Patents

Literature

31results about How to "Improve single well production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

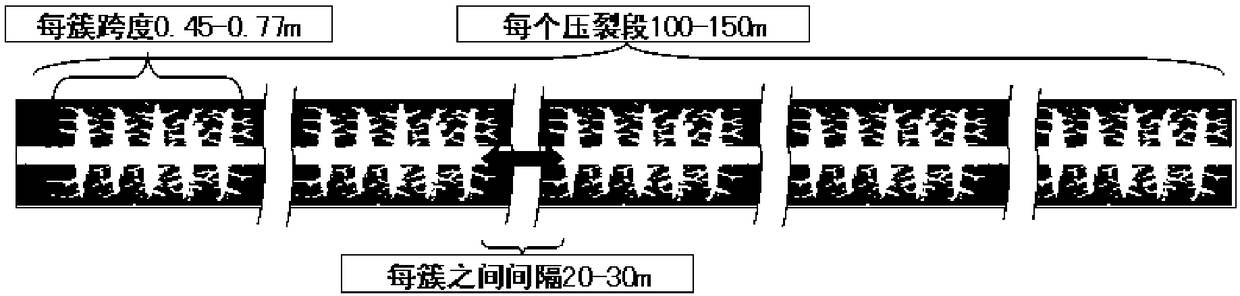

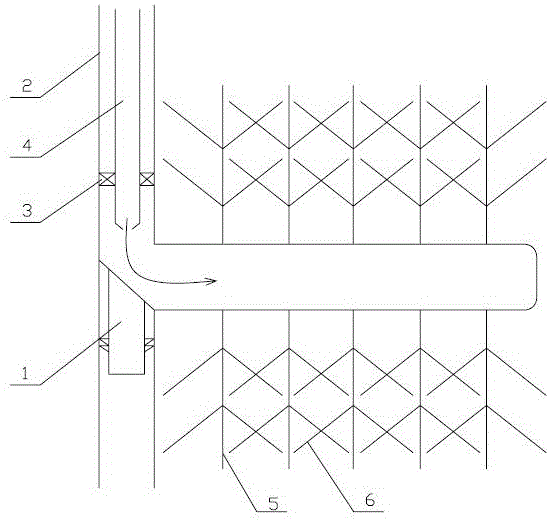

Pulse sand fracturing method realizing high fracture conductivity of cracks

InactiveCN104727799AImprove fracture conductivityImprove single well productionFluid removalPetrologyChannel network

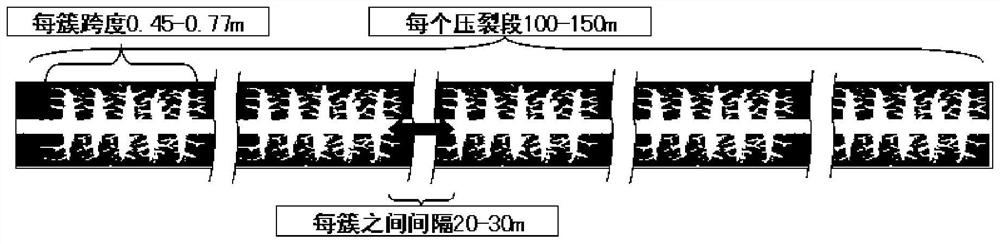

The invention discloses a pulse sand fracturing method realizing high fracture conductivity of cracks and belongs to the field of oilfield development. The pulse sand fracturing method includes steps of firstly, fracturing an ultralow-permeability reservoir horizontal well sectionally in multiple clusters, and judging whether high fracture conductivity of the cracks is formed or not by pulse sand fracturing by researching characteristics of the ultralow-permeability reservoir, if yes, executing a second step; secondly, solidifying sand by fiber fracturing fluid by pulse sand adding process in the fracturing process, and forming 'cylinder' support in an artificial crack, so that a channel network high in flow conductivity is formed in the artificial crack, and the artificial crack has high flow conductivity. By the pulse sand fracturing method realizing high fracture conductivity of the cracks, conductivity of the cracks can be improved, and single-well yield is greatly increased. The method has remarkable effect on the site, and by the method, via practical comparison, single-well yield is increased by 20% as compared with that of conventional fracturing optimized design of horizontal wells in the same area and is five to seven times of adjacent straight wells.

Owner:PETROCHINA CO LTD

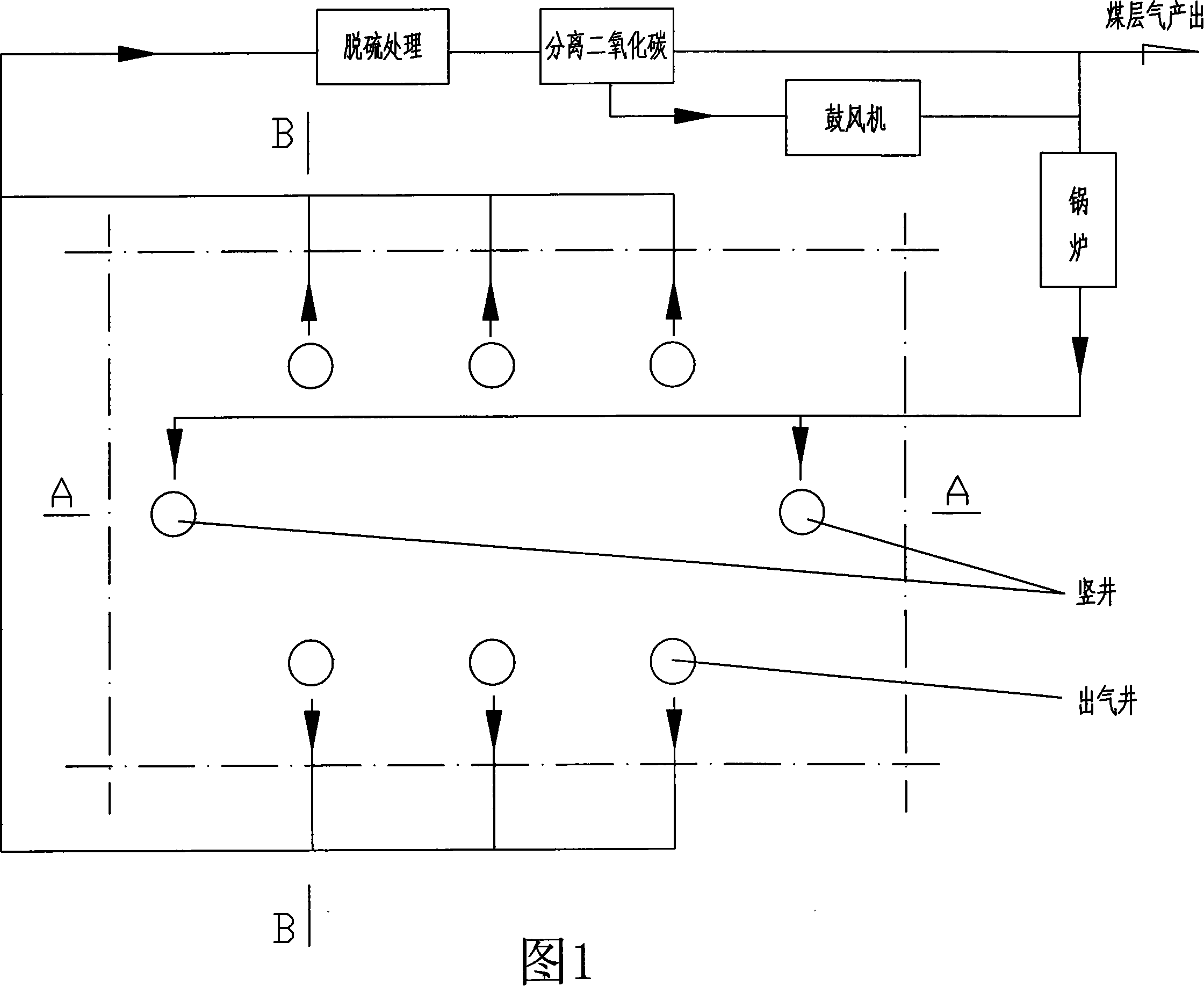

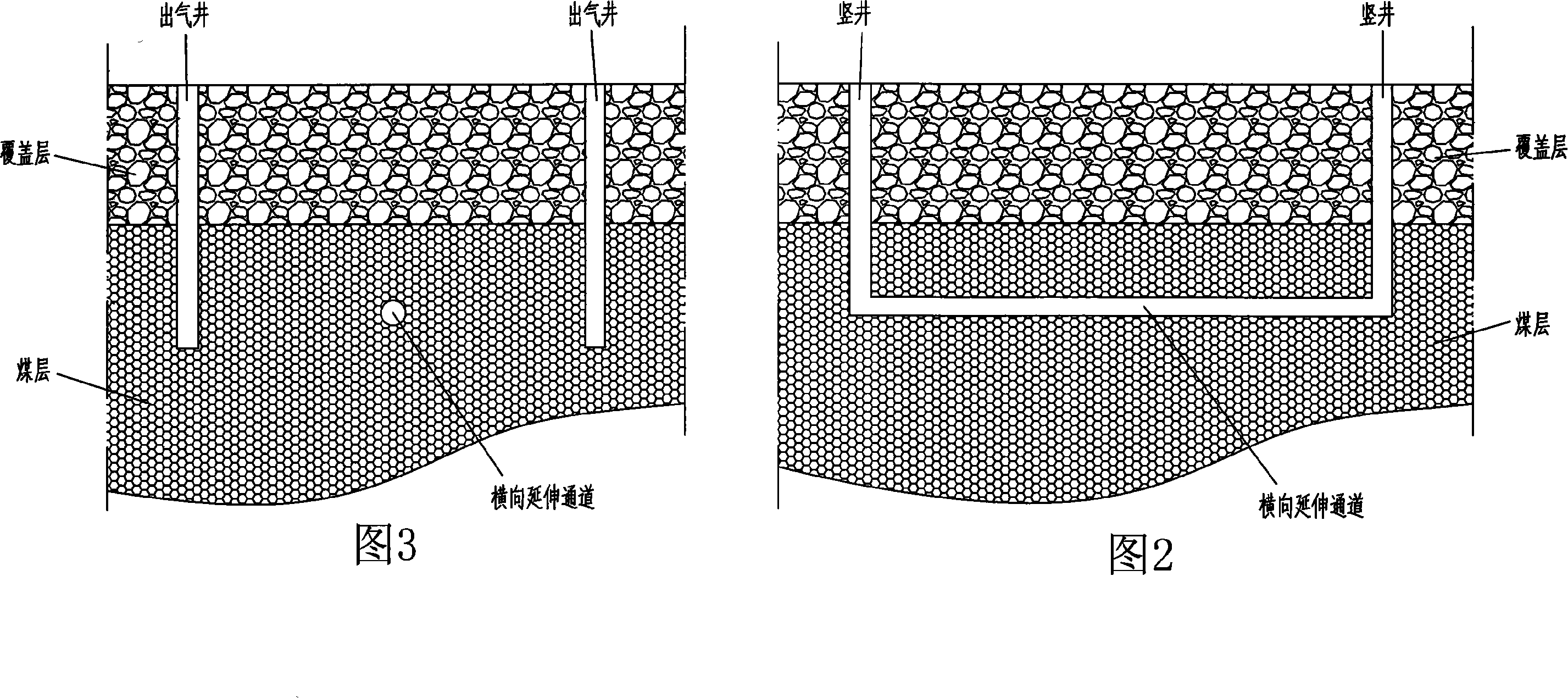

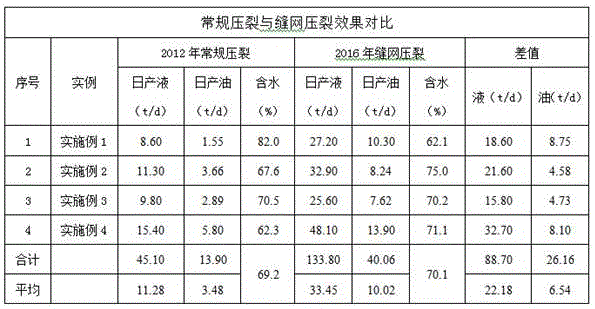

Coal bed gas mining novel technology

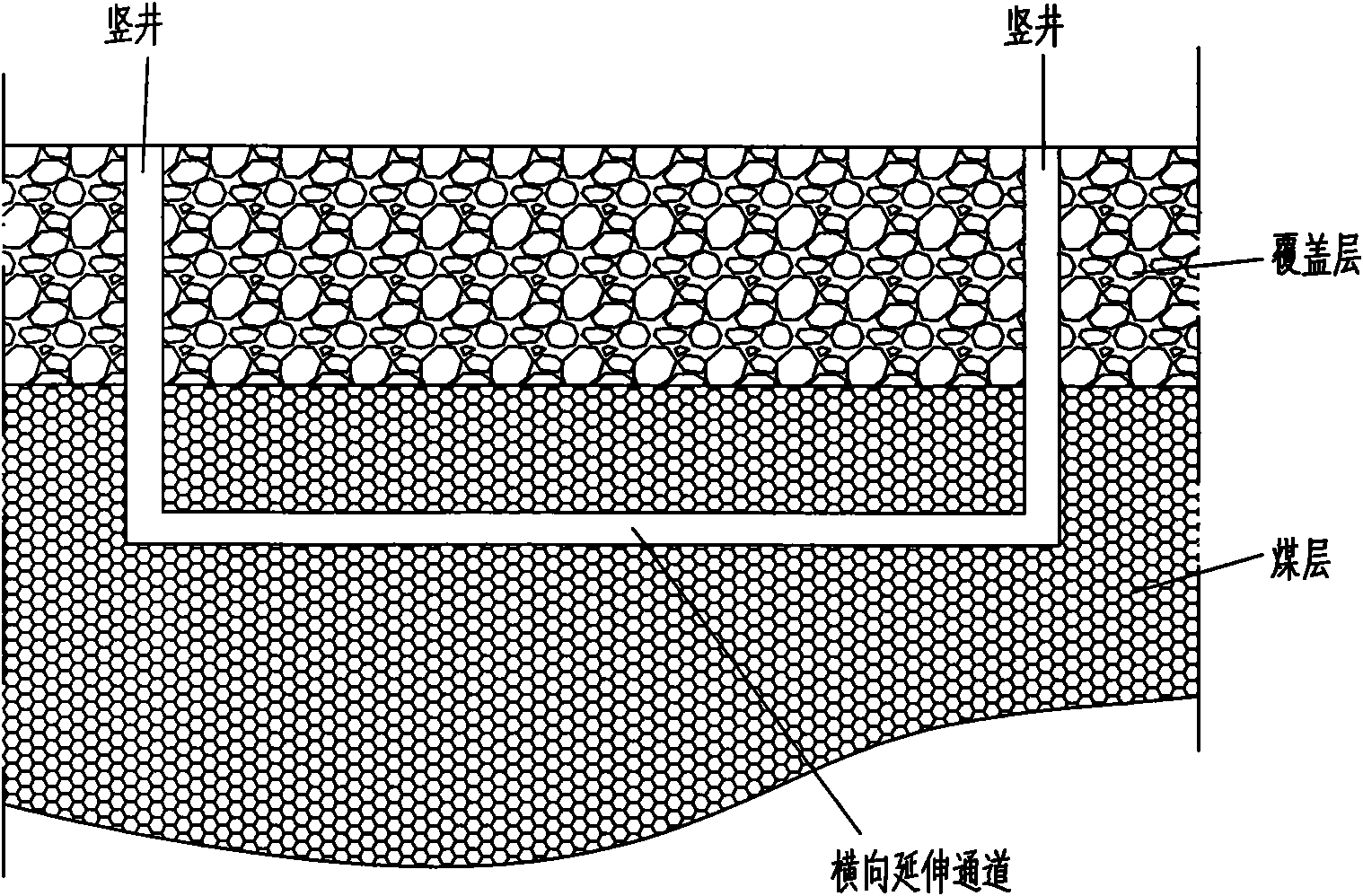

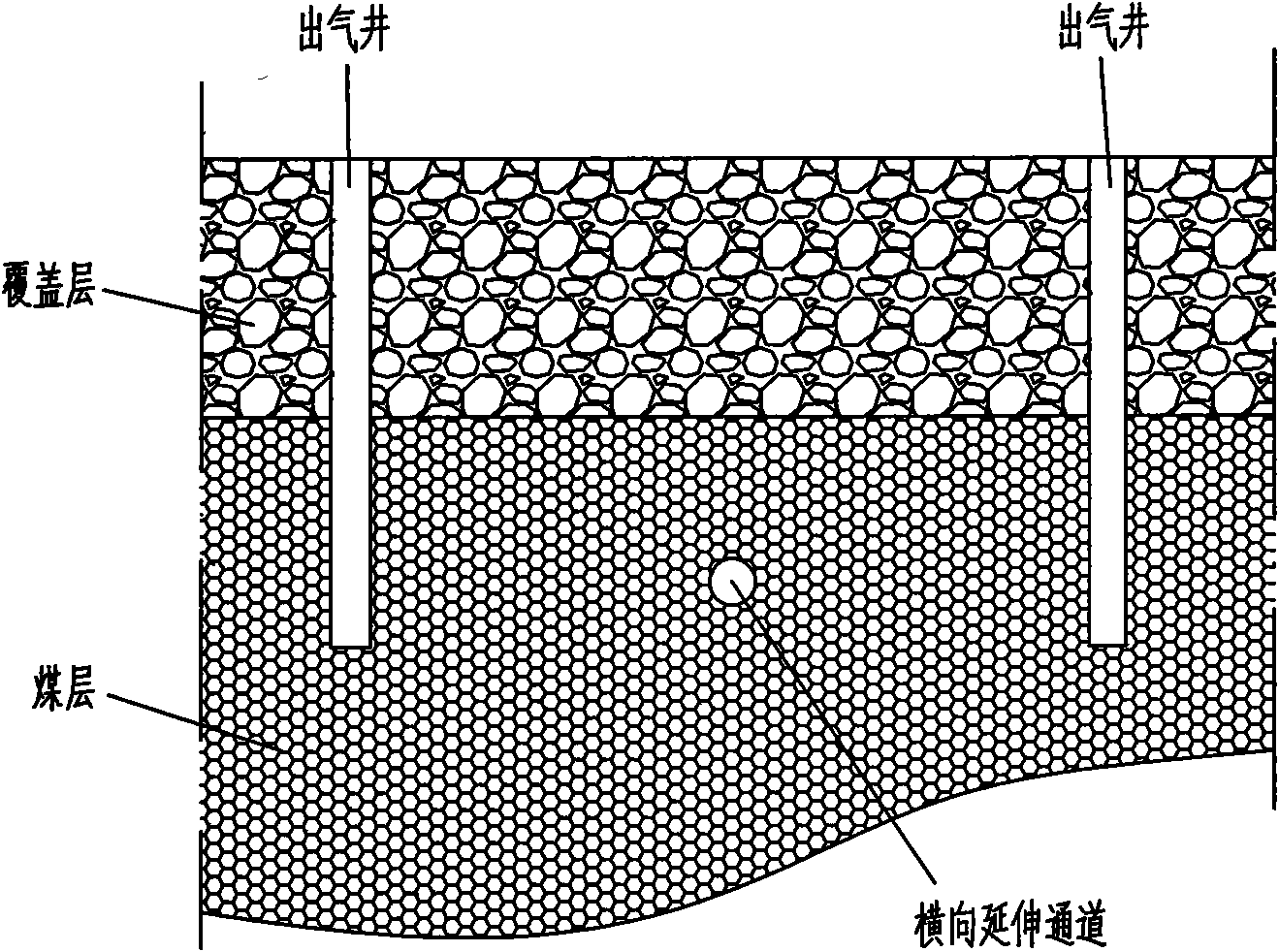

The invention discloses a new coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

