Patents

Literature

130 results about "Percentage reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The percentage decrease is the way of expressing a change in percentage of a relative quantity with respect to the quantity of reference. The simplest way to calculate percentage decrease is to divide the difference between reference number and relative number by the reference number and then multiplying it by 100 will...

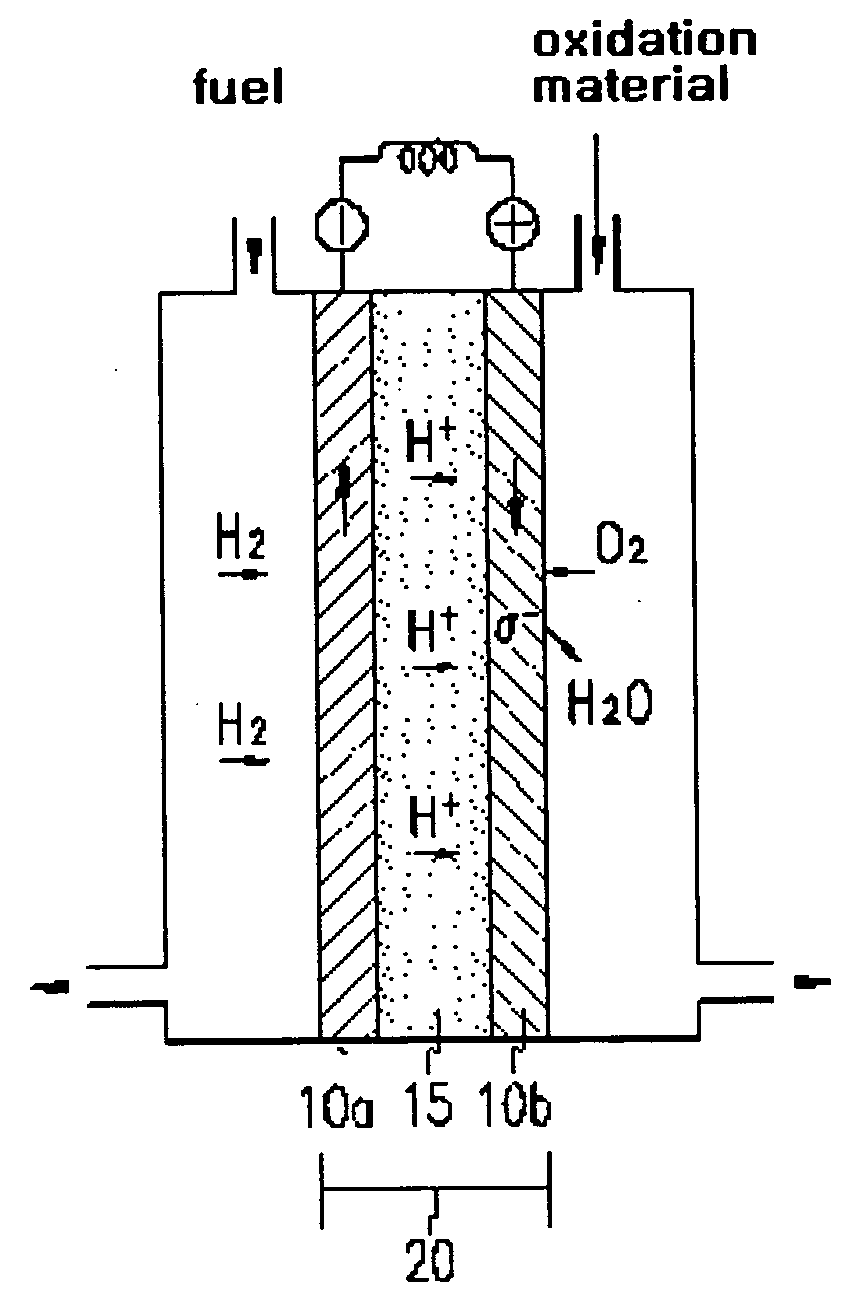

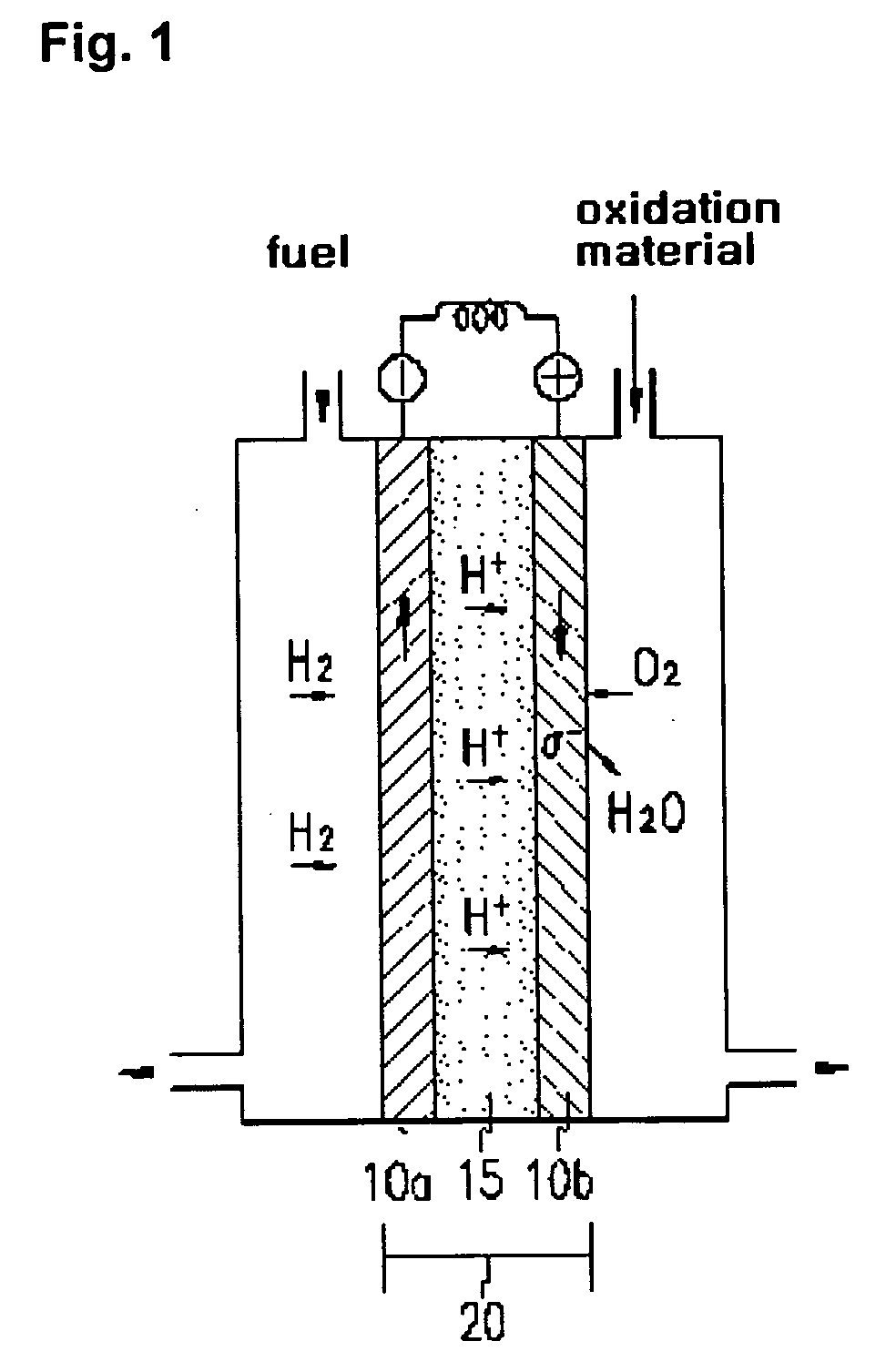

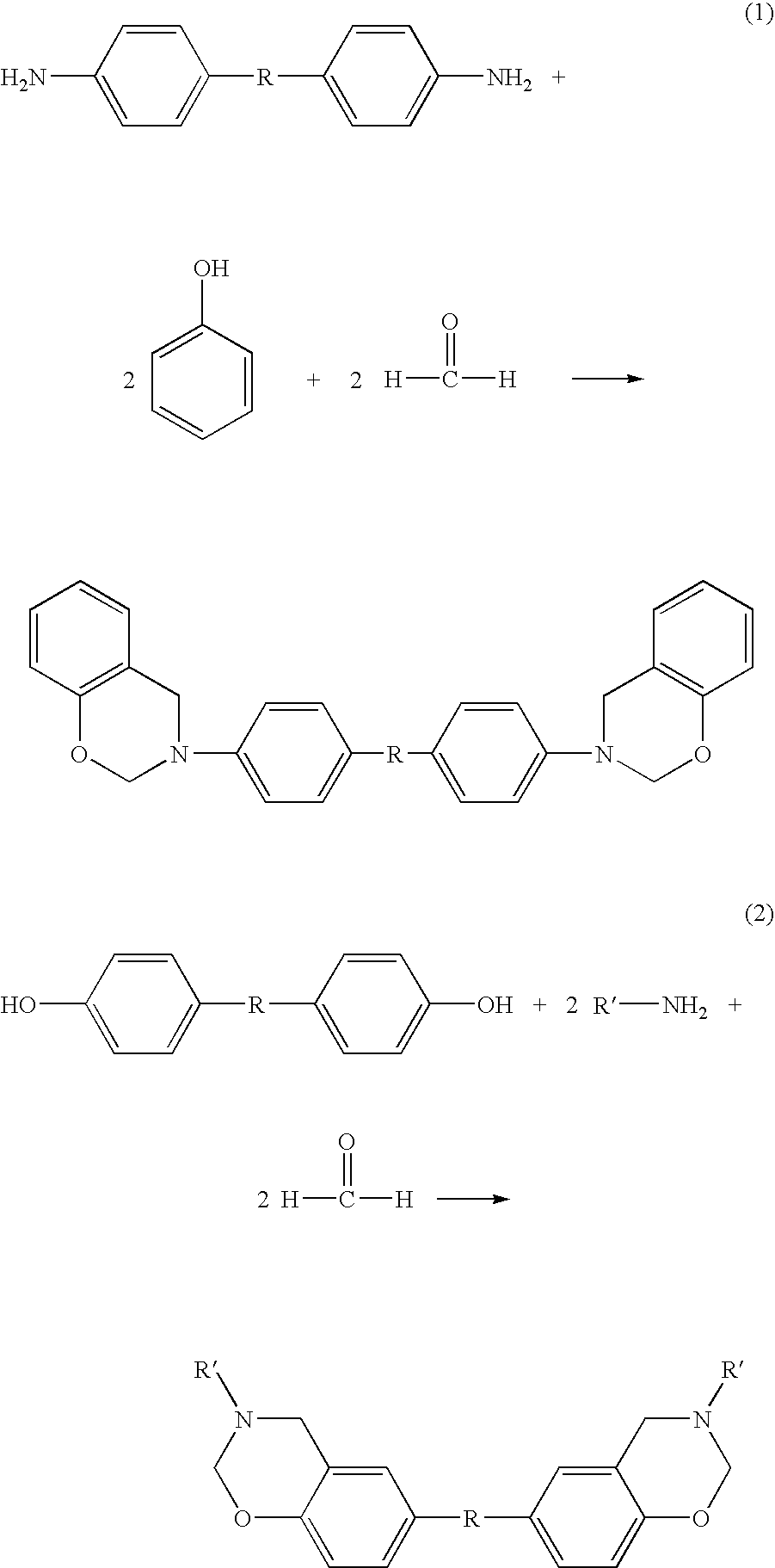

Composite material for bipolar plate

InactiveUS20050089744A1Reduce manufacturing costChemical and mechanical stabilityNon-metal conductorsFinal product manufactureFuel cellsPercentage reduction

A composite material for a bipolar plate of fuel cells is comprised of conductive carbon dispersed in polybenzoxazine matrix. The present invention also provides a composite material for preparing a bipolar plate for fuel cells comprising a polymer where a volume reduction percent is less than 5%, preferably 3%, and more preferably 1% after polymerization of the monomers with respect to total volume of the monomers before the polymerization thereof, and conductive carbon. The polymers of the present invention have good workability since there is little volume change during polymerization, and good mechanical and chemical properties, and they can be manufactured at a low cost.

Owner:SAMSUNG SDI CO LTD

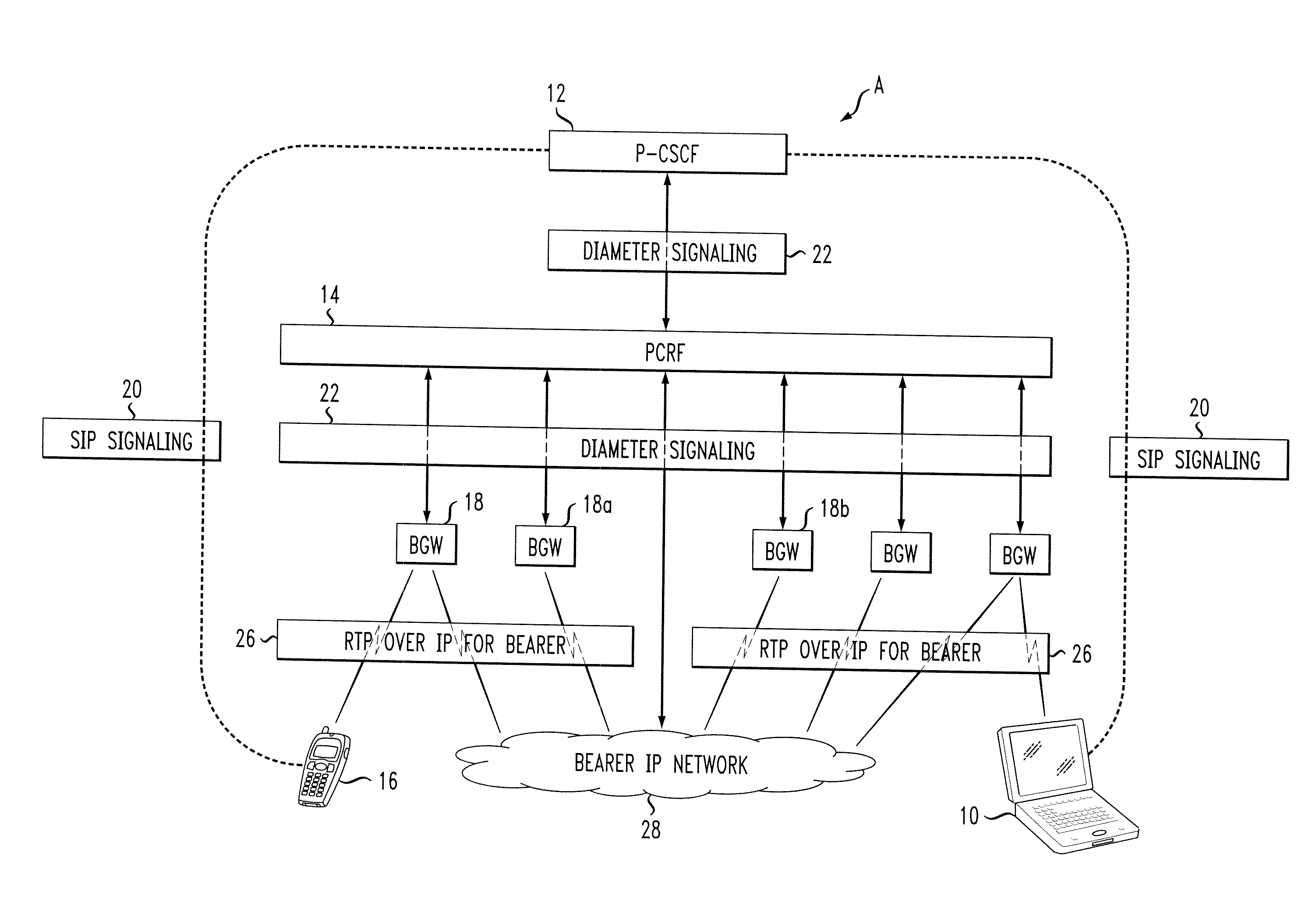

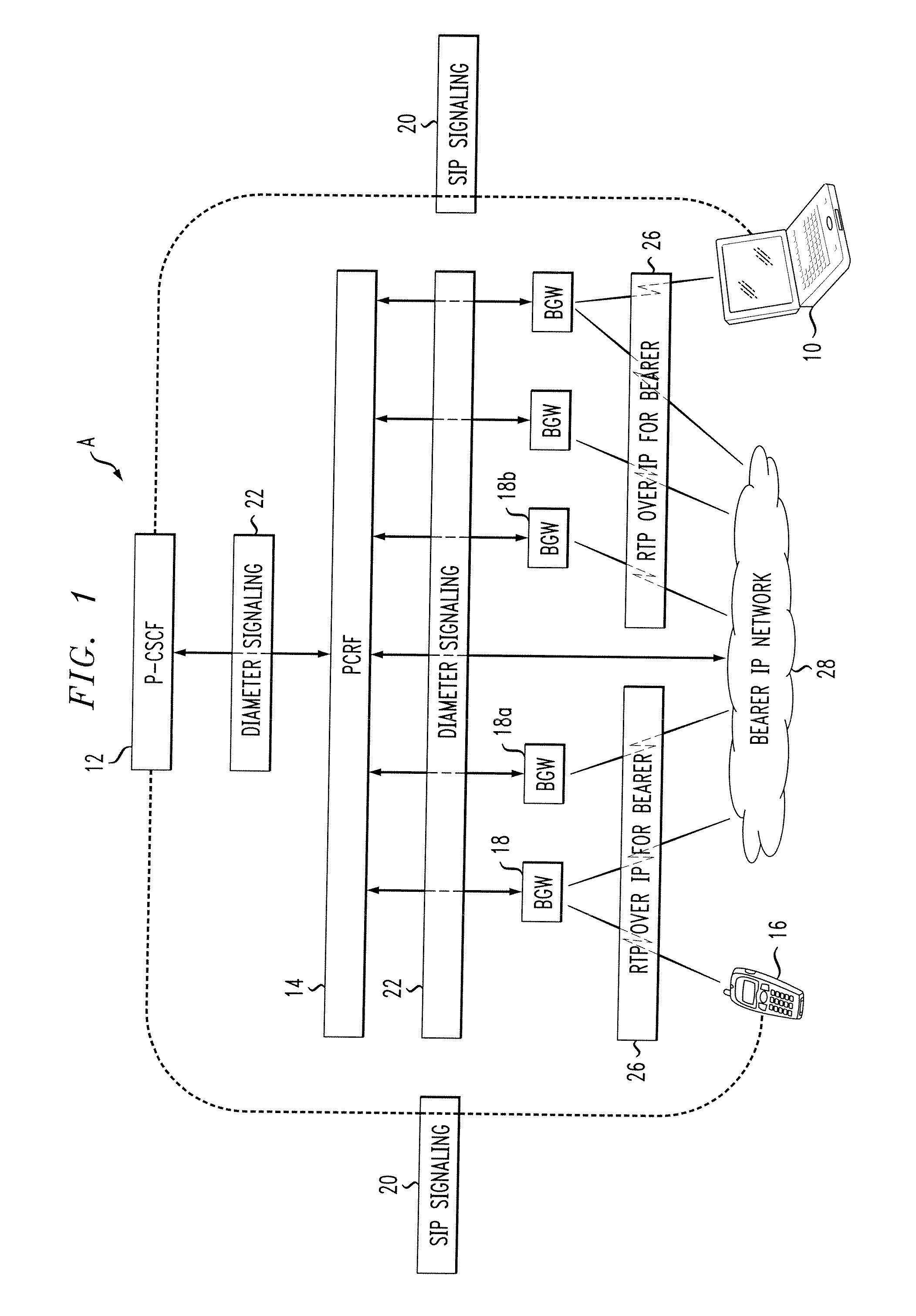

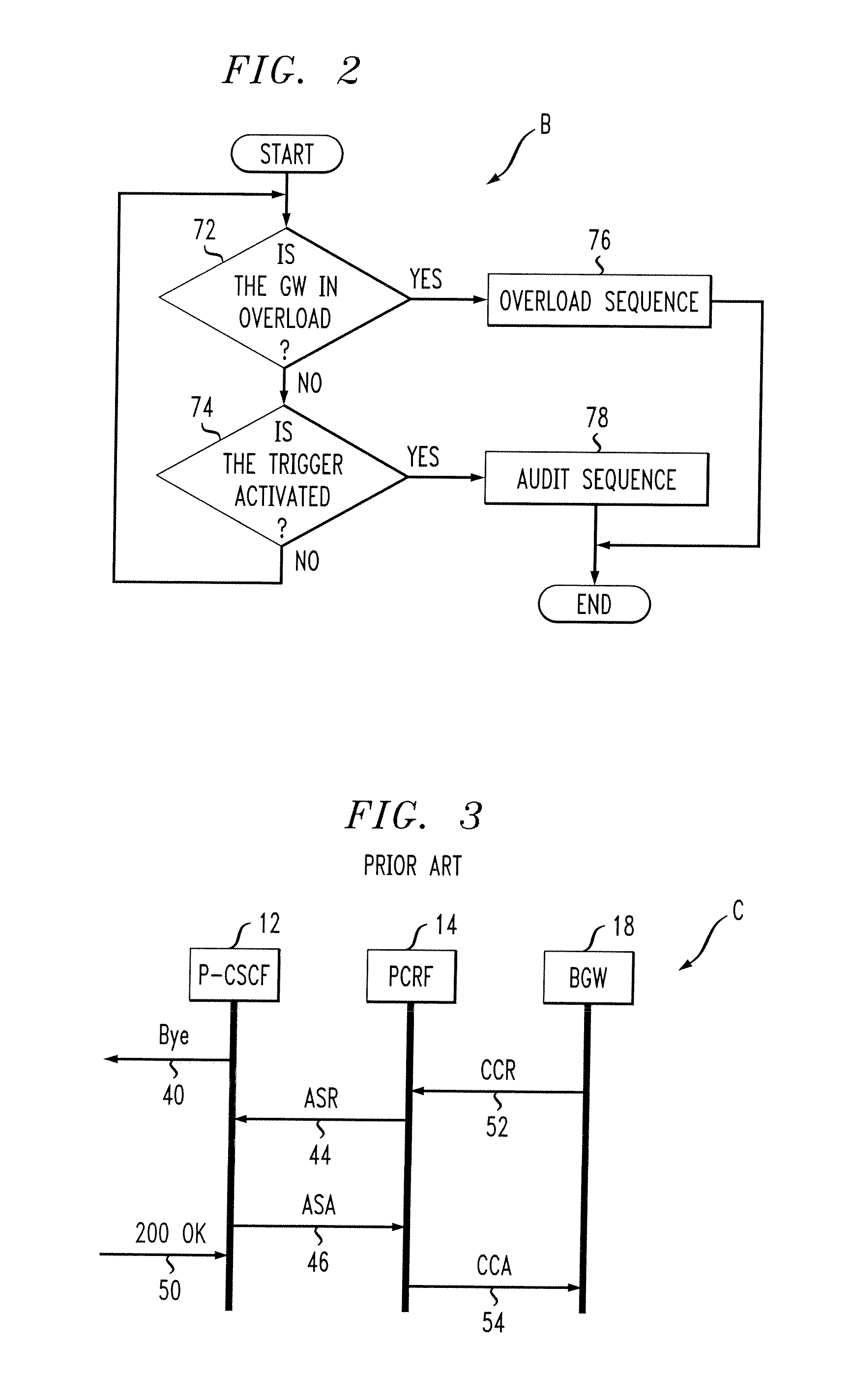

Method and apparatus for overload control and audit in a resource control and management system

ActiveUS20080250156A1Reduce probabilityEnergy efficient ICTMultiple digital computer combinationsOverload controlPercentage reduction

A system and method for resource control management implementing Diameter protocol is disclosed. The system includes a border gateway which is configured to send an overload message and a controller that is acting as a Diameter protocol server which is configured to receive the overload message and block a number of calls to the border gateway. The controller would also be configured to perform an audit function which includes clearing media resource ports. The overload message sent by the border gateway may also include a reduction percentage, which will dictate the percentage of calls which will be blocked.

