Building refuse treatment regeneration system

A construction waste and recycling system technology, applied in grain processing, construction waste recycling, sieving and other directions, can solve the problems of inability to classify construction waste, mixed components of recycled aggregates, and fewer types of products, so as to improve production efficiency. As well as productivity, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

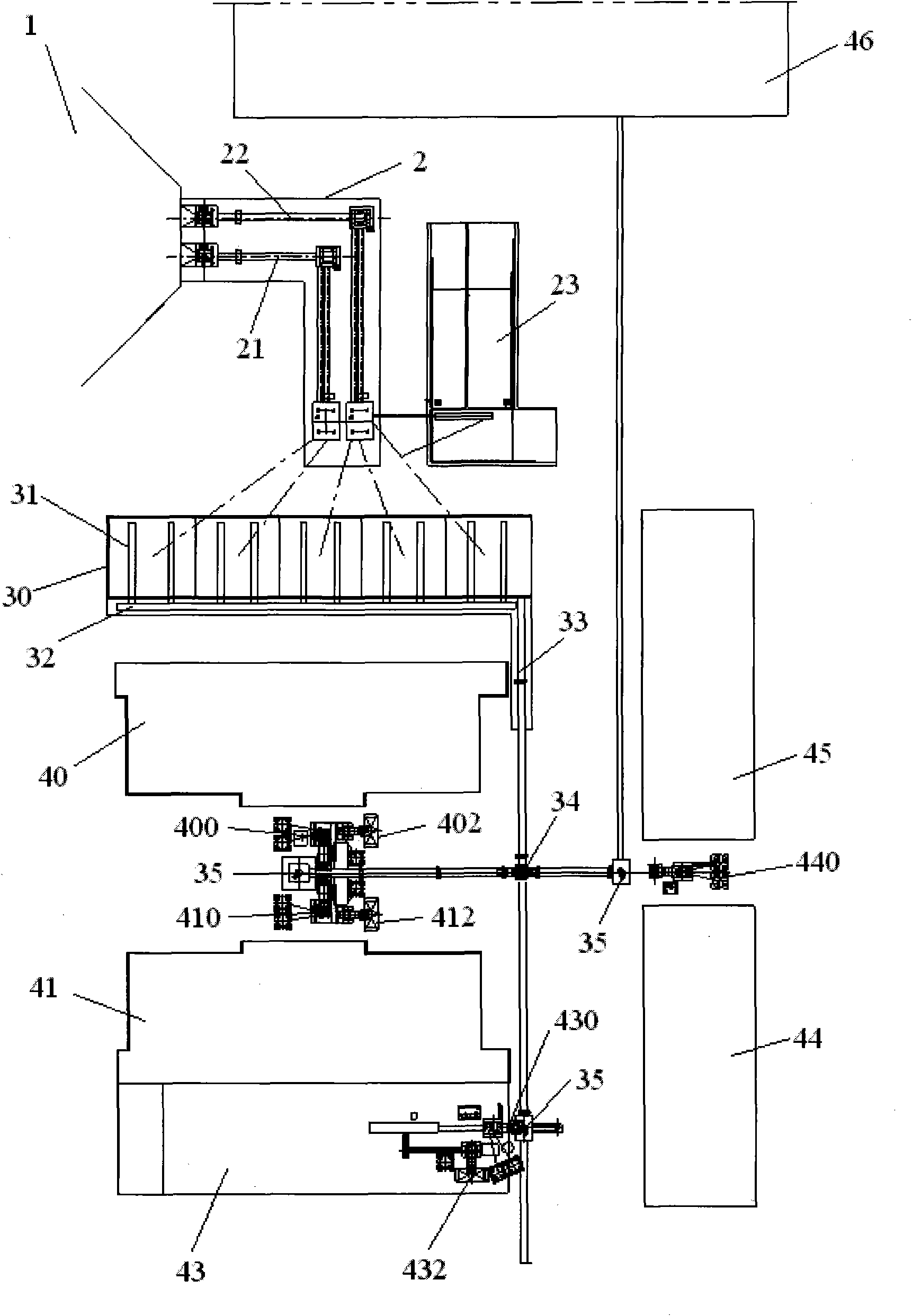

