Patents

Literature

52results about How to "Increase mining volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

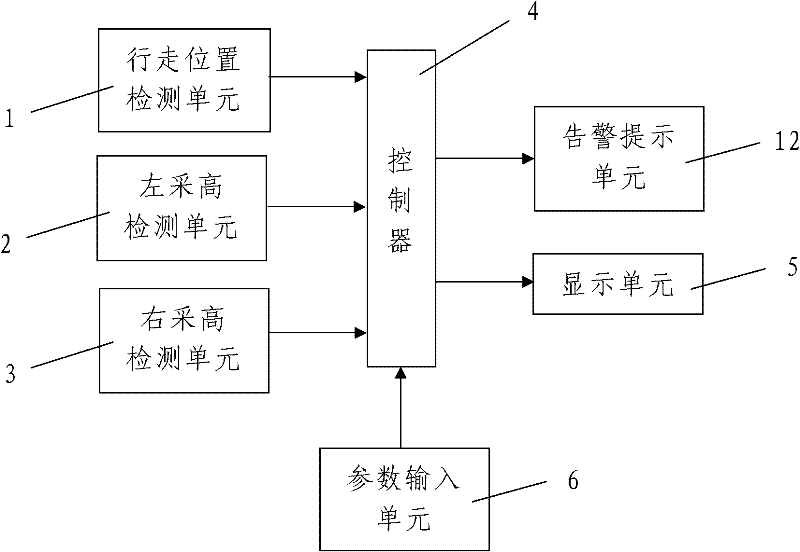

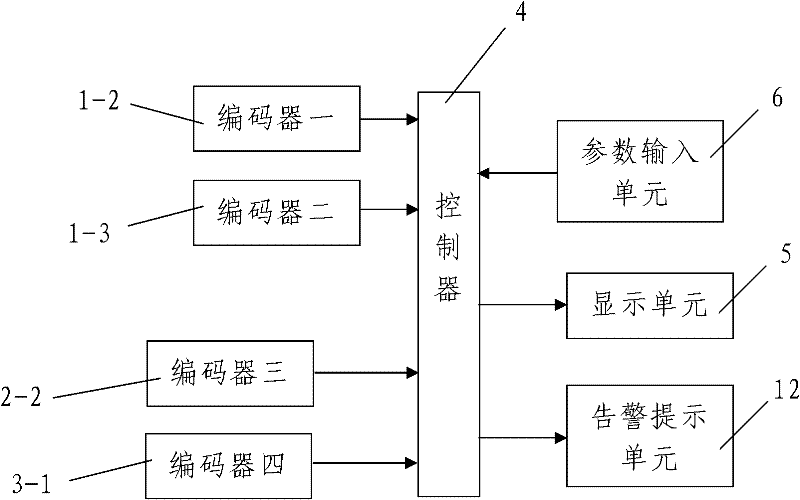

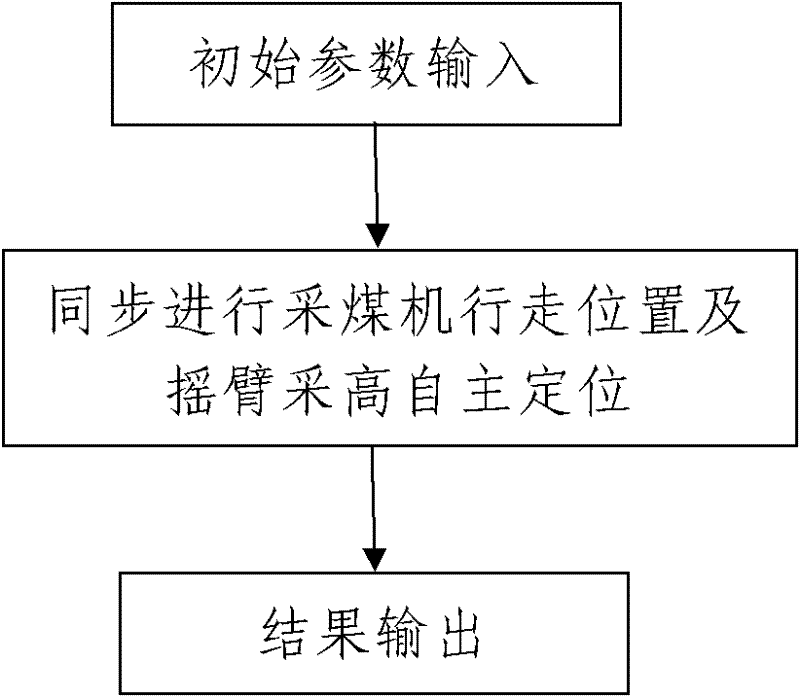

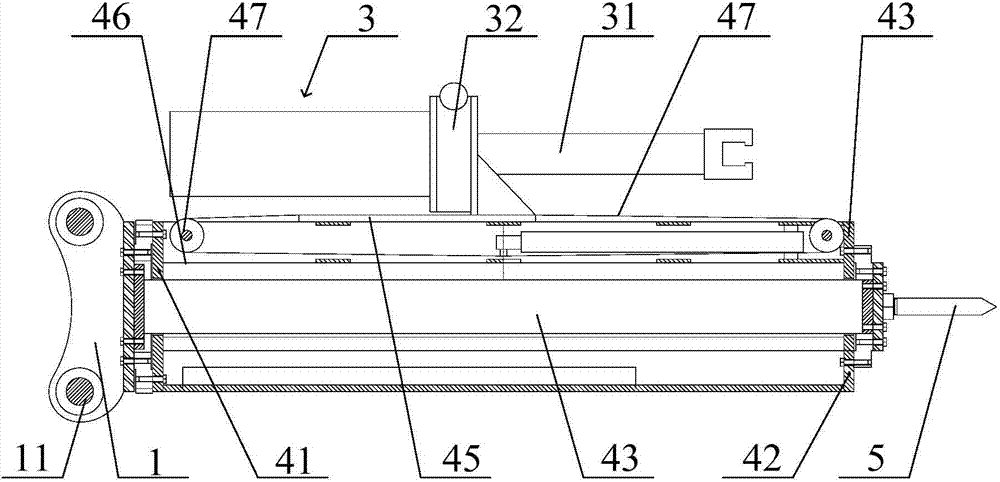

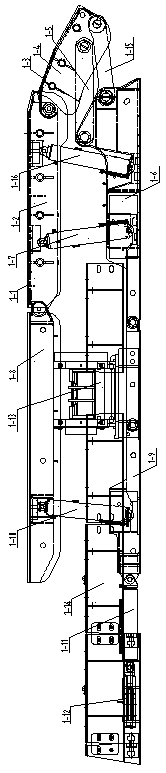

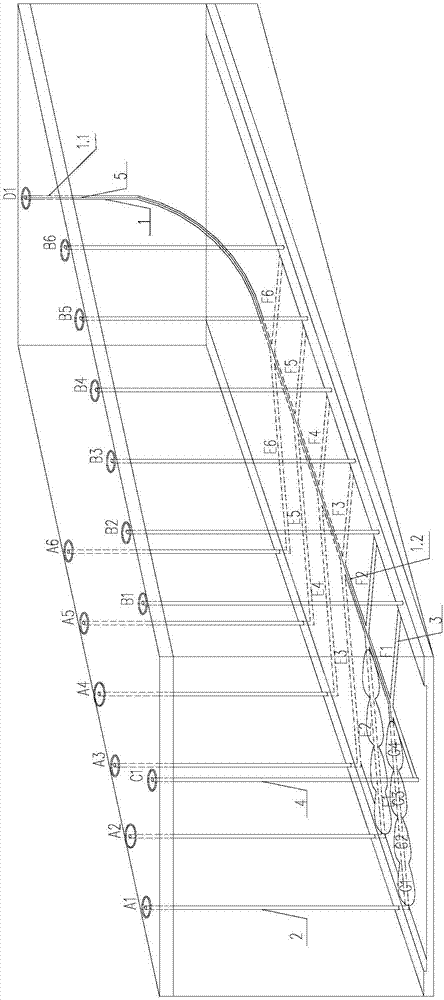

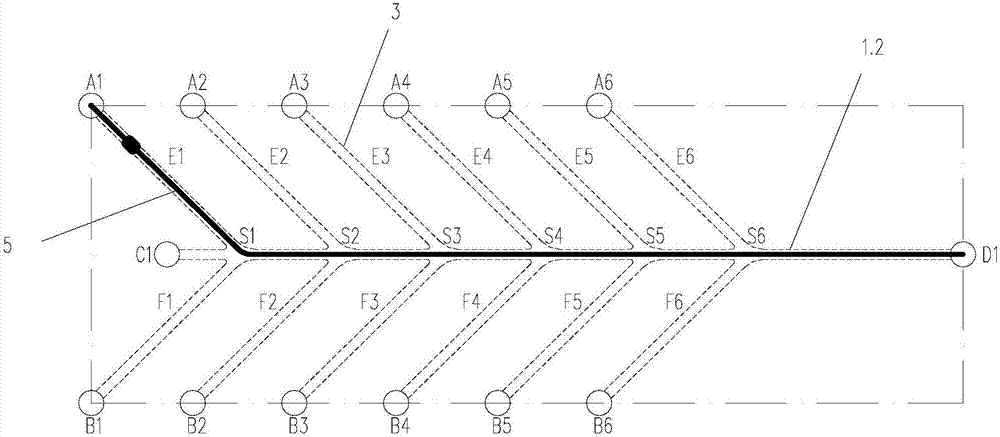

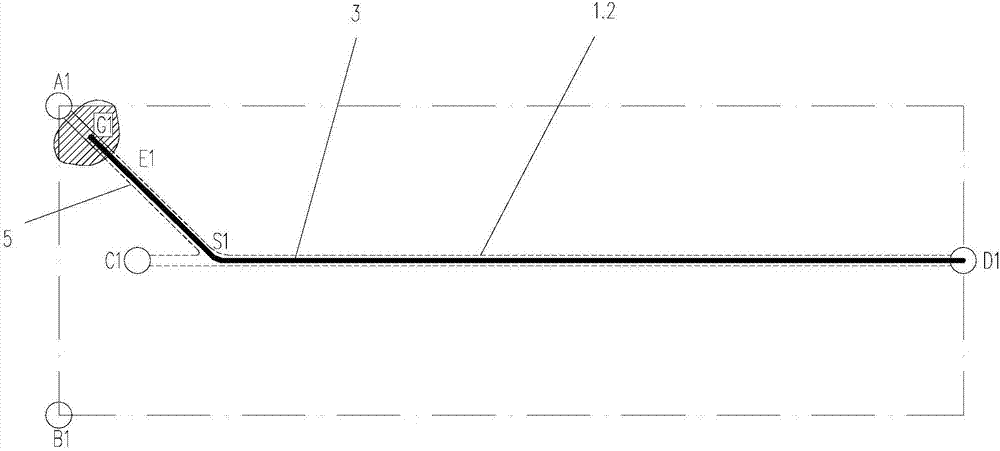

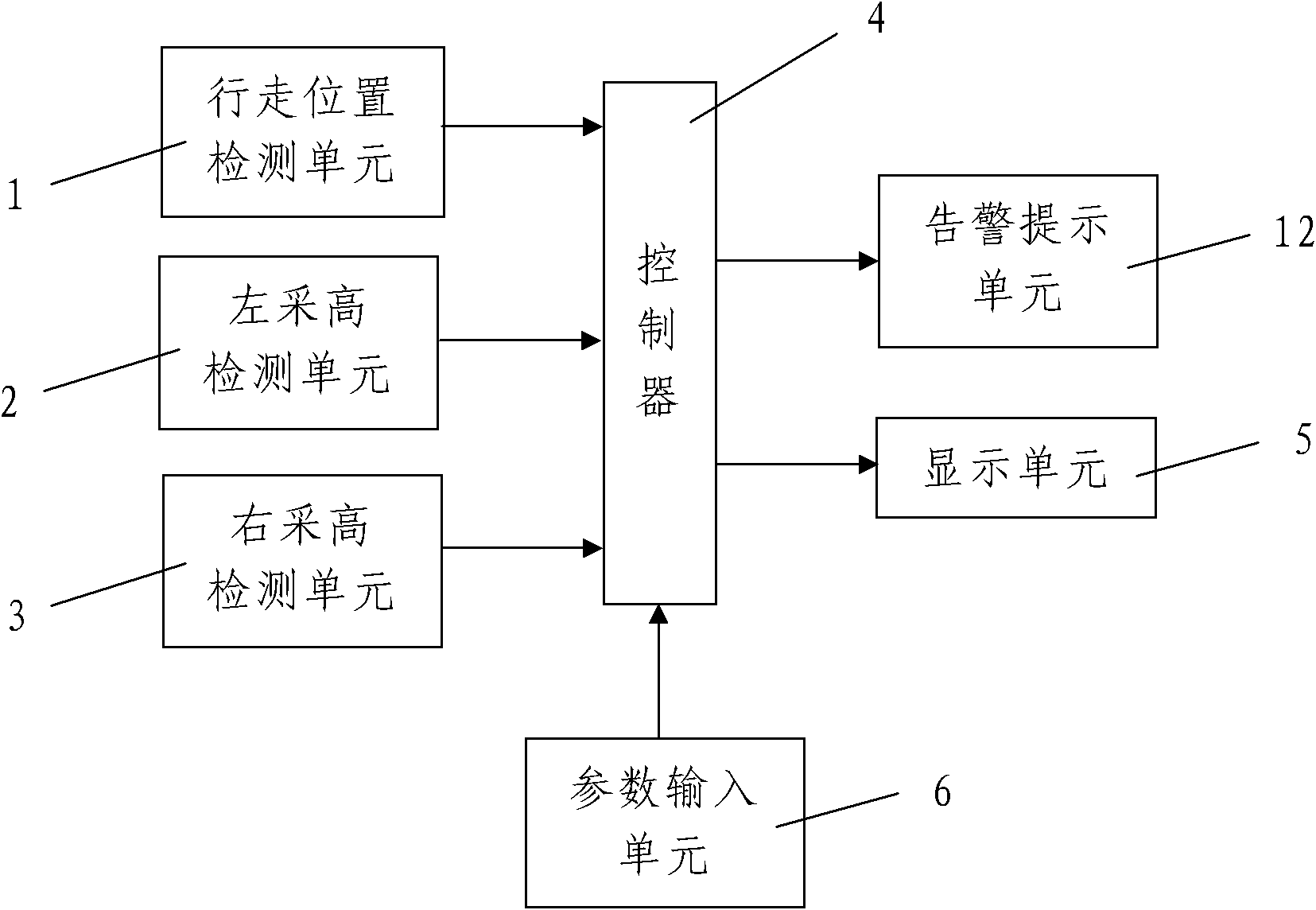

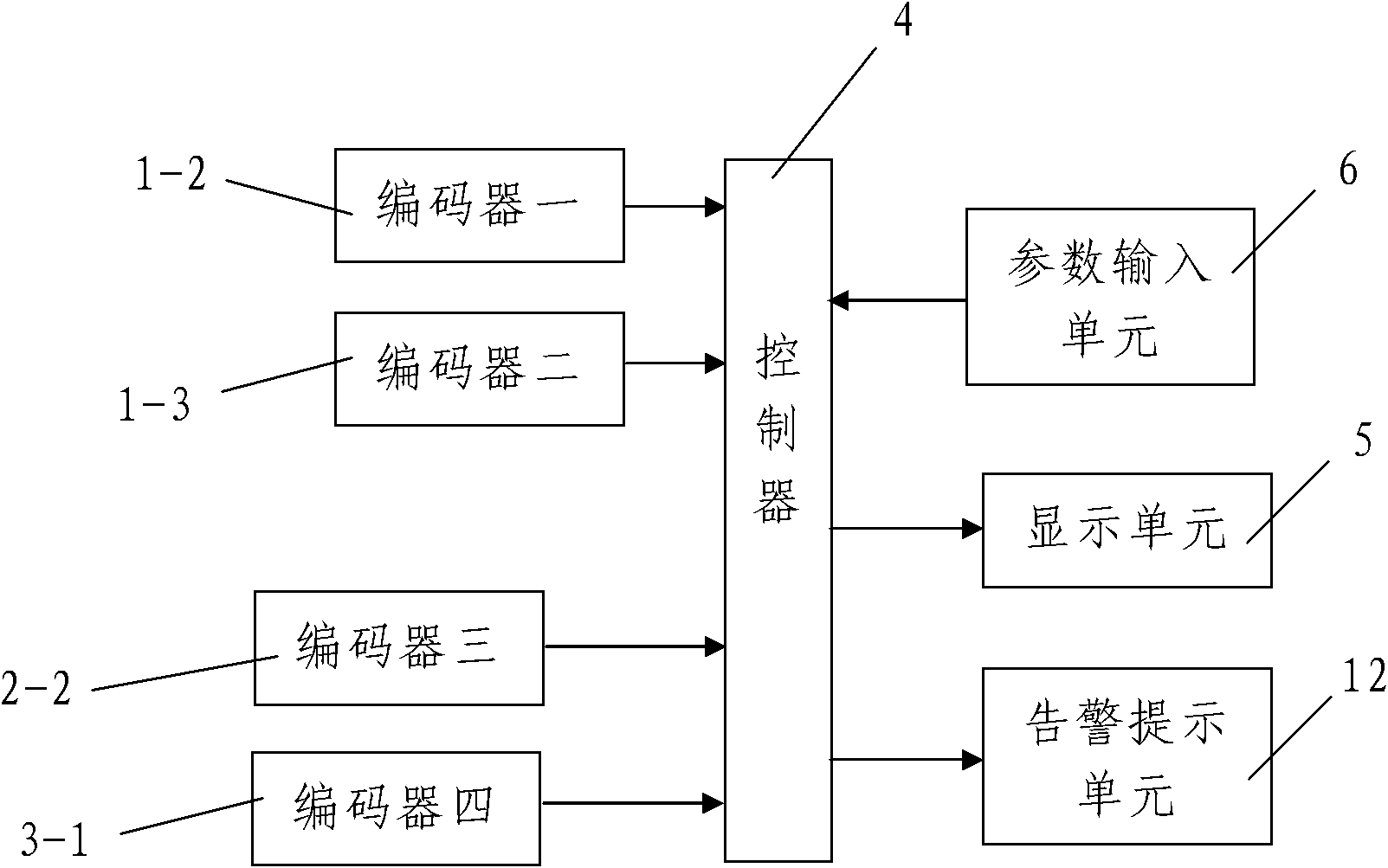

A coal mining machine autonomous positioning system and its autonomous positioning method

ActiveCN102287186AEasy to operateHigh degree of intelligenceMeasurement devicesDriving meansLocation detectionEngineering

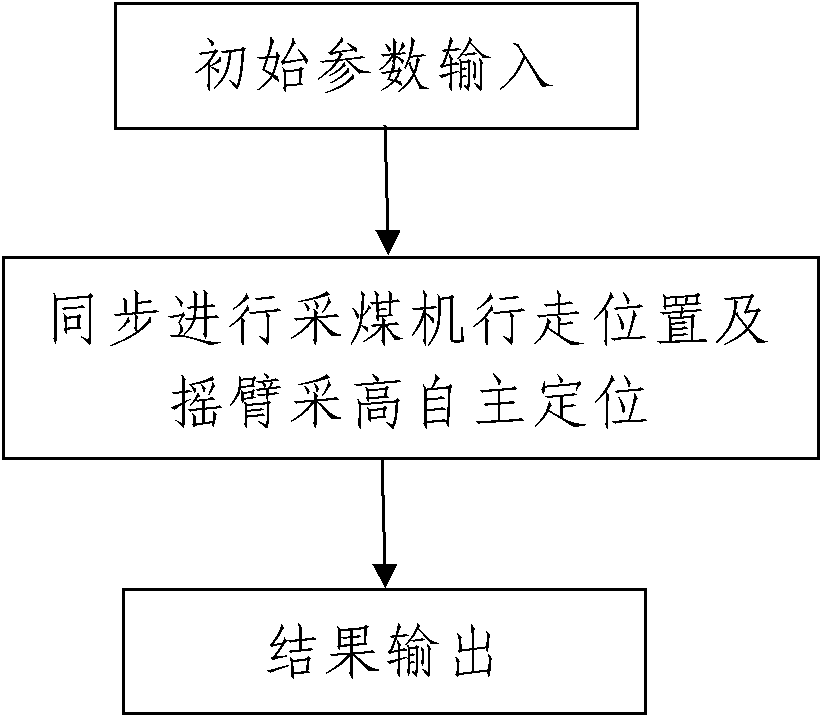

The invention discloses a self-positioning system and a self-positioning method for a coal mining machine. The self-positioning system comprises a controller, a walking position detection unit for detecting a walking position of the coal mining machine in real time, a left mining height detection unit for detecting the mining height of a left rocker arm of the coal mining machine in real time, a right mining height detection unit for detecting the mining height of a right rocker arm of the coal mining machine in real time, and a display unit and a parameter input unit which are connected withthe controller. The self-positioning method comprises the following steps of: 1, inputting initial parameters; 2, synchronously performing self-positioning of the walking position of the coal mining machine and the mining heights of the rocker arms; and 3, outputting results. The invention has the advantages that: the self-positioning system is reasonable in design, easy and convenient to use andoperate, convenient to implement, good in using effect and high in positioning accuracy, can automatically accurately position the walking position of the coal mining machine and the mining heights of the rocker arms, and various practical problems that the conventional coal mining machine has low automation and intelligent degrees, does not have self-positioning function, has high labor intensity and poor using effect and the like are effectively solved.

