Patents

Literature

42results about How to "Controllable nature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

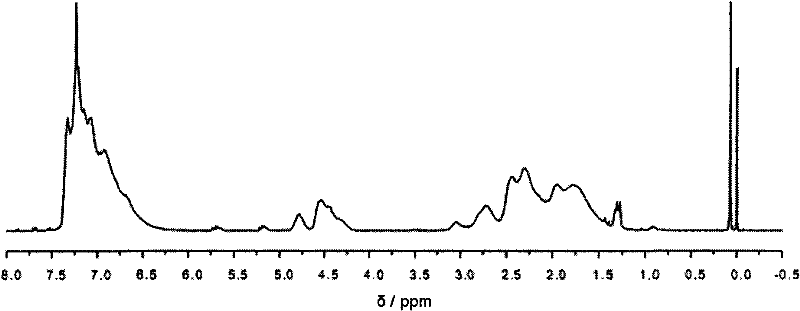

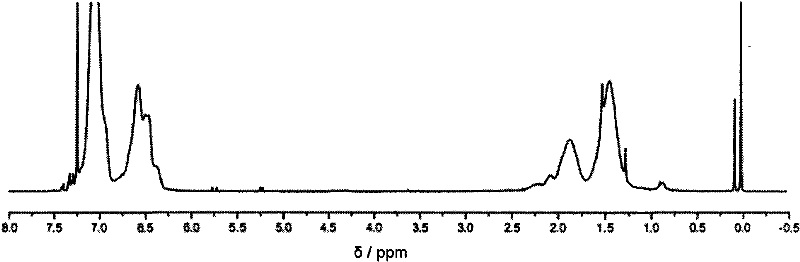

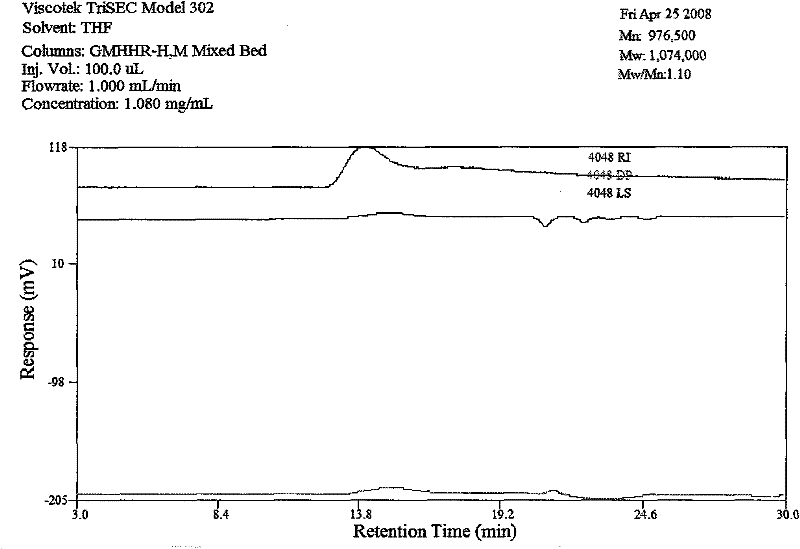

Multi-arm star-type polymer and preparation method thereof

The invention discloses a multi-arm star-type polymer and a preparation method thereof. The method synthesizes the multi-arm star-type polymer by a method with the following two steps of step one: taking a complex formed by a polydentate nitrogen-contained compound and a transitional metal halide as a catalytic system so as to catalyze the polymerization of atom transfer free radicals and self-condensing vinyl of a monomer, thus preparing and obtaining the halogen atom-contained hyperbranched polystyrene macromolecular initiator taken as the star-type polymer core; and step two: taking the complex formed by the the polydentate nitrogen-contained compound and the transitional metal halide as the catalytic system and taking the prepared halogen atom-contained hyperbranched polystyrene macromolecular as the initiator to initiate the polymerization of the atom transfer free radicals of the monomer, thus preparing and obtaining the multi-arm star-type polymer with controllable core structure, core size, core property, arm number, arm length and arm property and adjustable molecular weight within wider range.

Owner:INST OF CHEM CHINESE ACAD OF SCI

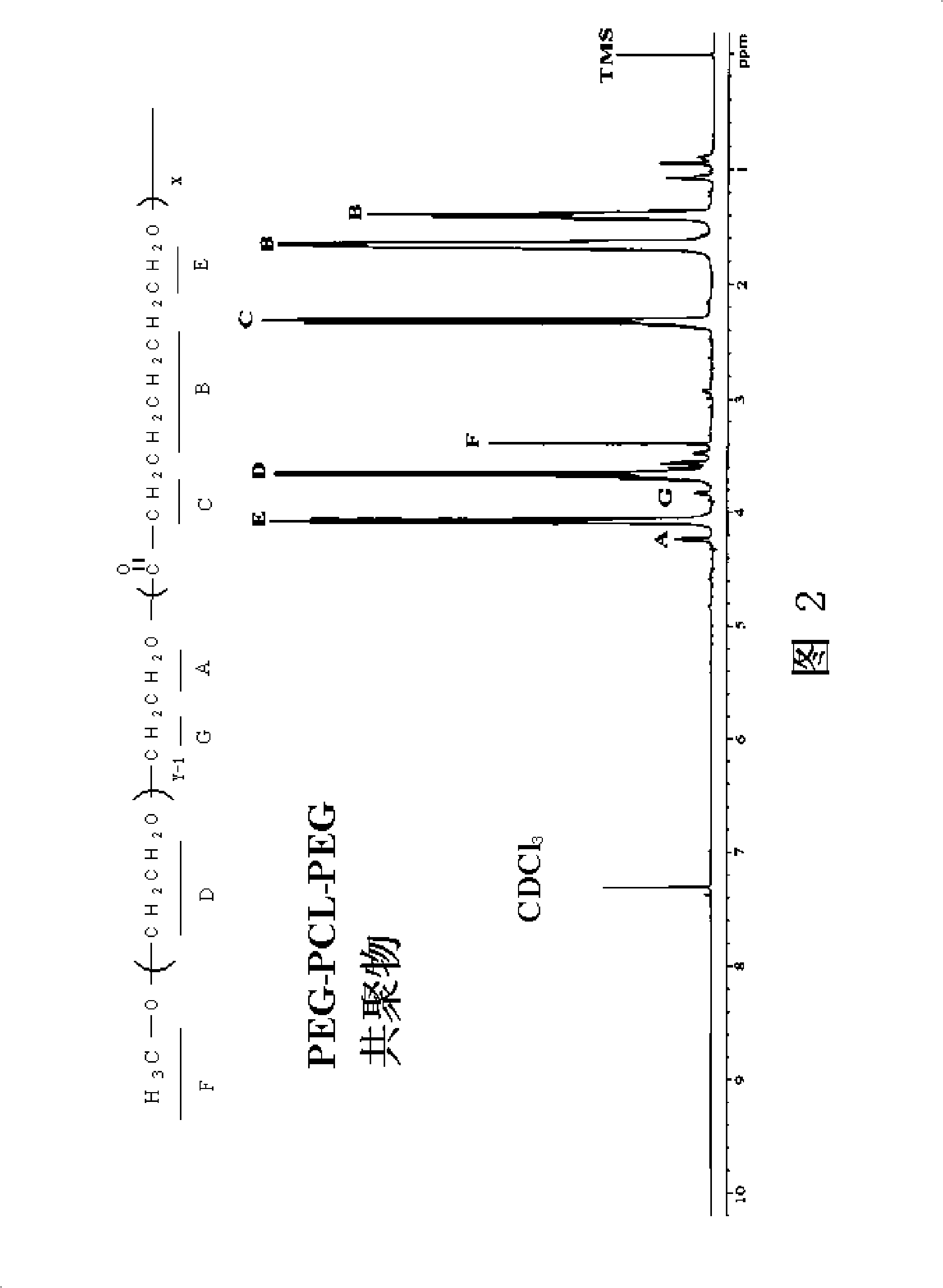

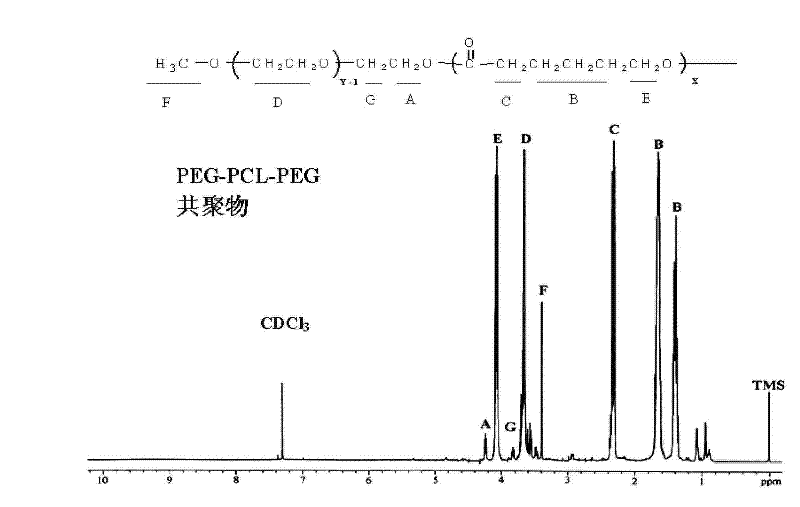

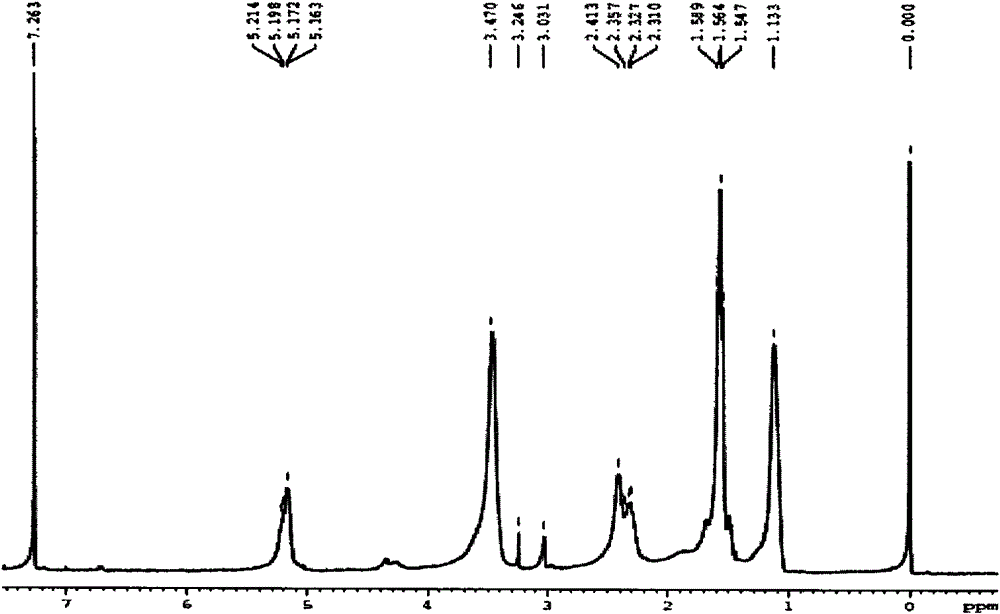

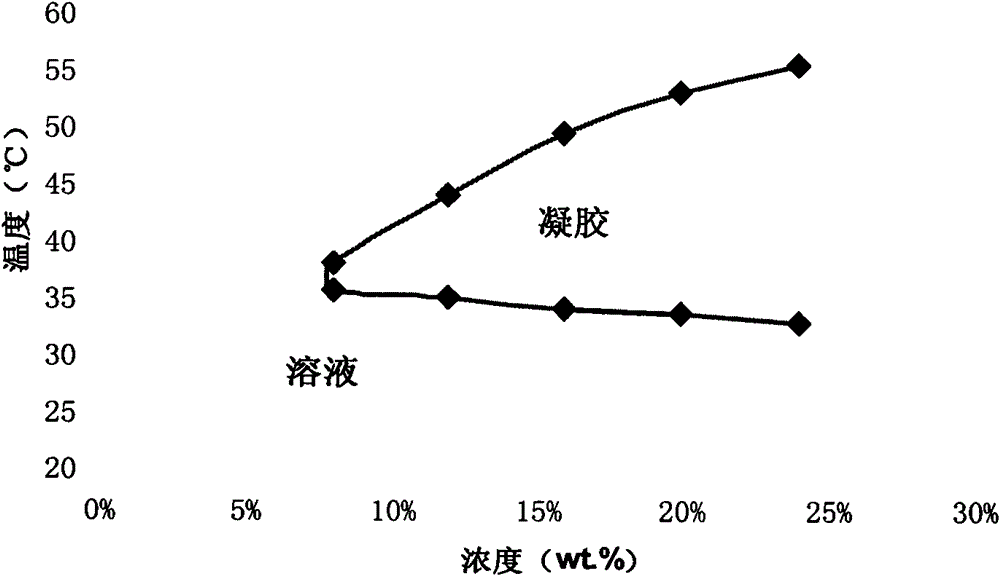

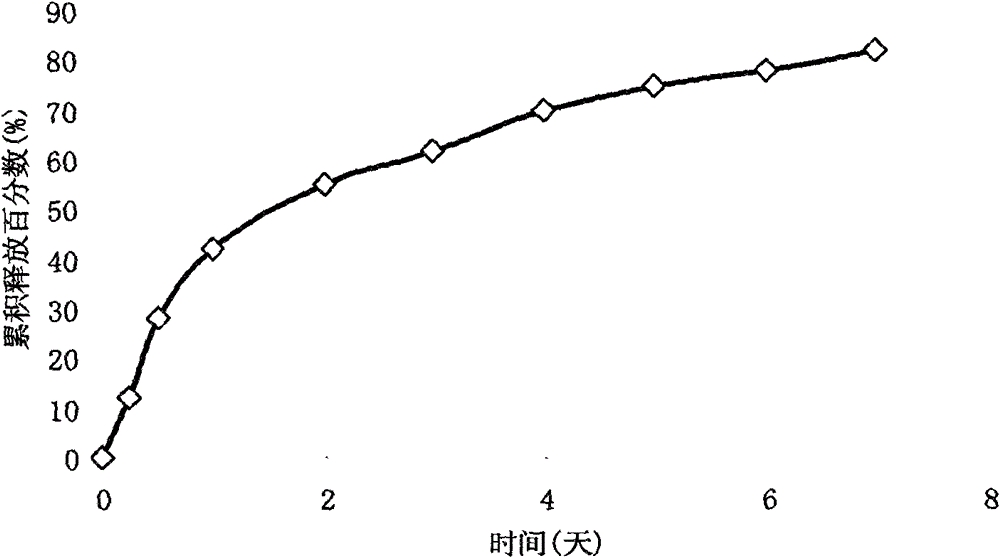

Thermo-sensitive tri-block polymer as well as preparation method and use thereof

InactiveCN101255234AAdjustable intensityGood biocompatibilitySurgeryPharmaceutical non-active ingredientsPolymer sciencePEG-PCL-PEG

The invention relates to medical polymers field, especially a temperature sensitive and biodegradable triblock copolymer with gel-sol transformation characteristics and preparation method thereof and usage. The triblock copolymer is PEG-PCL-PEG copolymer, the aqueous solution thereof performs Gel-Sol phase transformation along with the temperature rise and the phase transformation temperature is 40-55 degree. The PEG-PCL-PEG copolymer has a variety of excellent features to provide a new choice in field which is in need of temperature sensitive material.

