A Production Method of Branched Horizontal Well Based on Slip Coefficient

A technology of slippage coefficient and production method, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems of reducing the development life of gas wells and blocking the flow channel of shale gas, so as to save maintenance costs and slow down formation The effect of water channeling and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A kind of branch horizontal well mining method based on slippage coefficient of the present invention, specifically comprises the following steps:

[0043] Step 1: Determine the absolute core permeability k of the target reservoir 0 , core slip coefficient b and shale gas viscosity μ g , where the core absolute permeability k 0 Viscosity μ of shale gas is measured by an automatic core permeability tester g Obtained by curve fitting method;

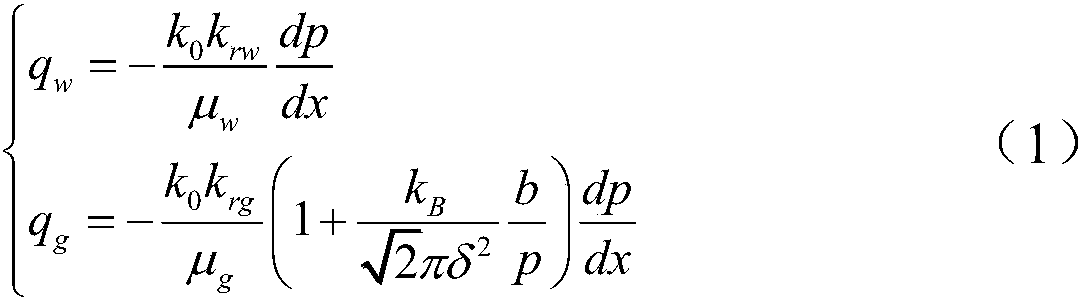

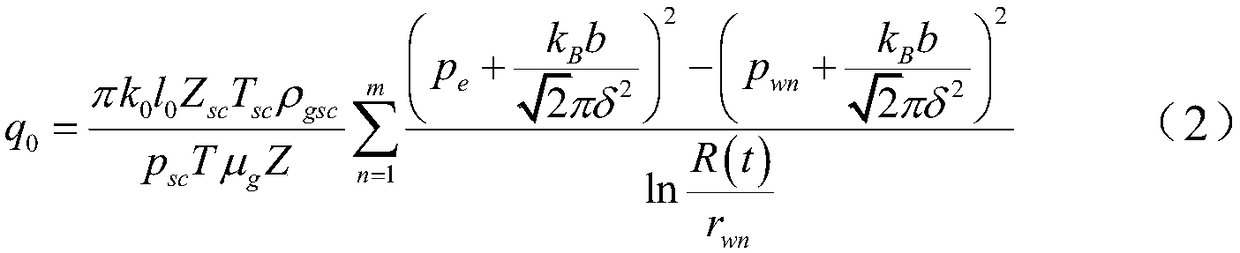

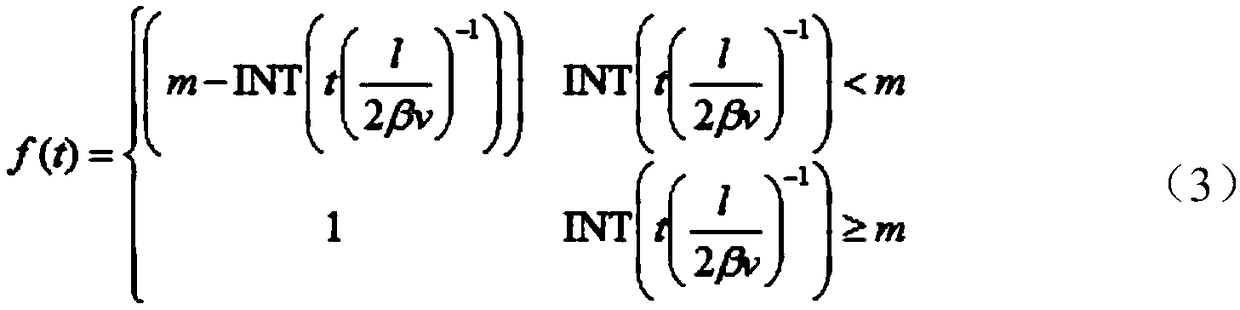

[0044] Step 2: Establish the gas-water two-phase seepage formula under the influence of slip coefficient:

[0045]

[0046] where k rwIndicates the relative permeability of the water phase; μ w Indicates the viscosity of the aqueous phase; Indicates the pressure gradient of the reservoir; q w Indicates the theoretical daily water production of branched horizontal wells; q g Indicates the daily gas production of branched horizontal wells; k rg Indicates the relative permeability of shale gas; k B Indicates the Boltzmann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com