Patents

Literature

49 results about "Kesterite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

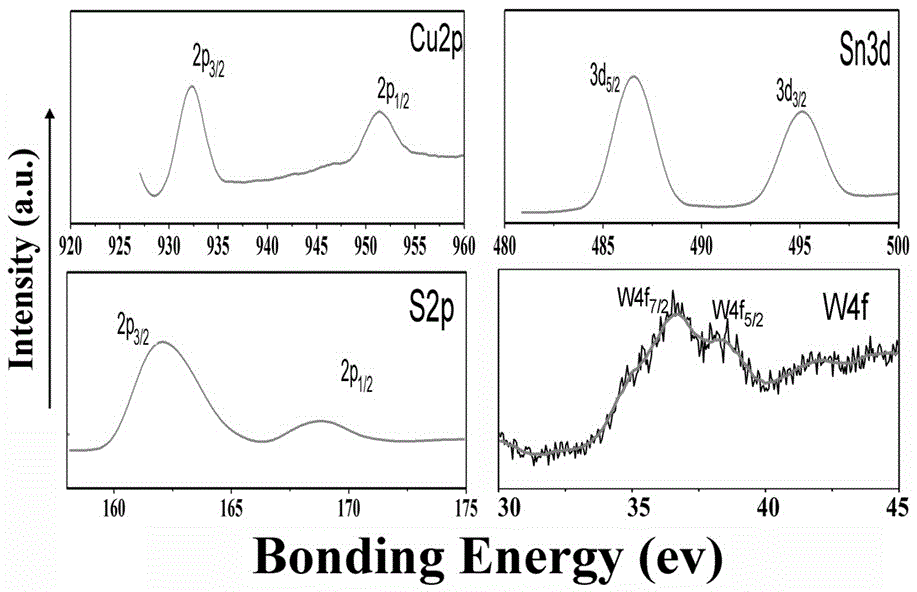

Kesterite is a sulfide mineral with a formula Cu₂(Zn,Fe)SnS₄. In its lattice structure, zinc and iron atoms share the same lattice sites. Kesterite is the Zn-rich variety whereas the Zn-poor form is called ferrokesterite or stannite. Owing to their similarity, kesterite is sometimes called isostannite. The synthetic form of kesterite is abbreviated as CZTS (from copper zinc tin sulfide). The name kesterite is sometimes extended to include this synthetic material and also CZTSe, which contains selenium instead of sulfur.

Aqueous-based method of forming semiconductor film and photovoltaic device including the film

InactiveUS20110097496A1Easy to controlOptimal rheologicalFinal product manufactureSemiconductor/solid-state device manufacturingHydrazine compoundThin layer

A method with enhanced safety characteristics of depositing a kesterite film, which includes a compound of the formula: Cu2−xZn1+ySn(S1−zSez)4+q, wherein 0≦x≦1; 0≦y≦1; 0≦z≦1; −1≦q≦1. The method includes contacting an aqueous solvent, ammonia, a source of hydrazine, a source of Cu, a source of Sn, a source of Zn, a source of at least one of S and Se, under conditions sufficient to form an aqueous dispersion which includes solid particles; applying the dispersion onto a substrate to form a thin layer of the dispersion on the substrate; and annealing at a temperature, pressure, and length of time sufficient to form the kesterite film. An annealing composition and a photovoltaic device including the kesterite film formed by the above method are also provided.

Owner:ELPIS TECH INC

Method of forming semiconductor film and photovoltaic device including the film

InactiveUS20110094557A1Reducing and avoiding necessityEasy to usePV power plantsConductive materialThin layerSolid particle

A method of depositing a kesterite film which includes a compound of the formula: Cu2−xZn1+ySn(S1−zSez)4+q, wherein 0≦x≦1; 0≦y≦1; 0≦z≦1; −1≦q≦1. The method includes contacting hydrazine, a source of Cu, and a source of at least one of S and Se forming solution A; contacting hydrazine, a source of Sn, a source of at least one of S and Se, and a source of Zn forming dispersion B; mixing solution A and dispersion B under conditions sufficient to form a dispersion which includes Zn-containing solid particles; applying the dispersion onto a substrate to form a thin layer of the dispersion on the substrate; and annealing at a temperature, pressure, and length of time sufficient to form the kesterite film. An annealing composition and a photovoltaic device including the kesterite film formed by the above method are also provided.

Owner:ELPIS TECH INC

Particle-Based Precursor Formation Method and Photovoltaic Device Thereof

InactiveUS20130037110A1Reducing and avoiding necessityReduce complexitySemiconductor/solid-state device manufacturingPretreated surfacesSurface layerSulfur

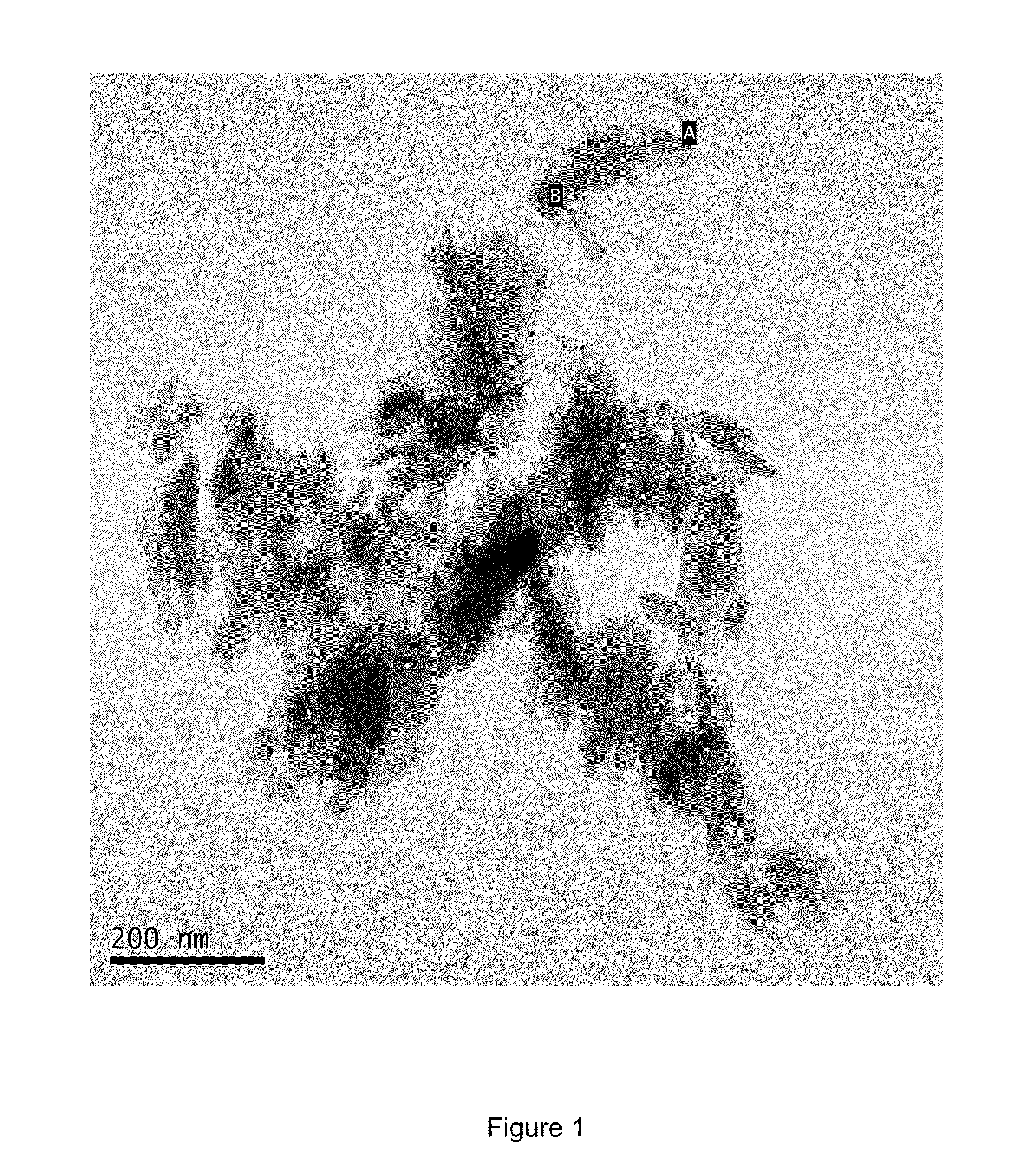

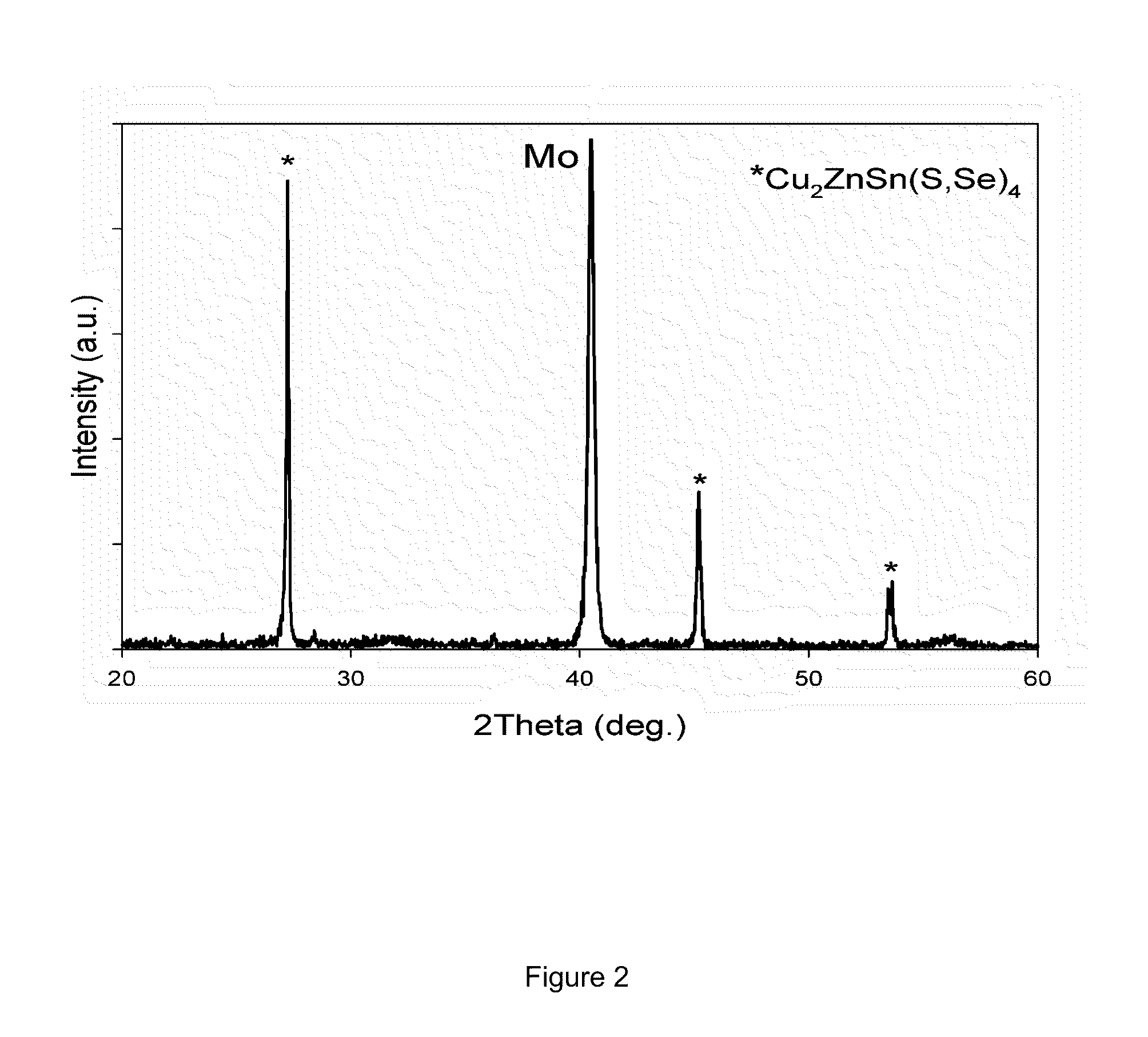

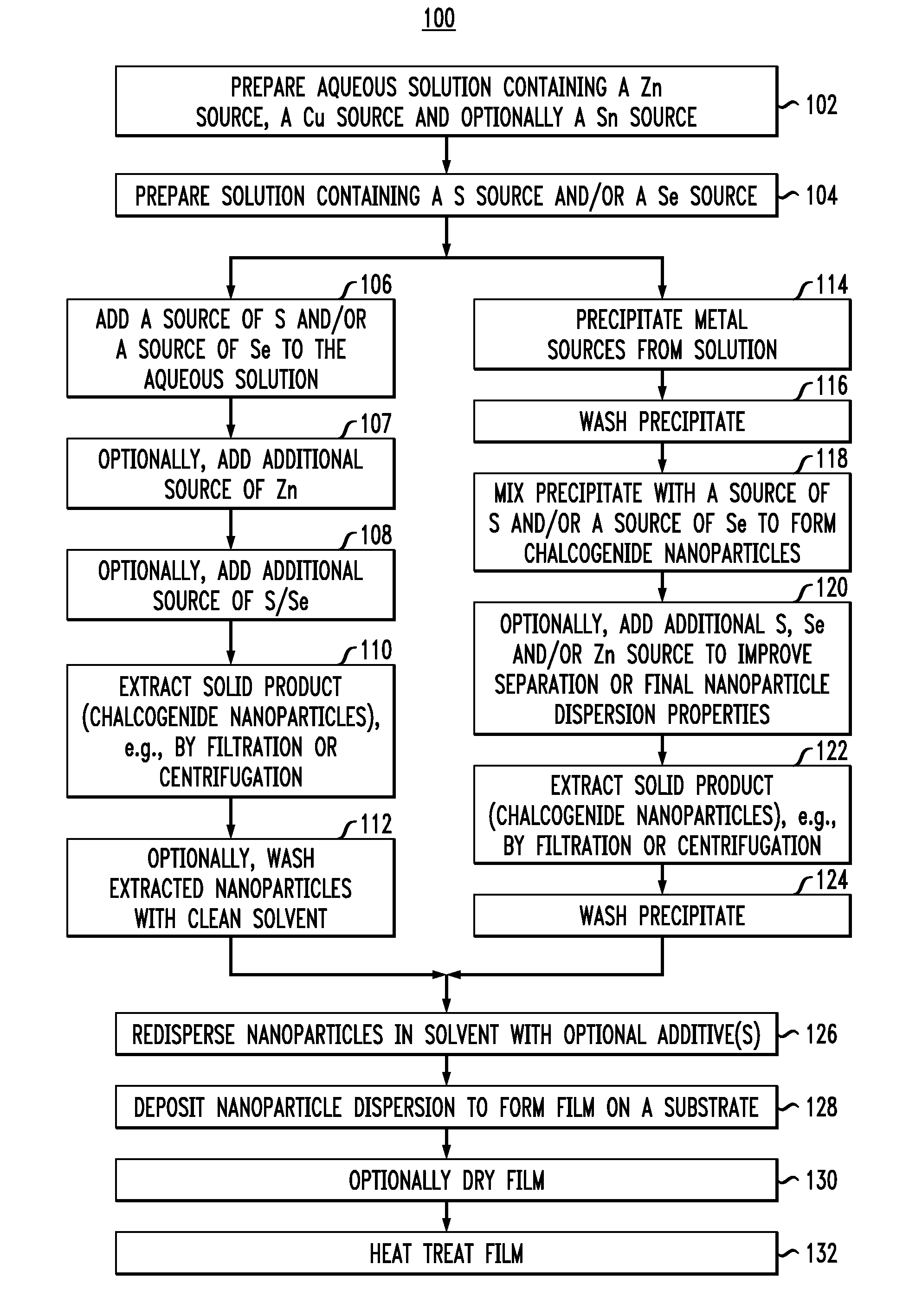

Techniques for fabrication of kesterite Cu—Zn—Sn—(Se,S) films and improved photovoltaic devices based on these films are provided. In one aspect, a method of forming metal chalcogenide nanoparticles is provided. The method includes the following steps. Water, a source of Zn, a source of Cu, optionally a source of Sn and at least one of a source of S and a source of Se are contacted under conditions sufficient to produce a dispersion of the metal chalcogenide nanoparticles having a Zn chalcogenide distributed within a surface layer thereof. The metal chalcogenide nanoparticles are separated from the dispersion and can subsequently be used to form an ink for deposition of kesterite films.

