Preparation method of polypropylene wax

A polypropylene wax and propylene technology, applied in the production of bulk chemicals, etc., can solve the problems of high polymer melt viscosity, no value, and difficult to achieve, and achieve uniform particles, reduce solvent usage, and improve the effect of shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of supported metallocene catalyst

[0052] Carrier treatment: under dry nitrogen flow, the silica gel was heat-treated at 600°C for 6 hours, and nitrogen protection was used for later use. Weigh 5.0 g of the treated silica gel, add it into a stirred glass reaction bottle, vacuumize, stir slowly and heat to 100° C. for 5 hours. Then nitrogen protection was introduced into the reaction bottle.

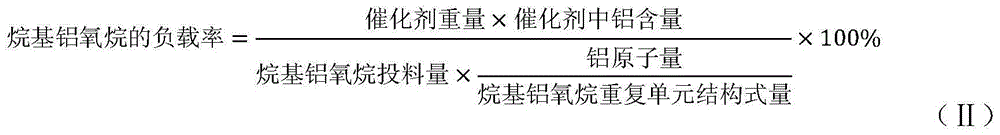

[0053] Loading methylaluminoxane: under the protection of nitrogen, add 5.0g methylaluminoxane and 20mL toluene to the reaction flask with mechanical stirring, stir to dissolve and keep the temperature to 100°C, then slowly add the above-mentioned treated silica gel into the methylaluminoxane solution, rinse the residual silica gel with 20 mL of toluene, stir at constant temperature for 3 hours, then wash with toluene at 100° C., filter, and dry to obtain a silica gel carrier loaded with methylaluminoxane.

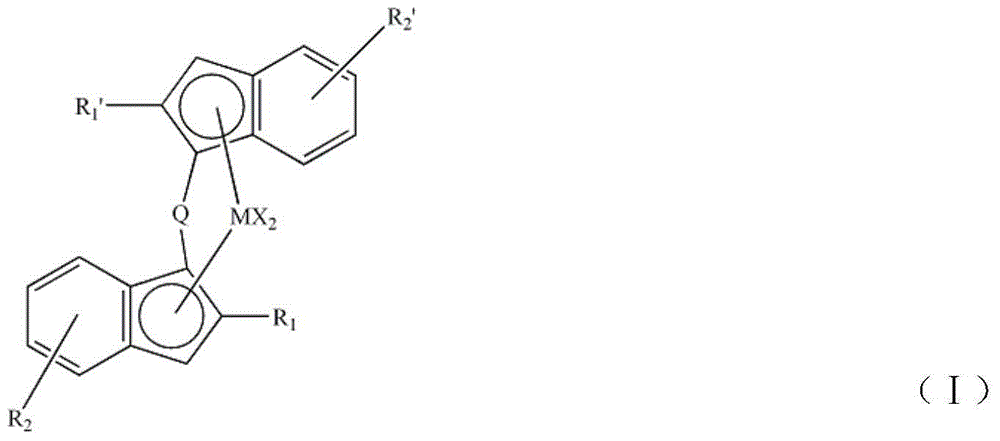

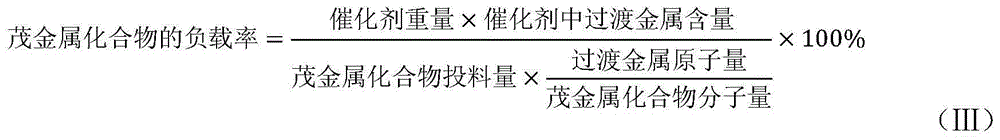

[0054] Loaded metallocene compound: under the...

Embodiment 2

[0055] Embodiment 2: Propylene bulk polymerization reaction

[0056] Polymerization was carried out in a 5 L autoclave. The polymerization kettle was first purged and replaced with dry nitrogen, and 220 mg of the supported metallocene catalyst prepared in Example 1 was suspended in 5 ml of n-hexane to make a slurry and added to the catalyst feeder, followed by the addition of 3.5 ml of 1 mol / L triisobutyl Start stirring the aluminum hexane solution, pour the catalyst and triisobutylaluminum into the reactor with 2.3 L of liquid propylene, raise the temperature to 70° C. and react for 1 hour to obtain 767 g of powdered polypropylene wax. The polymerization activity was 3486 g / gcat·hr, the number average molecular weight of the obtained polypropylene wax was 16500 g / mol, and the molecular weight distribution was 2.35.

Embodiment 3

[0057] Embodiment 3: Propylene bulk polymerization reaction

[0058] Polymerization was carried out in a 5 L autoclave. The polymerization kettle was first purged and replaced with dry nitrogen, and then 0.1MPa hydrogen was introduced. Suspend 205 mg of the supported metallocene catalyst prepared in Example 1 in 5 ml of n-hexane to make a slurry and add it to the catalyst feeder, then add 3.5 ml of triisobutylaluminum hexane solution with a concentration of 1 mol / L, start stirring, and use 2.3 L of liquid propylene flushed the catalyst and triisobutylaluminum into the reactor, raised the temperature to 70° C. and reacted for 1 hour to obtain 315 g of powdered polypropylene wax. The polymerization activity was 1536 g / gcat·hr, the number average molecular weight of the obtained polypropylene wax was 2300 g / mol, and the molecular weight distribution was 2.59.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com