Patents

Literature

88 results about "Propynal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propynal is an organic compound with molecular formula HC₂CHO. It is the simplest chemical compound containing both alkyne and aldehyde functional groups. It is a colorless liquid with explosive properties.

Organic compounds and processes for their manufacture

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing 1,3-propylene glycol

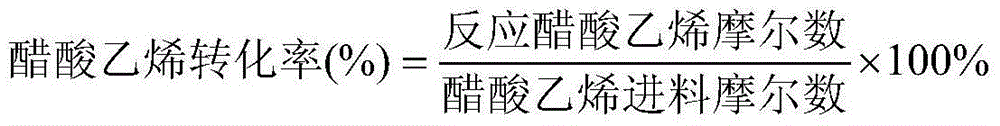

InactiveCN1431183ALow priceImprove securityPhysical/chemical process catalystsPreparation by oxygen reductionHigh activityPropanediol

A process for preparing 1,3-propanediol from formaldehyde and acetaldehyde includes such steps as under existance of alkali and organic solvent, reacting at 10-40 deg.C for 2-10 hr to obtain 3-hydroxypropanol, making the 3-hydroxypropanal in contact with catalyst, and hydrogenation reaction at 50-100 deg.c and 3-9 MPa. The said catalyst contains Ni (70-90 wt.%), Fe or Mo (0-9), P (1-5) and Al (rest). Its advantages are high output rate, high safety, and high activity and selectivity of said catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

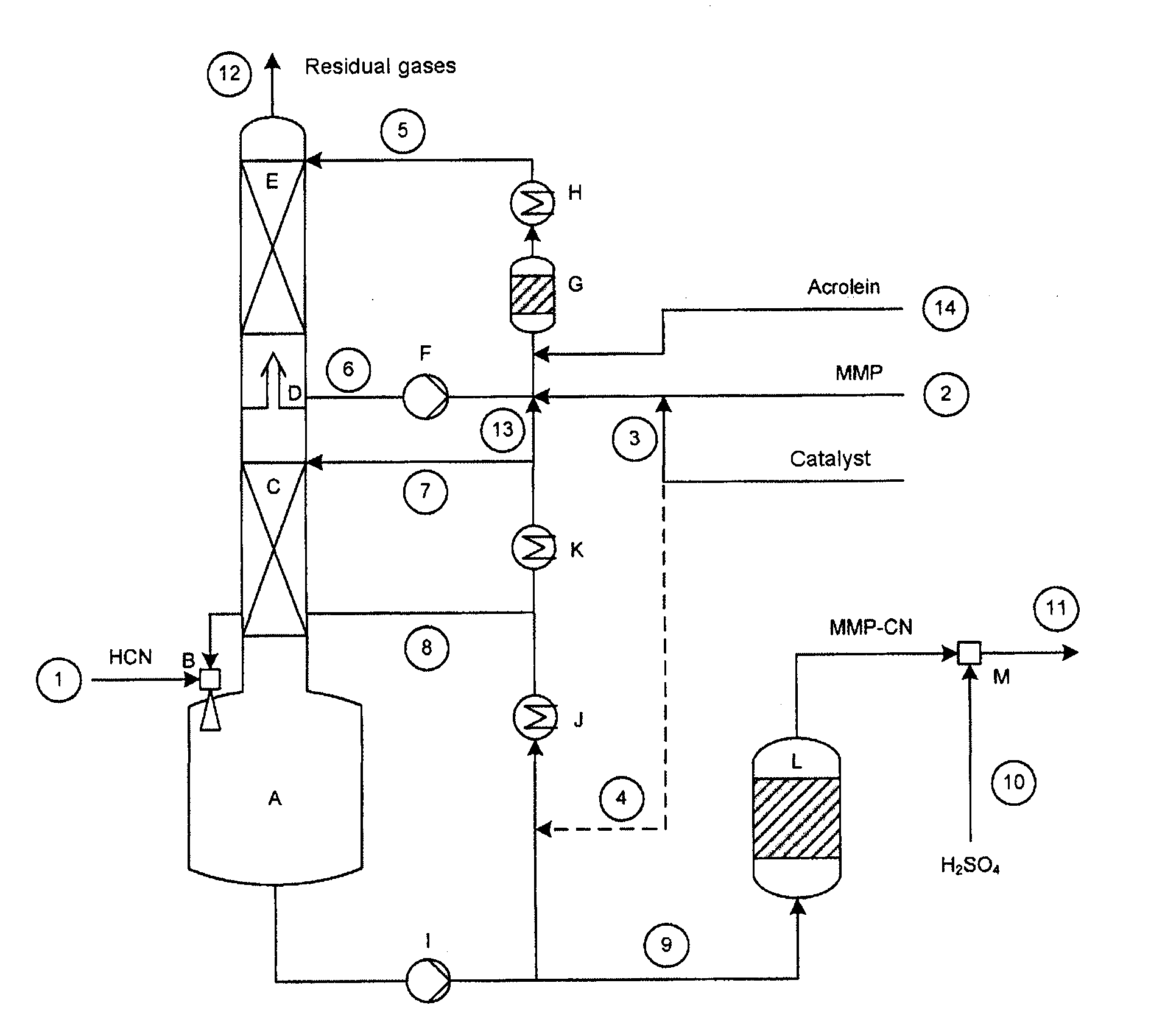

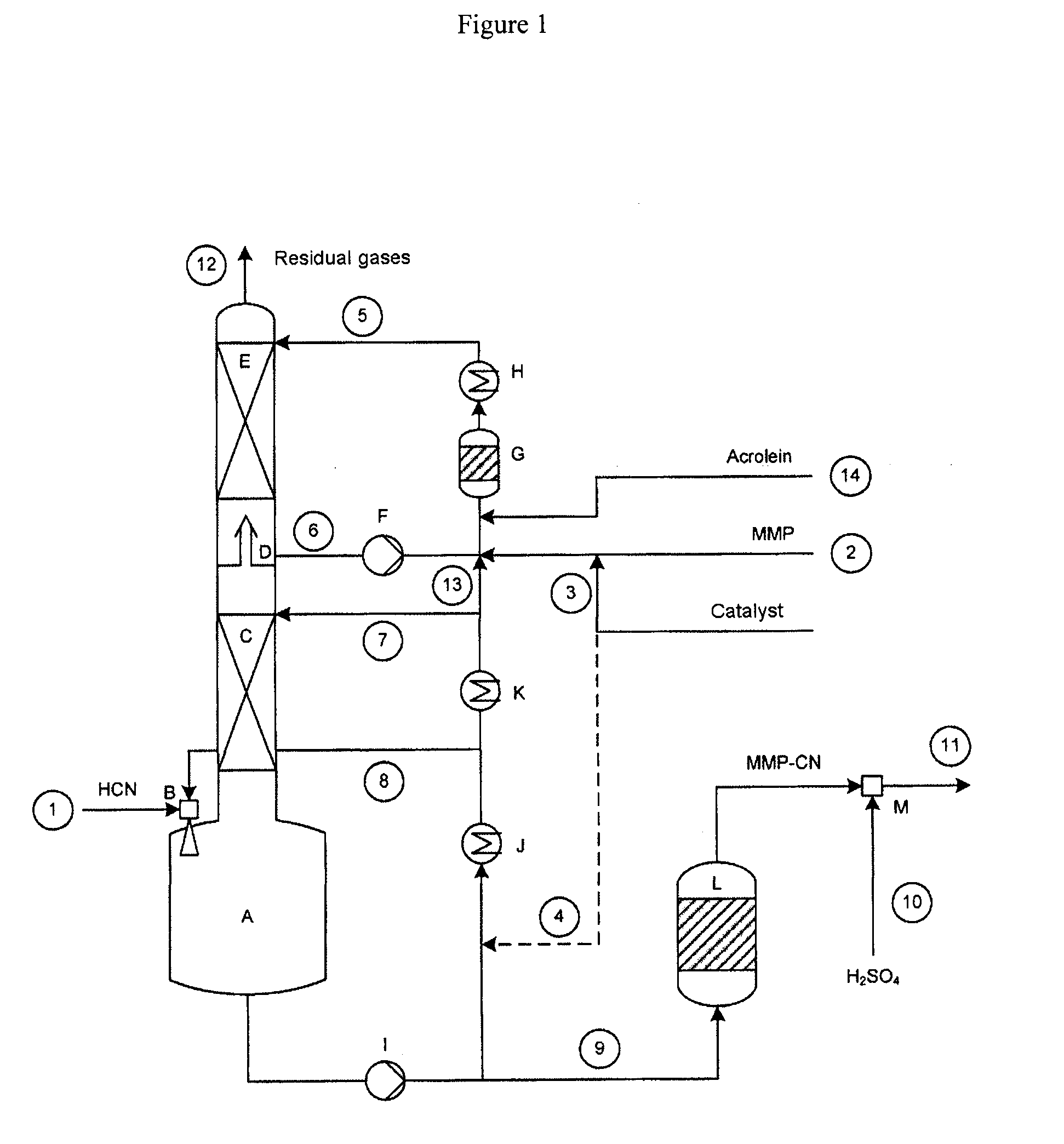

Method for the production of 2-hydroxy-4-(methylthio)butyronitrile from 3-(methylthio)propanal and hydrogen cyanide

ActiveUS20120215022A1Increase response rateLow byproduct formationOrganic compound preparationOrganic chemistry methodsCyanidePropynal

A method for the production of 2-hydroxy-4-(methylthio)butyronitrile having good storage stability in a multi-zone reactor, is provided. 3-methylmercaptopropionaldehyde is reacted with hydrogen cyanide in the presence of a base as catalyst in a main reaction zone of the multizone reactor to form a reaction mixture comprising the 2-hydroxy-4-(methylthio)butyronitrile, unreacted 3-methylmercaptopropionaldehyde, the catalyst and residual amounts of gaseous hydrogen cyanide. The residual gaseous hydrogen cyanide is removed from the main reaction zone to an absorption and post-reaction zone of the reactor which comprises a mixture of 3-methylmercaptopropionaldehyde and the catalyst; and the gaseous hydrogen cyanide is further reacted with the 3-methylmercaptopropionaldehyde in the absorption and post reaction zone. A molar ratio of hydrogen cyanide to 3-(methylthio)propanal in the main reaction zone is from 0.98 to 1.03.

Owner:EVONIK OPERATIONS GMBH

Hydrogenation catalyst and hydrogenation method

InactiveUS20060241325A1Preparation by oxo-reaction and reductionOrganic compound preparationPropynalRuthenium

The present invention provides a hydrogenation catalyst effective for hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol. The hydrogenation catalyst comprises an α-alumina support, nickel, ruthenium, and a promoter. The nickel is deposited on the α-alumina support, and the ruthenium and the promoter are deposited on the nickel and the α-alumina support. The α-alumina support comprises at least 92 wt. % of the catalyst, and the nickel comprises from 1 wt. % to 6 wt. % of the catalyst. The present invention also provides a process of hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol with the catalyst.

