Mining machine and mining method

A mining machine and mine seam technology, applied in ground mining, underground mining, special mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

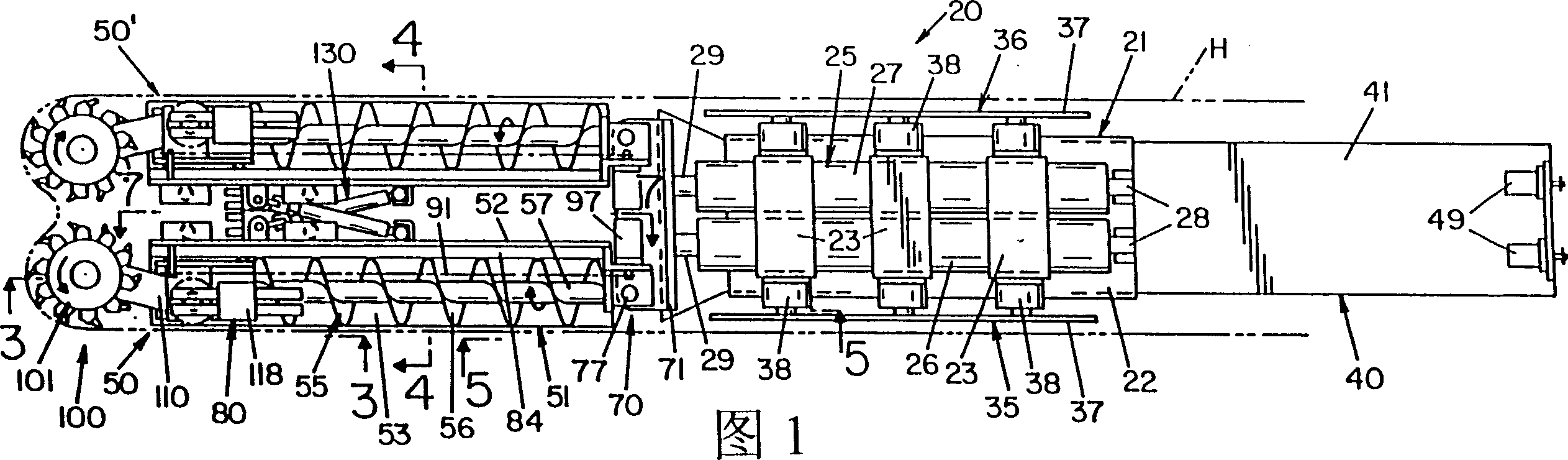

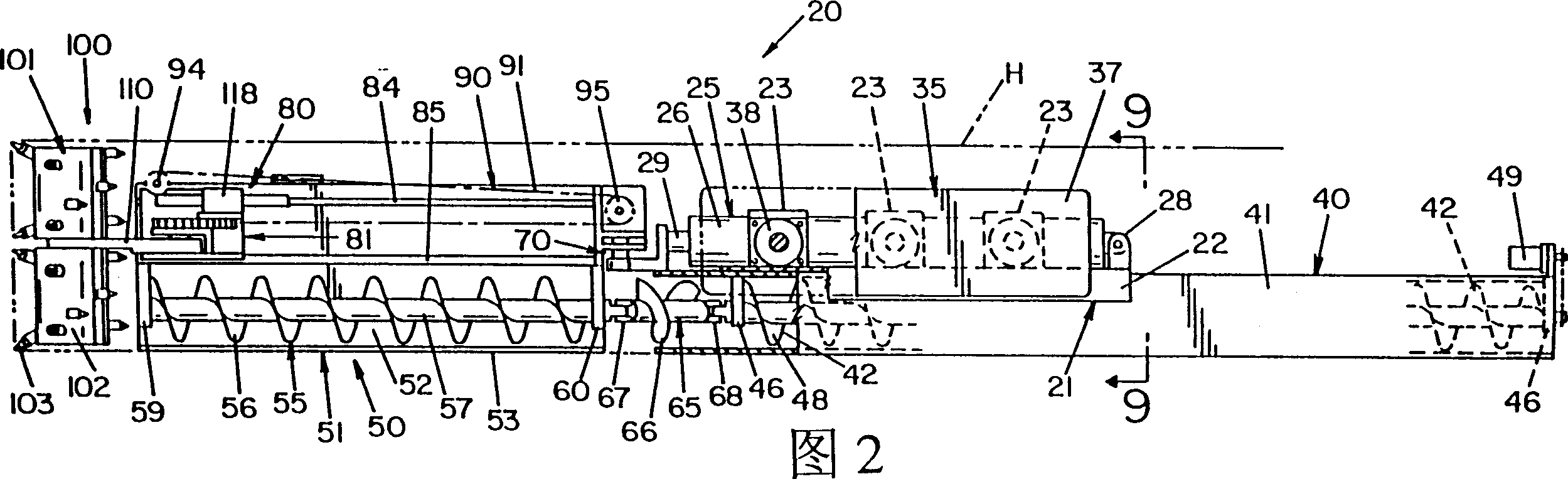

[0026] A mining machine in accordance with the principles of the present invention is indicated generally at 20 in FIGS. 1 and 2 . As shown, the mining machine 20 is depicted in terms of its operational relationship relative to the cutting hole H during the entry phase of a typical slope mining operation. For orientation, the mining machine 20 is shown as it advances from right to left in the cutting hole H, as shown in FIGS. 1 and 2 .

