Patents

Literature

398results about How to "Timely recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

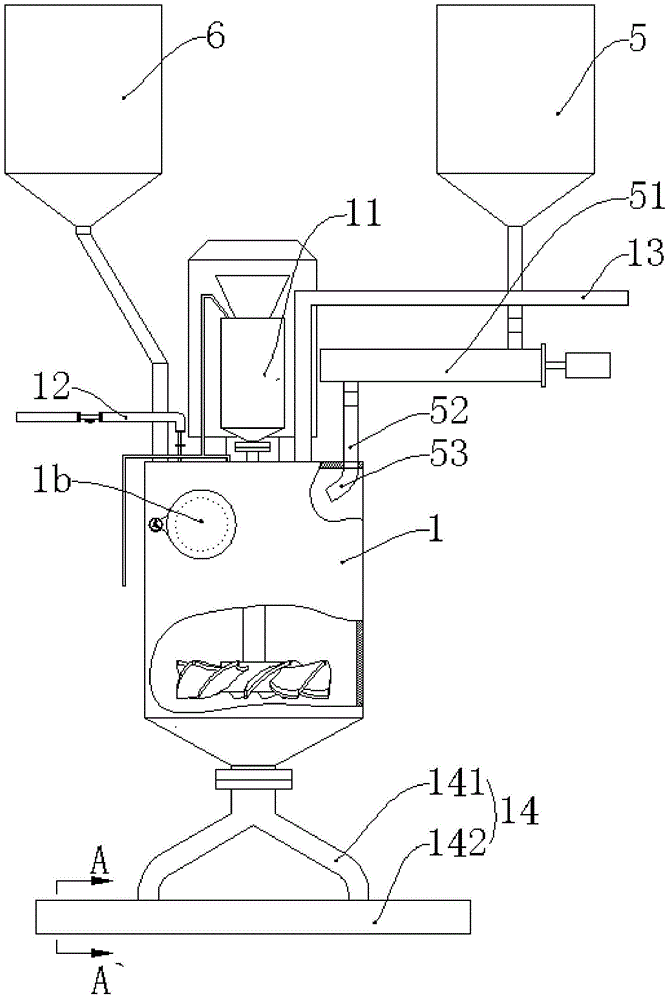

Crushing process of alumina crusting block and production line thereof

ActiveCN101767046ATimely recyclingIncrease productivityGas current separationGrain treatmentsProduction lineGranularity

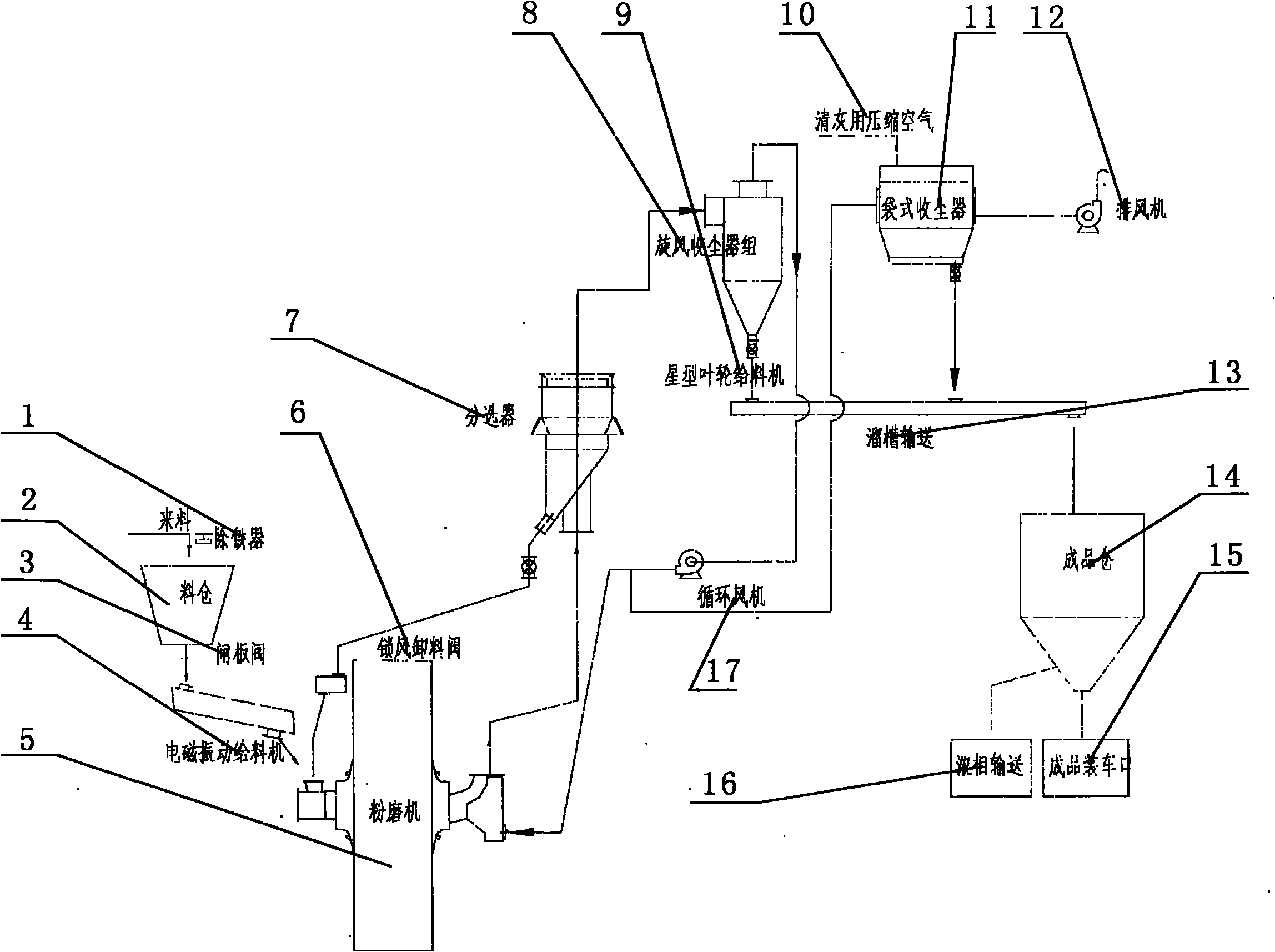

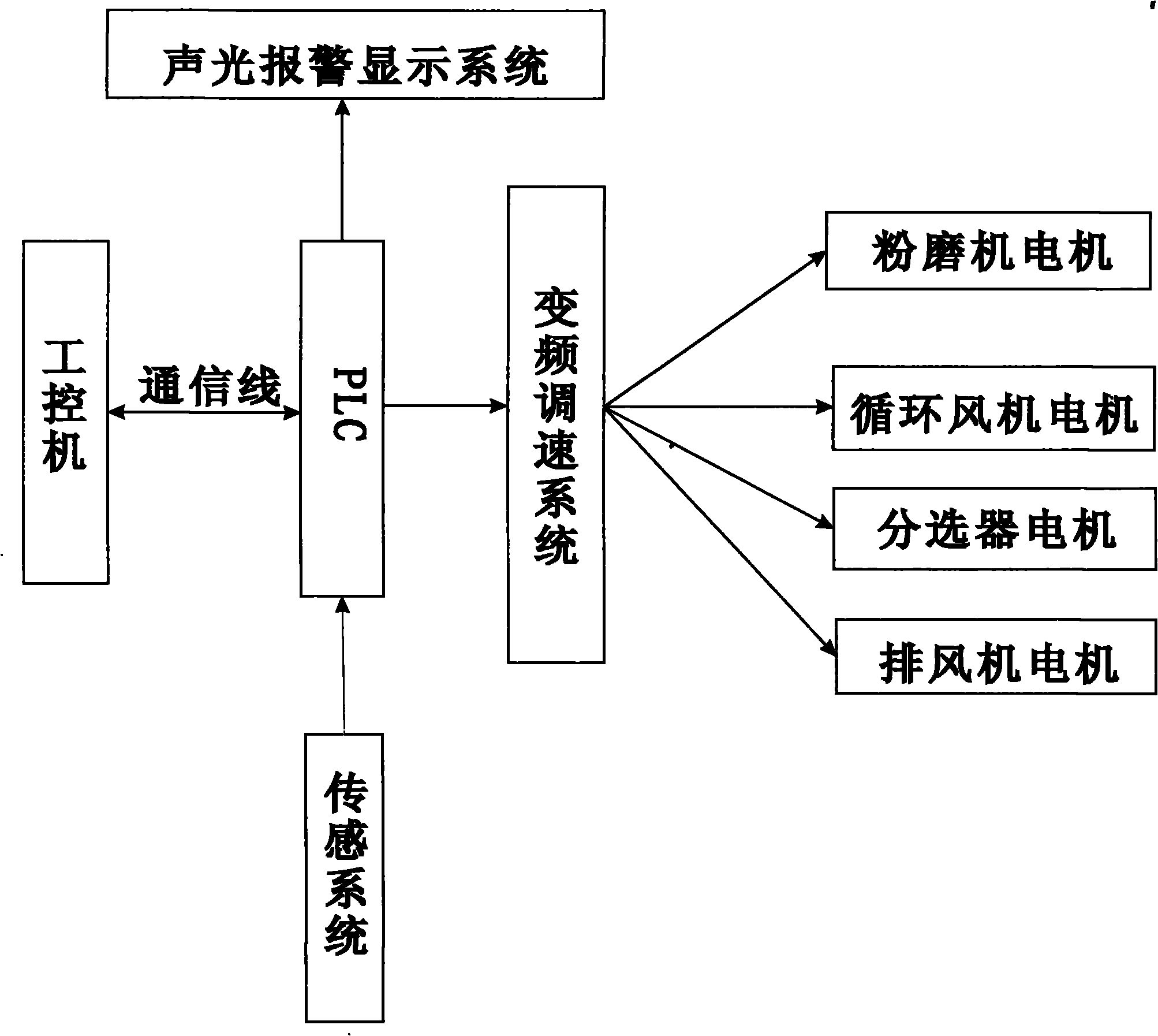

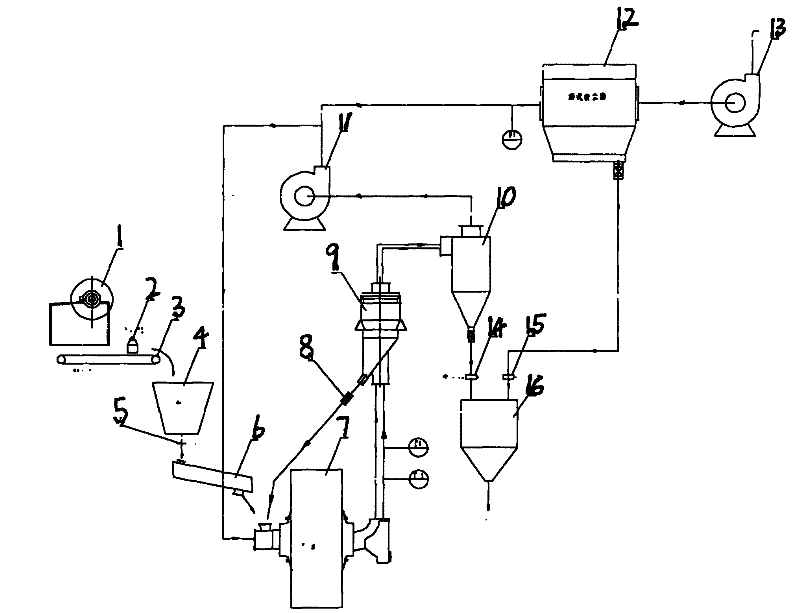

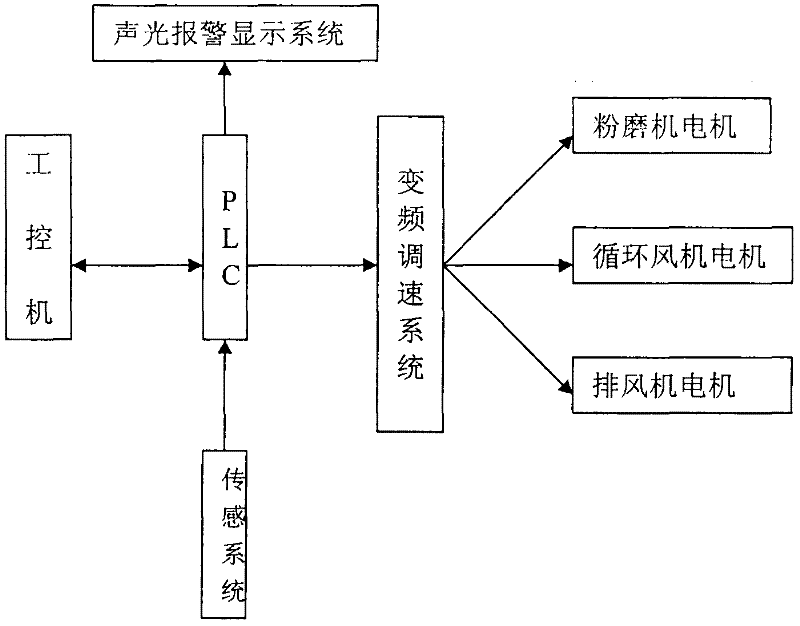

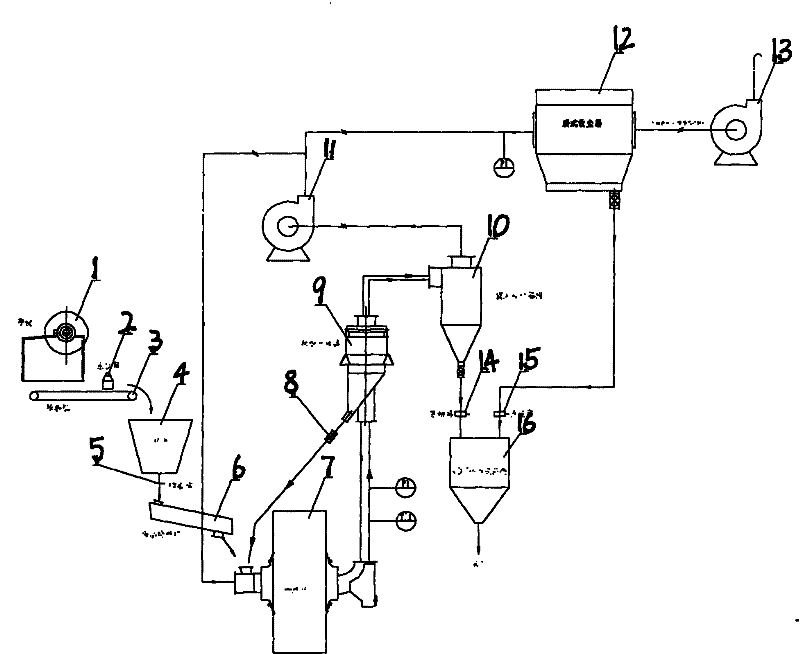

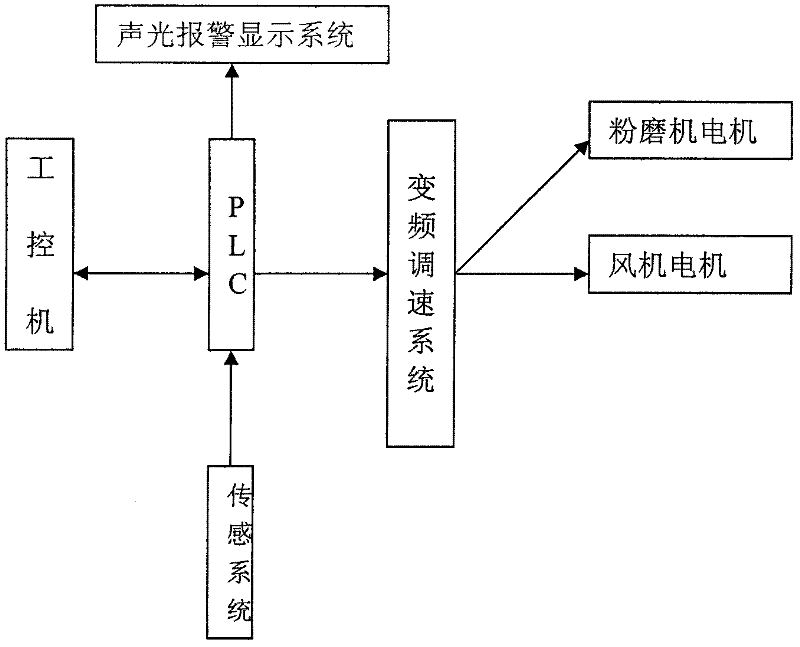

The invention relates to a crushing process of an alumina crusting block generated during the first-stage electrolytic aluminum production and a production line thereof. The crushing process includes the following steps: feeding, grinding, material separating, air supplementing, material collecting, dust collecting and material storing. As to the production line for realizing the crushing process of the alumina crusting block, a mechanical part comprises a raw material bin, a feeding machine, a grinding machine, a sorting machine, a cyclone dust collector, a bag type dust collector, a chute and a finished product bin which are sequentially connected with each other; an electric control part comprises an IPC (industrial personal computer), a PLC, a frequency changing and speed regulating system, an acousto-optic alarm display system and a sensing system. The crushing process and the production line thereof in the invention achieve the standard discharging granularity that usually 2 / 3-stage can achieve, increase the production efficiency, reduce consumption, and can timely recycle the alumina crusting block at the same time.

Owner:HENAN WANJI ALUMINUM +1

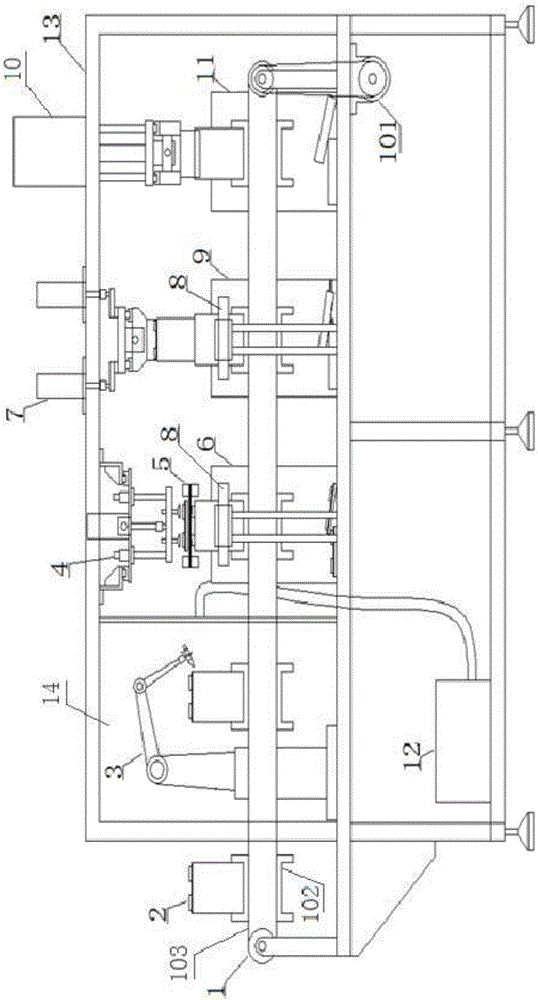

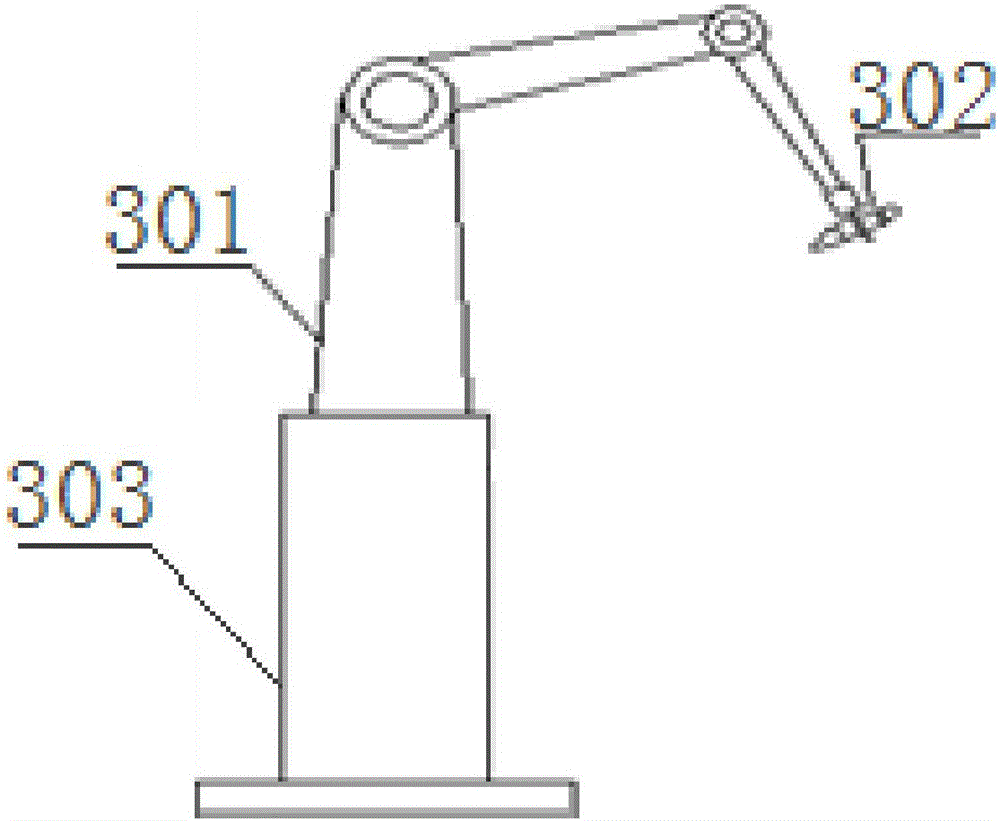

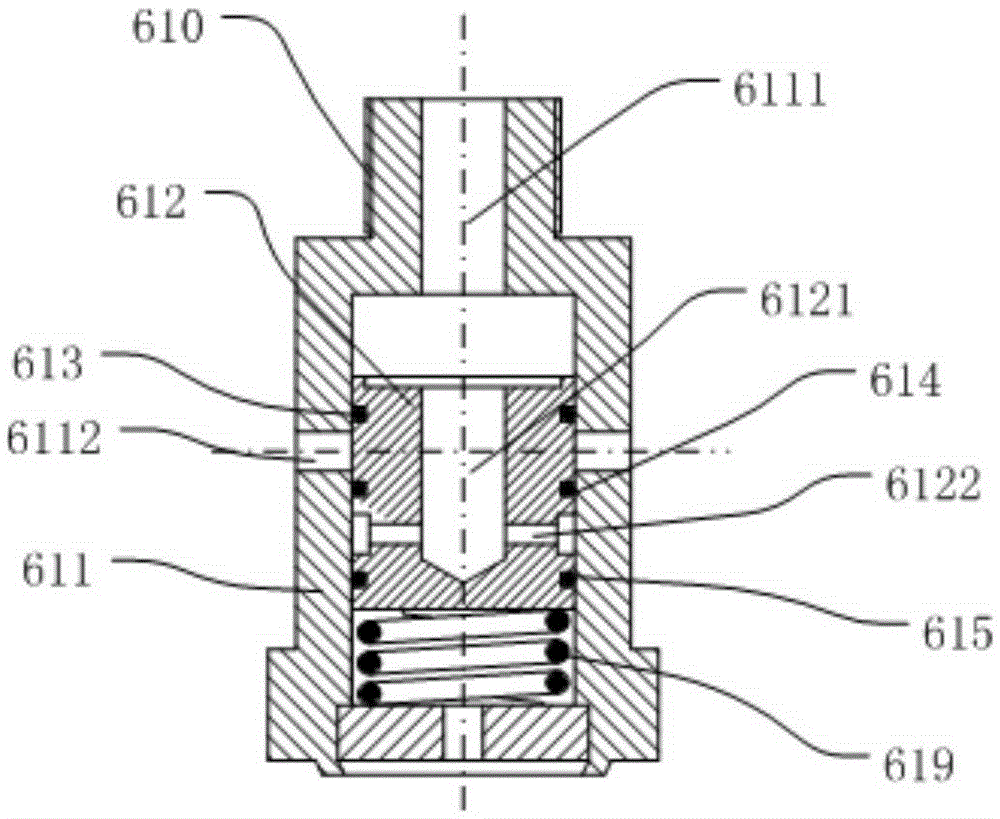

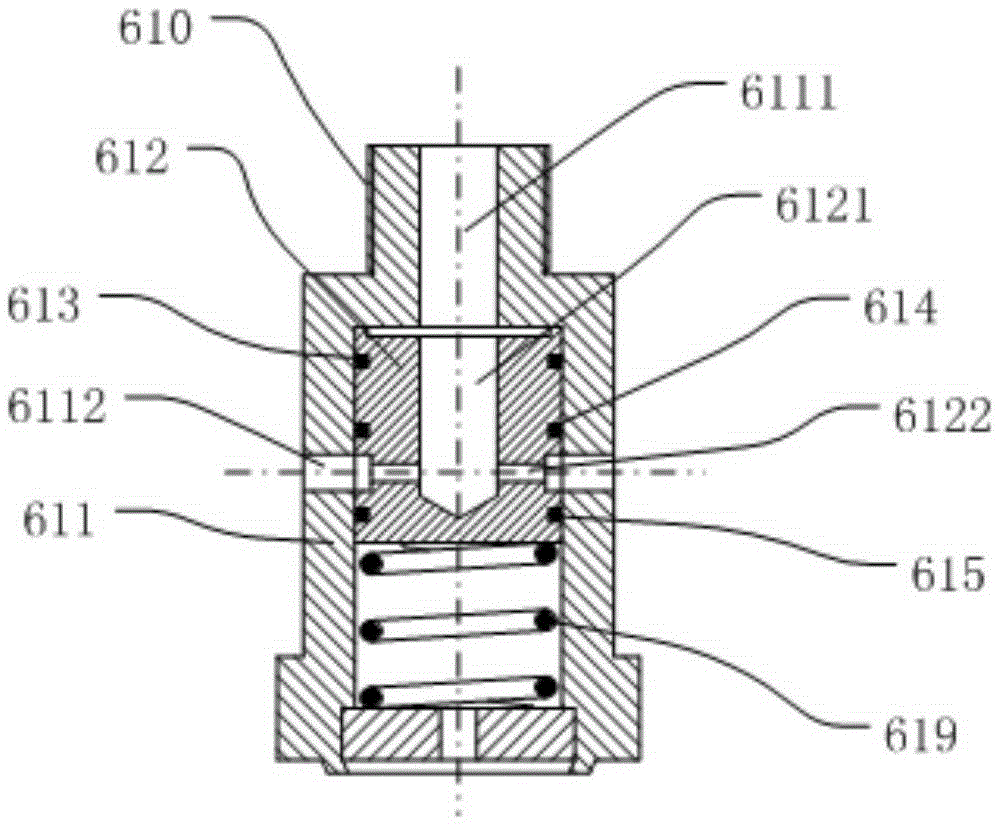

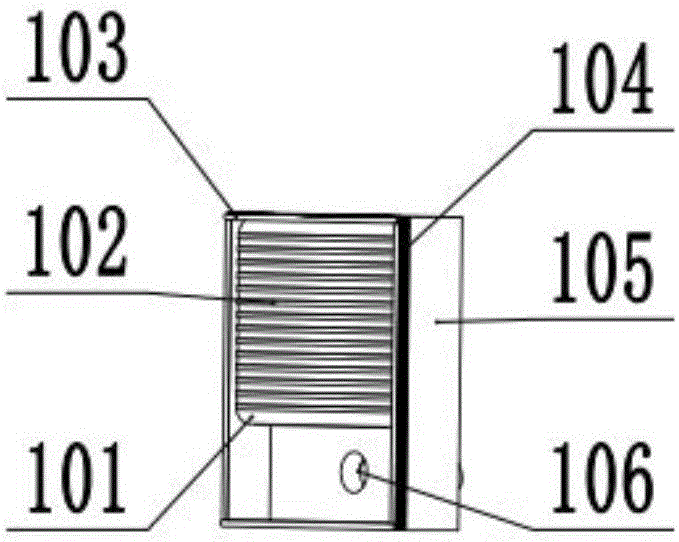

Lithium ion battery automatic dismantling device

ActiveCN106058357ANo deviationTimely recyclingWaste accumulators reclaimingBattery recyclingElectrical batteryEngineering

