Patents

Literature

31results about How to "Avoid interlayer interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Longitudinally superposed developing three-strata oil reservoir well pattern and deployment method thereof

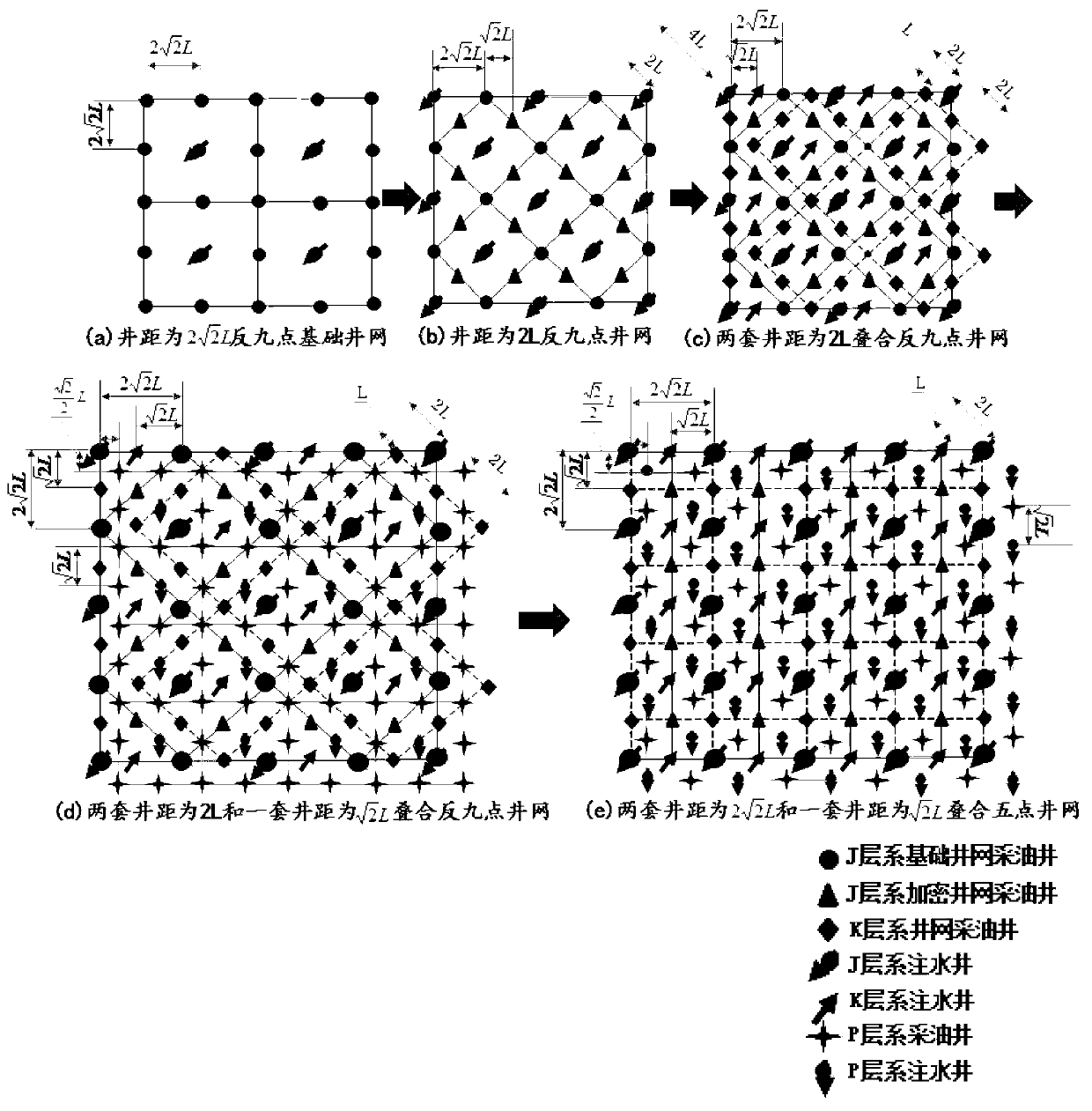

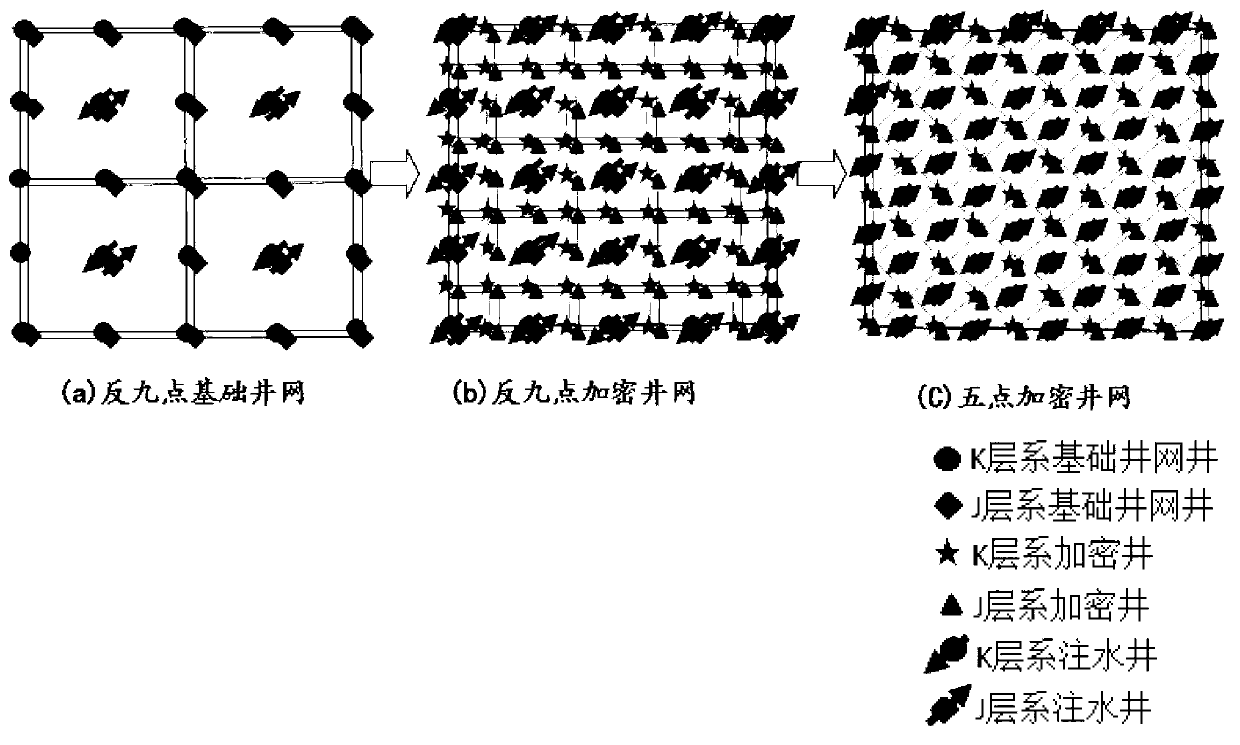

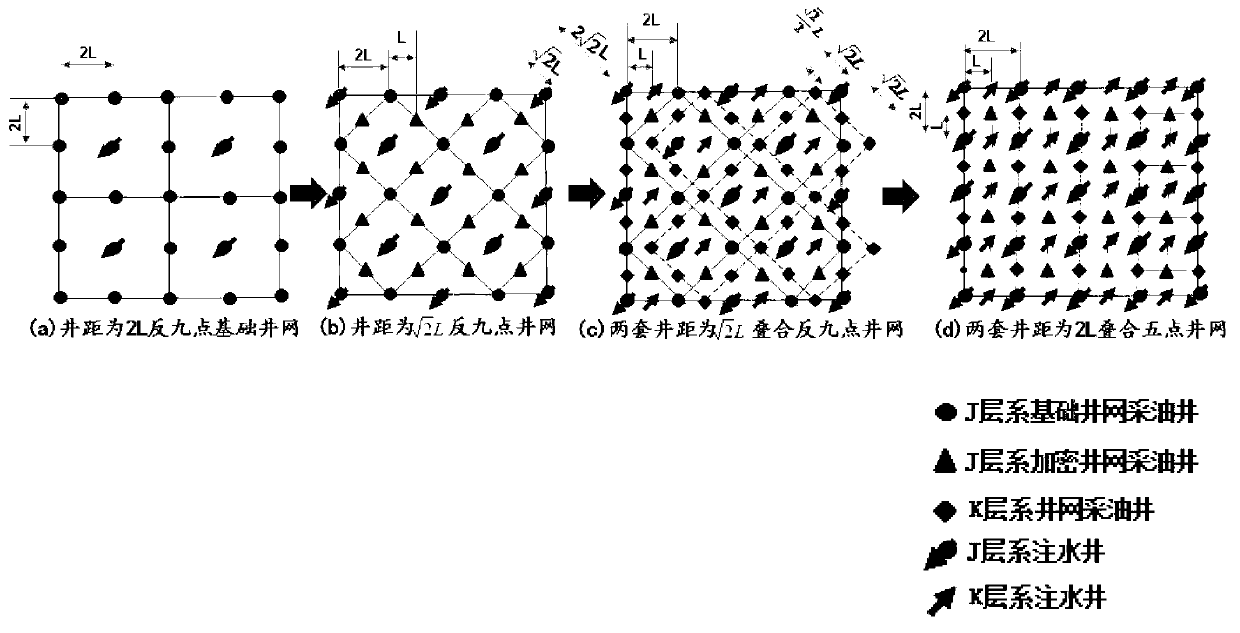

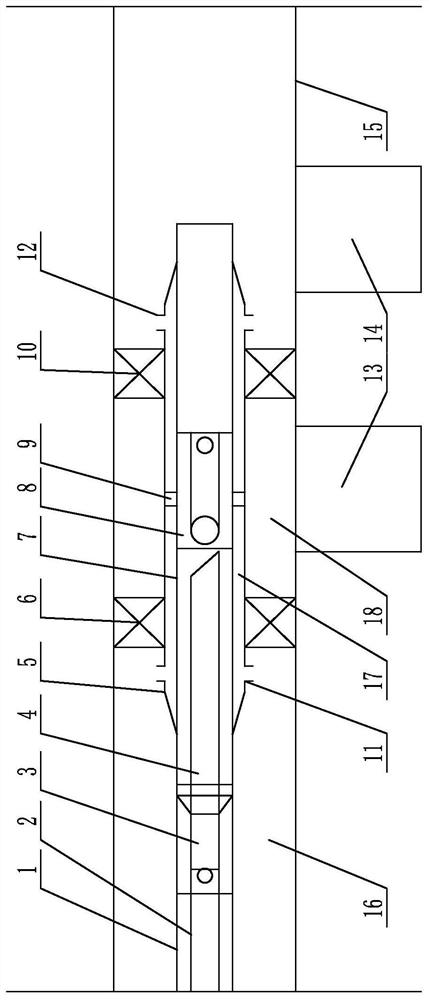

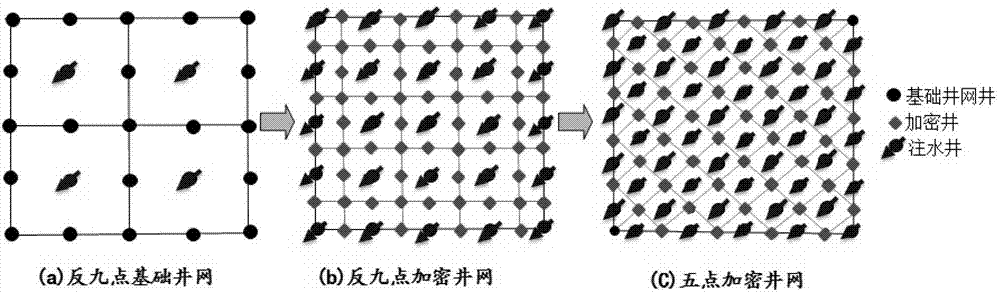

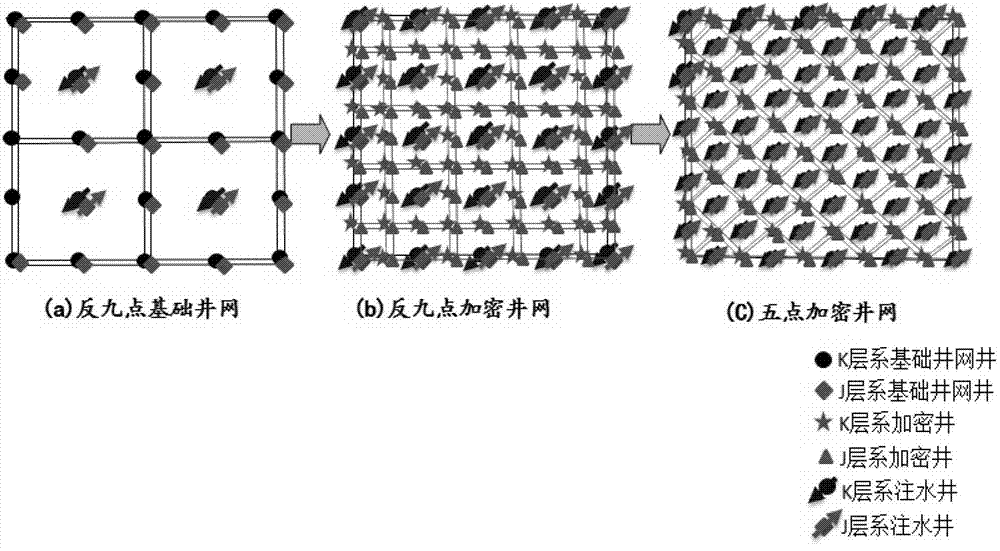

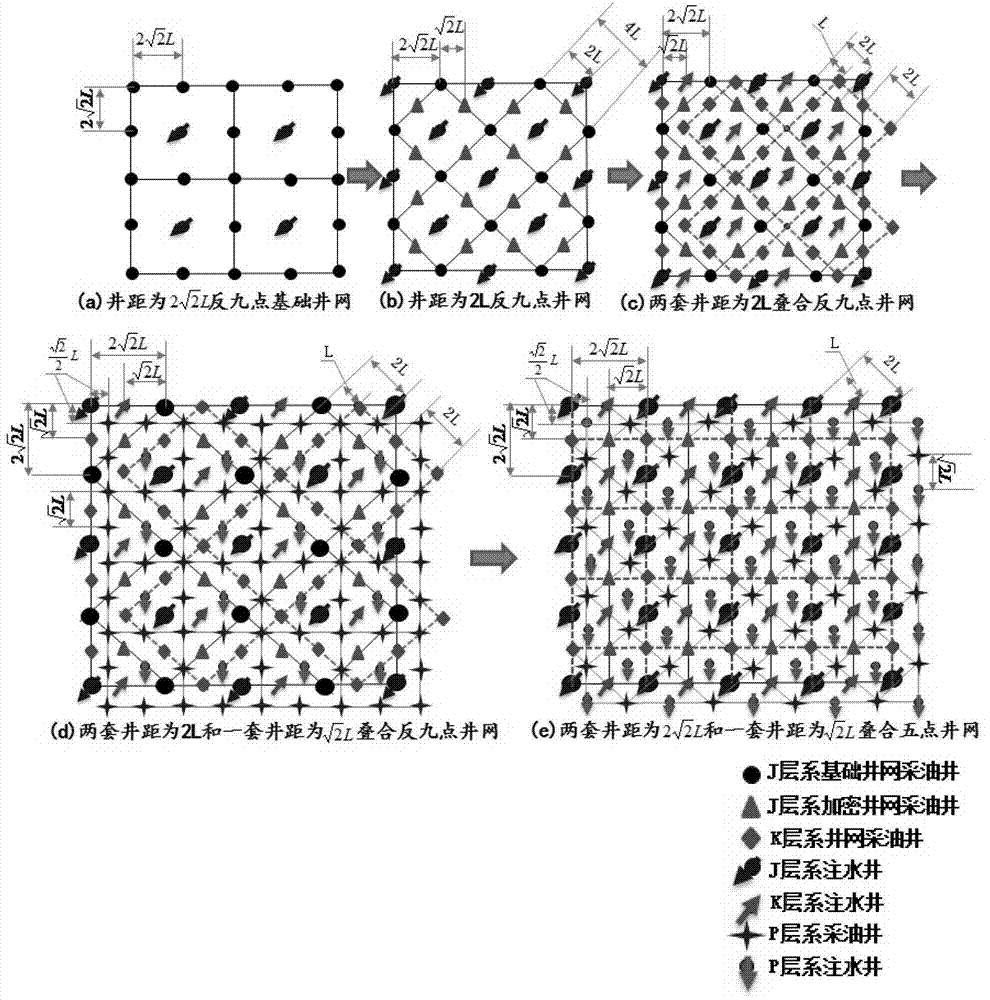

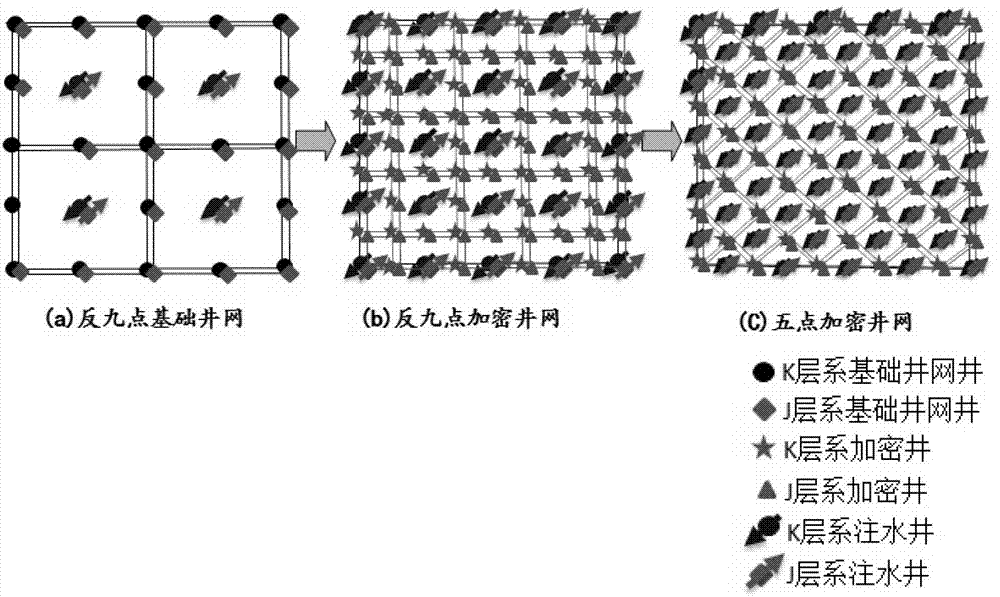

The embodiment of the invention discloses a longitudinally superposed developing three-strata oil reservoir well pattern and a deployment method of the longitudinally superposed developing three-strata oil reservoir well pattern. To the longitudinally superposed developing three-strata oil reservoir, the well spacing of a basic well pattern is 2*(square root of 2)*L; after being encrypted once, the well spacing of a middle transitional well pattern is 2L; after being encrypted twice, two superposed inverted nine-spot well patterns with well spacing of 2L are formed; after being encrypted for three times, two superposed inverted nine-spot well patterns with well spacing of 2L and one superposed inverted nine-spot well pattern with well spacing of (square root of 2)*L are formed; and after pairwise alternatively development, the well spacing of the plane well pattern of each strata has a rational well spacing of L; the evolution process of the well spacing is as follows: 2*(square root of 2)* L to 2L to (square root of 2)*L to L; the middle process of well patterns conversion with a well spacing of 2L and (square root of 2)*L is added; at the same drilling speed, well placement uniformity coefficient and reserve control speed are increased; the well spacing is encrypted in the alternation of well patterns; each well pattern can realize order development to each longitudinal strata; the utilization ratio of the well patterns is improved; meanwhile, the oil reservoir is uniformly used, so that the method is in favor of increasing accumulated oil production of an oil field and improving the recovery ratio; and interlayer interference generated by commingled extracting oil in multiple oil layers of longitudinal series of strata is avoided.

