Patents

Literature

282results about How to "Increase oil production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for improving hydrocarbon recovery by water flood intervention

InactiveUS20070039732A1Increase productionIncrease oil productionFluid removalFlushingHydrocotyle bowlesioidesCompound (substance)

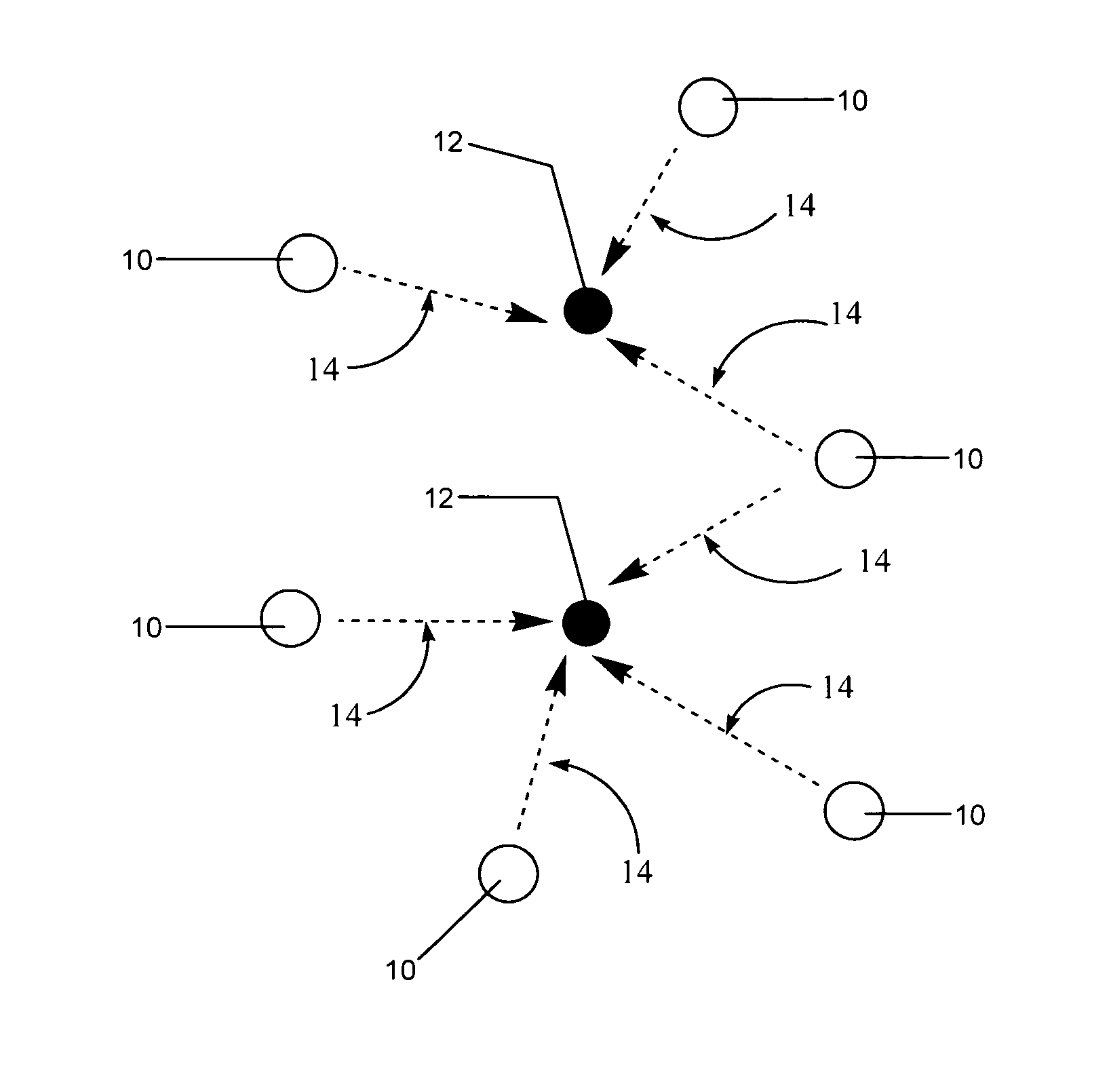

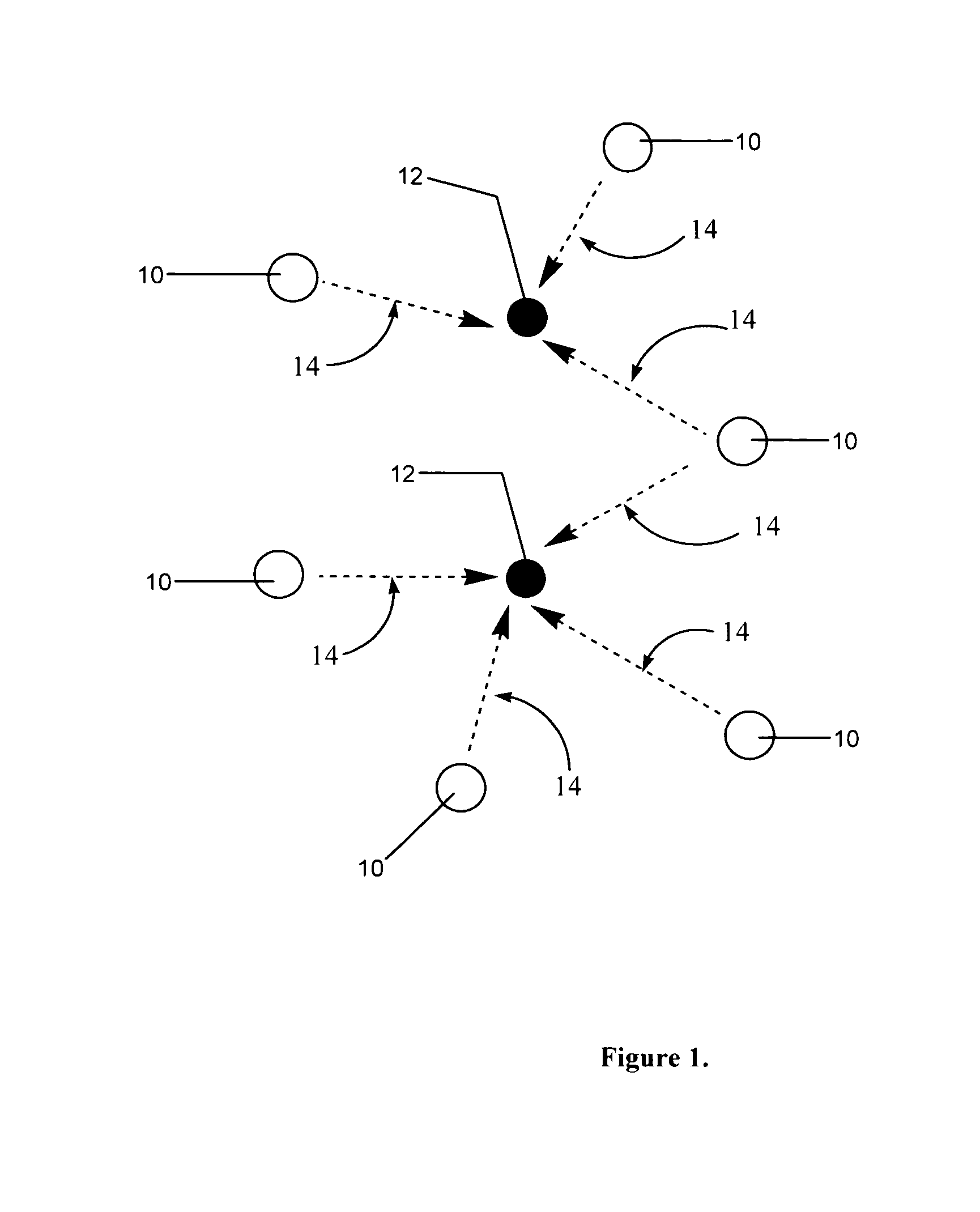

Methods useful in improving hydrocarbon recovery from subterranean formations using relative permeability modifier (RPM) macromolecules are described. The RPMs are typically crosslinked RPMs having K-values from 250-300 which, when injected into an injector well associated with a producer well, redirect the production water so as to improve the injection profile of the well and simultaneously improve hydrocarbon recovery from the producer well.

Owner:BAKER HUGHES INC

Aqueous displacement fluid injection for enhancing oil recovery from an oil bearing formation

InactiveUS20110306525A1Reduce ionic strengthIncrease oil productionFlushingDrilling compositionLow ionic strengthUltimate tensile strength

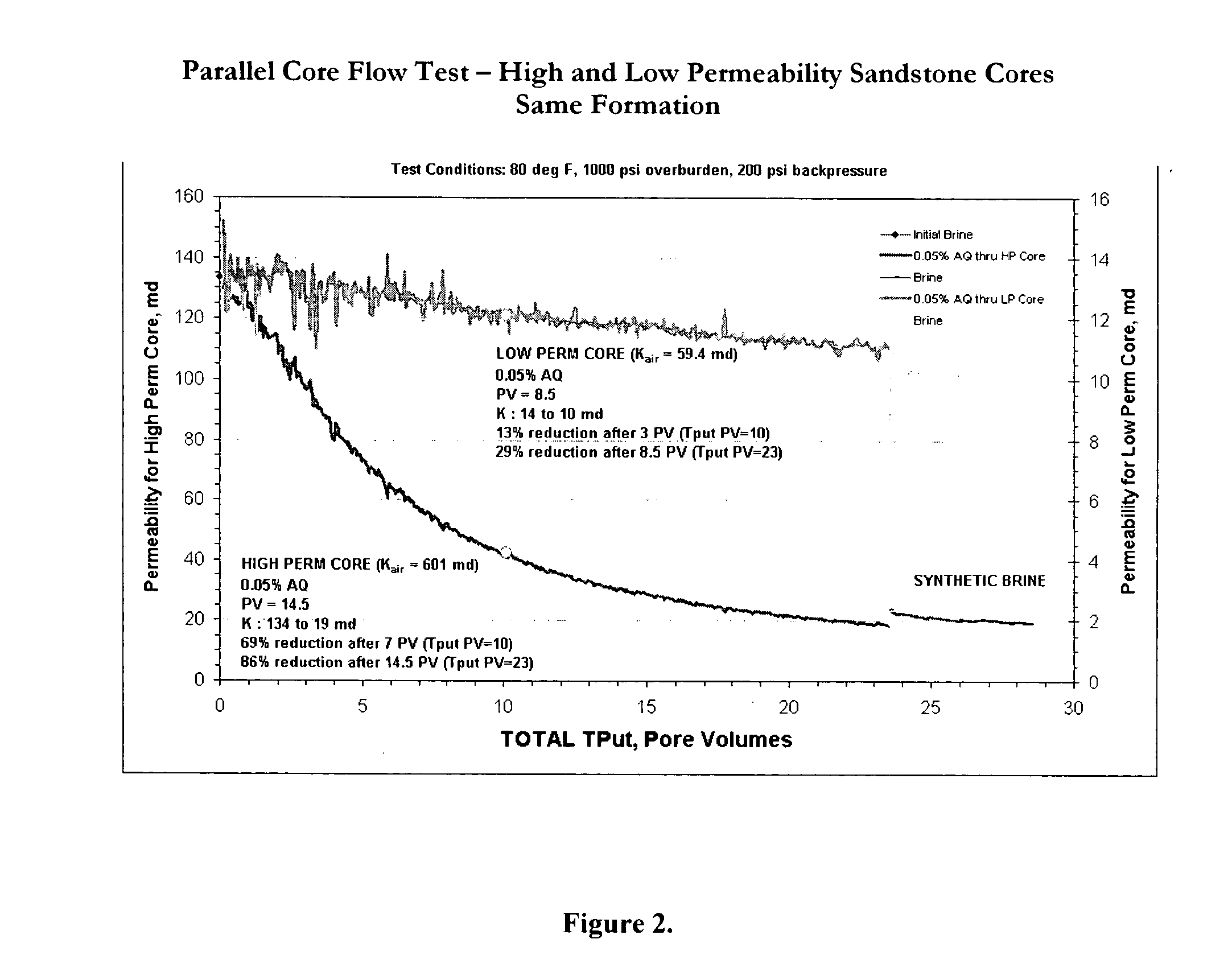

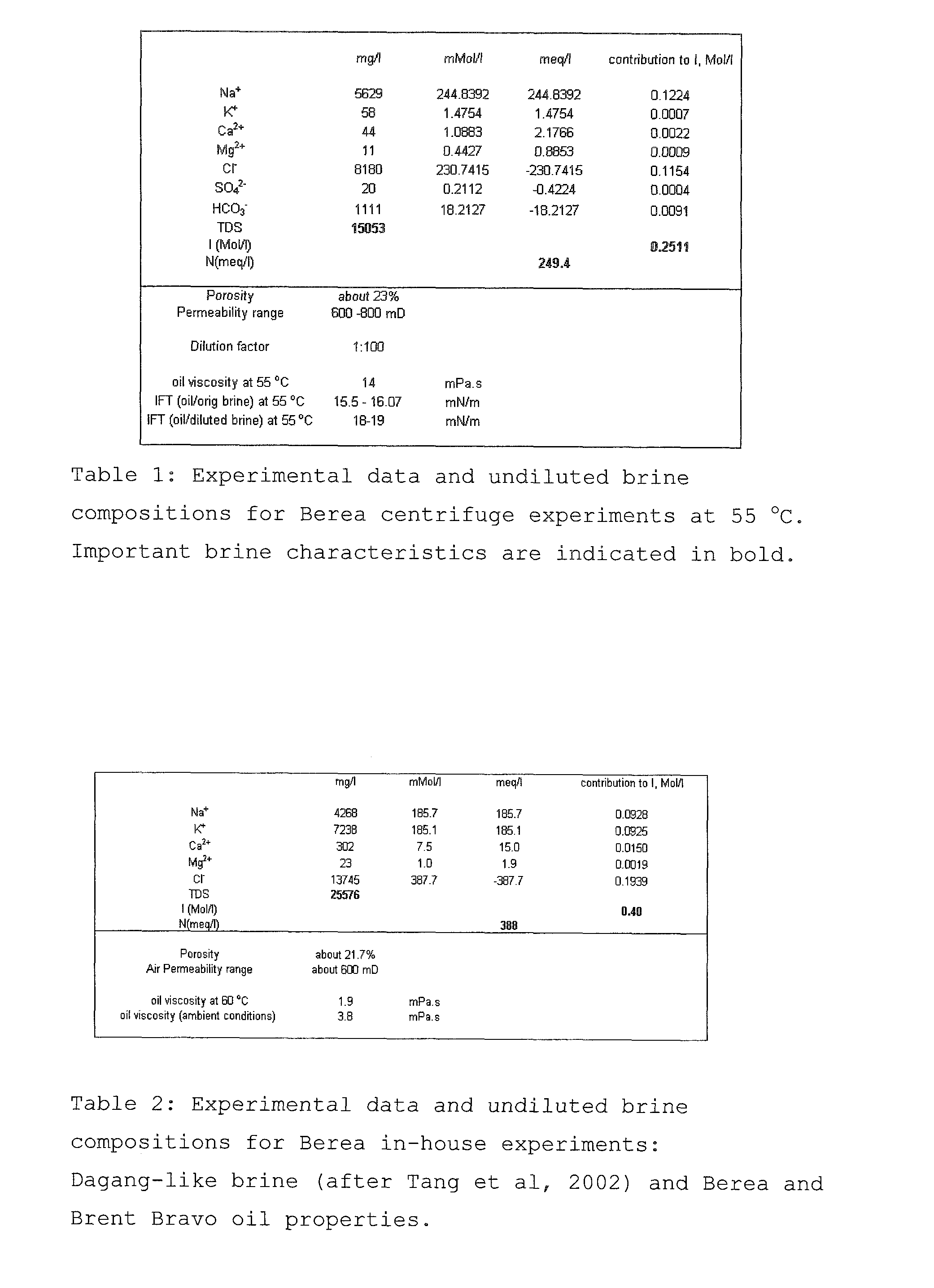

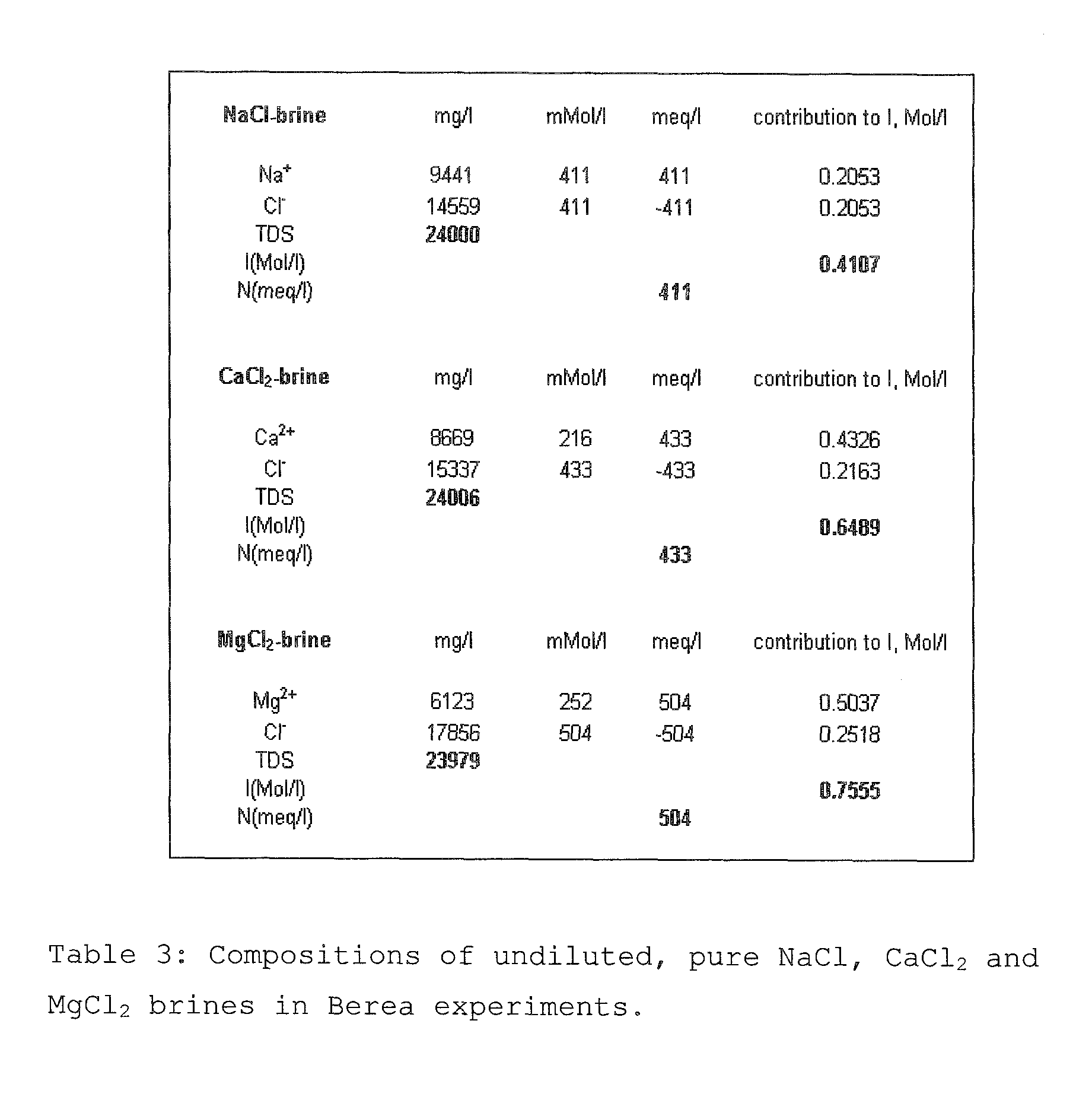

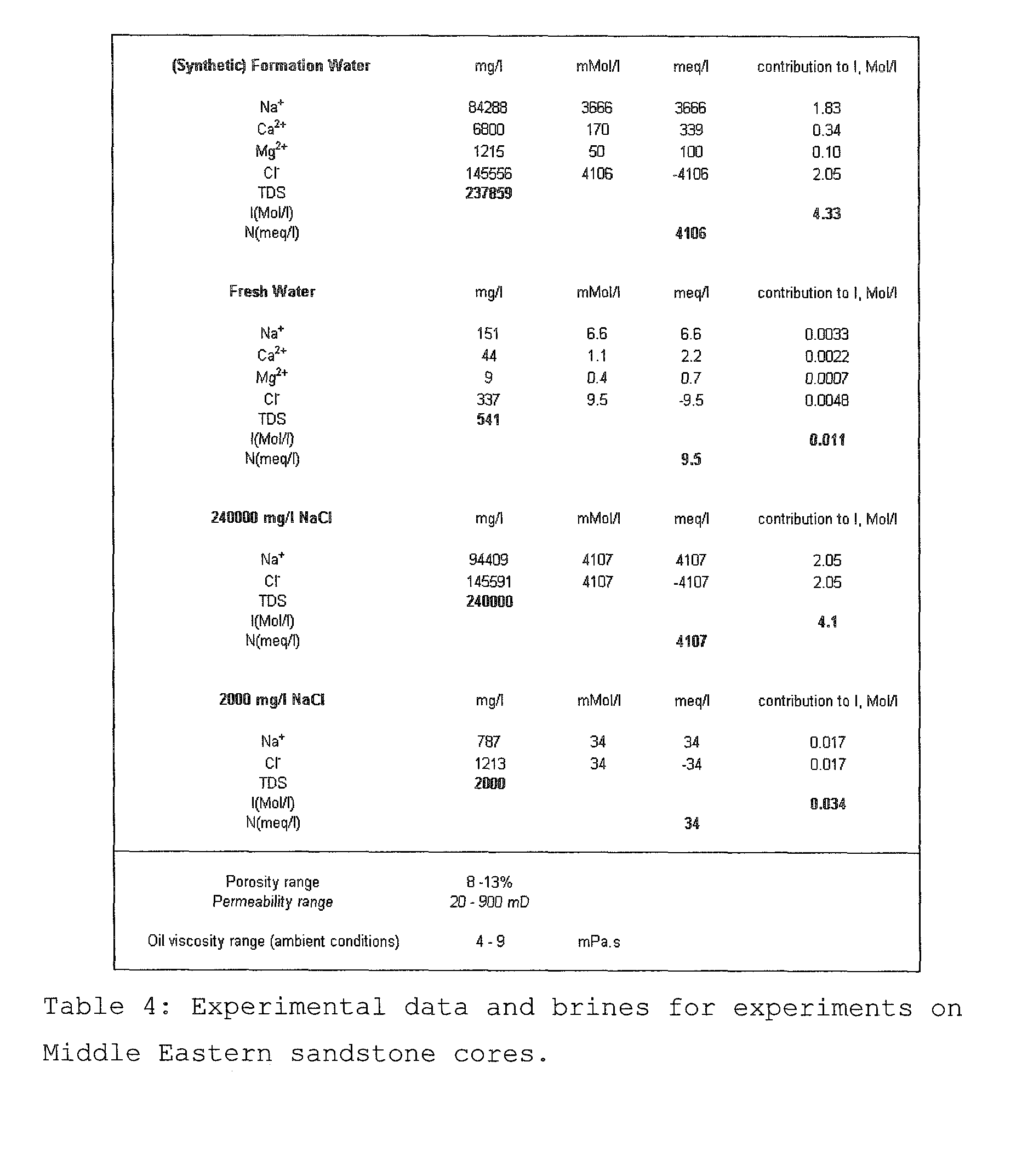

A method for enhancing recovery of crude oil from a porous subterranean formation of which the pore spaces contain crude oil and connate water comprises:—determining the Ionic Strength (Mol / l) of the connate water; and—injecting an aqueous displacement fluid having a lower Ionic Strength (Mol / l) than the connate water into the formation, which aqueous displacement fluid furthermore has an Ionic Strength below 0.15 Mol / l. FIGS. 13 and 16 and Table 4 demonstrate that injection of an aqueous displacement fluid with lower Ionic Strength than the connate water improves oil recovery (IOR).

