Patents

Literature

162results about "Preparation by oxo-reaction and reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

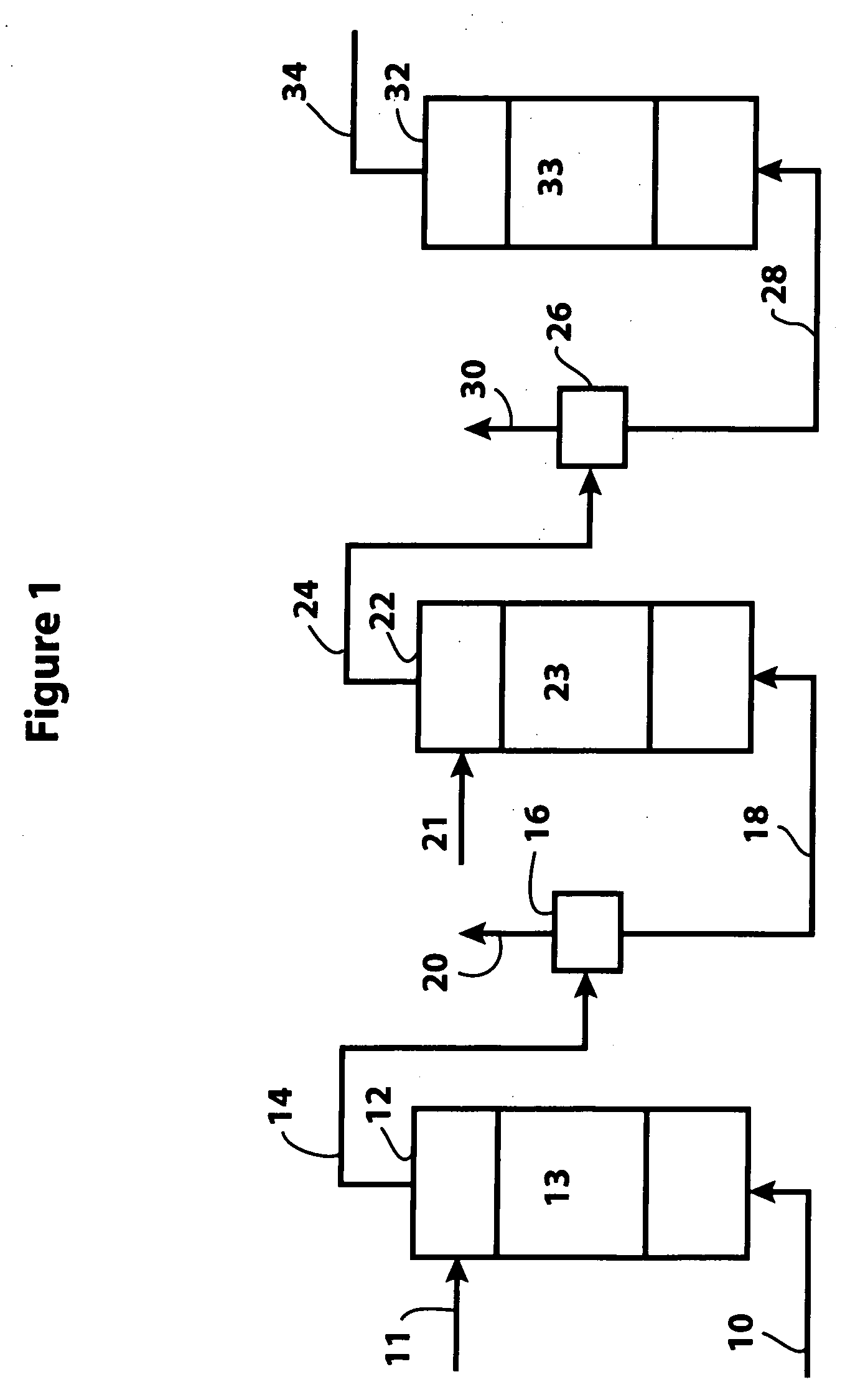

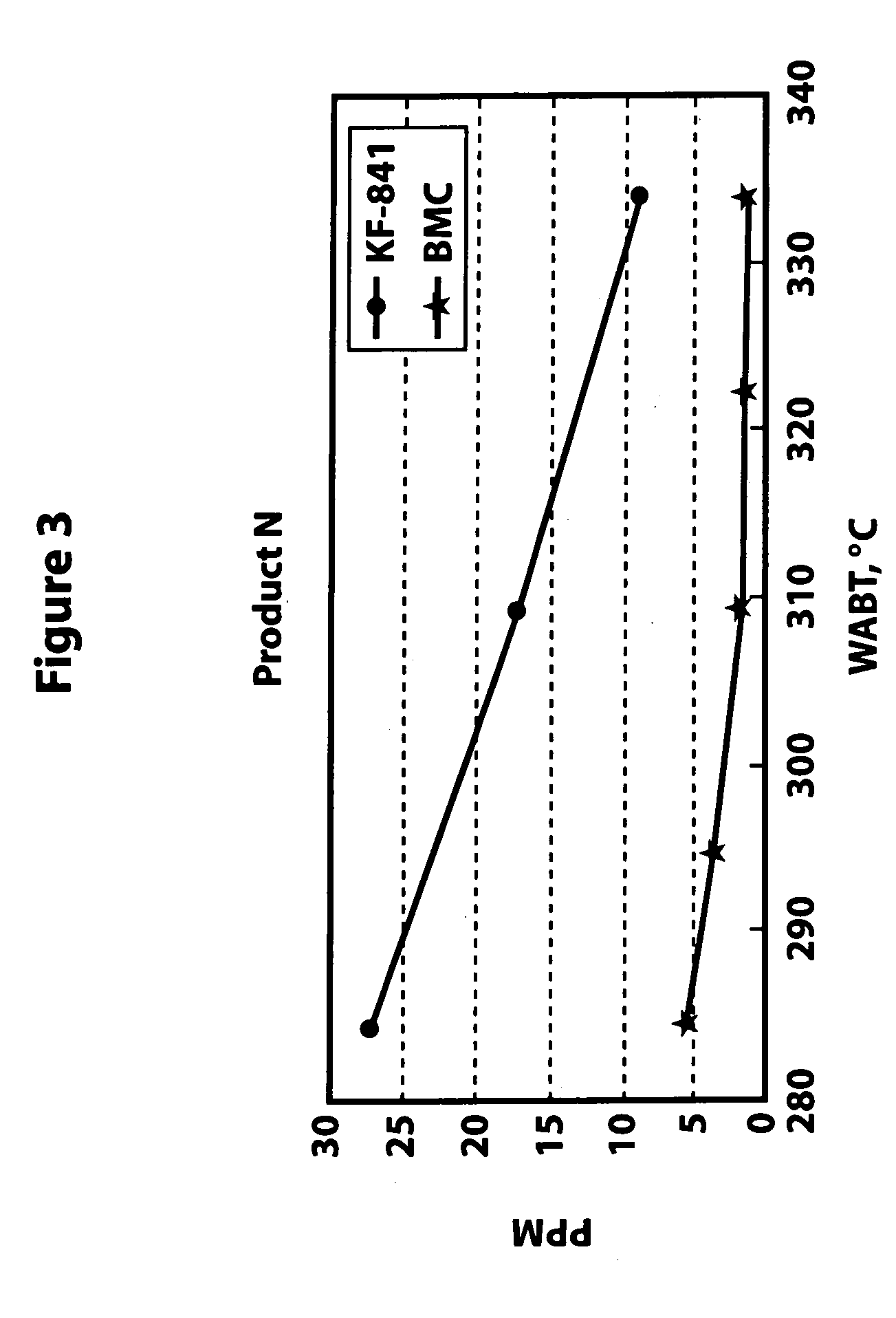

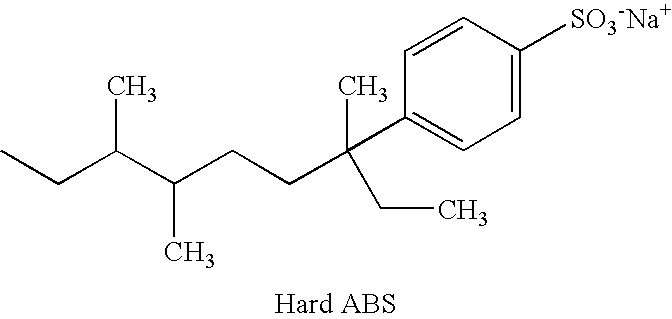

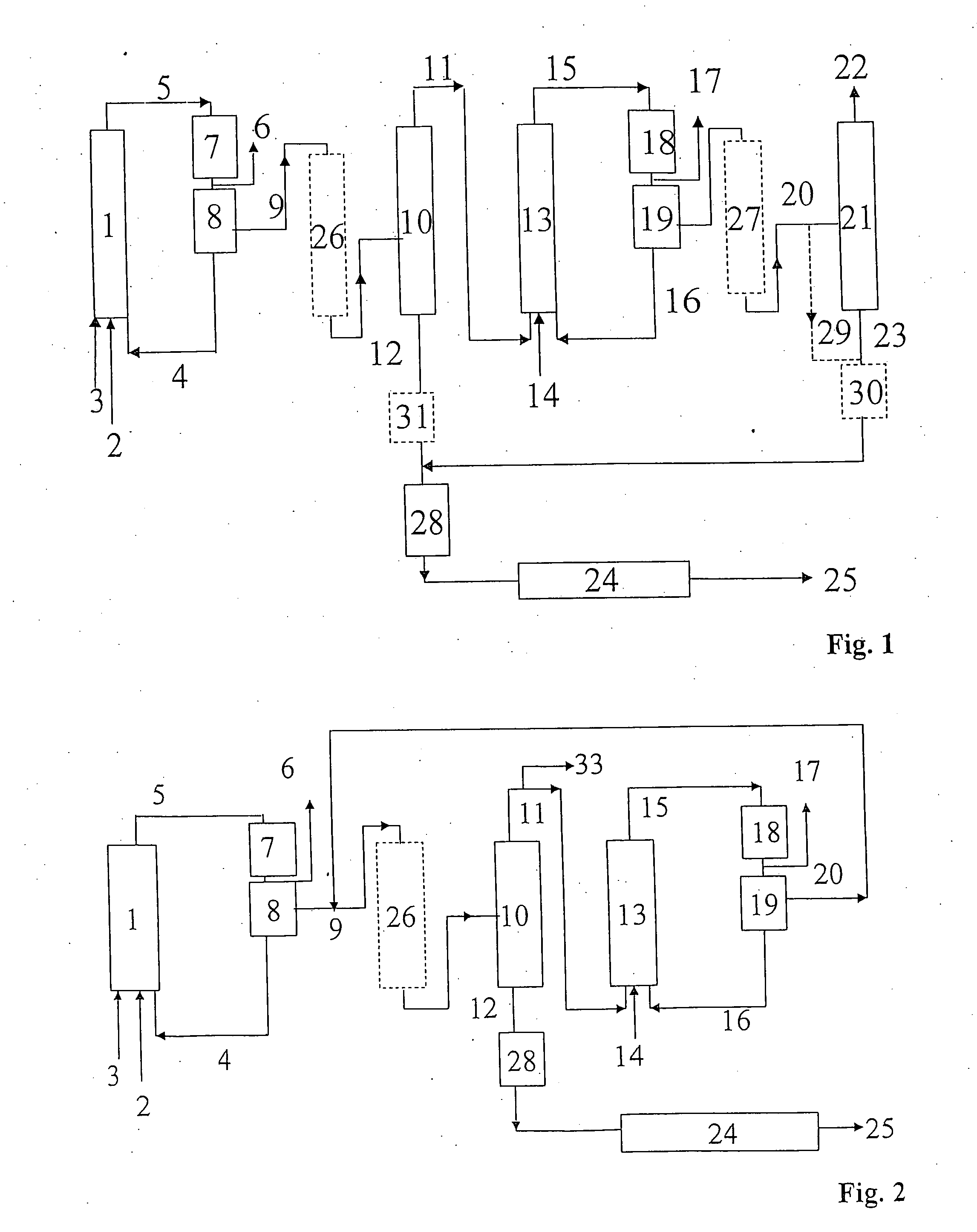

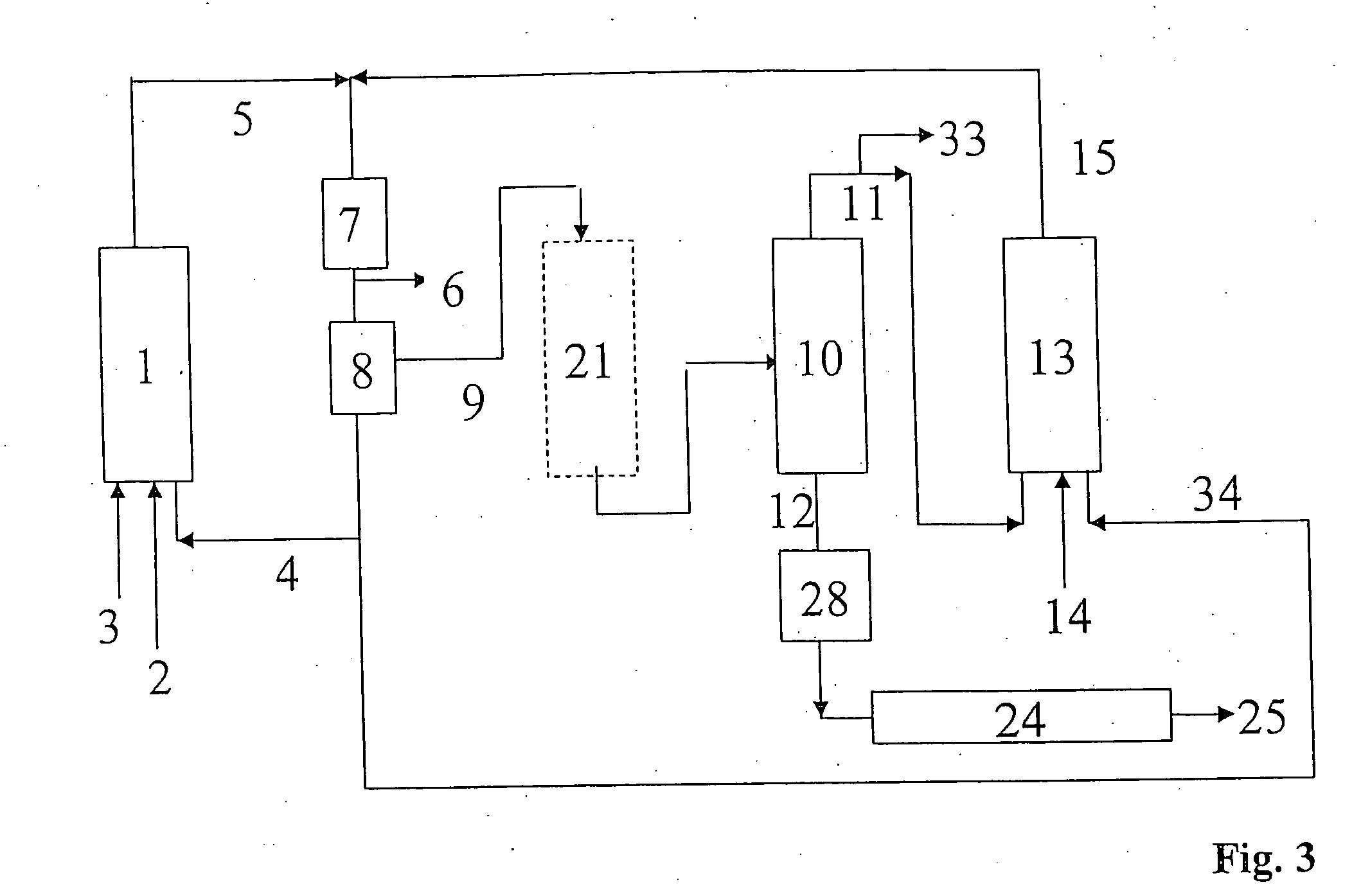

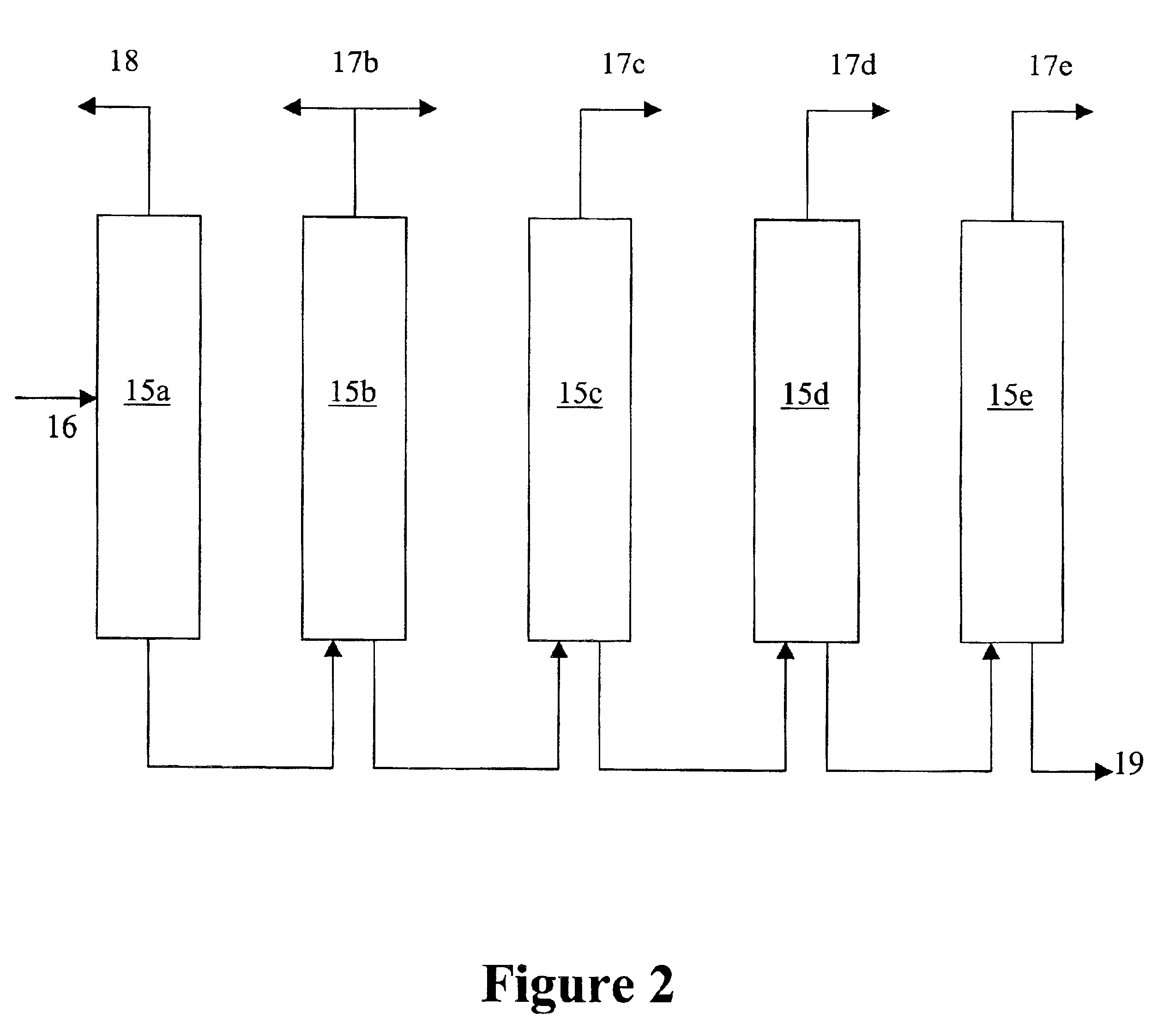

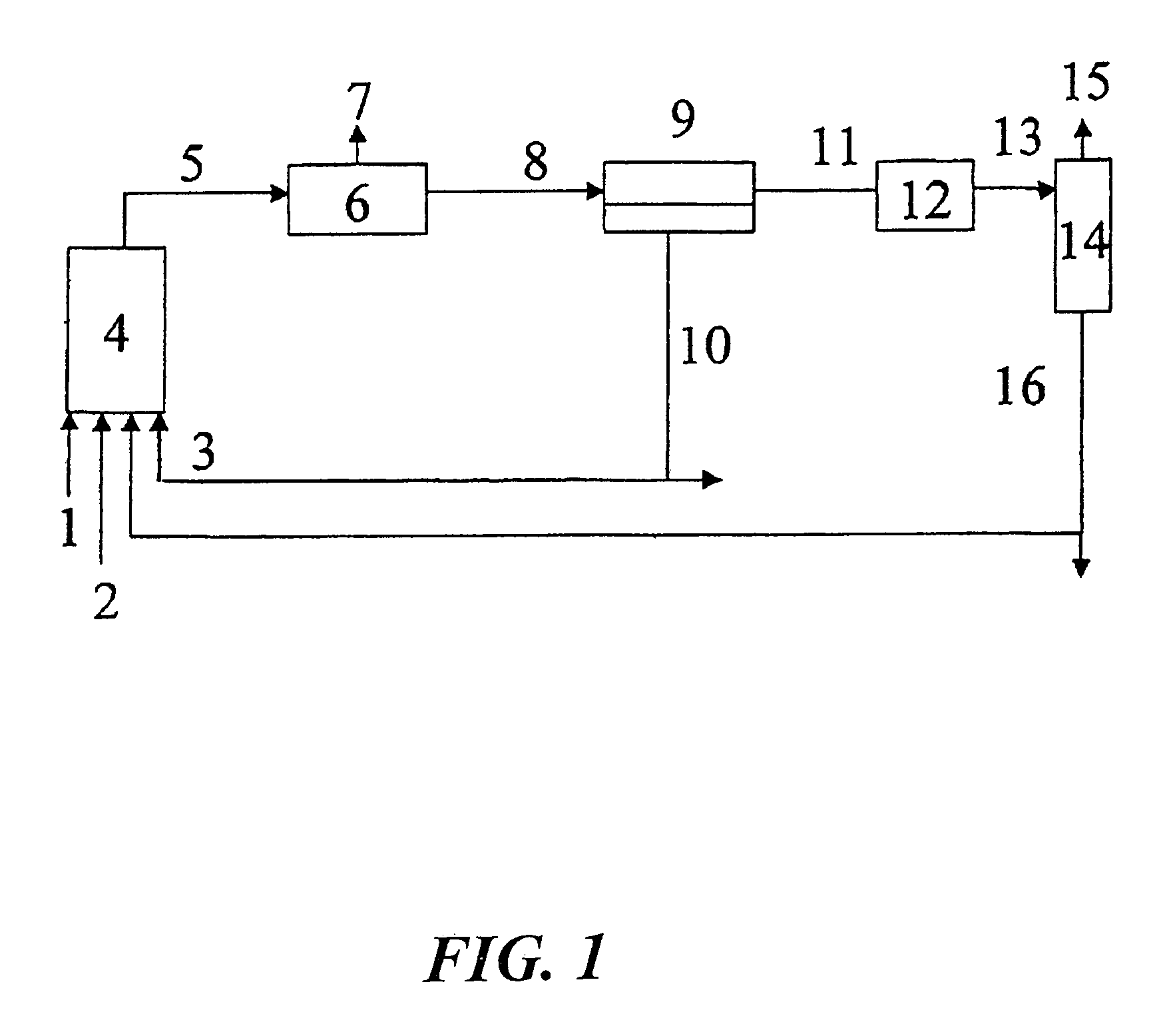

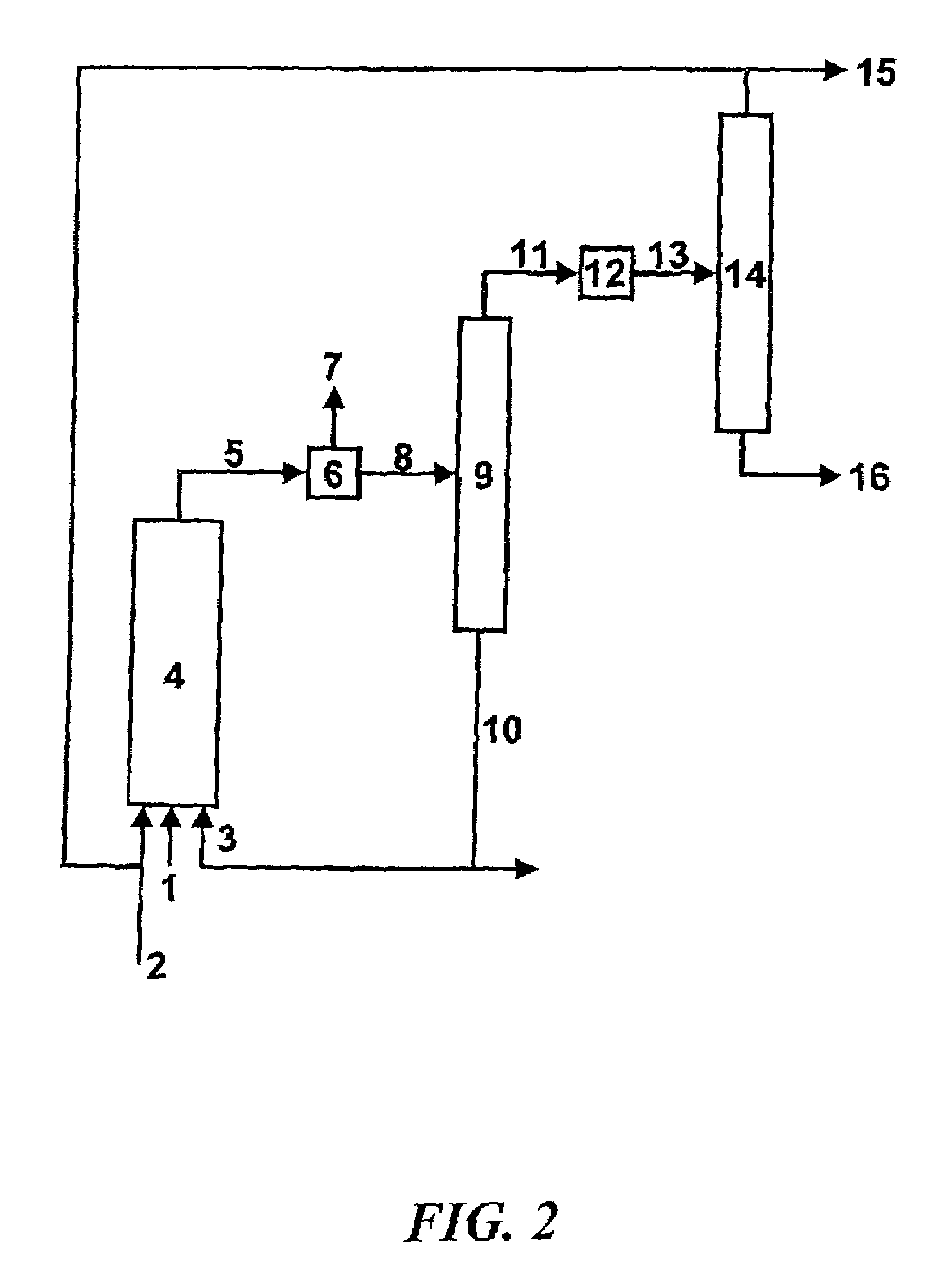

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Process for upgrading naphtha