Owner:PETROCHINA CO LTD

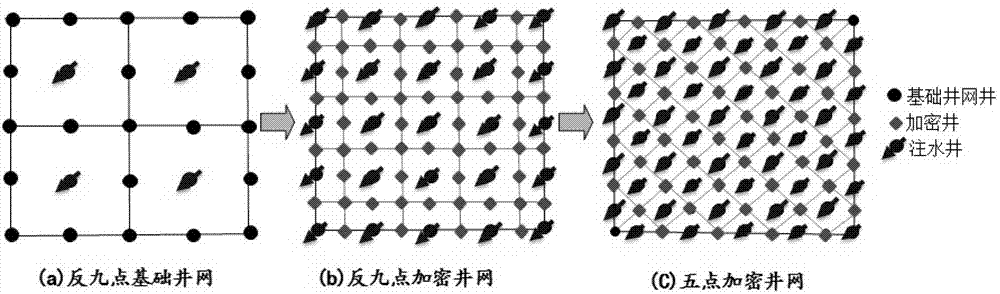

Longitudinally superposed developing two-strata oil reservoir well pattern, and arrangement method of two-strata oil reservoir well pattern

ActiveCN102839959AReduce developmentIncrease profitFluid removalWell drillingLongitudinal development

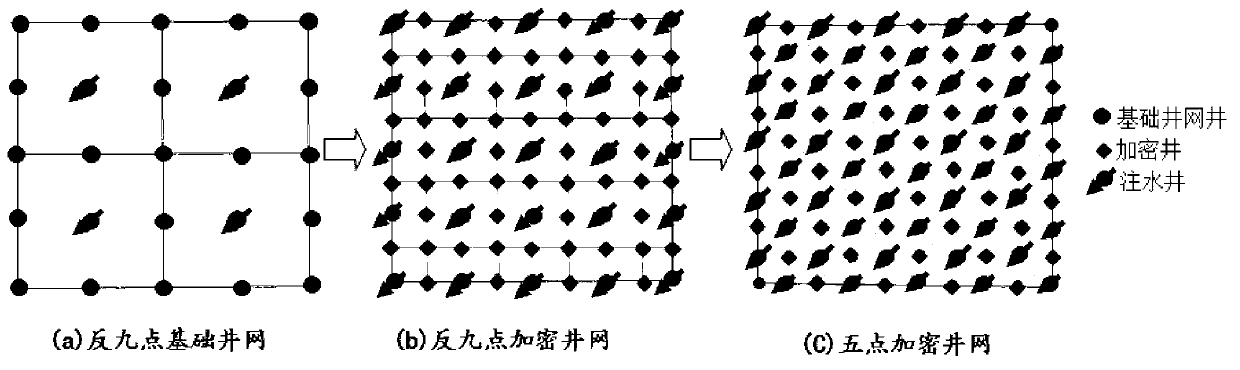

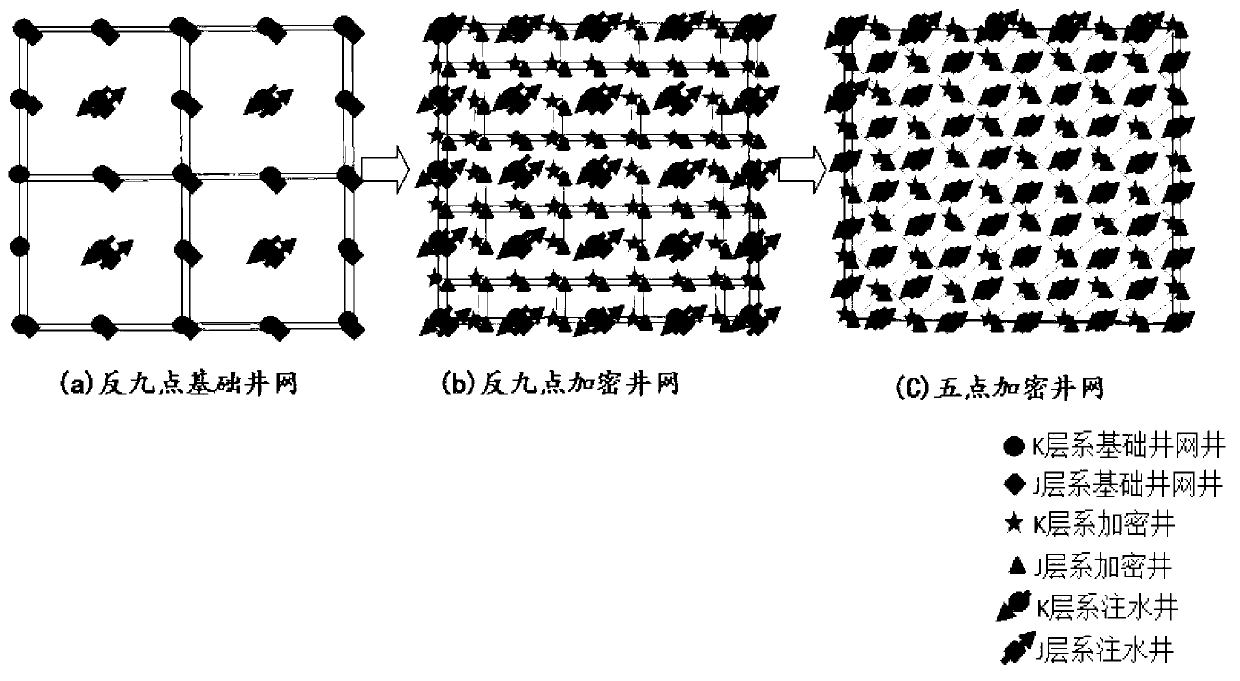

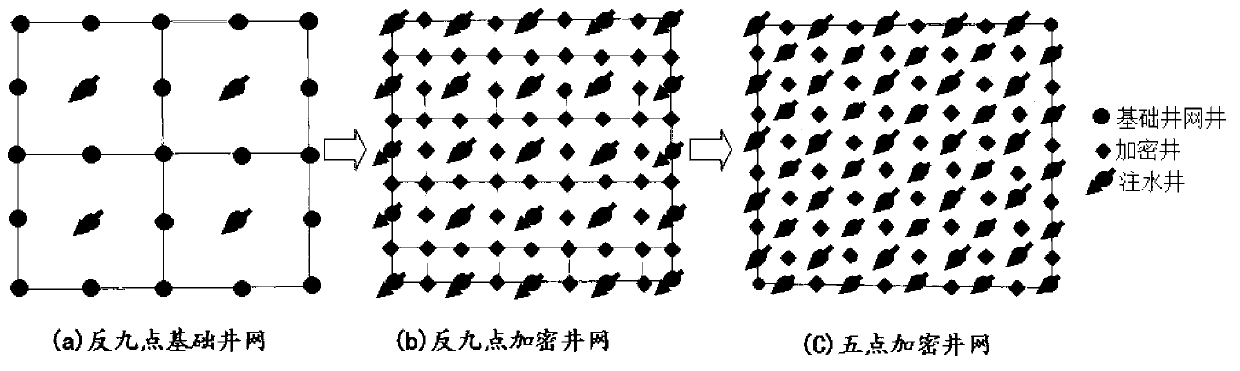

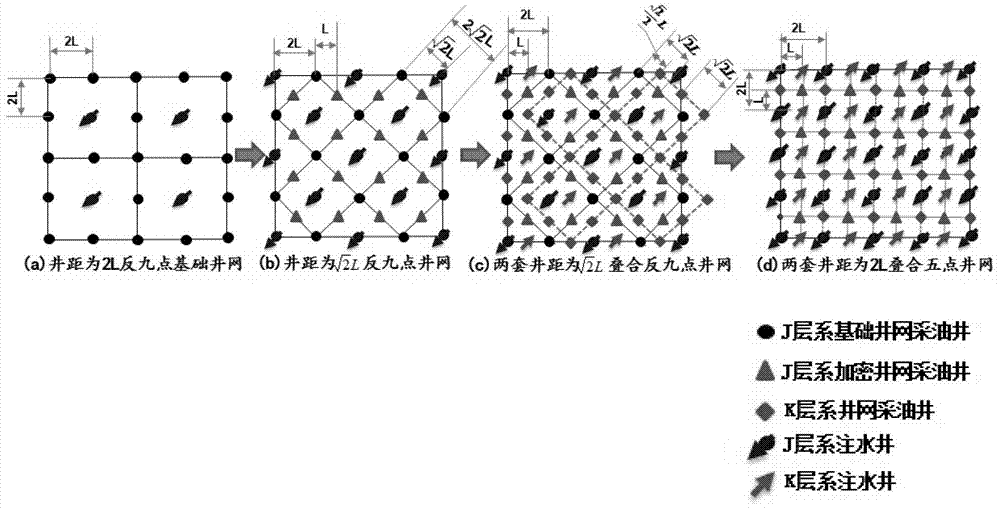

The embodiment of the invention discloses a longitudinally superposed developing two-strata oil reservoir well pattern, and an arrangement method of the two-strata oil reservoir well pattern. The method comprises the following steps: firstly determining the longitudinal development strata of the oil reservoir and the rational well distance, and determining the well spacing of a basic well pattern and the well spacing of a middle transitional well pattern according to the longitudinal development layer coefficient. According to the longitudinally superposed developing two-strata oil reservoir, the well spacing of the basic well pattern is 2L, after being encrypted once, the well spacing of a middle transitional well pattern is square root of 2 times L; after being encrypted twice, two superposed well patterns with a well spacing of square root of 2 times L are formed; the well spacing of the superposed well pattern after alternative strata development is L; the evolution process of the well spacing is as follows: 2L to 2 times square root of 2 L to L; the conversion middle process of a well pattern with a well spacing of square root of 2 times L; in the same drilling speed, well placement uniformity coefficient and reserve control speed are increased; the well spacing is encrypted in the alternation of well patterns; each well pattern can realize order development to each strata; the utilization ratio of the well patterns is improved; and meanwhile, the oil reservoir is uniformly used, so that the method is in favor of increasing accumulated oil production of an oil field and improving the recovery ratio; and interlayer interference generated by extracting oil in multiple oil layers of longitudinal series of strata is avoided.

Owner:PETROCHINA CO LTD

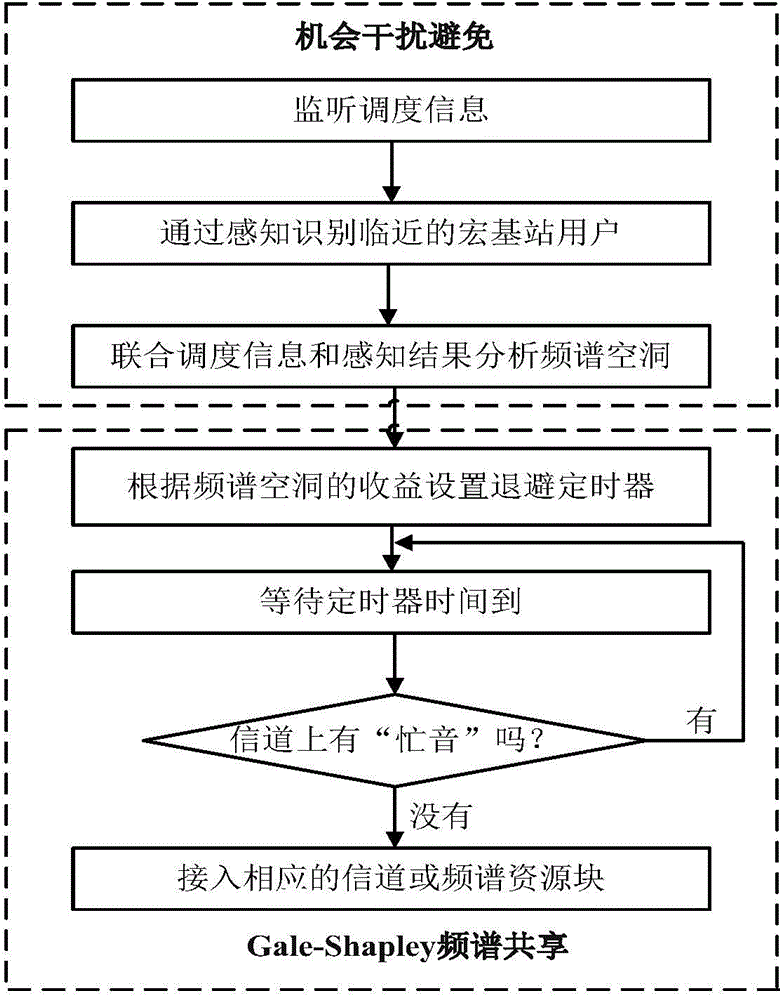

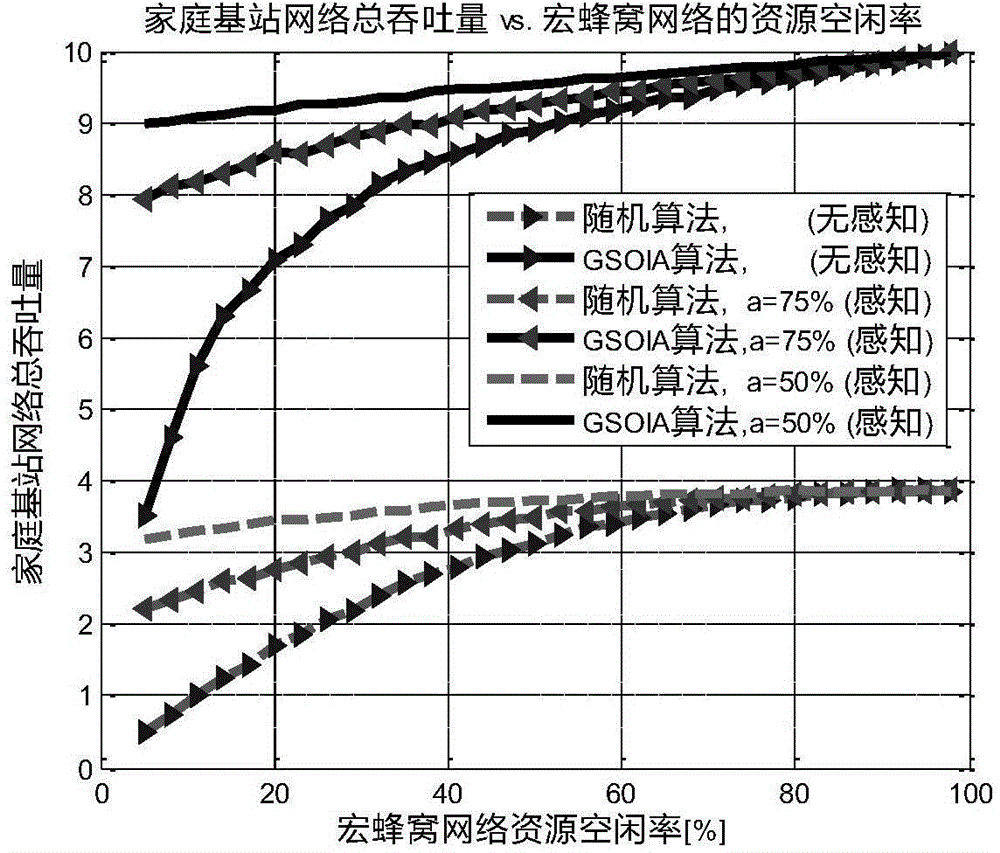

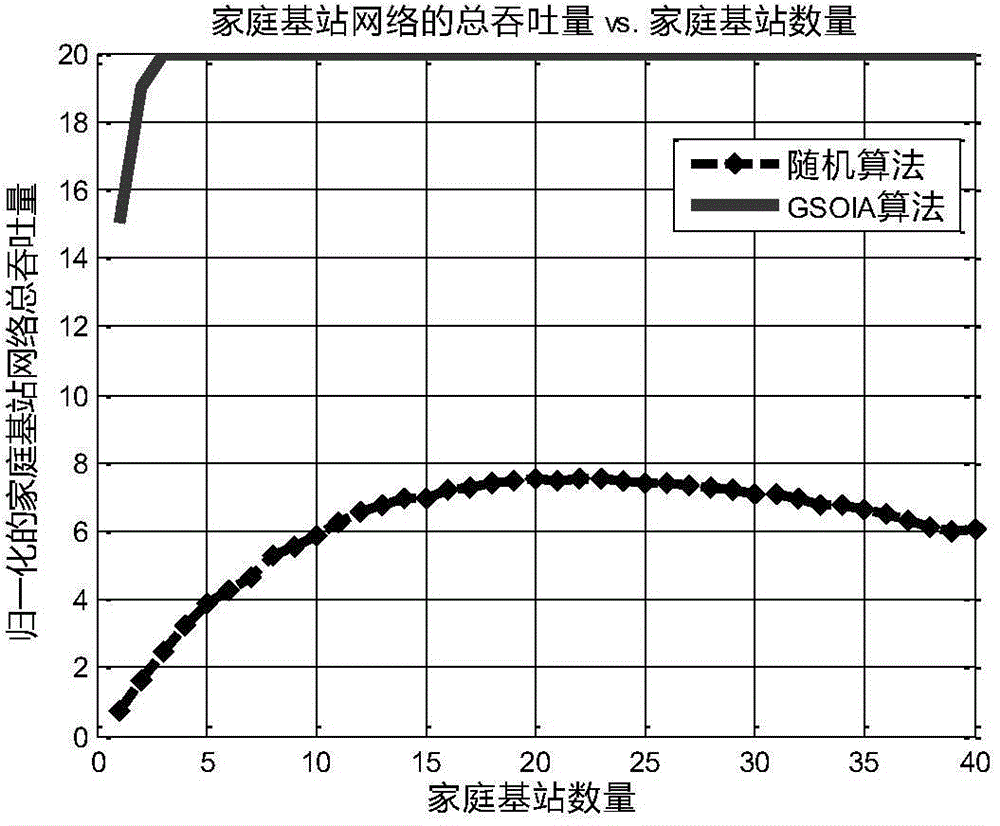

Cognition-based macro eNB and femtocell interference management method

InactiveCN104540142AEliminate distractionsIts spectral efficiency is lowNetwork planningResource distributionResource block

The invention discloses a cognition-based macro eNB and femtocell interference management method. A chance interference avoidance method and a Gale-Shapley frequency spectrum sharing method are combined. In the chance interference avoidance method, a femtocell acquires free frequency spectrum resources in a macro eNB network or available time-frequency resource blocks in orthogonal frequency division multiplexing through detection. In the G-S frequency spectrum sharing method, a one-to-one frequency spectrum resource distribution strategy is adopted in the femtocell, communication is carried out through obtained frequency spectrum resource holes, in the communication process, the femtocell periodically monitors the occupancy state of the frequency spectrum resources, and once a macro eNB user occupies frequency spectrum resource blocks, the femtocell stops communication. Compared with existing partial frequency spectrum resource sharing schemes, the method has many advantages, for example, the existing schemes are low in spectrum efficiency and cannot eliminate in-layer interference, the method of detecting macro eNB behaviors is adopted in the scheme, more resources can be sensed, and the spectrum efficiency is high; meanwhile, the in-layer interference is eliminated by combining the G-S theory.