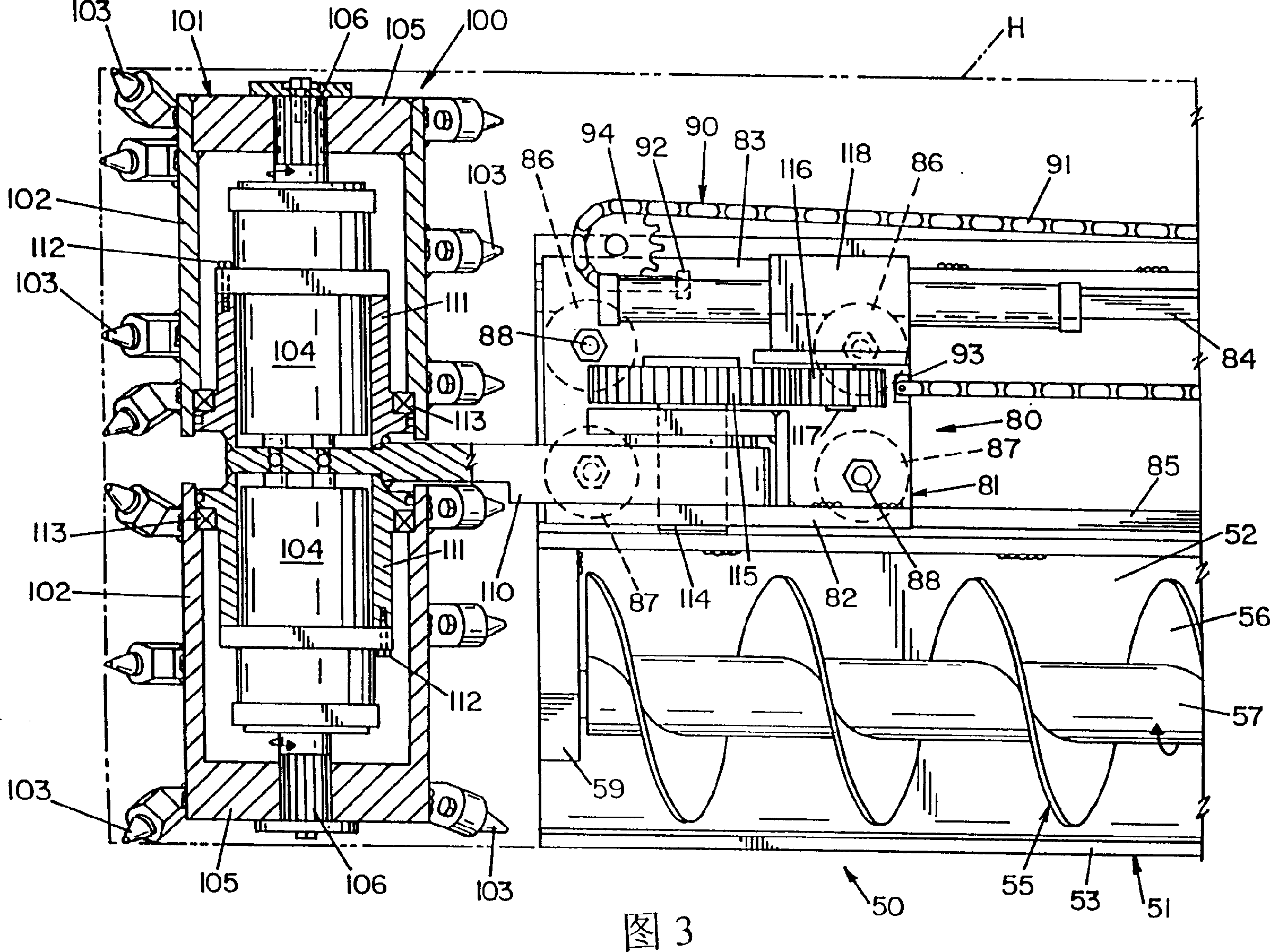

[0027] The mining machine 20 has as a major component a main frame assembly, indicated generally at 21, which is connected to a conveyor extending to the surface. The main frame assembly 21 has as the main structural member a platform 22 which may be a downwardly bent U-shaped element, as best seen in FIG. 9 . The upper surface of the platform 22 carries an attachment housing 23, and the housing 23 may also be a U-shaped structure bent downward. Still referring to FIGS. 1 , 2 and 9 , housing 23 encloses the main frame drive means generally ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com