Owner:WSOU INVESTMENTS LLC

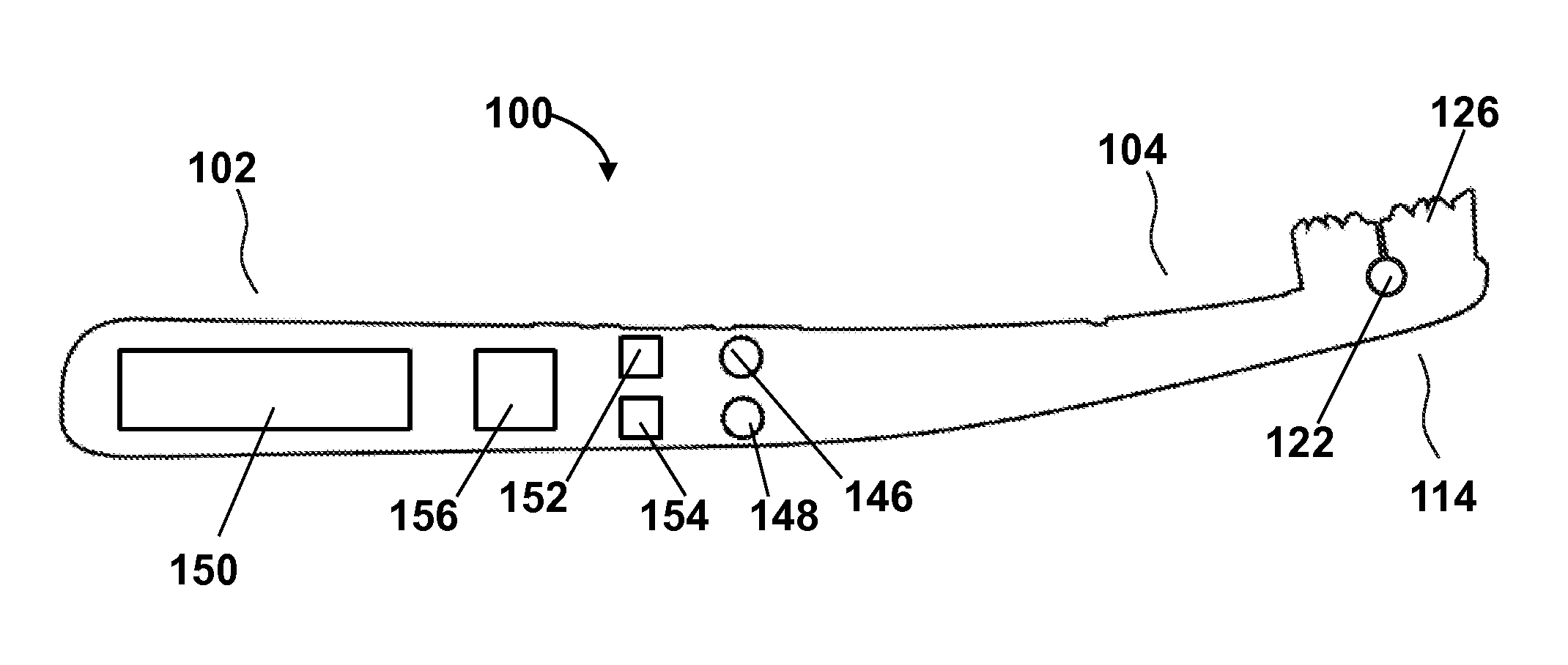

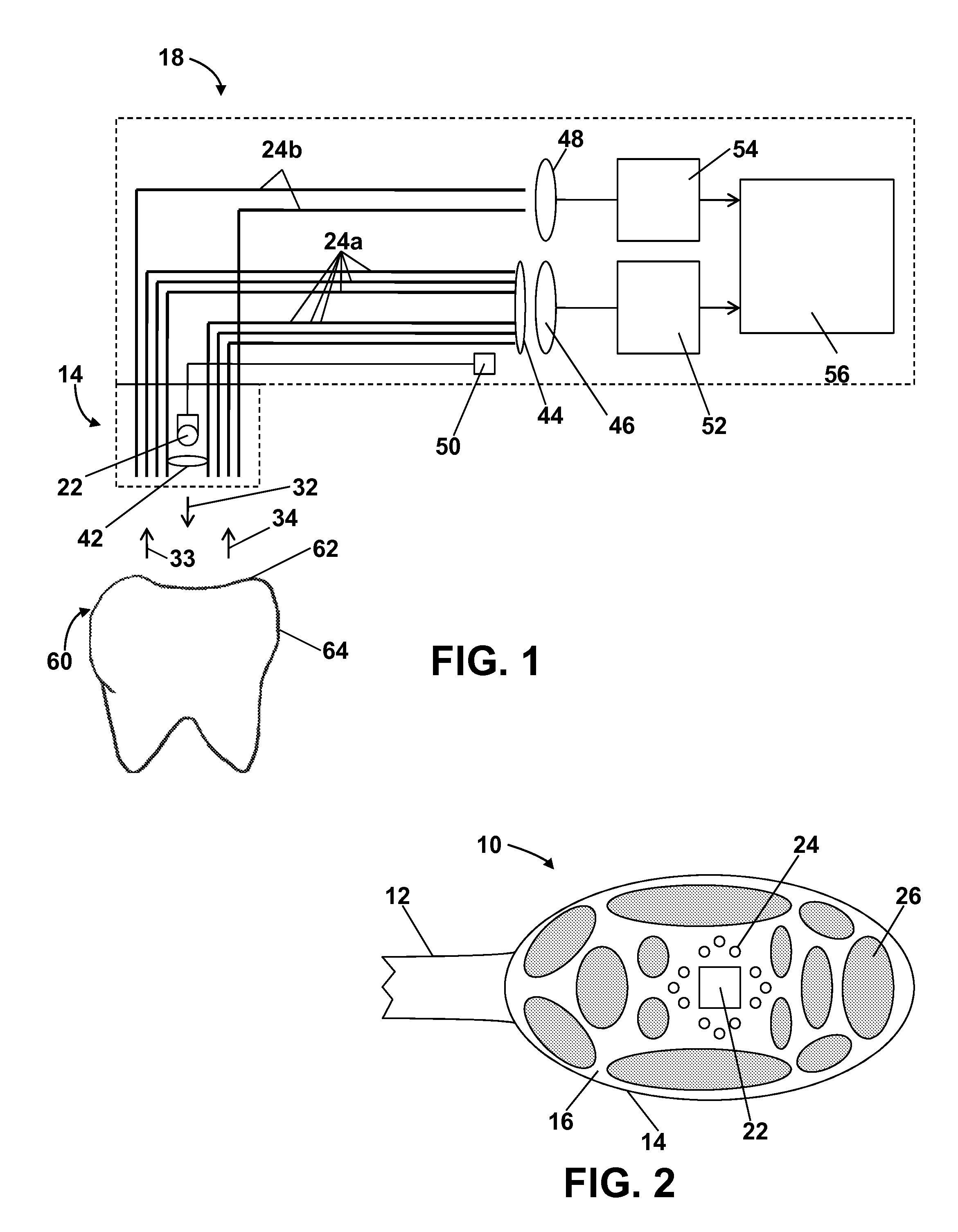

Device and method for cleaning the oral cavity

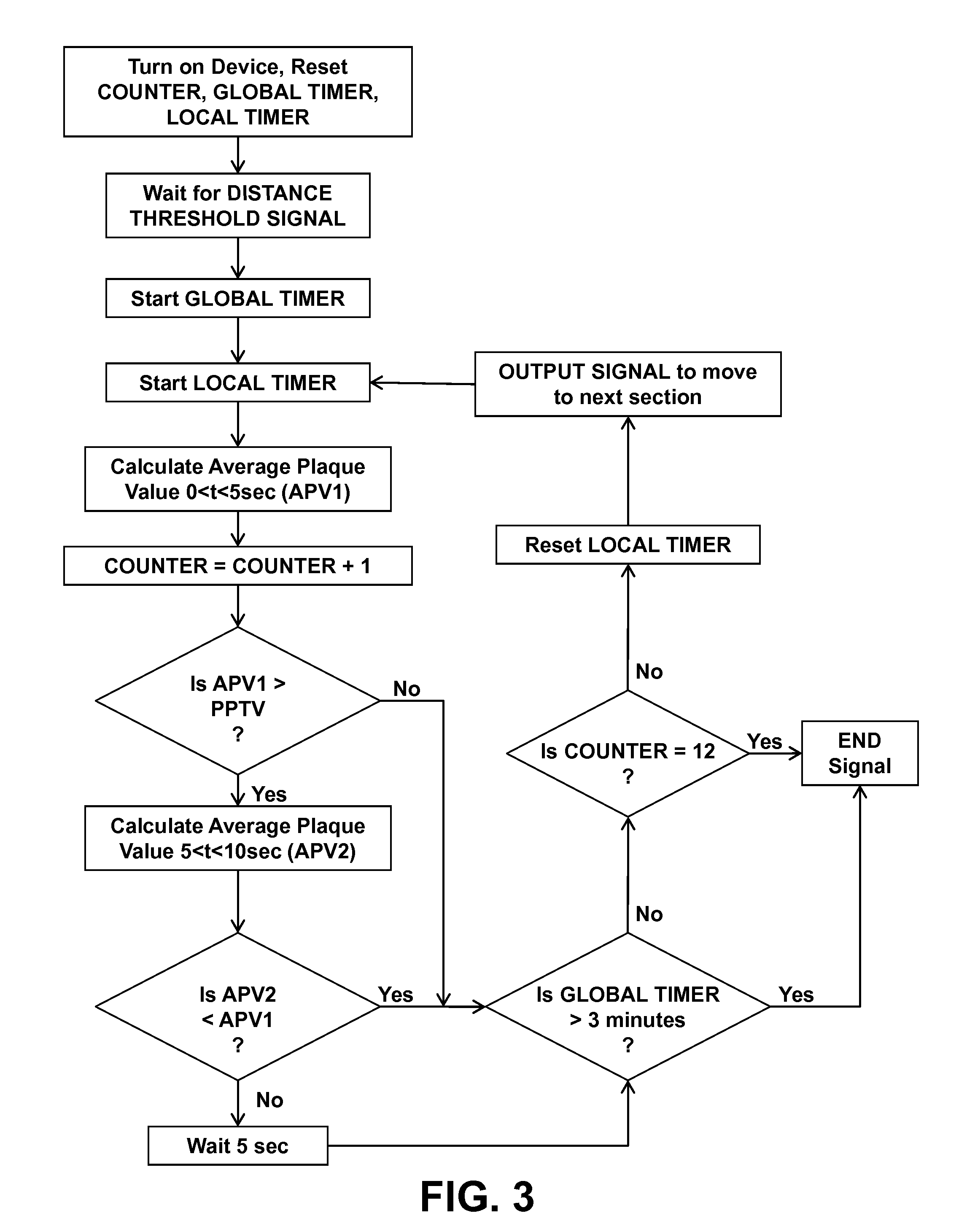

Devices and methods for cleaning an oral cavity by positioning a device suitable for detecting and removing plaque from the surface within the oral cavity having applied thereto a fluorescent agent capable of binding to plaque on the surface. The surface is substantially simultaneously cleaned and irradiated with a light of a wavelength effective to provide a fluorescent emission when contacted with said fluorescent agent. A portion of the fluorescent emission is collected (APV1), and compared to a predetermined threshold value (PPTV). If APV1 is less than PPTV, the device is moved to another section. If APV1 is greater than or equal to PPTV, then another portion of fluorescent emission is collected (APV2). The percent reduction from APV1 to APV2 determines when the device is moved to another section.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

