Patents

Literature

211 results about "Steam-assisted gravity drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

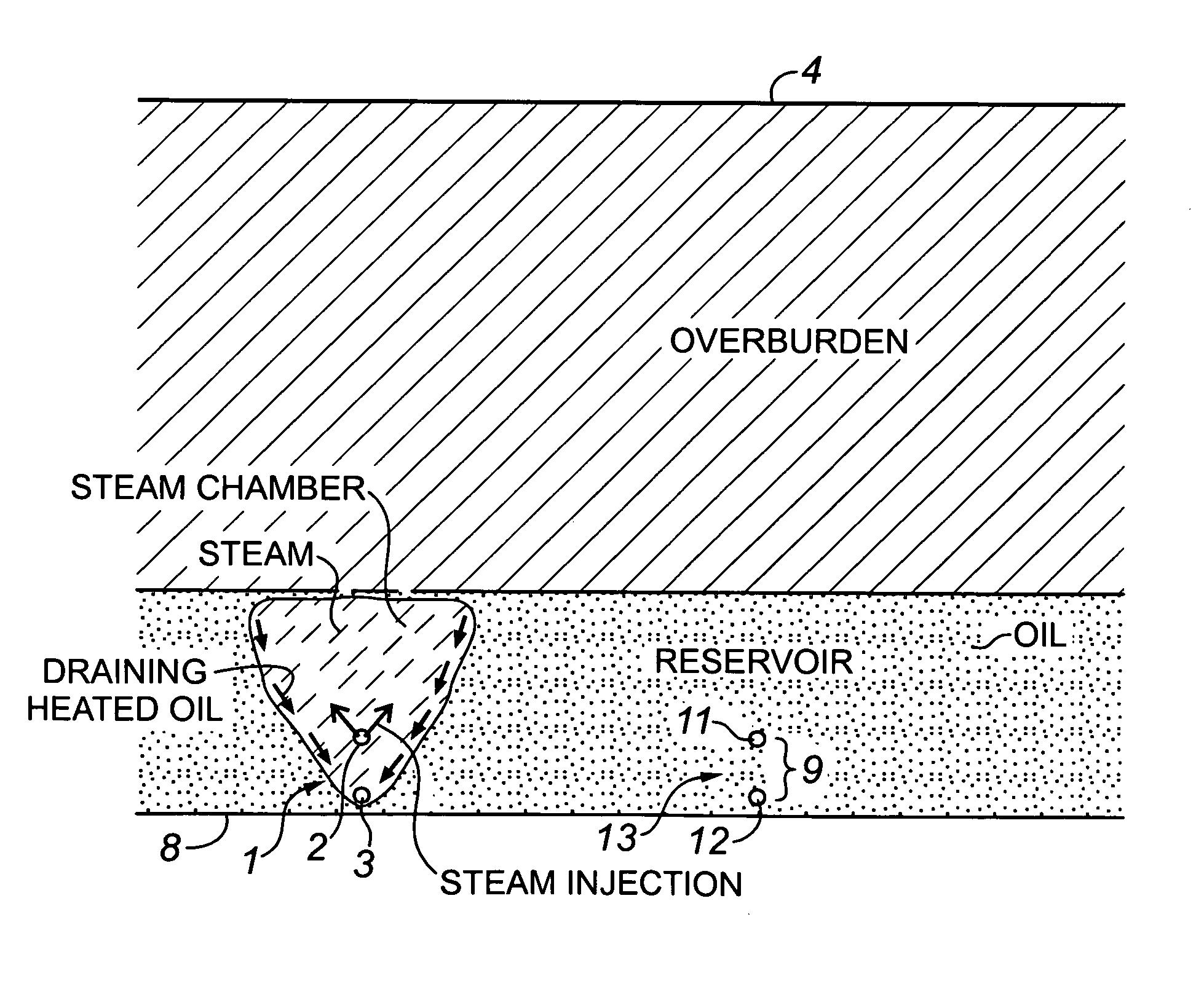

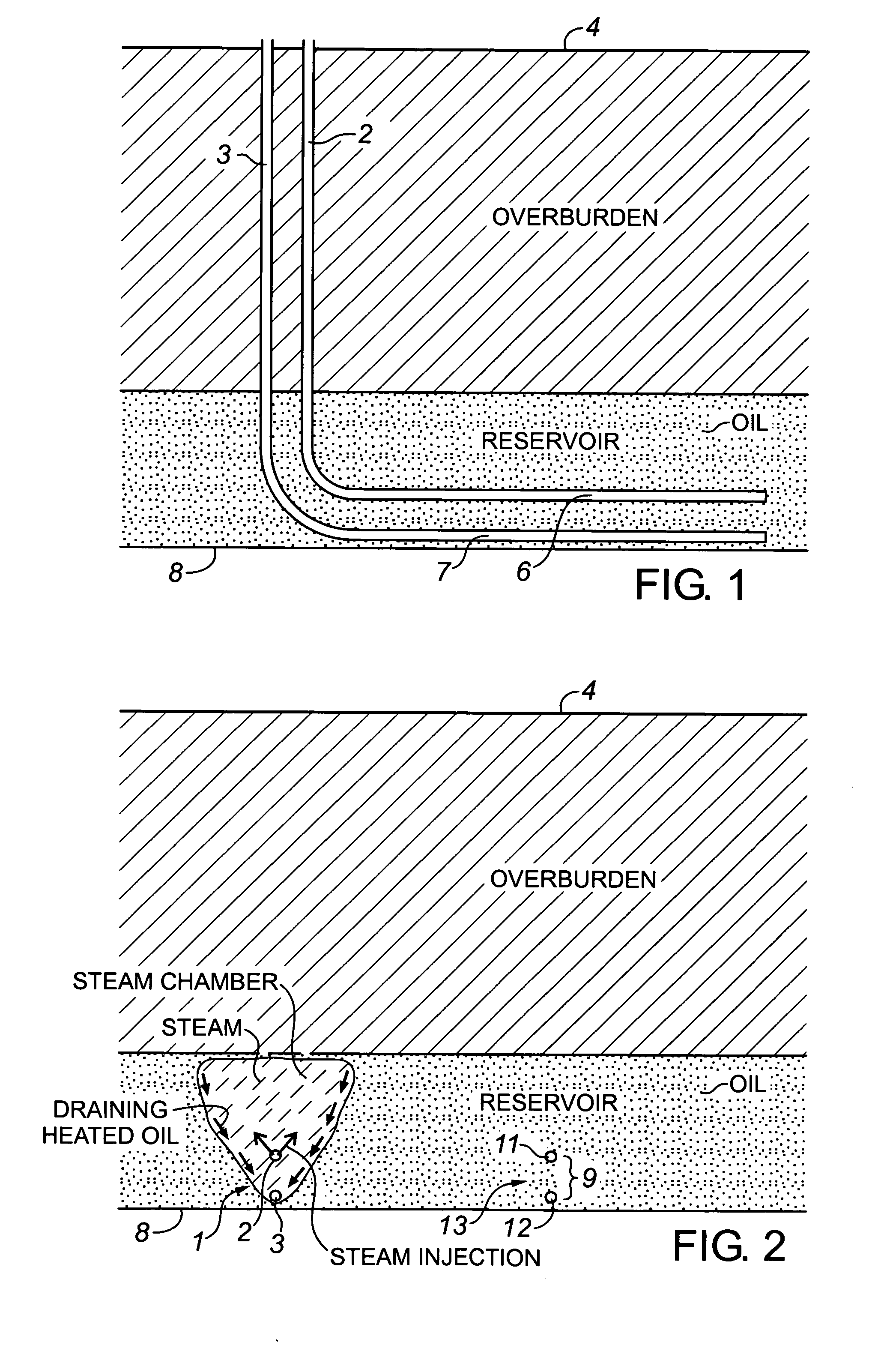

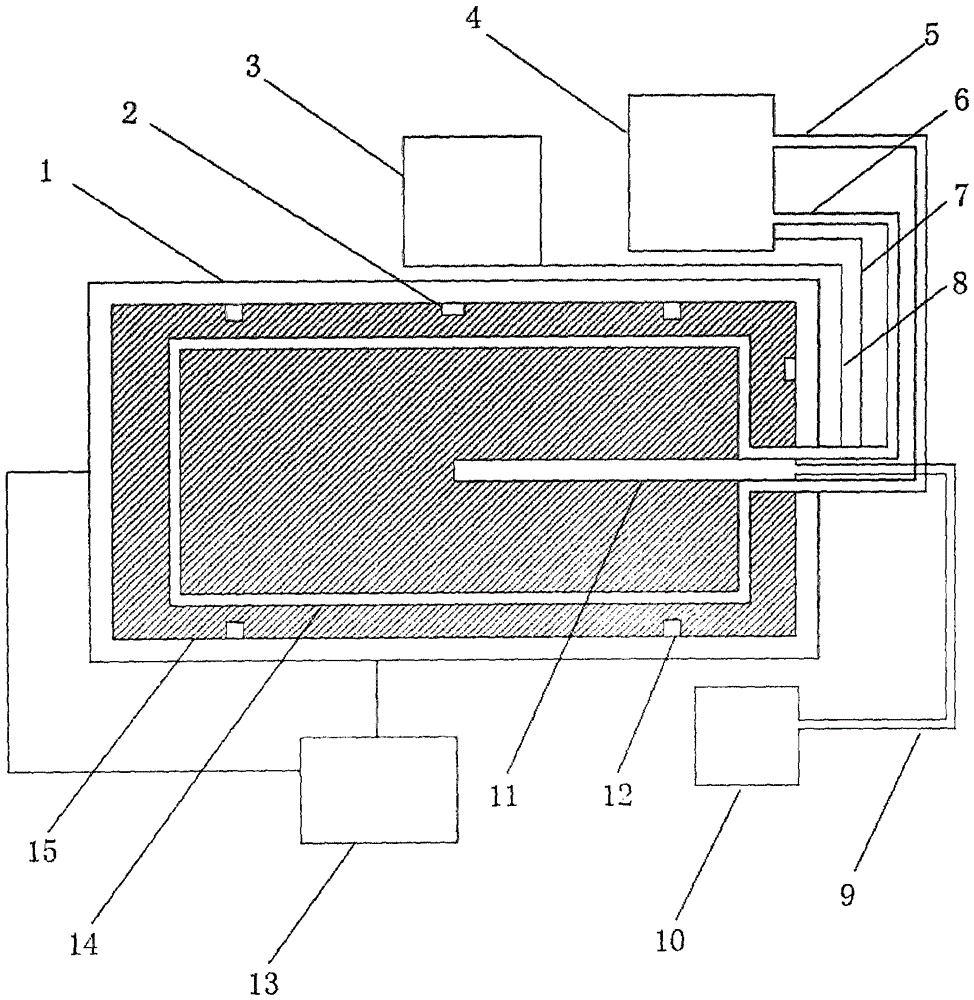

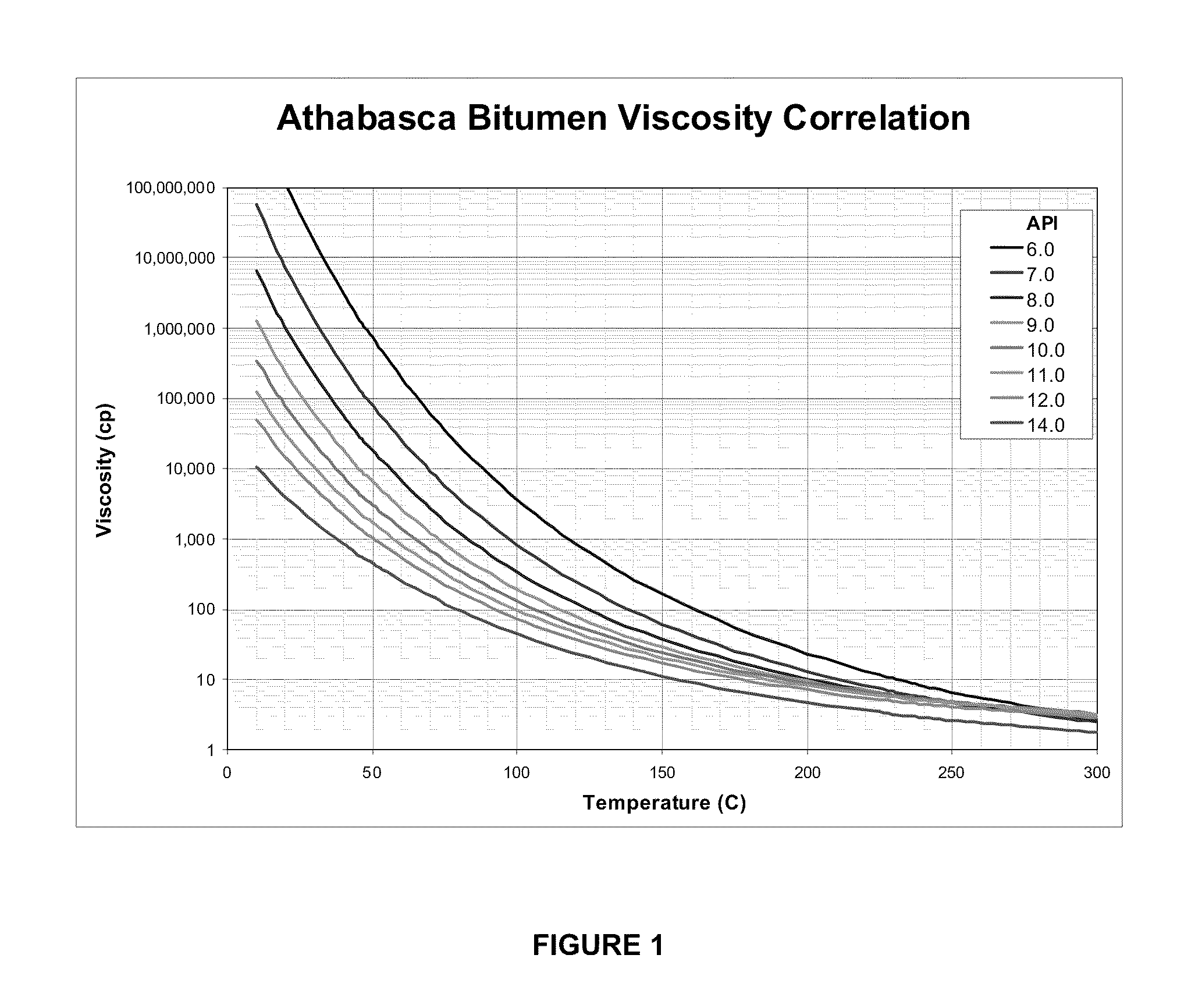

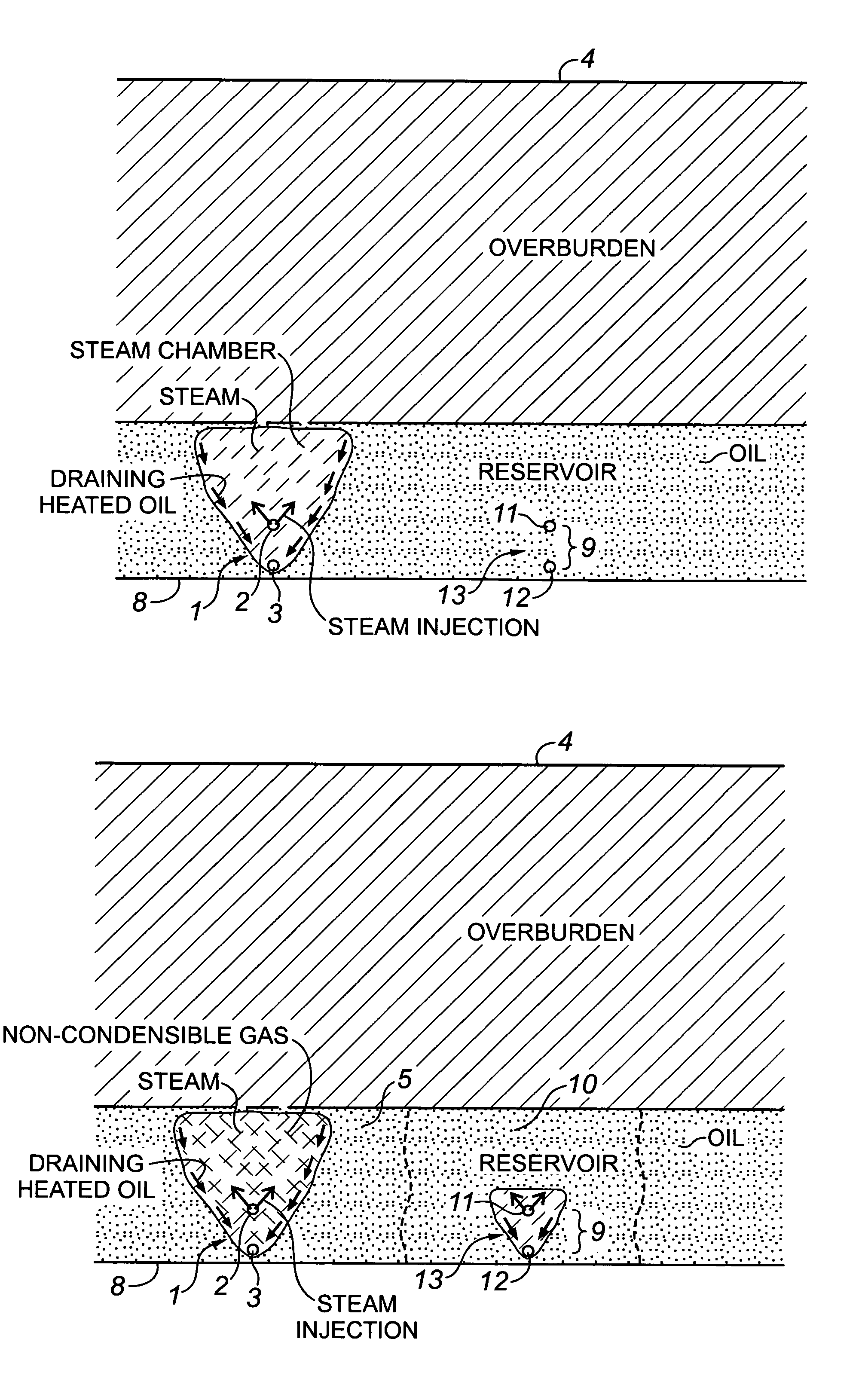

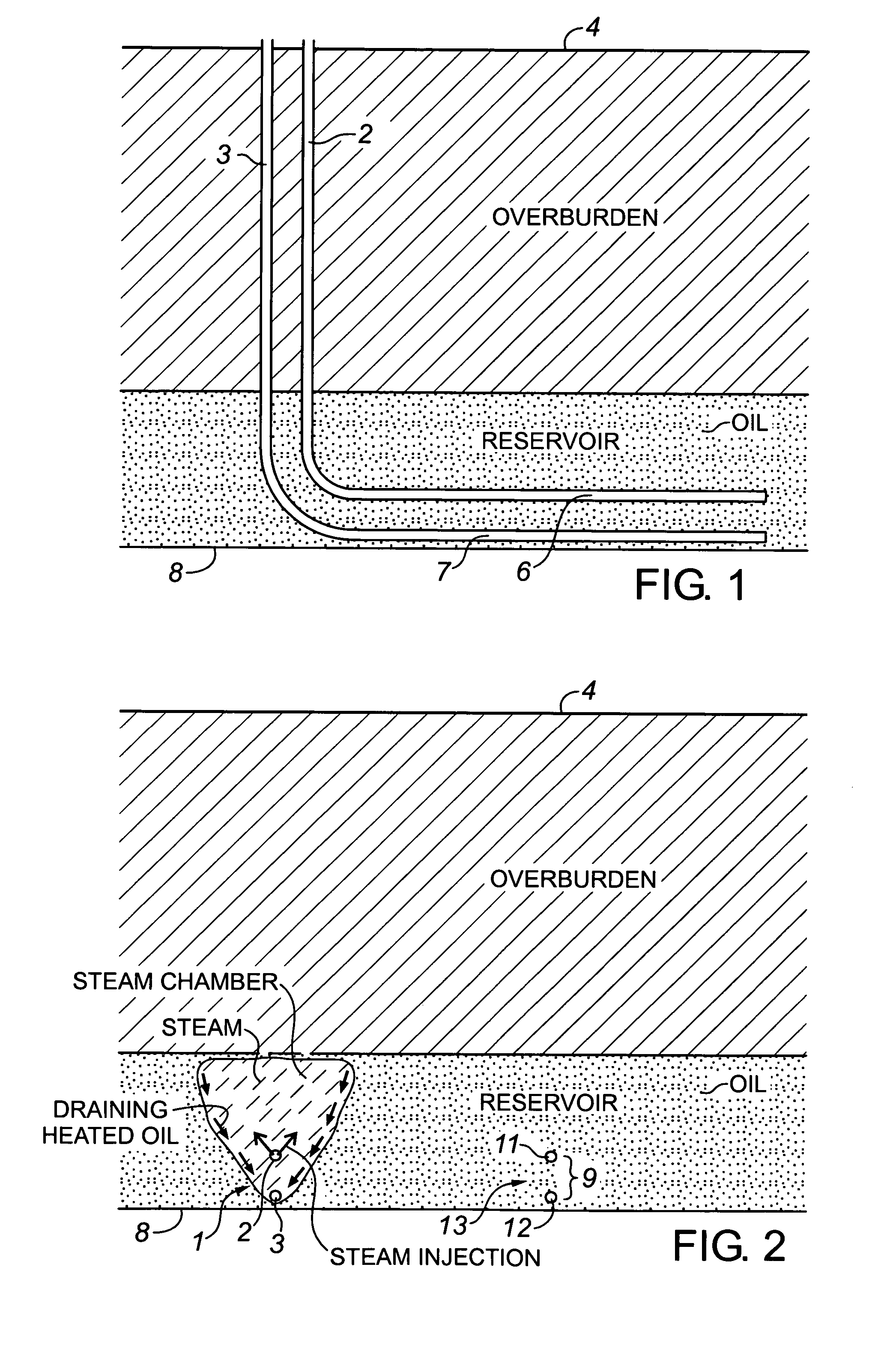

Steam-assisted gravity drainage (SAGD; "Sag-D") is an enhanced oil recovery technology for producing heavy crude oil and bitumen. It is an advanced form of steam stimulation in which a pair of horizontal wells is drilled into the oil reservoir, one a few metres above the other. High pressure steam is continuously injected into the upper wellbore to heat the oil and reduce its viscosity, causing the heated oil to drain into the lower wellbore, where it is pumped out. Dr. Roger Butler, engineer at Imperial Oil from 1955 to 1982, invented the steam assisted gravity drainage (SAGD) process in the 1970s. Butler "developed the concept of using horizontal pairs of wells and injected steam to develop certain deposits of bitumen considered too deep for mining". In 1983 Butler became director of technical programs for the Alberta Oil Sands Technology and Research Authority (AOSTRA), a crown corporation created by Alberta Premier Lougheed to promote new technologies for oil sands and heavy crude oil production. AOSTRA quickly supported SAGD as a promising innovation in oil sands extraction technology.

