Patents

Literature

103 results about "Shale oil extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

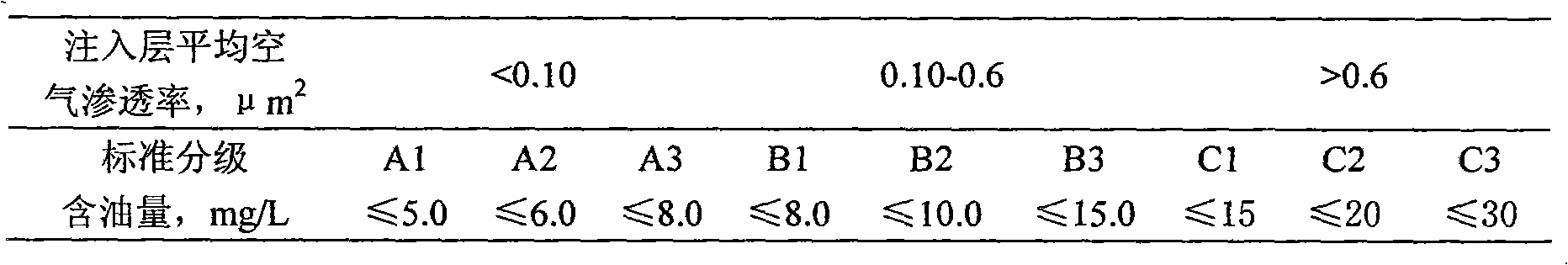

Shale oil extraction is an industrial process for unconventional oil production. This process converts kerogen in oil shale into shale oil by pyrolysis, hydrogenation, or thermal dissolution. The resultant shale oil is used as fuel oil or upgraded to meet refinery feedstock specifications by adding hydrogen and removing sulfur and nitrogen impurities.

Kind of laminated granule for oil extraction, proppant and oil extraction method using the proppant

InactiveCN101586024AIncrease surface tensionIncrease productionFluid removalDrilling compositionEpoxyShale oil extraction

The invention discloses a kind of laminated granule for oil extraction, proppant having the laminated granule and oil extraction method using the proppant. The laminated granule comprises aggregate granules and oil permeating waterproof thin film coated on surface of the aggregate granules. The oil permeating waterproof thin film comprises resin. Weight ratio of the resin to quartz sand is 0.2-15:100. The laminated granule is oil permeating waterproof granule. The oil permeating waterproof thin film is one formed by one or more of oleophylic hydrophobic ethoxyline resin, phenolic resin, polyurethane resin and silicon resin. The laminated quartz sand and proppant thereof are oil permeating and water proof at regular atmospheric pressure. Oil permeation resistance in pressurized condition is less than water permeation resistance. Therefore, in oil extraction industry, water yield is reduced effectively and oil yield is improved.

Owner:BEIJING RECHSAND SCI & TECH GRP

Foaming agent composition used for high temperature and high salt oil reservoir

Owner:CHINA PETROLEUM & CHEM CORP +1

Kerosene shale comprehensive utilization process

InactiveCN101113344ALarge amount of processingHigh utilization rate of dry distillationInternal combustion piston enginesGaseous engine fuelsWorking fluidSlag

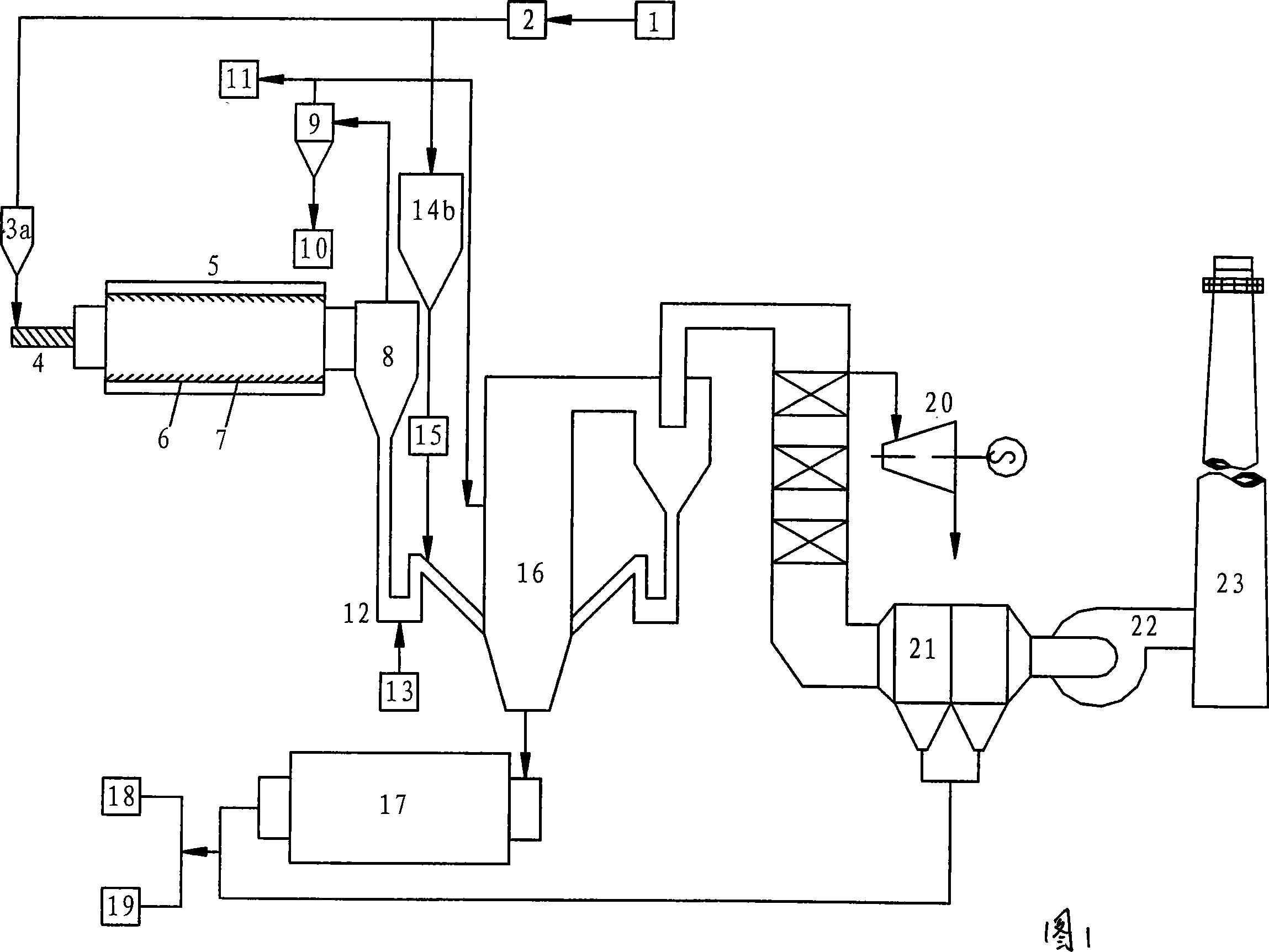

The invention relates to a comprehensive utilization process of oil shale. Oil shale raw ore is crushed by a crushing and screening device until the particle size is less than 15mm; one part of crushed oil shale particles are transported to a screw feeder and then to a microwave drum dry distillation device, the oil shale particles absorb microwave and generate high temperature methane gas, distilled char and methane gas are entered into a closed solid and gas separating device, separated high temperature methane gas is entered into a condensing and recycling device and cooled to separate the oil shale; low temperature methane gas after oil extraction is entered into an internal combustion engine to be combusted for power generation and / or entered into a circulating fluidized bed boiler to be combusted, heat quantity released from the combustion is transmitted to water by the heating surface of a boiler, the superheated steam is supplied as working fluid or sent into a steam turbine to generate electricity; carbon-content of the slag and ashes is less than 2 percent and the finished product can be directly as building raw materials without roasting. The invention has the advantages of short process, comparatively small occupying space, high comprehensive utilization, low cost, being scientific and rational, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

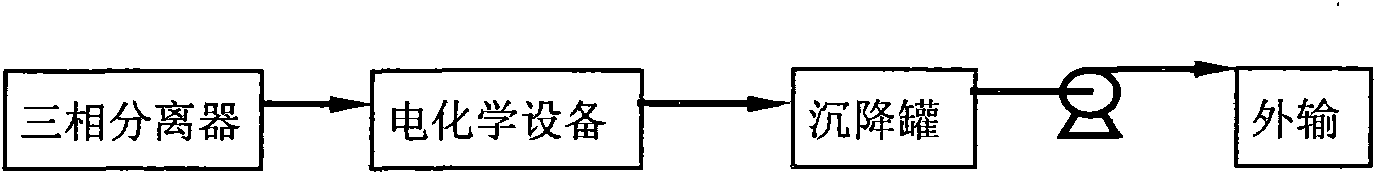

Electrochemical method of oil removal of wastewater produced in oil extraction by polymer flooding displacement

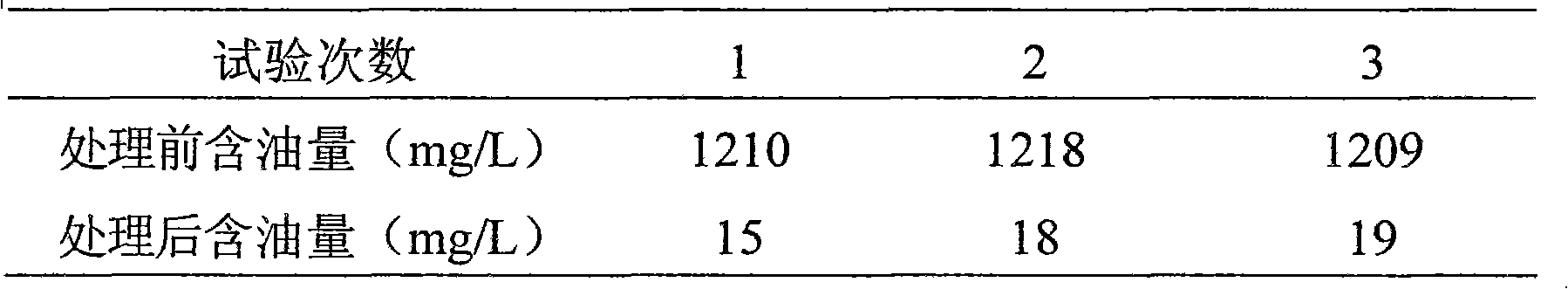

InactiveCN101602531AEasy to separateSave construction investmentWater/sewage treatment by flotationElectrolysisWater quality

The invention discloses an electrochemical method of oil removal by polymer flooding oil recovery wastewater, which comprises the following steps of: 1, electrolysis; 2, sedimentation. In the process of the electrolysis, tiny oil droplets in the wastewater lose electrons due to discharge on the surface of an anode, charges on the surface of the oil droplets are reduced, and electric potential of interface xi is decreased; and residual polymer pieces in the wastewater after the electrolysis are oxidized and degraded, viscosity of the wastewater is decreased, and water film intensity on the interface of oil / water is reduced. Therefore, the tiny oil droplets after the electrolysis are liable to be converged into large oil droplets and are rapidly separated from the wastewater under the action of cathode hydrogen. As treated by the method, crude oil in wastewater produced in oil extraction by polymer flooding displacement is quite easy for removal with no need for large use of sedimentation tanks, thus saving construction fund for oilfield; the invention has simple process, requires no drug, saves resource and cost and conforms to green chemistry process, quality of the wastewater after the oil removal is obviously crystal-clear; in addition, the device is convenient and safe in operation, easy to control and realize automation, extensively adapted to the amount of water, and convenient for popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

Pretreatment method for catalytic oil slurry for needle coke production

InactiveCN103497779ASuitable for useShort processTreatment with plural serial refining stagesPretreatment methodDistillation

The invention provides a pretreatment method for producing catalytic oil slurry for the needle coke production. The pretreatment method takes catalytic oil slurry as the raw material, and then carries out a pretreatment for the catalytic oil slurry through the following steps: extracting solvent, recycling and processing solvent from the raffinate, recycling solvent from the extracted liquid, and evaporating the target product. The pretreatment method can carry out oil extraction and reduced pressure distillation for the catalytic oil slurry to purify the oil slurry, which is suitable for being used as a raw material for the needle coke production, has the advantages of short process, energy saving, reduction on equipment usage, and increasing on yield, and can be used as a method for catalytic oil slurry pretreatment for needle coke production.

Owner:HULUDAO DESIGN INST PETROCHINA NORTHEAST REFINING & CHEM ENG

Novel process for preparing vegetable oil with steam explosion-aqueous solvent method

InactiveCN102154054AOvercoming crushed billetsOvercoming complexityFatty-oils/fats productionEdible oils/fatsFlavorCellulose

The invention provides a novel process for preparing vegetable oil from oil crops with a steam explosion-aqueous solvent method. The novel process comprises the steps of: firstly, feeding preimpregnated raw materials into a steam explosion tank, introducing saturated steam (with the pressure reaching 5-15Kg / cm<2>), preserving the pressure for a period of time (1-10min), and then quickly exploding to obtain steam explosion slurry; and then, freezing the steam explosion slurry, standing overnight, defreezing, and adding a certain amount of hot water or / and composite cellulose for oil extraction with an aqueous solvent method, wherein the oil extraction rate reaches 62.26-81.18%. The vegetable oil extracted with the steam explosion-aqueous solvent method has the characteristics of pure color, limpidity, transparency, natural and pleasing flavor and good quality. The novel process provided by the invention for preparing the vegetable oil is suitable to various plant oil raw materials, is beneficial to simplification of an oil seed treating process and solution to the problems of high energy consumption for mechanical pulverization, high treating cost and difficulty in propagation in the traditional process for preparing the vegetable oil with the aqueous solvent method, and has great importance for industrial production of preparing the vegetable oil with the aqueous solvent method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

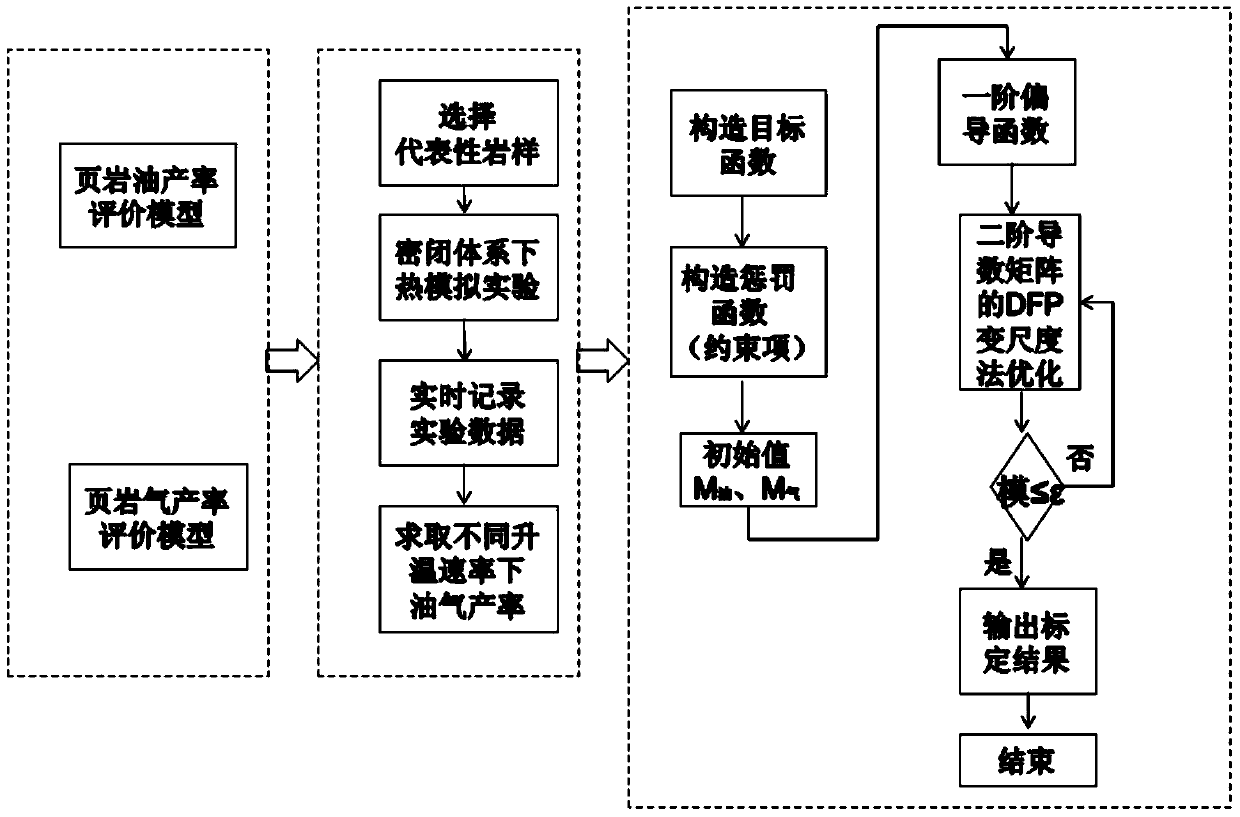

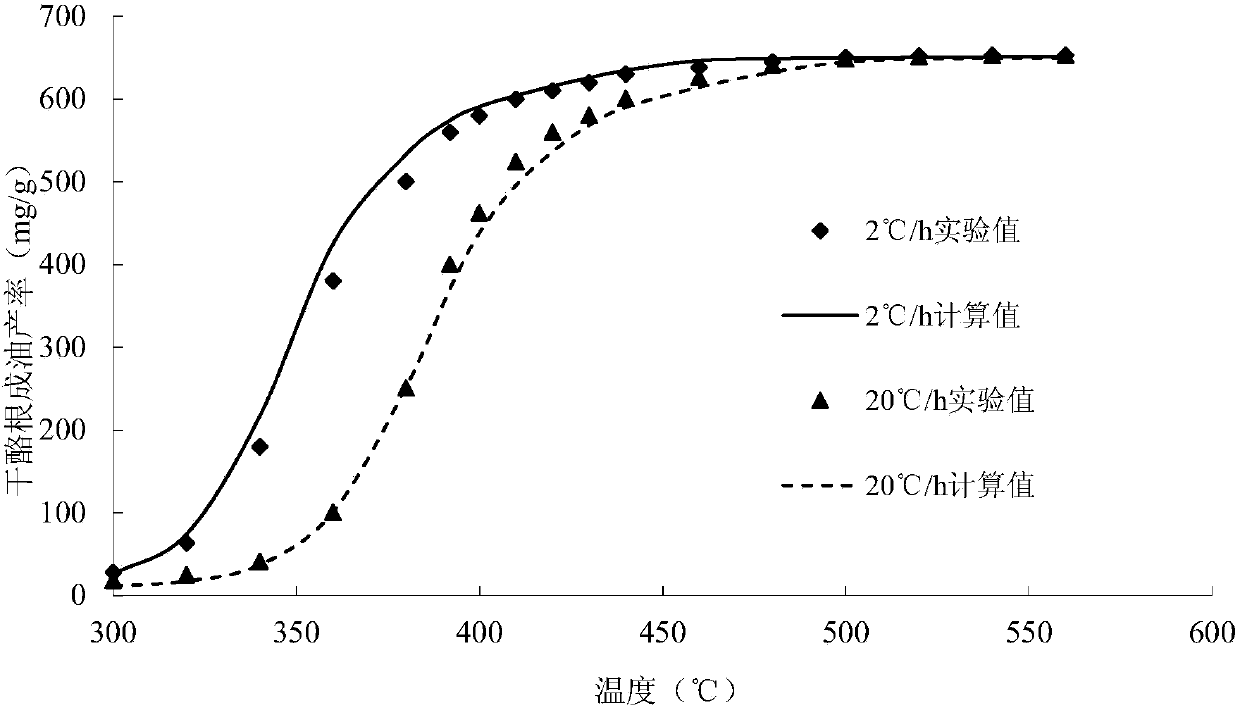

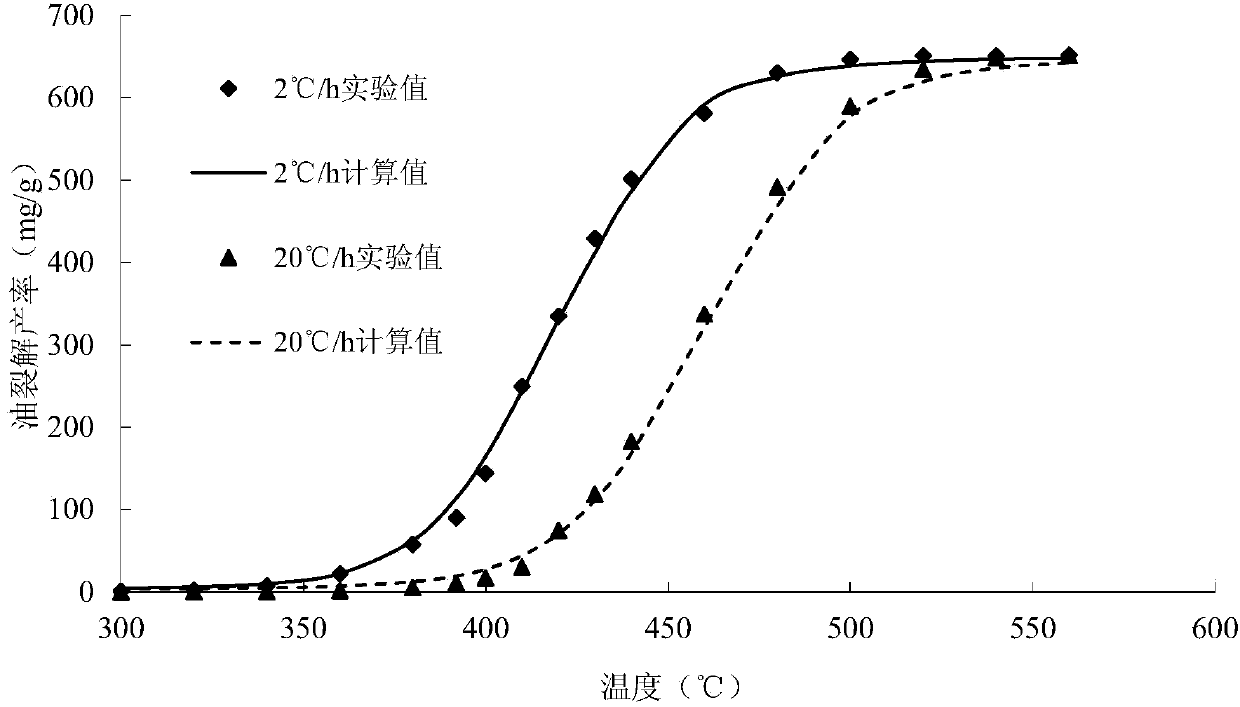

Shale oil and gas yield evaluation model building and parameter calibrating method applied under closed system