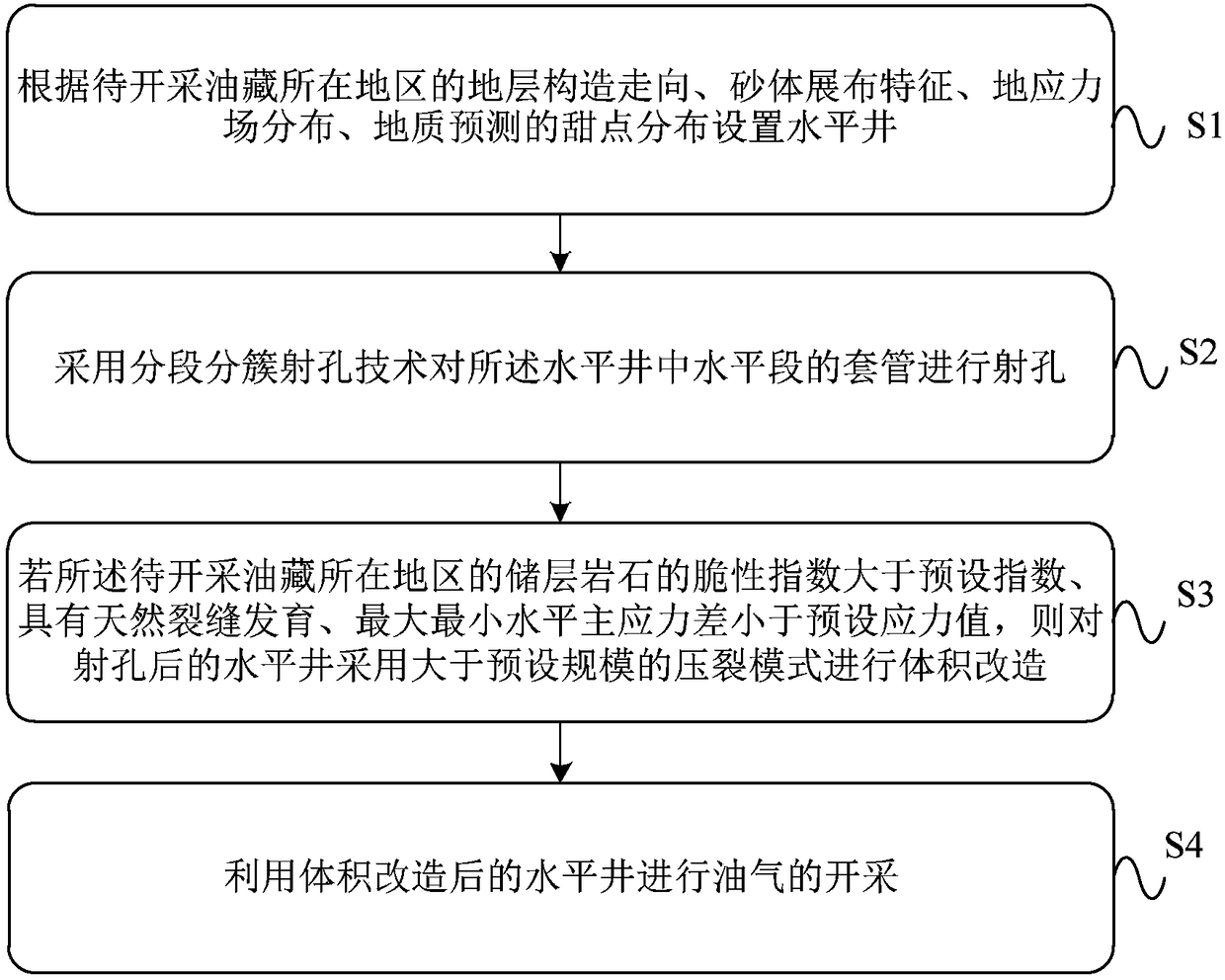

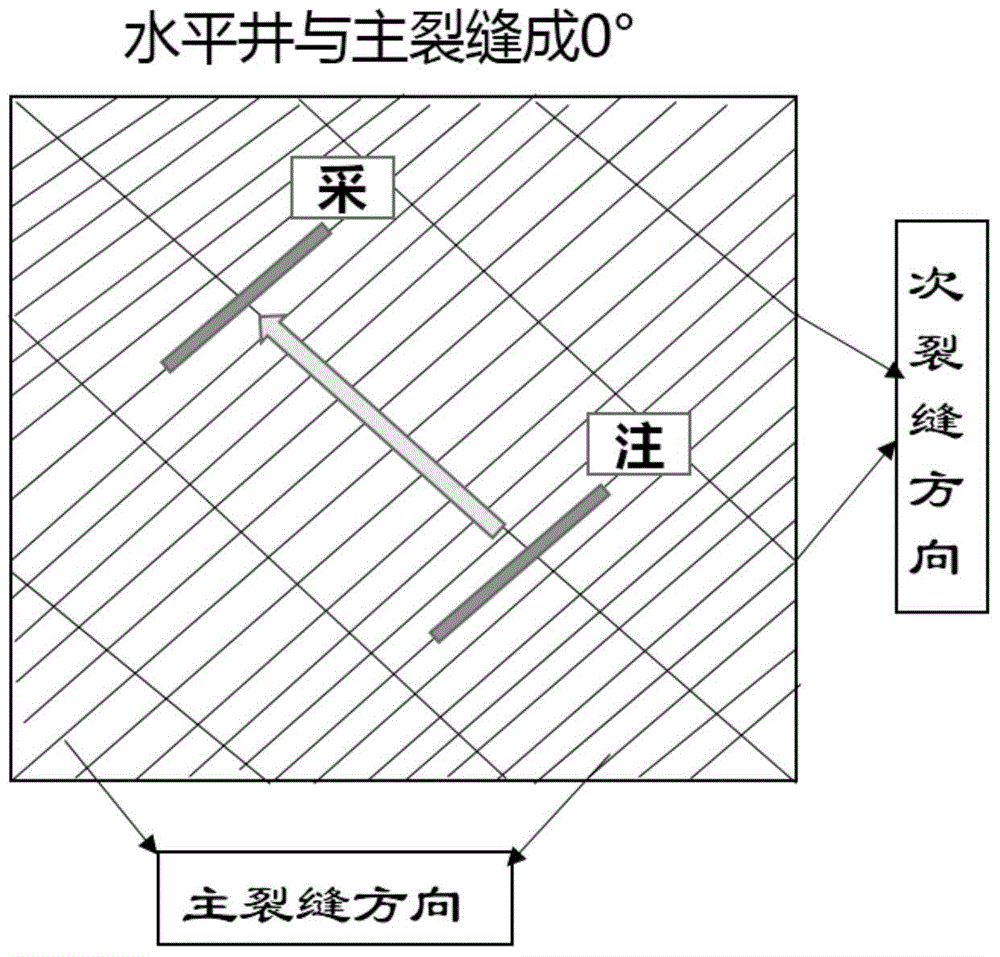

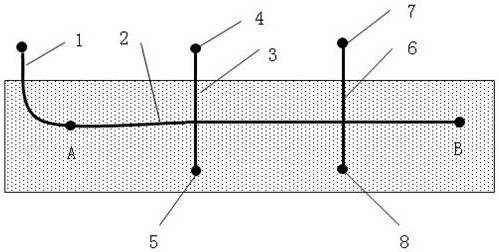

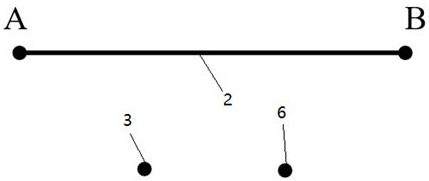

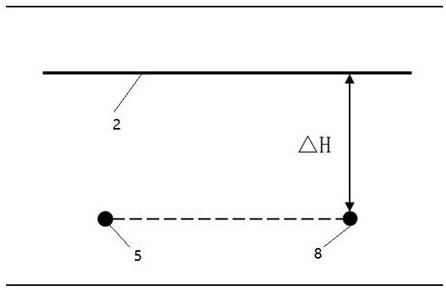

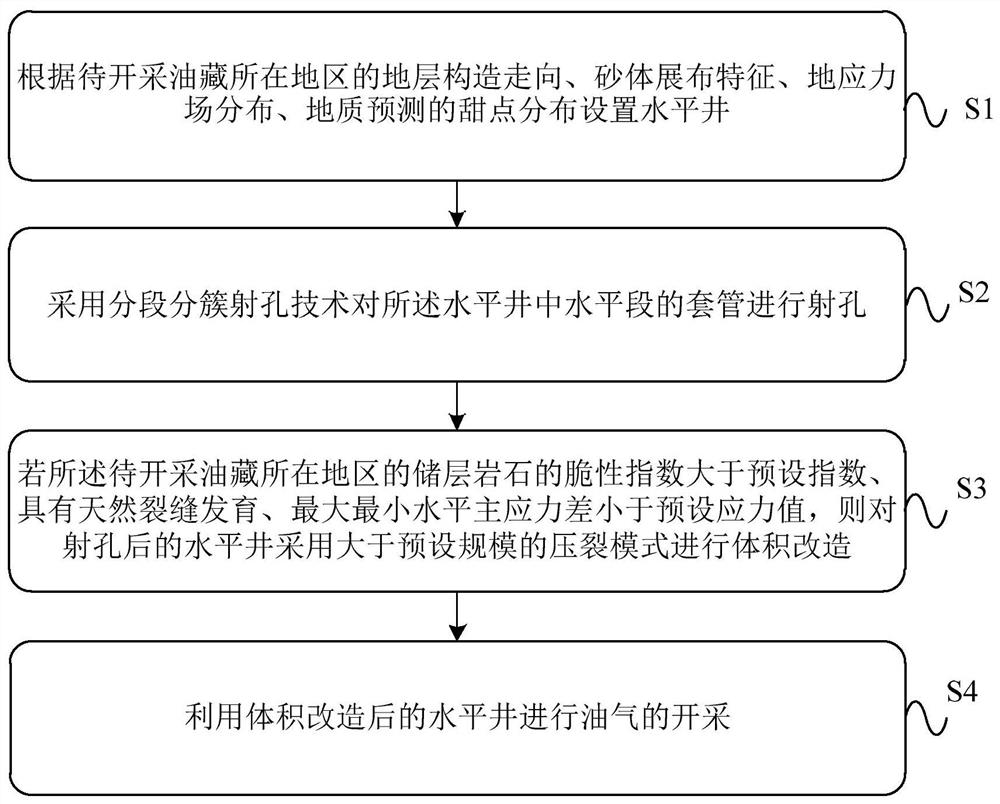

Oil and gas exploitation method for increasing recovery ratio through artificial crack control reserves

ActiveCN108561106AImprove single well productionIncrease productionFluid removalPressure differenceMaterial Perforation

The invention provides an oil and gas exploitation method for increasing the recovery ratio through artificial crack control reserves. The method comprises the steps of arranging a horizontal well according to the stratum structure trend, distribution features of sand bodies, distribution of stress fields and the like of an area where a to-be-exploited oil deposit is located; adopting a segmentedand clustered perforation technology for perforating a casing pipe in the horizontal well; adopting a pressing crack mode of which the scale is larger than a preset scale for conducting capacity cracking transformation on the perforated horizontal well if the brittleness index of reservoir rocks of the area where the to-be-exploited oil deposit is located is larger than a preset index, the reservoir rocks have natural crack development, and the max-min primary stress difference is smaller than a preset stress value; adopting the horizontal well which is subjected to capacity cracking transformation for exploiting oil and gas. According to the embodiment, the mode of well control reserves is converted into the mode of crack control reserves, the contact area of a matrix and the cracks is increased, the distance of fluid in the matrix to flow to the cracks is reduced, the pressure difference for driving the fluid in the matrix to flow to the cracks is lowered, and the per-well yield andthe recovery ratio of oil and gas exploitation are increased.

Owner:PETROCHINA CO LTD

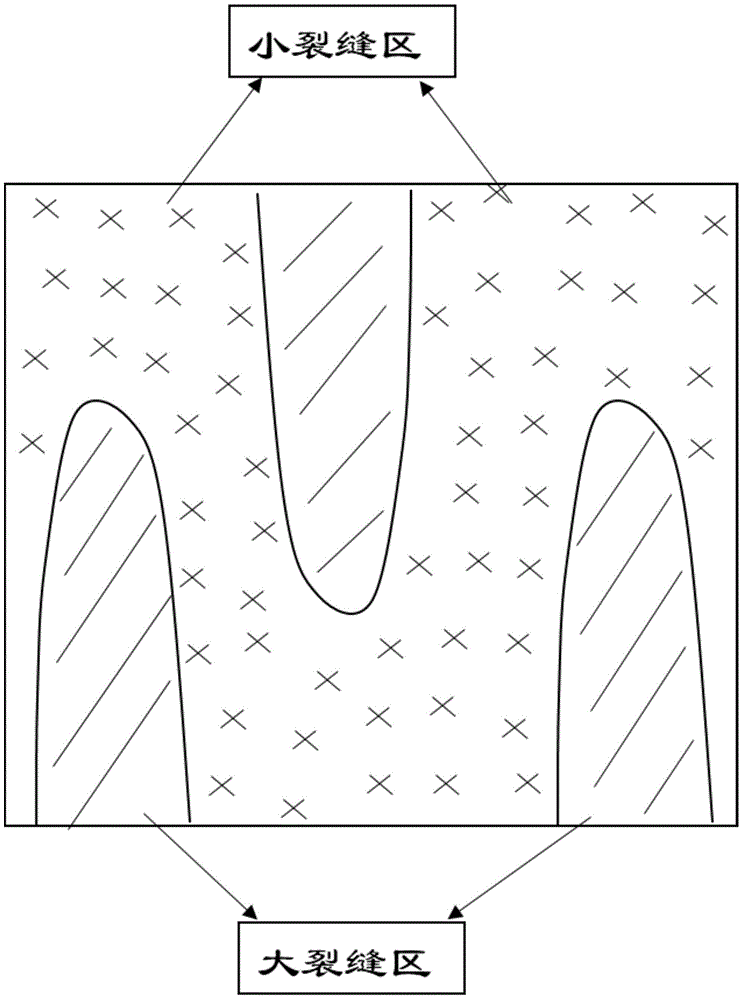

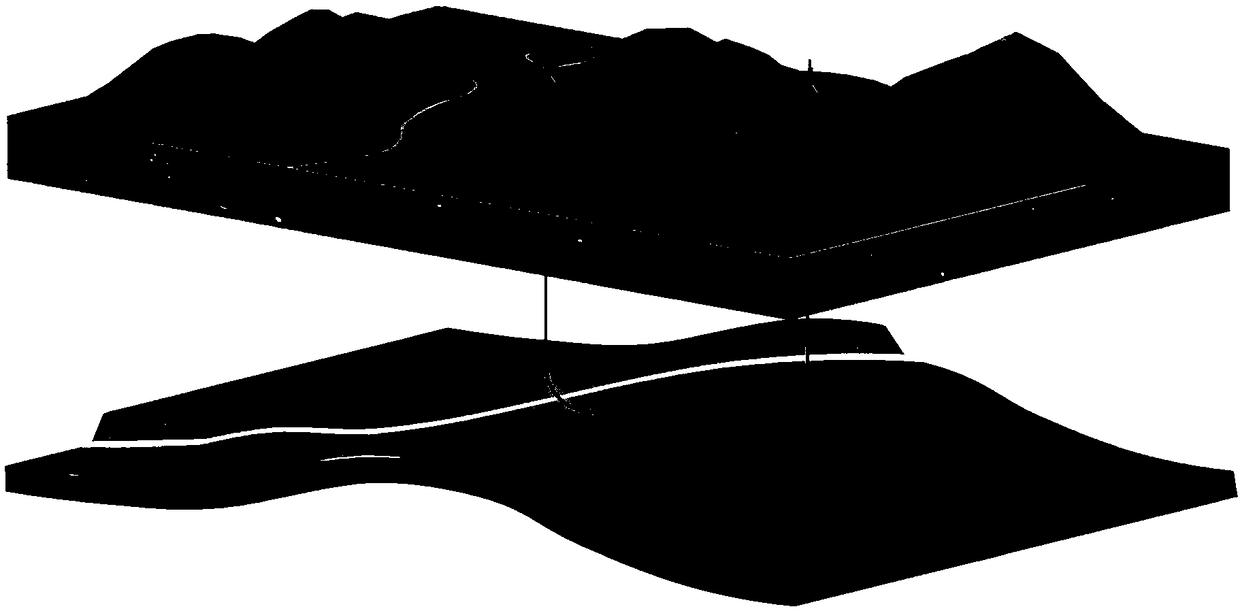

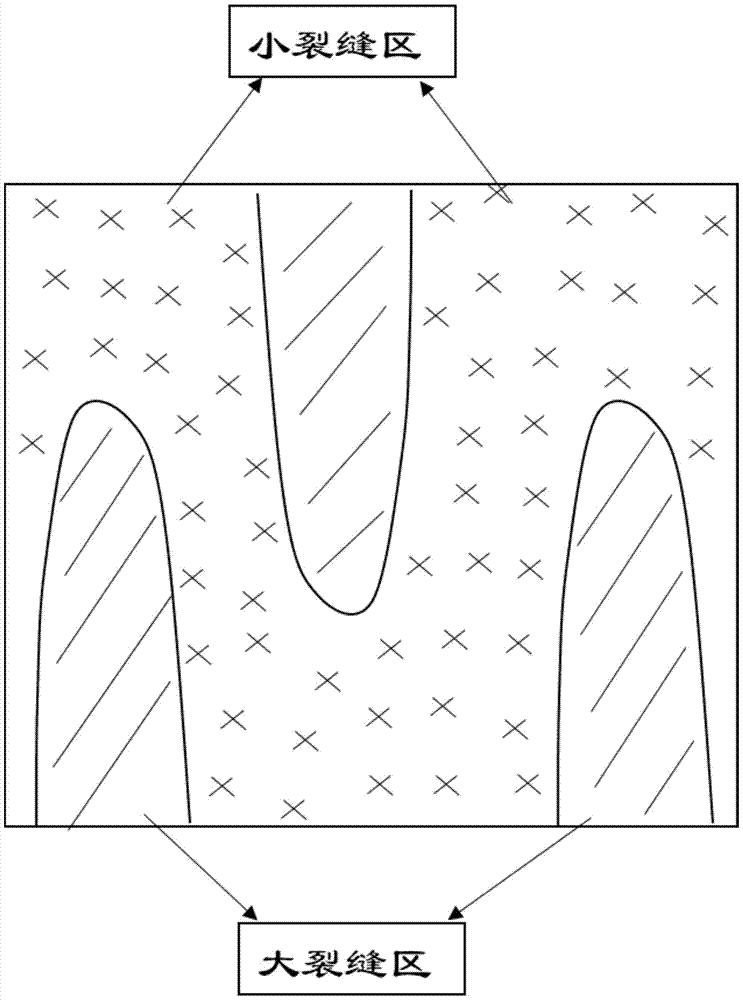

Well network deployment method of giant thick fractured and buried hill reservoir

ActiveCN104912537AGuaranteed encounterReduce production differential pressureFluid removalNetwork deploymentDistribution method

The invention relates to a well network deployment method of a giant thick fractured and buried hill reservoir. The method is characterized in that a set of large-fracture-injection small-fracture-production plane-staggering longitudinal-three-dimension bottom-injection and top-production horizontal well injection-production well network is deployed in the giant thick fractured and buried hill reservoir, wherein for the large-fracture injection, an injection well is deployed at a large fracture region of the giant thick fractured and buried hill reservoir; for the small-fracture production, a production well is deployed in a small fracture region of the giant thick fractured and buried hill reservoir; for the plane staggering, the projection of the injection well and the projection of the production well on the plane are mutually parallel but not rightly aligned; for the longitudinal three-dimension, the horizontal wells are in parallel arrangement at different depths in the giant thick fractured and buried hill reservoir, and a three-dimensional well network is formed in a direction parallel to the gravity and in a cross section perpendicular to a main shaft; and for the bottom injection and top production, a water injection well is arranged at the bottom of the giant thick fractured and buried hill reservoir, and a production well is arranged on the top of the giant thick fractured and buried hill reservoir. The well network deployment method can effectively solve the problem of well distribution difficulty of the giant thick buried hill reservoir, and belongs to an effective well distribution method of the giant thick fractured and buried hill reservoir.

