Patents

Literature

126results about How to "Adjustable molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

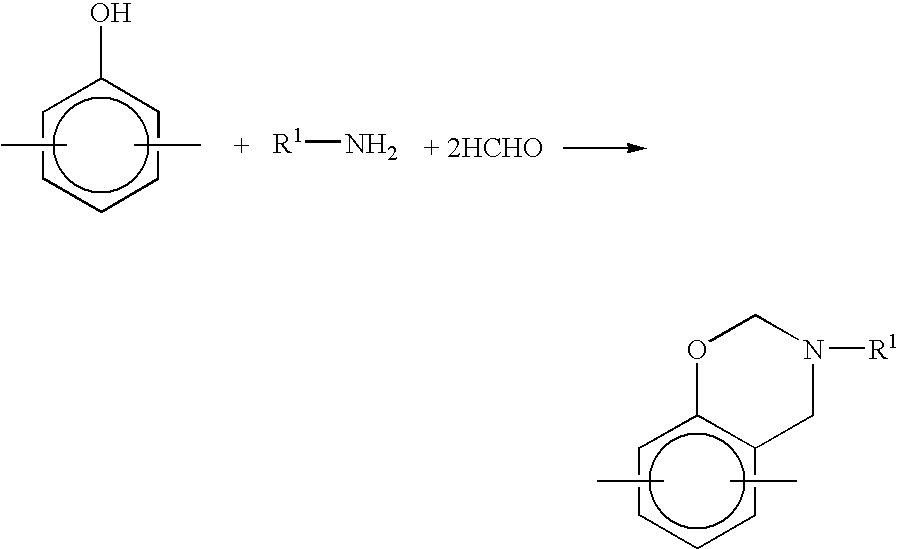

Method for producing benzoxazine resin

InactiveUS7041772B2Improve efficiencyPromote safe productionNatural resin processChemical/physical/physico-chemical stationary reactorsOrganic solventReaction system

The present invention discloses a process for producing a benzoxazine resin which comprises the steps of reacting a phenol compound, an aldehyde compound and a primary amine in the presence of an organic solvent to synthesize a benzoxazine resin and removing generated condensation water and the organic solvent from a system under heating and a reduced pressure, wherein a pressure in the reaction system at the time of removal is set to 260 mmHg or higher.

Owner:HITACHI CHEM CO LTD

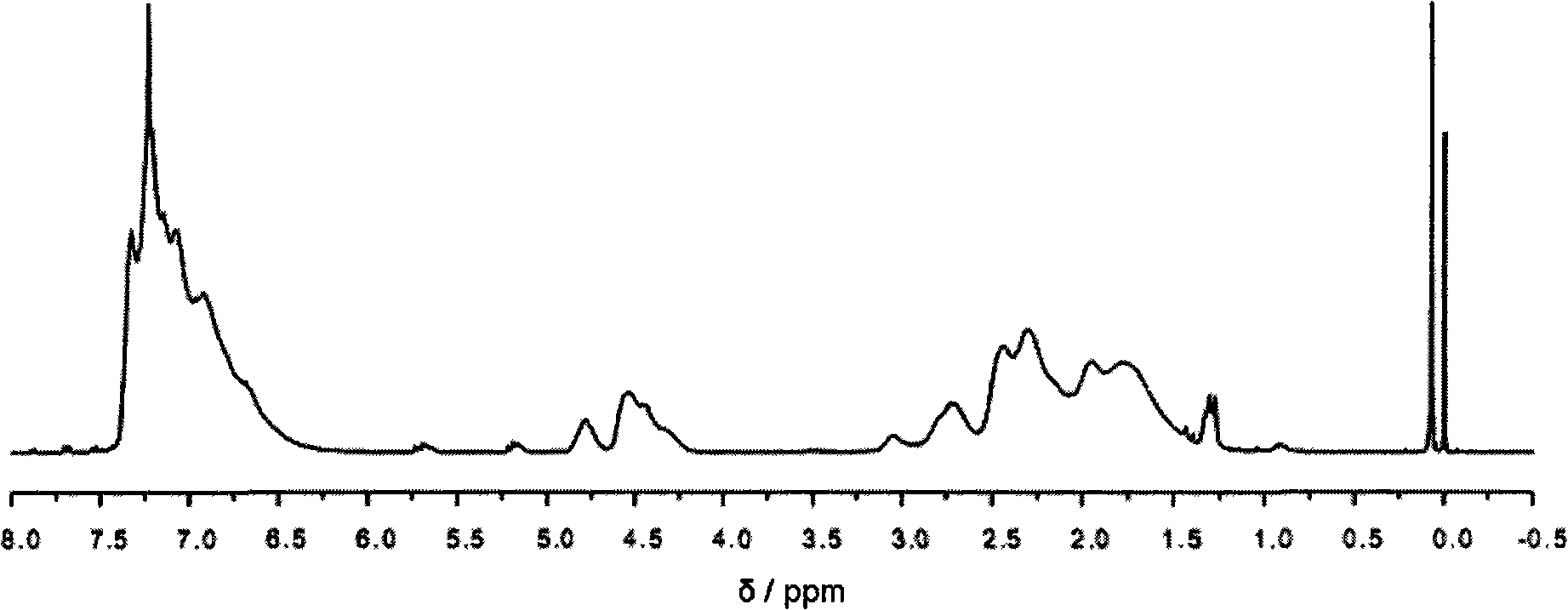

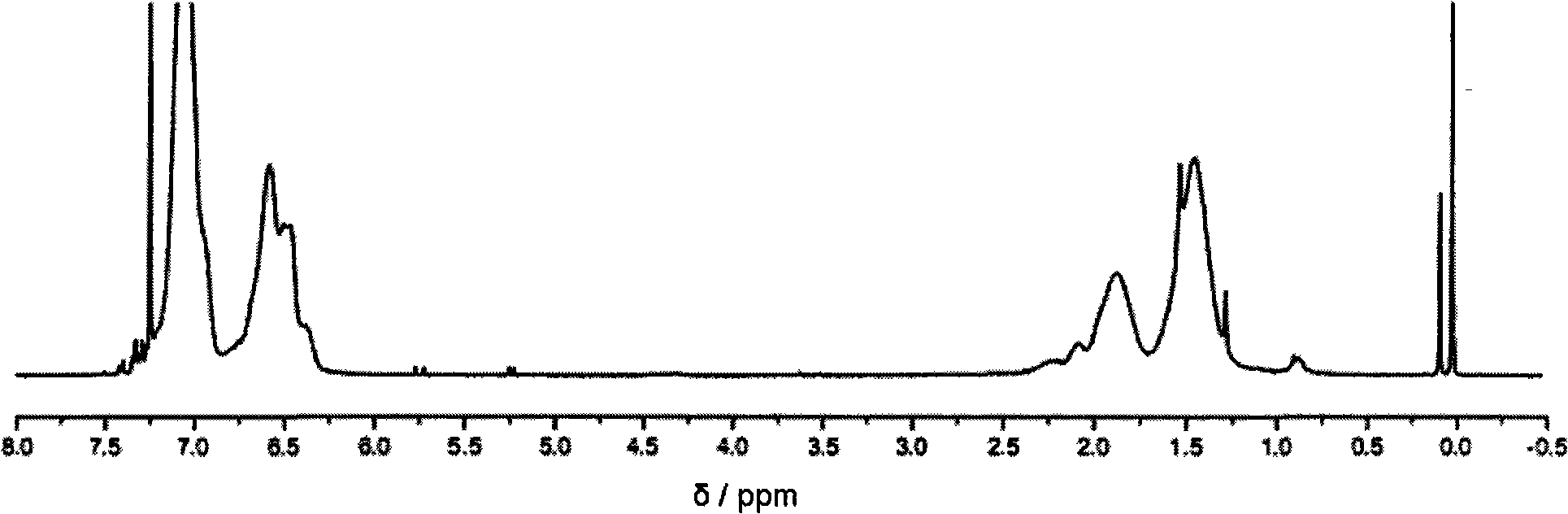

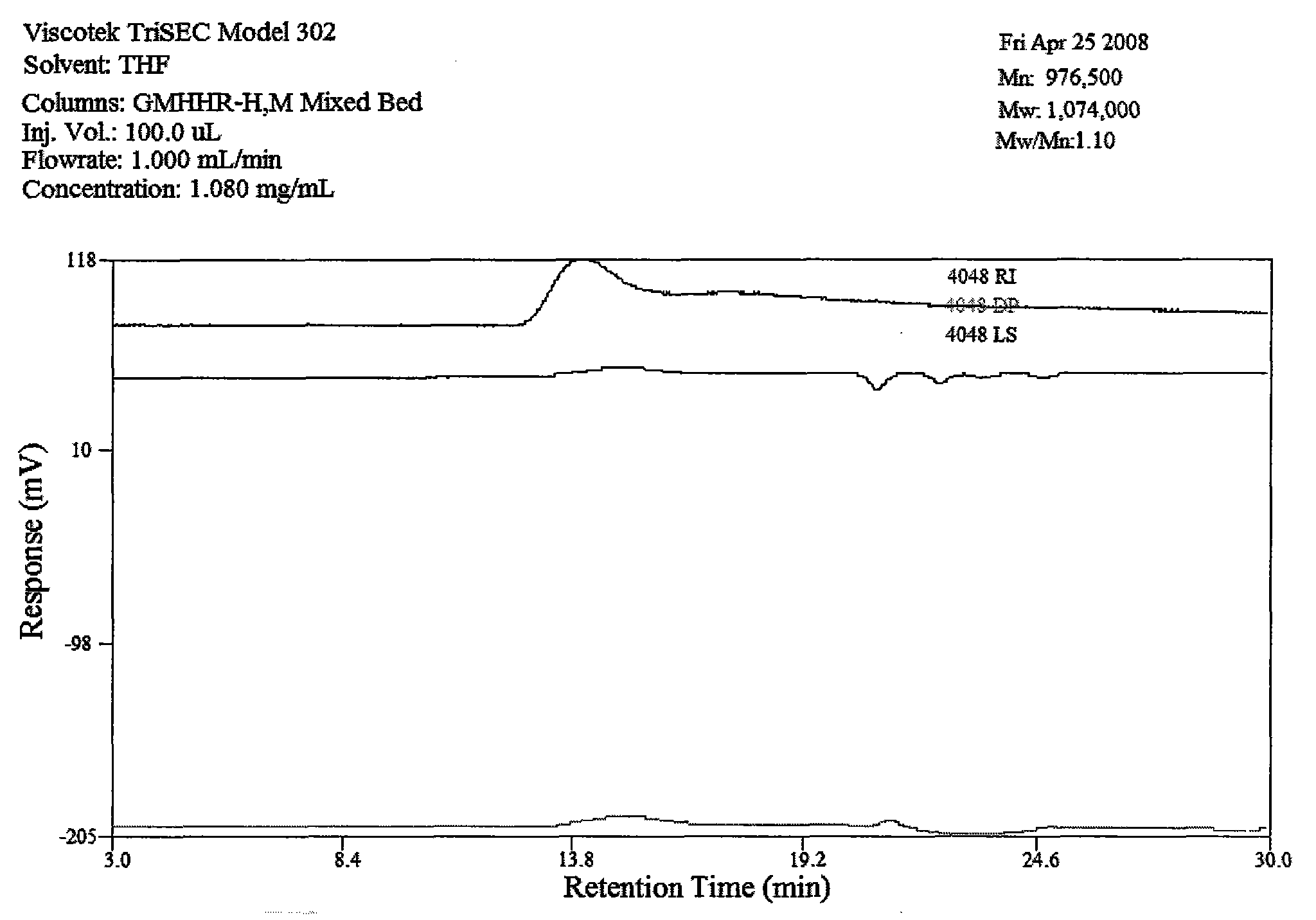

Multi-arm star-type polymer and preparation method thereof

The invention discloses a multi-arm star-type polymer and a preparation method thereof. The method synthesizes the multi-arm star-type polymer by a method with the following two steps of step one: taking a complex formed by a polydentate nitrogen-contained compound and a transitional metal halide as a catalytic system so as to catalyze the polymerization of atom transfer free radicals and self-condensing vinyl of a monomer, thus preparing and obtaining the halogen atom-contained hyperbranched polystyrene macromolecular initiator taken as the star-type polymer core; and step two: taking the complex formed by the the polydentate nitrogen-contained compound and the transitional metal halide as the catalytic system and taking the prepared halogen atom-contained hyperbranched polystyrene macromolecular as the initiator to initiate the polymerization of the atom transfer free radicals of the monomer, thus preparing and obtaining the multi-arm star-type polymer with controllable core structure, core size, core property, arm number, arm length and arm property and adjustable molecular weight within wider range.

Owner:INST OF CHEM CHINESE ACAD OF SCI

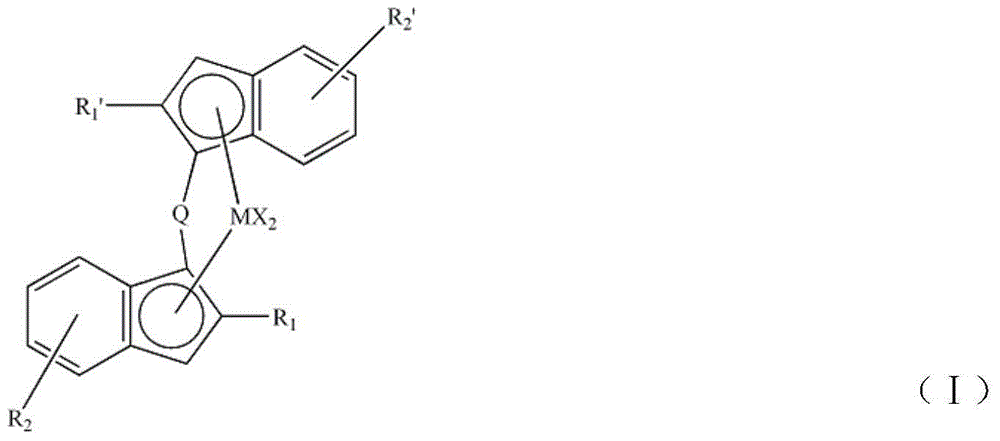

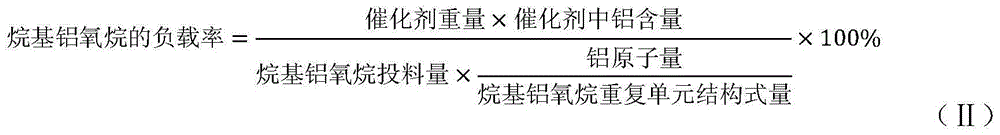

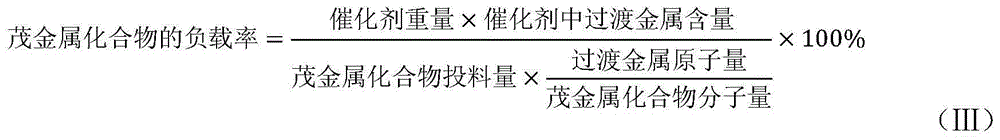

Preparation method of polypropylene wax

The invention relates to a preparation method of polypropylene wax. The method is characterized in that a liquid phase bulk polymerization technology is used, a supported metallocene catalyst is used, hydrogen is adopted as a molecular weight regulator, and a granular polypropylene wax product is directly obtained through catalyzing liquid propylene polymerization. The propylene polymerization reaction activity is not lower than 1000 times / h. The method has the characteristics of simple operation and high polymerization reaction activity, and the molecular weight of the polypropylene wax product obtained in the invention is adjustable and has narrow distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

