Patents

Literature

59results about How to "Improve indexing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tile map storage method based on aggregation files

ActiveCN103744855ASave storage spaceReduce time consumptionGeographical information databasesFile/folder operationsImage resolutionComputer science

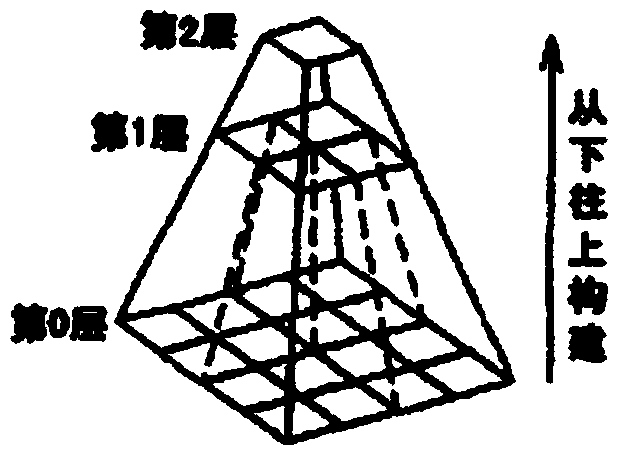

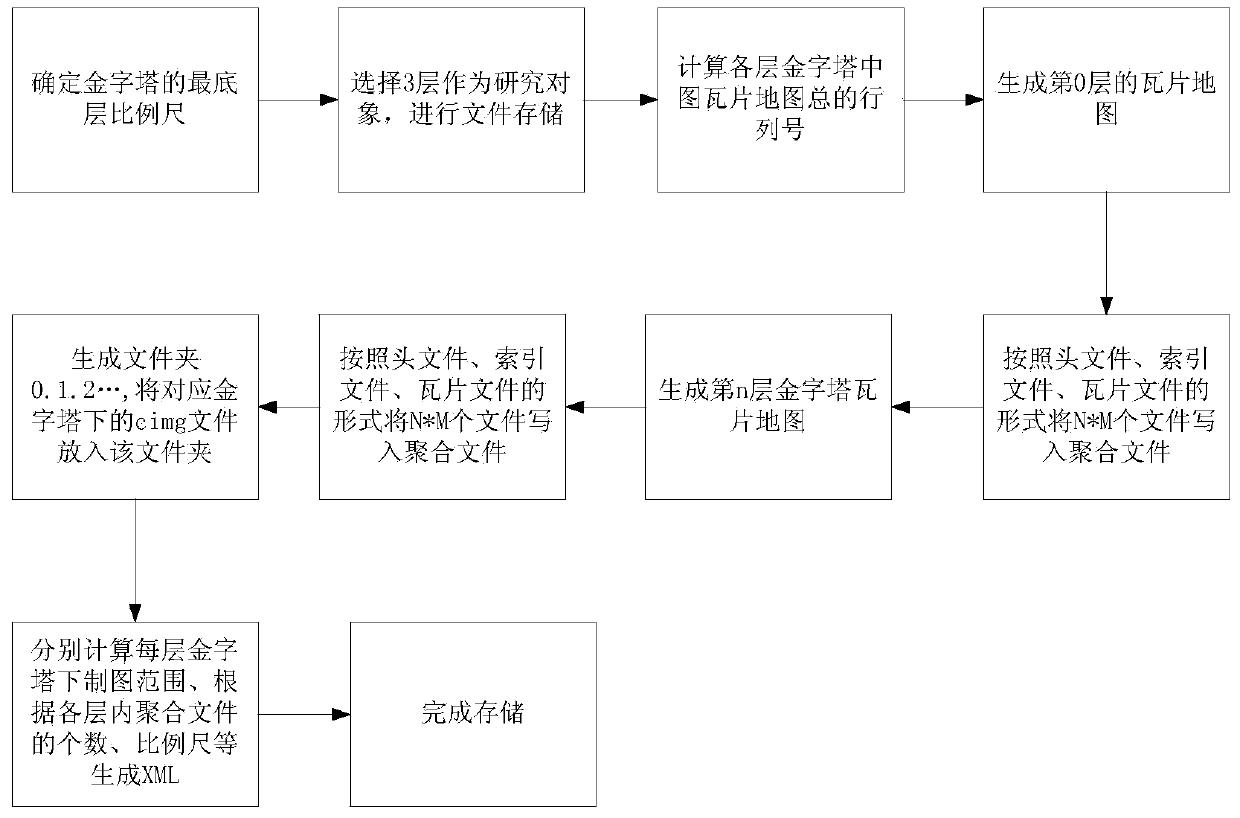

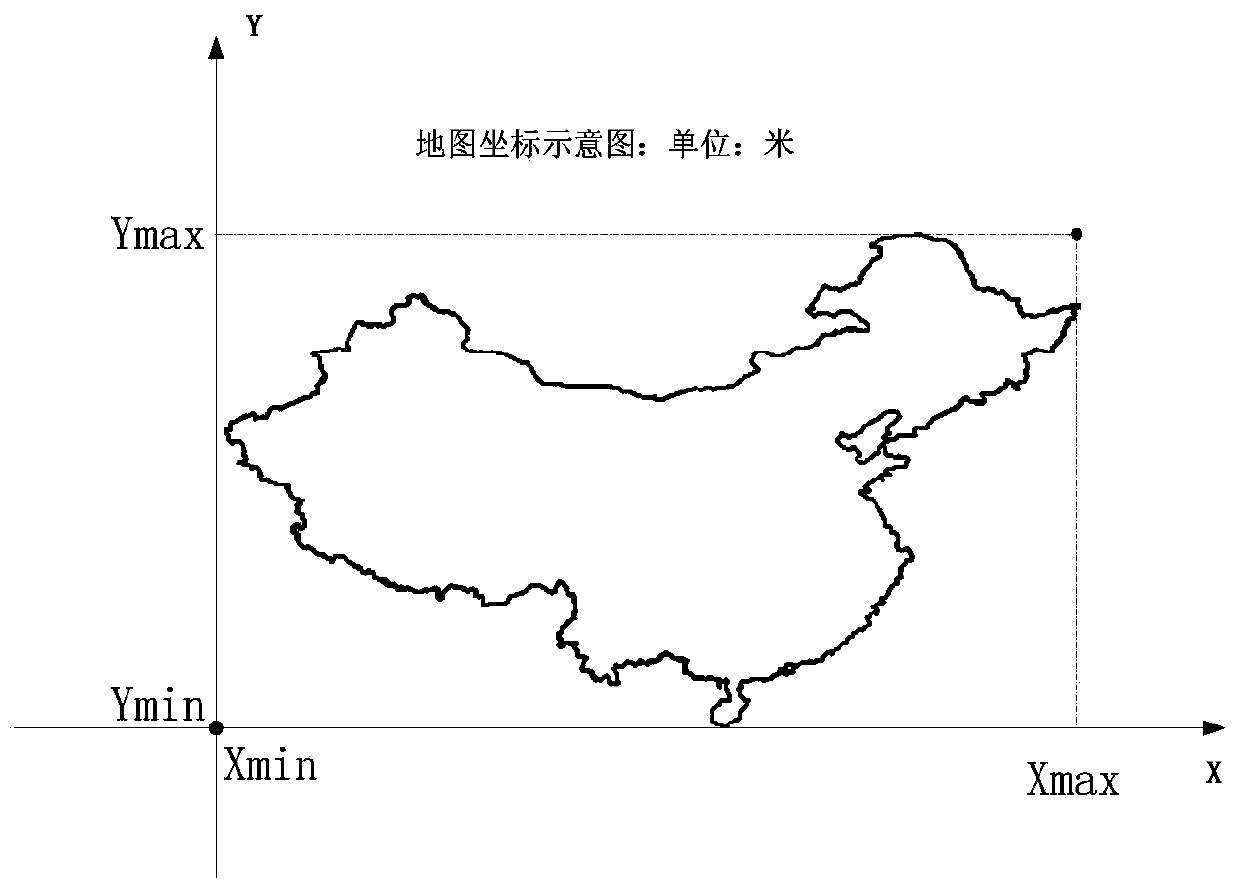

A tile map storage method based on aggregation files includes the steps that (1) a measuring scale of the bottommost map is determined and a map to be stored is layered on the basis of the measuring scale; (2) at least one layer is selected from the 0th layer and the middle layer as an analysis object, the total number of obtained tile images in the map on each layer is calculated, and a measuring scale of the selected layer is determined according to the measuring scale of the bottommost layer; (3) the selected tile images in the map of each layer are grouped in sequence, and each group of the tile images generates one aggregation file; (4) a folder is built for the map of each layer, all aggregation files of the layer are stored in the folder, and the name of the folder can represent the number of layers of a pyramid; (5) the number of the layers selected in the step (2), the name of the folder built in the step (4), resolution corresponding to each layer, the geographic range of the map of each layer and the number of the aggregation files of each layer are stored in the XML format.

Owner:SPACE STAR TECH CO LTD

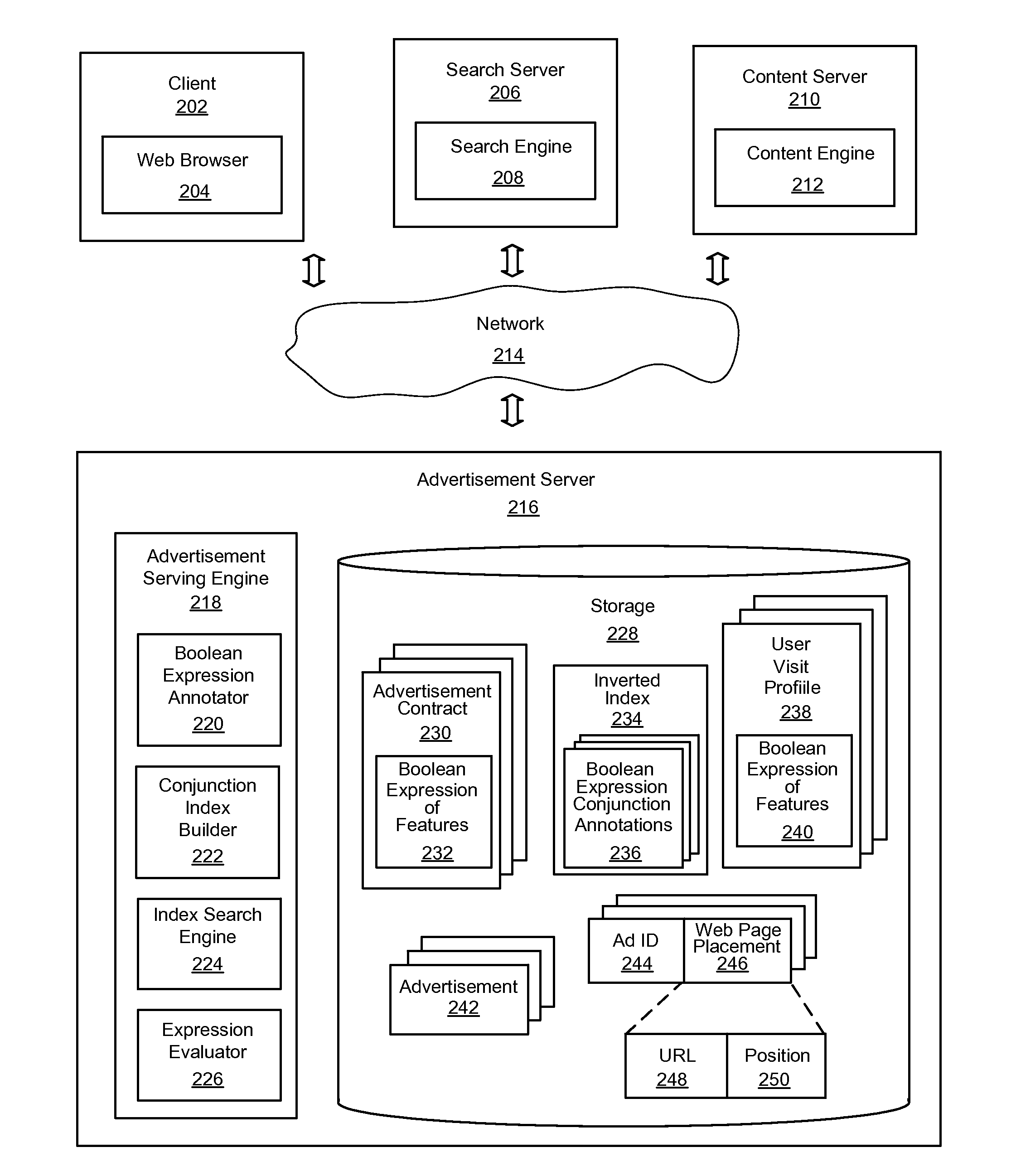

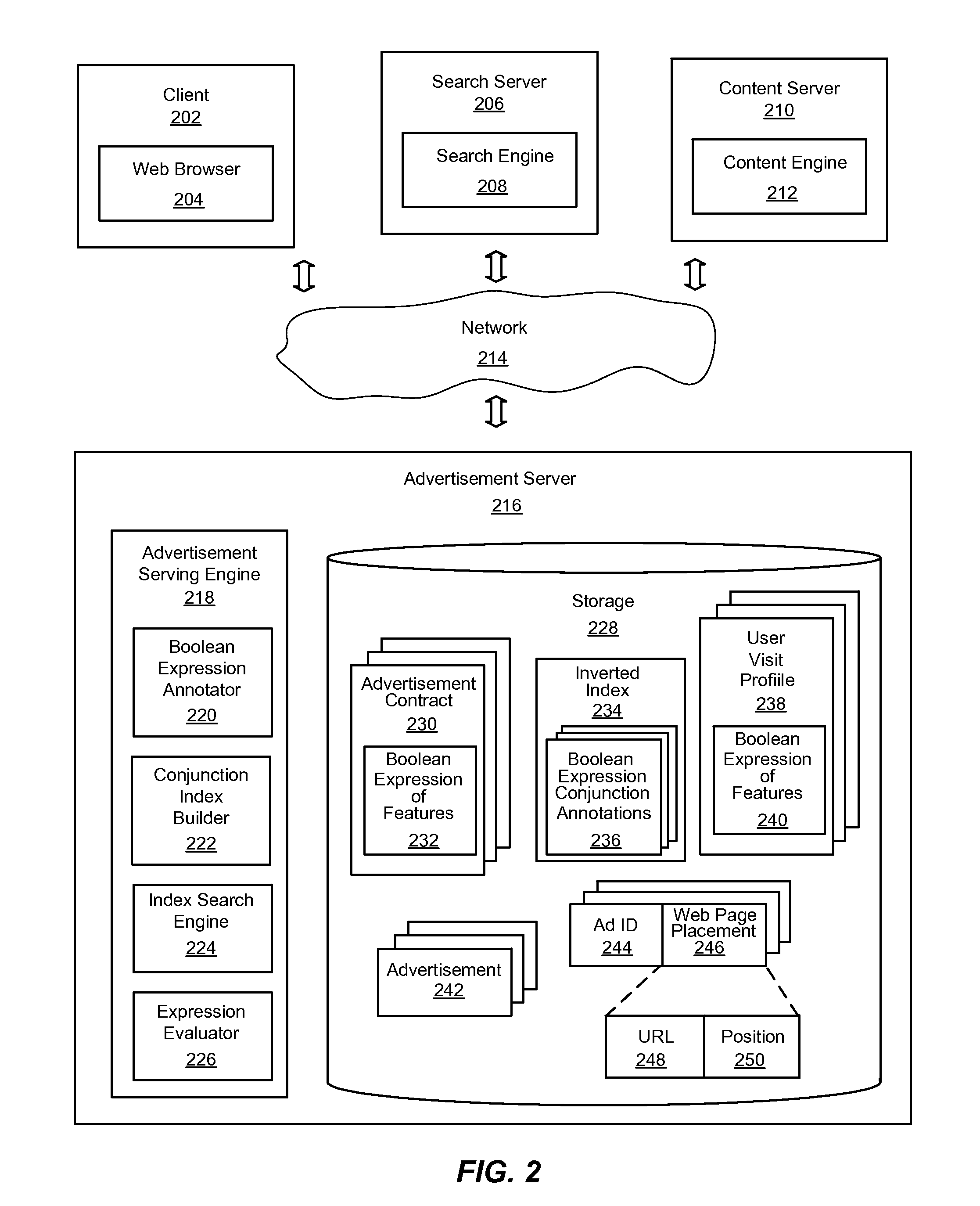

System and Method for Efficiently Evaluating Complex Boolean Expressions

InactiveUS20110225038A1Effective evaluationImprove indexing speedDigital data information retrievalDigital data processing detailsTheoretical computer scienceInverted index

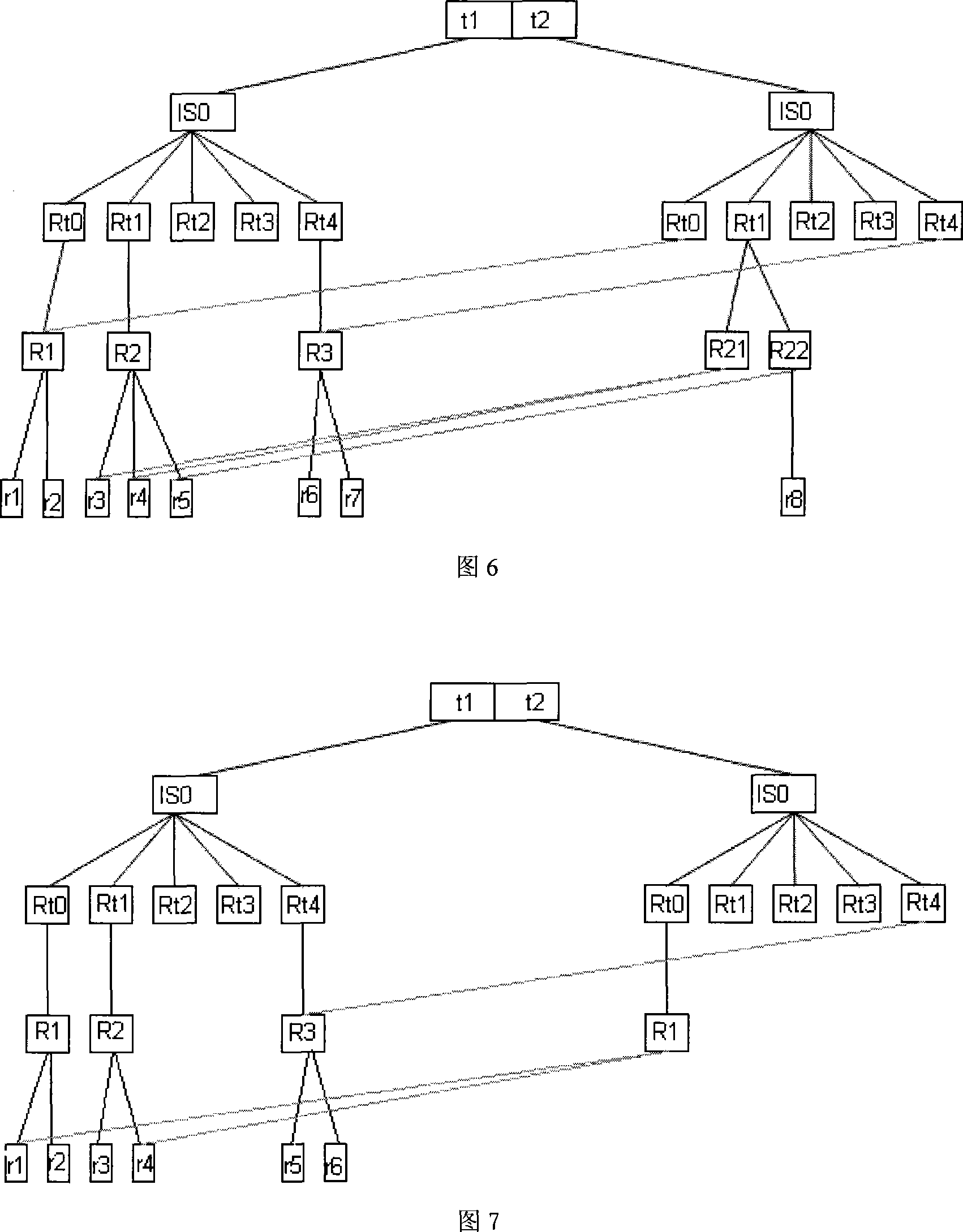

An improved system and method for efficiently evaluating complex Boolean expressions is provided. Leaf nodes of Boolean expression trees for objects represented by Boolean expressions of attribute-value pairs may be assigned a positional identifier that indicates the position of a node in the Boolean expression tree. The positional identifiers of each object may be indexed by attribute-value pairs of the leaf nodes of the Boolean expression trees in an inverted index. Given an input set of attribute-value pairs, a list of positional identifiers for leaf nodes of virtual Boolean expression trees may be found in the index matching the attribute-value pairs of the input set. The list of positional identifiers of leaf nodes may be sorted in order by positional identifier for each contract. An expression evaluator may then verify whether a virtual Boolean expression tree for each contract is satisfied by the list of positional identifiers.