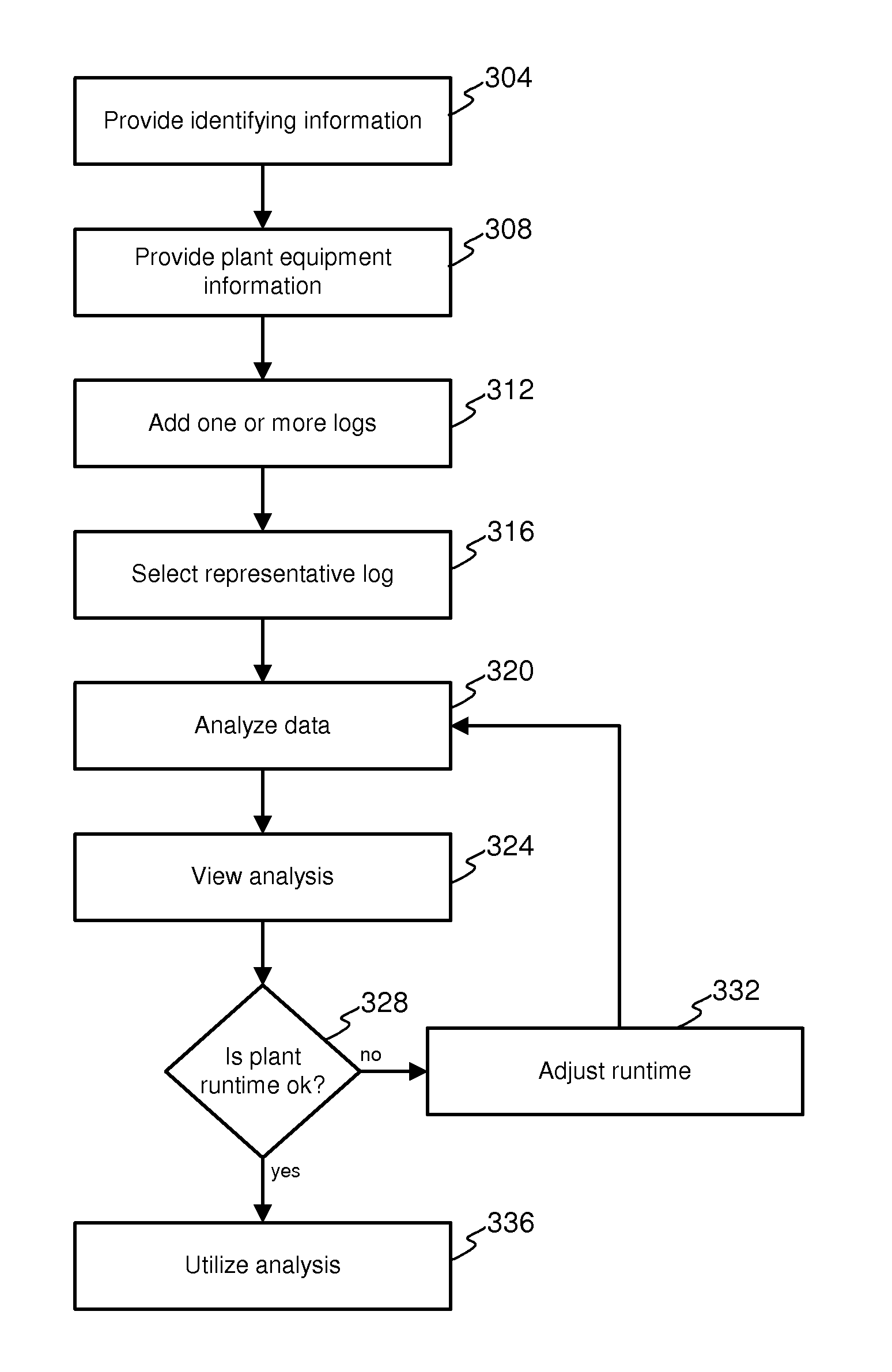

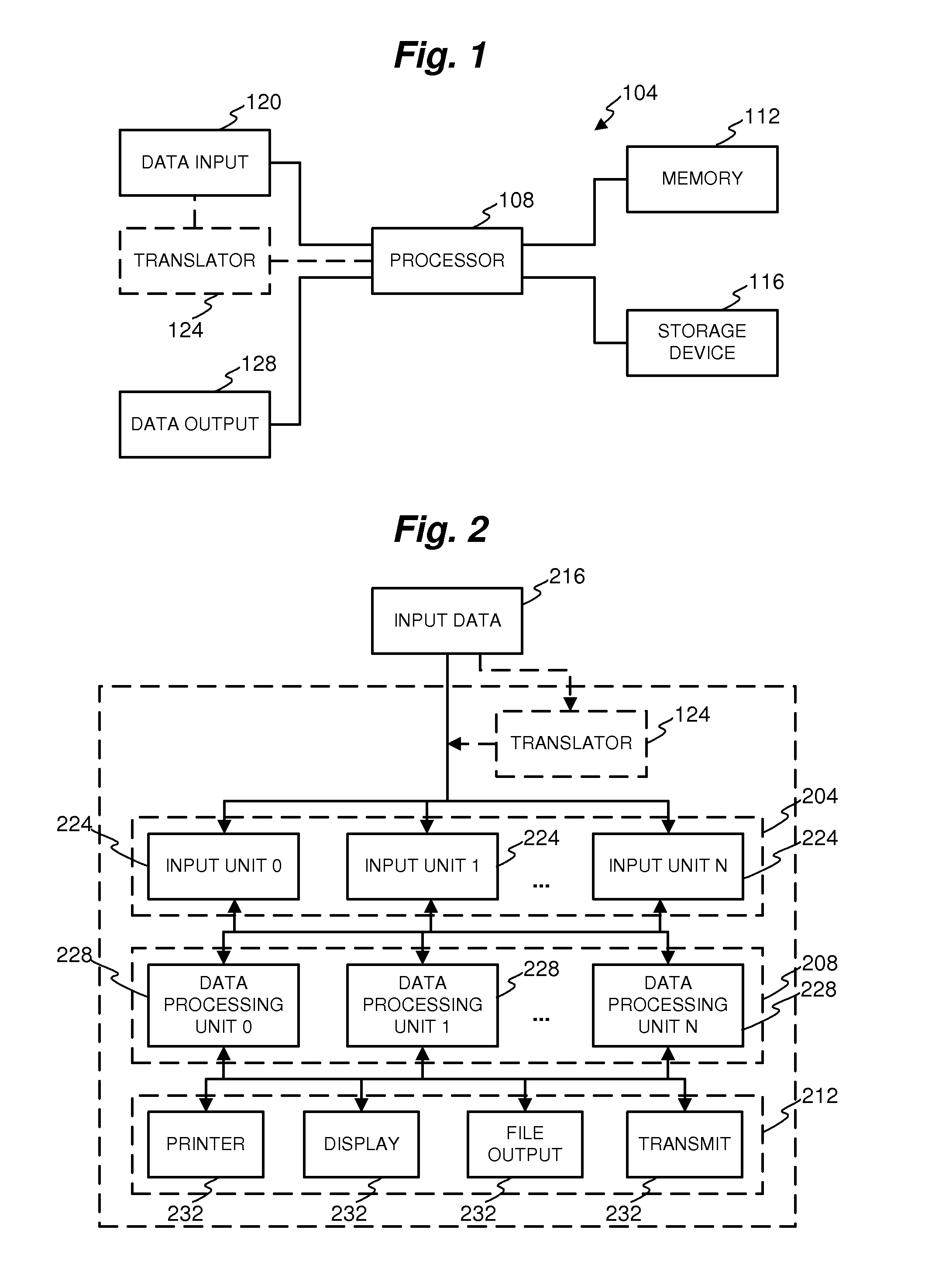

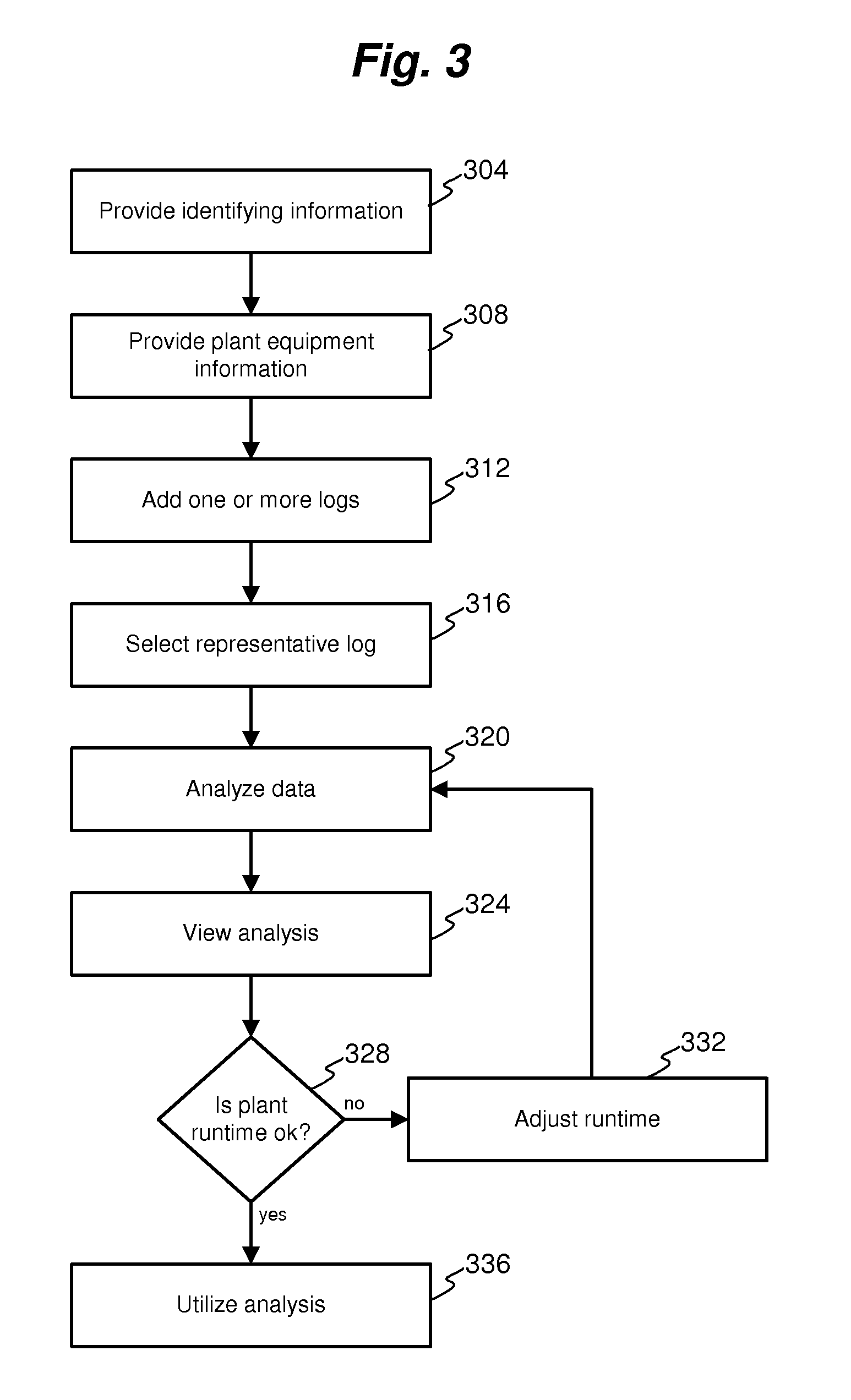

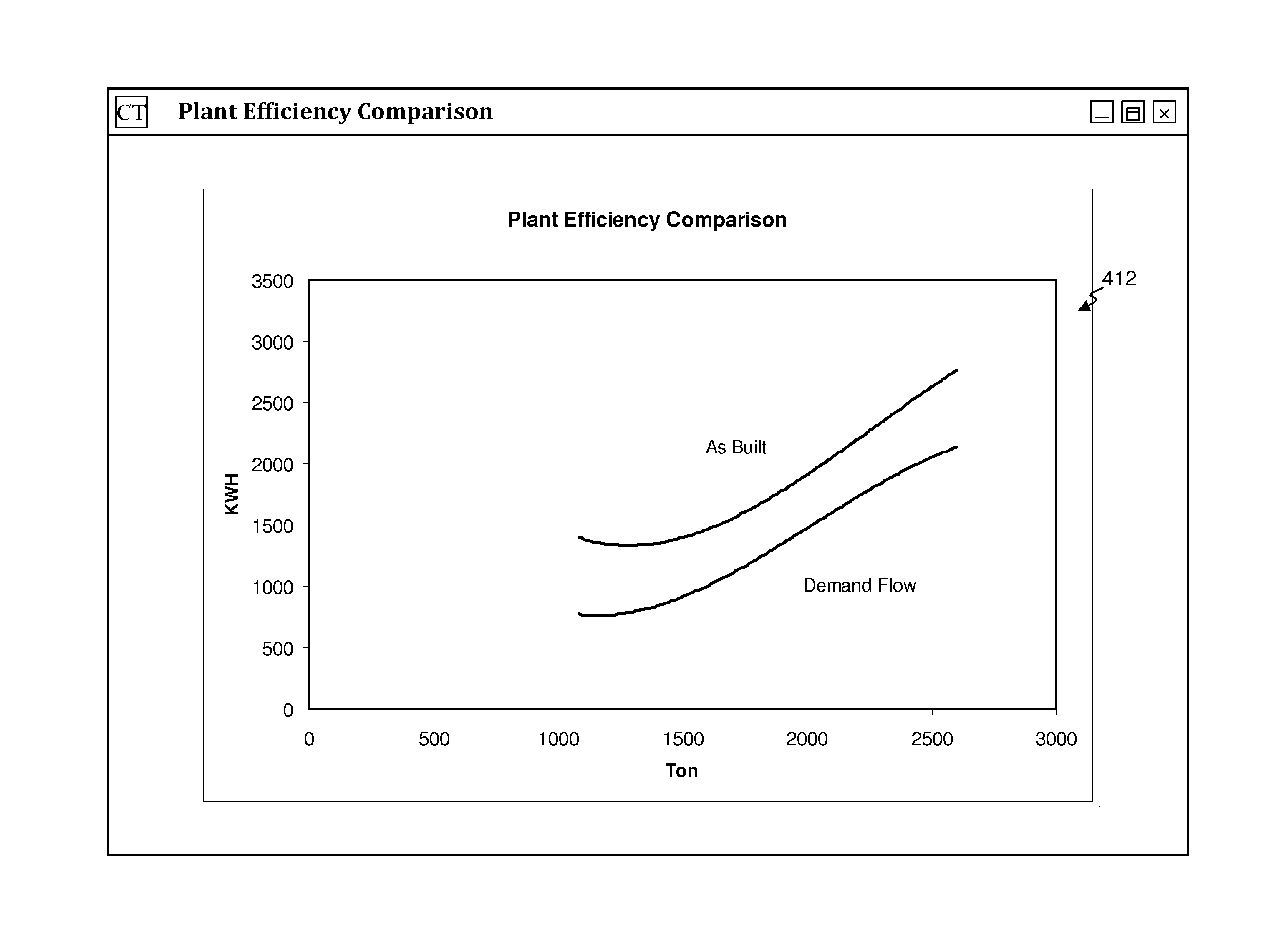

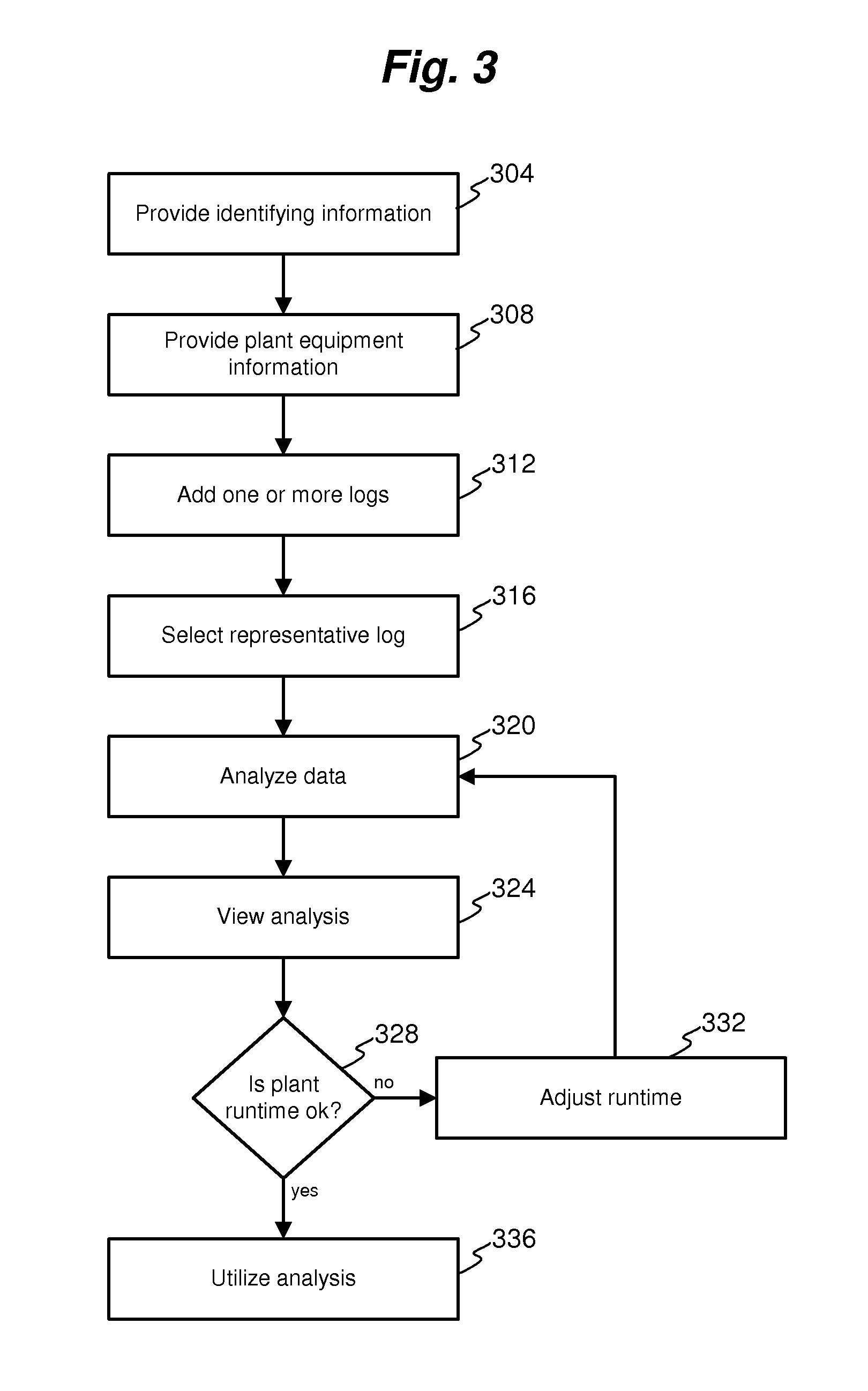

Qualification system and method for chilled water plant operations

ActiveUS8417392B2Accurately determineReduce settingsMechanical power/torque controlLevel controlChilled waterPercentage reduction

A qualification system for determining the effects of one or more upgrades or modifications to a chilled water plant is disclosed herein. The qualification system my collect various data from operating logs of a chilled water plant. The data may be collected in stages, where at least one first stage may be used to collect data used to identify representative log data. The representative log data may then be used to perform an accurate analysis to determine the effects of one or more upgrades or modifications. In this manner, the qualification system provides accurate analysis while reducing data entry. In addition, the qualification system may accept varying amounts of data such as to reduce percentage error or the like in its analysis.

Owner:SIEMENS IND INC

Process for producing precooked bacon slices

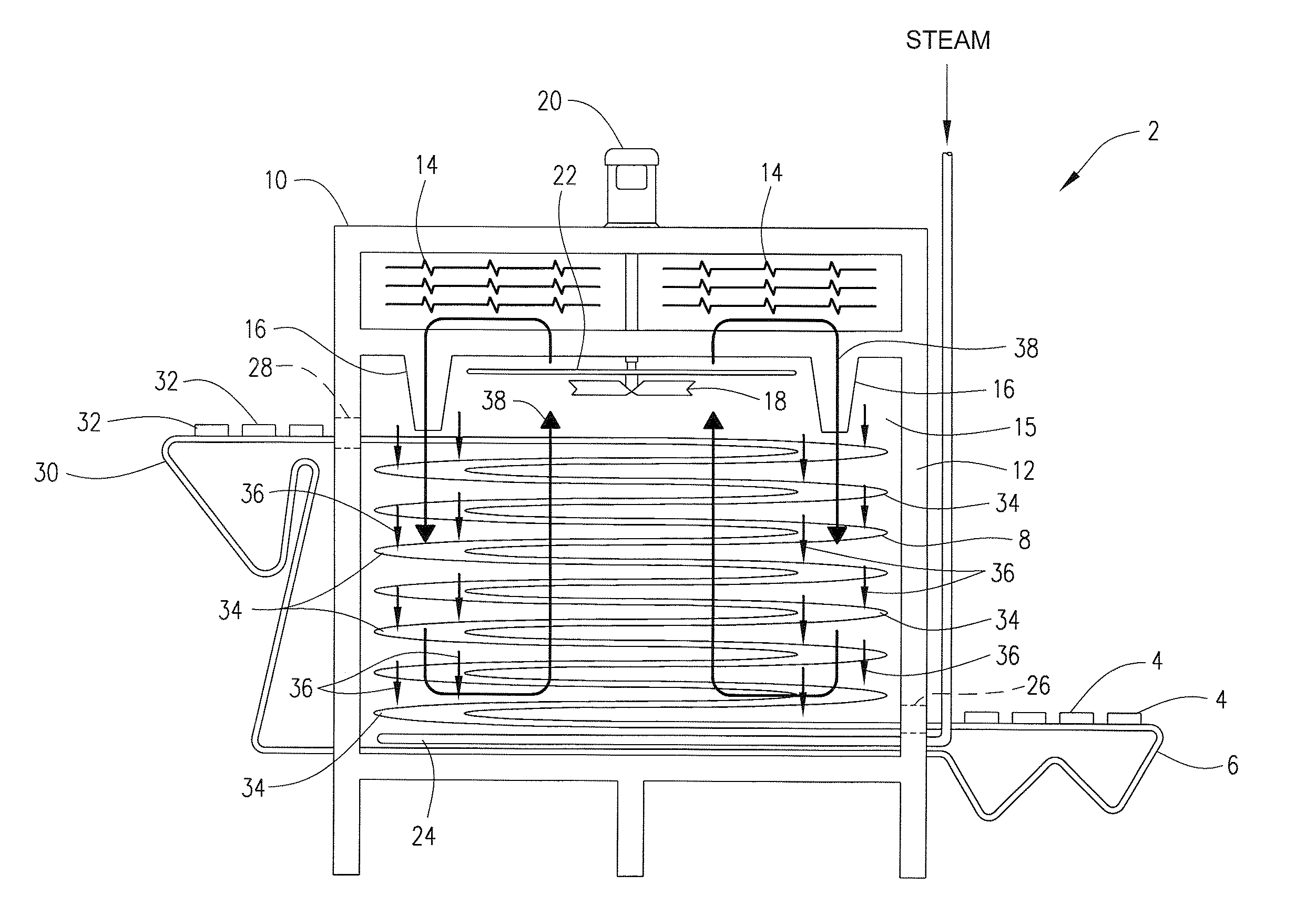

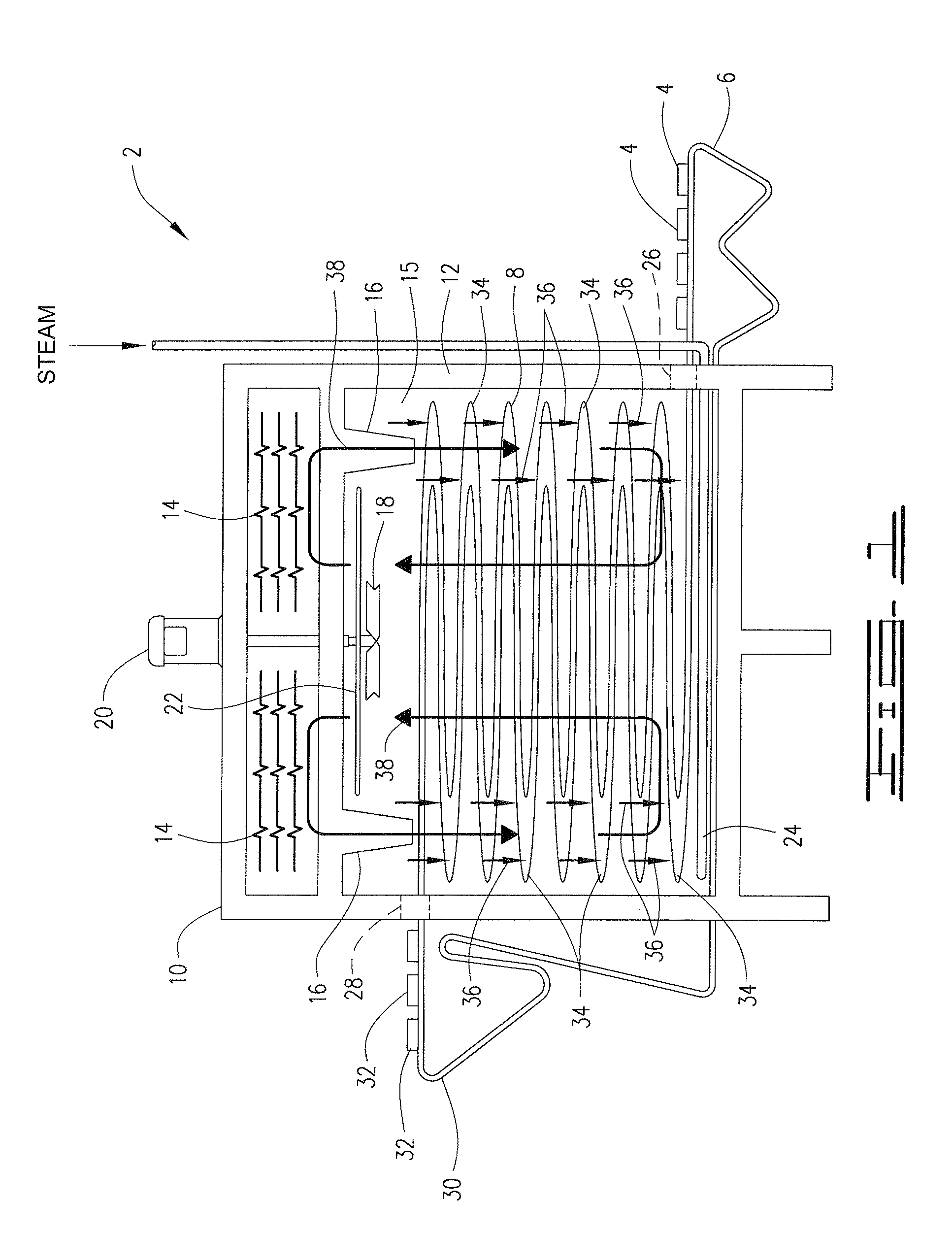

InactiveUS20090181138A1Small footprintEliminates orBaking ovenCooking vesselsProcess engineeringPercentage reduction

Owner:UNITHERM FOOD SYST LLC

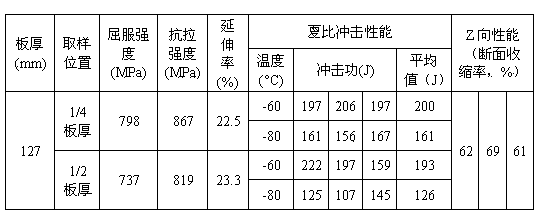

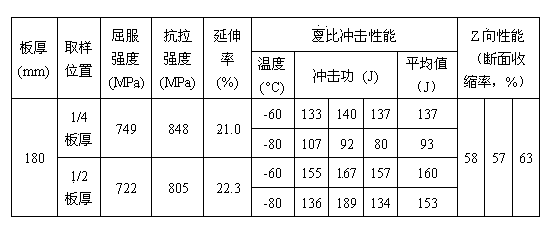

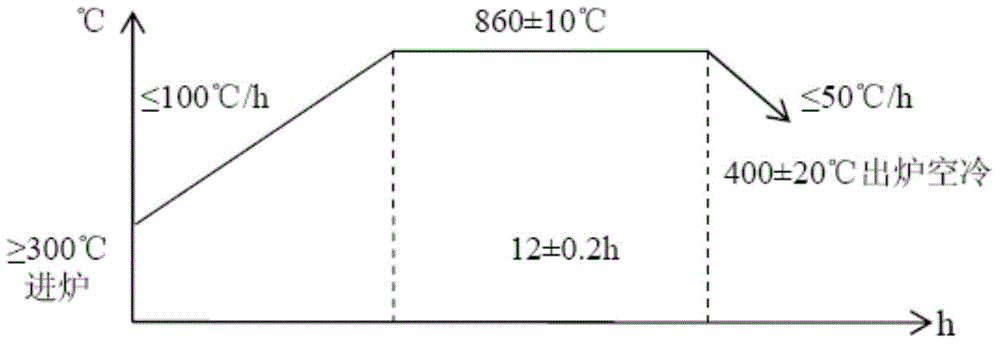

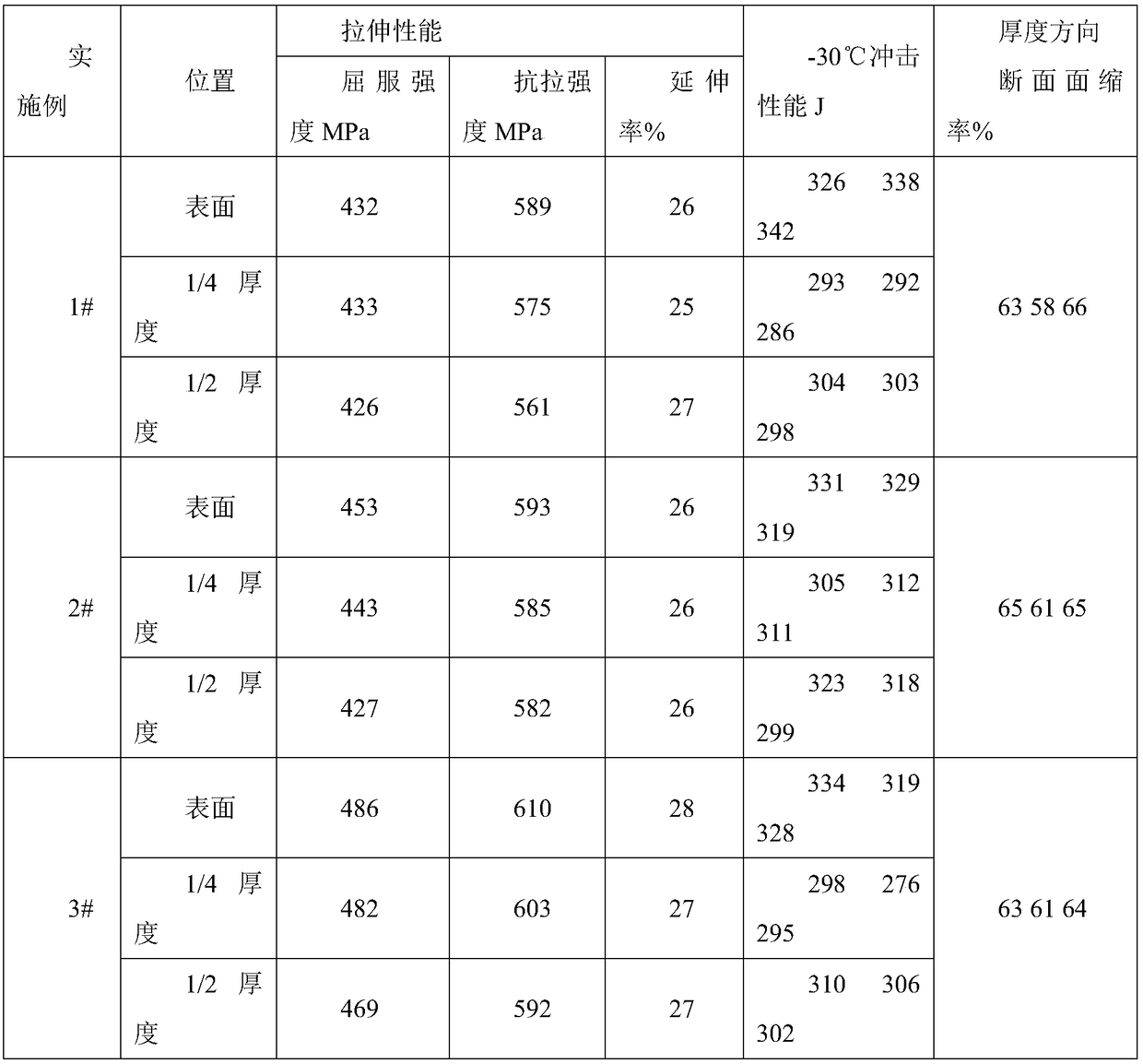

High-ductility Class F extra thick rack steel plate used at low temperature and manufacturing method of steel plate