Owner:SHELL OIL CO

Process for producing 1,3-propanediol

InactiveUS6911566B2High selectivityHigh yieldMolecular sieve catalystsOrganic compound preparationGas phaseSlurry

A process for producing 1,3-propanediol, comprising:hydrating acrolein in a liquid phase in the presence of a hydration catalyst to form 3-hydroxypropanal;separating any unreacted acrolein, if any is present; andcarrying out catalytic hydrogenation of the 3-hydroxypropanal in a liquid or gas phase with a hydrogenation catalyst,wherein the hydration catalyst is a catalyst comprising at least one member selected from the group consisting of the following materials (a) to (c) and has a pH of 6 or less at 20° C., when made into a slurry by dispersing the catalyst in a quantity of water 5 times as much as the quantity of catalyst by weight:(a) a metalloaluminophosphate molecular sieve,(b) an FER type zeolite, and(c) an oxide or compound oxide, excluding crystalline aluminosilicate zeolites, which comprises one or more element(s) selected from the elements belonging to group 4, group 13 and group 14 of the periodic table.

Owner:ASAHI KASEI KK

Catalyst for preparing 1,3-propanediol by hydrogenation of lactic aldehyde

InactiveCN1428190AHigh activityFacilitated DiffusionMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePropynal

The present invention relates to a catalyst for 3-hydroxypropanal hydrogenation to prepare 1,3-propylene glycol. Its active component is Ni-A, in which A is any one of Cr, Zn, Mo or Fe, the weight ratio of Ni and A is: Ni:A=1:0.01-1:0.1, its carrier is molecular sieve containing Al2O3 or SiO2 or containing both them, and the weight percentage content of active component of catalyst is 30-60%. Said catalyst can help to form high-activity nickel alloy cluster active centre, and can effectively modify pore channel of catalyst, and is favorable for diffusion of 3-hydropropanal so as to greatly raise the activity of catalyst.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

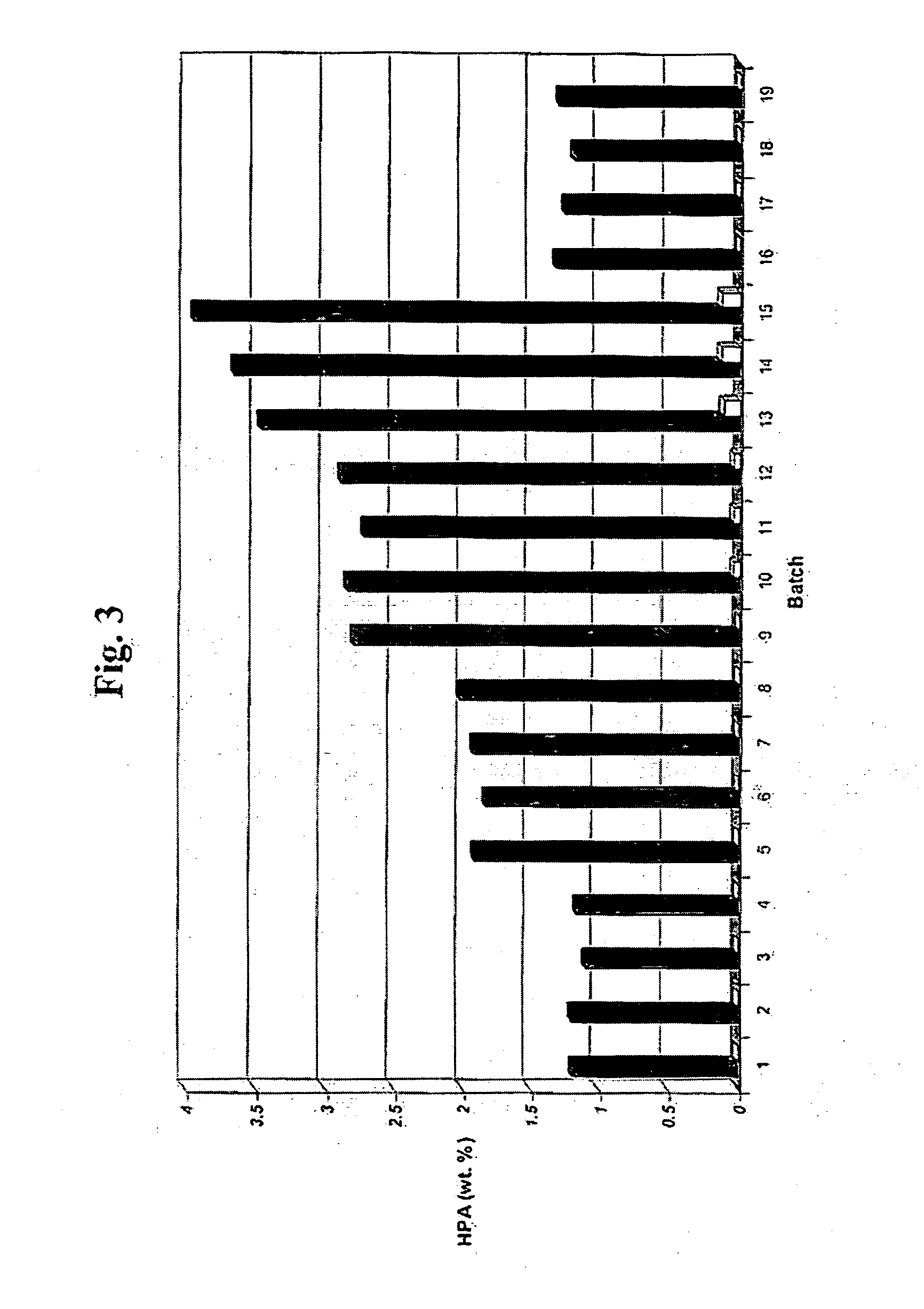

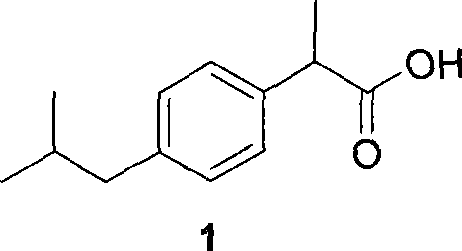

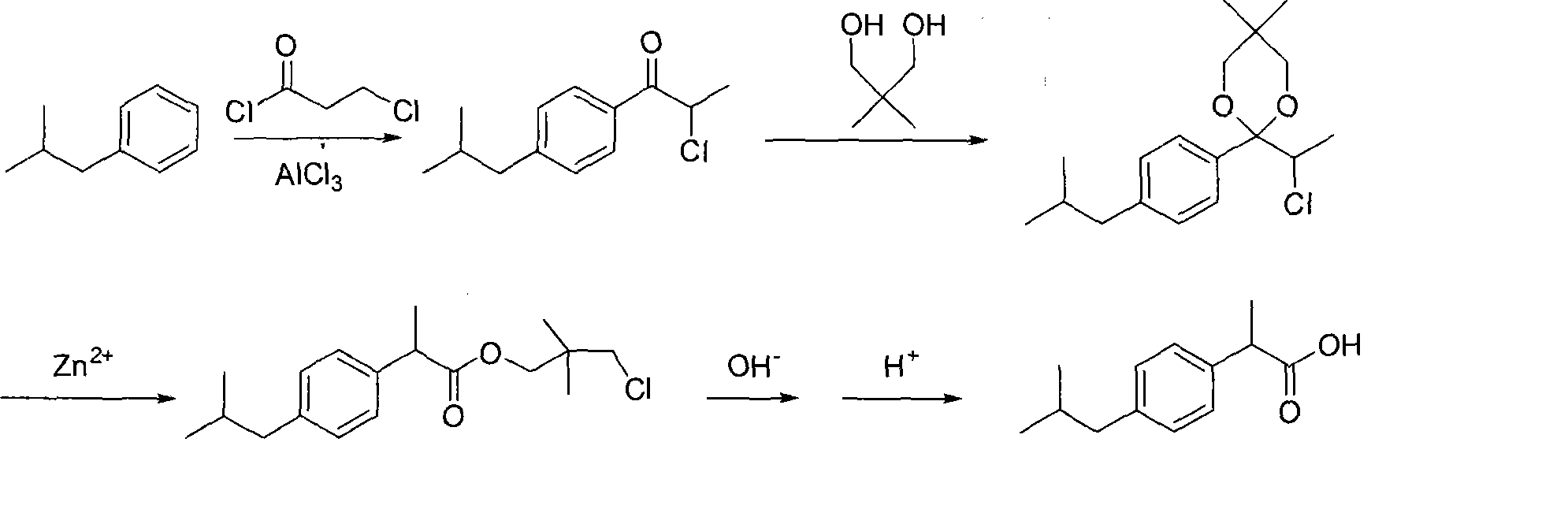

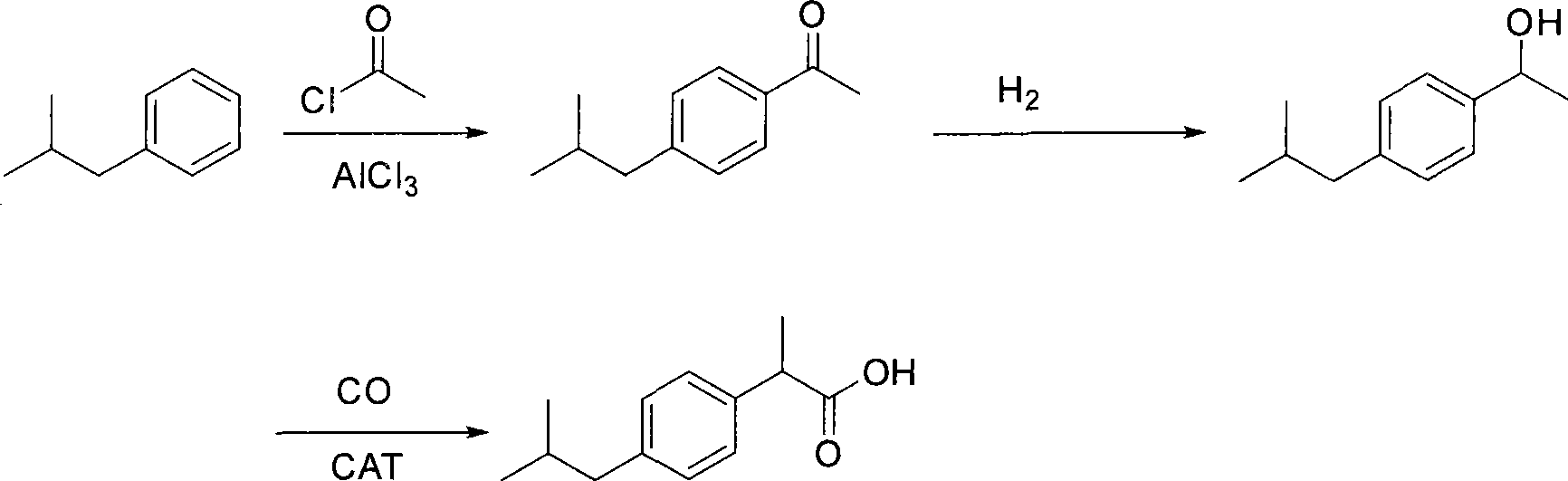

Method for preparing ibuprofen

InactiveCN101456808AAdapt to the requirements of industrializationSave raw materialsOrganic compound preparationCarboxylic compound preparationLewis acid catalysisSolvent

The invention provides a method for preparing ibuprofen. The method comprises: taking isobutyl-benzene as raw material, obtaining 4-isobutyl acetophenone by Friedel-Crafts reaction, obtaining 2-(4-isobutyl phenyl group)-1, 2-propylene oxide by epoxidation, obtaining 1-(4-isobutyl phenyl group) propionaldehyde through intramolecular rearrangement in the presence of Lewis acid catalysis, and obtaining the ibuprofen by oxidation of hydrogen peroxide. The preparation method has the advantages of nonuse of noble metal catalyst, low-priced material, simple process, mild reaction condition, high yield and little amount of the three wastes, and solvent used in the method meets industrialized requirements.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