Owner:HUAZHONG UNIV OF SCI & TECH

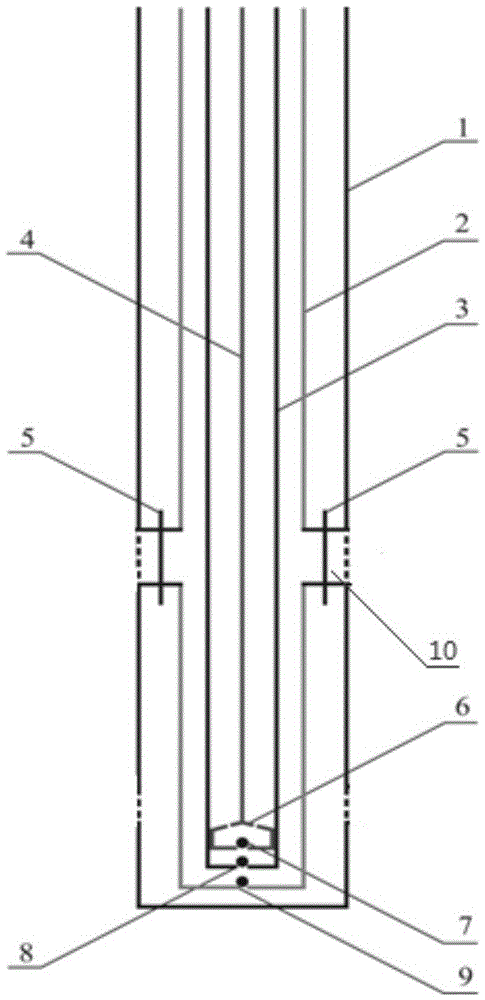

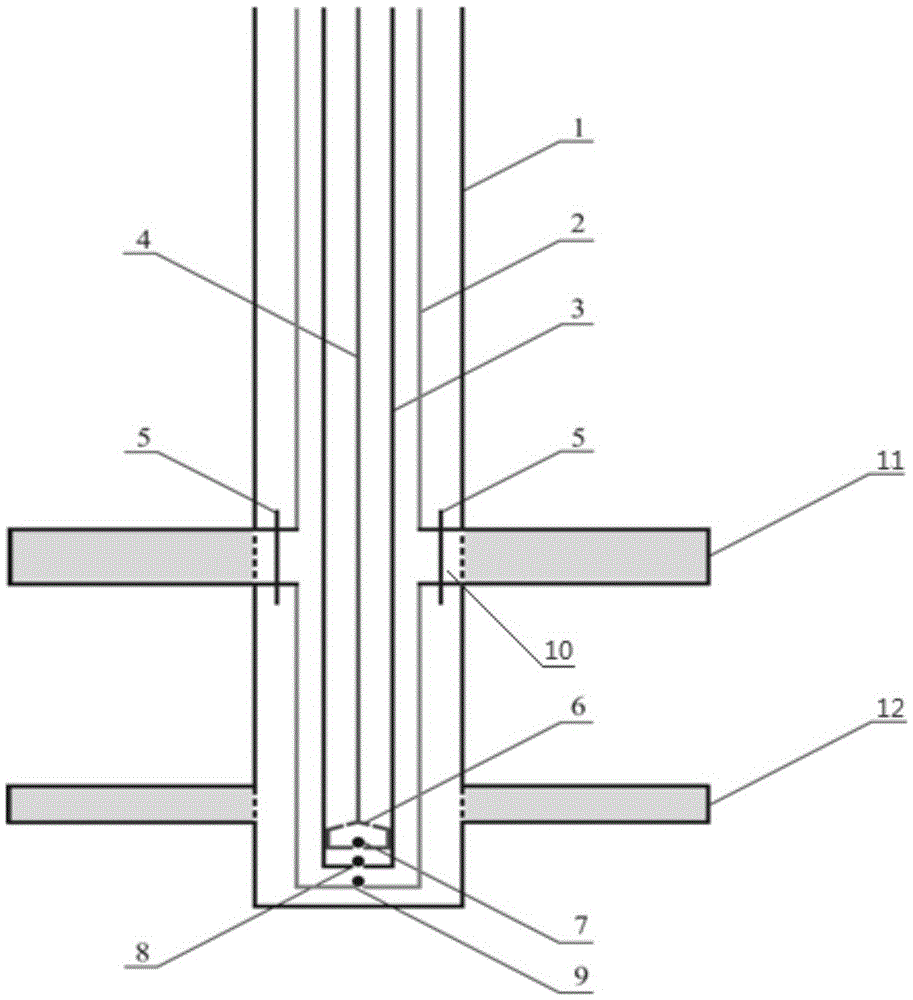

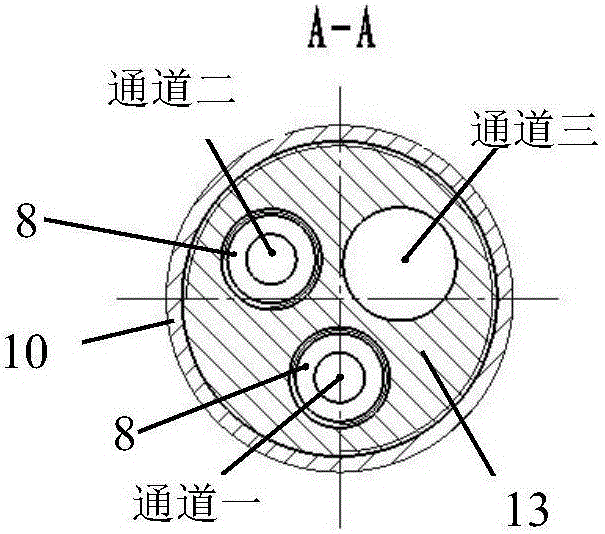

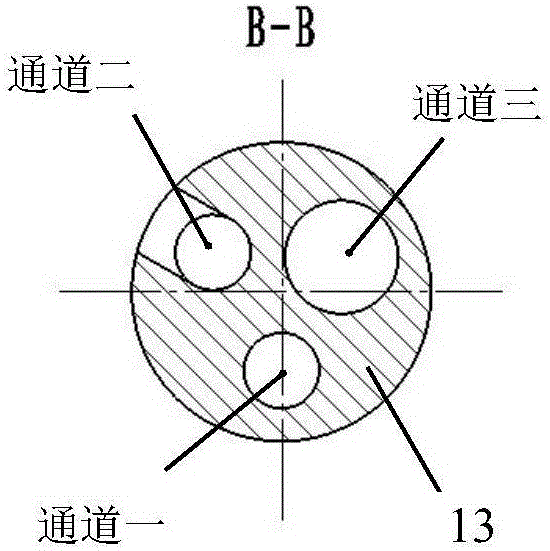

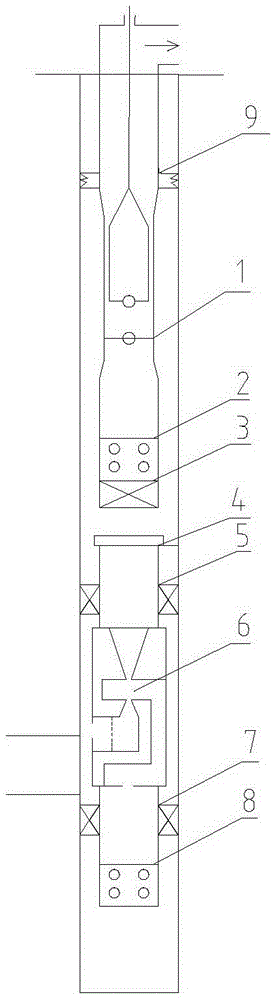

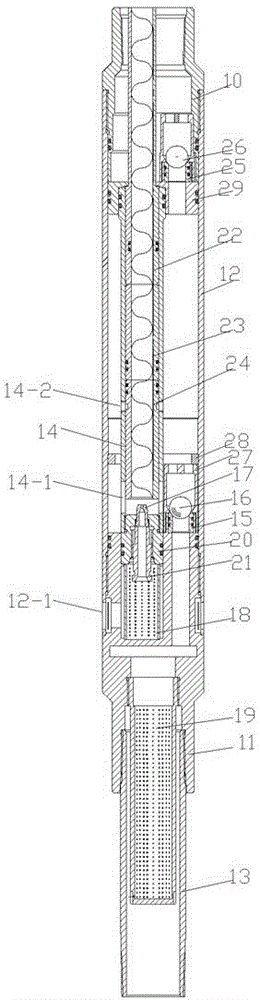

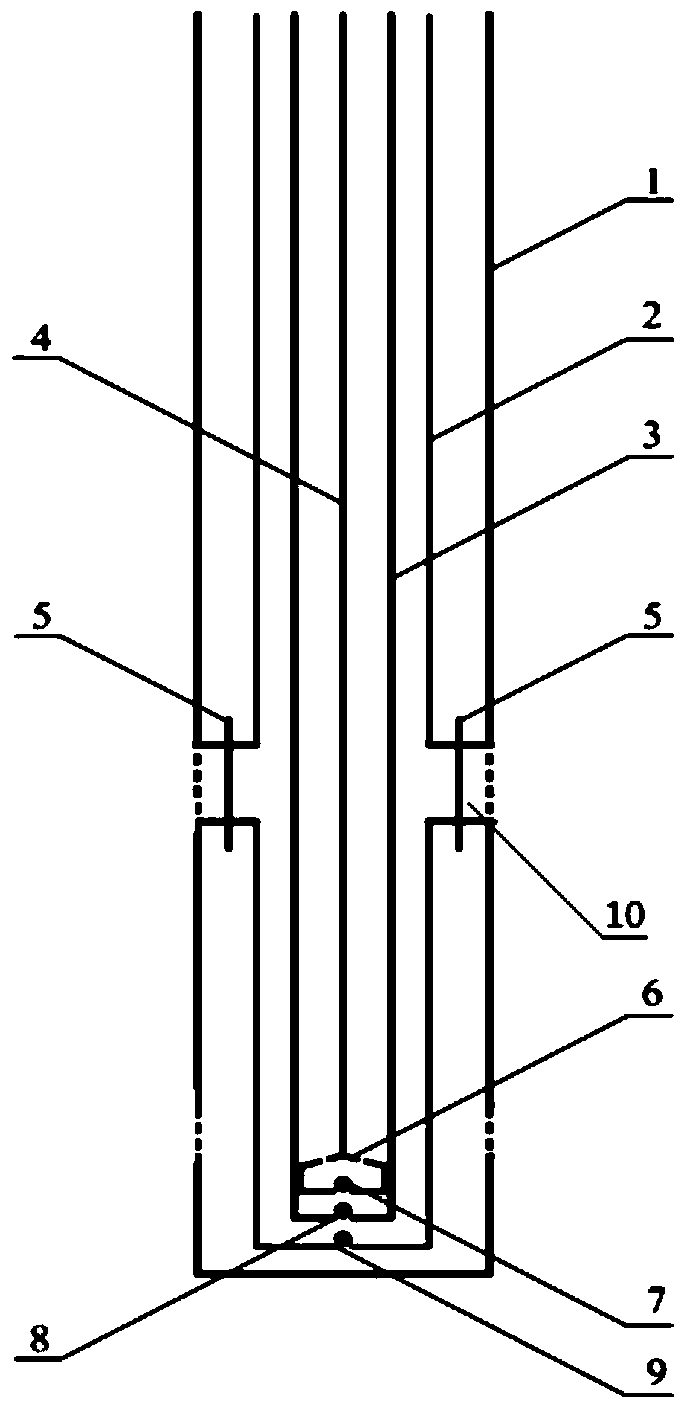

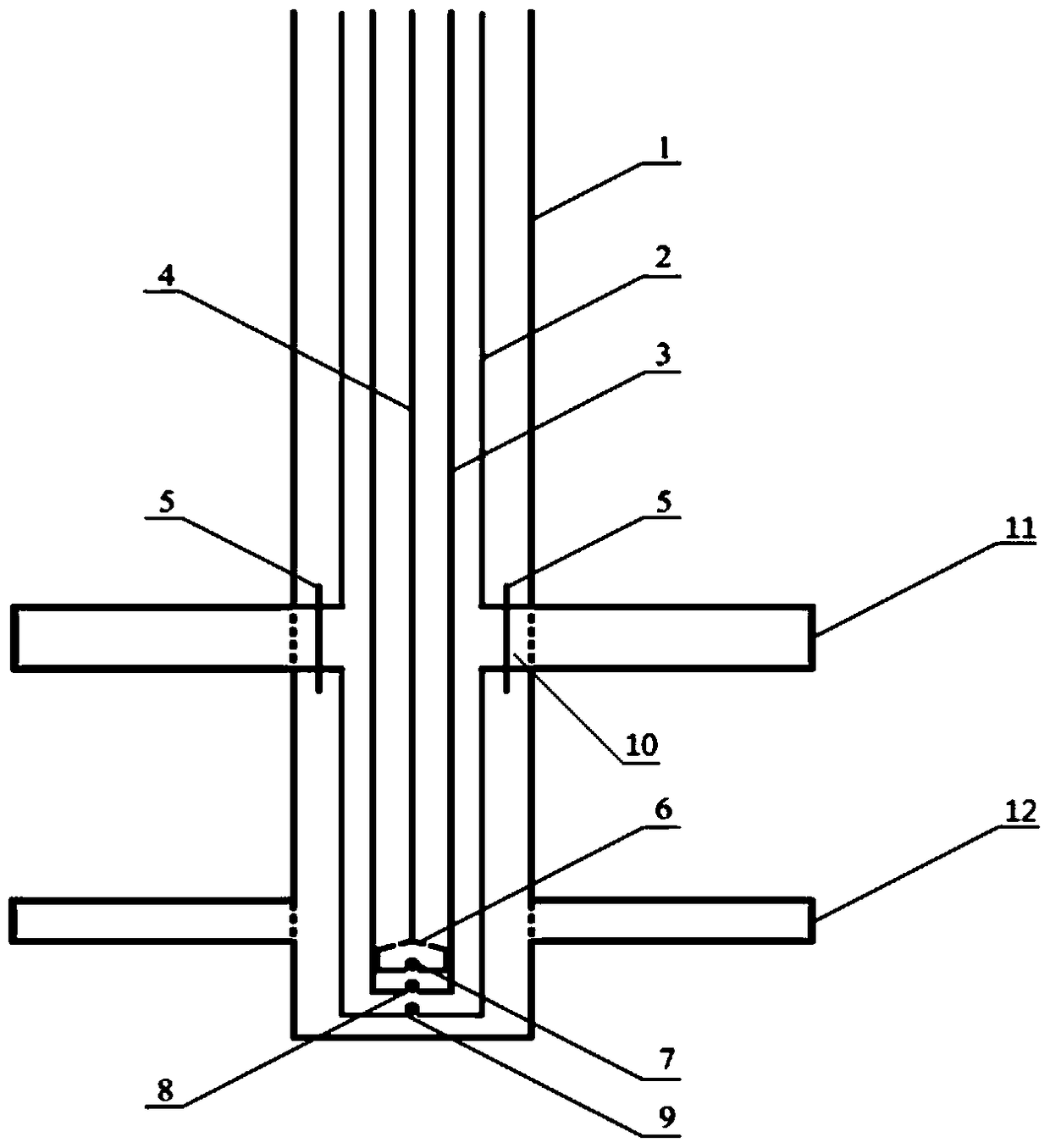

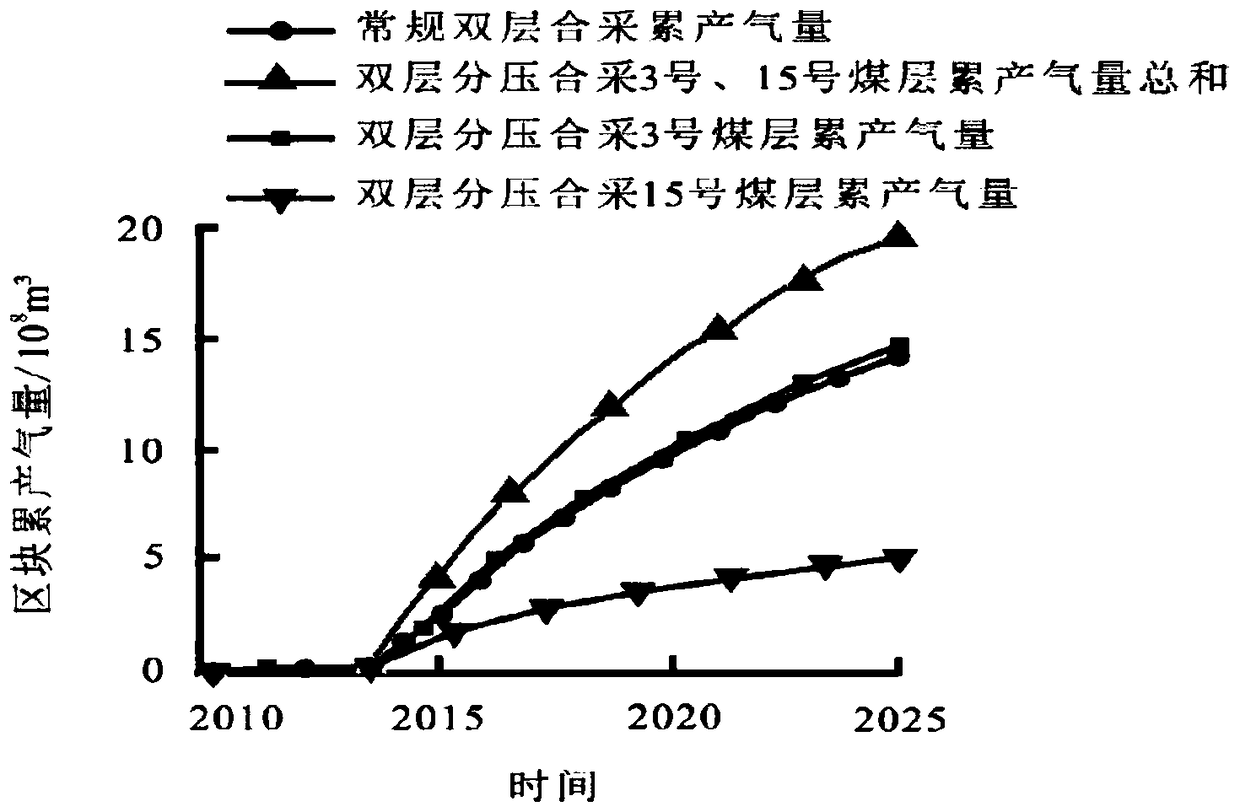

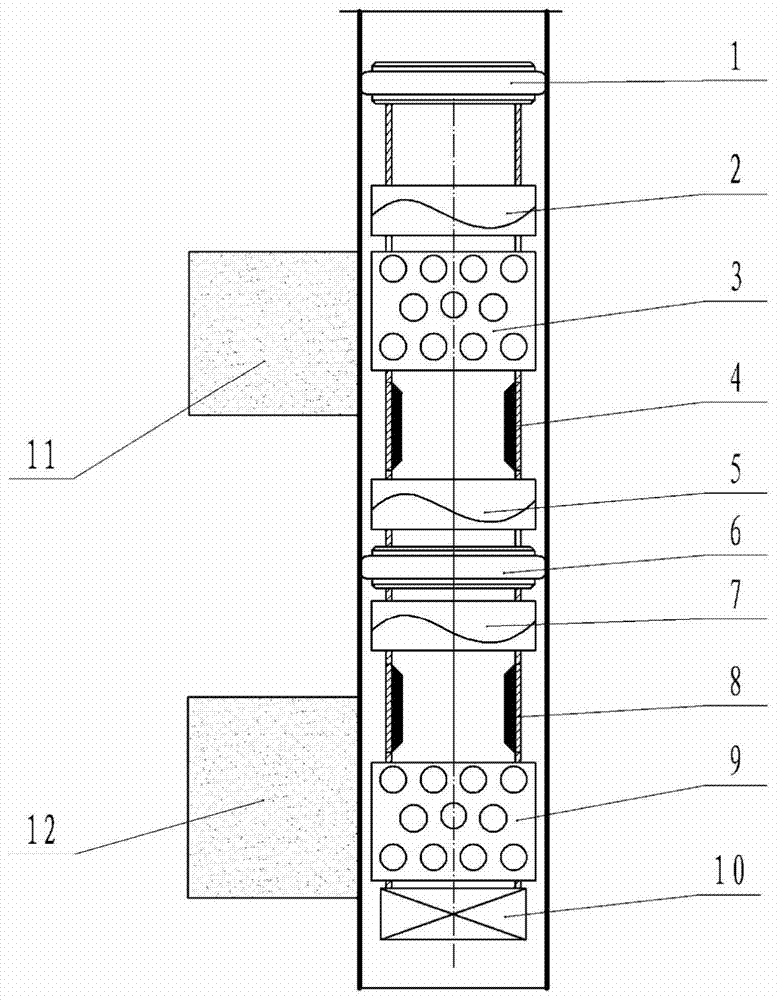

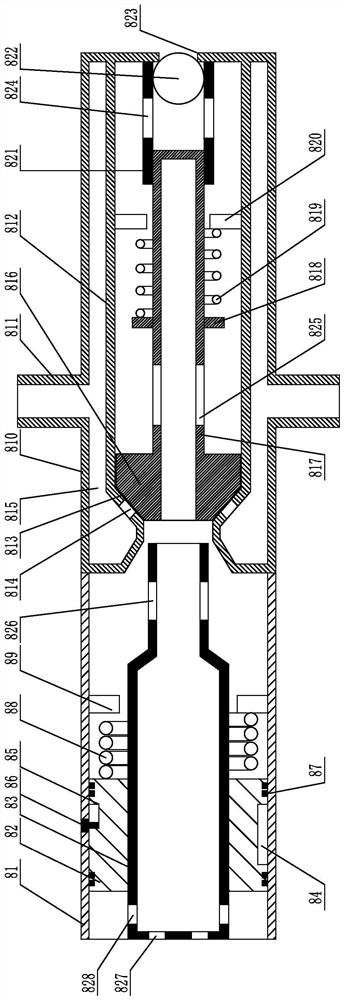

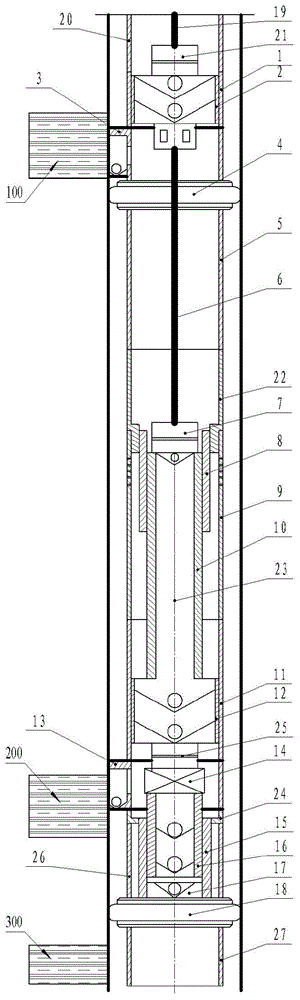

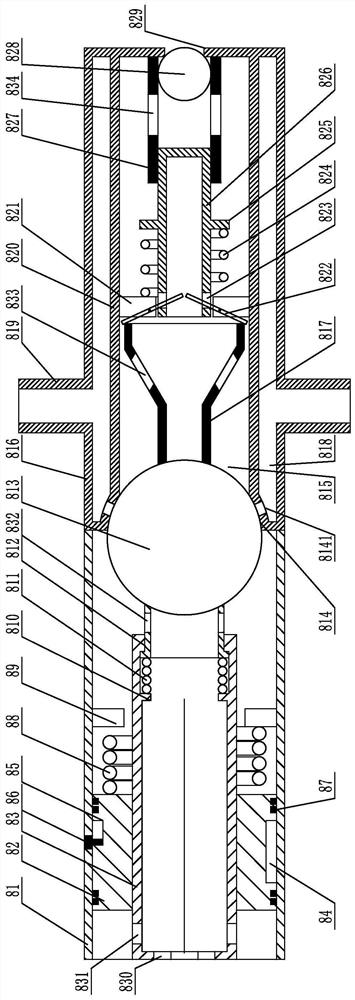

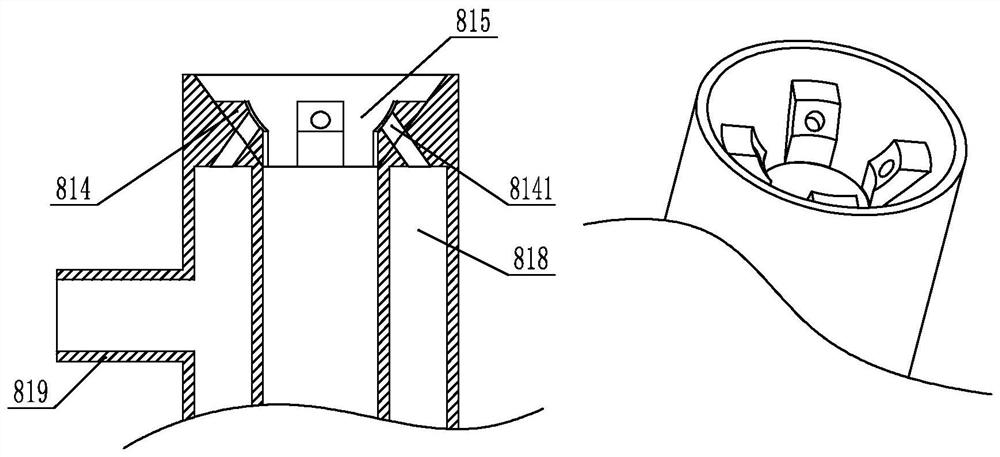

Vertical-well double-layer partial-pressure commingling method and device for coalbed methane

The invention relates to a vertical-well double-layer partial-pressure commingling method and device for coalbed methane. The method includes the steps that a pipe is arranged in the well, and three isolated channels including the first channel, the second channel and the third channel are arranged in the pipe; the side wall of the first channel and the side wall of the second channel are communicated with two coal beds respectively, gas of the two coal beds is discharged to a well opening through the first channel and the second channel respectively, liquid of the two coal beds flows to the bottom of the first channel and the bottom of the second channel respectively, and gas-liquid separation is achieved in the well; one-way valves are arranged between the first channel and the second channel and