Owner:XIAN COAL MINING MACHINERY

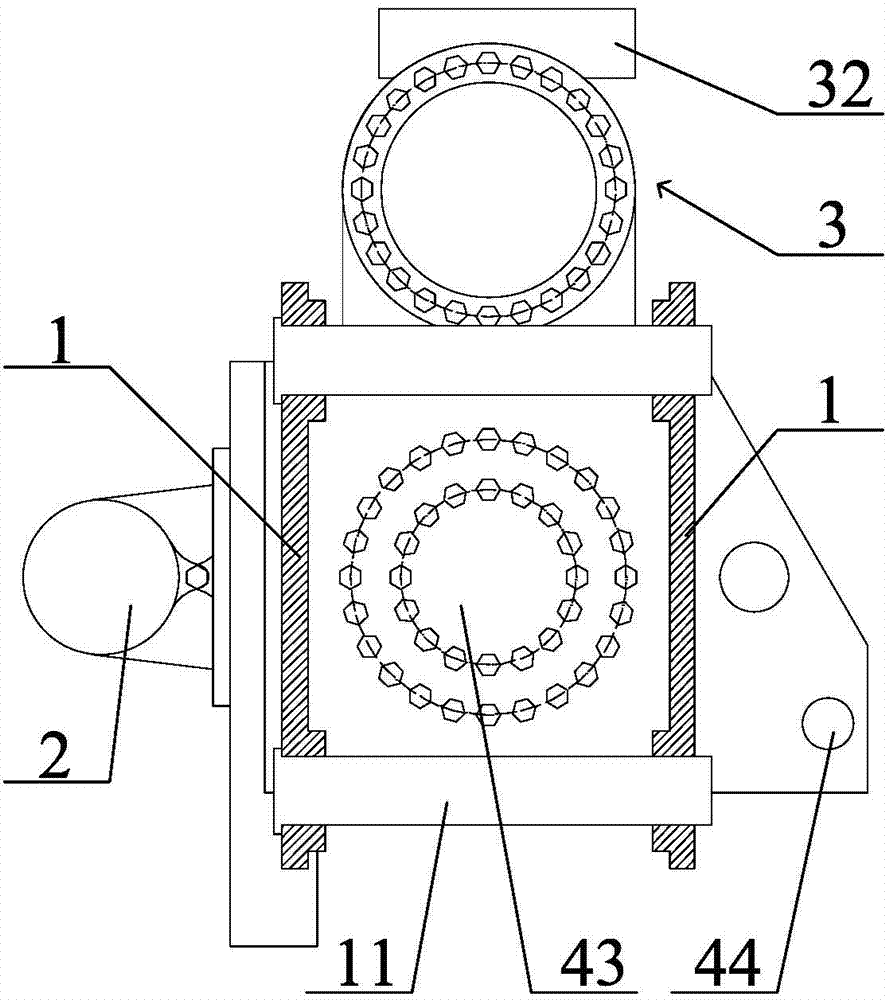

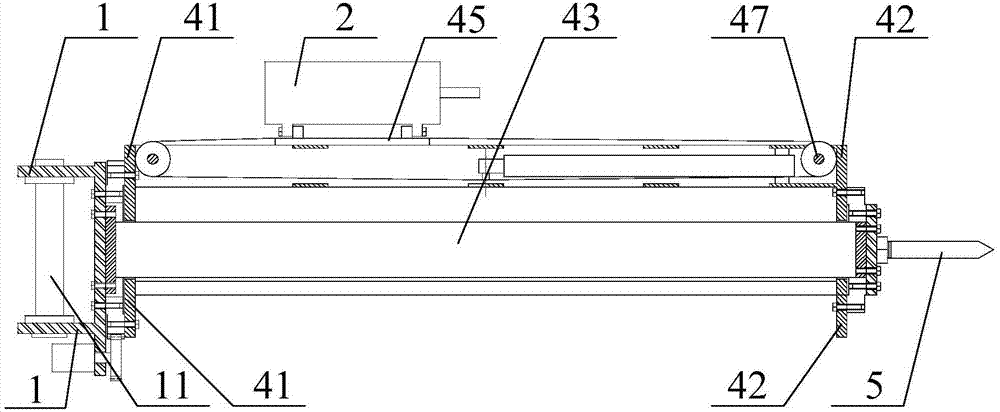

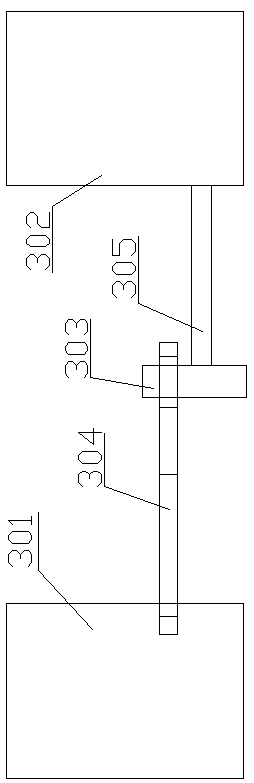

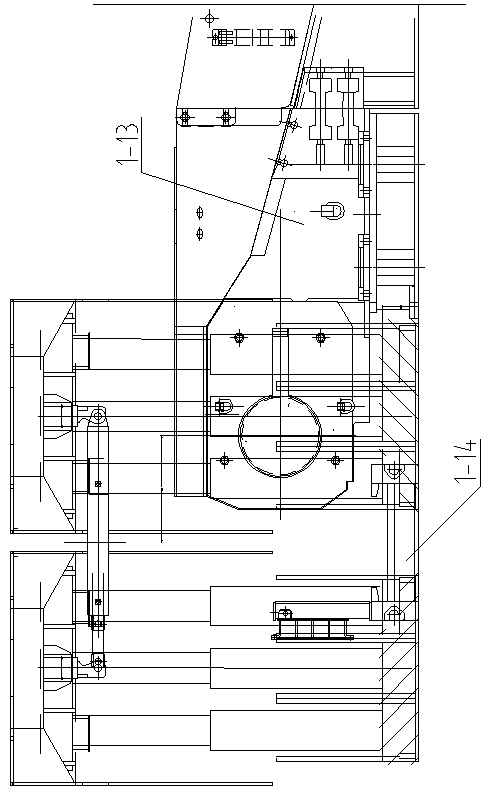

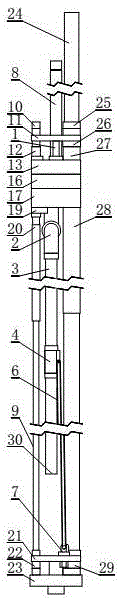

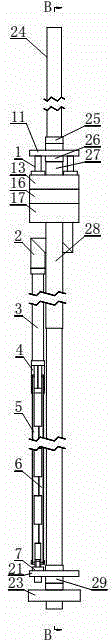

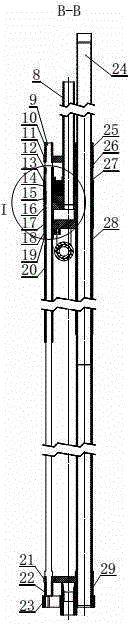

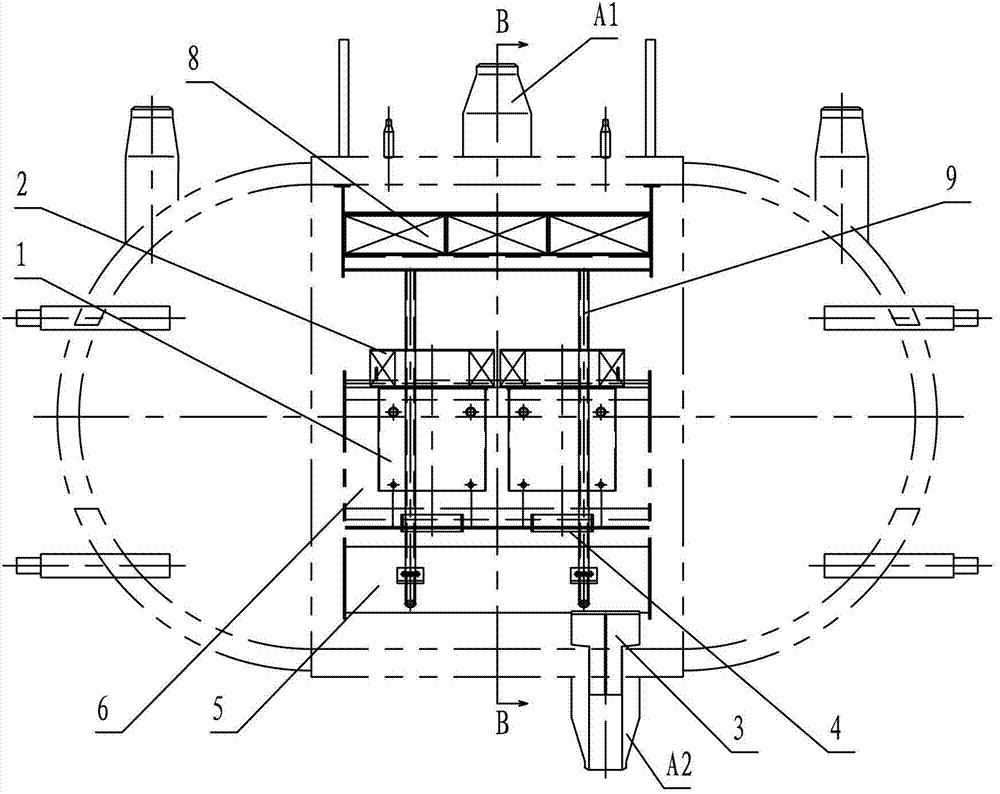

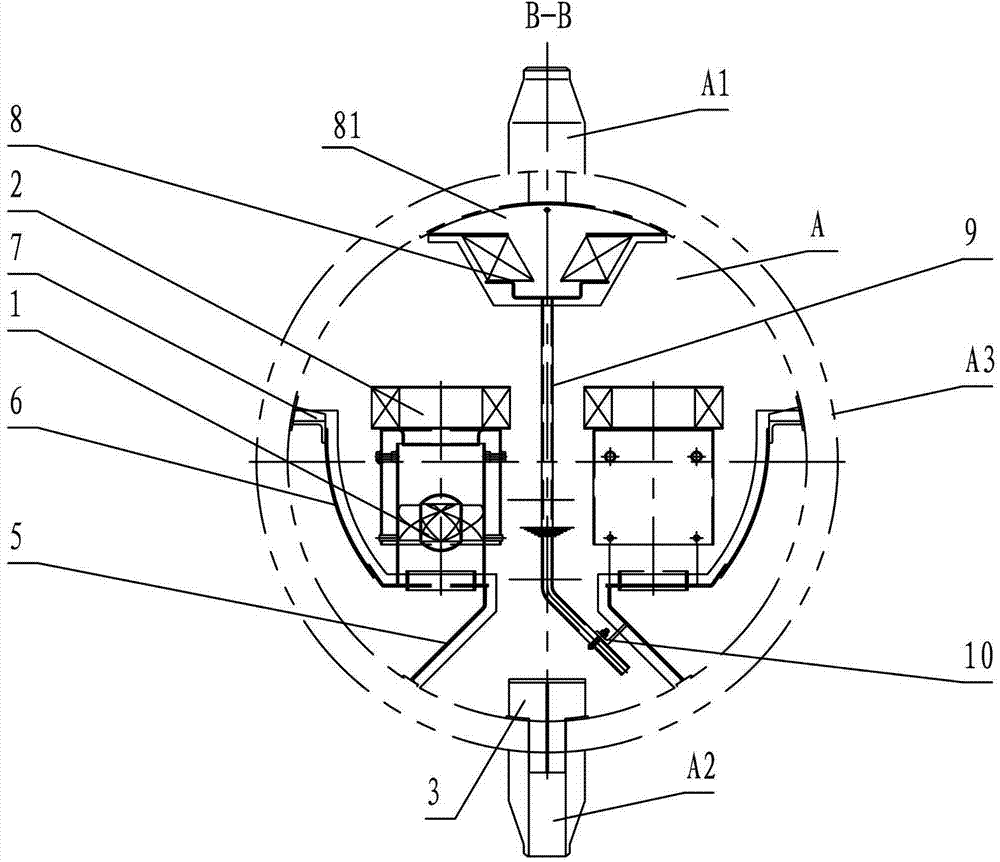

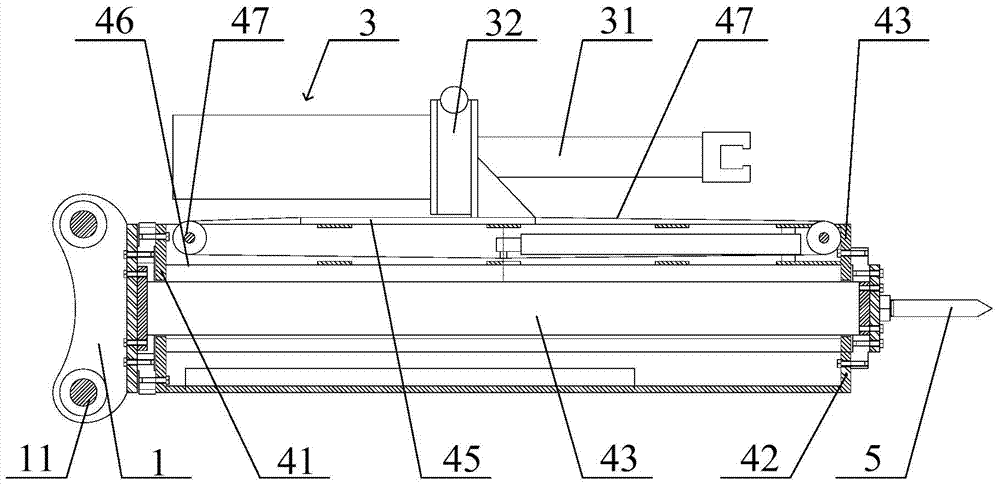

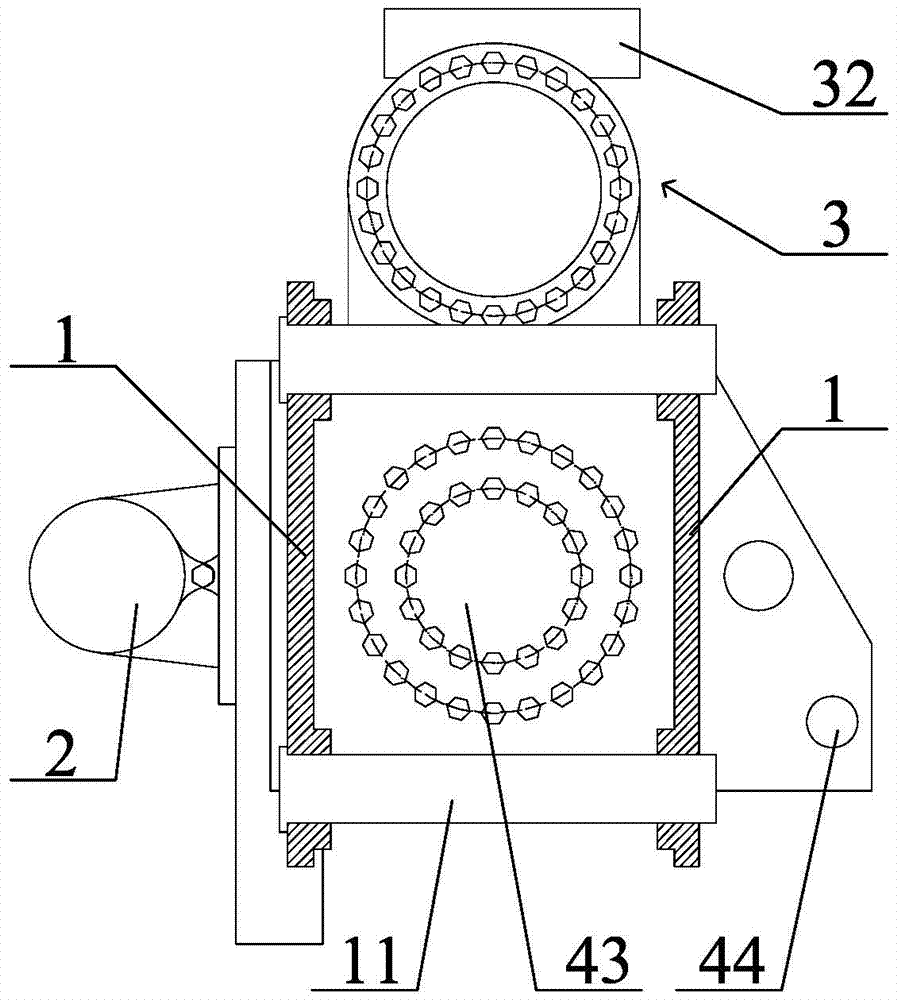

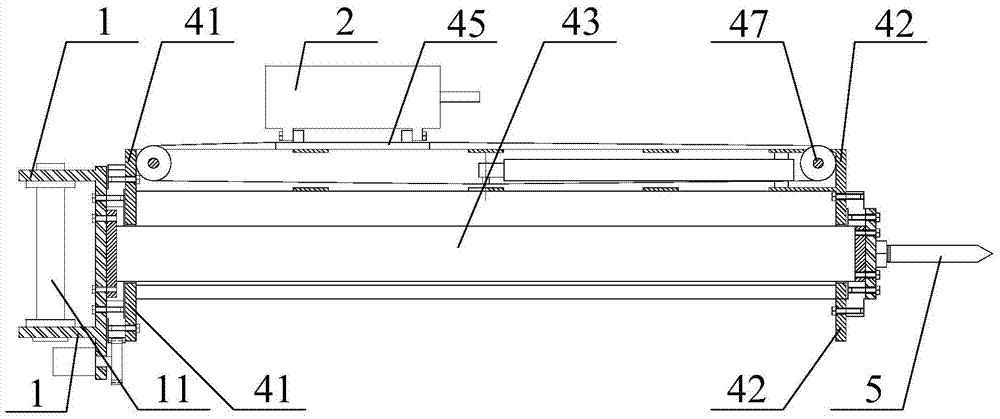

Explosion-free machine and explosion-free excavator

ActiveCN104727819AImprove work efficiencyReduce energy consumptionDisloding machinesSlitting machinesEngineeringExcavator

The invention provides an explosion-free machine and an explosion-free excavator. The explosion-free machine comprises a supporting mechanism, a slewing mechanism, a rock drilling machine and a splitting machine, wherein the slewing mechanism is arranged on the supporting mechanism; the rock drilling machine and the splitting machine are arranged on the slewing mechanism along the axial direction, can be driven to concyclically slew by the slewing mechanism and can move along the axial direction of the slewing mechanism. The explosion-free excavator comprises a hydraulic driving system and the explosion-free machine, wherein the explosion-free machine is fixedly connected to the explosion-free excavator through the supporting mechanism; the hydraulic driving system is capable of driving and controlling the slewing mechanism, the rock drilling machine and the splitting machine. According to the explosion-free machine, the rock drilling machine and the splitting machine can concyclically slew, so that the splitting machine can be accurately inserted into a drill hole without manually adjusting an angle, and the working efficiency of the explosion-free machine is improved; furthermore, the explosion-free machine further has the advantages that the energy consumption is low, the exploitation quantity is high, the equipment cost is low, and the damage caused to equipment in the operation is relatively little.