Owner:CHINA NAT OFFSHORE OIL CORP +1

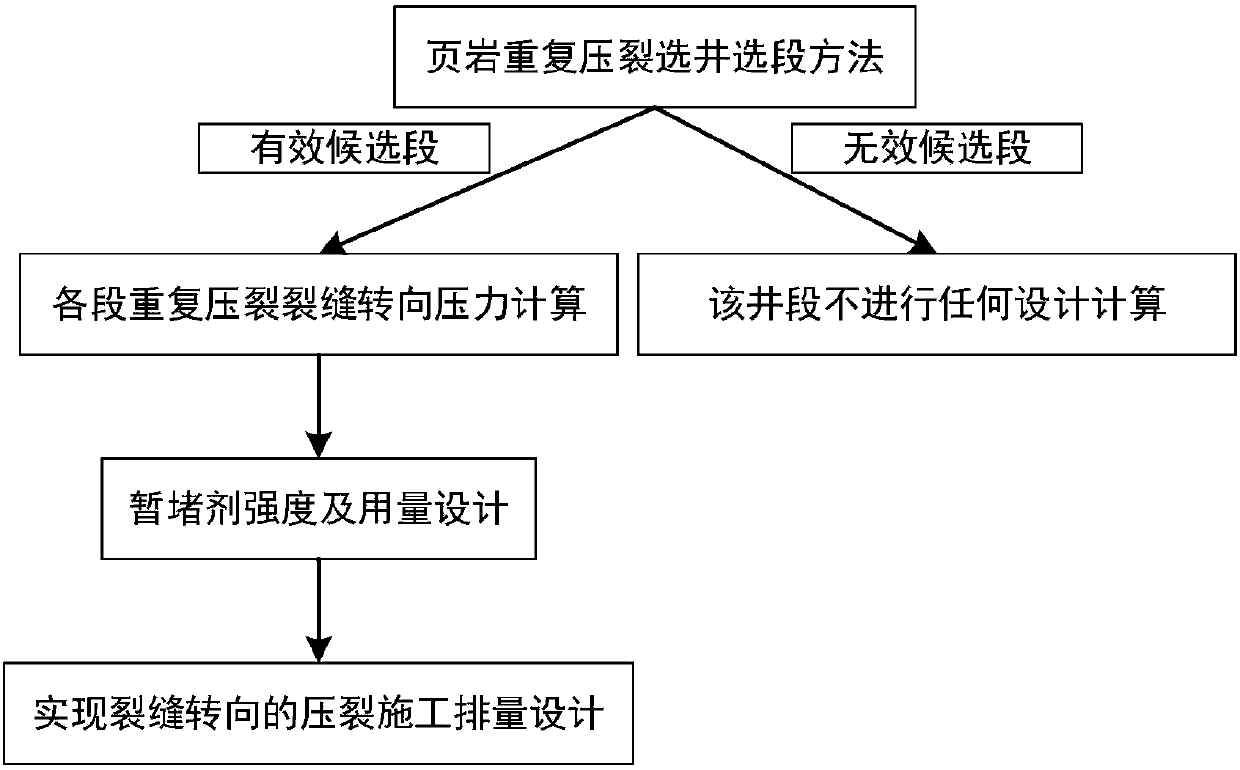

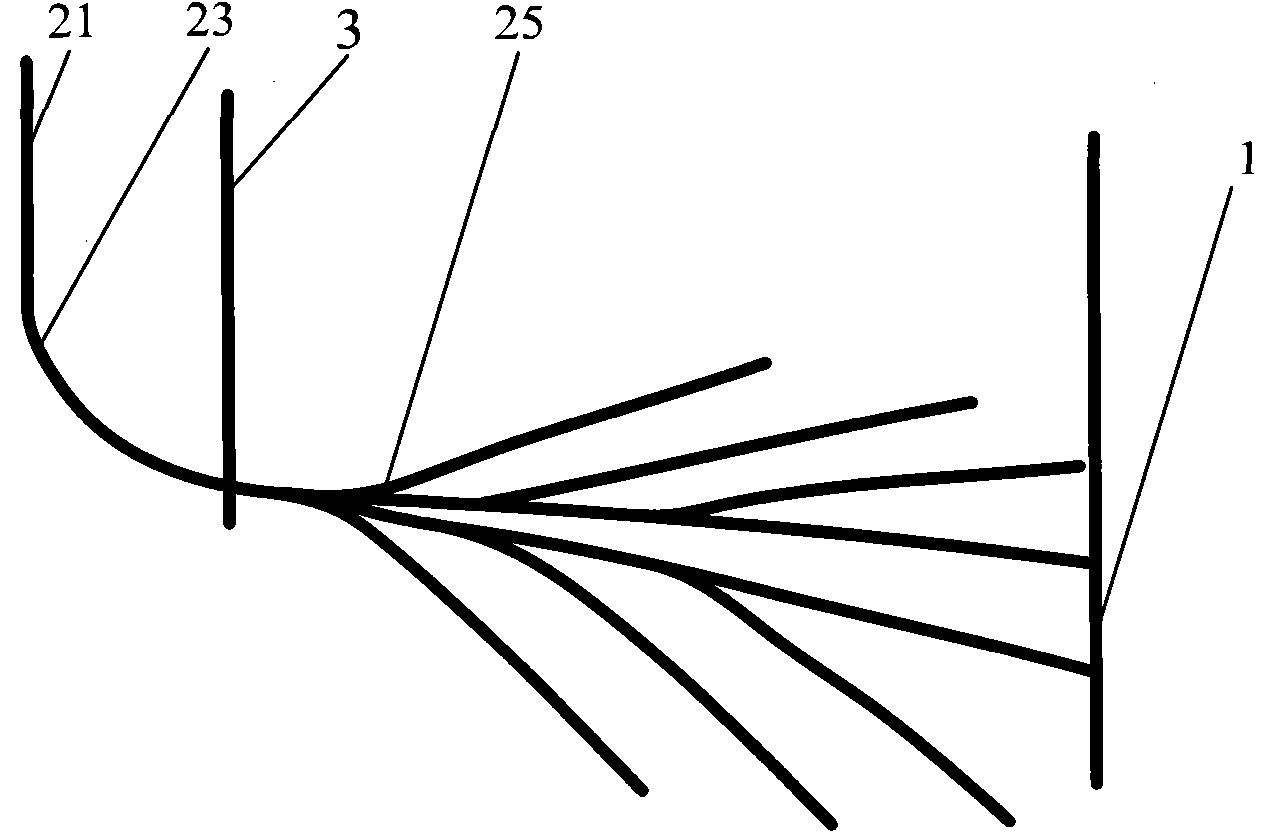

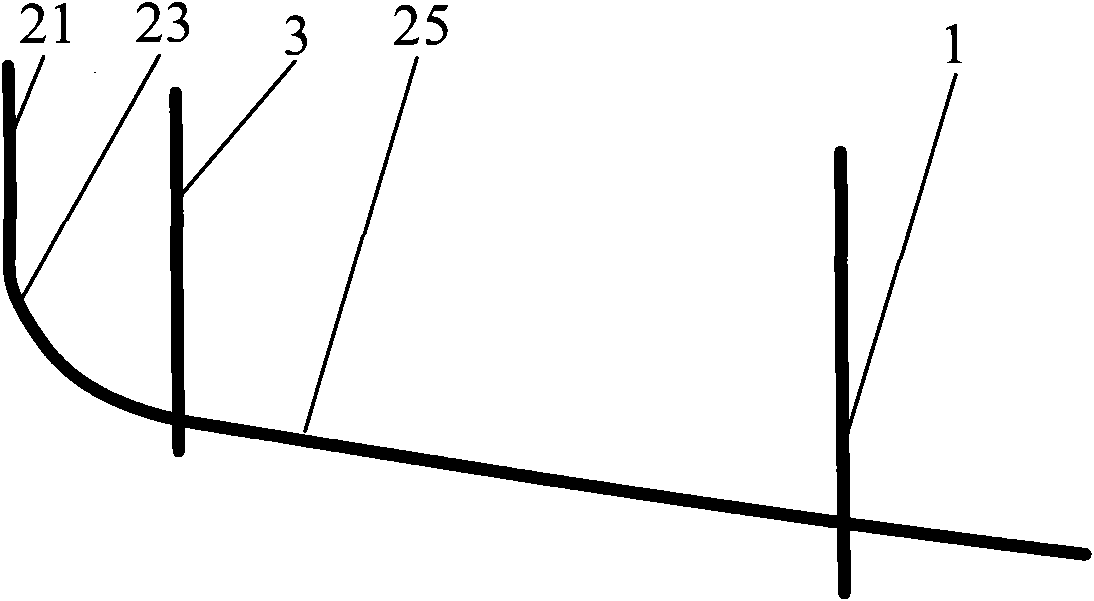

Re-fracturing process design method for improving shale seamed web complexity

ActiveCN107587867AHigh strengthConvenient amountFluid removalSealing/packingParticle densityUnconventional oil

The invention belongs to the technical field of unconventional oil and gas output increasing transformation, and particularly relates to a re-fracturing process design method for improving the shale seamed web complexity. The method includes the steps that re-fracturing well sections are selected according to basic data of all the well sections as well as gas-bearing data and primary fracturing output increasing transformation volume ratio data; as for the candidate well sections, a stress balancing equation of discrete fractures is established, normal stresses of a fracture unit are calculated, and steering pressure of new fractured shale stratum fractures is obtained; the strength and dosage of a temporary plugging agent are determined according to the fracture height, particle sedimentation rate, fracture width and temporary plugging agent particle density as well as the number of primary fracturing seamed webs; and steering extension construction displacement of the re-fractured seams is calculated and designed. The re-fracturing process design method provided by the invention covers the basic procedures of shale re-fracturing design, the shale re-fracturing process design canbe achieved conveniently, rapidly and effectively, and a technical design method is provided for re-fracturing process mine field implementation.

Owner:SOUTHWEST PETROLEUM UNIV

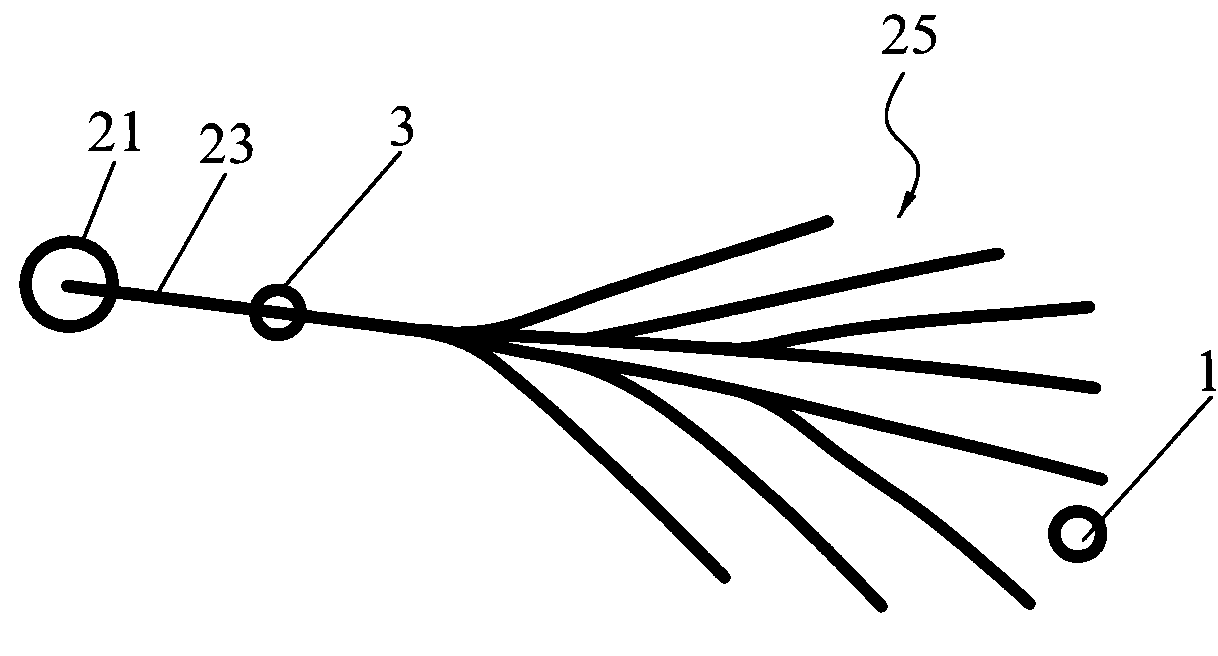

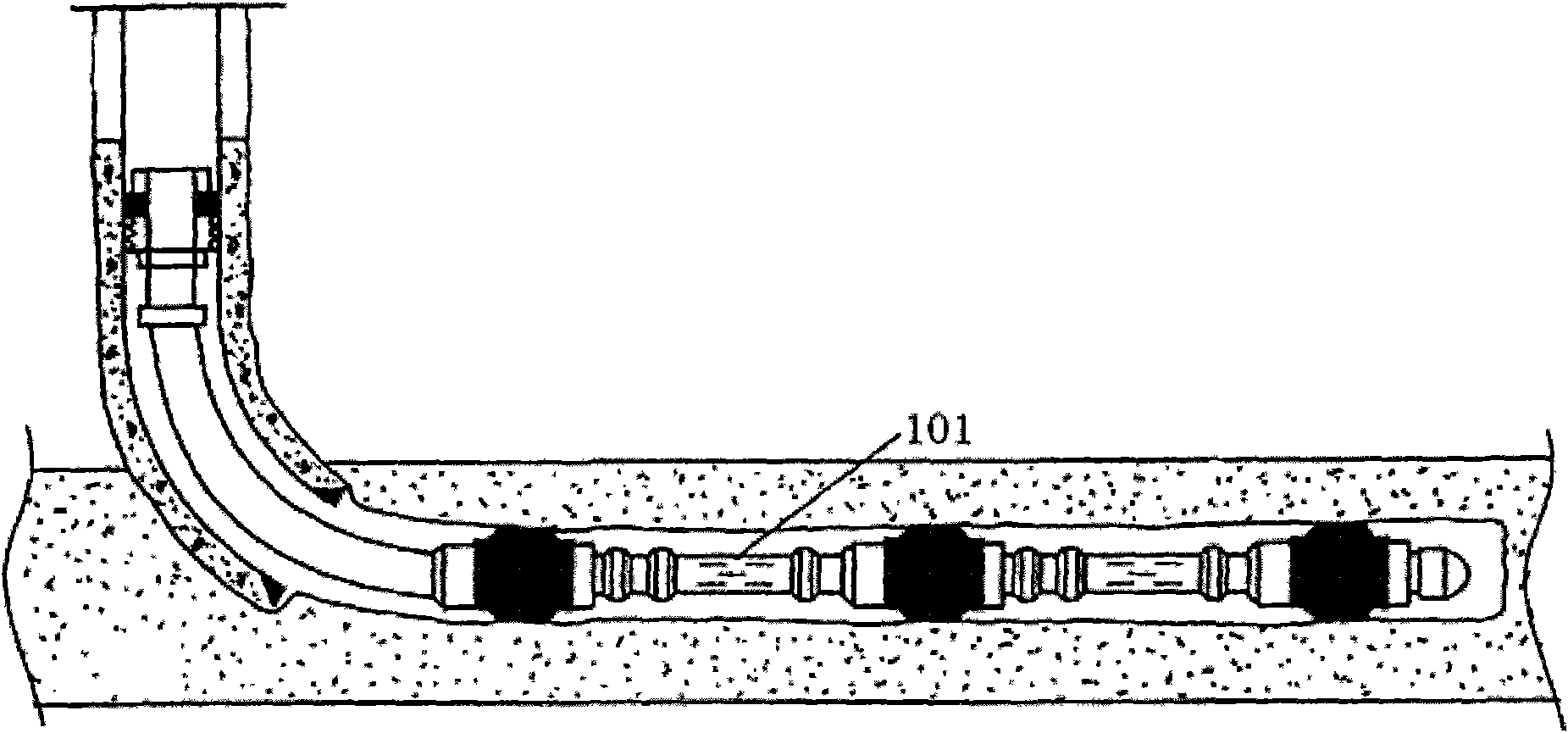

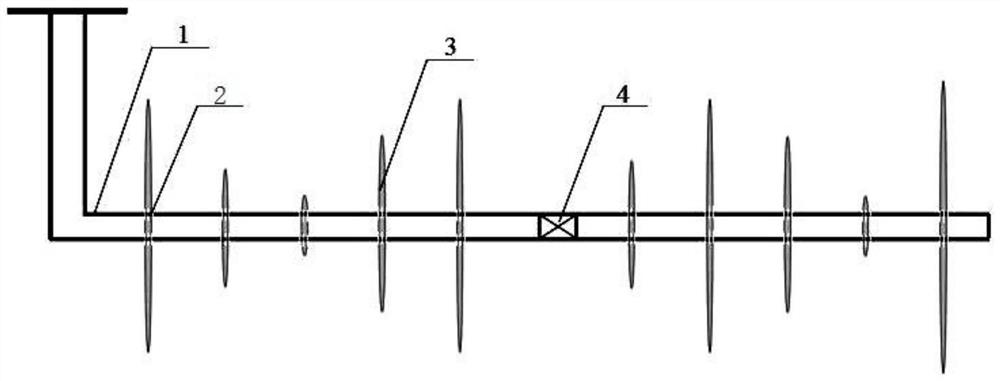

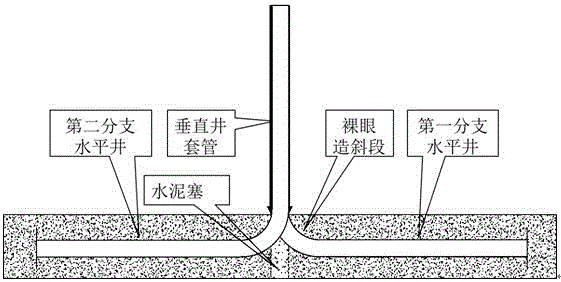

Coal bed methane multi-branch horizontal well system and auxiliary discharge well thereof

InactiveCN101979828ATo achieve the purpose of gas analysisReduce fluid pressureFluid removalDesorptionWell drilling

The invention discloses an auxiliary discharge well matched with a coal bed methane multi-branch horizontal well. The multi-branch horizontal well comprises a straight well section, a deflection section and a horizontal section which comprises a plurality of wellbores; and the auxiliary discharge well is arranged on the coal bed relief declination side in the horizontal section of the multi-branch horizontal well. In the invention, the auxiliary discharge well adopts a mode of arranging the drilling engineering at the tail end of the horizontal section of the horizontal well to reduce liquid pressure in branches and produces channels in a target geologic body by utilizing a newly drilled well to make the target geologic body communicated with the multi-branch horizontal well and assist the multi-branch horizontal well in draining and decompressing so as to fulfill the aim of gas desorption in the geologic body, improve the development efficiency of an assisted well and increase the well producing rate of the multi-branch horizontal well. Meanwhile, the invention also provides a coal bed methane multi-branch horizontal well system.