Owner:SHELL OIL CO

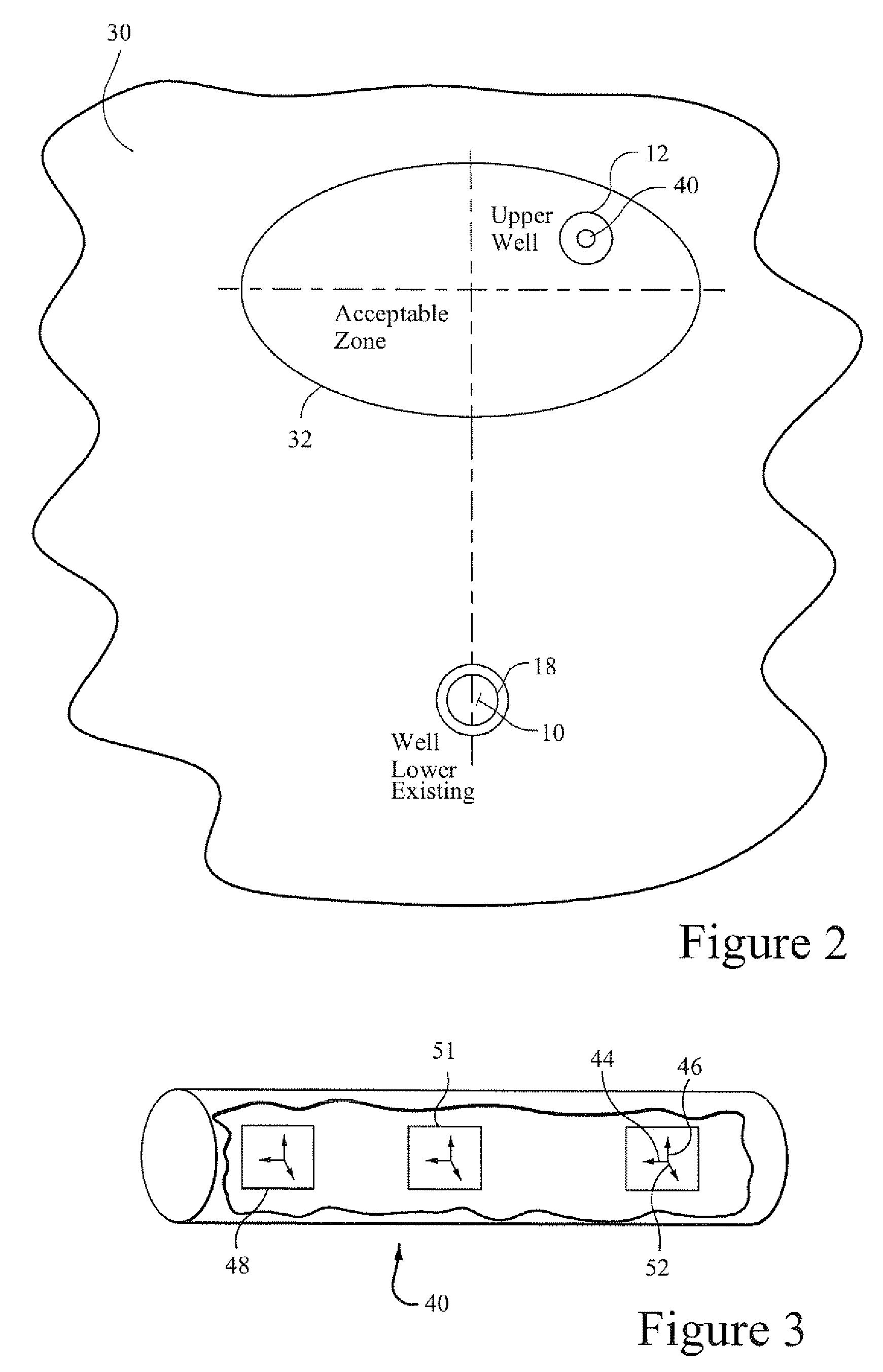

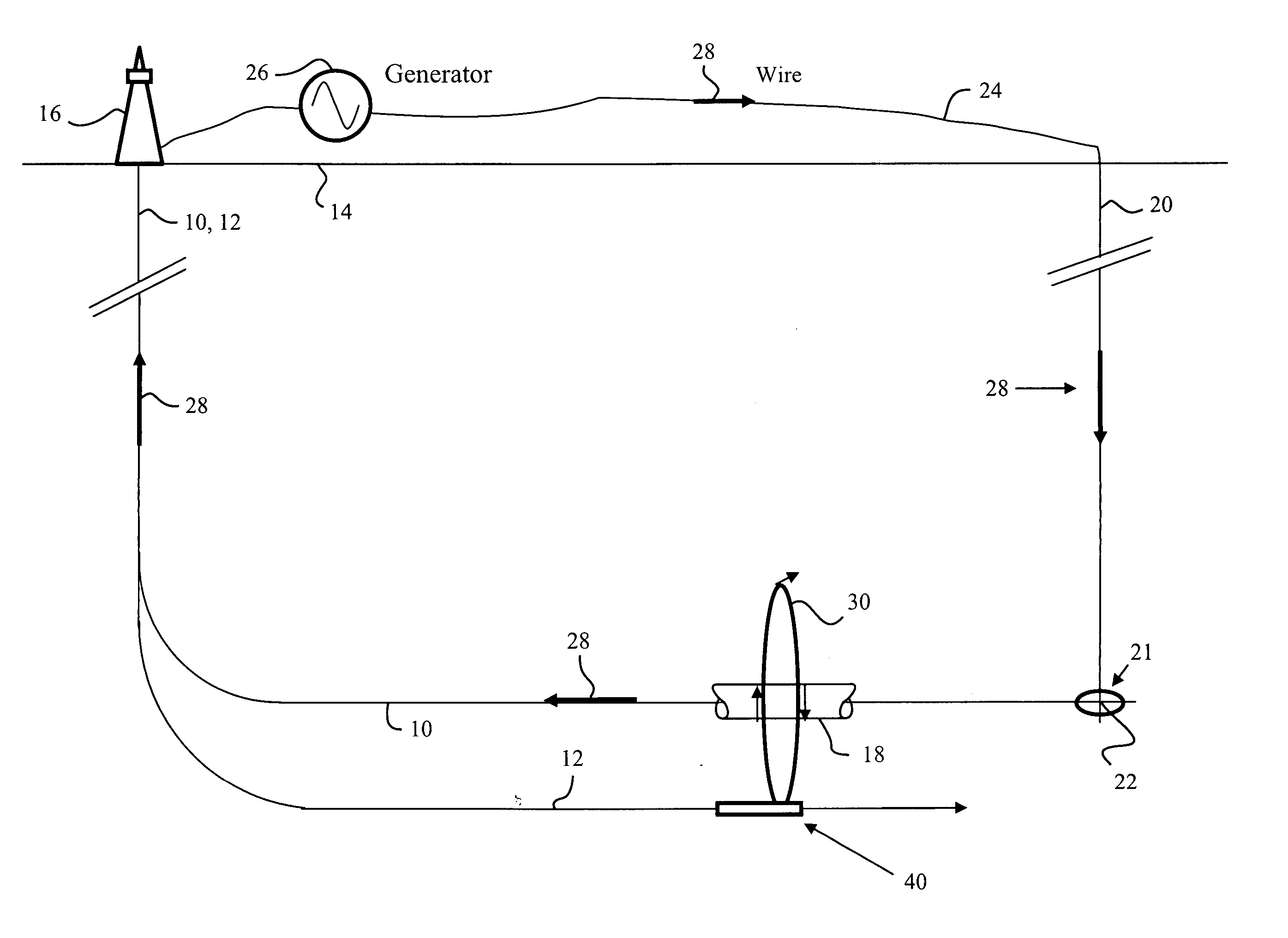

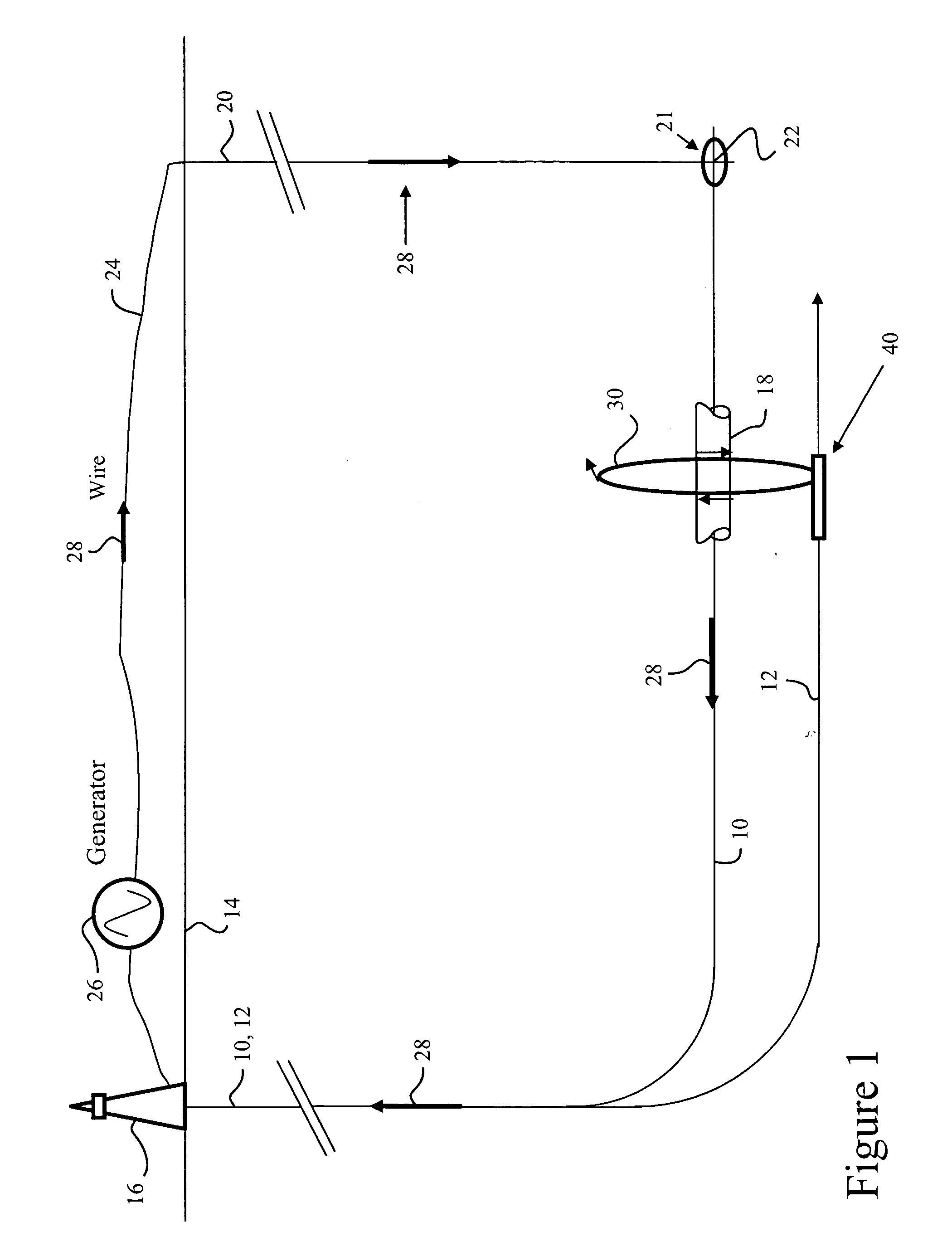

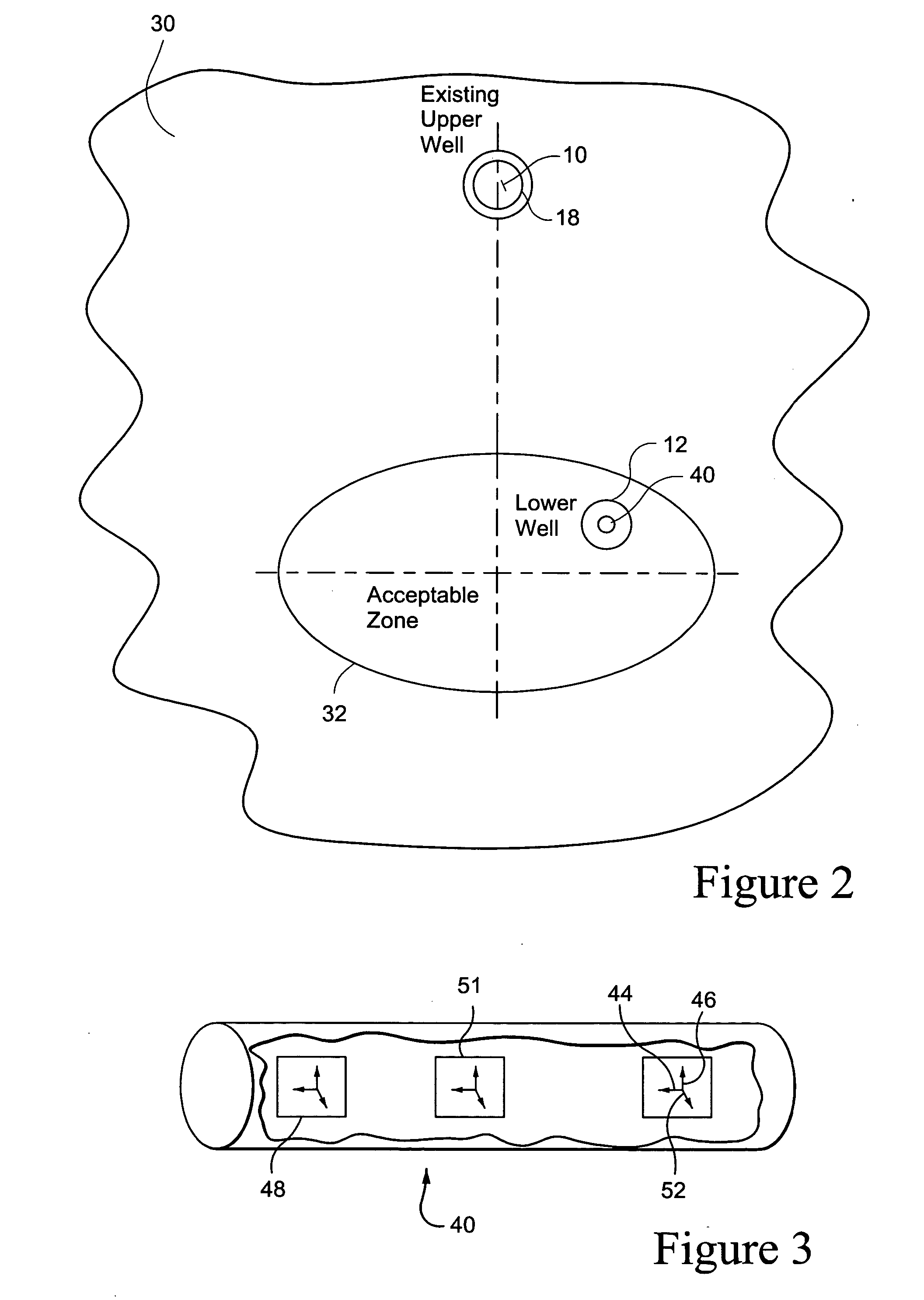

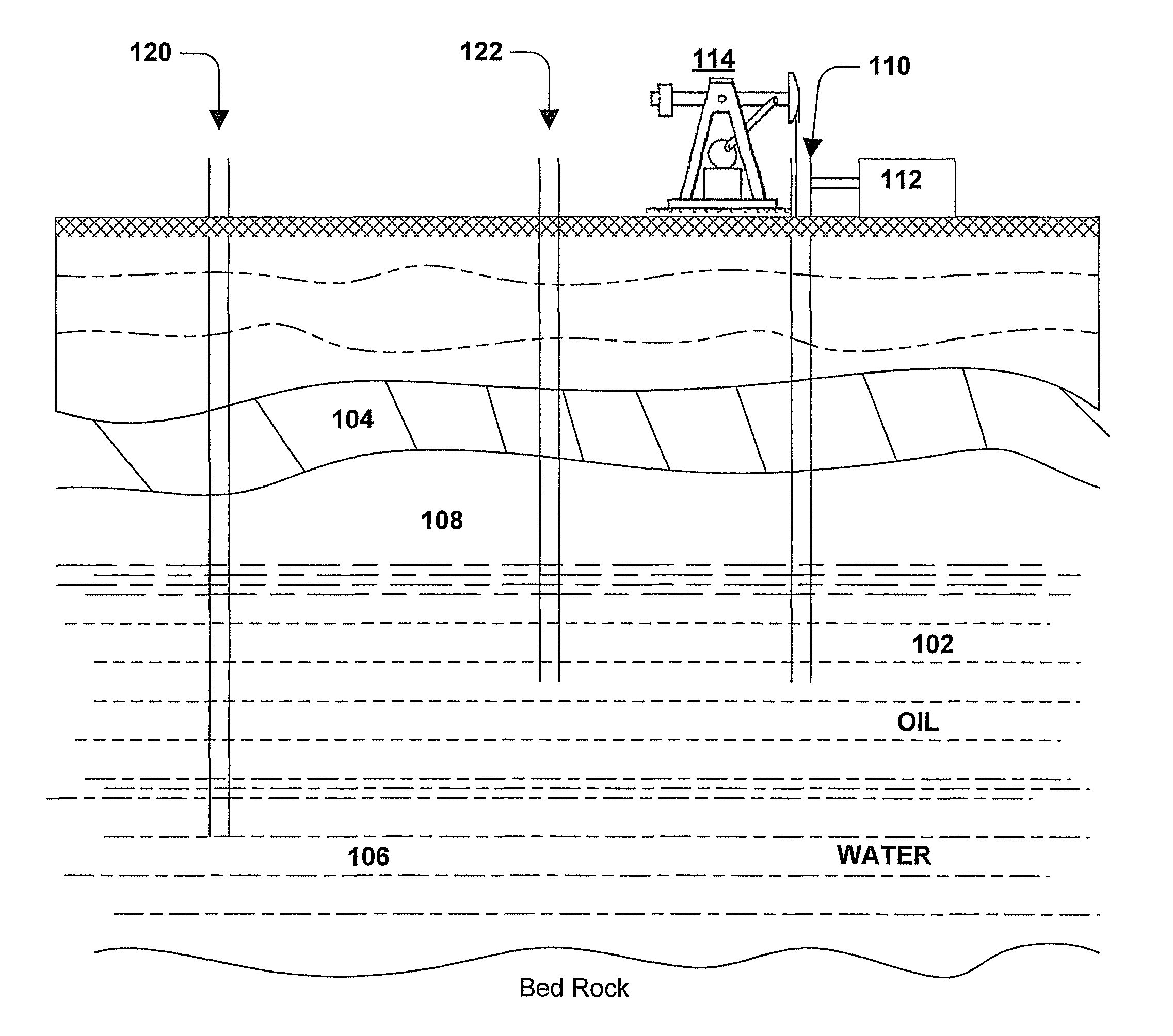

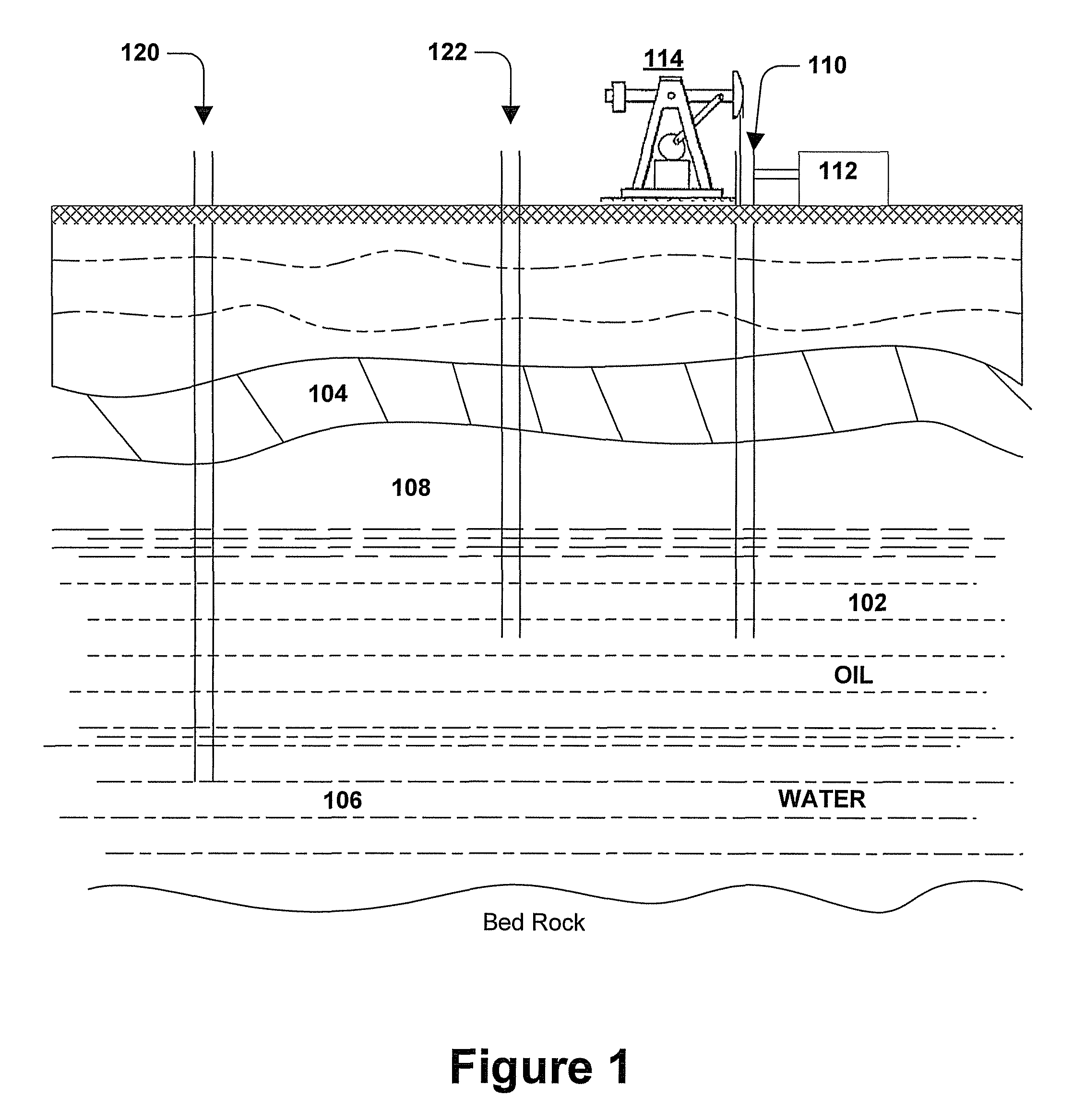

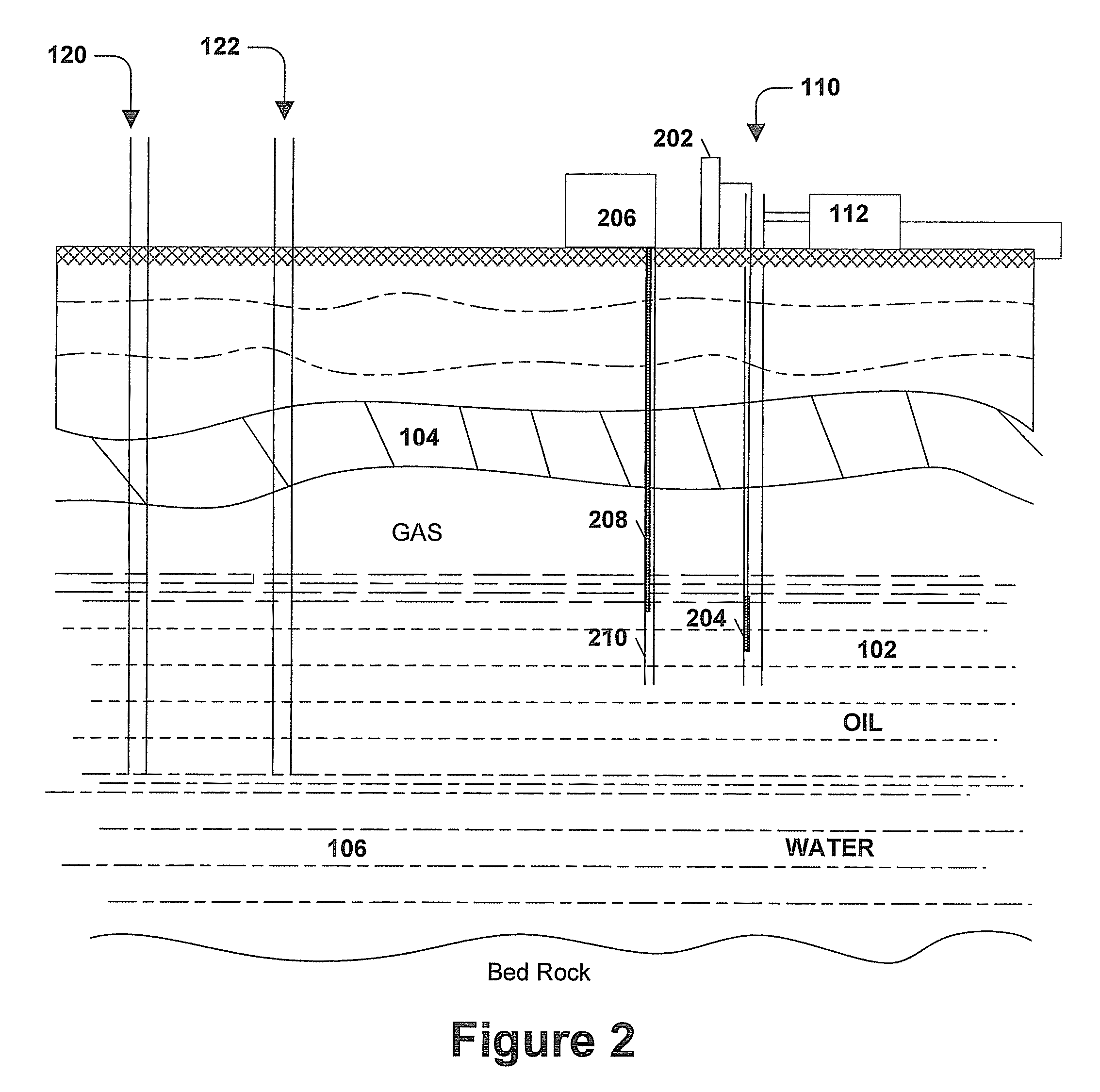

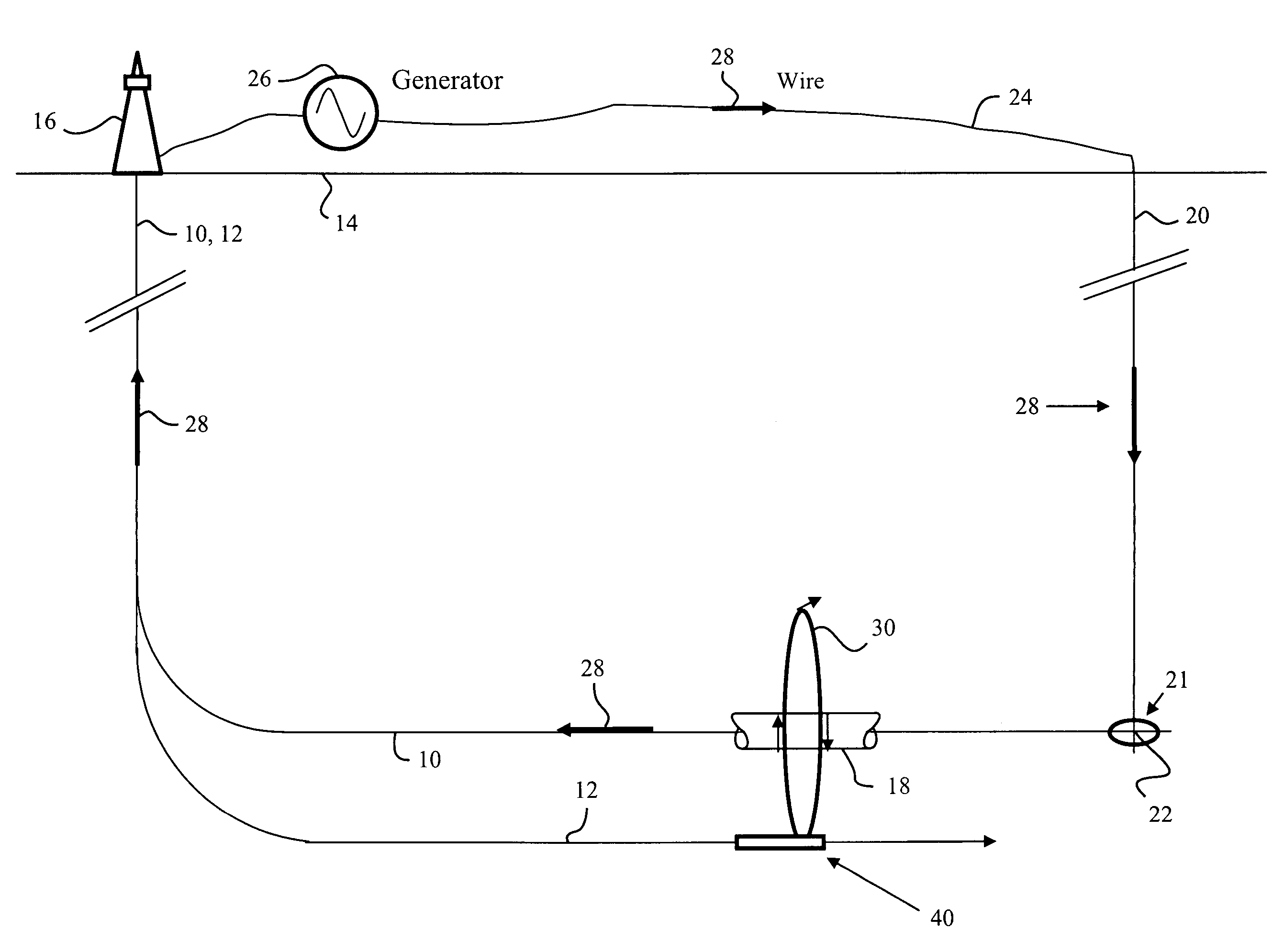

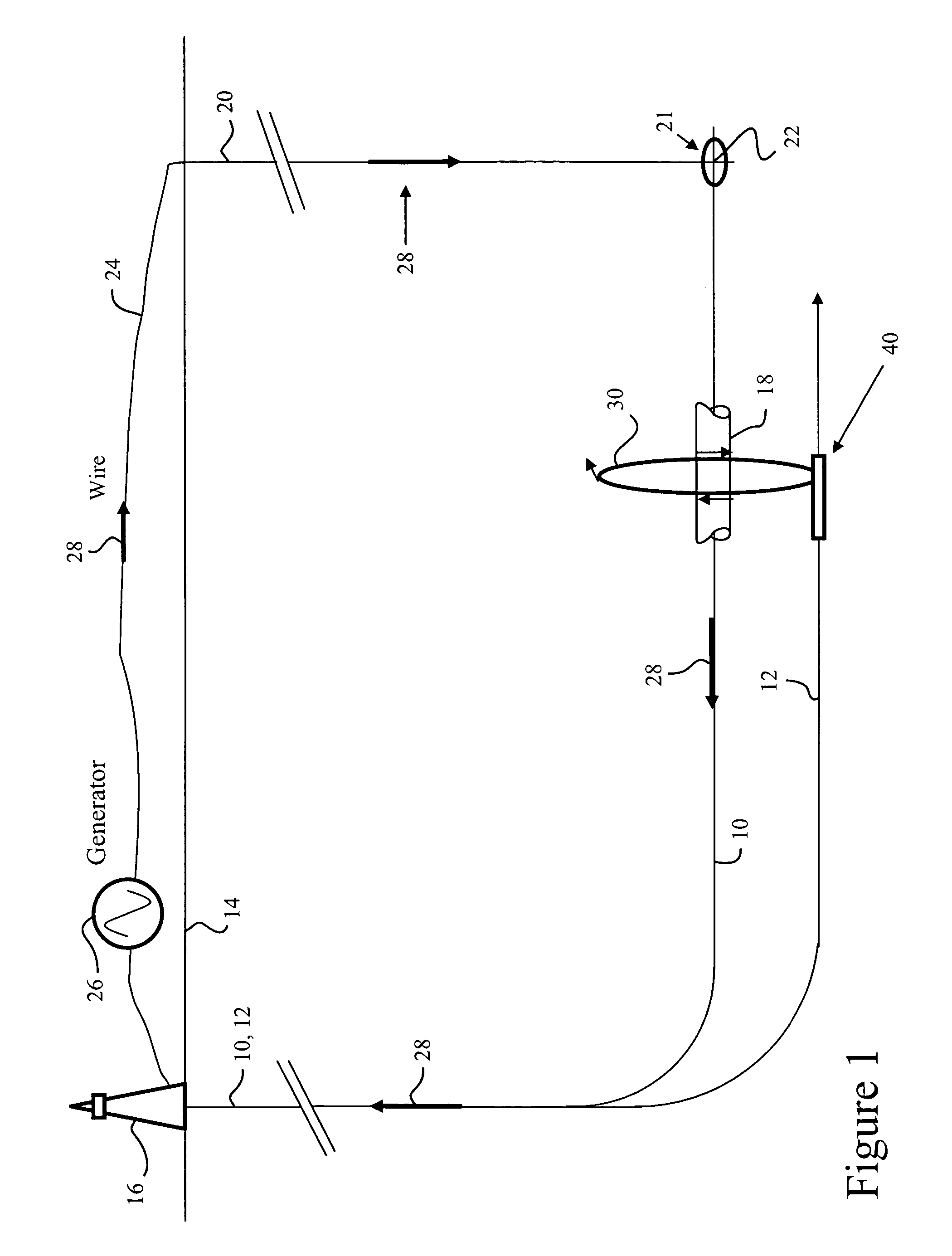

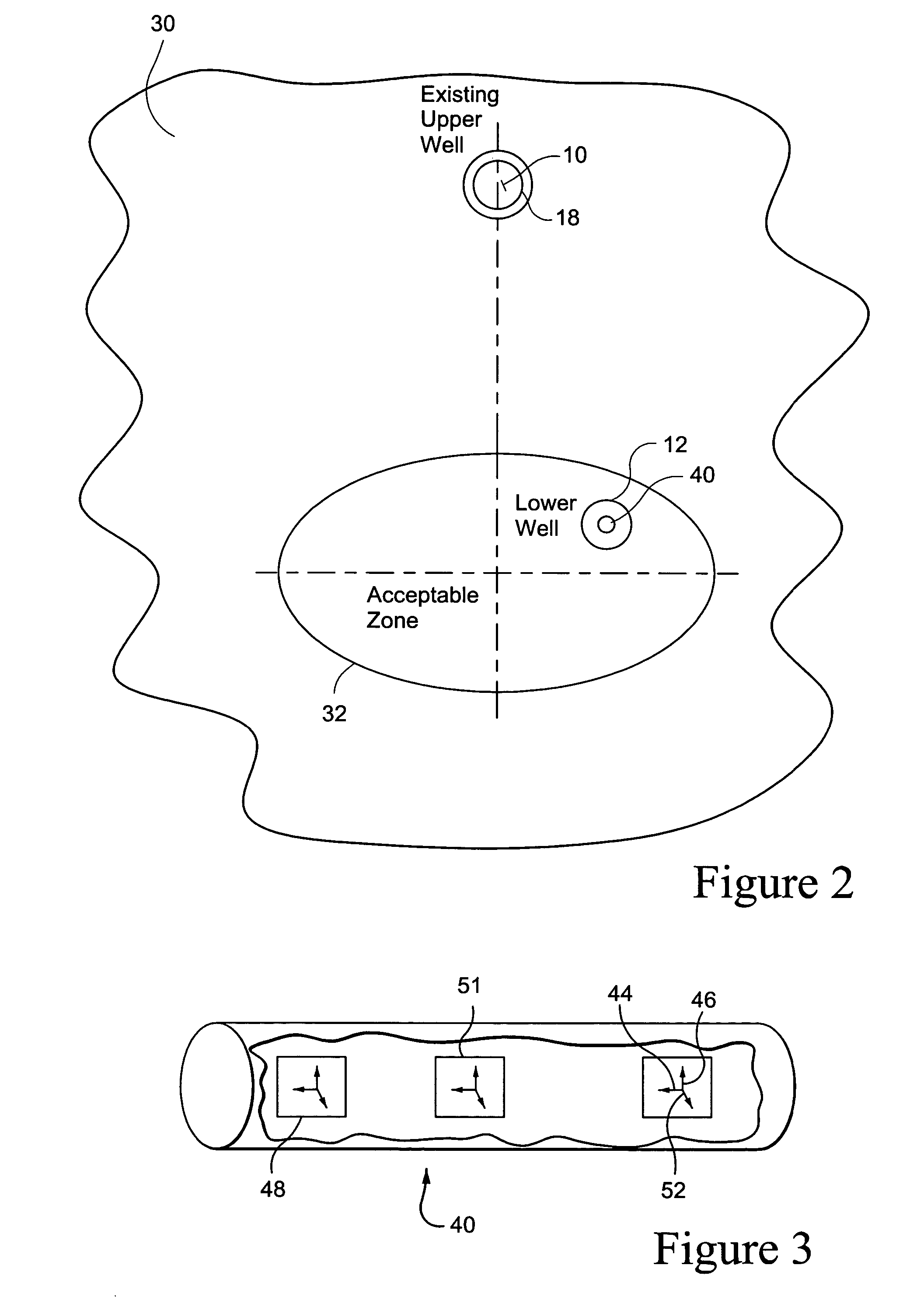

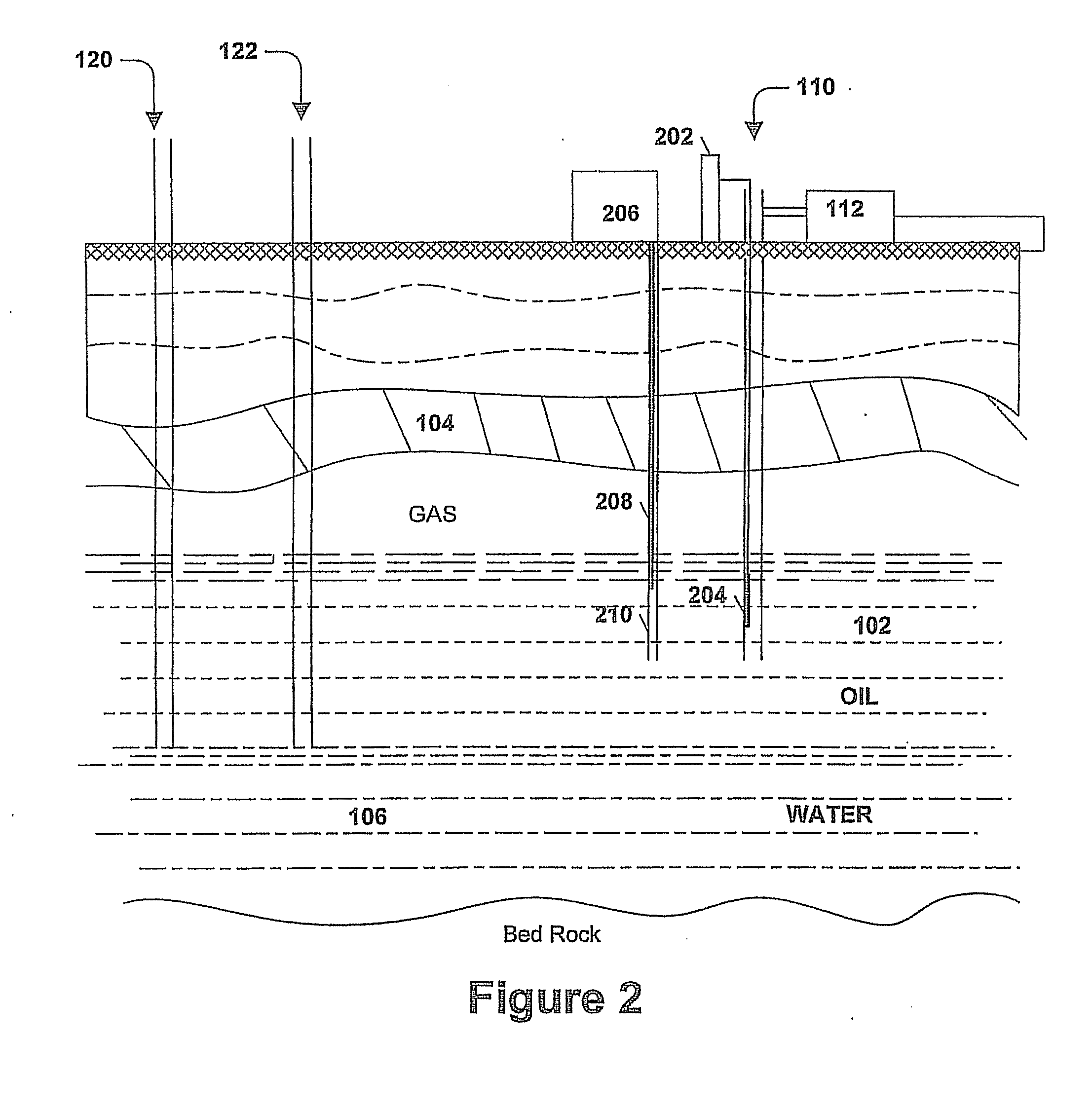

Method and system for precise drilling guidance of twin wells

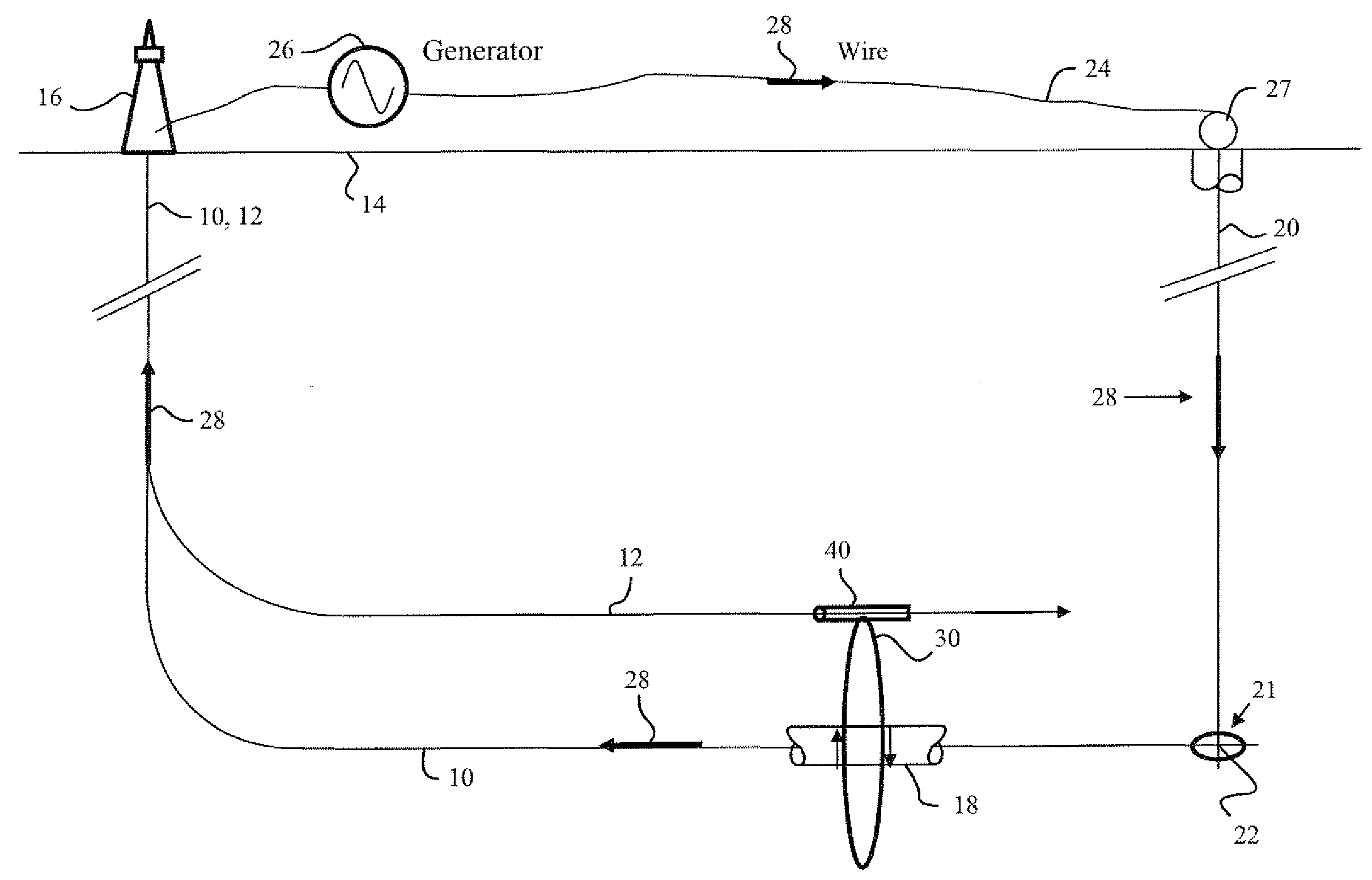

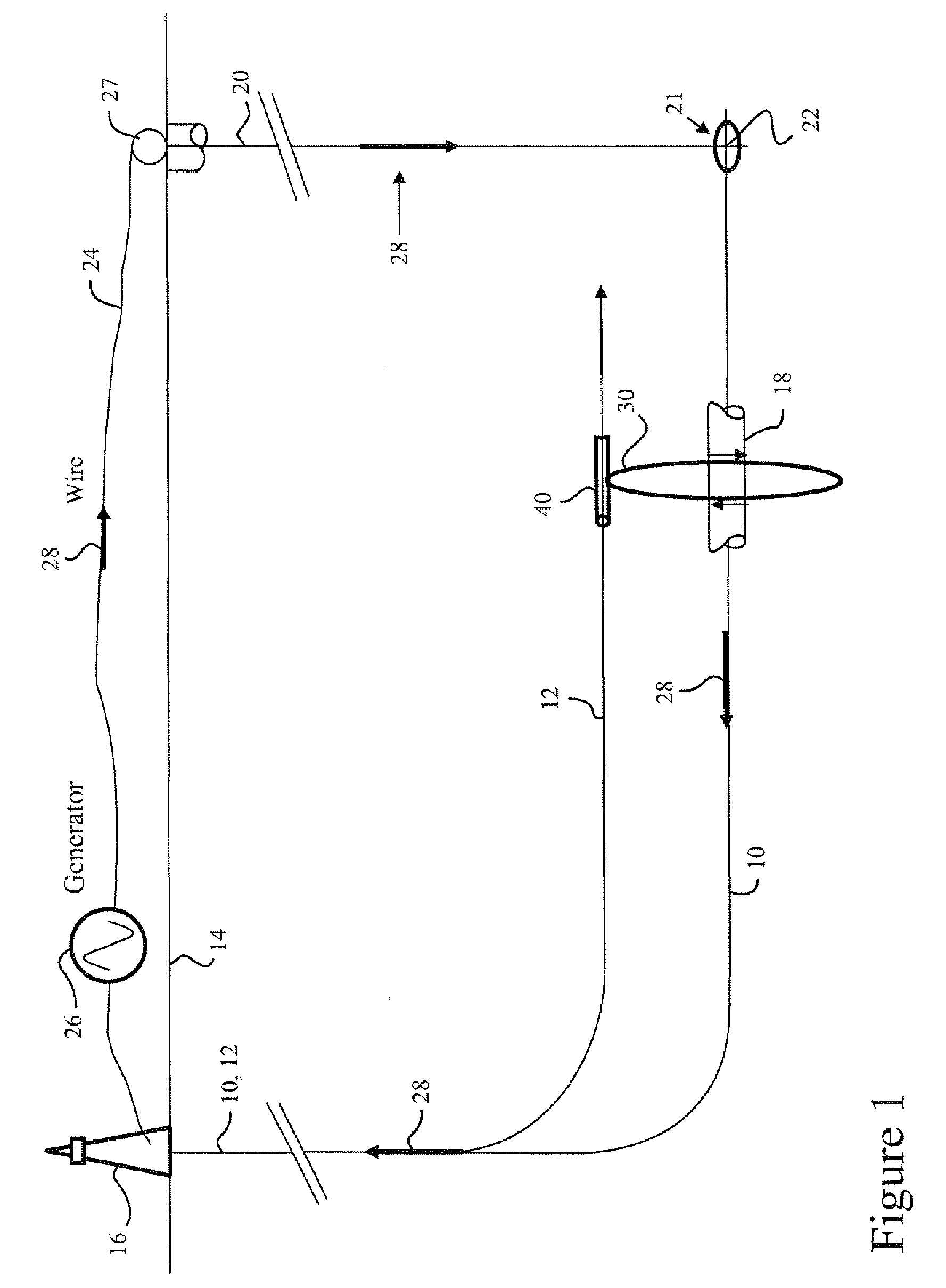

ActiveUS20090178850A1Increase oil productionAccurate trackingSurveyConstructionsPower flowEngineering

A method to guide a drilling path of a second well in proximity to a first well including: applying a time-varying electrical current to a conductive casing or liner of the first well; from the drilling path of the second well, sensing an electromagnetic field generated by the current in the first well, and guiding the drilling path trajectory of the second well using the sensed electromagnetic field.

Owner:PRIME DOWNHOLE MANUFACTRUING LLC

Method and system for precise drilling guidance of twin wells

InactiveUS20060113112A1Increase oil productionAccurate trackingSurveyConstructionsEngineeringElectromagnetic field

A method to guide a drilling path of a second well in proximity to a first well including: applying a time-varying electrical current to a conductive casing or liner of the first well; from the drilling path of the second well, sensing an electromagnetic field generated by the current in the first well, and guiding the drilling path trajectory of the second well using the sensed electromagnetic field.