Owner:SICHUAN UNIV

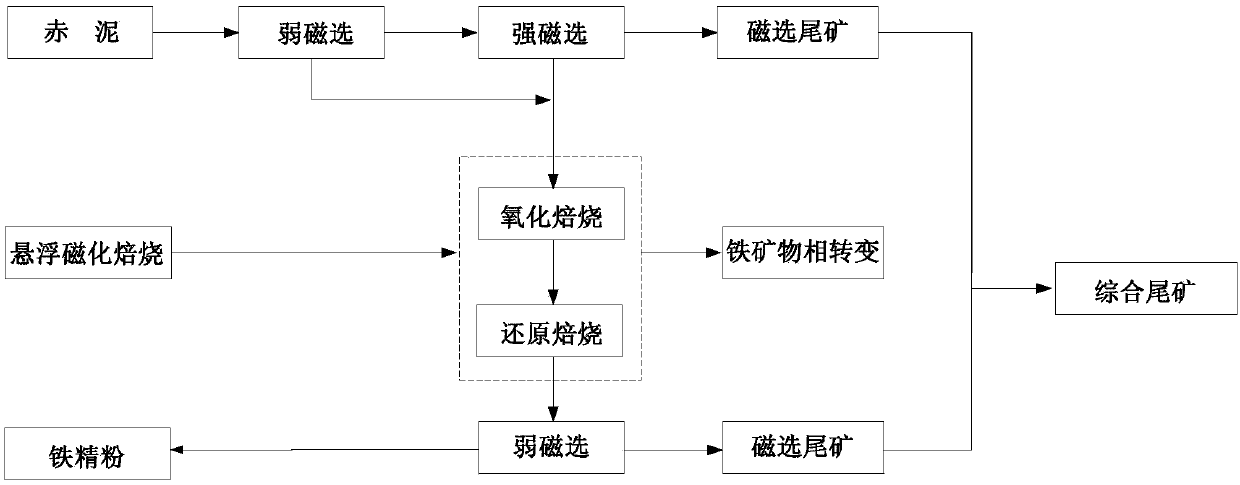

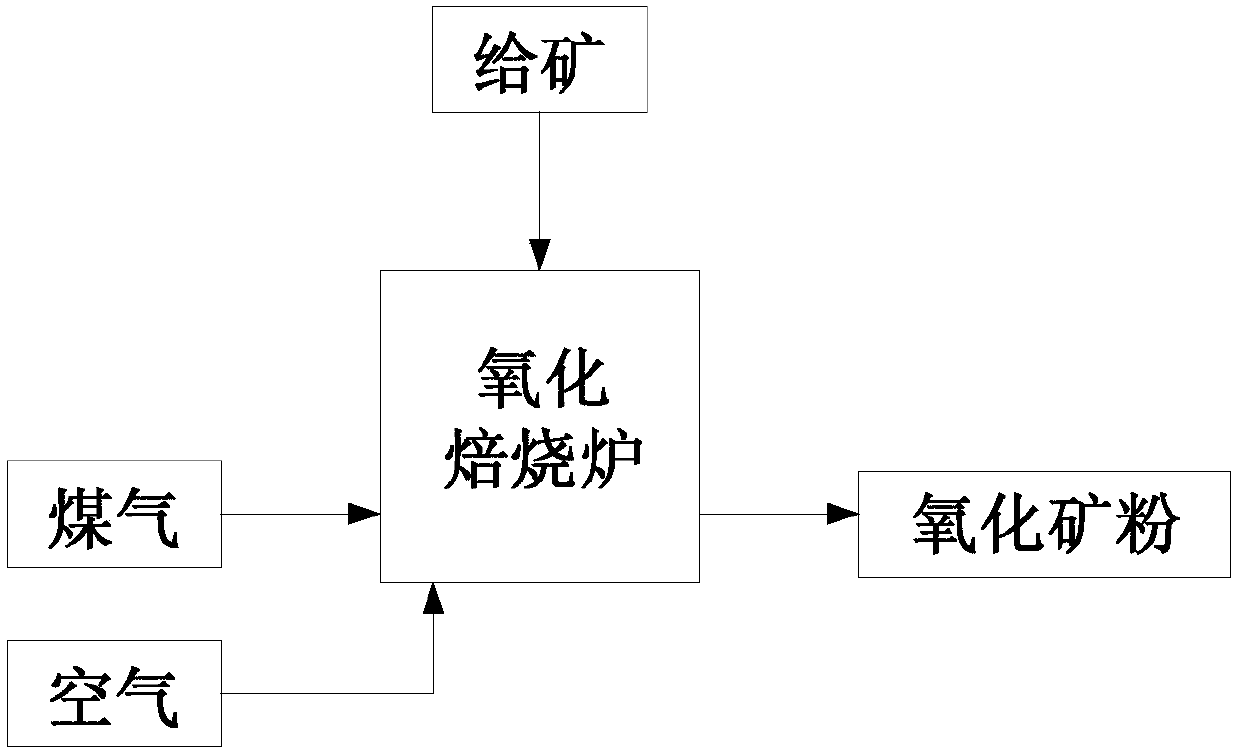

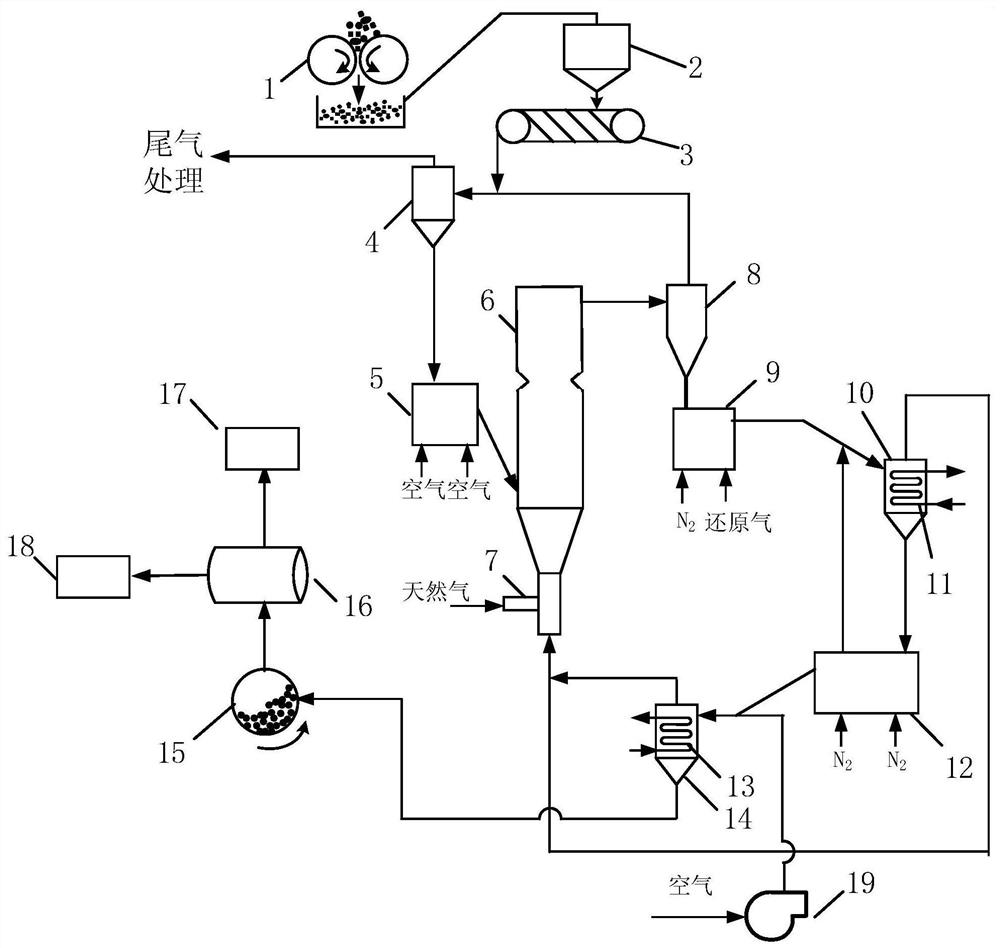

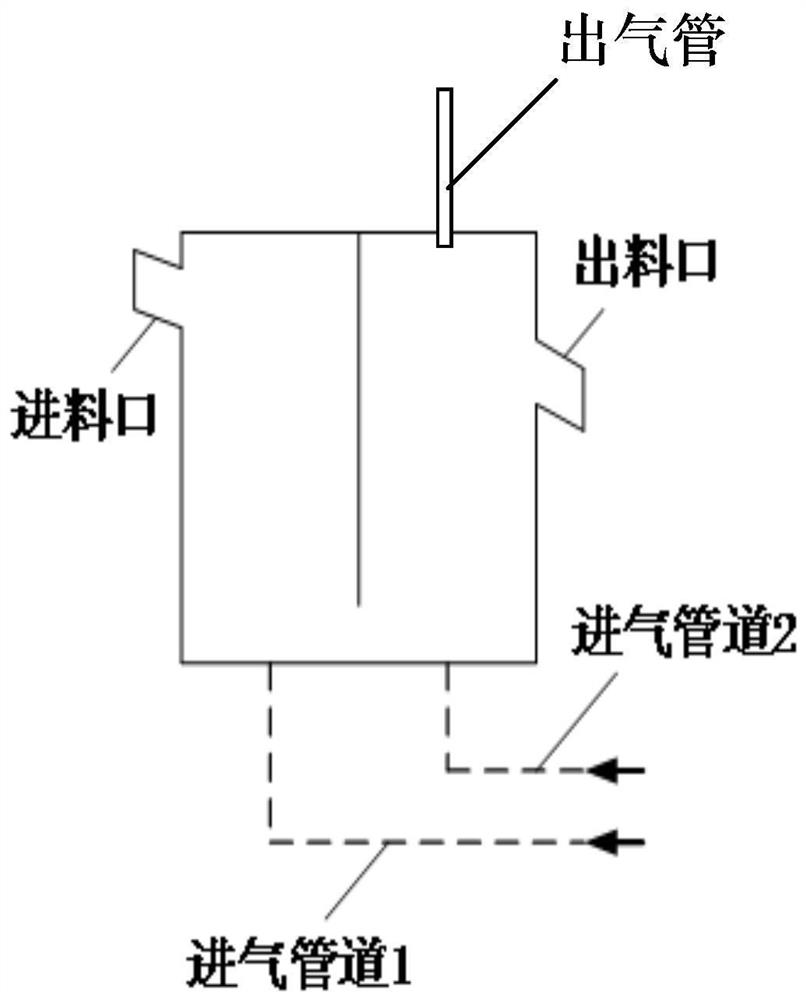

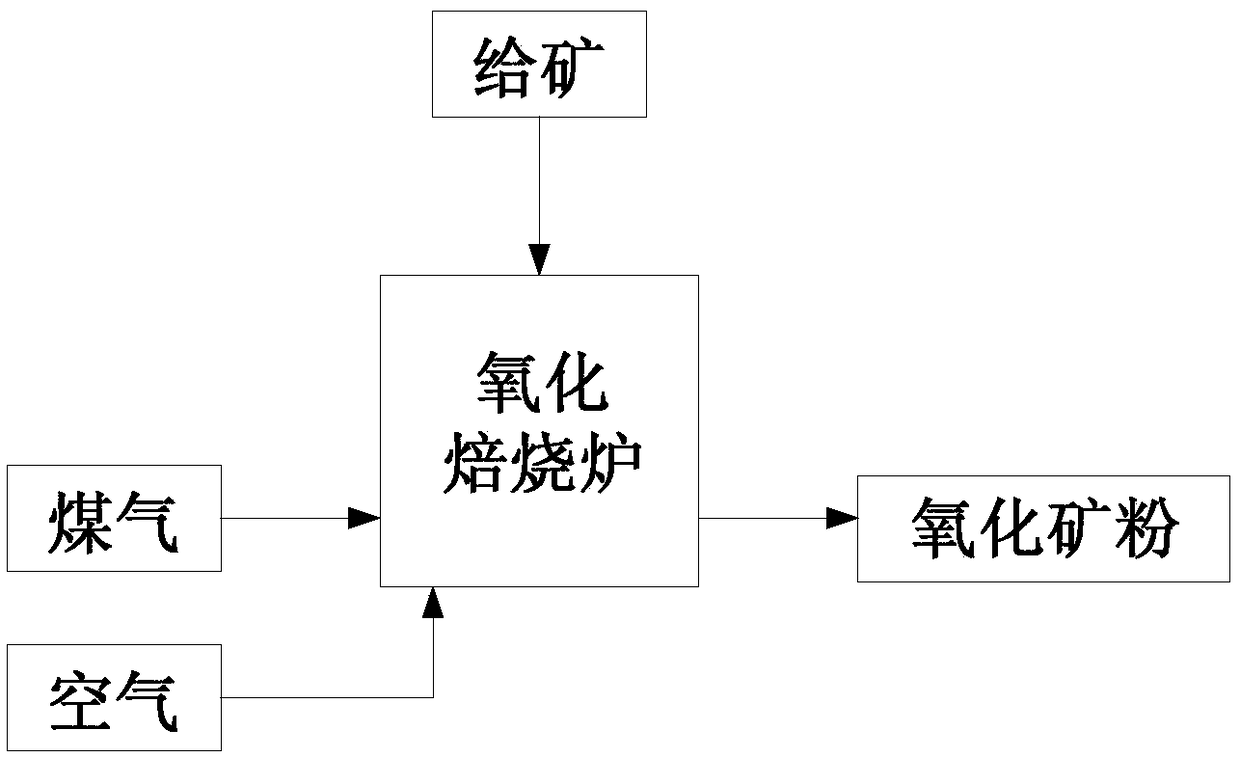

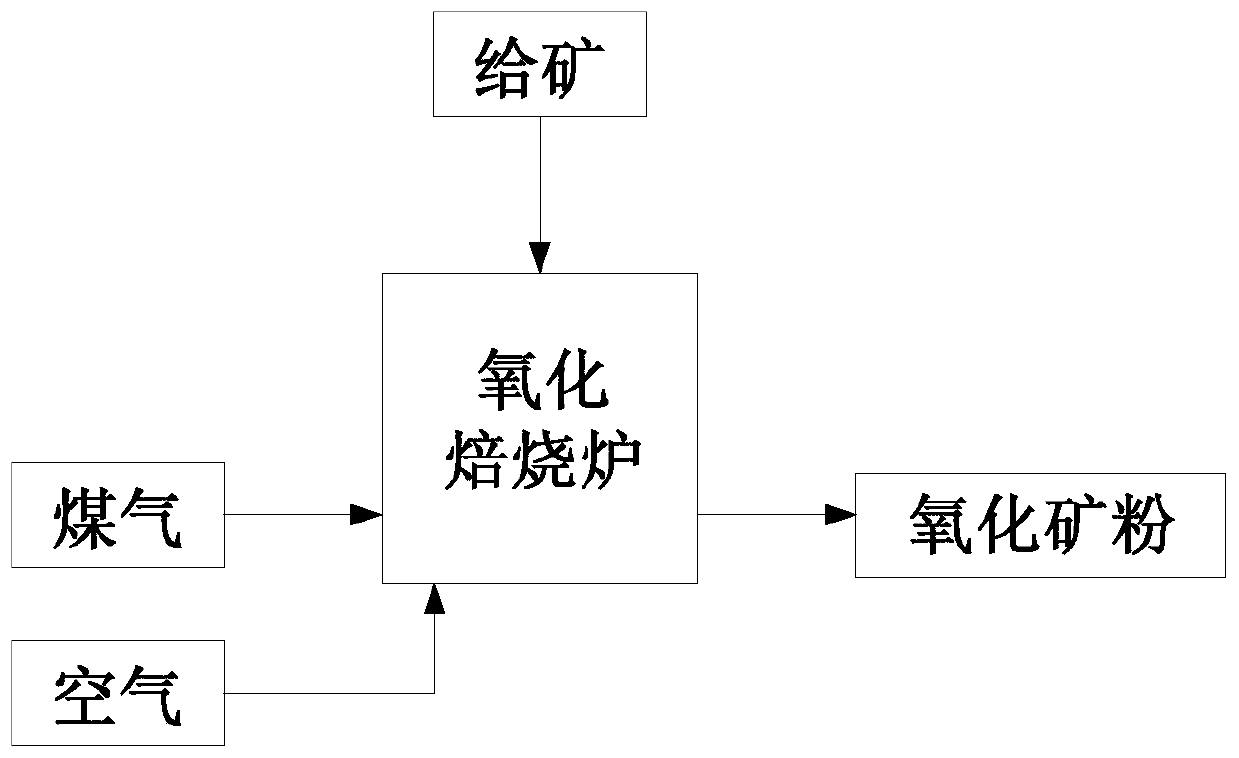

Method for preparing iron powder through red mud suspension roasting

The invention discloses a method for preparing iron powder through red mud suspension roasting, and belongs to the technical field of mineral processing. The method comprises following steps: firstly,red mud is subject to fine grinding and then subject to one-segment weak magnetic separation; secondly, one-segment weak magnetic separation tailings is subject to strong magnetic separation, and one-segment weak magnetic concentrate and strong magnetic concentrate are mixed to serve as preconcentration concentrate; thirdly, the preconcentration concentrate is placed in an oxidizing roaster, gasand air are led, and the preconcentration concentrate is subject to oxide roasting to obtain oxide powder ore; fourthly, the oxide powder ore is placed in a reduction roaster, nitrogen and reduction gas are led, and reduction roasting is carried out; fifthly, the roasted ore is subject to fine grinding, and then, second-segment weak magnetic separation is carried out. The method is simple in process flow, the equipment treatment amount is large, the product character is easily controlled, industrial application is achieved, the method is energy-saving and environment-friendly, and enlargementis easily achieved.

Owner:NORTHEASTERN UNIV LIAONING

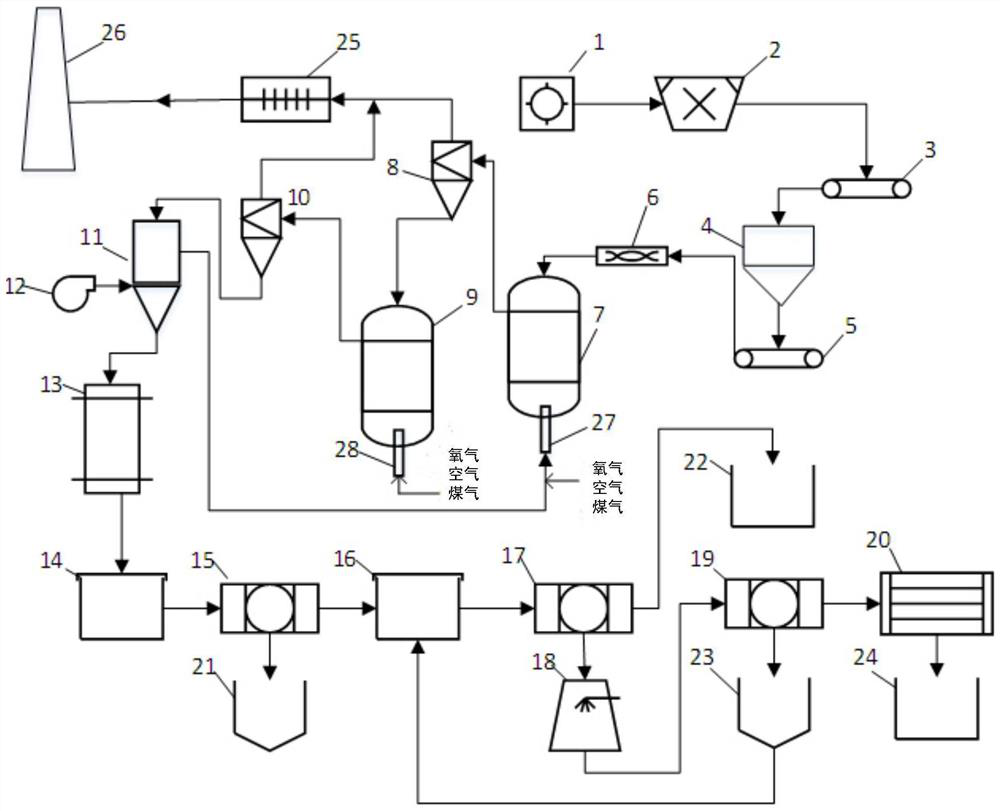

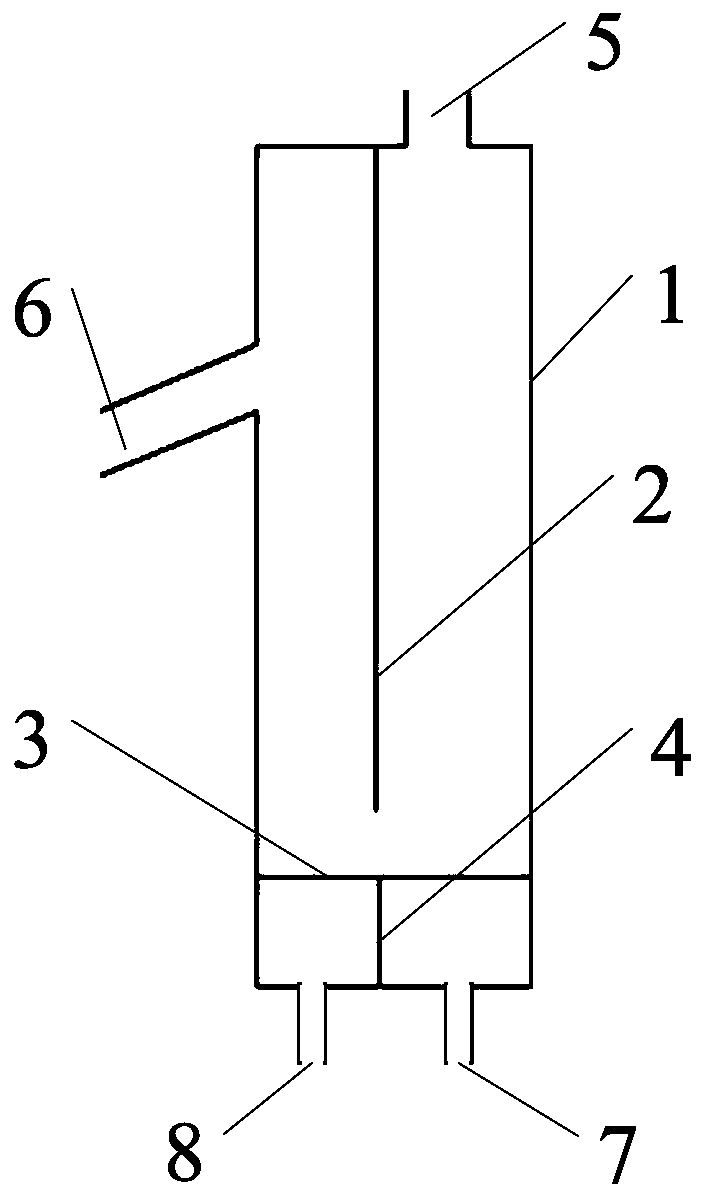

Stone coal vanadium ore oxidizing, crystal breaking, roasting and vanadium extracting comprehensive utilization system

ActiveCN111876616AHigh heat and mass transfer efficiencySolve problems such as secondary pollutionSilicaChemical industryDecarburizationCoal

The invention discloses a stone coal vanadium ore oxidizing, crystal breaking, roasting and vanadium extracting comprehensive utilization system. A crusher, a high-pressure roller mill, a first feeding belt, a feeding bin, a second feeding belt and a spiral feeder are sequentially matched with one another, and the discharging end of the spiral feeder is matched with a feeding port of a suspensiondecarburization roasting furnace; the suspension decarburization roasting furnace, a first cyclone separator, a suspension crystal breaking roasting furnace, a second cyclone separator and a cooler are sequentially communicated in series; a combustor and an air inlet are respectively arranged at the bottoms of the suspension decarburization roasting furnace and the suspension crystal breaking roasting furnace; an air inlet of the cooler is communicated with an air compressor; and a discharging hole in the bottom of the cooler is matched with a feeding hole of an acid mixing curing furnace; andthe acid mixing curing furnace, a first leaching tank, a first filtering device, a second leaching tank, a second filtering device, a pH value adjusting tank and a third filtering device are sequentially connected in series and matched with one another. The system provided by the invention is stable in operation, large in treatment capacity, low in energy consumption and cost of unit treatment capacity, and capable of easily controlling product properties and easily achieving large-scale equipment.

Owner:上海逢石科技有限公司

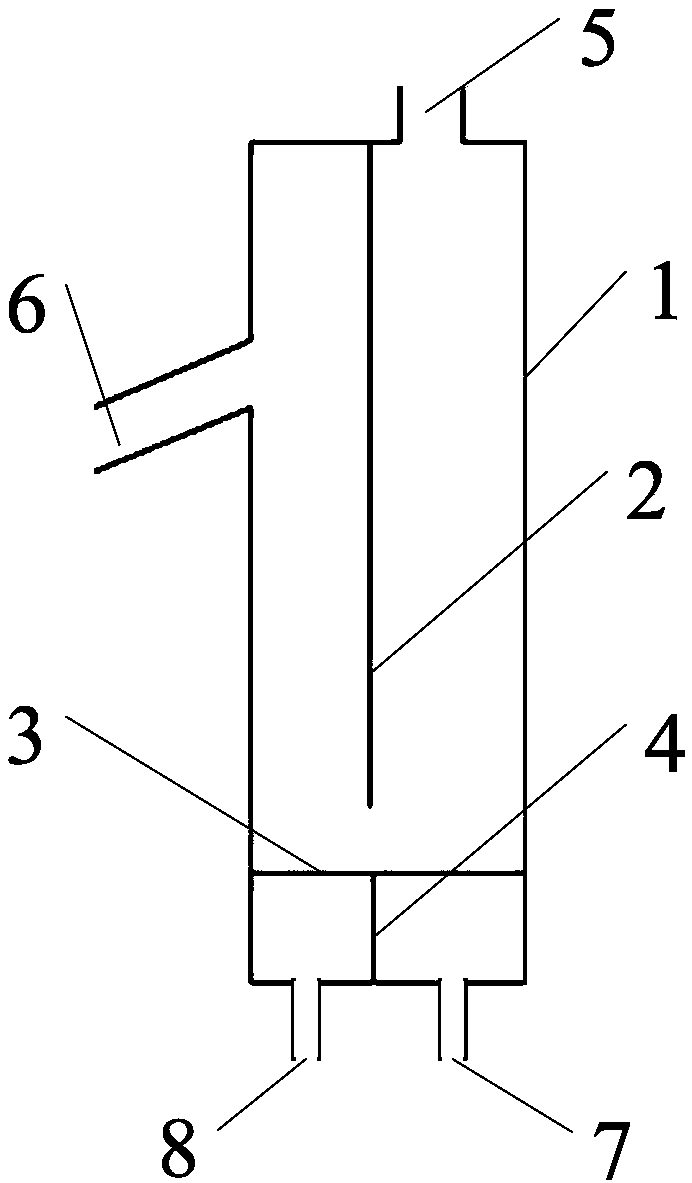

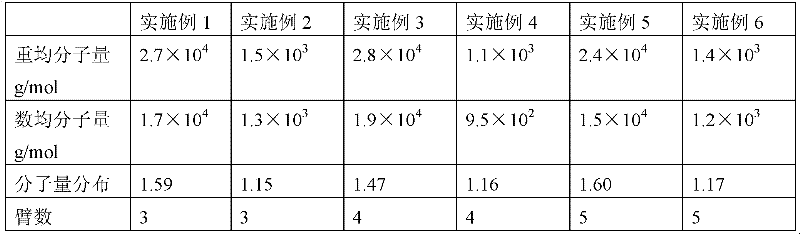

Preparation method of multi-arm star polyamide polymer

The method belongs to the technical field of polymeric material and specifically relates to a preparation method of a multi-arm star polyamide polymer. The method of the invention comprises the following steps: placing monomer, initiator 0.2-20% of a mole of the monomer and water 10-50 wt% of the monomer into a high pressure reaction kettle; sealing; filling the reaction kettle with nitrogen through a displacement method; heating to a temperature 20-50 DEG C higher than a melting point of an obtained polymer; adjusting a pressure to be at 1.8-2.5 MPa constantly; keeping the constant temperature for 20-120 min and operating a stirring device; reacting for 4-24 h, releasing pressure, vacuumizing and keeping at 10-4 MPa for 20-50 min; finally filling nitrogen to guarantee a pressure in the reaction kettle to reach 1.5-2.5 MPa, extruding the material, cooling and drying to obtain the multi-arm star polyamide polymer. Compared with a prior art, the invention has advantage of simpleness and easiness for enforcement; and the obtained multi-arm star polyamide polymer has controllable nucleus structure and property and controllable arm number, arm length and arm property, flexible and adjustable structure and can be modified conveniently for application in many fields.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

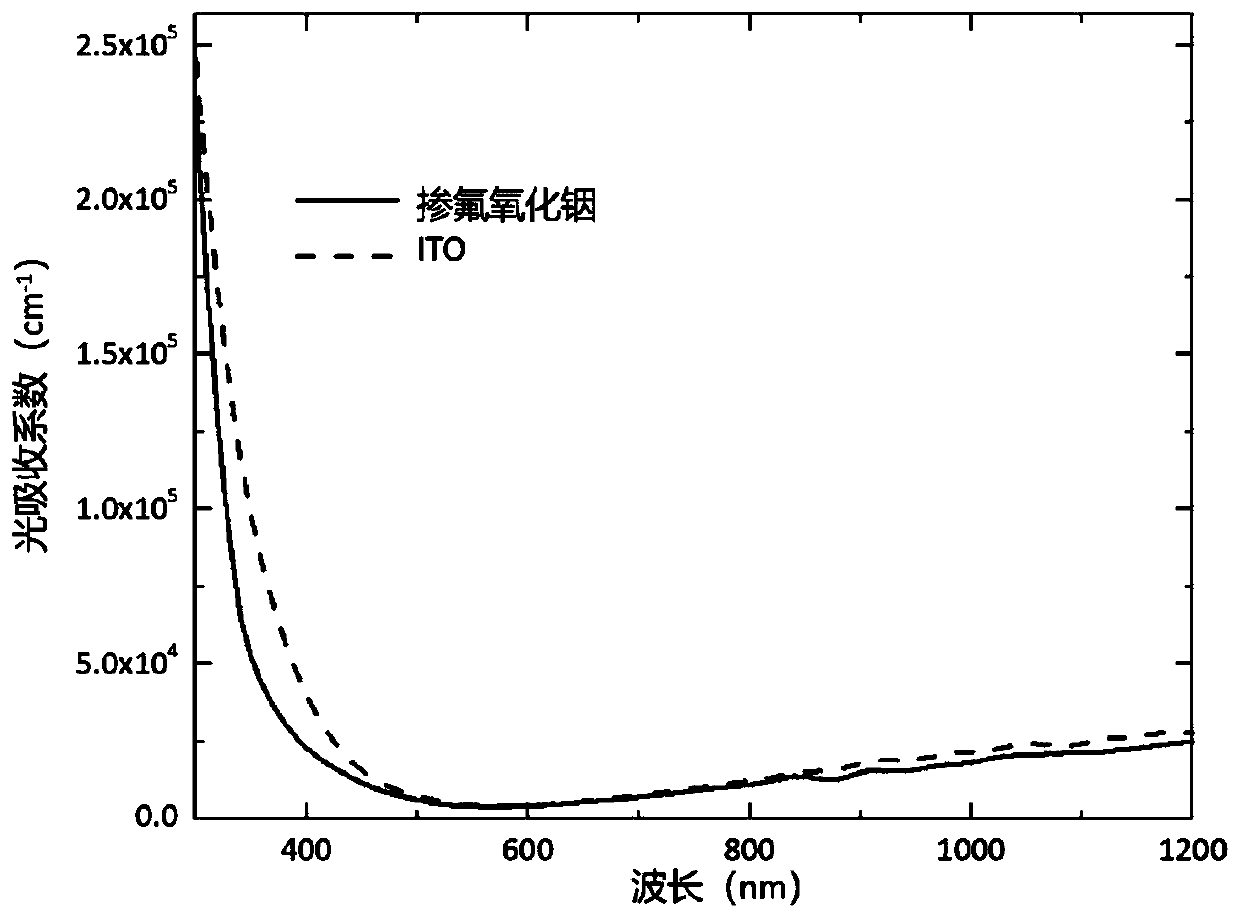

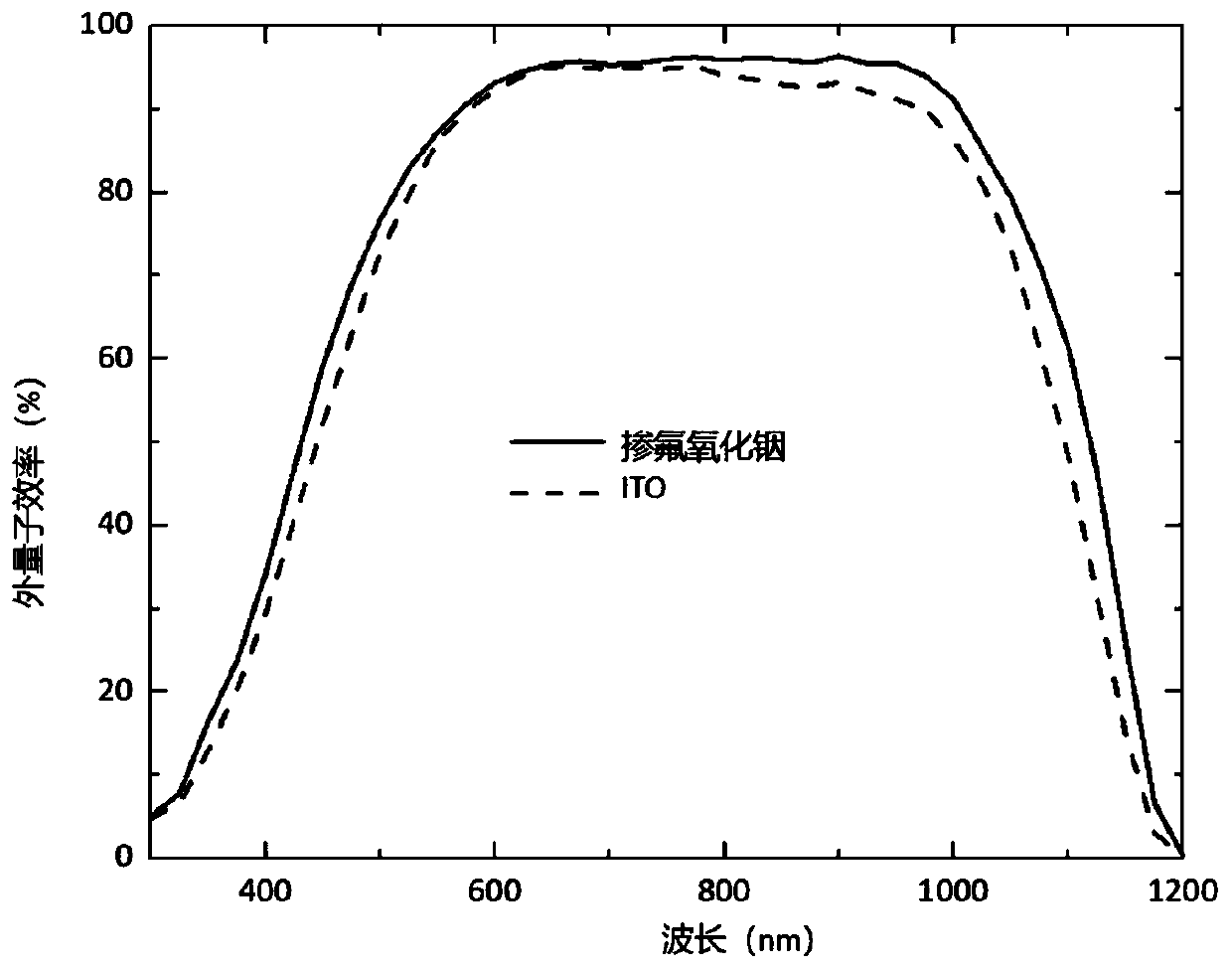

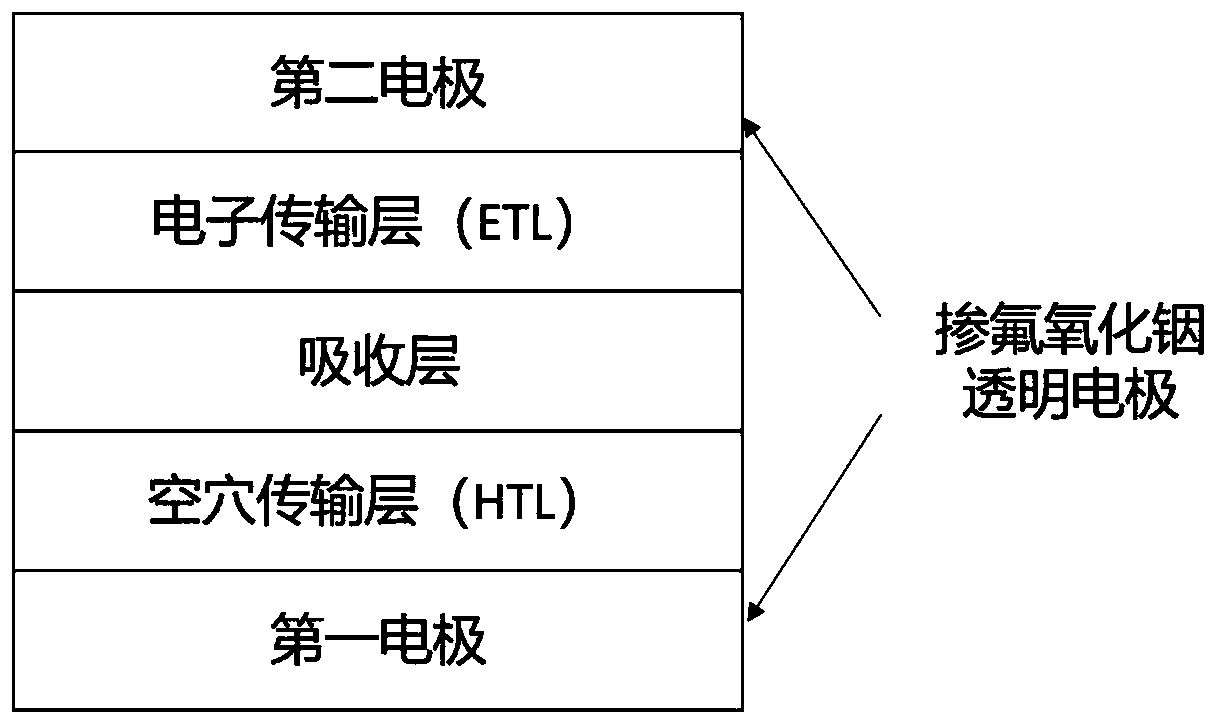

Preparation method and application of transparent conductive oxide film

InactiveCN111081812AImprove stabilityControllable natureFinal product manufactureSemiconductor devicesIndiumCharge carrier mobility