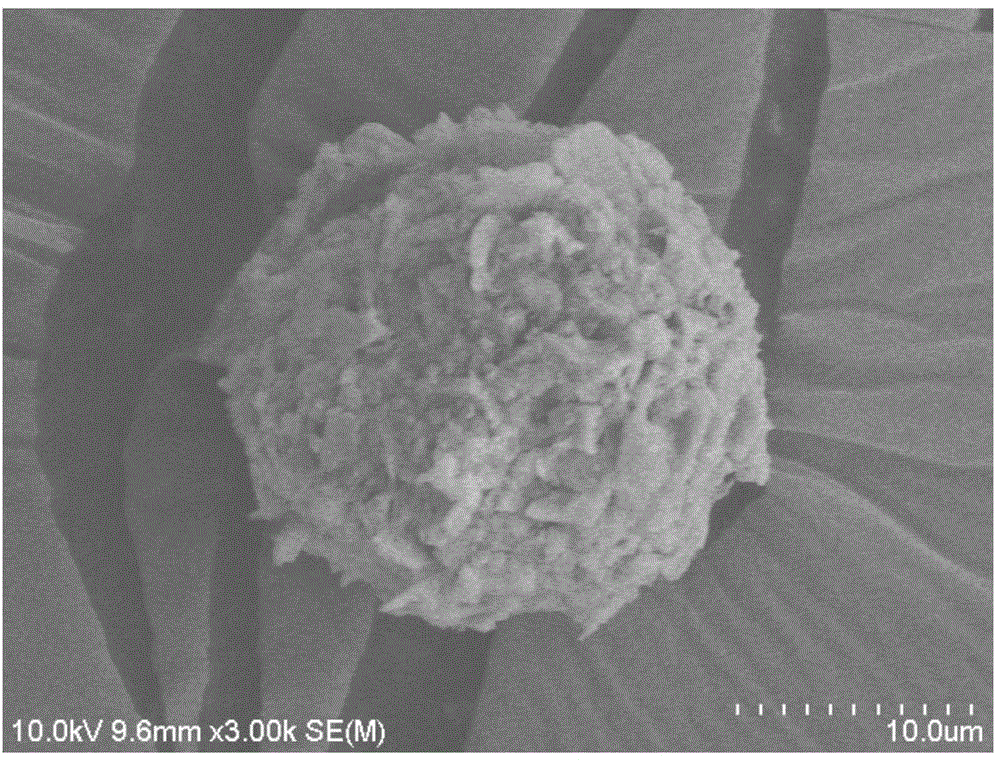

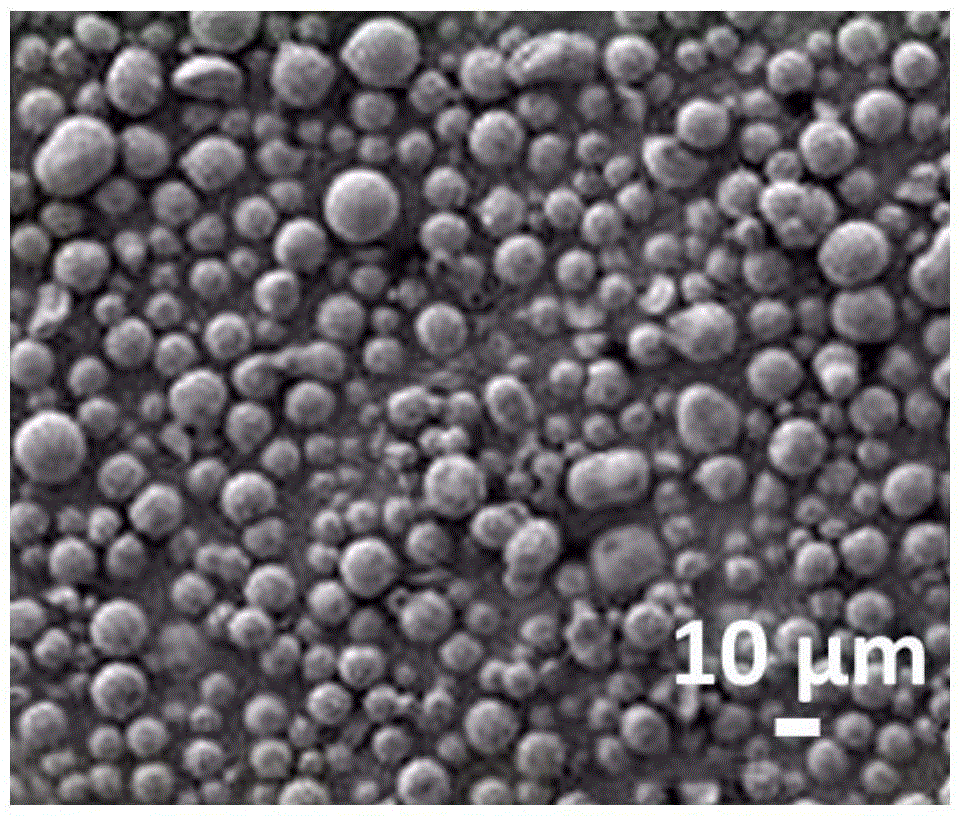

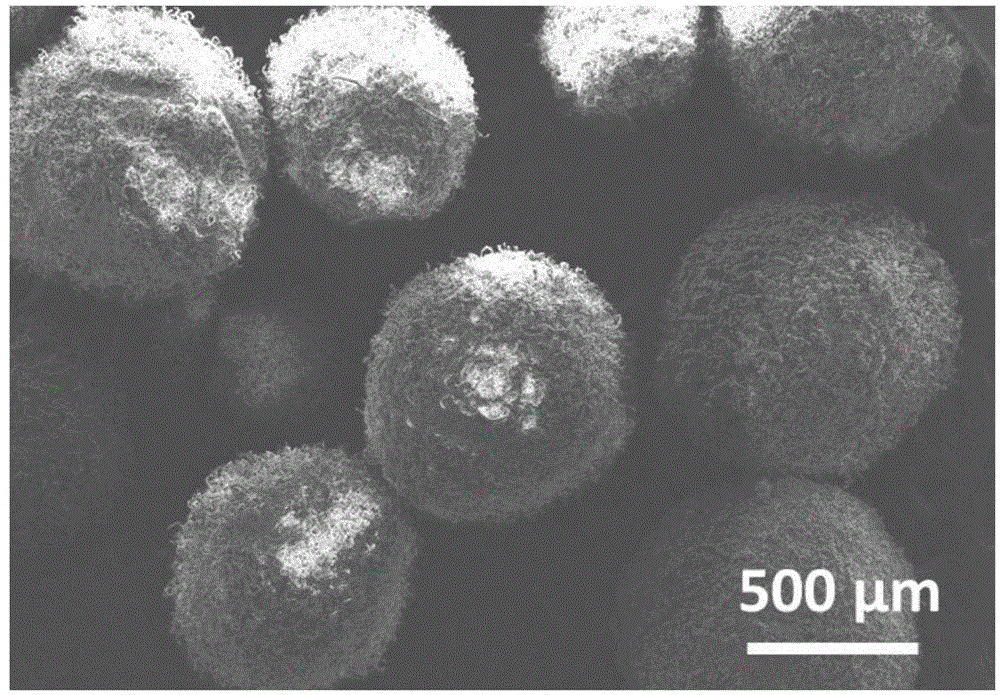

Polypropylene nanocomposite material capable of being used for 3D printing, and preparation method and application thereof

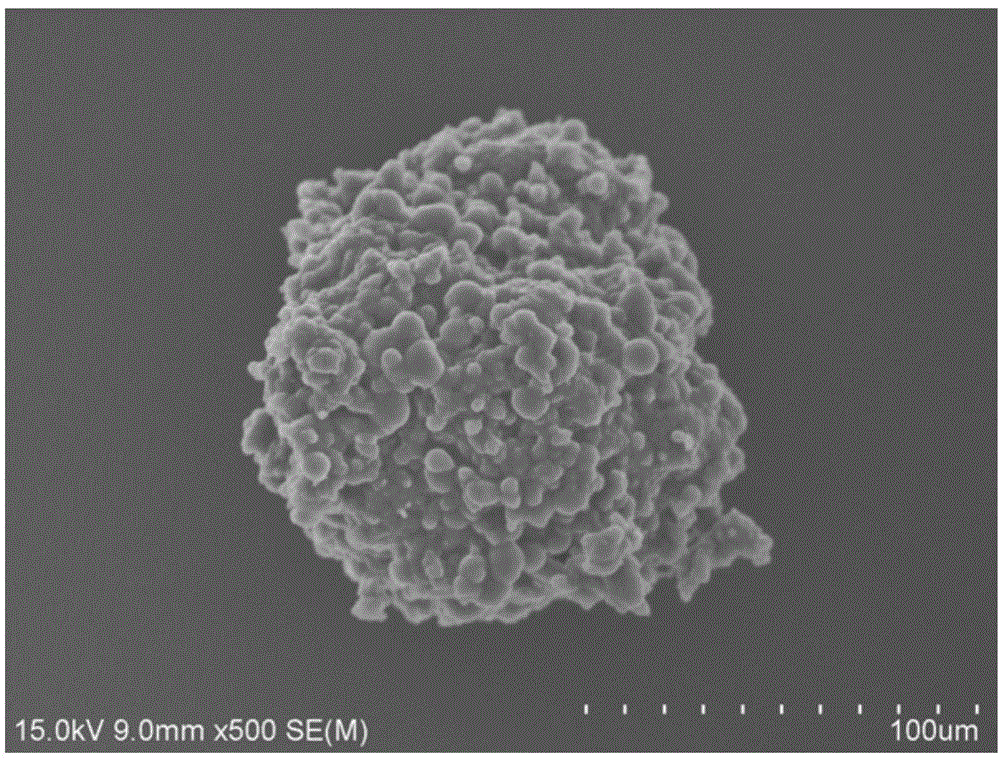

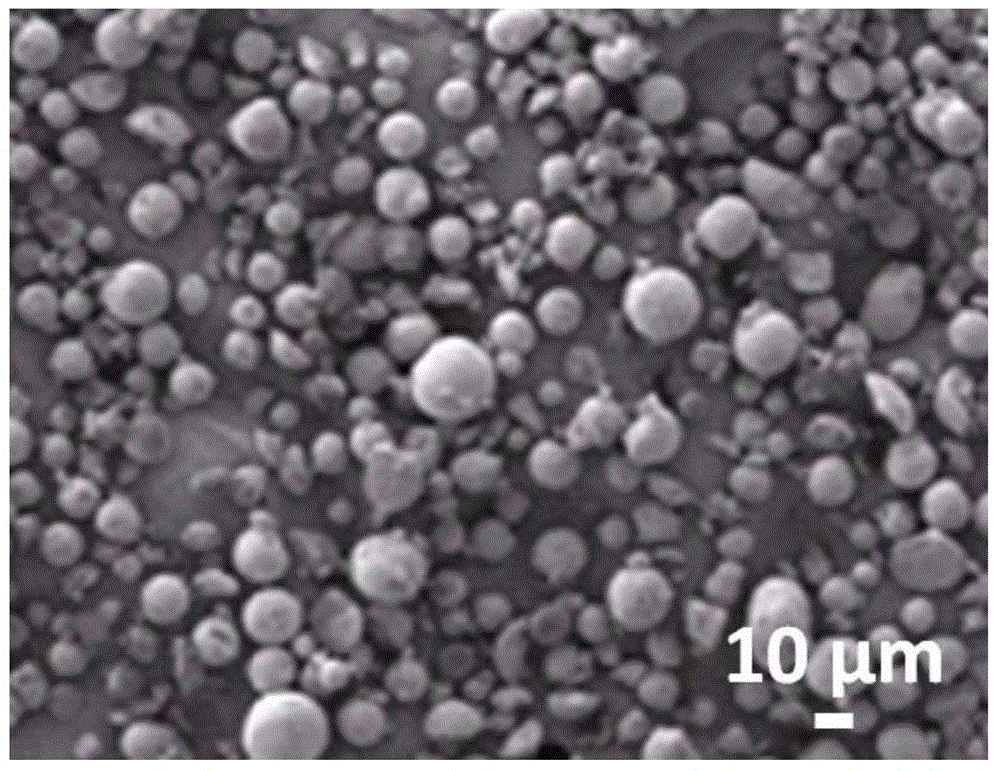

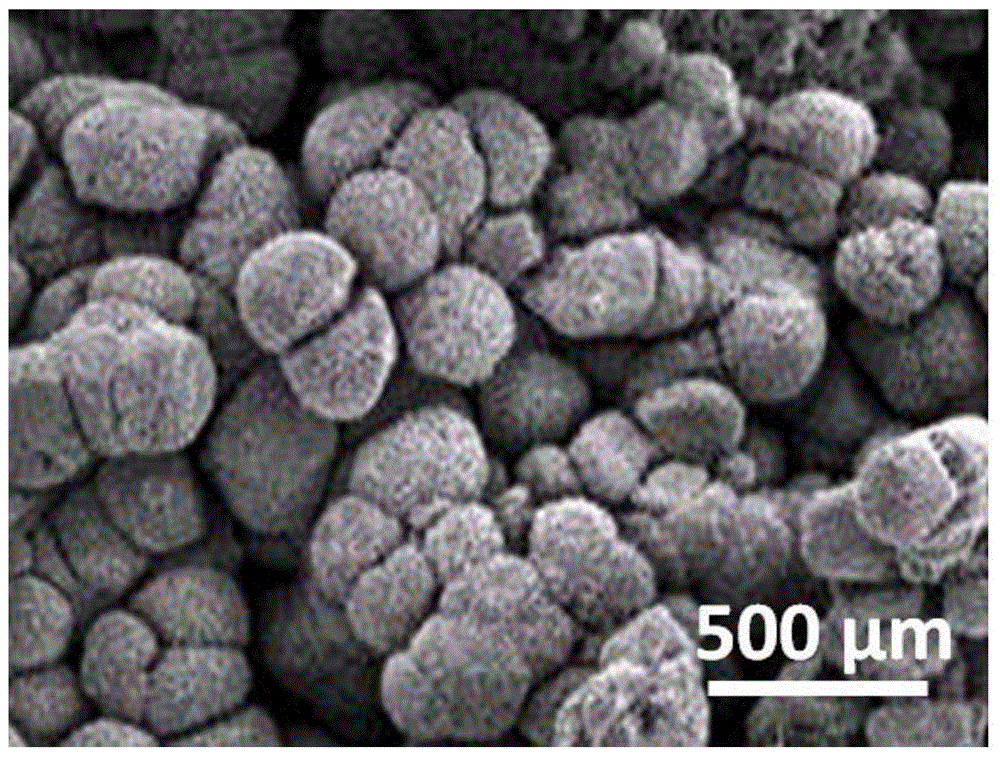

The invention discloses a polypropylene nanocomposite material capable of being used for 3D printing, and a preparation method and an application thereof. The polypropylene nanocomposite material is obtained by utilizing a catalyst including a nanoparticle carrier-type catalyst and catalyzing propylene to polymerize; the composite material is granular in shape, and the particle diameter is 50-1000 [mu]m. Because the composite material has small and uniform particle morphology, the composite material can be directly used as a raw material of 3D printing by adding a heat stabilizer, and is especially suitable for 3D printing prepared polypropylene nanocomposite material products which have high melt viscosity and are difficult to process and mold.

Owner:INST OF CHEM CHINESE ACAD OF SCI

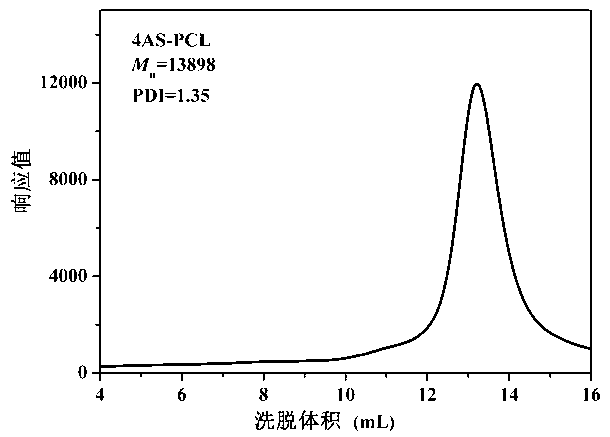

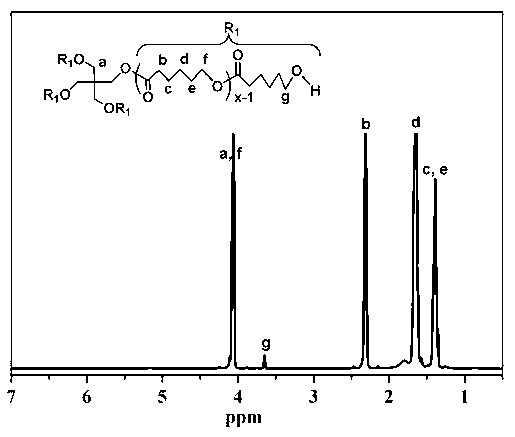

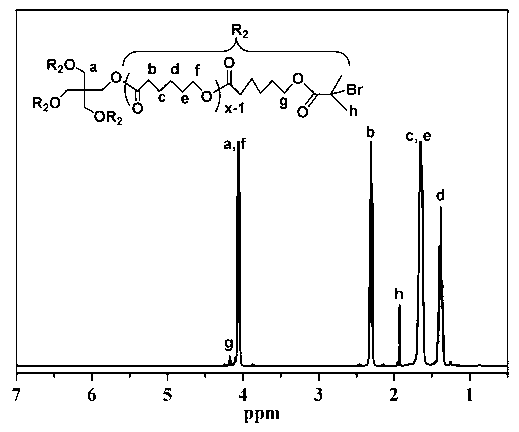

PH response four-arm star block copolymer and preparation method and application thereof

InactiveCN102702454AEasy to operateMild reaction conditionsPowder deliveryPharmaceutical non-active ingredientsAcylationRing-opening polymerization

The invention discloses pH response four-arm star block copolymer and a preparation method and application thereof. According to the copolymer, pentaerythritol is used as an inner core, each arm is connected with a hydrophobic group, a pH response group and a hydrophilic group; and the preparation method comprises the following steps of: performing ring opening polymerization on pentaerythritol to obtain hydrophobic group copolymer, performing acylation on the tail end of the hydrophobic group copolymer, and sequentially initiating pH response monomer and the hydrophilic group to perform electron transfer activating agent regeneration-atom transfer radical polymerization by using hydrophobic group copolymer of which the tail end is subjected to acylation and which is used as macroinitiator to obtain the pH response four-arm star block copolymer. The copolymer is self-assembled into nano micelle in an aqueous solution, so that insoluble medicines can be effectively solubilized; the copolymer is used for preparing a micelle medicine carrying system for insoluble anti-cancer medicines, and the medicines can be kept to be slowly released when pH of normal tissues is 7.4, and can be quickly released in a controllable way under the faintly acid condition that pH of cancer cells is 5 to 6; and the proportion of foundational groups of the copolymer is easy to control, and the copolymer is simple in synthesis process and high in yield.