InactiveCN104156593ASolving descriptions of complex processesFlexible settingsSpecial data processing applicationsShale oil extractionShale oil and gas

The invention relates to a shale oil and gas yield evaluation model building and parameter calibrating method applied under a closed system. The method includes the following steps of (1) building a shale oil yield evaluation model, (2) building a shale gas yield evaluation model, (3) measuring the shale oil yield and the shale gas yield through experiments, and (4) calibrating dynamic parameters in the shale oil yield evaluation model and the shale gas yield evaluation model. Due to the facts that shale oil generation and secondary cracking are considered at the same time and the shale oil yield evaluation model and the shale gas yield evaluation model are built in the closed system, considering from the degree of approximation between an experiment condition and a geological condition, the method effectively achieves description of the complex process that shale oil generation and secondary cracking exist at the same time under the closed system, and can describe shale oil and gas characteristics quantificationally and dynamically. The shale oil and gas dynamic parameters calibrated according to the method are combined with the thermal history of the burial history of an actual basin for geological extrapolation, and obtained shale oil and gas hydrocarbon generation history information is more accurate and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fleeing sealing sand-prevention ignition method of fireflooding oil extraction

ActiveCN103161437AShorten ignition timeHigh porosityFluid removalEconomic benefitsShale oil extraction

The invention provides a fleeing sealing sand-prevention ignition method of fireflooding oil extraction which comprises preheating an oil layer, coking the oil layer, adjusting coking zone hole permeability degrees, oxygen-enriched ignition and the other steps. The fleeing sealing sand-prevention ignition method of the fireflooding oil extraction is suitable for ignition of heavy oil reservoir fireflooding oil extraction. Due to the steam preheating oil layer, ignition time of an oil layer is reduced; due to gas injection well (ignition well) immediate vicinity of wellbore coking, a role of fleeing sealing sand-prevention function can be played, and coking products (petroleum coke) is used as fuel; due to oxygen-enriched combustion, rapid ignition can be achieved; due to adjusting coking zone hole permeability degrees, hole permeability degrees and permeability of a coking zone of a gas injection well are increased; success rate of ignition is improved, and fleeing sealing sand-prevention ignition method of the fireflooding oil extraction is of great significance of improving economic benefits of the fireflooding oil extraction.

Owner:PETROCHINA CO LTD

Preparation method of pharmaceutical composition preparation treating apoplexy sequelae

ActiveCN103182049AGood curative effectImprove medication complianceHeavy metal active ingredientsMammal material medical ingredientsBioavailabilityShale oil extraction

The invention relates to a preparation method of a pharmaceutical composition preparation treating apoplexy sequelae. The method includes volatile oil extraction and inclusion, ethanol extraction, water extraction, medicinal fine powder crushing, preparation molding and other steps. Compared with traditional preparations, the medication compliance of patients can be improved obviously. Under the premise of retaining original preparation efficacy, the pharmaceutical preparation prepared by the method provided in the invention can realize rapid absorption, effective components can intensively reach nidi to take fast effect, and the bioavailability is high. The pharmaceutical preparation prepared by the method disclosed in the invention has improved efficacy.

Owner:JINHE TIBETAN MEDICINE

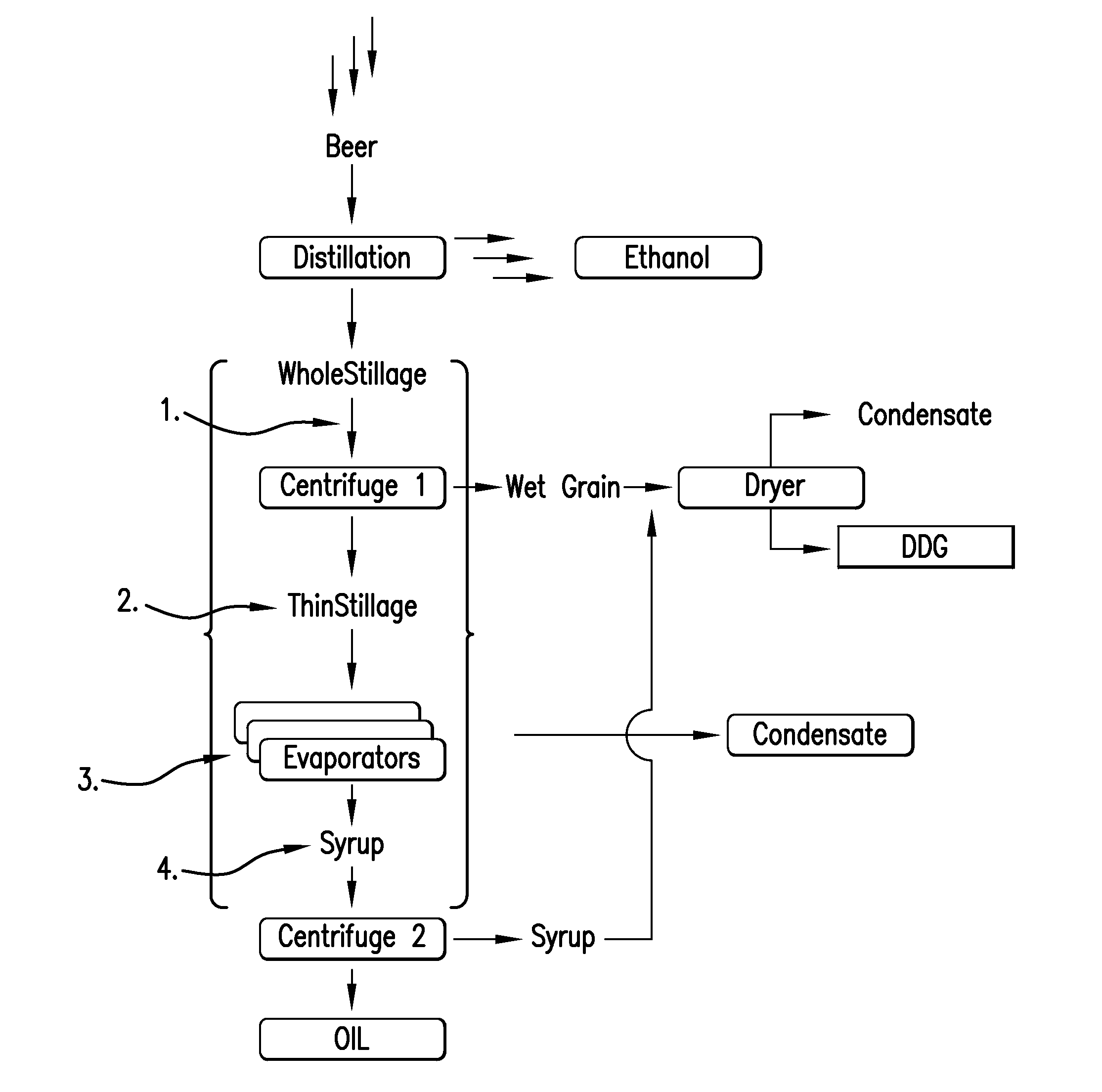

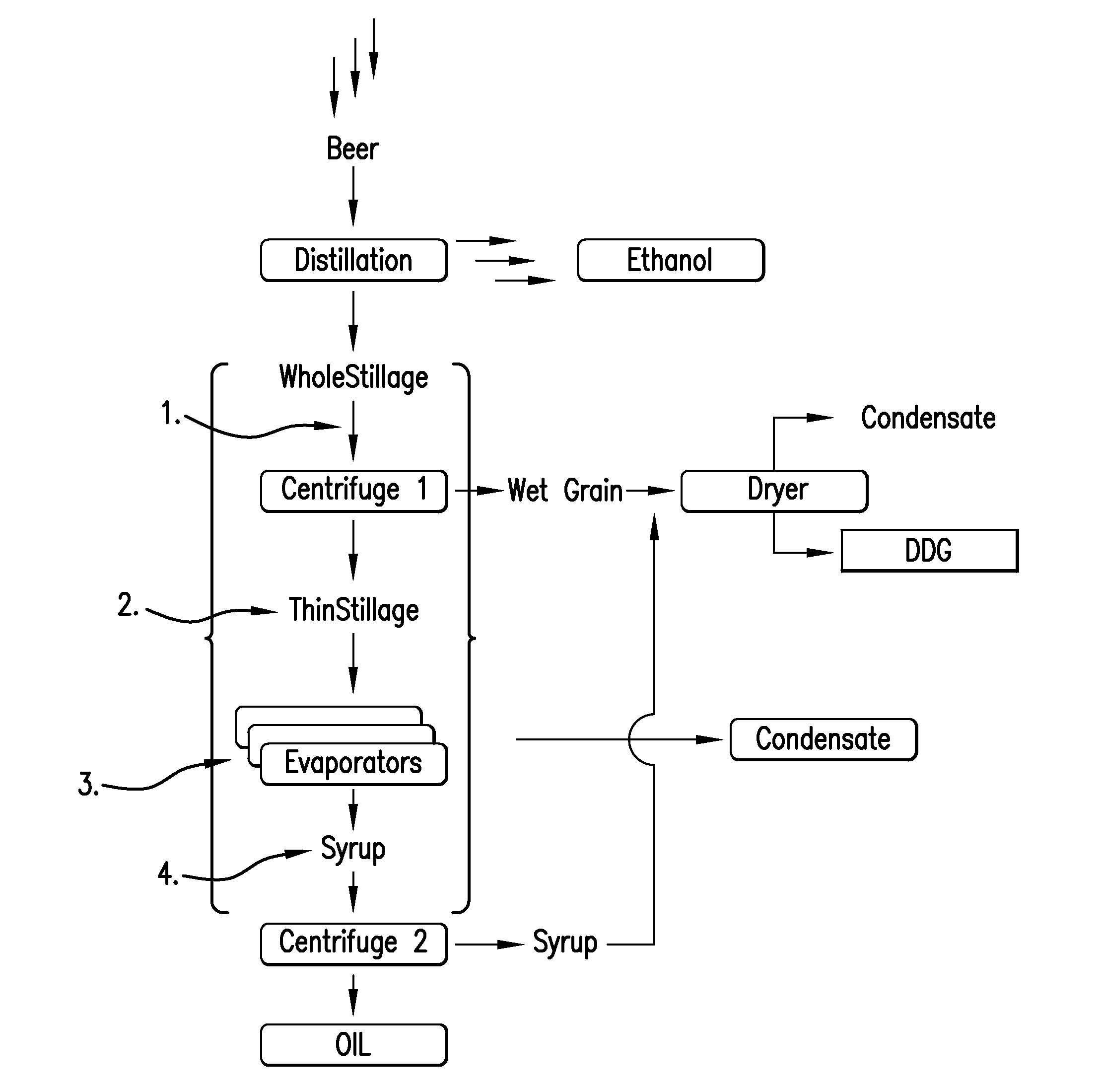

Oil extraction aids in grain processing

ActiveUS9353332B2Improve oil separationEasy to separateFatty oils/acids recovery from wasteBiofuelsShale oil extractionEthanol

Owner:SOLENIS TECH CAYMAN

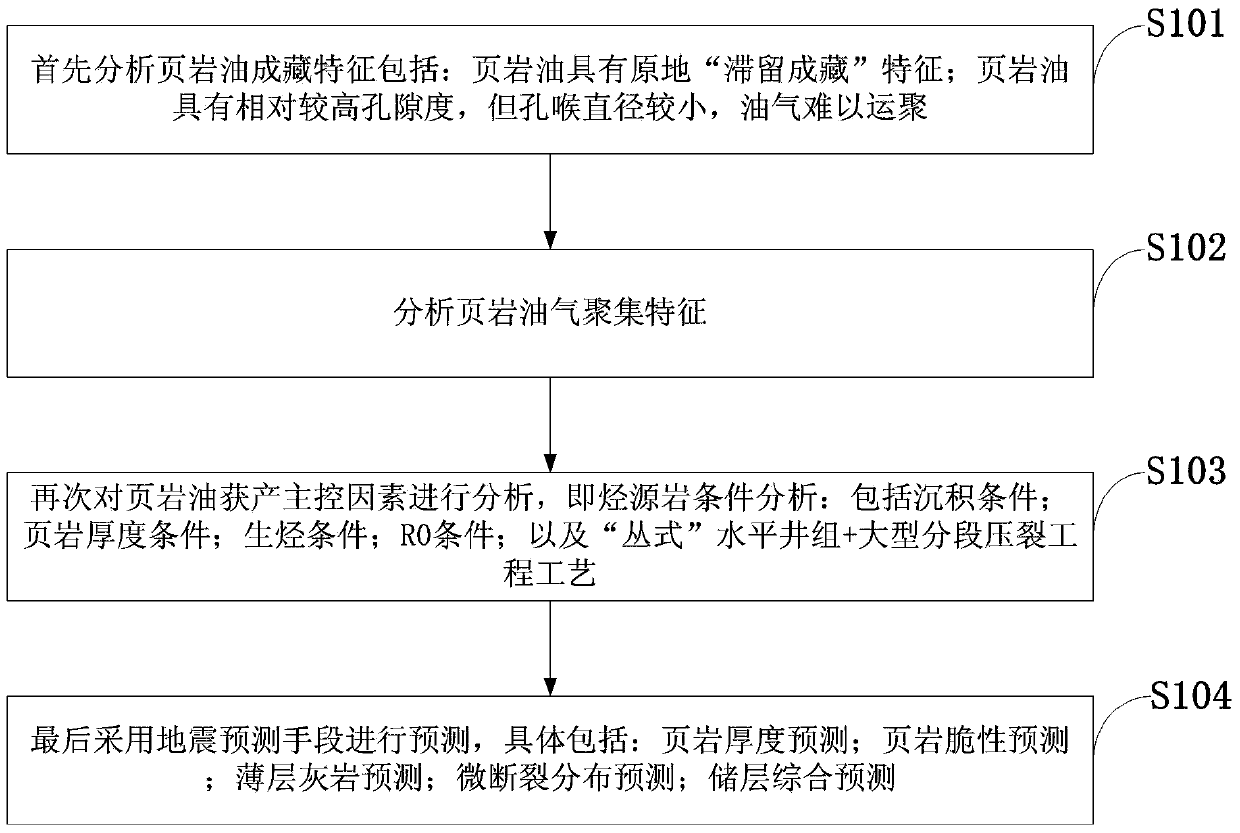

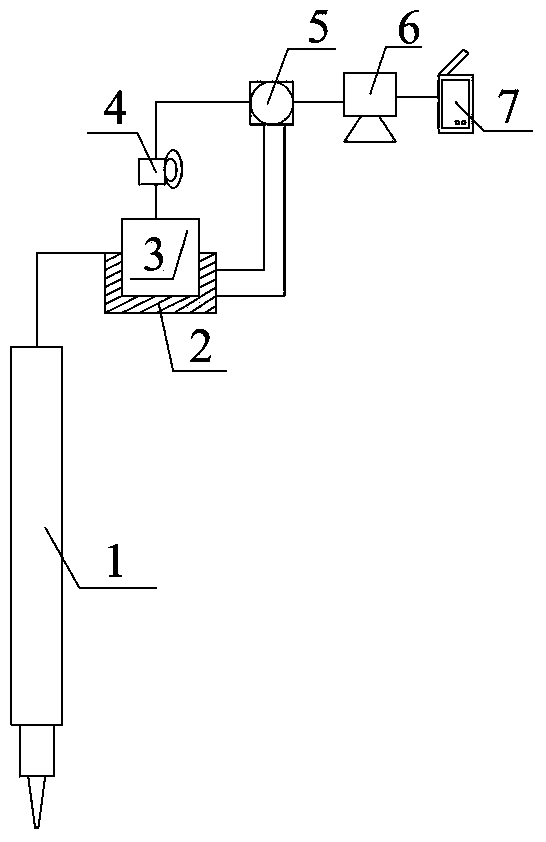

Main controlling factor analysis for shale oil production and earthquake prediction method and device

InactiveCN104199108AIncrease the chances of yieldingImprove oil recovery efficiencySeismology for water-loggingWell drillingEarthquake prediction

The invention discloses a main controlling factor analysis for shale oil production and an earthquake prediction method and device. The main controlling factor analysis for shale oil production and the earthquake prediction method and device are characterized in that the main controlling factor analysis for shale oil production is capable of establishing a shale oil and gas reservoir accumulation mode which plagues scientific research workers from a long time by means of analyzing shale oil and gas accumulation conditions, oil and gas geological characteristics and oil and gas accumulation characteristics; the earthquake prediction method and device conducts prediction by selecting a targeted earthquake prediction technique to ultimately realize comprehensive prediction of oil and gas enrichment region of a shale oil reservoir in Langzhong area of Sichuan province; the main controlling factor analysis for shale oil production and the earthquake prediction device mainly comprises a driller, a lifting base, an acoustic detector, a camera, a sensor, an analysis computer and a storage printer. Furthermore, the main controlling factor analysis for shale oil production and the earthquake prediction method and device determines main controlling factors of shale oil drilling production in Daanzhai section of Langzhong area to predict favorable areas for oil and gas via a corresponding earthquake and geological prediction technique, thereby improving oil recovery efficiency and laying the foundation for the further exploration of shale oil and gas in Sichuan area.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Demulsification method in production processes for extracting tea-seed oil extraction with participation of water phase

InactiveCN103396879AAvoid emulsificationSimple methodFatty-oils/fats refiningFatty-oils/fats productionOil and greaseOil water