The invention provides a preparation method and application of a transparent conductive oxide film. According to the preparation method and application of the transparent conductive oxide film, magnetron sputtering technology is adopted; through process regulation and control, the high-efficiency deposition of a high-quality thin film can be realized; the preparation of a transparent conductive oxide film with carrier mobility higher than 60cm<2>V<-1 >s<-1> can be realized under a low-temperature condition; the electrical property of the oxide film is equivalent to that of ITO; and the opticalabsorptivity of the oxide film in a UV-Vis-IR full-wave band range is obviously reduced compared with that of the ITO. The fluorine-doped indium oxide transparent conductive oxide film prepared by the invention has good thermal stability; heat treatment at 250 DEG C or below basically does not cause the deterioration of material properties; the performance of the fluorine-doped indium oxide filmsubjected to proper post-treatment can be further improved; in addition, transition metal elements are not used, and therefore, the performance of the oxide film is stable, and meanwhile, the opticalproperties of the oxide film can be effectively regulated and controlled; and since the transition metal elements are not used, preparation cost is low.

Owner:SHENZHEN INST OF WIDE BANDGAP SEMICON

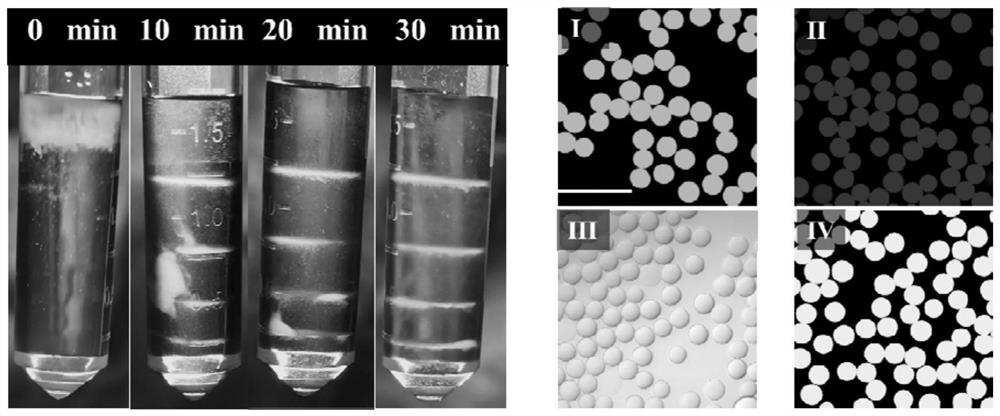

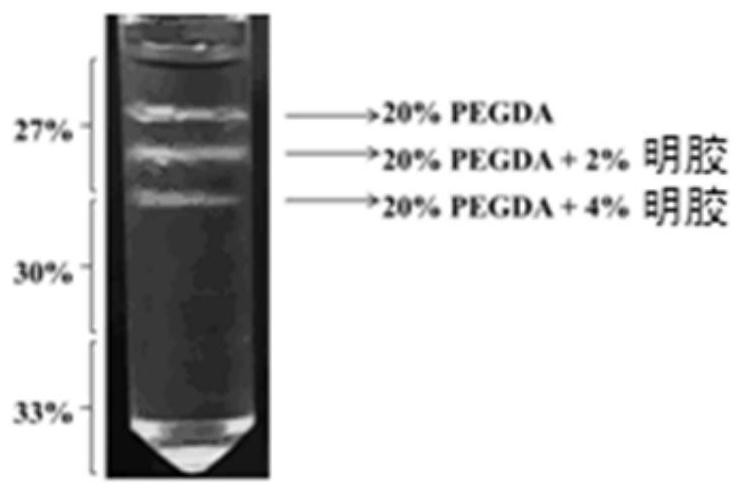

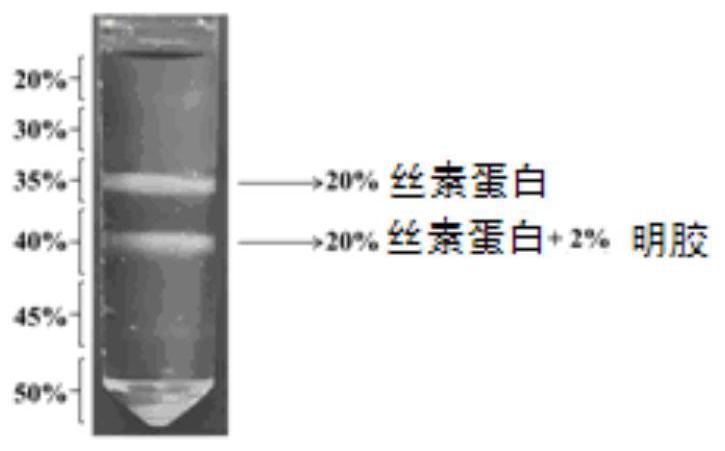

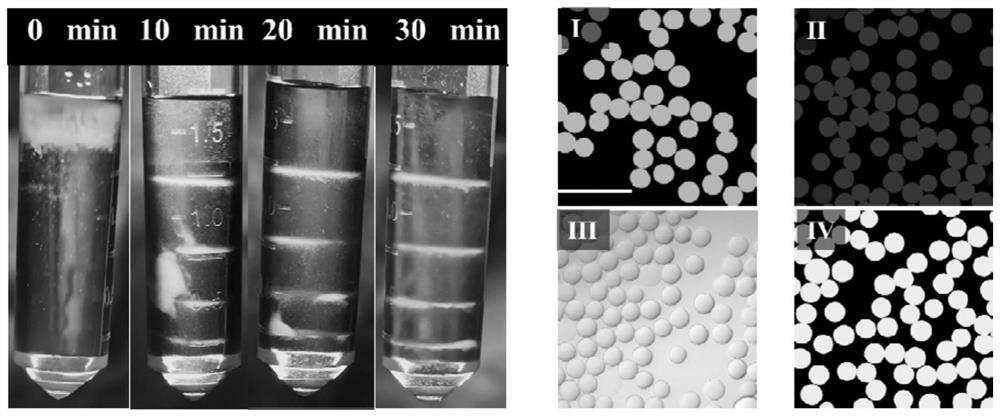

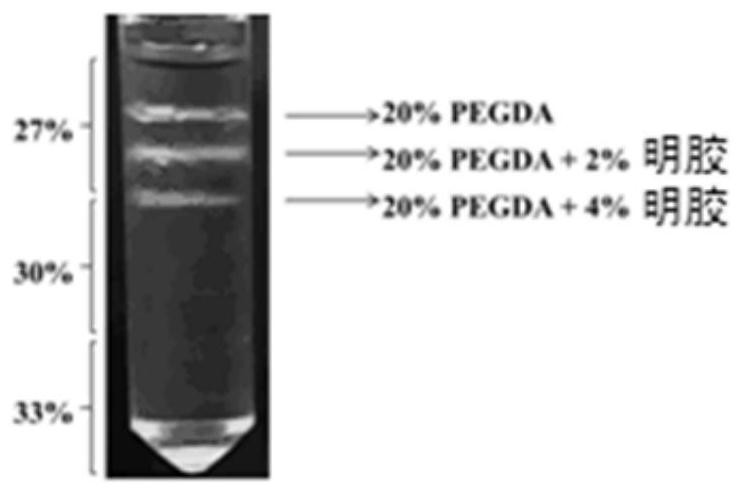

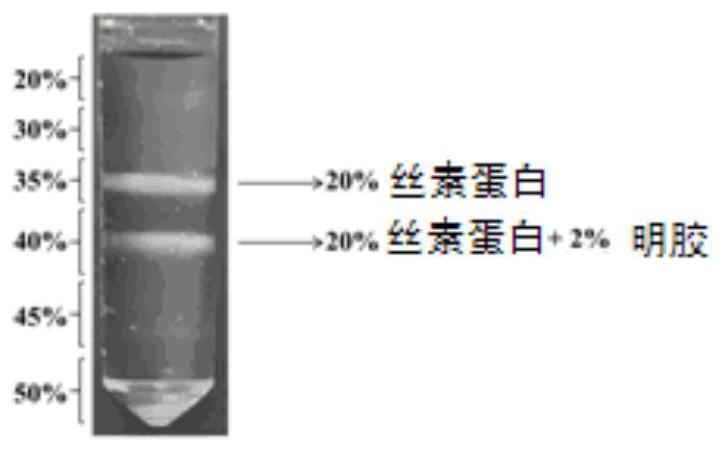

Hydrogel microcarrier and preparation method and application thereof

ActiveCN112048033AEasy to decodeReduce testing costsBiological testingFluorescence/phosphorescenceDiseaseActive agent

The invention discloses a hydrogel microcarrier and a preparation method and application thereof.The hydrogel microcarrier takes an oil phase solution as a carrier, an aqueous phase solution containing an initiator and two or more gelatinizing materials is dispersed in the oil phase solution, and the density-coded hydrogel microcarrier is formed by changing the concentration ratio of different gelatinizing materials. The preparation method comprises the following steps: mixing two or more gelatinizing materials with different concentration ratios with an initiator to obtain a water-phase solution; dissolving a surfactant and TEMED in an oil medium to obtain an oil phase solution, wrapping a water phase solution in the oil phase solution to form hydrogel liquid beads, and curing the hydrogel liquid beads to form the density-coded hydrogel microcarrier. The hydrogel microcarrier can realize multiple detection of disease-related proteins and visual detection of tumor-derived exosomes, andhas the advantages of simple decoding, low detection cost and the like.

Owner:HUNAN UNIV

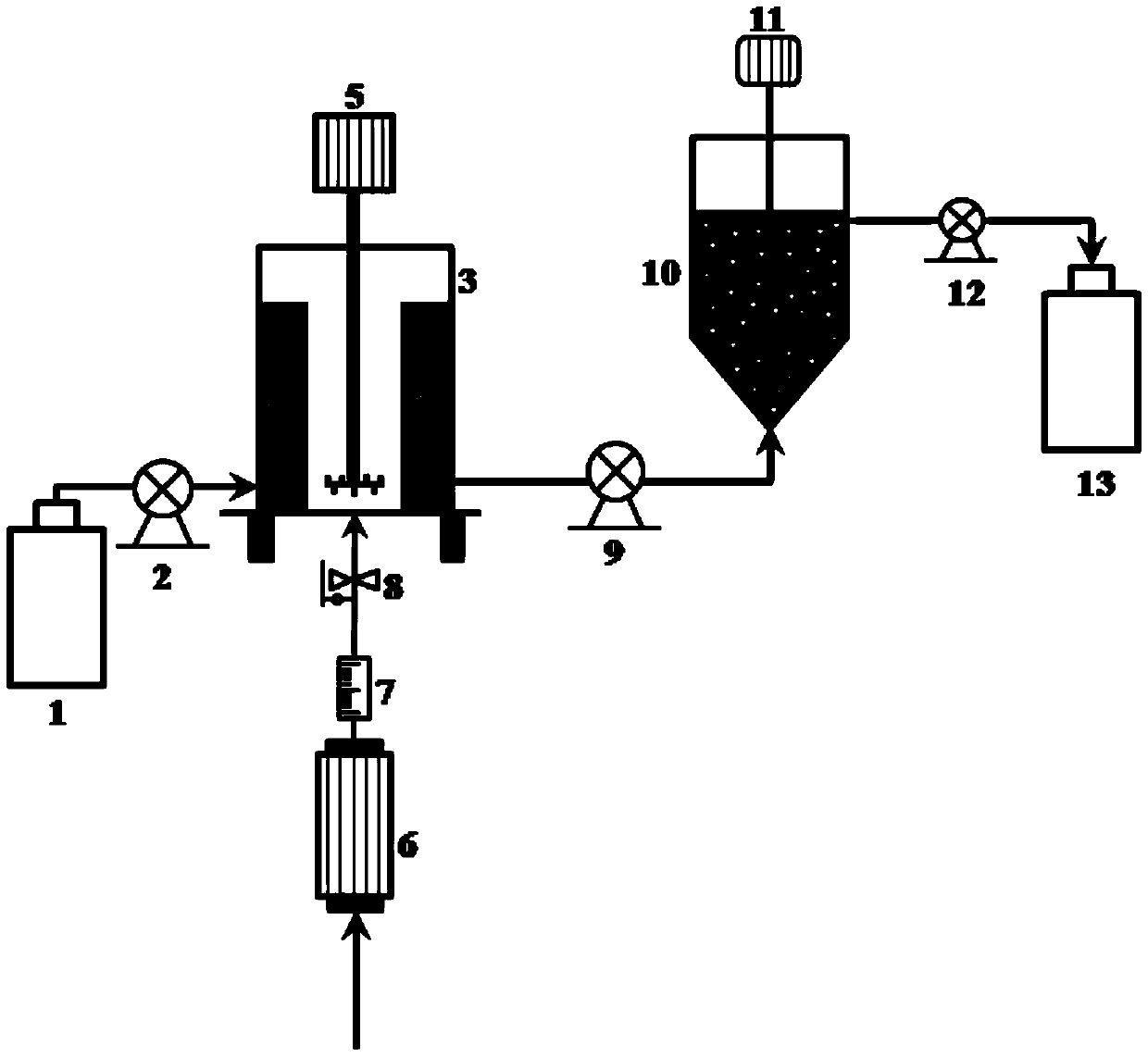

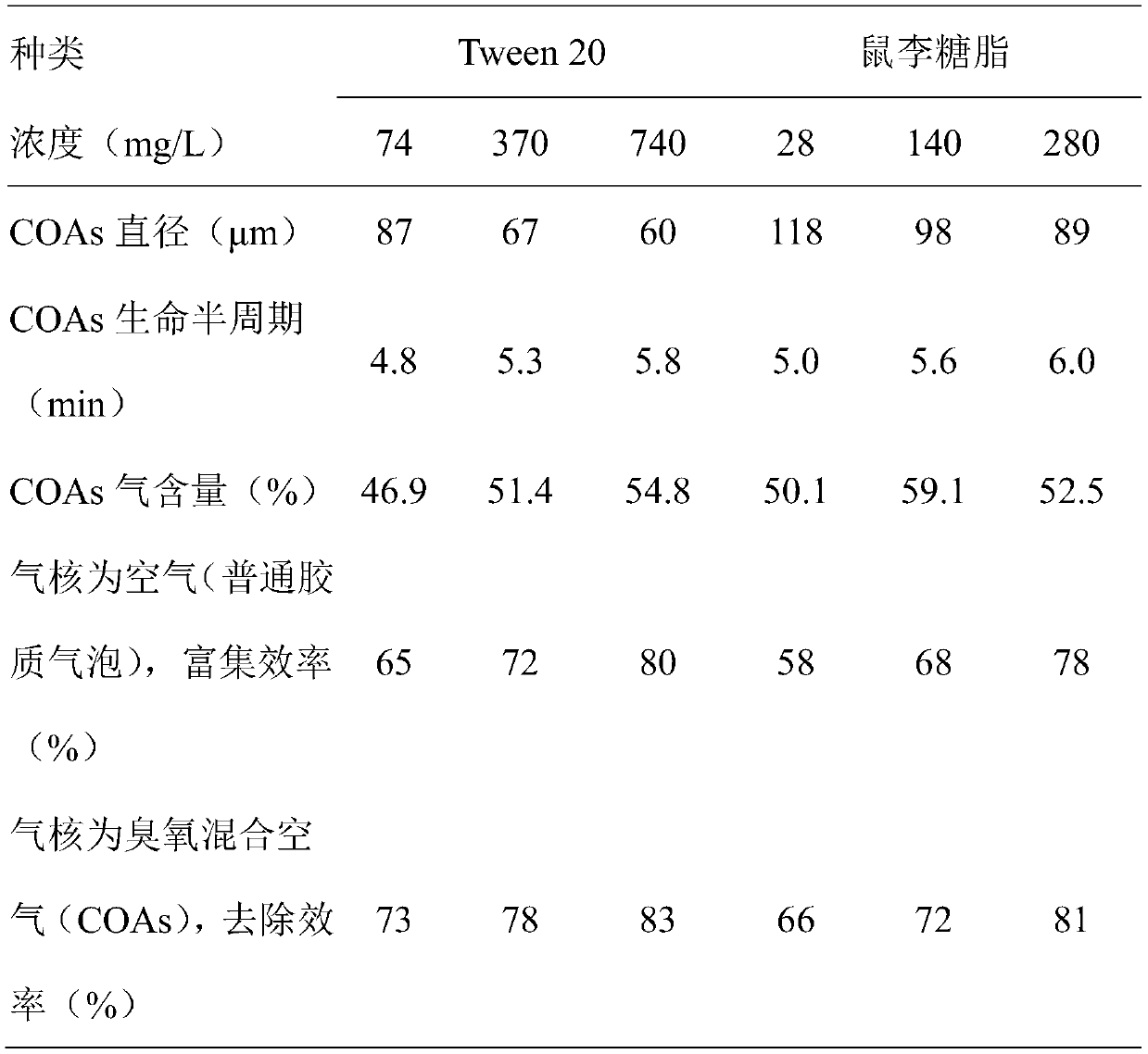

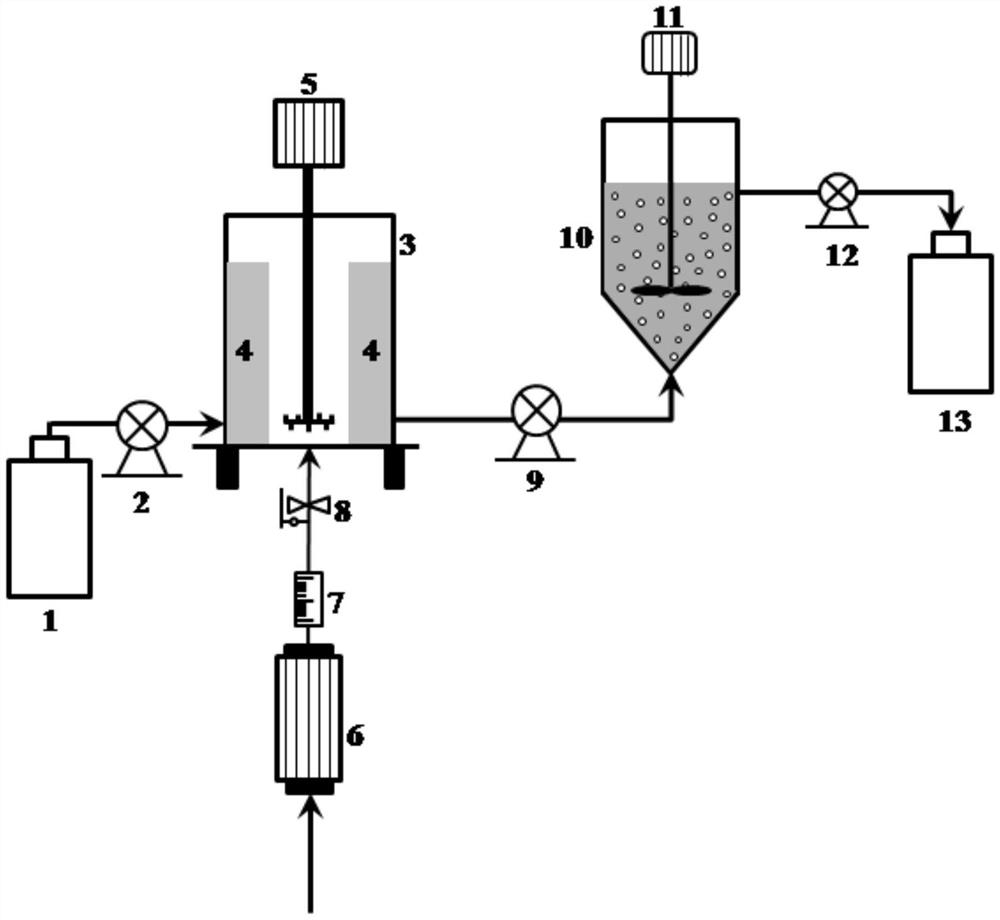

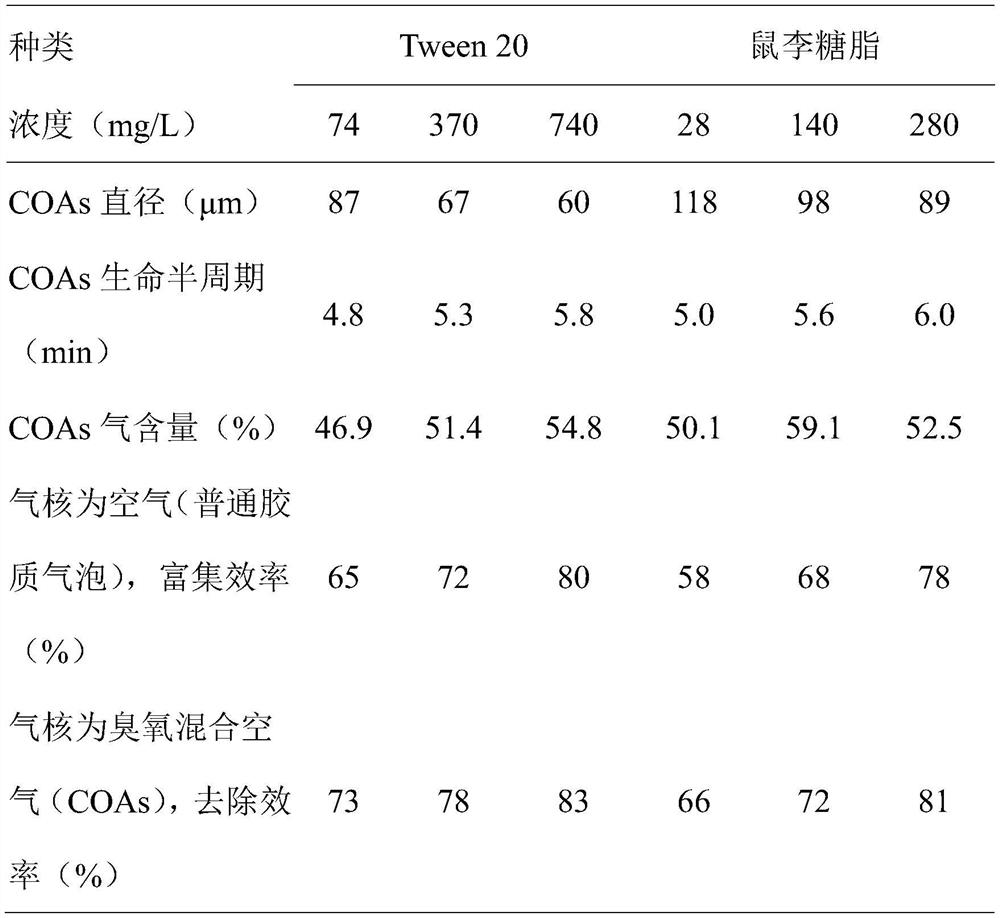

Colloid ozone bubble as well as preparation method and application thereof

ActiveCN110272112AIncrease profitLow priceWater contaminantsWater/sewage treatment by sorptionHigh concentrationHigh pressure

The invention discloses a colloid ozone bubble as well as a preparation method and application thereof. The preparation method of the colloid ozone bubble comprises the following steps: presetting a surfactant solution in a bubble generating tank in a mode of continuously producing bubbles, wherein the reserved amount of the surfactant solution accounts for 30-40% of the volume of the bubble generating tank; introducing the surfactant solution in a bubble generating fluid storage tank into the bubble generating tank via a liquid inlet pump at a flow velocity of 50-80mL / min, and introducing air into an air source ozone generator; supplying 3000V high voltage power to the ozone generator so as to rapidly convert oxygen into ozone, introducing the obtained high-concentration ozone-electric ion mixed air into the bubble generating tank from the air inlet at the bottom of the bubble generating tank at a flow velocity of 16.7-66.7mL / min, stirring the gas-liquid mixture by a high-speed stirrer for 40-80 seconds at 4000-6000 revolutions per minute, and producing bubble suspension, namely the colloid ozone bubble. The colloid ozone bubble disclosed by the invention is applied to treating polycyclic aromatic hydrocarbons (PAHs) contaminants in water body sediments.