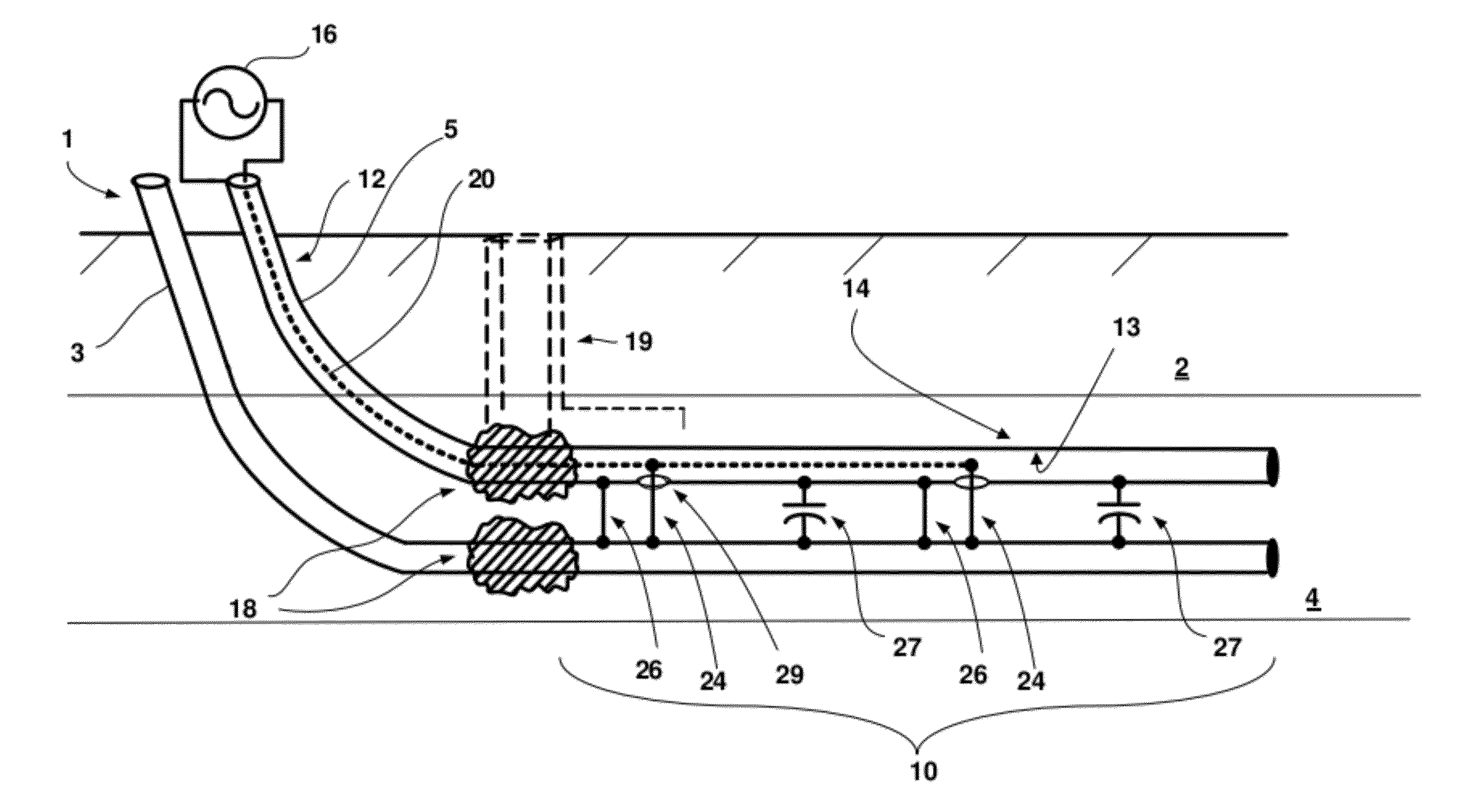

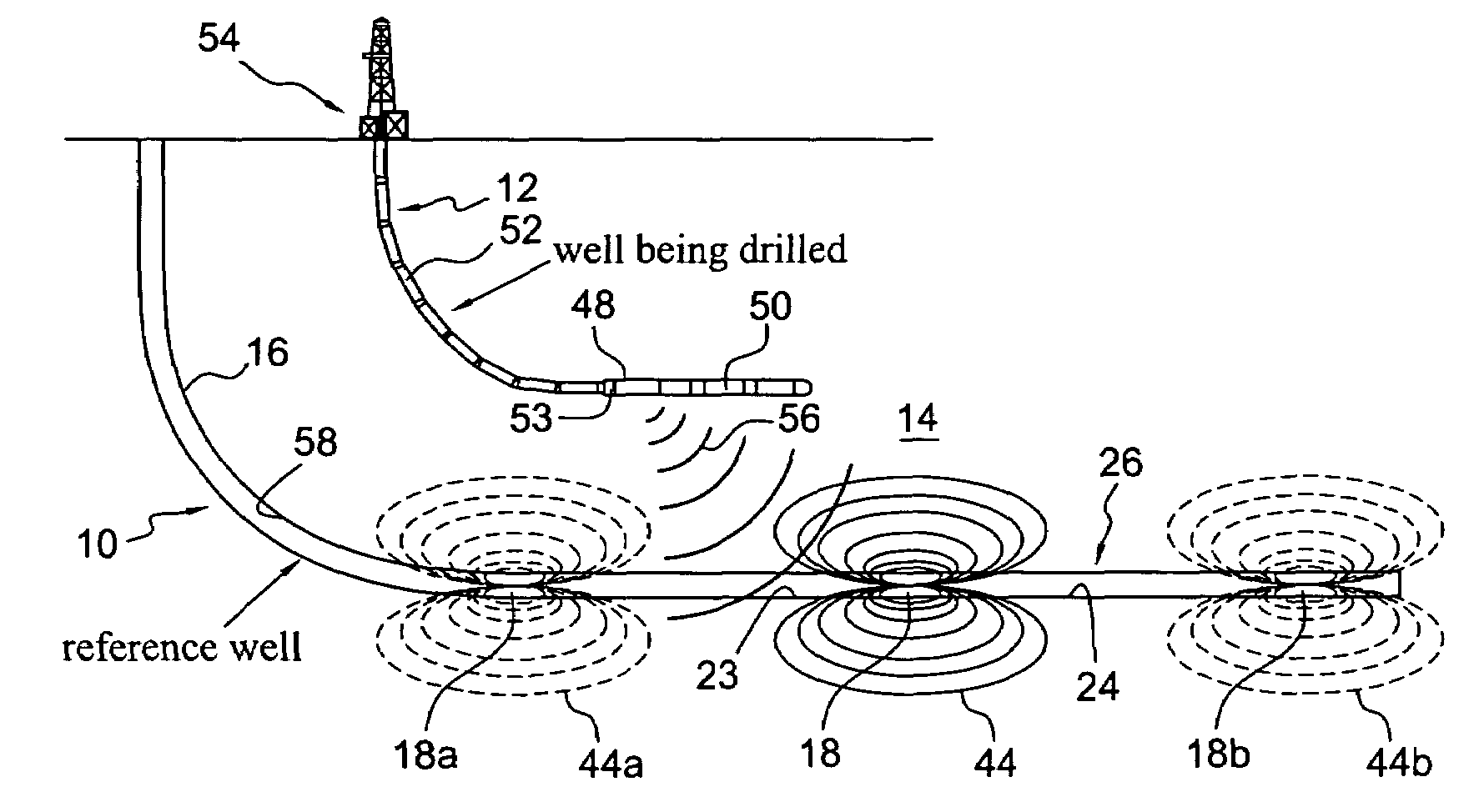

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

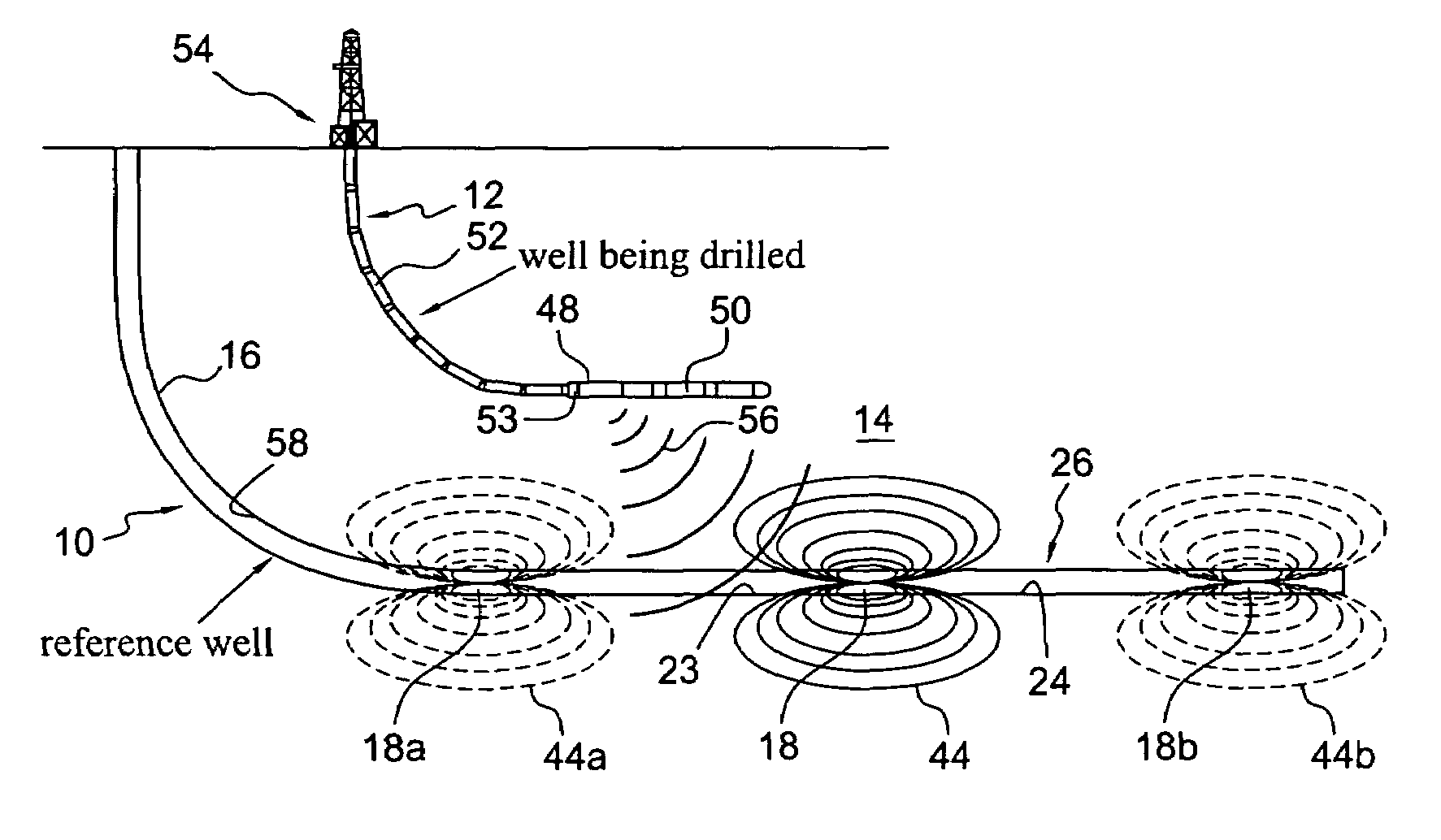

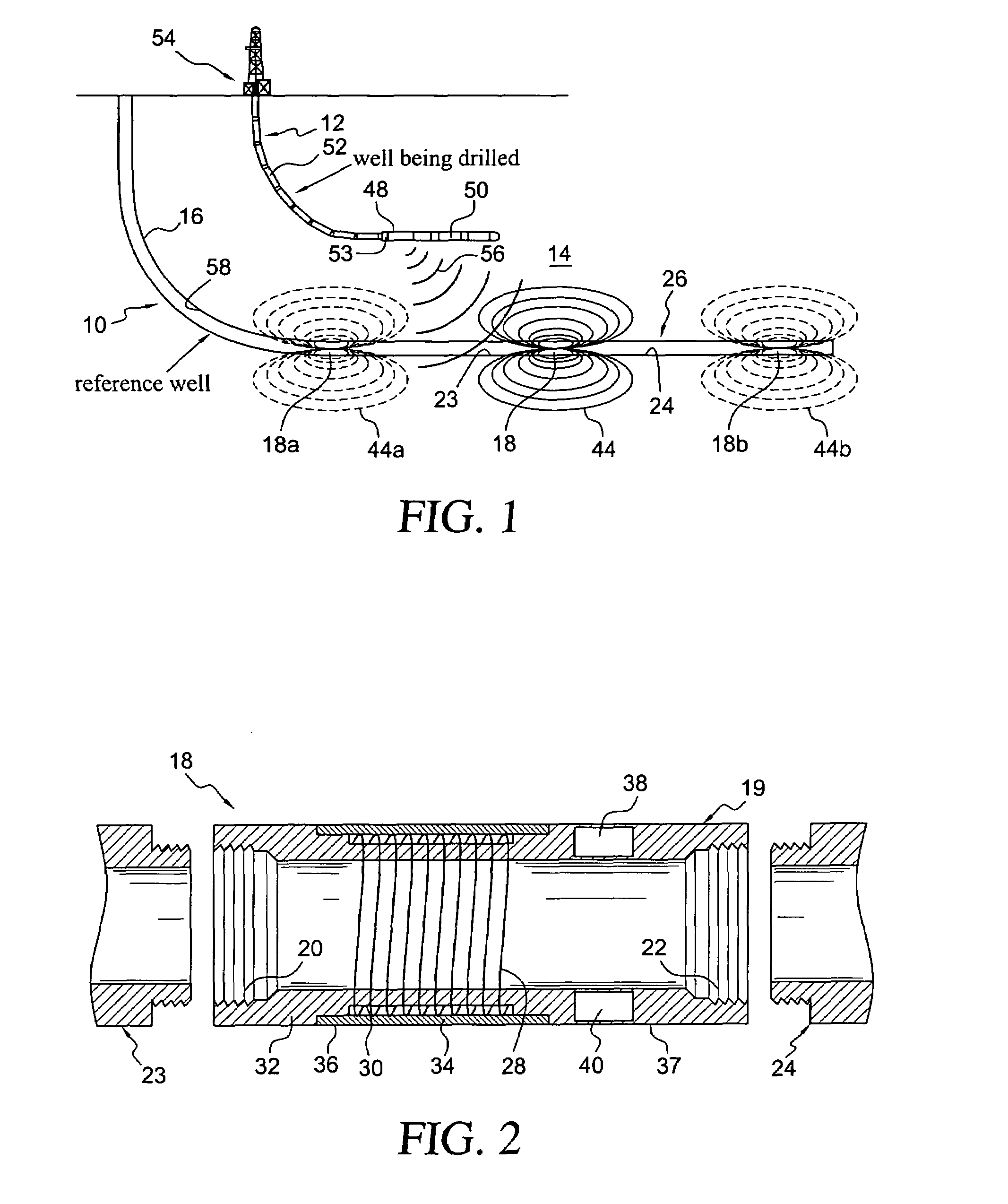

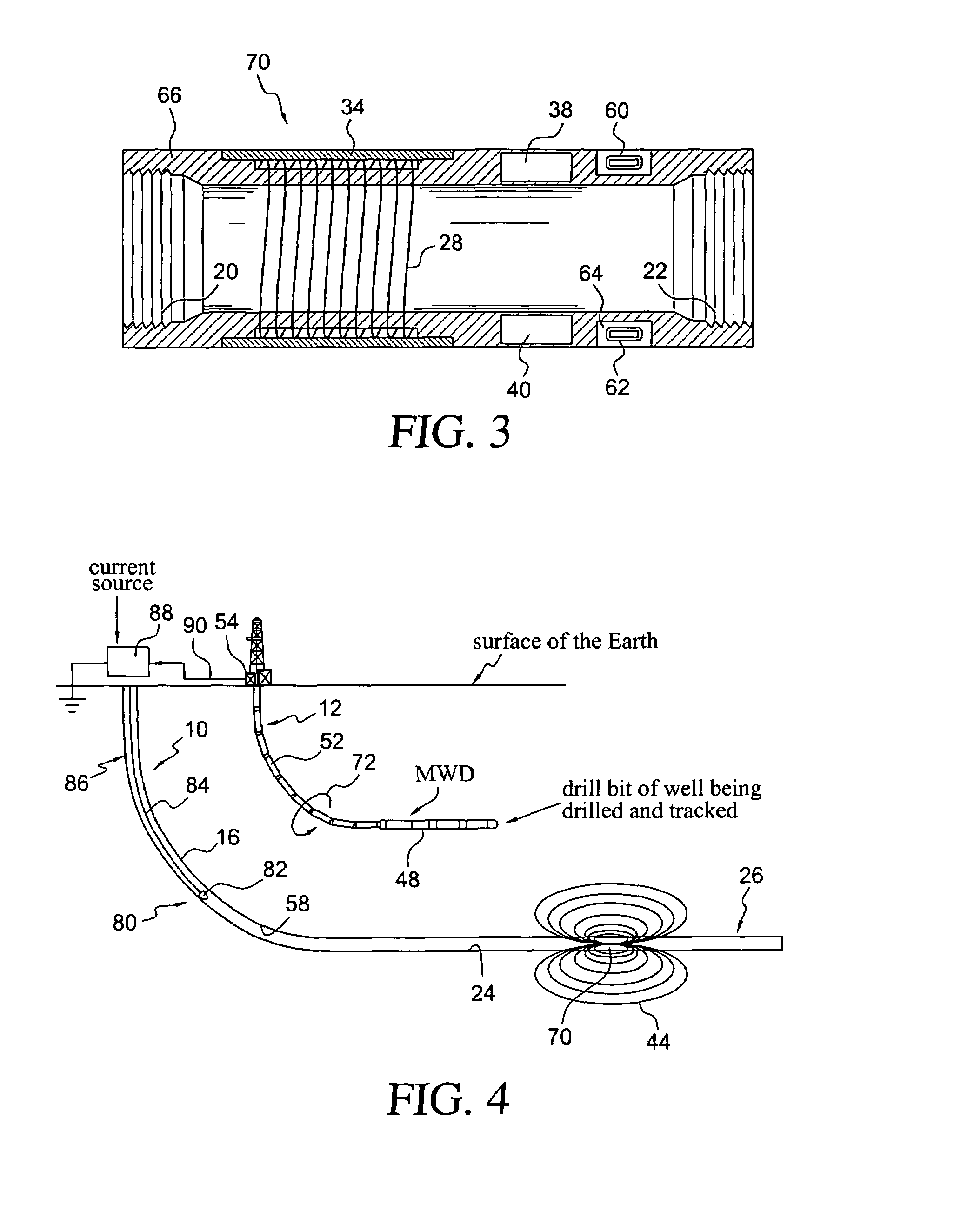

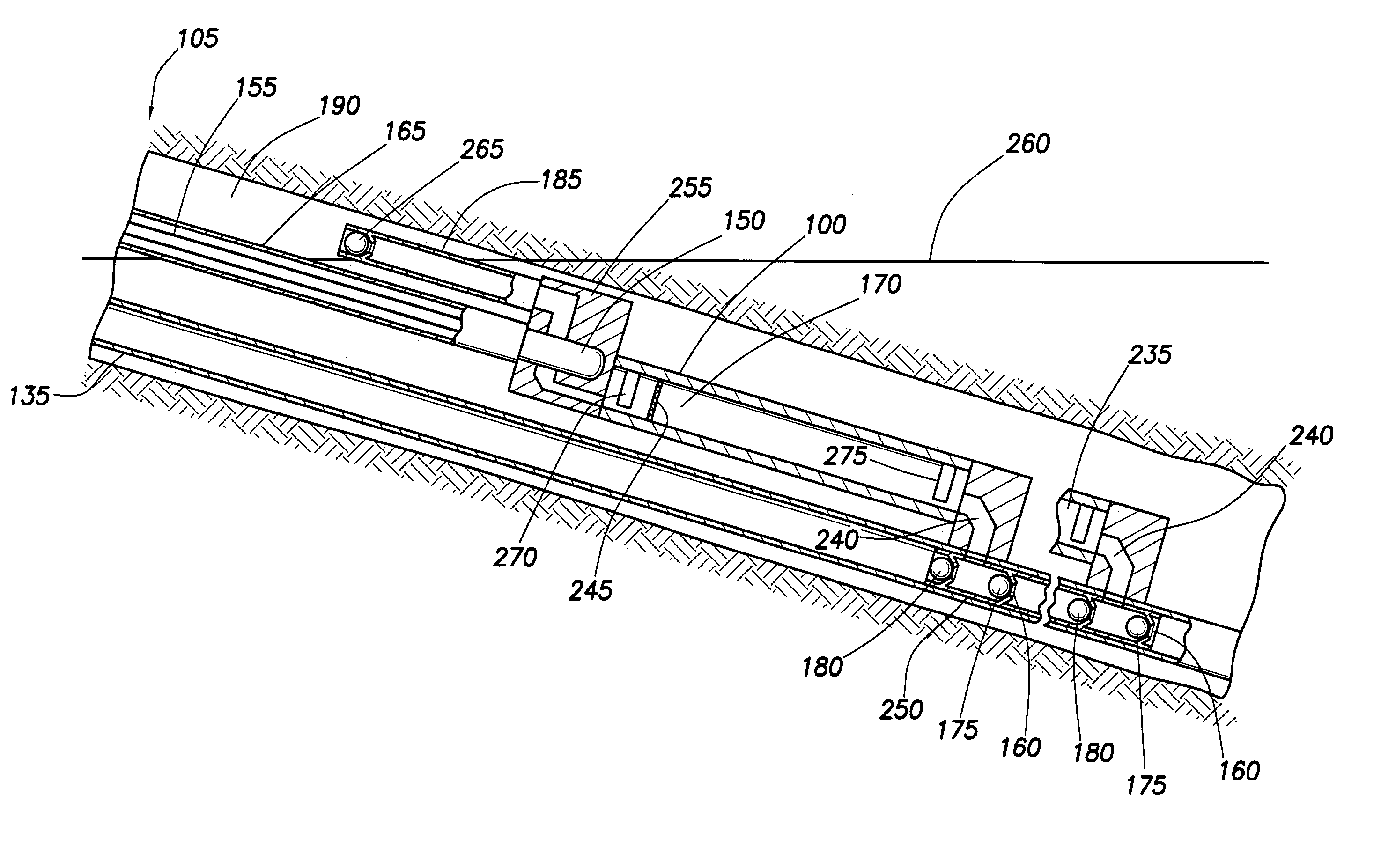

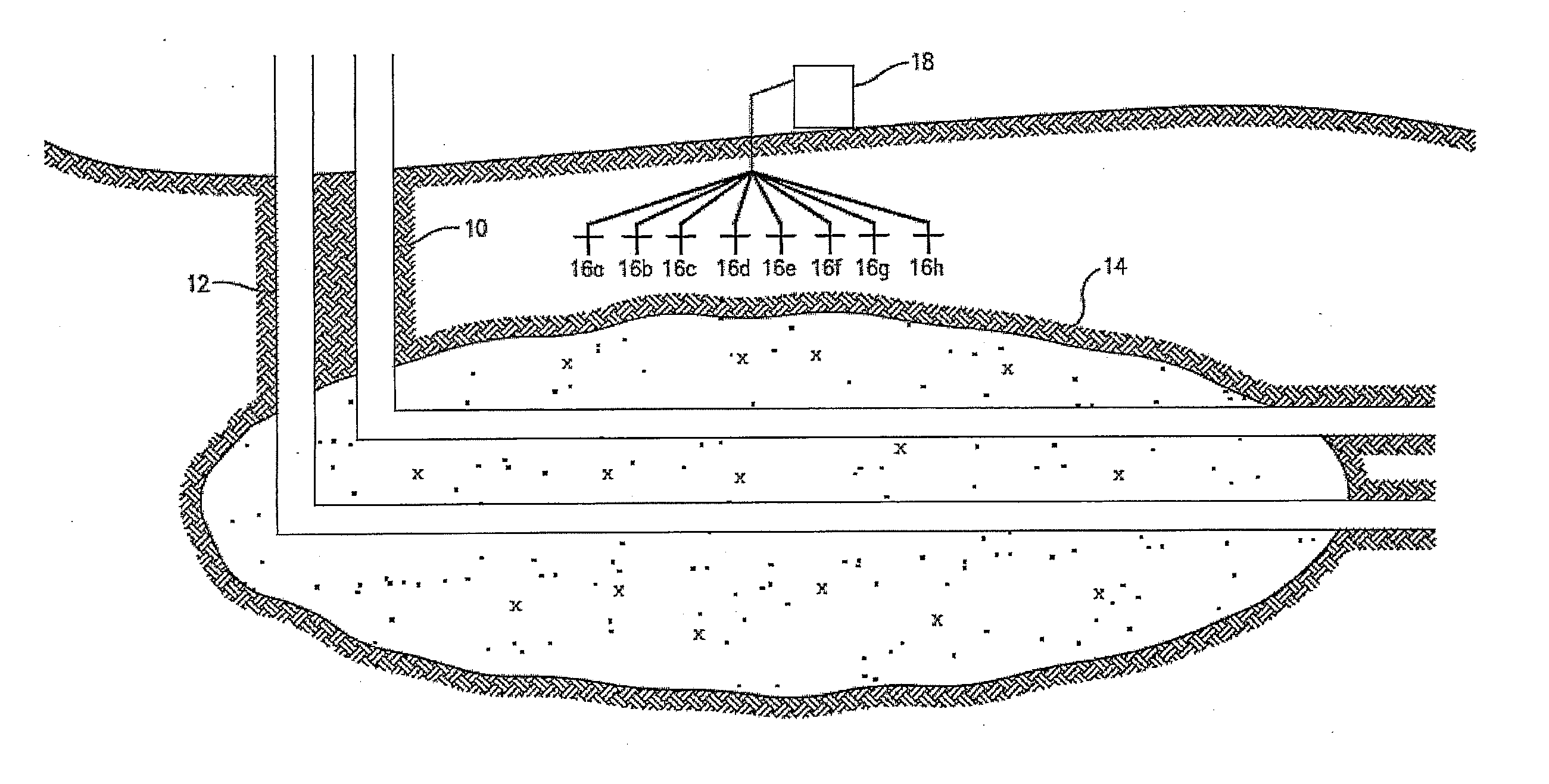

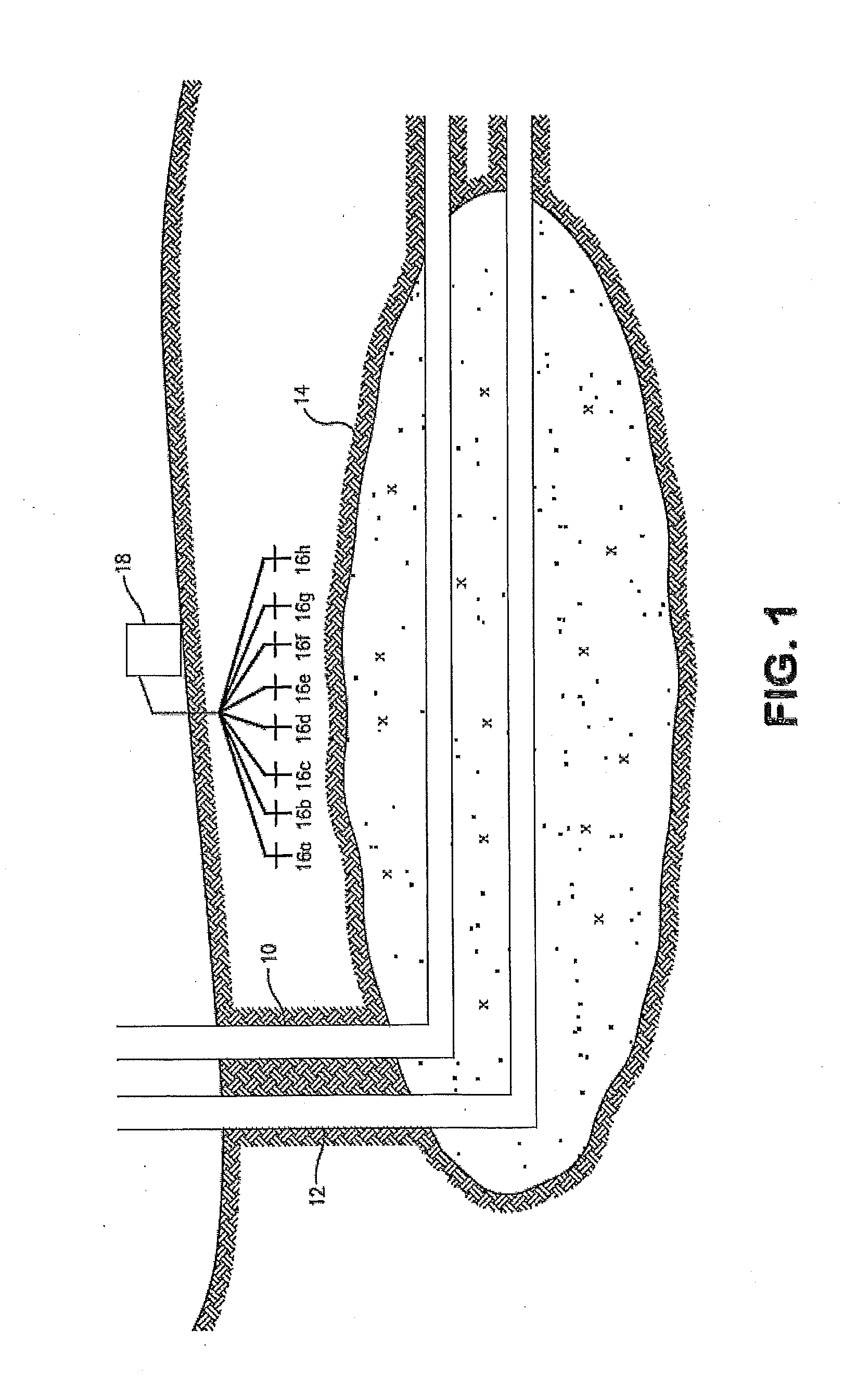

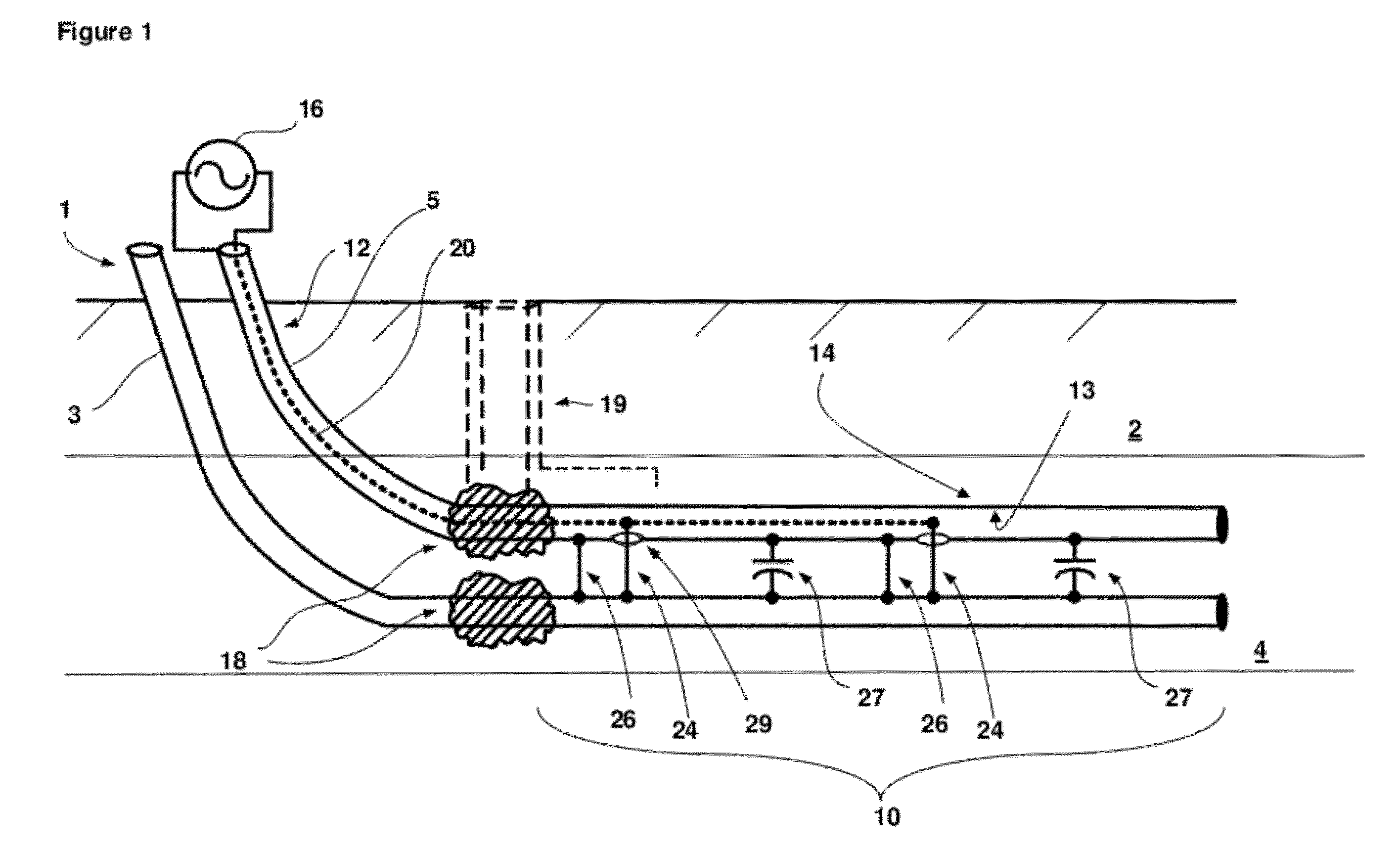

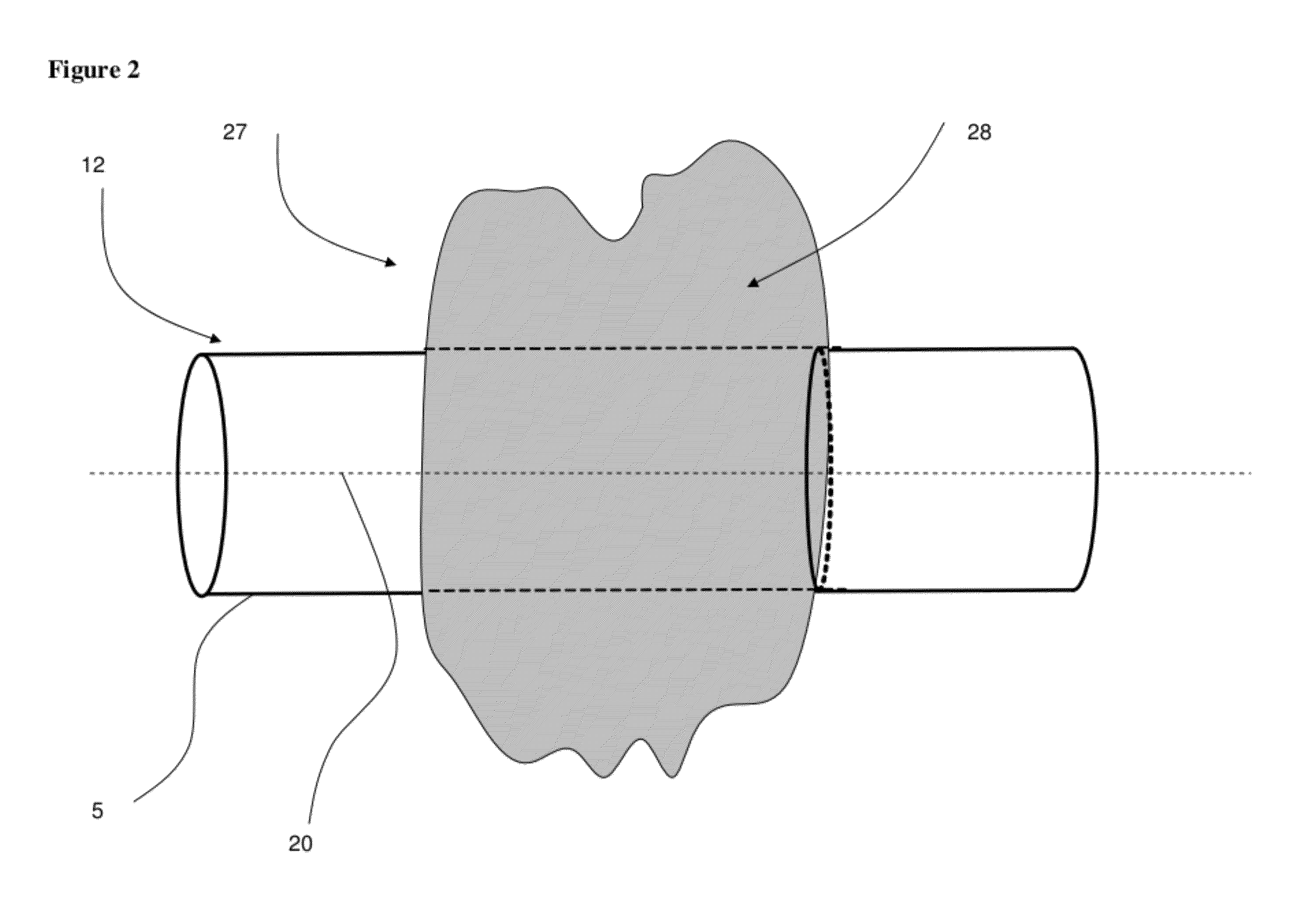

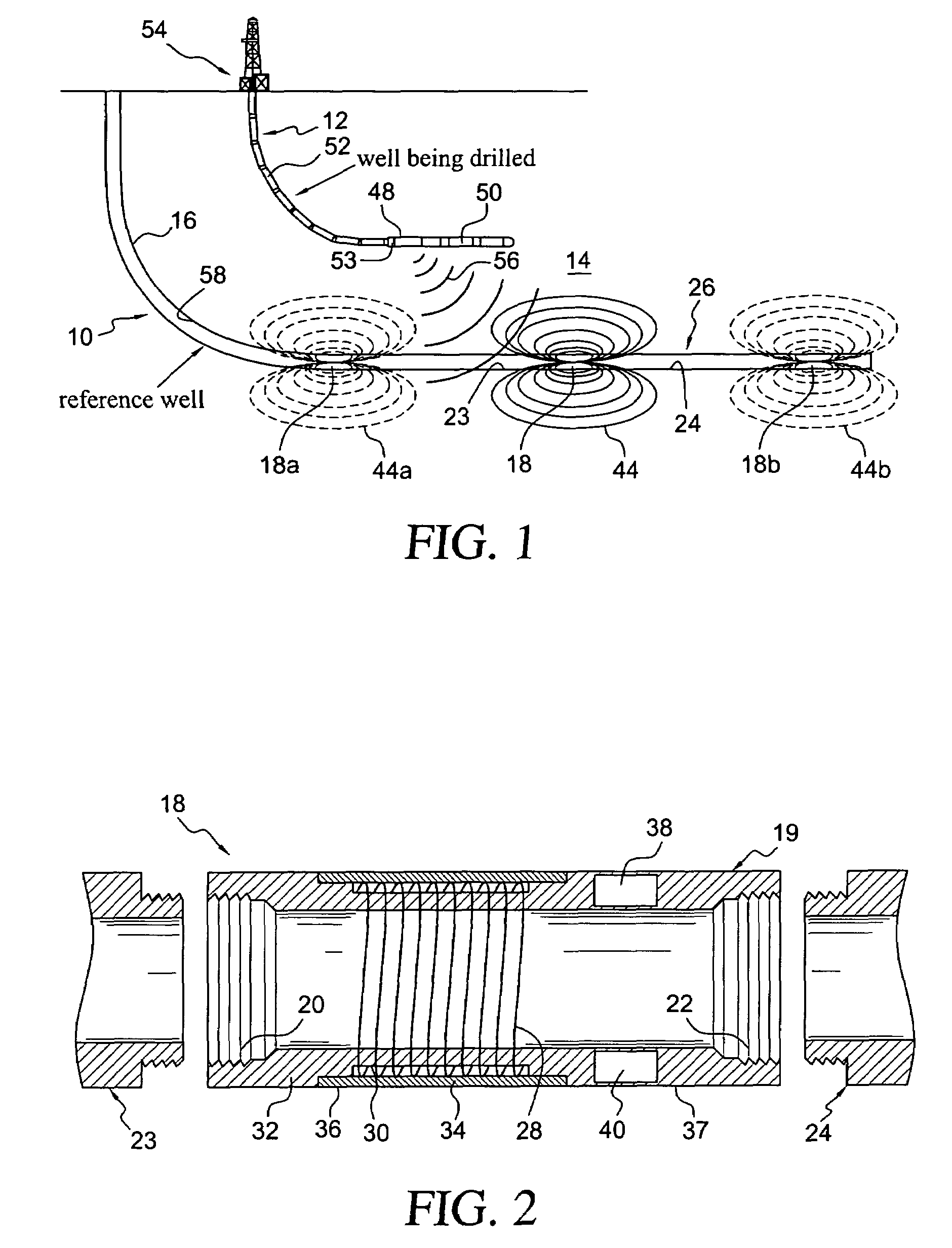

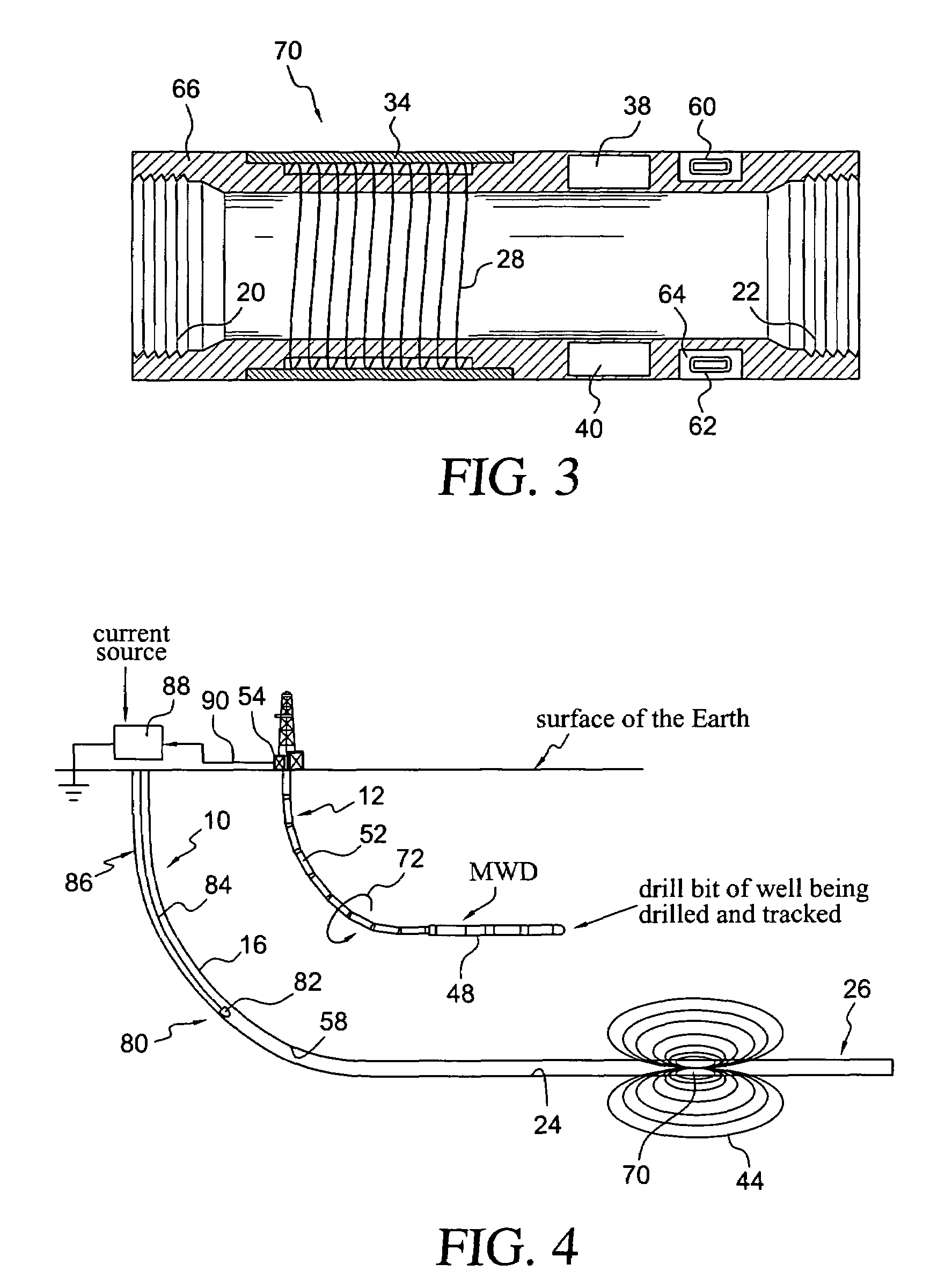

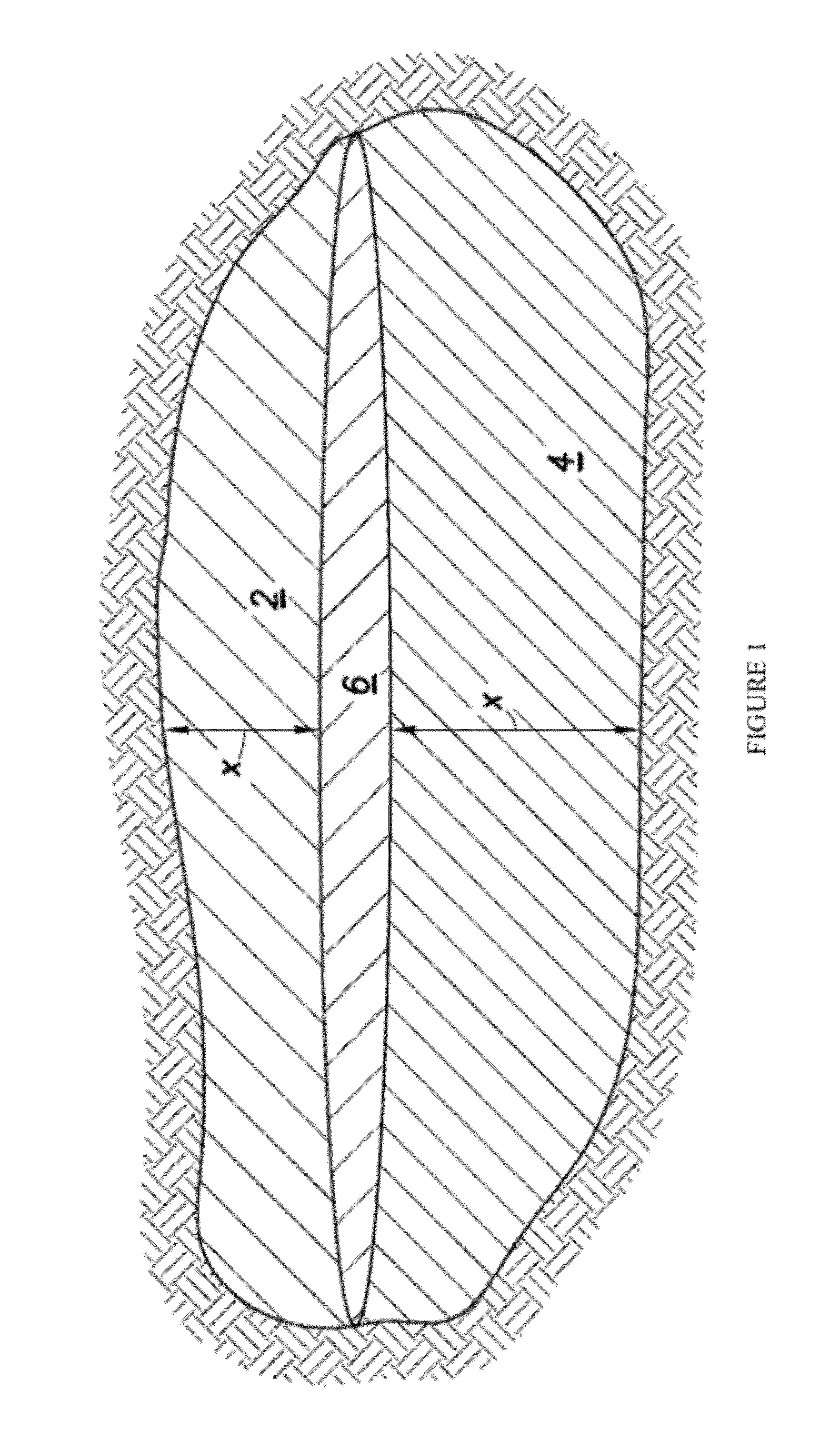

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously “listens” for, and recognizes, a “start” signal that is initiated by the driller. After a “start” signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronic packages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

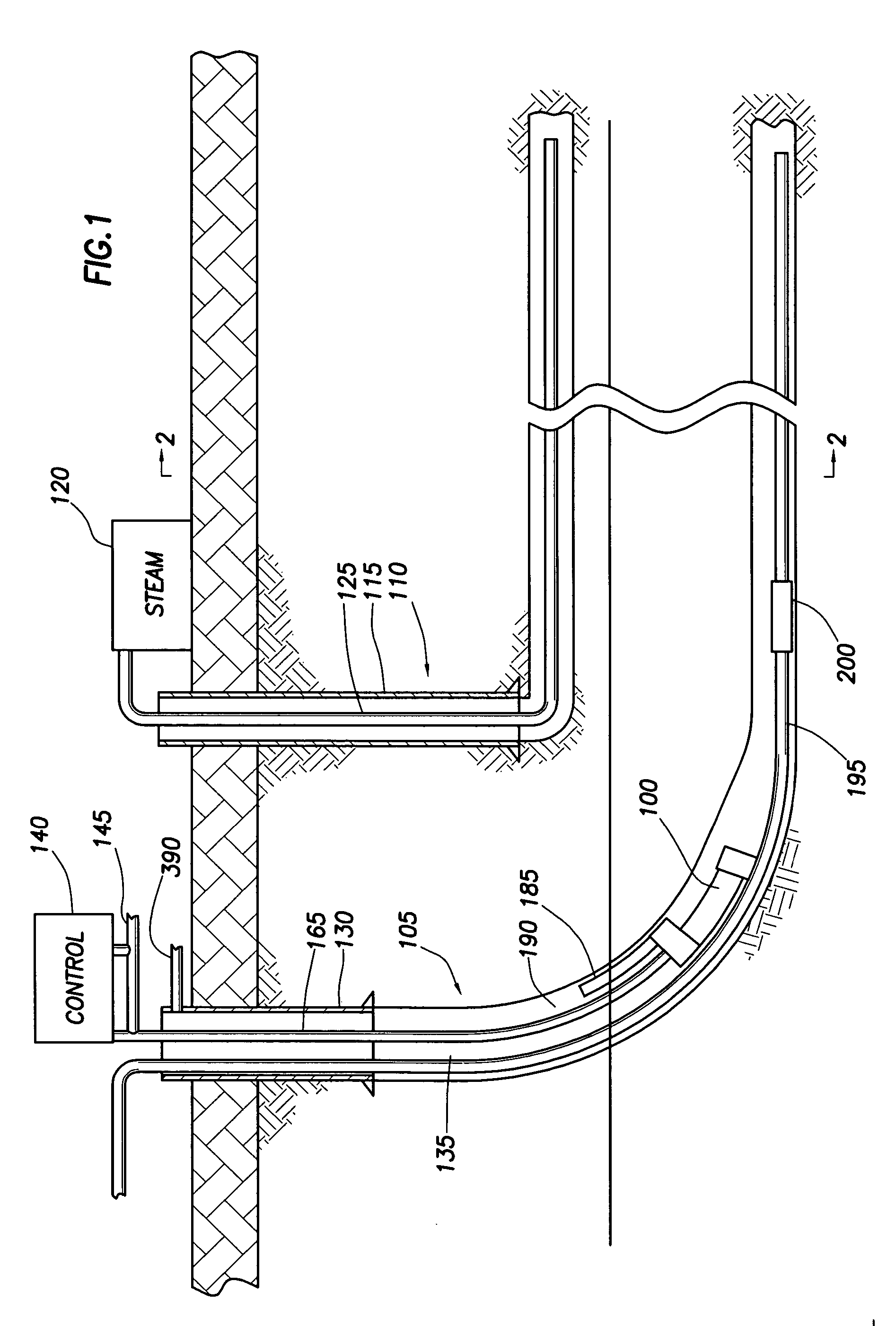

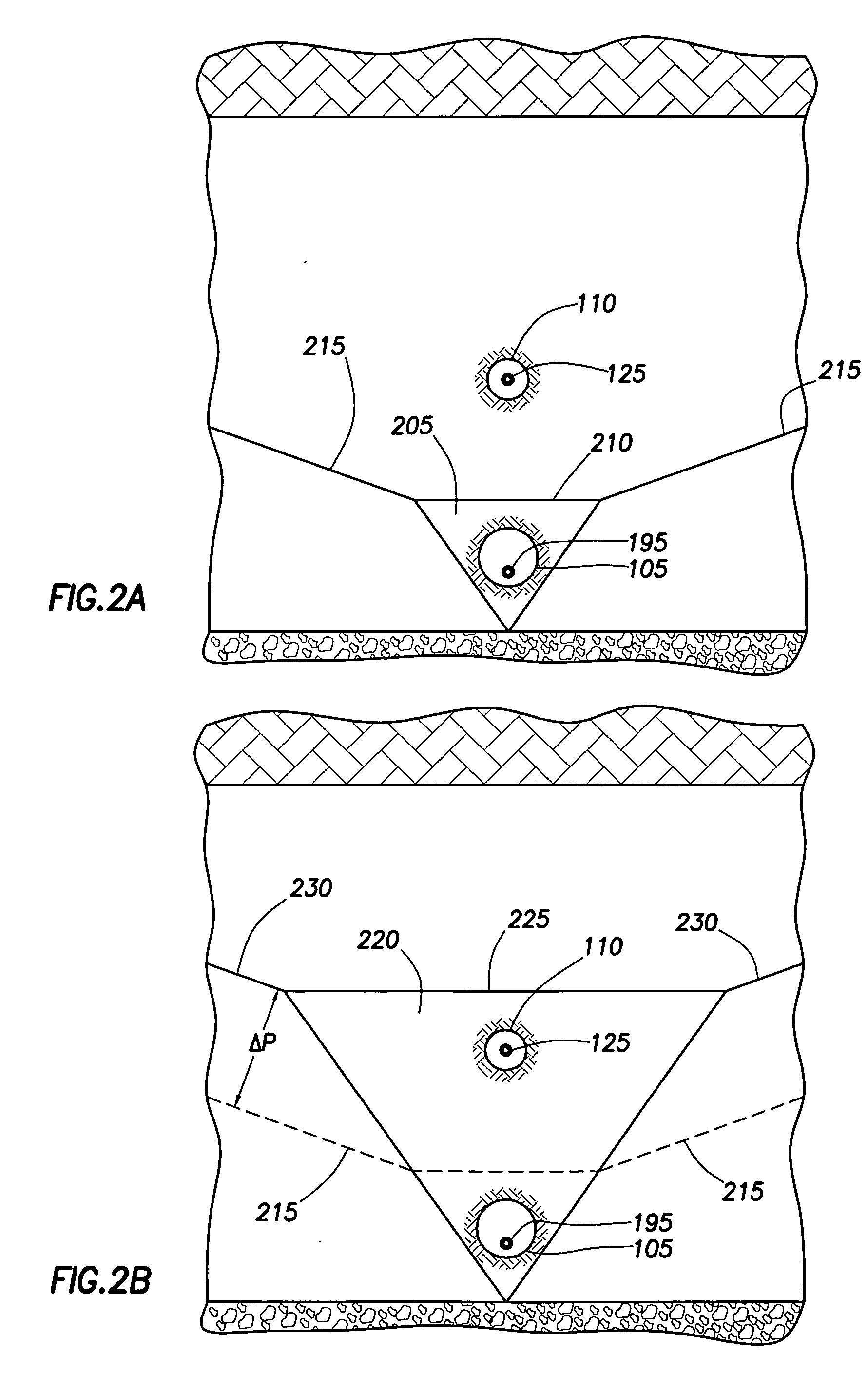

Gas operated pump for hydrocarbon wells

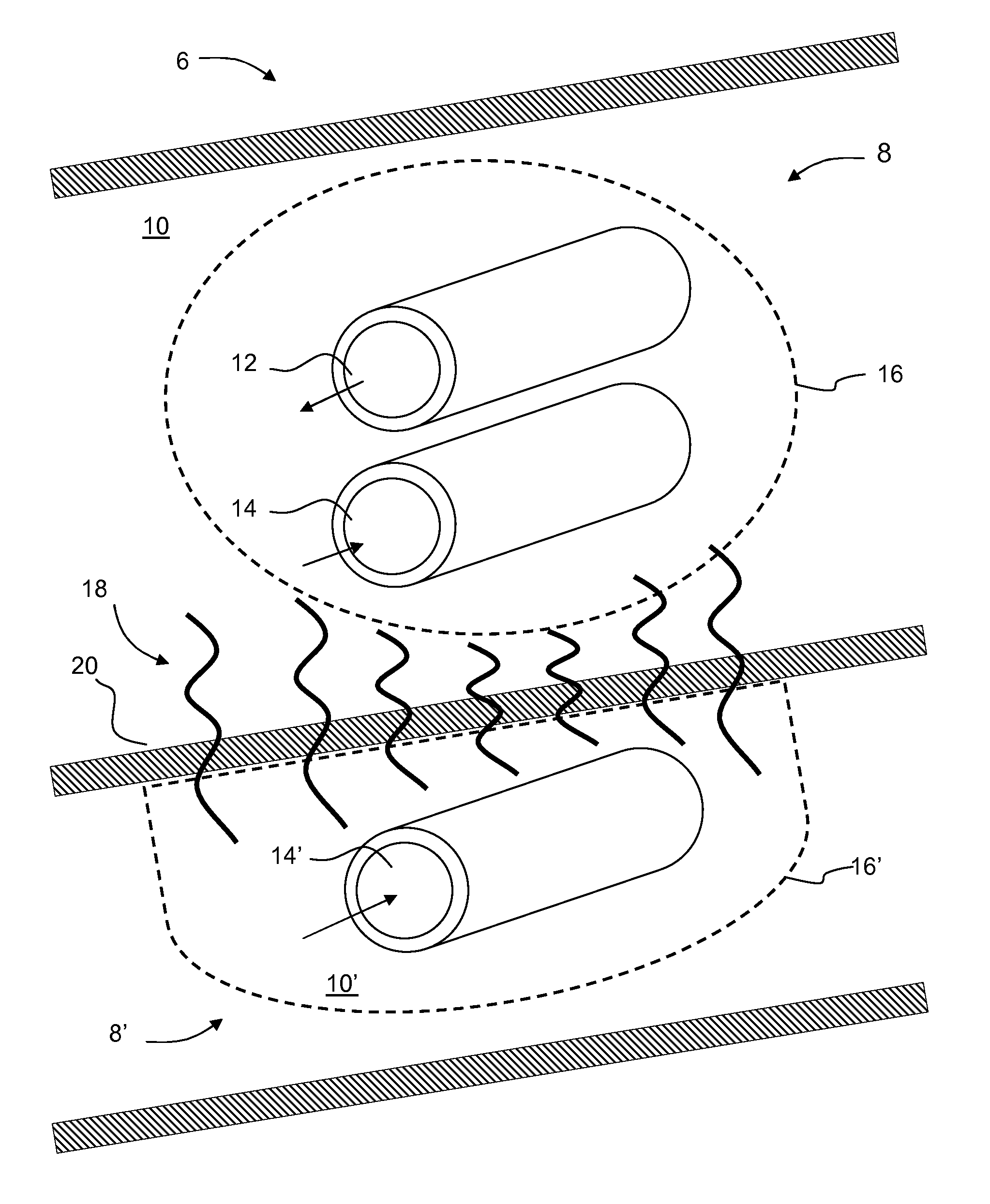

The present invention generally relates to an apparatus and method for improving production from a wellbore. In one aspect, a downhole pump for use in a wellbore is provided. The downhole pump includes two or more chambers for the accumulation of formation fluids and a valve assembly for filling and venting gas to and from the two or more chambers. The downhole pump further includes a fluid passageway for connecting the two or more chambers to a production tube. In another aspect, a downhole pump including a chamber for the accumulation of formation fluids is provided. In another aspect, a method for improving production in a wellbore is provided. In yet another aspect, a method for improving production in a steam assisted gravity drainage operation is provided. Additionally, a pump system for use in a wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

Accelerating the start-up phase for a steam assisted gravity drainage operation using radio frequency or microwave radiation

A method for preheating a formation prior to beginning steam assisted gravity drainage production. The method proceeds by forming a steam assisted gravity drainage production well pair within a formation. A preheating stage is then begun by injecting an activator into the formation. The preheating stage is then accomplished by exciting the activator with radio frequencies. This is followed by beginning the steam assisted gravity drainage operation.