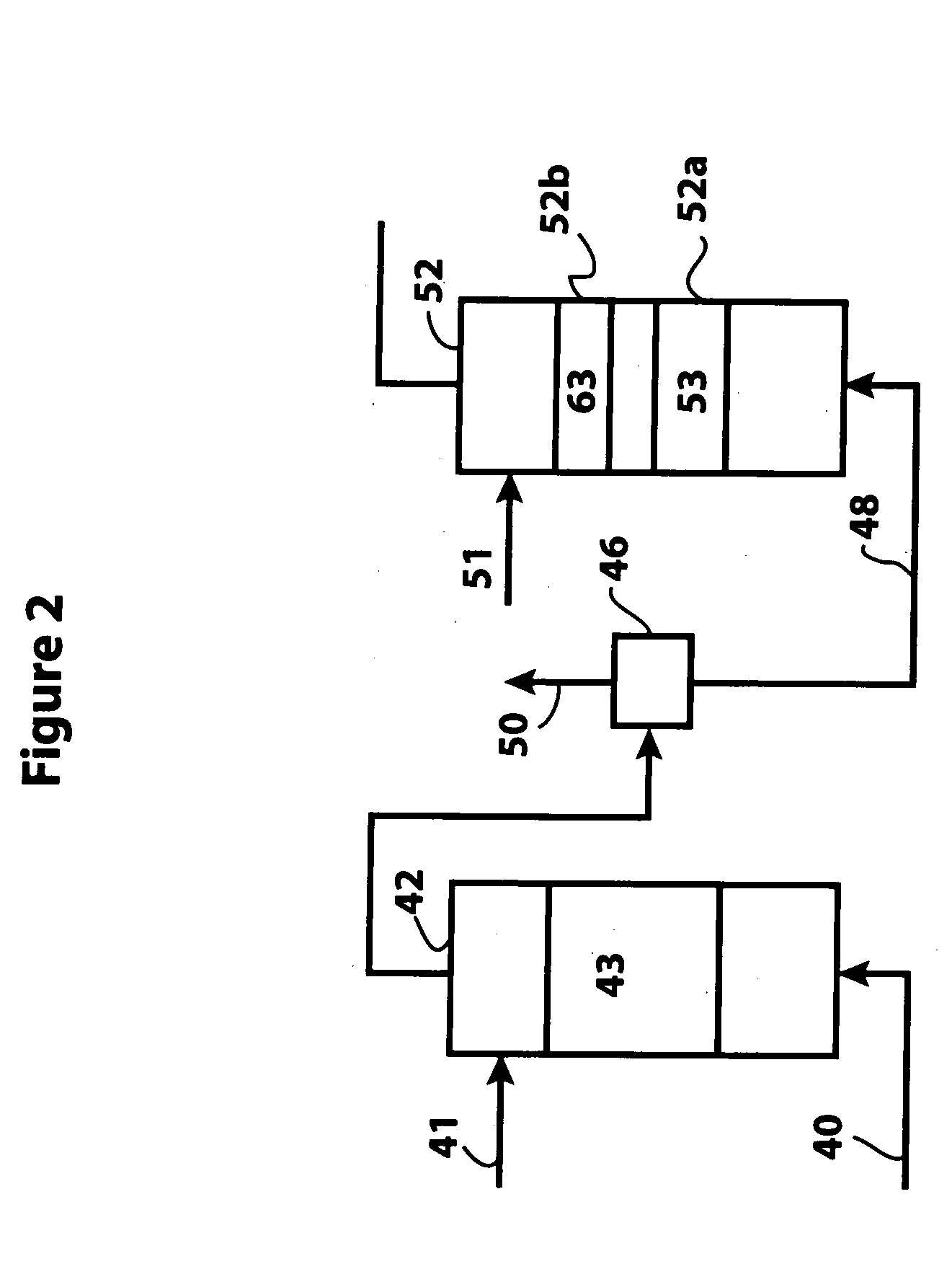

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

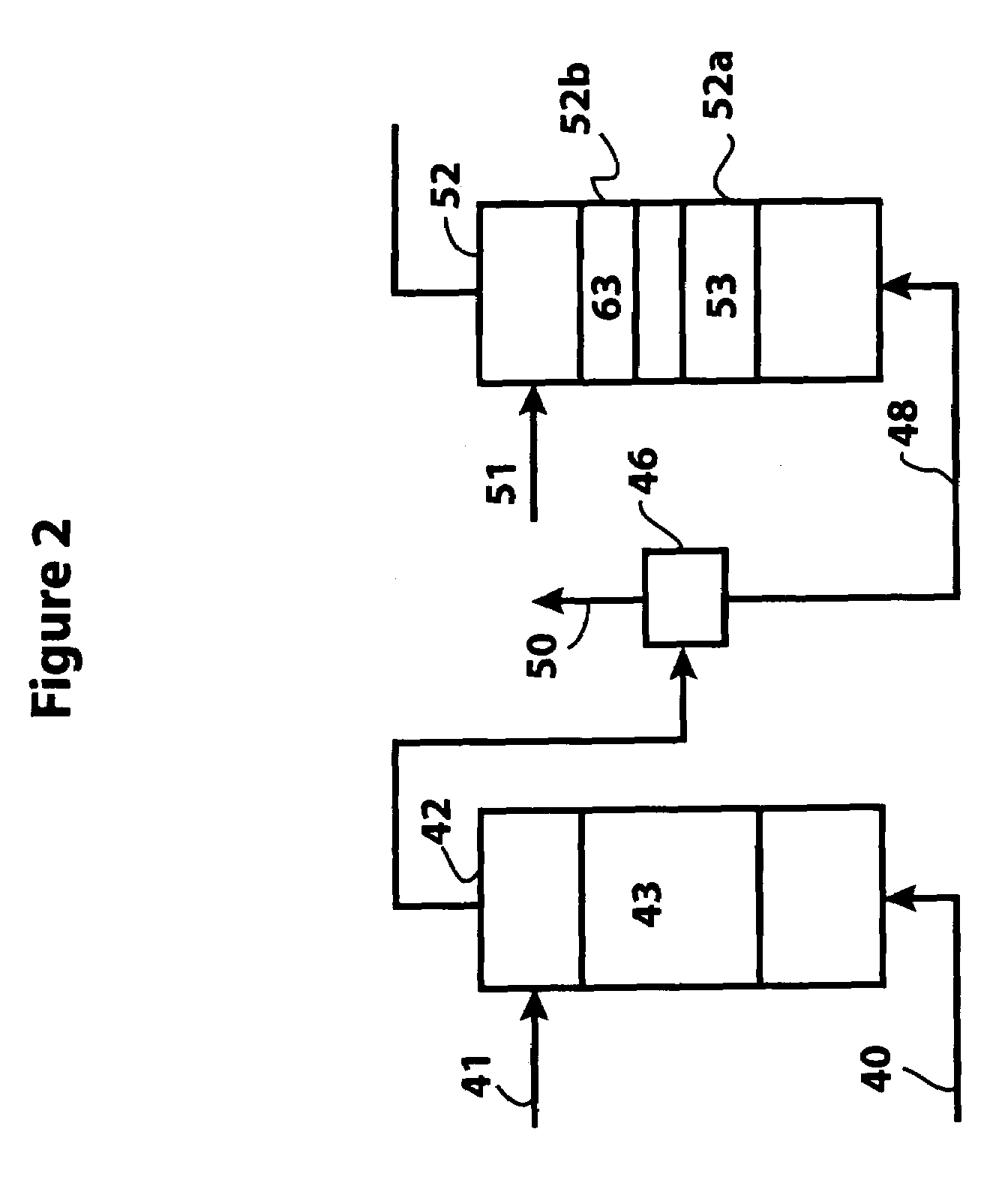

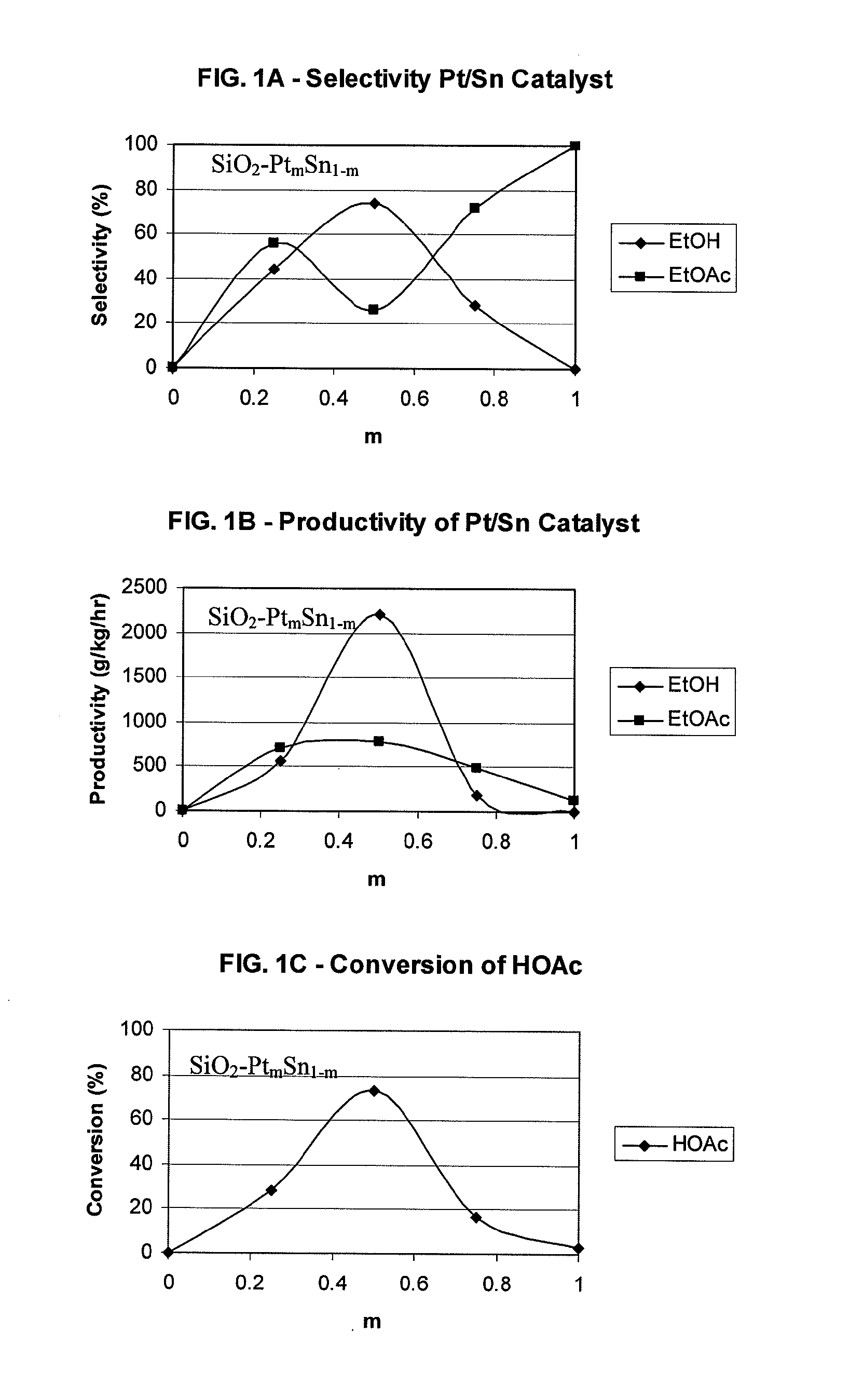

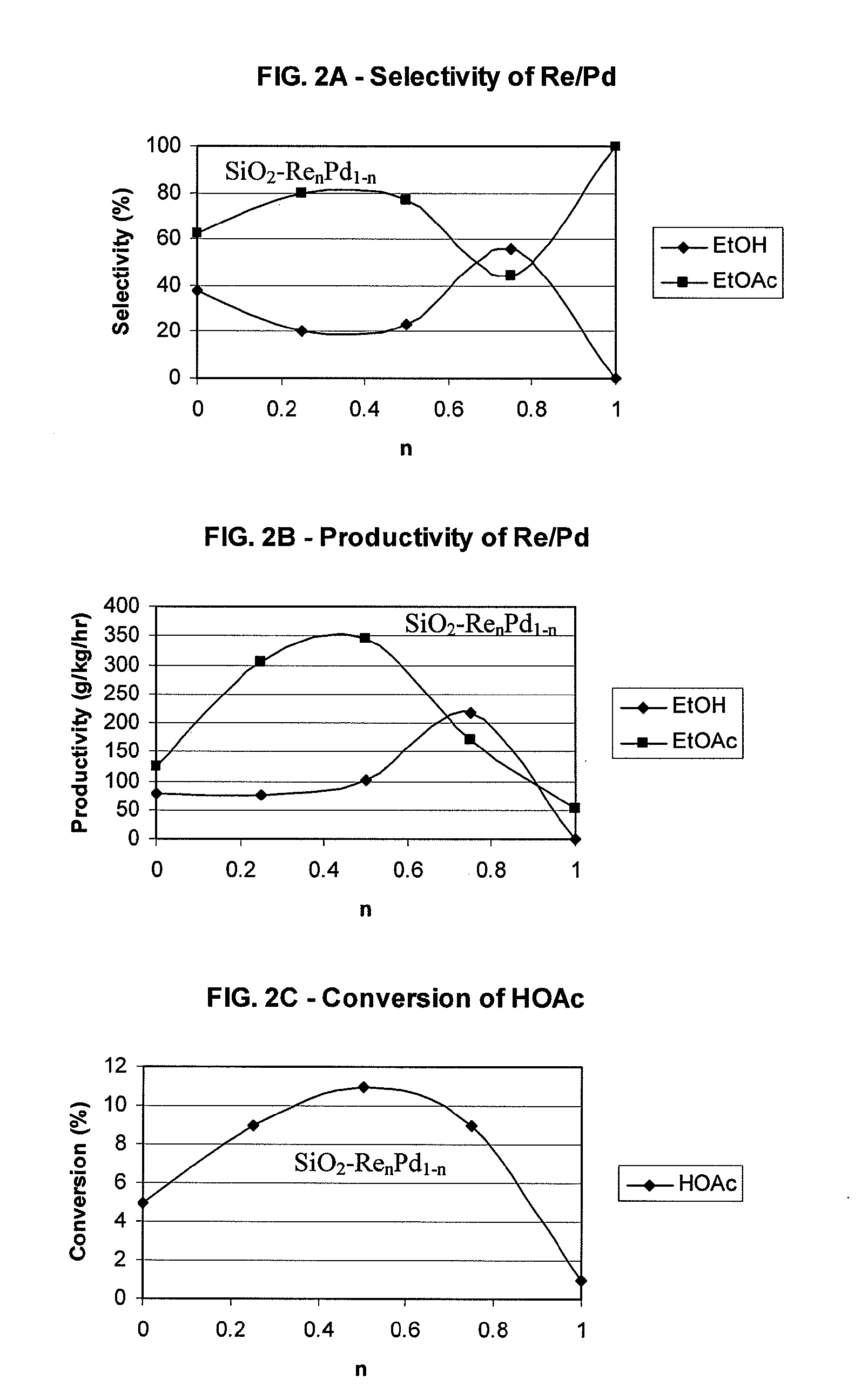

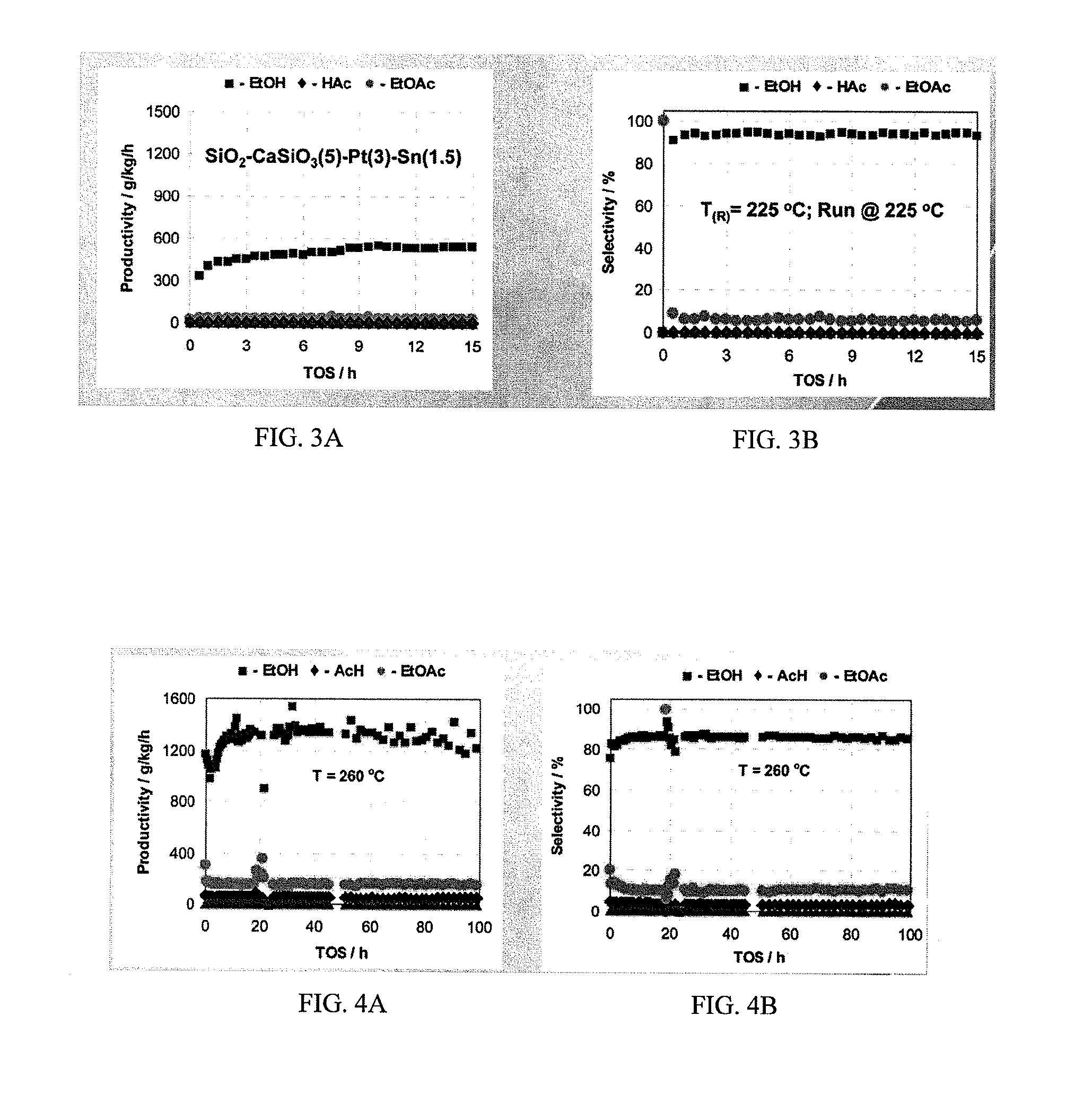

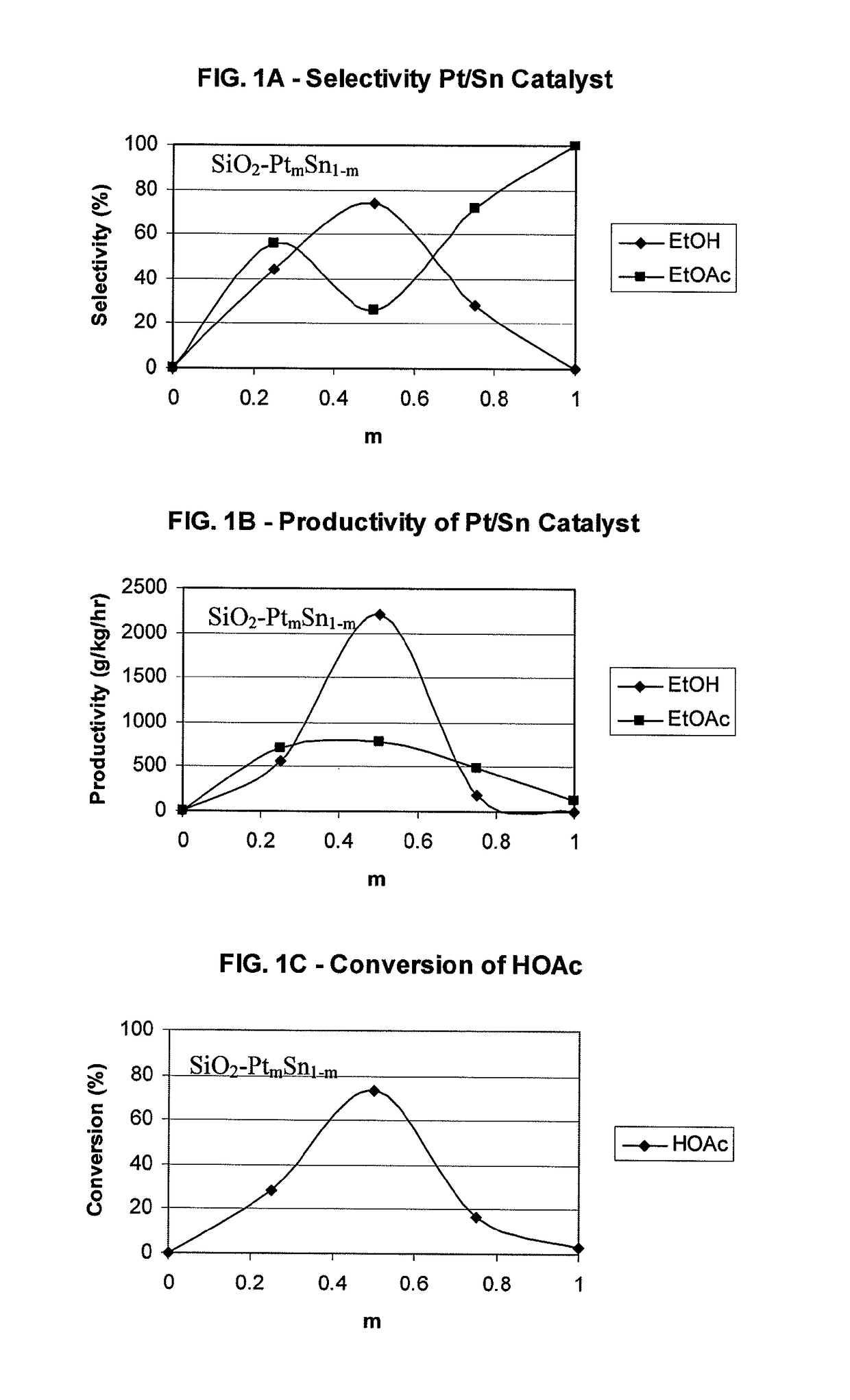

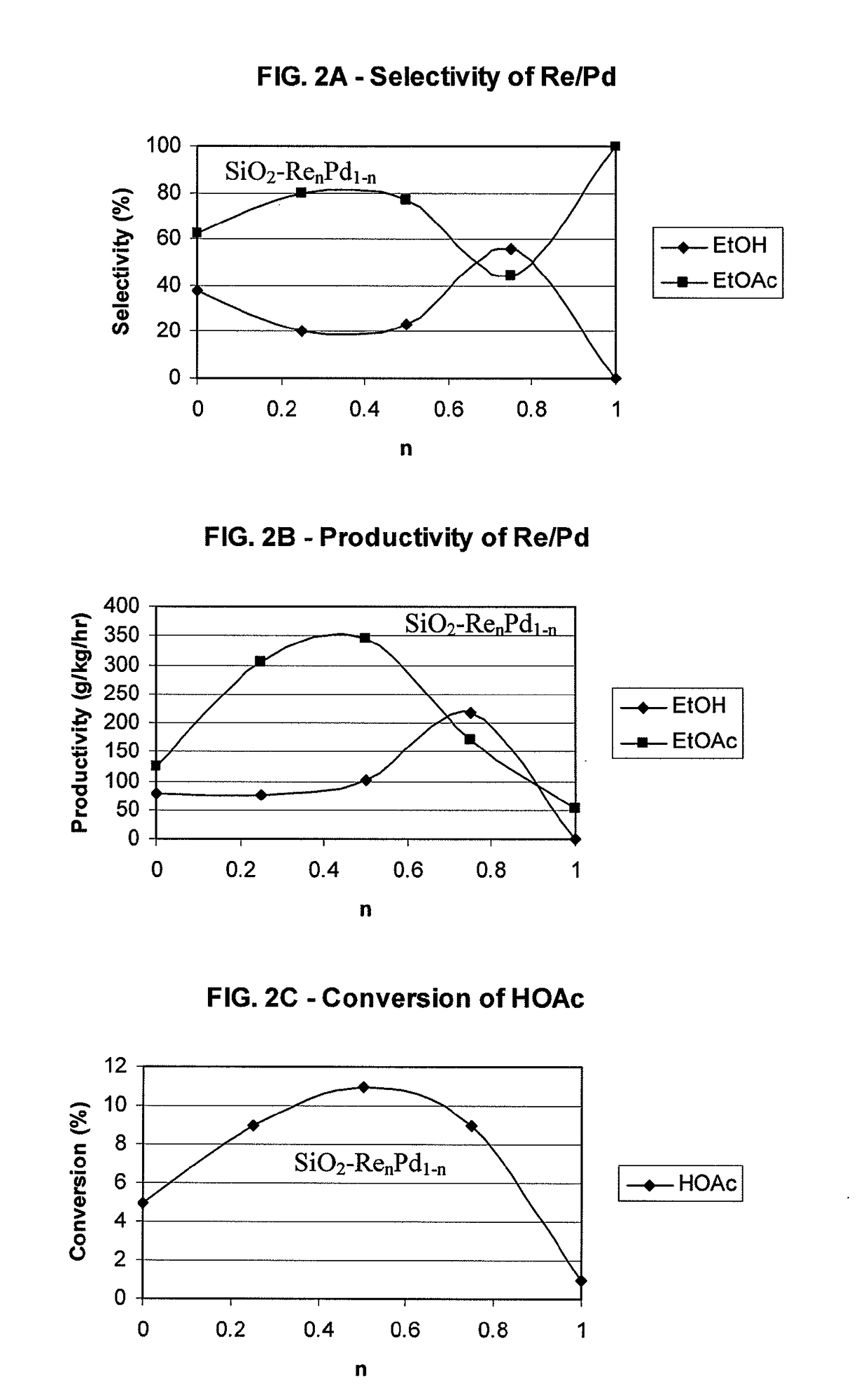

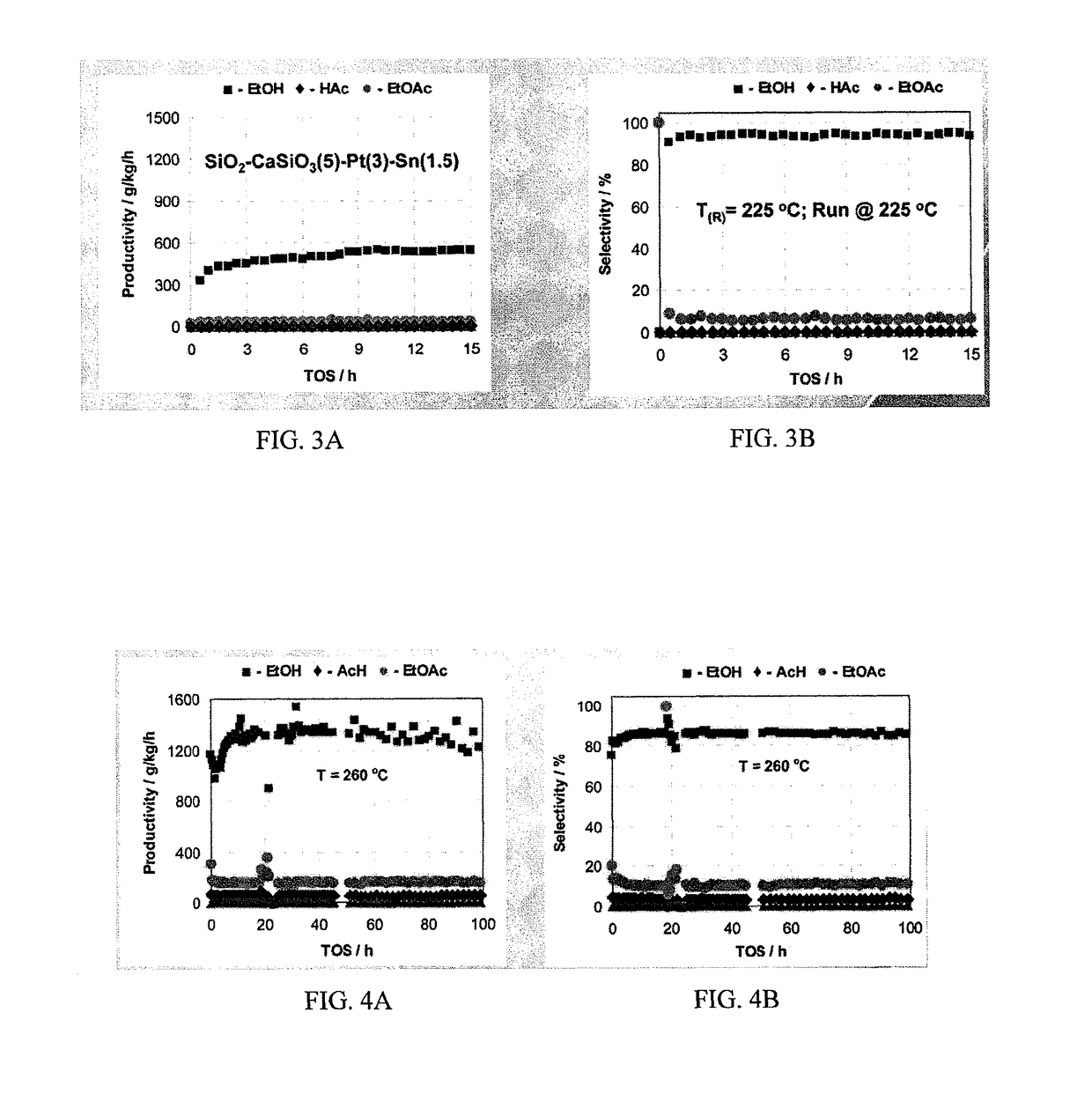

Processes for making ethanol from acetic acid

InactiveUS20100197985A1High selectivityPreparation by oxo-reaction and reductionEthylene productionCeriumCobalt

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

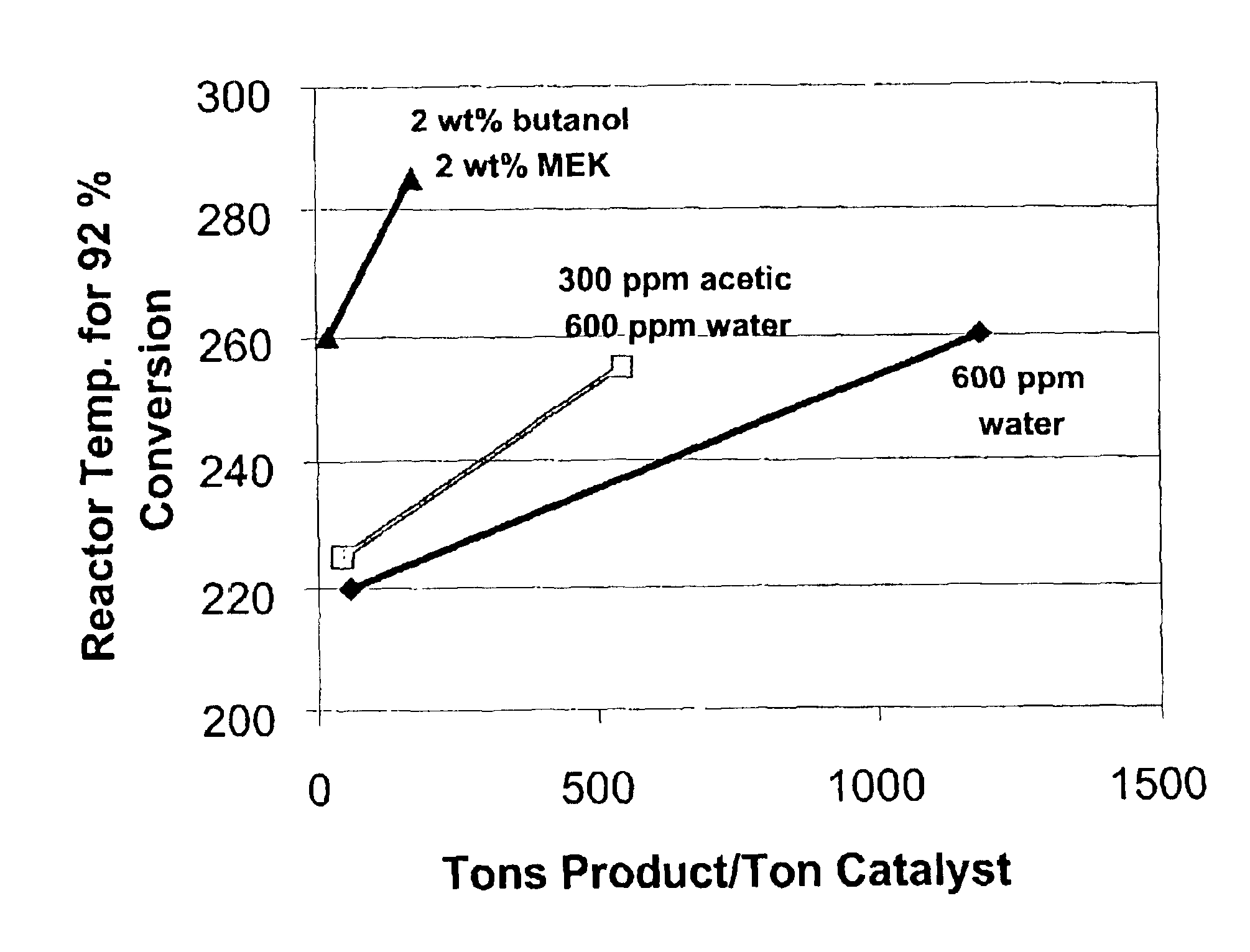

Hydrogenation process for hydrocarbon resins

InactiveUS20030150778A1Improve productivityIncrease volumePreparation by oxo-reaction and reductionCatalyst activation/preparationProduction rateHalogen

This invention provides a process for hydrotreating hydrocarbon resins, which process comprises contacting a feedstock comprising a hydrocarbon resin or rosin, under suitable hydrotreating conditions, with a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals and wherein the ratio of Group VIB metal to Group VIII non-noble metal is from about 10:1 to about 1:10. The process accord invention can achieve increased hydrocarbon resin productivity through increase in throughput volumes and effective catalyst lifetimes. The process of the invention is desirably practiced with a bulk catalyst consisting of only the combination of the metal species with the active metal components. The absence of carrier substrates largely removes the possibility of halogen accumulation on substrate surfaces that, in turn, can acidify metal catalysts such that additional, progressive cracking of the hydrocarbon resin molecules occurs.