Owner:ZHEJIANG UNIV OF TECH

Electrochemical polymerization process for forming solid electrolyte layer on solid electrolytic capacitor

InactiveCN101866750AThe method of pH control and adjustment is simplePerformance is easy to controlCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention provides an electrochemical polymerization process for forming a solid electrolyte layer on a solid electrolytic capacitor, which comprises the following step of: carrying out constant current polymerization in an electrochemical polymerization solution to prepare a second solid electrolyte layer by connecting the surface of an anode body on which a solid electrolyte layer is formed by a chemical polymerization process with an external electrode as an anode and using a conductive electrode as a cathode, wherein the pH value of the electrochemical polymerization solution is controlled to range from 3.0-6.0. The electrochemical polymerization process for forming a solid electrolyte layer on a solid electrolytic capacitor enables the properties of the solid electrolytic capacitor produced by the electrochemical polymerization process to be more controllable, the electrolytic capacitor prepared in the range of the pH value is better in properties such as capacitance, loss, ESR and the like, and the polymerization process simplifies the process flow and improves the process efficiency.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

Thermo-sensitive tri-block copolymer having sol-gel conversion characteristic and preparation thereof

InactiveCN101255235BAdjustable intensityGood biocompatibilitySurgeryPharmaceutical non-active ingredientsPEG-PCL-PEGAqueous solution

The present invention relates to medical polymers field, especially a temperature sensitive and biodegradable triblock copolymer with gel-sol transformation characteristics and preparation method thereof and usage. The triblock copolymer is PEG-PCL-PEG copolymer, the aqueous solution thereof performs Sol-Gel phase transformation along with the temperature rise and the phase transformation temperature is 25-35 degree. The PEG-PCL-PEG copolymer has a variety of excellent features to provide a new choice in field which is in need of temperature sensitive material.

Owner:SICHUAN UNIV

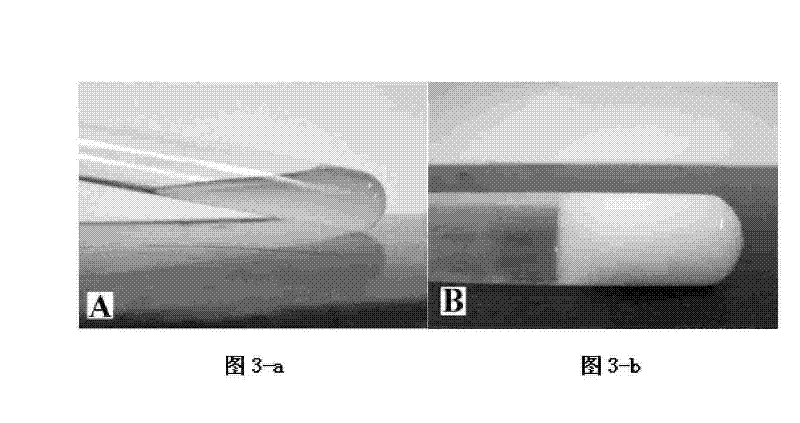

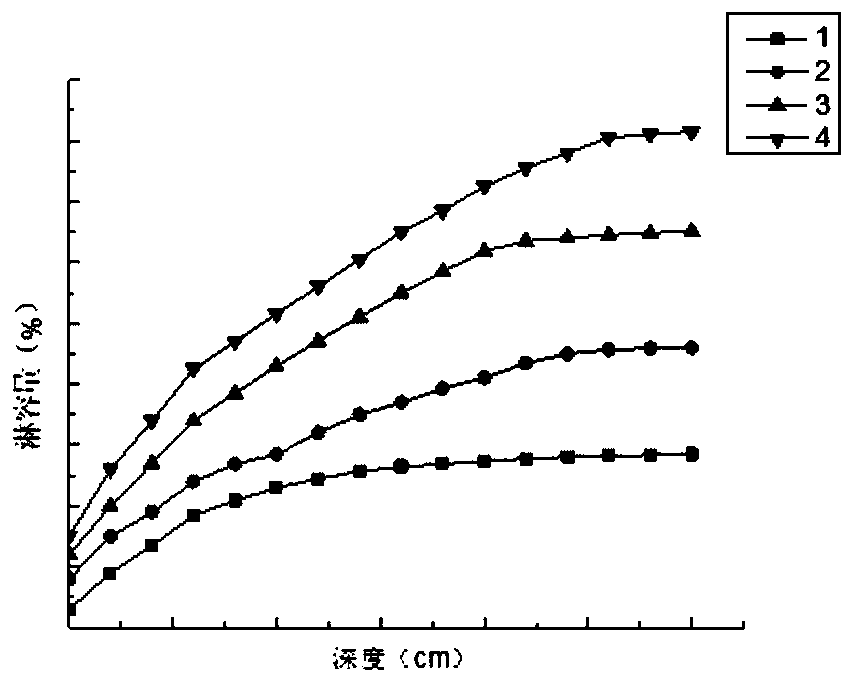

Chloroacetamide herbicide capsule suspension and production method thereof

InactiveCN109717187AEasy to adjust the release rateSmooth responseBiocideAnimal repellantsMicrobiologyChloroacetamide

The invention discloses chloroacetamide herbicide capsule suspension and a production method thereof. The produced hloroacetamide herbicide capsule suspension is stable in quality and controllable inrelease rate, and has quick release efficacy and slow release efficacy at the same time; and the production method is simple to operate, easy to control, high in production efficiency and short in production time.

Owner:JIANGSU ESSENCE AGROCHEM +1

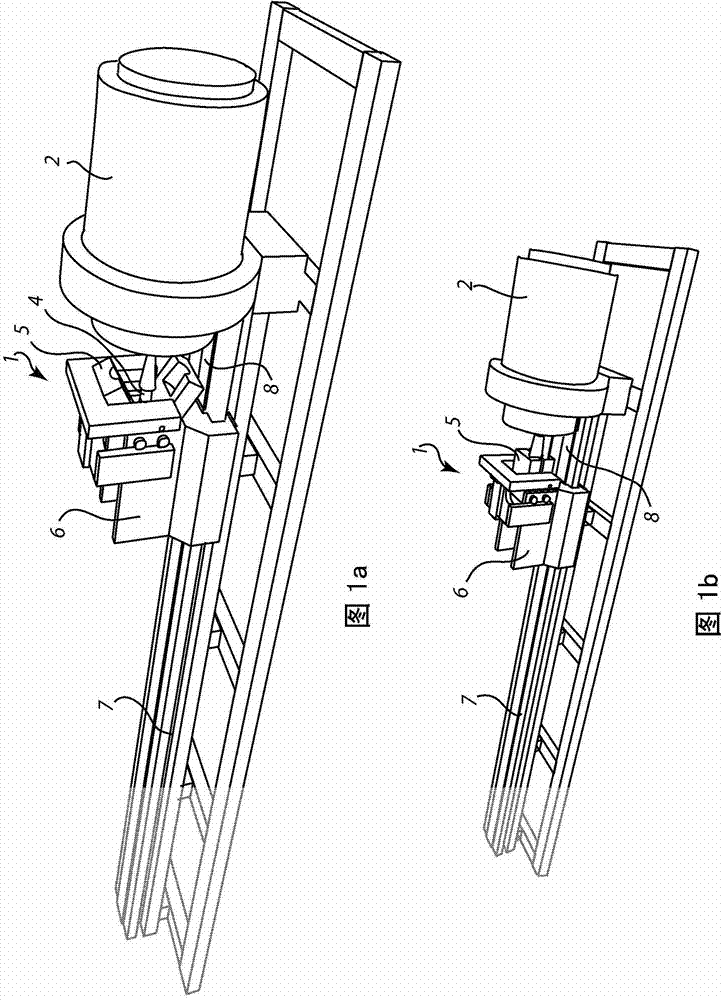

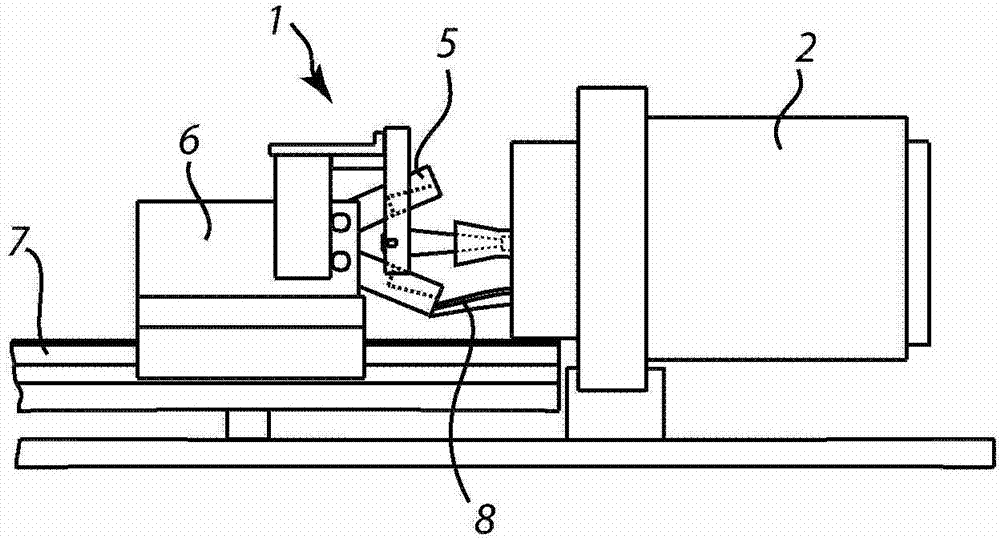

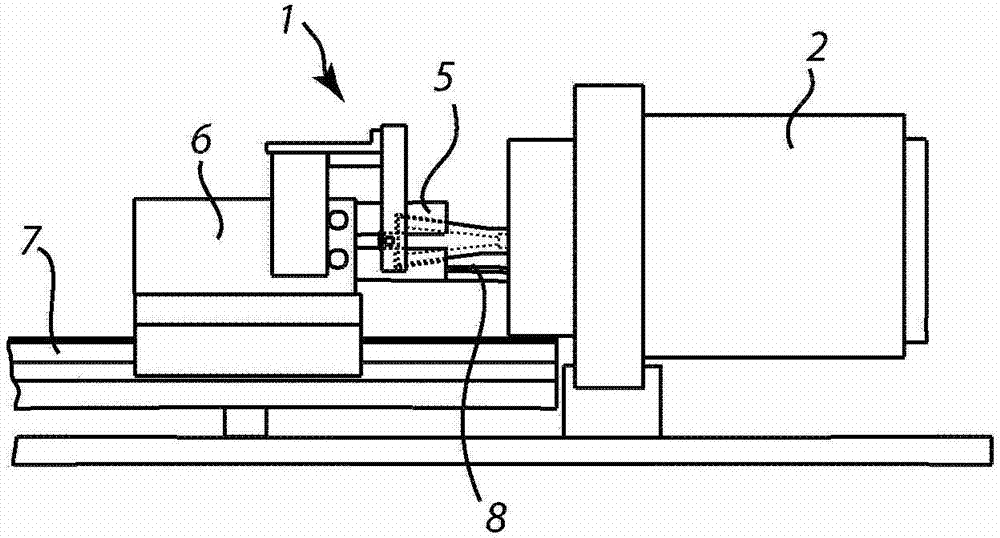

Method for manufacturing of a tubular object for insertion into a body passageway

InactiveCN103492156AReduced risk of breakageControllable natureCatheterDomestic articlesCatheterBiomedical engineering

Disclosed are a method and an apparatus for manufacturing a medical tubular object, such as a catheter, for insertion into a body passageway. The method comprises the steps of extruding a tube by pushing tube material though an extrusion nozzle and cutting the extruded tube at a predetermined length. Further, an initial part of the extruded tube is advanced onto a tapered mandrel arranged adjacent the extrusion nozzle such that a flared end is formed, and after a predetermined length of the extruded tube has been advanced onto the tapered mandrel, the tapered mandrel is moved away from the extrusion nozzle to prevent that the rest of the extruded tube is expanded by the tapered mandrel.

