Large-size 42 CrMo4 hardened and tempered steel manufacturing process for wind power gearbox outer main shaft

A manufacturing process and speed-increasing box technology, which is applied in the production field of large-scale 42CrMo4 quenched and tempered steel, can solve the problems that the production technology process is difficult to meet the technical requirements, achieve stable and qualified mechanical properties, solve the problem of impact toughness, and refine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, embodiment 2, embodiment 3 adopt the same technological process:

[0038] Electric furnace+LF+VD→die casting→forging (3500t fast forging machine)→normalizing treatment→quenching and tempering;

[0039] Example 1

[0040] Heat number: 16203011728, finished round steel specification Φ500mm

[0041] 1. Production process

[0042] ⑴Steelmaking process

[0043] ①The chemical composition of the finished product is shown in Table 4.

[0044] Table 4

[0045]

[0046] ⑵ forging process

[0047] Hold at 1210°C for 7h, press the clamp handle, upsetting, return to the furnace after upsetting, hold at 1180°C for 4h, draw out and elongate, the final forging temperature is 870°C, and the finished product is dehydrogenated and annealed after forging.

[0048] ⑶ normalizing process

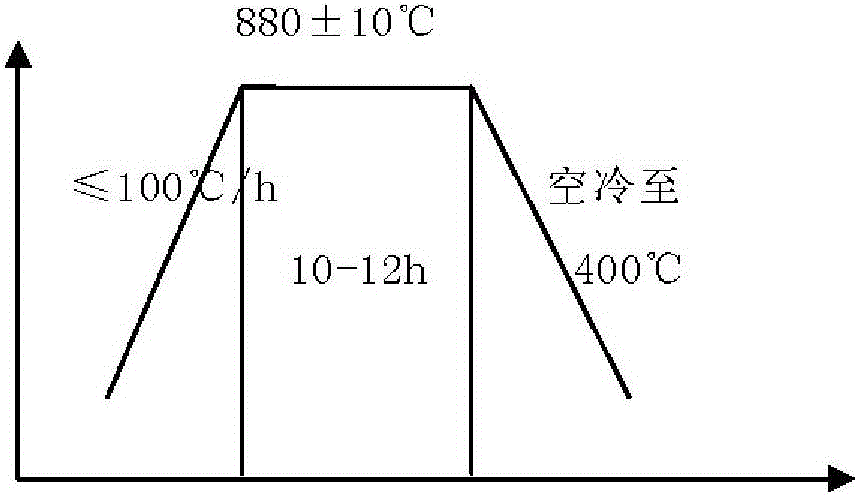

[0049] like figure 1 As shown in the figure, the temperature was raised to 880°C for 11 hours at a rate of no more than 100°C / h, and then the steel was air-cooled to below 400°C. ...

Embodiment 2

[0061] Heat number: 16203021229, the finished round steel specification is Φ500mm.

[0062] 1. Production process

[0063] ⑴Steelmaking process

[0064] The chemical composition of the finished product is shown in Table 7.

[0065] Table 7

[0066]

[0067] ⑵ forging process

[0068] Hold at 1220°C for 5h, press the clamp handle, upsetting, return to the furnace after upsetting, hold at 1190°C for 4h, draw out and elongate, the final forging temperature is 860°C, and the finished product is dehydrogenated and annealed after forging.

[0069] ⑶ normalizing process

[0070] like figure 1 As shown in the figure, the temperature is raised to 885°C at a rate of no more than 100°C / h for 11 hours, and then the steel is released from the furnace and air-cooled to below 400°C.

[0071] ⑷ Quenching and tempering process

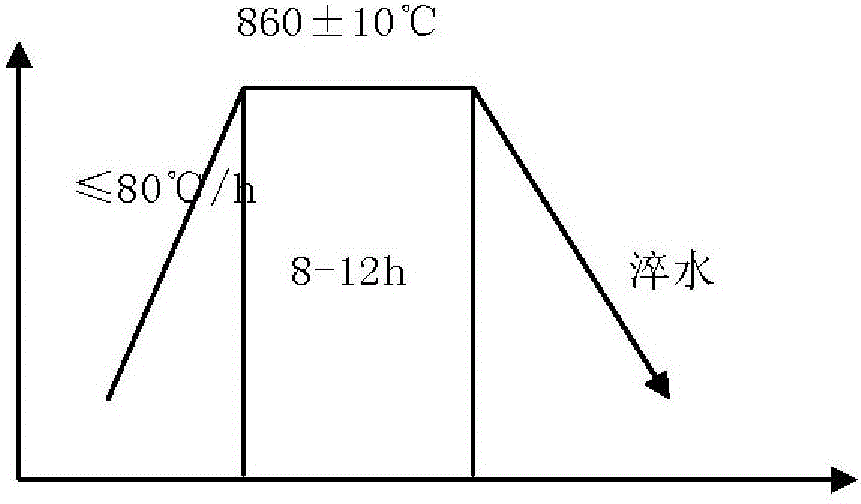

[0072] like figure 2 As shown in the figure, the temperature is raised to 858°C at a rate of not more than 80°C / h, and the temperature is kept for 8 hours...

Embodiment 3

[0082] Heat number: 16203011366, the finished round steel specification is Φ500mm.

[0083] 1. Production process

[0084] ⑴Steelmaking process

[0085] The composition of the finished product is shown in Table 10.

[0086] Table 10

[0087]

[0088] ⑵ forging process

[0089] Hold at 1200°C for 8h, press the clamp handle, upsetting, return to the furnace after upsetting, hold at 1180°C for 5h, draw out and elongate, the final forging temperature is 880°C, and the finished product is dehydrogenated and annealed after forging.

[0090] ⑶ normalizing process

[0091] like figure 1 As shown in the figure, the temperature was raised to 878°C for 10h at a rate of not more than 100°C / h, and then the steel was air-cooled to below 400°C.

[0092] ⑷ Quenching and tempering process

[0093] like figure 2 As shown in the figure, the temperature is raised to 852°C at a rate of no more than 80°C / h, and the temperature is kept for 12 hours. The time interval between the quenchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com