Process for producing precooked bacon slices

a technology of precooked bacon and bacon, which is applied in the field of continuously cooking bacon slices, can solve the problems of not being able to provide precooked bacon products having the same texture, taste, color, appearance, and bite, and the bacon cooking process has been used in the industry. , to achieve the effect of eliminating or reducing the footprin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

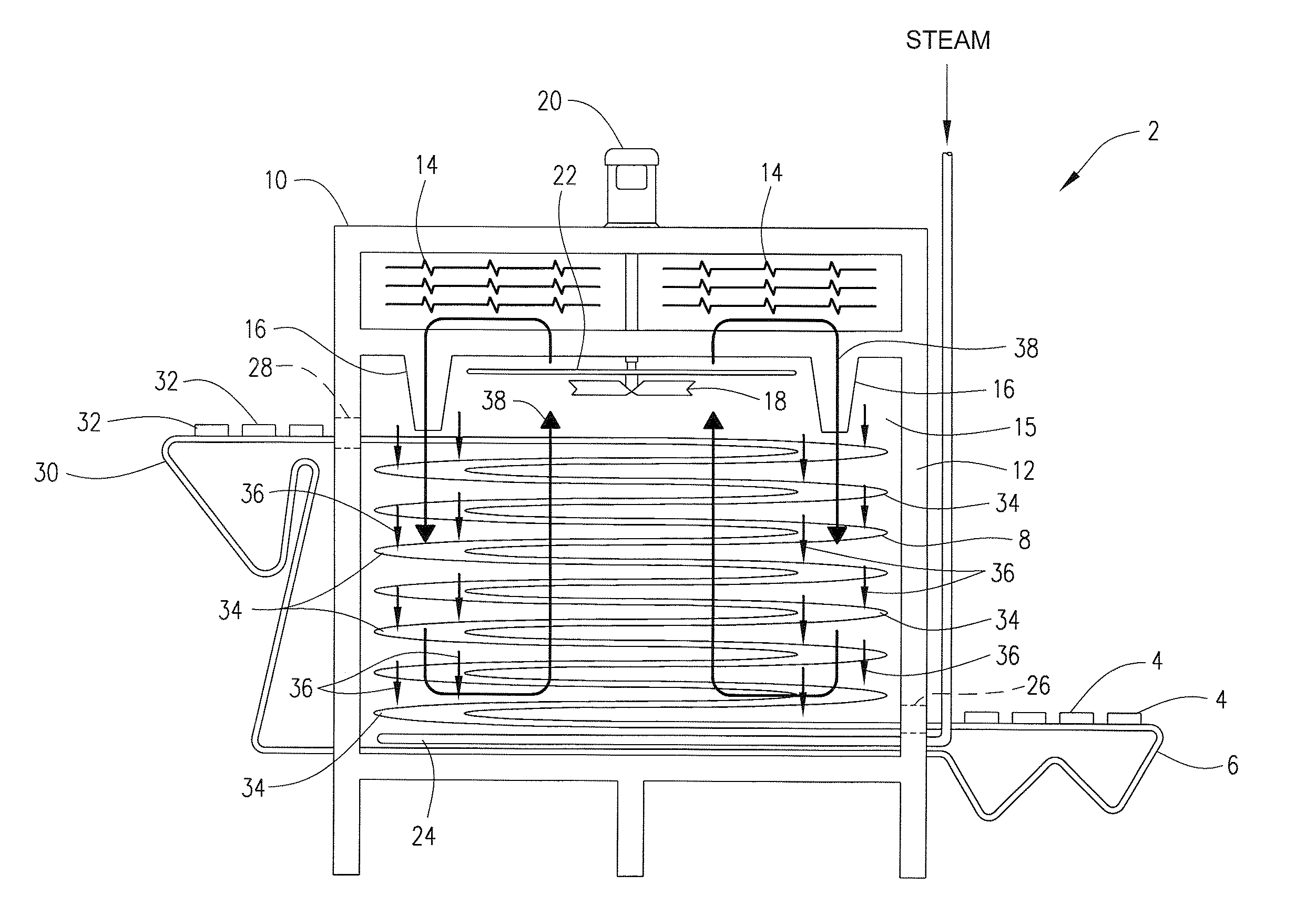

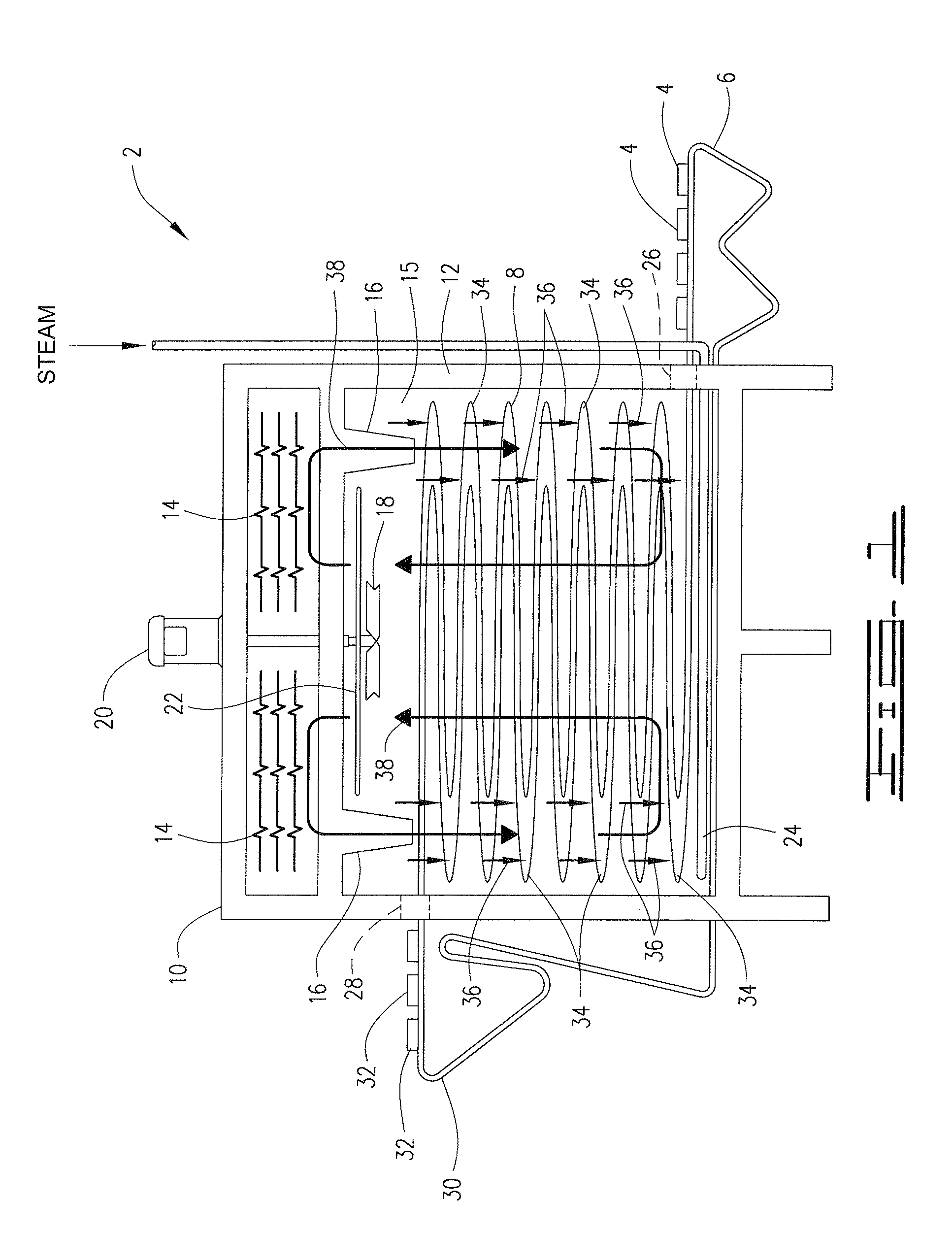

[0037]A Grote Slicer is used to cut bacon slices directly onto the conveyor infeed section 6 of a Unitherm Electric Spiral Oven 10 of the type illustrated in the drawing. The bacon slices are each two inches wide, 10 inches in length, and have a thickness of about 3 mm. The bacon slices have an initial surface temperature of −6° C. The belt 8 of the spiral oven 2 is an open wire mesh belt which is 36 inches wide and which receives and conveys the raw bacon slices in a three lane arrangement across the belt at a total rate of 900 raw slices per minute. This is equivalent to a total feed rate of 5400 pounds per hour of raw sliced bacon.

[0038]The oven 10 utilizes finned electrical elements 14 which are operated to provide an average cooking medium temperature within the cooking chamber 15 of 425° F. The cooking medium within the oven cooking chamber 15 is monitored using a Vaisala dry cup dew point analyzer. An analyzer value of 24% for the cooking medium is maintained by the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com