Owner:YAHOO INC

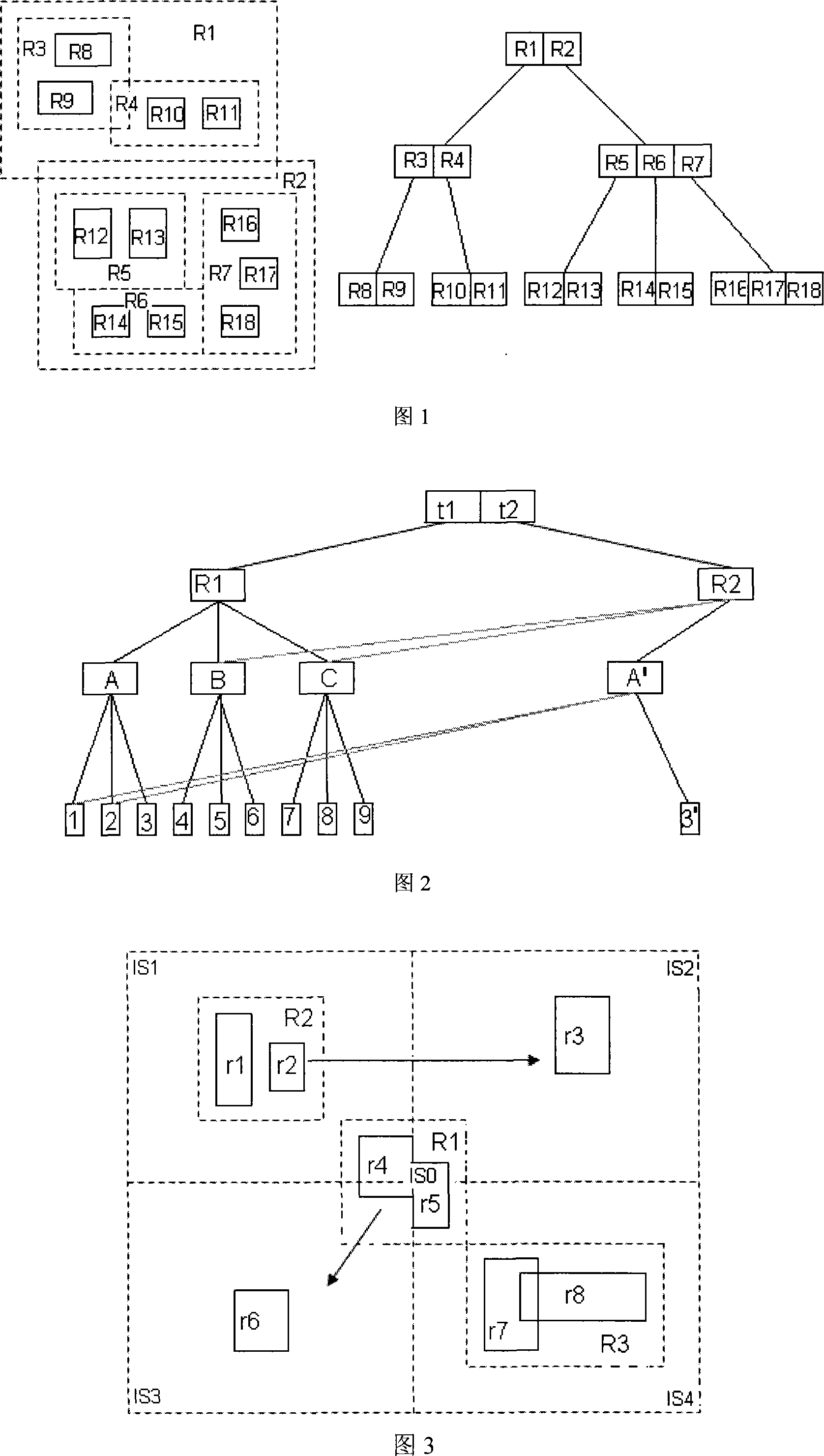

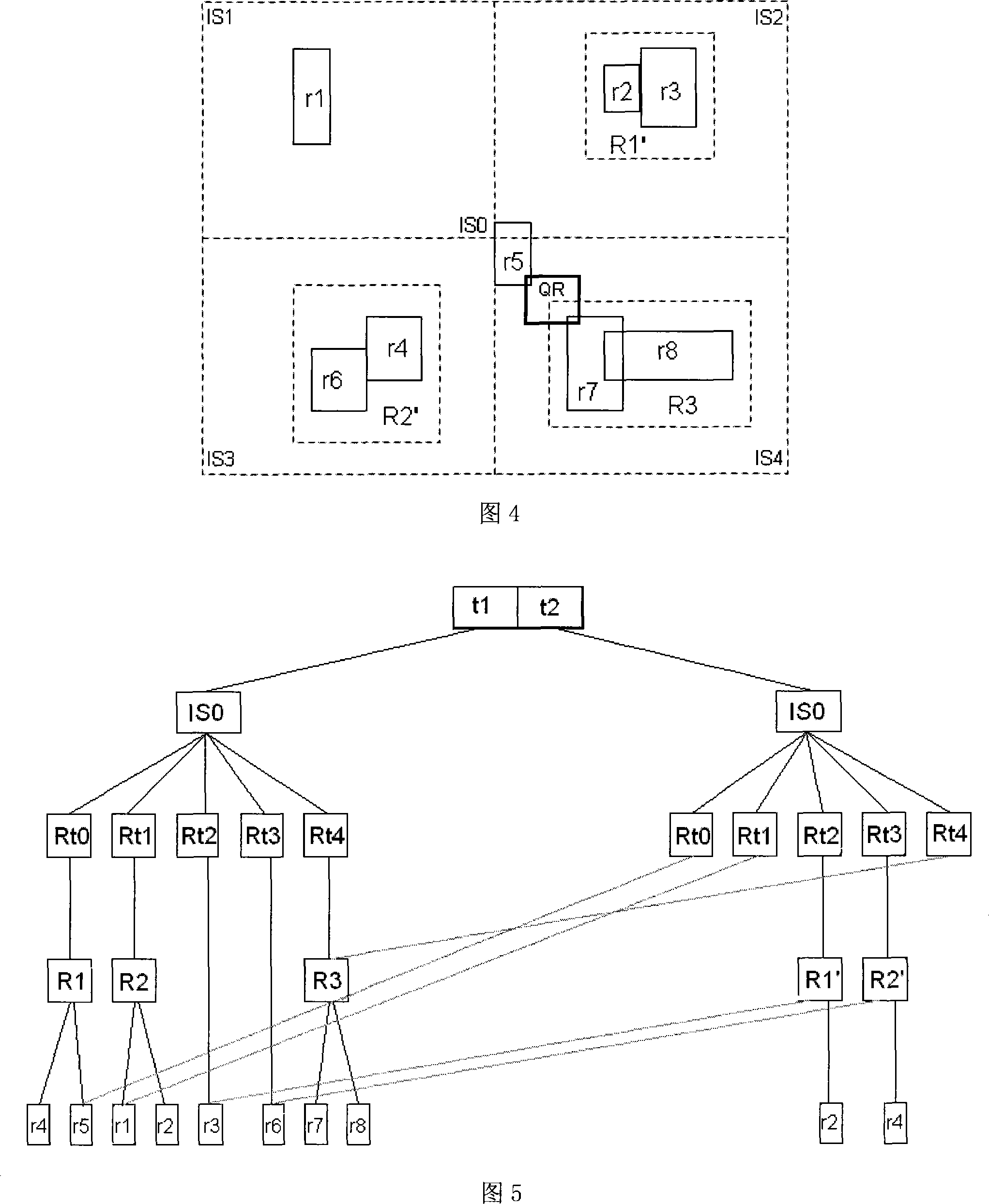

Rapid index method based on space-time data

InactiveCN101241511AImprove indexing speedSave storage spaceSpecial data processing applicationsSpatial partitionR-tree

The present invention provides a wireless communication computer field, in particular relating to a spatial-temporal data fast index method, it is a high effect indexing mechanism, storing different time stamp space-time state using overlapping indexed structure, if the adjacent time slices have identical R-tree index branch, only one version is kept, this reduces the storage space. At the same time, data on one time slice adopts blocking index mechanism based on the four-fork tree no longer finding whole index space, the whole space is divided into n=sumd-1i=0(2k)i sub-index spaces (d is depth of the four-fork tree, k is dimensionality of the index space), only need find one subspace therein, greatly reduces the index time. Utilizing the index method is used for high efficient location of multiple wireless move node and data monitor management.

Owner:BEIJING UNIV OF POSTS & TELECOMM

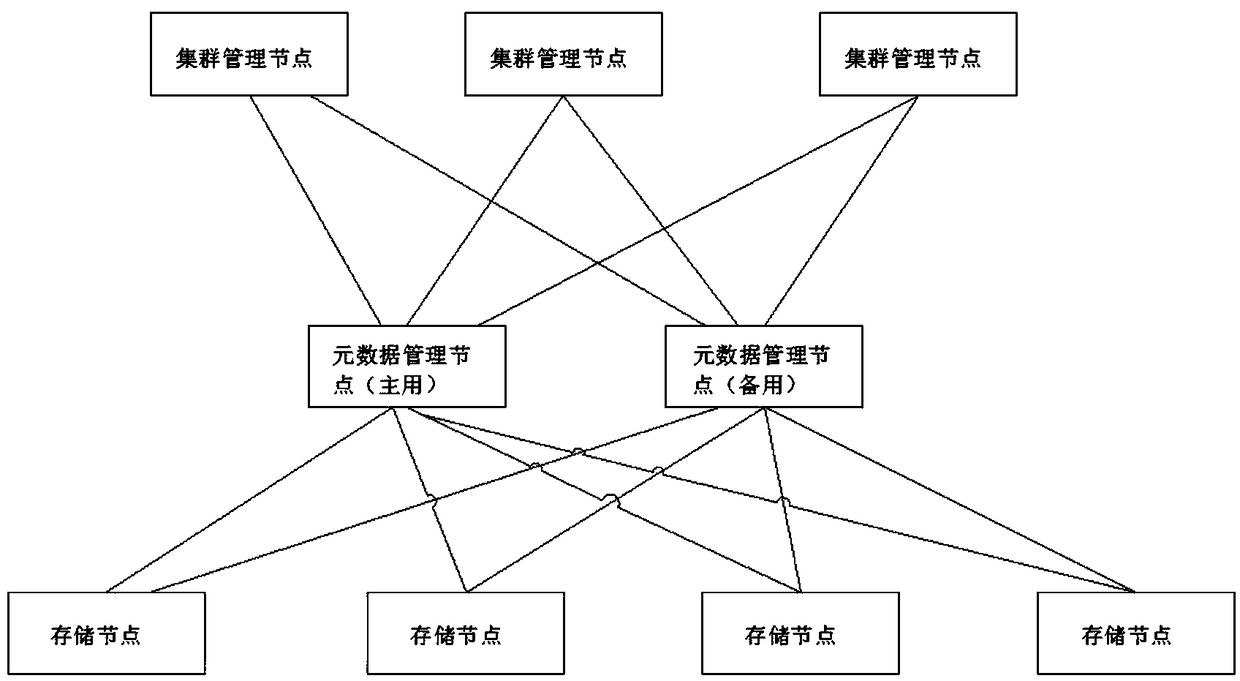

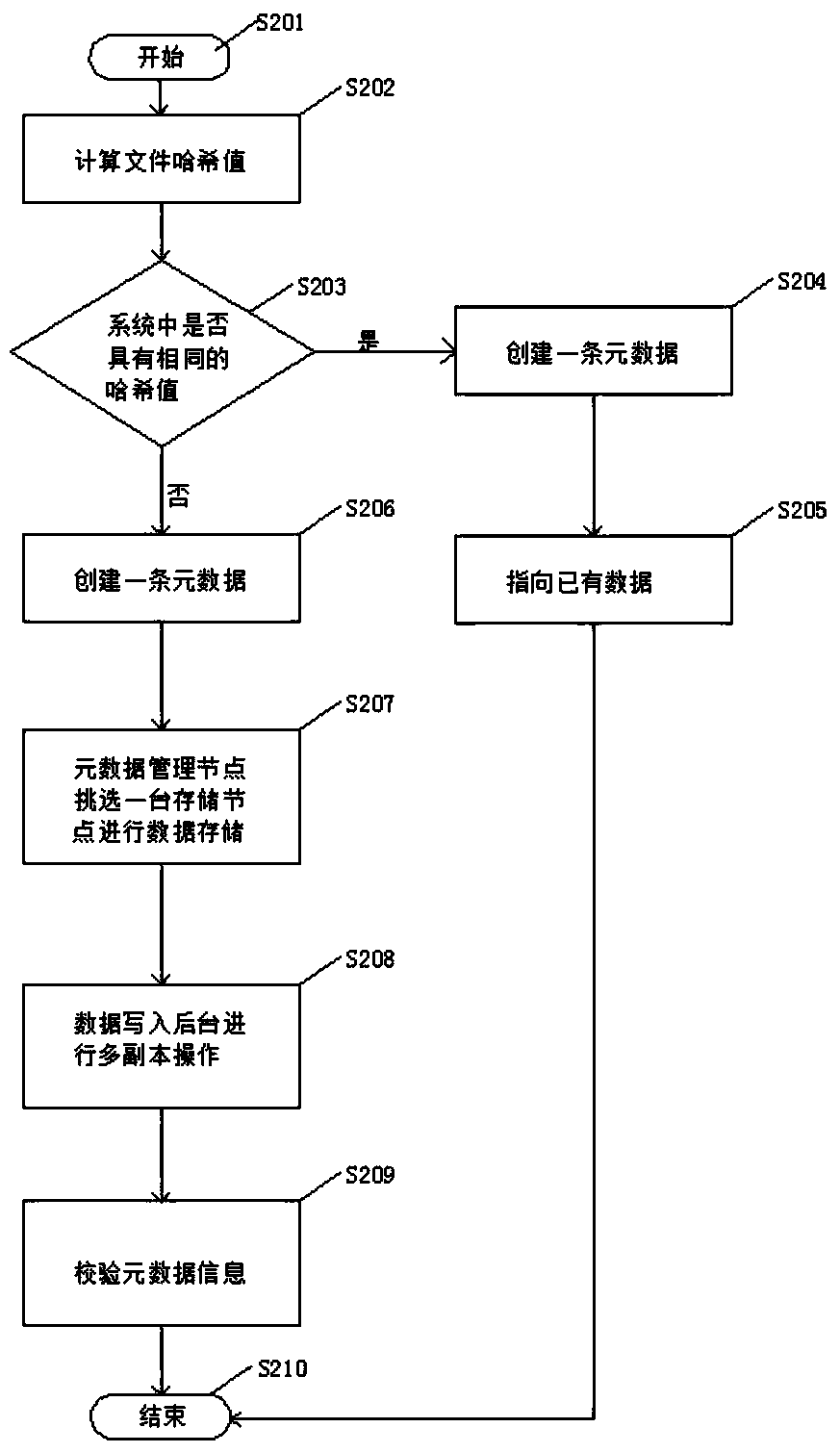

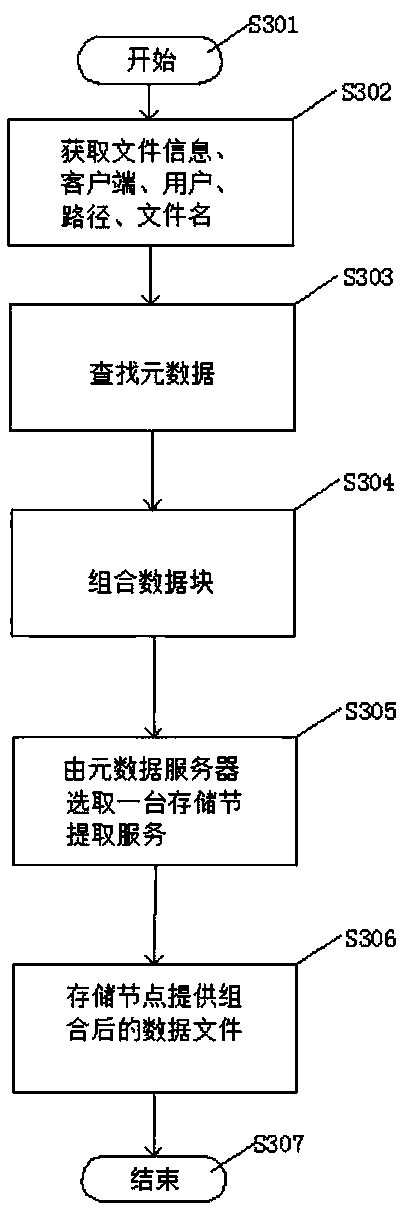

A distributed storage system and method for storing backup data

InactiveCN109284069AReduce in quantityImprove indexing speedInput/output to record carriersRedundant operation error correctionSystem administratorAuthorization

The invention provides a distributed storage system and a method for storing backup data, which uses a distributed storage system mode instead of an index mode to manage the backup data. A distributedstorage method includes a method for storage of backup data, a method of data recovery and a method of backing up data garbage collection. The data storage method can greatly utilize the advantages of high IOPS of disk device and high concurrency of cluster, the system design has redundancy, the system will not easily collapse, and saves a lot of environment of optimizing the backup server's owndata, which is convenient for system administrator to carry on system management and saves the authorization cost of the database. And different from the traditional backup system index management, itdoes not need to simulate the tape to manage the file system space, so that the data can be recovered in time when it is invalid, which improves the utilization of storage spa ce.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

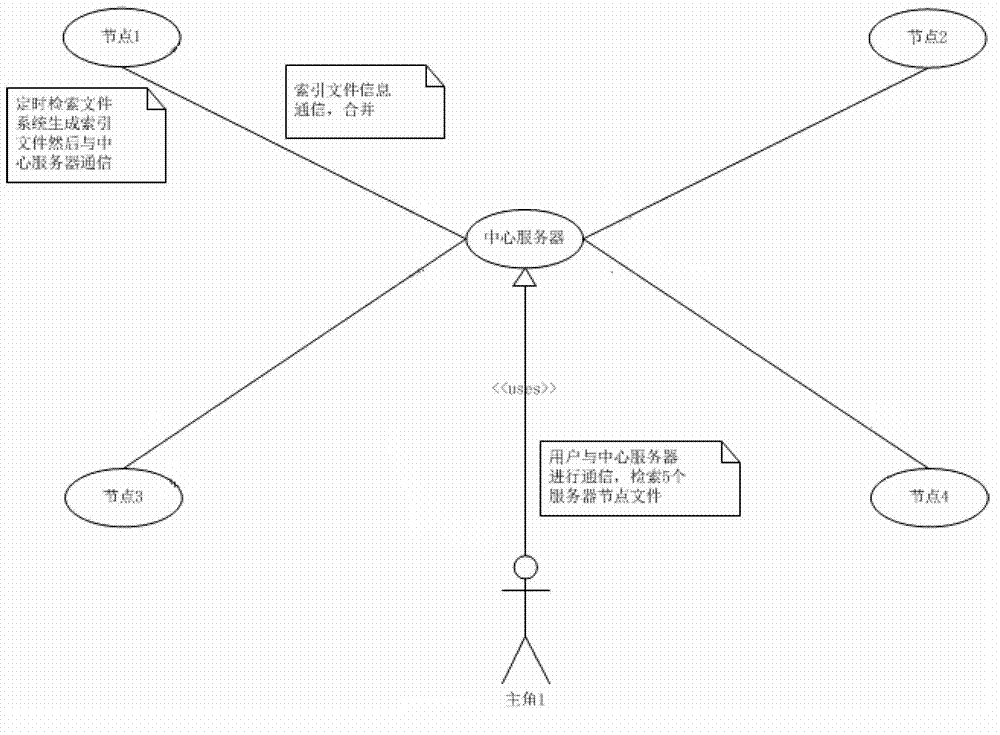

Distributed full-text retrieval system

InactiveCN102831253AImprove retrieval speedImprove stabilitySpecial data processing applicationsText retrievalLexicon

The invention belongs to the field of data processing and in particular relates to a distributed full-text retrieval system. The system consists of full-text retrieval servers comprising a distributed node server and a system center server which are arranged on each network node, wherein the distributed node server comprises a file information retrieval module and a server communication module; the file information retrieval module retrieves the full-text information of the file on the node server, segments words according to a defined lexicon, extracts the keyword information and establishes an index file; the server communication module realizes the information exchange between the distributed node server and the system center server; and the system center server merges the index files transmitted by each node server, provides a query interface for a user and shows the appropriate file which serves as a query result to the user.