The invention discloses a demulsification method in production processes for extracting tea-seed oil extraction with the participation of a water phase, relates to a technology for breaking an oil-water emulsification state during tea-seed oil production, and in particular to a technology for breaking emulsification in production processes for extracting tea-seed oil extraction with the participation of a water phase, such as an aqueous enzymatic method, an aqueous solution method or an aqueous extraction method. The technical scheme is as follows: after tea seeds are moderately crushed, an appropriate amount of water phase is added, and the purpose of breaking an oil-water emulsification phenomenon is achieved by virtue of the comprehensive methods of increasing temperature, regulating pH value and centrifugally separating. The method provided by the invention is simple, feasible and strong in practicability, solves the problem of a low oil yield caused by the fact that oil and water are seriously emulsified and difficult to separate in a water-phase oil extraction process, and is beneficial to actual industrial application and popularization for the water-phase tea-seed oil extraction process technology.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

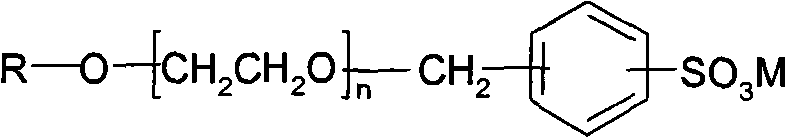

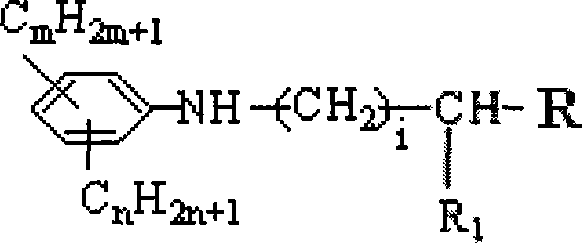

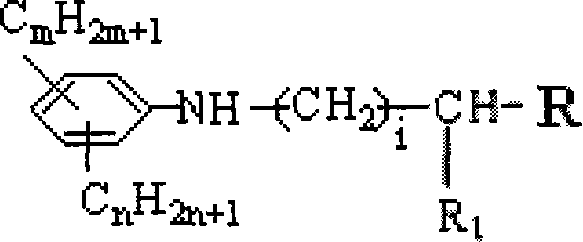

Alkylaniline carboxylate or sulphonate surfactant

InactiveCN101054514AAvoid harmMeet environmental protection requirementsOrganic chemistryDrilling compositionSulfonateShale oil extraction

The prescription system for oil extraction is provided with the carboxylate or mahogany sulfonate of the alkylbenzenamine surface active agent synthesized by alkylbenzenamine, polymer, alkali and water. The invention forms superlow surface tension of 10-3 to 10-5mN / m with the underground crude oil at the condition of no alkali or low alkali, which not only conquers the great damage to the stratum and oil well by the high-concentrated alkali, but also meets the environment requirement and can obtain an ideal oil recovery effect without damage to the equipments. Meanwhile, it can be used at highly mineralized stratum and has a biodegradation resistance, a low cost and increases the crude oil recovery ratio more than 27%.

Owner:孙安顺

Method for oil extraction in multi-bottom and multi-branch well by artesian injection

ActiveCN101956544AIncrease formation pressureEnhanced overall recoveryFluid removalWell drillingShale oil extraction

Owner:上海石油天然气有限公司

High-efficiency decompression and augmented injection agent used for oil extraction and production method thereof

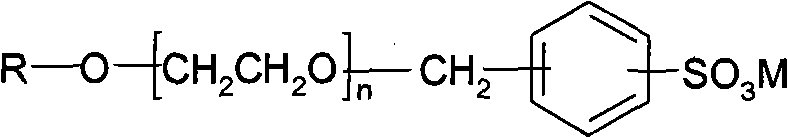

InactiveCN103113872AAdjustable molecular weightAchieve the purpose of the inventionDrilling compositionEthylenediamineEpoxy

The invention discloses a high-efficiency decompression and augmented injection agent used for oil extraction. The high-efficiency decompression and augmented injection agent is characterized by comprising the following components in parts by weight: 1.0-2.0 parts of epoxy chloropropane, 1.0-2.5 parts of dimethylamine, 1.0-4.0 parts of trimethylamine, 0.01-0.1 part of ammonium persulphate, 0.015-0.15 part of sodium hydrogen sulphite, 0.01-0.2 part of ethanediamine and 0.02-0.06 part of triethylene tetramine. The invention also discloses a production method of the high-efficiency decompression and augmented injection agent. The production method is characterized by comprising the following steps of: adding epoxy chloropropane into a porcelain enamel reaction kettle; slowly feeding a mixed solution of dimethylamine and trimethylamine, prepared at room temperature in proportion; after feeding is completed, adding the ammonium persulphate, then adding the sodium hydrogen sulphite, and maintaining temperature in the kettle to be not higher than 5 DEG C; after feeding is completed, heating until the temperature in the kettle is increased to 60-90 DEG C, and reacting for 7-9 hours, so that an intermediate product is obtained; cooling the intermediate product to 40 DEG C, and slowly adding a mixed solution of ethanediamine and triethylene tetramine; and reacting again at the temperature of 40 DEG C, so that the high-efficiency decompression and augmented injection agent finished product is obtained.