between the second channel and the third channel, and the liquid of the two coal beds is jointly drawn out of the well while accumulated liquid in the well bottom is avoided. According to the method and device, the gas and the water generated by the upper coal bed and the lower coal bed are jointly mined and jointly drawn through the single well, gas-liquid separation is carried out at the well bottom, the gas is drawn through a gas path, the liquid is drawn through a liquid path, pressure systems of the two coal beds are separated, interlayer interference generated during exploitation is reduced, and the gas yield is effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV +1

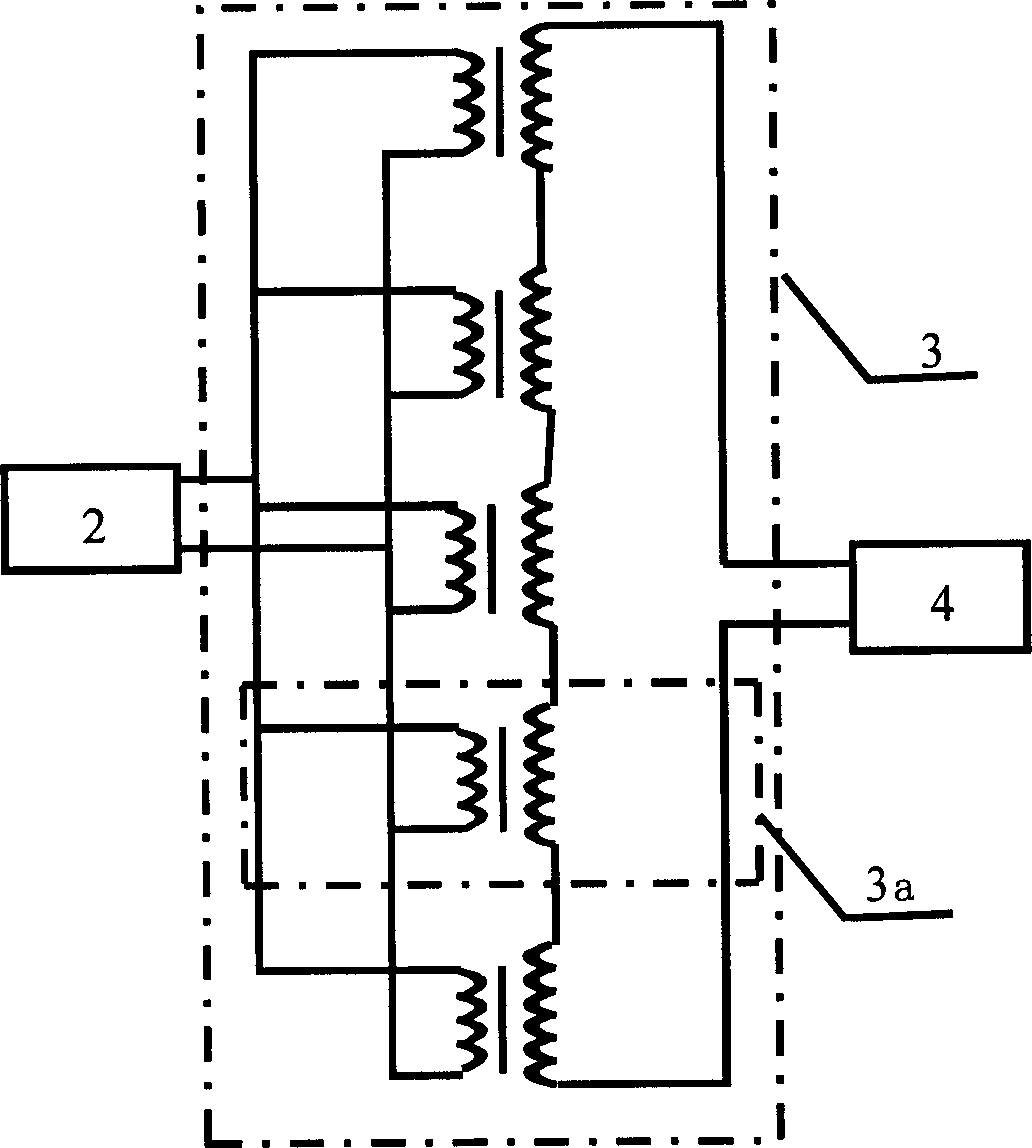

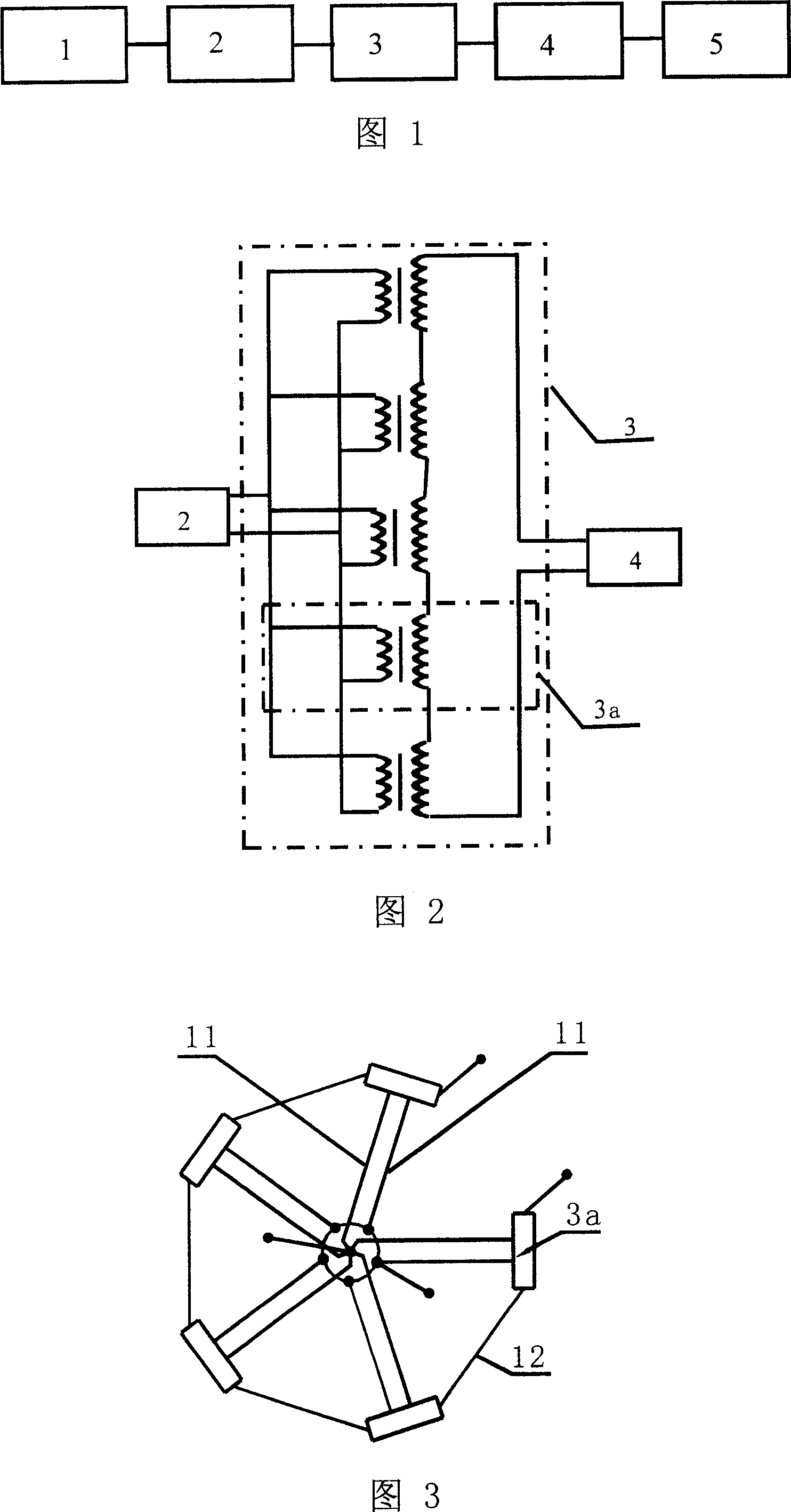

Insulation aging test device used for converter high voltage pulse equipment

InactiveCN1793989AMeet the requirements of insulation aging testSmall distortionElectrical testingTransformerFrequency conversion

An insulation ageing test device of frequency conversion high voltage pulse equipment is prepared as connecting output end of pulse generator to primary edge of high voltage boosting transformer with its secondary edge being connected to wire in insulation sleeve, applying 300H2 to lkH2, 1kH2 to 5kH2 , 5kH2 to 10k H2 and 10k H2 to 20k H2 as operation frequency of high voltage boosting transformer alternately, connecting said boosting transformer to output of pulse generator for outputting square wave to meet requirements of insulation ageing test.