Owner:武安市精诚机械设备科技有限公司

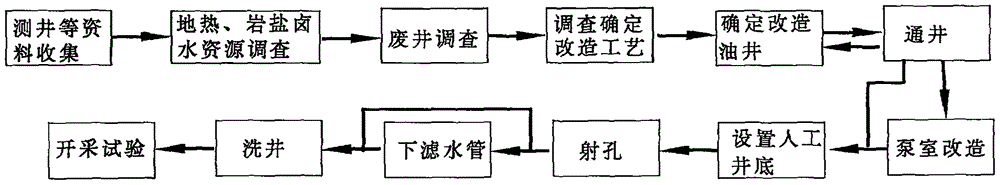

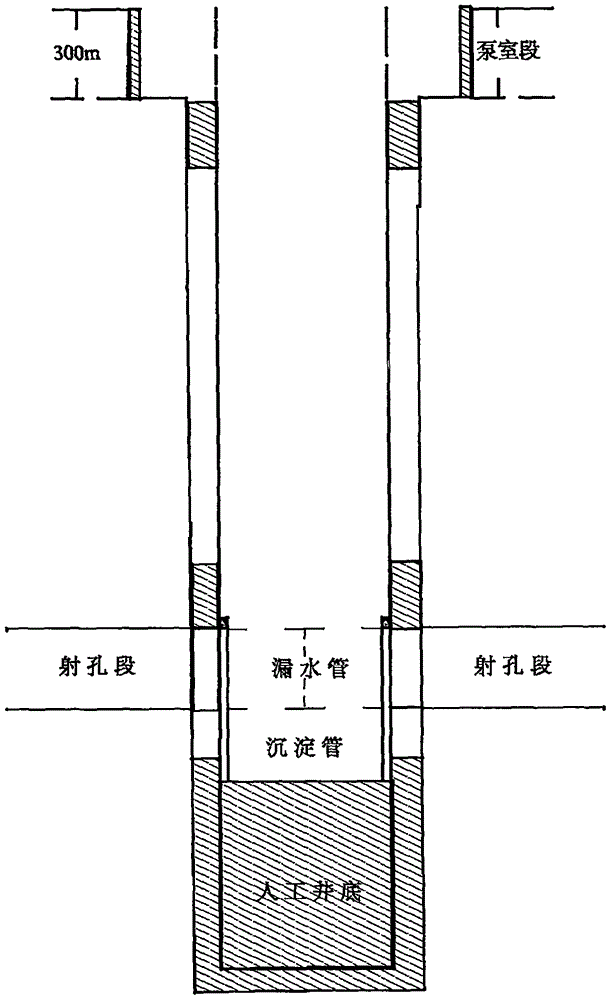

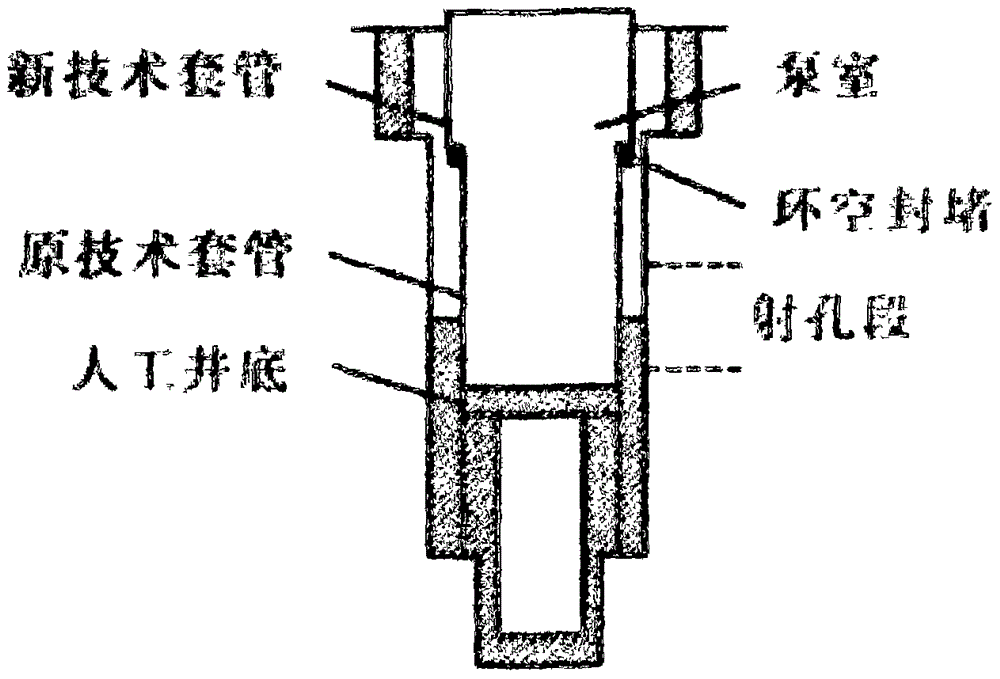

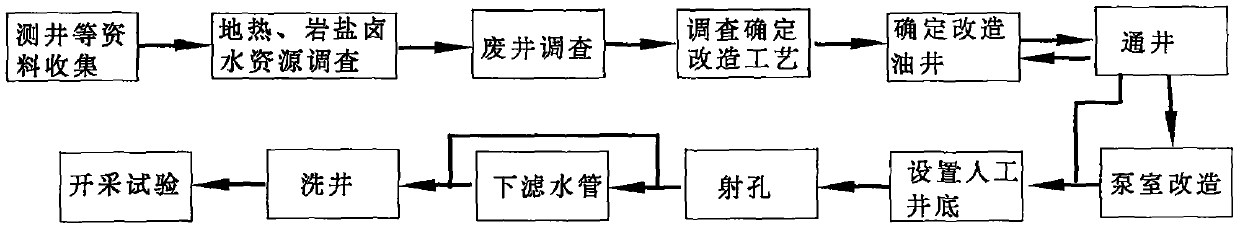

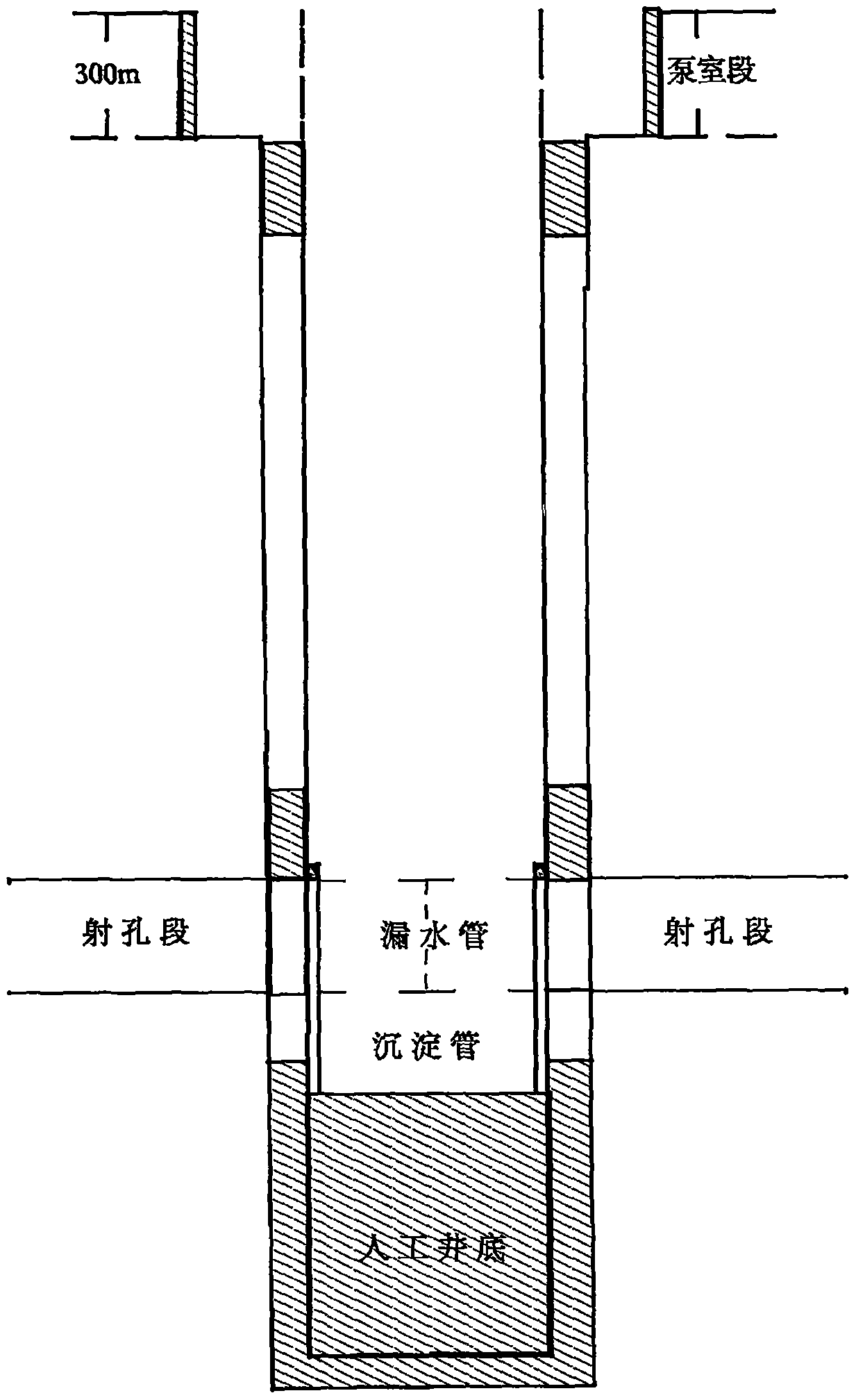

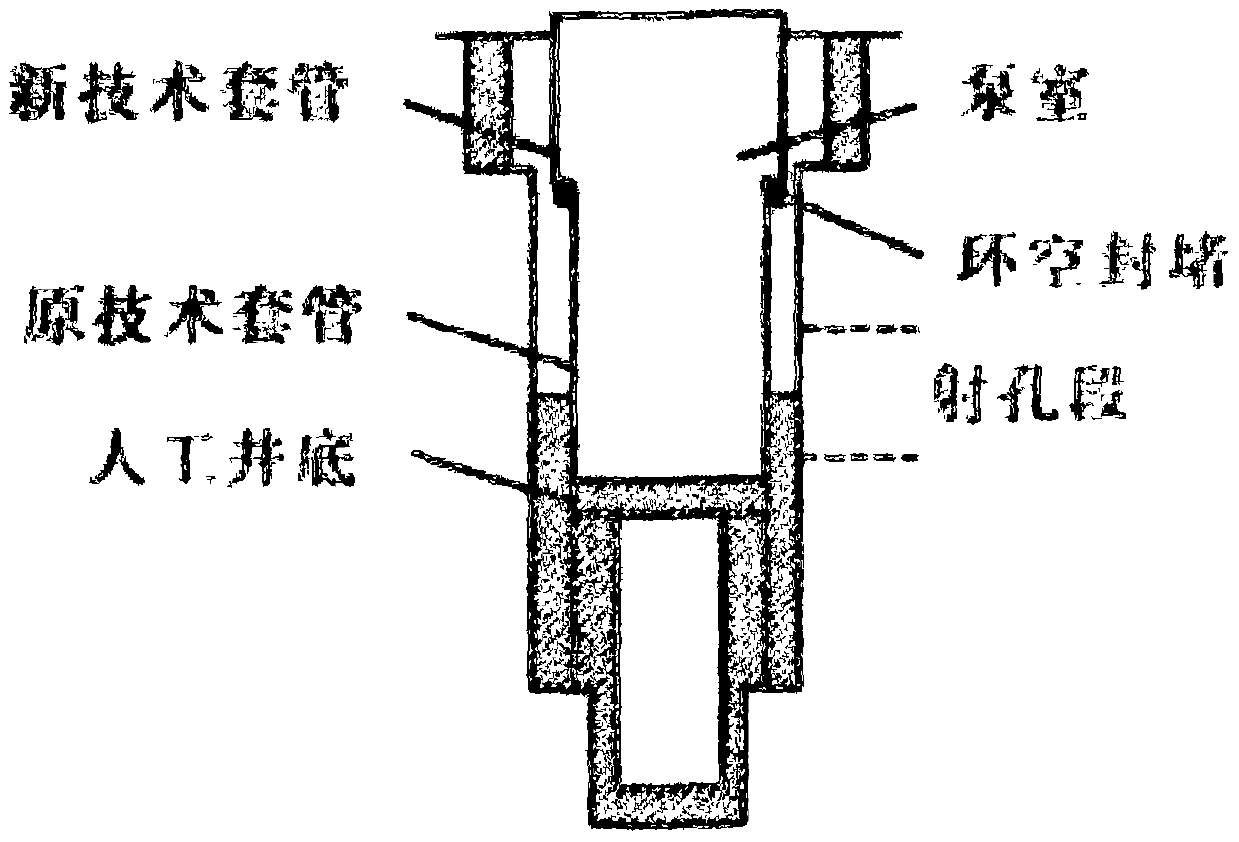

Method for transforming oil field abandoned well into geothermal well or brine well

ActiveCN106194122AIncrease mining volumeImprove efficiencyFluid removalSealing/packingWater filterEconomic benefits

The invention discloses a method for transforming an oil field abandoned well into a geothermal well or a brine well. The method comprises the steps that in an oil field exploitation area, an oil field abandoned well with a brine layer below an oil extraction layer or an oil field abandoned well with the bottom boundary of a geothermal reservoir layer 200 m above an oil extraction layer position is selected, a drill pipe drill rig is lowered into an oil layer casing pipe to carry out pigging, and when pigging is smoothly achieved and after it is determined that no abnormal condition exits in the well, the artificial bottom of the well is poured to seal the lower portion oil extraction layer position; a pump chamber section is transformed, and a water drainage pipe is additionally arranged on an exploitation layer; perforation construction is carried out on a technical casing pipe located on the exploited geothermal reservoir layer or the brine layer; a water filtering pipe is lowered into the exploitation layer, and for the transformed geothermal well or the brine well, sand washing well washing is directly carried out, or a water filtering pipe with a sediment pipe on the lower portion is lowered; after well washing, exploitation testing, sampling analysis and acceptance check are carried out. By means of the method, the oil field abandoned well resources are recycled, and the double effects of energy conservation and environment protection, and economic benefits of recycling of the oil field abandoned well resources are achieved.

Owner:SHANDONG INST OF GEOLOGICAL SCI +1

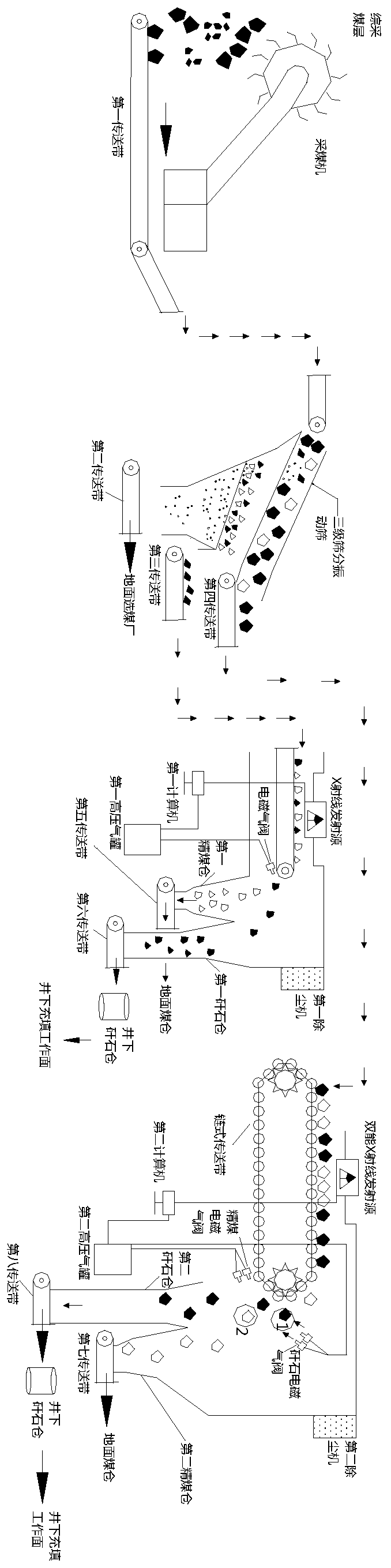

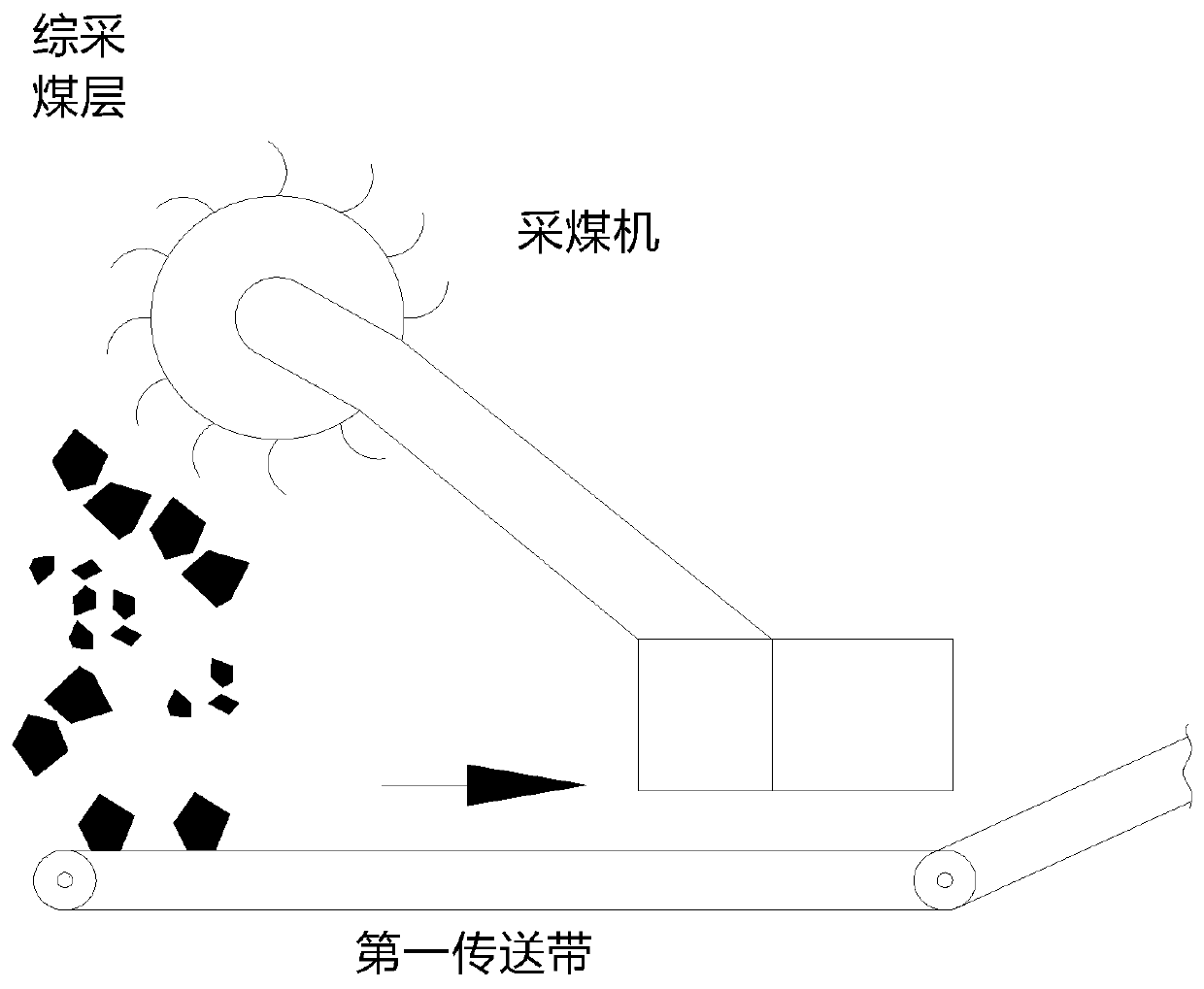

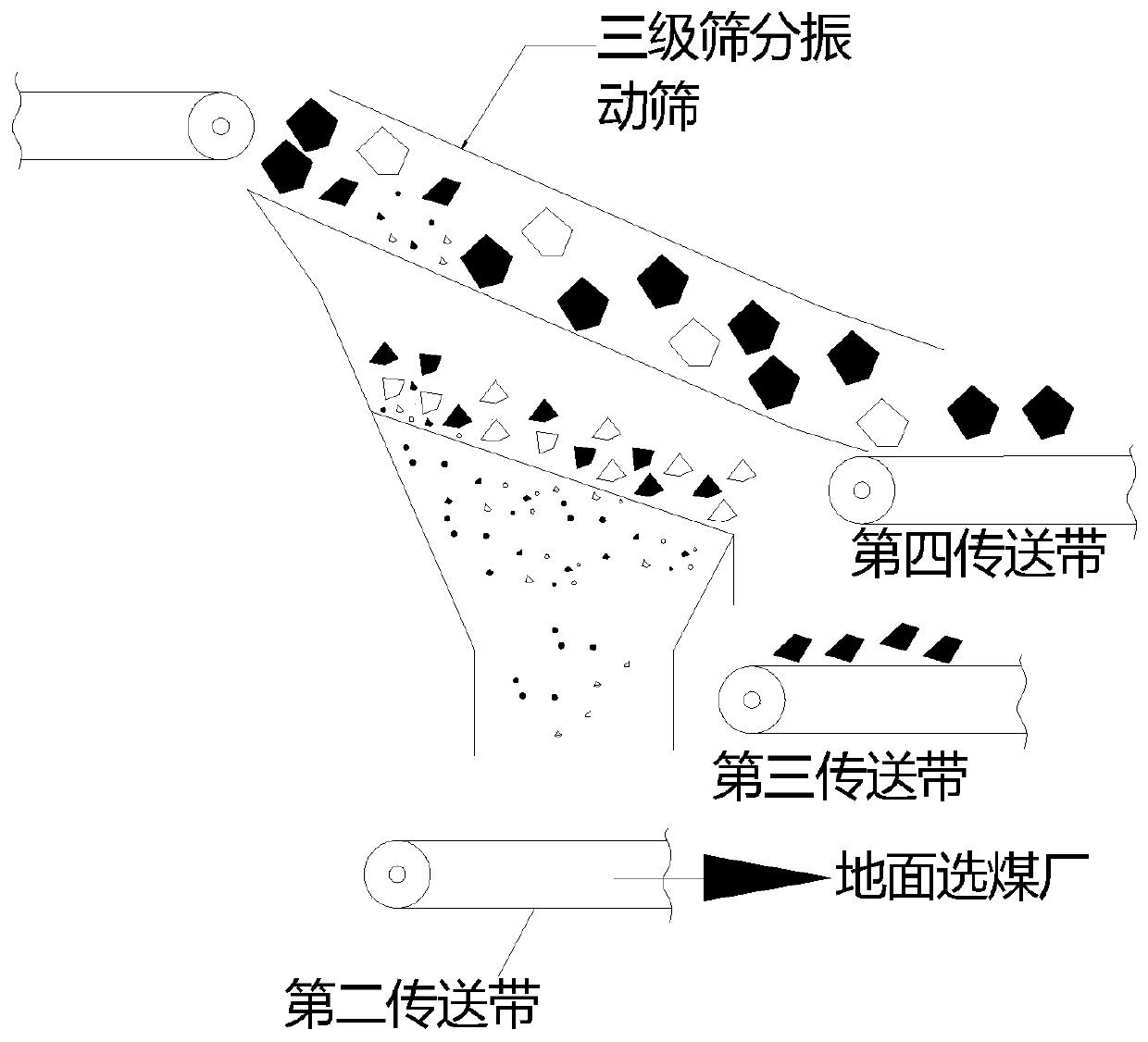

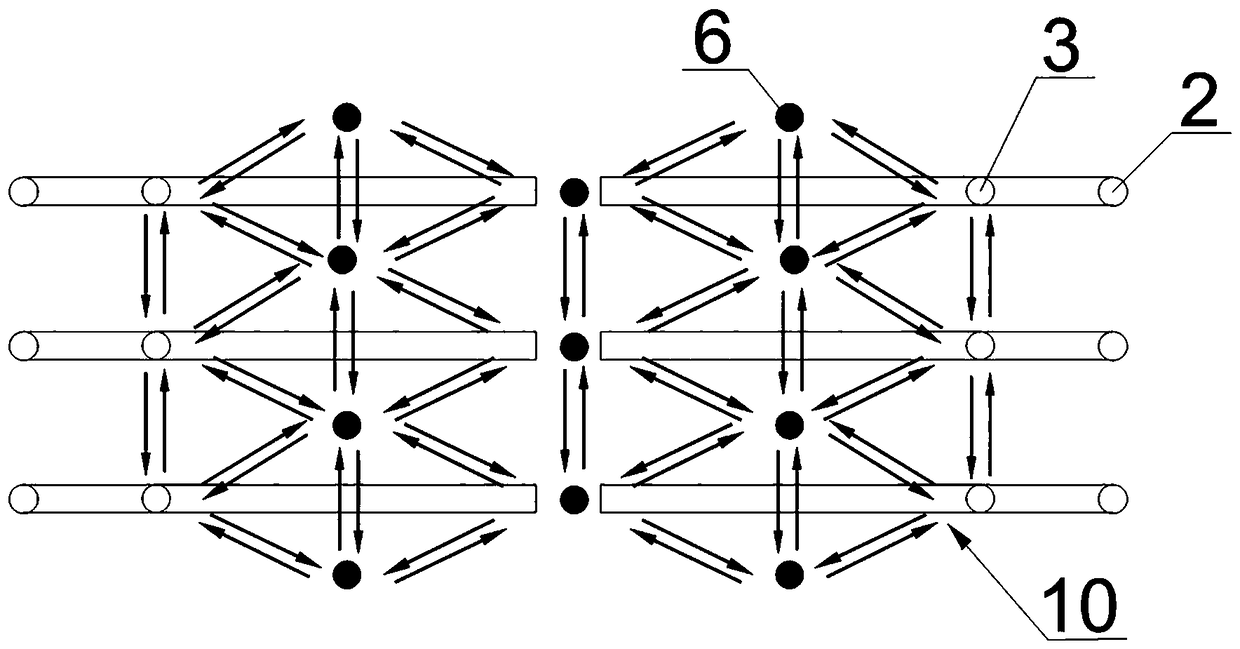

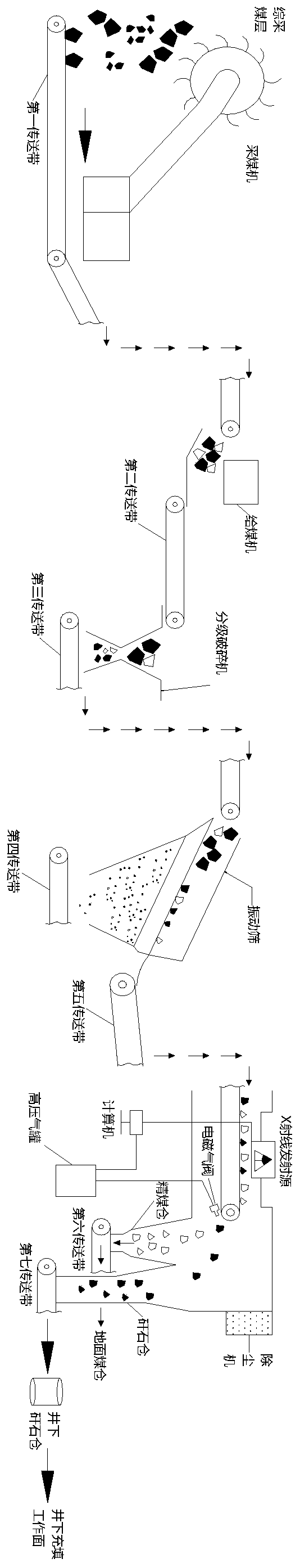

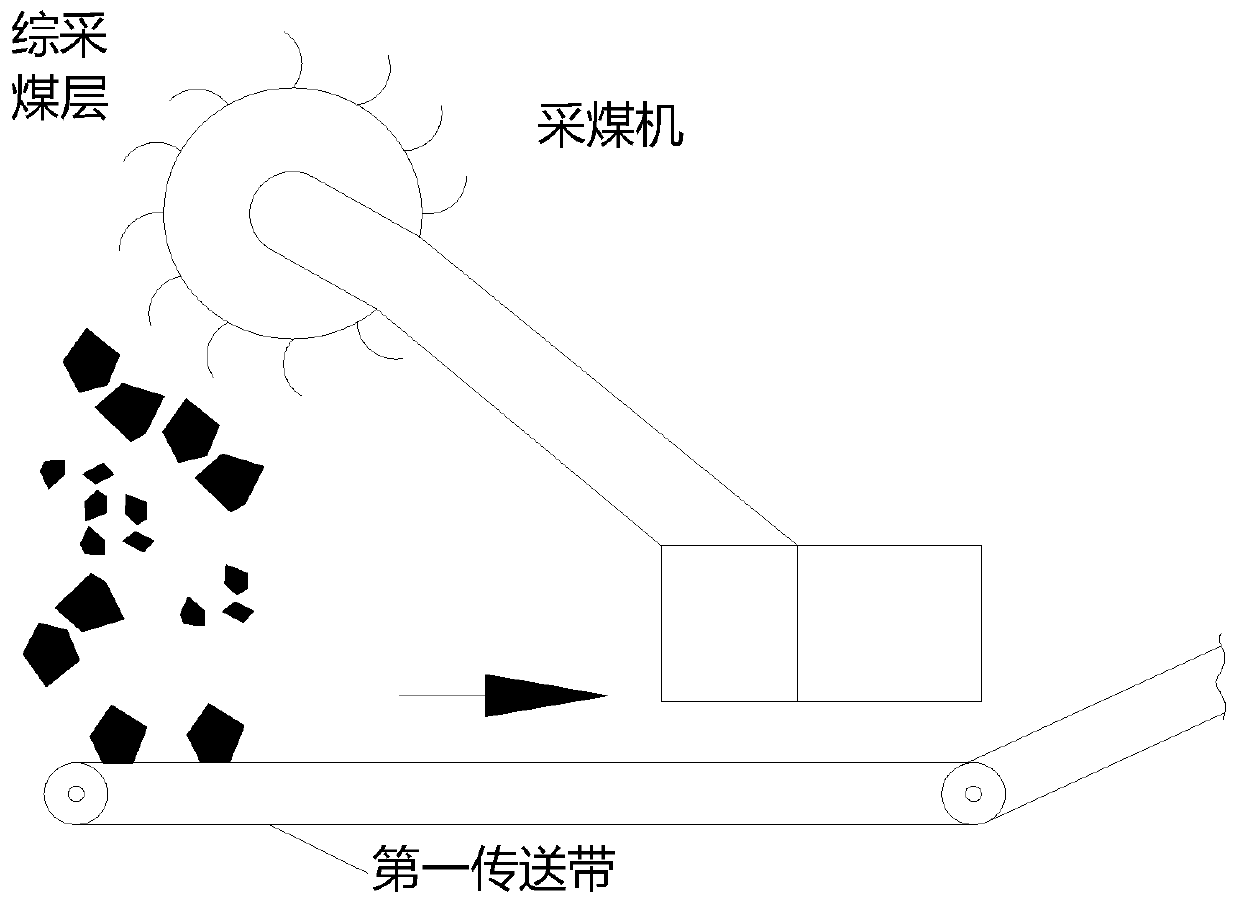

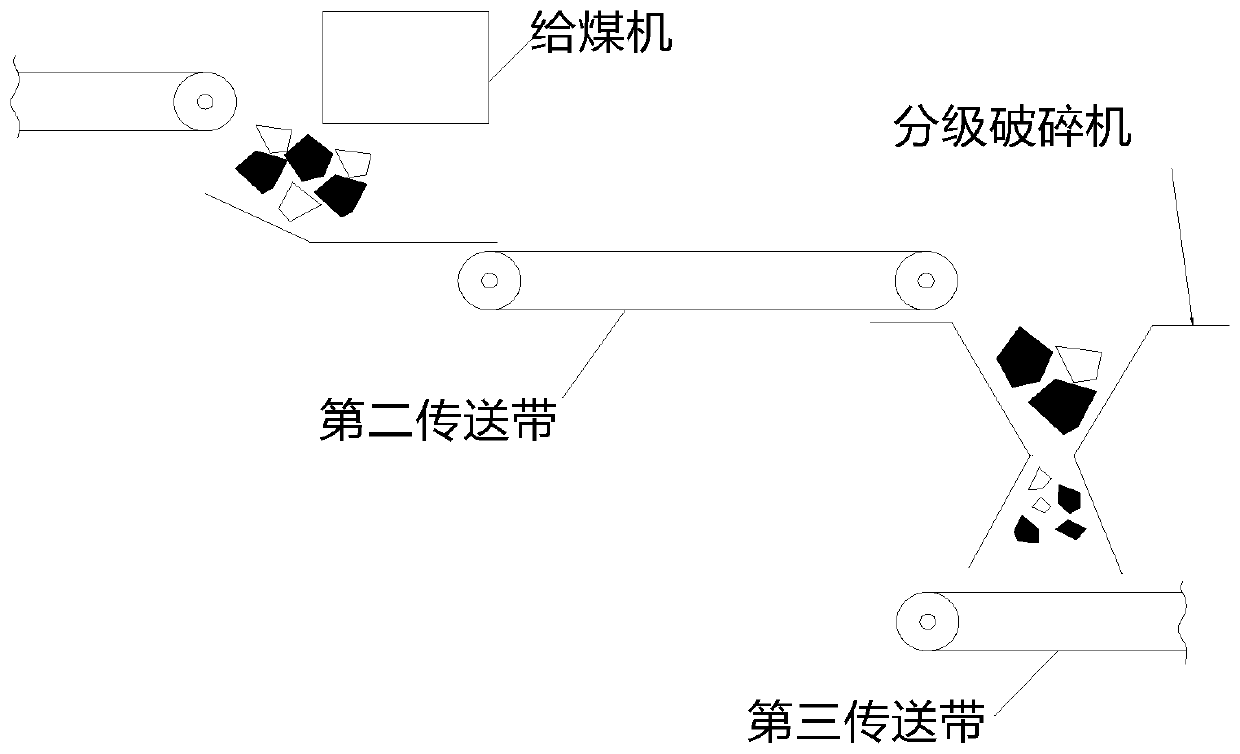

Underground arrangement process based on coal gangue photoelectric separation

InactiveCN111495790ASave transportation and filling costsReduce waste rock liftingSievingUnderground miningCoal miningCoal gangue

The invention discloses an underground arrangement process based on coal gangue photoelectric separation. A coal mine underground modular compact efficient separation system is constructed, full-size-fraction separation of +35mm raw coal is realized, traditional coal gangue photoelectric separation equipment is adopted for 35mm-150mm, and novel coal gangue photoelectric separation equipment is adopted for + 150mm; the coal gangue can be accurately positioned through a chain conveyor belt, and a clean coal electromagnetic valve and a gangue electromagnetic valve are respectively arranged, so that the problems of large gravity and insufficient throwing path of large-block materials are sufficiently solved. Process links of coal mining, raw coal preparation, coal gangue photoelectric separation, gangue backfilling and the like are accurately matched and collaboratively optimized, gangue can be discharged from an underground source of a coal mine, the gangue lifted to the ground is reduced, the transportation and filling cost is saved, and the environment-friendly requirement is met. Meanwhile, the coal gangue in the underground coal mine is efficiently sorted, the gangue lifting amount can be reduced, the mining amount and the production efficiency of the coal mine are effectively improved, and technical support is provided for coal mine underground mining-washing-filling cooperative operation.