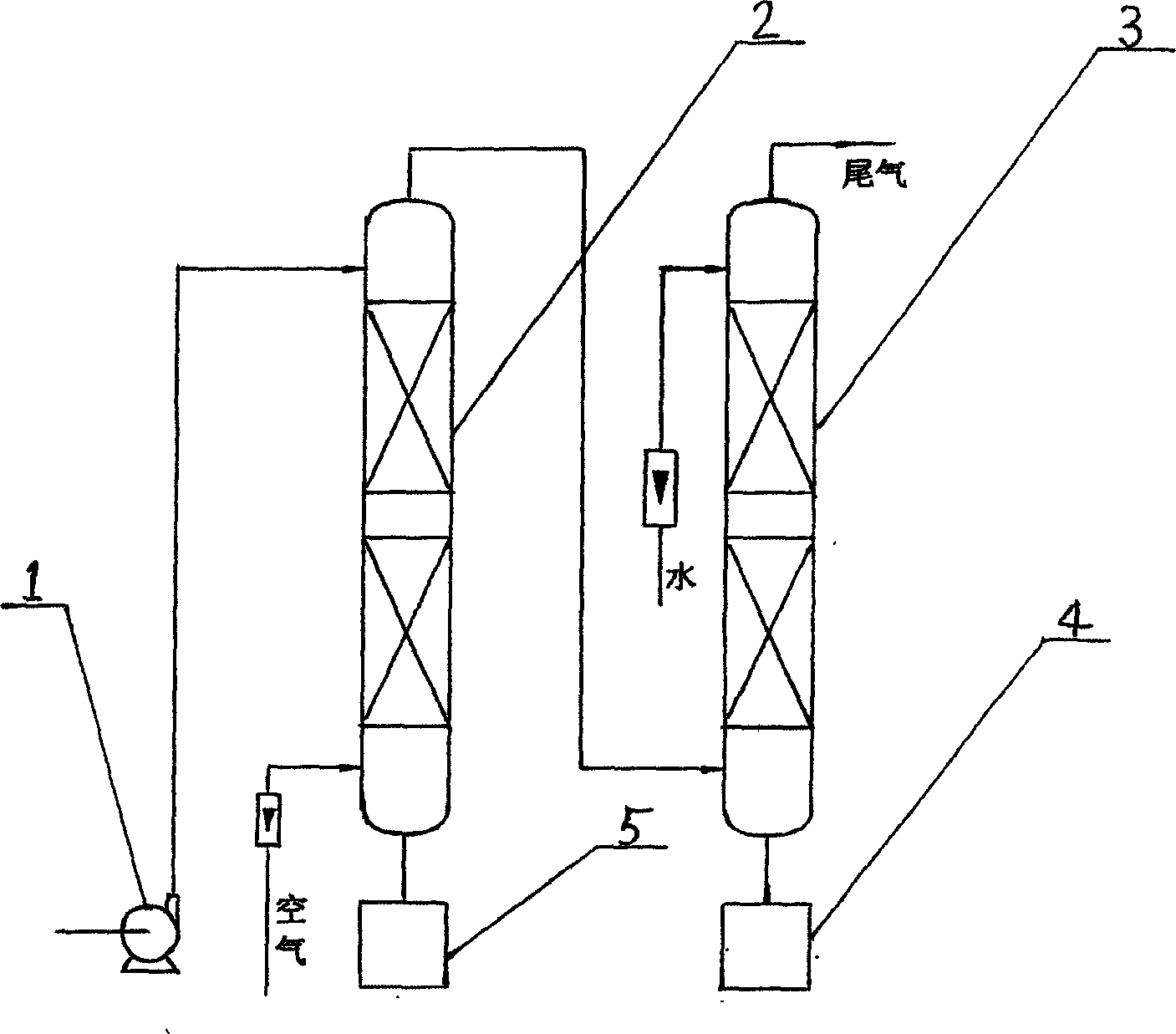

Method for separating and reclaiming acrolein

ActiveCN1803750ASeparation and recovery methods are easy to implementLower operating temperatureCarbonyl compound separation/purificationHydration reactionRecovery method

The provided separate and recovery method for non-reacted acrolein in preparation process of 3-hydroxypropionaldehyde comprises: leading gas into the tower bottom for gas stripping the acrolein from reaction product and absorb it in absorption tower with water. This invention has high recovery and prepares the material with the absorbed liquid for acrolein hydration reaction.

Owner:SHANGHAI HUAYI NEW MATERIAL

Method for removing micro aldehyde group from 1,3-propylene glycol

ActiveCN1803744ALow costGood dealdehyde effectPhysical/chemical process catalystsHydroxy compound separation/purificationHydrogenation reactionPropynal

The related stripping method for trace-amount aldehydo in 1, 3-dihydroxypropane comprises: adding proper solid super acidic catalyst of SO42- / MxOy into the 1, 3-dihydroxypropane solution with micro impurity dewatered and condensed from hydrogenation reaction production of 3-hydroxypropionaldehyde for dealdehydation treatment at given temperature; rectifying the solution under vacuum to obtain polymer-grade product that has 1, 3-dihydroxypropane content more than 99.7% and aldehyde content less than 10ppm and fit to material quality request for PTT.

Owner:SHANGHAI HUAYI NEW MATERIAL

Catalyst for hydrogenating 3-hydroxy propaldehyde to prepare 1, 3-propylene glycol

ActiveCN1810371AHigh activityImprove stabilityMolecular sieve catalystsOrganic compound preparationHigh activityHigh selectivity

The catalyst for hydrogenating 3-hydroxy propaldehyde to prepare 1, 3-propylene glycol is supported Ni-Mo-X / A catalyst with the molecular sieve, oxide or their mixture as carrier and Ni, Mo and one third metal as the active components. The catalyst is used in the hydrogenating water solution of 3-hydroxy propaldehyde to prepare 1, 3-propylene glycol, and has high activity, high selectivity, mild reaction condition and high stability.

Owner:SHANGHAI HUAYI NEW MATERIAL

Process for preparing 3-hydroxy propionic aldehyde and 1, 3-propylene glycol

ActiveCN1690033AReduce operating costsSave the inconvenience of subsequent processingPreparation by oxygen reductionPreparation from heterocyclic compoundsOxygenPropanediol

The process of preparing 3-hydroxy propionic aldehyde and 1, 3-propyelene glycol includes: the hydrogenation and formylation of ethylene oxide and synthetic gas inside the organic solvent with the shown expression and in the presence of carbonyl cobalt catalyst; introducing air or oxygen to oxidize the carbonyl cobalt catalyst into cobalt precipitate; centrifugally separating the cobalt precipitate from the solution, filtering and returning the cobalt precipitate to reactor for next reaction; adding deionized water into the filtrate and vacuum distilling the filtrate to obtain water solution containing 3-hydroxy propionic aldehyde; and final hydrogenating to produce 1, 3-propyelene glycol. The said process has high efficiency and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

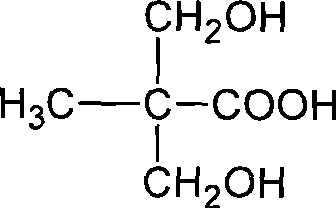

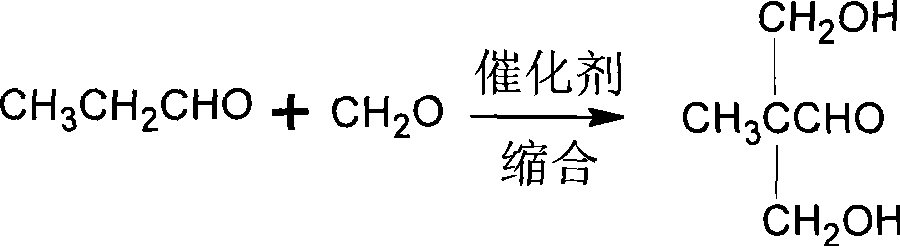

Method for synthesizing 2,2-bis(hydroxymenthyl)propinonic acid

InactiveCN101381300AEasy to controlMild reaction conditionsCarboxylic preparation by oxidationOrganic synthesisPropynal

The invention belongs to the field of fine organic synthesis. The invention uses a mixture of Ca(OH)2, Ba(OH)2, triethylamine and Ca(OH)2 or a mixture of triethylamine and Ba(OH)2 as a catalyst to prepare 2,2-hydroxymethylpropionic acid through a condensation reaction of propanal and formaldehyde under the oxidation of hydrogen peroxide or oxygen. The invention has the advantages of fewer side reactions due to preparation of the 2,2-hydroxymethylpropionic acid under alkaline conditions, higher yield of the 2,2-hydroxymethylpropionic acid and easy realization of industrialization.

Owner:QILU UNIV OF TECH

Hydrogenation catalyst and hydrogenation method

InactiveUS7335800B2Preparation by oxo-reaction and reductionOrganic compound preparationPropynalRuthenium

The present invention provides a hydrogenation catalyst effective for hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol. The hydrogenation catalyst comprises an α-alumina support, nickel, ruthenium, and a promoter. The nickel is deposited on the α-alumina support, and the ruthenium and the promoter are deposited on the nickel and the α-alumina support. The α-alumina support comprises at least 92 wt. % of the catalyst, and the nickel comprises from 1 wt. % to 6 wt. % of the catalyst. The present invention also provides a process of hydrogenating 3-hydroxypropionaldehyde to 1,3-propanediol with the catalyst.

Owner:SHELL OIL CO

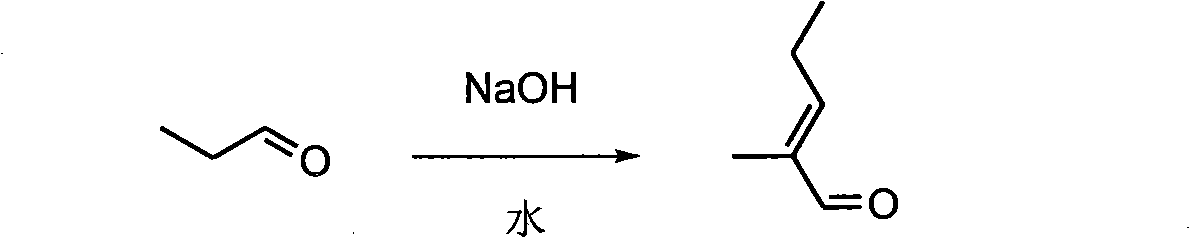

Production method for methylacrolein

InactiveCN104311403AOrganic compound preparationCarbonyl compound separation/purificationDepolymerizationParaformaldehyde

The invention relates to a production method for methylacrolein. The production method comprises the steps of depolymerizing paraformaldehyde in an organic solvent so as to produce a methanal organic solution, and carrying out aldol condensation reaction on the methanal organic solution and propyl aldehyde under the catalysis of ionic liquid so as to produce methylacrolein. According to the production method, the methanal organic solution obtained through depolymerization of paraformaldehyde substitutes for methanal water solution, so that a lot of waste water is prevented from the source, the output of the waste water is greatly reduced in production, and the burden of recycling of ionic liquid is relieved; furthermore, due to the organic solvent used in the depolymerization, the oil-water separation in aldol condensation reaction is changed into homogeneous reaction, so that the mass transfer rate is accelerated, and the conversion rate and selectivity of the reaction are further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