Owner:BEIJING KEDONG ELECTRIC POWER CONTROL SYST +1

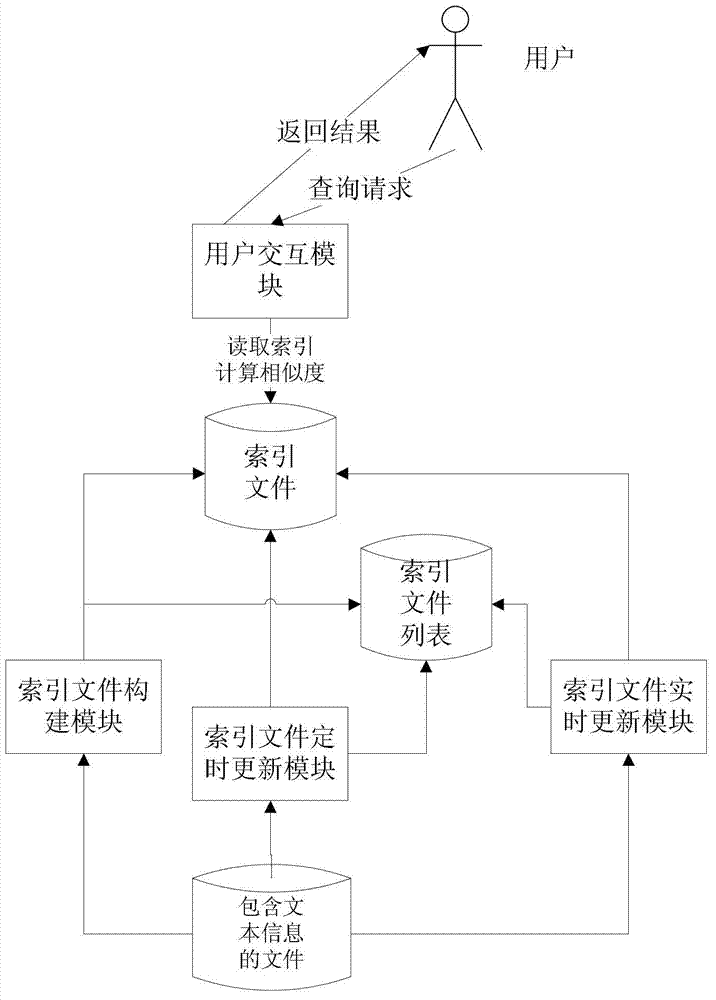

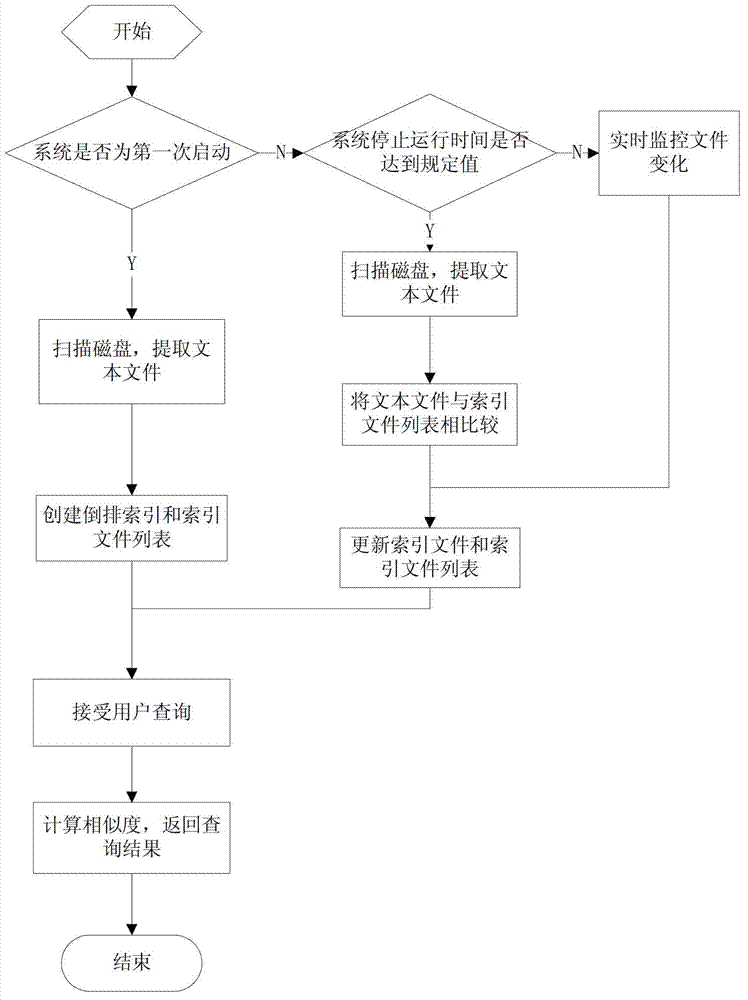

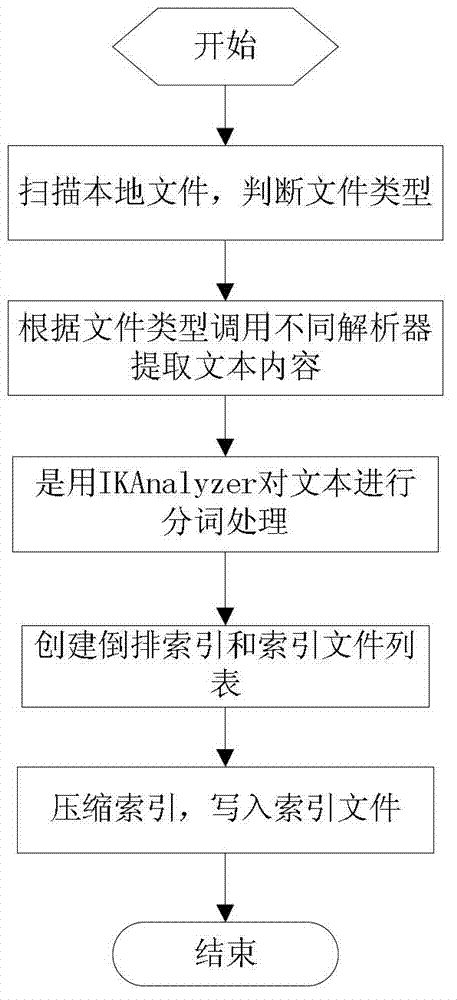

Lucene-based desktop searching system and method

ActiveCN102819592AImprove indexing speedEasy maintenanceSpecial data processing applicationsReverse indexDesktop search

The invention discloses a Lucene-based desktop searching system and method. The system expands a Chinese processing function and a text analyzing function on the basis of Lucene and comprises four modules, namely, an index file constructing module, an index file real-time updating module, an index file timing updating module and a user interaction module. The method comprises the following steps of: scanning a file which is stored on a local disk and contains text information; extracting key information such as a name, a path and contents of the file and establishing a reverse index; monitoring the operations of deleting and modifying the file and the like and updating the index to enable the file to be consistent with the index information; receiving a query request of a user, reading an index corresponding to the query request and carrying out similarity calculation; and returning the query results to the user from high to low to help the user quickly and accurately position the required information. The Lucene-based desktop searching system and method disclosed by the invention have the advantages of favorable real-time property, fewer occupied resources and higher recall ratio and precision ratio.

Owner:HOHAI UNIV

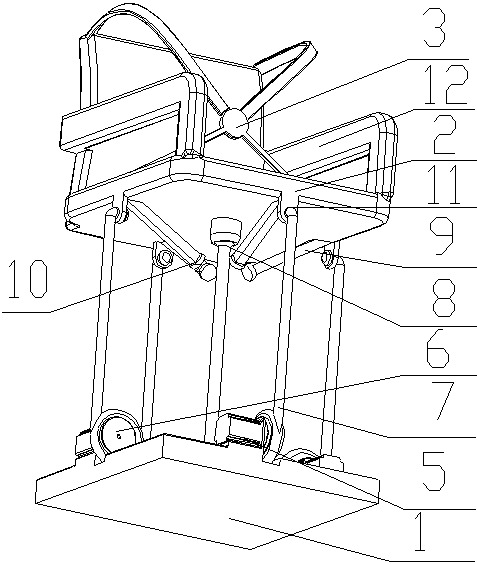

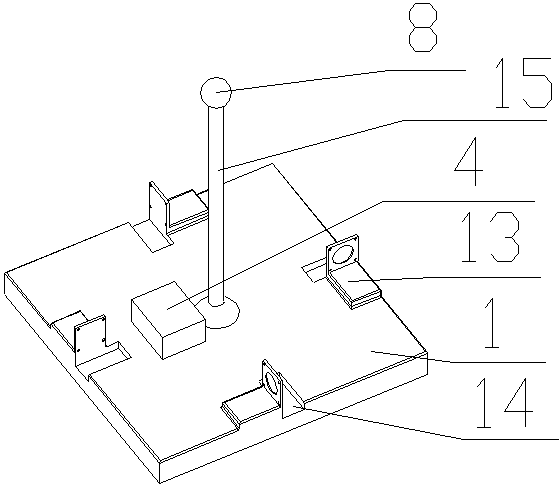

4D (4-Dimensional) seat

InactiveCN103349437AMeet the needs of useImprove reliabilityAmusementsCinema apparatusEngineeringWinch

The invention discloses a 4D (4-Dimensional) seat. The 4D comprises a base, a seat, a binding device, a control box, servomotors, winches and guy cables, wherein the servomotors are connected with the base and are distributed in central symmetry manner; the shafts of the servomotors are connected with the winches; the control box is arranged on the base; the base is connected with the seat through a ball head bearing; angle limit stop blocks are arranged below the seat; guy cable holes are formed in the periphery below the seat and are connected with the winches through the guy cables. Through the adoption of the structure, the 4D seat provided by the invention has the advantages of high reliability, accurate positioning, compact structure, safe use, low cost and the like, and has a wide market prospect in the home entertainment market.

Owner:TAICANG MINGJING TEXTILE

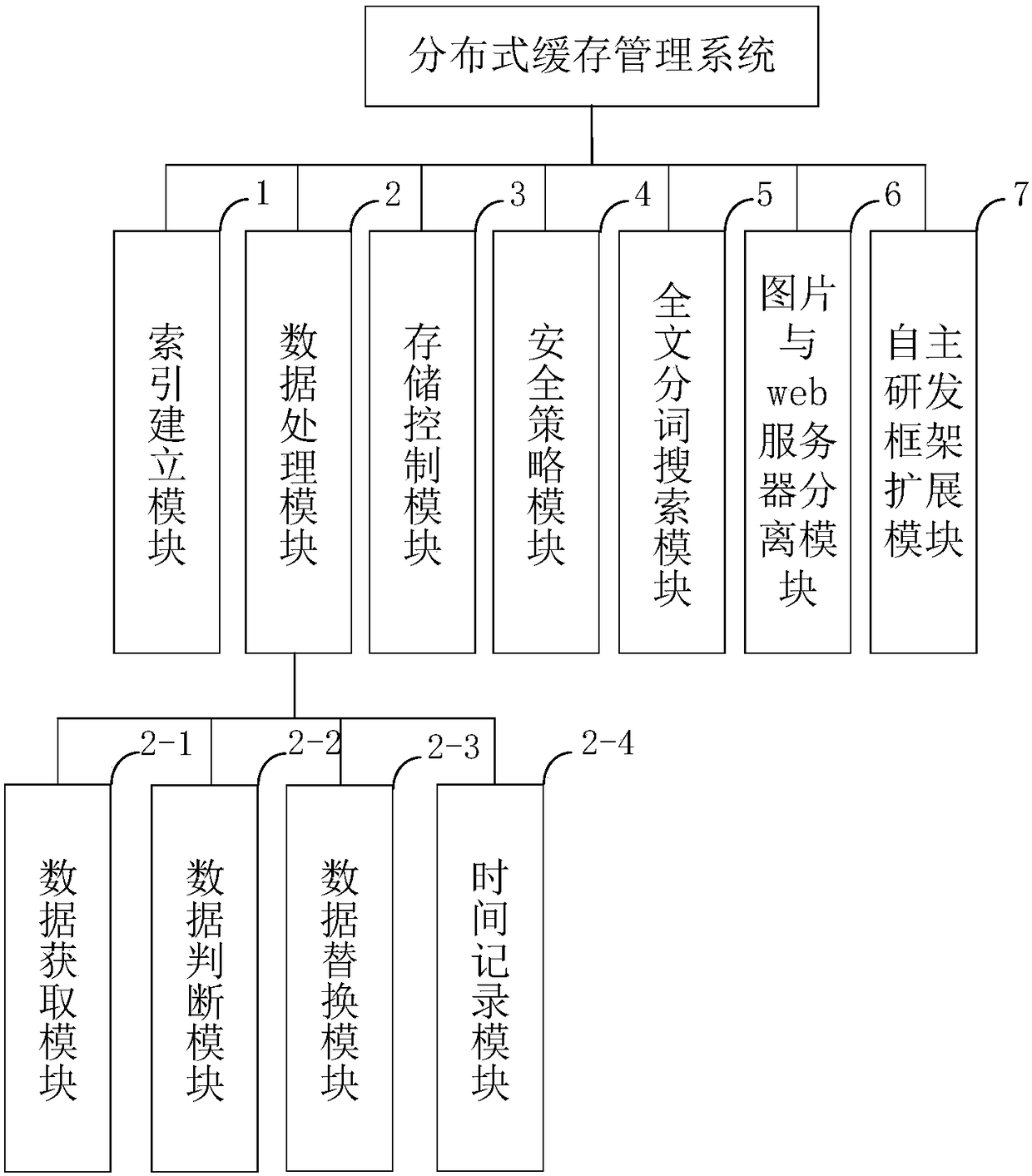

Distributed-cache management system and methods

InactiveCN108363764AEasy maintenanceClear structureTransmissionSpecial data processing applicationsWeb serviceDistributed cache

The invention belongs to the technical field of cache management, and discloses a distribute-cache management system and methods. The distributed cache management system includes an index establishment module, a data processing module, a storage control module, a security strategy module, a full-text word segment searching module, a picture and web server separation module and an independent-research / development framework extension module. According to the system, pressure of a database is reduced, time of requesting data by a user can be effectively reduced, response speed and load balancingcapability of a server can be improved, and thus experience of the user and smoothness of merchant marketing strategy laying-out can be improved; and a merchant utilizes excellent characteristics of aplatform better to implement a series of activities of marketing, planning, promotion and the like for products to realize a high commercial conversion rate, the user utilizes high support capabilityof the platform better to be close to the merchant and buy a product which is suitable for the same, and thus two-end profiting is enabled to be realized by communication of a near-zero distance between the merchant and the user.