The invention provides a lithium ion battery automatic dismantling device comprising a frame and a circulation carrier for transferring a waste battery; the frame bottom located at one side of the circulation carrier is successively fixedly provided with a cover plate recycling box, an electric core recycling box, and an outer shell recycling box; the bottom of the frame is successively fixedly provided with a cutting manipulator for annular cutting of a waste battery shell body and two outer shell clamping mechanisms for clamping and fixing the waste battery shell body along the running direction of the circulation carrier; the top of the frame is successively erected with a cover plate recycling mechanism for clamping a waste battery cover plate, an electric core taking-out mechanism for clamping a waste battery electric core, and an outer shell transfer mechanism for clamping the waste battery shell body along the running direction of the circulation carrier; the cover plate recycling mechanism and the electric core taking-out mechanism are respectively located at the top ends of the two outer shell clamping mechanisms; an electrode ear cutting mechanism for cutting a waste battery electrode ear is arranged between the cover plate recycling mechanism and the outer shell clamping mechanism. The automation degree is improved, the work efficiency is increased, and the intensity of work is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

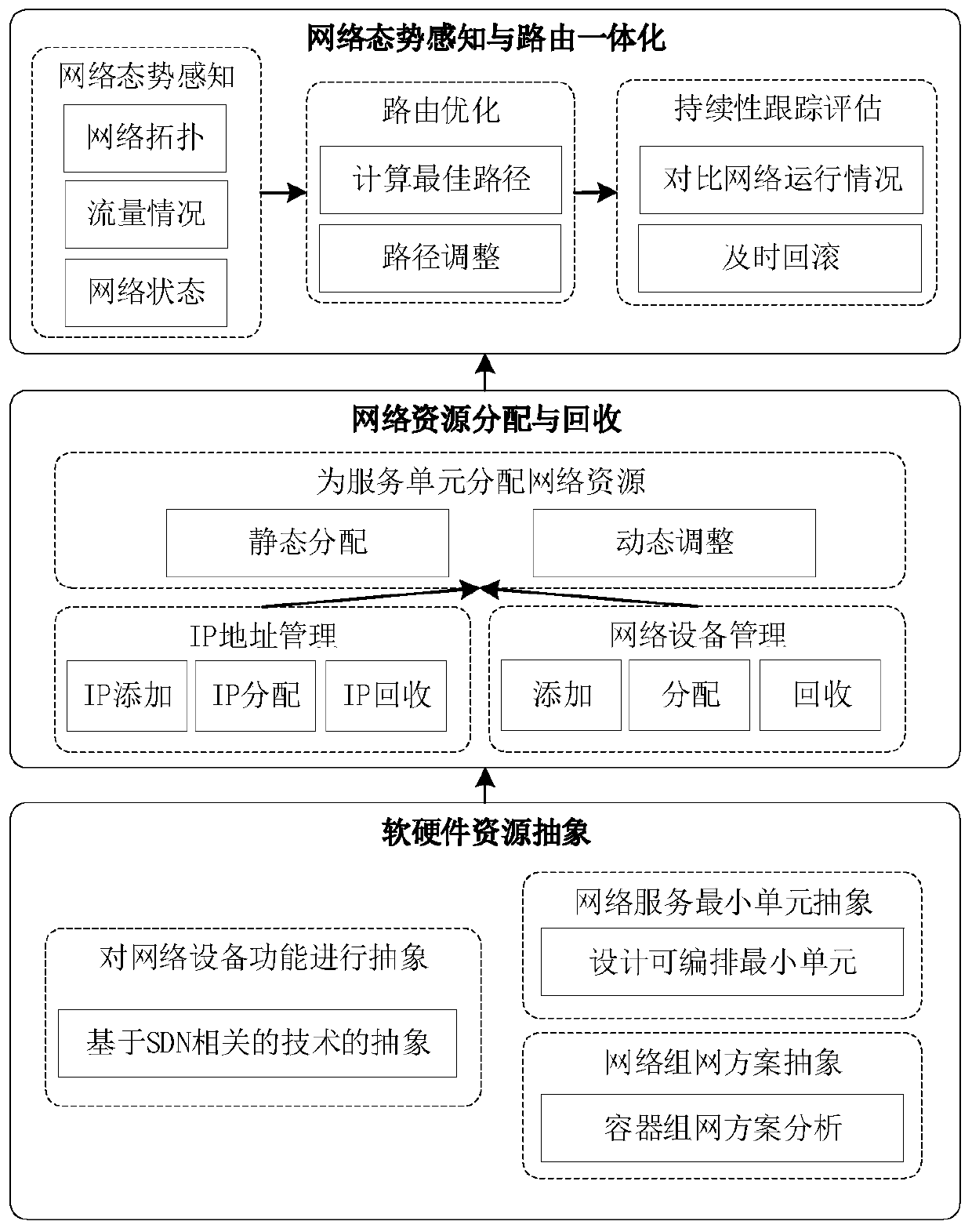

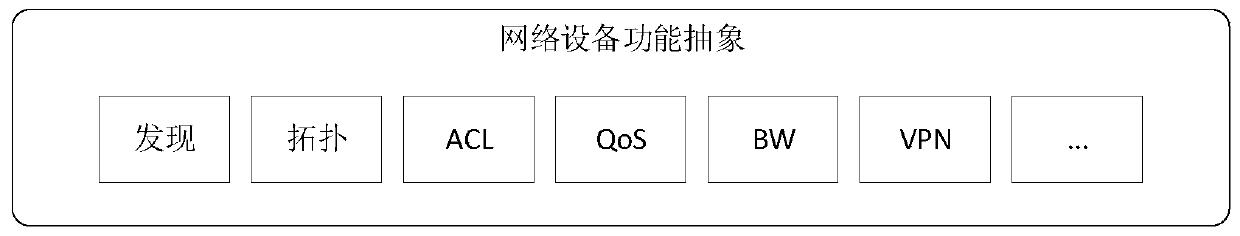

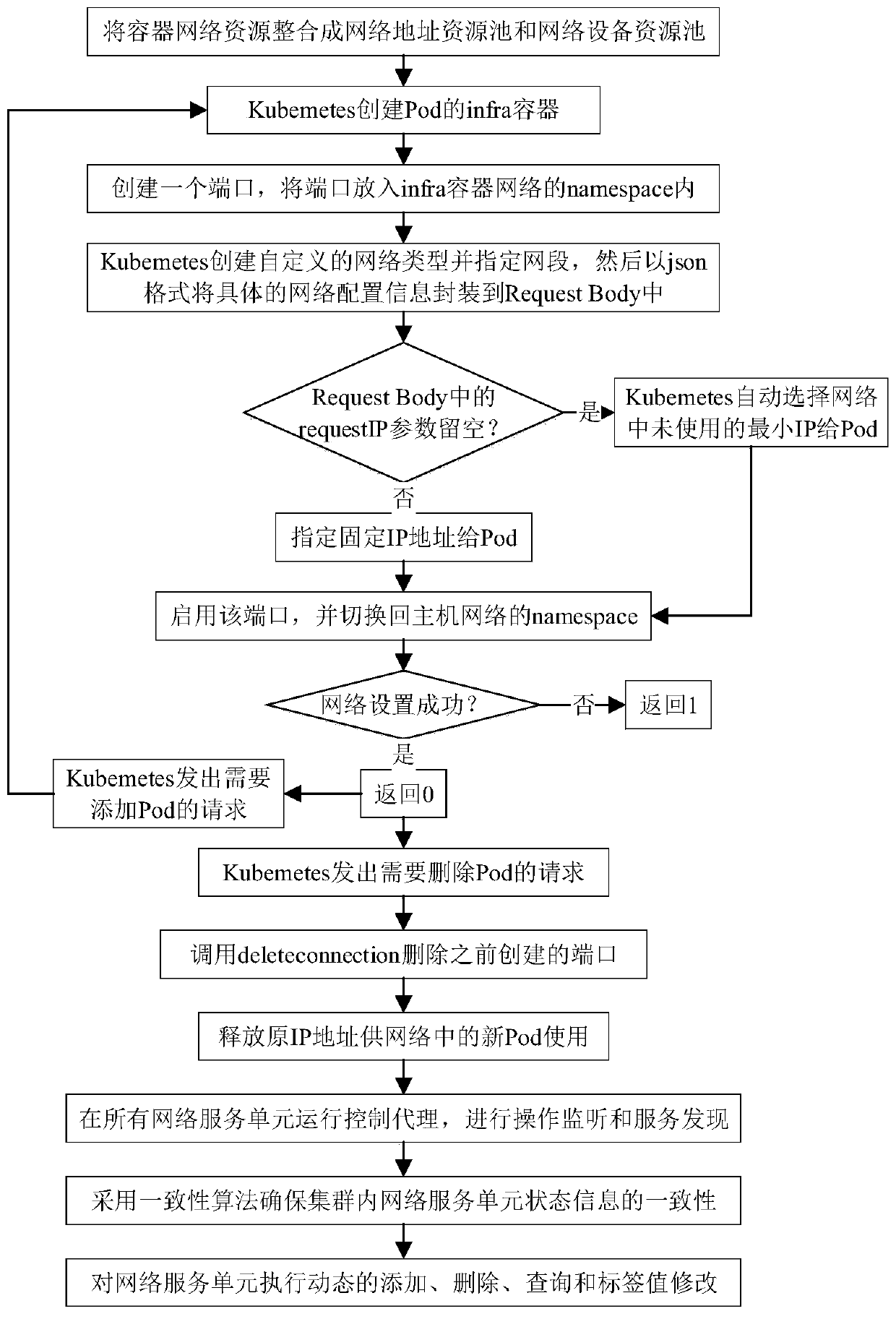

An SDN-based container network resource scheduling method

ActiveCN109743261AFully flexible sharingFlexible sharingData switching networksResource poolNetwork address

Aiming at the problem that resource segmentation and guarantee cannot be carried out according to requirements of a container network in the prior art, the invention provides an SDN-based container network resource scheduling method, which comprises the following steps of: 1, carrying out unified abstraction and description on network software and hardware resources based on an SDN / NFV technology;2, implementing resource allocation and recovery on the container network, integrating resources into a resource pool, establishing and managing a network address resource pool and a network equipment resource pool, providing network equipment resources as required, and recovering the network equipment resources in time when the network is destroyed; And step 3, based on the idea of SDN centralized control, deploying a centralized control server in the container network, and implementing network situation awareness and routing integration. The container network resource scheduling method integrates networking, routing and monitoring by intensively sensing the network situation and reasonably segmenting and recovering the container network resources in combination with the requirements oftasks, thereby realizing the optimal scheduling of the container network resources.

Owner:NAT UNIV OF DEFENSE TECH

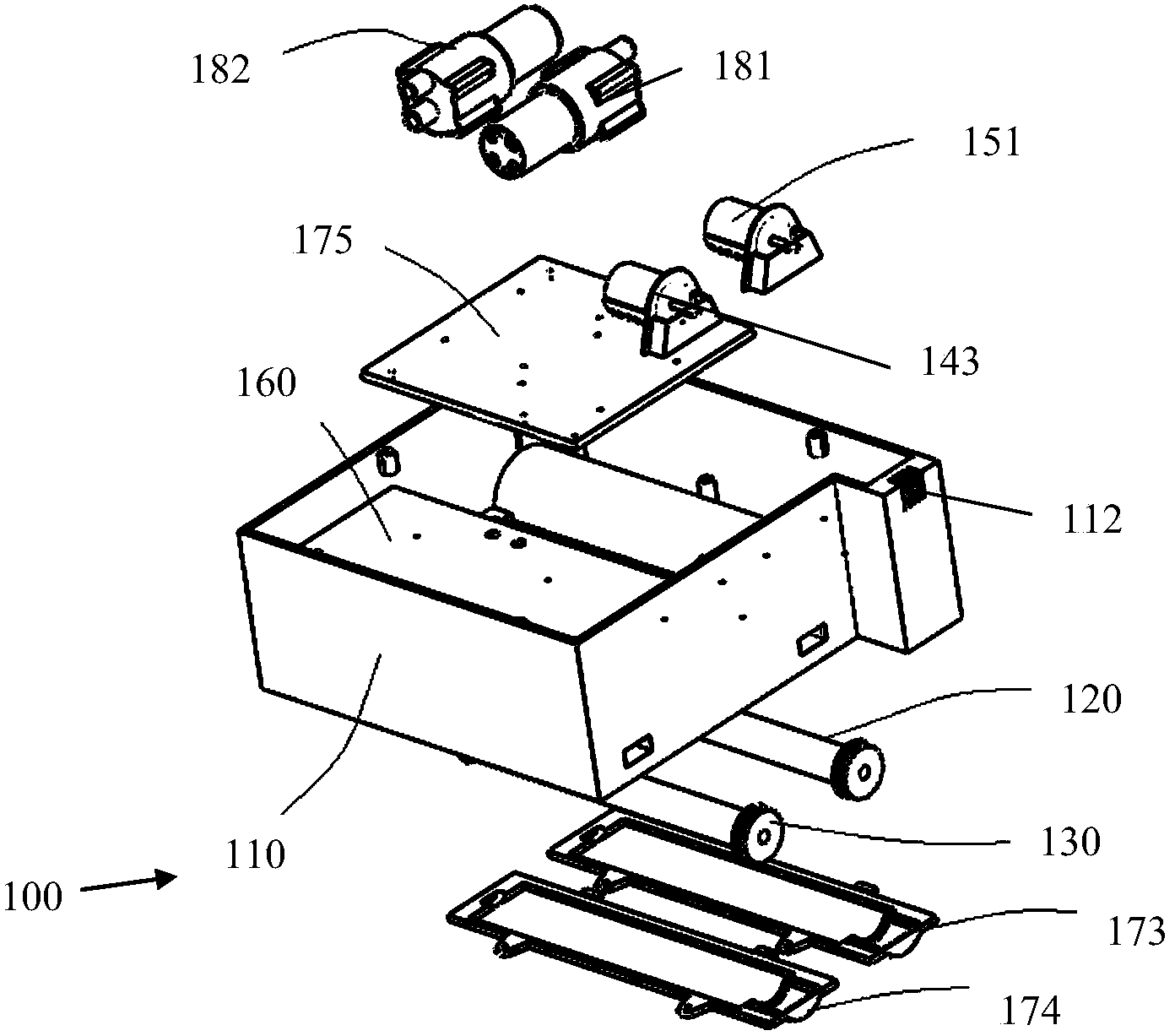

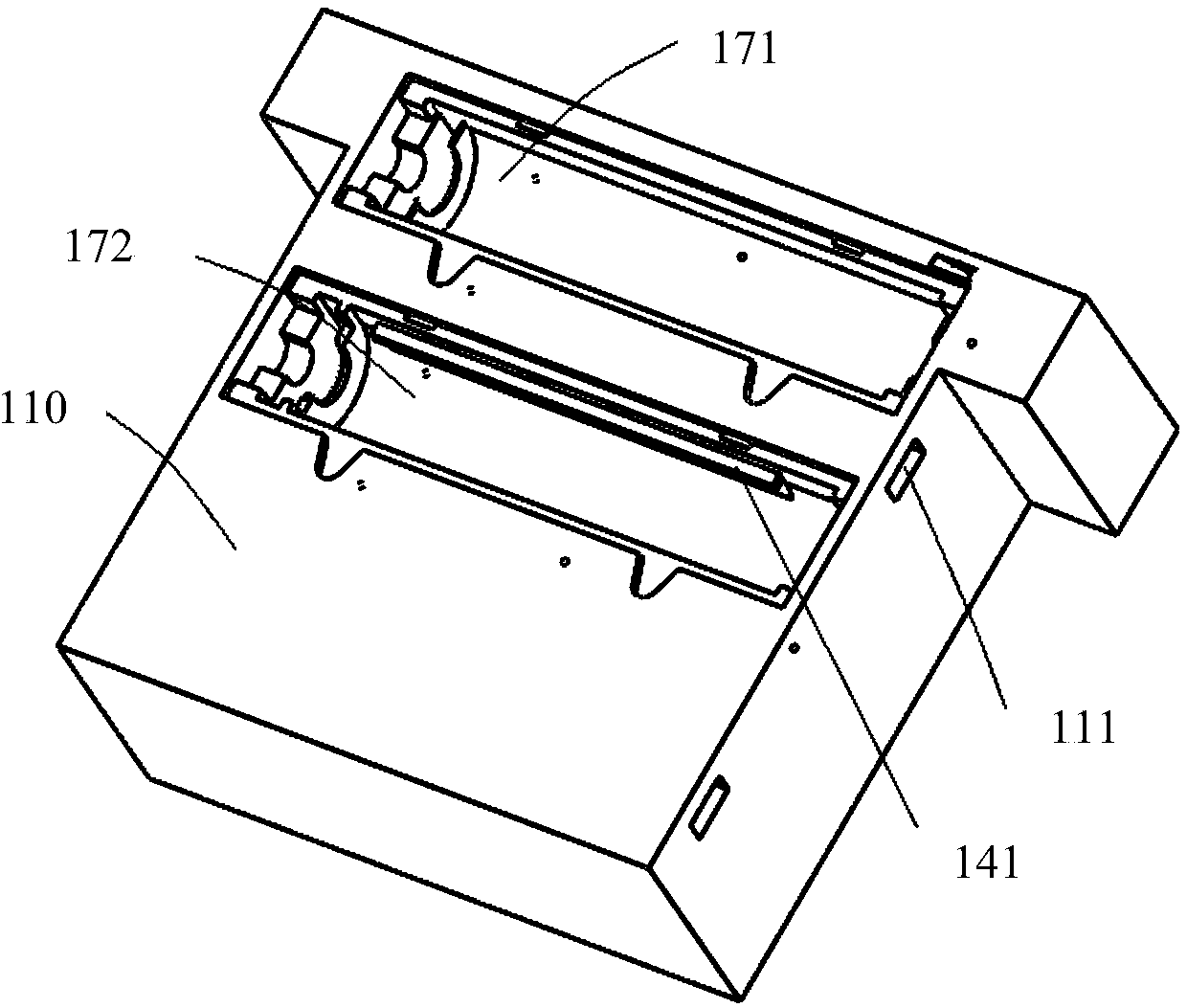

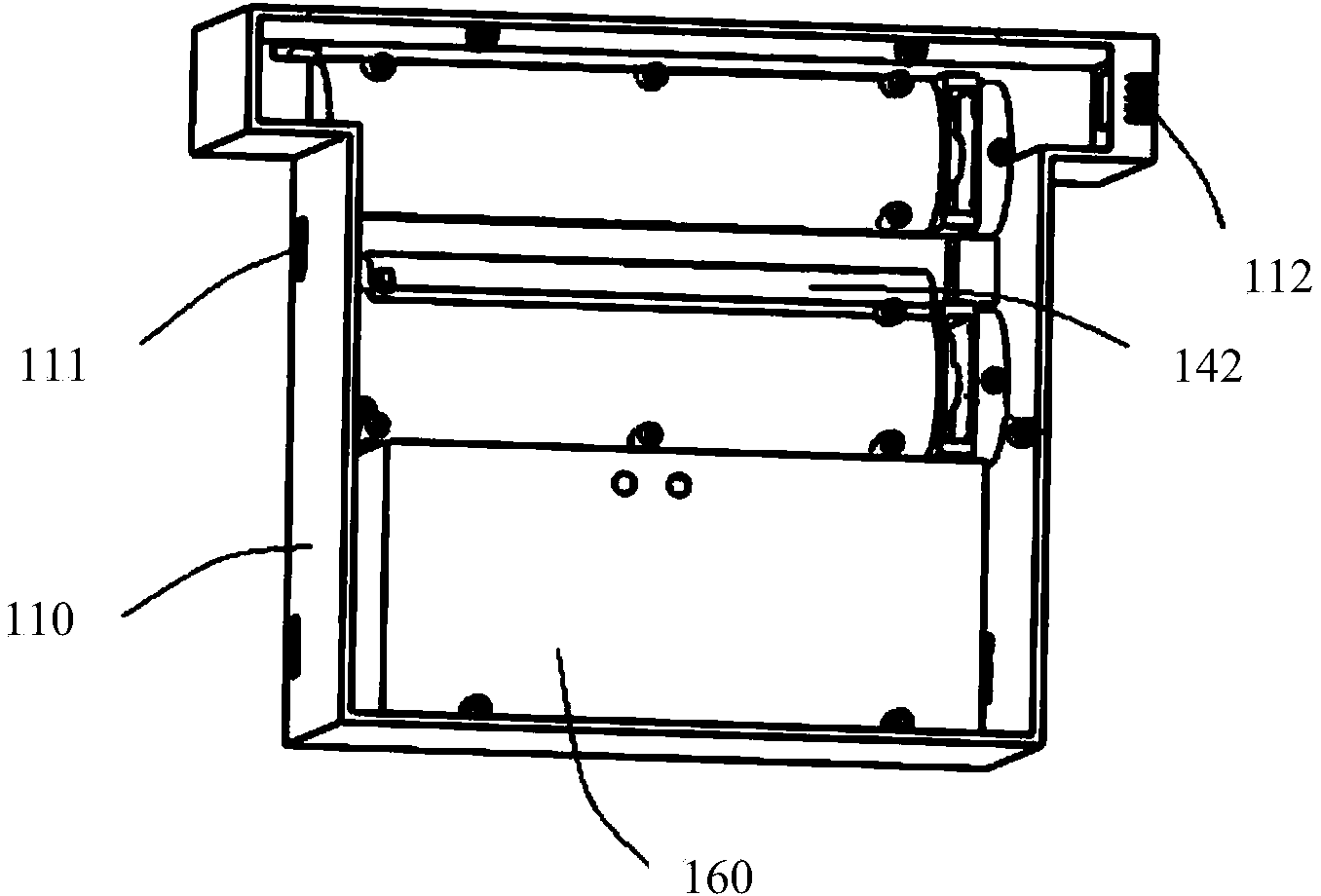

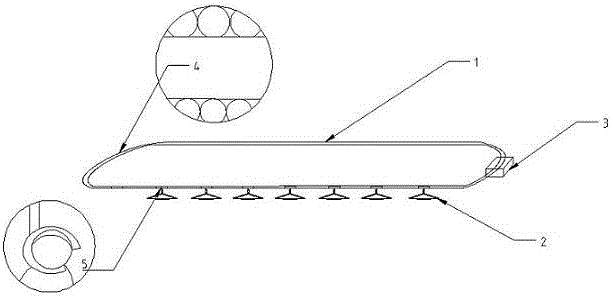

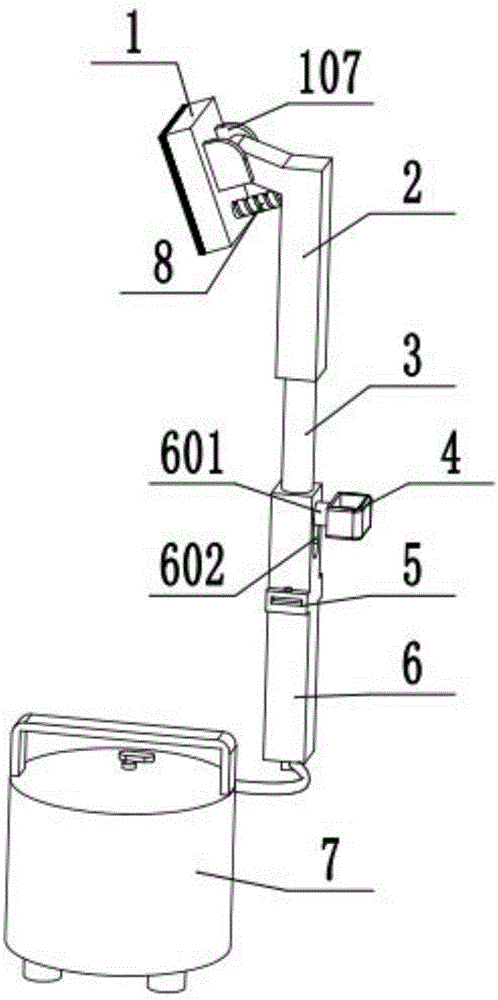

Floor mopping module and cleaning robot

InactiveCN103393384AEnsure the function of circulating water absorptionEasy to cleanCarpet cleanersFloor cleanersSewageEngineering

The invention discloses a floor mopping module and a cleaning robot. The floor mopping module comprises a mounting platform, as well as a nozzle, cleaning rolls, a water supply system and a power system which are mounted on the mounting platform, wherein the water supply system is connected with the nozzle and used for water supply of the nozzle; the power system is connected with the cleaning rolls and used for rotation driving of the cleaning rolls; the floor mopping module further comprises sponge rolls and a sewage recovery system which are mounted on the mounting platform; the sponge rolls are connected with the power system and used for the rotation driving of the sponge rolls; the sewage recovery system is connected with the sponge rolls and used for sewage recovery of the sponge rolls; the nozzle is positioned at the front end of the mounting platform; the cleaning rolls and the sponge rolls are positioned at the bottom of the mounting platform respectively; and the cleaning rolls are positioned at the fronts of the sponge rolls. The floor mopping module and the cleaning robot effectively solve the technical problem that sewage residues exist after a floor is cleaned, and are simple and compact in structure, convenient to use and low in manufacturing cost, thereby being suitable for large-scale popularization and application.

