Patents

Literature

35results about How to "Fully exploited" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

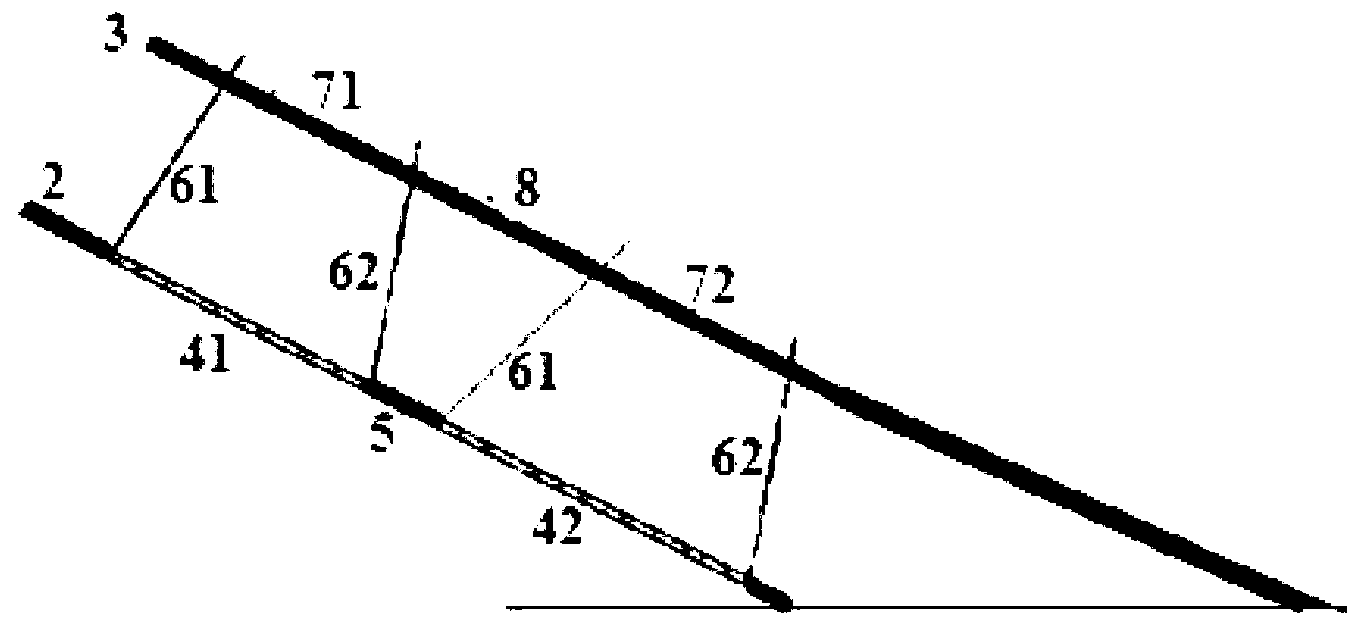

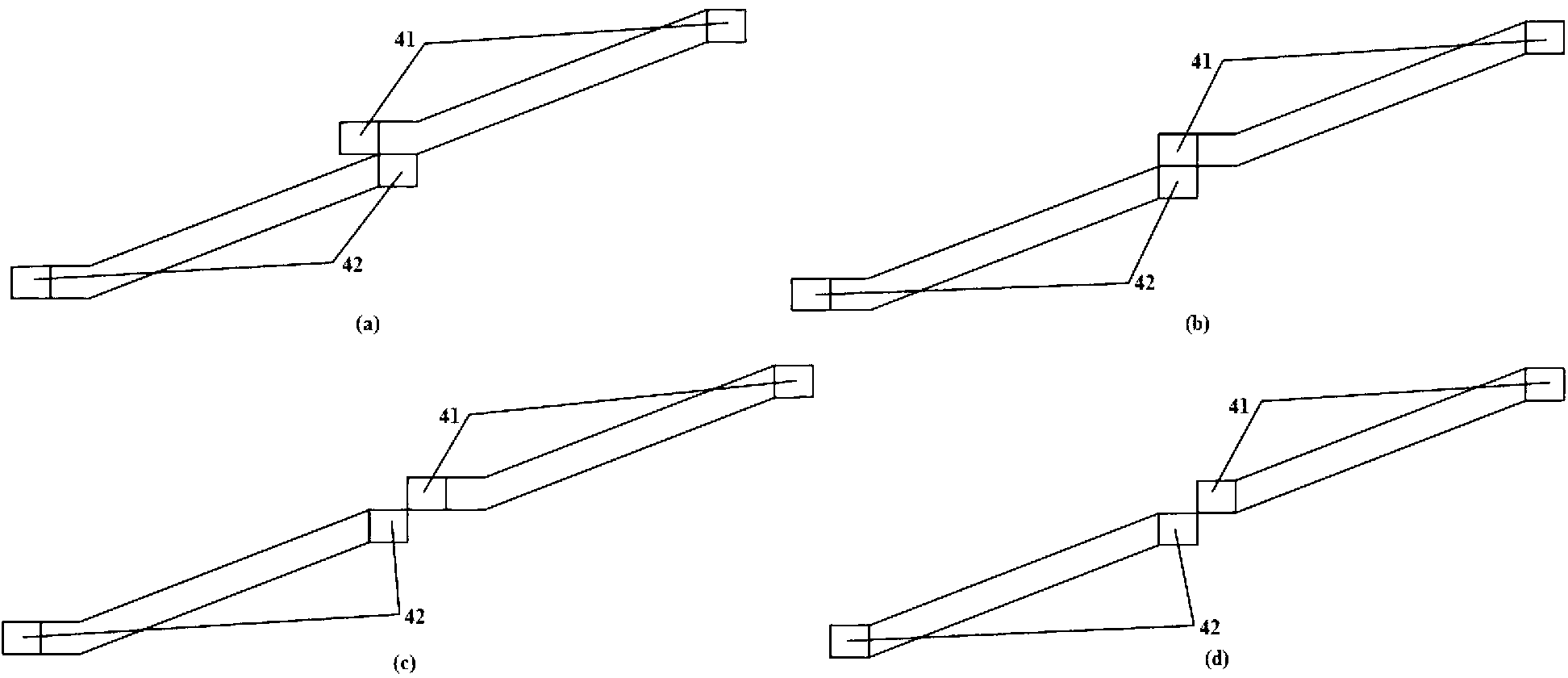

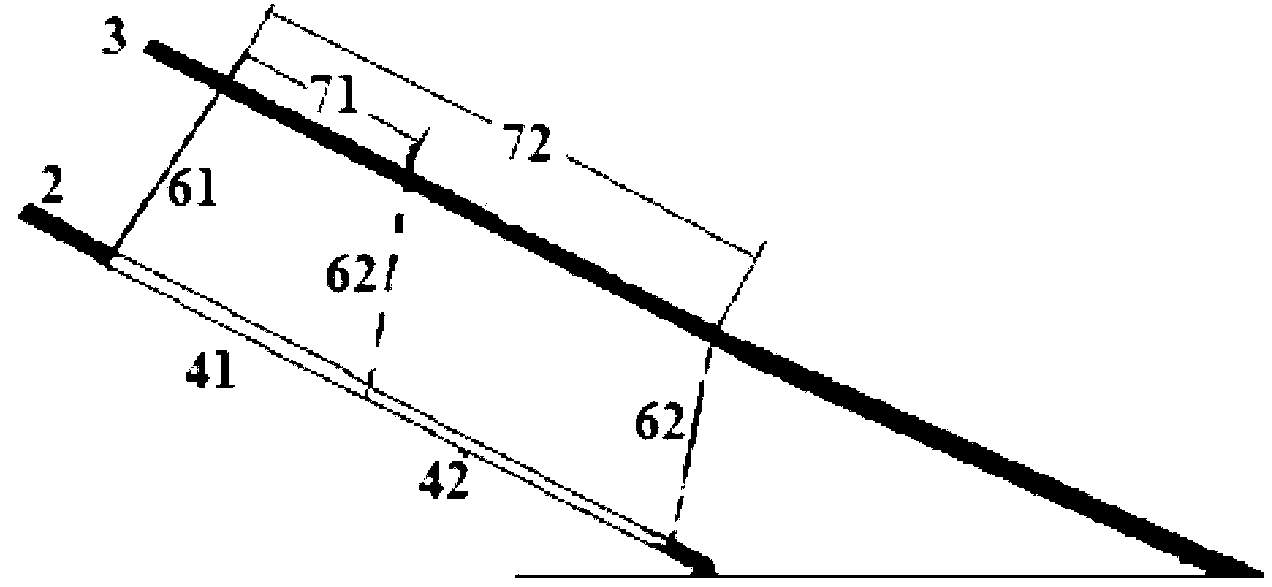

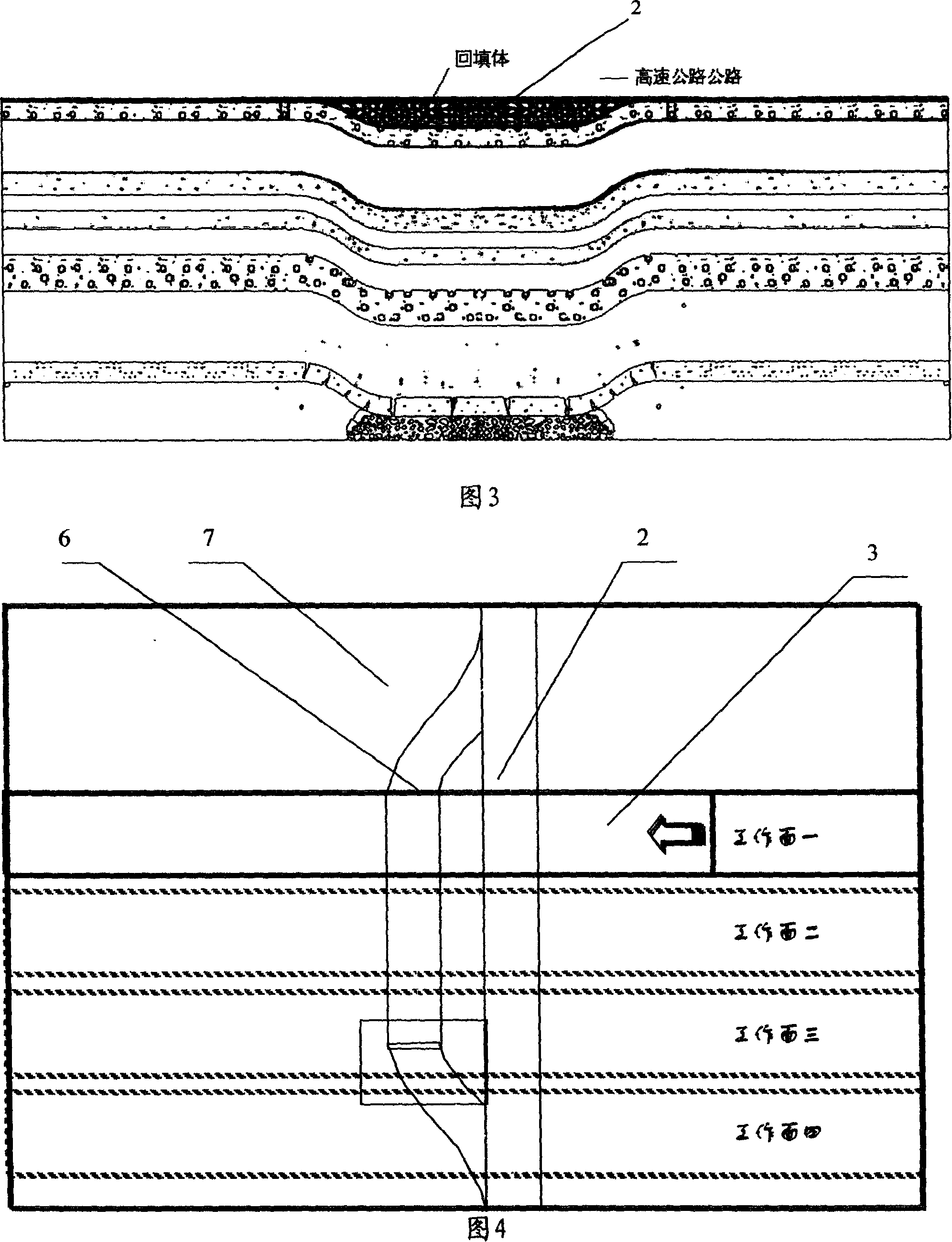

Application of non-coal-pillar coal mining method in under-protected stratum exploitation

ActiveCN103266893ARealize continuous recoveryAchieve economical miningUnderground miningSurface miningFracture zoneEngineering

The invention relates to an application of a non-coal pillar roadway layout in the under-protected stratum exploitation. The non-coal pillar roadway layout comprises a stagger arrangement or gob-side entry driving roadway layout, the non-coal pillar roadway layout is adopted in the under-protected stratum exploitation of a dynamic disaster coal stratum, and a coal pillar supporting overlying strata between adjacent work surfaces is removed, so the inclined continuous recovery of a stope is realized; and a fracture zone above the stope ascends and the arrangement of the protected coal stratum in the fracture zone descends with the increase of the exploitation range, so the application range of the under-protected stratum exploitation is widened, the mining is full, the destressing effect is obvious, and the protected stratum is not influenced by the installation of the coal pillar in the protected stratum, thereby the safe and economic exploitation of the protected stratum is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

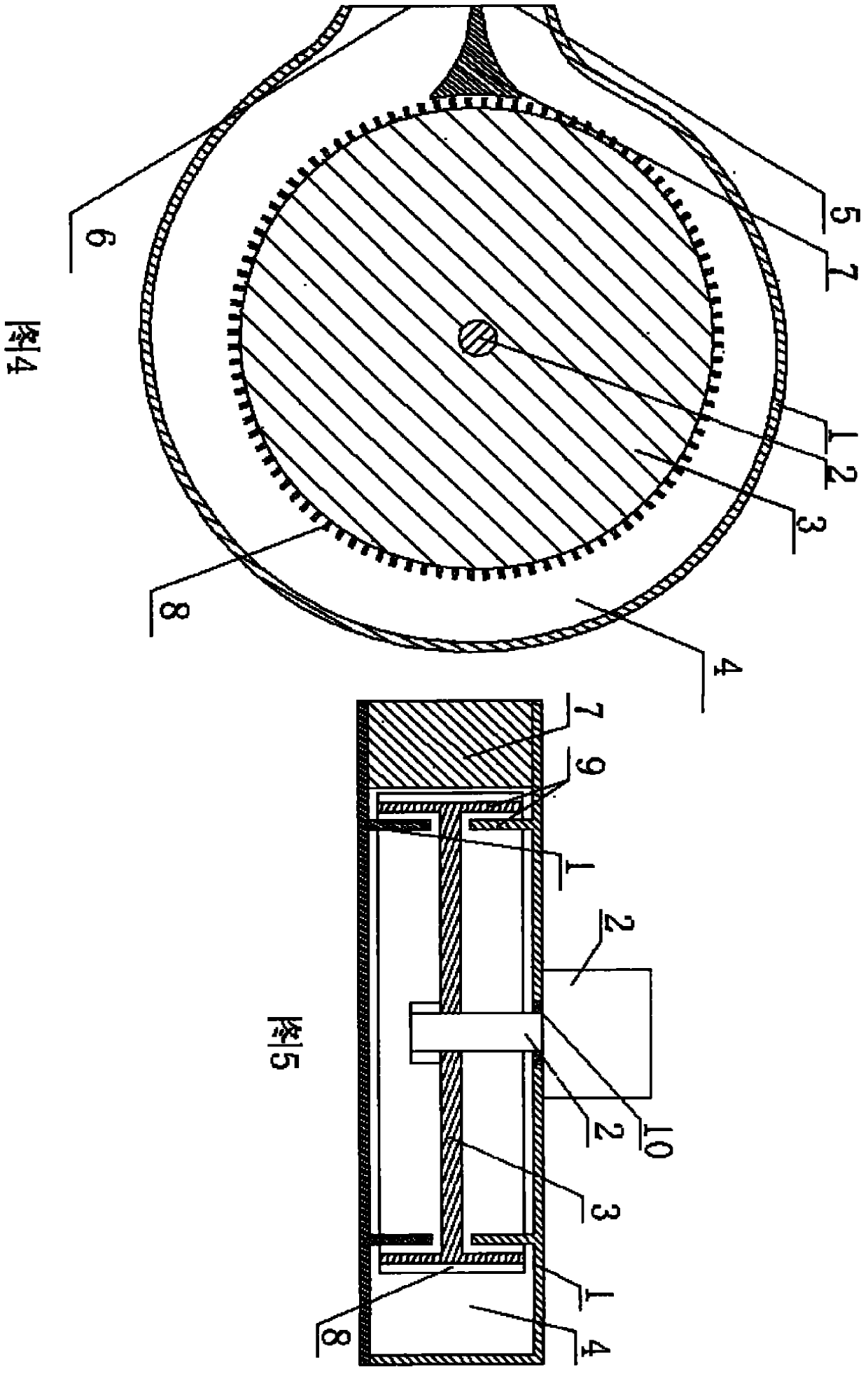

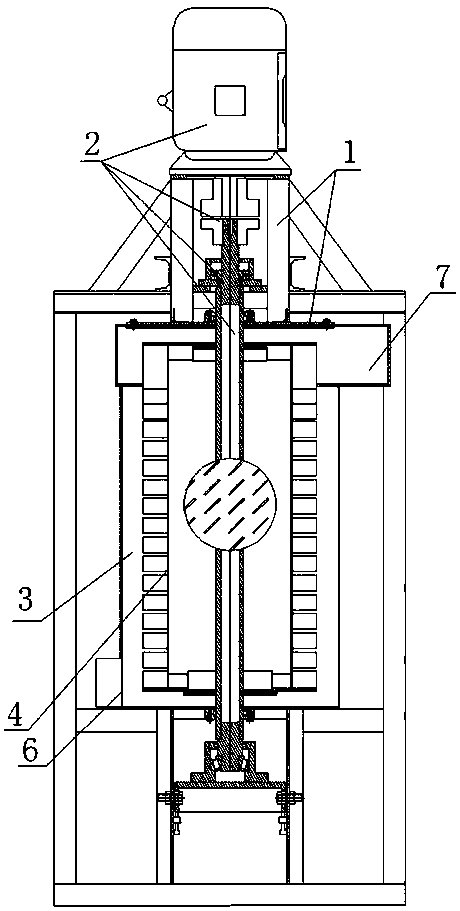

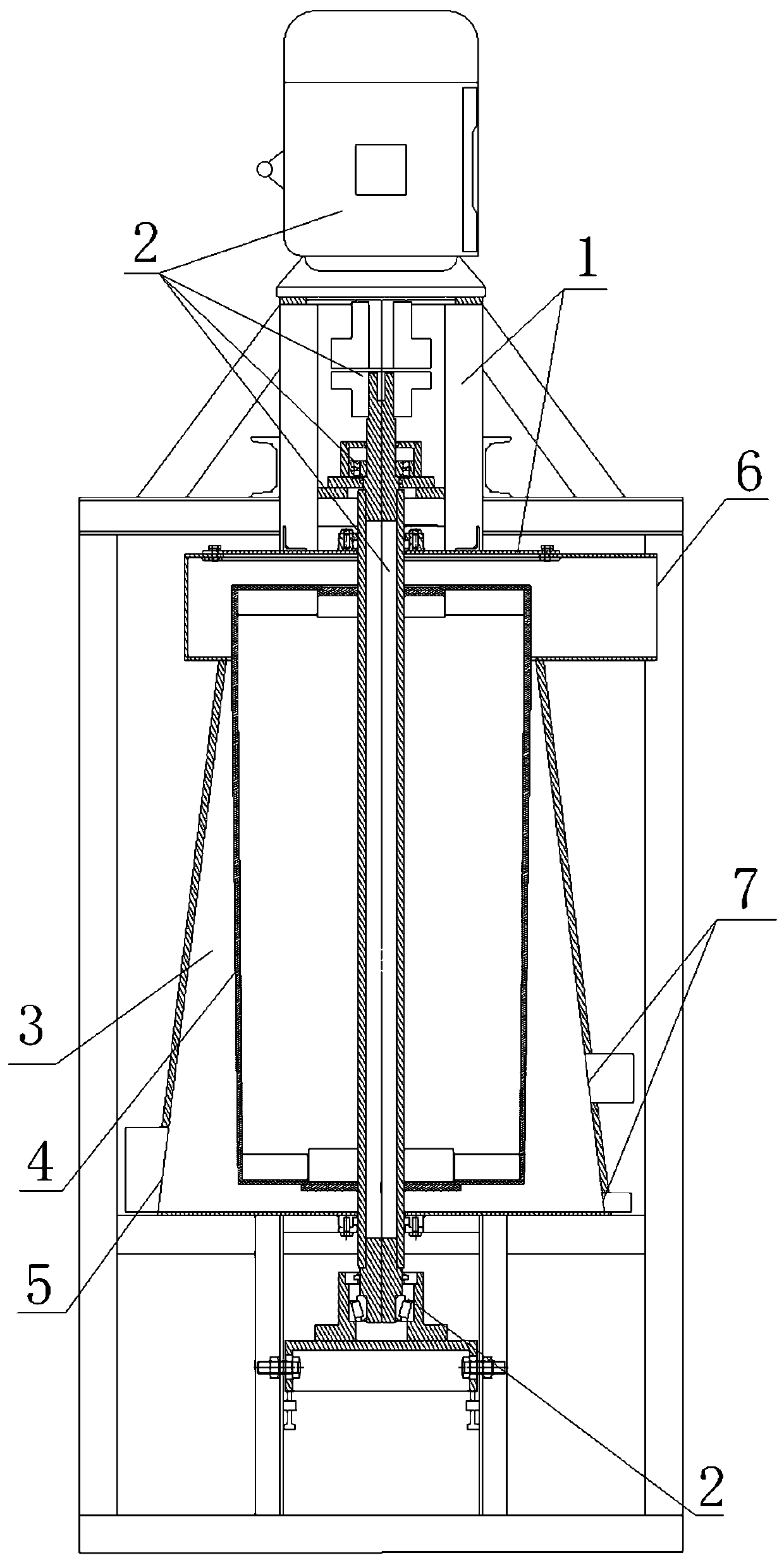

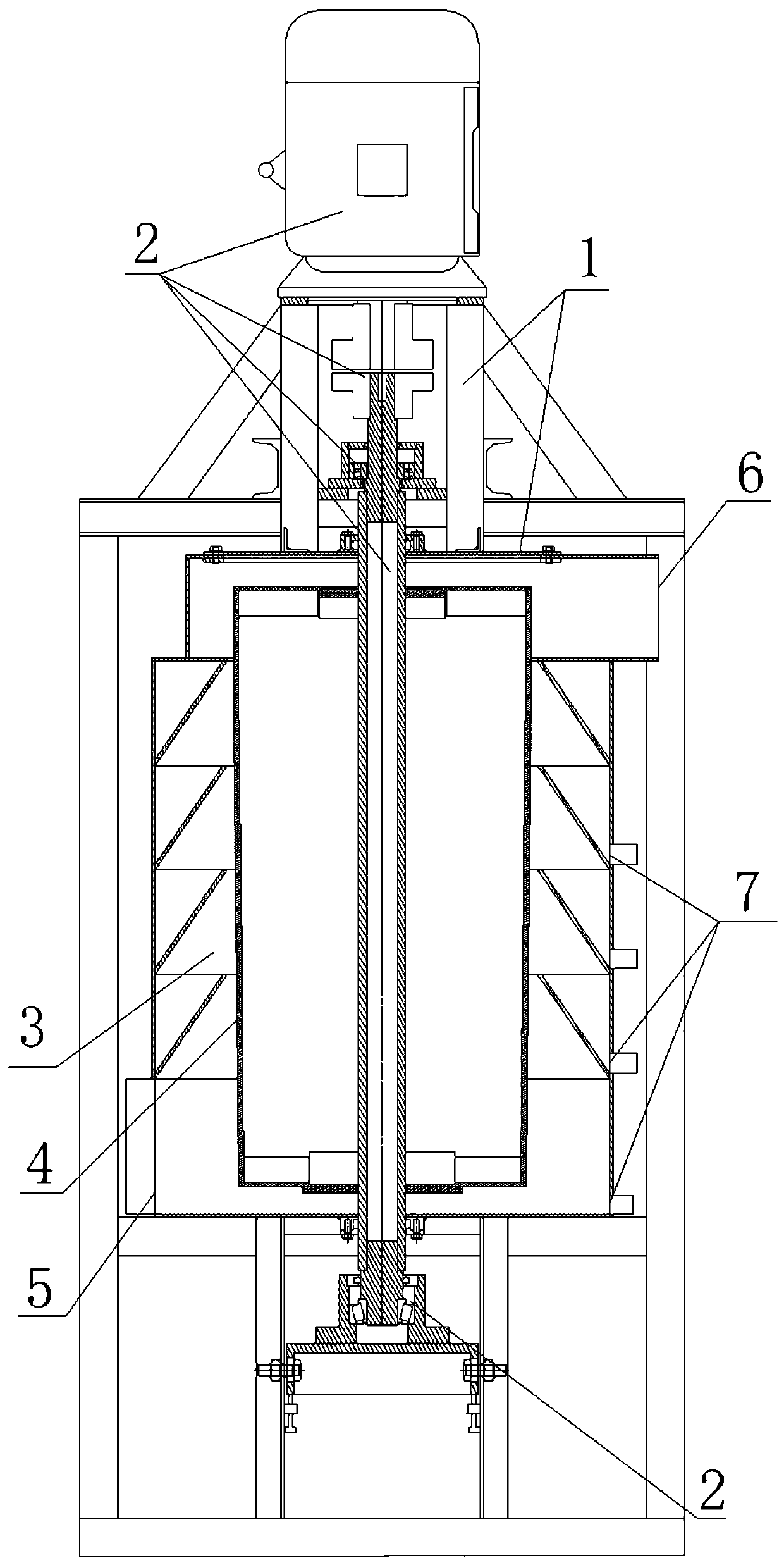

Circulator

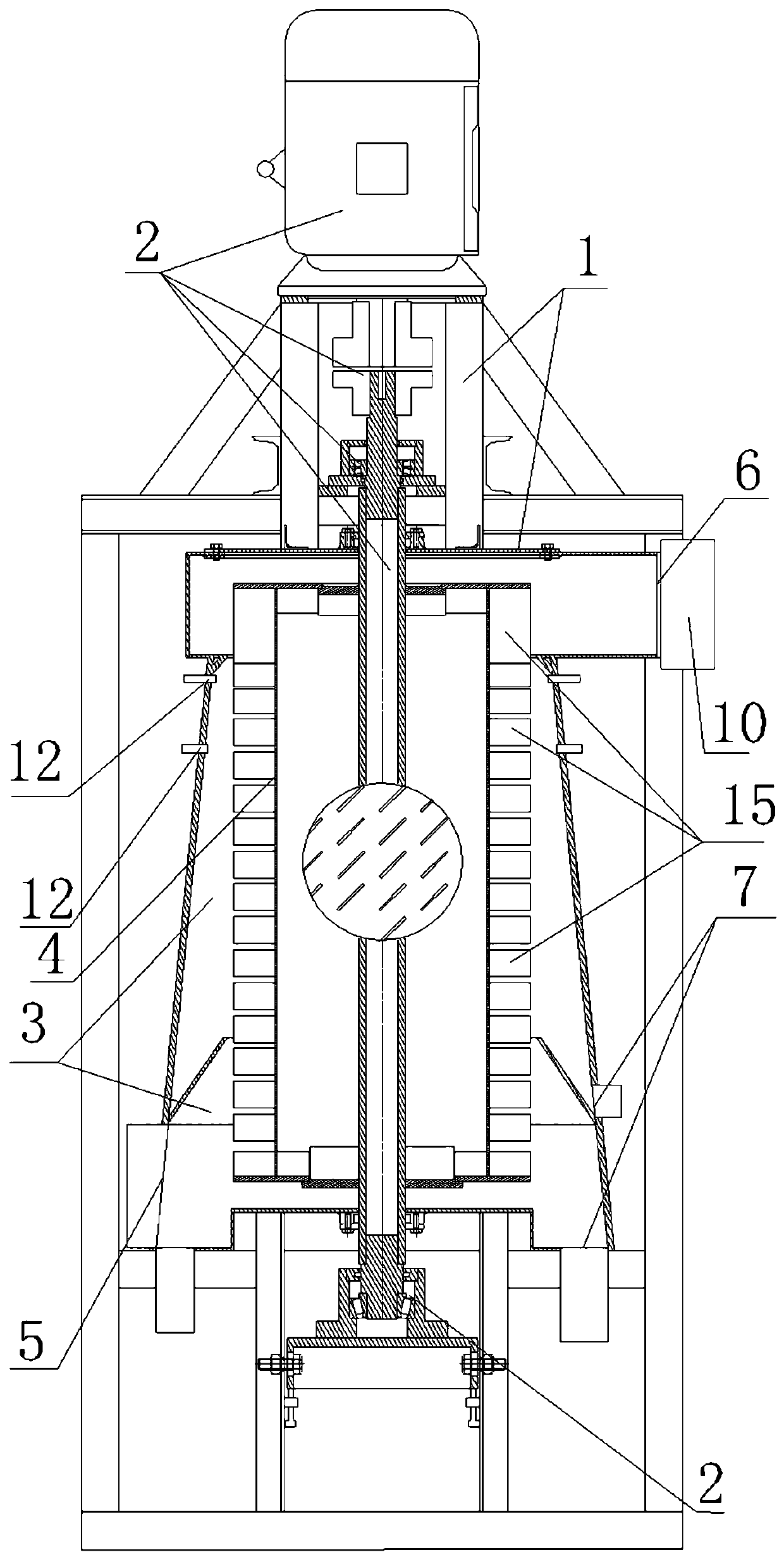

InactiveCN103216450AWonder Material PropertiesAchieve separationCircumferential flow pumpsPump componentsDust controlEngineering

The invention relates to a circulator. The circulator comprises a shell body and a transmission device, wherein the transmission device is mounted on the shell body, a rotary wheel is mounted on the transmission device, a plurality of vanes are arranged on the periphery of the rotary wheel, the rotary wheel is arranged in the shell body, a circulation cavity is formed in the inner wall of the shell body at the periphery of the rotary wheel, a circulation cavity port A is formed in one end of the circulation cavity, a circulation cavity port B is formed in the other end of the circulation cavity, and an isolating body is arranged on the inner wall of the shell body between the circulation cavity port A and the circulation cavity port B. According to the circulator provided by the invention, circular motion and fluid motion are used sufficiently; torsion is better converted into pressure through fluid; pressure is better converted into torsion through the fluid; and the fluid separation is realized by using vortex. The circulator provided by the invention can serve as a water pump, a slurry pump, a sewage pump, a blower, a compressor, spray equipment, a reactor, a steam turbine, vacuum equipment or a separator and be applied to wastewater treatment, seawater desalination, marine chemical engineering, mineral processing, waste disposal, hydrogen production, carbon dioxide decomposition, harmful gas decomposition, air purification, dedusting, dust absorption, refrigeration, oxygen production, oil refining and the like; and the blue sky and water can be completely realized, and foamed materials can be produced so as to bring a material revolution.

