A Well Pattern Deployment Method for Very Thick Buried Hill Fractured Reservoirs

A well pattern deployment and oil reservoir technology, applied in wellbore/well parts, earthwork drilling and production, production fluid, etc., can solve the problems of large differences and individual differences, achieve small production pressure difference, improve sweep The effect of high area and single well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

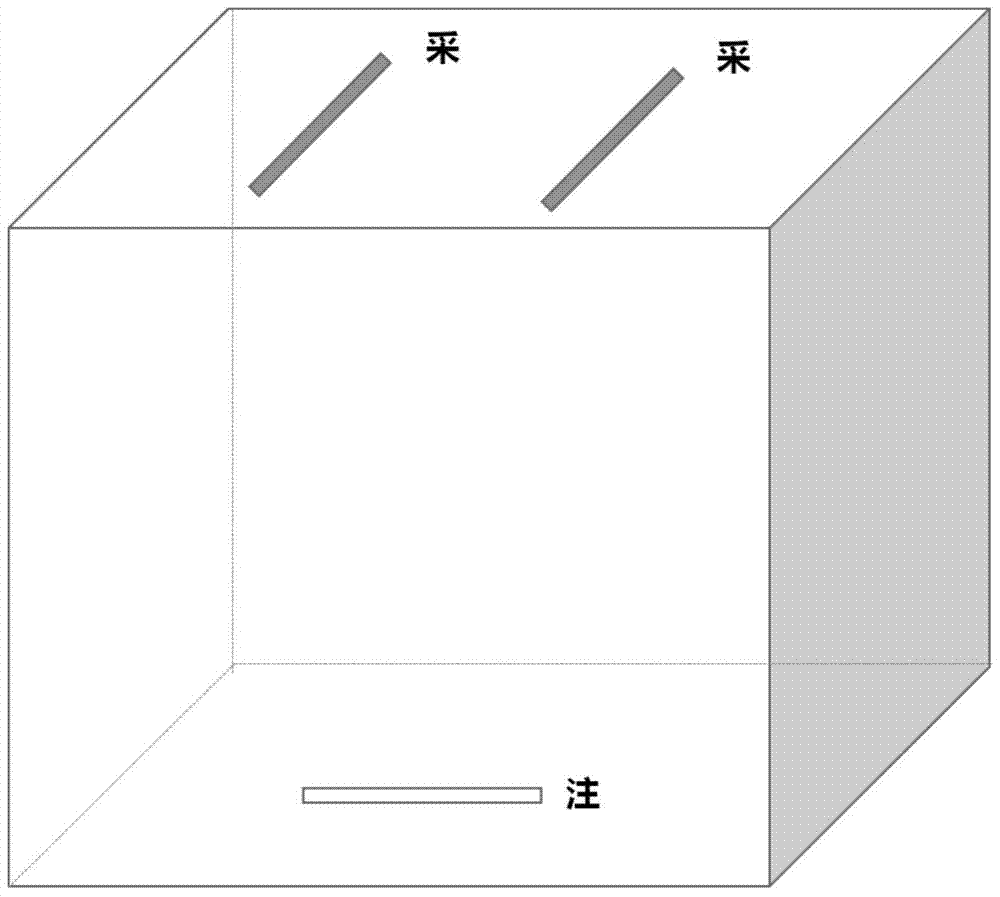

[0045] Before proposing the well pattern deployment method for extremely thick buried-hill fractured reservoirs of the present invention, it is first necessary to conduct relevant analysis on extremely thick buried-hill fractured reservoirs, specifically including:

[0046] 1. Analysis of characteristics of extremely thick buried hill fractured reservoirs:

[0047] (1) Extremely thick reservoirs: The effective thickness of extremely thick buried hill fractured reservoirs is hundreds of meters or even thousands of meters, and the vertical oil-bearing range is huge.