Owner:SOUTH CHINA UNIV OF TECH

Long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method

InactiveCN104497312AImprove utilization efficiencyImprove conversion rateSilicon organic compoundsNitrogen gasAlpha-olefin

The invention discloses a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method. The method includes the steps of subjecting tetramethyl tetra-hydrogen cyclotetrasiloxane and a catalyst of chloroplatinic acid to reaction, dropping styrene for reaction for some time, dropping long-chain alpha-olefin and a chloroplatinic acid isopropyl propanol solution to obtain an intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, subjecting the obtained intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, octamethylcyclotetrasiloxane, hexamethyldisiloxane and an acid catalyst to full reaction, fully cooling the obtained liquid, slowly adding calcium hydroxide to adjusting the PH value to 6-7, filtering out solids produced in neutralization with a vacuum pump, adding anhydrous magnesium sulfate to adsorb water produced in neutralization, and filtering to obtain a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent. The long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent prepared through the preparation method has the advantages of being simple in process, high in efficiency, low in cost, short in cycle and the like.

Owner:仪征市新源新材料科技有限公司

Process for preparing a flexographic printing plate from a photopolymerizable element

InactiveUS20060160025A1High color contrastSufficient color contrastPhotosensitive materialsSemiconductor/solid-state device manufacturingLeuco dyeEngineering

This invention relates to a photosensitive element for use as a flexographic printing plate and a process for preparing the plate from the element. The photosensitive element has at least one photopolymerizable elastomeric layer that comprises a binder, a monomer, a photoinitiator, an onium salt, and a leuco dye. Upon exposure to actinic radiation, the onium salt and leuco dye react resulting in a change of color in polymerized portions of the photopolymerizable layer. The color change provides enhanced image color contrast in the photosensitive element.

Owner:DUPONT ELECTRONICS INC

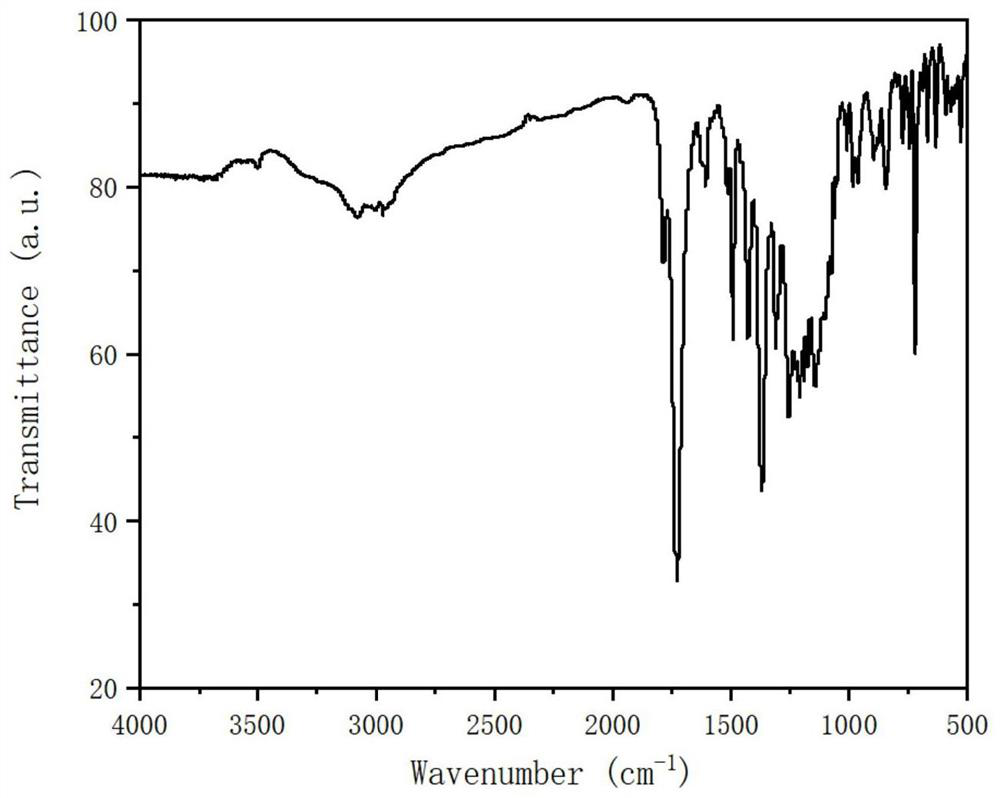

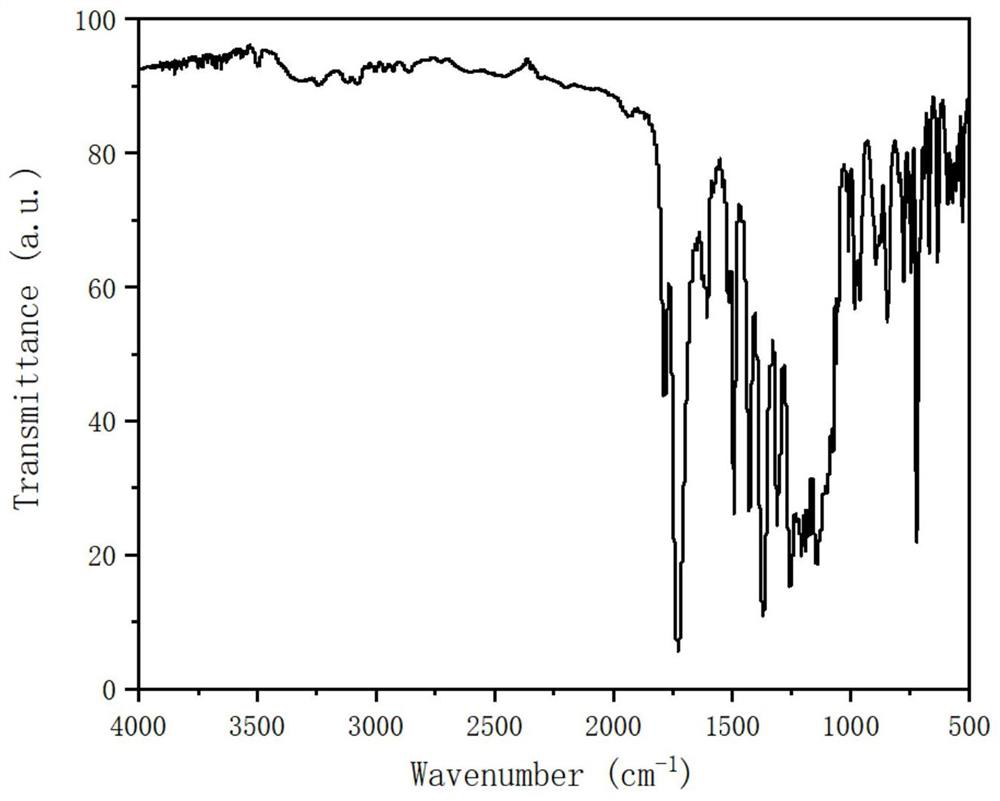

Metal composite catalyst for alkene polymerization and preparation method thereof

This invention relates to a preparation method of metal composite catalyst usd for olefinic polymerization. This metal composite catalyst includes : component I: a sort of Ti compound free of metal -PI bond; component II: one or more Ti at least containing one metal - PI bond, Zr, transition metal compound of V or Hf; component III: a sort of magnesium halide; component IV: : a sort of aluminium alkyl oxygen alkane or aluminium alkyl; component V: a sort of inside electron donor. This invention compound not homogeneous phase Ziegler - Natta catalyzer with metallocene catalyst component, not only be able to obtain polymer that has adjustable molecular weight at very widely extension and metabolic molecular weight distribution, furthermore may be able to may be able to adequate to production of adjustable polyolefine alloying, possess extensive application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

pH-responsive 6-arm star block copolymer and preparation method and application thereof

InactiveCN102702453AEasy to operateMild reaction conditionsPowder deliveryPharmaceutical non-active ingredientsAcylationRing-opening polymerization

The invention discloses a pH-responsive 6-arm star block copolymer and a preparation method and application thereof. In the structure of the copolymer, pentaerythritol is adopted as a kernel, and each arm is connected with a hydrophobic group, a pH-responsive group and a hydrophilic group. The preparation method comprises the steps of: carrying out ring opening polymerization of the pentaerythritol to obtain a hydrophobic group polymer, carrying out acylation of the end of the hydrophobic group polymer to prepare a macromolecular initiator, carrying out sequential initiation of regeneration of an electron transfer activator for a pH-responsive monomer and the hydrophilic group, i.e. radical polymerization for atom transfer, thereby obtaining the pH-responsive 6-arm star block copolymer. The polymer is self-assembled into nano micelles in aqueous solution, the dissolution of water-insoluble drugs can be enhanced effectively, the polymer can be applied in preparation of a micelle carrying system for water-insoluble anticancer drugs, and the drugs can be released slowly when the pH of normal tissues is 7.4 and rapidly in a controlled way under acidic conditions when the pH of tumor cells is 5-6; and the proportion of functional groups can be easily adjusted, the synthesis process is simple, and the yield is higher.

Owner:SOUTH CHINA UNIV OF TECH

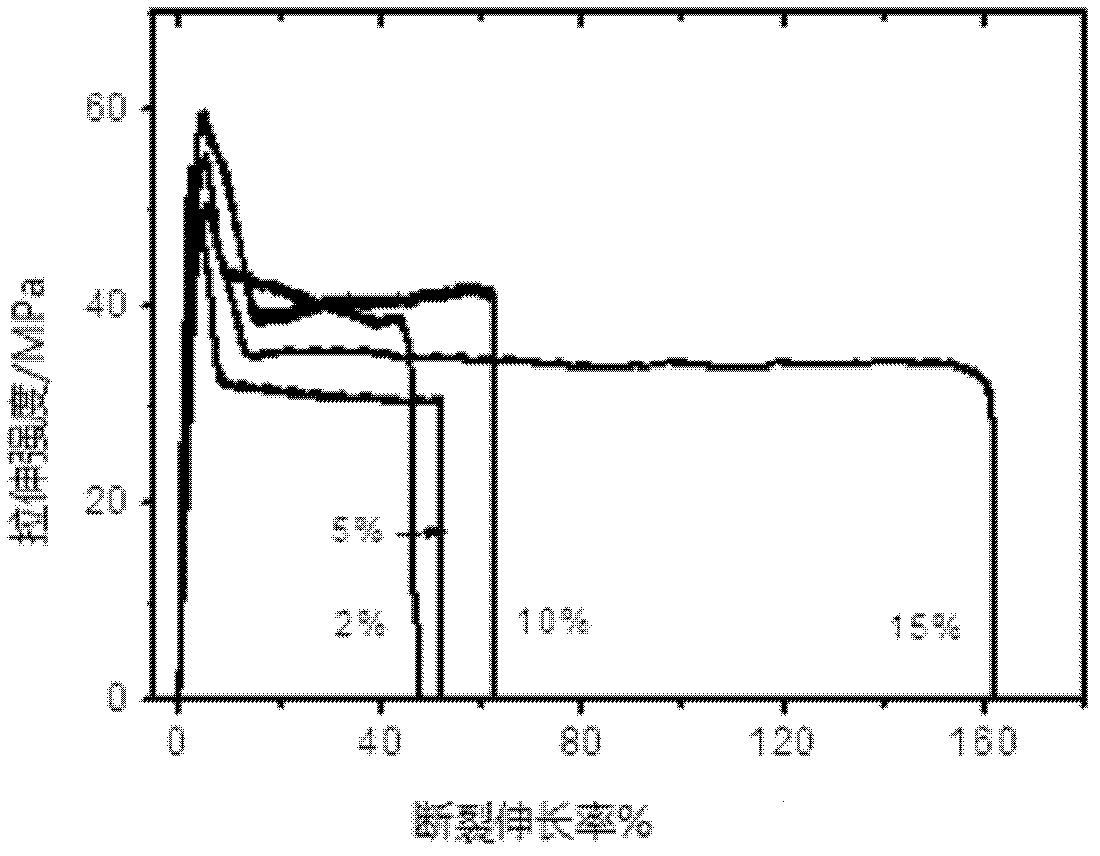

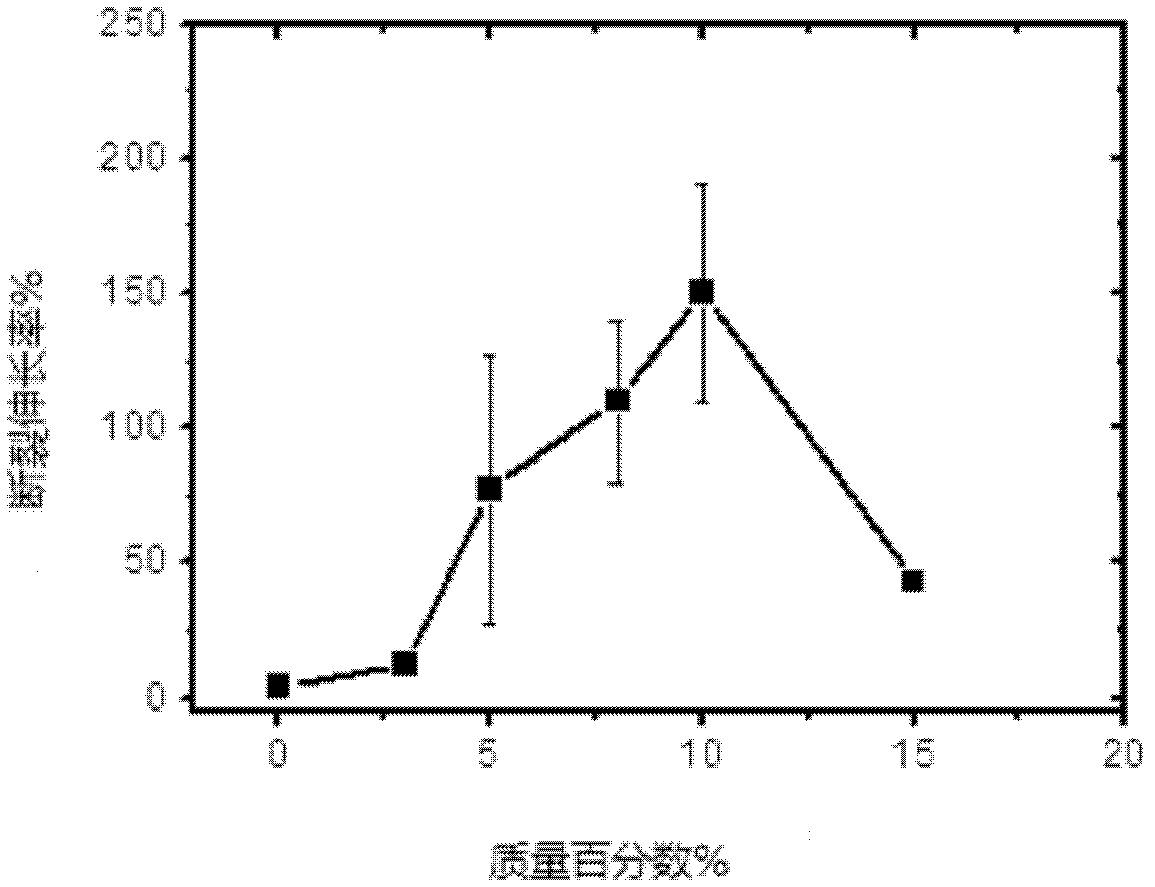

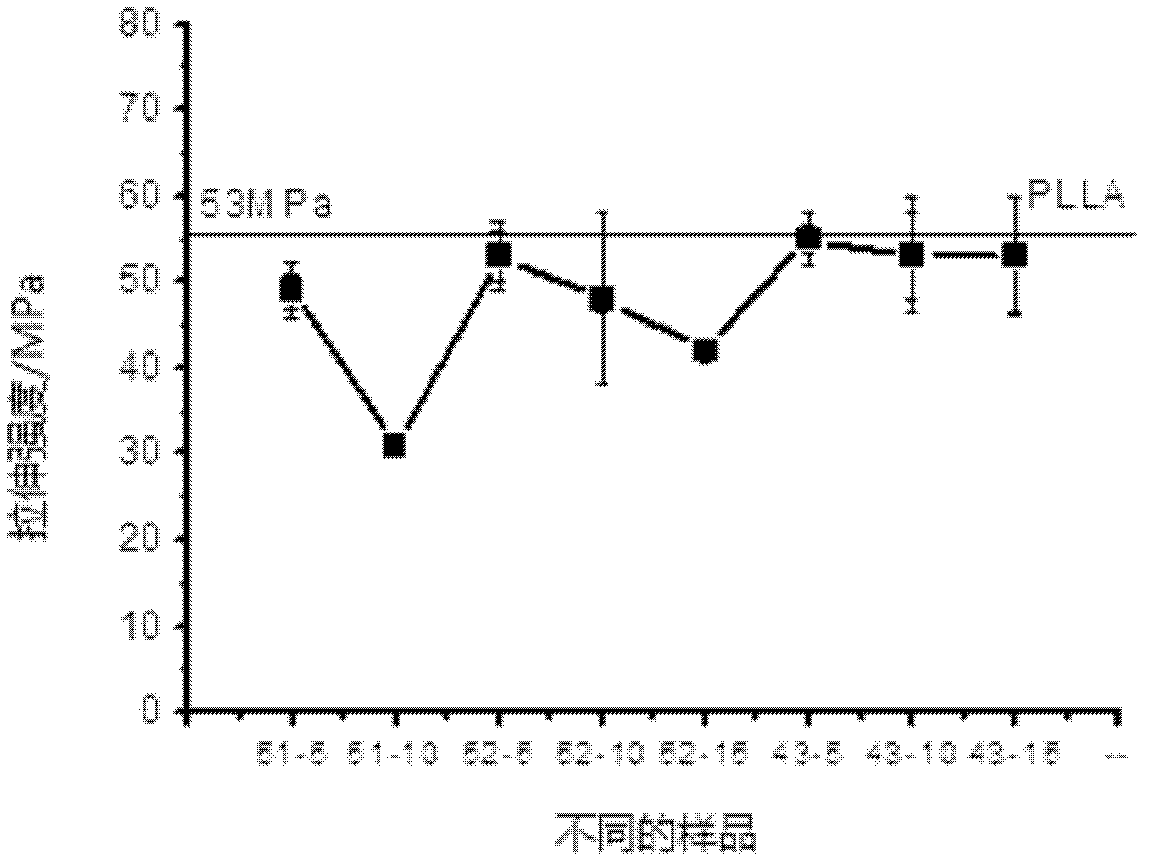

Preparation method for hyperbranched polyurethane, modified polylactic resin, and preparation method for modified polylactic resin