Owner:BEIJING ORION ENERGY TECH DEV

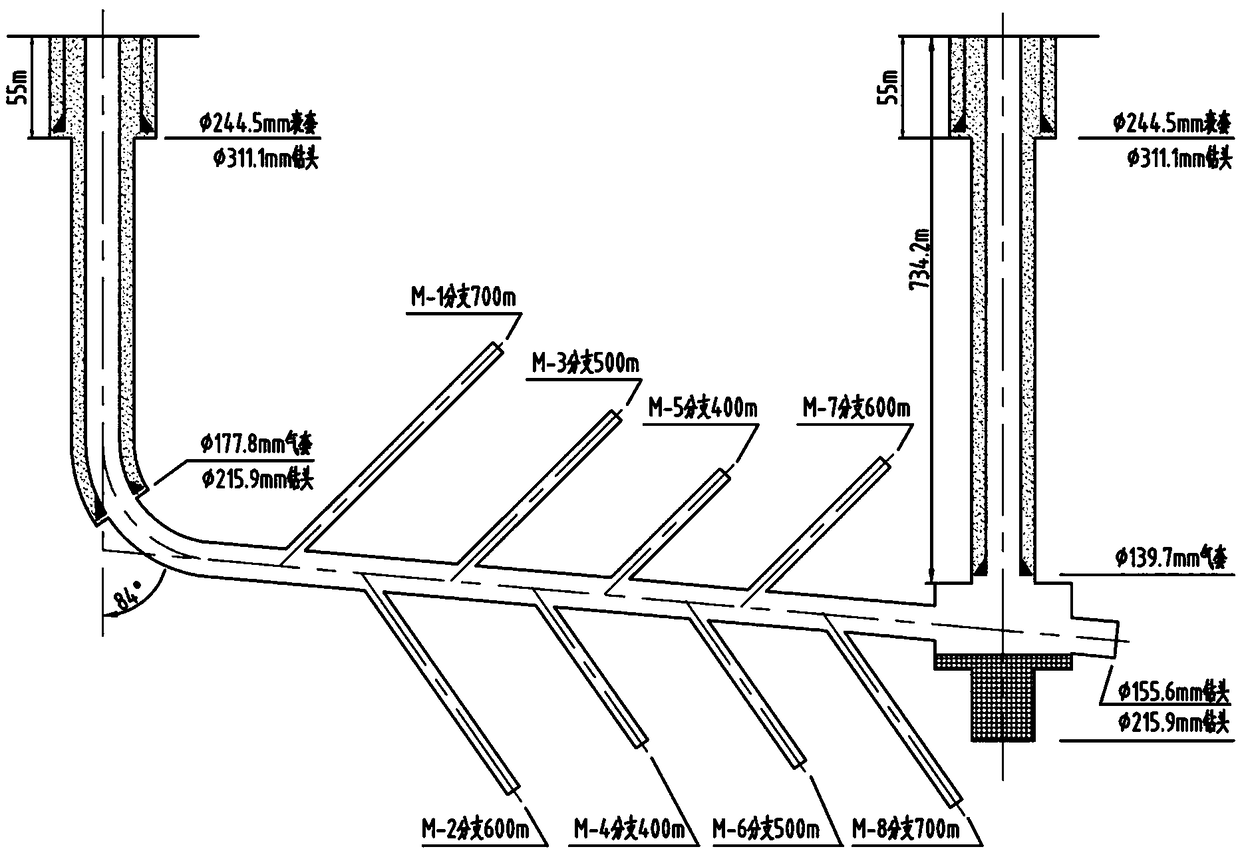

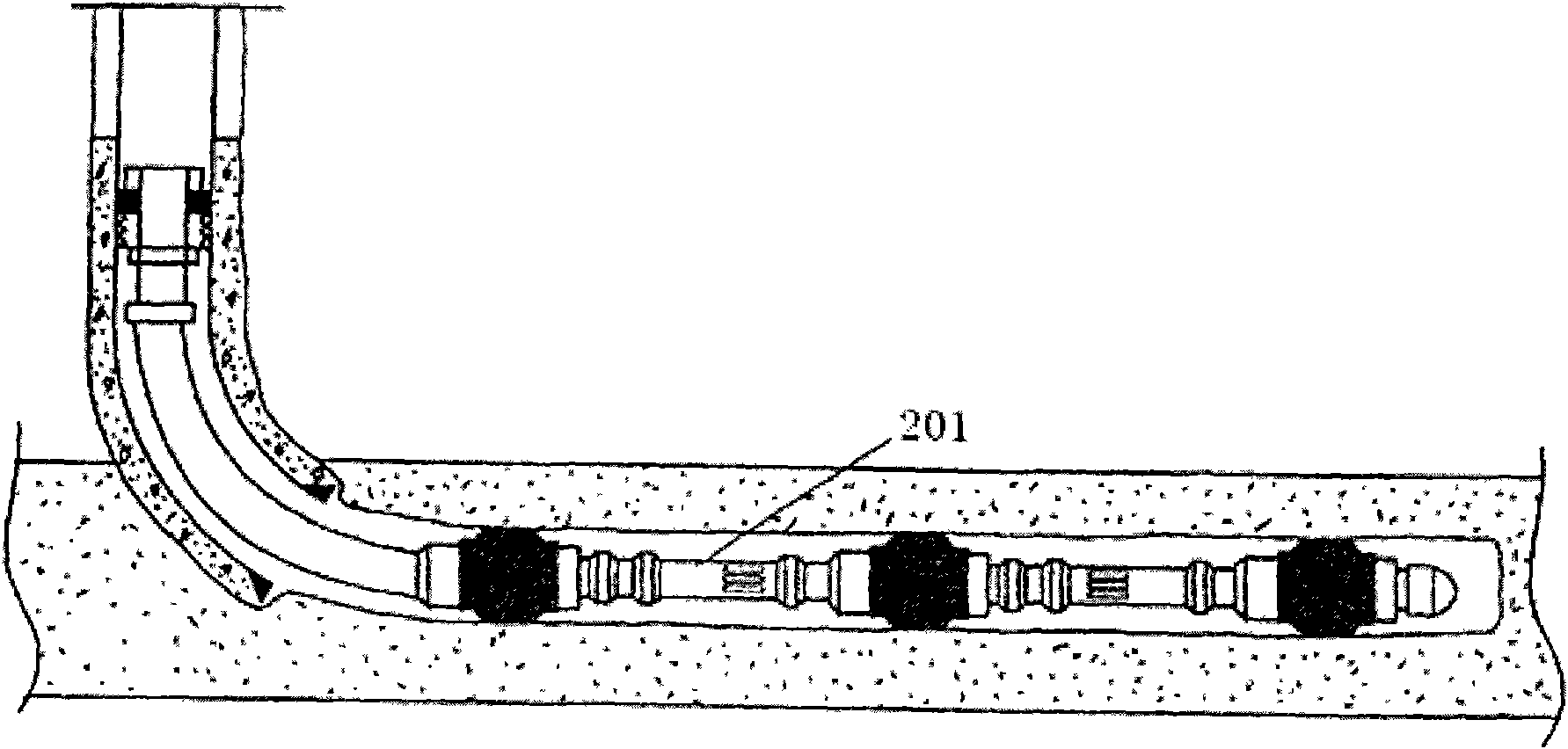

Exploitation method for coalbed methane multibranch remote-end communicated well

InactiveCN108716396AIncrease productionImprove diversion capacitySurveyConstructionsWell drillingWell cementing

The invention relates to the technical field of coalbed methane exploitation, and relates to an exploitation method for a coalbed methane multibranch remote-end communicated well. The method concretely includes the following steps: 1) using a drill bit with the phi being 311.1 mm to drill to the depth of a designed surface casing during first exploitation, and placing a casing with the phi being 244.5 mm to seal an upper layer section which is unstable and prone to leakage and collapse; 2) using a drill bit with the phi being 215.9 mm to drill to a designed target point during secondary exploitation, wherein the inclination angle of the well reaches 84 degree, and placing a technical casing with the phi being 177.8 mm to enhance the well and seal a stratum which is prone to leakage; 3) using a drill bit with the phi being 155.6 mm to drill to a designed target point in an inclined section during third exploitation; and 4) using drill bits with the phi being 155.69 mm to drill to designed target points in branch well sections. Compared with a vertical well and a horizontal well, the multibranch horizontal well is improved in conductivity increased in sweep area and greatly improvedin single well output. The method adopts drilling along the downdip direction of a reservoir stratum, which is beneficial to the well trajectory control, can help water in a coal seam flow into the bottom of the production well under the action of gravity, and can improve the efficiency of drainage and gas recovery of the production well.

Owner:LANZHOU CITY UNIV

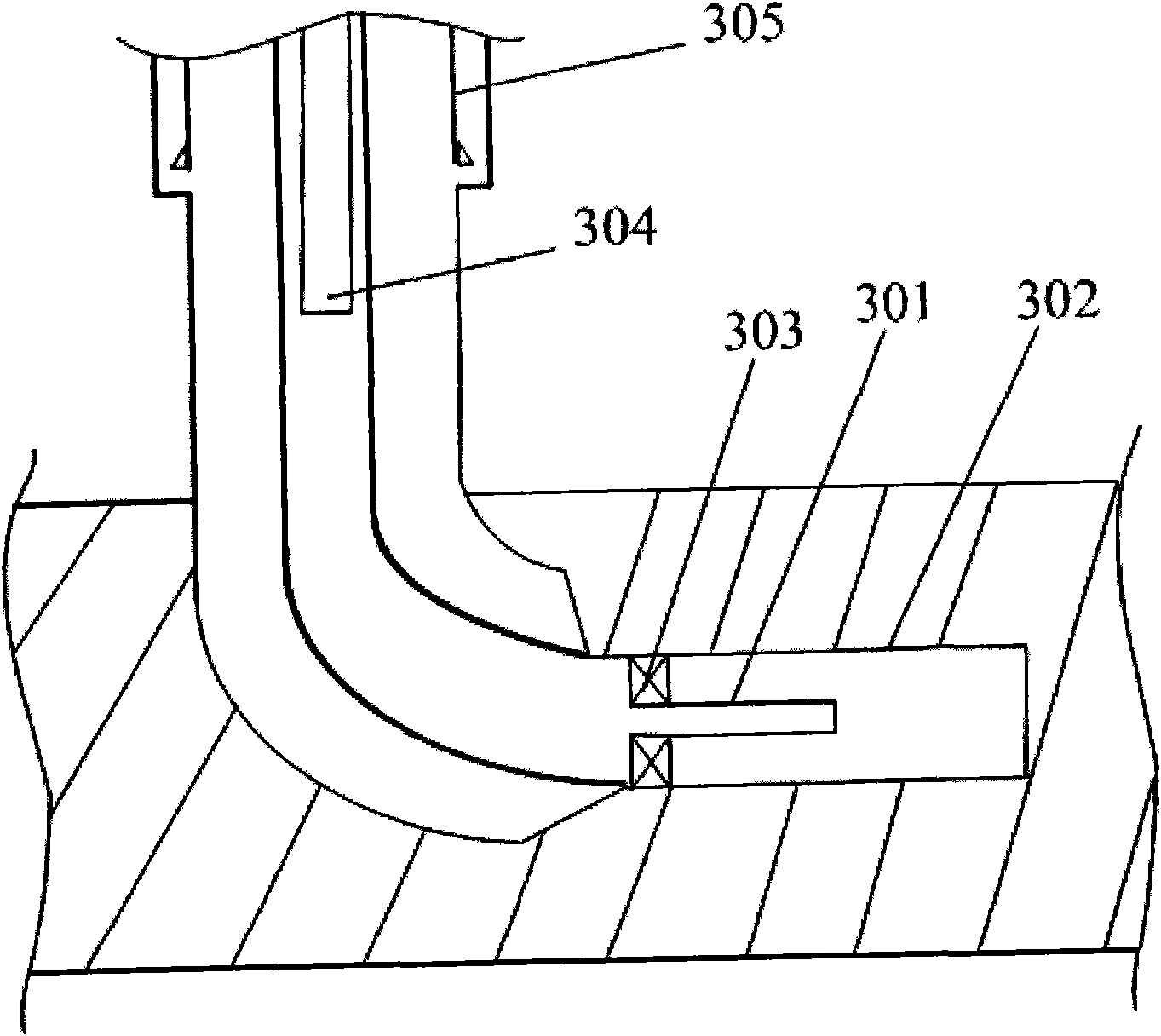

Well completion technique for efficiently controlling pressure and retaining water cone of horizontal well

InactiveCN101655007AImprove single well productionSimple well completion processFluid removalDirectional drillingOil fieldBottom water

The invention discloses a well completion technique for efficiently controlling pressure and retaining water cone of a horizontal well, comprising a method for efficiently controlling the pressure andretaining the water cone of the horizontal well, a device and matching technology and a theory. The method comprises the following steps: A, placing non-coupling oil tube with the function of controlling pressure and retaining bottom water coning at the middle position in the horizontal well channel; and B, setting an excluder in the horizontal well to exclude the annular space between the non-coupling oil tube and a barefoot well or to exclude the annular space between the non-coupling oil tube and a sieve tube, so that crude oil after emerging from stratum flows from two ends to the middleand only can be output by the non-coupling oil tube. The technique for efficiently controlling the pressure and retaining the water cone of the horizontal well not only can retain bottom water coning,but also can significantly improve individual-well producing rate, has simple completion technology, cheap and easily obtained raw materials, no environmental pollution, convenient oil field implementation, and low cost.

Owner:熊友明 +3

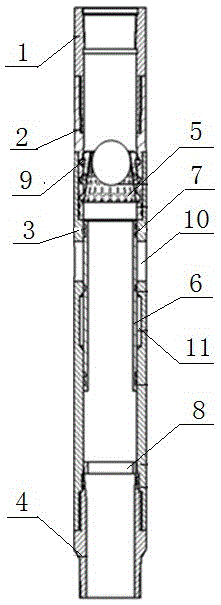

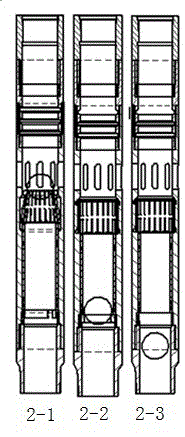

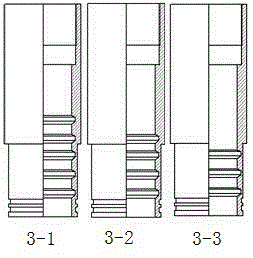

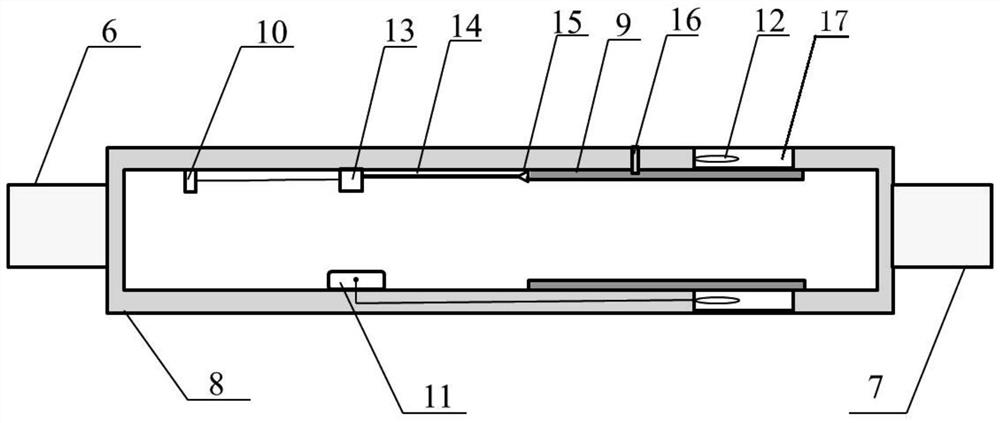

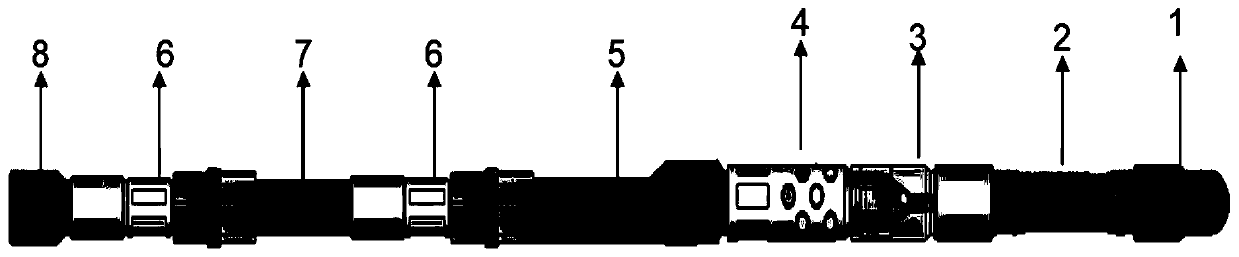

Well cementation casing or tubing sliding sleeve without limit on number of segments or clusters

ActiveCN105134131AImprove the effect of fracturingImprove single well productionFluid removalWell/borehole valve arrangementsWell cementingMultiple fracture

The invention relates to a well cementation casing or tubing sliding sleeve without limit on the number of segments or clusters, comprising an upper joint, a variable-diameter cylinder, a sliding sleeve body, and a lower joint. The upper joint is connected with the variable-diameter cylinder, the variable-diameter cylinder is connected with the sliding sleeve body, and the sliding sleeve body is connected with the lower joint. Grooves are arranged on the inner wall of the variable-diameter cylinder to make a variable-diameter area formed on the inner wall of the variable-diameter cylinder, and an elastic cylinder is installed in the variable-diameter area. Multiple fracturing ports are uniformly distributed in the middle of the sliding sleeve body along the circumference. The inner wall of the sliding sleeve body has a diameter expanding area which is disposed below the fracturing ports. An inner sliding sleeve is arranged inside the sliding sleeve body. The lower end inside the sliding sleeve body is equipped with a C ring. With the sliding sleeve, vertical and horizontal wells in oil and gas fields can be fractured in a layered manner under the conditions of an unlimited number of segments and an unlimited number of clusters between segments. Before fracturing, a wellbore is full-pass, and the sliding sleeve and a ball seat are non-throttled. The construction capacity is larger, the fracturing effect can be significantly improved, and the production capacity of a single well can be increased. After fracturing, a ball made of soluble material and the C ring are dissolved or drilled and ground, and the well bore is full-pass again, thus facilitating later production and operation.

Owner:PETROCHINA CO LTD

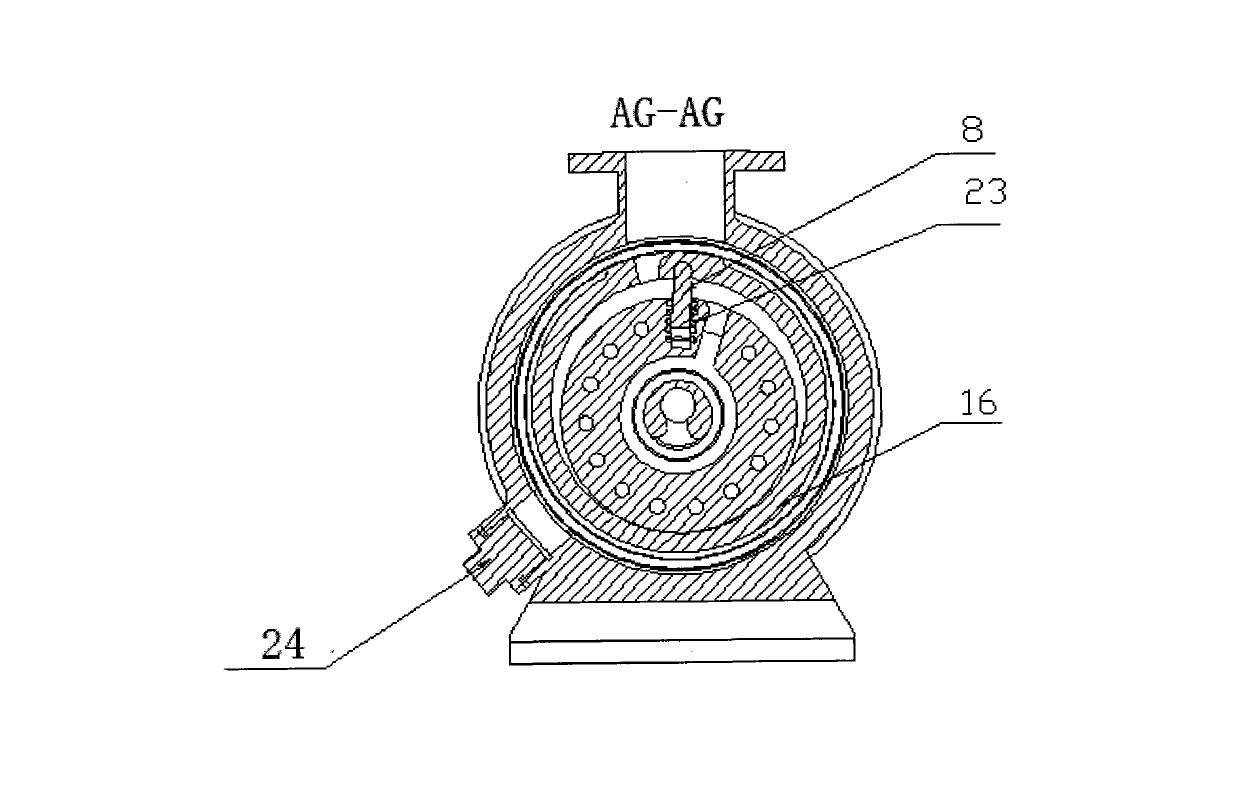

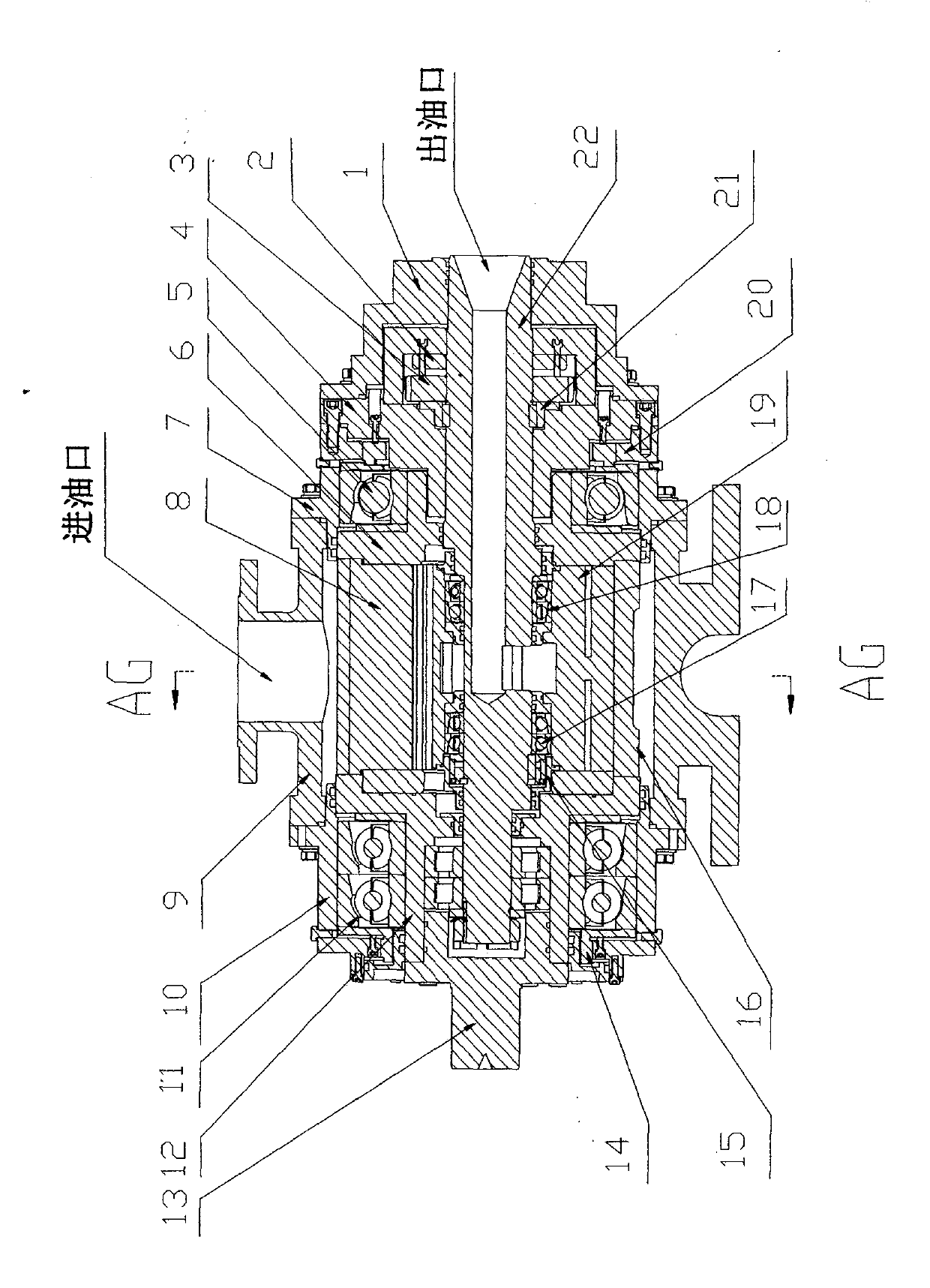

Synchronal rotary oil-gas multiphase pump

InactiveCN103133344AReduce wellhead back pressureImprove single well productionRotary piston pumpsRotary piston liquid enginesEngineeringSlide plate

The invention discloses a synchronal rotary oil-gas multiphase pump. A front end bearing seat, a rear end bearing seat, an oil cylinder, a rotor, a sliding plate, a left end cover, a right end cover, an eccentric shaft and an adjusting part are arranged inside a shell body. The adjusting part comprises a key, an adjusting nut, rear end adjustment, a rear end adjustment nut, a front end adjustment nut and a double-half-clamping structure. According to the synchronal rotary oil-gas multiphase pump, single pipeline mixed conveying, pressurization and long-distance multistage conveying of crude oil, natural gas, water and various thick materials can be achieved. An oil-gas-water separation link and an adding link in an intermediate conveying process are cancelled. Sleeve gas is recycled, and air is emptied. The well mouth return pressure is lowered, and the single well yield is improved. The synchronal rotary oil-gas multiphase pump can also be used in other industries which need long-distance pressurization conveying.