Owner:山东地主网络科技创新有限公司

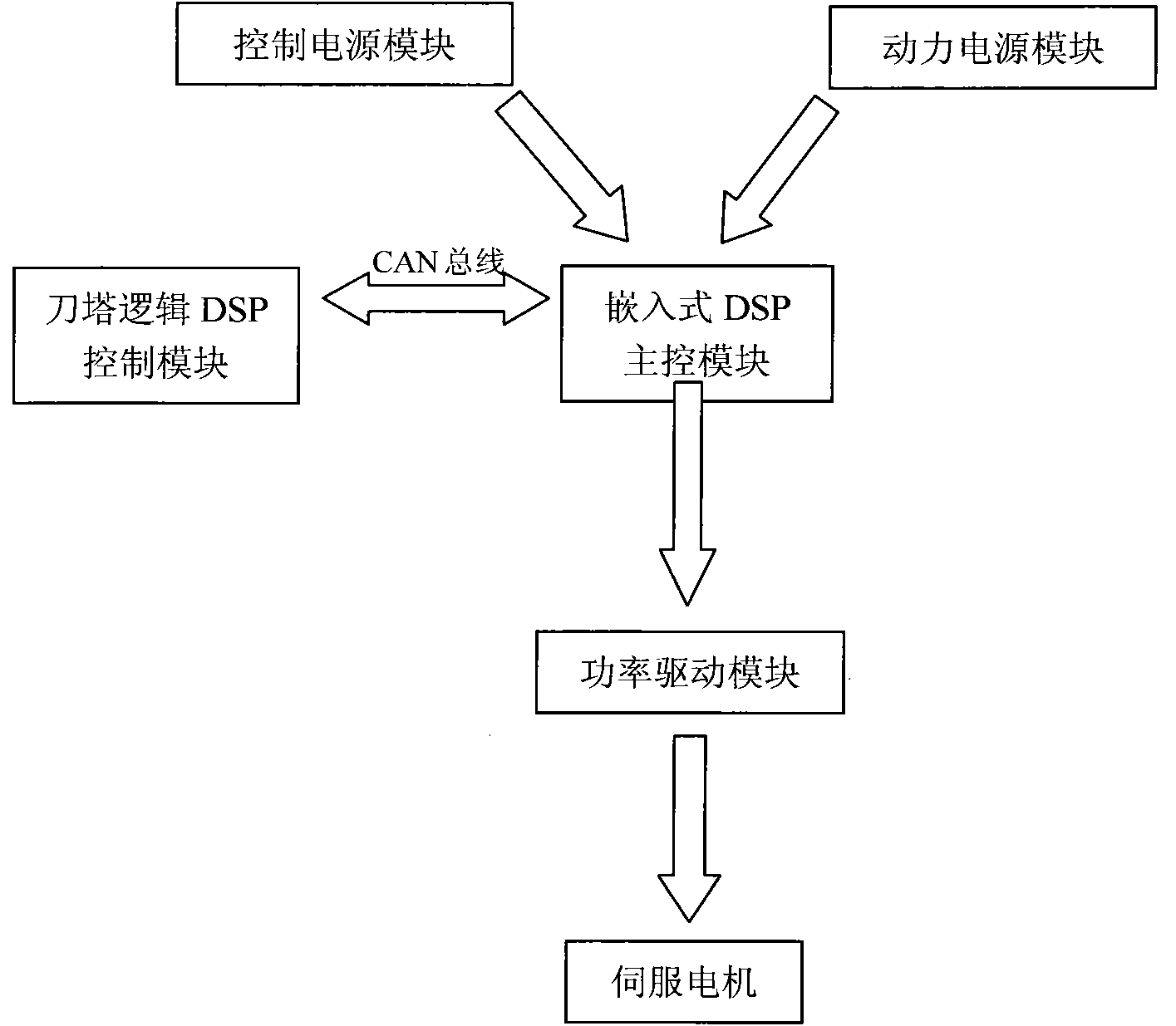

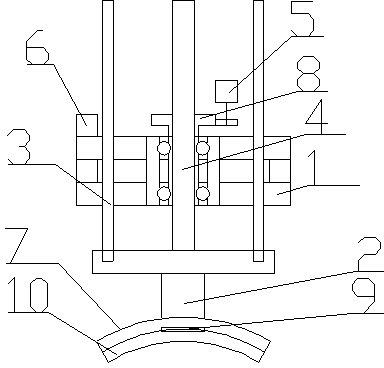

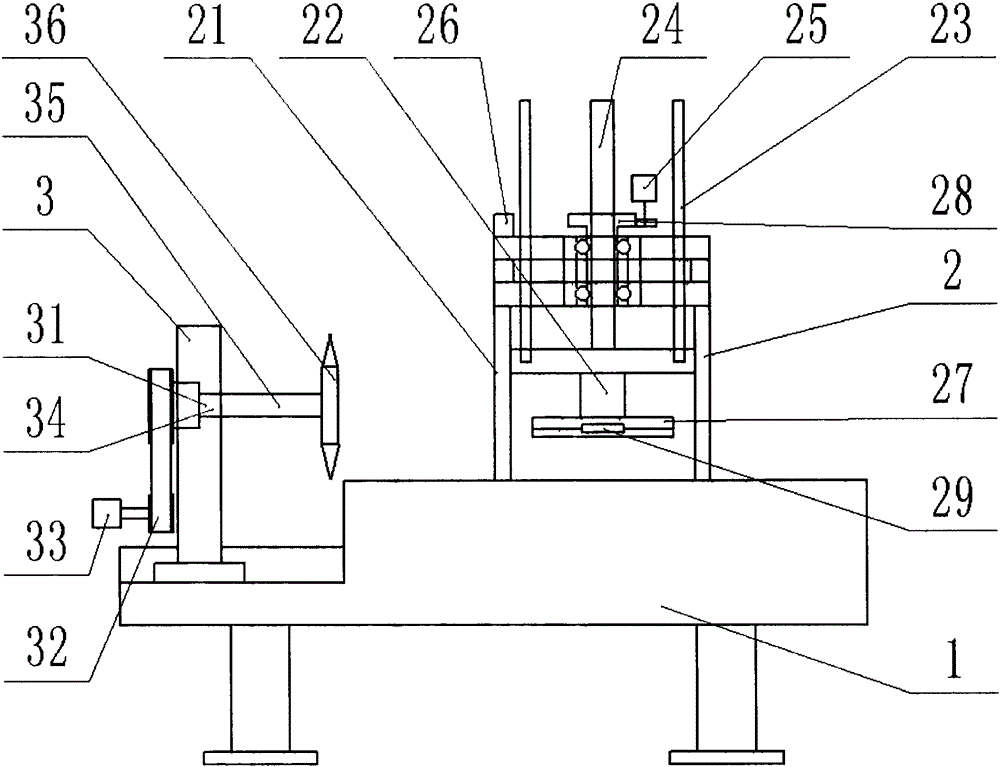

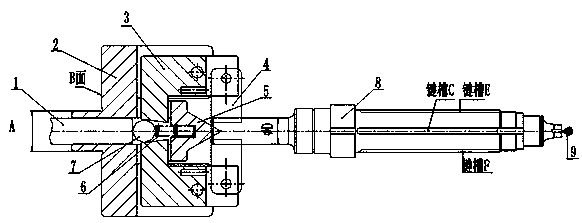

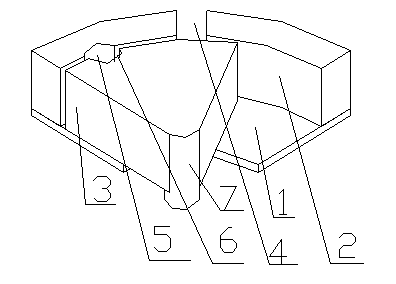

Control device for servo power turret

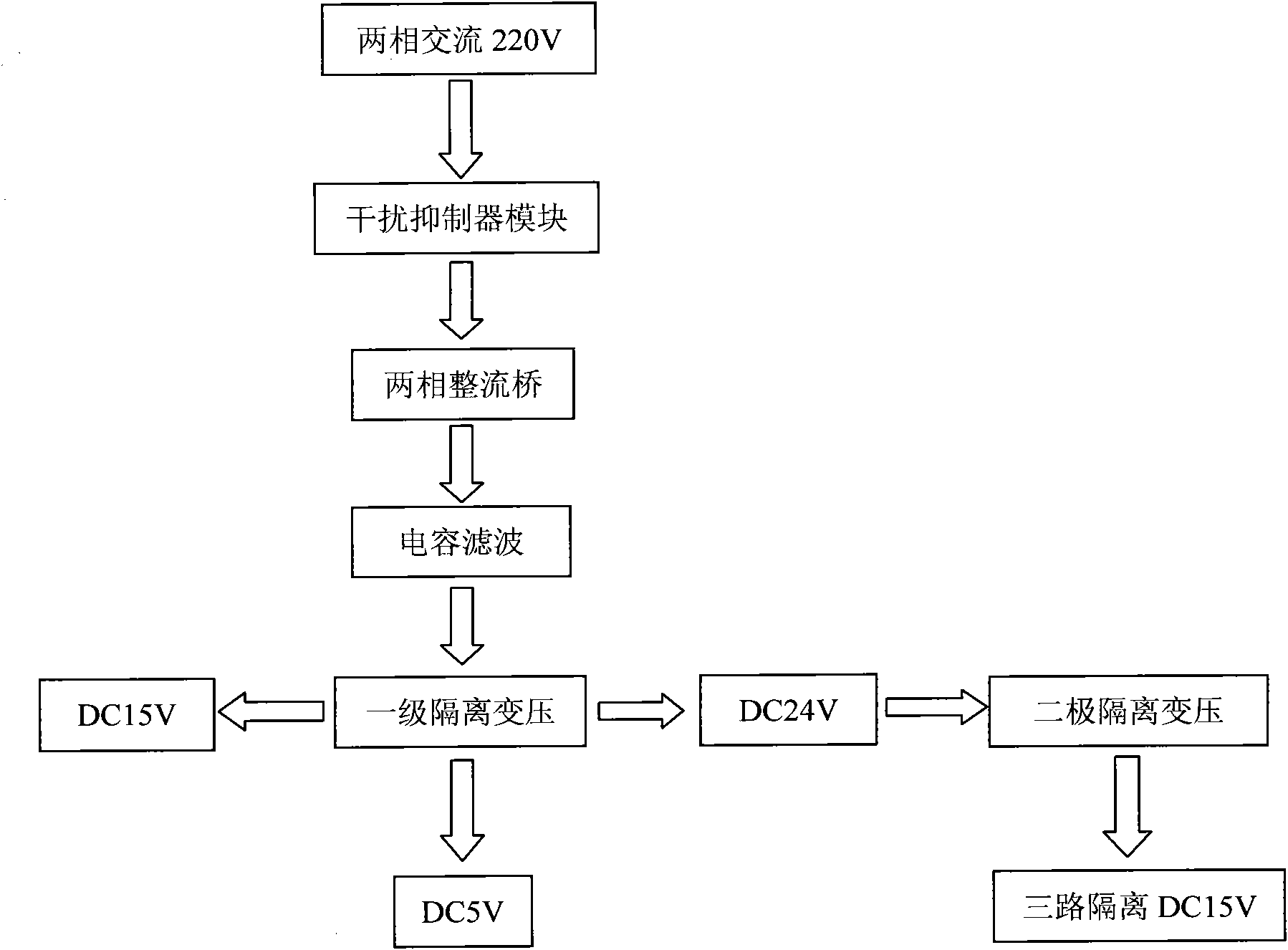

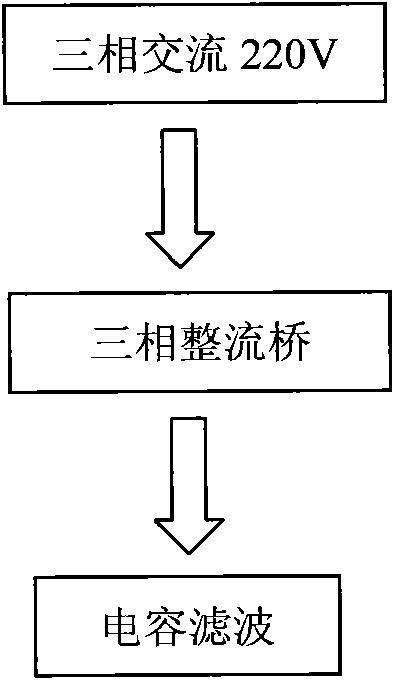

ActiveCN101846990AFast indexing speedReduce tool change timeNumerical controlMachine toolPush–pull output

The invention provides a control device for a servo power turret, which relates to a machine tool. A fully digital DSP processing chip, two central processing units (CPU), an embedded DSP main control module and a turret logical DSP control module are adopted by the device, wherein the embedded DSP main control module is a servo motor position control unit using TMS320LF2407 as a main processor, and the current, the position and the speed of a motor are controlled closely; the turret logical DSP control module is a user input / output management module using TMS320LF2406 as a co-processor; 74HC573 is used as a bus driving chip; and a push-pull output circuit of MOFET is adopted. The servo control turret has high transposition speed, can reduce the tool changing time of the turret, can improve the processing efficiency, the transposition precision and the tool changing accuracy of the machine tool, and can also improve the flexibility and the universality of control.

Owner:SHENYANG SHENGHUI MEASUREMENT & CONTROL TECH

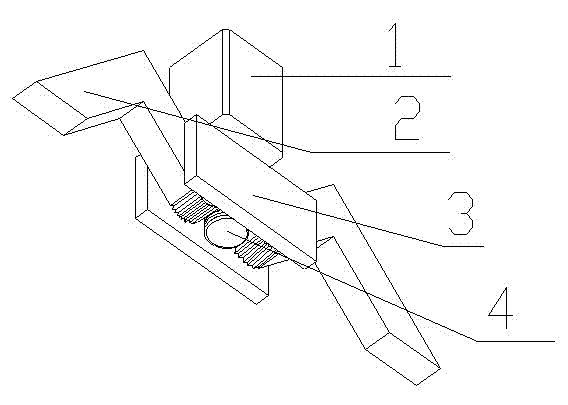

Mechanical gripper

InactiveCN103538075AImprove reliabilityPrecise positioningGripping headsWork holdersDrive motorEngineering

The invention discloses a mechanical gripper which comprises a drive motor, supports, jaws and a worm. The worm is arranged at the front end of the drive motor, the jaws are arranged on the supports, the motor is arranged between the supports, the jaws on the two sides are connected with the worm, and driving is achieved. Through the mode, the mechanical gripper has the advantages of being high in reliability performance, precise in locating, compact in structure, high in transposition speed, low in noise, low in price and the like, and meanwhile has wide market prospects in the field of automation.

Owner:CHANGZHOU YINGSHUN ELECTRONICS

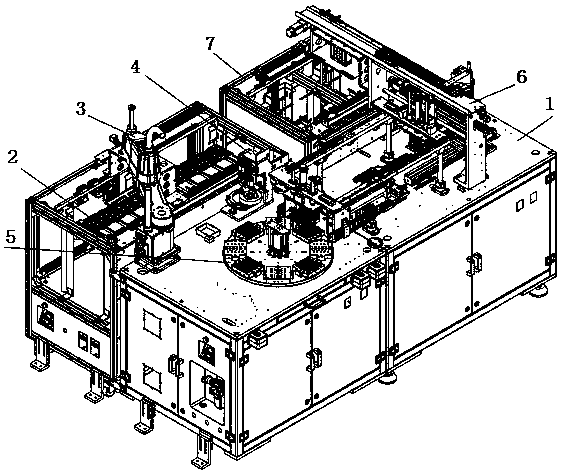

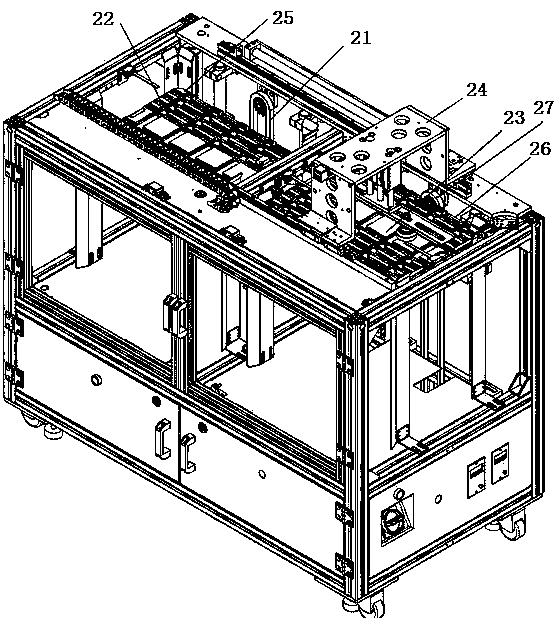

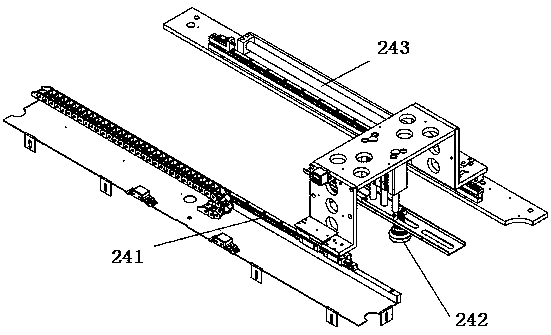

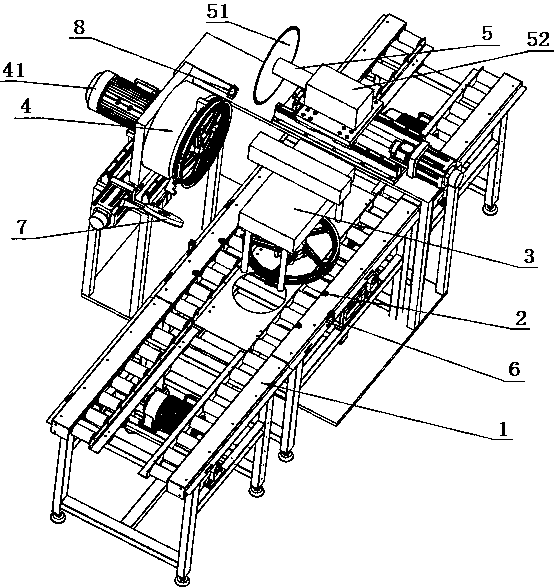

Automatic space key assembling system

ActiveCN108942137AReduce changeover timeReduce mistakesAssembly machinesMetal working apparatusManipulatorMultiple Models

The invention discloses an automatic space key assembling system. The automatic space key assembling system comprises a rack, and further comprises a space key lining feeding device, a four-axis mechanical arm, a CCD detecting device, a station rotating platform device, a roller press discharging device, a receiving device and a PLC which are arranged on the rack. By means of the above manner, theautomatic space key assembling system is characterized in that a tray feeding manner is adopted for automatic feeding, the mechanical arm is used for taking a material, CCD automatic detection is carried out, qualified space key linings are placed into key caps on positioning jigs, the linings and the key caps enter a roller press station to be subject to roller press after move loading and overturning, and pressed space keys are placed into the receiving device through the discharging device; in addition, the positioning jigs in multiple models are arranged in equipment, the procedure is orderly switched when model changing is needed without replacement of the jigs, and the model changing time is shortened; and meanwhile, errors generated by manual participation are reduced, the production efficiency is improved, and the advantages of being high in reliability, accurate in positioning, compact in structure, high in transposition speed, small in noise and the like are achieved.

Owner:苏州德机自动化科技有限公司

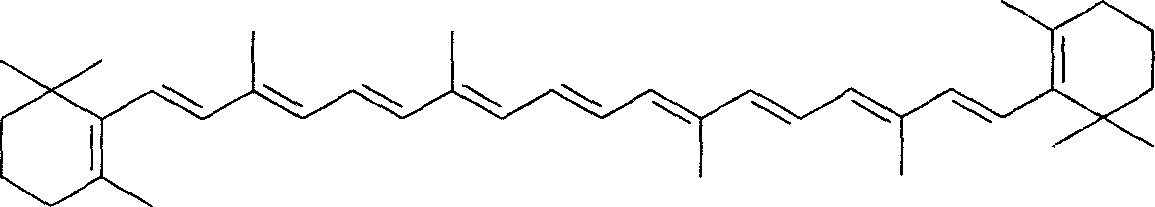

Method for preparing full-trans beta-carrotin

The invention discloses a total reversal beta-carotene preparing method, mixing beta-carotene and high-boiling point, low-toxicity polar solvent at 70-160 deg.C in the mass ratio of 1 to (1-10), reacting in protective nitrogen gas for 10-30 h, filtering and water-washing and drying to make it. And the invention has advantages of: 1) using low-toxicity solvent as reacting medium, safe and environmental-protection and applied to transposition of natural beta-carotene and synthetic beta-carotene in the courses of preparing drugs, food, feeds, and other preparation products at various levels; 2) high reaction temperature, fast transposition and basically having no by-products; 3) the selected solvent basically has no solubility to beta-carotene, and the reaction yield is high; 4) large beta-carotene processing quality of the selected solvent and less solvent utilization.

Owner:ZHEJIANG UNIV +3

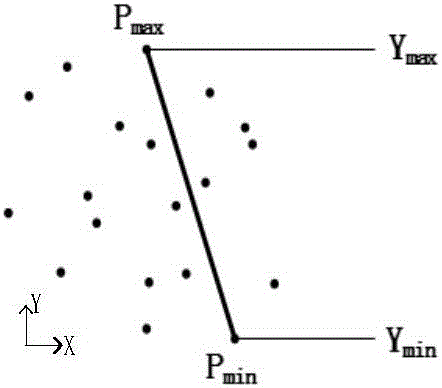

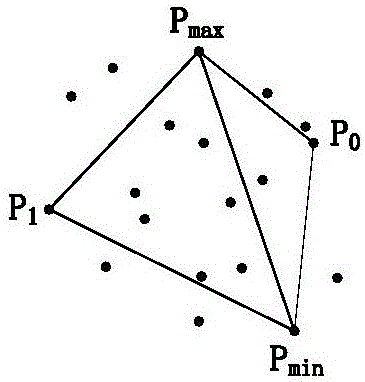

Grid association-based quadtree index point cloud sorting method

InactiveCN106780748ASatisfy the need for sortingEasy to divideDetails involving 3D image dataImage generationOriginal dataGrid based

The invention discloses a grid association-based quadtree index point cloud sorting method. The method comprises the following steps of: 1, carrying out plane fitting on point cloud data by adoption of a least square method, converting a three-dimensional coordinate of points on a projection plane to a two-dimensional coordinate; 2, solving convex hulls of the two-dimensional points and fitting four straight lines according to the convex hull points; 3, carrying out sorting initialization on the two-dimensional data points to obtain a sorting result of the two-dimensional points; and 4, counter-deducting a sorting result of the three-dimensional points according to the sorting condition of the two-dimensional points. Through above steps, the two-dimensional data points are associated with grids after two- dimensionalization, sorting is carried out according to the associated grids and data points, and an effect of geometrically sorting the three-dimensional data points is achieved through counter-deducting to the three-dimensional original data points through point names, so that the practical problem that the data points in the point cloud data are geometrically disordered on the whole is solved, and convenience is brought to the subsequent data analysis.

Owner:BEIHANG UNIV

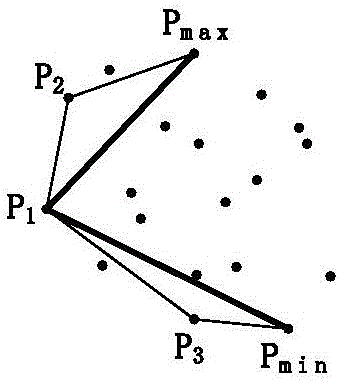

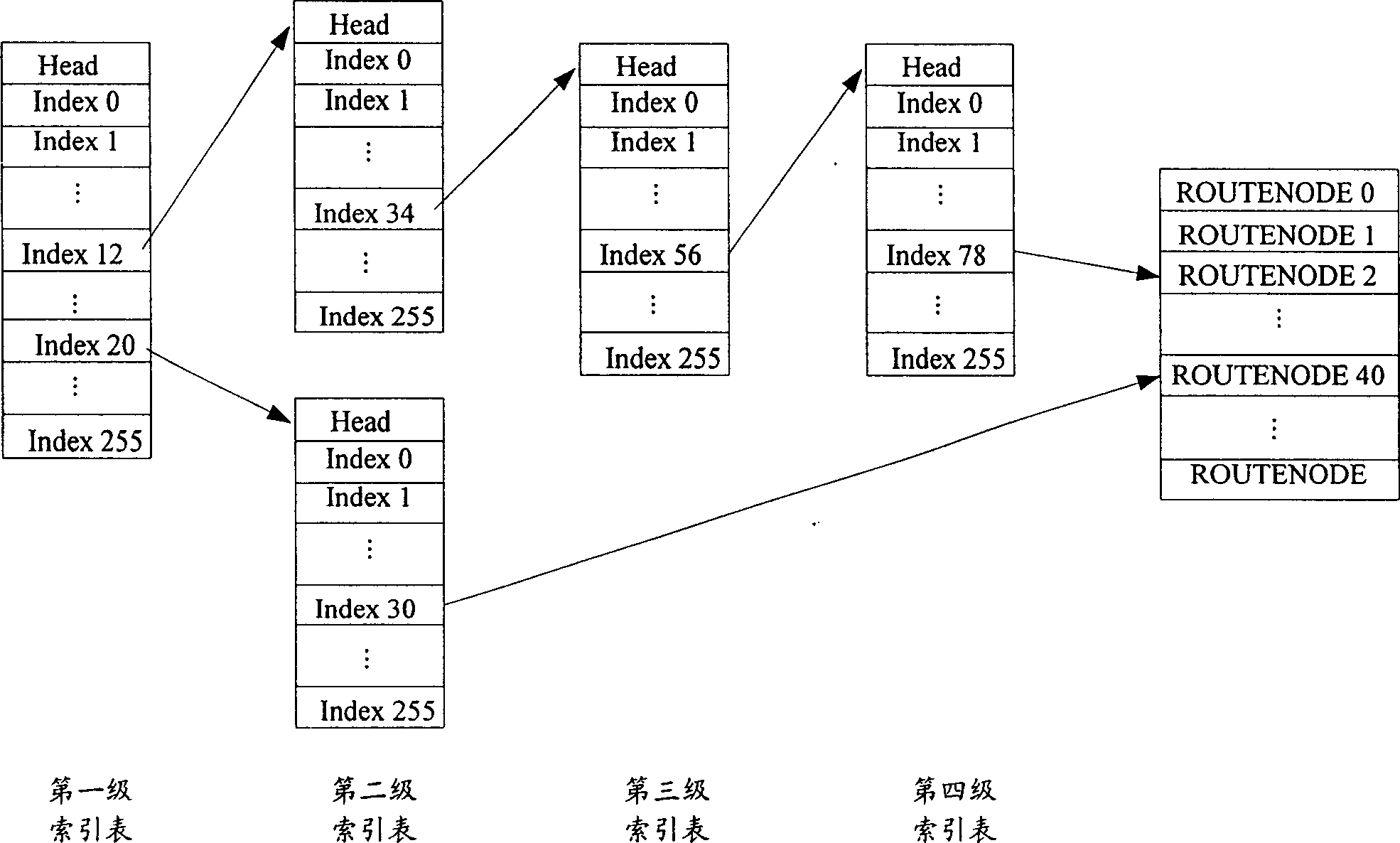

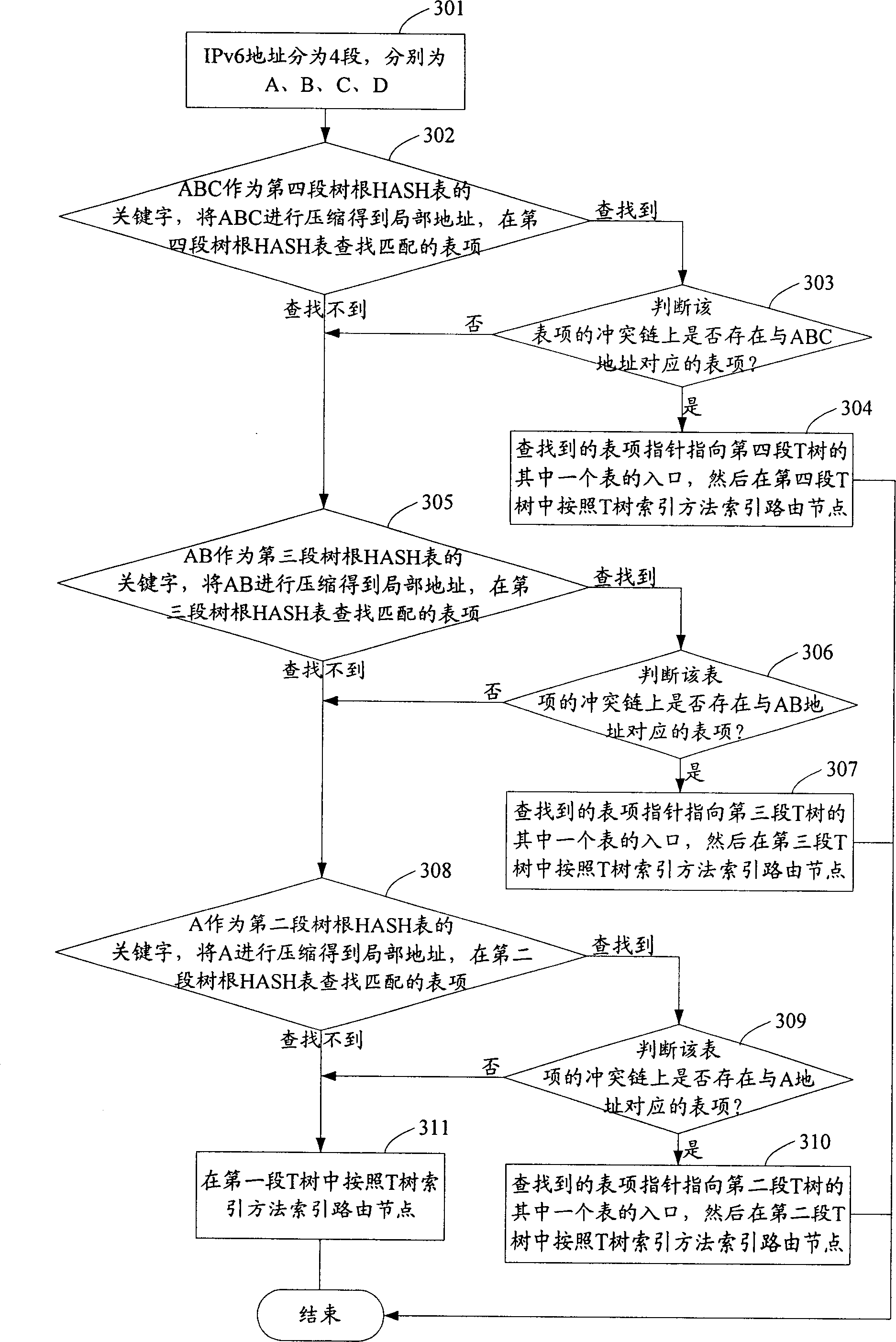

Fast indexing method

ActiveCN1852238AReduce the numberSave resourcesTransmissionSpecial data processing applicationsTree rootData mining

The method segments all indexed address in same type, and establishes tree root table for address of prefix segment of each segment, and establishes index table for addresses in each segment. The method includes steps: according to the said segment mode to segment index address to be indexed; determining current index table; if determining current table to be indexed is as index table in first segment, then using first segment address as keyword to carry out indexing in index table of first segment, ending flow; if determining current table to be indexed is as tree root table, then using address of prefix segment corresponding to tree root table as keyword looks up table item matched to the address of prefix segment in tree root table; if finding it out, then carrying out indexing by using the matched pointer of table item as entry, and using address of corresponding segment as keyword; ending this flow; if not finding it out, then determining current index table again.