Owner:EXXONMOBIL CHEM PAT INC

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

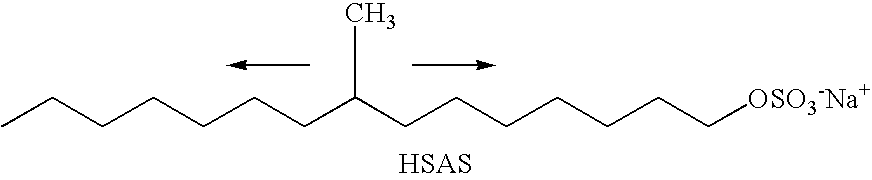

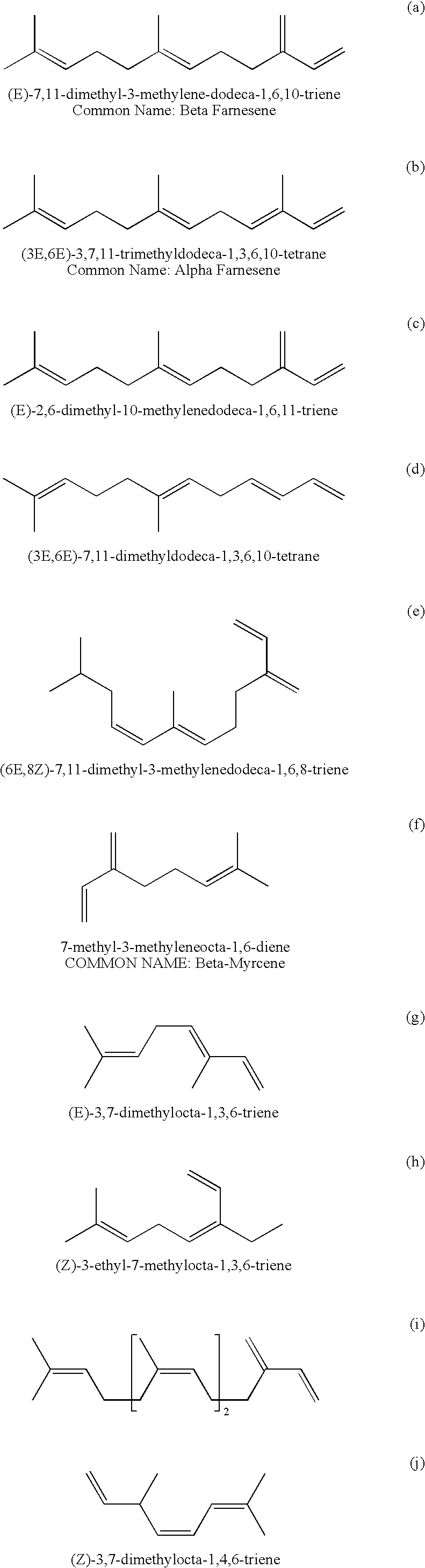

Specific Branched Aldehydes, Alcohols, Surfactants, and Consumer Products Based Thereon

ActiveUS20100137649A1Promote degradationImprove solubilityOxygen-containing compound preparationPreparation by oxo-reaction and reductionHydrogenAlcohol

A process for preparing a detergent alcohol mixture comprising the steps of providing one or more poly-branched poly-olefins, wherein the poly-branched poly-olefins must contain one non-branched terminal olefin and one or more additional branched olefins in the molecule; hydroformylating said poly-branched poly-olefins to produce a poly-branched olefin containing aldehyde product with one or more olefins or mixture thereof; reducing the aldehyde product of step (b) in the presence of hydrogen and a hydrogenation catalyst to form a poly-branched detergent alcohol mixture; and removing said poly-branched alcohol mixture from said catalyst and branched aldehydes, alcohols and surfactants produced from the products of this process.

Owner:PROCTER & GAMBLE CO

Hydroformylation process

InactiveUS6049011AAvoid the needReduce processingPreparation by oxo-reaction and reductionPreparation by hydrogenationEthyleneHydrocarbon

PCT No. PCT / EP96 / 00163 Sec. 371 Date Oct. 15, 1997 Sec. 102(e) Date Oct. 15, 1997 PCT Filed Jan. 17, 1996 PCT Pub. No. WO96 / 22265 PCT Pub. Date Jul. 25, 1996A dilute ethylene stream, e.g., one produced by steam cracking, is oxonated to yield propanal, without the need to separate other lower hydrocarbons.

Owner:EXXON CHEM PAT INC

Olefin oligomerization

InactiveUS6884914B2Preparation by oxo-reaction and reductionMolecular sieve catalystPolymer scienceAlkene

This invention is to a method of oligomerizing an olefin feed stream. The olefin feed stream contains at least one C2 to C12 olefin to obtain an olefin feed stream and has less than 1,000 ppm by weight oxygenated hydrocarbon. The olefin is oligomerized by contacting with an acid based oligomerization catalyst.

Owner:EXXONMOBIL CHEM PAT INC

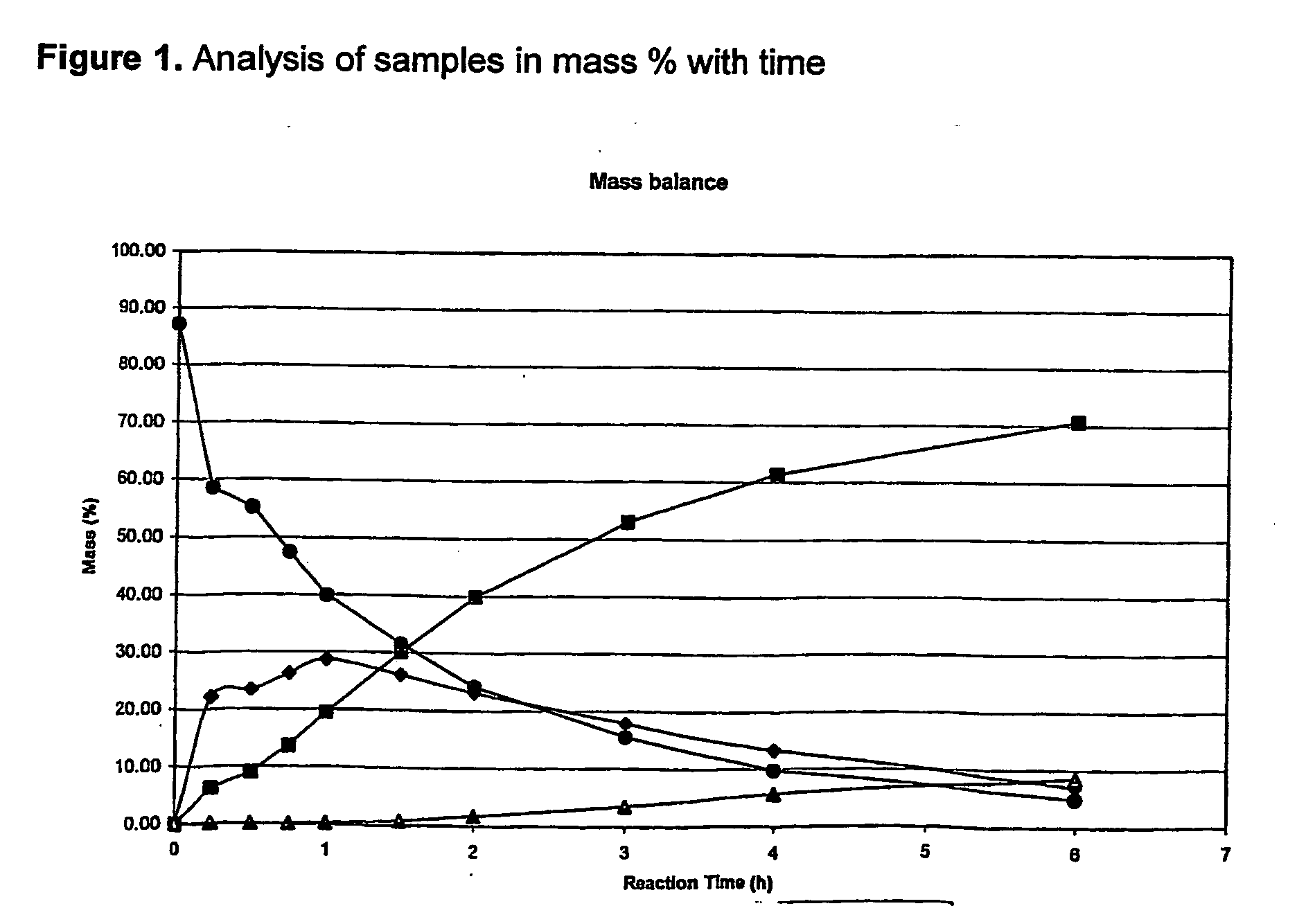

Process for preparing alcohols from olefins by hydroformylation and hydrogenation

InactiveUS20060129004A1Downtime costEasy to preparePreparation by oxo-reaction and reductionOrganic compound preparationCobalt saltOxygen

A process for preparing aliphatic alcohols that includes cobalt-catalyzed hydroformylation of olefins, treatment of a hydroformylation mixture with oxygen-containing gases in the presence of acidic, aqueous cobalt(II) salt solutions, separation of a mixture into an aqueous phase comprising cobalt salts and an organic phase comprising the aliphatic aldehydes, and hydrogenation of an aldehyde-containing organic phase wherein the organic phase and treatment with an adsorbent to separate off cobalt compounds prior to hydrogenation.

Owner:EVONIK DEGUSSA GMBH

Hydrogenation process for hydrocarbon resins

InactiveUS6755963B2Improve productivityIncrease volumePreparation by oxo-reaction and reductionOrganic compound preparationProduction rateHalogen

Owner:EXXONMOBIL CHEM PAT INC

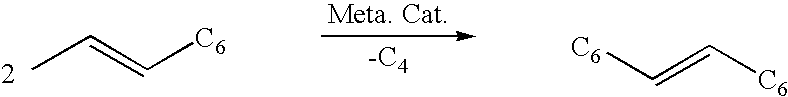

Production of higher olefins

InactiveUS6875899B2High strengthPreparation by oxo-reaction and reductionOrganic compound preparationButeneOxygenate

A method of making a higher olefin product from a C4+ fraction separated from the hydrocarbon product produced by an oxygenate to olefin reaction unit. The C4+ fraction primarily contains butenes which may be directed to a higher olefin reaction unit without removing isobutenes, butanes, and / or butadiene. The C4+ fraction is particularly well suited for the production of higher olefins because of its high olefin content, low branching number, and low contaminent levels. The invention is also directed to an olefin product composition that is produced by contacting the C4+ fraction with an oligomerization catalyst. The olefin composition is characterized by a relatively high octene content, and octene with a branching number less than 1.4.

Owner:EXXONMOBIL CHEM PAT INC

Olefin conversion process and olefin recovery process

InactiveUS20070225536A1Increase difference boiling pointEasy to separatePreparation by oxo-reaction and reductionMolecular sieve catalystBoiling pointAlkene

The present invention provides a process for converting olefins from a mixture of olefins and non-olefinic organic compounds of comparable boiling point to olefin products with a larger difference in boiling point from the boiling point of the non-olefinic organic compounds. Additional steps may be performed to recover the olefin product including separating the olefin product from the mixture produced in the conversion step.

Owner:LUTZ EUGENE FREDERICK

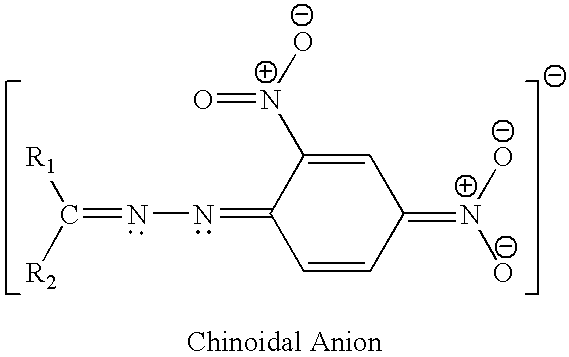

Lowering nitrogen-containing Lewis bases in molecular sieve oligomerisation

ActiveUS20070213575A1Reduce concentrationPreparation by oxo-reaction and reductionCarboxylic acid esters preparationMolecular sieveNitrogen

Nitrogen-containing Lewis bases act as poisons for molecular sieve catalysts used in oligomerisation reactions. A lowering of their presence in the feed prior to the contacting thereof with the molecular sieve brings a significant extension of catalyst life. Excessive elimination of these poisons may be disadvantageous. Lowering the levels of these catalyst poisons to more manageable concentrations is therefore preferred.

Owner:EXXONMOBIL CHEM PAT INC

Nonyl alcohols with a low degree of branching and their derivatives

ActiveUS20120310004A1Low degree of branchingImprove featuresPreparation by oxo-reaction and reductionOrganic compound preparationAlkylLower degree

The invention relates to nonyl alcohols with a low degree of branching and derivatives produced using them. In particular the present invention relates to mixture of primary nonyl alcohols in which at least 80% of the alkyl chains are linear and at least 15% of the alkyl chains are branched at the 2-carbon position and its derivatives. The low degree of branching produces derivatives that are more elongated and less bulky that similar derivatives produced with more highly branched alcohols.

Owner:SHELL USA INC

Processes for making ethanol from acetic acid

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

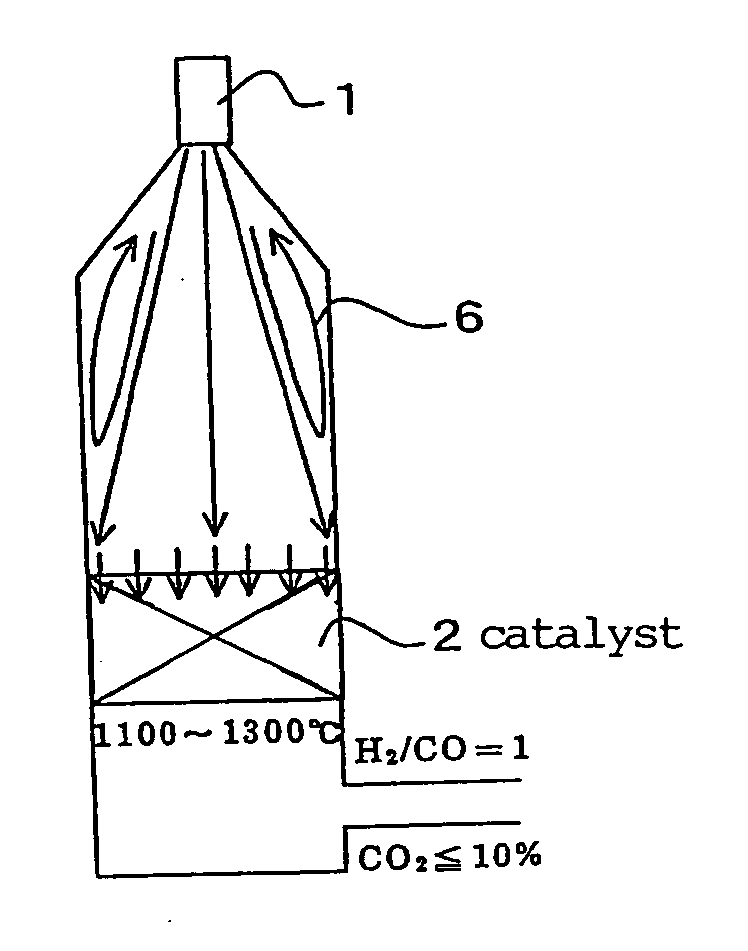

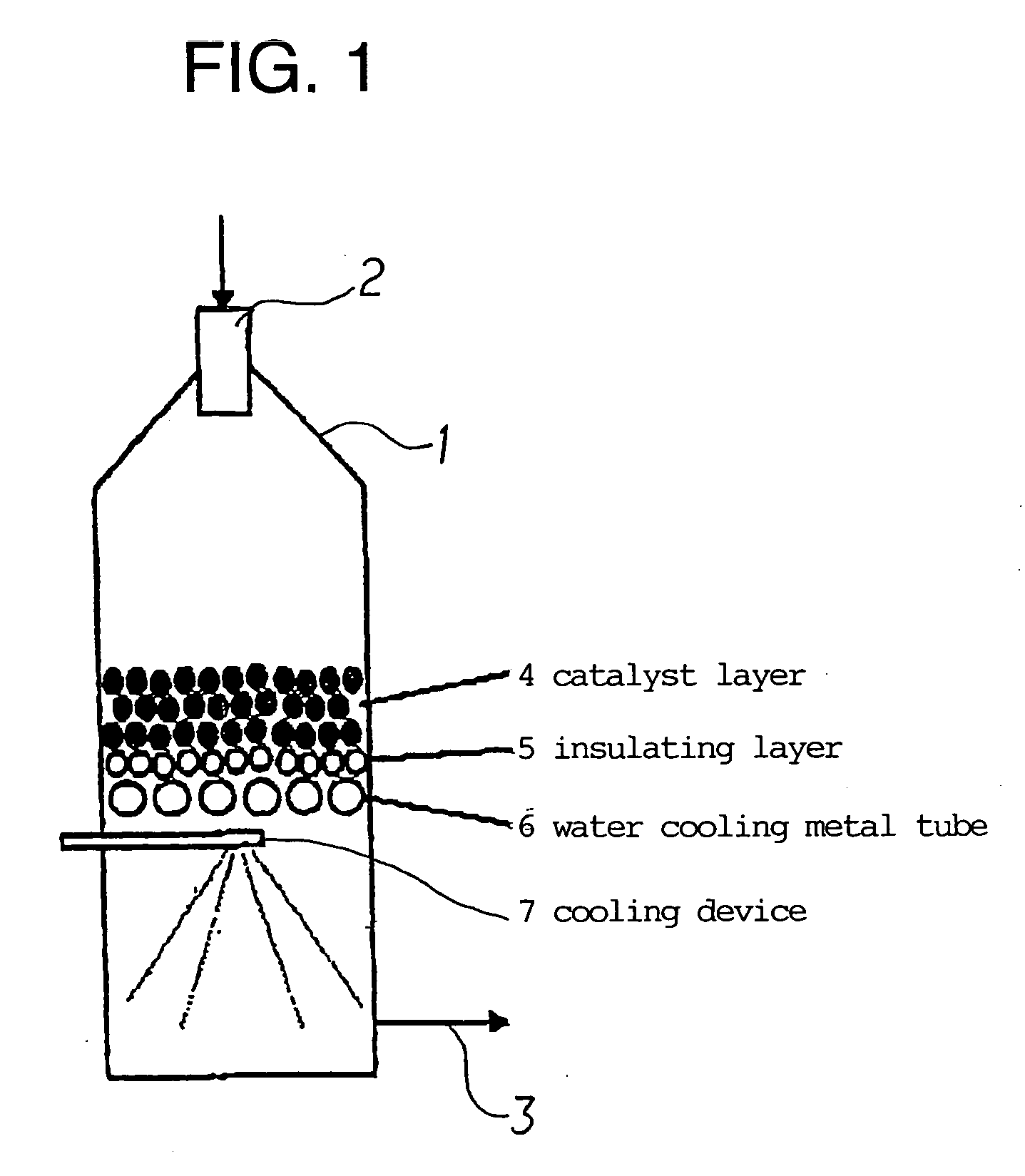

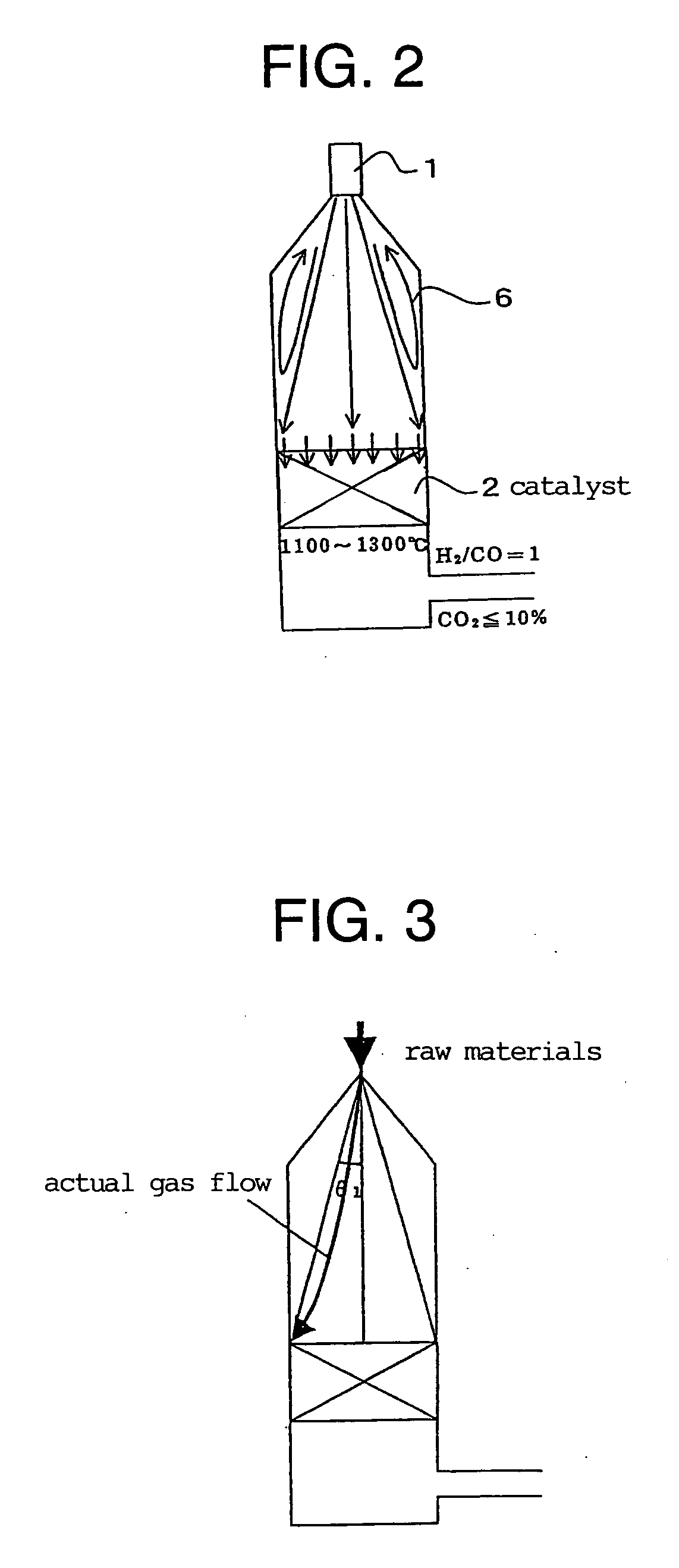

Method for preparing synthesis gas, method for preparing dimethyl ether using synthesis gas, and furnace for preparing synthesis gas

InactiveUS20060120953A1Efficient responseEfficient executionPreparation by oxo-reaction and reductionOrganic compound preparationSyngasCombustion

Disclosed is a process for producing a synthesis gas containing no hydrocarbon and reduced concentration of carbon dioxide among the produced synthesis gas. The process according to the present invention comprises reforming the gas generated by partial combustion of hydrocarbon using a catalyst in a furnace for generating the synthesis gas mounted on a catalyst layer inside the furnace, and producing the synthesis gas comprising hydrogen and carbon monoxide as a main components, and is characterized in that the temperature at outlet of the catalyst layer ranges from 1100 to 1300° C. and the concentration of carbon dioxide in the produced synthesis gas is not more than 10% by volume.