Owner:SUZHOU UNIV

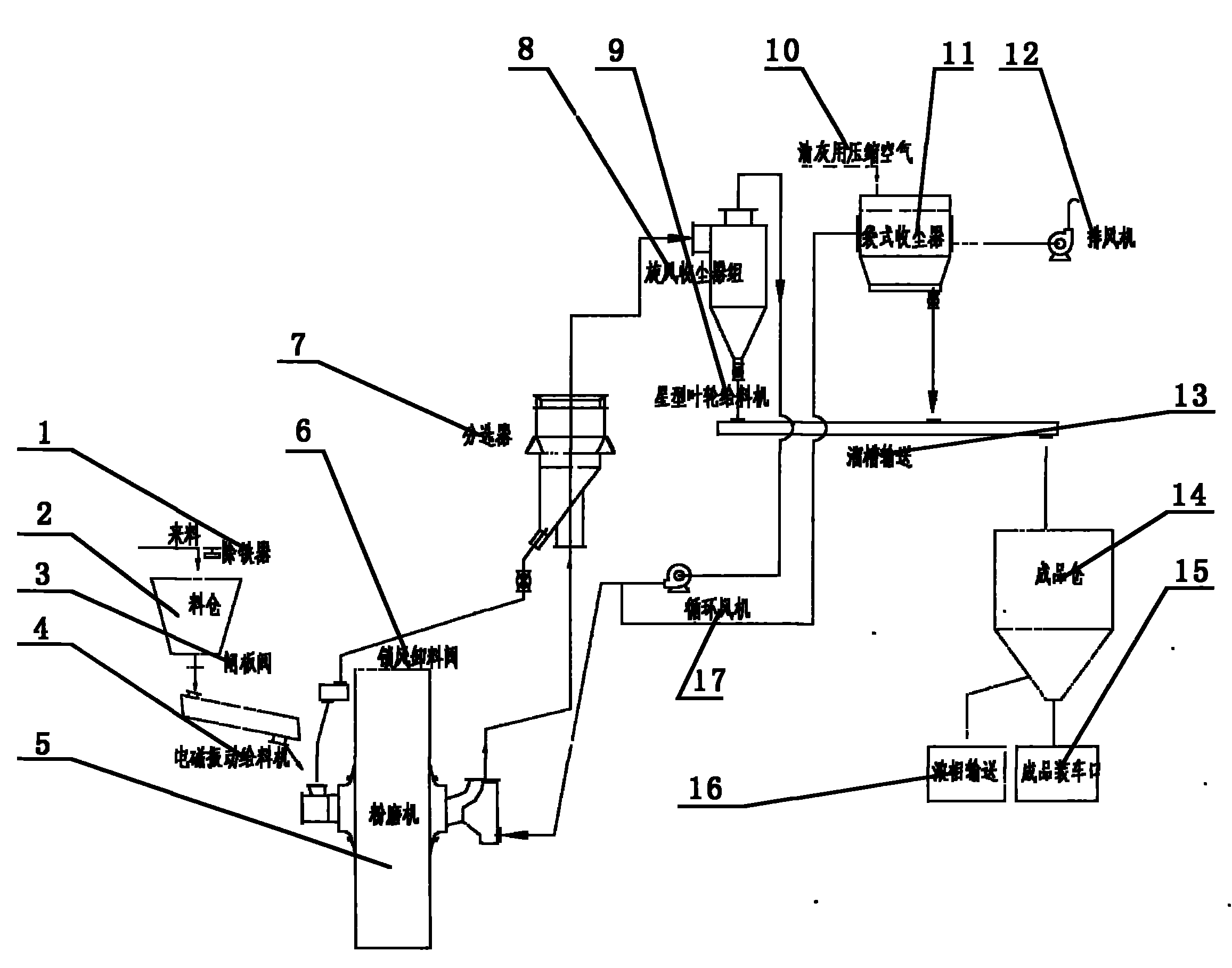

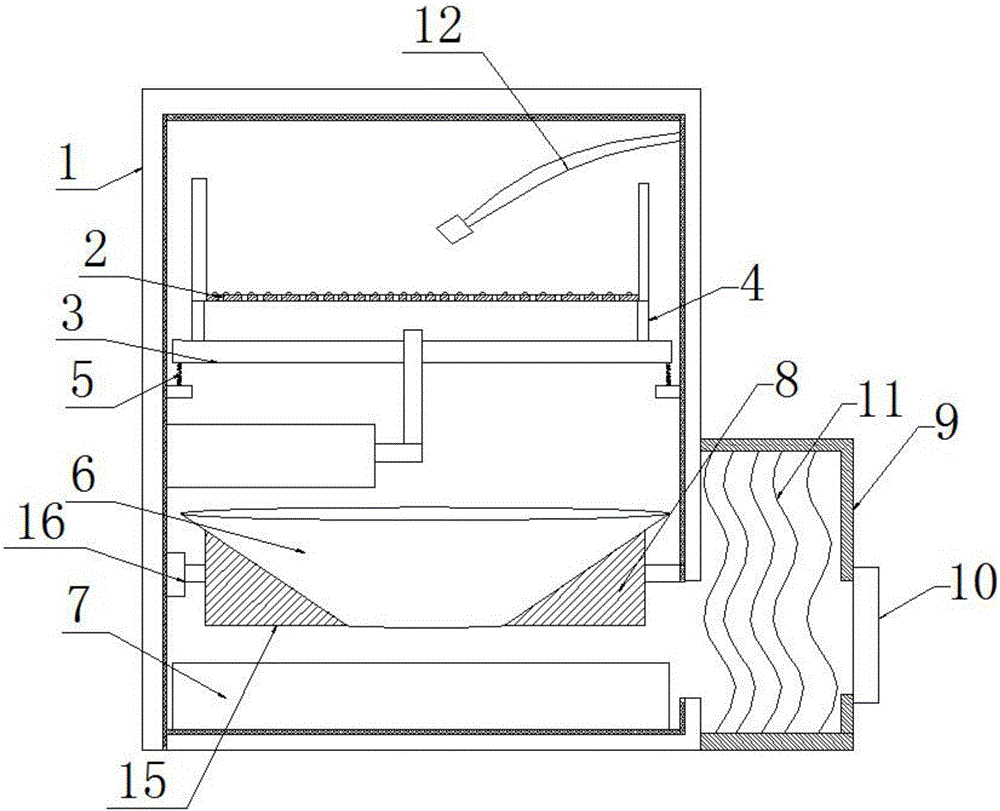

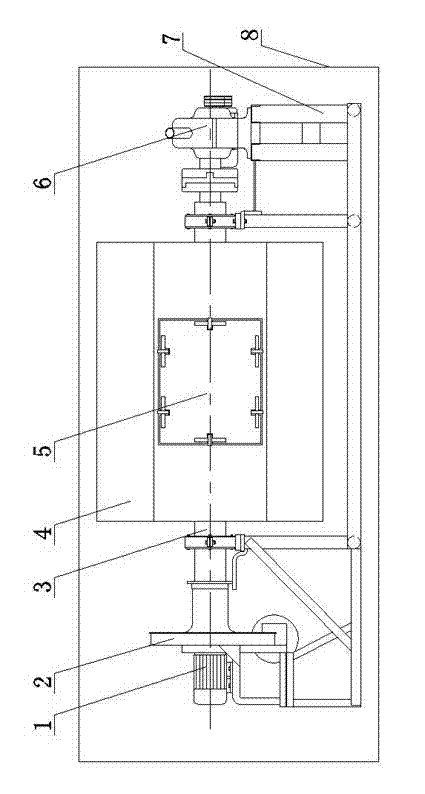

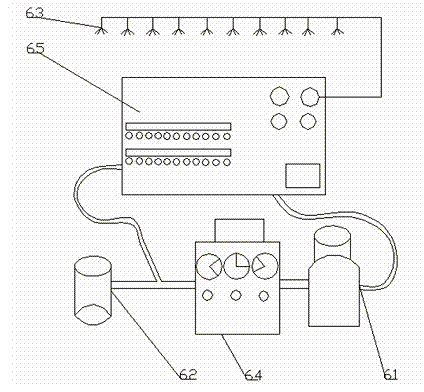

Closed type production line device and method for crushing aluminum oxide crusted blocks

InactiveCN102327804AInhibition of segregationImprove the grinding effectGrain treatmentsProduction lineEnvironmental resistance

The invention discloses a closed type production line device and a method for crushing aluminum oxide crusted blocks. In the invention, materials are crushed primarily on a production line, so that the feeding particle size is less than or equal to 300 millimeters, the discharging particle size is less than or equal to 1 millimeter, a standard discharging particle size which can only be reached by performing secondary and tertiary crushing is reached, the production efficiency is increased, the consumption is lowered, and aluminum oxide crusted blocks are recycled in time; and automatic running of the entire production line is controlled through an electric control system, so that dust purification in the crushing process is realized simultaneously. The closed type production line device consists of a mechanical part and an electric control part, wherein the mechanical part consists of a crusher, an iron remover, a conveyer, a raw material cabin, a gate valve, a vibratory feeder, a pulverizing mill, an air locking discharge valve, a coarse powder separator, a cyclone dust collector, a circular fan, a bag type dust collector, an exhaust fan, iron removers and a finished product cabin. The method for crushing the aluminum oxide crusted blocks comprises feeding, pulverizing, material separating, air replenishing, material and dust collecting and material storing in sequence. The device and the method are safe, environmentally-friendly and efficient, and energy is saved.

Owner:洛阳宇航重工科技股份有限公司

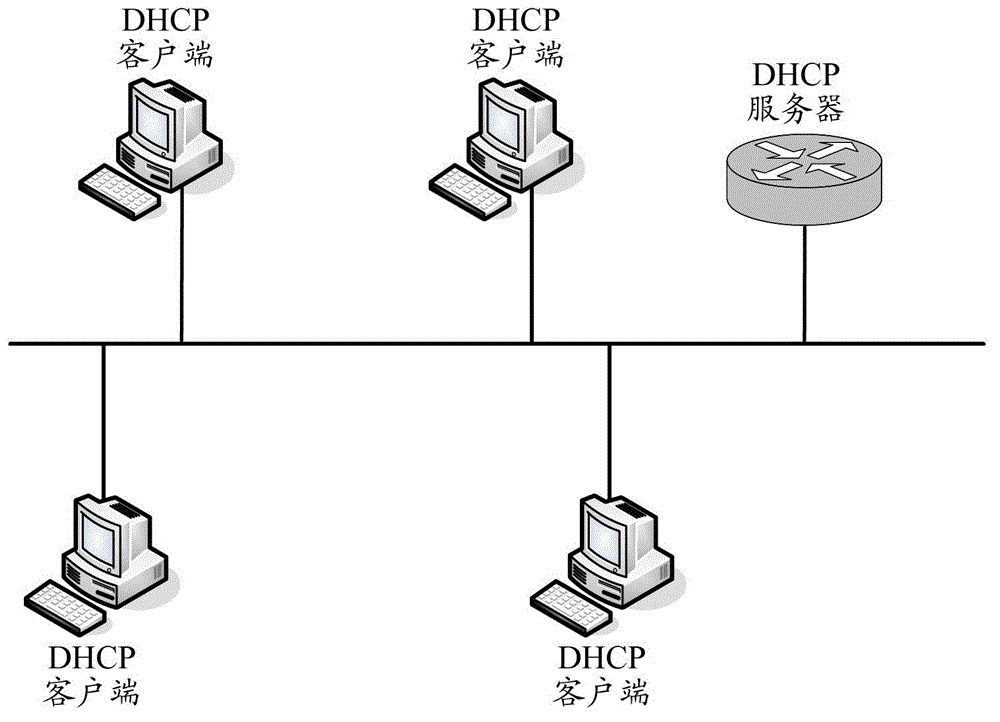

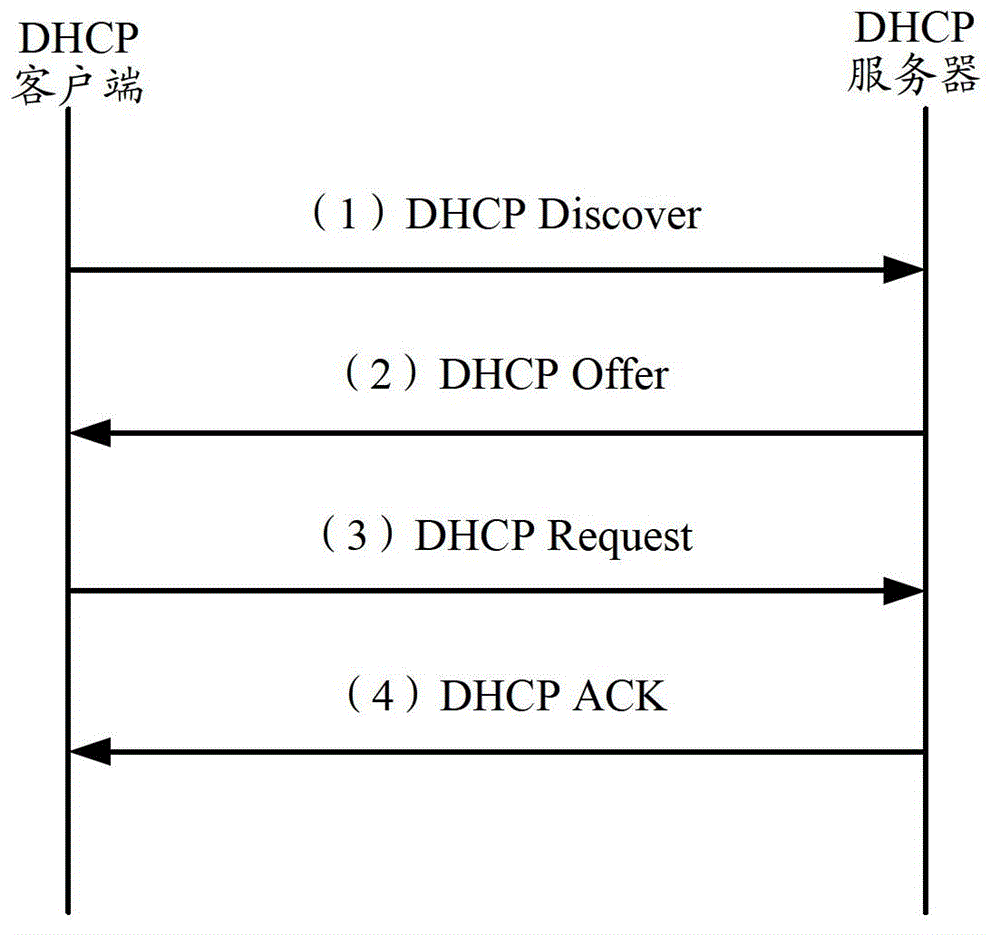

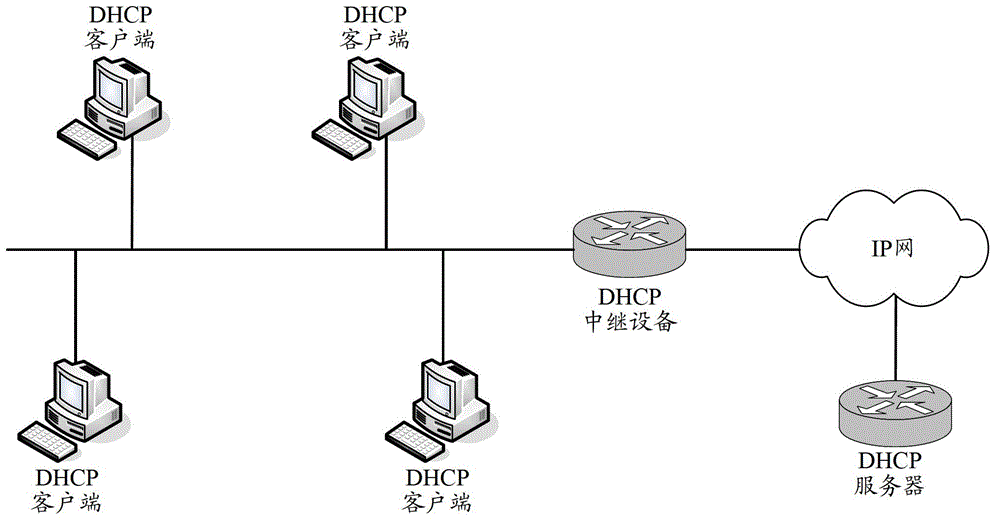

Method and device for recovering IP (Internet protocol) address of DHCP (dynamic host configuration protocol) client

ActiveCN104158917ATimely recyclingReduce load pressureTransmissionHigh level techniquesInternet protocol suiteIp address

Recovery of an Internet Protocol (IP) address allocated to a client using Dynamic Host Configuration Protocol (DHCP) is provided. Media Access Control (MAC) address and the IP address of the client are stored. When the client is determined as being offline, MAC address and IP address of the client are determined and a DHCP release message carrying the IP address of the client is sent to an address allocation server. The client is determined as being offline based on a shutdown status of a port to which the client is connected. The port may be on the relay device, or an access device that connects the client and the relay device.

Owner:NEW H3C TECH CO LTD

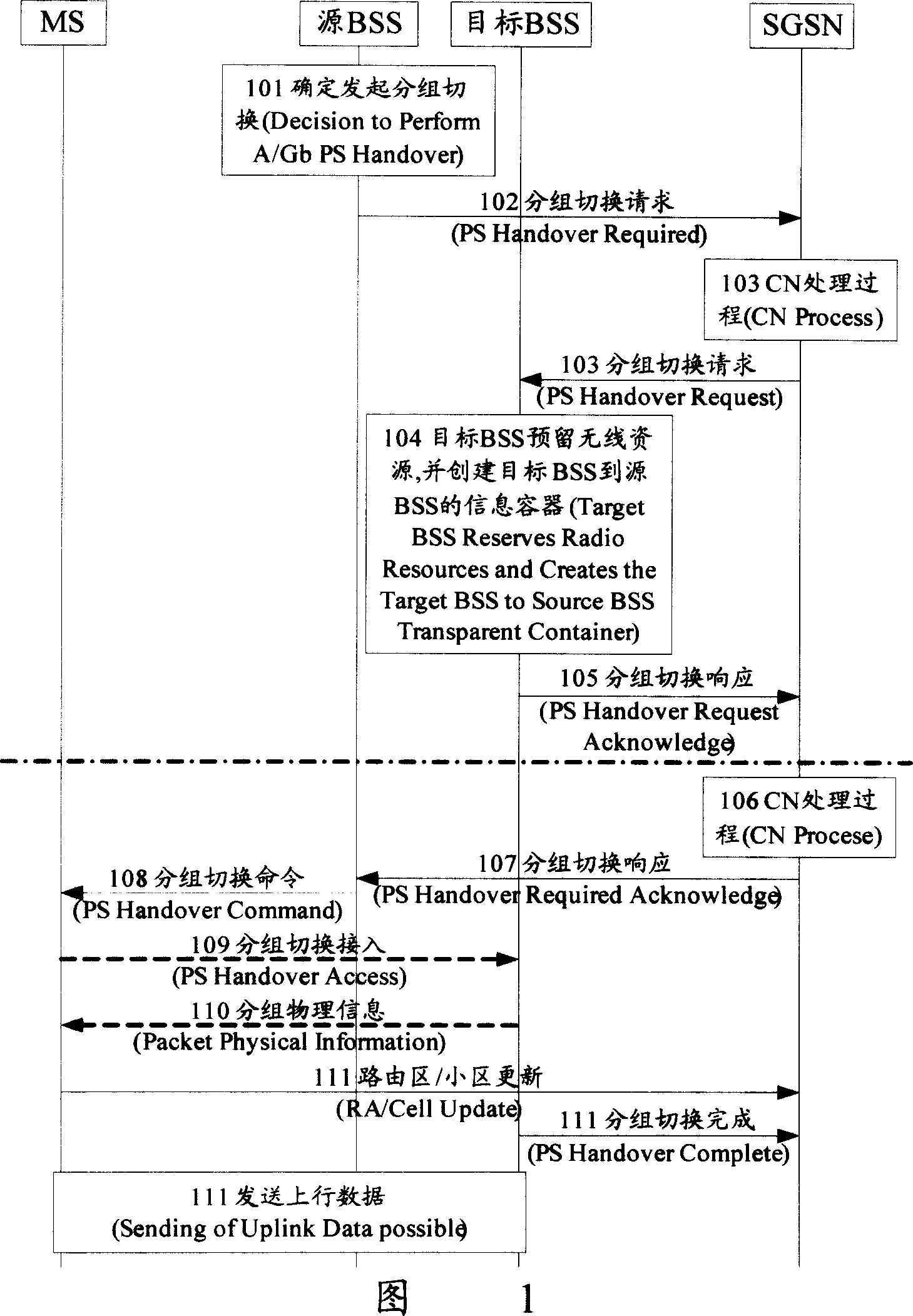

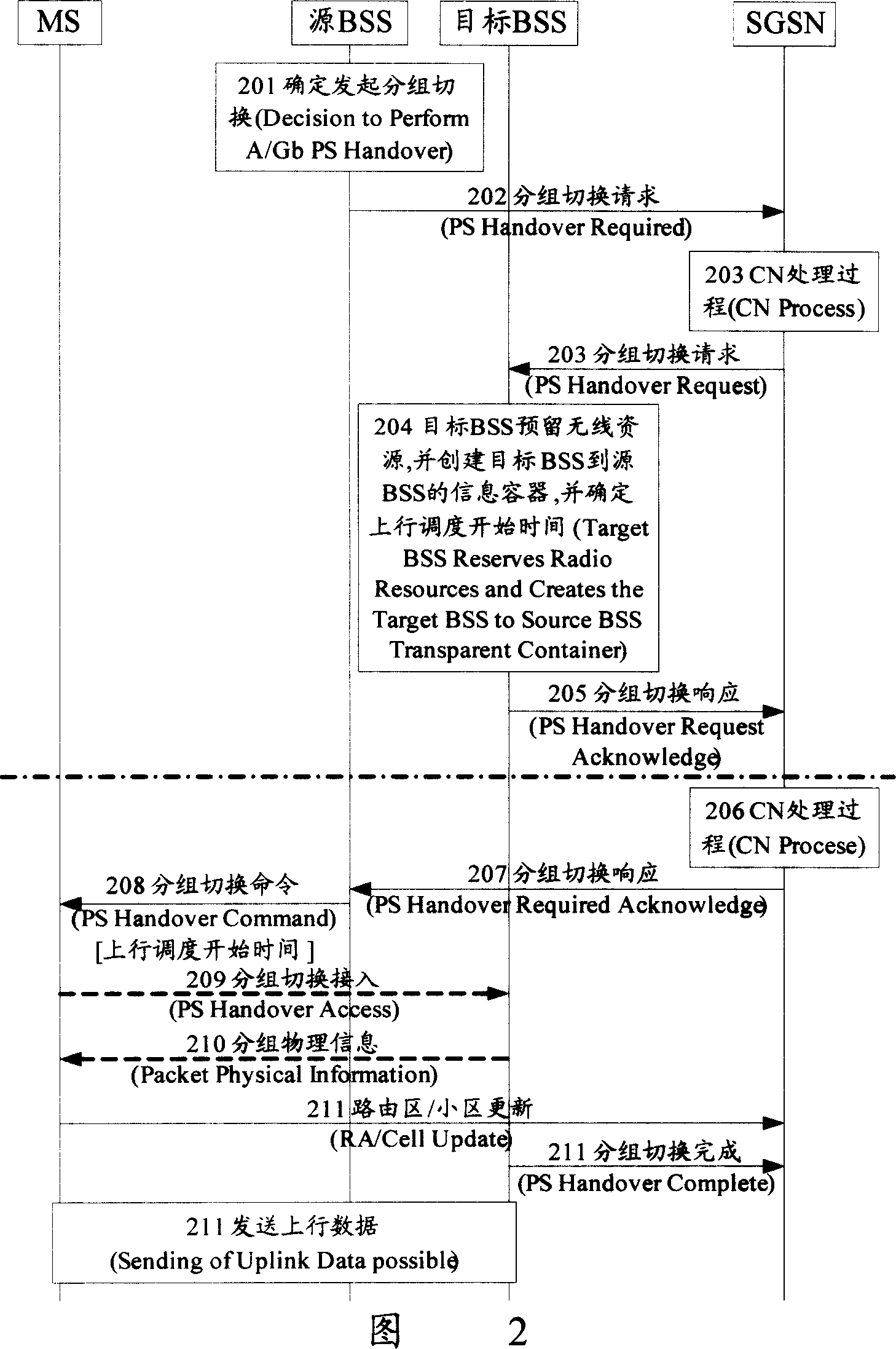

Method for scheduling system resource

InactiveCN101047622AReduce wasteImprove the speed of packet switchingNetwork traffic/resource managementRadio/inductive link selection arrangementsStart up timeDistributed computing