The invention discloses a preparation method for hyperbranched polyurethane. The method comprises the following steps of: mixing castor oil and diisocyanate in a molar ratio of (1-5):1 under the protection of nitrogen, raising temperature to 60 to 90 DEG C, and reacting to obtain the hyperbranched polyurethane. The preparation method for the hyperbranched polyurethane has the characteristics of simplicity, low cost, and adjustable molecular weight. The invention also provides modified polylactic resin and a preparation method thereof. A biomass material castor oil is used as the raw material, the degradable hyperbranched polyurethane prepared by a chemical method is used for modified polylactic acid, and the biodegradability of the modified polylactic acid can be guaranteed. The hyperbranched polyurethane is obtained by polymerizing the caster oil and diisocyanate, and hyperbranched structures, cross-linked structures and a large amount of hydrogen bonds are introduced by the hyperbranched polyurethane in a polylactic acid system in a melt blending process of the polylactic acid, so the mechanical property, the processability and compatibility of the polylactic acid are improved effectively.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Ultrahigh-molecular-weight atactic polypropylene resin capable of being used for 3D printing, and preparation method and application thereof

The invention discloses an ultrahigh-molecular-weight atactic polypropylene resin capable of being used for 3D printing, and a preparation method and an application thereof. The molecular weight of the ultrahigh-molecular-weight atactic polypropylene resin is 9*10<5>-5*10<6> g / mol, and the isotacticity (according to the percentage of a propylene unit isotactic sequence pentad [mmmm] in a polypropylene molecular chain) is 15-80%. The ultrahigh-molecular-weight atactic polypropylene resin is obtained by polymerization of propylene, the polymerized product is granular in shape, and the particle diameter is 50-1000 [mu]m. Because the resin has small and uniform particle morphology, the resin can be directly used as a raw material of 3D printing by adding a heat stabilizer, and is especially suitable for high-flexibility and high-ductility products molded by 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

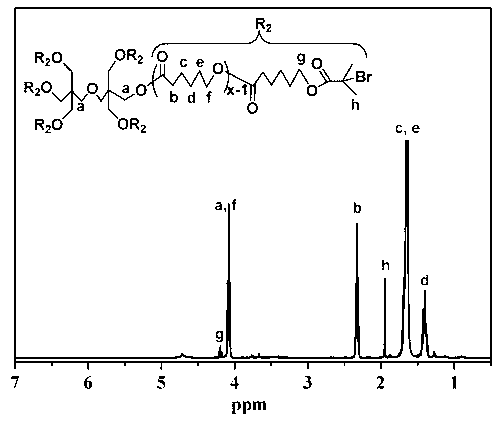

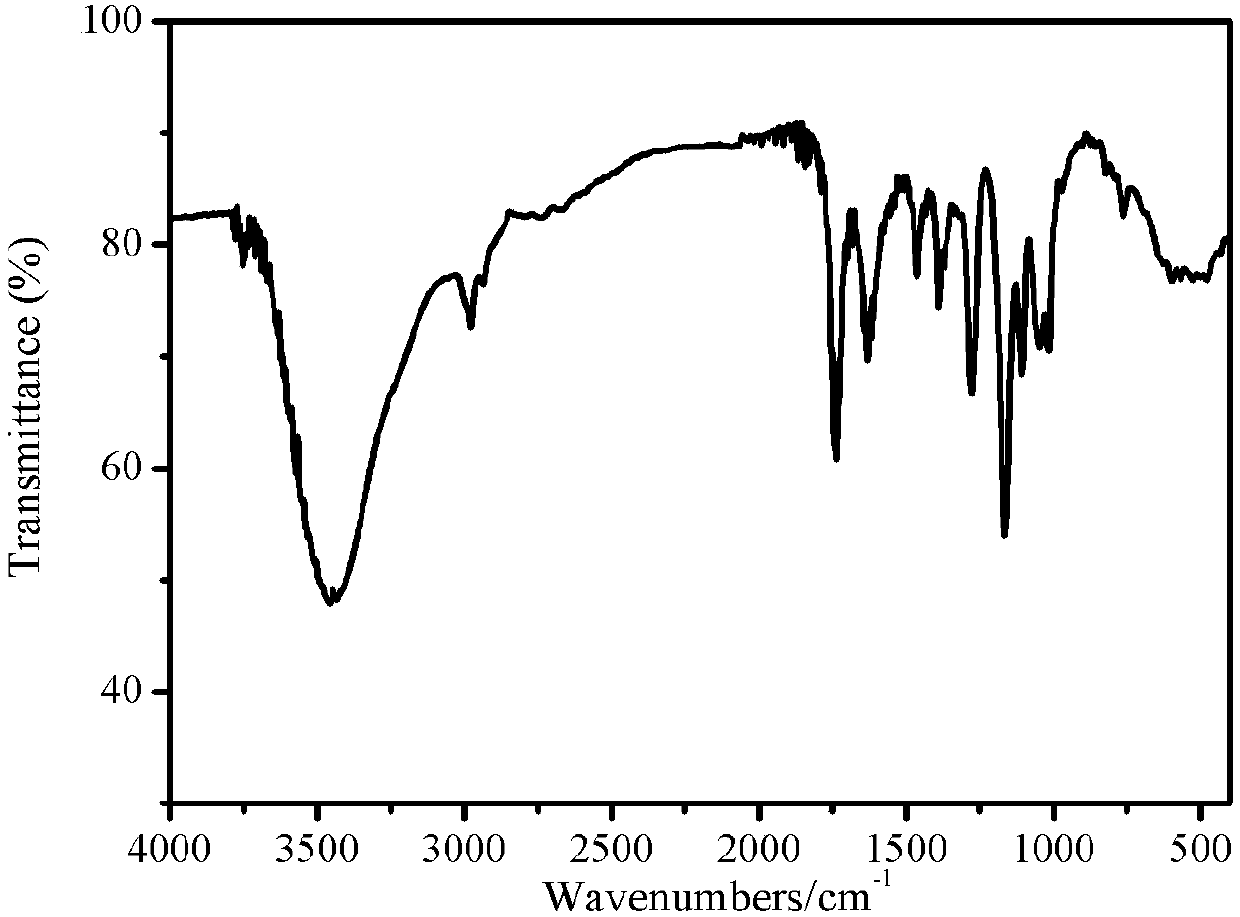

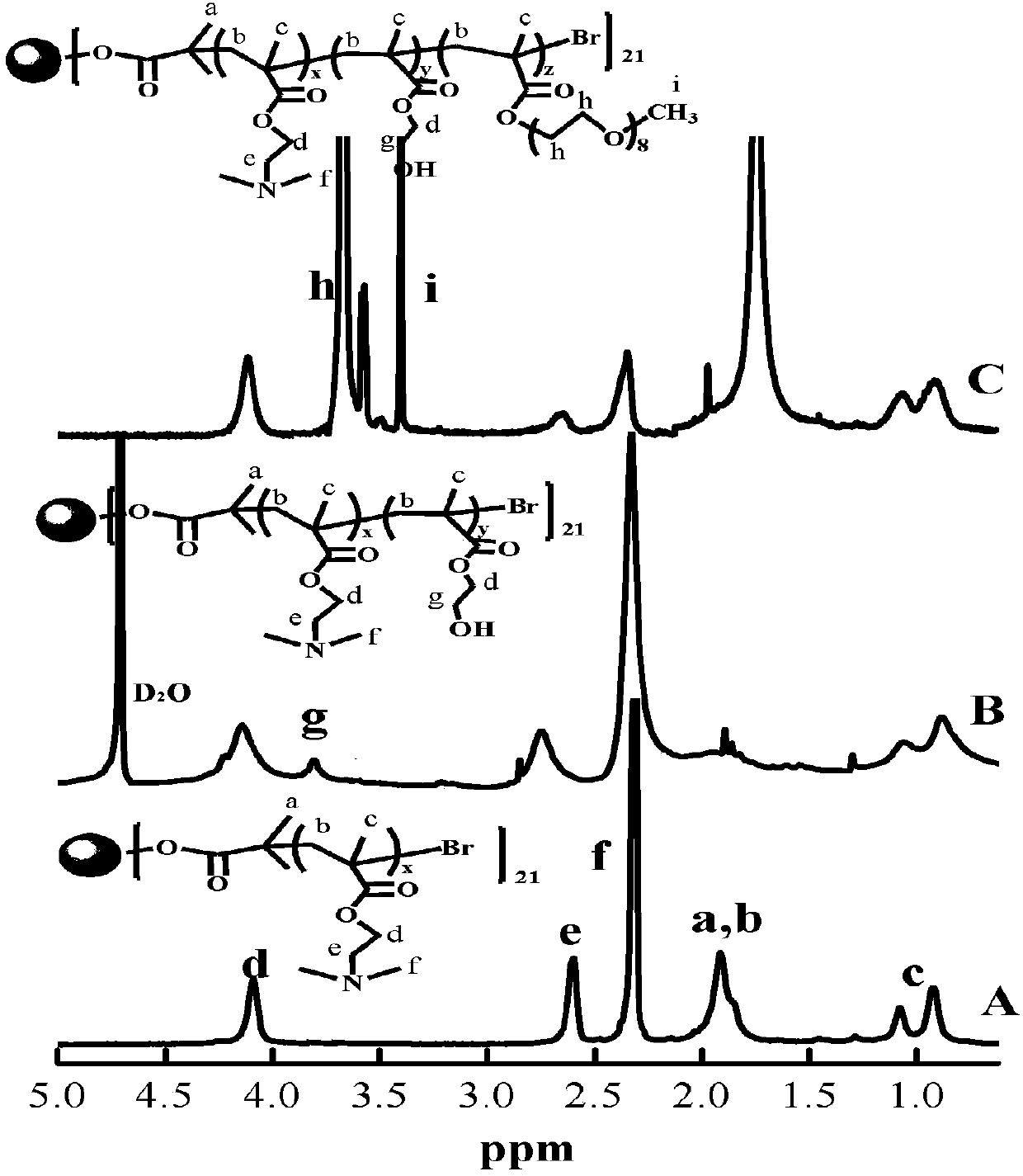

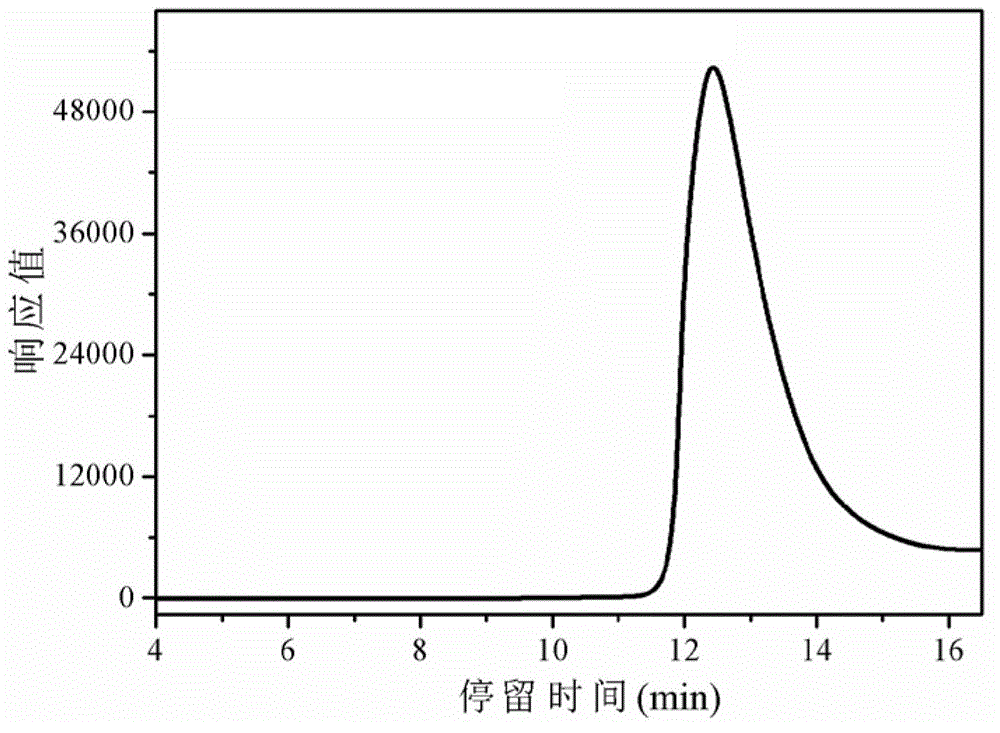

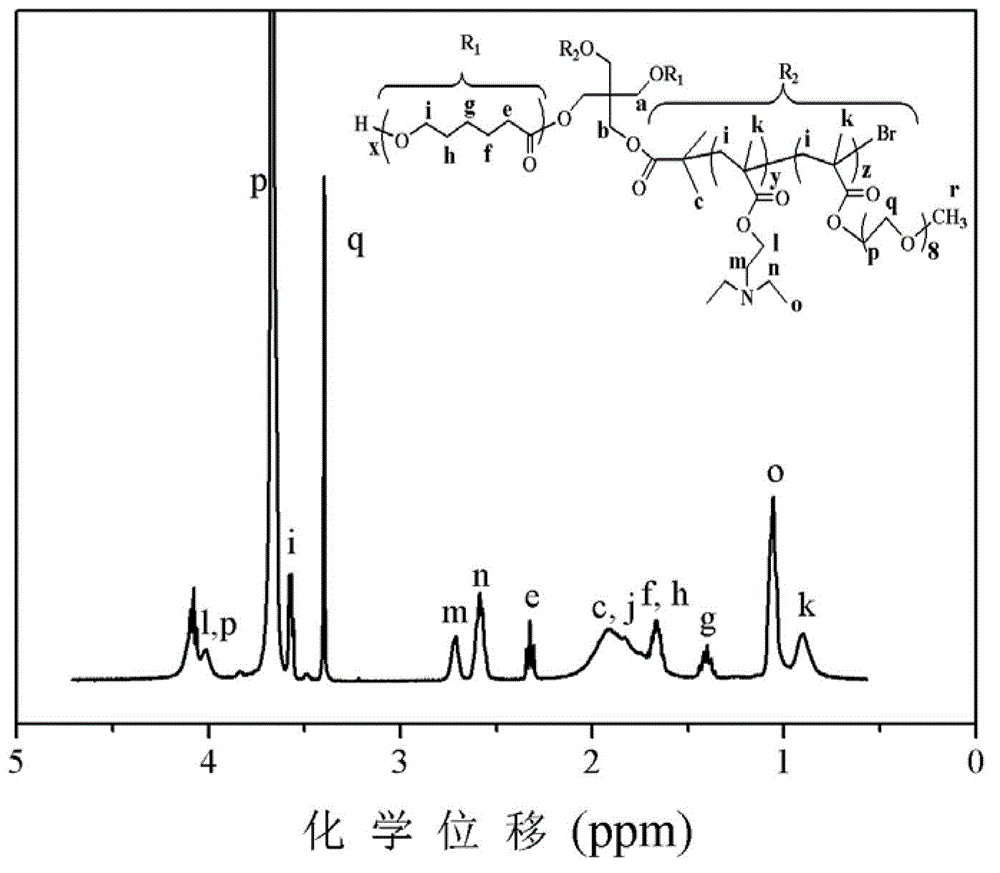

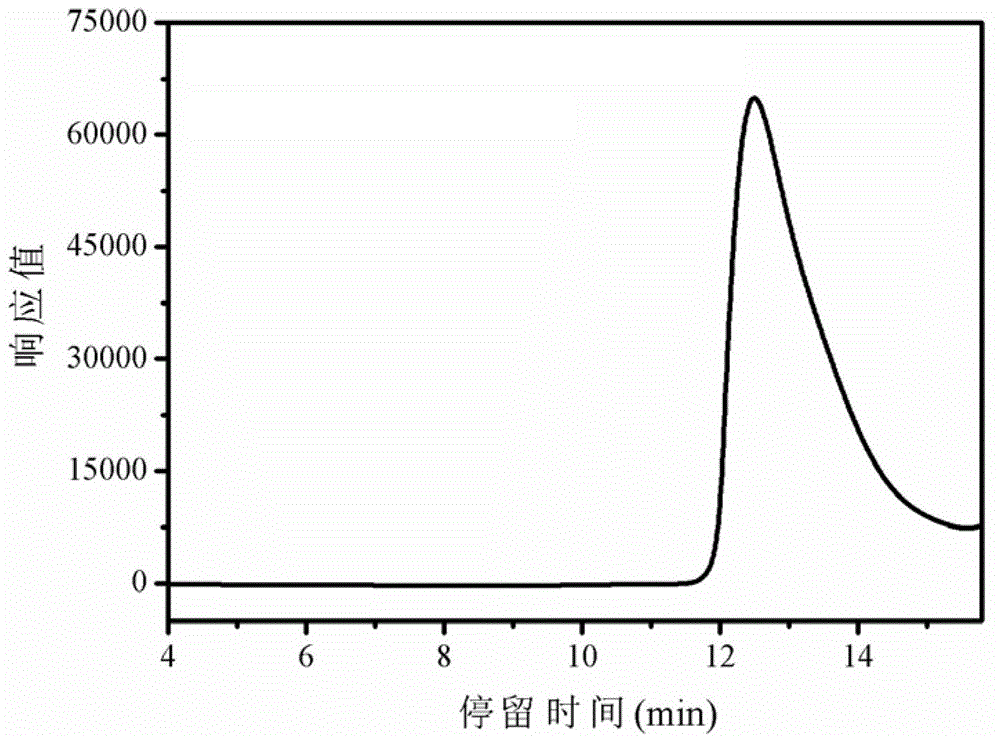

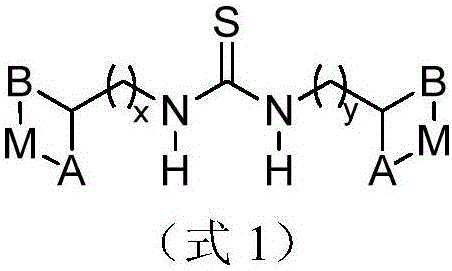

Beta-cyclodextrin based 21-arm star-shaped polymers as well as preparation method thereof and prepared monomolecular micelle/gold nanoparticle hybrid material