Owner:INPEX CORP +9

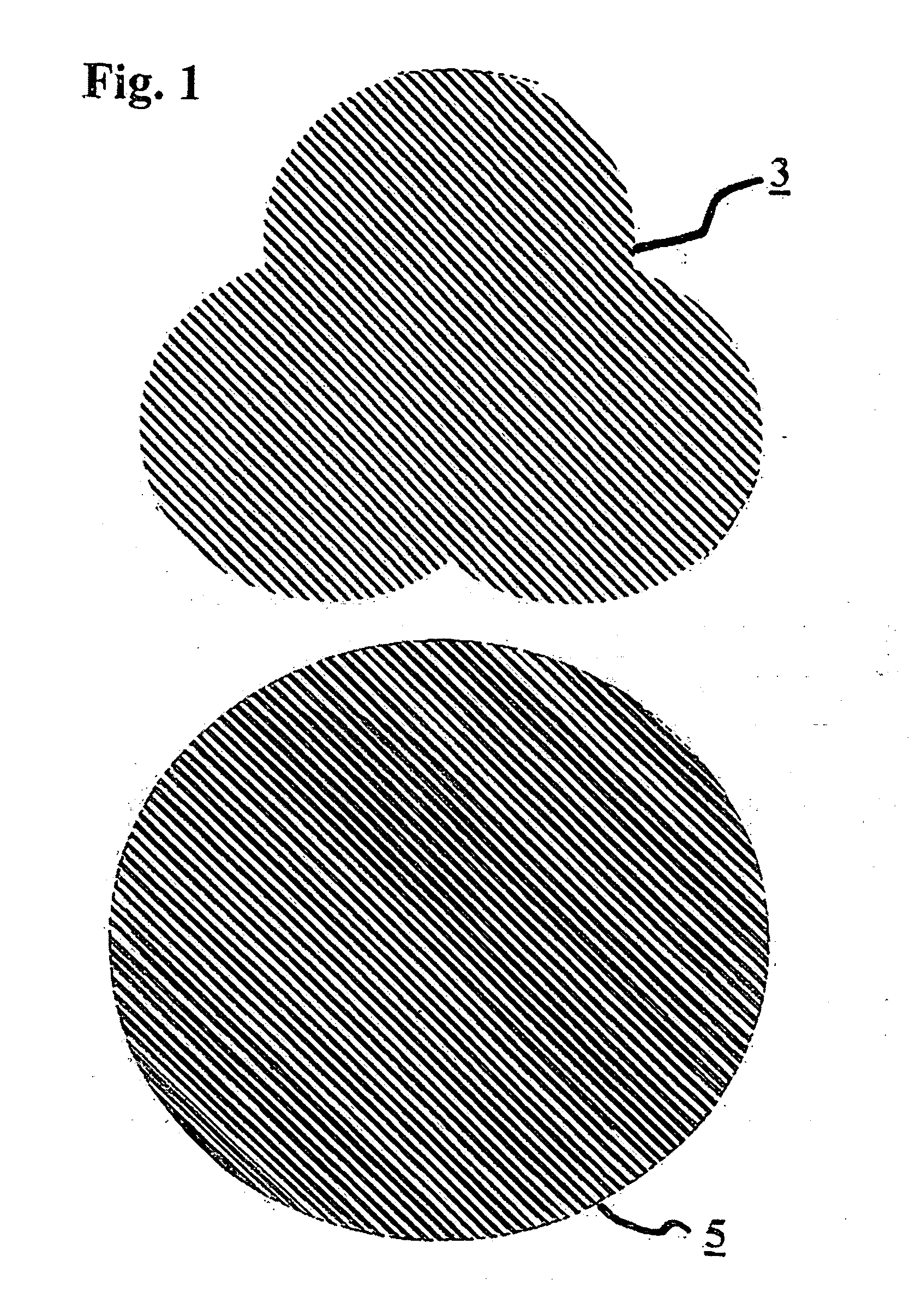

Hydrogenation catalyst and hydrogenation method

InactiveUS20060241325A1Preparation by oxo-reaction and reductionOrganic compound preparationPropynalRuthenium

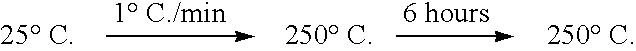

The present invention provides a hydrogenation catalyst effective for hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol. The hydrogenation catalyst comprises an α-alumina support, nickel, ruthenium, and a promoter. The nickel is deposited on the α-alumina support, and the ruthenium and the promoter are deposited on the nickel and the α-alumina support. The α-alumina support comprises at least 92 wt. % of the catalyst, and the nickel comprises from 1 wt. % to 6 wt. % of the catalyst. The present invention also provides a process of hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol with the catalyst.

Owner:SHELL OIL CO

Direct hydrocarbonylation process

A direct hydrocarbonylation process for the production of 1,4-butanediol is described. The process comprises reacting allyl alcohol with carbon monoxide and hydrogen in an alcohol solvent in the presence of a catalyst system comprising a rhodium complex, a trialkyl phosphine, and a diphosphine. The process gives a high yield of 1,4-butanediol in a one-step reaction.

Owner:LYONDELL CHEM TECH LP

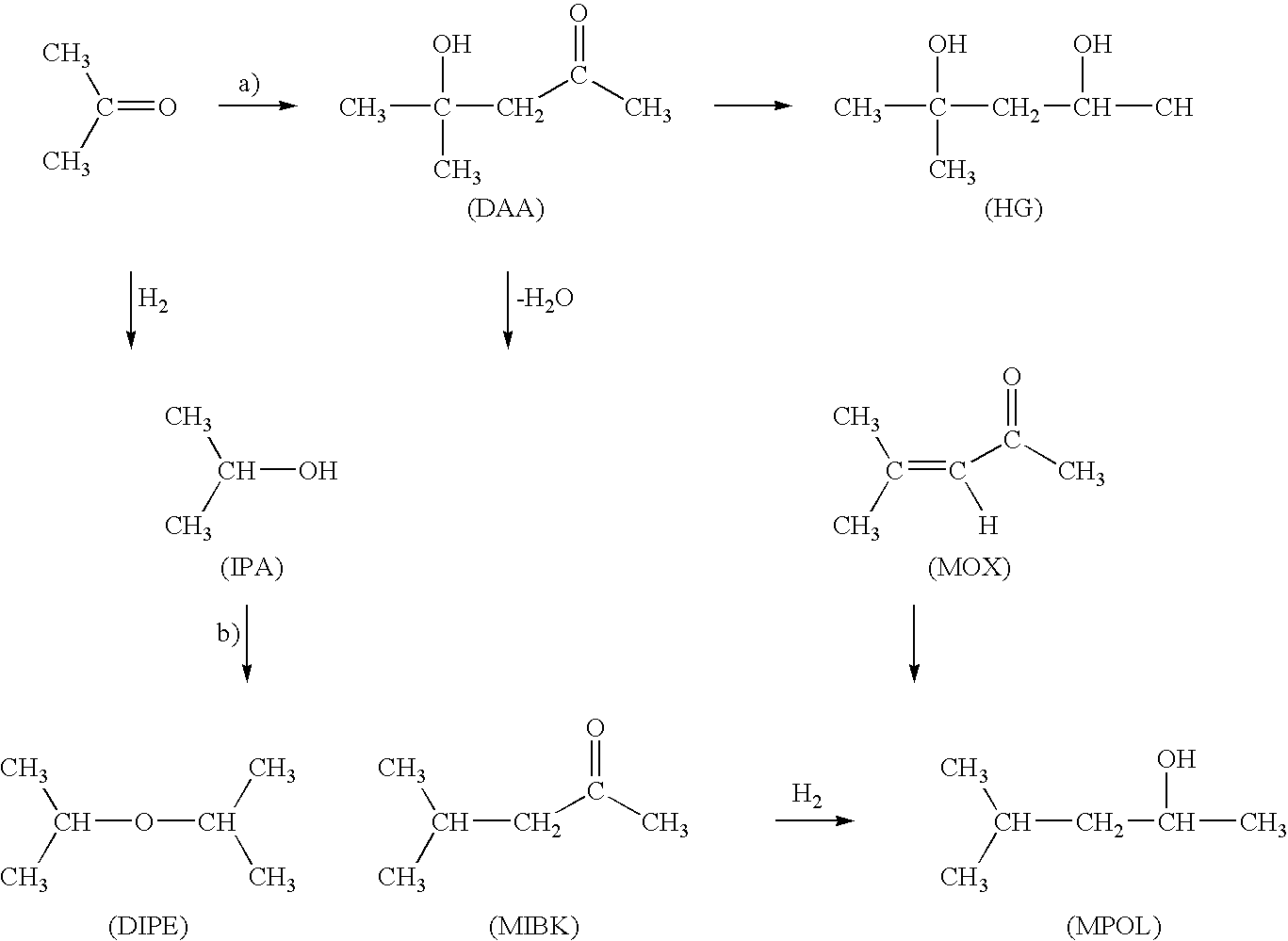

Process for the hydrogenation of acetone

InactiveUS6930213B1Effectively hydrogenatedHighly pure isopropanolPreparation by oxo-reaction and reductionOrganic compound preparationHydrogenation processHigh selectivity

Acetone is hydrogenated by a process comprising, conducting the liquid-phase hydrogenation of acetone in at least two hydrogenation process stages, thereby preparing isopropanol product with a high selectivity and in high purity.