Owner:CONOCOPHILLIPS CO

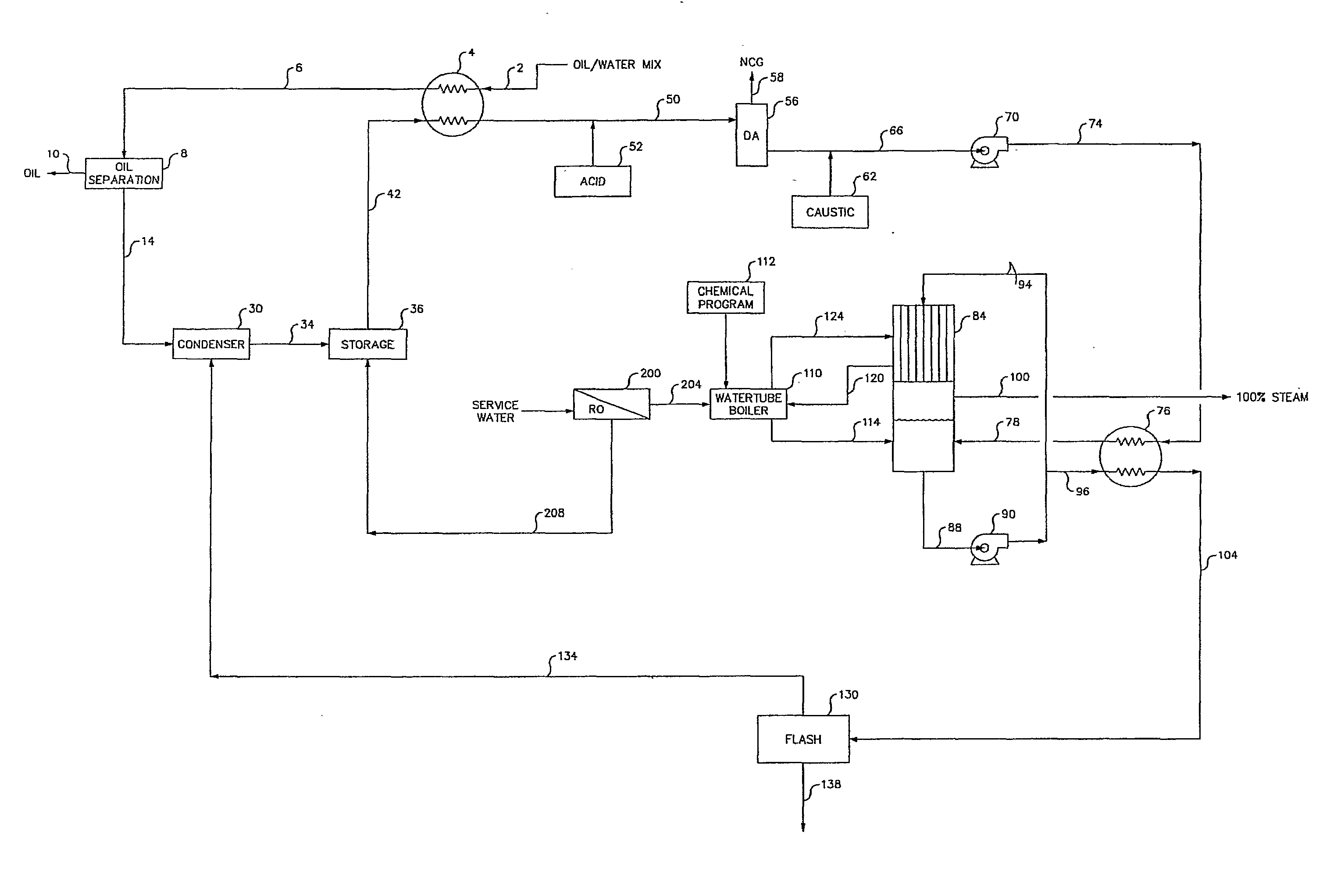

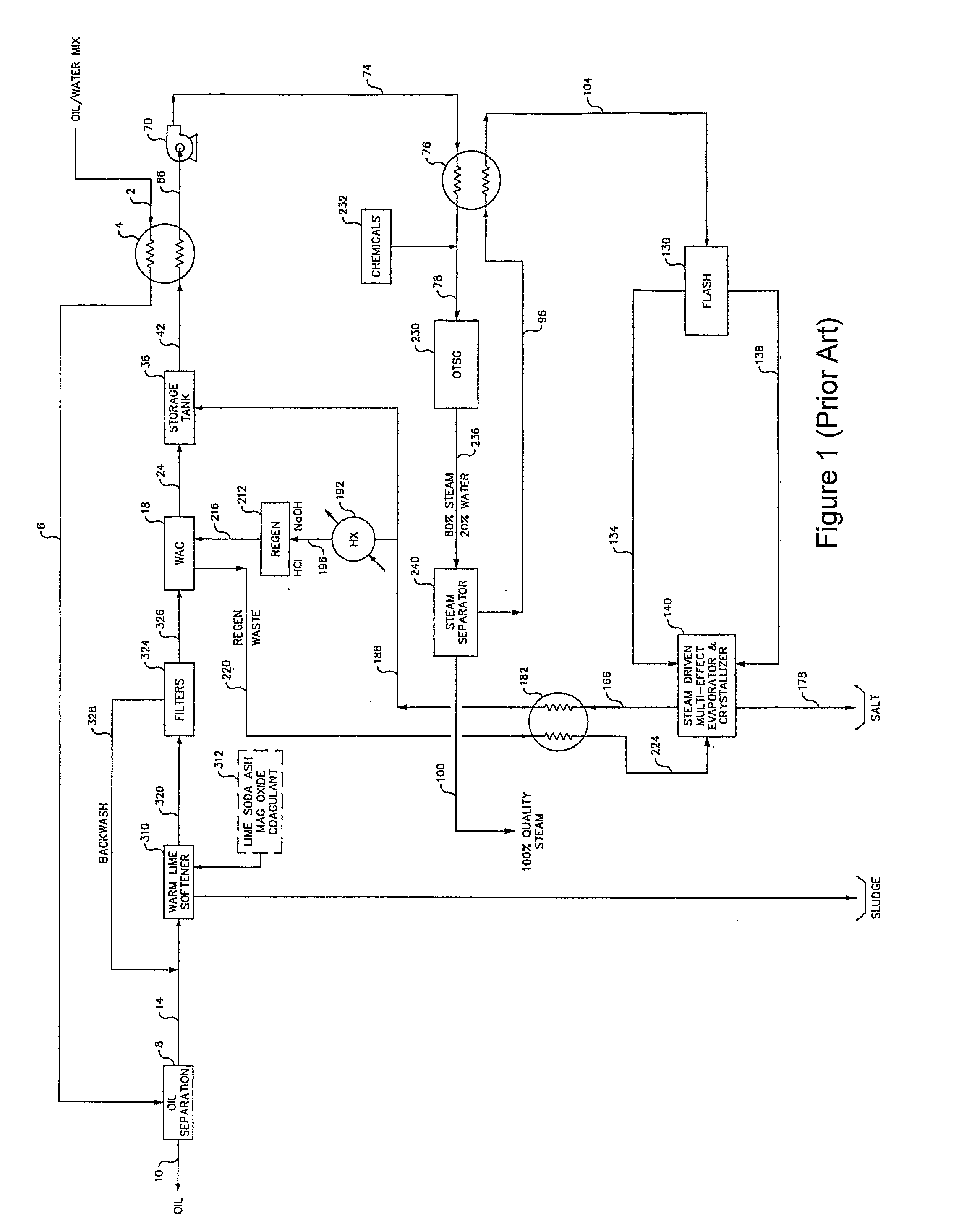

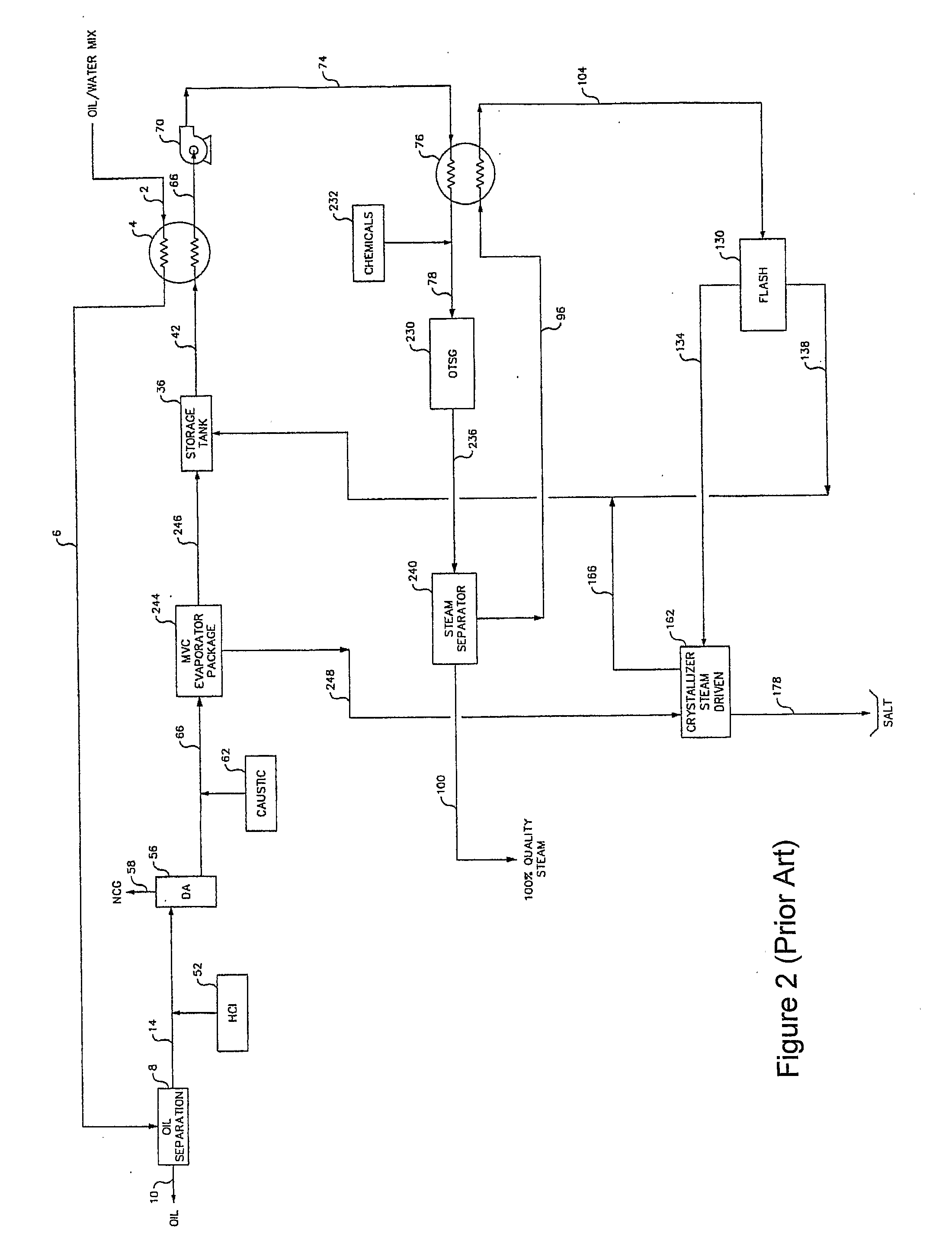

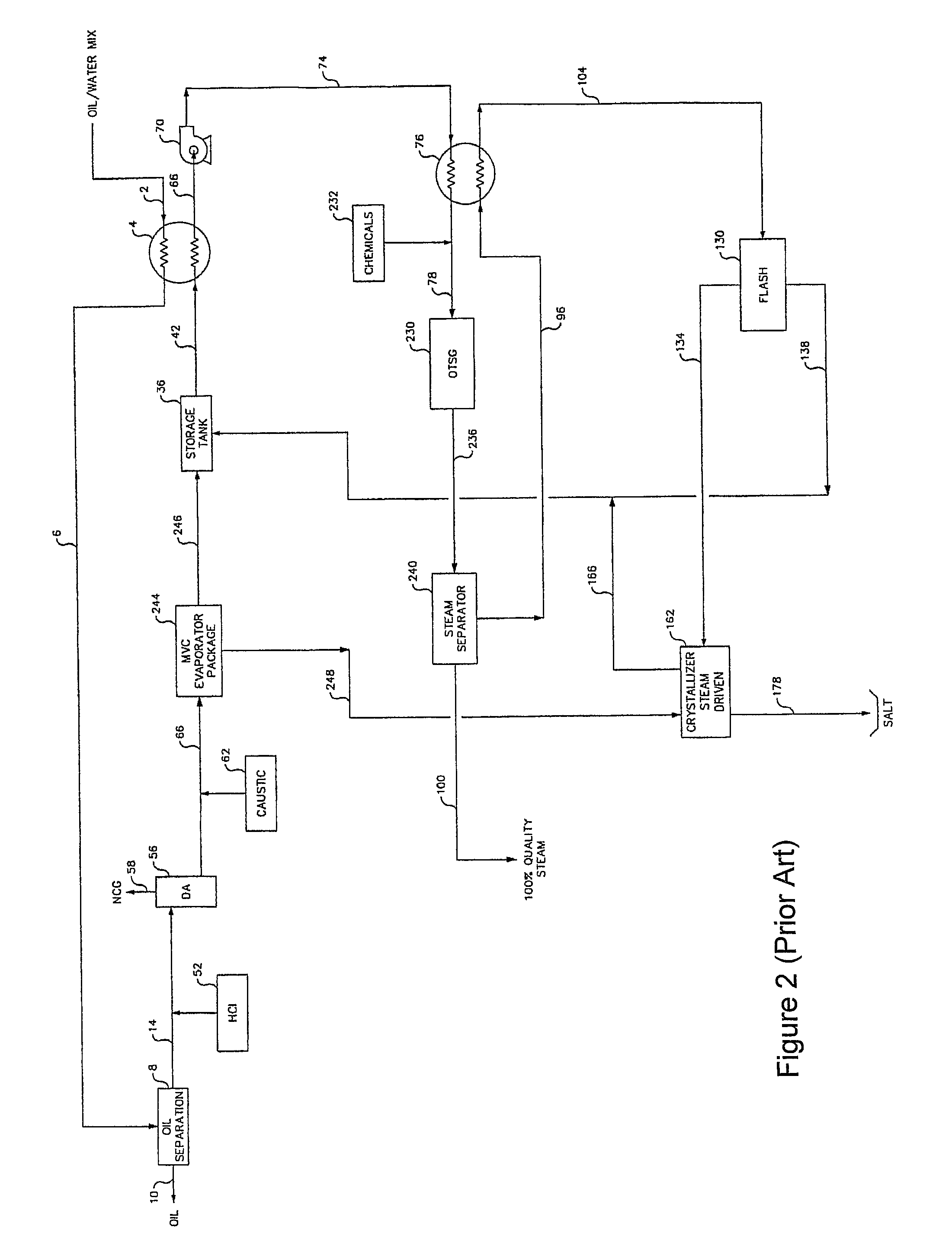

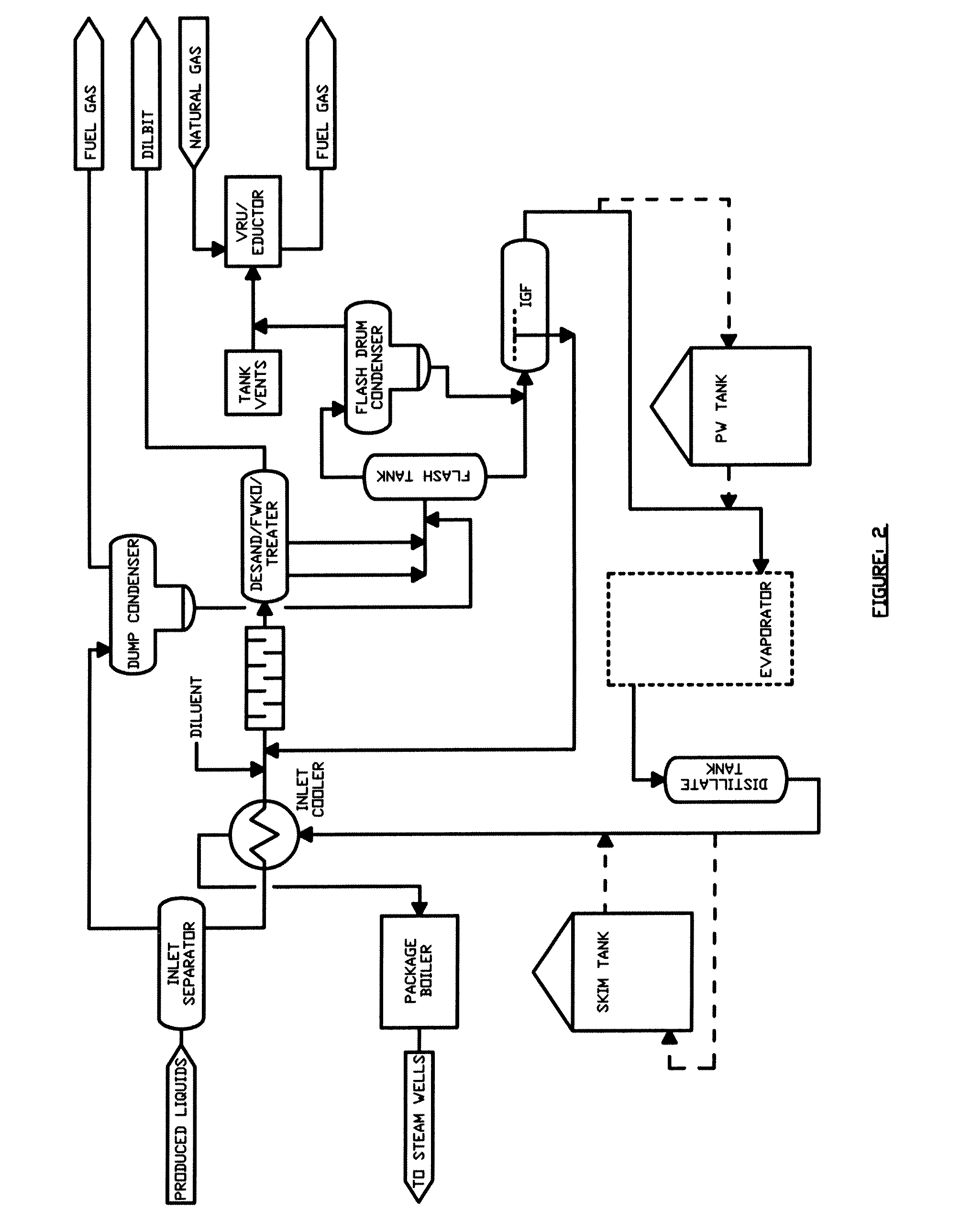

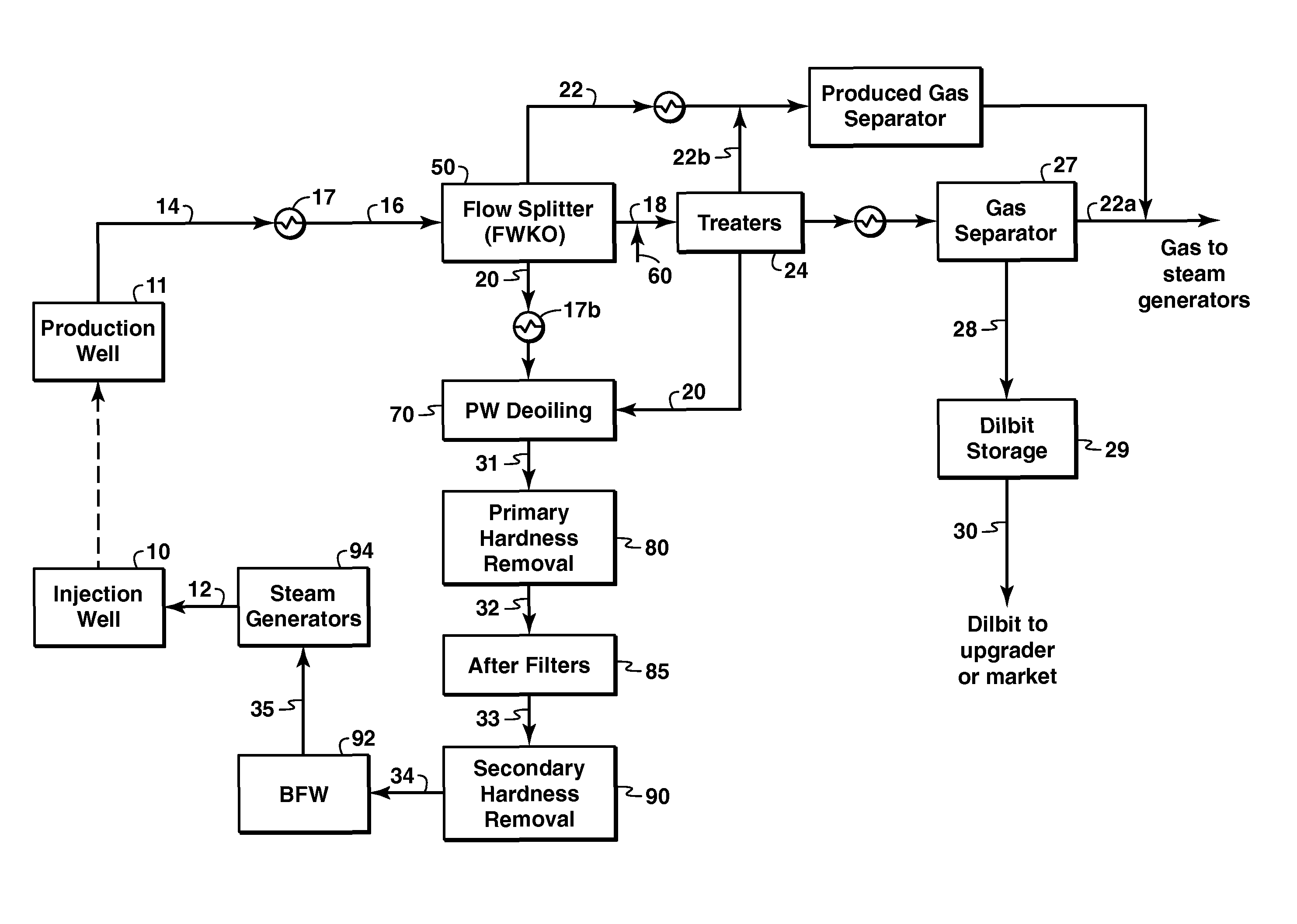

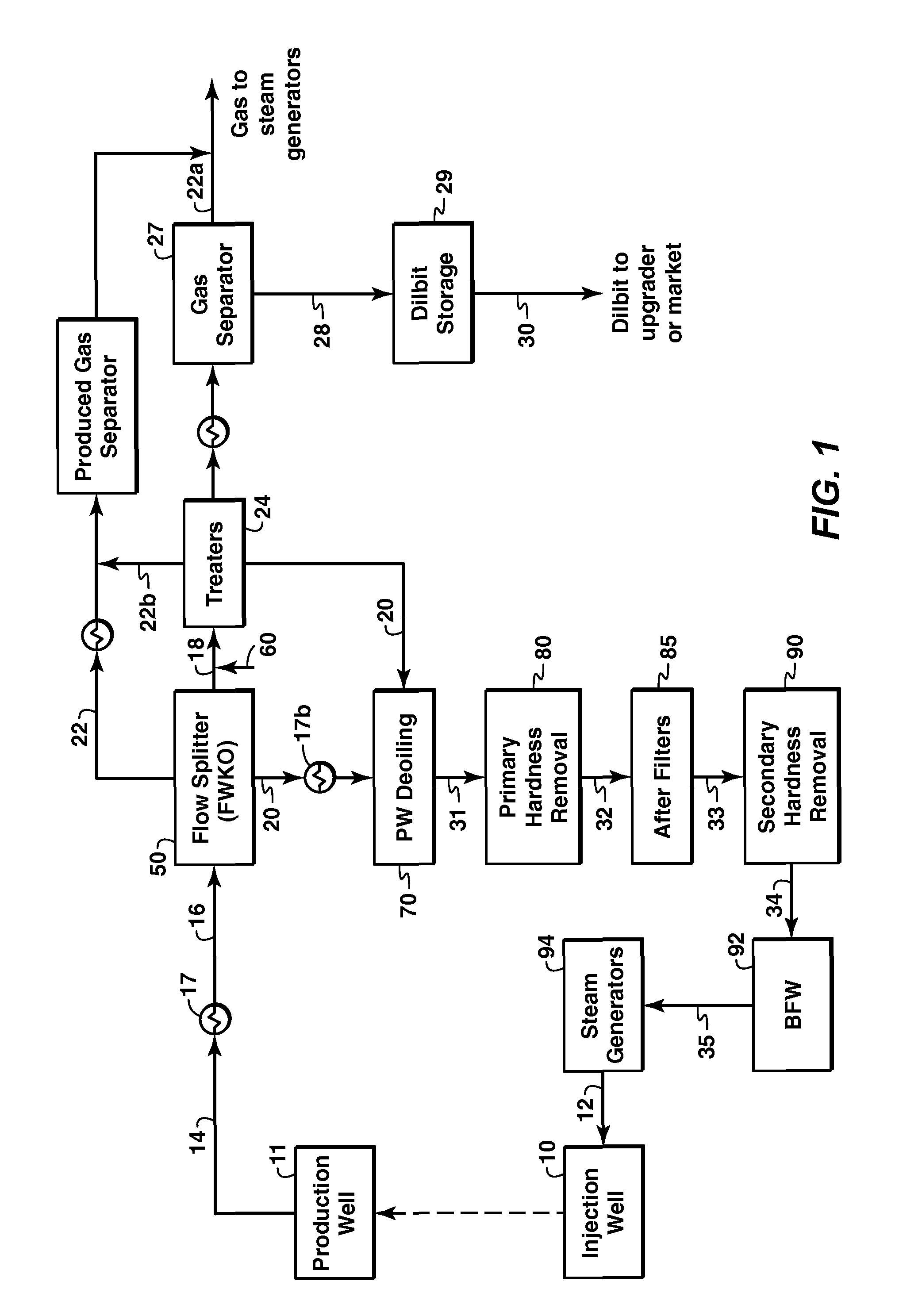

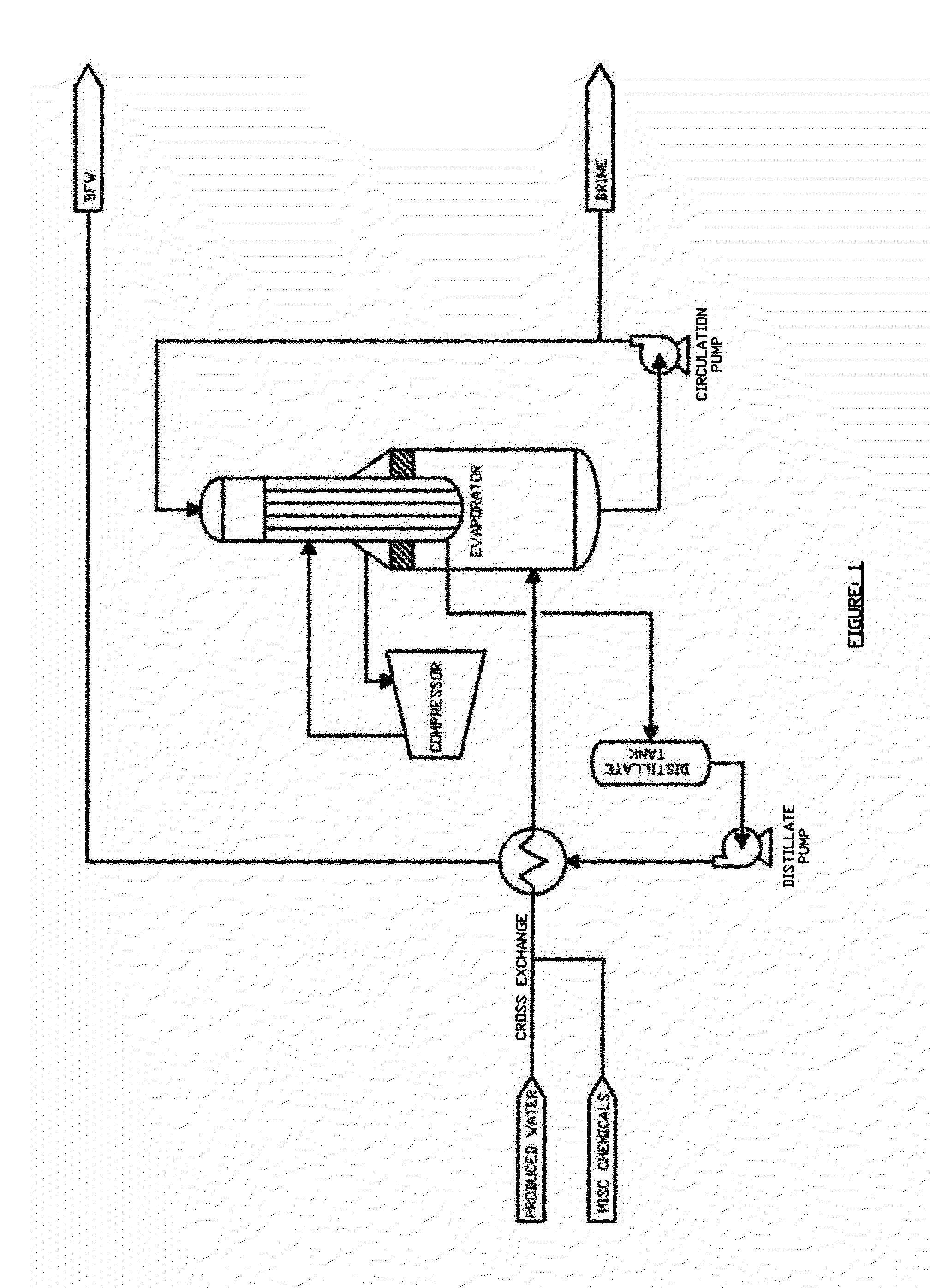

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

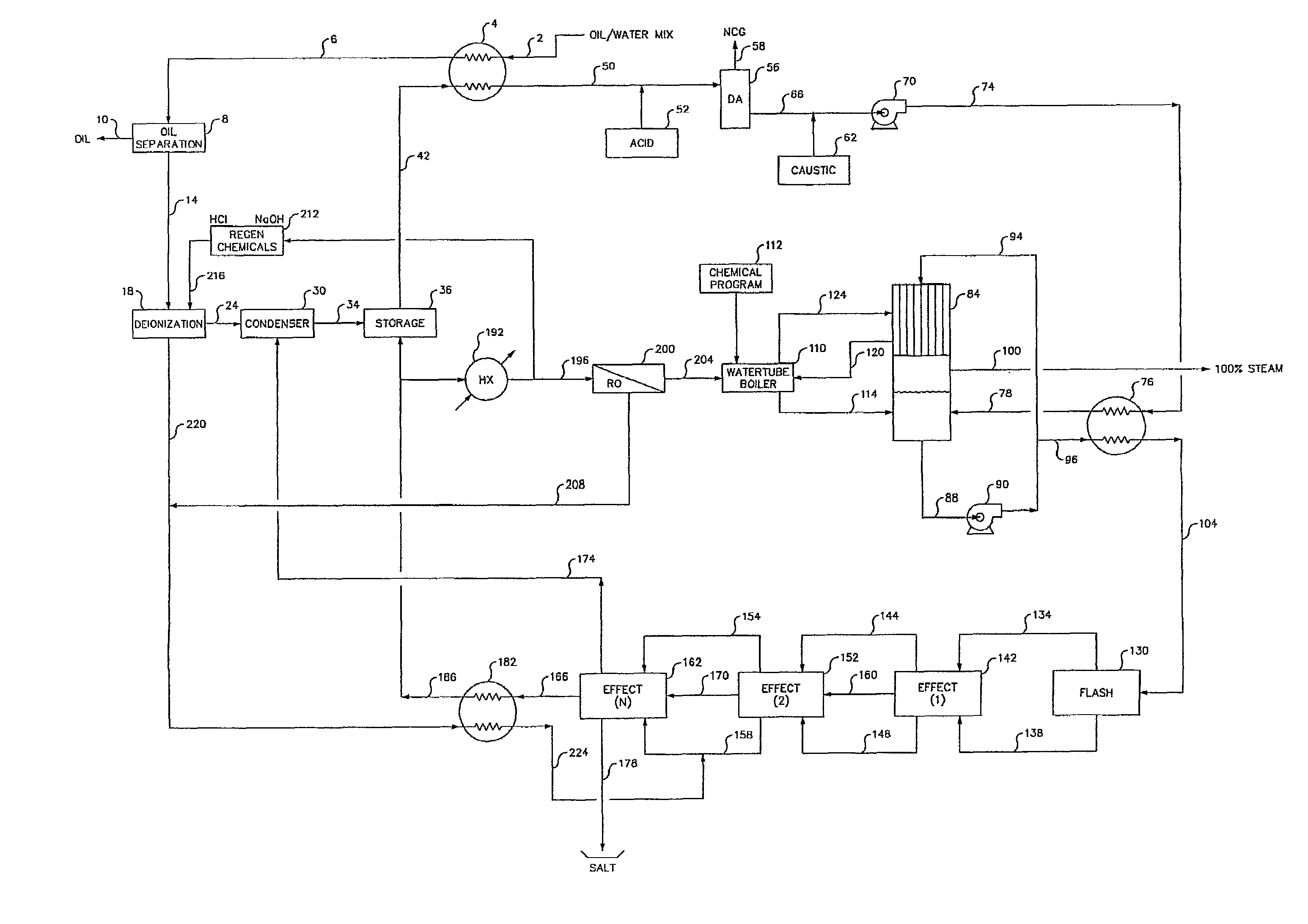

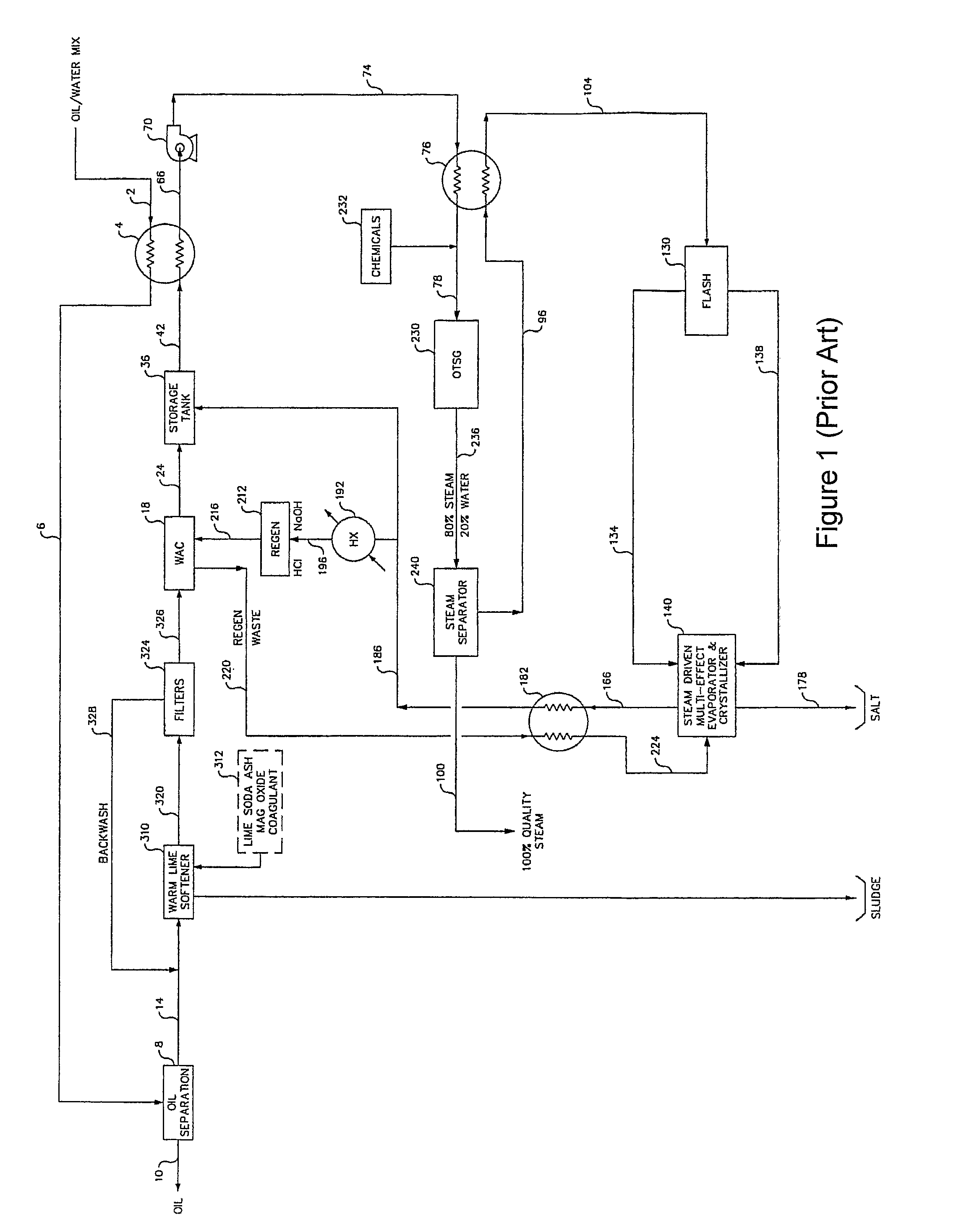

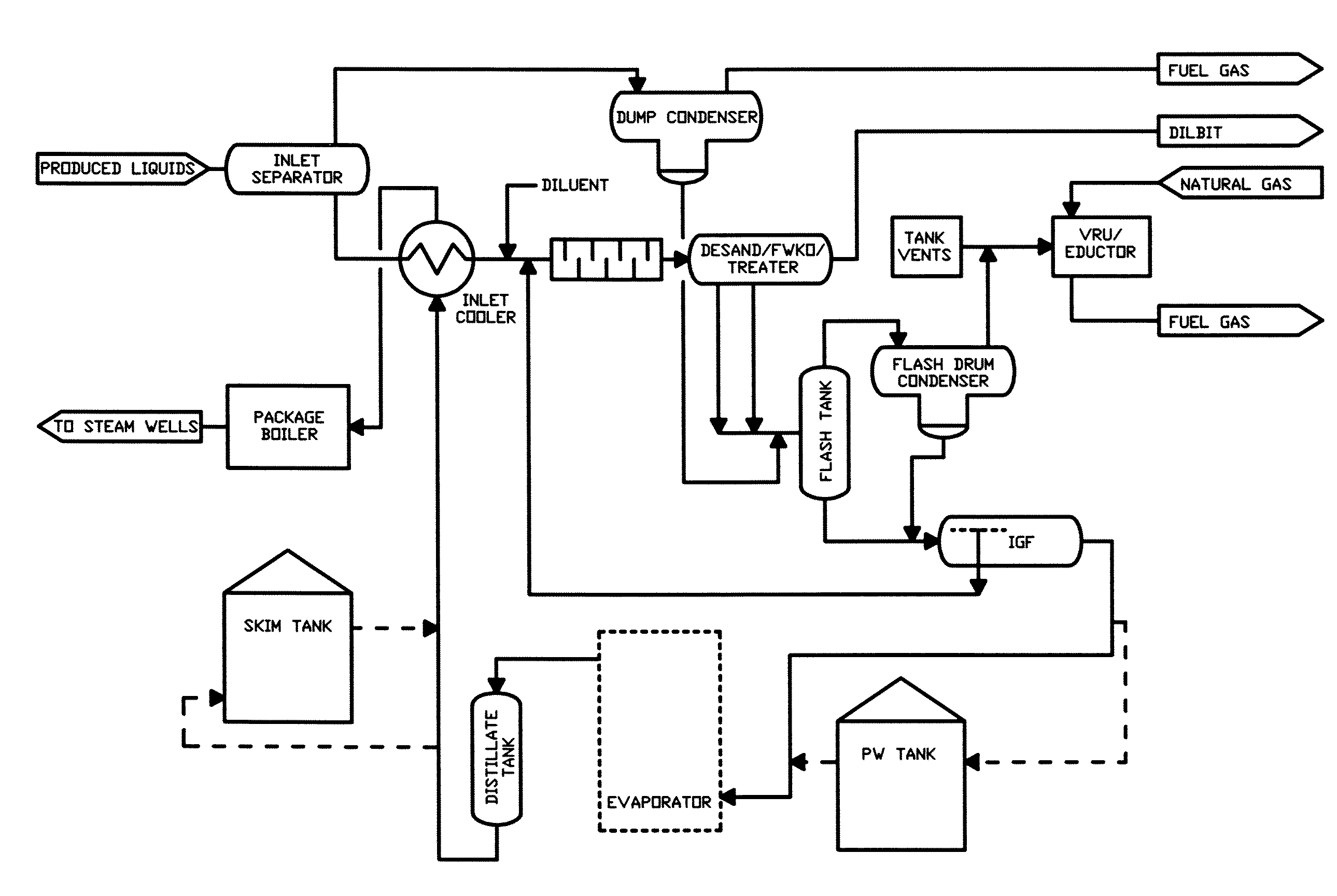

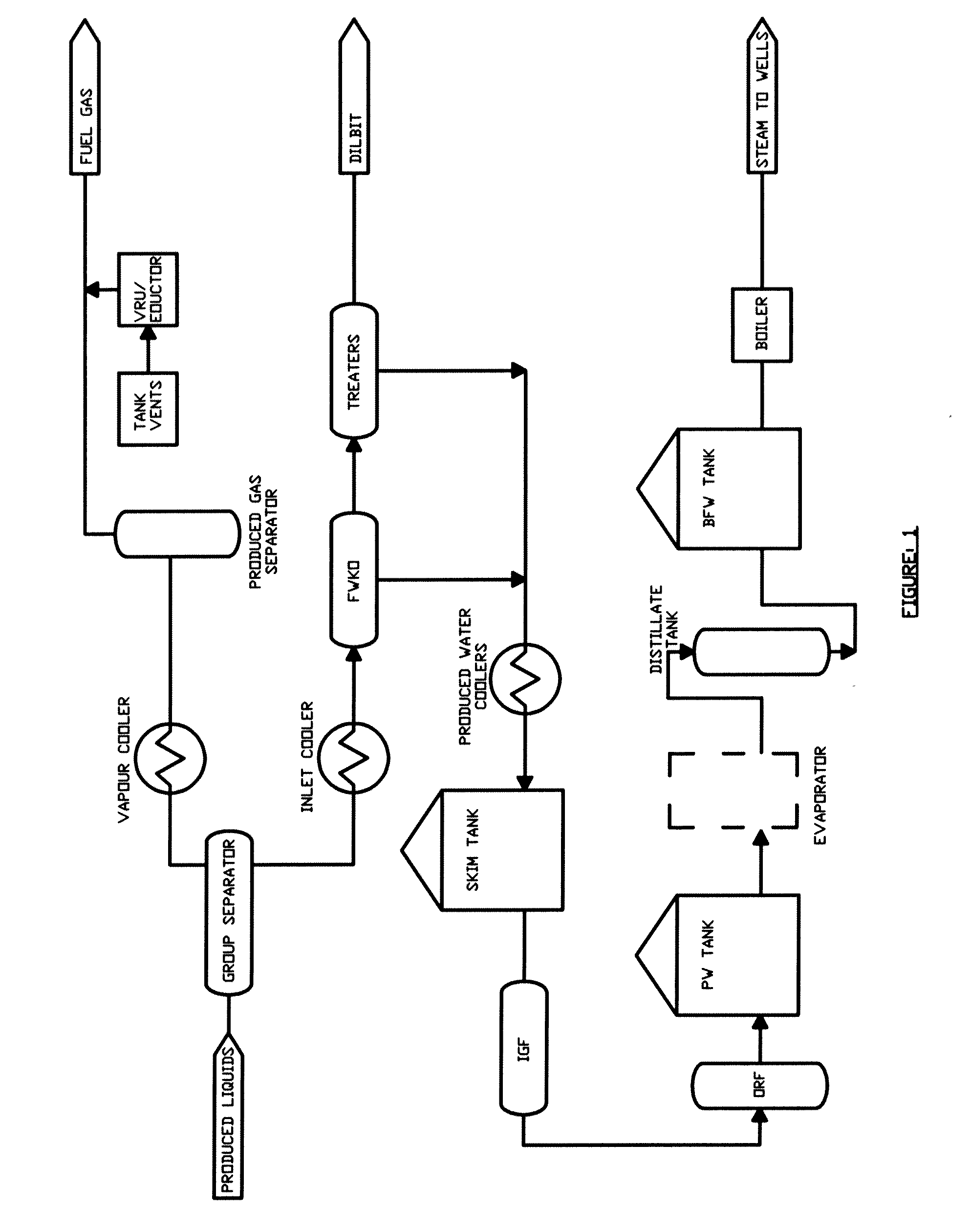

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

Radio frequency heat applicator for increased heavy oil recovery

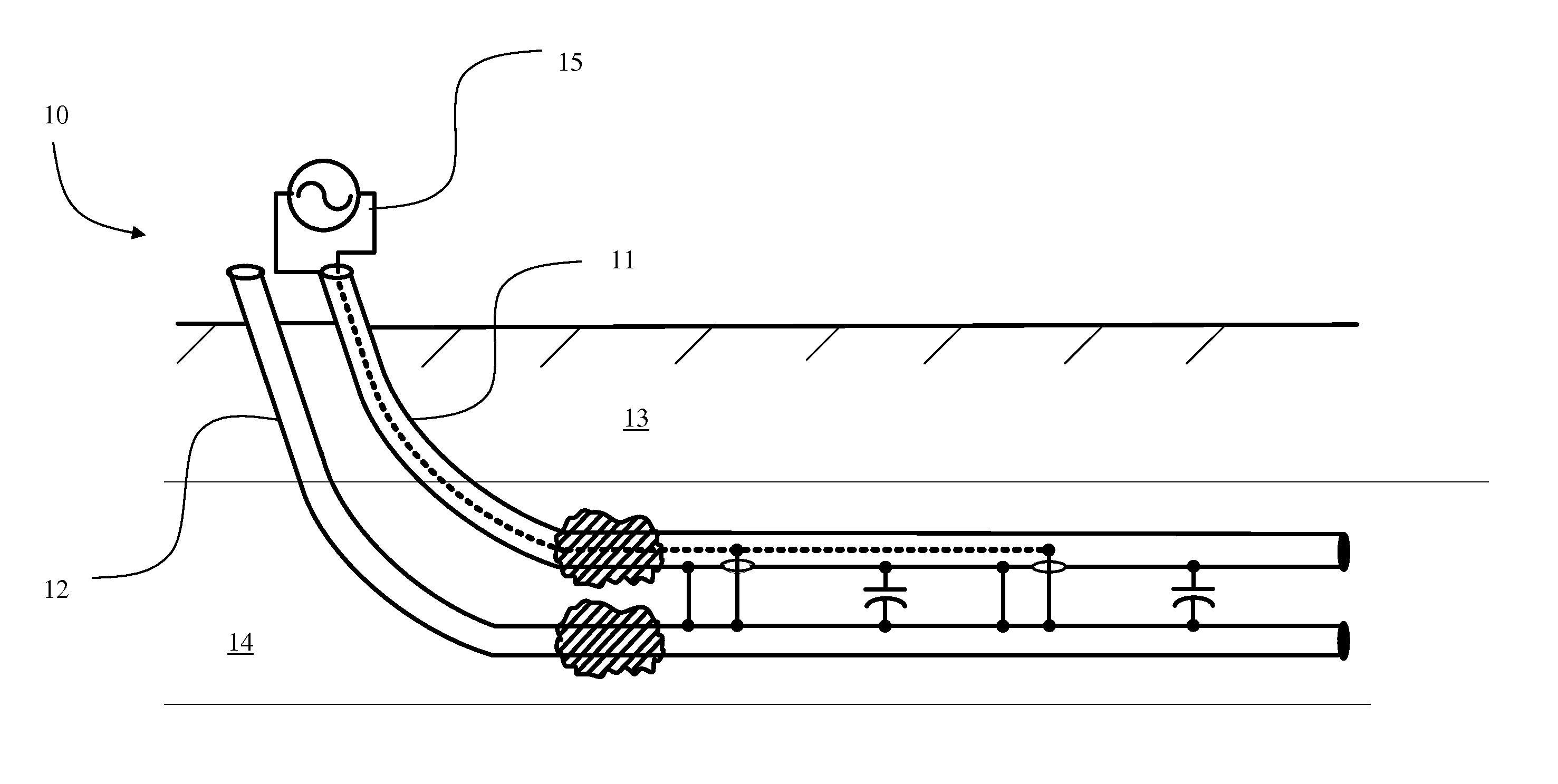

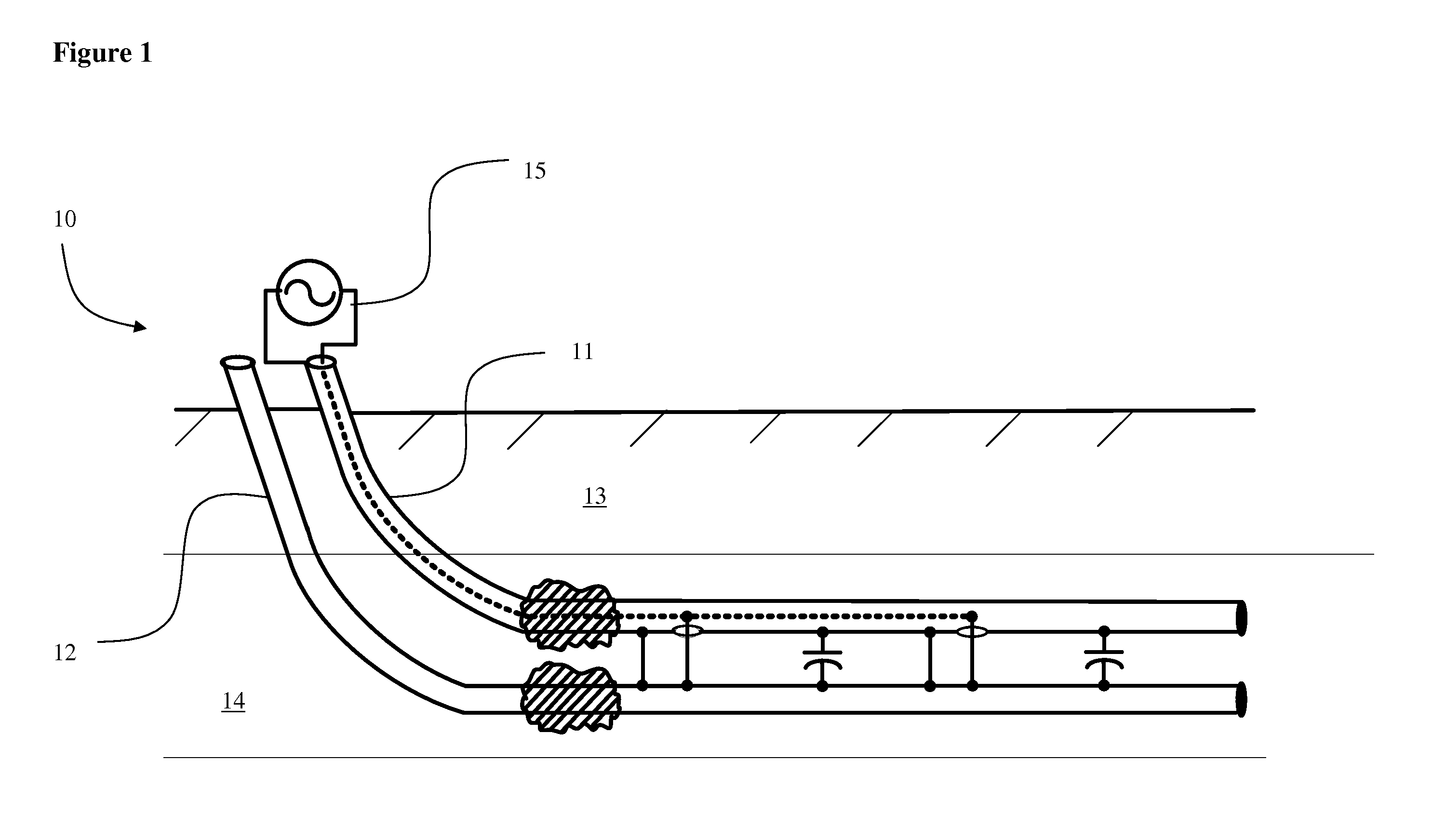

A radio frequency applicator and method for heating a geological formation is disclosed. A radio frequency source configured to apply a differential mode signal is connected to a coaxial conductor including an outer conductor pipe and an inner conductor. The inner conductor is coupled to a second conductor pipe through one or more metal jumpers. One or more current chokes, such as a common mode choke or antenna balun, are installed around the outer conductor pipe and the second conductor pipe to concentrate electromagnetic radiation within a hydrocarbon formation. The outer conductor pipe and the second conductor pipe can be traditional well pipes for extracting hydrocarbons, such as a steam pipe and an extraction pipe of a steam assisted gravity drainage (SAGD) system. An apparatus and method for installing a current choke are also disclosed.