Owner:陈久斌

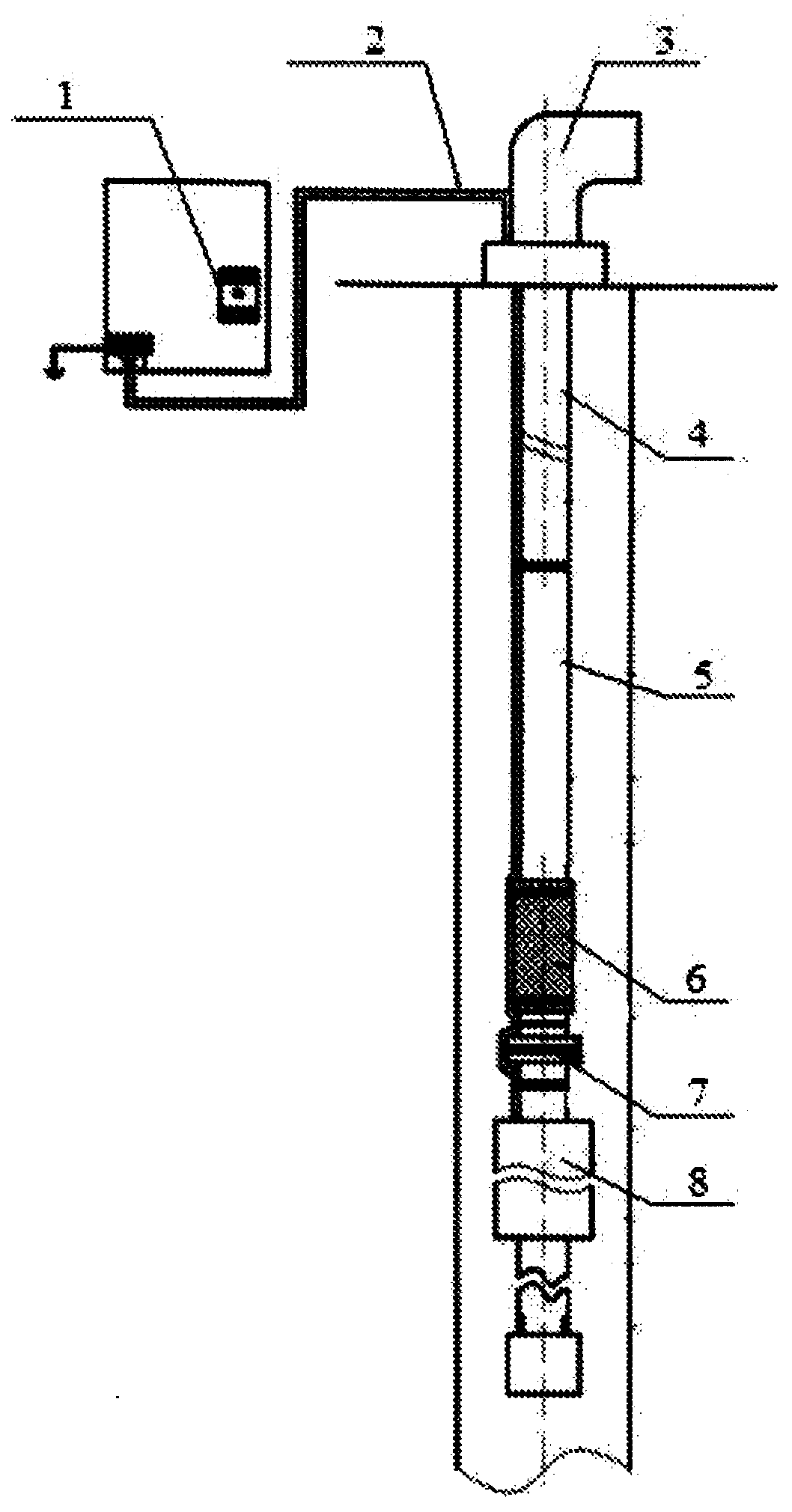

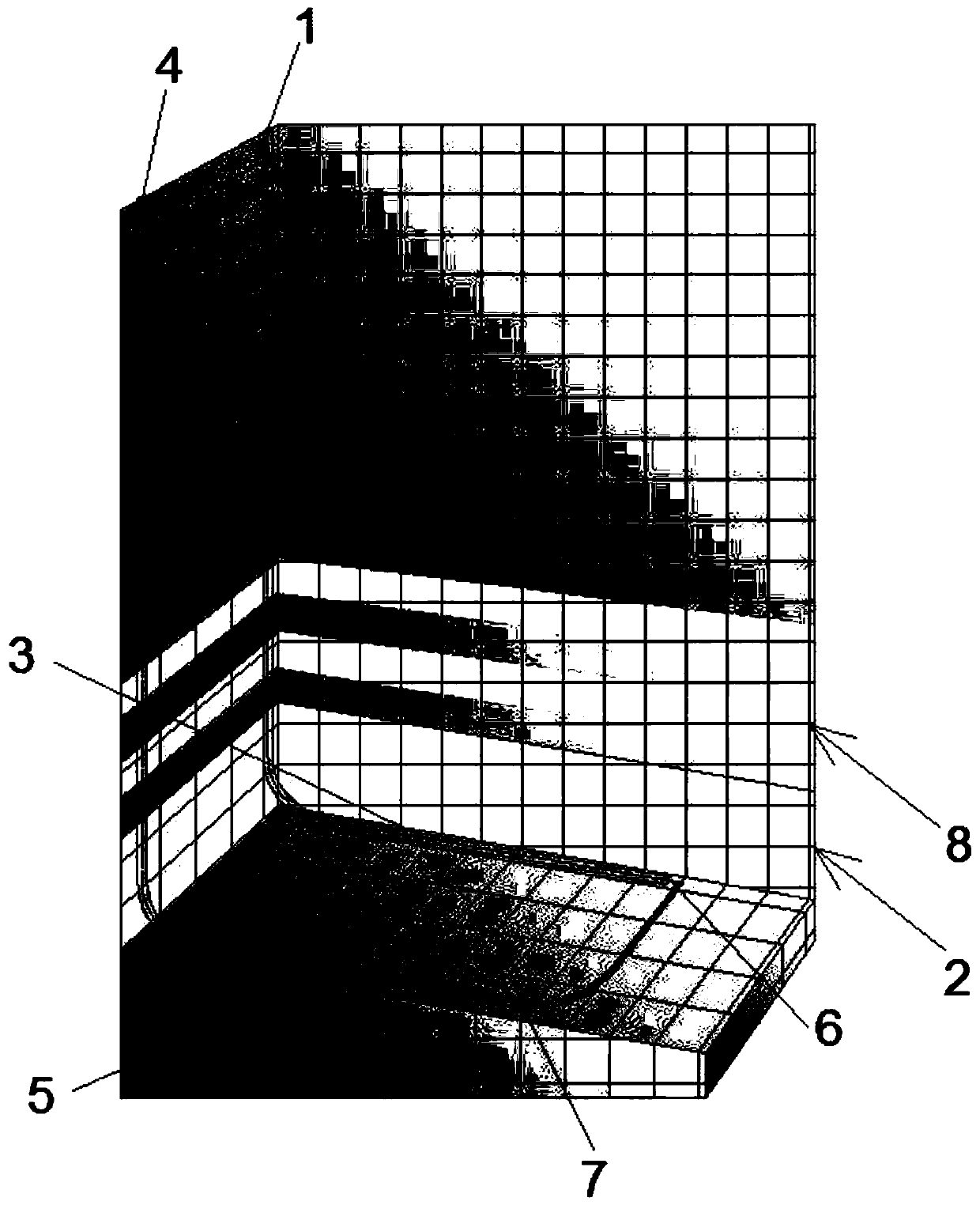

Well completion method for reinforcing hydrothermal type geothermal system

InactiveCN106968661ALarge displacementImprove efficiencyCollector components/accessoriesDrilling rodsMicroseismEnvironmental geology

The invention relates to the field of geothermal exploitation and provides a well completion method for reinforcing a hydrothermal type geothermal system. According to the method, a geothermal reservoir stratum is drilled through firstly, a microseism technology is utilized to conduct stratum microresistivity scanning imaging and dip angle combination logging, the stratum crack growing direction is recognized, then a branch hole is dilled in the perpendicular direction of crack growing, a hydraulic fracturing technology is adopted for fracturing a branch well section, thus a high-permeability geothermal reservoir stratum is constructed so as to enable a stratum fluid to enter a well drum along a fractured crack, the fluid is exploited to the ground through the well drum, and then power generation is conducted. According to the method, a branch well, microseism detection, a treatment system and the hydraulic fracturing technology are sufficiently utilized, the geothermal reservoir stratum crack is effectively recognized, the reservoir stratum is opened at a largest limitation, geothermal energy of the geothermal reservoir stratum is sufficiently utilized, and hydrothermal type geothermal energy exploitation efficiency is greatly improved.

Owner:CNPC DRILLING RES INST +1

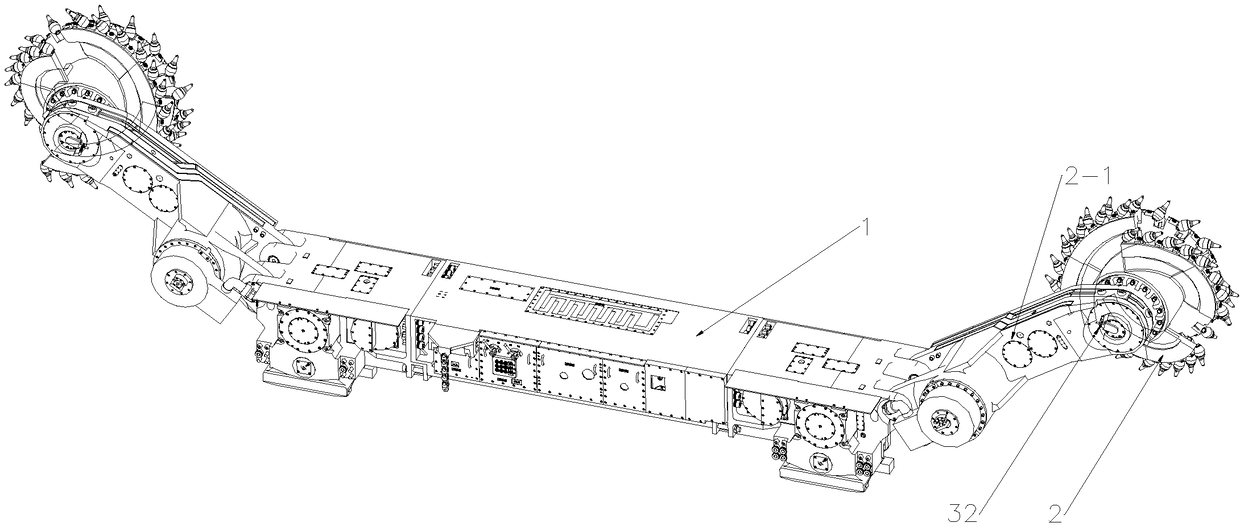

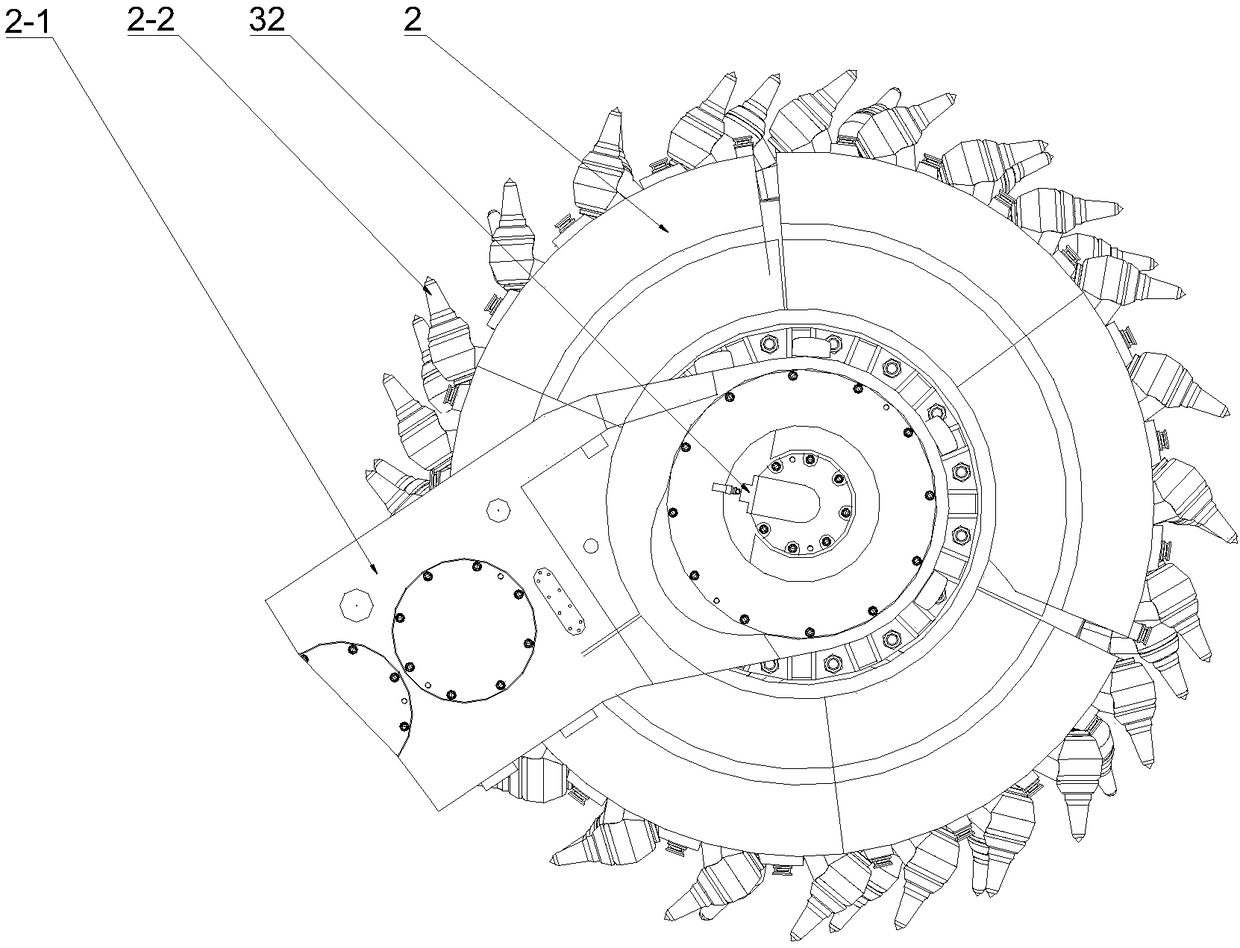

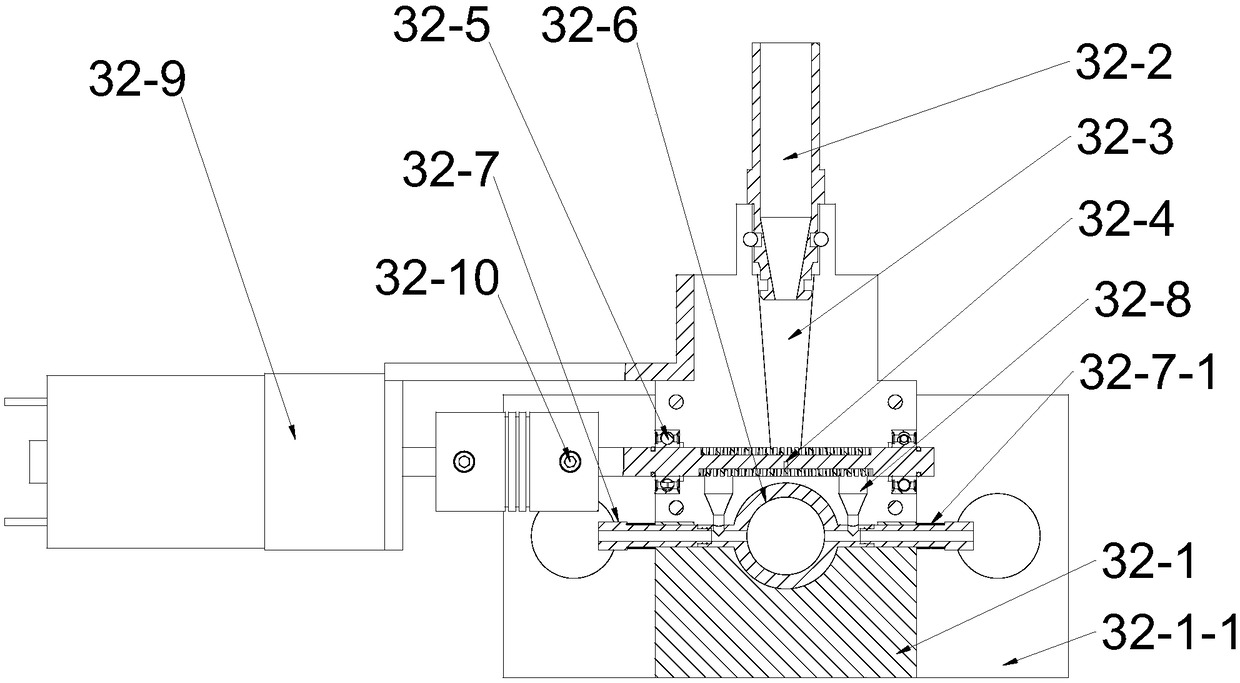

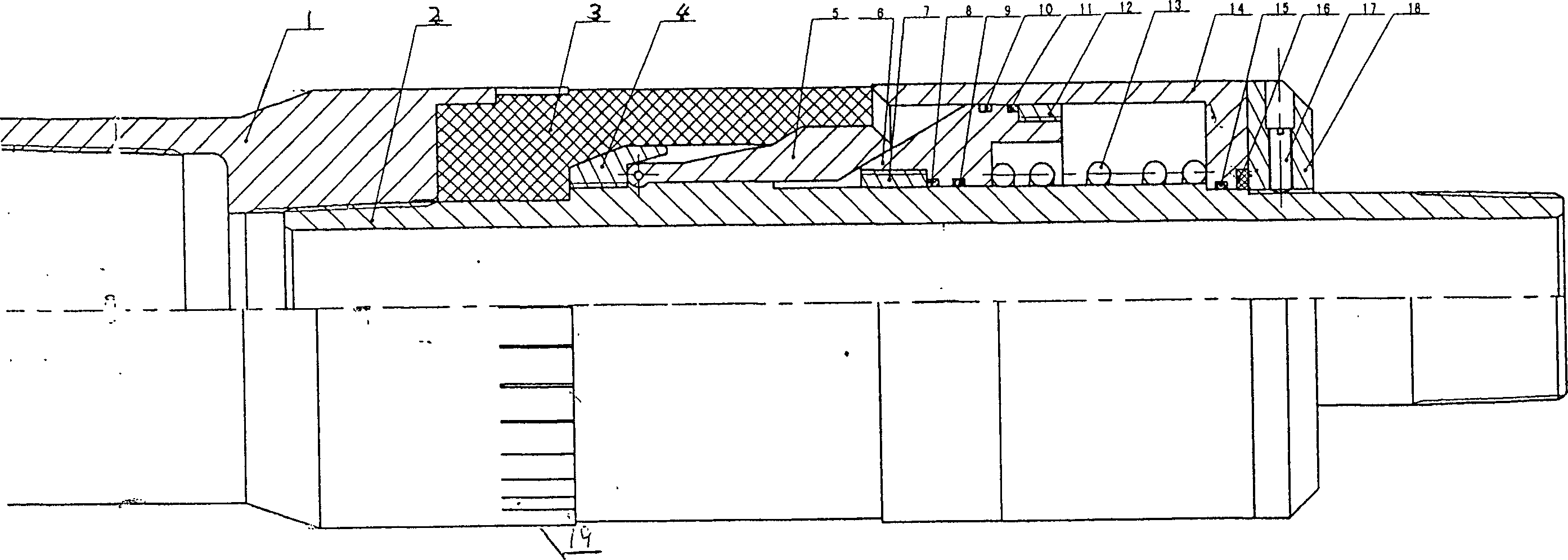

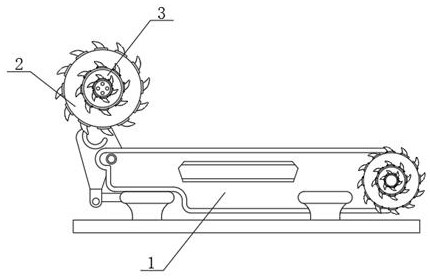

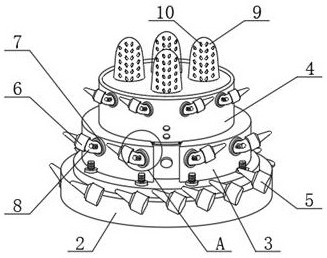

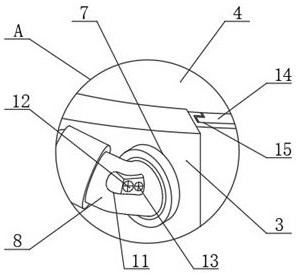

Device and method for breaking hard rocks by assisting coal mining machine with abrasive water jet

PendingCN108868762AReduce workloadReduce lossSlitting machinesCutting machinesControl systemWater flow

The invention discloses a device and a method for breaking hard rocks by assisting a coal mining machine with an abrasive water jet. The device for breaking the hard rocks by assisting the coal miningmachine with the abrasive water jet comprises an abrasive supply system and a control system; the abrasive supply system comprises an abrasive storage device and an abrasive mixing infusion device arranged on a drive rocker arm; and the control system comprises the components including a PLC controller, a flowmeter, a torque sensor and a variable pump. During control, when hard coal rocks are cut, the abrasive storage device is started, the pressure of high-pressure water is increased, a diversion screw rod is controlled to run at a proper speed according to a water flow rate and torque data,abrasive particles with a required flow rate is introduced into an abrasive mixing pipe pin, and then are mixed with high-pressure water in the abrasive mixing pipe pin and an abrasive mixing pipe for two times and are uniformly pumped into a cutting pick, so that in the process, the rotating speed of the diversion screw rod is matched with the water flow rate and the torque through PLC control,accurate control on concentration of an abrasive is realized, and rock breaking can be effectively assisted; and the coal mining machine successfully cut the hard coal rocks.

Owner:JIANGSU ZHONGJI MINE EQUIP

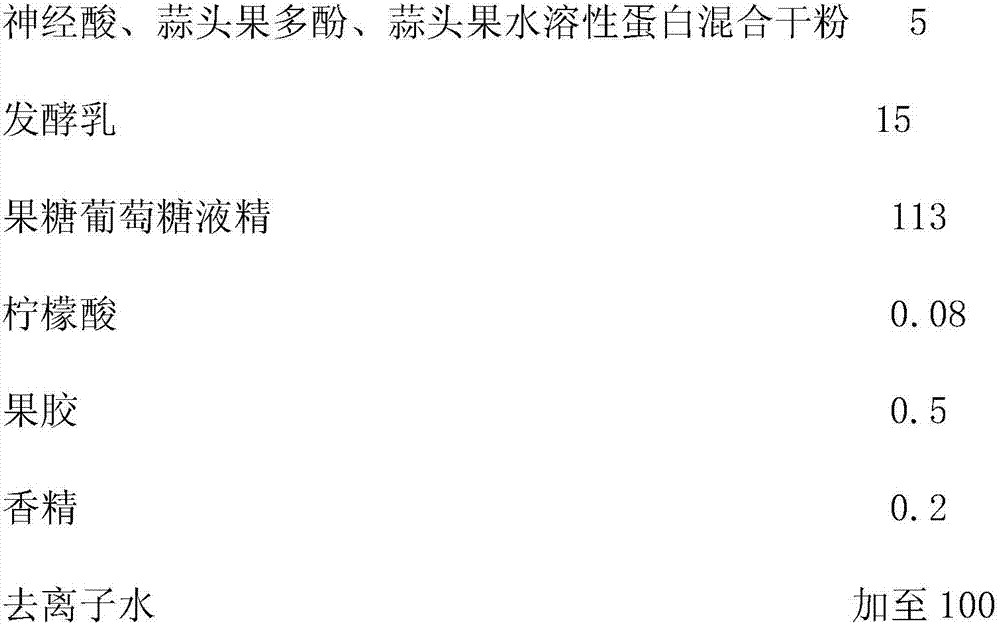

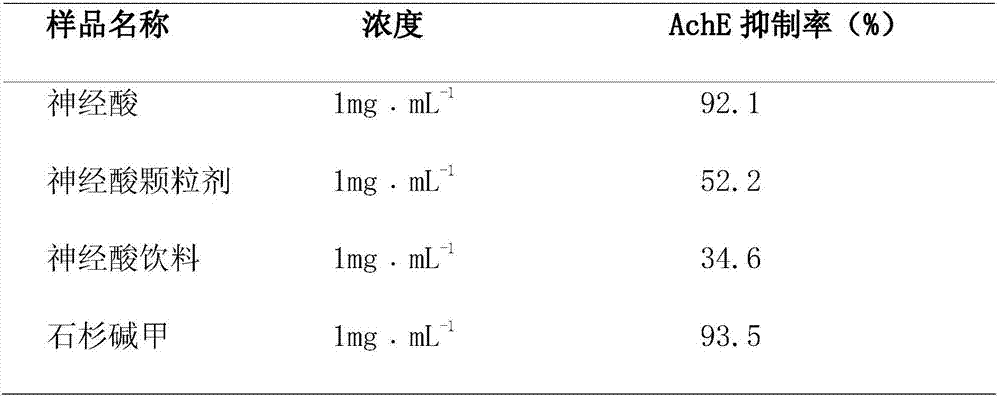

Alzheimer disease resistance composition containing active extract of semen malaniae oleifen and application thereof

InactiveCN107441130AReduce oil yieldNarrow distributionOrganic active ingredientsNervous disorderDiseaseNervonic acid

The invention relates to an alzheimer disease resistance composition containing an active extract of semen malaniae oleifen. The alzheimer disease resistance composition is prepared from the following components in parts by mass: 0 to 5 parts of nervonic acid, 0 to 10 parts of semen malaniae oleifen polyphenol, 0 to 10 parts of semen malaniae oleifen water-soluble protein and 1 to 80 parts of accessories, wherein the parts of the first to the third components cannot be equal to 0 simultaneously. Semen malaniae oleifen is used as a raw material; the plant nervonic acid, the semen malaniae oleifen polyphenol and the semen malaniae oleifen water-soluble protein are extracted from kernels of the malania oleifen by adopting a plant chemical separation purification means and form the alzheimer disease resistance medicinal composition. The alzheimer disease resistance composition is respectively prepared into health care foods, middle-aged and old-aged nutritious foods and brain-strengthening replenishers for application.