Owner:SOUTHWEST JIAOTONG UNIV

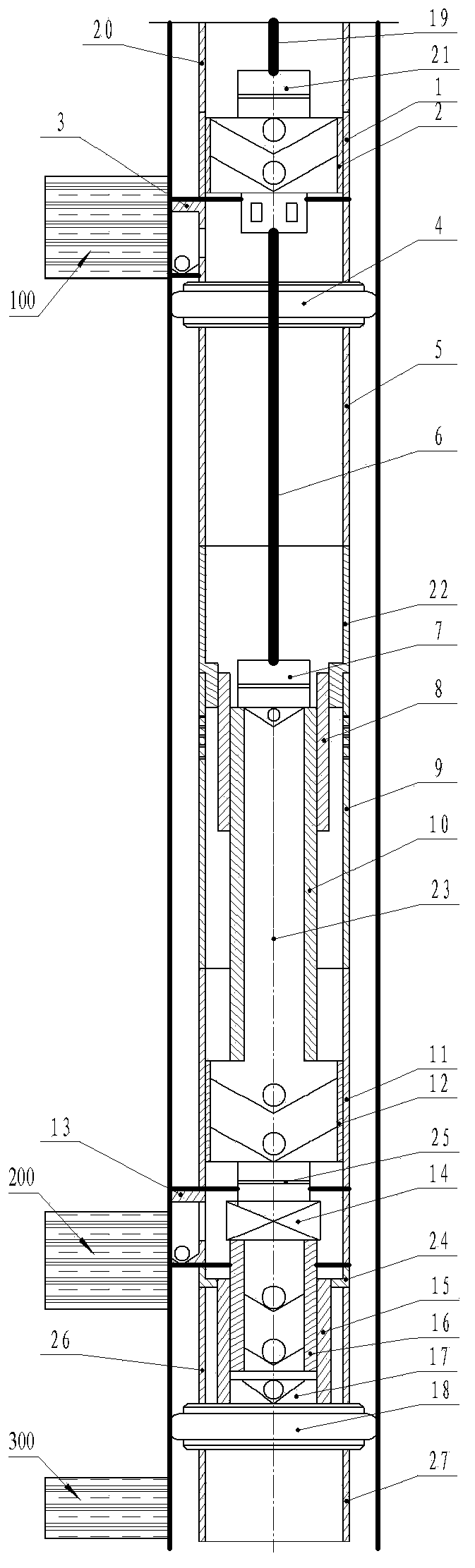

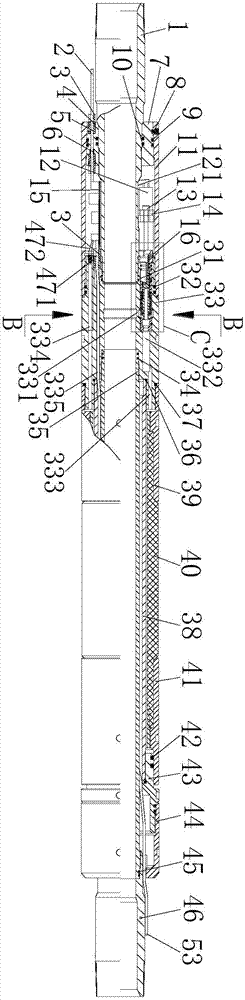

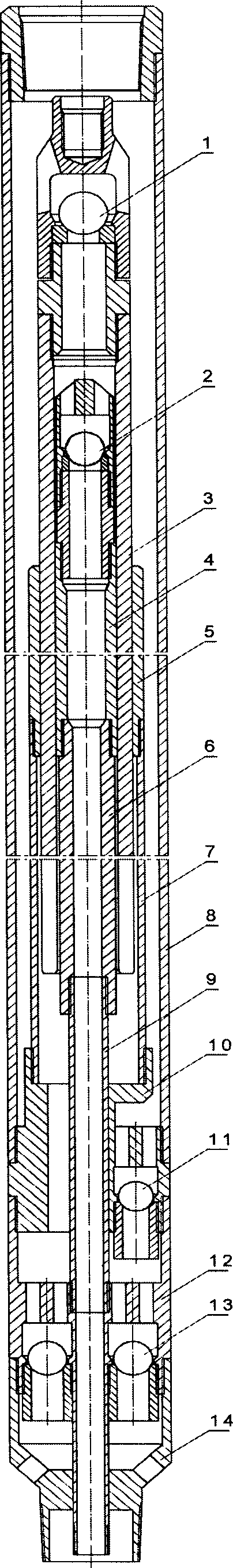

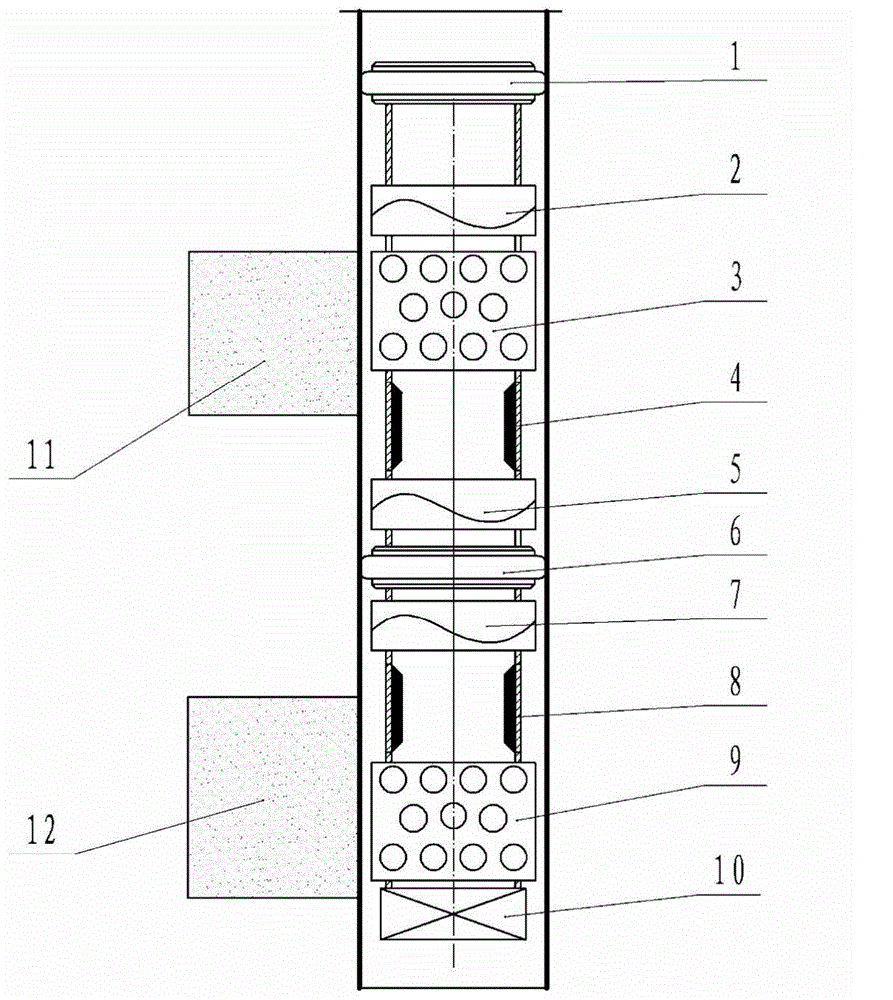

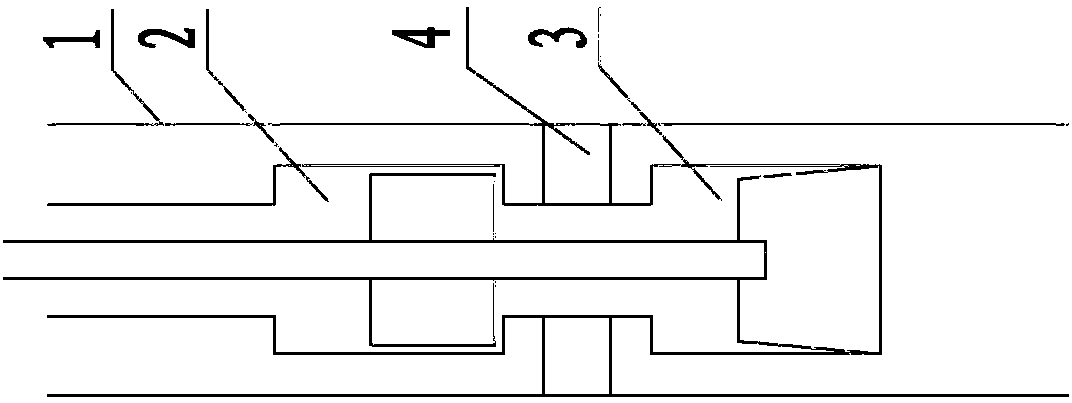

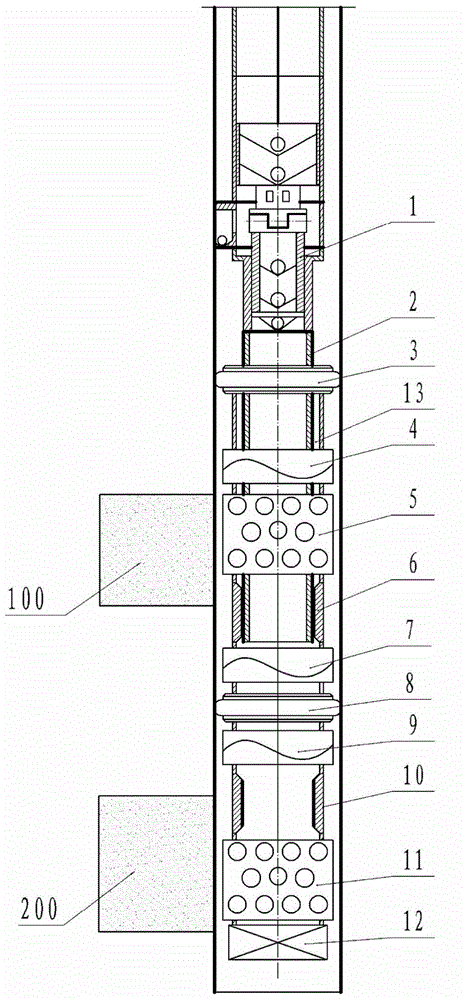

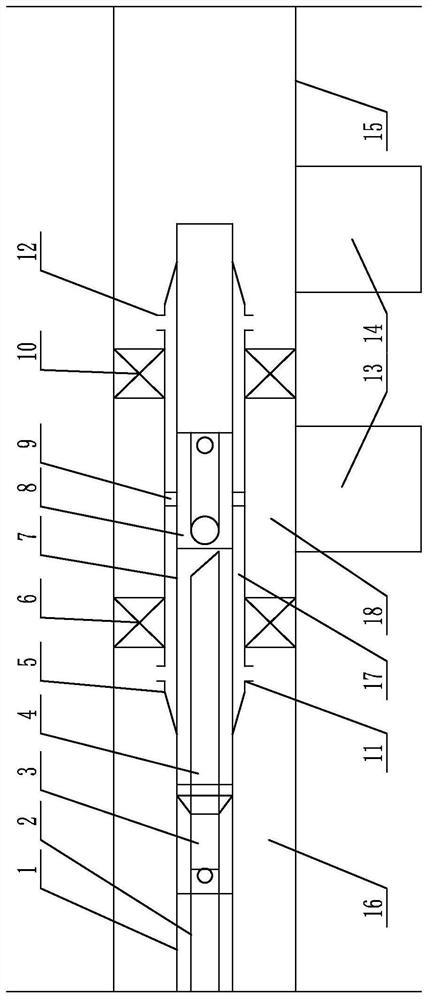

Three-stage layered commingled production string

The invention discloses a three-stage layered commingled production string. In order to overcome a defect that a production string cannot simultaneously exploit more than two oil layers in the prior art, the three-stage layered commingled production string is characterized in that the lower end of a tubing string is sequentially fixedly provided with a primary pump, an upper packer, an oil tube I, a suspension nipple I, an oil tube II, a secondary pump, a suspension nipple II, an oil tube III, a lower packer and a tail pipe, wherein the primary pump is positioned on an upper oil layer; the upper packer is positioned between the upper oil layer and a middle oil layer; the lower packer is positioned between the middle oil layer and a lower oil layer; internal threads at the lower end of the suspension nipple I are fixedly connected with the upper end of a seal cartridge; internal threads at the lower end of the suspension nipple II are fixedly connected with the upper end of a pump cylinder of a triple-stage pump; a hollow sealing rod of a plunger assembly is positioned in the seal cartridge; the diameter of the hollow sealing rod is smaller than the diameters of a primary pump plunger and a secondary pump plunger. The three-stage layered commingled production string has the beneficial effects that different oil layers are simultaneously exploited by feeding a string once, and the exploitation efficiency is improved.

Owner:DAGANG OIL FIELD GRP +2

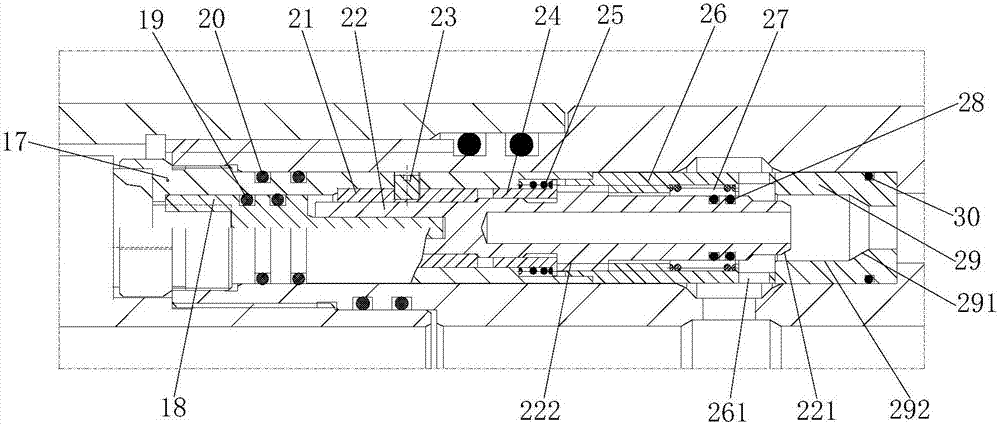

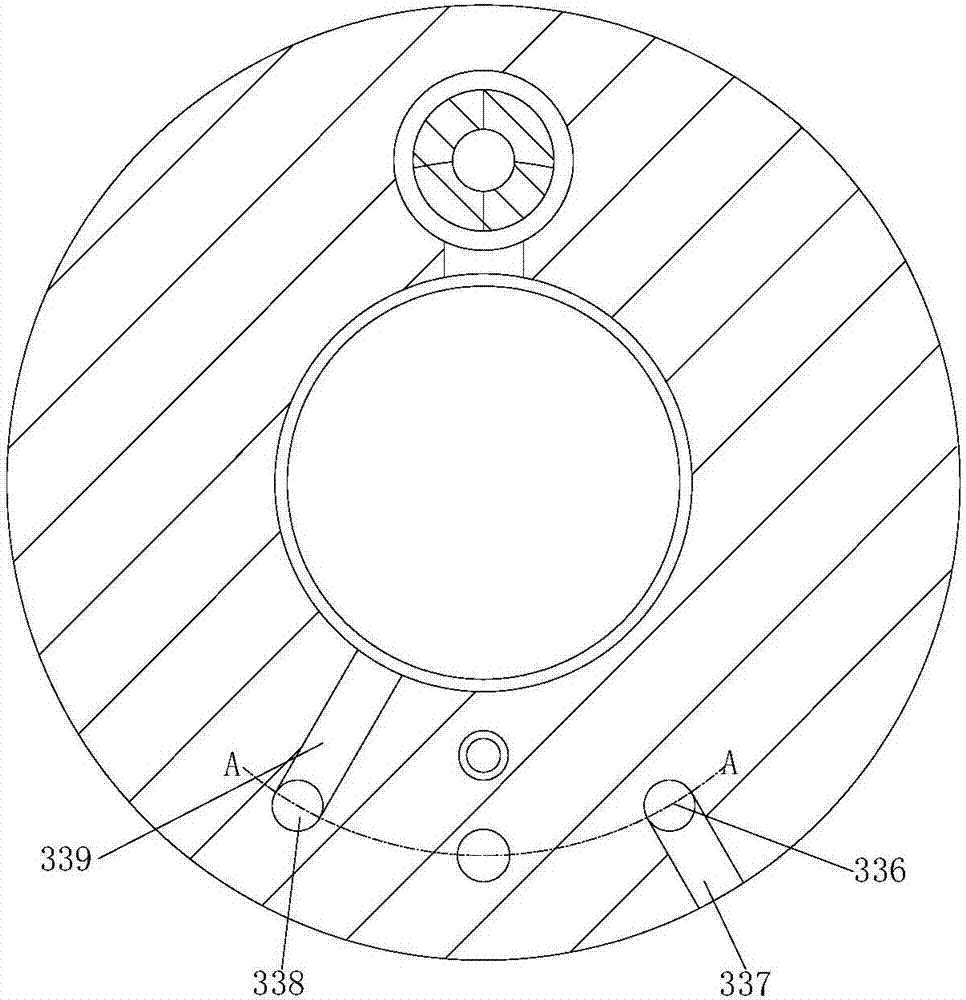

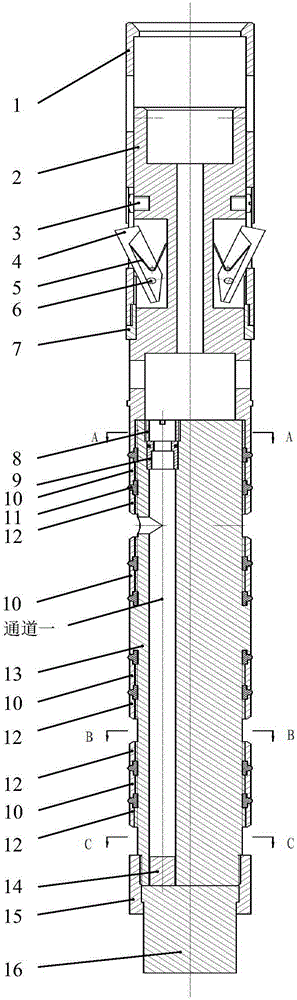

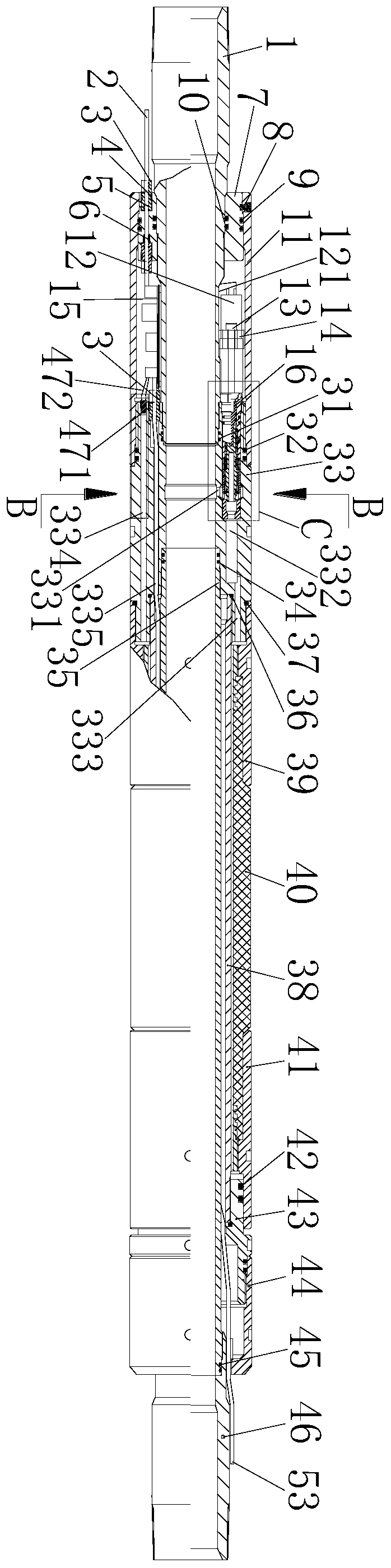

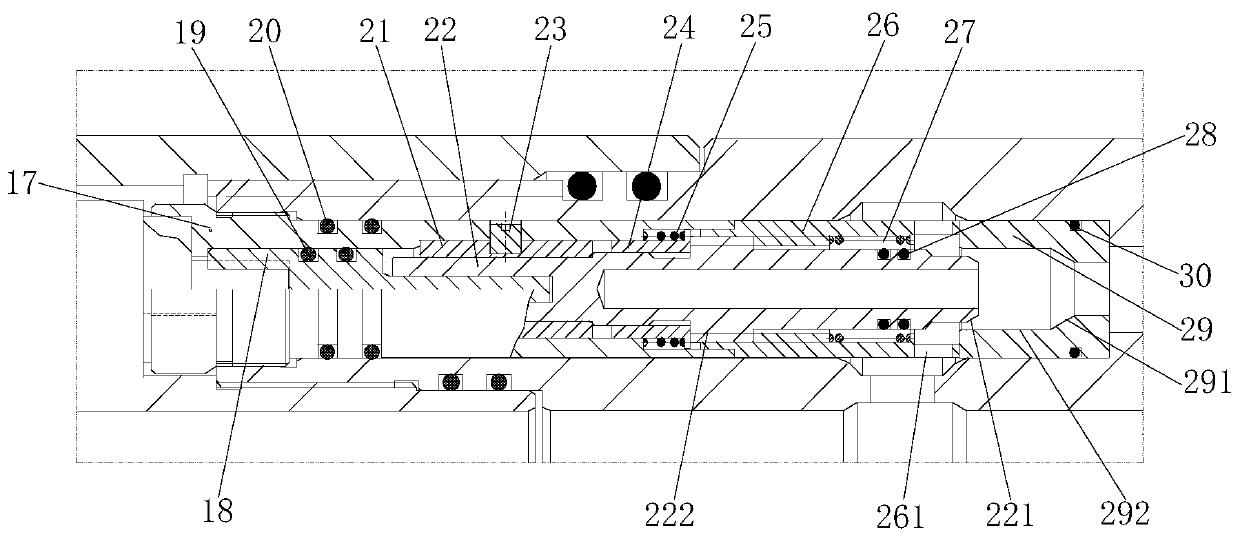

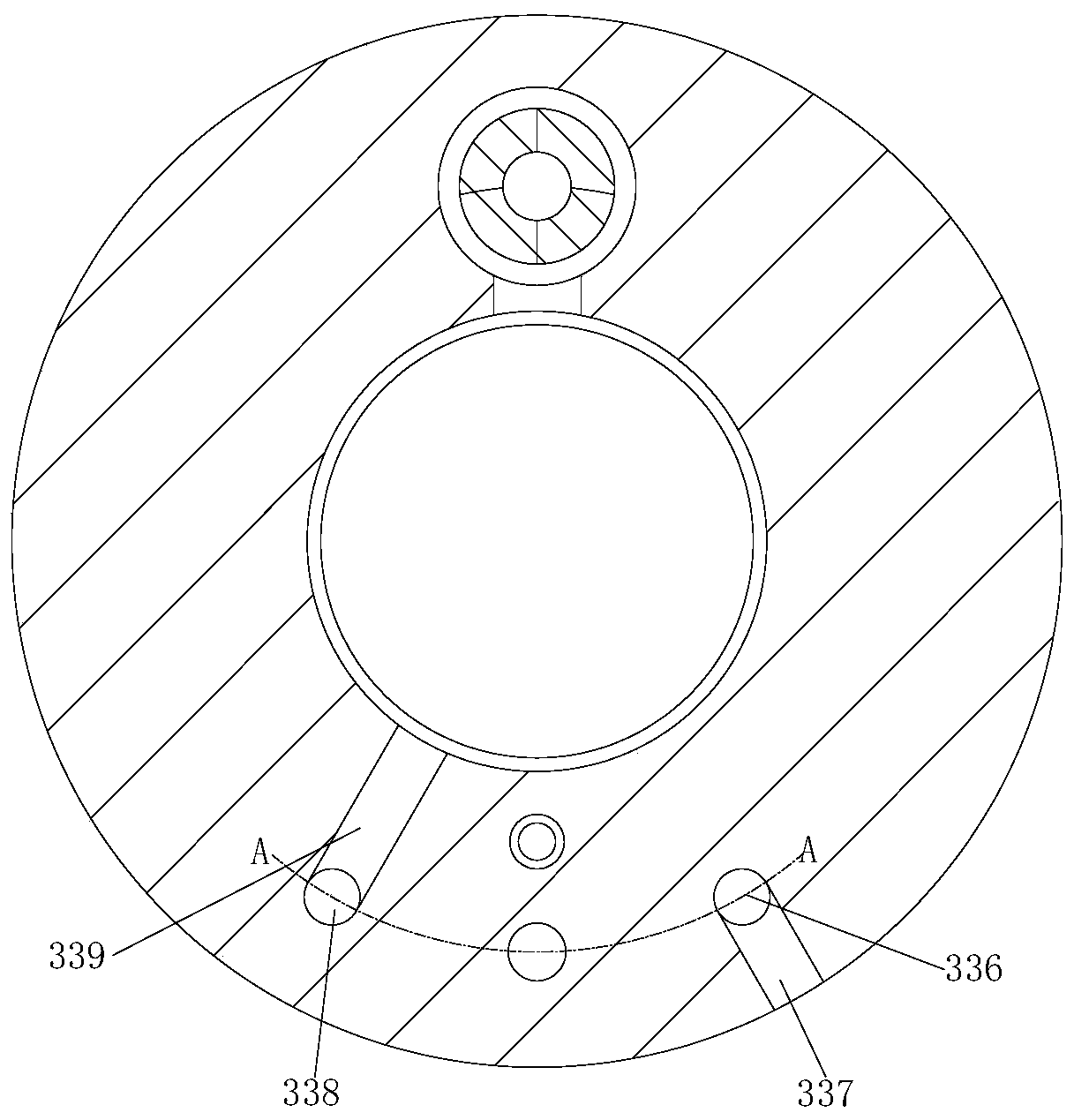

Downhole intelligent controlling type expansion packer

ActiveCN107489395ASimplify the inspection and sealing processReduce test costConstructionsWell/borehole valve arrangementsData transmissionFluid migration