Owner:HARRIS CORP

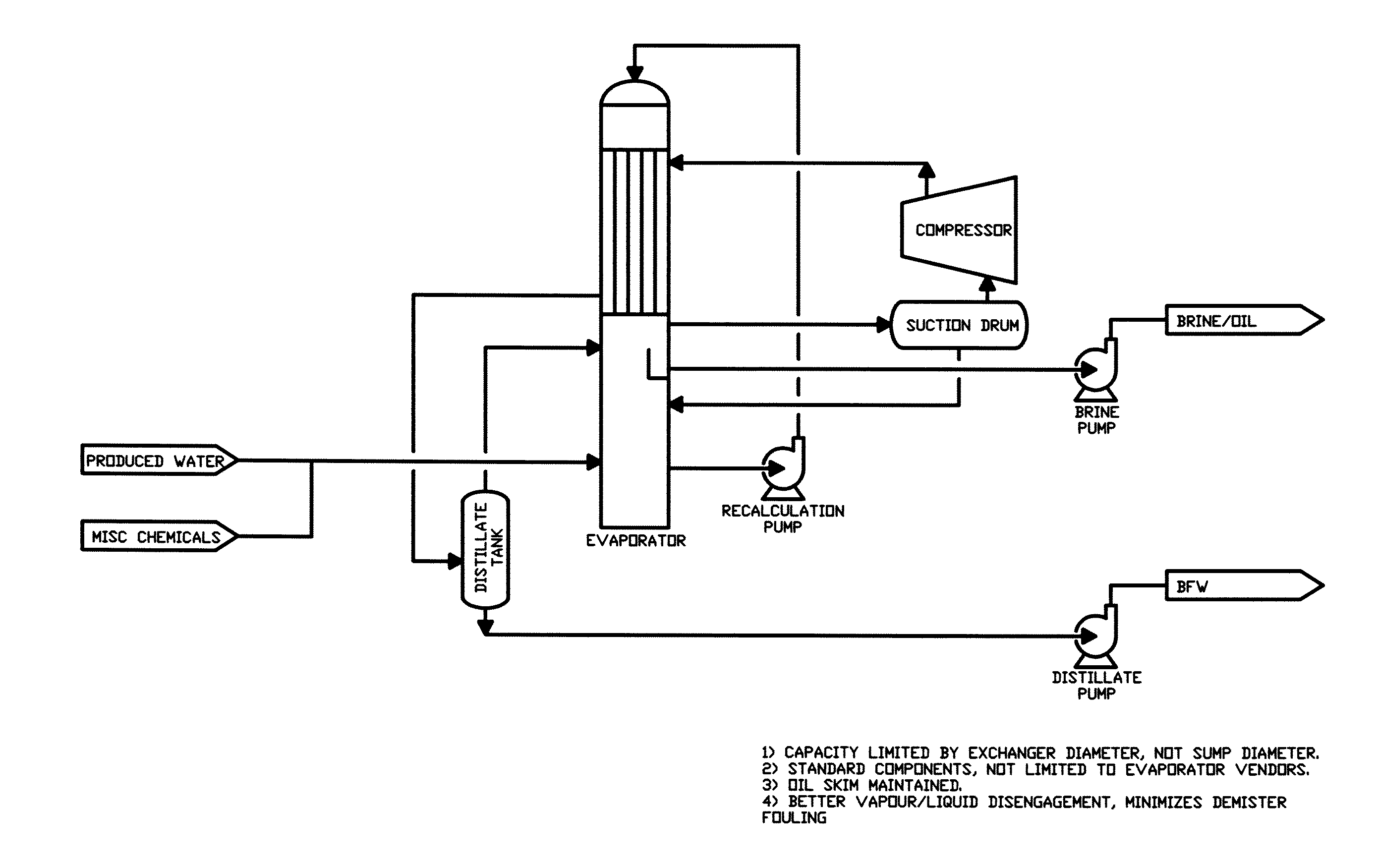

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

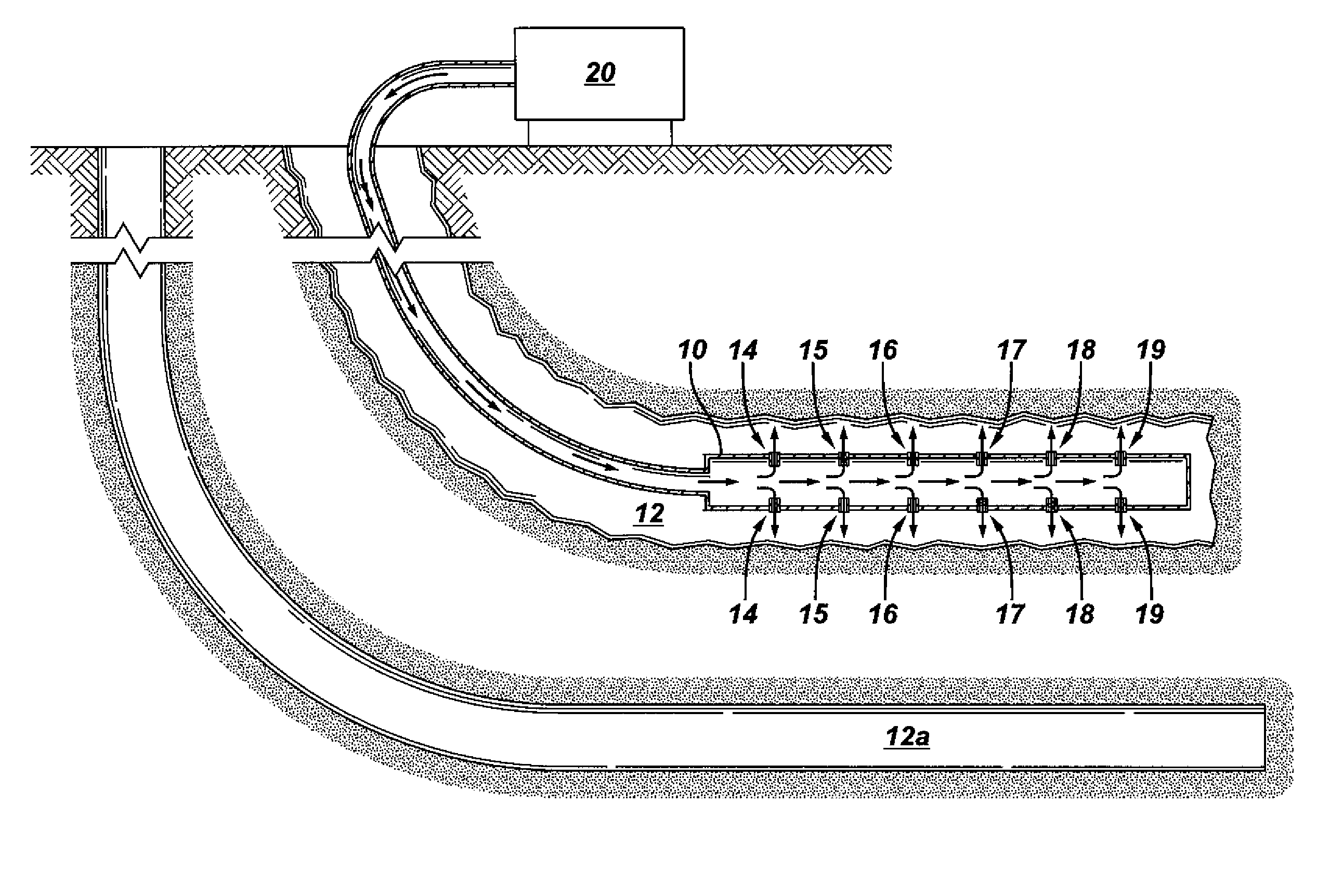

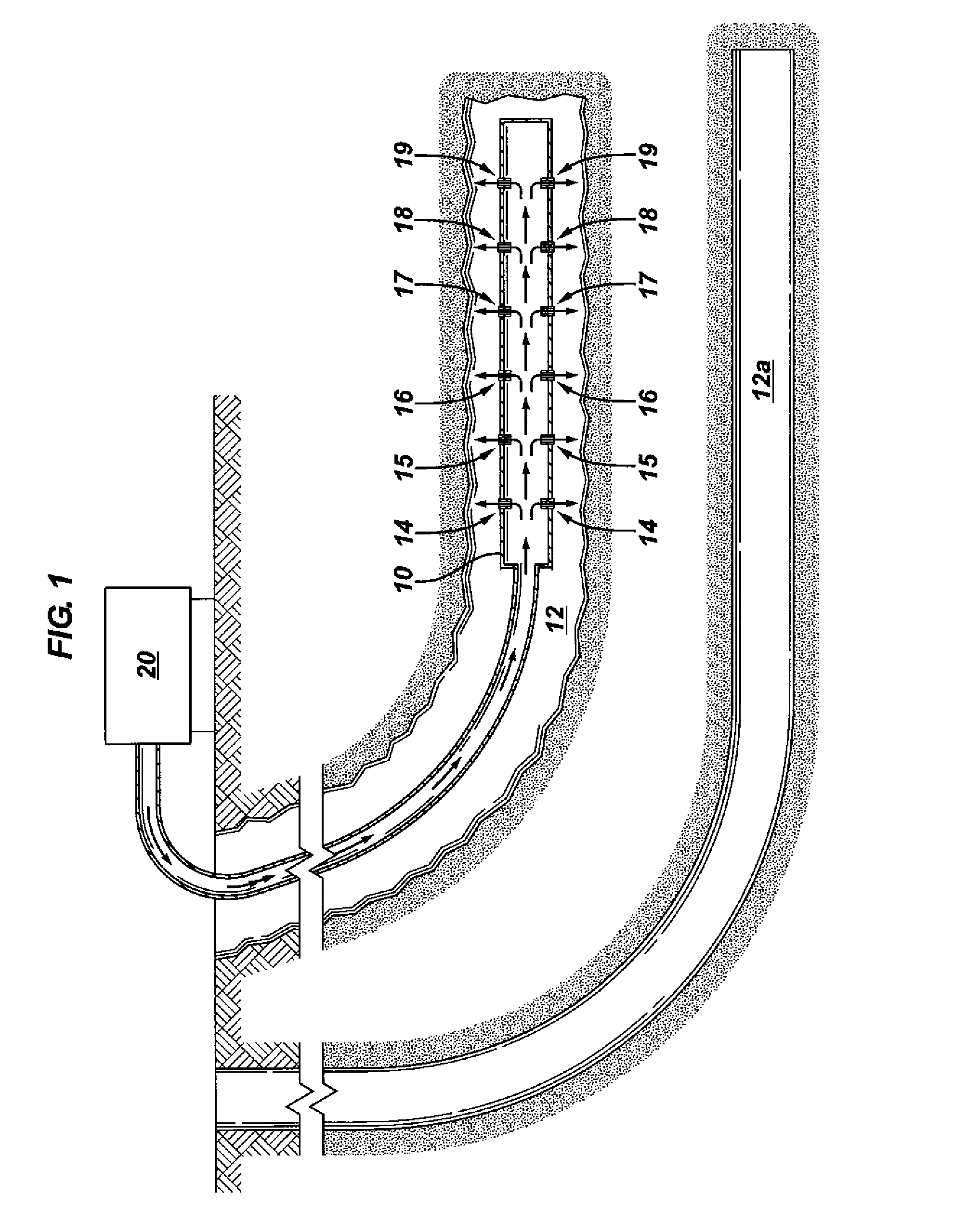

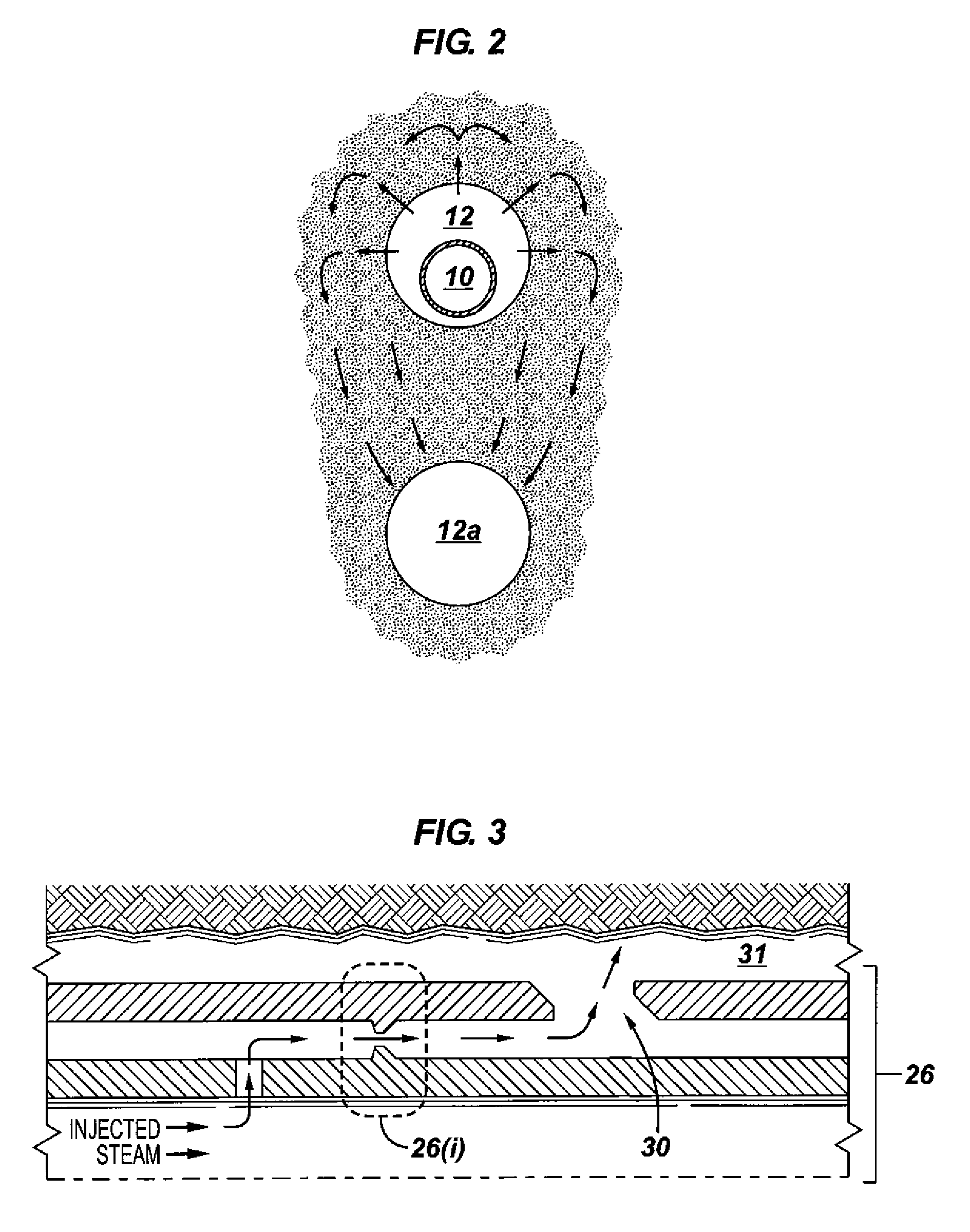

Steam injection apparatus for steam assisted gravity drainage techniques

InactiveUS20080251255A1Reduce erosionSpray nozzlesFluid removalSteam-assisted gravity drainageEngineering

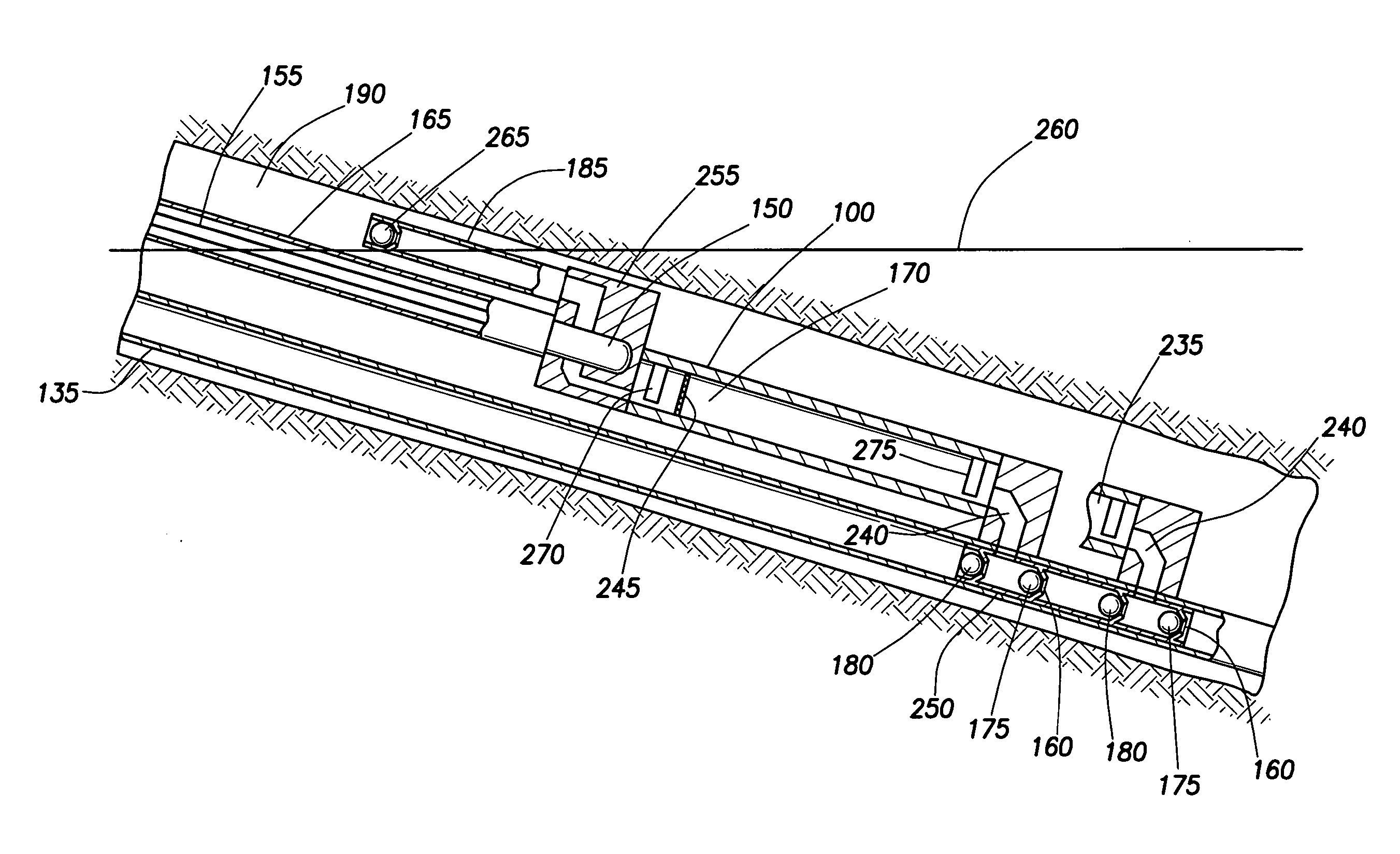

Steam injection pipe string apparatus is disclosed comprising an elongated tubular structure with first and second ends, and a plurality of orifices formed in the elongated tubular structure. The sizes of the orifices vary from one end of the elongated tubular structure to the other, and, in one embodiment, the sizes of the orifices increase from one end of the elongated tubular structure to the other. The elongated tubular structure may comprise a plurality of blank pipes in threaded engagement with one another or a plurality of subs with different sized orifices in the subs. The orifices may be formed in the elongated tubular structure using milling techniques or by inserting a nozzle in a threaded aperture formed in the structure. A system utilizing the steam injection pipe string apparatus is especially suitable for use in a steam assisted gravity drainage system.

