Oil field comprehensive sewage treatment device

A sewage treatment device and oilfield technology, applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the secondary pollution of oilfield water quality troubled by large investment, recovery and treatment Governance, long processing time and other problems, to achieve the effect of small investment in equipment, favorable promotion and use, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

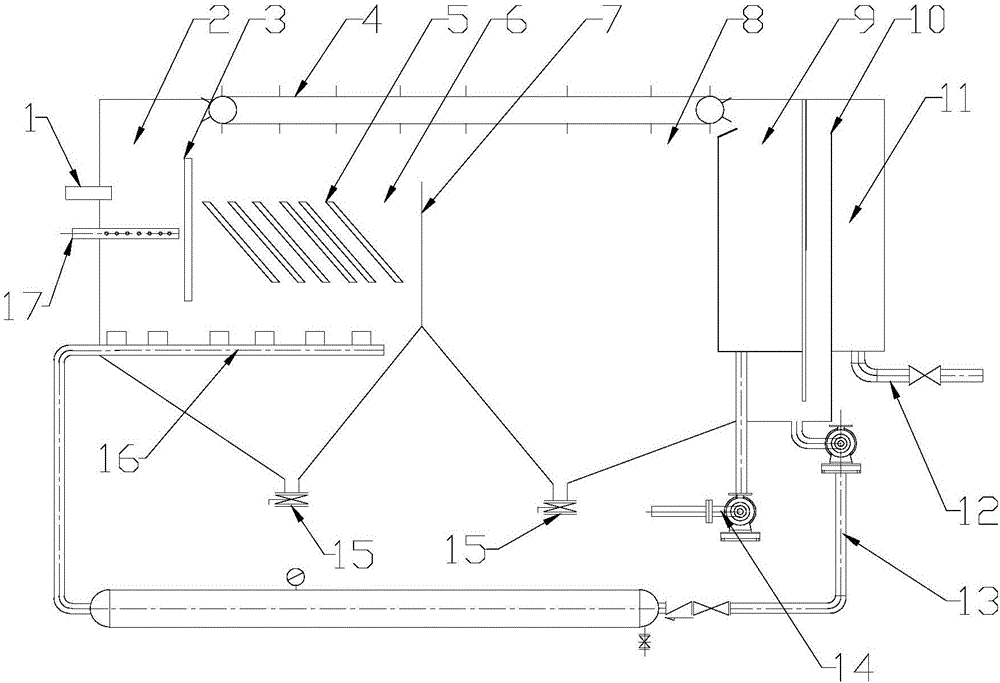

[0011] Depend on figure 1 As shown, the oil field comprehensive sewage treatment device includes a water inlet pipe 1, which is located in the middle of one side of the grease trap 2, and a dosing pipe 17 arranged in parallel is arranged below the water inlet pipe 1, and the dosing pipe 17 extends into the oil trap Inside the tank 2, an oil separator 3 is provided on the other side of the grease separator 2, and the inner side of the oil separator 3 is an air flotation tank 6, and a slant plate 5 is arranged inside the air flotation tank 6, and the air flotation tank 6 communicates with the bottom of the grease separator 2, The lower part of the position where the air flotation tank 6 communicates with the bottom of the grease trap 2 is the dissolved air release pipe 16 of the air flotation system 13, and the right side of the air flotation tank 6 is provided with an air fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com