Patents

Literature

2677results about "Jigging conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

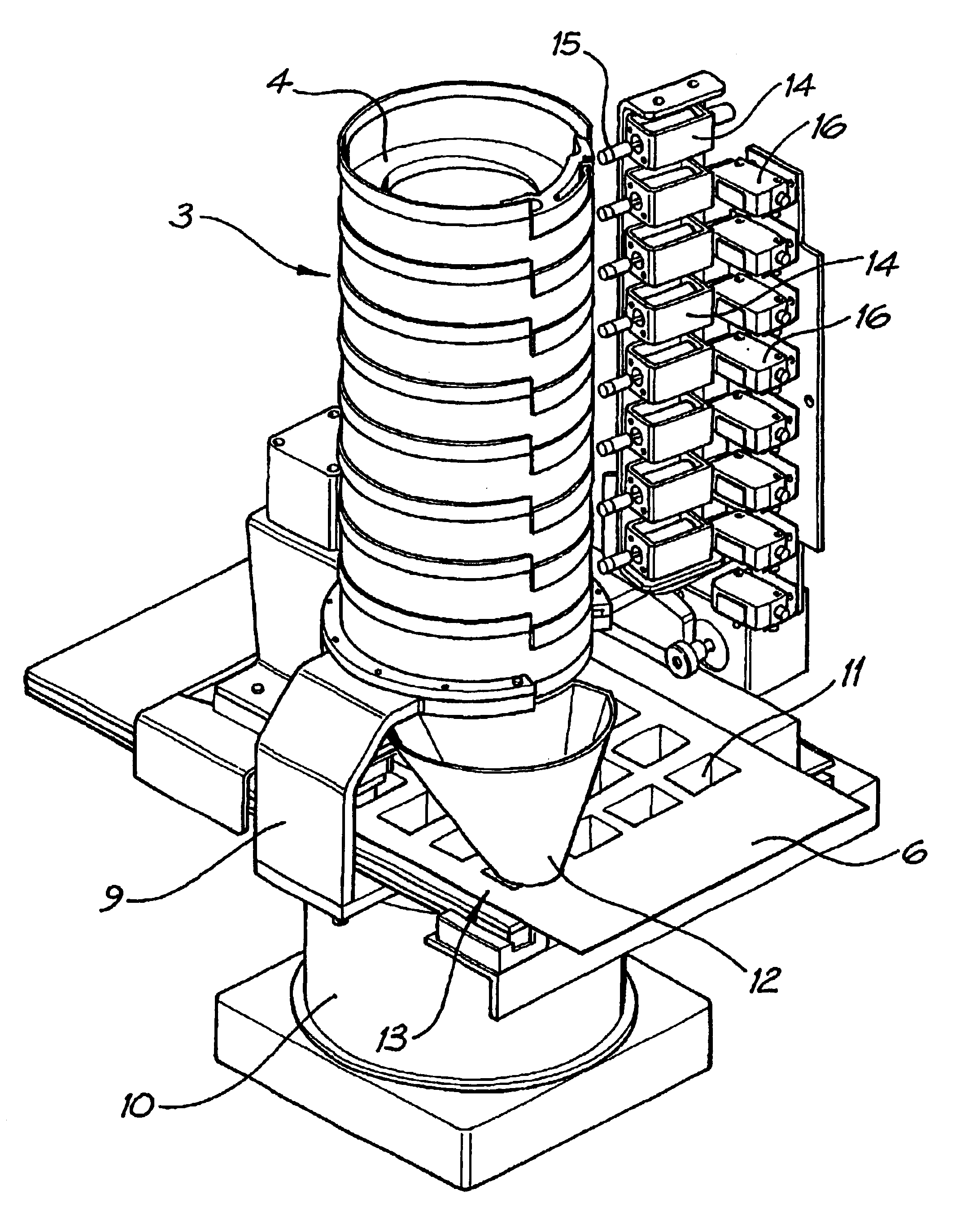

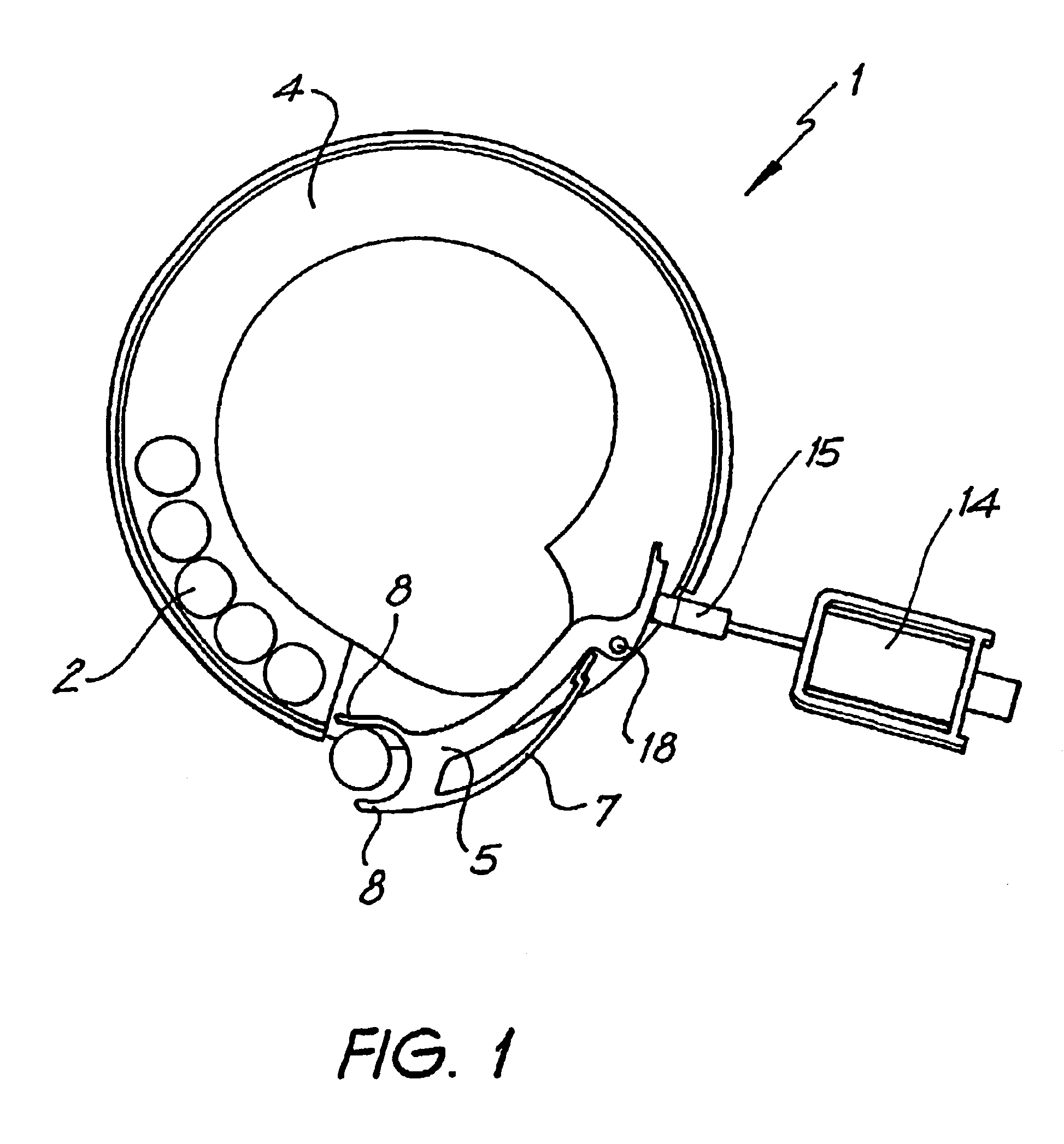

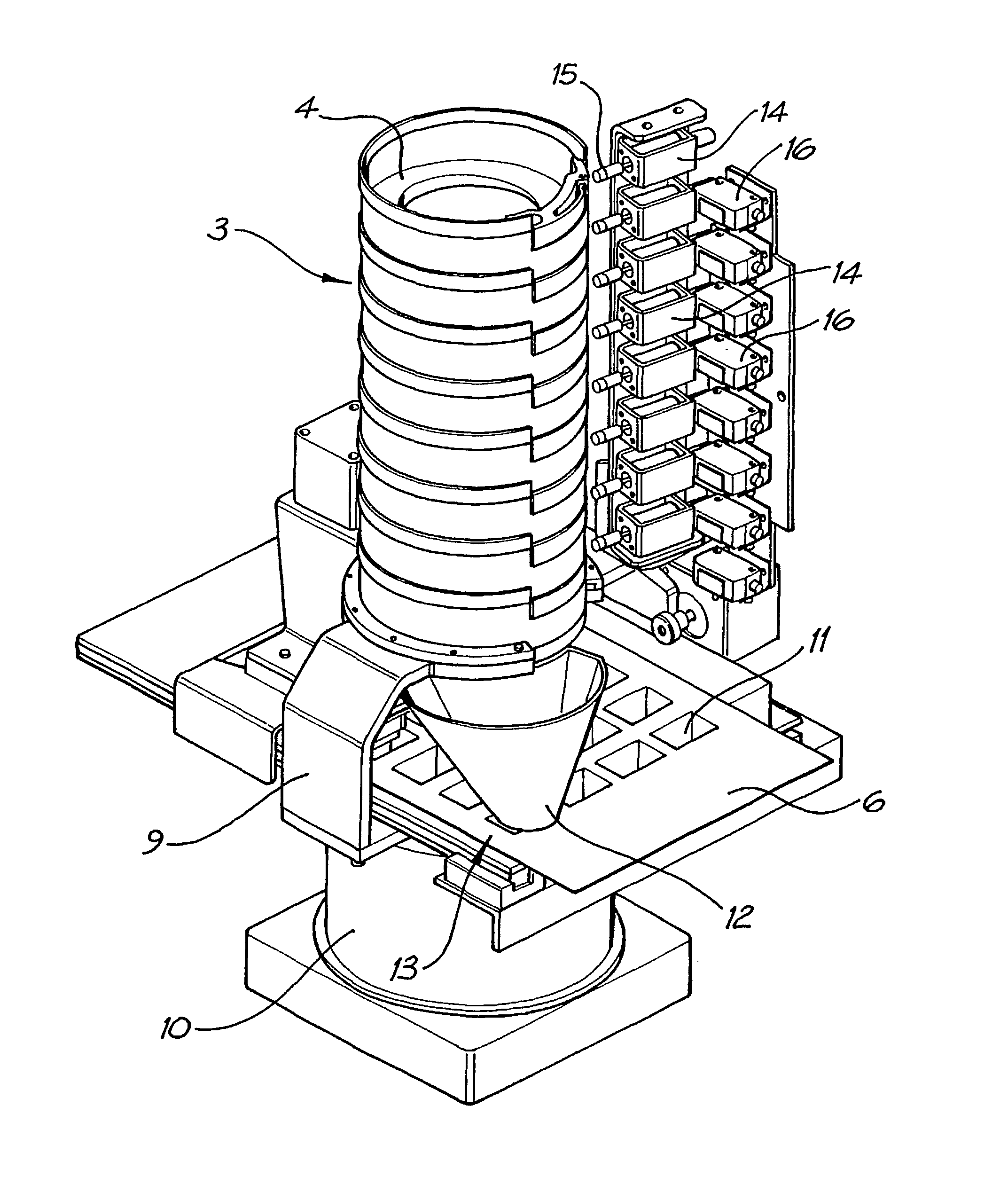

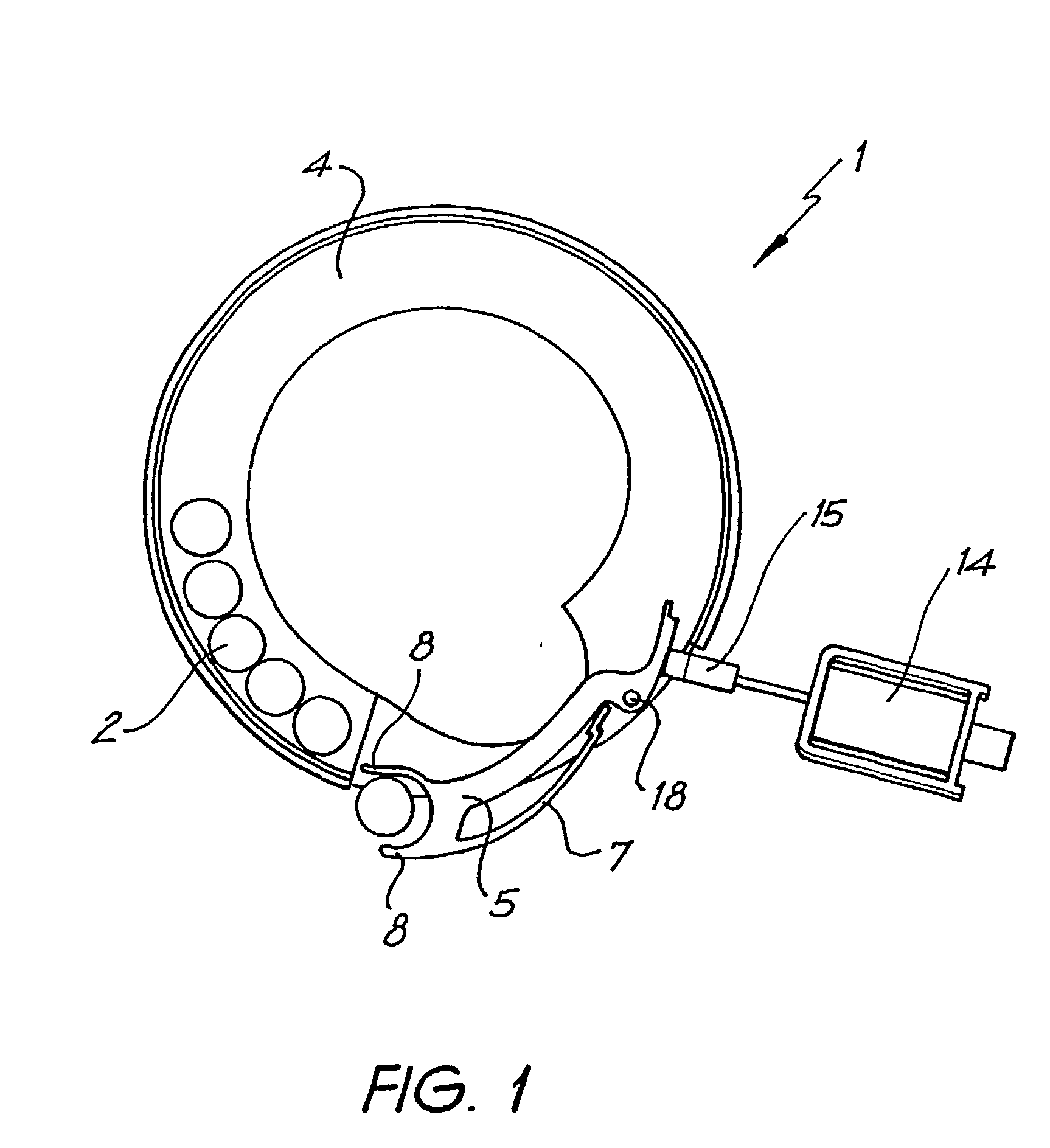

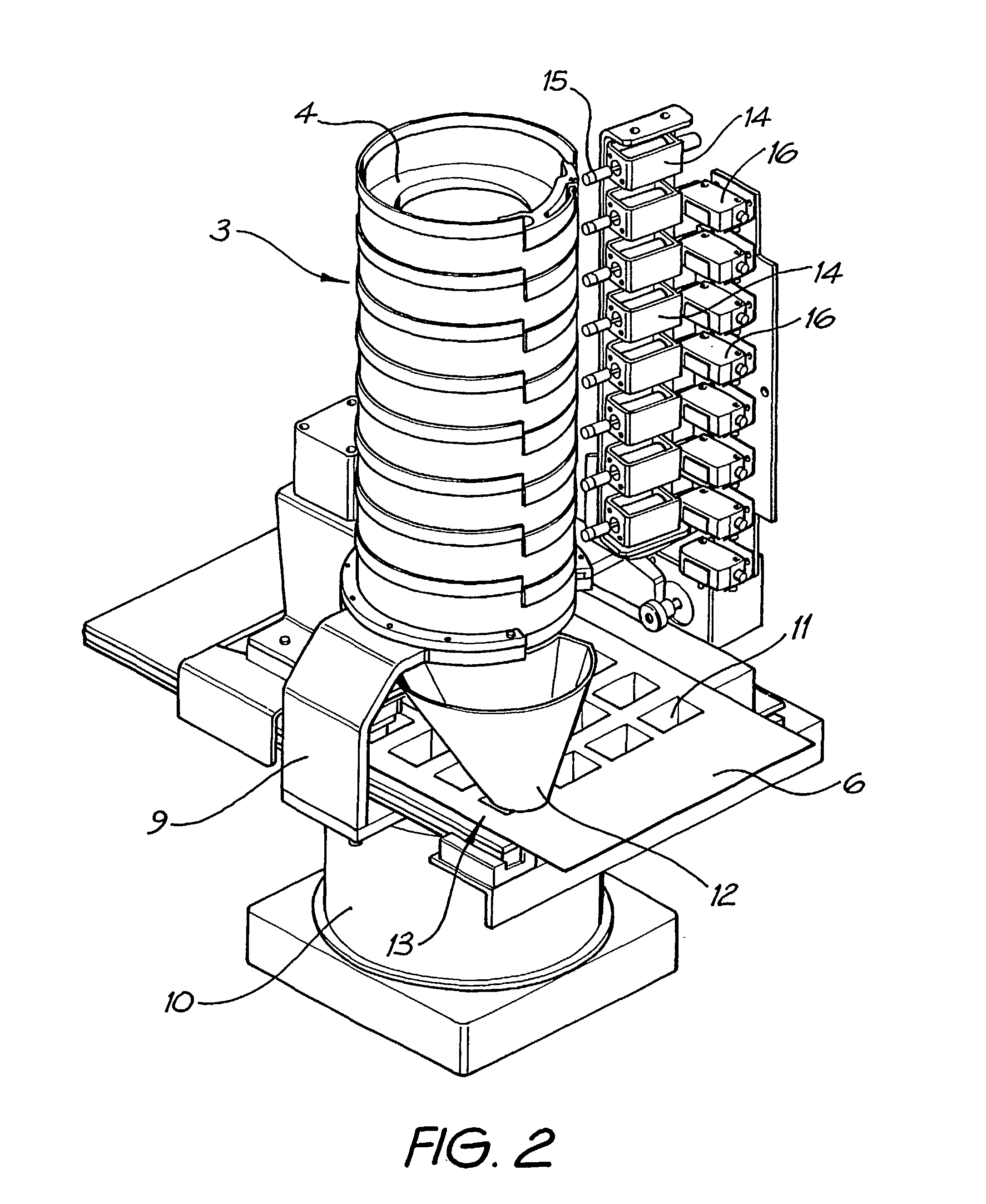

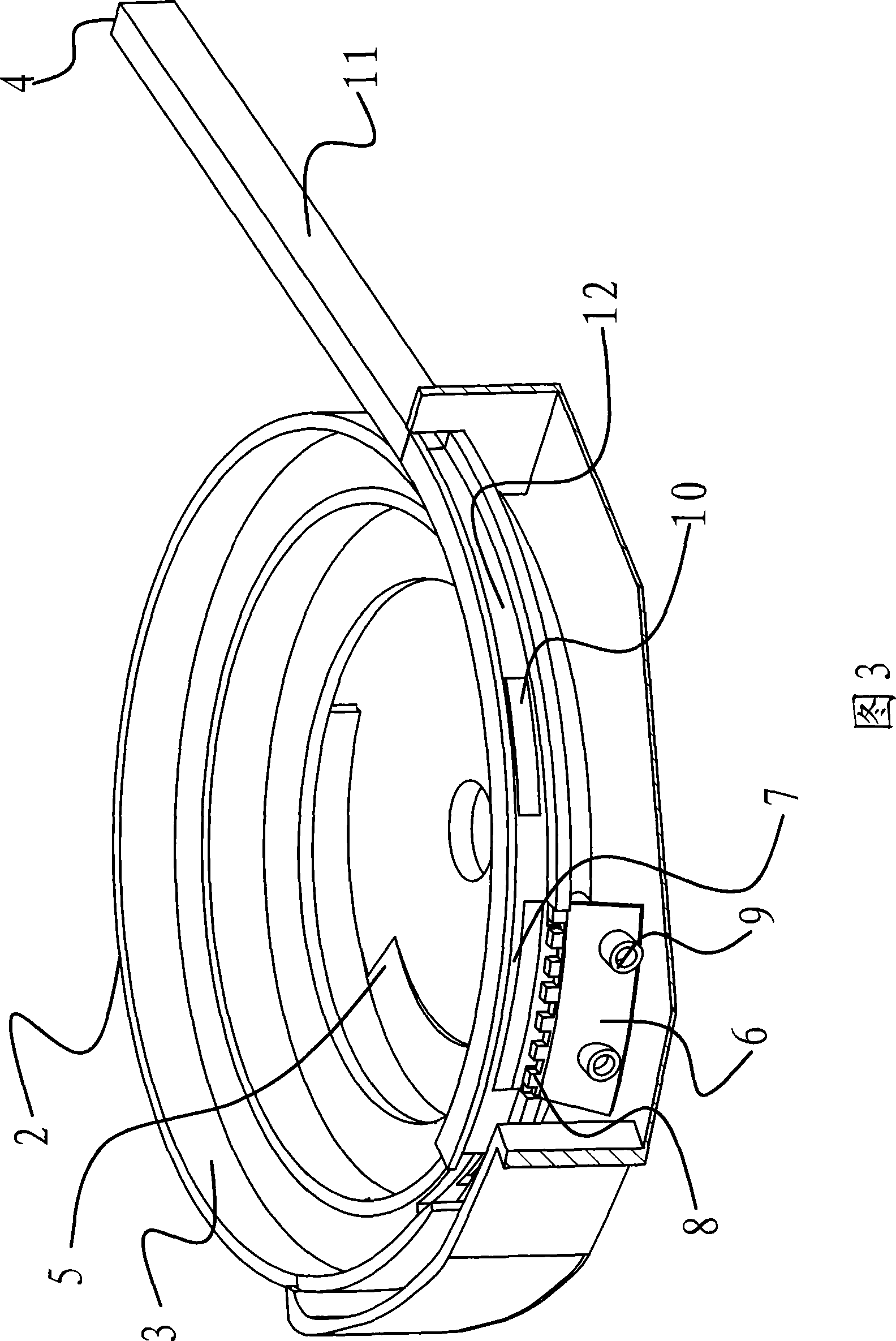

Medication dispenser

InactiveUS6805259B2Coin-freed apparatus detailsOral administration deviceMedication DispenserReciprocating motion

A medication tablet dispenser has an upright casing providing a tower which is subdivided by horizontal partitions into eight compartments which individually contain removable holders each containing a charge of tablets to be dispensed. The holders have framing portions which together provide a funnel opening downwardly into a cavity of a blister sheet. The casing is vibrated back and forth about its vertical axis through a small angle to cause tablets in the holders to progress towards an outlet leading into the funnel and having an associated ejector which discharges selected tablets into the funnel when required by a computer program. Conical vibration of the casing is prevented by a connection located on its vertical axis and held stationary by a fixed arm. The ejectors operate in response to slide-rods individually reciprocated by associated solenoids controlled by the computer program.