Owner:PRIME DOWNHOLE MANUFACTRUING LLC

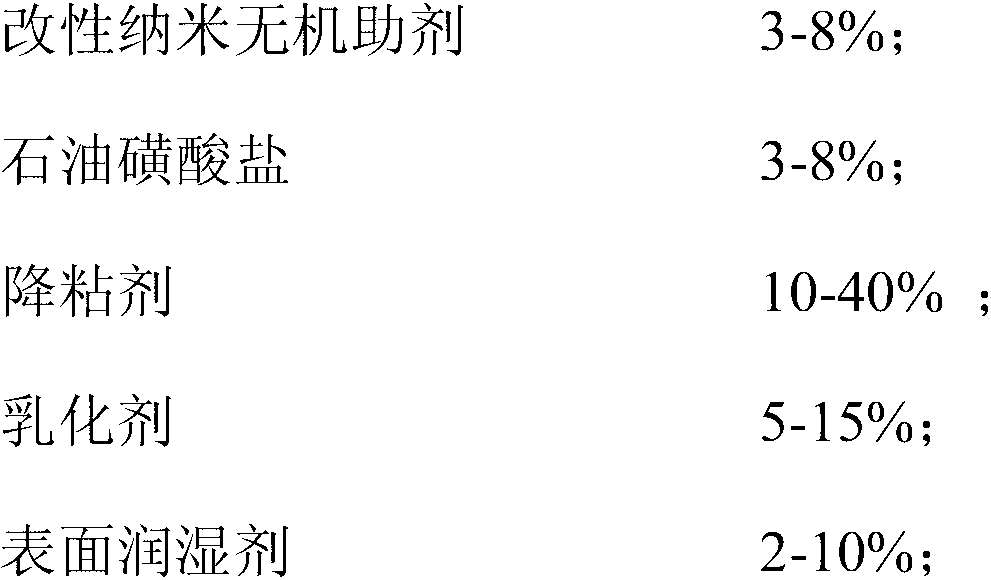

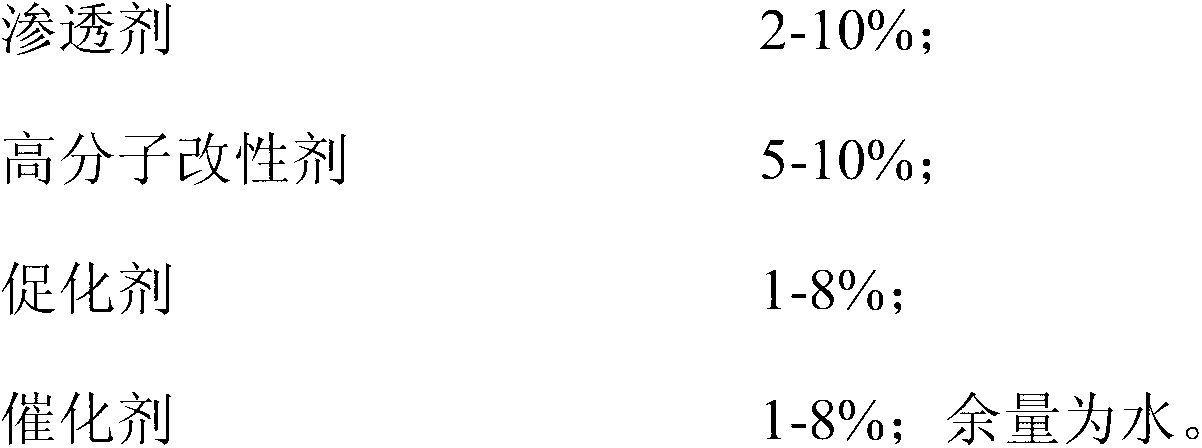

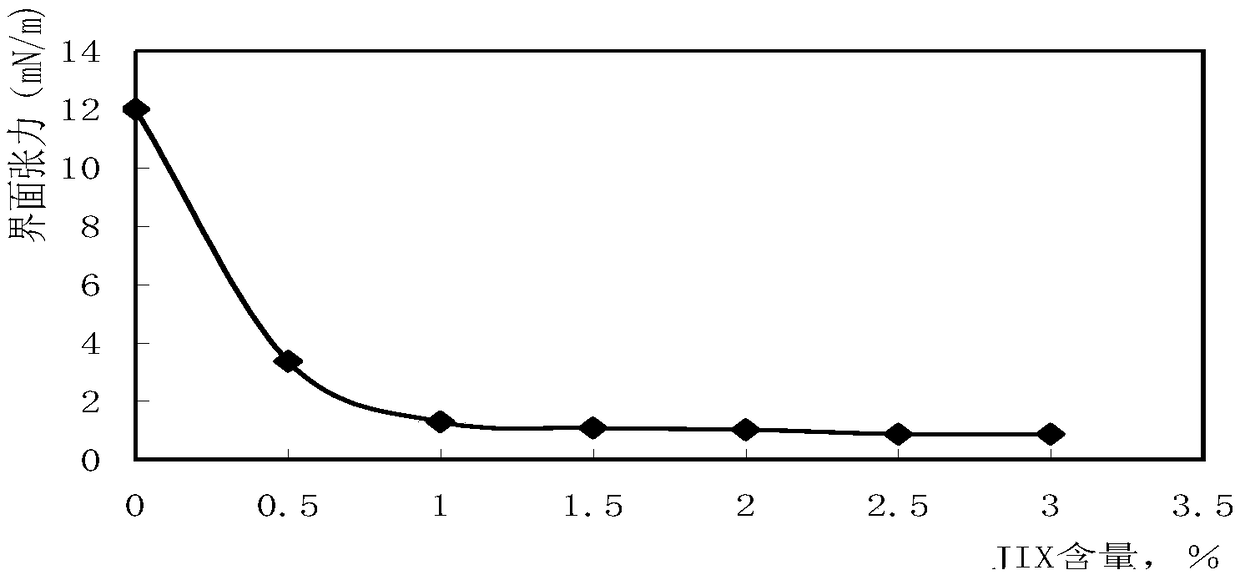

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

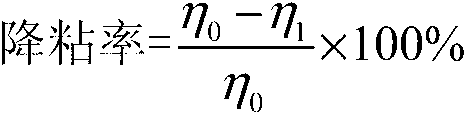

Nucleic acid segments encoding wheat acetyl-CoA carboxylase

InactiveUS6306636B1Reduce the amount requiredAlter fatty acid biosynthesisSugar derivativesBacteriaCarboxysomePolynucleotide

The present invention provides isolated and purified polynucleotides that encode plant polypeptides that participate in the carboxylation of acetyl-CoA. Also provided are methods for identifying such nucleic acid segments and polypeptides. Processes for altering acetyl-CoA carboxylation, increasing herbicide resistance of plants and identifying herbicide resistant variants of acetyl-CoA carboxylase are also provided.

Owner:ARCH DEVMENT

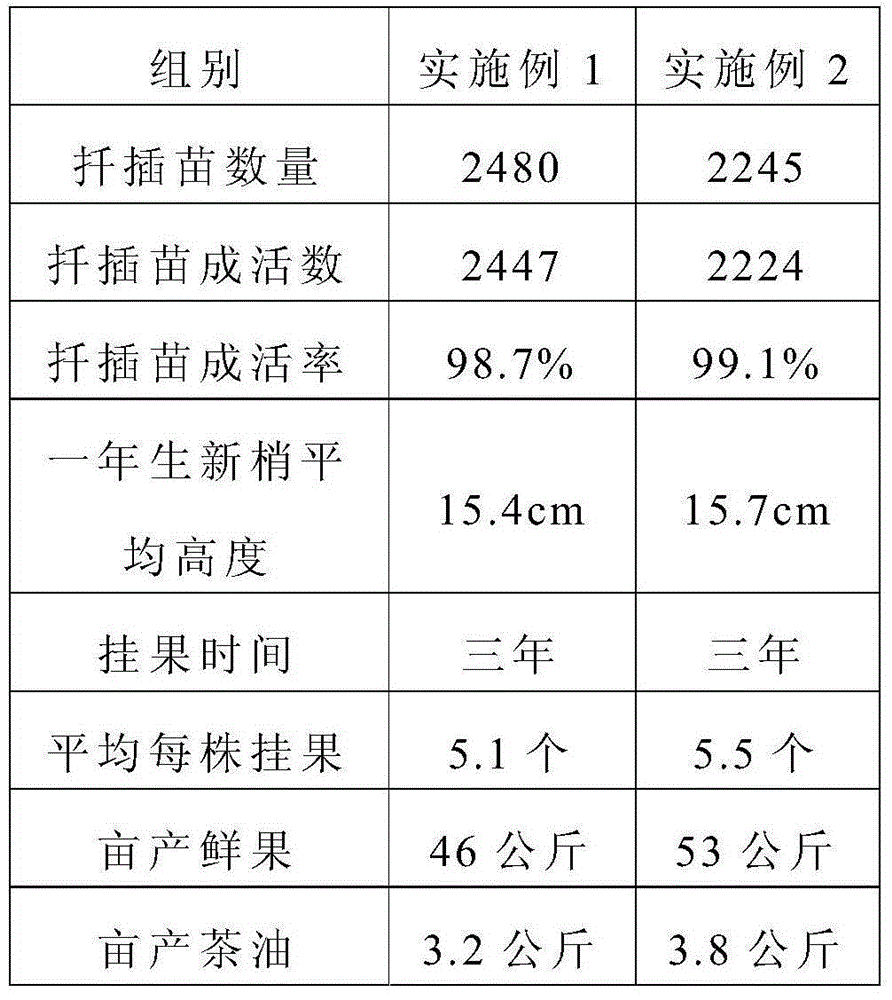

Camellia oleifera Abel planting method

ActiveCN105052655AIncrease growth rateIncrease oil productionCalcareous fertilisersAnimal corpse fertilisersCamellia oleiferaObserved Survival

The invention relates to a camellia oleifera Abel planting method and belongs to the technical field of plant planting. The method comprises the following steps: cutting, cutting management, seedling hardening, management before transplanting, field transplanting and field management. According to the camellia oleifera Abel planting method, through a reasonable cutting management method and camellia oleifera seedling fertilization and topdressing management, the survival rate and growth rate of the cutting seedlings are greatly improved; meanwhile, the camellia oleifera Abel can bear fruits after three years, and enter a full bearing period after five to six years; fruit-bearing rate is high; and oil extraction rate of the fruits is high.

Owner:张家界融和实业有限公司

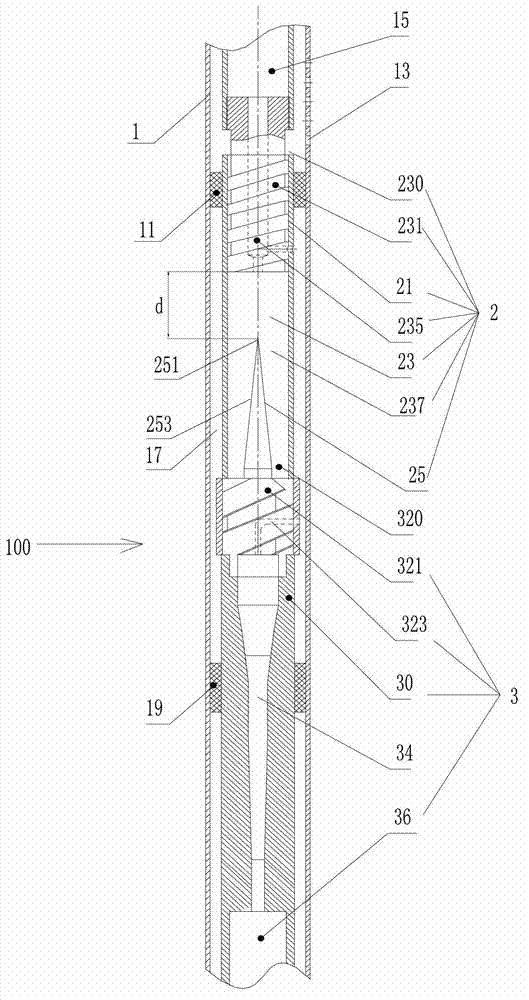

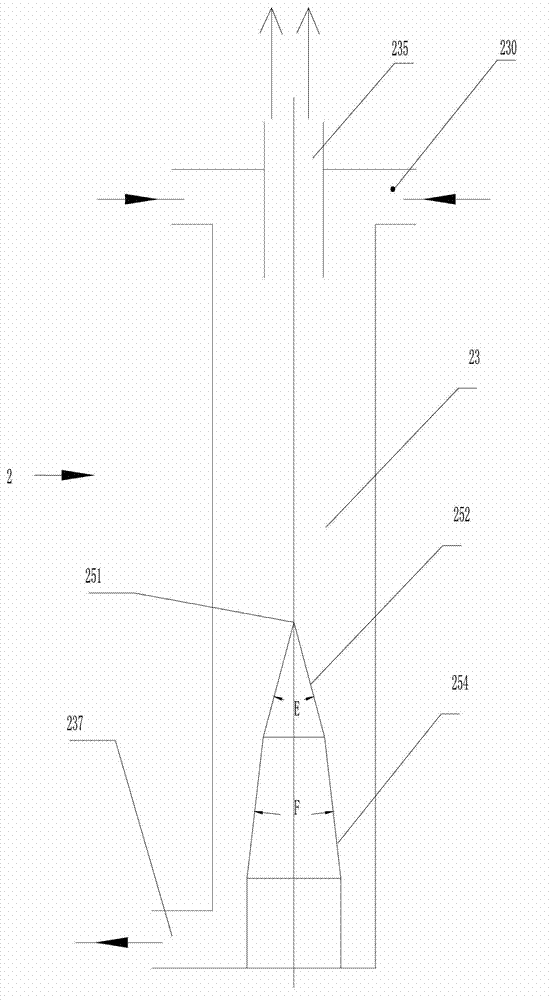

Underground two-stage cyclone separator

The invention provides an underground two-stage cyclone separator, which comprises an outer pipe, a first-stage cyclone separator, a second-stage cyclone separator and a rich oil flow channel, wherein the outer pipe is provided with a produced fluid inlet; the first-stage cyclone separator is arranged in the outer pipe, and comprises a first pipe wall and a first inner cavity in the first pipe wall; a first inlet, a first rich oil overflow channel and a first rich water drainage channel are formed in the first inner cavity; the second-stage cyclone separator is arranged in the outer pipe, and comprises a second pipe wall and a second inner cavity in the second pipe wall; a second inlet, a second rich oil overflow channel and a second rich water drainage channel are formed in the second inner cavity; the rich oil flow channel is arranged in the outer pipe, and is connected with the first rich oil overflow channel and the second rich oil overflow channel; the first-stage cyclone separator is connected in series with the second-stage cyclone separator; the first inlet is communicated with the produced fluid inlet; and the first rich water drainage channel is connected with the second inlet.

Owner:PETROCHINA CO LTD

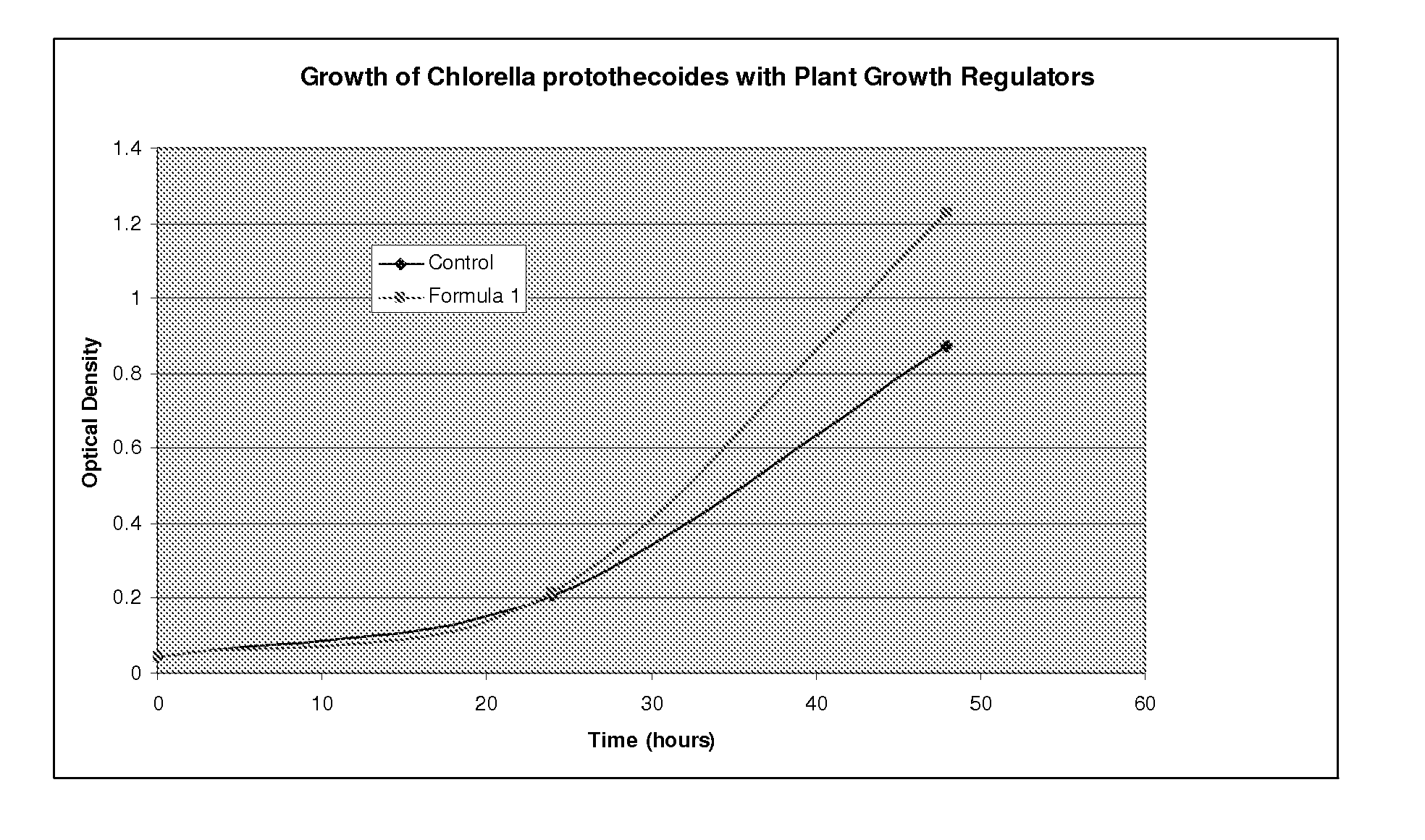

Optimization of Algal Product Production through Uncoupling Cell Proliferation and Algal Product Production

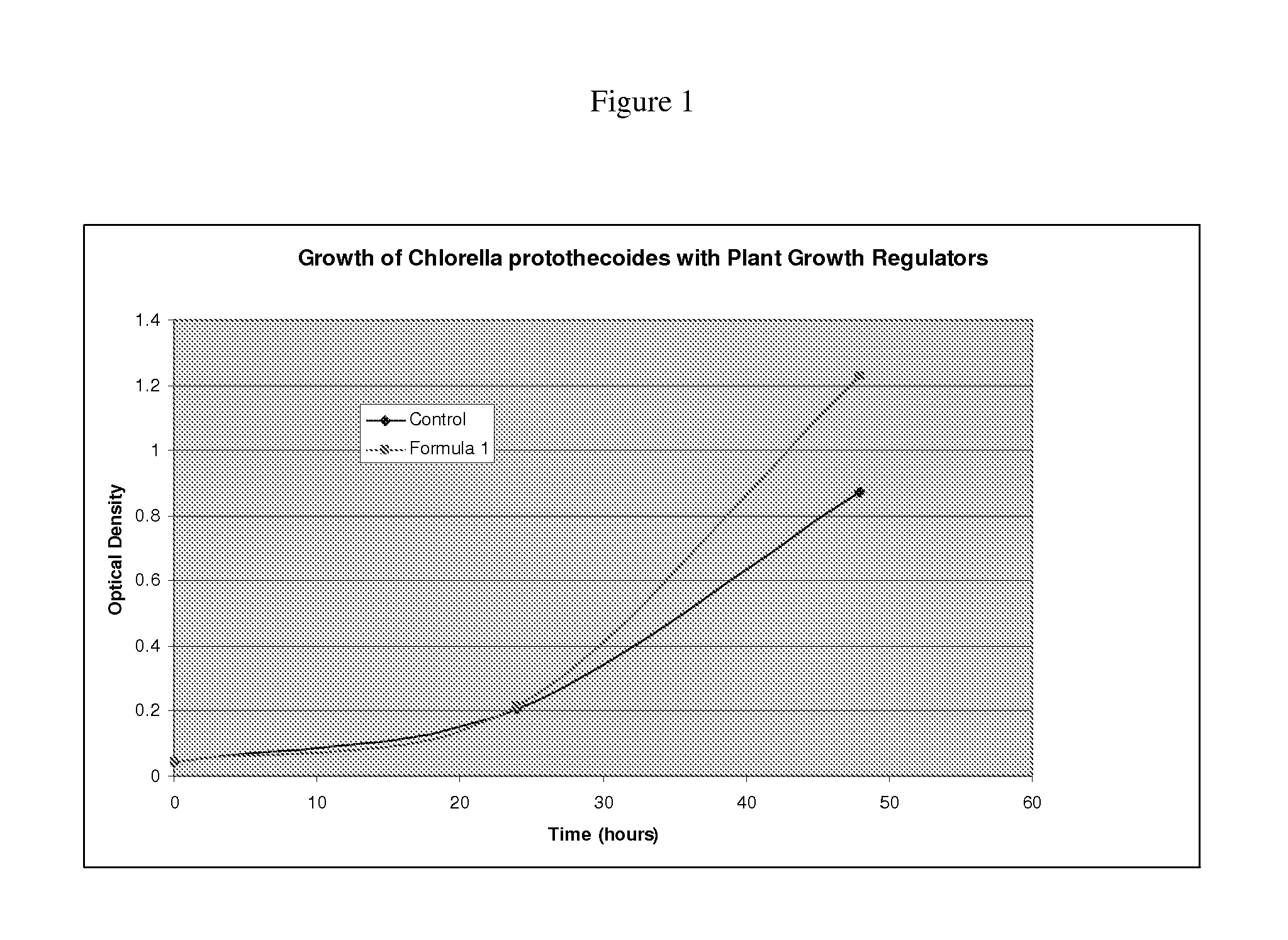

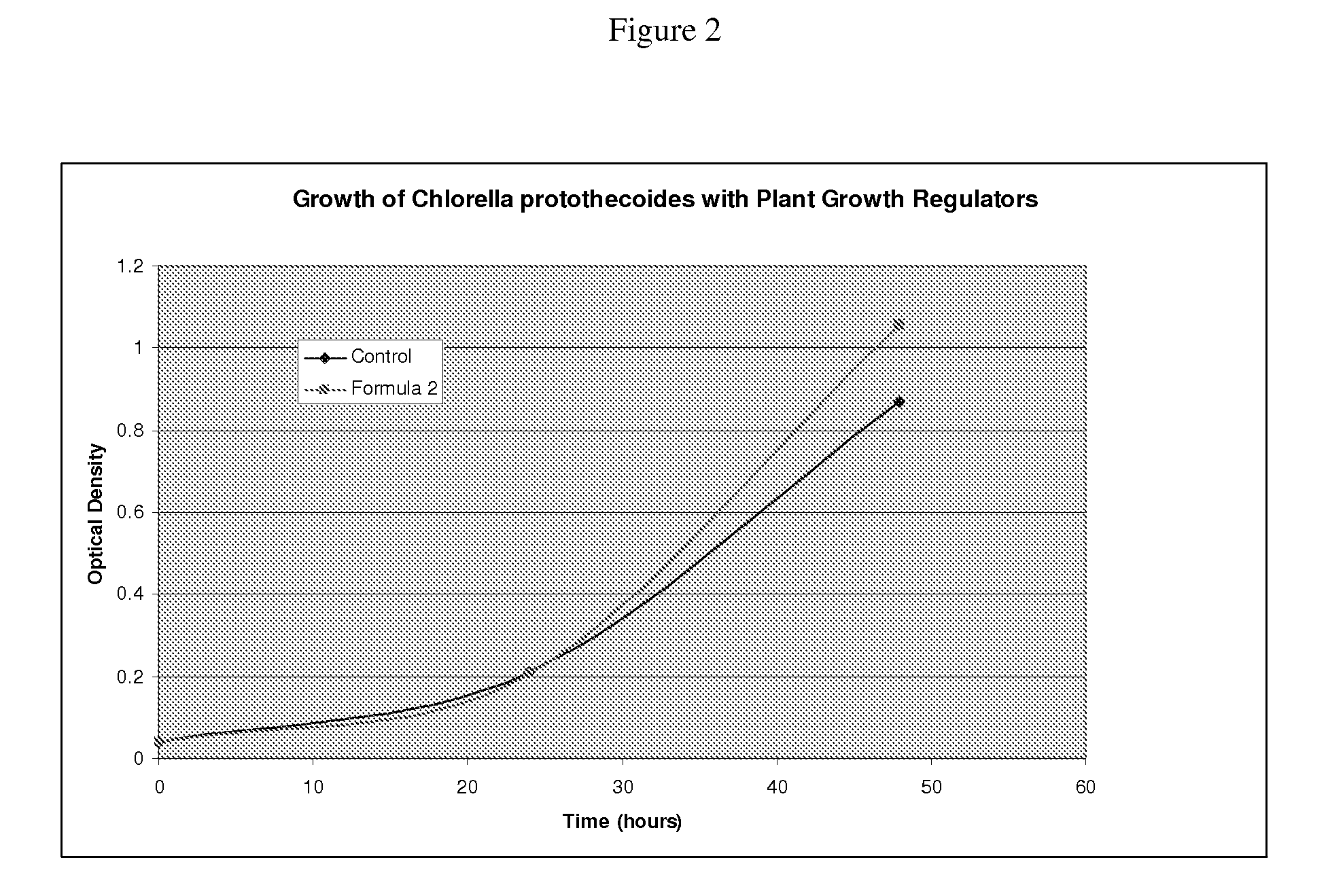

InactiveUS20100162620A1Increase productionIncrease typeAlgae productsUnicellular algaeLipid formationGrowth phase

In algae, the conditions for optimal production of biomass are different than the optimal conditions for oil / lipid production. Conventional processes require that both steps be optimized simultaneously which is necessarily sub optimal. The invention provides systems and processes for optimizing each type of production separately and independently, thereby improving overall production of oil, lipids and other useful products. This process is advantageous because it allows the optimization of the individual steps and growth phases in the production of oil from biomass. This allows the use of different feedstocks for various process steps.

Owner:MCCARTER & ENGLISH LLP

Technique for dissecting depth of sludge containing oil in injection well

InactiveCN1480627ASimple processEasy to implementFluid removalSealing/packingChemical treatmentSludge

A deep section regulating technique for regulating the water absorbing section of water injection well features that its section regulating agent is prepared from the additive and oil-contained sludge which has high compatibility to stratum. Its advantage is high plugging effect to high penetration stratum.