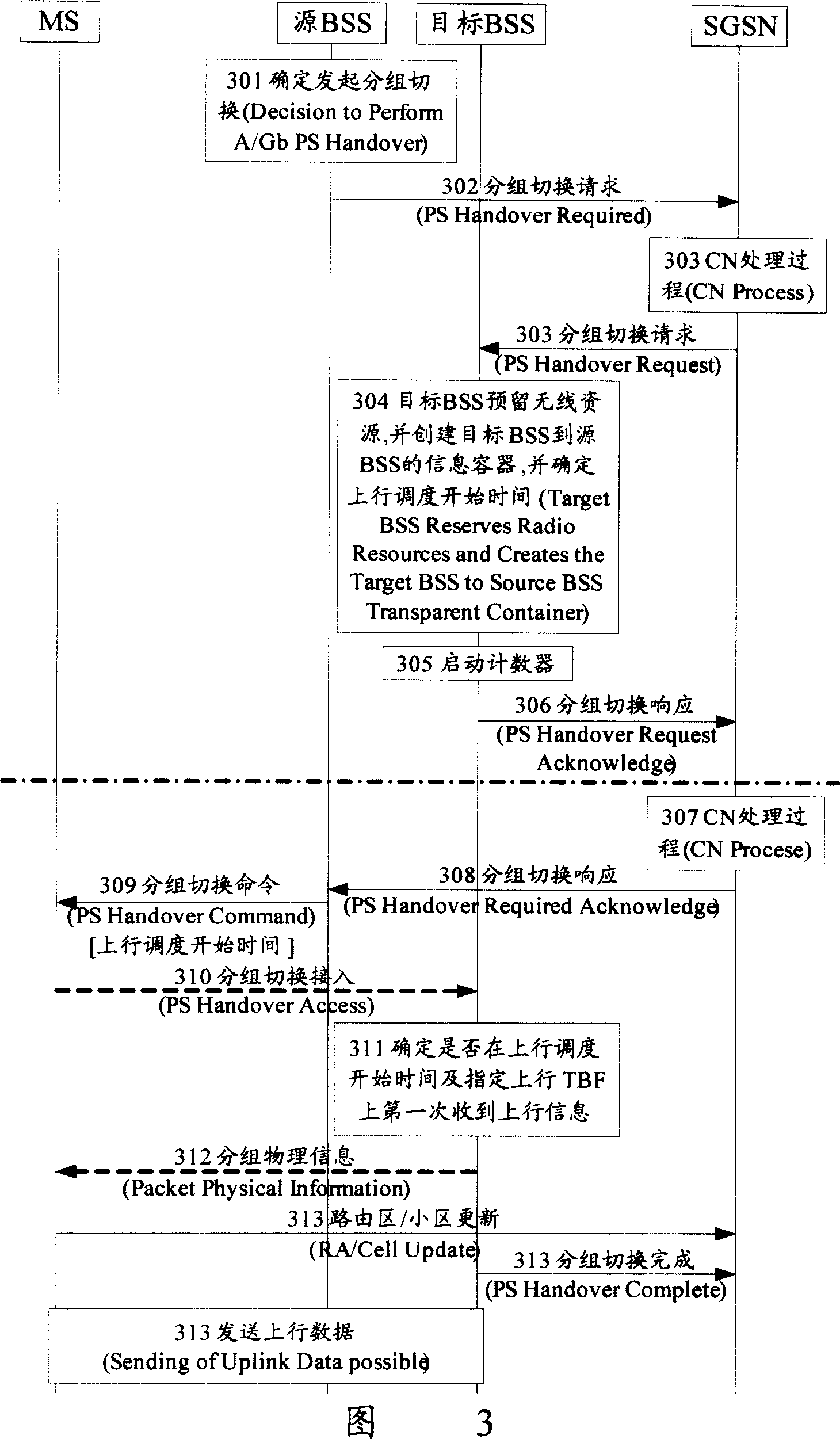

A method for dispatching resource of system includes informing MS the start-up time of uplink dispatch in packet switching-over process after resource is distributed and pre-reserved for MS by object BSS, sending uplink information to object BSS by MS after start-up time of uplink dispatch is up in order to make MS service resource be synchronized with object BSS dispatch resource.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

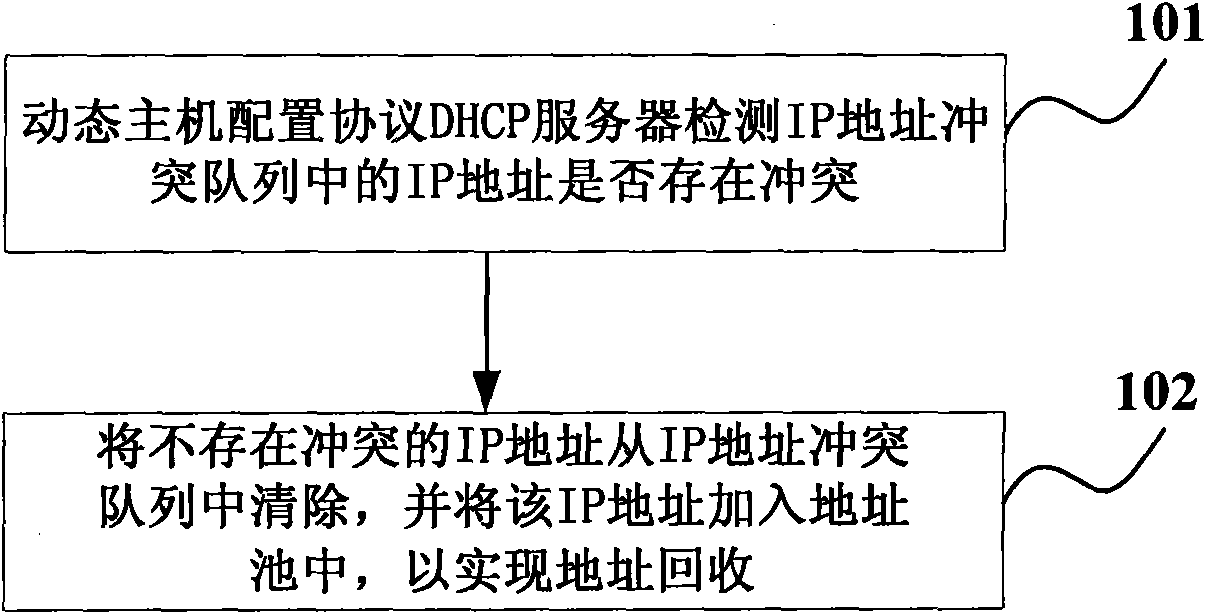

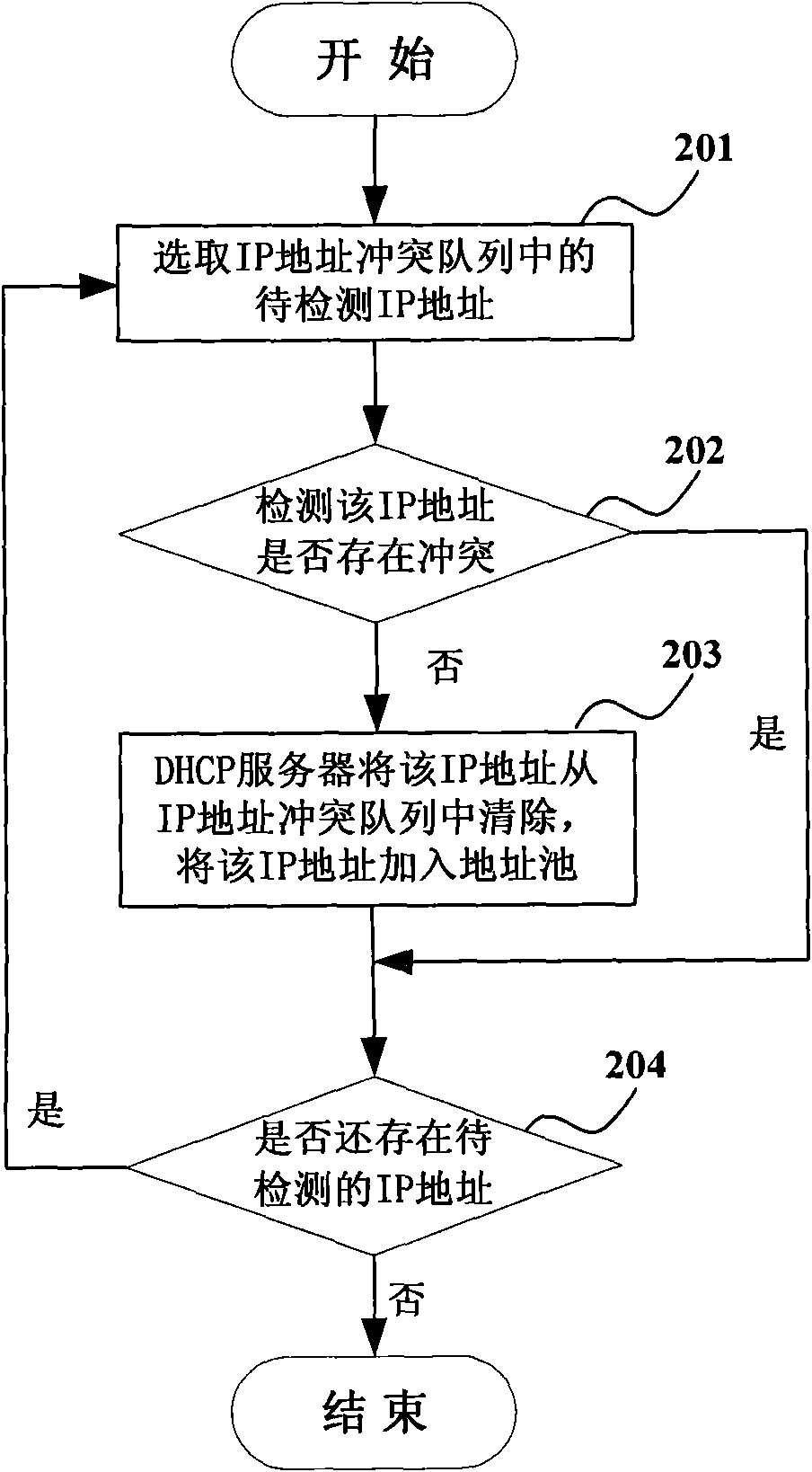

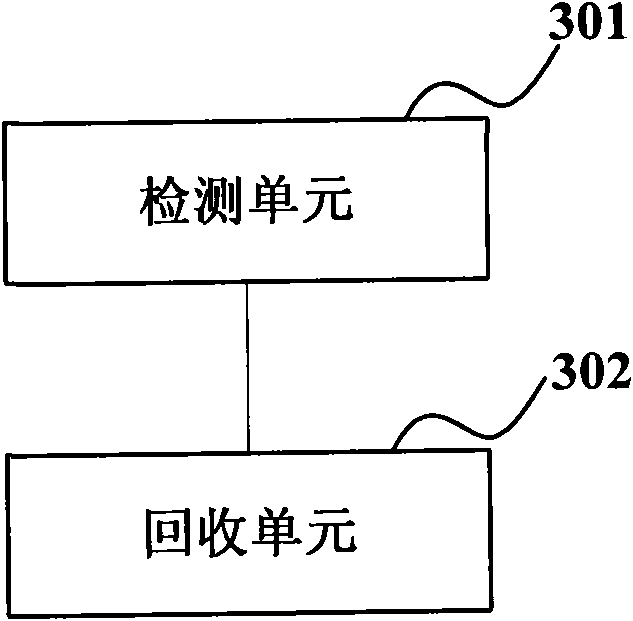

Recovering method of IP address and DHCP server

InactiveCN101674338AImprove usabilityTimely recyclingData switching networksAddress poolDevice Sensor

The embodiment of the invention provides a recovering method of an IP address and a DHCP server. The recovering method of the IP address comprises the following steps: a dynamic host configuration protocol (DHCP) server detects whether conflict exists in the IP address in an IP address conflict queue; the IP address with no conflict is eliminated from the IP address conflict queue; and the IP address is added to an address pool. By the embodiment of the invention, the conflict IP address can be recovered timely, thus ensuring that enough allocable IP addresses exist in the DHCP address pool and improving the availability of the DHCP service.

Owner:RUIJIE NETWORKS CO LTD

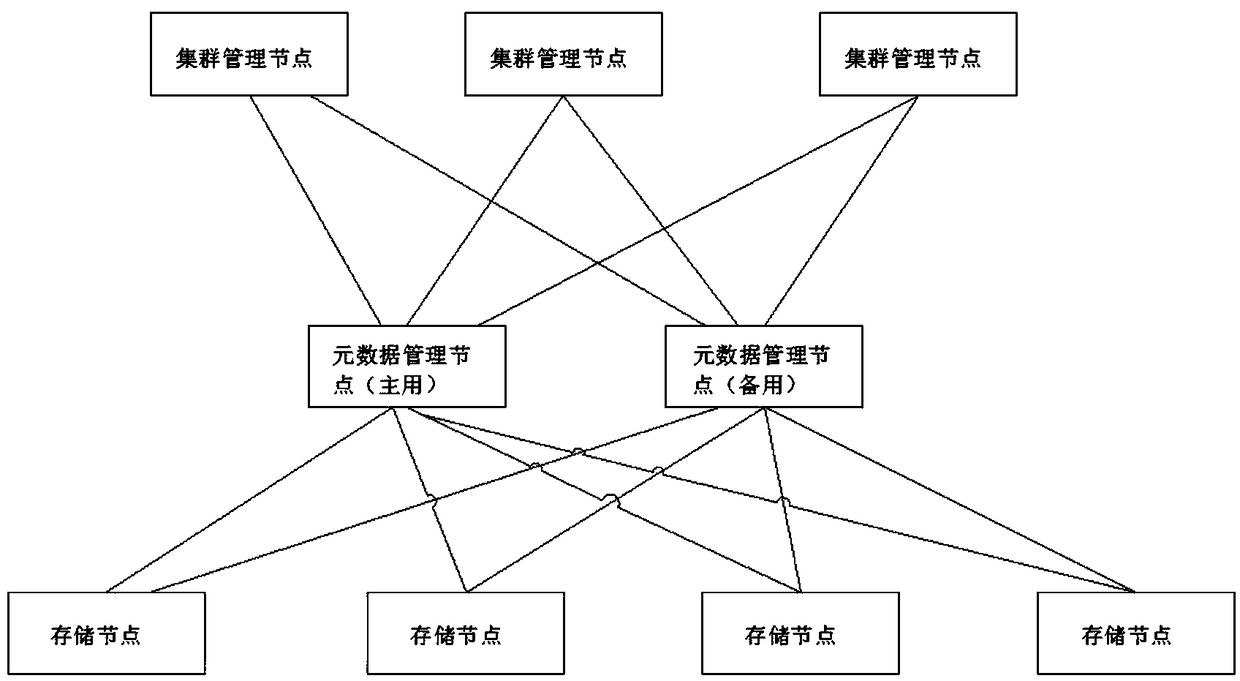

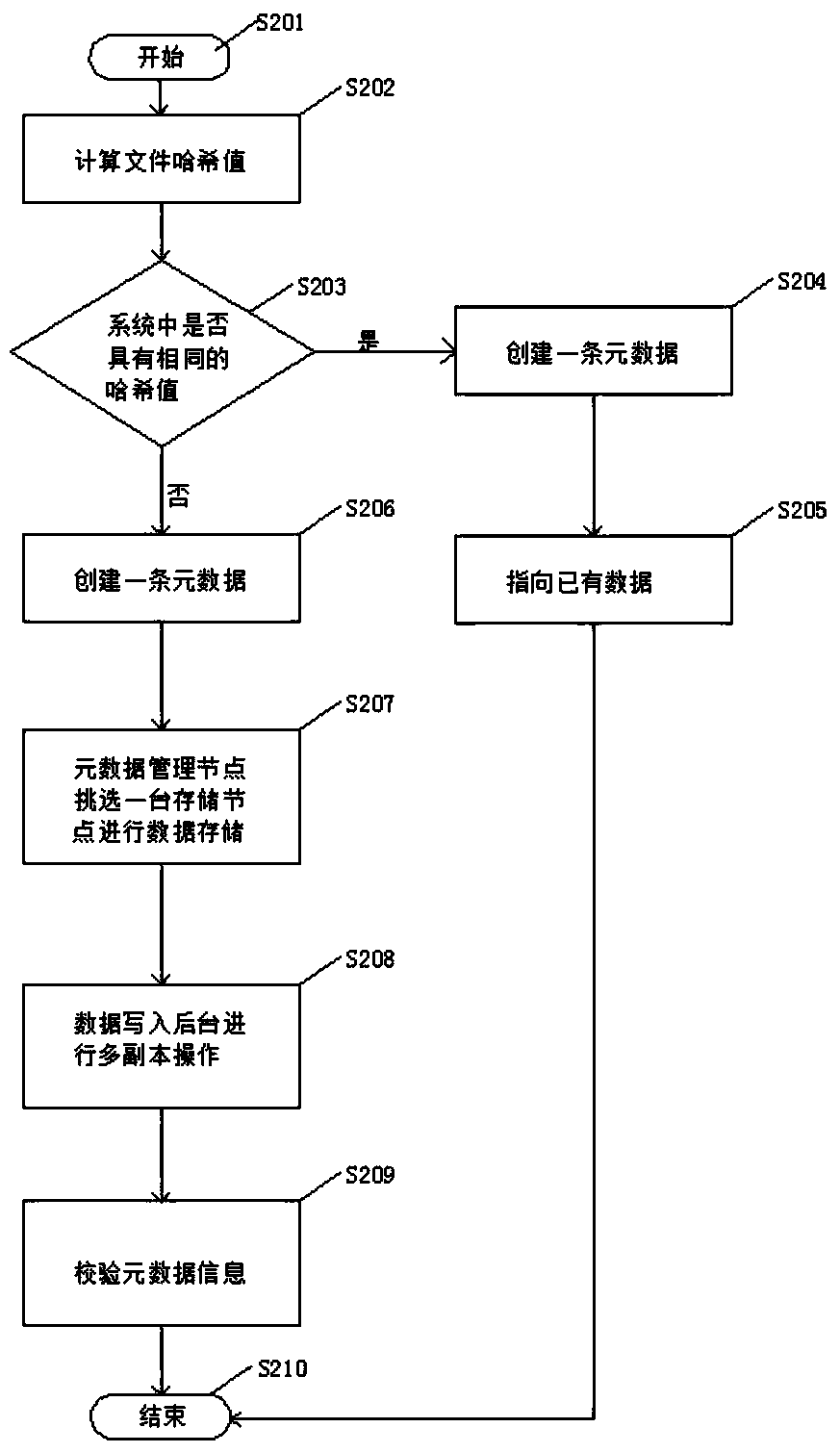

A distributed storage system and method for storing backup data

InactiveCN109284069AReduce in quantityImprove indexing speedInput/output to record carriersRedundant operation error correctionSystem administratorAuthorization

The invention provides a distributed storage system and a method for storing backup data, which uses a distributed storage system mode instead of an index mode to manage the backup data. A distributedstorage method includes a method for storage of backup data, a method of data recovery and a method of backing up data garbage collection. The data storage method can greatly utilize the advantages of high IOPS of disk device and high concurrency of cluster, the system design has redundancy, the system will not easily collapse, and saves a lot of environment of optimizing the backup server's owndata, which is convenient for system administrator to carry on system management and saves the authorization cost of the database. And different from the traditional backup system index management, itdoes not need to simulate the tape to manage the file system space, so that the data can be recovered in time when it is invalid, which improves the utilization of storage spa ce.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

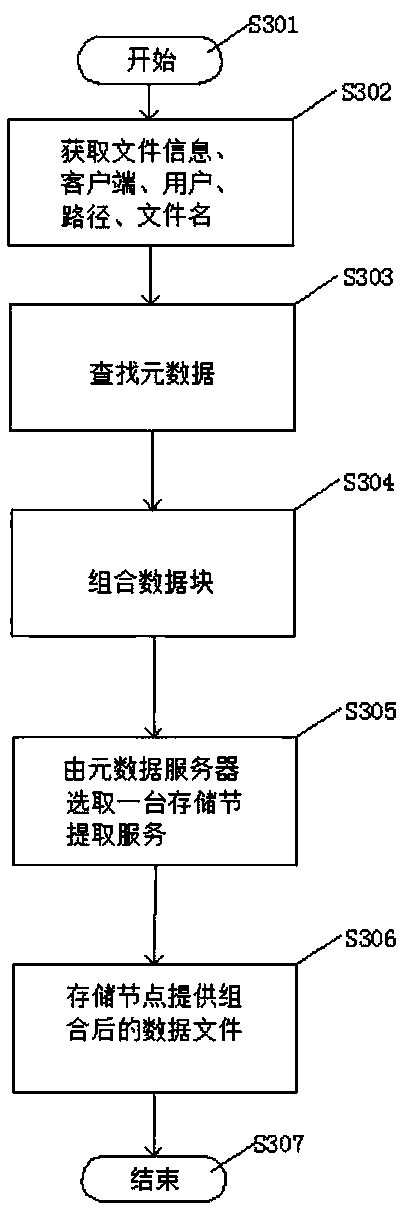

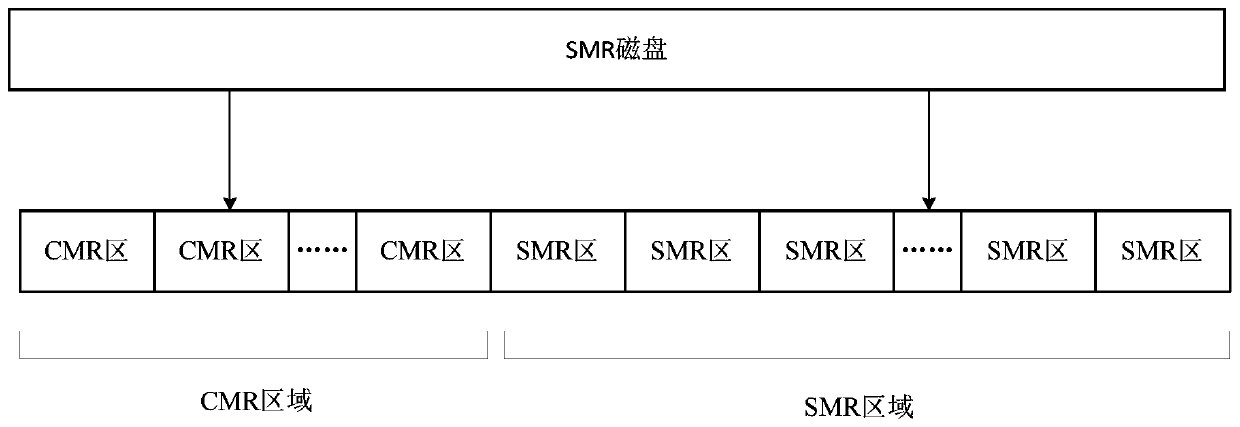

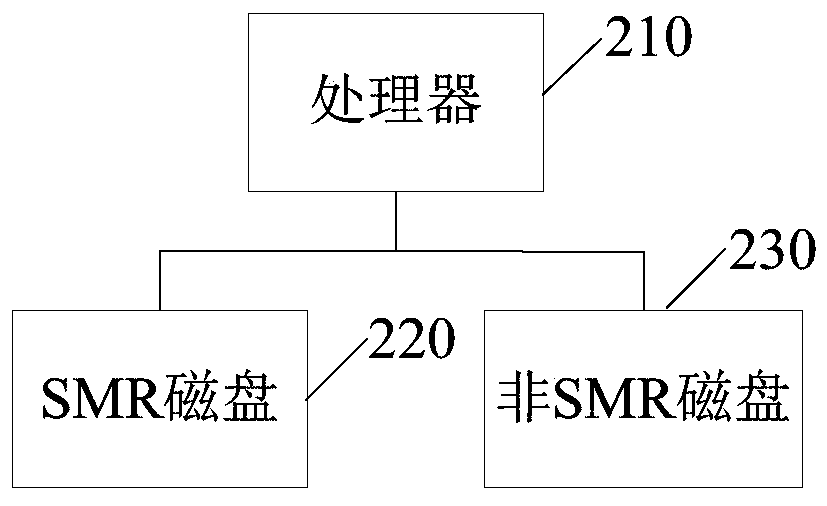

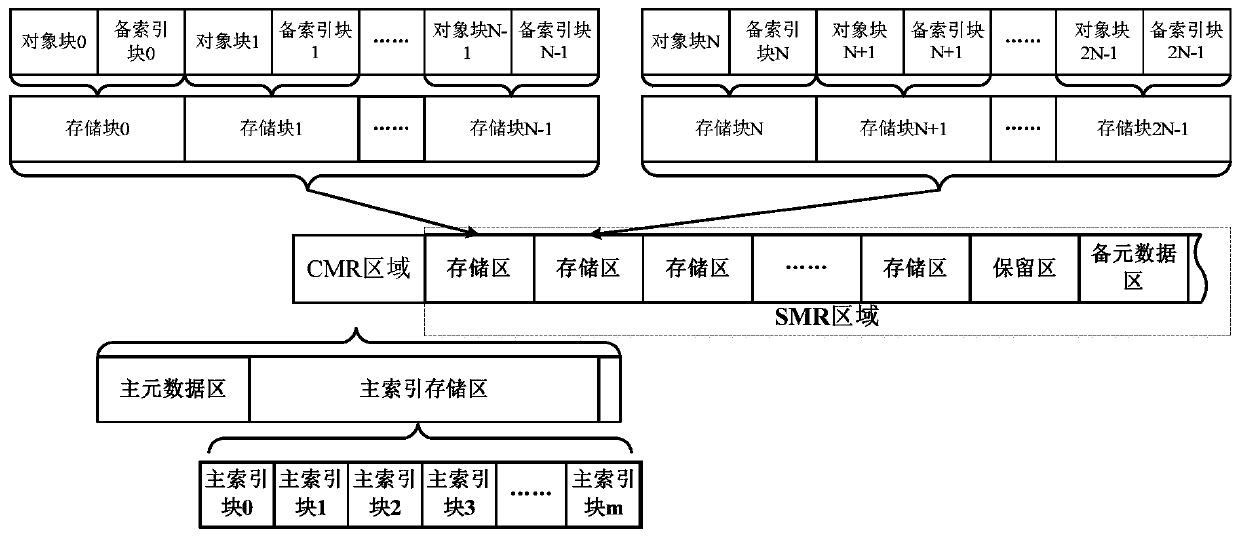

Data storage method and device and storage system

ActiveCN111399762AImprove storage resource utilizationTimely recyclingInput/output to record carriersRecord information storageData classDatabase index

The embodiment of the invention provides a data storage method and device and a storage system, and the method comprises the steps: determining the data type of to-be-stored data when the to-be-storeddata is obtained; determining a target storage area with the same data type as the to-be-stored data based on the data type of the data stored in each storage area in the SMR disk; determining a target storage block in which the to-be-stored data is to be written in the target storage area; based on the identifier of the target storage block, generating main index information and standby index information of the to-be-stored data; generating database index information of the to-be-stored data based on the to-be-stored data and the identifier of the target storage block; writing the standby index information of the to-be-stored data and the to-be-stored data into the target storage block, writing the main index information of the to-be-stored data into the CMR region or the non-SMR disk, and writing the database index information of the to-be-stored data into the non-SMR disk. Therefore, the storage resource utilization rate of the SMR disk can be improved.