Owner:PHENOLCHEM

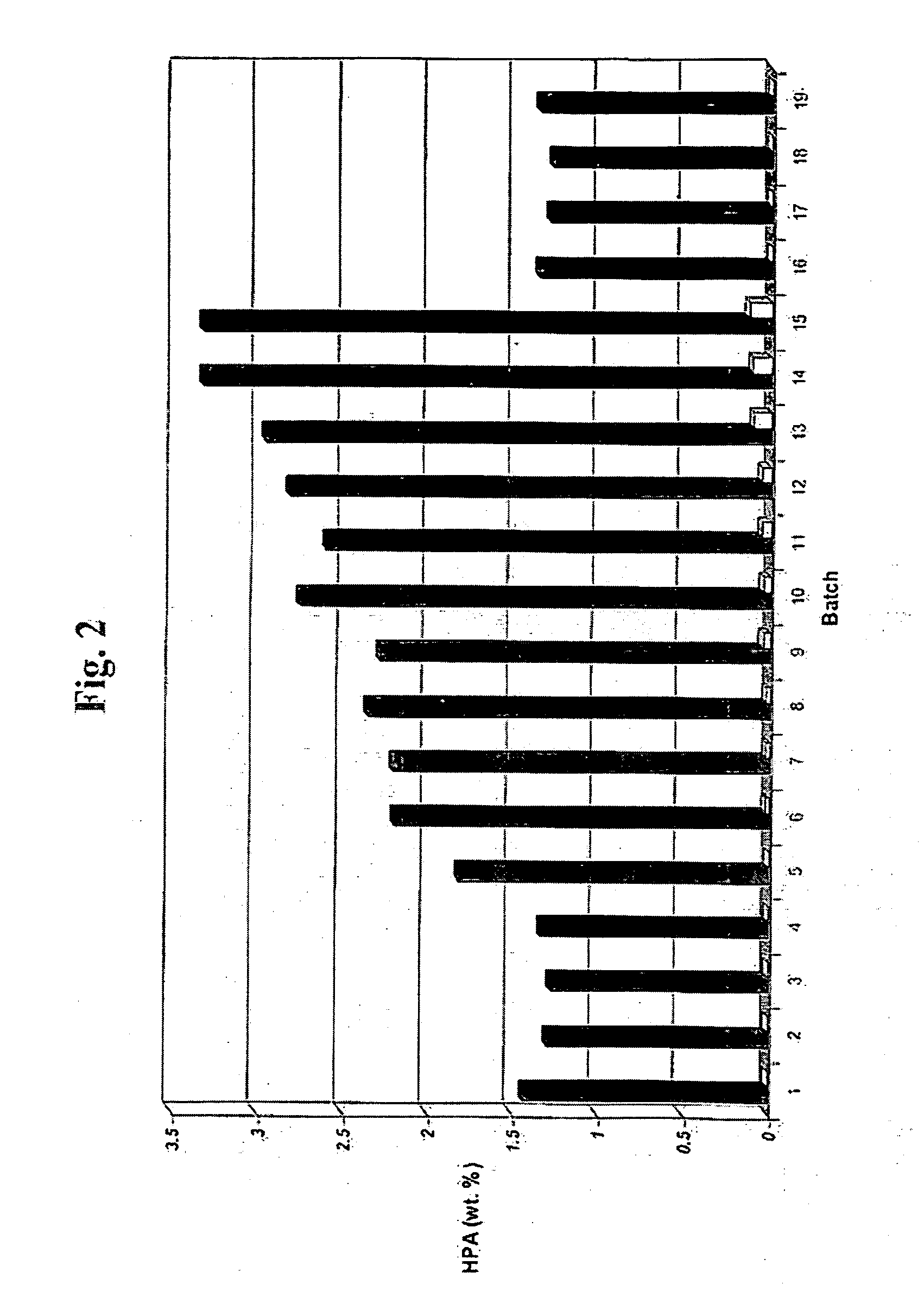

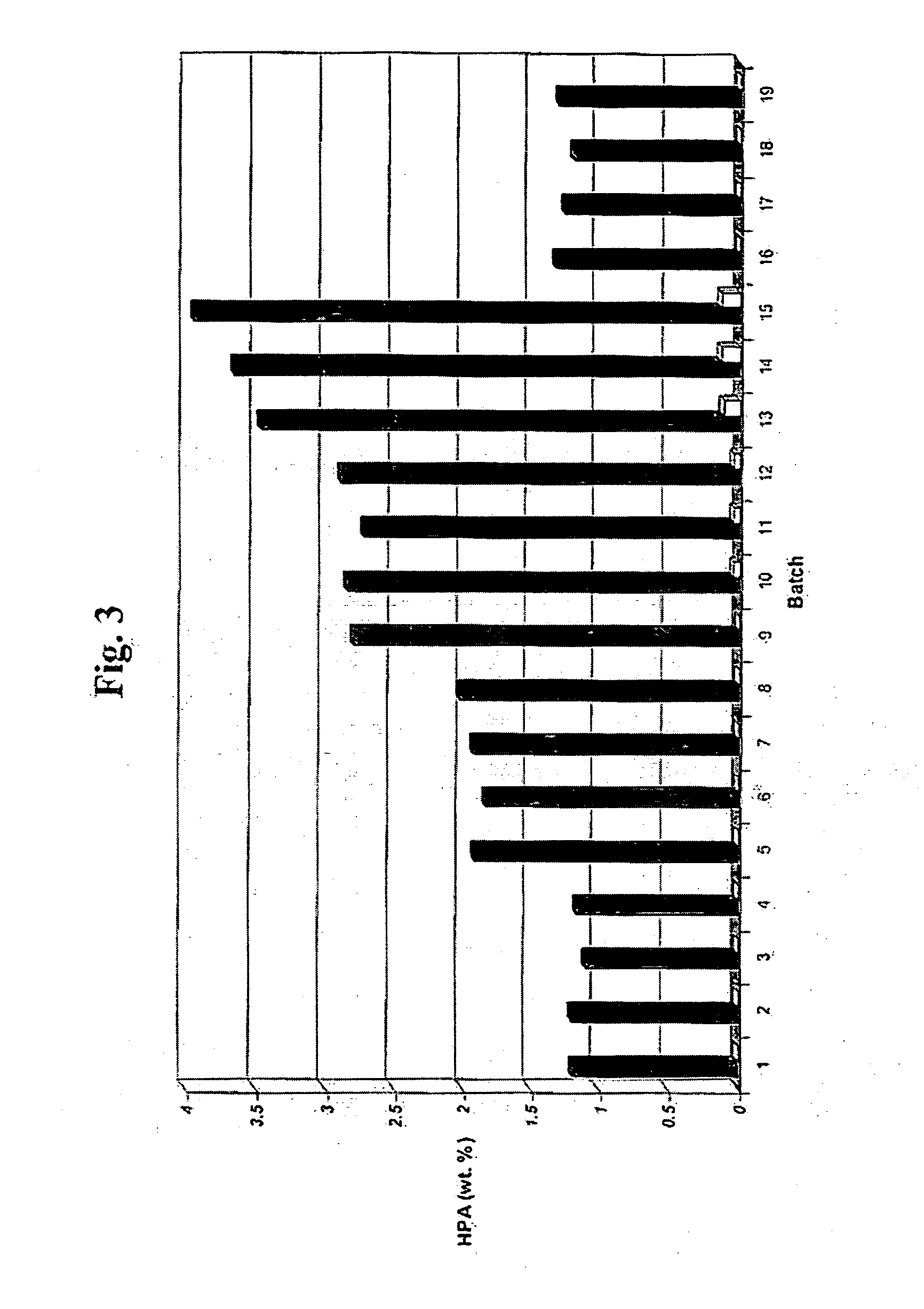

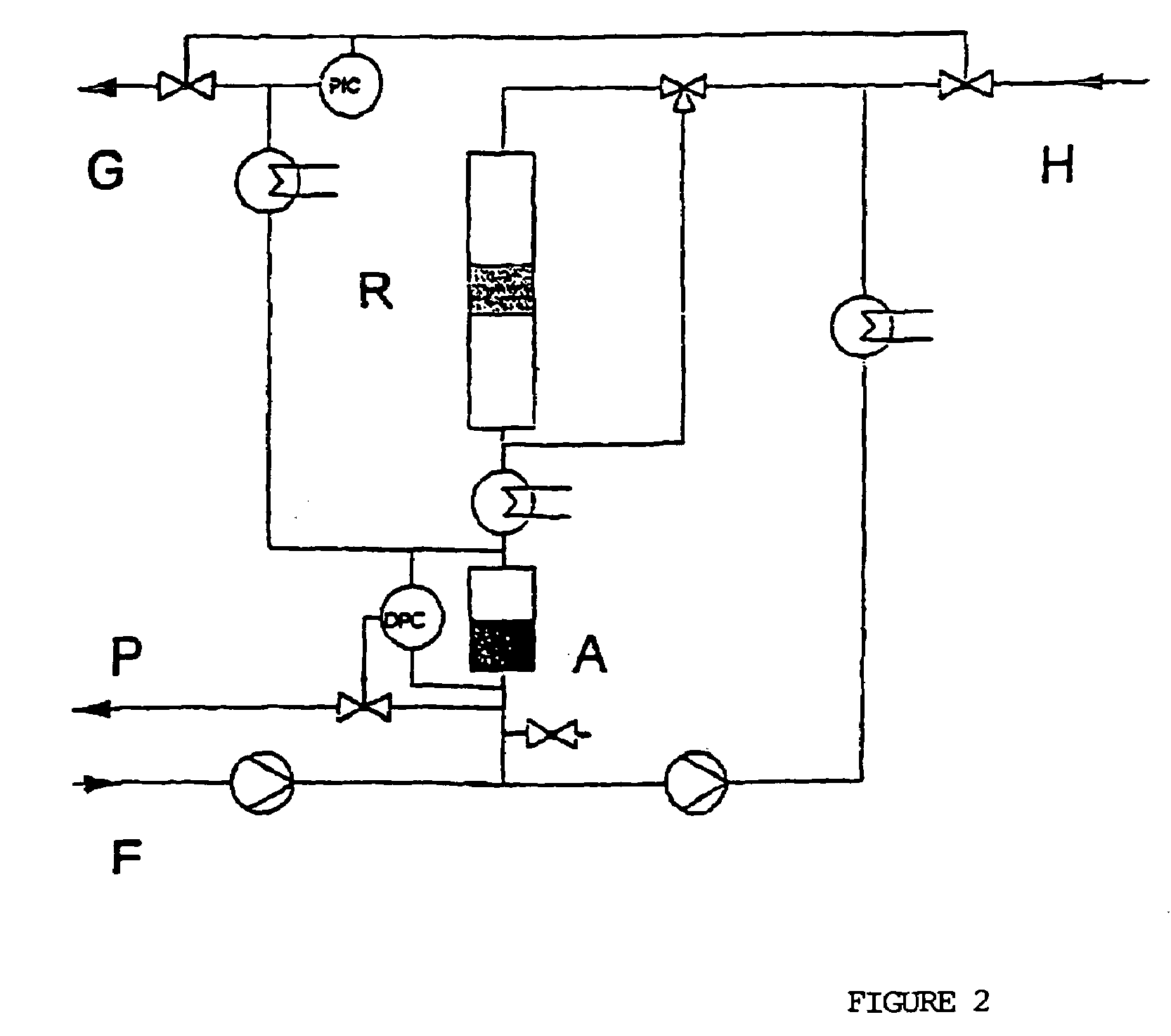

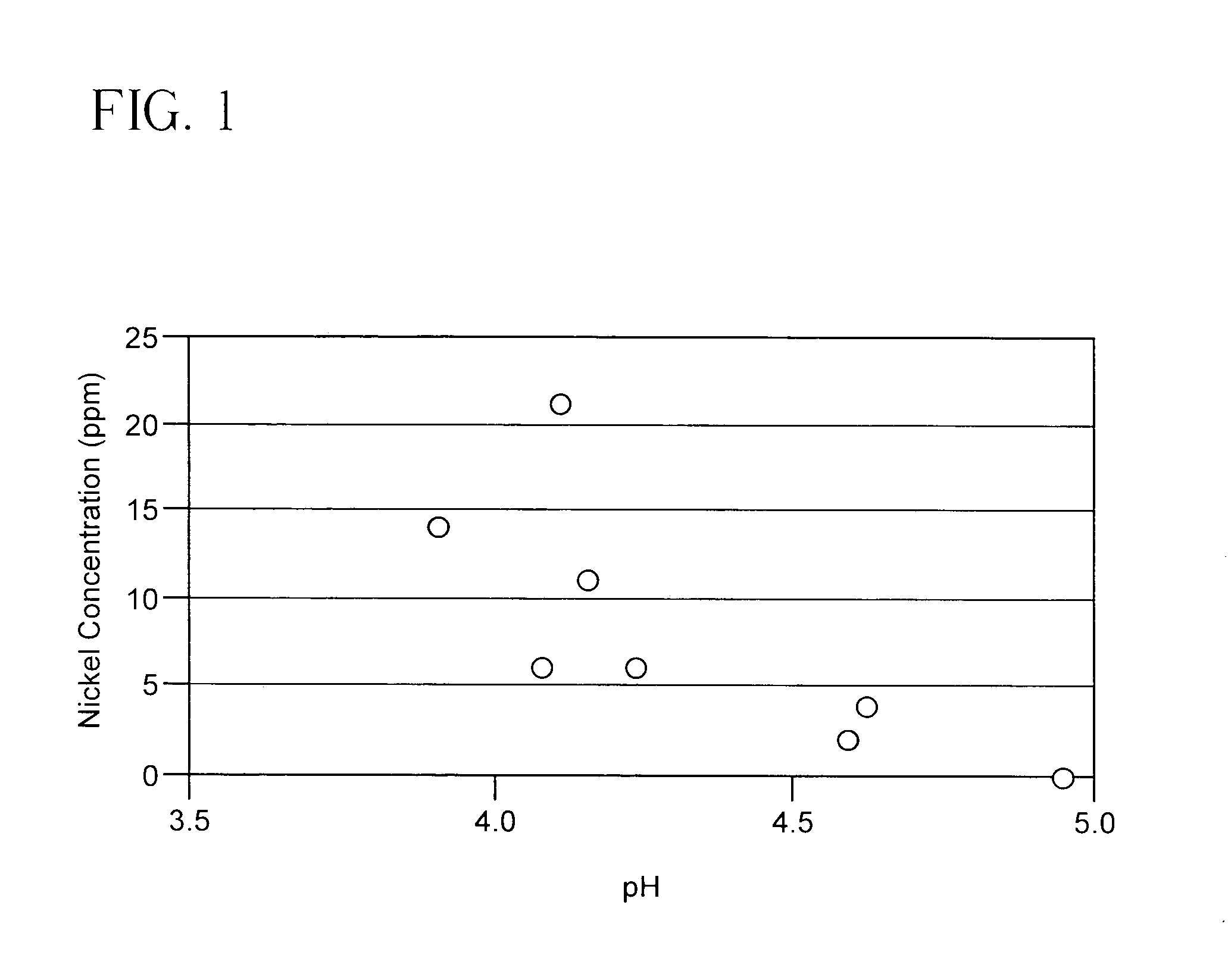

Production of butanediol

ActiveUS6969780B1Preparation by oxo-reaction and reductionOrganic compound preparationButanediolOrganic chemistry

The catalytic hydrogenation of HBA and / or HMPA is improved by either or both of (1) increasing the temperature in the hydrogenation zone from about 50 to 70° C. at the inlet to above 80° C. at the outlet and (2) raising the pH of the hydrogenation feed to 4.5–6.0 before hydrogenation.

Owner:LYONDELL CHEM TECH LP

Method for producing aldehydes by means of hydroformylation of olefinically unsaturated compounds, said hydroformylation being catalyzed by unmodified metal complexes in the presence of cyclic carbonic acid esters

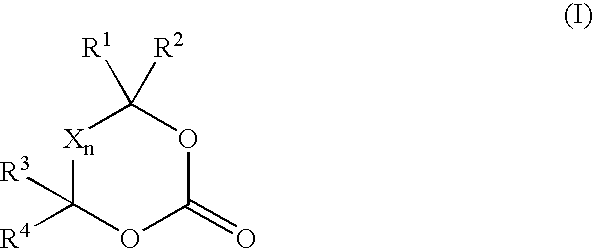

ActiveUS7193116B2Reduce catalyst deactivationSpeed up the processPreparation by oxo-reaction and reductionOrganic compound preparationChemistryAldehyde

The present invention relates to a process for preparing aldehydes by hydroformylation catalyzed by metals of groups 8 to 10 of the Periodic Table of the Elements in the presence of cyclic carbonic esters.

Owner:EVONIK DEGUSSA GMBH

Cobalt catalysts

InactiveUS20030144367A1Enhanced and superior initialHigh activityHydrocarbon from carbon oxidesCatalyst protectionParticulatesPorous catalyst

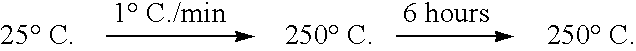

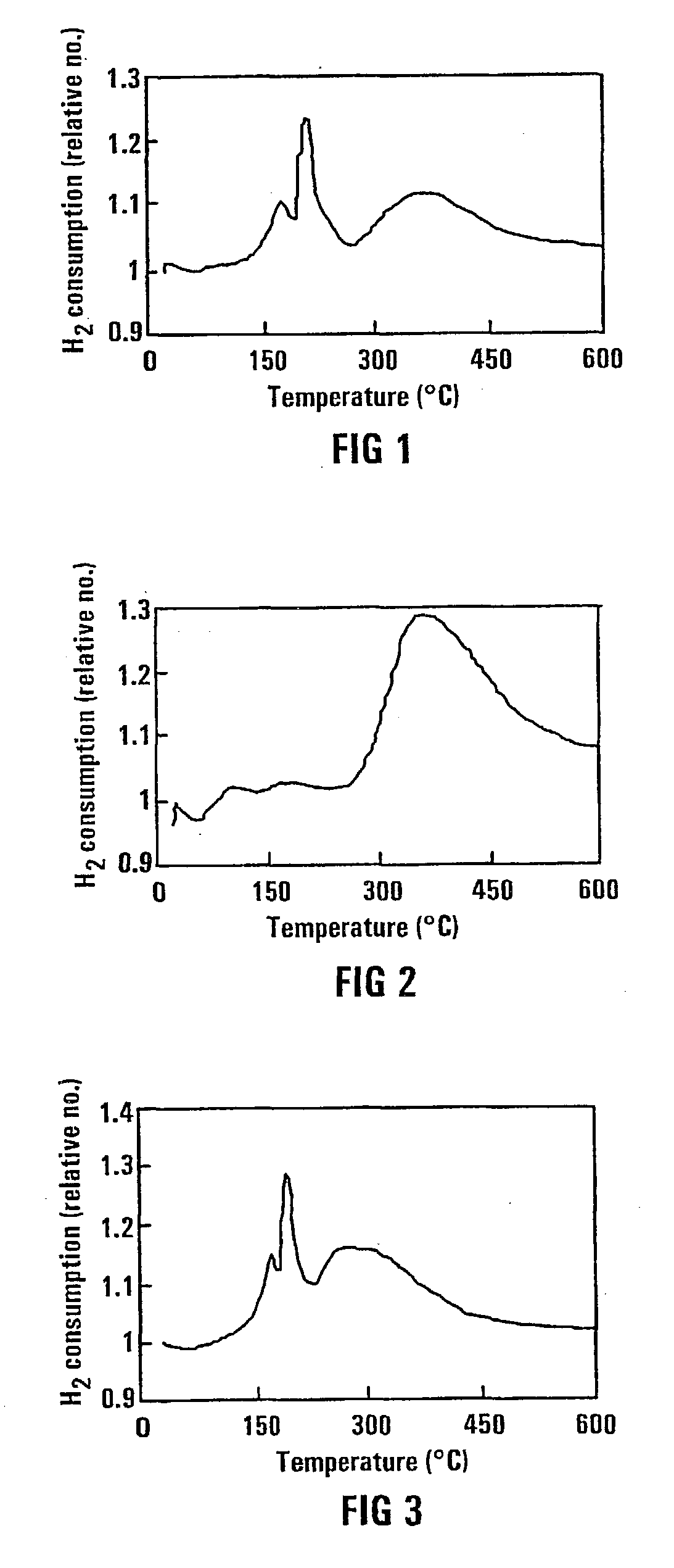

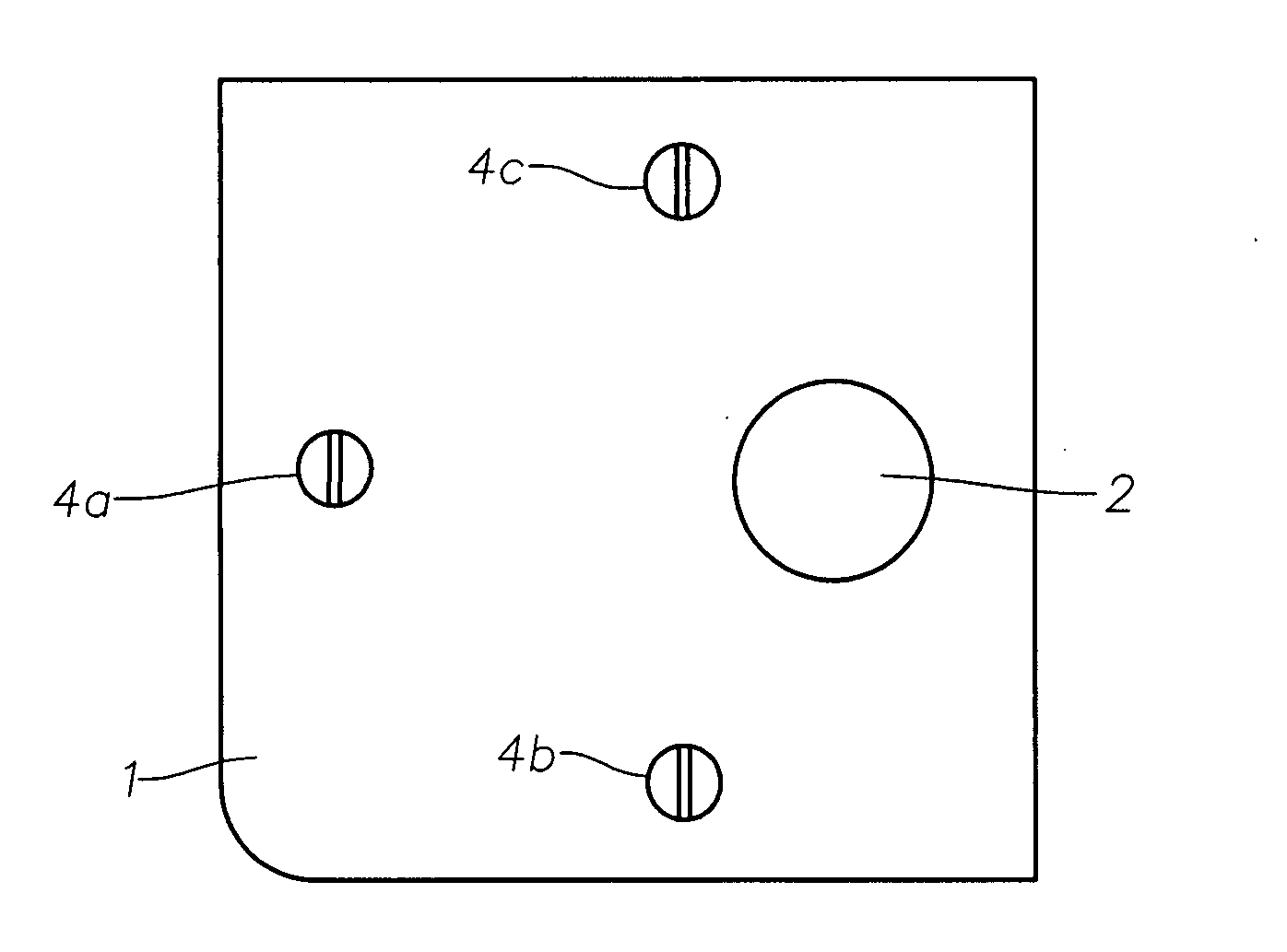

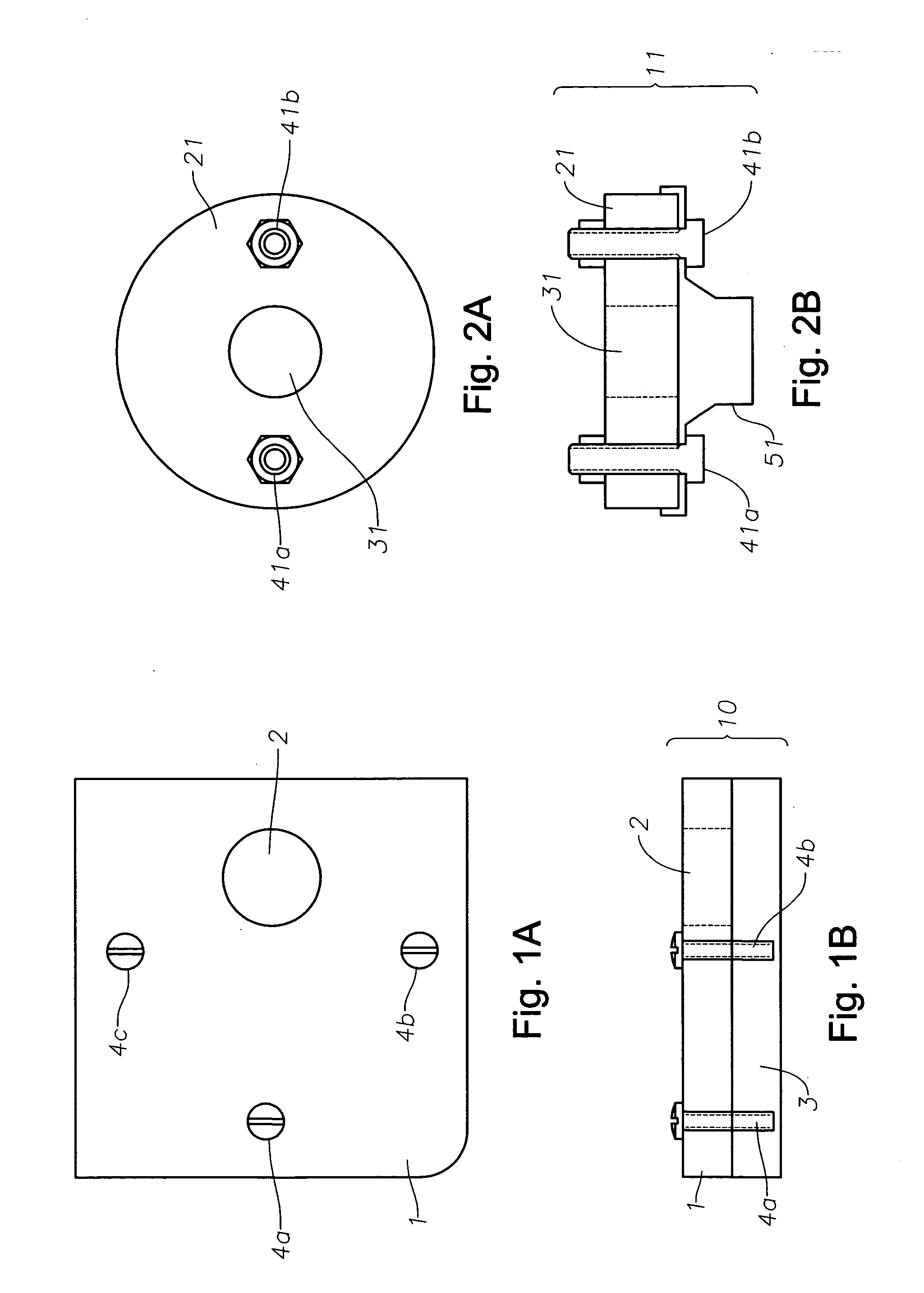

A process for preparing a cobalt based catalyst precursor includes in a first support impregnation / drying / calcination stage, impregnating a particulate porous catalyst support with a cobalt salt, partially drying the impregnated support, and calcining the partially dried impregnated support to obtain a calcined material. The calcined material is partially reduced. Thereafter, in a second support impregnation / drying / calcination stage, the partially reduced material is impregnated with a cobalt salt, partially dried and calcined, to obtain the cobalt based catalyst precursor.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD +1

Quantitative determination of analyte

InactiveUS20060105465A1The process is simple and effectiveReduce impurityAnalysis using chemical indicatorsPreparation by oxo-reaction and reductionAnalyteAlcohol

Owner:EXXONMOBIL CHEM PAT INC

Process for the hydrogenation of oxo aldehydes having high ester contents

InactiveUS7524997B2Low costHigh product yieldCatalyst protectionPreparation by oxo-reaction and reductionCobaltAldehyde formation