Owner:IBM CORP

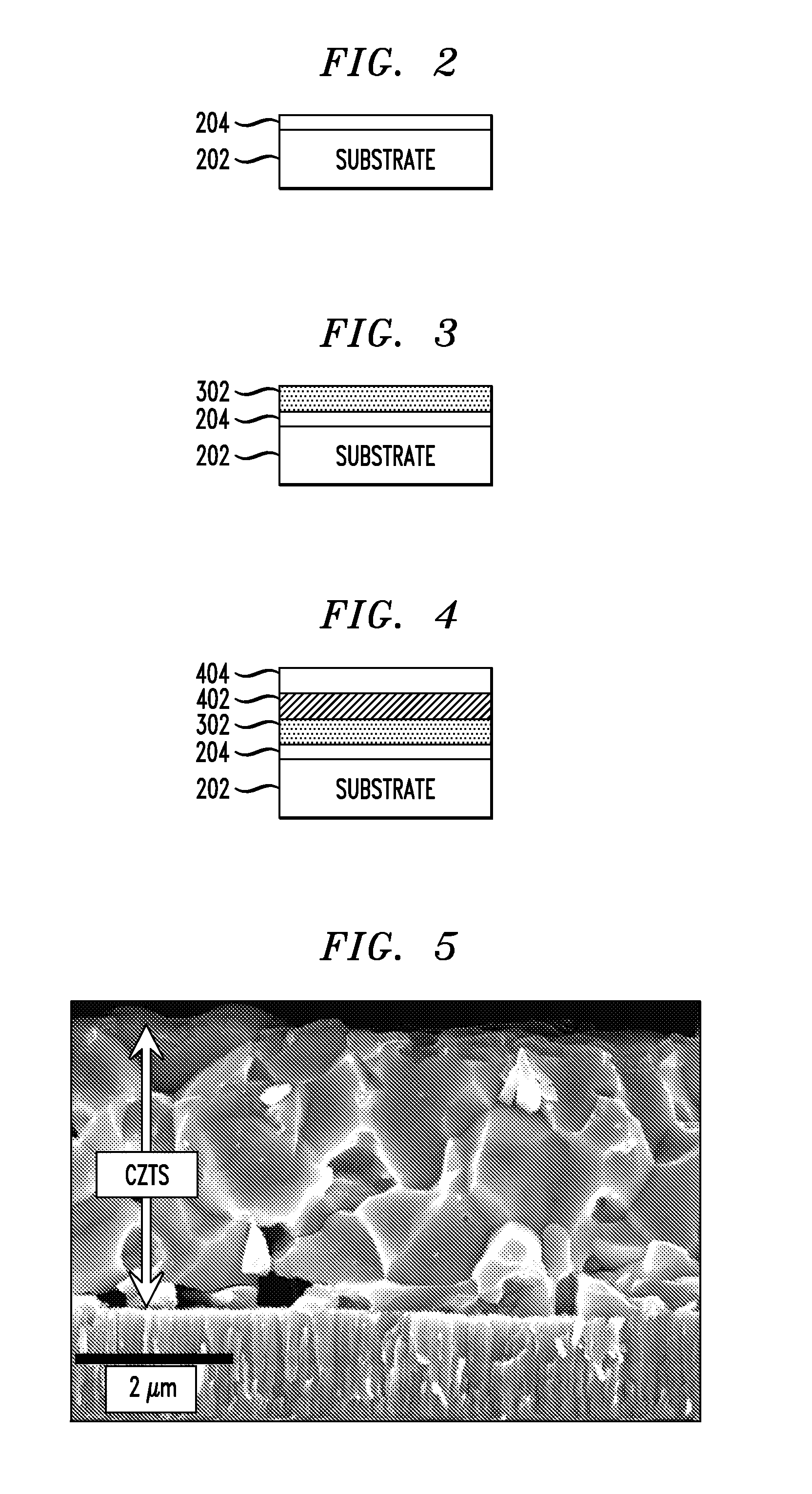

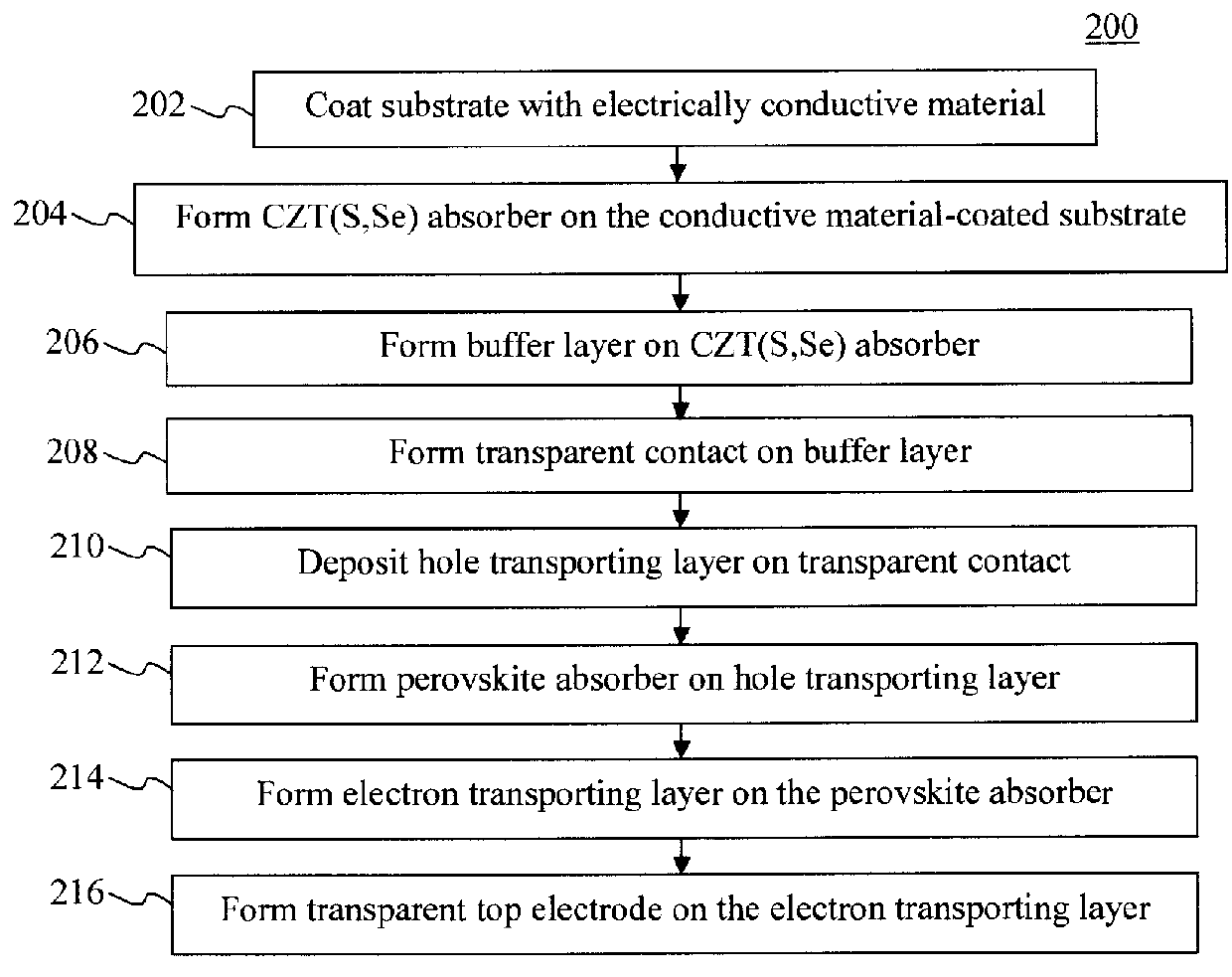

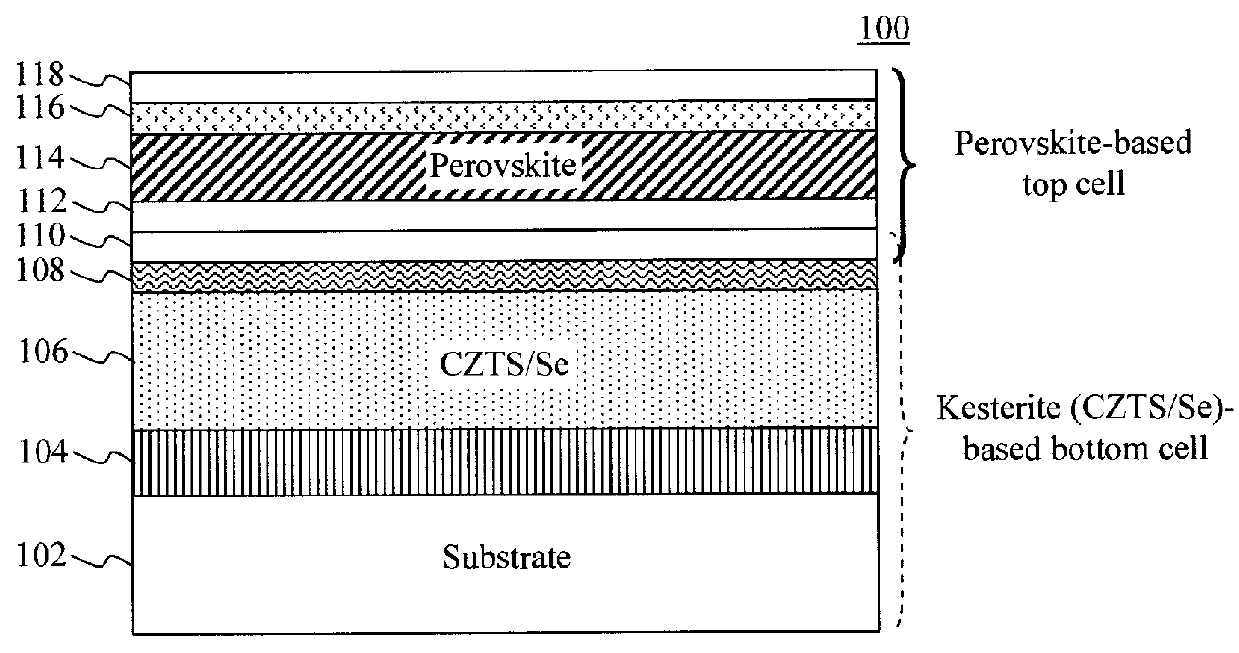

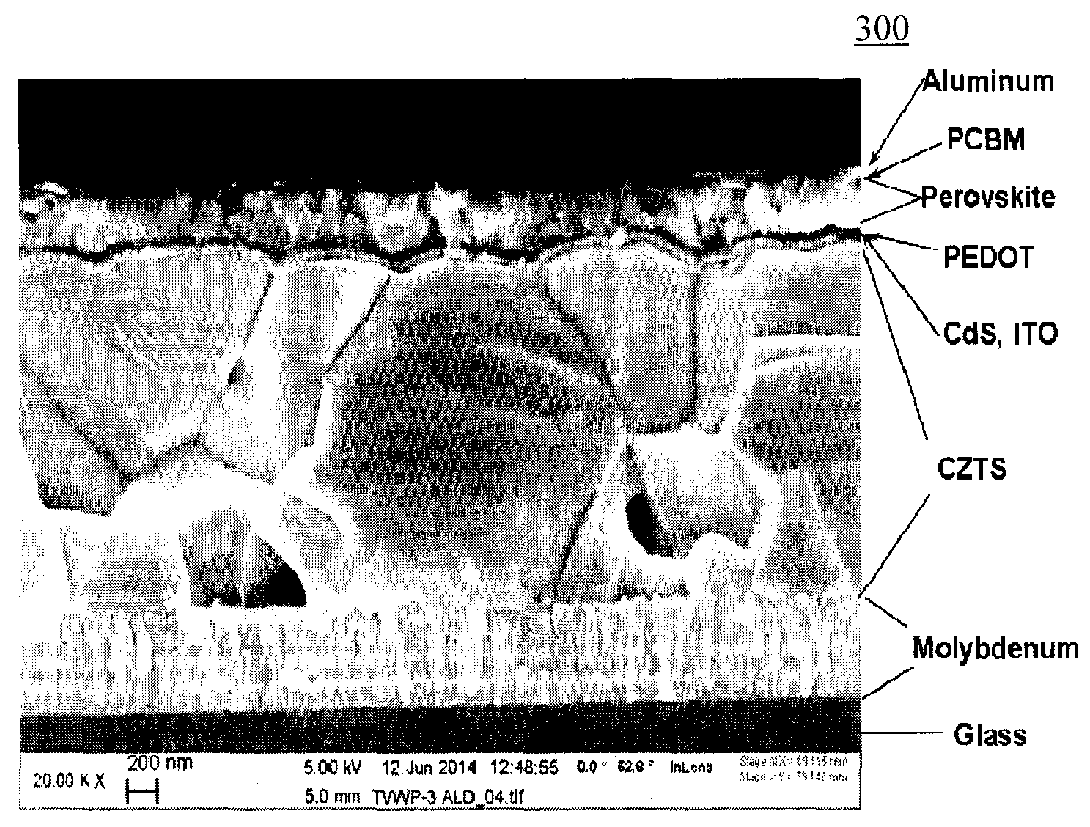

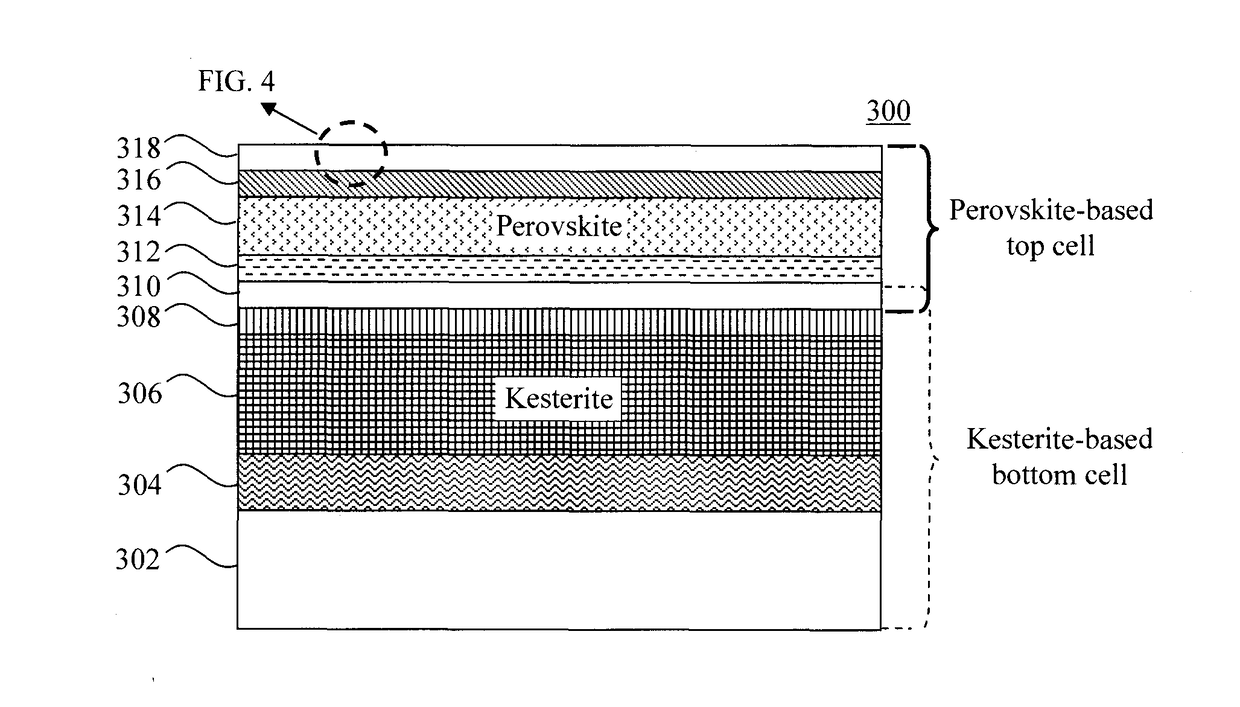

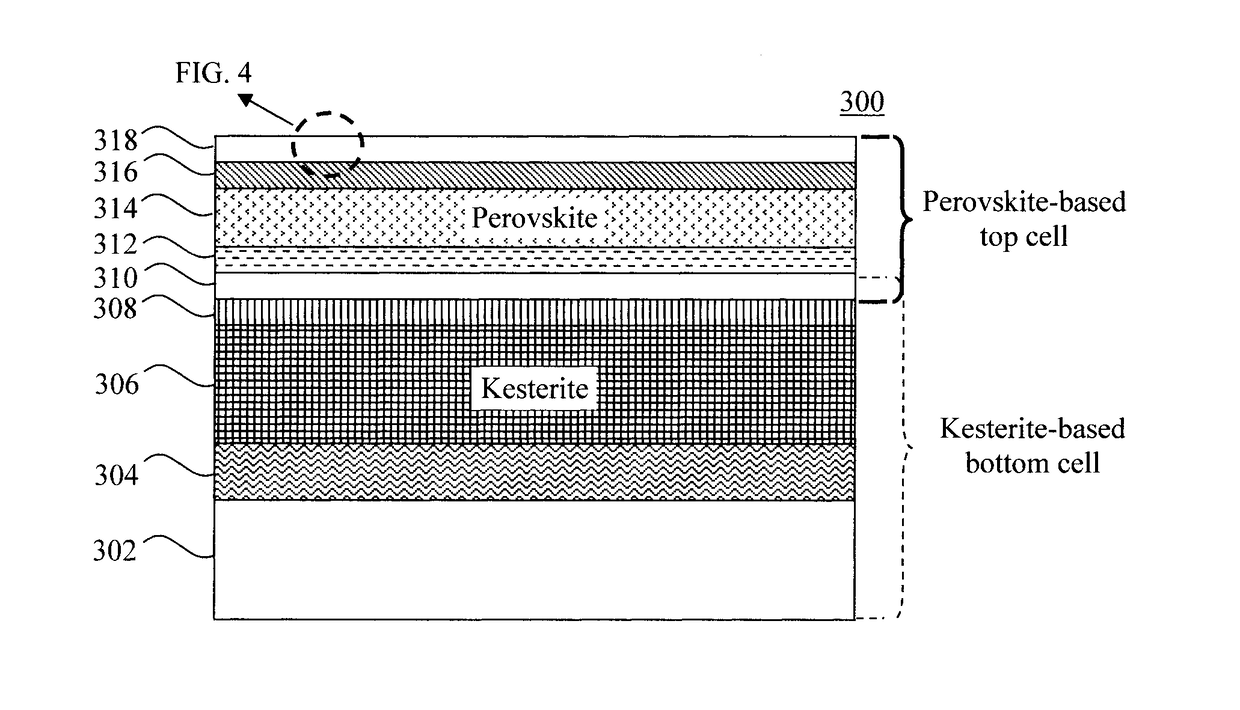

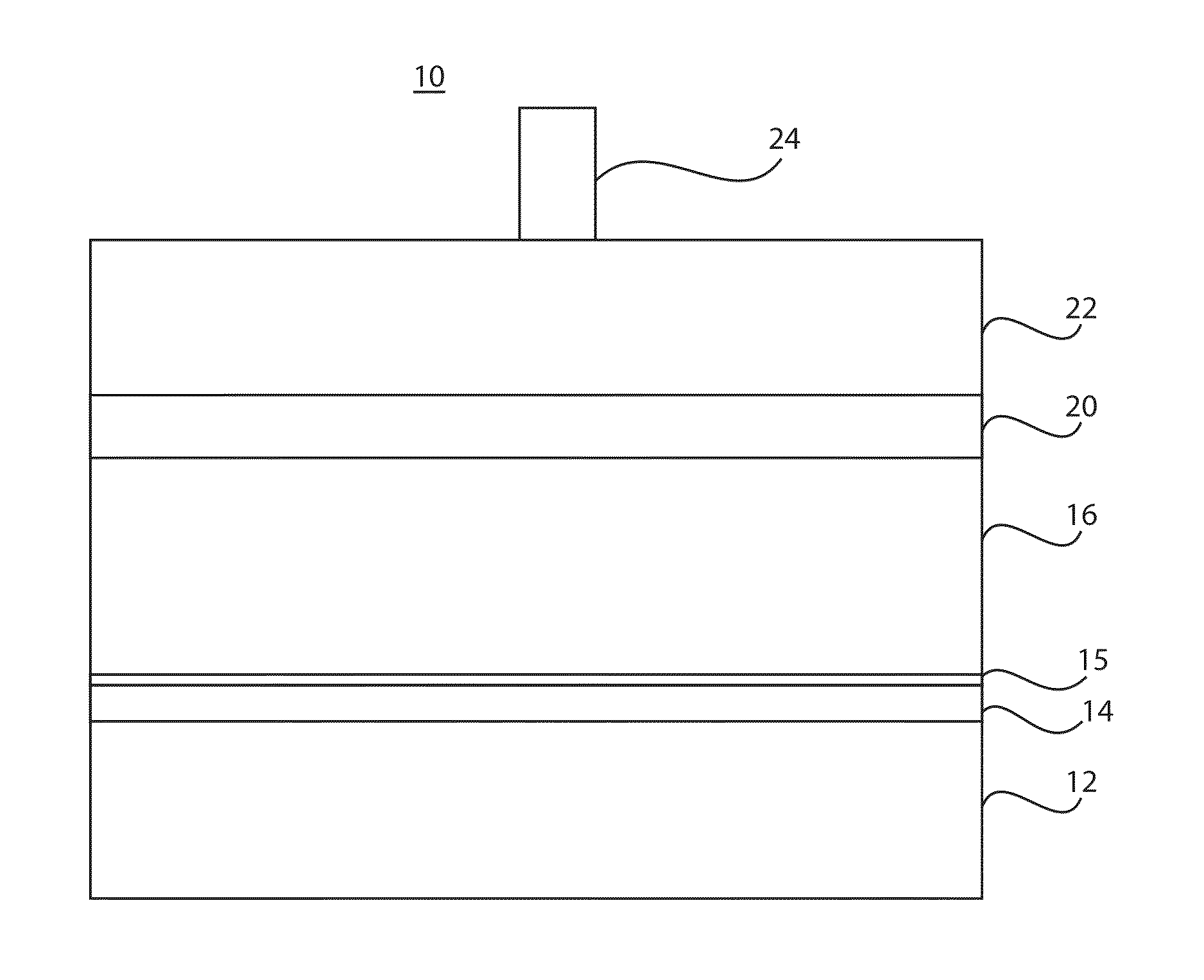

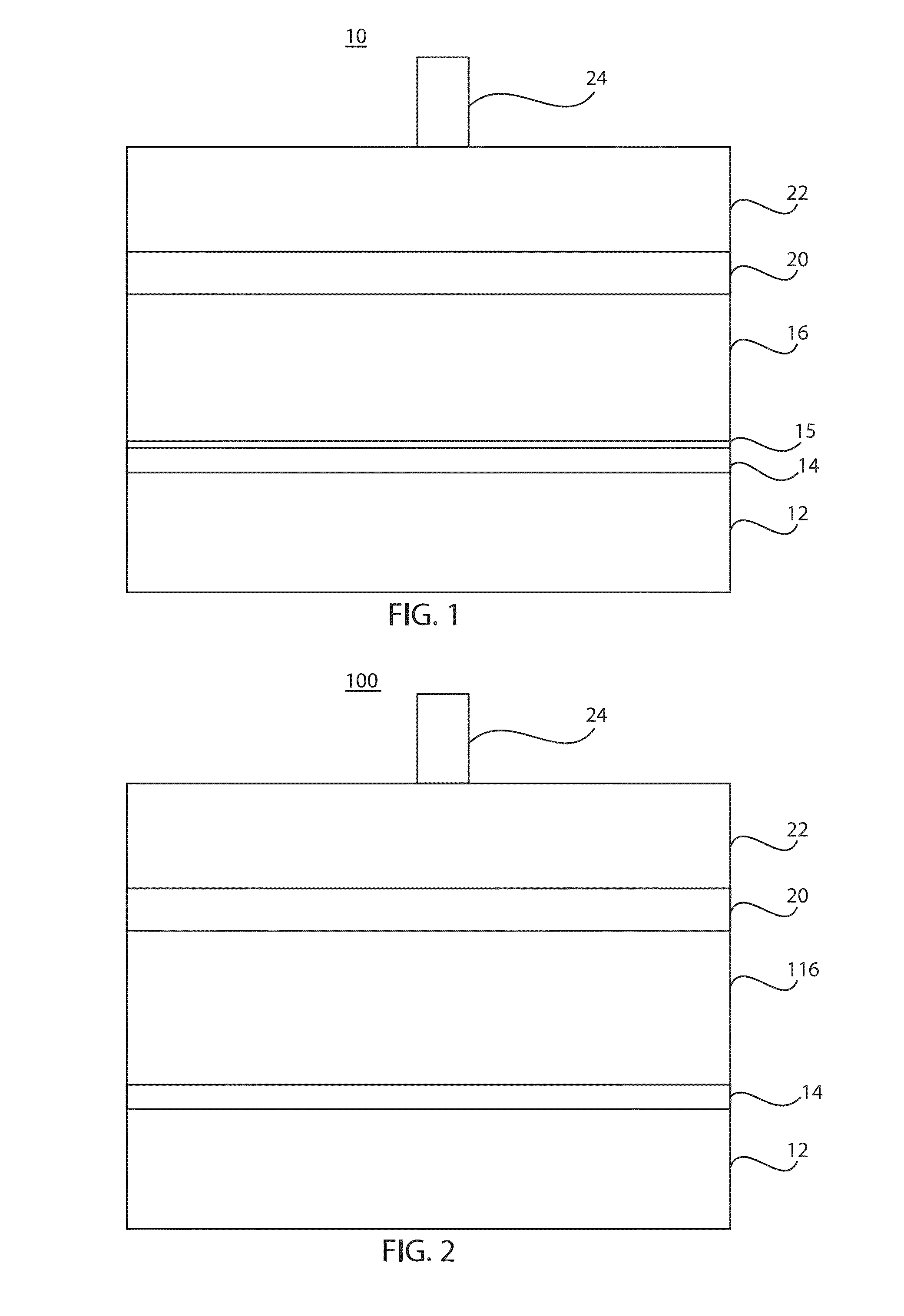

Tandem Kesterite-Perovskite Photovoltaic Device

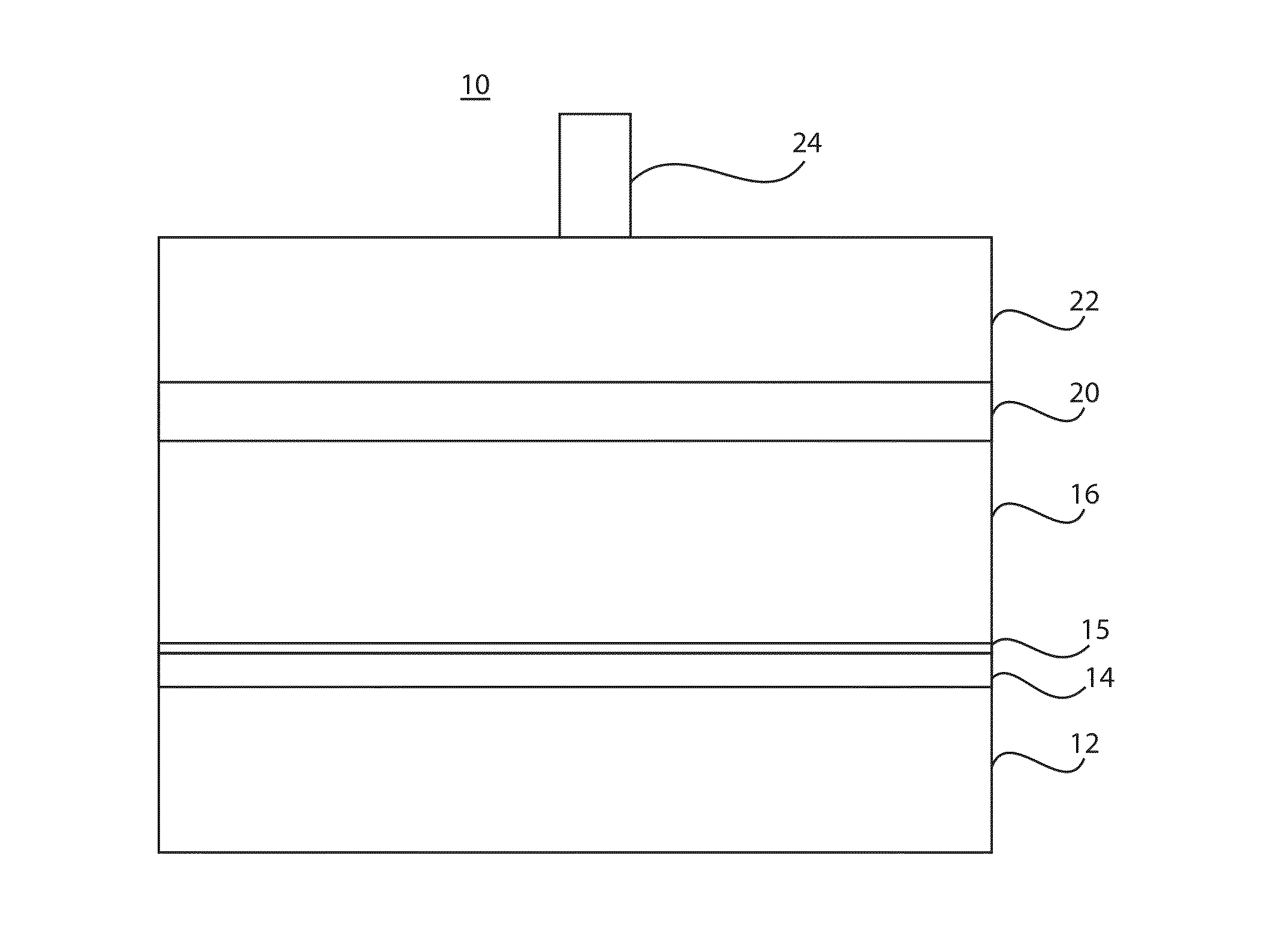

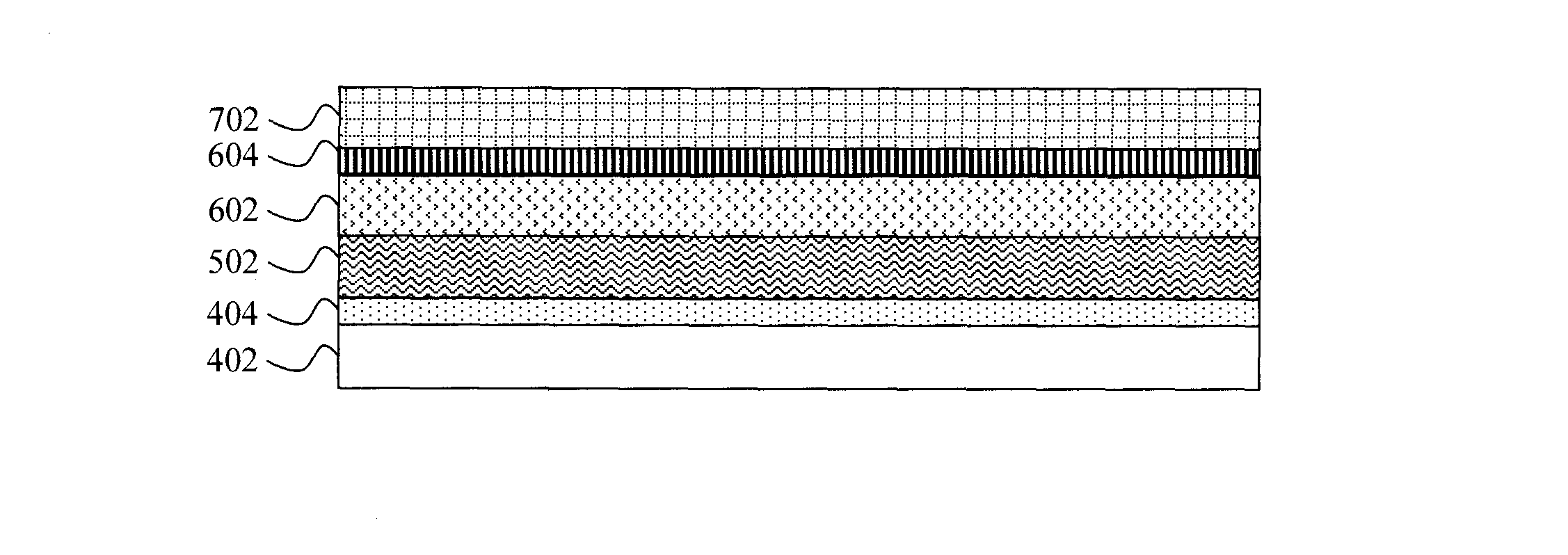

Tandem Kesterite-perovskite photovoltaic devices and techniques for formation thereof are provided. In one aspect, a tandem photovoltaic device is provided. The tandem photovoltaic device includes a bottom cell having a first absorber layer comprising copper, zinc, tin, and at least one of sulfur and selenium and a top cell connected in series with the bottom cell, the top cell having a second absorber layer comprising a perovskite material. A method of forming a tandem photovoltaic device is also provided.

Owner:IBM CORP

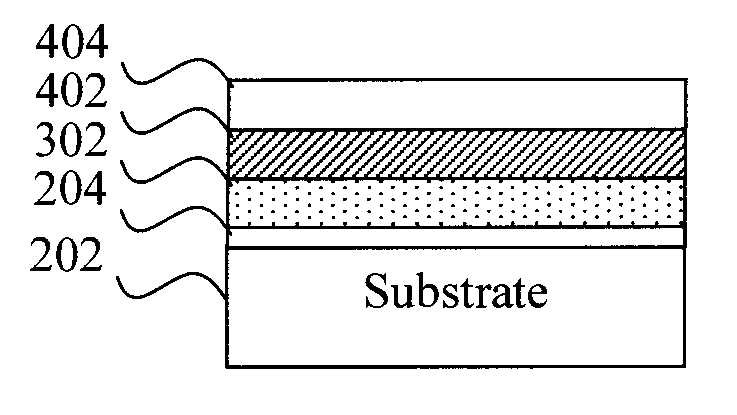

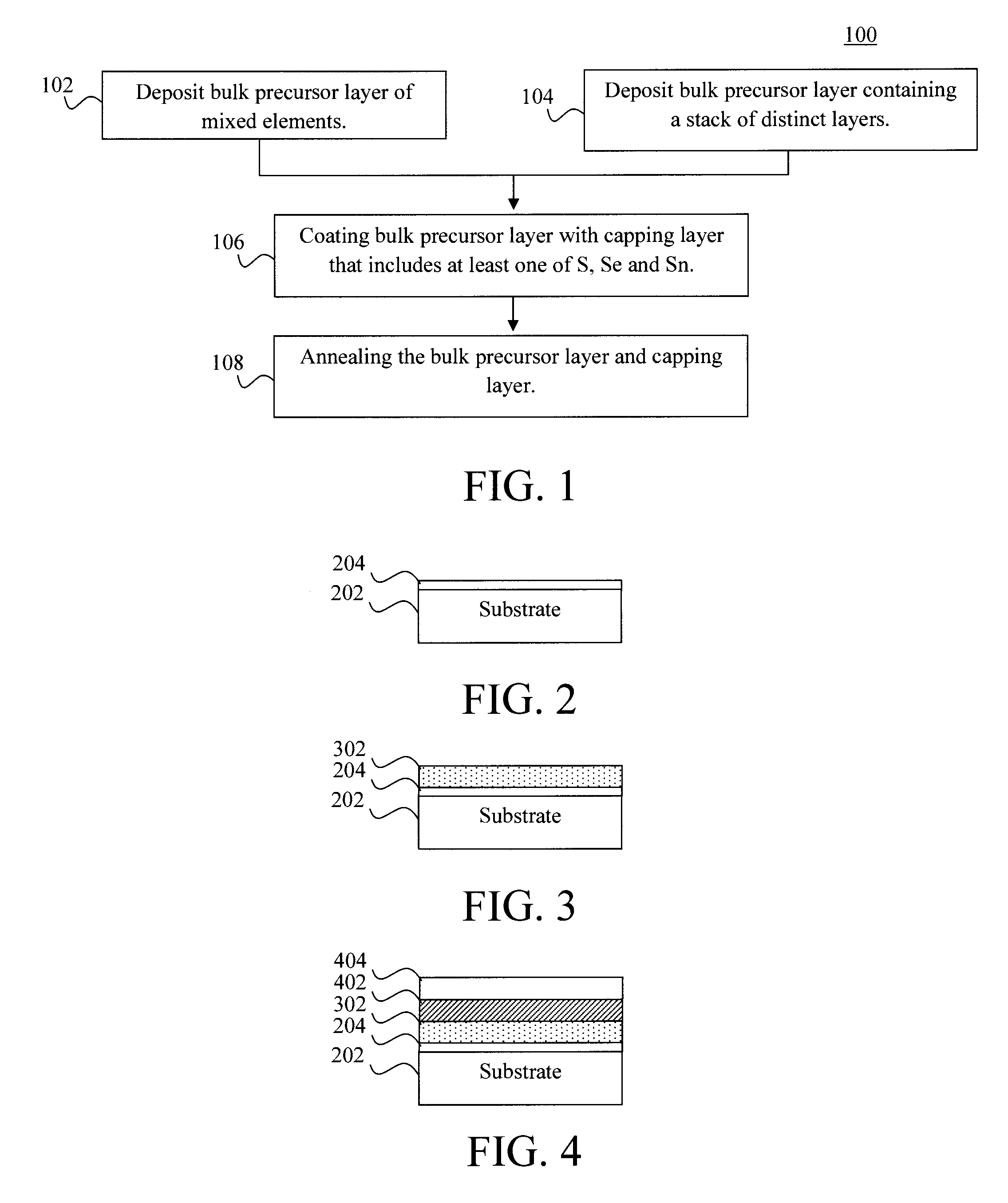

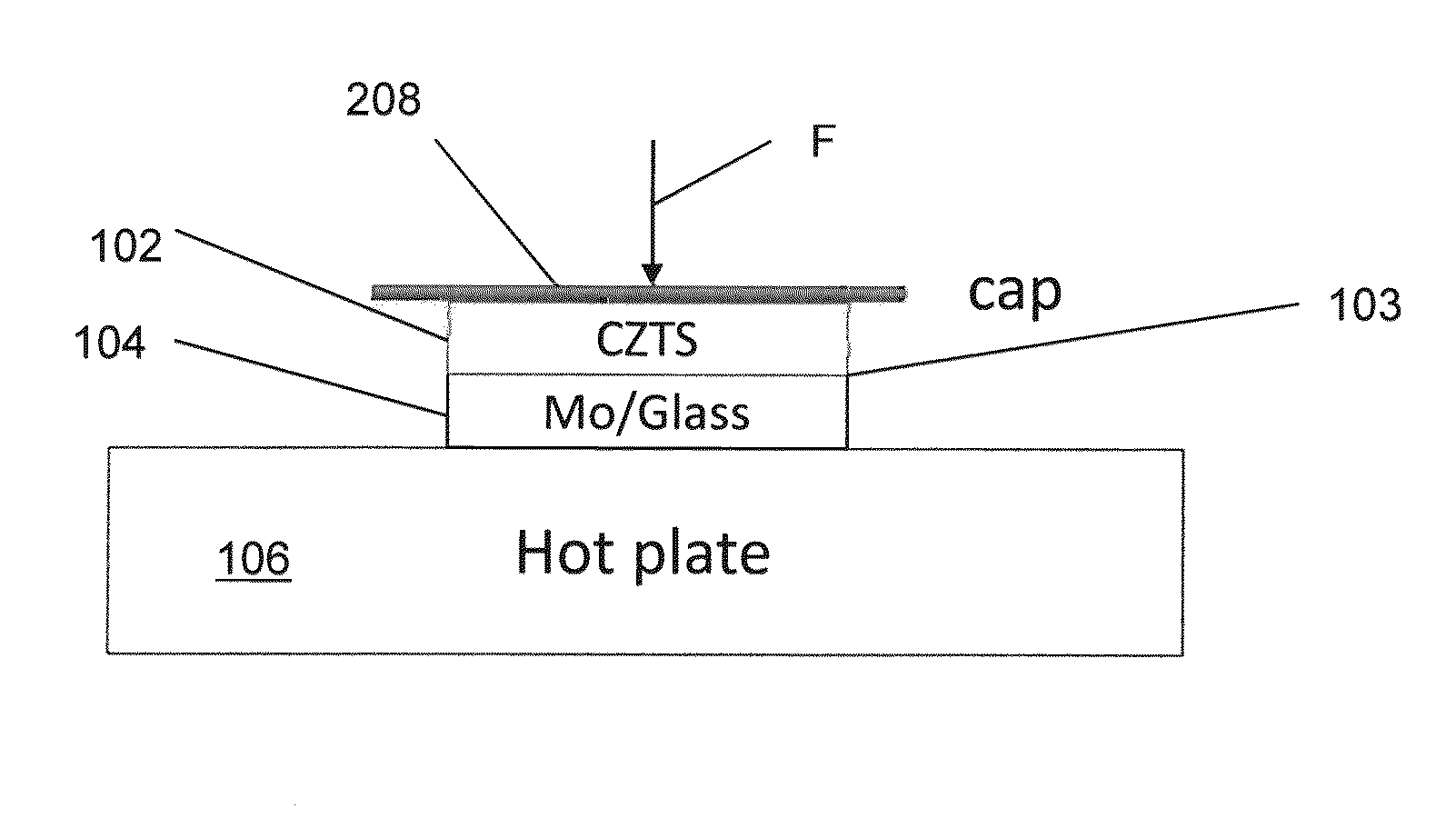

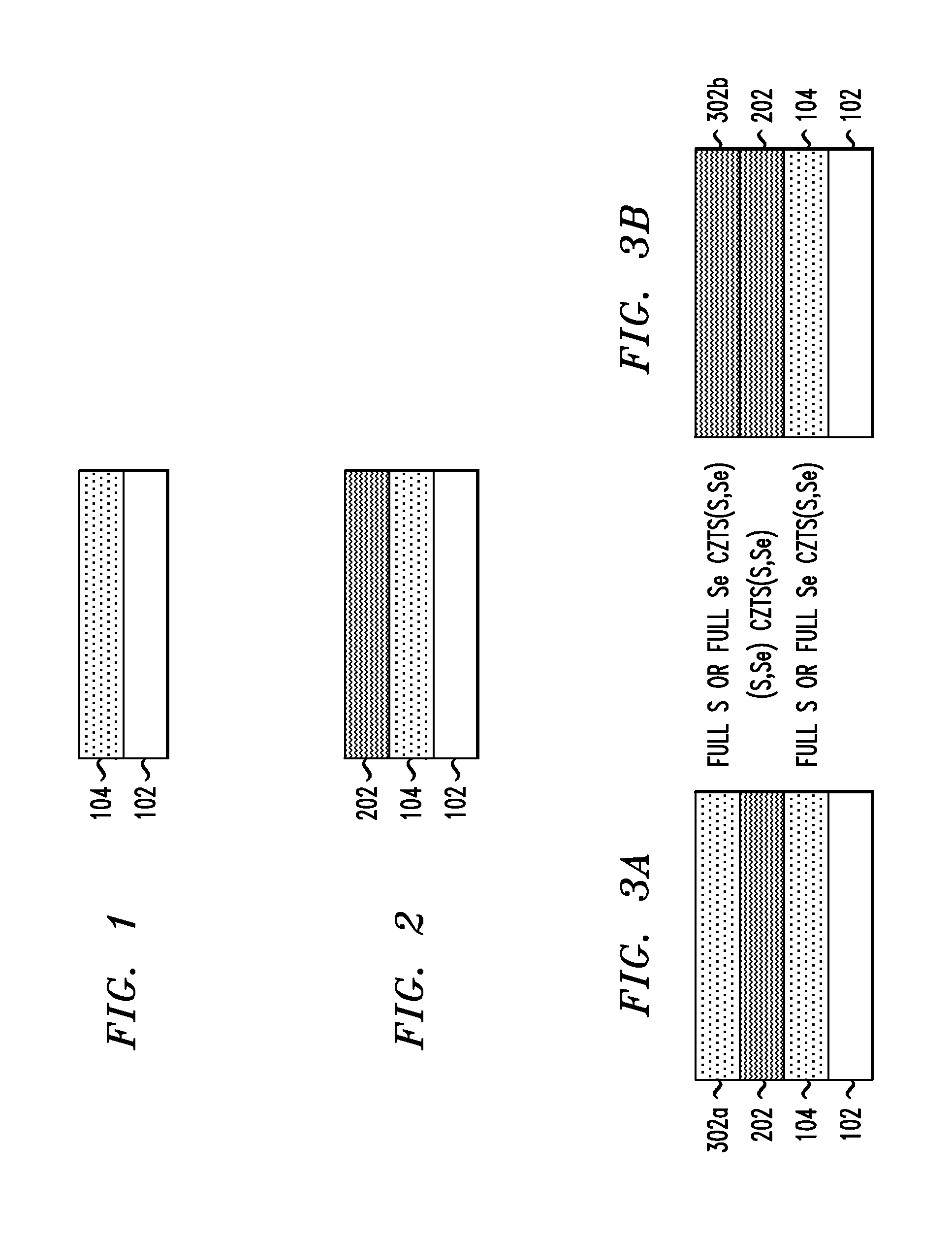

Capping Layers for Improved Crystallization

ActiveUS20130037090A1Improved photovoltaicVacuum evaporation coatingPretreated surfacesOptoelectronicsZinc

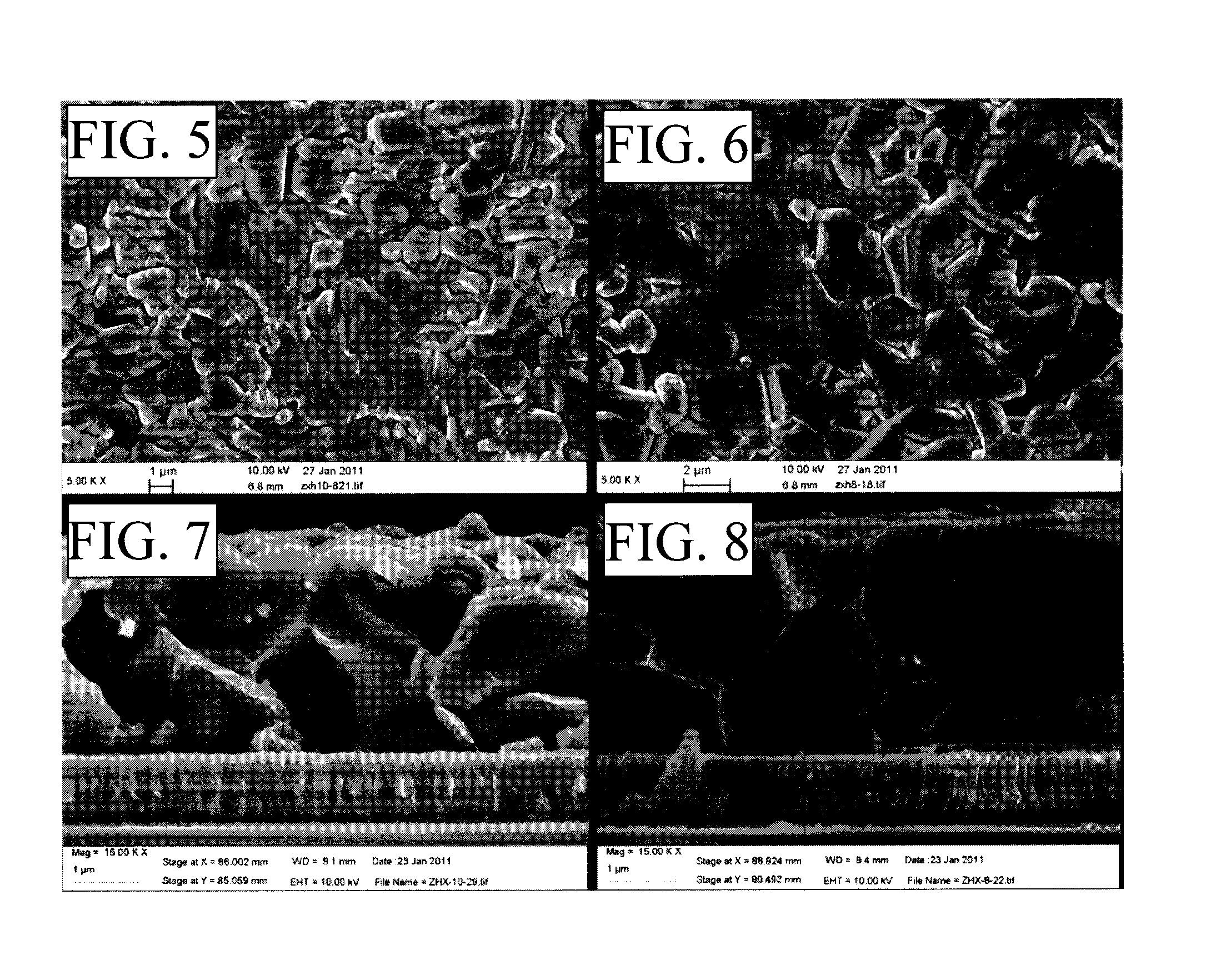

Techniques for fabrication of kesterite Cu—Zn—Sn—(Se,S) films and improved photovoltaic devices based on these films are provided. In one aspect, a method of fabricating a kesterite film having a formula Cu2−xZn1+ySn(S1−zSez)4+q, wherein 0≦x≦1; 0≦y≦1; 0≦z≦1; and −1≦q≦1 is provided. The method includes the following steps. A substrate is provided. A bulk precursor layer is formed on the substrate, the bulk precursor layer comprising Cu, Zn, Sn and at least one of S and Se. A capping layer is formed on the bulk precursor layer, the capping layer comprising at least one of Sn, S and Se. The bulk precursor layer and the capping layer are annealed under conditions sufficient to produce the kesterite film having values of x, y, z and q for any given part of the film that deviate from average values of x, y, z and q throughout the film by less than 20 percent.

Owner:IBM CORP

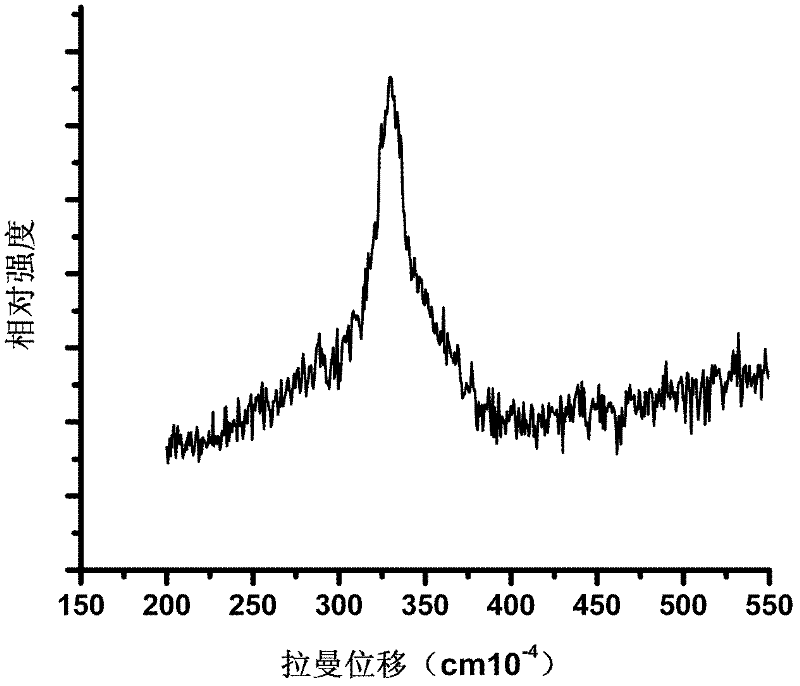

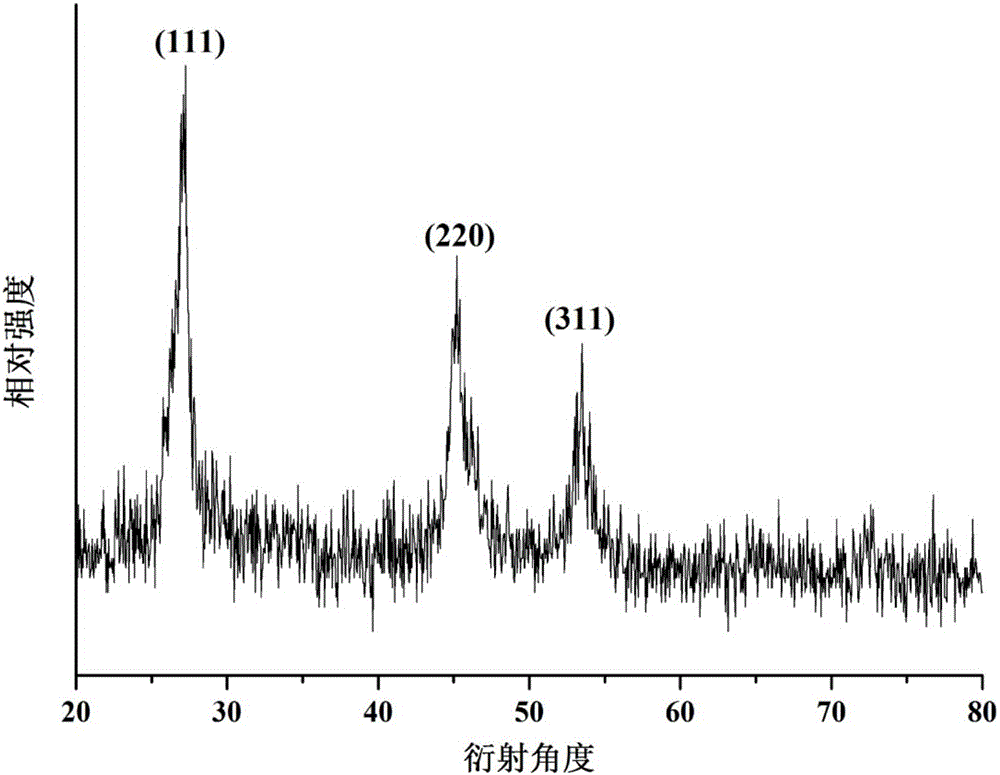

Kesterite structure Cu2ZnSnS4 powder material and liquid phase preparation method thereof

InactiveCN102500293AQuality improvementLow costTin compoundsFinal product manufactureBrickNitrogen gas

The invention discloses a kesterite structure Cu2ZnSnS4 powder material for a solar photovoltaic cell, and a liquid phase preparation method thereof; the liquid phase preparation method comprises the steps that: the material is weighed in the principle of CuCl2.2H2O:ZnCl2:SnCl4.5H2O:sulphur powder=2 (1 to 1. 5): (1 to 1. 5): (4 to 5) (molar ratio) and put into a round-bottom three-neck flask to be mixed, then organic solvent triethylene tetramine solution is added in, the mixture stays still for 3min to 5min, and uniform brick red solution is obtained; after nitrogen is fed in as protective gas, and the brick red solution is put into constant temperature oil bath to be heated to 120DEG C to 240DEG C, maintained for 0.5h to 12h, and then naturally cooled to room temperature; anhydrous ethanol and distilled water are used for sequentially washing a product, then the product is filtered and dried, and black powder is obtained. The liquid phase preparation method of the kesterite structure Cu2ZnSnS4 powder material is green, has no pollution, short reaction time and low required temperature, is convenient to operate, has low cost, and is applicable to the large-scale production of Cu2ZnSnS4 powder (for a photovoltaic cell absorption layer).