Owner:PETROCHINA CO LTD

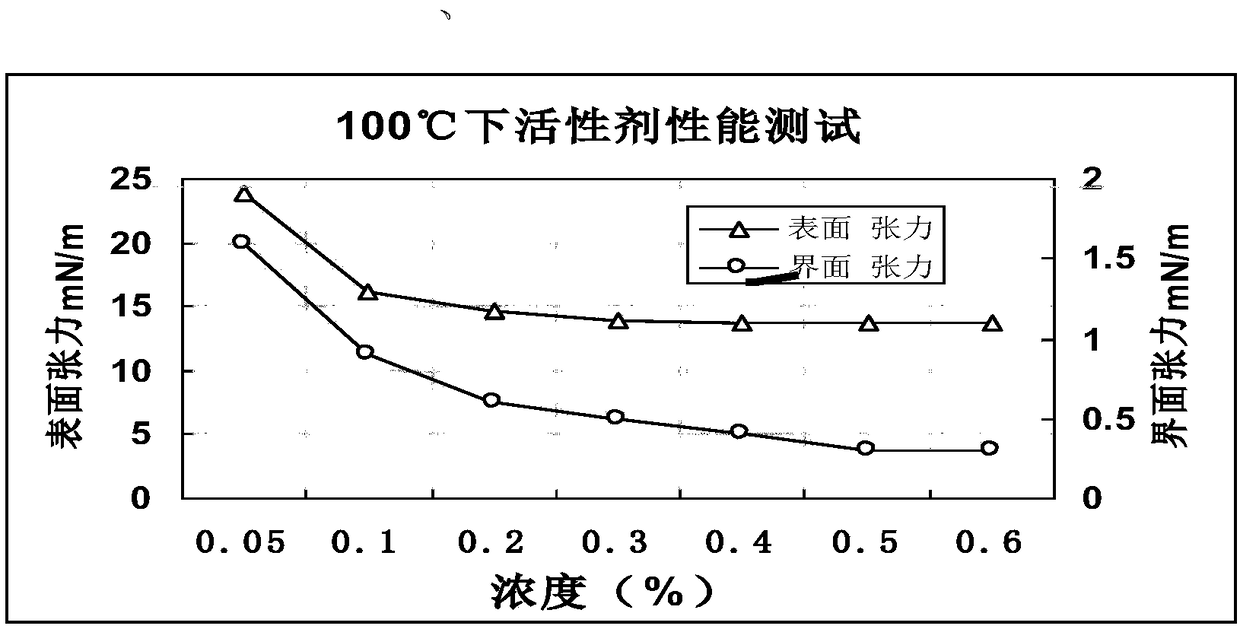

Surfactant composition

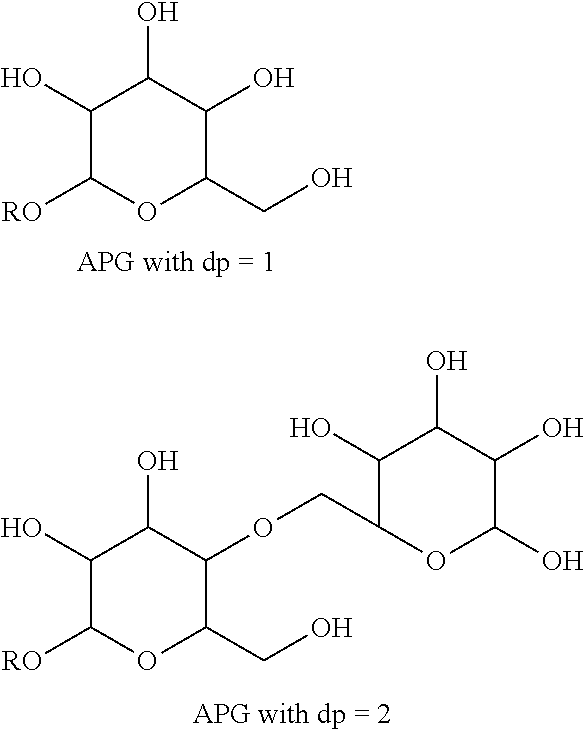

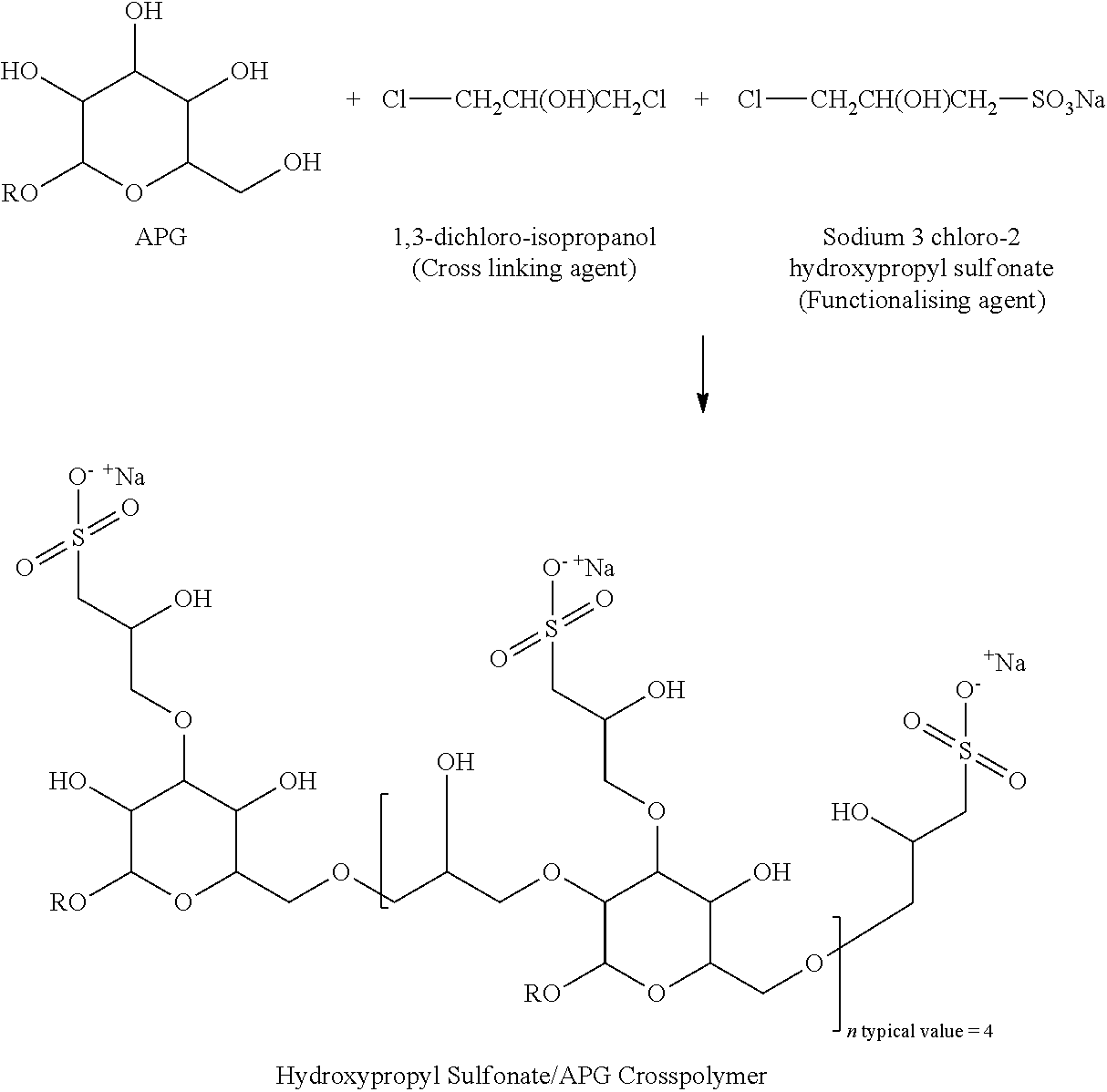

ActiveUS20150126417A1Reduce corrosionImproved aquatic toxicityFlushingDrilling compositionSURFACTANT BLENDHydrocarbon

The invention provides a synergistic surfactant composition comprising: (a) from 5 to 95 wt % of a first surfactant which is selected from derivatives of alkyl polyglucosides and mixtures thereof; and (b) from 5 to 95 wt % of a second surfactant which is selected from: amphoteric surfactants, cationic surfactants, anionic surfactants, non-ionic surfactants, and mixtures thereof. This surfactant composition may be used to generate foam that is used for unloading a liquid from a hydrocarbon reservoir. It may be that the liquid unloading of foam generated using the surfactant composition is greater than that of foam generated from the first and second surfactants when they are foamed individually.

Owner:ENERGY SOLUTIONS (US) LLC

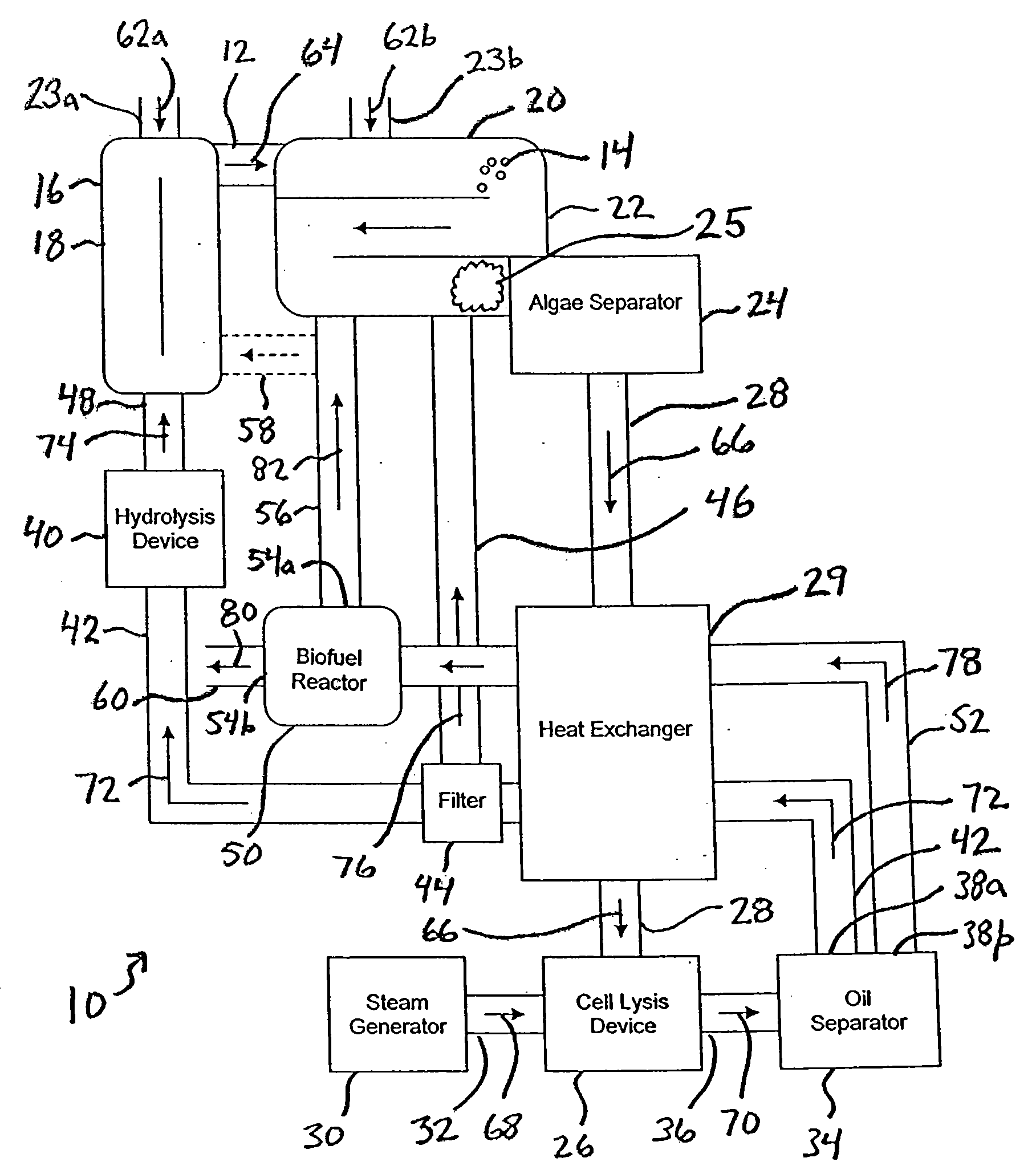

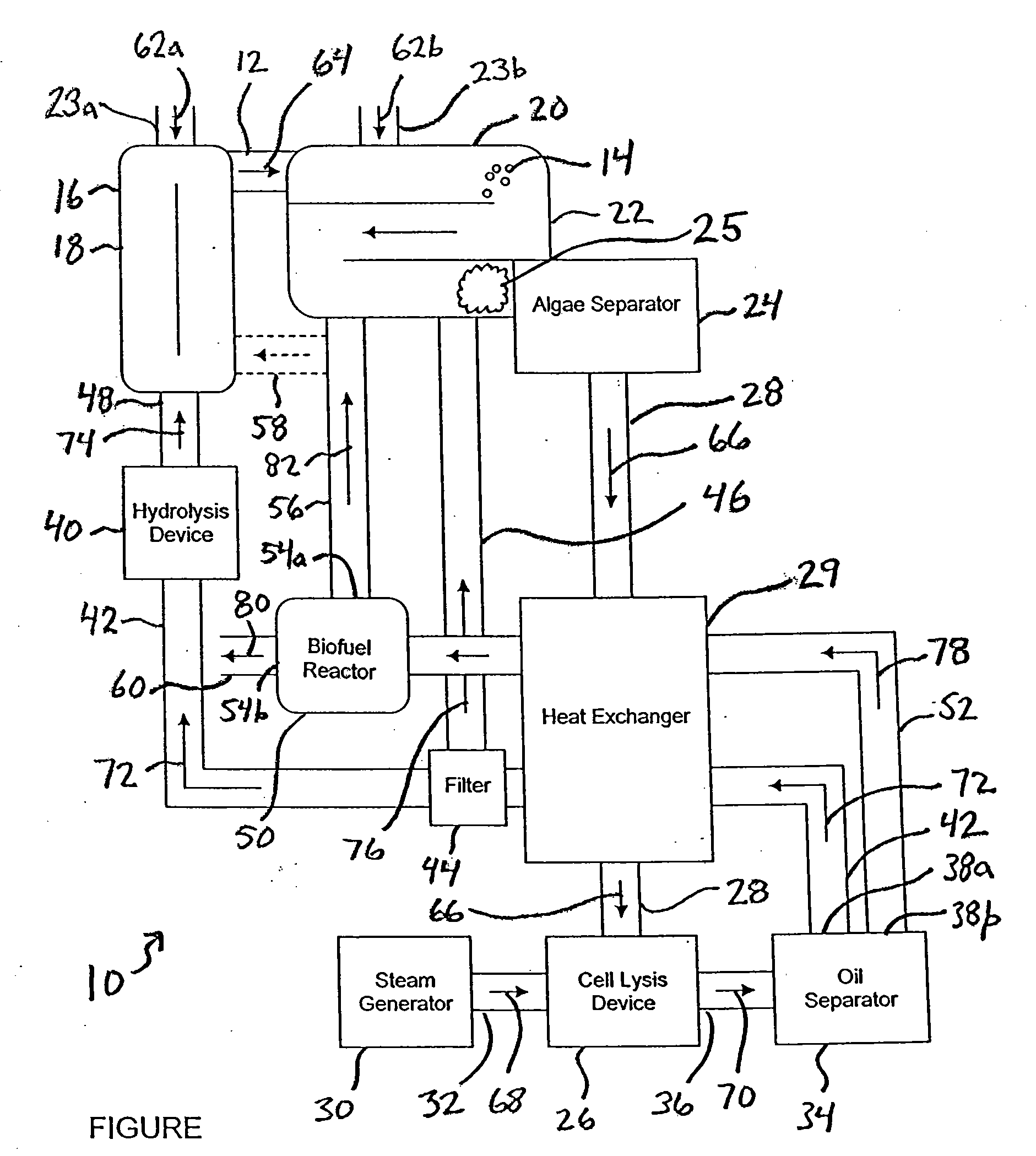

High efficiency separations to recover oil from microalgae

InactiveUS20090081742A1Lower heating costsIncrease ratingsBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaenanBiotechnology

A system and method for processing algae cells to create biofuel are disclosed. Specifically, the system and method utilize steam to rupture algae cells in order to utilize intracellular oil therein. The system includes a conduit for growing algae cells and a generator for creating steam. Further, the system includes a lysing device that mixes the algae cells and the steam to rupture the algae cells. In order to maximize the efficiency of the lysing process, the system may further include a heat exchanger for preheating the algae cells with the lysed cells. In addition, the system includes a bioreactor to synthesize biofuel from the unbound oil.

Owner:GENERAL ATOMICS

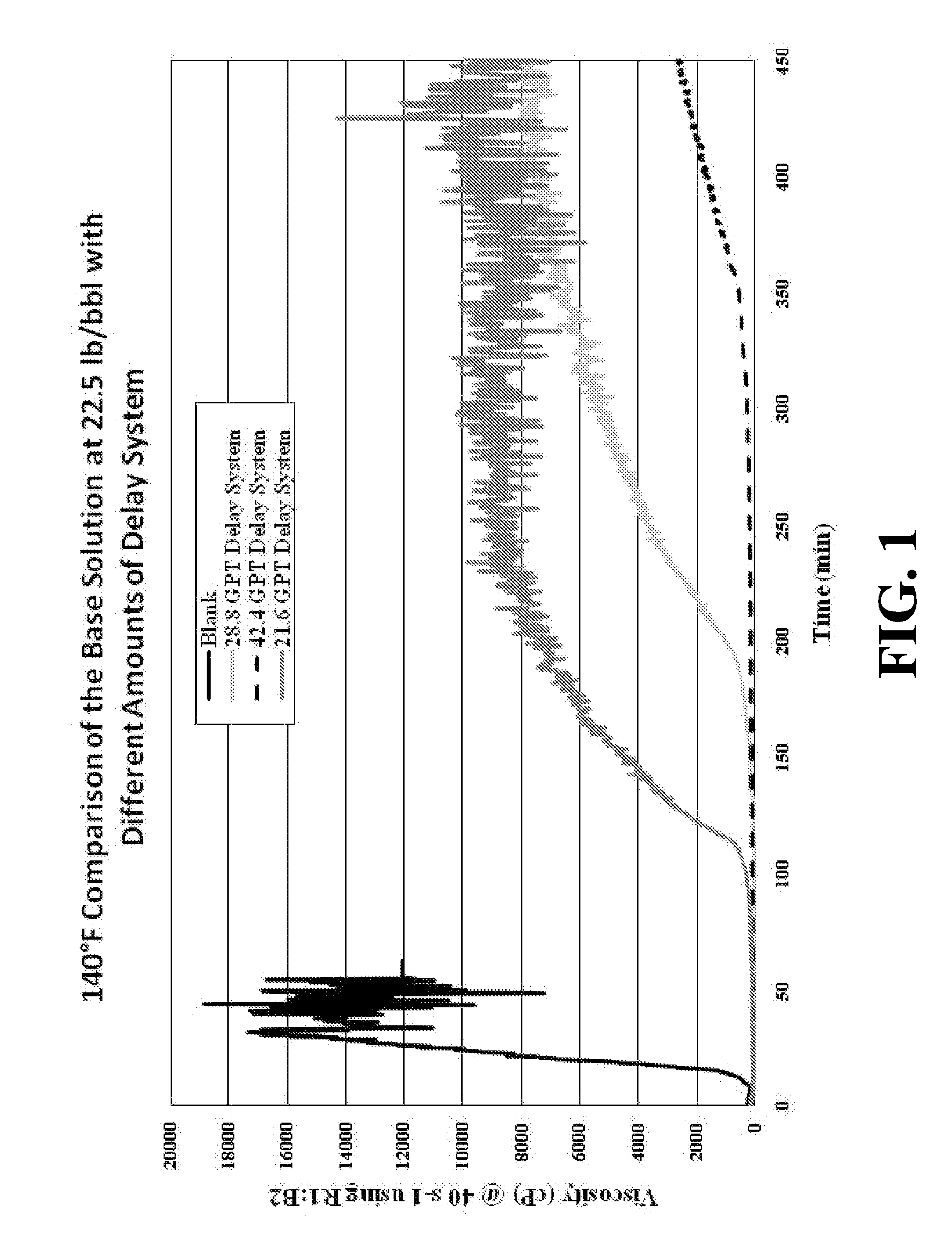

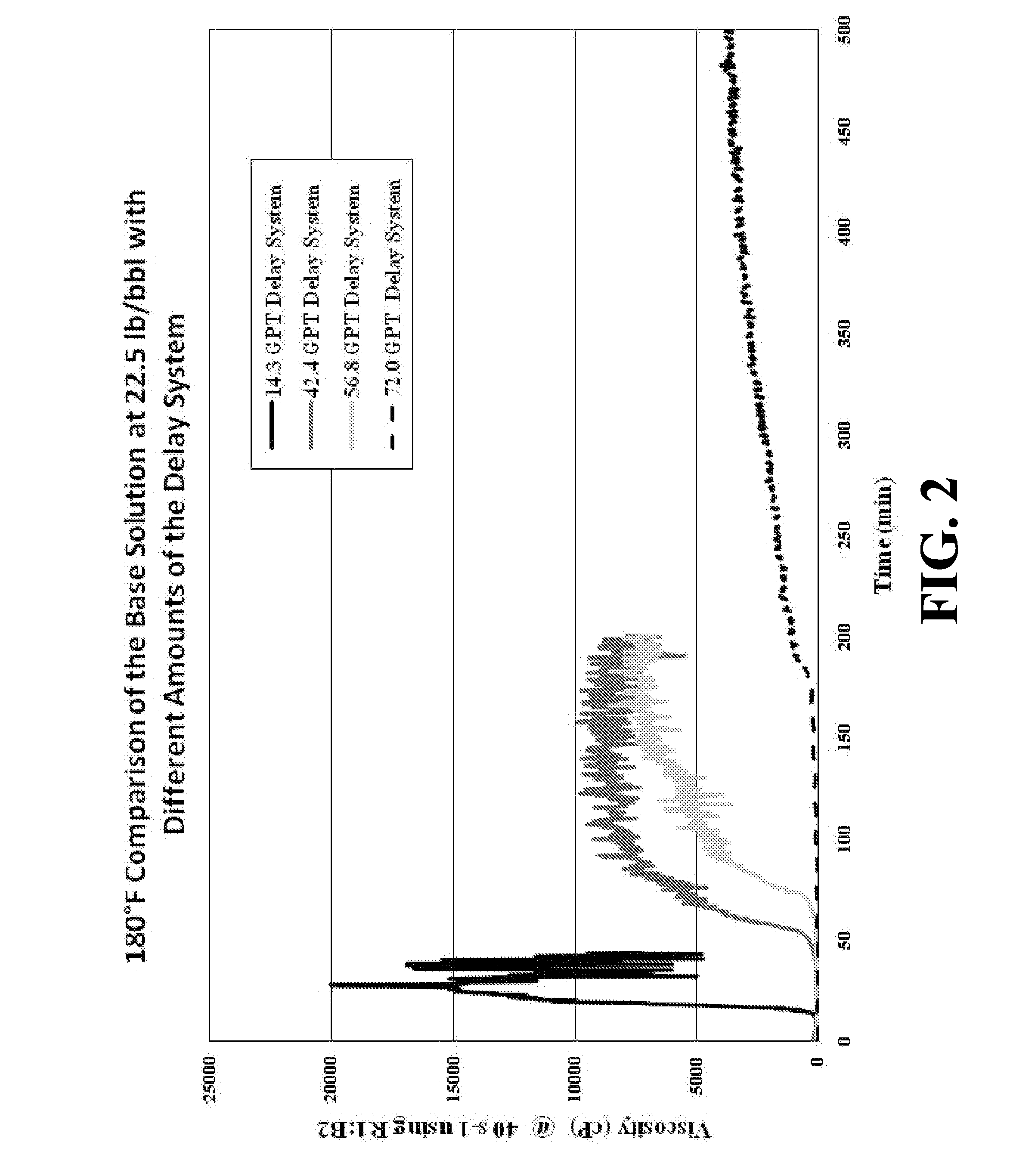

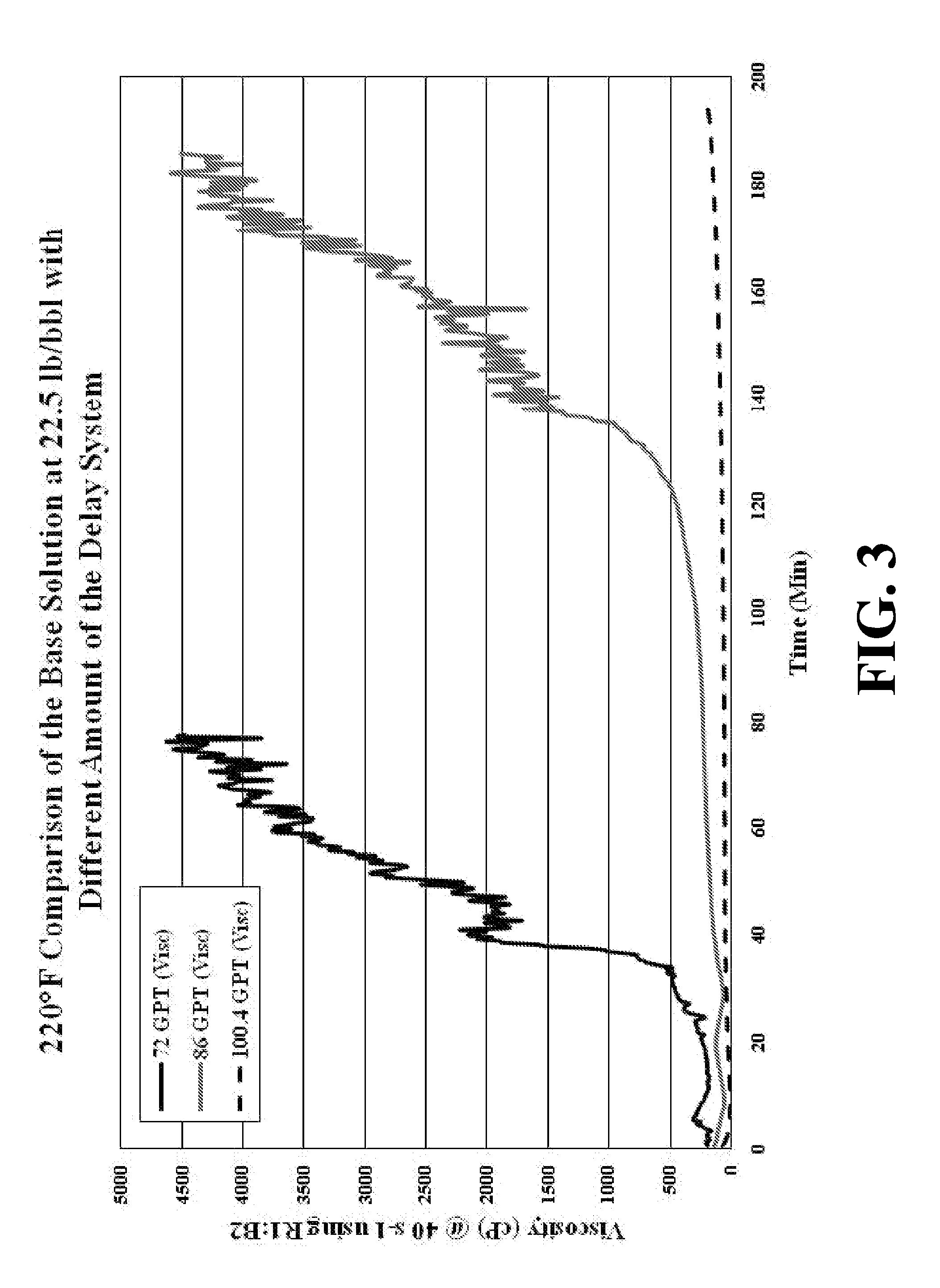

Enhancing delaying in situ gelation of water shutoff systems

InactiveUS20120279727A1Improves matrix conformanceImprove permeabilityFluid removalDrilling compositionCarboxylic saltWater soluble

Gel compositions are disclosed including a high molecular weight water-soluble acrylamide polymer, a chromium III / carboxylate complex capable of crosslinking the polymer and a buffered aqueous solvent. The gel compositions are prepared at the surface and injected into a zone of a formation assessable by a wellbore to form a continuous single-phase gel. The gel compositions may be tailored to a specific formation by predetermining gelation rate, gel strength and / or gel stability to form gels having predetermined properties suitable for the zone.