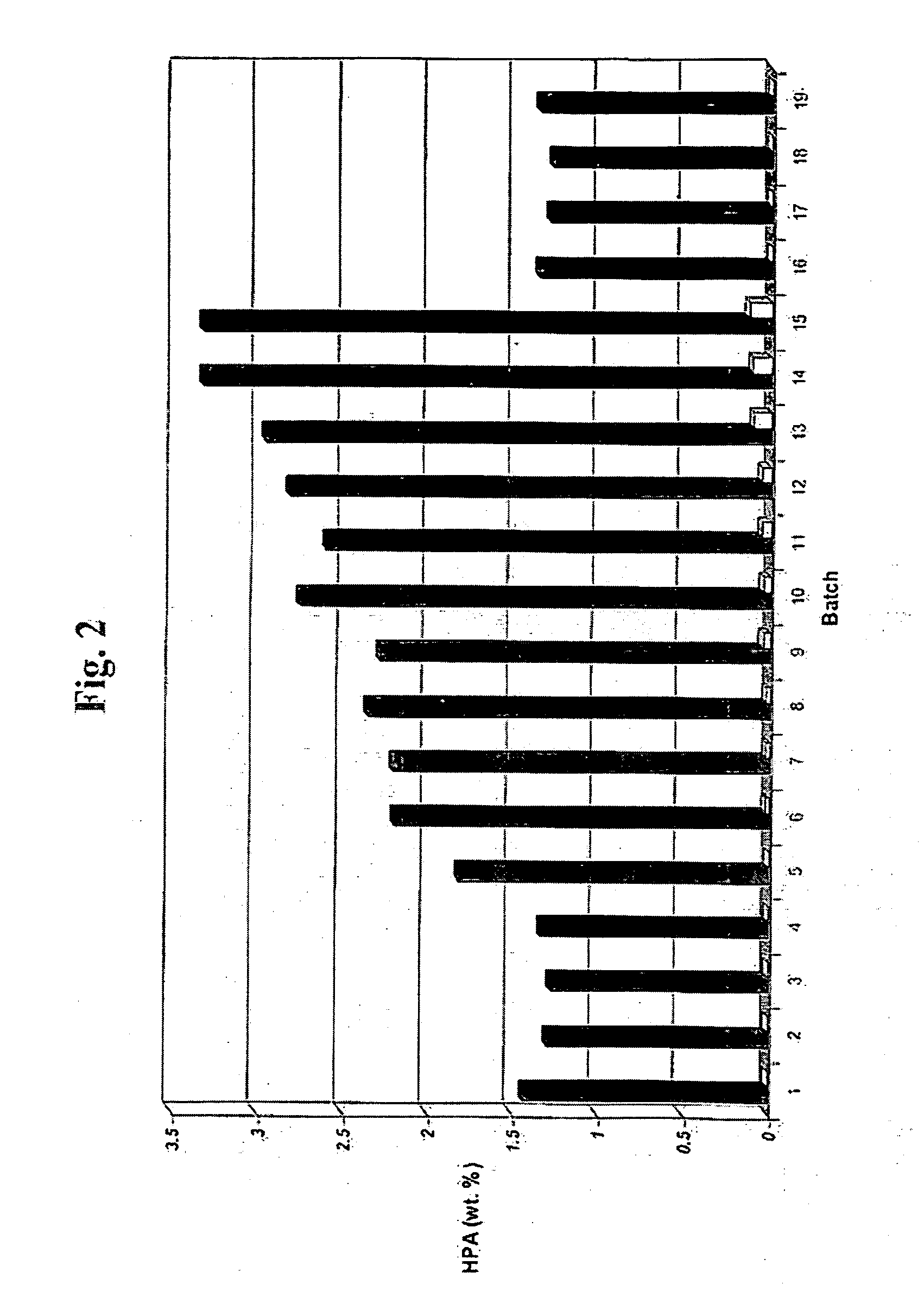

Heteropoly acid catalyzed process to eliminate micro aldehyde group from 1,3-propylene glycol

InactiveCN1810750ALow costGood dealdehyde effectHydroxy compound separation/purificationPolyesterPropynal

The heteropoly acid catalyzed process to eliminate micro aldehyde group from 1, 3-propylene glycol includes: adding heteropoly acid, salt of heteropoly acid or solid carried heteropoly acid catalyst into 1, 3-propylene glycol solution, obtained through dewatering 3-hydroxy propanal hydrogenating product and certain amount of aldehyde group, to eliminate aldehyde group; and decompression rectifying 1, 3-propylene glycol solution after eliminating aldehyde group to obtain 1, 3-propylene glycol product with purity higher than 99.6 % and aldehyde content lower than 10 ppm and meeting the requirement as polyester PTT producing material.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

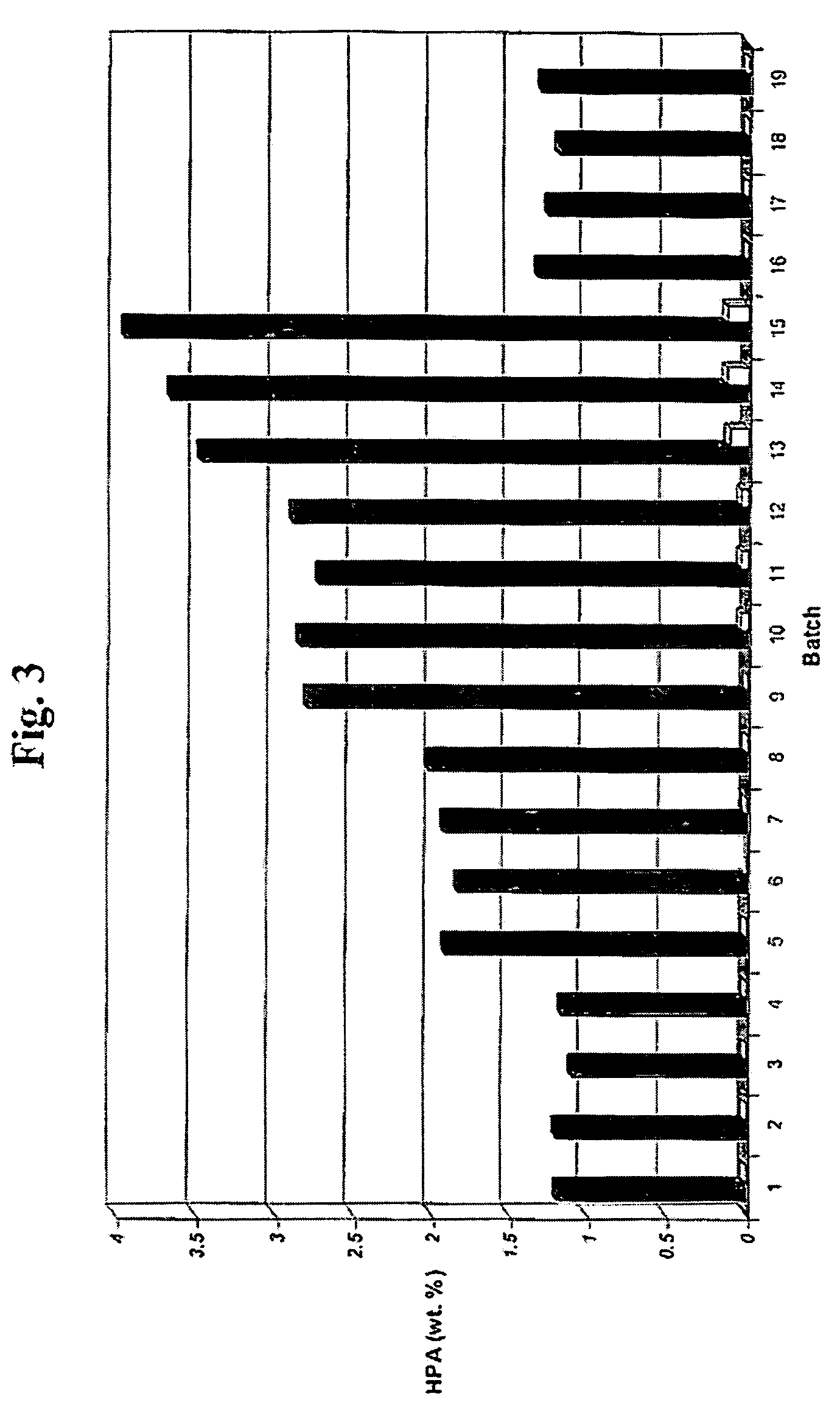

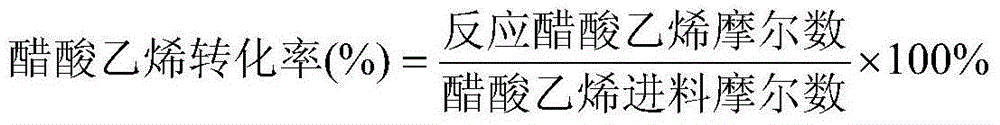

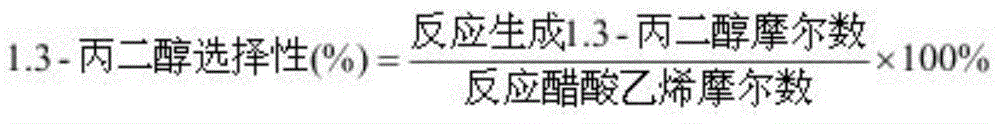

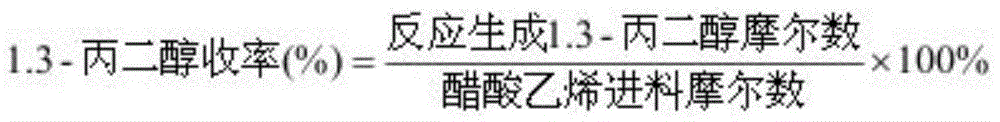

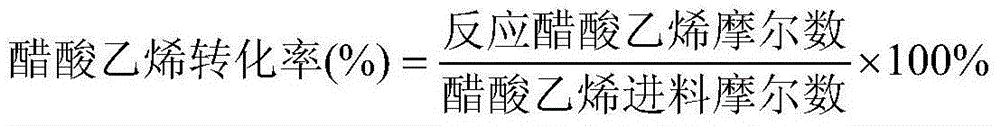

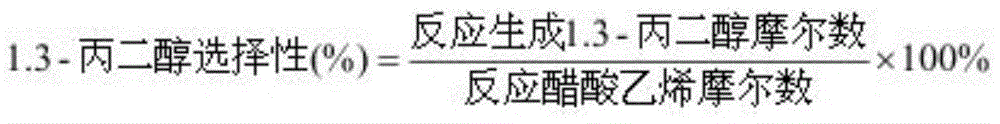

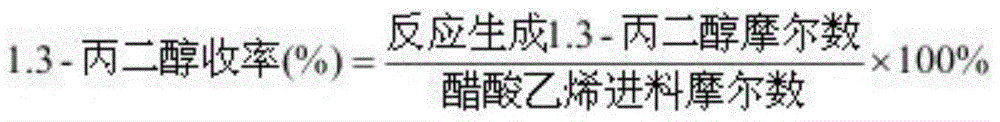

Method for preparing 1, 3-propanediol through hydroformylation of vinyl acetate

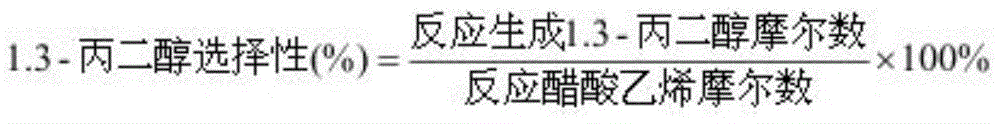

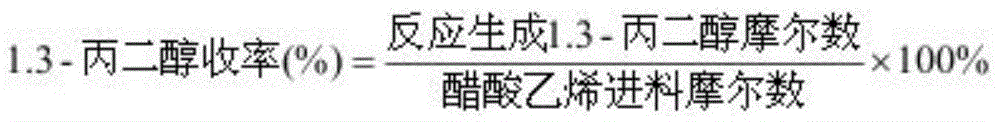

ActiveCN105523891AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metal1,3-Propanediol

