Automatic nut conveying device

A technology of automatic conveying device and nut, applied in the direction of vibrating conveyor, conveyor, conveyor objects, etc., can solve the problems of low production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] One of the examples

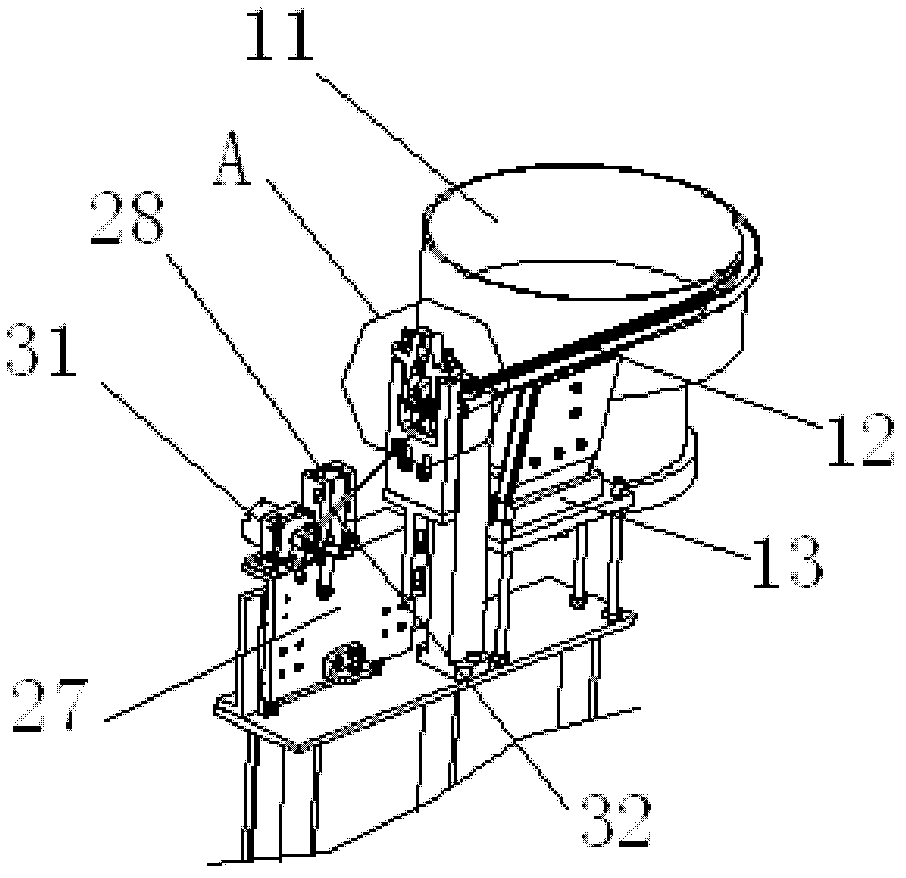

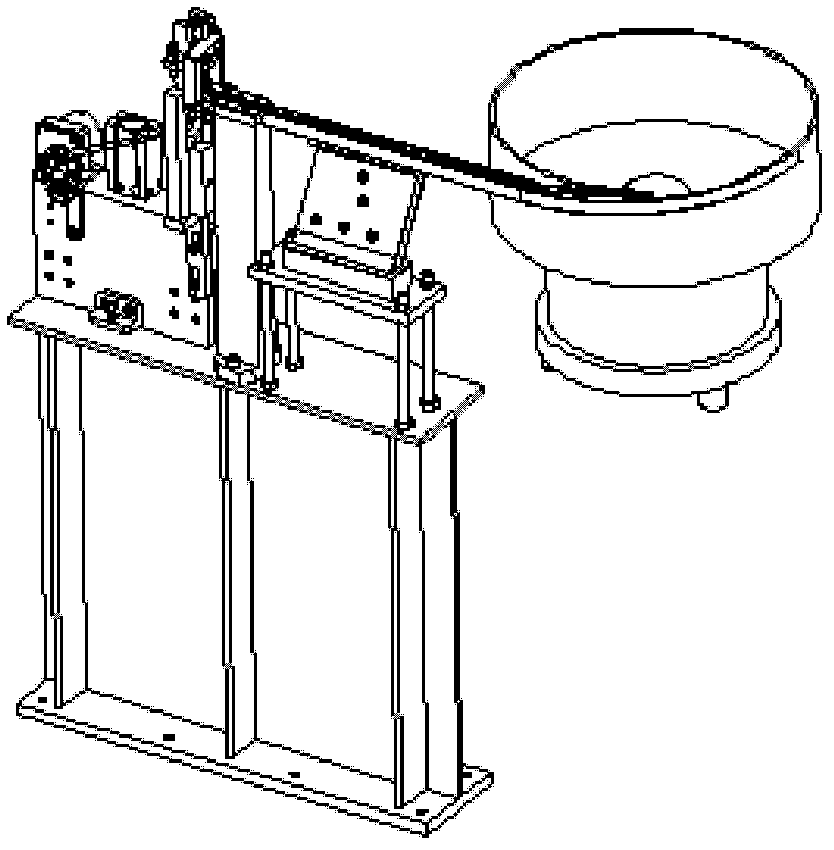

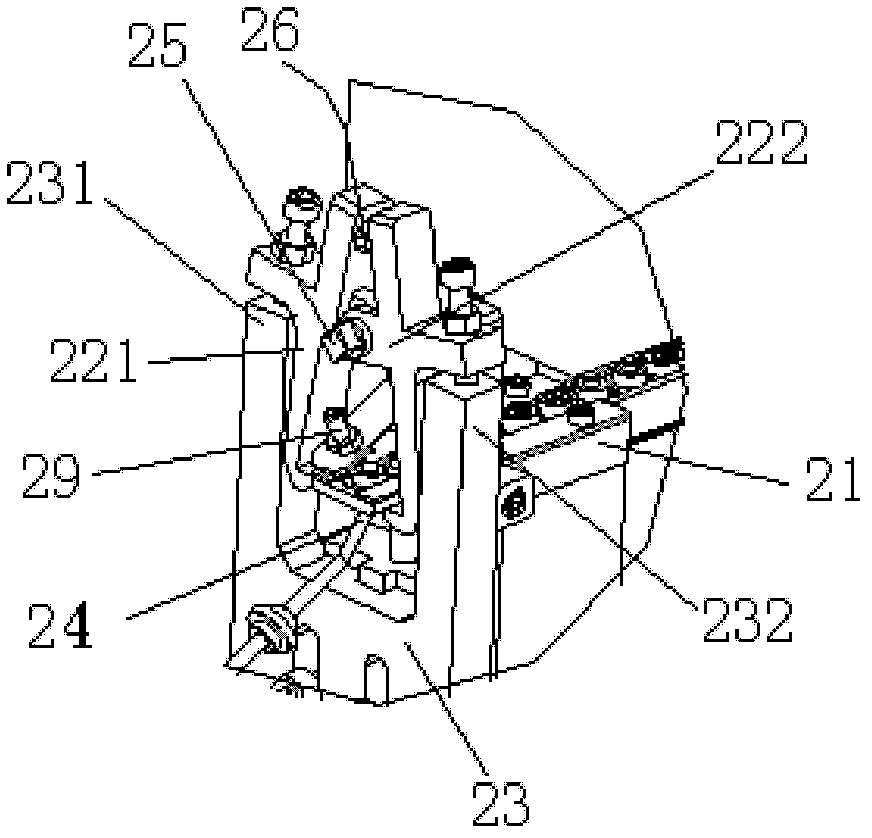

[0032] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , as described in detail below:

[0033] An automatic nut conveying device, including a feeding mechanism and a feeding mechanism, wherein:

[0034] 1) if figure 1 As shown, the feeding mechanism is composed of a vibrating plate 11 for storing nuts and a feeding rail 12 for conveying nuts. A linear vibrator 13 is arranged below the feeding rail 12, and the linear vibrator 13 vibrates by driving the feeding rail 12. As for the sliding of the nuts on the feeding track, the nuts are automatically conveyed along the feeding track 12 .

[0035] 2) if image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the feeding mechanism includes a material guide trough 21 connected to the feed rail 12, a pair of gear gates 221, 222 that can control the nuts on the material guide trough to drop one by one, and can penetrate upwards into the outlet of the material guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com