The invention discloses a downhole intelligent controlling type expansion packer. The downhole intelligent controlling type expansion packer comprises an upper joint and a lower joint; an intelligent controlling plate (15) is fixedly connected to the upper joint; an inner cavity pressure gauge (47), a sealing pressure gauge (54) and an in-pipe pressure gauge (55) which are connected with the intelligent controlling plate (15) are arranged on one side of a sealing main body (33); an electric switch is arranged in the sealing main body (33) and controls liquid inlet and liquid outlet of an inner cavity of a rubber barrel, steel pipe cables penetrate through a packer body, and locking and sealing mechanisms are arranged on the two extended ends of the steel pipe cables. According to the downhole intelligent controlling type expansion packer, the self power supply and data transmission problems are solved by utilizing the penetrating cables, a ground controlling system can control the packer to be set and unset and collect and upload data of the inner cavity, stratum and in-pipe pressure in time, the examining seal procedure of the packer is simplified, the accuracy of other downhole parameter admission is improved, fluid migration preventing pressure difference between layers during stopping injection is raised to over 15MPa, interlayer interference in an oil producing well is solved, and occurrence of downhole accidents is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

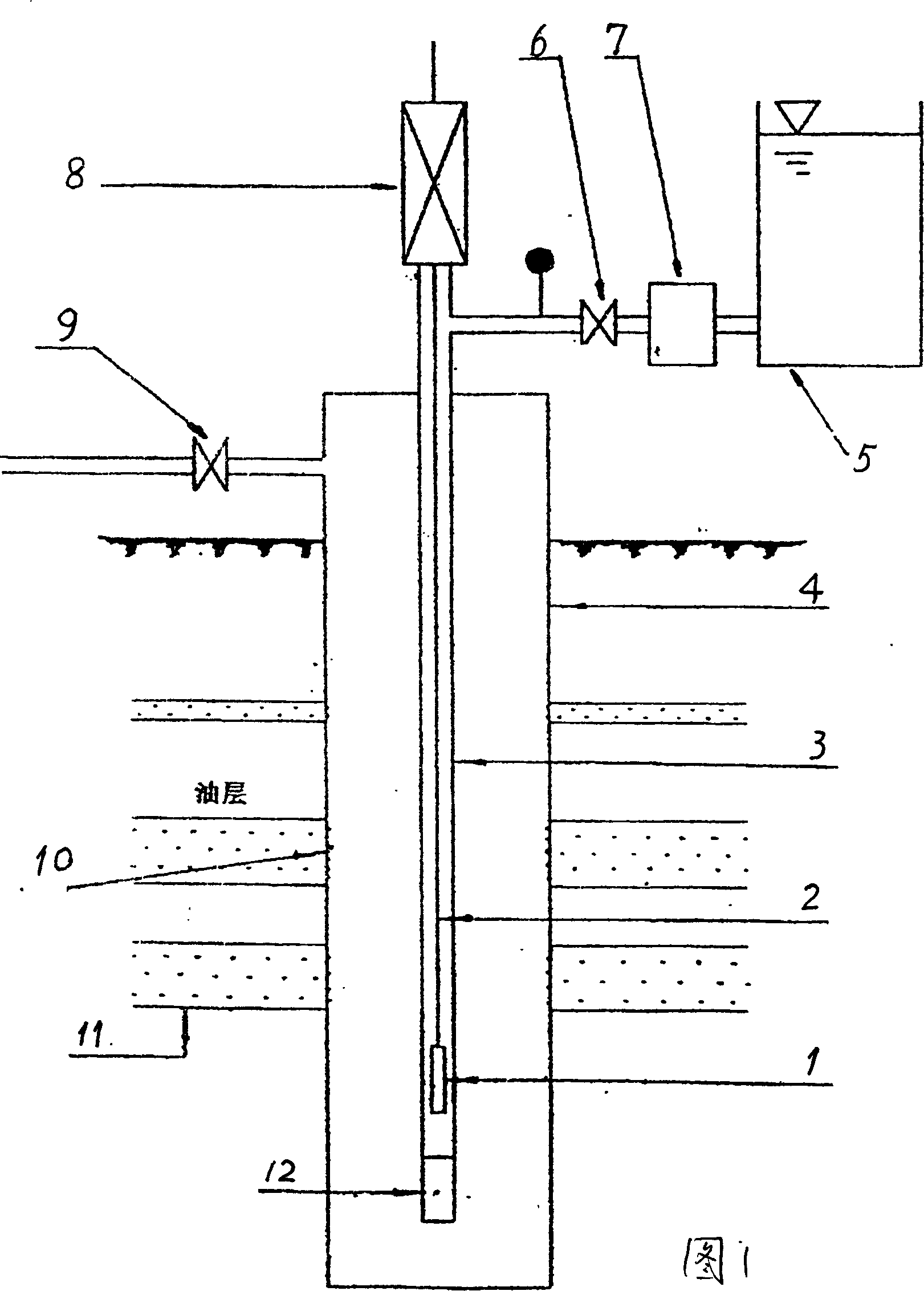

Regulating separate layer production string and separate layer oil production method

The invention relates to the technical field of oil field separate layer oil production engineering, in particular to a regulating separate layer production string and a separate layer oil production method. An oil pipe string of the regulating separate layer production string is vertically arranged in an oil well; the bottom end of an oil pipe string is sealed; a rod type oil sucking pump and a plurality of groups of sealing and distributing systems which are sequentially communicated are arranged on the oil pipe string; each group of sealing and distributing system comprises a packing device and an adjustable and controllable production regulator which are sequentially communicated; each packing device is arranged above an oil layer and is used for isolating and protecting the corresponding production regulator; and each production regulator is arranged at the middle upper part of the oil layer. The separate layer oil production method works on the basis of the regulating separate layer production string. The regulating separate layer production string and the separate layer oil production method have the advantages that through regulating and controlling the production regulators, the interlayer interference can be avoided; and the separate layer flowing pressure is controlled, so that the potentials of each layer are exerted to the maximum degree; the application of the production regulators is diversified; the separate layer oil production, water finding, water plugging and the like are subjected to integral construction; and three technical measures can be realized only through one pipe string.

Owner:北京千永科技股份有限公司

Layered testing and adjustment process for injection well

InactiveCN104863568AAvoid interlayer interferenceReduce distortionSurveyFluid removalInjection pressureSkill sets

A layered testing and adjustment process for an injection well mainly solves the problems that an existing testing and adjustment process is carried out separately under a well shutin circumstance, the number of devices and tools is large, and long time is consumed. The specific testing and adjustment process includes the following steps that firstly, according to an existing throwing and fishing method, blanking plugs in eccentric water distributors in various layers are fished out and then blockage type flowmeters are thrown into the eccentric water distributors in the layers; secondly, different types of injection pressure are adjusted at the mouth of the well, the injection allocation flow of the whole well is 0-150%, and three to six points are selected for pressure adjustment; thirdly, the blockage type flowmeters in the layers are fished out, and testing data are obtained; fourthly, packer seal examining is implemented; fifthly, layered flow adjustment is implemented; sixthly, layered well testing and pressure measurement are implemented. The layered testing and adjustment process for the injection well has the advantages that under a well non-shutin circumstance, layered pressure measurement is completed at the same time, the number of devices and tools is small, operators have no special skill requirements or testing and adjustment experience, and data can be synchronized.

Owner:黑龙江普测科技有限公司

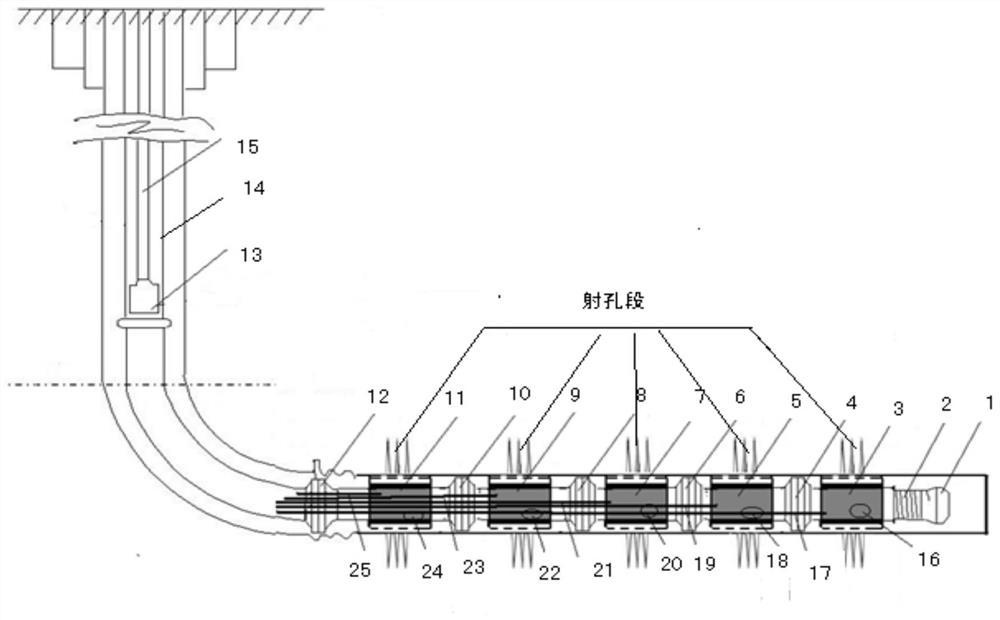

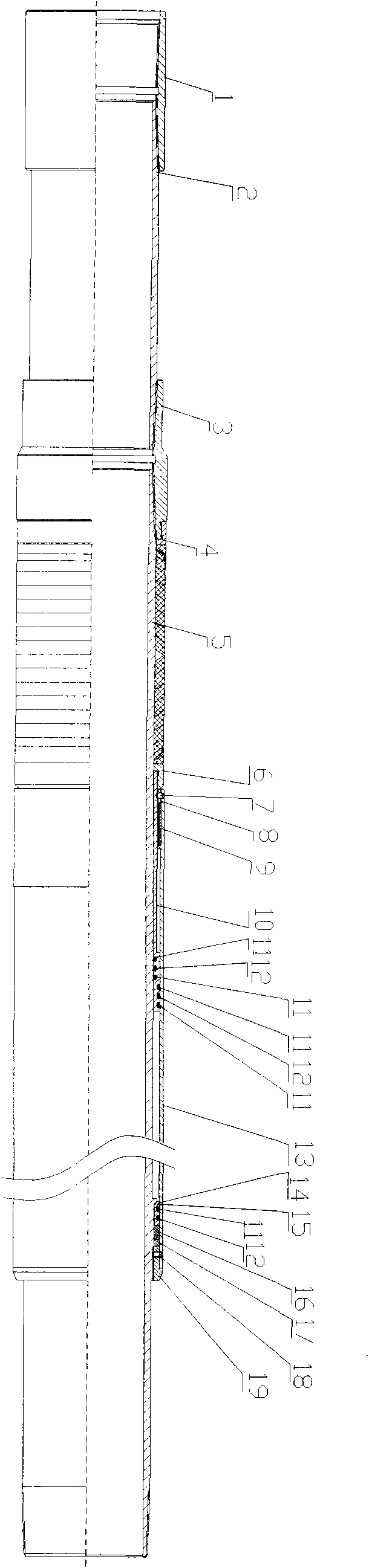

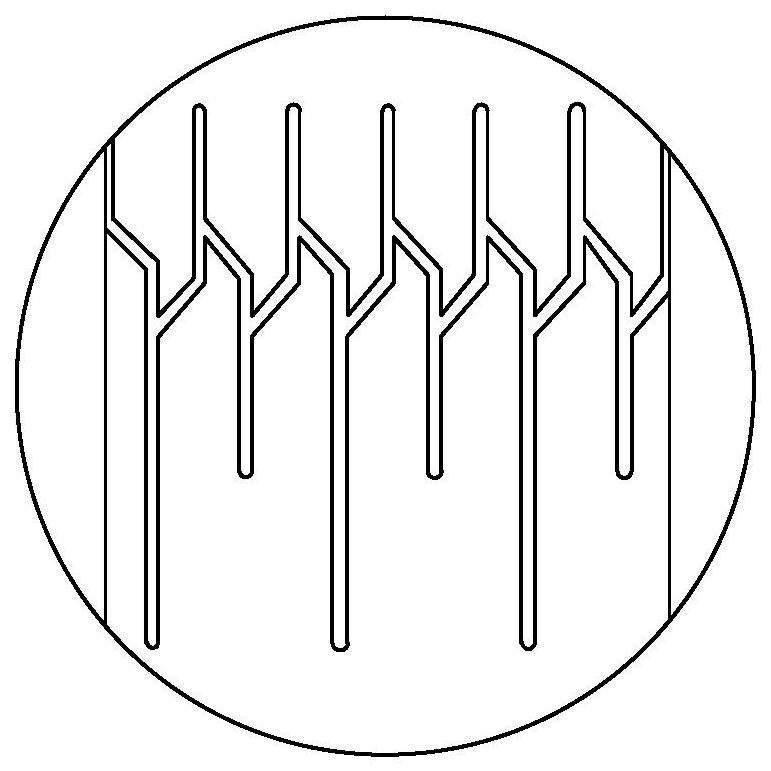

Multi-section fracturing horizontal well liquid production profile test string

ActiveCN111663929ANot affected by interlayer interferenceAvoid interlayer interferenceConstructionsGeothermal energy generationHorizontal wellsWater production

The invention discloses a multi-section fracturing horizontal well liquid production profile test string. The multi-section fracturing horizontal well liquid production profile test string comprises astring body connected with an oil pipe and a plurality of single-flow hole pipes arranged in the string body, each single-flow hole pipe is correspondingly arranged on a production layer section, anda packer is arranged between every two adjacent single-flow hole pipes; an oil liquid containing cavity is formed in each single-flow hole pipe, a tracer is arranged in each oil liquid containing cavity, and the tracers in the single-flow hole pipes are different in type; and each oil containing cavity is provided with an inlet and an outlet, the inlet of each oil containing cavity is in communication with an oil layer perforation of the corresponding production layer section, the outlet of each oil containing cavity is connected with an inlet of a single-flow channel, and an outlet of each single-flow channel sequentially penetrates through the single-flow hole pipe and the packer at the front end of the single-flow hole pipe to be in communication with the oil pipe. According to the test string, the water yield and the oil yield corresponding to each production layer section of an underground oil layer can be obtained, thus the production dynamic state of each production layer section can be determined, the accurate test of the liquid production profile of a multi-section fracturing horizontal well is realized, and an effective basis is provided for the later implementation of sectional oil extraction and water control and oil stabilization of the horizontal well.

Owner:PETROCHINA CO LTD

Bicavity oil pump

InactiveCN1556327AFully utilizeIncrease productionFlexible member pumpsFluid removalPumpjackVALVE PORT

Dual cavity type oil well pump is composed of upper suction valve, upper delivery valve, plunger pump barrel, small plunger, upper connecting tube, delivery valve joint, lower delivery valve, suction valve joint, and lower suction valve etc. When plunger pump barrel goes up, crude oil in one layer from lower delivery valve enters into chamber between lengthen tube and upper connecting tube, and crude oil in another layer from inlet tube connected to small screw below delivery valve joint enters into inner chamber of plunger pump barrel. When plunger pump barrel goes down, crude oil in one chamber is drained into annular space between outer tube and lengthen tube, and crude oil in another chamber is drained into upper part of delivery valve. Thus, oil in two layers is sucked respectively to make oil well reach maximum output.

Owner:于海涛

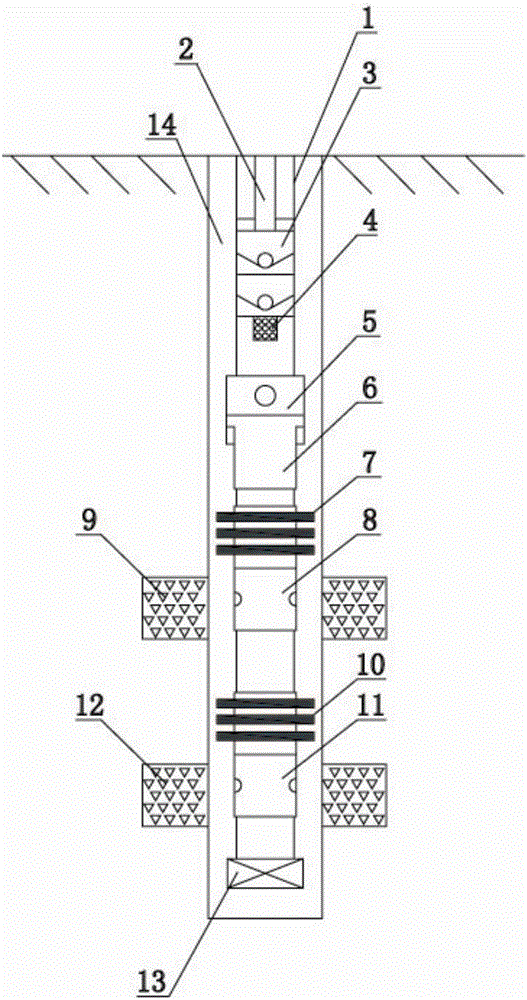

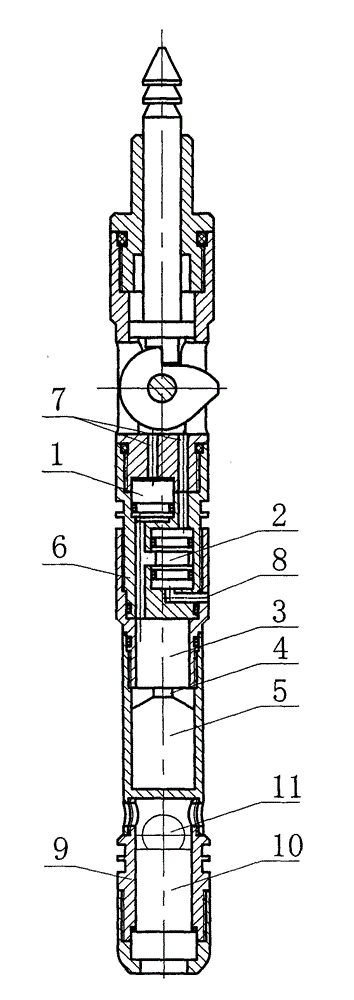

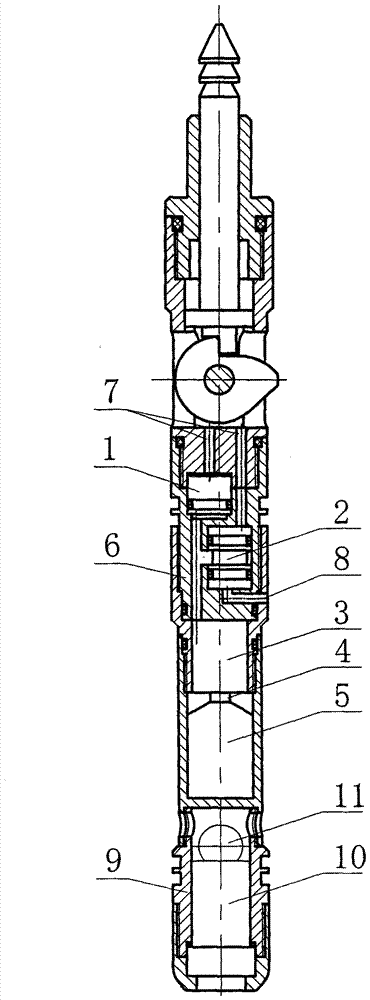

Gas well storage type integrated layered production allocation pressure gauge

ActiveCN105888650ASimple structureAvoid interlayer interferenceSurveyFluid removalOil productionProcess engineering

The invention relates to the technical field of oil production engineering, and belongs to a gas well storage type integrated layered production allocation pressure gauge, which solves the problem in the prior art that long-term pressure monitoring and productivity allocation during a dynamic production process of two gas producing zones cannot be realized at the same time. The gas well storage type integrated layering and production allocating pressure gauge is formed by a salvaging connector (1), a positioning main body (2), anti-rotation pins (3), positioning scissors (4), torsion springs (5), scissor pins (6), regulating sleeves (7), a pressing cap (8), an air faucet (9), regulating rings (10), sealing packings (11), pressing rings (12), a production allocation main body (13), a sensor (14), a back-up nut (15) and a pressure gauge cabin (16). The gas well storage type integrated layered production allocation pressure gauge disclosed by the invention has the advantages that the structure is simple and reliable, static and dynamic production of two kinds of gas producing zones and long-term monitoring on pressure in a shaft can be realized at the same time, and the like.