Owner:NANCHONG CITY JUXING CHEM CO LTD

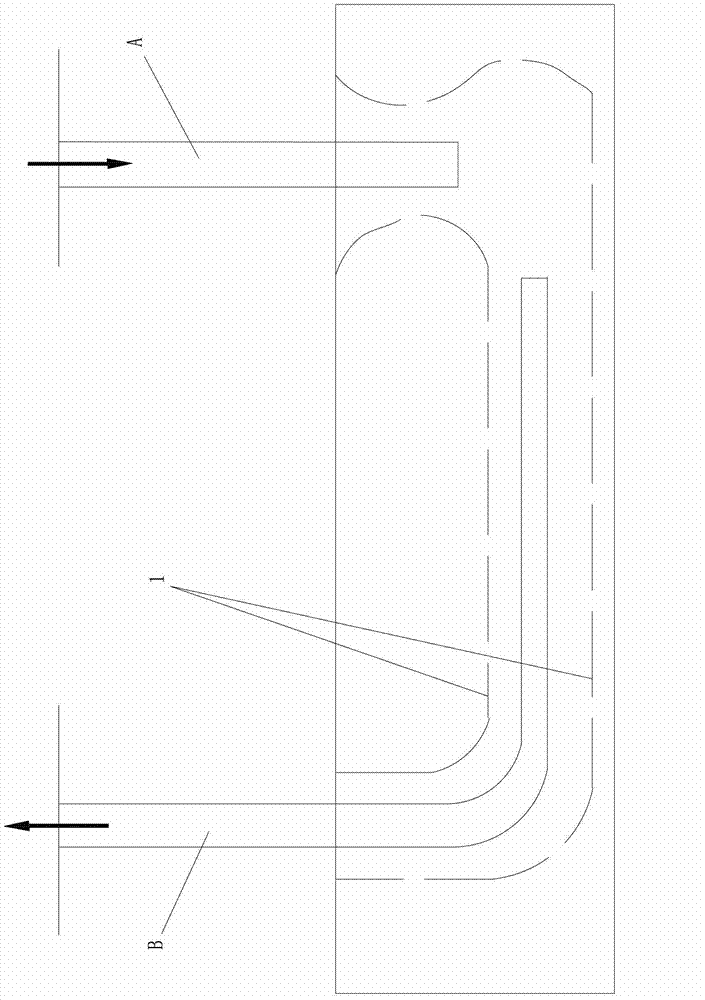

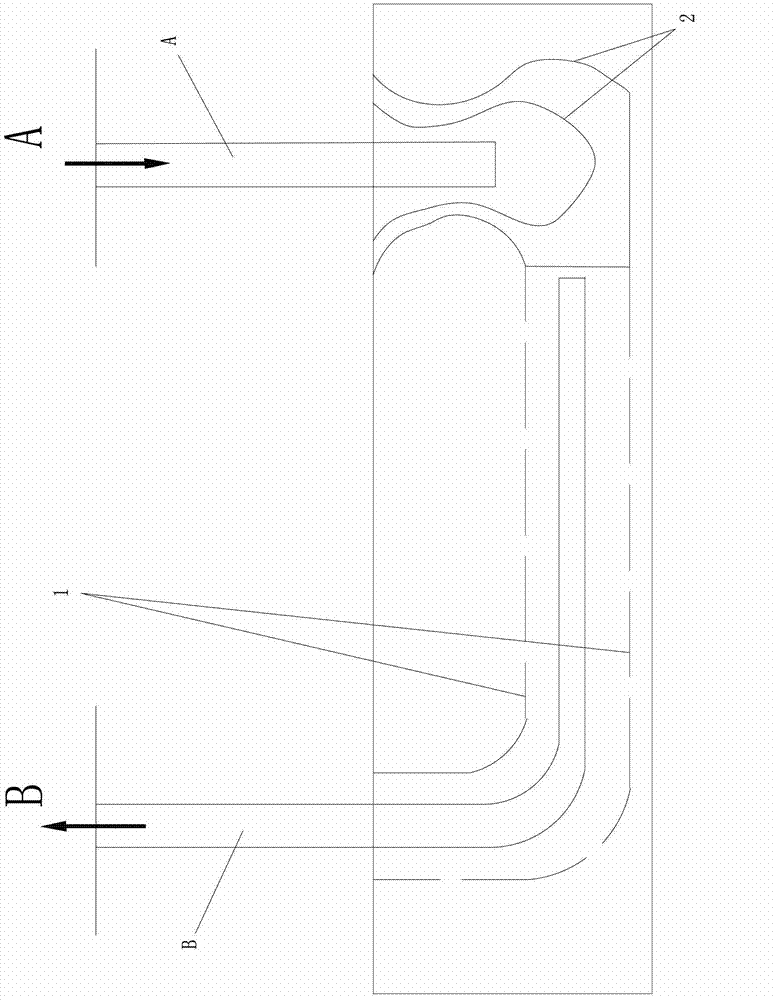

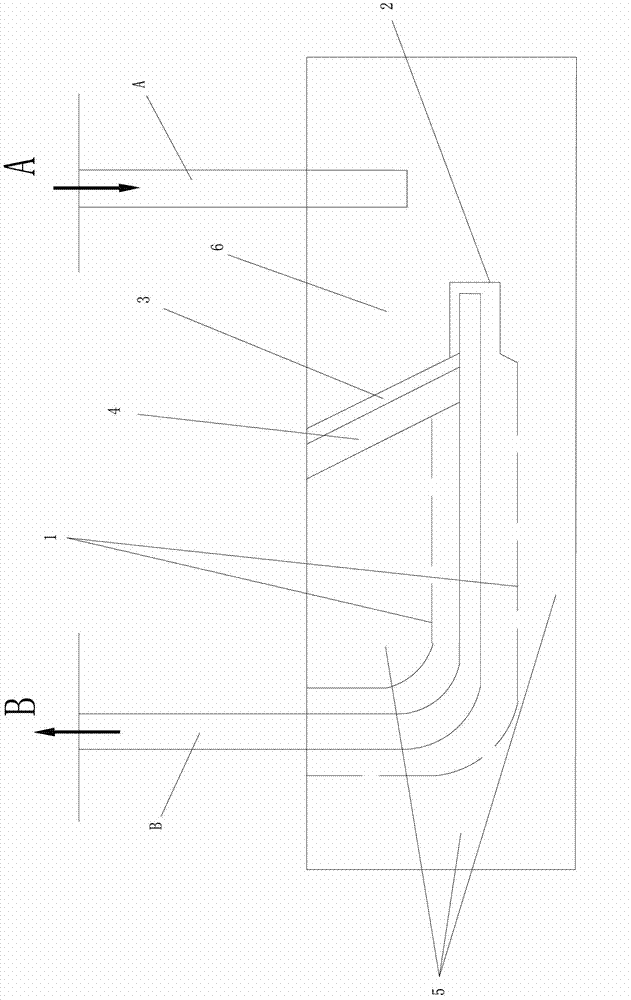

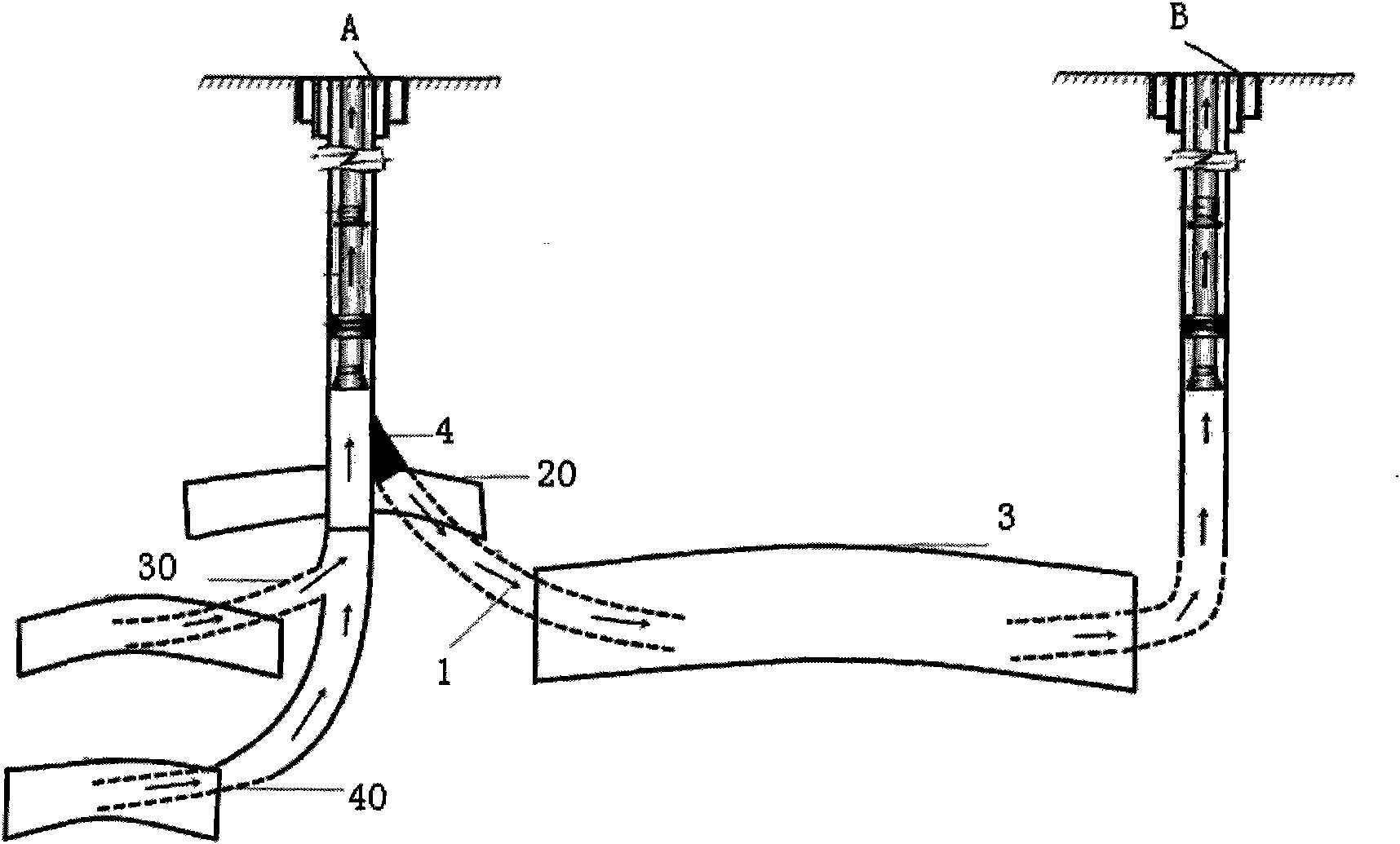

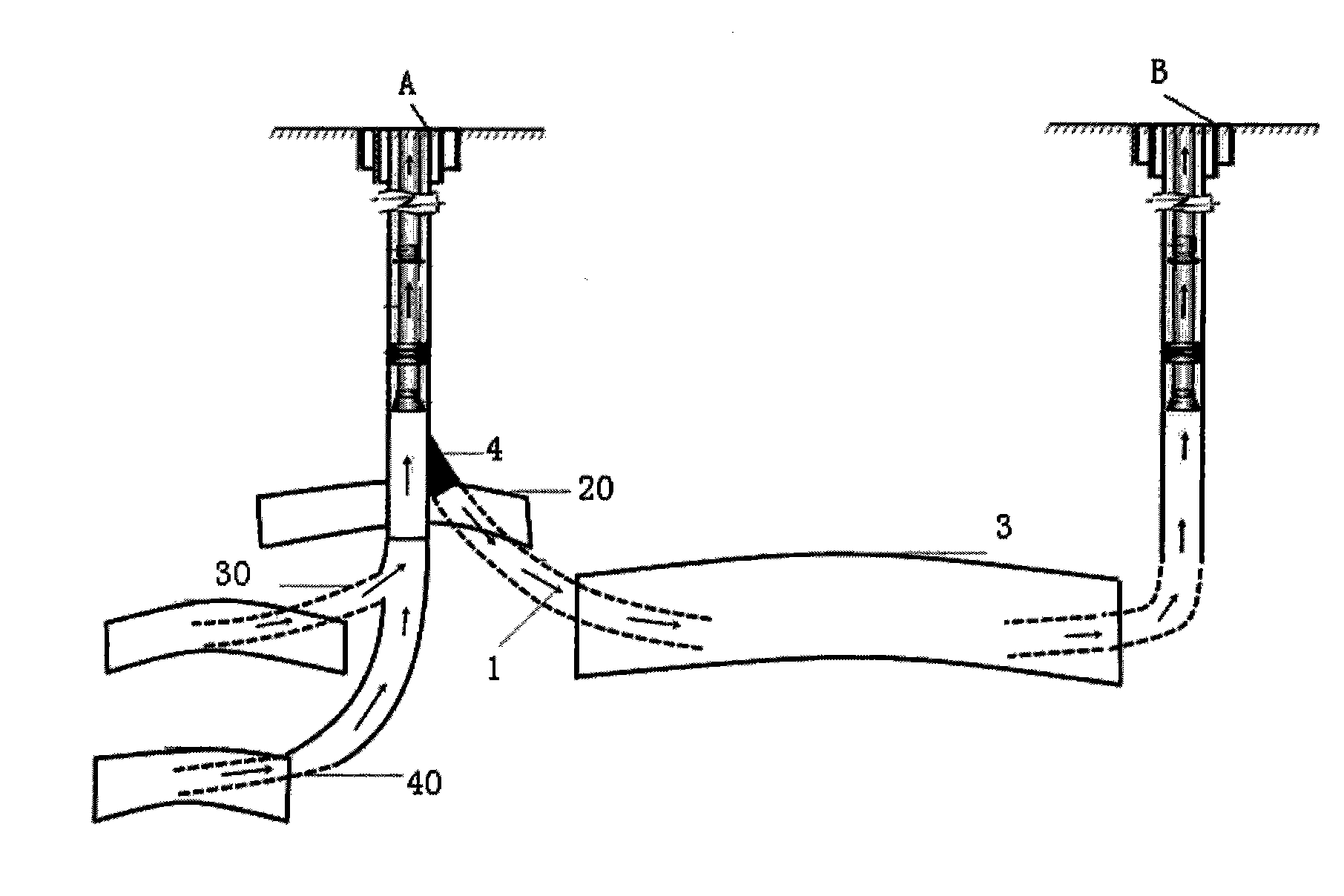

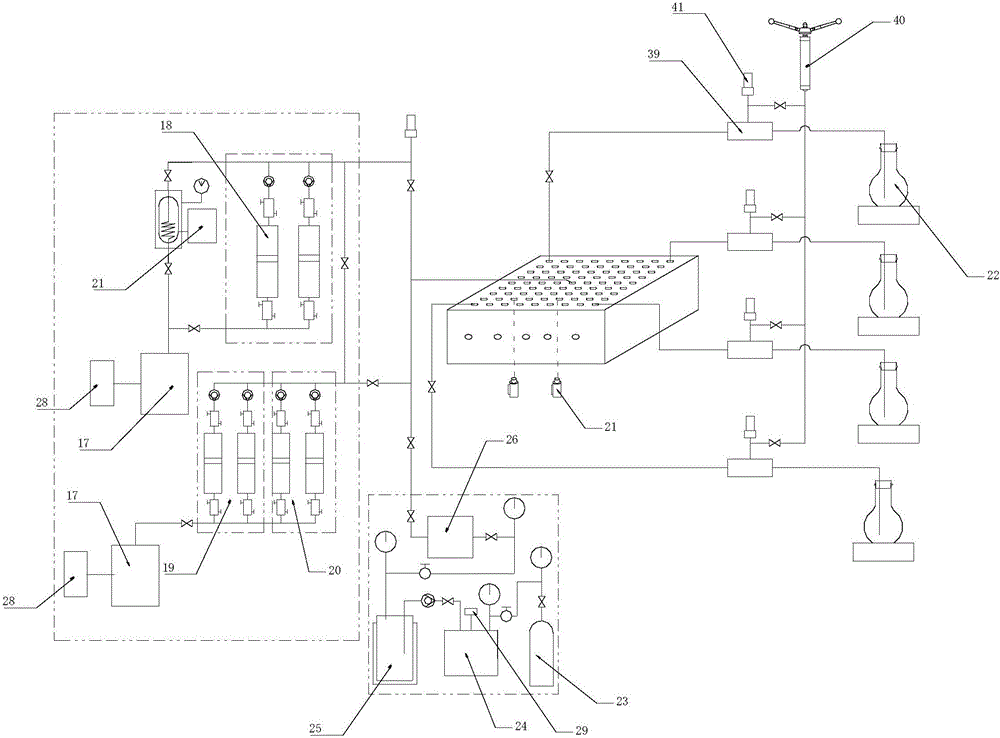

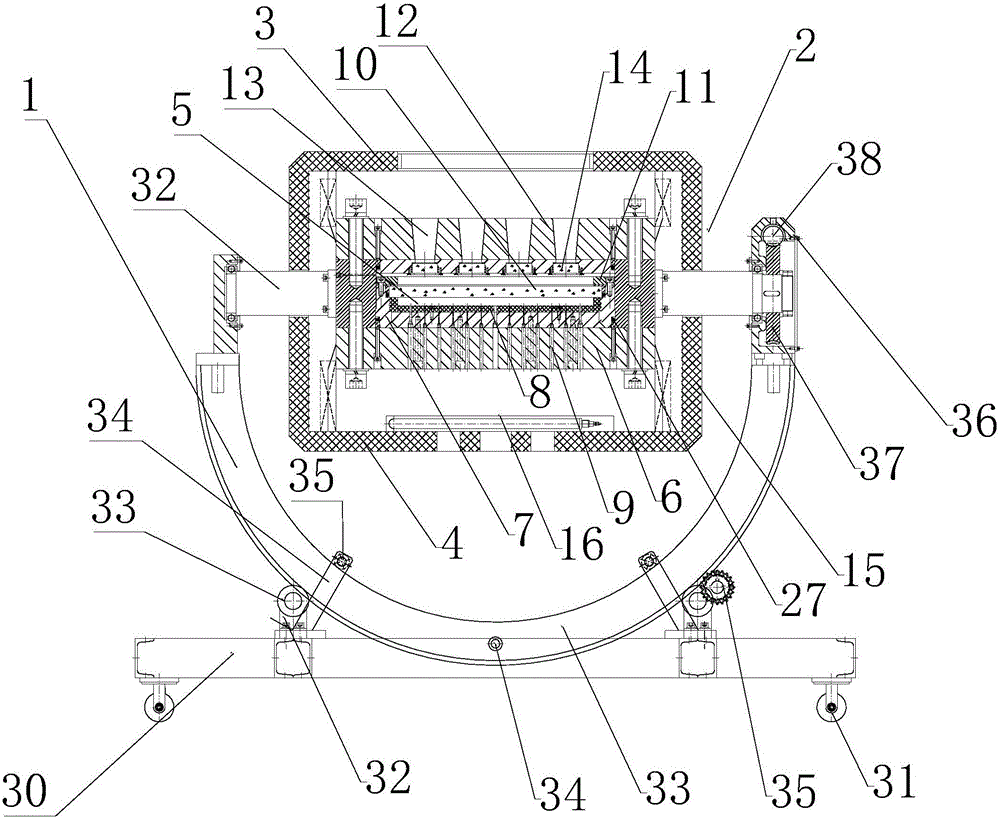

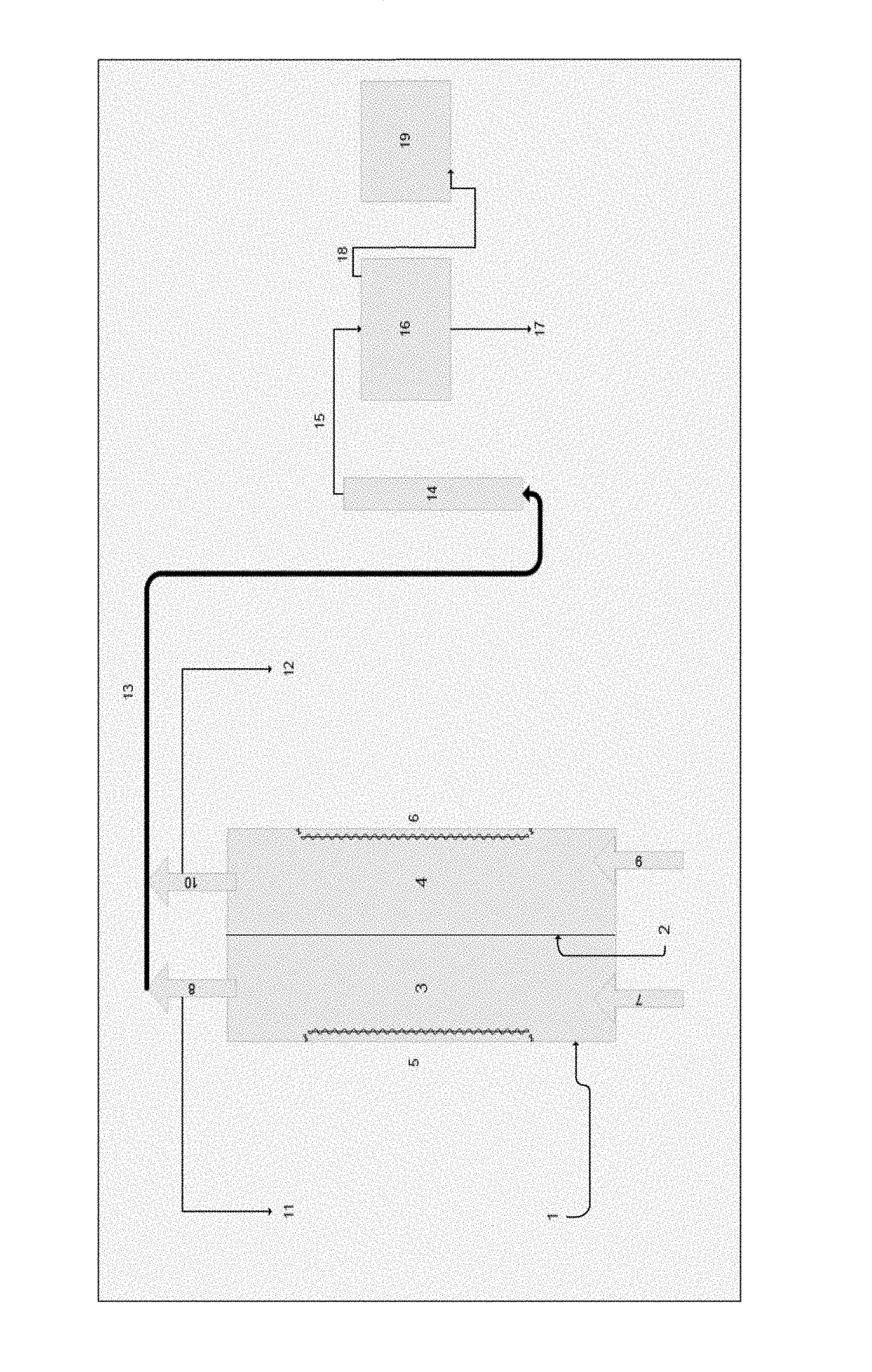

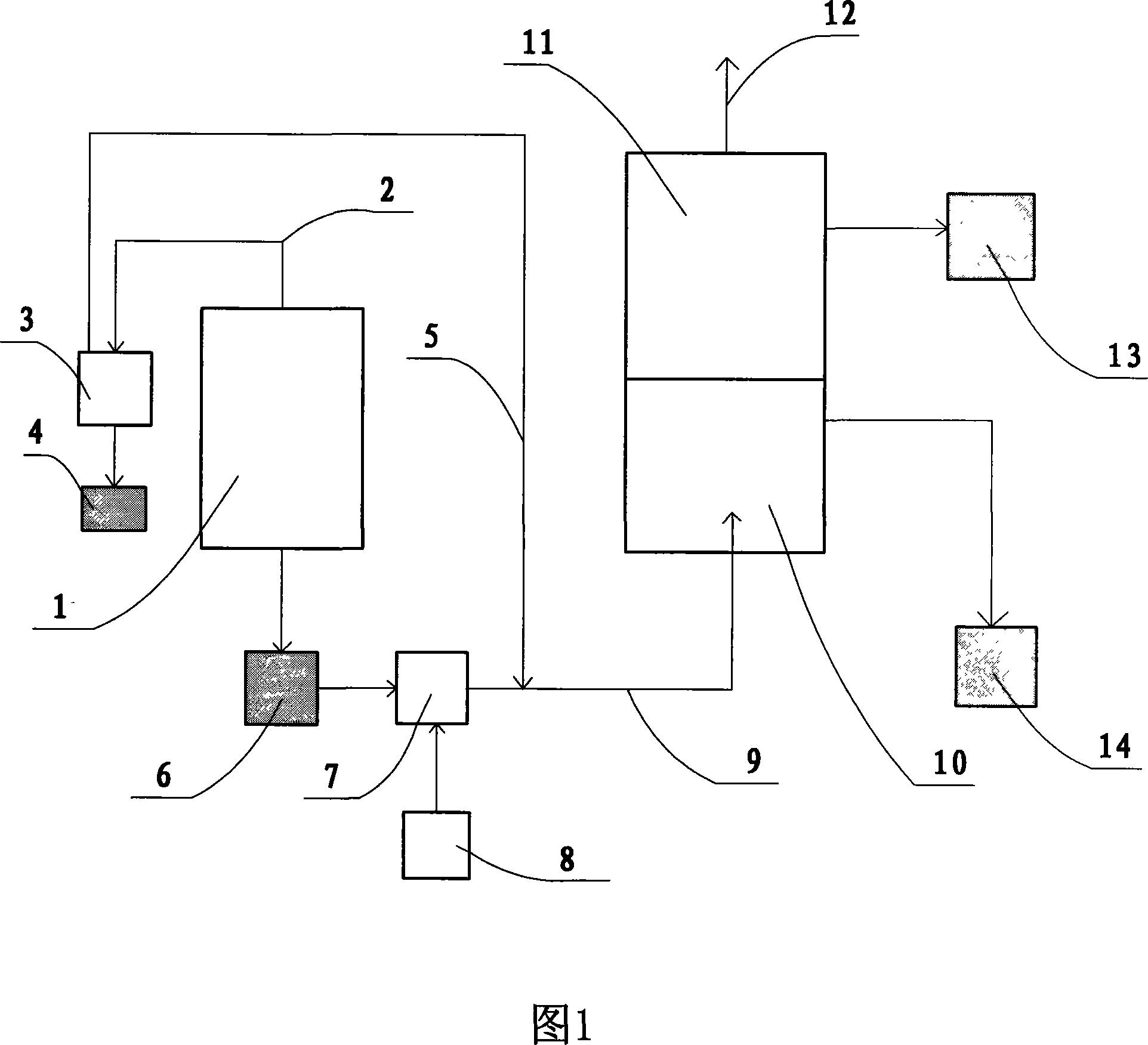

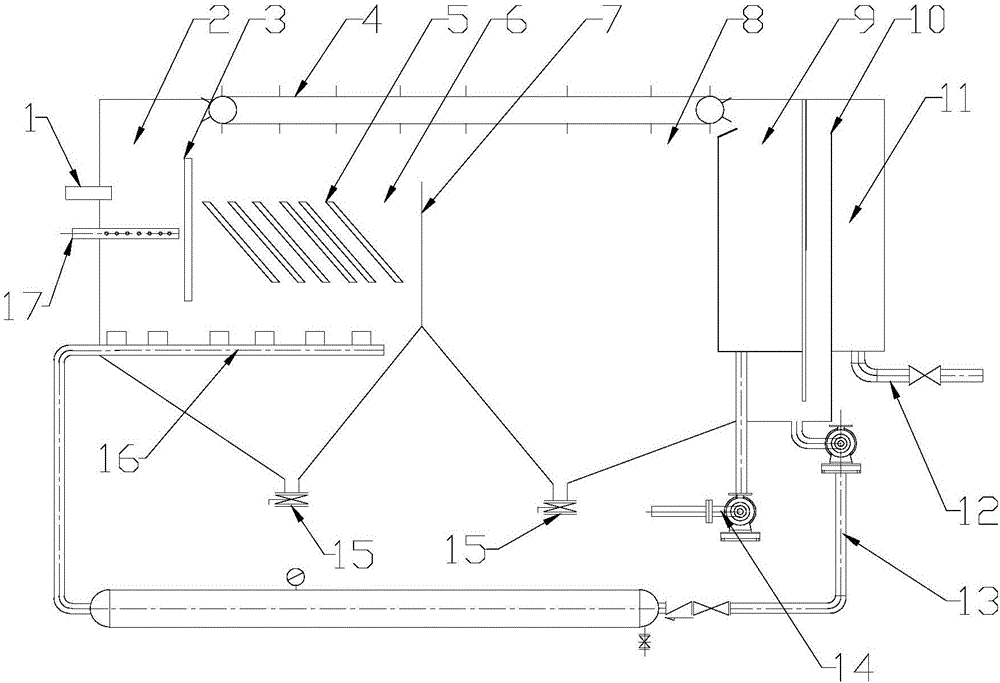

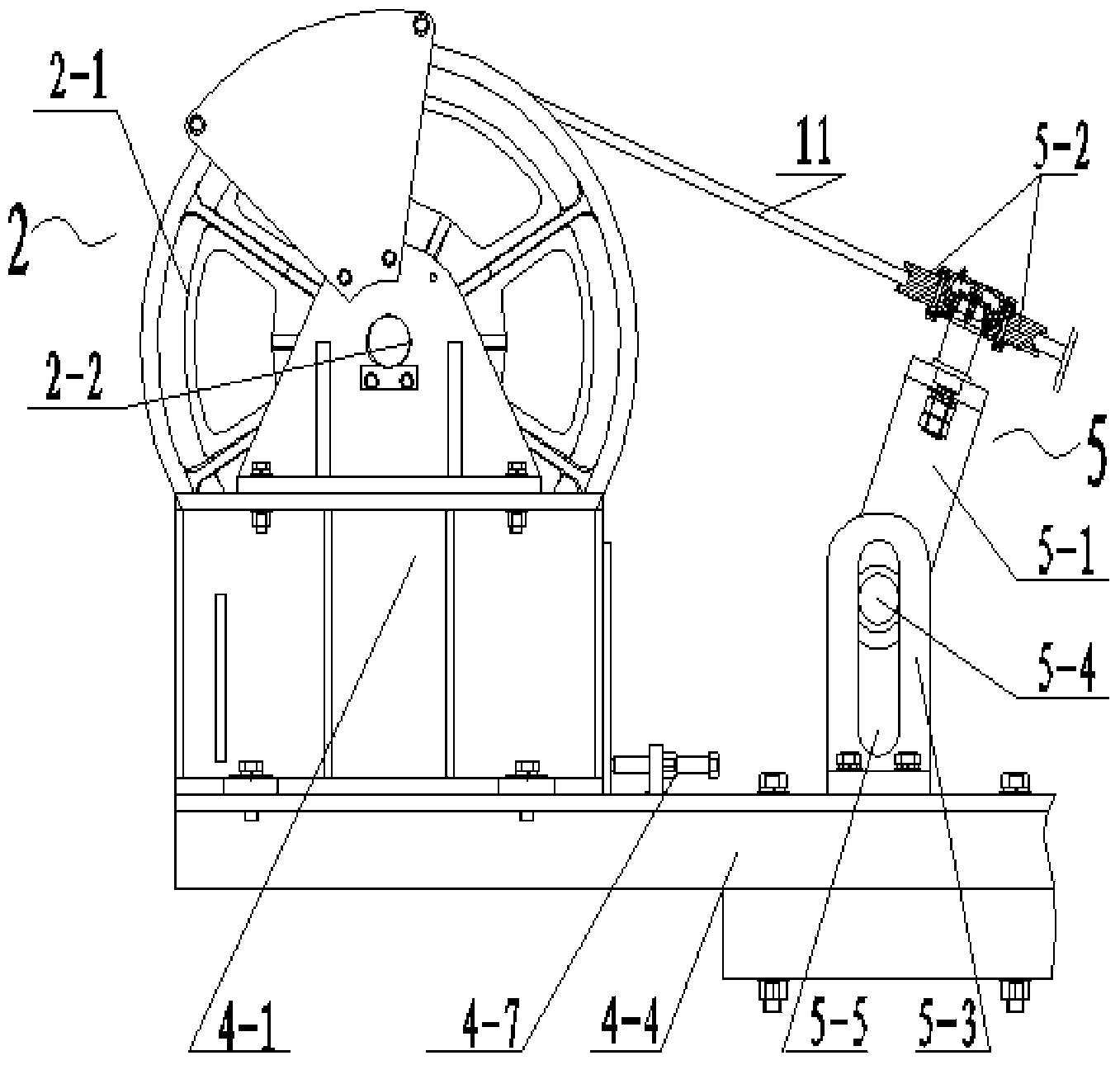

Visualized two-dimensional physical simulation experiment device for thermal thickened-oil extraction

The invention discloses a visualized two-dimensional physical simulation experiment device for thermal thickened-oil extraction. The visualized two-dimensional physical simulation experiment device comprises an injection system, a model system and a data acquisition and processing system which are connected in sequence, wherein the model system comprises an installing rack and a model body installed on the installing rack, the injection system comprises a simulation liquid injection unit and a multi-element hot fluid injection unit, and the data acquisition and processing system comprises a data acquisition board, a gas mass flow controller, a temperature sensor, a pressure sensor, an image pickup device corresponding to a high-pressure visual window and an automatic product liquid metering balance communicated with the model body. The multi-element hot fluid injection unit comprises a multi-element hot fluid gas source, a gas supercharging device, a high-pressure storage tank and a gas flow controller which are connected in sequence and is finally communicated to a simulating vertical well. The experiment device can simulate and carry out indoor simulation of a specific oil reservoir in the above developing mode and optimization of exploitation effect influence study.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