The invention relates to a method for preparing 1, 3-propanediol through hydroformylation of vinyl acetate. The method mainly solves the problem that the prior art has low 1, 3-propanediol catalyst activity and low selectivity. The method provided through the invention comprises vinyl acetate hydroformylation for 3-acetoxypropanal preparation, 3-acetoxypropanal hydrogenation for 3-acetoxypropanol preparation and 3-acetoxypropanol hydrolysis for 1, 3-propanediol preparation. A hydroformylation catalyst utilizes SiO2, Al2O3 or their mixture as a carrier and active ingredients comprise at least one of platinum metal elements, at least one of alkaline-earth metal elements and at least one of VB and IVA metals. The method well solves the above technical problem and can be used for 1, 3-propanediol industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 1,3-methyl glycol by catalytic hydrogenation of 3-hydroxy propanal

ActiveCN101041614AImprove stabilityLow reaction temperatureOrganic compound preparationHydroxy compound preparationHydrogen pressureReaction temperature

The invention discloses a making method of 1, 3-propylene glycol through hydrogenating 3-hydroxy propanal, which comprises the following steps: adopting load-typed non-crystal alloy as catalyst; using two-segment paralleling fixing bid to hydrogenate continuously under 20-60 deg.c for one-segment and 50-90 deg.c for two-segment; setting the condensing density of 3-hydroxy propanal to 2.0-40.0% with air speed at 0.1-5.0h-1; making the hydrogen pressure at 0.5-10.0Mpa and air speed at 100-2000h-1.

Owner:SHANGHAI HUAYI NEW MATERIAL

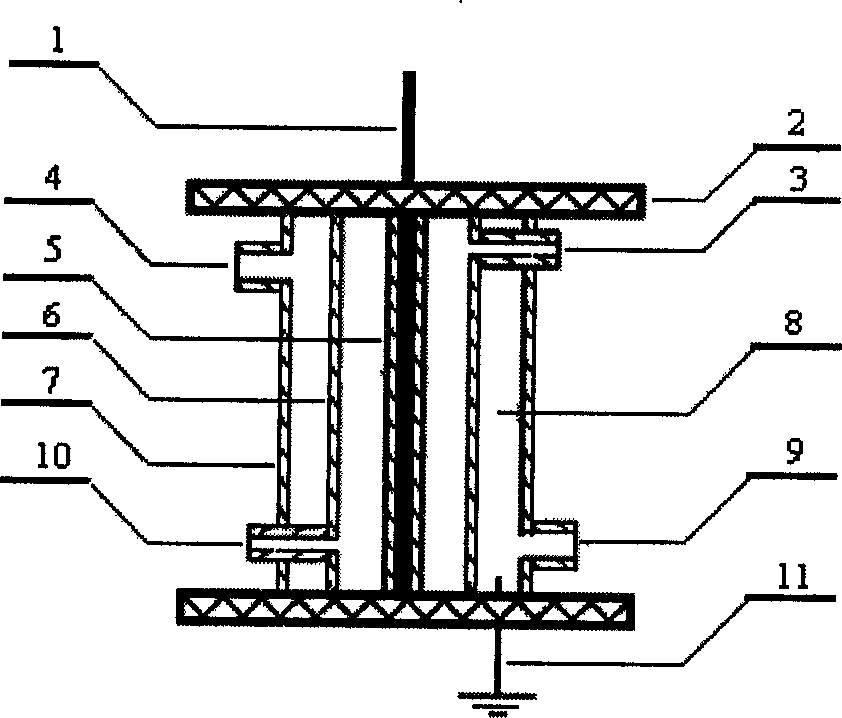

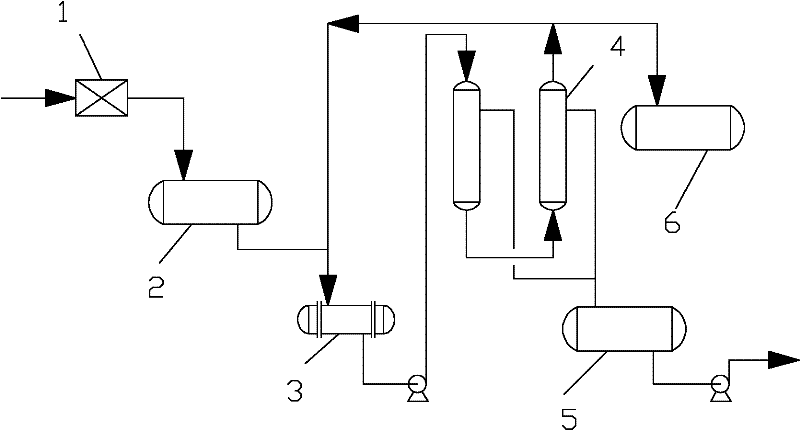

Device for preparing propionic aldehyde by directly oxidizing propylene with molecular oxygen

InactiveCN1900042AHigh yieldNo pollution in the processOrganic compound preparationCarbonyl compound preparationHigh energyOxygen ions

The present invention belongs to the field of low temperature plasma chemistry and basic chemical synthesizing technology, and is especially apparatus for preparing propionic aldehyde through direct oxidation of propylene with molecular oxygen. The apparatus has double medium discharge electrode structure to generate pure medium blocking discharge plasma. The propylene molecule is acted with the high energy electron formed in the plasma to form free radical with three connected carbon atoms, while the oxygen molecule is acted with the high energy electron formed in the plasma to form excited state oxygen molecule, oxygen atom, negative oxygen ion, positive oxygen ion and other active oxygen matters. These active oxygen matters and the free radical with three connected carbon atoms react to synthesize propionic aldehyde directly. The present invention has mild reaction condition, high reaction efficiency, high target product yield and environment friendship.

Owner:DALIAN MARITIME UNIVERSITY

New type resin catalyst for making 3-hydroxy inner aldehyde from acrolein hydration and its application

ActiveCN1830559AImprove conversion rateGood choiceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydration reactionSurface layer

A chelated ion exchange resin catalyst for preparing 3-hydroxypropanal from acrolein by hydrating reaction has a surface layer carrying amidocarboxylic acid groups and a basic body which is a three-element copolymer styrene-divinylbenzene- (methyl) acrylate (or acrylonitrile). It has low reaction temp and high conversion rate and selectivity.

Owner:SHANGHAI HUAYI NEW MATERIAL

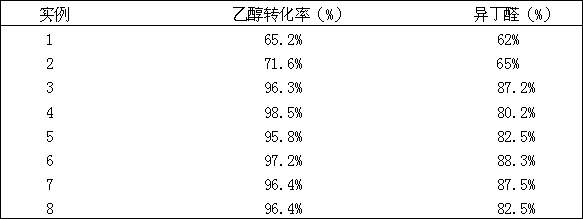

Method for synthesizing isobutyraldehyde catalyst by using methyl alcohol and ethanol in one step

InactiveCN102698767AHigh activityHigh selectivityCarbonyl compound preparation by condensationMetal/metal-oxides/metal-hydroxide catalystsSolubilitySolvent

A method for synthesizing an isobutyraldehyde catalyst by using methyl alcohol and ethanol in one step relates to a preparation method for the catalyst. The preparation method comprises the following steps of: dissolving a solubility vanadic salt and ferric salt in an aqueous solution, adding citric acid and one or two soluble salts of Ce, Zr and La, then stirring and evaporating a solvent, drying, molding and roasting after solvent evaporation is ended, and preparing the oxide catalyst, wherein the charging manner of a V salt solution and citric acid, Fe, Ce, Zr, La solutions is a positive addition method, a reverse addition method or a combining addition method, the evaporation temperature of the solvent is 30-95 DEG C, V is an active component, Fe, Ce, Zr and La are auxiliaries, a V metal salt is a vanadium soluble salt, and Fe, Ce, Zr and La salts are corresponding nitrates, the drying temperature is 80-150 DEG C, and the roasting temperature is 350-800 DEG C. The prepared product prepared by the method comprises main products such as high value-added acetaldehyde and propionaldehyde apart from isobutyraldehyde and few other by-products; and the catalyst has good stability, high activity and high selectivity.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

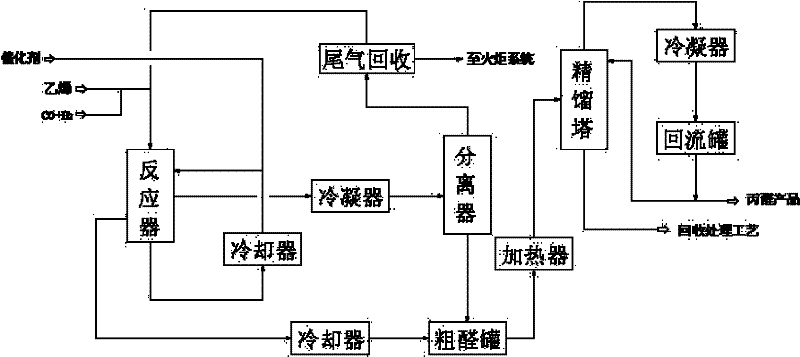

Technical method for producing propyl aldehyde through hydroformylation of ethylene

InactiveCN102336638ATimely recyclingSafe recyclingSemi-permeable membranesPreparation by carbon monoxide reactionPropynalPermeation

The invention discloses a technical method for producing propyl aldehyde through hydroformylation of ethylene and particularly relates to a method for processing a propyl aldehyde rectifying still solution. The method comprises the following steps of: (1), reacting ethylene with CO and H2 under the action of a soluble rhodium-phosphine complex catalyst to generate propyl aldehyde, obtaining a propyl aldehyde product on the tower top of a rectifying tower, and treating the tower solution with a still solution recovery technology; (2), in the recovery treatment technology, separating the rectifying still solution through a membrane separator, returning clear solution at a permeation side to a reactor and discharging materials at a concentrating side to a waste solution tank. The technical method has the advantages of simple technology and simpleness for operation, and but more, realizes water recovery and reduces the discharge of waste solution.