Owner:PETROCHINA CO LTD +1

Oil well gas prevention system

InactiveCN106567695AControl gas productionIncrease fluid productionFluid removalCarrying capacitySpray nozzle

The invention discloses an oil well gas prevention system and a using method. The oil well gas prevention system comprises an oil well casing and a gas prevention pump. The lower end of the gas prevention pump 1 is sequentially connected with an upper filter screen pipe and an upper screwed plug. A release sub located below the gas prevention pump 1 is arranged in the oil well casing. The release sub is located in the oil well casing through an upper packer arranged on the periphery of the release sub. The lower end of the release sub is connected with a gas prevention lifting pump. The gas prevention lifting pump is located and installed in the oil well casing through a lower packer. The lower end of the gas prevention lifting pump is connected with a lower filter screen pipe. A lower oil layer liquid inlet is formed below the gas prevention lifting pump. An upper oil layer liquid inlet is formed in one side of the gas prevention lifting pump. The oil well gas prevention system has the following advantages that the production pressure difference of the low-pressure oil layer is increased, the liquid production amoung of the low-pressure layer is increased, interlayer interference is avoided, the function of changing the motion direction of liquid and the acceleration function are achieved, the liquid carrying capacity of gas is improved, and the liquid production capacity of the low-pressure layer is improved; and secondary filter of well liquid is achieved, and a spray nozzle is effectively prevented from being blocked.

Owner:CHINA PETROLEUM & CHEM CORP

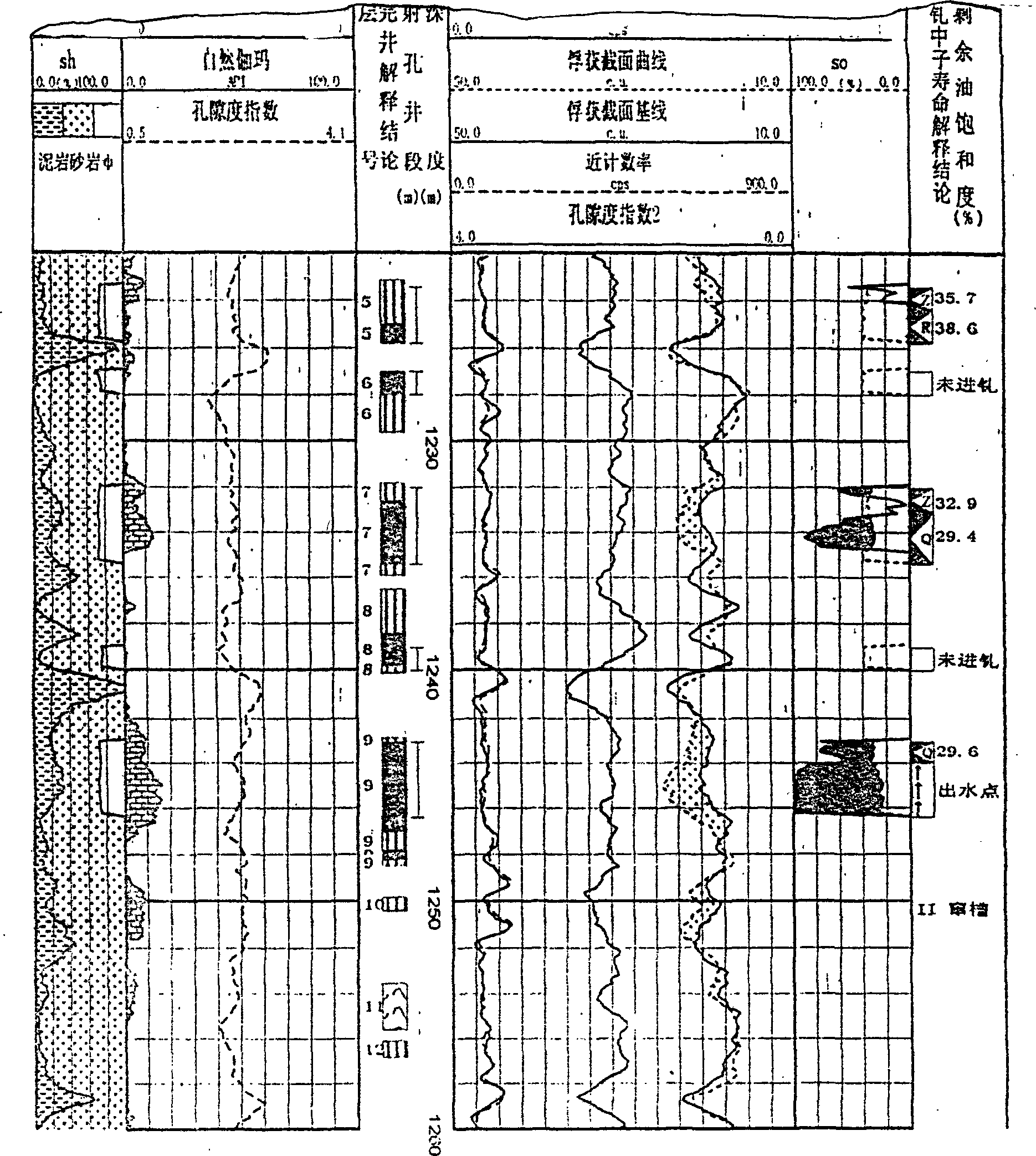

Water regime logging method for oil gas of oil well

InactiveCN1635262ALarge capture cross sectionFacilitate osmotic diffusionSurveyConstructionsNeutron captureOil distribution

The invention concerns an oil gas water dynamic logging method adapted for low mineralized stratum. It adopts neutron lifetime well logger to record the state of oil well stratum exploitation, oil extraction by the producing well and remaining oil distribution. The steps are: a. recording the neutron lifetime curve of oil well without injecting the thermal absorption agent by neutron lifetime well logger b. injecting gadolinium solution to the oil well then sealing the canister to pressurize for not less than 30 to 60 minutes c. recording neutron lifetime curve The invention has large neutrino capture cross-section accurate practical data, and small used dosage. It can provide basis for searching the water producer, finding out pending container rock, solving the interlayer interference and increasing the production, it can also provides the basic data for the multi -well remaining oil evaluation.

Owner:佟云龙 +2

Layering process pipe string

ActiveCN104420858AReasonable structural designAvoid interlayer interferenceFluid removalOil productionOil well

Disclosed is a layering process pipe string. In order to overcome the shortcoming that an existing oil well with serious interlayer interference enables oil production not to be smoothly carried out, and an existing separate production technology cannot meet the production needs, a packer I, a safety joint I, a screen pipe I, a sealing working cylinder I, a safety joint II, a packer II, a safety joint III, a sealing working cylinder II, a screen pipe II and a pipe plug are sequentially and fixedly connected from top to bottom through oil pipes; the packer I is arranged above an upper oil layer, and the packer II is arranged between the upper oil layer and a lower oil layer; the screen pipe I is arranged on the upper oil layer, and the screen pipe II is arranged on the lower oil layer; and the inner diameter of the sealing working cylinder I and the inner diameter of the sealing working cylinder II are smaller than the inner diameter of the oil pipes. The layering process pipe string has the beneficial effects that the structural design is reasonable, the pipe string is matched with lifting pipe strings of different types so as to avoid interlayer interference, and per-well production and the production limitation are effectively improved.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +2

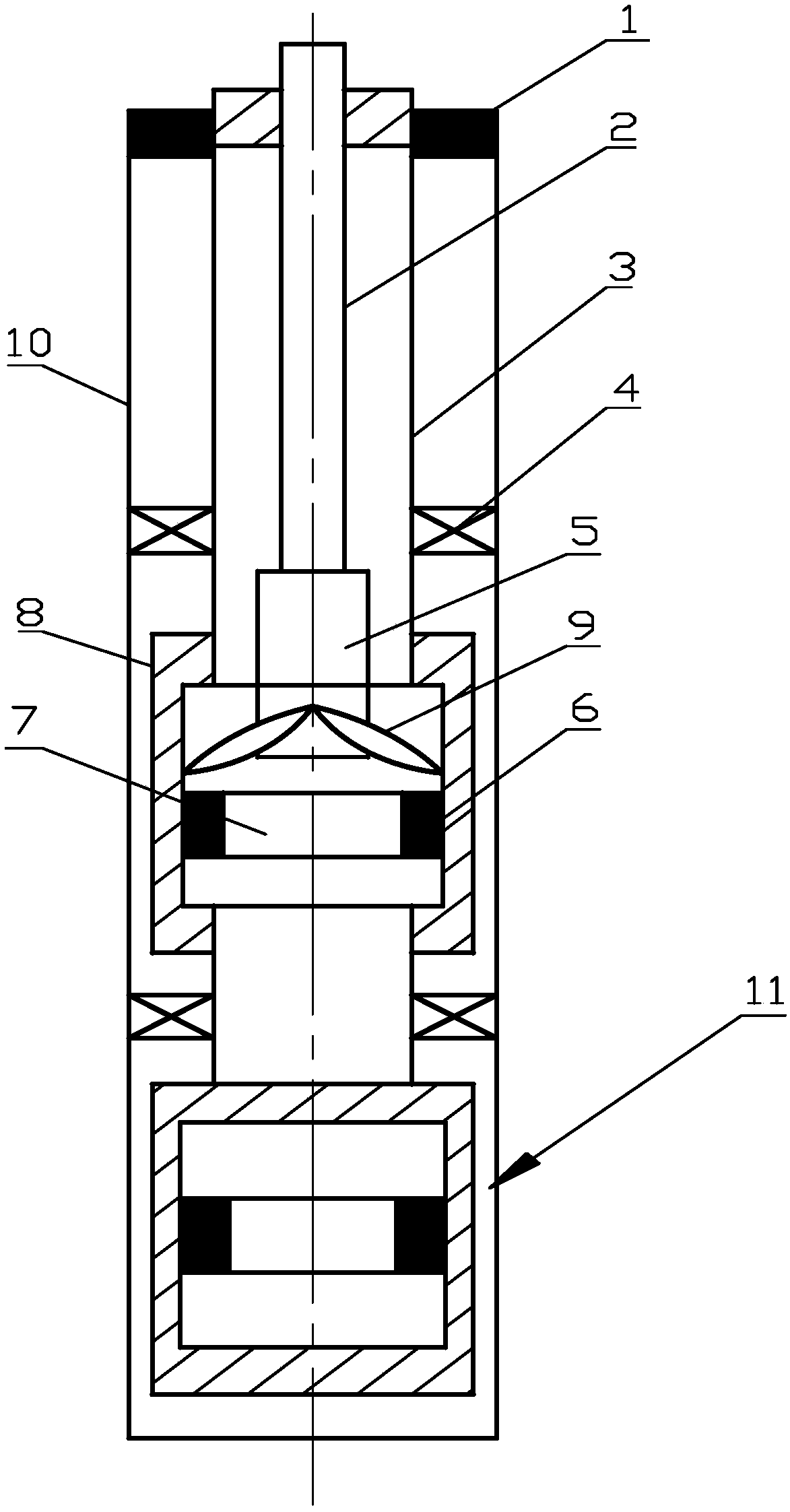

Layered oil production device

InactiveCN102953715AAvoid interlayer interferenceImprove pump efficiencyFluid removalOil productionOil well

The invention discloses a layered oil production device and relates to an oil production device, particular to a layered oil production device. The layered oil production device comprises a casing pipe, wherein the oil production device is arranged inside the casing pipe and is fixed in the casing pipe through a packer. The layered oil production device is characterized in that the oil production device comprises two oil-well pumps which are vertically arranged in series. According to the layered oil production device disclosed by the invention, the upper oil-well pump and the lower oil-well pump are independently arranged by using the packer, so that the interlayer interference phenomenon is effectively avoided; and meanwhile, the efficiency of the pumps can be increased. The layered oil production device disclosed by the invention is simple in structure and stronger in practicality.

Owner:SHAANXI ZHONGMING ENERGY INVESTMENT

Separate-layer sand blocking simultaneous production pipe string

ActiveCN104420834AAvoid the problem of not being able to lift the stringImprove single well productionDrilling rodsFluid removalOil productionOil well

Disclosed is a separate-layer sand blocking simultaneous production pipe string. In order to overcome the shortcoming that due to phenomena of sand jamming, sand blocking and sand burying of an existing oil well with the serious interlayer interference, oil production cannot be smoothly carried out, an upper packer, a safety joint I, a screen pipe I, a safety joint II, a lower packer, a safety joint III, a screen pipe II and a screwed plug of the separate-layer pipe string are sequentially and fixedly connected from top to bottom through oil pipes, and an upper sealing working cylinder is fixedly arranged between the screen pipe I and the safety joint II of the separate-layer pipe string. A lower sealing working cylinder is fixedly arranged between the safety joint III and the screen pipe II, and the inner diameter of the upper sealing working cylinder and the inner diameter of the lower sealing working cylinder are smaller than the inner diameter of the oil pipes. A hollow sealing pipe is fixedly arranged at the lower end of a separate-layer oil production pump of a lifting pipe string, and the lower end of the hollow sealing pipe is always matched with an inner hole of the upper sealing working cylinder. An annulus is formed between the hollow sealing pipe and an inner hole, above the upper sealing working cylinder, of the separate-layer pipe string. The separate-layer sand blocking simultaneous production pipe string has the beneficial effects of being reasonable in structural design, and capable of avoiding the interlayer interference, and effectively improving per-well production and production aging of a sandy well.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +2

Downhole intelligent control expansion packer

ActiveCN107489395BSimplify the inspection and sealing processContain sand productionConstructionsWell/borehole valve arrangementsFluid migrationUpper joint

The invention discloses a downhole intelligent controlling type expansion packer. The downhole intelligent controlling type expansion packer comprises an upper joint and a lower joint; an intelligent controlling plate (15) is fixedly connected to the upper joint; an inner cavity pressure gauge (47), a sealing pressure gauge (54) and an in-pipe pressure gauge (55) which are connected with the intelligent controlling plate (15) are arranged on one side of a sealing main body (33); an electric switch is arranged in the sealing main body (33) and controls liquid inlet and liquid outlet of an inner cavity of a rubber barrel, steel pipe cables penetrate through a packer body, and locking and sealing mechanisms are arranged on the two extended ends of the steel pipe cables. According to the downhole intelligent controlling type expansion packer, the self power supply and data transmission problems are solved by utilizing the penetrating cables, a ground controlling system can control the packer to be set and unset and collect and upload data of the inner cavity, stratum and in-pipe pressure in time, the examining seal procedure of the packer is simplified, the accuracy of other downhole parameter admission is improved, fluid migration preventing pressure difference between layers during stopping injection is raised to over 15MPa, interlayer interference in an oil producing well is solved, and occurrence of downhole accidents is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

External packer of high temperature pipe

The invention relates to an external packer of a high temperature pipe, comprising a coupling, a casing nipple, a central pipe and an upper joint; one end of the casing nipple and one end of the central pipe are fixedly connected or spin-connected by threads; the other end of the casing nipple and the coupling are fixedly connected or spin-connected by threads; the casing nipple, the upper joint sleeve and the central pipe are connected by threads; the external packer also comprises a high-temperature rubber barrel component and a bidirectional locking device; the high-temperature rubber barrel component and the bidirectional locking device are sleeved on the external surface of the central pipe; one end of the high-temperature rubber barrel component is contacted with the upper joint andthe other end thereof is contacted with the bidirectional locking device. The external packer can divide longer horizontal well section of a thick oil horizontal well into a plurality of small sections mutually independent for independent operation, solves the problem that the employed well sections are not even; and simultaneously the inner through diameters of the external packer of the high temperature pipe and a screening pipe are consistent, thus being capable of leading a steam injection pipe column and other pipe columns to be down smoothly.

Owner:中国石油辽河油田钻采工艺研究院

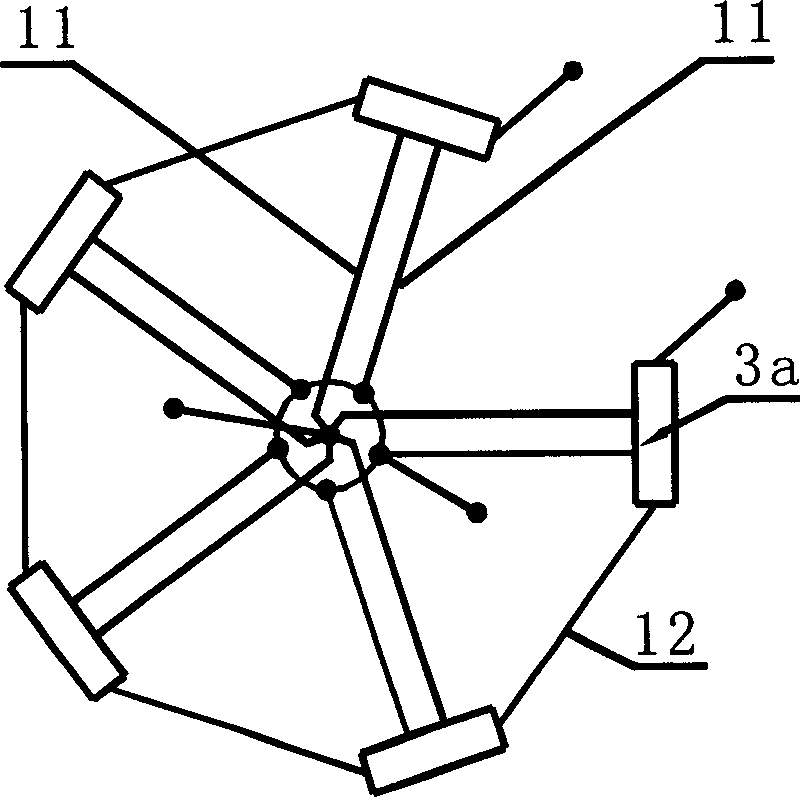

Multilayer-gas-lift water exploration device for oil field and water exploration method thereof

The invention relates to an oil-field water exploration device, in particular to a multilayer-gas-lift water exploration device. The multilayer-gas-lift water exploration device aims at achieving theeffects that multilayer repeating layer-adjusting water exploration can be achieved, layer limiting is avoided, and the water exploration efficiency is improved. The multilayer-gas-lift water exploration device comprises a well opening device (1), a gas-lift pipe column (2), a production pipe column (3) and water exploration layers (11); layering switches (6) are installed at the portions, corresponding to all the water exploration layers (11), on the production pipe column (3), and all the water exploration layers (11) are partitioned through packers (4); after the packers (4) are closed, a switch starter (5) enters a well along with the gas-lift pipe column (2) together, liquid is explored, and then the oil-water content of the explored liquid is analyzed to judge whether the layer is awater layer or not, and layering is accurate. The multilayer-gas-lift water exploration device has the advantages that the structure is simple, operation is flexible, lifting is convenient, and the clamping phenomenon is avoided; layering is accurate, multilayer repeating water exploration can be achieved through once pipe column, and layer section limiting is avoided.