Owner:SCHLUMBERGER TECH CORP

Gas operated pump for hydrocarbon wells

Owner:WEATHERFORD TECH HLDG LLC

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

Owner:HALLIBURTON ENERGY SERVICES INC

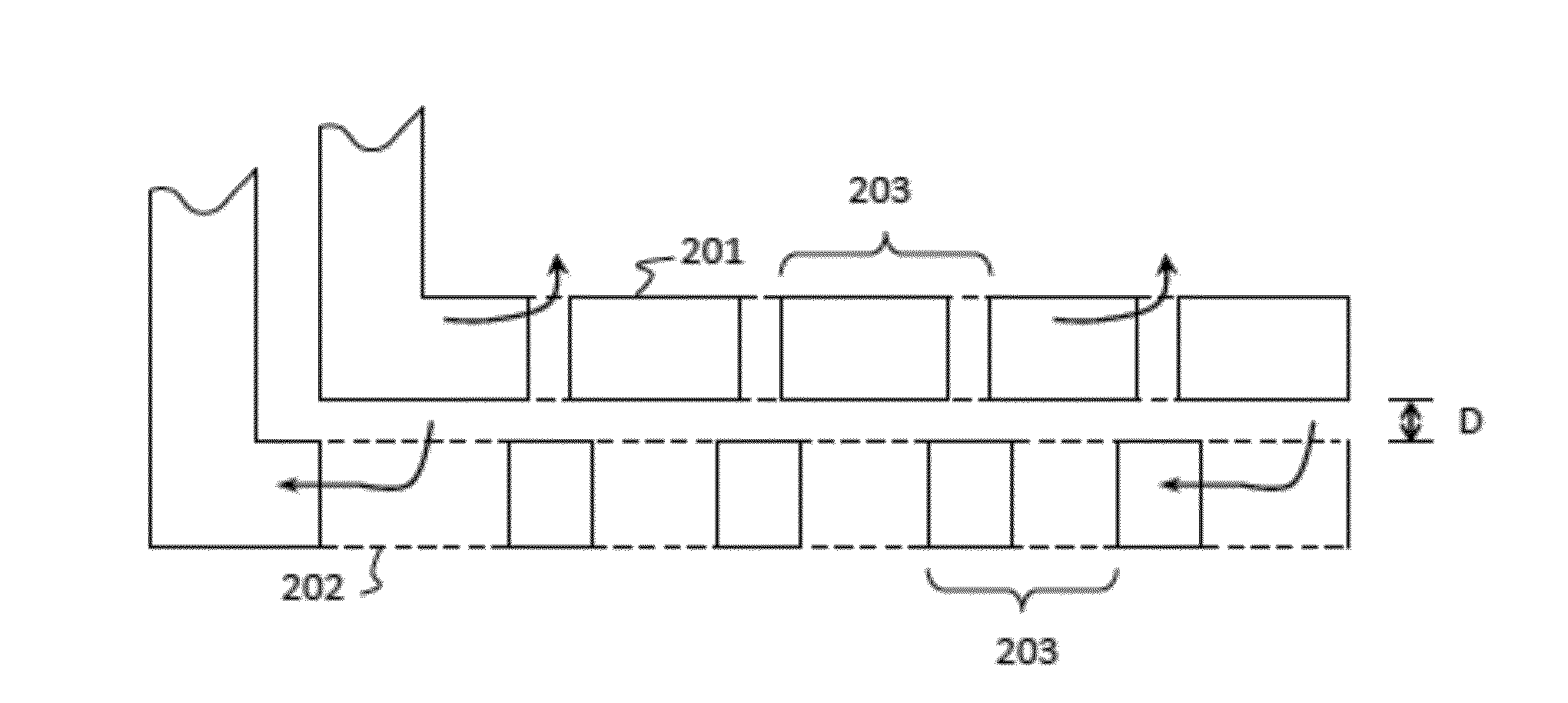

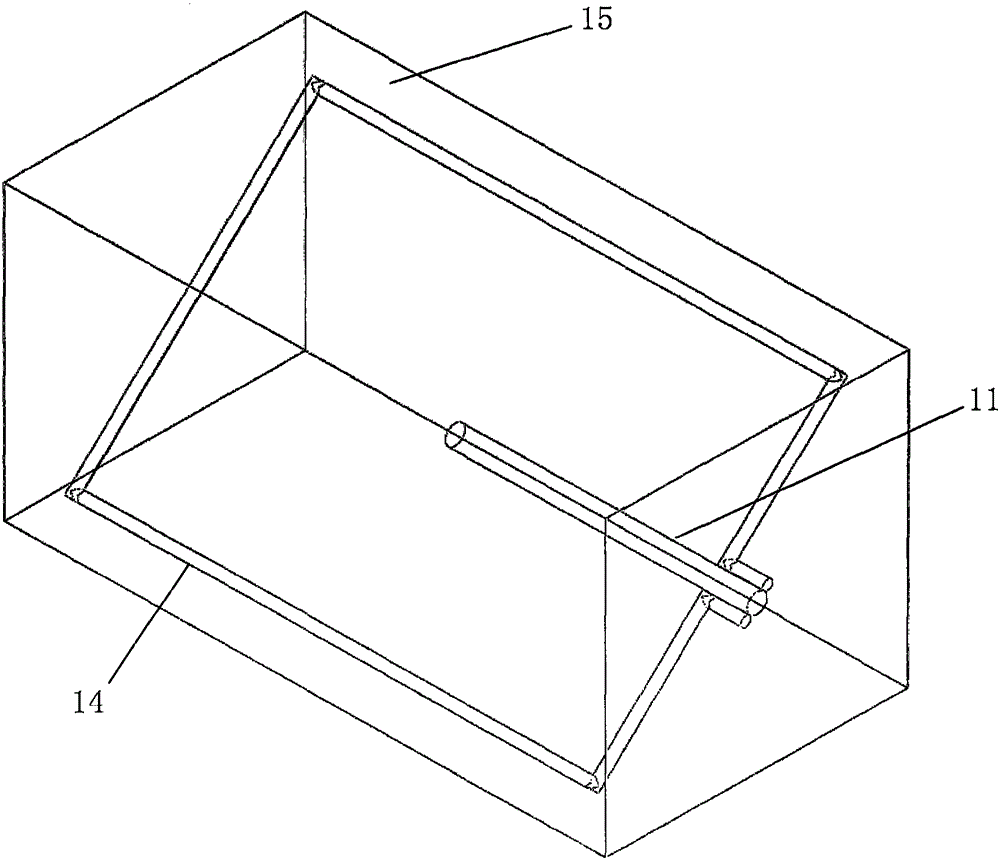

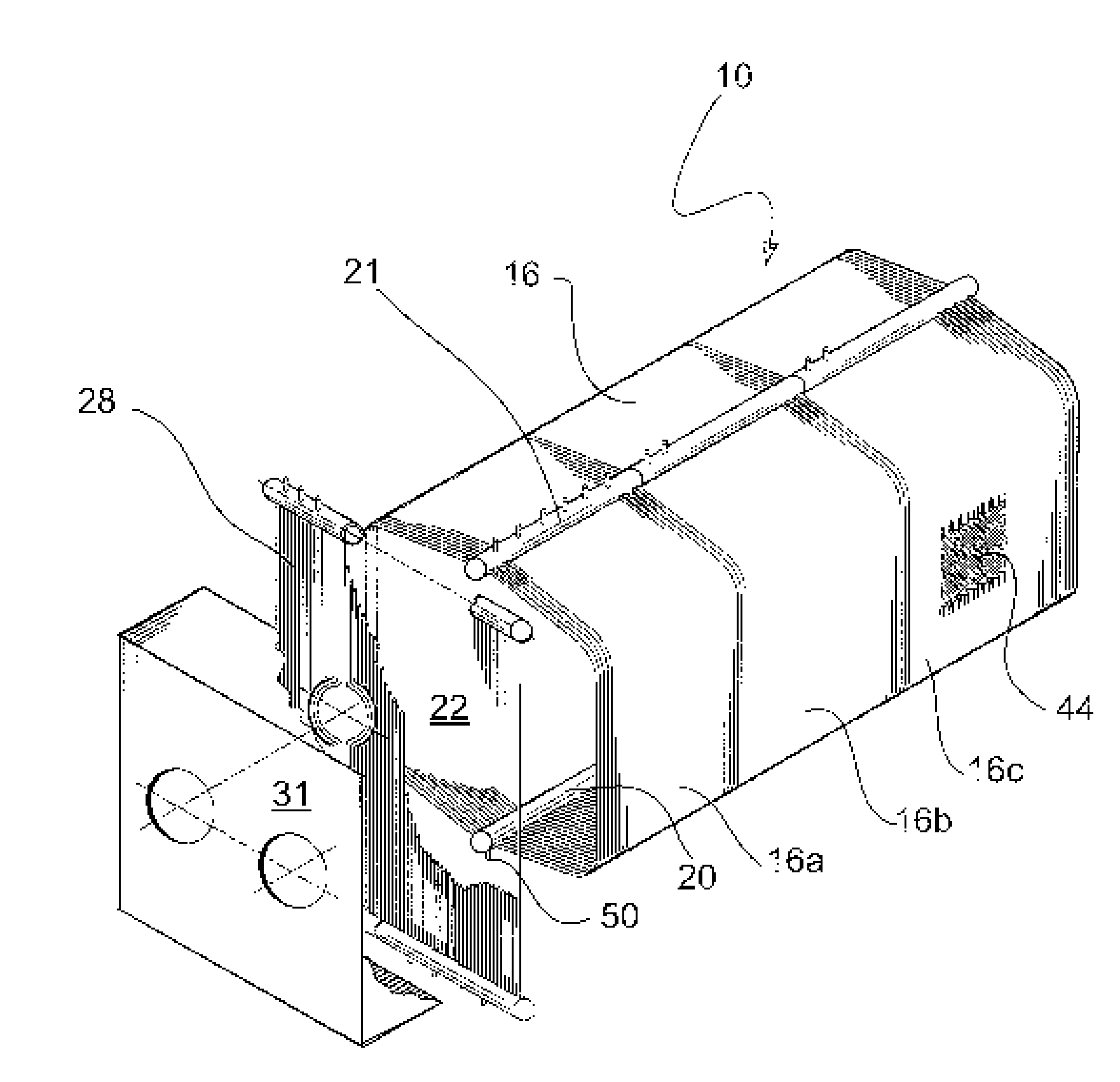

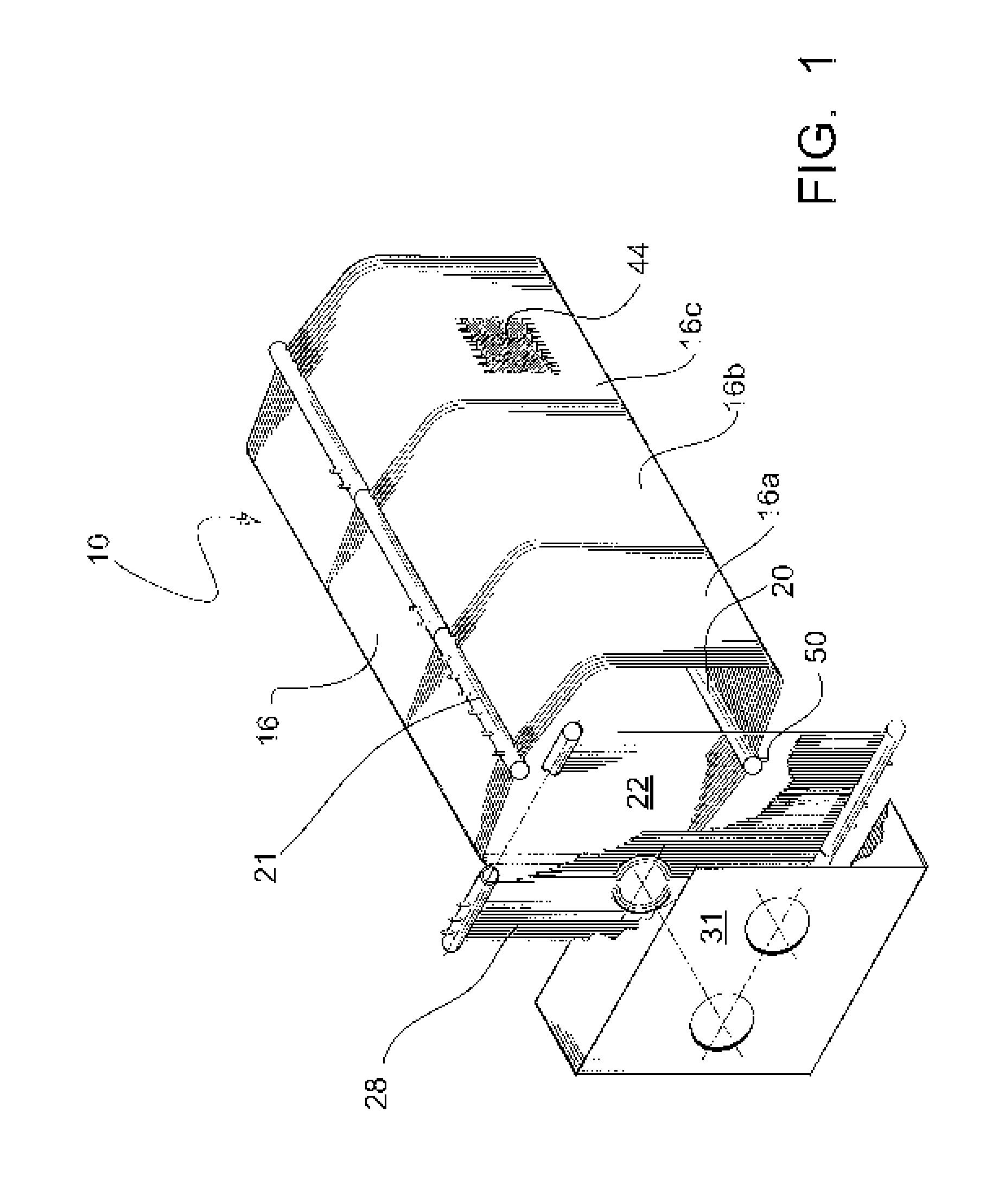

Modular Transportable System For SAGD Process

InactiveUS20120193093A1Easy interconnectionSmall sizeDrilling rodsInsulationProcess moduleSteam-assisted gravity drainage

A transportable modular process for exploiting a remote heavy oil resource or the like using steam assisted gravity drainage technology or the like. Said process comprising transportable preassembled and commissioned modules which when interconnected adjacent said remote heavy oil resource provide the ability to exploit said heavy oil resource or the like. Each module being preassembled and commissioned at the time of manufacture with the necessary piping and electrical wiring and other essential equipment for each module prior to being transported to adjacent the resource. Each module being, when transported to adjacent said resource, able to be readily interconnected with other process modules to enable an entire SAGD process or the like to be constructed adjacent said resource.

Owner:1NSITE TECH

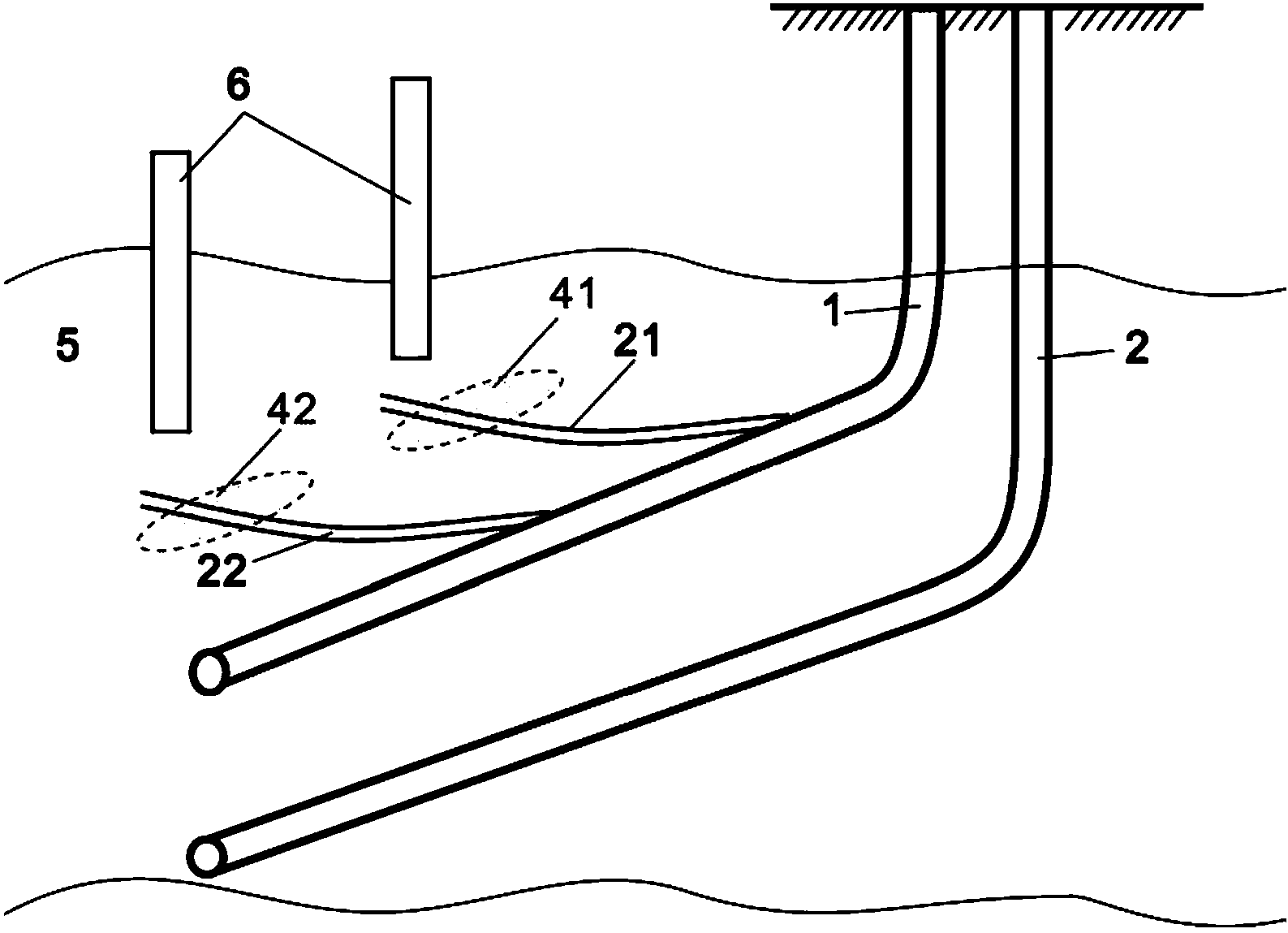

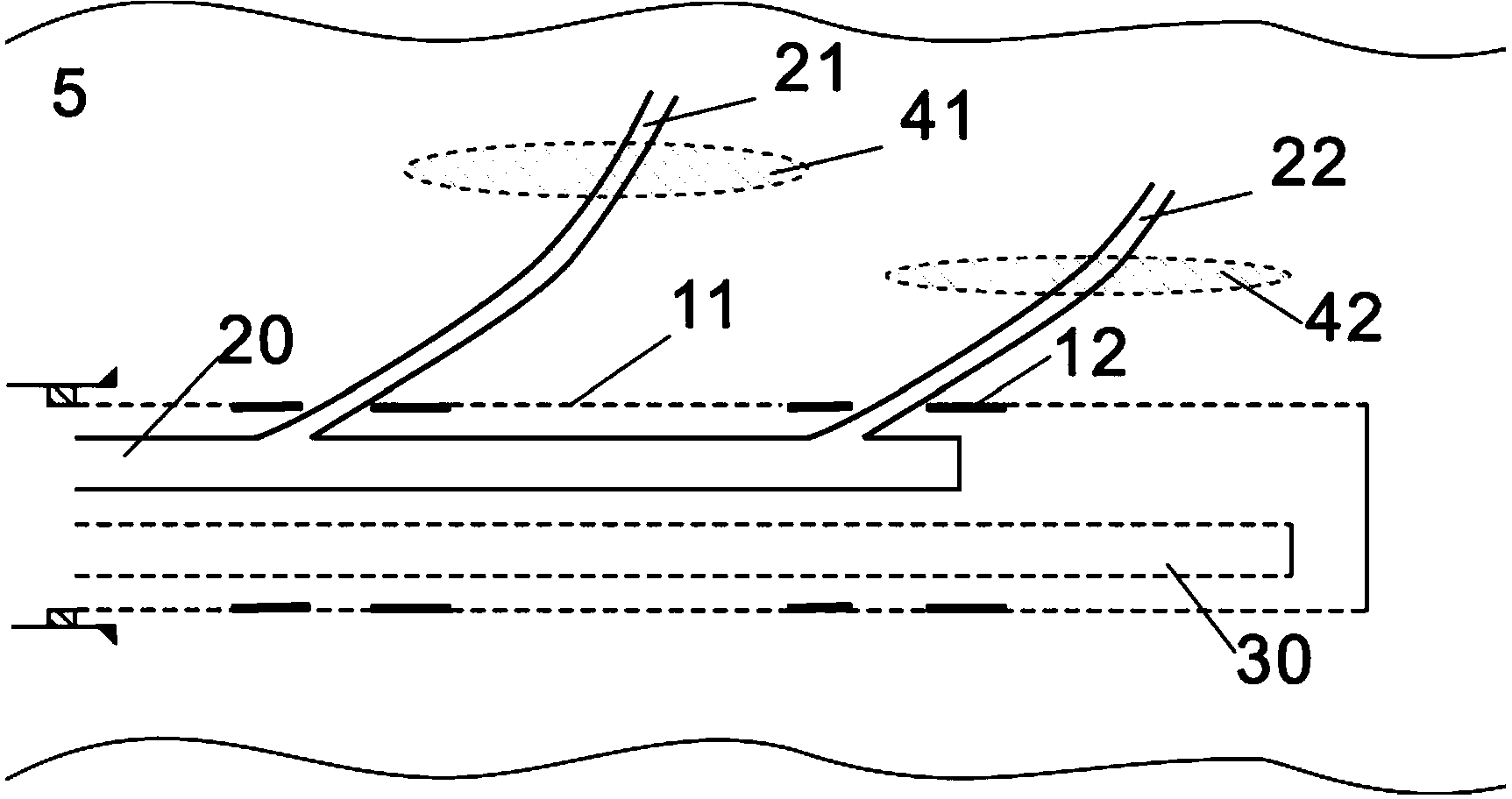

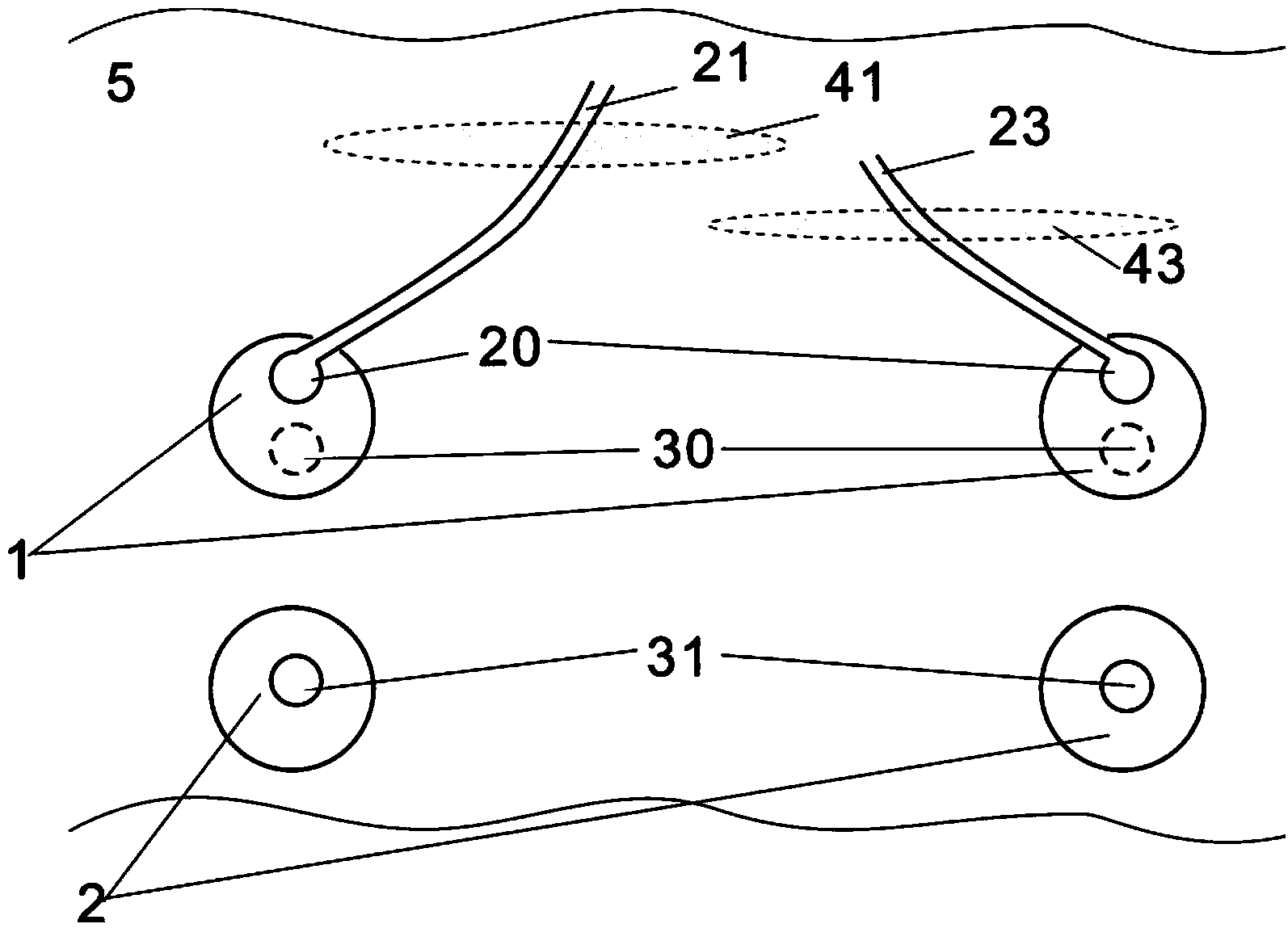

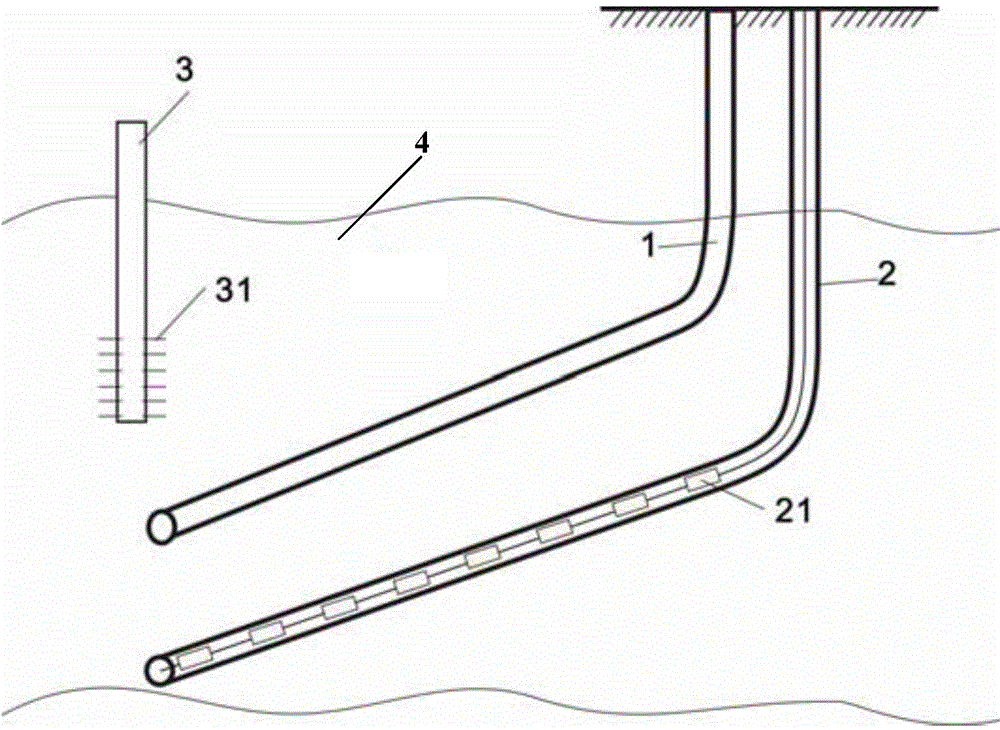

Method and well network structure for improving steam assisted gravity drainage for extracting heavy oil reservoirs by aid of solvents

The invention discloses a method and a well network for improving steam assisted gravity drainage for extracting heavy oil reservoirs by the aid of solvents. The well network comprises SAGD (steam assisted gravity drainage) horizontal well pairs; horizontal sections of steam injection wells are subjected to well completion by the aid of slotted screen pipes; branched well sections are drilled in the horizontal sections of the steam injection wells and penetrate the middles of inner sandwich layers in oil layers; the various branched well sections are subjected to well completion by the aid of tail pipes; first long oil pipes which extend to toes of the steam injection wells descend into screen pipes of the steam injection wells; solvent injection main pipes which are parallel to the first long oil pipes descend into the screen pipes of the steam injection wells and are hermetically connected with the tail pipes in the various branched well sections by tail pipe hangers; second long oil pipes descend into production wells and reach the tail ends of horizontal sections of the production wells; vertical monitoring wells are further deployed in the well network. The method and the well network have the advantages that steam flows into the oil layers to upwardly develop steam cavities, and the hot solvents and steam mixed systems flow into the oil layers on the upper portions of the sandwich layers from the main pipes via the tail pipes, so that heat communication and fluid communication among the oil layers and the steam cavities can be accelerated, the sandwich layers can be forcedly broken through, development of the steam cavities on the upper portions of the sandwich layers can be promoted, and the recovery efficiency can be greatly improved.

Owner:PETROCHINA CO LTD

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

ActiveCN101421483ALarge measuring rangeAccurate measurementSurveyConstructionsAc fieldSurvey instrument

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously 'listens' for, and recognizes, a 'start' signal that is initiated by the driller. After a 'start' signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronicpackages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

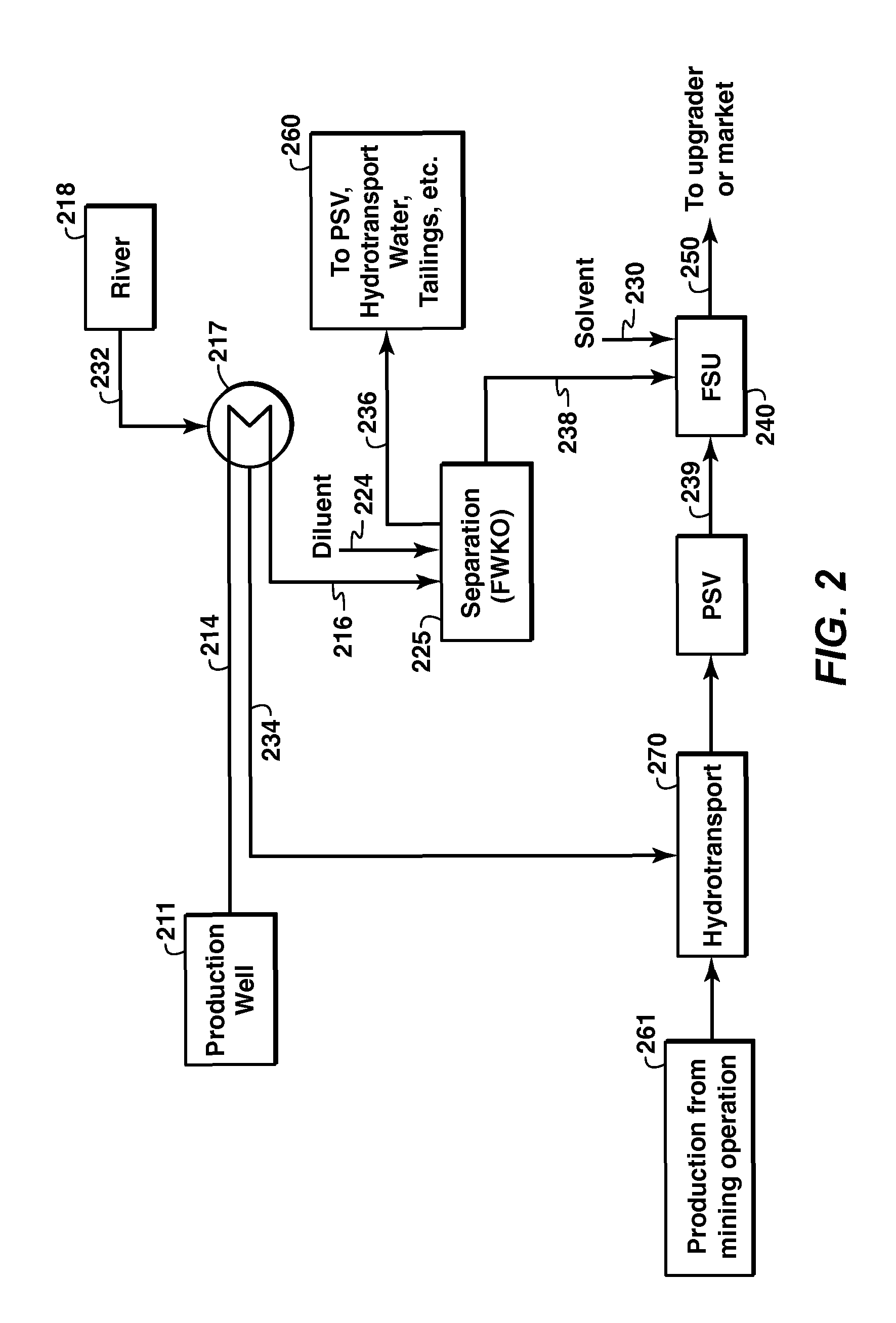

Integration of an in-situ recovery operation with a mining operation

InactiveUS20100276983A1Disloding machinesUnderground chambersSteam-assisted gravity drainageIntegrated systems

This description is directed to a method and system for integrating an in-situ bitumen recovery operation with a bitumen mining operation for improved efficiencies and synergies therebetween. The method comprises obtaining a production fluid from the in-situ bitumen recovery operation, directing the production fluid to the bitumen mining operation, and incorporating the production fluid into the bitumen mining operation. The basic integrated system comprises a production well for recovering production fluid from the in-situ bitumen recovery operation, a bitumen mining and extraction facility, and a transporter for directing the production fluid from the production well to the bitumen mining and extraction facility for incorporation into the mining and extraction operation. The in-situ recovery operation may be a thermal operation, such as steam-assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), or a derivative thereof.