Owner:CENT SOUTH UNIV

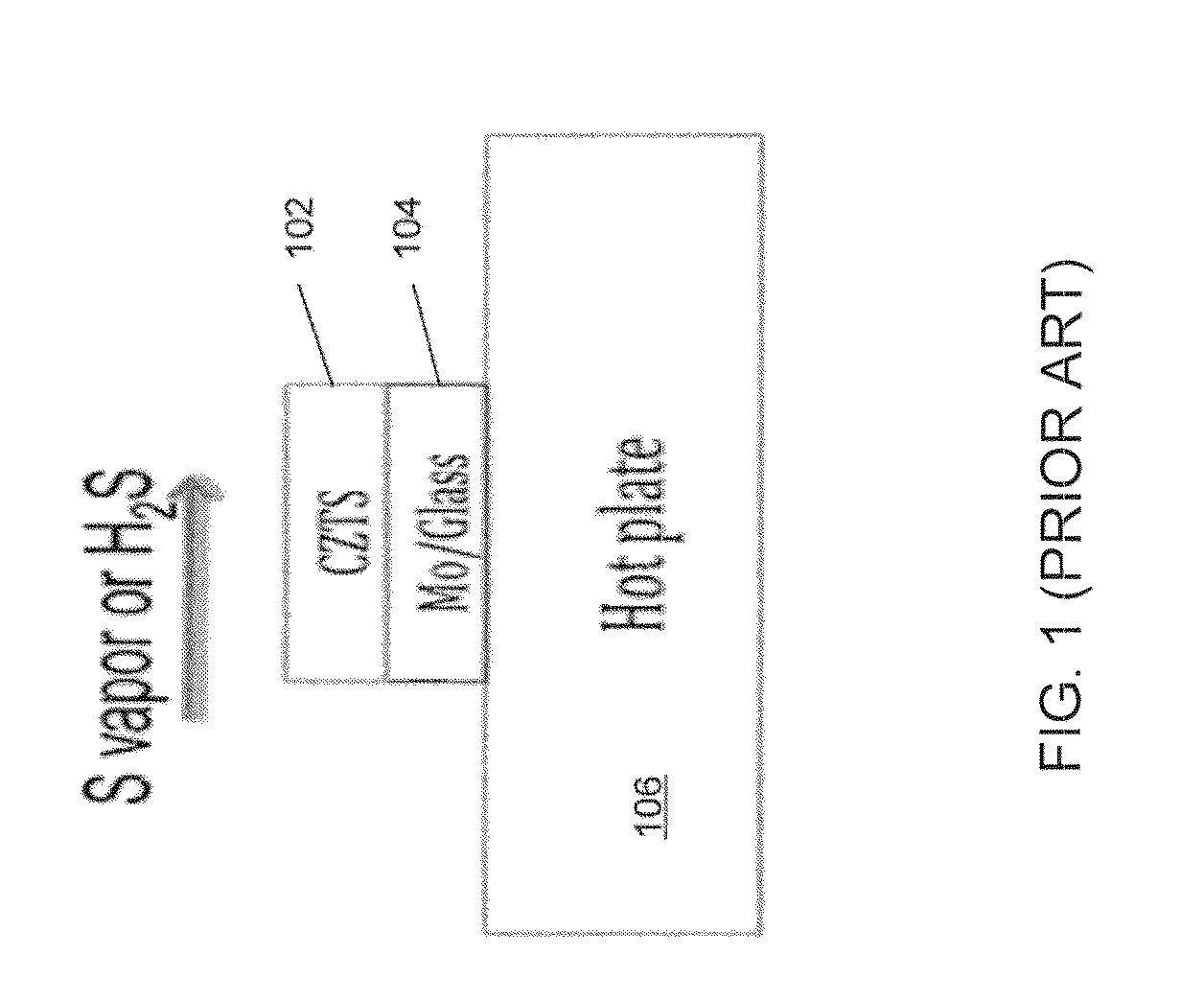

Annealing thin films

ActiveUS20120070936A1Final product manufactureSemiconductor/solid-state device manufacturingSufficient timeMetallurgy

In an annealing process, a Kesterite film is provided on a substrate. The Kesterite film and the substrate are generally planar, have an interface, and have a substrate exterior side and a Kesterite exterior side. An additional step includes locating the cap adjacent the Kesterite exterior side. A further step includes applying sufficient heat to the Kesterite film and the substrate for a sufficient time to anneal the Kesterite film. The annealing is carried out with the cap adjacent the Kesterite exterior side. In another aspect, the film is not limited to Kesterite, and the cap is employed without any precursor layer thereon. Solar cell manufacturing techniques employing the annealing techniques are also disclosed.

Owner:GLOBALFOUNDRIES US INC

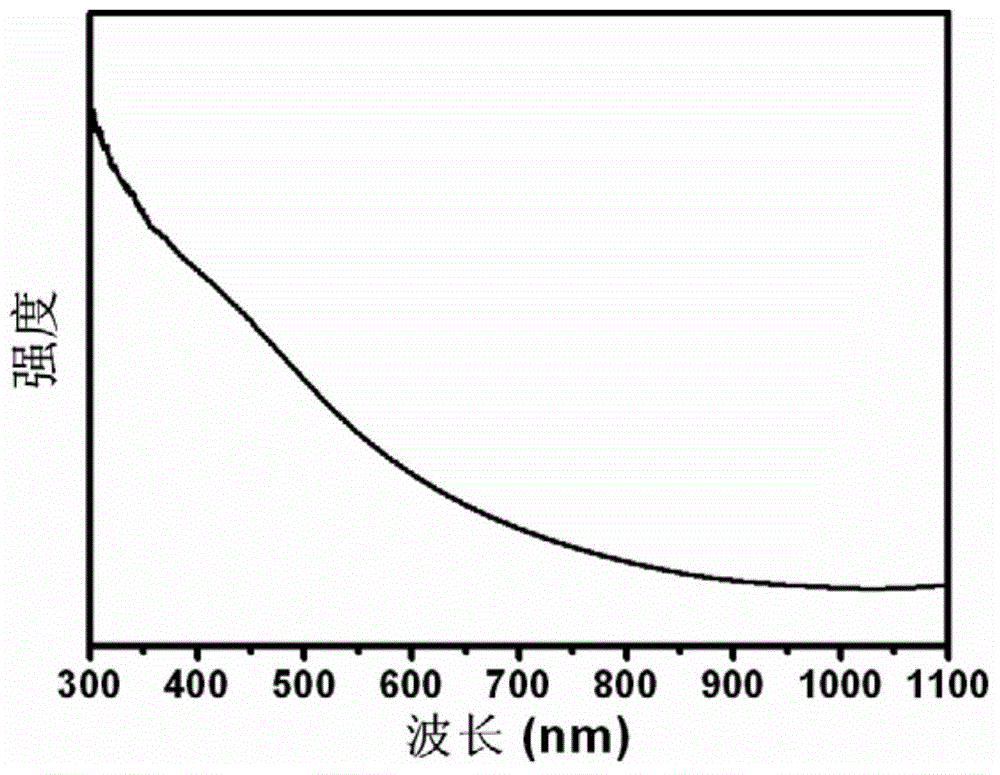

Single Target Sputtering of Copper Zinc Tin Sulfide Selenide, CZT(S, Se)

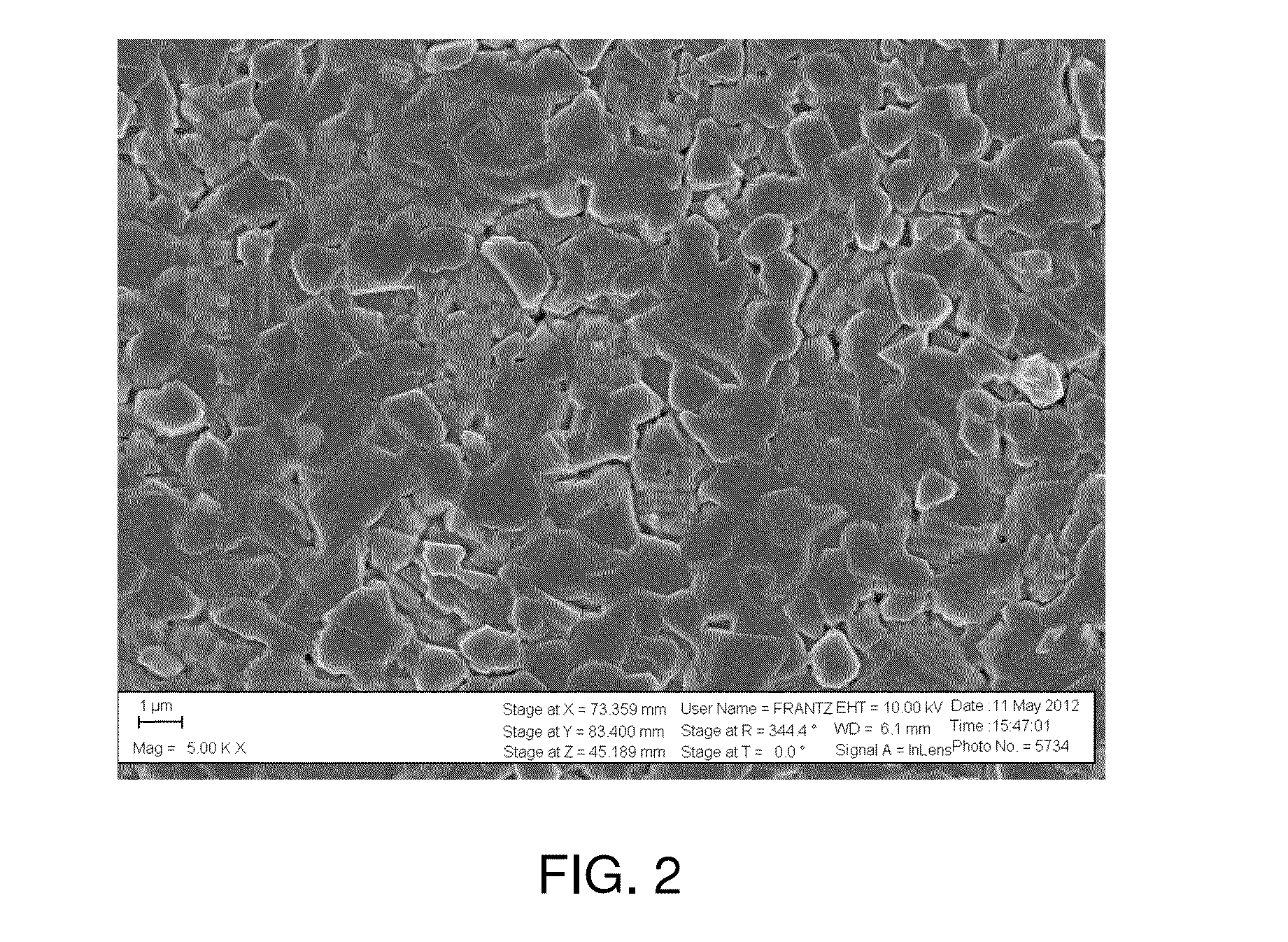

A method of forming a CZT(S,Se) thin film from a quaternary target involves sputtering a quaternary target onto a substrate, wherein the quaternary target comprises (a) copper, (b) zinc, (c) tin, and (d) selenium and / or sulfur, wherein each component (a) through (d) is present in the quaternary target within ±50% of a 2:1:1:4 molar ratio, respectively, thereby forming a CZT(S,Se) thin film on the substrate, wherein the CZT(S,Se) thin film has a kesterite crystalline phase and a band gap of about 1.0 to 1.5 eV. In an embodiment, a ternary target is employed.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