Owner:MANREX AUSTRALIA

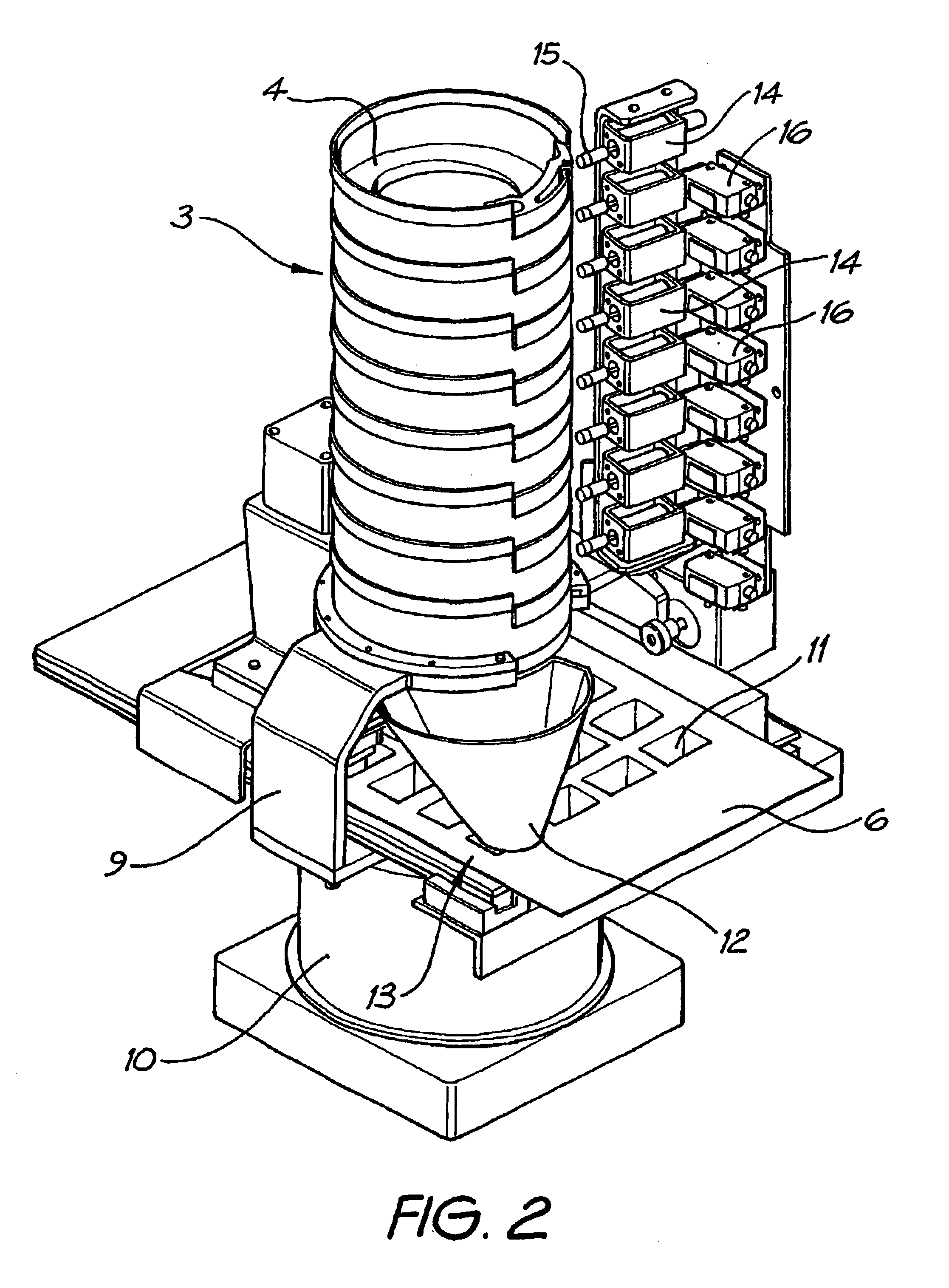

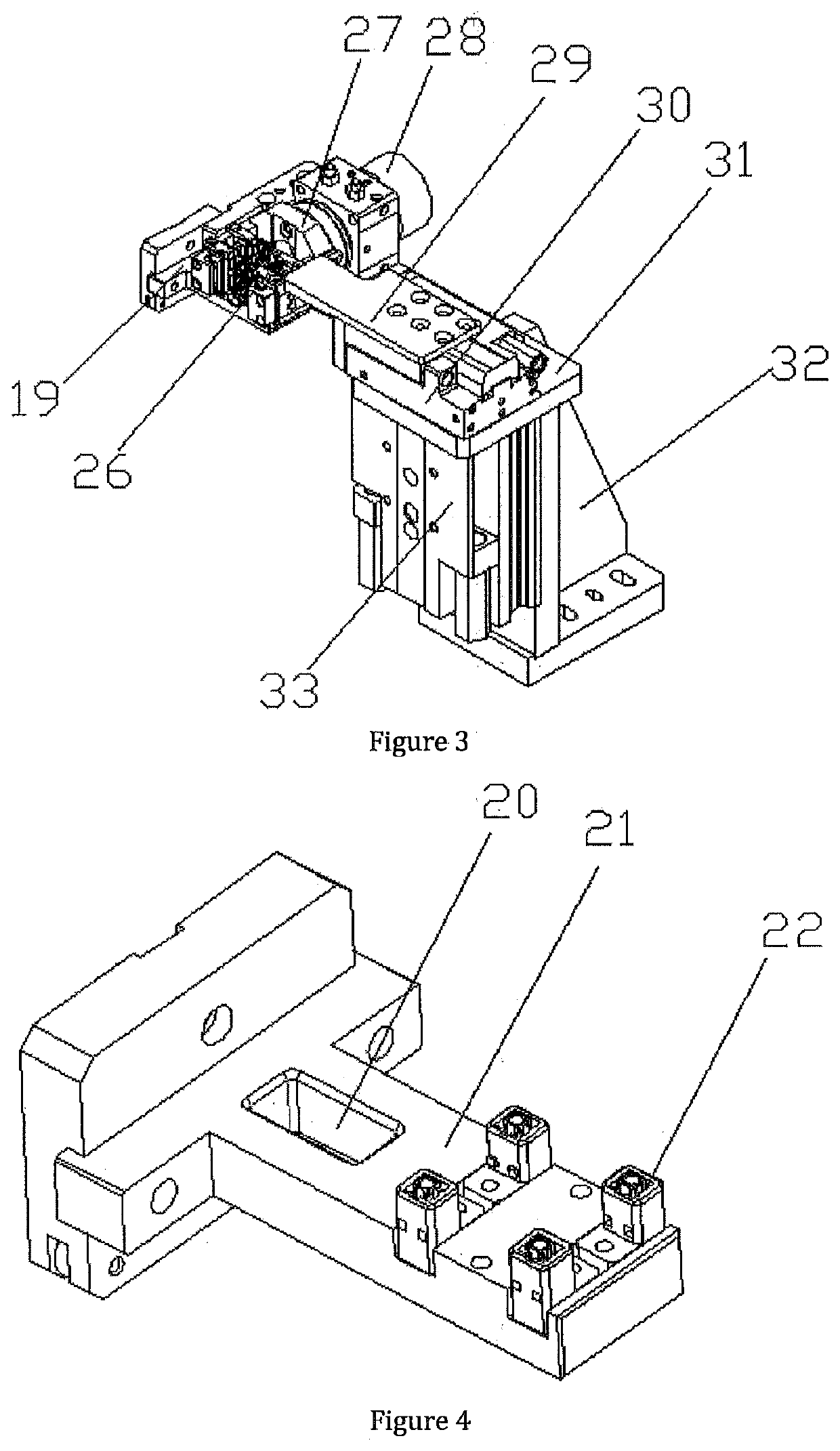

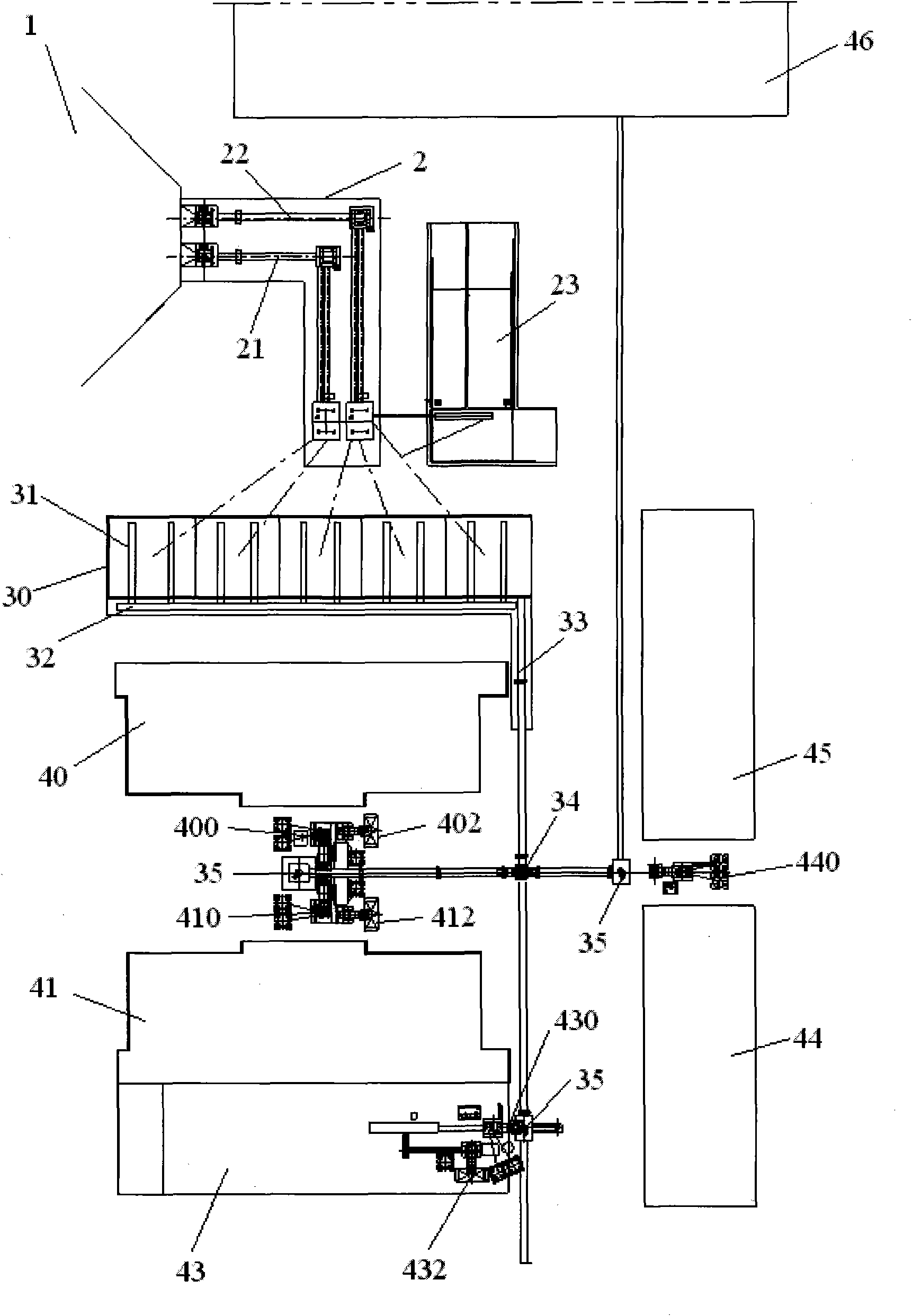

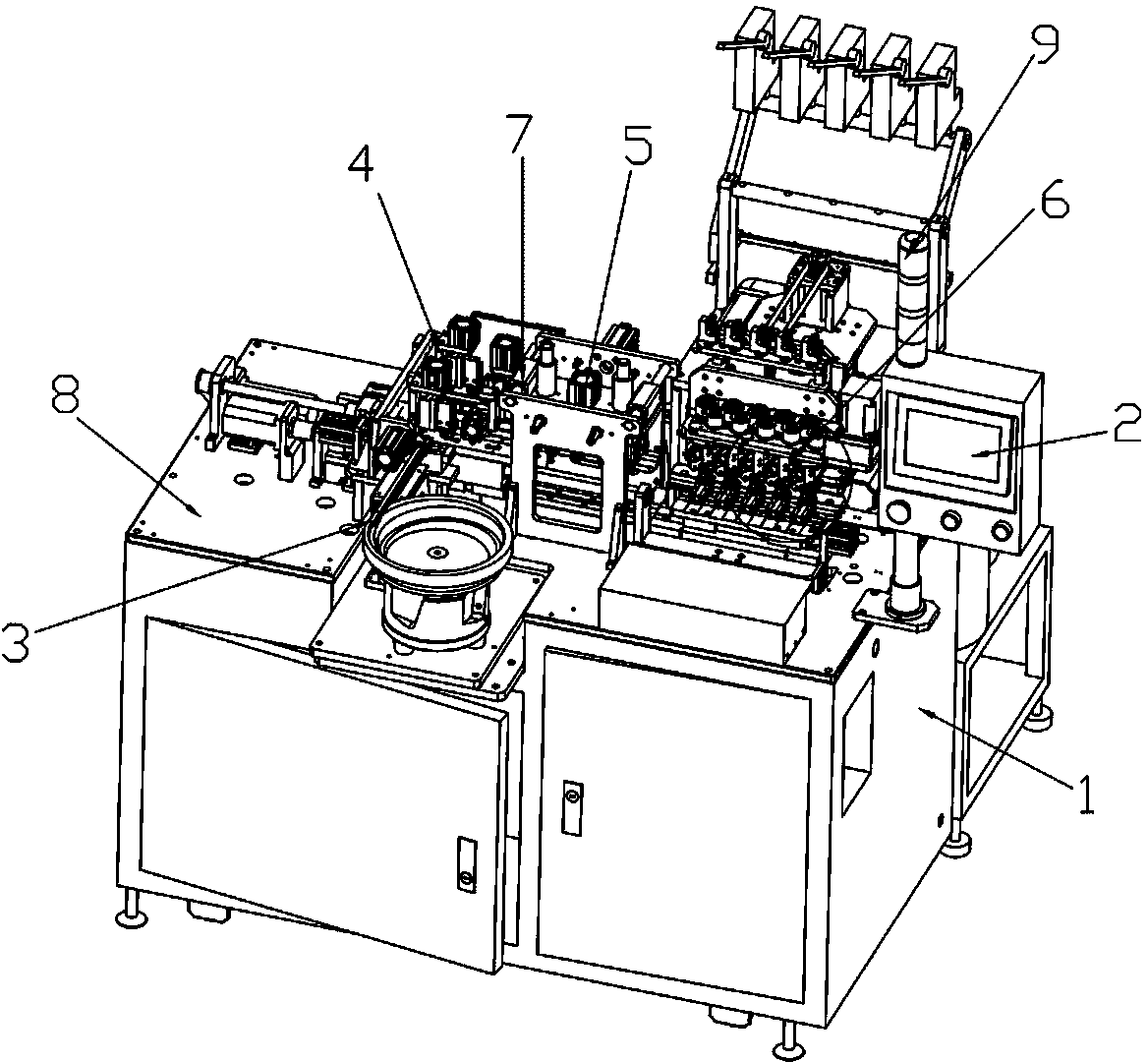

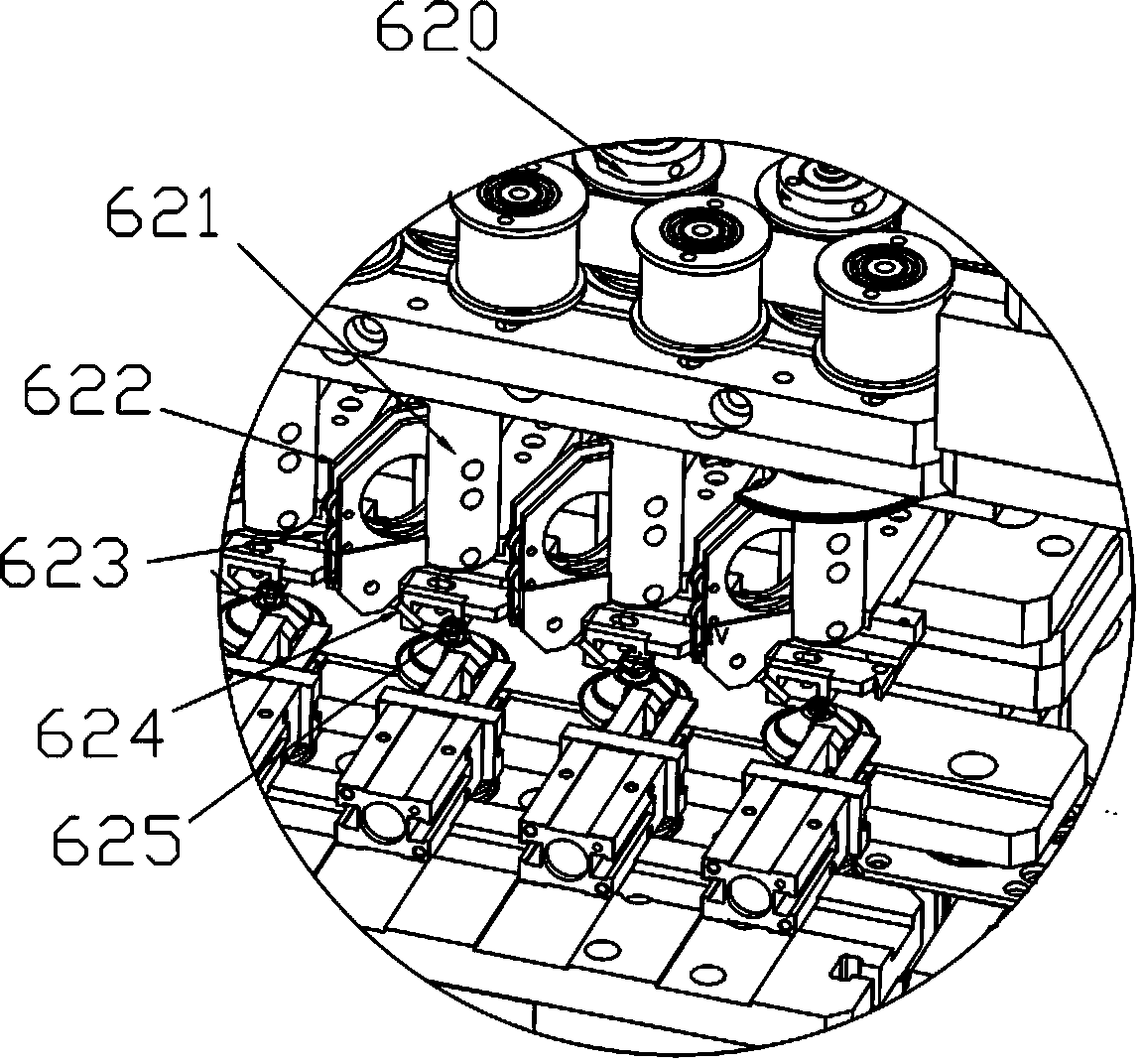

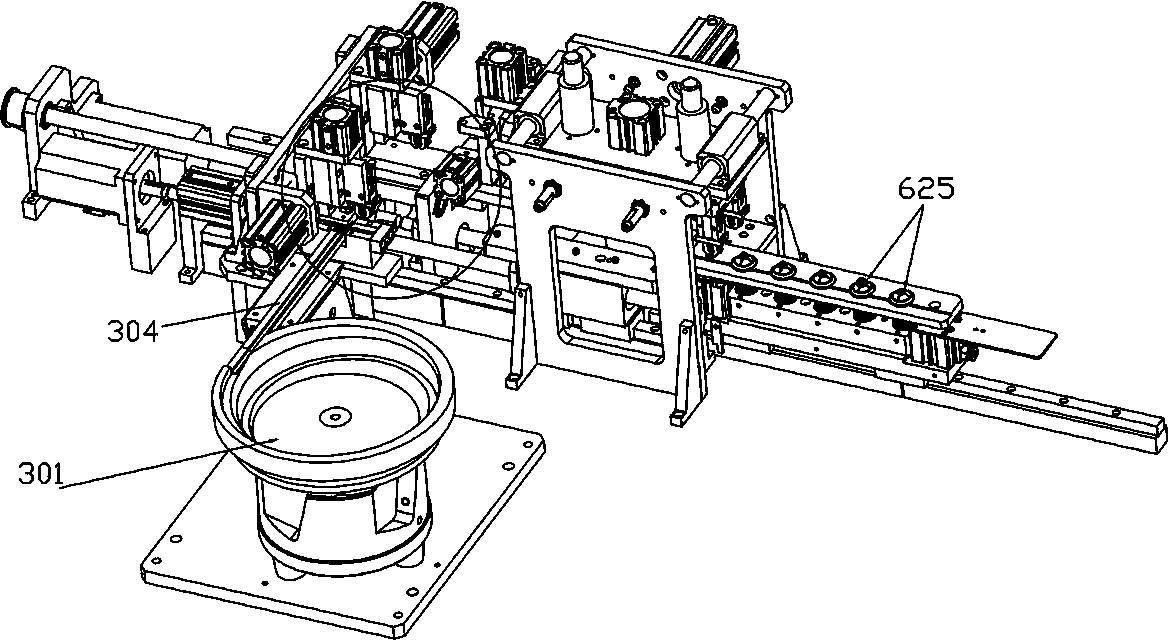

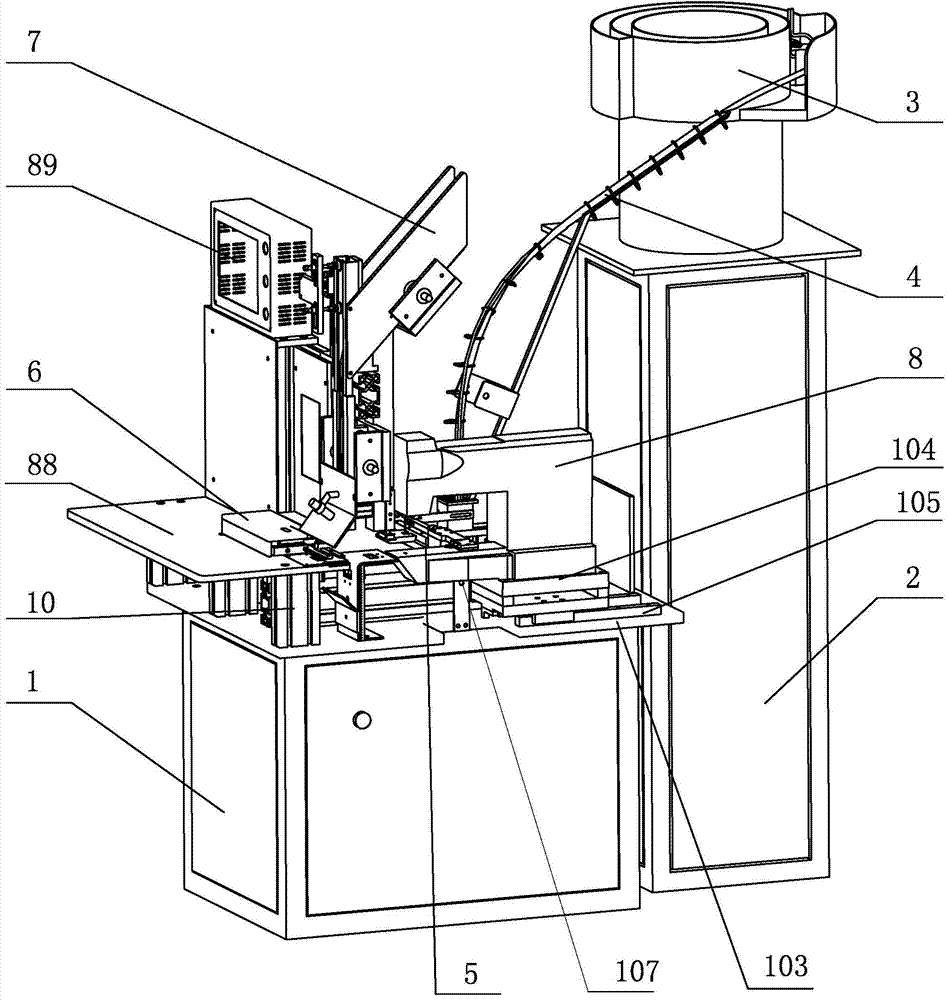

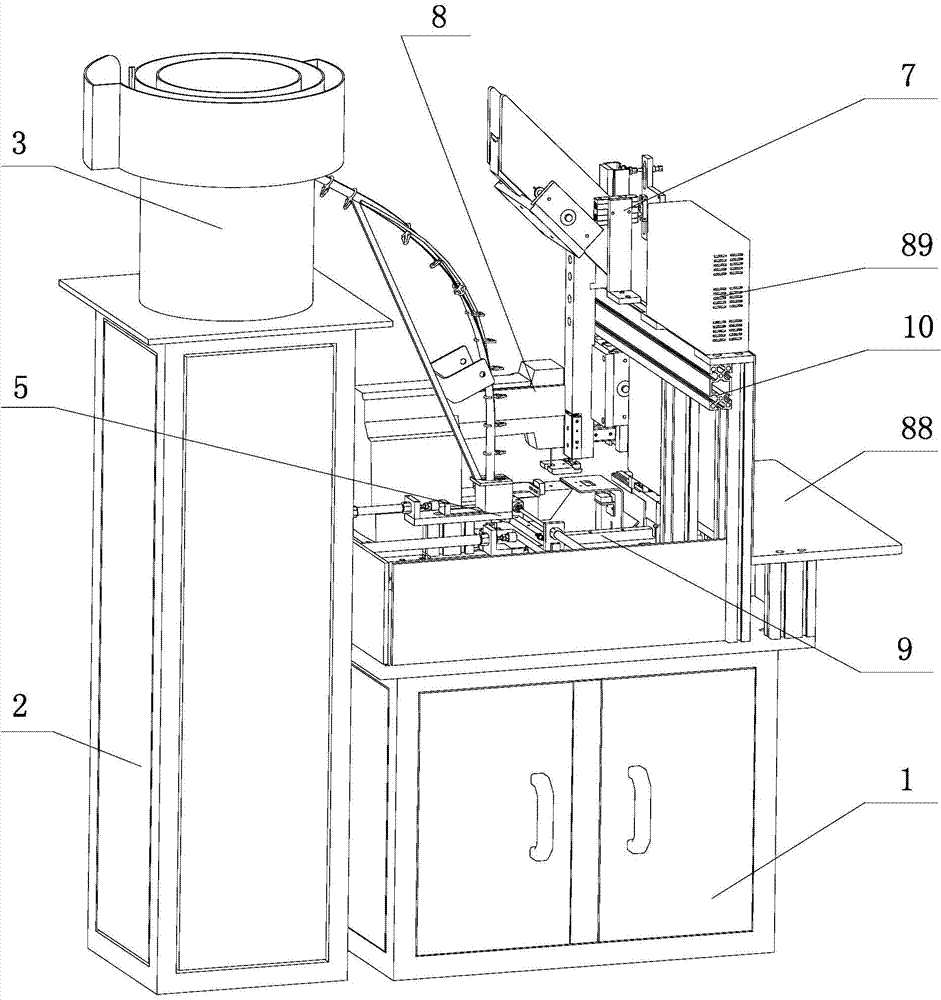

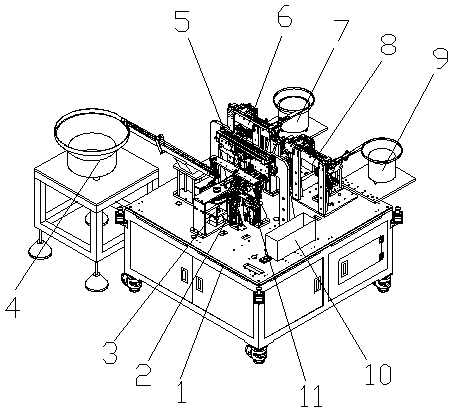

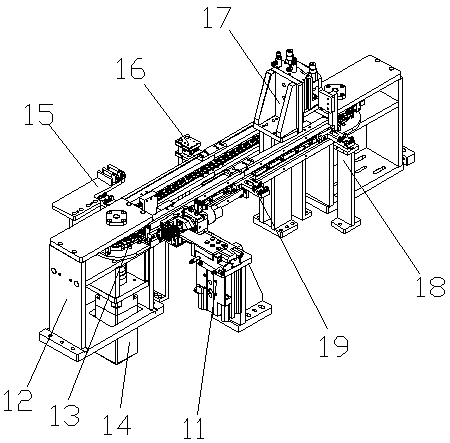

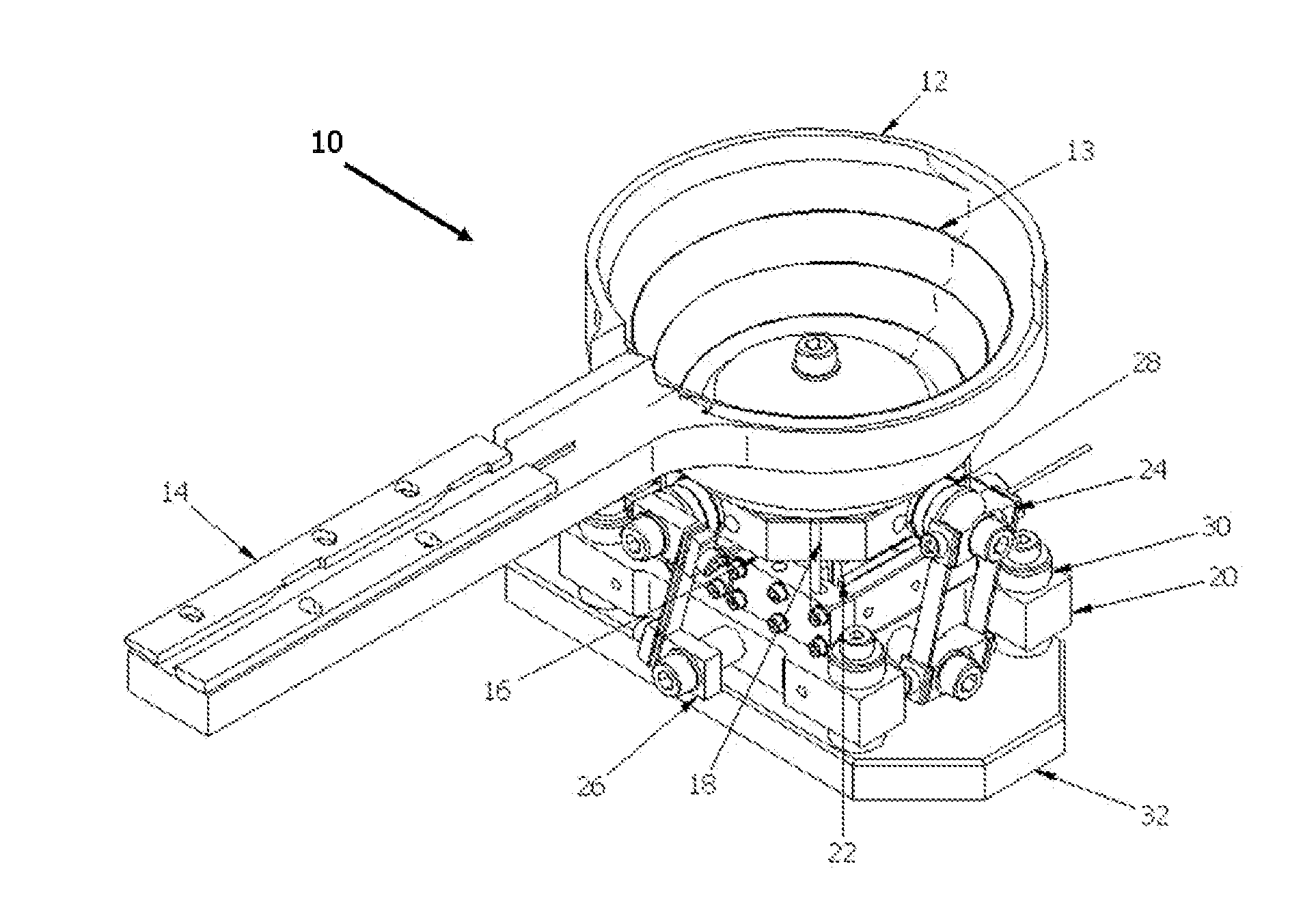

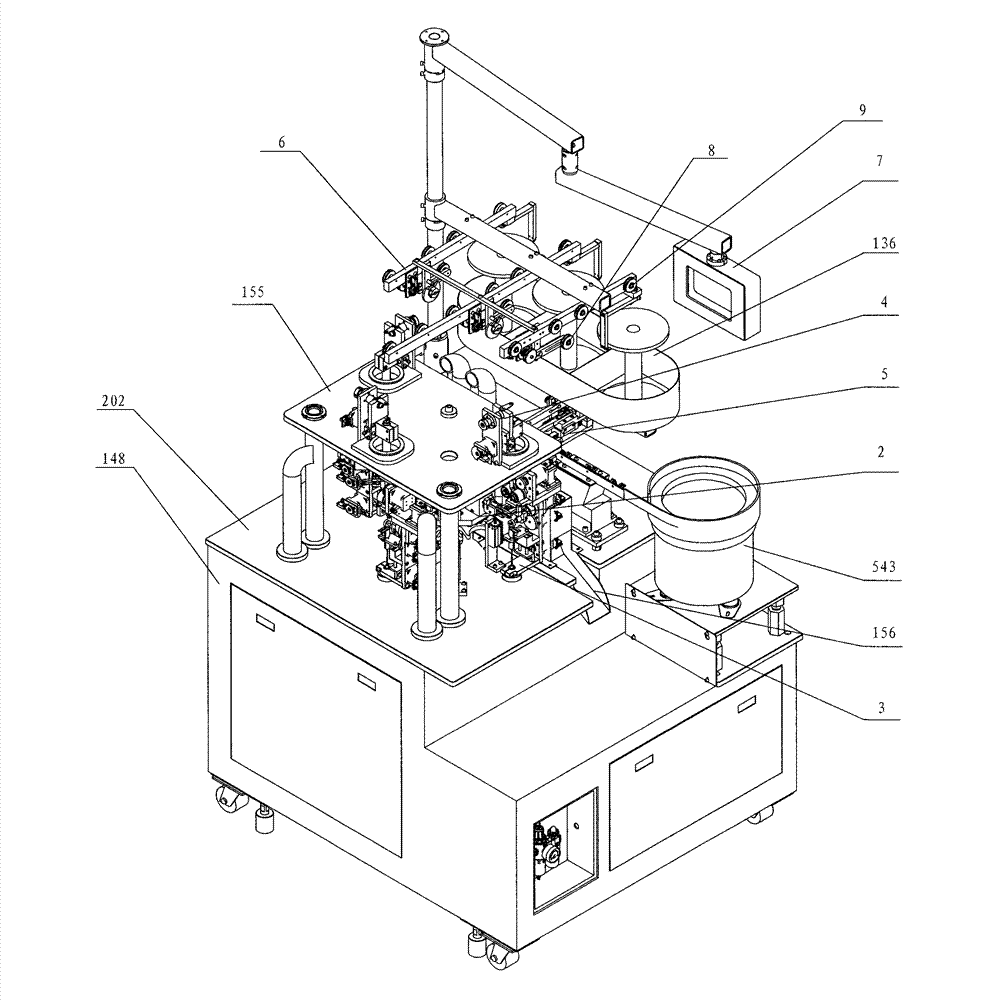

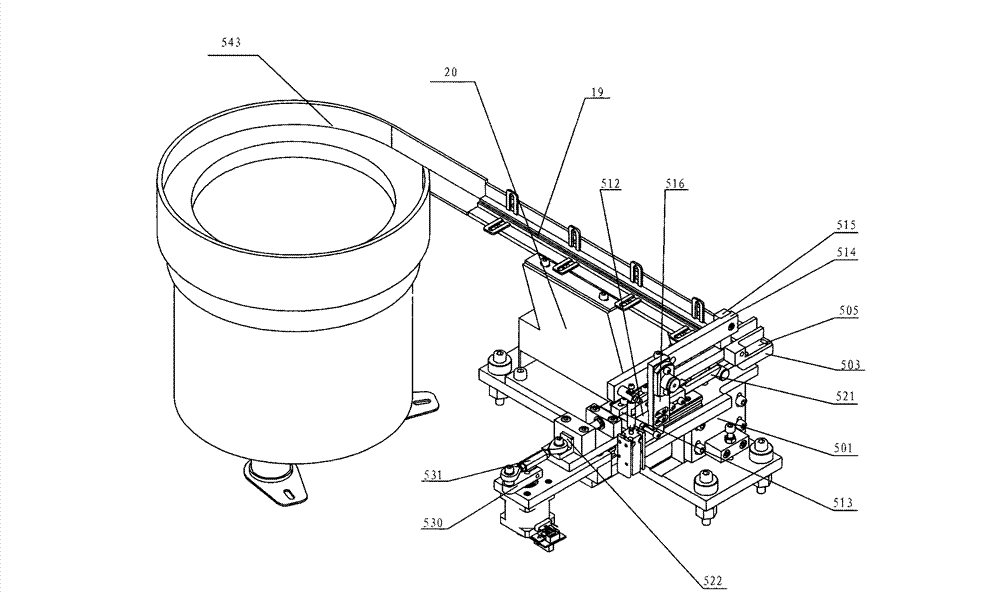

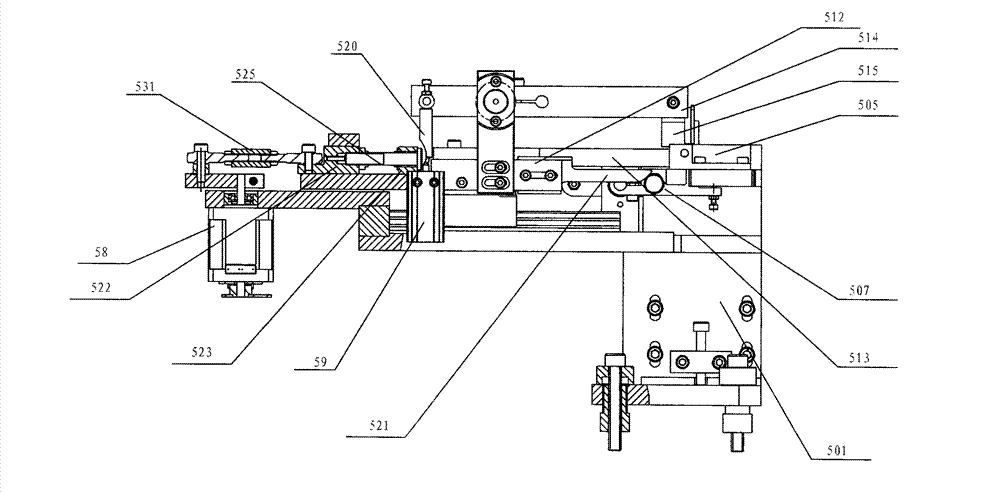

Automatic spring fastener assembly machine

ActiveUS20190337105A1Completed efficientlyCompleted fastContact member assembly/disassemblyAssembly machinesRobot handEngineering

The present invention relates to an automatic spring fastener assembly machine, including a rack and a power control box, and the rack is provided with a circulating conveying device, and a rubber casing feeding device, a fastener feeding device and a spring loading device which are in turn arranged around the circulating conveying device. The rubber casing feeding device includes a rubber casing vibration tray disposed to the left front side of the circulating conveying device, and the rubber casing feeding vibration tray is connected with a rubber casing distributing block through the rubber casing conveying track. The upper side of the circulating conveying device is provided with a rubber casing transportation manipulator, and the right front side thereof is provided with a rubber casing clamping device located below the rubber casing transportation manipulator, and a fastener pushing in device fitting the circulating conveying device is disposed under the rubber casing clamping device. In the present invention, material feeding and conveying is done by the circulating conveying device, and fasteners are fitted into corresponding holes on the rubber casings from a higher position with the fastener pushing in device, which can be completed fast and efficiently, is easy to operate, realize quick assembly of spring fasteners and improve working efficiency.

Owner:DONGGUAN UNIV OF TECH

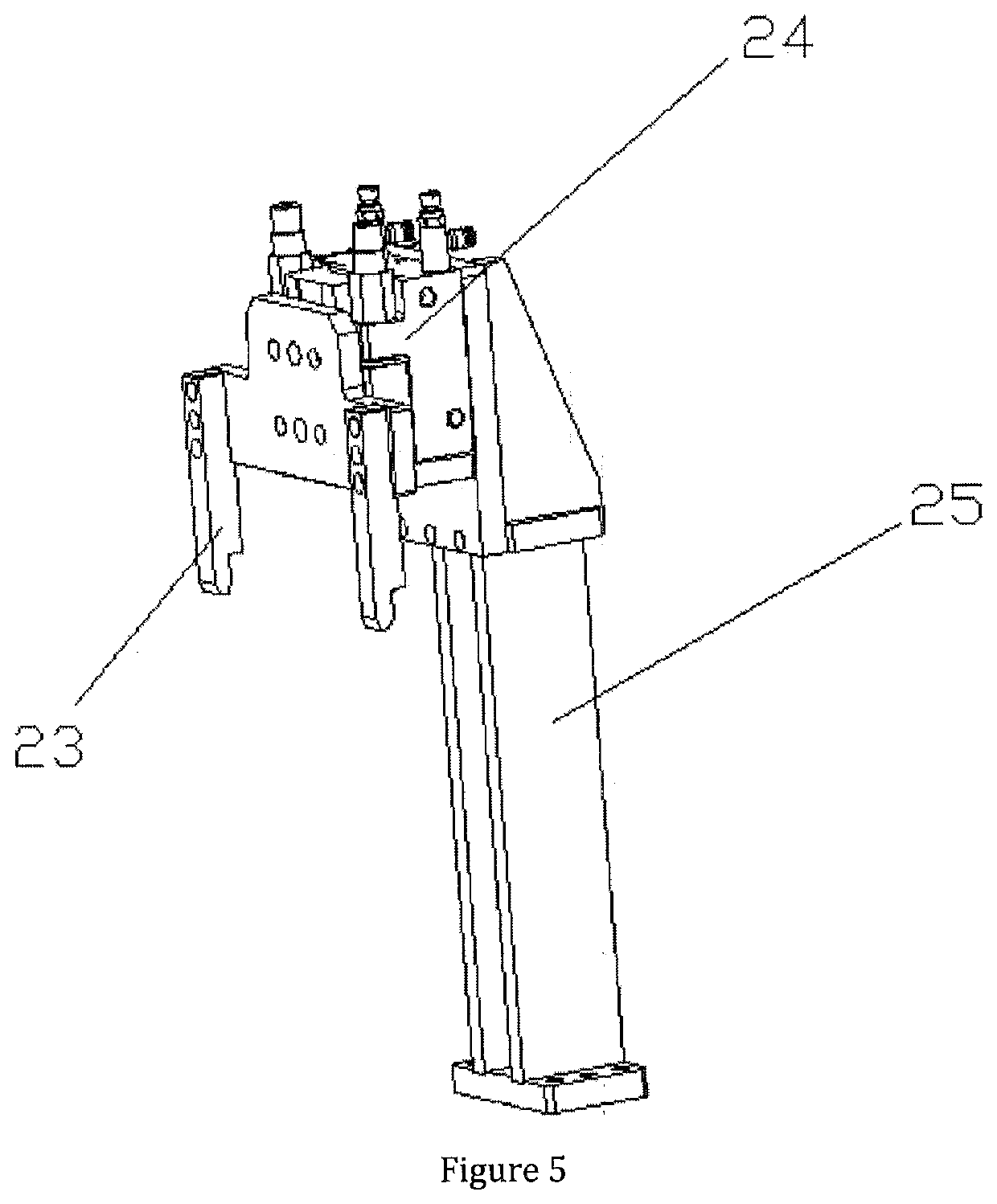

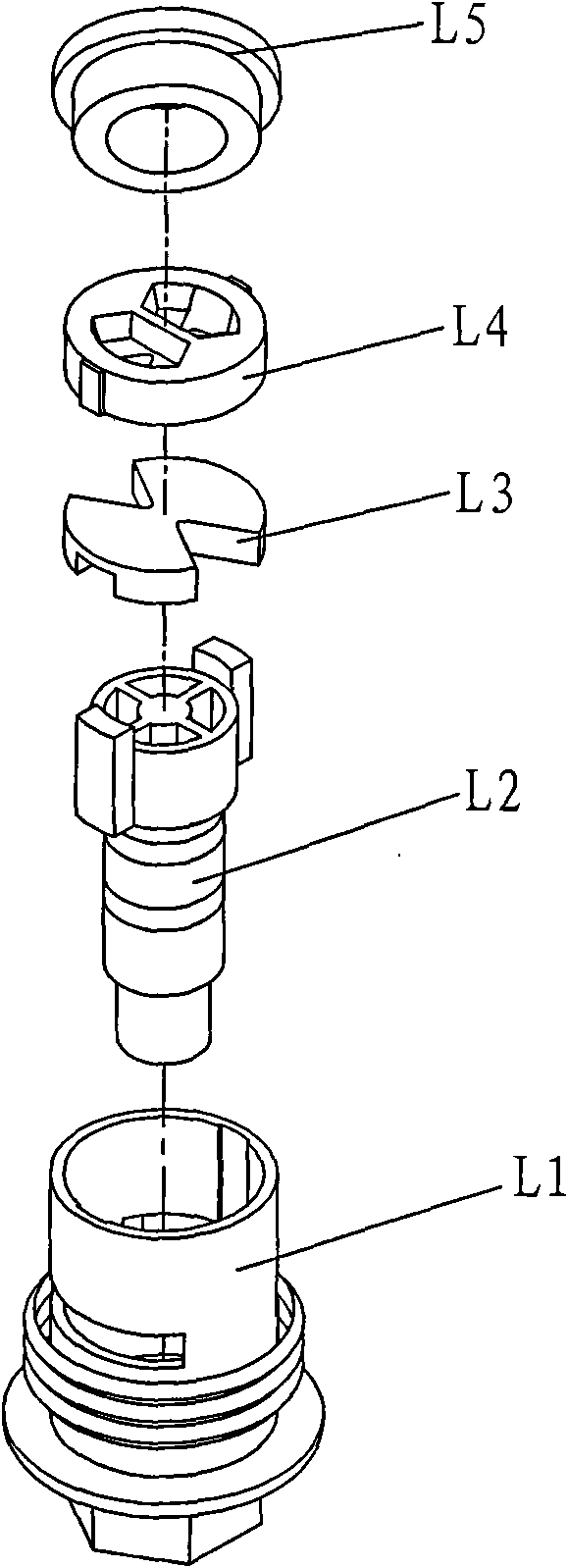

Method for assembling faucet valve core and fully automatic assembly machine

InactiveCN101590595ASmall footprintIncrease productivityAssembly machinesWork holdersEngineeringFully automatic

The invention discloses a method for assembling a faucet valve core and a fully automatic assembly machine. Before the assembly of the valve core, all parts are first sorted by a specially arranged vibration disk, then conveyed to specific positions through conveying pipes, and finally assembled into a whole through the action of a mechanical clamp and the positioning of a worktable. The middle of the fully automatic assembly machine is a working turntable; the periphery of the working turntable is provided with part vibration sorters; and the sorted parts are conveyed to the locking end of the turntable to assemble the core. The fully automatic assembly machine is provided with secondary pressure supplementing and product quality inspecting equipment. The fully automatic assembly machine adopts a circular production turntable to complete the assembly of the valve core, thereby having the advantage of small space occupation; and the working turntable cooperate with mechanical hands at the ends of the part conveying pipes to rotate a certain angle to complete a next assembly step, so the production efficiency is high.