Owner:EXXONMOBIL UPSTREAM RES CO

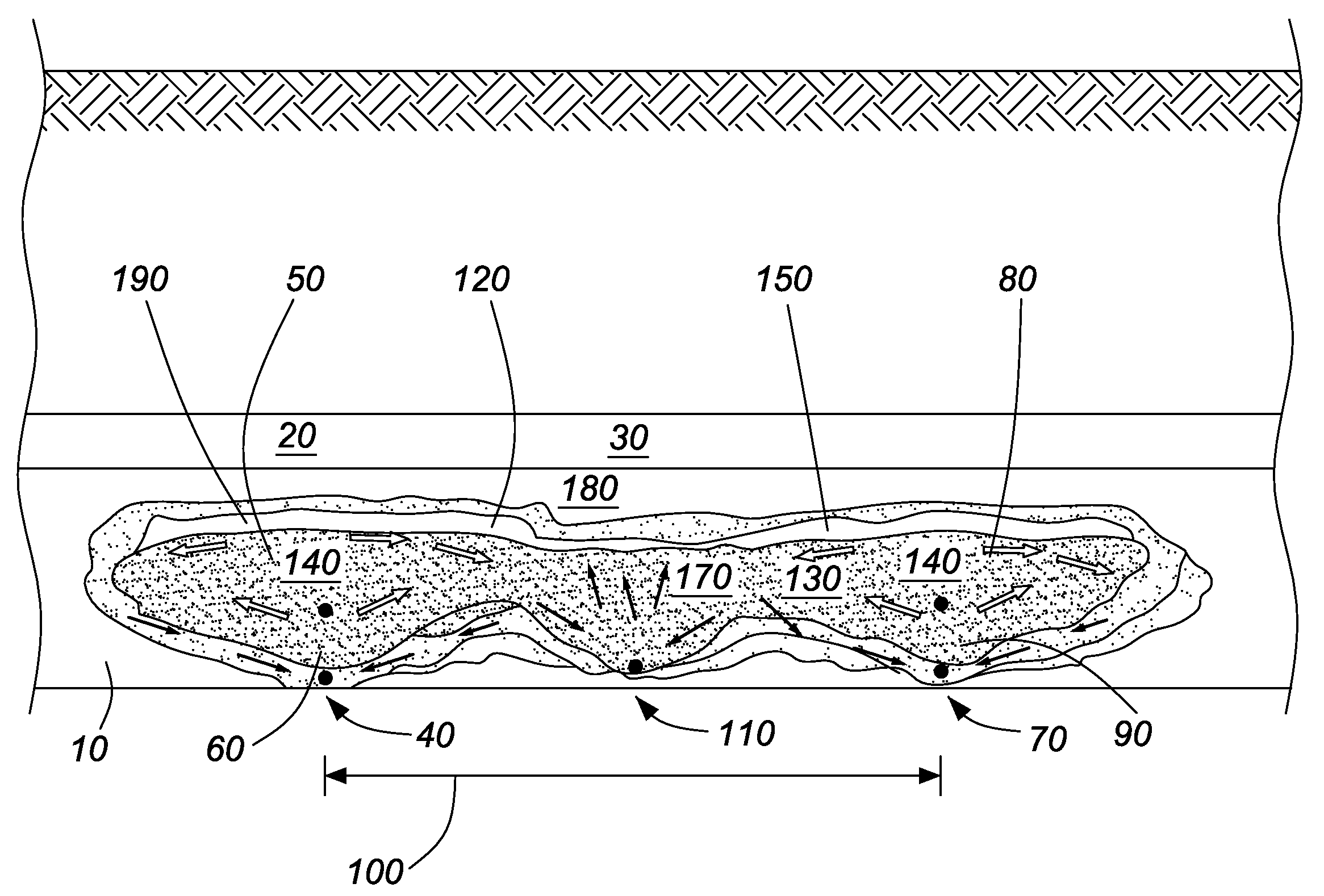

Low pressure recovery process for acceleration of in-situ bitumen recovery

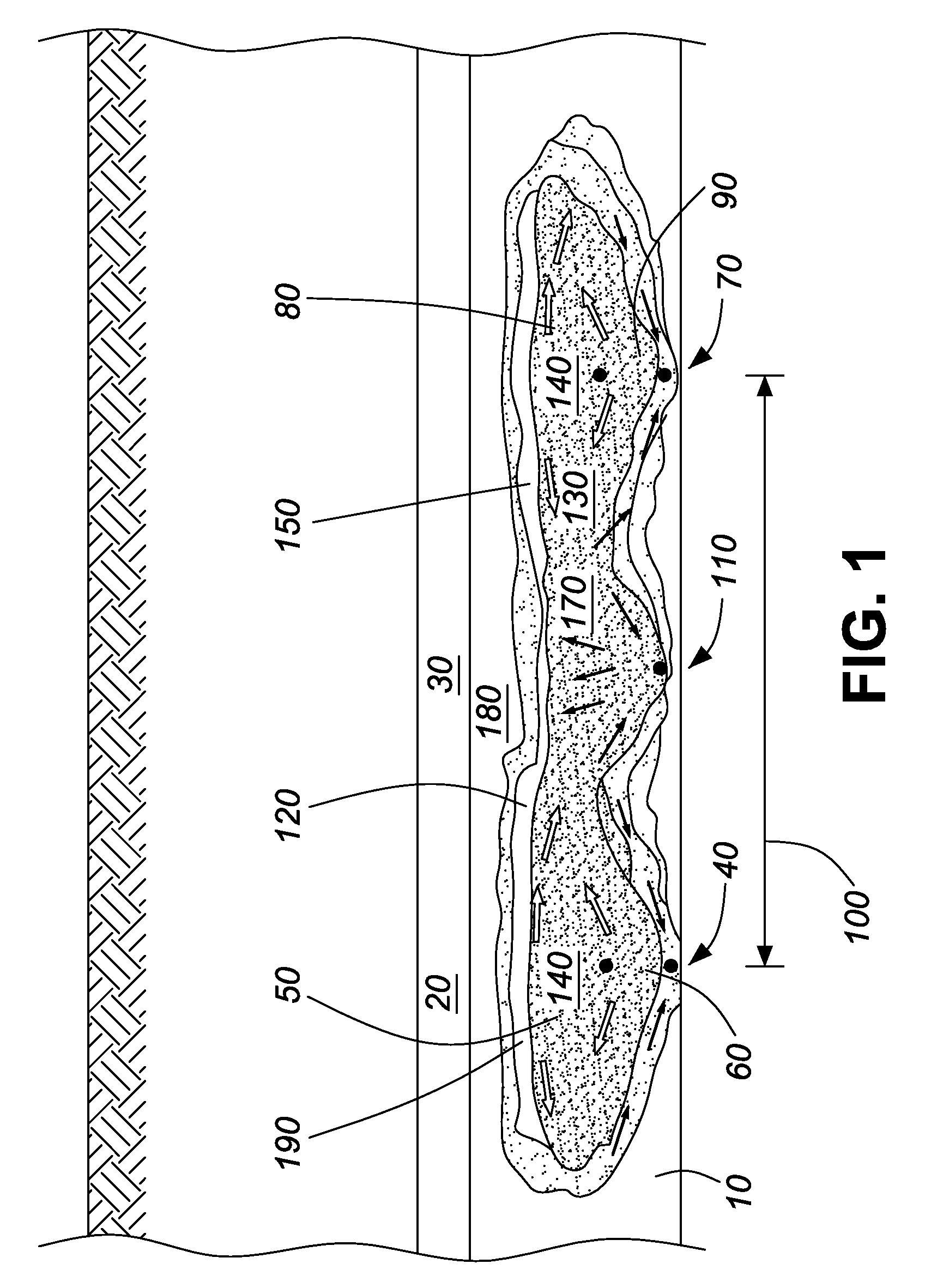

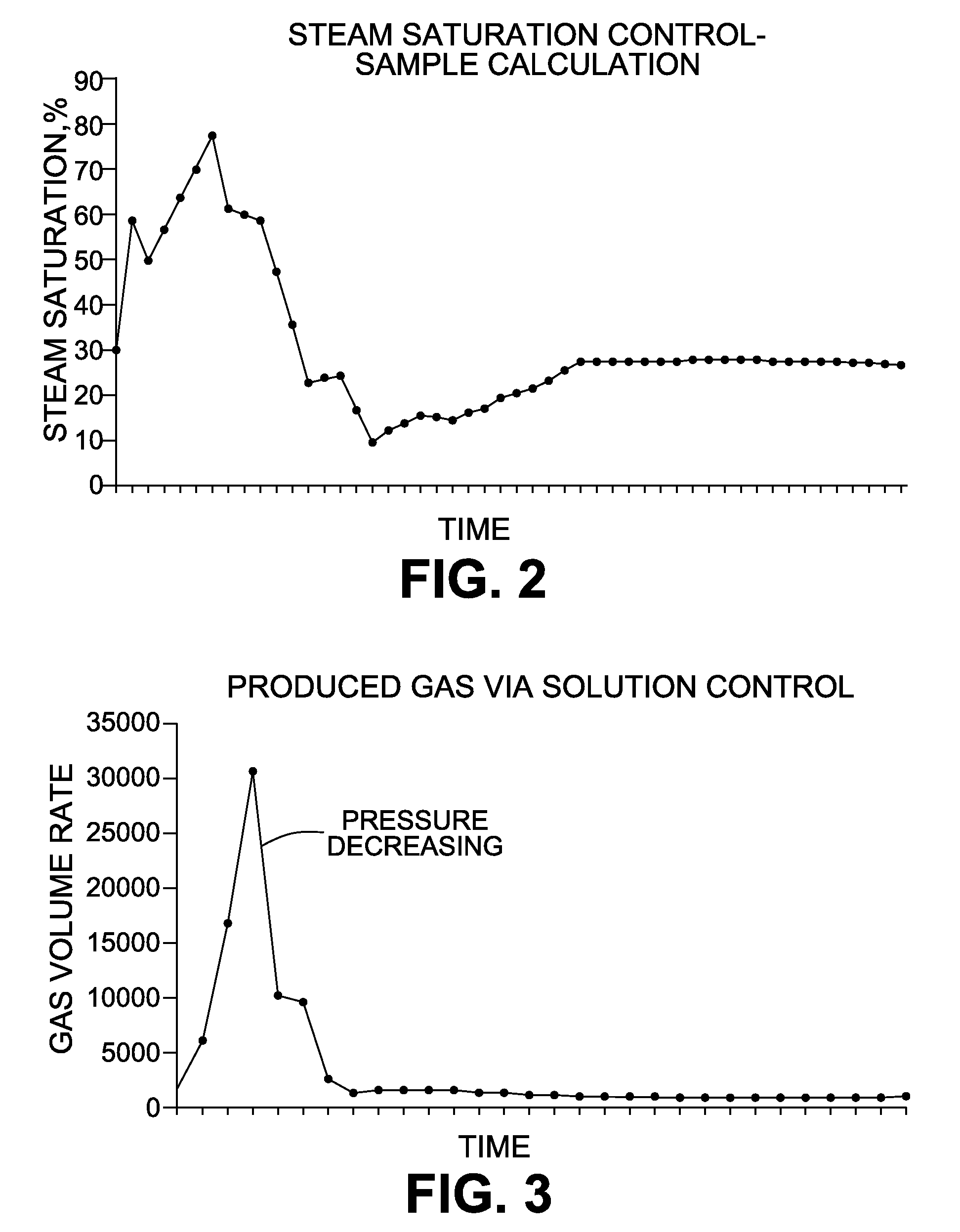

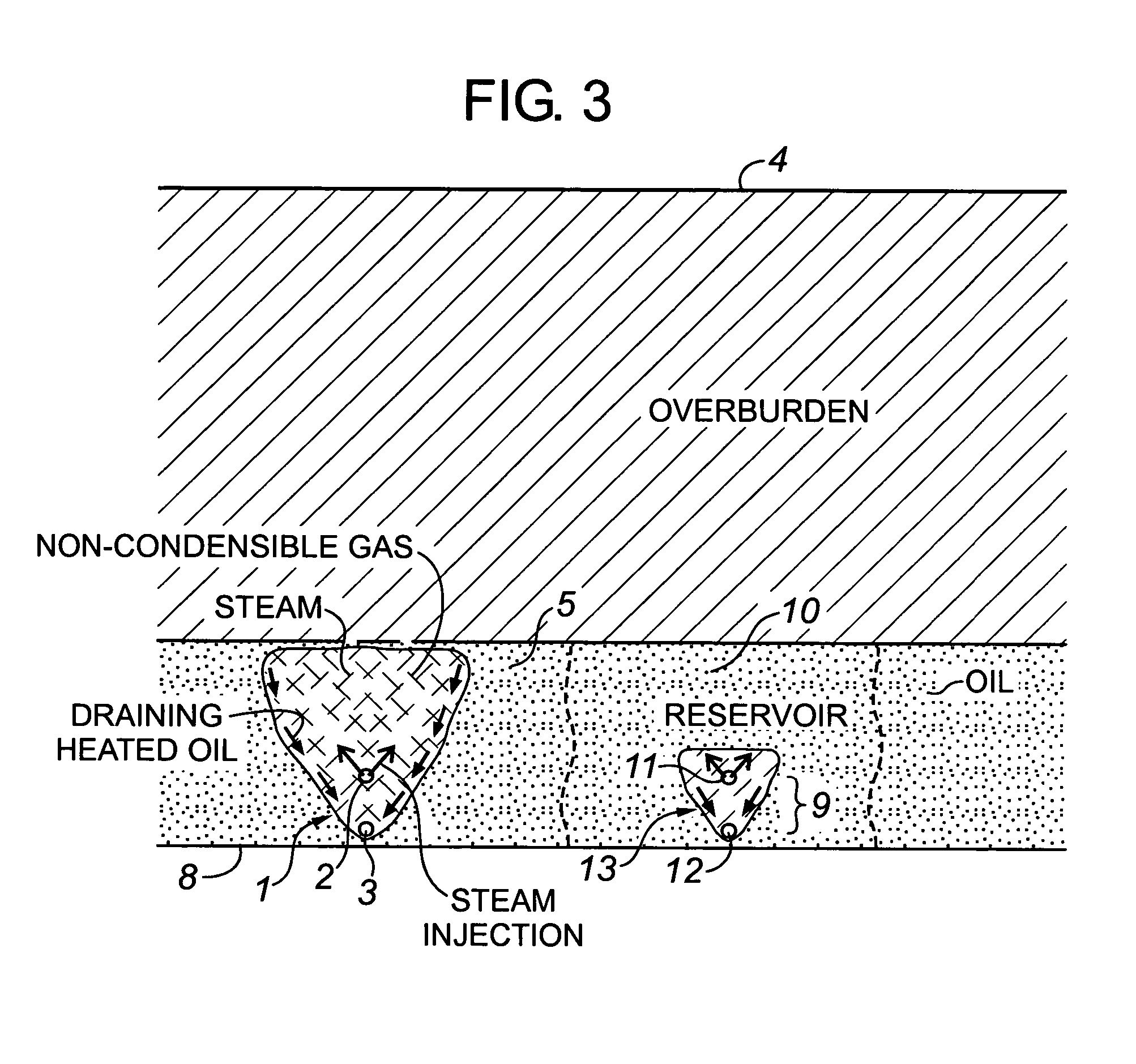

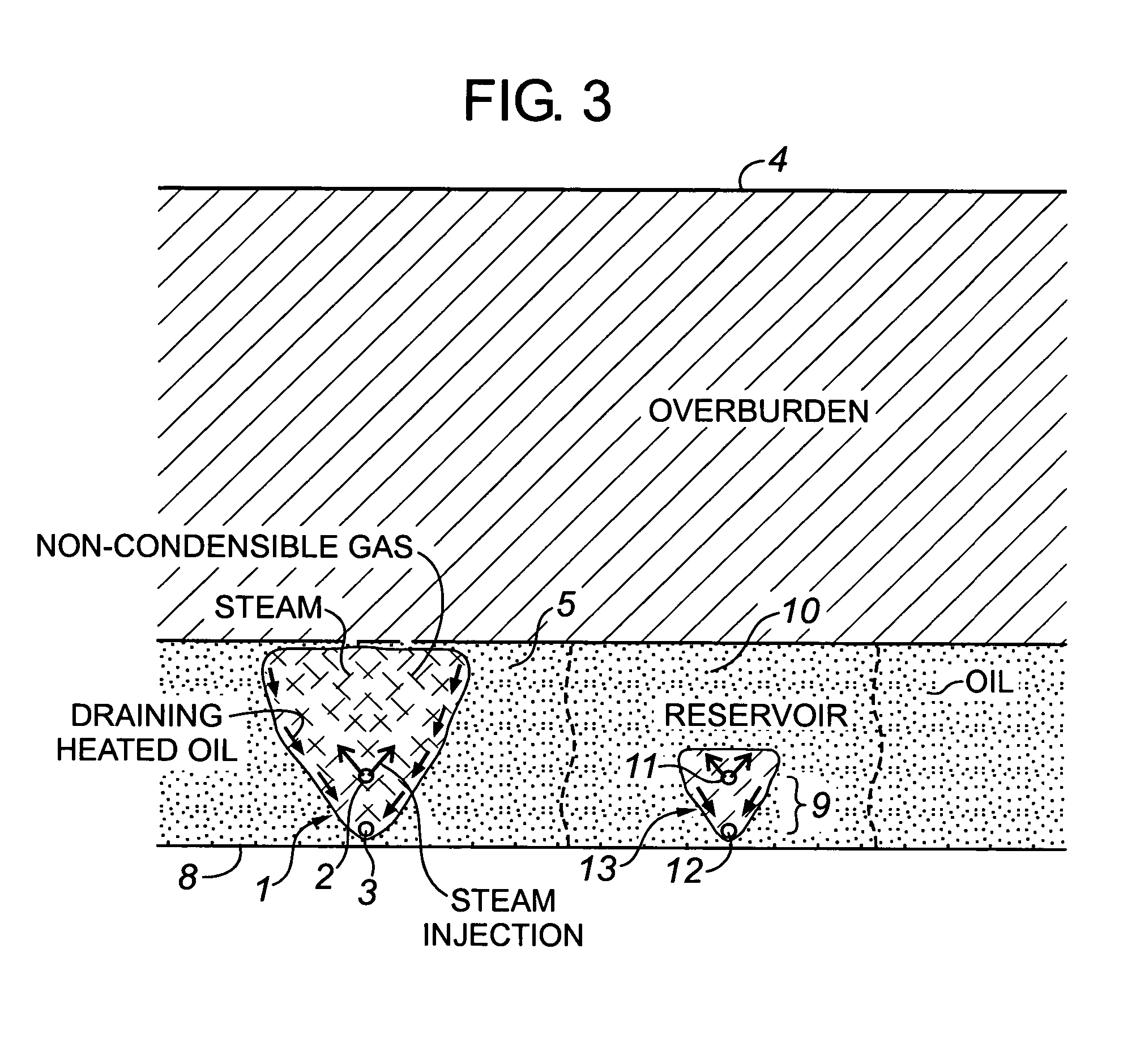

A method for recovery of hydrocarbons from a subterranean reservoir by operating adjacent injector producer well pairs under conditions of steam assisted gravity drainage (SAGD) with a lateral drainage well between and substantially parallel to them; the lateral drainage well is operated under conditions of intermittent steam injection and alternating oil, water and gas production; NCG is co-injected with steam into both the injector wells and the lateral drainage well at selected intervals, and in selected quantities in order to control the steam saturation of the SAGD steam chamber and the rise of the steam chamber, and to encourage lateral fluid communication between the adjacent well pairs and the LD well; controlling gas injection and production in order to control the rise of the steam chamber to improve production of oil; operating the well pairs and the LD well under conditions of a steam chamber pressure that is initially and briefly high to establish a steam chamber, but thereafter may be reduced to as low as 200 kPa; operating this low pressure SAGD in reservoirs that are at low pressure, due to factors such as depleted gas caps, regional geology, lack of cap rock, thief zones, or other low pressure zone or loss zones.

Owner:ATHABASCA OIL CORPORATION

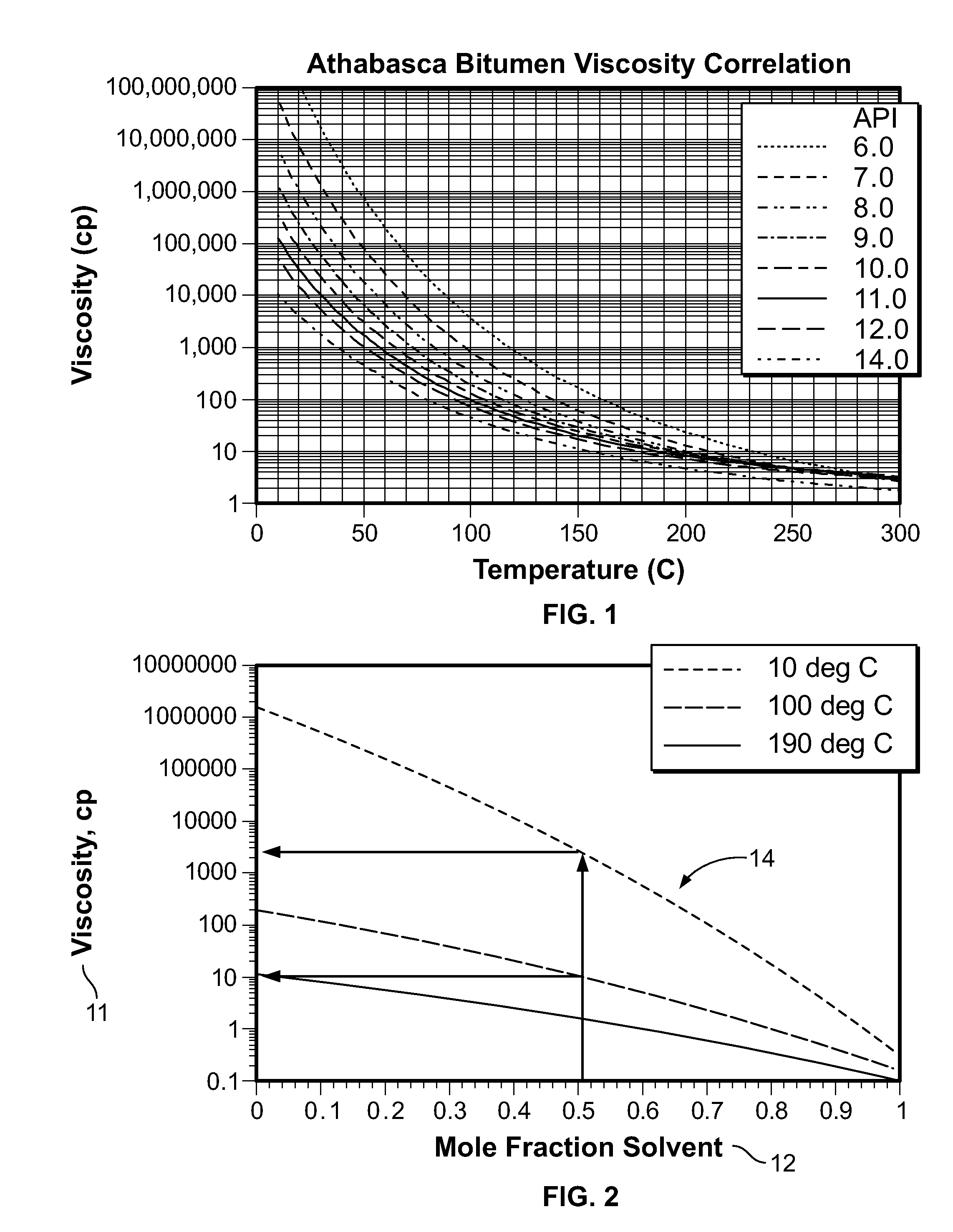

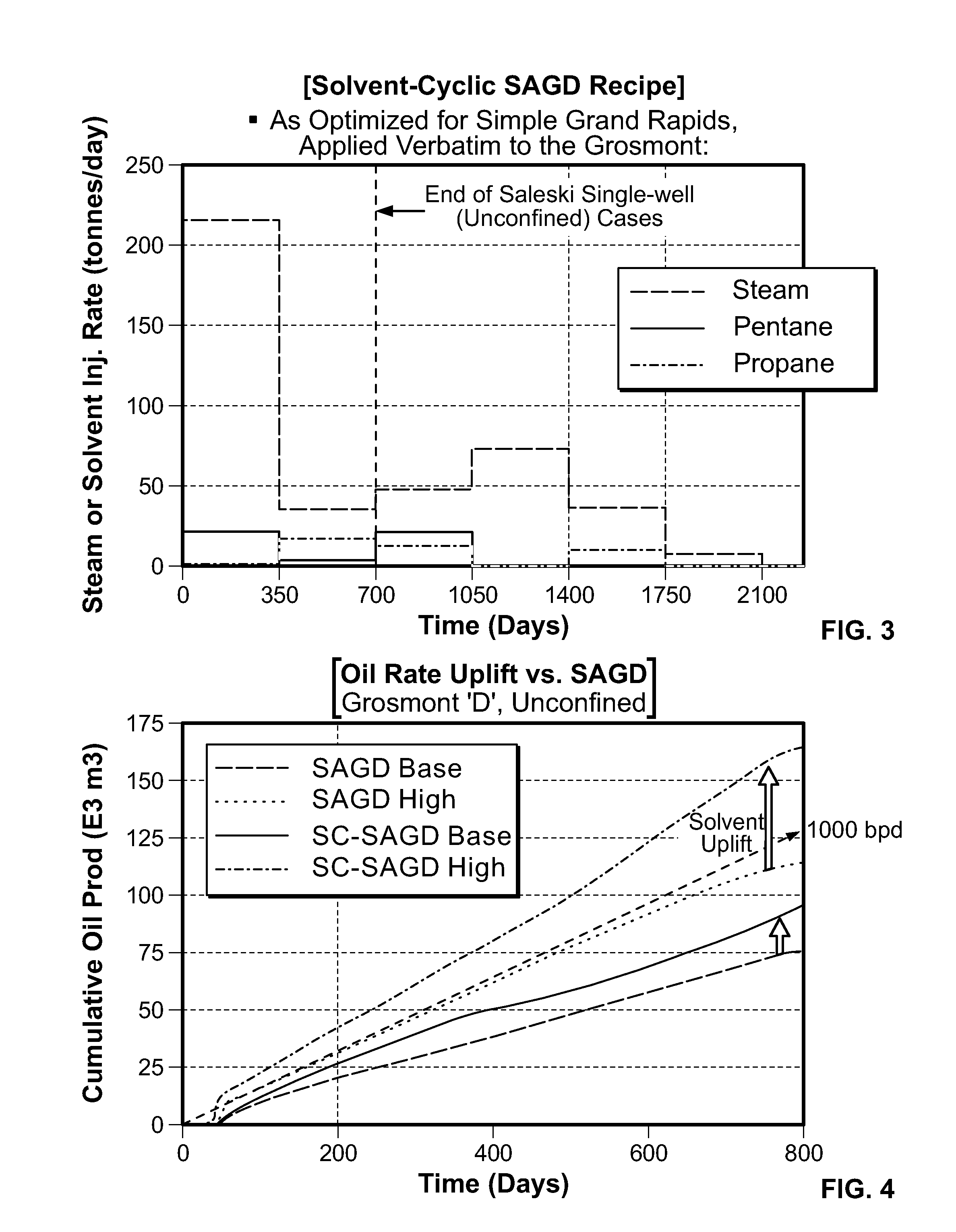

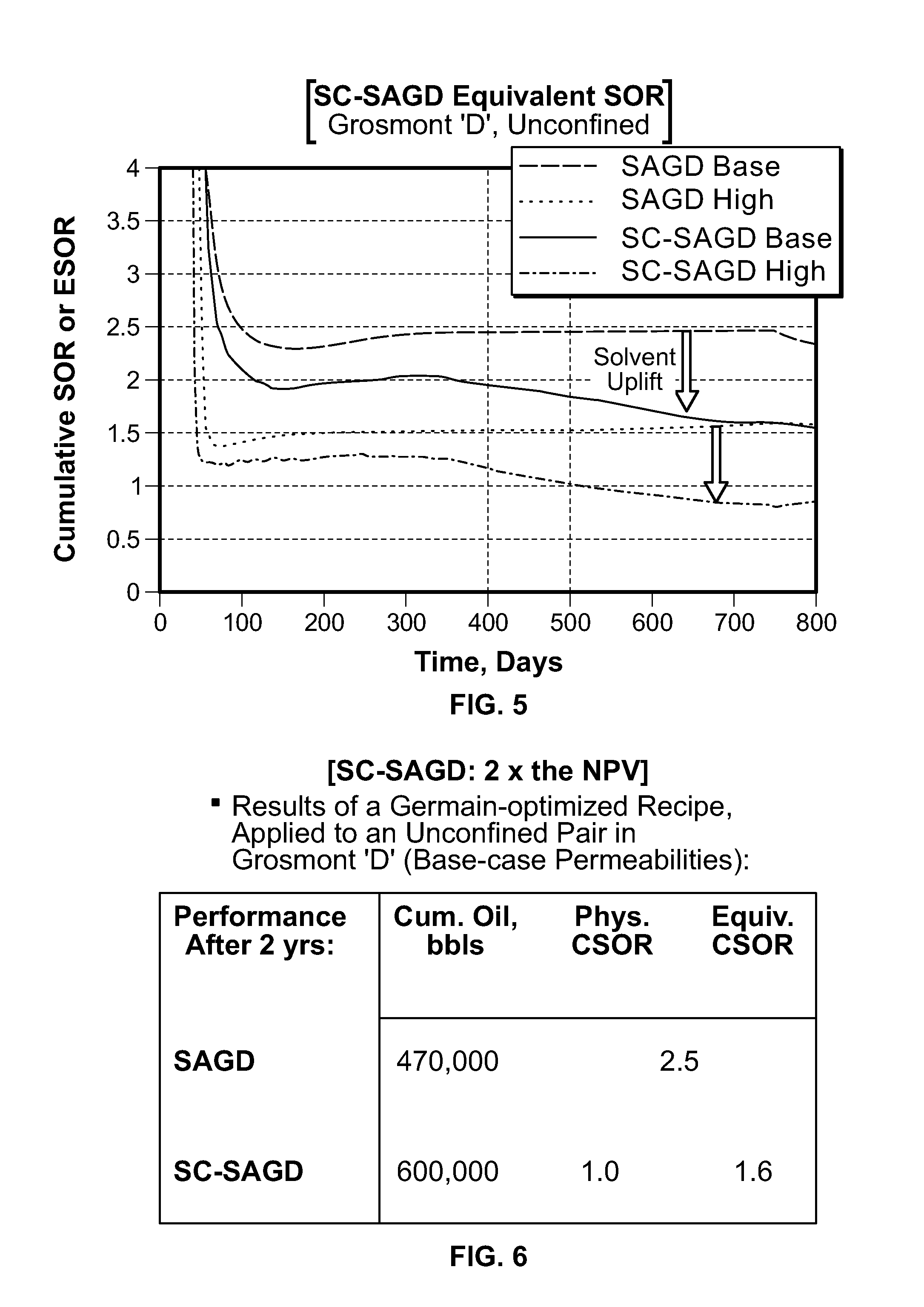

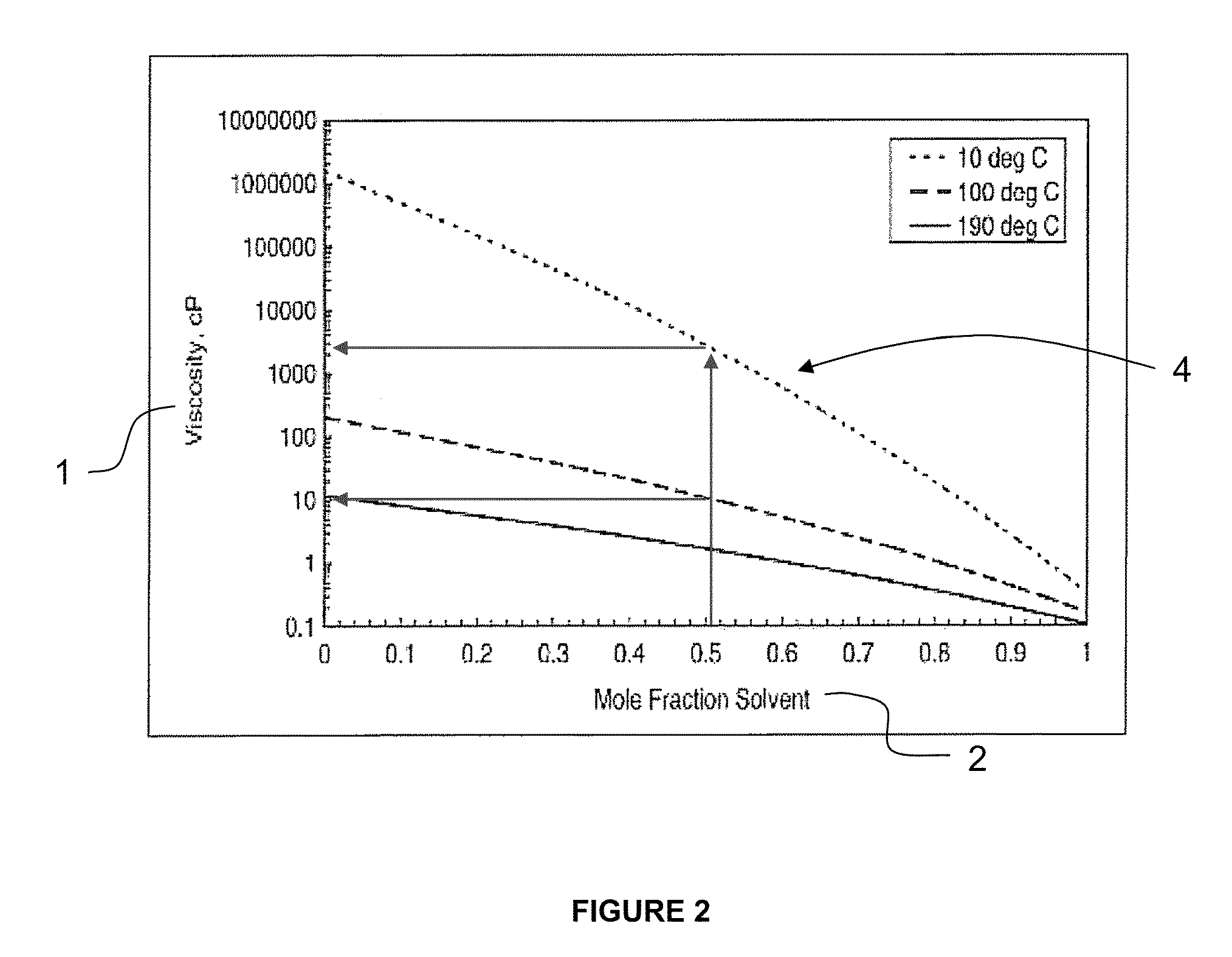

Method for Viscous Hydrocarbon Production Incorporating Steam and Solvent Cycling

A method for producing hydrocarbons from a reservoir containing the hydrocarbon comprises a steam assisted gravity drainage (SAGD) incorporating cyclic steam, heavy (e.g. greater than C4) solvent and light (e.g. C2 to C4) solvent injection. The method involves a series of steps wherein the injection of the respective streams is varied. The method provides a significant improvement in hydrocarbon extraction efficiency as compared to a SAGD process alone and mitigates many of the drawbacks associated with typical SAGD operations.

Owner:LARICINA ENERGY

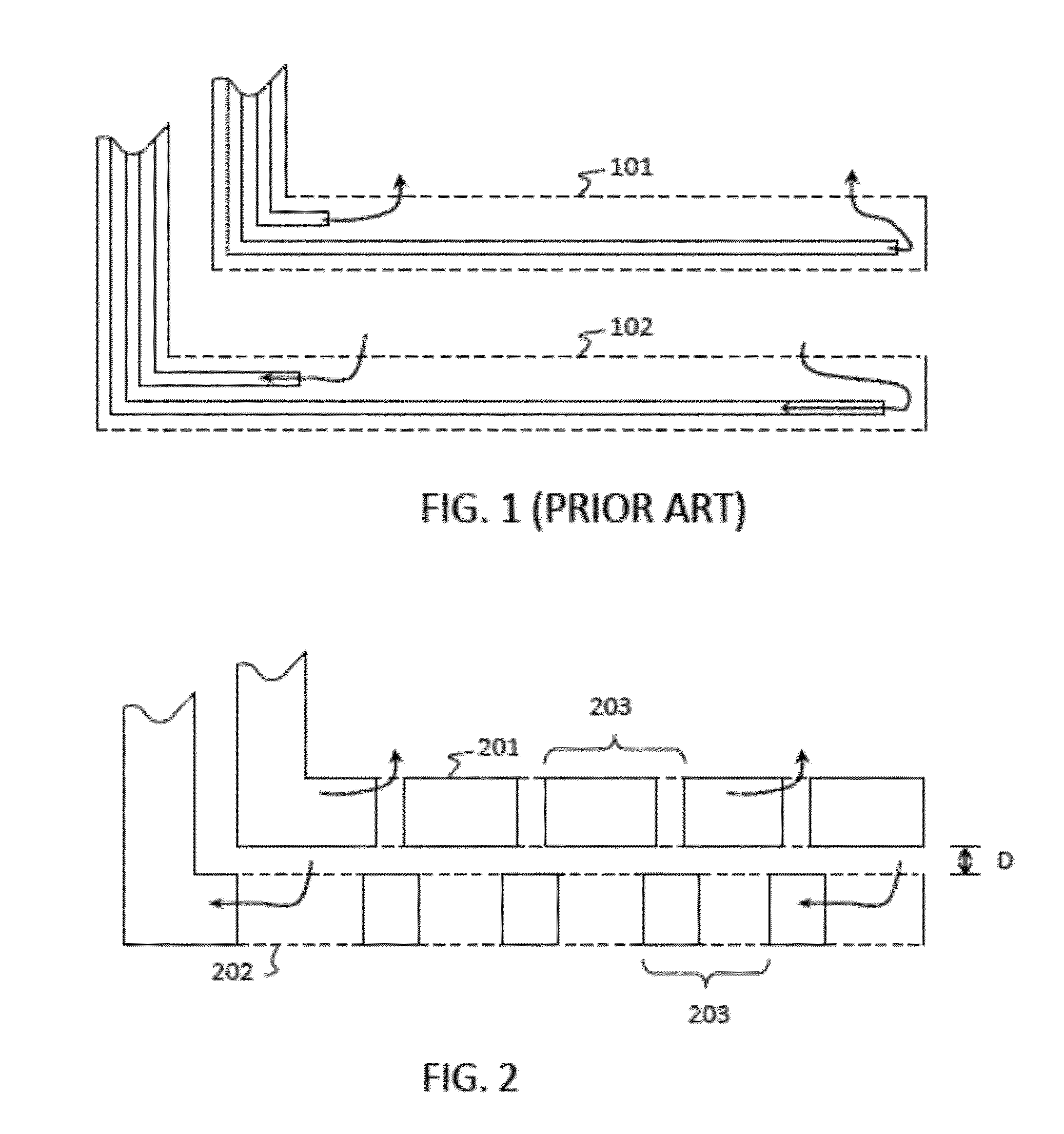

Process for sequentially applying SAGD to adjacent sections of a petroleum reservoir

Steam assisted gravity drainage (“SAGD”) is practised in a first section of a reservoir containing heavy oil. When steam / oil ratio rises sufficiently, steam injection into the first section is curtailed or terminated. Non-condensible gas is then injected into the section to pressurize it and production of residual oil and steam condensate is continued. Concurrently with pressurization, SAGD is practised in an adjacent reservoir section. As a result, some of the residual oil in the first section is recovered and steam loss from the second section to the first section is ameliorated.

Owner:ALBERTA INNOVATES - ENERGY & ENVIRONMENT SOLUTIONS

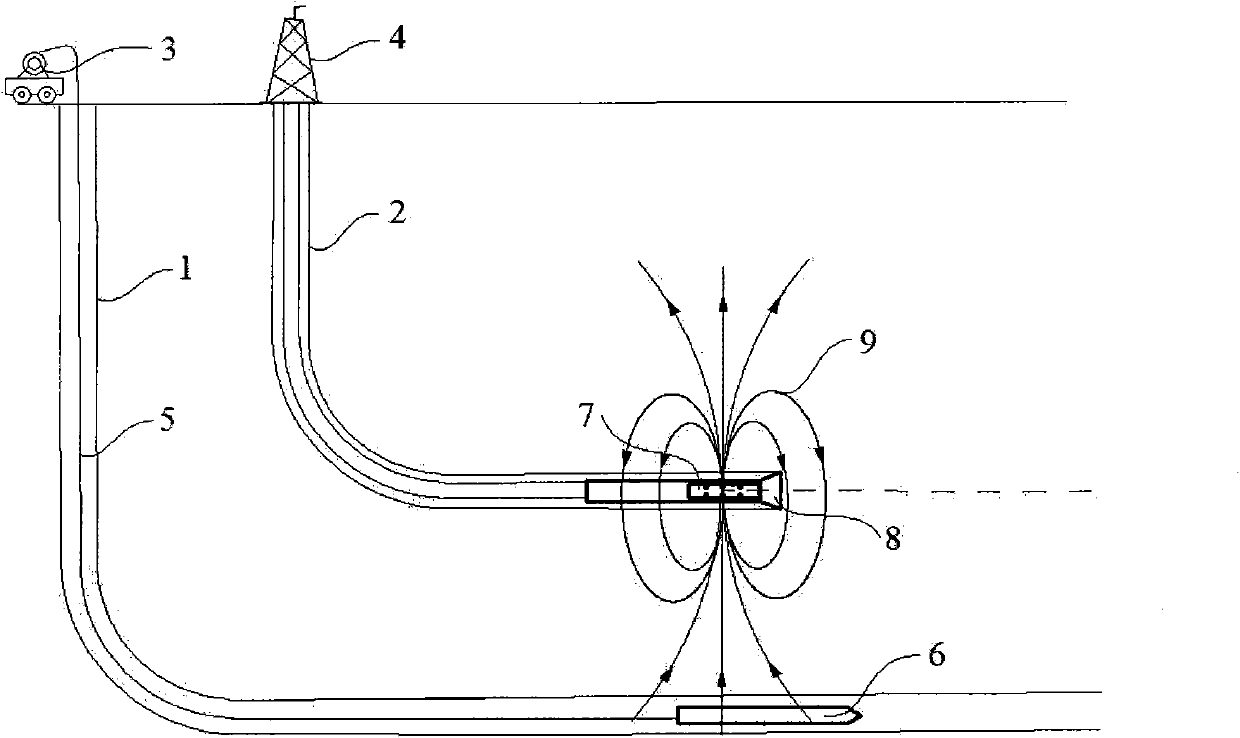

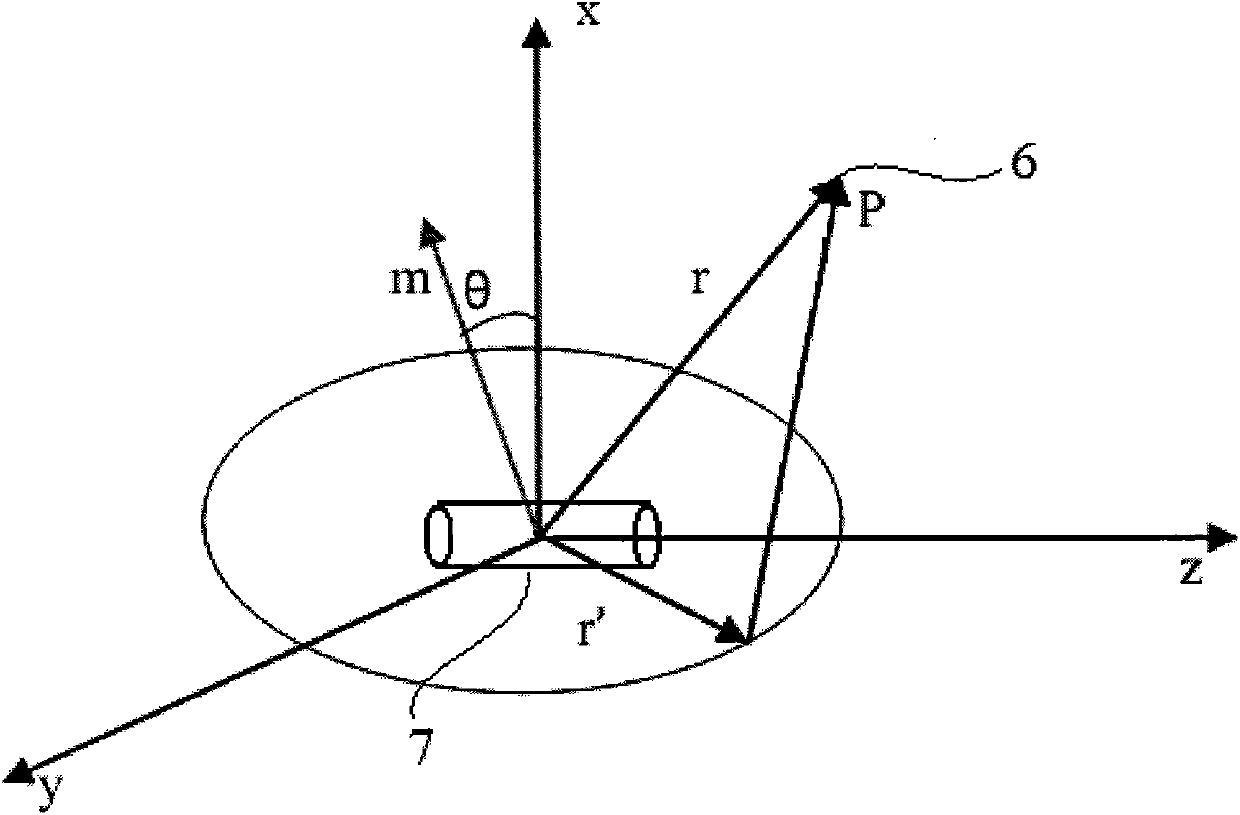

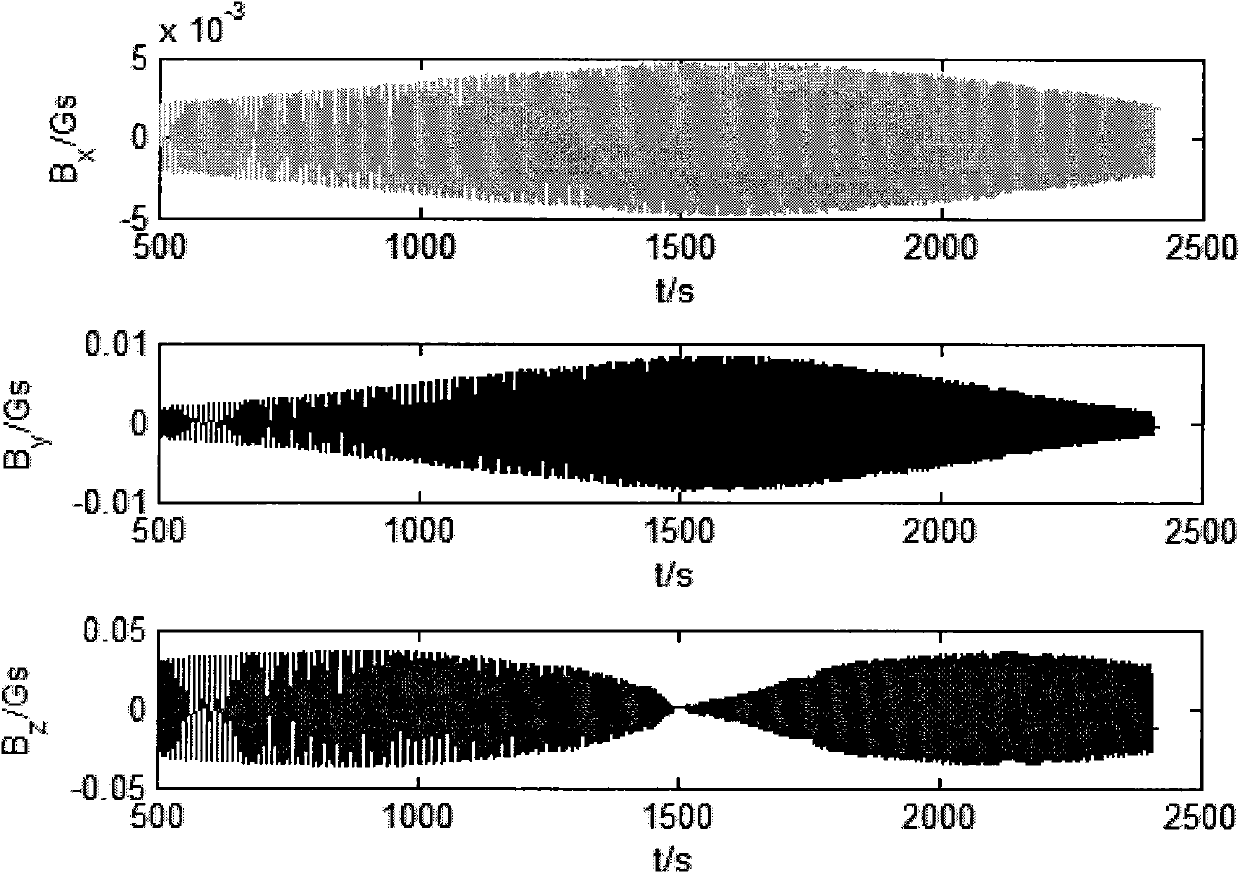

Calculating method for SAGD (Steam-Assisted Gravity Drainage) double-horizontal well drilling electromagnetic distance measurement guide