Owner:DENTSPLY IH AB

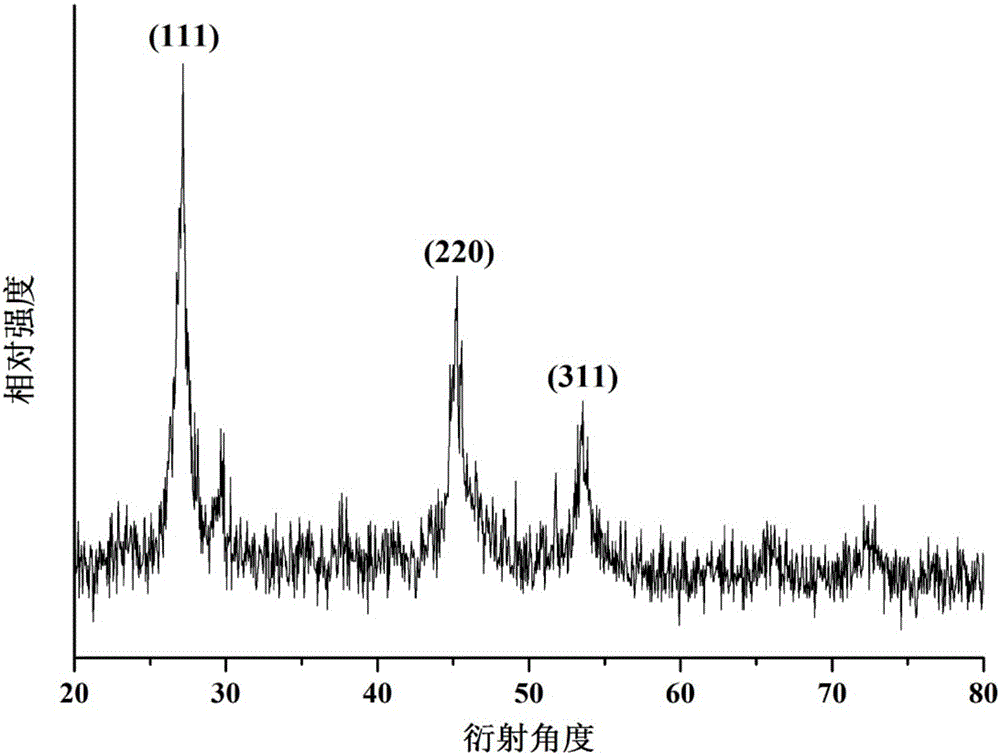

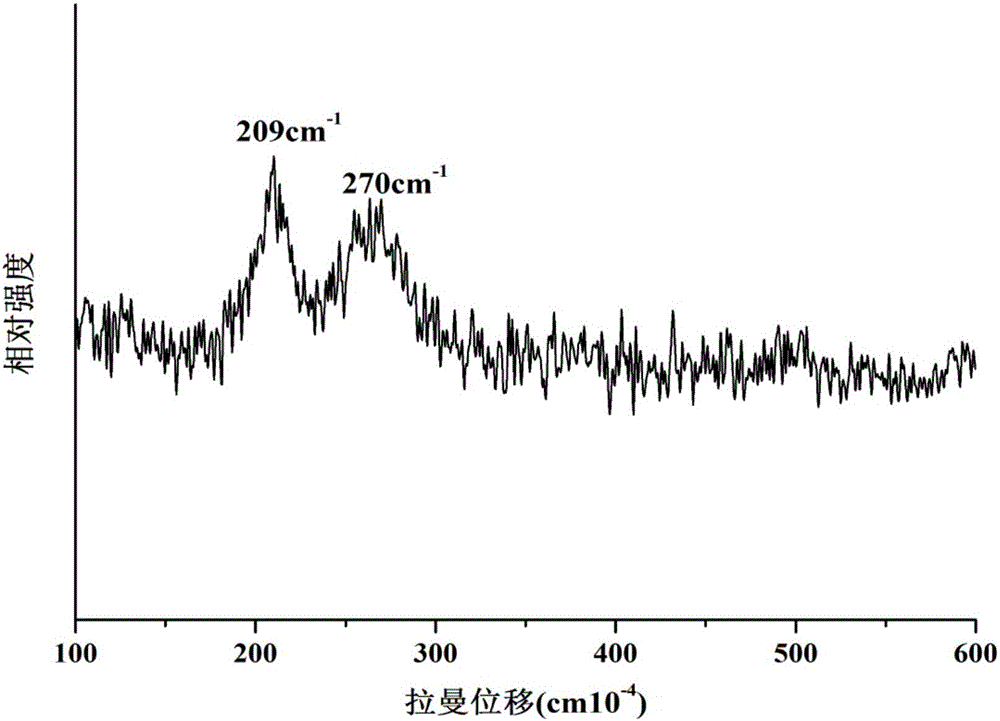

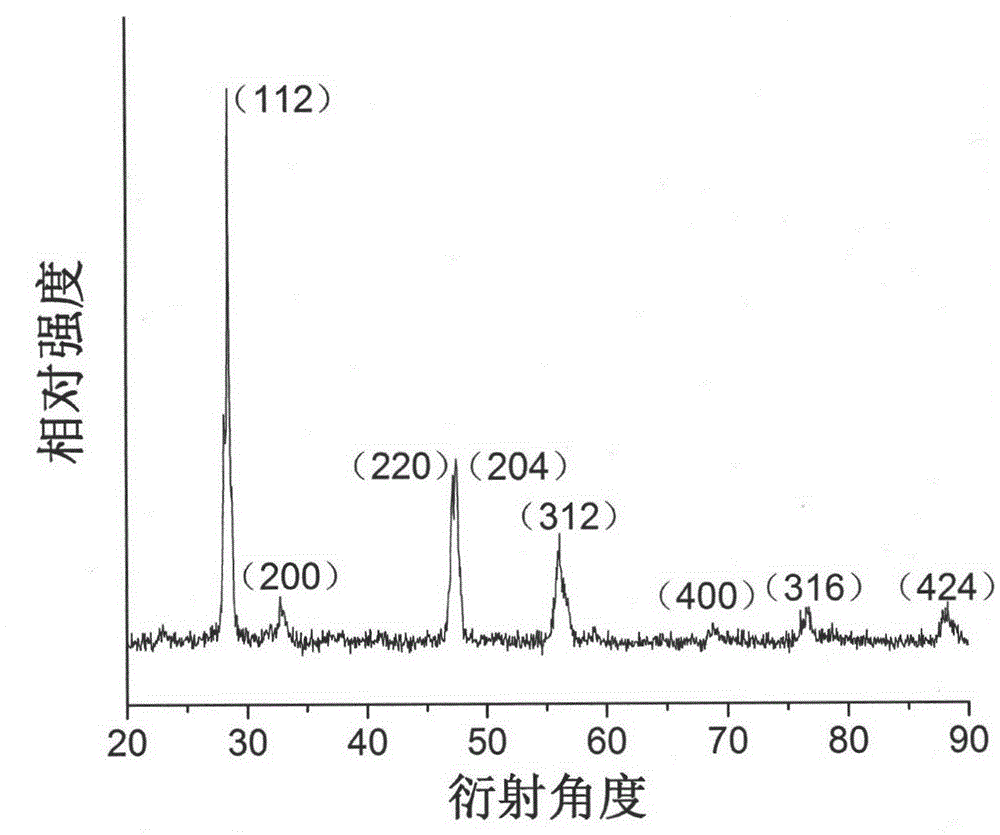

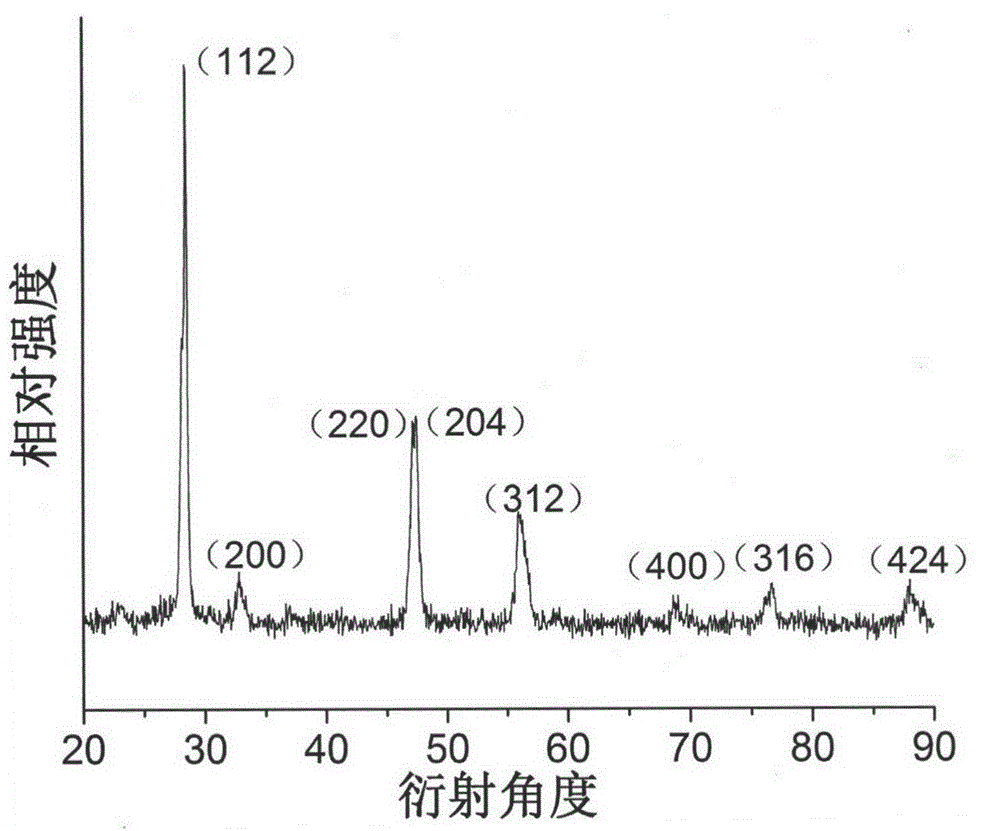

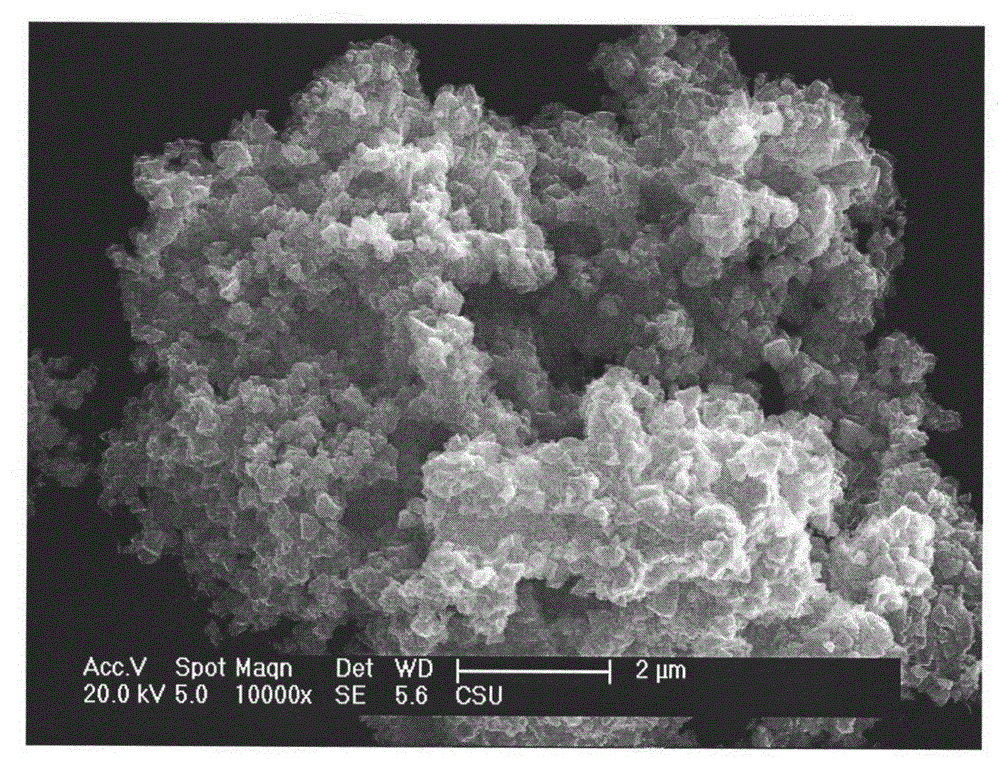

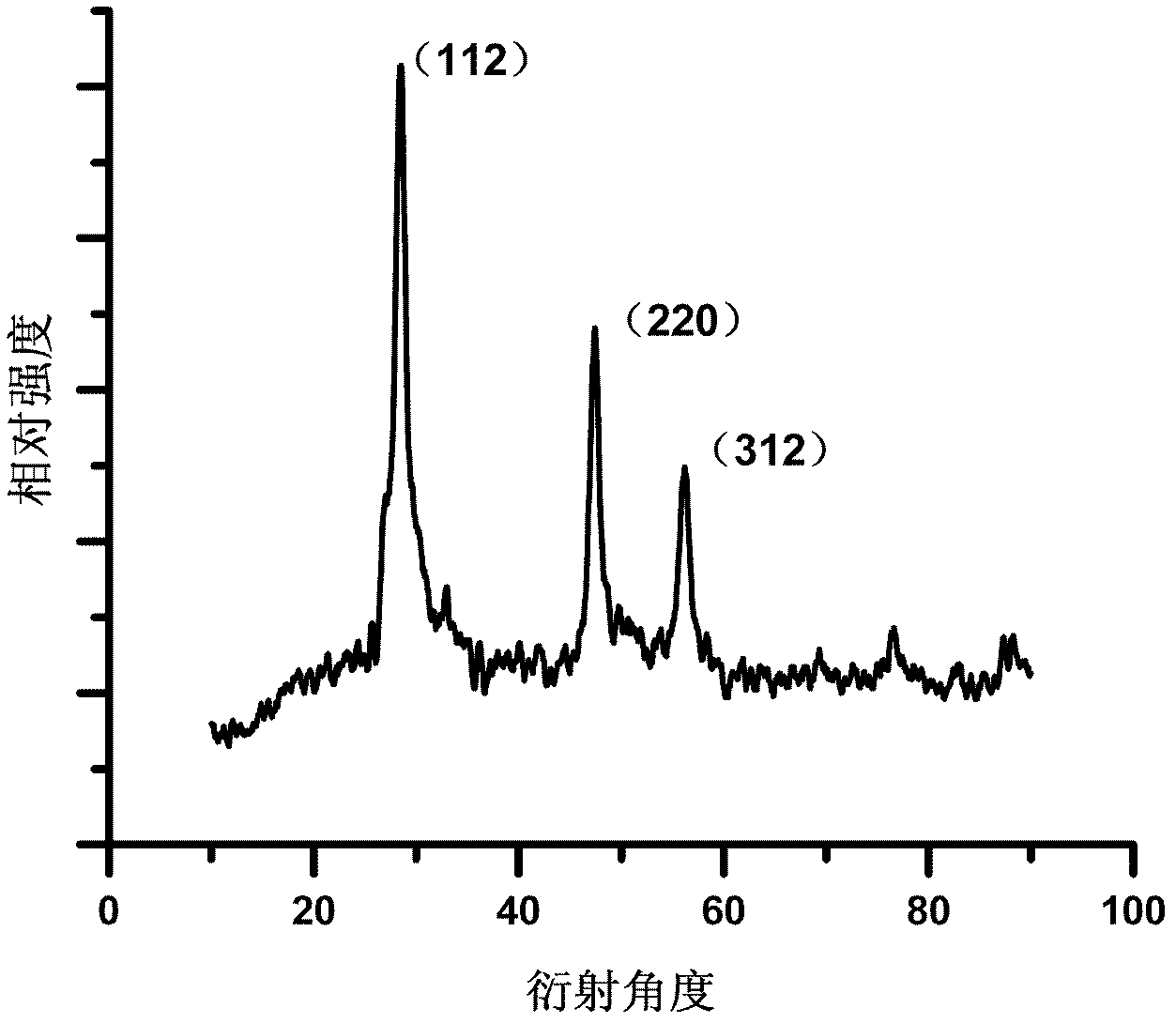

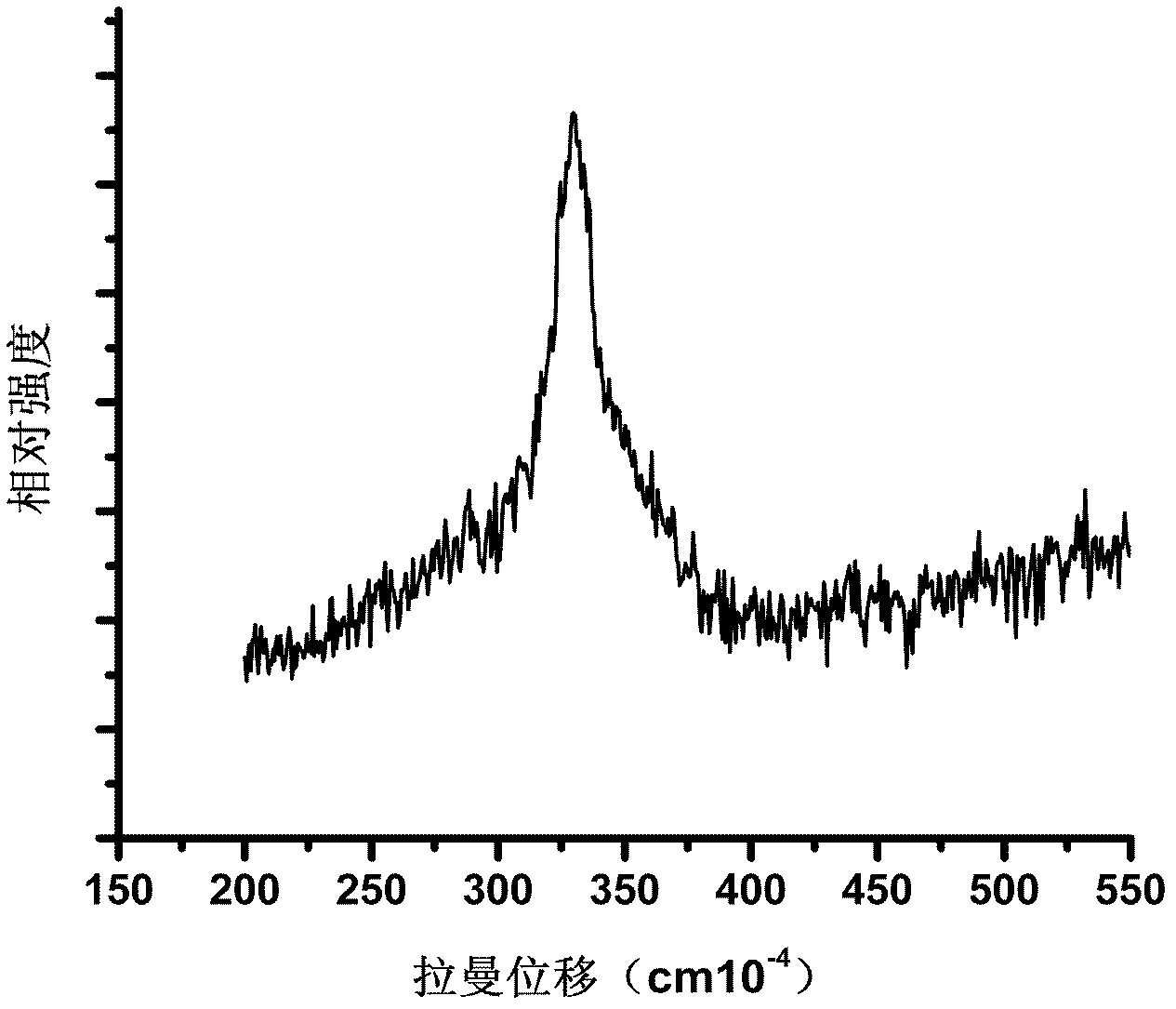

Stannite structure Cu2FeSnSe4 powder material and liquid phase preparation method thereof

InactiveCN105692567ALow costStrong reductionSelenium/tellurium compounds with other elementsShielding gasNitrogen gas

The invention discloses a kesterite structure Cu for solar photovoltaic cells 2 FeSnSe 4 A powder material and a liquid phase preparation method thereof, comprising the steps of: making the raw material CuCl 2 2H 2 O, FeCl 3 ·6H 2 O, SnCl 4 ·5H 2 O. The selenium powder is weighed by molar ratio and put into a three-necked round-bottomed flask for mixing, and then an organic solvent triethylenetetramine solution is added to obtain a uniform light blue solution; nitrogen is used as a protective gas and placed in a constant temperature oil bath Heated to 200-230°C in medium temperature and kept for 0.5-12 hours, then cooled to room temperature naturally; washed with absolute ethanol and distilled water in sequence, then filtered and dried to obtain a black powder. The kesterite structure Cu 2 FeSnSe 4 The liquid-phase preparation method of powder materials is green and pollution-free, the reaction time is short, the required temperature is low, the operation is simple, the cost is low, and it is suitable for Cu 2 FeSnSe 4 Powder materials are used in the industrialization of photovoltaic cell absorber layers.

Owner:CENT SOUTH UNIV

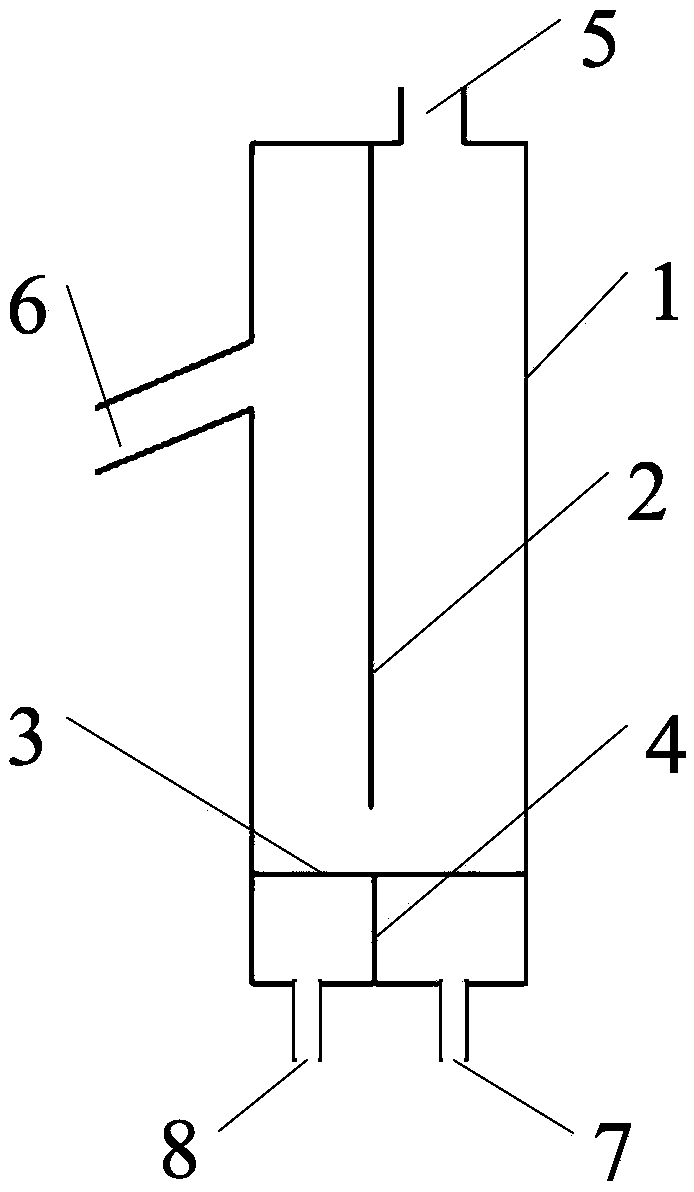

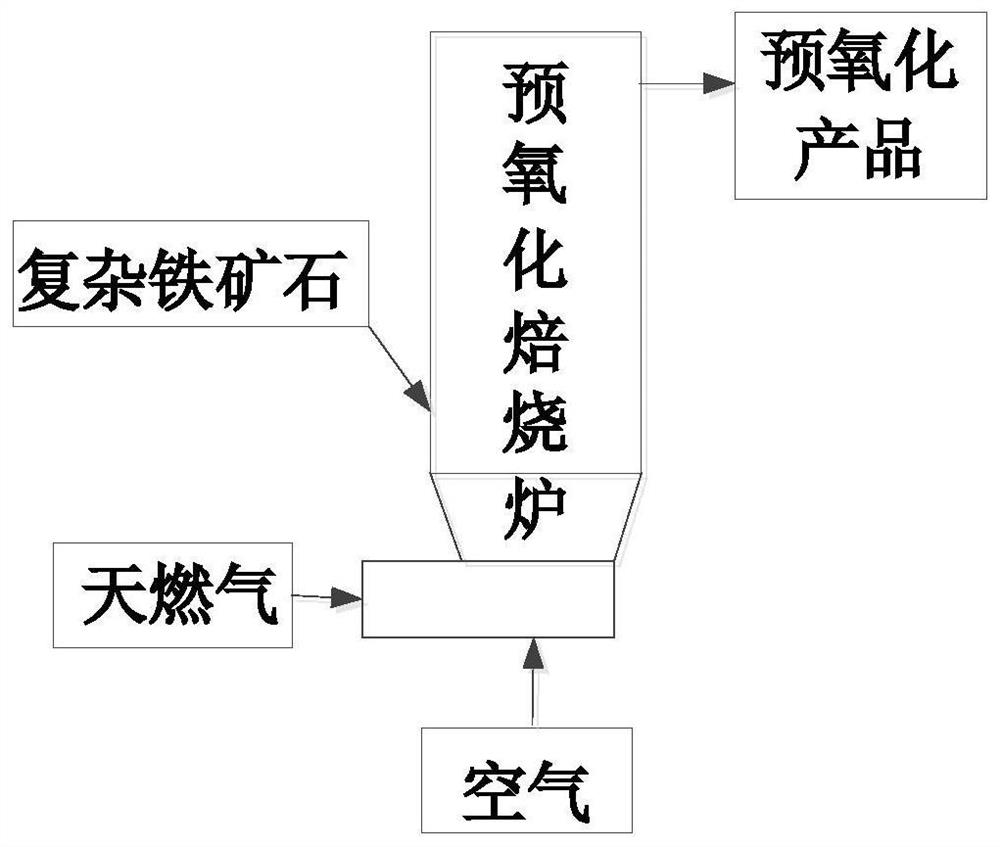

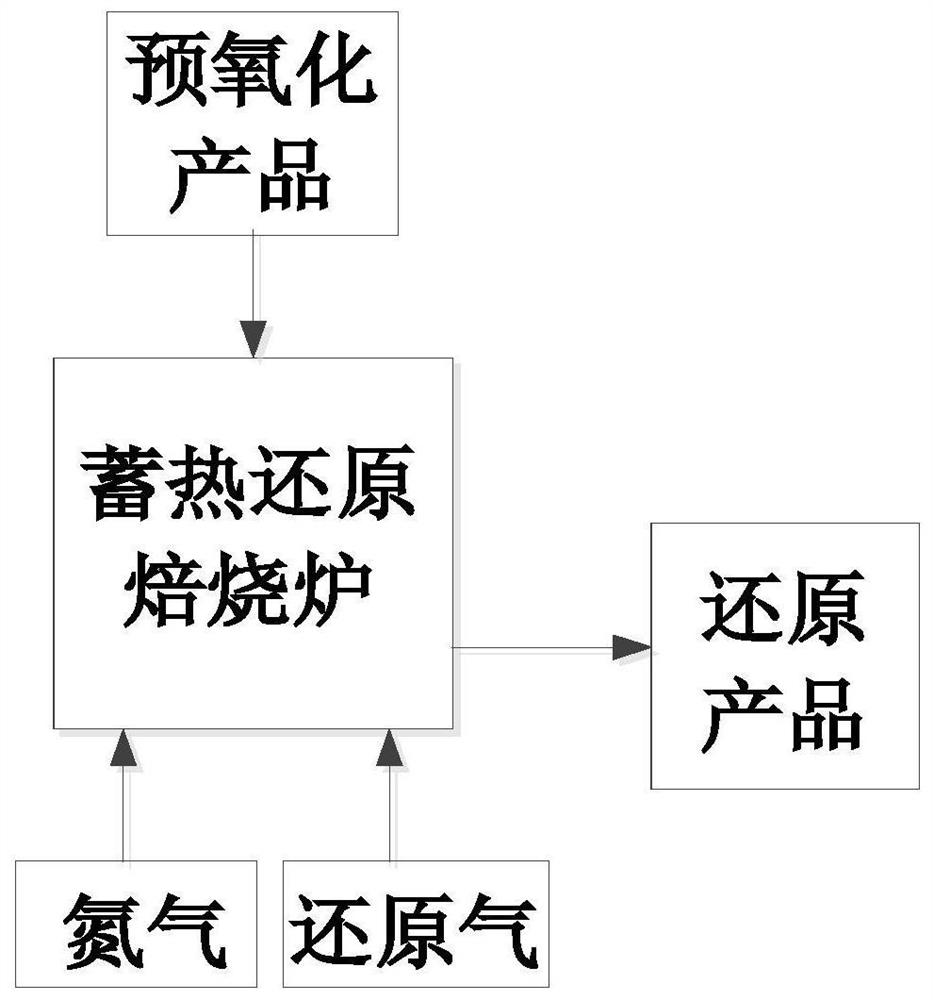

Suspension roasting system for heating, cracking and strengthening reduction of iron-containing material

ActiveCN111621638AEfficient separationAdd reactive sitesGrain treatmentsMagnetic separatorProcess engineering

The invention discloses a suspension roasting system for heating, cracking and strengthening reduction of the iron-containing material. A storage tank of a high-pressure roller mill is opposite to a feeding bin, and the feeding bin is matched with a first cyclone separator; the first cyclone separator and a first flow sealing valve communicate with a feeding hole of a pre-oxidation suspension roasting furnace in series; a discharge hole of the pre-oxidation suspension roasting furnace, a second cyclone separator and a heat storage reduction roasting furnace are communicated in series; a discharge hole of the heat storage reduction roasting furnace, a nitrogen cooling cyclone separator, a second flow sealing valve and an air cooling cyclone separator are communicated in series; and the aircooling cyclone separator, a ball mill and a magnetic separator are matched in sequence. The device and the system are stable in operation, large in treatment capacity, low in energy consumption and cost of unit treatment capacity, easy to control product properties and easy to realize large-scale equipment.

Owner:上海逢石科技有限公司

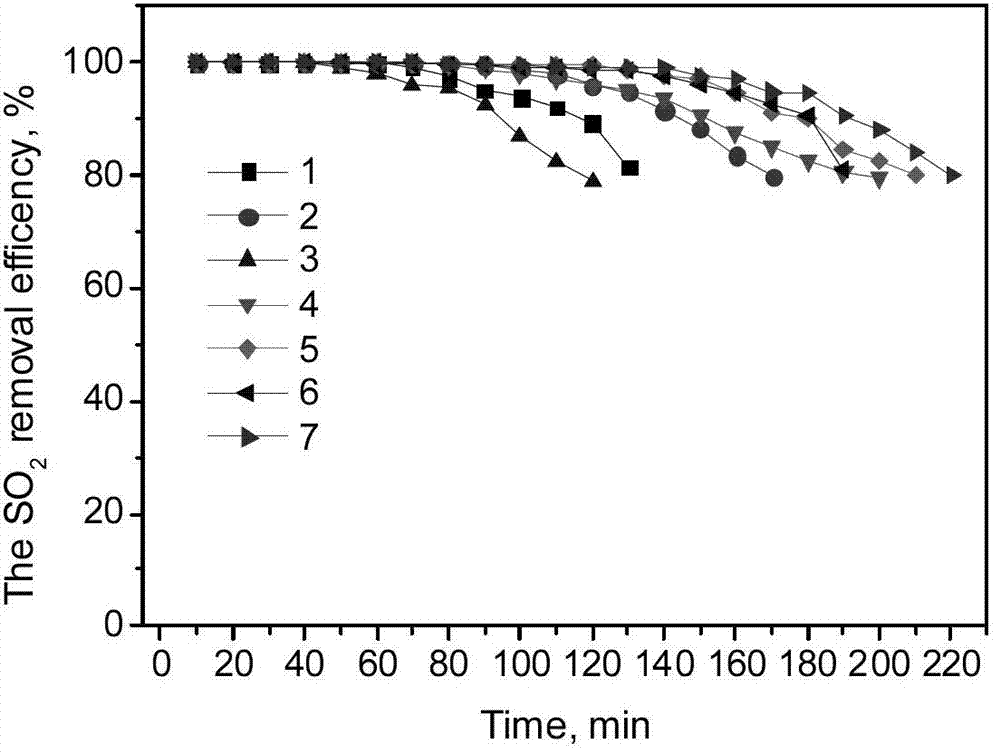

Method for preparing pillared magnesium-saponite catalytic cracking flue gas sulfur transfer additive

ActiveCN102755809BGood sulfur absorbing activityFacilitated DiffusionOther chemical processesDispersed particle separationOXALIC ACID DIHYDRATECerium nitrate

The invention relates to a preparation method of a pillared stesterite type catalytic cracking flue gas sulfur transfer agent. The method comprises the following steps: mixing magnesium saponite with water to obtain a magnesium saponite dispersion; mixing iron source, magnesium source, aluminum source and / or cerium source with water or oxalic acid, and adding NaOH solution to prepare a crosslinking agent solution ;Mix the magnesium saponite dispersion and the crosslinking agent solution, keep it at 10-80°C for 5-30h, and then keep it at 90-130°C for 1-40h to obtain crosslinked magnesium saponite; impregnate cerium nitrate on the crosslinked magnesium saponite , roasted to obtain the pillared magnesium saponite type catalytic cracking flue gas sulfur transfer agent. The pillared stesterite-type catalytic cracking flue gas sulfur transfer agent prepared by the method provided by the invention has good desulfurization activity.

Owner:PETROCHINA CO LTD +2

Hydrogel microcarrier and its preparation method and application

ActiveCN112048033BEasy to decodeReduce testing costsBiological testingFluorescence/phosphorescenceDiseaseActive agent

Owner:HUNAN UNIV

A kind of colloidal ozone bubble and its preparation method and application

ActiveCN110272112BIncrease profitLow priceWater contaminantsWater/sewage treatment by sorptionPolycyclic aromatic hydrocarbonActive agent

The invention discloses a colloidal ozone bubble and its preparation method and application. The preparation method of the colloidal ozone microbubble is as follows: in the mode of continuously generating bubbles, firstly, a surfactant solution is preset in a bubble generation tank , the reserved amount of the surfactant solution accounts for 30-40% of the tank volume of the bubble generation tank, and the surfactant solution in the bubble generation liquid storage tank is passed through the liquid inlet pump at a flow rate of 50-80mL / min Pass it into the bubble generation tank, and at the same time pass the air into the air source ozone generator, 3000V high voltage power supply to the ozone generator to work quickly convert oxygen into ozone, get high concentration of ozone ion mixed air from the bottom of the bubble generation tank The air inlet of the air inlet is passed into the bubble generation tank at a flow rate of 16.7-66.7mL / min, and the high-speed stirrer stirs the gas-liquid mixture at 4000-6000rpm, and the stirring time is 40-80s. The generated bubble suspension is colloidal ozone micro bubble. The colloidal ozone microbubbles described in the invention are applied to the treatment of polycyclic aromatic hydrocarbons (PAHs) pollutants in water body sediments.

