Photosensitive polyimide resin, polyimide photocuring coating and preparation method thereof

A technology of polyimide resin and polyimide light, applied in the direction of coating, etc., can solve the problem of inability to prepare high light transmittance and heat resistance photosensitive polyimide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

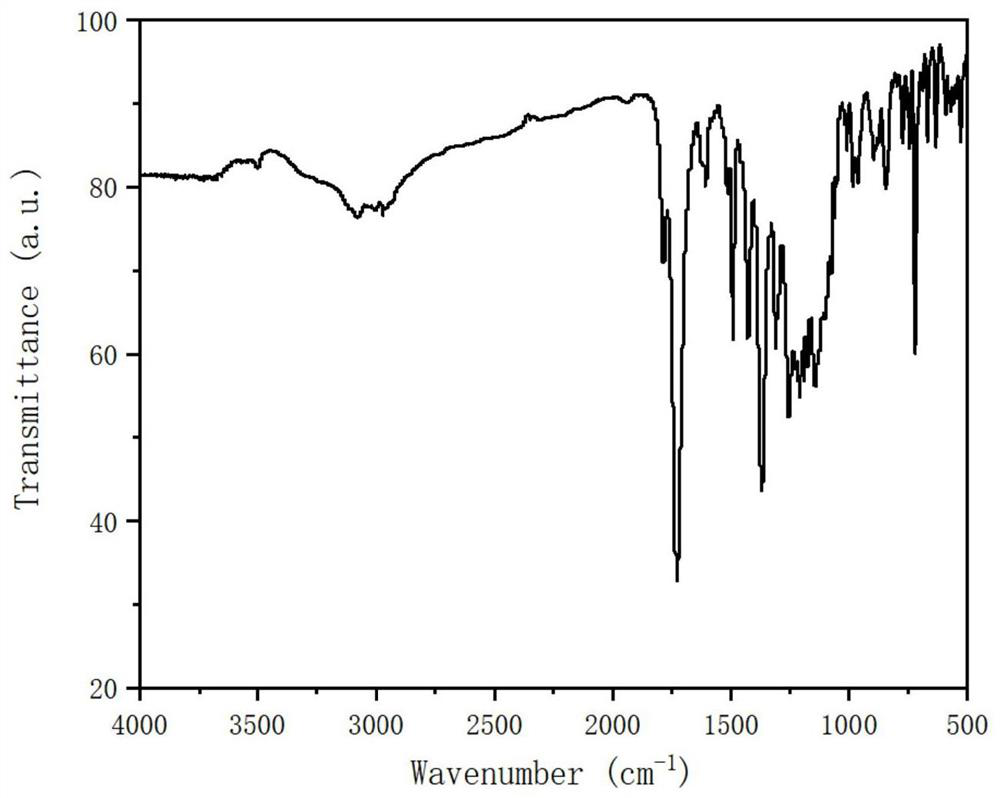

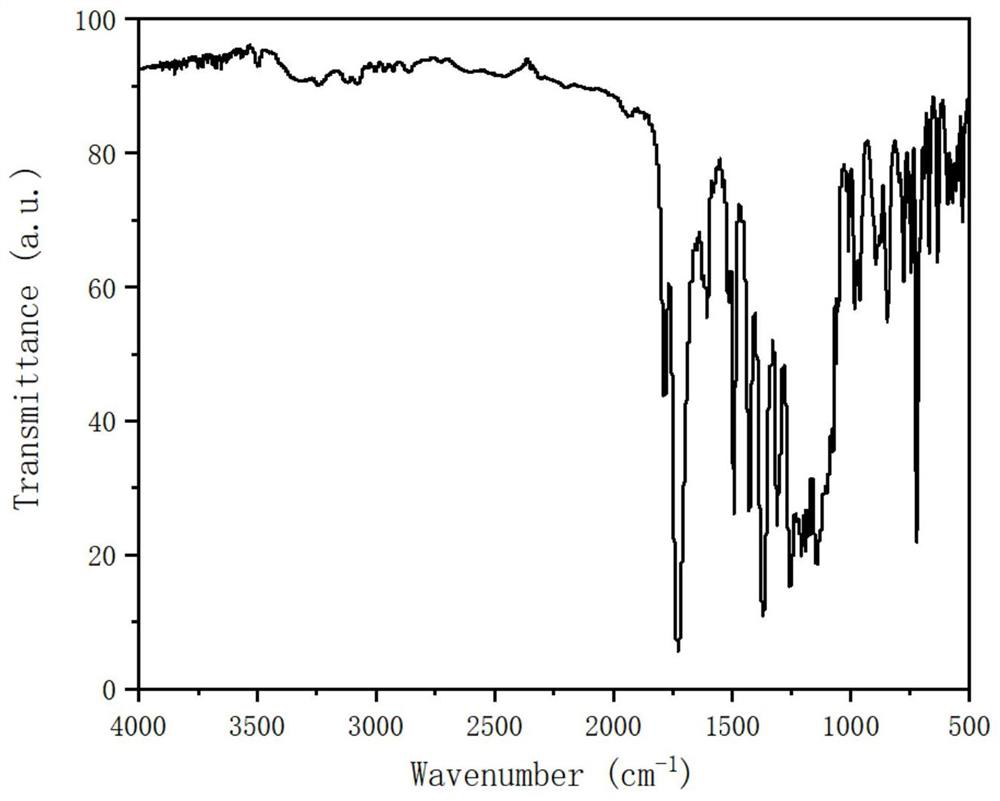

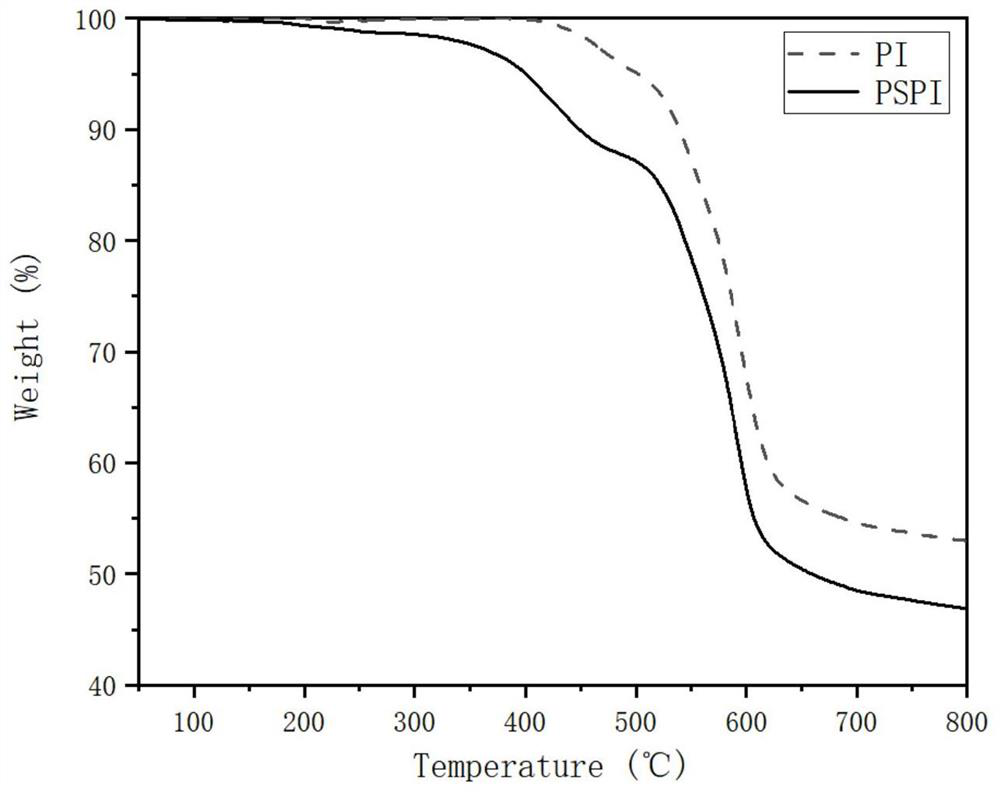

Image

Examples

Embodiment 1

[0065] A photosensitive polyimide resin and a polyimide photocurable coating.

[0066] (1) Photosensitive polyimide resin preparation:

[0067] S1: Room temperature is added to 250 ml of four-port round bottom flasks equipped with mechanical stirring and nitrogen, bis (trifluoromethyl) -4,4'-diaminobenzene and 25 g N-methylpyrrolidone , Stir until the clarified solution. Slowly mixed 5.553 g 2, 2'-double (3,4-dicarboxylic acid) hexafluoropropane dianhydride under vigorous stirring, and the last addition amount was less than or equal to half of the previous one. The reaction was at room temperature for 8 h.