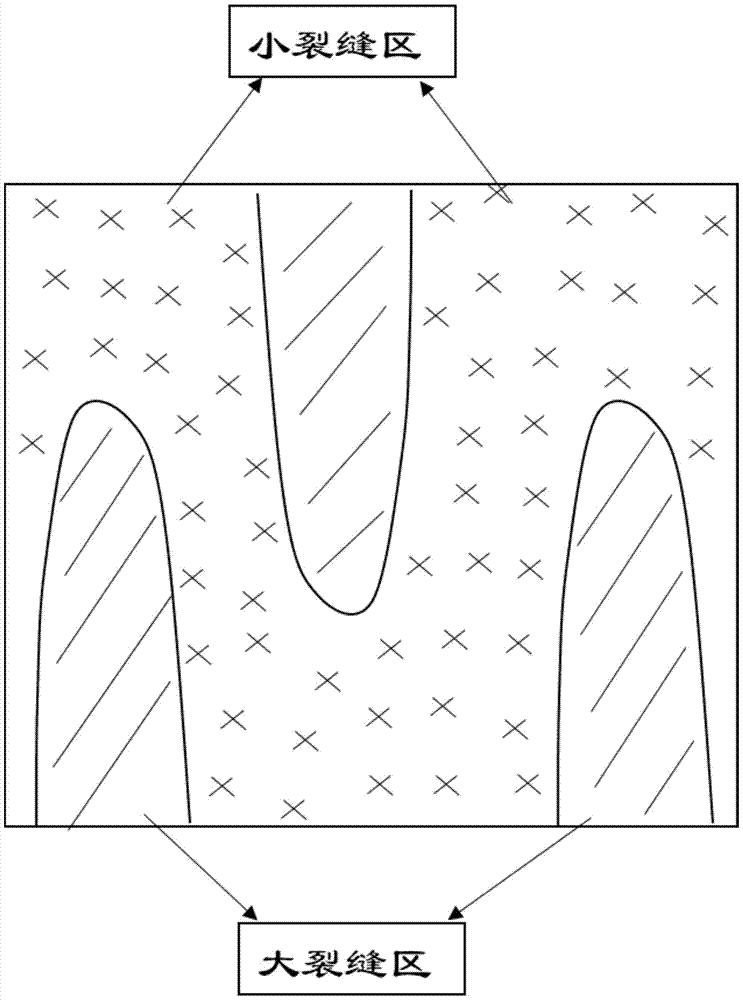

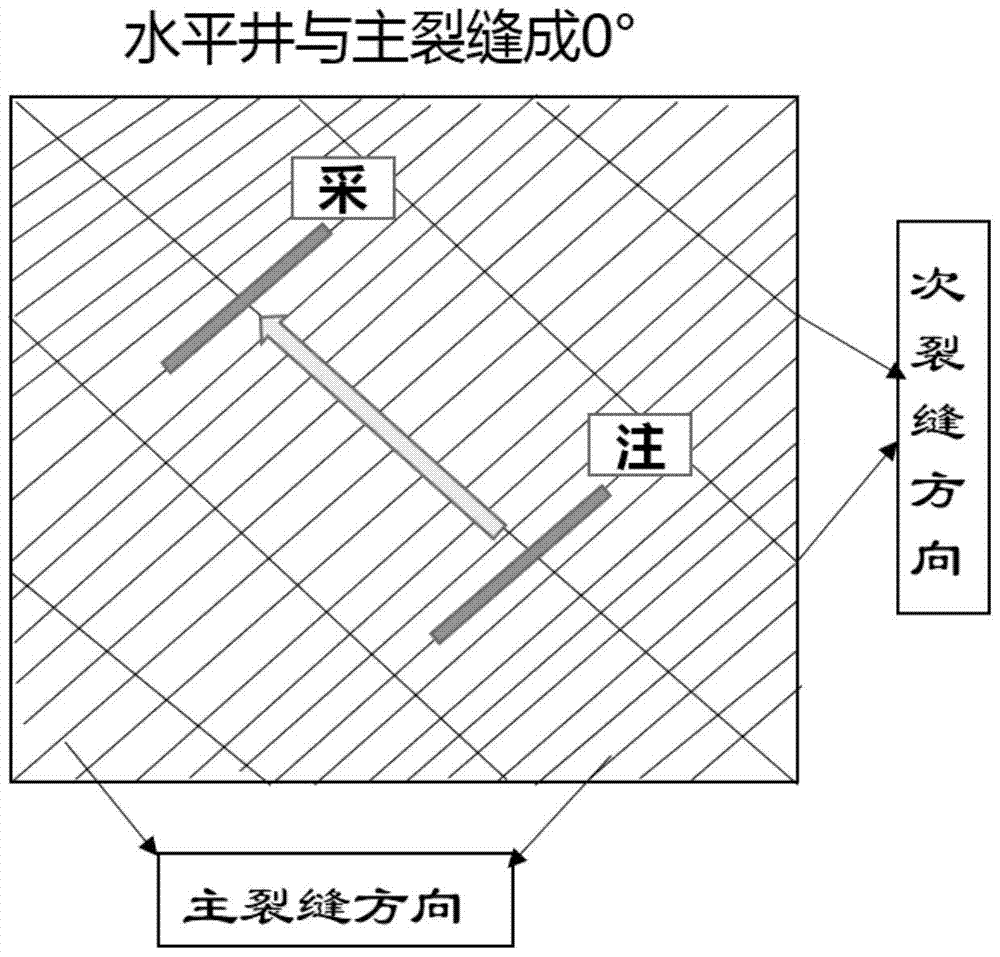

[0048] (2) Longitudinal high angle fractures: Affected by tectonic stress, fractured res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com