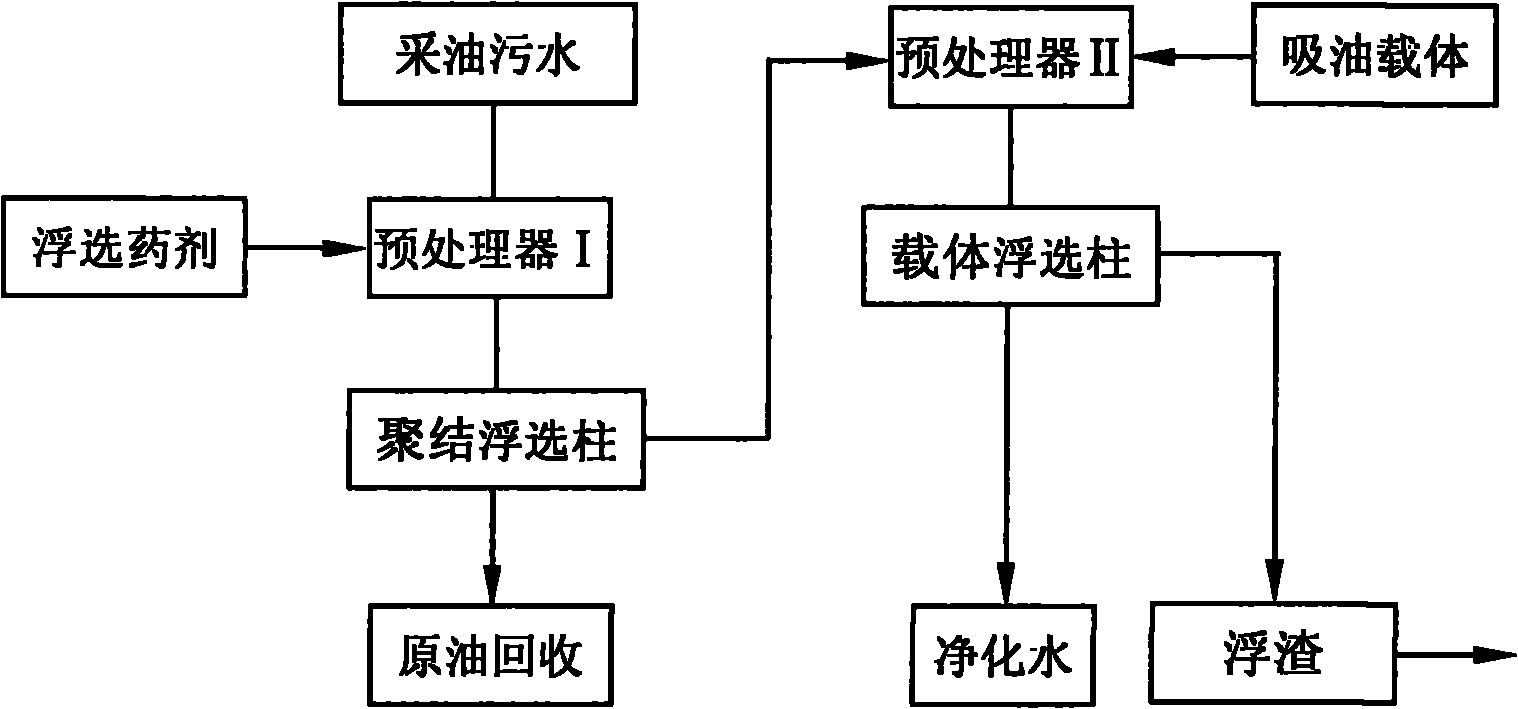

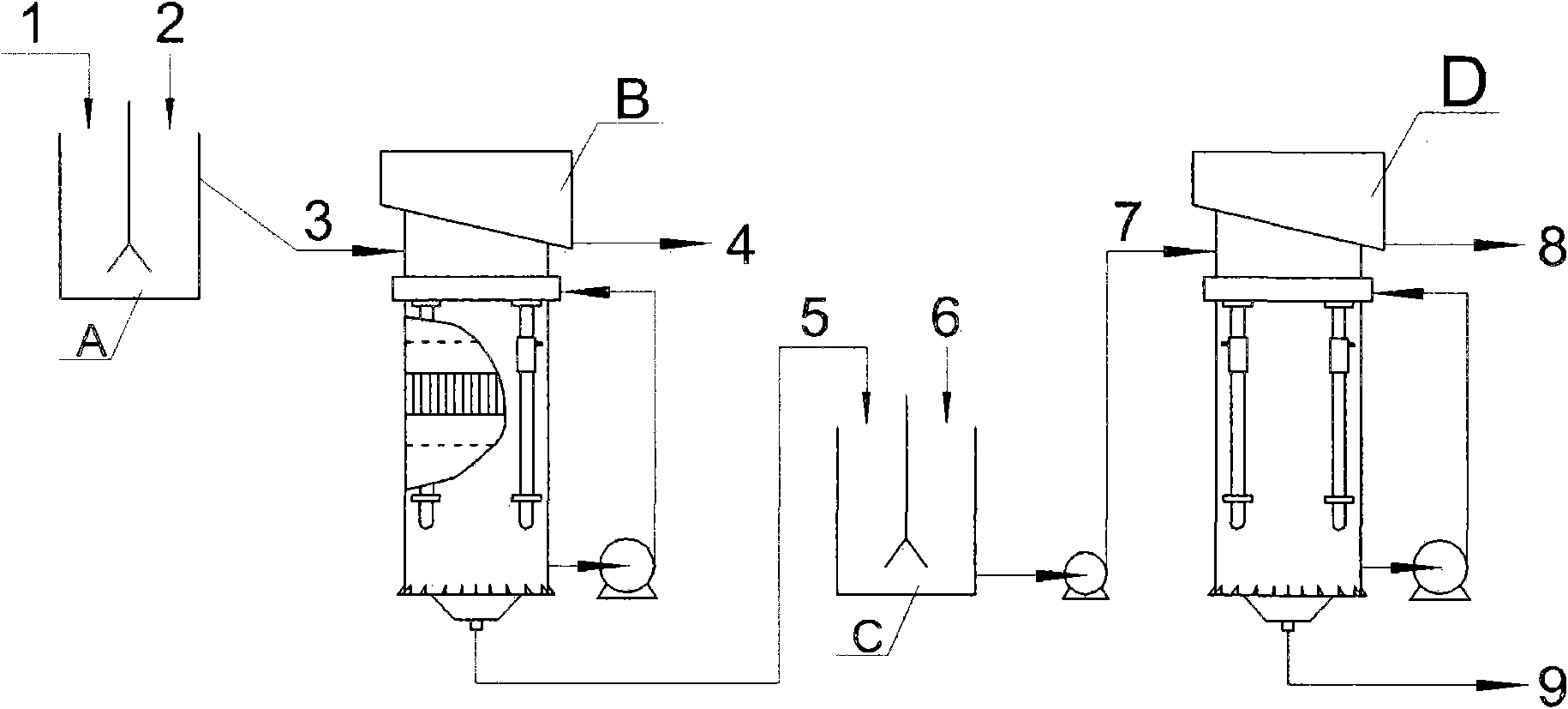

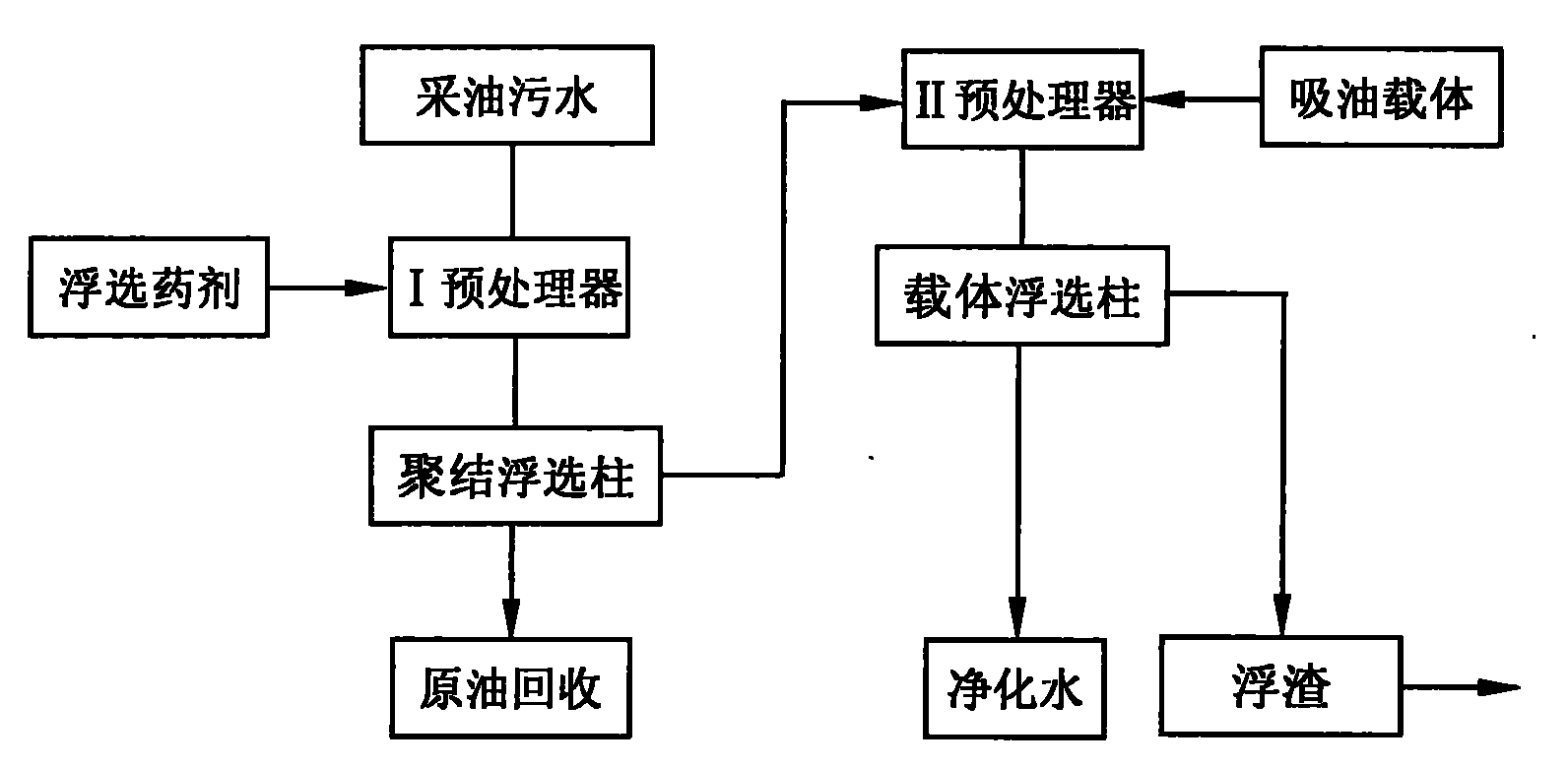

Technology for treating oil extraction-generated waste water

InactiveCN101805074ASmall granularity lower limitSpeed up granularity lower limitWaste water treatment from quariesWater contaminantsSludgeSlag

The invention provides a technology for treating oil extraction-generated waste water, which is particularly applied to separating crude oil from suspended matter in oil extraction-generated waste water in oil field. The technology adopts a 'coalescence flotation-carrier flotation' secondary oil extraction-generated waste water treatment technology, which comprises the following steps of: mixing the oil extraction-generated waste water with foaming agent through a I pretreater, and performing flotation to the mixture with a coalescence flotation column; after the coalescence flotation column coalescence and the flotation separation, adding oil-containing waste water which is discharged from the coalescence flotation column into a II pretreater; quantificationally adding coal powder or tar slag into the oil-containing waste water; mixing with the II pretreater, and performing the flotation to the mixture though a carrier flotation column again; discharging the scum which is formed by the carrier flotation column flotation separation of the crude oil, the suspended matter, the coal powder or the tar slag through a foam collecting slot from the top of the carrier flotation column; and discharging purified water from the bottom of the carrier flotation column to recover the crude oil and guarantee the quality of the discharged water. The technology has simple flow process, small lower limit of effective floating granularity, high treating efficiency, short separating time, large treating quantity, small floor area, low operation cost and no sludge.

Owner:CHINA UNIV OF MINING & TECH

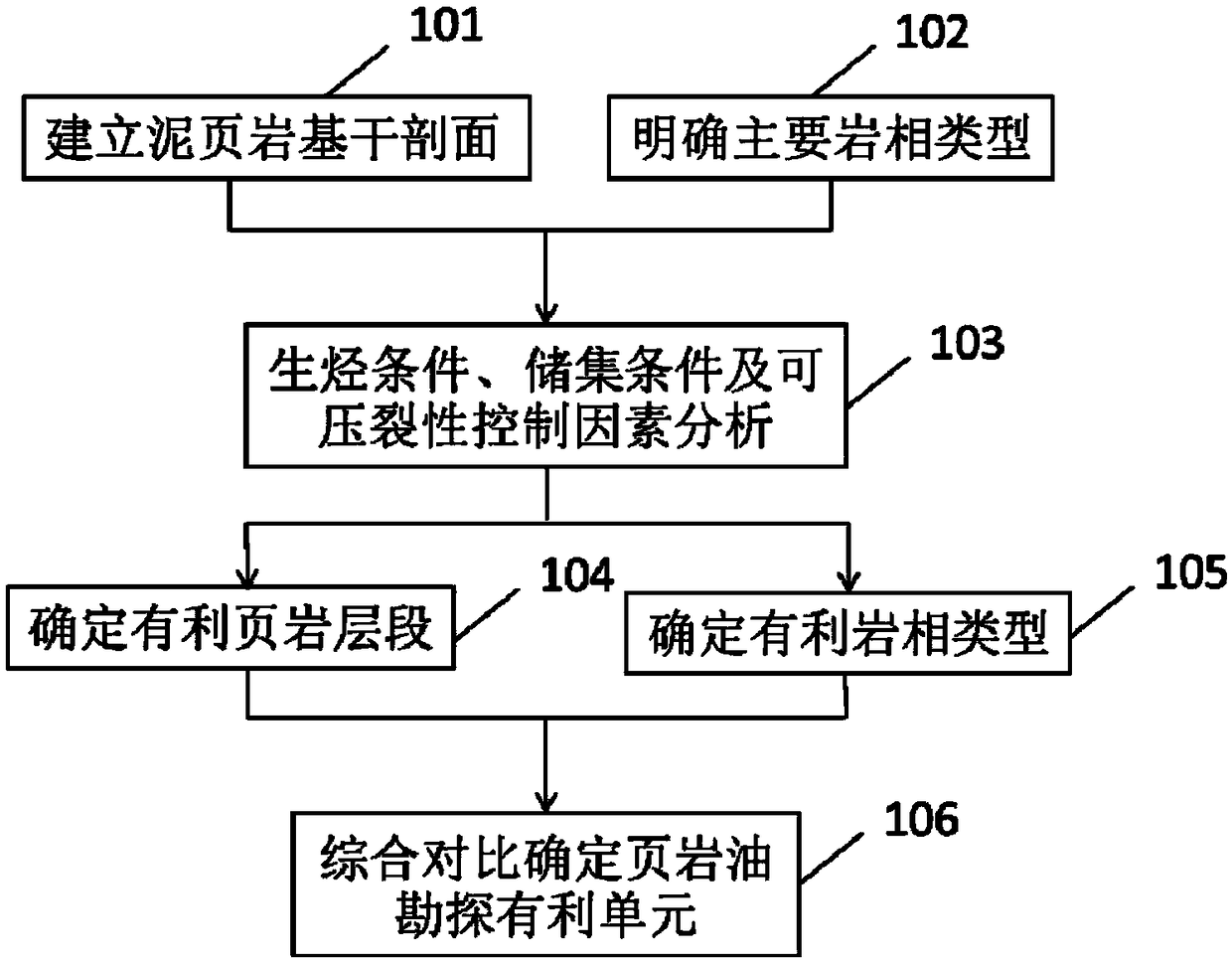

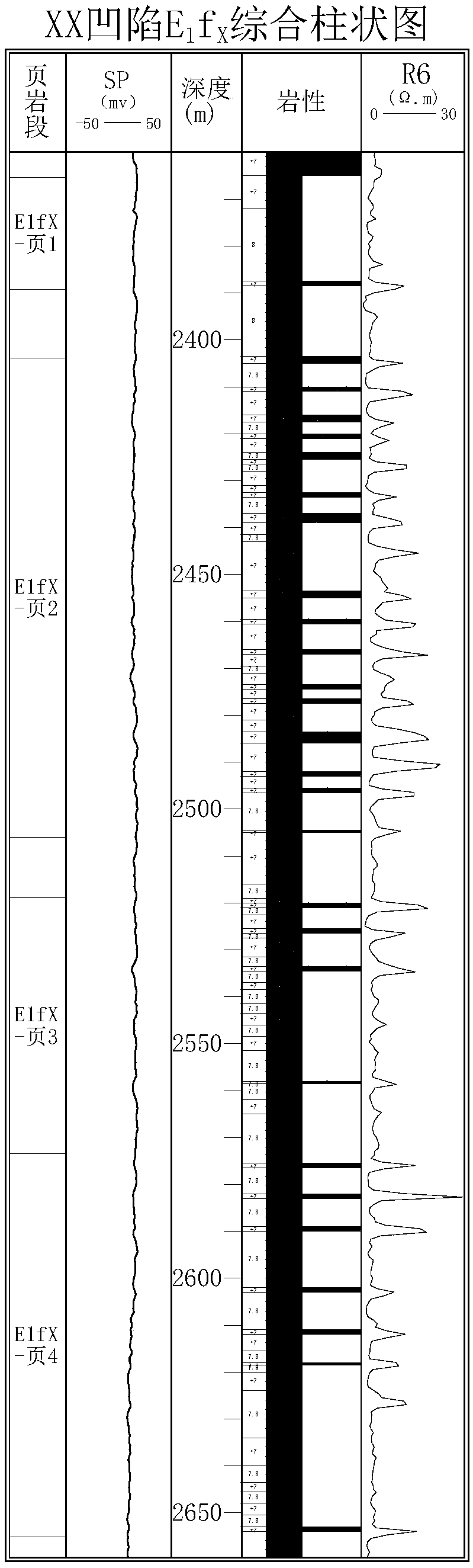

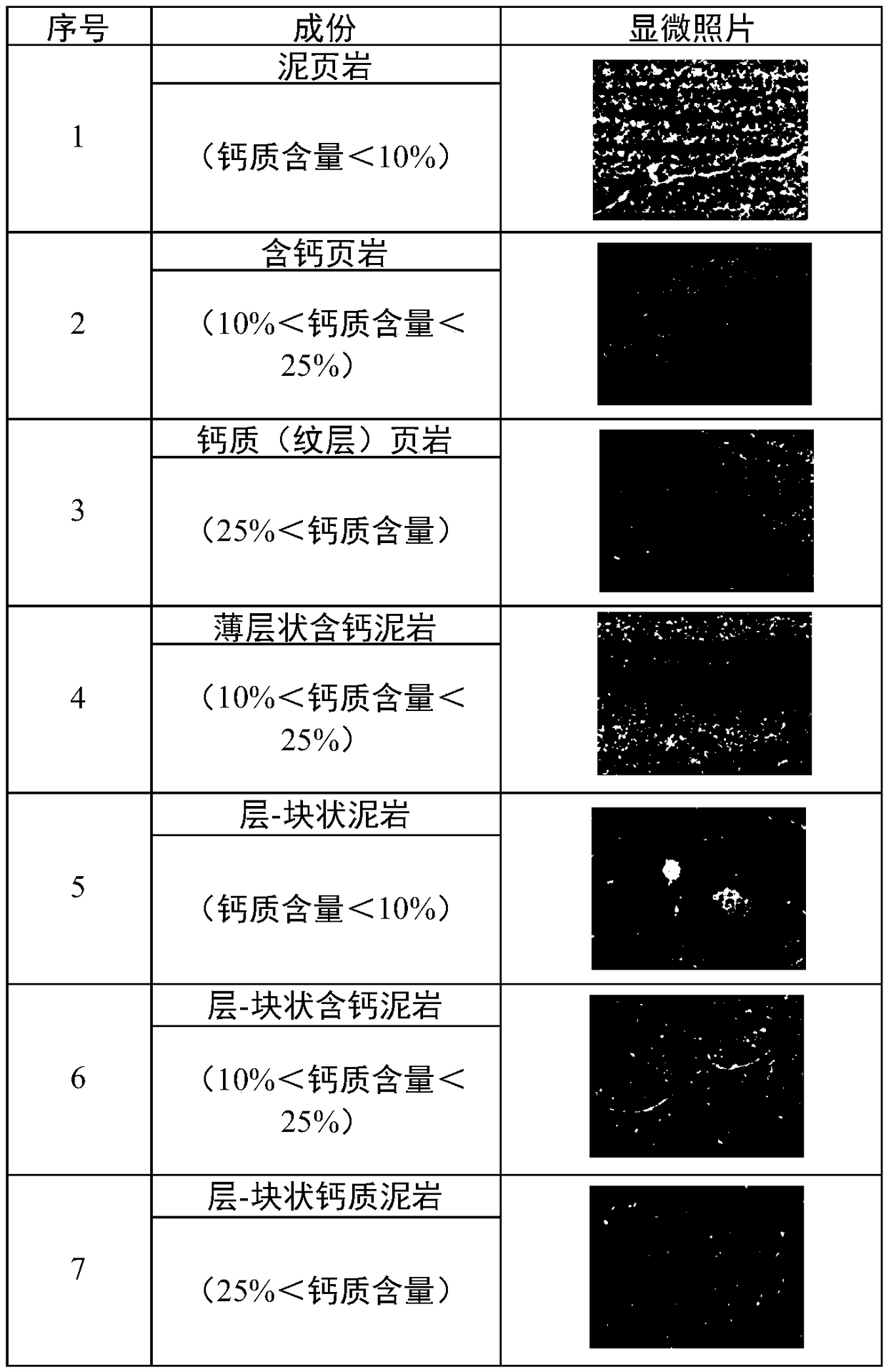

Method for determining favorable unit for continental shale oil exploration

ActiveCN109298449AEasy to operateComparison results are reliableAnalysis using nuclear magnetic resonanceSeismic signal processingOperabilityShale oil extraction

The invention discloses a method for determining a favorable unit for continental shale oil exploration, comprising the following steps of: step 1, establishing a mud shale foundation profile, and refining the lithofacies types; step 2, performing master control factor analysis on different shale strata and the lithofacies types, and determining favorable shale strata and lithofacies types; and steps 3, comparing and evaluating favorable strata and favorable lithofacies, and comparing and analyzing the favorable unit for the shale oil exploration comprehensively in a two-dimensional way. The analysis of the hydrocarbon generation conditions, the reservoir conditions, and the fracturing conditions is carried out for different lithofacies types in addition to considering the hydrocarbon generation conditions, the reservoir conditions, and the fracturing conditions of the shale development stage. The favorable unit for the shale oil exploration is determined through dual comparison of theshale strata and the lithofacies types. The method for determining the favorable unit for the continental shale oil exploration considers the operational steps systematically and comprehensively, hashigh operability and more reliable comparison result, and can provide a reliable basis for the evaluation of the continental shale oil selection area.

