Kesterite structure Cu2ZnSnS4 powder material and liquid phase preparation method thereof

A powder material, kesterite technology, applied in the preparation of microspheres, chemical instruments and methods, tin compounds, etc., can solve few problems, and achieve the effects of low cost, short reaction time, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

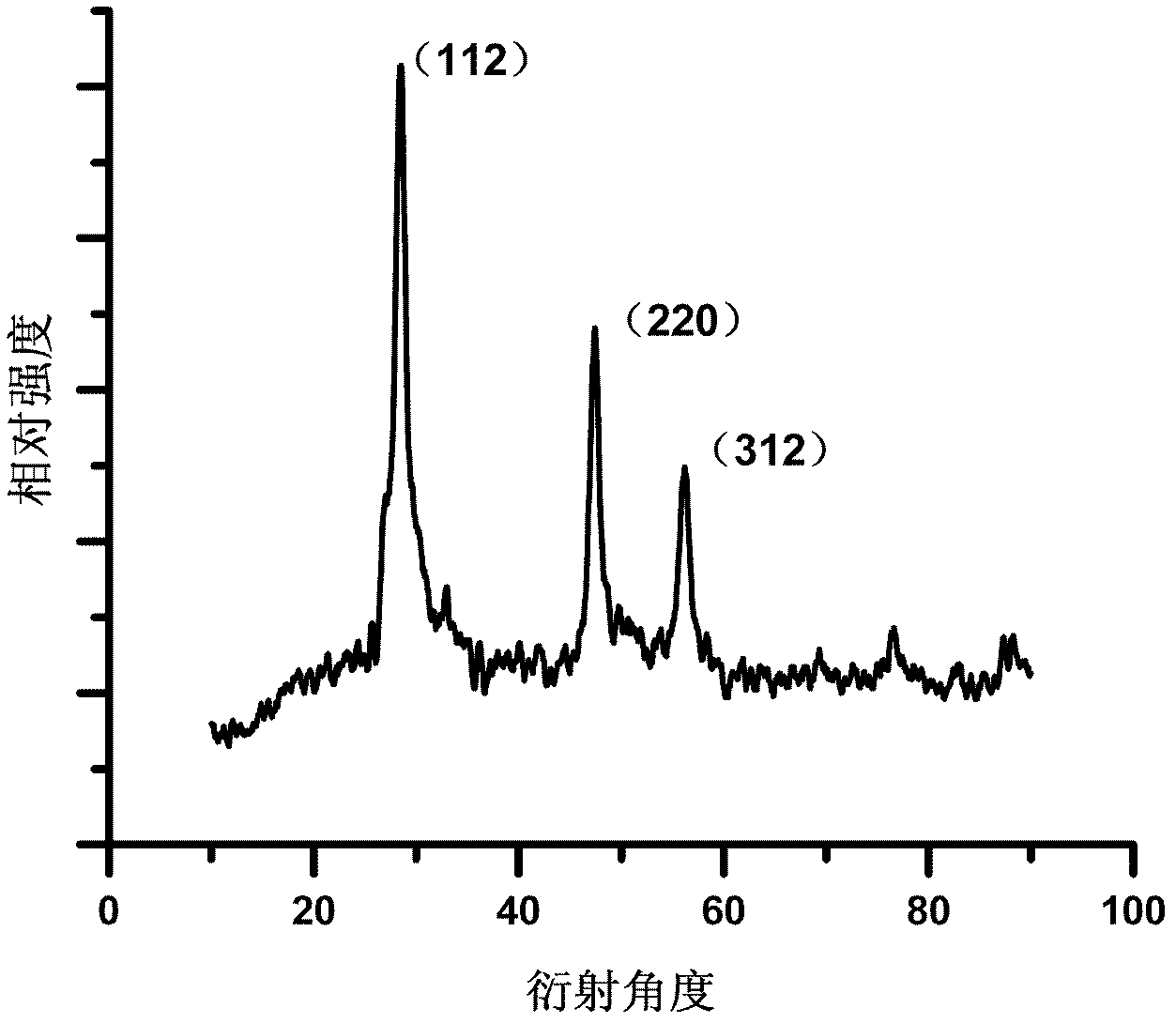

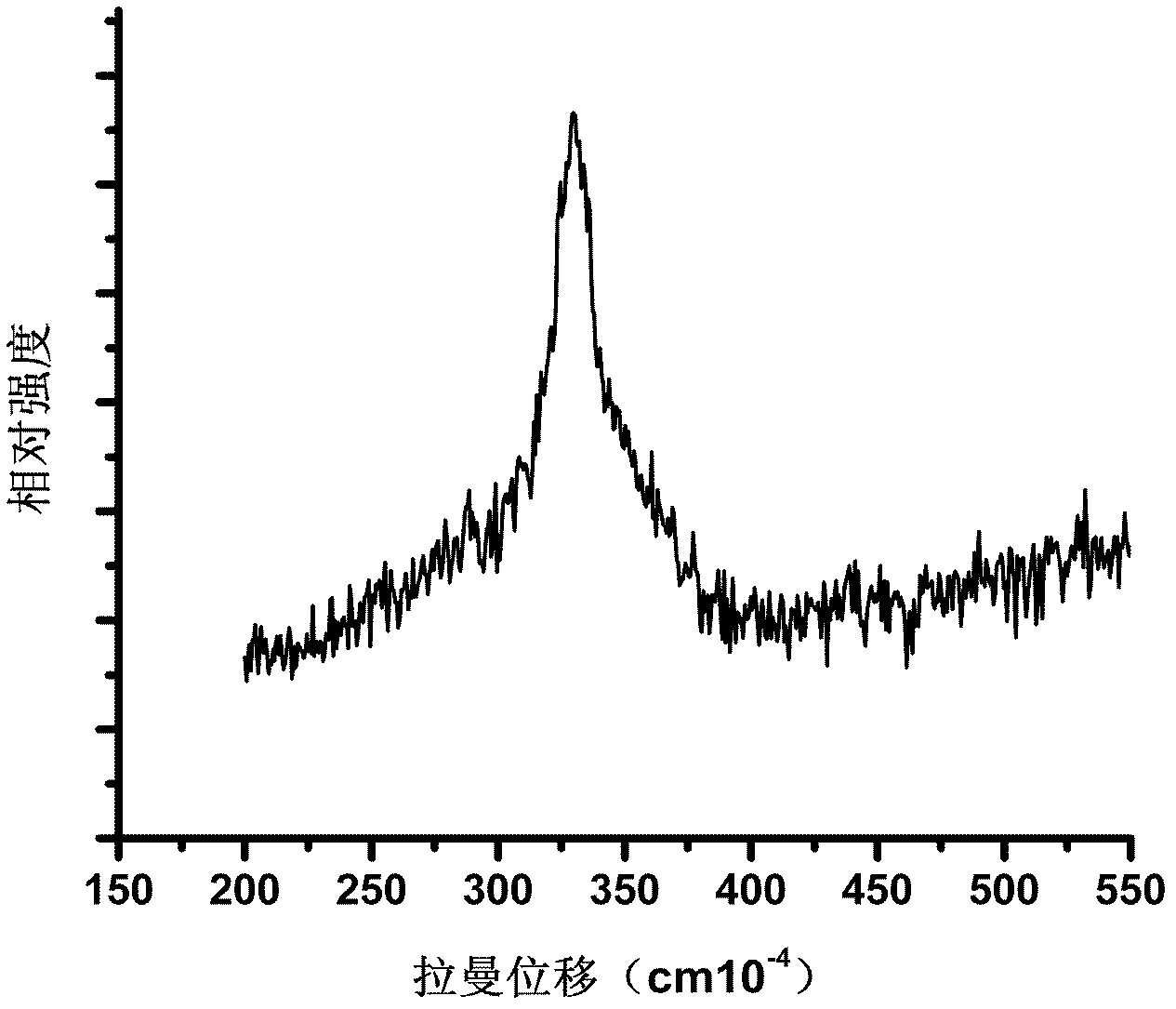

Embodiment 1

[0030] Weigh 0.01mmolCuCl 2 2H 2 O, 0.005 mmol ZnCl 2 , 0.005mmolSnCl 4 ·5H 2 O, 0.02mmol sulfur powder, put into a three-necked round-bottomed flask, add 50ml of triethylenetetramine, and leave it for 3-5 minutes to obtain a uniform brick-red solution, feed nitrogen as a protective gas, and place the three-necked round-bottomed flask Heated to 200°C in a constant temperature oil bath and kept for 2 hours, then naturally cooled to room temperature, washed with anhydrous ethanol and ionized water for 3 times, then filtered, and dried at 60°C in a drying oven for 6 hours to obtain black solid.