Owner:QINGYANG DUNBO TECH DEV CO LTD

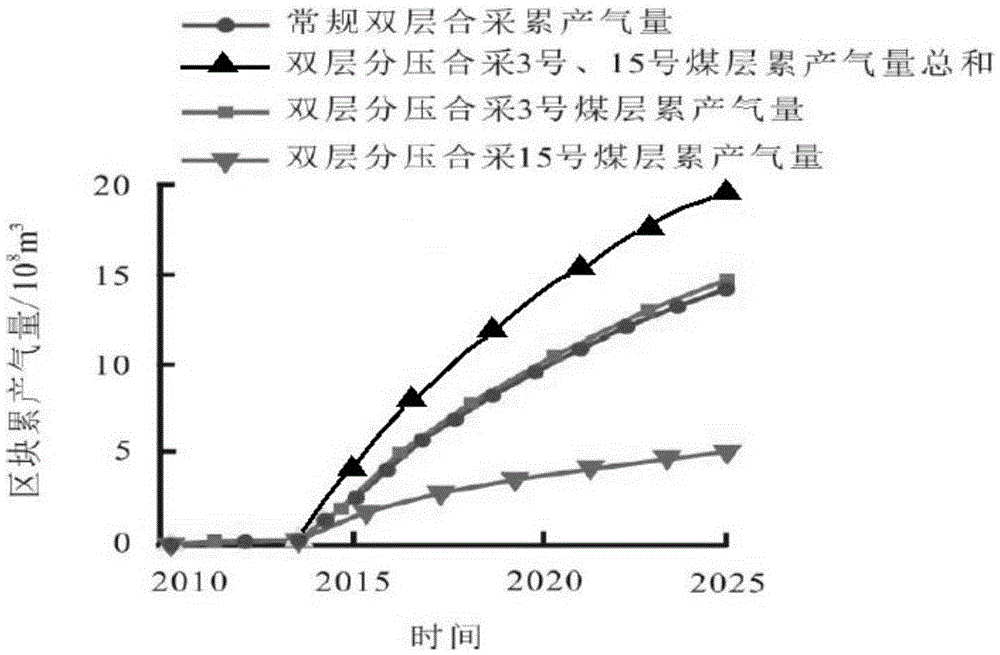

Coal bed methane vertical well double-layer partial pressure combined production method and its device

InactiveCN105649578BEffective separationAvoid interlayer interferenceFluid removalPressure systemEngineering

The invention relates to a vertical-well double-layer partial-pressure commingling method and device for coalbed methane. The method includes the steps that a pipe is arranged in the well, and three isolated channels including the first channel, the second channel and the third channel are arranged in the pipe; the side wall of the first channel and the side wall of the second channel are communicated with two coal beds respectively, gas of the two coal beds is discharged to a well opening through the first channel and the second channel respectively, liquid of the two coal beds flows to the bottom of the first channel and the bottom of the second channel respectively, and gas-liquid separation is achieved in the well; one-way valves are arranged between the first channel and the second channel and between the second channel and the third channel, and the liquid of the two coal beds is jointly drawn out of the well while accumulated liquid in the well bottom is avoided. According to the method and device, the gas and the water generated by the upper coal bed and the lower coal bed are jointly mined and jointly drawn through the single well, gas-liquid separation is carried out at the well bottom, the gas is drawn through a gas path, the liquid is drawn through a liquid path, pressure systems of the two coal beds are separated, interlayer interference generated during exploitation is reduced, and the gas yield is effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV +1

Layered process string

ActiveCN104420858BIncrease productionIncrease production capacityFluid removalOil productionOil well

Disclosed is a layering process pipe string. In order to overcome the shortcoming that an existing oil well with serious interlayer interference enables oil production not to be smoothly carried out, and an existing separate production technology cannot meet the production needs, a packer I, a safety joint I, a screen pipe I, a sealing working cylinder I, a safety joint II, a packer II, a safety joint III, a sealing working cylinder II, a screen pipe II and a pipe plug are sequentially and fixedly connected from top to bottom through oil pipes; the packer I is arranged above an upper oil layer, and the packer II is arranged between the upper oil layer and a lower oil layer; the screen pipe I is arranged on the upper oil layer, and the screen pipe II is arranged on the lower oil layer; and the inner diameter of the sealing working cylinder I and the inner diameter of the sealing working cylinder II are smaller than the inner diameter of the oil pipes. The layering process pipe string has the beneficial effects that the structural design is reasonable, the pipe string is matched with lifting pipe strings of different types so as to avoid interlayer interference, and per-well production and the production limitation are effectively improved.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +2

Injection well layered testing and deployment process

InactiveCN104863568BAvoid interlayer interferenceReduce distortionSurveyFluid removalInjection pressureEngineering

A layered testing and adjustment process for an injection well mainly solves the problems that an existing testing and adjustment process is carried out separately under a well shutin circumstance, the number of devices and tools is large, and long time is consumed. The specific testing and adjustment process includes the following steps that firstly, according to an existing throwing and fishing method, blanking plugs in eccentric water distributors in various layers are fished out and then blockage type flowmeters are thrown into the eccentric water distributors in the layers; secondly, different types of injection pressure are adjusted at the mouth of the well, the injection allocation flow of the whole well is 0-150%, and three to six points are selected for pressure adjustment; thirdly, the blockage type flowmeters in the layers are fished out, and testing data are obtained; fourthly, packer seal examining is implemented; fifthly, layered flow adjustment is implemented; sixthly, layered well testing and pressure measurement are implemented. The layered testing and adjustment process for the injection well has the advantages that under a well non-shutin circumstance, layered pressure measurement is completed at the same time, the number of devices and tools is small, operators have no special skill requirements or testing and adjustment experience, and data can be synchronized.

Owner:黑龙江普测科技有限公司

Insulation aging test device used for converter high voltage pulse equipment

InactiveCN100348989CMeet the requirements of insulation aging testSmall distortionElectrical testingTransformerFrequency conversion

An insulation ageing test device of frequency conversion high voltage pulse equipment is prepared as connecting output end of pulse generator to primary edge of high voltage boosting transformer with its secondary edge being connected to wire in insulation sleeve, applying 300H2 to lkH2, 1kH2 to 5kH2 , 5kH2 to 10k H2 and 10k H2 to 20k H2 as operation frequency of high voltage boosting transformer alternately, connecting said boosting transformer to output of pulse generator for outputting square wave to meet requirements of insulation ageing test.

Owner:SOUTHWEST JIAOTONG UNIV

Layered mining pipe string of rock salt mine and a layered mining method of rock salt mine

ActiveCN111236919BAvoid interlayer interferenceImprove mining efficiencyFluid removalSalt minePetroleum engineering

The invention discloses a rock salt mine layered-mining pipe string and a rock salt mine layered-mining method, and belongs to the technical field of rock salt mine mining. Through the rock salt minelayered-mining pipe string and the rock salt mine layered-mining method, the defect that the prior art lacks a layered water-injection huff and puff process pipe string and a related mining method torealize layered water-injection huff and puff mining of a rock salt mine is overcome. The rock salt mine layered-mining pipe string mainly comprises an oil pipe, a hollow rod, a hollow pump, a hollowjacking rod, an outer oil pipe, an upper packer, an inner oil pipe, a flow path conversion nipple, a bridge-type passage and a lower packer, the lower end of the oil pipe is connected with the hollowpump, the lower end of the hollow pump is connected with the outer oil pipe and the inner oil pipe through double fasteners correspondingly, the lower end of the outer oil pipe is sequentially connected with the upper packer, the bridge-type passage and the lower packer, the upper packer and the lower packer are sealed on the inner wall of a casing, the lower end of the inner oil pipe is connectedwith the flow path conversion nipple, the side face of the flow path conversion nipple is connected with the bridge-type passage, the hollow rod is arranged in the oil pipe in a sleeved mode, the lower end of the hollow rod continues to be connected with the hollow jacking rod through a hollow pump plunger, and a single-flow valve is mounted in the hollow jacking rod.

Owner:SHANDONG INST OF GEOLOGICAL SCI

Longitudinally superposed developing three-strata oil reservoir well pattern and deployment method thereof

The embodiment of the invention discloses a longitudinally superposed developing three-strata oil reservoir well pattern and a deployment method of the longitudinally superposed developing three-strata oil reservoir well pattern. To the longitudinally superposed developing three-strata oil reservoir, the well spacing of a basic well pattern is 2*(square root of 2)*L; after being encrypted once, the well spacing of a middle transitional well pattern is 2L; after being encrypted twice, two superposed inverted nine-spot well patterns with well spacing of 2L are formed; after being encrypted for three times, two superposed inverted nine-spot well patterns with well spacing of 2L and one superposed inverted nine-spot well pattern with well spacing of (square root of 2)*L are formed; and after pairwise alternatively development, the well spacing of the plane well pattern of each strata has a rational well spacing of L; the evolution process of the well spacing is as follows: 2*(square root of 2)* L to 2L to (square root of 2)*L to L; the middle process of well patterns conversion with a well spacing of 2L and (square root of 2)*L is added; at the same drilling speed, well placement uniformity coefficient and reserve control speed are increased; the well spacing is encrypted in the alternation of well patterns; each well pattern can realize order development to each longitudinal strata; the utilization ratio of the well patterns is improved; meanwhile, the oil reservoir is uniformly used, so that the method is in favor of increasing accumulated oil production of an oil field and improving the recovery ratio; and interlayer interference generated by commingled extracting oil in multiple oil layers of longitudinal series of strata is avoided.

Owner:PETROCHINA CO LTD

Three-stage stratified production string

The invention discloses a three-stage layered commingled production string. In order to overcome a defect that a production string cannot simultaneously exploit more than two oil layers in the prior art, the three-stage layered commingled production string is characterized in that the lower end of a tubing string is sequentially fixedly provided with a primary pump, an upper packer, an oil tube I, a suspension nipple I, an oil tube II, a secondary pump, a suspension nipple II, an oil tube III, a lower packer and a tail pipe, wherein the primary pump is positioned on an upper oil layer; the upper packer is positioned between the upper oil layer and a middle oil layer; the lower packer is positioned between the middle oil layer and a lower oil layer; internal threads at the lower end of the suspension nipple I are fixedly connected with the upper end of a seal cartridge; internal threads at the lower end of the suspension nipple II are fixedly connected with the upper end of a pump cylinder of a triple-stage pump; a hollow sealing rod of a plunger assembly is positioned in the seal cartridge; the diameter of the hollow sealing rod is smaller than the diameters of a primary pump plunger and a secondary pump plunger. The three-stage layered commingled production string has the beneficial effects that different oil layers are simultaneously exploited by feeding a string once, and the exploitation efficiency is improved.

Owner:DAGANG OIL FIELD GRP +2

Arrangement method of longitudinally superposed developing two-strata oil reservoir well pattern

ActiveCN102839959BIncrease profitImprove uniformityFluid removalWell placementLongitudinal development

Owner:PETROCHINA CO LTD

A layered mining pipe column for rock salt mine and a layered mining method for rock salt mine

ActiveCN111236918BAvoid interlayer interferenceImprove mining efficiencyFluid removalCheck valveSalt mine

Owner:SHANDONG INST OF GEOLOGICAL SCI

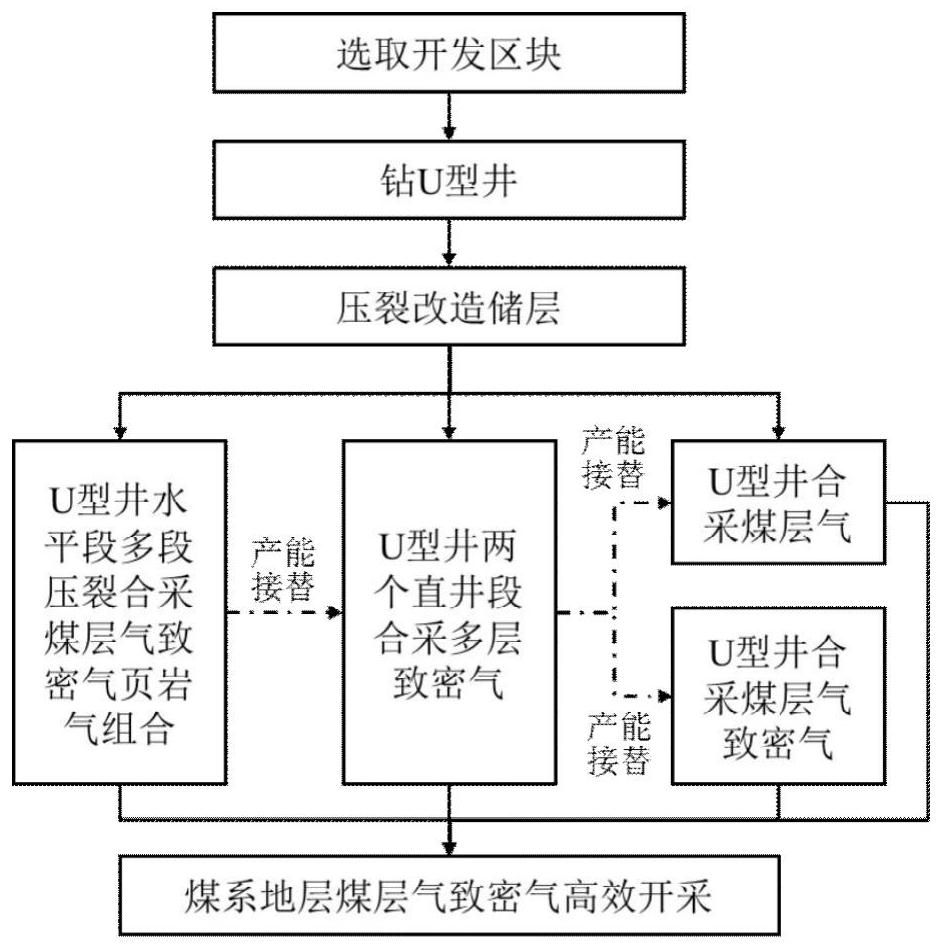

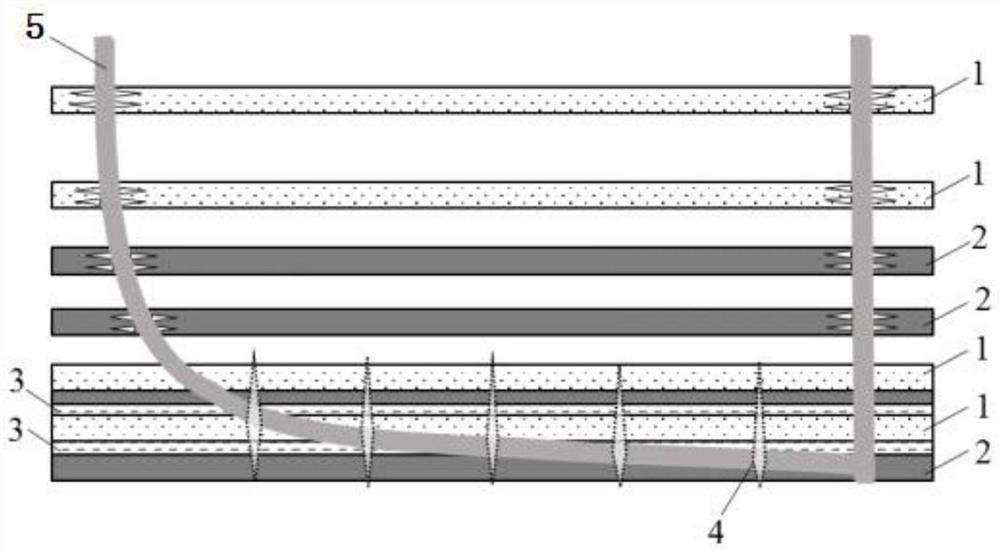

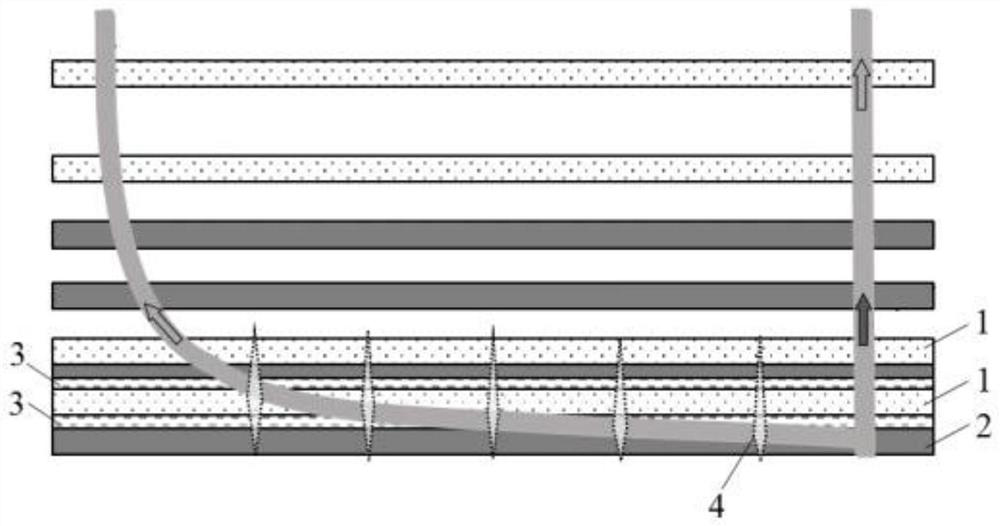

A method for multi-gas co-production and production capacity replacement in coal-measure strata

ActiveCN111894528BExpansion of mining areaRealize three-dimensional developmentFluid removalCoal measuresHorizontal wells

The invention discloses a method for multi-gas co-production and production capacity replacement of coal-measure strata, which comprises the following steps: Step 1, selecting a block in which coal seams and tight sandstone layers are relatively developed in coal-measure strata, and drilling a U-shaped block in the block Well, wherein, the horizontal section of the U-shaped well is in an inclined state, and the horizontal section passes through multiple reservoirs at the same time; step 2, the multiple reservoirs that the horizontal well section passes through are used for joint production by fracturing, and the high Gas production in the vertical well section at the structural position, drainage and fines discharge in the vertical well section at the low structural position and gas production; step 3, when the gas production of the horizontal well section decreases, use a packer to isolate the vertical well section from the horizontal section, and use The two vertical sections of the U-shaped well produce gas from the sandstone layer; step 4, when the gas production in step 3 decreases, all the reservoirs are combined for production. The method proposed by the invention solves the problems of coal seam water production and pressure mismatch between high-pressure and low-pressure reservoirs, reduces the interference of coal seam pulverization, and realizes production capacity replacement in coal-measure gas development.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com