Owner:CHINA PETROLEUM & CHEM CORP +1

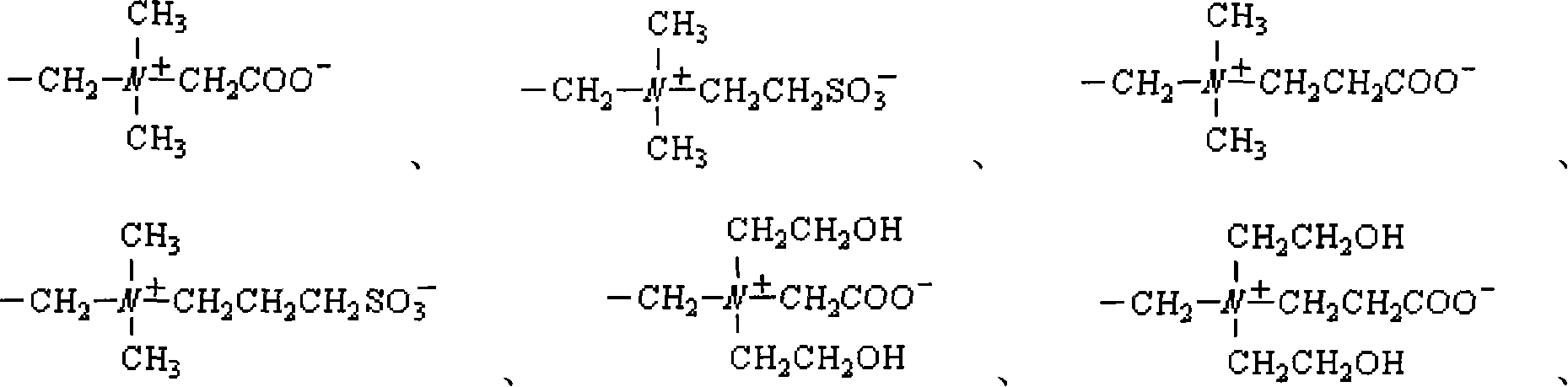

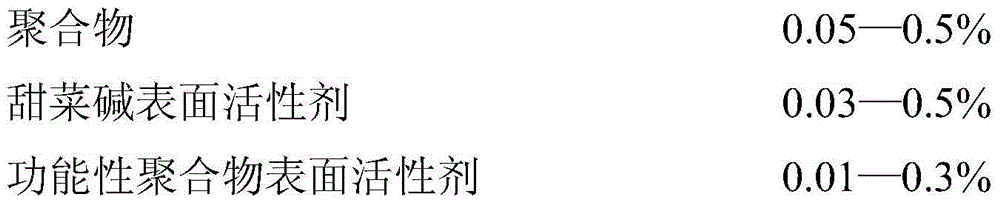

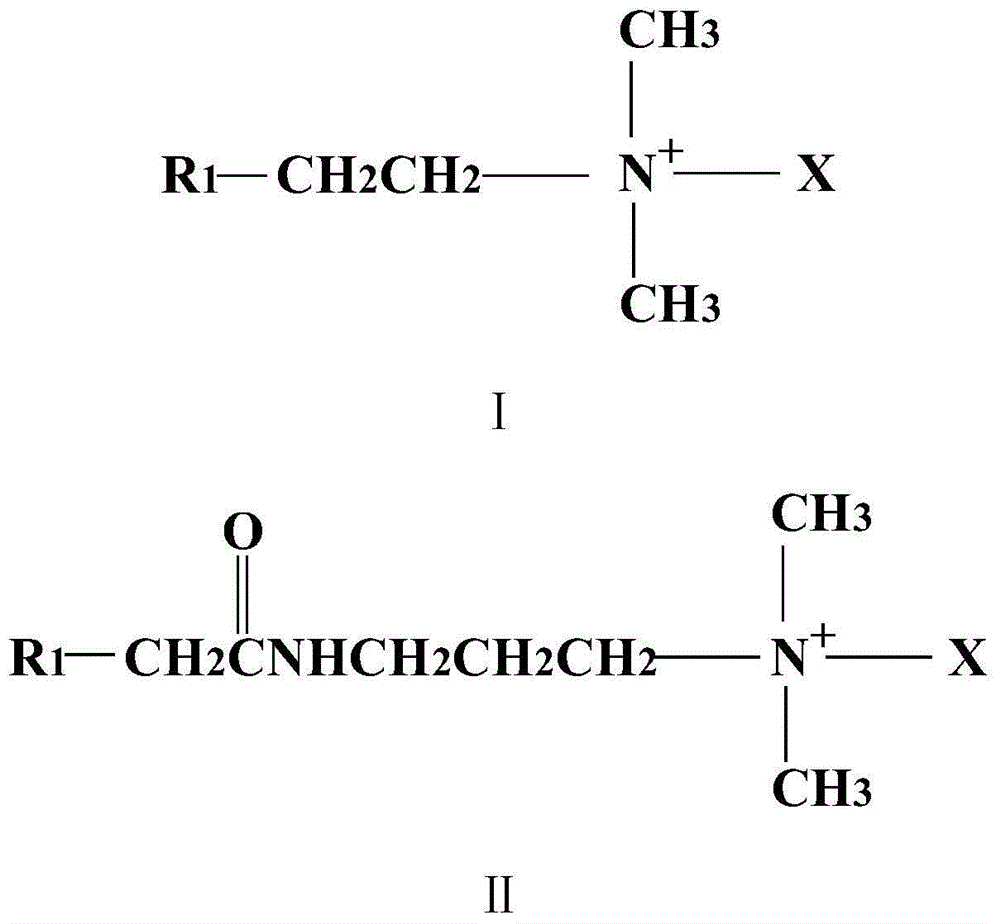

Functional polymeric surfactant-reinforced betaine composite flooding system and use thereof

InactiveCN104312566AExpand the affected volumeImprove oil washing efficiencyFluid removalDrilling compositionPolymeric surfaceBetaine

The invention discloses a functional polymeric surfactant-reinforced betaine composite flooding system and a use thereof. The functional polymeric surfactant-reinforced betaine composite flooding system comprises, by weight, 0.05-0.5% of a polymer, 0.03-0.5% of a betaine surfactant, 0.01-0.3% of a functional polymeric surfactant, 0.01-0.3% of a nonionic surfactant, 0.0-1.5% of an alkali and the balance water. The functional polymeric surfactant-reinforced betaine composite flooding system utilizes combination of a plurality of oil flooding mechanisms, can greatly improve crude oil extraction ratio, can realize further oil extraction of oil reservoir subjected to polymer flooding, can greatly improve final oil extraction ratio of the oil reservoir and has effects better than those of the existing oil flooding system.

Owner:大连东方创新科技有限公司

Extraction method for artemisia argyi essential oil

PendingCN109504539AEasy and effective removalReduce generationEssential-oils/perfumesWater vaporImpurity

The invention discloses an extraction method for artemisia argyi essential oil. The method comprises the following steps: raw material pretreatment, microwave assisted extraction, compound enzyme assisted extraction, steam distillation extraction, condensation and refining. According to the method, artemisia argyi leaves are placed in distilled water for ultrasonic cleaning, so that impurities such as protein and glucose can be simply, conveniently and effectively removed from surfaces of the artemisia argyi leaves, the generation of the impurities during essential oil extraction is reduced, the aim of improving purity of the essential oil is achieved, and extraction cost increase resulting from traditional solvent cleaning and the influence on the purity of the essential oil caused by solvent residual are avoided. Then, microwave assisted extraction, compound enzyme assisted extraction, steam distillation extraction and molecular distillation are combined, cell wall rupture and localswelling of intercellular substances are achieved by microwave assisted extraction and compound enzyme assisted extraction, and thus, intracellular substances are more easily dissolved out; subsequently, the essential oil is thoroughly refined by steam distillation extraction; finally, refining is carried out by molecular distillation, the separation of lightweight molecules from heavy molecules is achieved by dint of difference among mean free paths of molecular movement of different substances, and thus, the purity of the artemisia argyi essential oil is greatly improved.

Owner:贵州鼎立生物科技香料有限公司

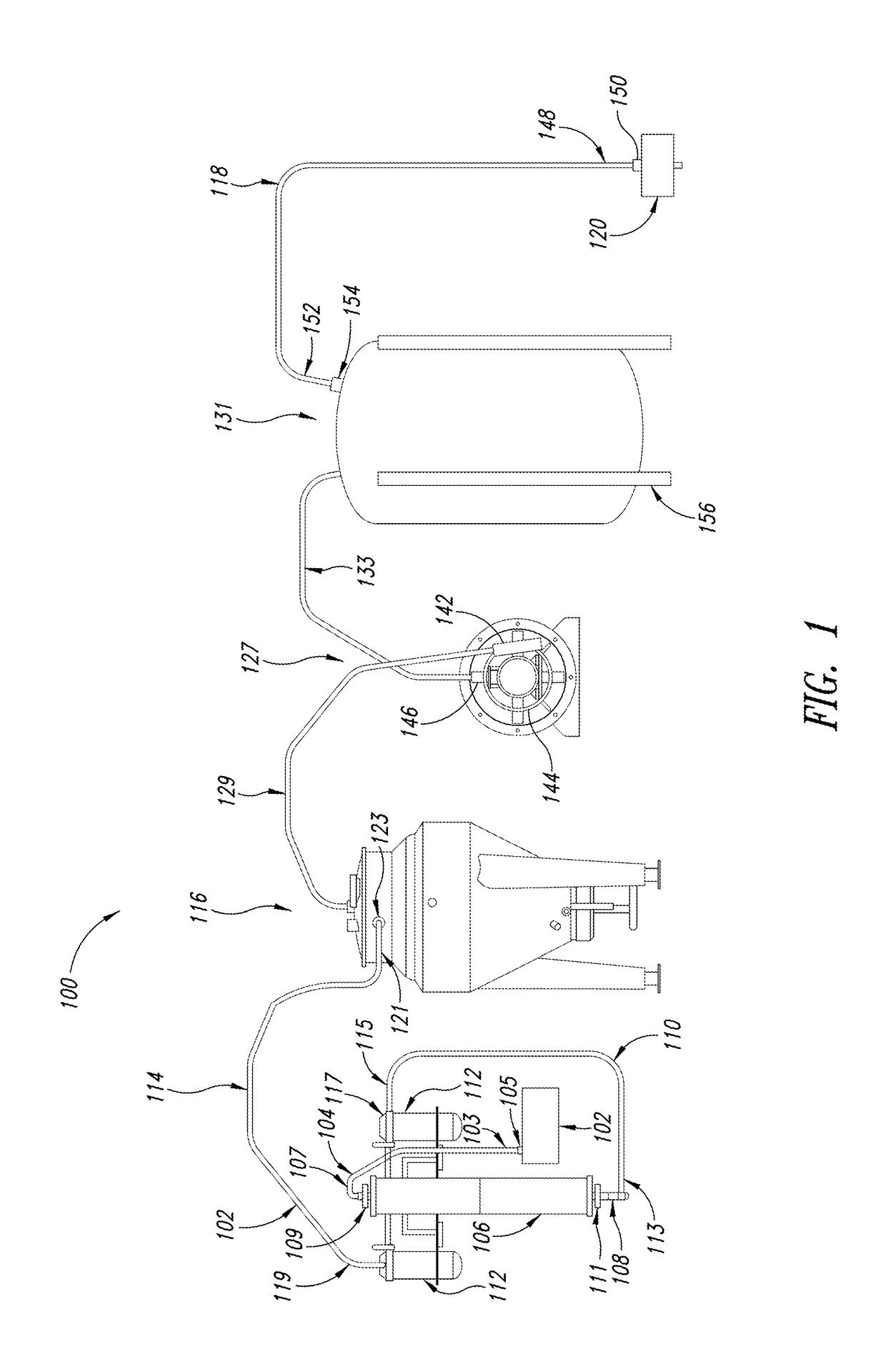

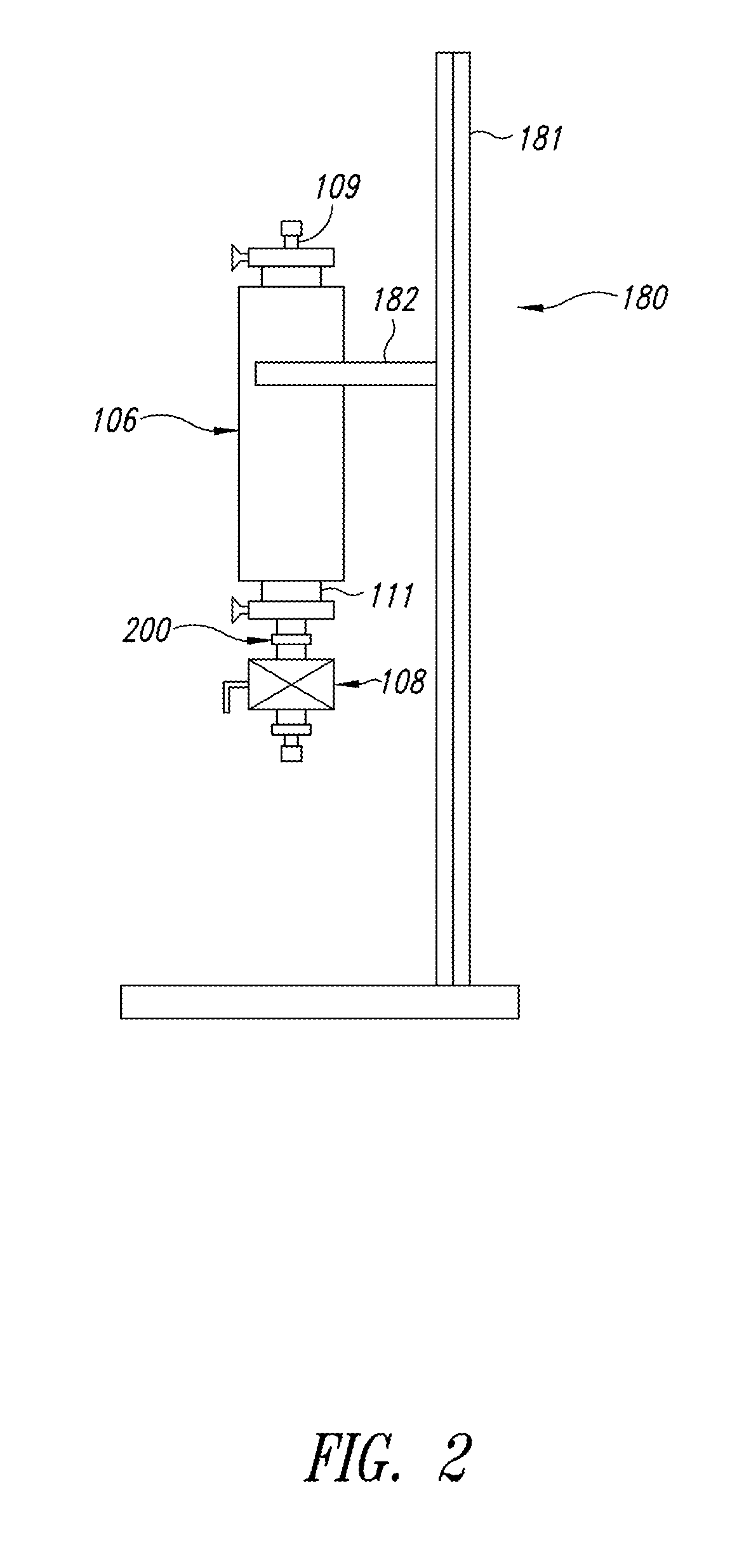

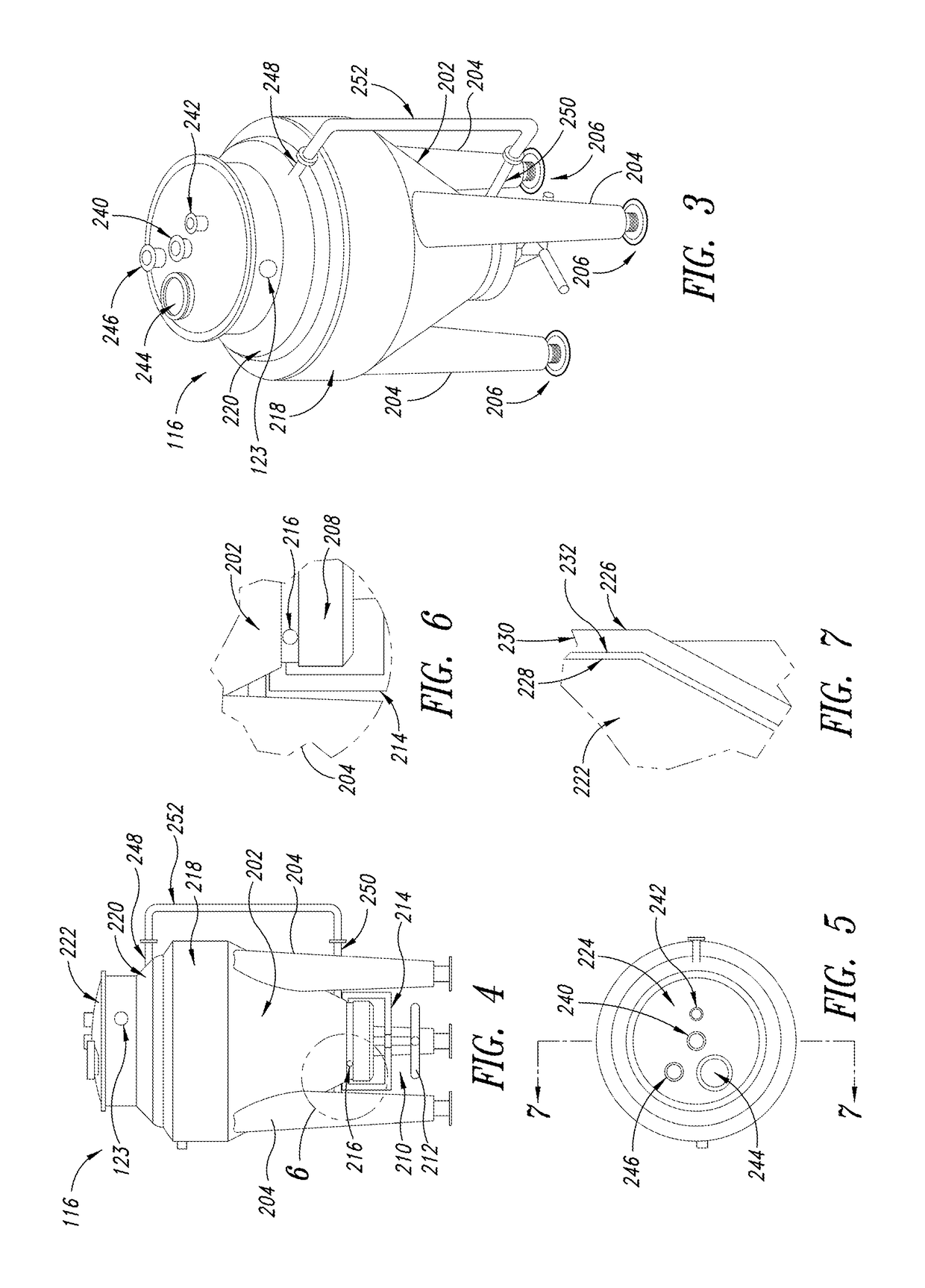

Enhanced essential oil extraction, recovery, and purge system and method

InactiveUS20190016989A1Increase air pressureReduce air pressureFatty-oils/fats productionSolid solvent extractionFiltrationEngineering

A system and method of extracting fluids from biomass material through the use of closed system capable of both low pressure and pressurized extraction that utilizes a combined vacuum and fluid collection tank, thus enabling different levels of pressure and vacuum to achieve a wide range of temperatures and allowing for variations in the chemical properties of the resultant extracted fluid. Although vacuum is preferred for safety, pressure is available when necessary, such as due to higher levels of filtration in which the use of vacuum is insufficient.