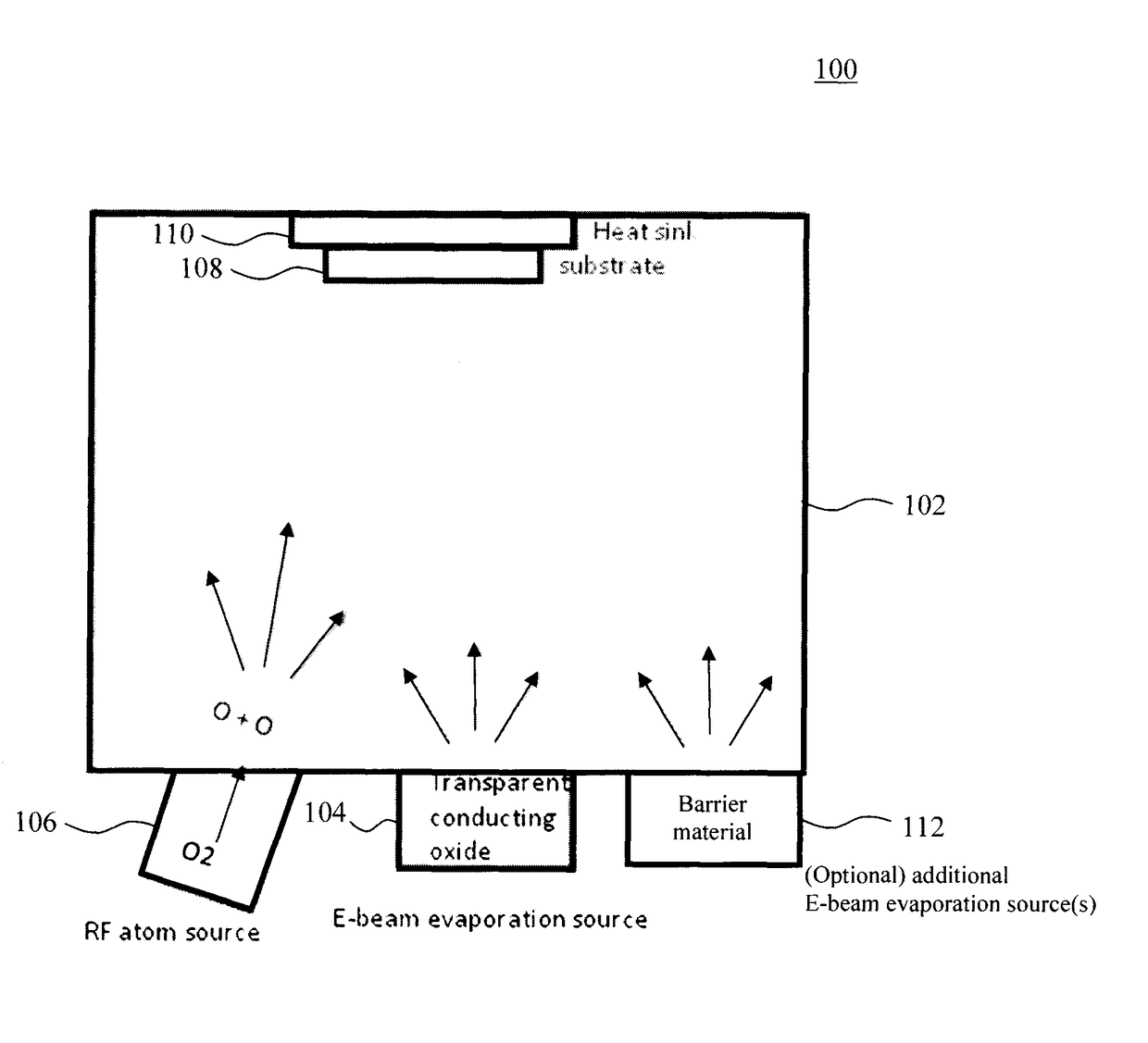

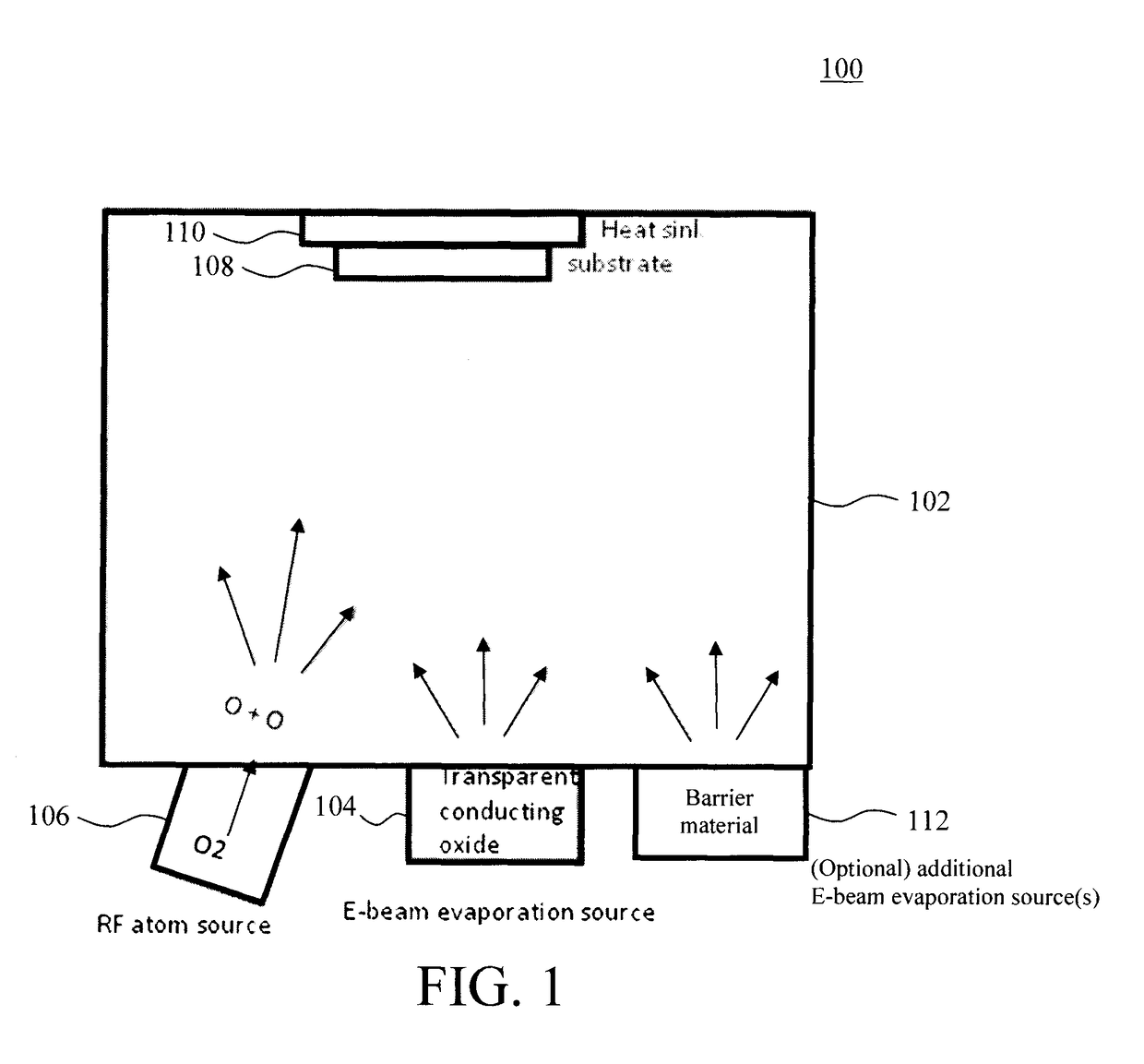

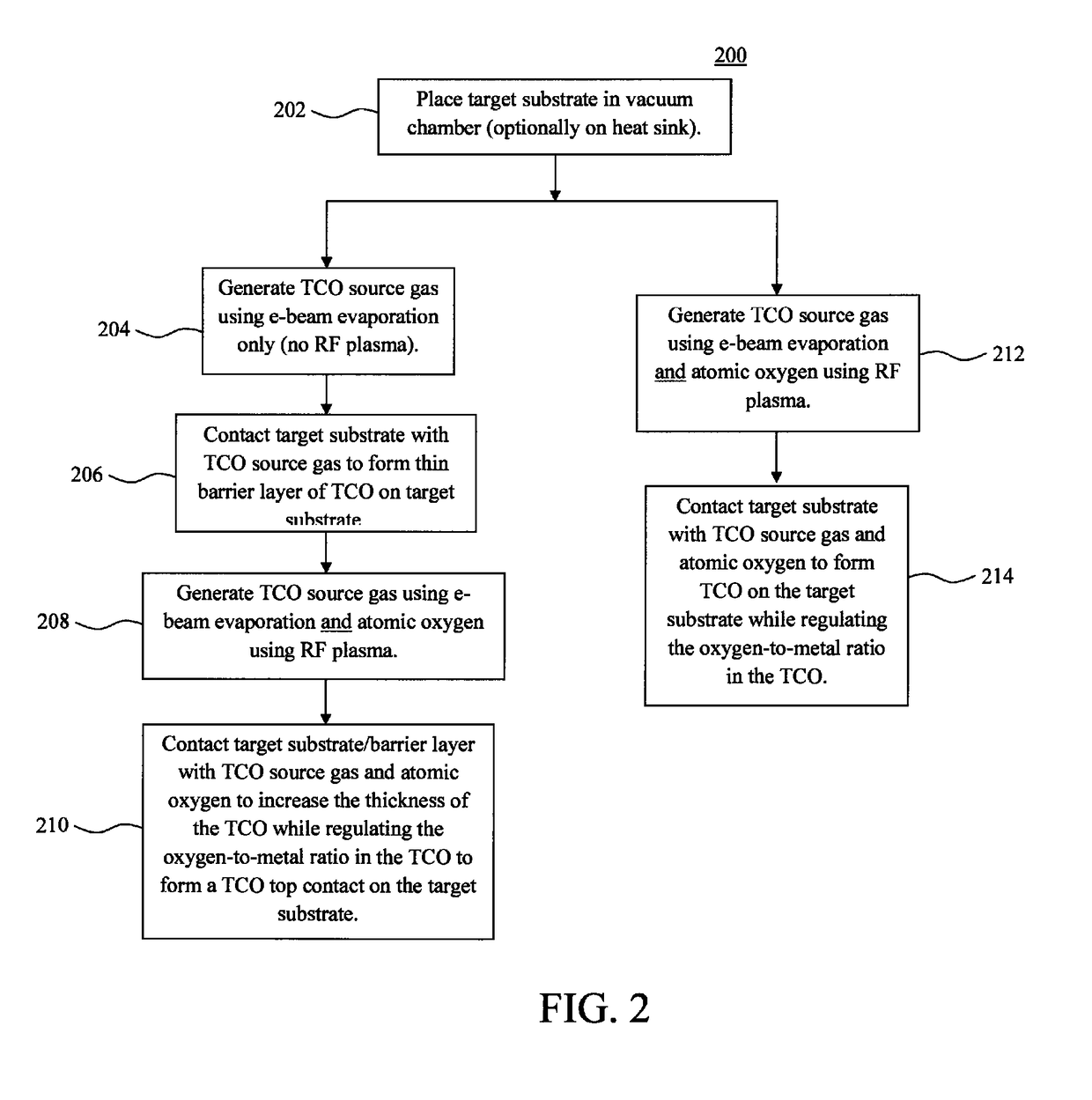

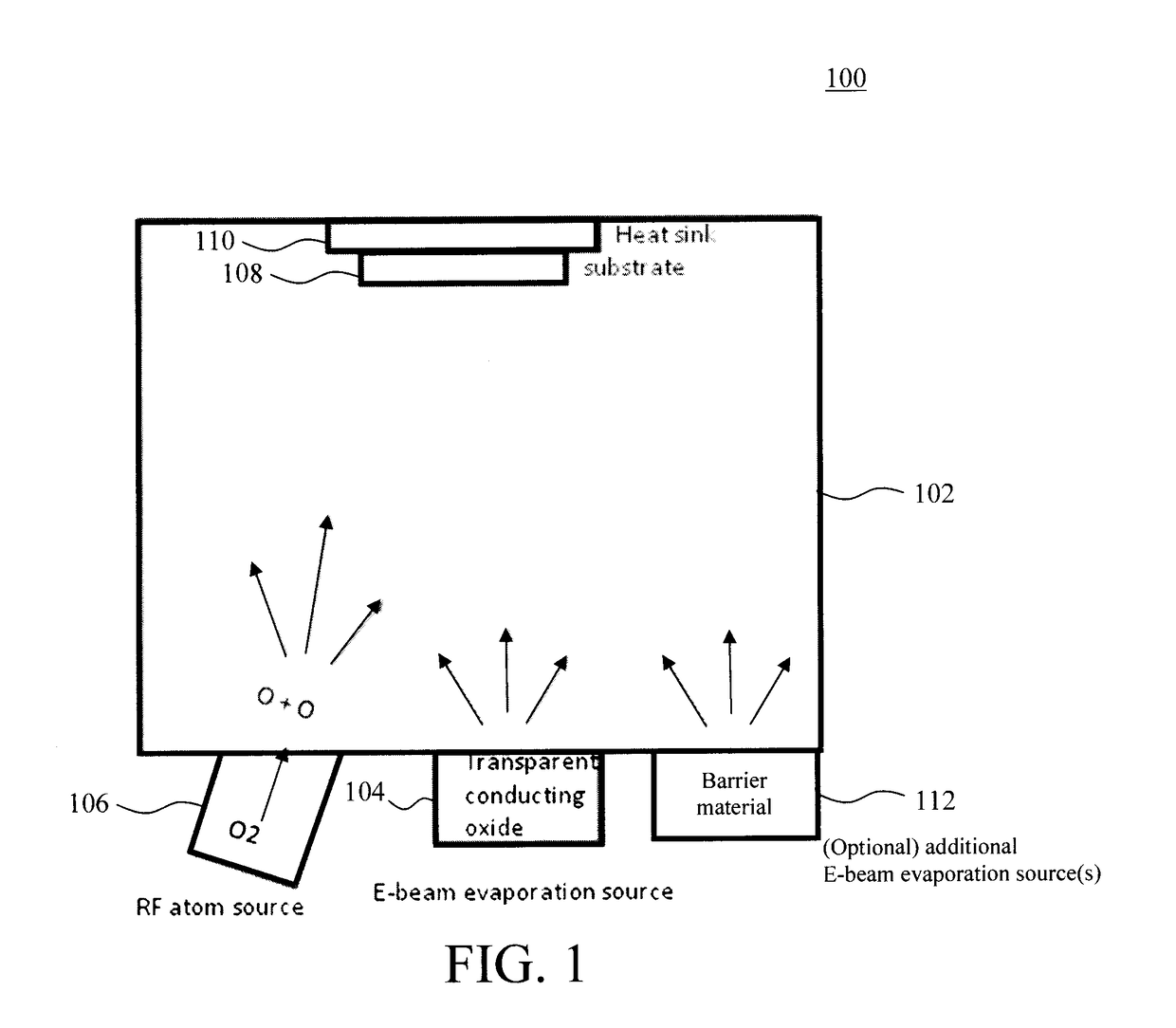

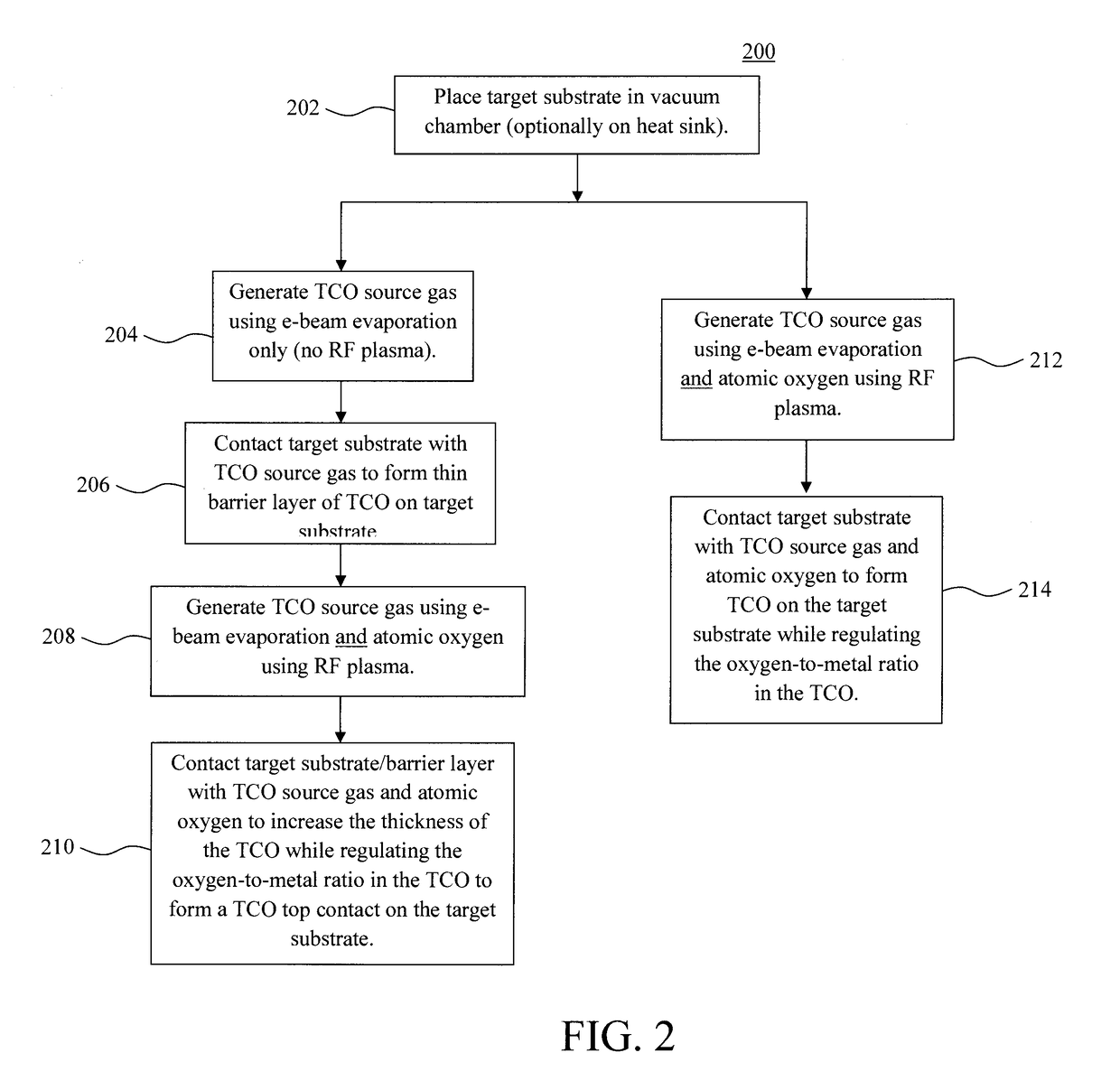

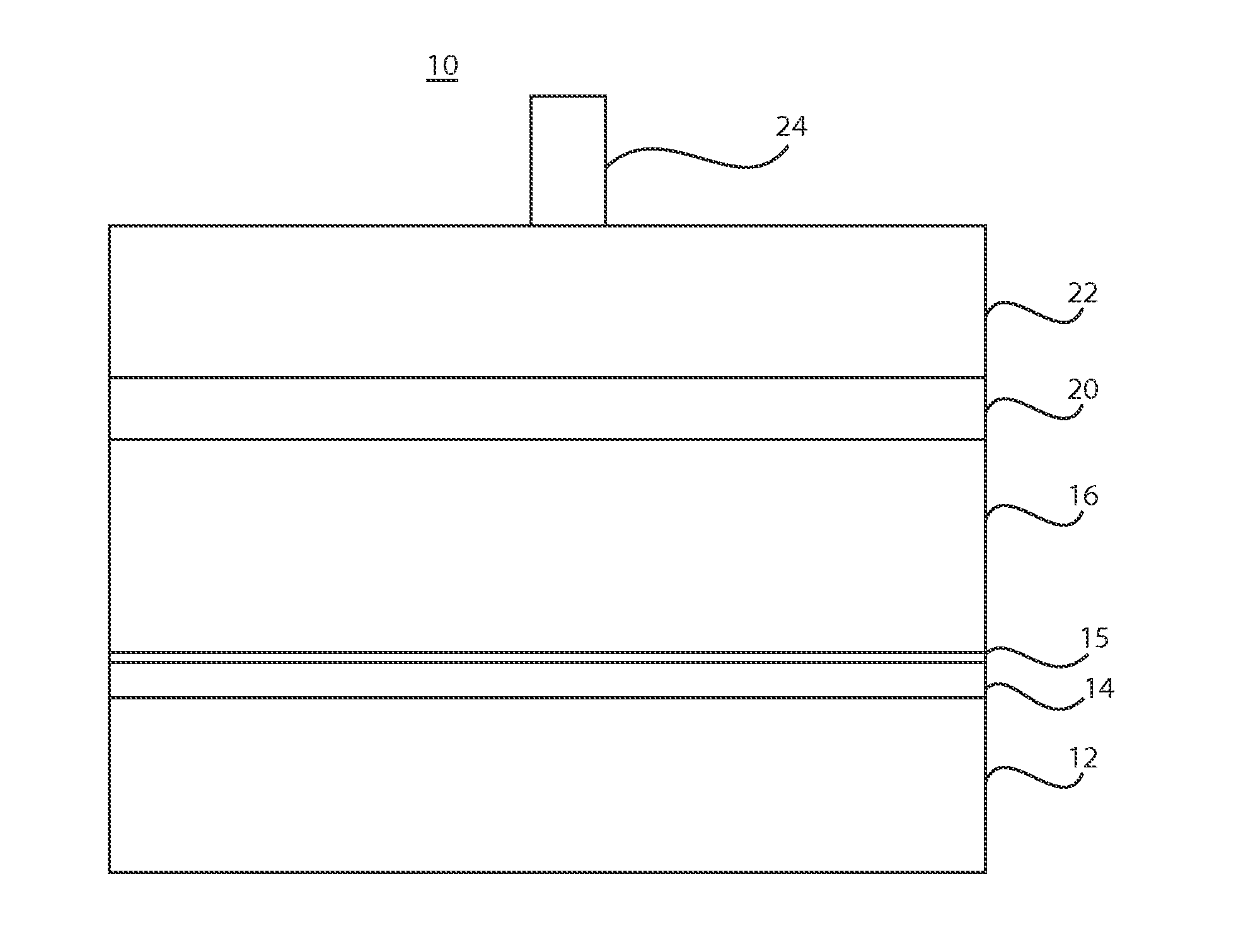

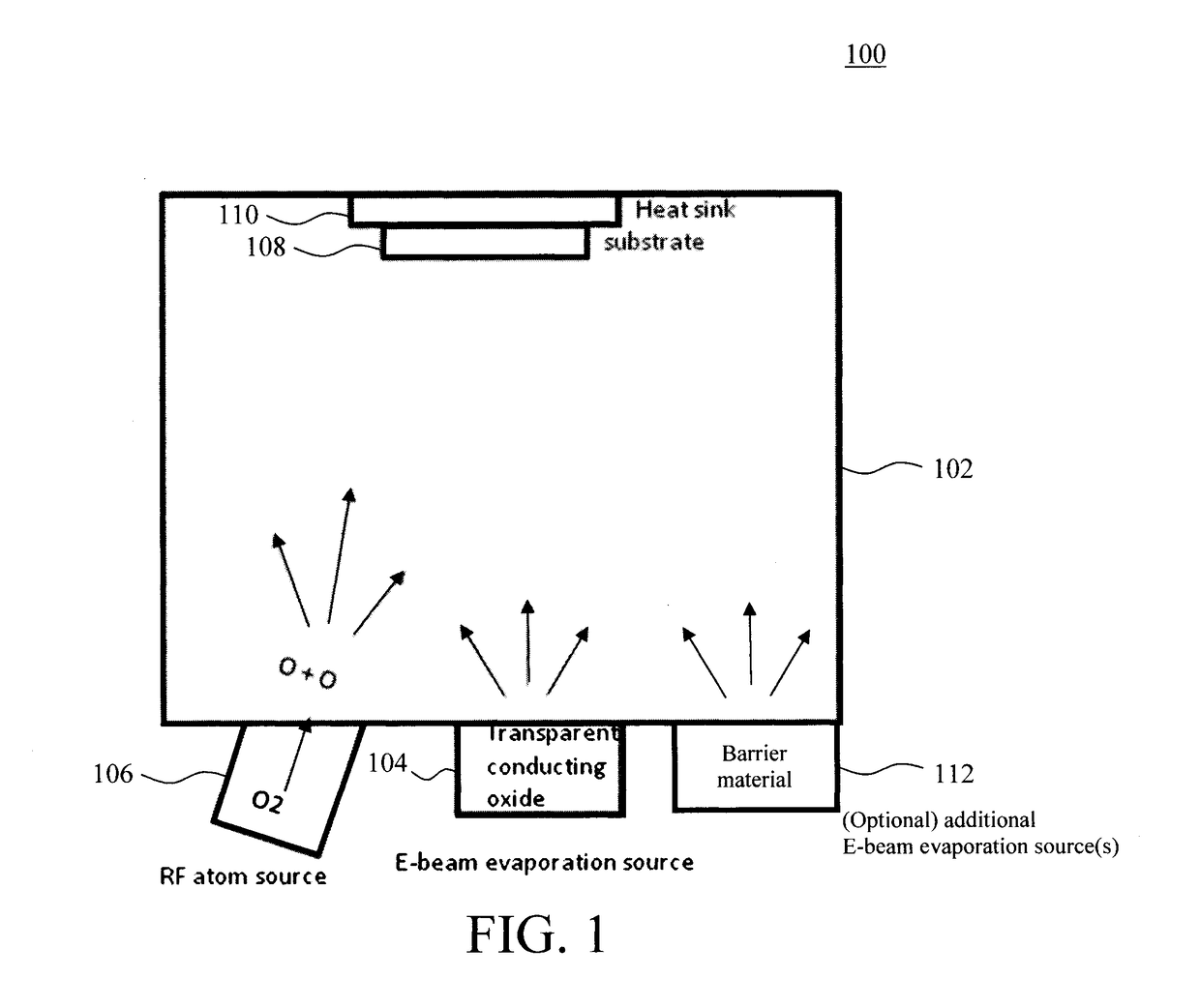

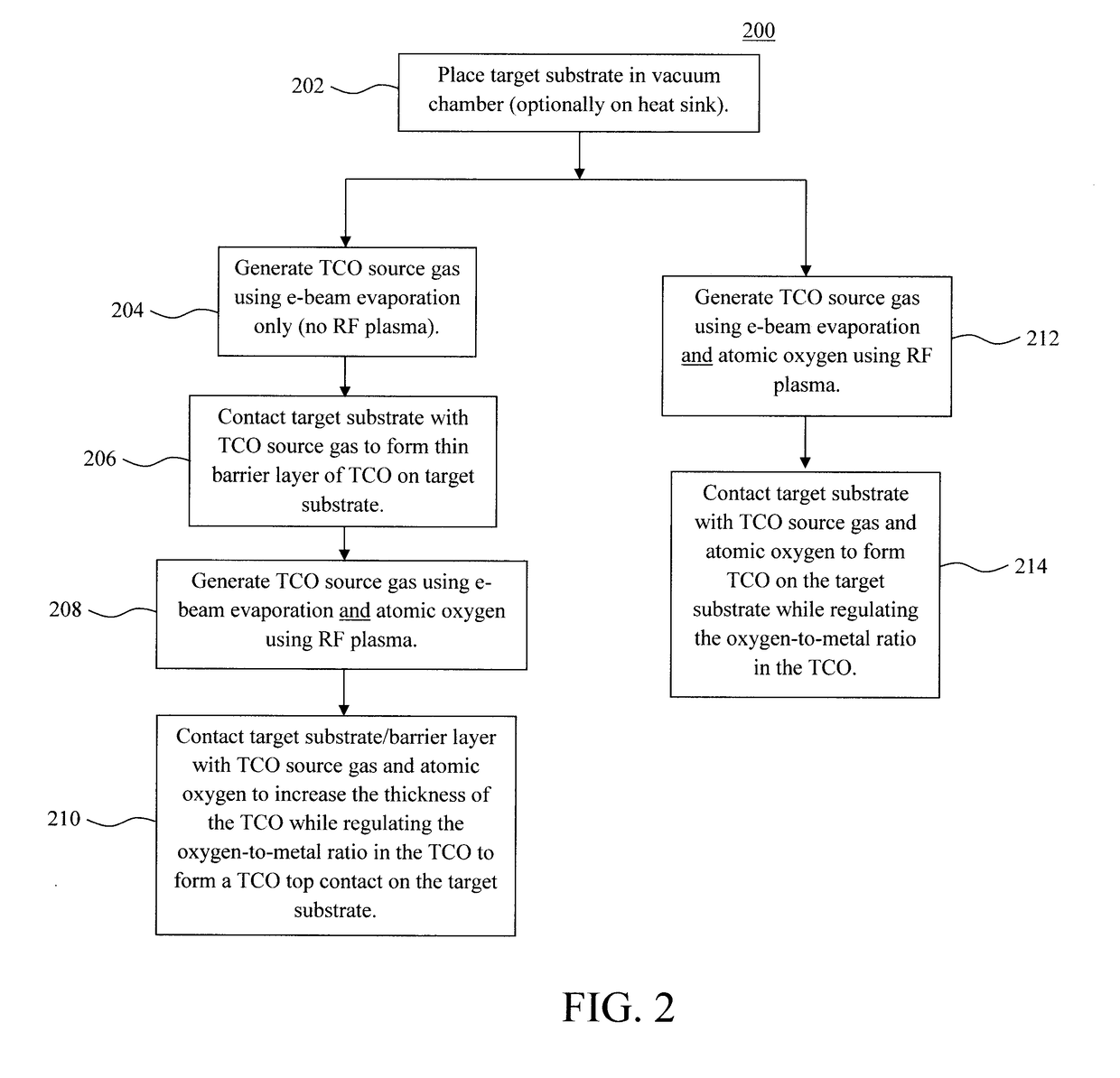

Transparent conducting oxide as top-electrode in perovskite solar cell by non-sputtering process

ActiveUS9911935B2Solid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEvaporation

Techniques for forming a transparent conducting oxide (TCO) top contact using a low temperature process are provided. In one aspect of the invention, a method of forming a TCO on a substrate is provided. The method includes the steps of: generating a source gas of the TCO using e-beam evaporation; generating atomic oxygen using RF plasma; and contacting the substrate with the TCO source gas and the atomic oxygen under conditions sufficient to form the TCO on the substrate. A photovoltaic device is also provided which includes a bottom cell; and a perovskite-based top cell on the kesterite-based bottom cell. The perovskite-based top cell includes a top electrode formed from a TCO.

Owner:INT BUSINESS MASCH CORP

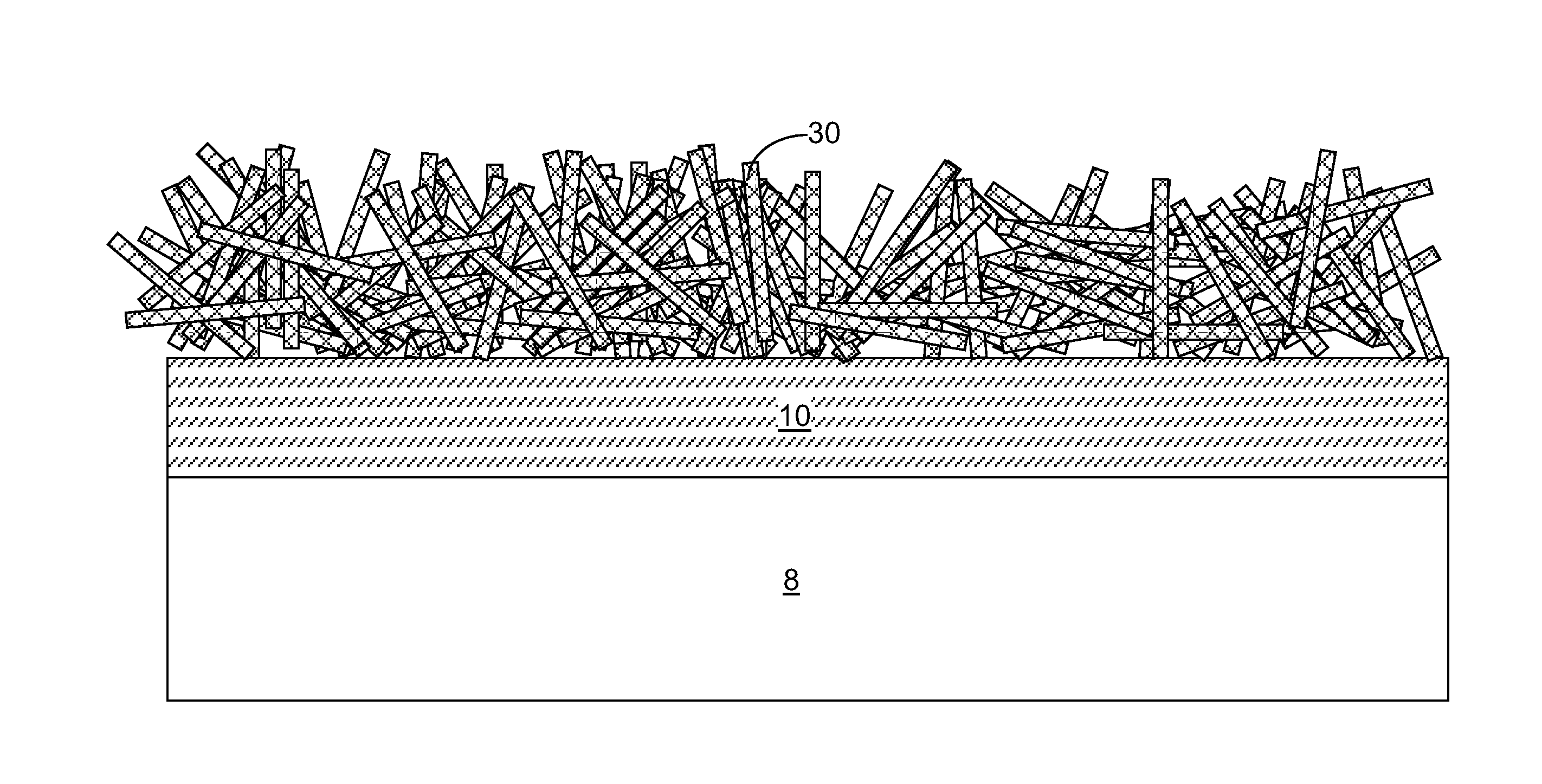

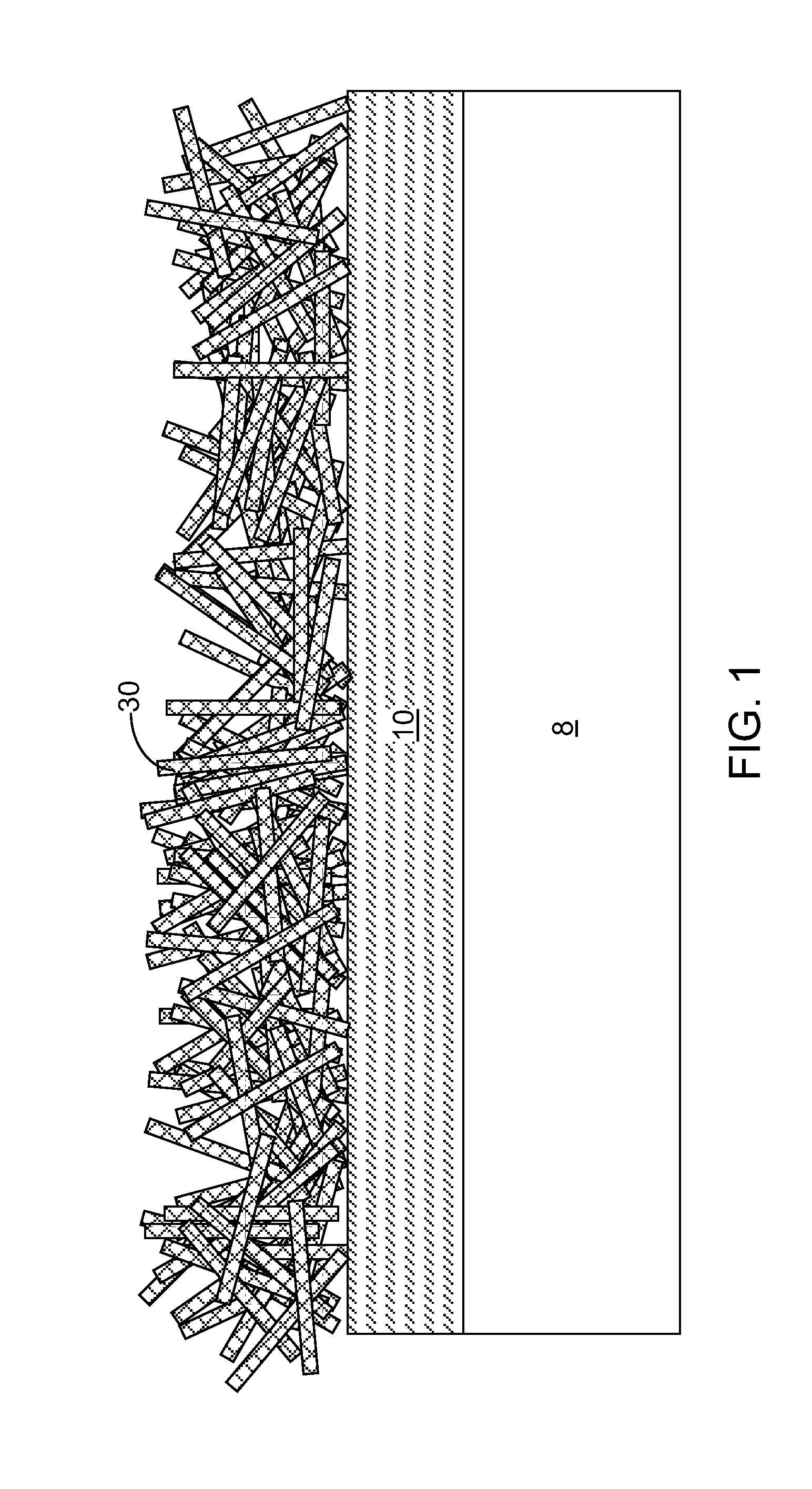

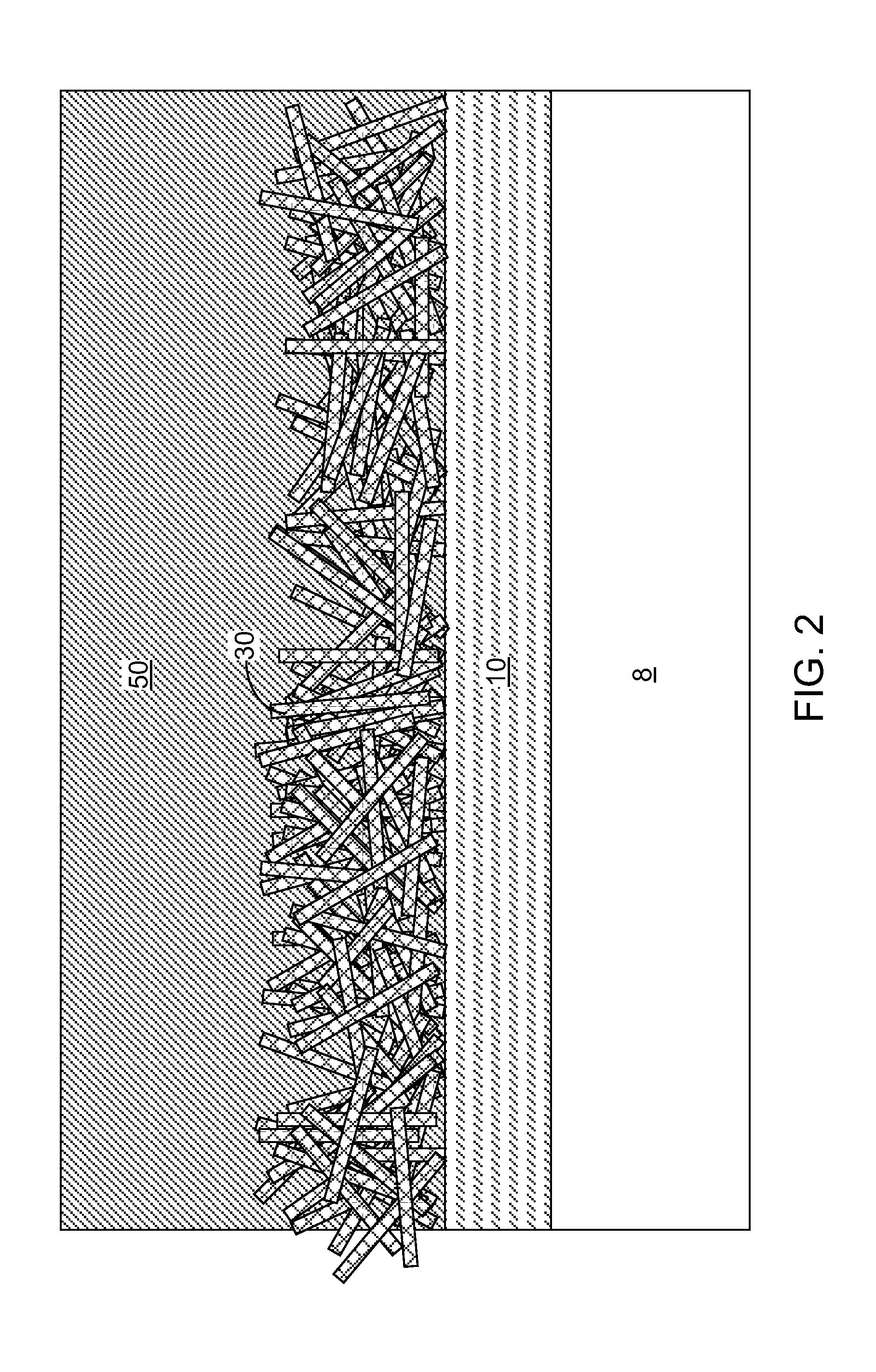

Ohmic contact of thin film solar cell

InactiveUS20140030843A1Reduce contact resistanceHigh solar efficiencyMaterial nanotechnologySemiconductor/solid-state device manufacturingSemiconductor materialsCarbon nanotube

A chalcogen-resistant material including at least one of a carbon nanotube layer and a high work function material layer is deposited on a transition metal layer on a substrate. A semiconductor chalcogenide / kesterite material layer is deposited over the chalcogen-resistant material. The carbon nanotubes, if present, can reduce contact resistance by providing direct electrically conductive paths from the transition metal layer through the chalcogen-resistant material and to the semiconductor chalcogenide material. The high work function material layer, if present, can reduce contact resistance by reducing chalcogenization of the transition metal in the transition metal layer. Reduction of the contact resistance can enhance efficiency of a solar cell including the chalcogenide semiconductor material.

Owner:IBM CORP

Method for manufacturing thin-film solar modules, and thin-film solar modules which are obtainable according to this method

InactiveUS20150068578A1Overcome disadvantagesReduce distancePV power plantsFinal product manufactureEngineeringSemiconductor

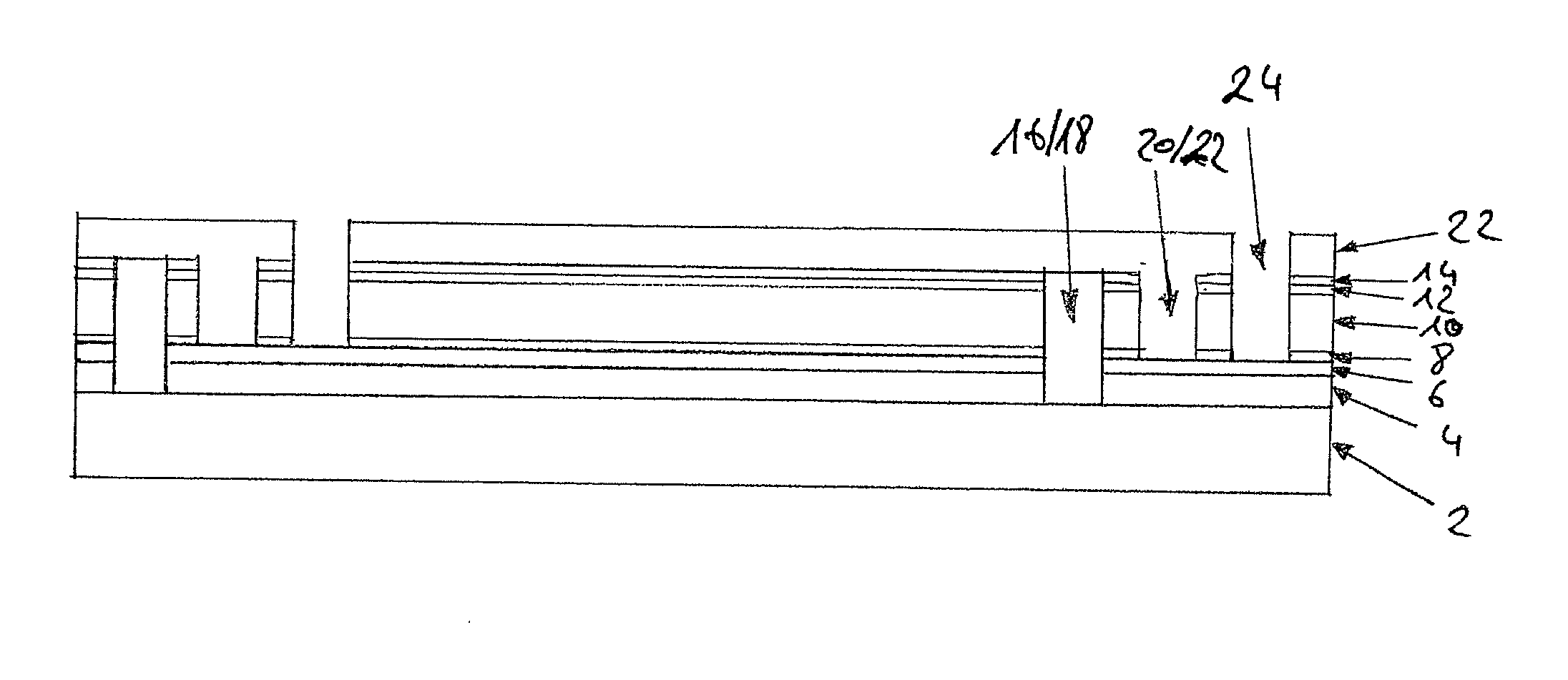

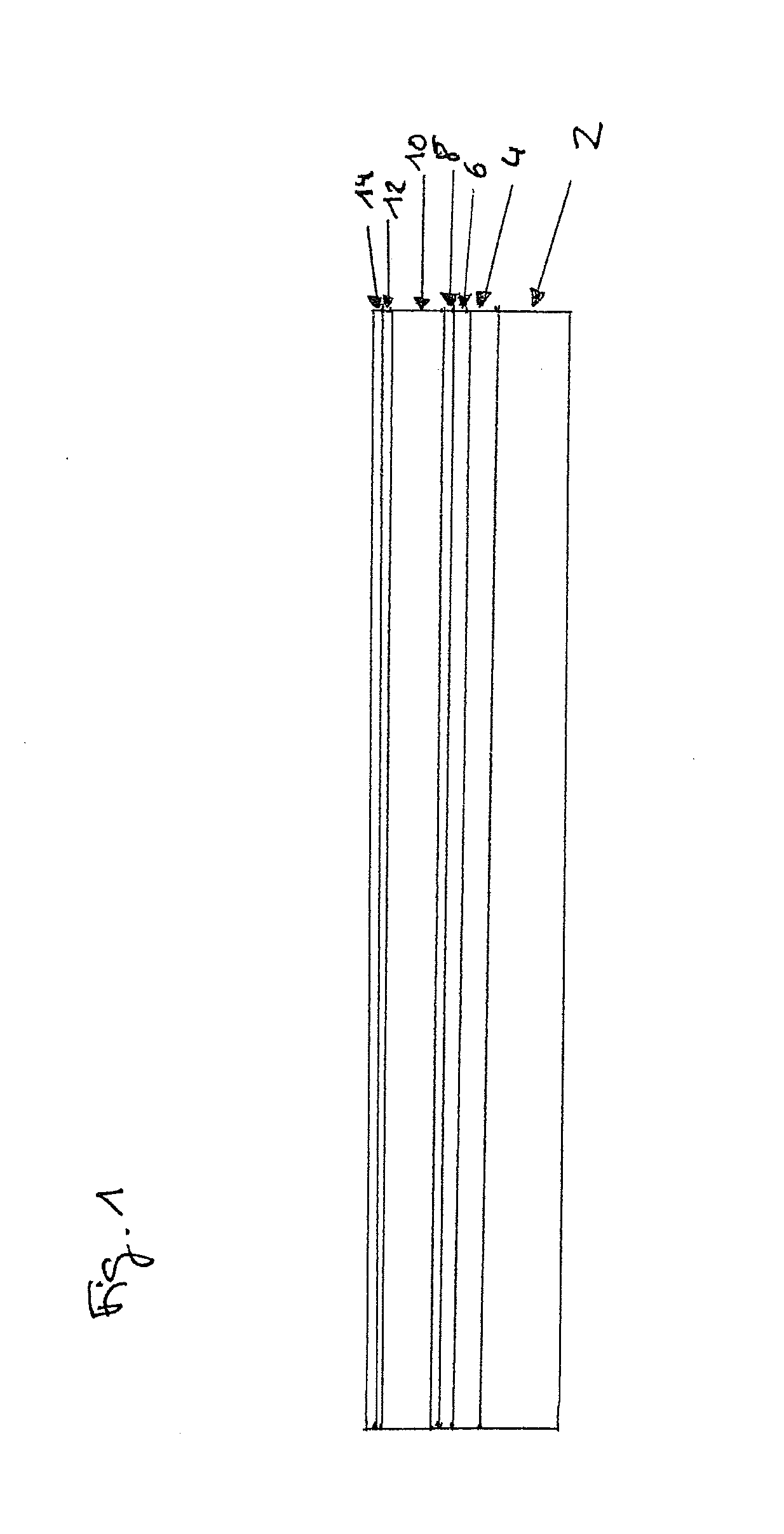

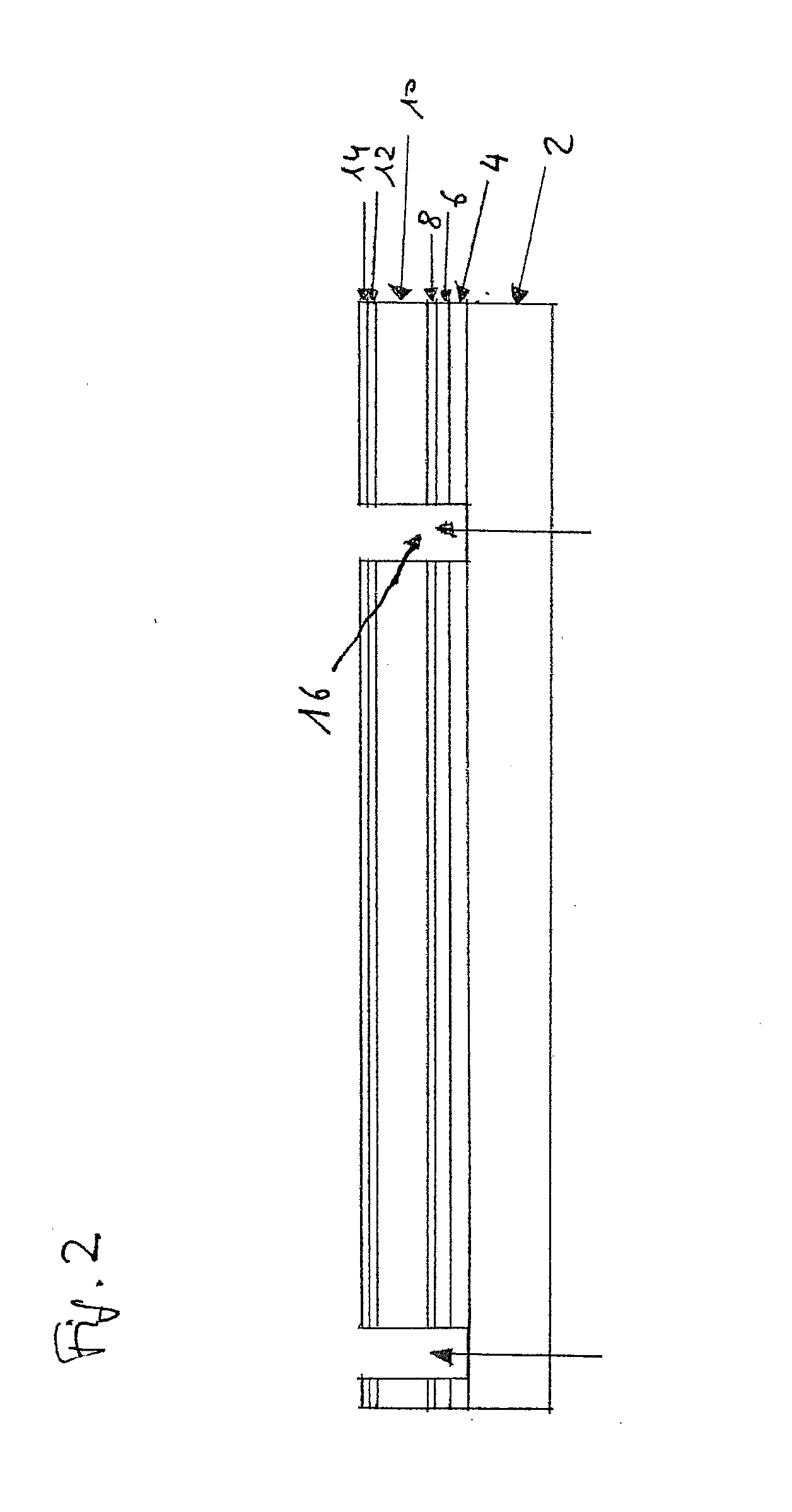

A method for manufacturing photovoltaic thin-film solar modules, including: applying a back electrode layer to a substrate, applying at least one conductive barrier layer, applying at least one contact layer, applying at least one kesterite or chalcopyrite semiconductor absorber layer, applying at least one buffer layer, removing the applied layers with laser treatment with formation of first separating trenches, filling the first separating trenches using at least one insulating material, removing layers extending from the barrier layer in the direction of the semiconductor absorber layer with formation of second separating trenches, or chemical phase transformation or thermal decomposition of layers extending from the barrier layer in the direction of the semiconductor absorber layer with the formation of first linear conductive areas, applying at least one transparent front electrode layer with filling and contacting of the second separating trenches or with contacting of the first linear conductive areas, so that adjacent solar cells are series connected, and removing the layers extending from the barrier layer in the direction of the front electrode layer with formation of third separating trenches. Described are such modules obtained by the method.