Owner:ANHUI UNIV OF SCI & TECH

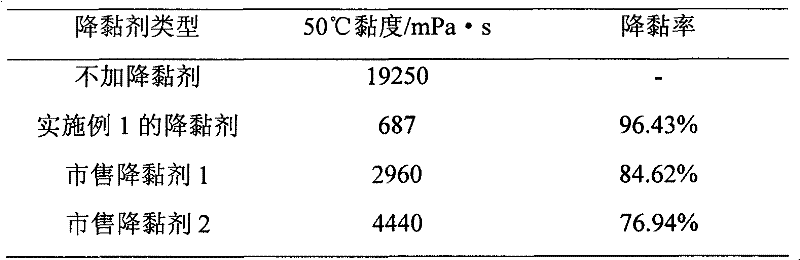

Low-cost environment-friendly oil-soluble viscosity reducing agent for super heavy oil

The invention provides a low-cost environment-friendly oil-soluble viscosity reducing agent for super heavy oil, which is prepared from the following raw materials by mass: 20-65% of a main agent, 35-80% of a solvent and 0.05-1% of an initiator, wherein the main agent is composed of gutter oil, aromatic hydrocarbons and alkenes containing anhydrides at a mass ratio of 3:1:(1-3):3:3. The oil-soluble viscosity reducing agent provided by the invention utilizes environmental waste (gutter oil) to reduce production cost and realizing the full utilization of waste resources, can greatly reduce the viscosity of super heavy oil, saves the use amount of thin oil, and meets the requirements of heavy oil recovery.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

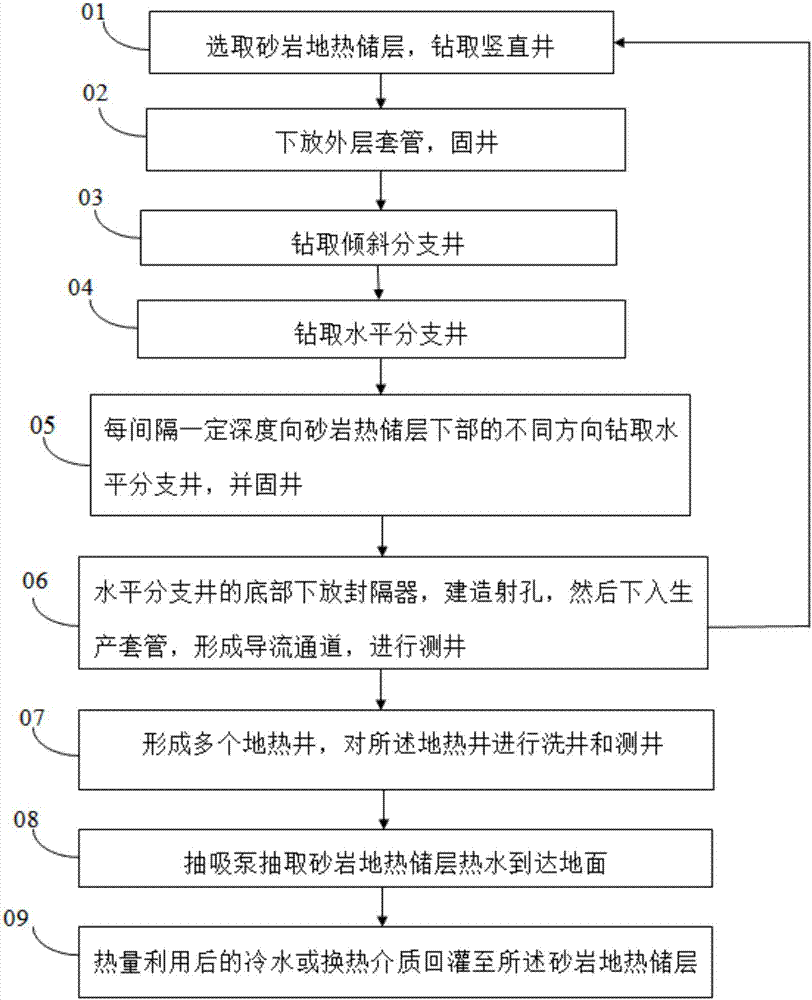

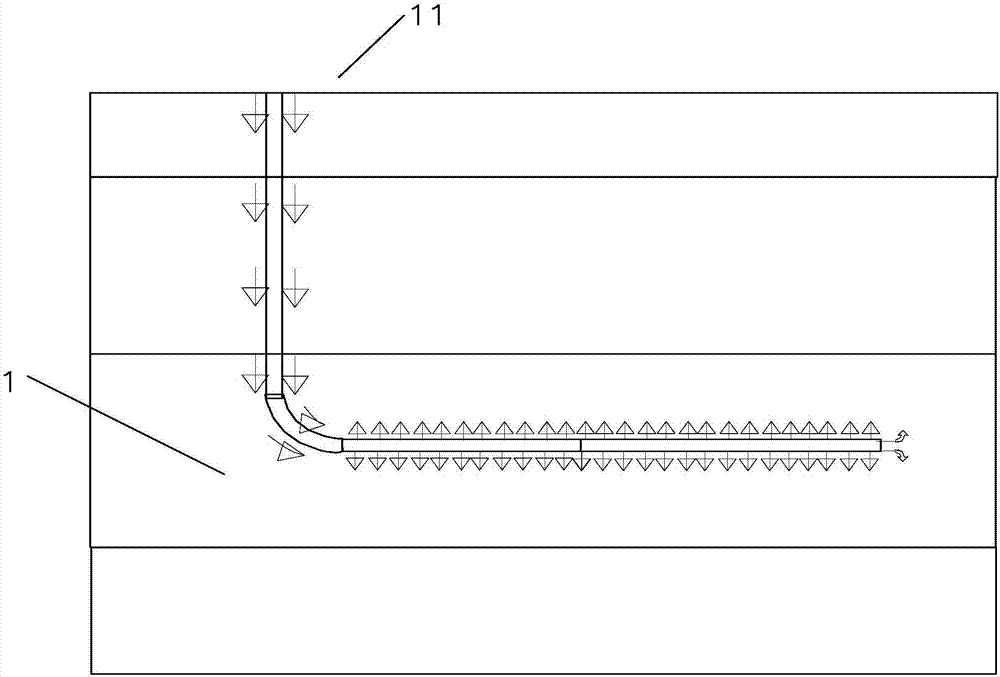

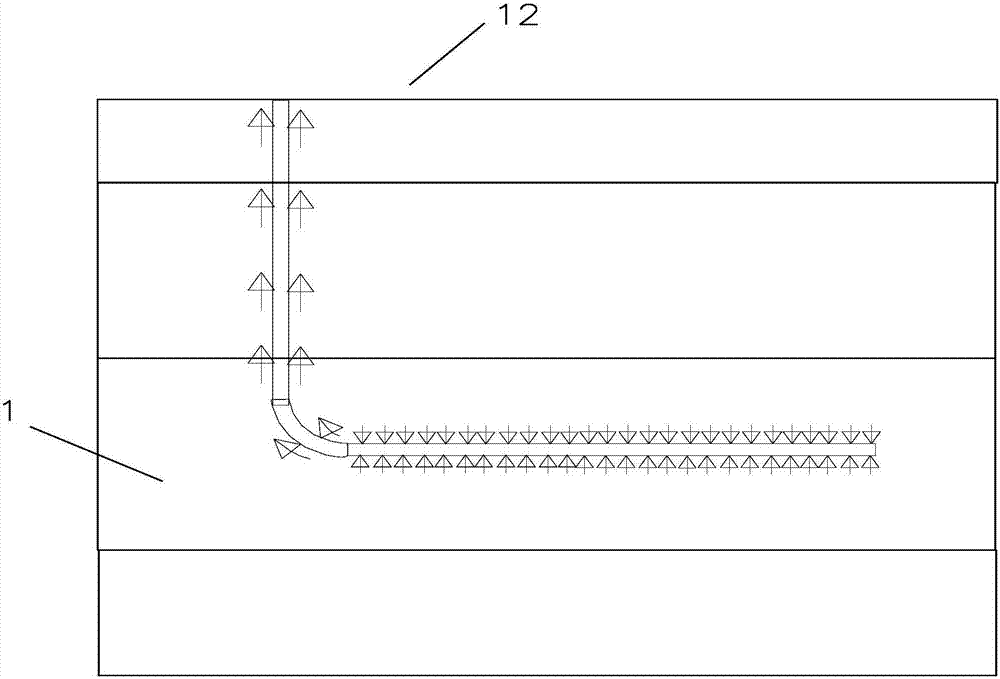

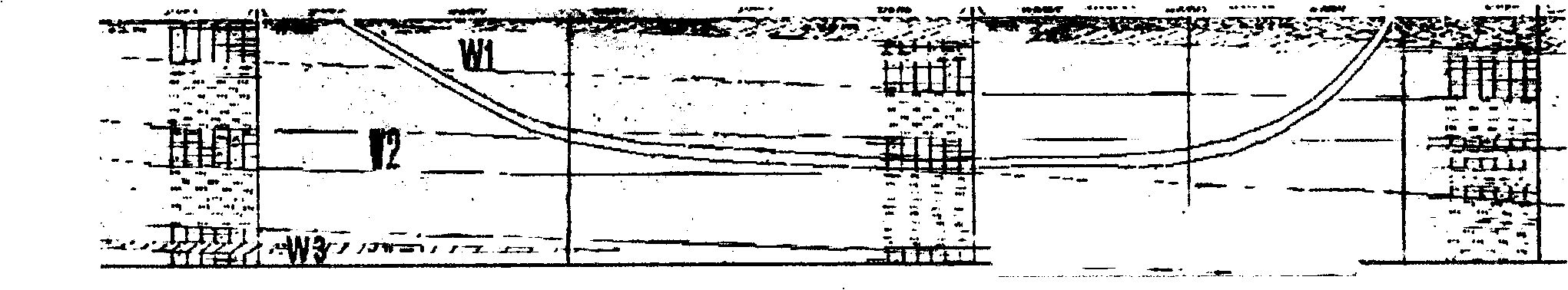

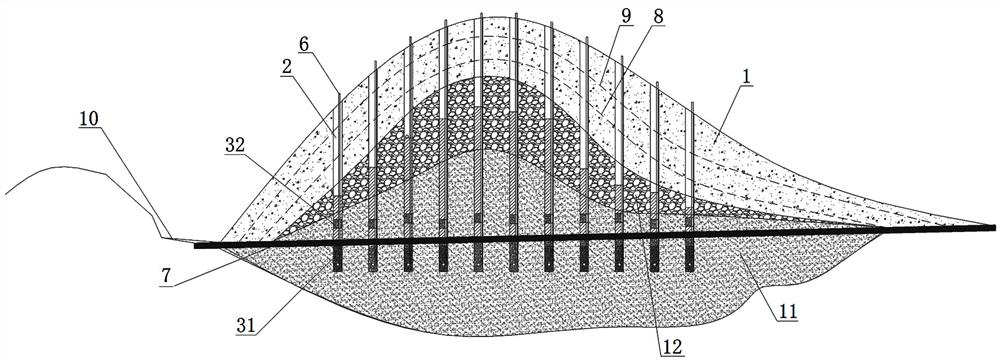

Medium-deep sandstone geothermal horizontal level exploitation method and structure

PendingCN106978993AIncrease geothermal mining productionSpeed up miningOther heat production devicesGeothermal energy generationWell drillingHorizontal wells

The embodiment of the invention discloses a medium-deep sandstone geothermal horizontal level exploitation method and structure. A horizontal well is built on a sandstone geothermal reservoir, a production well composed of a vertical well and the horizontal well is formed, and finally, the novel technology and method for exploiting and recharging the geothermal generation well are formed; the horizontal well is a single horizontal well or a plurality of parallel horizontal wells; the effective contact superficial area of the drilled well and the reservoir is increased, the exploitation and recharging efficiency is improved, the geothermal well yield is greatly increased, and economic benefits are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Metal quaternary ammonium oxyphosphate dispersoid and application of metal quaternary ammonium oxyphosphate dispersoid to exploitation of thickened oil

InactiveCN102614930ASurfactantHas a catalytic functionOrganic-compounds/hydrides/coordination-complexes catalystsDrilling compositionQuaternary ammonium cationCatalytic oxidation

The invention relates to a metal quaternary ammonium oxyphosphate dispersoid for developing the oil deposit of thickened oil to improve the exploitation rate of crude oil and application of the metal quaternary ammonium oxyphosphate dispersoid to the exploitation of the thickened oil. By the metal quaternary ammonium oxyphosphate dispersoid, the emulsification, catalytic viscosity reduction and dissolution in exothermic reaction of the thickened oil are realized. According to the technical scheme, the metal quaternary ammonium oxyphosphate dispersoid consists of quaternary ammonium cations and metal oxyphosphate anions. A preparation method comprises the following steps of: stirring an aqueous solution of Na2MoO4 or Na2WO4 or NaVO4 and a Na2HPO4 solution, heating, dripping concentrated hydrochloric acid for reacting, and extracting by using diethyl ether to prepare metal oxyphosphate; and adding alkyl trimethyl ammonium chloride, and stirring to prepare the metal quaternary ammonium oxyphosphate dispersoid. The thickened oil is heated to be melted, and metal quaternary ammonium oxyphosphate and hydrogen peroxide are added with stirring or air is introduced or peroxy-isobutane is added to perform reaction for 3 to 8 hours, so that the viscosity reduction of the thickened oil is realized under the condition of catalytic oxidation. The metal quaternary ammonium oxyphosphate has acatalytic effect, so that the thickened oil is subjected to the exothermic catalytic oxidation reaction under the action of an oxidant to reduce the viscosity and improve the exploitation rate.

Owner:SOUTHWEST PETROLEUM UNIV

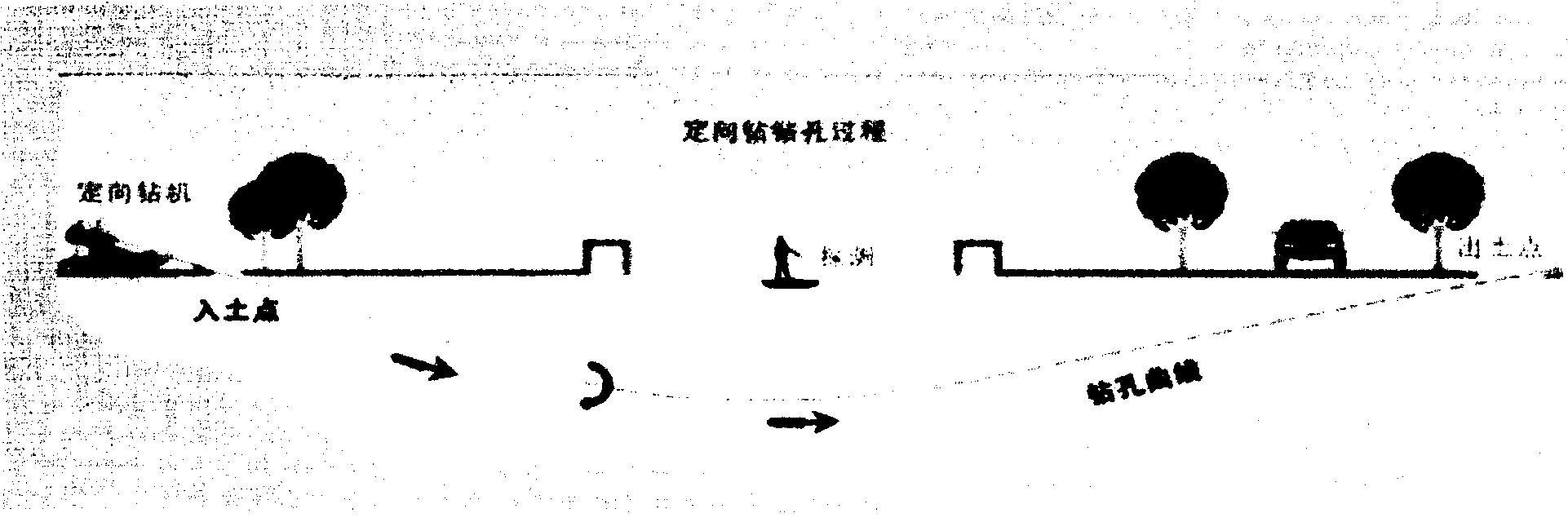

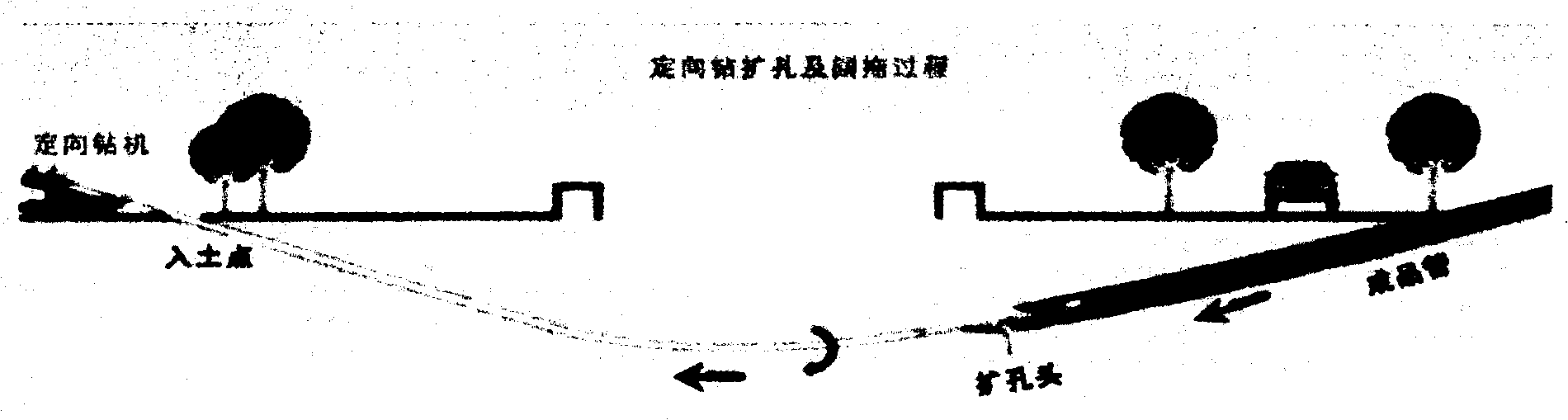

Exploration method for pressure bearing stored bitter and solid salts in saline

InactiveCN101598021AReduce consumptionIncrease mining volumeUnderground miningMineral miningSolventMagnesium

The invention belongs to the technical field of saline resource exploration, and in particular relates to an exploration method for pressure bearing stored bitter and solid salts in saline. The exploration method comprises the following steps: constructing and arranging shock tubes on a salt bed in a pressure bearing bitter storage layer by adopting a non digging directional pipe-laying drilling machine; inputting a selected solvent to the pressure bearing bitter storage layer at the soil inlet ends of the shock tubes, dissolving solid potassium magnesian salt minerals; and then sucking newly generated bitter inside and outside the shock tubes at the soil outlets of the shock tubes and conveying the bitter to the ground for use. Compared with the prior art, the exploration method greatly saves the construction investment, can eliminate the trouble of aggregating salt deposit during the sucking, substantially reduce the expense for exploring, transporting and maintaining the bitter, ensure that resources in the pressure bearing bitter storage layer of the saline cannot become useless mineral, can greatly reduce the consumption of fresh water resource and can explore solid salt and bitter resources in the lower layer.