Owner:王子颖

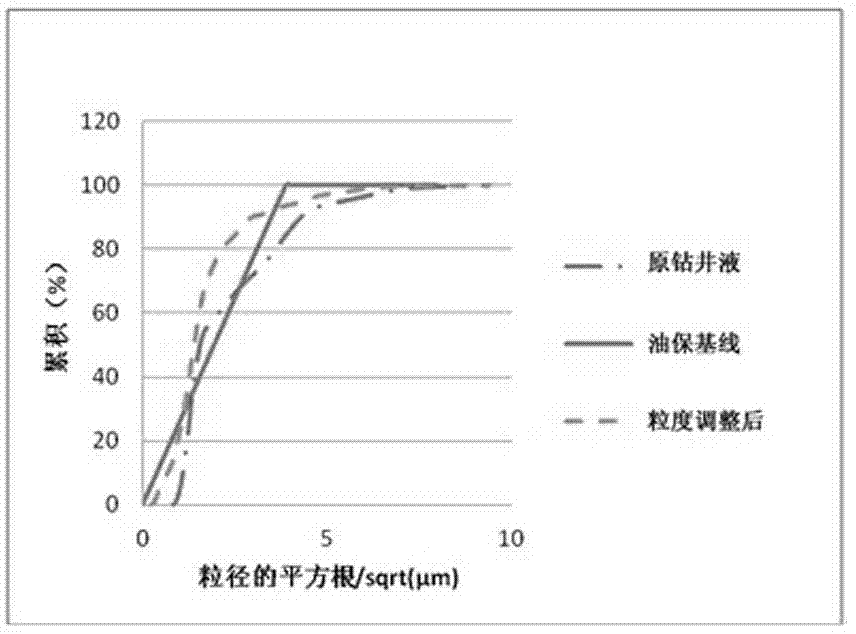

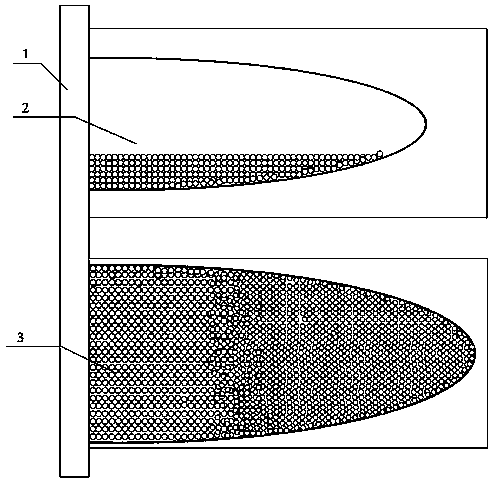

Method for regulating well drilling liquid granularity distribution

InactiveCN104514514AImprove single well productionReduce fluid lossDrilling compositionSealing/packingPhysicsGeotechnical engineering

The invention belongs to the technical field of reservoir stratum protection in petroleum and gas, and geologic prospecting well drilling, and particularly relates to a method for regulating well drilling liquid granularity distribution. The method for regulating the well drilling liquid granularity distribution includes: analyzing granularity distribution curves of well drilling liquid and blocking and shielding agents according to the maximum pore throat diameter D90 of a target reservoir stratum, and screening out particle diameter proportions of the well drilling liquid and the blocking and shielding agents. The method for regulating the well drilling liquid granularity distribution has the advantages of enabling filling of the well drilling liquid to conform to an ideal filling rule by analyzing well drilling liquid granularity on the scene and supplementing the blocking and shielding agents different in grain diameter proportion, and achieving the effects of reducing filtration loss of the well drilling liquid and reducing invasion of filter liquid. According to the method for regulating the well drilling liquid granularity distribution, a curve of a relationship between accumulative volumes (%) and grain diameter square roots is drawn by considering data of the well drilling liquid granularity distribution, and then a result finally obtained is true and reliable, conforms to actual situations on the scene, and therefore the reservoir stratum can be protected well, and an output of a single well is improved.

Owner:CHINA PETROCHEMICAL CORP +1

Method for increasing length of tight reservoir hydrofracturing effective prop fracture

InactiveCN110344808AImprove diversion capacityIncrease productionFluid removalDrilling compositionFracturing fluidFracture process

The invention provides a method for increasing the length of a tight reservoir hydrofracturing effective prop fracture. The method comprises the specific steps that 1, before tight reservoir hydrofracturing, a cable is used for transmitting firepower to perforate holes; 2, in the tight reservoir hydrofracturing process, an ultralow-density propping agent is selected, slickwater fracturing fluid isused in cooperation in the fracturing process, slug type pumping is adopted, and the combined grain size ultralow-density propping agent is carried and conveyed to the far end of the fracture; and 3,a well is shut in to wait for closing of the fracture. According to the method, a plug type pumping procedure is adopted, the combined grain size ultralow-density propping agent is carried and conveyed to the far end of the fracture. Due to the fact that the ultralow-density propping agent is in a full suspension state in the conveying process of slickwater, in combination with the plug type combined grain size injection manner, the conveying distance is long, the number of filled fractures is large, the prop fracture is long, it is avoided that due to the fact that the propping agent is sedimented too fast, the far end and the upper portion of the fracture cannot be effectively filled, and the fracture propping size and flow conductivity are reduced, and the per-well yield of a tight reservoir is increased.

Owner:PETROCHINA CO LTD

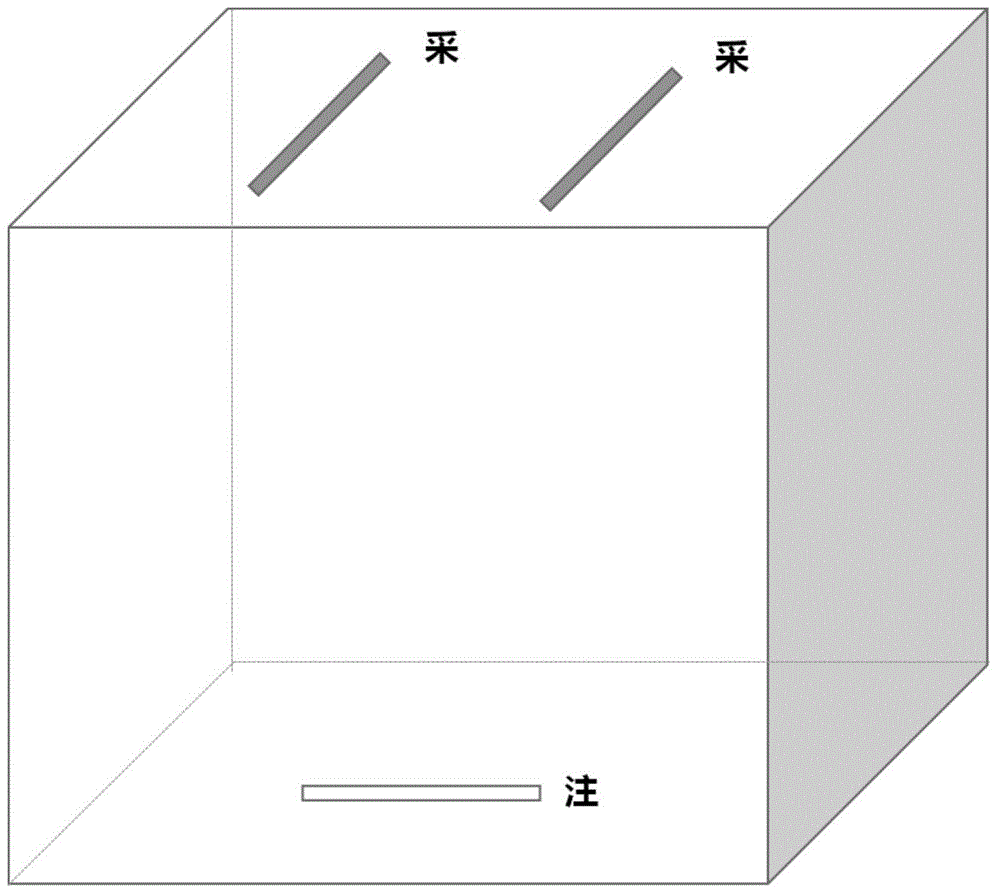

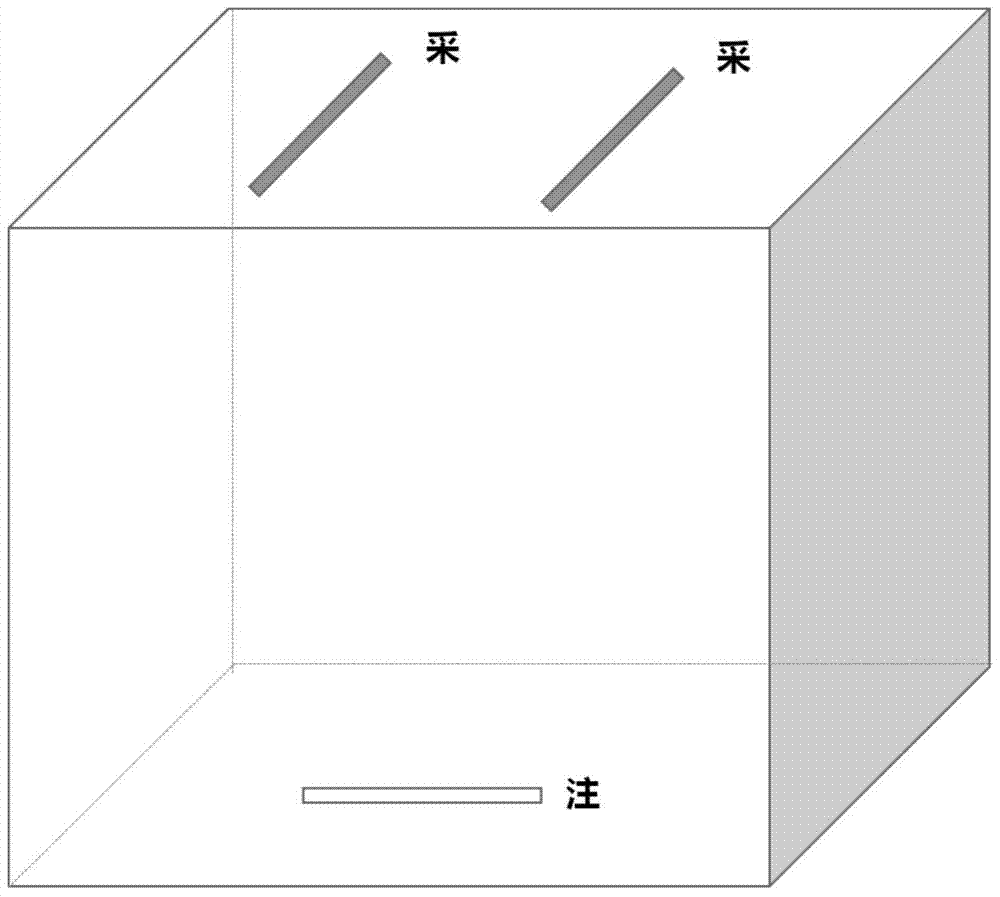

Well group well spacing method of microbial oil displacement oil recovery technology

The invention discloses a well group well spacing method of a microbial oil displacement oil recovery technology. A set of combined injection-production well pattern of horizontal well exploitation and vertical well injection is deployed in a thicker sandstone oil reservoir by utilizing a microbial tertiary oil recovery technology, and the combined injection-production well pattern needs to meet the requirements of plane correspondence, longitudinal three-dimension and bottom injection and top production; the vertical well injection refers to injecting microorganisms into a bottom area of a sandstone reservoir by using a vertical well, and the horizontal well exploitation refers to deploying the horizontal section of a production well in a top area of a thicker sandstone reservoir; the plane correspondence refers to overlapping the horizontal section of the injection vertical well and the horizontal section of the production well after being projected to the plane in an overlooking state, and an up-and-down corresponding relation is achieved; and the longitudinal three-dimensional refers to that the injection section of the vertical well and the horizontal section of the productionwell are arranged in parallel at different depths in the sandstone reservoir, and a three-dimensional well pattern is formed in the section parallel to the gravity direction and perpendicular to a main shaft of the horizontal section of the production well. The well group well spacing method has the advantages of being higher in oil sweeping efficiency, high in oil extraction capacity, higher infinal recovery ratio and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

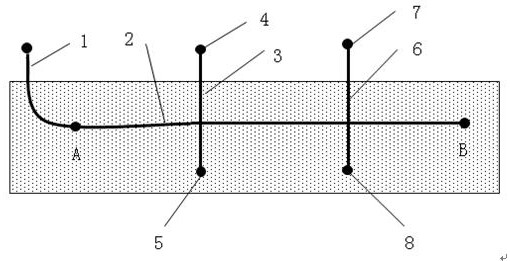

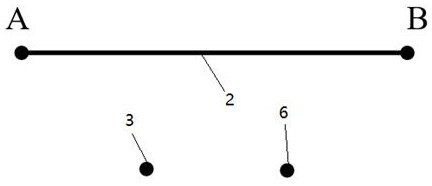

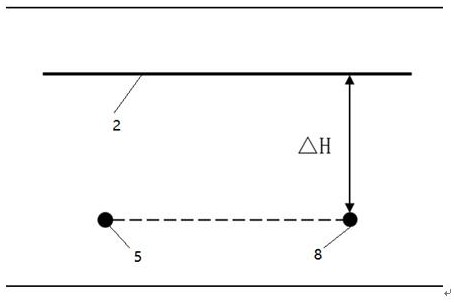

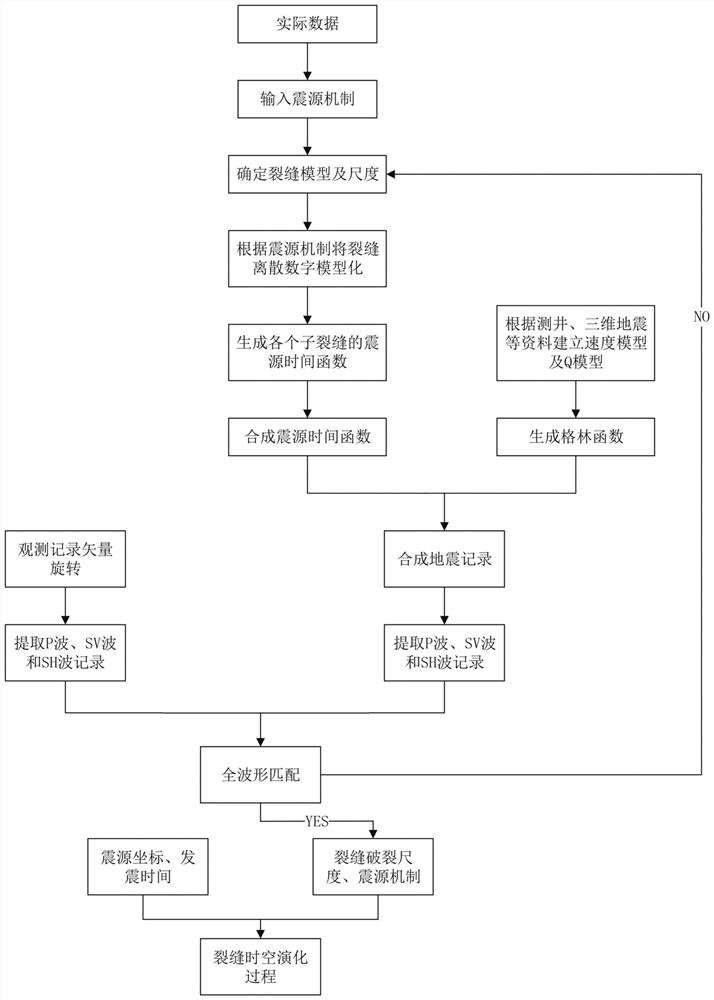

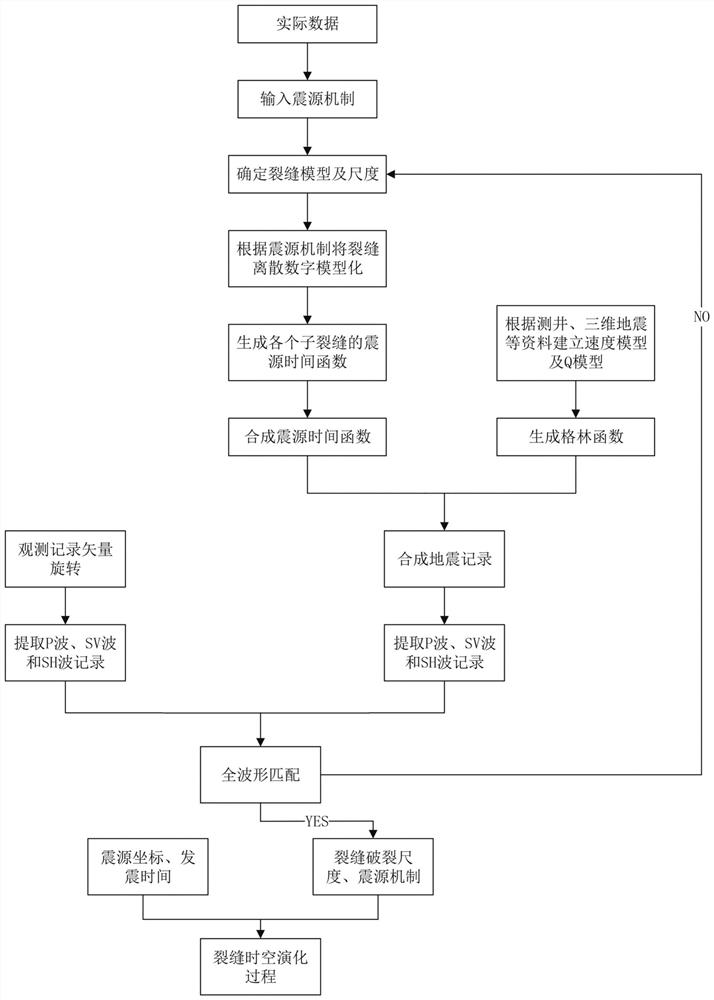

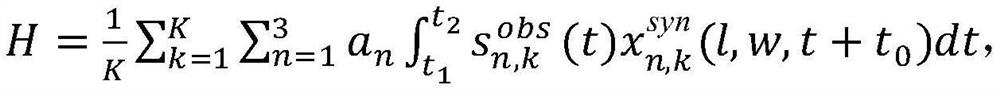

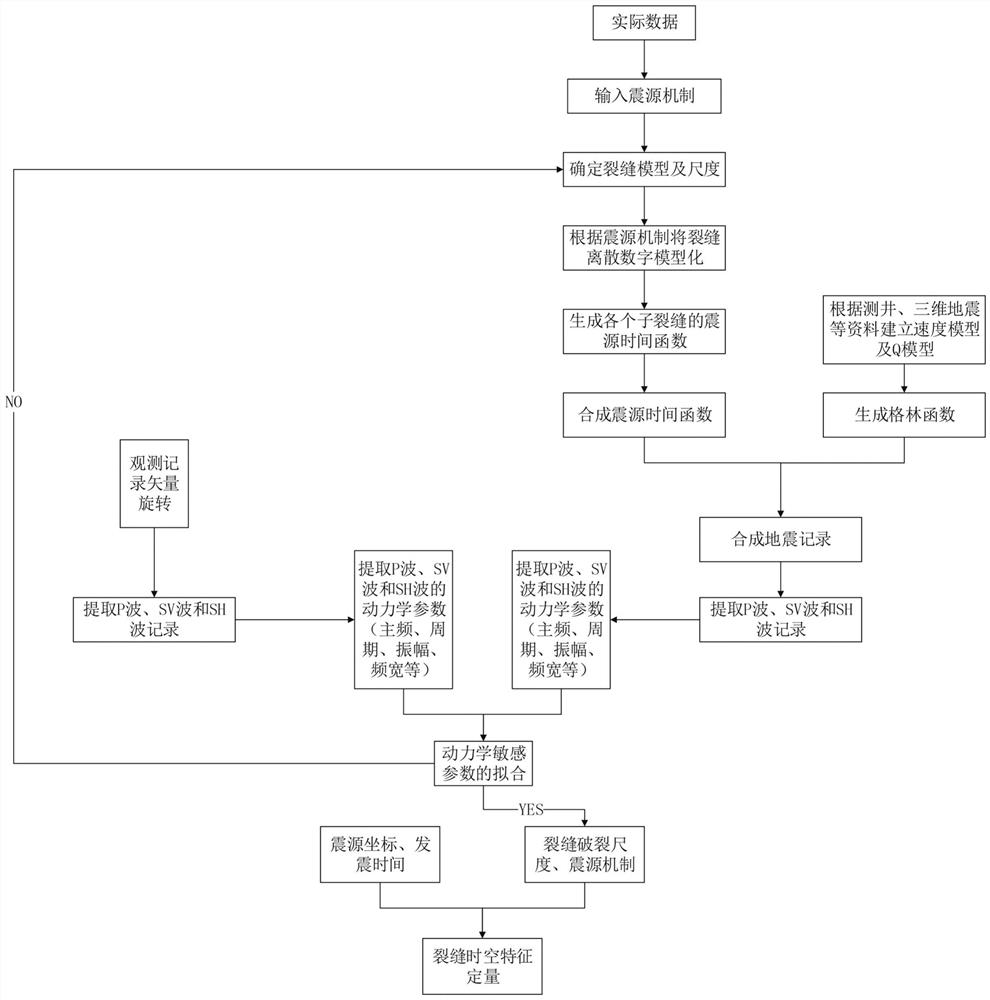

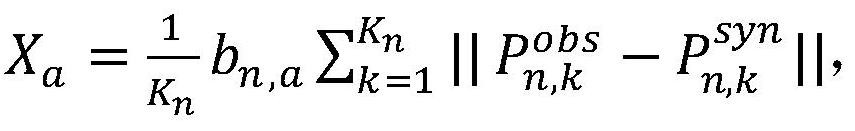

Description method of the crack fracture scale based on seismic wave full-waveform characteristics

