High-ductility Class F extra thick rack steel plate used at low temperature and manufacturing method of steel plate

A high-toughness, steel plate technology, applied in the field of high-toughness F-grade extra-thick rack steel plate and its manufacturing field, can solve the problem of inability to manufacture extra-thick rack steel plate for offshore platforms, and achieve high Z-direction performance and excellent tensile properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

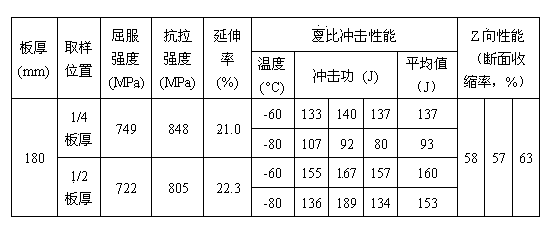

[0037] The thickness of the rack steel plate involved in this example is 180 mm, and the components and their mass percentages are: C: 0.12%, Si: 0.23%, Mn: 1.08%, P: 0.003%, S: 0.001%, Cr: 0.70 %, Mo: 0.50%, Ni: 2.51%, Cu: 0.24%, Alt: 0.077%, V: 0.040%, Nb: 0.022%, N: 0.0032%, B: 0.0018%, the balance is iron and unavoidable Impurity elements, carbon equivalent CEV ( = C + Mn / 6 + (Cr + Mo + V) / 5 + (Cu + Ni) / 15)) = 0.73.

[0038] The production process of the rack steel plate is as follows:

[0039] Allocation of smelting raw materials according to the above chemical composition of the rack steel plate followed by electric furnace smelting – LF refining – VD refining – die casting – slow cooling pit slow cooling – ingot heating – billet rolling – slow cooling under controlled conditions – billet heating – high pressure Water descaling - controlled rolling - straightening - stack slow cooling - quenching and tempering.

[0040] Calcium treatment is carried out by feeding silic...

Embodiment 2

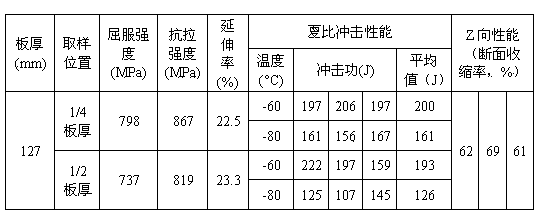

[0049] The thickness of the rack steel plate involved in this example is 127 mm, and the components and their mass percentages are: C: 0.14%, Si: 0.24%, Mn: 1.06%, P: 0.003%, S: 0.002%, Cr: 0.50 %, Mo: 0.49%, Ni: 1.40%, Cu: 0.25%, Alt: 0.07%, V: 0.039%, N: 0.0046%, B: 0.0015%, the balance is iron and unavoidable impurity elements, carbon equivalent CEV = 0.63.

[0050] The smelting and die-casting manufacturing process of this embodiment is basically the same as that of Embodiment 1, the main difference lies in the billet rolling, the controlled rolling of the billet and the subsequent quenching and tempering heat treatment, as follows:

[0051] The cleaned steel ingots are heated in a soaking furnace to 1260-1280°C for 16 hours, and then released from the furnace. After descaling by high-pressure water, the billets are rolled to form billets with a thickness of 380mm. After the steel billet is slowly cooled under controlled conditions (heated to 650 ° C for 24 hours and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com