Owner:HANGZHOU HIKVISION SYST TECH

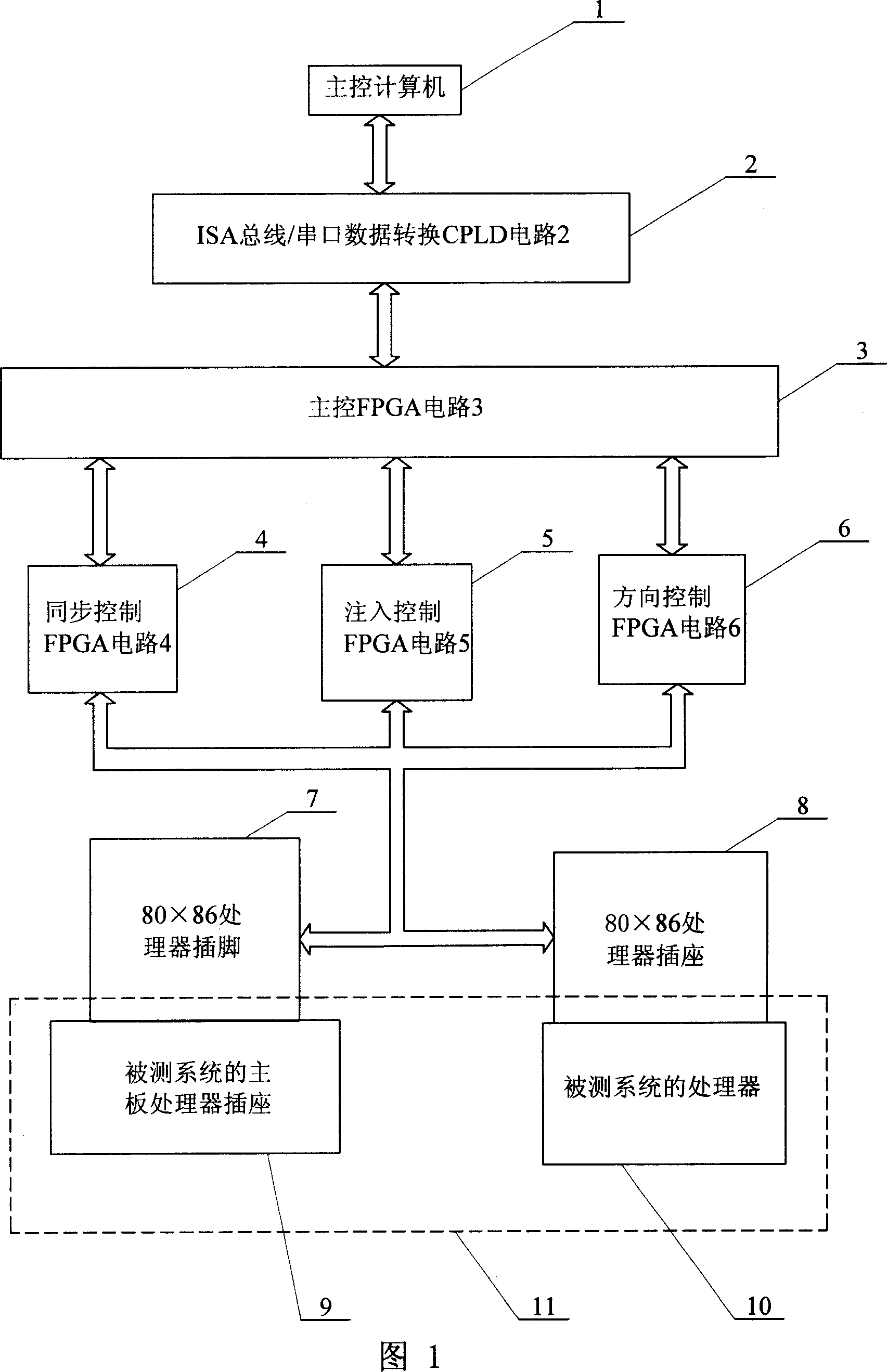

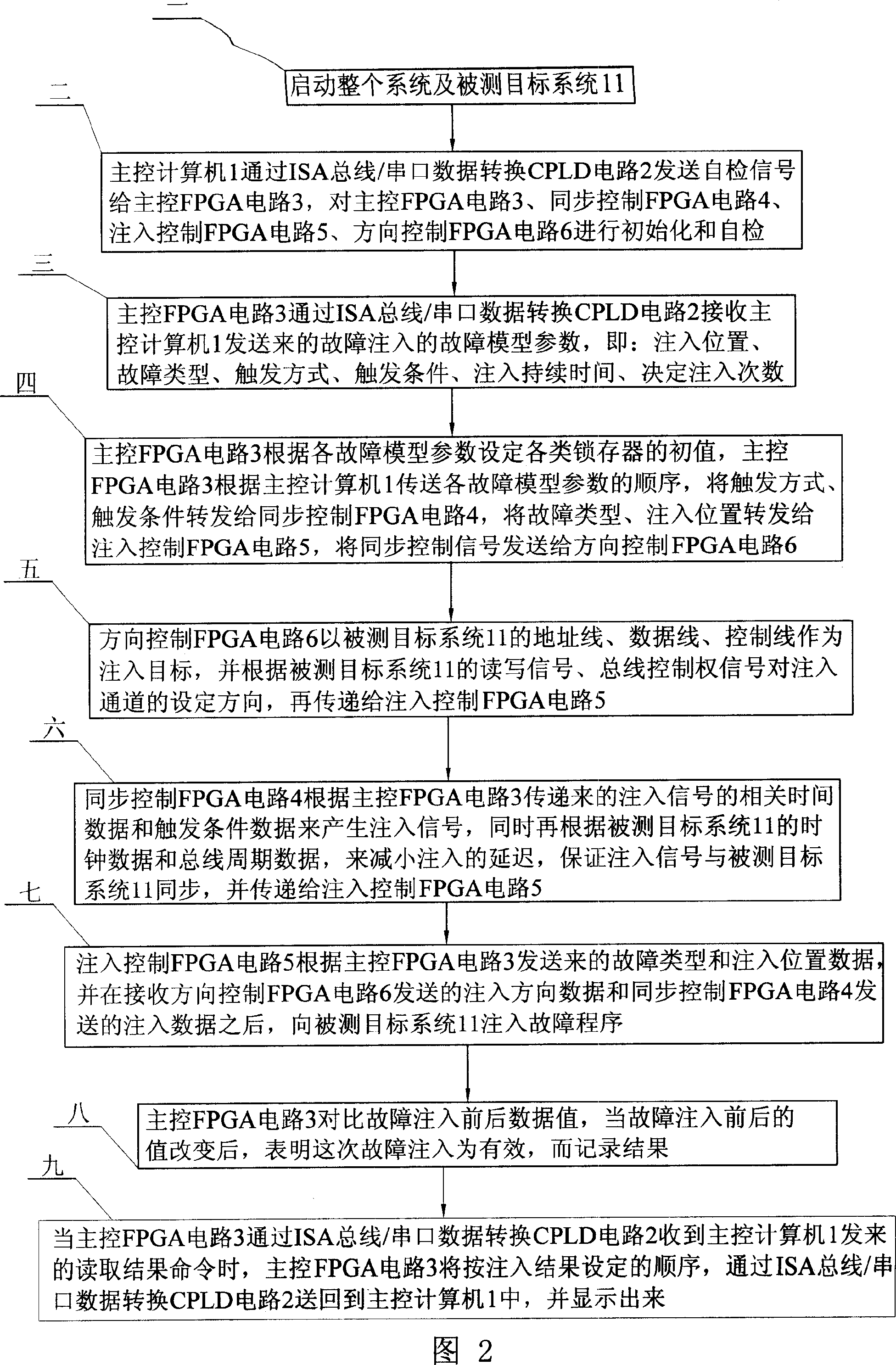

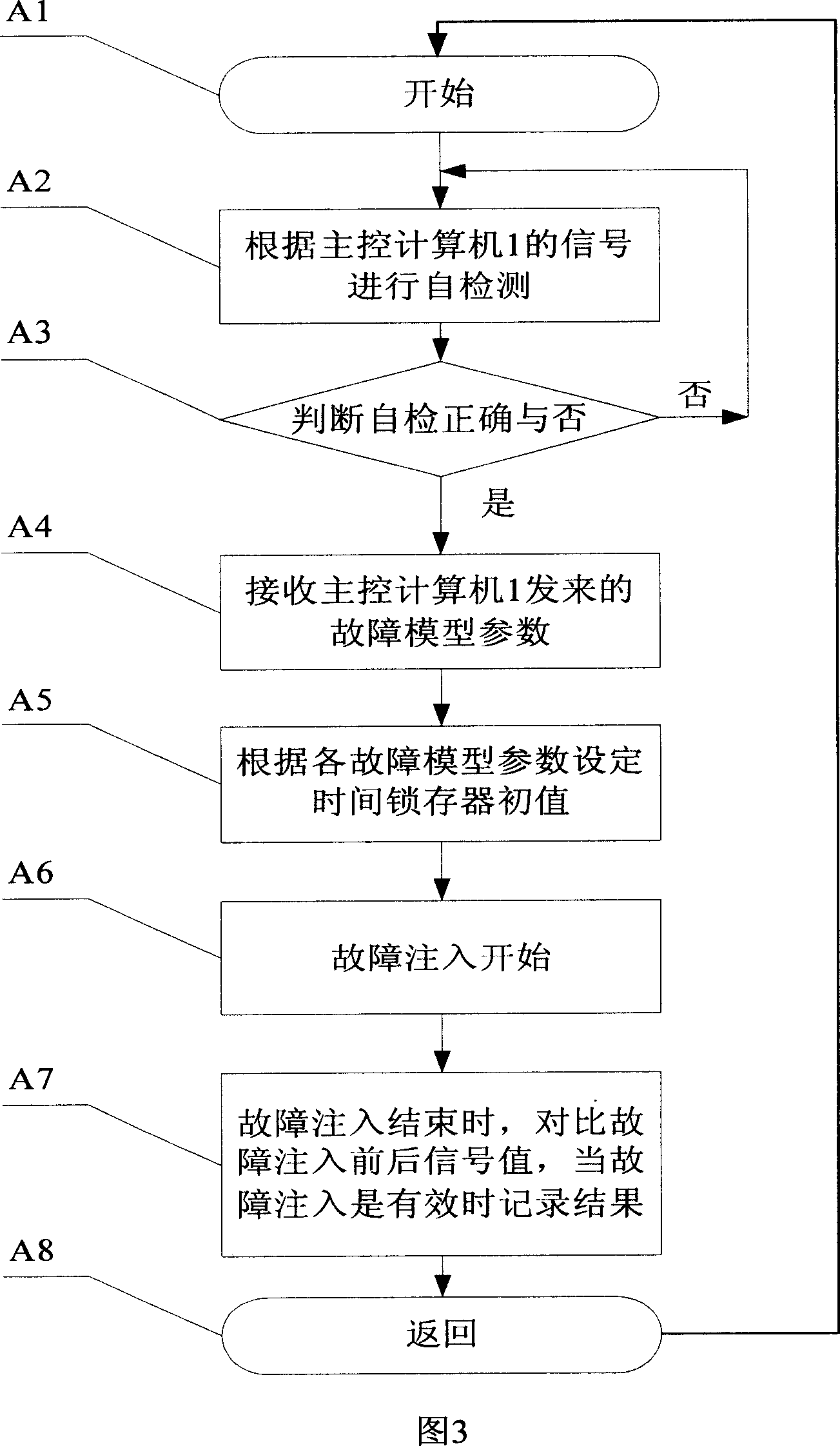

Embedded fault injection system and its method

InactiveCN1945547AEasy to detectMany ways to trigger faultsError detection/correctionData connectionSynchronous control

A fault injection system of embedding type and method relates to the technology of testing and evaluating the redundant computer system, which can overcome the problem that the existing technology can not test and evaluate the reliability of computer system correctly and accurately. Its control computer (1) connects with CPLD circuit (2), main control FPGA circuit (3) and synchronous control FPGA circuit (4), injection control FPGA circuit (5), direction control FPGA circuit (6), 80 * 86 processor pin (7), 80 * 86 processor socket (8) through ISA bus / serial data conversion. The steps are: (a) starting the system, (b) initializing and auto-examining, (c) transmitting the parameters of fault model, (d) setting the initial value of flip-latch, (e) the direction control FPGA circuit (6) sets the direction, (f) the synchronous control FPGA circuit (4) sets the synchronous data, (g) the injection control FPGA circuit (5) set the injection data, (h) recording results, (i) displaying results.

Owner:HARBIN INST OF TECH

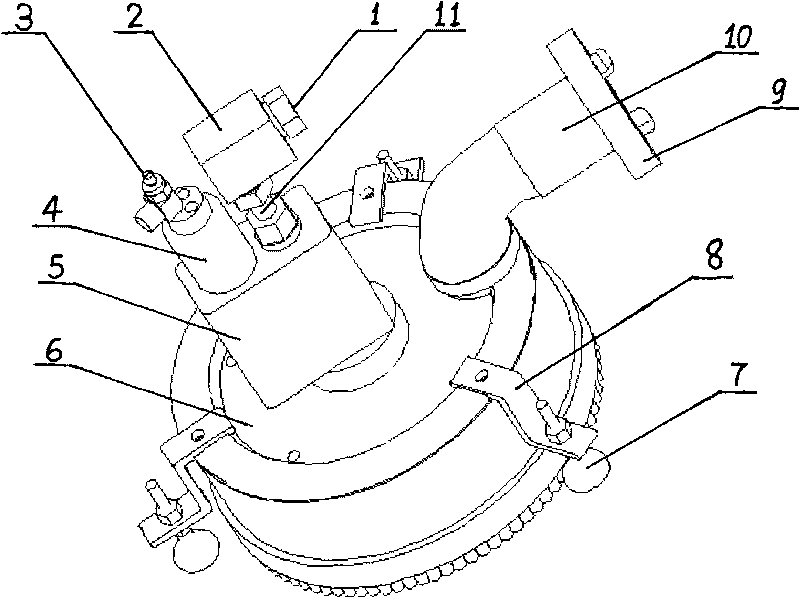

Water jet hull rust remover and operating method thereof

InactiveCN101704004AUniform derustingImprove rust removal effectCleaning using liquidsSlagEvaporation

The invention discloses a water jet hull rust remover and an operating method thereof. The rust remover comprises a high-pressure water tube interface, a high-pressure water tube interface seat, a rust removing disk, a high-pressure water tube interface seat support, a nozzle, and a nozzle rotary frame, and also comprises an air tube interface, an air tube interface seat, an air motor body, a vacuum recycling flange, a vacuum recycling tube, a vacuum recycling opening, and a high-pressure water sealing ring, wherein the vacuum recycling opening is embedded in the rust removing disk and connected with the vacuum recycling tube; the outlet end of the vacuum recycling tube is connected with the vacuum recycling flange; and the upper surface of the rust removing disk is also provided with a height adjusting support. The method comprises steps of height adjustment, rust removal and recycling. In the water jet hull rust remover, the rust removal by the superhigh pressure water jet and pumping and slag discharging by the vacuum system are compatibly designed into one body, the vacuum equipment recycles the rust, the high temperature, which is over 80 DEG C and generated by the water jet action, in the vacuum cavity can cause certain positive effects on the evaporation of water of the bulkhead, the rust removal drying is realized, and the hull is avoided from the return of rust.

Owner:DALIAN MARITIME UNIVERSITY

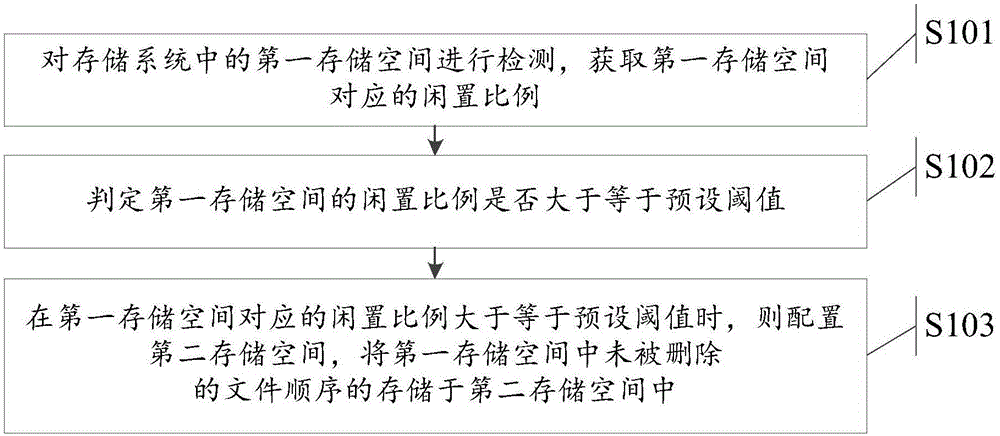

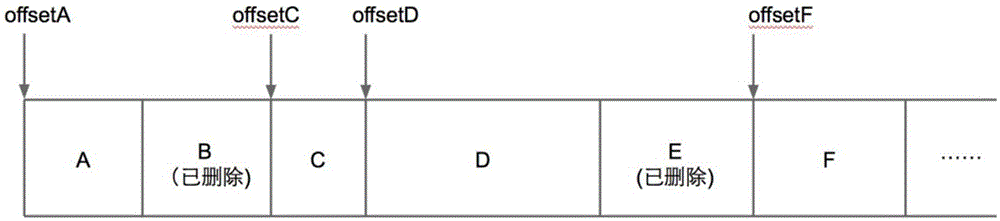

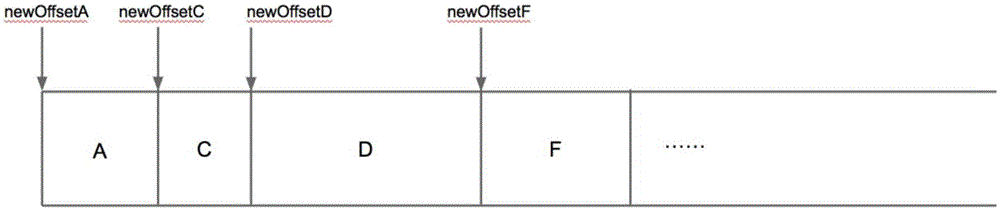

Storage space recycling method and storage system

InactiveCN105138282AIncrease profitAccelerateInput/output to record carriersFile deletionUtilization rate

The invention discloses a storage space recycling method and a storage system. The storage space recycling method comprises the following steps: detecting a first storage space in the storage system, obtaining an idle proportion corresponding to the first storage space, judging whether the idle proportion of the first storage space is more than or equal to a pre-set threshold value or not, configuring a second storage space when the idle proportion corresponding to the first storage space is more than or equal to the pre-set threshold value, and sequentially storing files, which are not deleted in the first storage space, in the second storage space. Namely, when more residual storage spaces reserved due to file deletion exist in the first storage space of the storage system, the storage system sequentially stores the files, which are not deleted in the first storage space, in the second storage space, so that the storage space occupied by the deleted files in the first storage space can be eliminated; therefore, the idle storage space in the storage system can be recycled; and the utilization rate of the storage space is improved.

Owner:SHANGHAI QINIU INFORMATION TECH

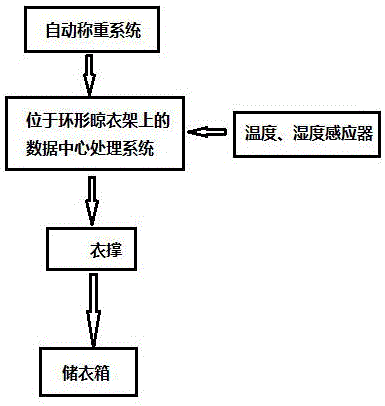

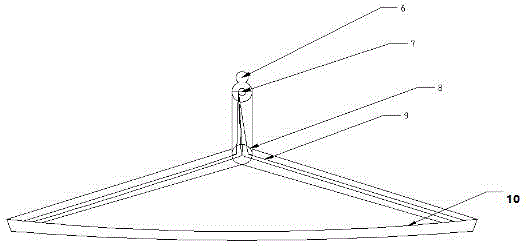

Automatic clothes airing system

ActiveCN105821630ASimple structureInnovative designApparel holdersTextiles and paperRound barClothes hanger

The invention provides an automatic clothes airing system. The automatic clothes airing system comprises an automatic clothes weighing system, a clothes hanger, an annular drying rack and a clothes storage box. The automatic weighing system is arranged in a washing machine and further comprises a data storage module, an information transmission module and a display screen for reading the weight of clothes. The clothes hanger comprises a round bar type hook, an upper clothes hanger rod and a lower clothes hanger rod. A rotating device is arranged above the upper clothes hanger rod, and a suspending device is arranged above the rotating device. The annular drying rack comprises a main rod, a connecting device is arranged on the lower side of the main rod, the suspending device is matched with the connecting device, a guide rail is arranged in the main rod, and a conveying belt is arranged in the guide rail. The clothes storage box comprises multiple supporting rods and a clothes storage box cover. A pressure responsive device is arranged in the clothes storage box. The clothes airing quality can be guaranteed, the influences of human factors are avoided, the clothes can be collected in time to guarantee the quality of the clothes, and the characteristic of intelligence can be shown.