Owner:EVONIK DEGUSSA GMBH

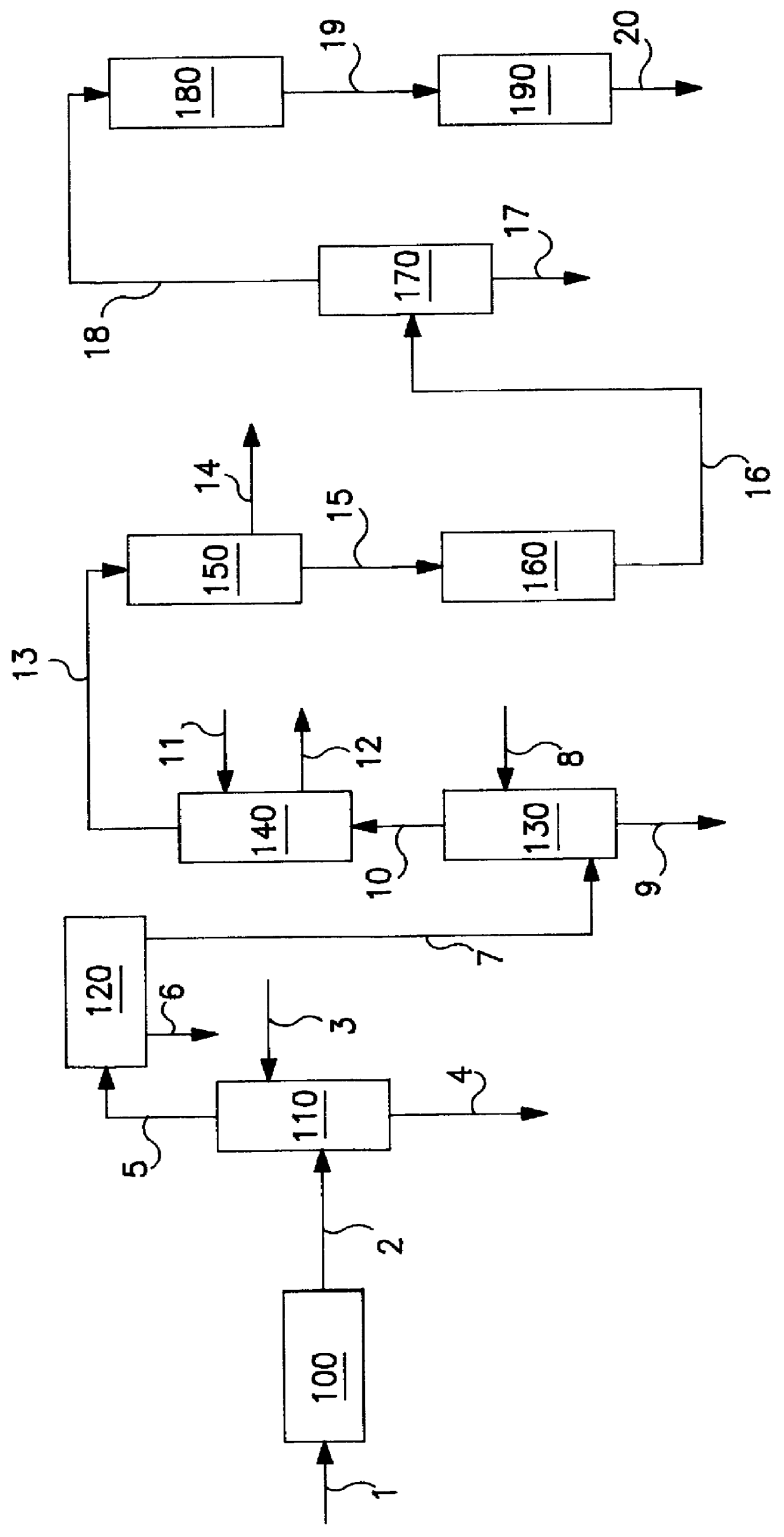

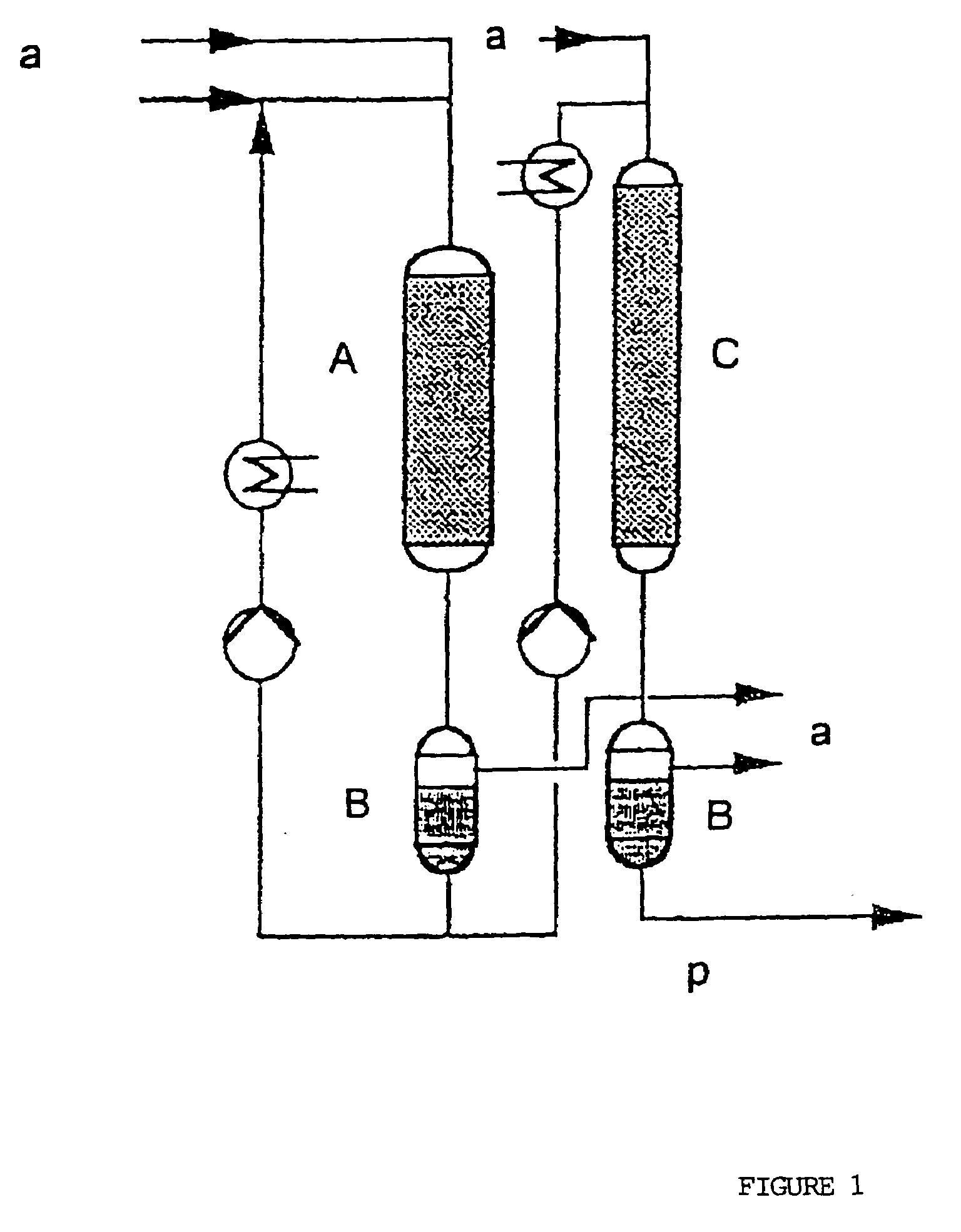

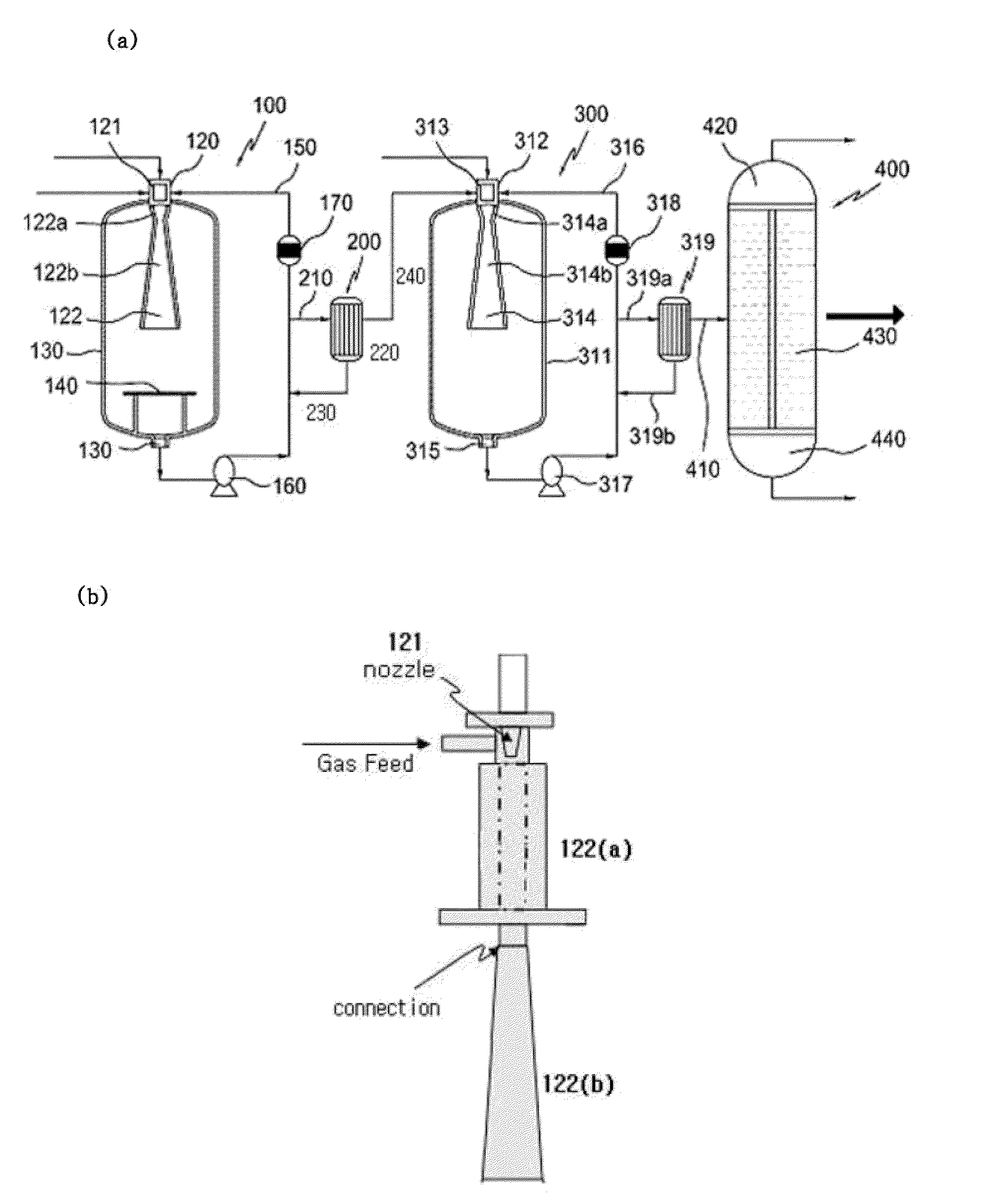

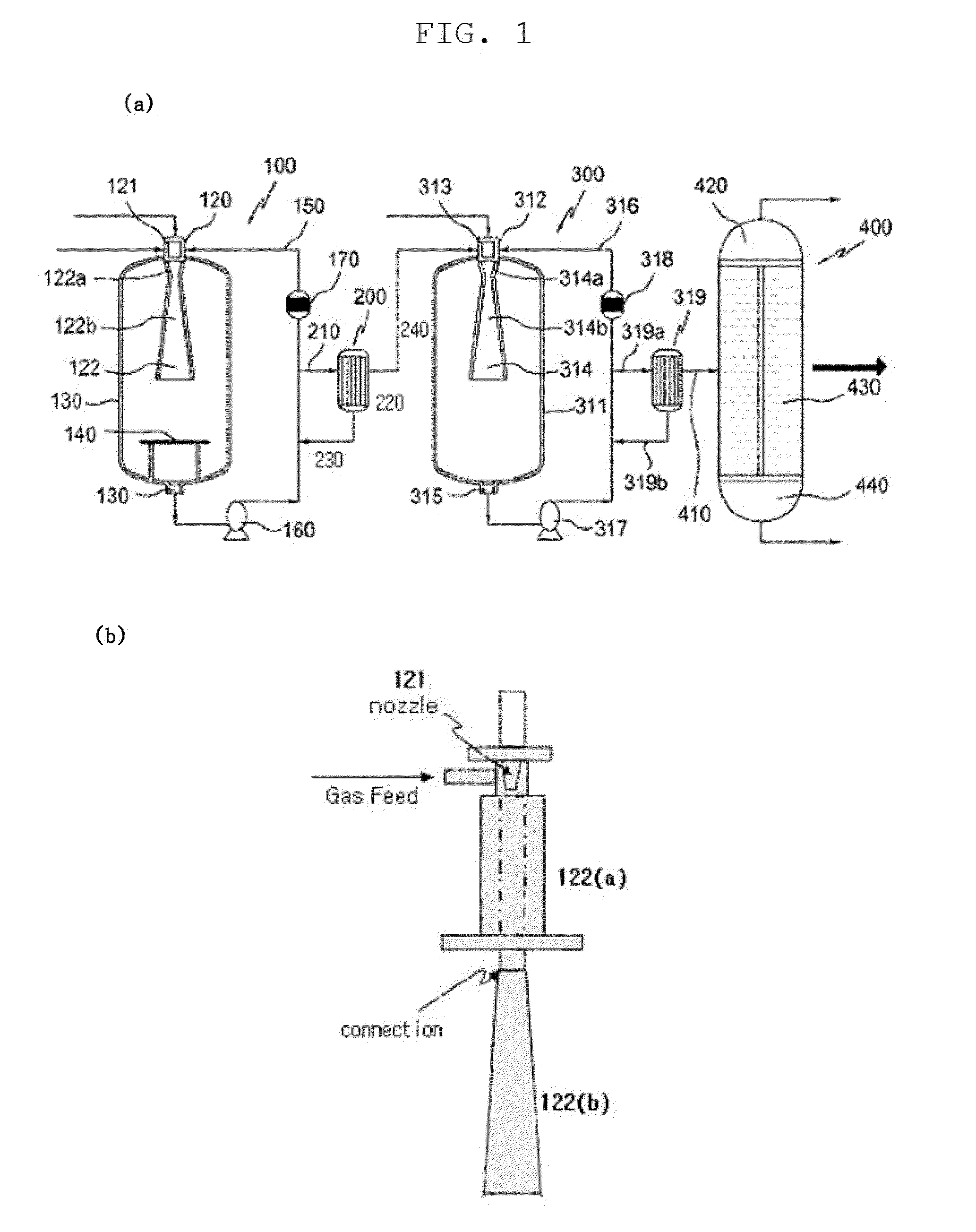

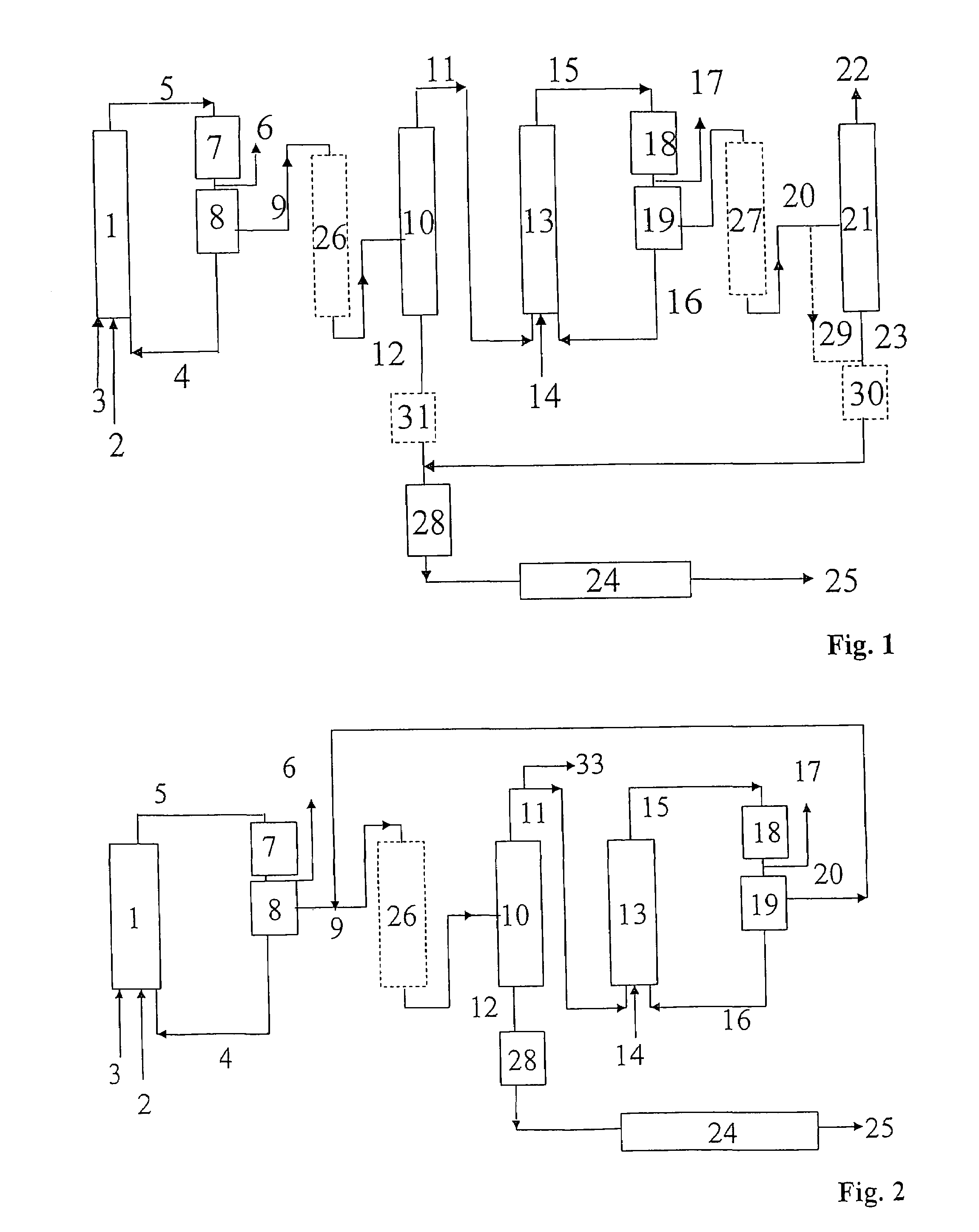

Apparatus for producing alcohols from olefins

ActiveUS20110282108A1Improve efficiencyEfficient productionPreparation by oxo-reaction and reductionPreparation by carbon monoxide reactionAlcoholDistillation