Owner:LUBRIZOL OILFIELD SOLUTIONS

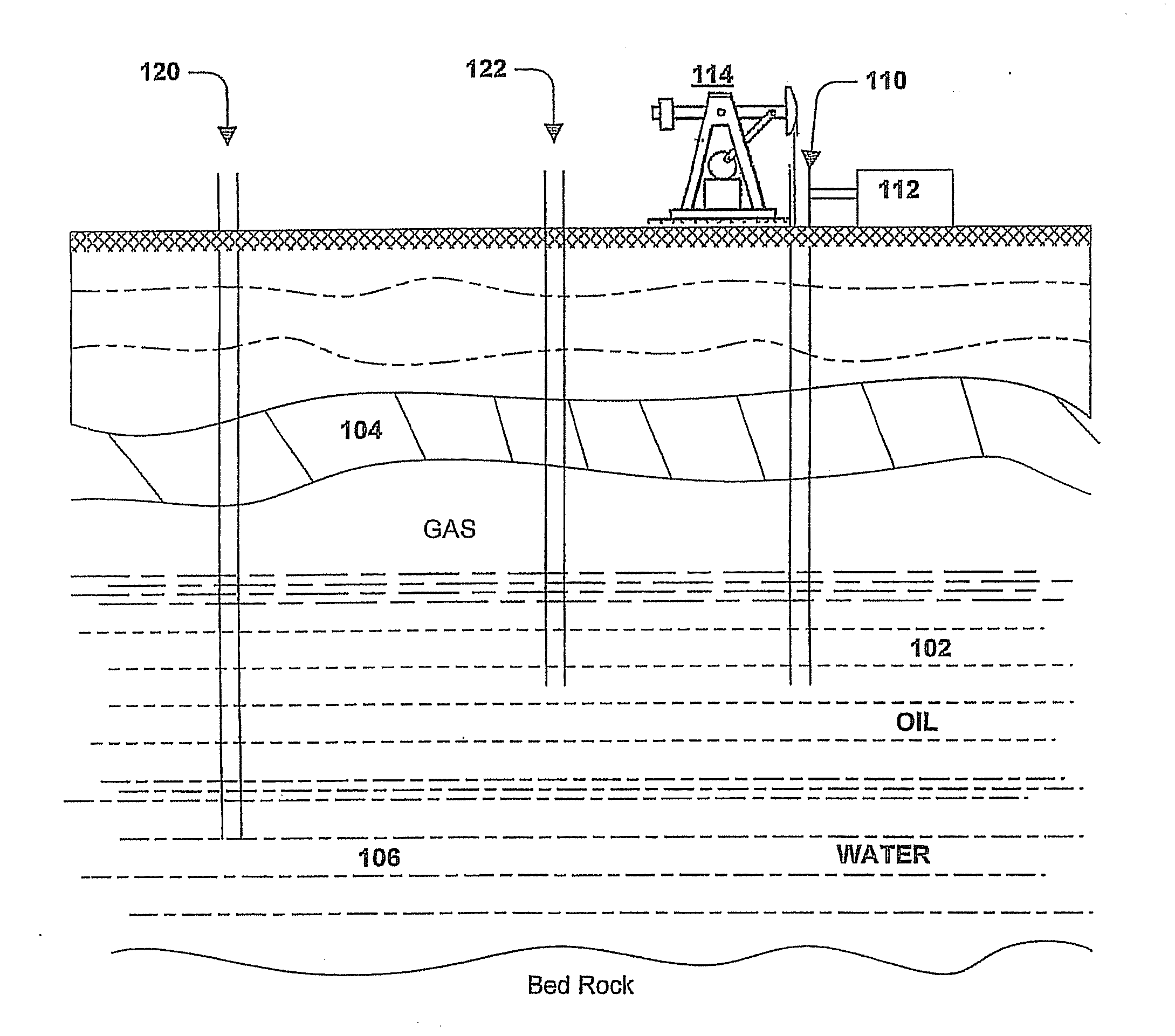

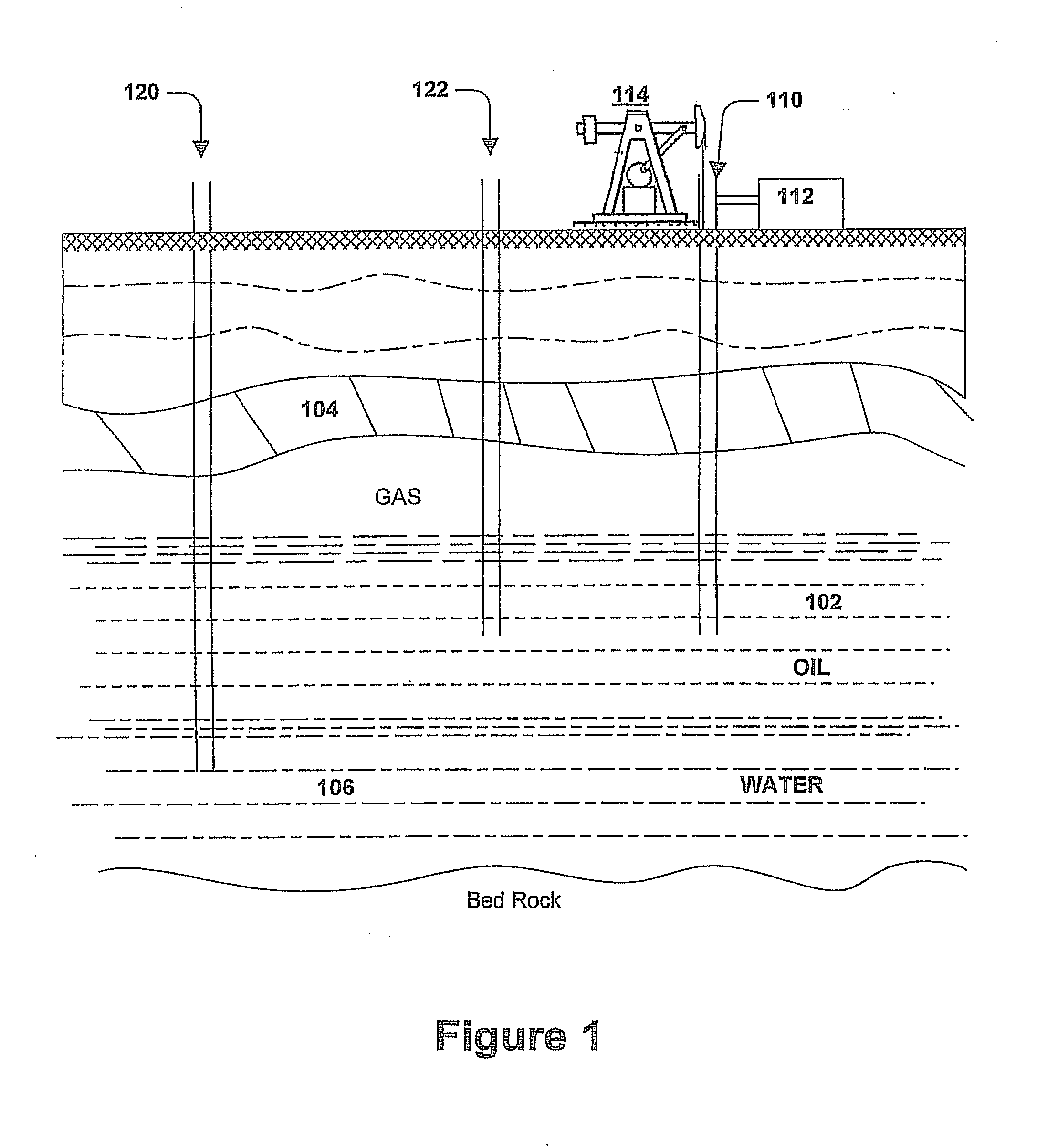

Methods for increasing oil production

InactiveUS8132628B2Low cost recyclingIncrease oil productionOther gas emission reduction technologiesFluid removalAlkaline earth metalOil production

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir.

Owner:YANG DUCK JOO +1

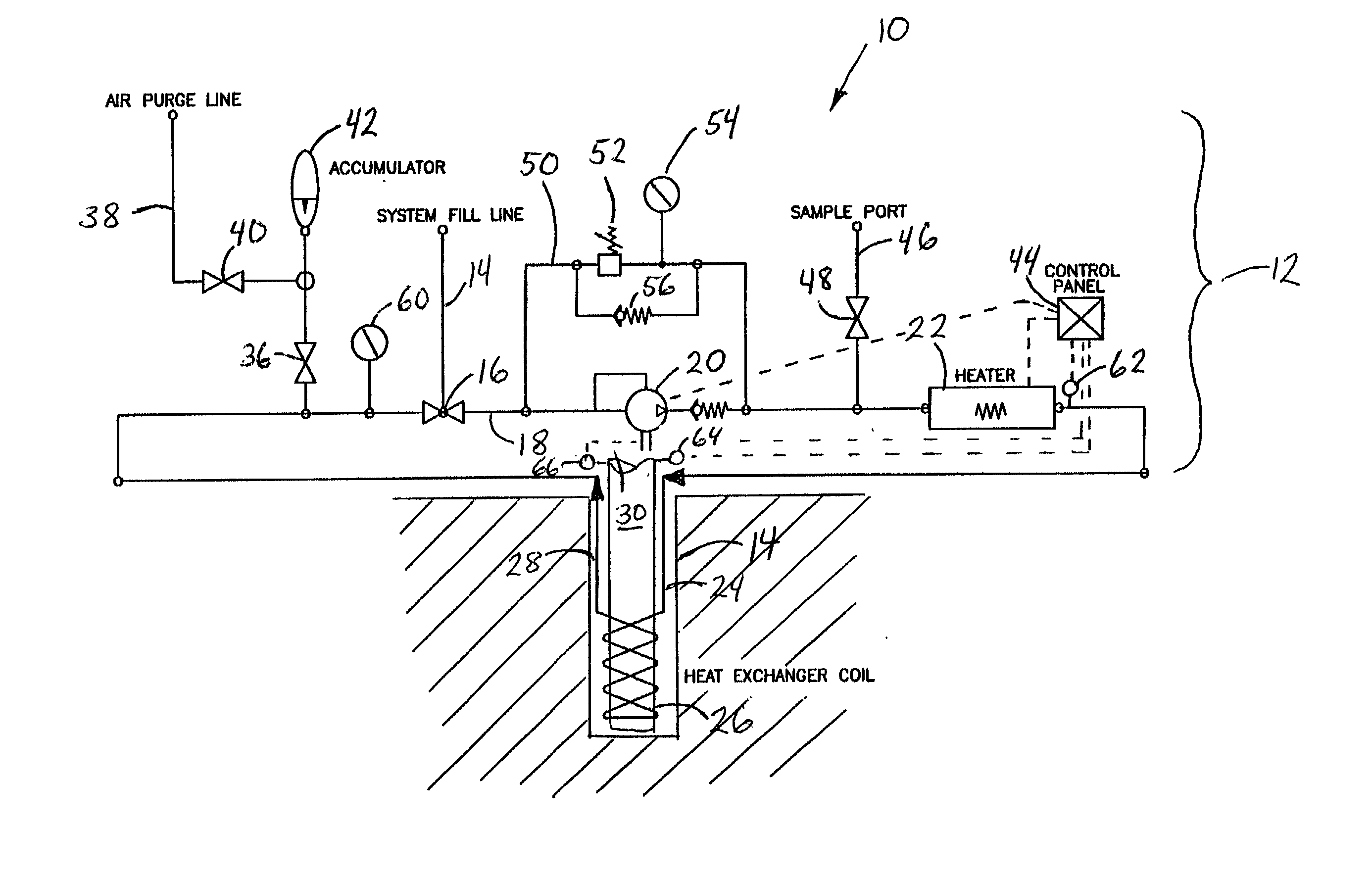

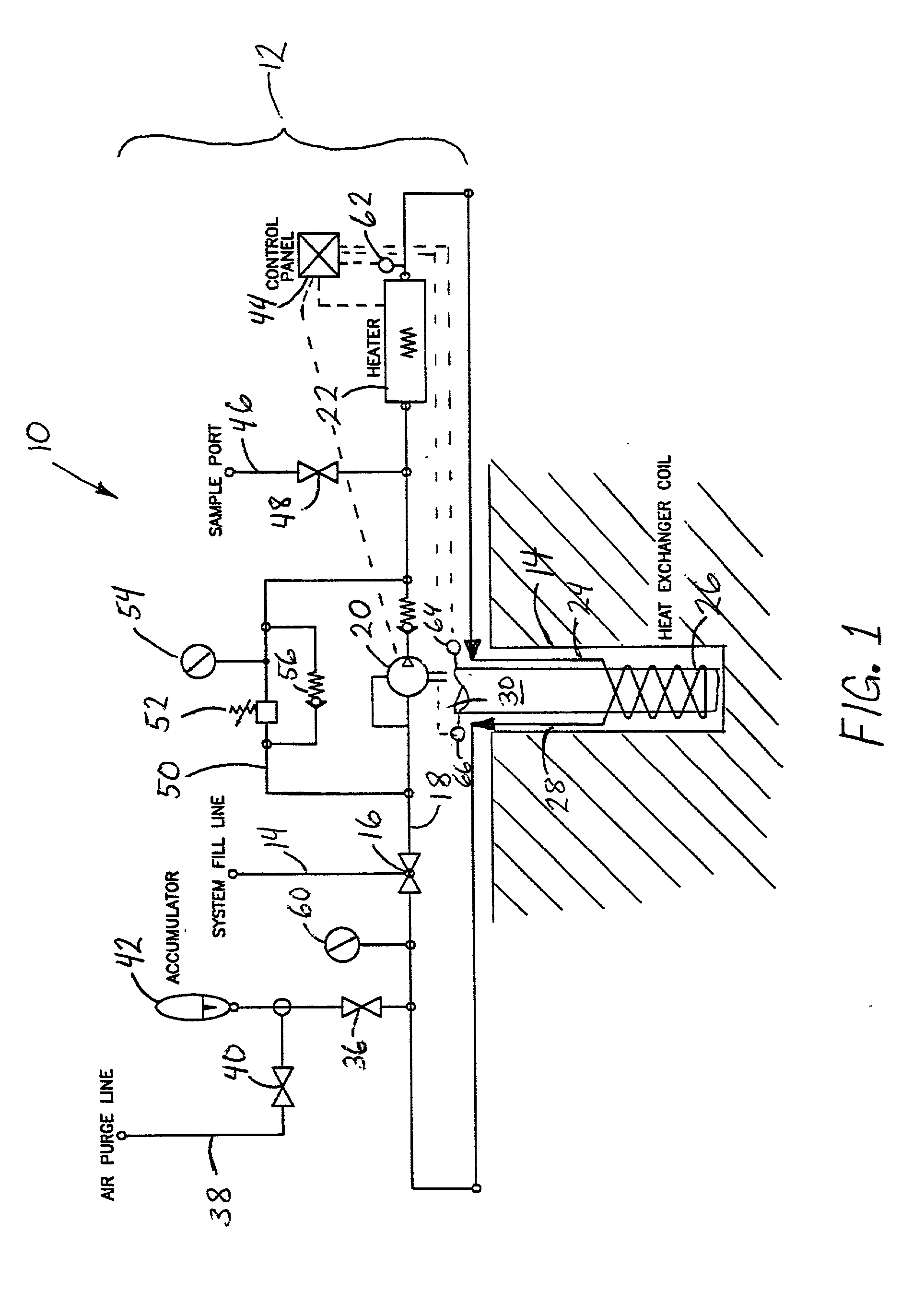

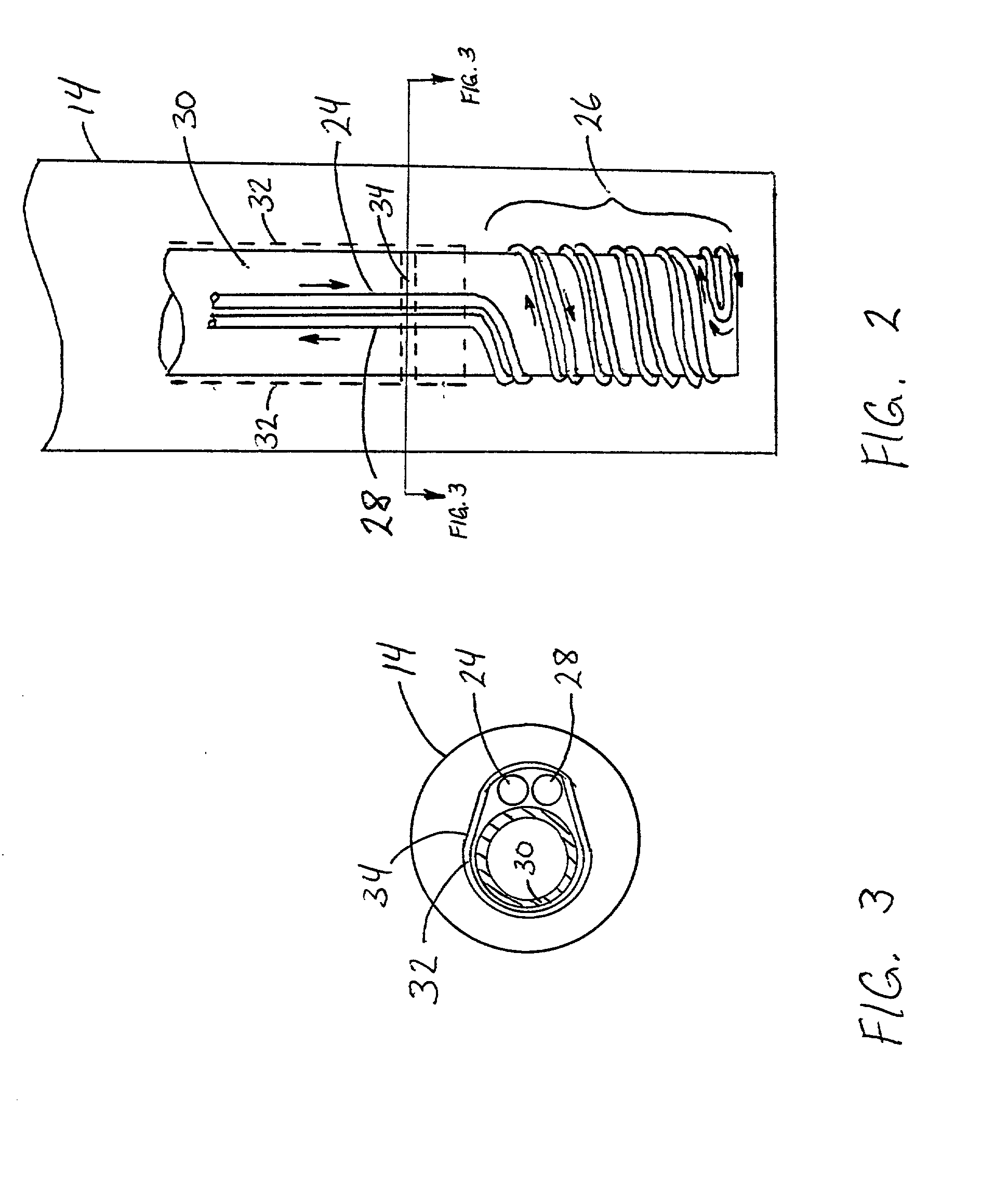

Enhanced oil well production system

InactiveUS20020100587A1Increase oil productionIncrease ratingsInsulationFluid removalParaffin waxOil viscosity

A closed loop heat transfer system located on the surface near the wellhead for transporting hot fluid through a tubing located in the annulus between the well casing and the outer surface of the production string. The tubing extends down along the production string to a coil submerged in the oil reservoir in the vicinity of the production pump and back to the surface for reheating and recirculation. The tubing provides heat transfer from the hot fluid to the production fluid, as well as the downhole pump and the region of the oil reservoir surrounding the pump. The system is preferably operated to transfer enough heat to the oil to prevent paraffins from coagulating and forming deposits on the production string or sucker rods, if used. The higher temperature lowers the viscosity of the oil and increases oil production.

Owner:HAWKEN GORDON GERALD MR

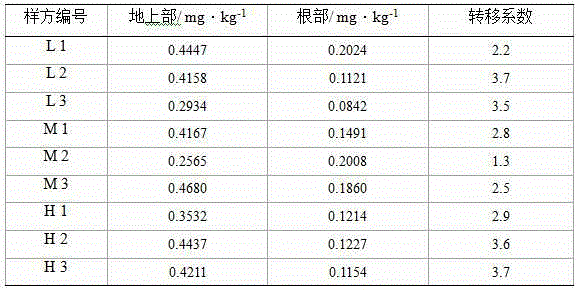

Method for restoring heavy metal polluted soil with energy crop castor

InactiveCN104785514AEfficient enrichmentDoes not destroy physical and chemical propertiesContaminated soil reclamationSoil scienceEnvironmental engineering

The invention relates to a method for restoring heavy metal polluted soil with an energy crop castor and belongs to the technical field of ecological restoring of a polluted environment. According to the method, the castor is planted in the heavy metal polluted soil, can grow normally and does not represent any toxicity phenomena; the heavy metal concentration of an above-ground part is higher than that of a root; and the castor represents extremely high transfer ability. According to the method, the plant is used for restoring the heavy metal polluted soil, heavy metal pollutants such as Cd, Ni, Cu, Mn, Zn and Pb in the soil can be removed via a plant extraction process, and the method has a certain economic value at the same time.