Owner:苏锦波

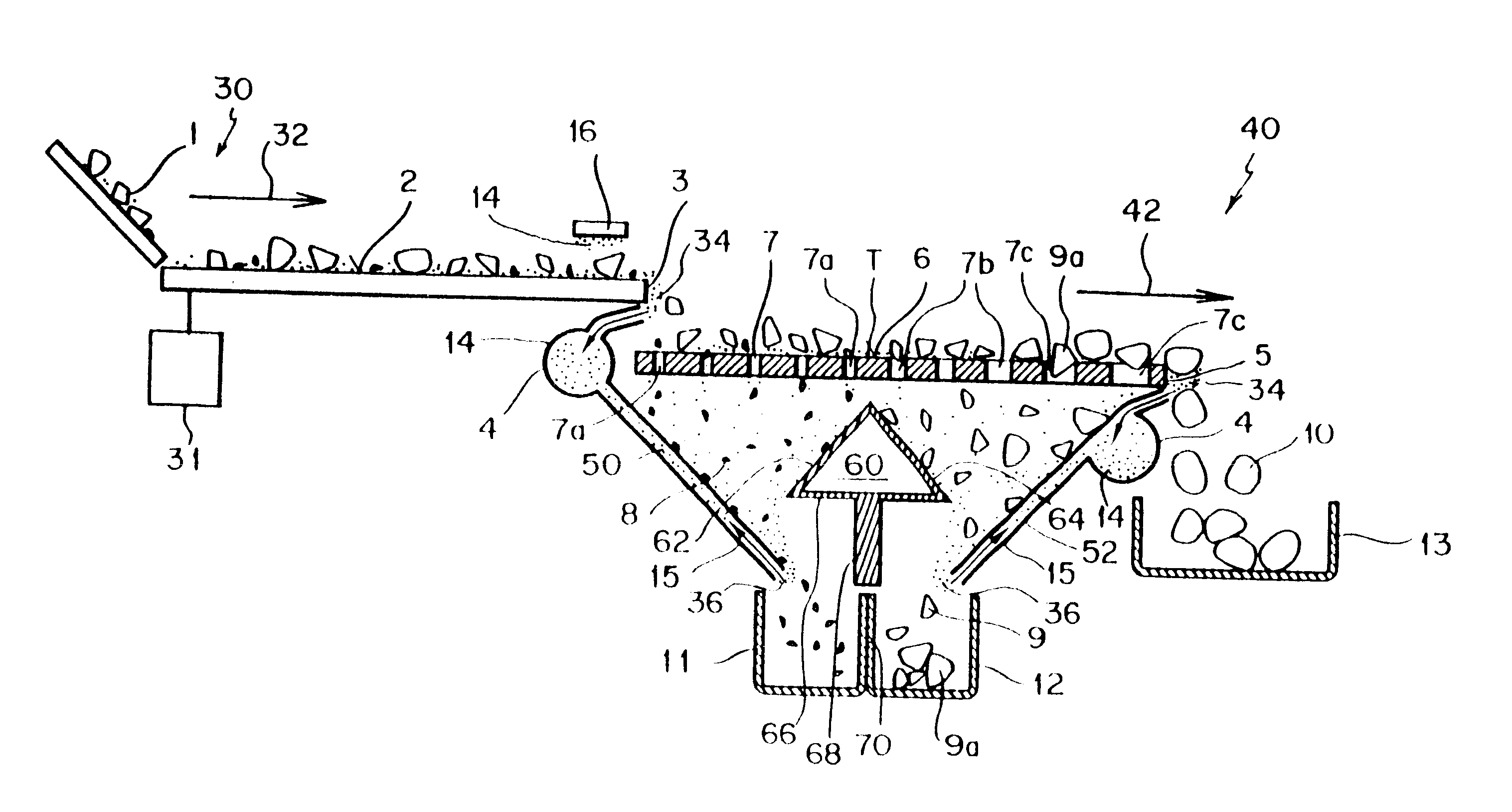

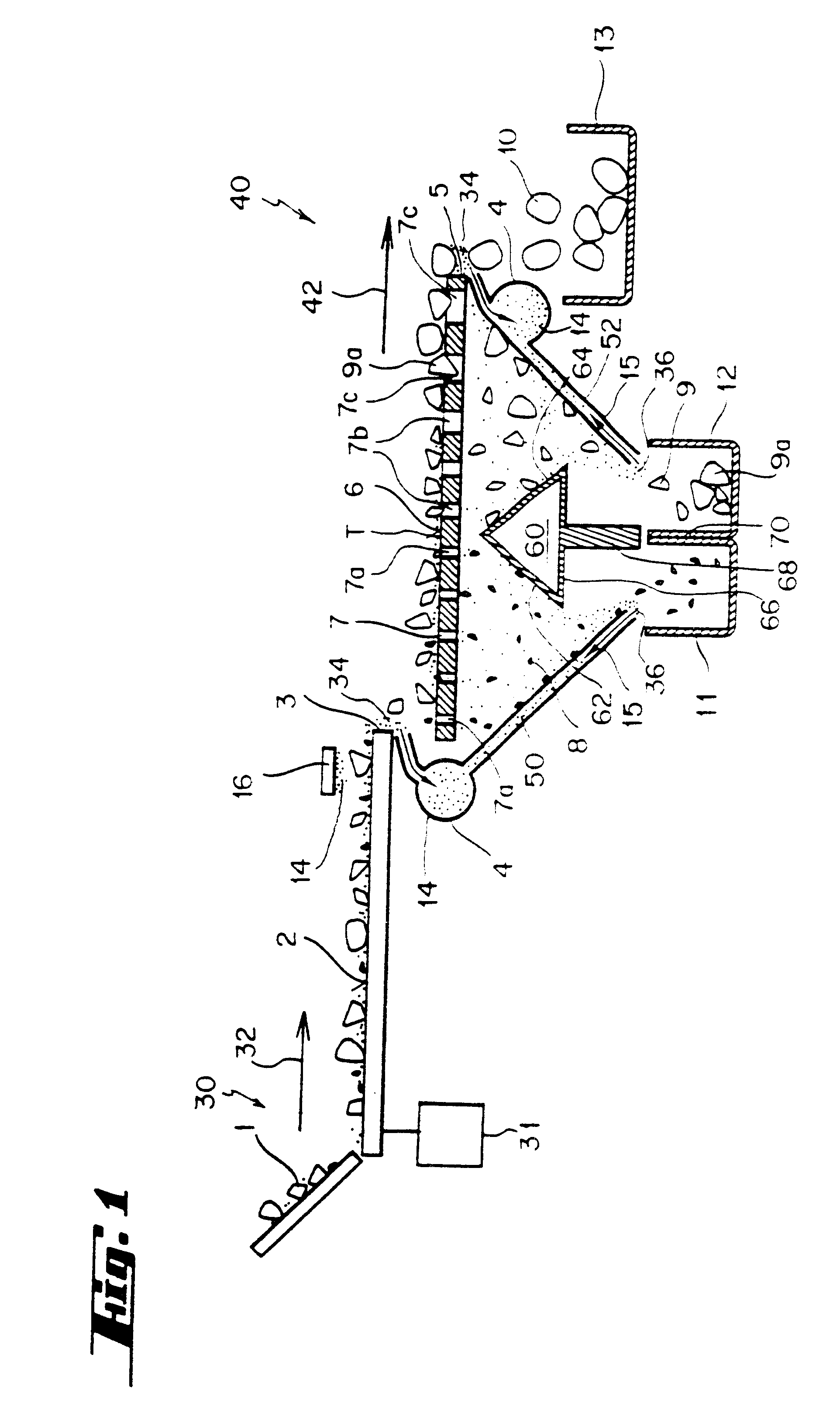

Vibrating conveyor and method for conveying silicon fragments

A method for conveying silicon fragments has the silicon fragments being conveyed over a conveyor surface, which is made from hyperpure silicon. There is a vibrating conveyor, and during the conveying, the sharp edges of the silicon fragments are rounded and mechanical-physical decontamination takes place. The vibrating conveyor has a conveyor surface which is made from hyperpure silicon. A second vibrating conveyor unit has a conveyor surface which is made from hyperpure silicon and has passage openings therethrough.

Owner:WACKER CHEM GMBH

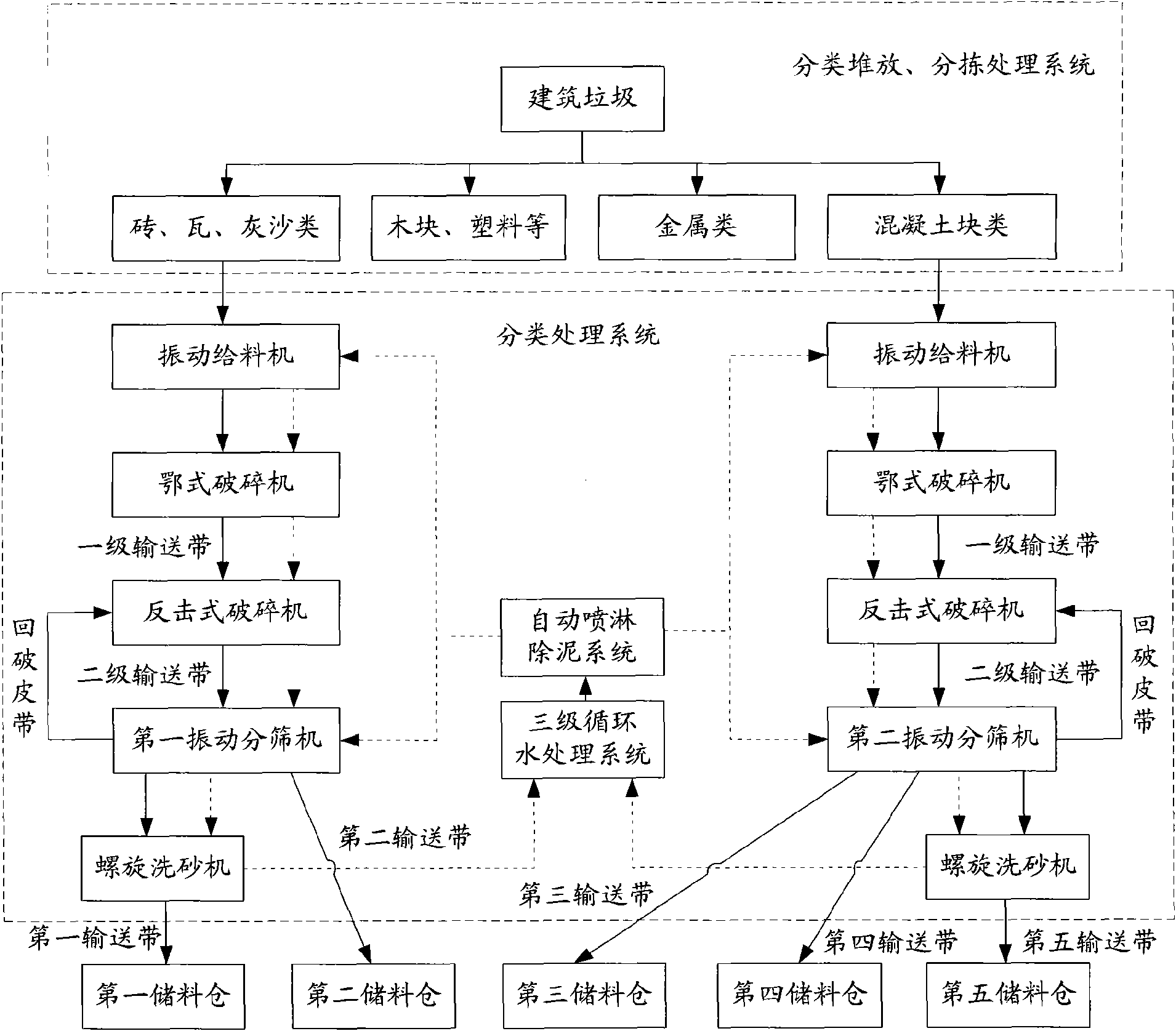

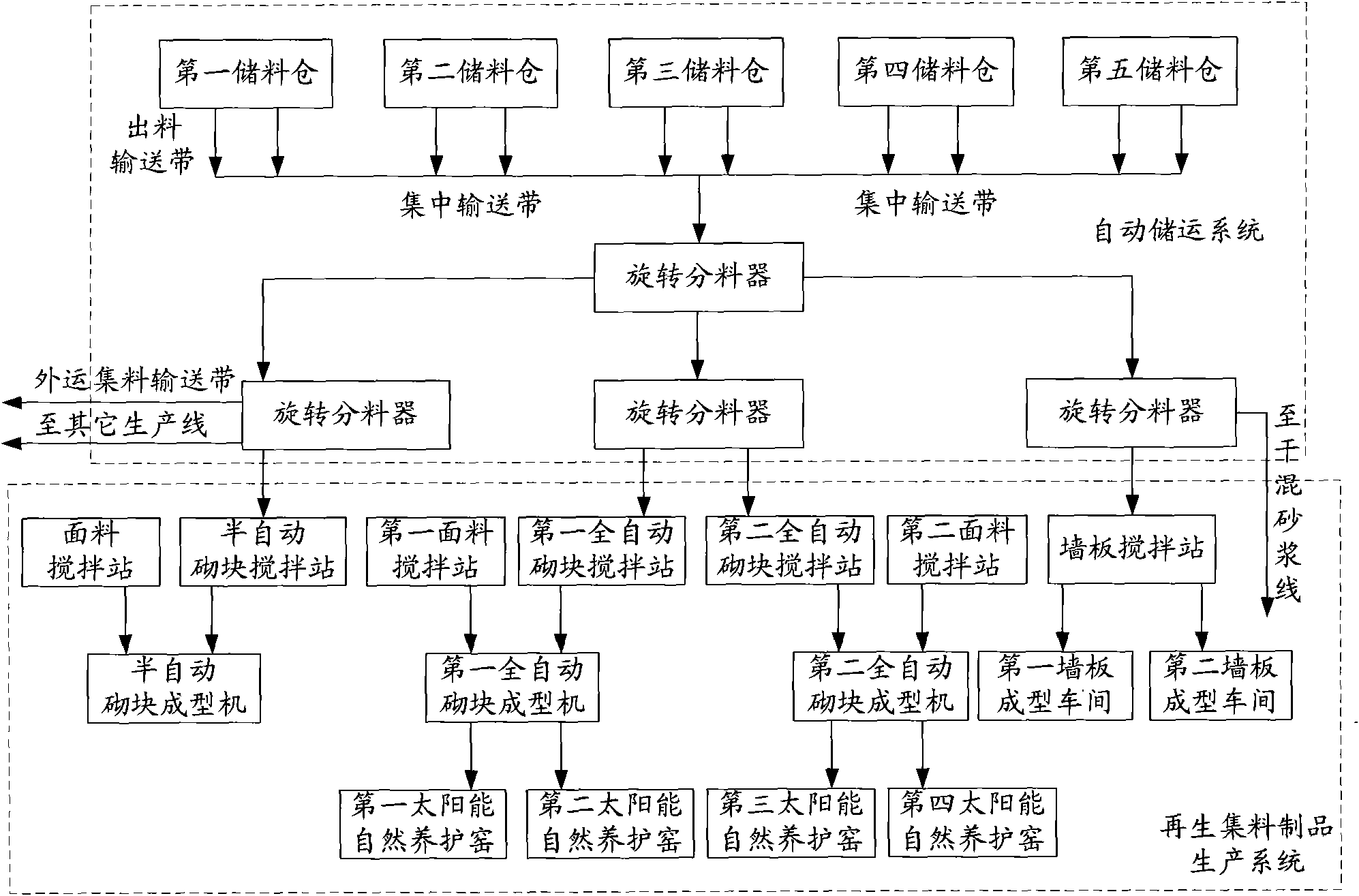

Building refuse treatment regeneration system

The embodiment of the invention discloses a building refuse treatment regeneration system, including a classification stacking, sorting processing system, a classification processing system and a plurality of storage bins, wherein, the classification processing system includes at least two parallel crushing screening process production lines and water circulating systems, each crushing screening process production line includes a feeder, crusher, as well as a screening machine connected in series in sequence, and a plurality of outlets of the screening machine are respectively connected to the plurality of storage bins through conveyor belts. By adoption of the building refuse treatment regeneration system of the embodiment of the invention, bricks, tiles, dust and sand and concrete blocks and the like in the building refuse can be divided into at least two production lines for parallel processing, which greatly enhancing the production efficiency and the purity of recycled aggregates, so that the recycled aggregates can be applied to a variety of uses, reproduced into a variety of high-quality recycled products, reducing the waste of resources and minimizing pollution that will be probably caused to the environment.