Owner:杨宇明

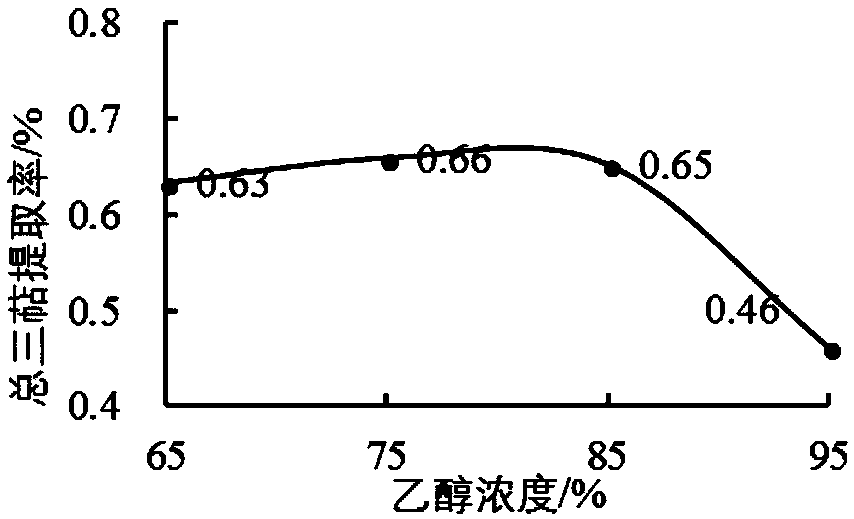

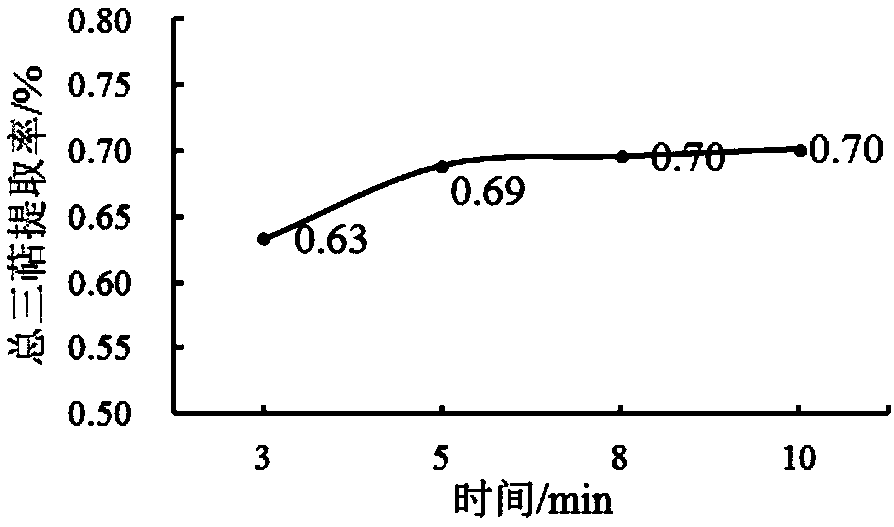

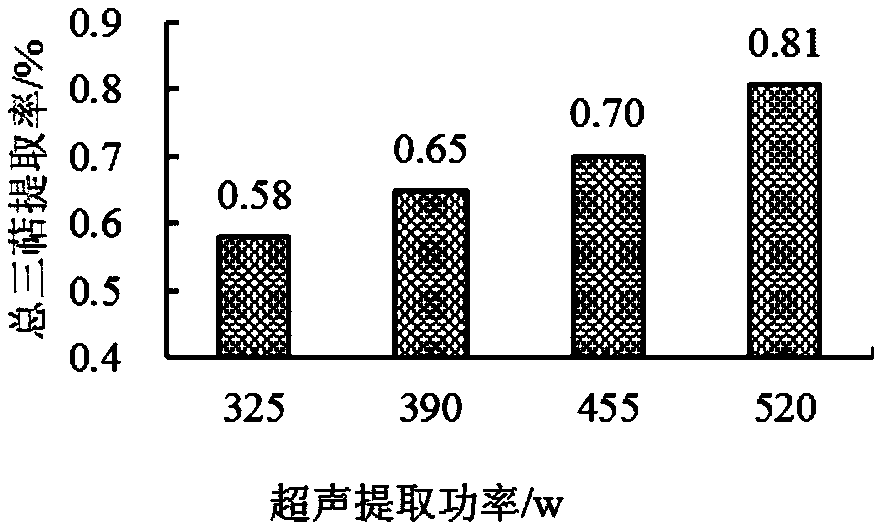

Comprehensive extraction method for total triterpenoids and polysaccharides in ganoderma lucidum germ bran

The invention discloses a comprehensive extraction method for total triterpenoids and polysaccharides in ganoderma lucidum germ bran. The comprehensive extraction method comprises pulverizing the ganoderma lucidum germ bran and then adding ethanol, adopting an ultrasonic cell crusher for ultrasonic extraction, performing centrifugation after the ultrasonic extraction, and obtaining filter residueand clear solution; concentrating the obtained clear solution and then performing extraction with chloroform, evaporating and concentrating a chloroform layer under reduced pressure to a paste shape,and recycling the chloroform; washing the paste with ethanol, drying the ethanol, and obtaining the total triterpenoids of the ganoderma lucidum germ bran; using water to digest the obtained filter residue, and performing filtration after the digestion, to obtain filtrate; after the filtrate is concentrated, adding ethanol for precipitation, taking precipitate and performing desalting and drying,and then performing smashing to obtain ganoderma lucidum germ bran polysaccharide.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

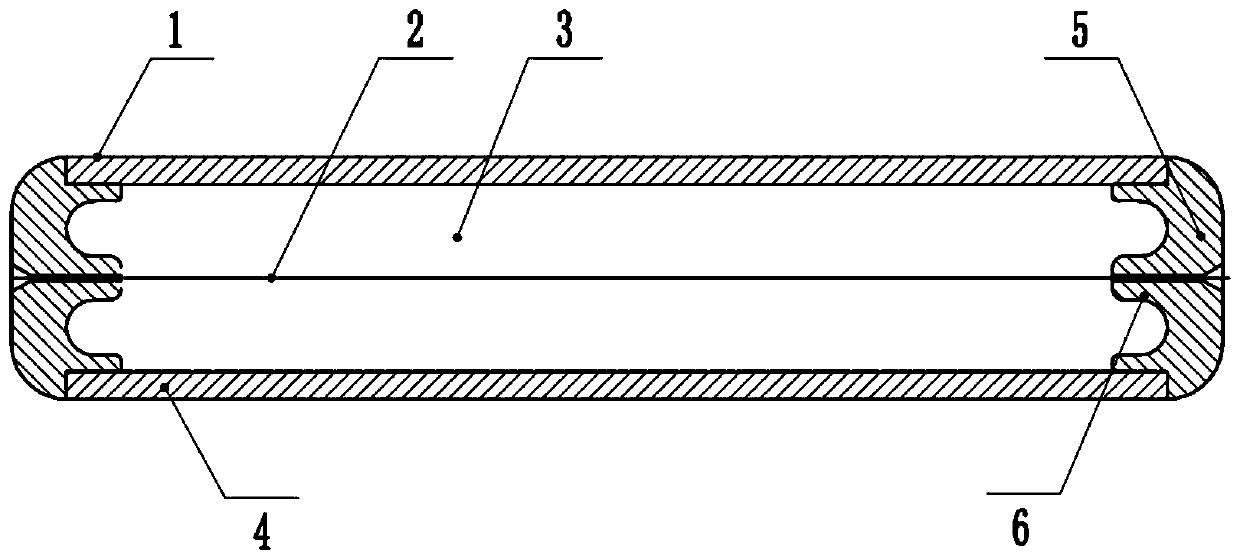

Rock breading rod for producing shock waves and manufacturing method of rock breaking rod

InactiveCN111472772AImprove securityGuarantee the safety of lifeDisloding machinesUnderground miningPolytetrafluoroethyleneAl powder

The invention relates to a rock breaking rod used for generating shock waves and a manufacturing method of the rock breaking rod, and aims to solve the problem that mining of mineral resources is restricted due to the defect that the electric energy storage density is low when the mineral resources are mined through metal wire electric explosion. The rock breaking rod for generating the shock waves comprises a shell which is a hollow straight pipe with two closed ends; a metal wire is arranged along an axis of the shell, and two ends of the metal wire extend out of the shell and are fixed andmounted; an energetic material is filled between the metal wire and the shell, wherein the energetic material is solid, and comprises 70%-80% by mass of polytetrafluoroethylene and 20%-30% by mass ofaluminum powder; and a groove is formed in an outer surface of a straight pipe. The manufacturing method of the rock breaking rod for generating the shock waves comprises the steps of machining an endcover and the straight pipe, and machining a longitudinal groove and an annular groove in an outer surface of the straight pipe; fixing the metal wire to one end cover to penetrate through the straight pipe, and then firmly binding the end cover and the straight pipe; manufacturing the energetic material and filling the energetic material into the straight pipe; and mounting another end cover.

Owner:西安闪光能源科技有限公司

Compressed high-temperature packer with gas propelling

A compressive vapor impellent high-heated packer belongs to packer type of thick oil fill into underground well. This invention is advanced than the existing technologies, which is composed of upper adapter, central tube, tube of rubber, control ring, claw of support, cone, spring, liquid vat, back bonnet etc. When switch-in the underground well filler pipe, gas expand which is in the liquid vat of the outside of the central tube and the rubber tube expand into casing which is impelled by cone and claw of support, then rubber tube expand to the inside wall of the casing to achieve the sealed-off. The technology can avoid accessories drop into the well, save fund etc. The equipment can be used for improving series of packers in diameters of 102-150mm with casing of 5, 7 or 9 inch.

Owner:潘昌德

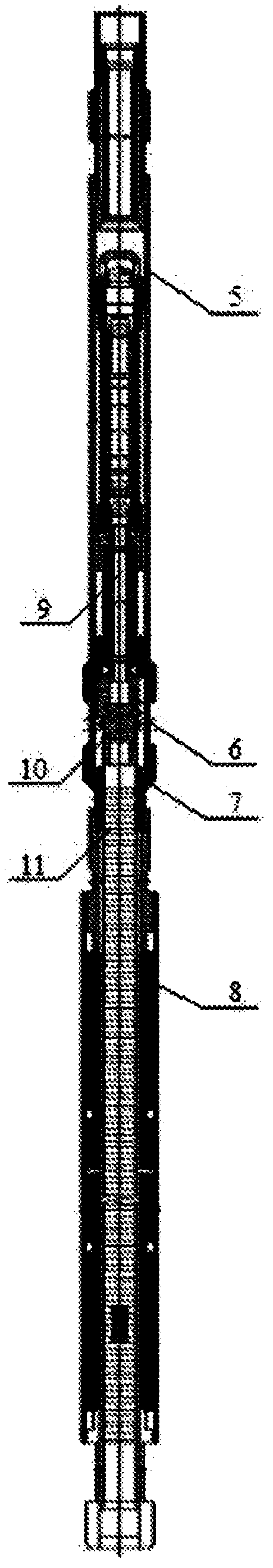

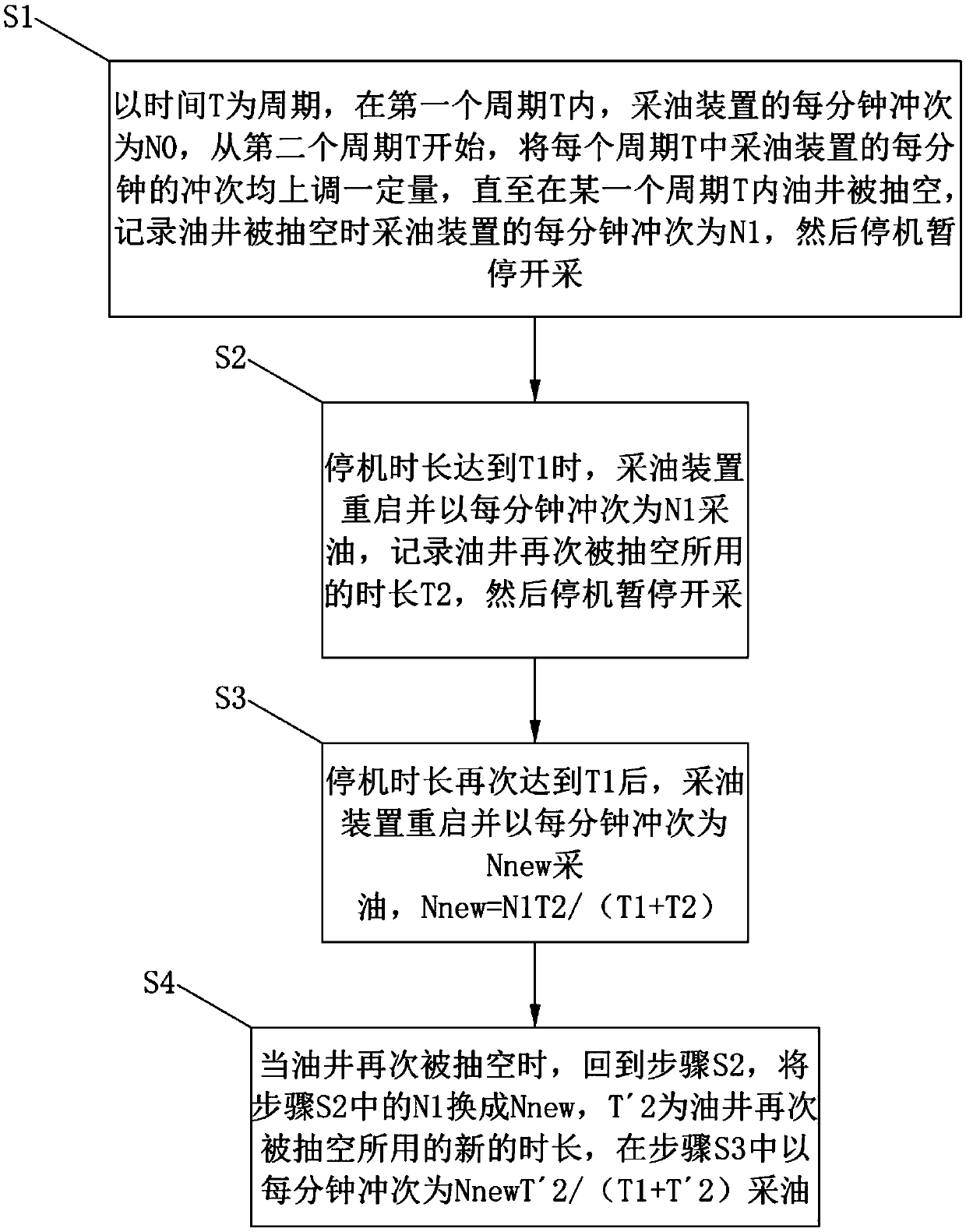

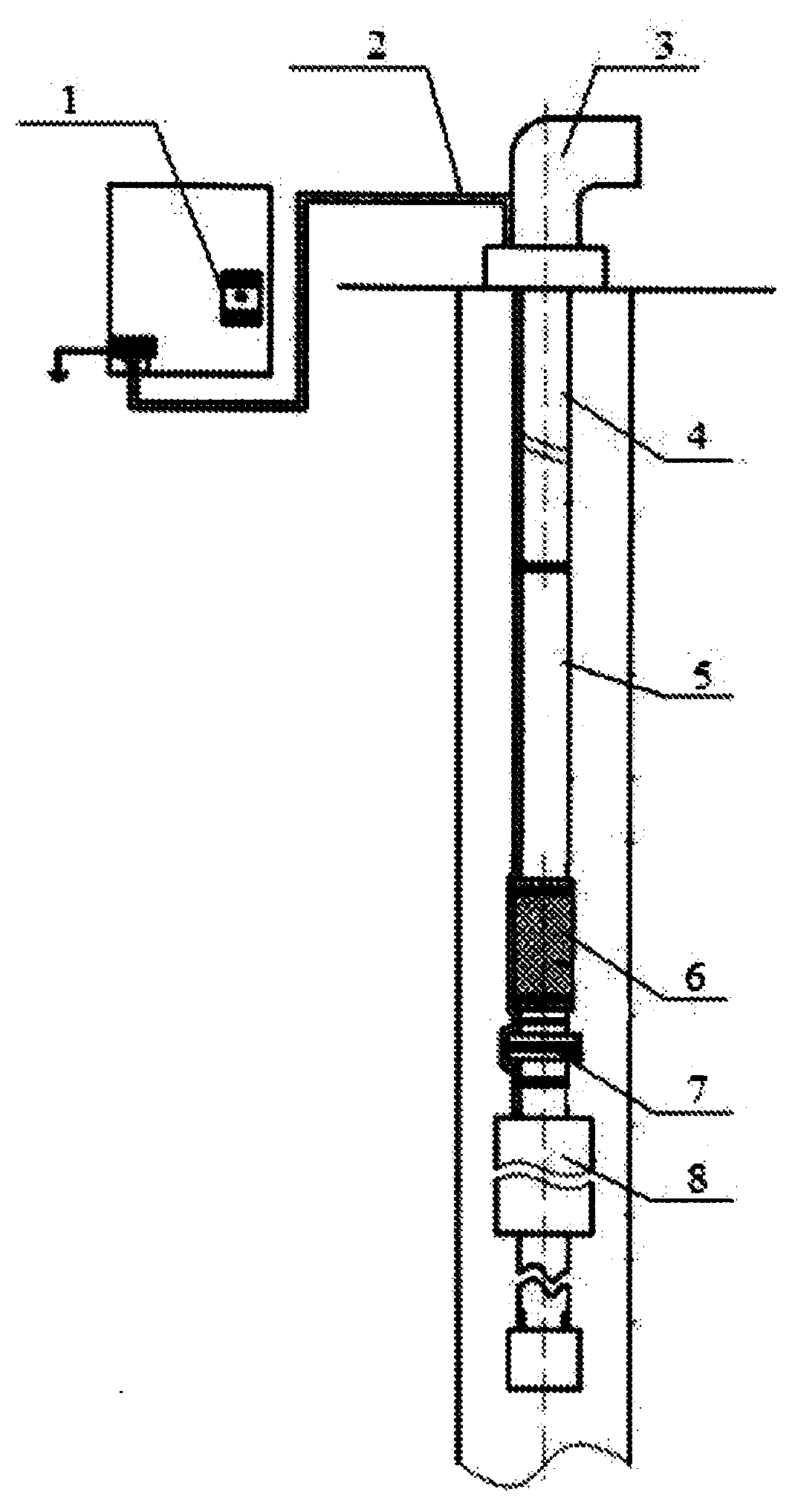

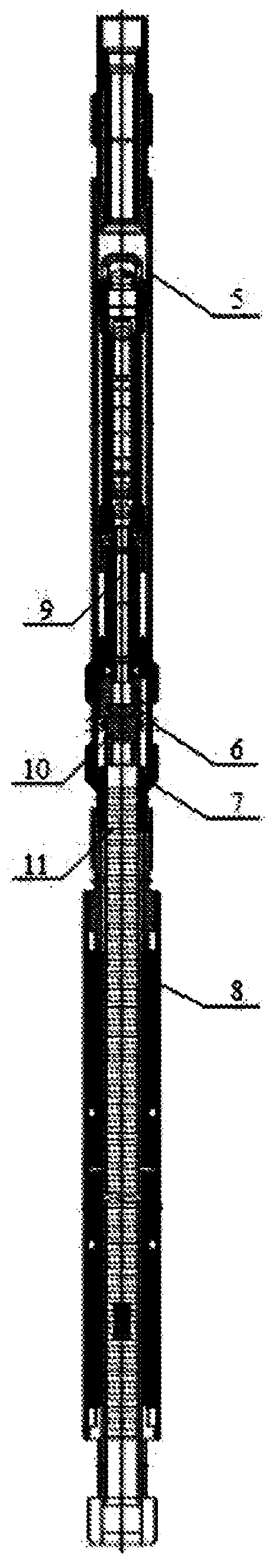

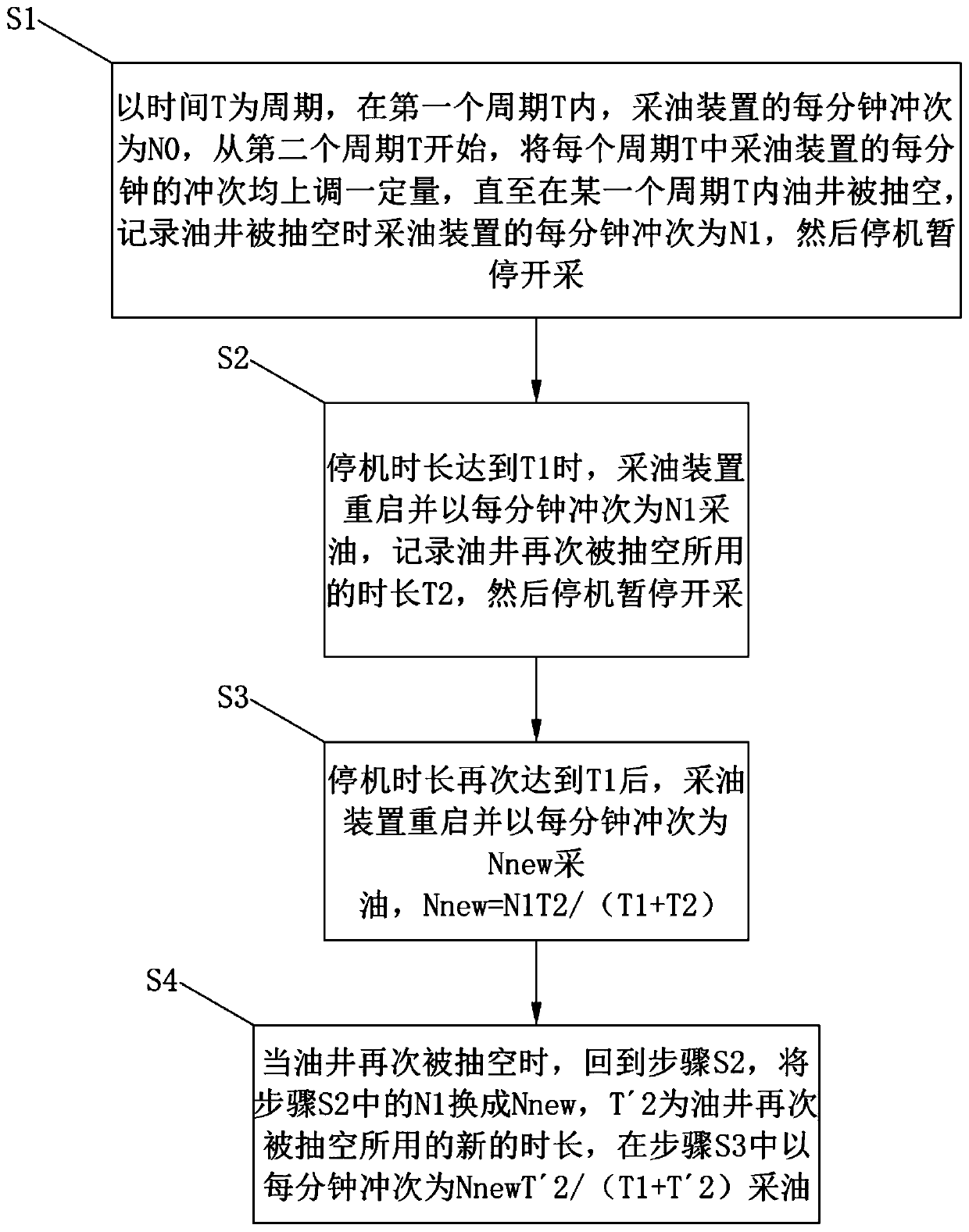

Self-adaptive pump stroke adjusting method for oil well pump of underground linear motor

ActiveCN109653999AAvoid overexploitationAvoid wasting resourcesPump testingFlexible member pumpsStop timeSelf adaptive

The invention provides a self-adaptive pump stroke adjusting method for an oil well pump of a underground linear motor. The method comprises the following steps that S1, the time T is taken as a period, in the first period T, pump strokes per minute of an oil extraction device is N0, the oil extraction device starts from the second cycle T, the pump strokes per minute of the oil extraction devicein each period T are all up-regulated by a certain amount, and the oil well is evacuated until an oil well is evacuated in the certain period T, when the oil well is evacuated, the pump strokes per minute of the oil extraction device in each period T is recorded as N1, and then the oil extraction device stops mining; S2, when the stop time of the oil extraction device reaches the T1, the oil extraction device is restarted, and the oil extraction device extracts oil with N1 pump strokes per minute, the time length T2 used for evacuating the oil well again is recorded, and then mining of the oilextraction device is stopped; S3, after the stop time of the oil extraction device reaches the T1 again, the oil extraction device is restarted, and the oil extraction device extracts oil with Nnew pump strokes per minute, wherein the Nnew is equal to N1T2 / (T1 + T2 ). The self-adaptive pump stroke adjusting method for the oil well pump of the underground linear motor has the beneficial effects ofsimple in process, high in precision and high in practicability.