Owner:SHANGHAI UNIV

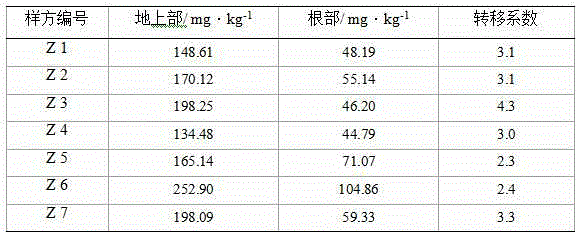

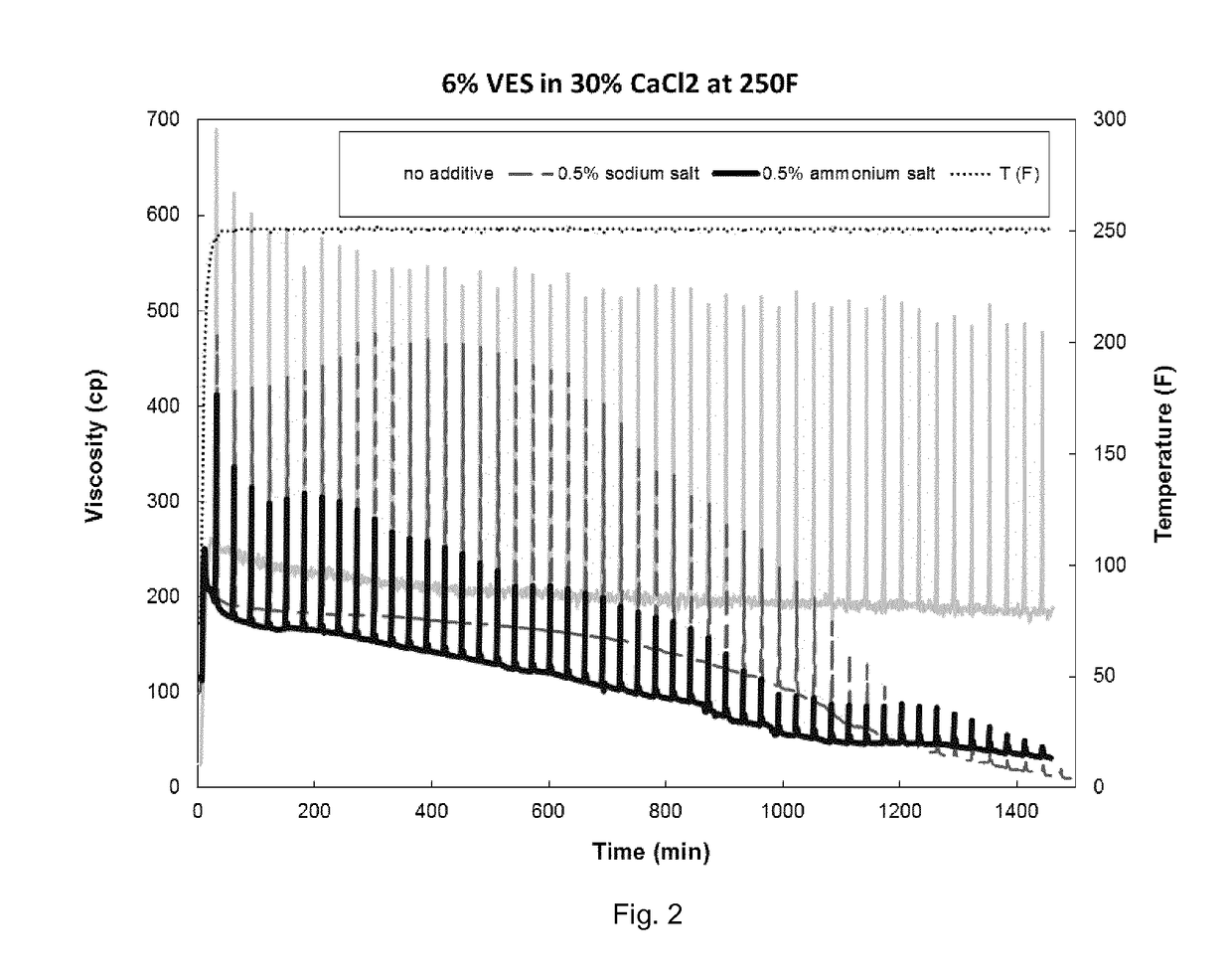

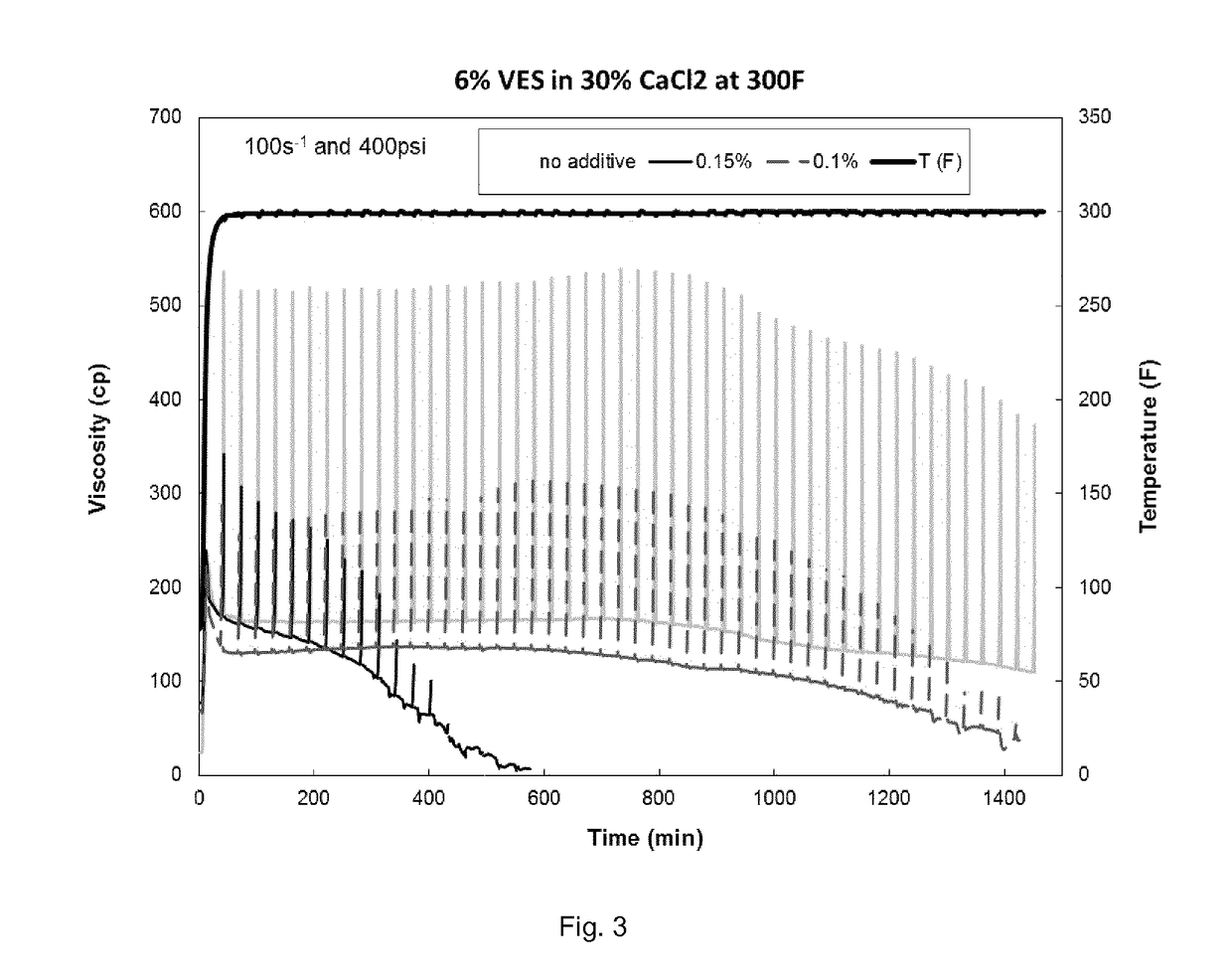

Delayed breaker for viscoelastic surfactant-based fluids

ActiveUS10066149B2Delayed breaking of VES-basedAvoid closingFluid removalDrilling compositionBetaineFluid composition

Compositions and methods are provided for delayed breaking of viscoelastic surfactant gels inside subterranean formations. Breaking is accomplished without mechanical intervention or use of a second fluid. The delayed breaking agent is selected from alkyl ether phosphates and salts thereof, alkylaryl ether phosphates and salts thereof, alkyl sulfates and salts thereof, alkylaryl sulfates and salts thereof, alkyl ether sulfates and salts thereof, alkylaryl ether sulfates and salts thereof, and mixtures of any of the foregoing. The viscoelastic surfactant can be a zwitterionic surfactant, and can be selected from the group consisting of sultaines, betaines, and amidoamine oxides.

Owner:AKZO NOBEL CHEM INT BV

Method and system for precise drilling guidance of twin wells

InactiveUS7475741B2Increase oil productionAccurate trackingSurveyConstructionsEngineeringElectromagnetic field

Owner:PRIME DOWNHOLE MANUFACTRUING LLC

Composition and method for stimulation of oil production in sandstone formations

ActiveUS20100288499A1Improve breathabilityIncrease ratingsFluid removalFlushingHydrofluoric acidGluconic acid

A method and a composition for stimulating oil production from wells which have ceased production by pumping in a mixture of gluconic, oxalic and citric acids, isopropanol, ethylene glycol and sodium citrate between pre-flush and over-flush intervals, which composition and method does not include the use of hydrochloric acid or hydrofluoric acid.

Owner:AL DHAFEERI ABDULLAH +1

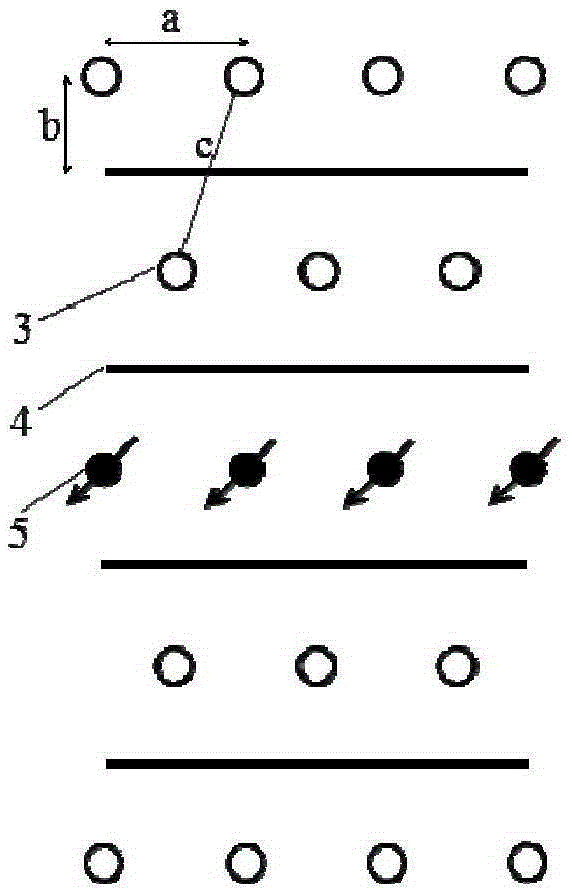

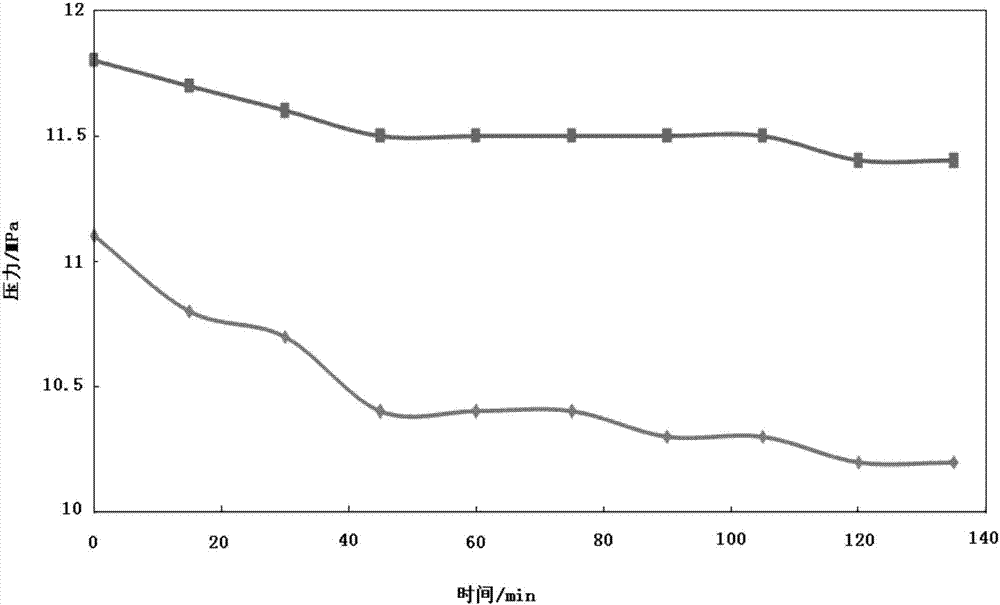

Method for controlling bottom water fingering by foam

The invention discloses a method for controlling oil well bottom water coning by foam. In the method, a mass of foam is injected at the oil-water boundary of an oil well so that a foam plugging area is formed. In the technical technology of controlling oil well bottom water coning by foam in the invention, a mass of foam is injected at the oil-water boundary of the oil well so that a stable foam plugging band is formed. The injected foam has the characteristic of selective water plugging that the foam is broken when meeting oil and is stable when meeting water, so that the foam is comparatively stable at the oil-water boundary and is not easy to be broken and raising of bottom water can be efficiently plugged; and at an oil reservoir, the foam stability becomes weakened due to damage of the oil to the foam, and the foam is easy to be broken, but the output of crude oil in the oil layer is not influenced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

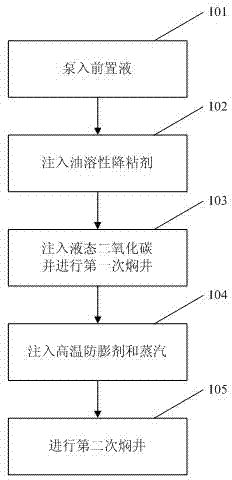

Method for raising recovery efficiency of super-deep low permeability heavy oil reservoir

The invention provides a method for raising the recovery efficiency of super-deep low permeability heavy oil reservoir. The method comprises steps of pumping a pad fluid, pumping pressure higher than stratum fracture pressure to extrude a sand carrying fluid and sand into the stratum, and stopping a pump and closing a well after a displacement fluid is injected; opening the well, and continuingly injecting an oil soluble viscosity reducer after the well is closed for one to two days; injecting liquid carbon dioxide after the oil soluble viscosity reducer is injected, and soaking the well for the first time; continuously injecting a high temperature anti-expansion agent and steam after the well is soaked; and soaking the well for the second time, staring to produce after the well is soaked. By adopting the method for raising the recovery efficiency of the super-deep low permeability heavy oil reservoir, the fluid injection pressure and the viscosity of crude oil of the super-deep low permeability heavy oil reservoir can be greatly reduced, and high flow transfusion channels are formed in the stratum through fracturing the stratum, the flow capability of the heavy oil in the stratum can be raised, and the steam injection efficiency and the effect of thermal recovery and exploitation can be greatly raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for increasing oil production

InactiveUS20120055685A1Enhance productionReduce solubilityOther gas emission reduction technologiesFluid removalOil productionChemistry

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells is disclosed. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir. Petroleum recovery can be further enhanced through the use of recycling.

Owner:JAMES K & MARY SANDERS FAMILY +1

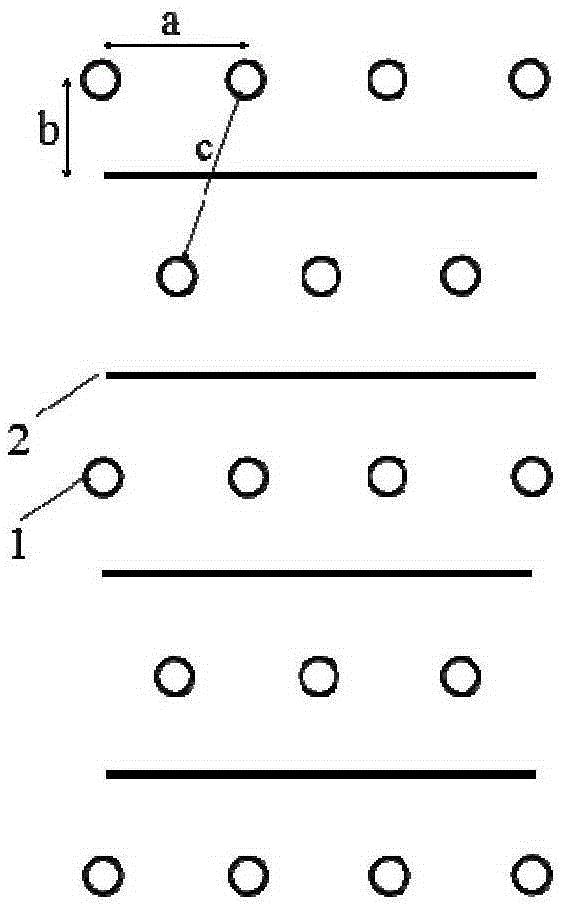

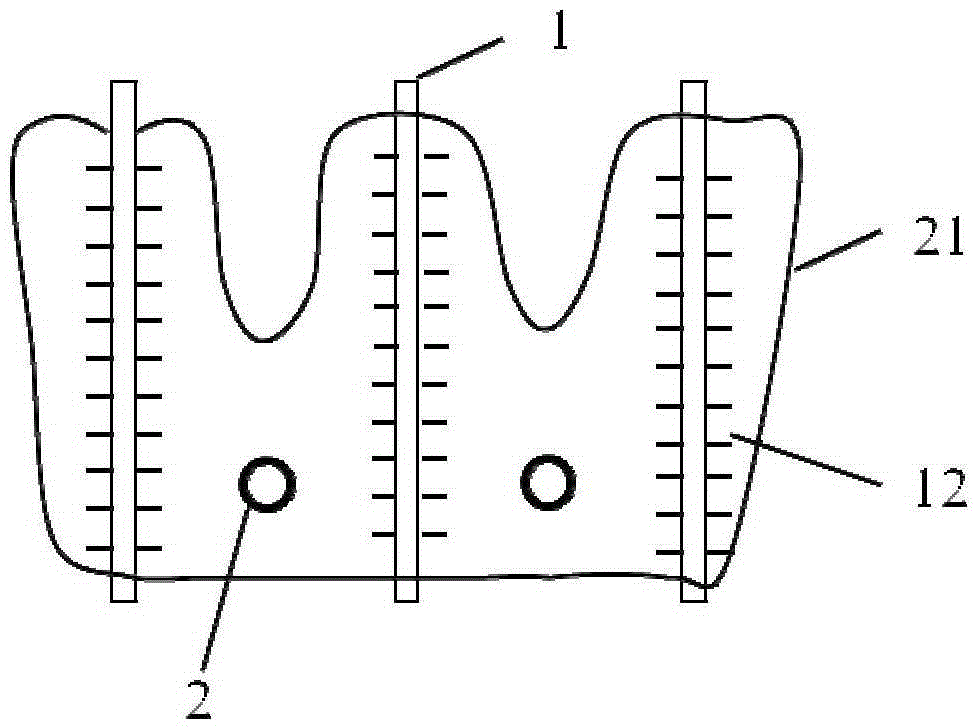

Heavy oil reservoir exploitation method

InactiveCN106593397ALow viscosityIncrease oil productionFluid removalHorizontal wellsTemperature curve

The invention provides a heavy oil reservoir exploitation method. The heavy oil reservoir exploitation method comprises that a vertical well-horizontal well row-column type well net is arranged in the mine section of a heavy oil reservoir the vertical well-horizontal well row-column type well net comprises vertical well rows and horizontal wells which are distributed alternatively, the well spacing a between adjacent vertical wells in each vertical well row is equal, the well spacing b between each vertical well and the adjacent horizontal well is equal, the well spacing c between adjacent vertical wells at two sides of one horizontal well and in adjacent vertical well rows satisfies the formula c= the square root of (a<2> / 4+4b<2>), steam is injected into all vertical wells and horizontal wells, steam huff and puff production is carried out until the stratum temperature reaches the temperature corresponding to the inflection point of a crude oil viscosity-temperature curve, the steam injection intensity of the vertical wells ranges from 100 t / m to 120 t / m, the steam injection intensity of the horizontal wells ranges from 15 t / m to 20t / m, after the steam huff and puff production, the vertical well arranged in the central position is selected as a steam injection well, after the oil layer is ignited, air is injected into the steam injection well, and linear fire flooding production is carried out. According to the invention, problems that in the heavy oil reservoir, the connectivity of injection and production wells is poor, and the recovery ratio is low are solved.

Owner:PETROCHINA CO LTD

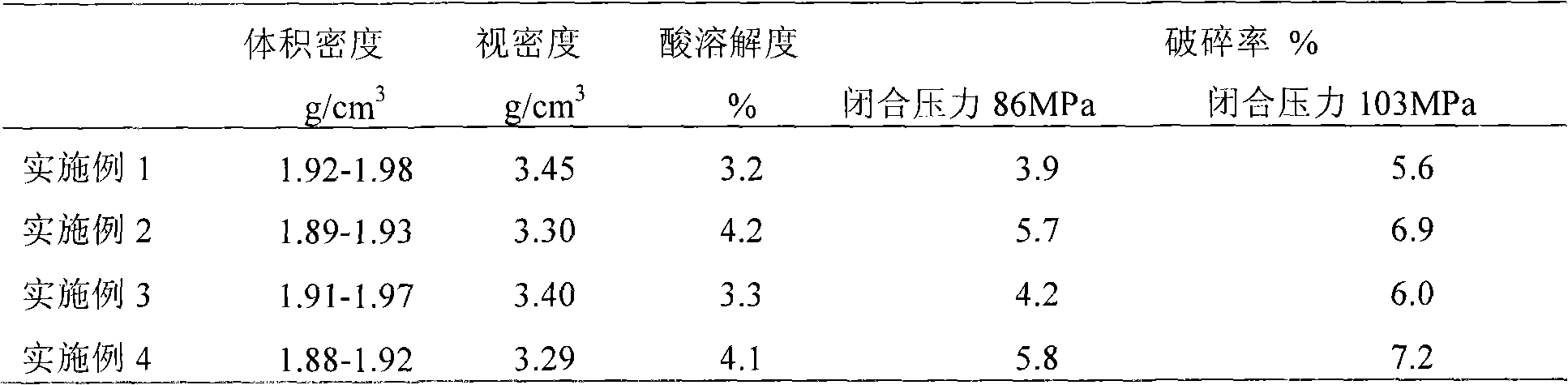

High-density ultra-strength petroleum compression fracture proppant and preparation method thereof

InactiveCN101580706AExcellent overall performanceIncrease oil productionFluid removalPetroleumOil well

The invention relates to a high-density ultra-strength petroleum compression fracture proppant and a preparation method thereof. The petroleum compression fracture proppant is prepared from waste alumina adsorbent taken as a main raw material and small amount of sintering aid and ceramic clay by milling, pelletizing and sintering. The petroleum compression fracture proppant prepared from the waste alumina adsorbent replacing industrial alumina has the characteristics of high density, ultra strength and acid resistance, has the volume concentration between 1.88 and 1.98, the apparent density between 3.20 and 3.50, the percentage of damage under 86MPa of closing pressure between 2.60 and 3.90 percent, the percentage of damage under 103MPa of closing pressure between 4.60 and 8.4 percent and the acid resistance between 3.40 and 5.20 percent, has excellent comprehensive performance, and can be used for petroleum compression fracture of deep oil wells.

Owner:JINGANG NEW MATERIALS

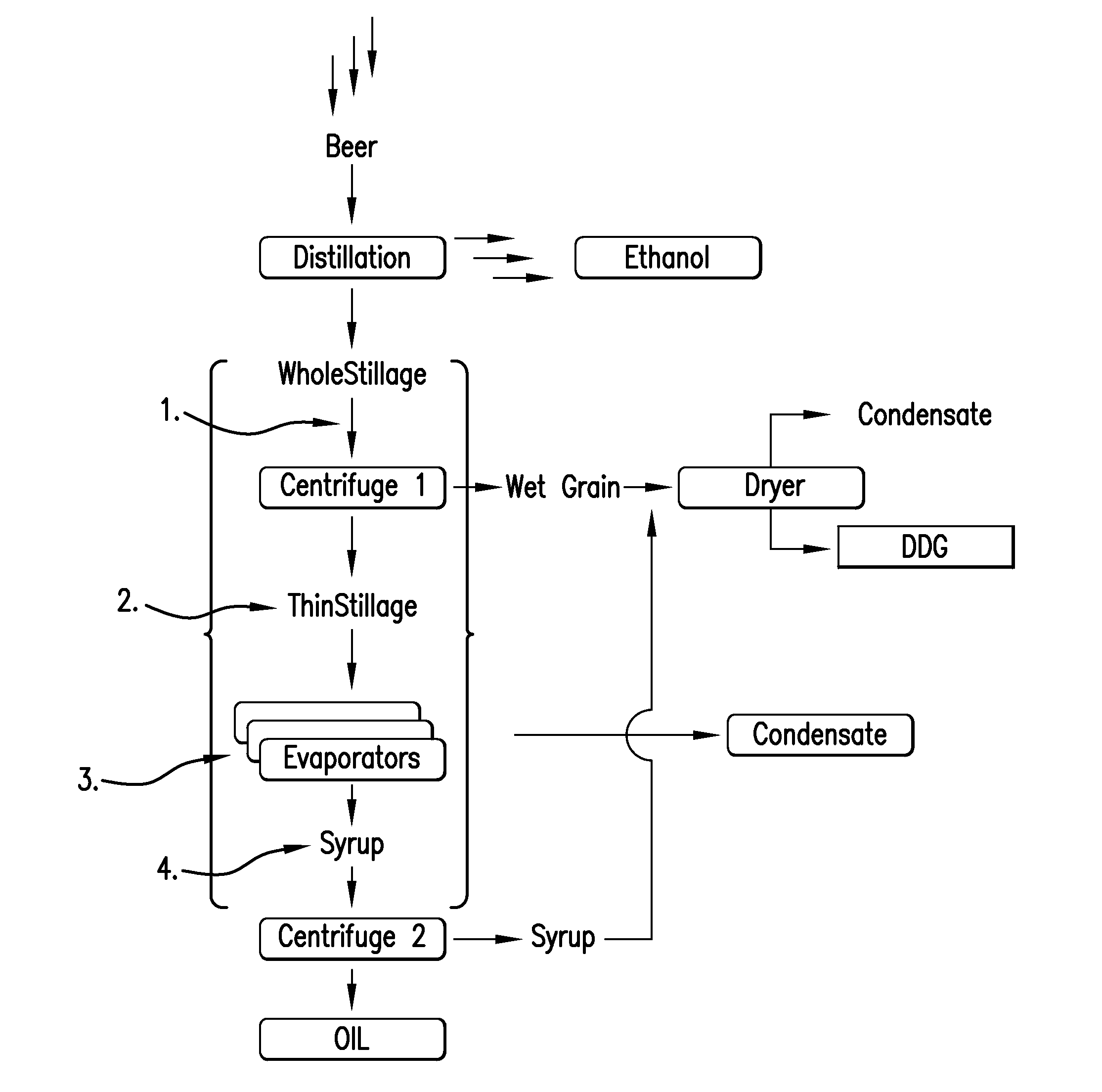

Oil extraction aids in grain processing

ActiveUS9353332B2Improve oil separationEasy to separateFatty oils/acids recovery from wasteBiofuelsShale oil extractionEthanol

Owner:SOLENIS TECH CAYMAN

Profile modification agent for amphion jelly

InactiveCN102153999AImprove gelation performanceHigh strengthDrilling compositionSodium acetateThiourea

The invention provides a profile modification agent for amphion jelly. The profile modification agent comprises the following components by weight percent: 0.1%-0.3% of amphion polymer, 0.1%-0.3% of compound cross-linking agent and the balance of water, wherein the molecule weight of the amphion polymer is above 1500 ten thousand. The compound cross-linking agent is prepared by a method comprising the following steps: firstly, adding phenol and formaldehyde in an enamel reaction kettle with a stirrer at a mass ratio of 1:1, heating and raising the temperature to 60 DEG C, then adding triethanolamine so that the phenol and formaldehyde are reacted to generate a mixture of monohydroxymethyl phenol, dihydroxymethyl phenol and trihydroxymethyl phenol for later use; next, adding sodium dichromate and thiourea in the reaction kettle with the stirrer at a weight ratio of 1:1, adding hydrochloric acid and a mixture of sodium acetate and sodium malonate which are at a weight ratio of 1:1 to react for 12 hours for later use; and mixing the products obtained from the former two steps at an isovolumetric ratio, and adding absolute ethyl alcohol for evenly stirring so as to obtain the compound cross-linking agent. According to the invention, the glue-forming property and glue-forming strength of the jelly profile modification agent in high-hypersalinity oil field water are improved, and the validity of the profile modification of the oil field is prolonged.