Owner:深圳市绿发鹏程环保科技有限公司

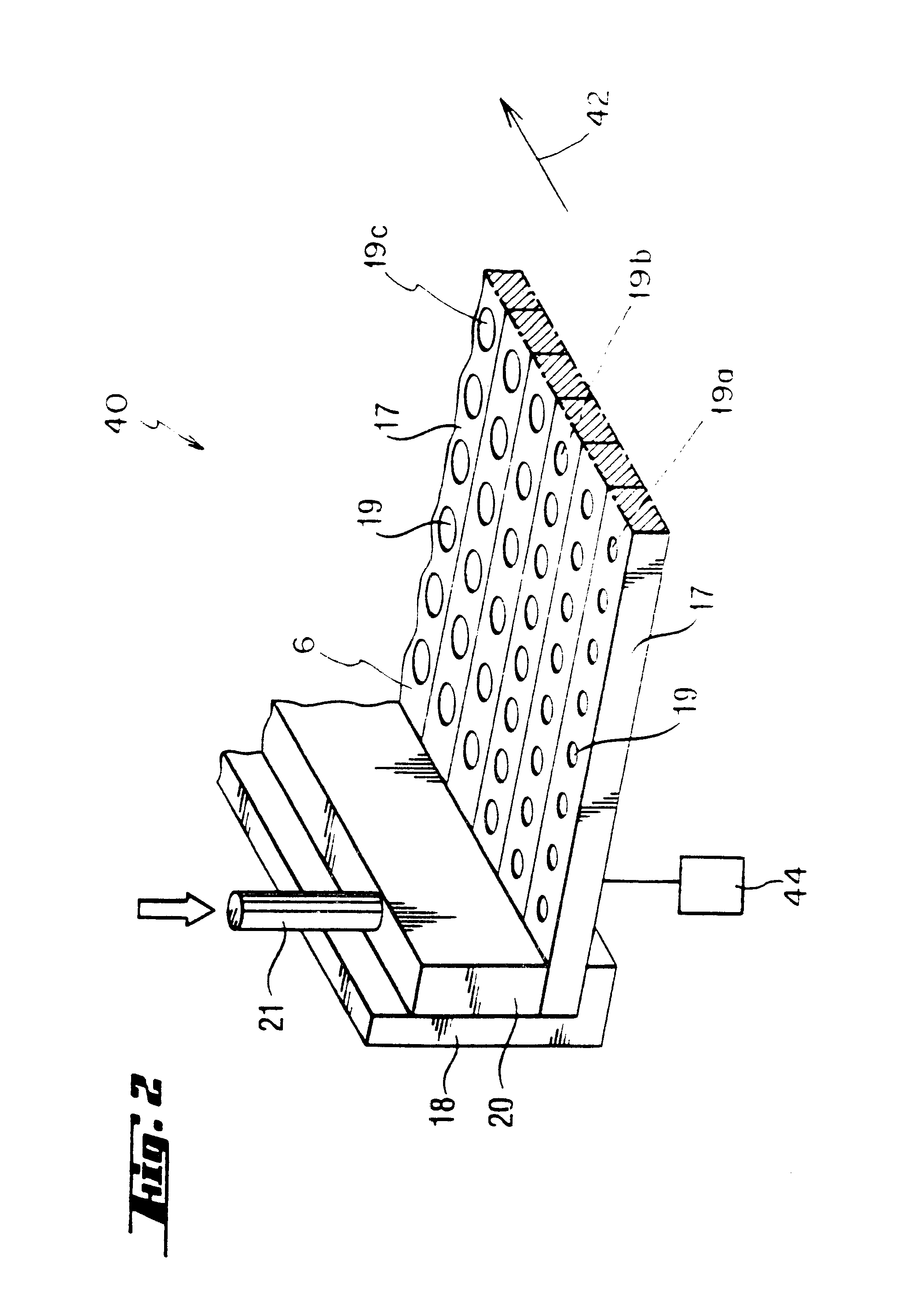

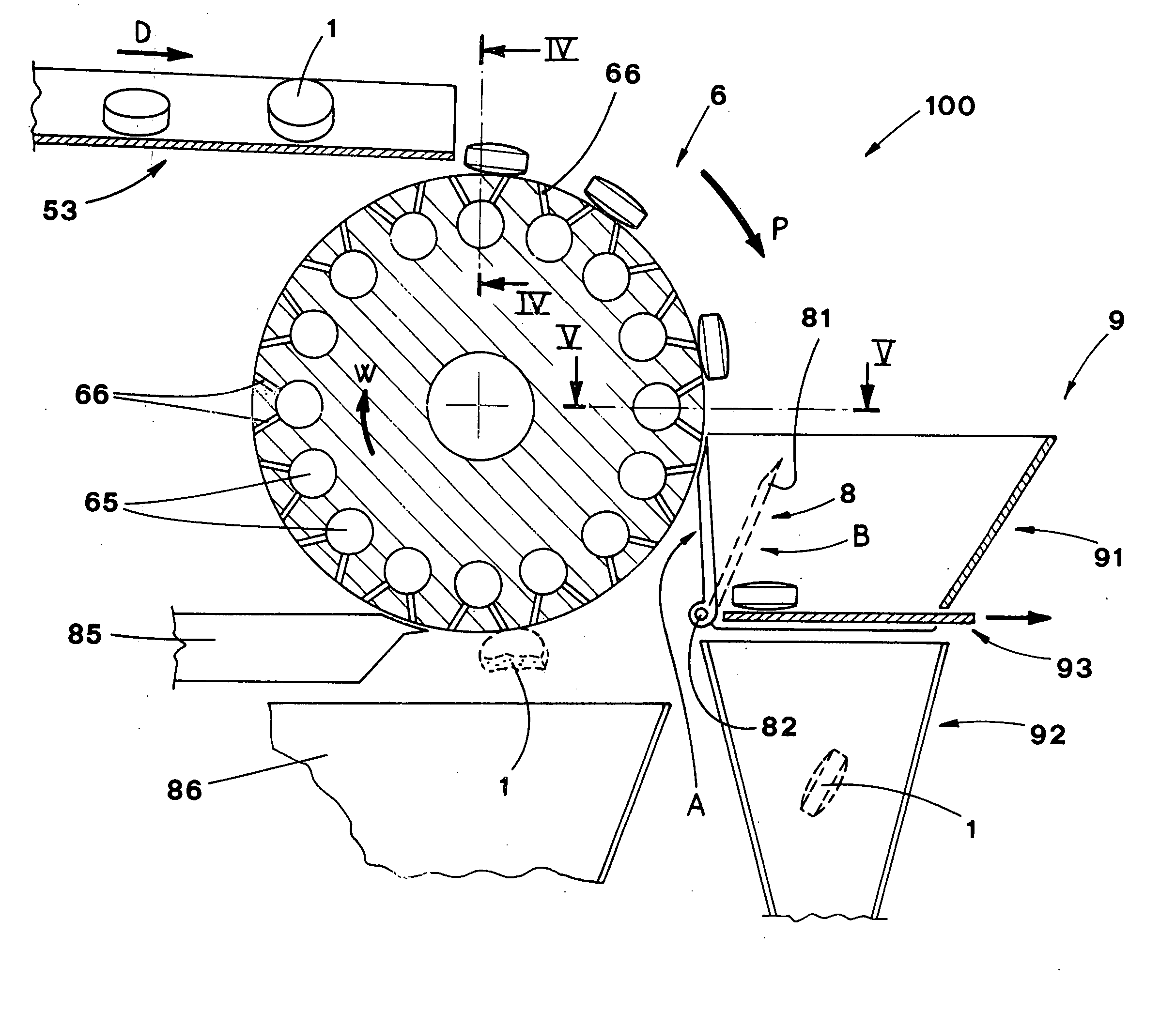

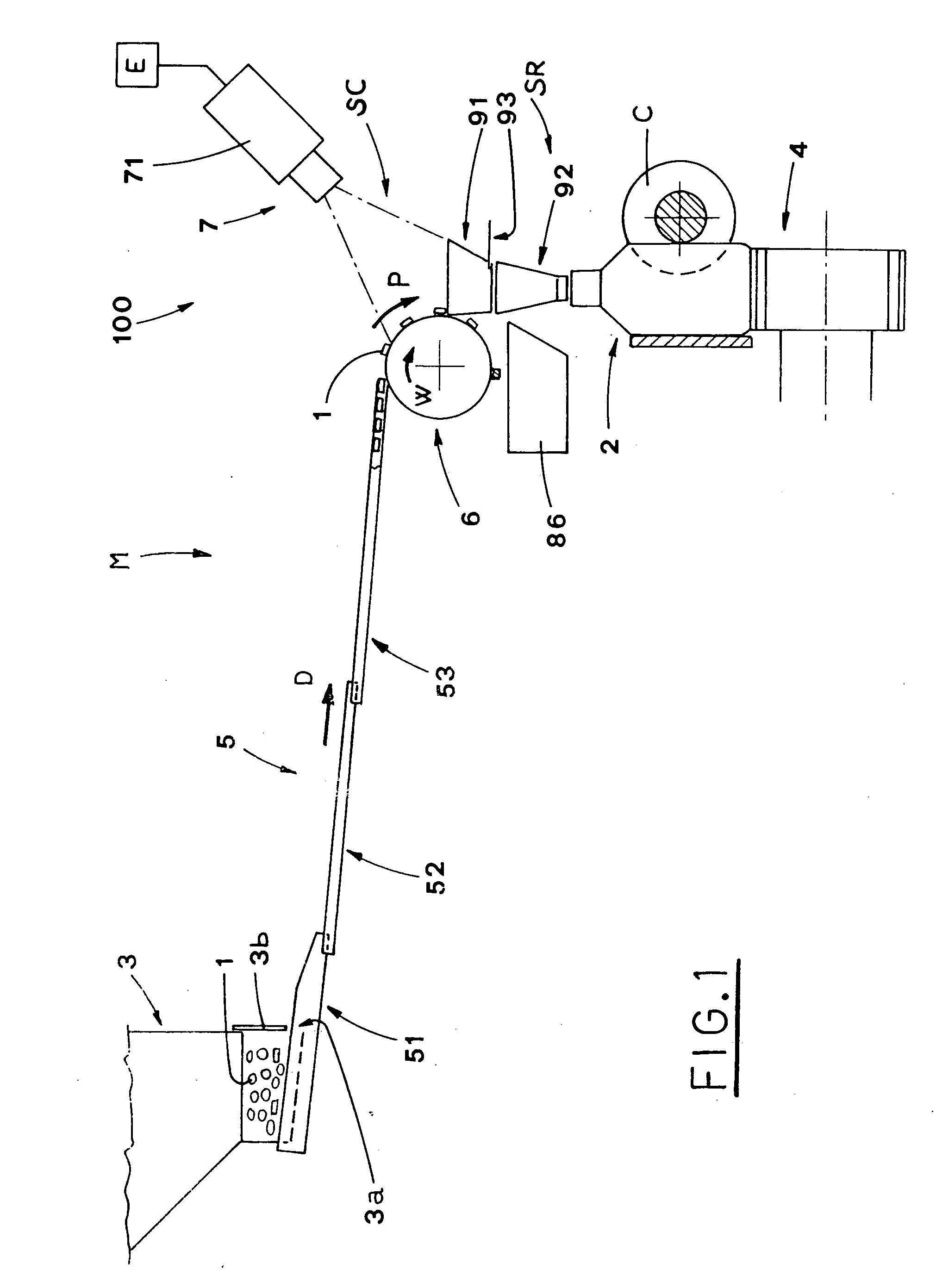

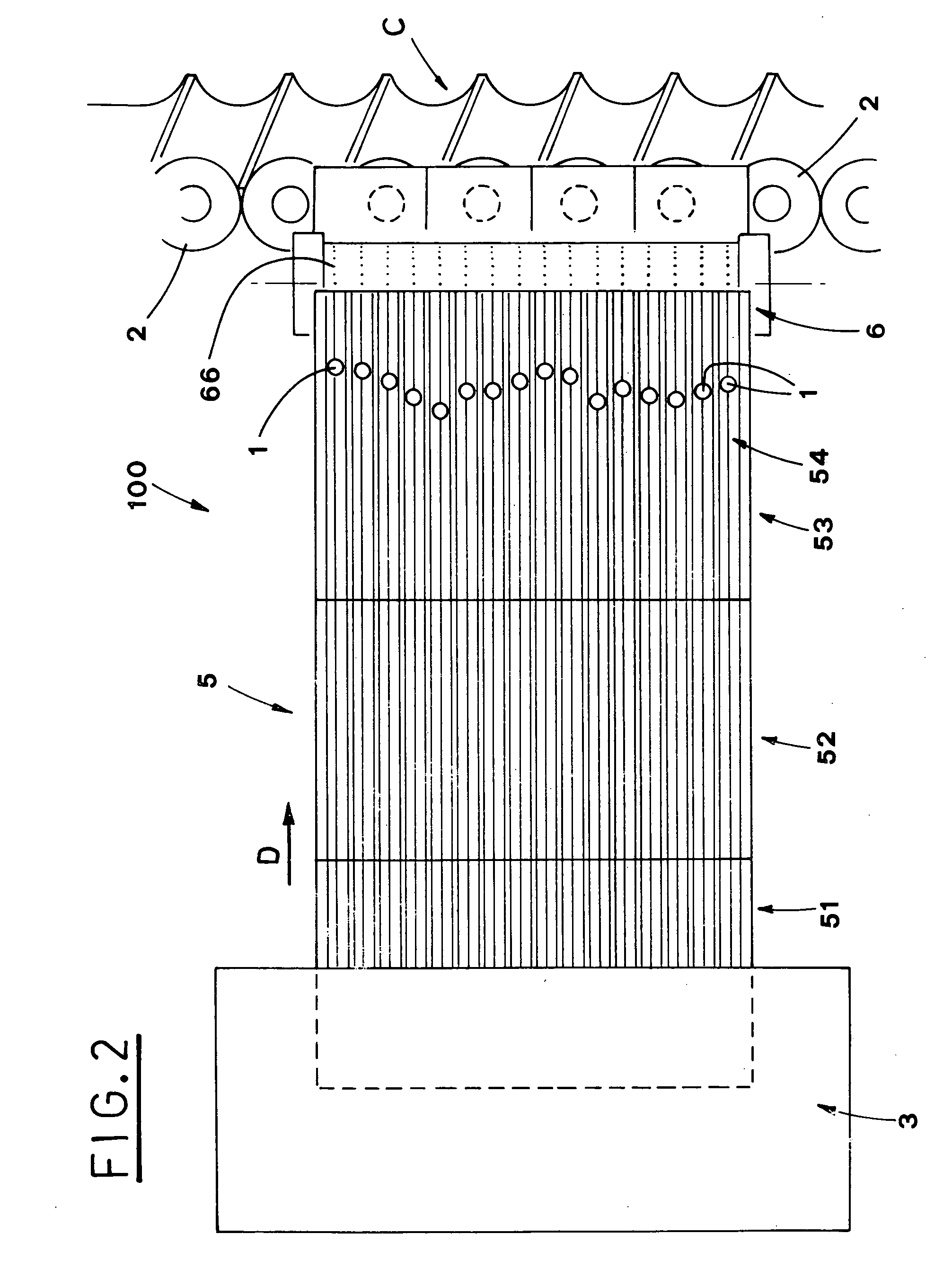

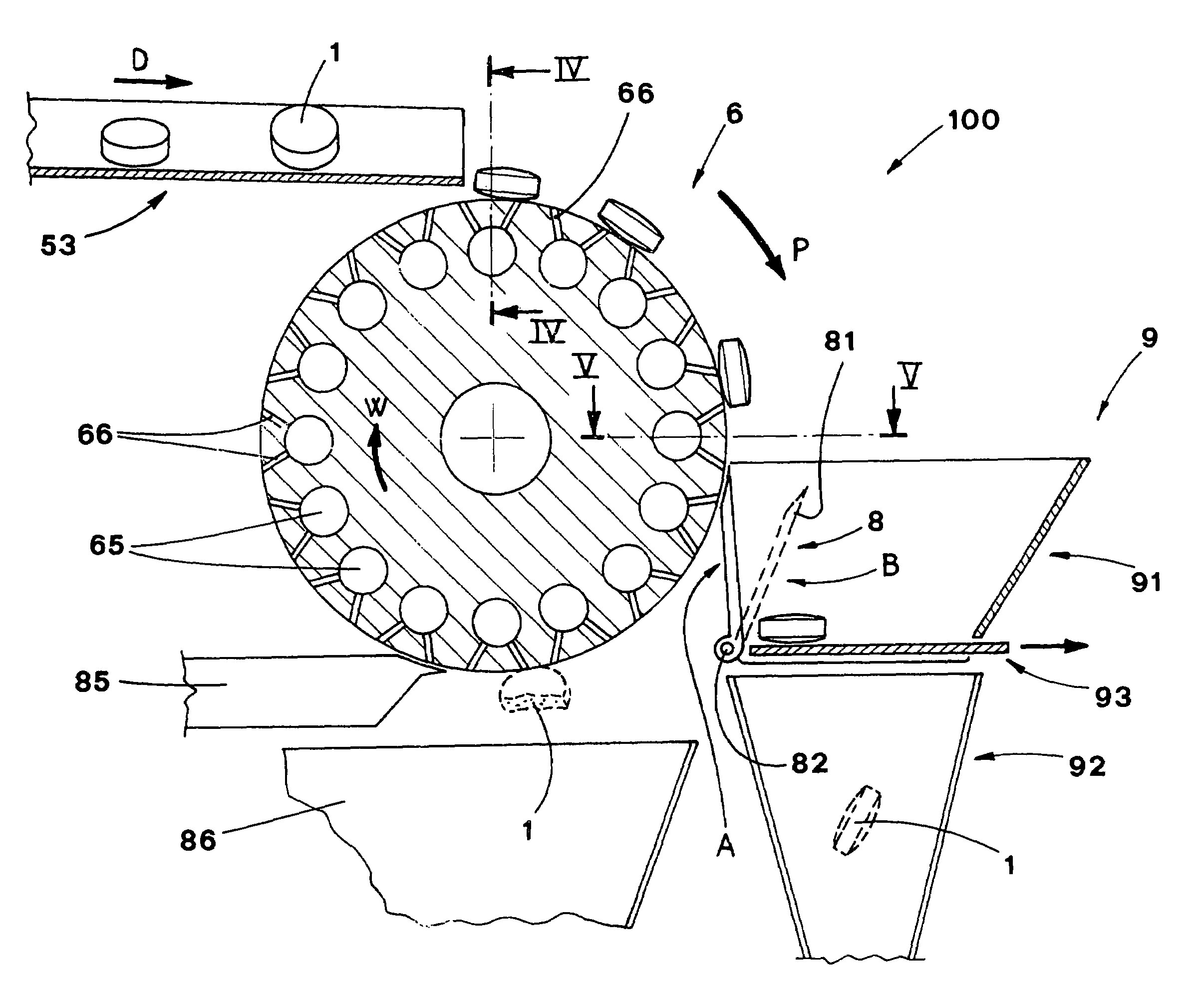

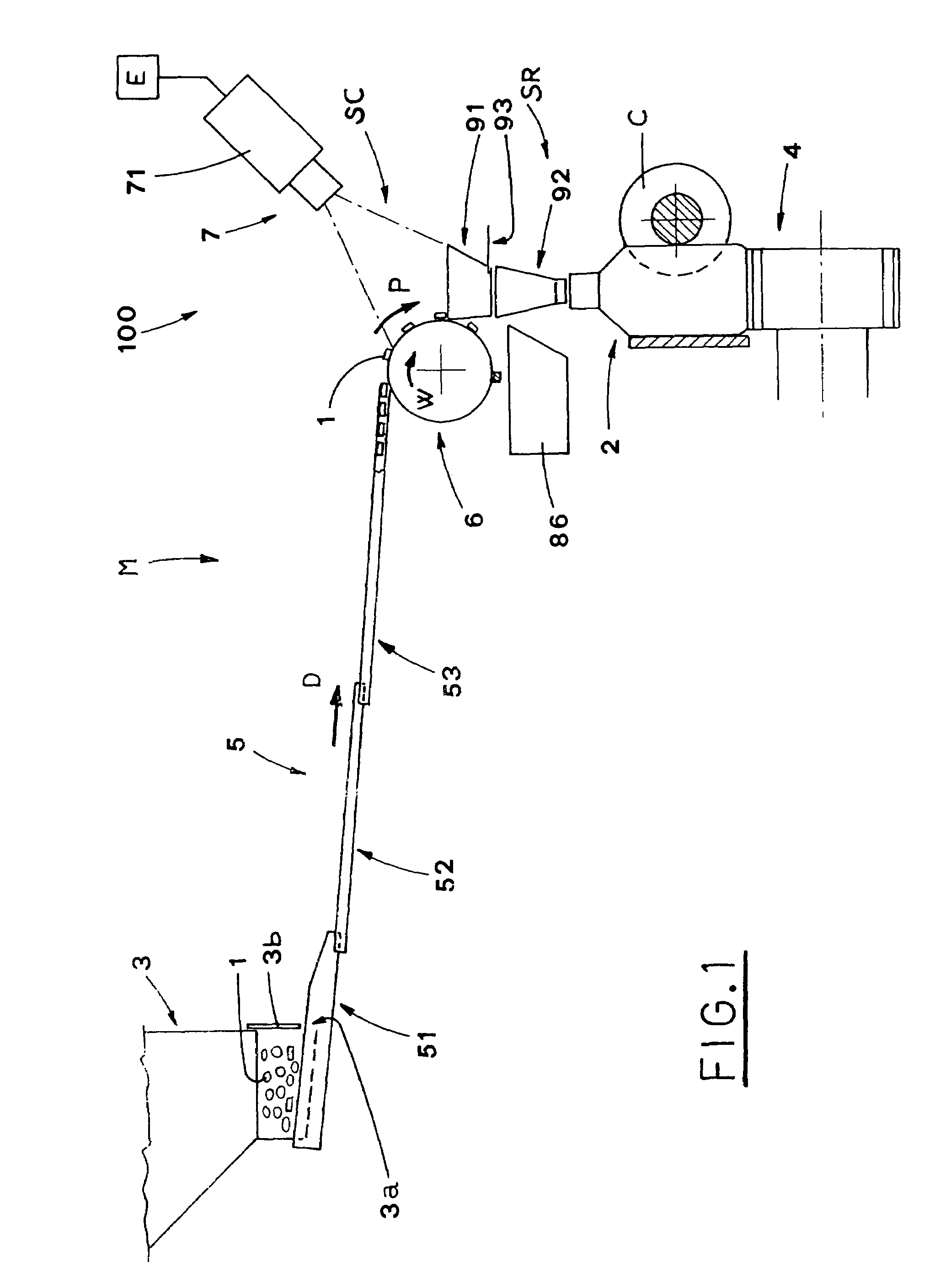

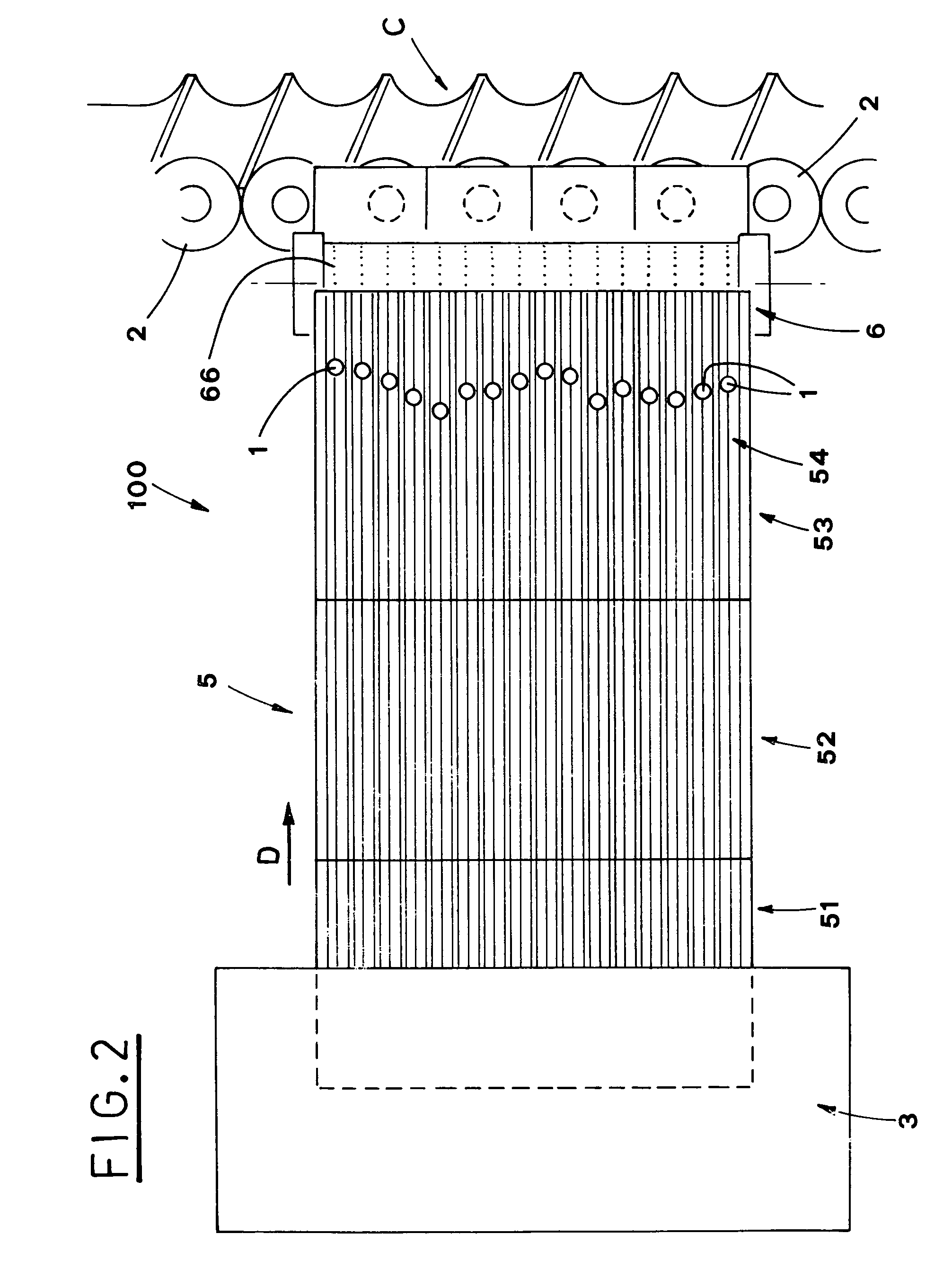

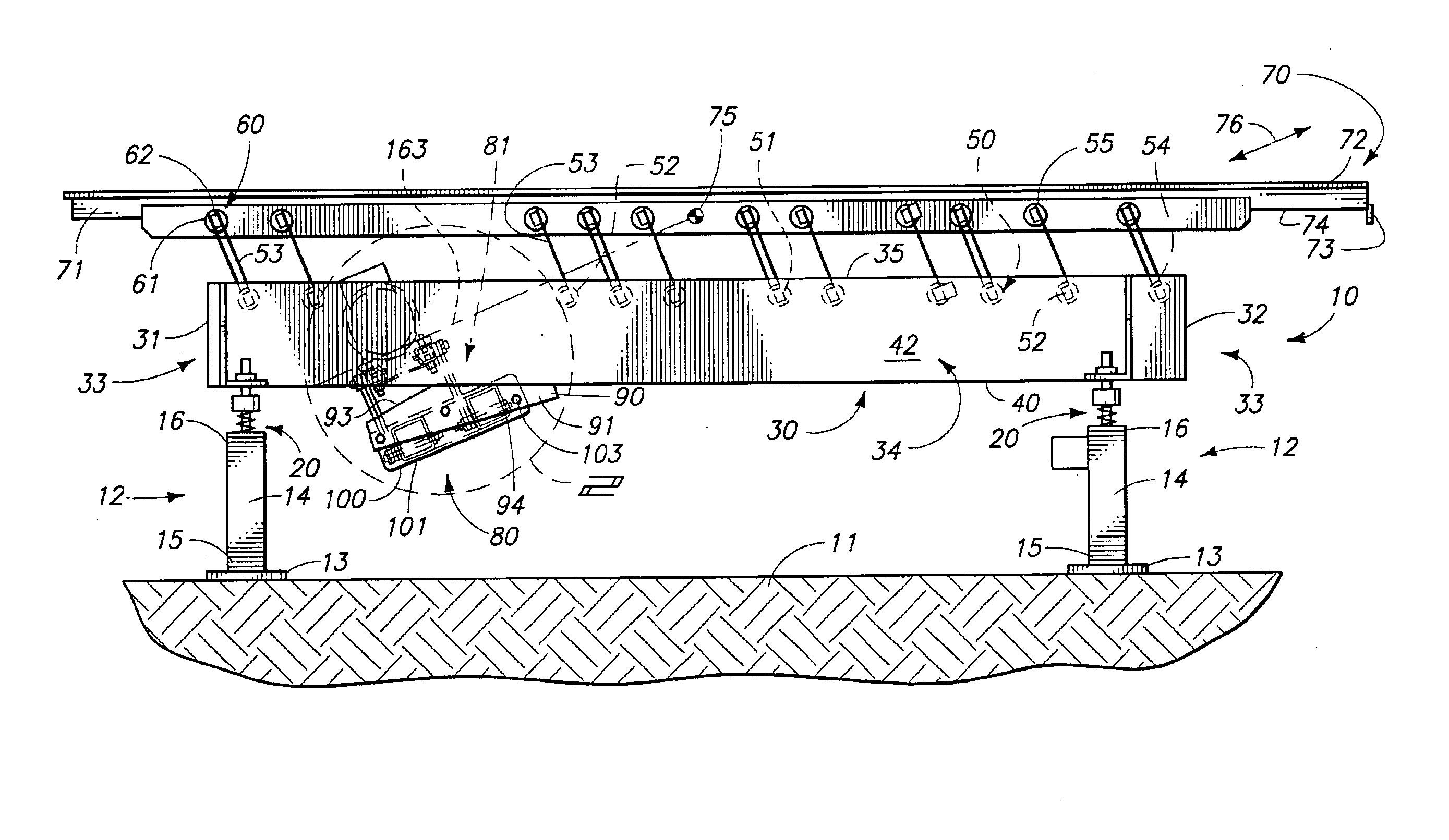

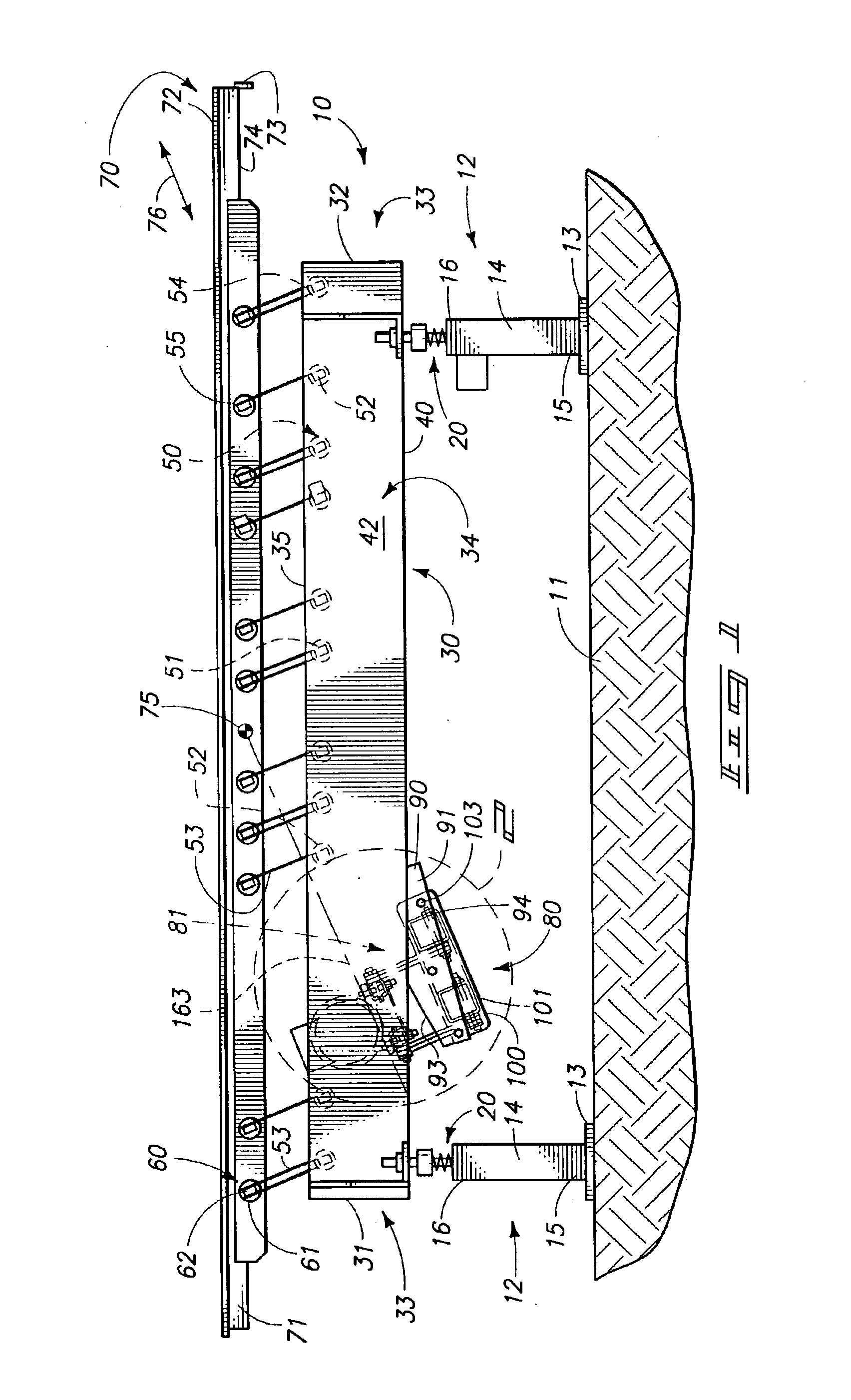

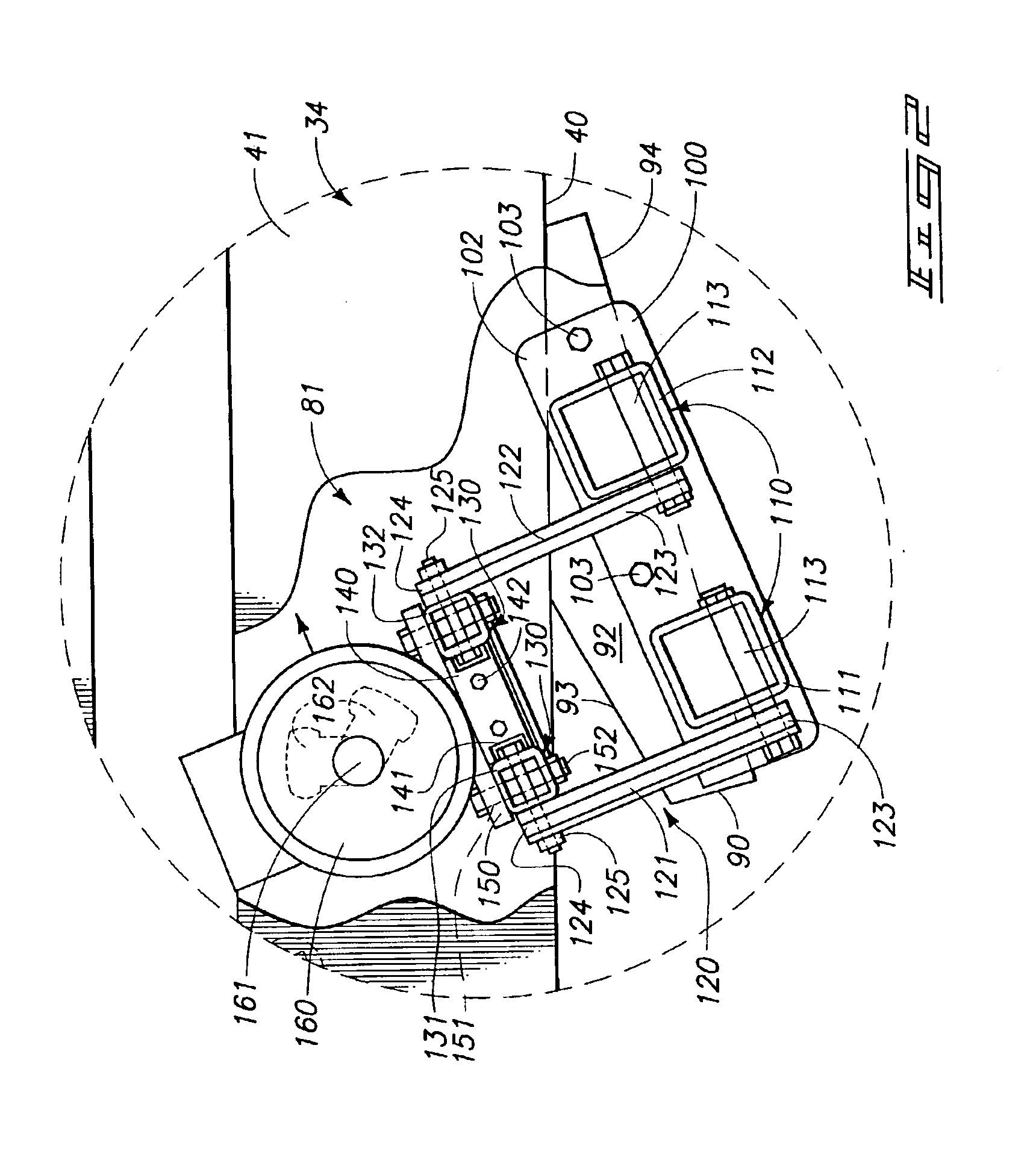

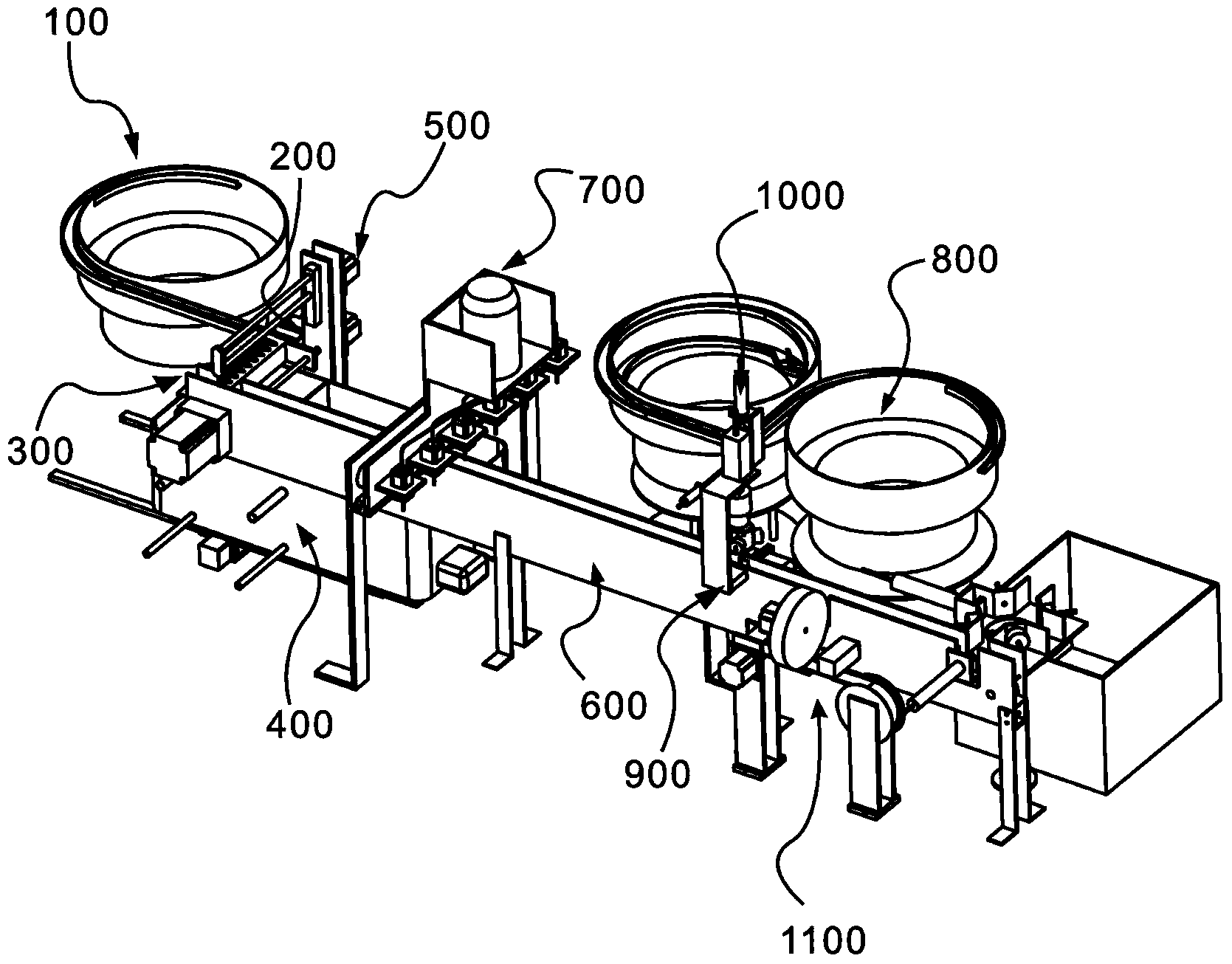

Unit for filling containers with products, in particular, pharmaceutical products

InactiveUS20050217208A1Rapid and safe feedingSimple structureCoin-freed apparatus detailsCounting objects on conveyorsSingle productProduct Containers

A unit (100) for filling containers (2) with products (1), in particular pharmaceutical products (1), includes a hopper (3,3a) containing a mass of products (1) in bulk, conveying means (5,6) aimed at feeding the products (1) leaving the hopper (3) along a predetermined path (P) up to a station (SR), where the containers (2) are filled with the products (1). The containers (2) are fed to the filling station (SR) by transporting means (4,C). A checking station (SC) for checking the products (1) is situated along the path (P) upstream of the filling station (SR). The conveying means (5,6) include first means (51,52,53) consisting of vibrating planes and second conveying means (6). The second conveying means (6) are situated at the checking station (SC) between the conveying vibrating planes means (51,52,53) and the filling station (SR). The second conveying means (6) are equipped with holding means (65) for holding single products (1) thus forming, on the second conveying means (6), a series of single products (1), spaced apart and moving forward to the filling station (SR) along a portion of the path (P).

Owner:IMA IND MASCH AUTOMATICHE SPA

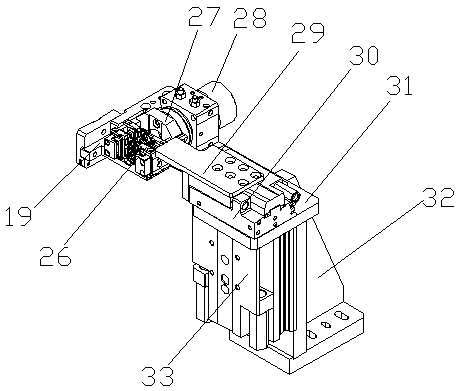

Full-automatic inductance winding machine and winding method thereof

InactiveCN103903852AImprove efficiencyImprove qualityJigging conveyorsCoils manufactureWinding machineCopper wire

The invention discloses a full-automatic inductance winding machine and a winding method of the full-automatic inductance winding machine, and belongs to the field of electronic component machining equipment. The full-automatic inductance winding machine comprises a support, a mechanical feeding mechanism, a mechanical discharging mechanism, a transfer mechanism, a winding mechanism and an operation panel and further comprises a secondary wire pressing mechanism. Compared with a traditional manual winding technology, the full-automatic winding machine has the advantages that efficiency is higher and quality is greatly improved. Compared with an existing automatic winding machine, the full-automatic inductance winding machine has the advantages that one cycle of the full-automatic inductance winding machine lasts for 7 seconds to 8 seconds, five products can be machined in one cycle, and therefore efficiency is not lower than that of a Rite winding machine; meanwhile the structure is simple, operation and maintenance are easy, manufacturing cost is 1 / 3 that of the Rite winding machine, and therefore more cost can be reduced; cut wire residues are shorter, 1 / 10 of copper wires are reduced compared with products with the same yield, it is estimated that ten thousand yuan of the copper wires can be reduced every year, the wire residues are firstly cut and then pressed, and therefore the treatment effect of the wire residues is better.

Owner:DONGGUAN KE RUI AUTOMATION TECH

Method and equipment for automatically feeding badminton feathers

InactiveCN102658958AReduce volumeReduce maintenance costsControl devices for conveyorsJigging conveyorsEngineeringFeather

The invention discloses a method and equipment for automatically feeding badminton feathers. The feathers are sorted, kept in the same direction and turned in the vibrating conveying process under the combined action of a vibrator, a guide channel, a large and small head distinguishing mechanism and a conveying channel, and the conveyed feathers meet the requirements of the same direction and consistent bending angles by combining the recheck control of a subsequent detection mechanism. The whole feather feeding process is automatically finished, conveying efficiency is high, conveying quality is stable and reliable, and the subsequent feather inserting process can be continuously performed for 24 hours; and the corresponding production equipment is small in size, low in maintenance and production cost, high in loading speed and completely suitable to be matched with the conventional badminton production equipment.

Owner:SHANTOU HONGSHEN SPORTS GOODS

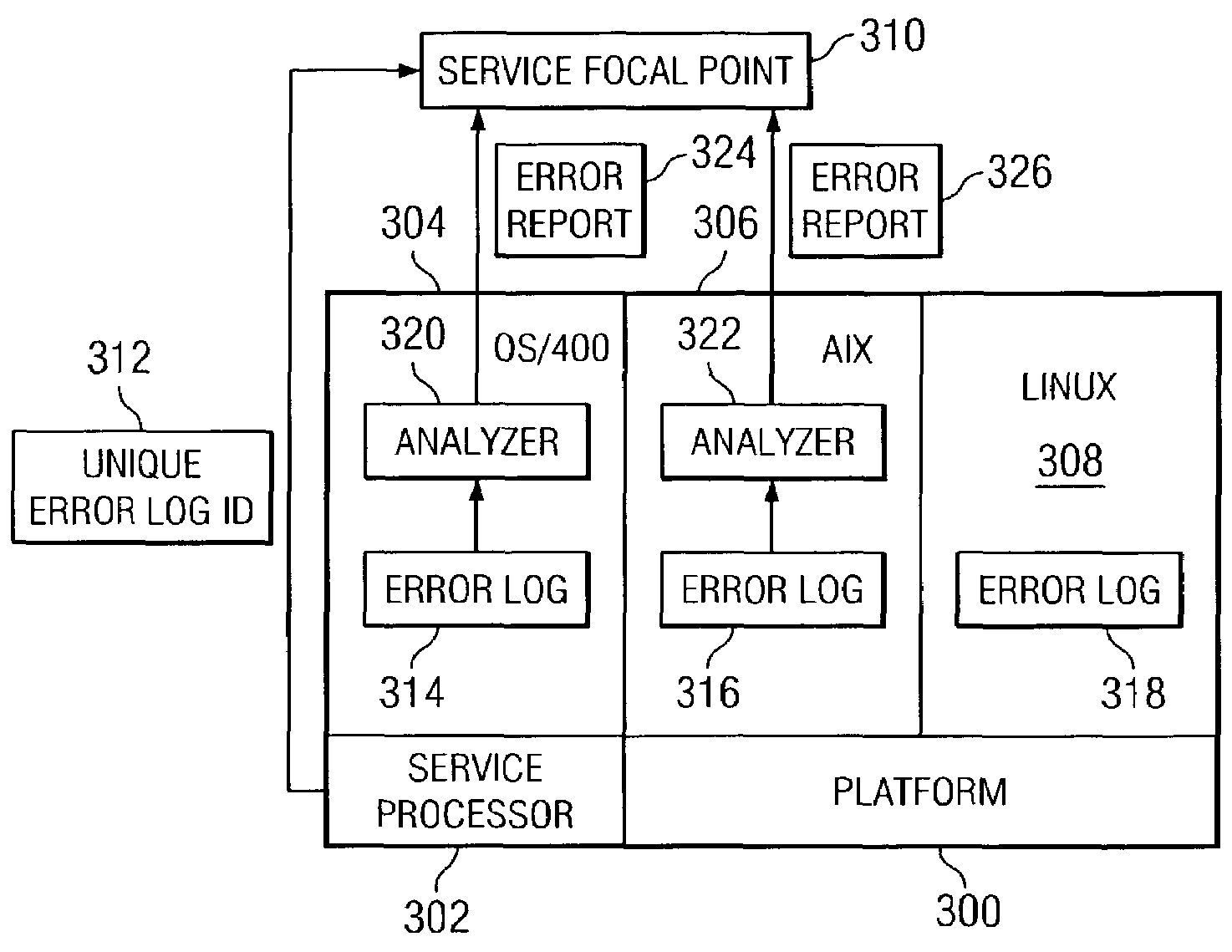

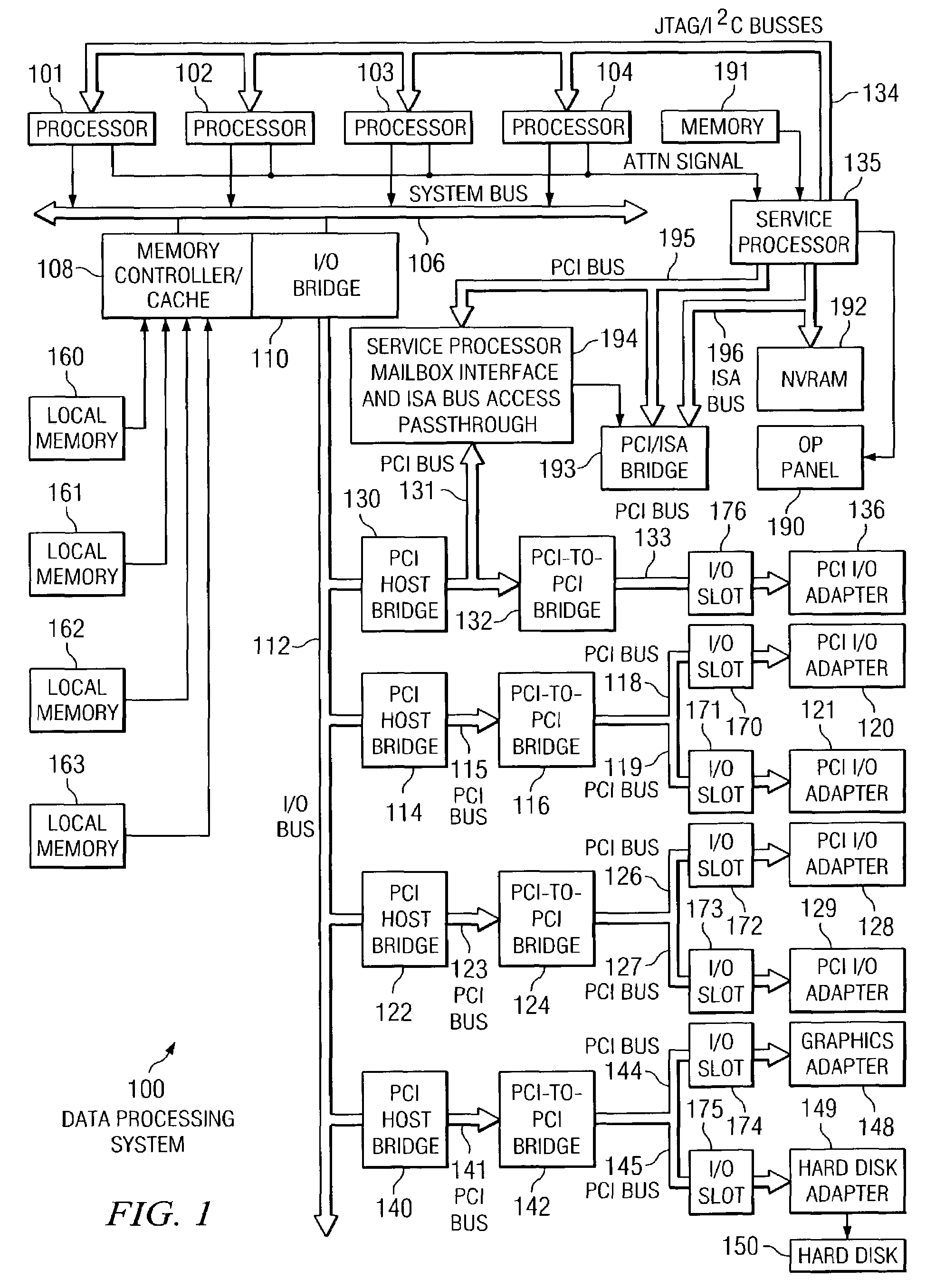

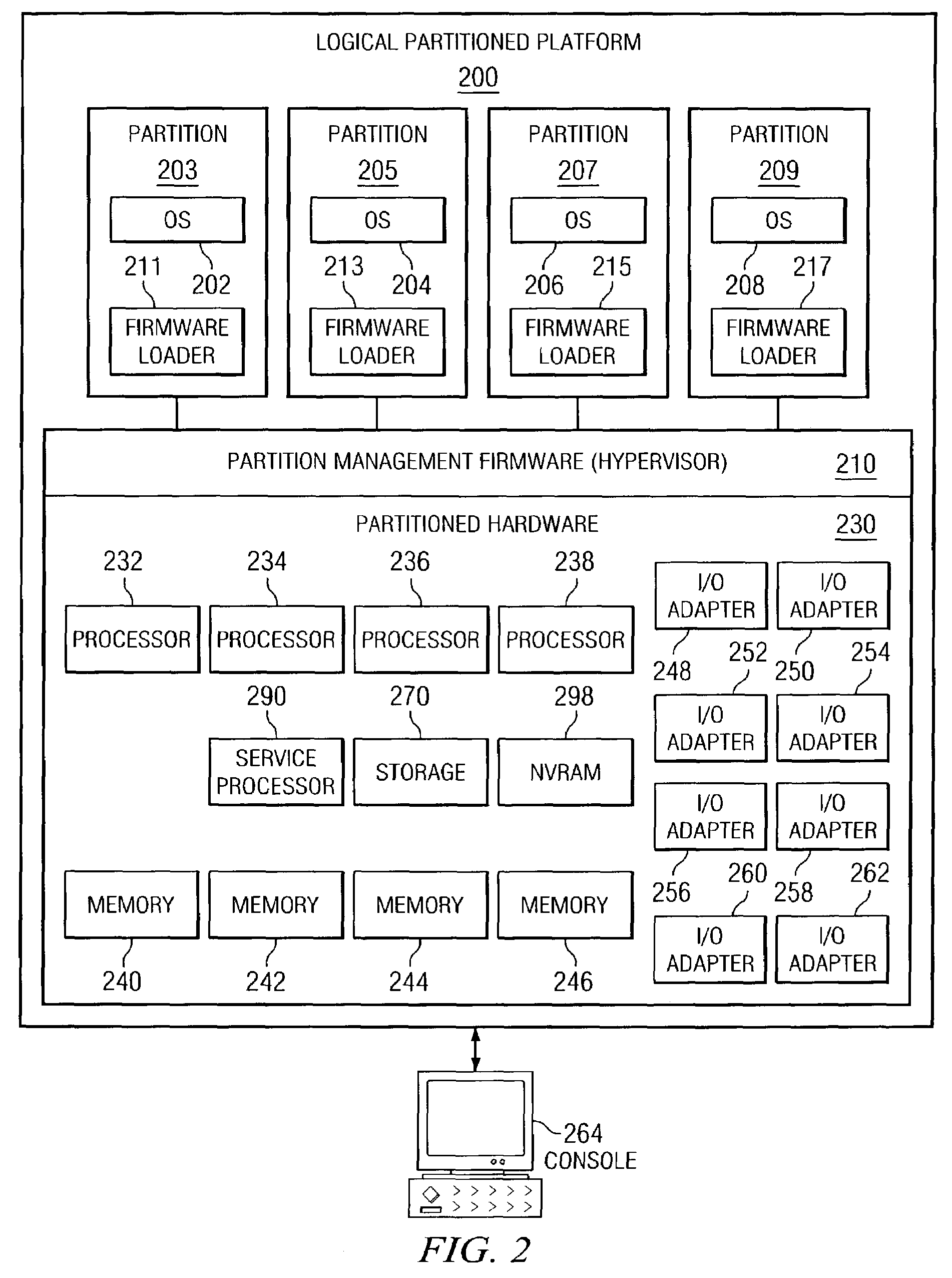

Method and apparatus for reporting global errors on heterogeneous partitioned systems

A method, apparatus, and computer instructions for reporting global errors in a logical partitioned data processing system having a plurality of partitions running different types operating systems. Responsive to detecting a global error, a unique identifier is assigned to the global error. The unique identifier is sent to a service focal point. The unique identifier also is sent to the partitions. Error information from the partitions is reported to the focal point. The partitions send error information to the focal point in association with the unique identifier. The focal point identifies error information sent from the partitions for the global error using the unique identifier.

Owner:IBM CORP

Tray charging method and vibratory tray charger

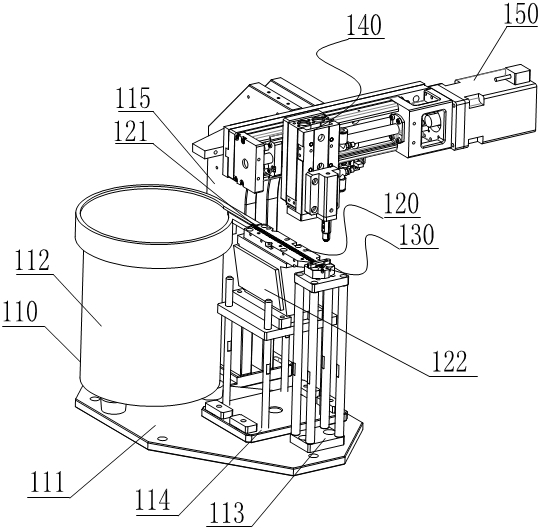

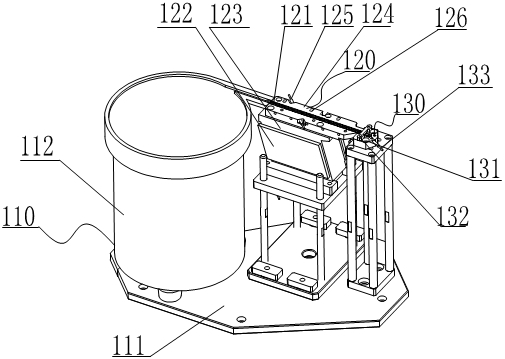

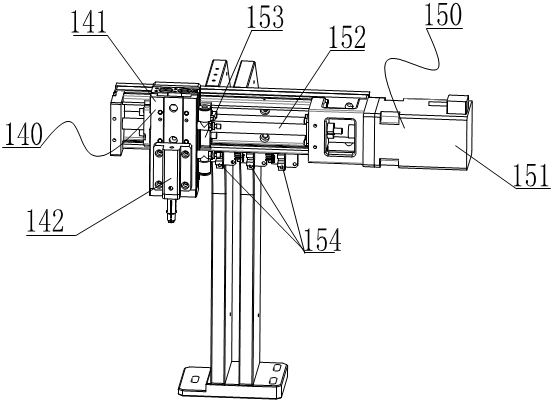

InactiveCN101885420AImprove stabilityTotal stroke is smallJigging conveyorsConveyor partsReciprocating motionEngineering

The invention discloses a tray charging method and a vibratory tray charger. The method comprises that: a hopper type vibrating device conveys integrated circuit blocks in accordance with position and direction requirements to a gripping reference position of a conveying guide rail corresponding to a fixed gripping position one by one; a tray adaptive charging device conveys troughs on a tray to a placing reference position corresponding to a fixed placing position one after another; a suction nozzle of a gripping and placing device reciprocates between the fixed gripping position and the fixed placing position according to a fixed path, and grips the integrated circuit blocks reaching the conveying position of the vibrating device when reaching the gripping position; then, the suction nozzle of the gripping and placing device moves the placing position; and when reaching the placing position, the suction nozzle places the integrated circuit blocks sucked by the suction nozzle into the troughs reaching the conveying position of the charging device. The method can improve the stability of the tray charger under the cooperation of the gripping and placing device and the charging device, and limit the total stroke of the suction nozzle to minimum.