Owner:杨智琛

Hydraulic support device and supporting method based on extending in roadway

Owner:山东塔高矿业机械装备制造有限公司

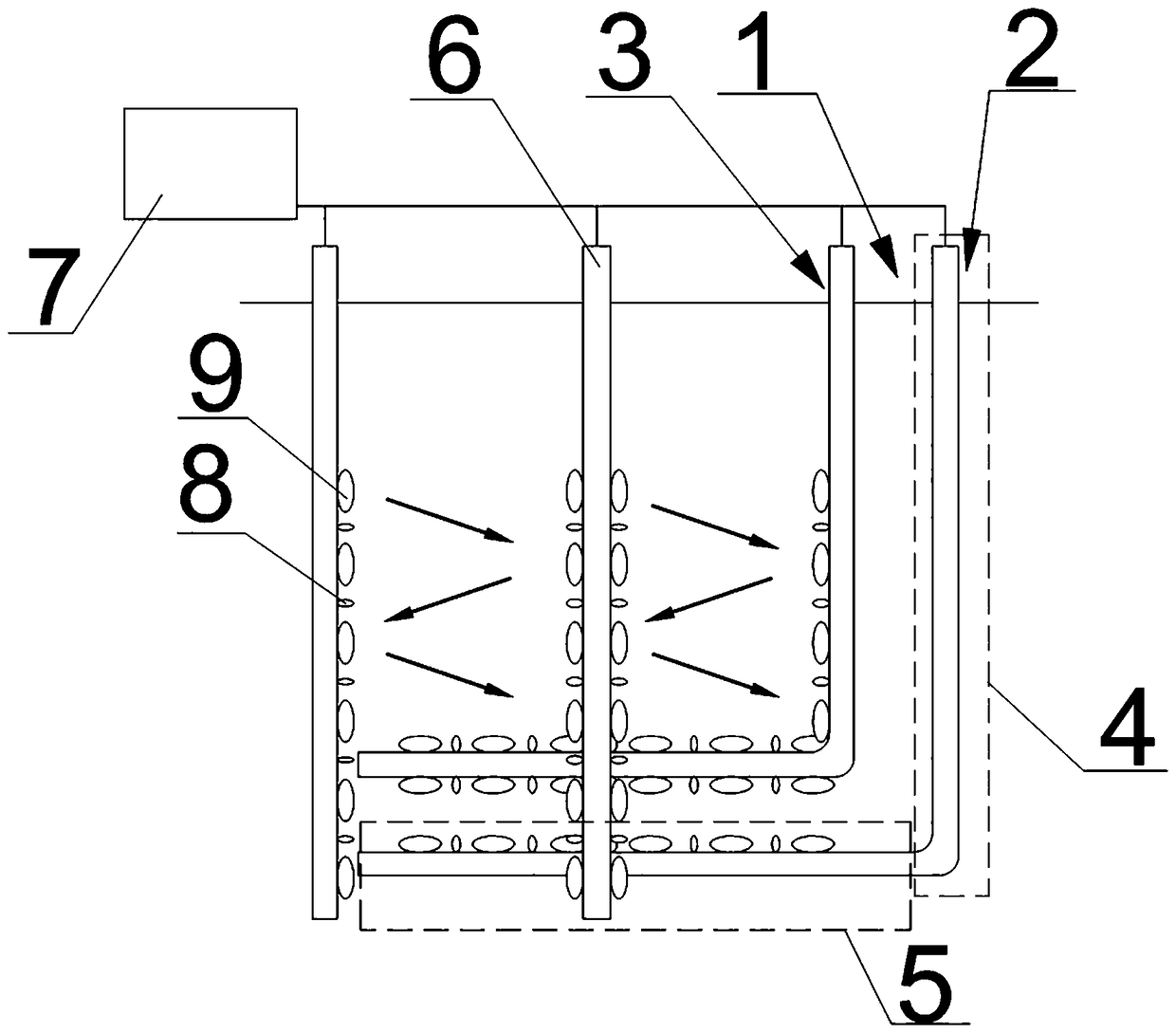

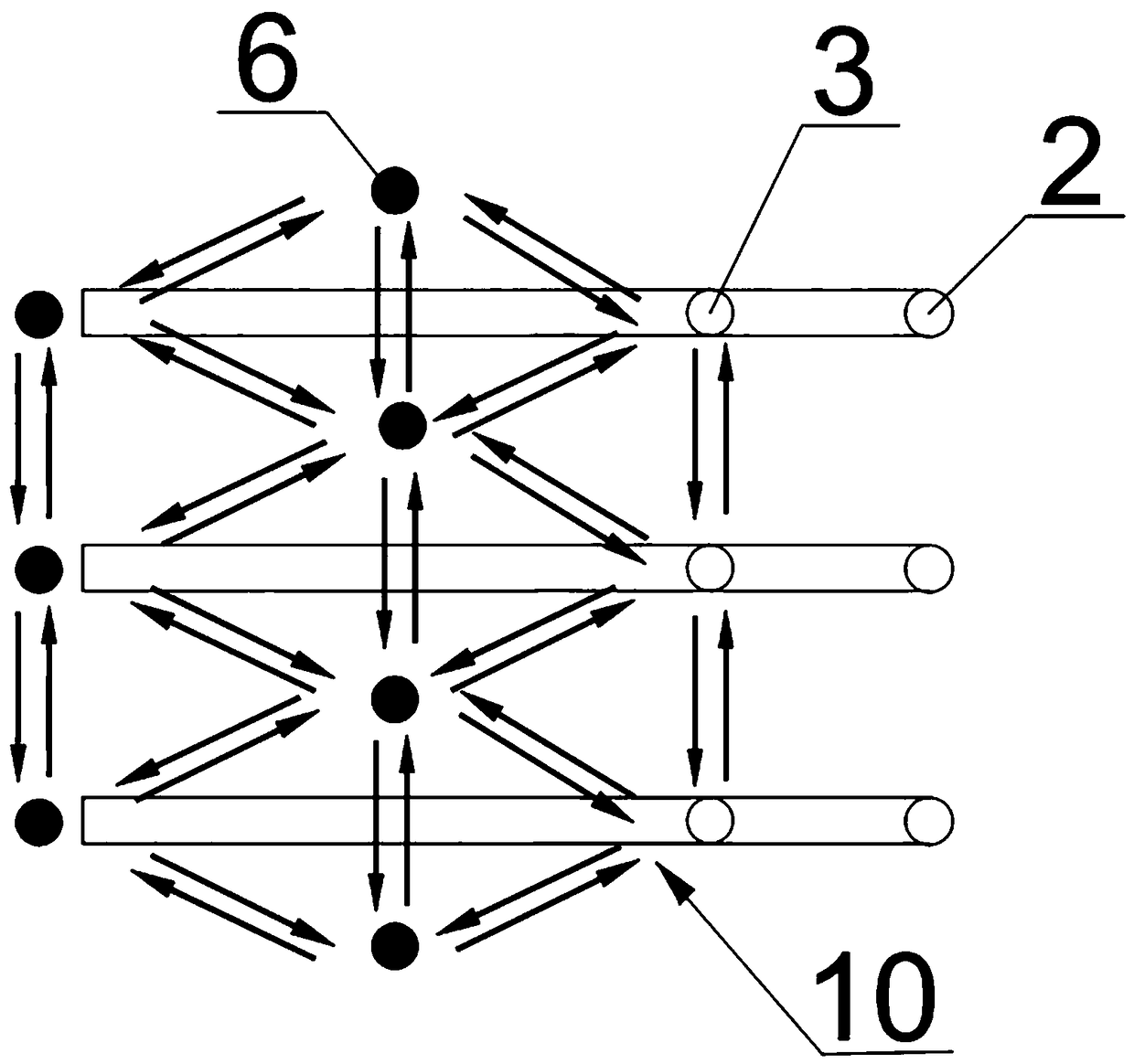

Super-heavy-oil oil reservoir mining mechanism and method

PendingCN108487887AReduce usageReduce mining costsConstructionsFluid removalHorizontal wellsMicrowave power

The invention discloses a super-heavy-oil oil reservoir mining mechanism, and further discloses a mining method using the mining mechanism. The super-heavy-oil oil reservoir mining mechanism comprisesat least one mining set, and each mining mechanism comprises horizontal wells and vertical wells; each horizontal well comprises an upper horizontal well body and a lower horizontal well body and isprovided with a horizontal section and a vertical section; the vertical wells are arranged nearby the horizontal wells; and microwave transmitting devices and microwave reflecting devices are mountedon the outer sides of the well walls of the vertical wells, and microwaves are reflected in a reciprocating mode between the microwave reflecting devices between every two vertical wells. The mining method comprises the steps that a formation is subjected to microwave preheating, steam is injected, and an initial production stage is started; and in the mining process, the formation is heated at any time according to needs. The super-heavy-oil oil reservoir mining mechanism and the mining method have the beneficial effects that using of the steam amount is reduced, and the mining cost is reduced; the formation can be quickly preheated, the time for breaking through a mining channel is shortened, and meanwhile, the mining amount in unit time is increased; the formation heating range is wider; and the formation temperature is monitored at any time, the microwave power is adjusted, thus a steam cavity is developed according to the given position, size and shape, and the steam cavity is evenly expanded.

Owner:SOUTHWEST PETROLEUM UNIV

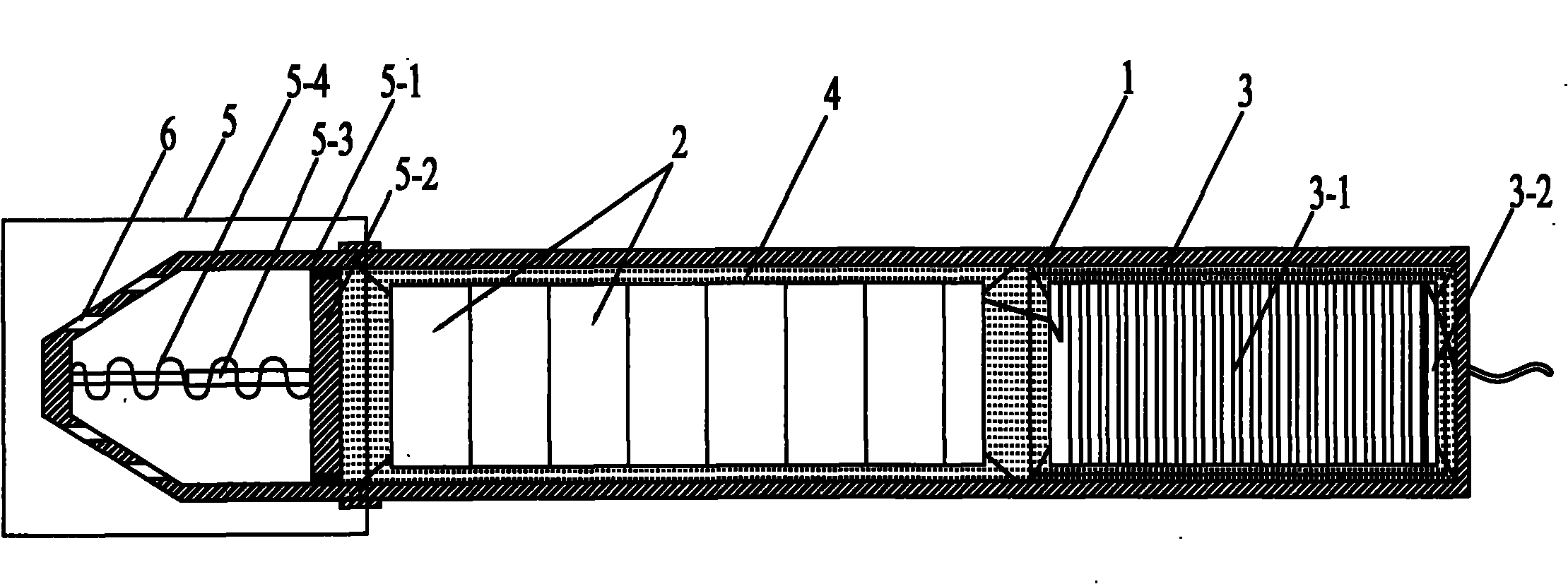

Telescopic water gun based on spring chuck control

InactiveCN104018839AIncrease single hole recoveryReduce mining costsHydraulic miningSlagWater delivery

The invention discloses a telescopic water gun with a spring chuck locking mechanism. The water gun consists of four parts, namely a high-pressure water delivery system, a telescopic control system, a water gun arm extending-retracting system and a slag discharging pipeline. The water gun arm adopts the spring chuck locking mechanism, the problems that the water jet speed of a fixed water gun is gradually reduced and the rock breaking capacity is reduced are solved, the single extraction amount of mineral products is improved, and the unit mining exploration cost of the mineral products is correspondingly reduced.

Owner:JILIN UNIV

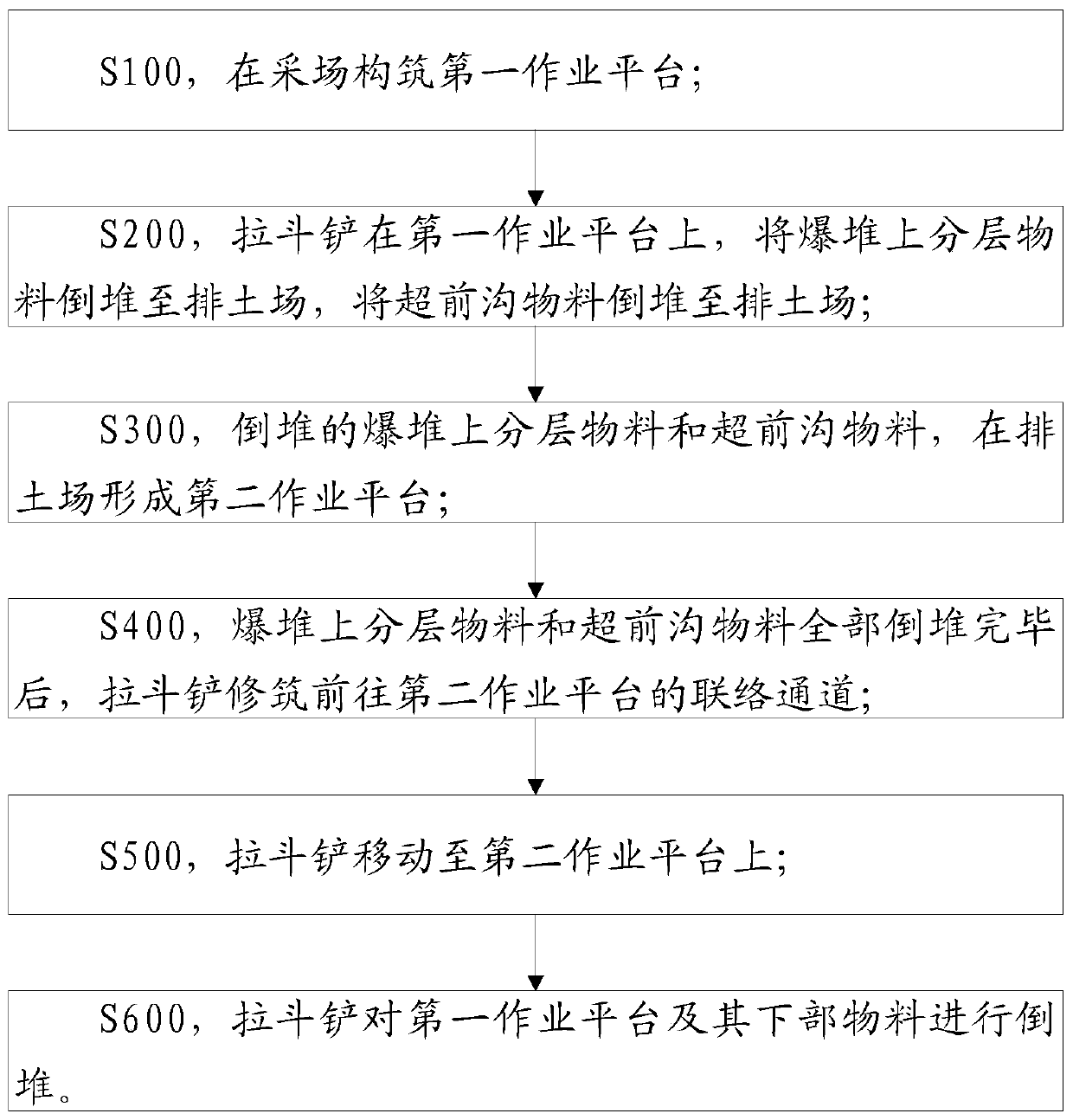

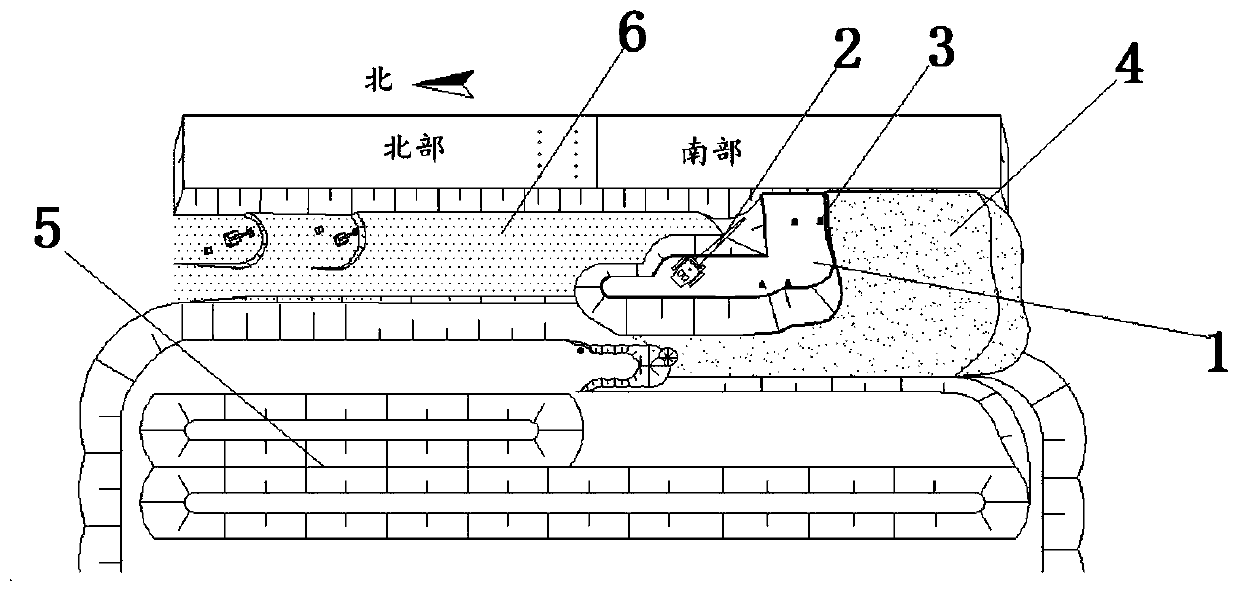

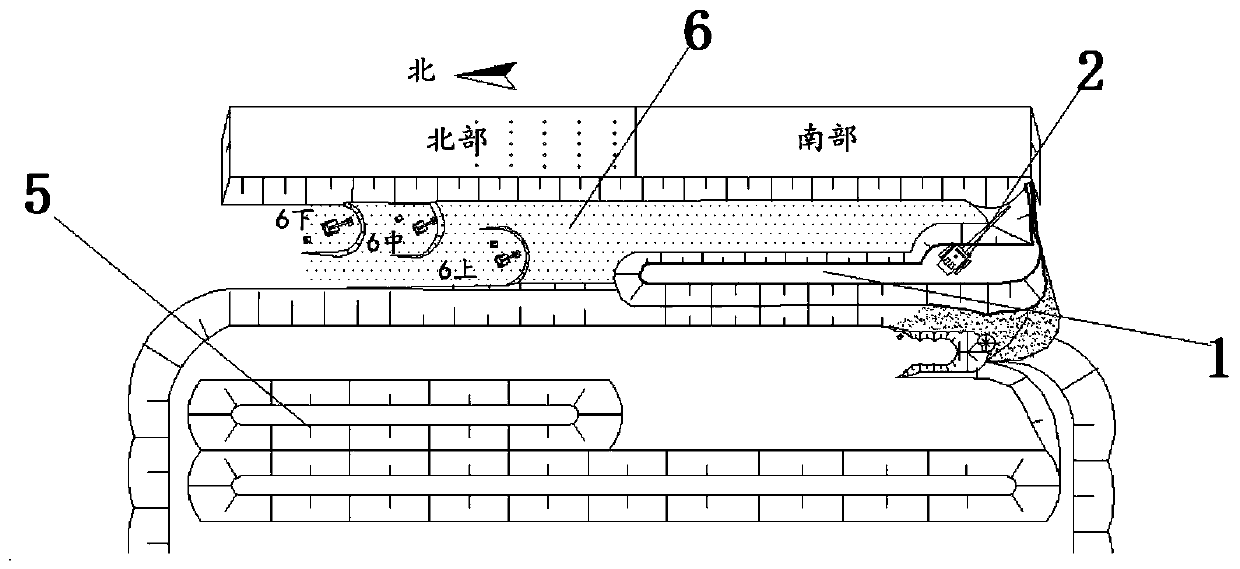

Drag bucket forklift operating method

InactiveCN110700837AReduced Quantity RequirementsLarge operating radiusOpen-pit miningWaste dumpEngineering

An embodiment of the invention discloses a drag bucket forklift operating method. The drag bucket forklift operating method comprises the steps that a first operating platform is built on the stope; adrag bucket forklift is located on the first operating platform, pushes layered materials on a blasting muck pile to a waste dump in an overcast mode and pushes leading ditch materials to the waste dump in an overcast mode; the pushed layered materials on the blasting muck pile and the pushed leading ditch materials are combined to form a second operating platform on the waste dump; after the pushed layered materials on the blasting muck pile and the pushed leading ditch materials are completely pushed in an overcast mode, the drag bucket forklift constructs a connection channel for the second operating platform; the drag bucket forklift moves to the second operating platform; and the drag bucket forklift pushes the first operating platform and materials at the bottom of the first operating platform in an overcast mode. By the use of the drag bucket forklift operating method, the operation that drag bucket forklifts are arranged on the stope and the waste dump is not required any longer, the requirement for the number of the drag bucket forklifts can be reduced, the operating radius of the drag bucket forklift is increased, the operating capacity of the drag bucket forklift is improved, the purchase cost is reduced, the exploitation quantity is increased, and the exploitation rate is improved.

Owner:SHENHUA ZHUNGER ENERGY

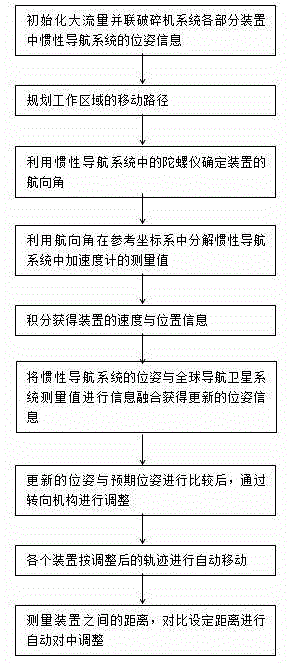

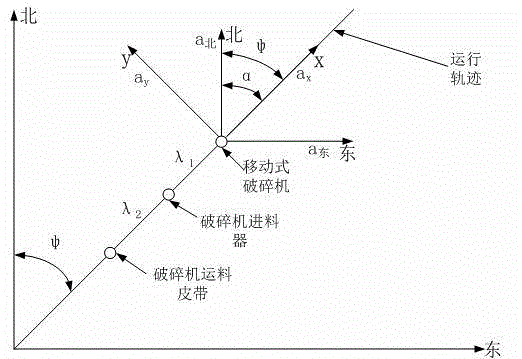

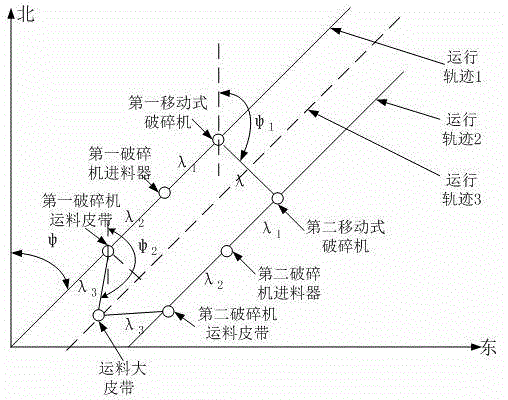

High-flow parallel crusher device and inertial navigation method thereof

InactiveCN104826719AIncrease mining volumeSolve the status quo that cannot be minedNavigation by speed/acceleration measurementsGrain treatmentsTraffic volumeSatellite

A high-flow parallel crusher device and an inertial navigation method thereof. The device includes a first movable crusher, a first crusher material feeder, a first crusher material conveyor belt, a second movable crusher, a second crusher material feeder, a second crusher material conveyor belt, a large material conveyor belt, and inertial navigation systems and global navigation satellite systems arranged on the apparatuses respectively. The inertial navigation method includes following steps: (1) initializing pose information of the inertial navigation systems on the apparatuses; (2) planning moving path in an operation area; and (3) by means of a method of route optimization, optimizing the motion tracks of the apparatuses of the system to achieve alignment among the apparatuses. In the invention, a parallel crusher device structure is employed so that compared with single crusher, the crusher device is greatly improved in exploitation quantity and mining efficiency of ore. In addition, by means of the inertial navigation systems for optimizing the moving path of the apparatuses, automatic alignment among the apparatuses is achieved without manual adjustment, so that the crusher device is greatly reduced in time, labor intensity and resource consumption in adjustment.