Owner:WUHAN HAIWANG TECH

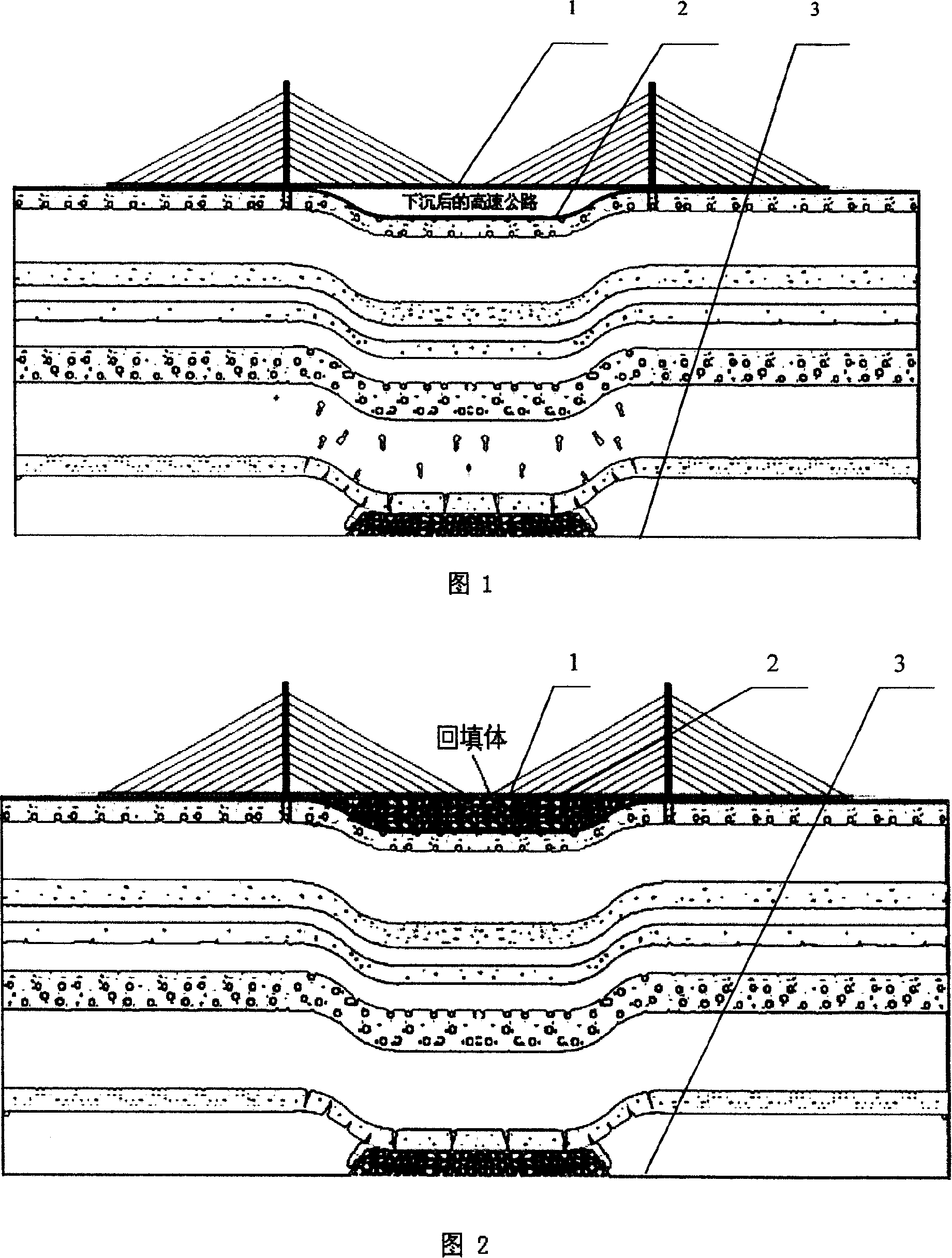

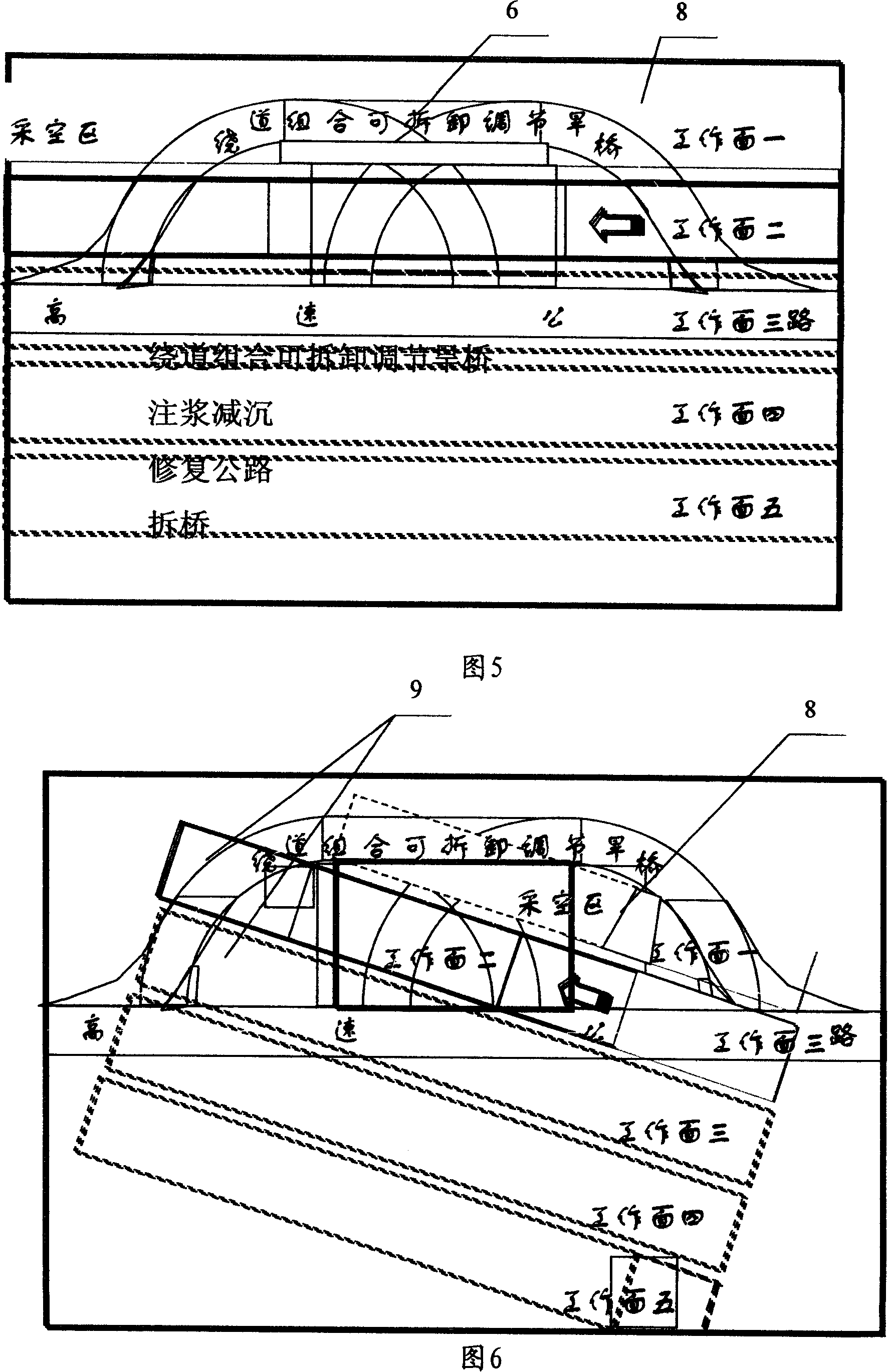

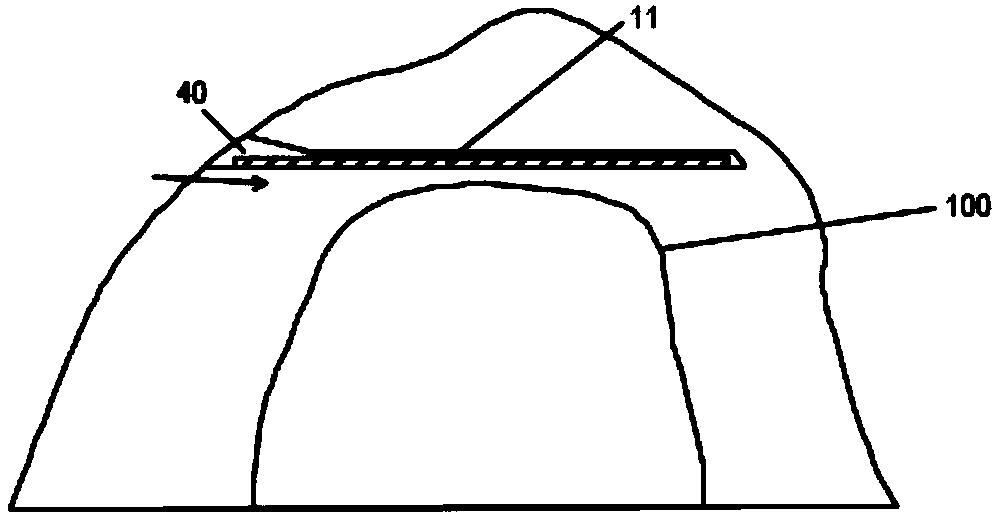

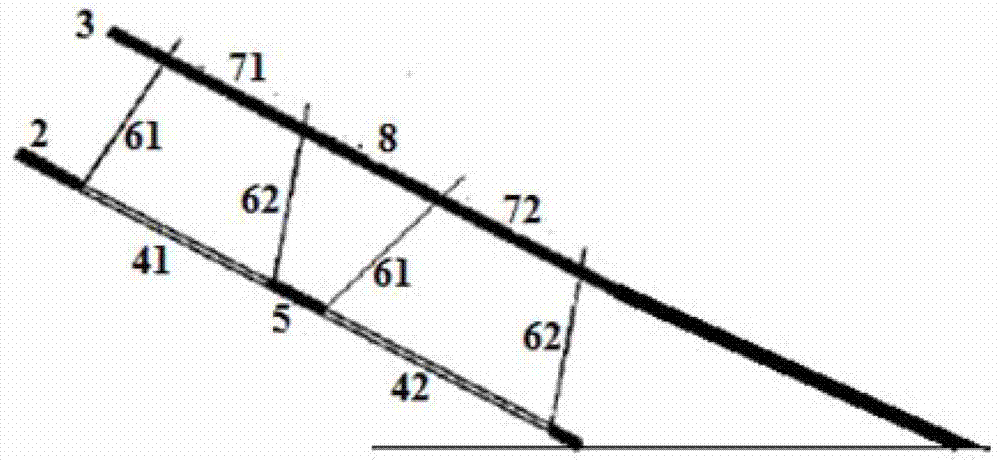

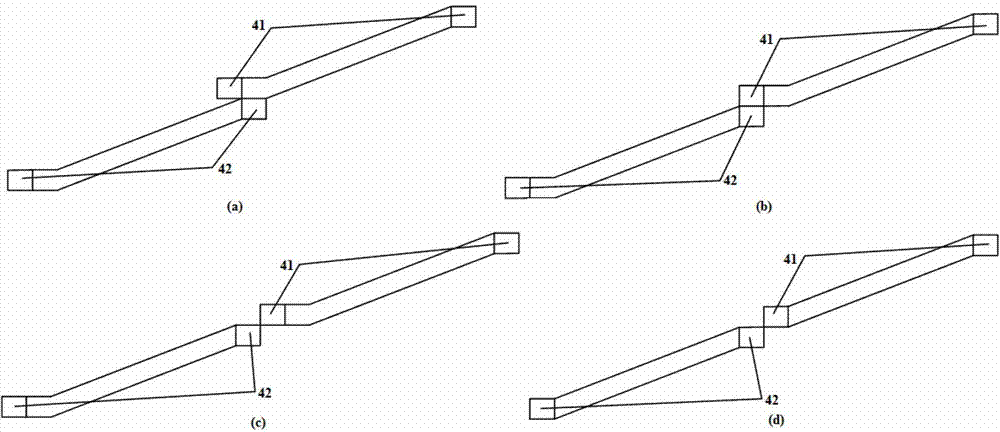

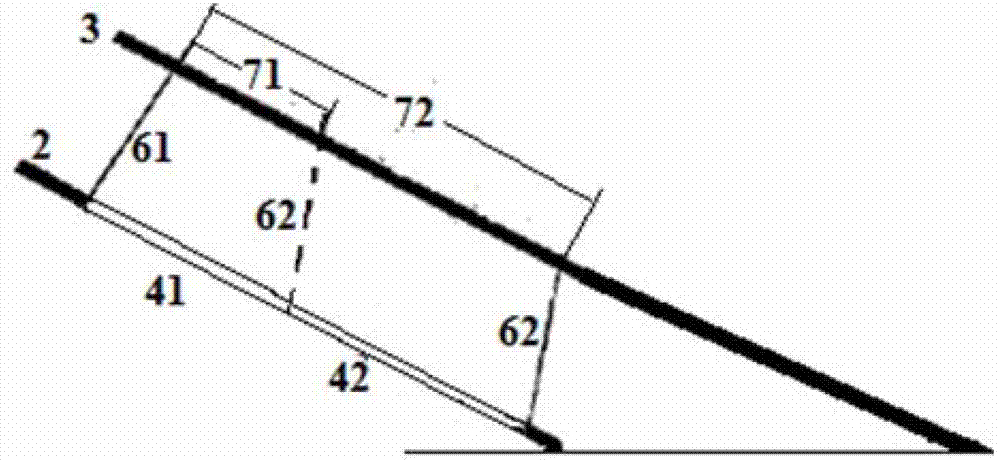

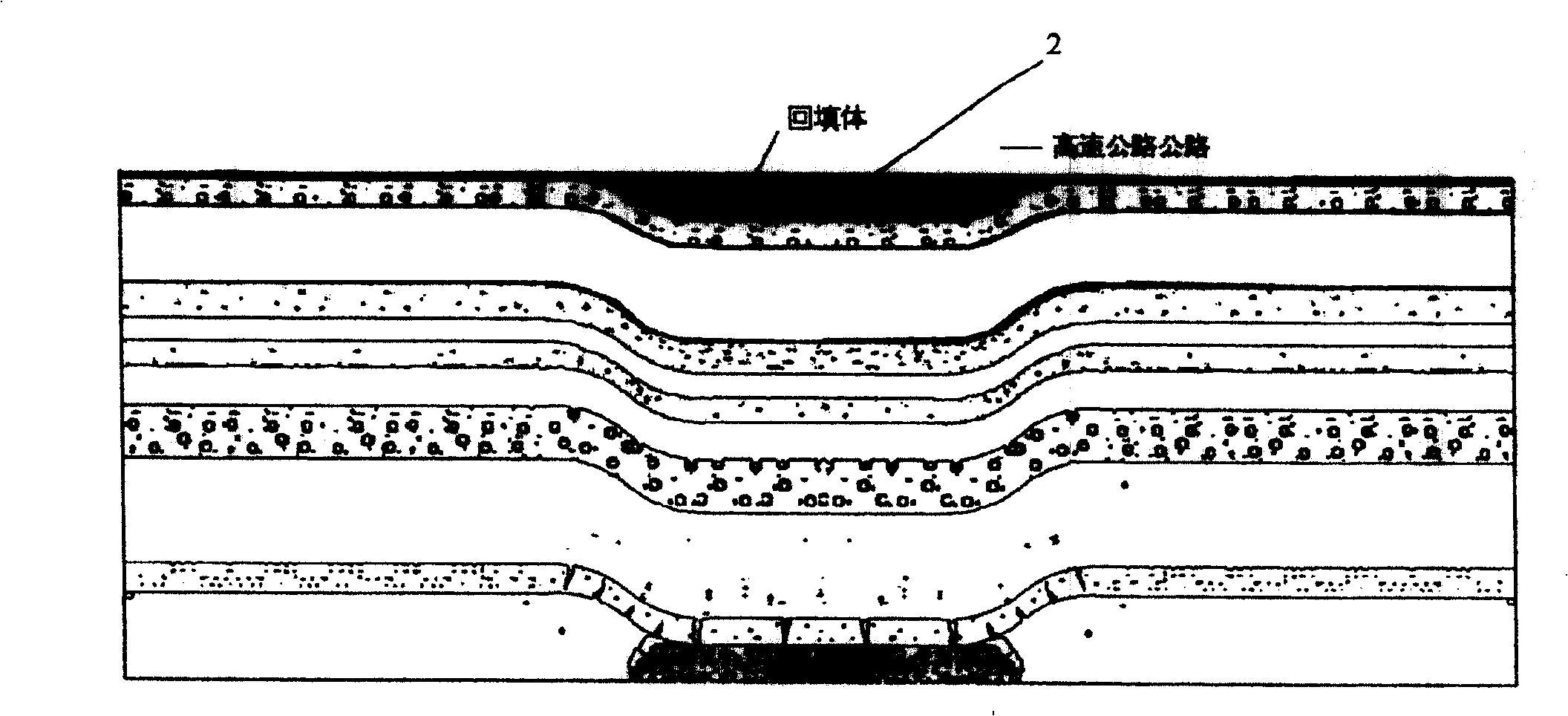

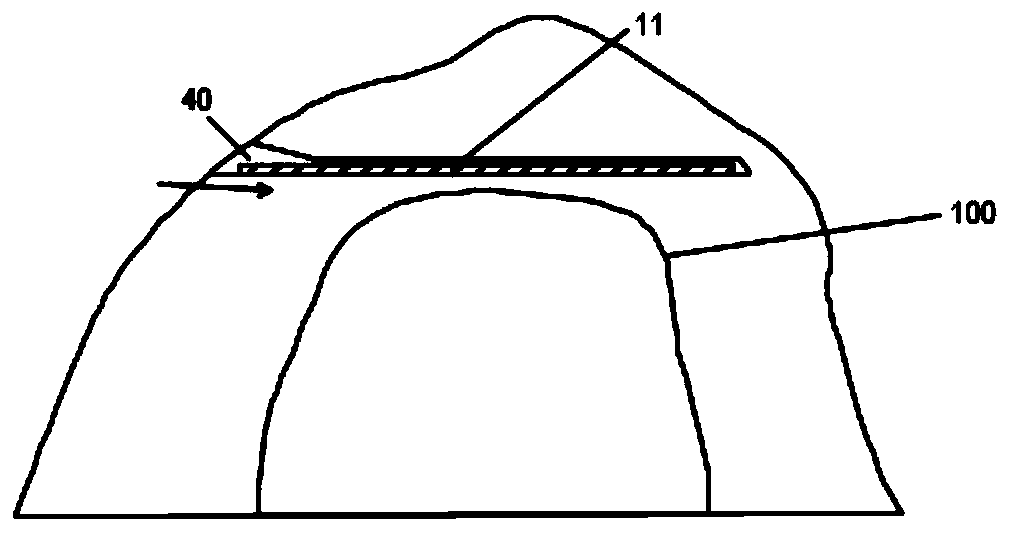

Land bridge method for recovery of pressed coal under highway

ActiveCN101139928AEasy to manufactureFully exploitedUnderground miningSurface miningEngineeringRoad surface

A dry bridge exploitation method for express highway lower press coals belongs to a method to maintain an express highway being continuously utilized, maintained and recovered during lower press coals exploitation under the express highway. For an express highway, traditional exploitation methods for express highway lower press coals cannot guarantee vehicles normally running on the highway during the underground exploitation. Meanwhile, the traditional methods might either cause traffic shutdown on an express highway, or result in too much recovery cost or too much waste of coals. The invention can fulfill that, before coal layer exploitation influences an express highway, erecting a large-span dry bridge to substitute the express highway segment in serving vehicles during the exploitation; after the exploitation influences are over, perform recovery for the express highway and dismantle the dry bridge to recovery traffic. Therefore, the scheme can fulfill the following targets of the invention: Provide a dry bridge exploitation method for express highway lower press coals, in order to guarantees normal traffic and traffic safety during exploitation of the underground coals; meanwhile, the invention can considerably lower cost of maintenance, curring and recovery for express highways, and moreover, expand press coal exploitation volume and sufficiently utilize resources..