Owner:ROBERT BOSCH GMBH

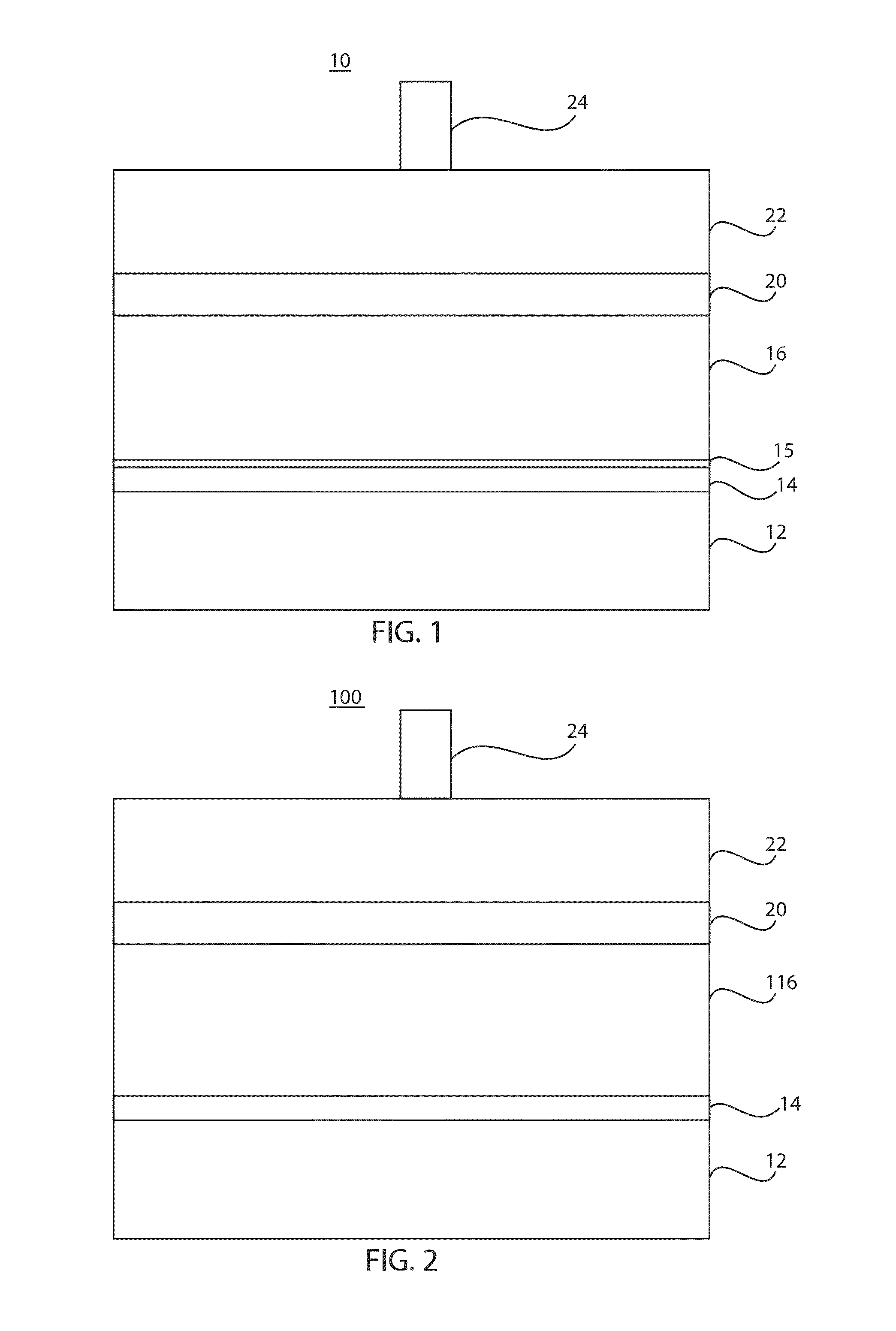

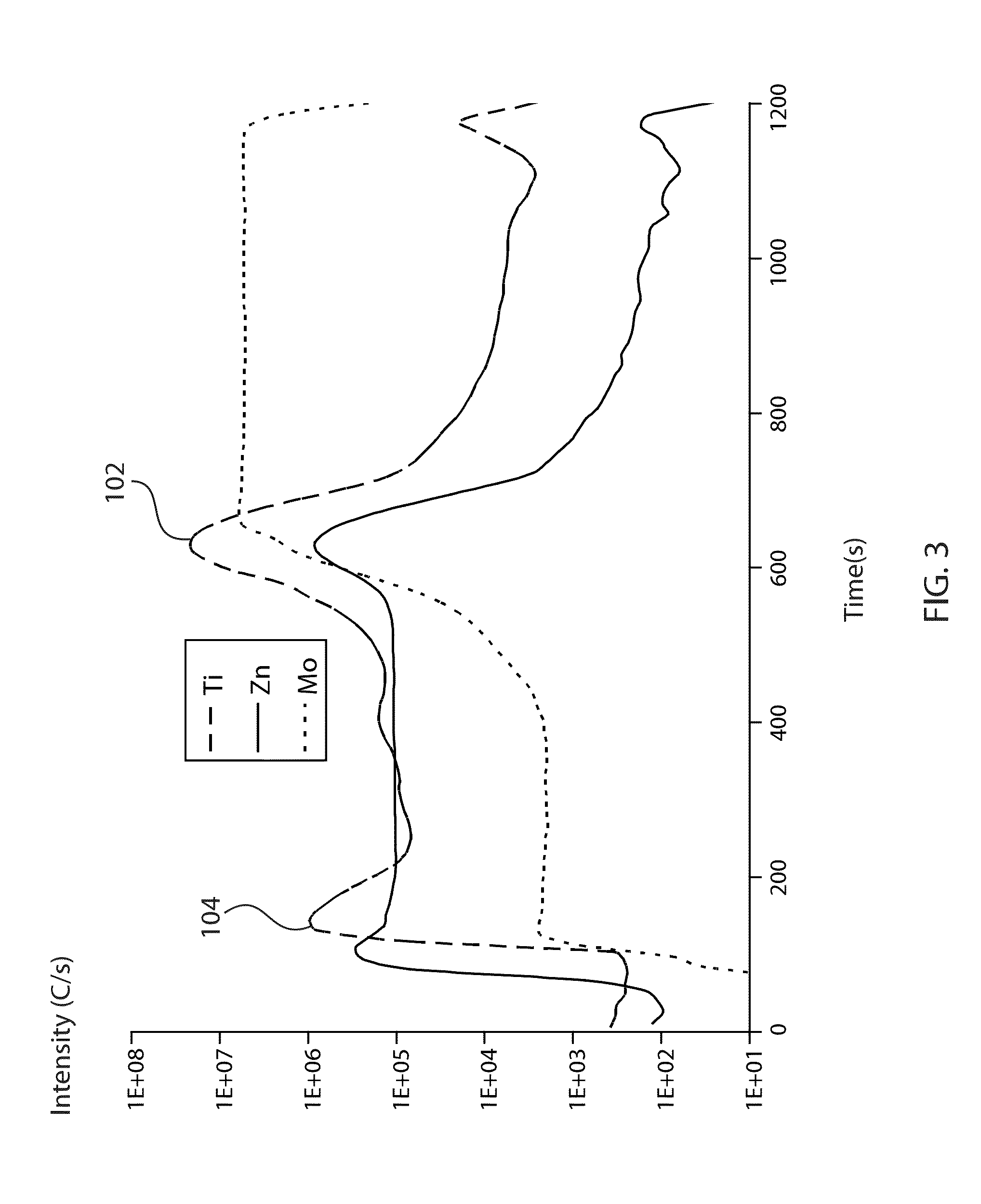

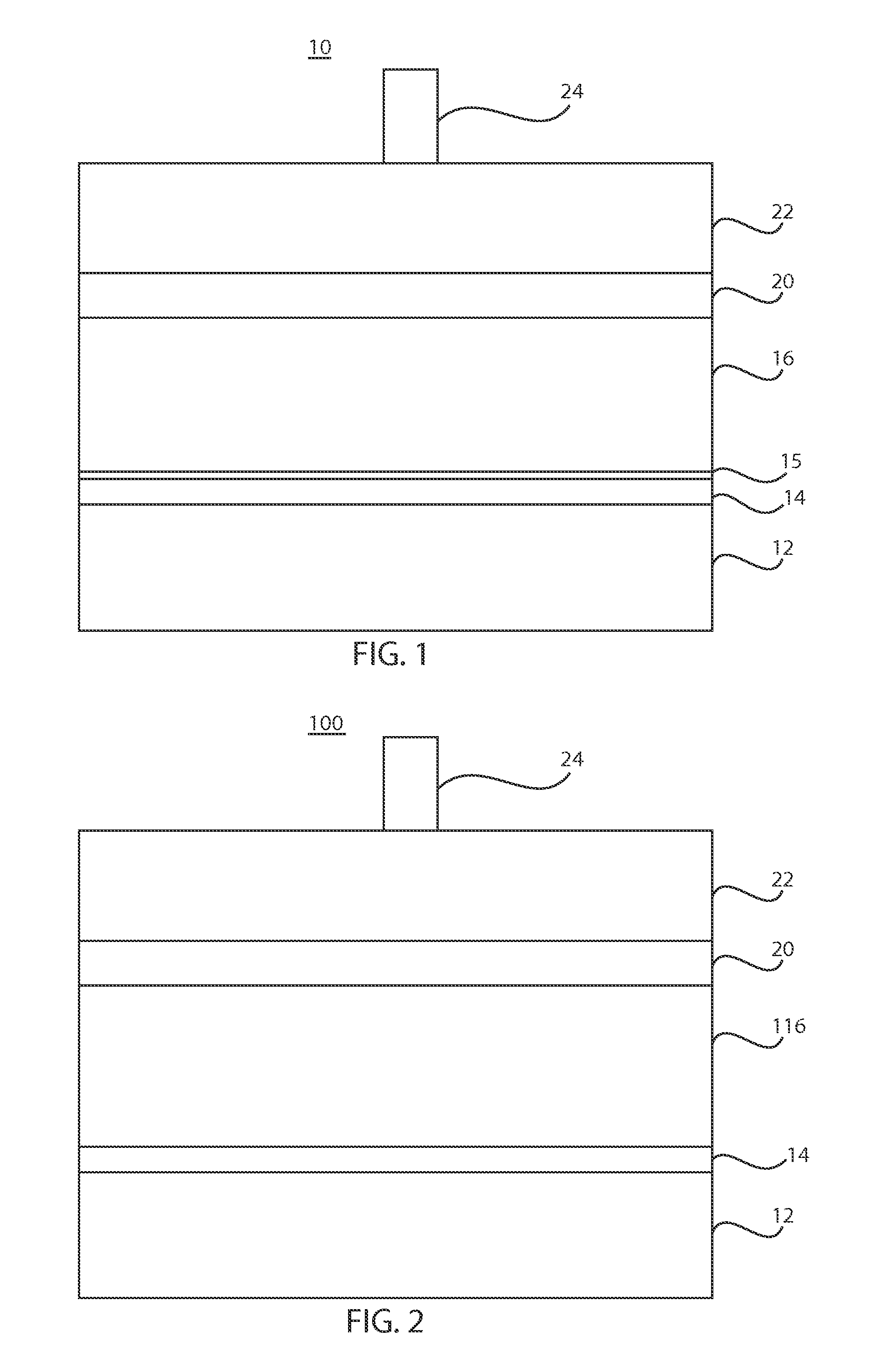

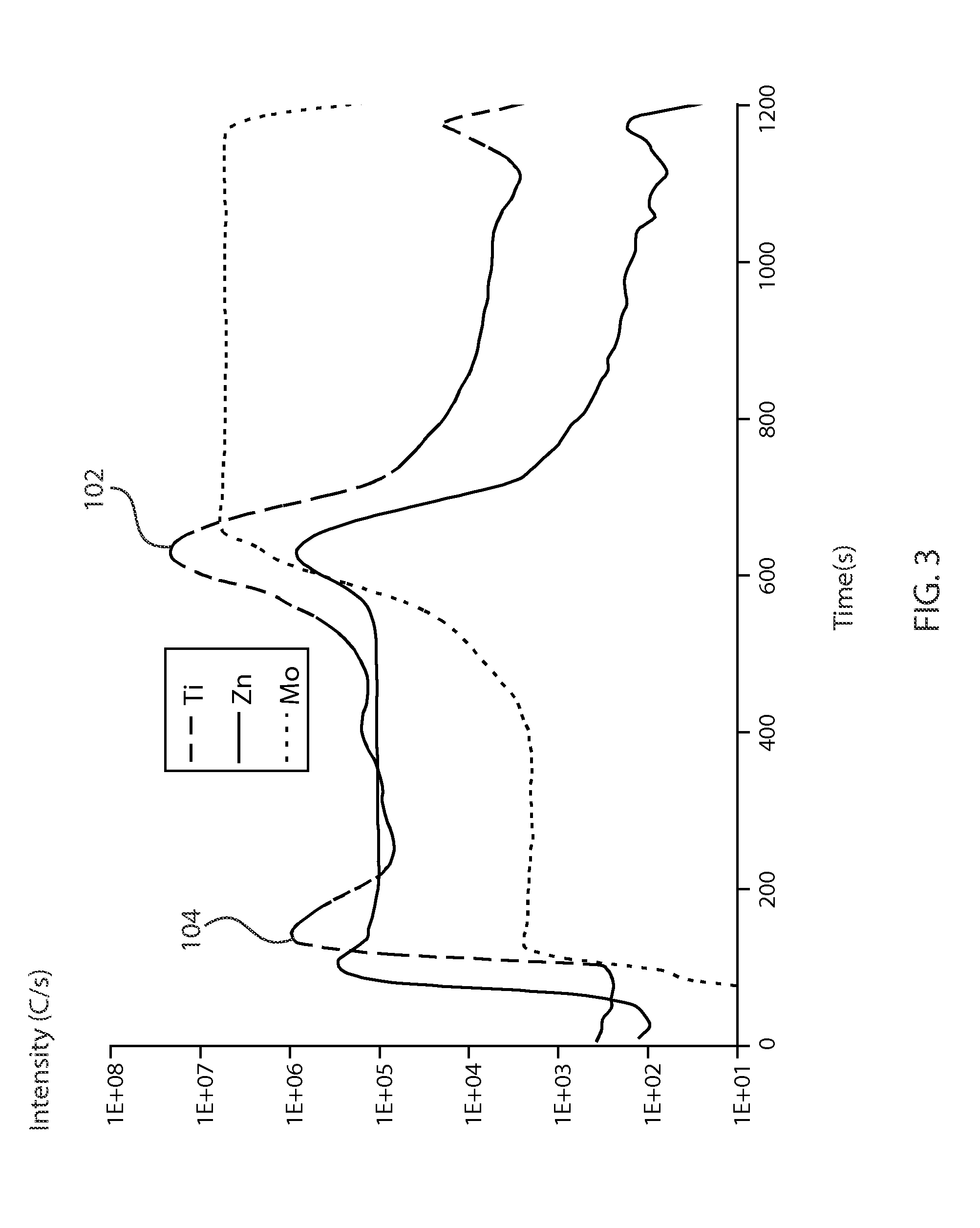

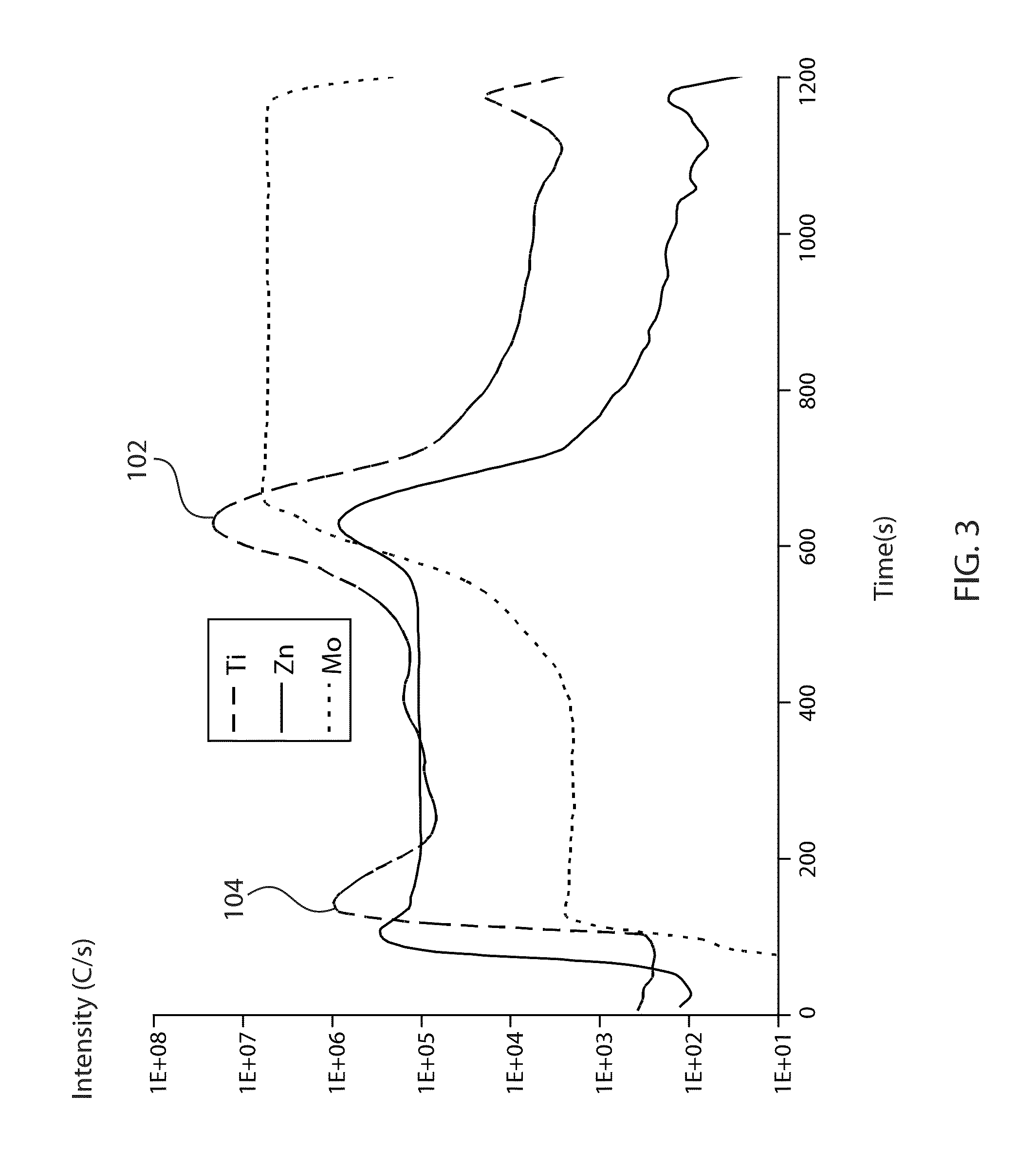

Titanium incorporation into absorber layer for solar cell

InactiveUS20150059855A1Final product manufactureSemiconductor/solid-state device manufacturingSulfurTitanium

Owner:GLOBALFOUNDRIES INC

Transparent Conducting Oxide As Top-Electrode In Perovskite Solar Cell By Non-Sputtering Process

ActiveUS20170069861A1Solid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEvaporation

Techniques for forming a transparent conducting oxide (TCO) top contact using a low temperature process are provided. In one aspect of the invention, a method of forming a TCO on a substrate is provided. The method includes the steps of: generating a source gas of the TCO using e-beam evaporation; generating atomic oxygen using RF plasma; and contacting the substrate with the TCO source gas and the atomic oxygen under conditions sufficient to form the TCO on the substrate. A photovoltaic device is also provided which includes a bottom cell; and a perovskite-based top cell on the kesterite-based bottom cell. The perovskite-based top cell includes a top electrode formed from a TCO.

Owner:IBM CORP

Titanium incorporation into absorber layer for solar cell

A method for fabricating a photovoltaic device includes forming a film including titanium on a conductive layer formed on a substrate. An absorber layer is formed including a Cu—Zn—Sn containing chalcogenide compound with a kesterite structure of the formula: Cu2-xZn1+ySn(S1-zSez)4+q wherein 0≦x≦1; 0≦y≦1; 0≦z≦1; −1≦q≦1 (CZTS) on the film. The absorber layer is annealed to diffuse titanium therein and to recrystallize the CZTS material of the film. A buffer layer is formed on the absorber layer, and a transparent conductive layer is formed on the buffer layer.