Owner:HUAWEI TECH CO LTD

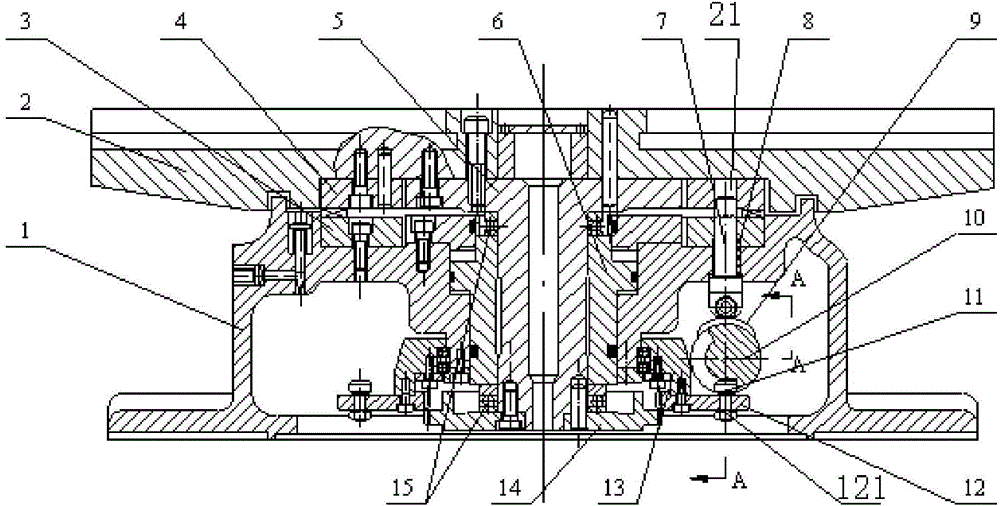

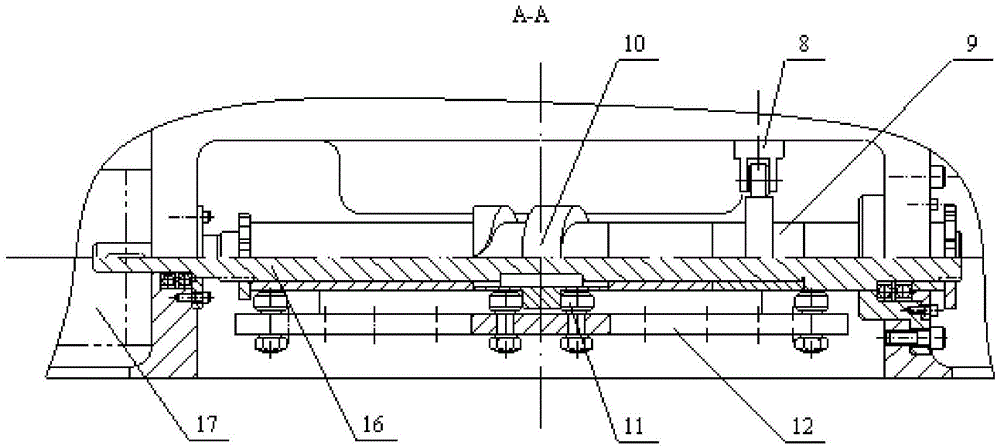

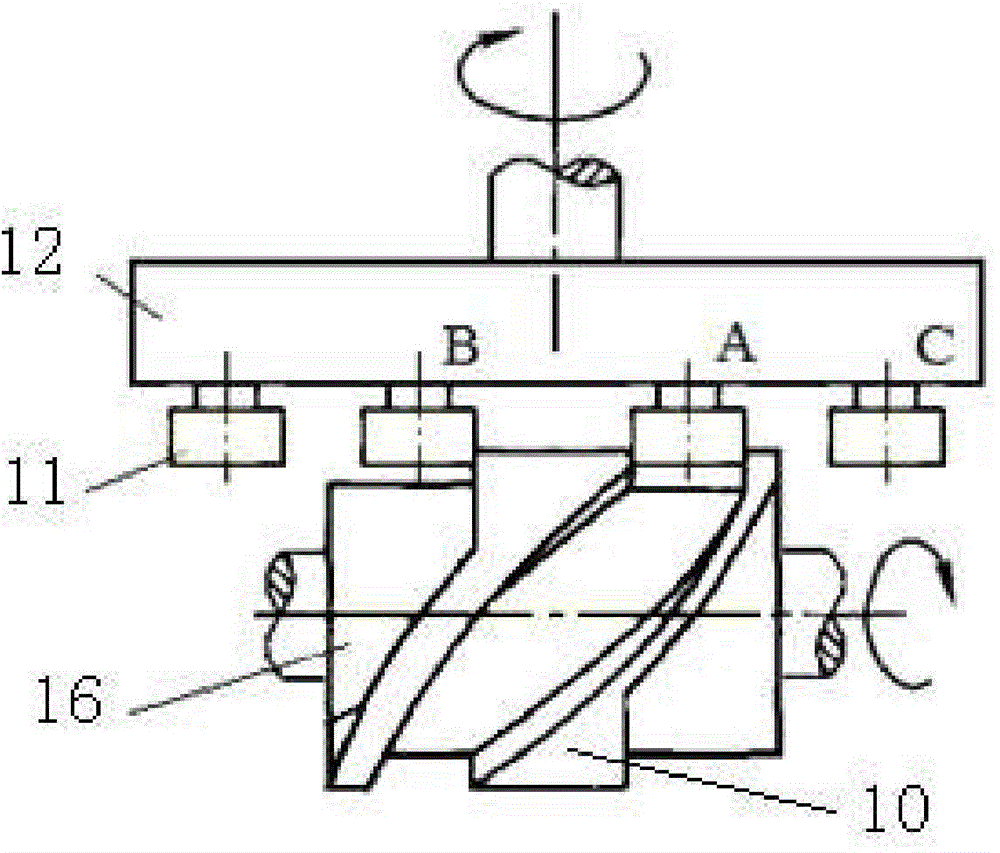

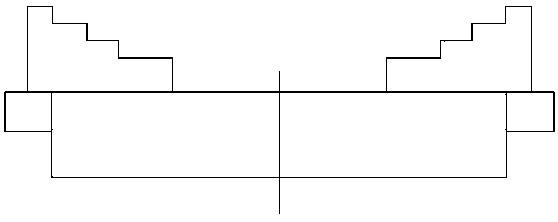

Cam positioning bidirectional continuous indexing worktable

InactiveCN104802031ASimple structureEasy to processPrecision positioning equipmentLarge fixed membersGear wheelEngineering

The invention discloses a cam positioning bidirectional continuous indexing worktable. The cam positioning bidirectional continuous indexing worktable comprises a base, a tabletop, a cam shaft, a positioning pin and a rotary positioning assembly, wherein the base is internally provided with a piston cylinder; a limiting assembly for limiting relative rotary positions of the tabletop and the base is arranged between the tabletop and the base; a plurality of indexing position holes are formed in the tabletop; the cam shaft is rotationally supported on the base; the outer wall of the cam shaft is provided with a cylindrical surface cam body and a plane cam body; one end of the positioning pin is matched with the plurality of indexing position holes and the other end of the positioning pin abuts against the plane cam body so that the other end of the positioning pin can be inserted into or released from the indexing position holes under the action of the plane cam body when the cam shaft rotates. Under the driving of a power source and the piston cylinder, the bidirectional continuous rotary indexing and the accurate positioning of the worktable can be automatically realized; compared with a common hydraulic indexing worktable, the problems of bidirectional continuous indexing, top tooth positioning and the like are solved; meanwhile, a gear / rack indexing mechanism is also cancelled, the indexing speed is rapid and the positioning is accurate and reliable.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

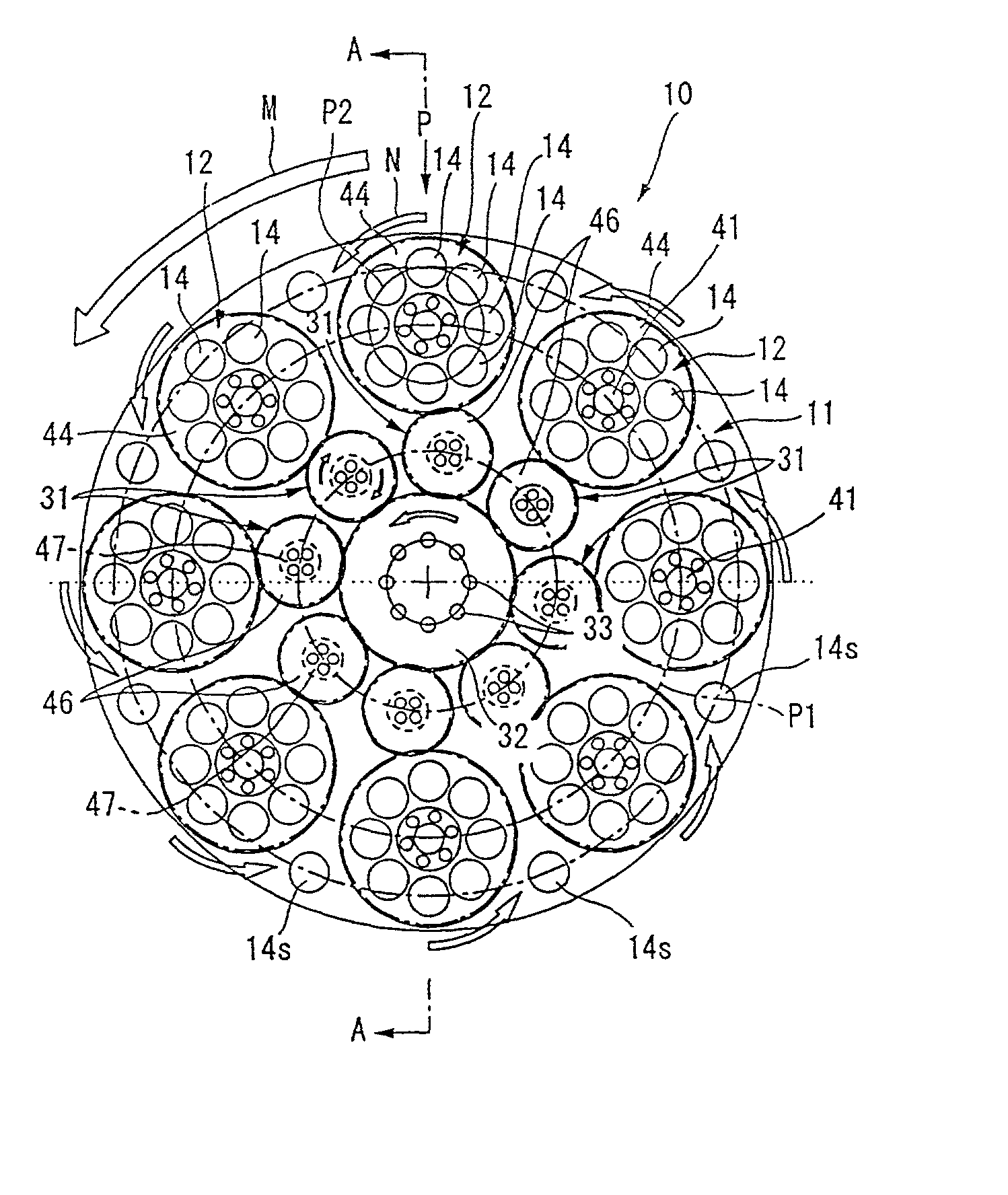

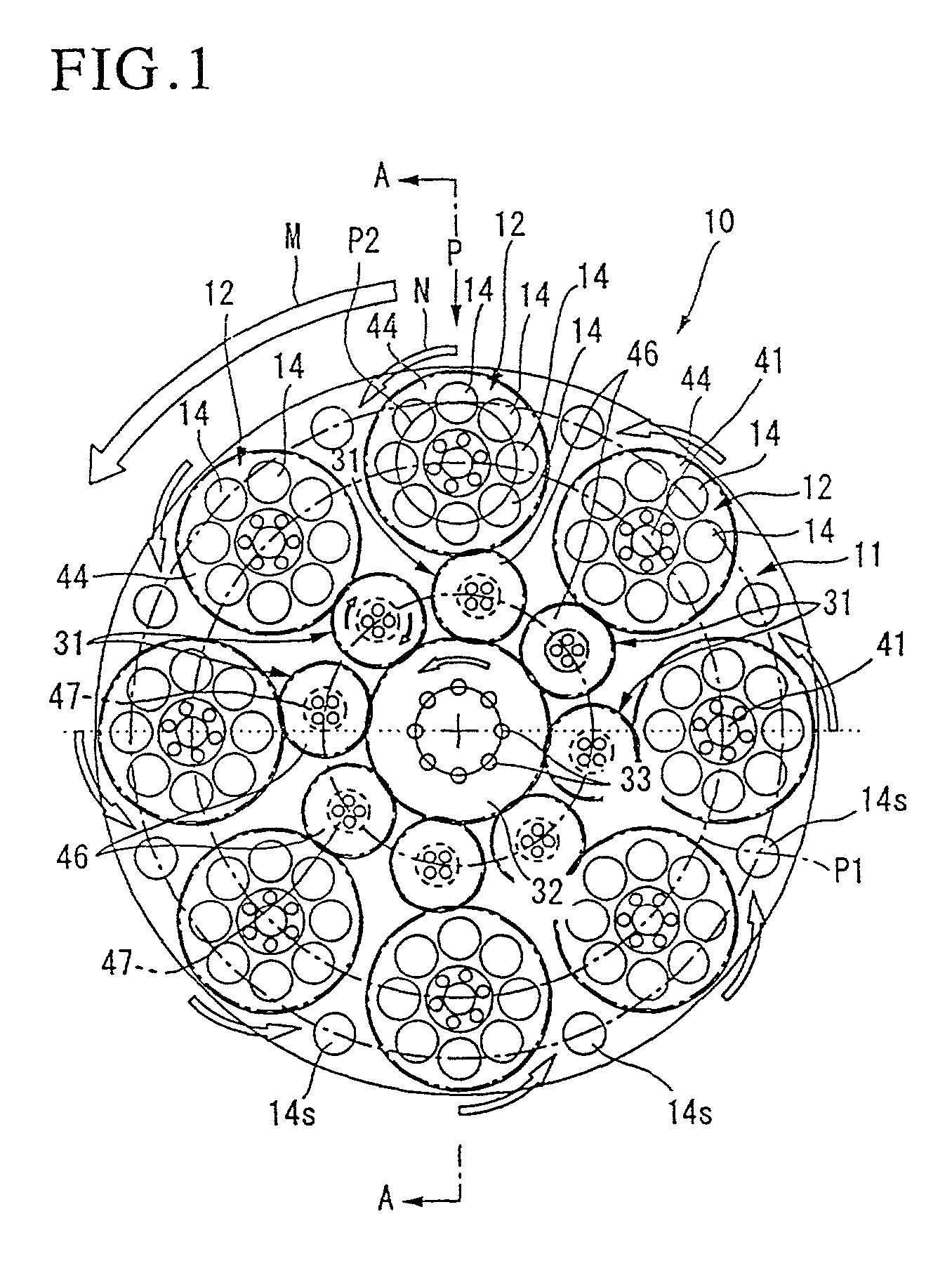

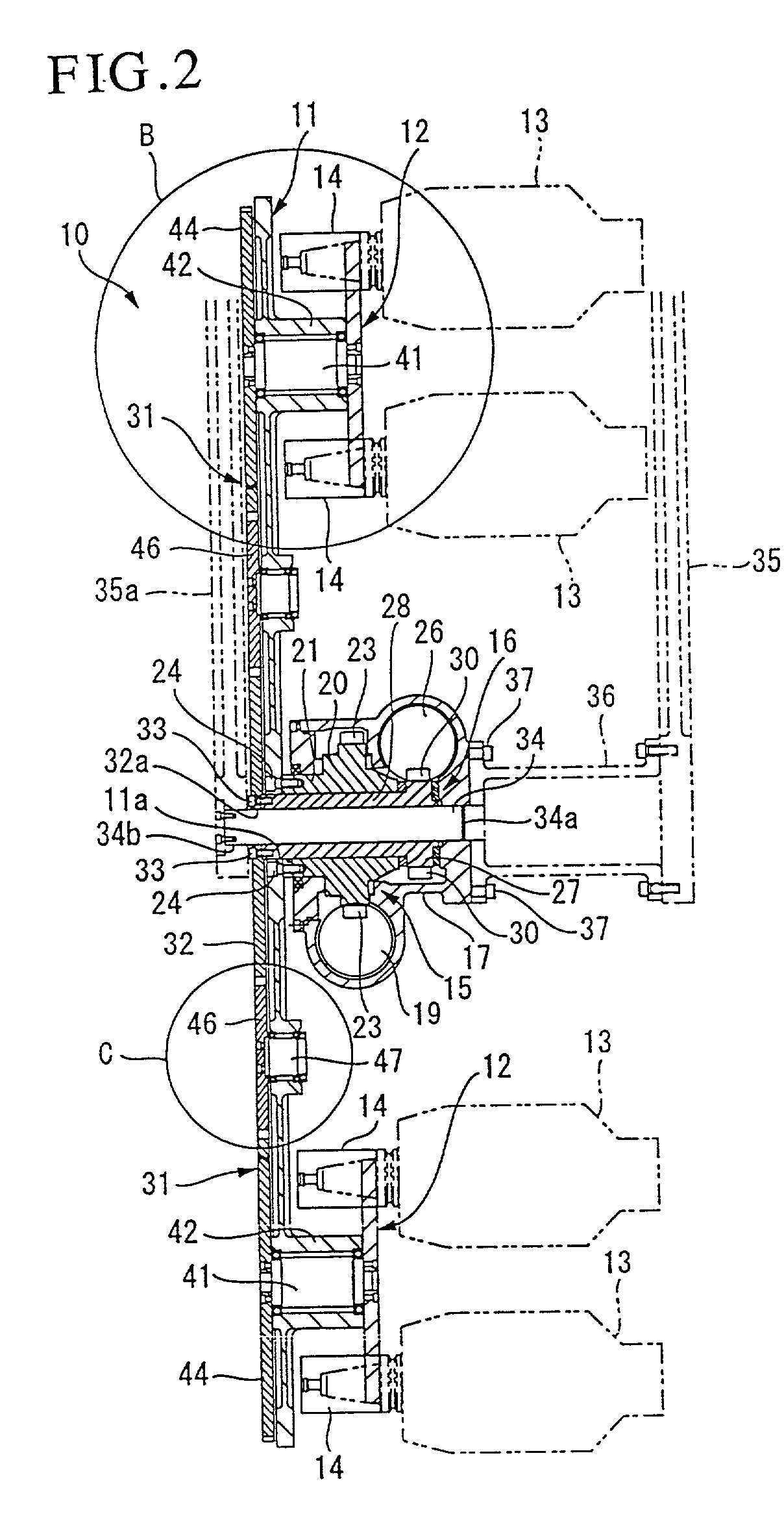

Tool magazine

InactiveUS20020043138A1Small sizeEfficient comprehensive utilizationAutomatic/semiautomatic turning machinesMechanical apparatusEngineeringMachining

A automatically indexing tool magazine, of the type attached to machining centers that incorporate an automatic tool change function, able to hold a relatively large number of tools in a compact space as means of improving space efficiency. The tool magazine is comprised of a rotatable main table and multiple sub-tables rotatably attached to the main table in a uniformly spaced radial pattern, each sub-table being equipped with a number of tool pots likewise arranged in a uniformly spaced radial pattern. The tool pots serve as containers into which machining tools can be inserted or removed. The main table and sub-tables are rotatably indexed by means of respective main table and sub-table indexing mechanisms. The tool pot holding the tool designated for removal is transported to a tool removal position through the rotational indexing movement of the main table and appropriate sub-table.

Owner:SANKYO SEISAKUSHO

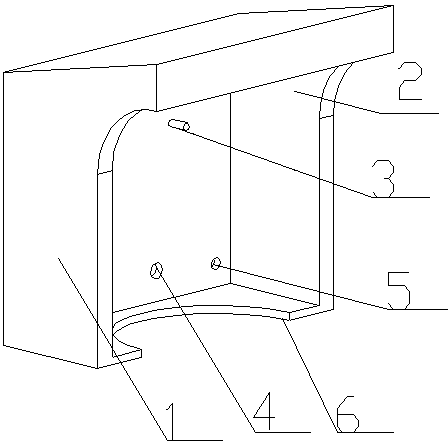

Sound-insulating telephone booth for ship

The invention discloses a sound-insulating telephone booth for a ship. The sound-insulating telephone booth comprises an outer layer housing, an inner layer housing, a telephone hanging rack, a wire-passing hole, a mounting rack and a sound-insulating material, wherein the inner layer housing is arranged on the inner side of the outer layer housing; the telephone hanging rack is arranged on a back plate of the inner layer housing; the wire-passing hole is formed in the inner layer housing; the mounting rack is arranged on the peripheries of the outer layer housing and the inner layer housing; the sound-insulating material is arranged between the outer layer housing and the inner layer housing. After the adoption of the method, the sound-insulating telephone booth for the ship is high in reliability, good in corrosion resistance and sound insulation, convenient to mount, long in service life, and low in price, and also has a wide market prospect in the field of ship equipment.