Owner:何满潮

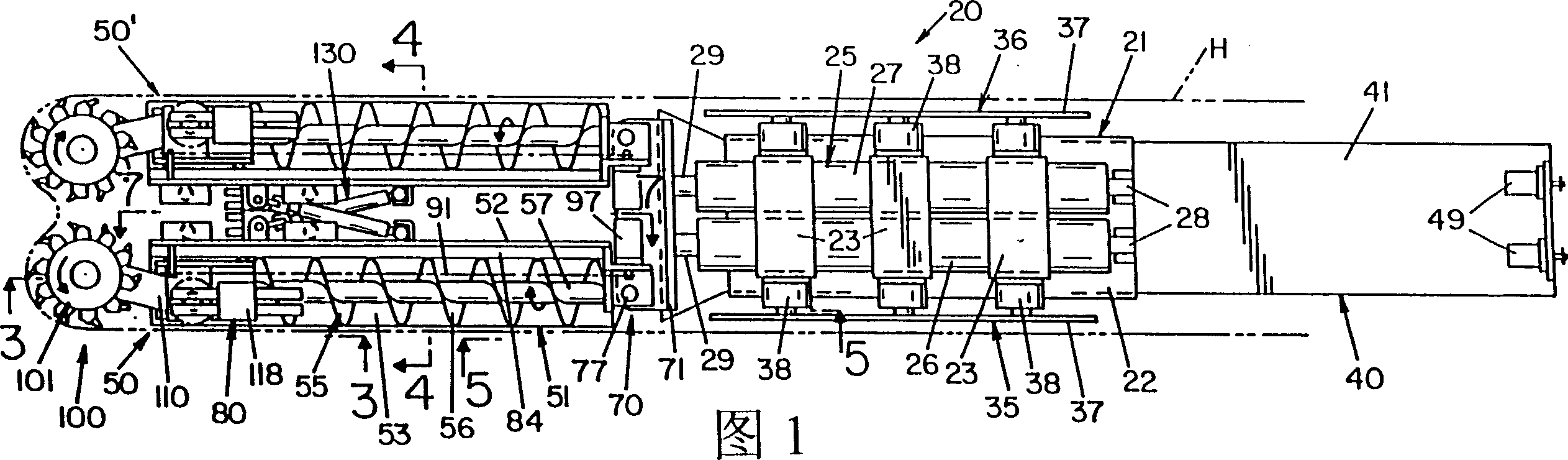

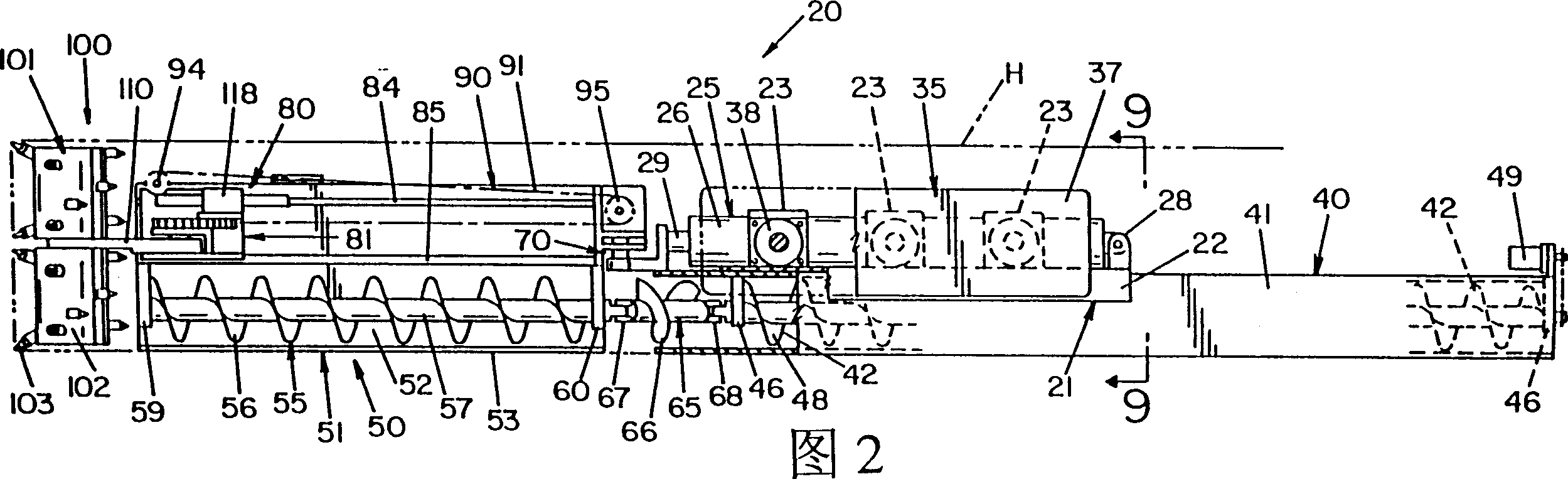

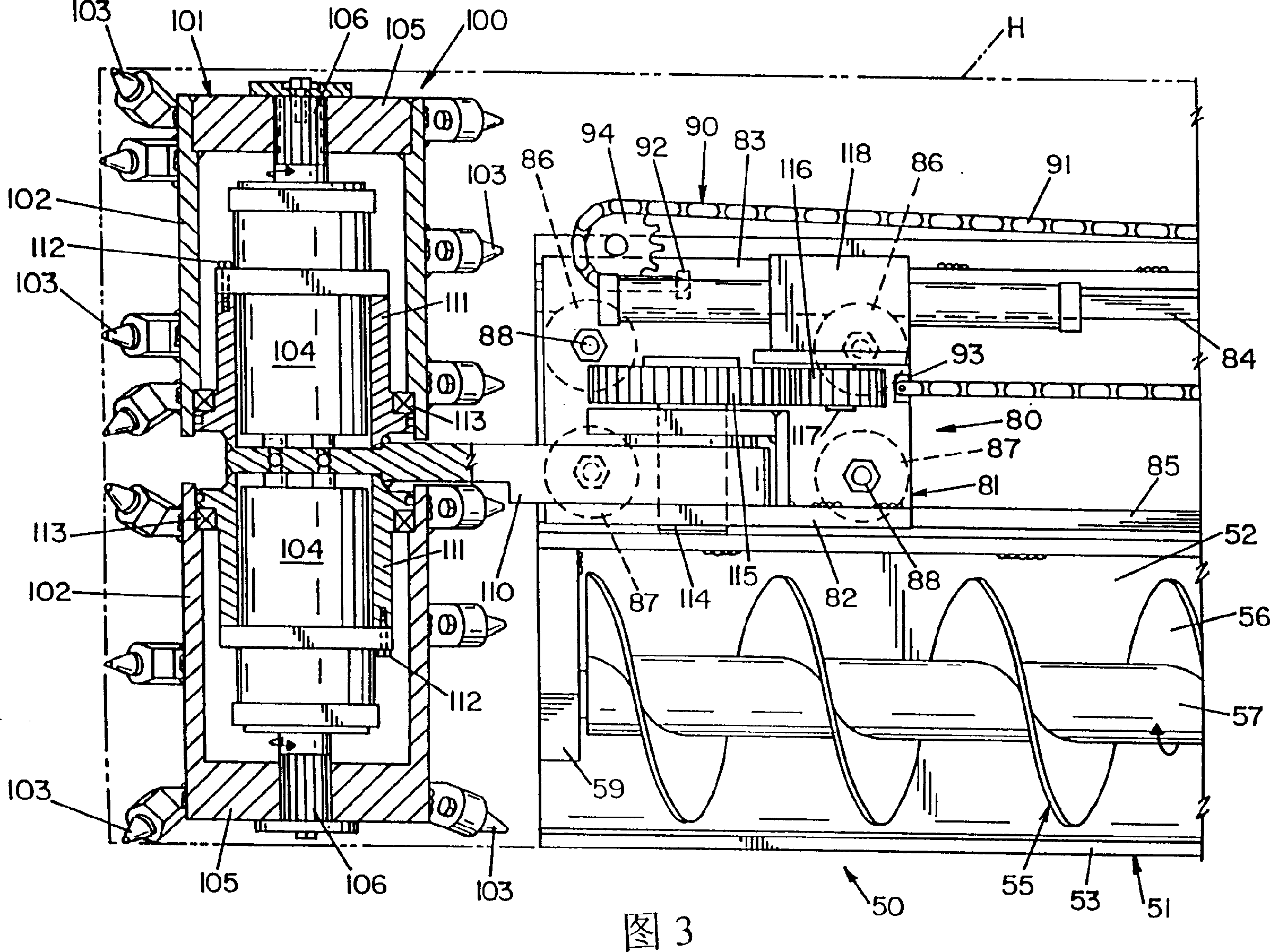

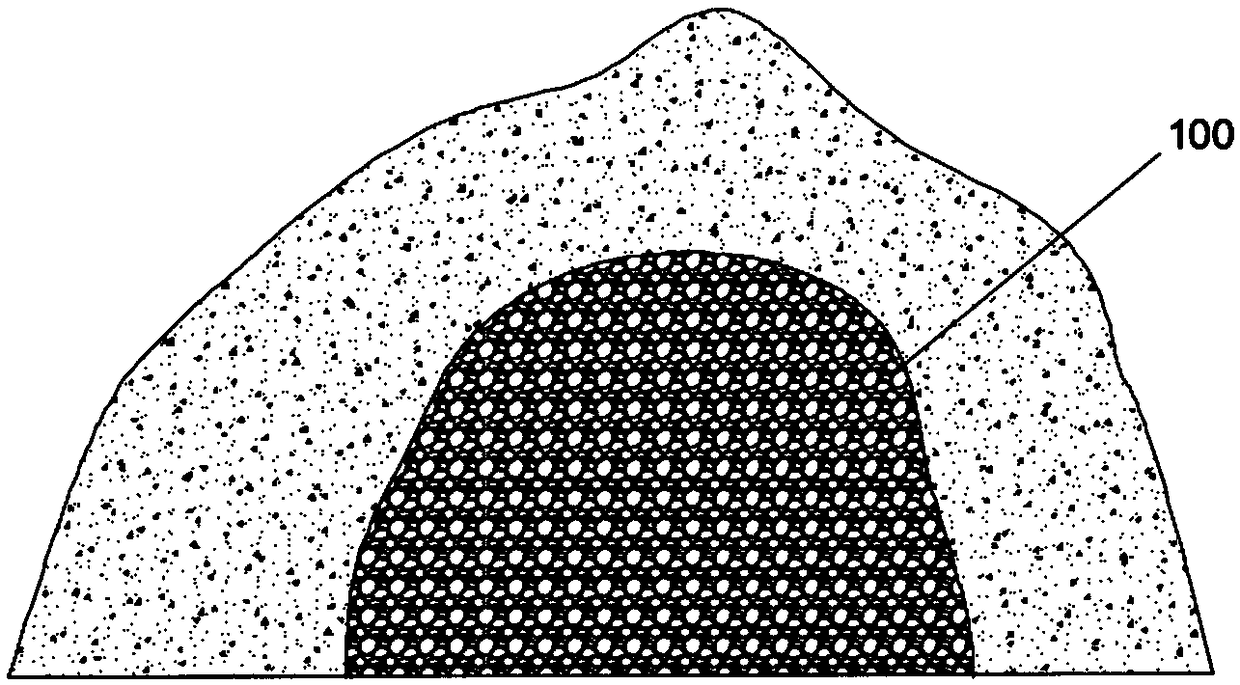

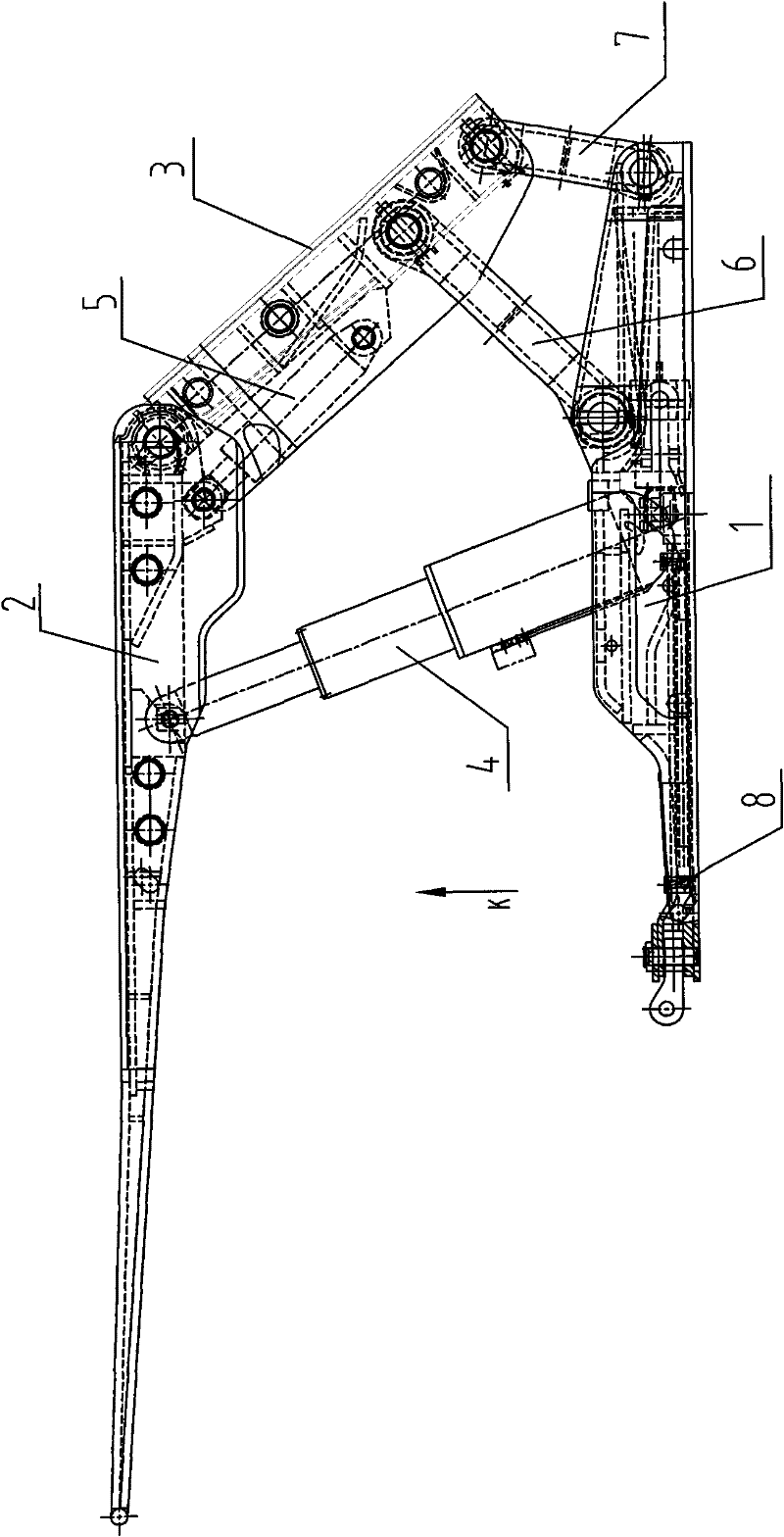

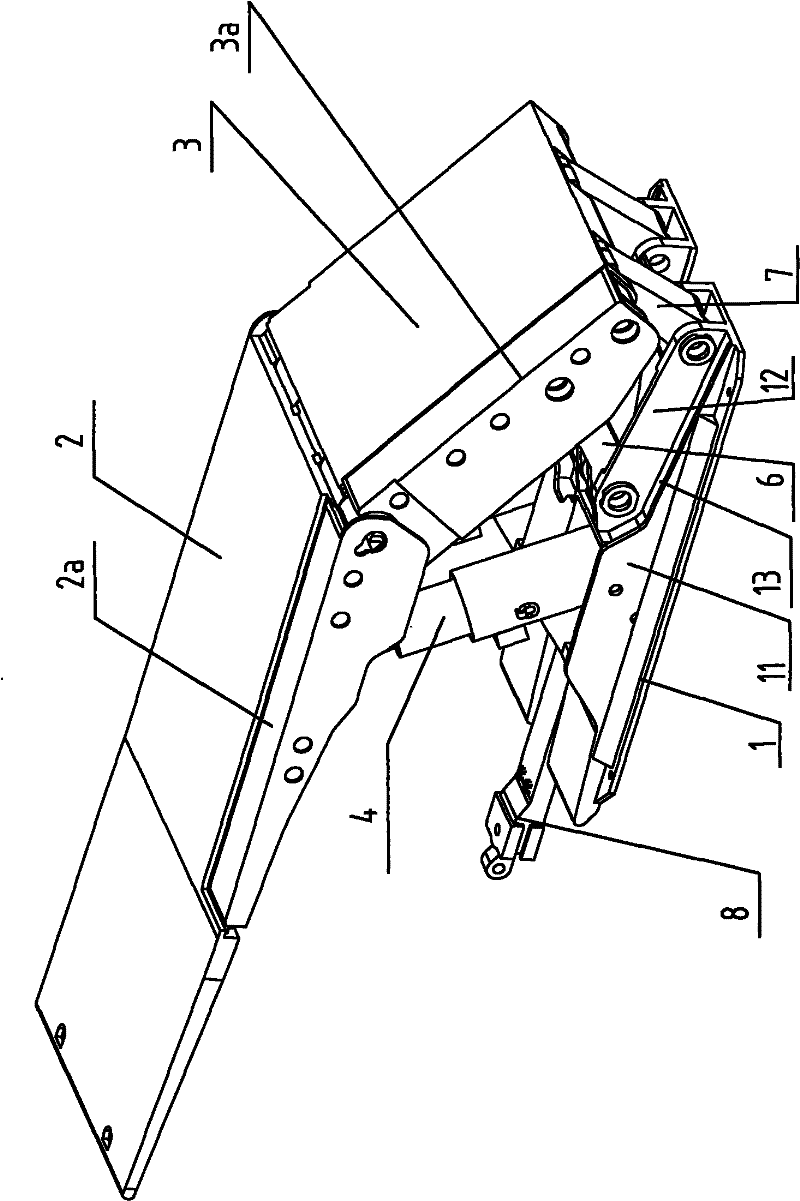

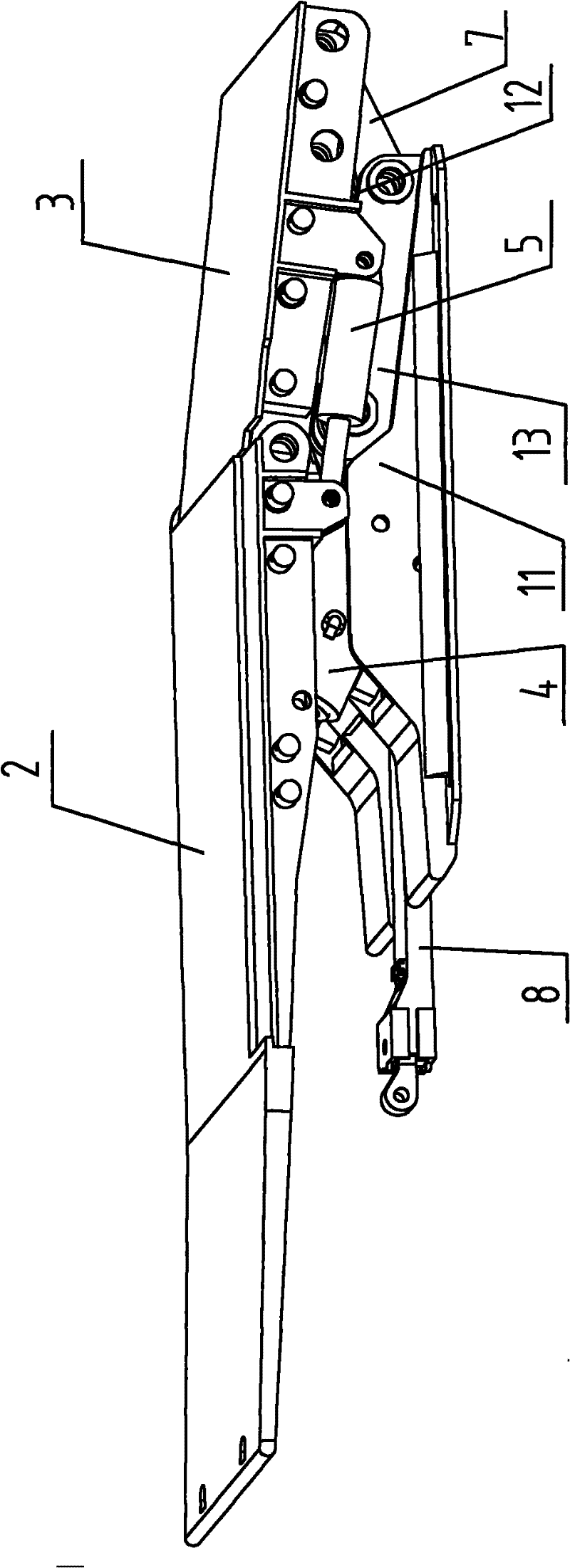

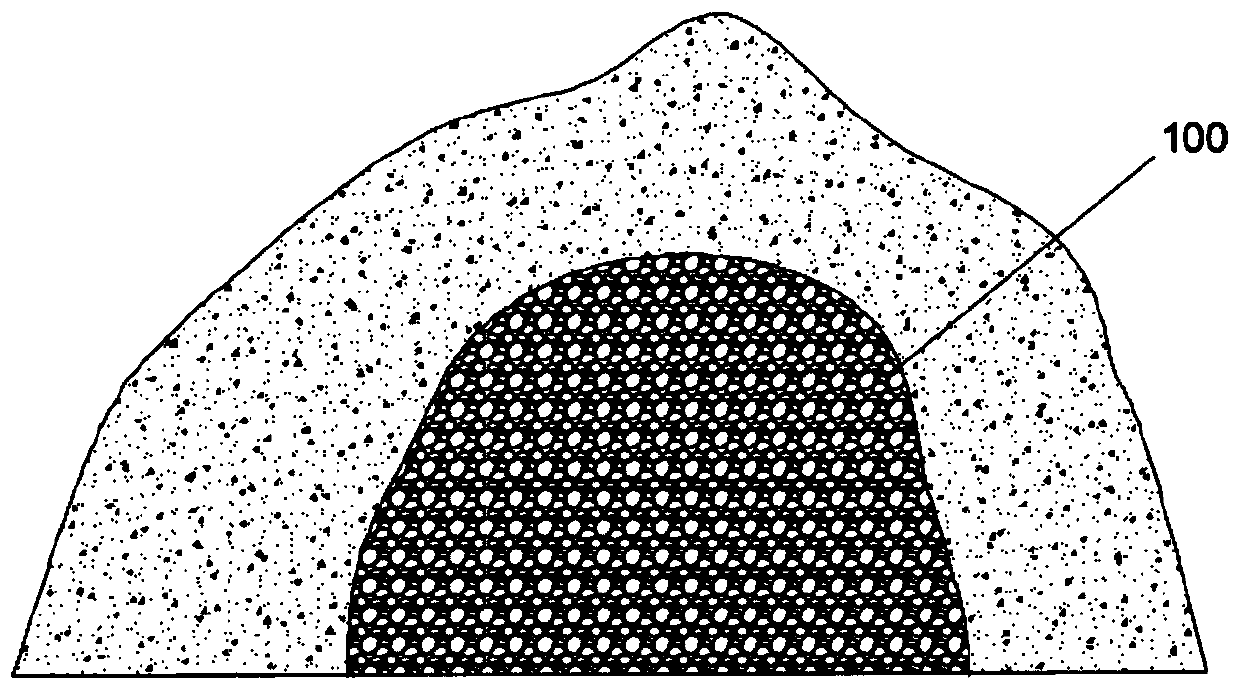

Mining machine and mining method

InactiveCN1204331CNot prone to accidental collapseIncrease mining volumeDrill bitsUnderground miningEngineeringAerospace engineering

A mining machine (20) for combined entry and retraction cutting of subterranean seam material, comprising: a movable main frame (21); a wing (50, 51) extending forwardly of the movable main frame; a cutter assembly (100) positionable near the end of the wing to drill holes in the material when the direction of travel of the wing and main frame is in line; a pivotal connection (130) between the main frame and wing ) for positioning the wings at an angle to the direction of movement of the main frame; and a mechanism (80) for moving the knife assembly along the wings during retraction of cutting material to cut material adjacent the wings.

Owner:HOLMES LIMESTONE CO

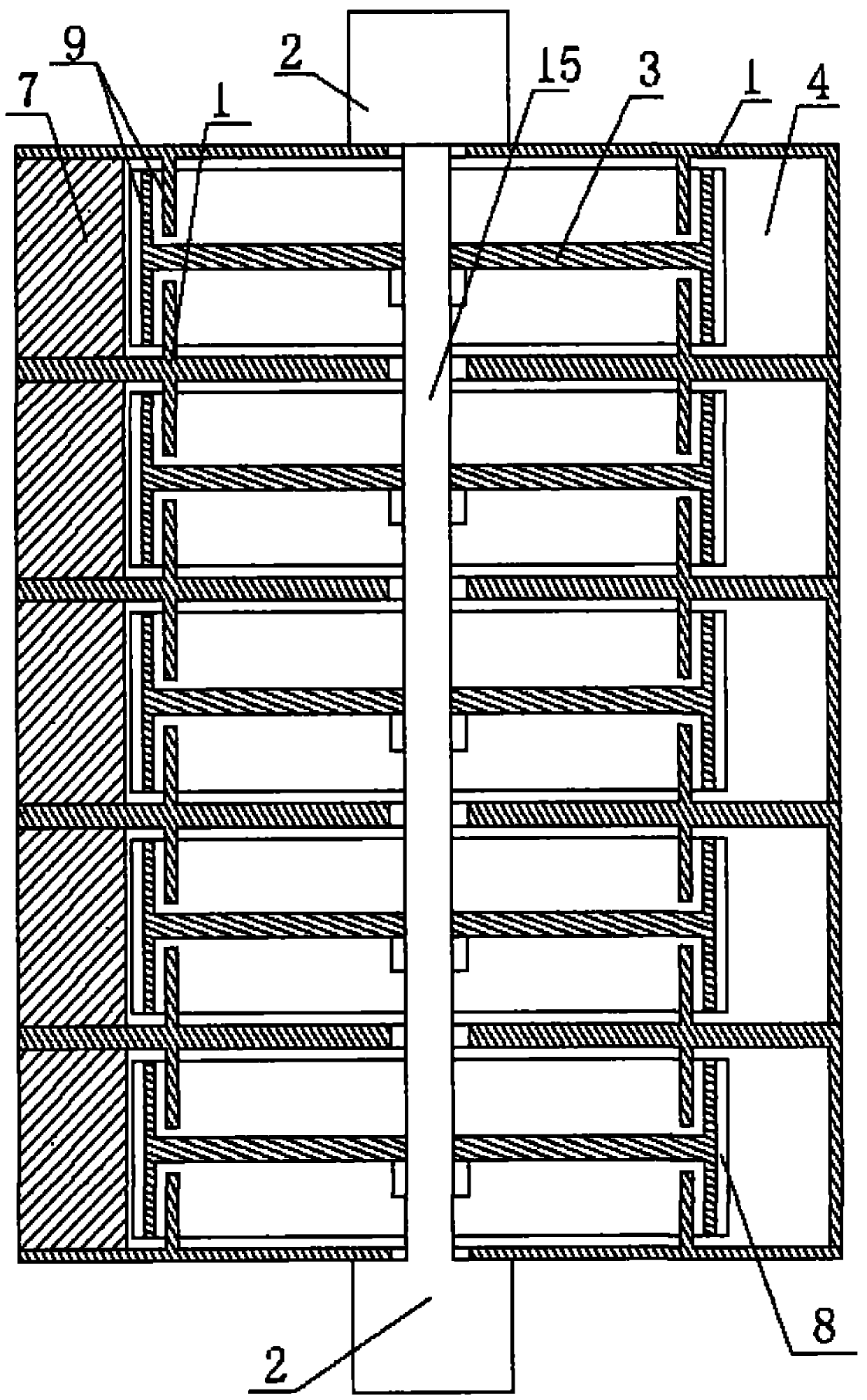

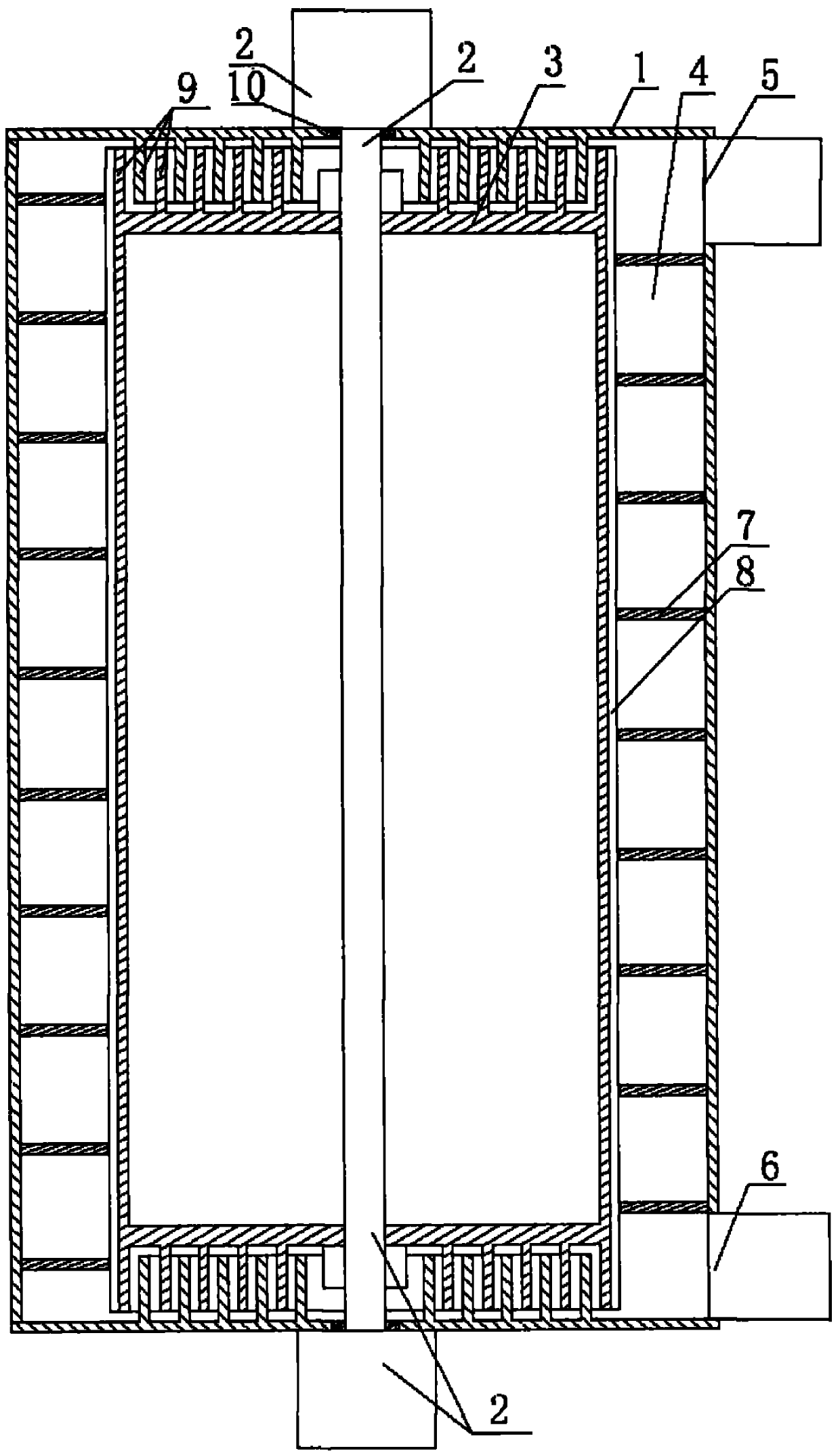

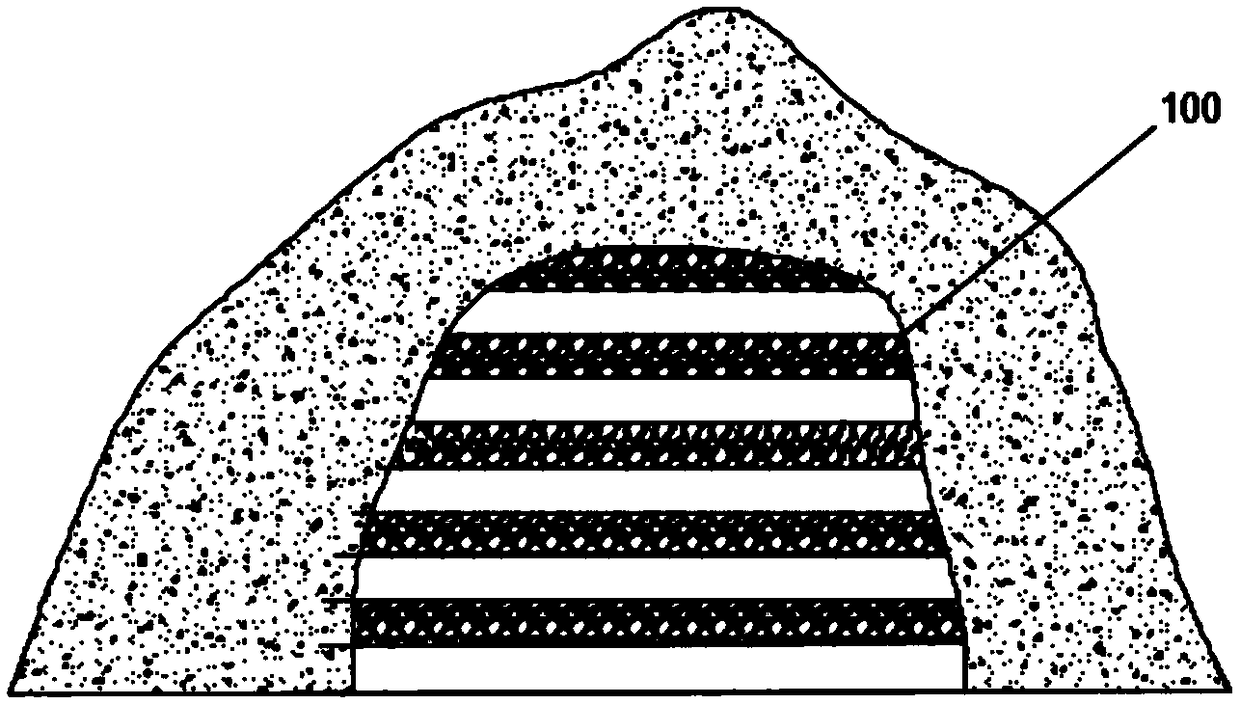

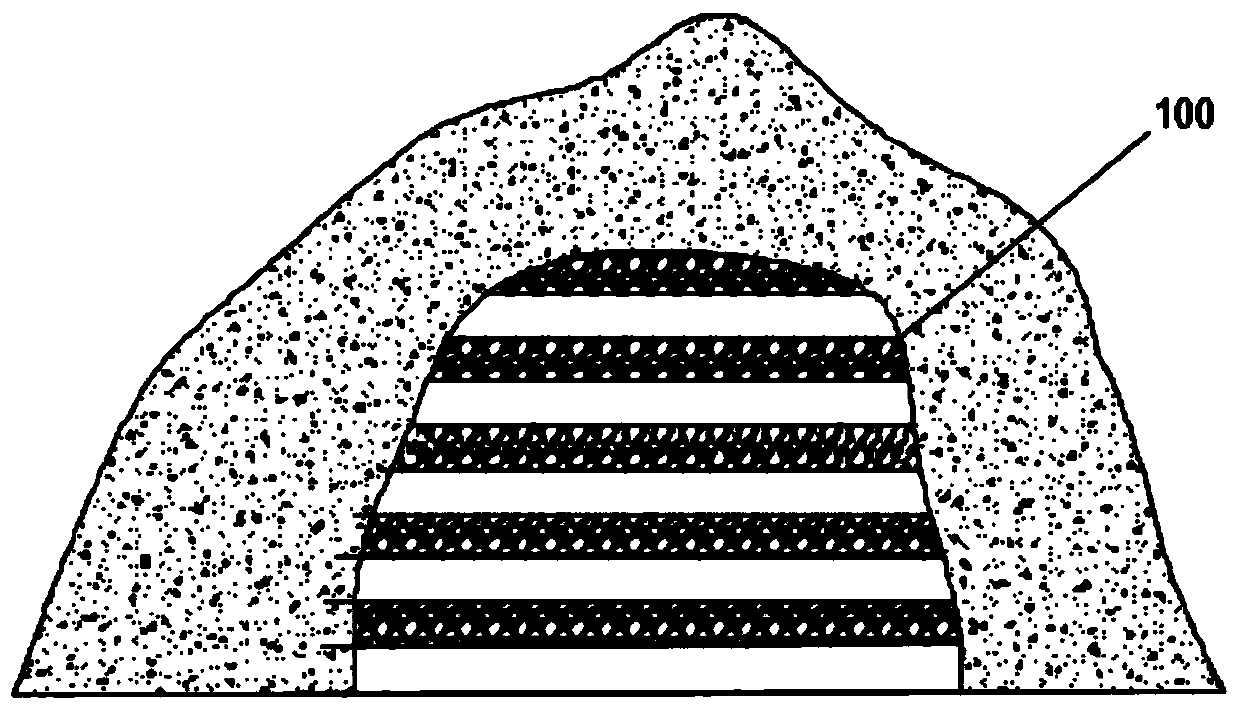

Environment-friendly anti-landslide mining method

InactiveCN109236294AAvoid vegetation damageStable structureUnderground miningSurface miningLandslideEngineering

The invention provides an environment-friendly anti-landslide mining method. The method comprises the following steps: arranging a first layer of top beams on the upper part of a mineral layer, pilingon the lower parts of the first layer of top beams and preparing a first layer of stand columns which upward reach the first layer of top beams; mining the minerals on the lower parts of the first layer of top beams; downward piling on the bottoms of a first layer of mining holes close to the bottoms of the first layer of stand columns, thereby acquiring a second layer of stand columns; preparinga second layer of top beams and pouring the bottoms of the first layer of stand columns and the tops of the second layer of top beams; mining a second layer of minerals on the lower parts of the second layer of top beams; downward pilling on the bottoms of a second layer of mining holes close to the bottoms of the second layer of stand columns, thereby acquiring a third layer of stand columns; preparing a third layer of top beams and pouring the bottoms of the second layer of stand columns and the tops of the third layer of stand columns; mining a third layer of minerals on the lower parts ofthe third layer of top beams; preparing the corresponding layers of stand columns and top beams in turn till mining the bottom layer of minerals. According to the method provided by the invention, the mining rate of minerals is increased, the mining safety is guaranteed and the happening of geological disasters can be prevented.

Owner:程昌胜 +1

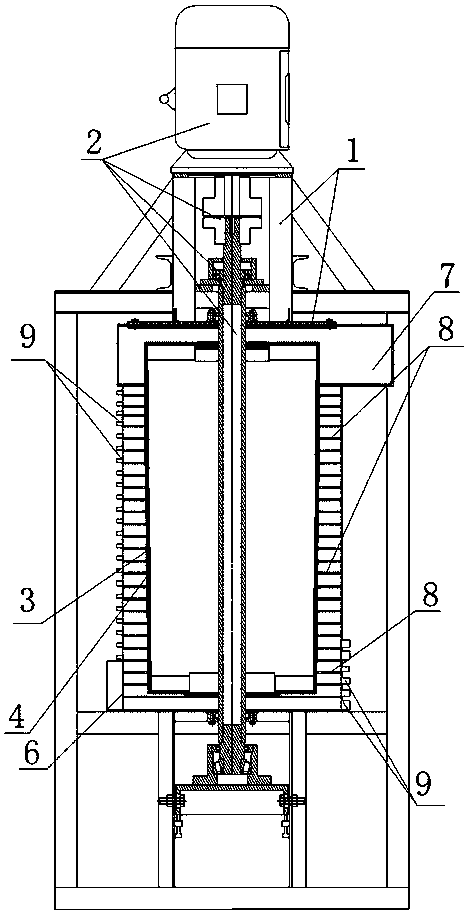

Separating reacting pulverizer

InactiveCN107638963AEfficient removalImprove operational efficiencyCentrifugesGrain treatmentsWater desalinationNitric oxide

A separating reacting pulverizer comprises a housing and a transmission device, the transmission device is arranged on the housing, a housing chamber is arranged in the housing, a vortex wheel is arranged in the housing chamber, the transmission device is connected with the vortex wheel, one end of the housing chamber is provided with a housing chamber inlet, and the other end of the housing chamber is provided with a housing chamber outlet. The separating reacting pulverizer is widely applicable to dust removal, desulfurization, denitrification, smoke removal, deodorization, vehicular and marine emission purification, lampblack suction, air purification, oil gas recycling, garbage treatment, nuclear waste treatment, powder separation, mineral separation, sea water desalination, wastewatertreatment, water purification, oil refining, oxygen production, reactors, boilers, combustors, pulverizing equipment and other fields, can provide deep purification for flue gas, can solve air pollution and water pollution, can eliminate haze, and allows water resource shortage, water pollution and environmental pollution to be thoroughly solved. The separating reacting pulverizer is suitable forproducing various powders, including nano powder, can provide low-temperature full combustion for fuels without producing nitric oxides, can provide intra-furnace dry desulfurization and dedusting, and allows a boiler to be completely green.

Owner:陈久斌

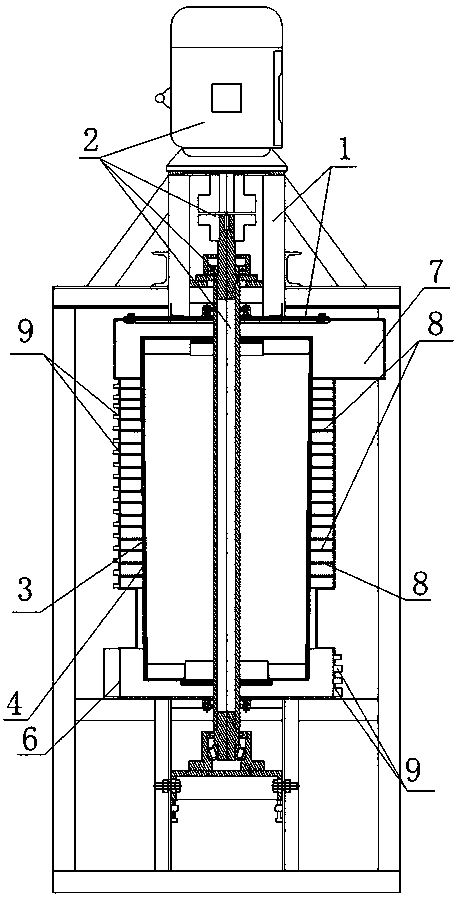

Vortex machine

InactiveCN109569902AAchieve fadeTake advantage ofReversed direction vortexCentrifugesOxygenSewage treatment

The invention discloses a vortex machine. The vortex machine includes a shell body and a transmission device; the transmission device is arranged on the shell body, a vortex current cavity is formed in the shell body, a transmission body with a working face of the outer periphery is arranged in the vortex current cavity, the transmission device is connected with the transmission body, when the transmission device drives the transmission body to rotate, the outer periphery of the transmission body drives a working medium to rotate and flow in the vortex current cavity at the periphery of the transmission body, and a vortex current cavity inlet is formed in one end of the vortex current cavity; and a vortex current cavity outlet is formed in the other end of the vortex current cavity, the inner diameter of at least one section of the vortex current cavity is gradually reduced towards the vortex current cavity outlet end, and at least one discharging opening is formed in the periphery ofthe vortex current cavity. The vortex machine can be widely used in the fields such as dust removal, desulfurization, de-nitrification, smoke removal, deodorization, vehicle and ship exhaust purification, oil smoke extraction, air purification, oil and gas recovery, waste disposal, nuclear waste treatment, powder selection, mineral processing, seawater desalination, sewage treatment, water purification, refining, oxygen production, reactors, boilers, burners, and grinding equipment, can achieve high degree purification of flue, can solve the air pollution and water pollution, and can prepare avariety of powders such as ultrafine powder and nano-powder.