The invention relates to a high-ductility Class F extra thick rack steel plate used at a low temperature and a manufacturing method of the steel plate. The steel plate takes Fe as a basic element and comprises C, Si, Mn, P, S, Cr, Mo, Ni, Cu, Al, V, Nb, N, B and the balance of Fe and impurity elements, wherein the carbon equivalent CEV is 0.75 pounds. The manufacturing method sequentially comprises the procedures of electric furnace smelting, LF (Ladle Furnace) refining, VD (Vacuum Distillation) refining, die casting, ingot heating, cogging rolling, slow cooling control, billet heating, rolling, thermal refining and the like. The thickness of the rack steel plate can reach 180mm, the yield strength is above 690MPa, the tensile strength is between 790-930MPa, the elongation<3> is 20%, the Z-direction performance (percentage reduction of area)<3> of the steel plate is 35%, the Charp impact work below -60 DEG C is greater than 100J, and the comprehensive mechanical property is excellent.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

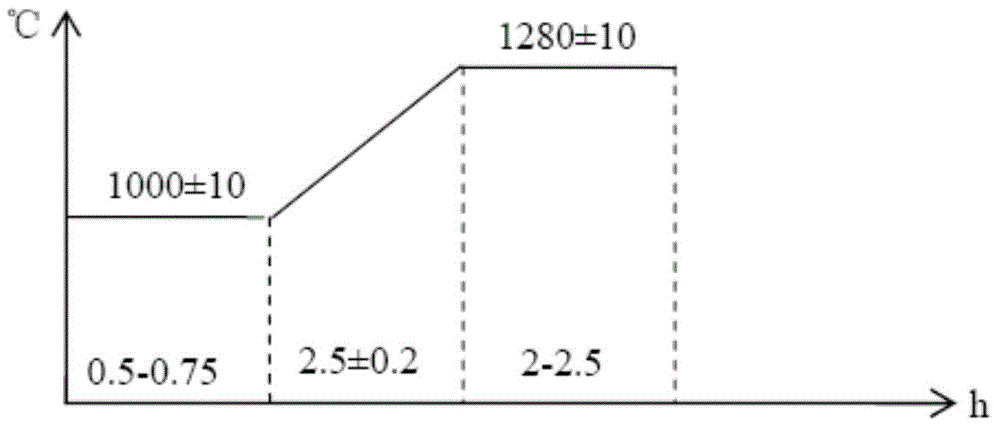

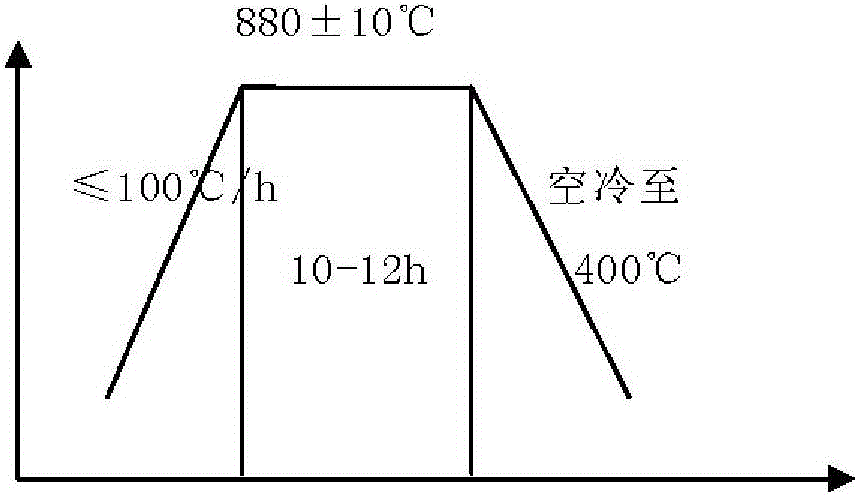

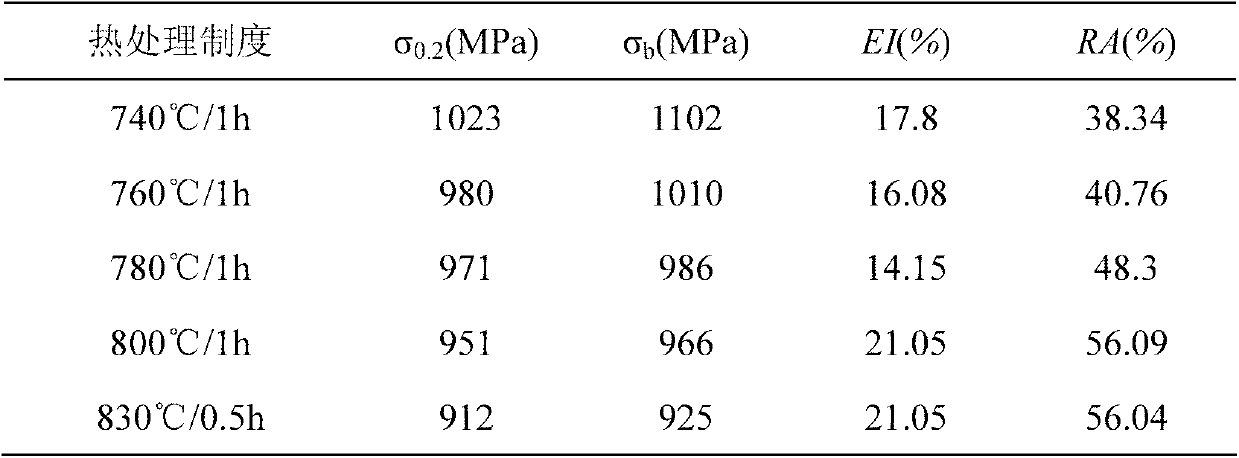

Martensitic stainless steel wire rod and production method thereof

The invention relates to a martensitic stainless steel wire rod and a production method thereof. The martensitic stainless steel wire rod is prepared from the following chemical components in weight percent: 0.30-0.65% of carbon, 0.20-0.50% of silicon, less than or equal to 0.60% of manganese, less than or equal to 0.30% of nickel, 11.50-17.00% of chromium, 0.20-0.50% of molybdenum, less than or equal to 0.25% of copper, less than or equal to 0.030% of sulfur, less than or equal to 0.040% of phosphorus, 0.02-0.20% of nitrogen, and the balance being ferrum and unavoidable impurities. The martensitic stainless steel wire rod which is excellent in surface, steady in performance and uniform in texture can be obtained by adopting the steps of smelting, casting, rolling, online hot charging annealing, salt bath, pickling, finishing to finished product inspecting and packaging, and the martensitic stainless steel wire rod has tensile strength of more than 600MPa, yield strength of more than 300MPa, elongation of more than 25%, percentage reduction of area of more than 50% and qualified product ratio of more than 85%. According to the invention, the comprehensive utilization performance of steel is improved, and the problem that surface stress cracking is easy to cause in annealing of high-carbon martensitic stainless steel in the prior art is solved on the basis of not increasing the smelting and rolling cost.

Owner:宝钢特钢有限公司

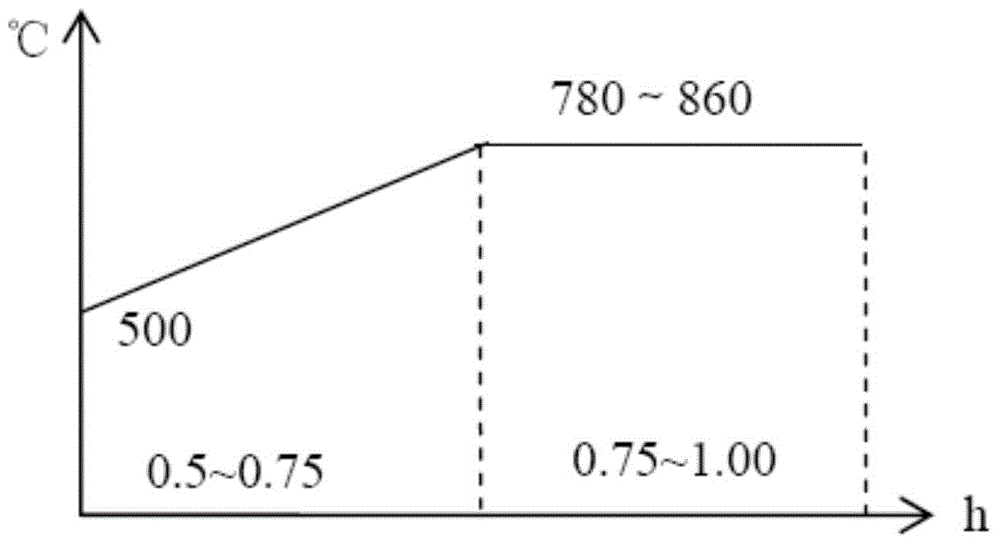

Alloy steel for large wind-driven power generation device and manufacturing process of workpiece made of same

The invention discloses alloy steel for a large wind-driven power generation device and a manufacturing process of a workpiece made of the same. The alloy steel contains the following chemical components: 0.30-4.0wt% of carbon, 0.30-0.80wt% of silicon, 1.20-1.80wt% of manganese, no more than 0.025wt% of phosphorus, no more than 0.015% of sulfur, 1.00-1.60wt% of chromium, 0.50-0.90wt% of molybdenum, 0.20-0.35wt% of vanadium, 0.05-0.12wt% of nitrogen, 0.02-0.07wt% of rare earth, and the balance of iron and inevitable impurities. The manufacturing process of a workpiece made of the alloy steel comprises the following steps: pretreating molten iron; smelting in a converter; carrying out external refining; casting into steel ingots; carrying out flame cleaning; heating; forging; annealing; carrying out heat treatment; mechanically processing; carrying out fault detection; checking; packaging; and warehousing. Compared with the alloy steel currently used by domestic and foreign wind-driven power generation stations, the tensile strength, yield strength, breakage elongation and percentage reduction in area of the alloy steel disclosed by the invention are all improved, and the low-temperature impact ductility is obviously improved. The atmospheric corrosion resistance rate and marine atmospheric corrosion resistance rate are both improved by two ranks.

Owner:JIANGYIN HENGRUN HEAVY IND

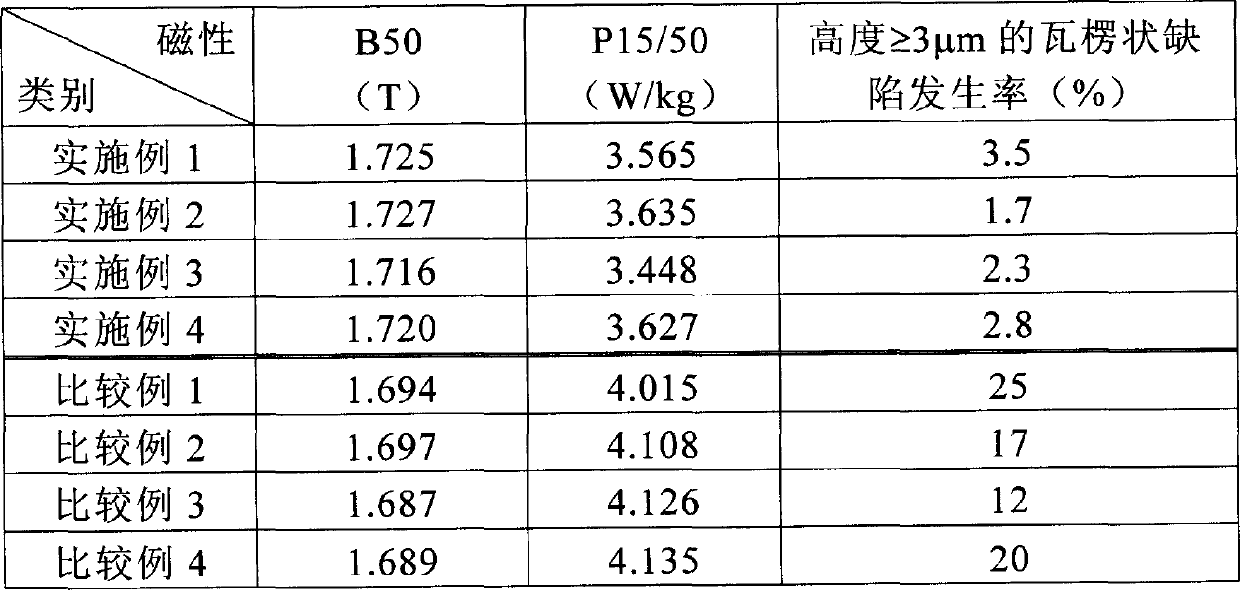

Indirectional electric steel plate without corrugated fault and its making process

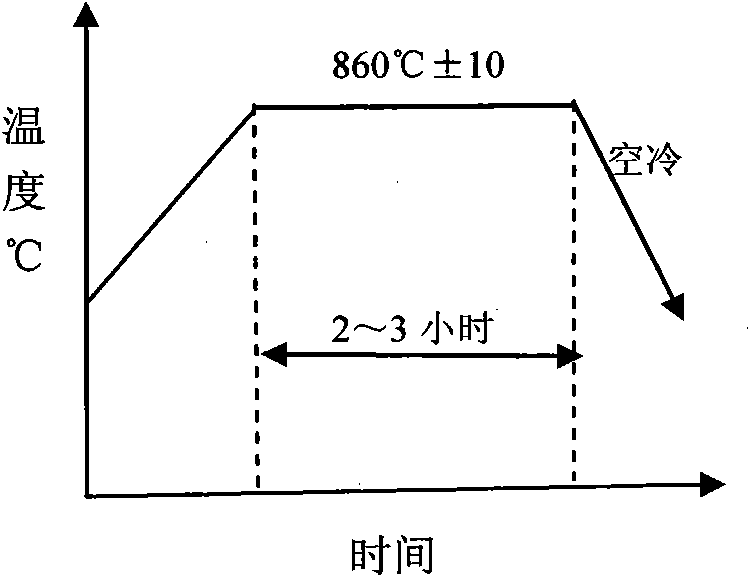

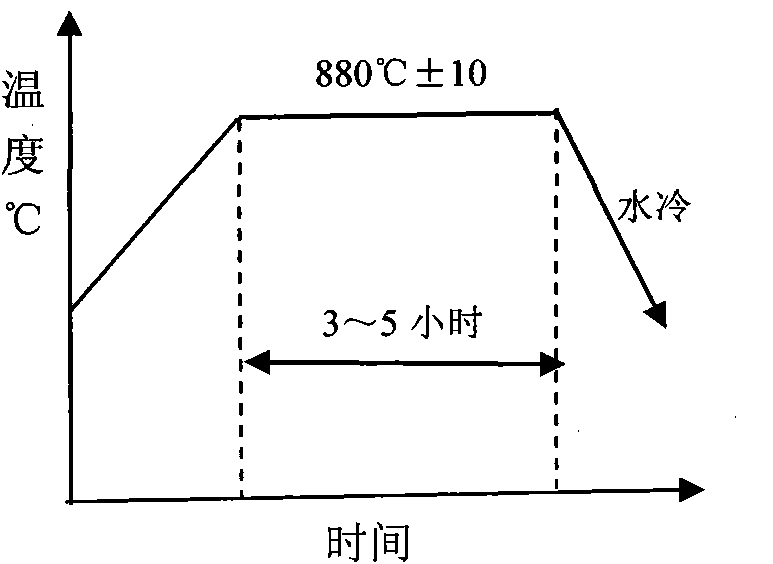

InactiveCN1548569AOmit the normalization processImprove physical performanceMetal rolling arrangementsSheet steelElectrical steel

The indirectional electrical steel plate without corrugated fault has the components including C0.006-0.01 wt%, Si 0-2.0 wt%, Al 0-0.4 wt% and Mn not higher than 1.0 wt% except Fe and inevitable impurity, with the Si / C ratio being 180-260. Its making process includes continuously casting plate blank; hot rough rolling for not more than 4 gates with total percentage reduction not less than 80 %, at least one gate of percentage reduction not less than 40 % and finish rolling temperature not lower than 980 deg.c; finish rolling with at least one roller of roughness not lower than 5 micron; and winding at temperature not lower than 710 deg.c. The optimized components and technological process mikes the steel plate product free from corrugated fault and high in physical performance. The omitting of normalizing step results in lowered production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

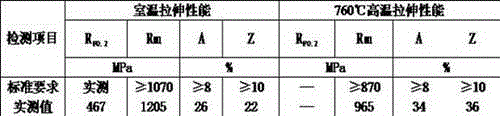

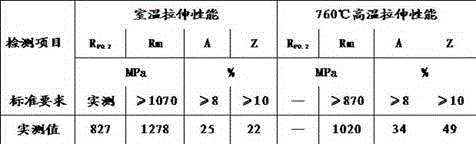

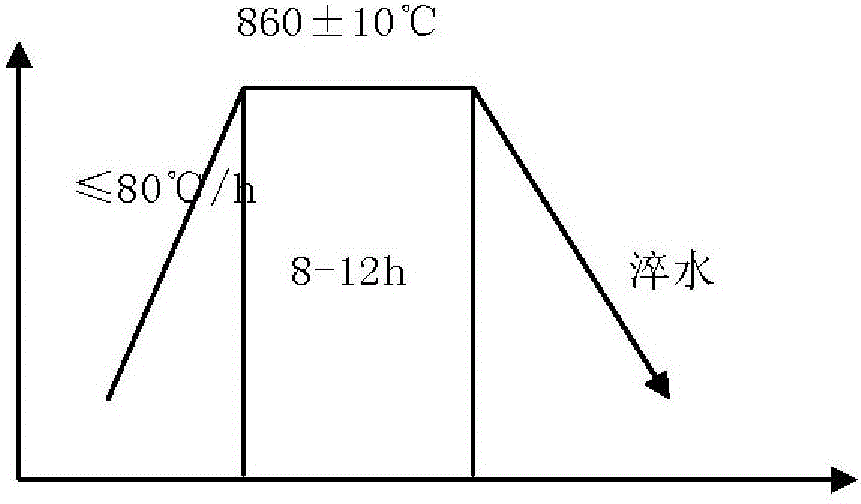

Processing process of difficult-to-deform high temperature alloy GH141 cold-drawn material

The invention discloses a processing process of a difficult-to-deform high temperature alloy GH141 cold-drawn material. On one hand, the structure of a cold-drawing blank and the ratio of cold drawing decrease section are controlled and the internal stress of a rod obtained after cold drawing is reduced by use of a special process; on the other hand, excellent usability is obtained by use of a reasonable thermal treatment process. The adopted technical scheme is as follows: 1, the internal structure of the cold-drawing blank is controlled; 2, softening annealing treatment is adopted; 3, a reasonable ratio of cold drawing decrease section is selected; 4, two different straightening processes are adopted after cold drawing; 5, a reasonable thermal treatment process is selected. The processing process of the difficult-to-deform high temperature alloy GH141 cold-drawn material has the advantages that the structure of the blank is controlled to be uniform, the grain is fine and the crack formation trend can be effectively reduced, the hardness of the cold-drawing blank is reduced by virtue of softening annealing, the internal stress of the rod obtained after cold drawing is reduced effectively by virtue of straightening, and due to the adopted reasonable heat treatment process, at a room temperature, the plastic percentage elongation after fracture of the cold-drawn rod is 25% and the percentage reduction of area is 22%, at 760 DEG C, the high temperature tensile plastic percentage elongation after fracture of the cold-drawn rod is 34% and the percentage reduction of area is 36%; in short, the difficult-to-deform high temperature alloy GH141 cold-drawn material is excellent in properties.

Owner:FUSHUN SPECIAL STEEL SHARES

High-strength steel plate with tensile strength of 800 MPa above and manufacturing method thereof

The invention provides a high-strength steel plate with tensile strength of 800 MPa above and a manufacturing method thereof. The steel plate produced by the manufacturing method comprises the following components in percentage by weight: 0.08-0.21% of carbon, 0.15-0.45% of silicon, 0.70-1.10% of manganese, at most 0.015% of phosphorus, at most 0.010% of sulfur, 0.40-0.65% of chromium, 0.10-0.25% of molybdenum, 0.030-0.080% of vanadium, 0.010-0.030% of titanium, 0.020-0.050% of aluminum, 0.0005-0.005% of boron, and the balance of iron and inevitable impurities. The tensile strength of the steel plate reaches higher than 800 MPa, the -20 DEG C transverse impact work is not less than 34J, the percentage reduction in area is not less than 45%, and the lateral swelling amount is not less than 0.38 mm; and the invention has the advantages of low cost and favorable welding performance.

