Cam positioning bidirectional continuous indexing worktable

An indexing table, cam technology, applied in precision positioning equipment, manufacturing tools, large fixed members, etc., can solve problems such as inability to locate, low reliability, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

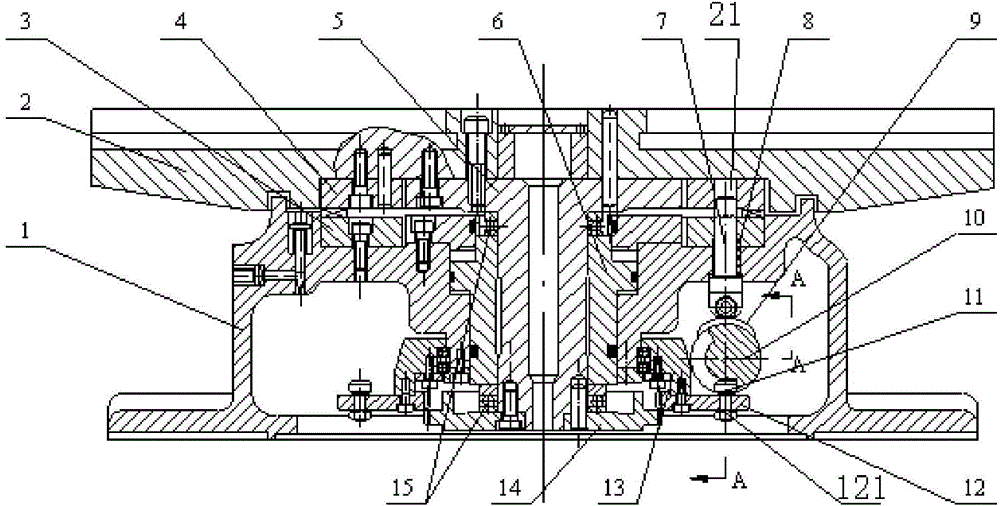

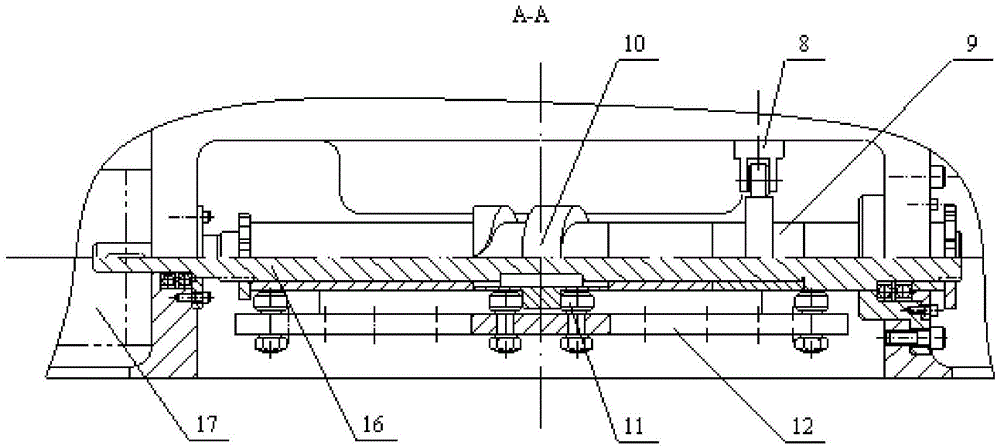

[0027] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0028] Such as Figure 1-7 As shown, a cam positioning bidirectional continuous indexing table, it includes:

[0029] A base 1, a piston cylinder is arranged in the base 1;

[0030] The table top 2 is provided with a limit assembly between the table top 2 and the base 1 to limit the relative rotational position of the table top 2 and the base 1, and the table top 2 is provided with a plurality of indexing position holes 21;

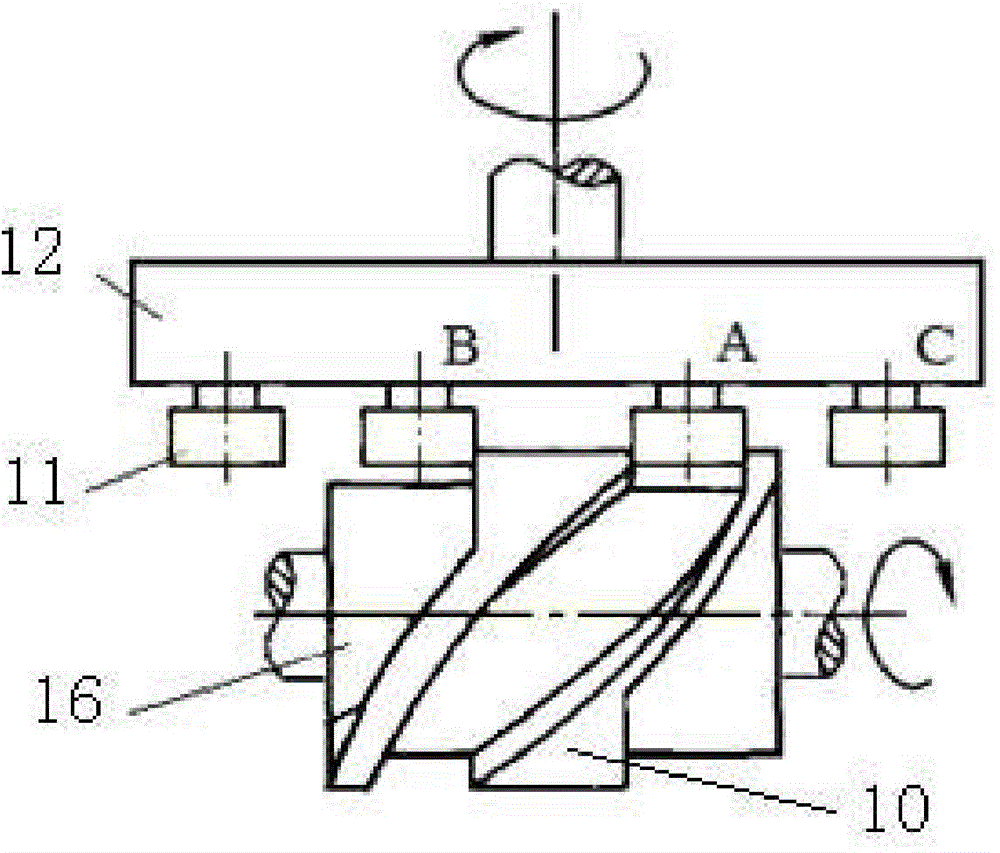

[0031] A camshaft 16, the camshaft 16 is rotatably supported on the base 1, and the outer wall of the camshaft 16 has a cylindrical cam body 10 and a plane cam body 9;

[0032] Locating pin 7, one end of locating pin 7 cooperates with a plurality of index position holes 21, and the other end of locating pin 7 abuts with plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com