Owner:南京荣欣化工有限公司

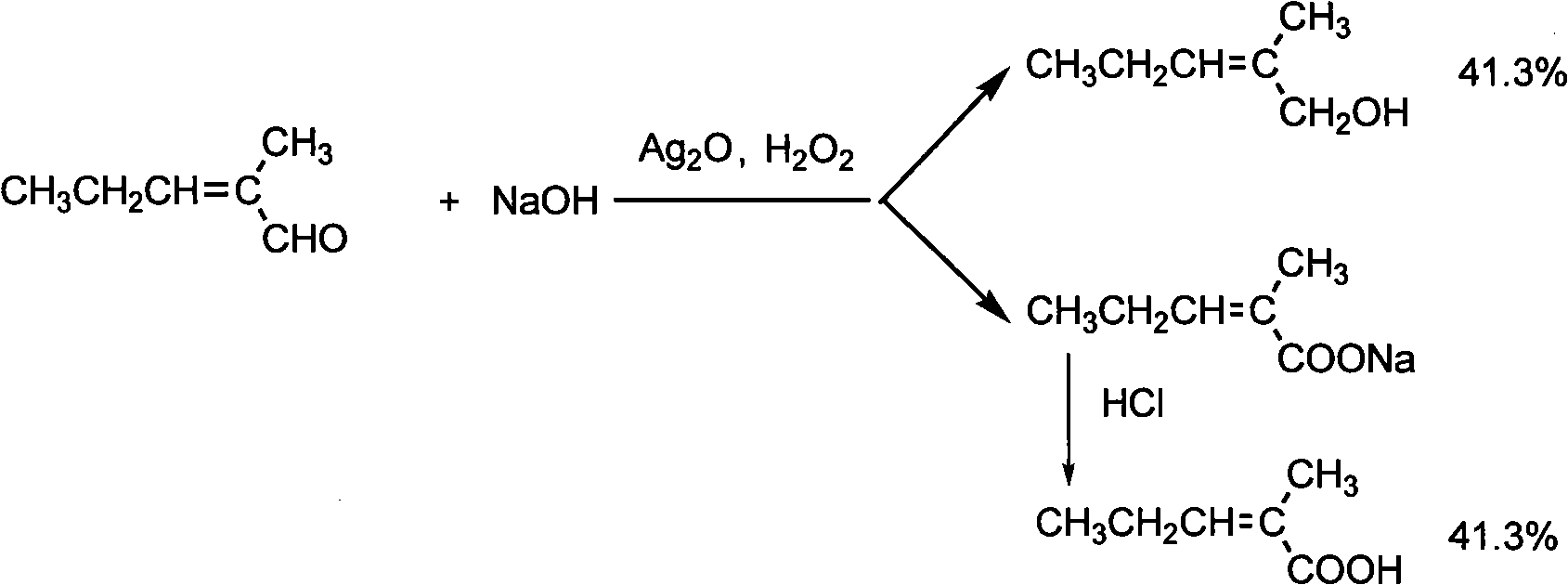

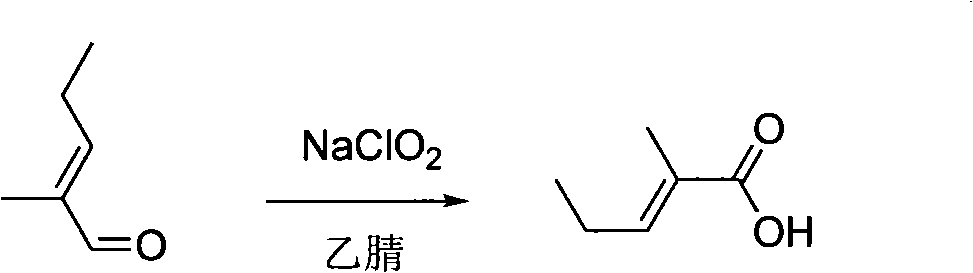

Production method of 2-methyl-2-pentenoic acid

InactiveCN102653510AMild reaction conditionsEasy to operateCarboxylic preparation by oxidationOrganic solventFlavoring essences

The invention discloses a production technique of 2-methyl-2-pentenoic acid. The 2-methyl-2-pentenoic acid is widely used in flavoring essences. The production method provided by the invention comprises the following steps: carrying out aldol condensation reaction on the propanal as the initial raw material under alkaline conditions, and oxidizing the intermediate 2-methyl-2-valeraldehyde in water to obtain the target product. The technique disclosed by the invention is characterized in that water is utilized to substitute the traditional organic solvent in the reaction process. Thus, the invention has the advantages of mild reaction conditions, small environmental pollution, simple technological operation, low equipment investment, accessible raw materials and short production cycle, and is a promising production technique.

Owner:SHANGHAI AIPU VEGETABLE TECH +1

Preparation of quaternary ammonium N-carboxyetbyl chitosan

The invention relates to a quaternization N-ethyl chitosan, which is a novel chitosan ramification with a good water-solubility, bacteriostasis, moisture absorption, moist storage and emulsification stability. The preparation process is characterized in that: under the pH of 3.0 to 12.0, the chitosan of the deacetylation of 30 percent to 90 percent is reacted with pyruvic acid and malonaldehydic acid to generate a chitosan Schiff base, and is deoxidized by sodium borohydride, potassium borohydride, sodium borohydride cyanoacrylate, cyano-group sodium borohydride and the mixture to obtain the N-ethyl chitosan; the N-ethyl chitosan in alcohol medium is processed by alkali, and is modified by glycidyl trimethyl ammonium chloride or 3-chlorine -2-hydroxy trimethyl ammonium chloride so as to get N-ethyl chitosan admixture with quaternization; the admixture is washed and dissolved by methyl alcohol or ethanol solution, then dialysis desalination, concentration in decompression or atmospheric pressure, absolute ethyl alcohol, or acet sedimentation and dehydration are conducted, finally the admixture is arranged in a vacuum airer at 60 DEG C to 150 DEG C for drying for vacuum freeze drying until the water volume is less than 10 percent.

Owner:YANCHENG INST OF TECH

Hydroformylation process

InactiveCN102428062AGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenPropynal

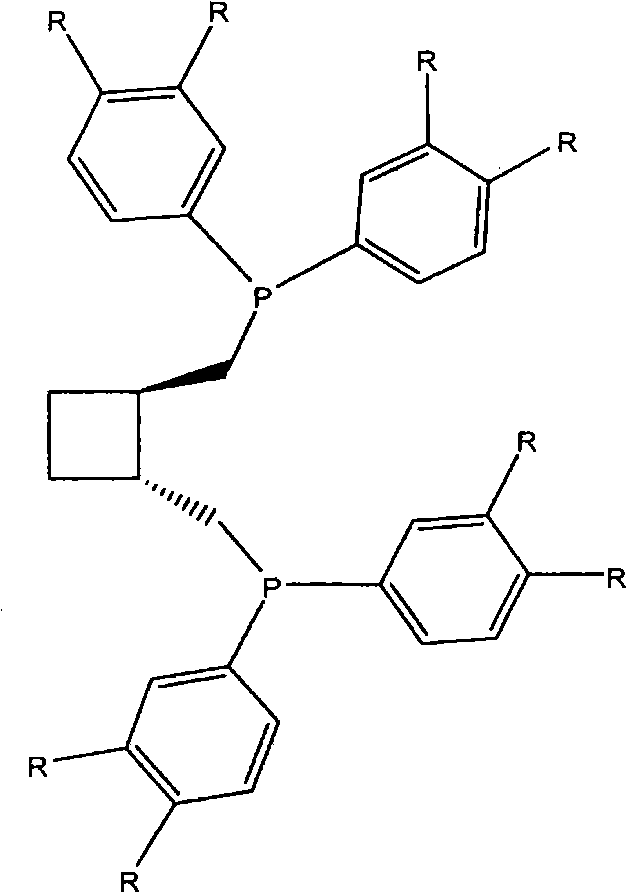

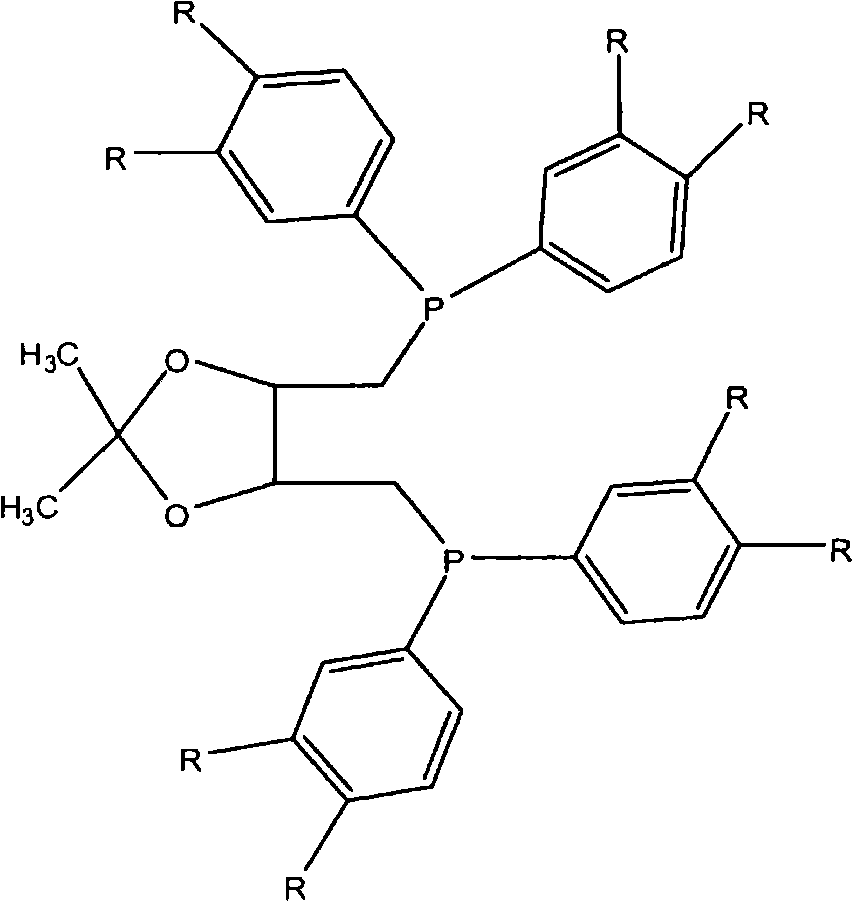

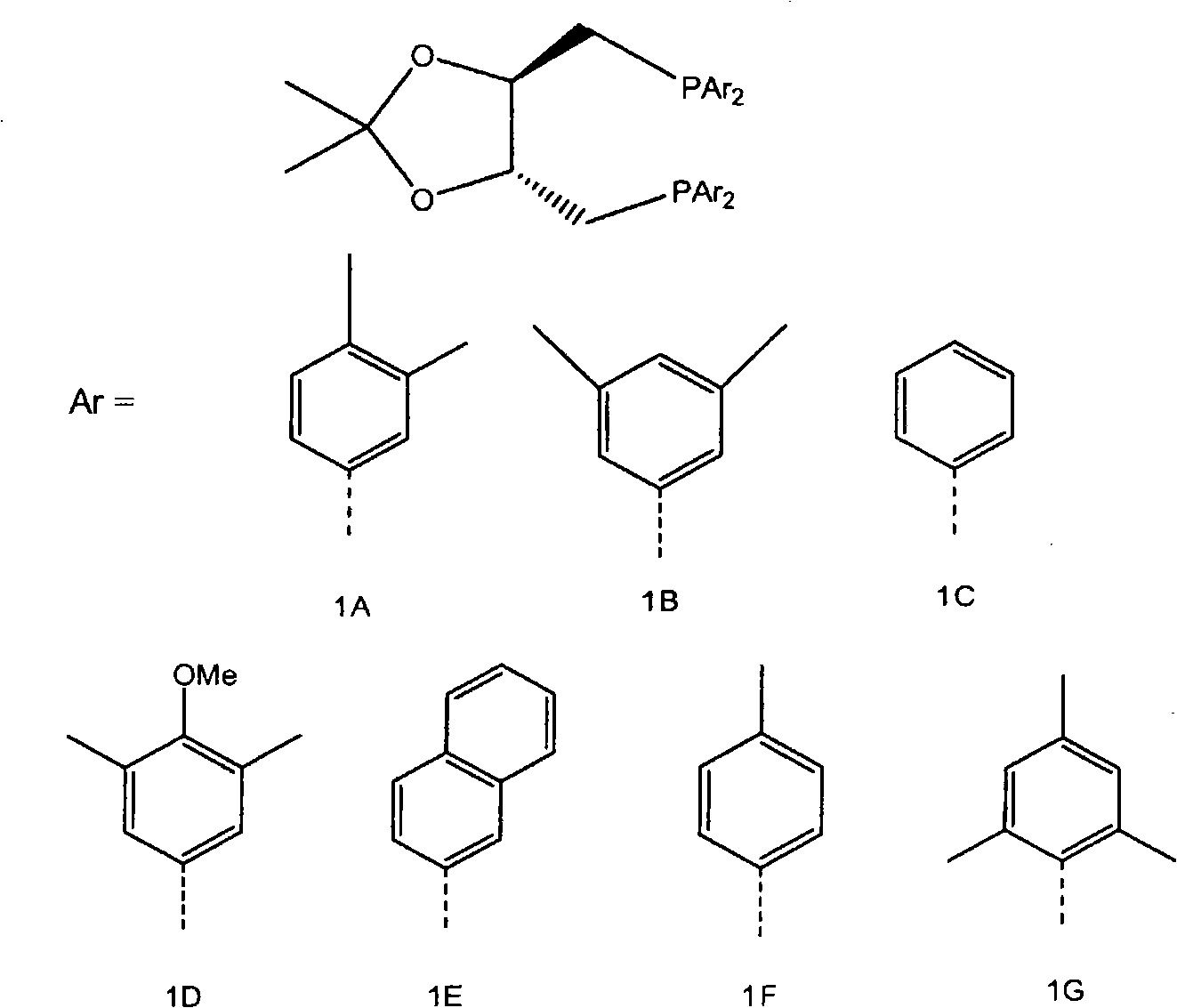

A process for the production of 4-hydroxybutyraldehyde is described. The process comprises reacting allyl alcohol with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst comprising a rhodium complex and a diphosphine. The diphoshine is a trans-1,2-bis(bis(3,4-di-n-alkylphenyl)phosphinomethyl)cyclobutane and / or a 2,3-O-isopropylidene-2,3-dihydroxy-1,4-bis[bis(3,4-di-n-alkylphenyl)phosphino] butane. The process gives high yield of 4-hydroxybutyraldehyde compared to 3-hydroxy-2-methylpropionaldehyde.

Owner:LYONDELL CHEM TECH LP

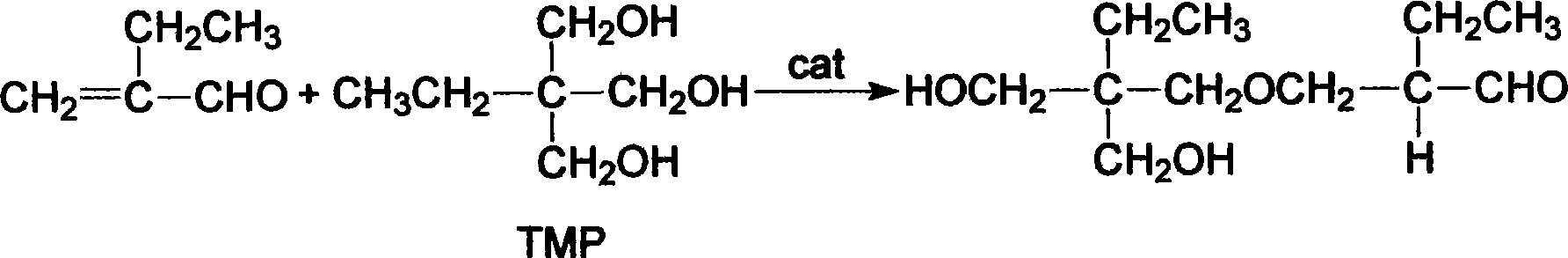

Process of synthesizing bis (trihydroxy methyl propane)

InactiveCN101066913ASimple processRaw materials are cheap and easy to getOrganic compound preparationEther preparationDisproportionationPhotochemistry

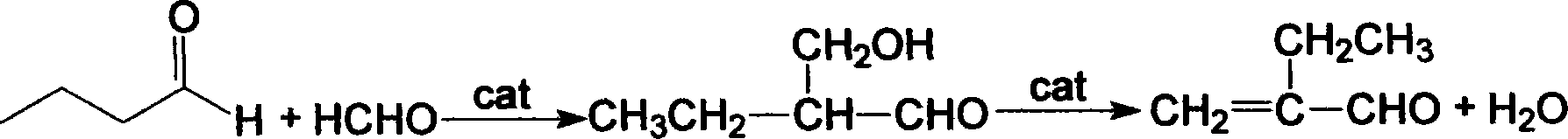

The present invention discloses process of synthesizing bis(trihydroxymetyl propane) by means of reaction of formaldehyde, n-butyl aldehyde and trihydroxymetyl propane. The synthesis of bis(trihydroxymetyl propane) includes the following steps: the aldol condensation reaction and dewatering reaction of n-butyl aldehyde and formaldehyde in the presence of alkaline catalyst to produce 2-ethyl acrylaldehyde, the subsequent addition reaction of 2-ethyl acrylaldehyde with added trihydroxymetyl propane in alkaline condition to produce intermediate product 2-ethyl-3-(beta, beta-demethylol-butoxy)-1-propanal, and adding formaldehyde into the intermediate product to produce aldol condensation reaction and crossed disproportionation reaction to produce bis(trihydroxymetyl propane). The process has high selectivity and high yield of bis(trihydroxymetyl propane) and other features, and is easy application in industrial production.

Owner:CNPC JILIN CHEM GROUP CORP

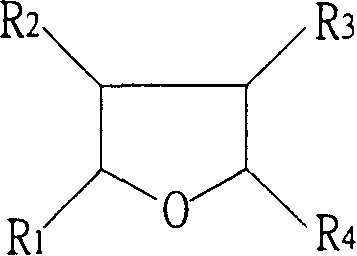

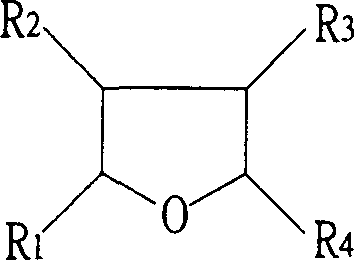

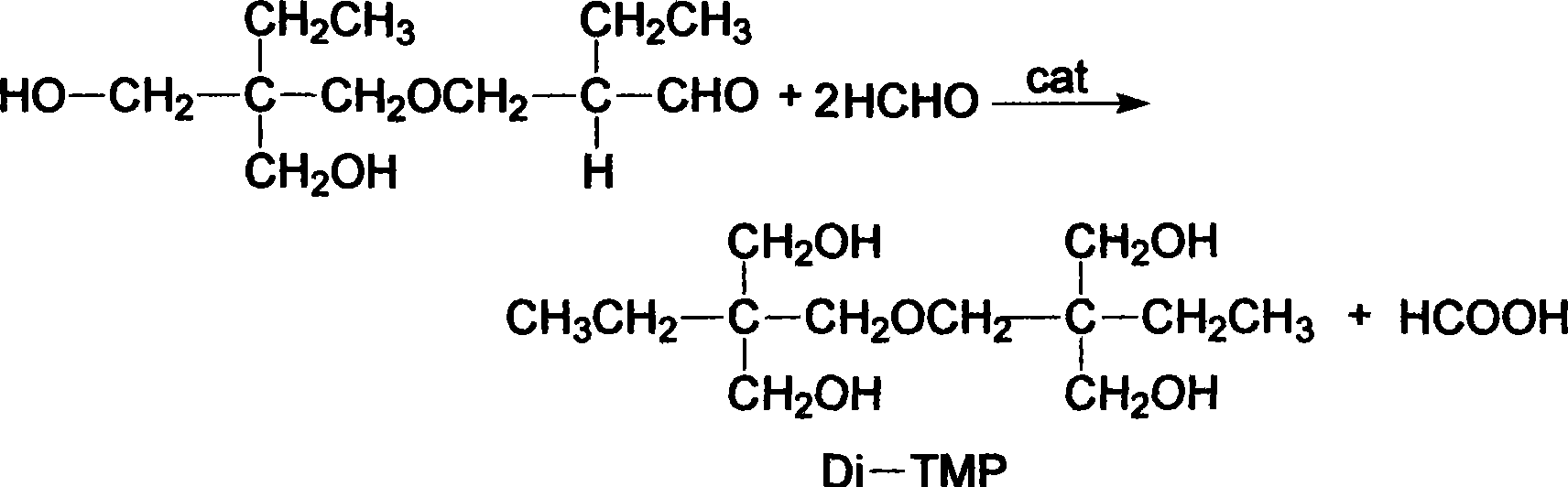

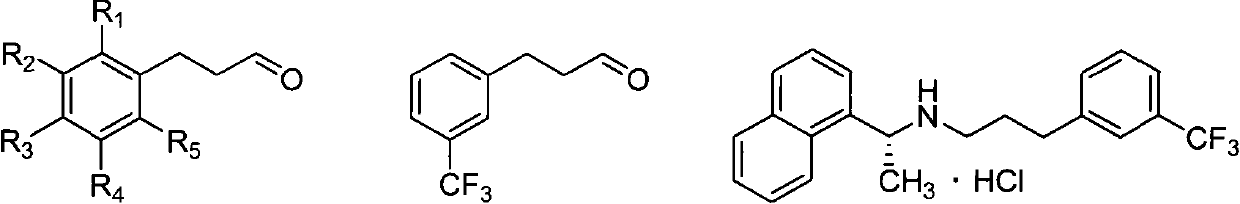

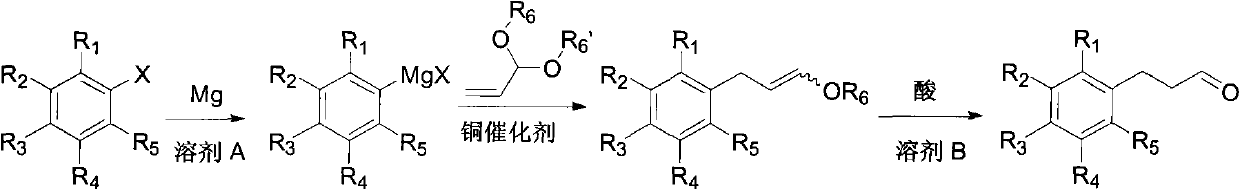

Method for preparing aryl propanal derivatives

InactiveCN102060679AExpensive to overcome source difficultiesHigh production equipment requirementsCarbonyl compound preparation by oxidationArylHydrogen

The invention relates to a method for preparing aryl propanal derivatives. The aryl propanal derivatives are prepared according to a route shown in the specifications, wherein R1, R2, R3, R4 and R5 independently represent hydrogen, C1 to C4 alkyl, C1 to C4 alkoxy, halogen, trihalogenated methyl or nitro respectively; R6 and R6' independently represent hydrogen, C1 to C4 alkyl, C1 to C4 trihalogenated alkyl, substituted benzyl or alkylacyl respectively, and are connected or not connected; and X represents fluorine, chlorine, bromine or iodine. For the method, raw materials are readily available and have low price, oxidation reaction and reduction reaction are not needed, the route is simple, reaction conditions are mild, the requirement on production equipment is low, the emission of three wastes is low, and industrial production is easy to implement, so the method can be widely applied to the synthesis of medicines, daily chemicals and the like.