Owner:JIGANG GRP

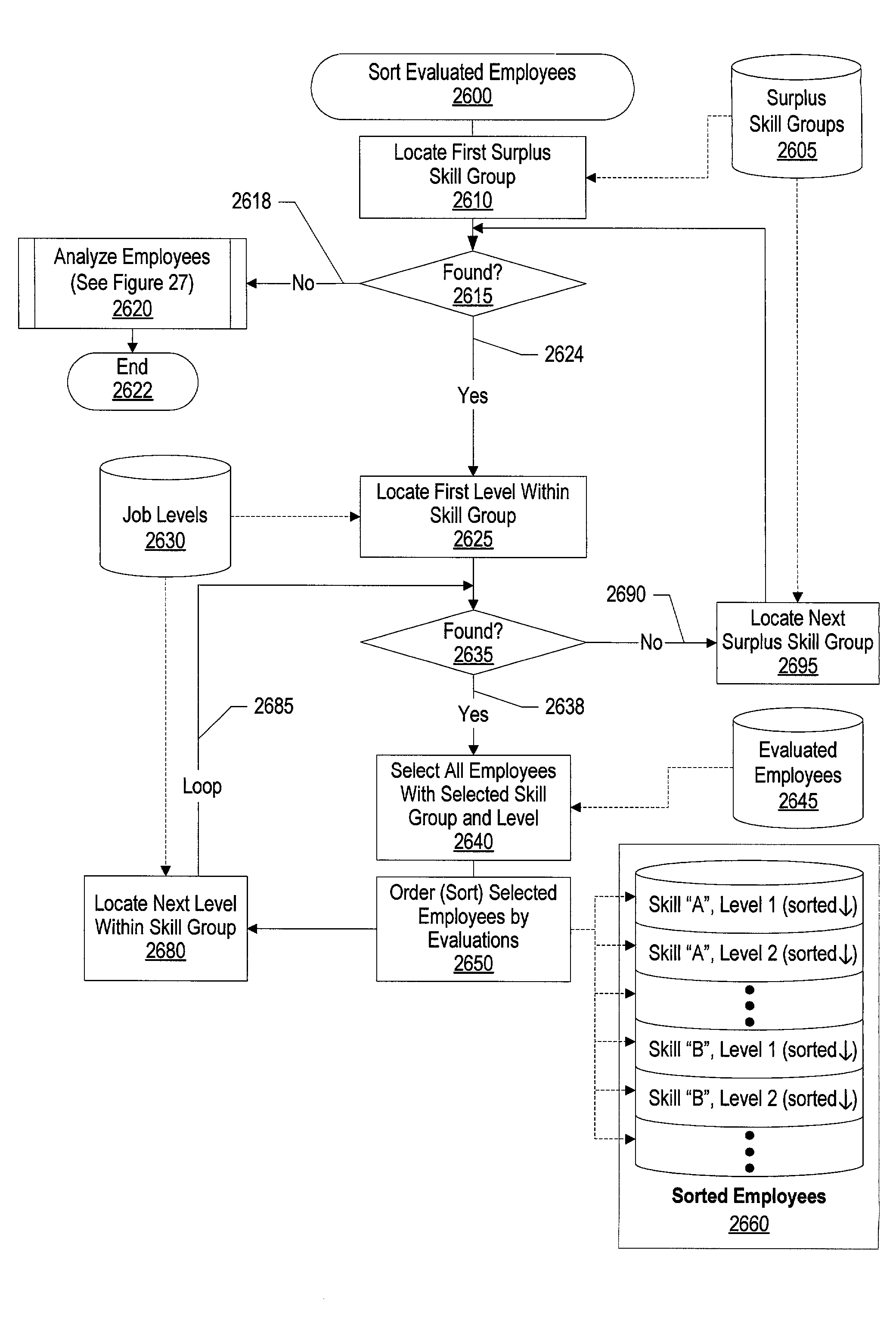

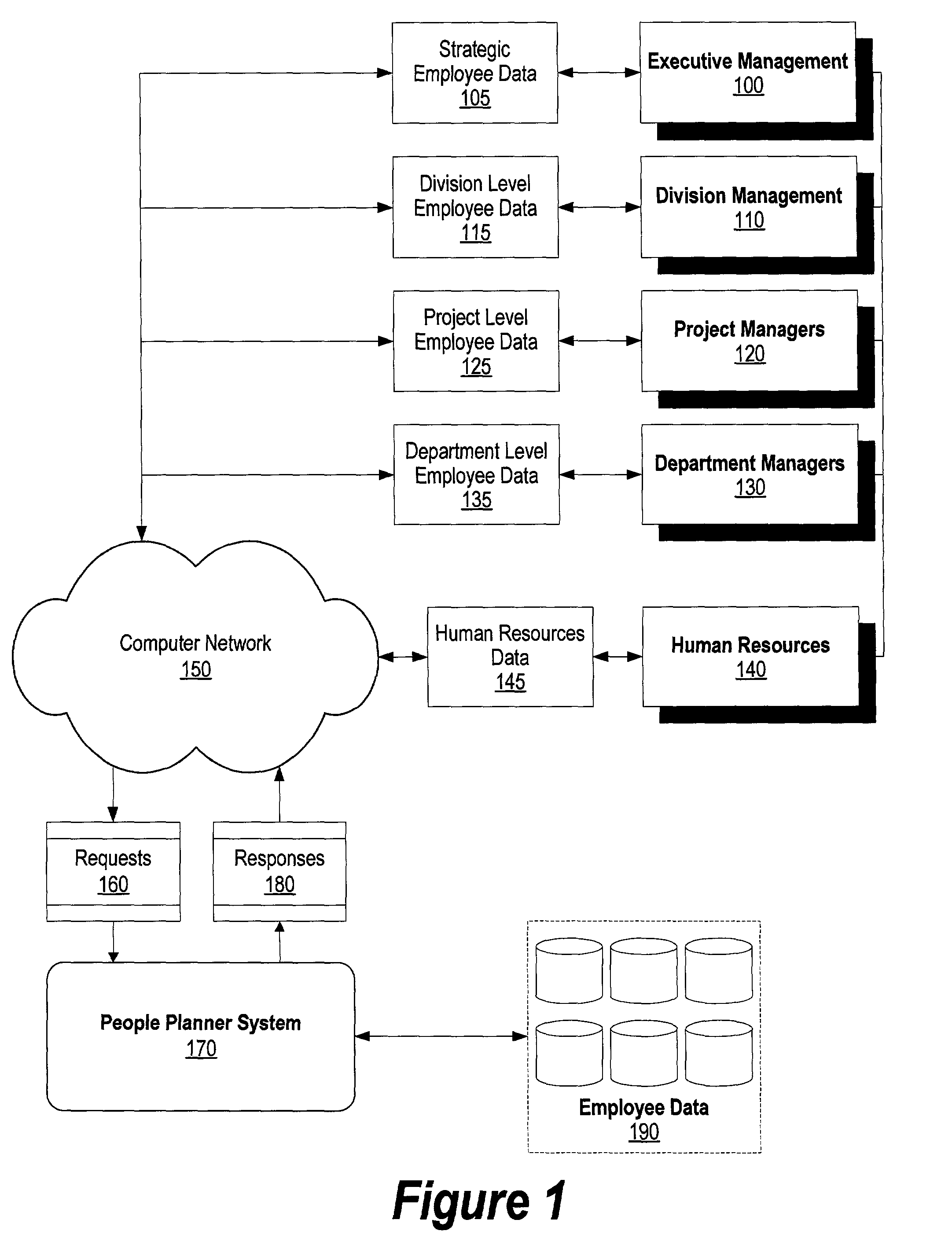

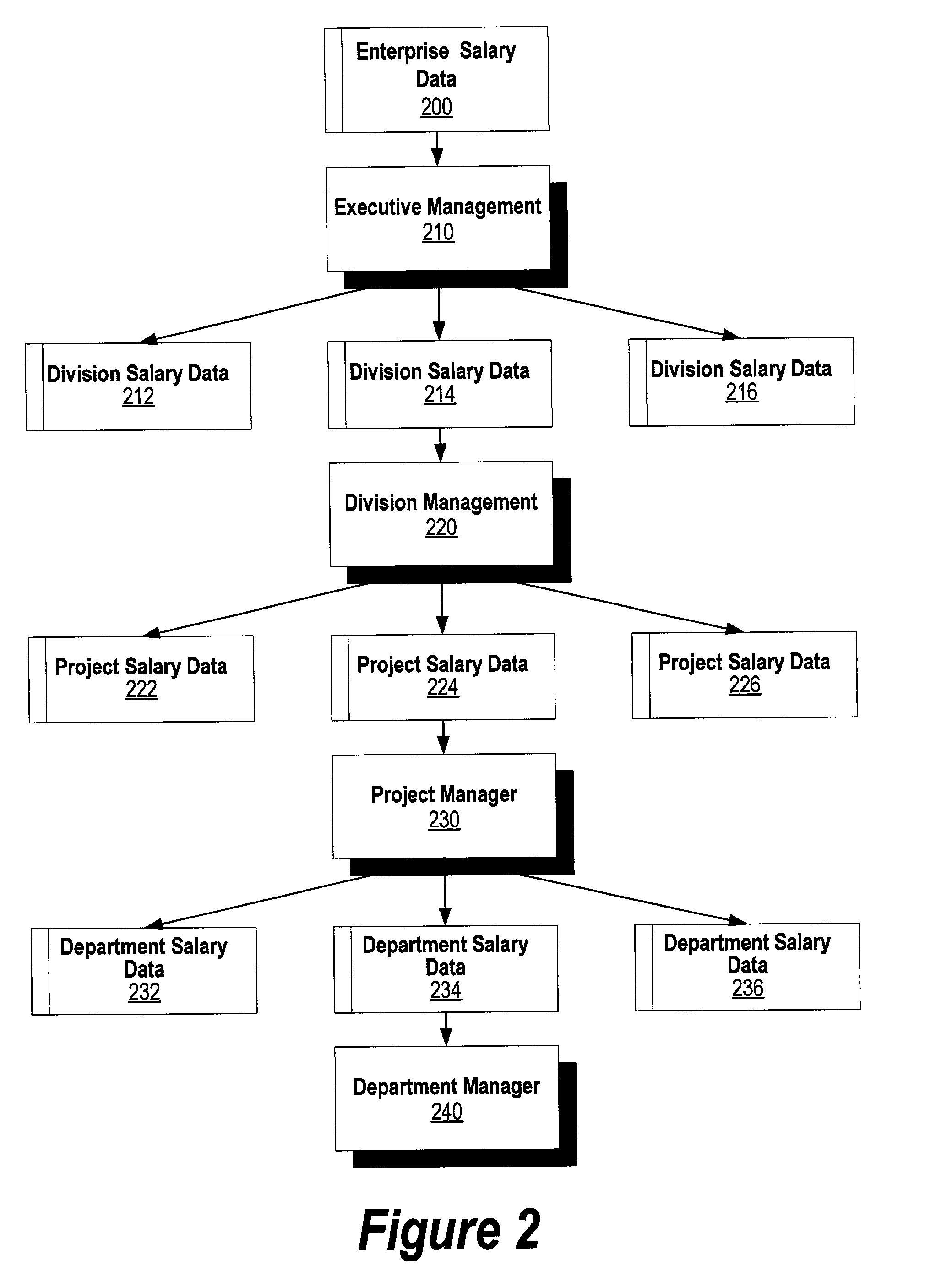

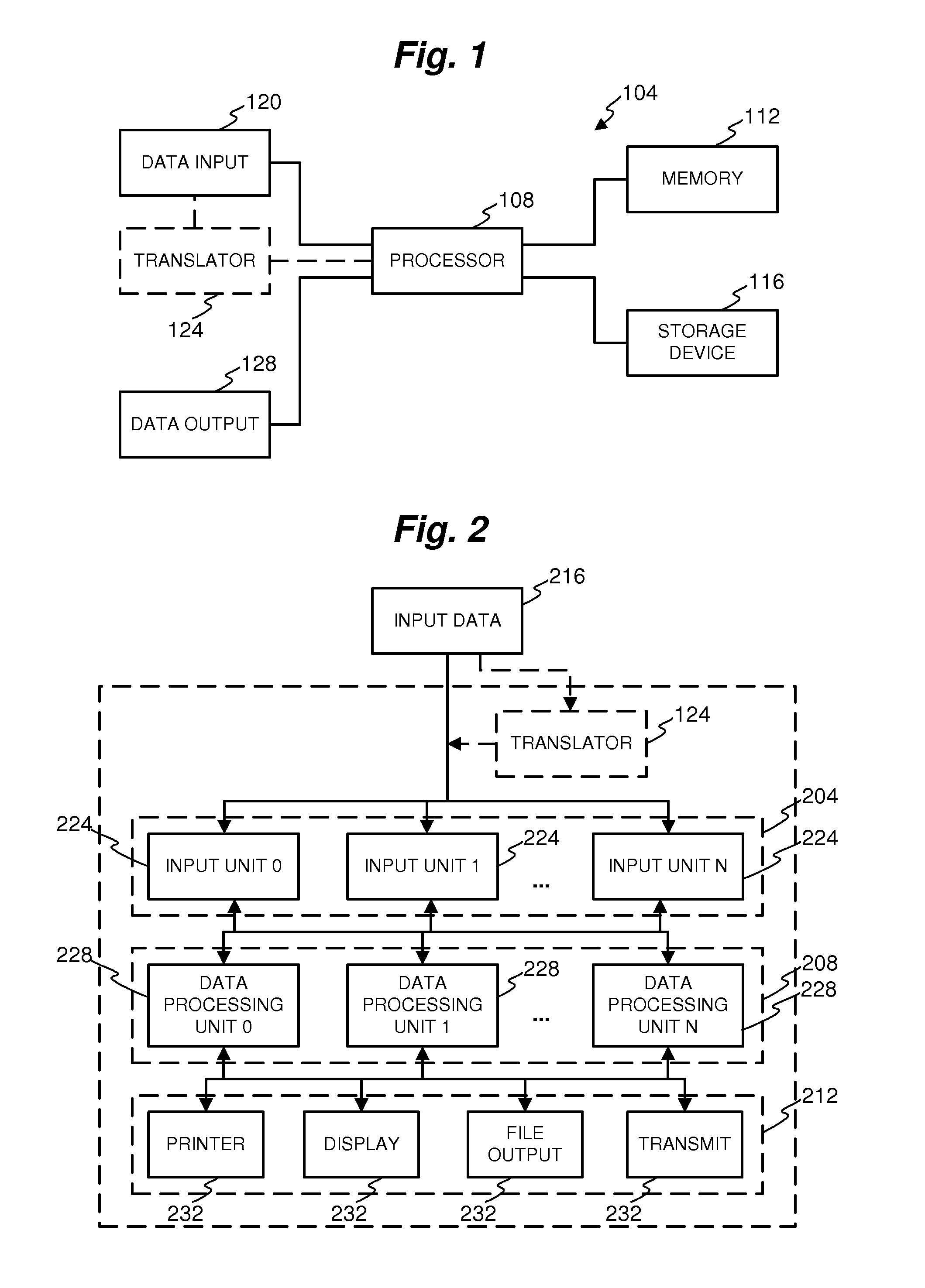

System and method for automated resource reduction analysis

A system and method that analyzes employee data and assists management with surplus determinations is used for automated resource reduction analysis. Areas within the organization are identified that include surplus resources. These areas are further identified to determine which skill groups have surplus skills. Skill groups can be broken down by level. A determination is made as to what decreases are desired for the identified skill groups and levels. Employees within the identified skill groups and levels are evaluated using common evaluation templates that set forth the expected skills employees should have for a given skill group and level. The evaluated employee records are sorted by the evaluations to determine the spectrum of skills within a particular skill group and level. The desired reduction percentage is then applied to the sorted records to identify surplus employees. These identified surplus employees are then reviewed using organizational surplus guidelines and applicable laws.

