LED lamp tube pipelining conveying equipment

A technology of LED lamp tubes and transmission equipment, which is applied to conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of high labor intensity, high labor cost, and difficulty in mass production, so as to reduce labor intensity and save manpower The effect of improving cost and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

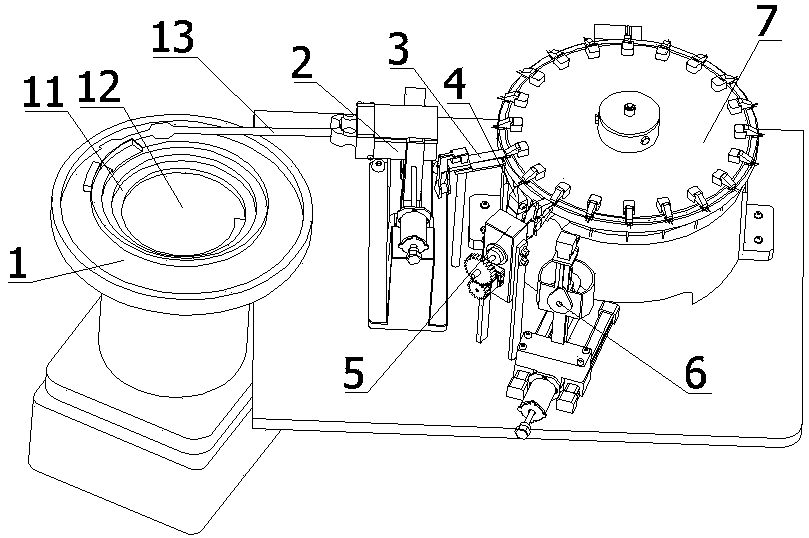

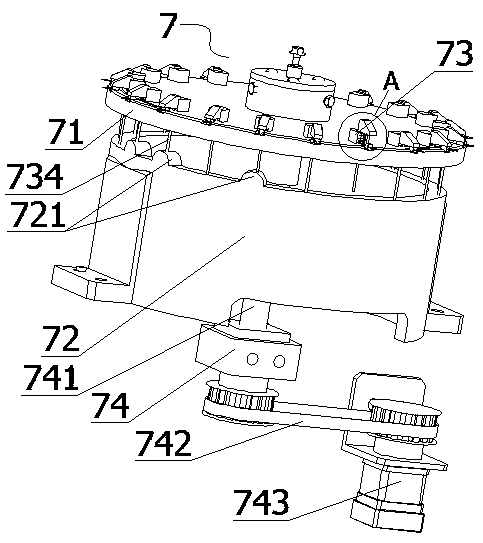

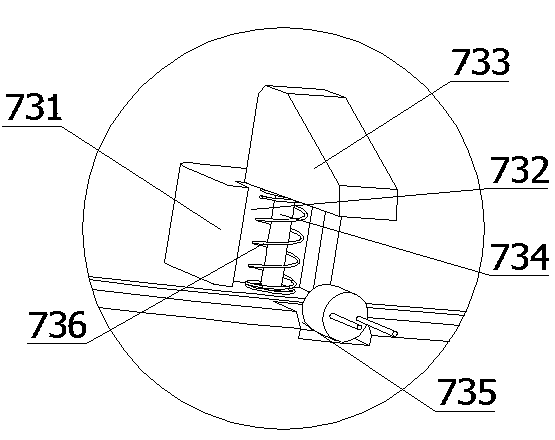

[0024] A kind of LED tube assembly line conveying equipment of this embodiment, such as figure 1 As shown, it includes a hopper 1, a transfer mechanism 2, a leveling device 3, a positive and negative electrode testing device 4, a turning device 5, a damage measuring device 6, a turntable structure 7 and a control system. The transfer mechanism 2 is arranged between the hopper 1 and the turntable structure 7 for transferring the LED light tubes in the hopper 1 to the turntable structure 7 . The above-mentioned transfer mechanism 2, leveling device 3, positive and negative electrode testing device 4, overturning device 5, and damage measuring device 6 are sequentially arranged around the turntable structure 7, and the turntable structure 7 is evenly arranged with a plurality of clamping devices along the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com