Owner:ZHEJIANG UNIV OF TECH

Kesterite structure cu2fesns4 powder material and its liquid phase preparation method

ActiveCN103641178BQuality improvementLow costIron halidesRenewable energy productsFluid phaseThiourea

Owner:CENT SOUTH UNIV

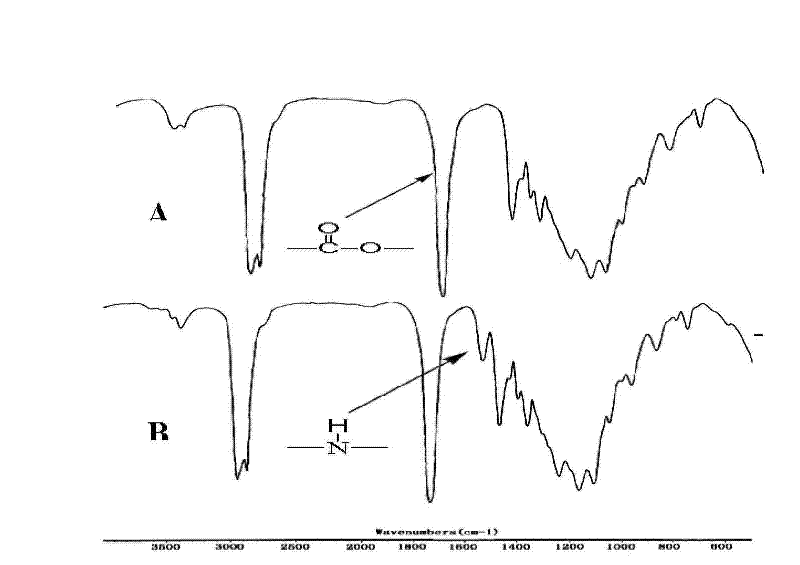

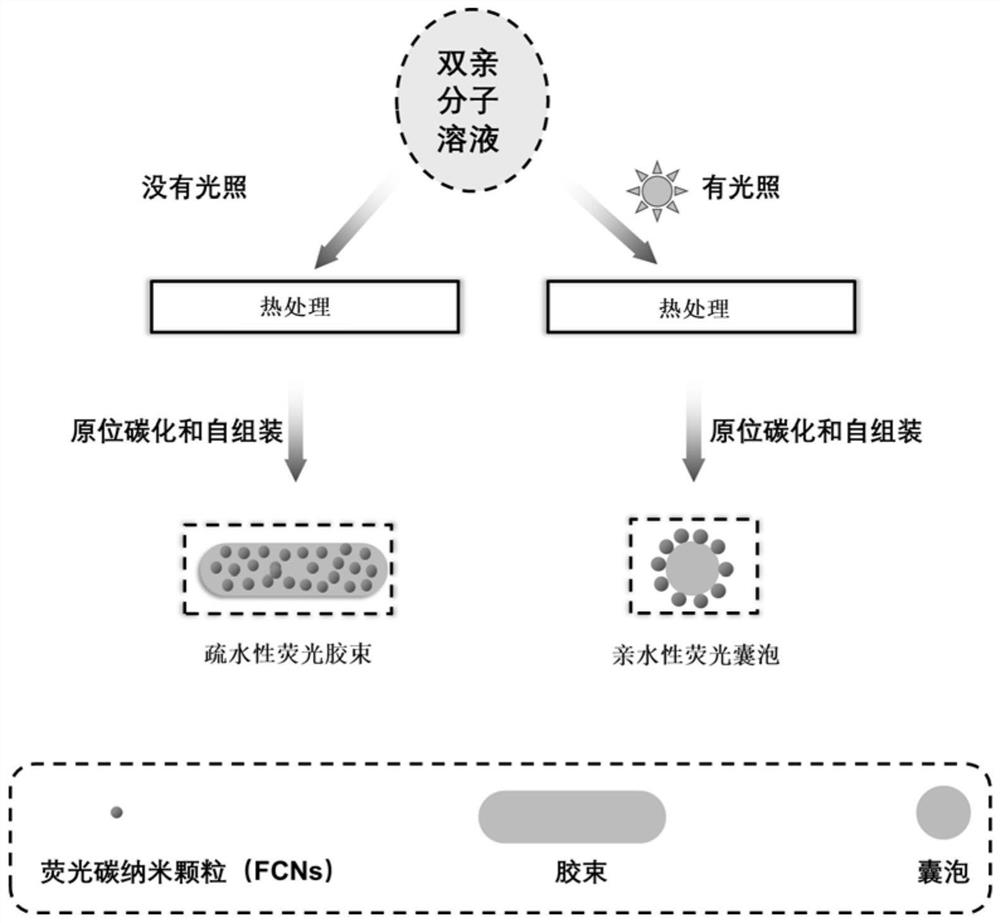

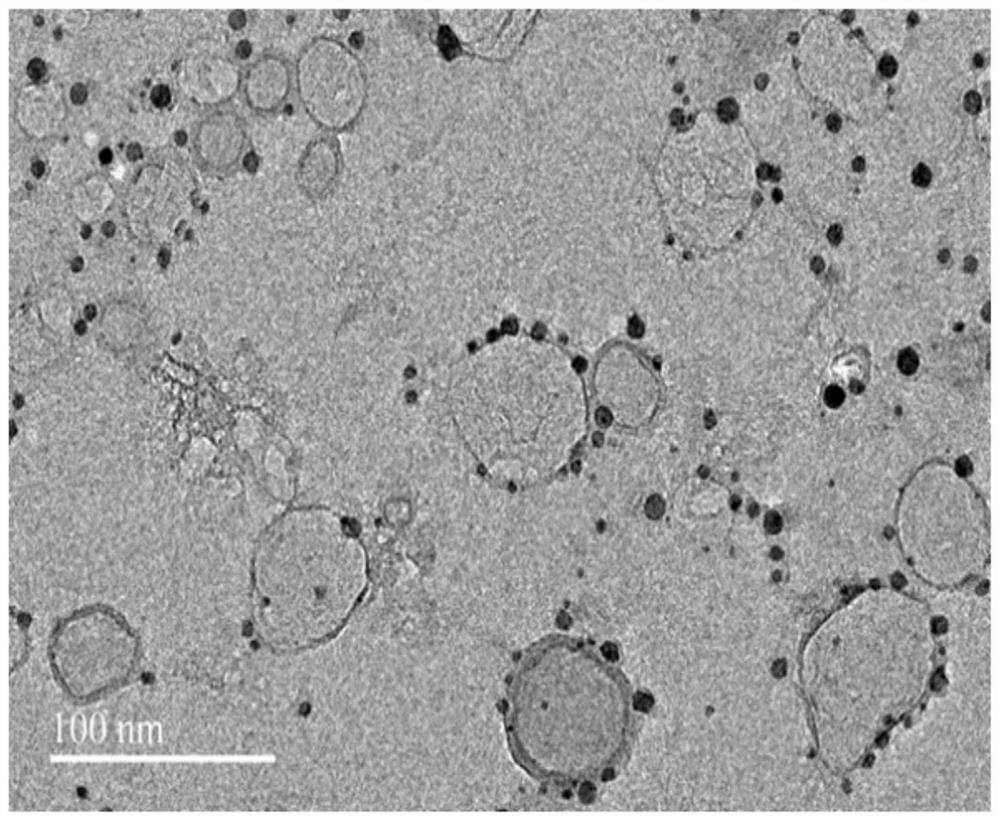

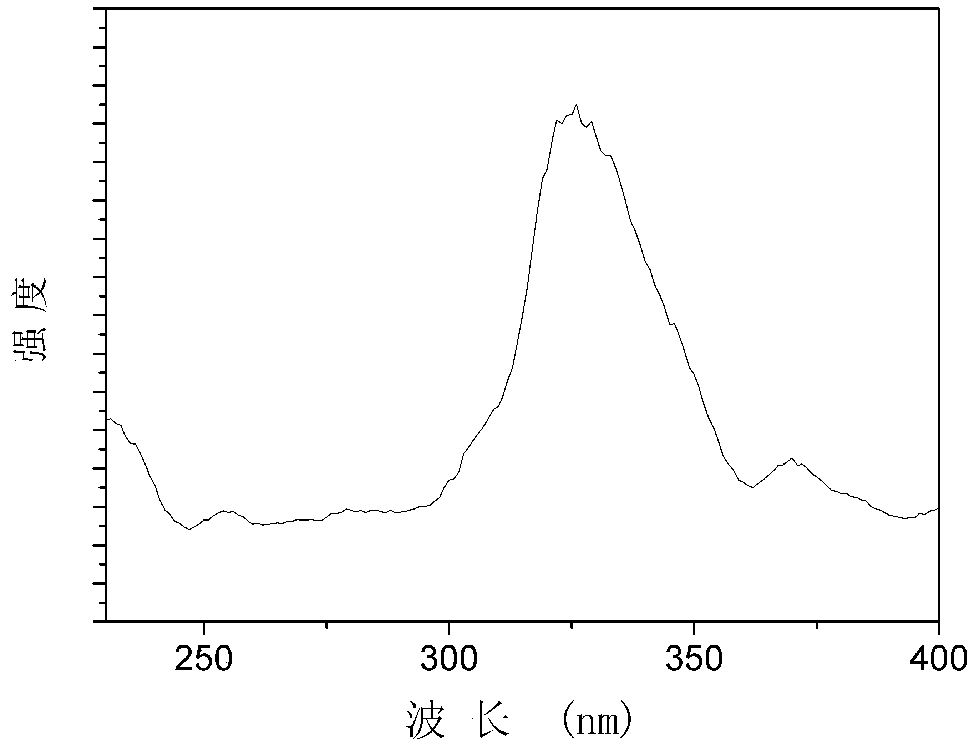

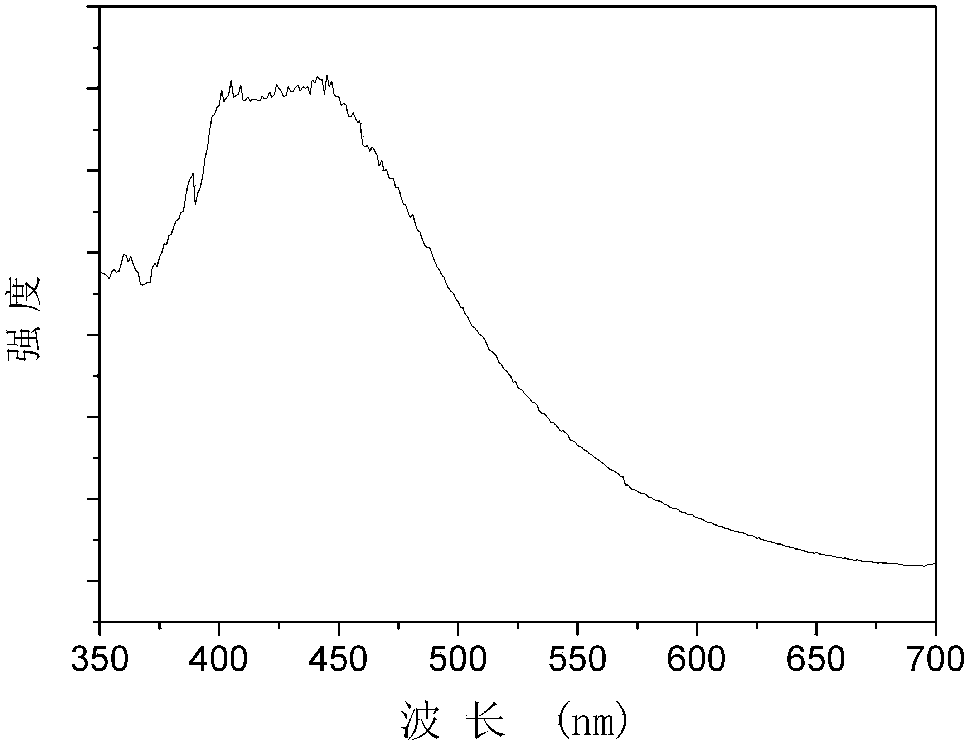

Preparation method and application of a fluorescent probe with controllable hydrophilicity and hydrophobicity

ActiveCN110317603BControllable natureShape is easy to controlFluorescence/phosphorescenceLuminescent compositionsFluoProbesFluorescence

The present invention provides a method for preparing a fluorescent probe with controllable hydrophilicity and hydrophobicity and its application. The method includes: using amphiphile molecules as raw materials, controlling the hydrophilicity and hydrophobicity of fluorescent vesicles and fluorescent micelles by turning on / off light The method provided by the present invention realizes the transformation of the hydrophilic and hydrophobic properties of the amphiphile solution through the control of the light switch, the process is green and simple, easy to operate, the whole process is easy to control, and the properties and morphology of the fluorescent vesicles and fluorescent micelles are realized. Controllable, the obtained fluorescent vesicles and fluorescent micelles can enter the nucleus for imaging, and have good application prospects in optoelectronic materials, bioimaging, diagnostic sensors, drug delivery materials, catalytic materials, or water treatment adsorption and degradation materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

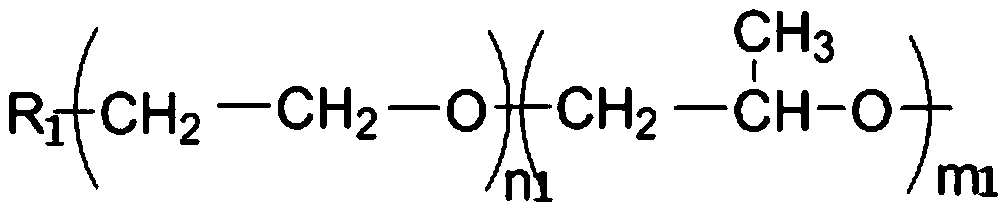

Temperature-sensitive block copolymers and their hydrogels and uses thereof

InactiveCN102731791BHigh yieldHigh puritySurgeryArtificial cell constructsPolyesterBiocompatibility Testing

Owner:PEKING UNIV

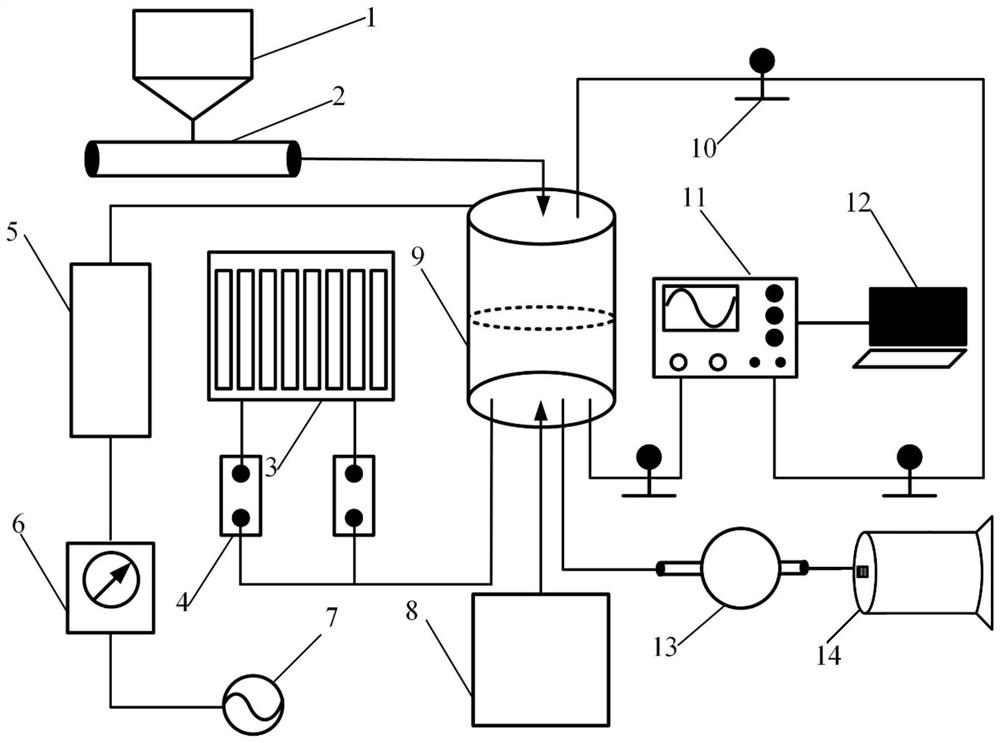

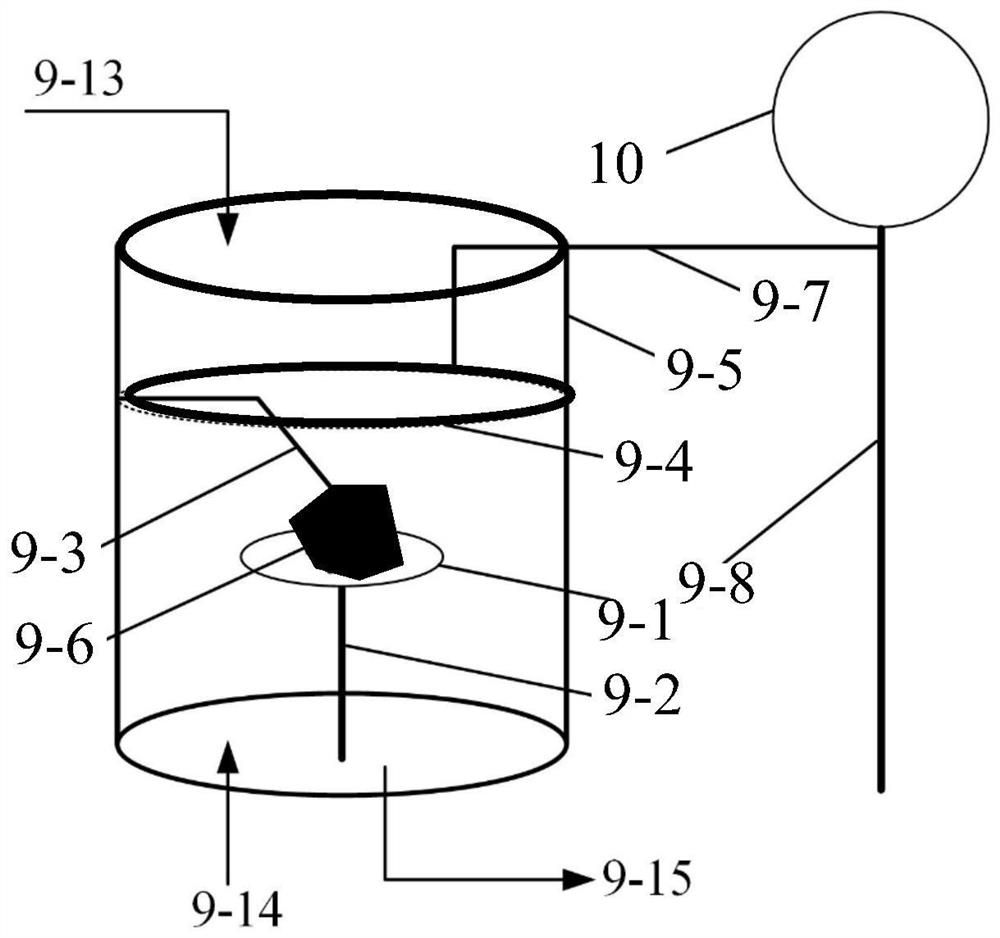

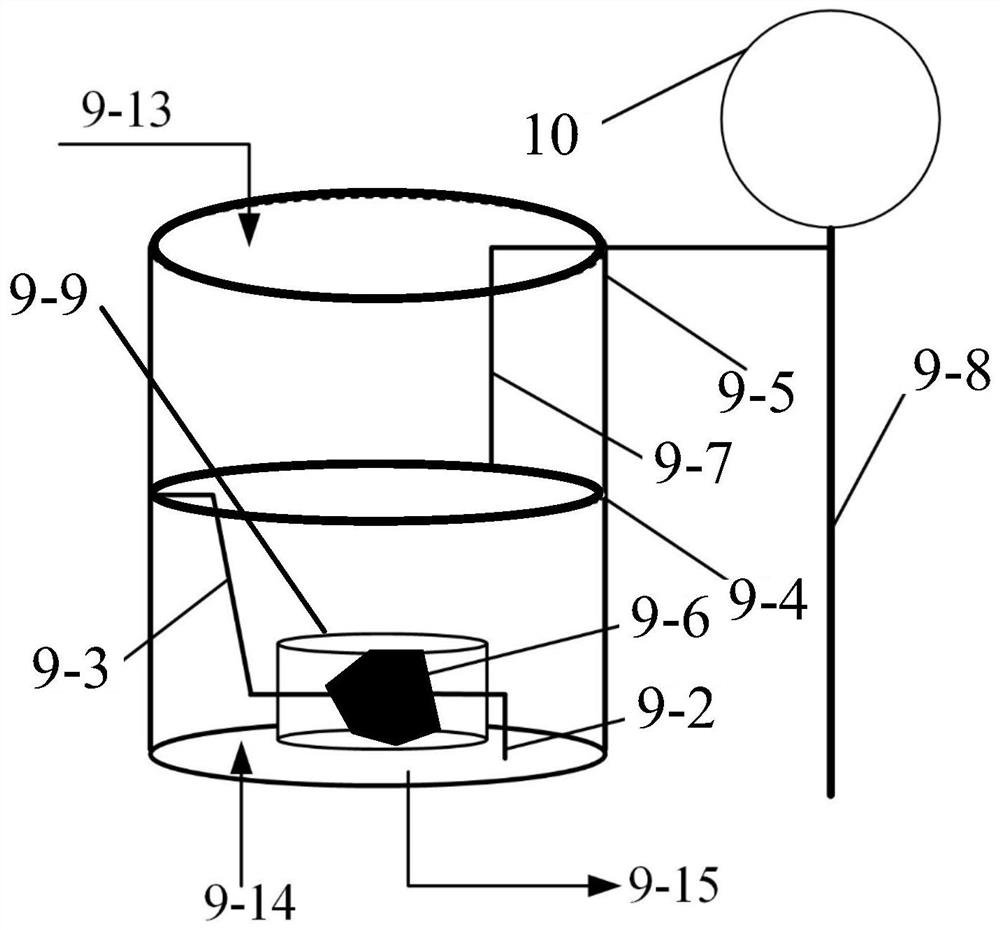

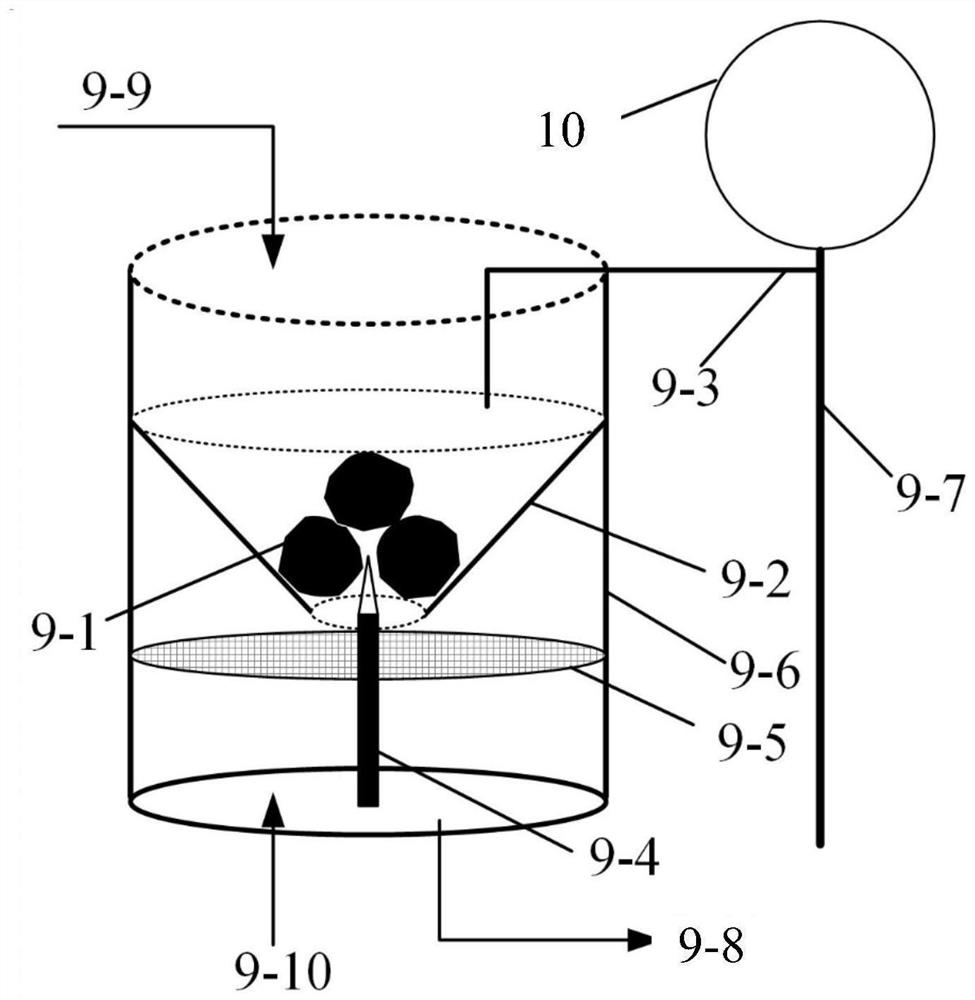

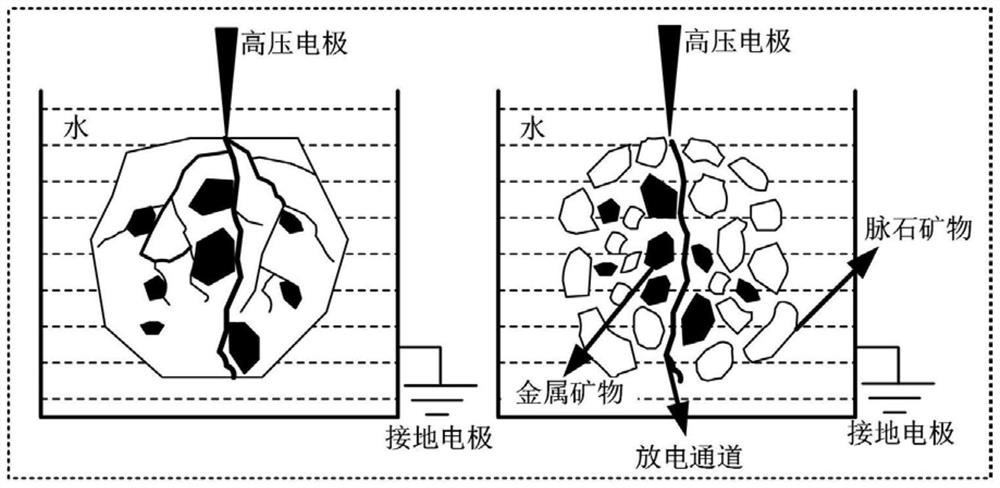

Ore high-voltage pulse discharge pretreatment system and using method thereof

ActiveCN112169965AImprove safety performanceAvoid wasting energyGrain treatmentsPhysicsVoltage pulse

The invention discloses an ore high-voltage pulse discharge pretreatment system and a using method thereof. The ore high-voltage pulse discharge pretreatment system comprises a feeding bin, a spiral feeder, a high-voltage electric pulse crushing cavity, a pulse high-voltage electric generator, an output power supply, an insulating liquid storage pool and an oscilloscope. The using method comprisesthe steps that (1) ore is conveyed to the high-voltage electric pulse crushing cavity through the feeding bin and the spiral feeder, and insulating liquid is introduced into the high-voltage electricpulse crushing cavity; (2) the voltage of the output power supply is controlled, the ore is in contact with a positive electrode and a negative electrode, electric current is conveyed to the pulse high-voltage generator, converting into an ultrahigh-voltage direct electric current is carried out, high-voltage electric pulse pretreatment is performed on the ore, and real-time monitoring is performed through the oscilloscope; and (3) the ore is subjected to high-voltage electric pulse pretreatment and then is continuously discharged along with the insulating liquid. The using method is simple in process, stable in system operation and easy in product property control; and the high-voltage electric pulse pretreatment enables internal cracks and gaps of the ore to be sharply increased, the mechanical property of the ore is weakened, and the ore grinding efficiency is remarkably improved.