Owner:太仓市金时利船用电器有限公司

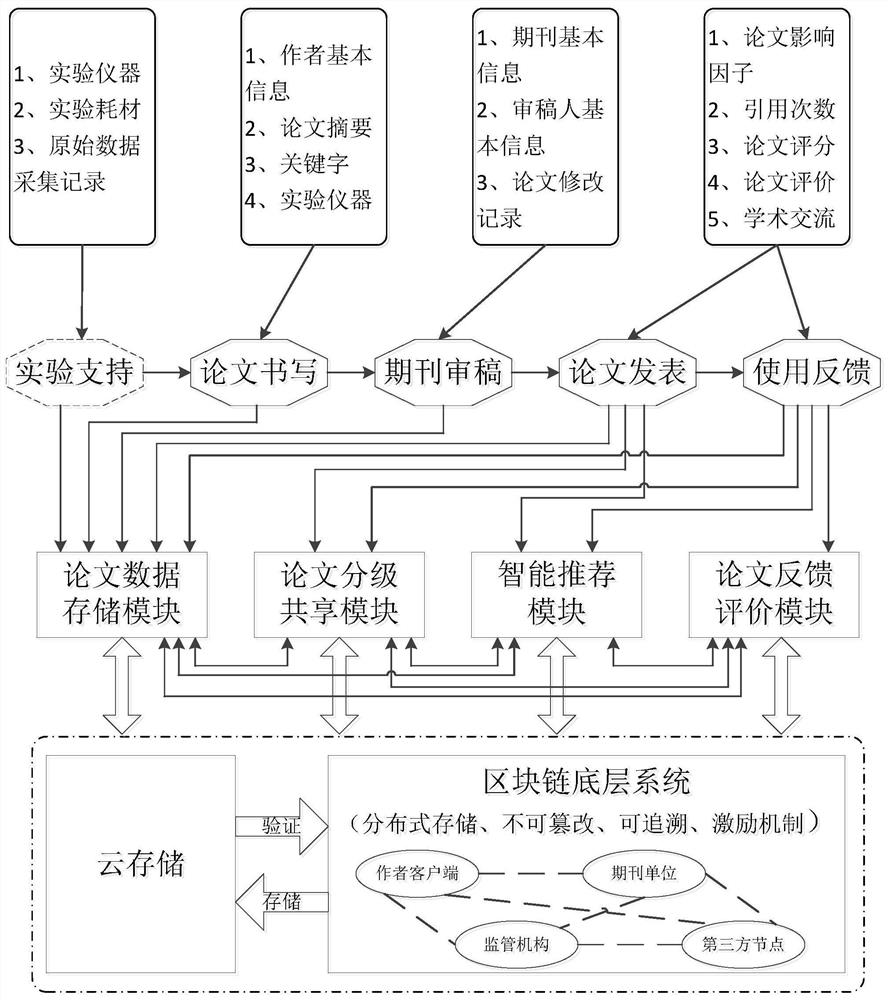

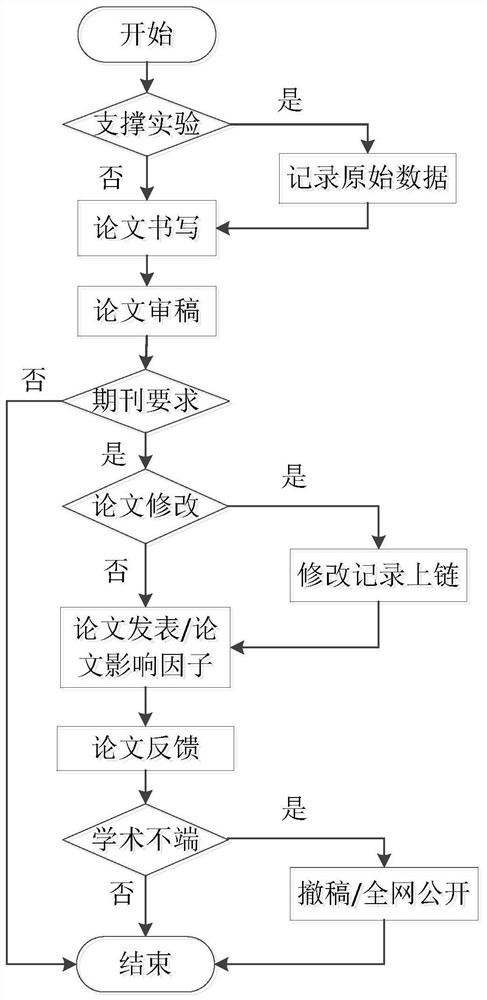

Paper indexing system based on block chain technology

InactiveCN111651462AImprove indexing speedAvoid regulationDatabase updatingDatabase distribution/replicationPaper data storageData Origin

The invention discloses a paper indexing system based on a block chain technology. According to the system, an information distributed storage, non-tampering, traceable and excitable blockchain platform is used as a bottom architecture, and the blockchain platform of the system is connected with four functional modules, including a paper data storage module, a paper hierarchical sharing module, anintelligent recommendation module and a paper feedback evaluation module; wherein data sources of the paper data storage module comprise authors, periodicals, manuscript reviewers and referers, and the paper data storage module is used for storing full-process information of each piece of paper from writing, submitting, manuscript reviewing, publishing, referencing and feeding back; the method has the advantages that the blockchain technology is utilized, the full life cycle of writing, submitting, reviewing, publishing, quoting and feeding back of each paper can be public and transparent, paper experiment data are public, transparent, credible and traceable, academic achievement counterfeiting can be effectively avoided, the paper index speed can be increased, and paper can be effectively supervised.

Owner:YANTAI UNIV

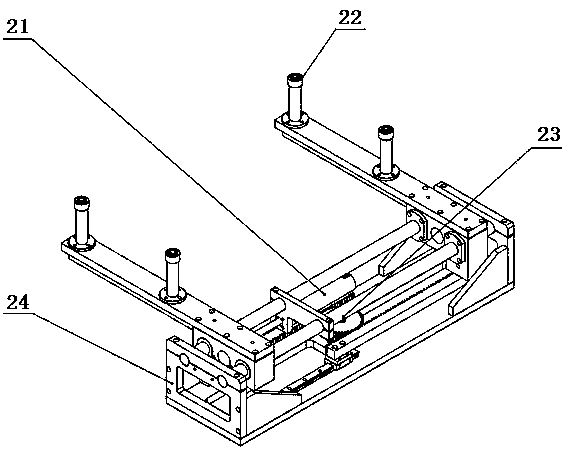

Clamping mechanism for automatic pipe cutter

InactiveCN103963095APrevent slidingAchieve clampingMetal working apparatusMechanical engineeringEngineering

The invention discloses a clamping mechanism for an automatic pipe cutter. The clamping mechanism comprises a support, a push rod, polish rods, a screw rod, a motor, a controller, a locking seat, a drive sleeve and a sensor. The motor is arranged on the support, the front end of the motor is connected with the drive sleeve, the push rod is connected with the screw rod and the polish rods, the screw rod and the polish rods are connected with the support, the screw rod is sleeved with the drive sleeve, the front end of the push rod is connected with the locking seat and the sensor, and the controller is arranged on the support. The clamping mechanism for the automatic pipe cutter has the advantages of being high in reliability, precise in locating, compact in structure, high in transfer speed, firm in fixing, low in cost, safe and clean and capable of effectively locking tubular objects.

Owner:SUZHOU GENFU MACHINERY SCI & TECH

Electric horizontal type pipe cutting machine for plastic pipes

The invention discloses an electric horizontal type pipe cutting machine for plastic pipes. The electric horizontal type pipe cutting machine for the plastic pipes comprises a frame body, a clamping mechanism and a pipe cutting mechanism. The clamping mechanism and the pipe cutting mechanism are arranged on the frame body. The clamping mechanism comprises a support, a push rod, an unthreaded rod, a lead screw, a first motor, a controller, a locking base, a driving sleeve and a sensor. The first motor is arranged on the support. The driving sleeve is connected to the front end of the first motor. The push rod is connected with the lead screw and the unthreaded rod. The lead screw and the unthreaded rod are connected with the support. The driving sleeve is connected to the lead screw in a sleeving mode. The locking base and the sensor are connected to the front end of the push rod. The controller is arranged on the support. The sensor is a pressure sensor and is arranged between the locking base and anti-slip rubber. The electric horizontal type pipe cutting machine for the plastic pipes has the advantages of being high in reliability, accurate in positioning, compact in structure, high in transposition speed, firm in fixation, low in price, safe, clean and capable of guaranteeing the cutting quality of pipe materials.

Owner:岑立强

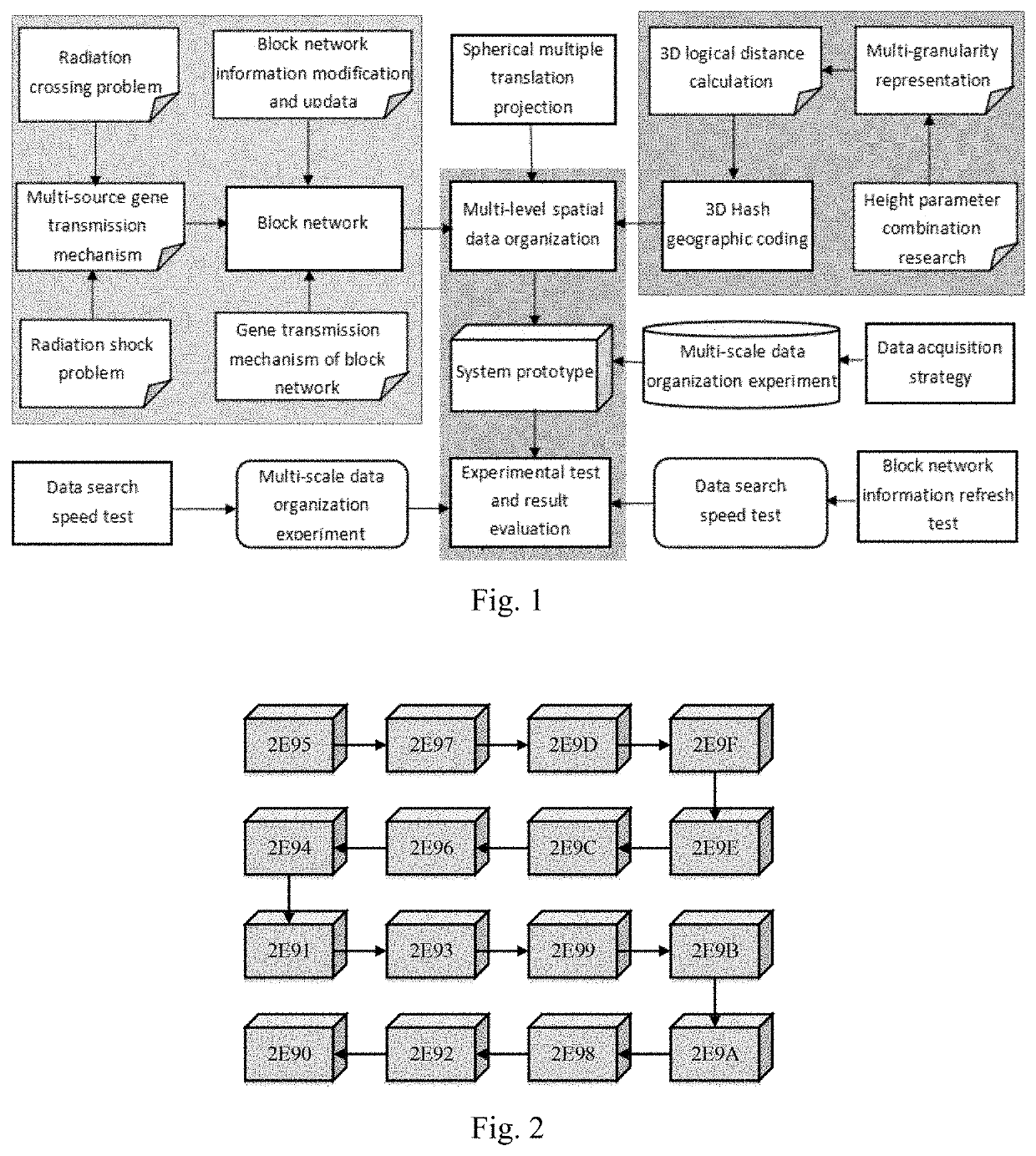

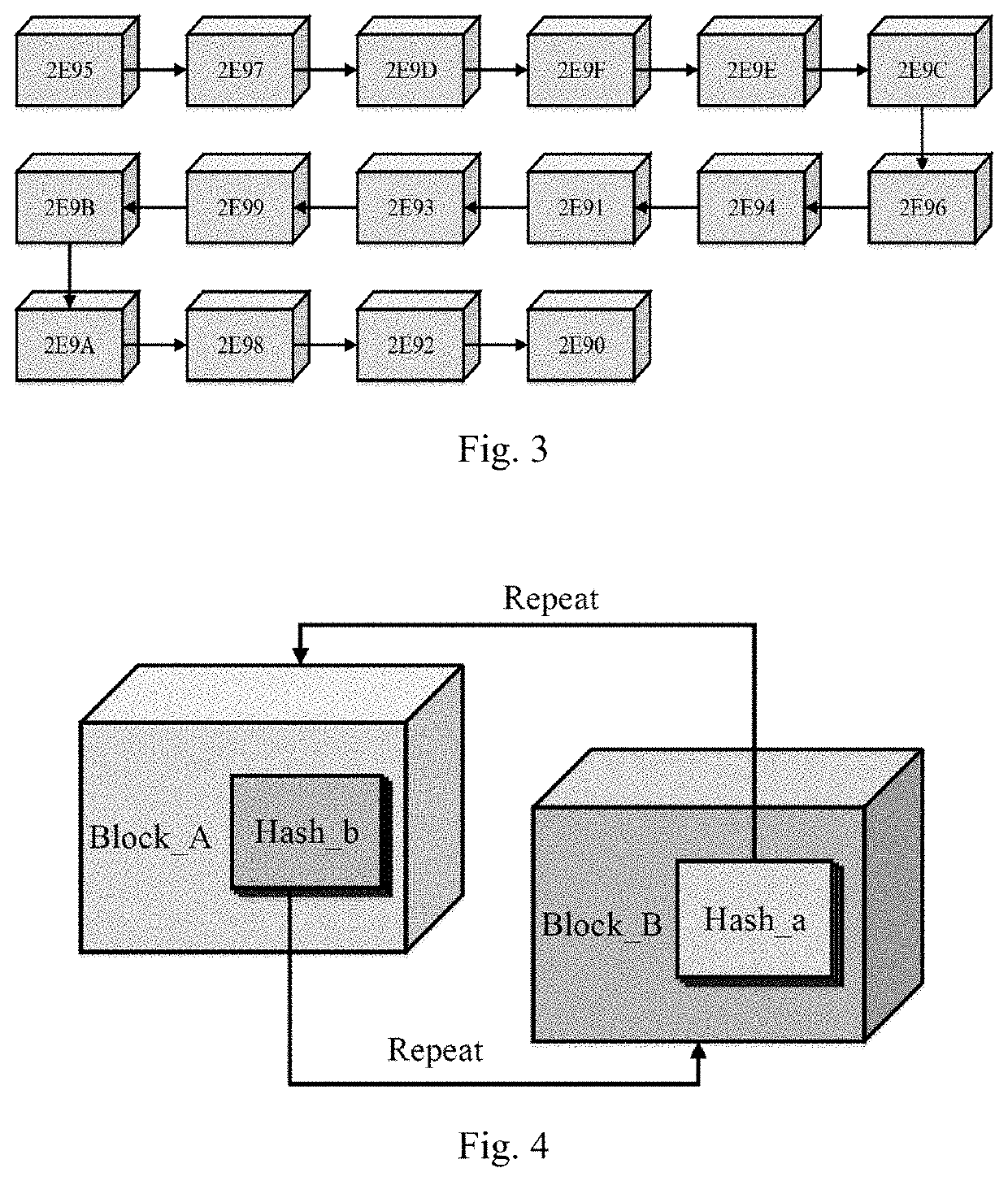

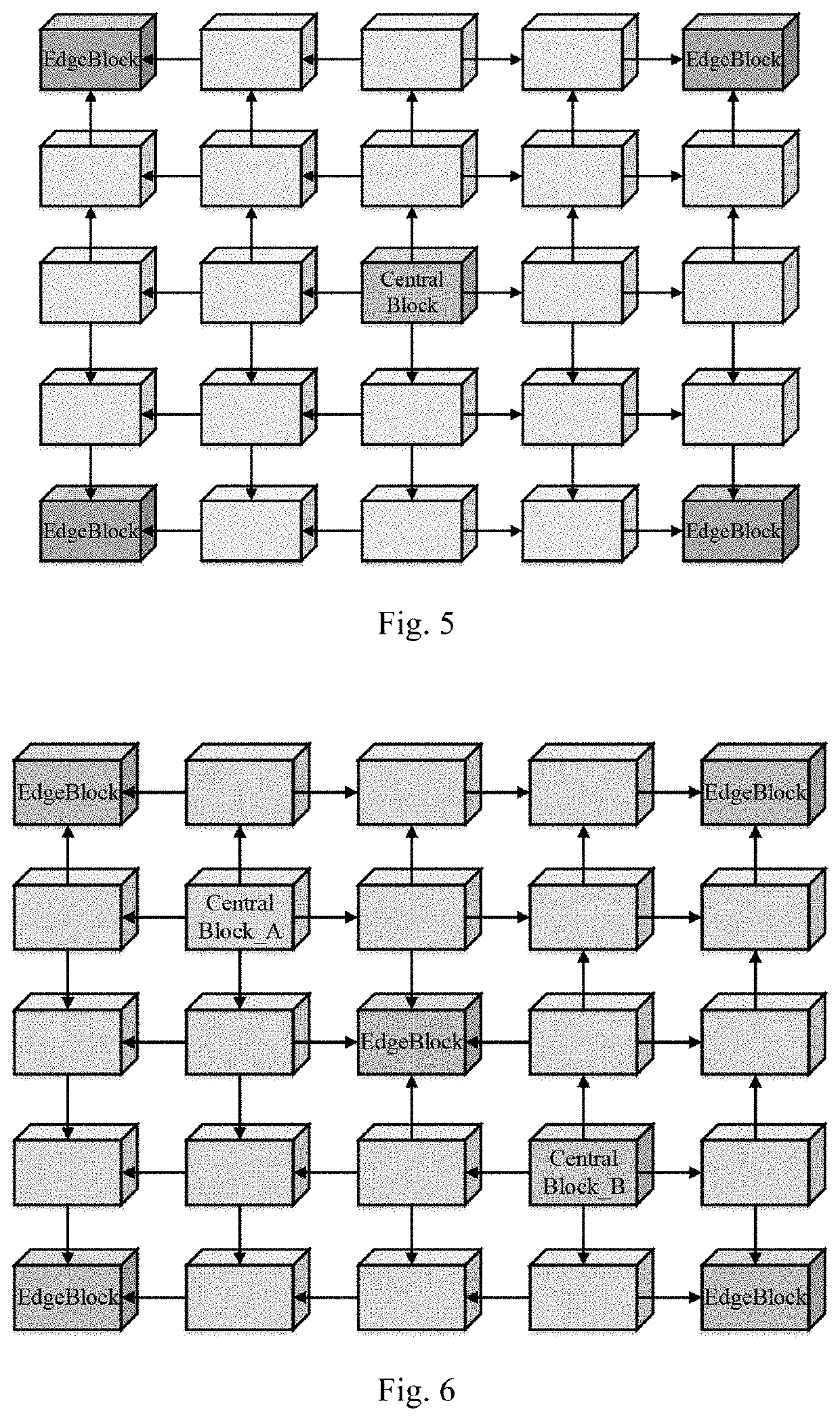

BlockNet security organization storage mapping method for spatial data

PendingUS20220121962A1Improve indexing speedIncrease spacingUser identity/authority verificationDatabase distribution/replicationAlgorithmEngineering

A BlockNet security organization storage mapping method for spatial data includes: first constructing a BlockNet gene propagation mechanism according to the characteristics of the BlockNet storage space data, and then designing multi-source gene propagation in a multi-space data center scenario mechanism. In the multi-source gene propagation mechanism, the propagation round control and the in / out-degree control mechanism are designed for the possible radiation crossover problems and radiation impact problems. A BlockNet information update plan is designed for data modification and update requirements in spatial data storage scenarios. In addition to realizing the unique primary key block coding of spatial data and accelerating the indexing speed, it also retains elevation information through multi-dimensional coding, expands the amount of information, improves the utilization efficiency of spatial data, and the security of data mapping and storage process is greatly improved.

Owner:QINGDAO UNIV

Embroidery cloth suitable for public

InactiveCN104088102APrecise tool changeImprove reliabilityEmbroidering machines apparatusBiochemical engineeringTextile

The invention discloses an embroidery cloth suitable for the public. The embroidery cloth comprises a base cloth, a binding layer and a printing layer, wherein the binding layer is arranged on the base cloth, and the printing layer is arranged on the binding layer. According to above way, the embroidery cloth suitable for the public has the advantages of high reliability, compact structure, good practicability, wide receiver, exquisite finished product and low cost, and is convenient to use and simple to operate; meanwhile, the embroidery cloth has wide market prospect on the embroidery market.