Owner:陈久斌

Application of Coal Pillarless Coal Mining Method in Lower Protective Layer Mining

ActiveCN103266893BRealize continuous recoveryAchieve economical miningUnderground miningSurface miningMining engineeringStructural engineering

The invention relates to an application of a non-coal pillar roadway layout in the under-protected stratum exploitation. The non-coal pillar roadway layout comprises a stagger arrangement or gob-side entry driving roadway layout, the non-coal pillar roadway layout is adopted in the under-protected stratum exploitation of a dynamic disaster coal stratum, and a coal pillar supporting overlying strata between adjacent work surfaces is removed, so the inclined continuous recovery of a stope is realized; and a fracture zone above the stope ascends and the arrangement of the protected coal stratum in the fracture zone descends with the increase of the exploitation range, so the application range of the under-protected stratum exploitation is widened, the mining is full, the destressing effect is obvious, and the protected stratum is not influenced by the installation of the coal pillar in the protected stratum, thereby the safe and economic exploitation of the protected stratum is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

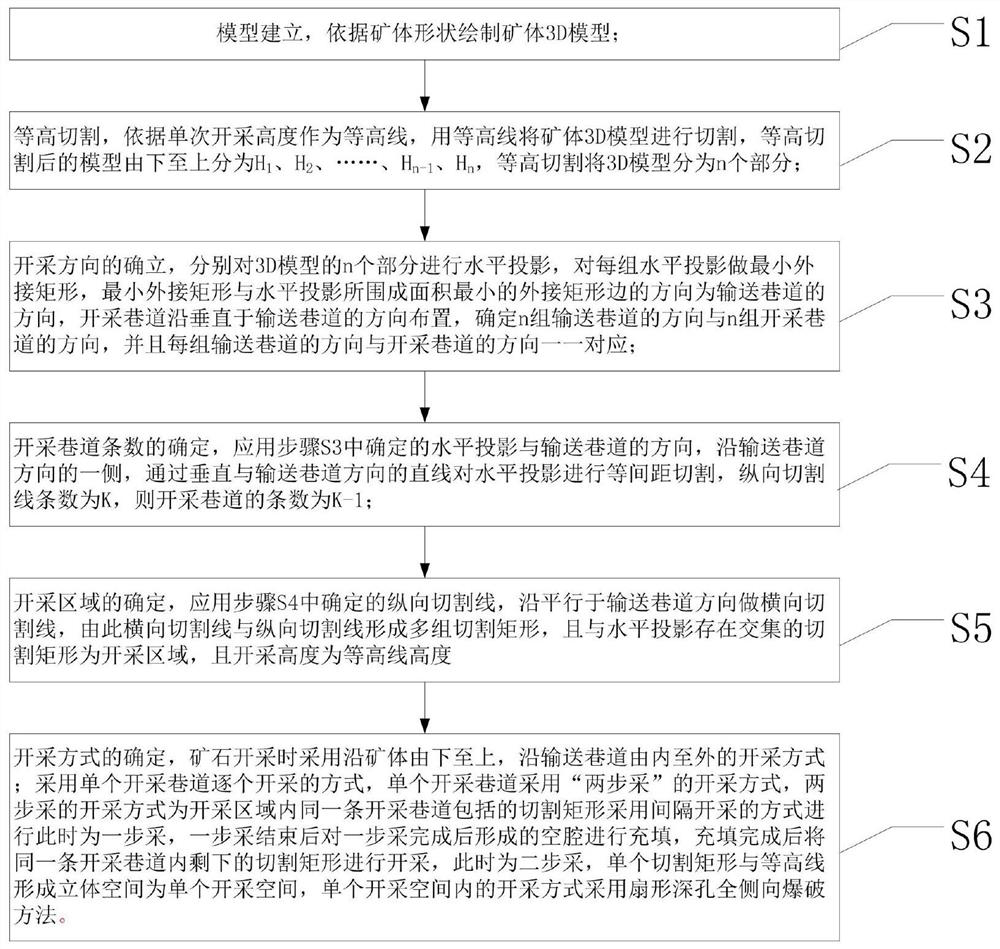

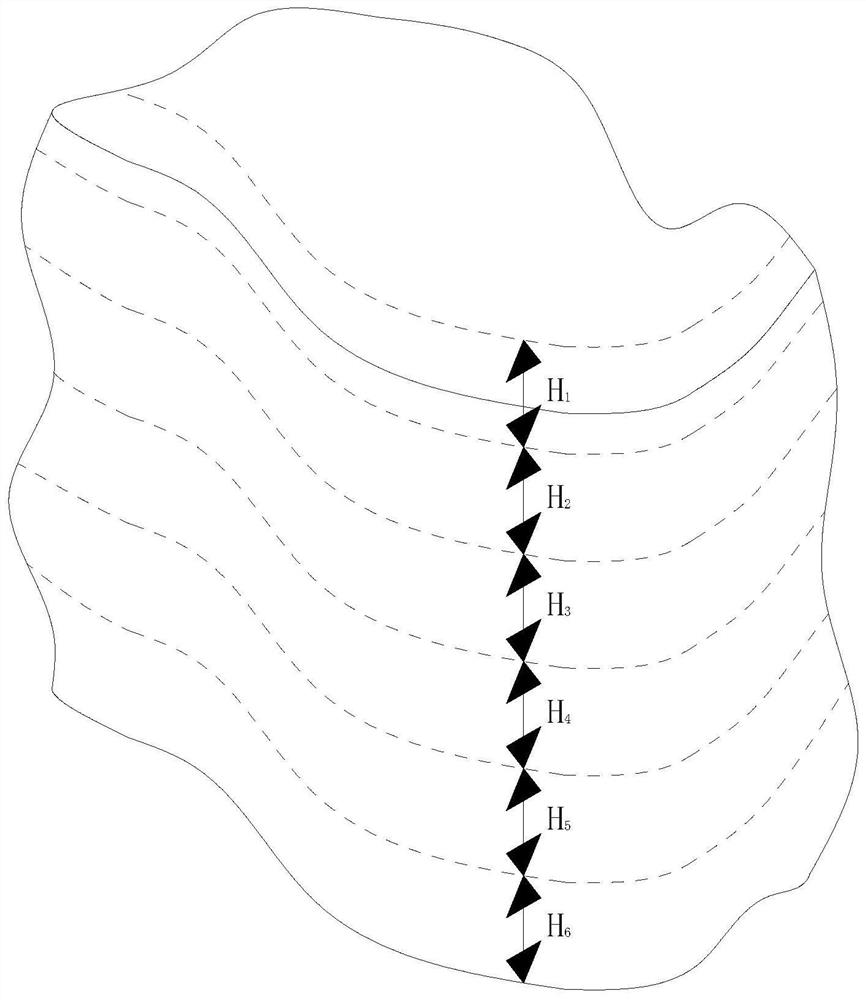

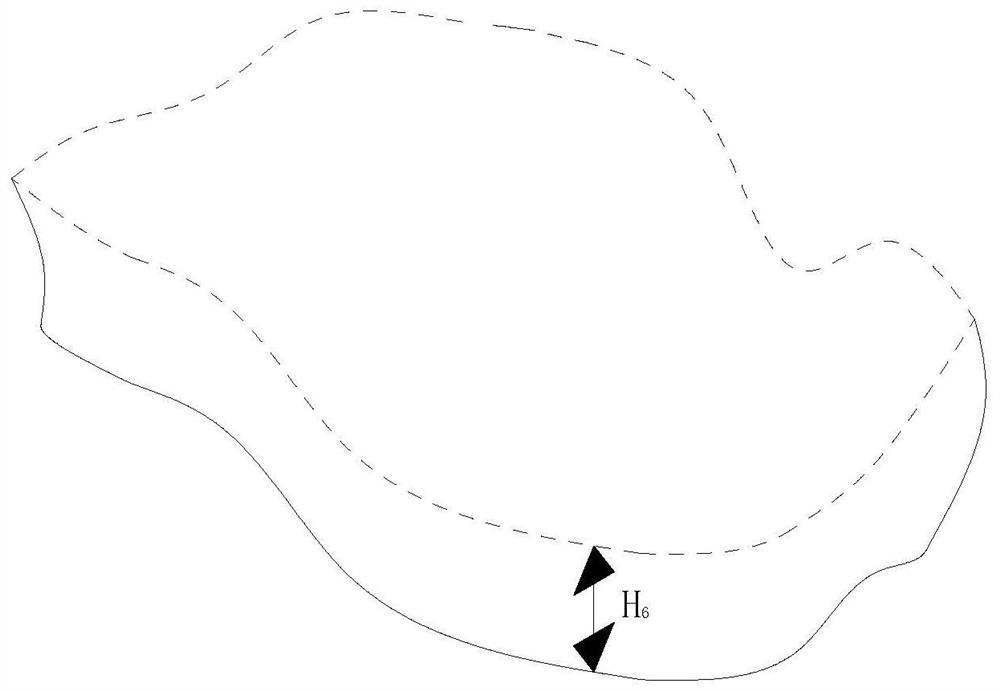

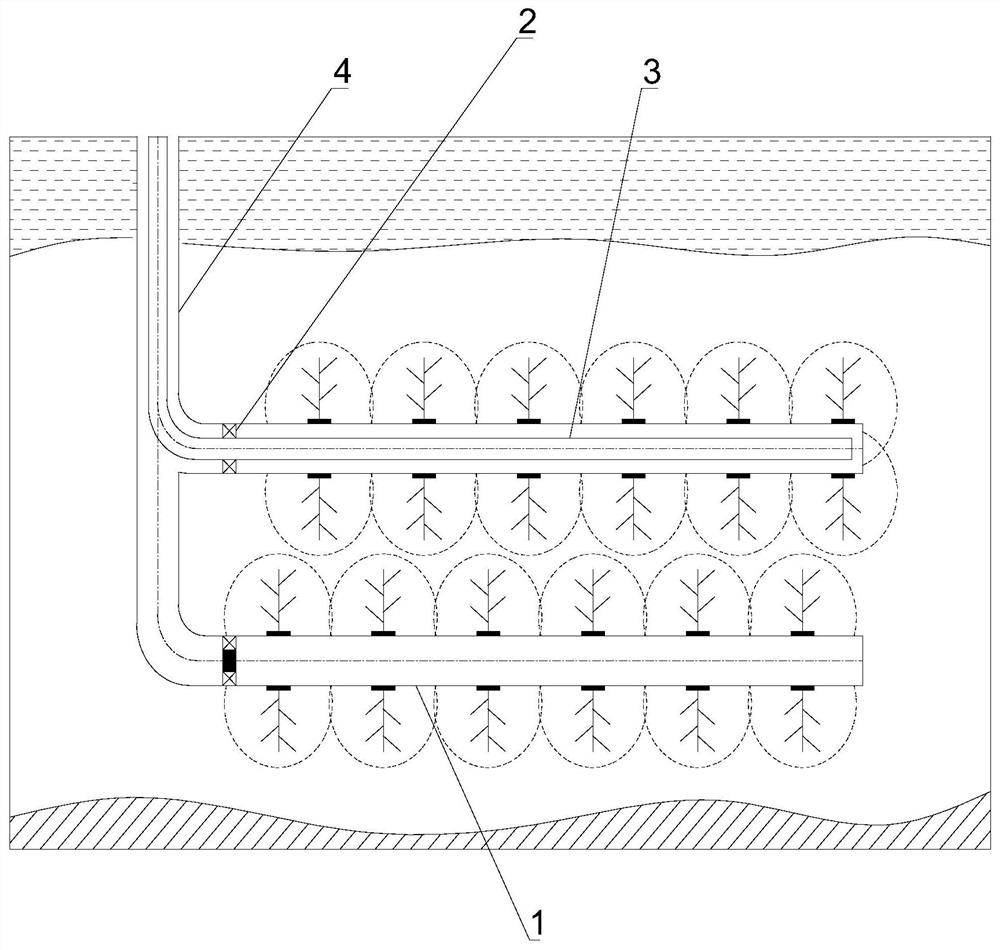

Blasting method for mining

InactiveCN111894590AFully exploitedReduce depletionUnderground miningBlastingMining engineeringDeep hole

The invention discloses a blasting method for mining. The method comprises the following steps of model building, equal-height cutting, determination of a mining direction, determination of the numberof mining roadways, and determination of a mining mode. During ore mining, mining is conducted from bottom to top along an ore body and from inside to outside along an ore receiving roadway. The mining roadways are mined one by one, each mining roadway adopts a two-step mining mode, a three-dimensional space formed by each cutting rectangle and the corresponding contour line is a mining space, and each mining space adopts a fan-shaped deep hole full-lateral blasting method for mining. According to the method, the ore body forms a 3D model, the model is subjected to equal-height cutting to form multiple sets of mining heights, the ore body part in each height is projected, and the mining area at each height is determined through a transverse cutting line and a longitudinal cutting line. Therefore, ore depletion is reduced under the condition of ensuring ordered ore mining, the mining cost is reduced, and the ore body is fully mined.