Owner:ESSENTIAL INNOVATIONS INC

Process and apparatus for generating or recovering hydrochloric acid from metal salt solutions

The present invention relates to an electrochemical process for generating or recovering hydrochloric acid from metal salt solutions such as acidic metal salt solutions and saline solutions. The process is useful for treating acidic salt solutions that are waste products from mineral processing or other industrial processes such as metal finishing, water softening, water treatment, reverse osmosis, electrodialysis, coal seam gas extraction, shale gas extraction and shale oil extraction, to generate high purity hydrochloric acid, metal salts and recycled water that may be re-used in the industrial process. An apparatus for performing the electrochemical process is also described.

Owner:AUSTRALIAN BIOREFINING

Delayed coking-hydrorefining process for shale oil

ActiveCN103102983ATake advantage ofEasy to operateTreatment with hydrotreatment processesNaphthaDistillation

The invention relates to a delayed coking-hydrorefining process for shale oil. The process comprises the following steps: (1) allowing a full shale oil fraction and a reaction product of delayed coking obtained in step (3) to enter into a distillation apparatus together and carrying out fractionation to obtain a light fraction and a heavy fraction, wherein fractionation temperature of the light fraction and the heavy fraction is 330 to 370 DEG C; (2) subjecting the mixed light fraction obtained in step (1) to hydrotreatment, wherein the light fraction obtained in step (1) comprises a light fraction in shale oil and a light fraction in the reaction product of delayed coking; and (3) subjecting the mixed heavy fraction obtained in step (1) to delayed coking and allowing the reaction product of delayed coking to enter into the distillation apparatus in step (1), wherein the mixed heavy fraction obtained in step (1) comprises a heavy fraction in the full shale oil fraction and a heavy fraction in the reaction product of delayed coking. Compared with the prior art, the invention has the following advantages: with the process, shale oil can be processed into high-quality naphtha and diesel oil, yield of light oil is increased, petroleum coke with a high added value can be obtained, and the process is favorable for stable running of a production apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

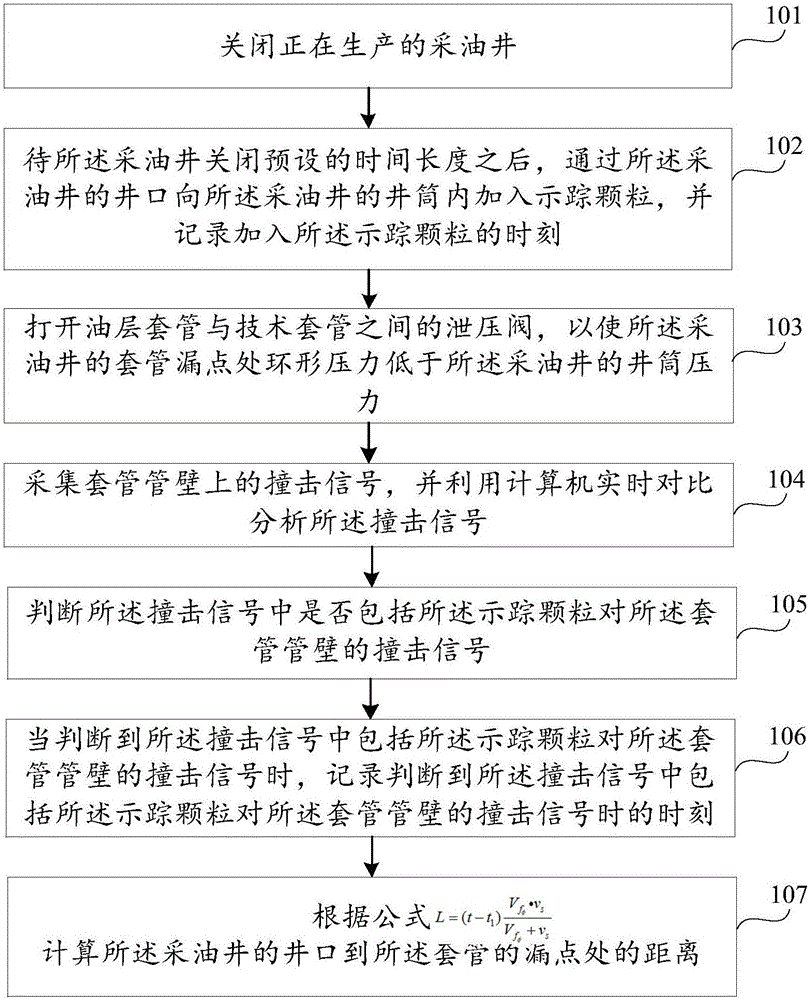

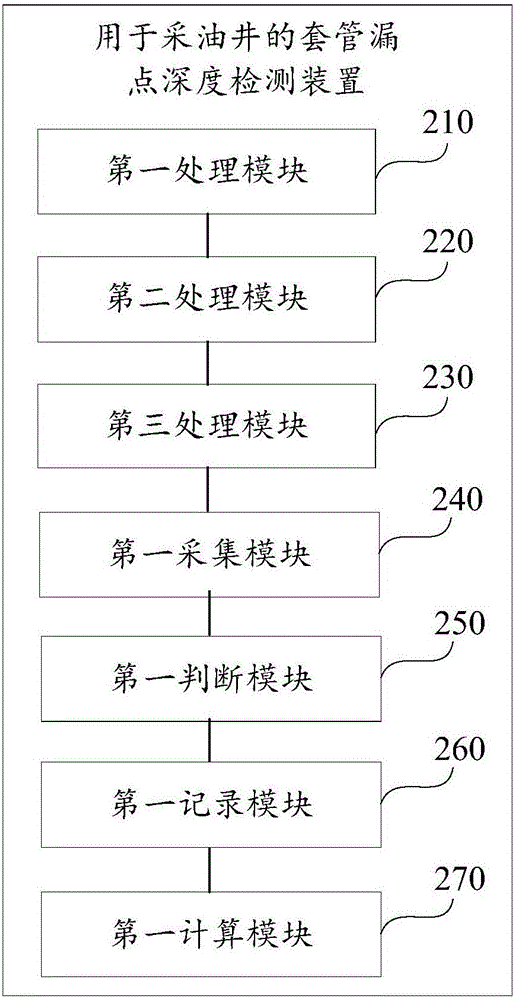

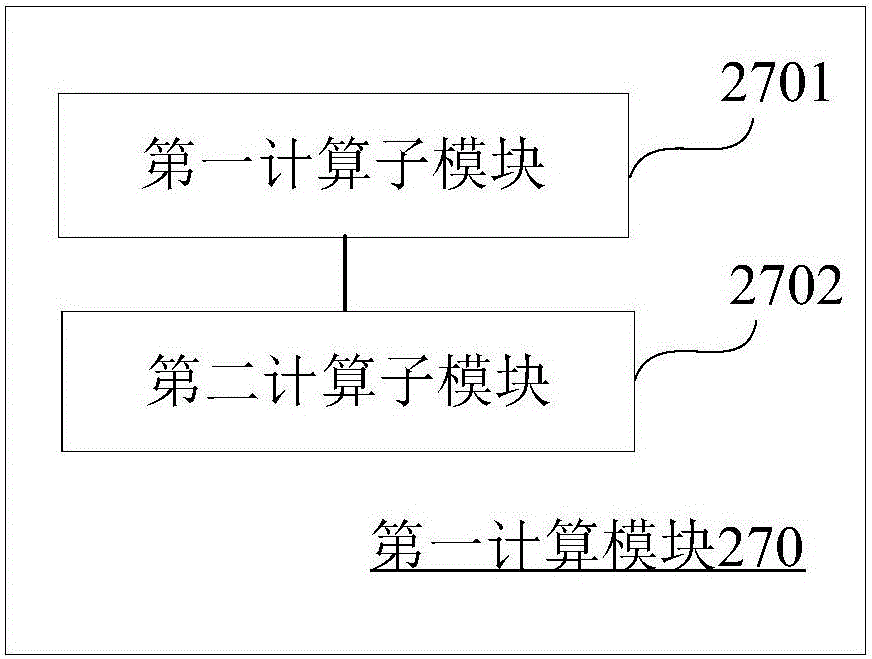

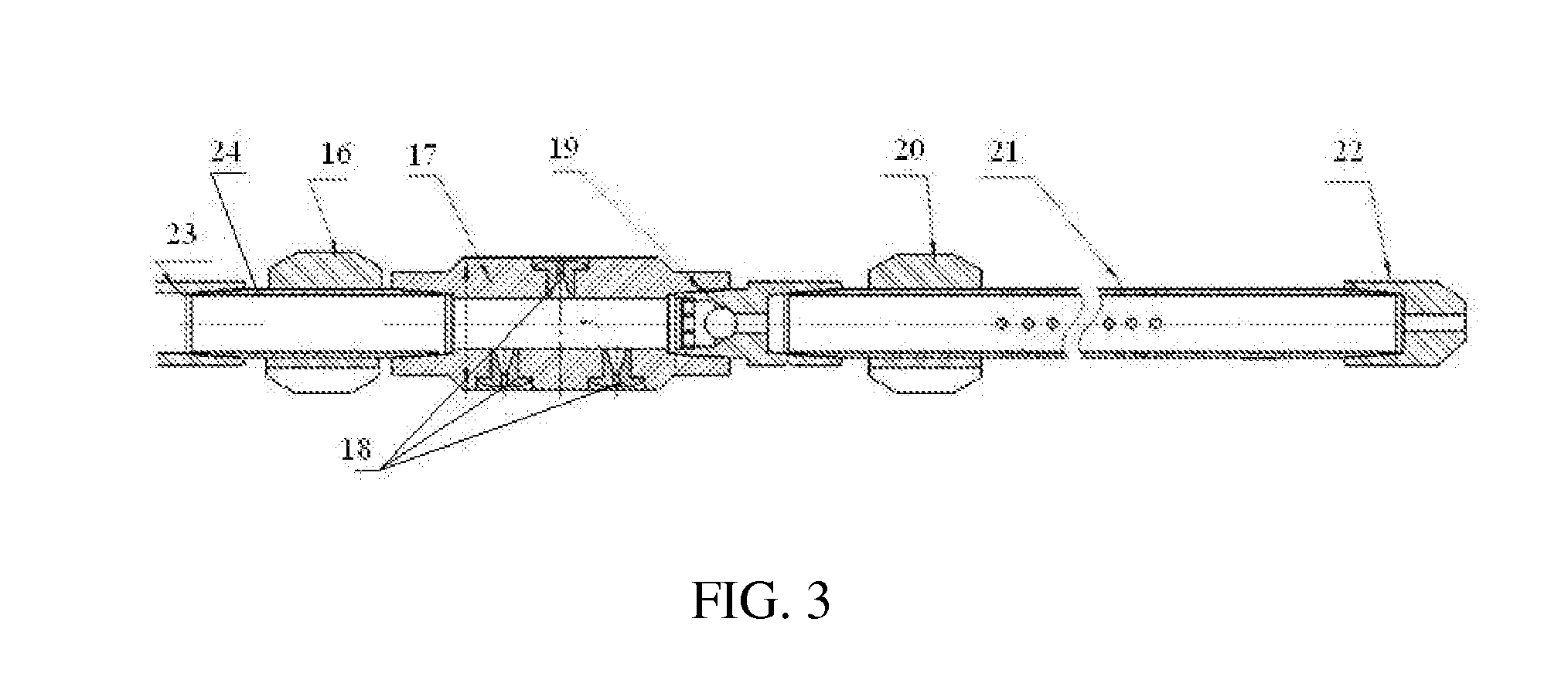

Casing leakage point depth detecting method and device for oil extraction well

The invention discloses a casing leakage point depth detecting method and device for an oil extraction well. According to the method, after fluid in a wellbore of the oil extraction well reaches a quiescent state, tagged particles are added into the wellbore, and the moment t when the tagged particles are added is recorded; then a decompression valve is opened to enable the annular pressure at a casing leakage point of the oil extraction well to be lower than the wellbore pressure of the oil extraction well, the purpose that the tagged particles can be sprayed out through the leakage point in a casing along with the fluid in the wellbore at a fast speed and impact the inner wall of an intermediate casing and the outer wall of an oil-string casing is ensured, and then impact signals on the casing walls are collected; the impact signals are compared and analyzed in real time through a computer, and the moment t1 in the impacting signals including the signals of impacting of the tagged particles on the casing walls is recorded and judged; and then the distance from a well mouth of the oil extraction well to the leakage point of the casing is calculated according to the formula (please see the specifications for the formula), so that quick and effective depth detecting of the casing leakage point is achieved, complexity and high cost of casing leakage point depth detecting are lowered, and assistance is provided for safe production of the oil extraction well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for generating power and producing cement clinker from oil shale slag and combustible gas

InactiveCN101143765ATake advantage ofAvoid pollutionCement productionMachines/enginesThermal energyCombustion chamber

The invention discloses a method for power generation and for making cement clinker with oil shale residue and flue gas, wherein, oil shale is fed into the an oil shale separator for heating and dry distillation to produce shale oil-gas, then shale oil, flue gas and oil shale residue can be obtained through treatment in a shale oil condenser. The oil shale residue and cement addictive can be crushed and mixed with flue gas prior to injecting into the combustion chamber of furnace, and then thermal energy can be generated through combustion to drive the generating unit for generating purpose. The shale slag following the combustion can be used as cement clinker directly. The invention employs directly the flue gas and shale oil residue generated in the process of dry distillation as the solid and gas flue to achieve thermal generation and cement clinker, thereby allowing comprehensive utilization of oil shale, avoiding environmental pollution and land consumption, which is suitable for shale oil extracting, cement clinker making and power generating application.