ActiveCN112068198AImprove targetingImprove effectivenessSeismic signal processingCorrelation coefficientWell logging

The invention provides a description method of the crack fracture scale based on seismic wave full-waveform characteristics. The description method of the crack fracture scale comprises the followingsteps: generating a composite seismic source time function through modeling of the crack fracture scale, obtaining a Green function from a seismic source to an observation station through logging and / or three-dimensional seismic data, obtaining a synthetic micro seismic wave according to the composite seismic source time function, the Green function and a seismic moment tensor, and obtaining a composite micro seismic wave; calculating correlation coefficients of the synthetic microseismic waves and the microseismic waves recorded by the observation station based on the full waveform characteristics of the seismic waves, and selecting the fracture fracture scale recorded by the synthetic microseismic waves with the correlation coefficients within a preset coefficient allowable range as thefracture scale. The invention has the beneficial effects that the problem that the fracture dimension of the crack cannot be quantitatively described in passive earthquake monitoring can be solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

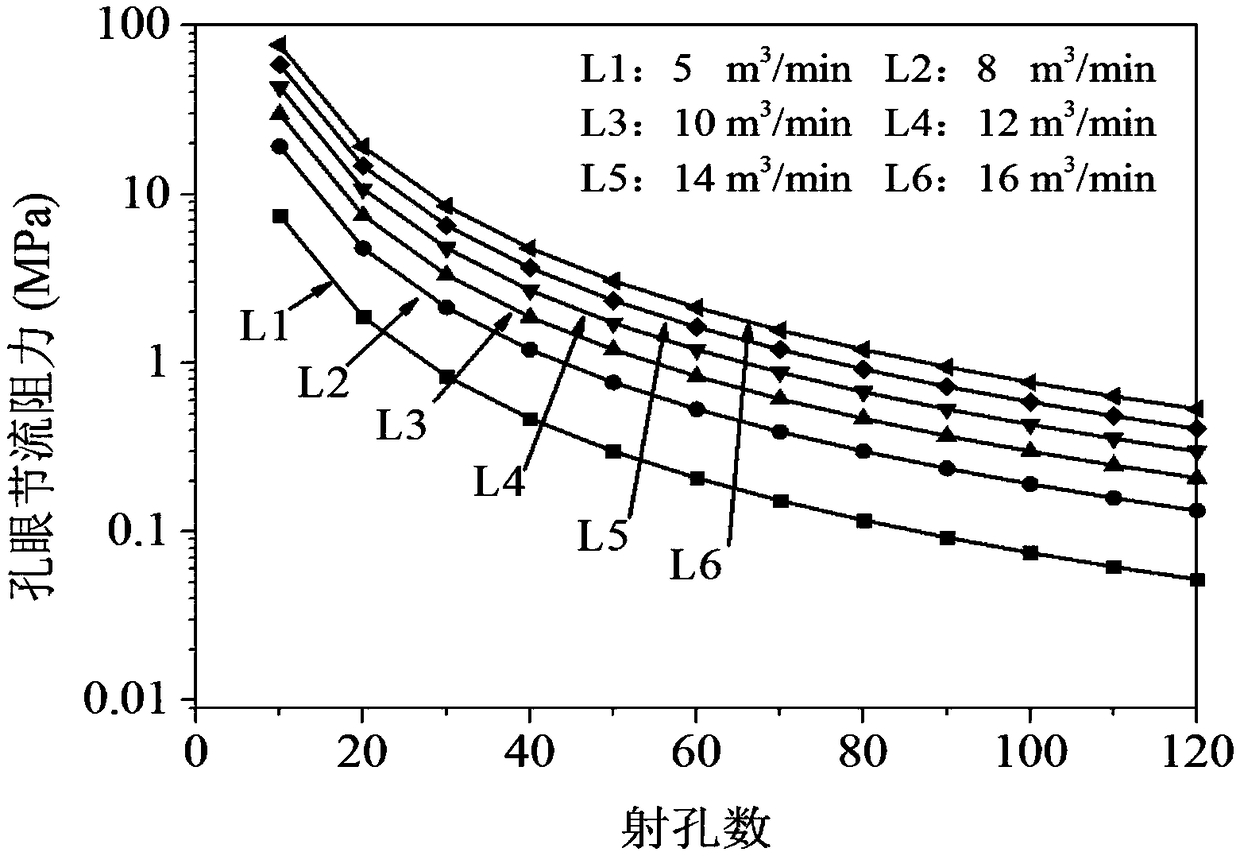

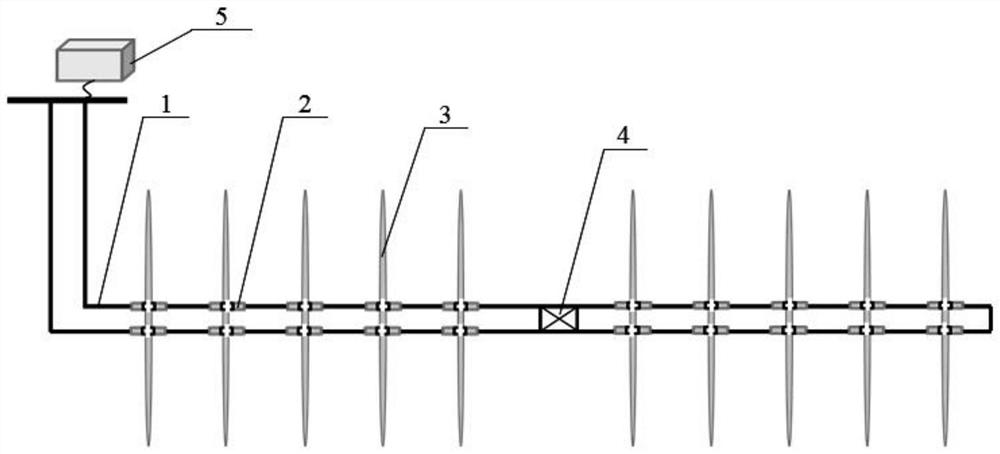

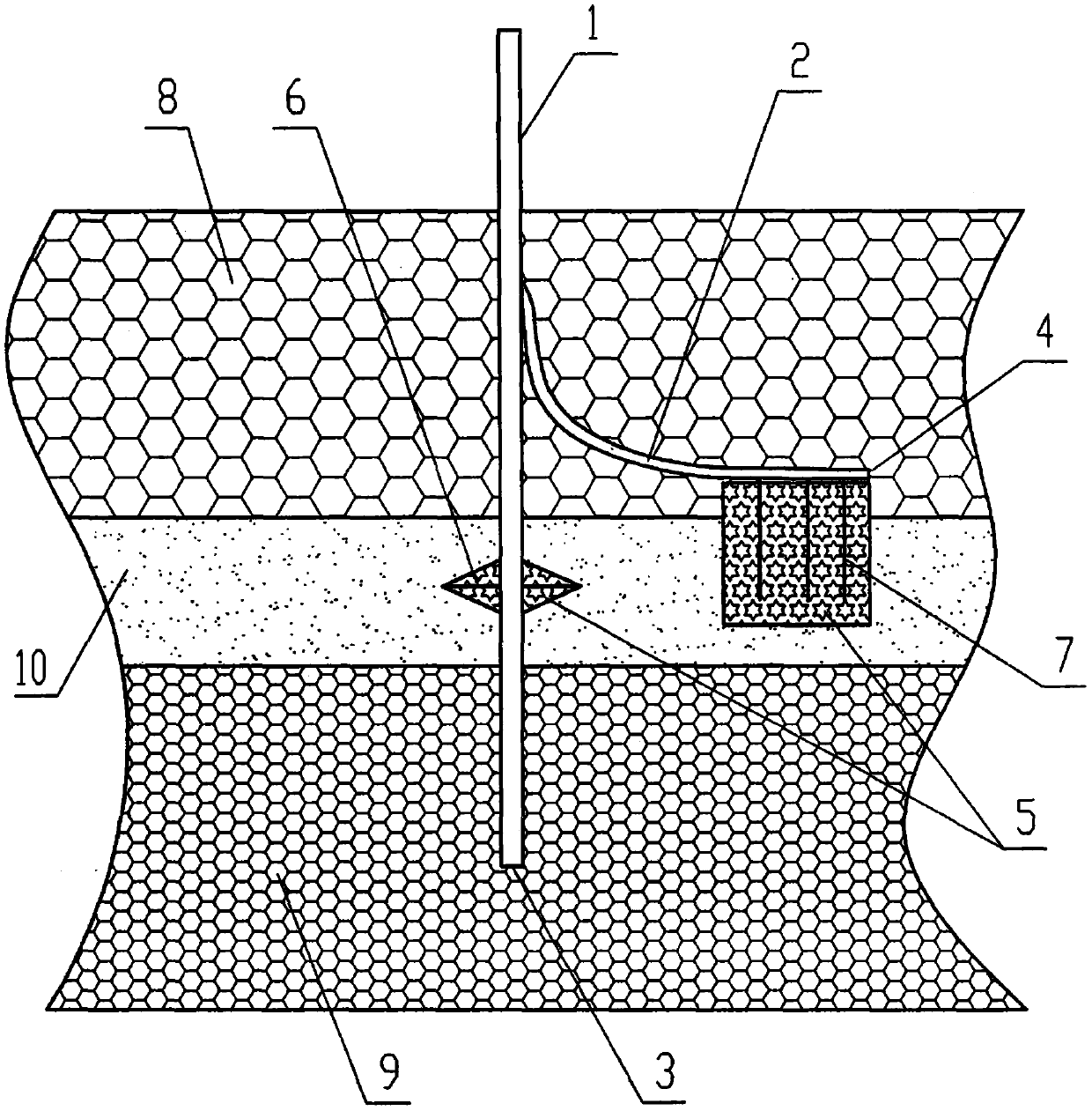

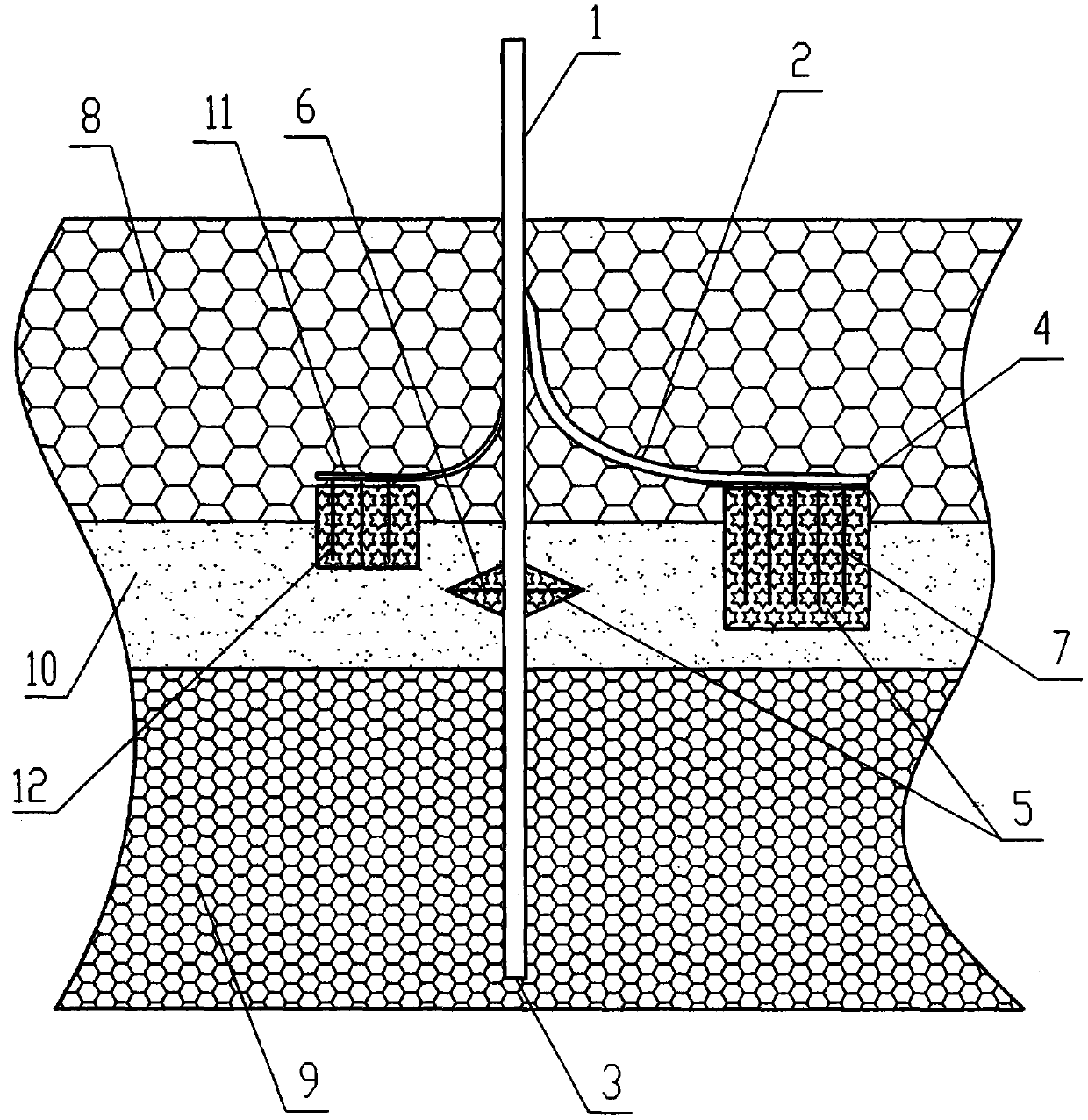

System and method for realizing staged multi-cluster fracturing and multi-crack balanced expansion of horizontal well

ActiveCN112360420AHigh degree of controlImprove single well productionFluid removalWell/borehole valve arrangementsStructural engineeringMechanical engineering

The invention belongs to the technical field of oil and gas field exploration and development, and particularly relates to a system and method for realizing staged multi-cluster fracturing and multi-crack balanced expansion of a horizontal well. The system for realizing staged multi-cluster fracturing and multi-crack balanced expansion of the horizontal well is composed of a horizontal well shaftcasing pipe, a bridge plug, intelligent casing pipe sliding sleeves and a ground controller, the bridge plug is arranged at the position, at the joint of the adjacent fracturing sections of the horizontal well, on the shaft casing pipe, the multiple intelligent casing pipe sliding sleeves are arranged, different clusters of the different fracturing sections of the horizontal well shaft casing pipeare each provided with one intelligent casing pipe sliding sleeve, and the ground controller is arranged on the ground and is in electric signal connection with the multiple intelligent casing pipe sliding sleeves. According to the system and method, the problems that multiple clusters cannot fracture completely and multiple cracks cannot be expanded and extended in a balanced manner in horizontal well staged multi-cluster fracturing are effectively solved, the multi-cluster fracturing effectiveness is improved to 100%, the multi-crack balanced expansion rate is improved to 90% or above, thecontrol degree of artificial cracks on a reservoir is remarkably improved, and finally the single-well yield of the low-permeability-dense oil and gas reservoir is greatly improved.

Owner:PETROCHINA CO LTD

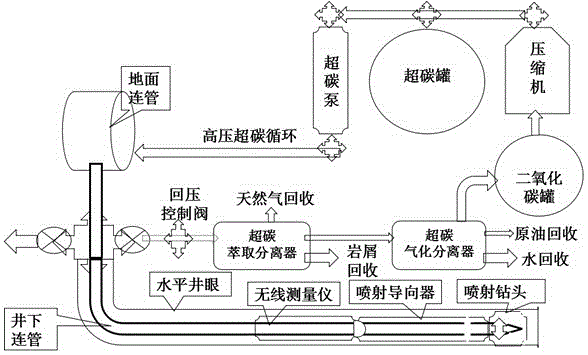

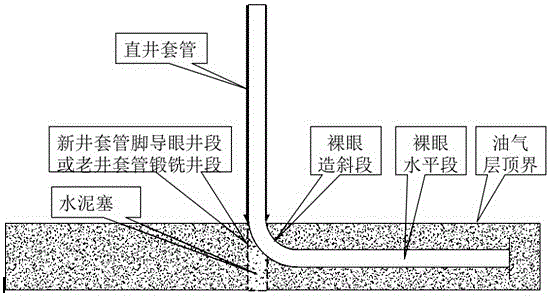

Ultra-carbon connecting tube jet drilling horizontal well system and jet drilling method

InactiveCN106351581AConducive to protectionImprove effective permeabilityConstructionsLiquid/gas jet drillingEnvironmental resistanceCoiled tubing

The invention discloses an ultra-carbon connecting tube jet drilling horizontal well system and a jet drilling method. The ultra-carbon connecting tube jet drilling horizontal well system comprises an ultra-carbon closed separation circulation unit and an ultra-carbon connecting tube jet drilling unit. Waste generated in the jet drilling process is jetted, guided and recovered by the aid of supercritical carbon dioxide, so that supercritical carbon dioxide is separated, serves as drilling fluid and is circulated into the ultra-carbon connecting tube jet drilling unit again, and jet drilling is performed. The system solves the problems of small borehole diameter, complicated horizontal section and borehole problems, more waste and large pollution of a current coiled tubing jet drilling radial horizontal well taking clear water, water base, oil base, foam and the like as the drilling fluid, the diameter of a well hole and the length of the horizontal well section can be greatly increased, drilling speed, oil-gas yield and environmental protection level are improved, and well site facilities and drilling and production costs are reduced.