Owner:安徽江南爆破工程有限公司

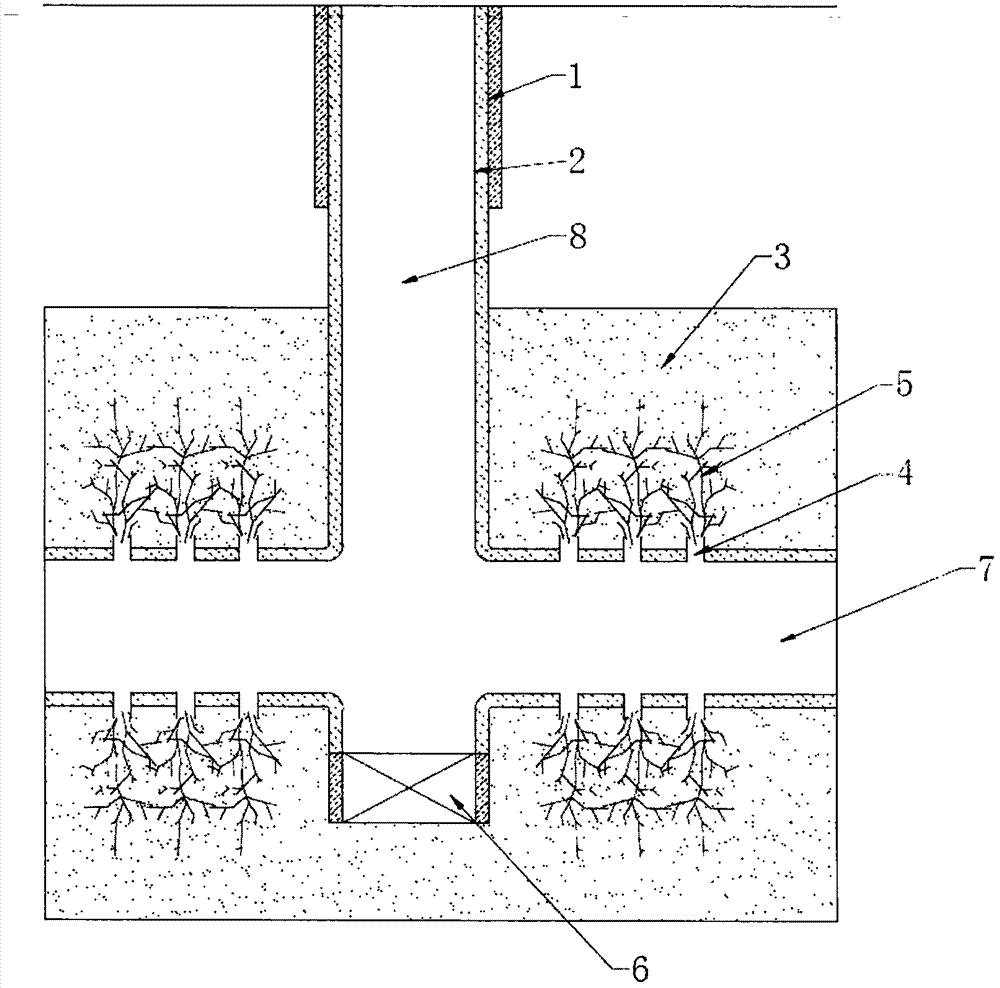

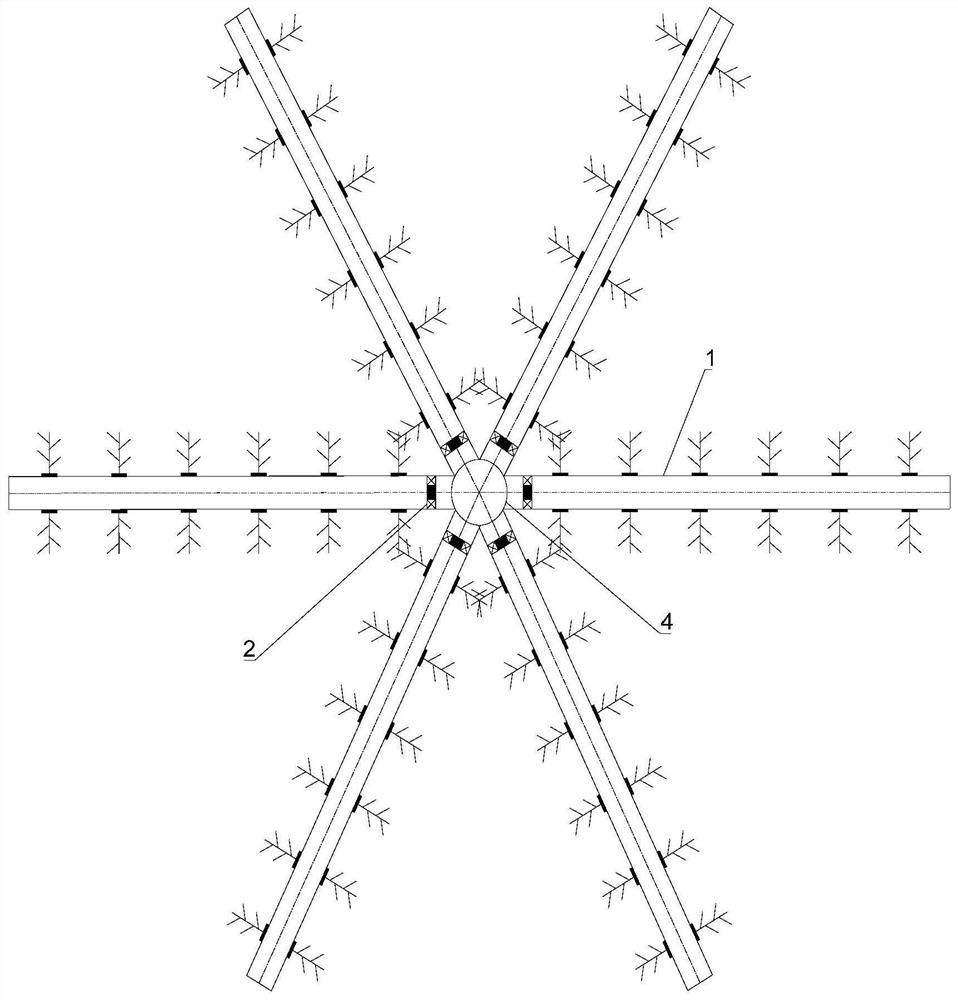

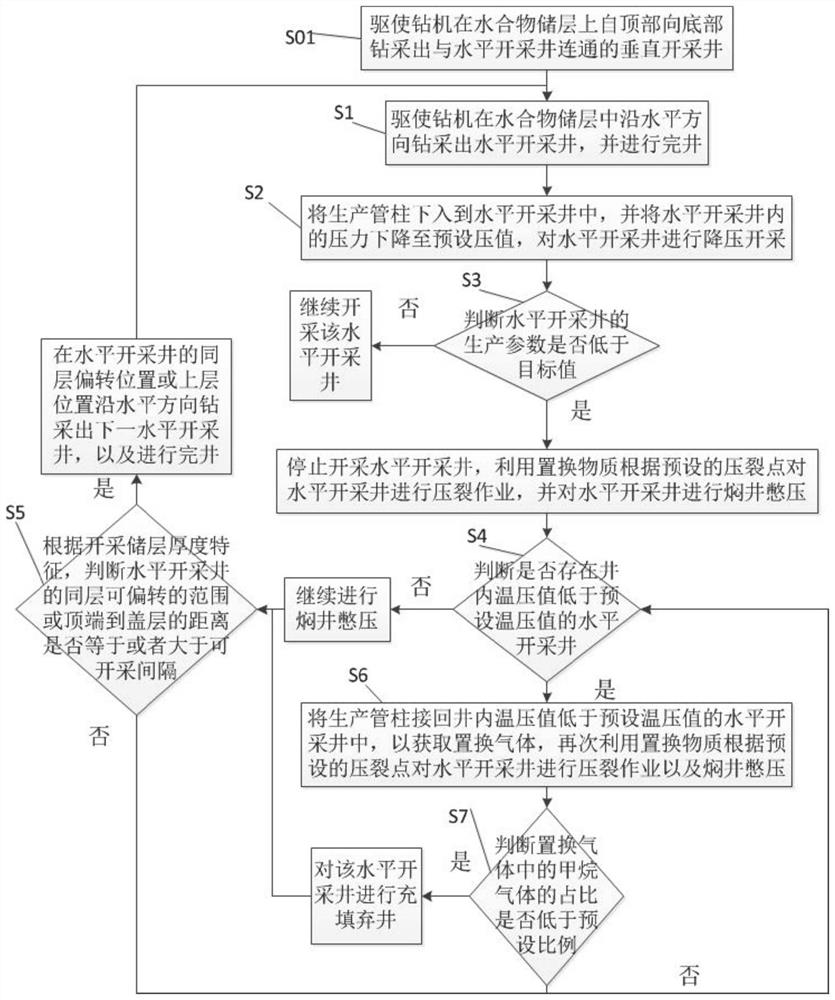

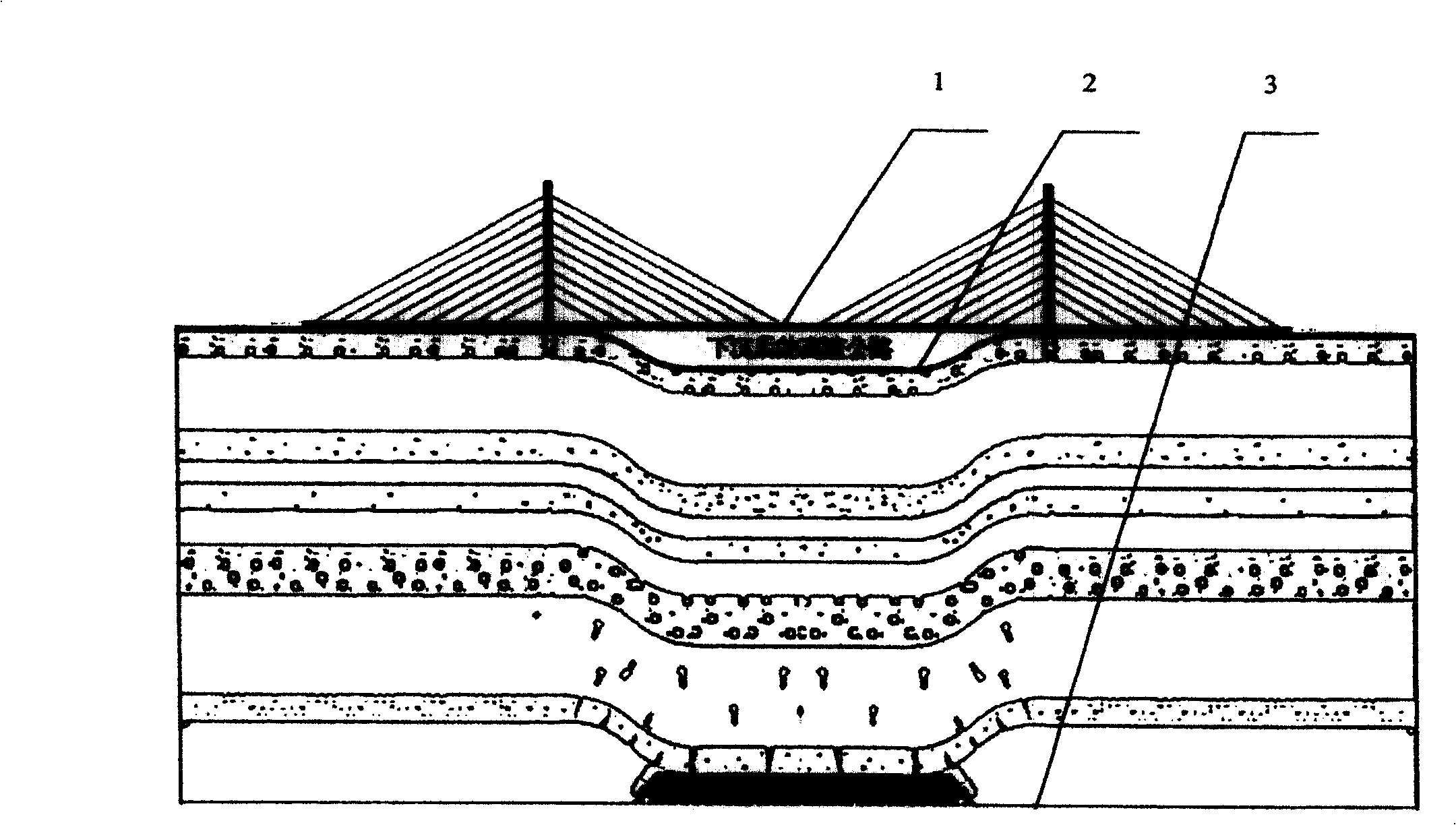

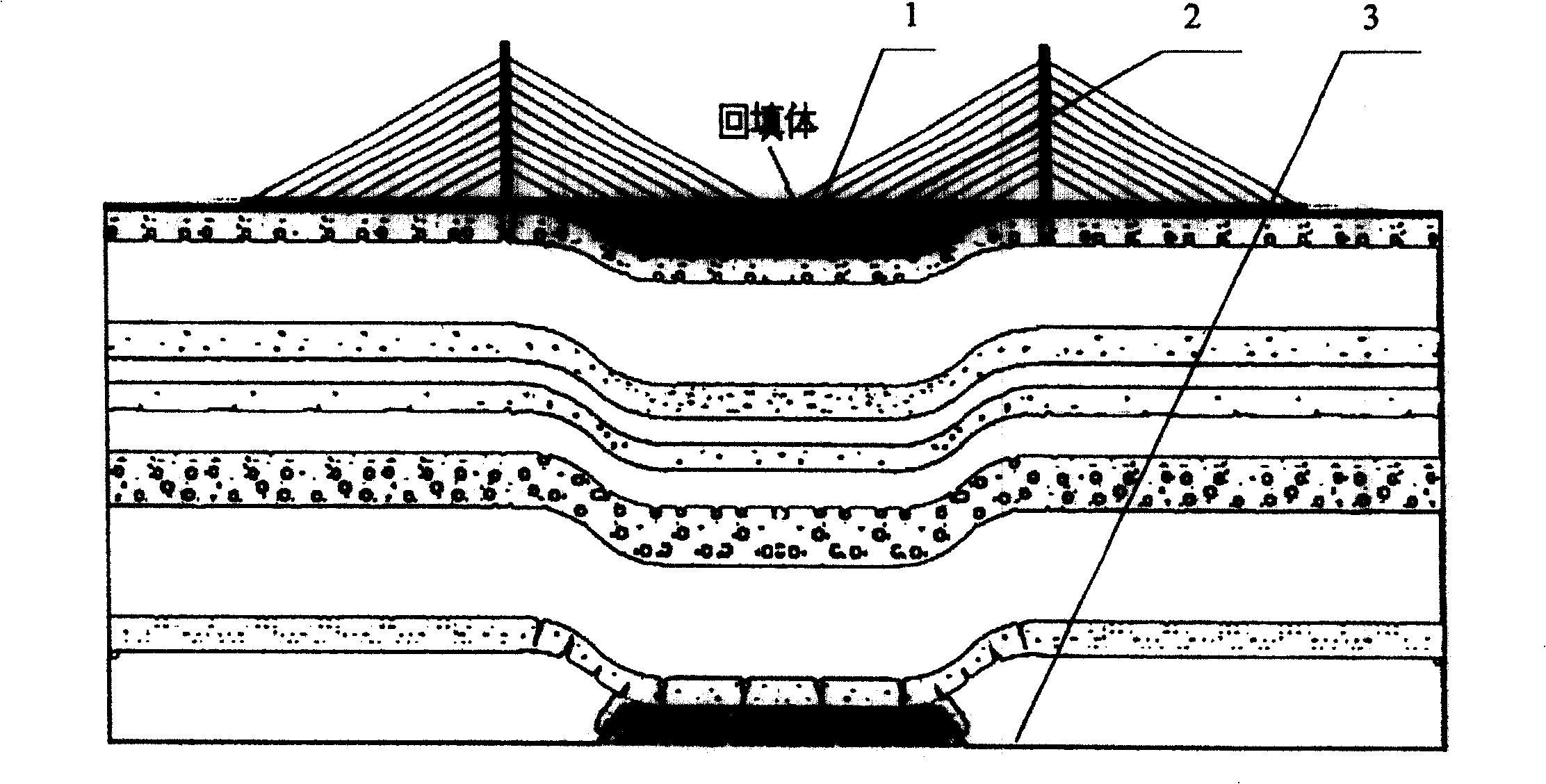

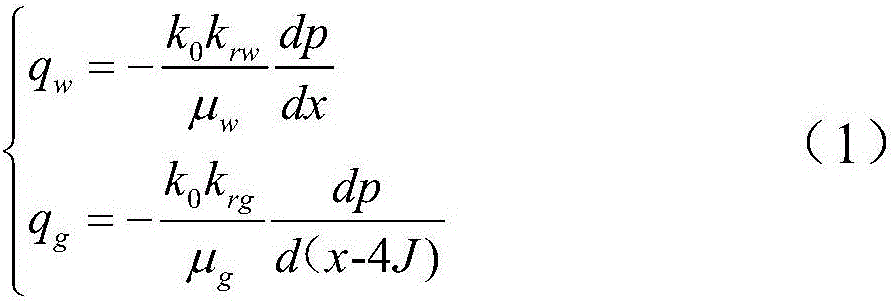

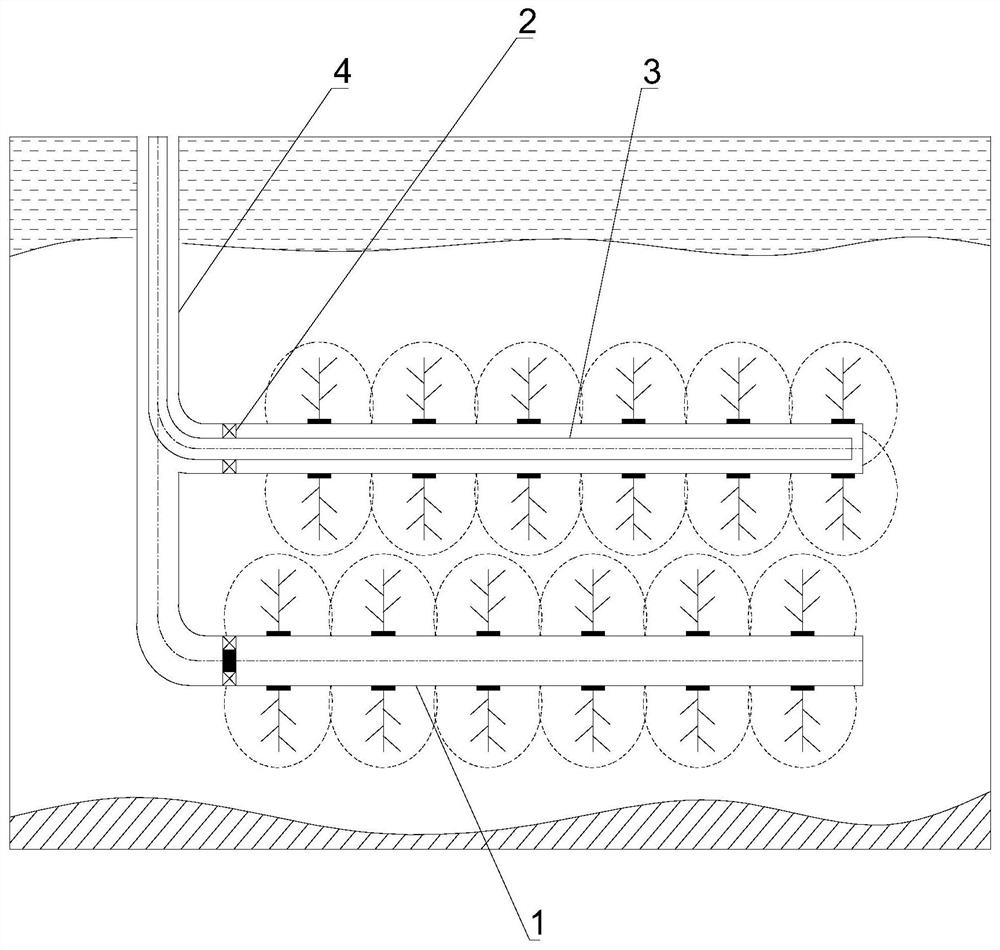

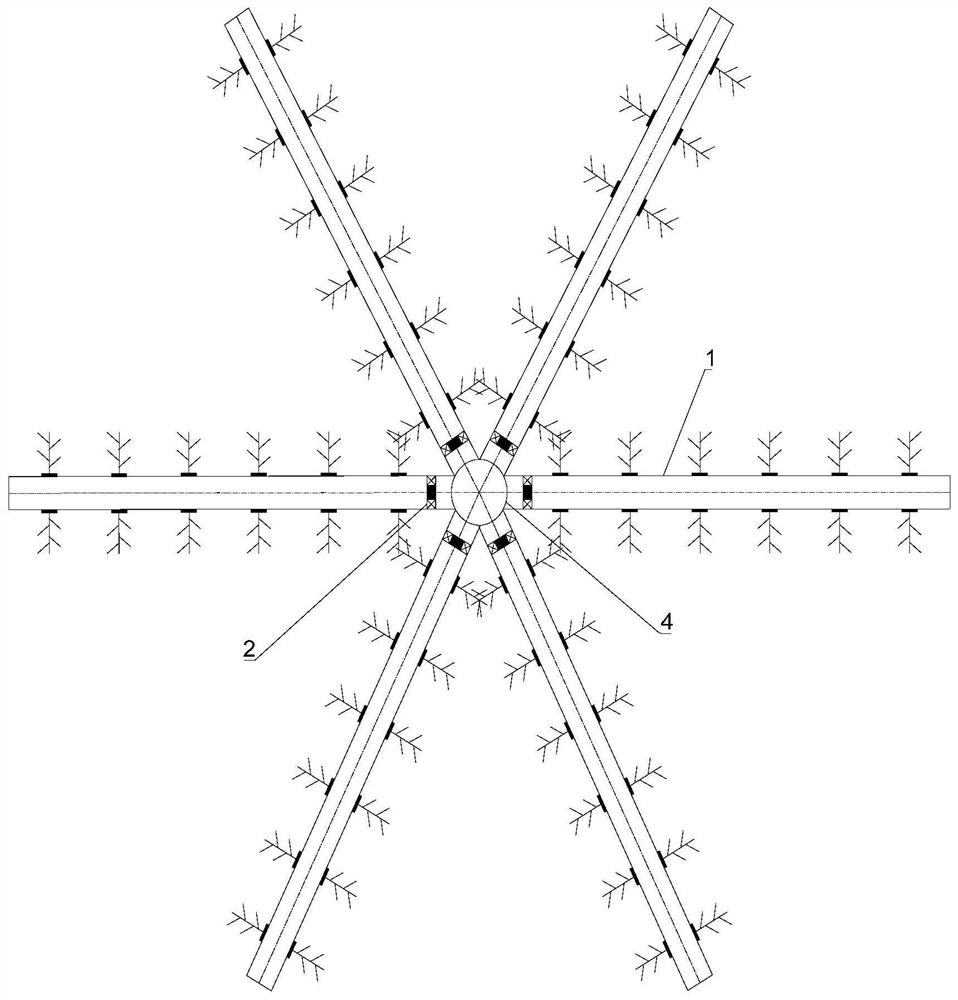

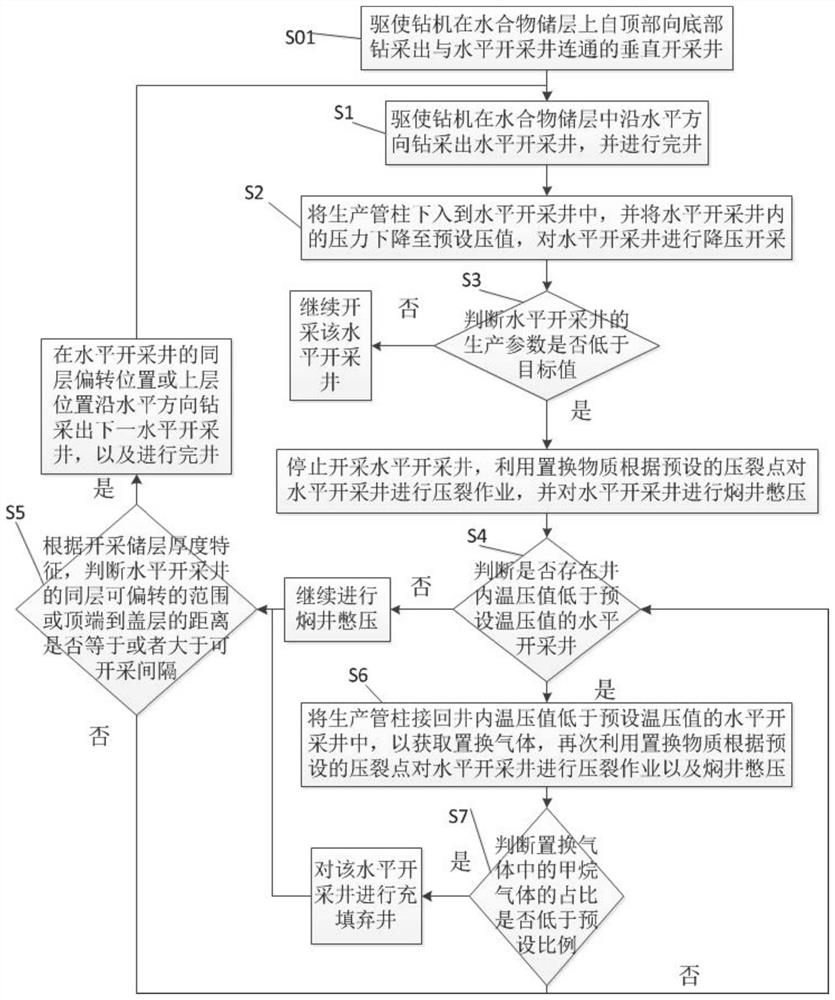

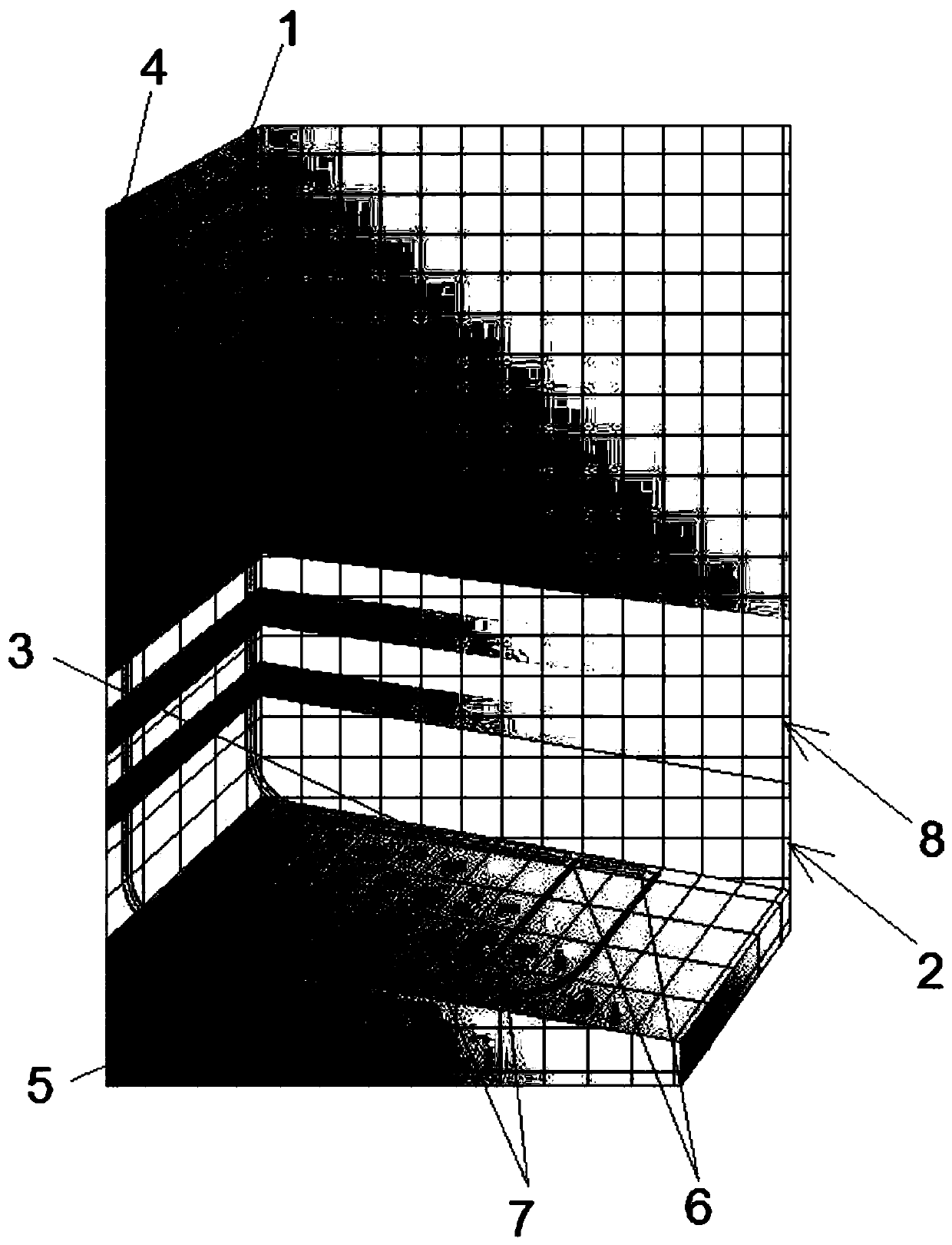

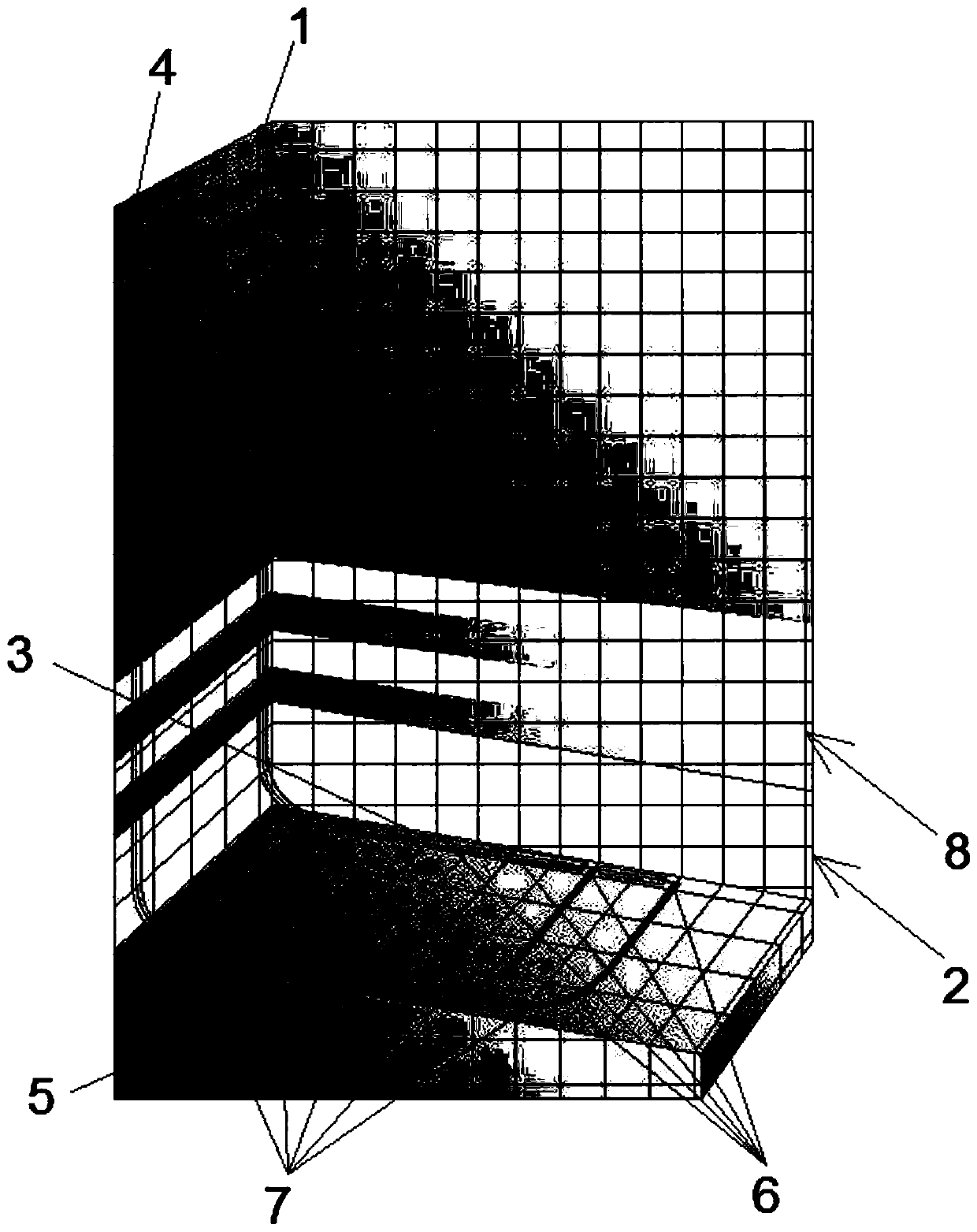

A multi-branch hydrate displacement mining method

ActiveCN113006764BRealize displacement miningFully exploitedFluid removalMining engineeringProcess safety

The invention discloses a multi-branch gas hydrate replacement mining method. By drilling and producing production wells in the horizontal direction in the hydrate reservoir, repeated consumption of a large amount of resources to penetrate the dense overlying layer of the hydrate is avoided, and the initial mining is utilized. The depressurization method is used to reduce the pressure of the horizontal production well, and then use the replacement material to fracturing the horizontal production well and suppress the pressure of the well, so that the replacement material can fully contact and react with the hydrate, and at the same time deflect in the same layer of the horizontal production well. The next horizontal production well can be drilled at the position or the upper layer, and hydrate production can be carried out at other positions while the replacement operation is realized, so that the production and replacement can be carried out at the same time, saving the time and cost required for the replacement operation, so that the vertical depth and plane direction can be multiplied. All layer and branch wells can exist at the same time, and the combination form of branch wells is not limited. It only needs to fully consider the thickness and range of the hydrate reservoir to be exploited, geological characteristics, drilling and production process safety and other factors to effectively realize the hydrate formation of the entire reservoir. replacement mining.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