Owner:CHINA UNIV OF MINING & TECH

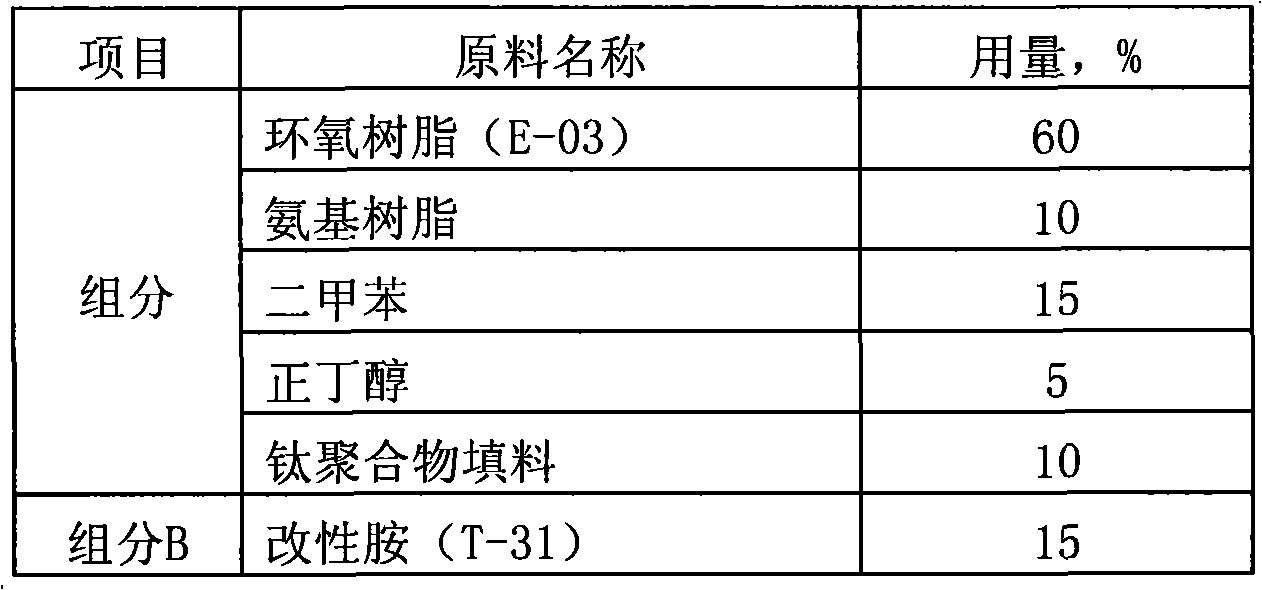

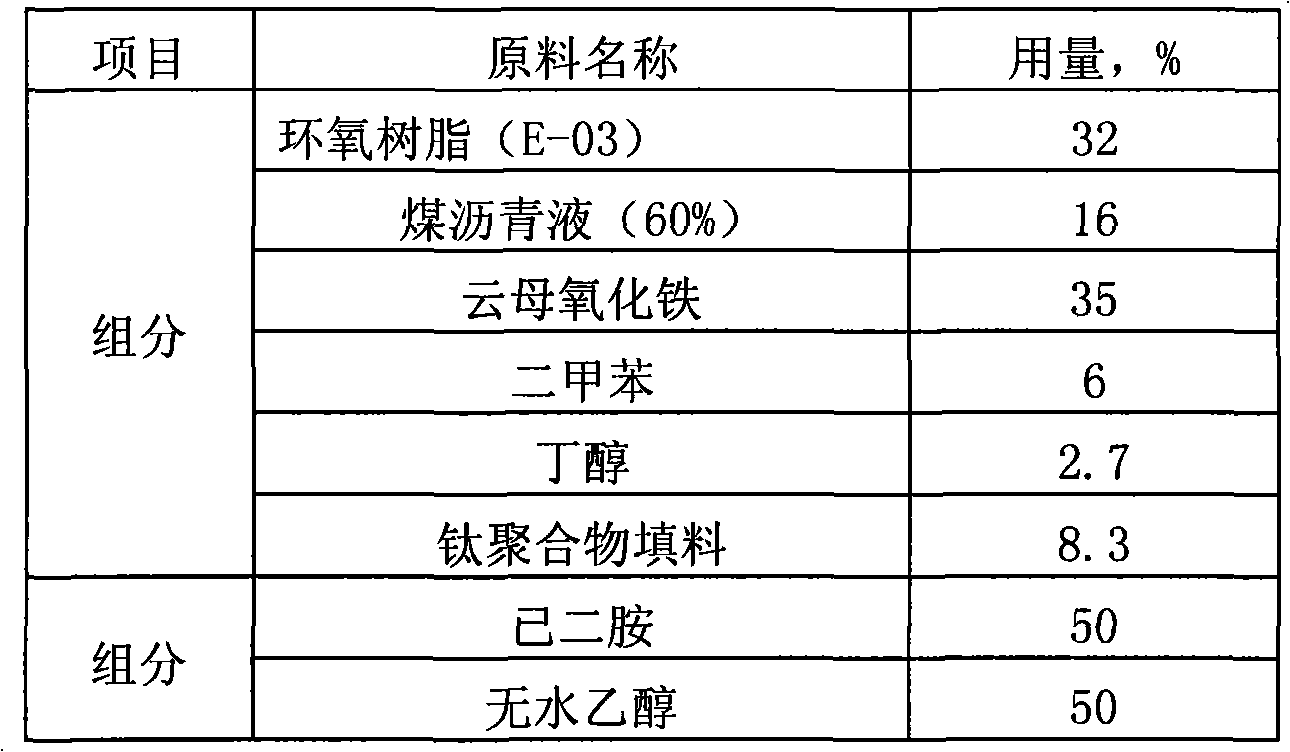

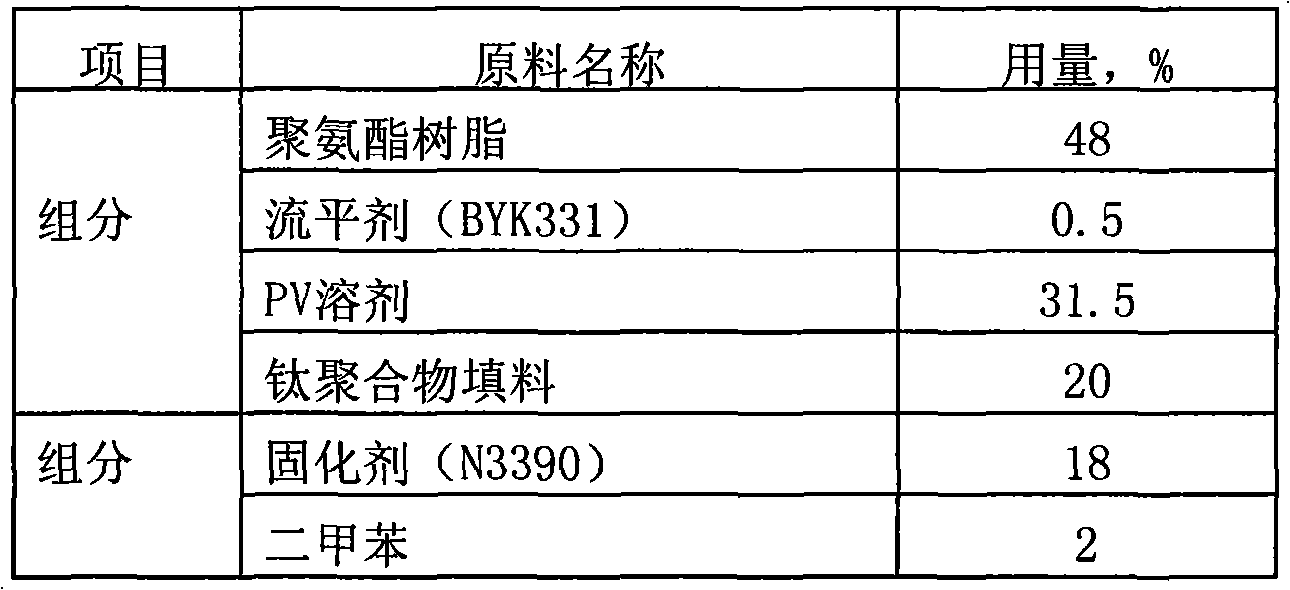

Method for producing titanium polymer resin anti-dirty corrosion-resistant oil pipe for oil field

InactiveCN101270845AIncrease resistanceStrong penetration resistanceCorrosion preventionPipe protection against corrosion/incrustationPolymer resinSpray coating

A preparation method for a titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field is disclosed. The preparation method for the titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field has the following procedures that the external and internal walls of the tube are coated with paint after the pre-treatment for the tube surface; the paint is produced that 7 percent to 20 percent titanium polymer fillings are added in the routine epoxy resin paint; the internal wall of the tube applies the high pressure, airless and stereo spray coating way; the external wall of the tube applies the stereo spray coating way with compressed air and three spray guns; the coating layers of the external and internal walls of the tube are adjusted and cured through an adjusting and curing furnace after the spray coating; the power of the furnace is 200KW, the temperature of the furnace is 50 degrees to 180 degrees and the curing time is 60 minutes; the tube rotates and moves forward in the adjusting and curing furnace; and the self-rotating speed of the tube is 30r / min to 80r / min. The preparation method solves the scaling and corrosion problem of the underground tube in the oil field under complex industrial and mining conditions, which protects the tube, prolongs the using life of the tube and saves the oil extraction cost.

Owner:DAQING PETROLEUM ADMINISTRATION

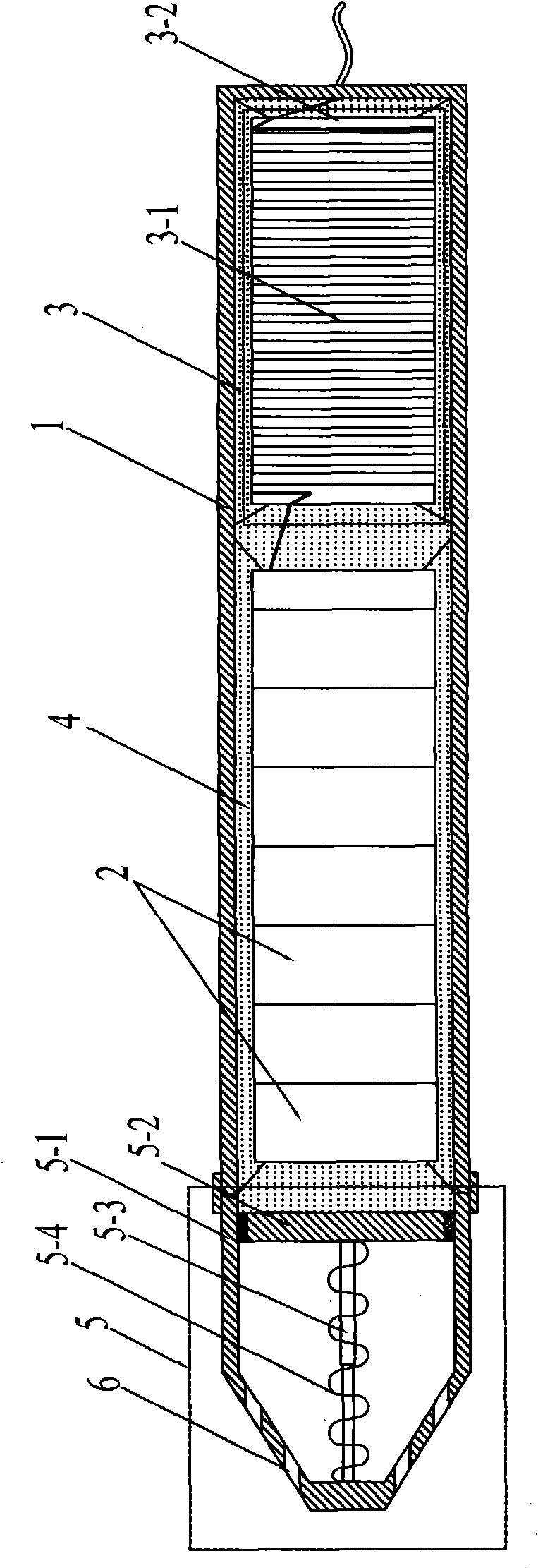

Underground ultrasonic oil-production transducer with matching device

InactiveCN101839116ALower capacitive impedanceReduce reactive currentVibration devicesElectricityFixed frame

The invention relates to an underground ultrasonic oil-production transducer with a matching device, in particular to a transducer for solving the problems of extremely low transmission efficiency and serious resource waste of a traditional piezoelectric ceramic transducer transmission system. A fixing frame with a plurality of fixed identical piezoelectric ceramic oscillators is fixedly arranged at the bottom of a cylindrical shell, a fixing frame with two identical fixed inductor matching devices is fixedly arranged at the top of the cylindrical shell, an inductor coil is tightly wound on a hollow cylindrical inductor frame, two incoming terminals of an inductor coil of an inductor matching device hermetically penetrate through the top end surface of the cylindrical shell and are connected with external transmission cables, two outgoing terminals of the inductor coil of the inductor matching device are connected with two incoming terminals of an inductor coil of the other inductor matching device, and two outgoing terminals of the inductor coil of the other inductor matching device are connected in parallel with two terminals of each piezoelectric ceramic oscillator. The invention has the advantages of high transmission efficiency and energy saving.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

Coal underground gasification furnace and gasification method

ActiveCN108005632AIncrease mining volumeEasy to controlConstructionsFluid removalEngineeringEarth surface

The invention discloses a coal underground gasification furnace and a gasification method. The coal underground gasification furnace comprises a gas inlet hole, a plurality of exhaust holes and a plurality of horizontal directional drilled holes, wherein the gas inlet hole comprises a vertical section and a horizontal section which communicate with each other; the top end of the vertical section is positioned on the ground surface; the horizontal section is positioned in a coal bed; the top ends of the various exhaust holes are positioned on the ground surface while the bottom ends of the exhaust holes are positioned in the coal bed; the horizontal directional drilled holes are in one-to-one correspondence to the various exhaust holes; and two ends of each horizontal directional drilled hole separately communicate with the bottom end of the corresponding exhaust hole and the horizontal section. According to the coal underground gasification furnace and the gasification method, the single long-distance air inlet hole cooperates with the exhaust holes, and thus, the coal extraction quantity of the single hole is increased; and meanwhile, the horizontal directional drilled holes can be short, and a gasification process for mobile gas injection can be controlled favorably.

Owner:XINJIANG GUOLIHENG CLEAN ENERGY TECH CO LTD

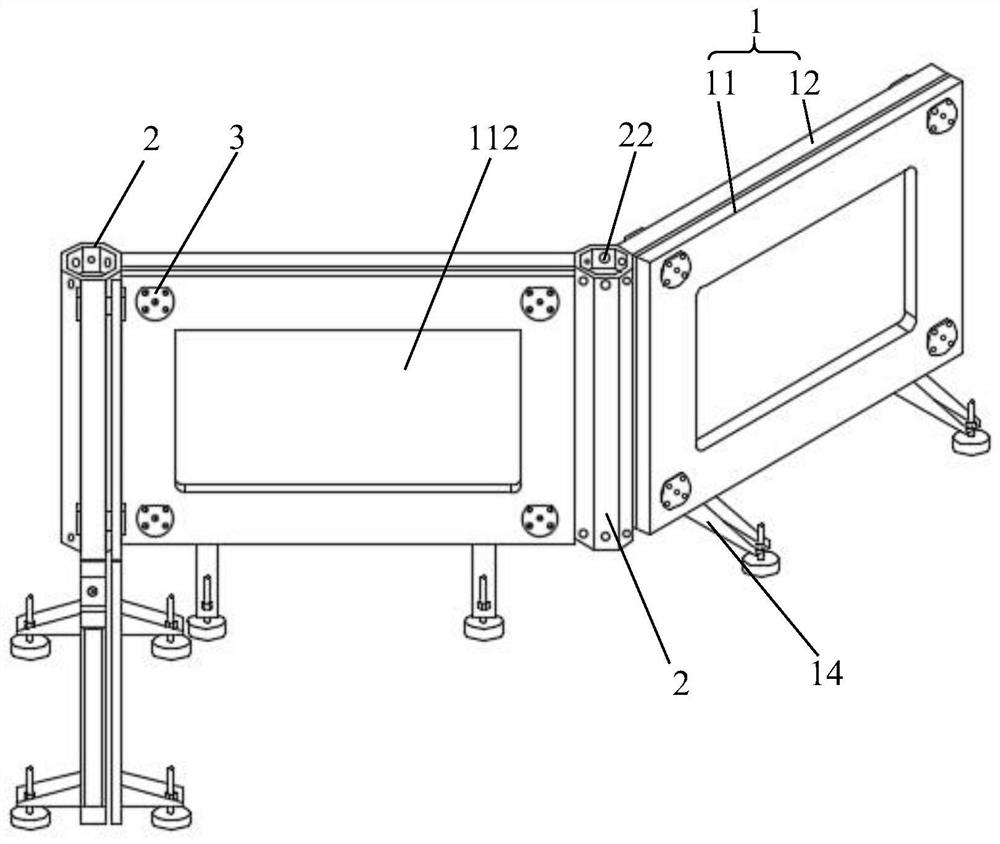

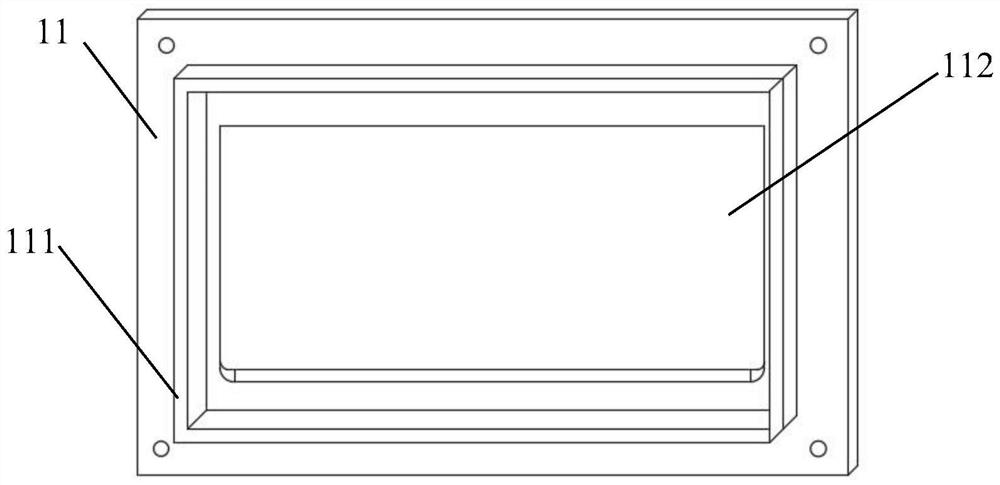

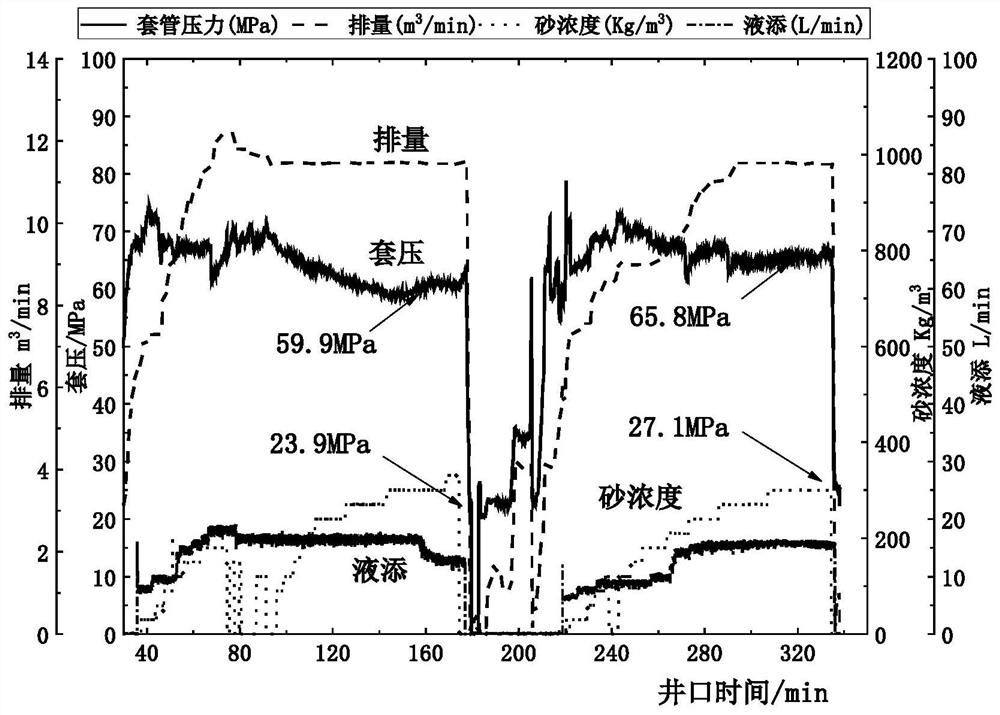

Test device and test method for simulating multi-scale branch cracks of shale

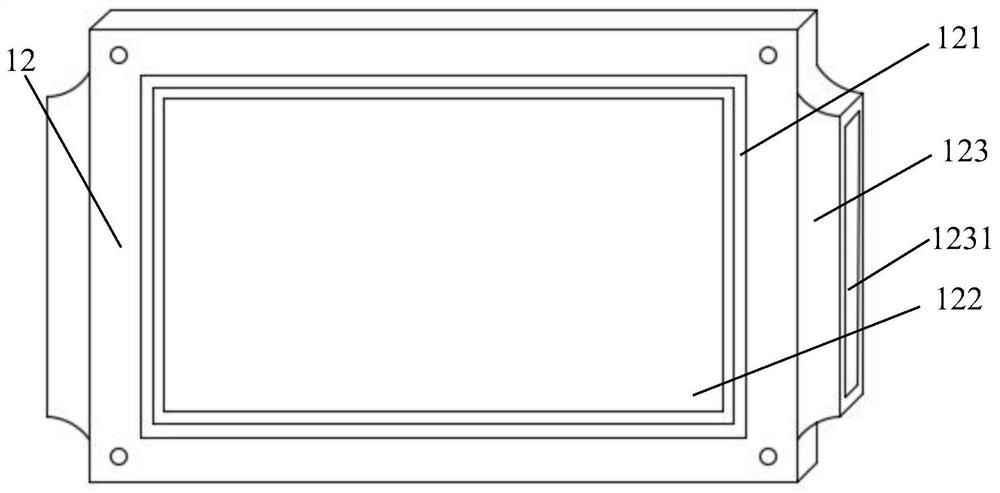

ActiveCN113027435AEasy to installEasy to disassembleConstructionsFluid removalStructural engineeringTest rig

The invention discloses a test device and a test method for simulating multi-scale branch cracks of shale. The test device comprises a plurality of crack simulation plug boards and a crack width adjusting assembly, wherein each crack simulation plug board comprises a front panel and a rear panel which are buckled with each other, branch cracks are formed between the front panel and the rear panel after the front panel and the rear panel are buckled, a hollow prism for communicating two adjacent branch cracks is connected between two adjacent rear panels, and supporting foot stands are fixed at the bottom ends of the front panel and the rear panel; and the crack width adjusting assembly is fixedly connected between the front panel and the rear panel and used for adjusting the width of the branch cracks. According to the test device and the test method, any angle setting among the plurality of branch cracks is realized through the hollow prisms to form the multi-scale branch cracks, so that simulation of the laying rule of a propping agent in the multi-scale branch cracks is realized, the simulation is closer to the actual construction and mining working condition, the obtained test data precision is higher, and theoretical support is provided for increasing the mining amount.

Owner:SOUTHWEST PETROLEUM UNIV

Photometric sorting process for coal gangues arranged in coal mine underground roadway

InactiveCN111495580AReduce boostRealize exhaustionEarth drilling and miningSortingMining engineeringCoal gangue

The invention discloses a photometric sorting process for coal gangues arranged in a coal mine underground roadway. According to the photometric sorting process for the coal gangues arranged in the coal mine underground roadway provided by the invention, on the basis of the development of an existing technology, by breaking through a traditional ground stacking type arrangement idea and optimizingspace-time connection of various working units in a process flow, a coal mine underground modular compact type high-efficiency sorting system is built, process steps such as coal mining, raw coal preparation, coal gangue photometric sorting, and gangue backfilling are accurately matched and cooperatively optimized, so that the coal mine underground modular compact type high-efficiency sorting system is suitable for a coal mine with the content of +150mm particle size in raw coal being below 10 percent and a brittle coal property, the coal mine underground gangues can be discharged from the source, the number of the gangues lifted to the ground is reduced, the transporting and filling cost is saved, and an environmental requirement is met. Meanwhile, according to high-efficiency sorting ofthe coal mine underground gangues provided by the invention, the gangue lifting amount can be reduced, the mining quantity and the production efficiency of a coal mine are effectively improved, and atechnical support is provided for coal mine underground mining-washing-filling cooperation work; and meanwhile, the sorting process provided by the invention has no special requirements on the coal mine underground roadway and a chamber, and is suitable for an underground narrow chamber space.

Owner:ANHUI UNIV OF SCI & TECH

Collection method of saline bearing brine reservoir brine and solid salts

InactiveCN101249973AIncrease mining volumeExtended service lifeAlkali metal chloridesSolventCapital investment

The invention belongs to the technical field of salt lake resources exploitation, in particular to a collecting method of salt lake bearing brine-storing layer brine and solid salts. The steps of the method comprise employing a trenchless construction drill to construct and arrange solvent floral tubes obliquely downwards for the bearing brine-storing layer, feeding solvent in the bearing brine-storing layer from the upper end of the solvent floral tubes, then constructing and arranging pumping floral tubes obliquely downwards for the bearing brine-storing layer and transporting the brine of the bearing brine-storing layer and the dissolved solid salts to the ground surface. According to preliminary estimate, the method can save more than 50% capital investment, can save more than 33% operating and maintenance cost of exploiting and transporting the brine, adds about 1-5 times of the exploitation quantity of the brine and the solid salts resources, and enables 'dead mine' to change into live mine, thereby having relatively large economic benefit and social benefit.

Owner:杨智琛

A method for transforming abandoned oilfield wells into geothermal wells or brine wells

ActiveCN106194122BIncrease mining volumeImprove efficiencyFluid removalSealing/packingMining engineeringWater filter

The invention discloses a method for transforming an oil field abandoned well into a geothermal well or a brine well. The method comprises the steps that in an oil field exploitation area, an oil field abandoned well with a brine layer below an oil extraction layer or an oil field abandoned well with the bottom boundary of a geothermal reservoir layer 200 m above an oil extraction layer position is selected, a drill pipe drill rig is lowered into an oil layer casing pipe to carry out pigging, and when pigging is smoothly achieved and after it is determined that no abnormal condition exits in the well, the artificial bottom of the well is poured to seal the lower portion oil extraction layer position; a pump chamber section is transformed, and a water drainage pipe is additionally arranged on an exploitation layer; perforation construction is carried out on a technical casing pipe located on the exploited geothermal reservoir layer or the brine layer; a water filtering pipe is lowered into the exploitation layer, and for the transformed geothermal well or the brine well, sand washing well washing is directly carried out, or a water filtering pipe with a sediment pipe on the lower portion is lowered; after well washing, exploitation testing, sampling analysis and acceptance check are carried out. By means of the method, the oil field abandoned well resources are recycled, and the double effects of energy conservation and environment protection, and economic benefits of recycling of the oil field abandoned well resources are achieved.