Owner:GRAND TECH SHENZHEN

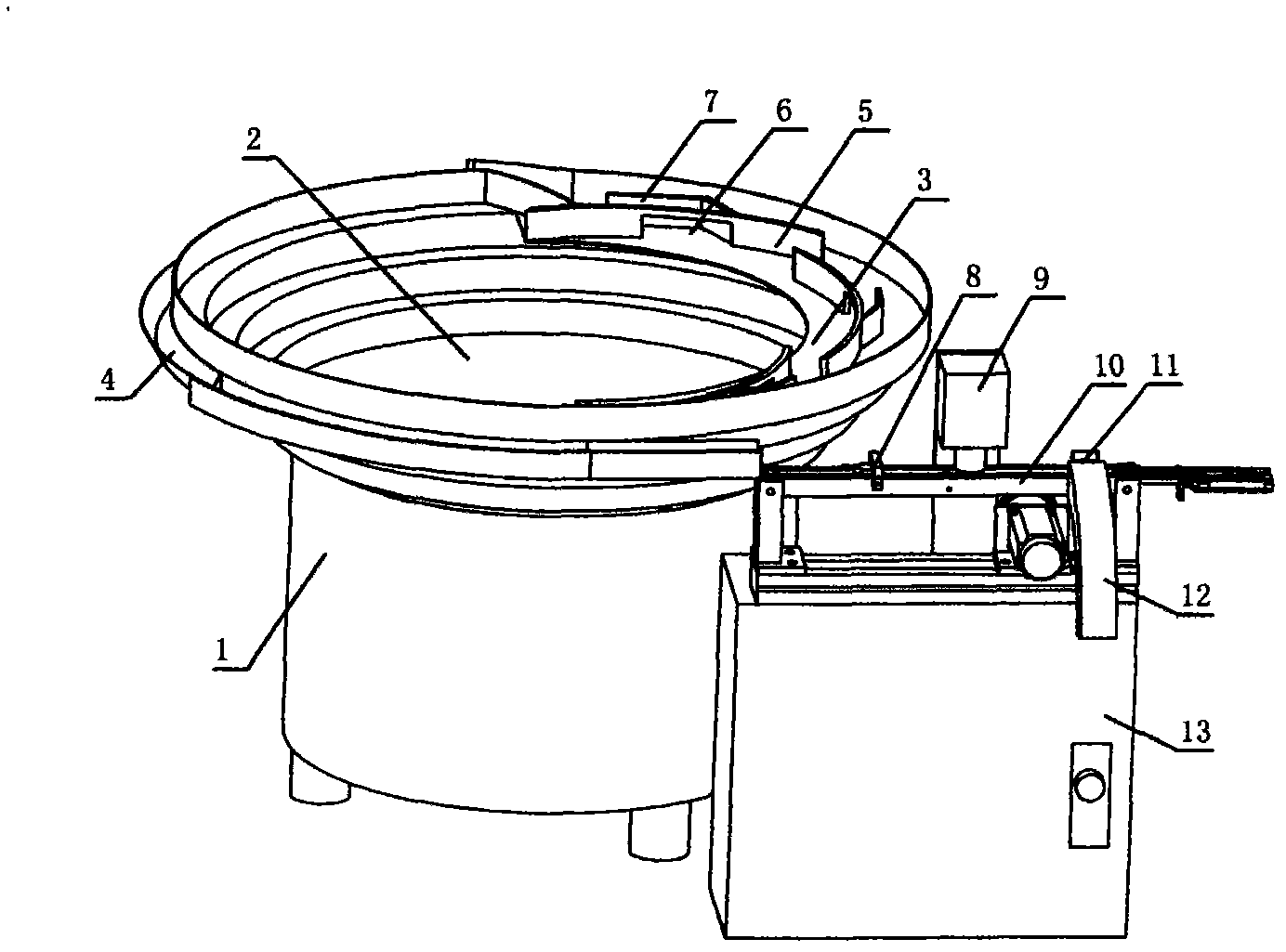

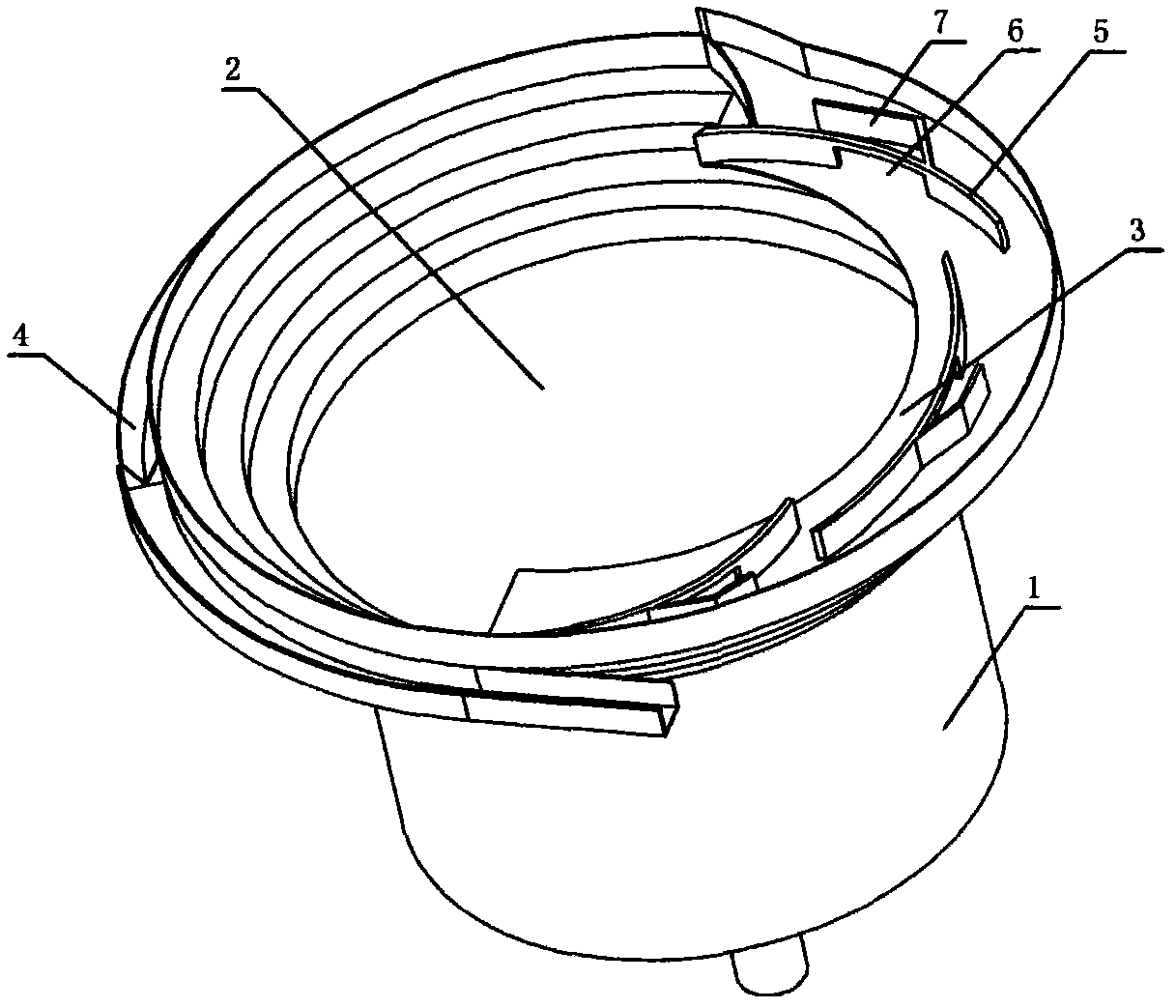

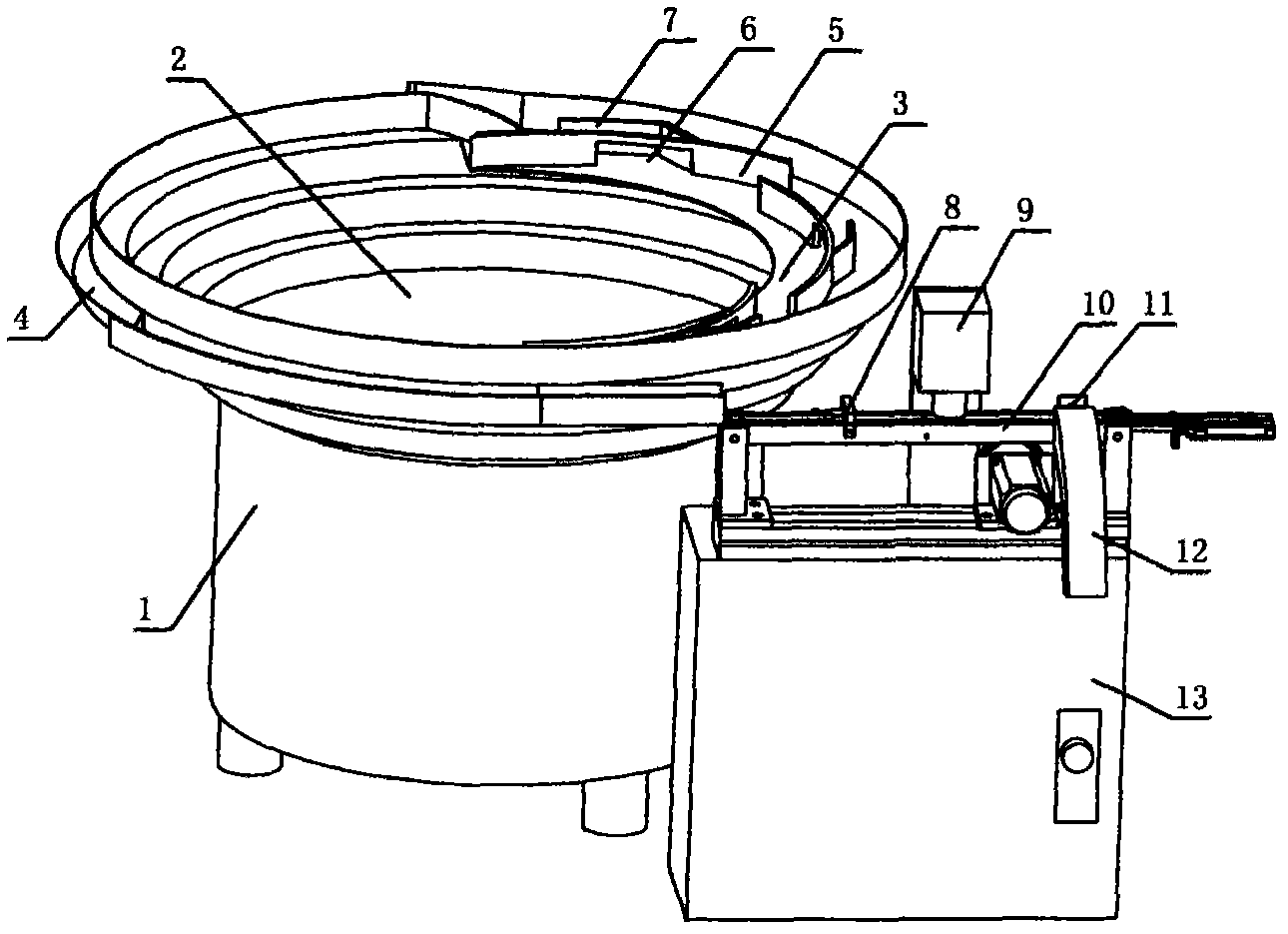

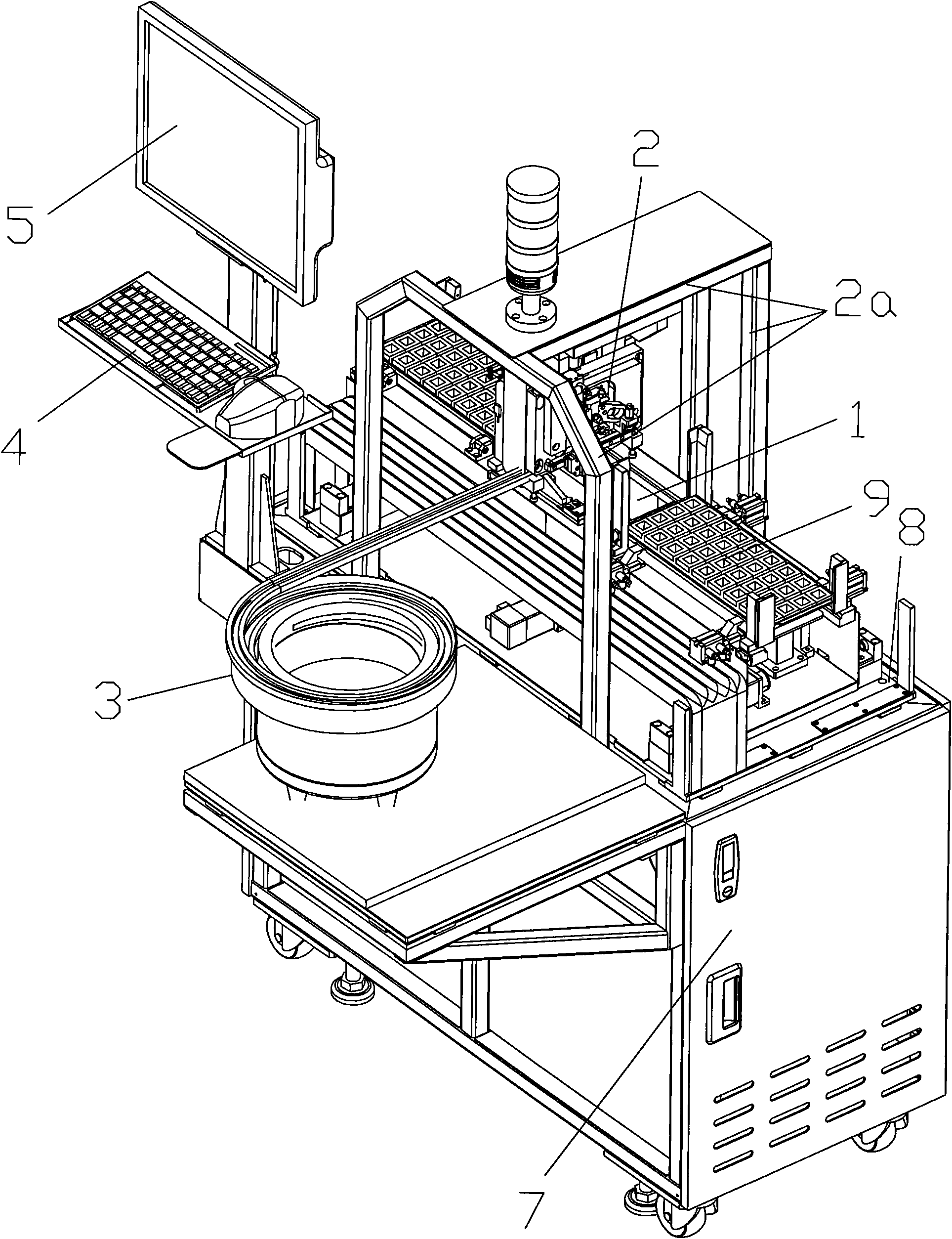

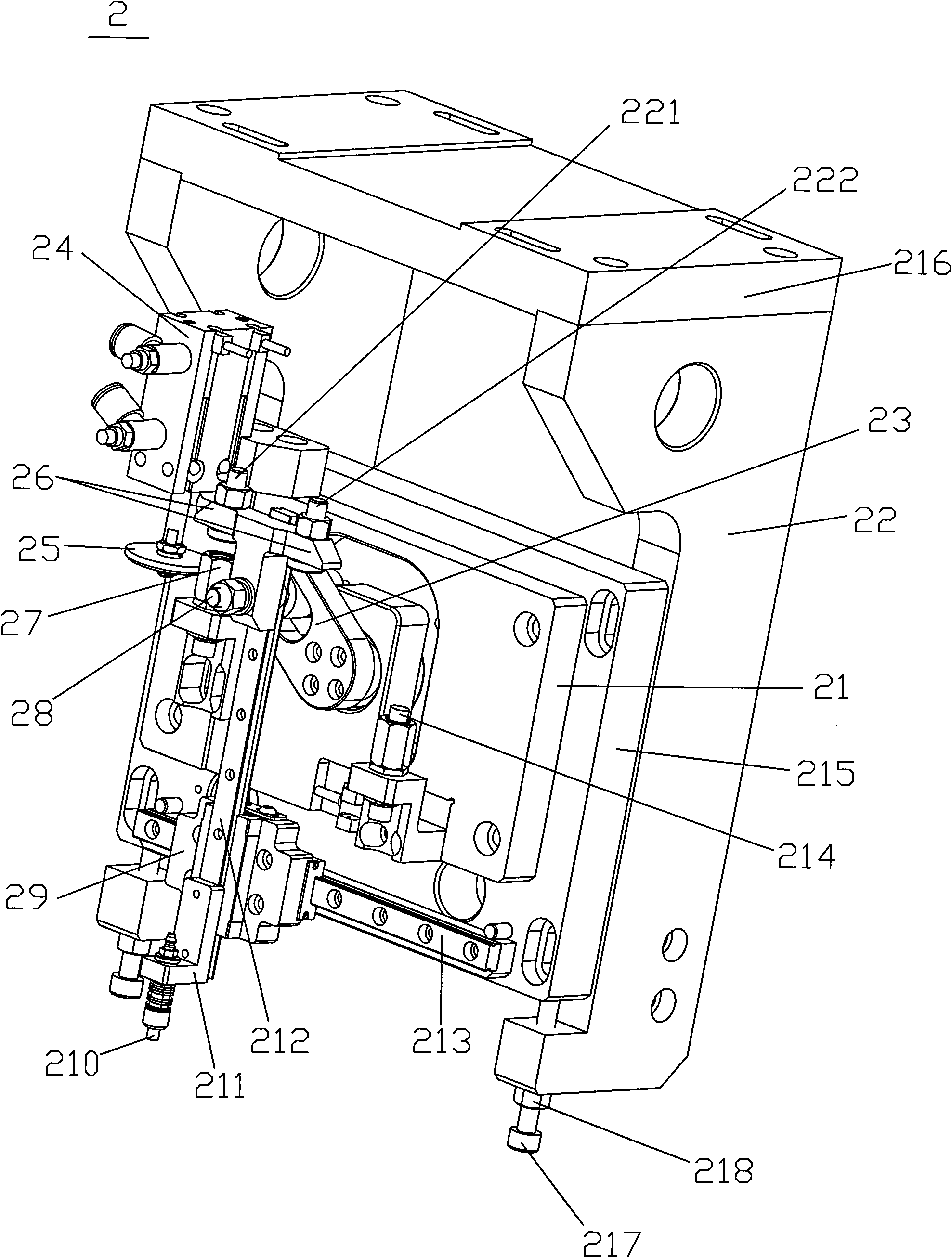

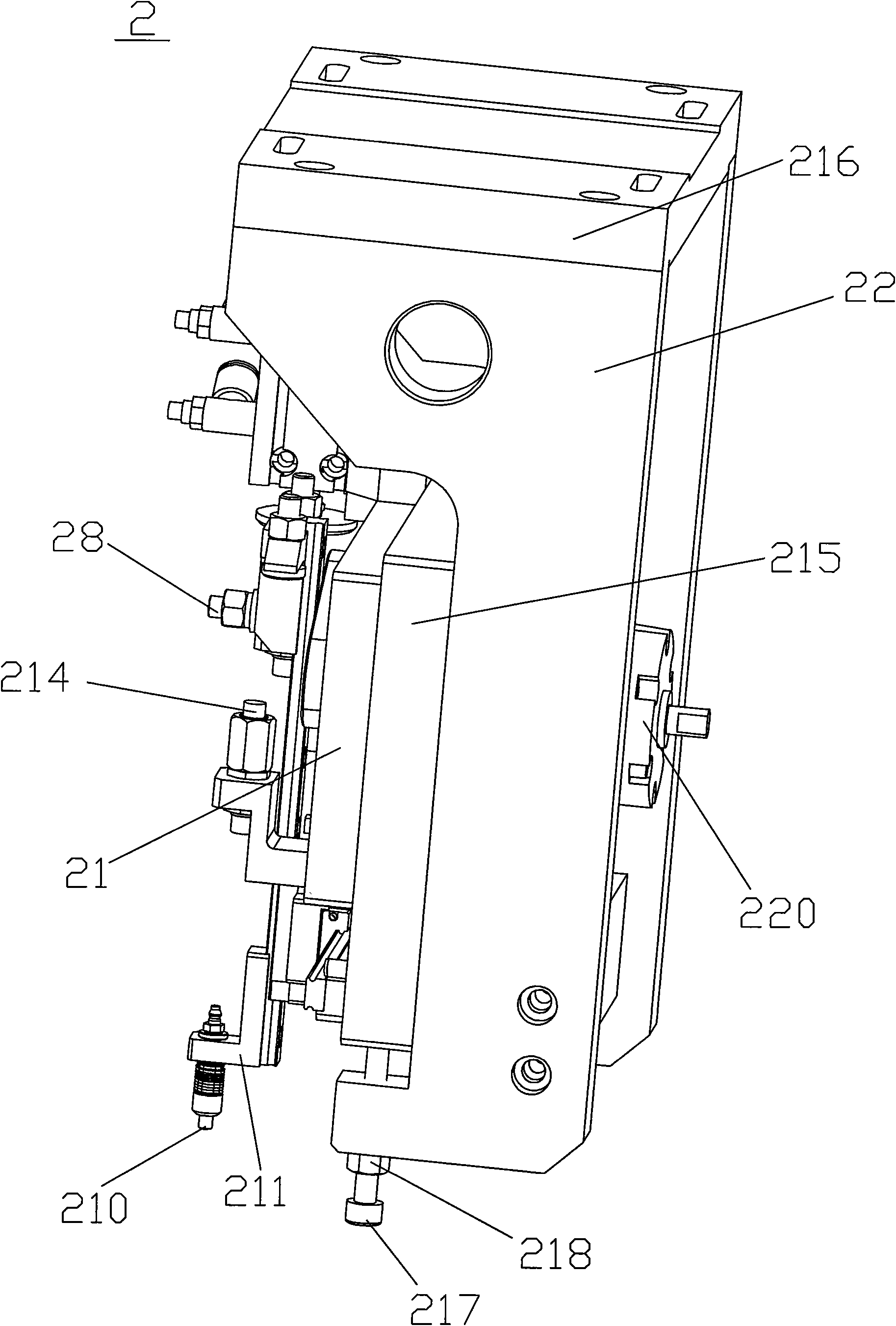

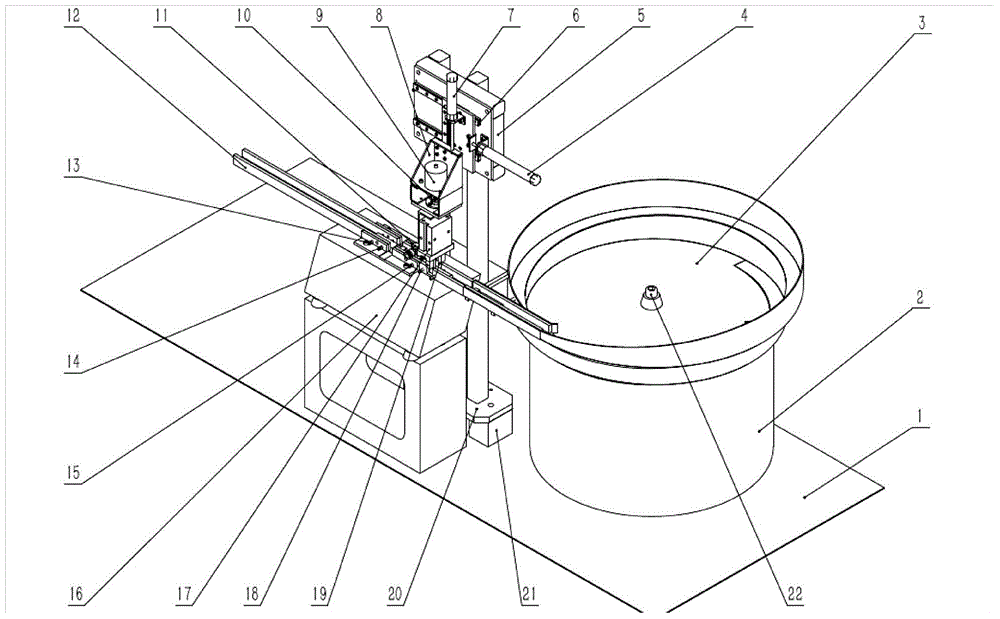

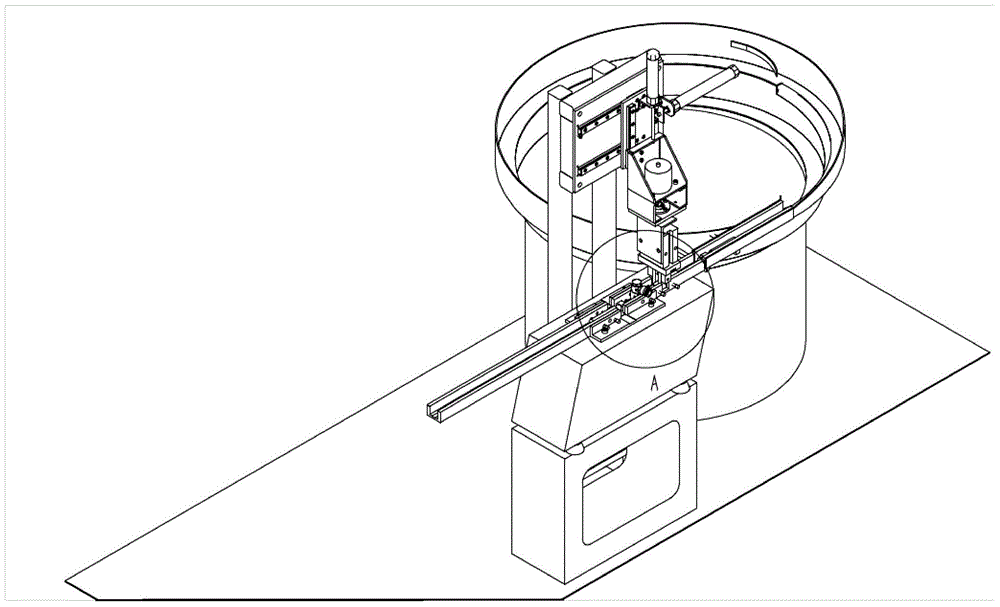

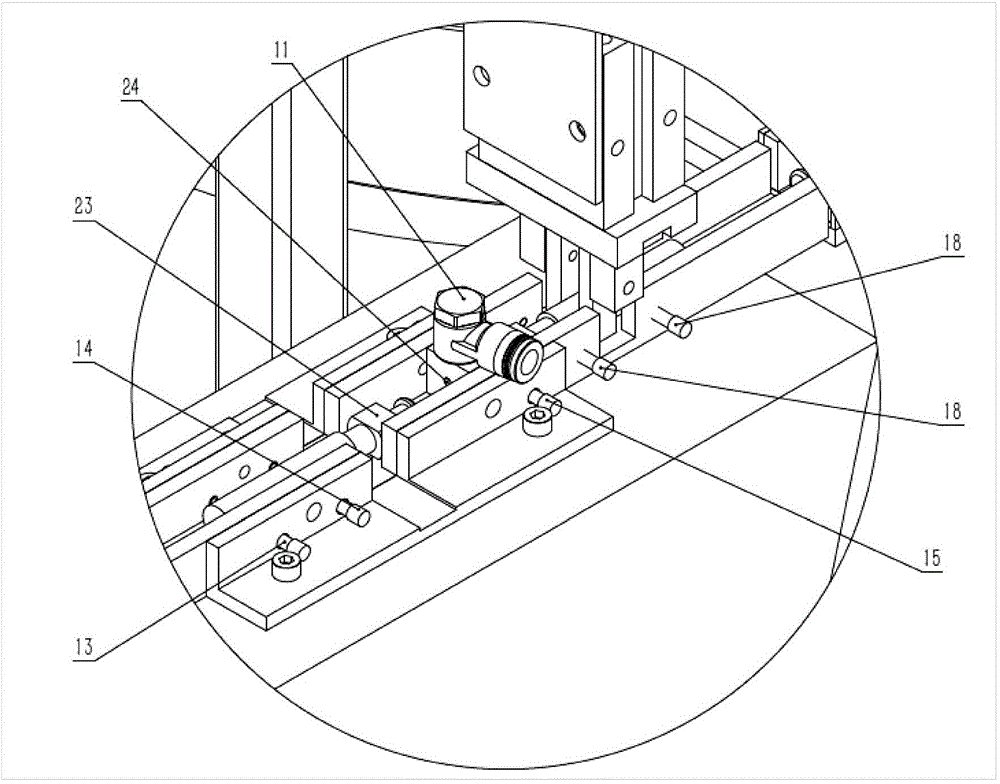

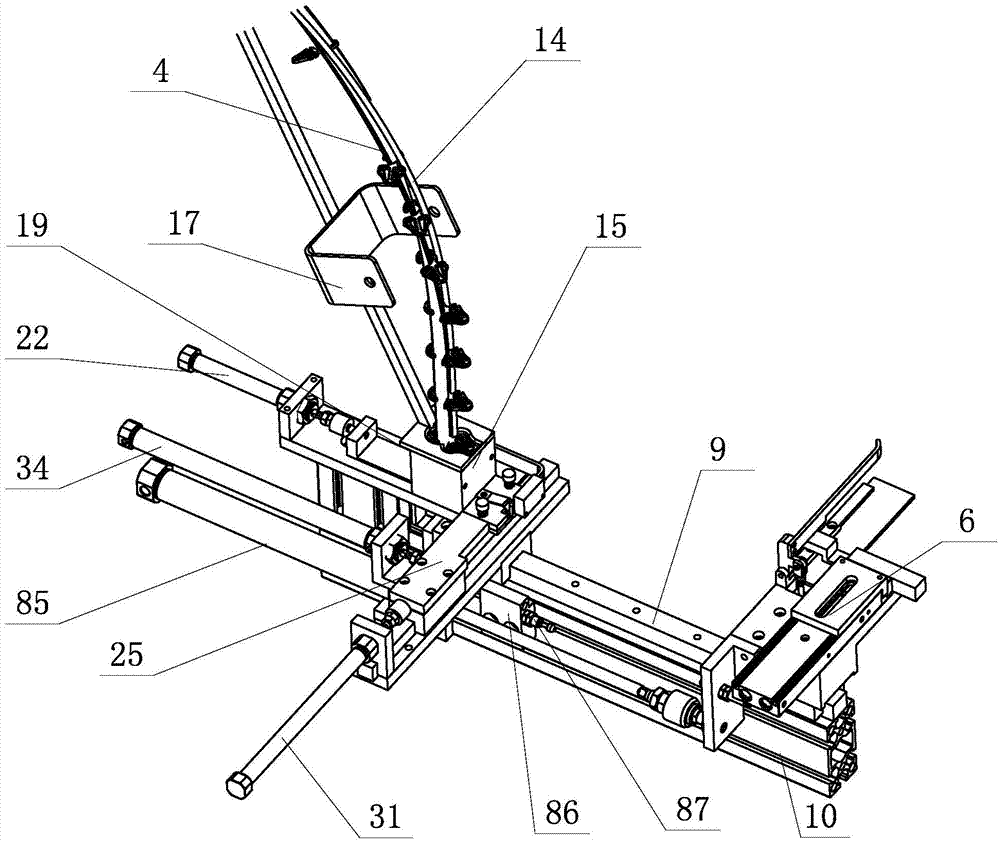

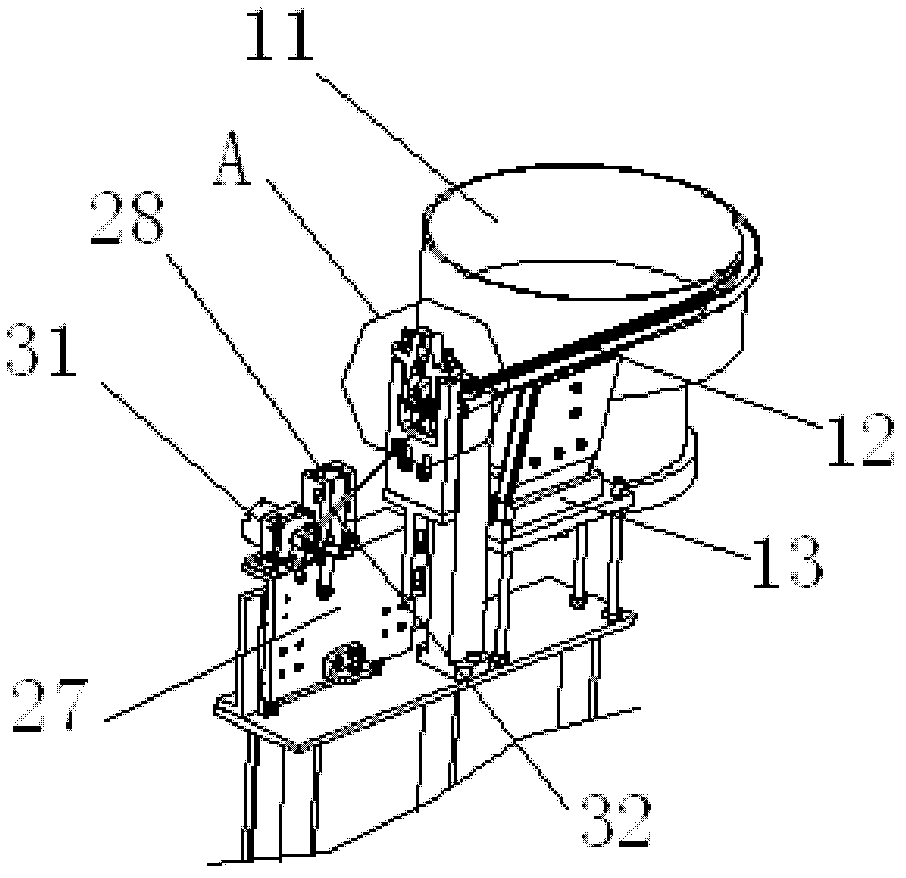

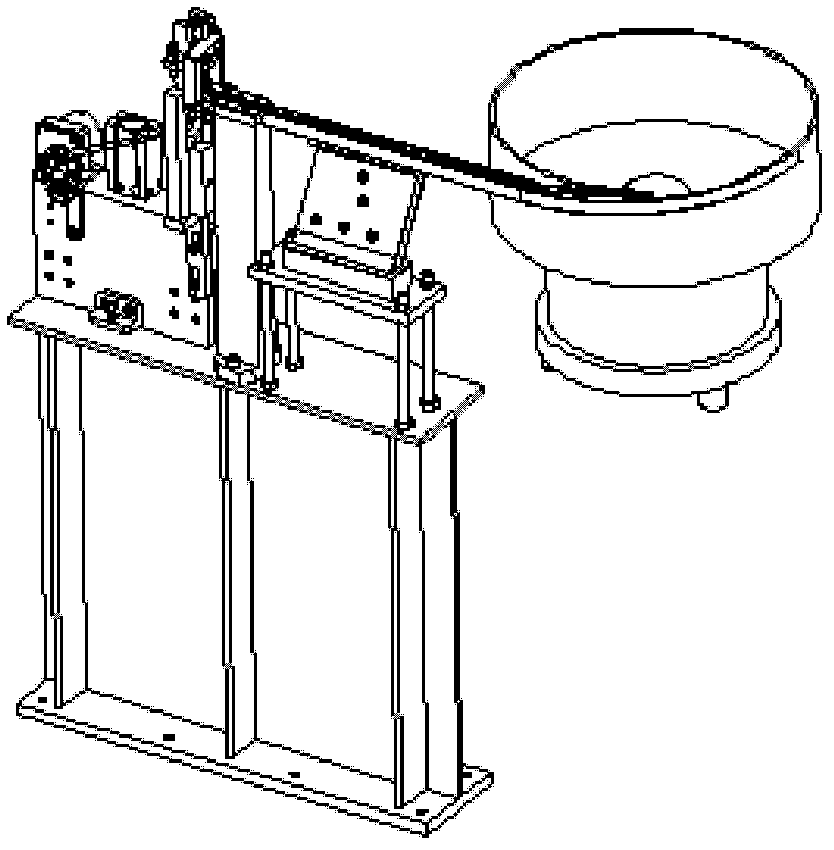

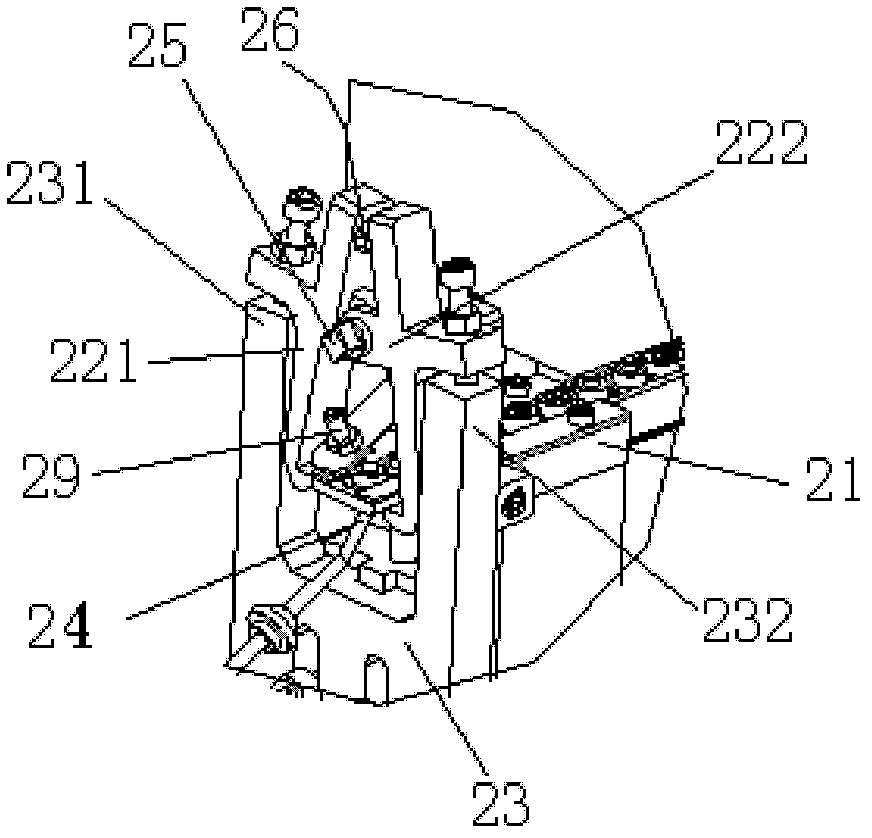

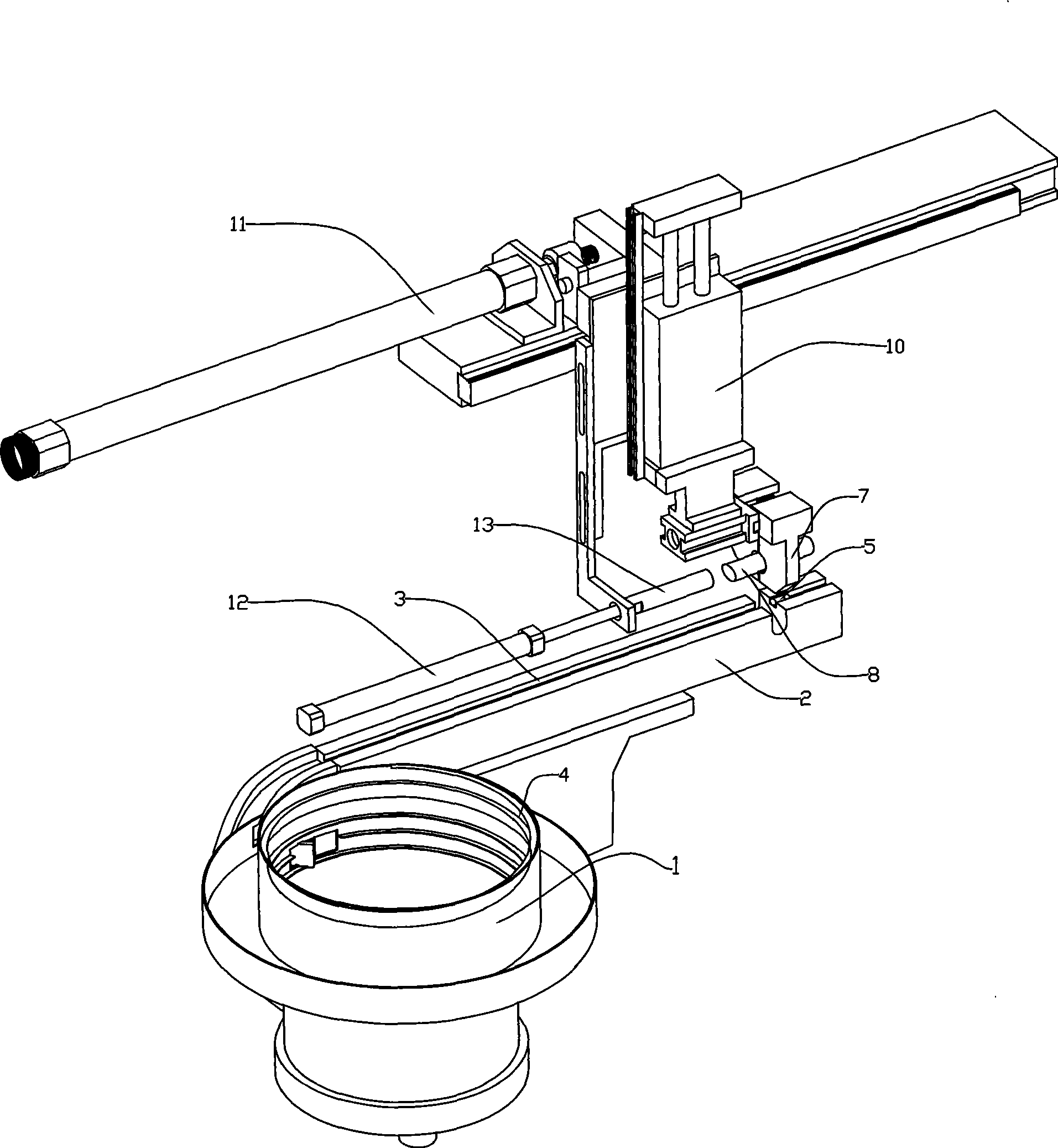

Automatic feeding device of plunger piston core of automobile fuel injection pump