The invention relates to a calculating method for SAGD (Steam-Assisted Gravity Drainage) double-horizontal well drilling electromagnetic distance measurement guide, which mainly comprises the steps of acquired data processing, calculation of rotating magnetic short section far-field magnetic induction intensity, inclination measurement and calculation of well hole track, neighboring well paralleldistance calculation, and the like. In the extracting process of unconventional oil and gas resources, such as thickened oil, natural gas hydrate, and the like, the precise control on the SAGD double-horizontal well horizontal section distance is one of the key technical links. In the invention, as for the application background, an approach for combining an inclination measurement and calculation method of the well hole track and drilling electromagnetic detection is adopted for monitoring a space relative position relationship of the double-horizontal well horizontal section in real time. Firstly, the distance of the double-horizontal well horizontal sections is obtained by utilizing a magnetic signal generated by a rotating magnetic short section received by a probe; and then, the calculating method which can confirm the relative orientation of the double-horizontal well horizontal section is invented by utilizing the inclination measurement and calculation of the well hole track and the drilling electromagnetic detection signal. The invention not only can be applied to the SAGD double-horizontal well guide drilling well detection but also can be applied to multiwell collision preventing and three-dimensional hinder-crossing monitoring calculation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

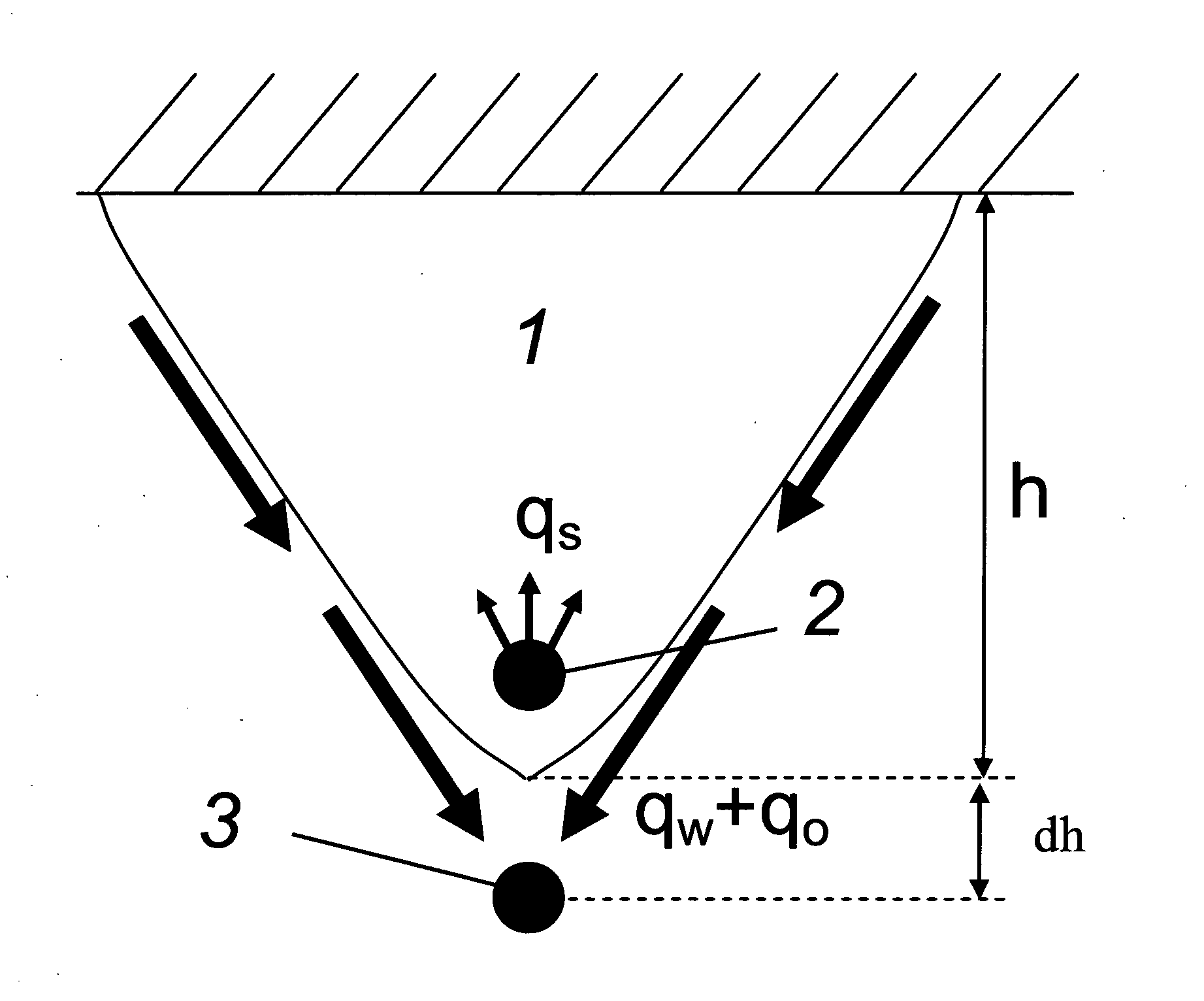

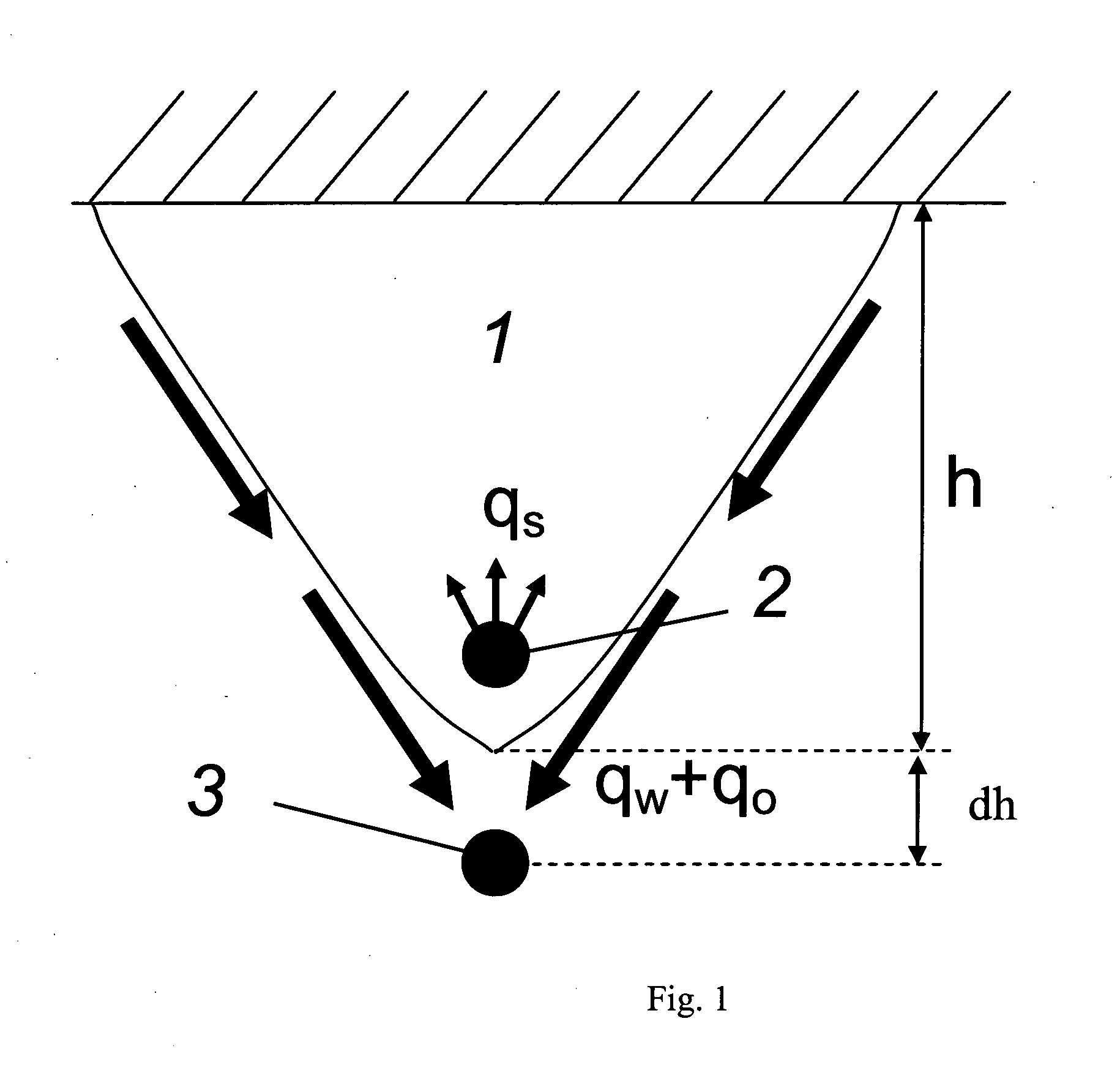

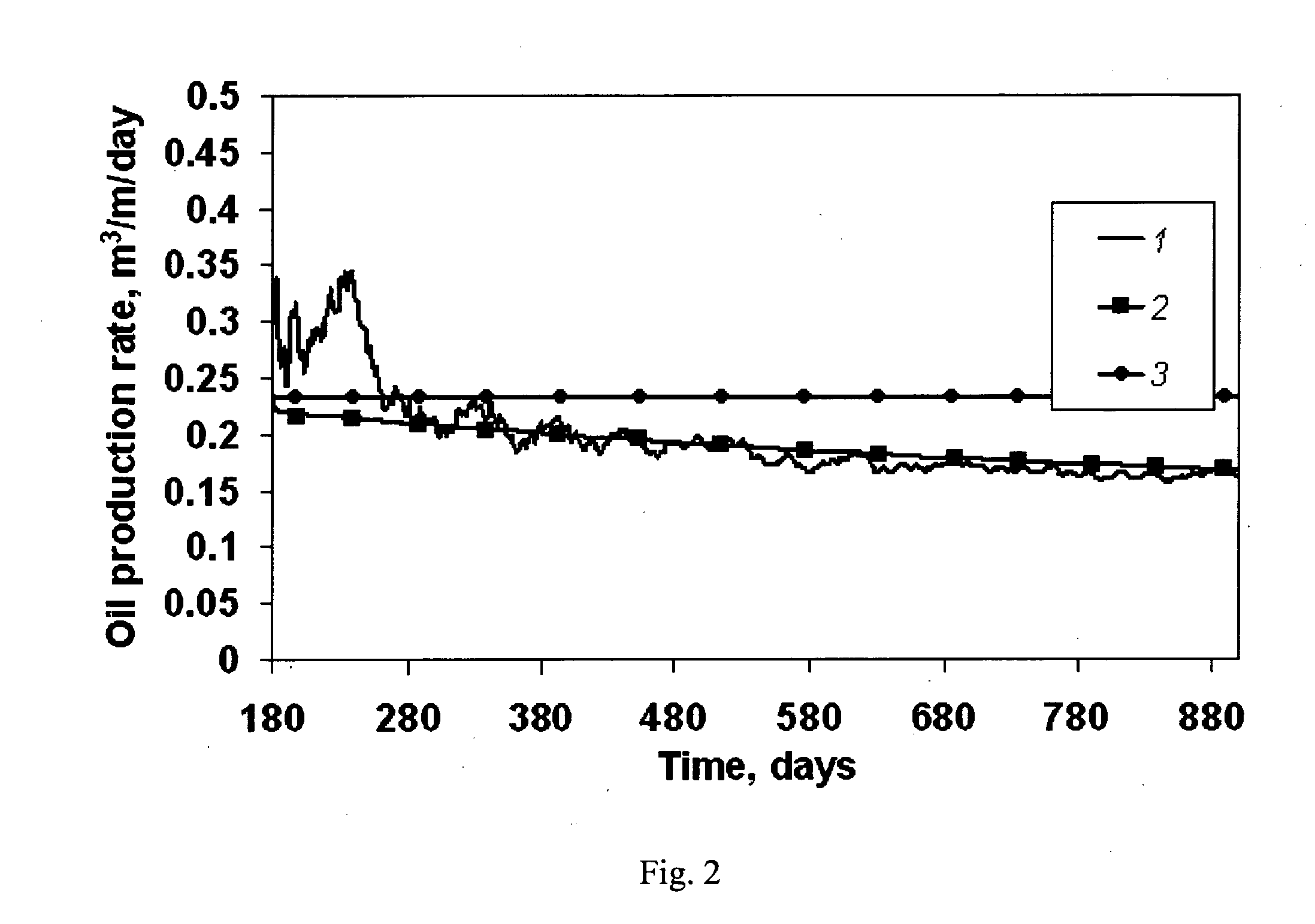

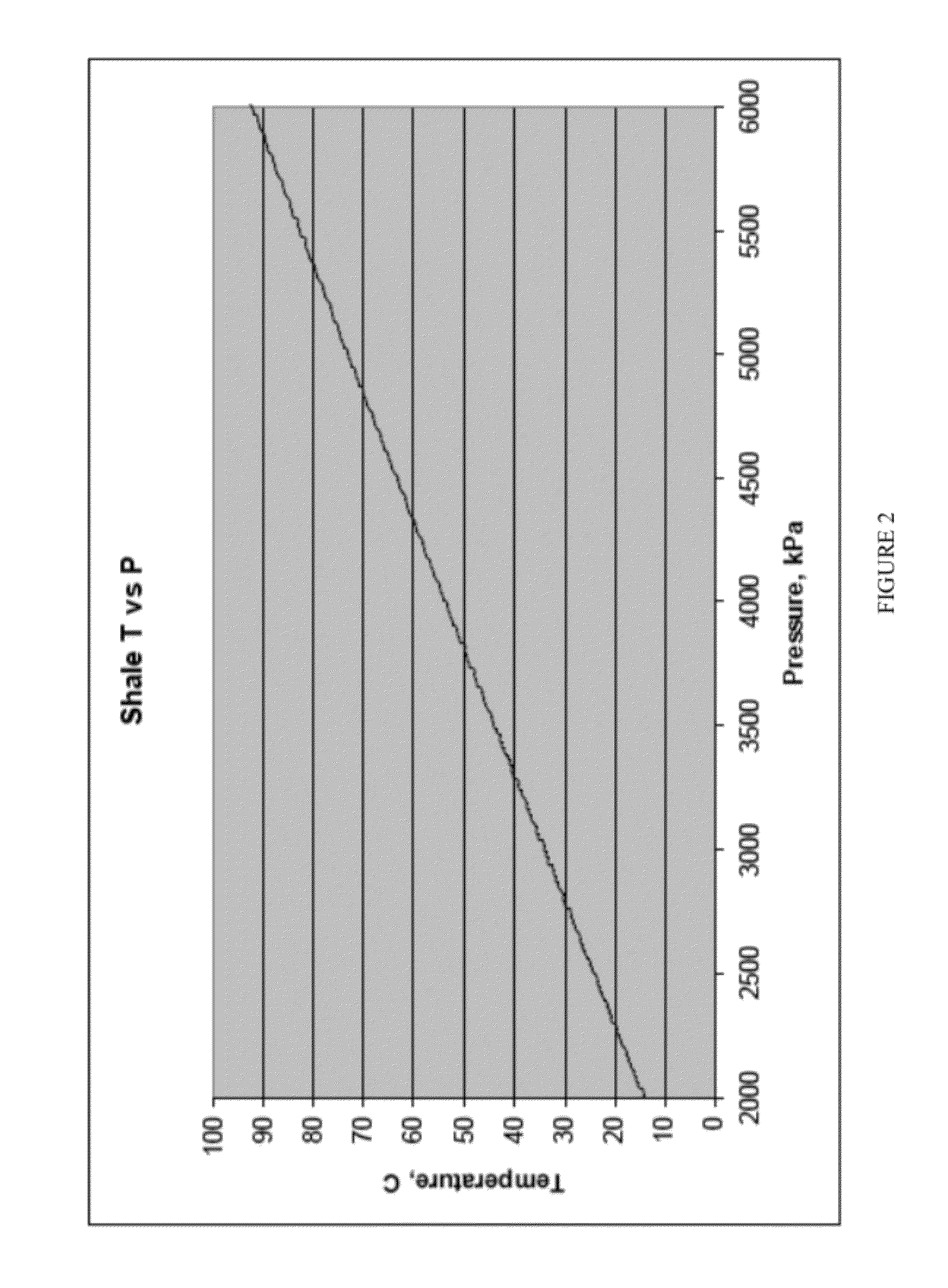

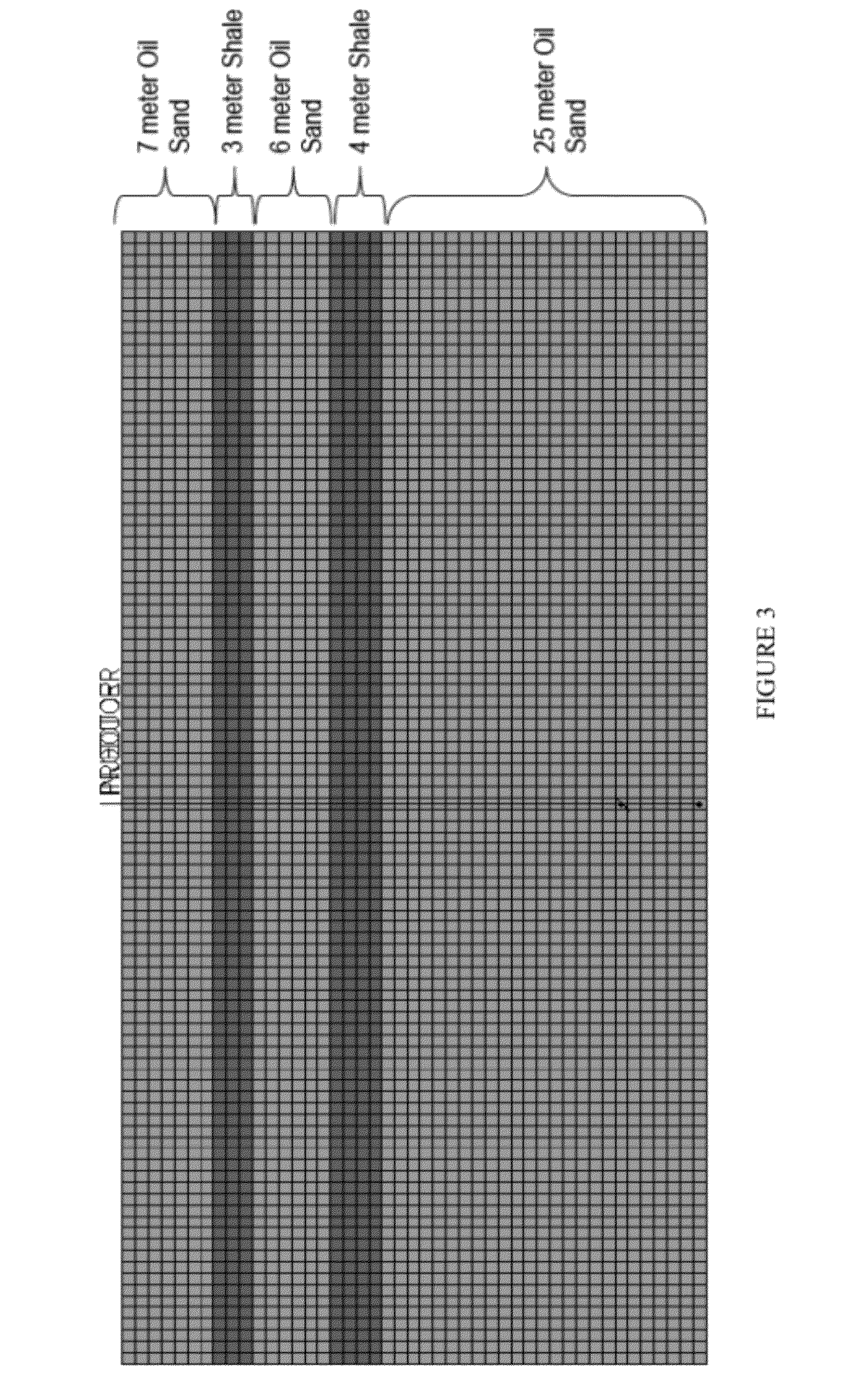

Method for estimation of sagd process characteristics

InactiveUS20110288778A1Fast and accurate and efficientElectric/magnetic detection for well-loggingSurveyVapor qualitySection plane

The invention relates to thermally stimulated oil recovery in horizontal wells, namely to the methods for estimation of Steam Assisted Gravity Drainage (SAGD) process characteristics. Method for estimation of SAGD process characteristics is characterized by the steps of measuring temperature along the injection well, measuring steam quality and injection rate at the inlet of the injection well, estimating the pressure distribution profile by using the data obtained, estimating steam injection profile by using the obtained pressure profile and injection rate combined with ID injection well model for pressure losses in the wellbore and heat exchange between injection well tubing and annulus. The obtained steam injection profile is used as an input parameter for a set of 2D cross-sectional analytical SAGD models taking into account reservoir and overburden formation properties impact on production parameters and SAGD characteristics. SAGD process characteristics are estimated on the basis of energy conservation law for condensed steam taking into account heat losses into the reservoir and overburden formation and hence the fluid production rate changing in time.

Owner:SCHLUMBERGER TECH CORP

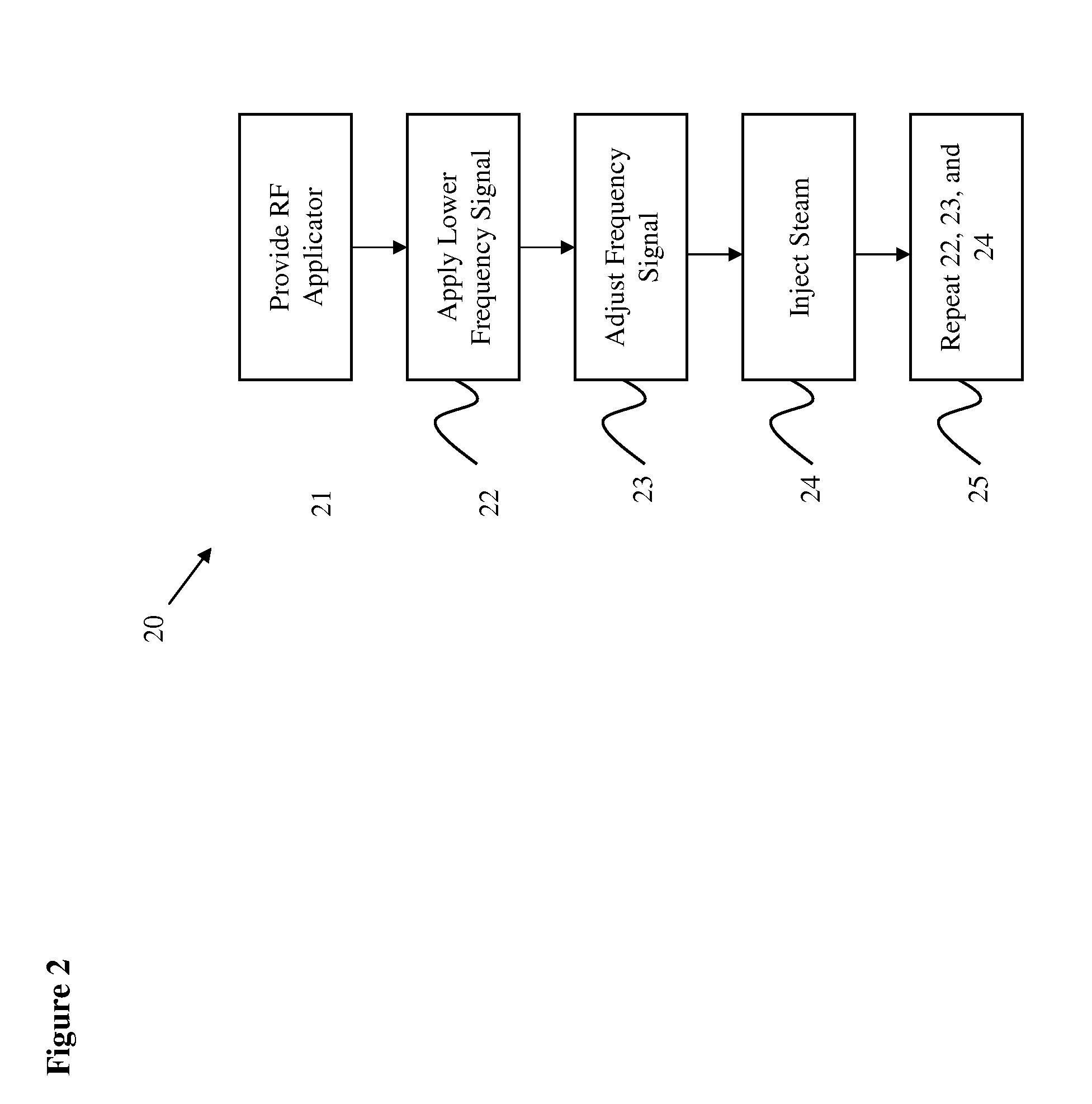

Radio frequency enhanced steam assisted gravity drainage method for recovery of hydrocarbons

ActiveUS20120067572A1Create efficientlyImprove efficiencyDielectric heatingFluid removalElectricityEngineering

A method for heating a hydrocarbon formation is disclosed. A radio frequency applicator is positioned to provide radiation within the hydrocarbon formation. A first signal sufficient to heat the hydrocarbon formation through electric current is applied to the applicator. A second or alternate frequency signal is then applied to the applicator that is sufficient to pass through the desiccated zone and heat the hydrocarbon formation through electric or magnetic fields. A method for efficiently creating electricity and steam for heating a hydrocarbon formation is also disclosed. An electric generator, steam generator, and a regenerator containing water are provided. The electric generator is run. The heat created from running the electric generator is fed into the regenerator causing the water to be preheated. The preheated water is then fed into the steam generator. The RF energy from power lines or from an on site electric generator and steam that is harvested from the generator or provided separately are supplied to a reservoir as a process to recover hydrocarbons.

Owner:HARRIS CORP

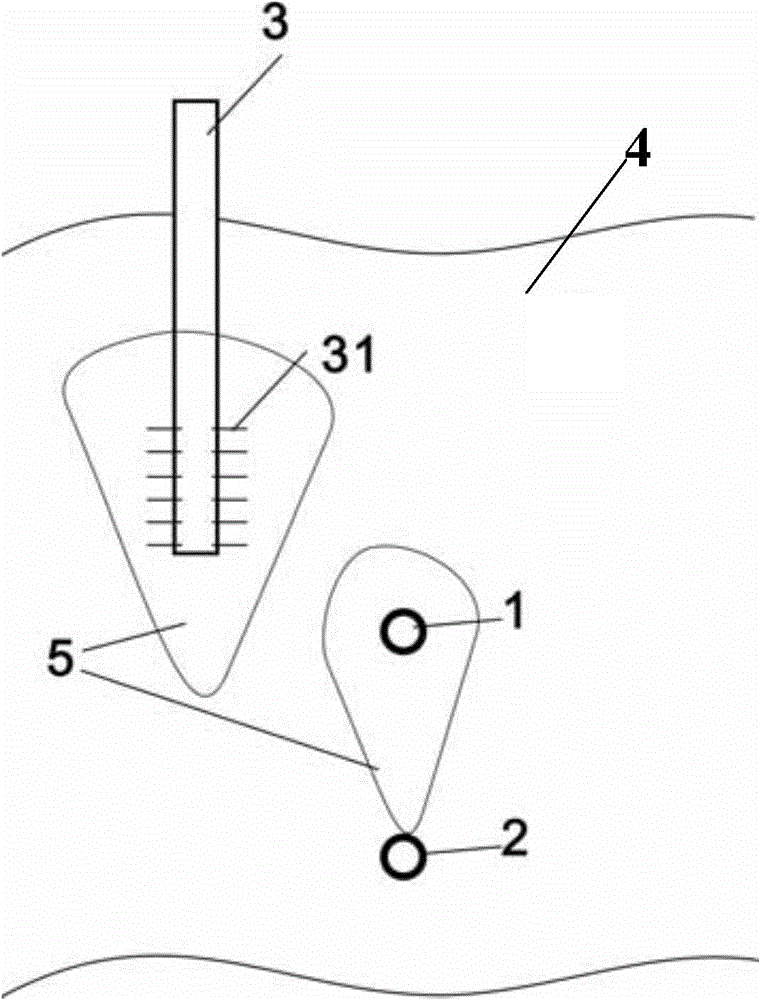

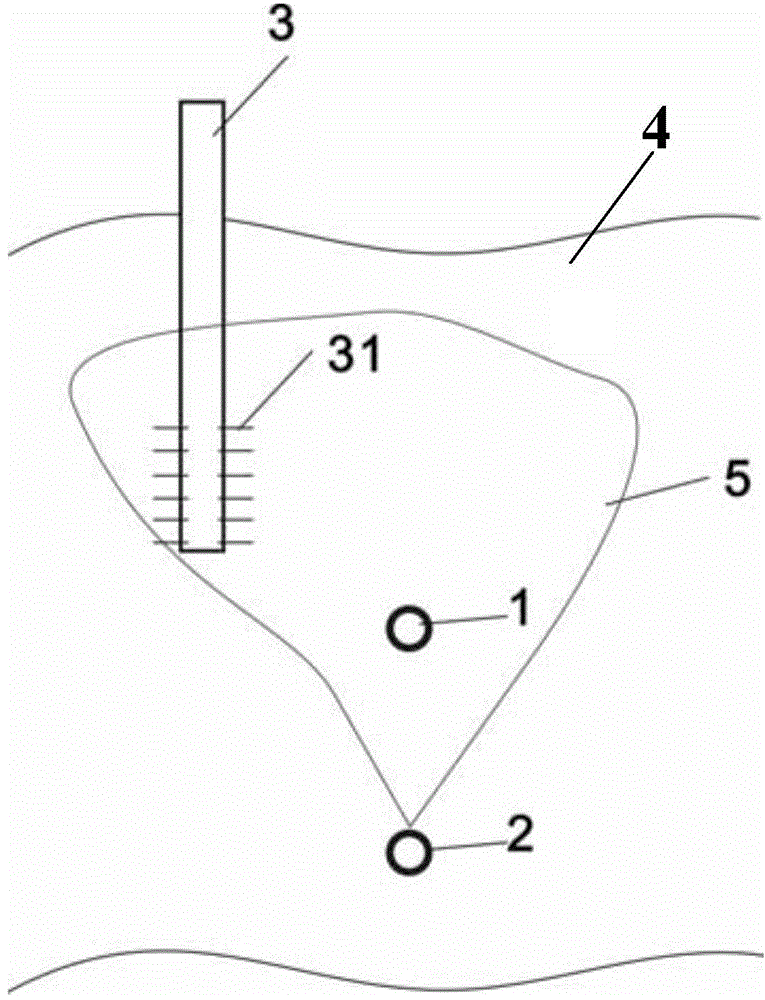

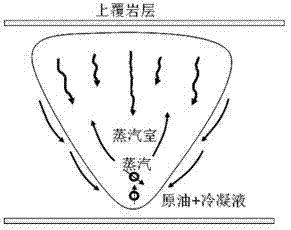

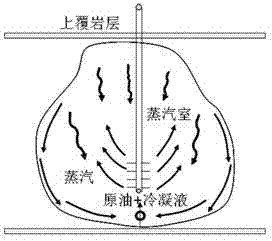

Method for exploiting heavy oil reservoir through steam-assisted gravity drainage (SAGD)

ActiveCN105649588AWell-developedNo chemistryFluid removalInjection wellSteam-assisted gravity drainage

The invention provides a method for exploiting a heavy oil reservoir through steam-assisted gravity drainage (SAGD). The SAGD includes the process of conducting oil recovery by adopting an injection-production well group. The injection-production well group comprises at least one pair of adjacent injection well and production well. The injection well is provided with an injection well horizontal section arranged in an oil layer of the heavy oil reservoir. The production well is provided with a production well horizontal section arranged in the oil layer. The injection well horizontal section is located above the production well horizontal section. During the middle and later periods of the SAGD, the method further comprises the steps that S1, a vertical well is arranged in the growth position of at least part of a steam-free chamber above the injection well horizontal section; and S2, steam is injected into the vertical well and the injection well, and oil recovery is carried out through the production well. According to the method, the vertical well is arranged in the growth position of the steam-free chamber during the later period of the SAGD, the steam is injected into the vertical well, and then steam-free chamber growth is promoted through heat of the steam, so that the effect of uniform growth of a steam chamber in the horizontal sections is achieved.

