Method for generating power and producing cement clinker from oil shale slag and combustible gas

A technology of oil shale slag and cement clinker, which is applied in cement production, machines/engines, mechanical equipment, etc., and can solve problems such as high cost, poor economy, and impact on use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

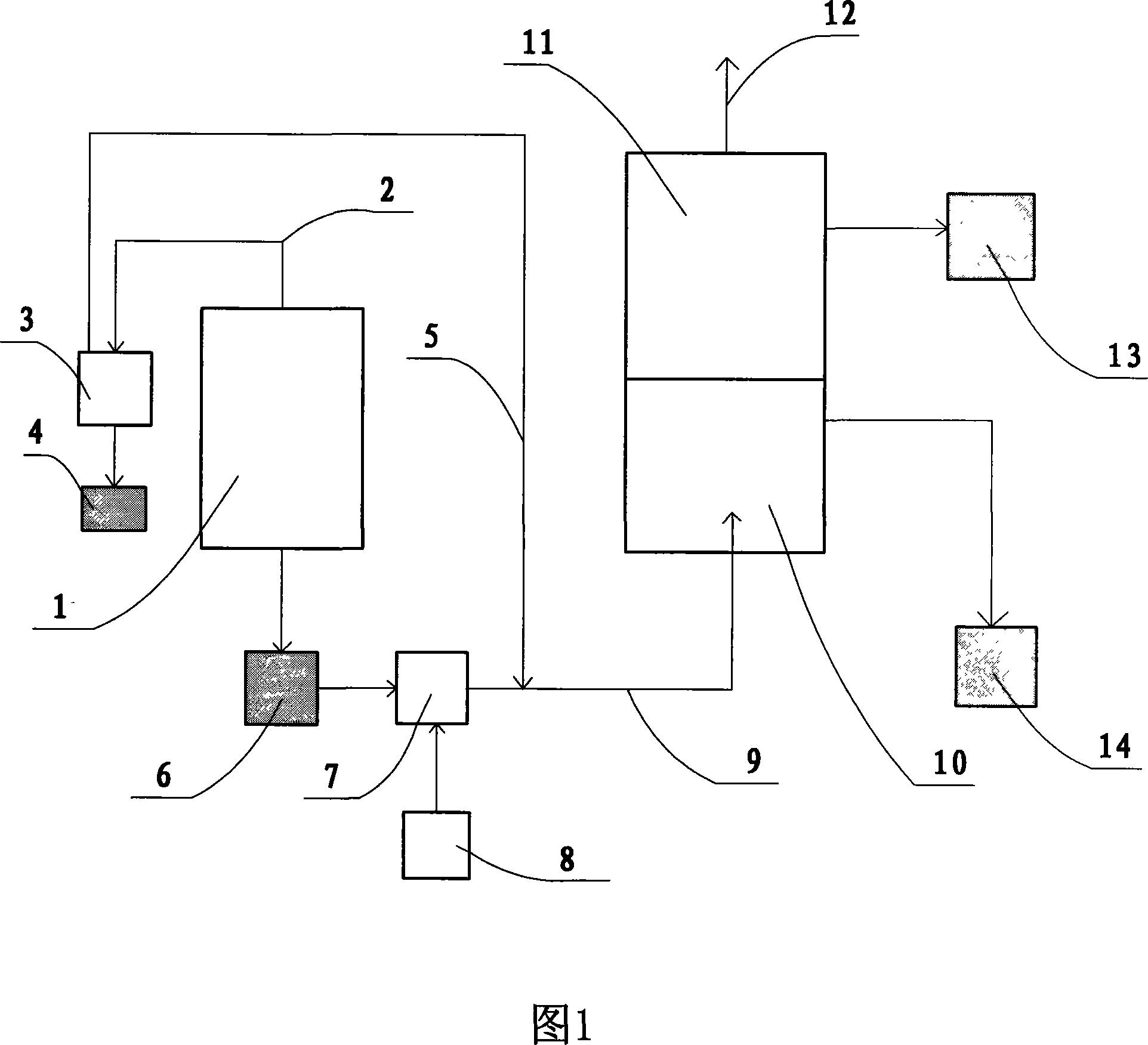

[0009] As shown in Figure 1, the oil shale is added to the oil shale dry distillation and extraction device 1 for heating and dry distillation, and the oil shale is affected by the temperature, and the organic volatiles volatilize to form shale oil gas 2, and the shale oil gas passes through the shale oil condenser 3 Condensate to obtain shale oil 4, and combustible gas 5 is separated from the condenser. After dry distillation, the shale slag 6 is taken out from the dry distillation device, and the shale slag and cement additive 8 are pulverized into powder by a pulverizer 7 and mixed with combustible gas to form a mixed flow 9 of shale slag and combustible gas, which is sprayed into the combustion chamber 10 of the electric fluidized fluidized furnace 11 Combustion in the furnace emits heat, and the furnace body is heated to make the water form steam, which drives the generator set 13 to generate electricity. The shale slag is fully burned in the combustion chamber to reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com