Owner:SHANDONG INST OF GEOLOGICAL SCI +1

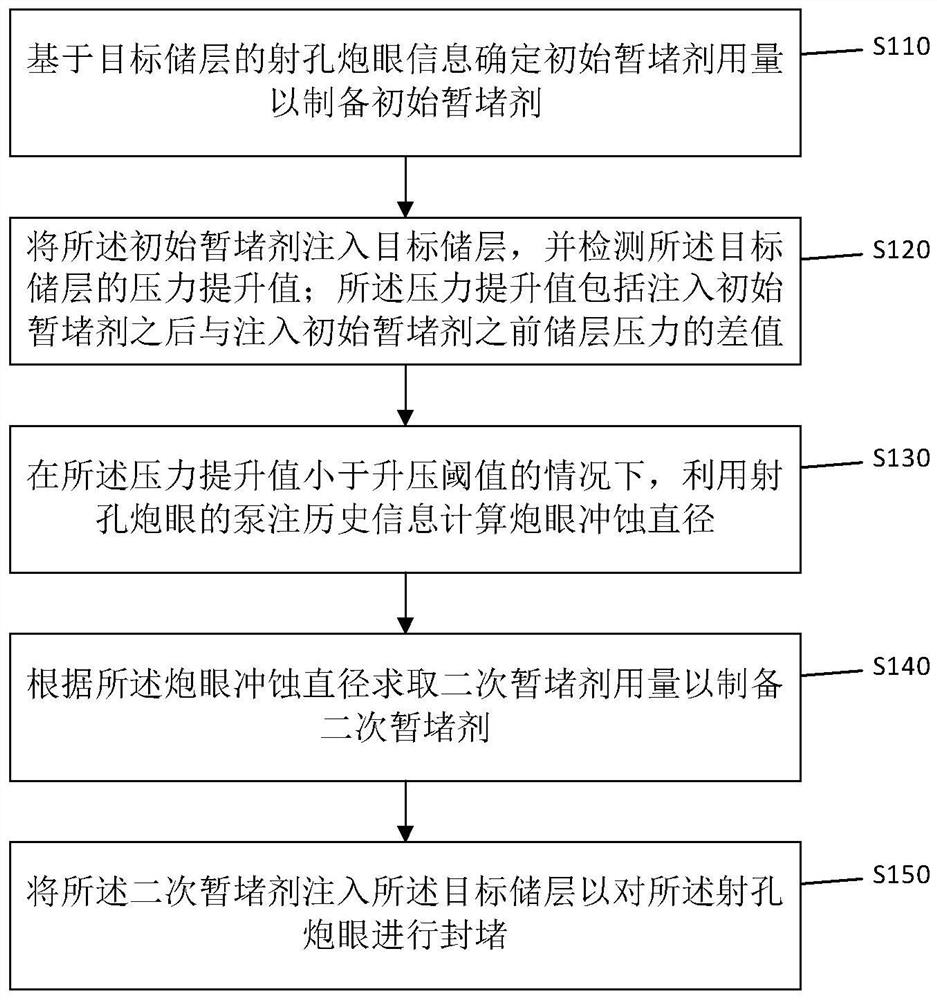

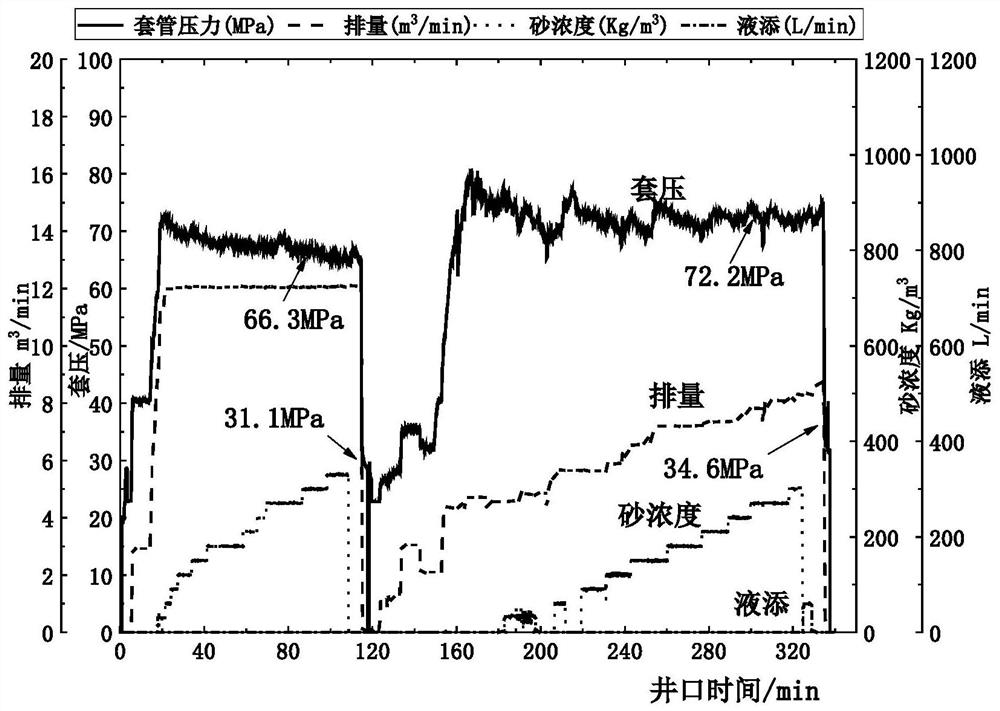

Construction method and device based on temporary plugging of reservoir

ActiveCN112302570AExtended Fracture NetworkOvercoming erosion problemsSurveySealing/packingMining engineeringReservoir pressure

The embodiment of the invention provides a construction method and device based on temporary plugging of a reservoir. The method comprises the steps of determining the dosage of an initial temporary plugging agent on the basis of perforation shot hole information of a target reservoir so as to prepare the initial temporary plugging agent; injecting the initial temporary plugging agent into the target reservoir, and detecting a pressure increasing value of the target reservoir, wherein the pressure increasing value comprises the pressure difference of the reservoir after the initial temporary plugging agent is injected and before the initial temporary plugging agent is injected; calculating the shot hole erosion diameter by utilizing pump injection historical information of a perforation shot hole in the condition that the pressure increasing value is smaller than a pressure increasing threshold value; obtaining the dosage of a secondary temporary plugging agent according to the shot hole erosion diameter so as to prepare the secondary temporary plugging agent; and injecting the secondary temporary plugging agent into the target reservoir so as to temporarily plug the perforation shot hole. According to the method, secondary temporary plugging is performed according to the pressure condition of the target reservoir, so that a good plugging effect can still be achieved in the condition that the perforation shot hole is eroded, and the exploitation quantity of oil and gas resources in the target reservoir is increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Steam-water separator of horizontal type steam-injection boiler

ActiveCN103499085BRealize large-scaleEasy maintenanceSteam separation arrangementsPulp and paper industryWater pipe

The invention relates to a steam-water separation device of a steam-injection boiler, in particular to a steam-water separator of a horizontal type steam-injection boiler. The steam-water separator of the horizontal type steam-injection boiler solves the problems that when a steam-water mixture of the dryness less than 80% is injected into a heavy oil mine, the oil recovery efficiency is low, the oil recovery requirements can not be met, large scale can not be achieved, and maintenance is inconvenient. A steam outlet pipe connector and a spray water outlet pipe connector are communicated to a barrel, a cross partition board is installed on the inner wall of the bottom of the barrel, a corrugated board dryer is installed on the inner wall of the top of the barrel, diversion devices, primary separator bodies and secondary separator bodies are arranged inside the barrel from bottom to top, the lower ends of the primary separator bodies are connected with the diversion devices, the upper ends of the primary separator bodies are connected with the secondary separator bodies, the two obverse faces of the two diversion devices on the left side and the two diversion devices on the right side are respectively connected with the barrel through a bent board, the two reverse faces of the two diversion devices on the left side and the two diversion devices on the right side are respectively connected with the barrel through an arc board, and water return pipes are communicated with the lower end of the corrugated board dryer. According to the steam-water separator of the horizontal type steam-injection boiler, large scale is achieved, and maintenance is convenient.

Owner:HARBIN XINBEIYUAN POWER EQUIP MFG

Preparation method of glossy transparent ultra-low-temperature glaze powder material

The invention discloses a preparation method of a glossy transparent ultra-low-temperature glaze powder material. The method comprises the following steps of (1) using a precision electronic balance for weighing 0-34.4 g of B2O3, 25.14-50 g of SiO2, 5-9.94 g of Al2O3, 3.81-7.58 g of CaO, 11.74-23.35 g of ZnO, 2.16-4.3 g of K2O, 1.57-16.11 g of Na2O, 1.04-2.07 g of BaO, 0.6-1.19 g of MgO, 48 g of borax, 1-1.2 g of SrO, 2.1-3.5 g of ball clay, 1.31-2.55 g of Li2O and 0.51-2.11 g of Na5P3O10 which are adopted as raw materials; (2) grinding the raw materials into 300 mesh sieve fineness through aball mill to form glaze powder at a working speed of 25 rad / min and then obtaining the ultra-low-temperature glaze powder material. The preparation method of the glossy transparent ultra-low-temperature glaze powder material utilizes the novel low-temperature fast-burning raw materials as fluxing agents for introducing alkali metal oxides or alkaline earth metal oxides, and since the raw materialsare characterized by completing a physicochemical reaction at a lower temperature, by utilizing this characteristic of the raw materials, low-temperature ceramic glaze is prepared, so that the purpose of fast burning at the low temperature is achieved. Moreover, the raw materials have few harmful impurities, less ignition loss, high melting performance and low viscosity at the high temperature, and a flat and smooth glaze surface is easily formed.

Owner:WUYI UNIV

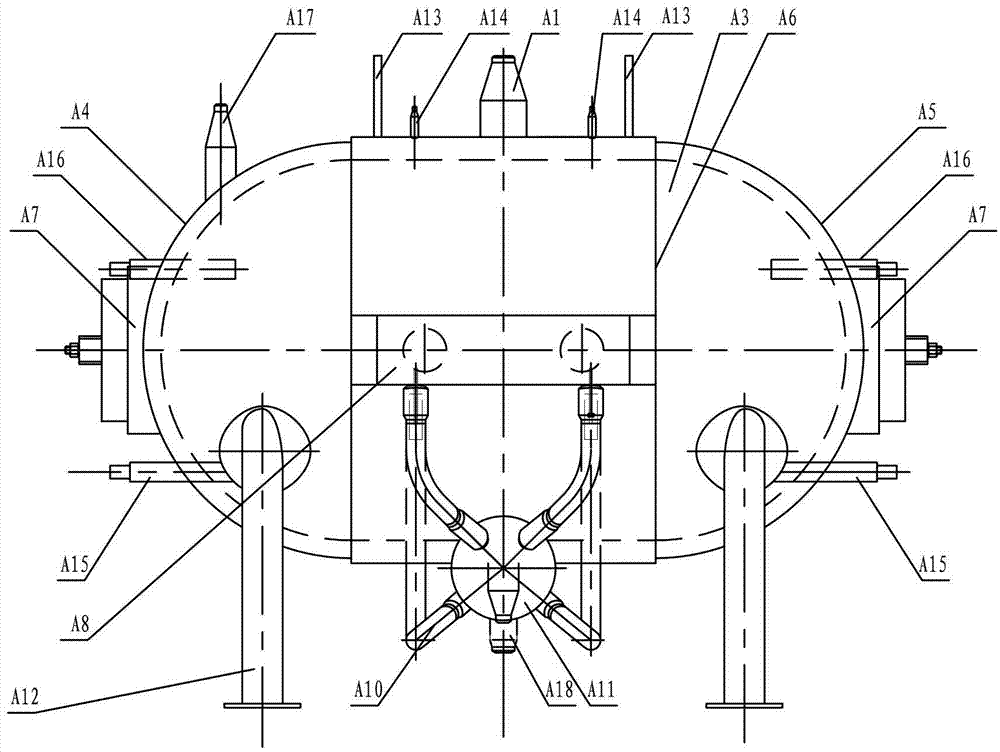

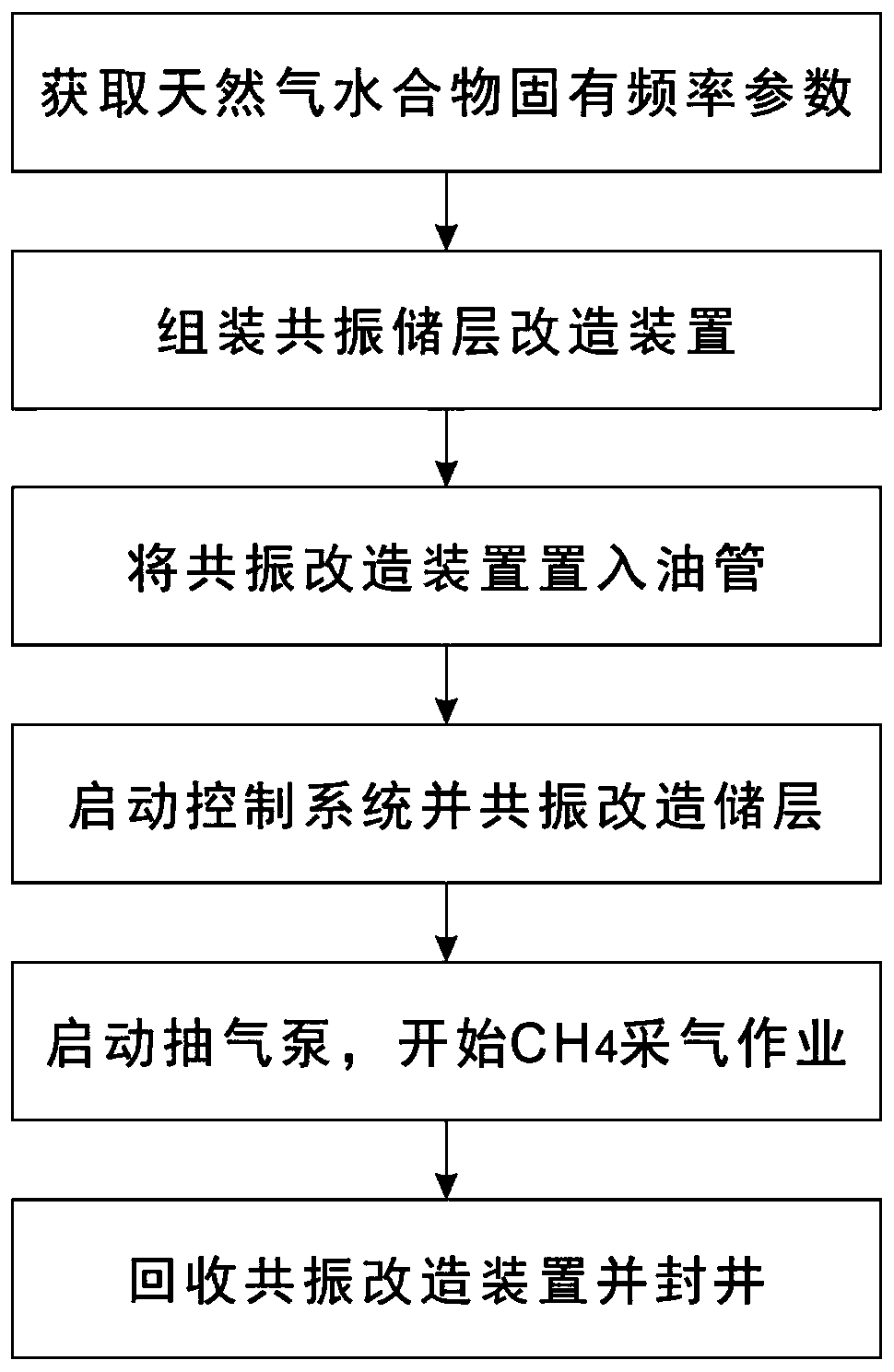

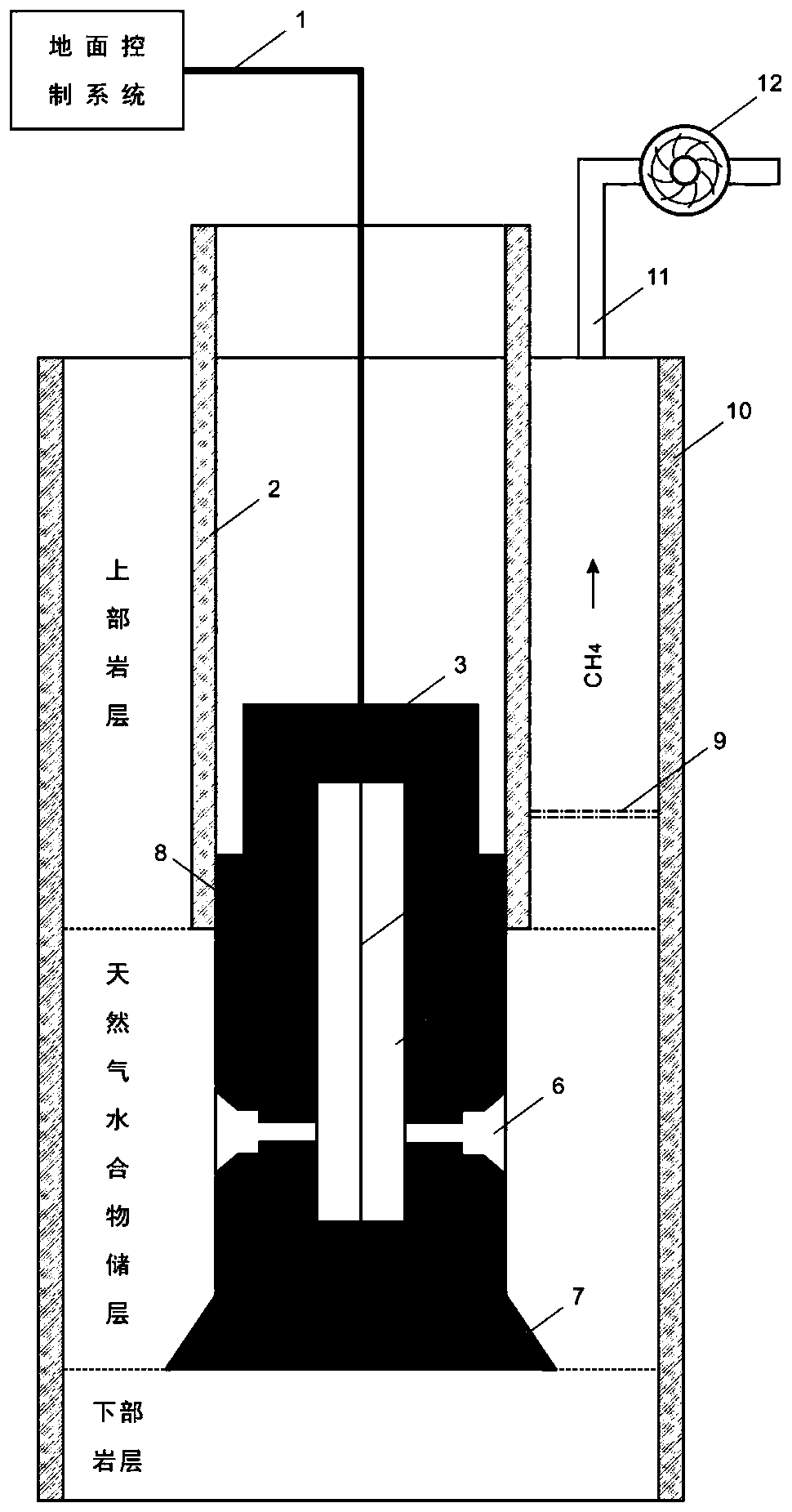

Transformation device of natural gas hydrate resonance reservoir

PendingCN111502606AIncrease mining volumeIncrease mining rateFluid removalVibration devicesGeotechnical engineeringGeophysics

The invention provides a transformation device of a natural gas hydrate resonance reservoir. The transformation device comprises a ground control system, a core resonance body, a gas production pipe and a casing pipe, one end of the casing pipe is arranged on the sea level, and the other end of the casing pipe sequentially penetrates through the sea level, an upper rock stratum and a natural gas hydrate reservoir and is arranged in a lower rock stratum; the core resonance body is arranged in the casing pipe, the lower part of the core resonance body is arranged in the natural gas hydrate reservoir, and the upper part of the core resonance body is arranged in the upper rock stratum at the upper part of the natural gas hydrate reservoir; a resonant cavity is formed in the core resonance body, and an explosion wire is placed in the resonant cavity and connected with the ground control system; and the gas production pipe is also arranged in the casing pipe, one end of the gas production pipe is arranged in the upper rock stratum at the upper part of the natural gas hydrate reservoir, and the other end of the gas production pipe is arranged on the sea level. By means of the transformation device, the permeability of the seabed natural gas hydrate reservoir can be effectively improved, and meanwhile the seabed reservoir can be transformed gently and stably.