InactiveCN107652410AEasy to control the degree of polymerizationMild reaction conditionsX-ray constrast preparationsNanoparticleHybrid material

The invention belongs to the technical field of biomedical polymer materials, and discloses beta-cyclodextrin based 21-arm star-shaped polymers as well as a preparation method thereof and a monomolecular micelle / gold nanoparticle hybrid material system based on the beta-cyclodextrin based 21-arm star-shaped polymers and an imaging application. The polymers have a structure represented by a following formula (1) in the description, wherein x is one selected from 4 to 20, y is one selected from 4 to 15, and z is one selected from 5 to 25. According to the invention, the ratio of each block of the polymers is easily regulated and controlled, so that monomolecular micelles with stable structures and small particle sizes can be prepared. The invention also provides gold nanoparticles with the small particle sizes and good stability prepared by an in-situ method based on the above polymer monomolecular micelle system, and the in-vitro CT imaging is realized, and the valuable preparation technology is provided for the future integrated treatment system.

Owner:GUANGDONG UNIV OF TECH

Process for synthesizing polyurethane elastomer containing poly-beta-hydroxybutyrate block

A process for synthesizing polyurethane elastomer containing poly-beta-hydroxybutyrate (PHB) block includes acid-catalytic alcoholyzing PHB to obtain beta-hydroxy butyrate, ester exchange reaction to obtain PHB diol, and reaction on 2,6-ethyl diisocyanate caproate. Its advantages are better biologic compatibility and degradability, and no toxic by-effect of its degradated resultant.

Owner:TSINGHUA UNIV

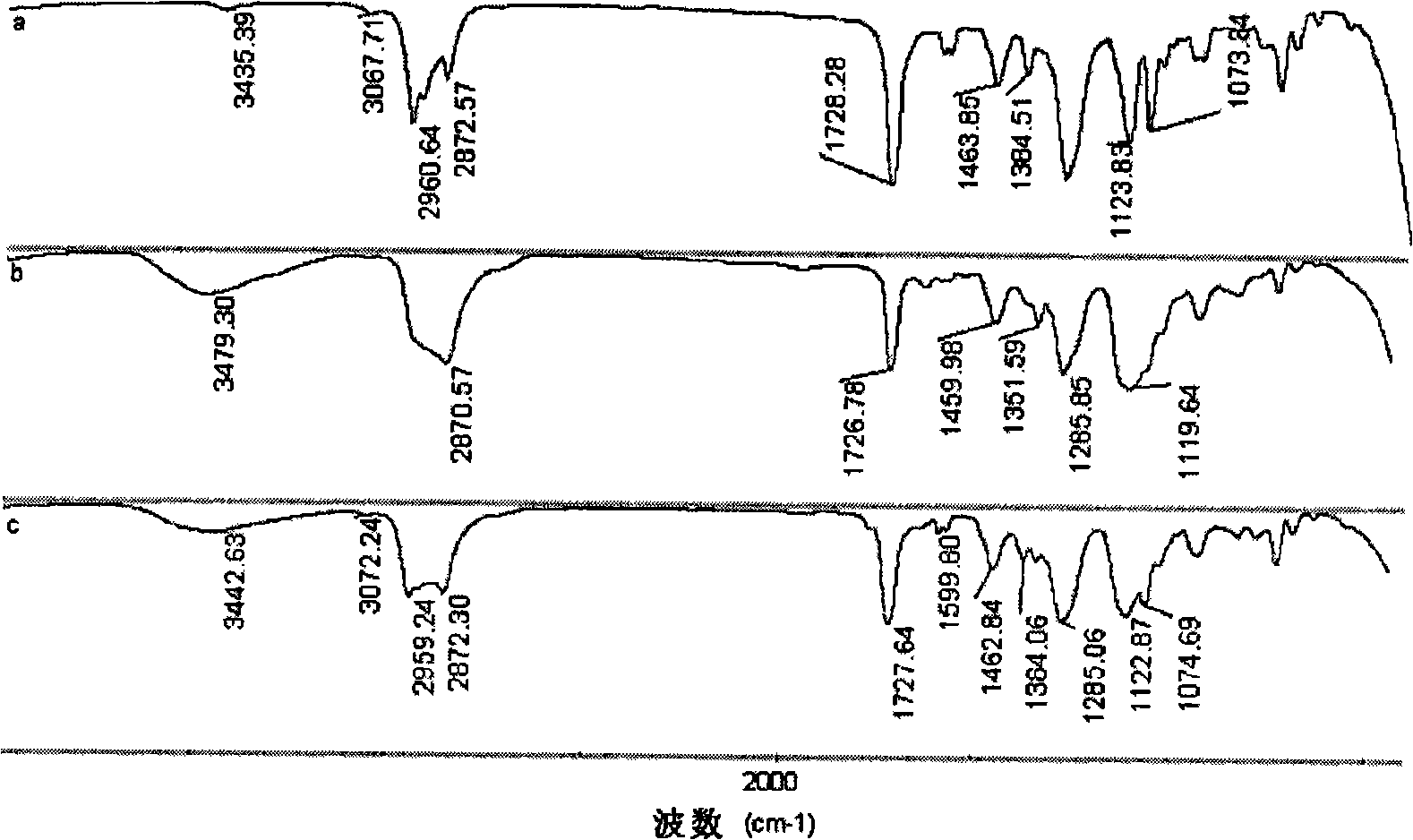

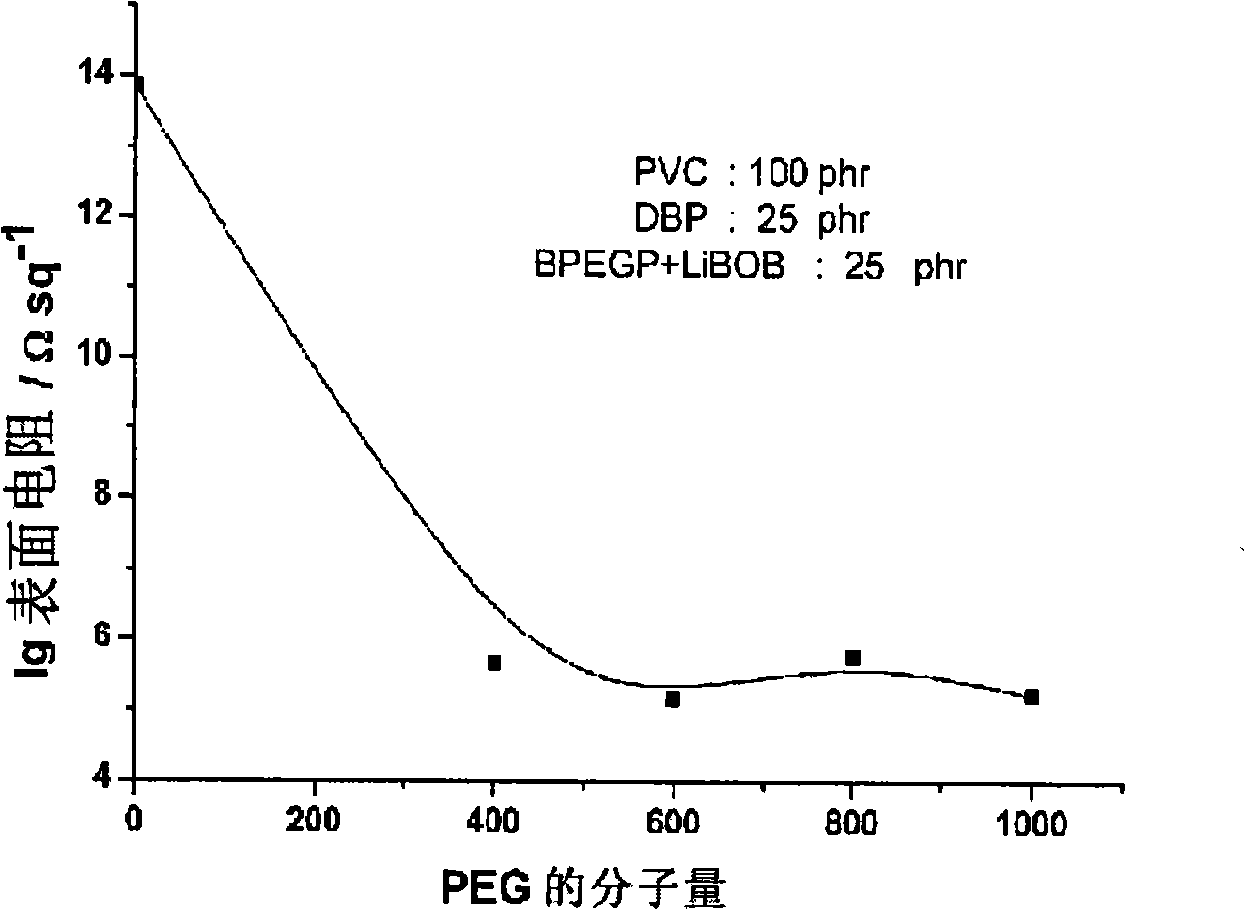

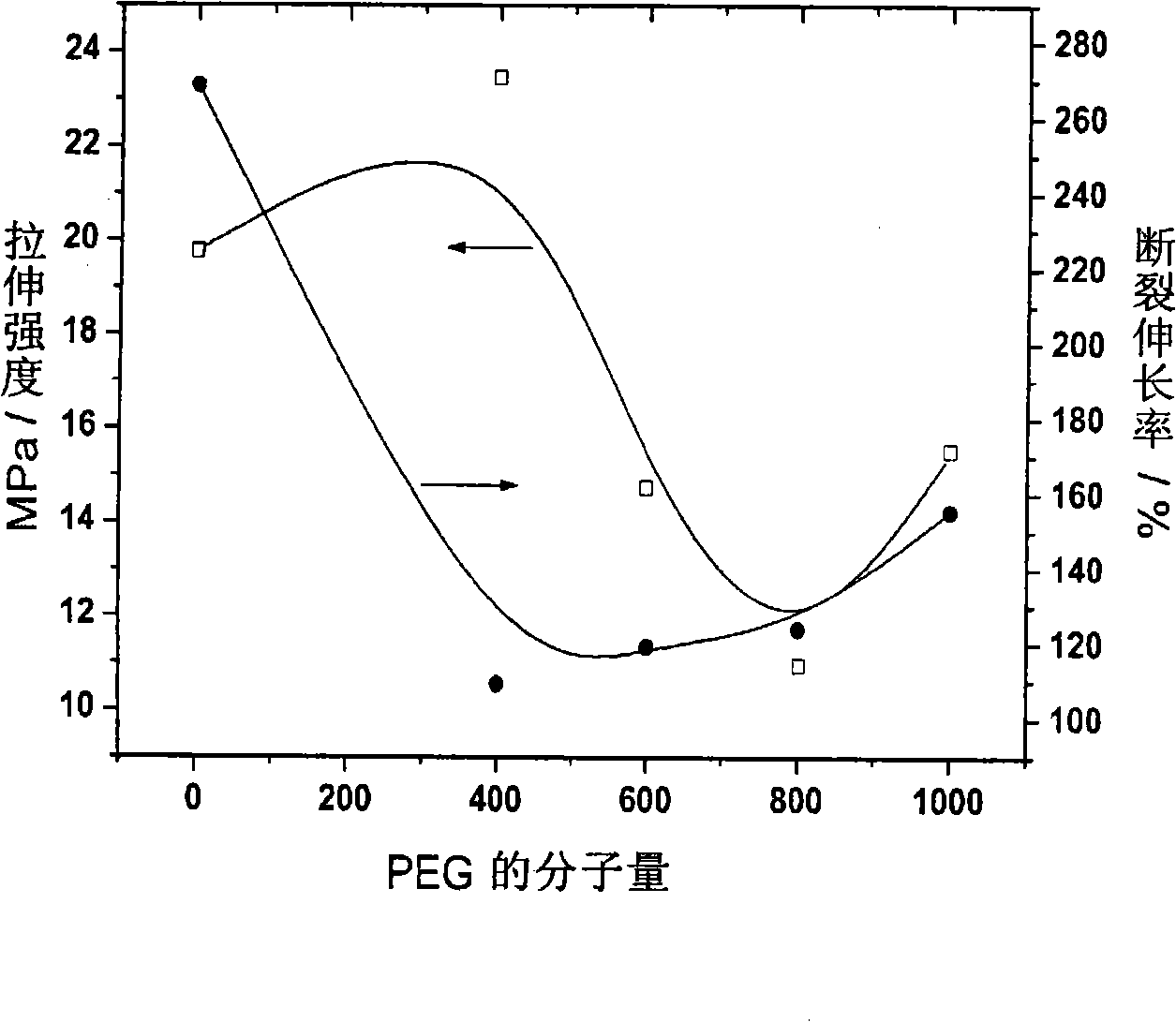

Method for preparing permanent antistatic agents

InactiveCN101358126AAdjustable molecular weightResponse conditions are relaxedOther chemical processesSolventLithium-ion battery

The present invention relates to a method for preparing a permanent antistatic agent. The method has the following characteristics: along with 0.1 to 5 mass portions of catalyst and 0 to 1000 mass portions of solvent, aromatic diester or aromatic diacid coupled with estolide compound thereof and ether alcohol compound are added into a reaction kettle provided with a thermometer, a stirrer and a reflux condenser according to a molar ratio of 1 : 1 to 2.5 to react under a temperature between 50 DEG C and 350 DEG C for one to twenty four hours, so that aromatic ester provided with a benzene ring and a polyether structure is synthesized; aromatic ether ester compound is obtained after the solvent and the unreacted monomers are removed; according to a mass ratio of 1 : 1 to 30, alkali metal salt and the compound are mixed so that the aromatic ether-ester permanent antistatic agent is produced. Even under a low humidity level, the aromatic ether-ester permanent antistatic agent can keep a good antistatic effect and can plasticize various polymer materials. The aromatic ether-ester permanent antistatic agent is used for the antistatic modification of general-purpose plastics and anti-corrosion, acid-and-alkali-resisting, anti-static and flame-retarding wind tubes, conveyer belts and gas-pumping-and-exhausting tubes used by coal mines, dust-free computer rooms, antistatic floorings, packages or lithium ion batteries.