Owner:GLOBALFOUNDRIES INC

Fabricating kesterite solar cells and parts thereof

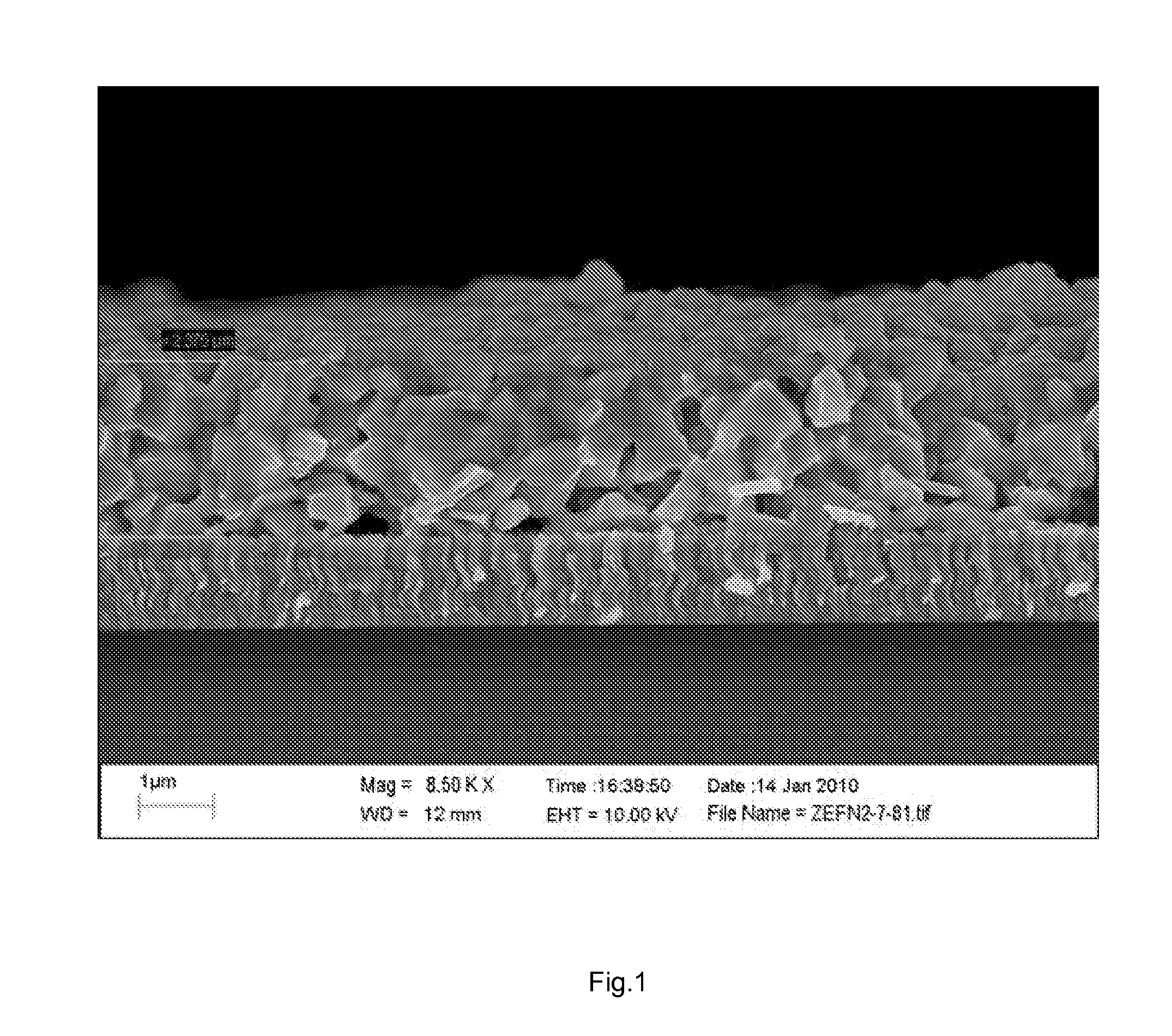

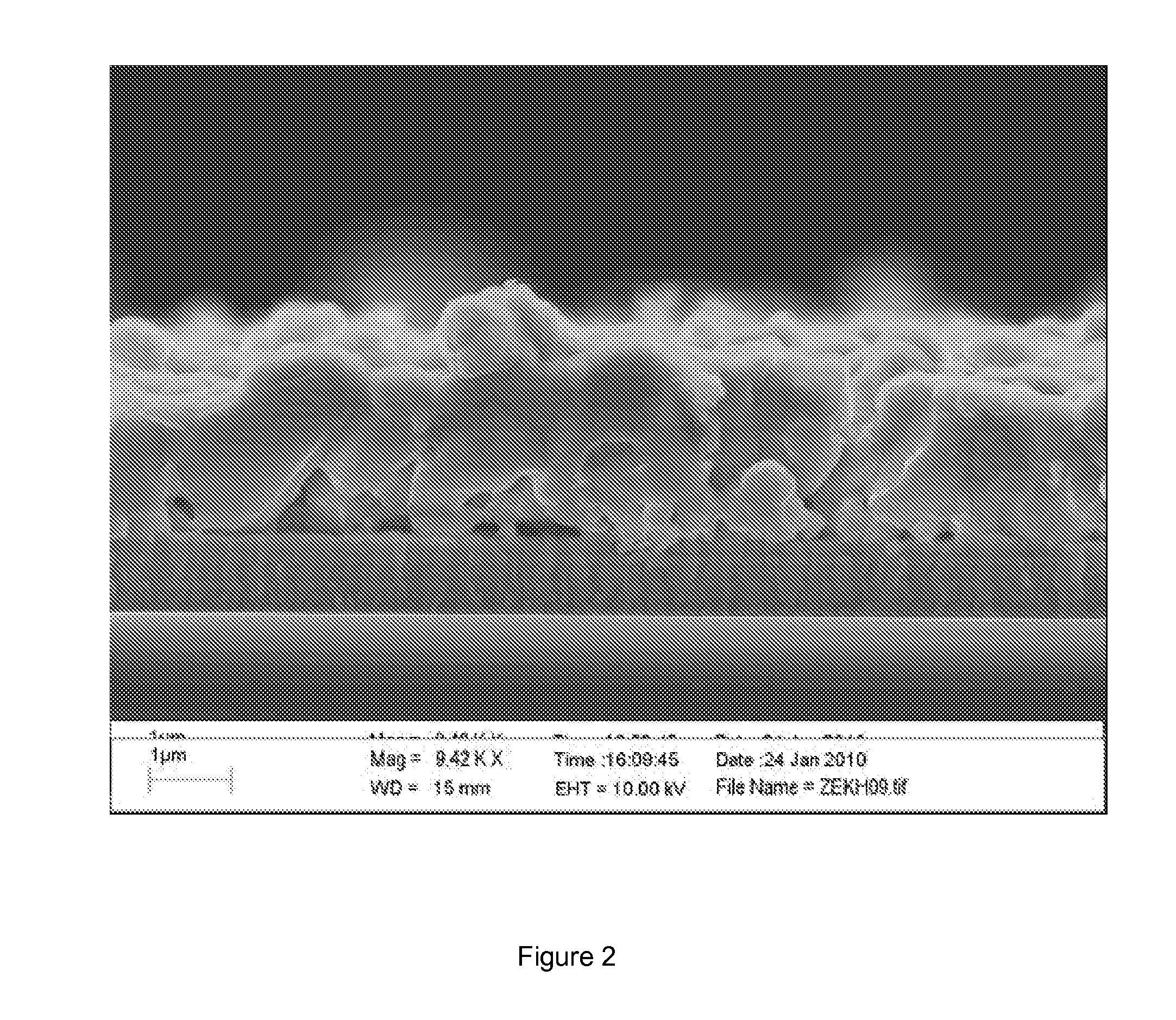

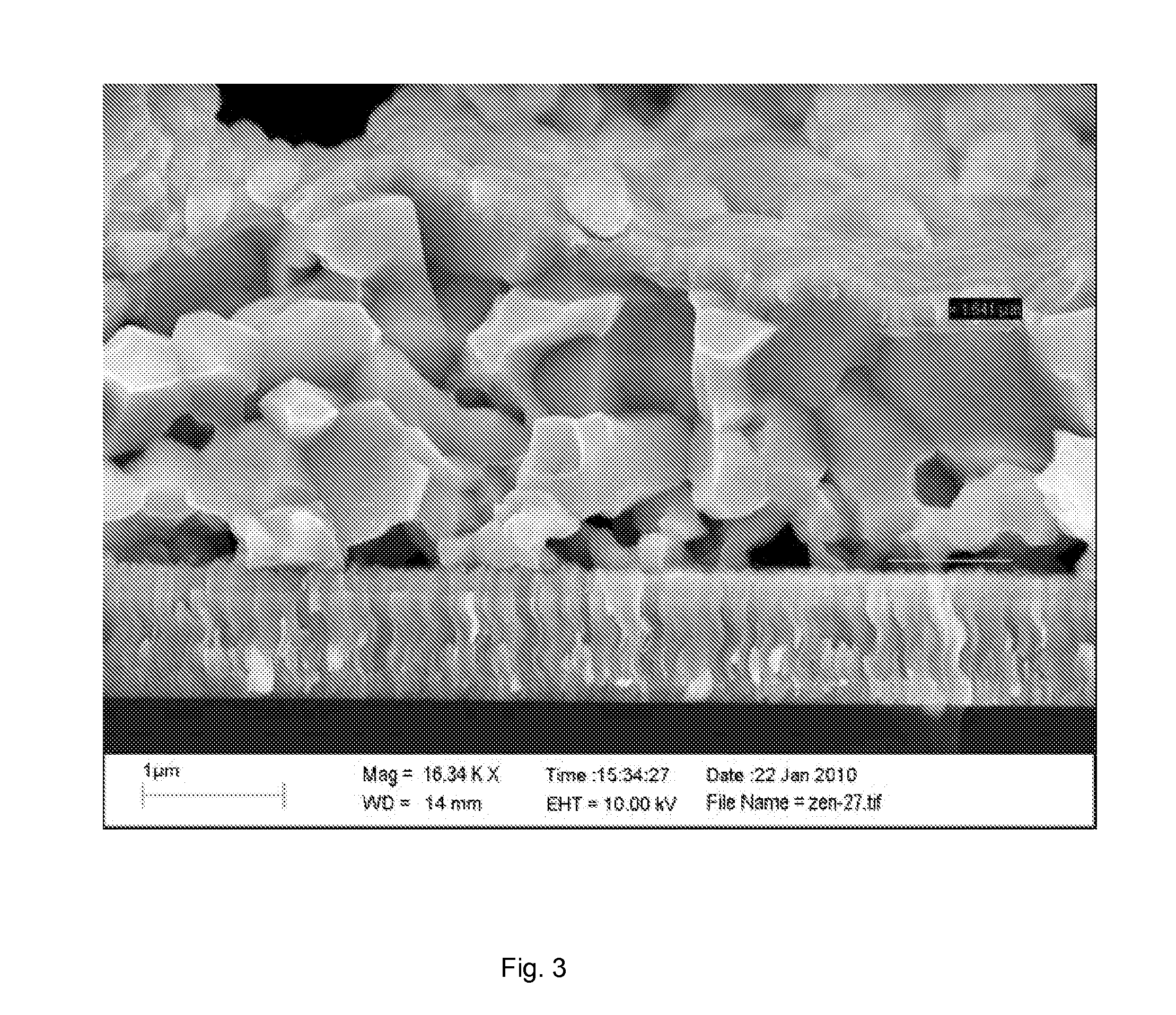

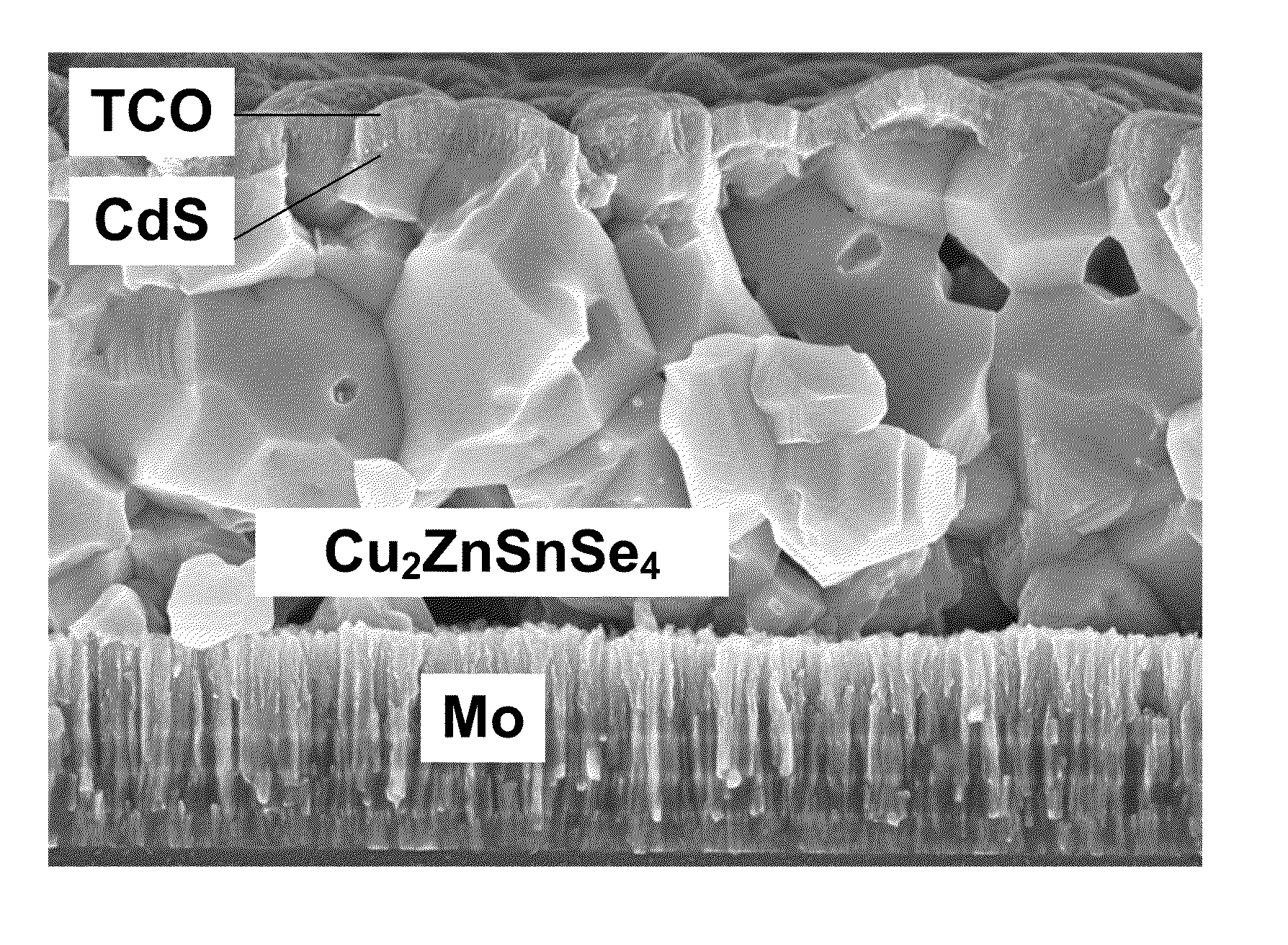

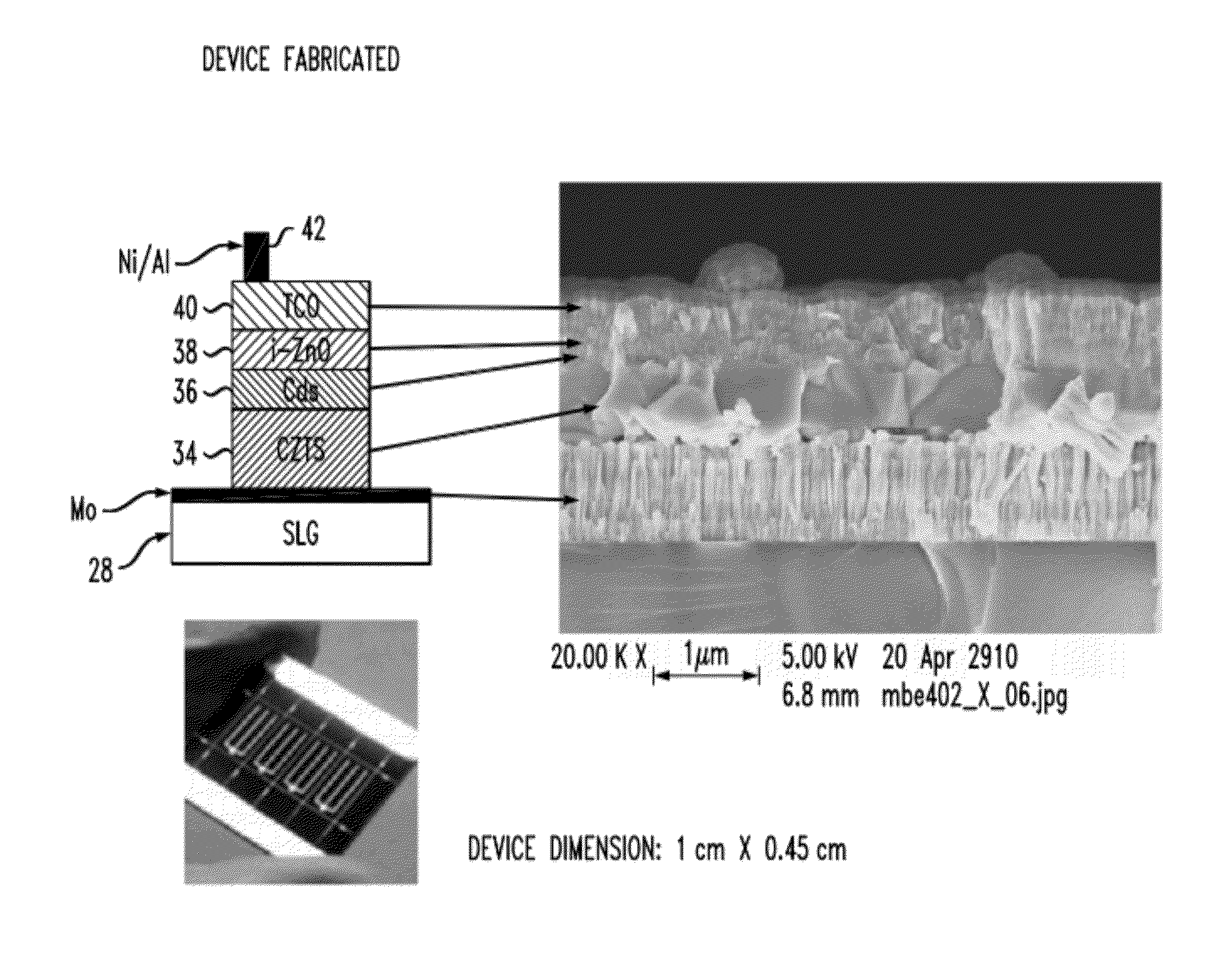

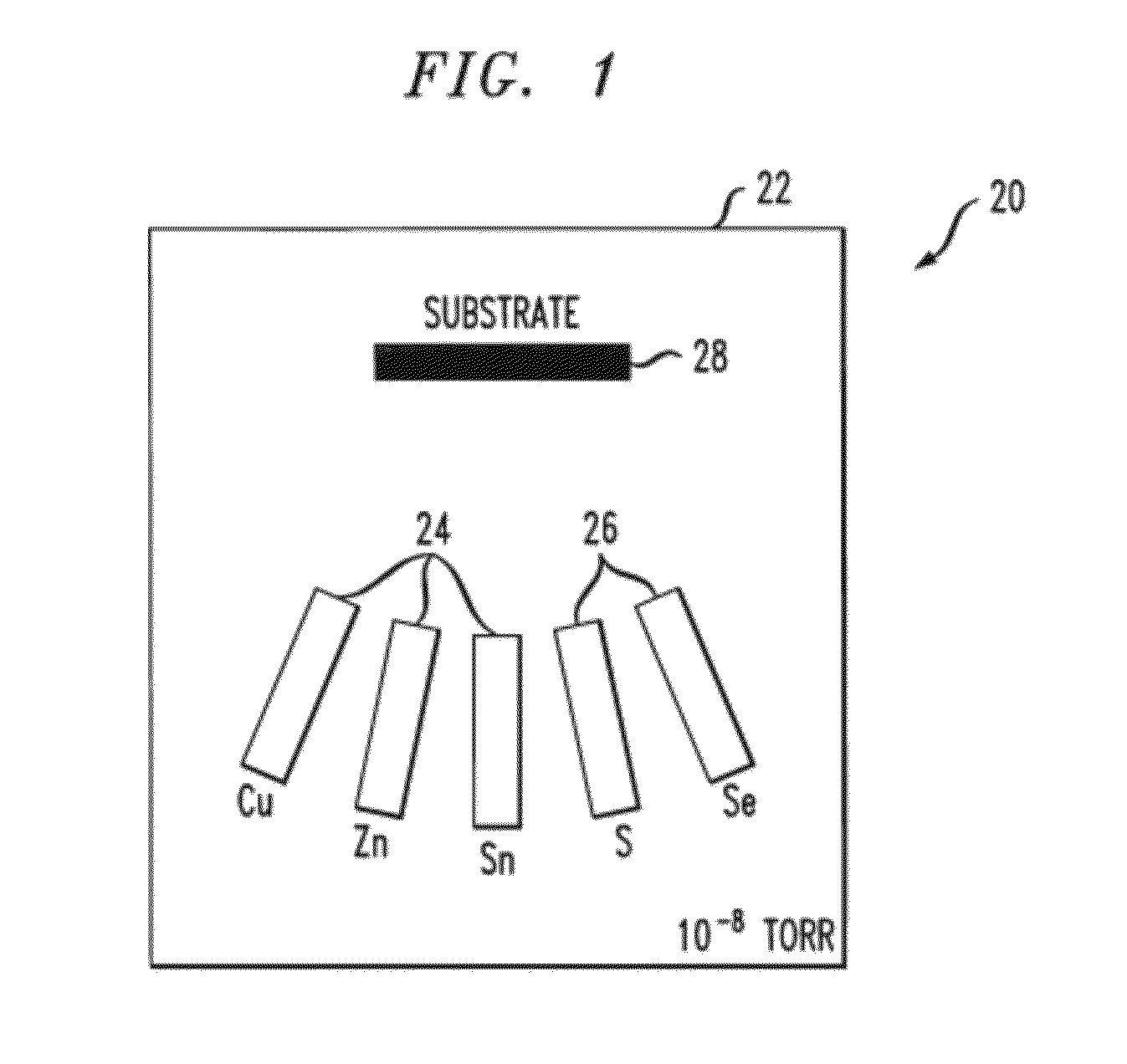

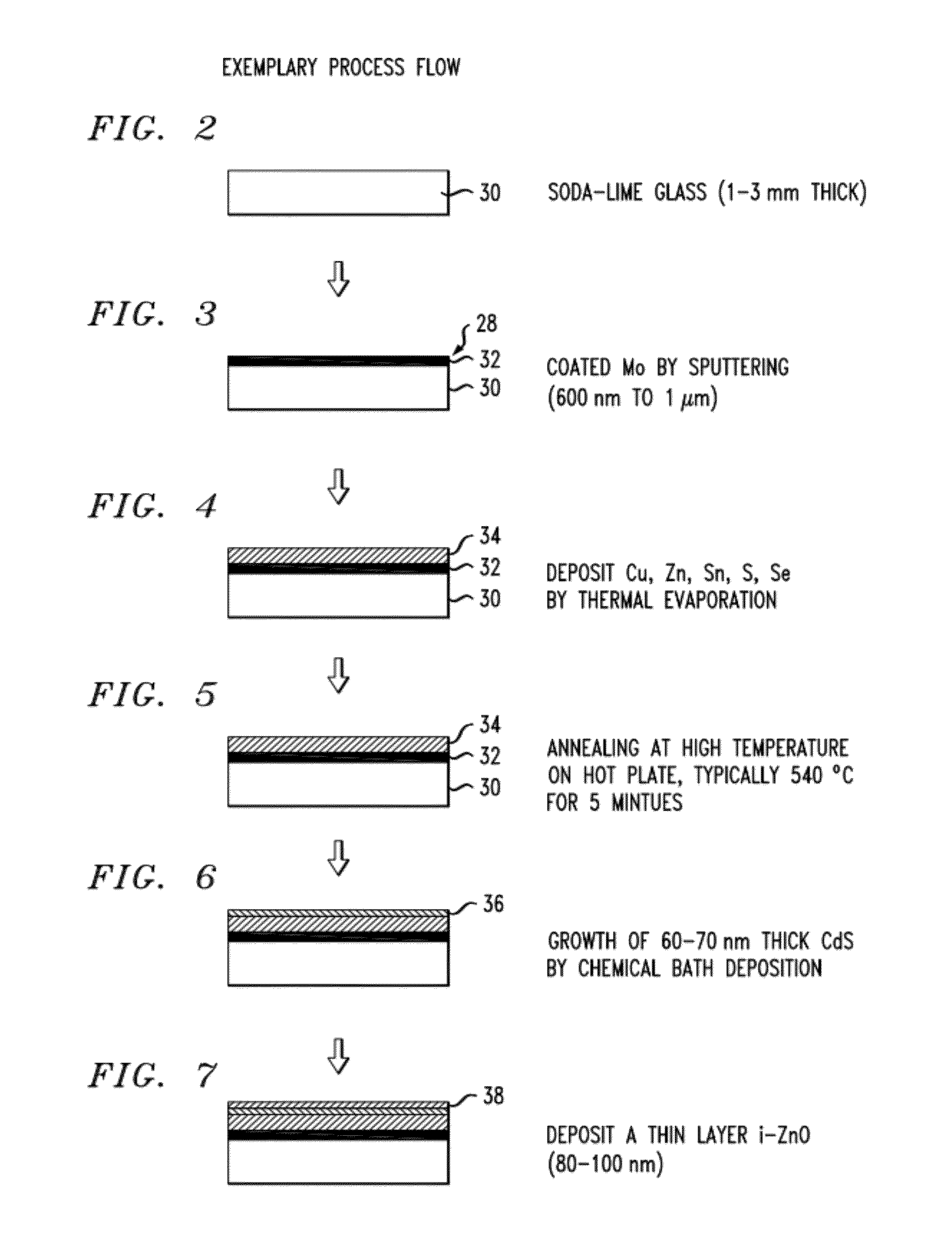

ActiveUS8440497B2Precise compositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSputteringEvaporation

A Kesterite film is vacuum deposited and annealed on a substrate. Deposition is conducted at low temperature to provide good composition control and efficient use of metals. Annealing is conducted at a high temperature for a short period of time. Thermal evaporation, E-beam evaporation or sputtering in a high vacuum environment may be employed as part of a deposition process.

Owner:GLOBALFOUNDRIES U S INC

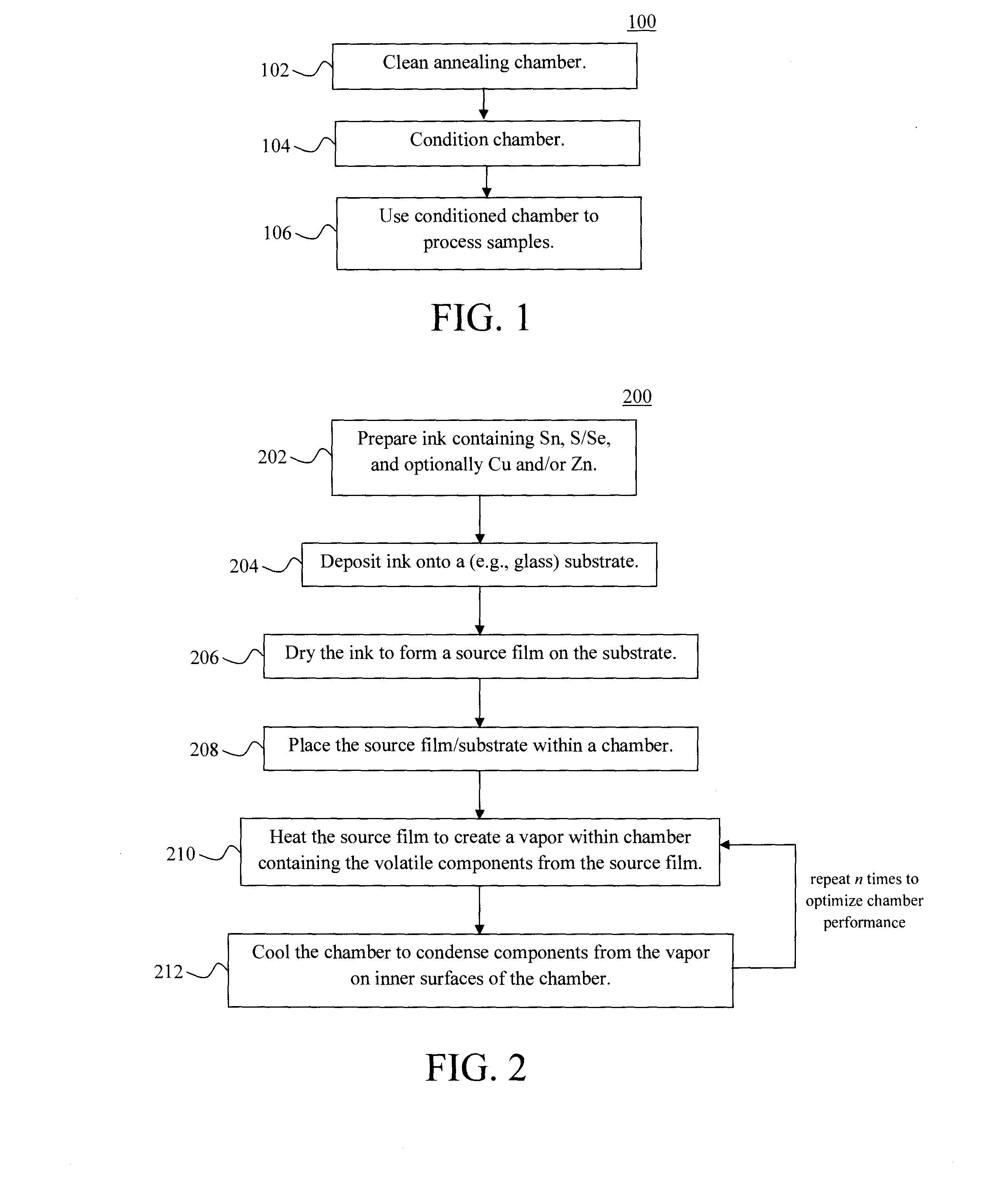

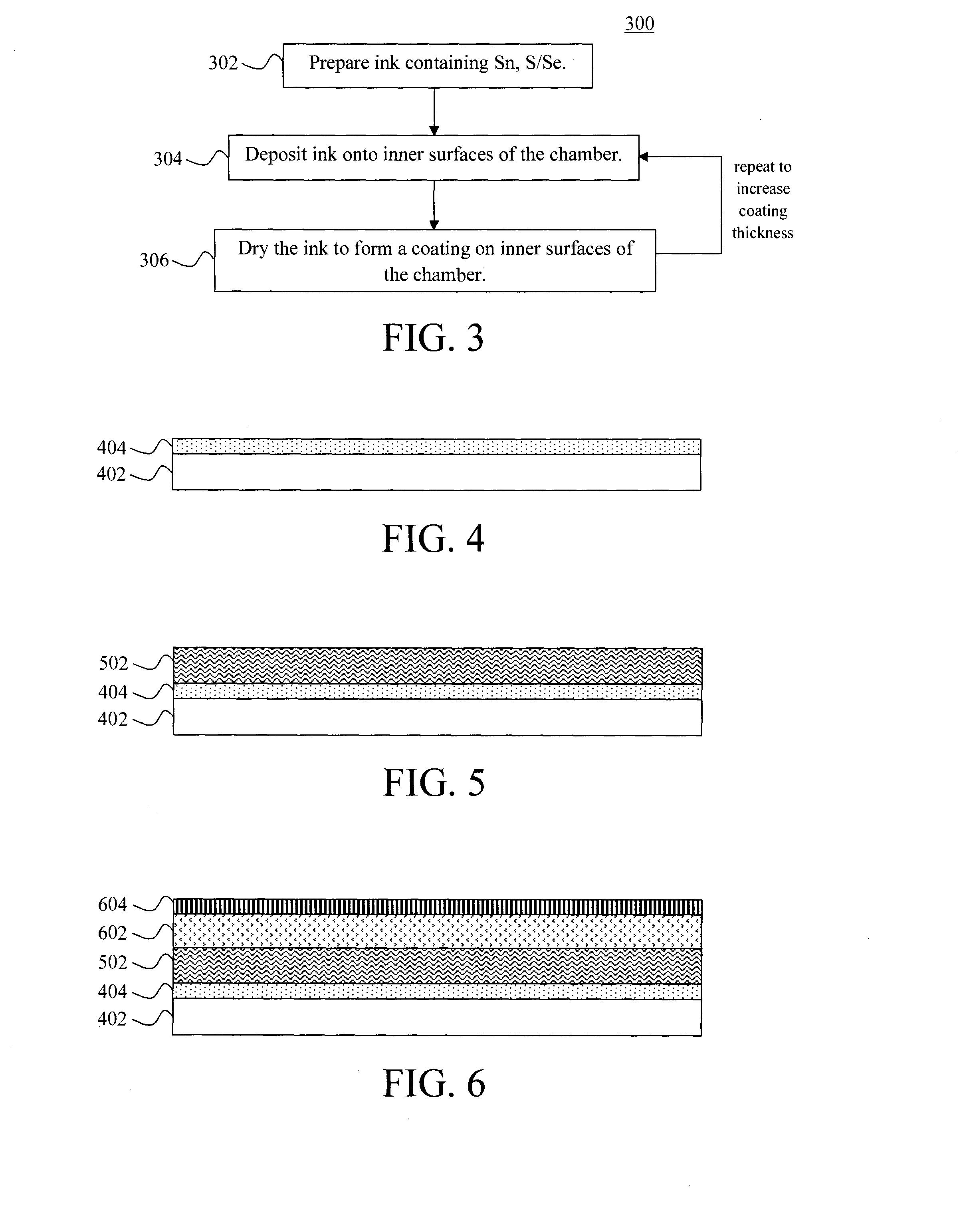

Method to Condition an Annealing Tool for High Quality CuZnSnS(Se) Films to Achieve High Performance Solar Cells Reliably

InactiveUS20170062634A1Increase productionFinal product manufacturePhotovoltaic energy generationSolar cellMaterials science

Techniques for improved kesterite film production through annealing chamber conditioning to achieve solar cells with a power conversion efficiency of greater than 12% are provided. In one aspect, a method of conditioning an annealing chamber for forming a kesterite film is provided. The method includes the step of: coating one or more inner surfaces of the annealing chamber with a film containing Sn and at least one of S and Se. A method for forming a kesterite film, a method for forming a solar cell, and a solar cell are also provided.

Owner:IBM CORP

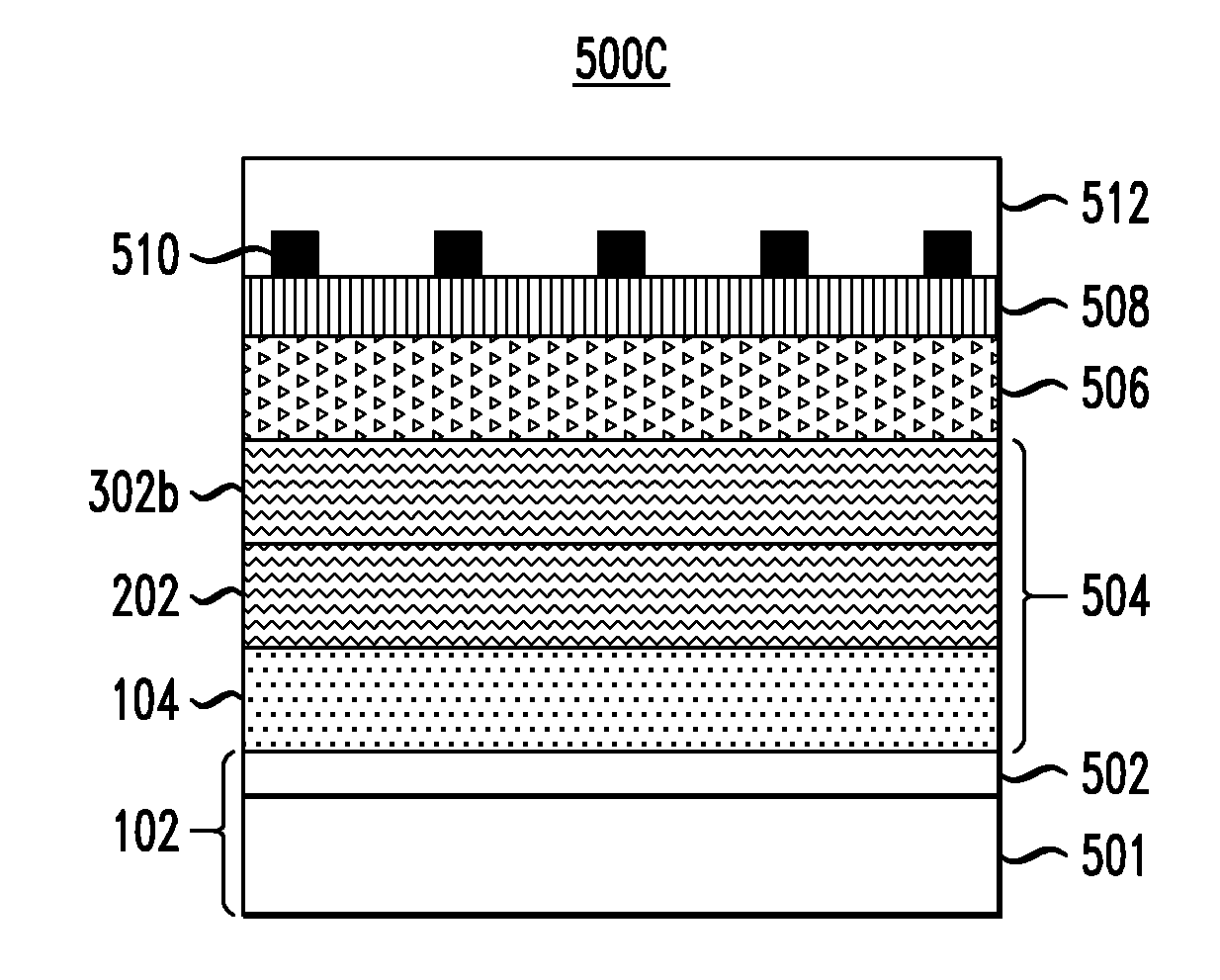

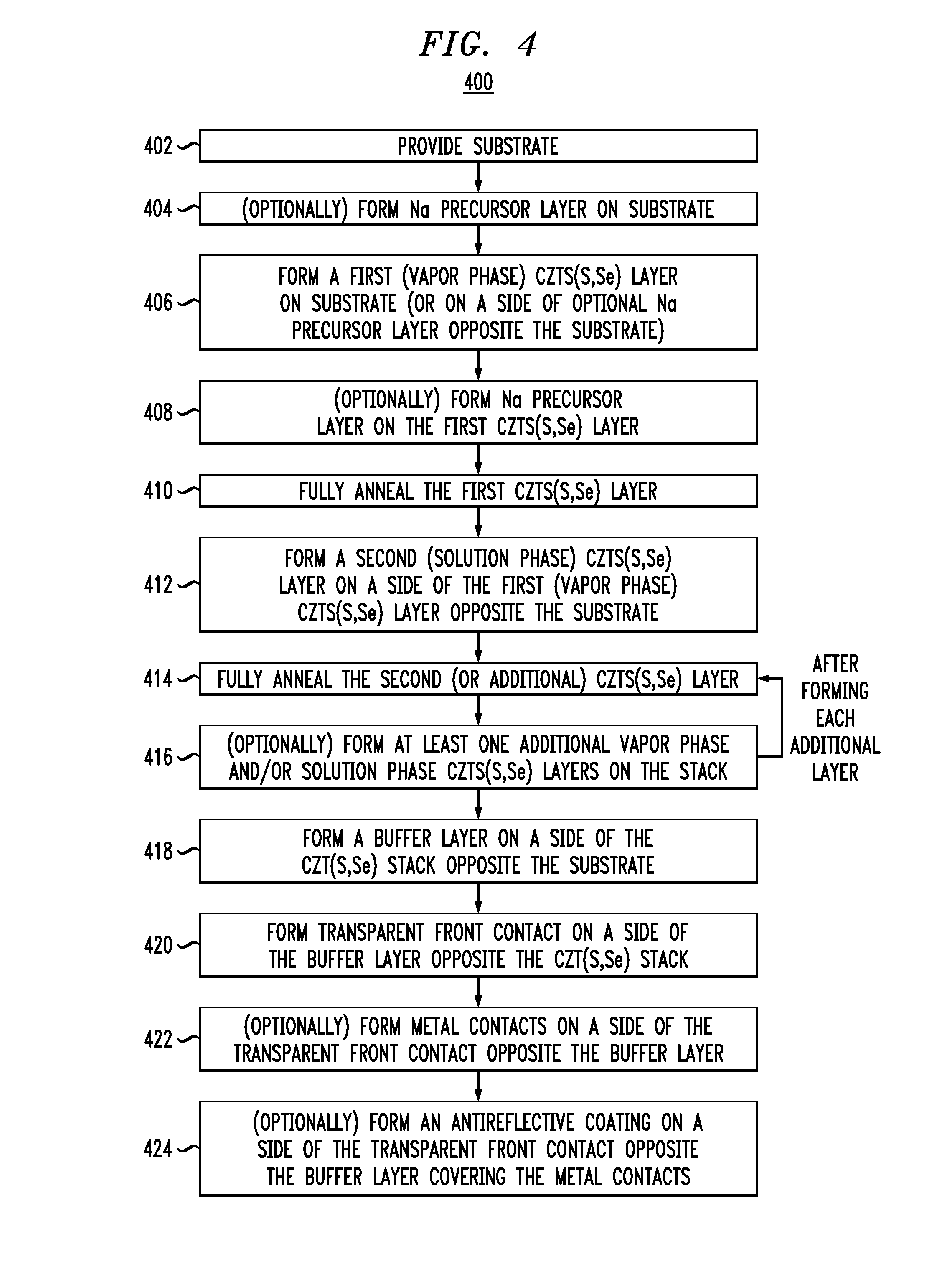

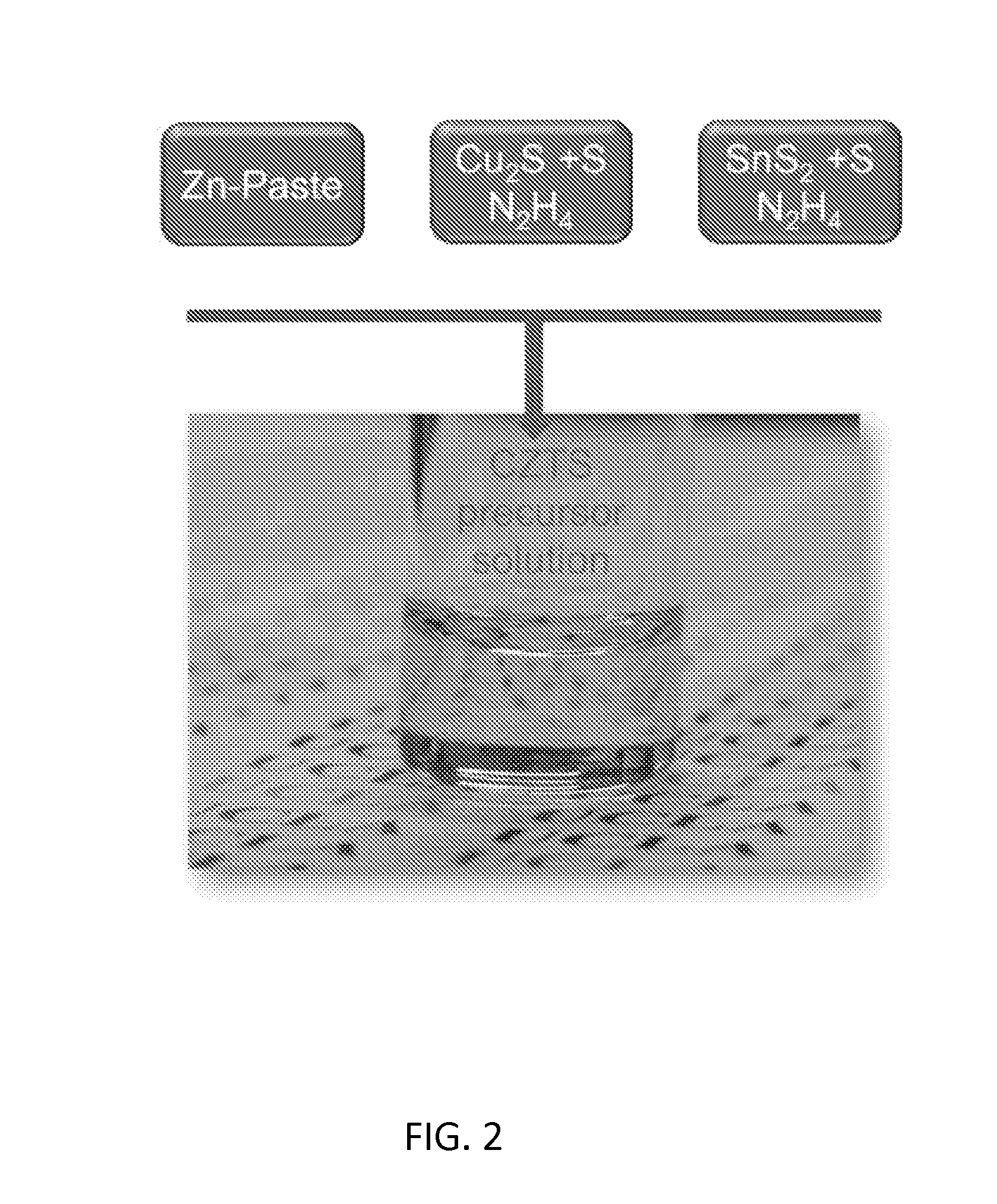

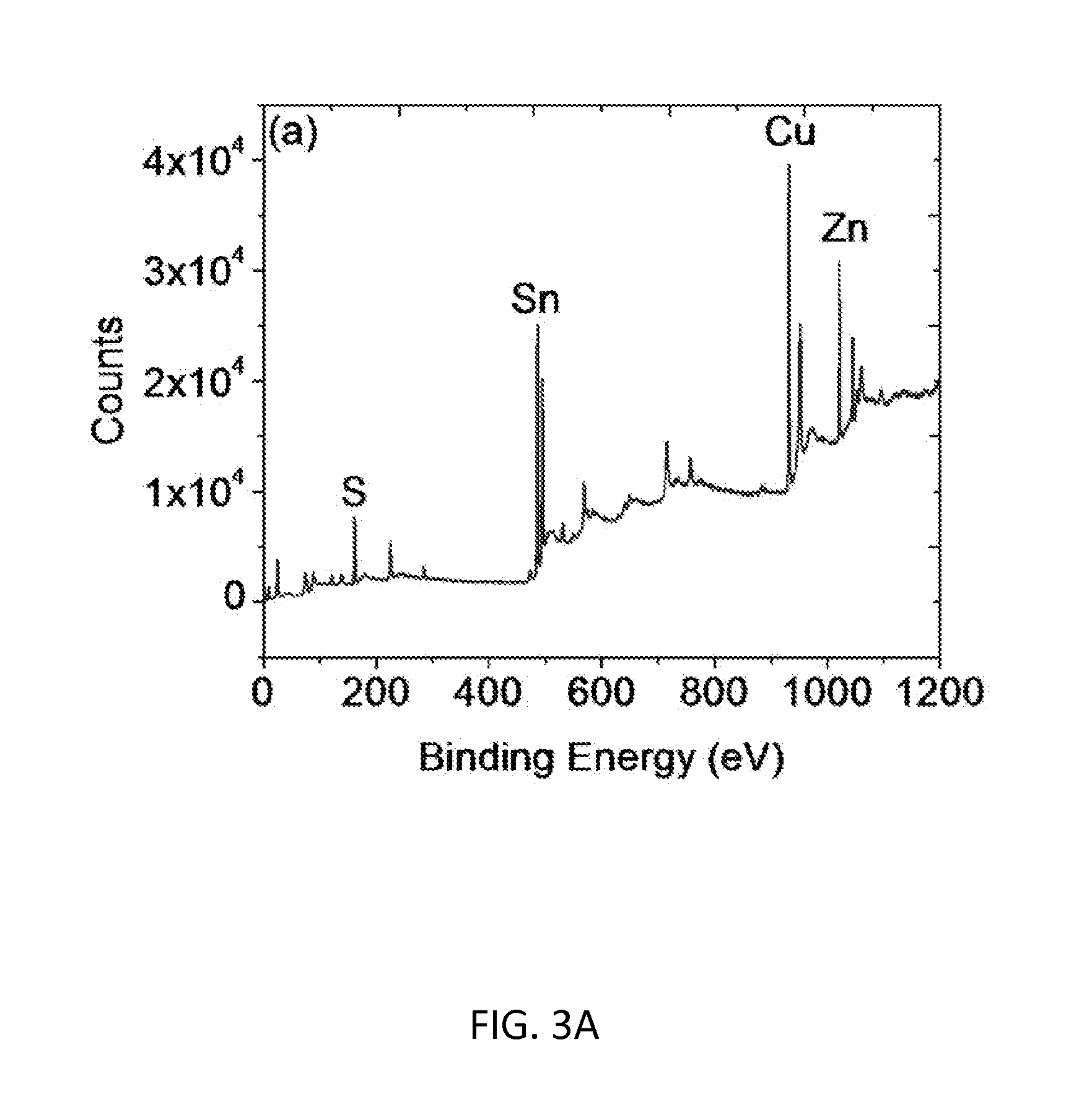

Hybrid Vapor Phase-Solution Phase Growth Techniques for Improved CZT(S,Se) Photovoltaic Device Performance

InactiveUS20160141434A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationPhysical chemistryDeposition process

A hybrid vapor phase-solution phase CZT(S,Se) growth technique is provided. In one aspect, a method of forming a kesterite absorber material on a substrate includes the steps of: depositing a layer of a first kesterite material on the substrate using a vapor phase deposition process, wherein the first kesterite material includes Cu, Zn, Sn, and at least one of S and Se; annealing the first kesterite material to crystallize the first kesterite material; and depositing a layer of a second kesterite material on a side of the first kesterite material opposite the substrate using a solution phase deposition process, wherein the second kesterite material includes Cu, Zn, Sn, and at least one of S and Se, wherein the first kesterite material and the second kesterite material form a multi-layer stack of the absorber material on the substrate. A photovoltaic device and method of formation thereof are also provided.

Owner:IBM CORP

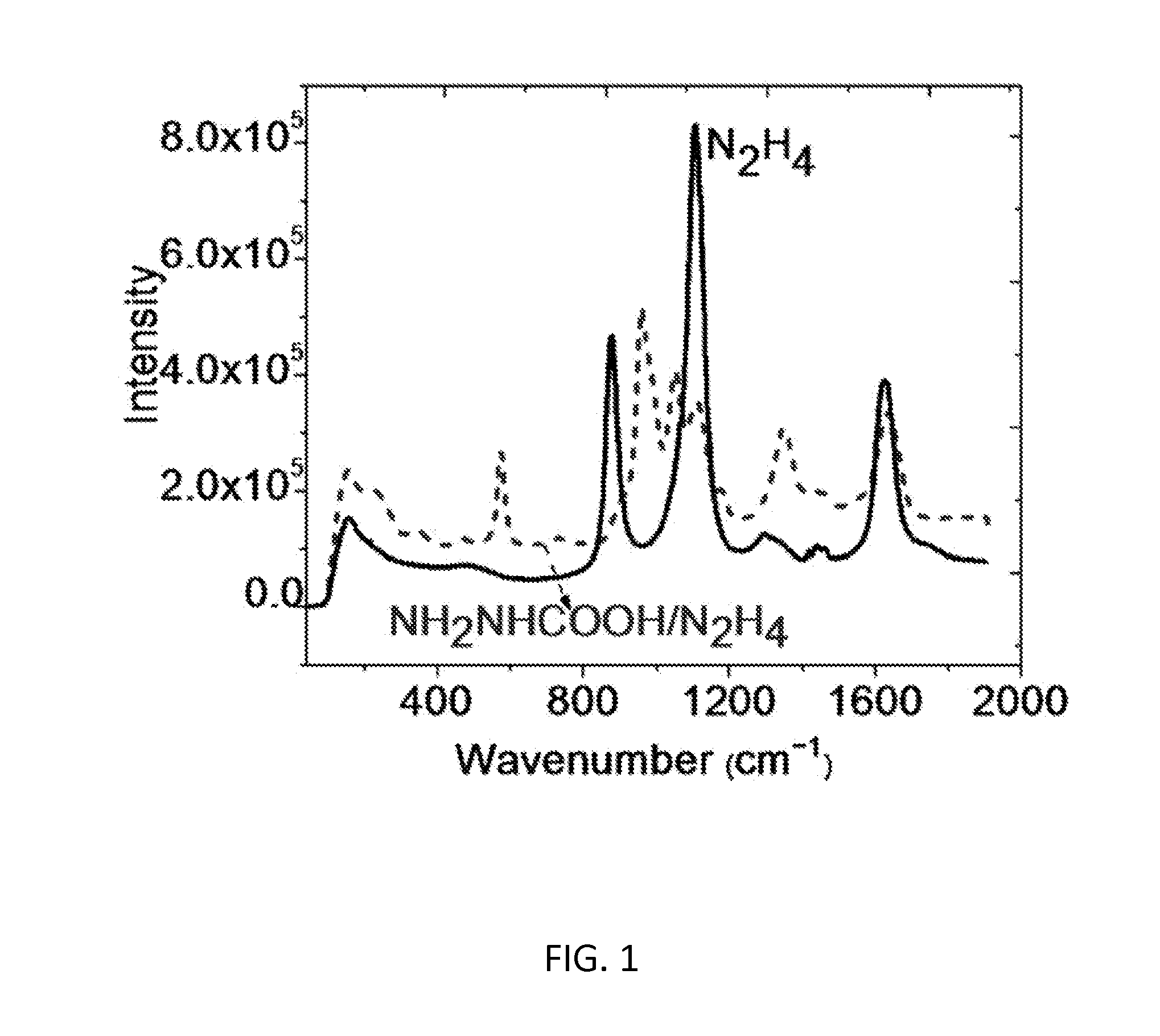

Inorganic solution and solution process for electronic and electro-optic devices

ActiveUS20140116512A1Conductive materialSemiconductor/solid-state device manufacturingAlkaline earth metalSolvent

A solution for forming at least a portion of an active layer of an electronic or electro-optic device includes a solvent, an additive mixed with the solvent to provide a solvent-additive blend, and a solute that includes at least one of a transition metal, an alkali metal, an alkaline earth metal, Al, Ga, In, Ge, Sn, or Sb dissolved in elemental form in the solvent-additive blend. The additive is selected from the group of additives consisting of NR1R2NHCOOH, NH2N—HCONHNH2, NH2COOH.NH3, NH2NHC(═NH)NH2.H2CO3, NH2NHCSNHNH2, NH2NHCSSH and all combinations thereof. R1 and R2 are each independently selected from hydrogen, aryl, methyl, ethyl and a linear, branched or cyclic alkyl of 3-6 carbon atoms. Methods of producing the solution, a method of producing a Kesterite film on a substructure and devices made with the solutions and methods are also provided.