InactiveCN104401689AEasy to processEasy to installJigging conveyorsConveyor partsCircular discEngineering

The invention discloses an automatic feeding device of a plunger piston core of an automobile fuel injection pump. The device comprises a base, a circular disc type electromagnetic vibration hopper, a linear electromagnetic vibration hopper, a plunger piston core direction adjusting mechanical arm, and a sensing and detection device, wherein the circular disc type electromagnetic vibration hopper, the linear electromagnetic vibration hopper and the plunger piston core direction adjusting mechanical arm are arranged on the base; the sensing and detection device is arranged on the linear electromagnetic vibration hopper. The circular disc type electromagnetic vibration hopper comprises a circular electromagnetic vibration hopper base and a spiral material disc connected with the vibration base; the linear electromagnetic vibration hopper comprises a linear vibration base, a linear material groove connected onto the base, and a workpiece movement pneumatic assisting device mounted on the material groove; an outlet end of the spiral material disc is in butt joint with an inlet end of the linear material groove. The direction adjusting mechanical arm is adsorbed on the base by a strong magnetic gauge stand; the sensing and detection device comprises a plunger piston core direction judging optical fiber sensor, and a workpiece in-place and displacement laser sensor. According to the automatic feeding device, the automatic oriented arrangement and transmission of the automobile fuel injection pump can be realized.

Owner:SOUTHEAST UNIV

Multi-workstation nut clamping and conveying device

InactiveCN102581605AImprove reliabilityImprove efficiencyMetal working apparatusJigging conveyorsEngineeringLinear vibration

The invention discloses a multi-workstation nut clamping and conveying device, which comprises a vibration disc module, a linear vibration conveying module, a nut positioning module, a nut picking module and a nut conveying module. The nut picking module is arranged above the nut positioning module, comprises a picking and gripping part with a nut picking, gripping and catching function and a descending cylinder driving the picking and gripping part to move vertically and is arranged above the nut conveying module through the descending cylinder; and the nut conveying module is used for moving nuts on the nut picking module to the corresponding direction under the control. Screening, feeding, positioning, picking, placing and conveying of the nuts are integrated into an automatic device, so that the defect that manual operation is required at each workstation is overcome, and a great quantity of labor and cost are saved. Meanwhile, reliability and efficiency of existing nut picking equipment are improved by the aid of the multi-workstation nut clamping and conveying device.

Owner:深圳市中科创安科技有限公司

Unit for filling containers with products, in particular, pharmaceutical products

InactiveUS7878366B2Rapid and safe feedingSimple structureCoin-freed apparatus detailsCounting objects on conveyorsMechanical engineeringSingle product

A unit (100) for filling containers (2) with products (1), in particular pharmaceutical products (1), includes a hopper (3,3a) containing a mass of products (1) in bulk, conveying means (5,6) aimed at feeding the products (1) leaving the hopper (3) along a predetermined path (P) up to a station (SR), where the containers (2) are filled with the products (1). The containers (2) are fed to the filling station (SR) by transporting means (4,C). A checking station (SC) for checking the products (1) is situated along the path (P) upstream of the filling station (SR). The conveying means (5,6) include first means (51,52,53) consisting of vibrating planes and second conveying means (6). The second conveying means (6) are situated at the checking station (SC) between the conveying vibrating planes means (51,52,53) and the filling station (SR). The second conveying means (6) are equipped with holding means (65) for holding single products (1) thus forming, on the second conveying means (6), a series of single products (1), spaced apart and moving forward to the filling station (SR) along a portion of the path (P).

Owner:IMA IND MASCH AUTOMATICHE SPA

Label sewing fully automatic socks packaging machine

ActiveCN103482108ARealize automatic delivery hookRealize automatic sewingPackagingArticle feedersSOCKSEngineering

The invention discloses a label sewing fully automatic socks packaging machine. The label sewing fully automatic socks packaging machine comprises a vibrating disk bracket, wherein the vibrating disk bracket is provided with a vibrating disk; a spiral material passage is arranged on the outer side of the vibrating disk; the lower end of the spiral material passage is connected with a hook mounting component; a socks feeding component is arranged in front of the hook mounting component; a vertical paper card bin component is arranged between the hook mounting component and the socks feeding component; a label sewing machine is arranged behind the socks feeding component; the hook mounting component and the socks feeding component are arranged on a same longitudinally arranged linear guide rail. The label sewing fully automatic socks packaging machine has the advantages that (1) the vibrating disk is arranged, so that automatic hook feeding can be realized, (2) the hook mounting component is arranged, so that automatic hook mounting can be realized, (3) the paper card bin component is arranged, so that automatic paper card feeding can be realized, (4) the socks feeding component is arranged, so that automatic socks feeding can be realized, and (5) the label sewing machine is arranged, so that automatic sewing can be realized.

Owner:佛山市南海大欣针织业有限公司

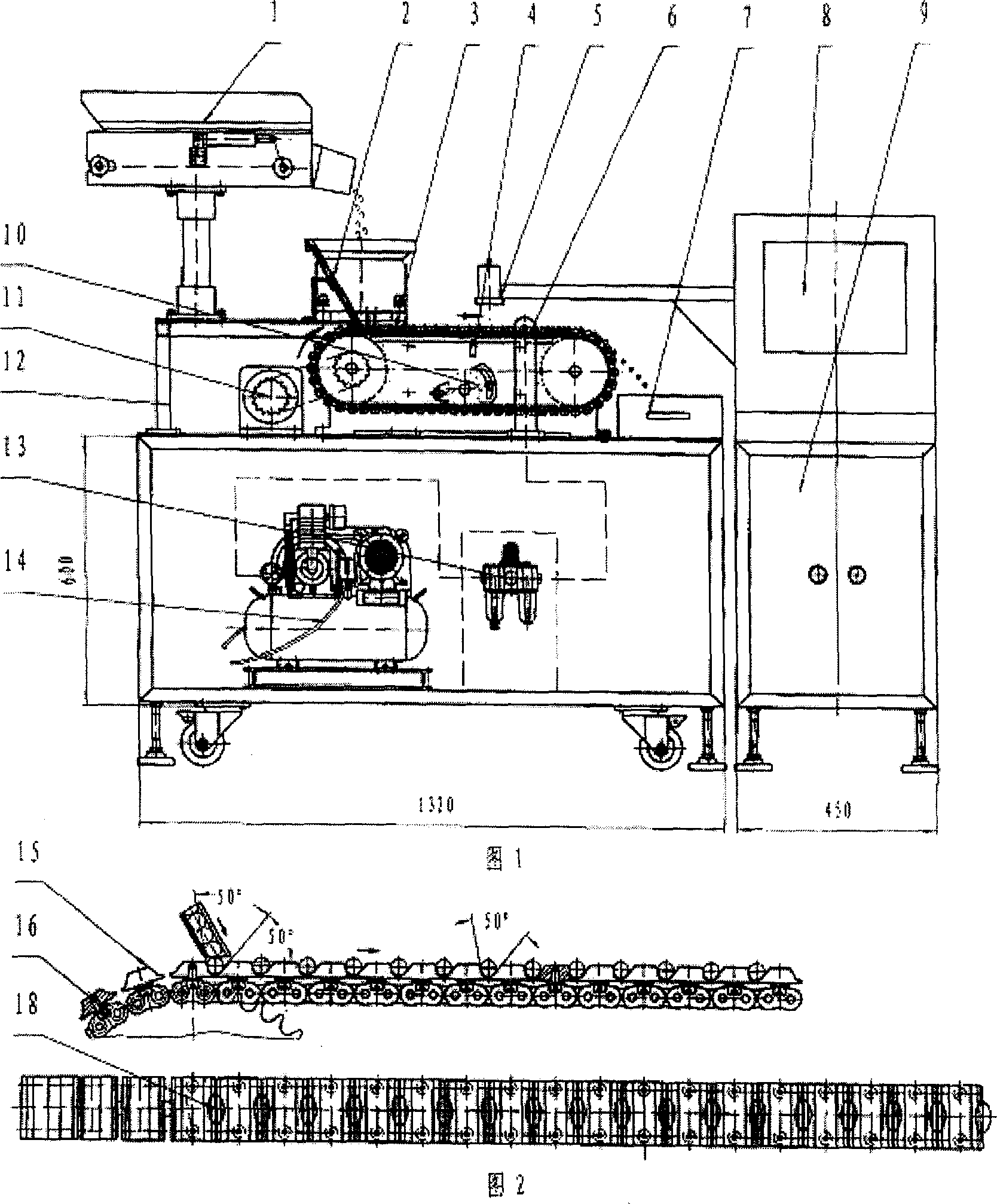

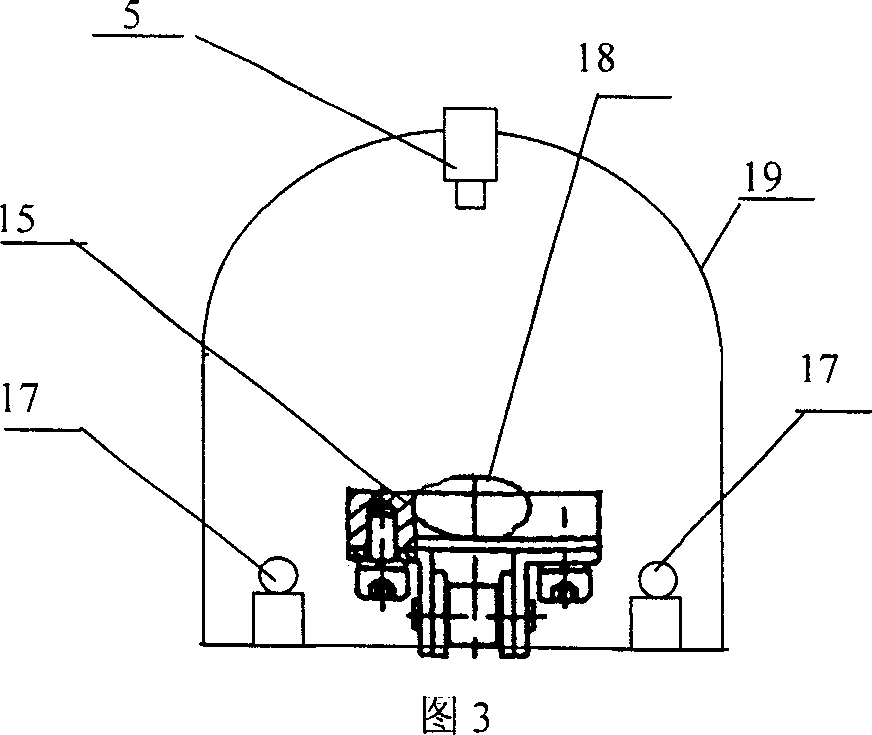

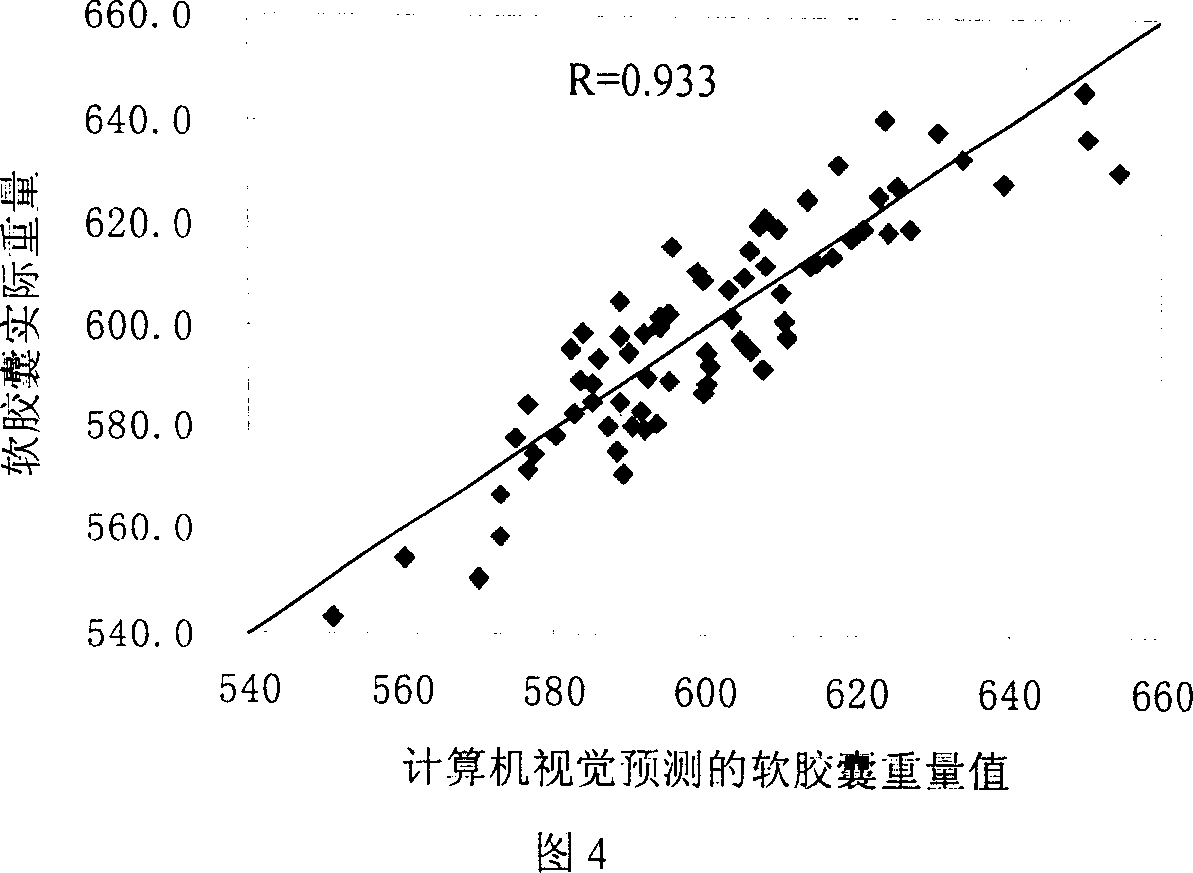

Online detecting device and method based on computer vision for soft capsule quality

InactiveCN1943886AGuaranteed accuracyGuaranteed detection speedInvestigating moving fluids/granular solidsCharacter and pattern recognitionComputer hardwareMachine vision

The present invention is computer vision detecting device and method for real-time on-line detection based on the characteristics of article. The device consists of one capsule arranging and conveying unit, one computer vision recognizing unit and one capsule eliminating unit; and features the computer vision recognizing unit with CCD camera mounted over the capsule arranging and conveying unit and the capsule eliminating unit mounted beside the conveying chain of the capsule arranging and conveying unit. The capsule arranging and conveying unit includes one vibrating feeder and one conveying chain mainly; the capsule eliminating unit eliminating soft capsules in unqualified weight and shape consists of air source, solenoid valve and nozzle connected successively; and the computer vision recognizing unit consists of video camera system, lighting box, photoelectronic sensor, control module and corresponding software.

Owner:JIANGSU UNIV

Automatic nut conveying device

InactiveCN102837937AEasy to operateRealize transformationJigging conveyorsConveyor partsEngineeringMechanical engineering

Owner:KUNSHAN SMART MACHINERY

Medication dispenser

InactiveUS20030057230A1Fast loadingCoin-freed apparatus detailsOral administration deviceMedication DispenserReciprocating motion

A medication tablet dispenser has an upright casing providing a tower which is subdivided by horizontal partitions into eight compartments which individually contain removable holders each containing a charge of tablets to be dispensed. The holders have framing portions which together provide a funnel opening downwardly into a cavity of a blister sheet. The casing is vibrated back and forth about its vertical axis through a small angle to cause tablets in the holders to progress towards an outlet leading into the funnel and having an associated ejector which discharges selected tablets into the funnel when required by a computer program. Conical vibration of the casing is prevented by a connection located on its vertical axis and held stationary by a fixed arm. The ejectors operate in response to slide-rods individually reciprocated by associated solenoids controlled by the computer program.

Owner:MANREX AUSTRALIA

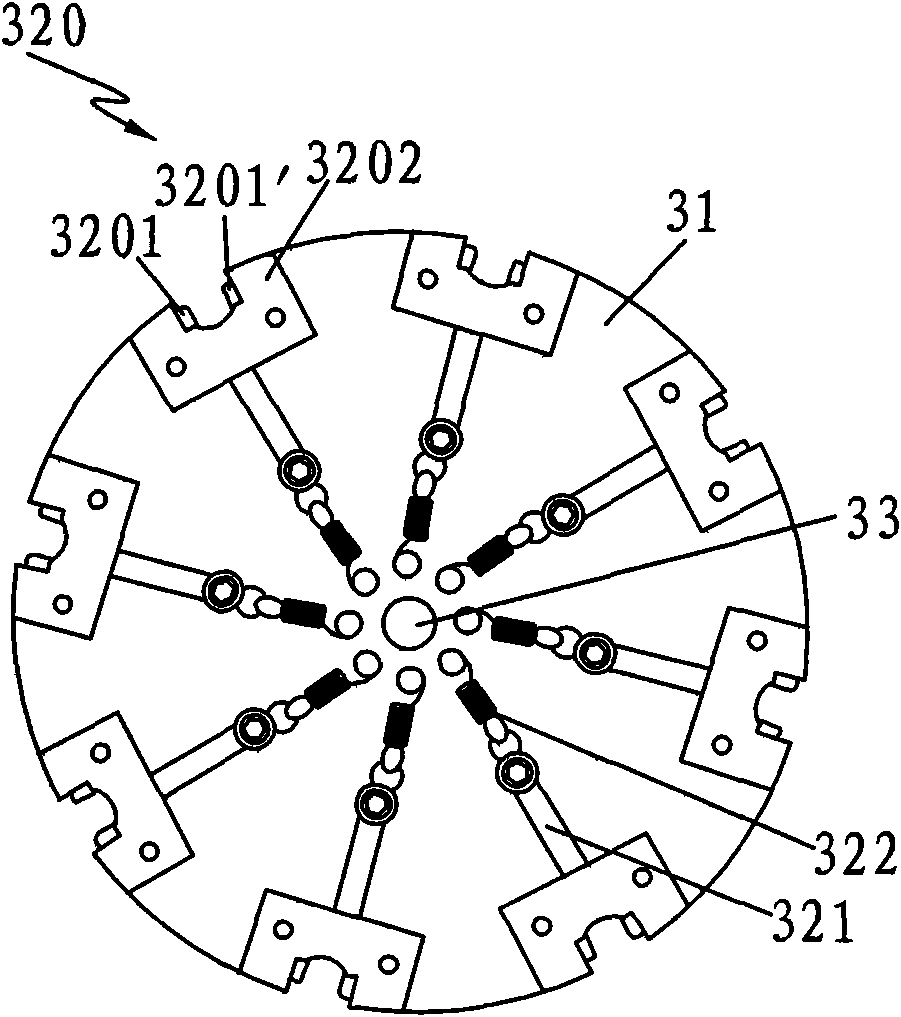

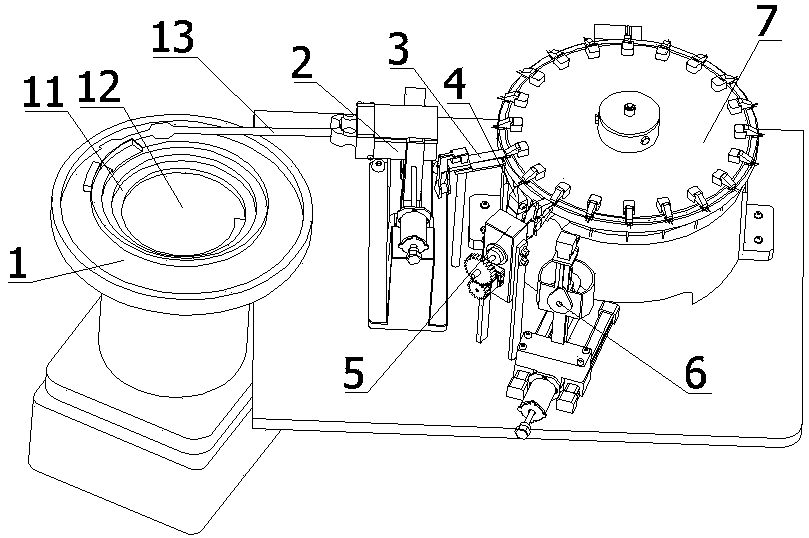

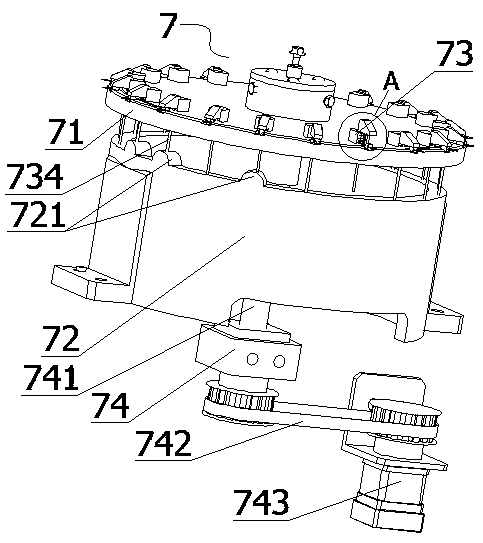

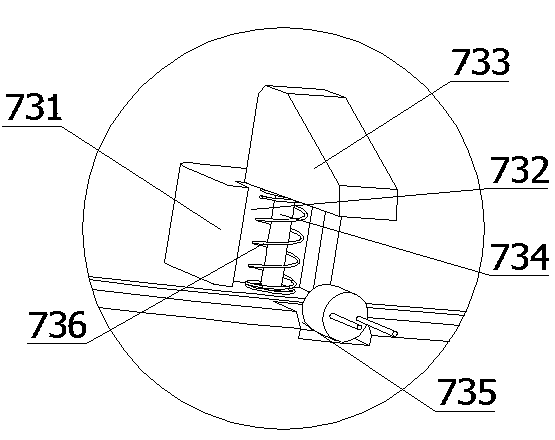

Fully automatic assembling machine for spring fasteners

InactiveCN108390236AQuick and automatic assemblyHigh efficiency of one-time assemblyContact member assembly/disassemblyAssembly machinesDistribution controlMaterial distribution

The invention relates to a fully automatic assembling machine for spring fasteners. The fully automatic assembling machine comprises a rack and a power distribution control box. The rack is provided with a circulation conveying device, a rubber shell feeding device, a fastener feeding device and a spring feeding device, wherein the rubber shell feeding device, the fastener feeding device and the spring feeding device are sequentially arranged on the periphery of the circulation conveying device. The rubber shell feeding device comprises a rubber shell feeding vibration disc disposed on the left front side of the circulation conveying device, and the rubber shell feeding vibration disc is communicated with a rubber shell material distribution block through a rubber shell conveying track; arubber shell conveying manipulator matched with the rubber shell material distribution block is disposed above the circulation conveying device, a rubber shell clamping device is arranged on the portion, below the rubber shell conveying manipulator, of the right front side of the circulation conveying device, and a fastener pushing-in device matched with the circulation conveying device is arranged under the rubber shell clamping device. The circulation conveying device is adopted for feeding and conveying materials, and the fasteners are pushed into insertion holes in a rubber shell from bottom to up through the fastener pushing-in device. The one-time assembling efficiency is high, the operation is convenient, fast and automatic assembly of the spring fasteners is achieved, and the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

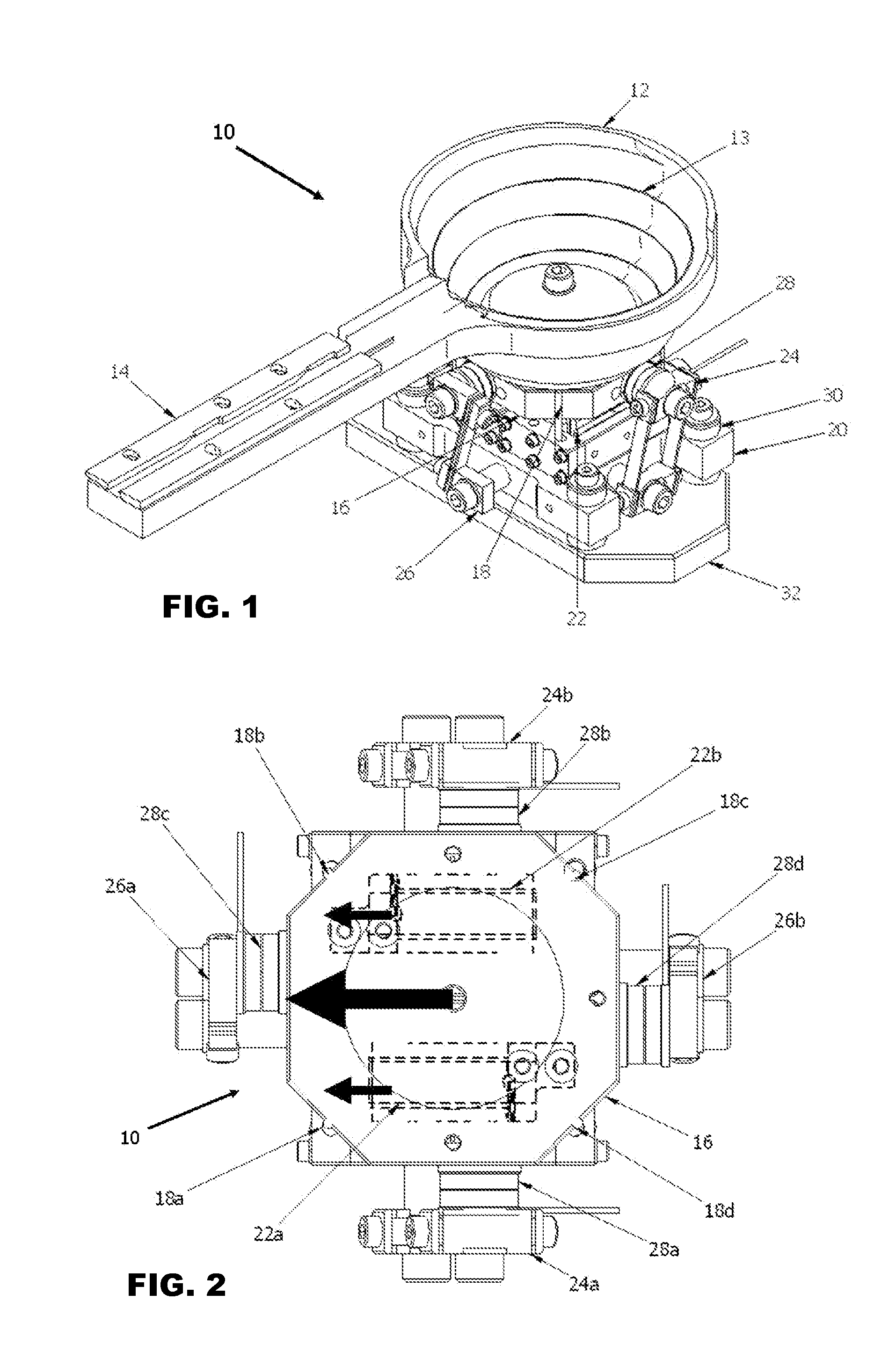

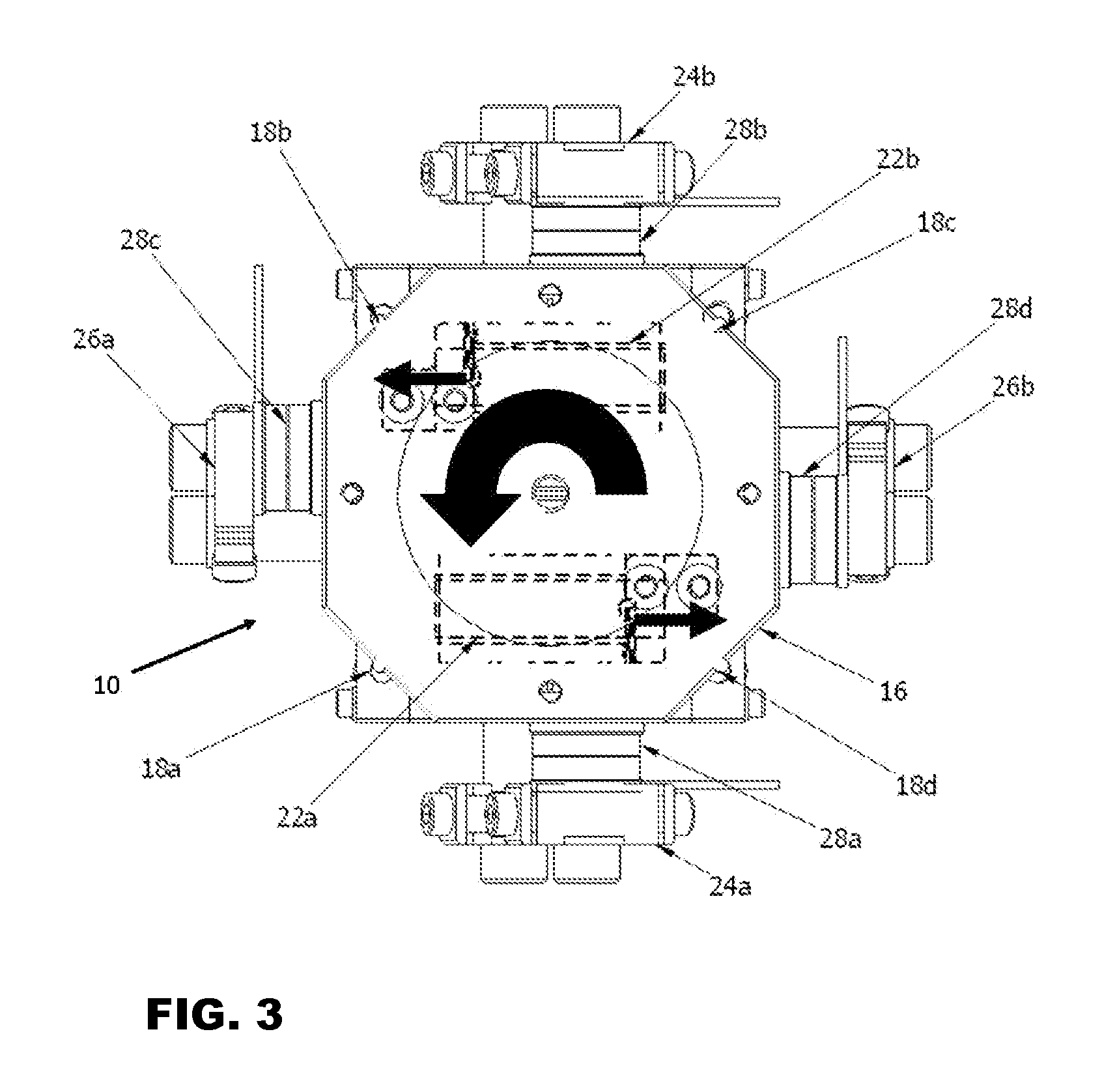

Conveying apparatus

A conveying apparatus is disclosed and which includes a supporting frame; an article transporting bed which is oriented in spaced relation relative to the supporting frame; a plurality of resilient supports mounted on both the supporting frame and the article transporting bed and which supports the article transporting bed in spaced relation relative to the supporting frame; and a drive assembly borne by the supporting frame and which provides an oscillating force having a plurality of components and which causes the article transporting bed to move reciprocally, and wherein the drive assembly amplifies the components of the oscillating force which are at a given angle relative to the resilient supports.