Owner:NORTHEASTERN UNIV

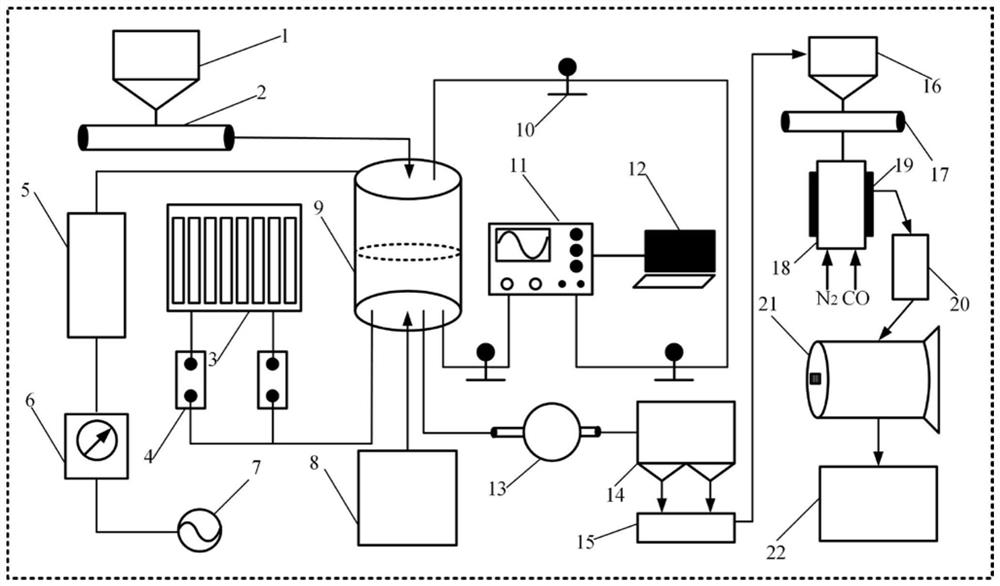

High-voltage electric pulse pretreatment-magnetizing roasting system and method for refractory iron ore

ActiveCN112080630AEnhanced porosity and crack densityPromote full accessGrain treatmentsMagnetic separatorElectric generator

The invention discloses a high-voltage electric pulse pretreatment-magnetizing roasting system and method for refractory iron ore. The system is composed of a high-voltage electric pulse pretreatmentpart and a magnetizing roasting part. The high-voltage electric pulse pretreatment part comprises a feeding bin, a spiral feeder, a high-voltage electric pulse crushing chamber, a pulse high-voltage electric generator, an output power supply, an insulating liquid storage pool and an oscilloscope. The magnetizing roasting part comprises a middle feeding bin, a middle spiral feeder, a suspension reduction roasting furnace, a cooler, a ball mill and a magnetic separator. The method comprises the steps of (1) conveying the ore to the high-voltage electric pulse crushing chamber through the feedingbin and the spiral feeder, and introducing insulating liquid into the high-voltage electric pulse crushing chamber; (2) carrying out high-voltage electric pulse pretreatment on the ore; (3) filteringand drying the pretreated ore; (4) conveying the ore to the suspension reduction roasting furnace for carrying out reduction reaction; (5) putting the ore into the ball mill after heat exchange; and(6) performing low-intensity magnetic separation after ore grinding. According to the high-voltage electric pulse pretreatment-magnetizing roasting system and method for the refractory iron ore provided by the invention, the method is simple in technological process, the system is stable in operation, and the product properties are easy to control.

Owner:NORTHEASTERN UNIV

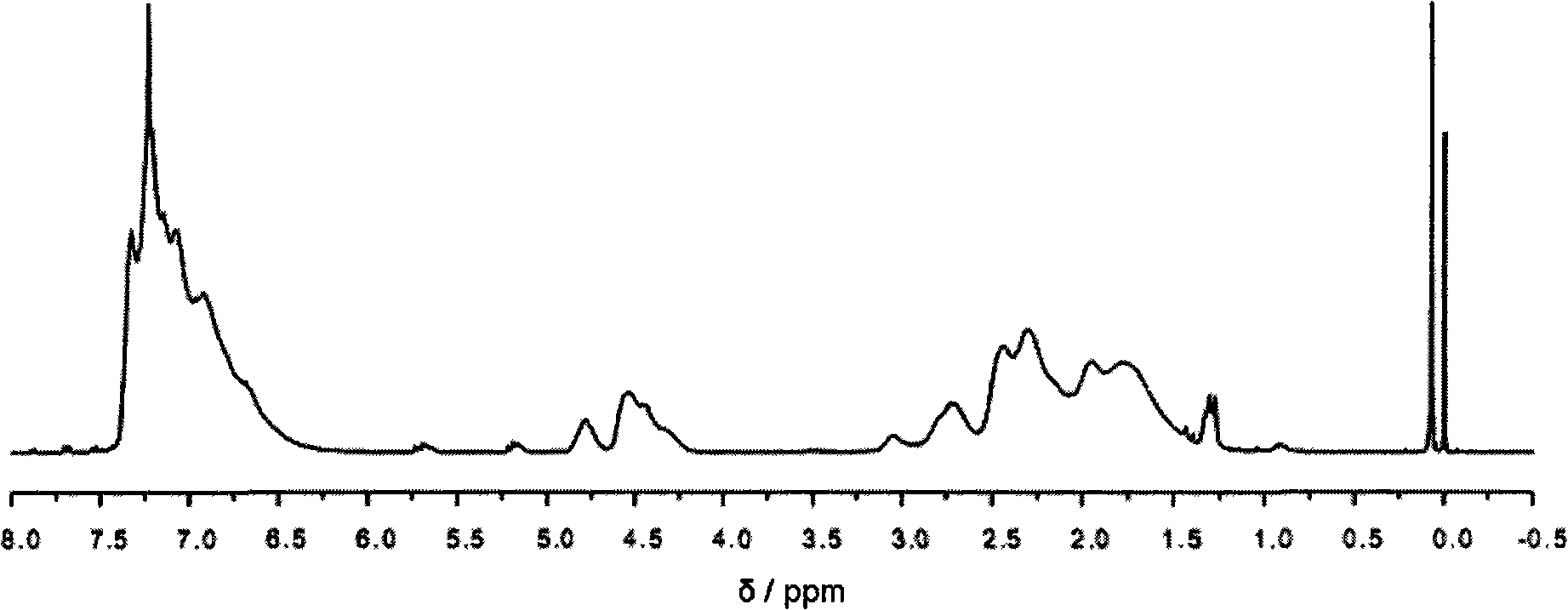

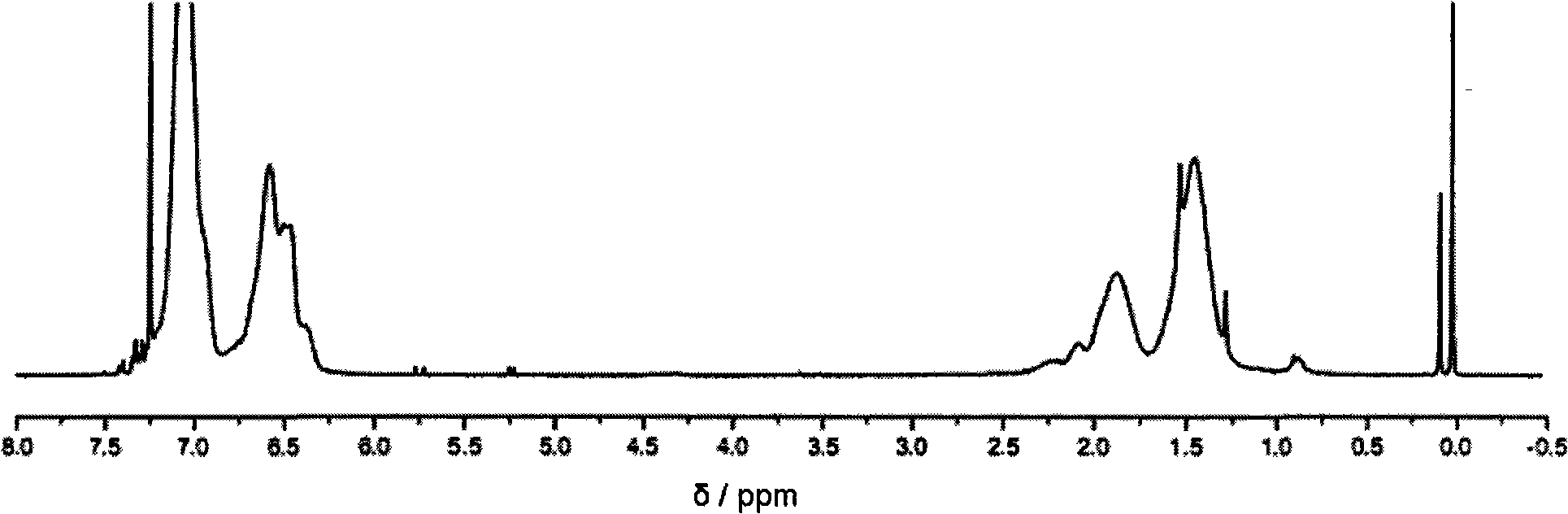

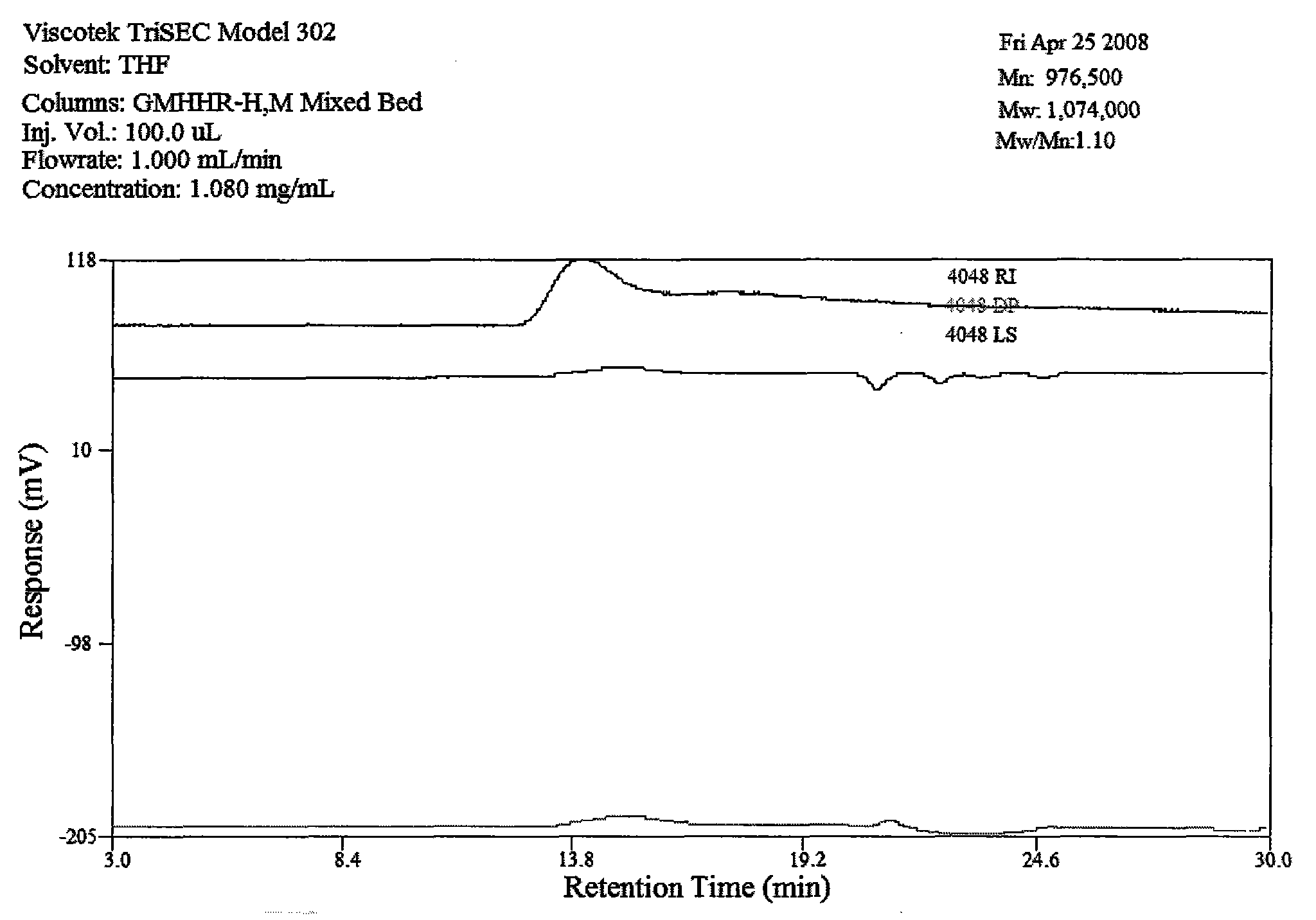

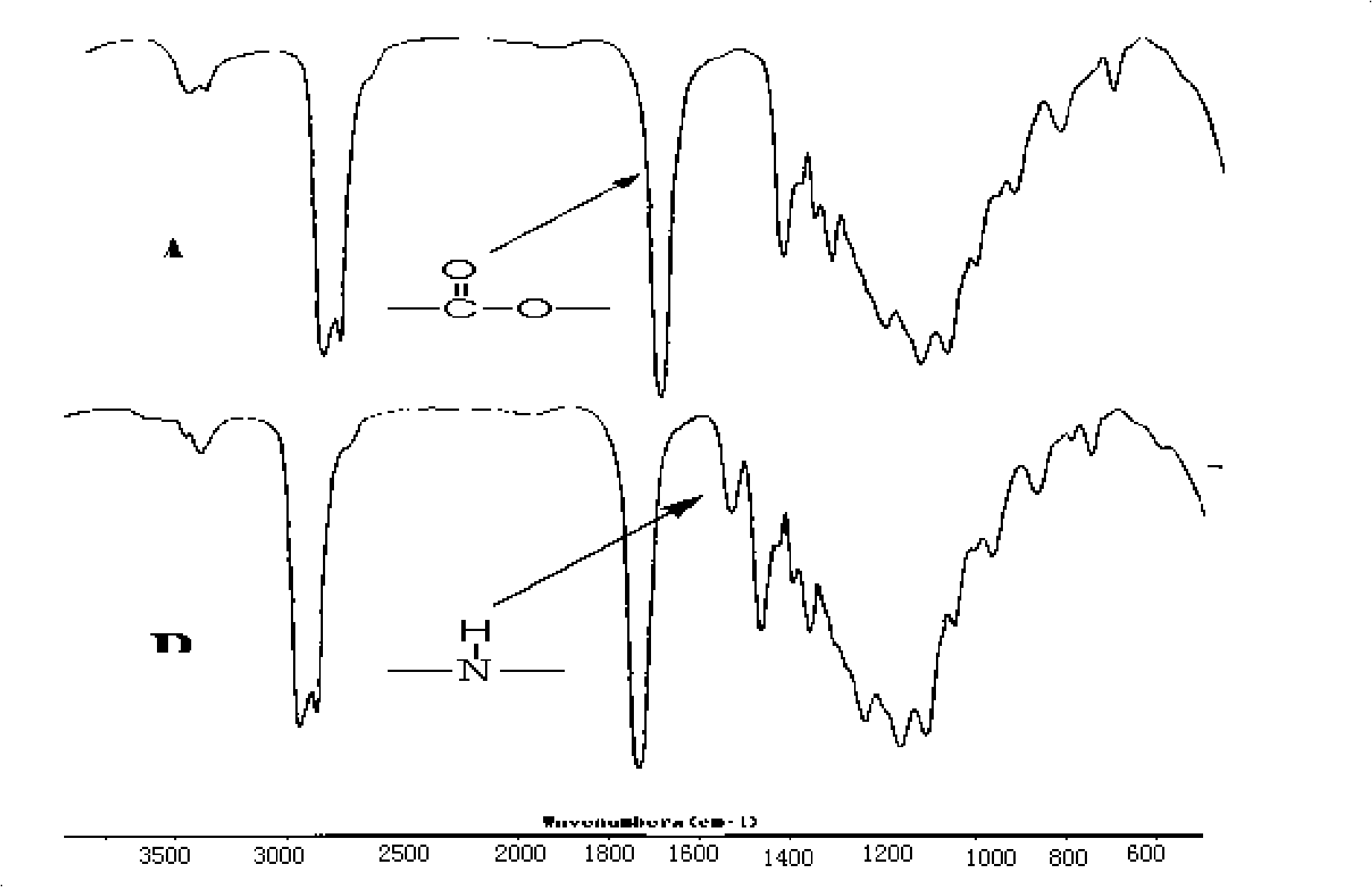

Multi-arm star-type polymer and preparation method thereof

The invention discloses a multi-arm star-type polymer and a preparation method thereof. The method synthesizes the multi-arm star-type polymer by a method with the following two steps of step one: taking a complex formed by a polydentate nitrogen-contained compound and a transitional metal halide as a catalytic system so as to catalyze the polymerization of atom transfer free radicals and self-condensing vinyl of a monomer, thus preparing and obtaining the halogen atom-contained hyperbranched polystyrene macromolecular initiator taken as the star-type polymer core; and step two: taking the complex formed by the the polydentate nitrogen-contained compound and the transitional metal halide as the catalytic system and taking the prepared halogen atom-contained hyperbranched polystyrene macromolecular as the initiator to initiate the polymerization of the atom transfer free radicals of the monomer, thus preparing and obtaining the multi-arm star-type polymer with controllable core structure, core size, core property, arm number, arm length and arm property and adjustable molecular weight within wider range.

Owner:INST OF CHEM CHINESE ACAD OF SCI

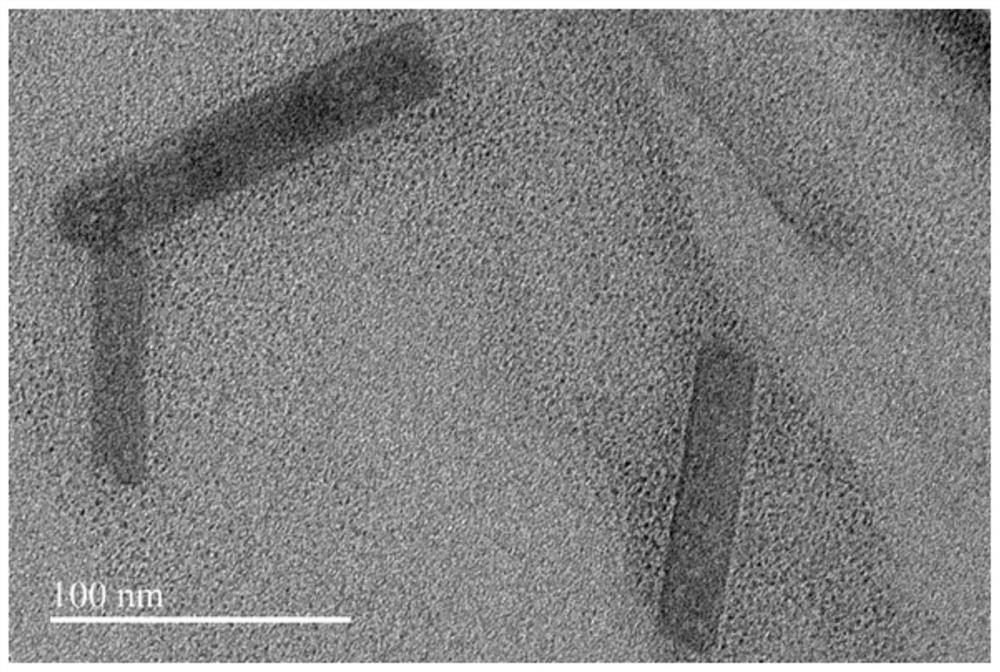

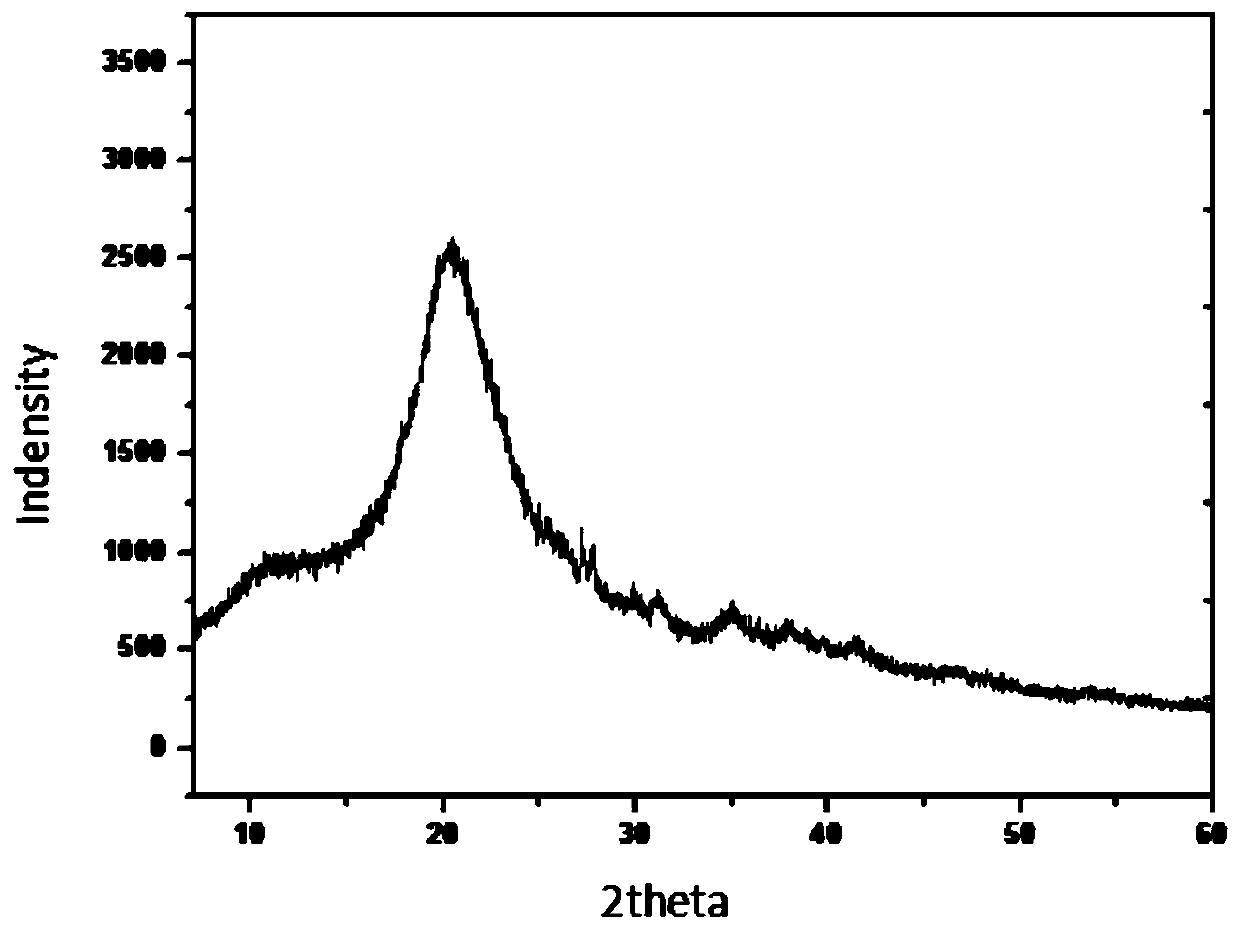

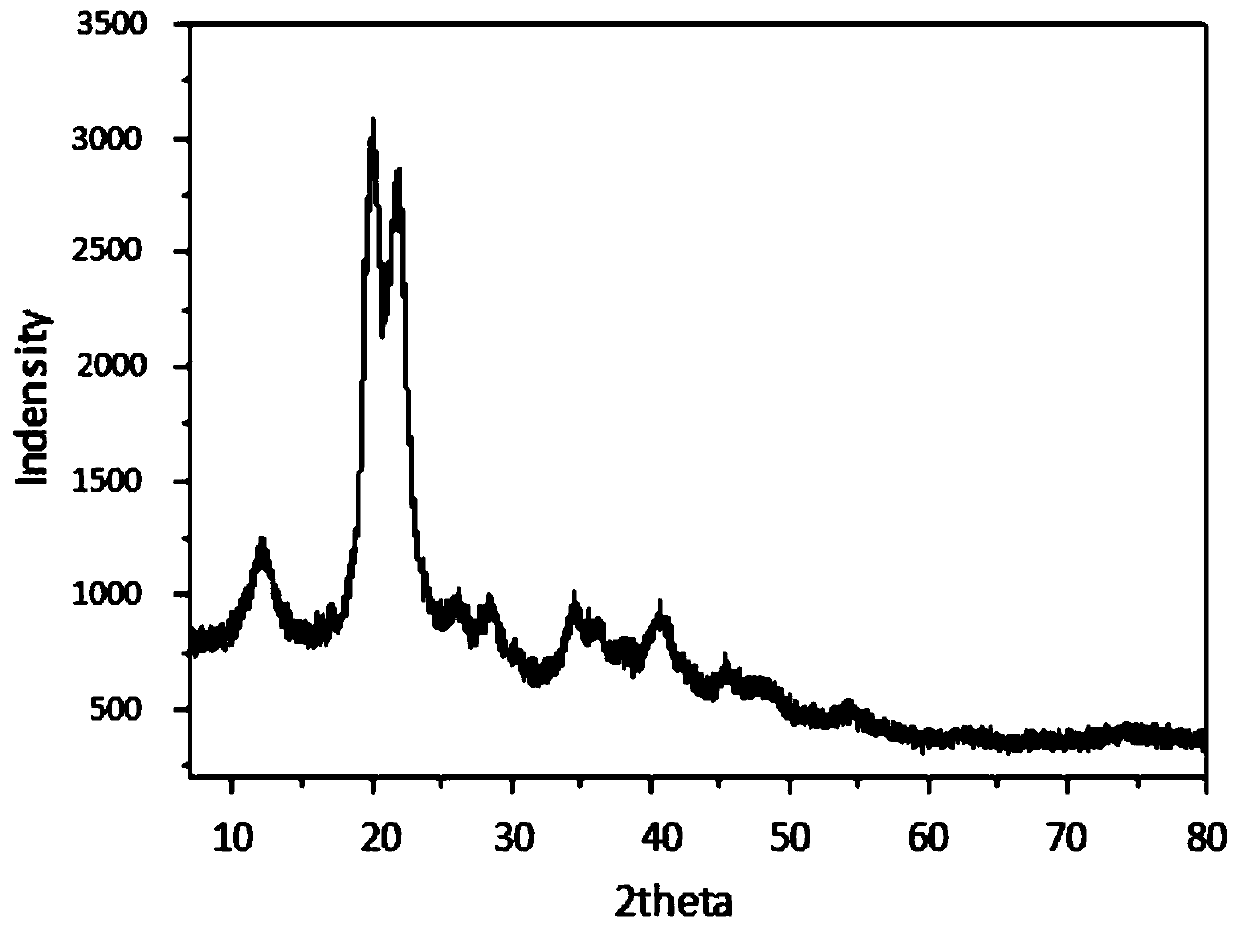

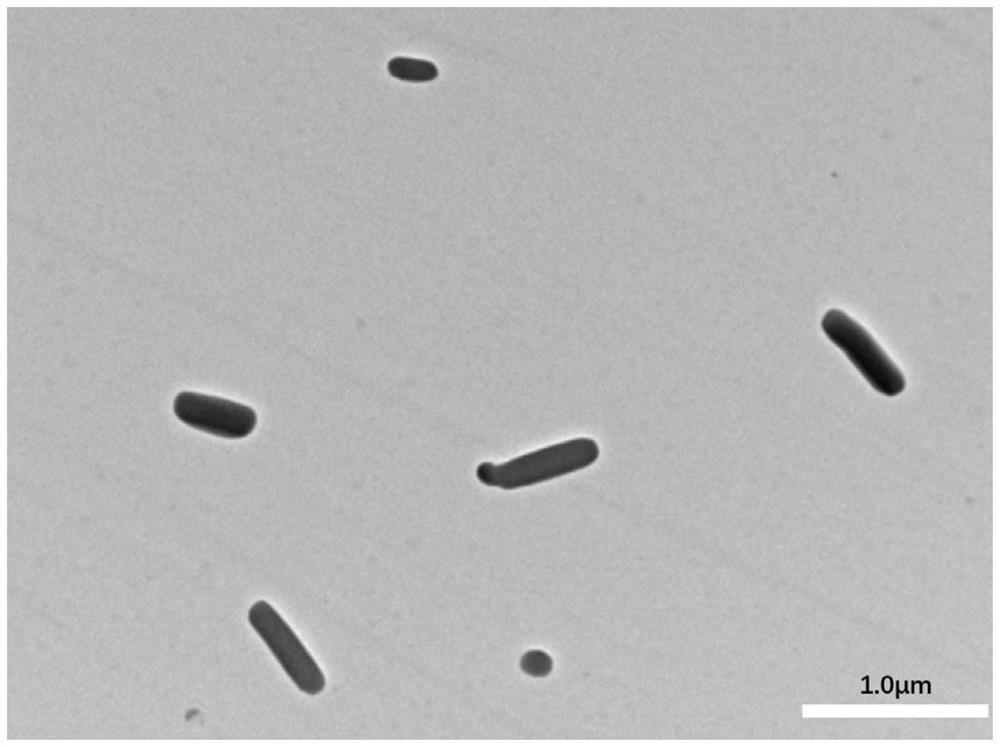

A kind of cellulose type II nanocrystalline particle and its preparation method and application