Owner:SICHUAN UNIV

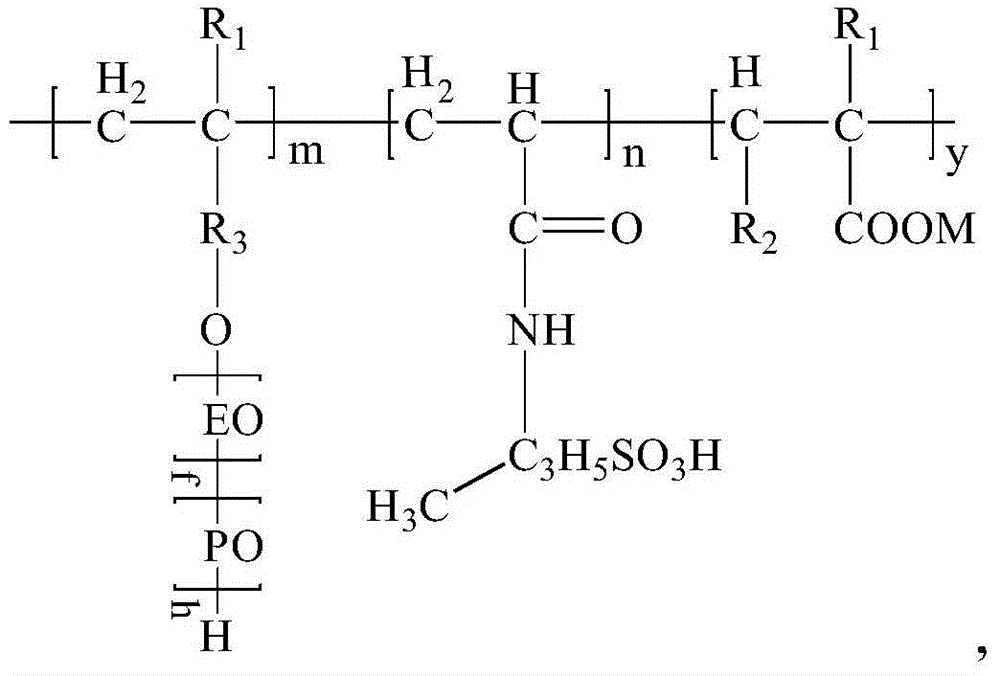

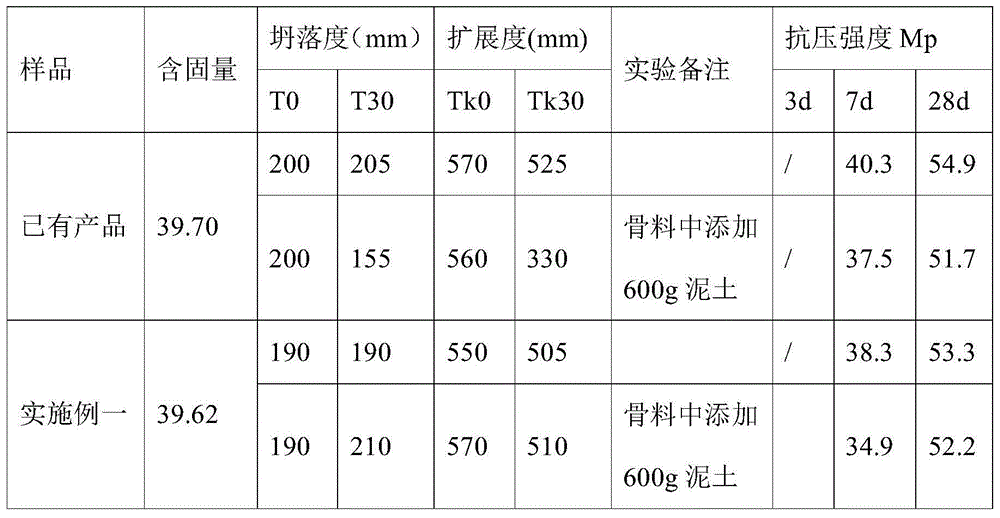

Polycarboxylate superplasticizer with mud preventing effect and preparation method of polycarboxylate superplasticizer

ActiveCN104530324AImprove performanceHigh initial water reduction effectSuperplasticizerWater reducer

The invention discloses a polycarboxylate superplasticizer with a mud preventing effect. The structural general formula of the polycarboxylate superplasticizer is as shown in the description, wherein R1 is H or CH3, R2 is H or COOM, R3 is an alkyl of C1 to C3, and M is H, Na, K or NH4. The invention also provides a preparation method of the polycarboxylate superplasticizer with the mud preventing effect. The superplasticizer synthesized by use of the process is applied to concrete within the aggregate mud content range of 0-8%, and a good application effect can be obtained through direct use without physical compounding.

Owner:SHAANXI KZJ NEW MATERIALS

Method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas

ActiveCN104725634AAvoid it happening againProcess environmental protectionHydrolysisSodium hydroxide

The invention relates to a method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas. The method comprises the following steps: performing substitution reaction of molten maleic anhydride and ammonia gas in a closed reactor and absorbing the residual gas after the completion of the substitution reaction; adding sodium hydrate solution into the reacted maleic anhydride and ammonia gas to perform neutrallzation reaction, so as to obtain a mixture of maleamic acid sodium and maleamic acid ammonium; directly heating the product in the closed reactor and performing condensation polymerization by stirring; steaming and drying the moisture after the completion of the condensation polymerization, so as to obtain the polysuccinimide solid; adding water in another reaction kettle and starting stirring; then adding the polysuccinimide solid into the reaction kettle and slowly adding sodium hydrate solution and heating to perform hydrolysis reaction, so as to obtain the polyaspartic acid solution. According to the method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas, the production process is simplified and the polyaspartic acid prepared according to the method has a weight-average molecular weight of 2000-15000 and a molecular weight distribution index of 1.5-1.65, so that molecular weight requirements of various application domains are met and environment-friendly production process is realized.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of macromolecule ultraviolet radiation absorbent

InactiveCN101096391ASimple manufacturing methodSimple post-processingOther chemical processesWeight changeAtom-transfer radical-polymerization

The invention discloses a method for preparing a high polymer ultraviolet absorbent, which is characterized by the following: preparing the dilute solution by dissolving narrow distribution (D<1.2)high polymer by (reverse direction)atom transferring free radical polymerization(ATRP)with the good solvent; proceeding with reflux reaction with 2, 4-dihydroxy benzophenone (UV-0)low molecule ultraviolet absorbent with equimolar ratio in the accelerant function for 30-70 hours; preparing narrow distribution high polymer ultraviolet absorbent. Nuclear magnetism result show that the method make the grafting ratio of UV-0 low molecule ultraviolet absorbent which is grafted by PMMA reach 25.4%; the molecular weight of PMMA film without high polymer ultraviolet absorbent reduces 32.7% after the same molecular weight PMMA and PMMA which is grafted by UV-0 low molecule ultraviolet absorbent are aged 740 hours quickly by the ultraviolet light, the distribution of the molecular weight changes from 1.17 to 1.42; the molecular weight of PMMA film with 27% high polymer ultraviolet absorbent reduces 6.7%, the distribution of the molecular weight changes from 1.17 to 1.23, so the test result shows that high polymer ultraviolet absorbent prepared with the method can improve the ultra-violet resistance property of the high polymer material.

Owner:SICHUAN UNIV

Phosphorus-nitrogen synergistic flame-retardant polyester diol and preparation method thereof

ActiveCN107417898AEffective dilution concentrationAct as protection against oxygen and heat insulationPolyesterDiethyl phosphate

The invention provides phosphorus-nitrogen synergistic flame-retardant polyester diol and a preparation method thereof. The phosphorus-nitrogen synergistic flame-retardant polyester diol is prepared through reaction of the following raw materials of dibasic acid, dibasic alcohol, [[bis(2-ethoxyl]amino)methyl]diethyl phosphate (FRC-6), a catalyst and azeotrope at a certain ratio. The phosphorus-nitrogen synergistic flame-retardant polyester diol is stable in structure and adjustable in content of phosphorus and nitrogen elements, the hydroxyl value is 120-160mgKOH / g, the phosphorus-nitrogen synergistic flame-retardant polyester diol is good in heat stability, high in char yield and good in flame retardant property, simple in preparation technology and environment-friendly, and can be used as a main reaction material of polymer materials, such as polyurethane.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for synthesizing isomerous tridecanol polyoxyethylene ether

The invention relates to a synthetic method of isomeric tridecanol polyoxyethylene ether, belonging to the organic compound synthesis technical field, which uses the materials of isometric tridecanol and ethylene oxide. The synthetic method is characterized in that: firstly, the polymerization reaction is carried out with the boron trifluoride catalyst, and then the isomeric tridecanol polyoxyethylene ether is obtained by the polymerization reaction carried out with the strong alkali catalyst; wherein, the addition of the boron trifluoride adopted in the reaction is 0.1 to 0.6 percent of the weight of the isometric tridecanol, the strong alkali catalyst is one of or the mixture of solid sodium methylate, methanol solution of sodium methylate, KOH and NaOH, the addition of the strong alkali catalyst is 0.05 to 0.2 percent of the weight of isomeric tridecanol polyoxyethylene ether. The synthetic method of isomeric tridecanol polyoxyethylene ether has the advantages that: the synthetic method adopts a two-step reaction technical proposal that: the polymerization reaction is carried out with the boron trifluoride catalyst at first, and then the polymerization reaction is carried out with the strong alkali catalyst, so the isomeric tridecanol polyoxyethylene ether has mild reaction conditions, high yield, no formation of impurities and environment friendly performance.

Owner:ZHEJIANG HUANGMA TECH

High-efficiency decompression and augmented injection agent used for oil extraction and production method thereof

InactiveCN103113872AAdjustable molecular weightAchieve the purpose of the inventionDrilling compositionEthylenediamineEpoxy

The invention discloses a high-efficiency decompression and augmented injection agent used for oil extraction. The high-efficiency decompression and augmented injection agent is characterized by comprising the following components in parts by weight: 1.0-2.0 parts of epoxy chloropropane, 1.0-2.5 parts of dimethylamine, 1.0-4.0 parts of trimethylamine, 0.01-0.1 part of ammonium persulphate, 0.015-0.15 part of sodium hydrogen sulphite, 0.01-0.2 part of ethanediamine and 0.02-0.06 part of triethylene tetramine. The invention also discloses a production method of the high-efficiency decompression and augmented injection agent. The production method is characterized by comprising the following steps of: adding epoxy chloropropane into a porcelain enamel reaction kettle; slowly feeding a mixed solution of dimethylamine and trimethylamine, prepared at room temperature in proportion; after feeding is completed, adding the ammonium persulphate, then adding the sodium hydrogen sulphite, and maintaining temperature in the kettle to be not higher than 5 DEG C; after feeding is completed, heating until the temperature in the kettle is increased to 60-90 DEG C, and reacting for 7-9 hours, so that an intermediate product is obtained; cooling the intermediate product to 40 DEG C, and slowly adding a mixed solution of ethanediamine and triethylene tetramine; and reacting again at the temperature of 40 DEG C, so that the high-efficiency decompression and augmented injection agent finished product is obtained.

Owner:NANCHONG CITY JUXING CHEM CO LTD

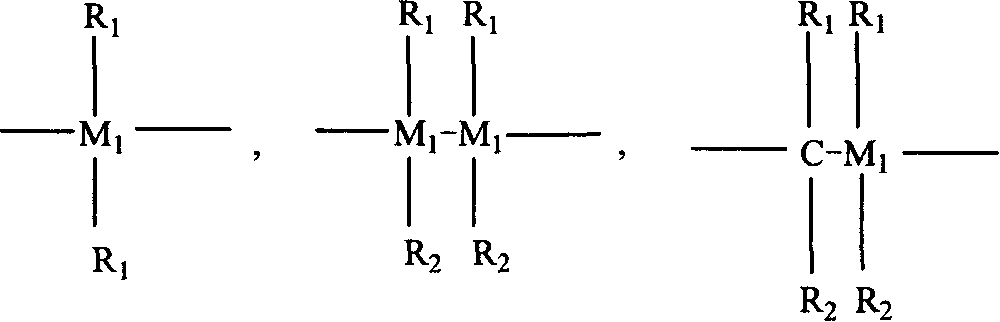

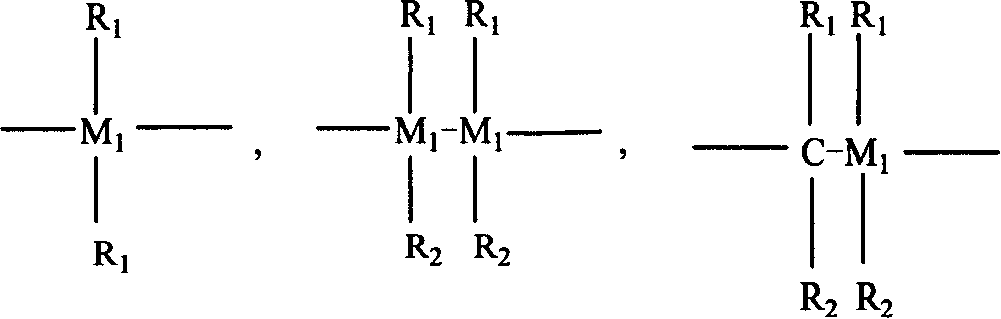

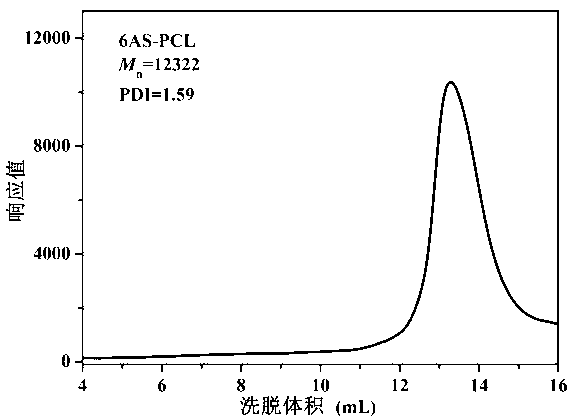

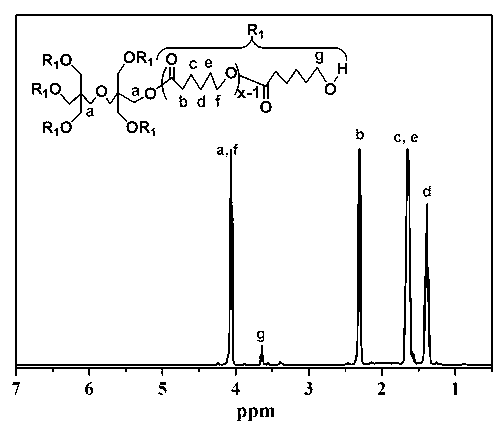

Amphiphilic pH-responsive 4/6 heteroarm star-shaped copolymer and preparation method thereof

ActiveCN103333301AEasy to operateMild reaction conditionsPharmaceutical non-active ingredientsWater insolubleDistillation

The invention belongs to the technical field of high molecular polymer materials for biomedicine, and discloses an amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer of which the number-average molecular weight is 30000-54000g / mol. The invention also discloses a preparation method of the amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer, which comprises the following steps: mixing epsilon-caprolactone, stannous octoate and low molecular initiator, reacting at 110-140 DEG C for 24-48 hours, performing reduced pressure distillation, precipitating, filtering, and drying to obtain polycaprolactone high molecular initiator; dissolving the polycaprolactone high molecular initiator, 2-diethylaminoethyl methacrylate, hexamethyltriethylenetetramine and copper bromide in toluene, stirring, then adding stannous octoate, and reacting at 60-90 DEG C for 5-12 hours; and adding methoxy polyoxyethylene methacrylate, continuously polymerizing for 5-12 hours, removing a catalyst, filtering, and performing posttreatment on the filtrate to obtain the amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer. The amphiphilic pH-responsive 4 / 6 heteroarm star-shaped copolymer is used for preparation of a micelle system for carrying water insoluble medicaments.

Owner:SOUTH CHINA UNIV OF TECH

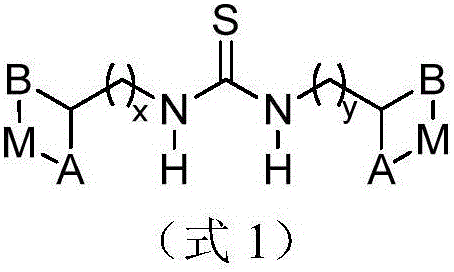

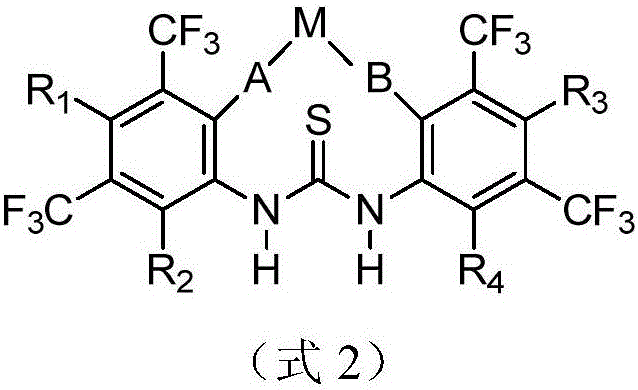

Metal complex for catalysis of caprolactone polymerization

InactiveCN105968036AHigh catalytic activityAdjustable molecular weightOrganic chemistryThioureaPolycaprolactone

The invention discloses a metal complex for efficient controllable ring opening of Epsilon-caprolactone, and specifically relates to thiourea metal salt. The metal complex is suitable for bulk polymerization and melt polymerization process of Epsilon-caprolactone and also suitable for slow controllable polymerization in a solution. The design of molecular weight of polycaprolactone is based on the ratio of a monomer to an initiator in the reaction system. The initiator is alcohol containing active hydroxyl terminal. The alcohol used as a co-initiator and the metal complex together have a synergistic effect on the catalysis system. The metal complex has rich selections of functional groups and is suitable for multiple polymerization conditions.