Owner:NANJING INST OF TECH

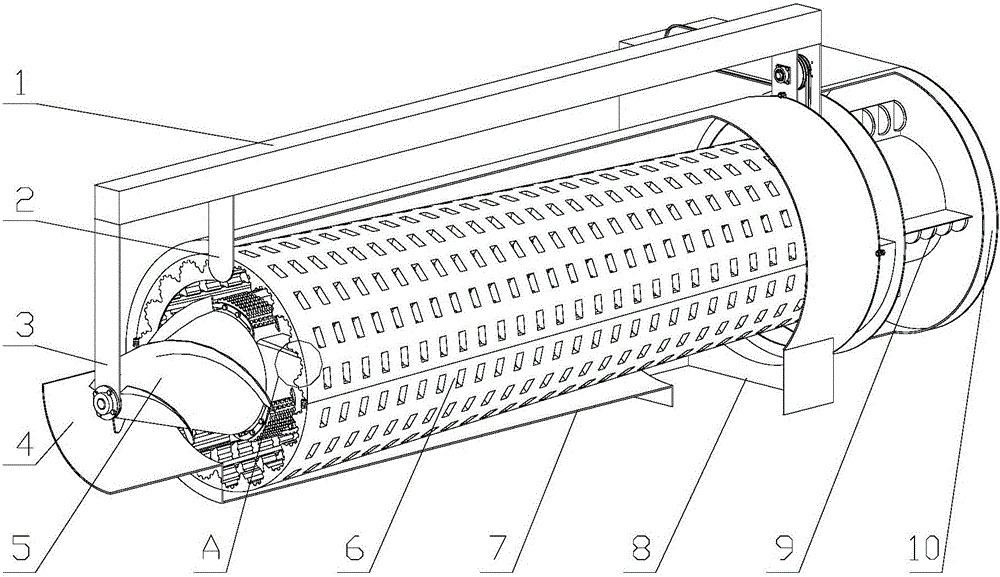

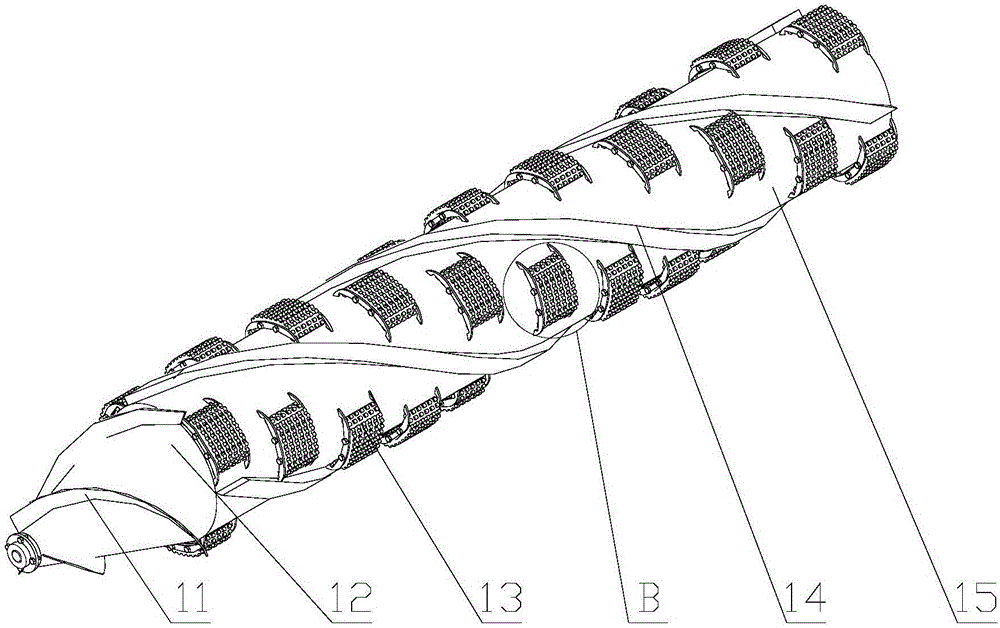

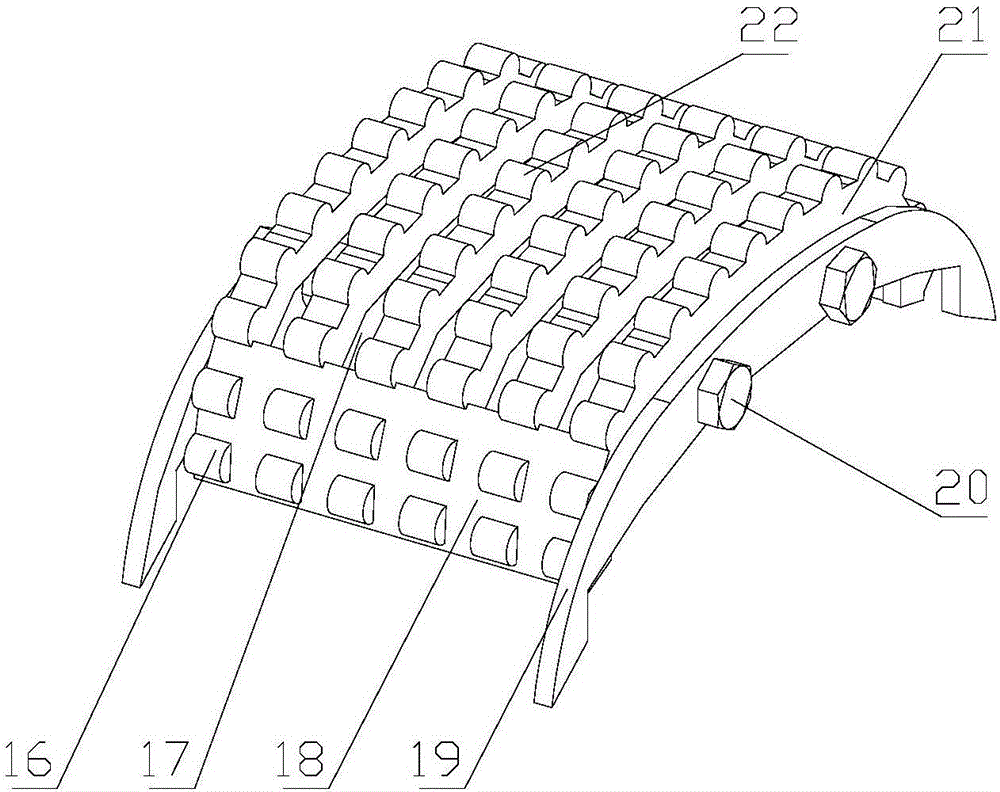

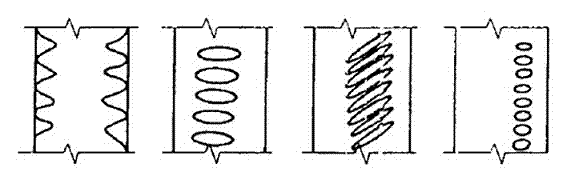

Axial rheological gap bionic corn threshing device

The invention discloses an axial rheological gap bionic corn threshing device. The axial rheological gap bionic corn threshing device comprises a machine frame, a threshing roller, a concave plate sieve, a machine cover and a corncob recycling mechanism, wherein the machine cover is fixed at the lower part of the machine frame; the concave plate sieve is fixed in the machine cover; the threshing roller is fixed in the concave plate sieve; the corncob recycling mechanism is fixed ar the back part of the machine cover; the cylindrical threshing roller and the conical concave plate sieve jointly form threshing gaps which are continuously changed from big to small to promote that corn ears are subjected to effective threshing action all the time; and threshing teeth on the outer surface of a bionic threshing bridge and threshing columns which are distributed on the inner surface of the concave plate sieve in a copying arc form jointly form the threshing functional surface, microscopic threshing moment is applied to corn grains, and the removed corn grains are separated out timely through a grain leaking groove in the surface of the bionic threshing bridge and a separating port in the surface of the concave plate sieve. The axial rheological gap bionic corn threshing device has high threshing efficiency and few crushed grains, and can synchronously collect the corncobs.

Owner:SHANDONG JUMING MASCH CO LTD

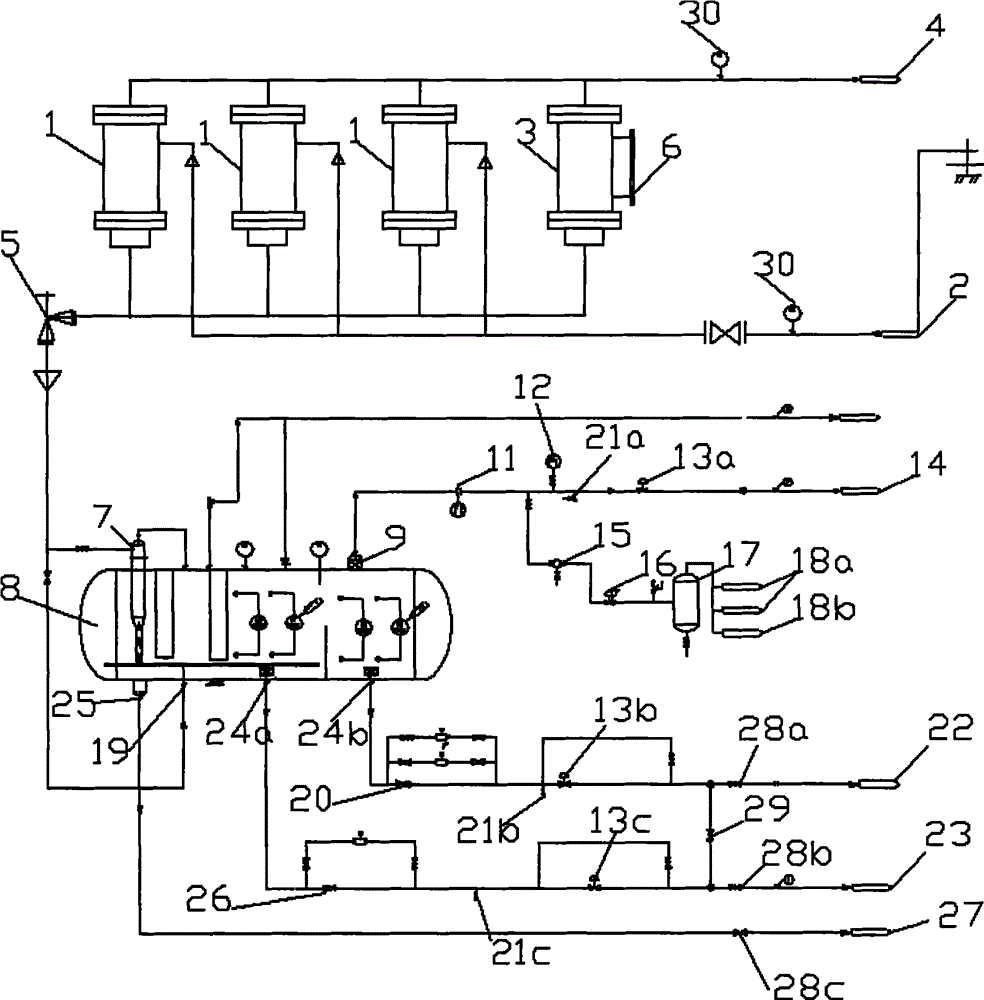

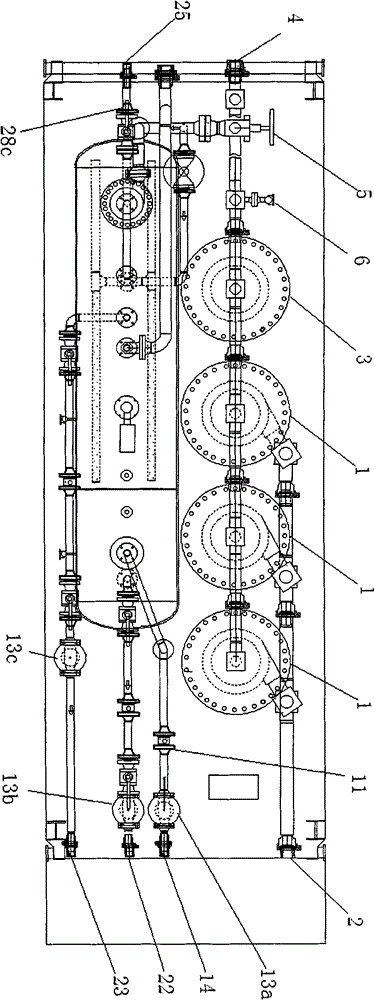

High-pressure oil, gas, water and solid four-phase separating and metering device for wellhead of skid-mounted oil and gas field

ActiveCN105239993AReduce labor intensityEmission reductionSurveyFluid removalAutomatic controlCompressed natural gas

The invention discloses a high-pressure oil, gas, water and solid four-phase separating and metering device for a wellhead of a skid-mounted oil and gas field. The high-pressure oil, gas, water and solid four-phase separating and metering device consists of a high-pressure gas separating module and a low-pressure gas, oil, water and solid separating module. The pressure of the mixture of natural gas, oil, water and solid particles which are discharged from a natural gas wellhead is lower than 70 MPa, and the mixture of which the pressure is not reduced can directly enter the device; as throttling depressurization does not exist in a separating process, the temperature cannot be reduced, media do not need to be heated, devices such as a water jacket heater and a throttle manifold are omitted, and the cost and space of the device are greatly reduced; an operator can know and control running conditions of the device at any time through a computer measurement and control center; the power supply of all meter automatic control systems of the device is 500 W only, power consumption of the device is lower than that of the original device by 100 KW every day, and the cost is reduced to a maximum extent; and if a natural gas pipeline network is not laid during production estimation of a new well, the pressure of a natural gas outlet can be regulated to 25-35 MPa, then natural gas can be directly charged into a high-pressure compressed natural gas truck and carried away to be recycled to the natural gas pipeline network or a gas station, energy is recycled in time, gas emission is reduced, and waste of the original pilot torch is avoided.

Owner:徐州海浩石油科技有限公司

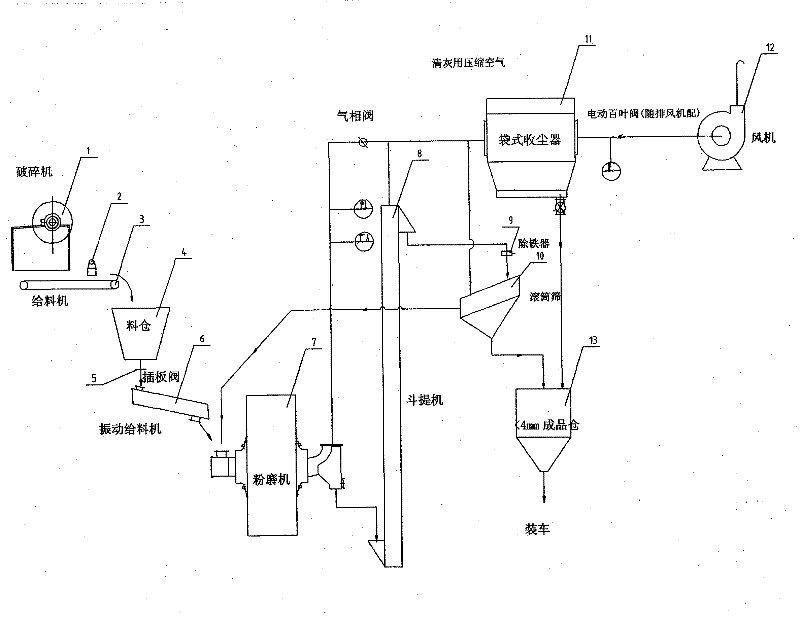

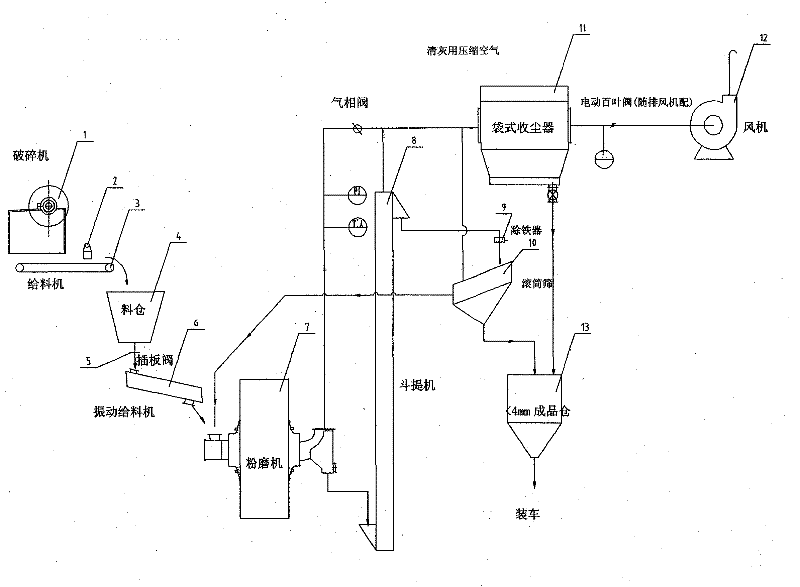

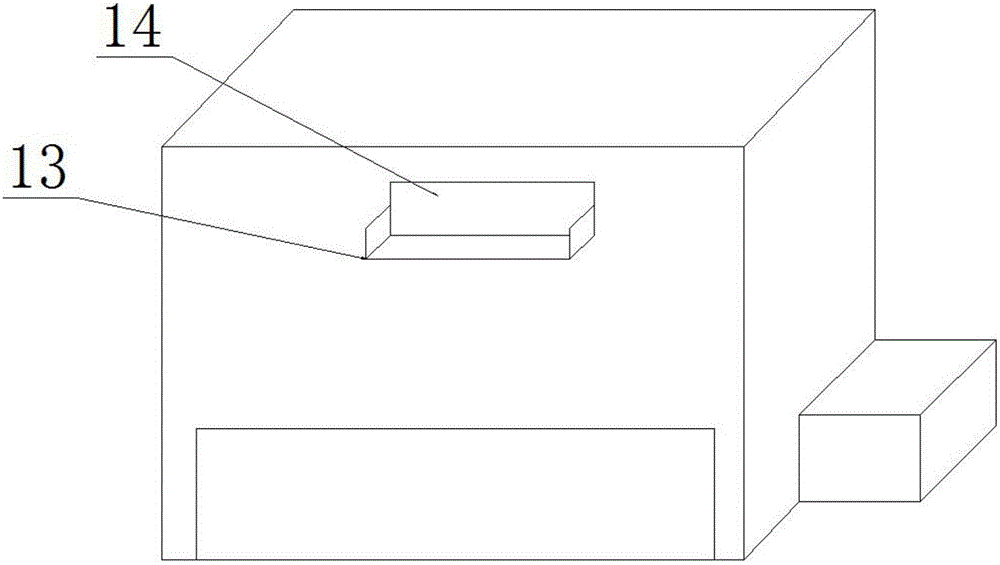

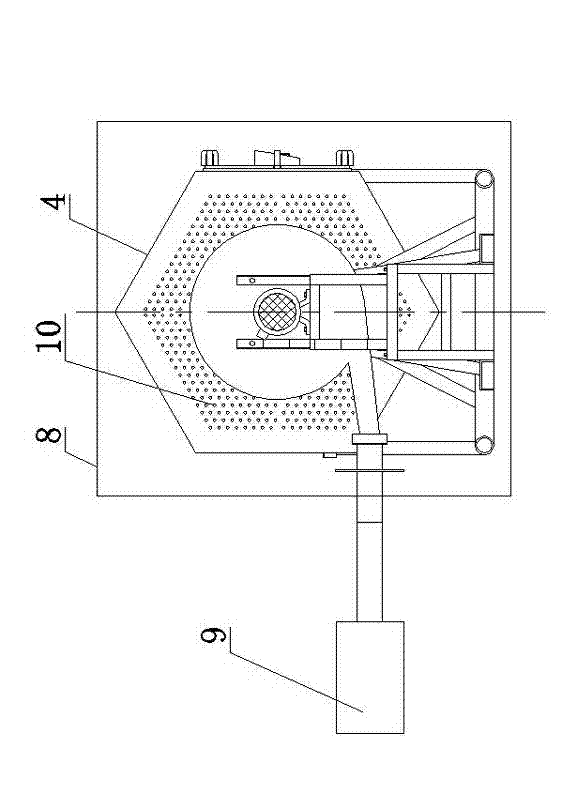

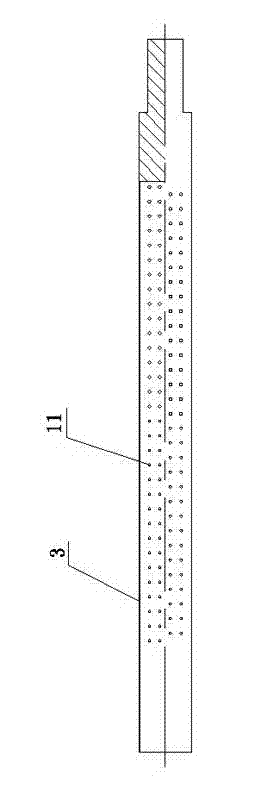

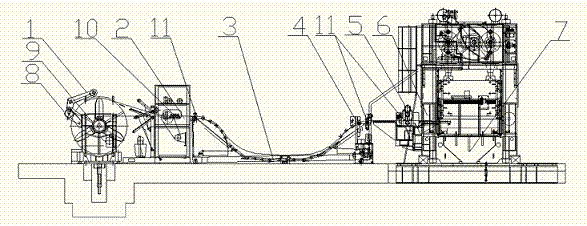

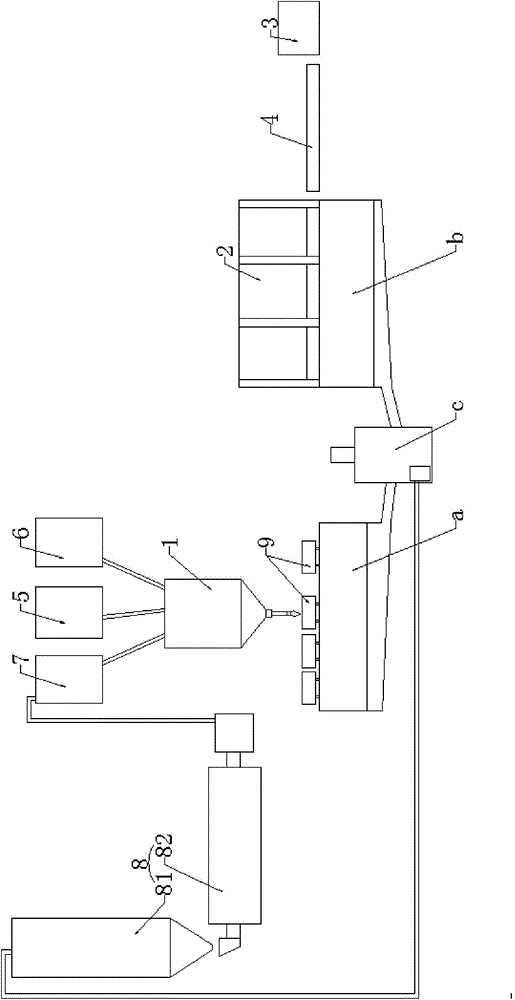

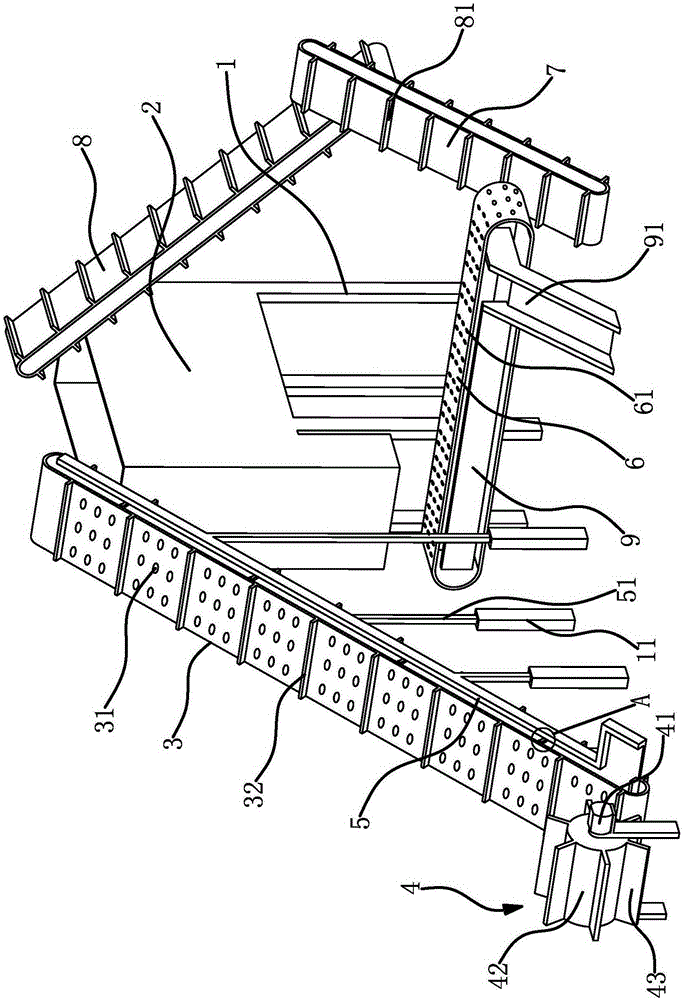

Bucket production line device and method for crushing aluminum oxide crusting blocks

The invention discloses a bucket production line device and a method for crushing aluminum oxide crusting blocks. A material is subjected to primary crushing on a production line, then the material feeding granularity is less than or equal to 300mm, the material discharging granularity is less than or equal to 4mm, and the standard material discharging granularity which can be reached by traditional two-time crushing and three-time crushing is reached. The automatic operation of the whole production line is controlled through an electric control system, so the production efficiency is improved, the consumption is reduced, the aluminum oxide crusting blocks are timely recycled, the failure and the maintenance are reduced, and the labor intensity of workers is reduced. The bucket production line device consists of a mechanical part and an electric control part, wherein the mechanical part consists of a crusher, a first iron remover, a conveyor, a raw material cabin, a gate valve, a vibration feeding machine, a pulverizer, a bucket, a second iron remover, a vibrating screen, a bag dust collector, an exhaust fan and a finished product cabin. The method for crushing the aluminum oxide crusting blocks sequentially comprises the following steps of: feeding the material, pulverizing the material, separating the material, collecting dust and storing the material. The device is simple in structure; the method is simply and quickly performed; energy is saved; the efficiency is high; and the device is safe and environment-friendly.