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

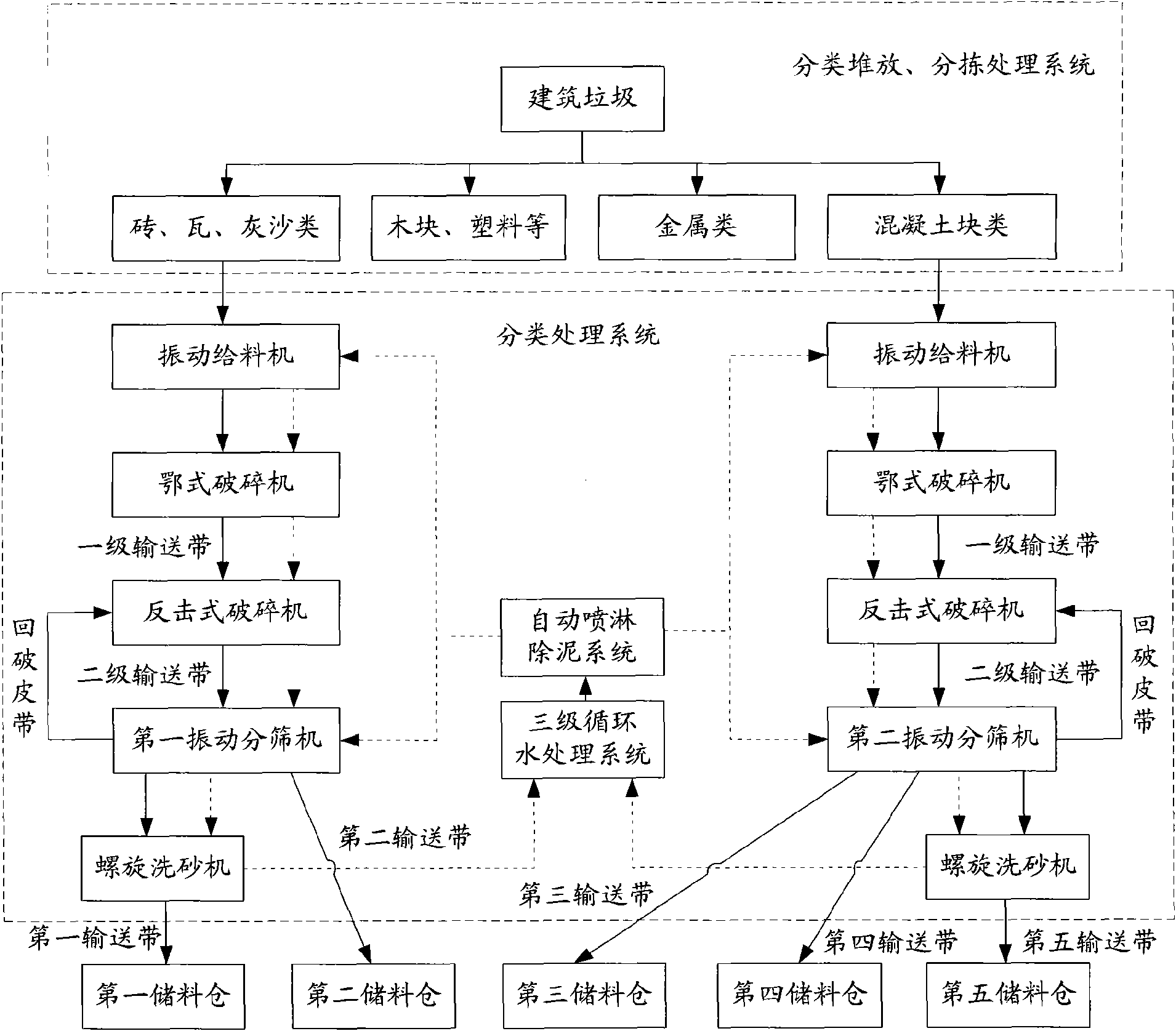

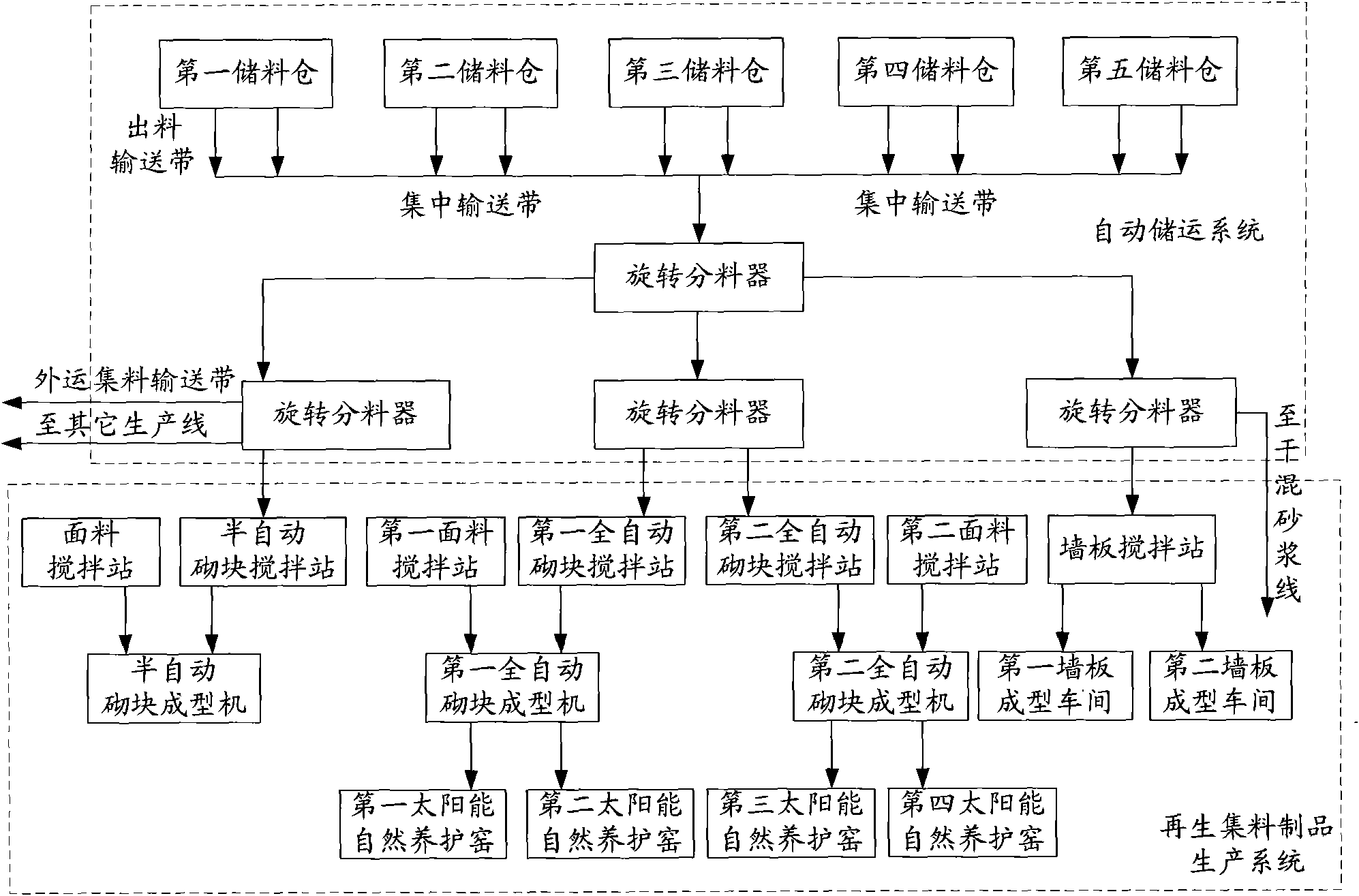

[0014] figure 1 and figure 2 It is the equipment flowchart of the construction waste treatment and regeneration system of the embodiment of the present invention. Please refer to figure 1 and figure 2 As shown, the construction waste treatment and regeneration system of the embodiment of the present invention includes classification stacking, sorting treatment system, classification treatment system, automatic storage and transportation system, recycled aggregate product production system and control system.

[0015] As a kind of waste, construction waste has a relatively complex composition, mainly composed of reinforced concrete, bricks, tiles, tiles, mortar, soil and so on. Due to the different physical and chemical properties of the recycled aggregates p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com