Preparation method and application of high-active-dispersibility nanometer titanium dioxide

A nano-titanium dioxide, dispersive technology, applied in chemical instruments and methods, water pollutants, chemical/physical processes, etc., can solve problems such as easy deactivation, easy agglomeration, uneven particle dispersion, etc., to achieve convenient operation and catalytic activity High and simple synthetic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare the alcohol solution A of titanium alkoxide with n-butyl titanate and isopropanol at a volume ratio of 1:0.35, and slowly add the solution A dropwise to the deionized aqueous solution B with a pH of 2 (adjusted by nitric acid) under stirring , the volume ratio of solution A to solution B is 1:6.1; then react at 80°C for 24h to obtain milky white water-dispersed anatase nano-TiO 2 .

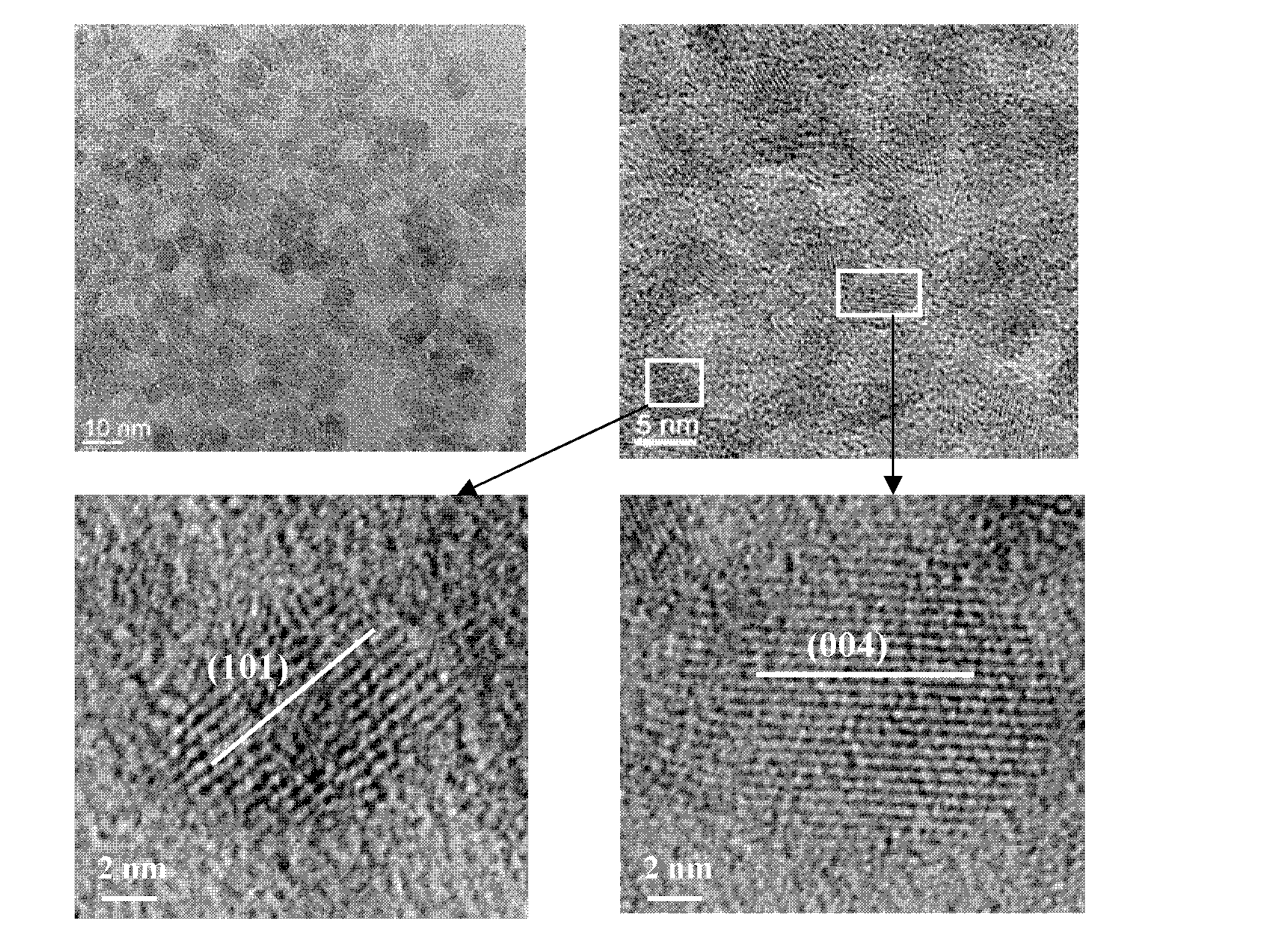

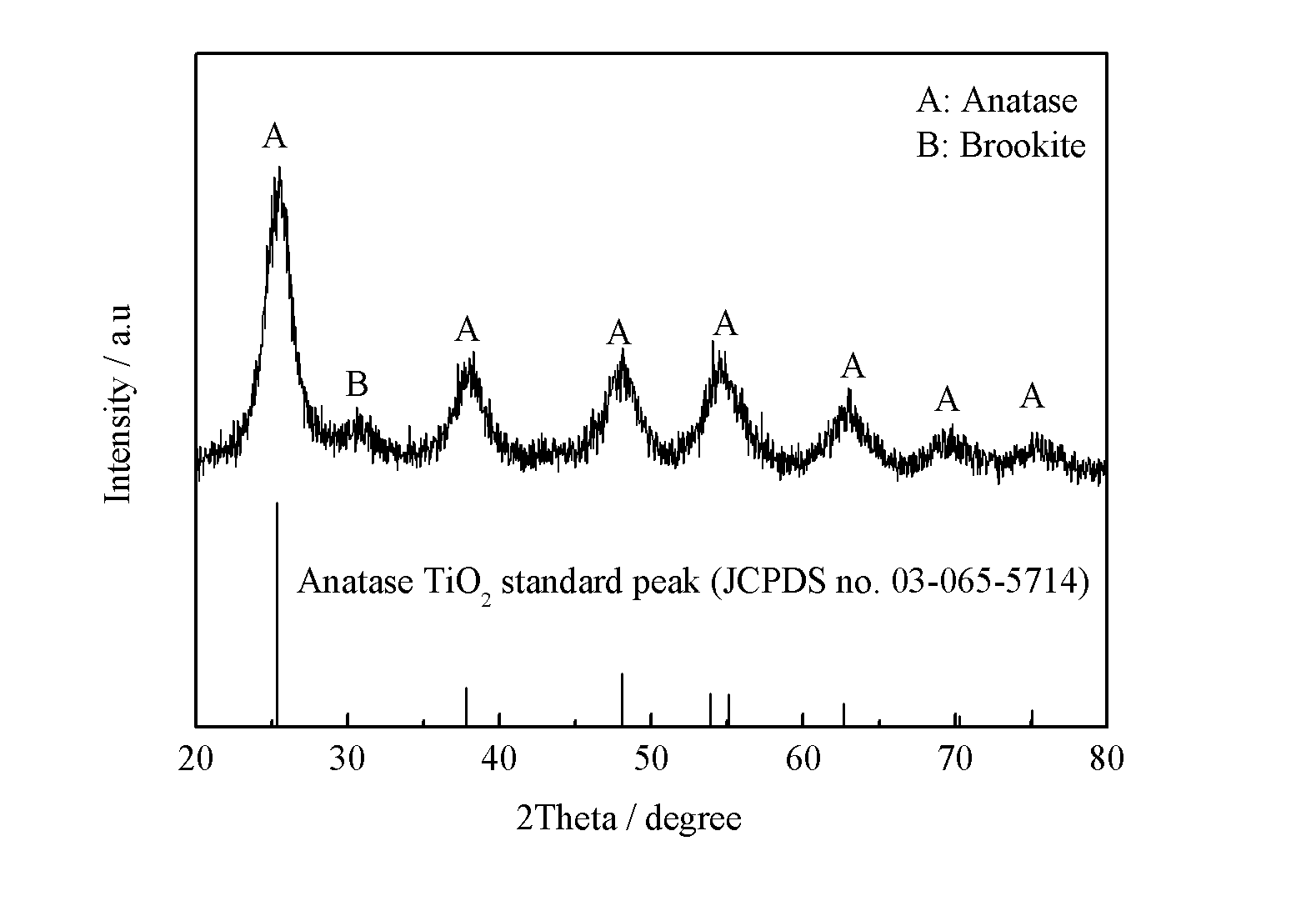

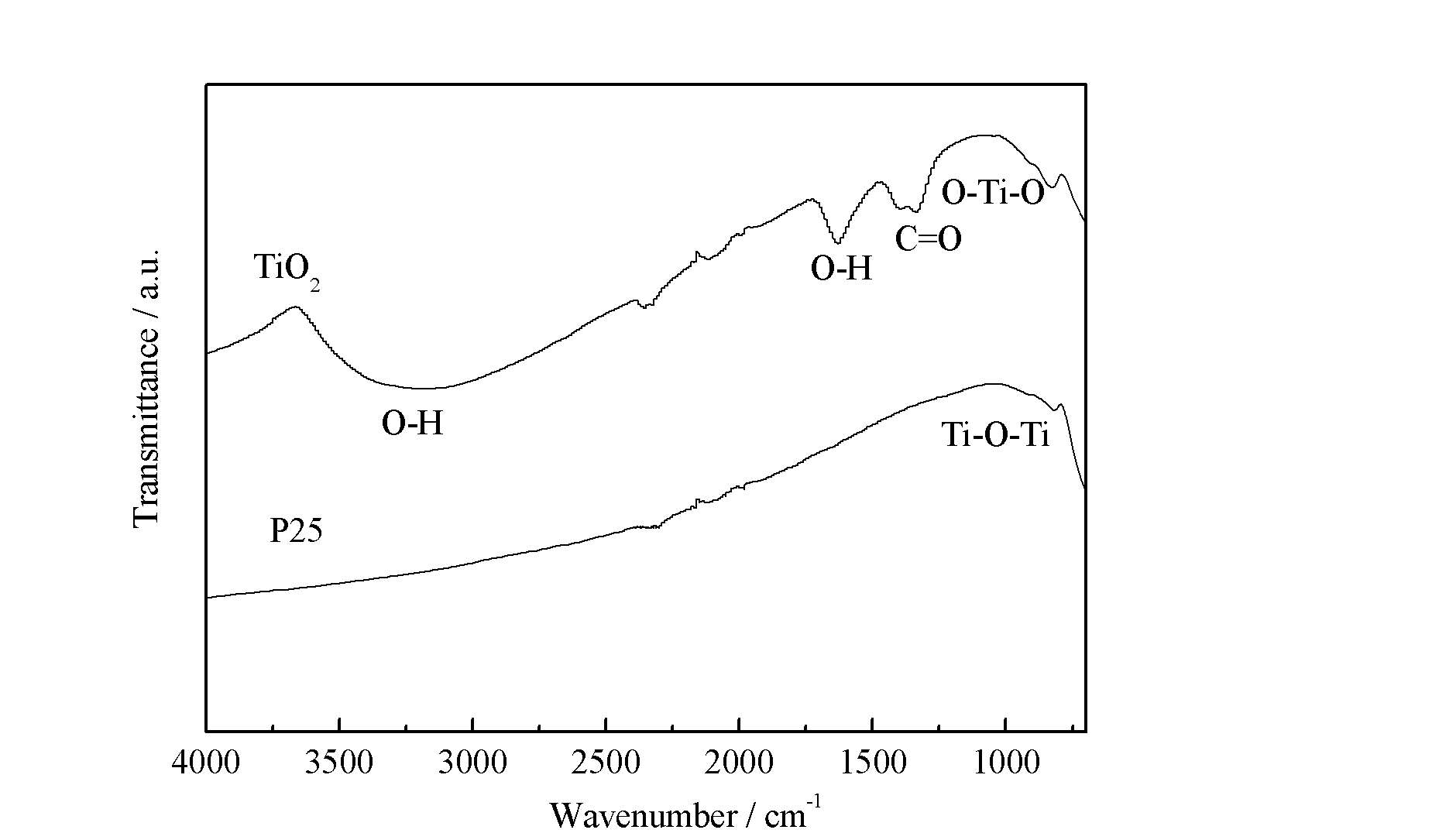

[0034] figure 1 Prepare gained nanometer TiO for this embodiment 2 From the TEM and HRTEM images, it can be seen that the grain size is 9.5-11nm. figure 2 Prepare gained nanometer TiO for this embodiment 2 The X-ray diffraction pattern, its diffraction peaks are similar to those of anatase TiO 2 The standard spectrum peak (JCPDS no.03-065-5714) matches, indicating that the obtained product is anatase TiO 2 . Using the Scherrer formula to calculate the particle size at the diffraction peak (101), the average particle size is 10.3 nm, which is consistent with the TEM observatio...

Embodiment 2

[0036] Prepare an alcoholic solution A of titanium alkoxide with n-butyl titanate and ethanol at a volume ratio of 1:0.34, and slowly add the solution A dropwise to the deionized aqueous solution B with a pH of 1 (adjusted by nitric acid) under stirring. The volume ratio of A to solution B is 1:4.0; then react at 70°C for 36h to obtain milky white water-dispersed anatase nano-TiO 2 .

Embodiment 3

[0038] Prepare alcohol solution A of titanium alkoxide with isopropyl titanate and butanol at a volume ratio of 1:1.56, and slowly add solution A to deionized aqueous solution B with a pH of 3 (adjusted by nitric acid) under stirring. The volume ratio of solution A to solution B is 1:1.9; then react at 90°C for 72h to obtain milky white water-dispersed anatase nano-TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com