Owner:KII TEKU INC

LED lamp tube pipelining conveying equipment

InactiveCN103879728ARealize large-scale productionReduce labor costsJigging conveyorsConveyor partsControl systemEngineering

The invention discloses LED lamp tube pipelining conveying equipment. The LED lamp tube pipelining conveying equipment comprises a feed hopper, a transferring mechanism, a flattening device, a positive- and negative-electrode testing device, a turnover device, a damage measuring device, a rotary plate structure and a control system. The transferring mechanism is arranged between the feed hopper and the rotary plate structure, the transferring mechanism, the flattening device, the positive- and negative-electrode testing device, the turnover device and the damage measuring device are sequentially arranged around the rotary plate structure, and a plurality of clamping mechanisms are uniformly distributed on the rotary plate structure circumferentially. The LED lamp tube pipelining conveying equipment further comprises a driving device arranged on the rotary plate structure for driving the same to rotate. By the LED lamp tube pipelining conveying equipment, feeding, transferring, flattening pins of lamp tubes, positive- and negative-electrode testing, turnover of the lamp tubes, damage measuring and the like are automatically completed, and monitoring one or more devices can be completed by only one person, so that labor cost is greatly saved, labor intensity is reduced, processing efficiency is improved qualitatively, and large-scale batch production of the LED colored string lamps is realized.

Owner:秦利明 +1

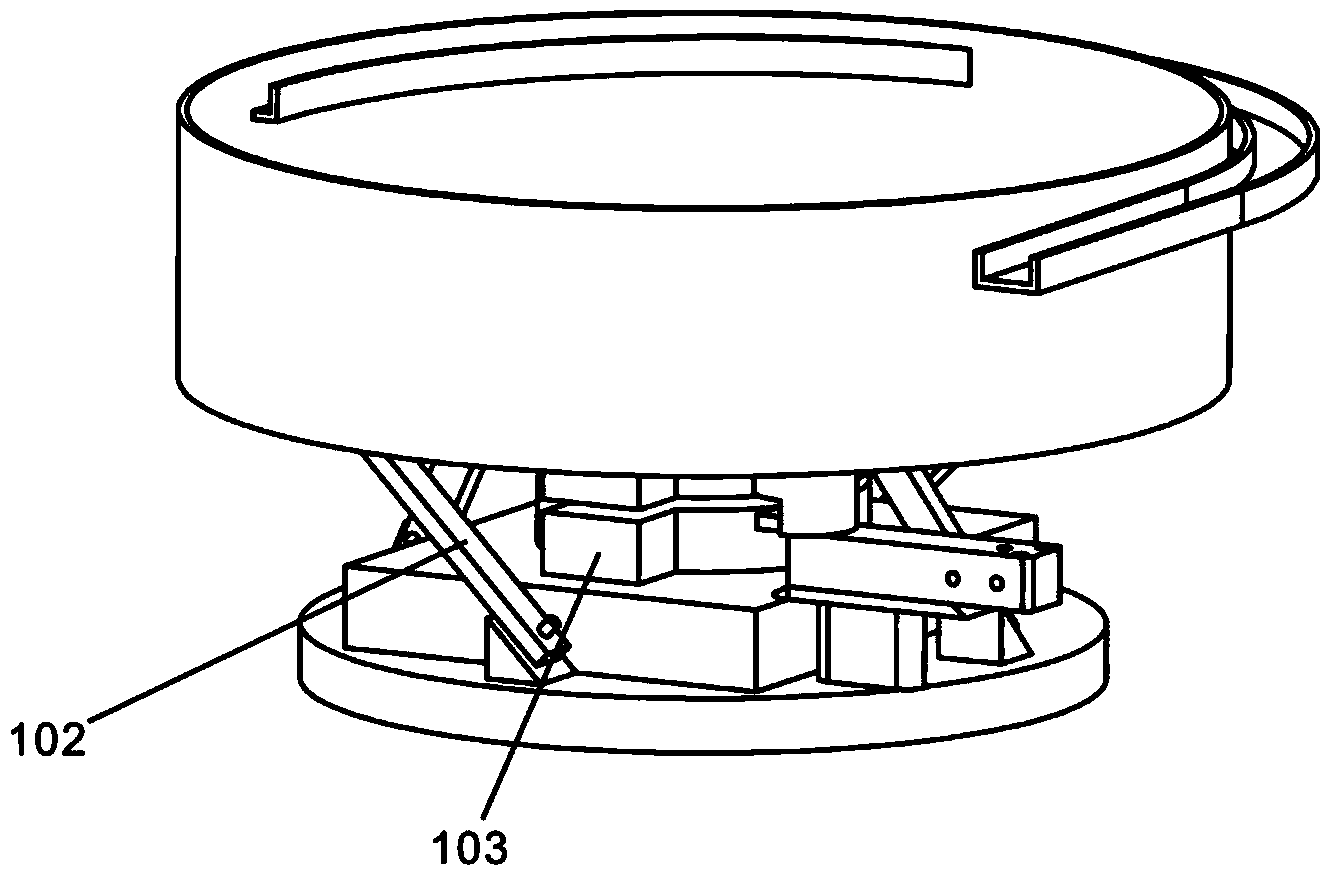

Vibratory feeder for conveying components

A vibration feeding apparatus comprises a receptacle for holding and conveying components, and first and second linear motors coupled to the receptacle. The first and second linear motors are spaced from each other and have respective coils that are aligned parallel to each other. The first and second linear motors are operative to be driven at a first operation mode whereby to impart rotary vibration to the receptacle, and at a second operation mode whereby to impart linear vibration to the receptacle.

Owner:ASMPT SINGAPORE PTE LTD

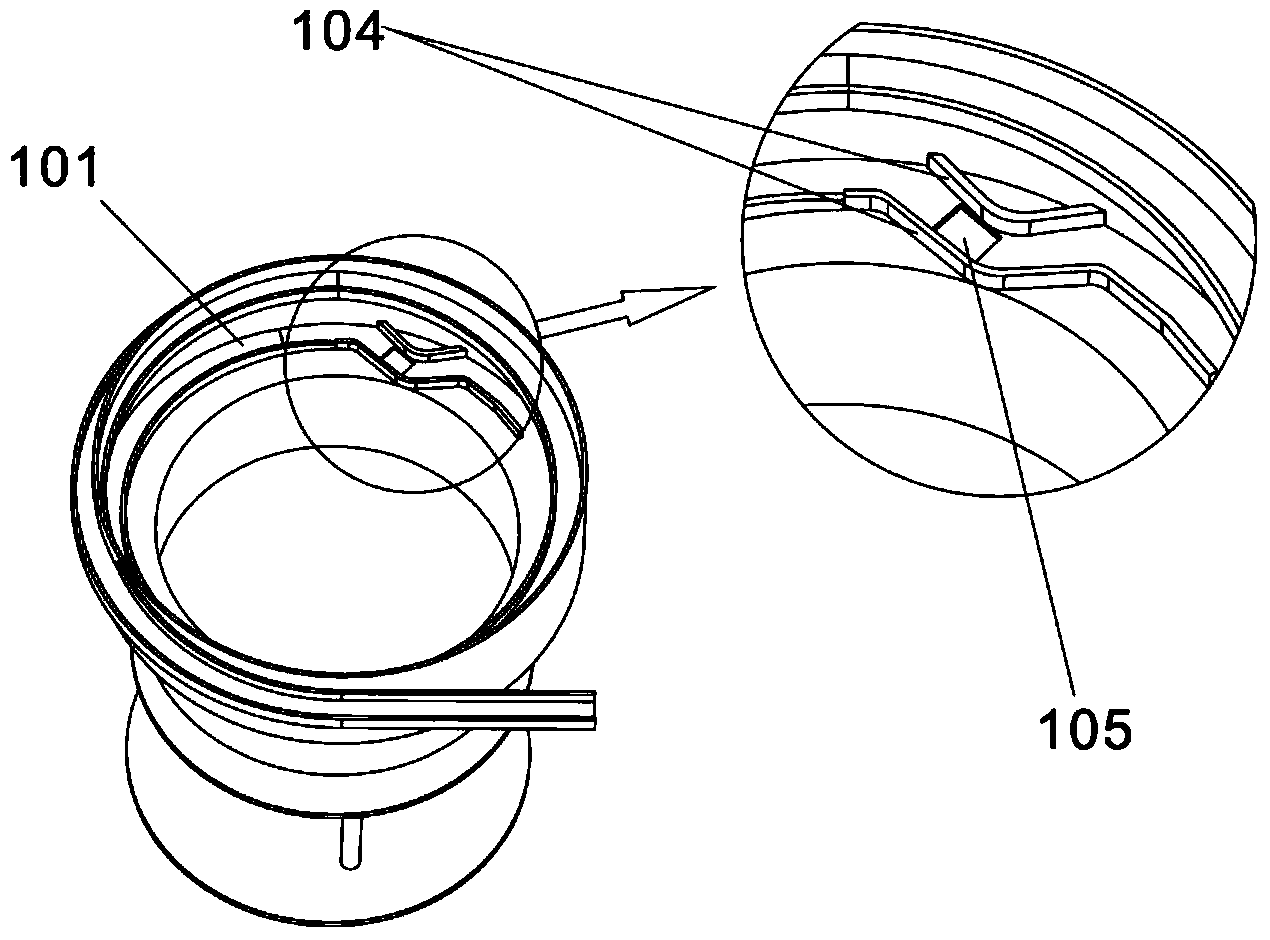

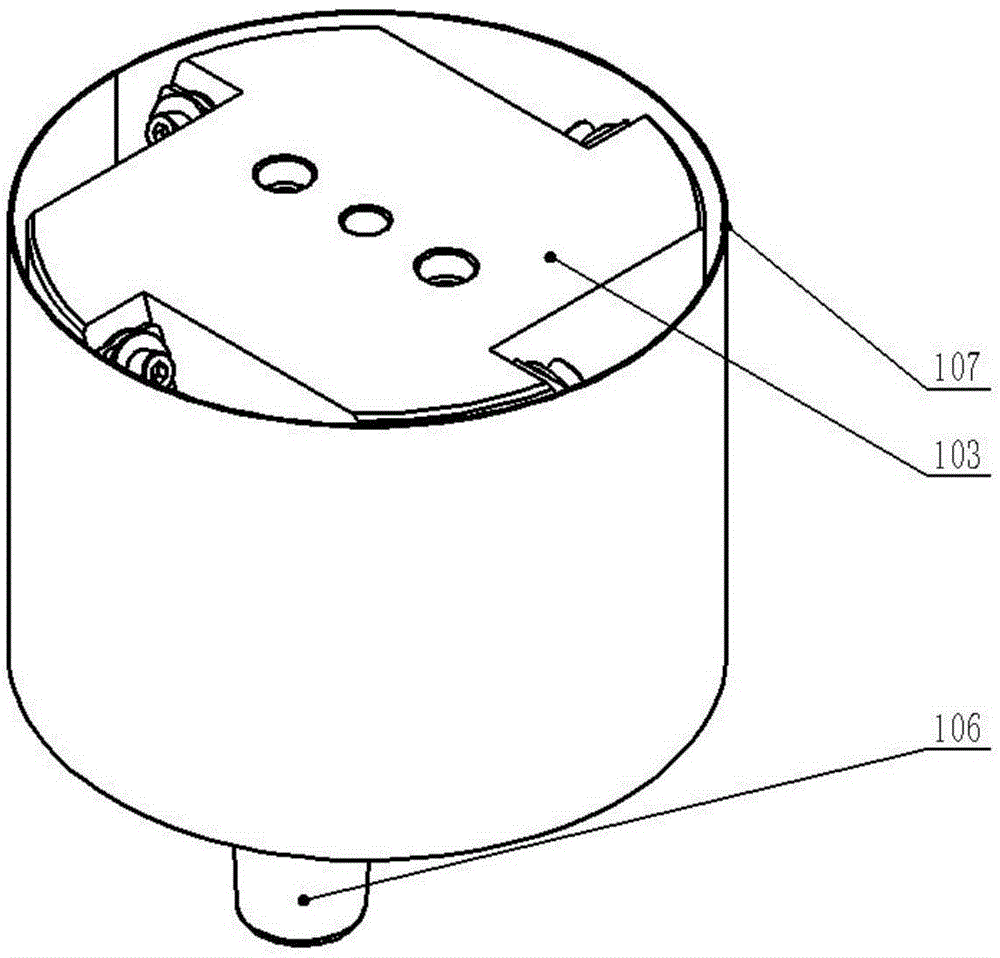

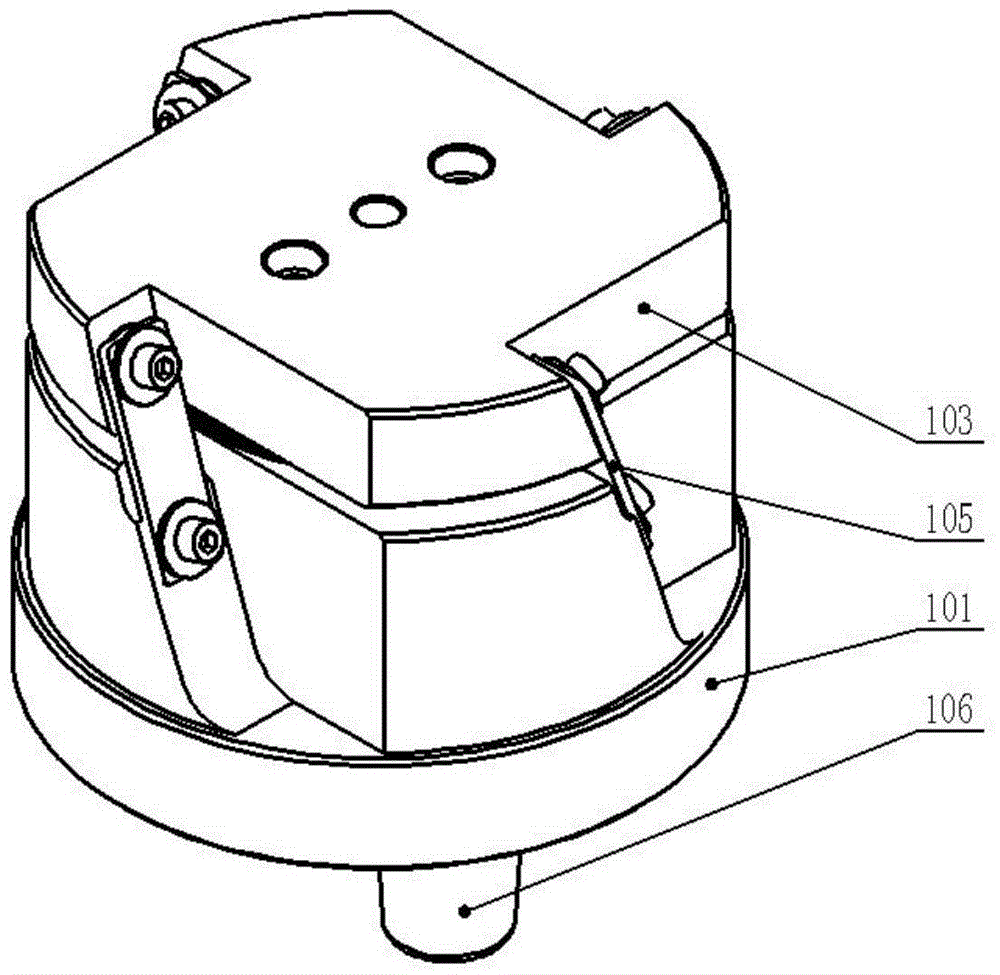

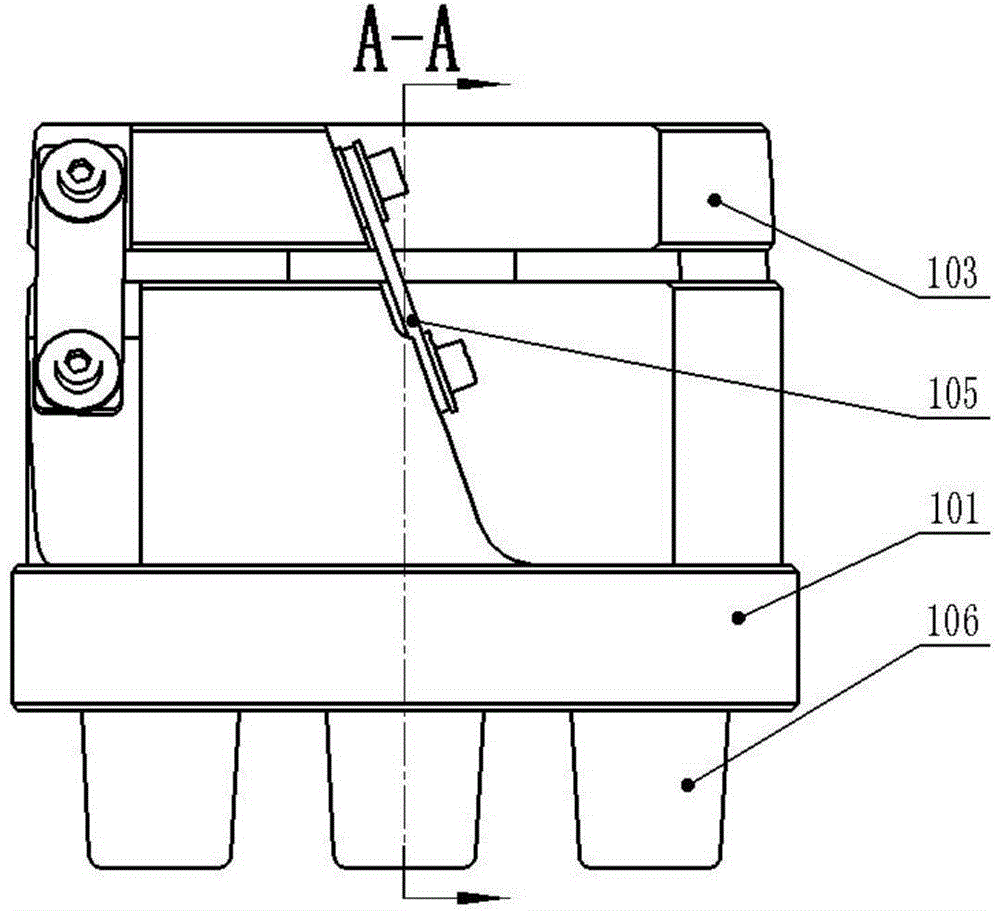

Vibrating hopper for conveying syringe rubber plug

InactiveCN101412468ASimple structureStable deliveryInfusion syringesJigging conveyorsEngineeringMedical treatment

The invention provides a vibrating hopper for feeding a rubber plug of an injector and belongs to the technical field of medical appliance. The vibrating hopper solves the technical problems that the prior vibrating hopper for feeding the rubber plug of the injector has poor feeding stability and the like. A helical rising feeding passage is arranged on the vibrating hopper for feeding the rubber plug of the injector; the highest part of the feeding passage is provided with a feed outlet; the lowest part of the feeding passage is provided with a feed inlet which is positioned on the bottom of the hopper; an arranging structure for outputting the rubber plugs uniserially is arranged on the feeding passage; a screening mechanism of which one end is upward is arranged on the feeding passage between the feed outlet and an arrangement mechanism; and the screening mechanism is used for screening the rubber plug out and is provided with a mounting hole. The vibrating hopper has the advantages of simple structure, stable feeding and the like.

Owner:王兴章

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

Novel magnet ring winding machine

InactiveCN102789886AImprove efficiencyHigh degree of automationJigging conveyorsCoils manufactureWinding machineConductor Coil

The invention discloses a novel magnet ring winding machine, which comprises a base plate, a vibration hopper, a blanking hopper, wire frames, a turntable mechanism, a feeding mechanism, wire feeding shearing mechanisms and wire penetrating rotation lifting mechanisms, that are arranged on a rack, wherein a working turntable in the turntable mechanism is an eight-square turnplate; workpiece clamping turning mechanisms are arranged on the eight-square turnplate at equal interface of being 45 degrees so as to clamp workpieces, and rotate the workpieces by 180 degrees, so that the winding overlapping can be avoided; and the feeding mechanism is arranged between the vibration hopper and a feeding station; a mechanical finger is used for automatically feeding, so that the accuracy rate and the speed are high; the wire penetrating rotation lifting mechanisms are arranged on the base plate, and are respectively arranged below the corresponding wire feeding shearing mechanisms; and the winding operation can be completed by the matching of electric wire pressing wheels and latch needles. Therefore, the novel magnet ring winding machine has the characteristics of high degree of automation, high machining quality, low manual cost, high machining efficiency and the like.

Owner:诸暨斯通机电设备制造有限公司

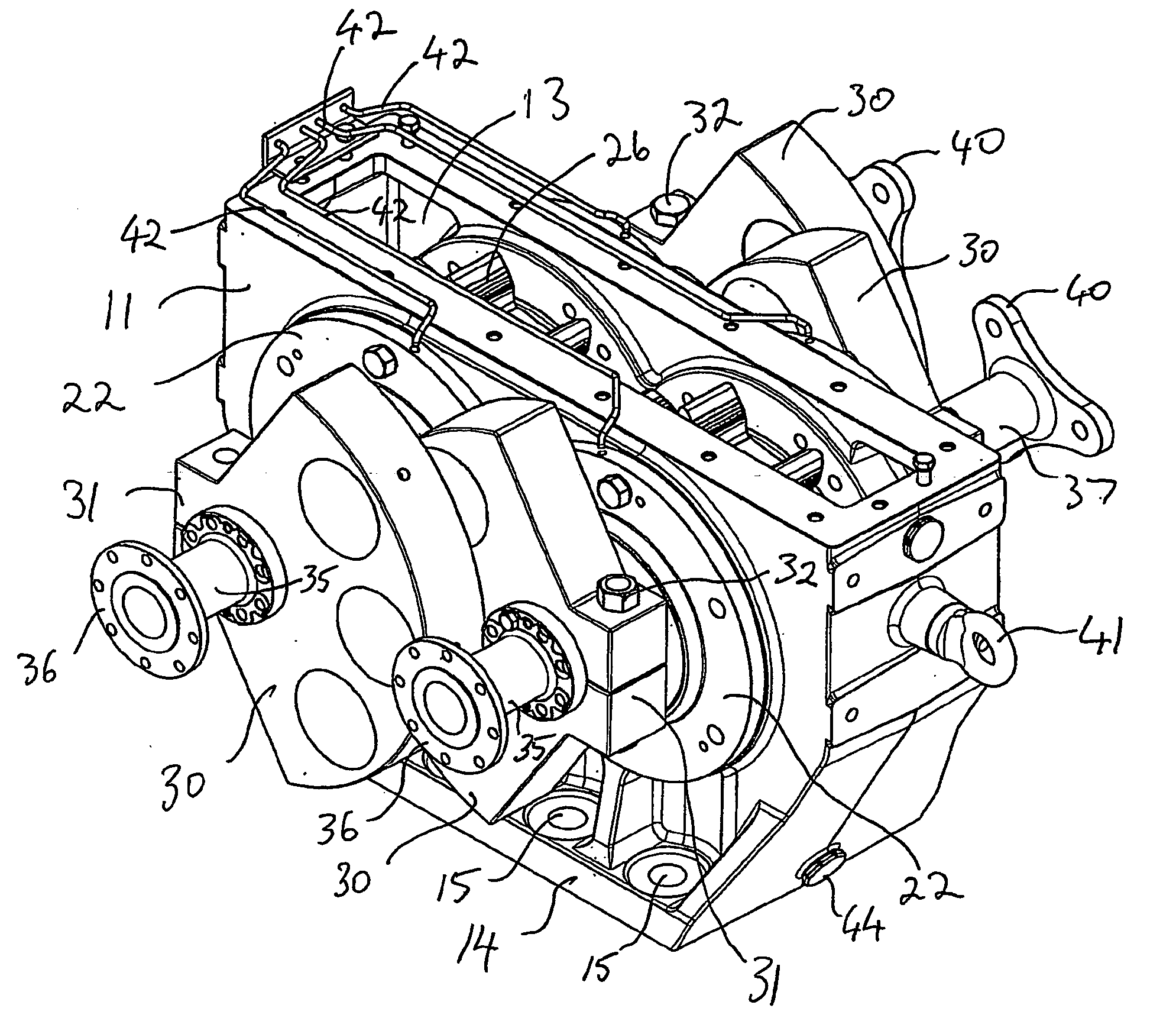

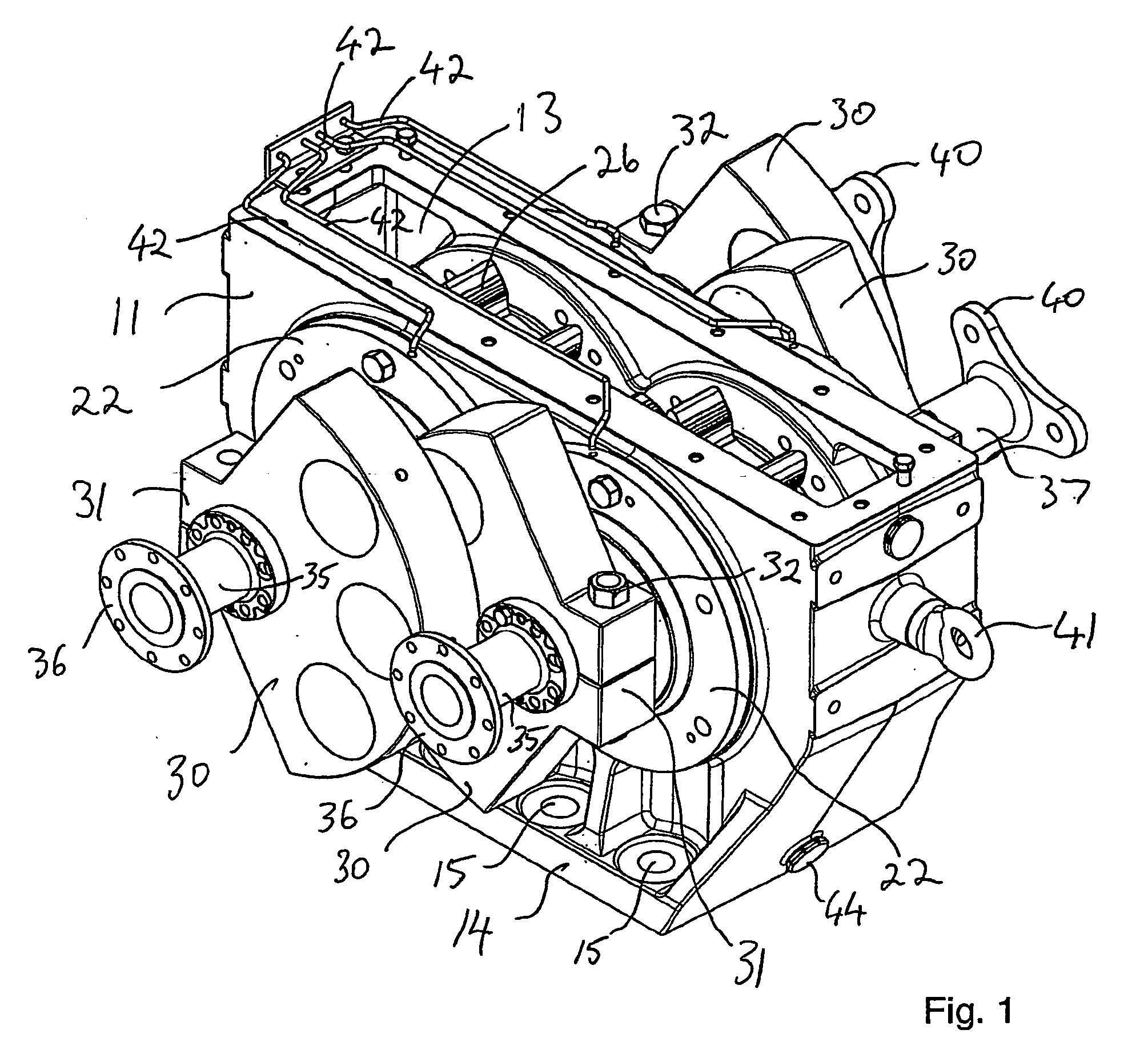

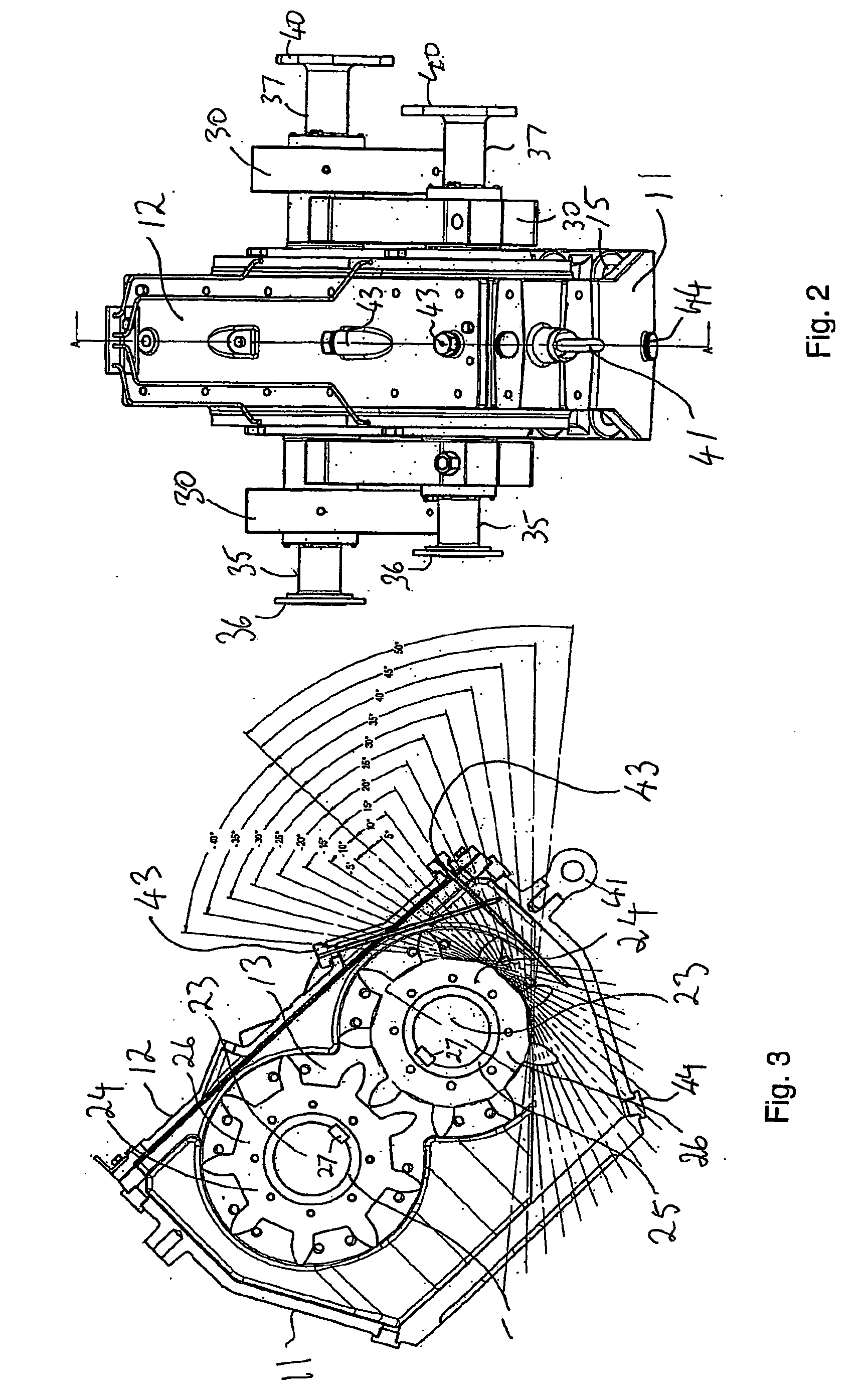

Exciter apparatus

InactiveUS20040045877A1Reduced Power RequirementsReduce sensitivitySievingScreeningCouplingGear wheel

There is provided exciter apparatus having a cast housing (11) and mounting base (14) secured to mounts bolted to the side plates of screening apparatus. A pair of shafts are mounted for rotation in and extend out of both sides of the cast housing (11). A gear assembly is keyed to each shaft t form a gear train coupling the shafts. The outer ends of each of the shafts are provided with eccentric masses (30) aligned on their respective shafts 180° out of phase. Drive spools (35) are driven by electric motors (not shown). Coupling spools (37) are adapted to accept flexible couplings for joining exciter units together. The gears (26) comprise 9 teeth of an 18-tooth module at 325.0 mm pitch circle diameter (PCD) and 65 mm axial dimension. The lands between the teeth are at a notional diameter 262.6 mm, the teeth having a corresponding notional tooth height of 31.2 mm to the PCD. The gear tooth chordal length at 34 mm is oversize for the module and the gear tooth involute surface extends past the gear tooth addendum to meet a 6.5 mm radius tooth tip. This configuration gives a lash of 9°, which enables the direction of excitation to shift to track the centre of gravity of the screen machine in use.