Owner:IBM CORP

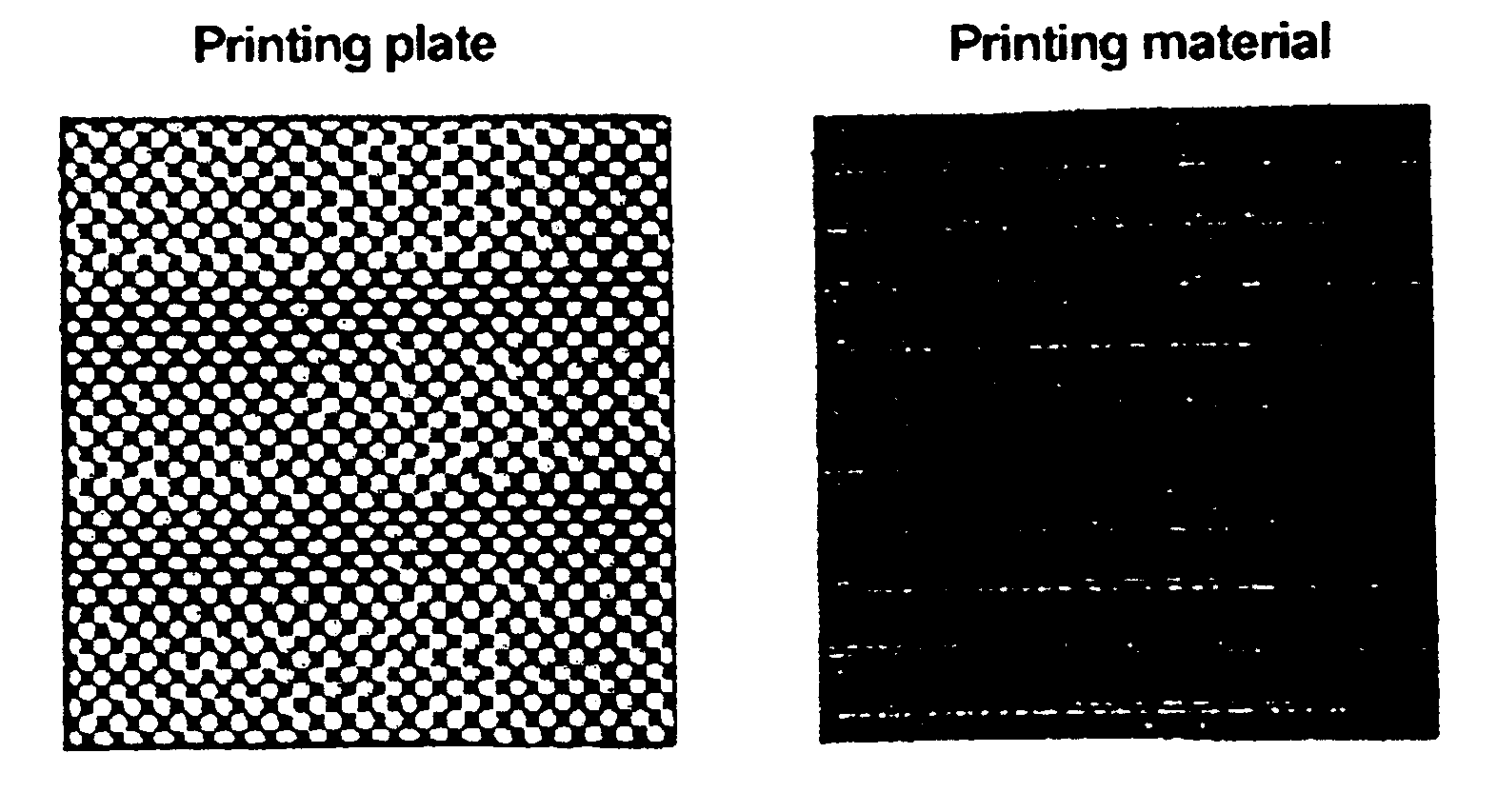

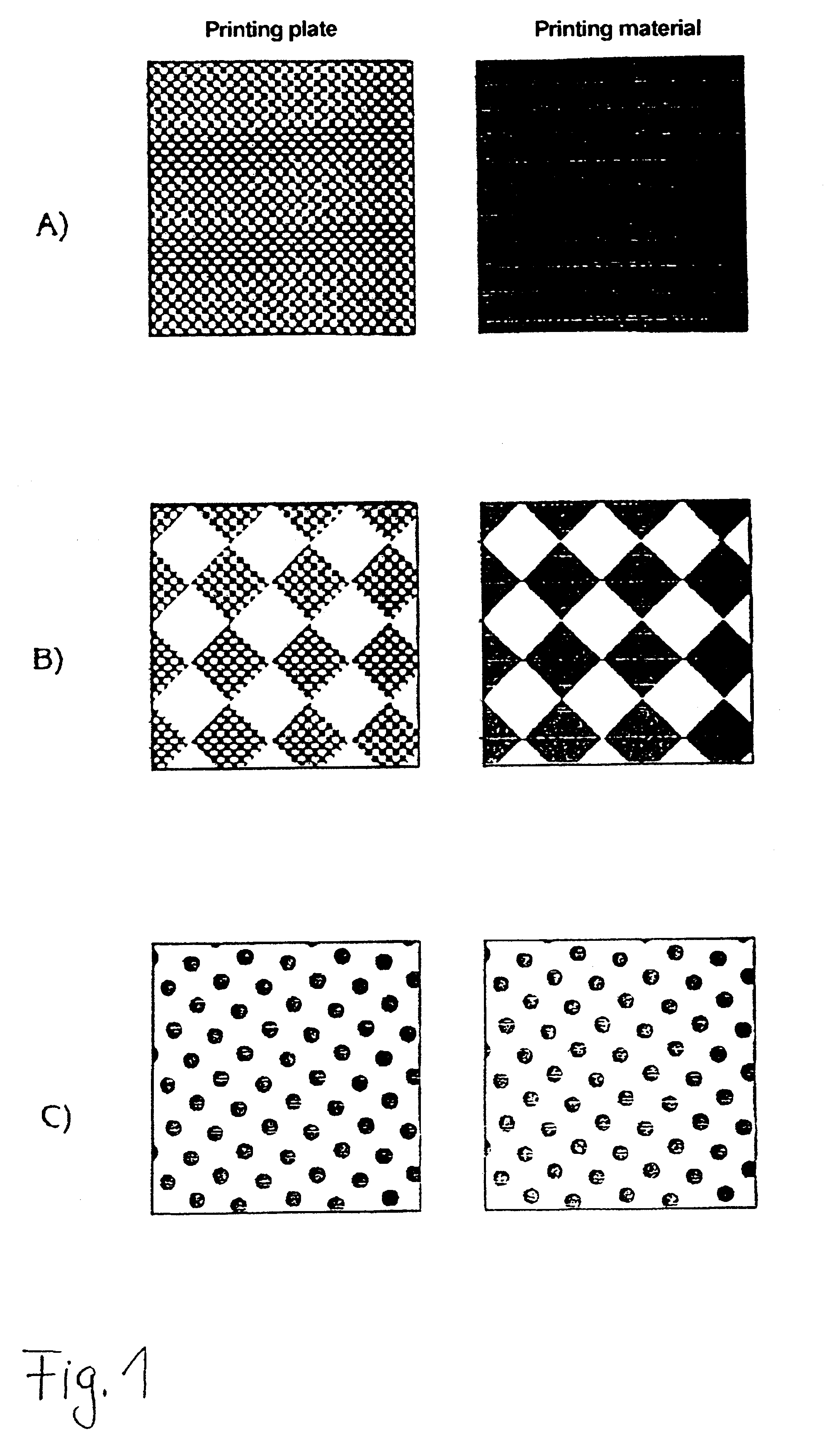

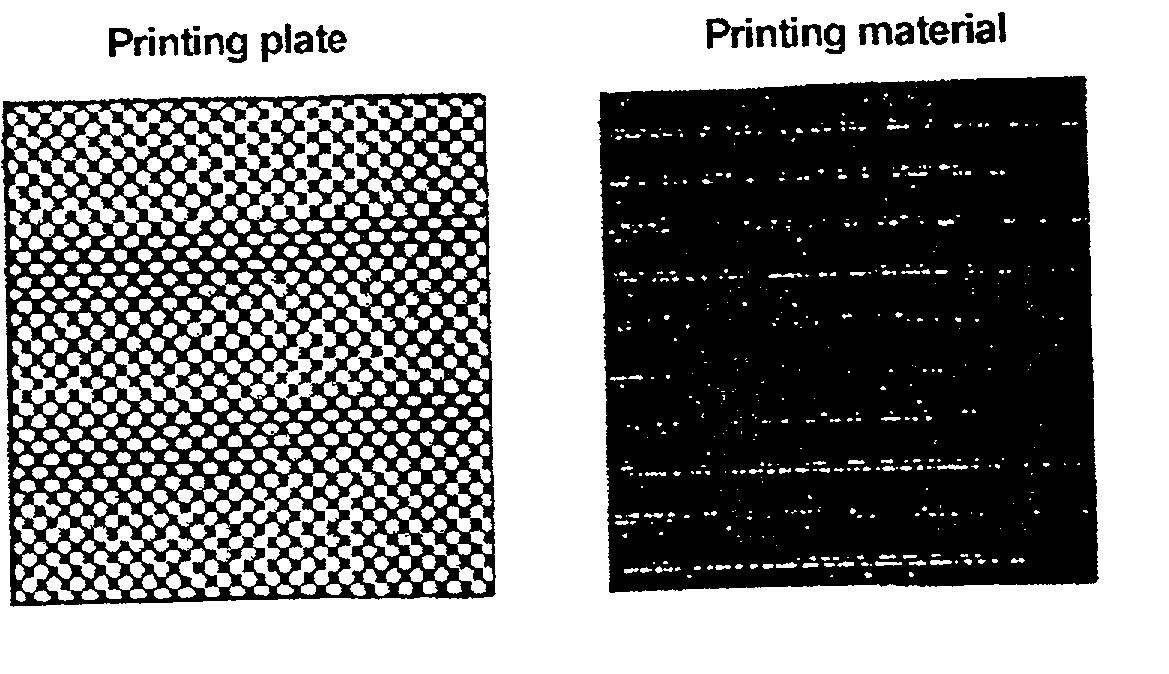

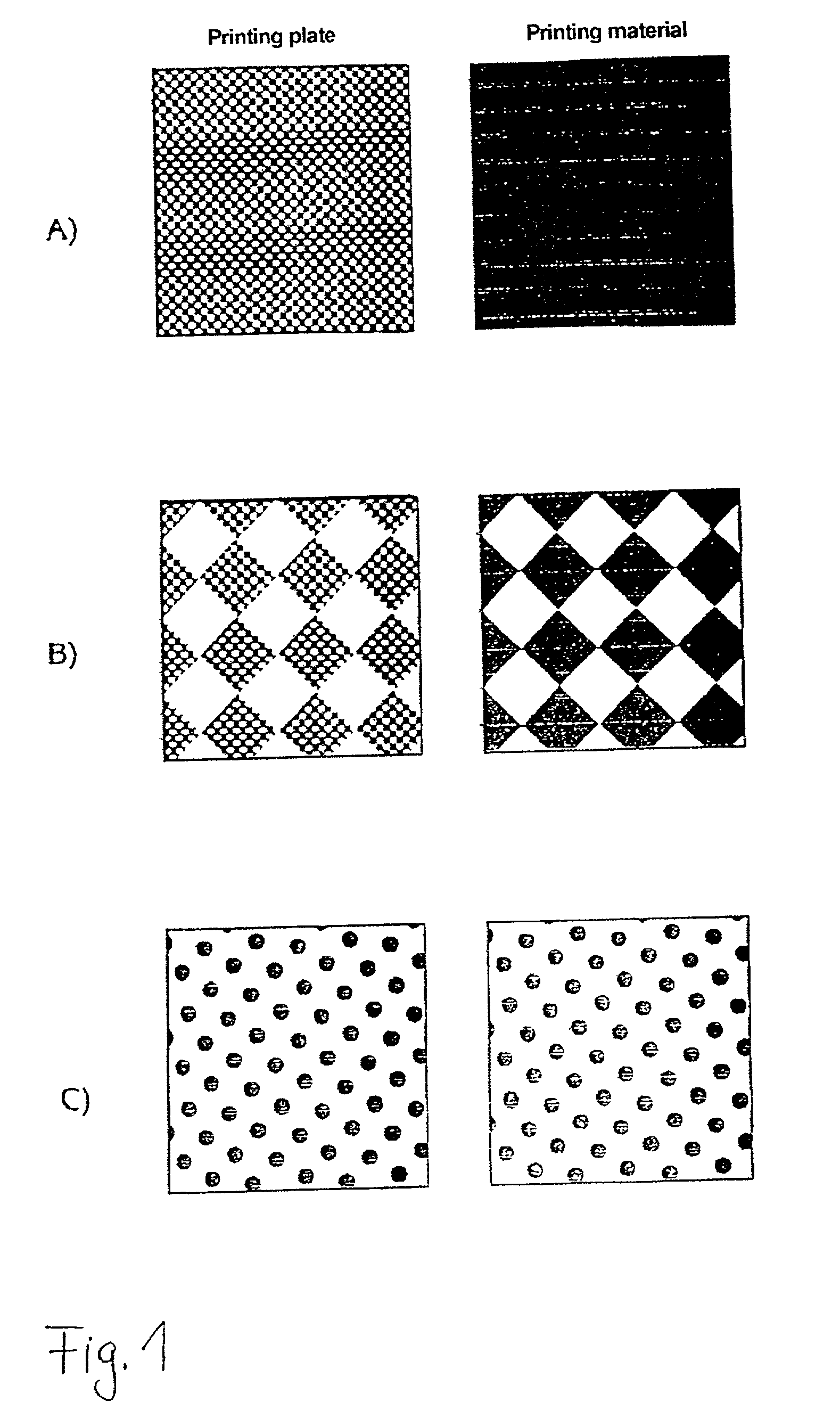

Method of varying the ink density of the full tone in offset printing within a rotary printing machine

A method of varying the ink density of the full tone in printing within a rotary printing machine with an ink application system which can provide a constant quantity of ink which, in spite of constant ink supply from the inking unit, permits control of the full-tone density or adaptation of the raster tonal values in the print. The method includes setting the binary image on a printing plate. A basic raster of raster points, which determines the area coverage of the binary image, is produced on the printing plate for the variable-area image information. The basic raster is then superimposed on a fine microraster in such way that the area coverage of the basic raster is reduced by a percentage which can be set between 0% and 100%.

Owner:MANROLANAD AG

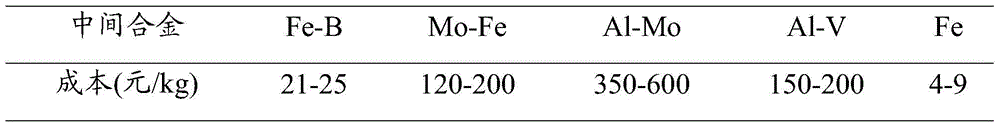

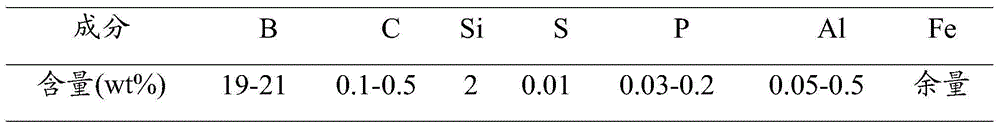

Low-cost and high-performance titanium alloy and preparation method thereof

The invention relates to a low-cost and high-performance titanium alloy and a preparation method thereof. The alloy is a quaternary titanium alloy which is formed by taking titanium as a main body element and additionally adding three elements. The alloy comprises the following components in percentage by mass: 1-5% of Fe, 0.1-0.4% of O, 0.1-0.3% of B and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: adding the raw materials into a suspended smelting furnace of a cold crucible where argon is introduced in a designed alloy component proportion; repeatedly smelting for several times to obtain cast ingots; cogging and forging the cast ingots above the phase transformation point to form sheared billets; then rolling the sheared billet to form rods; thermally treating the sampled rods; and finally representing structure and performance of the rods. The preparation process is simple in method, and the prepared alloy is uniform in component. The tensile strength reaches over 950MPa, the ductility is not less than 15%, and the percentage reduction of area is not less than 25%. The basic mechanical property of the alloy is equivalent to that of Ti-6Al-4V but the cost has the advantage of over 15% compared with that of the Ti-6Al-4V. The alloy can replace part of titanium alloys which are relatively high in price in some fields.

Owner:NANJING UNIV OF TECH

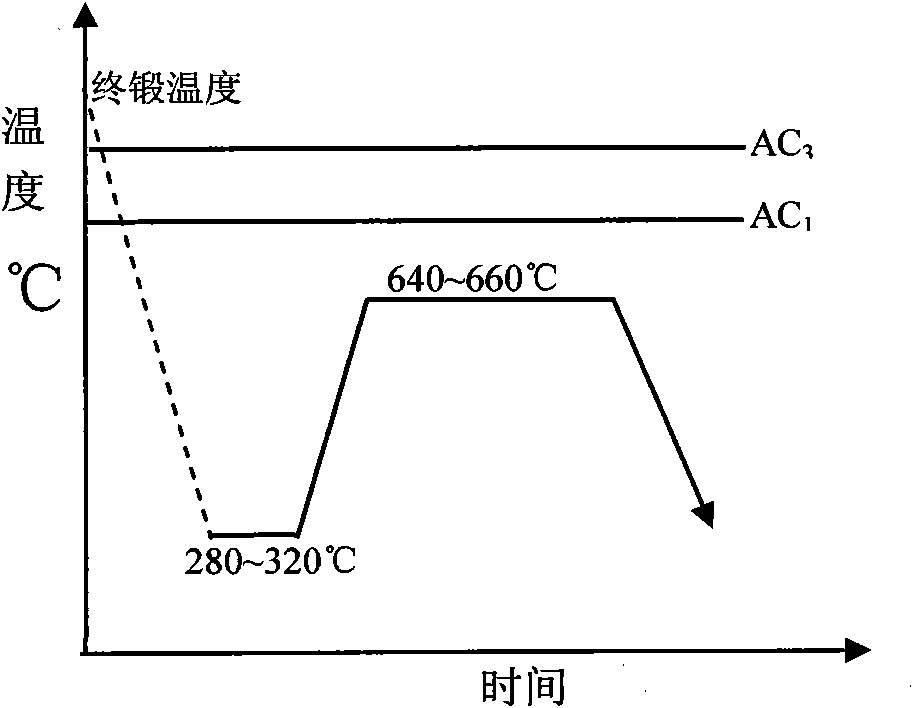

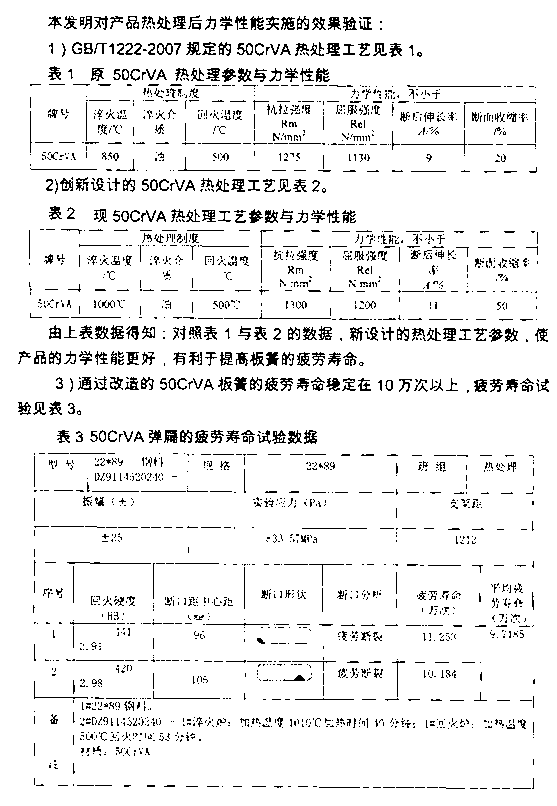

Technique for prolonging fatigue life of 50CrVA plate spring

ActiveCN103014533AGood deoxidation effectAvoid formingFurnace typesHeat treatment furnacesChemical compositionSlag

The invention provides a technique for prolonging the fatigue life of a 50CrVA plate spring. The technique includes the optimal design for the following chemical components of a 50CrVA flat spring steel: 0.49 to 0.53% of C, 0.20 to 0.30% of Si, 0.65 to 0.75% of Mn, 0.90 to 1.05% of Cr, 0.11 to 0.15% of V, 0.006 to 0.009% of Al, 0.018 to 0.020% of P, 0.016 to 0.020% of S, not greater than 0.25% of Ni, and not greater than 0.25% of Cu. The method for controlling and denaturating treatment on nonmetallic inclusion in steel comprises the following steps: (1) sealing a connector between a long nozzle of a large steel ladle and an intermediate submersed nozzle through an argon seal ring; controlling the amount of slag in tapping to 0 to 5kg / t; controlling the weight of the molten steel of the steel ladle to be not less than 7t; and controlling the molten steel level of a crystallizer to fluctuate within the scope of + / -2mm; and (2) carrying out denaturating treatment on inclusion; and adding SiCa wires at 2.1m / t through a wire feeder under a white slag condition, wherein the molten steel is at temperature of 1550 to 1580 DEG C; the parameters in heat treatment of the plate spring include quenching temperature of 1000 DEG C, tempering temperature of 500 DEG C, tensile strength of not less than 1300N / mm<2>, yield strength of not less than 1200N / mm<2>, percentage elongation after fracture of not less than 11%, and percentage reduction of area of not less than 50%.

Owner:XINJIANG BAYI IRON & STEEL

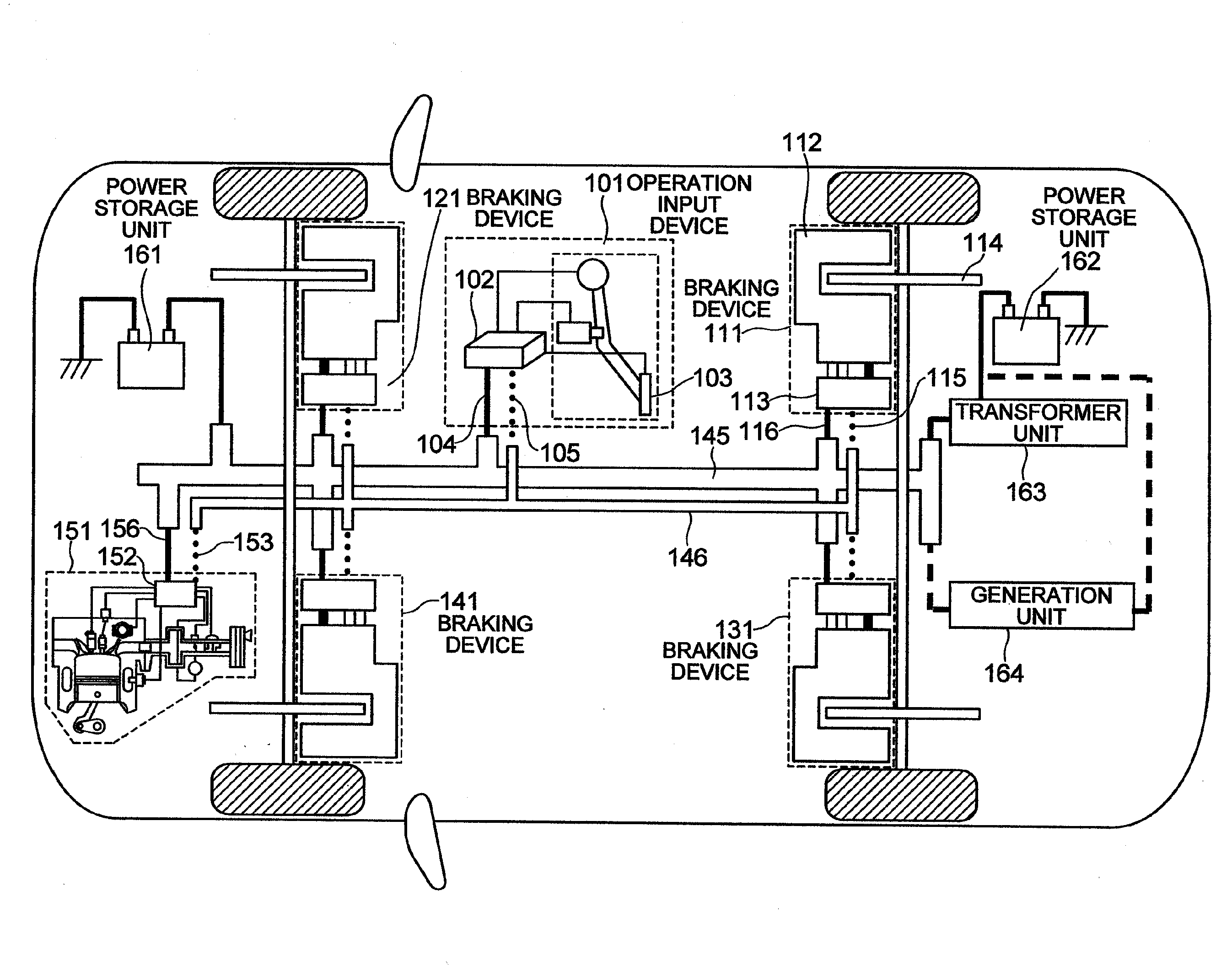

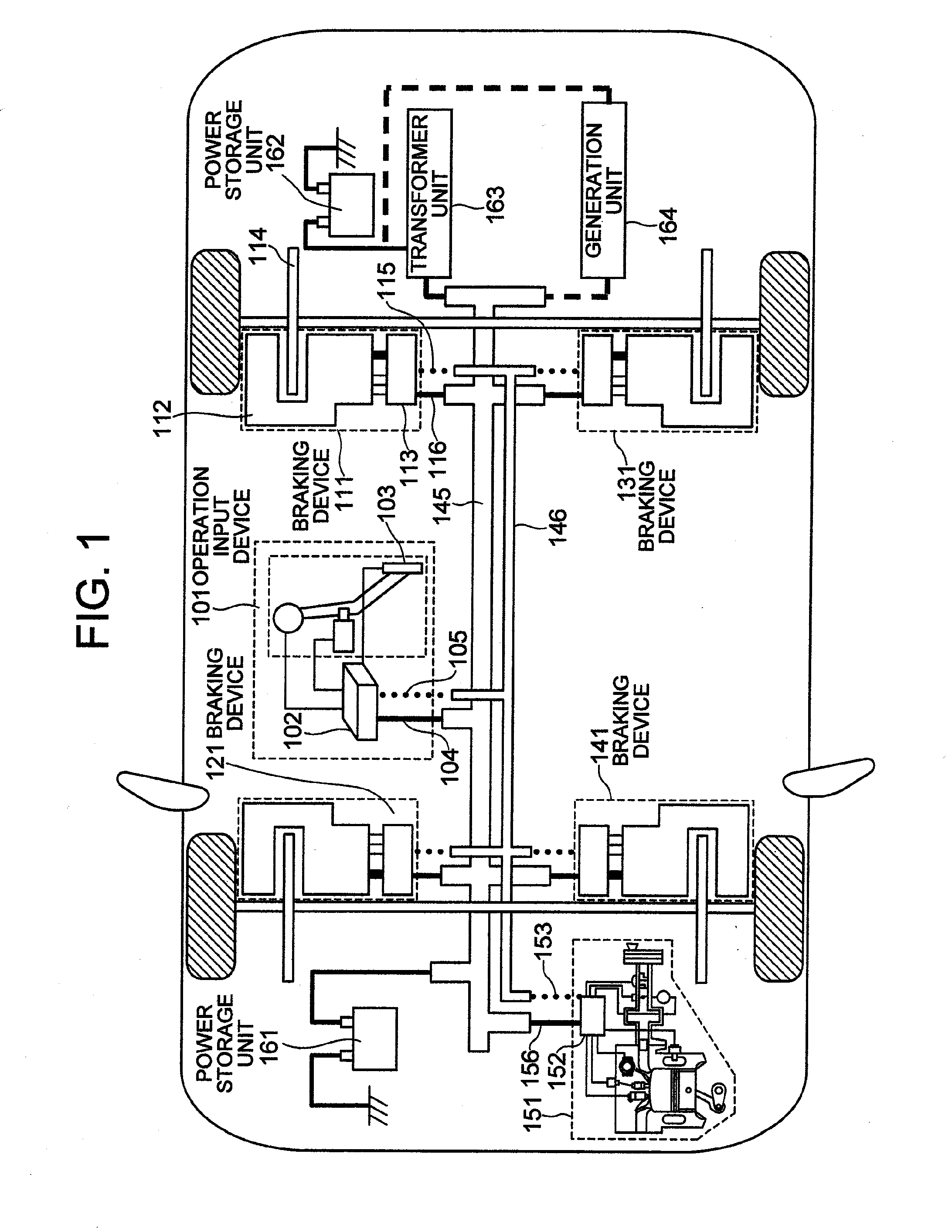

On-vehicle actuator system

InactiveUS20090026998A1Minimize the possibilityMotor/generator/converter stoppersAC motor controlPhase currentsEngineering

A motor is controlled to always consume power supplied from a power supply system or not to supply power to the power supply system, by performing control to advance or delay a phase of a 3-phase current flowing in the motor or to reduce a percentage of the generated torque with respect to an effective value of the 3-phase current of the motor, or by applying a d-axis current to the motor.