Owner:洛阳宇航重工科技股份有限公司

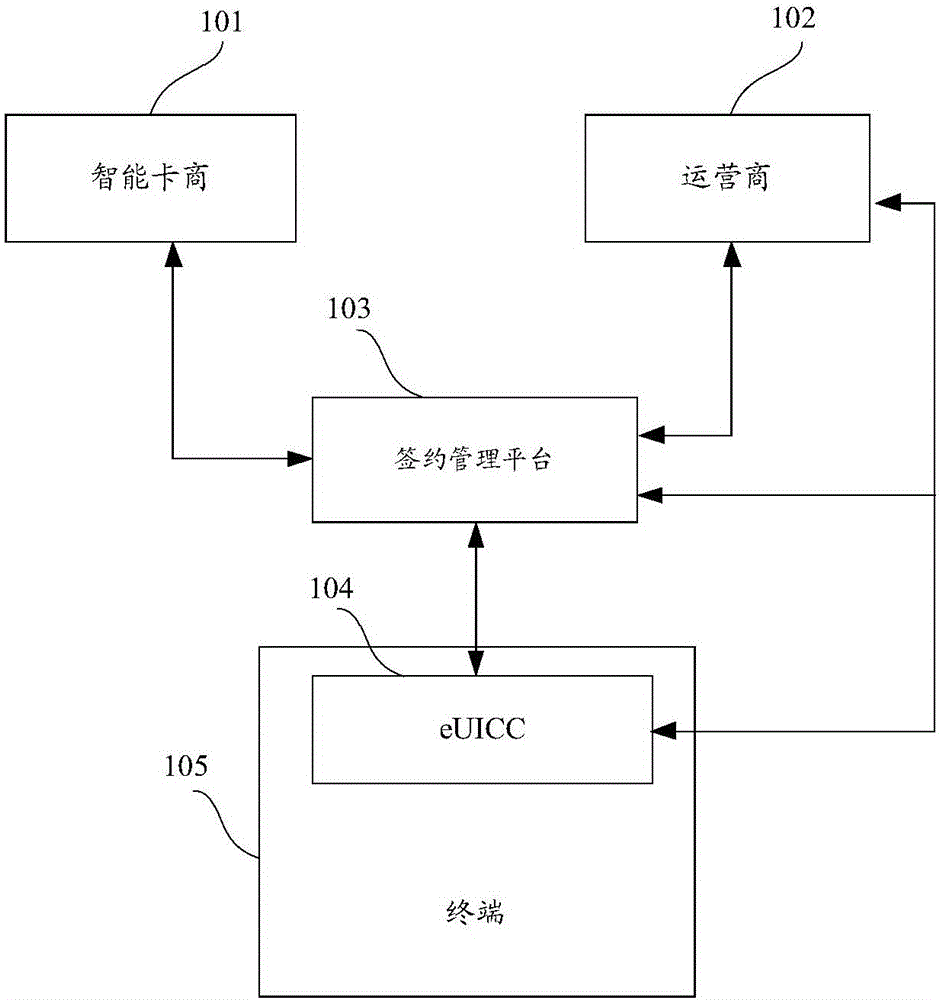

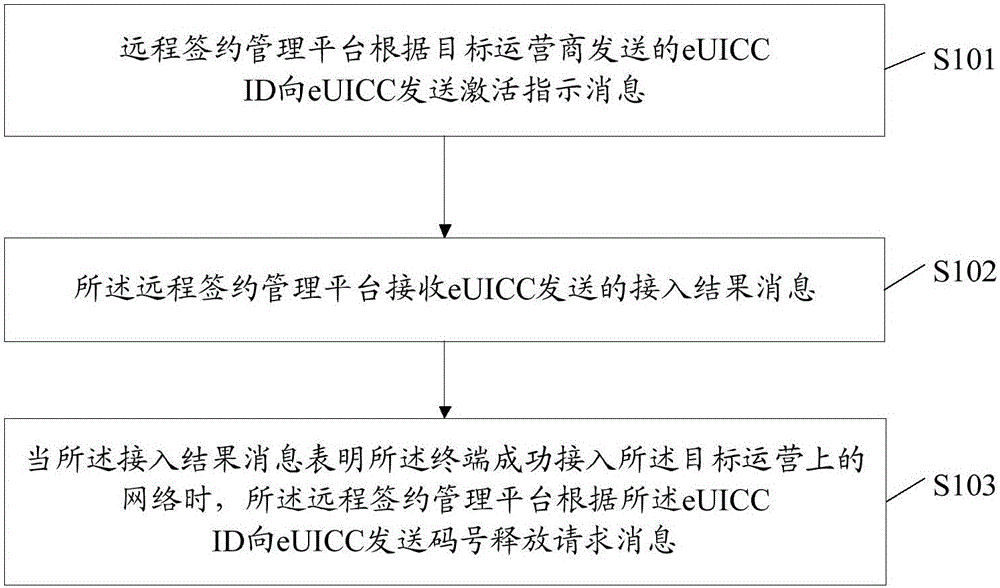

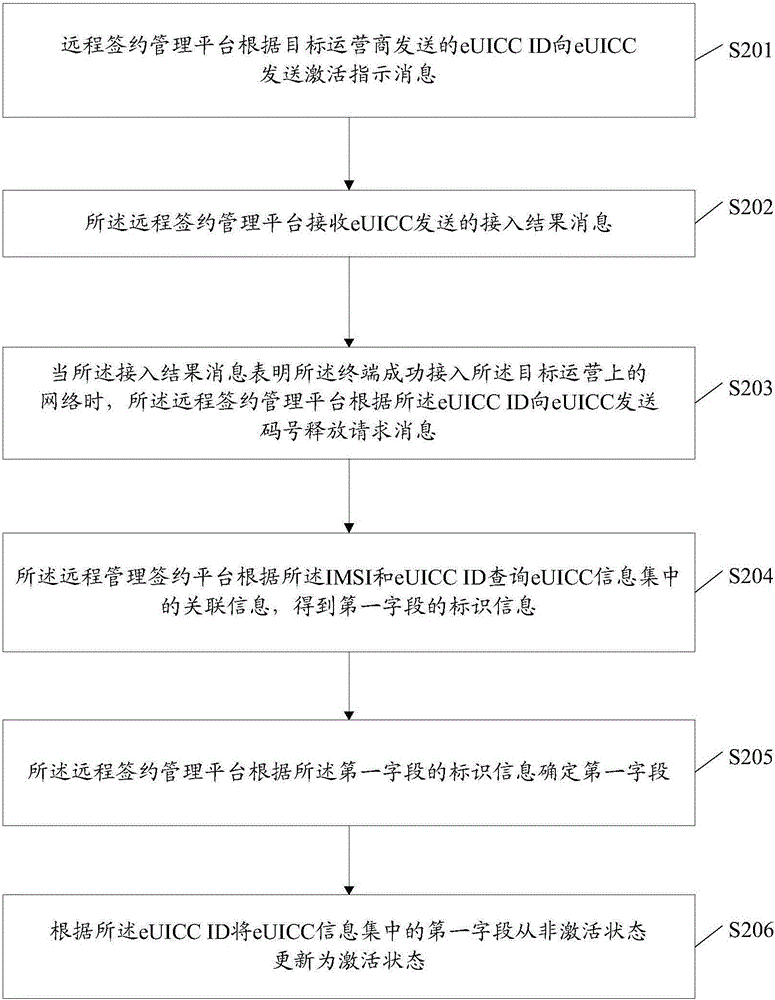

Smart card, its activating method, Internet of Things system, and remote contract signing management platform

InactiveCN106470415AImprove management efficiencyTimely recyclingAssess restrictionTransmissionInternet of ThingsNetwork providers

The invention discloses a smart card, its activating method, an Internet of Things system, and a remote contract signing management platform. The method comprises the following steps. The remote contract signing management platform sends activation indicating information to a smart card (eUICC) according to the identification information (ID) of the smart card (eUICC) sent by a target provider wherein the activation indicating information carries a temporary telephone number and an IMSI sent by the target provider. The remote contract signing management platform receives the accessing result information sent by the eUICC wherein the accessing result information contains the identification information of the eUICC and the target provider and is used to indicate whether a terminal corresponding to the eUICC has successfully accessed the network of the target network provider. When the accessing result information indicates that the terminal has successfully accessed the network of the target network provider, the remote contract signing management platform sends number releasing request information to the eUICC according to the identification of the eUICC wherein the number releasing request information is used to trigger the eUICC to release the temporary telephone number of the target provider.

Owner:ZTE CORP

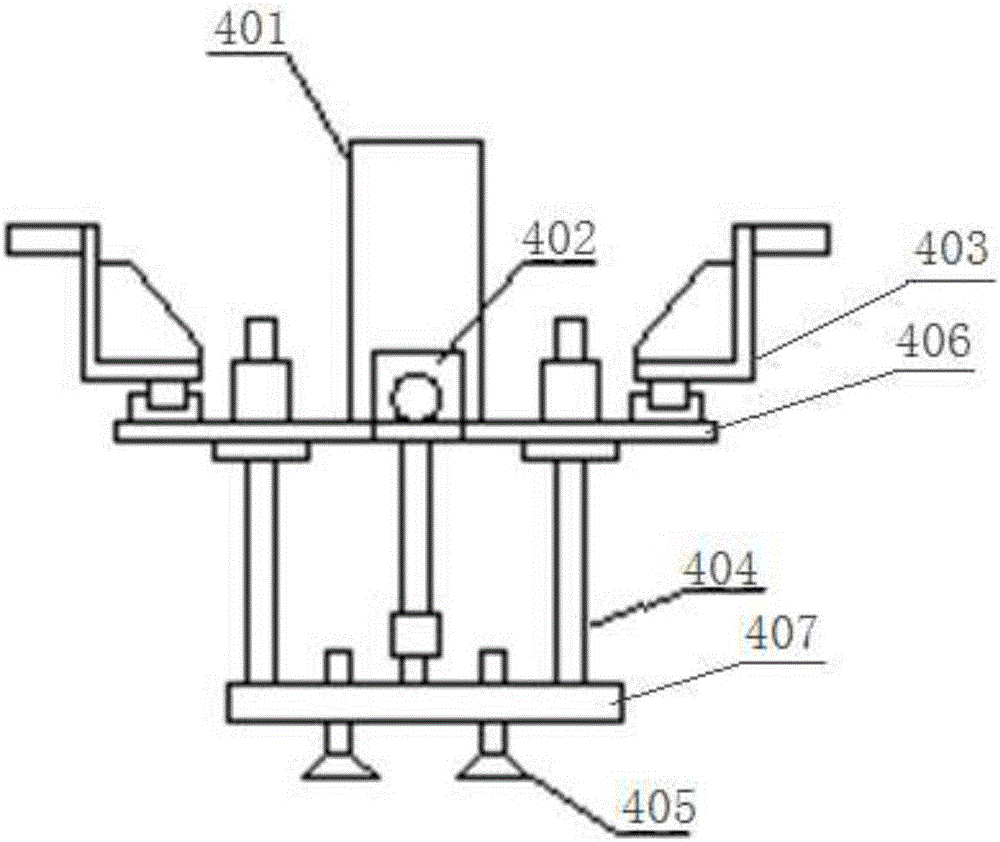

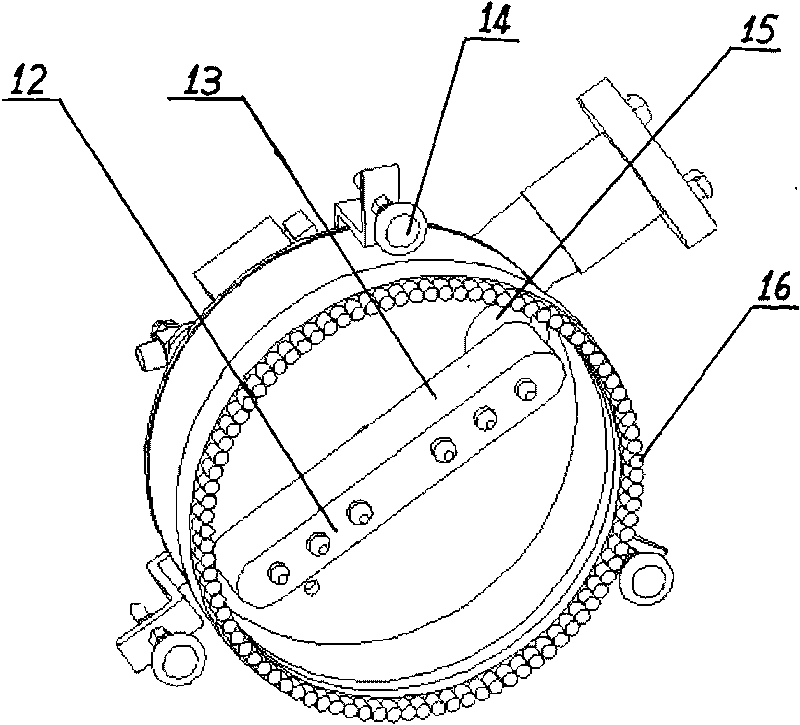

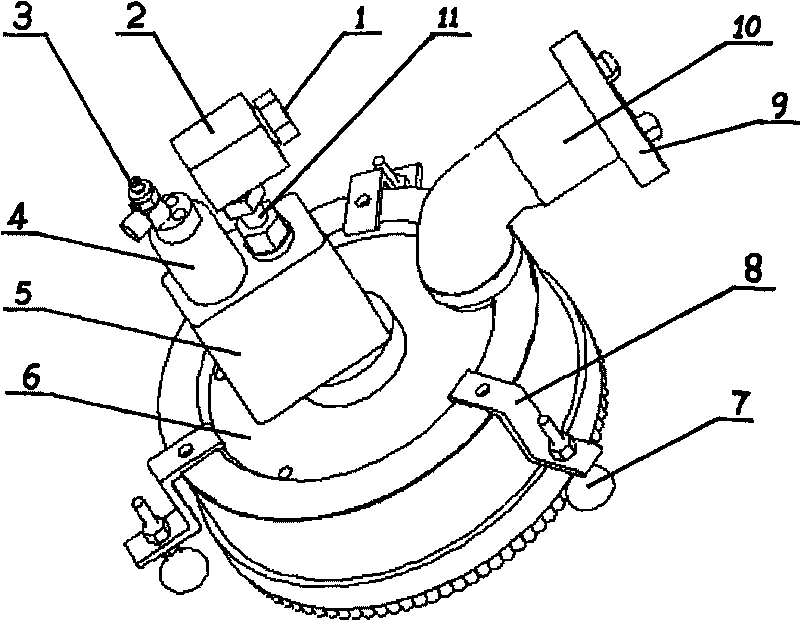

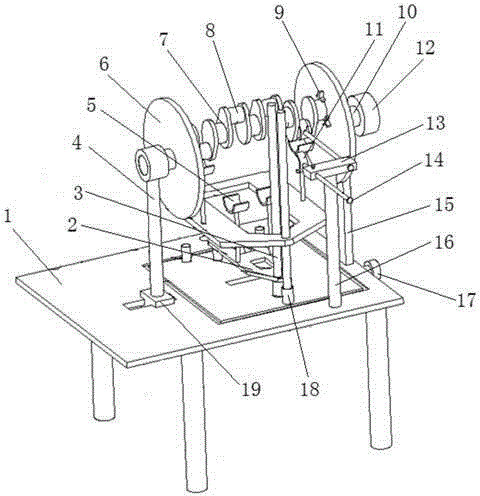

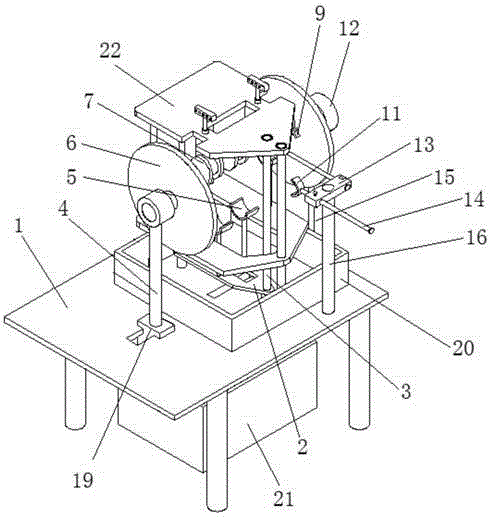

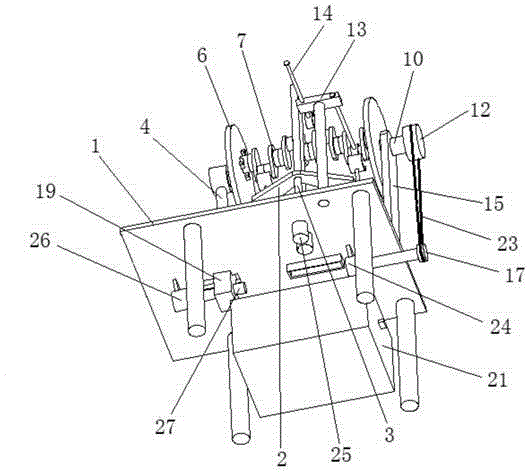

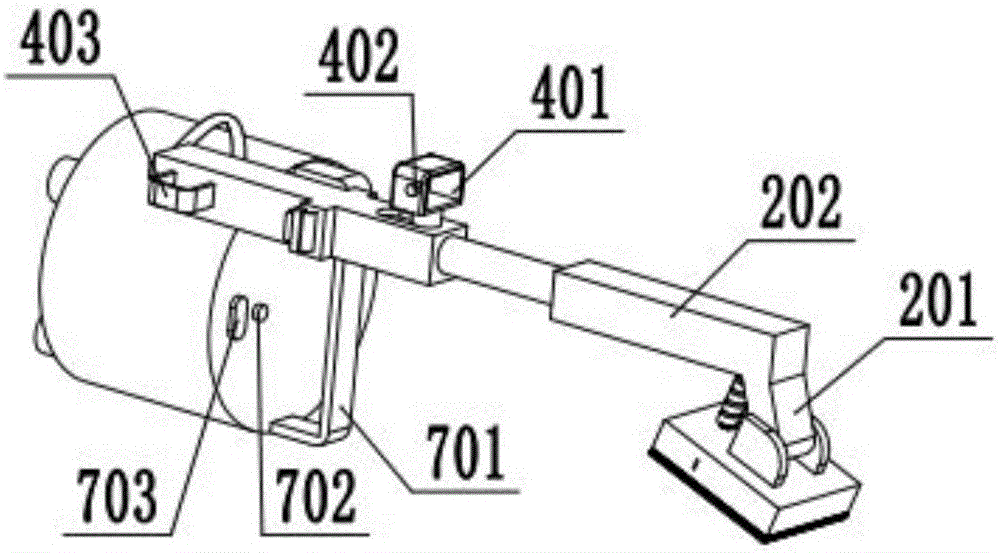

Crankshaft brush plating platform

ActiveCN104630851AImprove work efficiencyStable qualityElectrolysis componentsEngineeringElectroplating

The invention discloses a crankshaft brush plating platform which comprises a worktable, a fixing bracket, a moving bracket, rotating discs, chucks and brushes, wherein the fixing bracket is fixedly arranged on the right side of the worktable; the moving bracket is arranged on the left side of the worktable in a left-right sliding mode and is driven to slide by virtue of a moving device; the two rotating discs are respectively erected at the upper ends of the fixing bracket and the moving bracket in a rotatable mode; the rotating disc arranged on the fixing bracket is driven by a rotating device; the two chucks are respectively and eccentrically arranged on the two rotating discs; the brushes are in the shape of arcs which correspond to the cranks; multiple pairs of brushes are respectively arranged on the worktable by virtue of lifting devices; and after the crankshaft is arranged on the two rotating discs, the multiple pairs of brushes respectively correspond to the multiple pairs of cranks of the crankshaft. According to the platform disclosed by the invention, the crankshaft can be subjected to mechanical brushing electroplating, the crankshaft is conveniently mounted and positioned, the working efficiency is high, and the brushing electroplating quality of the crankshaft can be guaranteed.

Owner:GUANGXI UNIV

Novel shakeout machine

The invention discloses a novel shakeout machine comprising a rack, a shakeout device, a molding sand recovering device, a power unit, a noise reduction and dust removal device and a casting collecting device, wherein the rack is a rectangular box body; the shakeout device is mounted in the rack and is composed of a vibrating screen plate, a shakeout grate bed and a supporting rod, wherein the vibrating screen plate is located above the shakeout grate bed and is connected with the shakeout grate bed through the supporting rod, and the bottom of the shakeout grate bed is provided with a spring mounted on the rack; the power unit is mounted in the rack and is provided with a vibrating motor; a hole is formed in a central position at the bottom of the shakeout grate bed; an eccentric shaft is mounted in the hole, and a reduction gearbox is provided to be connected with the eccentric shaft and is connected with the vibrating motor; and the molding sand recovering device is mounted on the rack located below the shakeout device. The novel shakeout machine is obvious in molding sand and casting separation effect, timely in molding sand recovery and low in noise and pollution in the separation process.

Owner:霍山县忠福机电科技有限公司

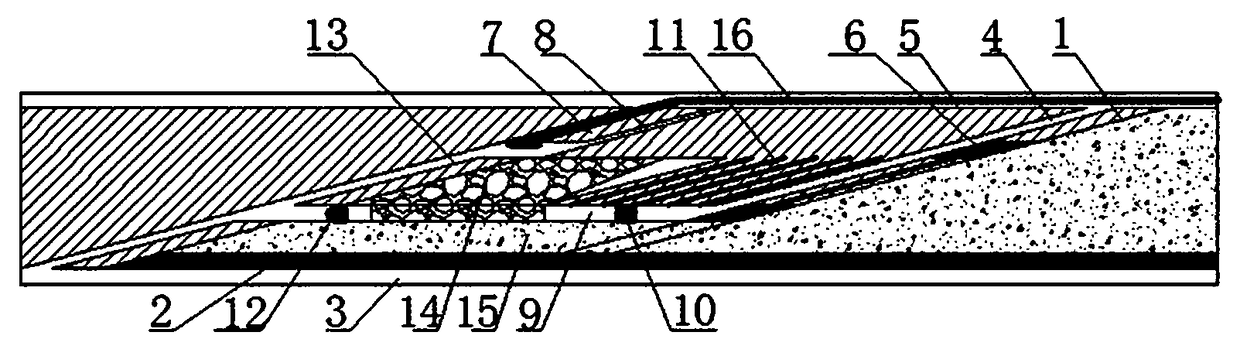

Upper mining method of steeply inclined thin ore body

ActiveCN108104816AImprove mining efficiencySimplify Acquisition EngineeringUnderground miningSurface miningMineralogyMineral Sources

The invention discloses an upper mining method of a steeply inclined thin ore body, and belongs to the technical field of underground mine mining. The mining method comprises the steps that the steeply inclined thin ore body is divided into inclined ore blocks, and by using a driving pulse interior inclined rampway as a channel of rock drilling and ore removal of a miniature rock drilling trolleyand a miniature carry-scraper, mechanical mining of the steeply inclined thin ore body is achieved; meanwhile, a pulse interior inclined rampway is used as an ore block rock drilling channel and alsoused as an ore removal channel of the adjacent ore blocks so as to simplify preliminary mining engineering; and in addition, according to the mining method, top columns are not reserved in the ore blocks, studdings only reserved on one sides of the ore blocks can be recycled in time in the layer mining process, and mineral resources are recycled to the utmost extent. The above processes can obviously improve the mining efficiency of the steeply inclined thin ore body, and compared with an existing mining method, the stope production capacity of the mining method can be improved by three times.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

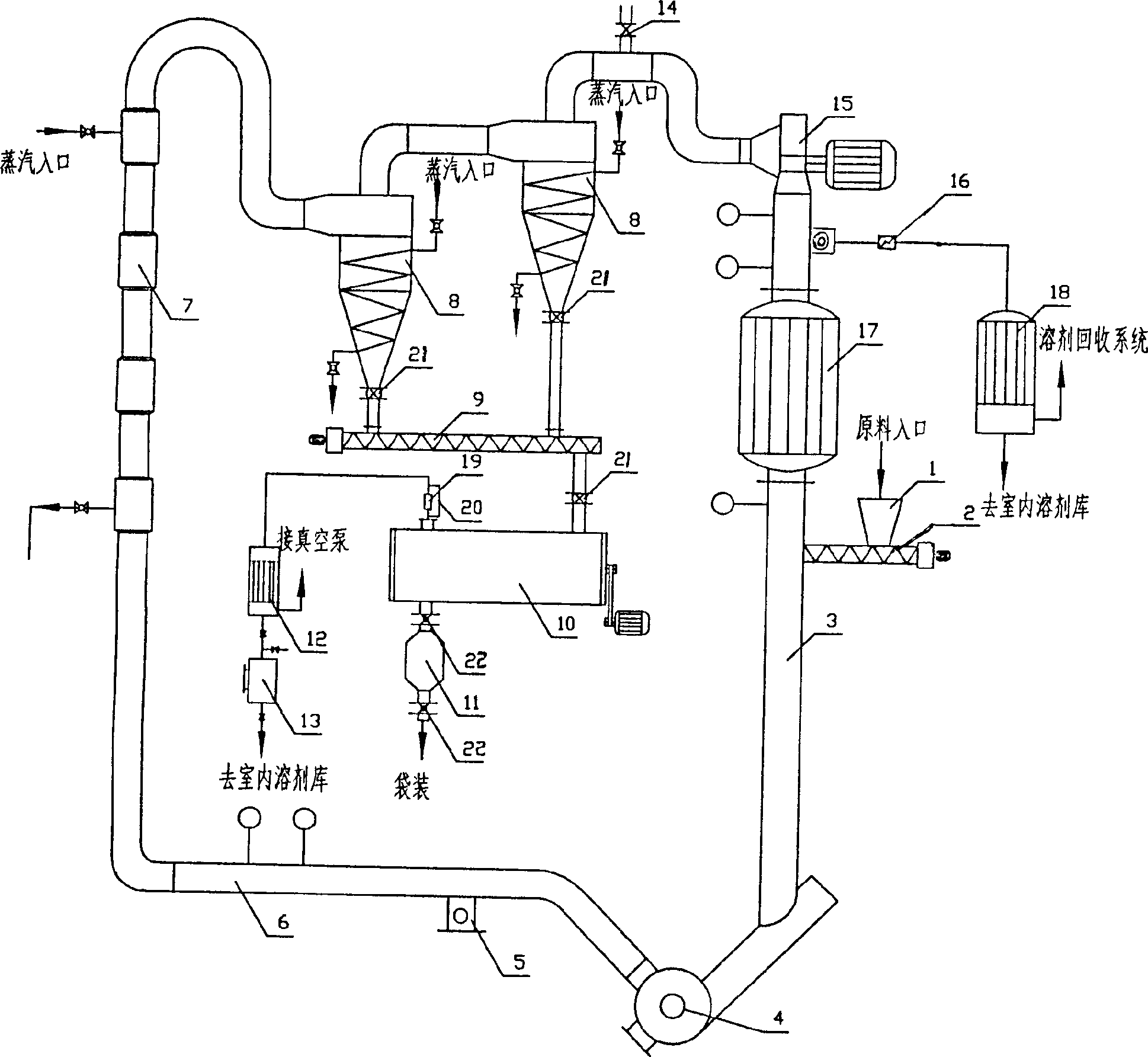

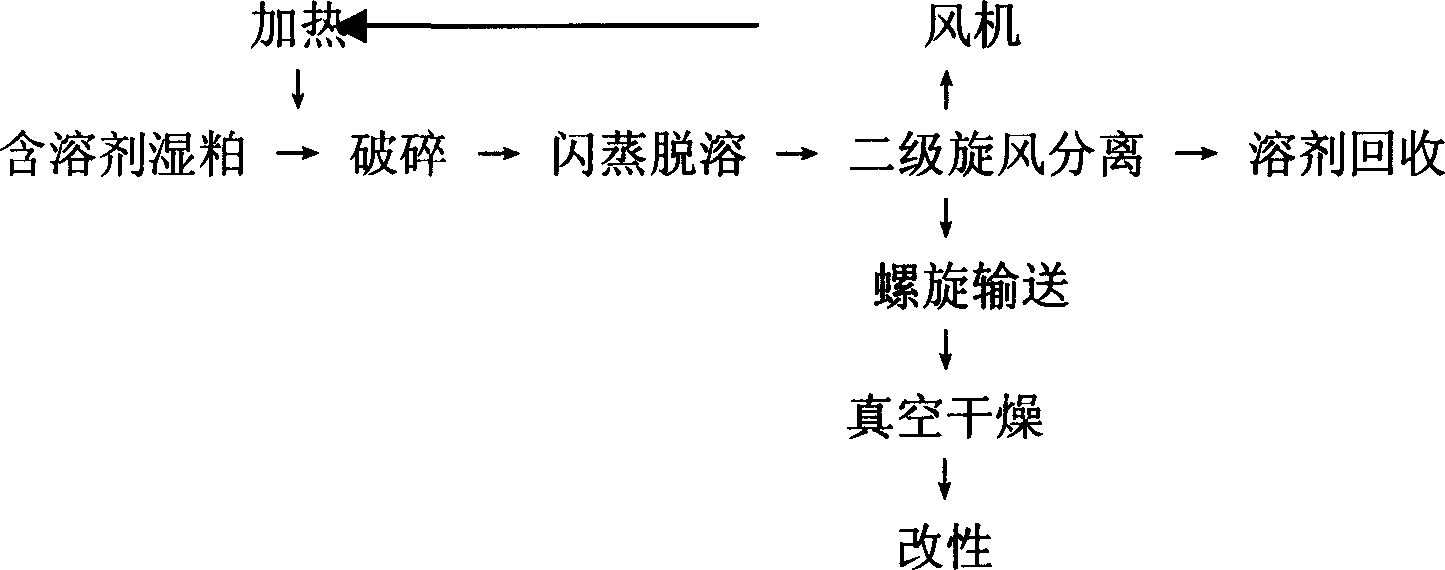

Method and appts of desolution of condensed soybean protein by alcohol process

InactiveCN1833525AShort heating timeSmall thermal denaturationVegetable proteins working-upThermal denaturationAlcohol

A method and apparatus for removing solvent from the concentrated soybean protein prepared by alcohol method in order to prevent its thermal denaturation is disclosed. Its advantages are simple operation, short time, and high effect.