Owner:牛辉英

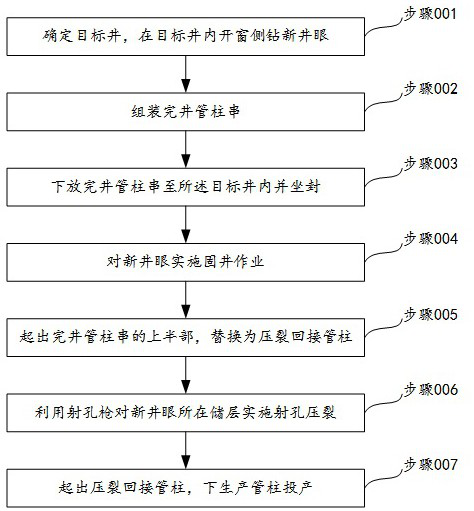

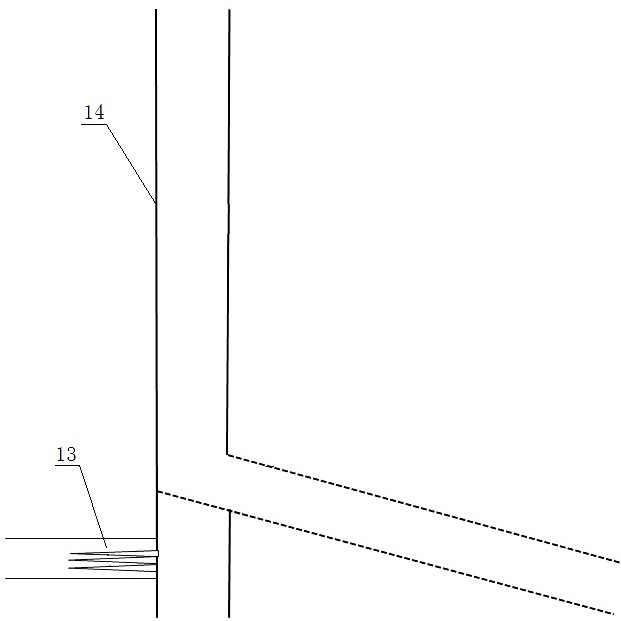

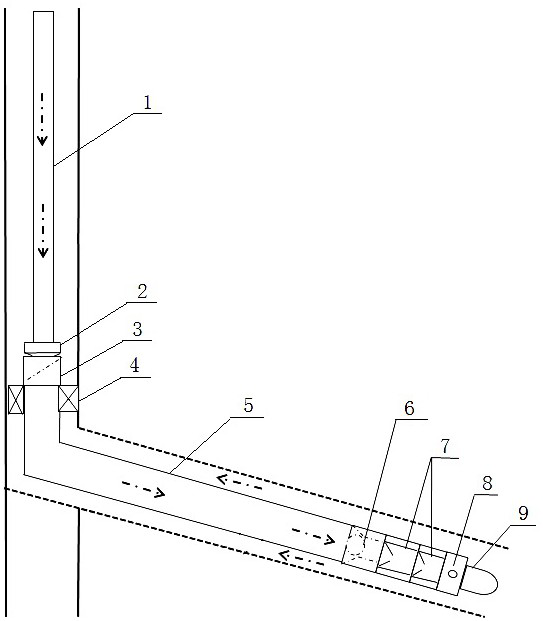

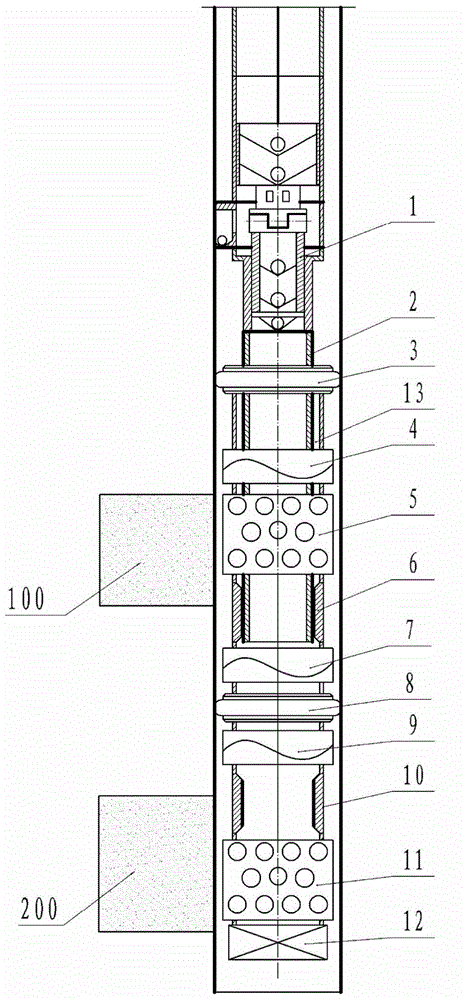

Full-bore well completion fracturing method for low-permeability reservoir sidetracking well

PendingCN112360421AIncrease utilizationImprove single well productionFluid removalSealing/packingPhysicsWell cementing

The invention provides a full-bore well completion fracturing method for a low-permeability reservoir sidetracking well. The method comprises the following steps: step 001, determining a target well,and opening a window in the target well to sidetrack a new borehole; step 002, assembling a well completion pipe string; step 003, lowering the well completion pipe string into the target well, and conducting setting; step 004, carrying out well cementation operation on the new borehole; step 005, pulling out the upper half portion of the well completion pipe string to be replaced with a fracturing tie-back pipe string; step 006, implementing perforating fracturing on the reservoir where the new borehole is located by a perforating gun; and step 007, pulling out the fracturing tie-back pipe string, and putting down a production pipe string to be put into production. According to the method provided by the invention, a brand-new wellbore can be built in the sidetracked slim hole of the low-permeability oil field, reservoir staged fracturing transformation or later repeated fracturing operation can be smoothly carried out, an old casing in an old wellbore is protected in the fracturing process, and the purposes of reducing the construction cost and increasing the final recovery ratio of an oil reservoir are achieved.

Owner:PETROCHINA CO LTD

Separate-layer sand blocking simultaneous production pipe string

ActiveCN104420834AAvoid the problem of not being able to lift the stringImprove single well productionDrilling rodsFluid removalOil productionOil well

Disclosed is a separate-layer sand blocking simultaneous production pipe string. In order to overcome the shortcoming that due to phenomena of sand jamming, sand blocking and sand burying of an existing oil well with the serious interlayer interference, oil production cannot be smoothly carried out, an upper packer, a safety joint I, a screen pipe I, a safety joint II, a lower packer, a safety joint III, a screen pipe II and a screwed plug of the separate-layer pipe string are sequentially and fixedly connected from top to bottom through oil pipes, and an upper sealing working cylinder is fixedly arranged between the screen pipe I and the safety joint II of the separate-layer pipe string. A lower sealing working cylinder is fixedly arranged between the safety joint III and the screen pipe II, and the inner diameter of the upper sealing working cylinder and the inner diameter of the lower sealing working cylinder are smaller than the inner diameter of the oil pipes. A hollow sealing pipe is fixedly arranged at the lower end of a separate-layer oil production pump of a lifting pipe string, and the lower end of the hollow sealing pipe is always matched with an inner hole of the upper sealing working cylinder. An annulus is formed between the hollow sealing pipe and an inner hole, above the upper sealing working cylinder, of the separate-layer pipe string. The separate-layer sand blocking simultaneous production pipe string has the beneficial effects of being reasonable in structural design, and capable of avoiding the interlayer interference, and effectively improving per-well production and production aging of a sandy well.

Owner:DRILLING TECH DEV CO LTD OF TIANJIN DAGANG OILFIELD PETROLEUM ENG INST +2

T-shaped well group and method for exploiting non-diagenetic natural gas hydrates

PendingCN111594131AGuarantee normal developmentEfficient developmentConstructionsFluid removalHorizontal wellsMechanics

The invention provides a T-shaped well group and a method for exploiting non-diagenetic natural gas hydrates. The T-shaped well group comprises a vertical well and a horizontal well located on one side of the vertical well, and the vertical well and the horizontal well share the same wellhead; a vertical well target point is located in a stable formation under a reservoir; a deflecting section, adeflection increasing section, a deflection stabilizing section and a horizontal section of the horizontal well are all located in a stable formation over the reservoir, and a horizontal well target point is located in the reservoir or the stable formation over the reservoir; both the vertical well and the horizontal well are provided with fracturing sand prevention layers, and a vertical well fracturing seam is a horizontal seam; and horizontal well fracturing seams are vertical seams, the lower ends of the horizontal well fracturing seams extend into the reservoir, and the number of the horizontal well fracturing seams is not less than two sections. The T-shaped well group and the method for exploiting the non-diagenetic natural gas hydrates have the beneficial effects that the verticalwell target point, and the deflecting section, the deflection increasing section, the deflection stabilizing section and the horizontal section of the horizontal well in the T-shaped well group are all arranged in the underlying stable formation or the overlying stable formation of the reservoir so that not only can the stability of wellbores of the whole well group and well control safety be improved, but also the contact area between the wellbores and the reservoir can be increased.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Describing Method of Fracture Scale Based on Full Waveform Characteristics of Seismic Waves

ActiveCN112068198BImprove targetingImprove effectivenessSeismic signal processingCorrelation coefficientWell logging

The invention provides a method for describing the fracture scale based on the full waveform characteristics of seismic waves. The description method of the crack rupture scale includes: generating a composite source time function by modeling the crack rupture scale, obtaining the Green's function from the source to the observation station through well logging and / or 3D seismic data, and according to the composite source time function and Green's function and the seismic moment tensor to obtain the synthetic micro-seismic wave, calculate the correlation coefficient based on the full waveform characteristics of the synthetic micro-seismic wave and the micro-seismic wave recorded by the observation station, and select the synthetic micro-seismic wave whose correlation coefficient is within the allowable range of the preset coefficient. The fracture rupture scale of is used as the fracture rupture scale. The beneficial effects of the present invention may include: being able to solve the difficult problem that the fracture scale cannot be quantitatively described in passive seismic monitoring.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Fracturing method for opening new crack through crack saturated filling sand

PendingCN112943208AIncrease utilizationImprove single well productionFluid removalGeotechnical engineeringOil field

The invention belongs to the technical field of oilfield development downhole operation fracturing, and particularly provides a fracturing method for opening a new crack through crack saturated filling sand. A proppant is continuously injected into a primary artificial crack according to a sand-liquid ratio of 20%, 30% and 40%, and a gel breaker is added in a process of adding the proppant, so that the saturated filling sand inside the primary artificial crack is enabled to cause sand plugging in the crack; meanwhile, the net pressure in the crack is further improved by improving the construction displacement, a lateral new crack is opened, effective support is formed for the new crack, the purposes of forming a complex crack system, expanding the using degree of lateral remaining oil and improving the single well yield and the final recovery efficiency of an oil well are achieved. The technological process is simple and easy to implement, the cost is lower, and the characteristics of high on-site temporary plugging and rising amplitude controllability can greatly improve the production benefit of an oil field, and has wide application prospects in the aspects of increasing the single-well yield of lateral low-yield oil wells of ultra-low permeability reservoirs and ultra-low permeability reservoirs and improving the water drive effect of the low permeability reservoirs.

Owner:PETROCHINA CO LTD

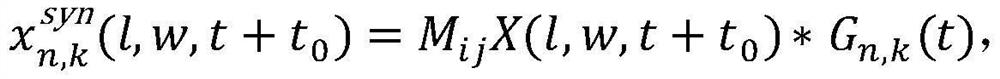

Horizontal drilling and coring of directional window cutting and matching methods

The invention relates to horizontal drilling and coring of directional window cutting and matching methods. The process comprises the steps: (1) drilling a horizontal hole using an ultra-short radius radial horizontal drilling tool guided by a whipstock; (2) plugging the position of a casing above the whipstock by using a packer; (3) injecting a fracturing fluid by using a fracturing string to form a major fracture in the stratum; (4) plugging the major fracture with a temporary plugging agent; and (5) improving the pressure of the fracturing liquid by 5-10 MPa, and injecting once more the fracturing liquid via the fracturing string to form a great quantity of secondary fractures around the major fracture in the stratum. According to the invention, ultra-short radius radial horizontal drilling and fracture network fracturing are combined so that the direction of a horizontal hole can be determined and a drilling diameter and a drilling length can be increased on the basis of the existing techniques; common fracturing is replaced by fracture network fracturing; thus, a new production-increasing and efficiency-raising technique is provided in the aspects of excavating potential remaining oil, improving low permeability reservoirs, etc., allowing tenfold increase or more in per-well production.

Owner:DAQING JINGTAI PETROLEUM ENG TECH

Coal bed gas mining technology

ActiveCN101113666BIncrease temperatureImprove single well productionFluid removalEngineeringHigh pressure

The invention discloses a coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

A Well Pattern Deployment Method for Very Thick Buried Hill Fractured Reservoirs

ActiveCN104912537BGuaranteed encounterReduce production differential pressureFluid removalHorizontal wellsWater well

The present invention relates to a well pattern deployment method for extremely thick buried-hill fractured oil reservoirs, which is characterized in that a set of large-fracture injection and small-fracture production is deployed in the extremely thick buried-hill fractured oil reservoirs. Injection-production well pattern of horizontal wells for injection and top production; Among them, large-fracture injection refers to deploying injection wells in large fracture areas of extremely thick buried-hill fractured reservoirs, and small-fracture production refers to deploying production wells in extremely thick buried-hill fractured reservoirs the small fracture area; plane stagger means that the injection wells and production wells are projected onto the plane and are parallel to each other but not facing each other; vertical three-dimensional means that the horizontal wells are arranged in parallel at different direction and perpendicular to the main wellbore to form a three-dimensional well pattern; bottom injection and top production mean that the water injection wells are arranged at the bottom of the extremely thick buried hill fractured reservoir, and the production wells are arranged at the top of the extremely thick buried hill fractured reservoir. The present invention can effectively solve the problem of well arrangement in extremely thick buried hill reservoirs, and is an effective well arrangement method for extremely thick buried hill fractured oil reservoirs.