Owner:中国中化股份有限公司 +1

Catalyst for hydrogenating 3-hydroxy propaldehyde to prepare 1, 3-propylene glycol

ActiveCN100344370CHigh activityImprove stabilityMolecular sieve catalystsOrganic compound preparationHigh activityPropanediol

Owner:SHANGHAI HUAYI NEW MATERIAL

Preparation method of 1,3-propylene glycol

ActiveCN105585445AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalysts1,3-PropanediolLanthanum

The invention relates to a preparation method of 1,3-propylene glycol and mainly solves the problem of low activity and selectivity of a 1,3-propylene glycol catalyst in the prior art. The preparation method includes the following steps: 1) performing hydroformylation to vinyl acetate to prepare 3-acetoxylpropyl aldehyde; 2) hydrogenating the 3-acetoxylpropyl aldehyde to prepare 3-acetoxylpropyl alcohol; and 3) hydrolyzing the 3-acetoxylpropyl alcohol to obtain the 1,3-propylene glycol. A catalyst for the hydroformylation is prepared with SiO2, Al2O3 or a mixture thereof as a carrier with active components including rhodium, lanthanum-series metals, and at least one metal element selected from the groups of IVA and VIB. The method solves the technical problem well and is used for industrial production of the 1,3-propylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesis of 1, 3-propanediol

ActiveCN105523886AHigh activityImprove stabilityOrganic compound preparationCarboxylic acid esters preparationLow activityAlkaline earth metal

The invention relates to a method for synthesis of 1, 3-propanediol. The method mainly solves the problem that a 1, 3-propanediol catalyst obtained by the prior art has low activity and low selectivity. The method comprises vinyl acetate hydroformylation for 3-acetoxypropanal preparation, 3-acetoxypropanal hydrogenation for 3-acetoxypropanol preparation and 3-acetoxypropanol alcoholysis for 1, 3-propanediol preparation. The hydroformylation catalyst utilizes SiO2, Al2O3 or their mixture as a carrier and active ingredients comprise rhodium, an alkaline earth metal and at least one of VA and IVB metals. The method well solves the problem and can be used for 1, 3-propanediol industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

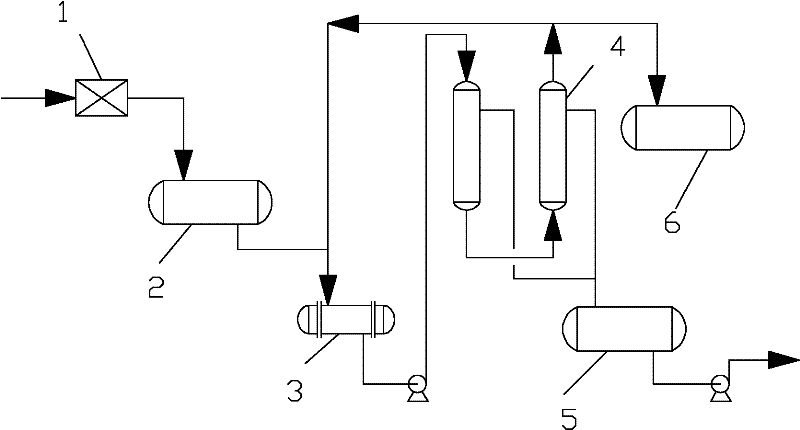

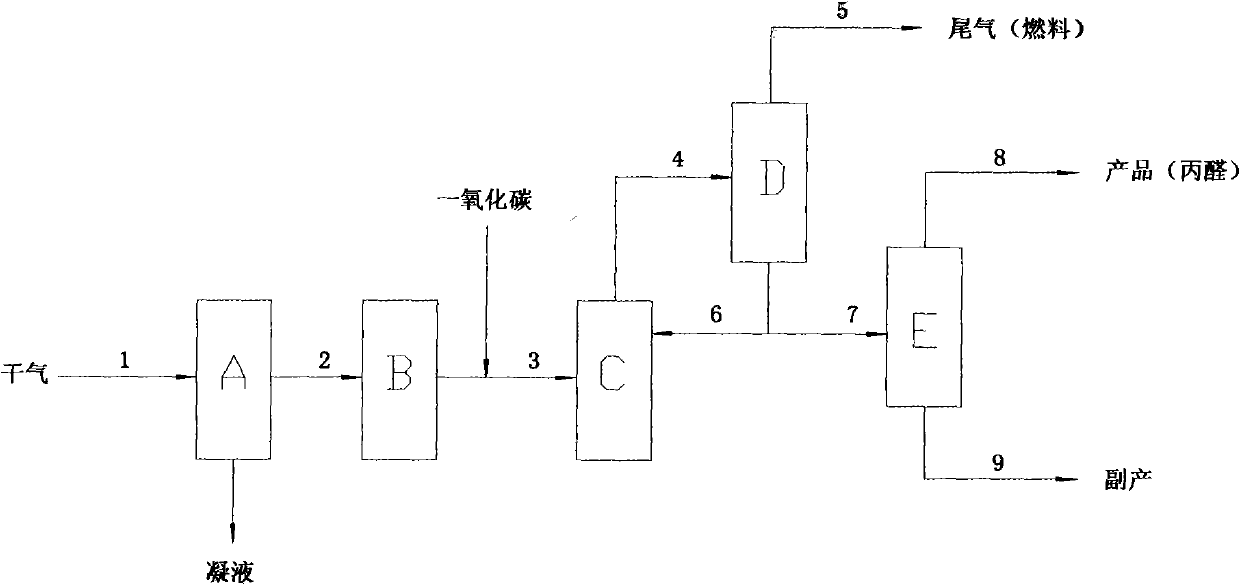

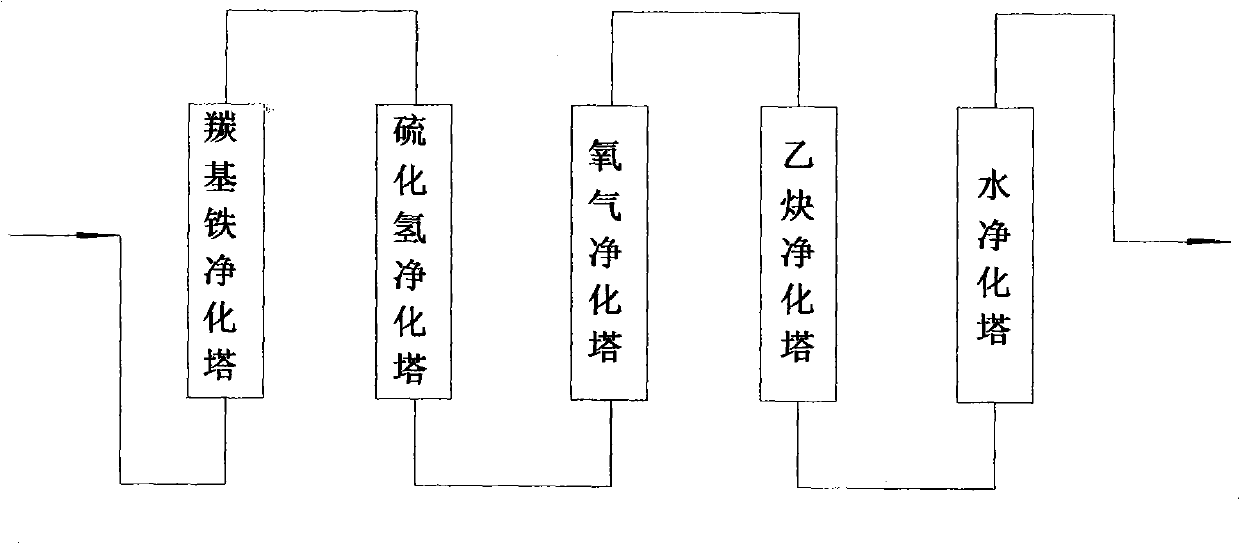

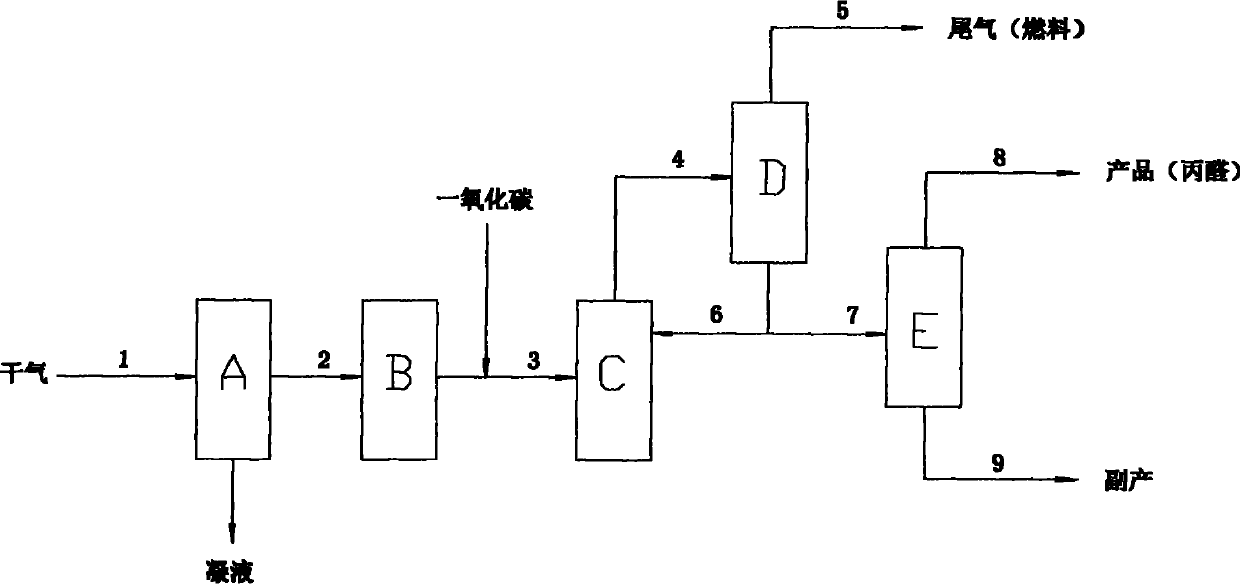

Method for preparing propionic aldehyde from ethylene in refinery dry gas

ActiveCN102442894ASimple processLess investmentPreparation by carbon monoxide reactionFormylation reactionGas phase

The invention discloses a method for preparing propionic aldehyde from ethylene in refinery dry gas so as to provide a technology for directly preparing propionic aldehyde from low-concentration ethylene in refinery dry gas. The method comprises the following steps: pressurizing raw dry gas in a pressurization system; feeding the obtained high-pressure dry gas into a purification system, and removing impurities; mixing the purified refinery dry gas and carbon monoxide containing no catalyst poison to form raw gas for hydroformylation reaction; carrying out hydroformylation reaction together with additional carbon monoxide under the action of a catalyst and a catalyst ligand; and discharging in a gas phase manner, and passing through a separation system, thus obtaining the propionic aldehyde product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com