Titanium incorporation into absorber layer for solar cell

a solar cell and absorber layer technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve the problems of large vsub>oc/sub>deficit of czts devices, difficult to achieve an efficiency above 11%, and relatively low performance of czts solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]For making Ti-free devices, solution A (3.3M Cu2S) was made by dissolving Cu and S in hydrazine. Similarly, Sn and Se were stirred in hydrazine to form slurry B (1.5 M SnSes); Solution A and slurry B were mixed together and transferred to a vial containing zinc formate, yielding solution C with final composition Cu / (Zn+Sn)=0.8, Zn / Sn=1.22 and nominal kesterite CZTSSe concentration of approximately 0.4 M. The thin film CZTS absorber layer with final thickness of 2-2.5 microns was prepared by spin coating this mixture over six consecutive layers at 600 rpm and then subsequently subjecting it to a short anneal on a ceramic hot plate with a set point of 630 degrees C.

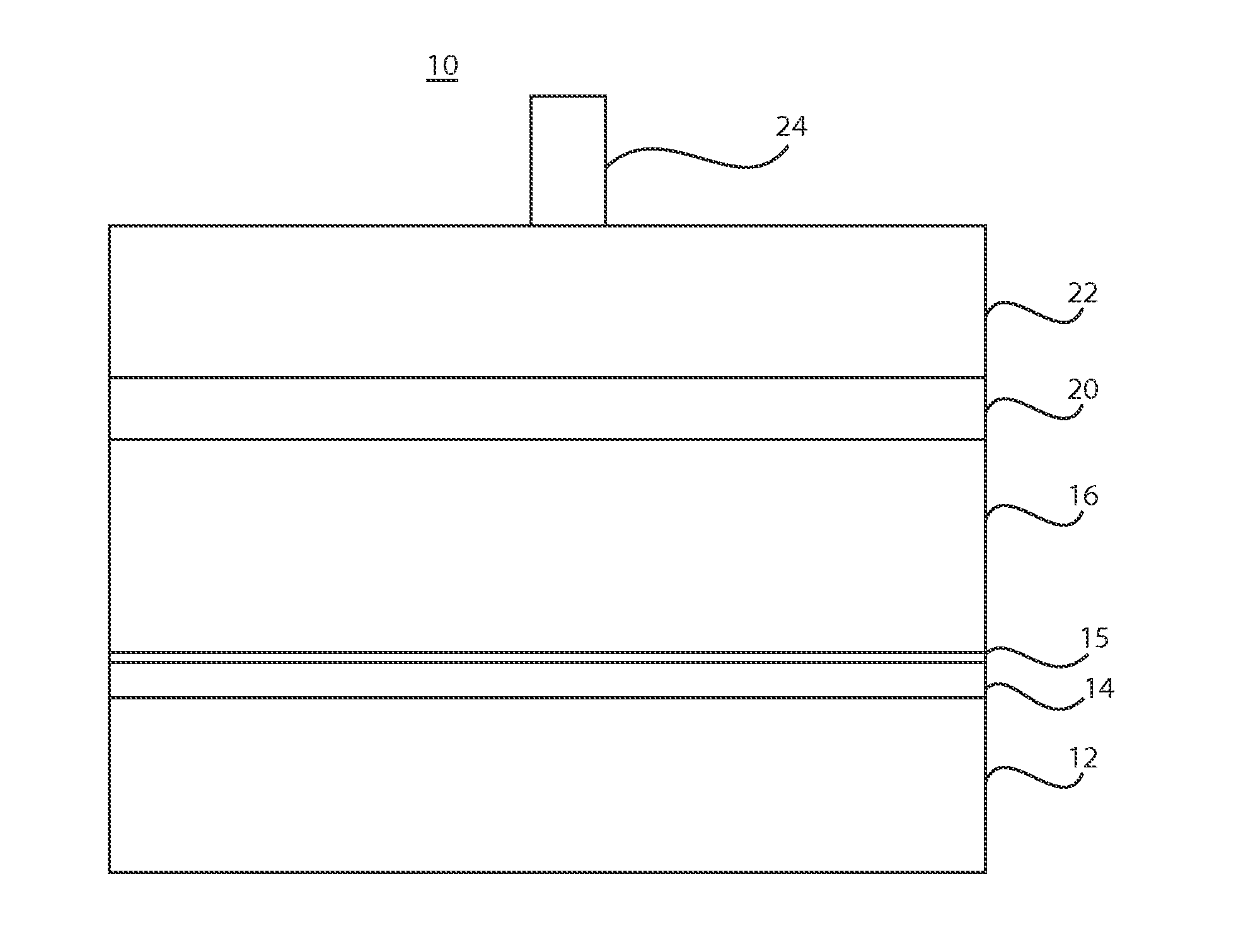

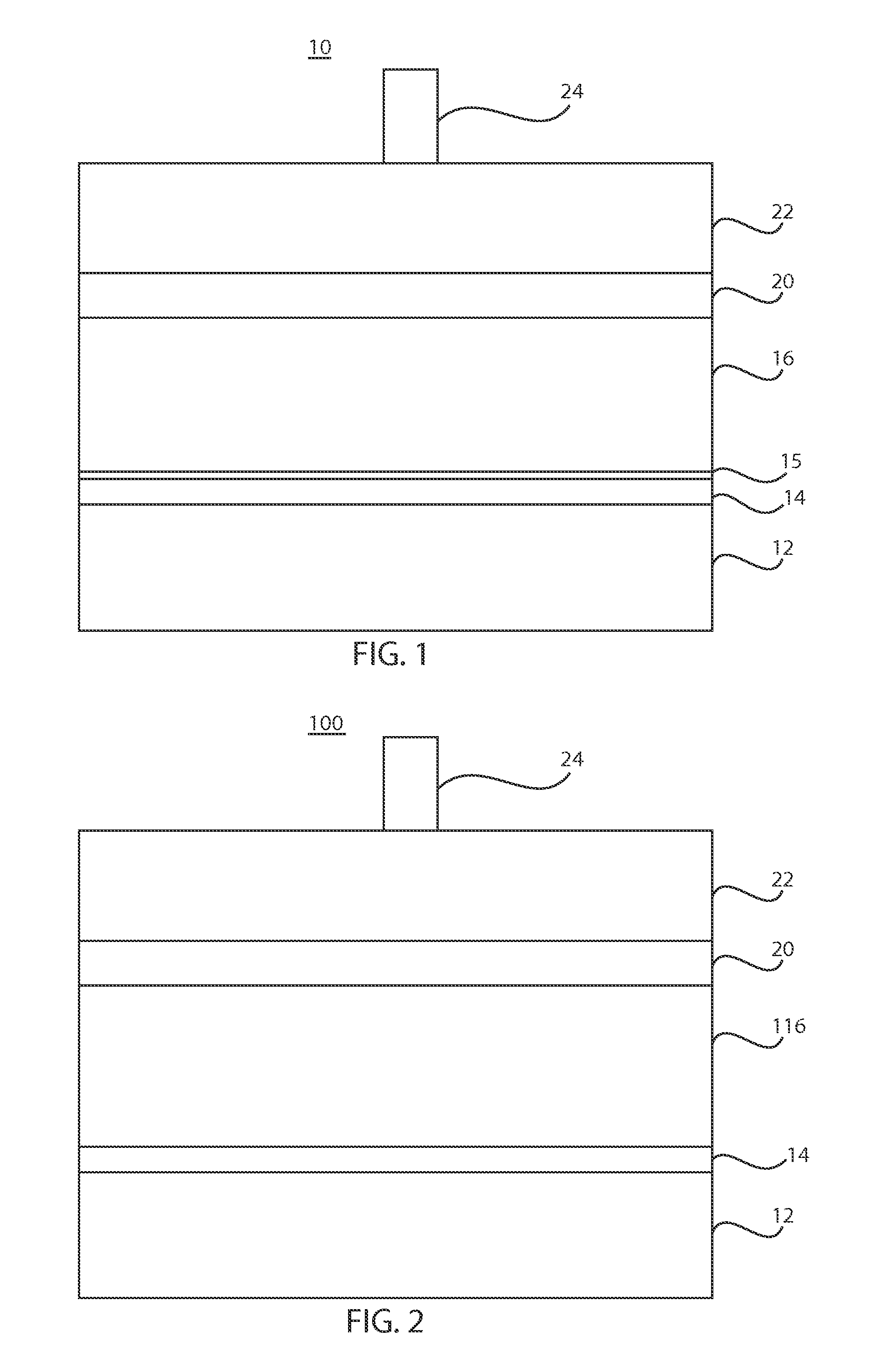

[0058]The CdS buffer, ZnO window, and indium doped tin oxide (ITO) layers were subsequently deposited by chemical bath deposition and RF magnetron sputtering, respectively, giving a CZTSSe device structure with a device area of approximately 0.45 cm2, as defined by mechanical scribing. A Ni / Al collection grid and 110-...