Owner:中粮工科(西安)国际工程有限公司

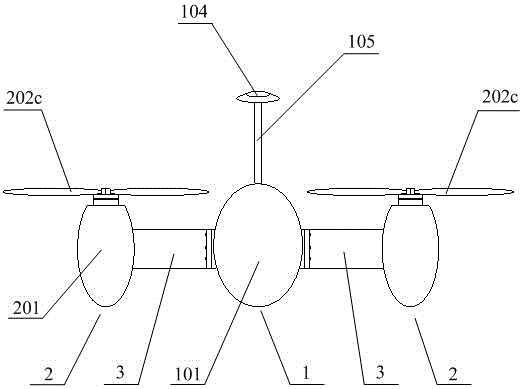

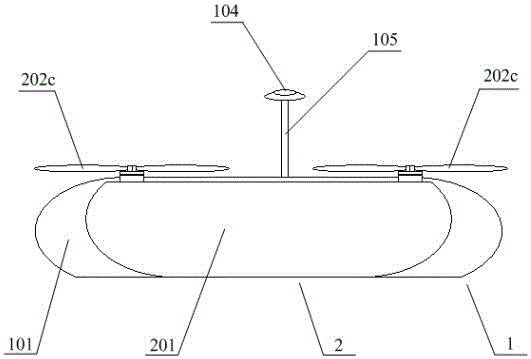

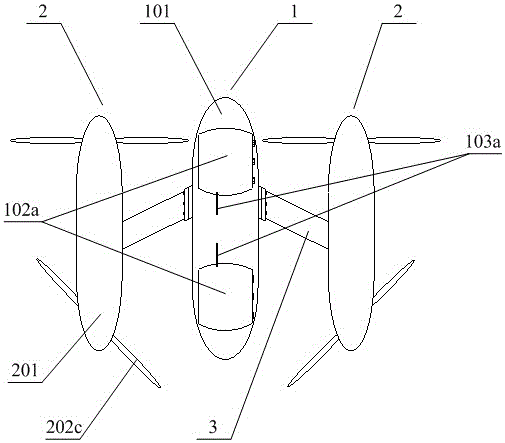

Rotor unmanned plane used for nest building, working method thereof, and flight remote control system

InactiveCN105974937AAvoid lossSmall sizeOther angling devicesPosition/course control in three dimensionsRemote controlArchitectural engineering

The invention relates to the fishing nest building device field, and discloses a rotor unmanned plane used for nest building, a working method thereof, and a flight remote control system. The rotor unmanned plane is combined with a nest building device, and therefore long-distance inflight nest building is realized by adopting a remote control way or a map positioning way, a use process is more convenient and safer, and at the same time, nest building efficiency and nest building precision are higher, and then user experience is greatly improved. The rotor unmanned plane is advantageous in that the overall size is small, the weight is light, the bait carrying capacity is high, the wind-resistant capability is strong, the inflight balance capability is good, and the maintenance is easy, and therefore the actual popularization and the actual application are facilitated.

Owner:NANCHONG YUYUN INNOVATIVE TECH CO LTD

Device for removing surface attachment of steel shovel

ActiveCN102814722AAvoid flying aroundAvoid harmEdge grinding machinesPolishing machinesIron powderCoupling

The invention relates to a device for removing the surface attachment of a steel shovel; the device comprises a frame, and a transmission motor and a reducing gear which are arranged on the frame and are connected together; a barrel is arranged at the middle part of the frame; one end which penetrates through the barrel shaft of the barrel is connected with the reducing gear through a bearing and a coupler; the barrel shaft is in a hollow structure; dust removal holes are uniformly distributed on the side wall of the barrel shaft; a draught fan is arranged on the frame; the air inlet of the draught fan is communicated with the other end of the barrel shaft; and the outer side of the frame is provided with a cyclone separator which is communicated with the air outlet of the draught fan. According to the device for removing the surface attachment of the steel shovel, the structure is simple, the surface attachment of the steel shovel is removed, meanwhile iron powder does not fly everywhere, the removed iron powder can be recovered in time, and a role of protecting the environment is played. The device is arranged in a sound-proof room with sound-proof boards, so that an operator is not harmed by the noise, the environment is not polluted, the product cost is reduced, and the economic benefits are improved.

Owner:TANGSHAN YANNAN SHOVEL MAKING

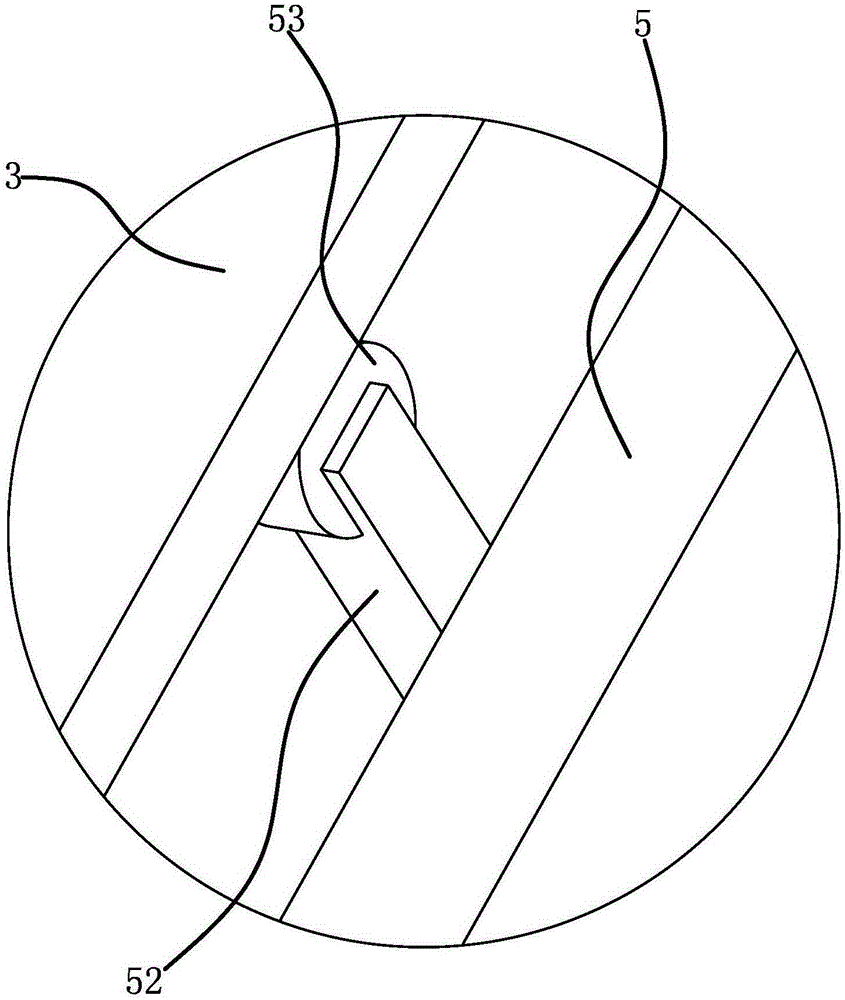

Aluminum coil stamping automation device and stamping method thereof

ActiveCN104759514AGuaranteed feed speedGuaranteed degree of deformationShaping toolsMetal-working feeding devicesControl engineeringProcess engineering

The invention discloses an aluminum coil stamping automation device and a stamping method thereof. The aluminum coil stamping automation device comprises an uncoiling mechanism, a leveling mechanism, a feeding mechanism, an oil injection mechanism and a machine tool which are arranged in turn; the uncoiling mechanism comprises a servo motor and a rolling wheel which are connected with each other; the rotational speed of the rolling wheel does not exceed 115 rounds every minute; the feeding mechanism comprises a servo motor and a feeding roller which are connected with each other; the clearance feeding of the feeding mechanism is performed and the feeding speed of the feeding mechanism and the stamping frequency of the machine tool are synchronized; a material lifting and conveying mechanism is arranged between the leveling mechanism and the feeding mechanism; a material buffering area is formed between the material lifting and conveying mechanism and the leveling mechanism; the deformation degree of aluminum coils does not exceed 30 I in the process that the aluminum coil are fed into the machine tool from the uncoiling mechanism. According to the aluminum coil stamping automation device and the stamping method thereof, the rotational speed of the feeding mechanism is controlled so as to effectively ensure that the deformation degree of the aluminum profile can be within the acceptable range in the production process, the quality of subsequent machining products is ensured, meanwhile the machining speed requirement can be met by the feeding speed of the materials, and the production efficiency is ensured.

Owner:奇昊汽车系统(苏州)有限公司

Aerated concrete block production system

InactiveCN104308977AAvoid entanglementIncrease productivityCeramic shaping plantsAuxillary shaping apparatusSlagScrap

The invention discloses an aerated concrete block production system. The aerated concrete block production system comprises a make-up tank, an aerated concrete block cutting machine, a still kettle, a slurry forming and delivering mechanism and a block transport mechanism, wherein the slurry forming and delivering mechanism is arranged between the make-up tank and the aerated concrete block cutting machine, the block transport mechanism is arranged between the aerated concrete block cutting machine and the still kettle, the make-up tank is communicated with a lime storage tank and a cement storage tank respectively, a grouting tank is arranged right below the make-up tank, a cutting tank is arranged right below the aerated concrete block cutting machine, the grouting tank and the cutting tank are communicated with a recycling tank, a recycling material tank is arranged above the make-up tank and is connected with the recycling tank via a circulating device and then communicated with the make-up tank. The aerated concrete block production system has the advantages that the structure of the make-up tank is optimized, feeding of raw materials is accurate, the raw materials are sufficiently and uniformly mixed, automatic and industrialized production is realized, various waste generated during production can be timely and comprehensively recycled, energy is saved, the environment is protected, and no slag and waste gas are discharged to cause environment pollution.

Owner:广安世宇建筑材料有限公司

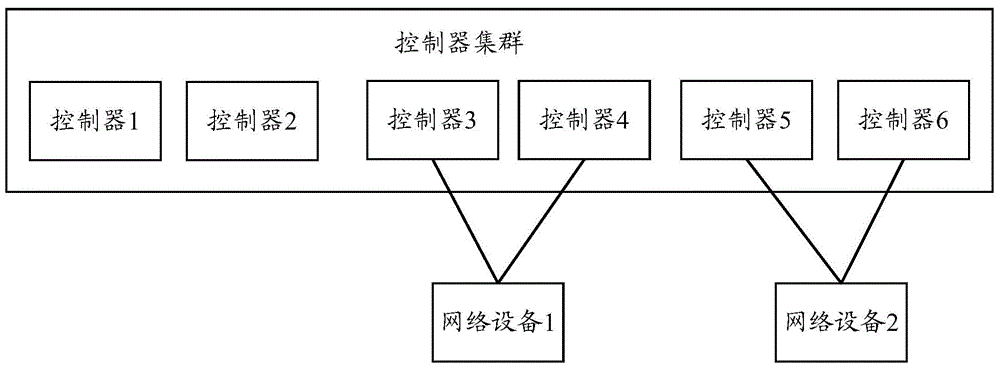

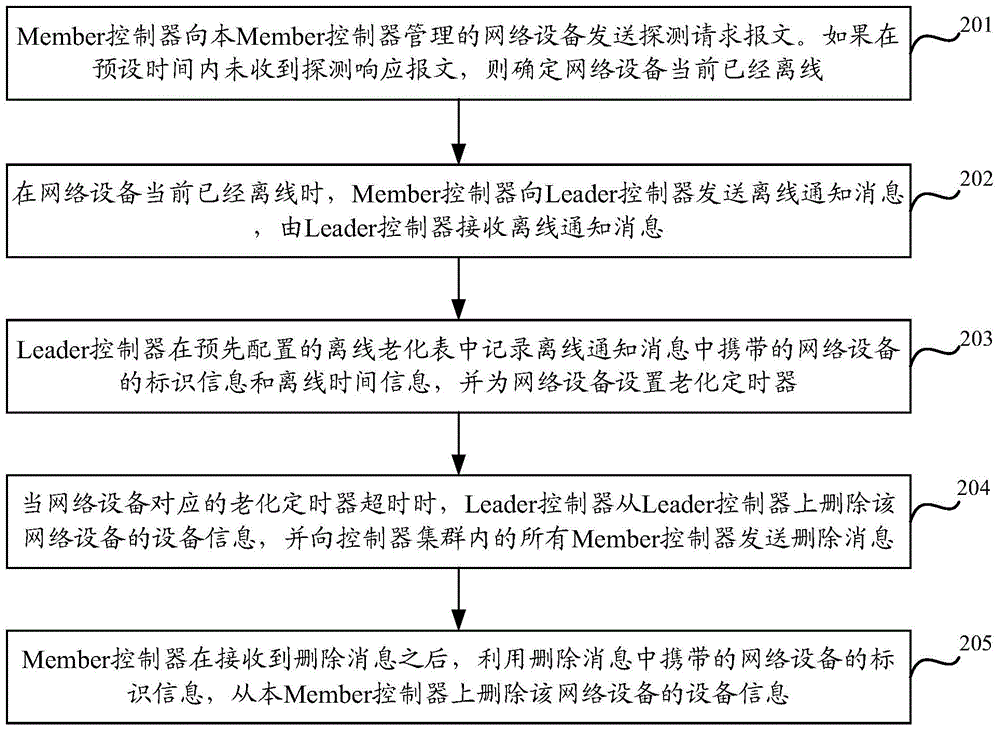

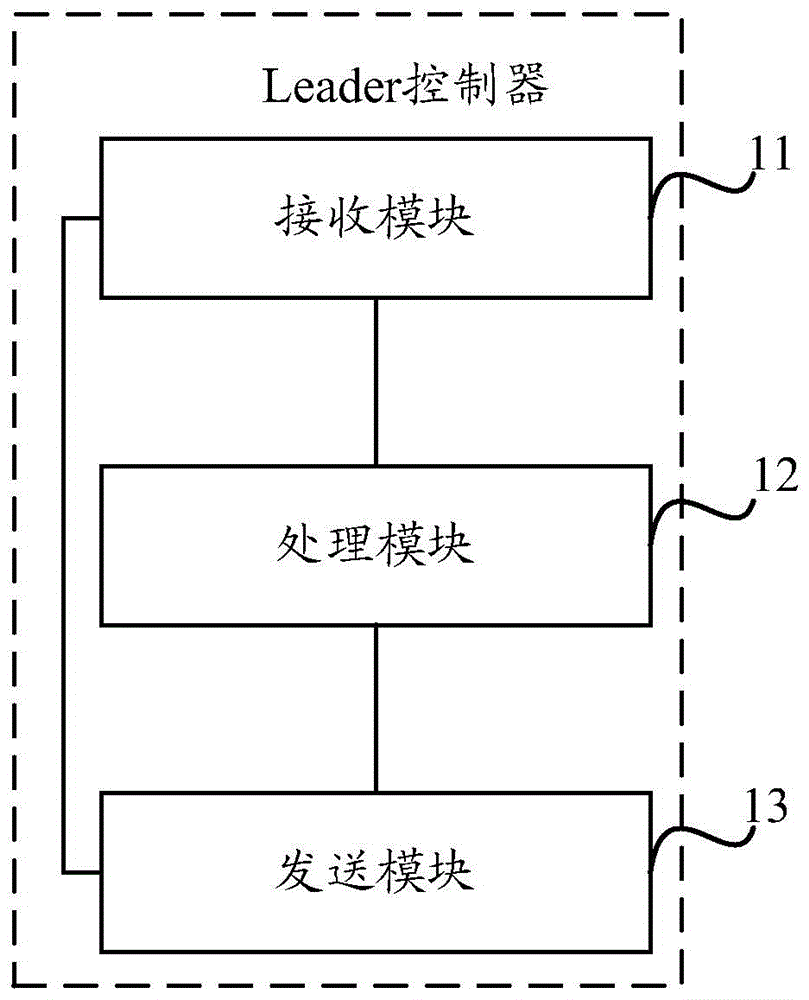

Automatic deleting method and device for offline network equipment

ActiveCN104468201AAvoid affecting deploymentImplement automatic deletionData switching networksTemporal informationWorkload

The invention discloses an automatic deleting method and device for offline network equipment. The method includes the steps that a Leader controller receives an offline notification message from a Member controller, wherein the offline notification message carries identification information and offline time information of the network equipment; the Leader controller records the identification information and the offline time information in an offline burn-in table and allocates a burn-in timer for the network equipment; when the burn-in timer exceeds preset time, the Leader controller deletes equipment information of the network equipment and sends deletion information to the Member controller, wherein the deletion information is used for indicating the Member controller to delete the equipment information of the network equipment. According to the method, the offline network equipment is automatically deleted, recovery efficiency of resources is improved, treatment efficiency is improved, and the workload of network managers is relieved.

Owner:NEW H3C TECH CO LTD

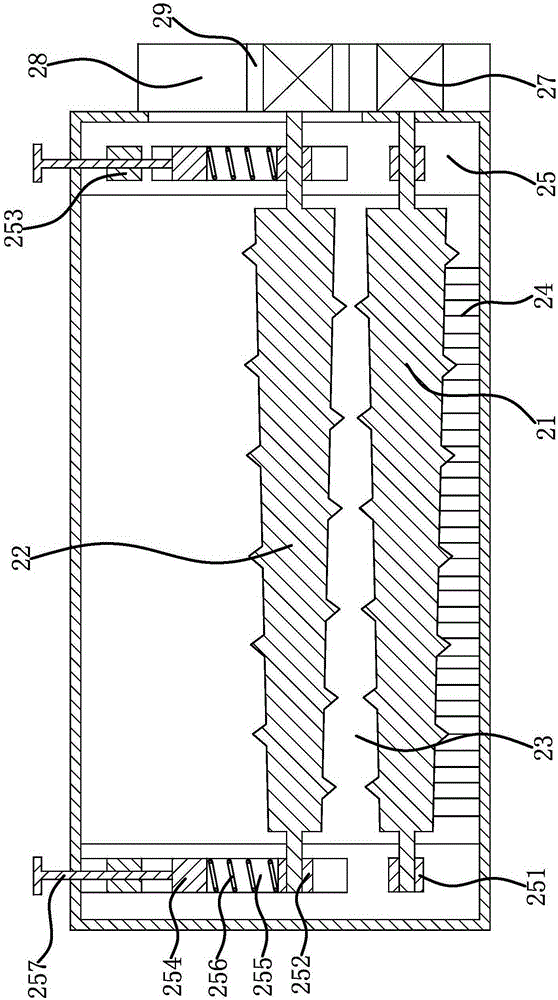

Concrete offcut recycling device

InactiveCN105195256ATimely recyclingIncrease workloadGrain treatmentsEngineeringMechanical engineering

The invention provides a concrete offcut recycling device, belongs to the technical field of civil construction equipment and solves the problem that existing concrete milling is high in labor intensity. The concrete offcut recycling device comprises a rack, a milling barrel is fixedly connected on the rack, a fixed screw and a movable screw are rotatably connected in the milling barrel, a milling passage is formed between the fixed screw and the movable screw, the rack is rotatably connected with an incoming material conveying belt on the outer side of the milling barrel, an output end of the incoming material conveying belt is positioned above one end, larger in width, of the milling passage, first grid holes are formed in the incoming material conveying belt, the rack is connected with a first recycling passage below the incoming material conveying belt, and the rack is further rotatably connected with a first returning material conveying belt, a second returning material conveying belt and a third returning material conveying belt on the outer side of the milling barrel. The concrete offcut recycling device can automatically mill and recycle concrete offcut and is high in milling quality and efficiency.

Owner:ZHEJIANG OCEAN UNIV

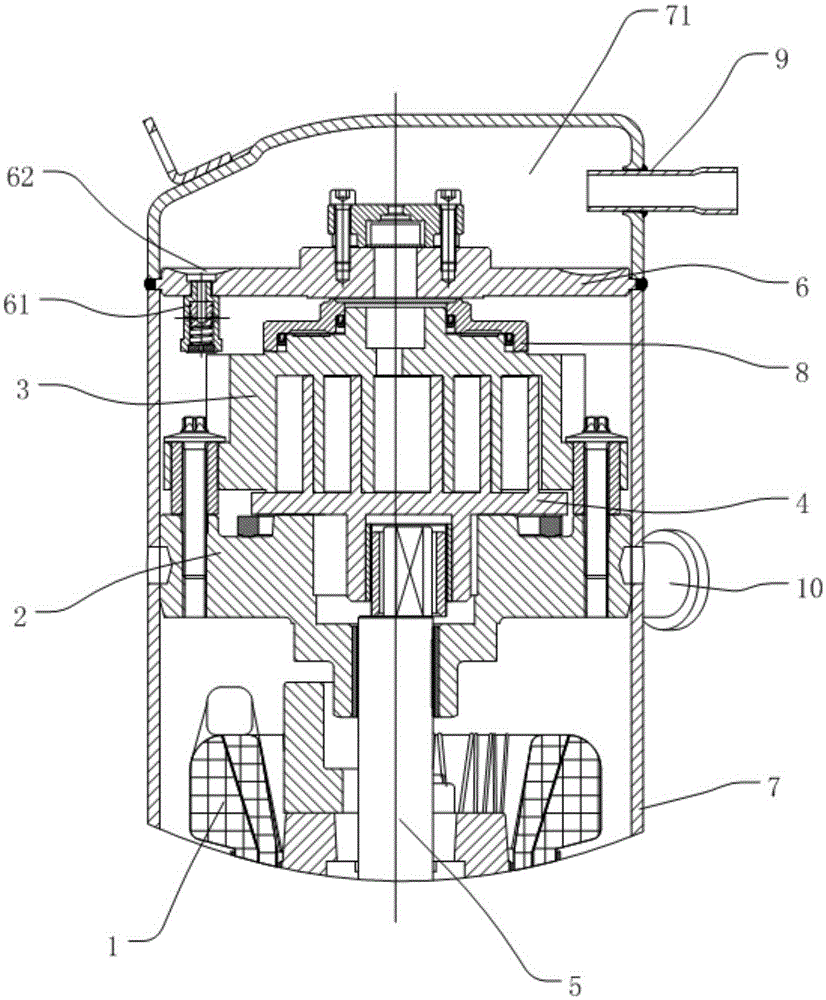

Oil return device of compressor, compressor and air conditioner

ActiveCN105275818ATimely recyclingAchieve recyclingRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention relates to an oil return device of a compressor, a compressor and an air conditioner, wherein one end of the oil return device is communicated with an exhaust cavity of the compressor. The oil return device comprises a valve shell and a valve core, wherein a cavity with an open upper end is formed in the valve shell, the valve core is arranged in the cavity and capable of sliding in the cavity up and down along the inner wall of the cavity, so that the valve core has a first position and a second position in the cavity; and at the first position, the oil return device is in an open state, and at the second position, the oil return device is in a closed state. In the oil return device of the compressor, the compressor and the air conditioner, which are disclosed by the invention, by arranging the oil return device on a partition plate for a high-pressure cavity and a low-pressure cavity, residual lubricant oil in the exhaust cavity can be timely recovered, thus the loss of the lubricant oil is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Building wall polishing device

InactiveCN107520702AAvoid interferenceCooperate wellPlane surface grinding machinesGrinding/polishing safety devicesPolish teethArchitectural engineering

The invention discloses a building wall polishing device. The building wall polishing device consists of a polishing device, a dust sucking device, a support rod, an auxiliary belt and an operation handle; the polishing device consists of a polishing box, an extension cover and a polishing belt; the polishing belt is rotationally connected with the polishing box through a bearing; polishing teeth are arranged on the polishing belt; the extension cover fixedly connected is arranged at an opening end of the polishing box; a dust sucking hole is formed in a receiving box, and is provided with a dust sucking pipe; a connecting plate is arranged at the back end of the polishing box, and is rotationally connected with the support rod; and the support rod consists of an upper support rod, a connecting column and a lower support rod. The support rod can be fixed on a body through cooperation of an insertion port and an insertion head to share the weight of an arm, so that the operation is easier; and the building wall polishing device can realize adjustment of the polishing angle and polishing of a top wall.

Owner:WUHAN YIWEIDENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com