Owner:安徽红太阳新材料有限公司

Ultrahigh-molecular-weight isotactic polypropylene resin for 3D printing, preparation method and application thereof

The invention discloses an ultrahigh-molecular-weight isotactic polypropylene resin for 3D printing, a preparation method and an application thereof. The ultrahigh-molecular-weight isotactic polypropylene resin has a molecular weight ranging from 1*10<6> to 5*10<6> g / mol, an isotacticity being more than 90% and a melting point being more than 160 DEG C. The ultrahigh molecular weight isotactic polypropylene is prepared from propylene by a polymerization reaction. A polymerization product is granular with granule sizes ranging from 50-1000 microns. Because the resin is small and uniform in particle form, the resin can be directly used as a raw material of 3D printing with addition of a thermal stabilizer and is especially suitable for moulding high-strength, high-impact-resistant and high-wear-resistant products through 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

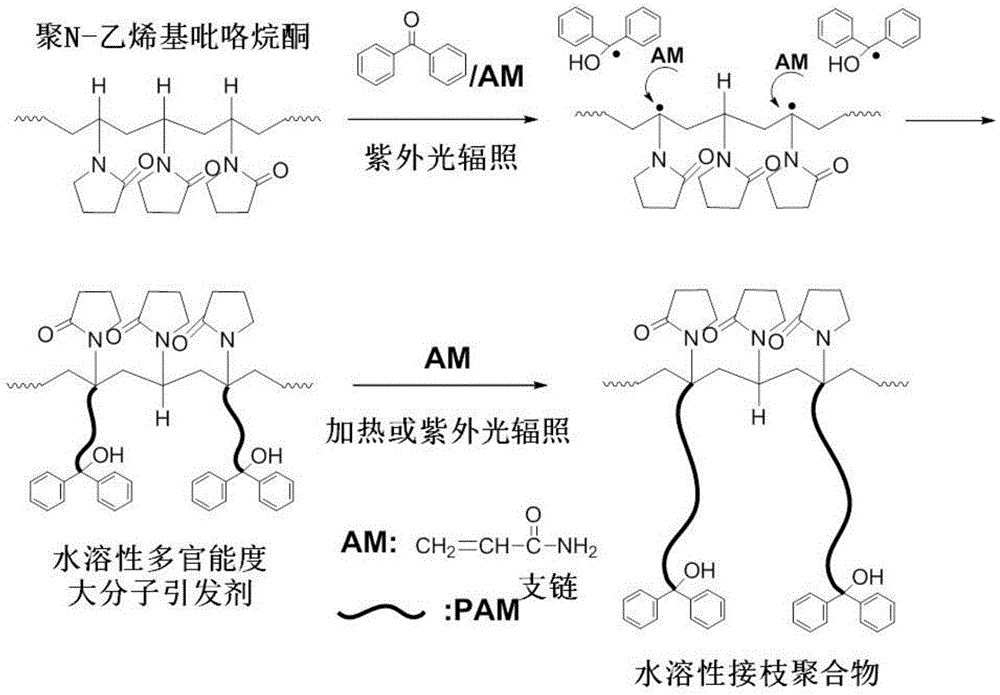

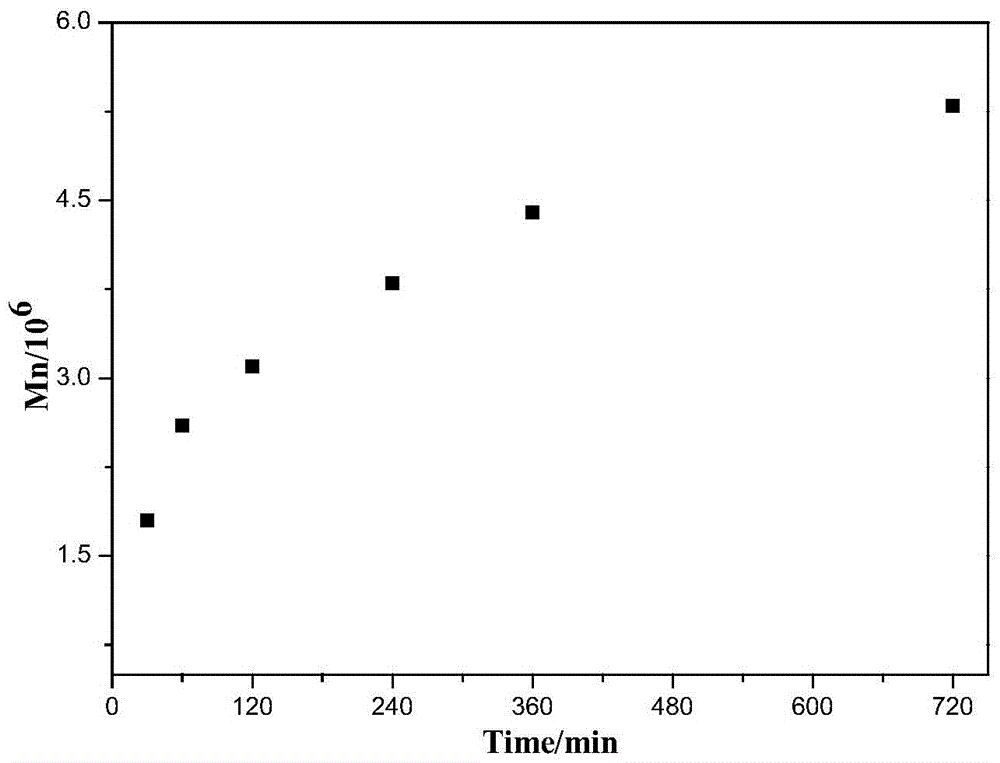

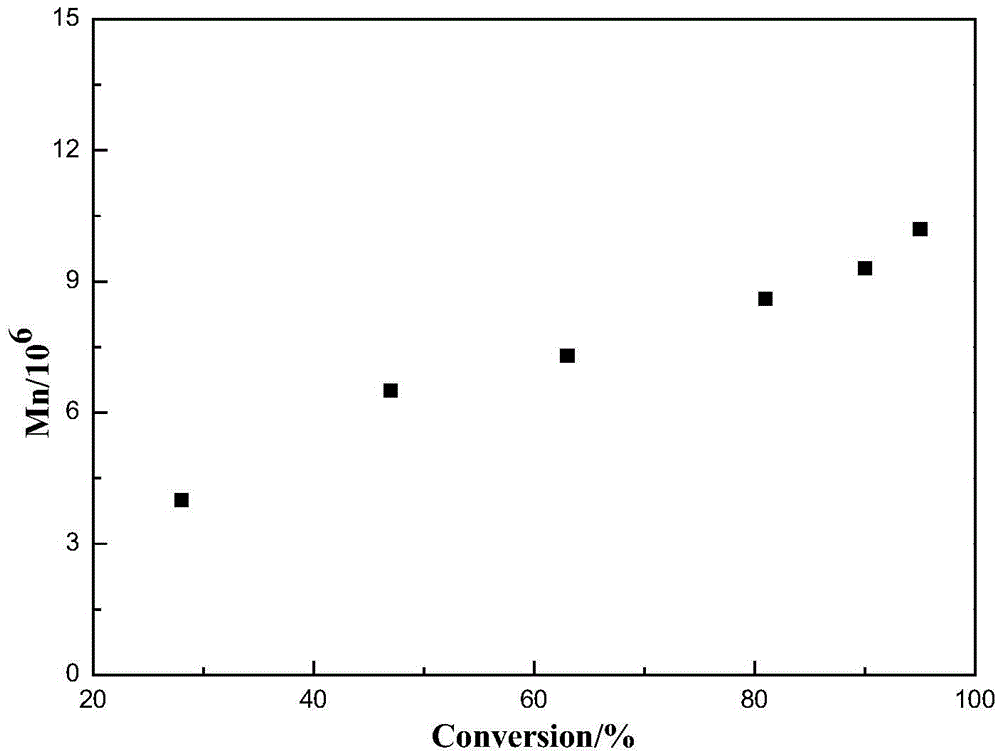

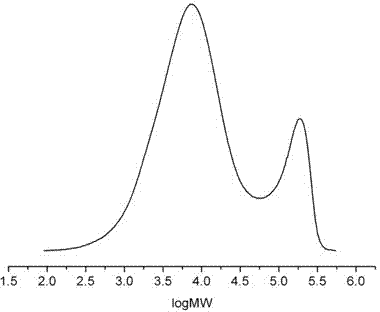

Method for preparing water-soluble graft polymers based on active/controllable radical polymerization

The invention discloses a method for preparing water-soluble graft polymers through active / controllable radical polymerization. The method can be used for controllable radical polymerization of various water-soluble monomers of a (methyl) acrylamide monomer, (methyl) acrylic acid, (methyl) acrylate and the like, so as to prepare the water-soluble graft polymers with different molecular weights. The preparation method is particularly realized through the following steps: firstly, preparing a water-soluble polyfunctional macroinitiator by adopting a chemical modification manner; secondly, initiating active / controllable radical polymerization of the water-soluble monomers by the macroinitiator under the heating or visible light / ultraviolet light irradiation condition, and preparing the molecular weight and chemical constitution controllable water-soluble graft polymers. The method is simple in synthetic route, low in production cost and safe and convenient to operate; the prepared macroinitiator is high in dissolution rate in water phase and high in initiating activity, and can be used for preparing the chemical constitution and molecular weight controllable water-soluble graft polymers.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing cation type hyperbranched ethylene or acrylamide polymer

The invention discloses a method for preparing a cation type hyperbranched ethylene or acrylamide polymer. The method comprises the following steps of: carrying out reversible addition-fragmentation transfer (RAFT) polymerization; and highly conversing in a polar solvent system by adopting a diene monomer and a chain transferring agent of the RAFT polymerization with low proportion through a semicontinuous operation process to prepare the cation type hyperbranched ethylene or acrylamide polymer. The polymerization process of the method is easily controlled, and molecular weights of a final product and distribution thereof can be controlled.

Owner:ZHEJIANG UNIV

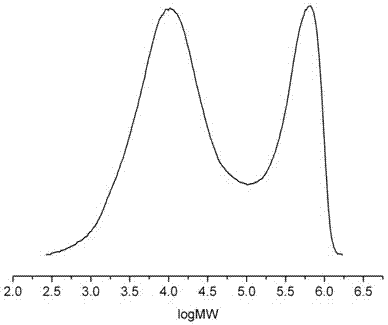

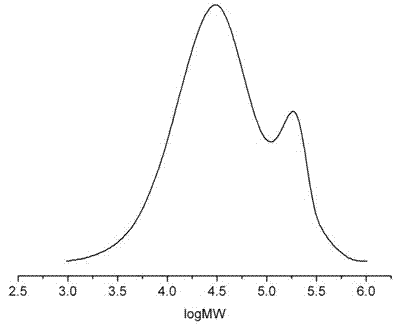

Method for preparing double-peak or broad-peak polyethylene with adjustable molecular weight

The invention discloses a method for preparing double-peak or broad-peak polyethylene with adjustable molecular weight. The method comprises the following steps of: replacing a reactor with nitrogen for 3 to 4 times at the high temperature of 100 DEG C to 150 DEG C; replacing the reactor with ethylene for 3 to 4 times; adding 100-50ml of anhydrous and oxygen-free organic solvent in ethylene atmosphere and stirring, wherein the stirring rate is 400-1000 rpm, the temperature is controlled to be at 0 DEG C to 150 DEG C, and the pressure is controlled to be at 0.1MPa to 10.0MPa; adding 0.01mmol to 100mmol of cocatalysts; adding 5mumol to 20mumol of main catalysts for polymerization reaction; after reacting for 1 to 30minutes, adding 100mumol to 2000mumol of chain transfer agents for continuous reaction for 10 to 20 minutes; and adding 4ml to 10ml of acidified ethanol for termination reaction. In the method for preparing the double-peak or broad-peak polyethylene with adjustable molecular weight, a piecewise polymerization process is adopted, and two peak values in a molecular weight distribution curve of the obtained double-peak polyethylene or the molecular weight size and the distribution of the obtained broad-peak polyethylene are adjusted by adjusting the feeding time of the chain transfer agent and / or adjusting the stoichiometric ratio of the chain transfer agents to the cocatalysts.

Owner:ZHEJIANG UNIV

Block polymer dispersant synthesized by reversible addition-fragmentation chain transfer (RAFT) technique

The invention relates to a block polymer dispersant synthesized by a reversible addition-fragmentation chain transfer (RAFT) technique. The prepared block polymer dispersant has adjustable molecular weight and narrow molecular weight distribution. Because the contained anchor groups (sulfo-group and amino group) can be easily adsorbed on the surfaces of glaze particles and exert a dispersion effect, and the water molecules adsorbed by hydration cations in the glaze slurry can be released, the viscosity of the glaze slurry is decreased, and thixotropy cannot occur easily. The invention also provides a preparation method of the block polymer dispersant synthesized by the RAFT technique. The synthesis of the dispersant by waterborne RAFT reagent component can realize industrialization, controllable molecular weight, controllable groups, and high dispersion efficiency. The block polymer dispersant synthesized by the RAFT technique can be used in coating, printing, energy, electronics, ceramics, pigment and filler, and commodity industries.

Owner:UNION FOSHAN CHEM +1

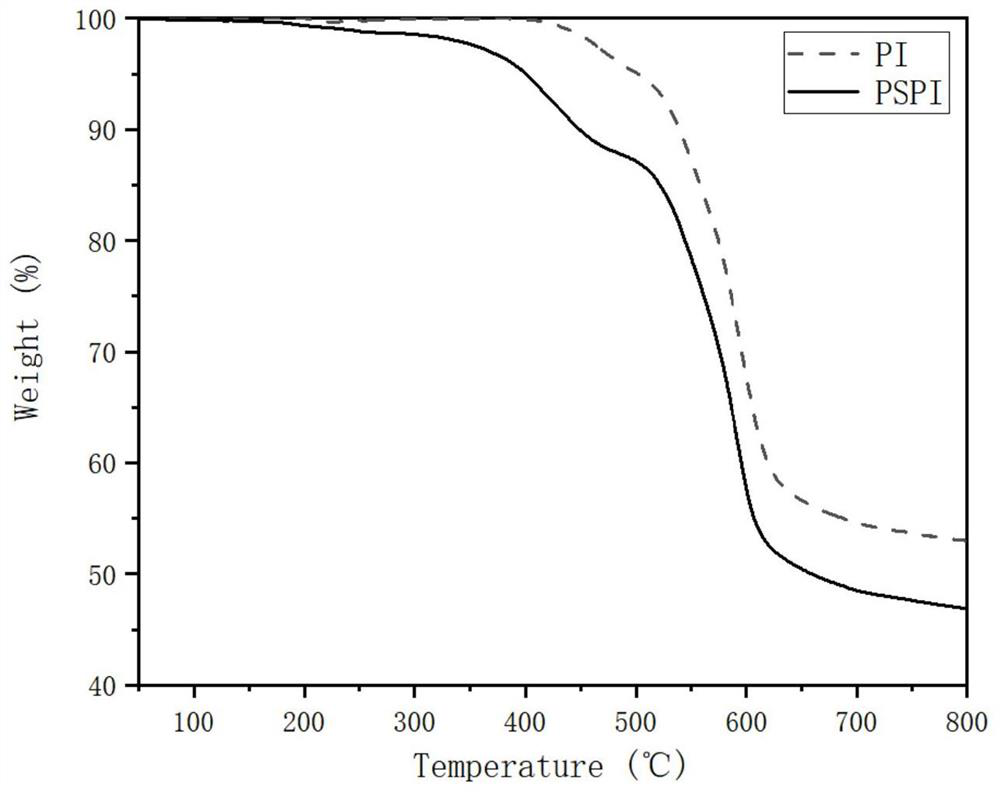

Photosensitive polyimide resin, polyimide photocuring coating and preparation method thereof

The invention discloses a photosensitive polyimide resin, a polyimide photocuring coating and a preparation method thereof. The structure of the photosensitive polyimide resin is as follows: a main chain structure contains a large number of alicyclic and benzene ring structures, and photosensitive groups are introduced at the tail end of the polyimide resin through benzene ring and carboxyl structures, so that the photosensitive polyimide resin is enabled to have good heat resistance and light sensitivity; and the main chain structure contains fluorine functional groups, so that the solubility of polyimide is improved, and the transparency and hydrophobicity of a polyimide photocuring coating are improved. The polyimide photocuring coating prepared by adopting an ultraviolet curing technology has photosensitivity, high transparency and good heat resistance, the light transmittance of the polyimide photocuring coating can reach 90%, and the polyimide photocuring coating can be widely applied to the fields of space flight and aviation, automobile industry and microelectronics.