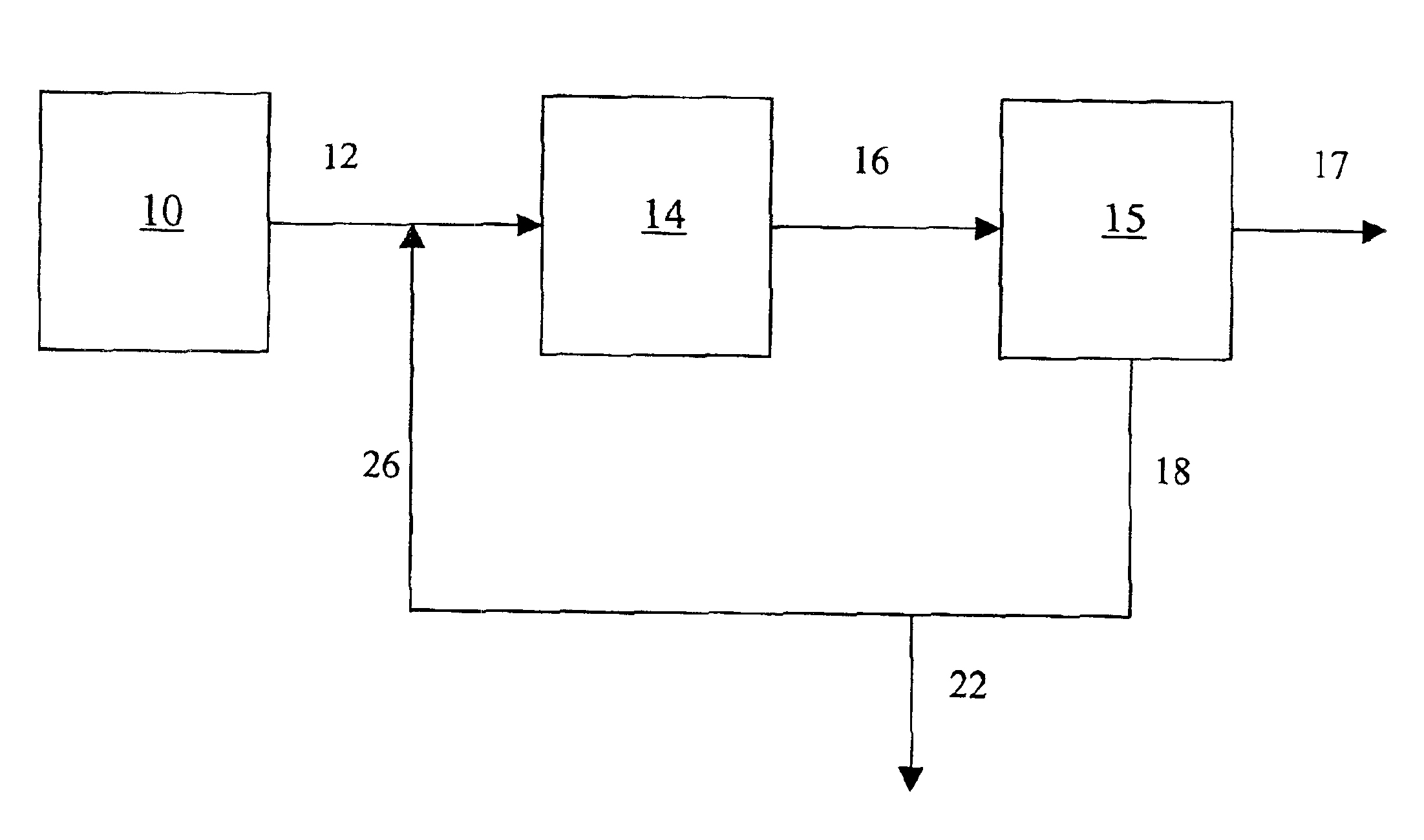

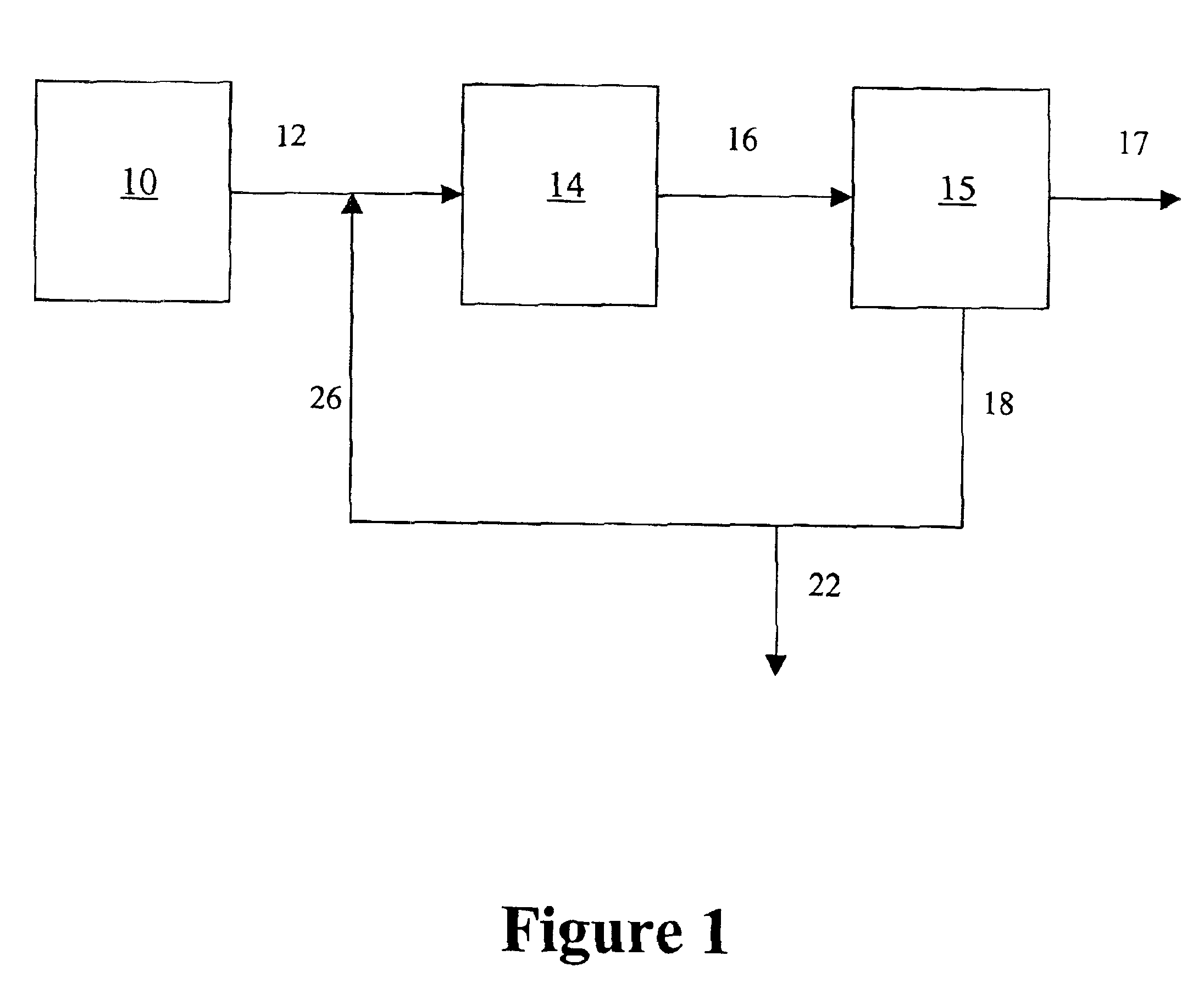

The present invention relates to an apparatus for producing alcohols from olefins, comprising: a hydroformylation reactor wherein aldehydes are produced from olefins; a catalyst / aldehydes separator; a hydrogenation reactor wherein the aldehydes are hydrogenated to produce alcohols; and a distillation column. The hydroformylation reactor is equipped with a distributor plate, which has a broad contact surface for providing sufficient reaction area for reactants such as olefins and synthesis gas, and allows the reaction mixture to circulate and mix sufficiently, which contribute to excellent efficiency in terms of production of aldehydes. In addition, the hydrogenation reactor suppresses sub-reactions to improve the production yield of alcohols.

Owner:LG CHEM LTD

Cobalt flash process

InactiveUS7081553B2Extended service lifeAvoid corrosionPreparation by oxo-reaction and reductionOrganic compound preparationAcetic acidAlcohol

The Cobalt Flash Process is modified by replacing formic acid with acetic acid as process acid. Efficiency using acetic acid as process acid is achieved by two improvements which may be added separately and independently: (1) separation of acetic acid and water from the condensate distilled off in the cobalt salt concentration stage; and (2) removal of formic acid from the system by reaction with the product alcohol in the preformer.

Owner:EXXONMOBIL CHEM PAT INC

Process for preparing alcohols from olefins by hydroformylation and hydrogenation

InactiveUS7154012B2Downtime costPreparation by oxo-reaction and reductionOrganic compound preparationCobalt saltOxygen

A process for preparing aliphatic alcohols that includes cobalt-catalyzed hydroformylation of olefins, treatment of a hydroformylation mixture with oxygen-containing gases in the presence of acidic, aqueous cobalt(II) salt solutions, separation of a mixture into an aqueous phase comprising cobalt salts and an organic phase comprising the aliphatic aldehydes, and hydrogenation of an aldehyde-containing organic phase wherein the organic phase and treatment with an adsorbent to separate off cobalt compounds prior to hydrogenation.

Owner:EVONIK DEGUSSA GMBH

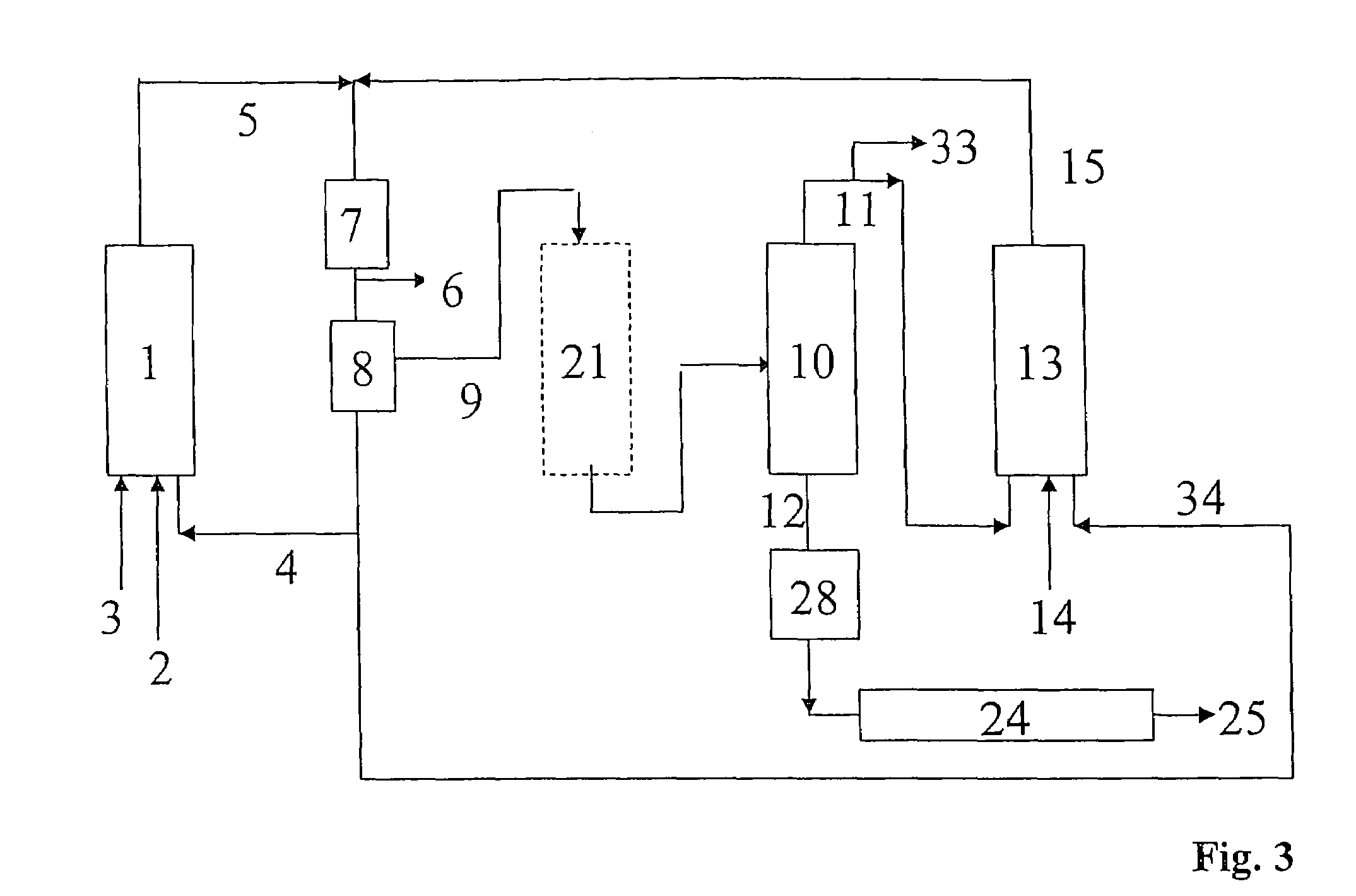

Process for producing alcohol-ether hydrazine under medium/low-pressure

InactiveCN101602649AAvoid disadvantages such as increased energy consumptionReduced Compression Power ConsumptionPreparation by oxo-reaction and reductionOxygen compounds by oxo-reactionProduction lineState of art

The invention provides a process for producing alcohol-ether hydrazine under medium / low-pressure, which solves the disadvantages of an alcohol-combining process in the prior art. A competitive replacement choice of the process is to serially connect alcohol-ether synthesis and ammonia synthesis into one production line, wherein alcohol-ether synthesis is performed first, and then ammonia synthesis is performed, but alcohol-ether synthesis and ammonia synthesis are relatively independent of the separation of respective products thereof; different proportion and the yield proportion of two products are flexible to regulate; ammonia synthesis does not need the process of additionally adding synthesis gas for compression; and the total pressure is 4 to 15 MPa. The process has the advantages of effectively reducing the power consumption of compression, realizing the flexible proportion regulation of alcohol or ether products, improving the efficiency of the whole technological process, reducing production cost to the utmost extent and laying a foundation for technical progress of the coal chemical industry and large-scale comprehensive development.

Owner:FUZHOU UNIV +1

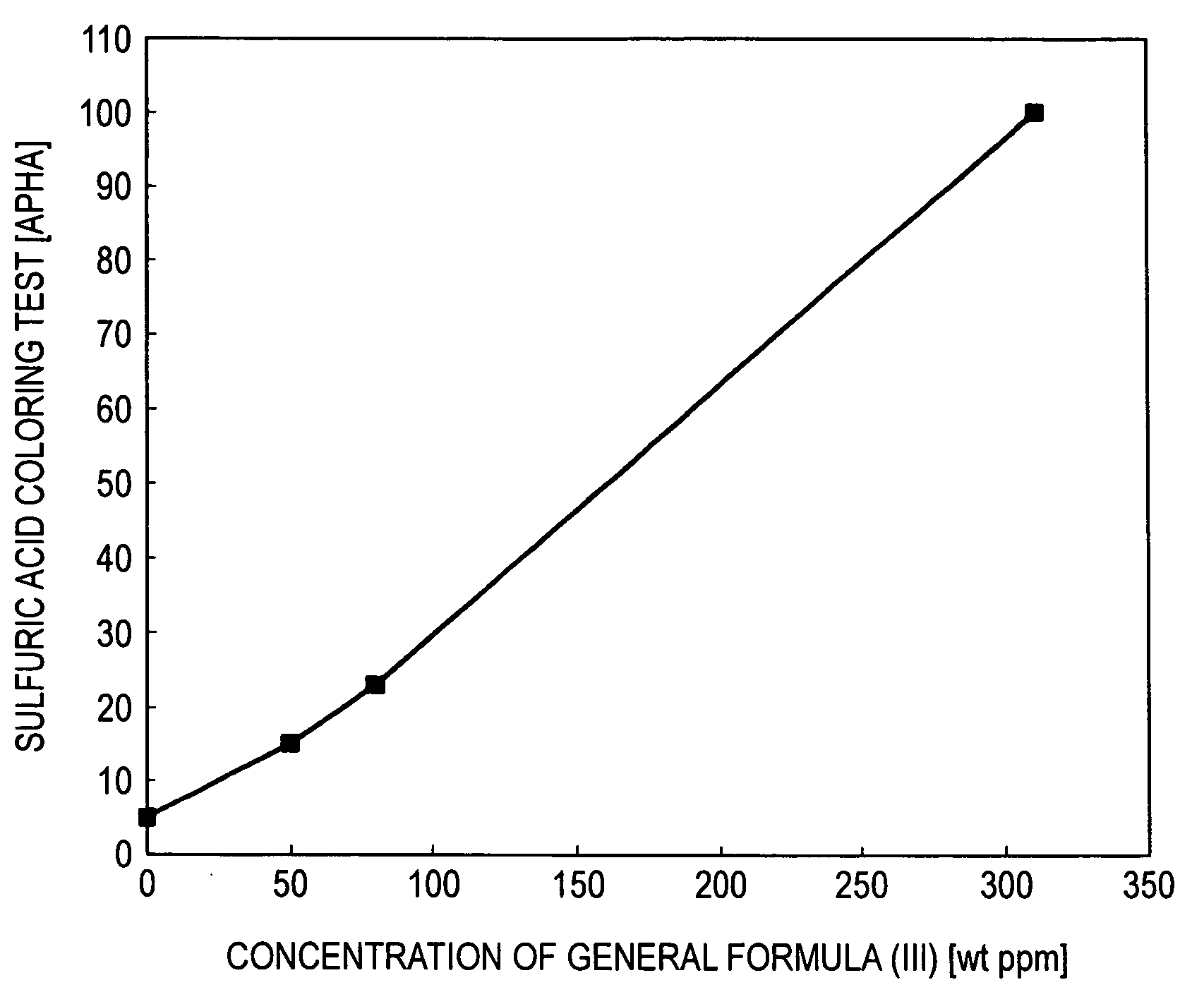

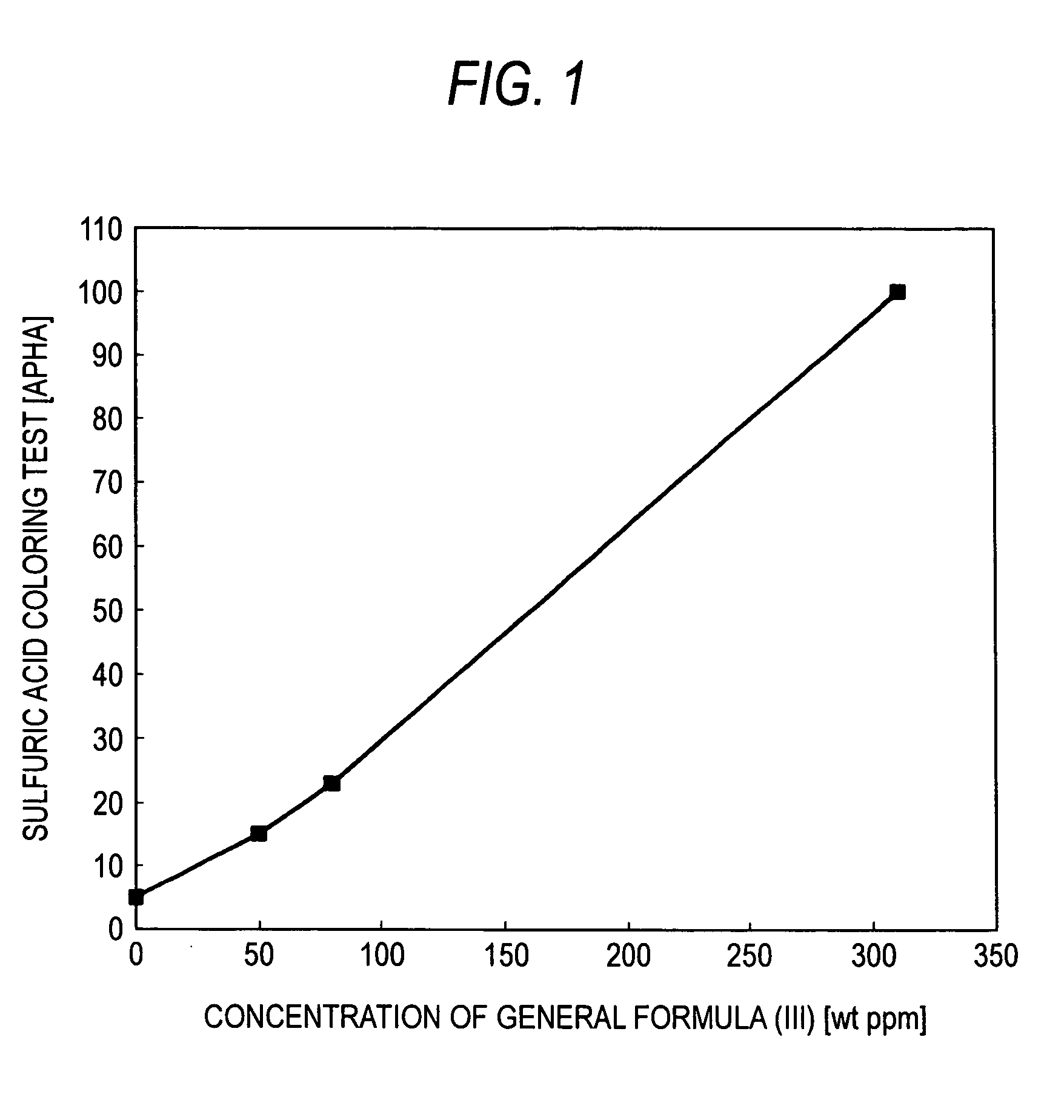

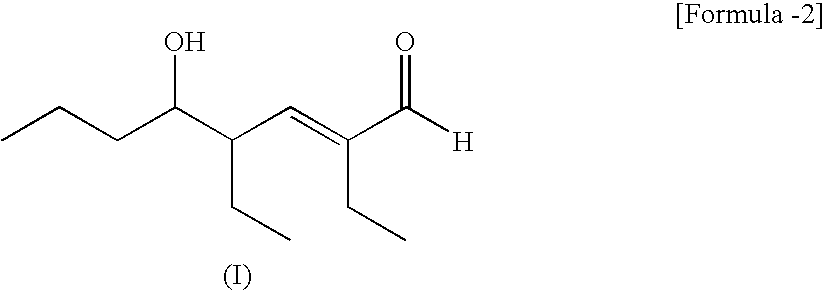

Process for Production of Purified Alcohols

ActiveUS20080242899A1Satisfied with the resultPreparation by oxo-reaction and reductionOrganic compound preparationAlcoholDouble bond

A process for producing purified alcohols yielding good results in the acid wash color test which comprises the condensation step of subjecting an aldehyde to aldol condensation and dehydration to obtain a corresponding condensate, the hydrogenation step of hydrogenating the condensate into a crude alcohol, and the purification step of distilling the crude alcohol to obtain a purified alcohol, characterized by feeding into the purification step a crude alcohol containing compounds having oxygenic heterocycles bearing carbon-carbon double bonds in the cycle in a concentration of as low as 200 ppm by weight or below. In particular, the aldehyde is n-butyraldehyde, the condensate is 2-ethylhexenal, and the alcohol is 2-ethylhexanol.

Owner:MITSUBISHI CHEM CORP

Method of increasing the carbon chain length of olefinic compounds

InactiveUS20050065389A1Preparation by oxo-reaction and reductionOrganic compound preparationAlcoholCarbon chain

According to the present invention there is provided a process of increasing the carbon chain length of an olefinic compound comprising the steps of providing a starting olefinic compound and subjecting it to hydroformylation to produce an aldehyde and / or alcohol with an increased carbon chain length compared to the starting olefinic compound. Optionally the aldehyde that may form during the hydroformylation reaction is hydrogenated to convert it to an alcohol which has an increased carbon chain length compared to the starting olefinic compound. The alcohol with the increased carbon chain length is subjected to dehydration to produce an olefinic compound with an increased carbon chain length compared to the starting olefinic compound. The invention also relates to olefinic compounds produced by the process.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com