Owner:F L SMIDTH & CO AS

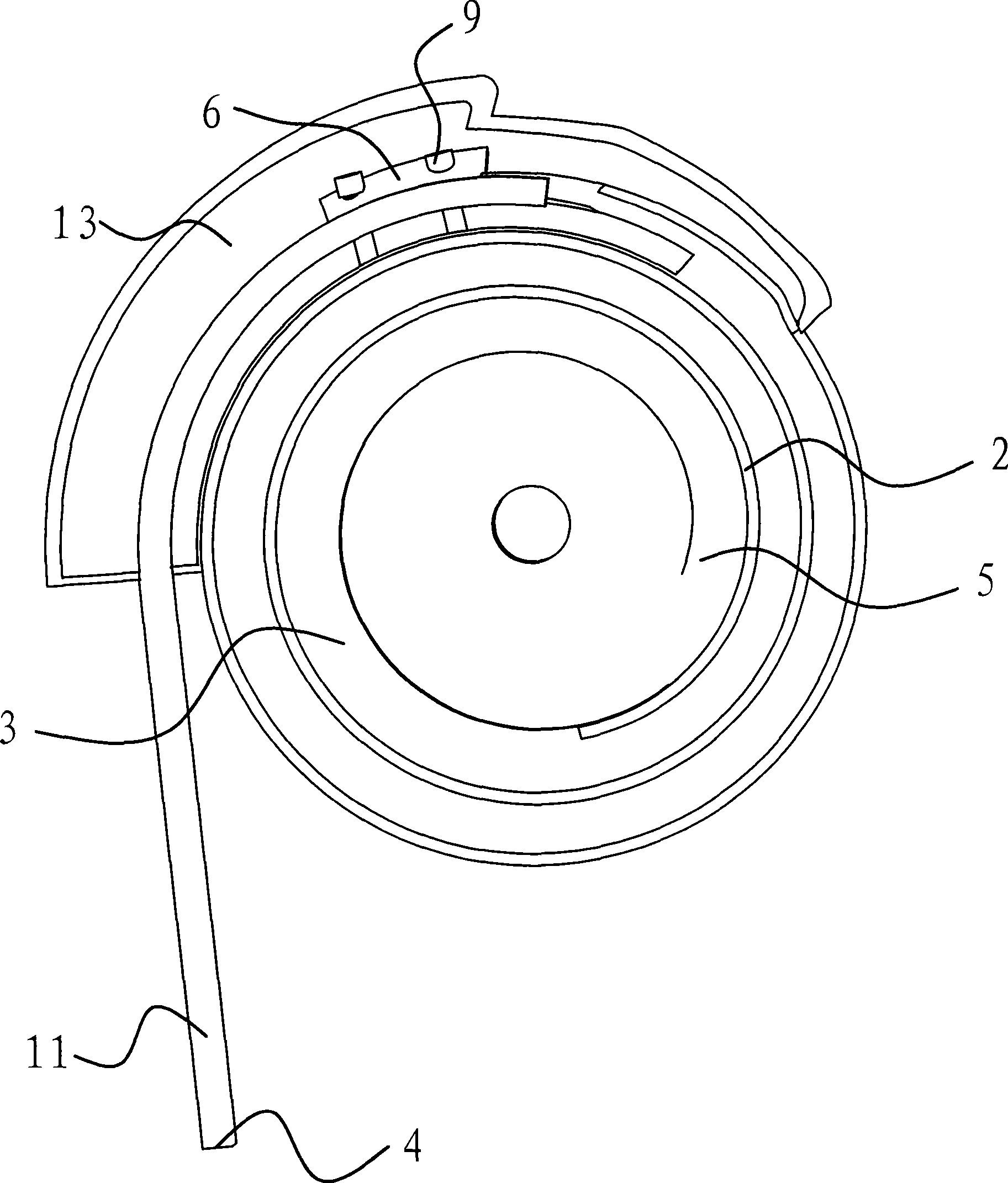

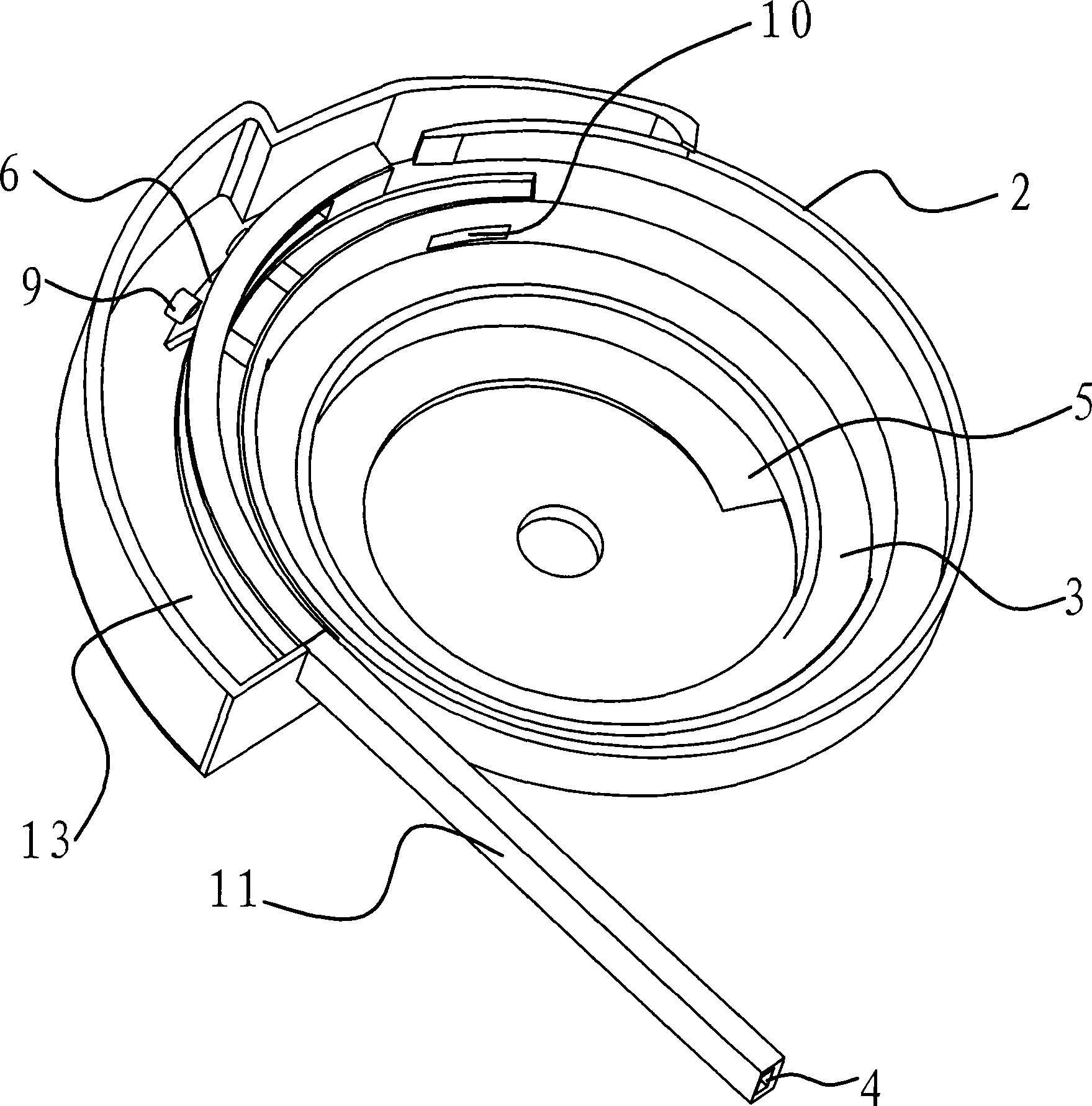

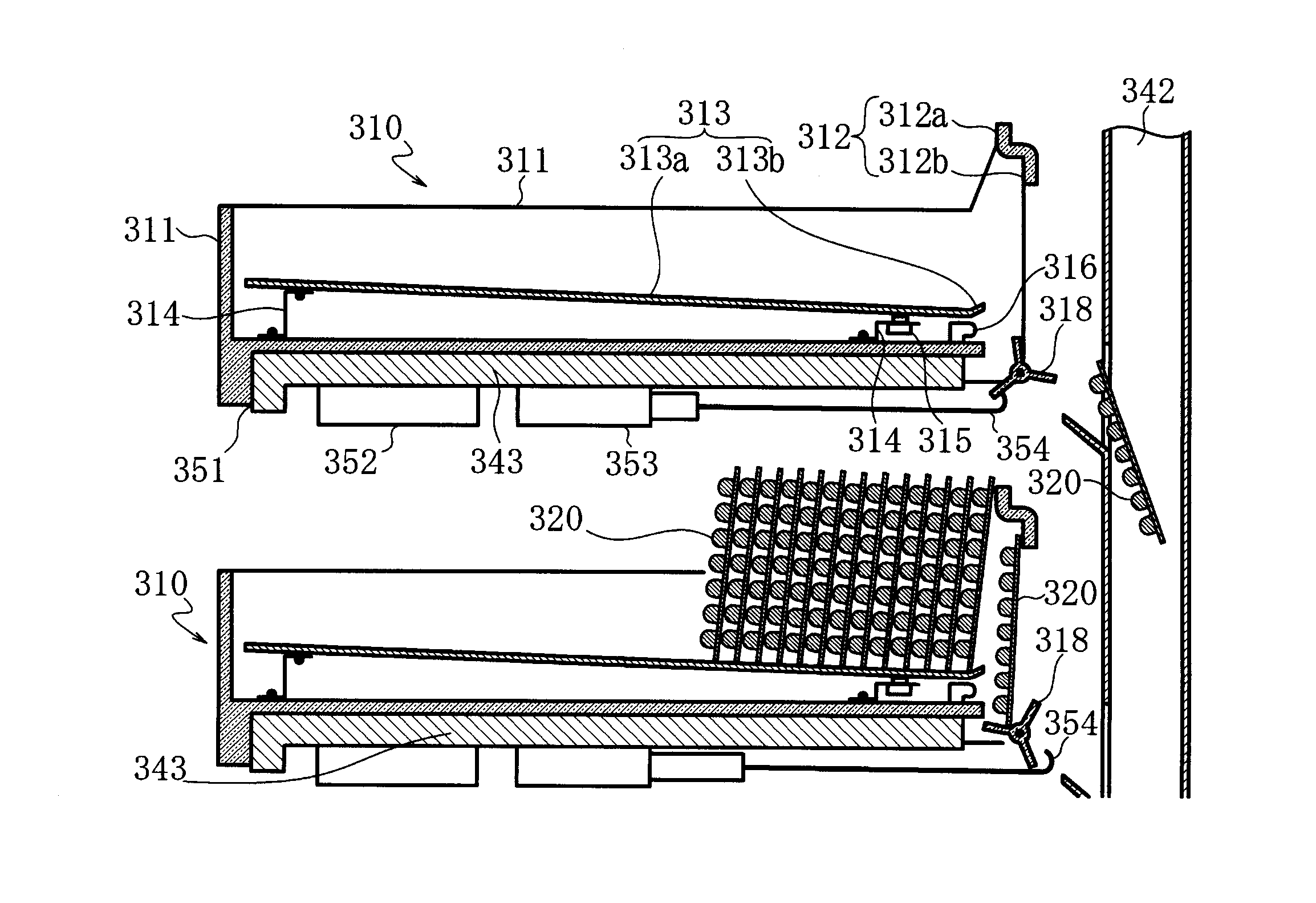

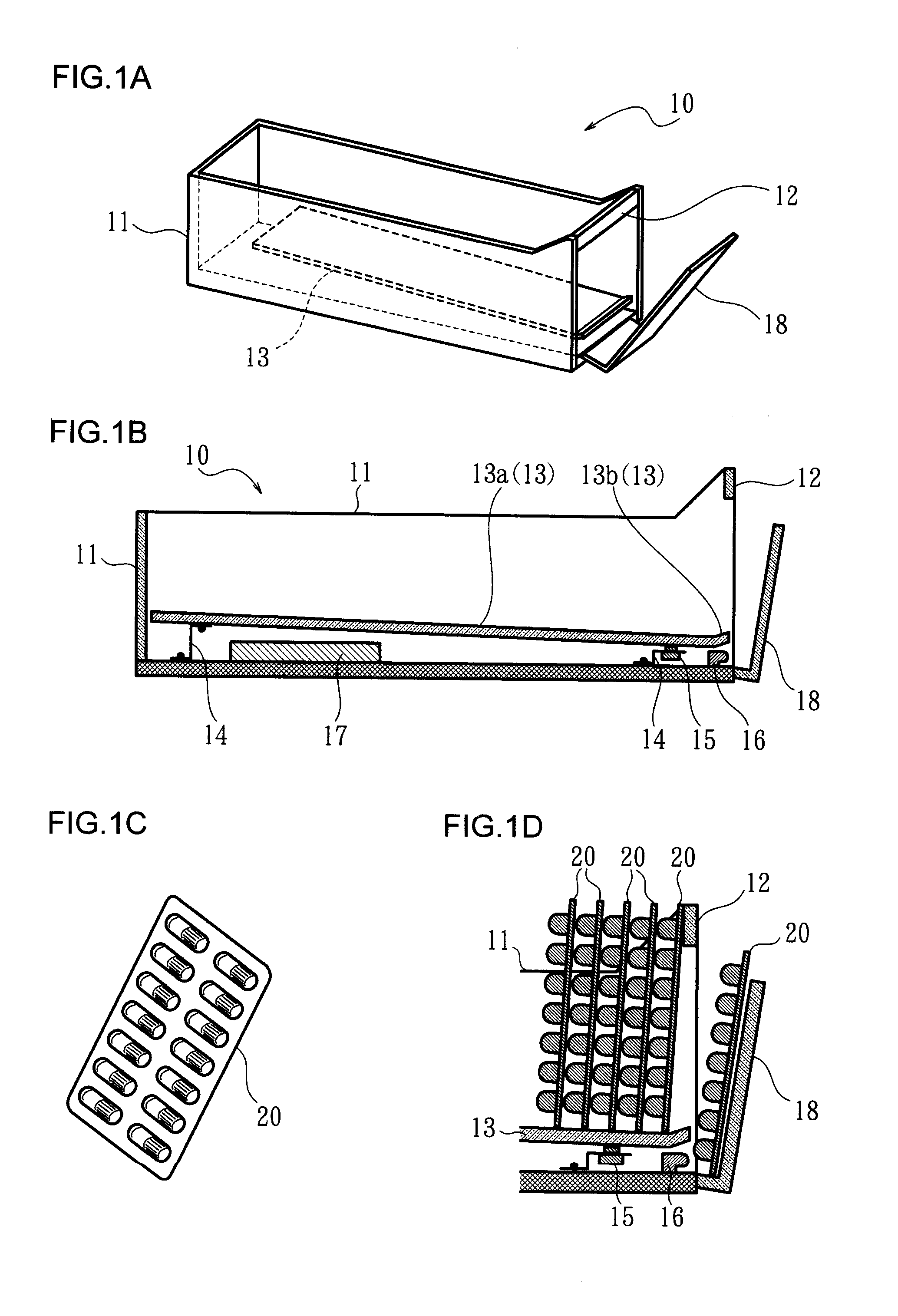

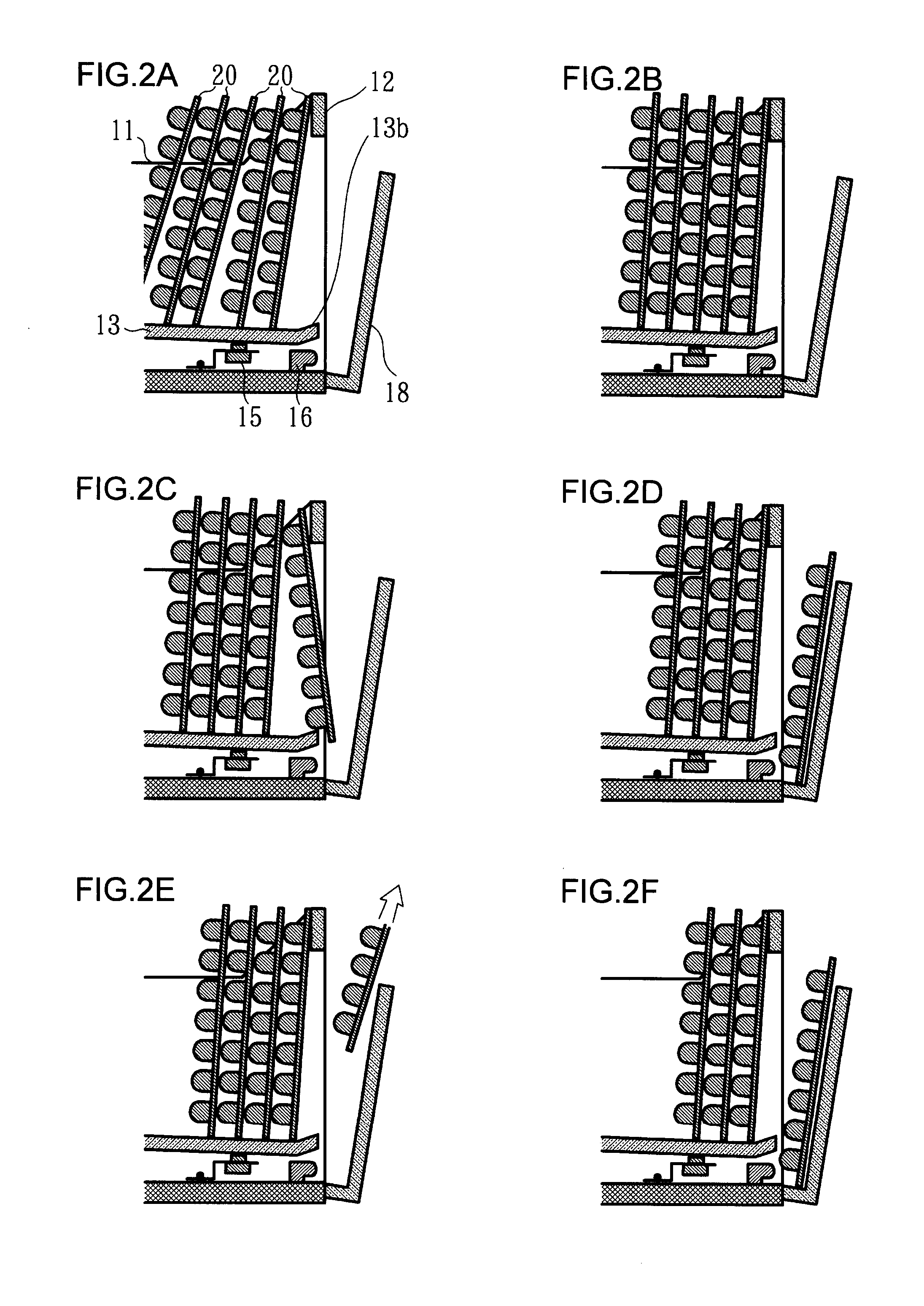

Vibration-based ejection cassette, drug dispensing apparatus, PTP dispensing apparatus, pharmaceutical product storage apparatus and PTP dispensing system

A vibration-assisted ejection cassette includes: outer plates 11 which align PTP-packaged drugs 20 for storage; a top frame 12 which is provided above an open front and which prevents accommodated drugs from being falling forward; an inner plate 13 which carries the accommodated drugs and advances the drugs when vibrated; and a vibrating member 15 which vibrates the inner plate 13. Thereby, vibration is exploited to maintain the drugs 20 in alignment with each other, advance the drugs while maintaining the drugs in alignment and eject them one by one. Additionally, a retention member 18 for retaining an ejected drug is provided in front of the open front. A control circuit 17 activates or stops activating the vibrating member 15 in accordance with whether or not an ejection detecting member detects that a drug is being retained. In this way, it is ensured that drugs are either manually picked up one by one or ejected by an automatic mechanism in an equally easy and stable manner.

Owner:TOSHO INC

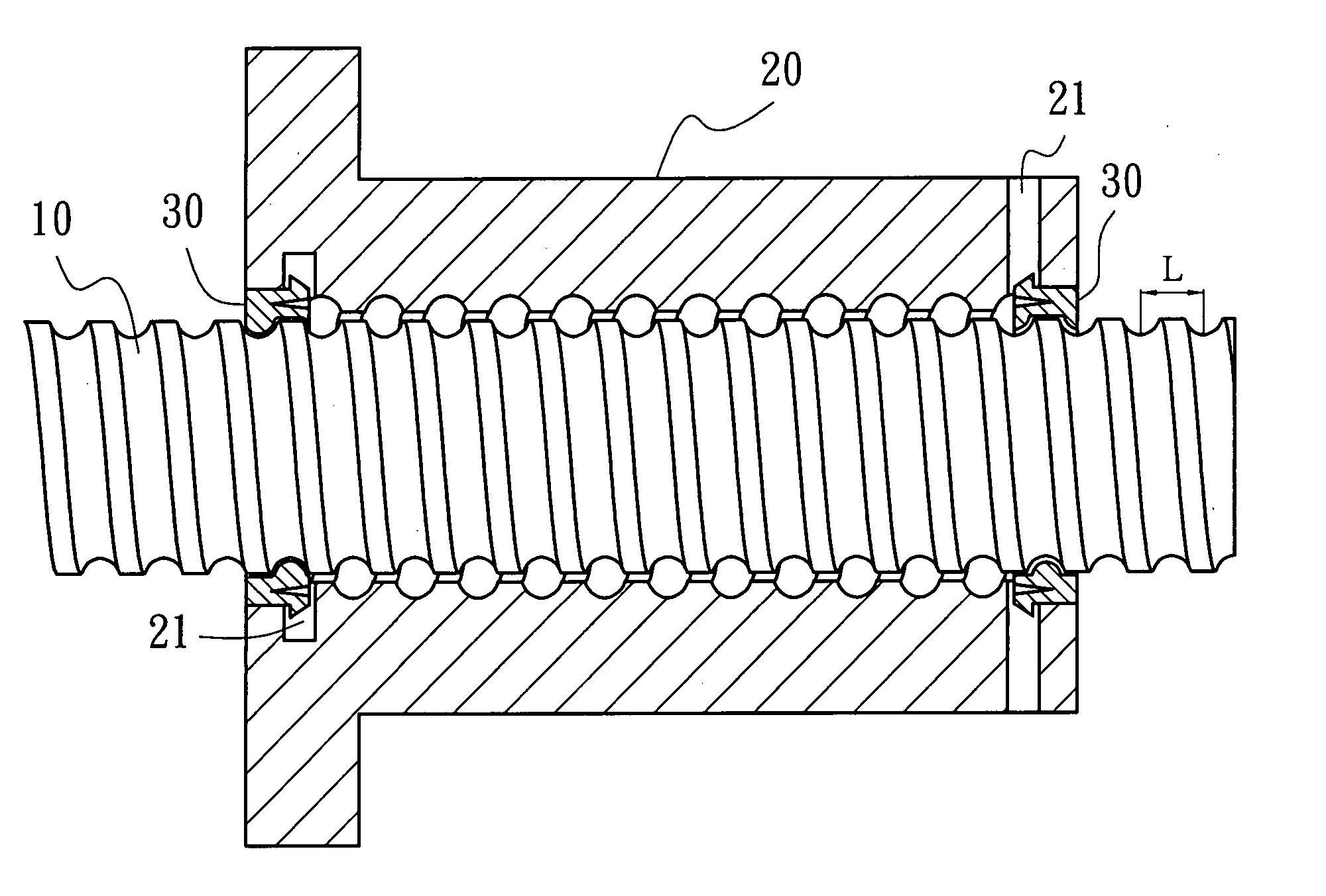

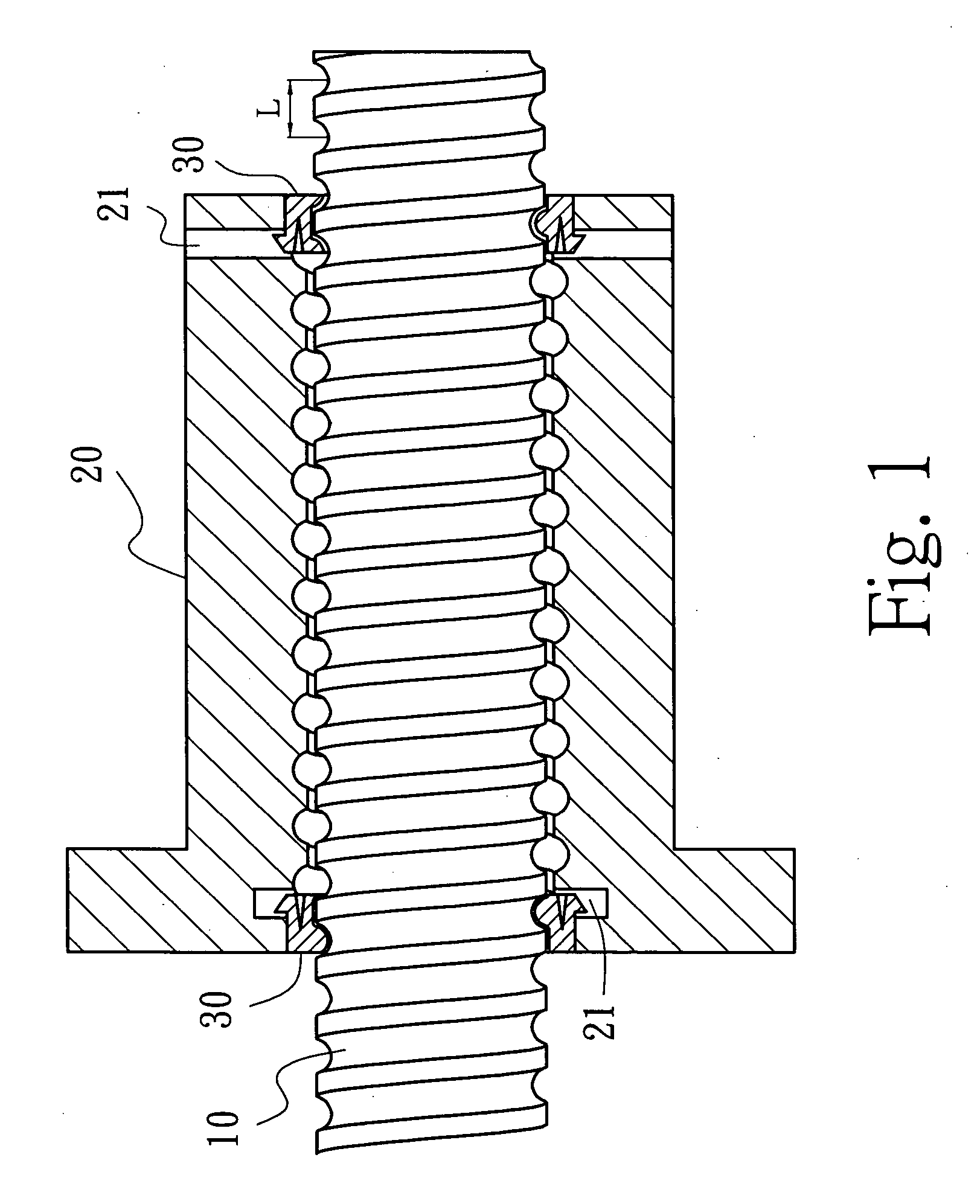

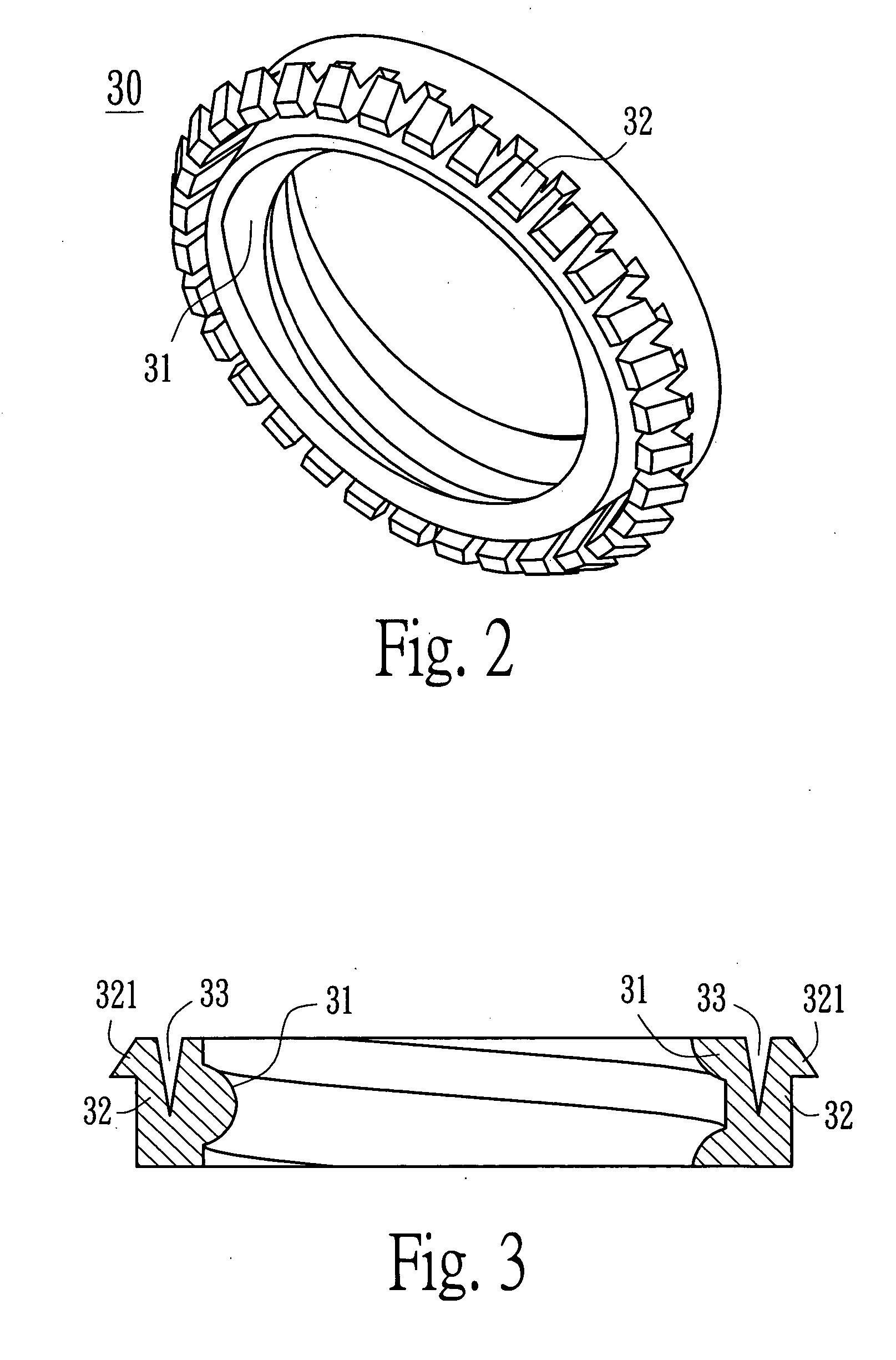

Hooked dust scraper for ball screw unit

ActiveUS20060076214A1Simplify the assembly processLow production costEngine sealsToothed gearingsBall screwEngineering

A hooked dust scraper for ball screw unit includes a plurality of tooth portions and corresponding number of hook portions. It is characterized that the scraper is hooked on the nut of the ball screw unit without employing screw engagement so that the ball screw unit associated with this scraper is easy to fabricate, assemble, and detach thereby saving the production and assembly cost.

Owner:HIWIN TECH

Automatic conveying apparatus for parts

ActiveCN101508384AControl insertion depthControlThread cutting feeding devicesMetal-working feeding devicesEngineeringManipulator

The invention discloses an automatic conveying device for parts. A groove for conveying the parts on a vibrating groove is connected with the outlet end of a conveying groove spirally arranged on a vibrating disc, the tail end of the vibrating groove is provided with a manipulator for clamping a workpiece, the manipulator is arranged on a first cylinder which is arranged on a second cylinder, the manipulator is moved in the vertical direction and the horizontal direction by driving the first cylinder and the second cylinder, the automatic conveying device for the parts also comprises a third cylinder, the front end of the third cylinder is provided with a pushing block for pushing the third cylinder to move forwards and backwards, and the position of the pushing block is opposite to a feed opening of a processing device. The automatic conveying device can automatically finish the conveying process of the parts, has high conveying efficiency, does not need a special personnel, reduces the manpower cost, can accurately control the inserting depth and the force through the pushing block driven by the cylinder to push the parts to be inserted into the processing device, and can reduce the defective index of the processed parts.

Owner:广州市新豪精密科技有限公司

Automatic light adhesive material feeding vibration hopper

InactiveCN104444132AContinuous deliveryConvey evenlyJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic light adhesive material feeding vibration hopper which comprises a main magnetic vibration machine and a material tray. The vibration hopper generates electromagnetic force through an electromagnetic coil of the main magnetic vibration machine, the material tray with vibration plate springs is stimulated to vibrate, boosting nuts in the material tray vibrate and ascend along a spiral feeding rail, light adhesive materials in the material tray are cyclically boosted to transmit along the feeding rail, and in the discharging stage, air blowing pipes are used for blowing air in an oriented mode, so that the materials are finally conveyed. The air blowing pipes located accurately are used in cooperation with the boosting nuts, so that the light adhesive materials are automatically and rapidly fed in order. According to the automatic light adhesive material feeding vibration hopper, structural design is reasonable, certain universality is achieved, the materials which are adhesive, low in mass, small in inertia and the like can be continuously and evenly conveyed to the position to be machined, the conveying speed is high, work efficiency is improved, and production cost is reduced.

Owner:SOUTHEAST UNIV

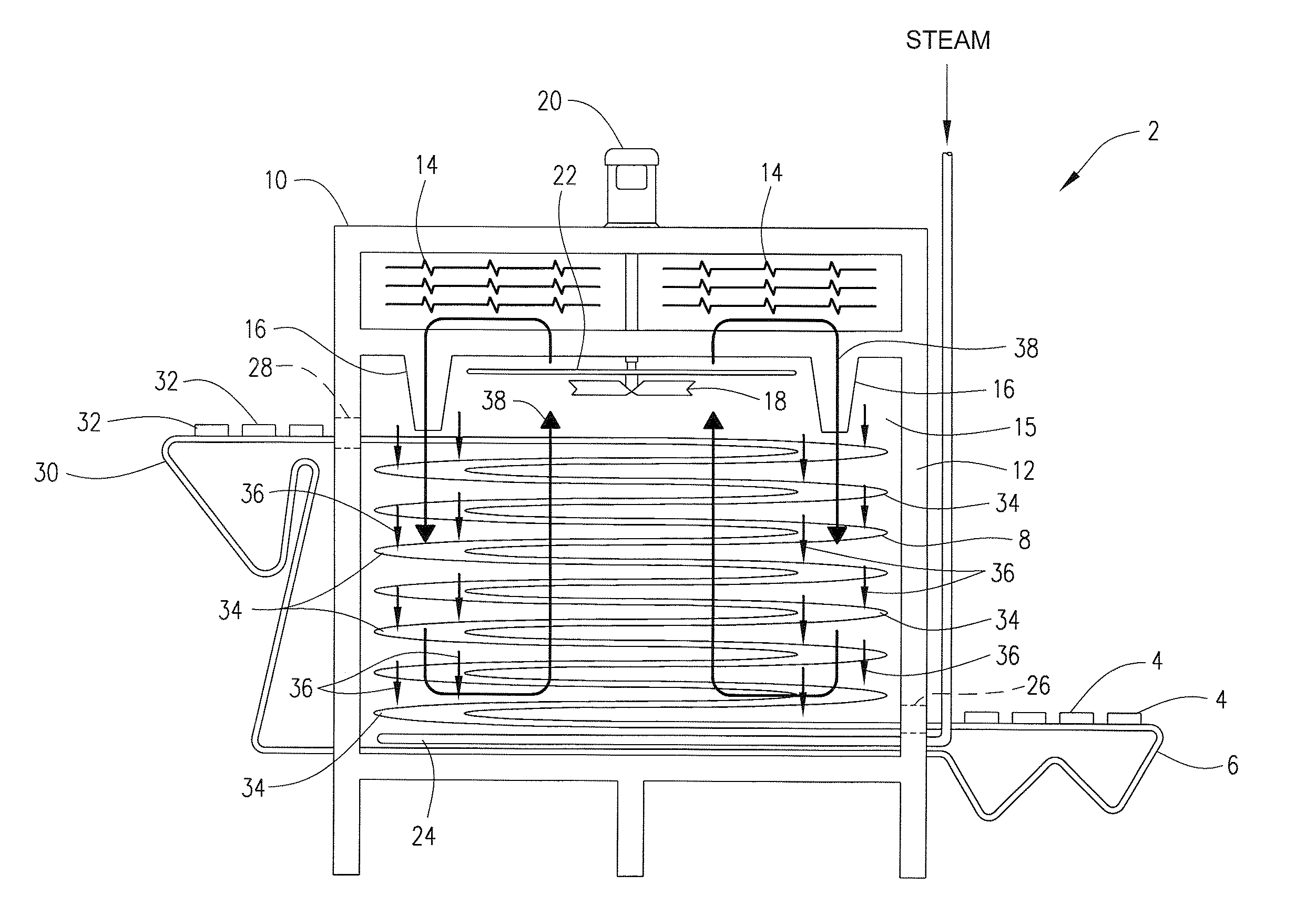

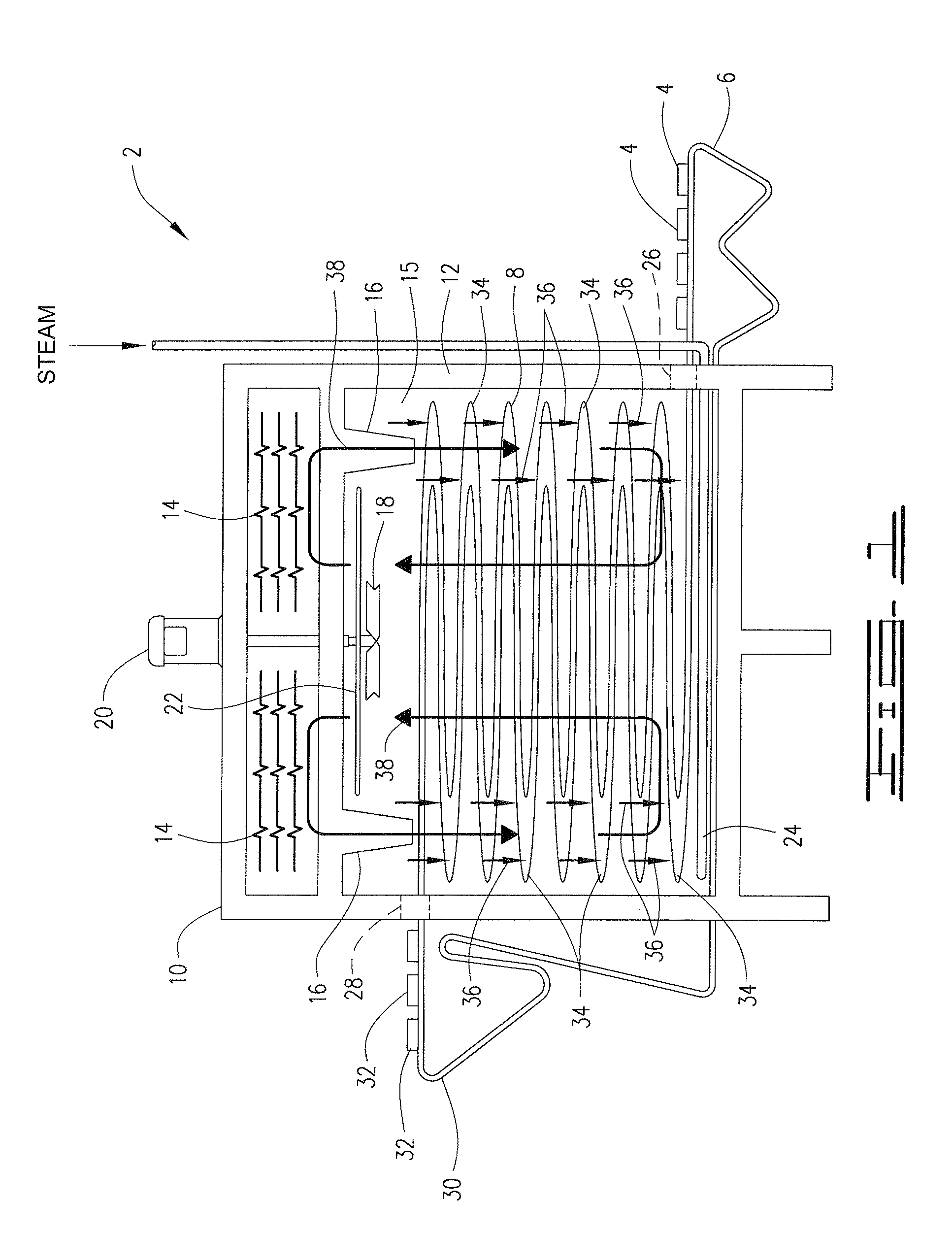

Process for producing precooked bacon slices

InactiveUS20090181138A1Small footprintEliminates orBaking ovenCooking vesselsProcess engineeringPercentage reduction

Owner:UNITHERM FOOD SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com