Owner:GUANGDONG UNIV OF TECH

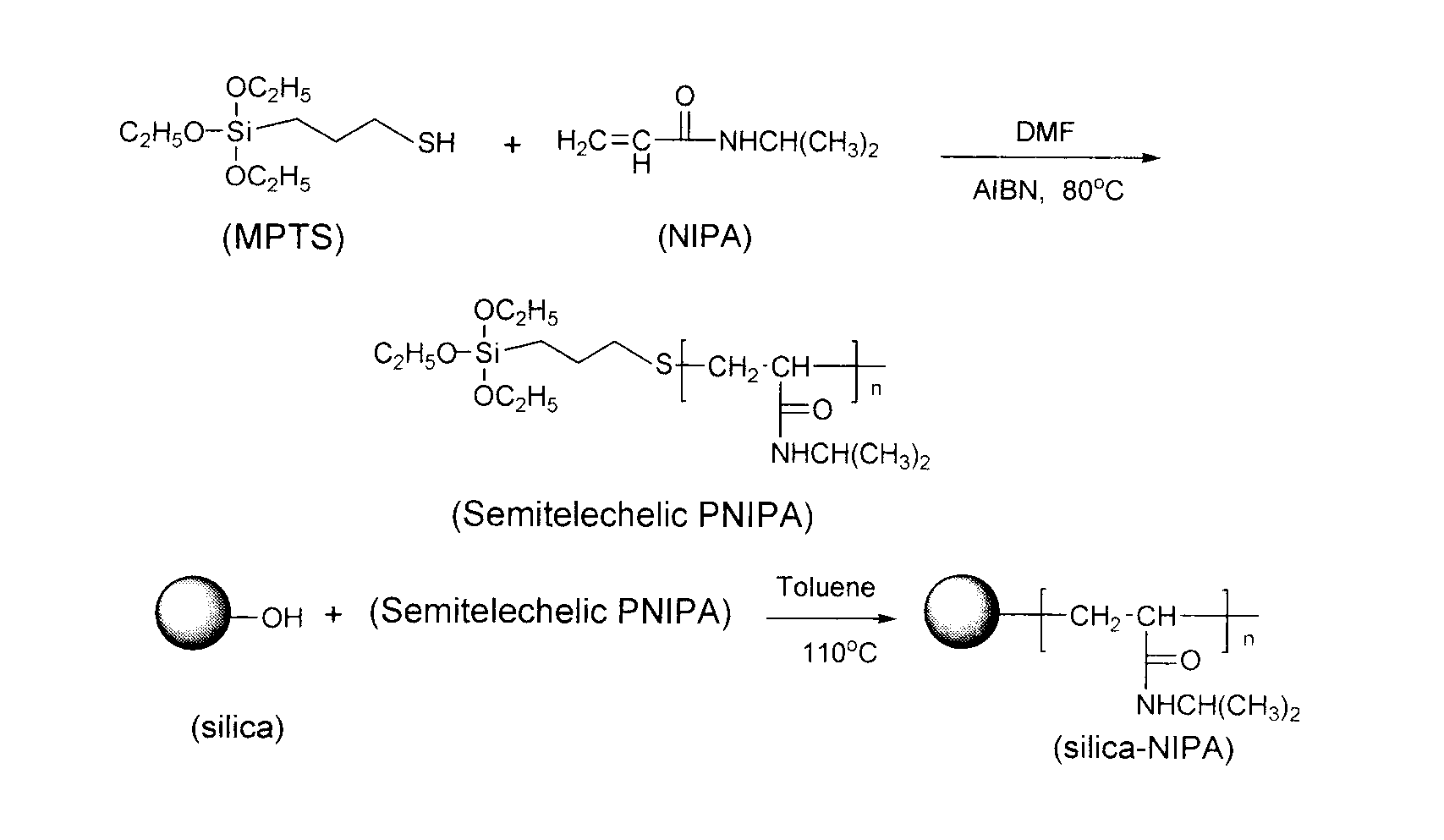

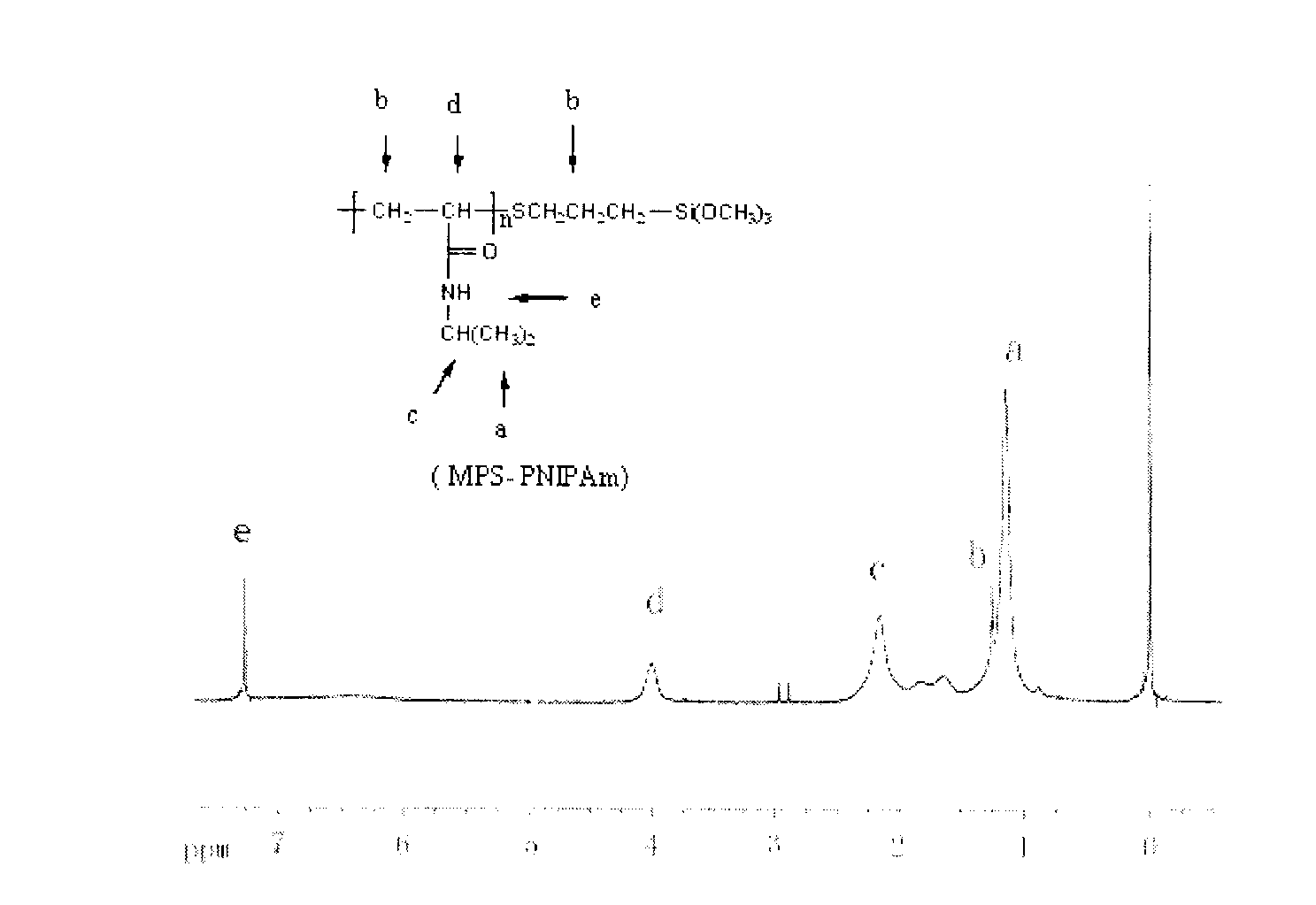

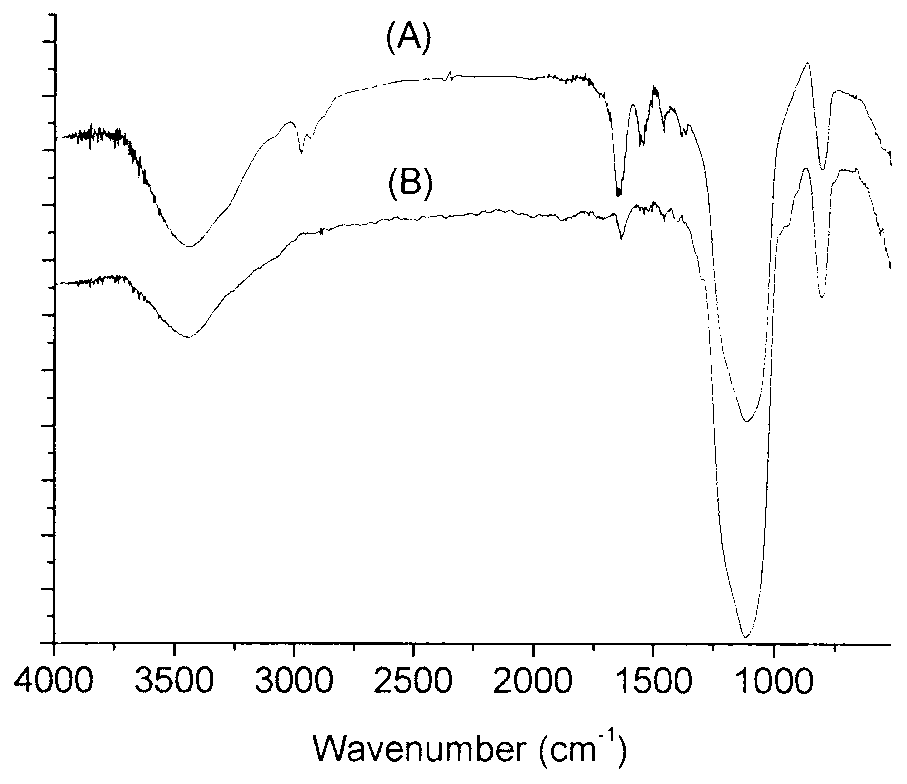

Preparation method for temperature-sensitive core-shell structured microspheres and application thereof in separation

InactiveCN102977242AIncrease profitEasy Coupling ReactionIon-exchange process apparatusOther chemical processesColloidal silicaMicrosphere

A preparation method for temperature-sensitive core-shell structured microspheres and an application thereof in separation. According to the present invention, first mercaptopropyl triethoxysilane (MPT) and N-isopropyl acrylamide are reacted to generate semi-telechelic polymers, then the semi-telechelic polymers are coupled with ultrafine colloidal silica particles, so composite particles with poly-N-isopropyl acrylamide as the shells and colloidal silica particles as the cores are prepared. Differential scanning calorimetry tests show that the composite particles are temperature-sensitive. The prepared composite particles are used as a stationary phase in high pressure liquid chromatography, and water is used as a main ingredient of a mobile phase, and naphthalene derivatives are separated successfully through the control of column temperatures, achieving good separation effect.

Owner:JIANGNAN UNIV

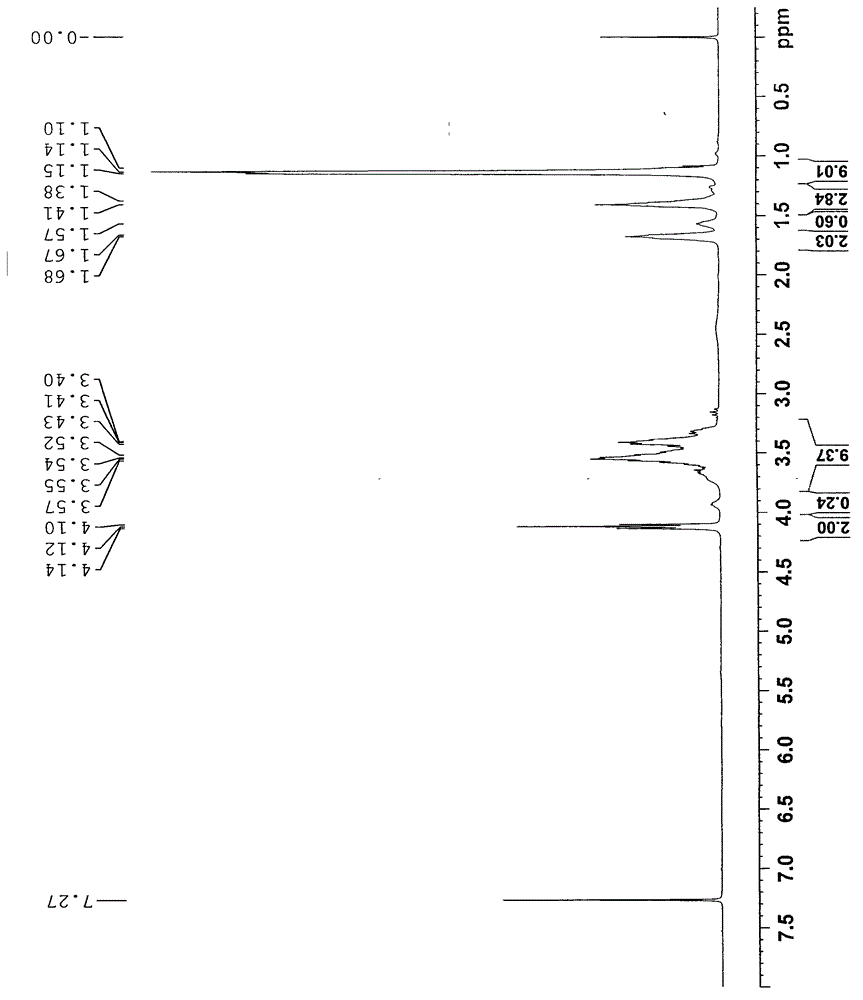

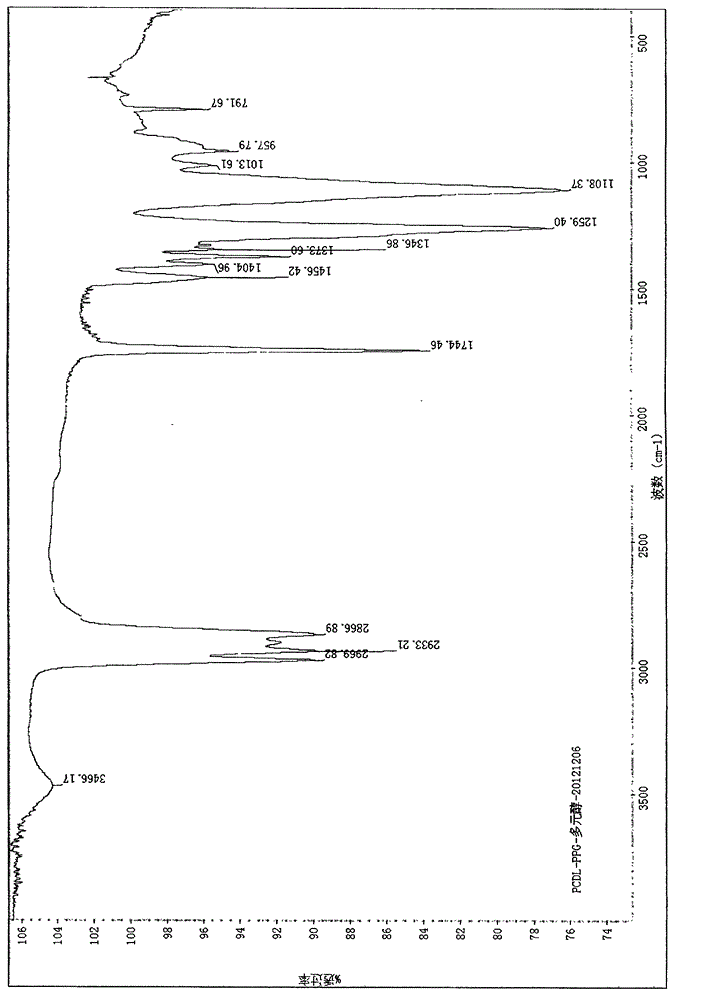

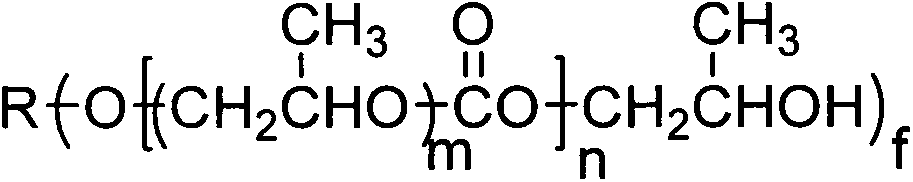

Preparation method for block oligomeric dihydric alcohol with controllable structure

The invention relates to block oligomeric dihydric alcohol with a controllable structure and a preparation method thereof. The main chain of the block oligomeric dihydric alcohol is a controllable block structure and is obtained by performing propoxylation or ethoxylation / propoxylation on polycarbonate, the terminal group is hydroxyl, the number-average molecular weight is 500-10000, and the molecular weight of carbonate chains and oxidized propylene / ethylene chains is adjustable. The preparation method of the block oligomeric dihydric alcohol comprises the following steps: firstly adding polycarbonate diol and a double-metal cyanide complex catalyst into a reaction kettle, heating to a certain temperature, and performing vacuum dewatering; then adding a part of an epoxide under the condition of 100-180 DEG C to perform an induction reaction, and after the induction reaction is finished, dropwise adding the residual epoxide; and after the reaction is finished, removing the unreacted epoxide to obtain oligomeric dihydric alcohol. The oligomeric dihydric alcohol is mainly applied to synthesis a polyurethane material.

Owner:WANHUA CHEM GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com