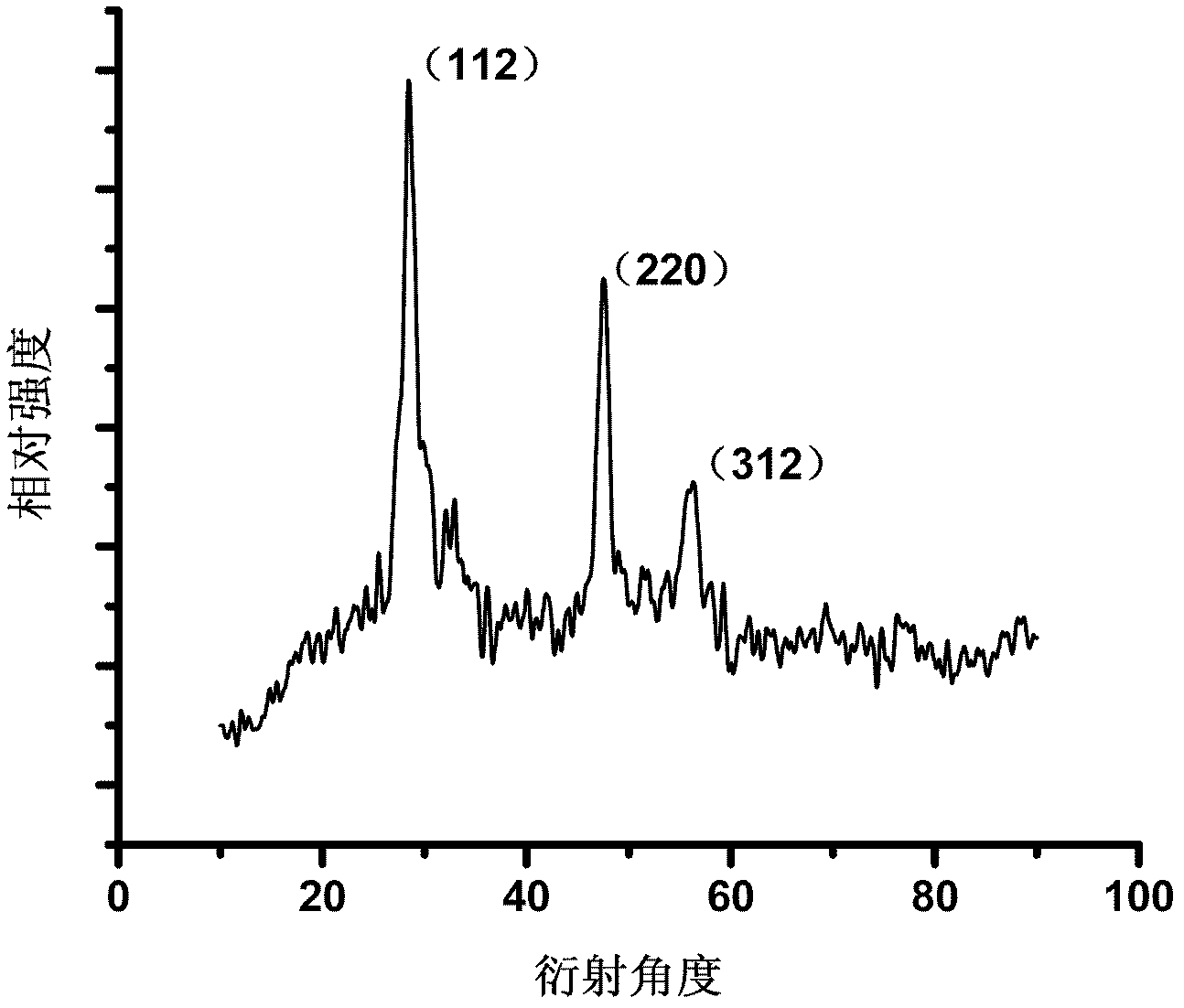

Embodiment 2

[0032] Weigh 0.015mmolCuCl 2 2H 2 O, 0.008 mmol ZnCl 2 , 0.008mmolSnCl 4 ·5H 2 O, 0.04mmol sulfur powder, put into a three-necked round-bottomed flask, add 60ml of triethylenetetramine, leave it for 3-5 minutes to obtain a uniform brick-red solution, feed nitrogen as protective gas, and place the three-necked round-bottomed flask Heated to 150°C in a constant temperature oil bath and kept for 2 hours, then naturally cooled to room temperature, washed with absolute ethanol and ionized water for 3 times, then filtered, and dried at 60°C in a drying oven for 6 hours to obtain black solid.

Embodiment 3

[0034] Weigh 0.015mmolCuCl 2 2H 2 O, 0.008 mmol ZnCl 2 , 0.008mmolSnCl 4 ·5H 2O, 0.04mmol sulfur powder, put into a three-necked round-bottomed flask, add 60ml of triethylenetetramine, leave it for 3-5 minutes to obtain a uniform brick-red solution, feed nitrogen as protective gas, and place the three-necked round-bottomed flask Heated to 150°C in a constant temperature oil bath and kept for 6 hours, then cooled naturally to room temperature, washed with absolute ethanol and ionized water for 3 times, then filtered, and dried at 60°C in a drying oven for 6 hours to obtain black solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com