Owner:HITACHI LTD

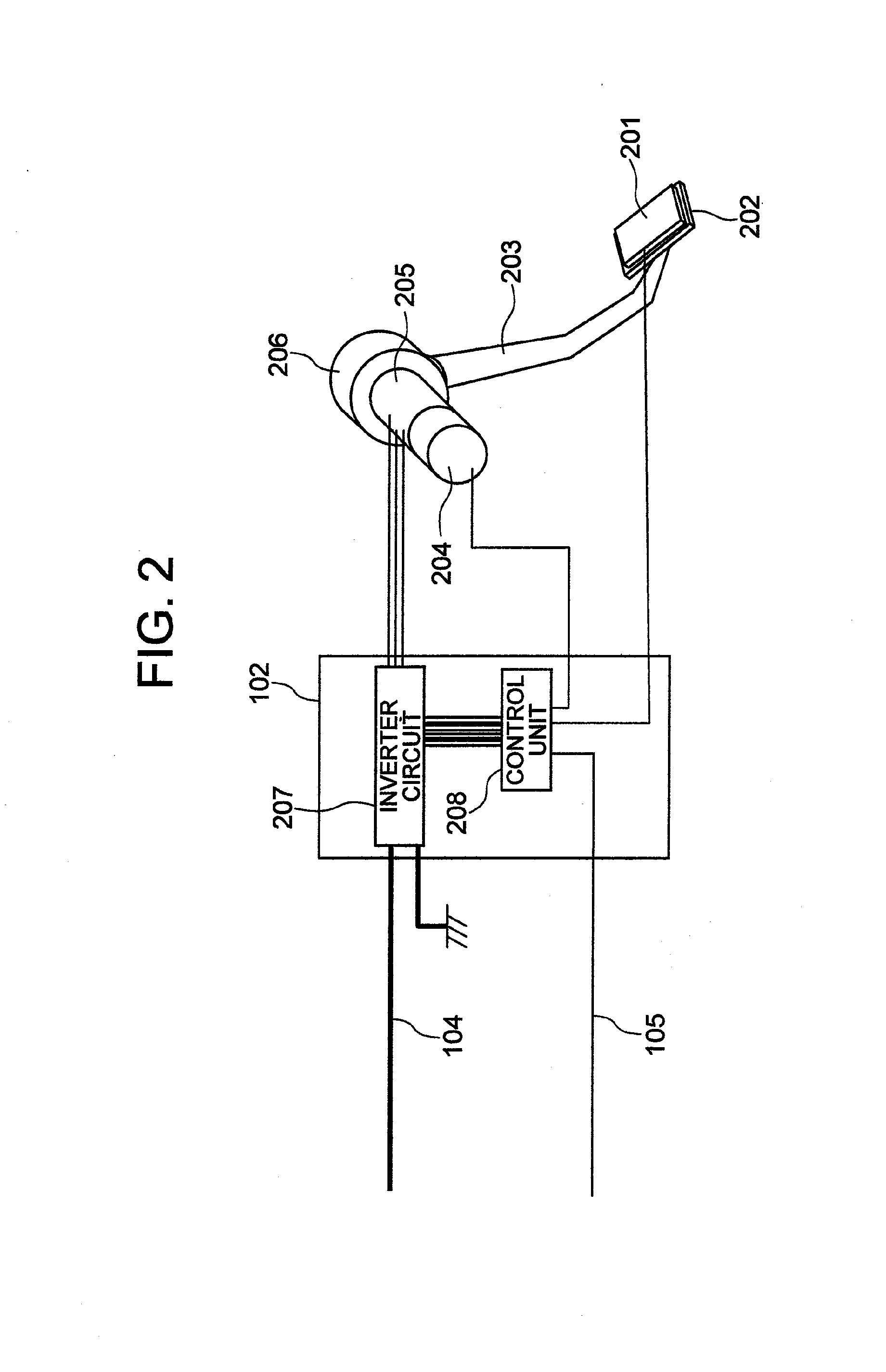

High-strength tough non-quenched and tempered steel suitable for compound forge forming

ActiveCN104593671AImprove mechanical propertiesAvoid difficulty in forgingYield ratioPercentage reduction

The invention discloses high-strength tough non-quenched and tempered steel suitable for compound forge forming. By means of a microalloying effect, the recrystalization temperature of non-quenched and tempered steel is increased, so that the steel is suitable for compound forge forming (hot forging+warm forging) and the strength and toughness of the non-quenched and tempered steel are improved. For the non-quenched and tempered steel after compound forge forming, the tensile strength of a forge Rm is greater than or equal to 900MPa, the yield strength Rp0.2 is greater than or equal to 750MPa, the yield ratio is greater than or equal to 0.85, the ductility A is greater than or equal to 17%, and the percentage reduction of area Z is greater than or equal to 50%. The forge can satisfy the performance requirement of high impact load, has the mechanical property which is comparable to quenched and tempered steel with same use and meanwhile has the advantages of shortening the process flow, saving the energy and lowering the cost.

Owner:NANJING INST OF TECH

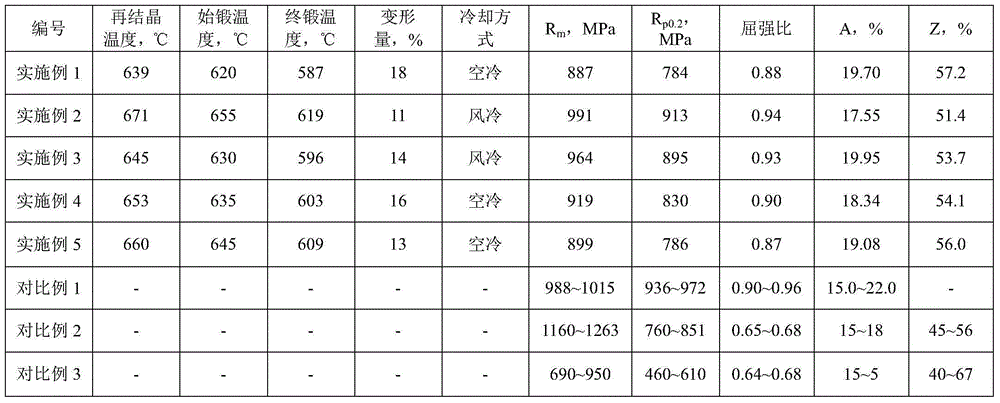

Control method for improving plasticity of bearing steel wire rod

The invention discloses a control method for improving the plasticity of a bearing steel wire rod, belonging to the control field of a steel rolling process of bearing steel. The method adopts processes of temperature control rolling, low-temperature finish rolling, two-stage alternate control water cooling, low-temperature spinning and air cooling control; the low-temperature finish rolling is performed at 820-850 DEG C in an austenite single-phase re-crystallization region so that 95% of net carbide-level small-specification net carbon of the original wire rod of bearing steel is reduced to below the level 1, the tensile strength is 1,180-1,460Mpa, and the percentage reduction of area is improved to 20-25%; 90% of the net carbon level of a large-specification wire rod is reduced to below the level 1.0, the tensile strength is 1,200-1,350Mpa, and the percentage reduction of area is improved to 15-20%. By adopting the method disclosed by the invention, the net carbide of bearing steel is reduced, the percentage reduction of area of the bearing steel is improved, the service life of the bearing steel wire rod can be prolonged, the wear resistance of the steel is enhanced, the probability of brittle failure of the bearing steel is remarkably reduced, and the product yield is improved.

Owner:SHOUGANG CORPORATION

Large-size 42 CrMo4 hardened and tempered steel manufacturing process for wind power gearbox outer main shaft

The invention discloses a tempered steel 42 CrMo4 manufacturing process for a wind power main shaft with the diameter not smaller than 450 mm, and the technical aims of high intensity, high tenacity and stable mechanical property of large and round tempered steel are achieved. According to the technical scheme, the manufacturing process is characterized in that (1) the process route includes operation through electric furnace + LF + VD, die casting, forging (through a 3500t high-speed forging machine), normalization and tempering; and (2) by optimizing the internal control ingredients, the mechanical property of the steel is guaranteed to be stable, intensified elements such as vanadium, niobium and nickel are added into smelting ingredients, and the steel intensity is improved; through pretreatment before tempering, normalizing is carried out the steel to homogenize the texture and refine grains, and the good impact toughness is obtained after tempering; and temper brittlement is avoided through air cooling of tempered furnace discharge steel. The tempered steel 42 CrMo4 manufacturing process has the beneficial effects that the stable and qualified mechanical property of the large and round tempered steel is achieved, the strength of extension (Rm) ranges from 760 MPa to 910 MPa, the yield strength (Re) is not smaller than 535 MPa, the percentage reduction of area (A) is not smaller than 15%, the impact absorbing energy (AkV) is not smaller than 38 J; and the impact toughness is improved.

Owner:FUSHUN SPECIAL STEEL SHARES

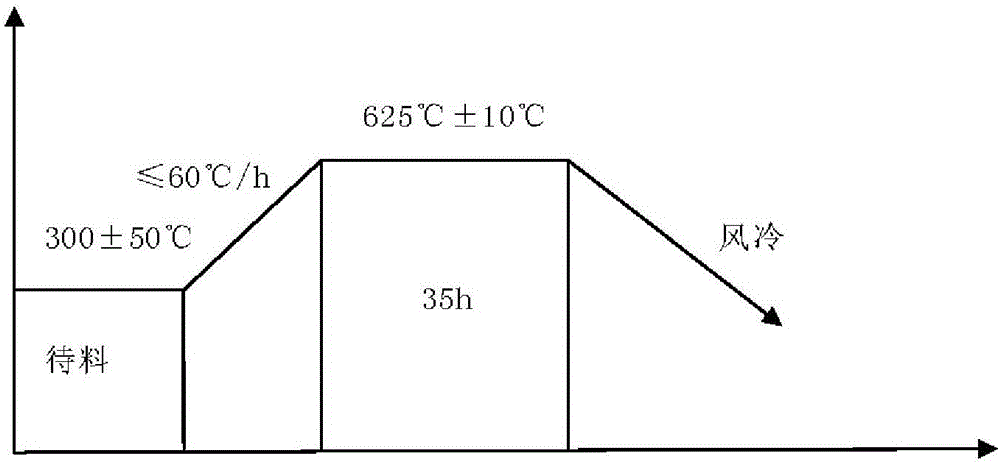

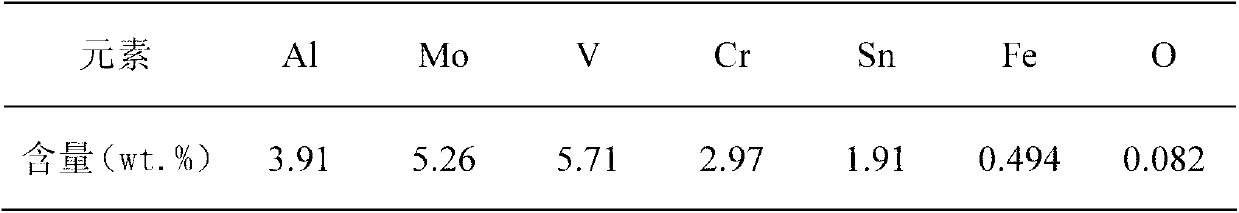

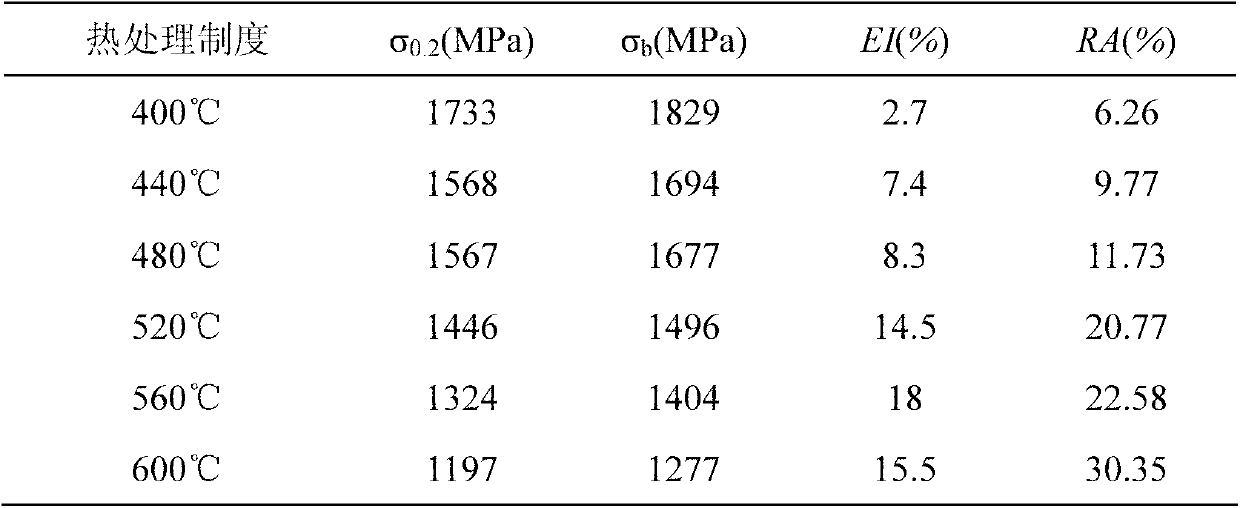

Ultrahigh-strength titanium alloy and preparation method thereof

The invention relates to an ultrahigh-strength titanium alloy and a preparation method thereof, and aims to solve the problem that the existing high-strength titanium alloy can not have high strength and high ductility simultaneously. The ultrahigh-strength titanium alloy comprises Al, Mo, V, Cr, Sn, Fe and the balance of Ti and inevitable impurities in certain percentage by weight. The preparation method comprises the following steps: 1, weighing all the components; 2, preparing a monoblock electrode; 3, preparing a consumable electrode; 4, preparing a cast ingot; 5, preparing a forging blank; and 6, performing upsetting and finish-forging to obtain the ultrahigh-strength titanium alloy. According to the invention, after the ultrahigh-strength titanium alloy is subjected to solid solution and aging, the strength and ductility can be as follows: the tensile strength is up to 1496 MPa, the elongation percentage is 14.5%, and the percentage reduction in area is 20.77%. The invention can be used for preparation of the ultrahigh-strength titanium alloy.

Owner:HARBIN INST OF TECH

Manufacturing process for yaw gear ring for wind generating set

The invention discloses a manufacturing process for a yaw gear ring for a wind generating set. The manufacturing process comprises the steps of raw material smelting, blanking, heating before forging,blank making, ring rolling, normalizing, rough turning, thermal refining, semi-finish turning, distressing treatment, gear milling, gear surface hardening and tempering, finish turning, non-working surface corrosion preventing and working face surface protection. The yaw gear ring manufactured through the manufacturing process can meet the following technical requirements: the strength of extension Rm (MPa) is 750-900, the yield strength Rp 0.2 (MPa) is larger than or equal to 500, the ductility A (%) is larger than or equal to 14, the percentage reduction of area Z (%) is larger than or equal to 55, the hardness HB is 228-270, and the ballistic work (J) is larger than or equal to 35. Nonmetallic inclusion of a forge piece meets the following requirements that A: the thick series is smaller than or equal to 1.0, and the thin series is smaller than or equal to 1.5; B: the thick series is smaller than or equal to 1.0, and the thin series is smaller than or equal to 1.5; C, the thick series is smaller than or equal to 1.0, and the thin series is smaller than or equal to 1.0; D: the thick series is smaller than or equal to 1.0, and the thin series is smaller than or equal to 1.5; andDS is smaller than or equal to 1.5. The macrostructure flaw level of the forge piece meets the following requirements: the general porosity is smaller than or equal to second level, the center porosity is smaller than or equal to second level, and segregation is smaller than or equal to second level.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

Qualification system and method for chilled water plant operations

ActiveUS20110022241A1Accurately determineReduced data setMechanical power/torque controlLevel controlChilled waterPercentage reduction

A qualification system for determining the effects of one or more upgrades or modifications to a chilled water plant is disclosed herein. The qualification system my collect various data from operating logs of a chilled water plant. The data may be collected in stages, where at least one first stage may be used to collect data used to identify representative log data. The representative log data may then be used to perform an accurate analysis to determine the effects of one or more upgrades or modifications. In this manner, the qualification system provides accurate analysis while reducing data entry. In addition, the qualification system may accept varying amounts of data such as to reduce percentage error or the like in its analysis.

Owner:SIEMENS IND INC

Hot die forging forming method for titanium material cartridge shape cover

The invention belongs to a hot die forging forming method for a titanium material cartridge shape cover. The method includes the following steps that firstly, a column-shaped blank material is subjected to heat preservation for 1-2 h at 850-950 DEG C, and is placed into a preheated prefabricated mold, and the column-shaped blank material is subjected to heading forming on a hydraulic machine to form a prefabricated blank; secondly, the prefabricated blank is taken out of the prefabricated mold and placed into a preheated final forging die, and is forged on the hydraulic machine into a cartridge shape cover forged piece; and thirdly, the cartridge shape cover forged piece is subjected to annealing treatment for 0.25-1.25 h under 500-700 DEG C. The grain size of the forged piece is larger than 6.5, the elongation percentage A (%) is larger than 26%, and the percentage reduction of area Z (%) is larger than 60%.

Owner:ZHENGZHOU UNIV

Ultra-thick alloy steel sheet with excellent low-temperature toughness and preparation method thereof

ActiveCN109112423AImprove low temperature toughnessImprove internal qualitySheet steelPercentage reduction

The invention relates to an ultra-thick alloy steel sheet with excellent low-temperature toughness. The ultra-thick alloy steel sheet is characterized in that a continuous casting blank subjected to annealing is used as a base blank to complete three-blank compounding; the thickness of the compounded blank is greater than 900mm; the procedures of vacuum electronic beam welding, compounded blank heating, rolling, and quenching-tempering heat treatment are performed, so as to produce the ultra-thick alloy steel sheet with thickness of 210mm for a pressure container. A manufacturing method of theultra-thick alloy steel sheet has the advantages that the process is short, the technology is simple, the finished rate is high, the cost is low, the production cycle is short, the efficiency is high, and the like. The mechanical properties of the produced ultra-thick alloy steel sheet can meet the requirements that the unit value of core transverse impact is greater than or equal to 200J; the percentage reduction of area along a thickness direction is greater than or equal to 60%; the ultrasonic flaw detection of the steel sheet can meet the highest level requirement of NB / T47013.3.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method of varying the ink density of the full tone in offset printing within a rotoary printing machine

InactiveUS20020152911A1Improve area coverageCylinder pressesDigitally marking record carriersGratingEngineering

A method of varying the ink density of the full tone in printing within a rotary printing machine with an ink application system which can provide a constant quantity of ink which, in spite of constant ink supply from the inking unit, permits control of the full-tone density or adaptation of the raster tonal values in the print. The method includes setting the binary image on a printing plate. A basic raster of raster points, which determines the area coverage of the binary image, is produced on the printing plate for the variable-area image information. The basic raster is then superimposed on a fine microraster in such way that the area coverage of the basic raster is reduced by a percentage which can be set between 0% and 100%.

Owner:MANROLANAD AG

Alloy nodular cast iron roll

InactiveCN103320676AImprovement ingredientsImprove flexural strengthRollsMetal rolling arrangementsAlloyPercentage reduction

The invention discloses an alloy nodular cast iron roll which comprises the following components in percentage by mass: 3.6-3.8 percent of C, 1.7-2.0 percent of Si, 0.6-0.7 percent of Mn, less than 0.025 percent of P, less than 0.02 percent of S, 0.1-0.3 percent of Cr, 1.5-2.0 percent of Ni, 0.4-0.6 percent of Mo, 0.04-0.06 percent of Mg and the balance of Fe and inevitable impurities. Due to the mode, according to the alloy nodular cast iron roll, the bending strength, impact toughness, deflection, percentage reduction of area, percentage elongation after fracture and yield of the roll can be improved.