Owner:SUZHOU YEXIU CRAFTS FACTORY

Shaft type workpiece floating clamping and driving device for four-axis machining center

ActiveCN109176099ASolve processabilitySolve the problem of different axis of the center holePositioning apparatusMetal-working holdersSteel ballMachining

The invention discloses a shaft type workpiece floating clamping and driving device for a four-axis machining center. The shaft type workpiece floating clamping and driving device comprises a supporting body and a rotating arm which is rotatable; a hole is transversely formed in the supporting body; an ejection rod is transversely moved to transversely penetrate through the hole; a transverse tapered hole is formed in the rotating arm; a steel ball is fit in the tapered hole; a pressure spring for return is arranged on the steel ball; clamping arms are arranged at the front end of the rotatingarm; after being pushed by the ejection rod, the steel ball pushes the rotating arm to drive the clamping arms to radially move toward the center, generating acting force for clamping; a center tip is arranged on the inner side of the front end of the rotating arm and correspondingly fit with the positions of the clamping arms; and the center lines of the ejection rod, the steel ball and the center tip are located at the same horizontal line. By means of the shaft type workpiece floating clamping and driving device, the problem that the excircle of a to-be-machined shaft type product and a center hole are not coaxial can be solved, and the effect that two clamping jaws clamp the excircle in a floating manner in the case that the center hole is centered can still be achieved. The shaft type workpiece floating clamping and driving device can obtain very high machining precision and improve the machining efficiency of equipment.

Owner:重庆升科精锻科技有限公司

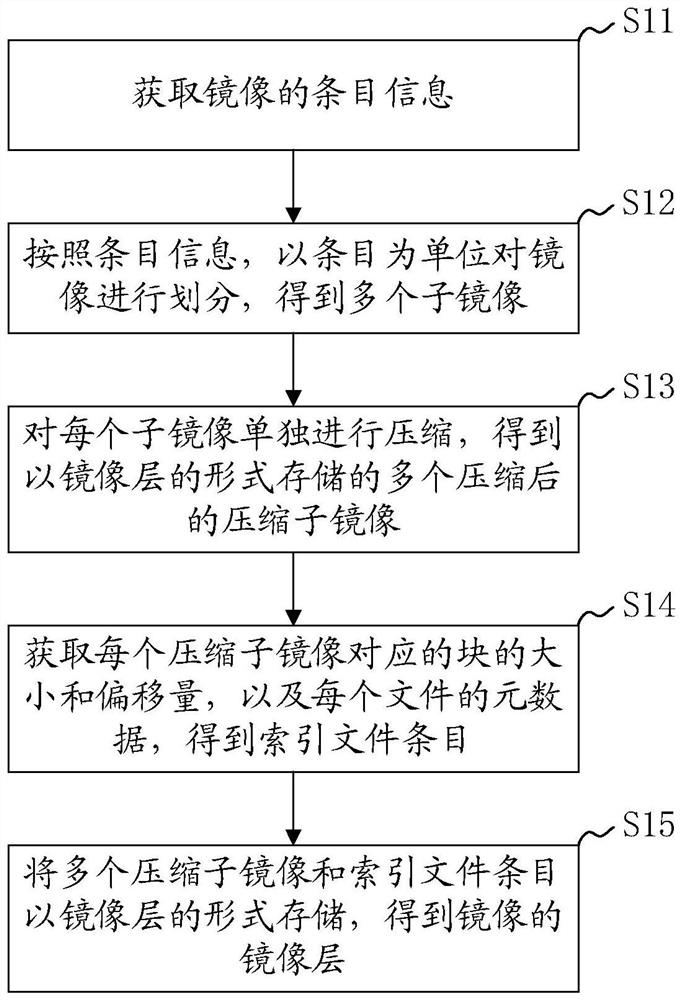

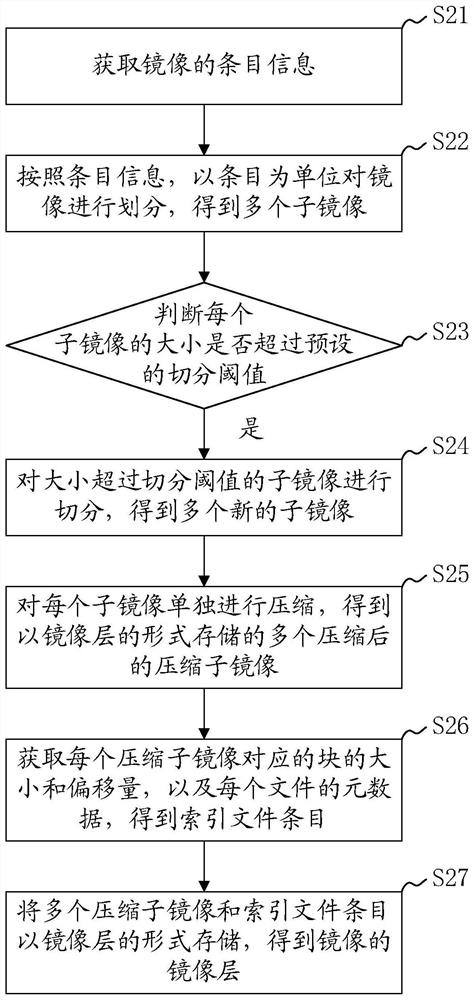

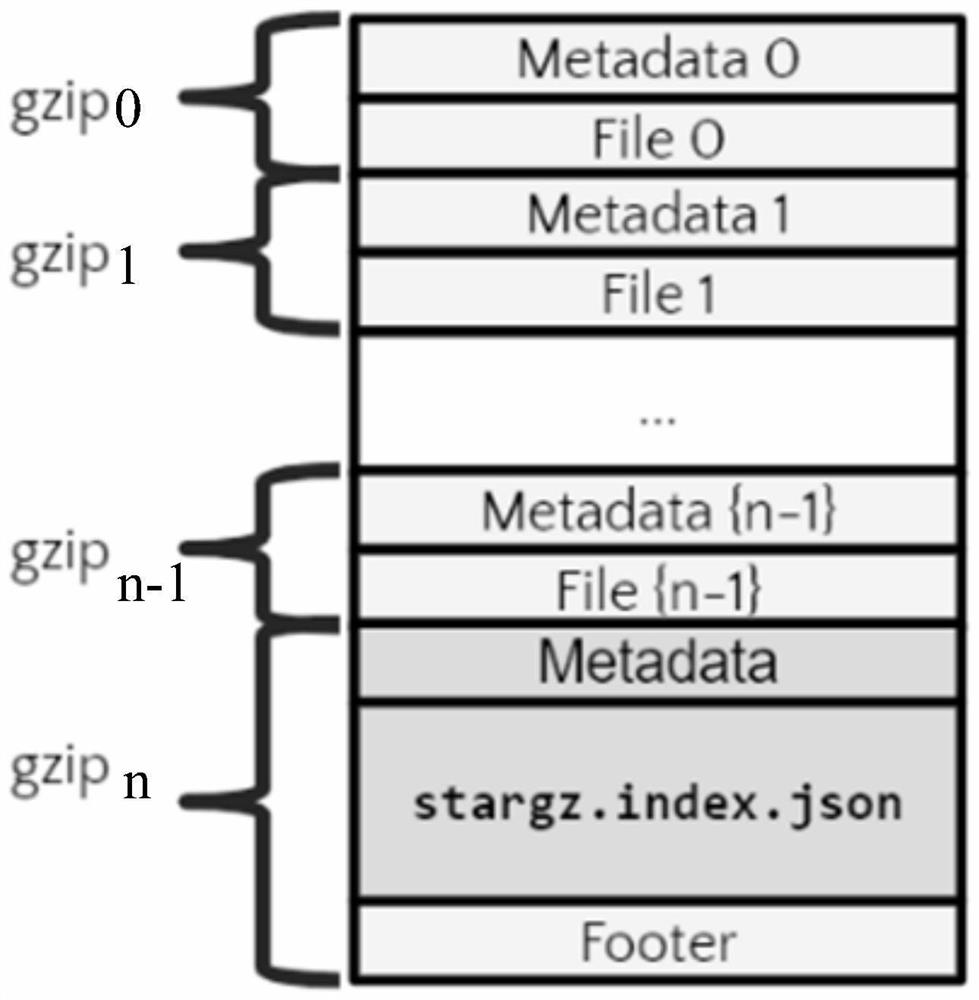

Docker container mirror image storage method and device, docker container mirror image pulling method and device and computer readable storage medium

PendingCN112433810AImprove loading speedImprove indexing speedTransmissionSoftware simulation/interpretation/emulationComputer graphics (images)Mirror image

The invention discloses docker container mirror image storage and pulling methods and devices and a computer readable storage medium. The docker container mirror image storage method comprises the steps of obtaining entry information of a mirror image; according to the entry information, dividing the mirror image by taking an entry as a unit to obtain a plurality of sub-mirror images; independently compressing each sub-mirror image to obtain a plurality of compressed sub-mirror images stored in a mirror image layer form; obtaining the size and offset of a block corresponding to each compressedsub-mirror image and metadata of each file to obtain an index file entry; and storing the plurality of compressed sub-images and the index file entry in the form of an image layer to obtain the imagelayer of the image. According to the method, the whole mirror image is divided into the plurality of sub-mirror images according to the entries and is independently compressed, so that part of the compressed sub-mirror images can be directly obtained without obtaining all the sub-mirror images at a time and setting index file entries, the index speed of the compressed sub-mirror images is increased, and a premise is created for increasing the mirror image loading speed.

Owner:北京浪潮数据技术有限公司

Automatic loader for swing-type pipettor

ActiveCN104176313ASimple structureAvoid missingIndividual articlesJigging conveyorsPipetteEngineering

The invention discloses an automatic loader for a swing-type pipettor. The automatic loader comprises a vibrating disc, a linear vibrator, a swing mechanism, a movable base and a loading disc, the vibrating disc is connected with the linear vibrator, one end of the linear vibrator is connected with the swing mechanism, the movable base is arranged below the swing mechanism, the loading disc is arranged on the movable base, and the swing mechanism and the movable base are controlled by a controller. By the above mode, the automatic loader has the advantages of high reliability, accuracy in positioning, compact and simple structure, high transposition speed, accuracy in placing, freeness of missing placement and mistaken placement, convenience in operation and the like, and has wide market prospect in packaging market.

Owner:JIANGSU LONGRUN IRRIGATION & DRAINAGE

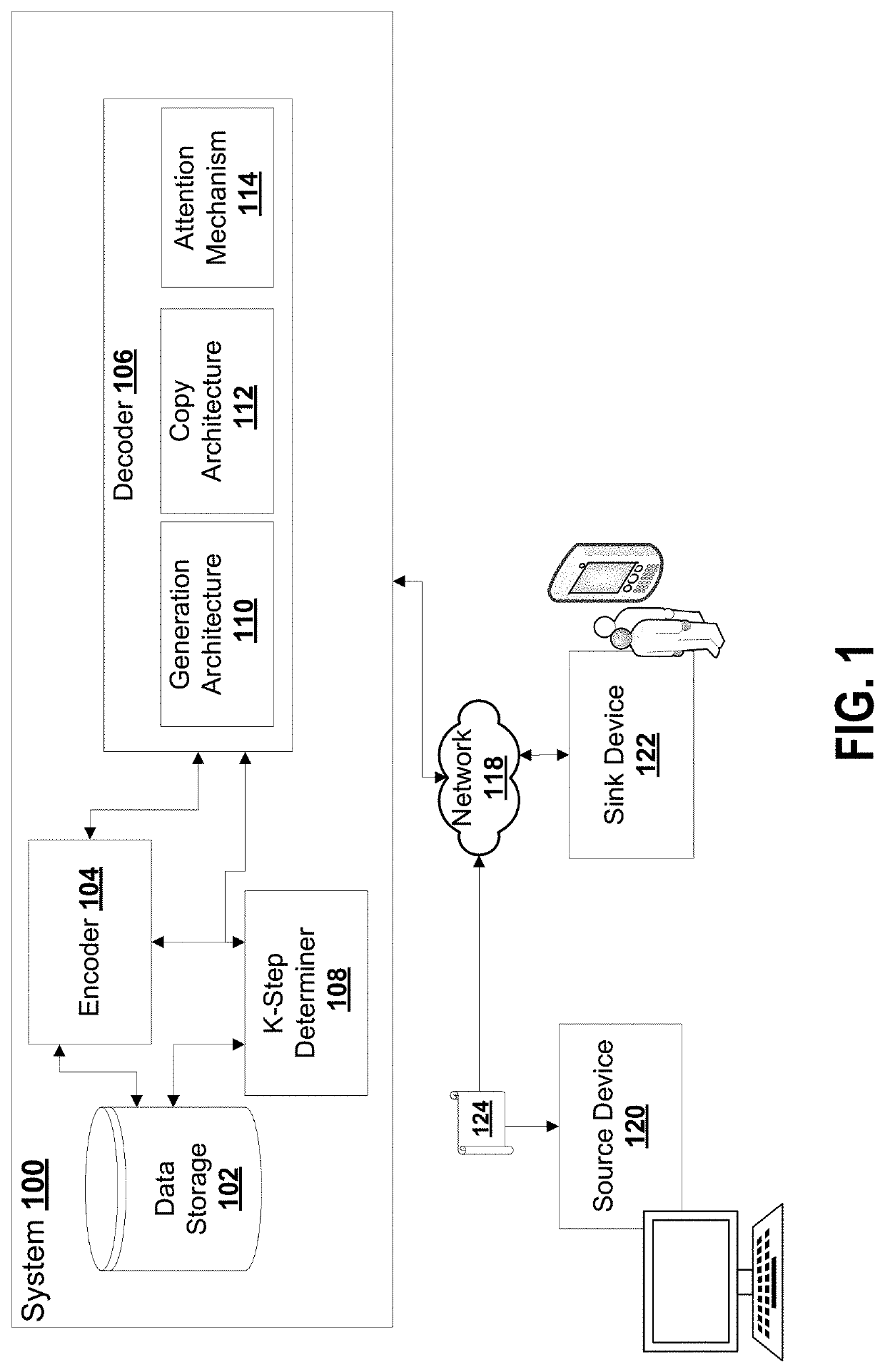

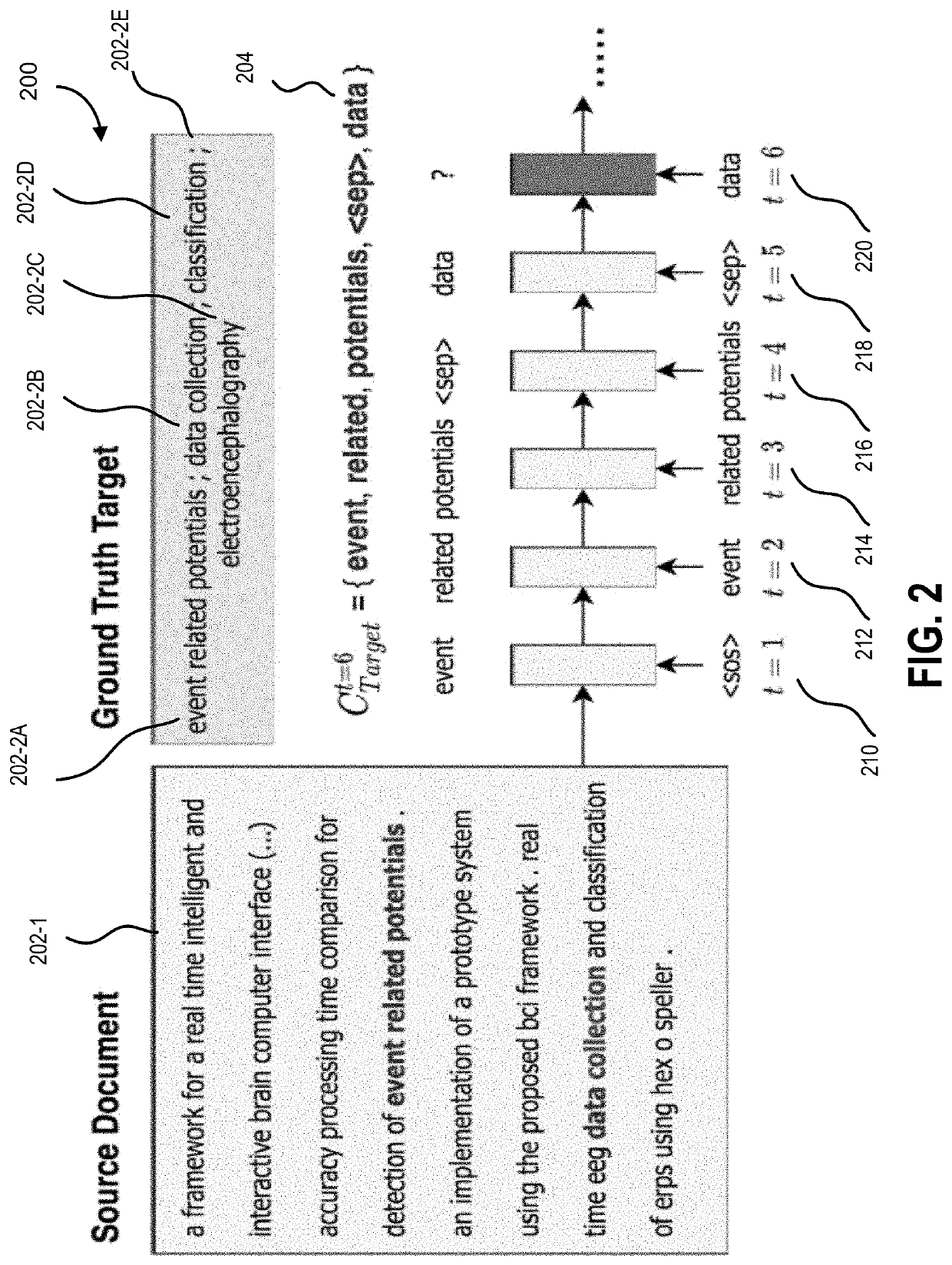

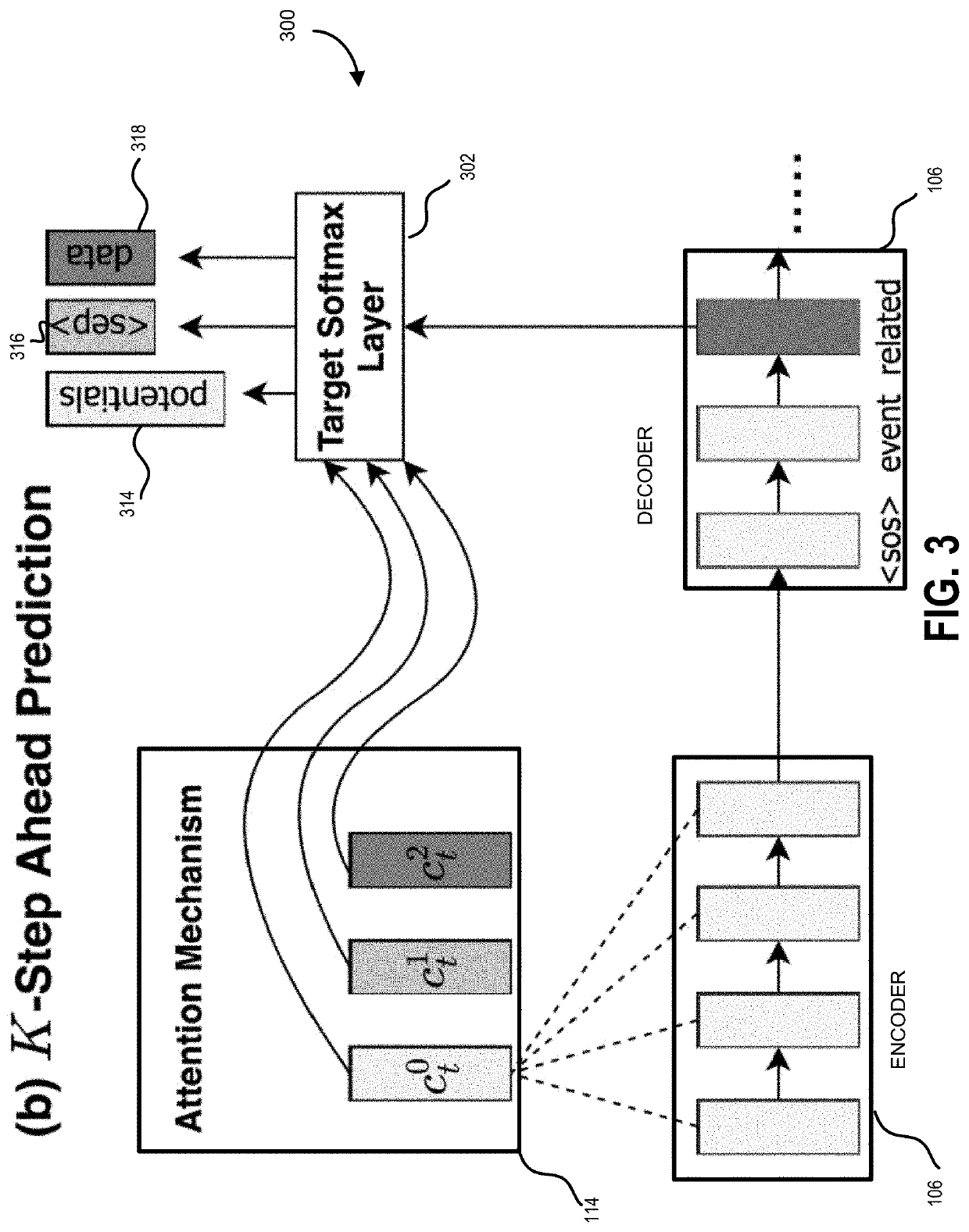

Systems and methods for diverse keyphrase generation with neural unlikelihood training

PendingUS20220004712A1Avoid repetitionTechnical challenge to overcomeSemantic analysisMachine learningAlgorithmEngineering

Computer implemented methods and systems are provided for generating diverse key phrases while maintaining competitive output quality. A system for training a sequence to sequence (S2S) machine learning model is proposed where neural unlikelihood objective approaches are used at (1) a target token level to discourage the generation of repeating tokens, and (2) a copy token level to avoid copying repetitive tokens from the source text. K-step ahead token prediction approaches are also proposed as an additional mechanism to augment the approach to further enhance the overall diversity of key phrase outputs.