Owner:RGT UNIV OF CALIFORNIA

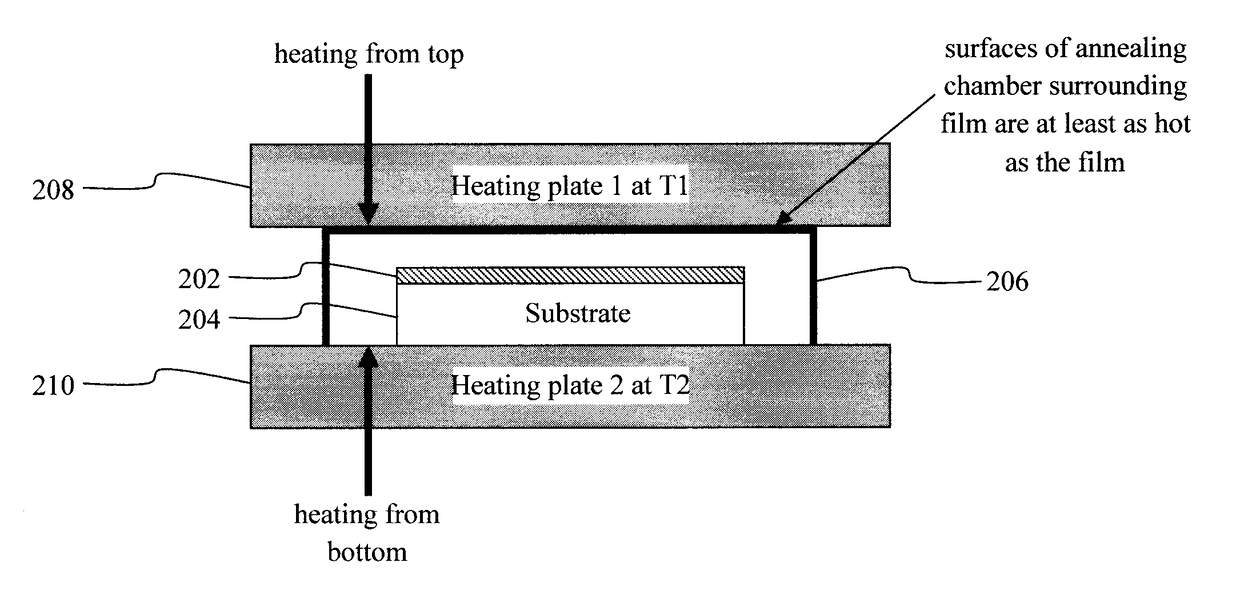

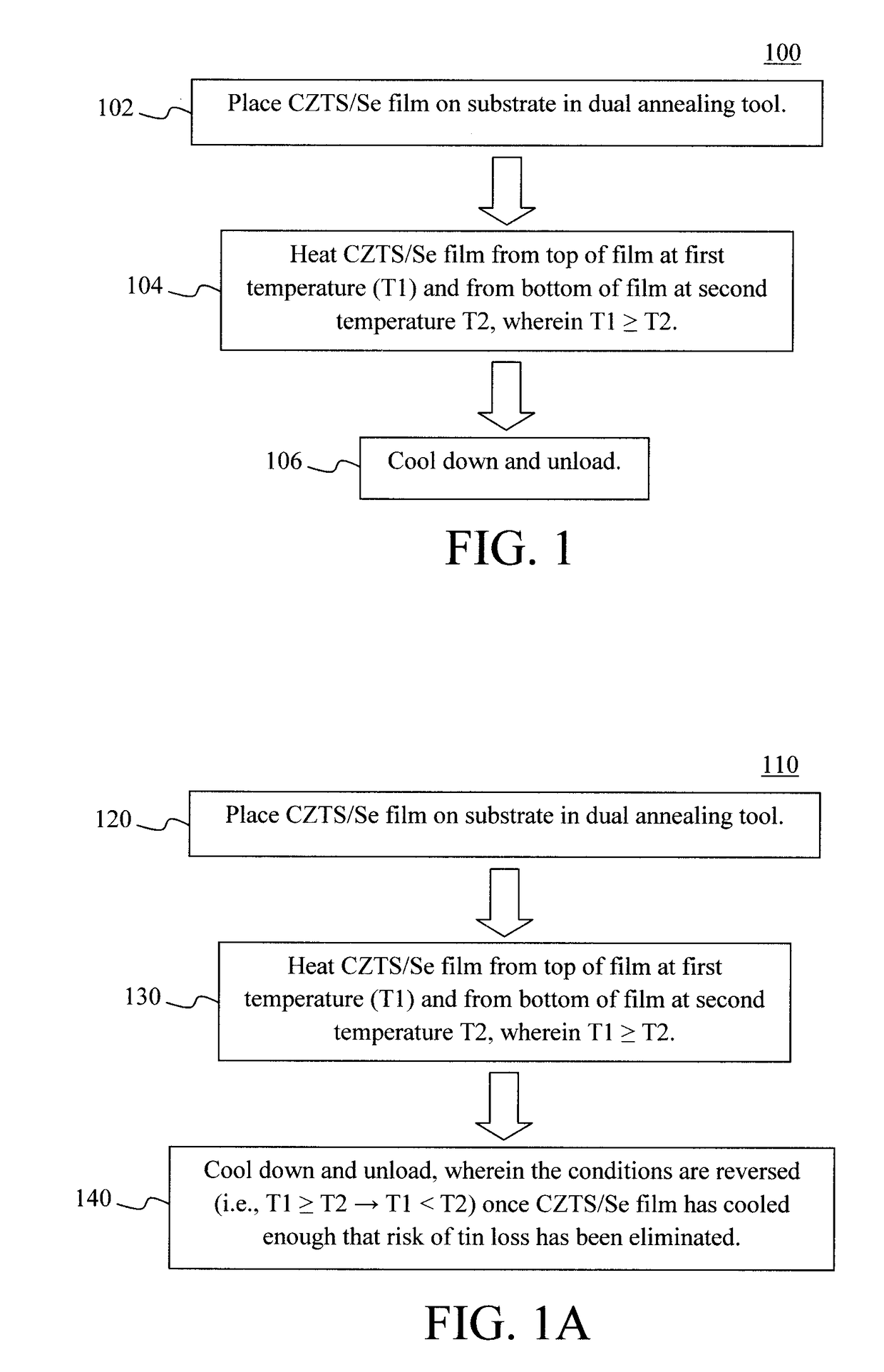

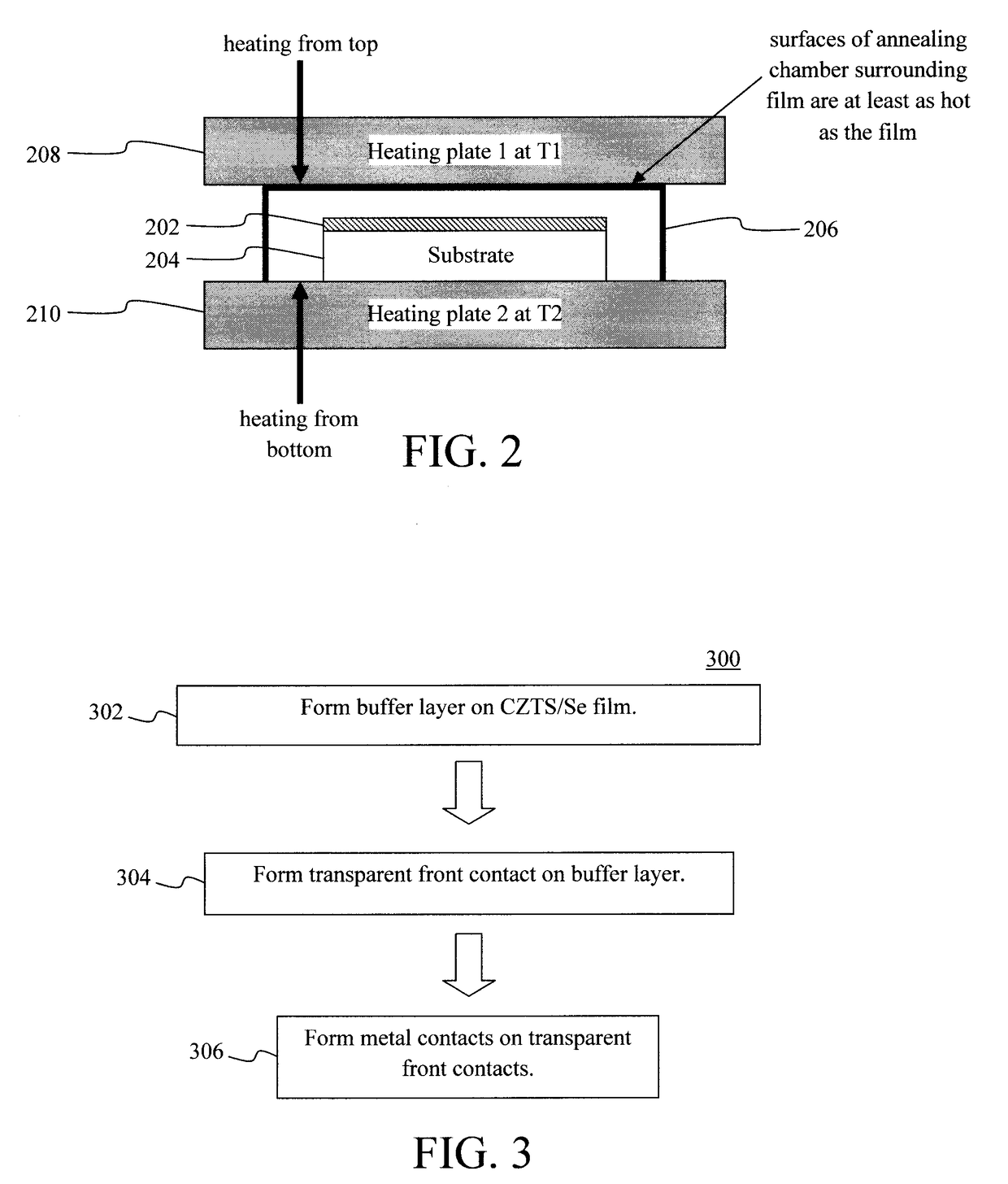

Minimizing Tin Loss During Thermal Processing of Kesterite Films

ActiveUS20180069146A1Reduce lossesTin compoundsSemiconductor/solid-state device manufacturingCassiteriteThin membrane

Techniques for minimizing loss of volatile components during thermal processing of kesterite films are provided. In one aspect, a method for annealing a kesterite film is provided. The method includes: placing a cover over the kesterite film; and annealing the cover and the kesterite film such that, for an entire duration of the annealing, the cover is at a temperature T1 and the kesterite film is at a temperature T2, wherein the temperature T1 is greater than or equal to the temperature T2. Optionally, during a cool down segment of the annealing, conditions can be reversed to have the temperature T1 be less than the temperature T2. A solar cell and method for formation thereof using the present annealing techniques are also provided.

Owner:IBM CORP

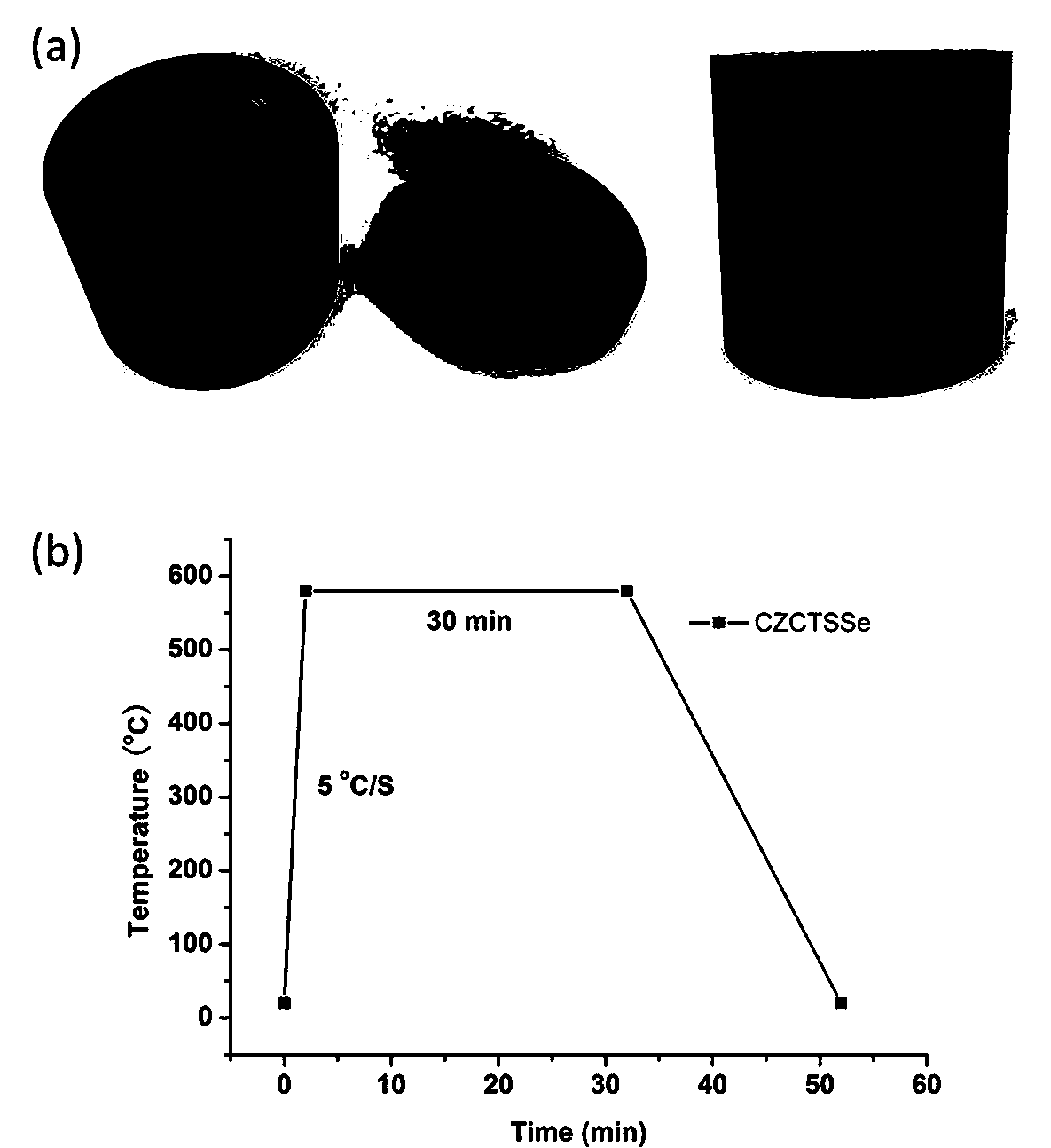

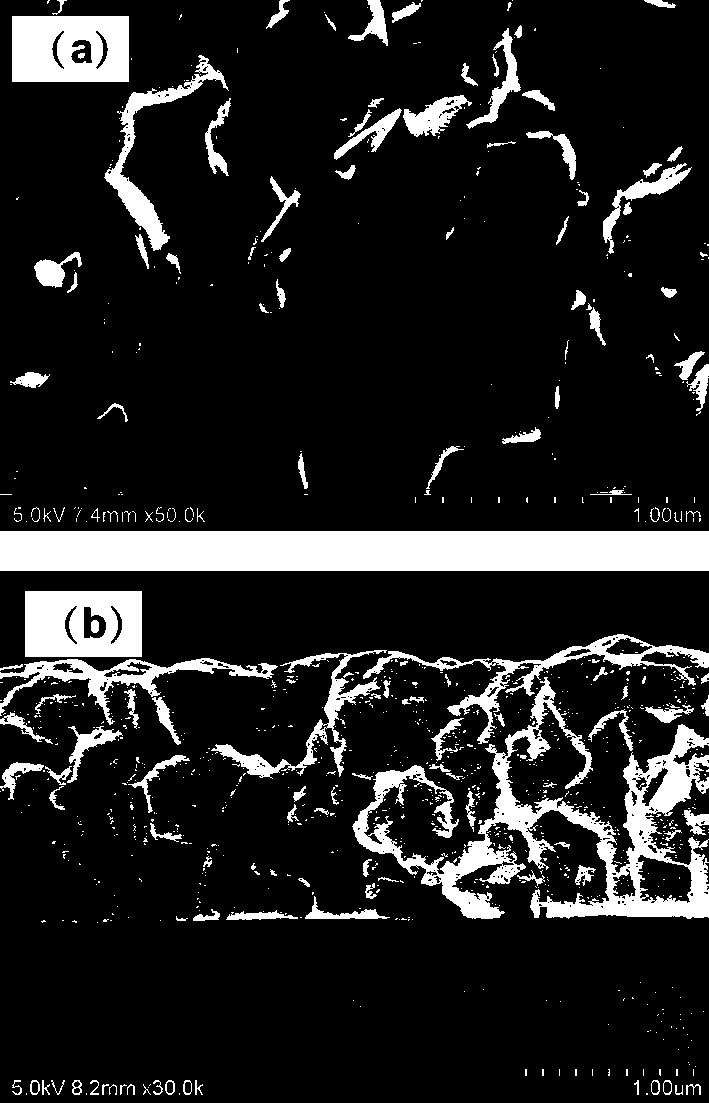

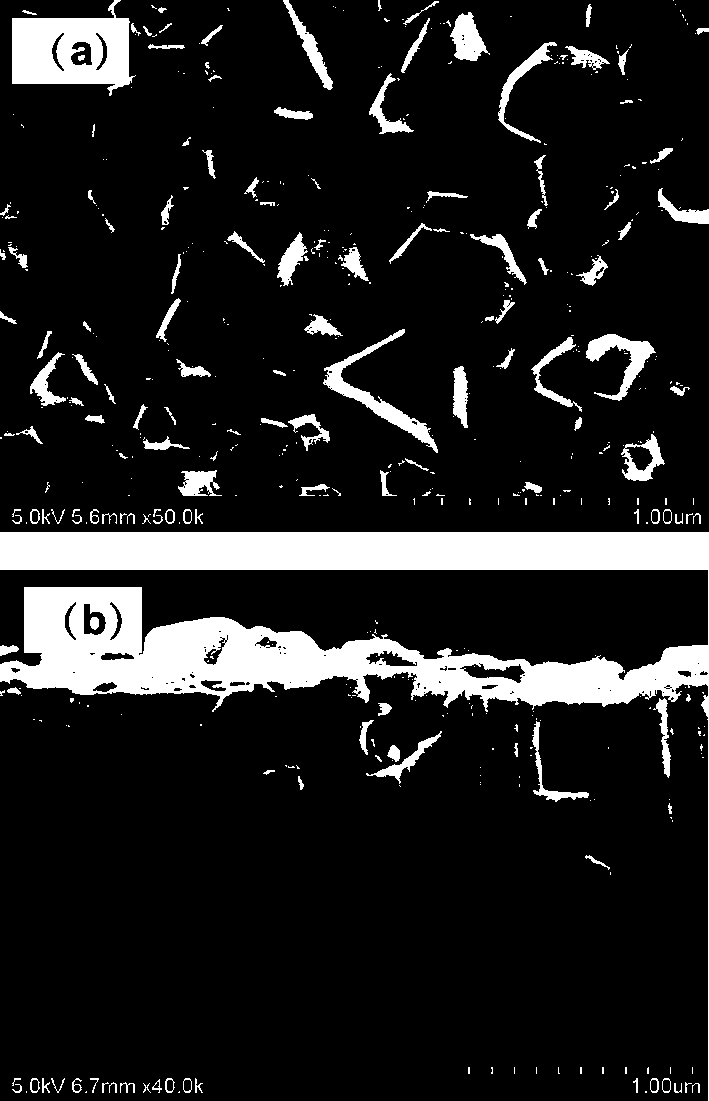

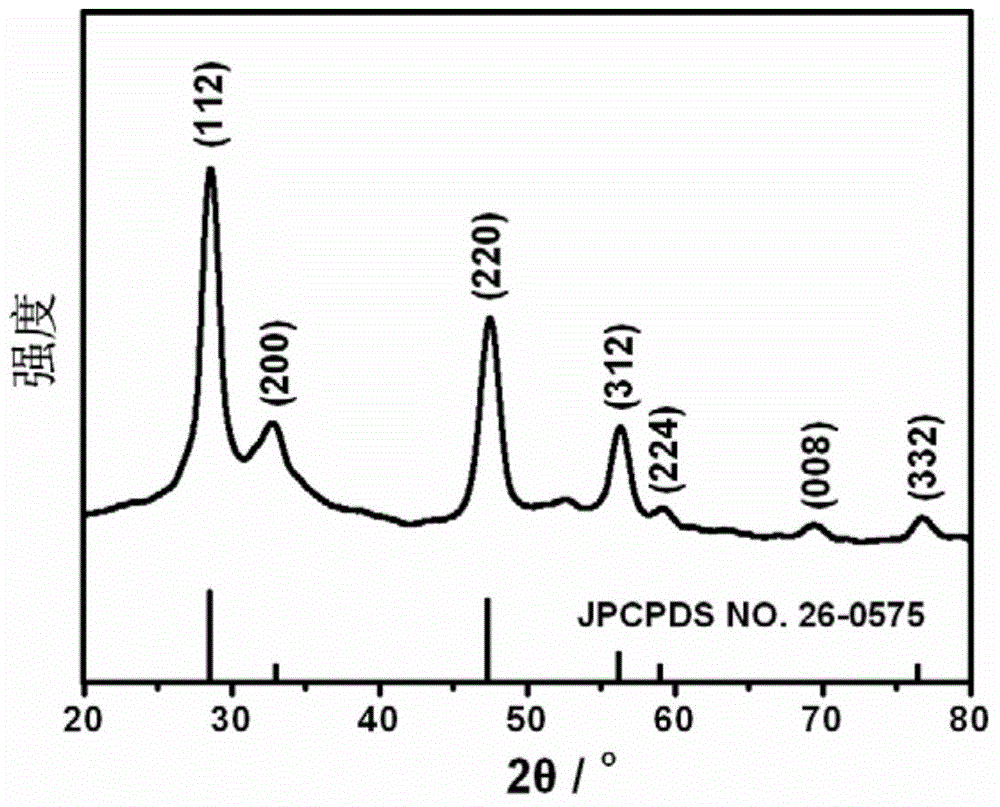

Preparation process of copper zinc tin sulfide selenide (CZTSSe) thin film

The invention relates to a preparation process of a copper zinc tin sulfide selenide (CZTSSe) thin film. The thin film which is of a single kesterite structure and has high acrystallization degree can be formed under 500 DEG C selenization annealing temperature; the thin film has a low-copper component; with the increase of temperature, the content of the Se element is increased, and finally tends to be stable, and while, the content of the S element is decreased at first and then trends to increase. The preparation process of the invention specifically includes following steps that: (1) some inert gas is added into a reaction container, the reaction container is made to maintain a certain pressure, an then, temperature rise begins; (2) a reaction is carried out for one hour under 280 DEG C, and then, centrifugal washing is carried out, nanoparticles are isolated from a reaction solution, and are dried under an inert environment, and as a result, nanoparticles under two different kinds of conditions can be obtained; and (3) the prepared CZTS nanocrystals are dissolved in a certain amount of hexanethiol, so that a nano slurry solution can be obtained, and a CZTS thin film can be prepared on a soda-lime glass substrate through adopting a dispensing mode, and the CZTS thin film is subjected to selenization annealing treatment, so that the CZTSSe thin film can be obtained.

Owner:陈玉梅

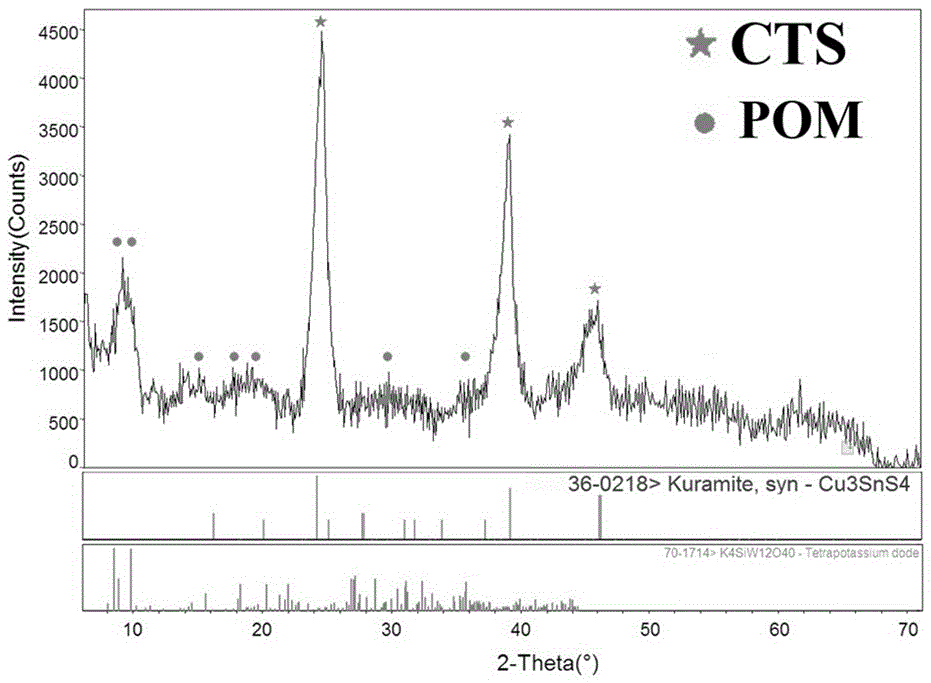

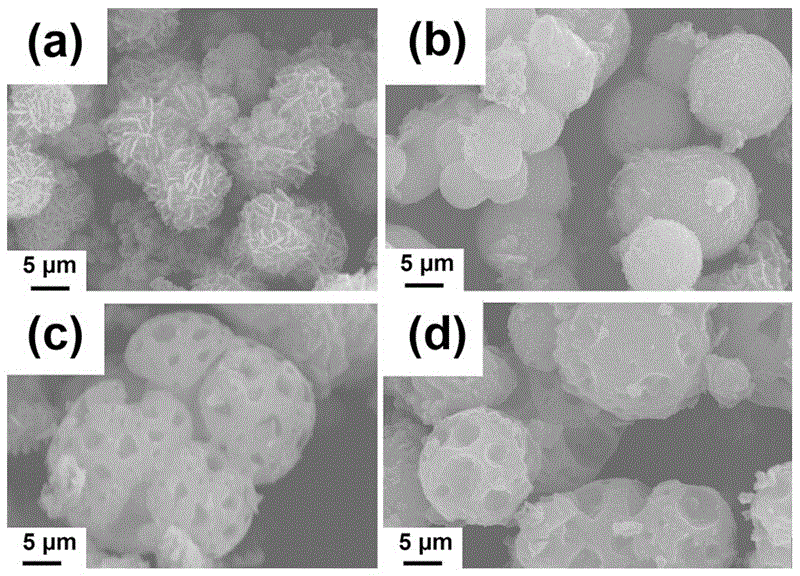

Sulfur-copper-tin-zinc hollow-structure microsphere and preparation method and application thereof

InactiveCN105562037AEasy to operateHave not reunitedPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereThiourea

The invention discloses a sulfur-copper-tin-zinc hollow-structure microsphere and a preparation method and application thereof. The kesterite hollow-structure microsphere is 10-15 Mum in diameter, the surface of the microsphere is in a porous geometrical configuration, the pore size is 1-3 Mum, and the pore depth is 1-3 Mum. The preparation method comprises the following steps: dissolving in ethylene glycol the materials, copper chloride, stannous chloride, thiourea and K4SiW12O40 according to a molar ratio of 1:1:3:10-3, to form a sample solution, and thermally treating to obtain the target sulfur-copper-tin-zinc hollow-structure microsphere. The application refers to application of the sulfur-copper-tin-zinc hollow-structure microsphere in the preparation of photocatalysts. The preparation method of the invention is simple to perform and has very high catalytic effect in terms of light degradation of Rhodamine B(RhB) and hydrogen production by photocatalytic degradation of water.

Owner:KUNMING UNIV

Transparent Conducting Oxide As Top-Electrode In Perovskite Solar Cell By Non-Sputtering Process

InactiveUS20180123066A1Solid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEvaporation

Techniques for forming a transparent conducting oxide (TCO) top contact using a low temperature process are provided. In one aspect of the invention, a method of forming a TCO on a substrate is provided. The method includes the steps of: generating a source gas of the TCO using e-beam evaporation; generating atomic oxygen using RF plasma; and contacting the substrate with the TCO source gas and the atomic oxygen under conditions sufficient to form the TCO on the substrate. A photovoltaic device is also provided which includes a bottom cell; and a perovskite-based top cell on the kesterite-based bottom cell. The perovskite-based top cell includes a top electrode formed from a TCO.

Owner:INT BUSINESS MASCH CORP

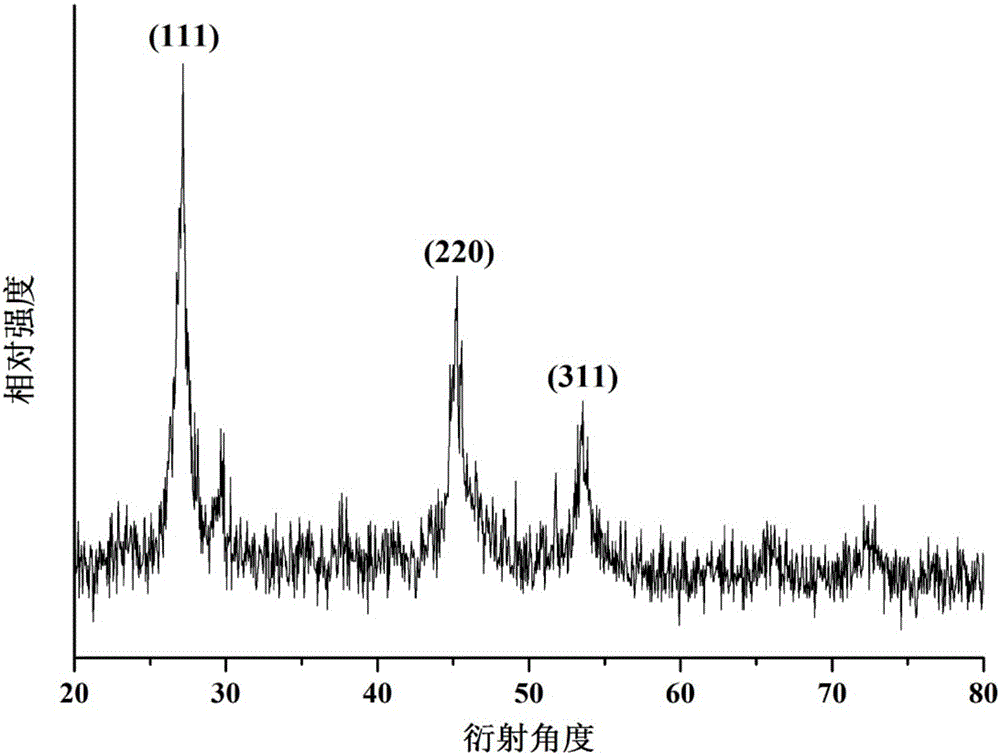

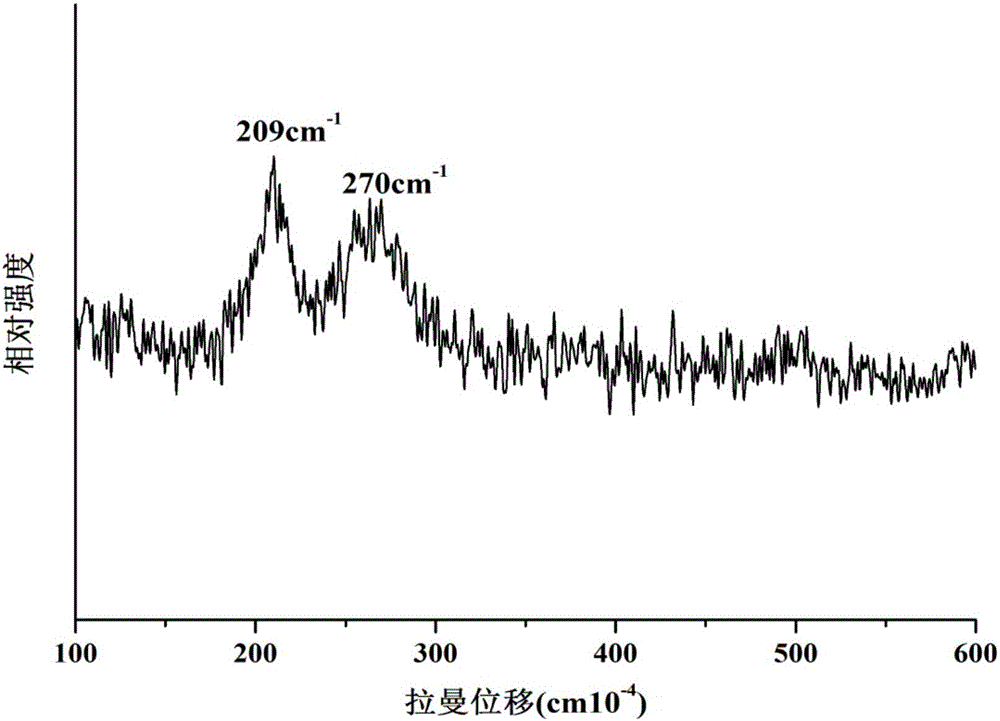

Stannite structure Cu2FeSnSe4 powder material and liquid phase preparation method thereof

InactiveCN105692567ALow costStrong reductionSelenium/tellurium compounds with other elementsShielding gasNitrogen gas

The invention discloses a kesterite structure Cu for solar photovoltaic cells 2 FeSnSe 4 A powder material and a liquid phase preparation method thereof, comprising the steps of: making the raw material CuCl 2 2H 2 O, FeCl 3 ·6H 2 O, SnCl 4 ·5H 2 O. The selenium powder is weighed by molar ratio and put into a three-necked round-bottomed flask for mixing, and then an organic solvent triethylenetetramine solution is added to obtain a uniform light blue solution; nitrogen is used as a protective gas and placed in a constant temperature oil bath Heated to 200-230°C in medium temperature and kept for 0.5-12 hours, then cooled to room temperature naturally; washed with absolute ethanol and distilled water in sequence, then filtered and dried to obtain a black powder. The kesterite structure Cu 2 FeSnSe 4 The liquid-phase preparation method of powder materials is green and pollution-free, the reaction time is short, the required temperature is low, the operation is simple, the cost is low, and it is suitable for Cu 2 FeSnSe 4 Powder materials are used in the industrialization of photovoltaic cell absorber layers.