Owner:CHINA HUANENG GRP CO LTD +1

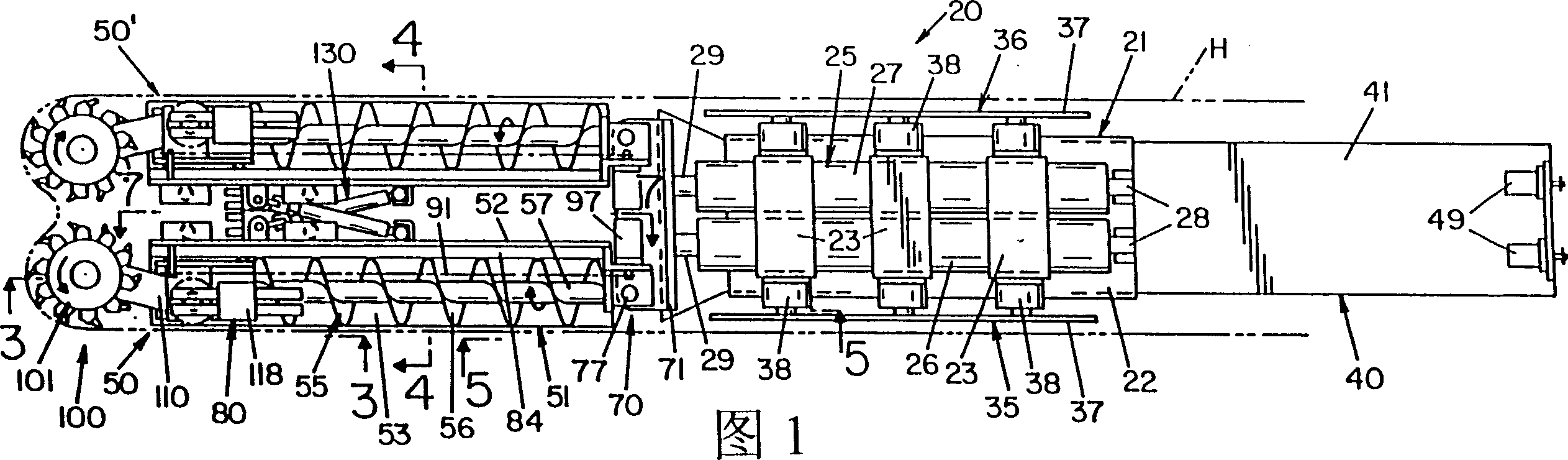

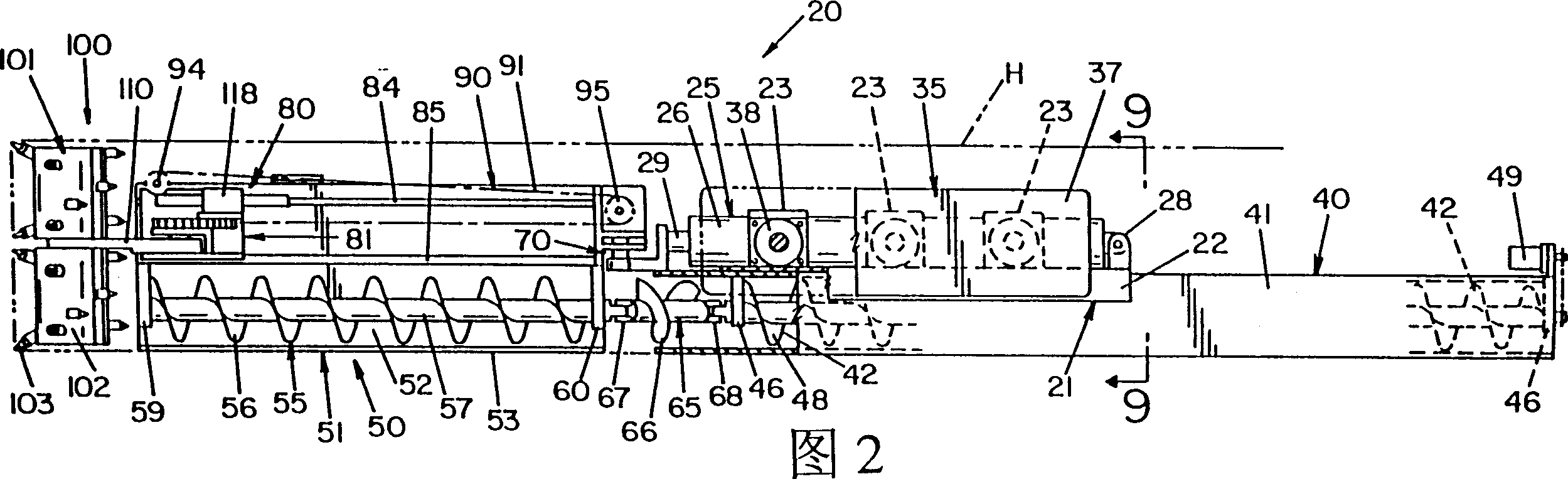

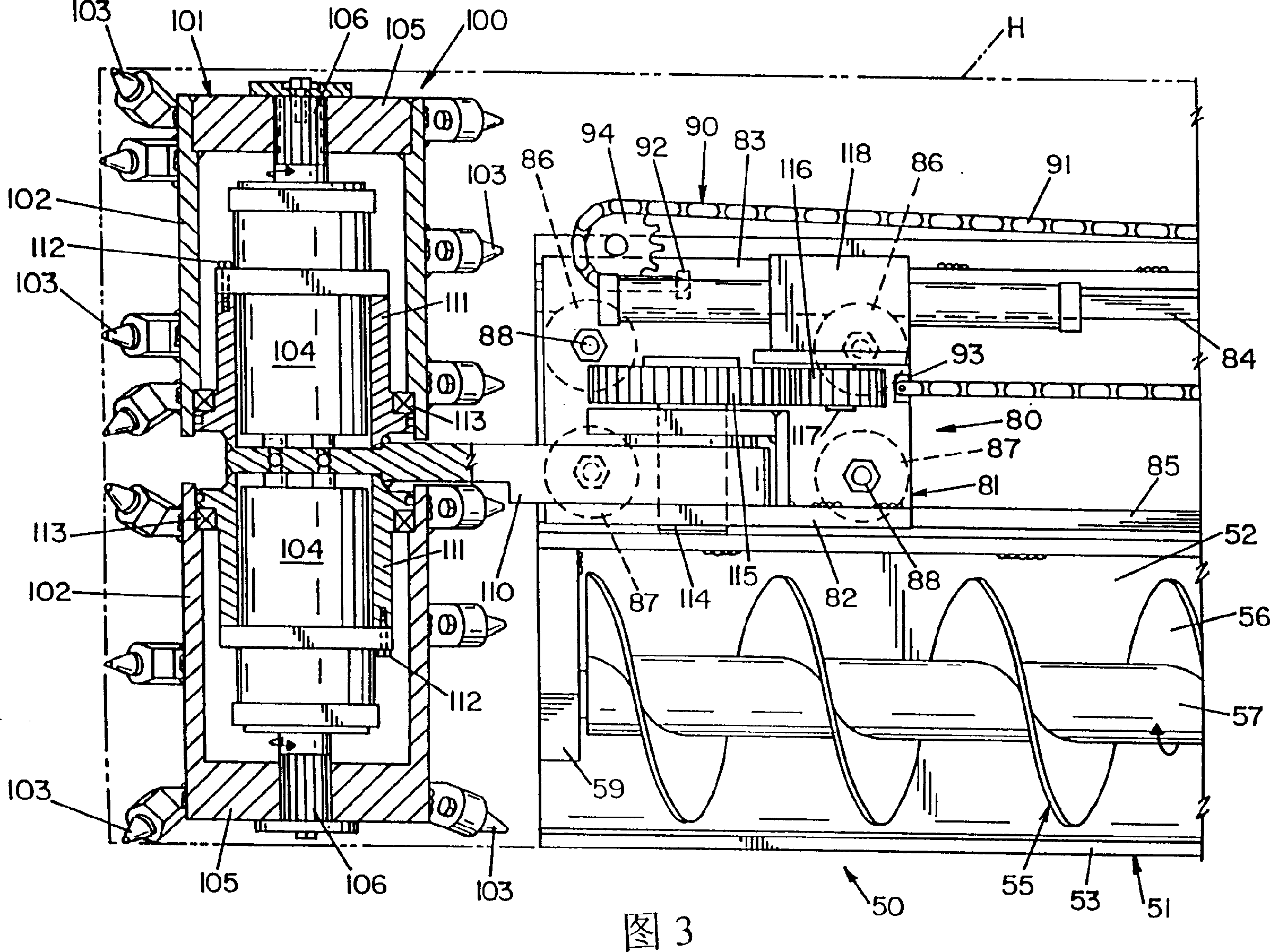

Mining machine and mining method

InactiveCN1204331CNot prone to accidental collapseIncrease mining volumeDrill bitsUnderground miningEngineeringAerospace engineering

A mining machine (20) for combined entry and retraction cutting of subterranean seam material, comprising: a movable main frame (21); a wing (50, 51) extending forwardly of the movable main frame; a cutter assembly (100) positionable near the end of the wing to drill holes in the material when the direction of travel of the wing and main frame is in line; a pivotal connection (130) between the main frame and wing ) for positioning the wings at an angle to the direction of movement of the main frame; and a mechanism (80) for moving the knife assembly along the wings during retraction of cutting material to cut material adjacent the wings.

Owner:HOLMES LIMESTONE CO

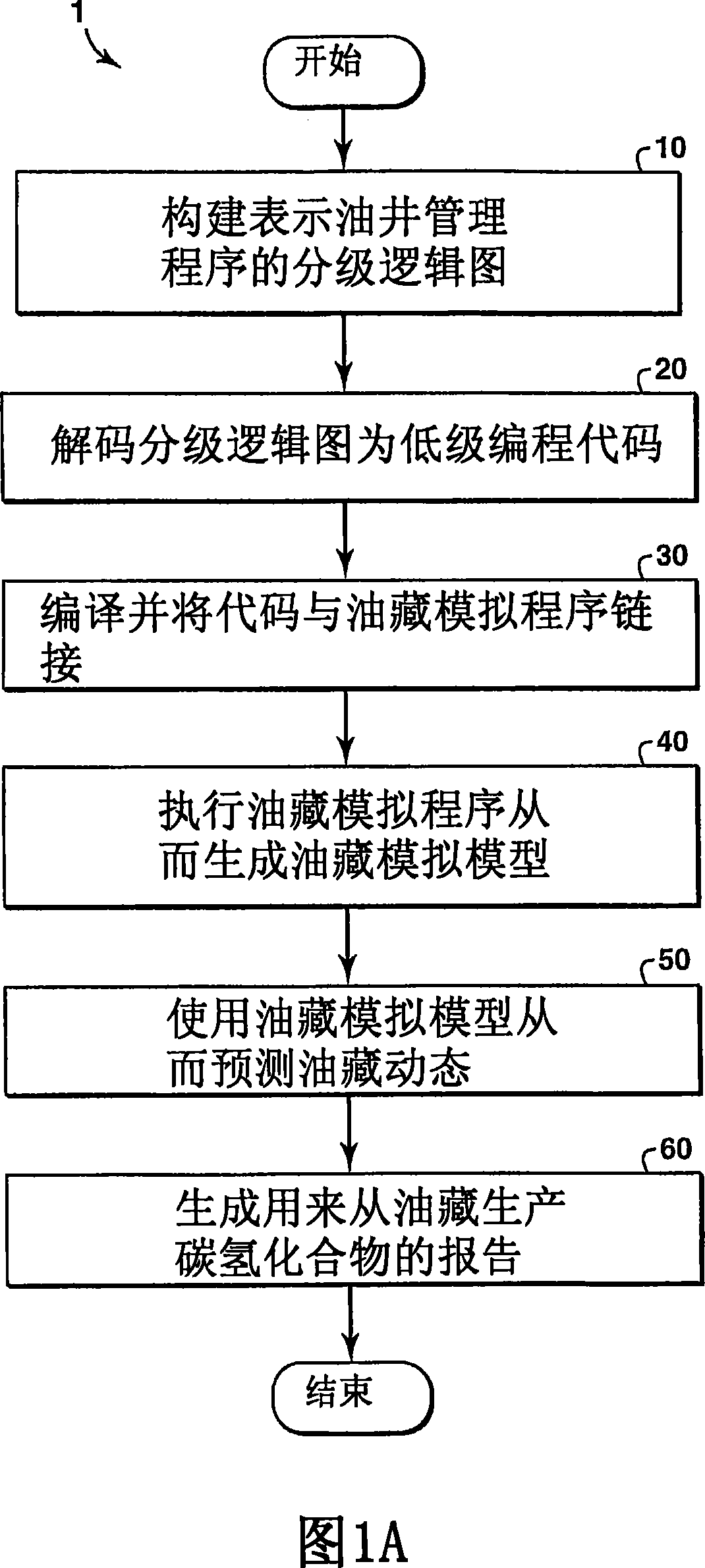

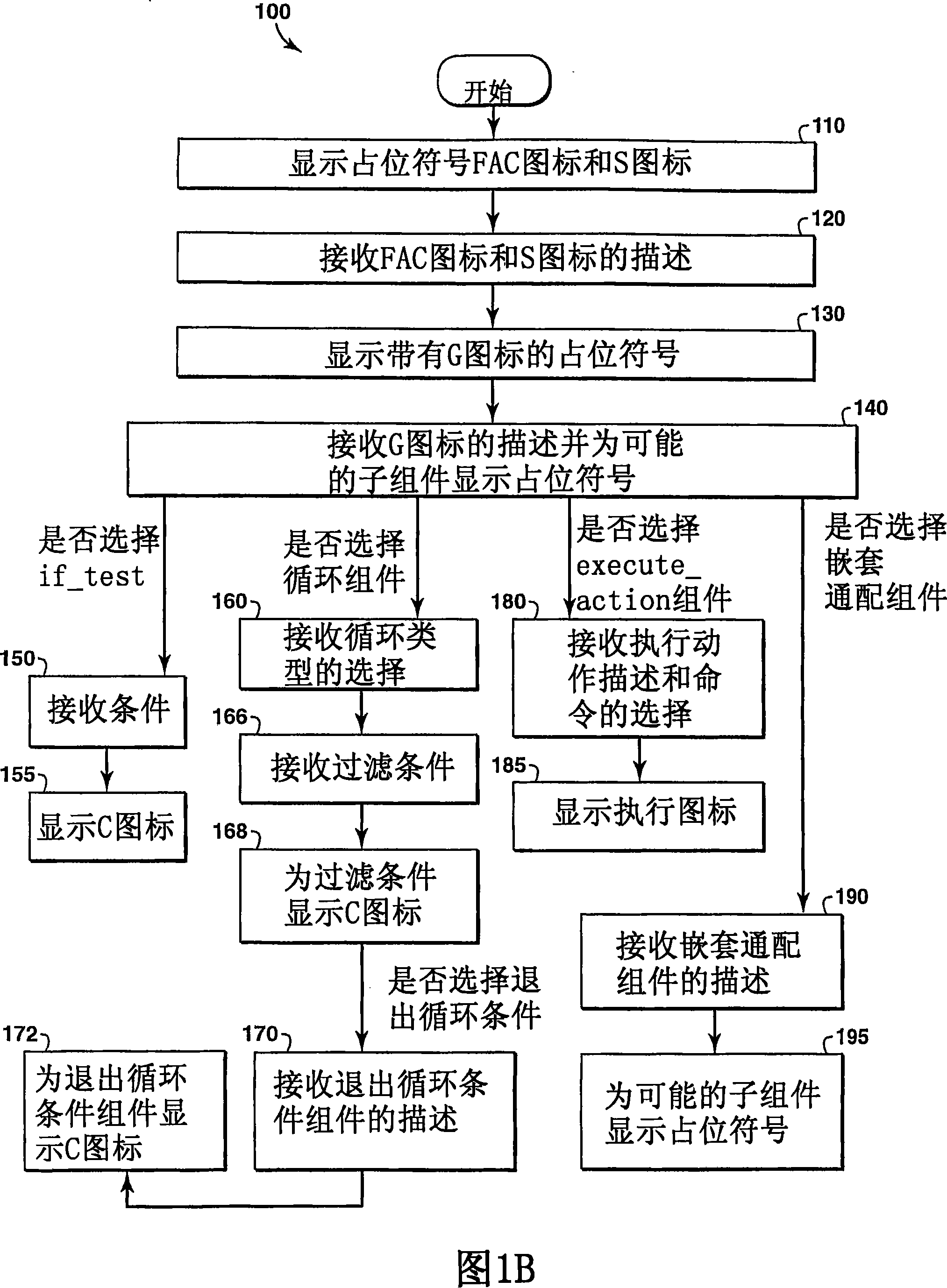

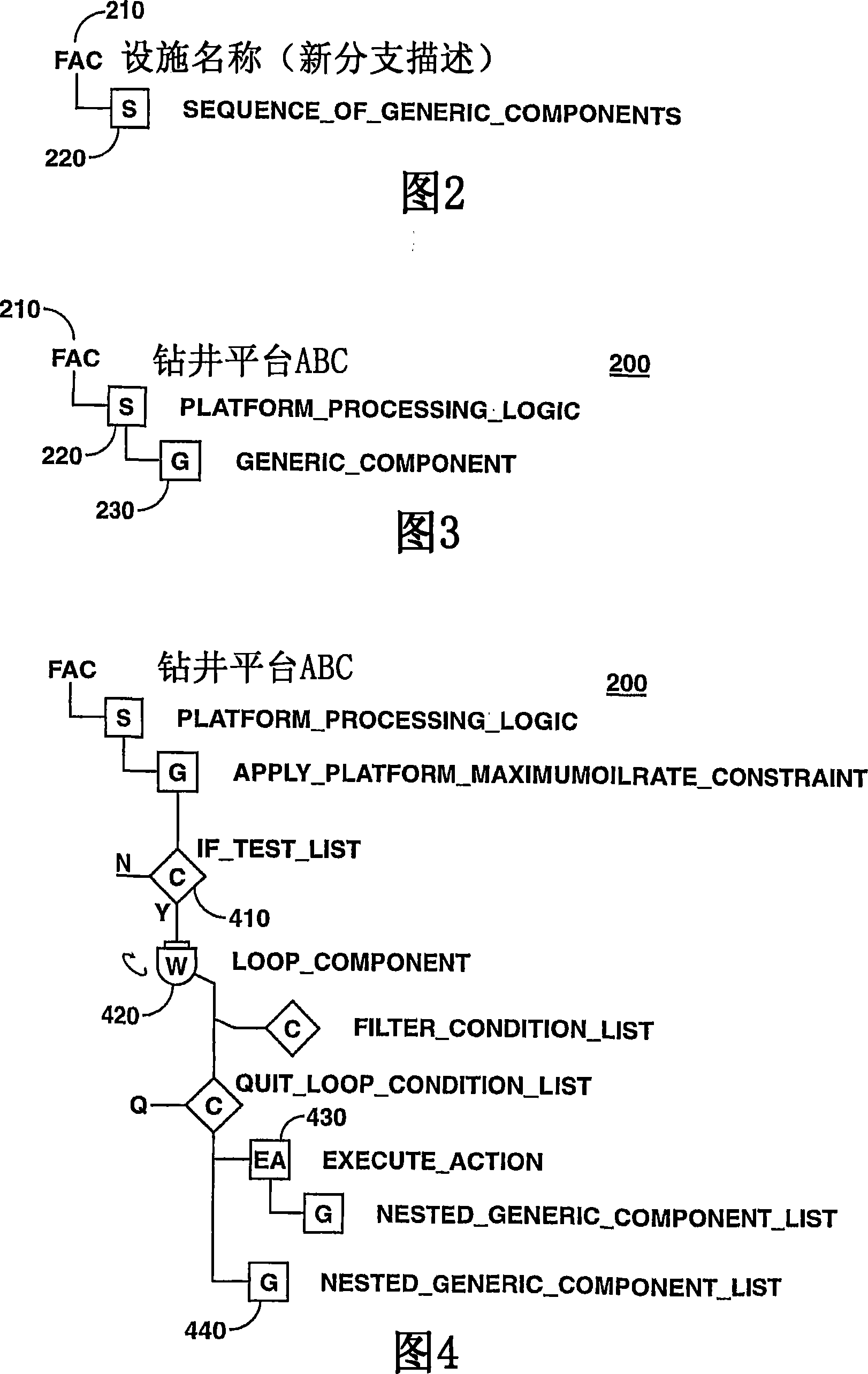

High-level graphical programming language and tool for oil well management programming

InactiveCN101203862APredict future stateIncrease mining volumeFluid removalVisual/graphical programmingGraphicsTheoretical computer science

A method of reservoir simulation comprising constructing a hierarchical logic diagram (10) having one or more components. Each component represents a set of programming code. The method further includes converting the hierarchical logic diagram into programming code (20) configured to manage a simulation of the reservoir (40).

Owner:EXXONMOBIL UPSTREAM RES CO

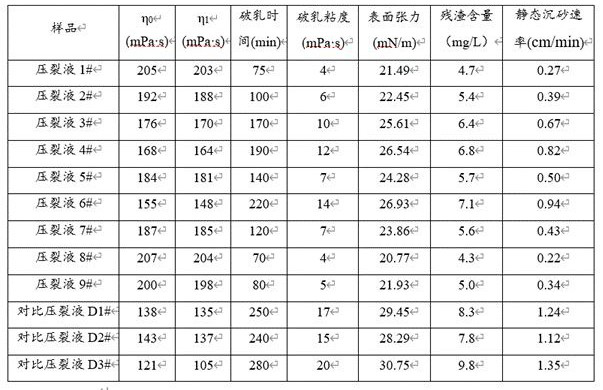

Composite carbon dioxide fracturing fluid and preparation method thereof

ActiveCN113881424AImprove sand carrying capacityImprove foam stabilityDrilling compositionPolymer scienceFracturing fluid

The invention discloses a composite carbon dioxide fracturing fluid and a preparation method thereof, belonging to the technical field of carbon dioxide fracturing. The composite carbon dioxide fracturing fluid comprises the following components in parts by weight: 10-20 parts of gaseous carbon dioxide, 0.1-2 parts of a thickening agent, 0.2-4 parts of ethanol and 80-100 parts of liquid carbon dioxide, wherein the thickening agent is obtained through polymerization of a first monomer and a second monomer, the first monomer is obtained through a reaction of N,N-diethyl-2-chloroacetamide, 4-hydroxybutyl vinyl ether and 1,4-butyl sultone, and the second monomer is obtained through a reaction of 9-decenal and benzylamine. The fracturing fluid is simple in formula, convenient to construct on site and small in damage to strata; and the thickening agent is formed by polymerizing the first monomer and the second monomer, is good in solubility in carbon dioxide, has excellent sand-carrying capacity and can remarkably improve the temperature resistance and shear resistance of the fracturing fluid.

Owner:SHANDONG DESHI CHEM IND CO LTD +1

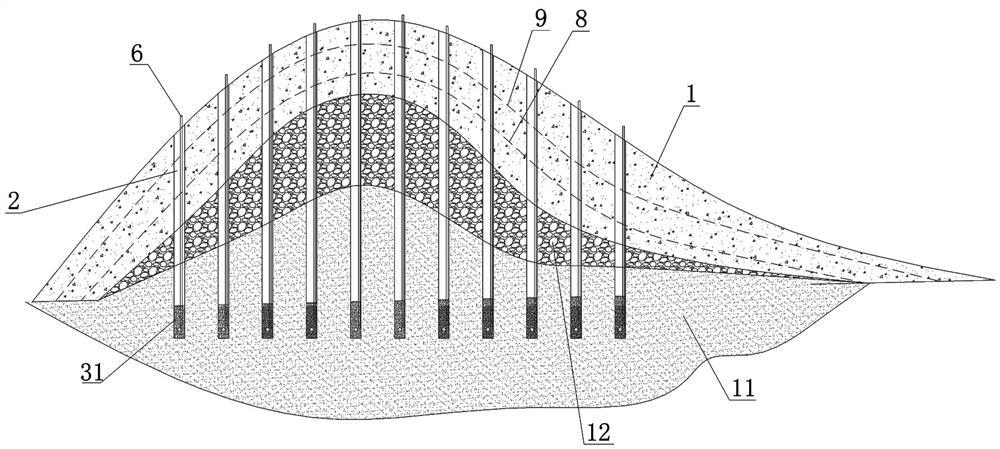

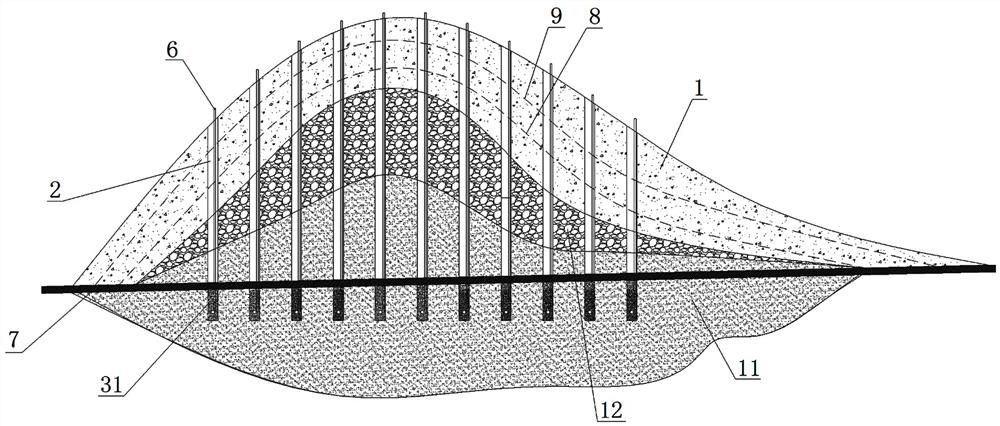

A kind of in-situ leaching mining method of ion-type rare earth ore

ActiveCN109469472BIncrease mining volumeSimplify mining processFluid removalProcess efficiency improvementAutomatic controlMineralogy

The invention discloses an ionic type rare earth ore in-situ leaching and mining method. The method includes the steps of extracting ionic type rare earth ore liquid from a shallow mine layer and extracting ionic type rare earth ore liquid from a deep mine layer. The method has the advantages that the mining process is simple, mining is safe, the mining amount of the ionic type rare earth ore liquid is improved, seepage pressure can be monitored in real time, and automatic control and precise liquid injection are realized.

Owner:四川共拓岩土科技股份有限公司

A drilling and splitting integrated machine and an explosion-free excavator

ActiveCN104727819BImprove work efficiencyReduce energy consumptionDisloding machinesSlitting machinesEngineeringExcavator

The invention provides an explosion-free machine and an explosion-free excavator. The explosion-free machine comprises a supporting mechanism, a slewing mechanism, a rock drilling machine and a splitting machine, wherein the slewing mechanism is arranged on the supporting mechanism; the rock drilling machine and the splitting machine are arranged on the slewing mechanism along the axial direction, can be driven to concyclically slew by the slewing mechanism and can move along the axial direction of the slewing mechanism. The explosion-free excavator comprises a hydraulic driving system and the explosion-free machine, wherein the explosion-free machine is fixedly connected to the explosion-free excavator through the supporting mechanism; the hydraulic driving system is capable of driving and controlling the slewing mechanism, the rock drilling machine and the splitting machine. According to the explosion-free machine, the rock drilling machine and the splitting machine can concyclically slew, so that the splitting machine can be accurately inserted into a drill hole without manually adjusting an angle, and the working efficiency of the explosion-free machine is improved; furthermore, the explosion-free machine further has the advantages that the energy consumption is low, the exploitation quantity is high, the equipment cost is low, and the damage caused to equipment in the operation is relatively little.

Owner:武安市精诚机械设备科技有限公司

Self-positioning system and self-positioning method for coal mining machine

ActiveCN102287186BEasy to operateHigh degree of intelligenceMeasurement devicesDriving meansEngineeringSelf positioning

The invention discloses a self-positioning system and a self-positioning method for a coal mining machine. The self-positioning system comprises a controller, a walking position detection unit for detecting a walking position of the coal mining machine in real time, a left mining height detection unit for detecting the mining height of a left rocker arm of the coal mining machine in real time, a right mining height detection unit for detecting the mining height of a right rocker arm of the coal mining machine in real time, and a display unit and a parameter input unit which are connected withthe controller. The self-positioning method comprises the following steps of: 1, inputting initial parameters; 2, synchronously performing self-positioning of the walking position of the coal mining machine and the mining heights of the rocker arms; and 3, outputting results. The invention has the advantages that: the self-positioning system is reasonable in design, easy and convenient to use andoperate, convenient to implement, good in using effect and high in positioning accuracy, can automatically accurately position the walking position of the coal mining machine and the mining heights of the rocker arms, and various practical problems that the conventional coal mining machine has low automation and intelligent degrees, does not have self-positioning function, has high labor intensity and poor using effect and the like are effectively solved.

Owner:XIAN COAL MINING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com