Owner:PETROCHINA CO LTD

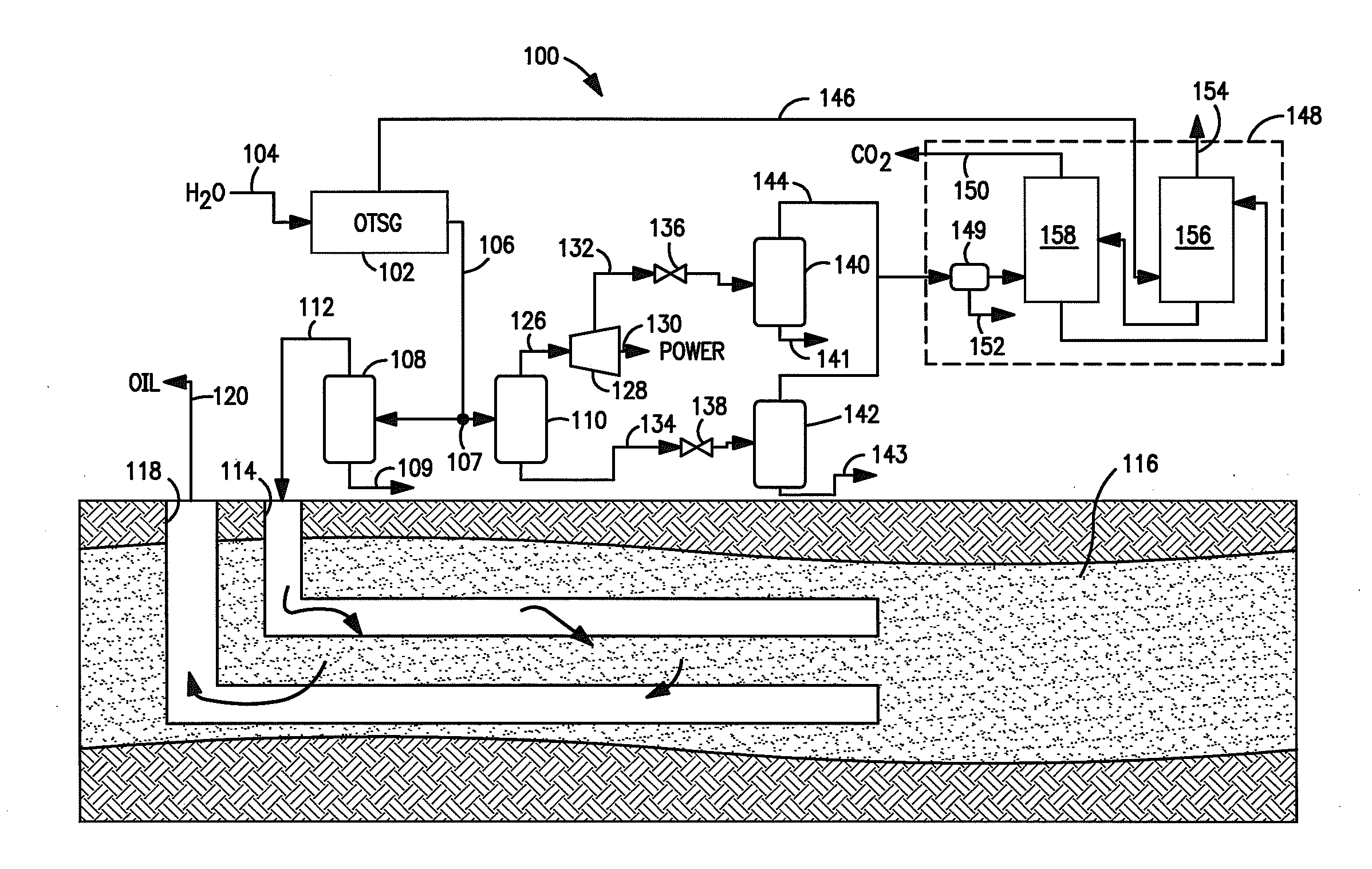

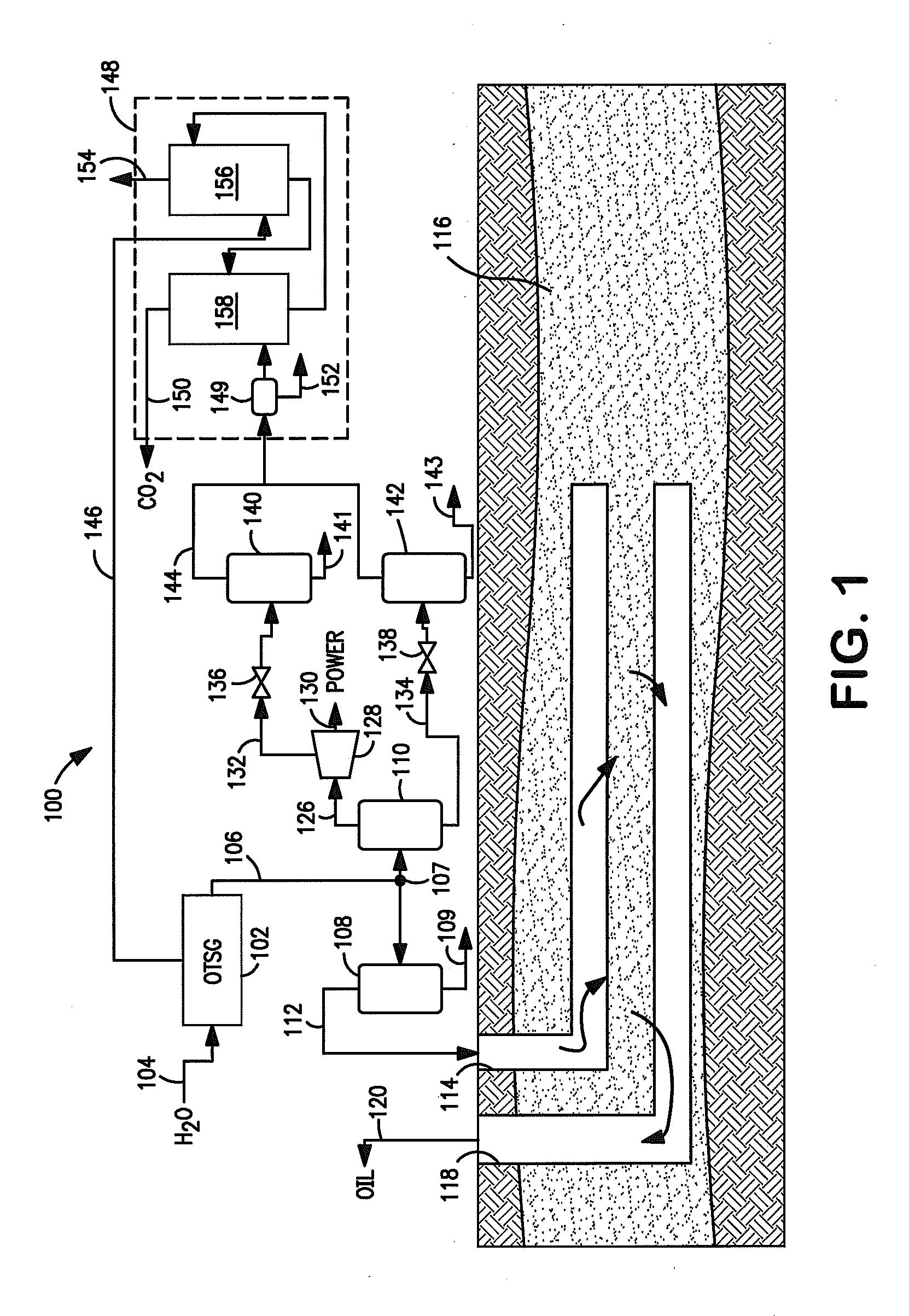

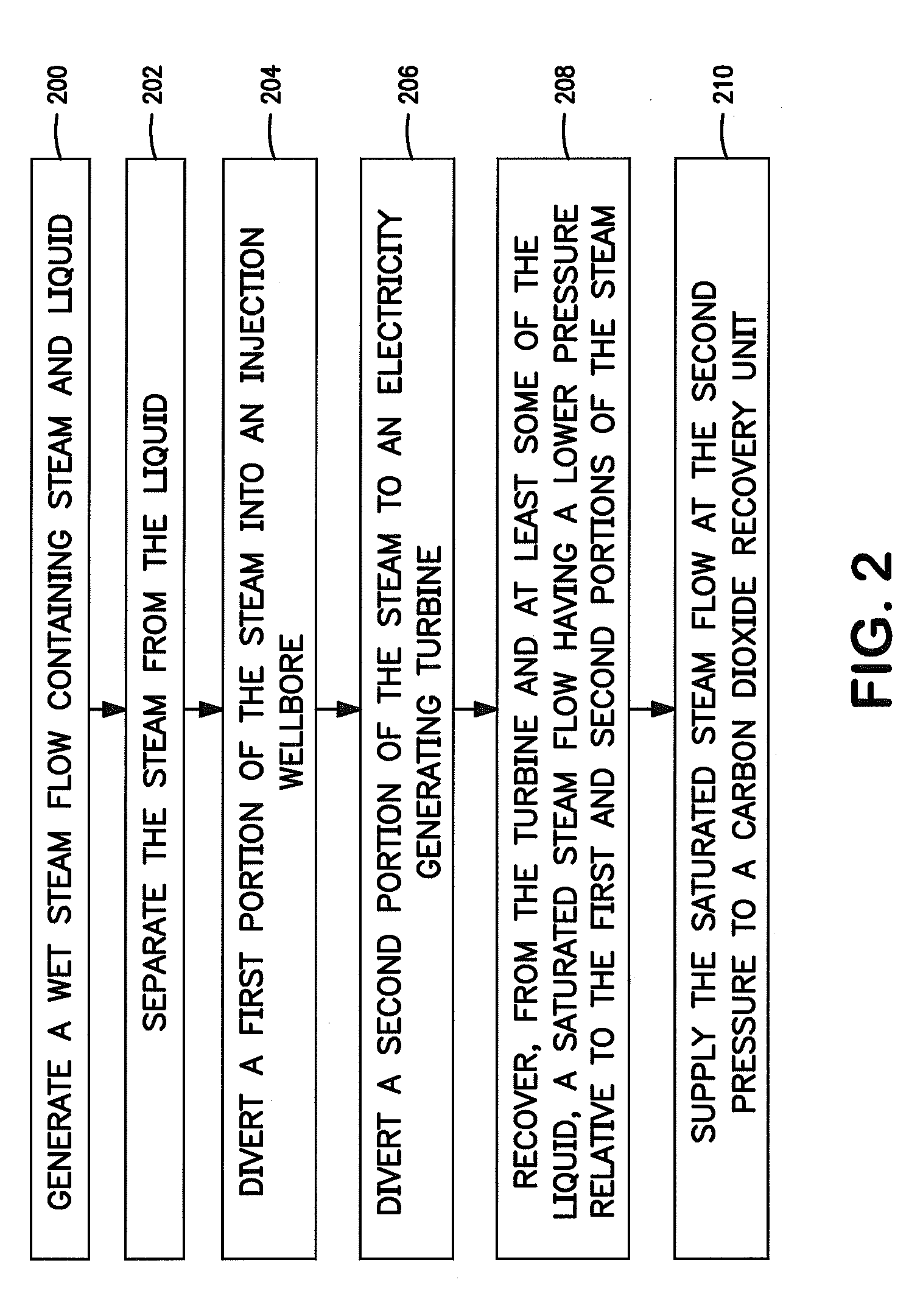

Steam assisted oil recovery and carbon dioxide capture

Methods and systems relate to generating a flow of steam and splitting the flow of steam to enable both its injection into a formation to assist in oil recovery and its introduction into a pathway where the steam is used for generating electricity and capturing carbon dioxide (CO2). At least part of the CO2 that is captured comes from burning of fuel used to generate the steam. Steam assisted gravity drainage requires the steam that is injected to have a higher pressure than the steam that is needed for CO2 capture. Exhaust steam from a steam turbine used to generate the electricity reduces pressure of the steam prior to use of the steam for capturing CO2.

Owner:CONOCOPHILLIPS CO

Sagd steam trap control

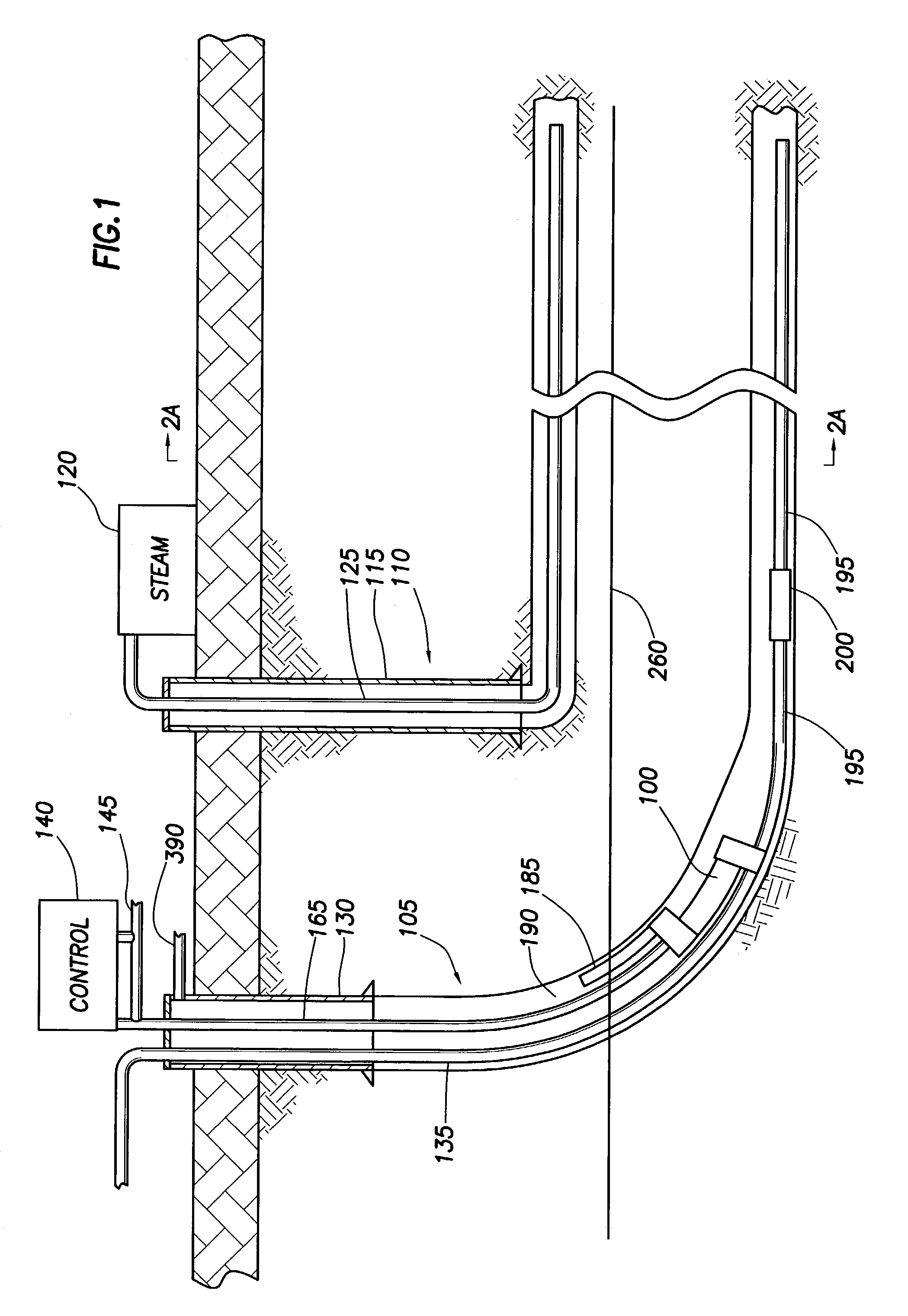

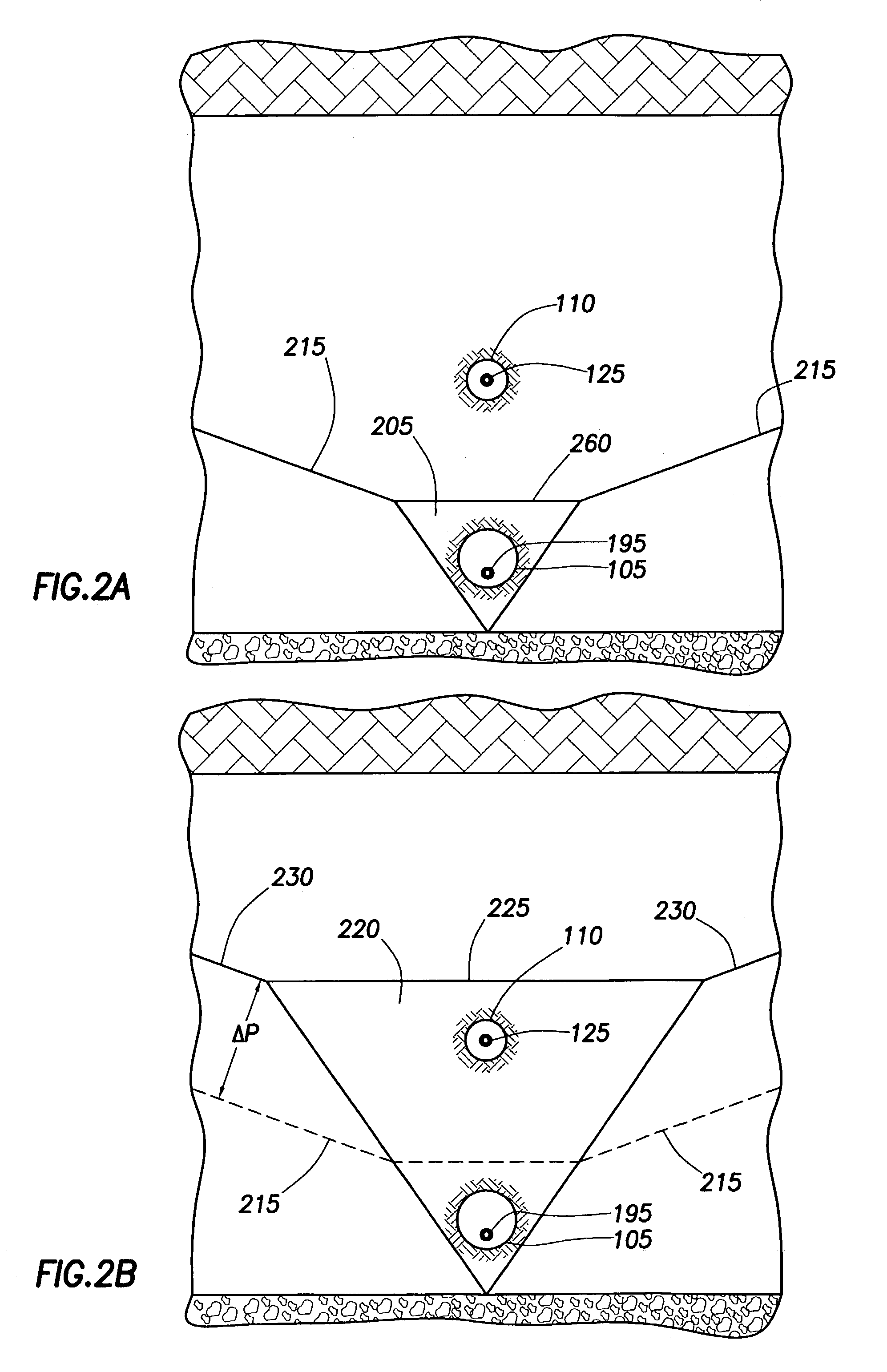

ActiveUS20130213652A1Reduce startup timeLow costFluid removalDrinking water installationStart up timeEngineering

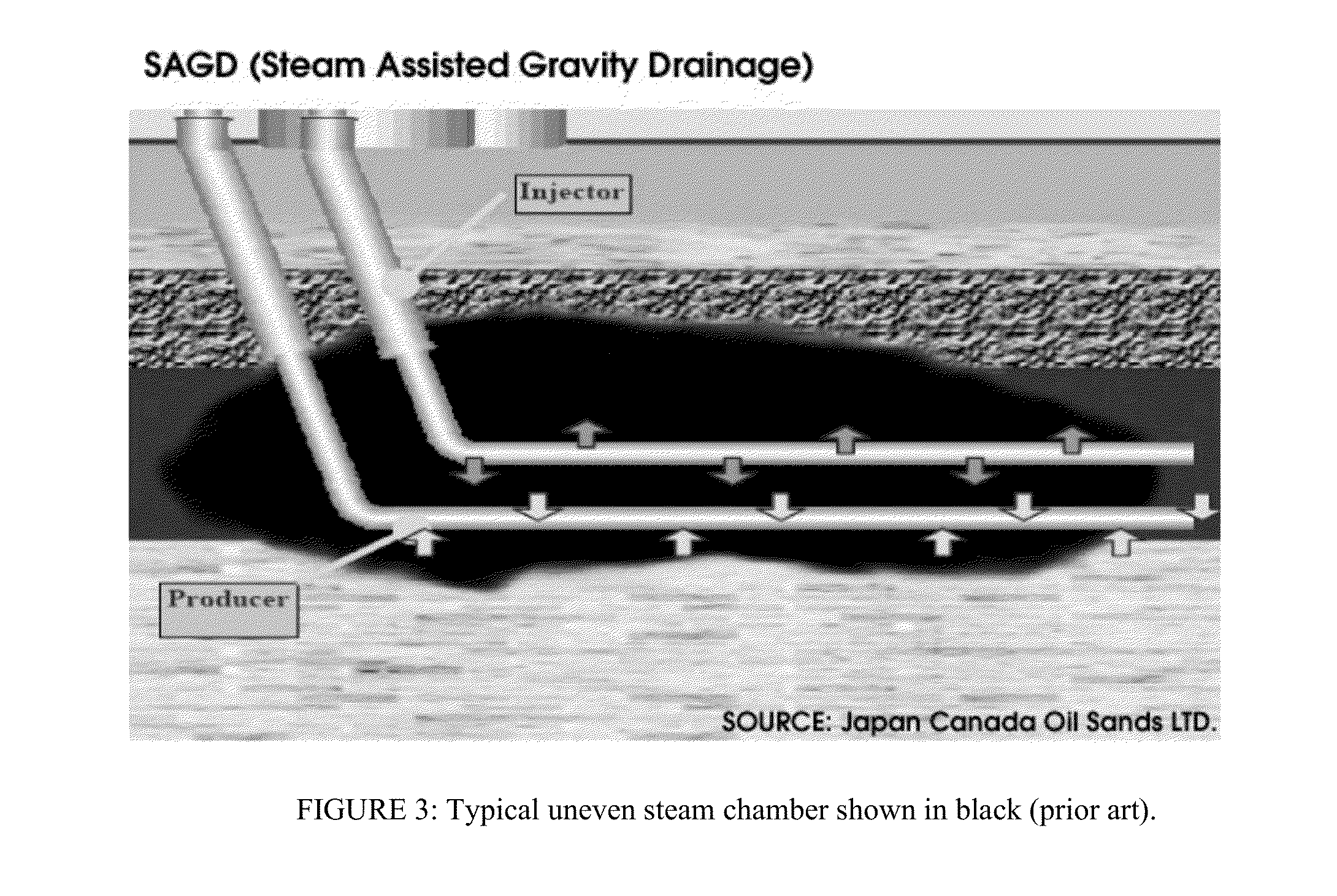

This present disclosure describes methods and systems related to SAGD injection and / or production wells that utilize flow distribution control devices. Additionally, methods and systems using limited vertical spacing separating the wells are described. These methods and systems improve steam assisted gravity drainage (SAGD) oil production, reduce SAGD start-up time and costs, and improve overall SAGD performance.

Owner:CONOCOPHILLIPS CANADA RESOURCES +2

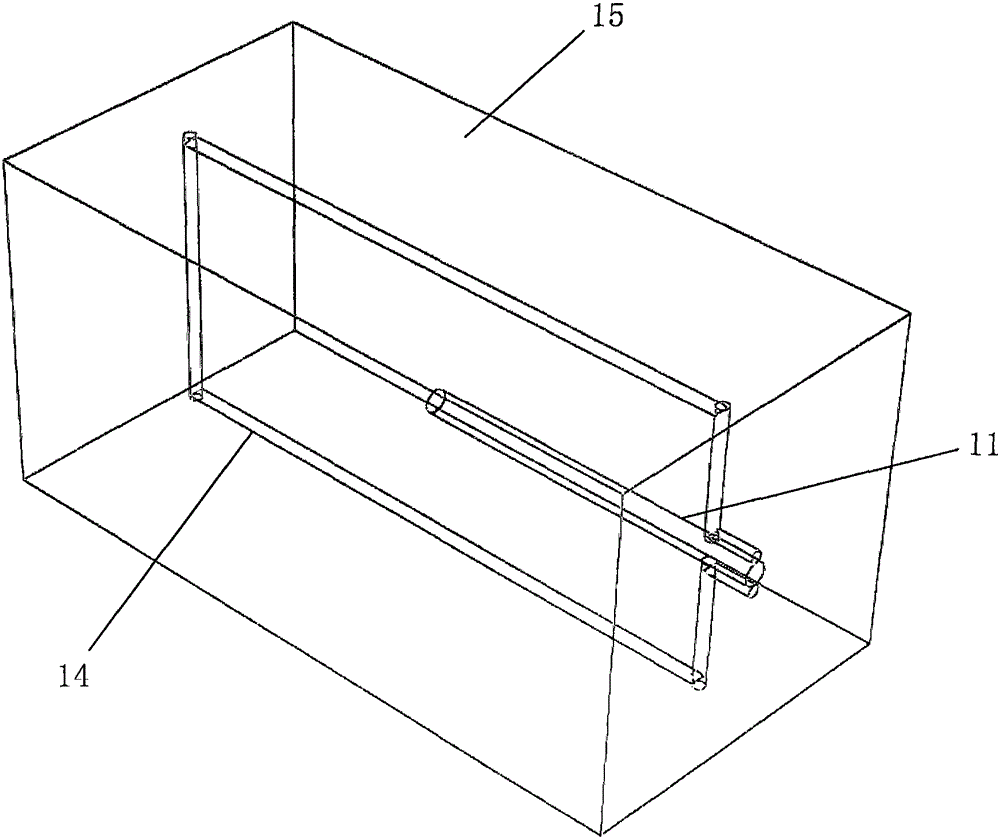

Experimental device for simulating hydrofracture action mechanism in steam assisted gravity drainage (SAGD) process

The invention discloses an experimental device for simulating a hydrofracture action mechanism in the steam assisted gravity drainage (SAGD) process. The experimental device comprises a true triaxial stress loading device, a steam heating device, a fracture device and an acoustic emission monitoring device. The true triaxial stress loading device can apply stress in three directions to an experimental rock sample through a pressure chamber. The steam heating device locally heats the experimental rock sample through a hot steam circulation pipeline prefabricated in the experimental rock sample and monitors the temperature of the experimental rock sample through a temperature sensor arranged on the surface of the experimental rock sample. The fracture device injects fracturing fluid into the experimental rock sample through a shaft prefabricated in the experimental rock sample. The acoustic emission monitoring device monitors acoustic emission signals generated inside the experimental rock sample and determines the crack spatial position through a corresponding positioning algorithm. By the adoption of the experimental device, the SAGD hydrofracture process under a high-temperature and high-pressure condition is simulated, and thus true and effective evaluation and reference are provided for hydrofracture construction design of a thickened-oil oilfield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

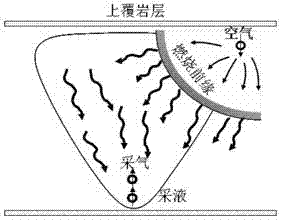

Later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation

The invention relates to a later-period air injection exploitation method for super heavy oil reservoir using steam assisted gravity drainage (SAGD) exploitation. The method comprises the following steps of: newly drilling a straight well as an air injection well at a position where a steam cavity of the super heavy oil reservoir develops poorly; perforating on the upper part of the air injection well to complement a perforation section with the length of 2-3m; continuously injecting air by the air injection well at the speed of 20,000-80,000m<3> / day and firing to exploit; and stopping injecting the air when the volume percentage of the oxygen in the produced gas reaches 3 percent or the volume ratio of the volume of the injected air and the volume of the produced crude oil reaches over 3,000m<3> / m<3>. With the adoption of the method, the later-period heat loss is reduced by using the SAGD technology, and the stable production of the whole system is maintained by utilizing heat energy released by reacting substances in the oil reservoir.

Owner:PETROCHINA CO LTD

Passive heating assisted recovery methods

ActiveUS7934549B2Low viscositySufficient viscosityInsulationFluid removalRecovery methodPre-condition

A method for producing hydrocarbons from a region having adjacent strata divided by an impermeable or partially permeable barrier and, wherein at least one of the strata contains hydrocarbons, comprises of sufficiently heating one of the stratum to allow heat to be conducted to the hydrocarbon containing stratum and producing hydrocarbons therefrom. In one aspect, both strata contain hydrocarbons, such as bitumen, and heat is generated by a steam assisted gravity drainage process to the adjacent stratum. Heat may also be generated by in-situ combustion of hydrocarbons to preheat an adjacent stratum, or by electrical heating. Once pre-conditioned to a higher in-situ temperature, hydrocarbon production may be facilitated by diluting the target pre-heated hydrocarbon bearing stratum with solvent injection.

Owner:LARICINA ENERGY

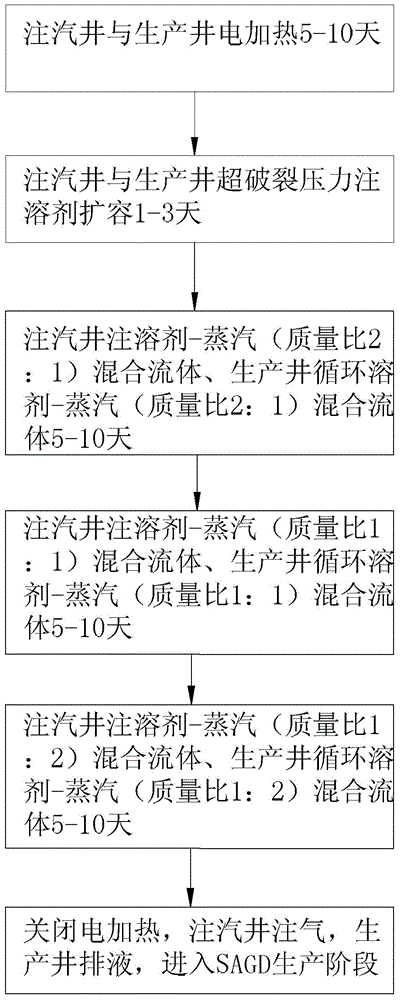

Rapid start method for heavy oil reservoir steam assisted gravity drainage

ActiveCN104453805ABuild pressure connectionIncrease the range of viscosity reductionFluid removalSolventInjection well

The invention discloses a rapid start method for heavy oil reservoir steam assisted gravity drainage. The rapid start method for heavy oil reservoir steam assisted gravity drainage comprises the following steps that (1) a steam injection well and a producing well are electrically heated at a large power; (2) a solvent is injected into a long oil pipe and a short oil pipe of the steam injection well and a long oil pipe and a short oil pipe of the producing well at the same time; (3) a solvent and steam liquid mixture is injected into the long oil pipe and the short oil pipe of the steam injection well at the same time, the solvent and steam liquid mixture is injected into the long oil pipe of the producing well, and the short oil pipe of the producing well discharges liquid; (4) electric heating is stopped, pure steam is injected into the long oil pipe of the steam injection well and the short oil pipe of the seam injection well at the same time, and the long oil pipe and the short oil pipe of the producing well discharge liquid at the same time. Compared with a conventional preheating start method, time is shortened by over two thirds, so that the heat energy utilization rate is greatly increased, rapid preheating start of SAGD can be achieved, and the production speed of SAGD is increased. In addition, through rapid solvent volume expansion and super fracture pressure injection, an even oil drainage channel can be established, and the purposes of increasing the yield and the recovery rate are achieved.

Owner:PETROCHINA CO LTD

RF fracturing to improve sagd performance

ActiveUS20120061081A1Improve fracturing efficiencyIncreased cost-effectivenessInsulationFluid removalFuel oilEngineering

A method of producing heavy oil from a heavy oil formation with steam assisted gravity drainage. The method begins by drilling a borehole into a heavy oil formation comprising a steam barrier between a first pay zone and a second pay zone, wherein the steam barrier prevents a steam chamber to be formed between the first pay zone and the second pay zone. The steam barrier is then heated with a radio frequency. The steam barrier is then fractured to permit a steam chamber to be formed within the first pay zone and the second pay zone. Heavy oil is then produced from the heavy oil formation with steam assisted gravity drainage.

Owner:HARRIS CORP +1

Natural Circulation Industrial Boiler for Steam Assisted Gravity Drainage (SAGD) Process

A gravity feed, natural circulation boiler for an SAGD process using low quality feedwater for carbonatious material recovery, has a large diameter steam drum with downcomers. A furnace of the boiler has individually replaceable membrane wall modules, each with upper and lower headers and membrane roof, wall and floor parts connected to the drum and defining a fire box having an inlet end and an outlet end. The furnace includes a membrane front wall connected to the drum with a windbox upstream of the front wall. Burners at the inlet end of the firebox heat the firebox and riser pipes are connected between the steam drum and the upper header for supplying steam to the steam drum when the firebox in heated, the downcomer pipes being connected to the lower header for supplying water from the stream drum under gravity feed so that each module defines a single circuit. Furnace outlet screen bank and subsequent generating banks each with upper and lower headers and associated feeder and riser tubes complete the boiler.

Owner:BABCOCK & WILCOX CANADA LIMITED

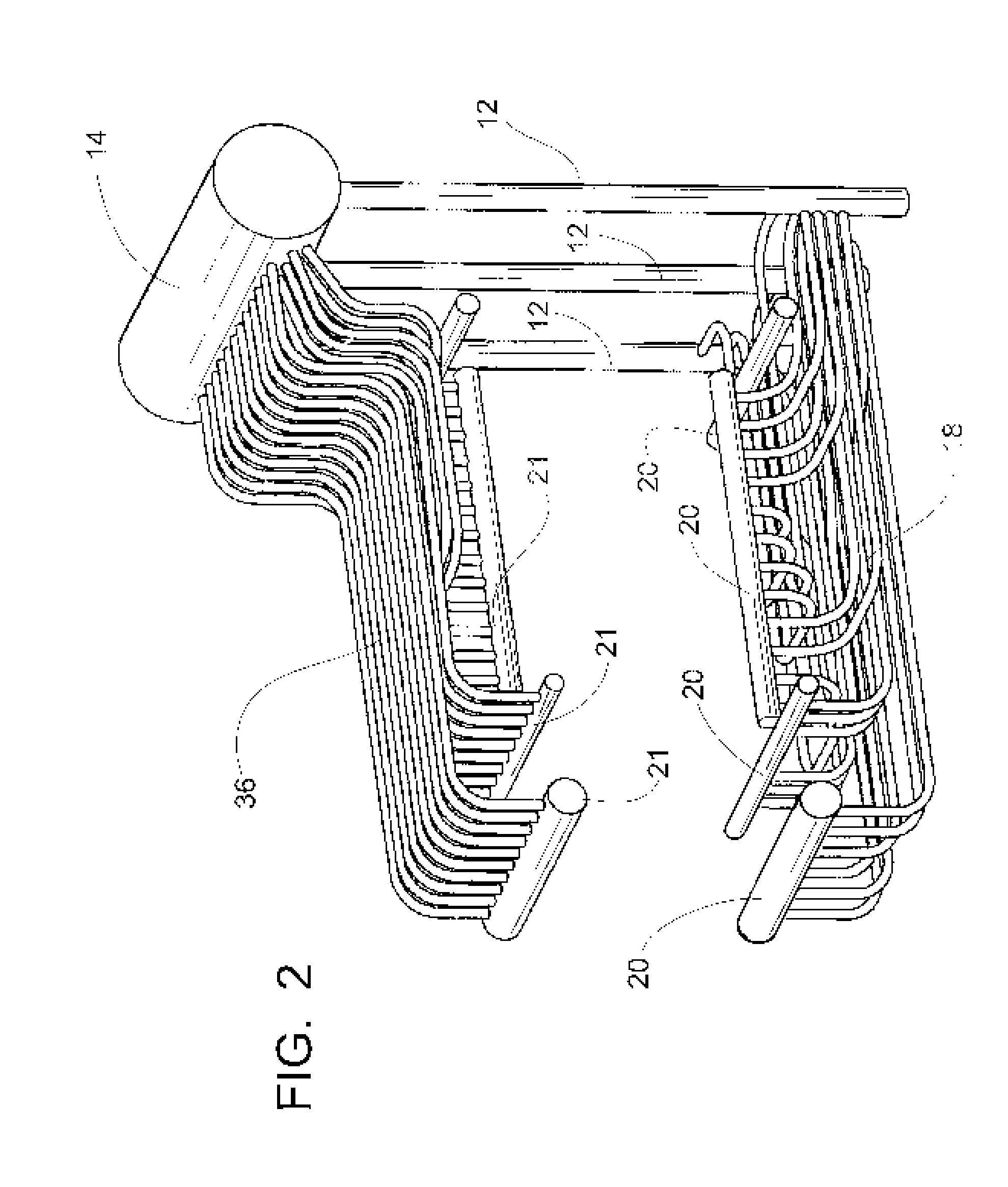

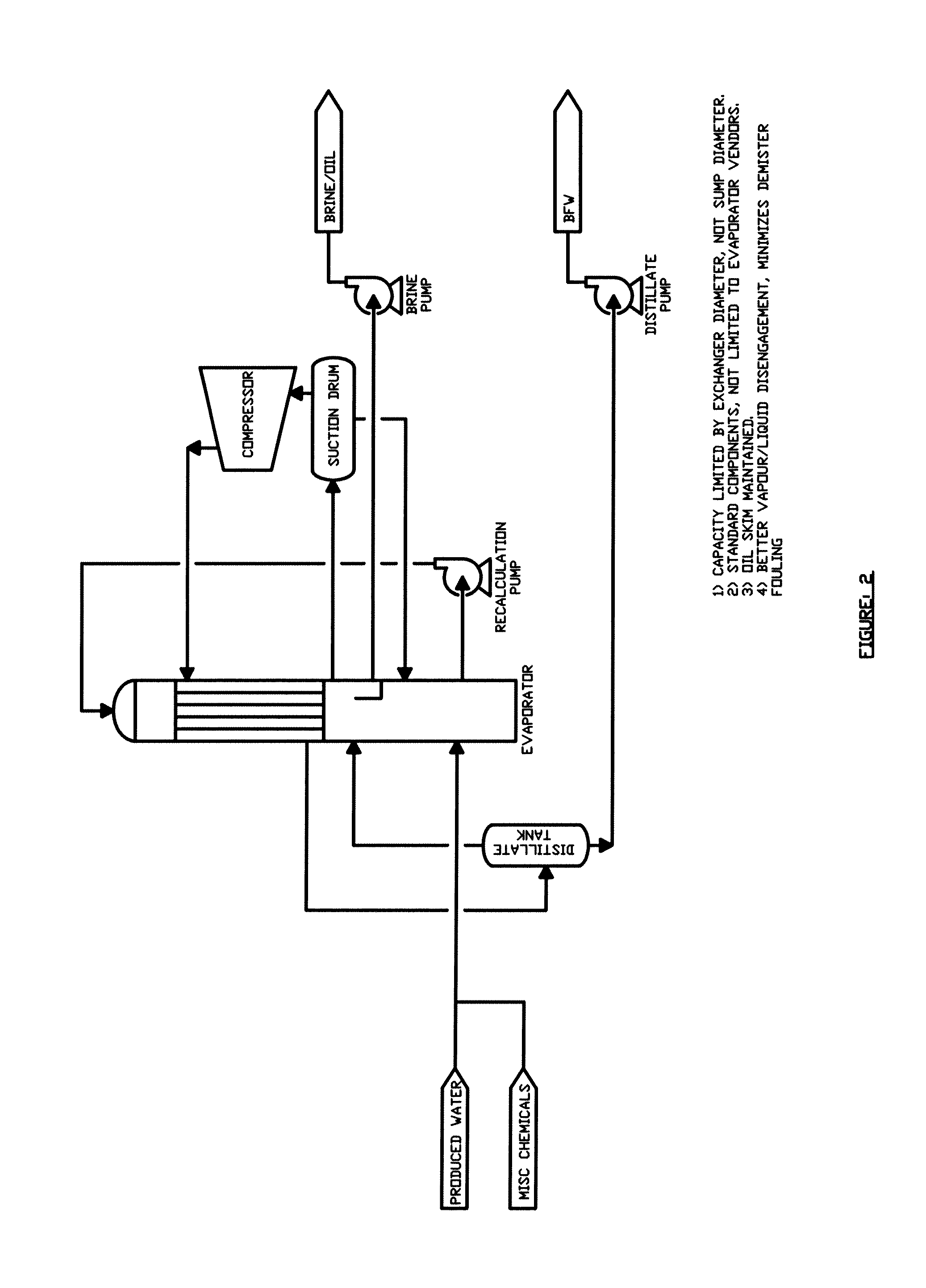

Compact Evaporator for Modular Portable SAGD Process

ActiveUS20120193213A1Reduce dirtReduce the required powerAuxillariesEvaporation with vapour compressionPlate heat exchangerDistilled water

A modular portable evaporator system for use in a Steam Assisted Gravity Drainage (SAGD) systems having an evaporator, with a sump comprising an oil skimming weir, a short tube vertical heat exchanger including an outer shell containing the short tubes provided for lower water circulation rate. A system further having, external to the evaporator, a compressor compressing evaporated steam from the tube-side of the heat exchanger and routing to the shell side of the same exchanger, a distillate tank to collect hot distilled water, a recirculation pump to introduce liquids from the sump into the heat exchanger and an external demister protecting the compressor from liquid impurities. The evaporator system receives produced water from the process into the sump and provides cleaned hot water to the boiler.

Owner:PRIVATE EQUITY OAK LP

Process for sequentially applying SAGD to adjacent sections of a petroleum reservoir

Steam assisted gravity drainage (“SAGD”) is practised in a first section of a reservoir containing heavy oil. When steam / oil ratio rises sufficiently, steam injection into the first section is curtailed or terminated. Non-condensible gas is then injected into the section to pressurize it and production of residual oil and steam condensate is continued. Concurrently with pressurization, SAGD is practised in an adjacent reservoir section. As a result, some of the residual oil in the first section is recovered and steam loss from the second section to the first section is ameliorated.

Owner:ALBERTA INNOVATES - ENERGY & ENVIRONMENT SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com