[0068] S2: Slowly add 1.8 g of 4-aminobenzoic acid, 12.5 g of dichlorobenzene, 5 g of N-methylpyrrolidone, at room temperature under stirring at room temperature, to obtain a polyamic acid solution having a carboxyl group having a carboxyl group. The thermimidation reaction was 10 h heated to 240 ° C, and the thermimidation reaction was 12 h in the case of solvent reflux.

[0...

Embodiment 2

[0074] A photosensitive polyimide resin and a polyimide photocurable coating.

[0075] (1) Photosensitive polyimide resin preparation:

[0076] S1: Room temperature was added 1.685 g4, 4'-diaminiphenylene ether and 25 g of N-methylpyrrolidone, stirred to a clear solution. Slowly mixed 5.553 g 2, 2'-double (3,4-dicarboxylic acid) hexafluoropropane dianhydride under vigorous stirring, and the last addition amount was less than or equal to half of the previous one. The reaction was at room temperature for 8 h.

[0077] S2: Slowly add 1.8 g of 4-aminobenzoic acid, 12.5 g of dichlorobenzene, 5 g of N-methylpyrrolidone, at room temperature under stirring at room temperature, to obtain a polyamic acid solution having a carboxyl group having a carboxyl group. Thermimidation reaction was heated to 230 ° C, and the thermimidation reaction was 12 h under the case of solvent reflux.

[0078] S3: Cooling to 110 ° C, slowly add 1.4 g of methacrylate, 0.042 g of phenol, 0.042 g of triphenylphosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uv absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com