High-strength tough non-quenched and tempered steel suitable for compound forge forming

A non-quenched and tempered steel, forging forming technology, applied in the field of non-quenched and tempered steel for composite forging and high-strength toughness non-quenched and tempered steel, can solve the problems of forging forming difficulties, reduce the yield of finished products, and die wear, and achieve superior mechanical properties , The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

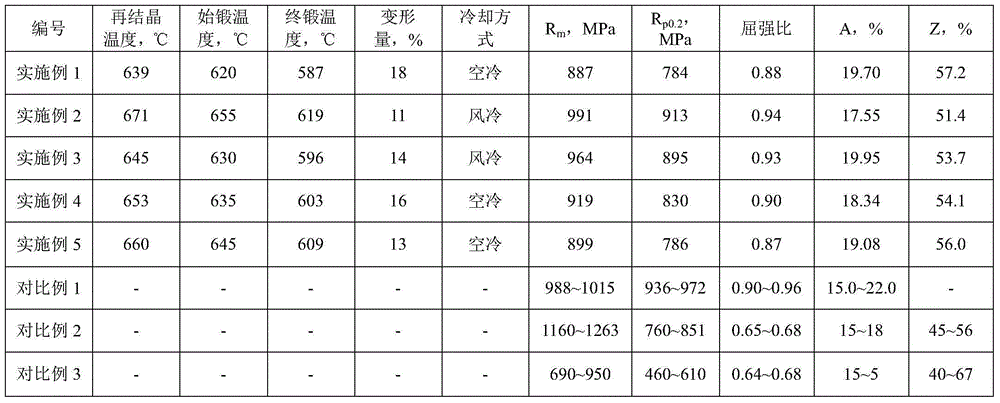

[0025] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0026] The present invention provides five examples in total, and the detailed chemical composition and mass percentage of each example are shown in Table 1.

[0027] serial number

C

mn

Si

Al

V

N

Nb

RE

P

S

Ti

W

Mo

Example 1

0.28

1.81

0.45

0.077

0.071

0.018

0.033

0.0017

0.011

0.0020

-

-

-

Example 2

0.38

1.04

0.78

0.090

0.019

0.011

0.012

0.0034

0.006

0.0014

-

-

-

Example 3

0.33

1.42

0.53

0.038

0.021

0.013

0.008

0.0066

0.017

0.0019

0.13

-

-

Example 4

0.36

1.27

0.59

0.043

0.034

0.015

0.037

0.0051

0.022

0.0034

0.089

0.044

-

Example 5

0.30

1.70

0.34

0.065

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com