ActiveCN108264569BAvoid excessive degradationLoose structureMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcid hydrolysis

The invention relates to the field of cellulose nanocrystals, in particular to a cellulose II type nanocrystal particle and its preparation method and application. The crystallinity of the cellulose II type nano crystal particles is more than or equal to 80%, the number average molecular weight is 1200-2500, and the molecular weight distribution coefficient Mw / Mn is less than or equal to 1.30. The preparation method of the cellulose type II nanocrystalline particles includes: first performing amorphization and reconstruction of the cellulose raw material, recrystallization and acid hydrolysis, and the crystallization and acid hydrolysis can be carried out under low-concentration acidic conditions, and the cellulose nanocrystalline material is realized. efficient, clean production and quality control. The cellulose type II nanocrystalline particles prepared by the method have high crystallinity, small molecular weight, narrow molecular weight distribution, narrow size distribution, clear surface conformation and great surface chemical modification potential, and can be used for catalyst carrier, composite material reinforcement and other purposes.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

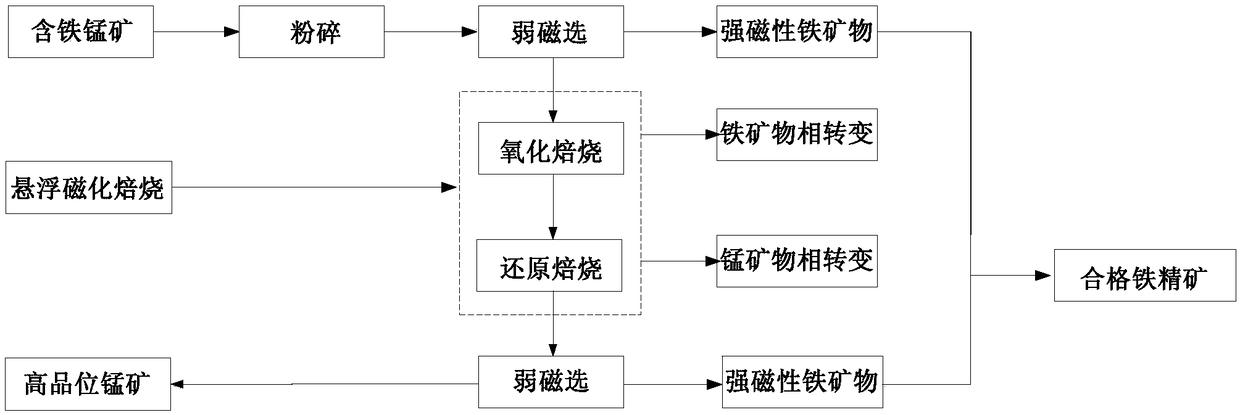

A kind of suspension roasting ferromanganese separation treatment method of ferromanganese ore

Owner:NORTHEASTERN UNIV LIAONING

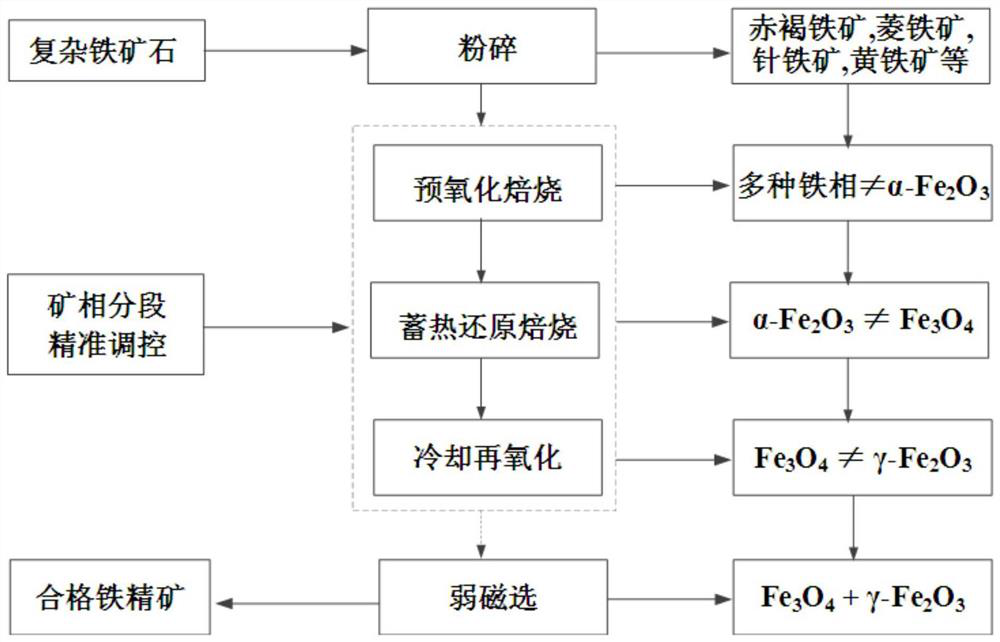

An enhanced separation method for complex iron ore based on precise regulation of ore phase segmentation

ActiveCN111644267BEfficient separationReduced magnetic agglomerationReversed direction vortexMagnetic separationIronstoneCyclonic separation

An intensified sorting method for complex iron ores based on accurate control of ore phase segmentation, which is carried out in the following steps: (1) crushing and grinding the complex iron ores; (2) transporting the ore powder to a pre-oxidation roaster , carry out pre-oxidation roasting in a suspension state, and then enter the cyclone separator; (3) After the pre-oxidation roasting material is separated by a cyclone, it is discharged into the regenerative reduction roaster, and the reduction roasting is carried out in a suspension state; (4) The reduced material enters the first-stage Cooling cyclone separator, nitrogen cooling to 200~300°C; (5) Cooling and reducing materials enter the secondary cooling cyclone separator through the flow seal valve, and re-oxidize with air, and the temperature drops to ≤100°C; (6) Carry out weak Magnetic separation to obtain iron concentrate. The method of the invention has simple flow, low energy consumption and cost per unit of processing capacity, easy control of product properties, and easy realization of large-scale equipment.

Owner:NORTHEASTERN UNIV LIAONING

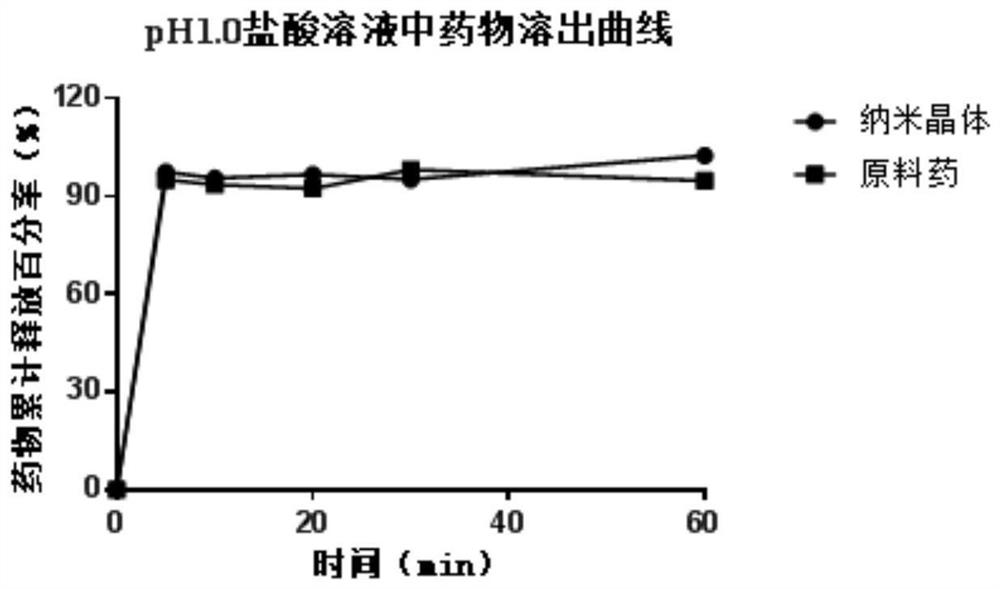

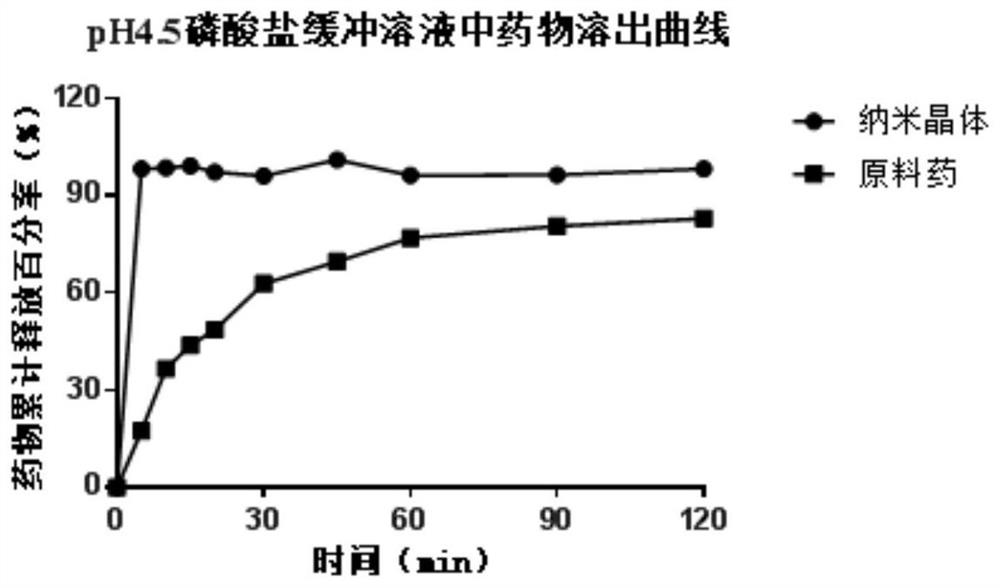

A kind of loratadine nano crystal and preparation method thereof

ActiveCN111249239BSmall particle sizeNarrow distributionPowder deliveryOrganic active ingredientsTabletingBiology

The invention belongs to the field of pharmaceutical preparations and discloses a preparation method of loratadine nano crystals and oral tablets thereof. Loratadine is a kind of BCS Ⅱ medicine, and its solubility is extremely low and is pH-dependent. In order to improve the dissolution rate and bioavailability of the medicine and improve individual variability, the present invention adopts high-speed shearing combined with high-pressure homogenization method to prepare loratadine. The radadine nano crystal adopts the powder direct compression method to prepare the loratadine nano crystal oral tablet. The preparation process of the invention is simple, fast, environment-friendly and easy for industrialized large-scale production. The dissolution rate was evaluated by an in vitro dissolution test. The loratadine nanocrystals and tablets prepared by this method can be rapidly dissolved in various pH media, thereby improving bioavailability and improving individual variability.

Owner:CHINA PHARM UNIV

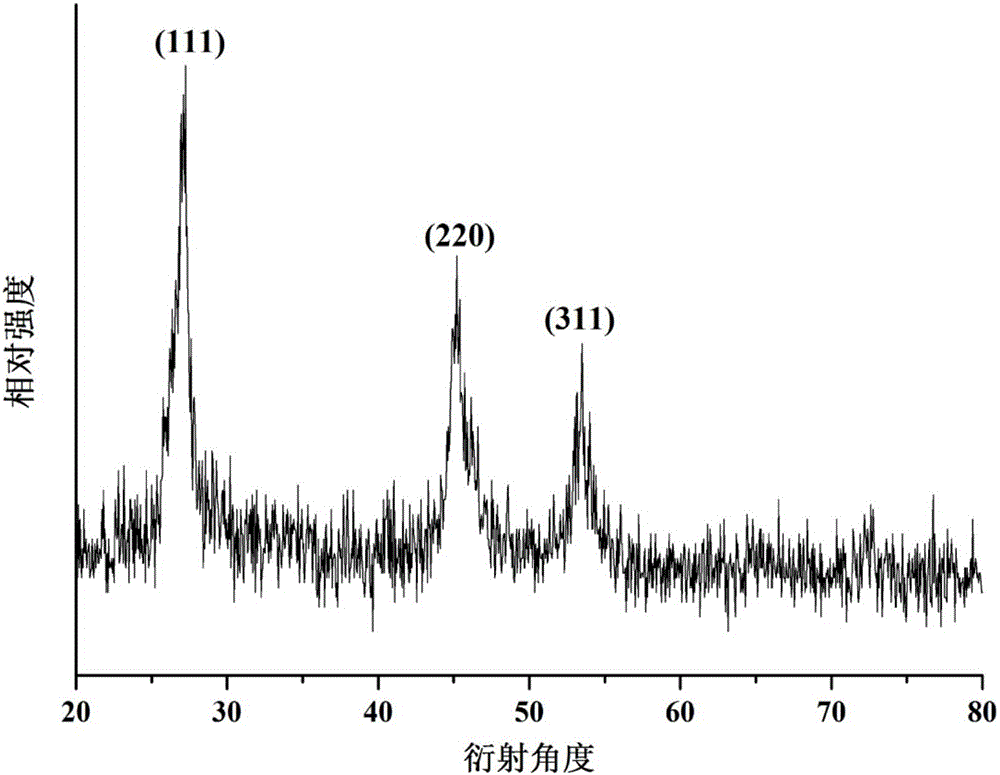

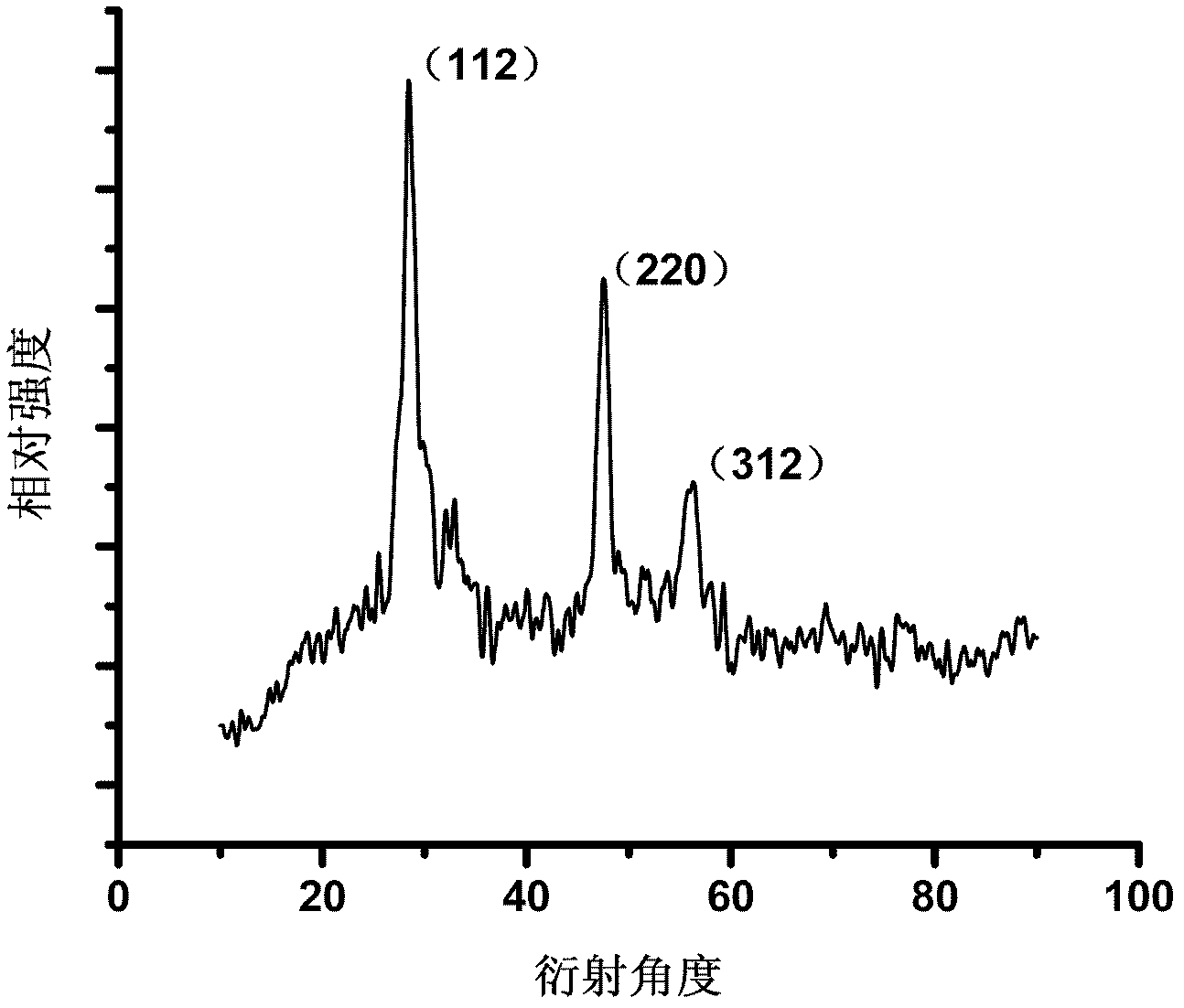

Kesterite structure Cu2ZnSnS4 powder material and liquid phase preparation method thereof

InactiveCN102500293BQuality improvementLow costTin compoundsMicroballoon preparationBrickNitrogen gas

The invention discloses a kesterite structure Cu2ZnSnS4 powder material for a solar photovoltaic cell, and a liquid phase preparation method thereof; the liquid phase preparation method comprises the steps that: the material is weighed in the principle of CuCl2.2H2O:ZnCl2:SnCl4.5H2O:sulphur powder=2 (1 to 1. 5): (1 to 1. 5): (4 to 5) (molar ratio) and put into a round-bottom three-neck flask to be mixed, then organic solvent triethylene tetramine solution is added in, the mixture stays still for 3min to 5min, and uniform brick red solution is obtained; after nitrogen is fed in as protective gas, and the brick red solution is put into constant temperature oil bath to be heated to 120DEG C to 240DEG C, maintained for 0.5h to 12h, and then naturally cooled to room temperature; anhydrous ethanol and distilled water are used for sequentially washing a product, then the product is filtered and dried, and black powder is obtained. The liquid phase preparation method of the kesterite structure Cu2ZnSnS4 powder material is green, has no pollution, short reaction time and low required temperature, is convenient to operate, has low cost, and is applicable to the large-scale production of Cu2ZnSnS4 powder (for a photovoltaic cell absorption layer).

Owner:CENT SOUTH UNIV

Method for preparing (Zn,Cd)S quantum dot

The invention relates to a method for preparing a (Zn,Cd)S quantum dot, which comprises the following steps of: (1) dissolving soluble salt of zinc or / and and cadmium and thioacetamide raw materials into water or water-ethanol mixed liquor and adjusting a pH value to weak acidity with weak acid to obtain homogeneous reaction system mother liquor; and (2) transferring the homogeneous reaction system mother liquor obtained in the step (1) into a hydrothermal reactor for automatically generating pressure for sealing, heating to 70-100 DEG C and reacting for 30minutes to 24 hours to obtain the (Zn,Cd)S quantum dot. Compared with the prior art, the invention has the advantages of low cost, controllable process and product property, high uniformity, energy saving, high efficiency, pure water phase preparation and environmental protection.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

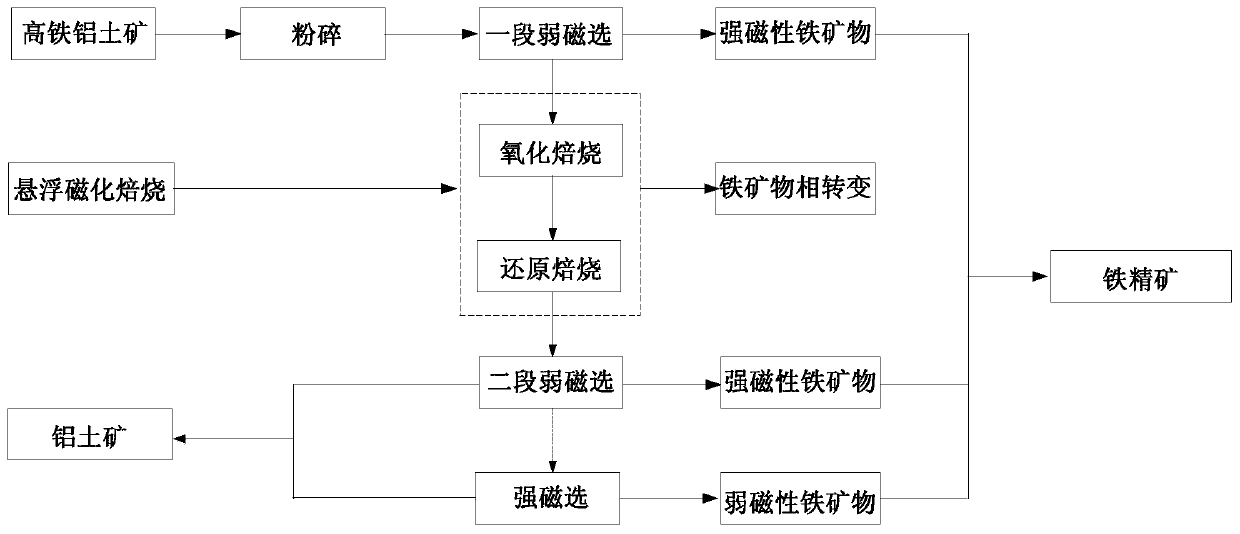

A method for separating aluminum and iron by suspension roasting of high-iron bauxite

ActiveCN107686886BEfficient separationMeet the requirements of the alumina production industryMaceralMineral processing

A method for separating aluminum and iron by suspension roasting of high-speed iron bauxite, which belongs to the field of mineral processing technology and is carried out according to the following steps: (1) crush and grind the high-speed iron bauxite; (2) perform a stage of weak magnetic separation; (3) The tailings of the first stage of magnetic separation are oxidized and roasted; (4) the oxidized powdered ore is put into the reduction roasting furnace for reduction roasting; (5) the reduced ore powder is subjected to the second stage of weak magnetic separation; (6) the tailings of the second stage of magnetic separation are Carry out strong magnetic separation; combine the strong magnetic separation concentrate and the second-stage weak magnetic separation concentrate as the finished iron ore concentrate. The process of the invention is simple, the equipment processing capacity is large, the product properties are easy to control, the industrial application is energy-saving and environmentally friendly, and it is easy to realize large-scale production.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com