Owner:ROYAL BANK OF CANADA

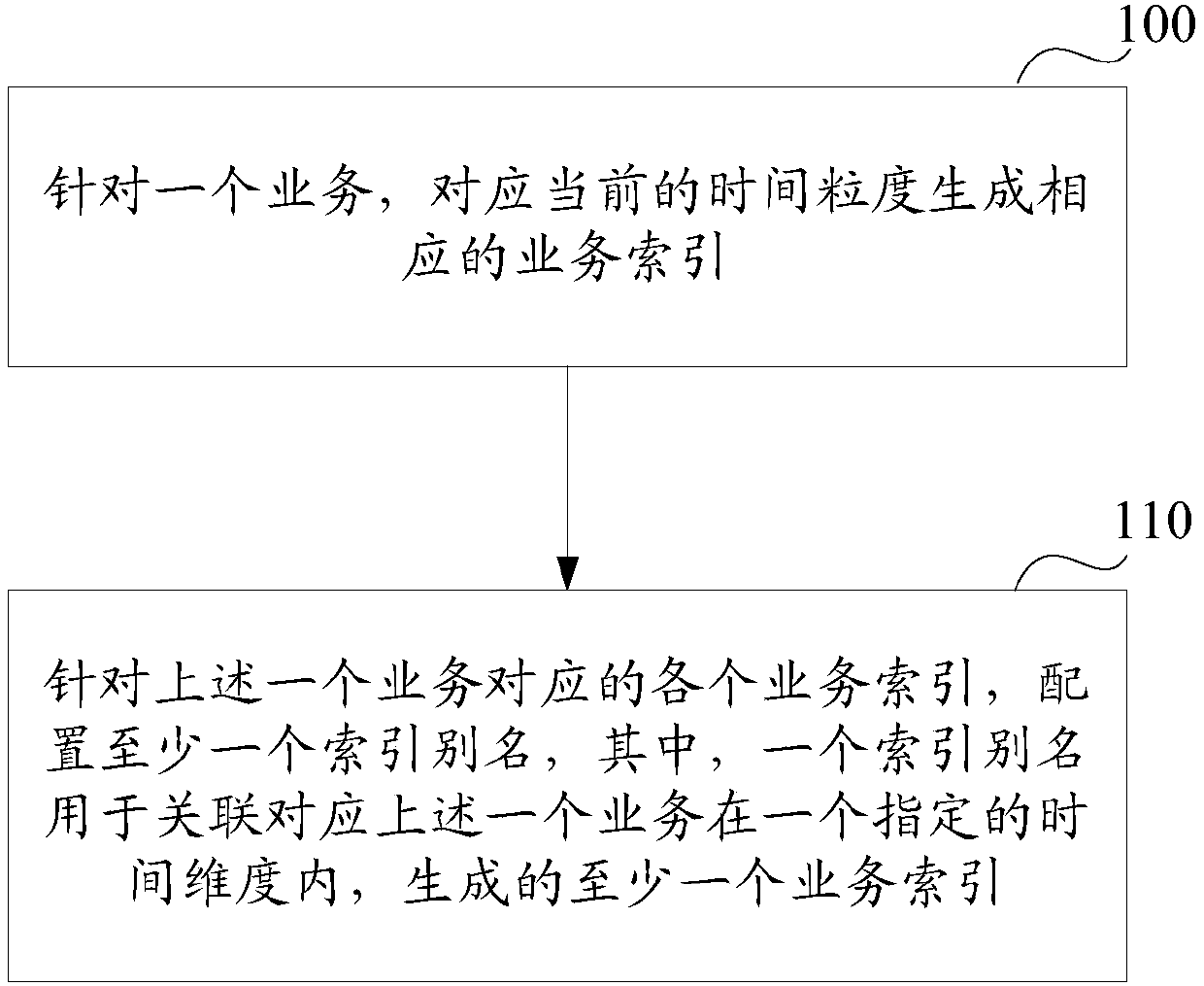

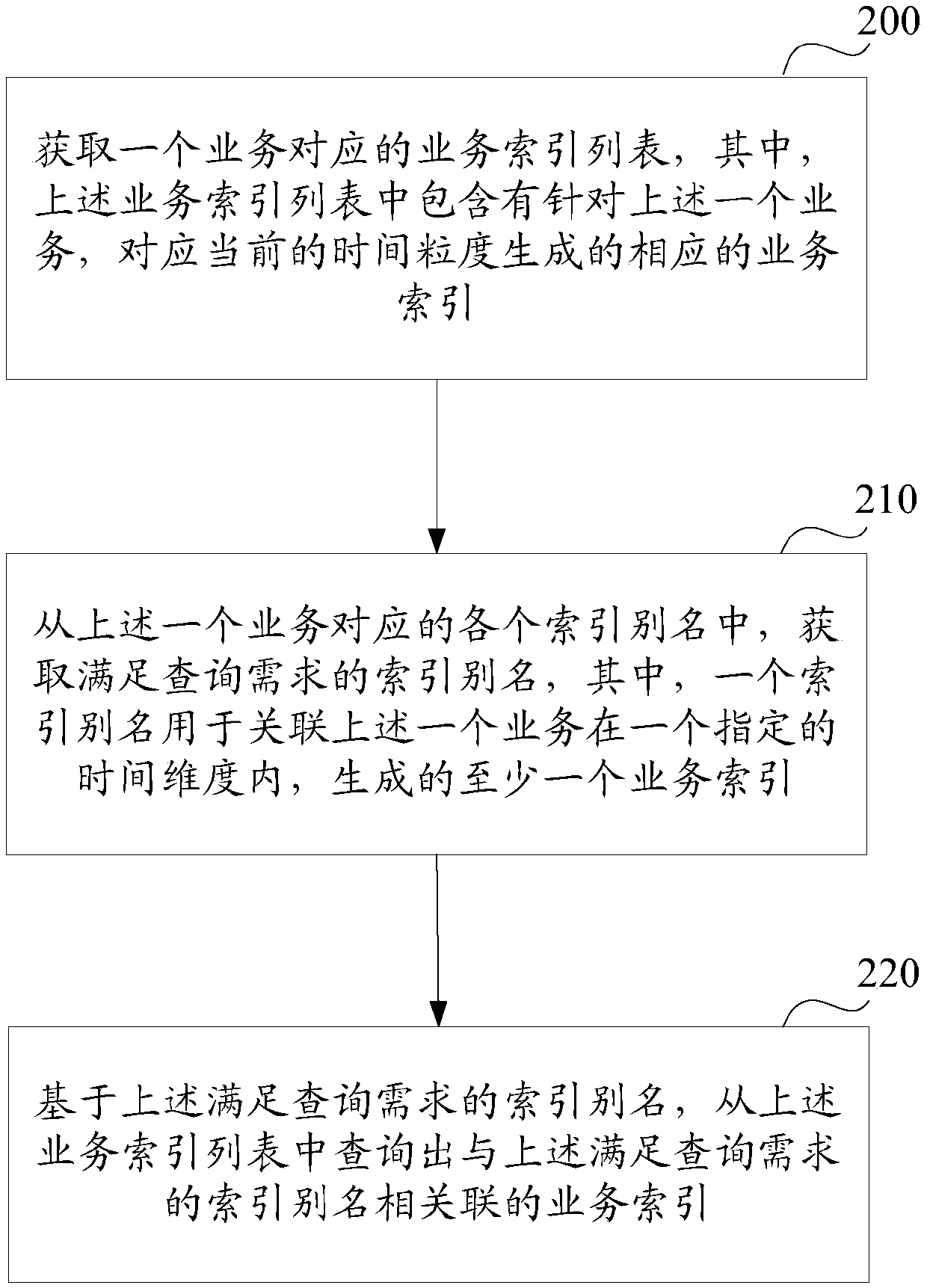

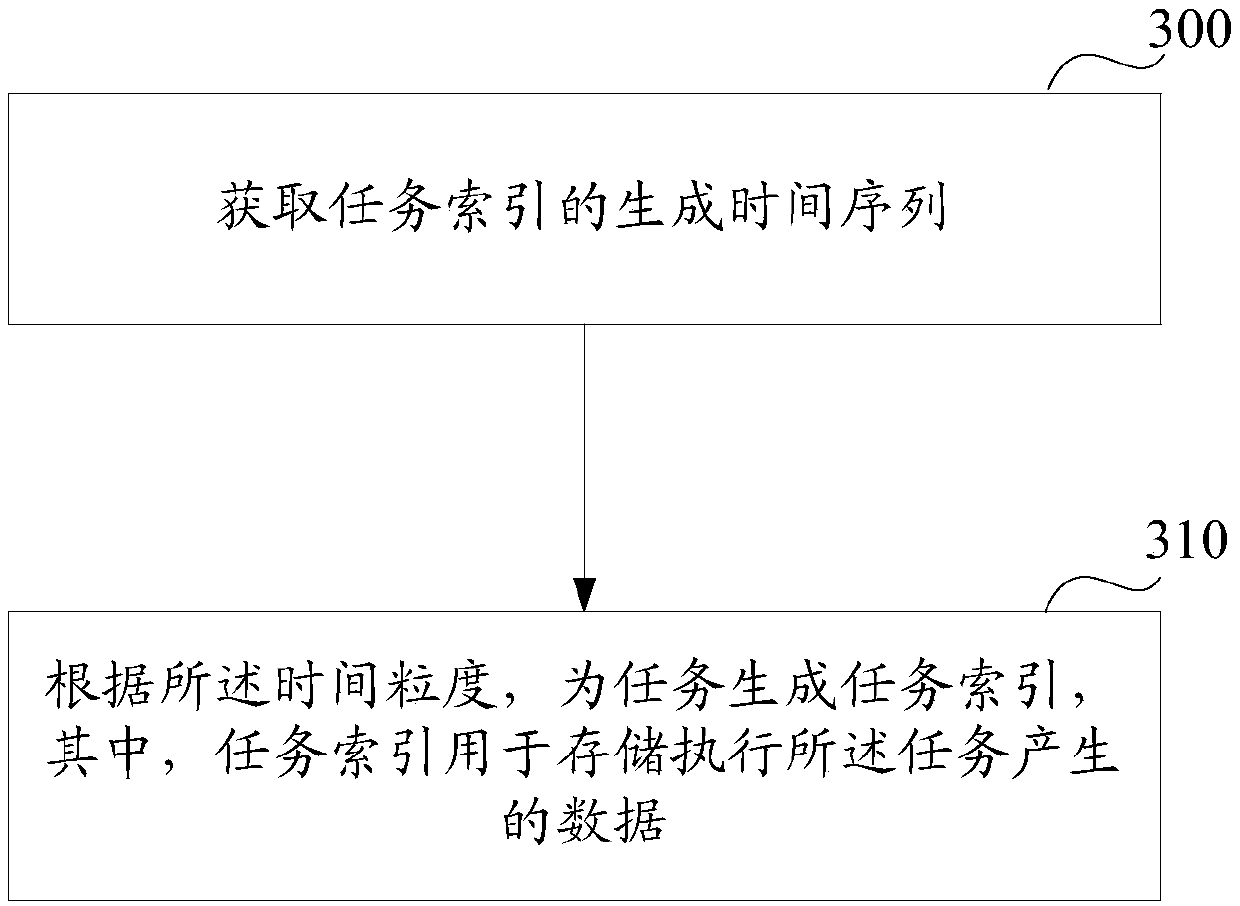

Index establishing and using method and device

ActiveCN110019200AAchieve decouplingReduce coding difficultySpecial data processing applicationsDatabase indexingCurrent timeData processing

The invention relates to the technical field of data processing, in particular to an index establishing and using method and device. The method comprises the following steps: for each service, generating a corresponding service index corresponding to a current time granularity, the time granularity being a period for generating a corresponding service index for a certain service; and respectivelyexecuting the following operations on each service in each service: for each service index corresponding to one service, configuring at least one index alias, one index alias being used for associating at least one service index generated by the corresponding service in a specified time dimension. According to the method, a single service index does not need to bear the service data correspondingto one service, so that the indexing speed is increased, the required service index can be inquired through the corresponding index alias configured for the index corresponding to one service, decoupling between the service and the index is realized, and the coding difficulty of the service code is reduced.

Owner:ALIBABA GRP HLDG LTD

Hub flexible casting riser machining system based on machine vision

The invention discloses a hub flexible casting riser machining system based on machine vision. The hub flexible casting riser machining system comprises a conveying line, a centering mechanism for positioning a hub, a feeding and discharging mechanism for moving and overturning the hub, a machine vision positioning device for determining a machining surface of a saw blade, a tool clamp and a cutting system for cutting a hub riser. According to the hub flexible casting riser machining system based on machine vision, in this way, clamping of different models of hubs is achieved by adopting a step-type hydraulic clamp, the cutting surface of the saw blade is determined through the machine vision positioning device, the hub flexible casting riser machining system has the advantages that reliable performance is high, positioning is accurate, the structure is compact, the transposition speed is high, the adaptability is high, and the efficiency is high, and meanwhile, the hub flexible casting riser machining system has wide market prospects in application and popularization of hub machining.

Owner:XIANGNONG INTELLIGENT TECH CO LTD

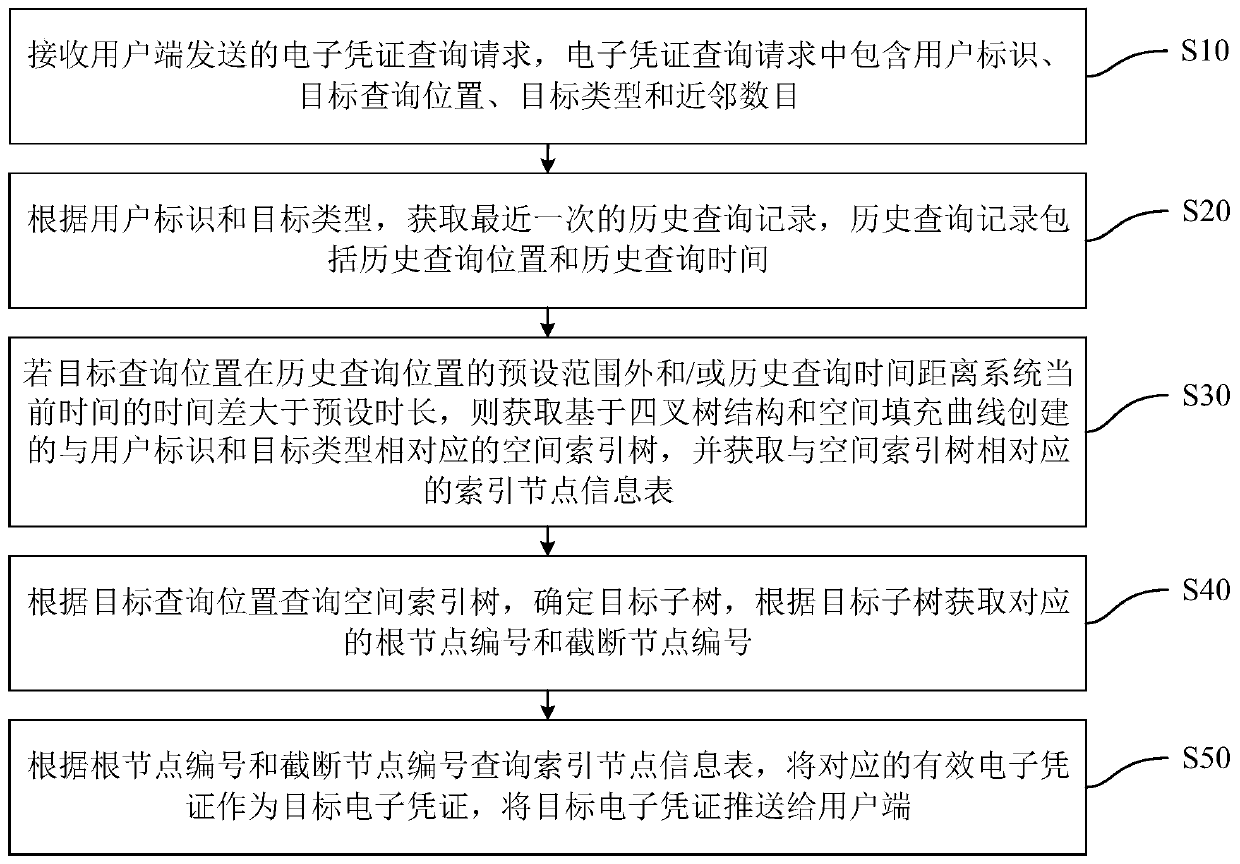

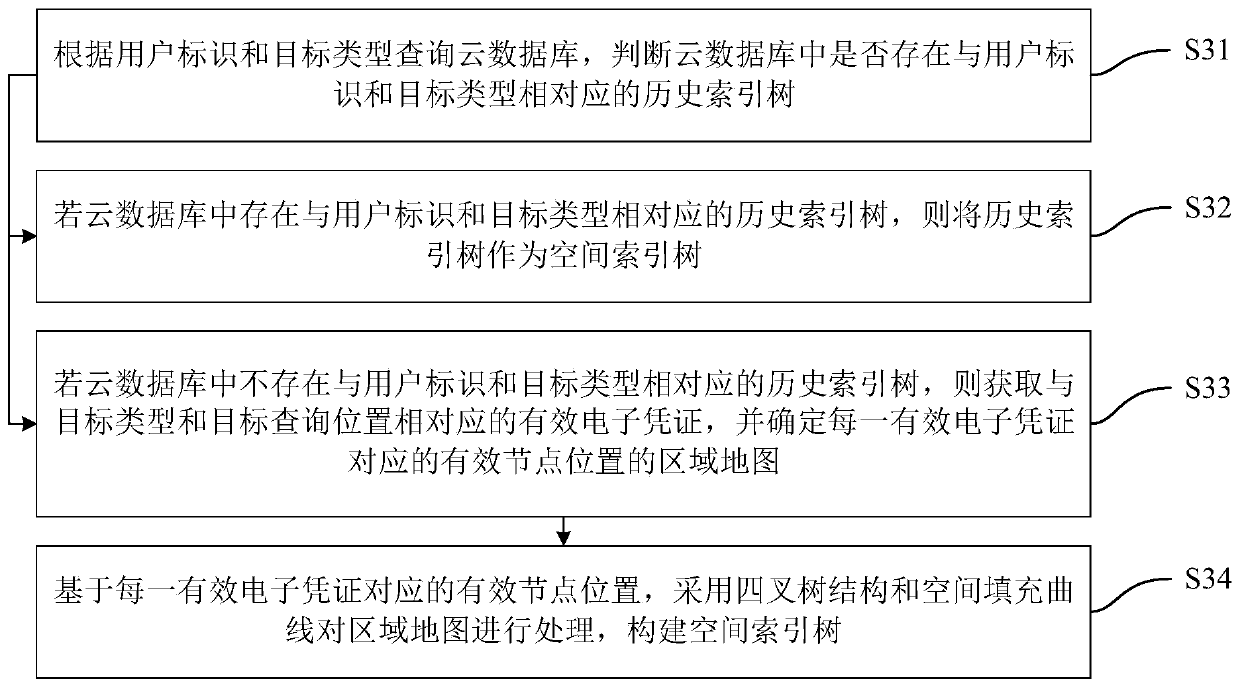

Electronic certificate prompting method and device, computer equipment and storage medium

ActiveCN110532437AImplement index queryAcquisition speed is fastOther databases indexingOther databases queryingUser identifierInode

The invention discloses an electronic certificate prompting method and device, computer equipment and a storage medium. The method comprises the steps of receiving an electronic certificate query request sent by a user side; according to the user identifier and the target type, obtaining a latest historical query record, wherein the historical query record comprises a historical query position andhistorical query time; if the target query position is out of the preset range of the historical query position and / or the time difference between the historical query time and the current time of the system is greater than the preset duration, obtaining a spatial index tree corresponding to the user identifier and the target type, and obtaining an index node information table corresponding to the spatial index tree; querying a spatial index tree according to the target query position, determining a target sub-tree, and obtaining a corresponding root node number and a truncation node number according to the target sub-tree; and querying the index node information table according to the root node number and the truncation node number, and taking the corresponding effective electronic certificate as the target electronic certificate, thereby realizing a problem that the pushed electronic certificate is more accurate.

Owner:PING AN TECH (SHENZHEN) CO LTD

Swing-out pipette tip autoloader

ActiveCN104176313BSimple structureAvoid missingIndividual articlesJigging conveyorsPipetteEngineering

The invention discloses an automatic loader for a swing-type pipettor. The automatic loader comprises a vibrating disc, a linear vibrator, a swing mechanism, a movable base and a loading disc, the vibrating disc is connected with the linear vibrator, one end of the linear vibrator is connected with the swing mechanism, the movable base is arranged below the swing mechanism, the loading disc is arranged on the movable base, and the swing mechanism and the movable base are controlled by a controller. By the above mode, the automatic loader has the advantages of high reliability, accuracy in positioning, compact and simple structure, high transposition speed, accuracy in placing, freeness of missing placement and mistaken placement, convenience in operation and the like, and has wide market prospect in packaging market.

Owner:JIANGSU LONGRUN IRRIGATION & DRAINAGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com