Owner:XI'AN PETROLEUM UNIVERSITY

Water injection well multi-slug profile control method

InactiveCN106988715AIncrease profitEffective blockingFluid removalDrilling compositionSludgeEngineering

The invention provides a water injection well multi-slug profile control method. A multi-slug injection method is adopted, wherein a first slug adopts an organic jelly glue aqueous solution system including volume expansion grains; and a last slug comprises two stages, the first stage adopts an organic jelly glue aqueous solution system including volume expansion grains, and a profile control agent adopted by the second stage is a microsphere deep profile control modifying and flooding agent. In the water injection well multi-slug profile control method, a jelly glue type profile control agent selected and used by the first slug can form a powerful 'baffle' at the well bottom water injection front end, and the phenomena that a medicament is subsequently injected, and oily sludge directly dashes into an extraction oil well are avoided. In the last slug, the sizes of micro hole passageways are reduced through expansion performance of polymeric microspheres, depressurization and augmented injection are conducted through adsorbability of the polymeric microspheres, and well group oil production is increased through displacement performance of the polymeric microspheres. In the injection method adopting the three slugs, while consuming the oily sludge in a massive dose mode, the second slug enters large hole passageways and cracks to block a high-permeability layer band.

Owner:SHAANXI HEZHUN ENERGY SCI & TECH CO LTD

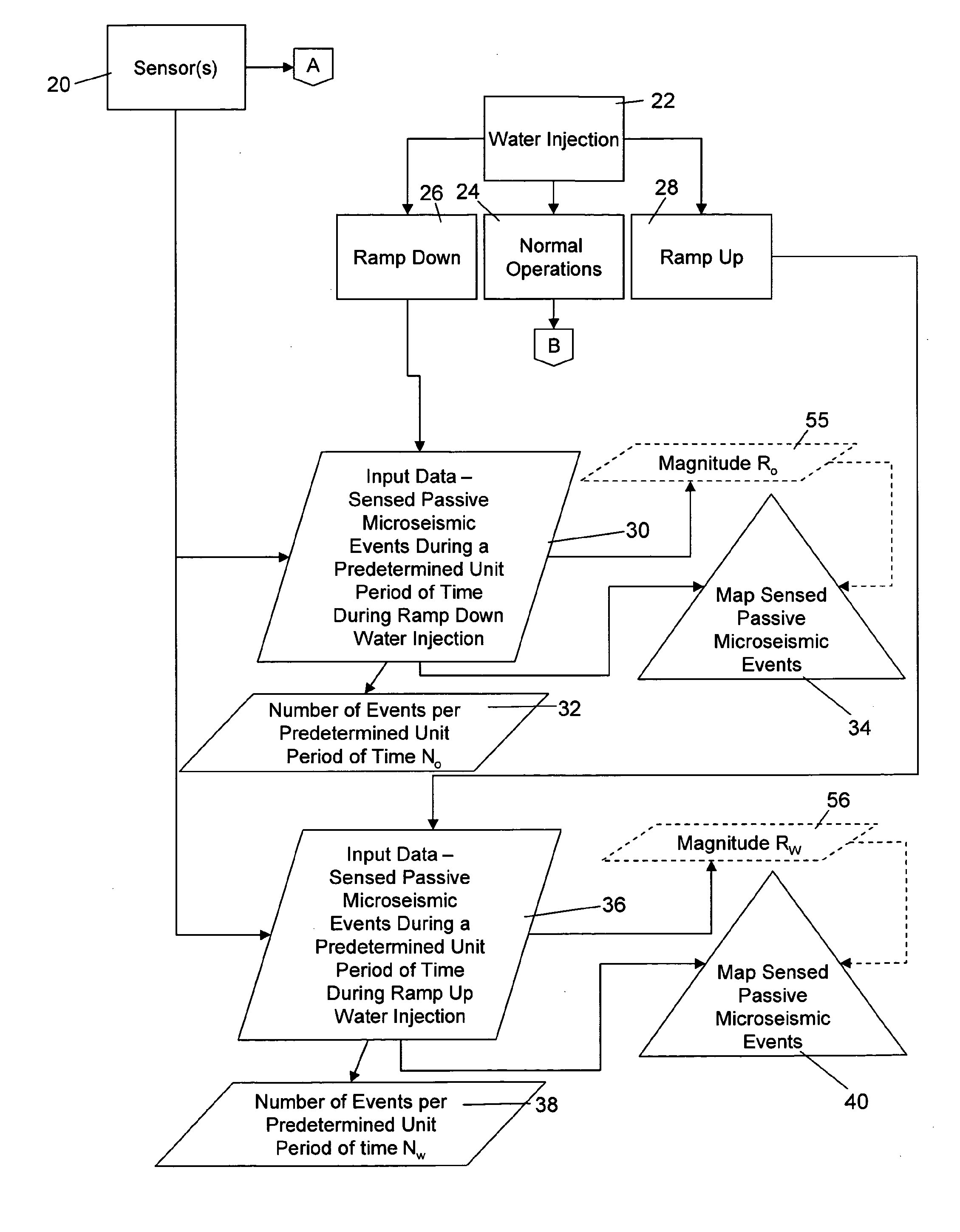

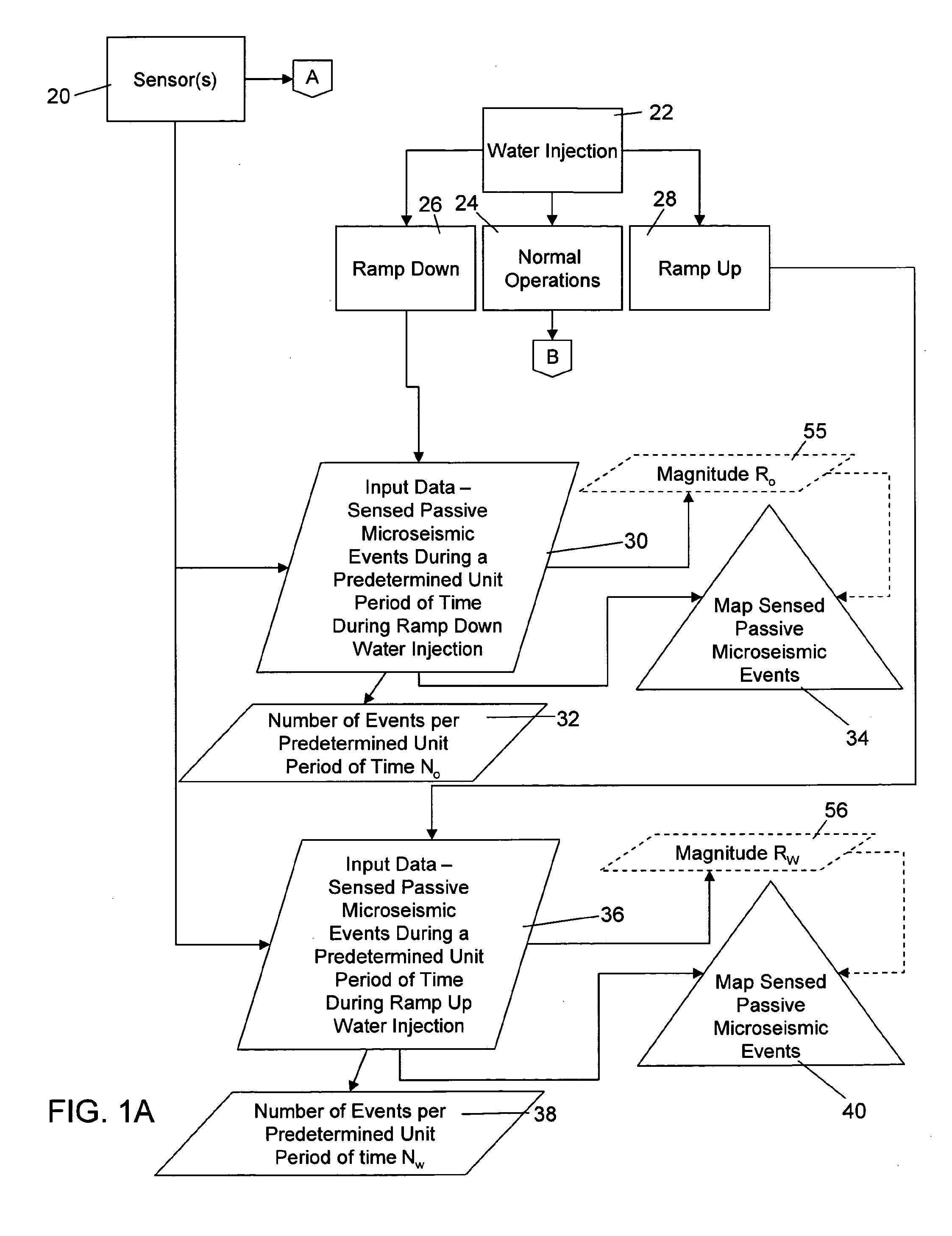

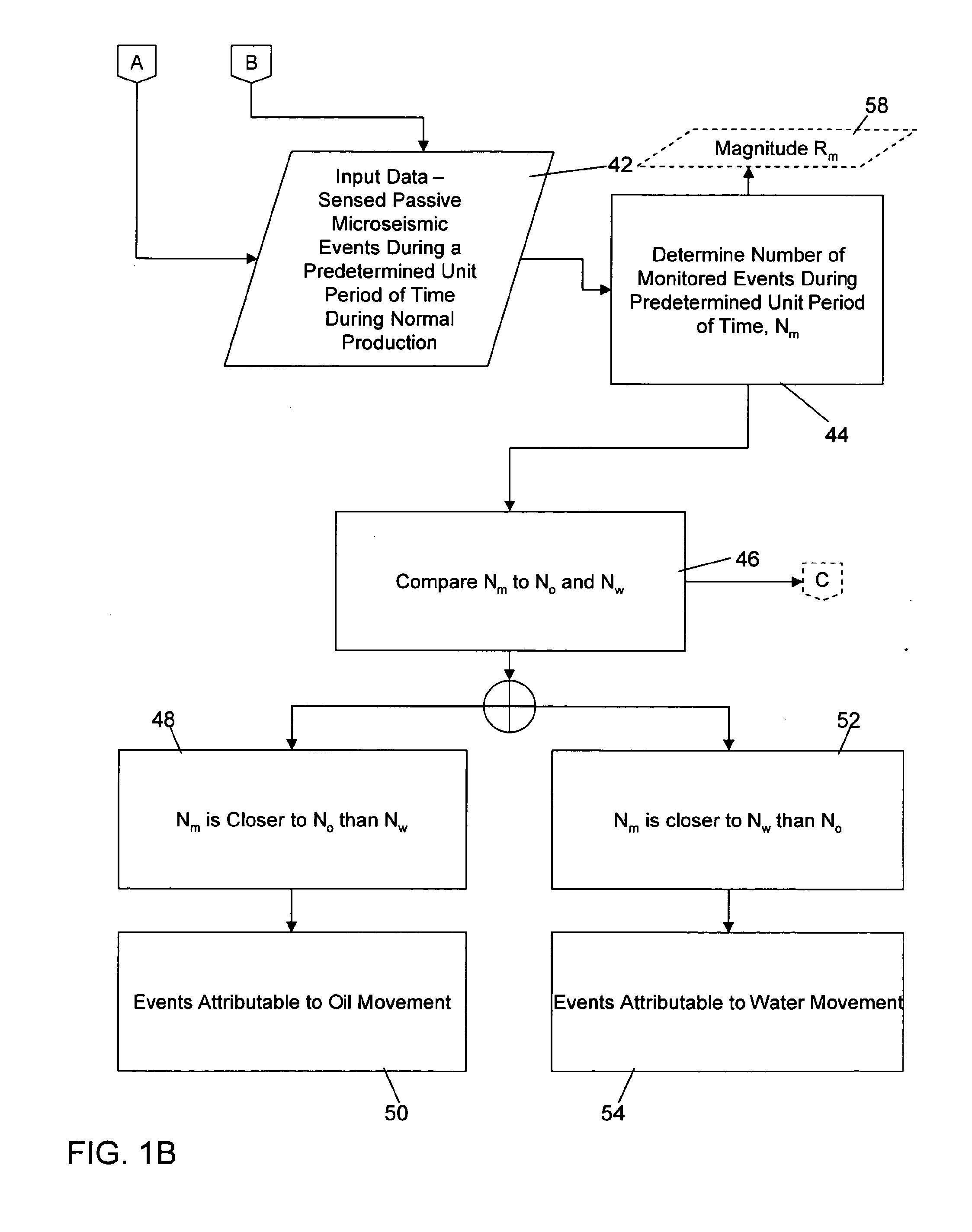

Monitoring of reservoir fluid moving along flow pathways in a producing oil field using passive seismic emissions

ActiveUS20130282291A1Increase oil productionSimple methodElectric/magnetic detection for well-loggingSeismic signal processingReservoir fluidOil production

A system of and method for determining whether a liquid moving in an oil-bearing reservoir rock formation is water or oil is provided. The oil-bearing rock formation includes at production well(s) and source(s) of injected water during normal oil production. A fluid pathway is identified, baseline number of passive microseismic events is established, passive microseismic events in the fluid pathway are monitored during oil production to sense microseismic events, the sensed microseismic events are compared to a baseline number of passive microseismic events. The fluid causing the microseismic events is determined to be water if the sensed number of microseismic events approaches the baseline number of passive microseismic events per the predetermined unit, and if the baseline number of passive microseismic is measured during a time period when the water injection is greater than the rate of water injection during normal oil production.

Owner:SAUDI ARABIAN OIL CO

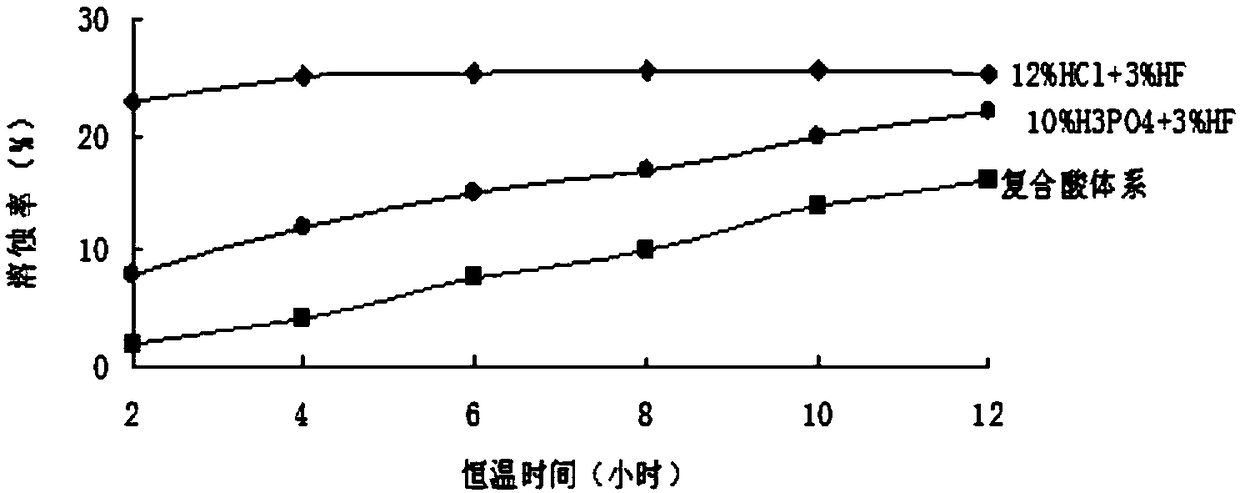

Compound acid blockage removing fluid for oil-water wells of ultralow-permeability oil fields

InactiveCN108822819ASlow reaction speedStrong penetrating abilityDrilling compositionEnvironmental chemistryCorrosion

The invention discloses a compound acid blockage removing fluid. The blockage removing fluid is prepared from raw materials in parts by weight as follows: 4-6 parts of a foam flushing fluid, 20-30 parts of a prepad fluid, 70-100 parts of main acid and 10-20 parts of postpad fluid. The acid fluid has higher capacity of removing organic sediment pollution and high acid residue and emulsifying resistance. The acid fluid has low corrosion speed and good swelling inhibition and does not change the original water wetting characteristic of the stratum.

Owner:兰州凯宏中原石油科技有限公司

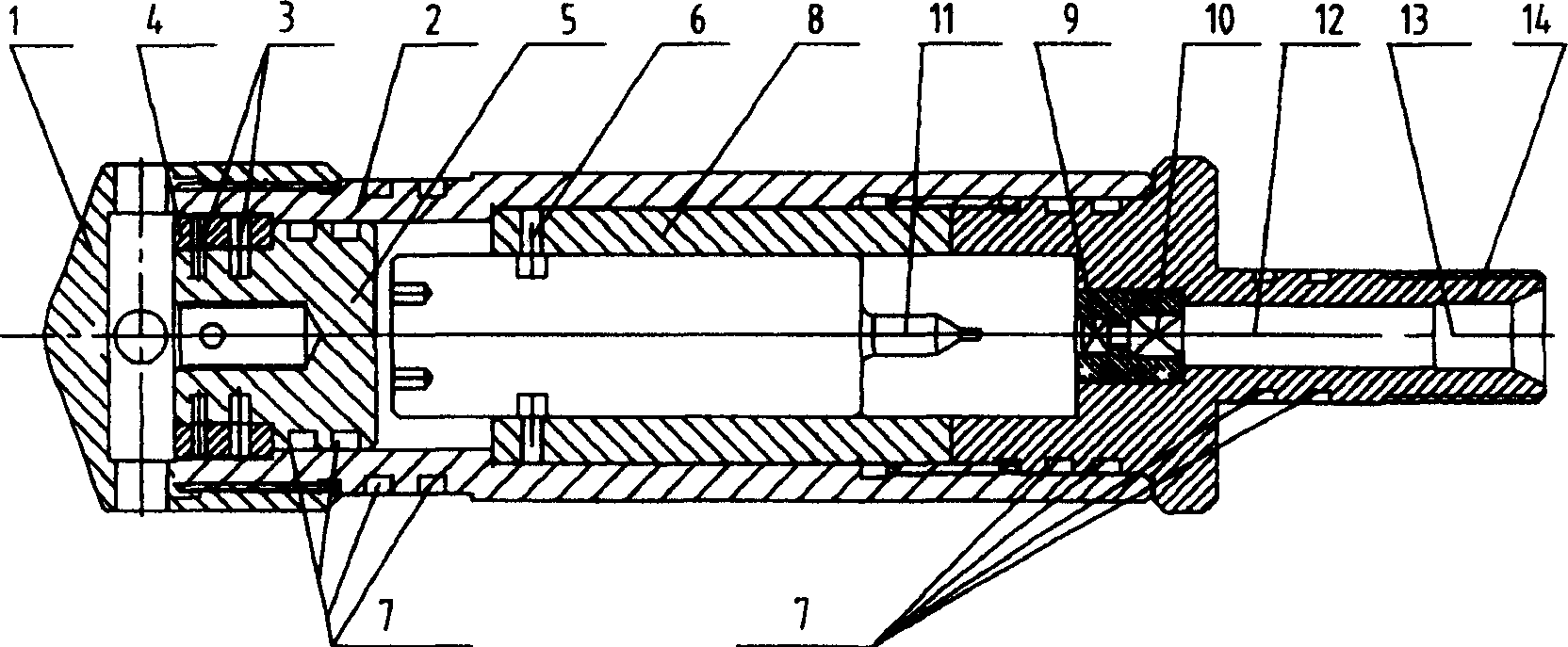

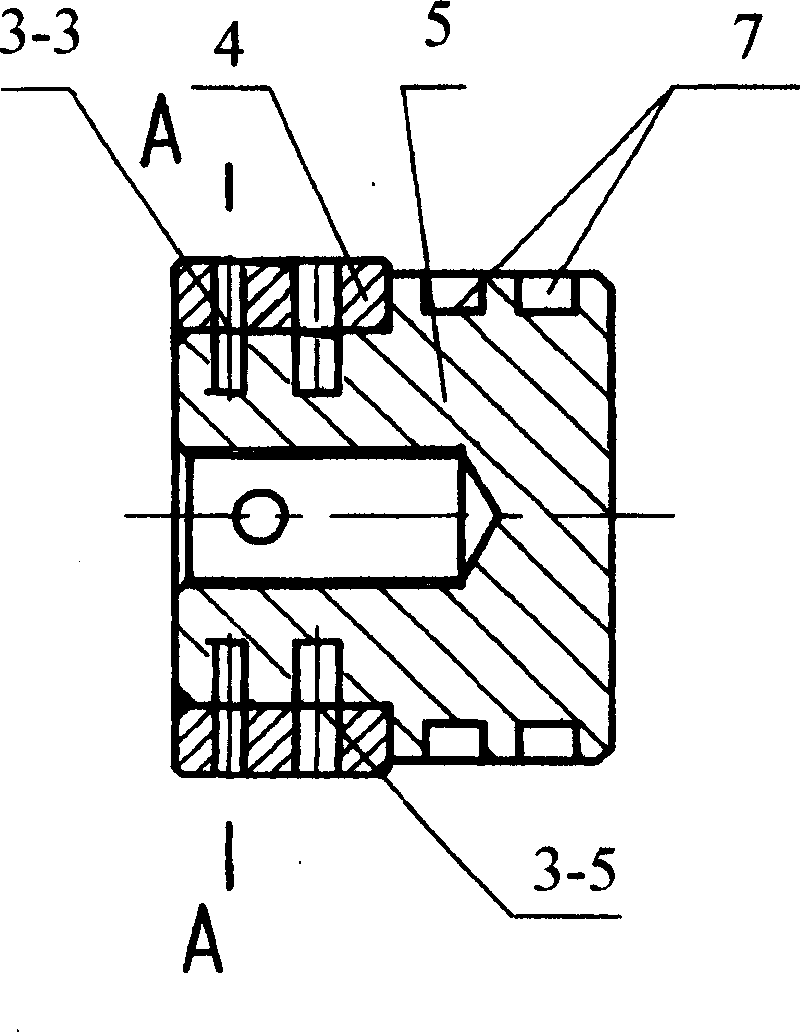

Throwing type fracturing equipment

InactiveCN1664307ARealize the ignition functionPrecise and reliable ignitionFluid removalHigh energyObject store

The invention discloses a throwing compression fracture machine that is suited to oil or gas throwing compression fracture effect increasing technology. It is made up of piezo ignition machine and high energy gas generator. The feature is that the piezo ignition machine could cut off the pressure bearing bolt by function of the liquid column, and make the plunger move to drive the firing pin to knock percussion cap. The percussion cap would fire the starting cartridge, powder and powder column. The fire output by the piezo ignition machine would fire the plural powder columns in high energy gas generator and compressing the object storing layers to fracture. The invention is easy to operate and sharply decreases the consumption of manpower and material.

Owner:中国兵器工业第二一三研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com