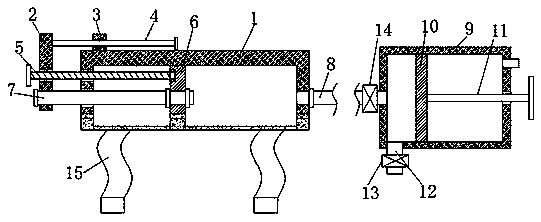

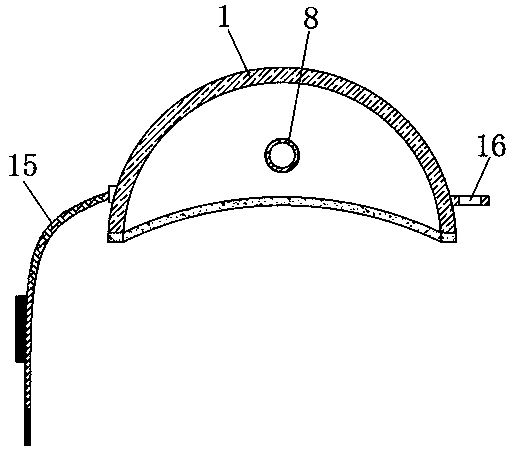

General surgery anti-effusion type wound irrigator

The invention discloses a general surgery anti-effusion type wound irrigator. The irrigator comprises a flushing cover, the flushing cover is arranged in a semi-cylindrical hollow structure, one end of the flushing cover is provided with a connecting plate, one end, close to the connecting plate, of the outer side wall of the flushing cover is fixedly connected to a fixing ear, a limiting rod is fixedly connected to the top of the side, close to the flushing cover, of the connecting plate, the limiting rod is slidably mounted on the fixing ear, a screw rod is connected in the middle of the side wall of the connecting plate, one end, close to the flushing cover, of the screw rod threadly penetrates through the side wall of the flushing cover and extends to the flushing cover and is rotatably connected with a moving plate, the moving plate fits the inner wall of the flushing cover, the moving plate is slidably mounted in the flushing cover, and an inlet tube is fixedly connected betweenthe side wall borrom of the connecting plate and the moving plate. The irrigator has novel structure and convenient operation, can control and adjust the size of the cleaning area, can timely extracta used cleaning liquid to avoid liquid accumulation, and provides convenience for medical staff to clean up after and during operation.

Owner:王京涛

Application of skin care composition

ActiveCN108578279ASolve insufficient resourcesEasy to getCosmetic preparationsToilet preparationsCourse illnessDiabetic foot

The invention discloses application of a skin care composition in diabetic foot care or sutured wound surface care. The skin care composition is comprised from, in percentage by weight, the followingcomponents: 1%-20% of a film-forming agent, 0.5%-10% of a thickener, 0.5%-10% of a plasticizer, 0.01%-2% of a bacteriostatic agent, 0.01%-2% of a skin-conditioning agent and the balance of solvent. After the skin care composition is applied on the skin, a transparent thin film with suitable tenacity and strength can be formed, the transparent thin film further has good wet fastness, abrasion resistance, water resistance and antibacterial activity, therefore, the damaged skin can be isolated from the outside world, is not prone to be damaged by abrasion or infected by pathogenic bacteria, remains moist and is not prone to chap, and thus damaged skin healing is facilitated; thus a very good effect of protecting diabetic feet and a sutured wound surface can be achieved, a hard-to-heal wound surface of the foot skin of a diabetic patient is prevented, and disease cause development of the diabetic feet is blocked to a certain extent; meanwhile, deterioration of a sutured wound of the sutured wound surface can be prevented, healing of the sutured wound is facilitated, and it is convenient to observe the healing condition of the wound surface.

Owner:广州昕生医学材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com