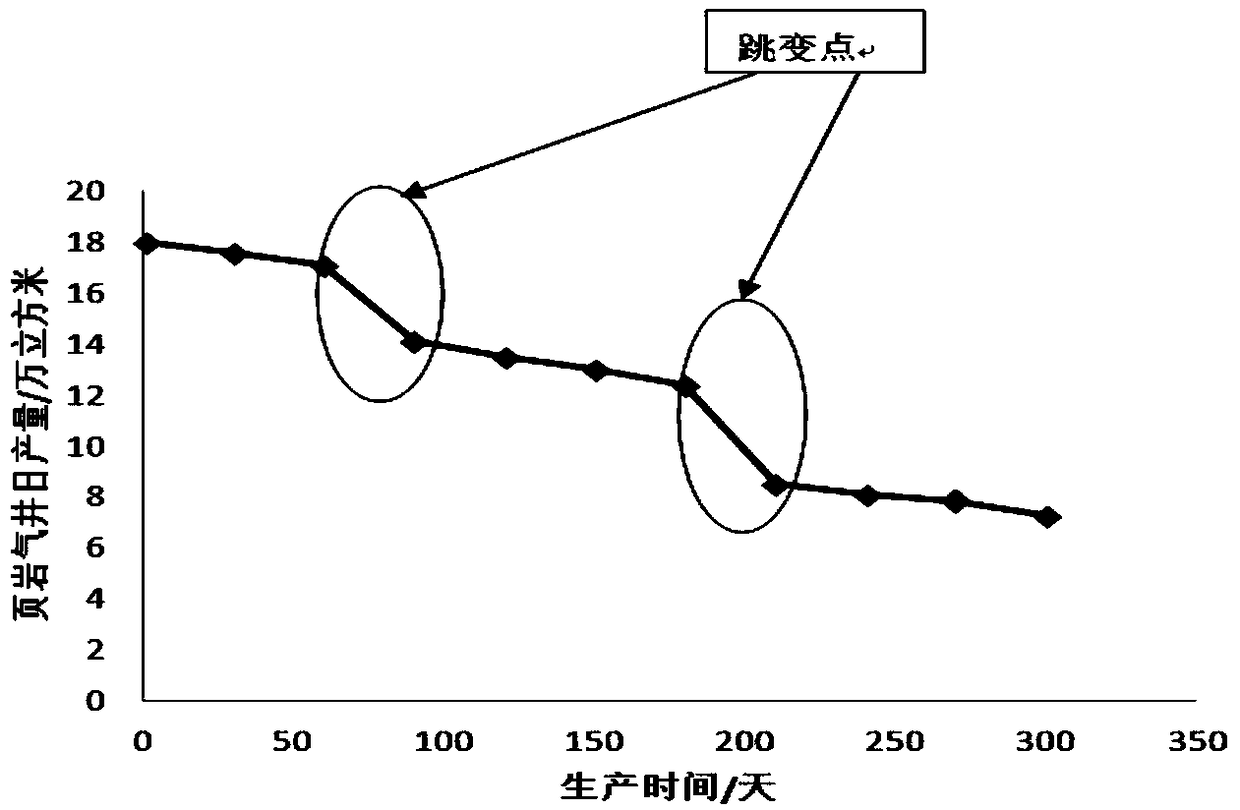

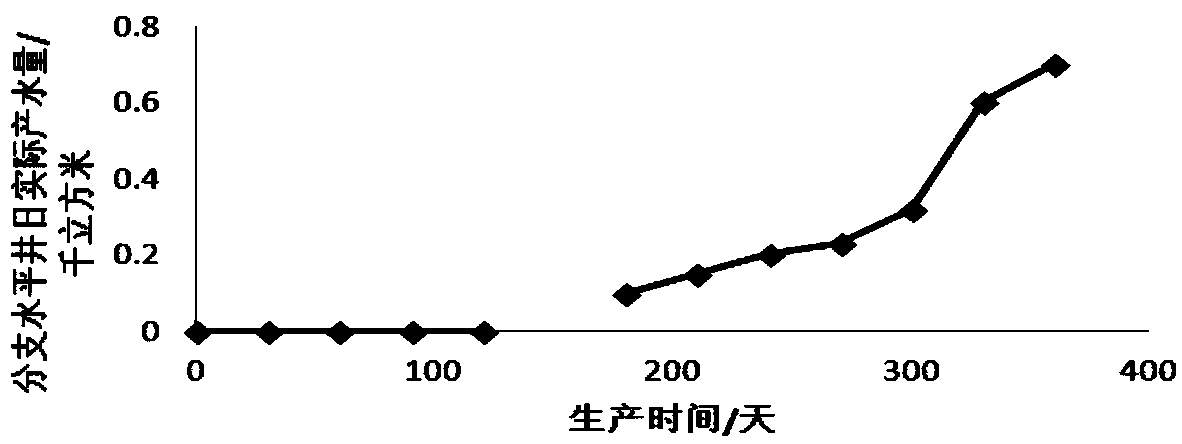

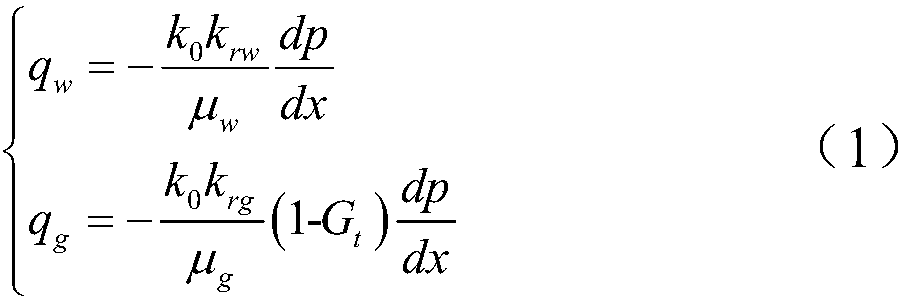

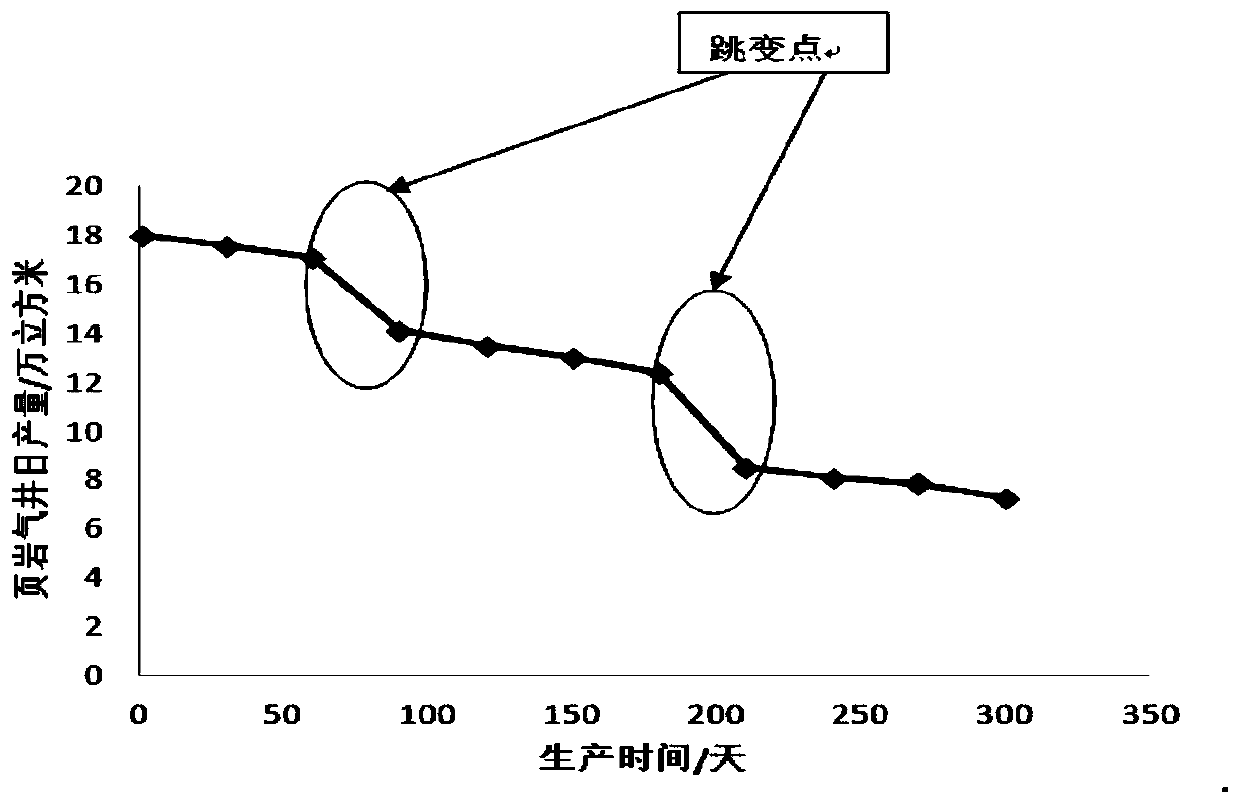

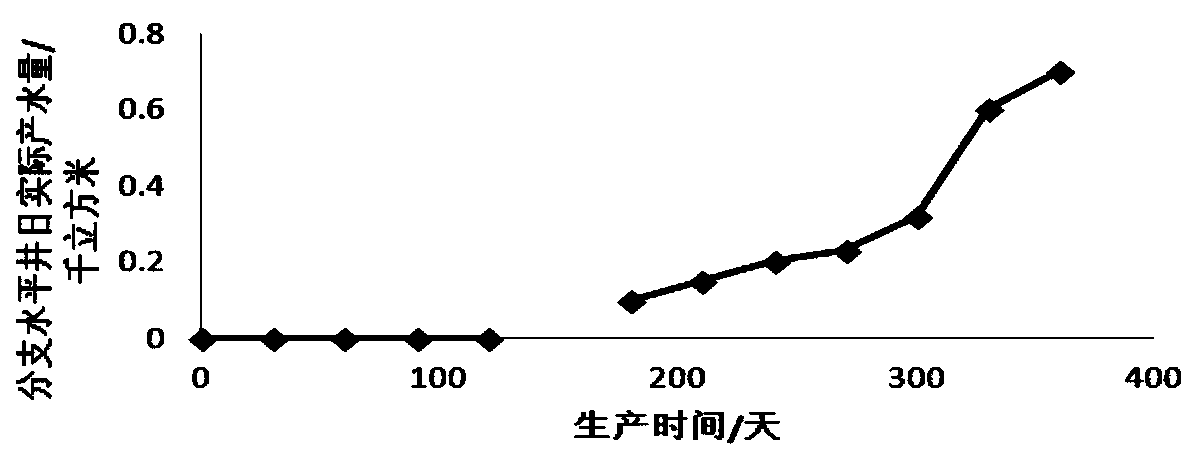

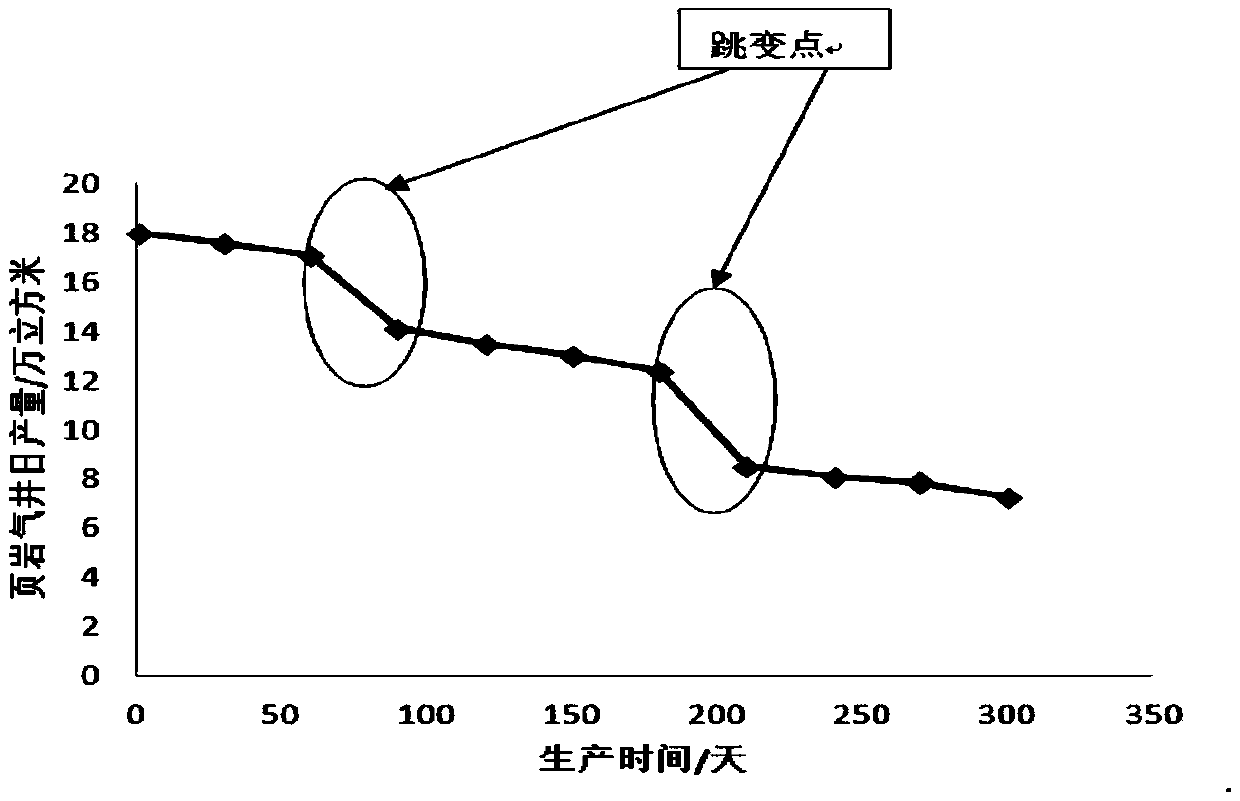

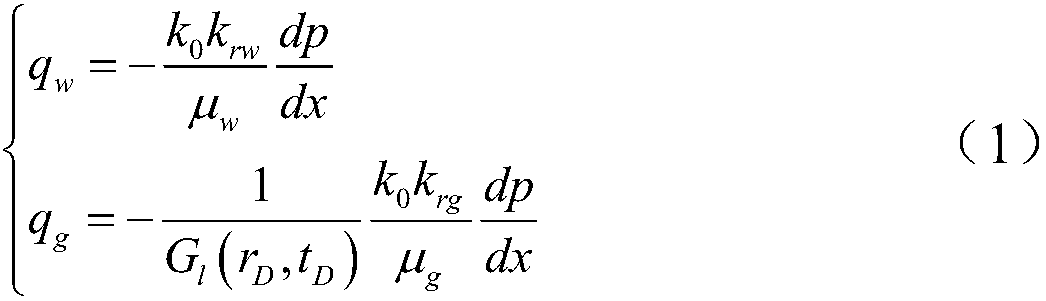

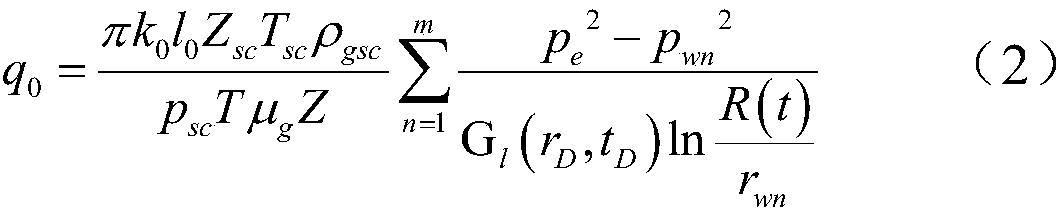

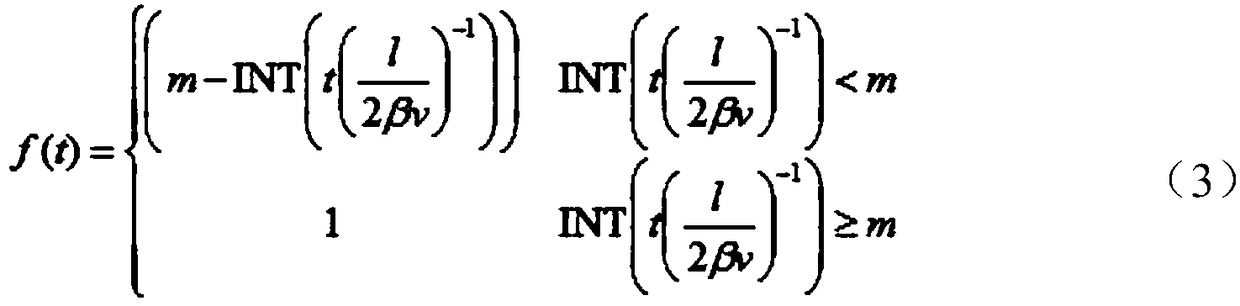

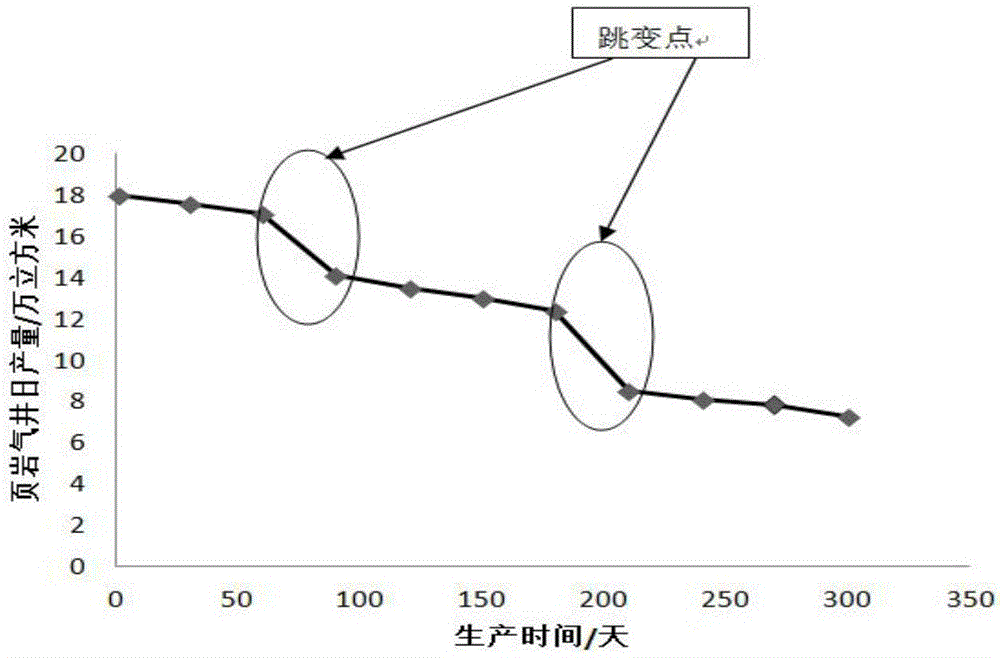

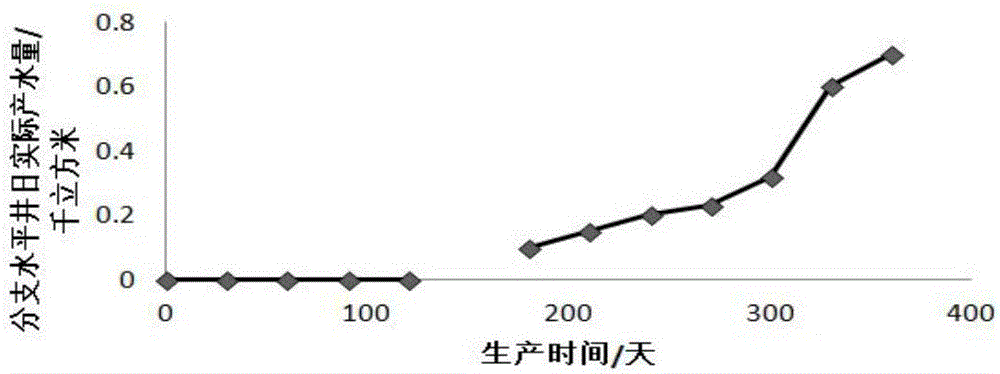

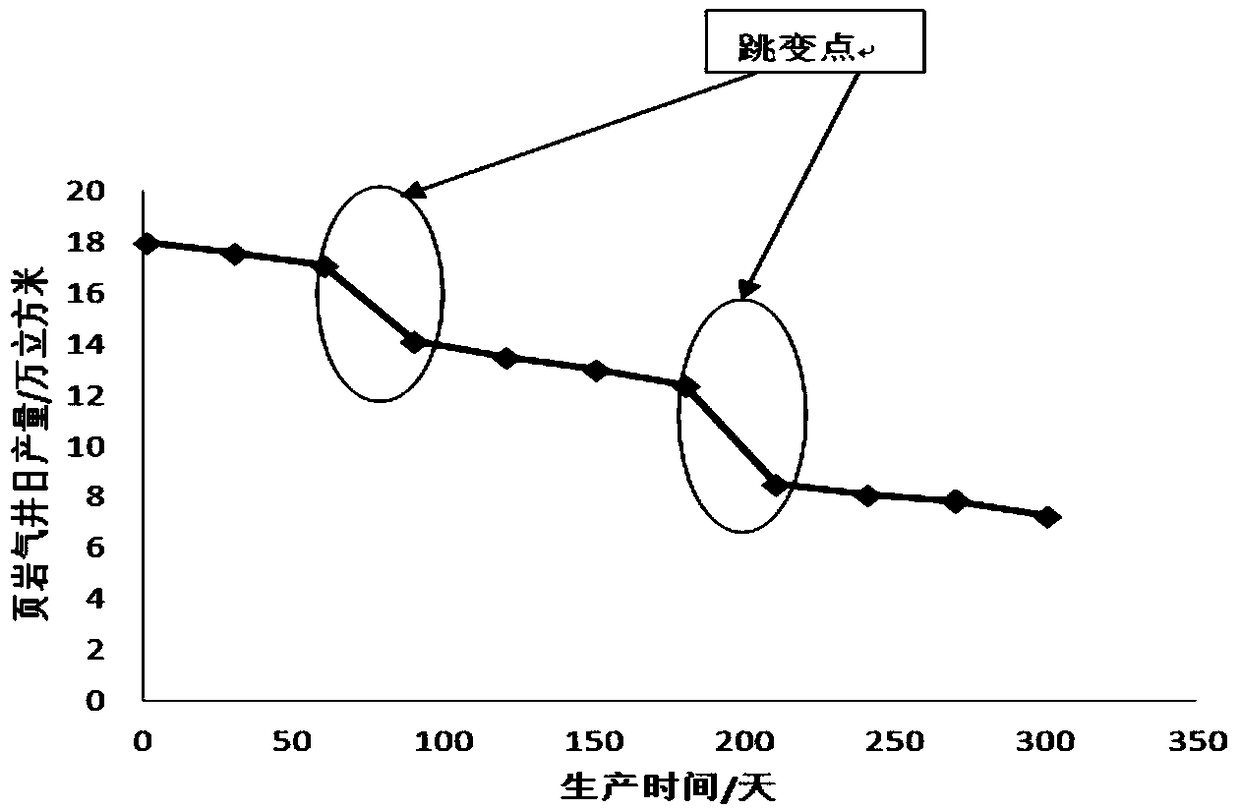

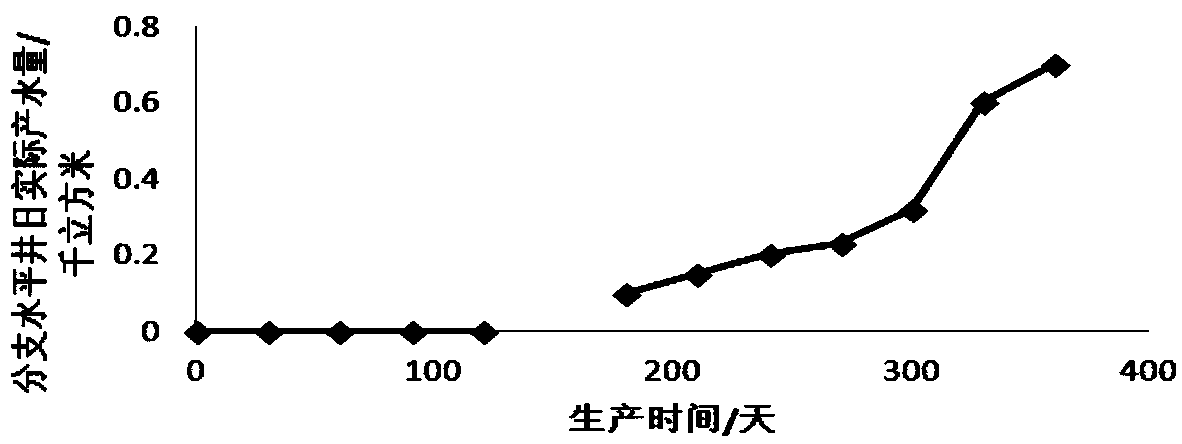

A kind of branch horizontal well production method based on starting pressure gradient

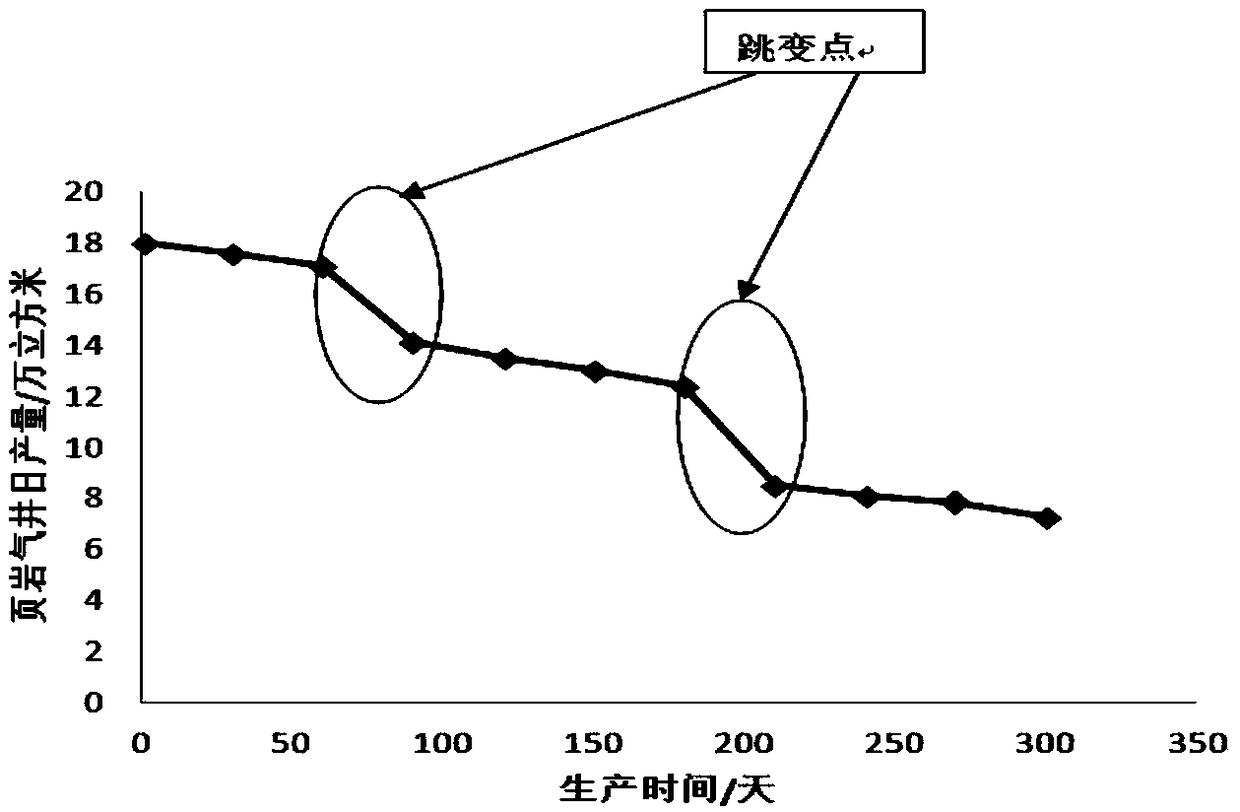

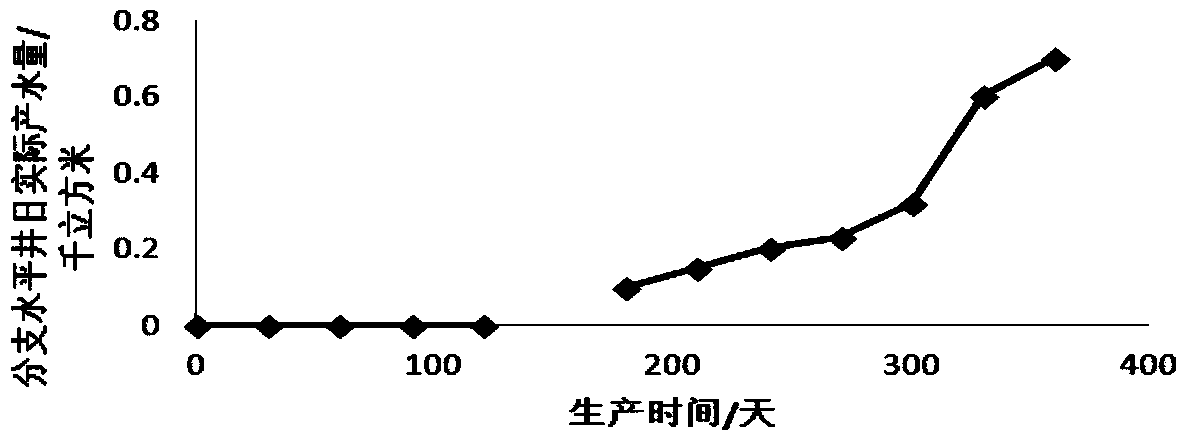

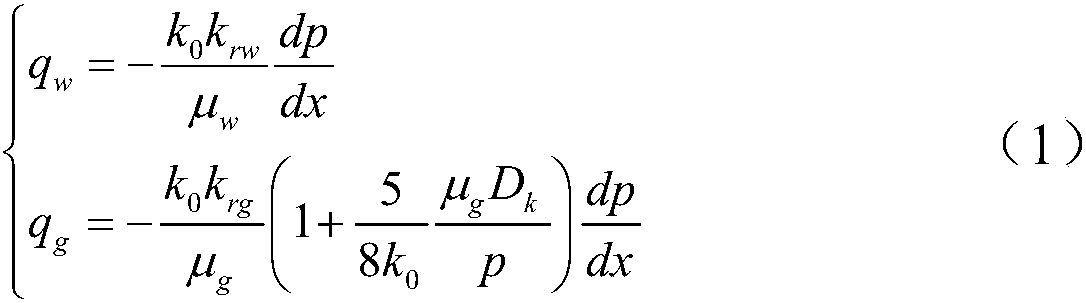

InactiveCN106437629BFully exploitedEnhanced overall recoveryFluid removalPore pressure gradientShale gas

The invention discloses a branch horizontal well mining method based on a starting pressure gradient. The branch horizontal well mining method comprises the following steps: firstly, calculating the theoretical value of the shale gas yield in a branch horizontal well; according to the theoretical value, carrying out the actual production of the branch horizontal well, and drawing a curve graph of the actual daily yield and time of the branch horizontal well; when a jump point occurs in the curve graph, adjusting the production until the jump point does not appear in the curve graph; when accumulated water yield is equal to critical water yield, determining that the branch horizontal well is scrapped. According to the branch horizontal well mining method, by adjusting the production when the jump point occurs, the output water in the horizontal wellbore can be timely carried by shale gas, the harm of the gas and water mixture returning to the bottom of the well is thus reduced and the gathering of the output water on the bottom of the well is reduced, therefore, maintenance charge is reduced, efficiency is high and maintenance cost is saved.

Owner:YANAN UNIV

A self-adaptive stroke adjustment method for downhole linear motor oil well pump

ActiveCN109653999BEnsure output balanceAvoid wastingPump testingFlexible member pumpsElectric machineLinear motor

The invention provides a self-adaptive pump stroke adjusting method for an oil well pump of a underground linear motor. The method comprises the following steps that S1, the time T is taken as a period, in the first period T, pump strokes per minute of an oil extraction device is N0, the oil extraction device starts from the second cycle T, the pump strokes per minute of the oil extraction devicein each period T are all up-regulated by a certain amount, and the oil well is evacuated until an oil well is evacuated in the certain period T, when the oil well is evacuated, the pump strokes per minute of the oil extraction device in each period T is recorded as N1, and then the oil extraction device stops mining; S2, when the stop time of the oil extraction device reaches the T1, the oil extraction device is restarted, and the oil extraction device extracts oil with N1 pump strokes per minute, the time length T2 used for evacuating the oil well again is recorded, and then mining of the oilextraction device is stopped; S3, after the stop time of the oil extraction device reaches the T1 again, the oil extraction device is restarted, and the oil extraction device extracts oil with Nnew pump strokes per minute, wherein the Nnew is equal to N1T2 / (T1 + T2 ). The self-adaptive pump stroke adjusting method for the oil well pump of the underground linear motor has the beneficial effects ofsimple in process, high in precision and high in practicability.

Owner:WUHAN HAIWANG TECH

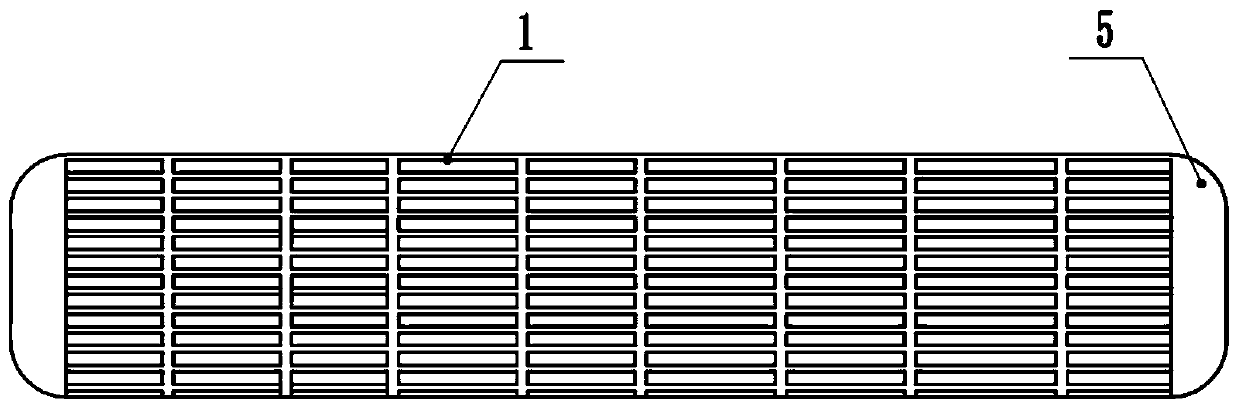

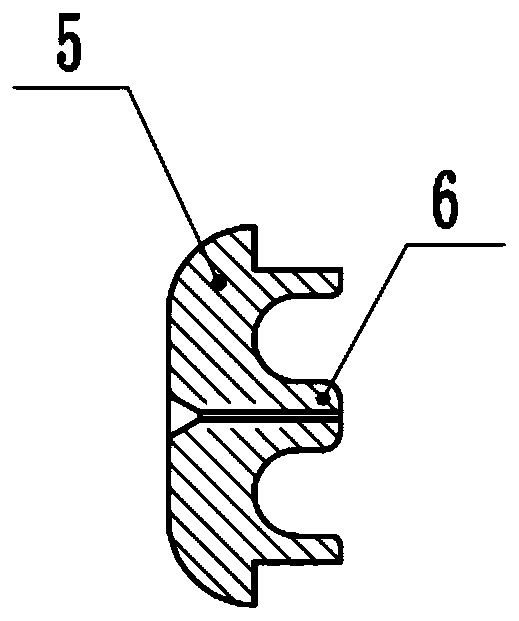

Highly telescopic hydraulic support for low coal seam

The invention discloses a highly telescopic hydraulic support for a low coal seam, which comprises a base, a top beam and a shield beam, wherein two upright posts are symmetrically arranged between the top beam and the base, and two balancing jacks are symmetrically arranged between the top beam and the shield beam hinged with the top beam; a front connecting rod and a rear connecting rod are respectively hinged between the shield and the base, the middle part of the base is provided with a push jack, and the push jack is hinged with a push rod; an axial slotted hole is arranged in the wall of a middle cylinder of the upright posts, an upper opening and a lower opening, which are communicated with the slotted hole, are arranged in the internal wall and the external wall of the middle cylinder, the upper opening is communicated with the upper cavity of the middle cylinder, and the lower opening is communicated with the upper cavity of an external cylinder; the rear part of the base is provided with two free positions corresponding to the balancing jacks; the front end and the rear end of the push rod are respectively provided with a pair of joint seats; each joint seat is provided with a through hole communicated with a liquid inlet and outlet steel pipe arranged in the cavity of the push rod and a fixing hole, of which the side wall is provided with a holding hose; and the topbeam and the base are made of Q800 material. The support is highly telescopic, has a reasonable pedestrian passageway in a low position state, and can satisfy the mining requirement of an unstable high coal seam.

Owner:CCTEG COAL MINING RES INST

A Production Method of Branched Horizontal Well Based on Bessel Function

InactiveCN106354957BFully exploitedEnhanced overall recoveryData processing applicationsFluid removalProduced waterShale gas

The invention discloses a branch horizontal well exploitation method based on the Bessel function. The method specifically includes the following steps that firstly, the theoretical value of the shale gas yield of a branch horizontal well is calculated; secondly, according to the theoretical value, the branch horizontal well goes into operation according to daily actual yield, a curve chart of the daily actual yield and time of the branch horizontal well is drawn, when trip points appear in the curve chart, the curve chart is adjusted till no trip points appear in the curve chart, and when cumulative water yield is equal to critical water yield, the branch horizontal well is scrapped. Adjustment is conducted after trip points are generated, shale gas can conveniently carry produced water in a horizontal well shaft, damage caused when gas and water mixtures go back to the well bottom is reduced, and accumulation of the produced water at the well bottom is reduced, so that maintenance expenses are reduced, efficiency is high, and maintenance cost is saved.

Owner:YANAN UNIV

Land bridge method for recovery of pressed coal under highway

ActiveCN100439651CEasy to manufactureFully exploitedUnderground miningSurface miningEngineeringRoad surface

A dry bridge exploitation method for express highway lower press coals belongs to a method to maintain an express highway being continuously utilized, maintained and recovered during lower press coals exploitation under the express highway. For an express highway, traditional exploitation methods for express highway lower press coals cannot guarantee vehicles normally running on the highway during the underground exploitation. Meanwhile, the traditional methods might either cause traffic shutdown on an express highway, or result in too much recovery cost or too much waste of coals. The invention can fulfill that, before coal layer exploitation influences an express highway, erecting a large-span dry bridge to substitute the express highway segment in serving vehicles during the exploitation; after the exploitation influences are over, perform recovery for the express highway and dismantle the dry bridge to recovery traffic. Therefore, the scheme can fulfill the following targets of the invention: Provide a dry bridge exploitation method for express highway lower press coals, in order to guarantees normal traffic and traffic safety during exploitation of the underground coals; meanwhile, the invention can considerably lower cost of maintenance, curring and recovery for express highways, and moreover, expand press coal exploitation volume and sufficiently utilize resources..

Owner:何满潮

A Production Method of Branched Horizontal Well Based on Green's Function

The invention discloses a branch horizontal well exploitation method based on the Green's function. The branch horizontal well exploitation method based on the Green's function specifically includes the following steps that firstly, a theoretical value of the shale gas yield of a branch horizontal well is calculated; secondly, according to the theoretical value, production at the daily practical yield of the branch horizontal well is conducted, and a curve chart of the daily practical yield of the branch horizontal well and time is drawn; when a jump point occurs in the curve chart, the daily practical yield of the branch horizontal well is adjusted until no jump point occurs in the curve chart; and when the accumulated water yield is equal to the critical water yield, the branch horizontal well is scrapped. According to the branch horizontal well exploitation method based on the Green's function, adjustment is carried out after the jump point occurs, so that shale gas better carries produced water in a horizontal well shaft in time, the danger that a gas-water mixture returns to the well bottom is reduced, and gathering of the produced water at the well bottom is reduced; and accordingly, maintenance cost is lowered, and efficiency is high.

Owner:YANAN UNIV

An environment-friendly mining method for preventing landslides

InactiveCN109236294BAvoid vegetation damageStable structureUnderground miningSurface miningMining engineeringStructural engineering

The invention provides an environment-friendly anti-landslide mining method. The method comprises the following steps: arranging a first layer of top beams on the upper part of a mineral layer, pilingon the lower parts of the first layer of top beams and preparing a first layer of stand columns which upward reach the first layer of top beams; mining the minerals on the lower parts of the first layer of top beams; downward piling on the bottoms of a first layer of mining holes close to the bottoms of the first layer of stand columns, thereby acquiring a second layer of stand columns; preparinga second layer of top beams and pouring the bottoms of the first layer of stand columns and the tops of the second layer of top beams; mining a second layer of minerals on the lower parts of the second layer of top beams; downward pilling on the bottoms of a second layer of mining holes close to the bottoms of the second layer of stand columns, thereby acquiring a third layer of stand columns; preparing a third layer of top beams and pouring the bottoms of the second layer of stand columns and the tops of the third layer of stand columns; mining a third layer of minerals on the lower parts ofthe third layer of top beams; preparing the corresponding layers of stand columns and top beams in turn till mining the bottom layer of minerals. According to the method provided by the invention, the mining rate of minerals is increased, the mining safety is guaranteed and the happening of geological disasters can be prevented.

Owner:程昌胜 +1

Coal mine drum shearer

ActiveCN110374589BImprove practicalityFully exploitedSlitting machinesCutting machinesMining engineeringMechanical engineering

The invention belongs to the technical field of coal cutters, and particularly relates to a coal mine drum-type coal cutter. The coal mine drum-type coal cutter comprises a coal cutter body, a drum installed on the coal cutter body, and a first crushing head installed on the surface of the drum; one side of the drum is fixedly connected with a first connection layer through bolts, the side, away from the drum, of the first connection layer is provided with a second connection layer, and second crushing heads are annularly distributed on the outside of the first connection layer and the outsideof the second connection layer; the coal cutter body is moved to the proper position, then, the relative distance between the first connection layer and the second connection layer is adjusted to a certain extent under the adjusting and fixing effects of a rotary knob according to the specific situation of the coal mine layer plane thickness, accordingly, when the drum is rotated, the coal mine is sufficiently exploited through cooperation of the second crushing heads on the first connection layer and the second connection layer as well as convex blocks and crushing bocks on one side of the second connection layer, and the problem that an original coal mine drum-type coal cutter cannot exploit the coal mine layer on the plane to a great extent is solved.

Owner:XIAN UNIV OF SCI & TECH

Branch horizontal well exploitation method based on Bessel function

InactiveCN106354957AFully exploitedEnhanced overall recoveryData processing applicationsFluid removalOil shale gasProduced water

The invention discloses a branch horizontal well exploitation method based on the Bessel function. The method specifically includes the following steps that firstly, the theoretical value of the shale gas yield of a branch horizontal well is calculated; secondly, according to the theoretical value, the branch horizontal well goes into operation according to daily actual yield, a curve chart of the daily actual yield and time of the branch horizontal well is drawn, when trip points appear in the curve chart, the curve chart is adjusted till no trip points appear in the curve chart, and when cumulative water yield is equal to critical water yield, the branch horizontal well is scrapped. Adjustment is conducted after trip points are generated, shale gas can conveniently carry produced water in a horizontal well shaft, damage caused when gas and water mixtures go back to the well bottom is reduced, and accumulation of the produced water at the well bottom is reduced, so that maintenance expenses are reduced, efficiency is high, and maintenance cost is saved.

Owner:YANAN UNIV

Multi-branch hydrate displacement mining method

ActiveCN113006764ARealize displacement miningFully exploitedFluid removalMining engineeringProcess safety

The invention discloses a multi-branch hydrate displacement mining method. A mining well is drilled in a hydrate reservoir in the horizontal direction, so that the situation that a large number of resources are repeatedly consumed to penetrate through a compact overlying layer of hydrate is avoided; initial mining is conducted, pressure reduction mining is conducted on the horizontal mining well through a pressure reduction means, then fracturing and soaking pressure building are conducted on the horizontal mining well through a displacement substance, so that the displacement substance makes full contact with and reacts with the hydrate; and meanwhile, a next horizontal mining well is drilled in the same-layer deflection position or the upper-layer position of the horizontal mining well, hydrate mining can be conducted in other positions while displacement operation is achieved, thus mining and displacement are conducted simultaneously, the time cost needed by displacement operation is saved, a plurality of layers of branch wells in the vertical depth direction and the plane direction can exist simultaneously, the combination form of the branch wells is not limited, and hydrate displacement mining of the whole reservoir is effectively achieved only by fully considering the factors such as the thickness and range of the mined hydrate reservoir, the geological characteristics and the drilling and mining process safety.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

A Production Method of Branched Horizontal Well Based on Diffusion Coefficient

The invention discloses a branch horizontal well mining method based on a diffusion coefficient. The branch horizontal well mining method comprises the following steps: firstly, calculating the theoretical value of the shale gas yield in a branch horizontal well; according to the theoretical value, carrying out the actual production of the branch horizontal well, and drawing a curve graph of the actual daily yield and time of the branch horizontal well; when a jump point occurs in the curve graph, adjusting the production until the jump point does not appear in the curve graph; when accumulated water yield is equal to critical water yield, confirming that the branch horizontal well is scrapped. According to the branch horizontal well mining method, by adjusting the production when the jump point occurs, the output water in the horizontal wellbore can be timely carried by shale gas, the harm of the gas and water mixture returning to the bottom of the well is thus reduced and the gathering of the output water on the bottom of the well is reduced, therefore, maintenance charge is reduced, efficiency is high and maintenance cost is saved.

Owner:YANAN UNIV

A salt mine mining method using horizontal branch holes butt joint well group

ActiveCN109026002BReduce drilling development costsImprove mining efficiencyUnderground miningFluid removalWell drillingHorizontal wells

The invention discloses a salt mining method using a horizontal branch hole butted well group. The method comprises the following steps: 1) drilling a first vertical well section to a lower salt bed of a salt mine, drilling a first lower horizontal well section to a preset horizontal branch hole target along the lower salt bed after deviation, and forming a first brine well by the first vertical well section and the first lower horizontal well section; 2) putting a casing into the first brine well for well cementation; 3) drilling a second vertical well section to the lower salt layer a set distance from the wellhead of the first brine well, drilling a second horizontal well section along the lower salt layer to the starting point of a preset horizontal branch hole after deviation, and forming a second brine well by the second vertical well section and the second lower horizontal well section; and other steps. By adopting the horizontal branch hole butted well group, the mining effectof multiple pairs of butted wells is achieved by drilling a pair of drilling holes, thereby lowering the drilling development cost to the greatest extent, and improving the mining efficiency effectively at the same time.

Owner:中盐勘察设计院有限公司

A Production Method of Branched Horizontal Well Based on Fractal Dimension

The invention discloses a branch horizontal well exploitation method based on fractal dimension. The method is implemented in the specific steps that firstly, the theoretical value of the shale gas yield of a branch horizontal well is calculated; secondly, according to the theoretical value, the branch horizontal well goes into operation according to daily actual yield, a curve chart of the daily actual yield and time of the branch horizontal well is drawn, when trip points appear in the curve chart, the curve chart is adjusted till no trip points appear in the curve chart, and when cumulative water yield is equal to critical water yield, the branch horizontal well is scrapped. Adjustment is conducted after trip points are generated, shale gas can conveniently carry produced water in a horizontal well shaft, damage caused when gas and water mixtures go back to the well bottom is reduced, and accumulation of the produced water at the well bottom is reduced, so that maintenance expenses are reduced, efficiency is high, and maintenance cost is saved.

Owner:YANAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com