example 2

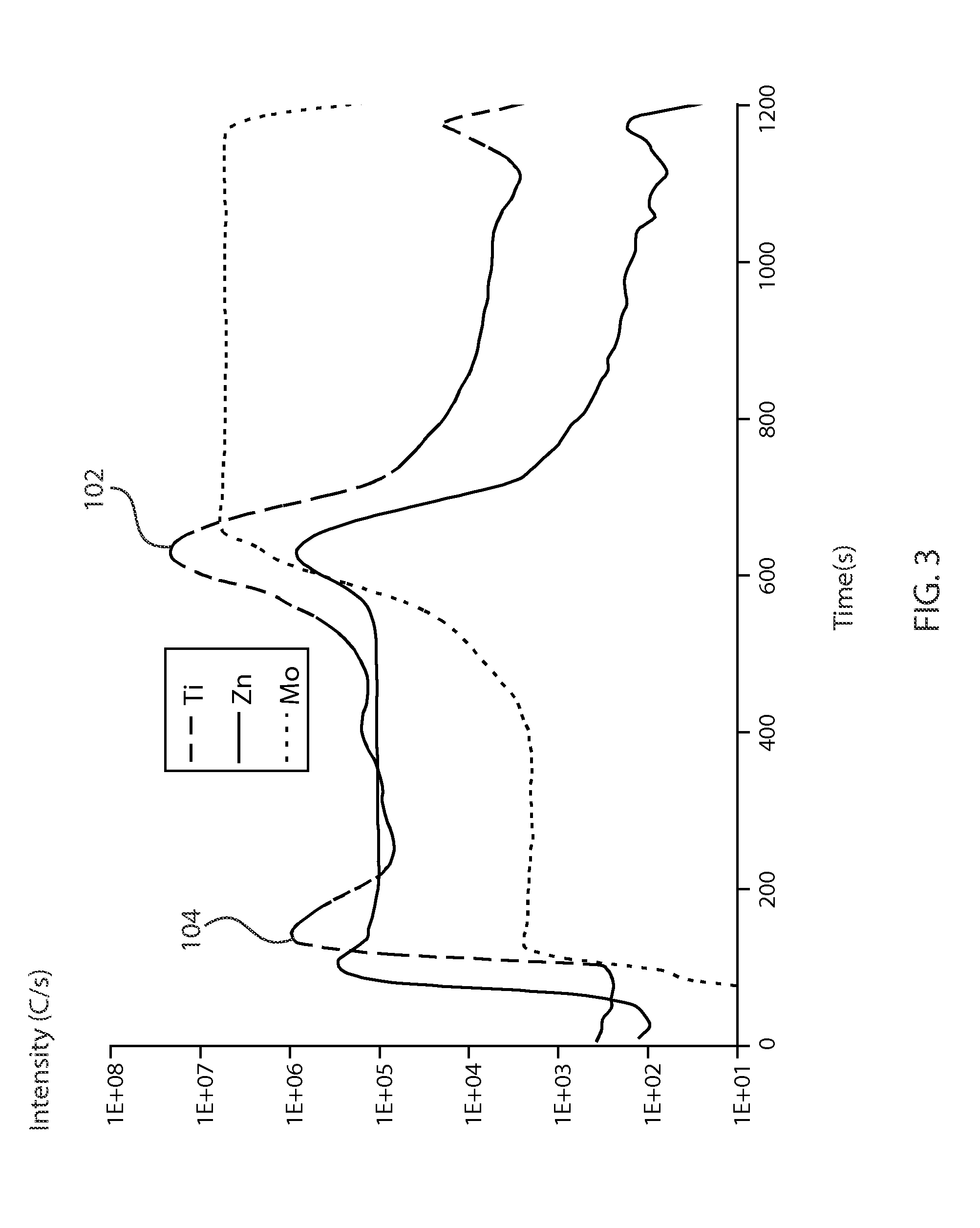

[0059]For making Ti-incorporating devices, a solution A (3.3M Cu2S) was made by dissolving Cu and S in hydrazine. Similarly, Sn and Se were stirred in hydrazine to form slurry B (1.5 M SnSes); Solution A and slurry B were mixed together and transferred to a vial containing zinc formate, yielding solution C with final composition Cu / (Zn+Sn)=0.8, Zn / Sn=1.22 and nominal kesterite CZTSSe concentration of approximately 0.4 M. A 20 nm titanium thin film was deposited on molybdenum-coated glass by electron-beam evaporation. The Ti- and Mo-coated glass was used as a substrate for CZTS deposition.

[0060]The thin film CZTS absorber layer with final thickness of 2-2.5 microns was prepared by spin coating this mixture over six consecutive layers at 600 rpm and then subsequently subjecting it to a short anneal on a ceramic hot plate with a set point of 630 degrees C. The CdS buffer, ZnO window, and indium doped tin oxide (ITO) layers were subsequently deposited by chemical bath deposition and RF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| open circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com