Super-heavy-oil oil reservoir mining mechanism and method

A production method and oil-oil technology, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems of unknown temperature in the area above the horizontal well net and small cycle preheating range, so as to shorten the production time, The effect of reducing mining costs and increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

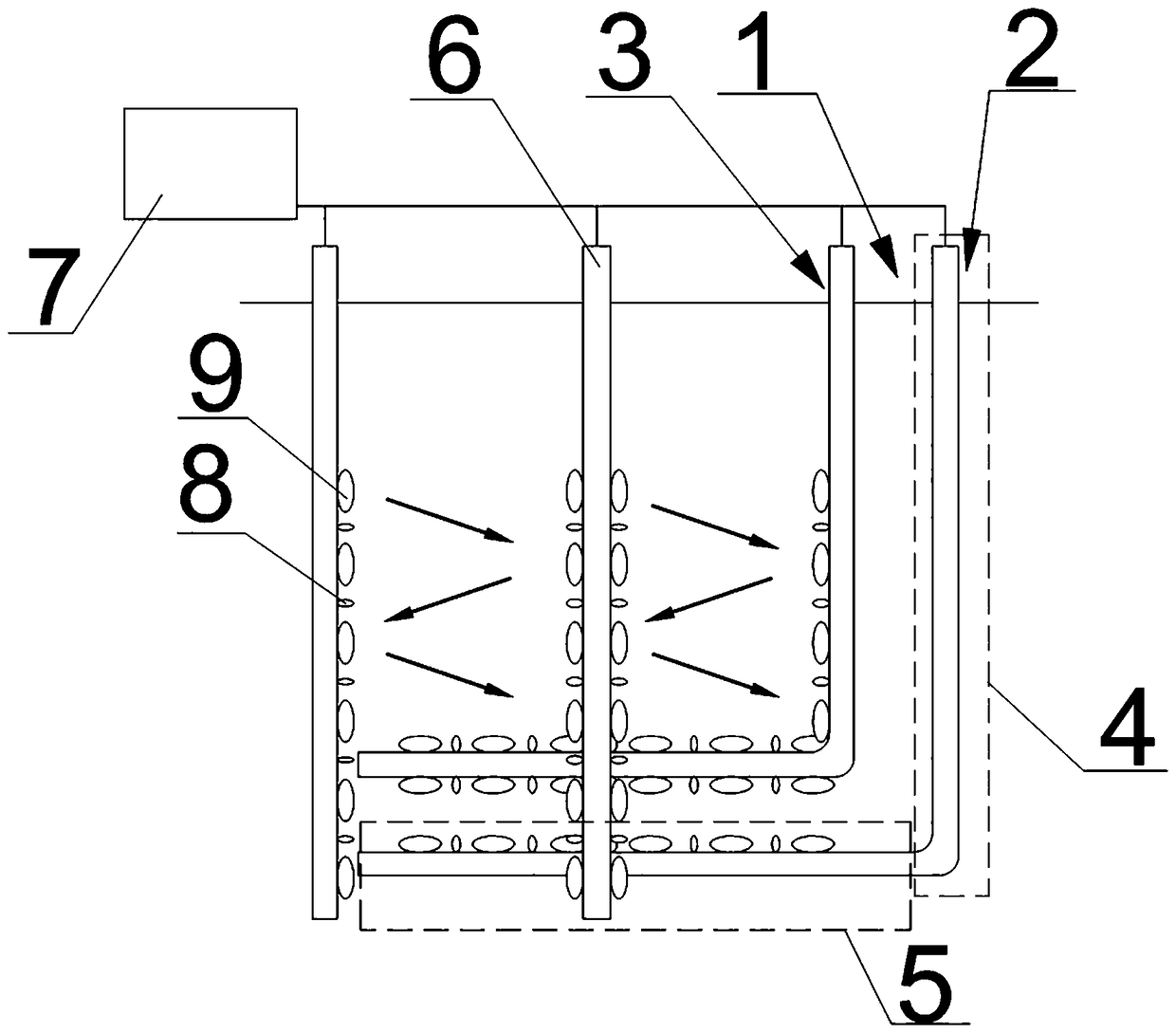

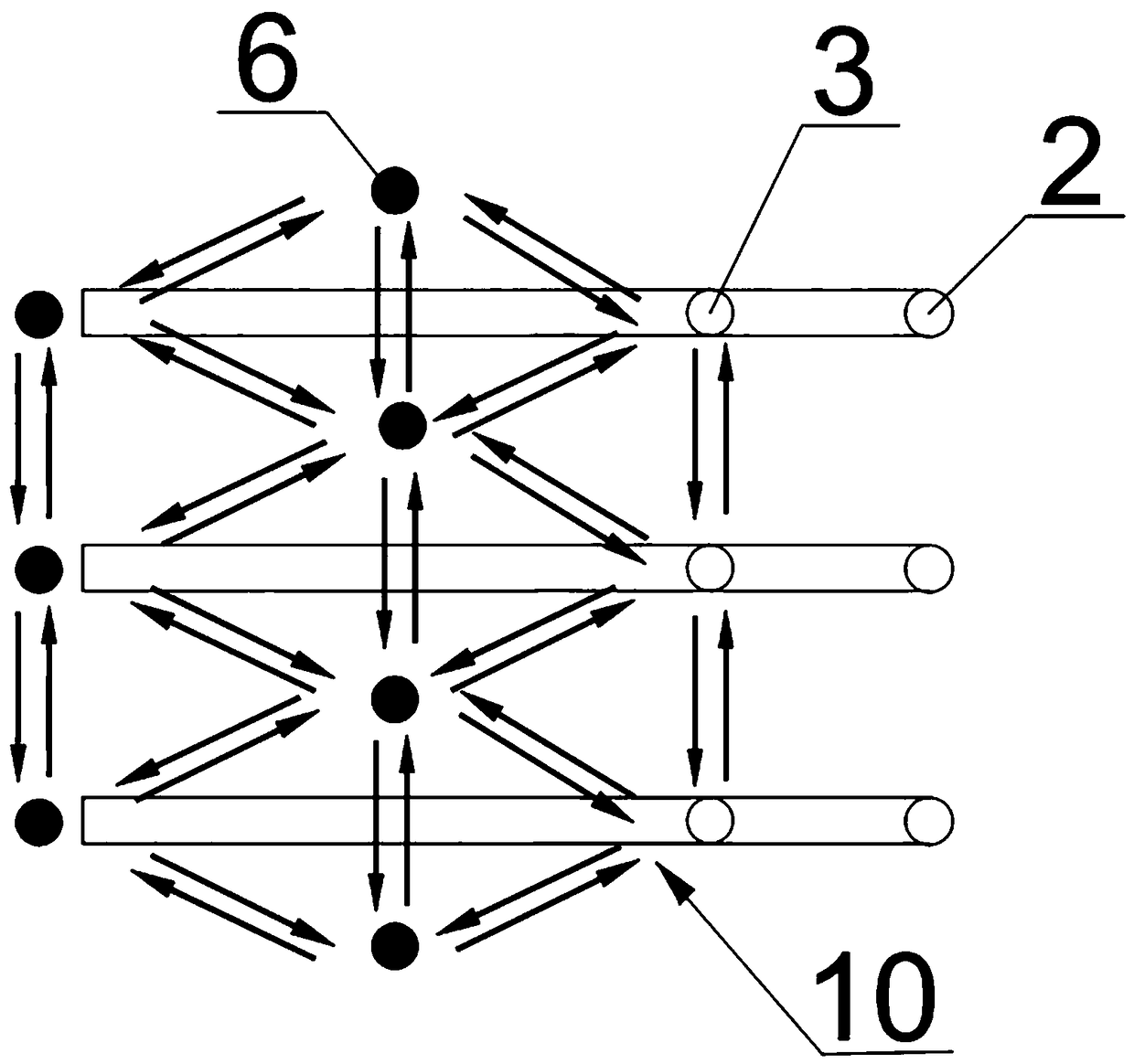

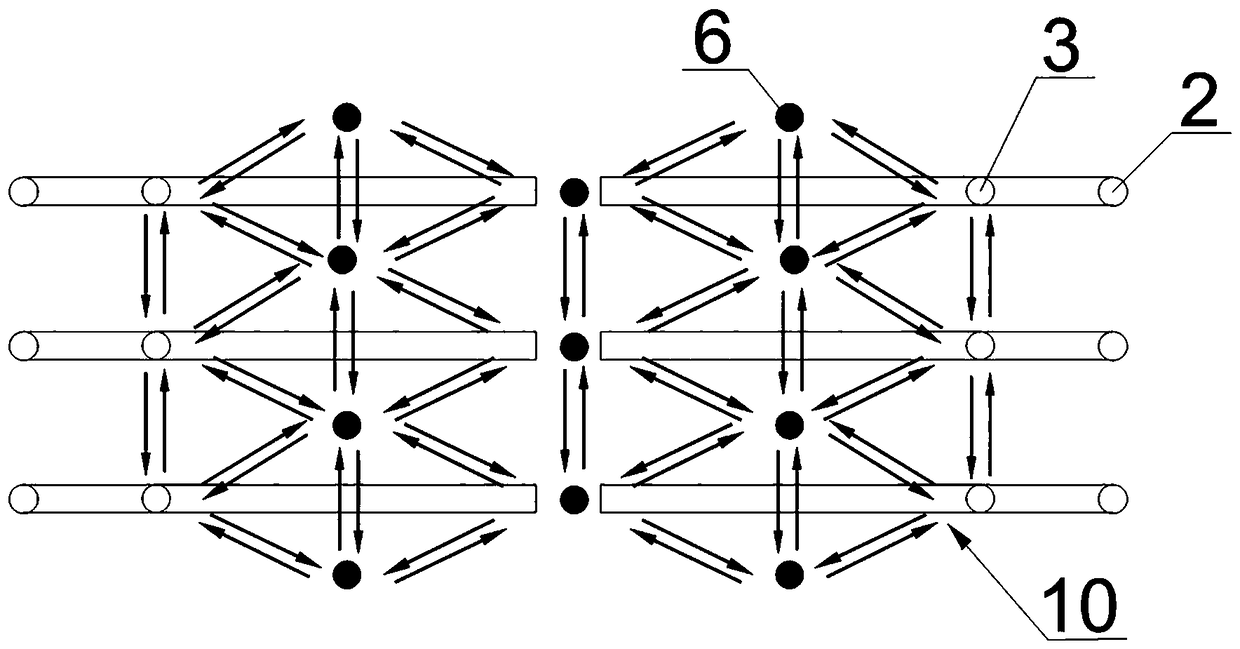

[0031] Such as figure 1 and figure 2 As shown, the present invention provides a super heavy oil reservoir production mechanism, including at least one group of production groups 10, each group of production groups 10 includes a horizontal well 1 and a vertical well 6; a horizontal well 1, which includes an upper horizontal well 3 and a lower water well Flat well 2 and horizontal well 1 both have horizontal section 5 and vertical section 4; vertical well 6 is arranged near horizontal well 1; microwave emitting device 8 and microwave reflecting device 9 are installed on the outside of vertical well 6, and microwave The microwave reflection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com