Owner:关范 +1

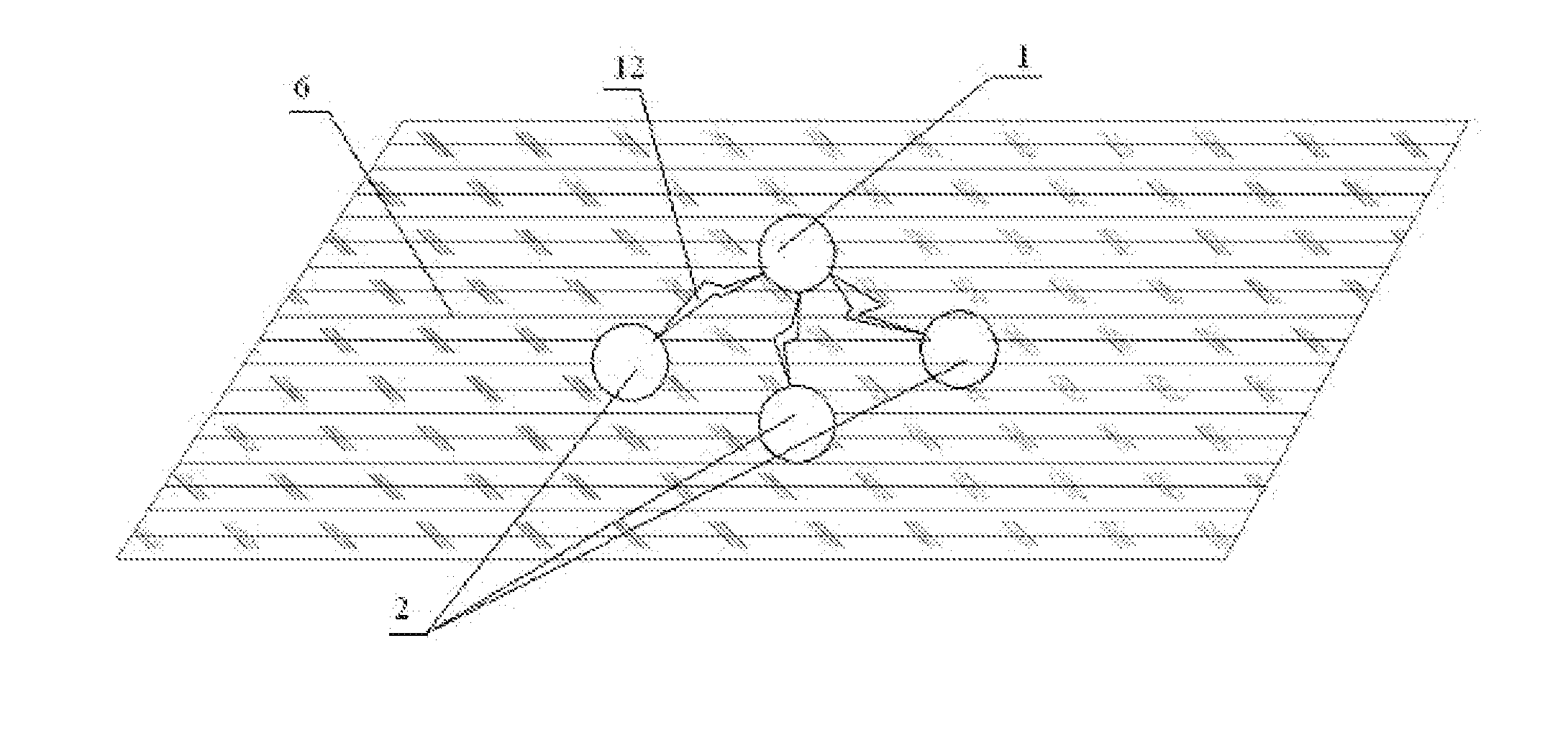

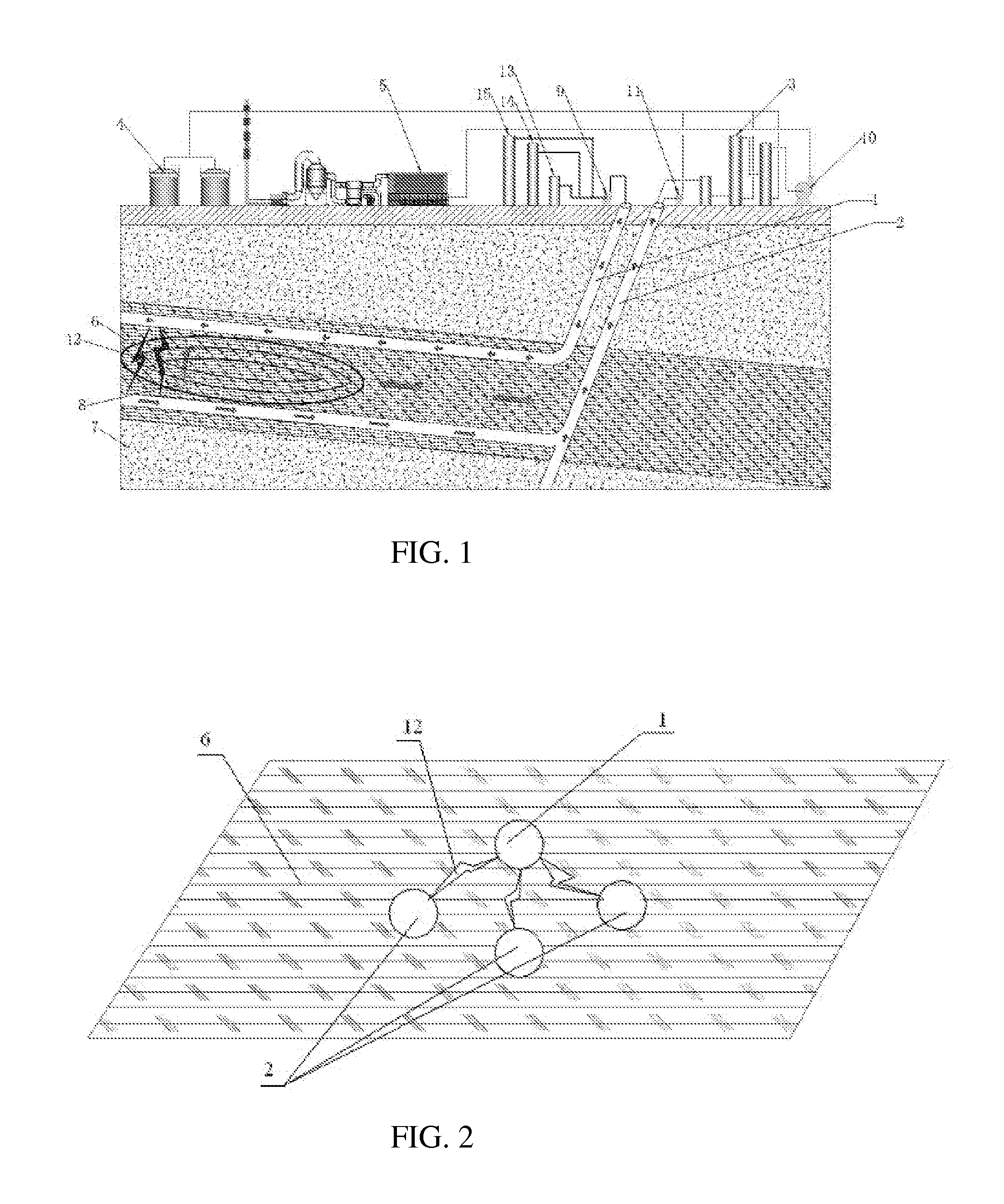

Method and process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ horizontal well

ActiveUS20160076350A1Avoid environmental pollutionSmall investmentArtificial islandsFluid removalOil shale gasHigh pressure

A method and a process for extracting shale oil and gas by fracturing and chemical retorting in oil shale in-situ horizontal well. An inclined well is drilled from the ground to the upper part of an underground oil shale stratum, and a horizontal well is drilled in parallel to the oil shale stratum in the upper part of the oil shale stratum. Behind the horizontal well and the inclined well in the upper part, an inclined well leading to the lower part of the oil shale stratum is drilled, and a horizontal well is drilled in parallel to the lower part of the oil shale stratum. Highly pressurized media (air, water, and quartz sand) are injected into the horizontal well in the upper part of the oil shale stratum, cracks of 1 to 3 mm are fractured in the oil shale stratum with the horizontal well in the upper part of the oil shale stratum serving as the center and are filled with a gap support, and, an oil and gas channel connecting the horizontal well in the lower part is established. A heating apparatus is added into the horizontal well in the upper part of the oil shale stratum, the oil shale stratum is heated to 550 DEG C., the oil shale is initially retorted, shale oil and gas are extracted, and the shale oil and gas are led out of the ground from the horizontal well in the lower part via the oil and gas passages, and then are introduced to an oxidant for oxidization reaction with asphaltenes and fixed carbon contained in the oil shale when retorted, where the heat generated is used as a heat source for subsequent retorting, thus implementing underground in situ shale oil extraction. The shale oil that is led out of the ground is separated via a ground-level gas-liquid separation apparatus, and the separated shale oil is transferred to a product oil tank for storage and sale, while a combustible gas is transferred to a combustible gas power generation apparatus for use in power generation. This solves the problem that existing ground-level retorting has in terms of large recovery costs, difficult treatment of tailings, a variety of environmental issues, and large land-use footprint. In addition, there disclose a process implementing the method and a nozzle used in the method.

Owner:JILIN ZHONGCHENG AUTOMOTIVE SERVICE CHAIN +1

Oil field comprehensive sewage treatment device

ActiveCN106045125AImplement extractionAchieve separationWaste water treatment from quariesFatty/oily/floating substances removal devicesWater qualitySmall footprint

The invention provides an oil field comprehensive sewage treatment device. A chemical feed pipe is arranged below a water inlet pope; an air floating tank is arranged on the other side of an oil separation tank; an inclined plate is arranged in the air floating tank; a sedimentation tank is arranged on the right side of the air floating tank; a scraper conveyor is arranged on the upper sides of the sedimentation tank and the air floating tank; an oil collection tank is arranged at the terminal end of a scraper of the scraper conveyor; the bottom of the oil collection tank is connected with an oil collection pump through a pipeline; the sedimentation tank is provided with a water outlet weir plate; a discharge tank is arranged on the outer side of the water outlet weir plate; the bottom of the sedimentation tank is connected with an air floating system through a pipeline; a water outlet pipe of the air floating system is connected with a dissolved gas release pipe. The oil field comprehensive sewage treatment device, aiming at the characteristic of high treatment difficulty of oil filed settled sewage, rinse water of water injection main lines and water for well-flushing, is short in treatment time and hydraulic retention time through crude oil separation, flocculant adding, air floating, sedimentation and matching with the inclined plate for treatment, can realize crude oil extraction and sludge separation in sewage, has the advantages of stable outlet water quality, system sludge minimization, small equipment investment, small floor space and no backflushing, and is beneficial to promotion and application.

Owner:大庆中科清溪水处理技术服务有限公司

Dehydrated demulsifier of crude oil extraction from thick oil pool

ActiveCN1952052AAdd lessExcellent demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationDemulsifierActive agent

The invention relates to a kind of dehydrator and emulsion-breaker as well as its preparing method. The characteristic of the invention includes: preparing two kinds of surface active agent; putting the active agents, N-ethyl perfluoro-octyl sulfamine polyoxyethylene ether into the reactor by turns, reacting at a certain temperature for some time to get a dry agent; putt the dry agent into the mixing caldron and dropping water into the caldron slowly to get the dehydrator and emulsion-breaker, the demulsificating and dehydrating effect is better than the present emulsion-breaker. The dehydrating process uses less dehydrator and emulsion-breaker; after the process, the water content of the crude oil is less than 0.2% which can fulfill the water content request; the oil content in the waste liquid has decreased from 20% to less than 50mg / l.

Owner:PETROCHINA CO LTD

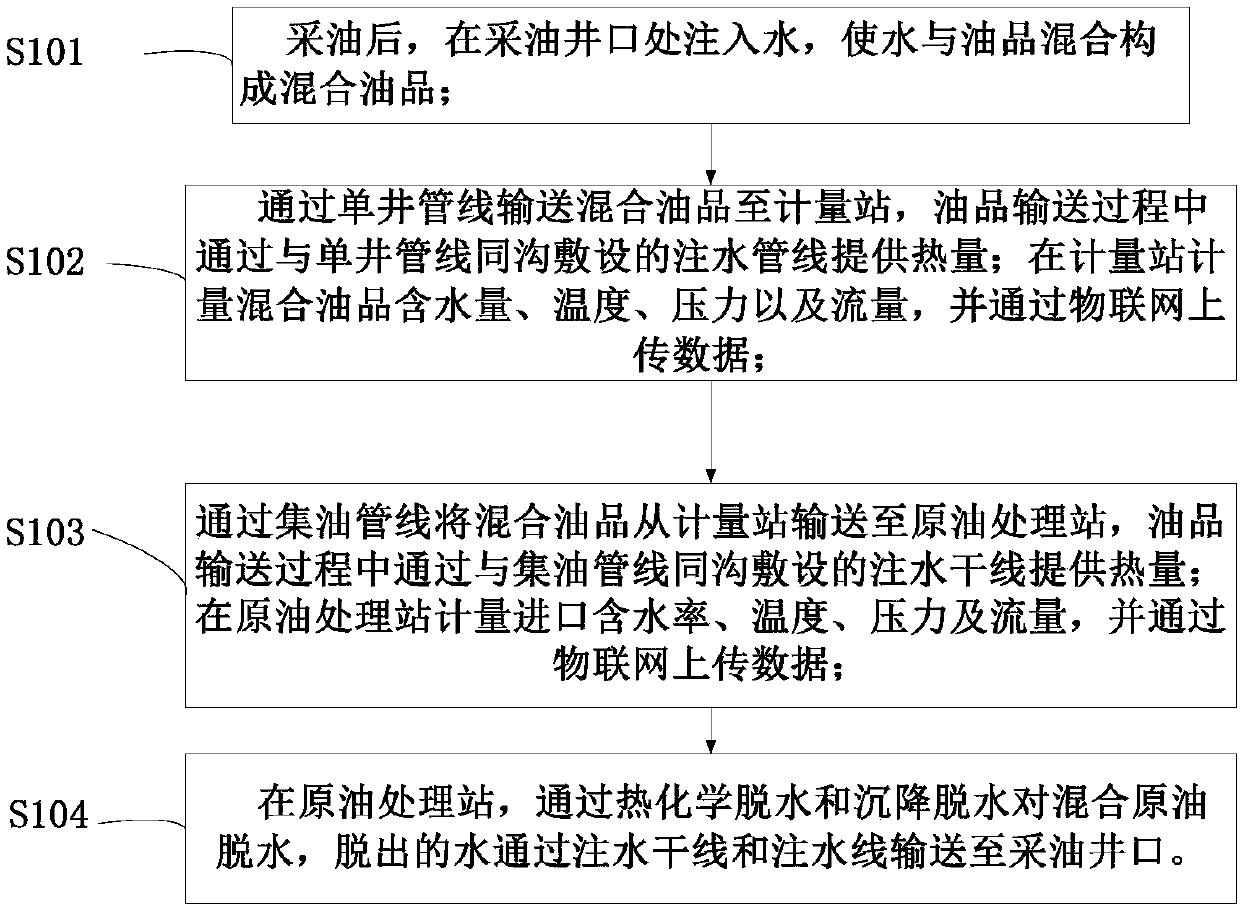

Thick oil extraction, gathering and conveying integrated process method based on Internet-of-things technology

InactiveCN107939346AReduce wasteEmission reductionFluid removalPipeline systemsThe InternetProcess engineering

The invention provides a thick oil extraction, gathering and conveying integrated process method based on an Internet-of-things technology. According to an existing oil extraction, gathering and conveying process, the segment production management mode is adopted, the thick oil gathering and conveying process adopts the single heating conveying mode, thus, unified management is disadvantageous, and energy is wasted; according to the thick oil extraction, gathering and conveying integrated process method based on the Internet-of-things technology, the heating conveying mode and the oil-in-wateremulsification viscosity reduction conveying mode are adopted in the gathering and conveying process for taking the synergistic effect so that energy waste can be reduced greatly, and carbon emissioncan be reduced; meanwhile, the oil extraction and oil gathering integrated process technology is adopted, and thus, unified management and maintenance are facilitated; and through the Internet of Things, data are allocated, compared and calculated in a unified mode, and various parameters are adjusted, so that the oil yield of an oil field can be improved, energy consumption is reduced, and costreducing and efficiency improving are achieved.

Owner:申娟

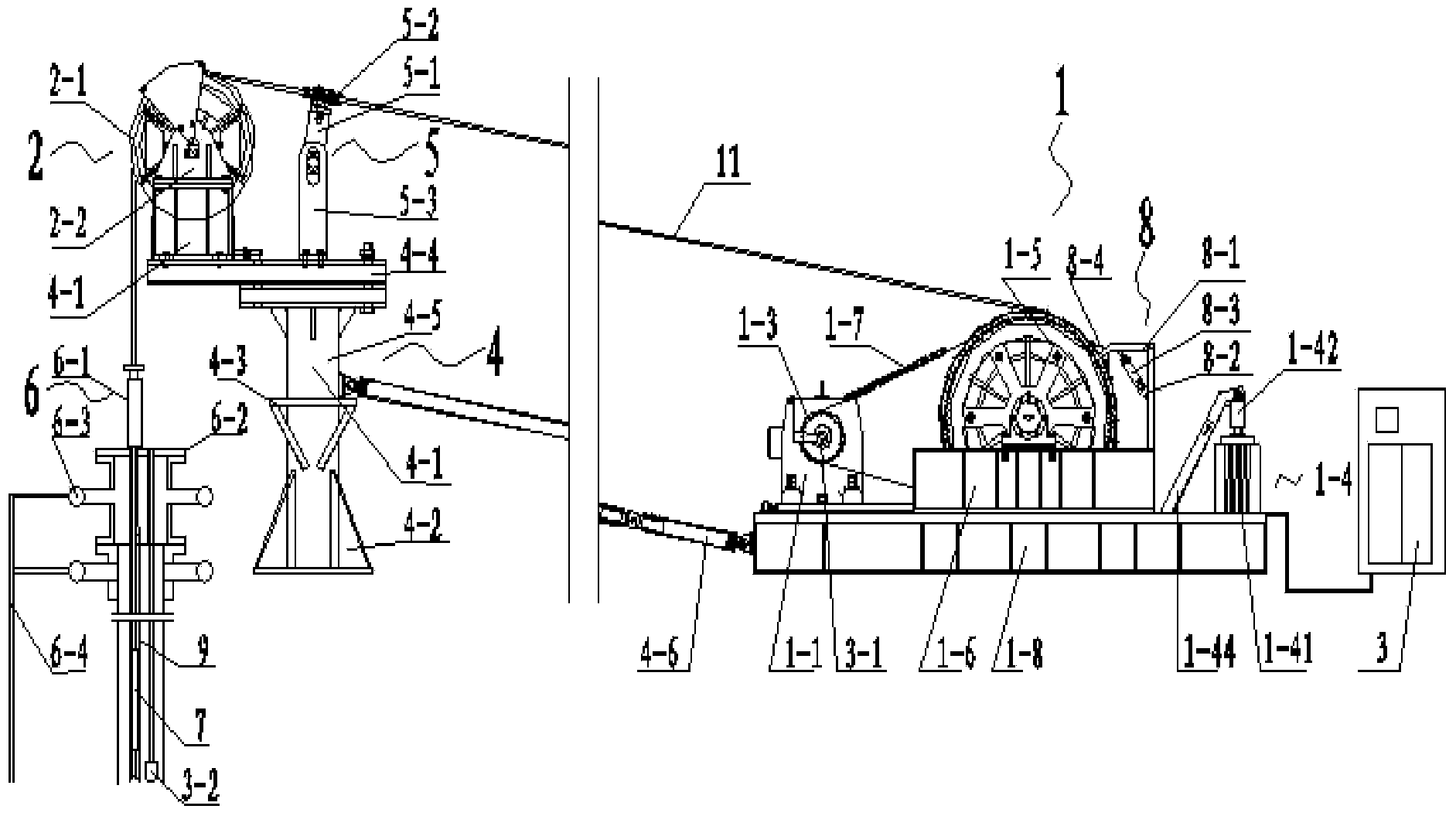

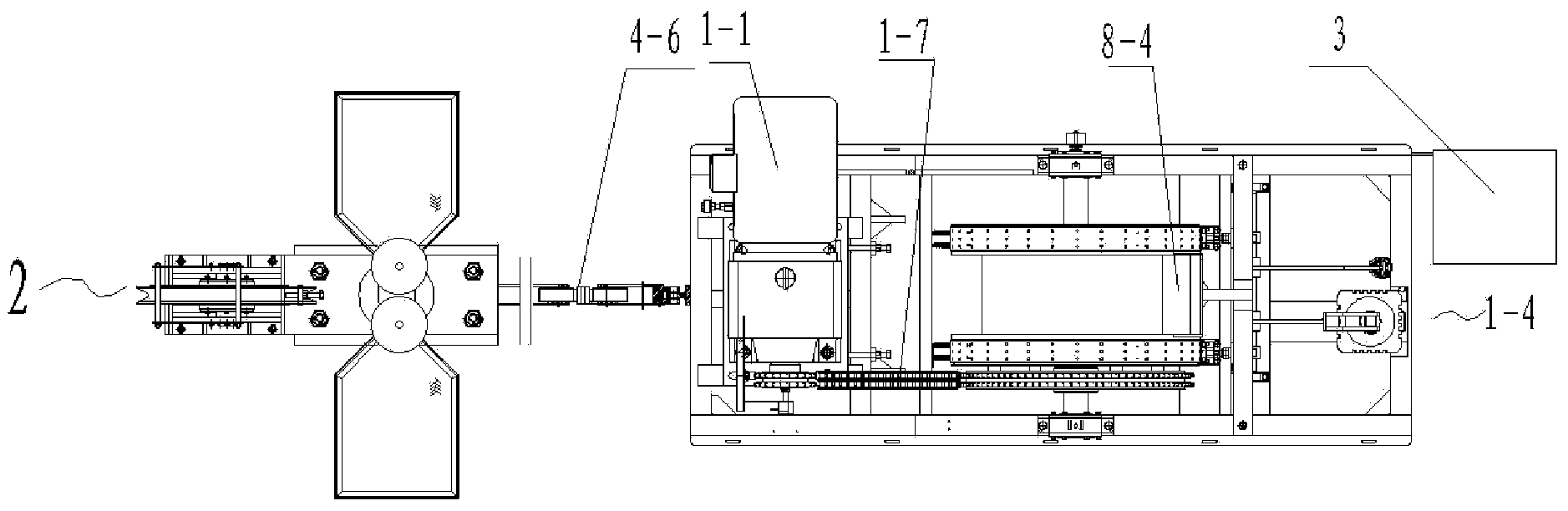

Short intelligent-control hoist type lifting oil extraction system with ultra long stroke and working method

The invention relates to a short intelligent-control hoist type lifting oil extraction system with an ultra long stroke and a working method. The oil extraction system comprises a motor, a winding drum, a fixed pulley, a derrick, a slide and swing device, a control assembly, an oil extraction rope and a down-hole multi-stage plunger ultra long stroke oil well pump; the control assembly controls the motor to start, rotate forwards and backwards and halt for waiting according to set parameters such as the stroke, down-hole liquid pressure, halt waiting time and the like; the winding drum is driven to rotate forwards and backwards and halt, the oil extraction rope on the winding drum drives multi-stage plungers of the down-hole multi-stage plunger ultra long stroke oil well pump to reciprocate at the set stroke in an ultra long pump cylinder, a whole well operation mode that a plunger of a conventional hoist type bailing oil extraction device lifts a well liquid from the well bottom to the well mouth is changed, a non whole well operation mode is realized, the whole unit structure is compact, the size is small, material consumption is reduced, energy is saved, the cost is reduced remarkably, and one-time investment of an oil well can be reduced by almost 40%. The short intelligent-control hoist type lifting oil extraction system with the ultra long stroke is applicable to a deep well, a stripper well and a heavy oil well, and the oil well yield-increasing effect is improved remarkably.

Owner:鄂德刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com