Control method for improving plasticity of bearing steel wire rod

A control method and technology of bearing steel, which is applied in the field of bearing steel rolling process control, can solve the problems of unmentioned plasticity index and high capacity requirements, and achieve the effect of improving comprehensive mechanical properties, improving comprehensive properties, and uniform and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The specification of the original wire rod of bearing steel is Φ6.5mm

[0018] Rolling process: the heating temperature of the heating furnace is 1140°C, the rolling start temperature is 1020°C, the first four passes of the rough rolling adopt head-off tension-free rolling, the inlet temperature of the rolling mill after head-off is 970°C, the inlet temperature of the pre-finishing mill is 950°C, the pre-finishing The cooling speed of the water cooling section between the rolling and finishing mills is 30°C / s, the finishing rolling temperature is 850°C, the cooling speed of the water cooling section after finishing rolling is 100°C / s, the spinning temperature is 800°C, and the opening of the first fan is 30% , Open the fifth insulation cover to the 18th insulation cover, and pack the rolls into the warehouse at a temperature below 440°C.

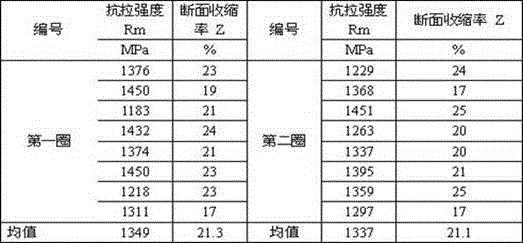

[0019] The test samples produced by this controlled cooling process took five metallographic test samples and tested the ...

Embodiment 2

[0020] Example 2: The specification of the original wire rod of bearing steel is Φ9.5mm

[0021] Rolling process: the heating temperature of the heating furnace is 1150°C, the rolling start temperature is 1030°C, the first four passes of rough rolling adopt head-off tension-free rolling, the inlet temperature of the rolling mill after head-off is 980°C, the inlet temperature of the pre-finishing mill is 960°C, the pre-finishing The cooling speed of the water cooling section before rolling and finishing rolling is 40°C / s, the finishing rolling temperature is 840°C, the cooling speed of the water cooling section before finishing rolling is 190°C / s, the spinning temperature is 790°C, the opening of the first fan is 50%, open the fifth insulation cover to the 18th insulation cover, and pack the rolls into the warehouse at a temperature below 440°C.

[0022] For the test samples produced by the controlled cooling process, five metallographic test samples and two laps of mechanical ...

Embodiment 3

[0023] Example 3: The specification of the original wire rod of bearing steel is Φ10.5mm

[0024] Rolling process: the heating temperature of the heating furnace is 1160°C, the rolling start temperature is 1050°C, the first four passes of the rough rolling adopt head-off tension-free rolling, the inlet temperature of the rolling mill after head-off is 990°C, the inlet temperature of the pre-finishing mill is 970°C, the pre-finishing The cooling speed of the water cooling section before rolling and finishing rolling is 60°C / s, the finishing rolling temperature is 830°C, the cooling speed of the water cooling section before finishing rolling is 180°C / s, the spinning temperature is 780°C, the opening of the first fan is 50%, open the fifth insulation cover to the 18th insulation cover, and pack the rolls into the warehouse at a temperature below 445°C.

[0025] For the test samples produced by the controlled cooling process, five metallographic test samples and two laps of mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com