Owner:CHINA NAT OFFSHORE OIL CORP +1

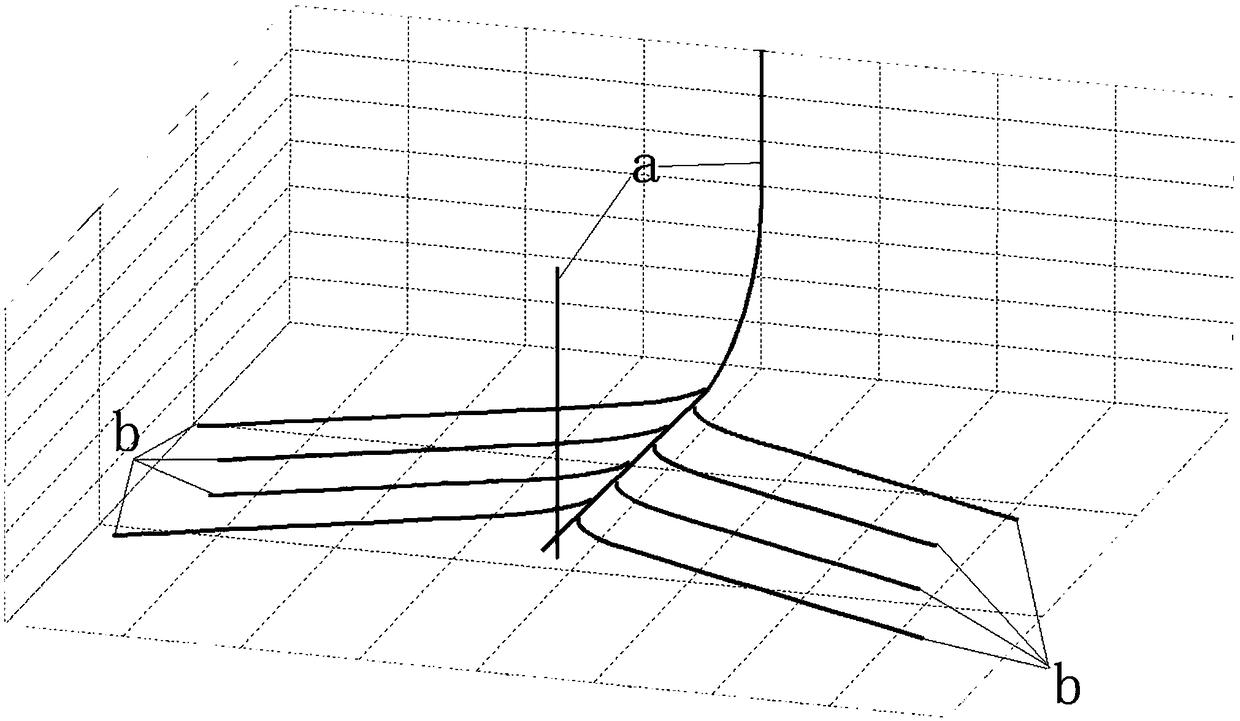

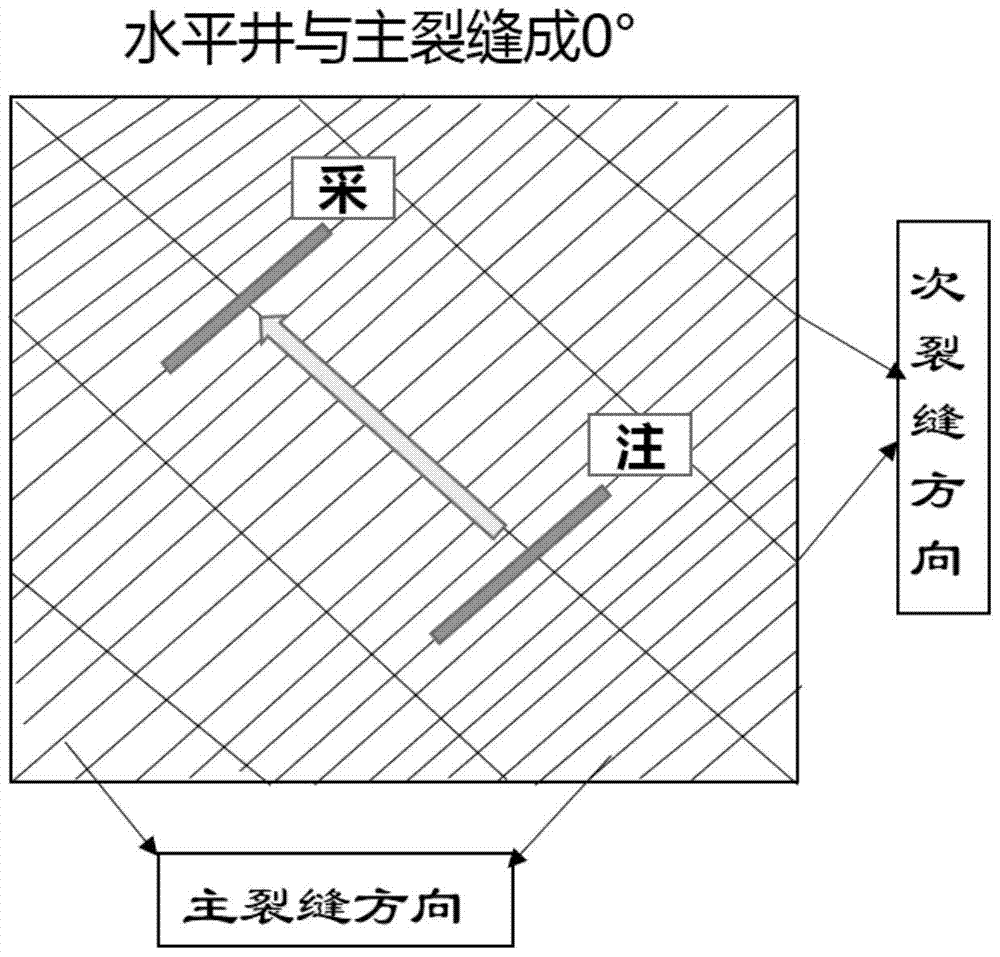

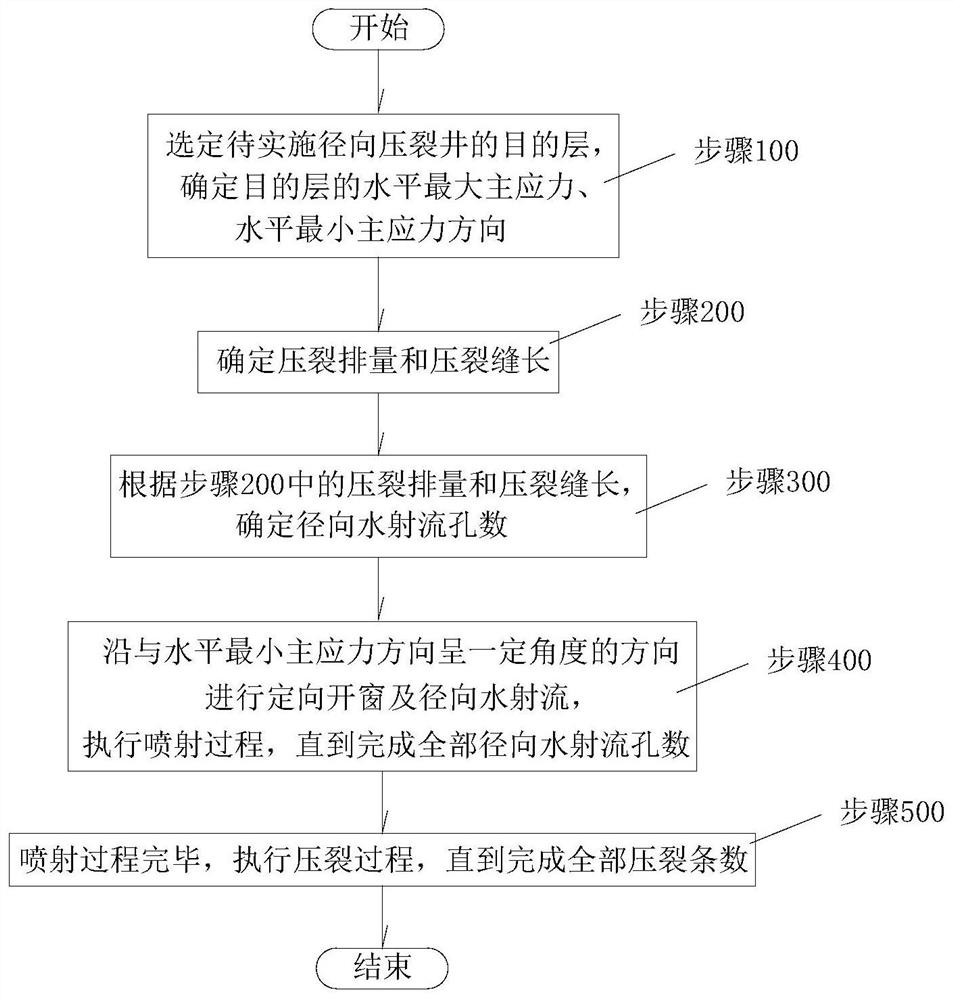

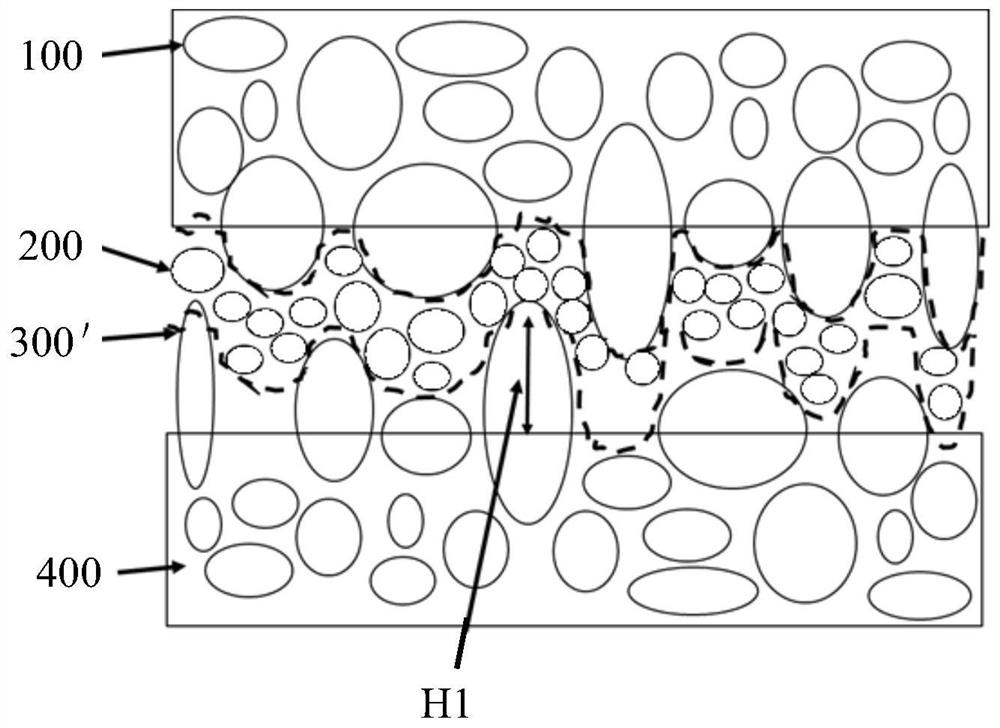

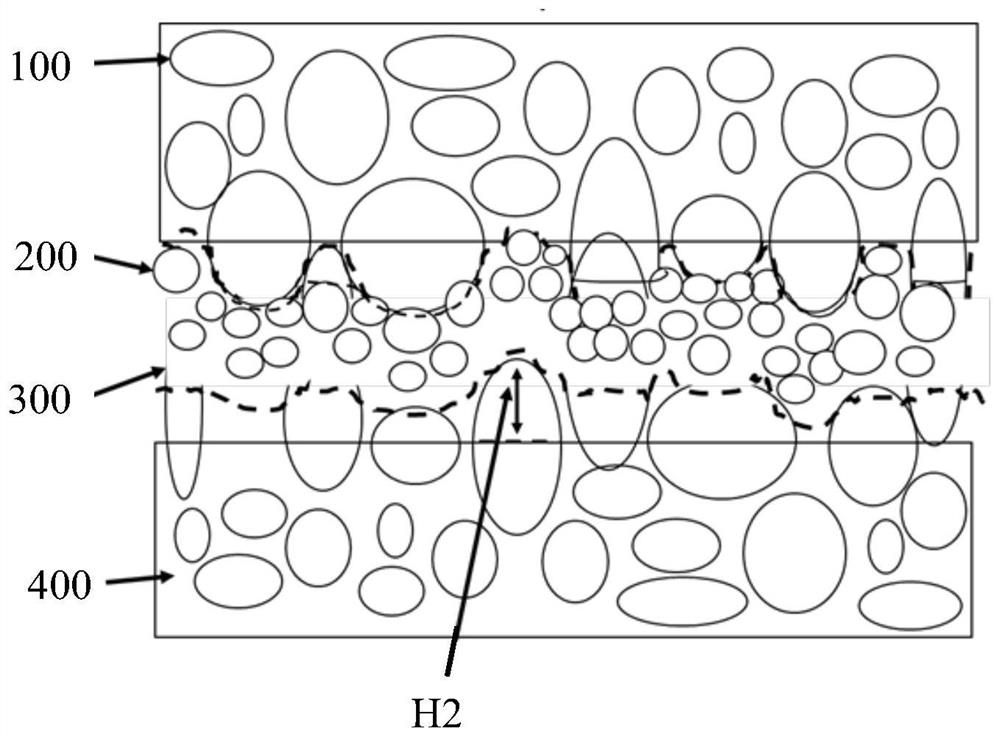

Radial well volume fracturing method

PendingCN113622889ALarge spreading areaImprove single well productionFluid removalPrincipal stressHorizontal wells

The invention relates to the technical field of later-stage exploitation of oil and gas fields, and discloses a radial well volume fracturing method. The method comprises the following steps of 100, selecting a target layer of a well to be subjected to radial fracturing, and determining the horizontal maximum principal stress direction and the horizontal minimum principal stress direction of the target layer; 200, determining the fracturing displacement and the fracturing crack length; 300, determining the number of radial water jet holes according to the fracturing displacement and the fracturing crack length in the step 200; 400, performing directional windowing and radial water jet in the direction forming a certain angle with the horizontal minimum principal stress direction, and executing the jet process till all the radial water jet holes are completed; and 500, after the jet process is completed, executing the fracturing process until all fracturing strips are completed. By means of radial water jet in the vertical well, volume fracturing is achieved in the reservoir section, the purpose of similar horizontal well fracturing is achieved, the fracture swept area is enlarged, oil and gas reserves are effectively used, and compared with conventional one-time fracturing, the single-well yield of a low-permeability oil and gas well can be greatly increased.

Owner:新疆宝成信能源技术有限公司

Describing Method of Fracture Scale Based on Seismic Wave Dynamic Parameters

ActiveCN112068197BImprove targetingImprove effectivenessSeismic signal processingWell loggingSeismic wave

The invention provides a description method of crack rupture scale based on seismic wave dynamic parameters. The description method of the crack rupture scale includes: generating a composite source time function by modeling the crack rupture scale, obtaining the Green's function from the source to the observation station through well logging and / or 3D seismic data, and according to the composite source time function and Green's function and the seismic moment tensor to obtain the synthetic microseismic wave, and fit the synthetic microseismic wave with the microseismic wave recorded by the observation station based on the dynamic characteristics of the seismic wave to obtain the inversion threshold value, and select the inversion threshold value within the preset threshold allowable range The crack rupture scale recorded by the synthetic microseismic waves in the system is used as the fracture rupture scale. The beneficial effects of the present invention may include: being able to solve the difficult problem that the rupture scale of artificial fracturing fractures cannot be described quantitatively.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

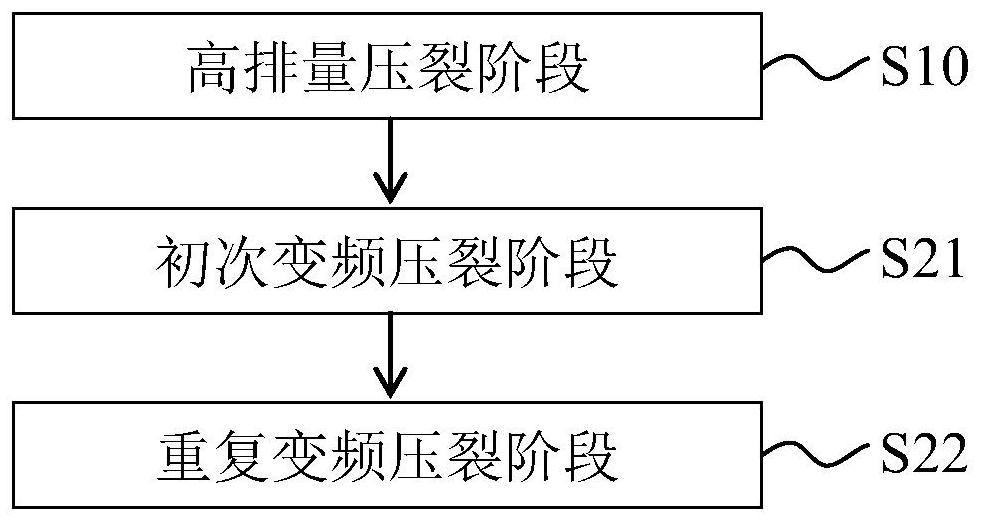

Fracturing method for improving gravel penetration rate of conglomerate and glutenite reservoirs

ActiveCN113775322AImprove gravel penetration rateImprove single well productionGeothermal energy generationFluid removalFracturing fluidConglomerate

The invention provides a fracturing method for improving the gravel penetration rate of conglomerate and glutenite reservoirs. The fracturing method comprises the steps that S10, fracturing fluid is pumped into a target reservoir at a preset high displacement, so that a main fracture is generated in the target reservoir; and S20, the fracturing fluid is pumped into the target reservoir at a preset low displacement lower than the preset high displacement for multiple times, and the pumping time of single-time pumping of the fracturing fluid is gradually prolonged along with the increase of the pumping times, so that variable-frequency cyclic fracturing is achieved. According to the fracturing method, a variable-frequency cyclic fracturing mode is adopted, the gravel penetration rate of hydraulic fractures can be effectively increased, the roughness of hydraulic fracture surfaces is reduced, seepage channels with high flow conductivity are formed in the conglomerate and glutenite reservoirs, and the fracturing method has important significance for increasing the single-well yield of the hydraulic fractures in the conglomerate and glutenite reservoirs and other gravel-containing reservoirs.

Owner:PETROCHINA CO LTD

A well group layout method for microbial flooding oil recovery technology

The invention discloses a well group well arrangement method for microbial flooding oil production technology, using microbial tertiary oil recovery technology to deploy a set of combined injection-production well pattern of horizontal well production and vertical well injection in thicker sandstone reservoirs, the combined injection-production The well pattern should meet the requirements of plane correspondence, vertical three-dimensional, bottom injection and top production; vertical well injection refers to the use of vertical wells to inject microorganisms into the bottom area of sandstone reservoirs, and horizontal well production refers to the deployment of horizontal sections of production wells in thick sandstone reservoirs. The top area; plane correspondence means that the horizontal section of the injection vertical well and the production well overlap after being projected onto the plane in a top view, which is a corresponding relationship between up and down; vertical three-dimensional means that the vertical well injection section and the production well horizontal section are in the sandstone reservoir. Different depths are arranged in parallel, and a three-dimensional well pattern is formed in the section parallel to the gravity direction and perpendicular to the main wellbore of the horizontal section of the production well; the invention has high oil sweeping efficiency, high oil recovery capacity and high ultimate recovery factor Etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method of oil and gas production with artificial seam control for enhanced oil recovery

ActiveCN108561106BImprove single well productionIncrease productionFluid removalHorizontal wellsWell control

The invention provides an oil and gas exploitation method for increasing the recovery ratio through artificial crack control reserves. The method comprises the steps of arranging a horizontal well according to the stratum structure trend, distribution features of sand bodies, distribution of stress fields and the like of an area where a to-be-exploited oil deposit is located; adopting a segmentedand clustered perforation technology for perforating a casing pipe in the horizontal well; adopting a pressing crack mode of which the scale is larger than a preset scale for conducting capacity cracking transformation on the perforated horizontal well if the brittleness index of reservoir rocks of the area where the to-be-exploited oil deposit is located is larger than a preset index, the reservoir rocks have natural crack development, and the max-min primary stress difference is smaller than a preset stress value; adopting the horizontal well which is subjected to capacity cracking transformation for exploiting oil and gas. According to the embodiment, the mode of well control reserves is converted into the mode of crack control reserves, the contact area of a matrix and the cracks is increased, the distance of fluid in the matrix to flow to the cracks is reduced, the pressure difference for driving the fluid in the matrix to flow to the cracks is lowered, and the per-well yield andthe recovery ratio of oil and gas exploitation are increased.

Owner:PETROCHINA CO LTD

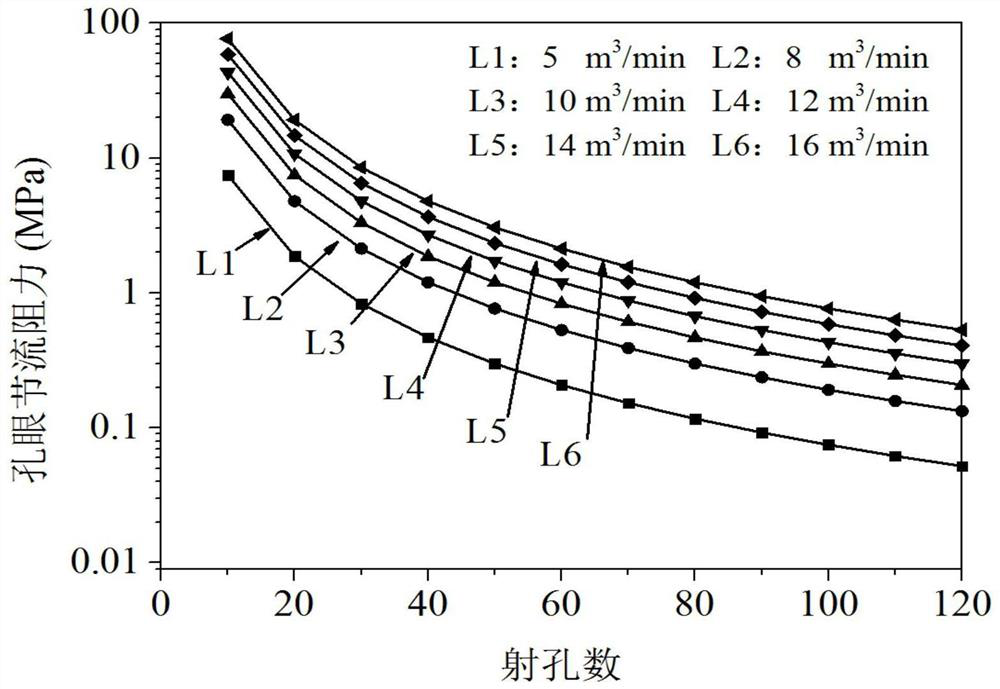

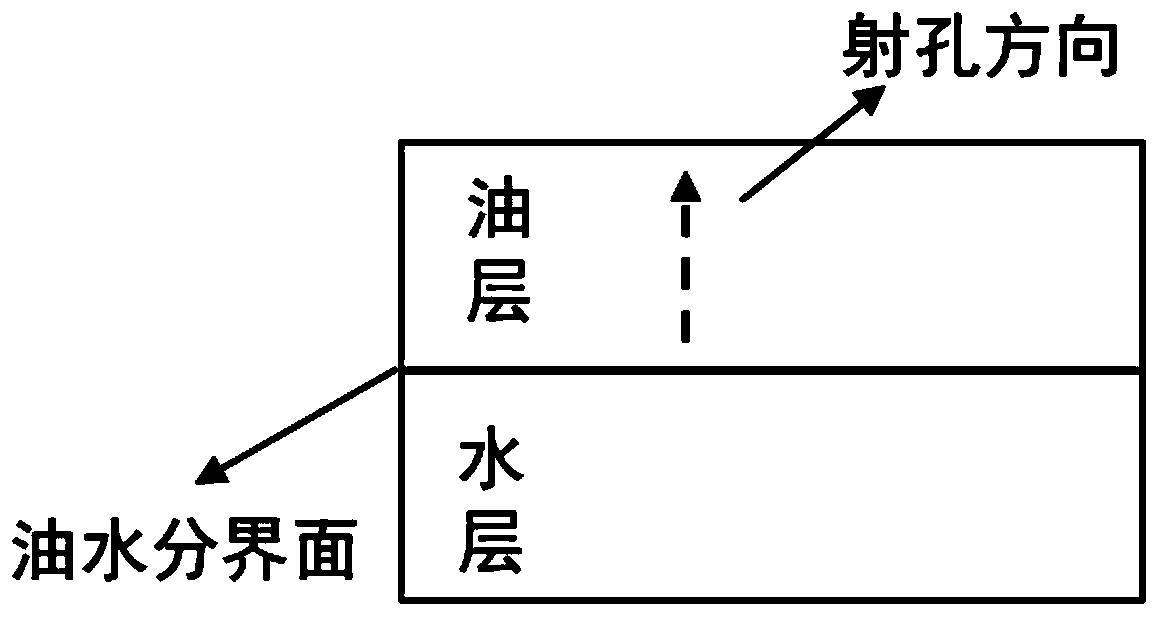

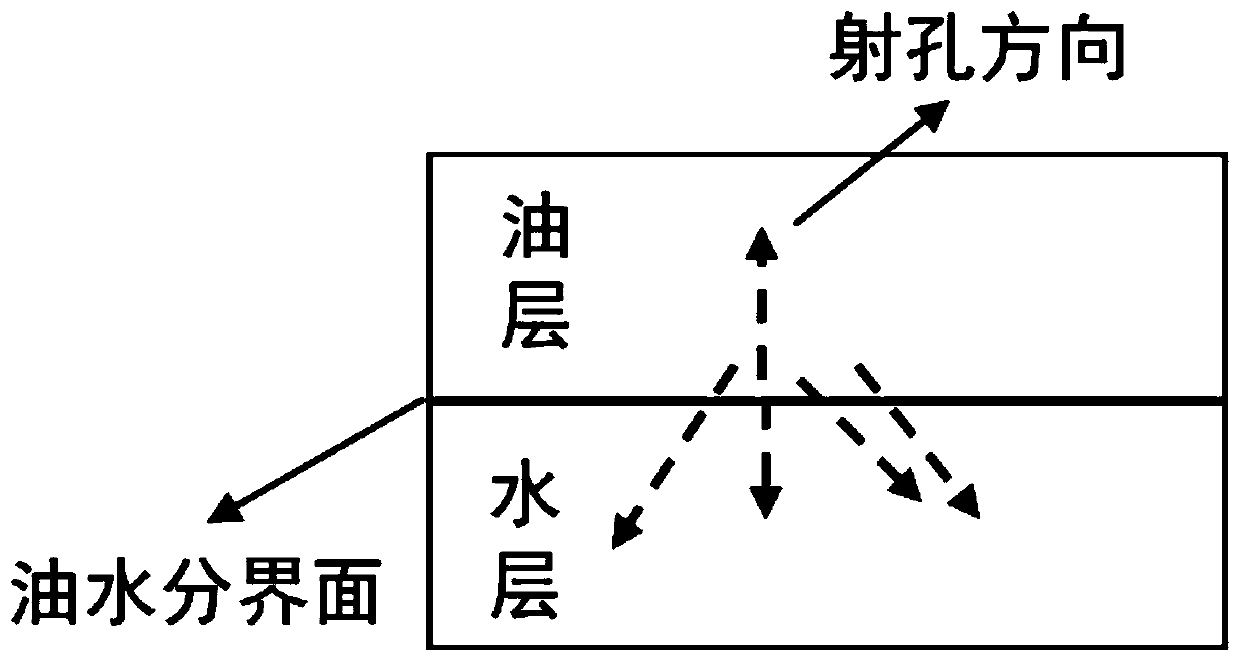

Fracturing method for improving single well yield of low-permeability bottom water reservoir horizontal well

InactiveCN111350484AAvoid pressure channelingEffective transformationFluid removalSoil scienceHorizontal wells

The invention discloses a fracturing method for improving single well yield of a low-permeability bottom water reservoir horizontal well. The characteristic of hydraulic sand blasting perforation fracturing point source fracturing initiation is utilized, a high point is preferably constructed to serve as a perforation position, meanwhile, a directional perforation process is combined, namely, upward perforation is conducted, a water layer is prevented from being perforated, upward expansion of cracks is achieved by controlling the fracturing displacement in fracturing, downward expansion of the cracks is controlled, and therefore effective transformation of a bottom water reservoir is achieved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com