High-performance heat resistant steel, and preparation method and application thereof

A heat-resistant steel, high-performance technology, used in mechanical equipment, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve incompetent, incompetent titanium alloy oxidation resistance and flame retardancy, etc. problems, to achieve excellent high temperature resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

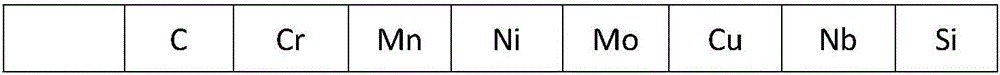

[0037] Alloy materials were prepared by using elements with different contents. A total of 5 different formulations were used. The composition of each element is shown in Table 1, and in Table 1, all are mass percentage values.

[0038] The composition of various elements in the embodiment 1-5 of table 1

[0039]

[0040]

[0041] Preparation:

[0042] (1) Get required chemical element according to Table 1, smelt in non-vacuum induction furnace, regulate the content of chemical element in the smelting process, make its percentage by weight as Table 1:

[0043] And control the content of impurity elements as low as possible, after AOD refining, cast into self-consumable electrodes;

[0044] (2) Remelt and refine the consumable electrode in an electroslag furnace to further reduce the content of impurity elements so that it meets the following requirements:

[0045] S≤0.005(weight percent) P≤0.020(weight percent)

[0046] N≤0.030(weight percent) V≤0.10(weight percent) ...

Embodiment 6

[0054] Material Performance Testing

[0055] Sampling on the finished steel bars to check the mechanical properties, and carry out corresponding mechanical property tests;

[0056] The heat treatment steps and process parameters of the sample are as follows:

[0057] 1), Nb / C=13~15

[0058] Solution treatment: 1038±5°C for 40-180 minutes Cooling method: oil cooling or medium cooling with a cooling rate equivalent to oil cooling;

[0059] Aging treatment: 515±5℃ for 8-10 hours Cooling method: air cooling.

[0060] 2), Nb / C=9~12

[0061] Solution treatment: 1038±5°C for 40-180 minutes Cooling method: oil cooling or medium cooling with a cooling rate equivalent to oil cooling;

[0062] Aging treatment: 500±5℃ for 8-10 hours Cooling method: air cooling.

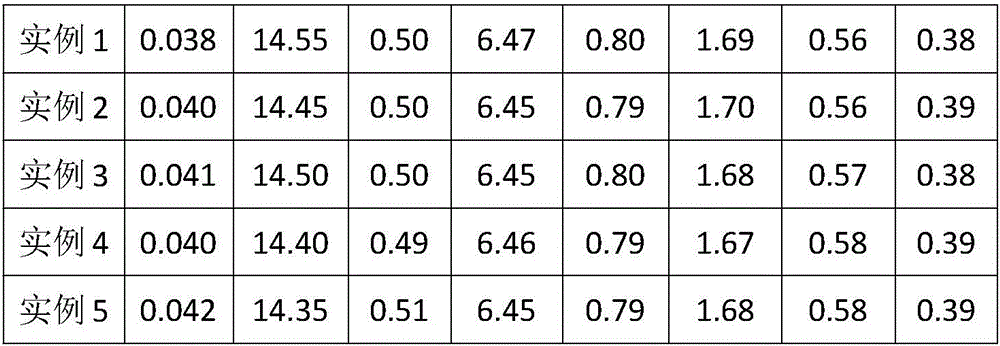

[0063] The finished steel bar made by embodiment 1-5 is carried out performance test

[0064] The tensile test at room temperature shows that its mechanical properties fully meet the design requirements. The test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com