Owner:WUXI CAIYUN MACHINERY & EQUIP

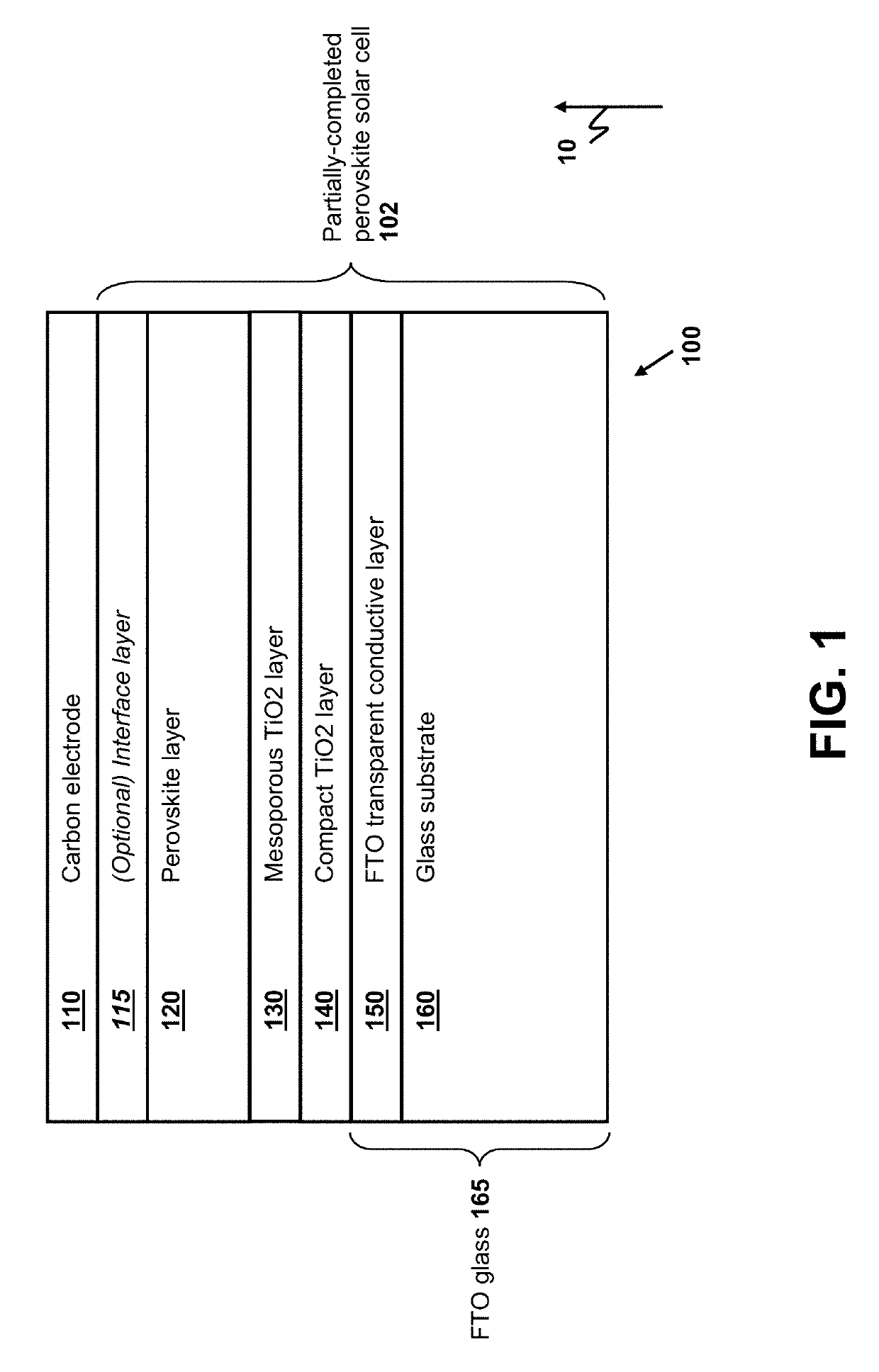

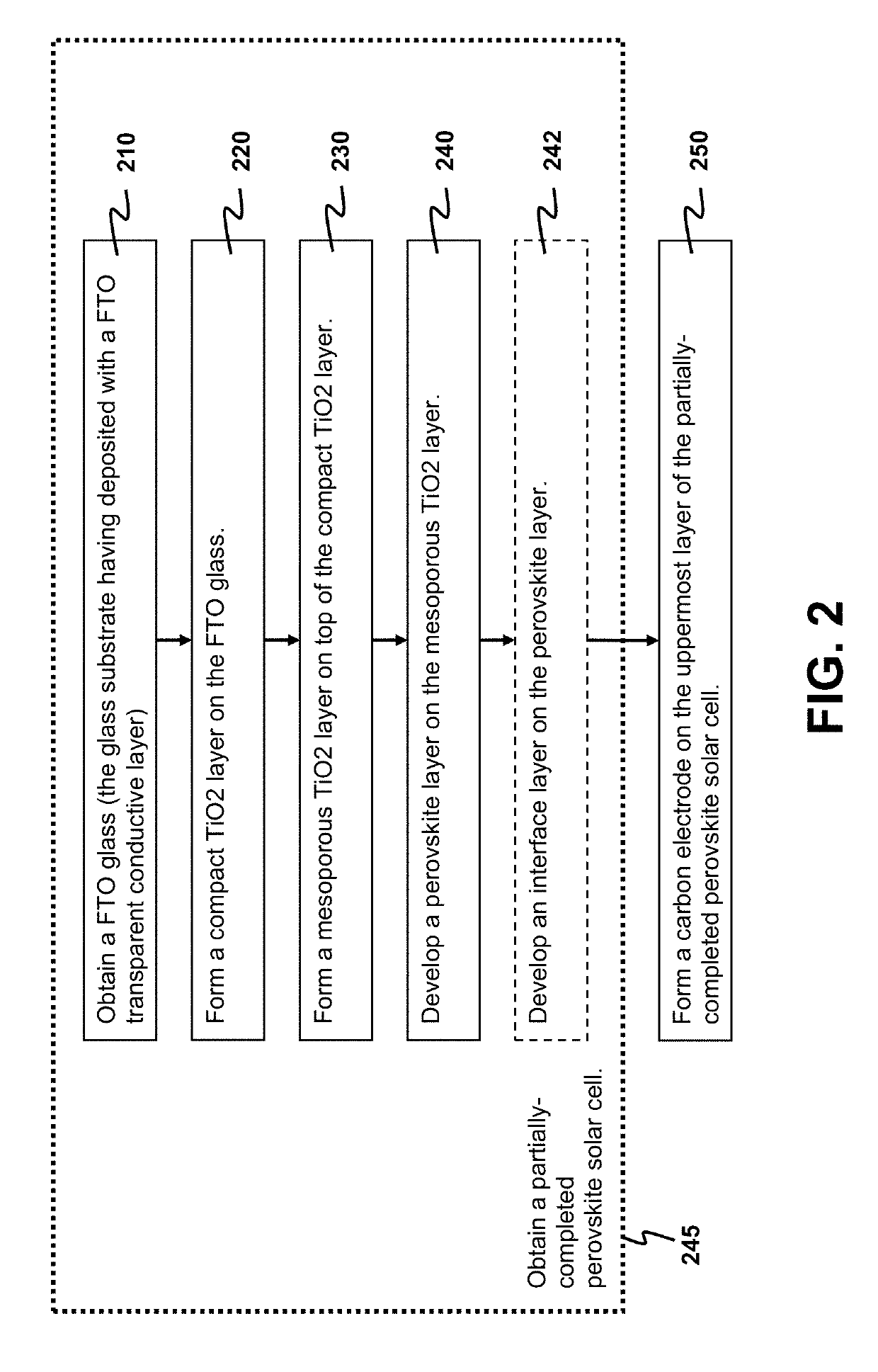

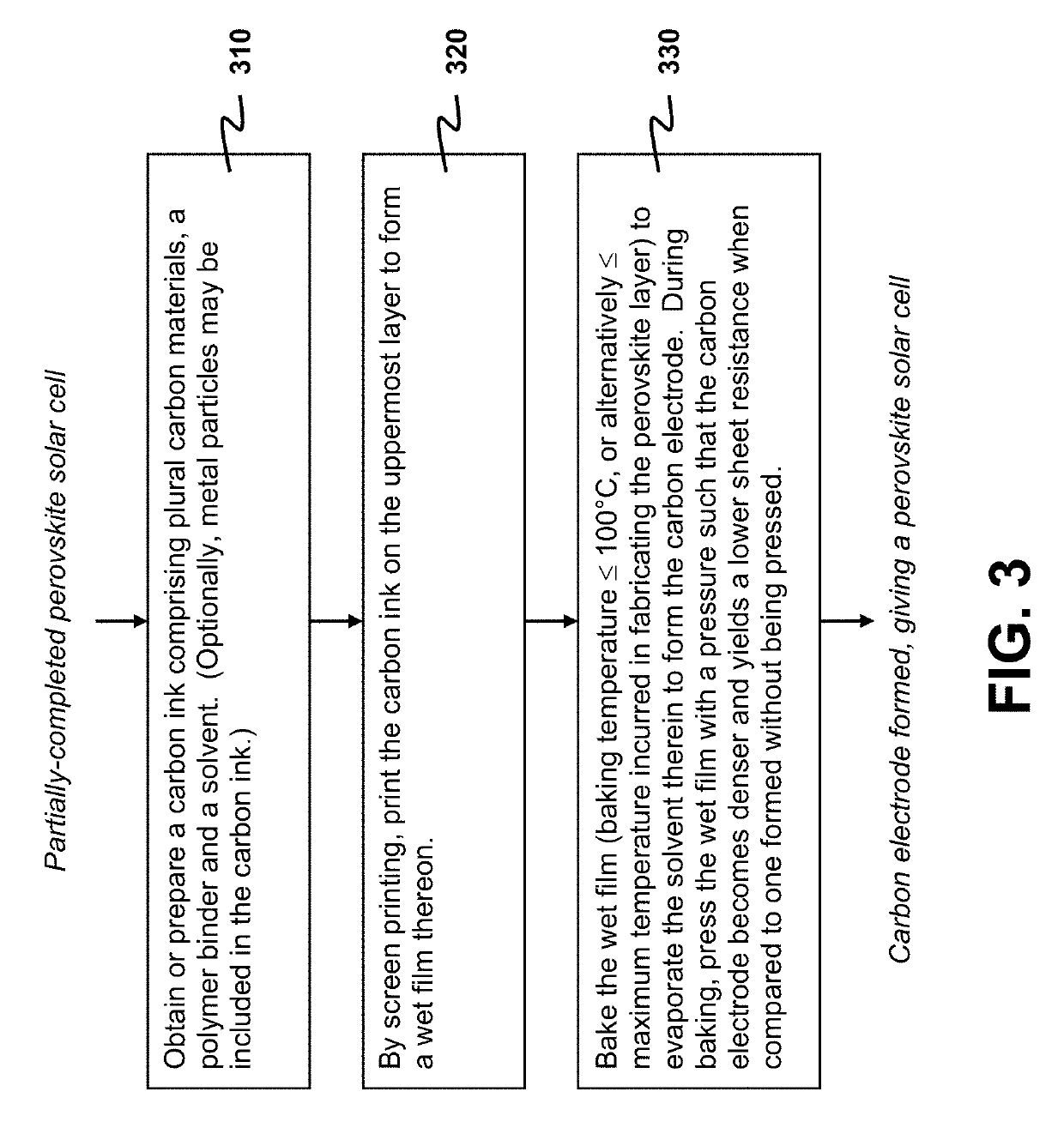

Method for forming perovskite solar cell with printable carbon electrode

InactiveUS10290432B1Reduce sheet resistanceLight-sensitive devicesFinal product manufactureElectrical resistance and conductancePerovskite solar cell

To fabricate a perovskite solar cell (PSC), a printable carbon electrode is formed on an uppermost layer, either a perovskite layer or an interface layer thereon, of a partially-completed PSC. A carbon ink is first prepared by dispersing carbon materials in a mixture of a polymer binder and a solvent. Then the carbon ink is screen-printed on the uppermost layer to form a wet film thereon. The wet film is baked with a baking temperature not exceeding 100° C. to evaporate the solvent to form the carbon electrode. Advantageously, the wet film is pressed with a pressure during baking such that the carbon electrode becomes denser and yields a lower sheet resistance when compared to one formed without being pressed. Preferably the pressure is at least 16,000 Pa. Experimental results show that the percentage reduction of sheet resistance can reach 40%.

Owner:NANO & ADVANCED MATERIALS INST

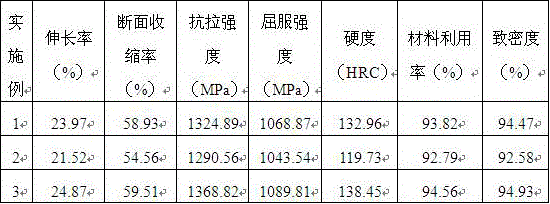

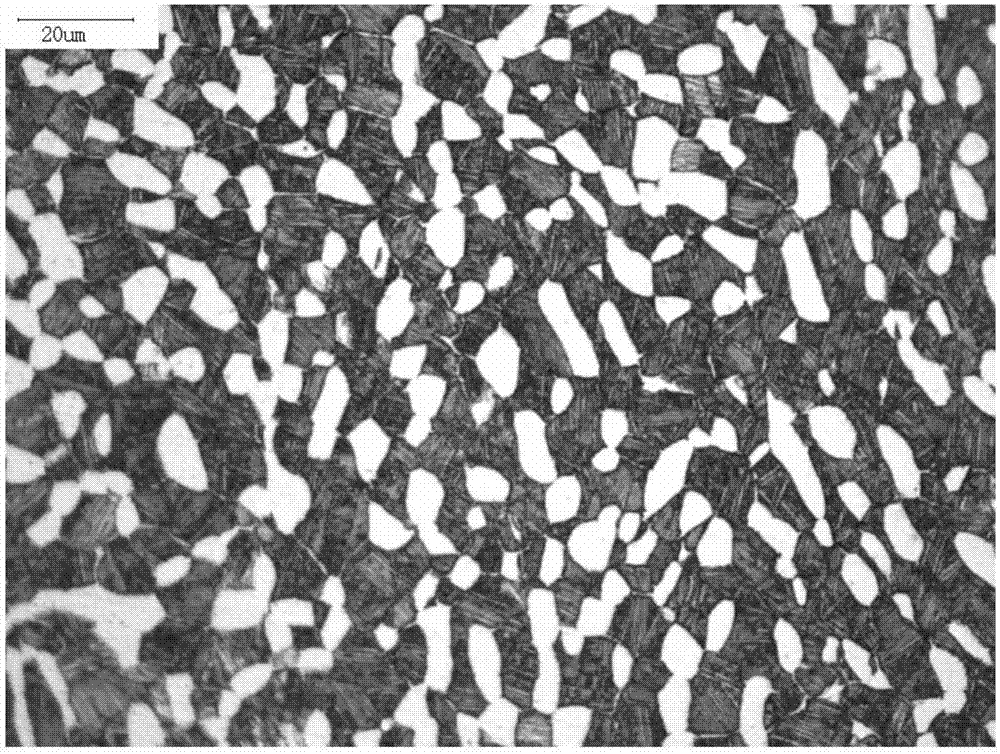

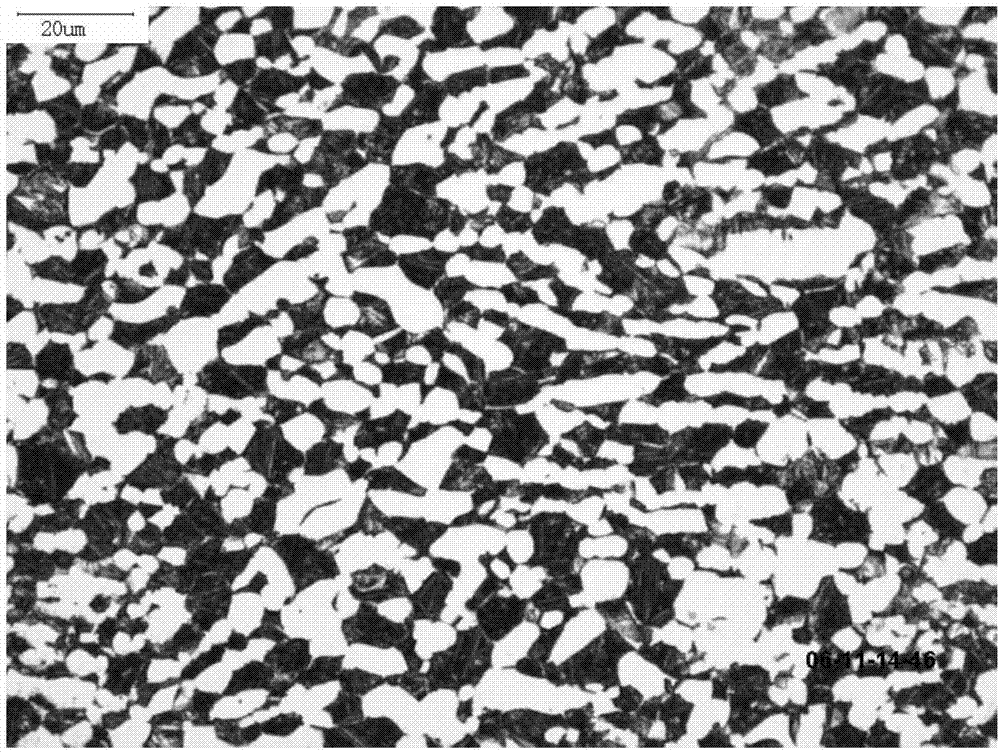

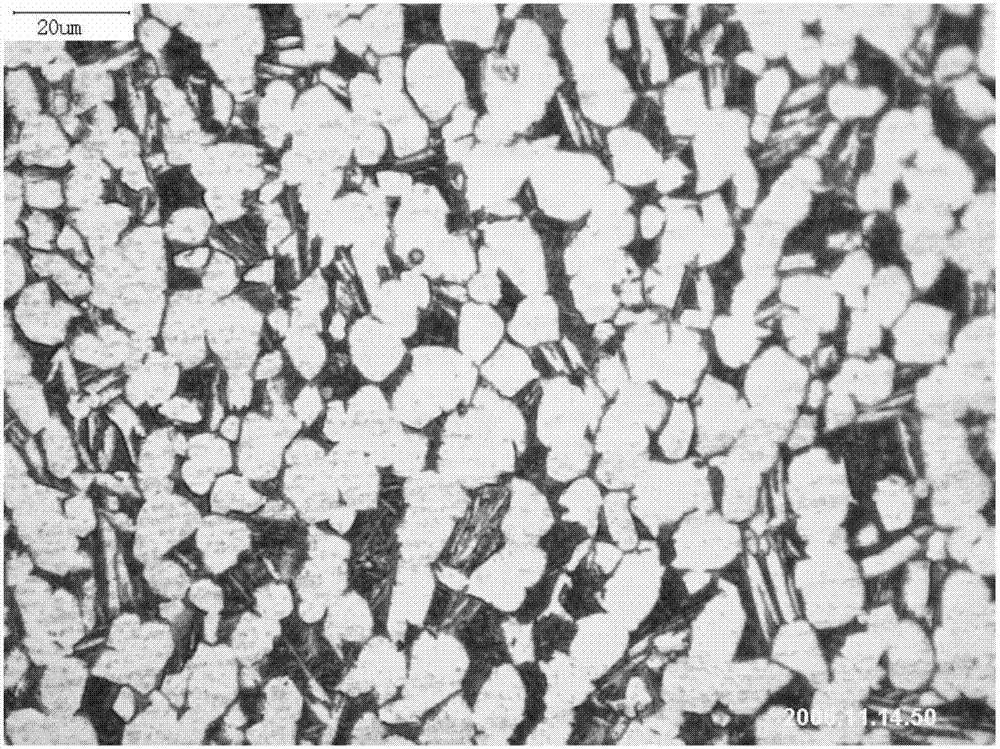

High-wear-resistance automobile shaft component powder metallurgy material

InactiveCN106270495AImprove performanceHigh densityTransportation and packagingMetal-working apparatusPolyvinyl chlorideTitanium carbide

The invention discloses a high-wear-resistance automobile shaft component powder metallurgy material. The high-wear-resistance automobile shaft component powder metallurgy material comprises the following raw materials: iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, alumina powder, graphene powder, tetramethylolmethane, stearic acid, polyvinyl chloride fiber, basalt fibers, ethylene glycol monoethyl ether acetate, hypromellose, ethylene bisstearamide, chlorinated paraffin, glycidoxypropyl trimethoxysilane, silicon carbide, manganous sulphide, alcohol acid resin, an inhibitor, a binding agent, a reinforcing agent, a cutting agent, a lubricant, a cross-linking agent, a dispersant and a regulator. By the specific ingredient proportion, the high-wear-resistance automobile shaft component powder metallurgy material is uniform in integral density, high in compactness, high in extend rate and percentage reduction of area, good in wear resistance, strength and hardness and high in material utilization rate, and is suitable for quickly producing the high-performance automobile shaft component powder metallurgy material on a large scale.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

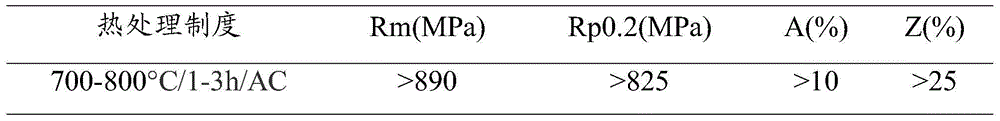

Moderate intensity titanium alloy and preparing method thereof

The invention relates to a moderate intensity titanium alloy and a preparing method thereof. The moderate intensity titanium alloy comprises chemical components, by mass percent, 3.5%-4.5% of Al, 2.5%-3.5% of V, 0.5%-1.5% of Mo, 1.0%-2.0% of Fe, not larger than 0.10% of C, not larger than 0.15% of O, not larger than 0.05% of N, not larger than 0.0125% of H and the balance Ti and unavoidable impurities. According to the moderate intensity titanium alloy prepared through the method, the tensile strength Rm is larger than or equal to 895 MPa, the yield strength Rp0.2 is larger than or equal to 825 MPa, the ductility A is larger than or equal to 10%, the percentage reduction Z of the area is larger than or equal to 25%, and the ballistic work AKV is larger than or equal to 50 J. The strength and the plasticity of the titanium alloy are equal to those of a TC4 alloy, the impact toughness is greatly improved, and the moderate intensity titanium alloy can be applied to the working conditionswith high impact requirements.

Owner:宝武特种冶金有限公司

High-performance heat resistant steel, and preparation method and application thereof

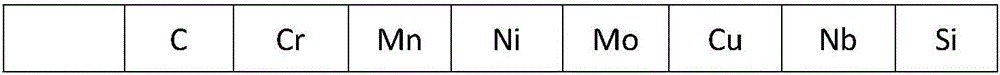

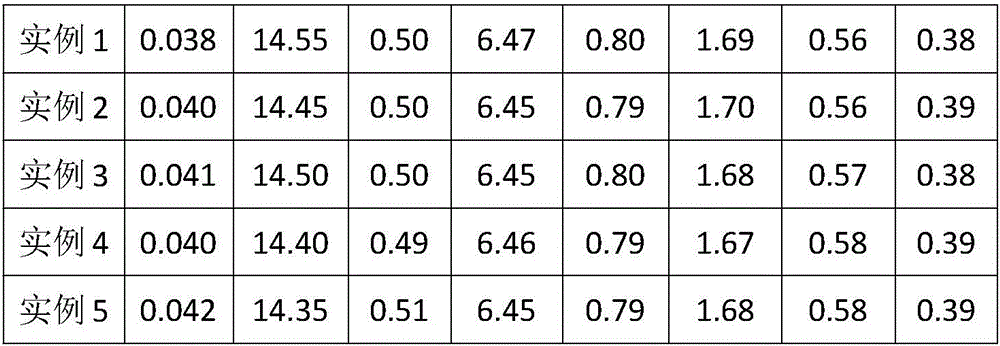

InactiveCN105886949AImprove high temperature resistanceImprove mechanical propertiesPump componentsPumpsRoom temperatureSuperalloy

The invention discloses high-performance heat resistant steel, and belongs to the technical field of high-temperature alloy materials. The high-performance heat resistant steel is composed of, by weight percentage, 0.03-0.05% of C, 14.0-16.0% of Cr, 0.60-1.00% of Mo, 6.20-6.80% of Ni, 1.35-1.75% of Cu, 0.30-0.80% of Mn, 0.24-0.75% of Nb, 0.20-0.50% of Si, and the balance Fe. The invention further discloses a preparation method and application of the high-performance heat resistant steel. The high-performance heat resistant steel has excellent high temperature resistance and mechanical properties. According to the mechanical properties at the room temperature of 25 DEG C, the tensile strength Rm at the room temperature tensile test is greater than or equal to 1245 Mpa, the yield strength RP0.2 is greater than or equal to 1030 N / mm<2>, the elongation A is greater than or equal to 13.5%, the percentage reduction of area Z is greater than or equal to 58%, the impact energy AKv is greater than or equal to 94 J, and the hardness HB is greater than or equal to 393.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com