Owner:CENT SOUTH UNIV

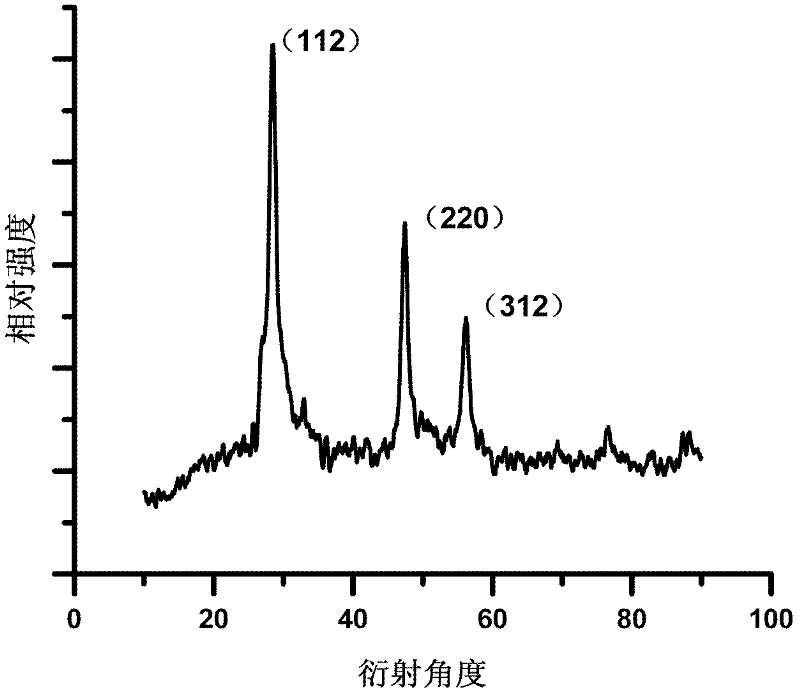

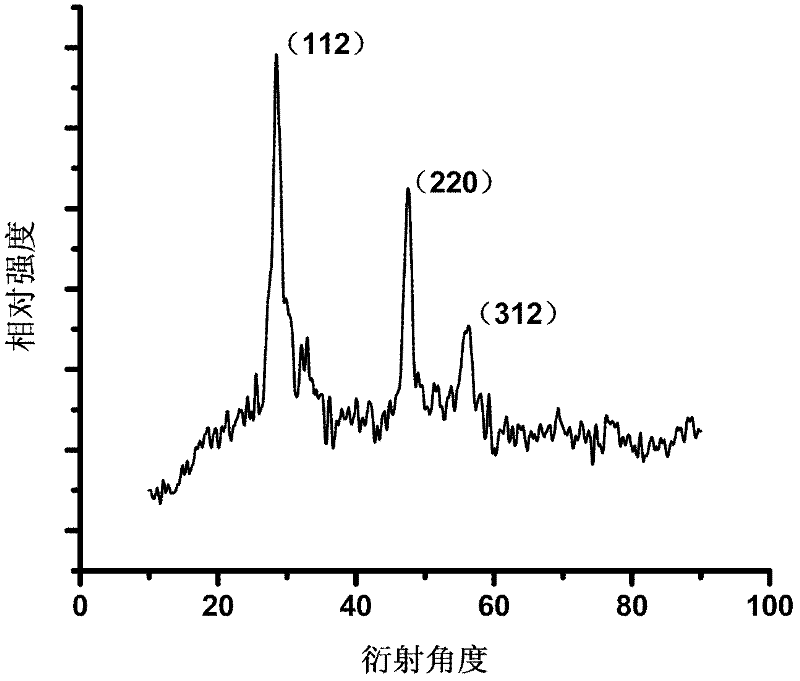

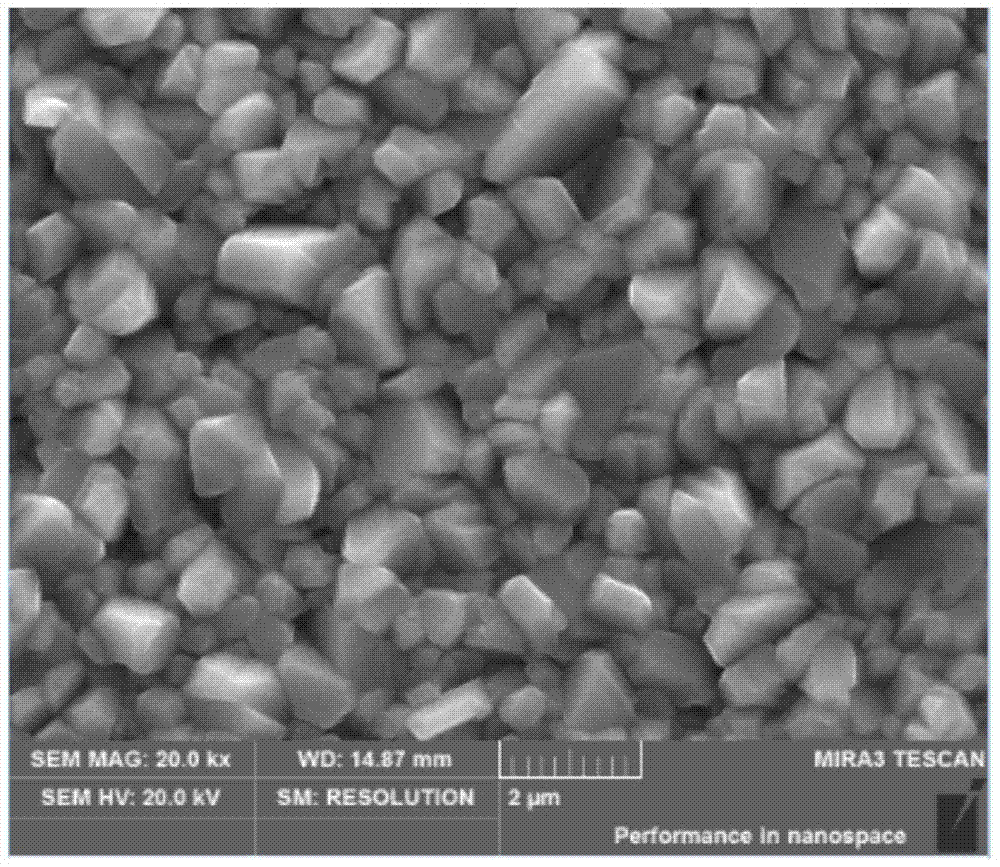

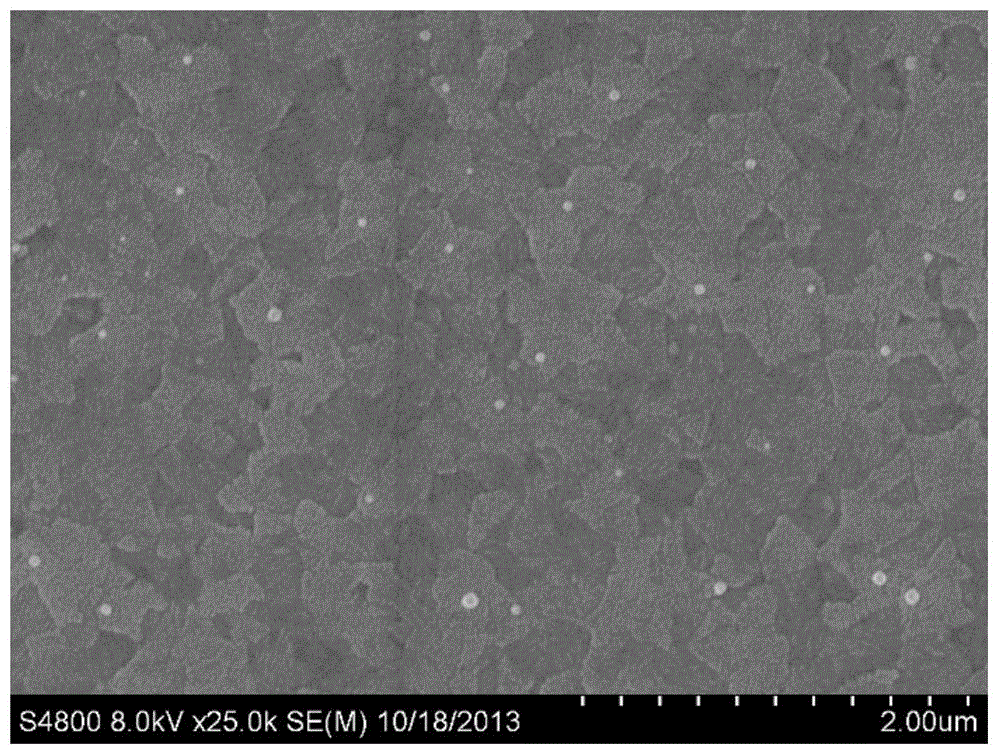

Preparation of columnar granular copper zinc cadmium sulfur (CZCTSSe) thin-film absorption layer and application of layer in solar cell

ActiveCN107611019AImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingCadmium CationAbsorption layer

The invention provides preparation of a columnar granular copper zinc cadmium sulfur (CZCTSSe) thin-film absorption layer and application of the layer in a solar cell and belongs to the technical field of thin-film solar cells. The surface of the absorption layer is compact, the grain size is 200-500 nm. The cross section of the absorption layer consists of columnar grains arranged tightly, and nohole nor crack exists in a thin film. The columnar granular CZCTSSe absorption layer is smaller and uniform in grain size, and formed columnar grains can effectively decrease holes. The absorption layer is of a single-phase Kesterite-class sphalerite structure preferentially growing along a (112) crystal surface. The columnar grains CZCTSSe are used as an absorption layer to synthesize a Mo / CZCTSSe / CdS / i-ZnO / ZnO: Al / Al copper-based thin-film solar cell. Consequently, it is found that the open circuit voltage of four solar cells synthesized under the same conditions is 0.38-0.43 V; the short circuit current is 30.9-35.1 mA cm<2>; the conversion efficiency is 7.03%-7.12%. It indicates that the conversion efficiency of the solar cells is stable, floating is small and the efficiency is high.

Owner:JILIN INST OF CHEM TECH

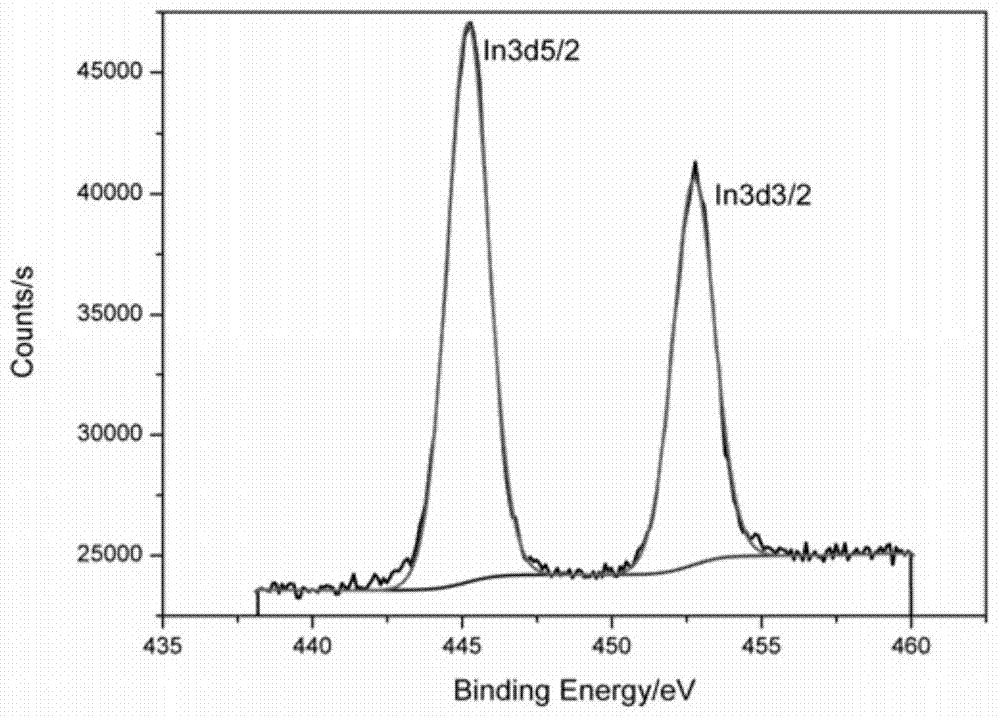

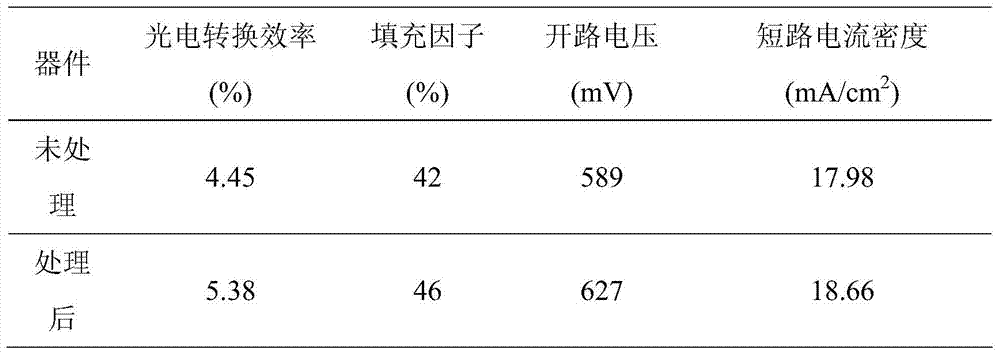

A surface treatment method for a light-absorbing layer of a kesterite-structured thin-film solar cell

ActiveCN104617186BIncrease the open circuit voltageImprove fill factorFinal product manufacturePhotovoltaic energy generationZincAbsorption layer

Owner:浙江铱太科技有限公司

Titanium incorporation into absorber layer for solar cell

Owner:GLOBALFOUNDRIES INC

Preparation method and product of vitamin C-coated copper zinc tin sulfide nanoparticles

ActiveCN105776320ARegular shapeUniform particle sizeMaterial nanotechnologyTin compoundsVitamin CThiourea

The invention discloses a preparation method of vitamin C-coated copper zinc tin sulfide nanoparticles. According to the invention, metal sources and vitamin C are mixed with dimethyl sulfoxide, such that a metal source solution is obtained, wherein the metal sources are metal chloride or metal acetate; a sulfur source is mixed with a mixed solvent of protic solvent / dimethyl sulfoxide, such that a sulfur source solution is obtained, wherein the sulfur source is sodium sulfide, ethanethiol or thiourea; the sulfur source solution is dropped into the metal source solution, and a reaction is allowed for 2-20h under a temperature of 100-180 DEG C; and through centrifugal separation, the vitamin C-coated copper zinc tin sulfide nanoparticles are obtained. The preparation method of the vitamin C-coated copper zinc tin sulfide nanoparticles is carried out under a normal pressure. The reaction conditions are mild, and the reaction process is controllable, such that the method is suitable for large-scale industrialized production. With the method, coated copper zinc tin sulfide nanoparticles with vitamin C as a ligand and with a kesterite crystal form are obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

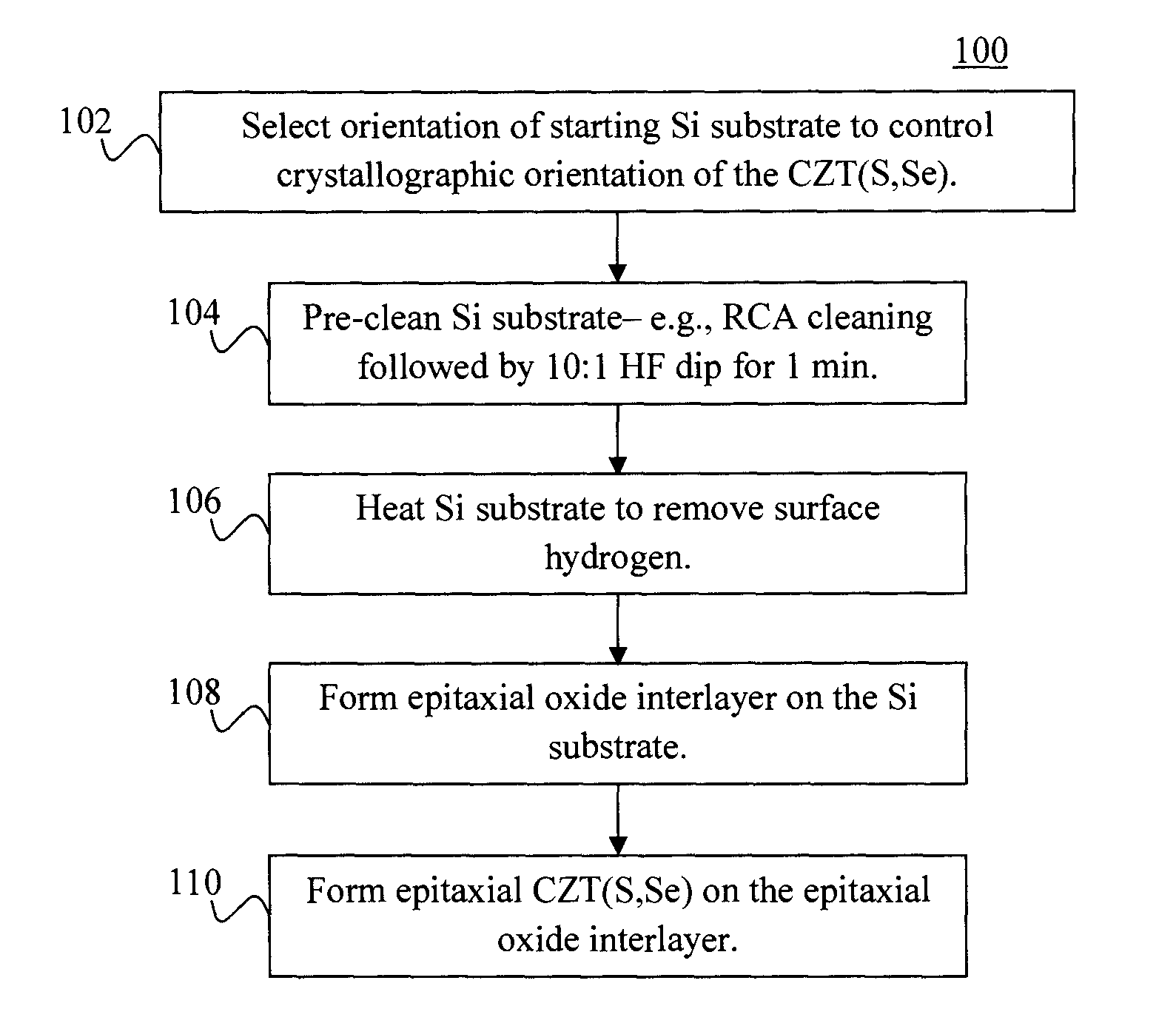

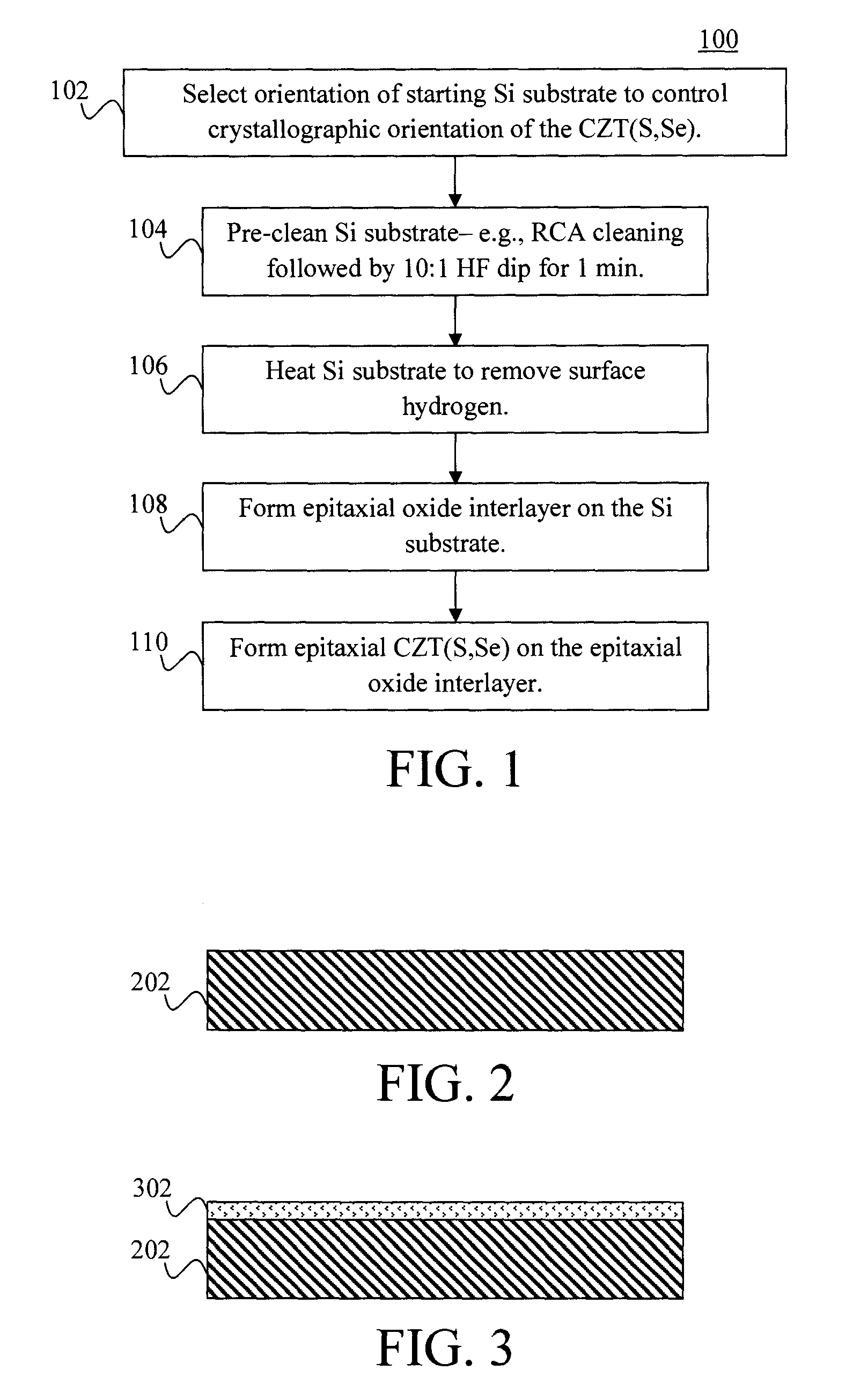

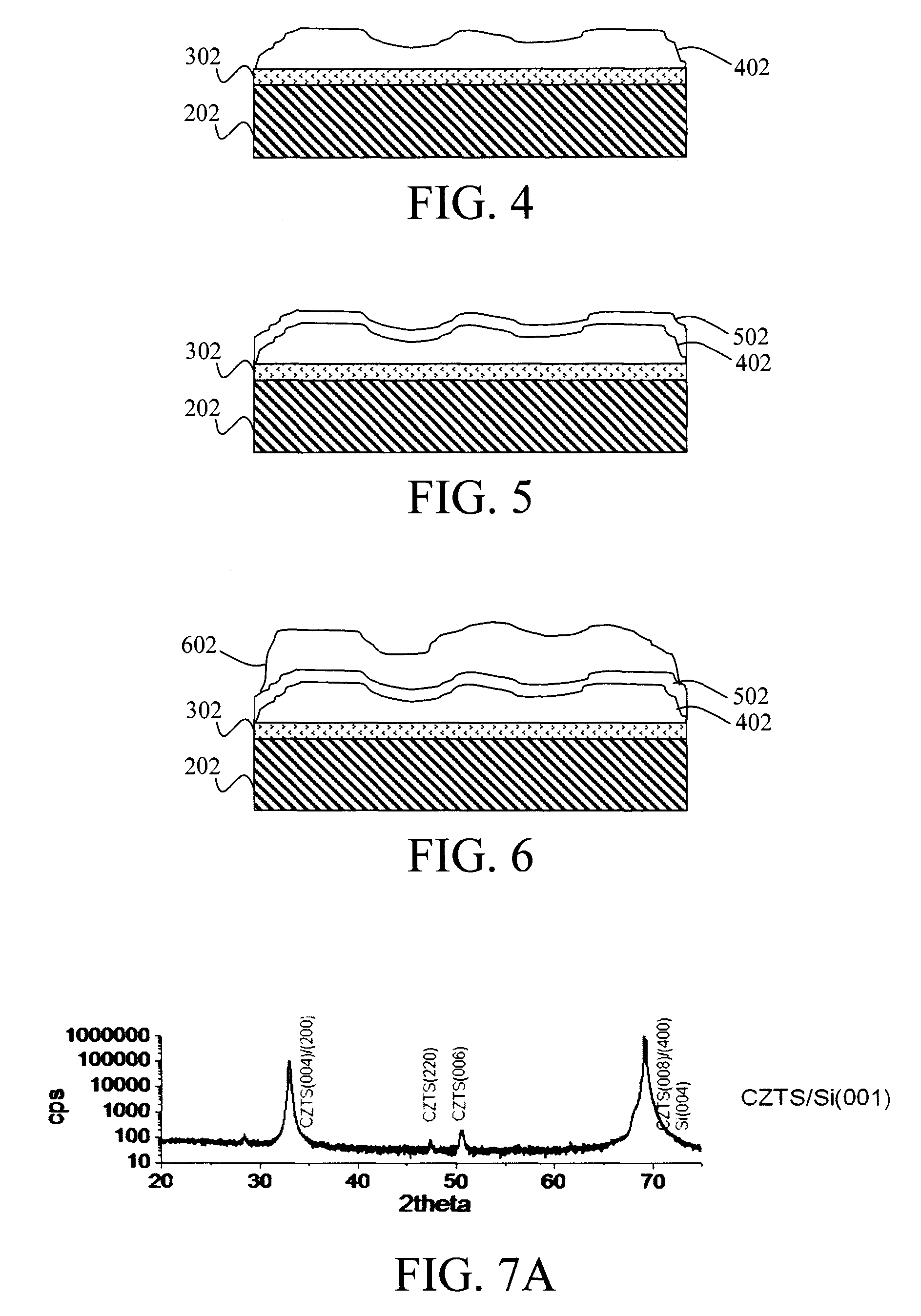

Epitaxial growth of CZT(S,Se) on silicon

ActiveUS9287426B1Improve wettabilitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationZincSilicon

Techniques for epitaxial growth of CZT(S,Se) materials on Si are provided. In one aspect, a method of forming an epitaxial kesterite material is provided which includes the steps of: selecting a Si substrate based on a crystallographic orientation of the Si substrate; forming an epitaxial oxide interlayer on the Si substrate to enhance wettability of the epitaxial kesterite material on the Si substrate, wherein the epitaxial oxide interlayer is formed from a material that is lattice-matched to Si; and forming the epitaxial kesterite material on a side of the epitaxial oxide interlayer opposite the Si substrate, wherein the epitaxial kesterite material includes Cu, Zn, Sn, and at least one of S and Se, and wherein a crystallographic orientation of the epitaxial kesterite material is based on the crystallographic orientation of the Si substrate. A method of forming an epitaxial kesterite-based photovoltaic device and an epitaxial kesterite-based device are also provided.

Owner:IBM CORP

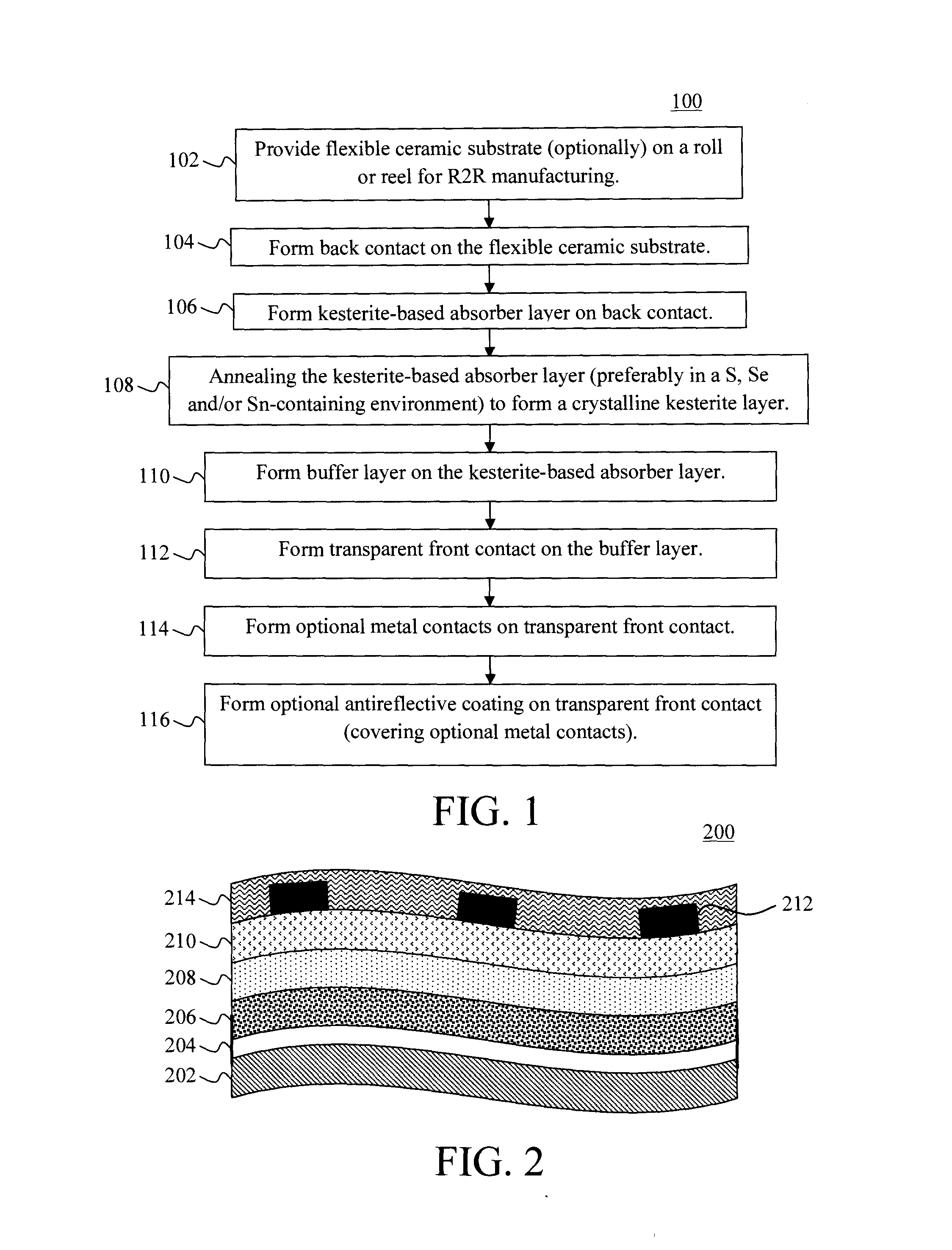

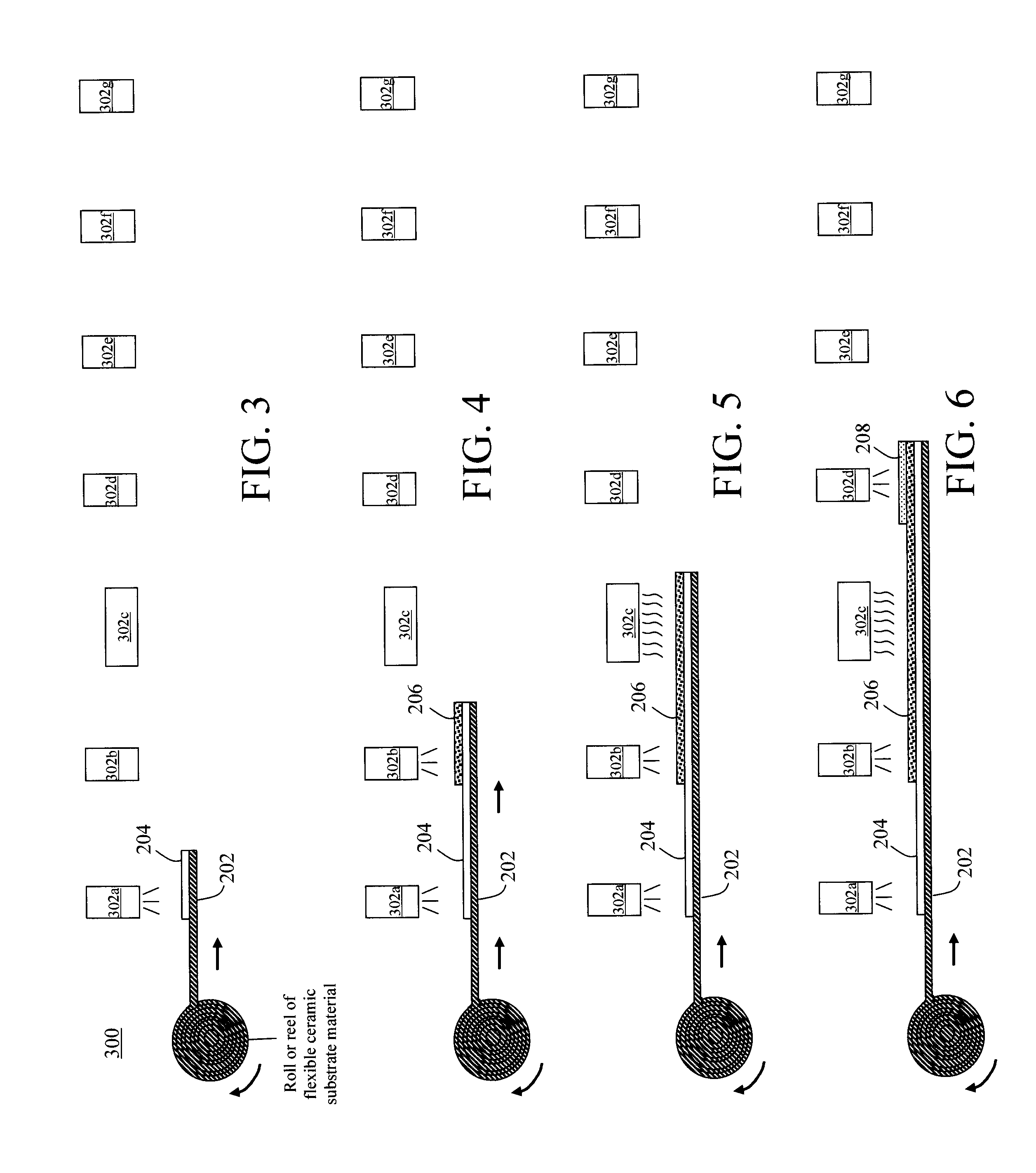

Flexible Kesterite Photovoltaic Device on Ceramic Substrate

InactiveUS20160126377A1Final product manufactureSemiconductor/solid-state device manufacturingDevice formOptoelectronics

Kesterite-based photovoltaic devices formed on flexible ceramic substrates are provided. In one aspect, a method of forming a photovoltaic device includes the steps of: forming a back contact on a flexible ceramic substrate; forming a kesterite absorber layer on a side of the back contact opposite the flexible ceramic substrate; annealing the kesterite absorber layer; forming a buffer layer on a side of the kesterite absorber layer opposite the back contact; and forming a transparent front contact on a side of the buffer layer opposite the kesterite absorber layer. A roll-to-roll-based method of forming a photovoltaic device and a photovoltaic device are also provided.

Owner:IBM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com